Ingersoll-Rand WSC092H, WSC048H, WSC072E, WSC090E, WSC072H Installation, Operation And Maintenance Manual

...

Installation, Operation,

and Maintenance

Packaged Rooftop Air Conditioners

Precedent™ — Heat Pump

3 to 10 Tons — 60 Hz

Model Numbers

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

April 2018

WSC036H-WSC060H

WSC072H, WSC090E, WSC102H & WSC120H

W/DHC036H-W/DHC060H

SAFETY WARNING

RT-SVX23M-EN

Introduction

Read this manual thoroughly before operating or servici ng

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

CAUTIONs

NOTICE:

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

and HCFCs such as saturated or unsaturated HFCs and

HCFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified according to local rules. For

the USA, the Federal Clean Air Act (Section 608) sets forth

the requirements for handling, reclaiming, recovering and

recycling of certain refrigerants and the equipment that is

used in these service procedures. In addition, some states

or municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

WARNI NG

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNI NG

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

© 2018 Ingersoll Rand RT-SVX23M-EN

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in

death or serious injury.

• All Ingersoll Rand personnel must follow Ingersoll

Rand Environmental, Health and Safety (EHS)

policies when performing work such as hot work,

electrical, fall protection, lockout/tagout, refrigerant

handling, etc. All policies can be found on the BOS

site. Where local regulations are more stringent than

these policies, those regulations supersede these

policies.

• Non-Ingersoll Rand personnel should always follow

local regulations.

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Introduction

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

Updated to include new WSC102H, WSC120H

RT-SVX23M-EN 3

Table of Contents

Model Number Descriptions . . . . . . . . . . . . . . 6

Model Number Notes . . . . . . . . . . . . . . . . 7

General Information . . . . . . . . . . . . . . . . . . . . . 8

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . 8

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unit Nameplate . . . . . . . . . . . . . . . . . . . . . 8

Compressor Nameplate . . . . . . . . . . . . . . . 8

Unit Description . . . . . . . . . . . . . . . . . . . . . 8

Economizer Control Actuator (Optional) . 8

System Input Devices & Functions . . . . . . 9

Low Pressure Control . . . . . . . . . . . . . . . . . 9

High Pressure Control . . . . . . . . . . . . . . . 10

Power Exhaust Control (Optional) . . . . . 10

Lead/Lag Control (Dual Circuit Only) . . . 10

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dimensions and Weights . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Horizontal Units . . . . . . . . . . . . . . . . . . . . 20

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Roof Curb . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General Unit Requirements . . . . . . . . . . . . 23

Factory Installed Economizer . . . . . . . . . 23

Temperature Limit Switch Usage for Electric

Heat Units . . . . . . . . . . . . . . . . . . . . . . . . . 23

Horizontal Discharge Conversion WSC036H,

WSC048H,

W/DHC036H

. . . . . . . . . . . . . . . . . . . . . . . . . . 23

Horizontal Discharge Conversion WSC060H120E/H, W/DHC048-120H

TCO-A Instructions . . . . . . . . . . . . . . . . . . 25

Return Air Smoke Detector . . . . . . . . . . . 25

. . . . . . . . . . . . . . . 24

Air-Fi™ Wireless Communication Interface 26

Main Electrical Power Requirements . . . . 27

Through-the-Base Gas Installation . . . . . . 27

Requirements for Gas Heat . . . . . . . . . . . . 27

Electric Heat Requirements . . . . . . . . . . . 28

Low Voltage Wiring

(AC & DC) Requirements . . . . . . . . . . . . . 28

Condensate Drain Configuration . . . . . . . . .28

Filter Installation . . . . . . . . . . . . . . . . . . . . .29

Field Installed Power Wiring . . . . . . . . . . . .29

Standard Wiring . . . . . . . . . . . . . . . . . . . . . 29

Optional TBUE Wiring (Through-the-Base

Electrical Option) . . . . . . . . . . . . . . . . . . . .29

Field Installed Control Wiring . . . . . . . . . . 30

Controls Using 24 VAC . . . . . . . . . . . . . . .30

Controls Using DC Analog Input/Outputs

(Standard Low Voltage Multiconductor Wire)

30

Space Temperature Averaging (ReliaTel™

only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Pre-Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Voltage Imbalance . . . . . . . . . . . . . . . . . . . . .37

Electrical Phasing (Three Phase Motors) . .37

Compressor Crankcase Heaters . . . . . . . .38

ReliaTel™ Controls . . . . . . . . . . . . . . . . . . 38

Test Modes . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Unit Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Sequence of Operation . . . . . . . . . . . . . . . . . . .41

ReliaTel™ Controls . . . . . . . . . . . . . . . . . . 41

ReliaTel™ Controls - Constant Volume (CV)

41

ReliaTel™ Control Cooling without an Econo-

mizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Three-Stages of Cooling . . . . . . . . . . . . . .41

ReliaTel™ Control Evaporator Fan Operation

(for Gas Units) . . . . . . . . . . . . . . . . . . . . . .41

ReliaTel™ Control Evaporator Fan Operation

(for Cooling Only Units) . . . . . . . . . . . . . . . 42

Low Ambient Operation . . . . . . . . . . . . . .42

Multi-Speed Indoor Motor . . . . . . . . . . . . .42

Fan Output% . . . . . . . . . . . . . . . . . . . . . . . . 42

Multi-Zone VAV Sequence of Operation . .42

Supply Air Pressure Control . . . . . . . . . . .42

Supply Air Static Pressure Limit . . . . . . . .43

Supply Air Temperature Controls . . . . . . .43

Supply Air Setpoint Reset . . . . . . . . . . . . .43

Zone Temperature Control . . . . . . . . . . . .43

4 RT-SVX23M-EN

Table of Contents

Variable Air Volume Applications (Single

Zone VAV)

Discharge Air Cool Setpoint Adjustment 44

ReliaTel™ Control Cooling with an Economiz-

er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ReliaTel™ Control Dehumidification . . . 45

Dehumidification Coil Purge Cycle . . . . . 45

ReliaTel™ Control Cooling with an Economiz-

er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Economizer Set-Up . . . . . . . . . . . . . . . . . 46

ReliaTel™ Control Heating Operation (for

Cooling Only Units) . . . . . . . . . . . . . . . . . 46

ReliaTel™ Control Heating Operation (for Gas

Units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Ignition Module . . . . . . . . . . . . . . . . . . . . 46

Drain Pan Condensate Overflow Switch (Op-

tional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Sequence of Operation - Heat Pumps . . . . . 48

Heating Operation . . . . . . . . . . . . . . . . . . . . 48

Demand Defrost . . . . . . . . . . . . . . . . . . . . . . 48

Emergency Heat Operation . . . . . . . . . . . . 48

Verifying Proper Air Flow . . . . . . . . . . . . . . 48

Units with 5-Tap Direct Drive Indoor Fan 48

Units with Belt Drive Indoor Fan . . . . . . . 49

Units with Constant CFM Direct Drive Indoor

Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3 to 5 Ton 17 Plus/WHC/DHC units with the

constant CFM direct drive indoor fan . . . 49

ReliaTel™ Units Equipped with Direct Drive

Indoor Plenum Fan (optional except for 10

Ton Units) . . . . . . . . . . . . . . . . . . . . . . . . . 50

Return Air Smoke Detector . . . . . . . . . . . 51

Economizer Start-Up . . . . . . . . . . . . . . . . 51

Compressor Start-Up . . . . . . . . . . . . . . . . 52

Heating Start-Up . . . . . . . . . . . . . . . . . . . . 52

Final System Setup . . . . . . . . . . . . . . . . . 53

Heating Season . . . . . . . . . . . . . . . . . . . . .55

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . .58

ReliaTel™ Control . . . . . . . . . . . . . . . . . . . . .58

System Status Checkout Procedure . . . . . .58

Method 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Resetting Cooling and Heating Lockouts .59

Zone Temperature Sensor (ZTS) Service Indicator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Clogged Filter Switch . . . . . . . . . . . . . . . . . 60

Fan Failure Switch . . . . . . . . . . . . . . . . . . .60

Condensate Overflow Switch . . . . . . . . . .60

Zone Temperature Sensor (ZTS) Test . . . .60

Test 1 Zone Temperature Thermistor

(ZTEMP) . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Test 2 Cooling Set Point (CSP) and Heating

Set Point (HSP) . . . . . . . . . . . . . . . . . . . . . .60

Test 3 System Mode and Fan Selection . .60

Test 4 LED Indicator Test, (SYS ON, HEAT,

COOL & SERVICE) . . . . . . . . . . . . . . . . . . .60

Programmable & Digital Zone

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . .61

Mixed Air Temperature Low Limit Diagnostic

63

Troubleshooting Procedures for Direct Drive

Plenum Fan

. . . . . . . . . . . . . . . . . . . . . . . . . . .63

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . .64

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . .66

Heat Pump WCD, WCH, WSC, WHC and DHC

(Parts Only) . . . . . . . . . . . . . . . . . . . . . . . . .66

Models Less Than 20 Tons for Commercial

Use* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Fan Belt Adjustment - Belt Drive Units . . . 54

Monthly Maintenance . . . . . . . . . . . . . . . . . 55

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Return Air Smoke Detector Maintenance 55

Condensate Overflow Switch . . . . . . . . . 55

Cooling Season . . . . . . . . . . . . . . . . . . . . 55

RT-SVX23M-EN 5

Model Number Descriptions

Digit 1 - Unit Type

W Packaged Heat Pump

D Dual Fuel Heat Pump

2

Digit 2 - Efficiency

S Standard Efficiency

HHigh Efficiency

Digit 3 - Airflow

C Convertible

Digit 4,5,6 - Nominal Gross

Cooling Capacity (MBh)

036 3 Ton

048 4 Ton

060 5 Ton

072 6 Ton

090 7.5 Ton

102 8.5 Ton

120 10 Ton

Digit 7 - Major Design Sequence

Digit 8 - Voltage Selection

3 208-230/60/3

4 460/60/3

W 575/60/3

Digit 9 - Unit Controls

R ReliaTel™ Microprocessor

Digit 10 - Heating Capacity

Note: Applicable to Digit 1,W models

0 No Electric Heat

B6 kW

C9 kW

E12 kW

G18 kW

J 23 kW

K 27 kW

N 36 kW

P 54 kW

Note: Applicable to Digit 1,D models

L Low Heat

M Medium Heat

H High Heat

X Low Heat, Stainless Steel Heat

Y Medium Heat, Stainless Steel Heat

Z High Heat, Stainless Steel Heat

only.

only

Exchanger

Exchanger

Exchanger

Digit 11 - Minor Design

Sequence

A First Sequence

Digit 12,13 - Service Sequence

** Factory Assigned

Digit 14 - Fresh Air Selection

0No Fresh Air

A Manual Outside Air Damper 0-50%

B Motorized Outside Air Damper

C Economizer, Dry Bulb 0-100%

D Economizer, Dry Bulb 0-100%

10

0-50%

without Barometric Relief

with Barometric Relief

4

4

E Economizer, Reference Enthalpy

0-100% without Barometric Relief

F Economizer, Reference Enthalpy

0-100% with Barometric Relief

G Economizer, Comparative

Enthalpy 0-100% without

Barometric Relief

4

H Economizer, Comparative

Enthalpy 0-100% with Barometric

4

Relief

K Low Leak Economizer with

Barometric Relief

M Low Leak Economizer with Reference

Enthalpy with Barometric Relief

P Low Leak Economizer with

Comparative Enthalpy with

Barometric Relief

1

4

4

Digit 15 - Supply Fan/Drive Type/

Motor

0 Standard Drive

1 Oversized Motor

2 Optional Belt Drive Motor

6 Single Zone Variable Air

Vol u m e (SZVAV)

