Page 1

VSD Output Monitoring

The VSD output monitoring kits (for variable speed inverter drive units) are designed to

provide a speed (output) feedback signal to the control and monitoring system.

This feature enables the management system to optimize efficiency by accurately monitoring

the performance and behavior of a variable speed drive compressor unit.

Specification:

Variable Speed Drive AC Inverter type (not suitable for DC or SR drives)

Drive Frequency Range 3Hz to 400Hz

Drive Operating Voltage 200Vac to 575Vac

Compressor Motor Size 7.5kW to 500kW

The VSD output monitoring kit can be fitted to an X - Series Automation CX or VSD Box.

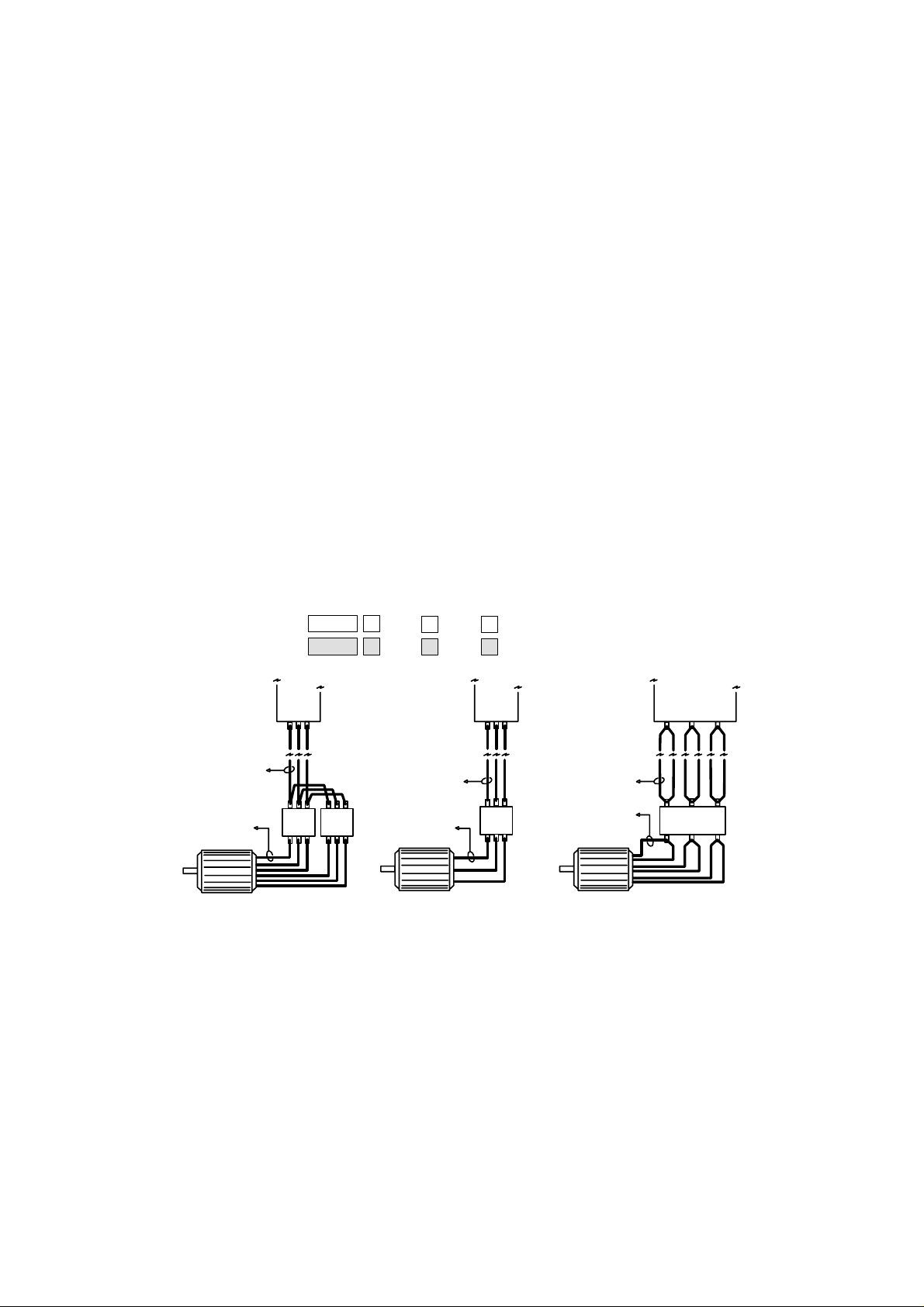

Kit Selection

There are two kits available; each kit is designed to cover a different current range.

