Ingersoll-Rand twe065e13fa1 Installation, Operation And Maintenance Manual

Installation, Operation,

and Maintenance

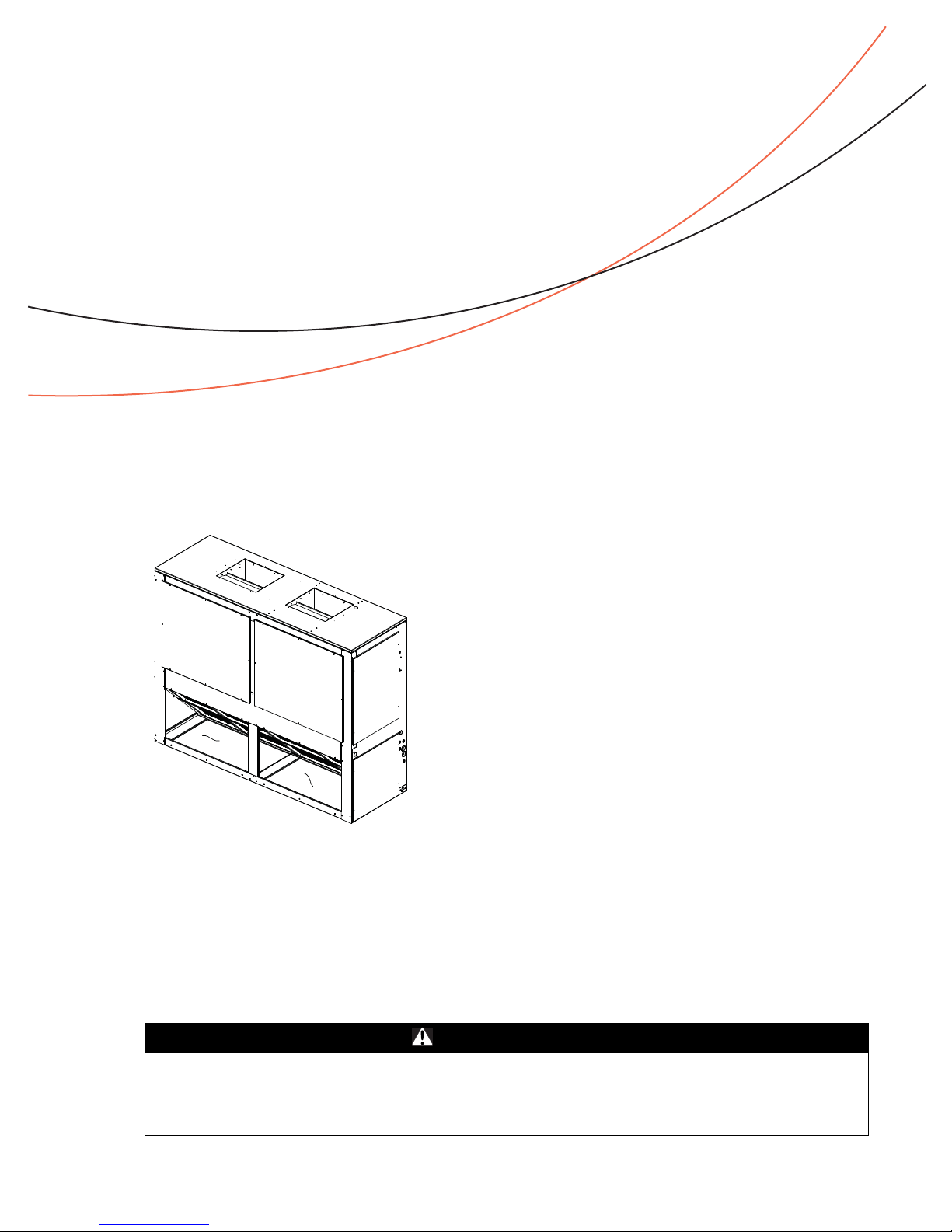

Split System Air Handlers

5-20 Tons

Model (60 Hz) Model (50 Hz)

TWE061D/E***A TWE051D***A

TWE090D/E***A TWE076D***A

TWE120D/E***A TWE101D/E***A

TWE150E***A TWE126E***A

TWE180E***A TWE156E***A

TWE240E***A TWE201E***A

Only qualified personnel should install and service the equipment. The installation, starting up, and

servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific

knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could

result in death or serious injury. When working on the equipment, observe all precautions in the literature

and on the tags, stickers, and labels that are attached to the equipment.

January 2012 SSA-SVX06B-EN

SAFETY WARNING

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings, cautions and notices appear at

appropriate intervals throughout this manual. Warnings are provide to alert installing contractors

to potential hazards that could result in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in personal injury, while notices indicate a

situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance

of these precautions.

Read this manual thoroughly before operating or servicing this unit.

ATTENTION: Warnings, Cautions and Notices appear at appropriate sections throughout this

literature. Read these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It could also be used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only

accidents

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the earth’s naturally

occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the

identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine

and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all

refrigerants containing these compounds have the same potential impact to the environment.

Trane advocates the responsible handling of all refrigerants-including industry replacements for

CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must be

certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these

service procedures. In addition, some states or municipalities may have additional requirements

that must also be adhered to for responsible management of refrigerants. Know the applicable

laws and follow them.

Important: DO NOT release refrigerant to the atmosphere! If adding or removing refrigerant is

required, the service technician must comply with all federal, state, and local laws.

Important: One copy of this document ships inside the control panel of each unit and is

customer property. It must be retained by the unit’s maintenance personnel.

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

© 2012 Trane All rights reserved SSA-SVX06B-EN

WARNI NG

Warnings, Cautions and Notices

WARNI NG

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical

hazards.

• Before installing/servicing this unit, technicians MUST put on all Personal Protective

Equipment (PPE) recommended for the work being undertaken. ALWAYS refer to appropriate

MSDS sheets and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS

sheets and OSHA guidelines for information on allowable personal exposure levels, proper

respiratory protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put on all Personal Protective Equipment

(PPE) in accordance with NFPA 70E or other country-specific requirements for arc flash

protection, PRIOR to servicing the unit.

Failure to follow recommendations could result in death or serious injury.

WARNING

Refrigerant under High Pressure!

System contains oil and refrigerant under high pressure. Recover refrigerant to relieve pressure

before opening the system. See unit nameplate for refrigerant type. Do not use non-approved

refrigerants, refrigerant substitutes, or refrigerant additives. Failure to recover refrigerant to

relieve pressure or the use of non-approved refrigerants, refrigerant substitutes, or refrigerant

additives could result in an explosion which could result in death or serious injury or

equipment damage.

WARNING

R-410A Refrigerant under Higher Pressure than R-22!

The units described in this manual use R-410A refrigerant which operates at higher pressures

than R-22 refrigerant. Use ONLY R-410A rated service equipment or components with these

units. For specific handling concerns with R-410A, please contact your local Trane

representative.

Failure to use R-410A rated service equipment or components could result in equipment

exploding under R-410A high pressures which could result in death, serious injury, or

equipment damage.

This booklet describes proper installation, operation, and maintenance procedures for air cooled

systems. By carefully reviewing the information within this manual and following the instructions,

the risk of improper operation and/or component damage will be minimized. It is important that

periodic maintenance be performed to help assure trouble free operation. Should equipment

failure occur, contact a qualified service organization with qualified, experienced HVAC technicians

to properly diagnose and repair this equipment.

Important: All phases of this installation must comply with the NATIONAL, STATE & LOCAL

CODES. In addition to local codes, the installation must conform with National

Electric Code -ANSI/NFPA NO. 70 LATEST REVISION.

Any individual installing, maintaining, or servicing this equipment must be properly trained,

licensed and qualified.

Important: Do not remove the VFD without first contacting technical support! For performance

-related questions and diagnostic support in North America call 1-877-872-6363. Any

return requires a claim number FIRST. Removal of the VFD prior to this step will void

the unit’s warranties.

SSA-SVX06B-EN 3

Table of Contents

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Data - Standard, SZVAV and 2-Speed VFD . . . . . . . . . . . . . . . . . . . . . . 23

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Initial Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Lifting Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Repositioning Drain Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Field Conversion to 460 Volt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installations, Limitations and Recommendations . . . . . . . . . . . . . . . . . . 13

Horizontal Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Condensate Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Duct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Air Flow Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Thermostat and Control Connections for Electromechanical Controls . 45

Thermostat and Control Connections for ReliaTel™ Controls . . . . . . . . 46

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4 SSA-SVX06B-EN

Variable Air Volume Applications (SZVAV) . . . . . . . . . . . . . . . . . . . . . . . . 48

2 Speed VFD Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fan Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Annually (Cooling Season) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Precautionary Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

First Aid Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Central Air Conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Commercial Equipment Rated 20 Tons and Larger and Related Accessories

(Parts Only)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Wiring Diagram Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

SSA-SVX06B-EN 5

Model Number Description

T W E 2 4 0 E 3 0 0 ** *

1 2 3 4 5 6 7 8 9 10 11 12

Model Number Description

All products are identified by a multiple-character model number that precisely identifies a particular type of

unit. An explanation of the alphanumeric identification code is provided. Its use will enable the owner/

operator, installing contractors, and service engineers to define the operation, specific components, and

other options for any specific unit.