7 Multi-Speed Indoor Fan

8 Single Zone Variable Air Volume

(SZVAV) w/Oversized Motor

E Multi-Zone Variable Air Volume

(MZVAV)

F Multi-Zone Variable Air Volume

(MZVAV) w/Oversized Motor

3

3

14

12

14

14

14

Digit 16 - Hinged Service

Access/Filters

0 Standard Panels/Standard Filters

A Hinged Access Panels/Standard

Filters

B Standard Panels/2” MERV 8 Filters

C Hinged Access Panels/2” MERV 8

Filters

D Standard Panels/2” MERV 13 Filters

E Hinged Access Panels/2” MERV 13

Filters

Digit 17 - Condenser Coil

Protection

0 Standard Coil

1 Standard Coil with Hail Guard

2 Black Epoxy Pre-Coated Condenser

Coil

3 Black Epoxy Pre-Coated

Condenser Coil with Hail Guard

Digit 18 - Through-the-Base

Provisions

0 No Through-the-Base Provisions

A Through-the-Base Electric

5

Digit 19 - Disconnect/Circuit

Breaker (three-phase only)

0 No Disconnect/No Circuit Breaker

1 Unit Mounted Non-Fused

Disconnect

2 Unit Mounted Circuit Breaker

5

5

Digit 20 - Convenience Outlet

0 No Convenience Outlet

A Unpowered Convenience Outlet

B Powered Convenience Outlet

(three-phase only)

6

Digit 21 - Communications

Options

0 No Communications Interface

1 Trane® Communications Interface

2 LonTalk® Communications Interface

6 BACnet® Communications Interface

7 Air-Fi™ Wireless Communications

15

Digit 22 - Refrigeration System

Option

0 Standard Refrigeration System

7

Digit 23 - Refrigeration Controls

0 No Refrigeration Control

1Frostat™

11

2 Crankcase Heater

3 Frostat and Crankcase Heater

2

16

11 ,16

Digit 24 - Smoke Detector

0 No Smoke Detector

A Return Air Smoke Detector

B Supply Air Smoke Detector

C Supply and Return Air Smoke

Detectors

8

D Plenum Smoke Detector

8

Digit 25 - System Monitoring

Controls

0 No Monitoring Control

1 Clogged Filter Switch

2 Fan Failure Switch

3 Discharge Air Sensing Tube

4 Clogged Filter Switch and Fan

Fail Switch

5 Clogged Filter Switch and Discharge

Air Sensing Tube

6 Fan Fail Switch and Discharge Air

Sensing Tube

7 Clogged Filter and Fan Fail Switches

and Discharge Air Sensing Tube

A Condensate Drain Pan Overflow

Switch

B Clogged Filter Switch and

Condensate Drain Pan Overflow

Switch

C Fan Failure Switch and Condensate

Drain Pan Overflow Switch

D Discharge Air Sensing and

Condensate Drain Pan Overflow

Switch

E Clogged Filter Switch, Fan Failure

Switch and Condensate Drain Pan

Overflow Switch

F Clogged Filter Switch, Discharge

Air Sensing Tube and Condensate

Drain Pan Overflow Switch

G Fan Failure Switch, Discharge Air

6 RT-SVX23M-EN

Model Number Descriptions

Sensing Tube and Condensate

Drain Pan Overflow Switch

H Clogged Filter Switch, Fan Failure

Switch, Discharge Air Sensing

and Condensate Drain Pan Overflow

Switch

Digit 26 - System Monitoring

Controls

0 No Monitoring Controls

A Demand Control Ventilation (CO

B Low Leak Economizer with FDD

(Fault Detection & Diagnostics)

C FDD (Fault Detection & Diagnostics)

with DCV (Demand Control

Ventilation)

13

)

2

Digit 27 - Unit Hardware

Enhancements

0 No Enhancements

1 Stainless Steel Drain Pan

Digit 31 - Advanced Unit

Controls

0 Standard Unit Controls

1 Human Interface

Model Number Notes

1. Manual outside air damper will

ship factory supplied within the

unit, but must be field installed.

2. High pressure control is standard

on all units.

3. Multi-stage, direct drive standard

on 3 to 5 ton models. Belt drive

standard on 6 to 8.5 ton standard

efficiency models. Variable speed

direct drive standard on 10 ton

model.

4. Economizer with barometric

relief is for downflow configured

units only. Order economizer

without barometric relief for

horizontal configuration.

Barometric relief for horizontal

configured units must be ordered

as field installed accessory.

5. Through-the-base electric

required when ordering

disconnect/circuit breaker

options.

6. Requires use of disconnect or

circuit breaker.

7. Standard metering devices are

TXVs.

8. The return air smoke detector

may not fit up or work properly on

the Precedent™ units when used

in conjunction with 3rd party

accessories such as bolt on heat

wheels, economizers and power

exhaust. Do not order the return

air smoke detectors when using

this type of accessory.

9. Requires hinged access panels.

10. Motorized outside air damper is

not available on Multi-Speed or

SZVAV (Single Zone Variable Air

Vol ume)

Variable Air Volume)

or MZVAV (Multi Zone

products.

11. Frostat™ standard on multispeed and SZVAV (single zone

variable air volume)

products.

12. Multi-speed indoor fan only

available on 8.5 and 10 ton

products.

13. Demand control ventilation

option includes wiring only. The

sensor is a field-installed

CO

2

only option.

14. SZVAV/MZVAV available only on

3 to 5 tons high efficiency and

SZVAV available on 8.5 and 10 ton

standard efficiency unit.

15. Must be used with BACnet® open

protocol.

16. Crankcase heater is standard on

all heat pumps.

RT-SVX23M-EN 7

General Information

Unit Inspection

As soon as the unit arrives at the job site

• Verify that the nameplate data matches the data on the

sales order and bill of lading (including electrical data).

• Verify that the power supply complies with the unit

nameplate specifications.

• Visually inspect the exterior of the unit, including the

roof, for signs of shipping damage.

If the job site inspection of the unit reveals damage or

material shortages, file a claim with the carrier

immediately. Specify the type and extent of the damage on

the “bill of lading” before signing.

• Visually inspect the internal components for shipping

damage as soon as possible after delivery and before

it is stored. Do not walk on the sheet metal base pans.

• If concealed damage is discovered, notify the carrier’s

terminal of damage immediately by phone and by

mail. Concealed damage must be reported within 15

days.

• Request an immediate joint inspection of the damage

by the carrier and the consignee. Do not remove

damaged material from the receiving location. Take

photos of the damage, if possible. The owner must

provide reasonable evidence that the damage did not

occur after delivery.

• Notify the appropriate sales representative before

installing or repairing a damaged unit.

Storage

Take precautions to prevent condensate from forming

inside the unit’s electrical compartments and motors if:

1. the unit is stored before it is installed; or,

2. the unit is set on the roof curb, and temporary heat is

provided in the building. Isolate all side panel service

entrances and base pan openings (e.g., conduit holes,

Supply Air and Return Air openings, and flue

openings) from the ambient air until the unit is ready

for start-up.

Note: Do not use the unit’s heater for temporary heat

without first completing the start-up procedure

detailed under the Unit Start-Up chapter.

The manufacturer will not assume any responsibility for

equipment damage resulting from condensate

accumulation on the unit’s electrical and/or mechanical

components.

Unit Nameplate

A Mylar unit nameplate is located on the unit’s corner

support next to the filter access panel. It includes the unit

model number, serial number, electrical characteristics,

refrigerant charge, as well as other pertinent unit data.

Compressor Nameplate

The nameplate for the compressors are located on the side

of the compressor.

Unit Description

Before shipment, each unit is leak tested, dehydrated,

charged with refrigerant and compressor oil, and run

tested for proper control operation.

The condenser coils are aluminum fin, mechanically

bonded to copper tubing.

Direct-drive, vertical discharge condenser fans are

provided with built-in thermal overload protection.

The ReliaTel™ Control Module is a microelectronic control

system that is referred to as “Refrigeration Module”

(RTRM). The acronym RTRM is used extensively

throughout this document when referring to the control

system network.

These modules through proportional/integral control

algorithms perform specific unit functions that governs

unit operation in response to; zone temperature, supply air

temperature, and/or humidity conditions depending on

the application. The stages of capacity control for these

units is achieved by starting and stopping the

compressors.

The RTRM is mounted in the control panel and is factory

wired to the respective internal components. The RTRM

receives and interpret information from other unit

modules, sensors, remote panels, and customer binary

contacts to satisfy the applicable request for cooling.

Economizer Control Actuator (Optional)

The ECA monitors the mixed air temperature, return air

temperature, minimum position setpoint (local or

remote), power exhaust setpoint, CO

ambient dry bulb/enthalpy sensor or comparative

humidity (return air humidity against ambient humidity)

sensors, if selected, to control dampers to an accuracy of

+/- 5% of stroke. The actuator is spring returned to the

closed position any time that power is lost to the unit. It is

capable of delivering up to 25 inch pounds of torque and

is powered by 24 VAC.

RTCI - ReliaTel™ Trane® Communication

Interface (Optional)

This module is used when the application calls for an

ICSTM building management type control system. It

allows the control and monitoring of the system through

an ICS panel. The module can be ordered from the factory

or ordered as a kit to be field installed. Follow the

installation instruction that ships with each kit when field

installation is necessary.

setpoint, CO2, and

2

8 RT-SVX23M-EN

General Information

RLCI - ReliaTel™ LonTalk® Communication

Interface (Optional)

This module is used when the application calls for an

ICSTM building management type control system that is

LonTalk. It allows the control and monitoring of the system

through an ICS panel. The module can be ordered from the

factory or ordered as a kit to be field installed. Follow the

installation instruction that ships with each kit when field

installation is necessary.

RBCI - ReliaTel™ BACnet® Communications

Interface (Optional)

This module is used when the application calls for an open

BACnet protocol. It allows the control and monitoring of

the system through an ICS panel. The module can be

ordered from the factory or as a kit to be field installed.

Follow the installation instructions that ships with each kit

when field installation is necessary.

RTOM – ReliaTel™ Options Module

The RTOM monitors the supply fan proving, clogged filter,

supply air temperature, exhaust fan setpoint, supply air

tempering, Frostat™ and smoke detector. Refer to system

input devices and functions for operation.

This module is standard on 10 ton products.

System Input Devices & Functions

The RTRM must have a zone sensor or thermostat input in

order to operate the rooftop unit. The flexibility of having

several mode capabilities depends upon the type of zone

sensor thermostat selected to interface with the RTRM.

The descriptions of the following basic Input Devices used

within the RTRM network are to acquaint the operator with

their function as they interface with the various modules.

Refer to the unit’s electrical schematic for the specific

module connections.

The following controls are available from the factory for

field installation.

Supply Fan Failure Input (Optional)

The Fan Failure Switch can be connected to sense indoor

fan operation:

FFS (Fan Failure Switch) If air flow through the unit is not

proven by the differential pressure switch connected to the

RTRM (factory set point 0.07 “w.c.) within 40 seconds

nominally, the RTRM will shut off all mechanical

operations, lock the system out, send a diagnostic to ICS,

and the SERVICE output will flash. The system will remain

locked out until a reset is initiated either manually or

through ICS.

Clogged Filter Switch (Optional)

The unit mounted clogged filter switch monitors the

pressure differential across the return air filters. It is

mounted in the filter section and is connected to the

RTOM. A diagnostic SERVICE signal is sent to the remote

RT-SVX23M-EN 9

panel if the pressure differential across the filters is at least

0.5" w.c. The contacts will automatically open when the

pressure differential across the filters decreases to

approximately 0.4" w.c. The clogged filter output is

energized when the supply fan is operating and the

clogged filter switch has been closed for at least 2 minutes.