To establish the correct kit for an application:

1) Determine the compressor motor kW rating (establish from motor data plate)

2) Determine the motor operating voltage (establish from motor data plate)

3) Check the intended positioning of the kit current sensor and establish if the sensor

will be detecting ‘Half Direct’, ‘Direct’ or ‘Delta Loop’ motor current.

4) Use the kit selection table below to determine the appropriate kit (1 or 2) and sensor

connection 1, 2 or 3.

CCN: 39266150

CCN: 39266143

Kit 1

Kit 2

Drive

Unit

A

A

25A

200A

B

B

50A

400A

C

C

Drive

Unit

100A

600A

Drive

Unit

Direct

Delta

Loop

MD

Direct

Direct

M

Half

*

Direct

Half

*

Direct

M

* If the sensor position is ‘Half Direct’ (each of the three motor phase connections has two

wires, and the sensor is placed on one of the two wires) divide the motor kW rating in half

before making a ‘Direct’ kit/connection selection. Select the kit for the ‘half’ kW rating – use

the nearest kW rating if the ‘half’ rating does not result in an exact match.

Page 2

For example: if the motor is 185kW @ 400V (185kW divided by 2 = 92.5kW; use ‘Direct’

90kW @ 400V), select Kit 2, Connection B.

Kit Selection Table

Motor

kW 200V 380V 575V 200V 380V 575V

HP

Direct Delta Loop

250V 460V 250V 460V

Example:

Motor Size 55kW

Voltage 400V

7.5 1B 1A 1A 1A 1A 1A

10

11 1B 1B 1A 1B 1A 1A

15

15 1C 1B 1B 1B 1A 1A

20

18.5 1C 1B 1B 1B 1B 1A

25

22 2A 1C 1B 1C 1B 1A

30

30 2A 1C 1C 1C 1B 1B

40

37 2A 2A 1C 2A 1C 1B

50

45 2B 2A 1C 2A 1C 1B

60

55 2B 2A 2A 2A 1C 1C

75

75 2B 2B 2A 2B 1C 1C

100

90 2C 2B 2A 2B 2A 1C

125

110 2C 2B 2B 2B 2A 2A

150

132 2C 2B 2B 2B 2A 2A

180

165 2C 2C 2B 2C 2B 2A

220

185 2C 2B 2C 2B 2B

250

200 2C 2C 2C 2B 2B

270

250 2C 2C 2C 2B 2B

340

300 2C 2C 2C 2C 2B

400

400 2C 2C 2C

540

500 2C 2C 2C

680

Motor FLC 102A

Sensor Position

Kit

Connection

Direct

2

A

A

1

231

2

34

2

The current sensor is used to detect frequency only; accuracy of current reading is

unimportant. Sensor selection and sensor connection is dependent on the nominal running

current at maximum motor speed. The maximum motor speed current should be

approximately 50% (+-20%) of the current sensor connection rating and the motor minimum

speed current should be no less than 10% the of the current sensor connection rating. The

sensor and frequency detection module are designed to accept motor starting peak current

levels without malfunction or damage.