Note: When ordering replacement parts or requesting service, be sure to refer to the specific model number,

serial number, and DL number (if applicable) stamped on the unit nameplate.

DIGITS 1 - 3: Product Type

TWE = Split System Heat Pump/Cooling Air Handler

DIGITS 4 - 6: Nominal Gross Cooling Capacity (MBh)

061 = 5 Tons (60 Hz) 051 = 4.6 Tons (50 Hz)

090 = 7½ Tons (60 Hz) 076 = 6.25 Tons (50 Hz)

120 = 10 Tons (60 Hz) 101 = 8.33 Tons (50 Hz)

150 = 12½ Tons (60 Hz) 126 = 10.4 Tons (50 Hz)

180 = 15 Tons (60 Hz) 156 = 13 Tons (50 Hz)

240 = 20 Tons (60 Hz) 201 = 16.7 Tons (50 Hz)

DIGIT 7: Major Development Sequence

D = Single Circuit

E = Dual Circuit

DIGIT 8: Electrical Characteristics

1 = 208-230/60/1 W = 575/60/3

3 = 208-230/60/3 D = 380-415/50/3

4 = 460/60/3 K = 380/60/3

DIGITS 9 - 10: Factory Installed Options

00 = Packed Stock (Standard)

03 = 2-speed Variable Frequency Drive (VFD) Standard Motor Electromechanical Condenser only

04 = 2-speed Variable Frequency Drive (VFD) Oversized Motor Electromechanical Condenser only

R3 = Single Zone Variable Air Volume (VFD) Standard Motor - Reliatel Cond only

R4 = Single Zone Variable Air Volume (VFD) Oversized Motor - Reliatel Cond only

DIGITS 11: Minor Design Sequence

* = Current Design Sequence

1

DIGITS 12: Service Digit

* = Current Design Sequence1

1

* = sequential alpha character

6 SSA-SVX06B-EN

General Information

Installation procedures should be performed in the sequence that they appear in this manual. Do

not destroy or remove the manual from the unit. The manual should remain weather-protected with

the unit until all installation procedures are complete.

Note: It is not the intention of this manual to cover all possible variations in systems that may

occur or to provide comprehensive information concerning every possible contingency that

may be encountered during an installation. If additional information is required or if specific

problems arise that are not fully discussed in this manual, contact your local sales office.

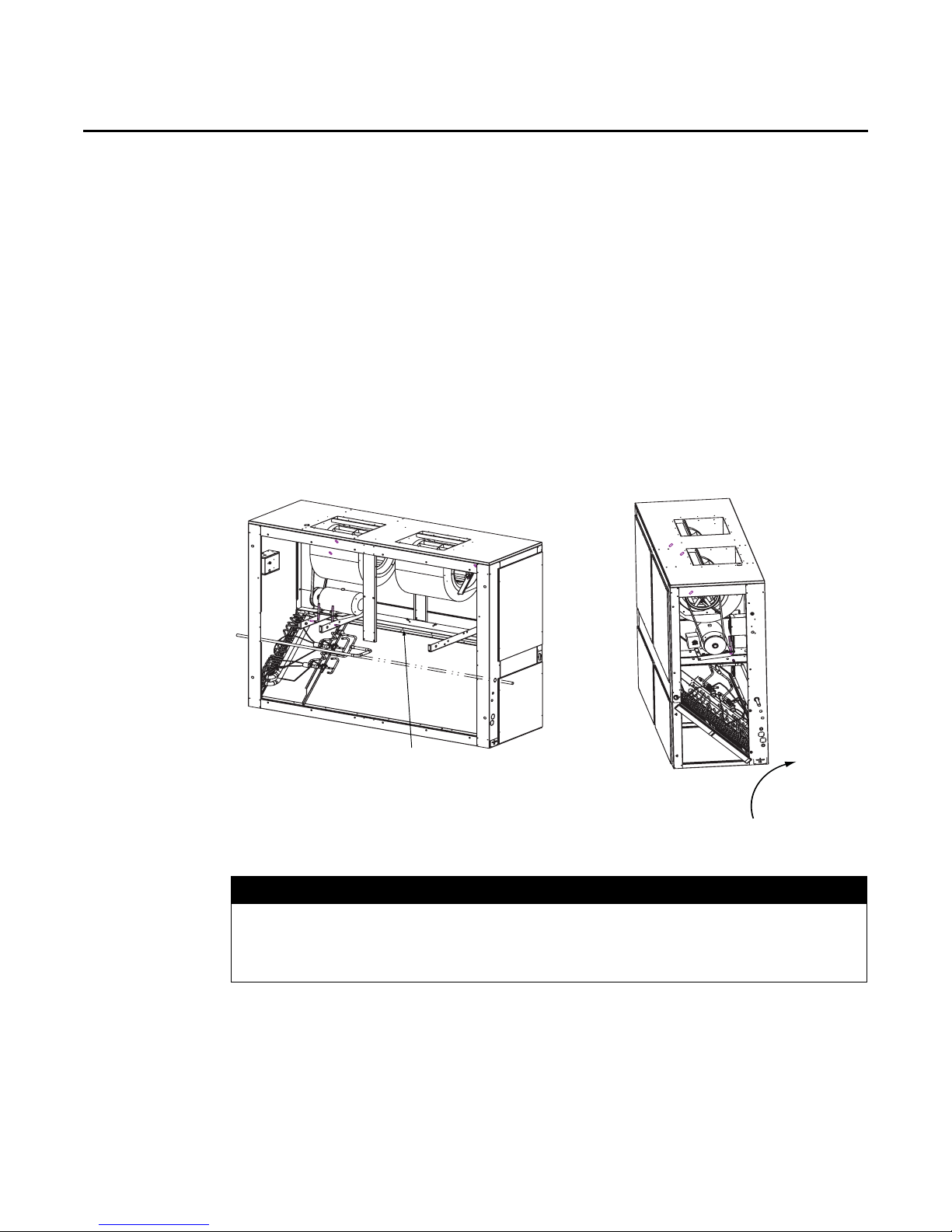

This manual covers installation of the TWE air handlers. These air handler models incorporate a

single slab coil assembly, improved application flexibility, servicing, maintenance accessibility and

an improved accessory line. They are fully convertible, (vertical to horizontal discharge) without

field removal of the coil assembly. They are shipped ready for horizontal installation.

All units have one drain pan that can be installed in any one of four positions. This allows for vertical

or horizontal applications and right or left exit.

Important: All dual circuit (digit 7 = E) have an intertwined coil

Installation Checklist

An “Installation Checklist” is provided at the end of the installation section of this manual. Use the

checklist to verify that all necessary installation procedures have been completed. Do not use the

checklist as a substitute for reading the information contained in the manual. Read the entire

manual before beginning installation procedures.

Unit Inspection

Inspect material carefully for any shipping damage. If damaged, it must be reported to, and claims

made against the transportation company. Compare the information that appears on the unit

nameplate with ordering and submittal data to ensure the proper unit was shipped. Available

power supply must be compatible with electrical characteristics specified on component

nameplates. Replace damaged parts with authorized parts only.

Initial Leak Test

All TWE units are shipped with a holding charge of nitrogen in each circuit. Remove the access

panel shown in Figure 12, p. 21. Locate the liquid line or suction line access valve for each circuit.

Install gauges to determine if the circuits are still pressurized. If not, the charge has escaped. Repair

as required to obtain a leak-free circuit.

Lifting Recommendations

WARNING

Improper Unit Lift!

Each of the cables (chains or slings) used to lift the unit must be capable of supporting the

entire weight of the unit. Lifting cables (chains or slings) may not be of the same length. Adjust

as necessary for even unit lift. Other lifting arrangements may cause equipment or propertyonly damage. Test lift unit approximately 24 inches to verify proper center of gravity lift point.

To avoid dropping of unit, reposition lifting point if unit is not level.

Failure to properly lift unit could result in unit dropping and possibly crushing operator/

technician which could result in death or serious injury and possible equipment or propertyonly damage. Refer to Ta b l e 1 and Ta b l e 2 for unit weight.