The system will continue to operate regardless of the

status of the filter switch.

Note: On units equipped with factory installed MERV 13

filters, a clogged filter switch with different

pressure settings will be installed. This switch will

close when the differential pressure is

approximately 0.8' w.c. and open when the

differential falls to 0.7" w.c.

Condensate Drain Pan Overflow Switch

(Optional)

ReliaTel™ Option

This input incorporates the Condensate Overflow Switch

(COF) mounted on the drain pan and the ReliaTel Options

Module (RTOM). When the condensate level reaches the

trip point for 6 continuous seconds, the RTOM will shut

down all unit functions until the overflow condition has

cleared. The unit will return to normal operation after 6

continuous seconds with the COF in a non-tripped

condition. If the condensate level causes unit shutdown

more than 2 times in a 3 days period, the unit will be

locked-out of operation requiring manual reset of

diagnostic system through Zone Sensor or Building

Automation System (BAS). Cycling unit power will also

clear the fault.

Compressor Disable (CPR1/2)

This input incorporates the low pressure control (LPC) of

each refrigeration circuit and can be activated by opening

a field supplied contact installed on the LTB.

If this circuit is open before the compressor is started, the

compressor will not be allowed to operate. Anytime this

circuit is opened for 1 continuous second during

compressor operation, the compressor for that circuit is

immediately turned “Off”. The compressor will not be

allowed to restart for a minimum of 3 minutes should the

contacts close.

If four consecutive open conditions occur during the first

three minutes of operation, the compressor for that circuit

will be locked out, a diagnostic communicated to the

remote panel (if installed), and a manual reset will be

required to restart the compressor.

Low Pressure Control

When the LPC is opened for 1 continuous second, the

compressor for that circuit is turned off immediately. The

compressor will not be allowed to restart for a minimum

of 3 minutes.

If four consecutive open conditions occur during an active

call for cooling, the compressor will be locked out, a

diagnostic communicated to ICS™, if applicable, and a

General Information

manual reset required to restart the compressor. On dual

compressor units only the affected compressor circuit is

locked out.

High Pressure Control

The high pressure controls are wired in series between the

compressor outputs on the RTRM and the compressor

contactor coils. If the high pressure control switch opens,

the RTRM senses a lack of current while calling for cooling

and locks the compressor out.

If four consecutive open conditions occur during an active

call for cooling, the compressor will be locked out, a

diagnostic communicated to ICS™, if applicable, and a

manual reset required to restart the compressor. On dual

compressor units only the affected compressor circuit is

locked out.

Power Exhaust Control (Optional)

The power exhaust fan is started whenever the position of

the economizer dampers meets or exceed the power

exhaust setpoint when the indoor fan is on.

The setpoint panel is located in the return air section and

is factory set at 25%.

Lead/Lag Control (Dual Circuit Only)

Lead/Lag is a selectable input located on the RTRM. The

RTRM is configured from the factory with the Lead/Lag

control disabled. To activate the Lead/Lag function, simply

cut the wire connected to J3-8 at the RTRM. When it is

activated, each time the designated lead compressor is

shut off due to the load being satisfied, the lead

compressor or refrigeration circuit switches. When the

RTRM is powered up, i.e. after a power failure, the control

will default to the number one circuit compressor.

Zone Sensor Module (ZSM) (BAYSENS107*)

This electronic sensor features three system switch

settings (Heat, Cool, and Off) and two fan settings (On and

Auto). It is a manual changeover control with single

setpoint. (Cooling Setpoint Only)

Zone Sensor Module (ZSM) (BAYSENS109*)

This electronic sensor features four system switch settings

(Heat, Cool, Auto, and Off) and two fan settings (On and

Auto). It is a manual or auto changeover control with dual

setpoint capability. It can be used with a remote zone

temperature sensor BAYSENS077*.

Programmable Zone Sensor - (BAYSENS119*)

This 7 day programmable sensor features 2, 3 or 4 periods

for Occupied or Unoccupied programming per day. If the

power is interrupted, the program is retained in

permanent memory. If power is off for an extended period

of time, only the clock and day may have to be reset.

The zone sensor allows selection of 2, 3 or 4 system modes

(Heat, Cool, Auto, and Off), two fan modes (On and Auto).

It has dual temperature selection with programmable start

time capability.

The occupied cooling set point ranges between 45 and 98

degrees Fahrenheit. The heating set point ranges between

43 and 96 degrees Fahrenheit.

A liquid crystal display (LCD) displays zone temperature,

temperature set points, day of the week, time, and

operational mode symbols.

The Option Menu is used to enable or disable applicable

functions, i.e.; Morning Warm-up, Economizer minimum

position override during unoccupied status, Fahrenheit or

Centigrade, Supply air tempering, Remote zone

temperature sensor, 12/24 hour time display, Smart fan,

and Computed recovery.

During an occupied period, an auxiliary relay rated for 1.25

amps @ 30 volts AC with one set of single pole double

throw contacts is activated.

Status Inputs (4 Wires Optional). The ZSM can be wired to

receive four (4) operating status signals from the RTRM

(HEAT, COOL, SYSTEM “ON”, SERVICE). Four (4) wires

from the RTRM should be connected to the appropriate

terminals (7, 8, 9 & 10) on the ZSM.

Remote Zone Sensor (BAYSENS073*)

This electronic sensor features remote zone sensing and

timed override with override cancellation. It is used with a

Trane Integrated Comfort™ building management

system.

Remote Zone Sensor (BAYSENS074*)

This electronic sensor features single setpoint capability

and timed override with override cancellation. It is used

with a Trane Integrated Comfort™ building management

system.

Remote Zone Sensor (BAYSENS016*)

This bullet type temperature sensor can be used for;

outside air (ambient) sensing, return air temperature

sensing, supply air temperature sensing, remote

temperature sensing (uncovered). Wiring procedures vary

according to the particular application and equipment

involved. Refer to the unit’s wiring diagrams for proper

connections.

Remote Zone Sensor (BAYSENS077*)

This electronic sensor can be used with BAYSENS106*,

108*, 110*, 119* Remote Panels. When this sensor is wired

to a BAYSENS119* remote panel, wiring must be 18 AWG

shielded twisted pair (Belden 8760 or equivalent). Refer to

the specific remote panel for wiring details.

Wireless Zone Sensor (BAYSENS050*)

This electronic sensor features five system settings (Auto,

Off, Cool, Heat, and Emergency Heat) and with On and

Auto fan settings. It is a manual or auto changeover control

with dual setpoint capability. Other features include a

timed override function, lockable system settings, and

10 RT-SVX23M-EN

General Information

Fahrenheit or Celsius temperature display. Included with

the wireless zone sensor will be a receiver that is to be

mounted inside the unit, a mounting bracket, and a wire

harness.

High Temperature Sensor (BAYFRST001*)

This sensor connects to the RTRM Emergency Stop Input

located on the LTB and provides high limit “shutdown” of

the unit and requires a manual reset. The sensor is used to

detect high temperatures due to fire in the air conditioning

or ventilation ducts. The sensor is designed to mount

directly to the sheet metal duct. Each kit contains two

sensors. The return air duct sensor (X1310004001) is set to

open at 135°F. The supply air duct sensor (X1310004002) is

set to open at 240°F. The control can be reset after the

temperature has been lowered approximately 25°F below

the cutout setpoint.

Evaporator Frost Control

This input incorporates the Frostat™ control (FOS) located

on the indoor coil and can be activated by closing a field

supplied contact installed in parallel with the FOS.

If this circuit is closed before the compressor is started, the

compressor will not be allowed to operate. Anytime this

circuit is closed for 1 continuous second during

compressor operation, the compressor for that circuit is

immediately turned “Off”. The compressor will not be

allowed to restart for a minimum of 3 minutes should the

FOS open.

Frostat™ is standard on multi-speed indoor motors and

single zone VAV products (SZVAV).

Smoke Detector Sensor (Optional)

This sensor is only applicable on units equipped with a

RTOM. It provides high limit “shutdown” of the unit and

requires a manual reset. The sensor is used to detect

smoke due to fire in the air conditioning or ventilation

ducts.

Important:

• The supply air smoke detector samples supply air. The

return and plenum air smoke detectors sample return

air. The smoke detectors are designed to shut off the

unit if smoke is sensed in the supply air stream or

return air stream. This function is performed by

sampling the airflow entering the unit at the return air

opening. Follow the instructions provided below to

assure that the airflow through the unit is sufficient for

adequate sampling. Failure to follow these instructions

will prevent the smoke detectors from performing it's

design function.

• Airflow through the unit is affected by the amount of

dirt and debris accumulated on the indoor coil and

filters. To insure that airflow through the unit is

adequate for proper sampling by the return air smoke

detector, complete adherence to the maintenance

procedures, including recommended intervals

between filter changes, and coil cleaning is required.

• Periodic checks and maintenance procedures must be

performed on the smoke detector to insure that it will

function properly. For detailed instructions concerning

these checks and procedures, refer to the appropriate

section(s) of the smoke detector Installation and

Maintenance Instructions provided with the literature

package for this unit.

In order for the supply air smoke detector or return air

smoke detector to properly sense smoke in the supply air

stream or return air stream, the air velocity entering the

smoke detector unit must be between 500 and 4000 feet

per minute. Equipment covered in this manual will

develop an airflow velocity that falls within these limits

over the entire airflow range specified in the evaporator

fan performance tables.

Phase Monitoring protection

Precedent units with 3-phase power are equipped with

phase monitoring protection as standard. These devices

protect motors and compressors against problems caused

by phase loss, phase imbalance, and phase reversal

indication.

This sensor monitors voltage between the 3 conductors of

the 3 phase power supply. Two LED lights are provided.

The green light indicates that a balanced 3 phase supply

circuit is properly connected. The red light indicates that

unit operation has been prevented. There are two

conditions that will prevent unit operation. The power

supply circuit is not balanced with the proper phase

sequence of L1, L2, L3 for the 3 conductors of a 3 phase

circuit. The line to line voltage is not between 180 volts and

633 volts.

Human Interface - 5 Inch Color Touchscreen

(Optional)

The 5 inch Color Touchscreen Human Interface provides an

intuitive user interface to the rooftop unit that speeds up

unit commissioning, shortens unit troubleshooting times,

and enhances preventative maintenance measures. The

human interface includes several features including:

• Data trending capabilities by means of time series

graphs

• Historical alarm messages

• Real-time sensor measurements

• On board system setpoints

• USB port that enables the downloading of component

runtime information as well as trended historical

sensor data

• Customized reports

RT-SVX23M-EN 11

Pre-Installation

WARNI NG

Fiberglass Wool!

Exposition to glass wool fibers without all necessary

PPE equipment could result in cancer, respiratory, skin

or eye irritation, which could result in death or serious

injury. Disturbing the insulation in this product during

installation, maintenance or repair will expose you to

airborne particles of glass wool fibers and ceramic

fibers known to the state of California to cause cancer

through inhalation. You MUST wear all necessary

Personal Protective Equipment (PPE) including gloves,

eye protection, a NIOSH approved dust/mist respirator,

long sleeves and pants when working with products

containing fiberglass wool.

Precautionary Measures

• Avoid breathing fiberglass dust.

• Use a NIOSH approved dust/mist respirator.

• Avoid contact with the skin or eyes. Wear long-sleeved,

loose-fitting clothing, gloves, and eye protection.

• Wash clothes separately from other clothing: rinse

washer thoroughly.

• Operations such as sawing, blowing, tear-out, and

spraying may generate fiber concentrations requiring

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

First Aid Measures

Eye Contact - Flush eyes with water to remove dust. If

symptoms persist, seek medical attention.