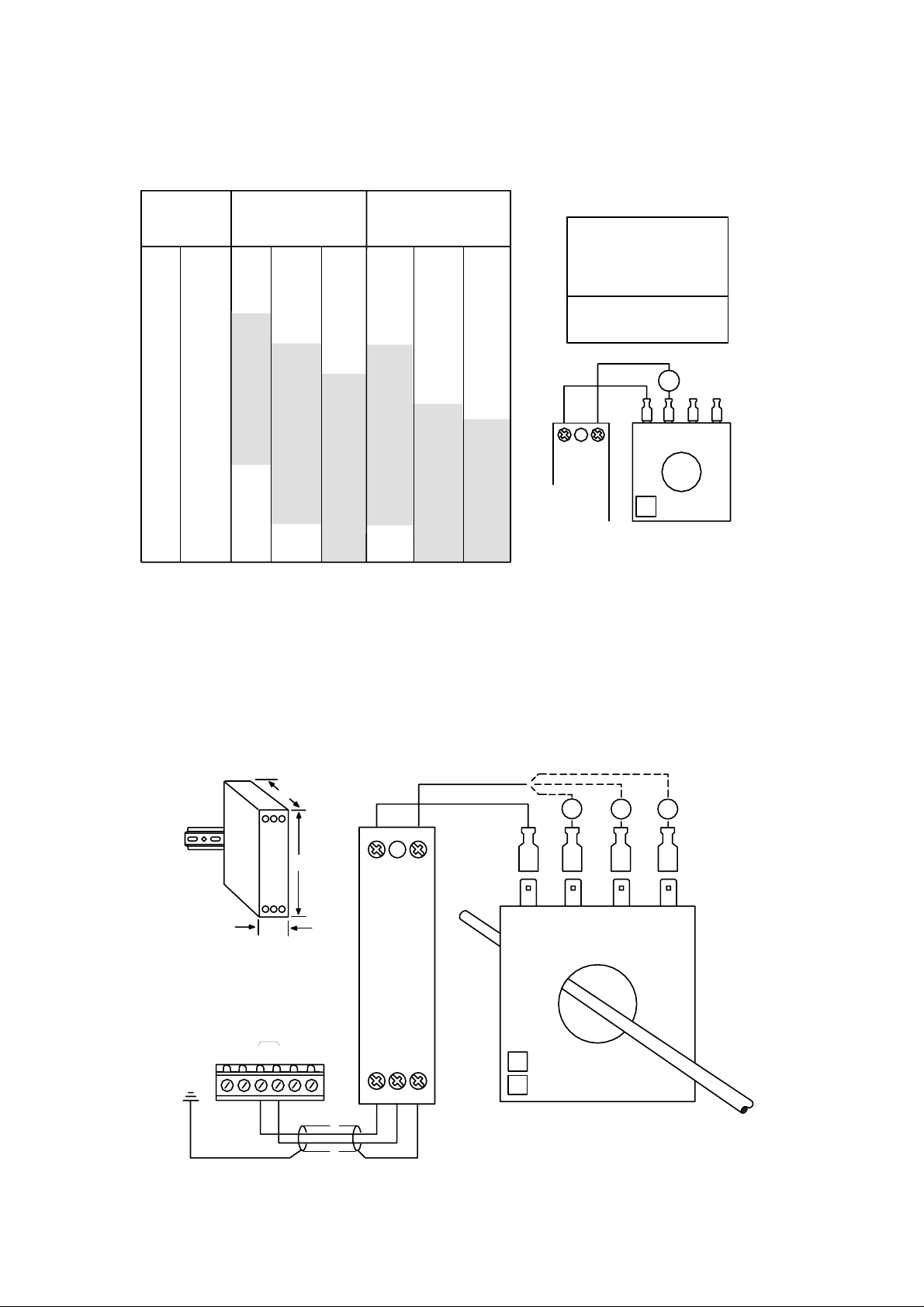

Installation

35mm

DIN Rail

Mount

VSD Box

X05

182217

+20Vdc

20mm

C

D

V

4

2

+

192120

75mm

80mm

l

a

n

ig

S

d

e

e

p

S

signal

231

Frequency

Detect

Module

564

A

12 3 4

Current

Sensor

1

25A/50A/100A

200A/400A/600A

2

B

C

Page 3

1) Ensure power to the compressor and driv e unit is switched off and securely isolated.

2) Mount the ‘Frequency Detect Module’ within the compressor starter or control panel area.

3) Mount the ‘Current Sensor’ on to one of the three phase power supply cables of the main

drive motor, it is not important which cable is selected. Ensure the current sensor is

secured and is not positioned near to, or is able to come into contact with, exposed high

voltage terminals.

4) Connect the Current Sensor to the Frequency Detect Module using single core 1.0mm³ to

1.5mm³ cable with a suitable insulation rating. Use the kit selection table to determine the

correct connections to the current sensor dependant on motor kW rating, operating voltage

and sensor positioning.

WARNING: VERY HIGH VOLTAGE POTENTIAL

Never apply power to the compressor motor with the current sensor terminals

unconnected. Always protect unused terminals with spare connectors or

insulation material.

The frequency detect module derives operating power from the CX or VSD connection; there

is no requirement to provide a separate power supply.

Harmonic and Drive Switching Frequency Interference

For variable frequency/speed (VSD, VFD) drives that are not fitted with motor side chocks

and/or electrical filtration devices the current sensor may be subject to harmonics and/or

switching frequencies. This can result in the sensor detecting and re porting frequencies much

higher than the fundamental drive frequency. For example; if the variable frequency drive is

providing 60Hz for maximum speed (100%) and 30Hz for minimum speed (50 % ) the reported

frequency may be 180Hz at 100%; three times the intended maximum fundamental

frequency. This value is typical of high harmonic frequencies being present on the motor

phase wires. In other instances the detected and reported frequency may be much high than

expected and the frequency reading erratic and non-consistent. This is typical of high drive

switching frequency interference being present on the motor phase wires.

To overcome this:

1) The sensor should be located as far away from the drive unit as possible; near as

possible to the motor.

2) Select the next higher current sensor rating/connection. For example, if the

rating/connection is 2A, use 2B instead; this will reduce the level of

harmonic/switching frequency pick-up. Note: If the current sensor rating/connection is

1C, then kit 2 will be required and rating/connection 2A used.

3) Fit ‘chocks’ to each of the drive unit motor phase outputs and locate the sensor

downstream of the phase ‘chock’ device.

4) Fit high interference frequency filter to the drive phase outputs and locate the sensor

downstream of the filter device.

Loading...

Loading...