SSA-SVX06B-EN 7

General Information

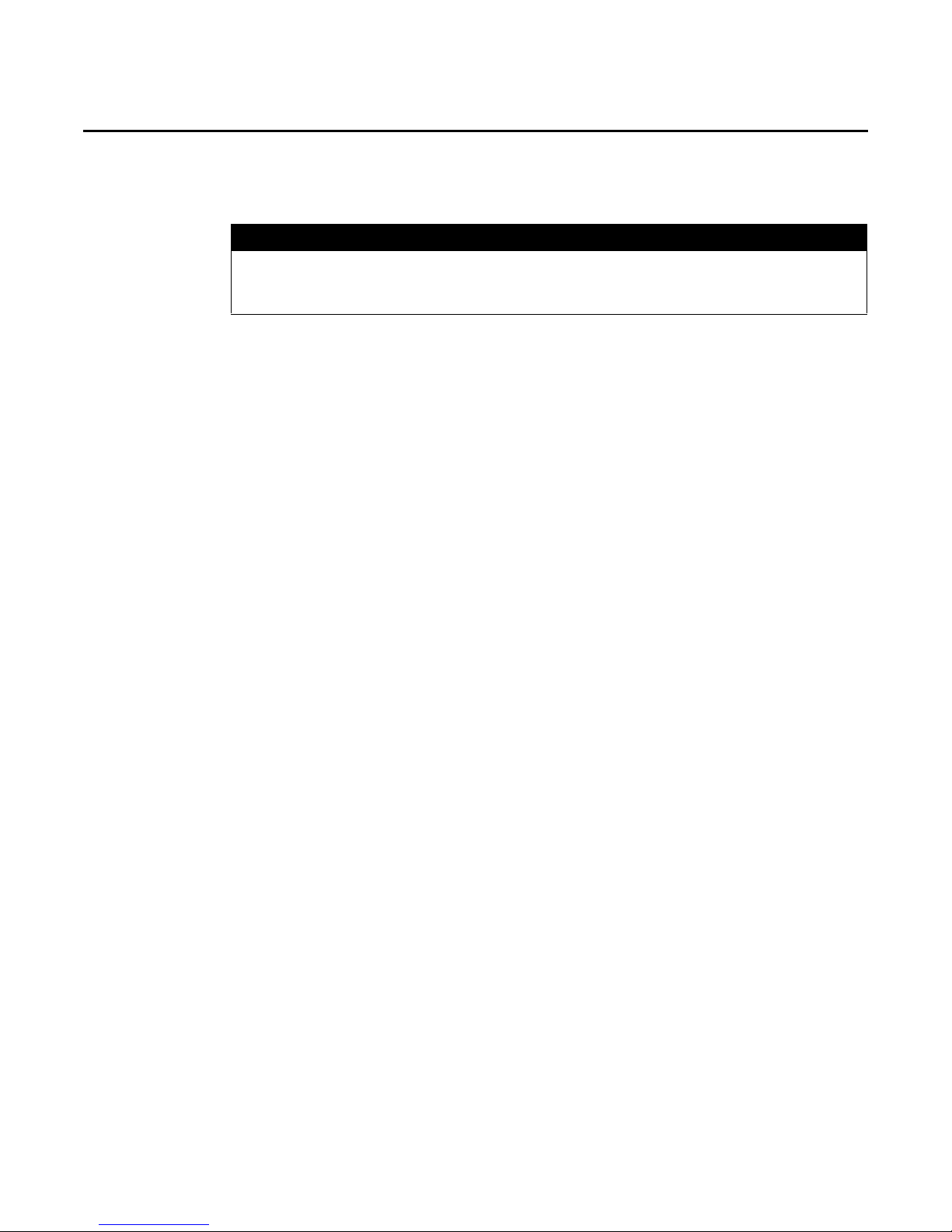

NOTICE:

Equipment Damage!

Use spreader bars to prevent straps from damaging the unit. Install the bars between lifting

straps, both underneath the unit and above the unit. This will prevent the straps from crushing

the unit cabinet or damaging the unit finish.

Before preparing the unit for lifting, estimate the approximate center of gravity for lifting safety.

Because of placement of internal components, the unit weight may be unevenly distributed.

Approximate unit weights are given in Ta b le 1 and Ta b l e 2, p. 8.

The crated unit can be moved using a forklift of suitable capacity. For lifting the unit into an elevated

mounting position, run lifting straps or slings under the unit and attach securely to the lifting device.

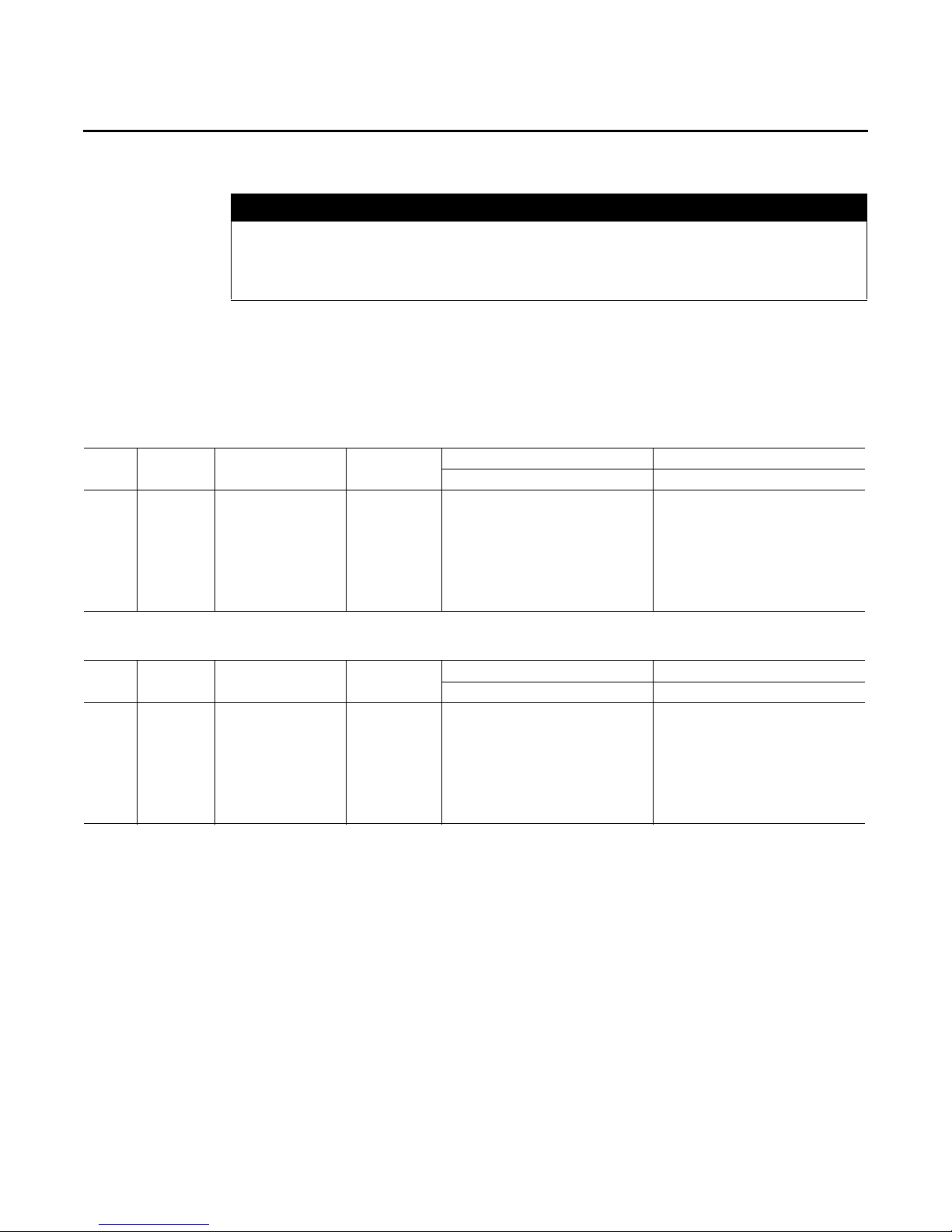

Table 1. TWE Unit and Corner Weights - lbs (60 Hz)

Corner Weights - Vertical Corner Weights - Horizontal

Tons Model No. Shipping Max (lbs) Net Max (lbs)

5 TWE061D/E 263 232 55 71 51 55 54 67 50 61

7½ TWE090D/E 360 323 67 99 75 82 56 92 87 88

10 TWE120D/E 429 393 77 121 110 85 79 118 77 119

12½ TWE150E 730 676 168 192 181 135 196 164 145 171

15 TWE180E 729 675 167 192 181 135 196 163 145 171

20 TWE240E 891 818 258 168 161 231 256 181 146 235

1234ABCD

Table 2. TWE Unit and Corner Weights - kg (50 Hz)

Corner Weights - Vertical Corner Weights - Horizontal

Tons Model No. Shipping Max (kg) Net Max (kg)

5 TWE051D/E 118 104 25 32 23 25 24 30 23 27

7½ TWE076D/E 162 145 30 45 34 37 25 41 39 40

10 TWE101D/E 193 177 35 54 50 38 36 53 35 54

12½ TWE126E 329 304 76 86 81 61 88 74 65 77

15 TWE156E 328 304 75 86 81 61 88 73 65 77

20 TWE201E 401 368 116 76 72 104 115 81 66 106

1234ABCD

8 SSA-SVX06B-EN

Pre-Installation

The final position for the air handler must be dictated by required service access to it, weight

distribution over structural supports, and by the locations of electrical, refrigerant and condensate

drainage connections. After this is determined, the following preparations should be made.