Skin Contact - Wash affected areas gently with soap and

warm water after handling.

12 RT-SVX23M-EN

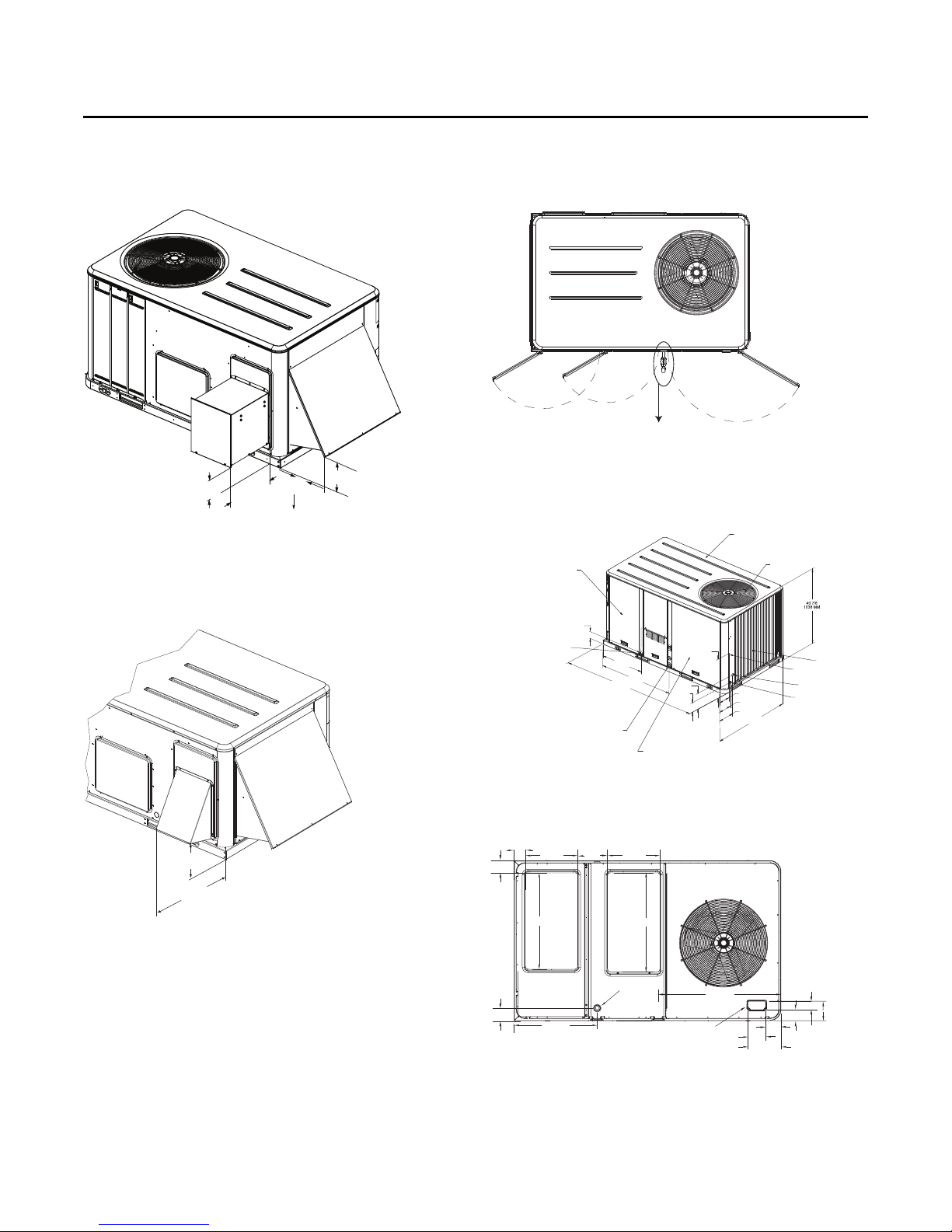

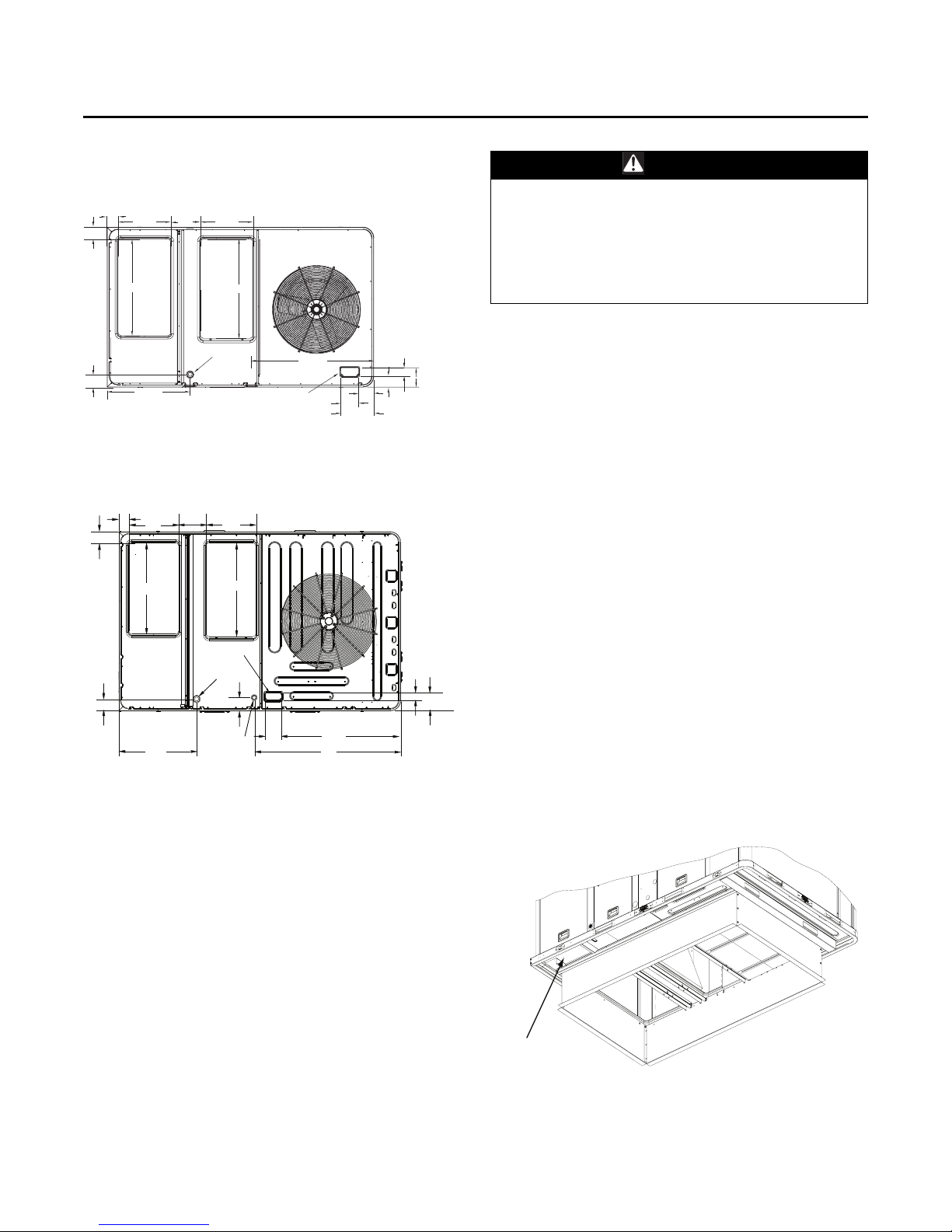

Dimensions and Weights

WSC036-048H, W/DHC036H Units

WSC060-120E/H, W/DHC048-060H Units

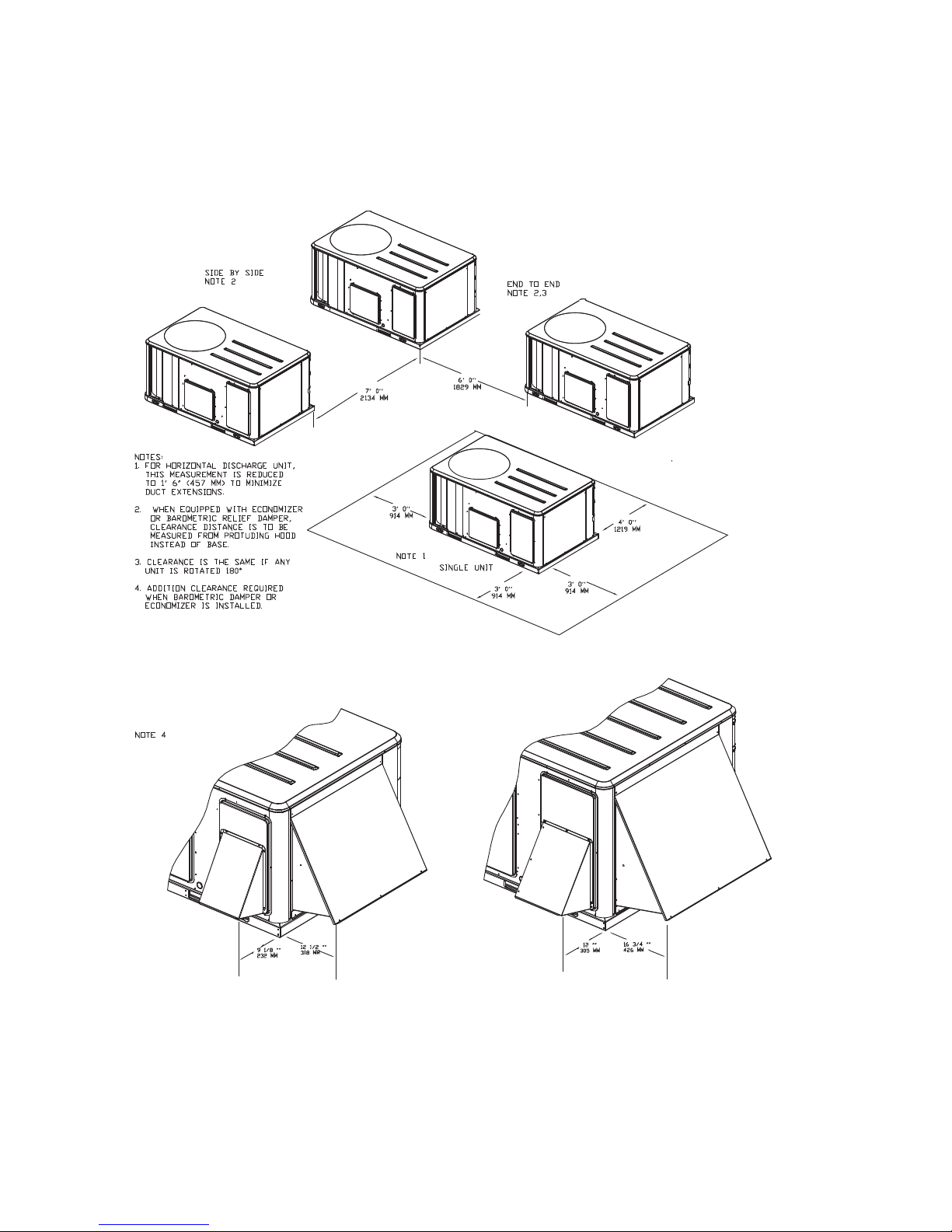

Figure 1. Typical installation clearances for single & multiple unit applications

RT-SVX23M-EN 13

Dimensions and Weights

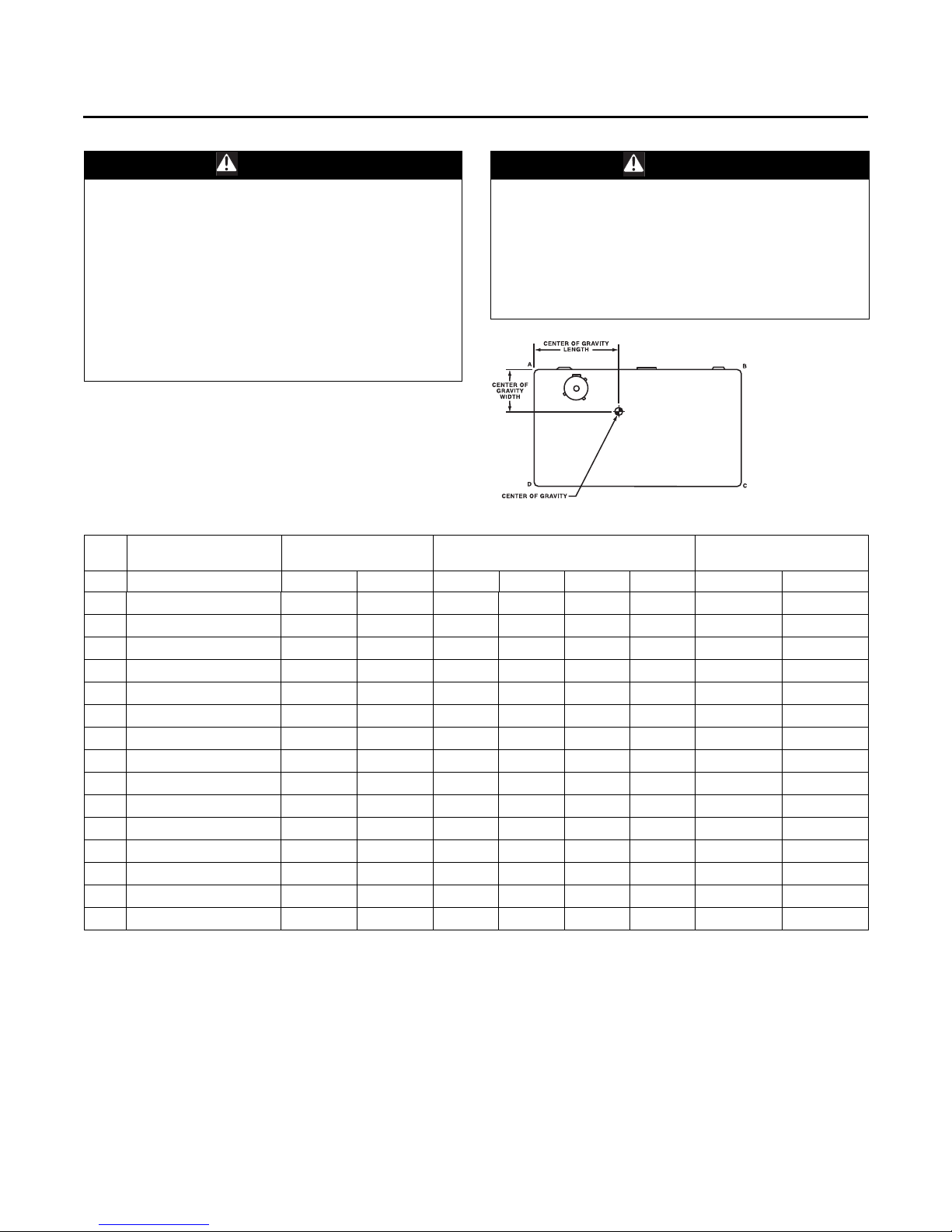

WARN ING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

Improper Unit Lift!

Failure to properly lift unit could result in unit dropping

and possibly crushing operator/technician which could

result in death or serious injury, and equipment or

property-only damage. Test lift unit approximately 24

inches to verify proper center of gravity lift point. To

avoid dropping of unit, reposition lifting point if unit is

not level.

WARNI NG

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

Table 1. Maximum unit & corner weights (lbs) and center of gravity dimensions (in.)

Unit

Tons Model No. Shipping Net A B C D Length Width

3 WSC036H 612 507 144 122 110 130 32 21

4 WSC048H 645 540 165 131 108 136 31 20

5 WSC060H 777 682 228 177 114 163 38 22

6 WSC072E/H 835 740 235 196 140 168 40 22

7.5 WSC090E/H 902 804 255 217 153 180 41 22

7.5 WSC092H 894 796 252 204 163 177 41 23

8.5 WSC102H 927 829 286 183 195 164 40 23

10 WSC120E 1388 1199 342 328 259 270 49 28

10 WSC120H 948 850 303 170 218 159 40 24

3 WHC036H 619 514 142 120 111 142 31 22

4 WHC048H 768 673 222 175 114 162 38 22

5 WHC060H 773 678 225 176 114 162 38 22

3 DHC036H 658 553 145 137 125 145 33 22

4 DHC048H 845 750 234 192 146 178 40 23

5 DHC060H 849 754 235 193 147 179 40 23

(a) Weights are approximate.

(b) Corner weights are given for information only.

Maximum Model

Weights

(a)

Corner Weights

(b)

Center of Gravity (in.)

14 RT-SVX23M-EN

Figure 2. Rigging and center-of-gravity data

Dimensions and Weights

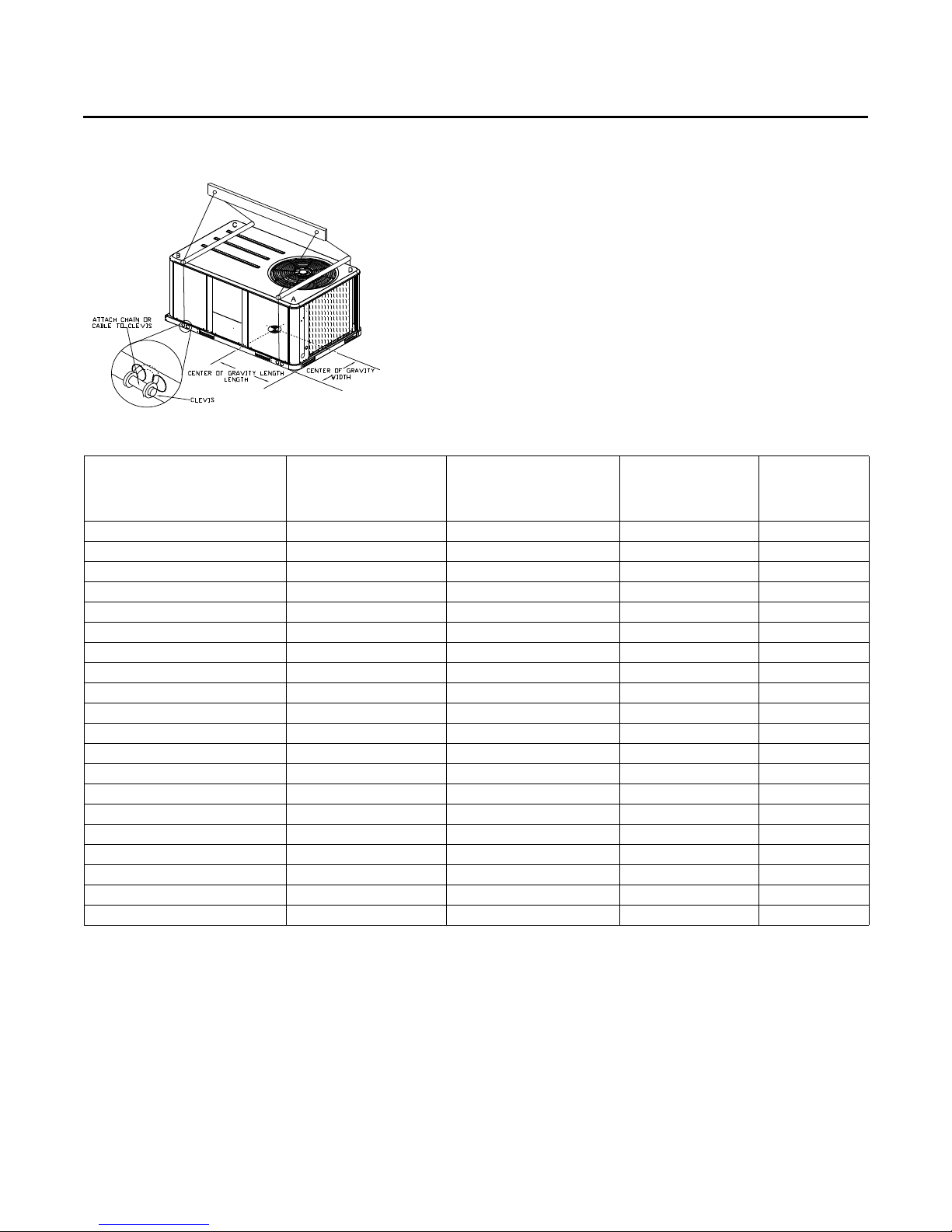

Table 2. Factory installed options (fiops)/accessory net weights (lbs)

WSC036H-048H,

W/DHC036H

Net Weight

Accessory

460V/575V IDM Transformer

Barometric Relief 7 10 10 10

Coil Guards 12 20 20 30

Economizer 26 36 36 36

Electric Heaters

Hinged Doors 11 12 12 12

Low Leak Economizer 68 93 93 93

Manual Outside Air Damper 16 26 26 26

Motorized Outside Air Damper 20 30 30 30

Oversized Motor 8 8 8 —

Powered Convenience Outlet 38 38 38 50

Powered Exhaust 40 80 80 80

Roof Curb 61 78 78 89

Smoke Detector, Supply 5 5 5 5

Smoke Detector, Return 7 7 7 7

Stainless Steel Heat Exchanger

Through-the-Base Electrical 8 13 8 13

Through-the-Base Gas(e) 55——

Unit Mounted Circuit Breaker 5 5 5 5

Unit Mounted Disconnect 5 5 5 5

(a) Weights for options not listed are <5 lbs.

(b) Net weight should be added to unit weight when ordering factory-installed accessories.

(c) Applicable to W/DHC 460/575V units.

(d) Applicable to heat pump units only (W*C).

(e) Applicable to dual fuel units only (D*C).