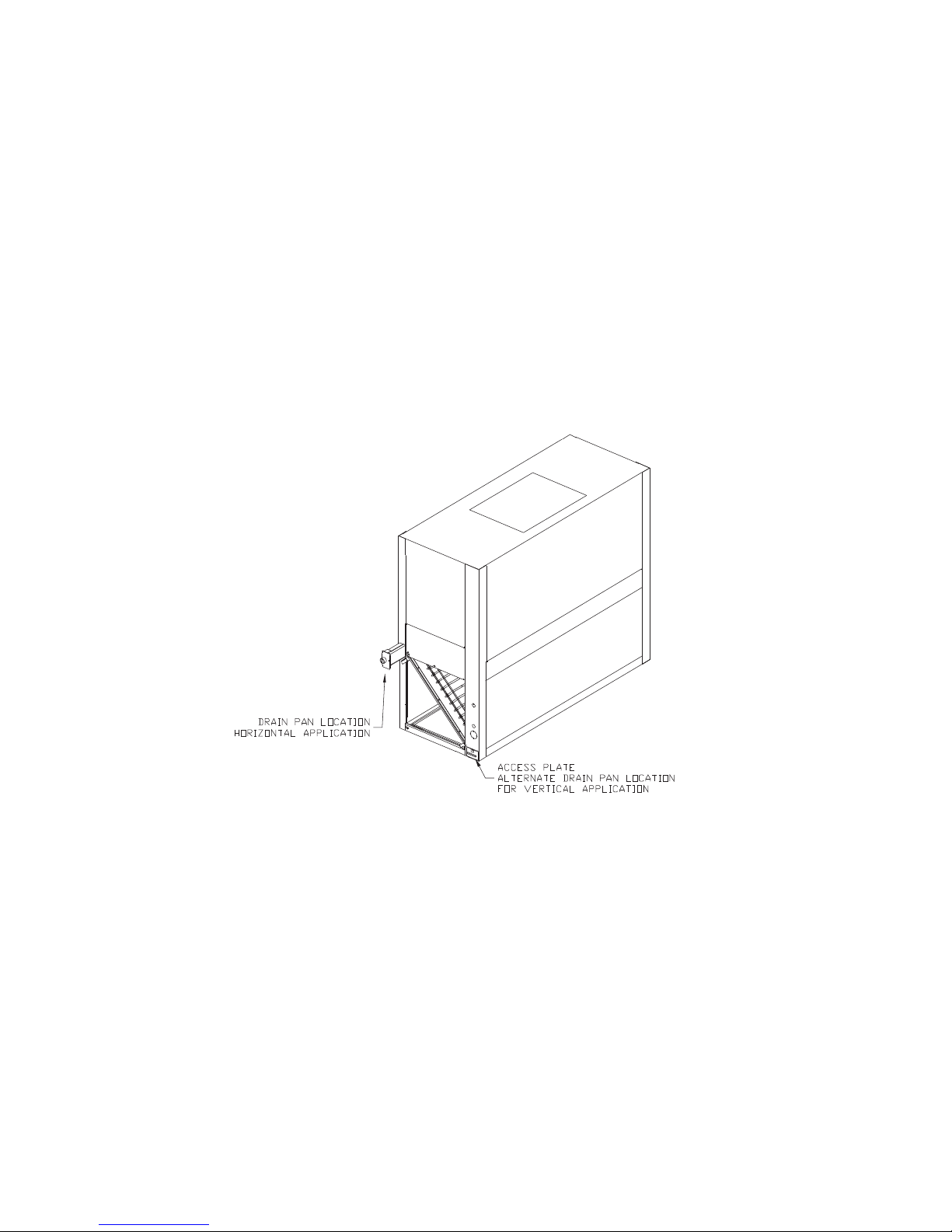

Repositioning Drain Pan

These air handlers come with one drain pan that can be installed in any one of four positions; this

allows for vertical or horizontal application and right or left condensate line connection. The drain

pan can also be easily removed for periodic cleaning.

Note: Important! All air handlers are shipped with the drain pan installed in the horizontal position

and the connection on the left side (as shown in Figure 1. If an alternate position is required,

the drain pan should be repositioned before setting the air handler.

Figure 1. Drain Pan Location

SSA-SVX06B-EN 9

Pre-Installation

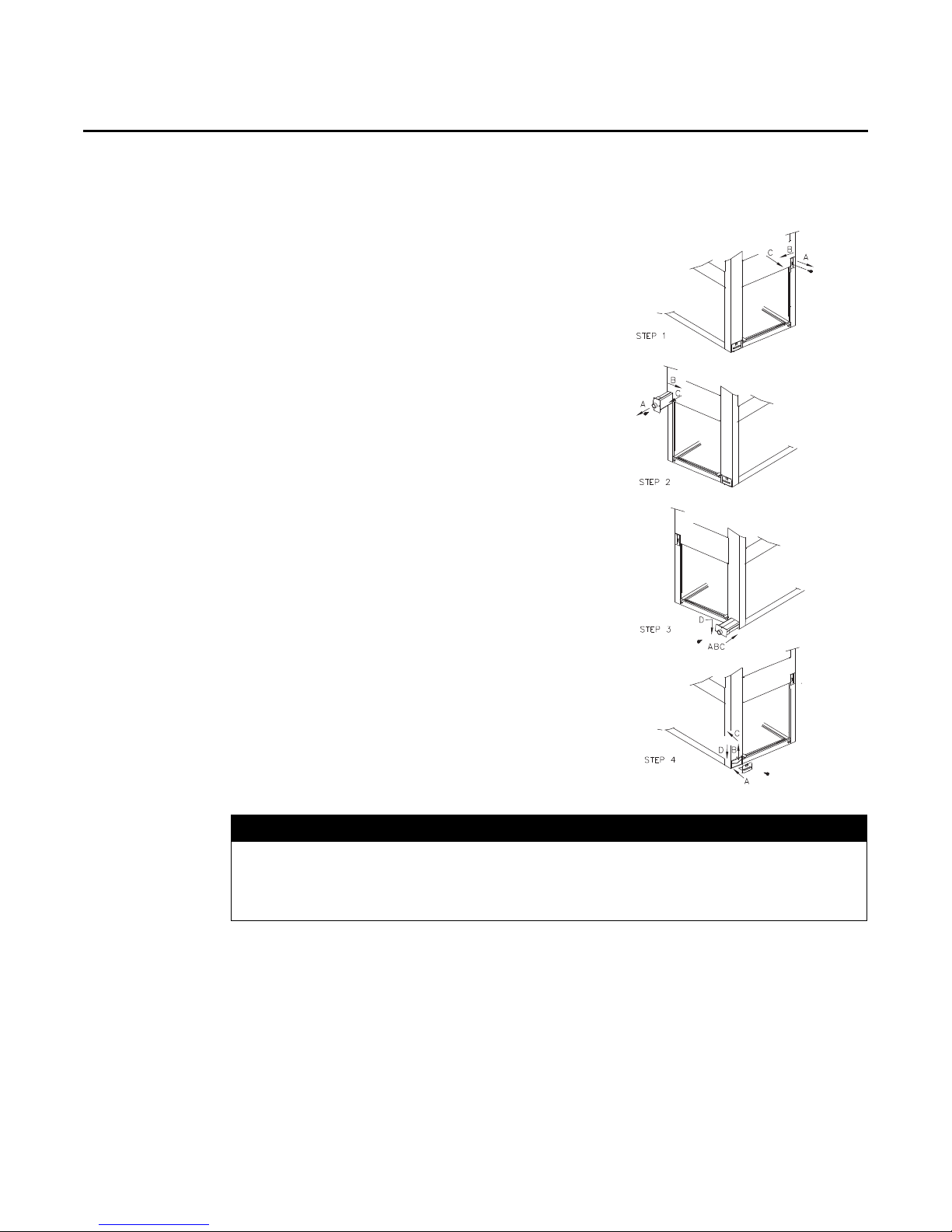

Process for Drain Pan Relocation

1. Remove the access plate at the opposite end of the drain

connection. This plate secures and lifts the back end of

the drain pan for sloping. It must be removed before the

drain pan can be removed. This is done as follows:

a. Remove the screw

b. Lift the access plate up

c. Pull the plate out. If the drain pan is to be moved to

the vertical position also remove the other two

access plates.