(d)

(c)

(e)

3 to 4 Tons

29 29 — —

15 30 30 40

45——

W/DHC048-060H

Net Weight

4 to 5 Tons

(a),(b)

WSC060H,

WSC072H-120E/H

Net Weight

6 to 10 Tons

W/DHC120H

Net Weight

10 Tons

RT-SVX23M-EN 15

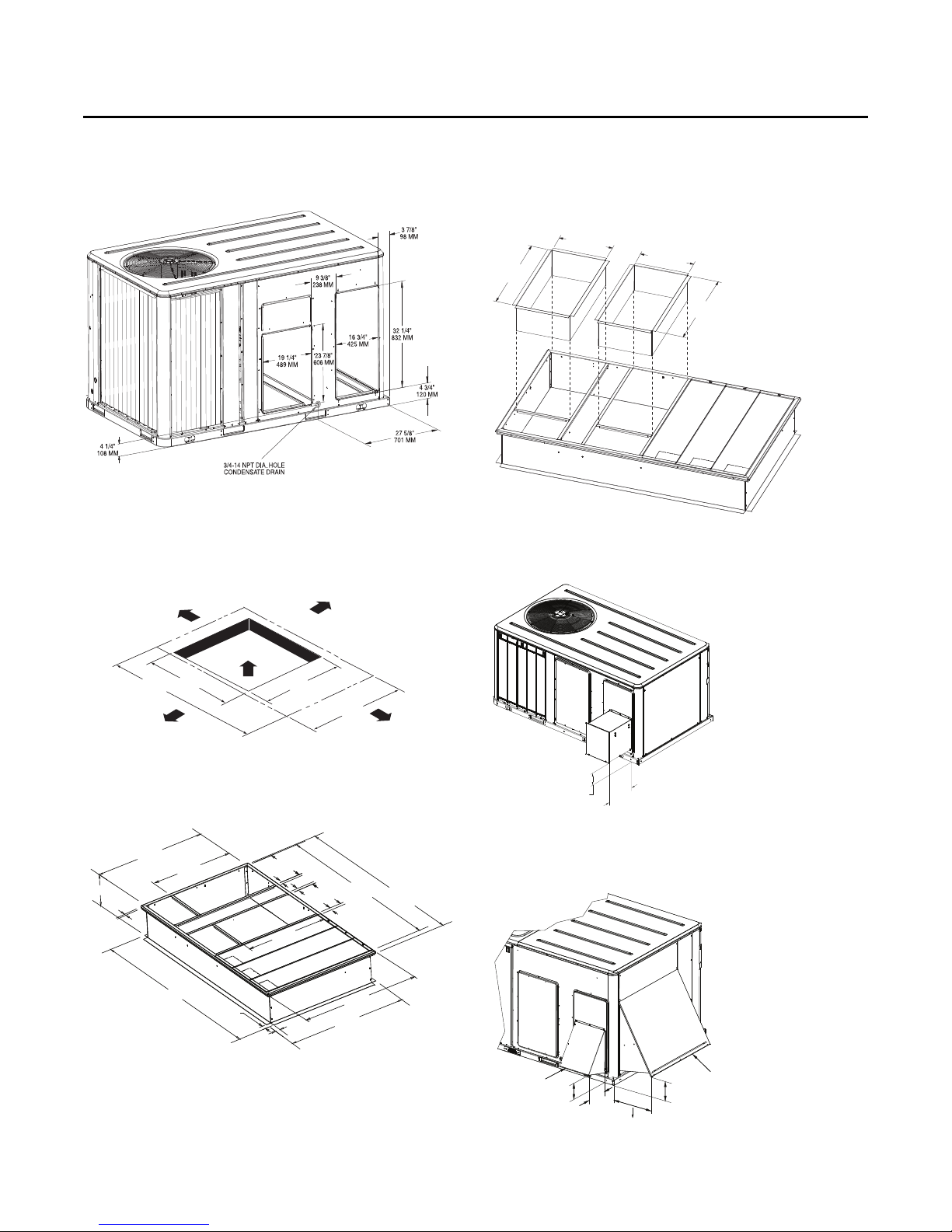

Dimensions and Weights

EVAPORATOR SECTION

ACCESS PANEL

ALTERNATE

CONDENSATE DRAIN

3/4 - 14 NPT DIA. HOLE

1/2 NPT GAS CONNECTION

TOP PANEL

CONDENSER FAN

CONDENSER COIL

UNIT CONTROL WIRE

7/8” (22 MM) DIA. HOLE

SERVICE GAUGE PORT ACCESS

1 3/8” (35 MM) DIA. HOLE

UNIT CONTROL WIRE

2” (51 MM) DIA. HOLE

40 7/8”

1038 MM

4 1/4”

108 MM

69 7/8”

1749 MM

42 1/4”

1073 MM

23 9/16”

598 MM

5 5/8”

143 MM

9 5/8”

244 MM

CONTROL AND COMPRESSOR

ACCESS PANEL

44 1/4”

1124 MM

7 5/8”

194 MM

5 9/16”

141 MM

4 1/4”

108 MM

20 1/4”

514 MM

THROUGH

THE BASE GAS

(Y_C/DHC MODELS ONLY)

THROUGH

THE BASE

ELECTRICAL

SUPPLY

RETURN

TBU CONDENSATE

3 5/8”

92 MM

14”

356 MM

9 1/4”

235 MM

15 1/2”

394 MM

4”

102 MM

24”

610 MM

18”

457 MM

27 9/16”

701 MM

4 3/16”

106 MM

4 9/16”

116 MM

23 1/2”

597 MM

2 13/16”

71 MM

6 1/2”

165 MM

3 11/16”

94 MM

4 7/8”

124 MM

5 1/16”

128 MM

9 15/16”

253 MM

SUPPLY

RETURN

3/4-14 NPT

DRAIN CONNECTION

CONDENSER COIL

17 1/4”

438 MM

8 7/8”

225 MM

13 1/4”

337 MM

23 1/4”

591 MM

3 3/16”

81 MM

14 3/4”

375 MM

4 3/4”

121 MM

CLEARANCE 36” (914 MM)

CLEARANCE 48” (1219 MM)

TYPICAL ROOF OPENING

CLEARANCE 36” (914 MM)

CLEARANCE FROM

TOP OF UNIT 72”

CLEARANCE

HORIZONTAL FLOW - 18” (457 MM)

DOWNFLOW 36” (914 MM)

68 3/16”

1732 MM

40”

1016 MM

37”

940 MM

44 1/2”

1130 MM

7

CLEARANCE 36” (914 MM)

CLEARANCE 36” (914 MM) FOR DOWNFLOW

CLEARANCE 18” (457 MM) FOR HORIZONTAL

CLEARANCE 36” (914 MM)

CLEARANCE 48” (1219 MM)

RETURN

SUPPLY

14”

356 MM

37 7/16”

951 MM

25 3/16”

640 MM

1 3/4”

44 MM

65 13/16”

1670 MM

1 3/4”

44 MM

14 9/16”

370 MM

8 3/8”

213 MM

61 13/16”

1568 MM

65 3/16”

1656 MM

16 3/4”

425 MM

2”

51 MM

2”

51 MM

40 7/8”

1038 MM

41 7/16”

1053 MM

Figure 3. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency

Note: 2” electrical connection: single point power when heat installed

(WSC, W/DHC)

Figure 4. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - downflow airflow supply/

return - through-the-base utilities

Figure 6. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - unit clearance and roof

opening

Figure 7. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - roof curb

Figure 5. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - horizontal airflow supply/

return

16 RT-SVX23M-EN

Figure 8. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - downflow duct

connections - field fabricated

Note: Reference tabular information for duct clearance to combustible

materials in the application consideration chapter.

14 1/16”

24 3/8”

(619 MM)

14”

(356 MM)

(357 MM)

RETURN

16 3/16”

(411 MM)

SUPPLY

17 1/16”

(433 MM)

ALL FLANGES 1 1/4” (32 MM)

Dimensions and Weights

6 15/16”

176 MM

9 1/8”

232 MM

17 7/8”

454 MM

16”

406 MM

22 1/4”

565 MM

Applicable to

Y_C models only

EVAPORATOR SECTION

ACCESS PANEL

ALTERNATE CONDENSATE DRAIN

CONNECTION 3/4 - 14 NPT DIA. HOLE

4 1/4”

108 MM

27 5/8”

701 MM

47 7/8”

1216 MM

88 5/8”

2251 MM

18 1/2”

470 MM

9 5/8”

244 MM

5 5/8”

143 MM

1/2 NPT GAS CONNECTION

[60 MBh, 80 MBh, 100 MBh, 120 MBh,

130 MBh (not applicable to DHC)]

3/4 NPT GAS CONNECTION

(130 MBh (DHC only), 150 MBh, 200 MBh, 250 MBh)

CONTROL AND COMPRESSOR

ACCESS PANEL

4 1/4”

104 MM

5 5/8”

143 MM

7 5/8”

194 MM

53 1/4”

1353 MM

TOP PANEL

CONDENSER FAN

CONDENSER COIL

UNIT CONTROL WIRE

7/8” (22 MM) DIA. HOLE

SERVICE GAUGE PORT ACCESS

1 3/8” (35 MM) DIA. HOLE

UNIT POWER WIRE

1 3/8” (35 MM) DIA. HOLE

3 5/8”

92 MM

17 1/2”

444 MM

4”

102 MM

9 7/8”

251 MM

17 1/2”

444 MM

32 1/8”

816 MM

RETURN

SUPPLY

33”

838 MM

4 1/8”

104 MM

27 5/8”

701 MM

THROUGH THE

BASE CONDENSATE

40 3/4”

1035 MM

THROUGH THE

BASE ELECTRICAL

5 7/8”

149 MM

5”

127 MM

10 7/8”

276 MM

3 3/4”

95 MM

2 3/4”

71 MM

6 1/2”

165 MM

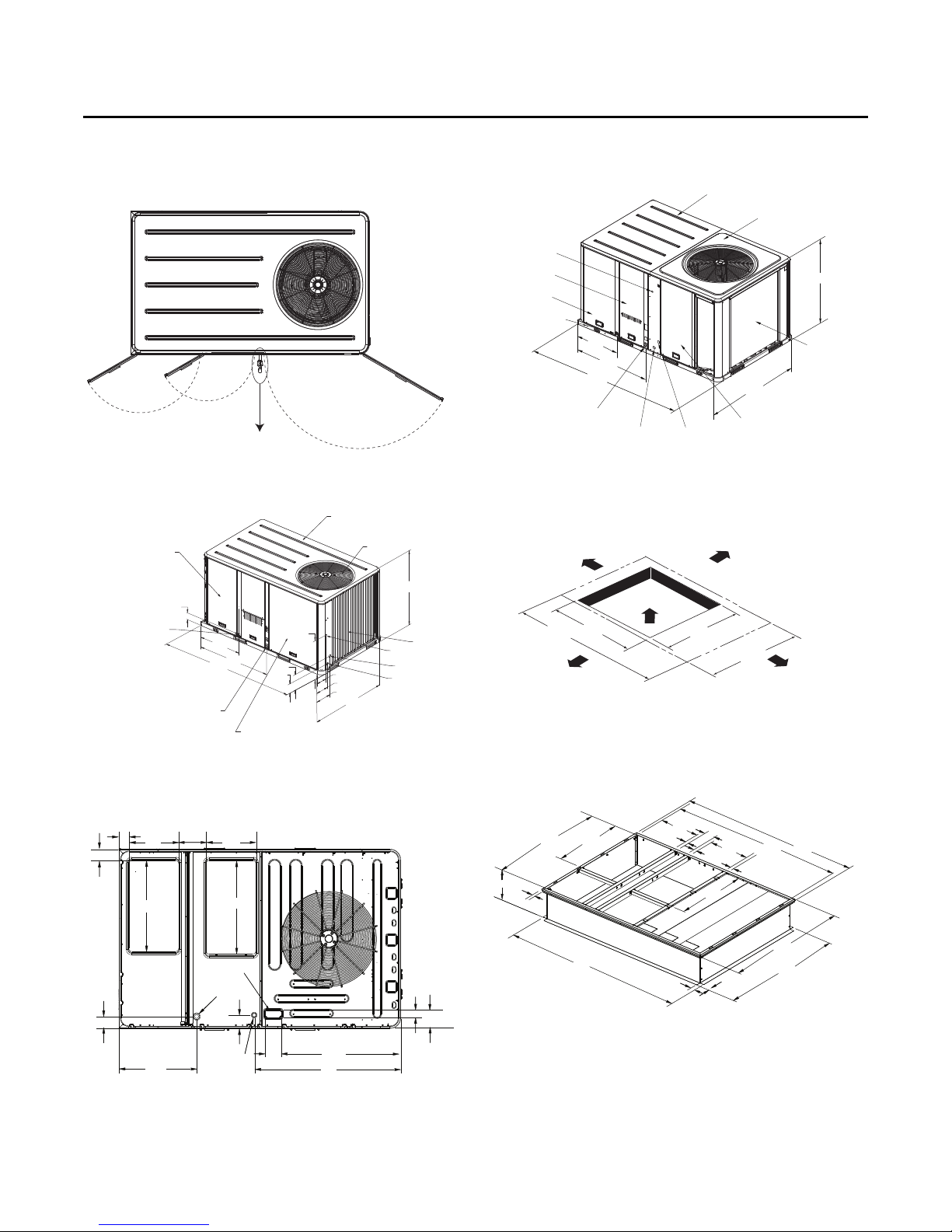

Figure 9. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - economizer, manual or

motorized fresh air damper; power exhaust

16 1/4”

159 MM

6 3/16”

157 MM

12 1/2”

16 1/2”

318 MM

419 MM

Dimensions extends to 16 1/2"/419 MM

when powered exhaust is coupled

with low leak economizer

Figure 10. Heat pump 3 to 4 tons standard efficiency, 3

ton high efficiency - economizer & barometric

relief damper hood

Figure 11. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - swing diameter for

hinged door(s) option

Figure 12. Heat pump - 5 to 10 tons standard efficiency, 4

to 5 ton high efficiency

Note: 2” electrical connection: single point power when heat installed

(WSC, W/DHC)

RT-SVX23M-EN 17

Figure 13. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - downflow airflow

supply/return - through-the-base utilities

Dimensions and Weights

Supply

Return

CLEARANCE 36” (914 MM)

CLEARANCE FROM

TOP OF UNIT 72”

TYPICAL ROOF OPENING

CLEARANCE 48” (1219 MM)

CLEARANCE 36” (914 MM)

CLEARANCE

HORIZONTAL FLOW - 18” (457 MM)

DOWNFLOW - 36” (914 MM)

53 1/4”

1352 MM

46”

1168 MM

46”

1168 MM

88 5/8”

2251 MM

CLEARANCE 36” (914 MM)

CLEARANCE 36” (914 MM)

CLEARANCE 48” (1219 MM)

CLEARANCE 36” (914 MM) FOR DOWNFLOW

CLEARANCE 18” (457 MM) FOR HORIZONTAL

46 3/8”

1178 MM

1 3/4”

44 MM

46 3/8”

1178 MM

34 3/8”

873 MM

84 1/2”

2146 MM

2”

51 MM

34 3/8”

873 MM

1”

25 MM

49 7/8”

1267 MM

50 3/8”

1280 MM

2”

51 MM

83 7/8”

2130 MM

80 1/2”

2045 MM

18 1/2”

470 MM

1”

25 MM

6 5/8”

168 MM

18 1/4”

470 MM

1”

25 MM

RETURN

SUPPLY

BAROMETRIC RELIEF HOOD

ECONOMIZER HOOD

Dimensions extends to 21 5/8"/549 MM

when powered exhaust is coupled

with low leak economizer

7 3/4”

198 MM

12”

304 MM

16 3/4”

425 MM

6 7/8”

175 MM

Figure 14. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - horizontal airflow

supply and return

Figure 15. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - unit clearance and

roof opening

Figure 17. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - downflow duct

connections field fabricated

Note: Reference tabular information for duct clearance to combustible

materials in the Installation chapter.

17 3/4”

33 3/4”

857 MM

451MM

17 3/4”

451MM

33 3/4”

857 MM

ALL FLANGES 1 1/4" (31 MM)

RETURN

SUPPLY

Figure 18. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - power exhaust

Figure 16. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - roof curb

18 RT-SVX23M-EN

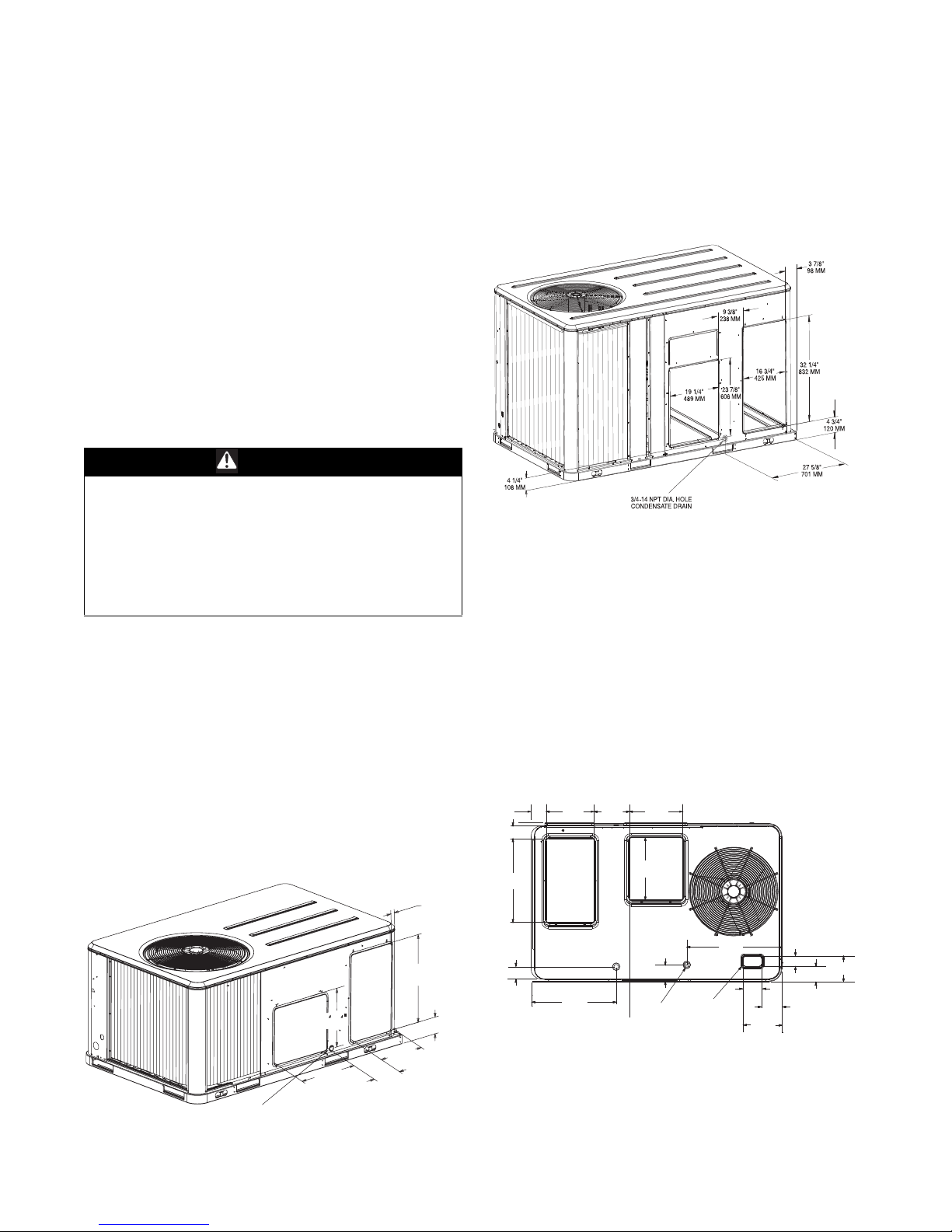

6 11/16”

16 1/2”

170 MM

419 MM

Figure 19. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - economizer, manual

or motorized fresh air damper

BAROMETRIC RELIEF HOOD

7 3/4”

198 MM

12”

16 3/4”

304 MM

425 MM

Dimensions extends to 21 5/8"/549 MM

when powered exhaust is coupled

with low leak economizer

6 7/8”

175 MM

ECONOMIZER HOOD

Dimensions and Weights

21 3/8”

543 MM

17”

432 MM

34 5/8”

879 MM

Applicable to

Y_C/DHC models only

1/2 NPT GAS CONNECTION

(80 mbh, 120 mbh)

3/4 NPT GAS CONNECTION

(150 mbh, 200 mbh, 250 mbh)

(YC MODELS)

EVAPORATOR SECTION

ACCESS PANEL

ALTERNATE CONDENSATE DRAIN

CONNECTION 3/4 - 14 NPT DIA. HOLE

4 1/4”

108 MM

27 5/8”

701 MM

88 5/8”

2251 MM

47 7/8”

1216 MM

24 1/2”

622 MM

9 5/8”

244 MM

5 5/8”

143 MM

4 1/4”

108 MM

5 5/8”

143 MM

7 5/8”

194 MM

53 1/4”

1353 MM

CONDENSER COIL

UNIT CONTROL WIRE

7/8” (22 MM) DIA. HOLE

SERVICE GAUGE PORT ACCESS

1 3/8” (35 MM) DIA. HOLE

UNIT CONTROL WIRE

1 3/8” (35 MM) DIA. HOLE

46 7/8”

1190 MM

CONDENSER FAN

TOP PANEL

CONTROL AND COMPRESSOR

ACCESS PANEL

RETURNRETURN

SUPPLYSUPPLY

3 5/8”3 5/8”

92 MM92 MM

17 1/2”17 1/2”

444 MM444 MM

9 7/8”9 7/8”

251 MM251 MM

17 1/2”17 1/2”

444 MM444 MM

32 1/8”32 1/8”

816 MM816 MM

33”33”

838 MM838 MM

4”4”

102 MM102 MM

THROUGH THE THROUGH THE

BASE ELECTRICALBASE ELECTRICAL

THROUGH THE THROUGH THE

BASE CONDENSATEBASE CONDENSATE

4 5/8”4 5/8”

119 MM119 MM

THROUGH THETHROUGH THE

BASE GASBASE GAS

5 7/8”5 7/8”

149 MM149 MM

27 5/8”27 5/8”

701 MM701 MM

42 3/16”42 3/16”

1072 MM1072 MM

6 3/8”6 3/8”

163 MM163 MM

2 3/4”2 3/4”

71 MM71 MM

51 3/16”51 3/16”

1316 MM1316 MM

4 1/8”4 1/8”

104 MM104 MM

UNIT CONTROL WIRE

7/8” (22 MM) DIA. HOLE

CONTROL BOX SECTION

ACCESS PANEL

EVAPORATOR SECTION

ACCESS PANEL

ALTERNATE CONDENSATE DRAIN

CONNECTION 3/4 - 14 NPT DIA. HOLE

1/2 NPT GAS CONNECTION

(120 MBh)

3/4 NPT GAS CONNECTION

(150 MBh, 200 MBh, 250 MBh)

27 5/8”

701 MM

47 7/8”

1216 MM

99 11/16”

2532 MM

63 3/16”

1605 MM

50 7/8”

1292 MM

UNIT POWER WIRE

1 3/8” (35 MM) DIA. HOLE

SERVICE GAUGE

PORT ACCESS

1 3/8” (35 MM) DIA. HOLE

COMPRESSOR ACCESS PANEL

CONDENSER COIL

OUTDOOR TOP PANEL

INDOOR TOP PANEL

CLEARANCE 36” (914 MM)

CLEARANCE

HORIZONTAL FLOW - 18” (457 MM)

DOWNFLOW 36” (914 MM)

TYPICAL ROOF OPENING

CLEARANCE 36” (914 MM)

CLEARANCE 48” (1219 MM)

CLEARANCE FROM

TOP OF UNIT 72”

63 3/16”

1605 MM

46”

1168 MM

46”

1168 MM

99 11/16”

2532 MM

56 3/8”

1432 MM

14”

356 MM

1 3/4”

44 MM

34 3/8”

873 MM

18 1/2”

470 MM

1”

25 MM

6 5/8”

168 MM

1”

25 MM

18 1/2”

470 MM

1”

25 MM

80 1/2”

2045 MM

83 7/8”

2130 MM

CLEARANCE 36” (914 MM) FOR DOWNFLOW

CLEARANCE 18” (457 MM) FOR HORIZONTAL

34 3/8”

873 MM

59 7/8”

1521 MM

60 3/8”

1534 MM

2”

51 MM

2”

51 MM

84 1/2”

2146 MM

Figure 20. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - swing diameter for

hinged door(s) option

Figure 21. Heat pump - 7.5 to 10 tons standard efficiency

Figure 23. Heat pump - 10 tons high efficiency

Note: 2" Electrical Connection: Single Point Power When Heat Installed.