2. Remove the screw securing the drain pan.

a. Lift the pan up

b. Slide the pan out

3. Install the drain pan into the new position.

a. Slide the drain pan into the opening

b. Lift the drain pan up

c. Push it in all the way

d. Drop it down over the lip of the opening, secure with

screw

4. Install the access plate on the opposite end of the drain

pain.

a. Slide the edge of the access plate under the drain pan

b. Lift the access plate and drain pan up

c. Push the access plate in

d. Drop the access plate down over the lip of the

opening, secure with screw. If the drain pan is being

moved to the vertical position, install the other

access plates over the horizontal position opening.

Figure 2. Drain Pan Relocation

System Component Damage!

These air handlers are shipped with a dry nitrogen holding charge in the coil. Depress or

remove the access valve core to bleed off the nitrogen prior to brazing. Temporarily cap off

tubes if the refrigerant line connections are to be made later.

10 SSA-SVX06B-EN

NOTICE:

Field Conversion to 460 Volt

Hazardous Voltage w/Capacitors!

Disconnect all electric power, including remote disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/tagout procedures to ensure the power

cannot be inadvertently energized. For variable frequency drives or other energy storing

components provided by Trane or others, refer to the appropriate manufacturer’s literature for

allowable waiting periods for discharge of capacitors. Verify with an appropriate voltmeter that

all capacitors have discharged. Failure to disconnect power and discharge capacitors before

servicing could result in death or serious injury.

For additional information regarding the safe discharge of capacitors, see PROD-SVB06A-EN

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded

field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding as described in NEC and your

local/state electrical codes. Failure to follow code could result in death or serious injury.

Pre-Installation

WARNING

WARNING

• Available power supply must agree with electrical data on component nameplate.

• Some standard air handlers are shipped wired for 208-230 volt applications and can be

converted for 460 volt by rewiring the blower motor, see Figure 3. (This includes models

TWE090D3, TWE090E3, TWE120D3, TWE120E3, TWE150E3 and TWE180E3).

Converting Motor to 460 Volt

1. Ensure power is disconnected to unit by

following the warning above.

2. Remove unit access panels closest to

motor.

3. Open terminal cover on lead end of

motor.

4. Pull voltage selector plug from low

voltage selection (see Figure 3).

5. Shift the plug (or rotate 180°) to align

plug for high voltage selection and reinsert plug.

Important: When re-inserting voltage

selection plug, ensure it is

fully seated.

6. Replace terminal cover on lead end of

motor.

7. Replace unit access panels.

Figure 3. Voltage Change Plug

SSA-SVX06B-EN 11

Pre-Installation

Top bracket screws

Rotate 4°

clockwise

Refrigerant Piping

Evaporator Coil Orientation

Important: Applies only to TWE126/150 and 156/180 when positioned for vertical upflow. Unit

Process for reorienting evaporator coil on TWE126, 150, 156 and 180 only.

1. Remove screws from top evaporator coil bracket (bracket that attaches coil to cabinet and runs

2. Rotate evaporator coil approximately 4 degrees clockwise - looking from the control box end

3. Reinsert screws in evaporator coil bracket.

Figure 4. Evaporator Coil Reorientation for TWE126, 150, 156, 180

is shipped in the horizontal position. If installing in the vertical position, the coil

must be reoriented by rotating the coil 4 degrees (control box side) from the

shipped position. See instructions and Figure 4 below.

the length of the unit).

(see Figure 4). When the evaporator coil is rotated, the lower set of evaporator coil bracket holes

will align with the support bracket (from which it was originally fastened).

Preparation

Equipment Damage!

Do not apply heat to remove seal caps until the gauge port cores have been removed. If seal

caps are intact, application of heat may generate excessive pressure in the unit and result in

damage to the coil or expansion valve.

The air handler is designed so that refrigerant piping can enter from either the right or left hand

side. It is shipped with the intent that the refrigerant lines will enter from the left hand side. To

convert to right hand entry, unbraze the elbow on the suction line and rotate 180° and rebraze.

Important: Access to refrigerant lines is limited in all horizontal and some vertical applications.

12 SSA-SVX06B-EN

NOTICE:

Therefore, refrigerant lines should be stubbed out and temporarily capped prior to

setting the air handler. Protect adjacent surfaces from heat damage when brazing in

and around the air handler.

Installations, Limitations and Recommendations

System Component Damage!

Properly insulate all refrigerant gas piping to prevent possible water damage due to

condensation and to prevent capacity loss and possible compressor damage.

The general location of the air handler is normally selected by the architect, contractor and/or

buyer. For proper installation the following items must be considered.

• Available power supply must agree with electrical data on component nameplate.

• If external accessories are installed on the unit, additional clearances must be provided.

• All duct work should be properly insulated to prevent condensation and heat loss.

• Refrigerant gas piping must be insulated.

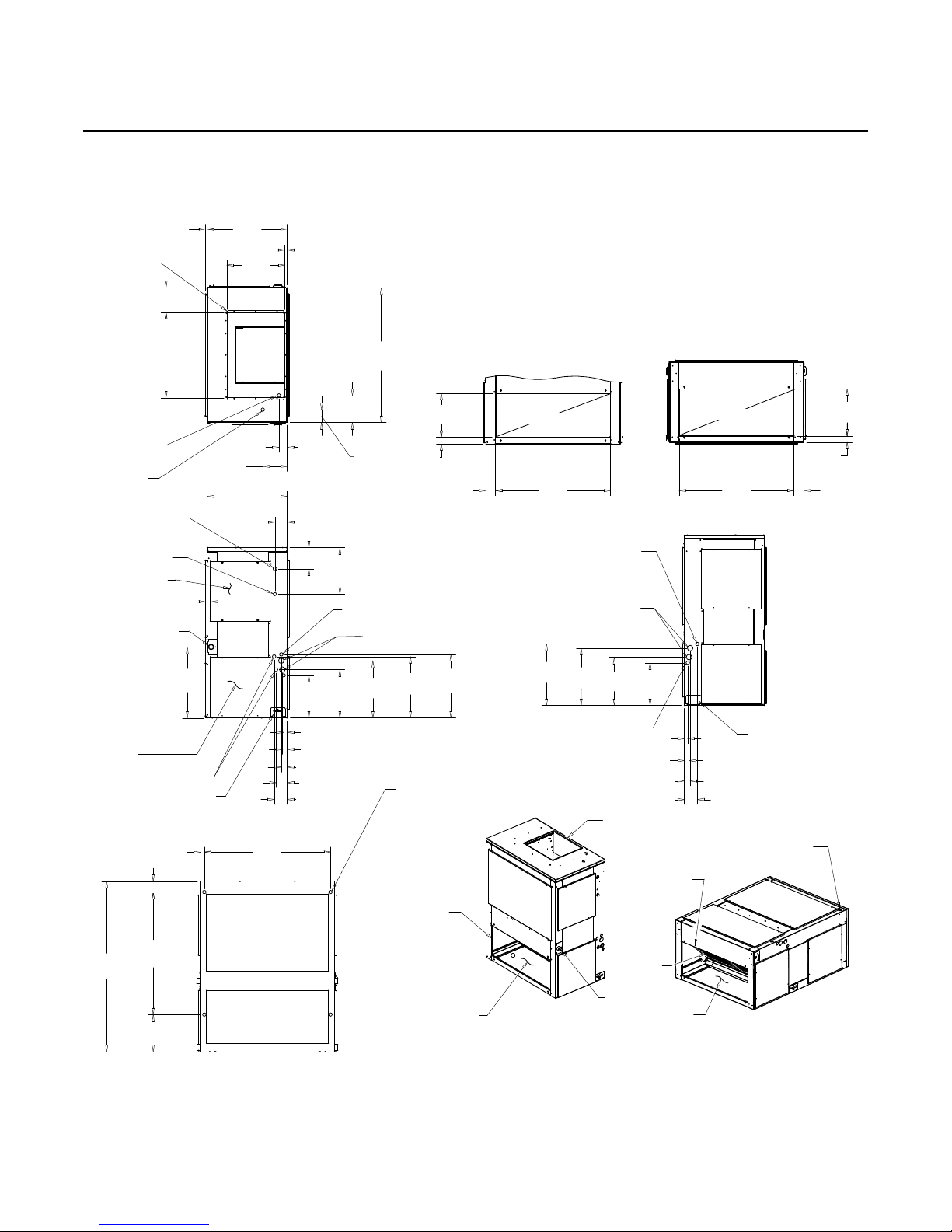

It is recommended that the outline drawings (Figure 6, p. 15 - Figure 13, p. 22) be studied and

dimensions properly noted and checked against the selected installation site. By noting in advance

which features are to be used, proper clearance allowances can be made for installation and

possible future service.

Important: When installing these units “free standing” with discharge grills and isolators, a top

support with isolator should be added to prevent tipping. Support and isolator can

be attached to a wall or other appropriate structure.

Important: If adding external accessories to the unit, additional clearances must be considered

for the overall space needed.

For installation of accessories available for this air handler, follow the instructions packed with each

accessory.

Pre-Installation

NOTICE:

SSA-SVX06B-EN 13

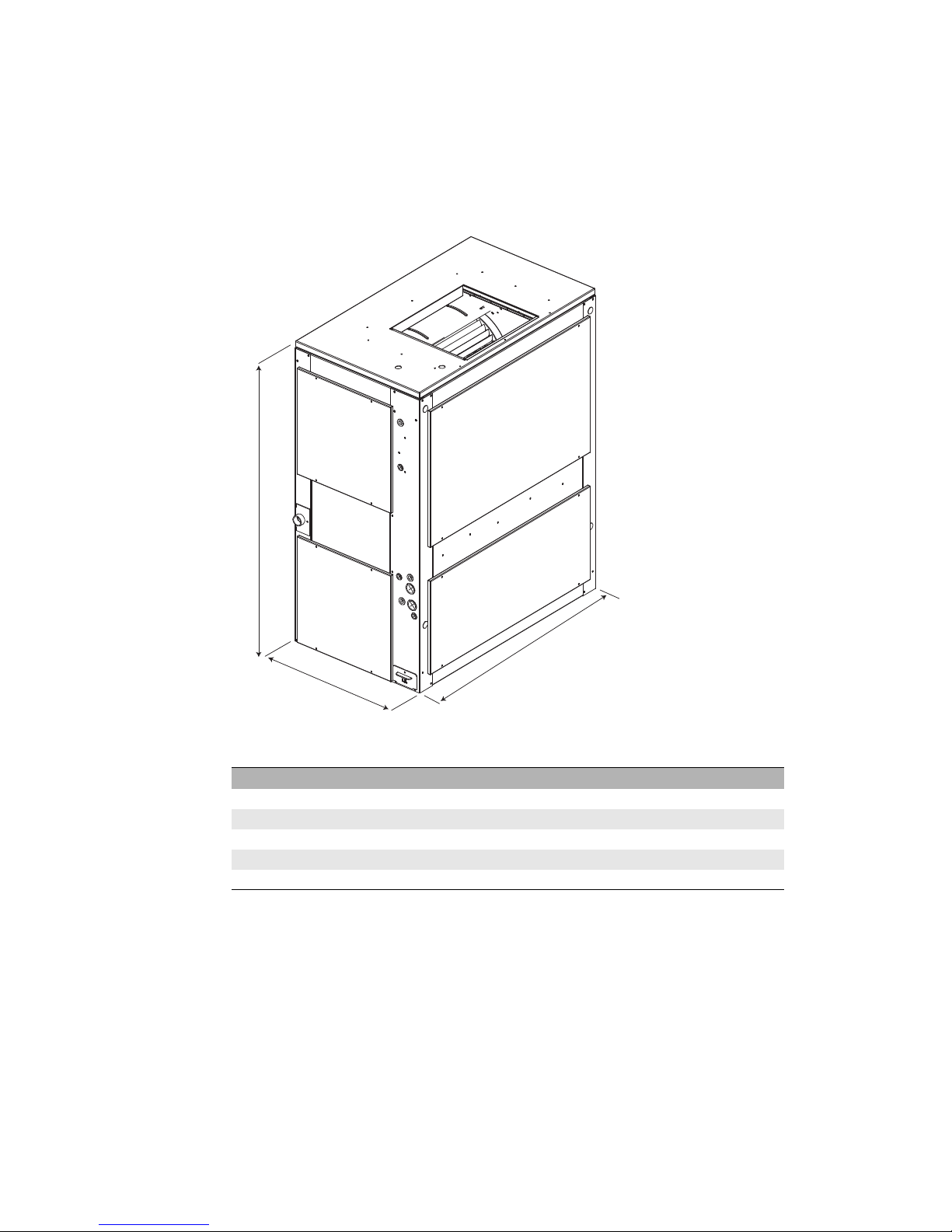

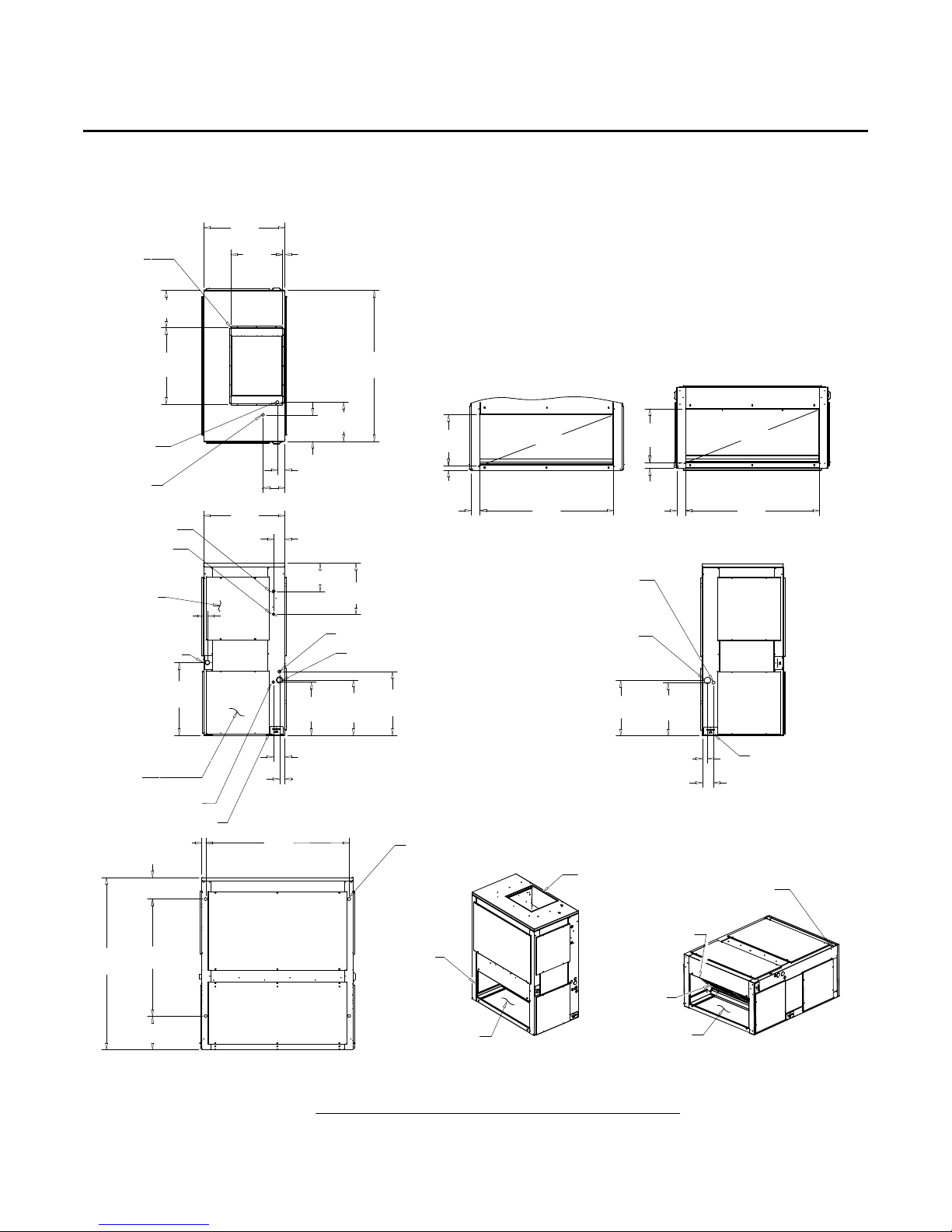

Dimensional Data

H

D

W

Figure 5. TWE Quick Reference

Note: Full dimensional data available on next pages.