Figure 24. Heat pump - 10 tons high efficiency - unit

clearance and roof opening

Figure 22. Heat pump - 10 tons high efficiency -

downflow airflow supply/return through-thebase utilities

RT-SVX23M-EN 19

Figure 25. Heat pump - 10 tons high efficiency - roof curb

Note: 2" Electrical Connection: Single Point Power When Heat Installed

18 1/2”

470 MM

1”

25 MM

2”

51 MM

356 MM

56 3/8”

34 3/8”

1432 MM

873 MM

14”

1 3/4”

44 MM

84 1/2”

2146 MM

6 5/8”

168 MM

1”

25 MM

34 3/8”

873 MM

2”

51 MM

CLEARANCE 36” (914 MM) FOR DOWNFLOW

CLEARANCE 18” (457 MM) FOR HORIZONTAL

80 1/2”

18 1/2”

2045 MM

470 MM

1”

25 MM

59 7/8”

1521 MM

60 3/8”

1534 MM

83 7/8”

2130 MM

Installation

SUPPLY

RETURN

3/4-14 NPT

DRAIN CONNECTION

CONDENSER COIL

17 1/4”

438 MM

8 7/8”

225 MM

13 1/4”

337 MM

23 1/4”

591 MM

3 3/16”

81 MM

14 3/4”

375 MM

4 3/4”

121 MM

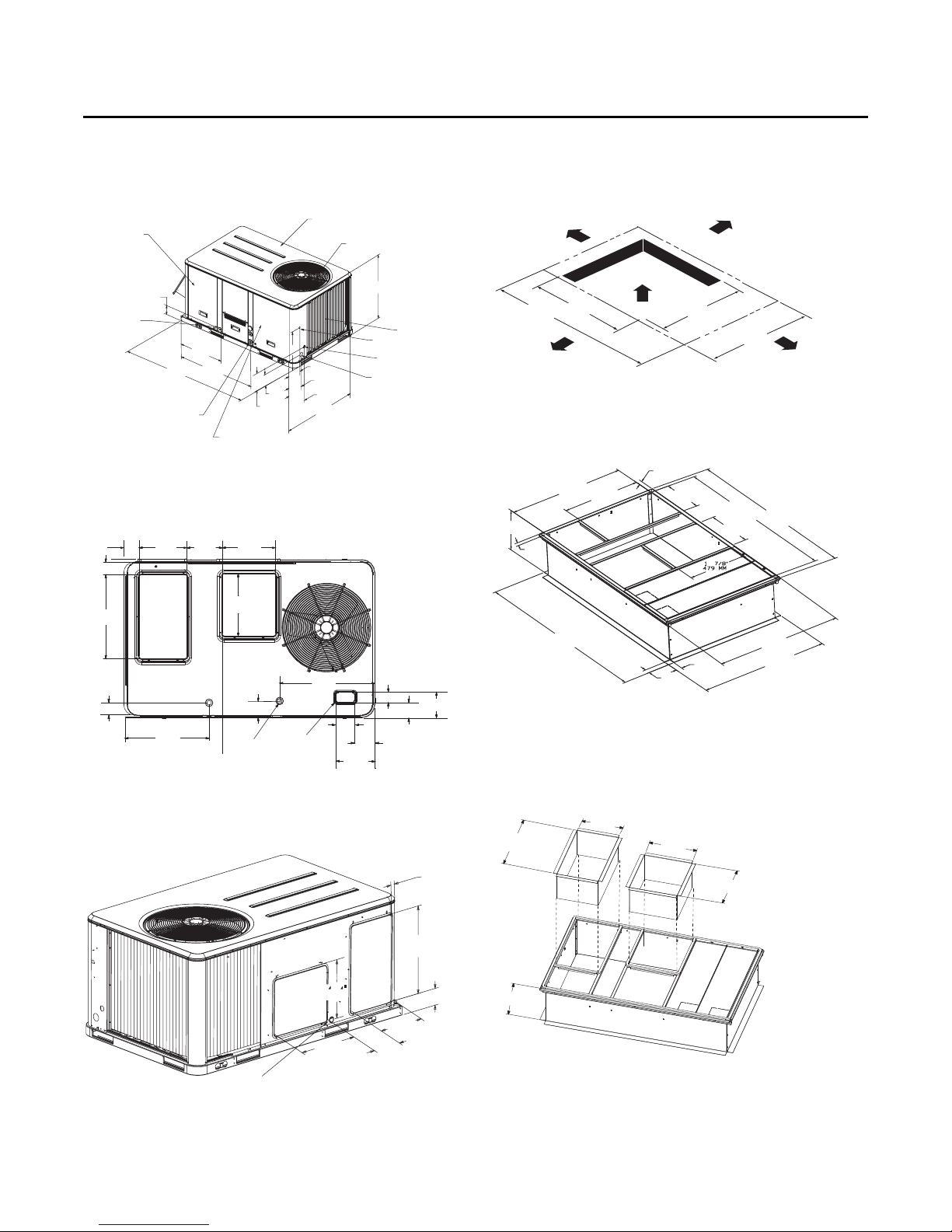

Foundation

Horizontal Units

If the unit is installed at ground level, elevate it above the

snow line. Provide concrete footings at each support

location with a “full perimeter” support structure or a slab

foundation for support. For the unit’s operating and point

loading weights when constructing a footing foundation,

refer to the maximum unit/corner weights table in the

weights section of this manual.

If anchoring is required, anchor the unit to the slab using

hold down bolts or isolators. Isolators should be installed

to minimize the transmission of vibrations into the

building.

WARNING

Risk of Roof Collapsing!

Failure to ensure proper structural roof support could

cause the roof to collapse, which could result in death

or serious injury and property damage. Confirm with a

structural engineer that the roof structure is strong

enough to support the combined weight of the

roofcurb and the unit. Refer to the weights section for

typical unit and curb weights.

For rooftop applications, ensure the roof is strong enough

to support the combined unit and support structural

weight. If anchoring is required, anchor the unit to the roof

with hold-down bolts or isolators.

Check with a roofing contractor for proper waterproofing

procedures.

Ductwork

Supply and return air openings as viewed from the rear of

the unit are shown in the following drawings.

Figure 26. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - horizontal airflow supply/

return

Figure 27. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - horizontal airflow

supply and return

Return

Supply

Supply and return air openings as viewed from a

downflow configuration to 5 are shown in the following

drawings.

Elbows with turning vanes or splitters are recommended

to minimize air noise due to turbulence and to reduce static

pressure.

When attaching the ductwork to the unit, provide a watertight flexible connector at the unit to prevent operating

sounds from transmitting through the ductwork.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

Figure 28. Heat pump - 3 to 4 tons standard efficiency, 3

ton high efficiency - downflow airflow supply/

return - through-the-base utilities

3 5/8”

92 MM

102 MM

610 MM

24”

4”

RETURN

14”

356 MM

9 1/4”

235 MM

15 1/2”

394 MM

18”

457 MM

SUPPLY

20 RT-SVX23M-EN

4 3/16”

106 MM

TBU CONDENSATE

23 1/2”

597 MM

4 9/16”

116 MM

THROUGH

THE BASE GAS

(Y_C/DHC MODELS ONLY)

ELECTRICAL

27 9/16”

701 MM

THROUGH

THE BASE

4 7/8”

124 MM

9 15/16”

253 MM

5 1/16”

128 MM

2 13/16”

71 MM

3 11/16”

94 MM

6 1/2”

165 MM

Installation

3 5/8”

92 MM

17 1/2”

444 MM

4”

102 MM

9 7/8”

251 MM

17 1/2”

444 MM

32 1/8”

816 MM

RETURN

SUPPLY

33”

838 MM

4 1/8”

104 MM

27 5/8”

701 MM

THROUGH THE

BASE CONDENSATE

40 3/4”

1035 MM

THROUGH THE

BASE ELECTRICAL

5 7/8”

149 MM

5”

127 MM

10 7/8”

276 MM

3 3/4”

95 MM

2 3/4”

71 MM

6 1/2”

165 MM

RETURNRETURN

SUPPLYSUPPLY

3 5/8”3 5/8”

92 MM92 MM

17 1/2”17 1/2”

444 MM444 MM

9 7/8”9 7/8”

251 MM251 MM

17 1/2”17 1/2”

444 MM444 MM

32 1/8”32 1/8”

816 MM816 MM

33”33”

838 MM838 MM

4”4”

102 MM102 MM

THROUGH THE THROUGH THE

BASE ELECTRICALBASE ELECTRICAL

THROUGH THE THROUGH THE

BASE CONDENSATEBASE CONDENSATE

4 5/8”4 5/8”

119 MM119 MM

THROUGH THETHROUGH THE

BASE GASBASE GAS

5 7/8”5 7/8”

149 MM149 MM

27 5/8”27 5/8”

701 MM701 MM

42 3/16”42 3/16”

1072 MM1072 MM

6 3/8”6 3/8”

163 MM163 MM

2 3/4”2 3/4”

71 MM71 MM

51 3/16”51 3/16”

1316 MM1316 MM

4 1/8”4 1/8”

104 MM104 MM

Base Alignment Bracket

Figure 29. Heat pumps - 5 to 10 tons standard efficiency,

4 to 5 ton high efficiency - downflow airflow

supply/return - through-the-base utilities

Figure 30. Heat pump - 10 tons high efficiency -

downflow airflow supply/return through-thebase utilities

Roof Curb

The roof curbs for these units consists of a "full perimeter"

enclosure to support the unit just inside of the unit base

rail. The WSC120E, W/DHC120H unit contains a support

base alignment rail and will extend past the end of the roof

curb as shown in figures below.

Before installing any roof curb, verify;

• It is the correct curb for the unit,

• The necessary gaskets and hardware are included,

• The purposed installation location provides the

required clearance for proper operation.

• Insure that the curb is level and square. The top surface

RT-SVX23M-EN 21

of the curb must be true to assure an adequate curb-tounit seal.

WARNING

Combustible Materials!

Failure to maintain proper clearance between the unit

heat exchanger, vent surfaces and combustible

materials could cause a fire which could result in death

or serious injury or property damage. Refer to unit

nameplate and installation instructions for proper

clearances.

Verify that appropriate materials were used in the

construction of roof and ductwork. Combustible materials

should not be used in the construction of ductwork or roof

curb that is in close proximity to heater elements or any

hot surface. Any combustible material on the inside of the

unit base should be removed and replaced with

appropriate material.

Step-by-step curb assembly and installation instructions

ship with each accessory roof curb kit. Follow the

instructions carefully to assure proper fit-up when the unit

is set into place.

Note: To assure proper condensate flow during

operation, as well as proper operation of the

condensate overflow switch (if equipped), the unit

and curb must be level.

If the unit is elevated, a field constructed catwalk around

the unit is strongly recommended to provide easy access

for unit maintenance and service.

Recommendations for installing the Supply Air and Return

Air ductwork joining the roof curb are included in the curb

instruction booklet. Curb ductwork must be fabricated and

installed by the installing contractor before the unit is set

into place.

Note: For sound consideration, cut only the holes in the

roof deck for the ductwork penetrations. Do not cut

out the entire roof deck within the curb perimeter.

Figure 31. View for base to roof curb alignment

WSC120E, W/DHC120H on 50 x 84 roof curb

Loading...

Loading...