H - in. (mm) W - in. (mm) D - in. (mm)

TWE051, 061 48-1/8” (1222.4) 39-5/8” (1006.5) 23-5/8” (600)

TWE076, 090 54-1/8” (1374.8) 49-1/8” (1247.8) 26-1/2” (673.1)

TWE101, 120 54-1/8” (1374.8) 65-1/8” (1654.2) 26-1/2” (673.1)

TWE126, 150, 156, 180 69-1/8” (1756) 81-1/4” (2063.7) 30 (762)

TWE201, 240 71-7/8” (1806.6) 94-1/4” (2394) 32-1/8” (816)

14 SSA-SVX06B-EN

3" (76.2)

48 1/16"

(1220.8)

10 7/16"

(265.1)

34 9/16"

(877.9)

35 5/8"

(904.9)

1 1/8"

(28.6)

12"

(304.8)

13 9/16" (344.5)

20 1/16"

(509.6)

1 11/16"

(42.9)

5 15/16"

(150.8)

13 3/16" (335)

12"

(304.8)

13 9/16"

(344.5)

13 5/16"

(338.14)

1 3/4"

(44.45)

2 3/4"

(69.9)

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3, 5 )

32 1/2"

(825.5)

12 7/16"

(315.9)

1 3/8"

(34.9)

.99" (25.15)

.99" (25.15)

1 3/8" (34.9)

3 3/16" (81)

3 7/16" (87.3)

22 5/8"

(574.7)

22 5/8"

(574.7)

16 1/4"

(412.8)

.77"

(19.6)

.50" (12.7)

3 9/16"

(90.5)

7 9/16"

(192.1)

37 15/16"

(963.6)

24 1/16"

(611.2)

2 5/16"

(58.7)

6 7/8"

(174.6)

6 15/16" (176.2)

BOTTOM RETURN

SIDE RETURN

CONTROL BOX

ACCESS PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOSITE DRAIN CONNECTION MUST BE REMOVED TO

SLIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

SLIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

DIMENSIONAL DRAWING

4.6 - 6.25 TON AIR HANDLER

(SINGLE CIRCUIT)

SEE NOTES 2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR HORIZONTAL

SUSPENSION

COPPER LIQUID LINE

FIELD CONNECTION

COPPER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

1 3/8" (34.9) O.D. SUCTION LINE

REMOTE BULB TXV

FILTER ACCESS PANEL

22" (558.8) MIN. DISTANCE

BOTH SIDE

FILTER

SUPPLY OPENING

BOTTOM RETURN

SIDE RETURN

BOTTOM RETURN

SUPPLY VERTICAL RETURN HORIZONTAL /

RETURN VERTICAL

SUPPLY HORIZONTAL RETURN VERTICAL /

RETURN HORIZONTA L

(4) - HOLE FOR HORIZONTAL

SUSPENSION

SIDE RETURN

CONTROL WIRING

LINE VOLTAGE

DUCT FLANGE

1" (25.4)

HEIGHT

SUPPLY

OPEN

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE POWER

ENTRY WIRES

32 1/2"

(825.5)

2 3/4"

(69.9)

Figure 6. TWE051, 061 Air Handler, Single Circuit — in (mm)

Dimensional Data

SSA-SVX06B-EN 15

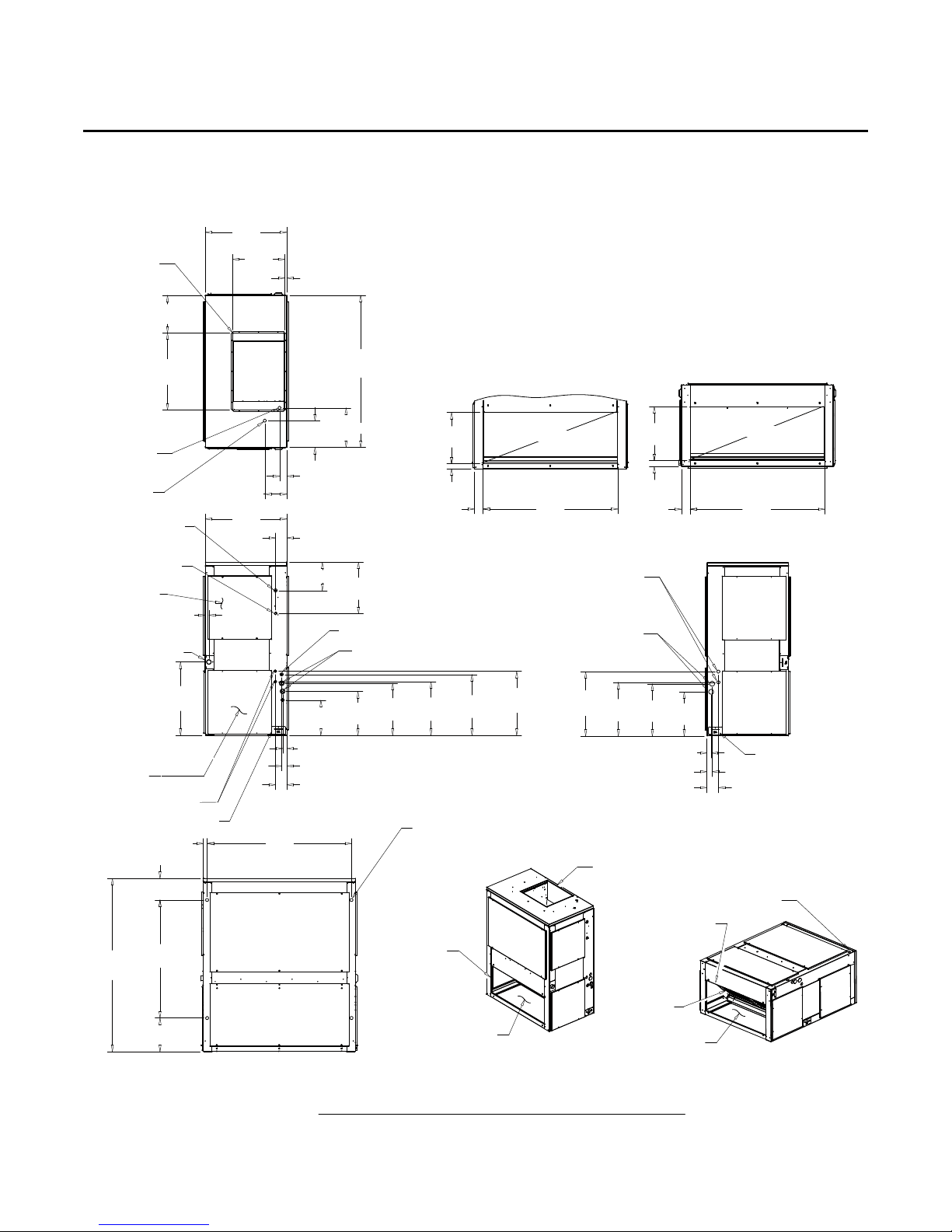

Dimensional Data

3" (76.2)

48 1/16"

(1220.8)

10 7/16"

(265.1)

34 9/16"

(877.9)

35 5/8"

(904.9)

1 1/8"

(28.6)

12"

(304.8)

13 9/16"

(344.5)

20 1/16"

(509.6)

1 11/16"

(42.9)

5 15/16"

(150.8)

13 3/16" (335)

16 1/8"

(409.6)

17 5/16"

(439.7)

17 7/8"

(454)

12"

(304.8)

13 9/16"

(344.5)

16 1/8"

(409.6)

17 5/16"

(439.7)

13 5/16"

(338.14)

1 3/4"

(44.45)

2 3/4"

(69.8)

32 1/2"

(825.5)

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

12 7/16"

(315.9)

3 11/16" (93.7)

1 11/16" (42.9)

1 3/8" (34.9)

.99" (25.15)

.99" (25.15)

1 3/8" (34.9)

1 11/16" (42.9)

3 3/16" (81)

3 11/16" (93.7)

3 7/16" (87.3)

22 5/8"

(574.7)

1 13/16"

(46.04)

22 5/8"

(574.7)

16 1/4"

(412.8)

.77" (19.6)

.50" (12.7)

3 9/16"

(90.5)

7 9/16"

(192.1)

37 15/16"

(963.6)

24 1/16"

(611.2)

2 5/16"

(58.7)

6 7/8"

(174.6)

6 15/16"

(176.2)

BOTTOM RETURN

SIDE RETURN

DUCT FLANGE

1" (25.4) HEIGHT

SUPPLY

OPEN

CONTROL WIRING

LINE VOLTAGE

CONTROL BOX

ACCESS PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOSITE DRAIN CONNECTION MUST BE REMOVED TO

SLIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

SLIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION VE

RTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

DIMENSIONAL DRAWING

5 TON AIR HANDLER

(DUAL CIRCUIT)

SEE NOTES 2,3,4

SEE NOTES 2,3,4

SUPPLY VERTICAL RETURN HORIZONTAL /

RETURN VERTICAL

SUPPLY HORIZONTAL RETURN VERTICAL /

RETURN HORIZONTAL

(4) - HOLE FOR HORIZONTAL

SUSPENSION

COPPER LIQUID LINE

FIELD CONNECTION

COPPER SUCTION LINE

FIELD CONNECTION

LIQUID LINES

(2) REMOTE BULB TXV

FILTER ACCESS PANEL

22" (558.8) MIN. DISTANCE

BOTH SIDE

SIDE RETURN

SIDE RETURN

BOTTOM RETURN

BOTTOM RETURN

SUPPLY OPENING

FILTER

(4) HOLE FOR

HORIZONTAL

SUSPENSION

DRAIN CONNECTION

SUCTION LINE

COPPER LIQUID LINE

FIELD CONNECTION

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE POWER

ENTRY WIRES

32 1/2"

(825.5)

2 3/4"

(69.8)

Figure 7. TWE061 Air Handler, Dual Circuit — in (mm)

16 SSA-SVX06B-EN

Figure 8. TWE076, 090 Air Handler, Single Circuit — in (mm)

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOSITE DRAIN CONNECTION MUST BE REMOVED TO

SLIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

SLIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION VE

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

47 1/2"

(1206.5)

16 1/16"

(408)

1 9/16"

(39.7)

2 3/4"

(69.85)

DUCT FLANGE

1" (25.4)

HEIGHT

11 11/16"

(296.8)

24 1/16"

(611.2)

HEATER CONTROL

AND SINGLE POWER

ENTRY WIRES

HEATER

VENTILATION

CONTROL WIRING

LINE VOLTAGE

CONTROL BOX

ACCESS PANEL

DRAIN CONNECTION

1 3/16" (30.2)

FOR HORIZONTAL

(SEE NOTE 2,3,5)

25 1/2"

(647.7)

16 1/4"

(412.8)

SUPPLY

OPEN

6 13/16"

(173)

25 1/2"

(647.7)

.70"

(17.8)

12 5/16"

8 5/16"

(312.7)

(211.1)

2 1/4" (57.15)

3 1/2" (88.9)

8 13/16" (223.8)

16"

(406.4)

REMOTE BULB TXV

SUCTION LINE

SIDE RETURN

42"

(1066.8)

COPPER LIQUID LINE

FIELD CONNECTION

COPPER SUCTION LINE

FIELD CONNECTION

16 7/8"

(428.6)

1 13/16"

(46)

2 3/4"

(69.85)

Dimensional Data

RTICAL CONFIGURATION.

BOTTOM RETURN

42"

(1066.8)

22 7/8"

(581)

FILTER ACCESS PANEL

22" (558.8) MIN. DISTANCE

BOTH SIDE

LIQUID LINES

SEE NOTES 2,3,4

1 3/16" (30.16)

6 3/4"

(171.45)

54 1/16"

(1373.2)

36 7/8"

(936.6)

10 7/16"

(265.1)

45 1/8"

(1146.2)

16 11/16"

(423.9)

3 5/8" (92.1)

1 11/16" (42.9)

17 7/16"

(442.9)

20"

(508)

(4) - HOLE FOR

HORIZONTAL SUSPENSION

SIDE RETURN

BOTTOM RETURN

6.25 - 7.5 TON AIR HANDLER

DIMENSIONAL DRAWING

SUPPLY VERTICAL RETURN HORIZONTAL /

RETURN VERTICAL

(SINGLE CIRCUIT)

17 3/8"

(441.3)

1 9/16" (39.7)

3 1/2" (88.9)

SUPPLY OPENING

BOTTOM RETURN

FILTER

SIDE RETURN

16 11/16"

(423.9)

SUPPLY HORIZONTAL RETURN VERTICAL /

RETURN HORIZONTAL

SEE NOTES 2,3,4

(4) HOLE FOR

HORIZONTAL

SUSPENSION

SSA-SVX06B-EN 17

Dimensional Data

16 7/8"

(406.4)

1 13/16"

(46)

2 3/4"

(69.9)

42"

(1066.8)

1 9/16"

(39.7)

16 1/16"

(408)

20 1/16"

(509.6)

16 3/4"

(425.5)

16 1/4"

(412.8)

13 3/4"

(349.3)

3 5/8" (92.1)

1 5/8" (41.3)

1 5/16" (33.3)

11 1/16"

(281)

13 3/4"

(349.2)

16 1/4"

(412.8)

16 3/4"

(425.5)

19 1/16"

(484.2)

20 1/16"

(509.6)

3 5/8" (92.1)

1 5/8" (41.3)

1 5/16" (33.3)

16"

(406.4)

8 13/16" (223.8)

3 1/2" (88.9)

1 3/16" (30.2)

22 7/8"

(581)

45 1/8"

(1146.2)

6 3/4"

(171.5)

36 7/8"

(936.6)

10 7/16"

(265.1)

54 1/16"

(1373.2)

1 3/16" (30.2)

25 1/2"

(647.7)

16 1/4"

(412.8)

.70"

(17.78)

25 1/2"

(647.7)

24 1/16"

(611.2)

11 11/16"

(296.9)

47 1/2"

(1206.5)

8 5/16"

(211.1)

12 5/16"

(312.7)

2 1/4" (57.15)

6 13/16" (173)

BOTTOM RETURN

SIDE RETURN

CONTROL WIRING

LINE VOLTAGE

CONTROL BOX

ACCESS PANEL

NOTES:

1. PANEL DEPTH 1/2" (12.7) (TYP. ALL PANELS).

2. REMOVABLE DRAIN PAN AND ATTACHED DRAIN CONNECTION MAY BE INSTALLED ON END

OF UNIT IN EITHER THE VERTICAL OR HORIZONTAL CONFIGURATION, PLASTIC DRAIN PAN

ACCESS PLATE ON THE END OF UNIT OPPOSITE DRAIN CONNECTION MUST BE REMOVED TO

SLIDE DRAIN PAN OUT OF UNIT FOR CLEANING. ACCESS PLATE MUST BE RE-INSTALLED AFTER

SLIDING DRAIN PAN BACK INTO UNIT.

3. IF PERIODIC DRAIN PAN CLEANING IS REQUIRED, ALLOW ROOM FOR PARTIAL REMOVAL OF

DRAIN PAN CONNECTION AT END OF UNIT.

4. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION VERTICAL CONFIGURATION.

5. 1" (25.4) FEMALE SCHED. 40 (10.2) PVC PIPE DRAIN CONNECTION HORIZONTAL CONFIGURATION.

DIMENSIONAL DRAWING

7.5 TON AIR HANDLER

(DUAL CIRCUIT)

SEE NOTES 2,3,4

SEE NOTES 2,3,4

(4) - HOLE FOR HORIZONTAL

SUSPENSION

COPPER LIQUID LINE

FIELD CONNECTION

COPPER SUCTION LINE

FIELD CONNEC TI O N

LIQUID LINES

SUCTION LINE

(2) REMOTE BULB TXV

FILTER ACCESS PANEL

22" (559) MIN. DISTANCE

BOTH SIDE

DRAIN CONNECTION

FOR HORIZONTAL

(SEE NOTE 2,3,5)

FILTER

SUPPLY OPENING

BOTTOM RETURN

SIDE RETURN

BOTTOM RETURN

SUPPLY VERTICAL RETURN HORIZONTAL /

RETURN VERTICAL

SUPPLY HORIZONTAL RETURN VERTICAL /

RETURN HORIZONTAL

(4) HOLE FOR

HORIZONTAL

SUSPENSION

SIDE RETURN

DUCT FLANGE

1" (25.4)

HEIGHT

SUPPLY

OPEN

HEATER

VENTILATION

HEATER CONTROL

AND SINGLE POWER

ENTRY WIRES

42"

(1066.8)

2 3/4"

(69.9)

Figure 9. TWE090 Air Handler, Dual Circuit — in (mm)

18 SSA-SVX06B-EN

Loading...

Loading...