Ingersoll-Rand TEM6A0B24H21S, TEM6A0C48H41S, TEM6A0B30H21S, TEM6A0D48H41S, TEM6A0D60H51S Installer's Manual

...

Installer’s Guide

Convertible Air Handlers

2 — 5 Ton

TEM6A0B24H21S

TEM6A0B30H21S

TEM6A0C36H31S

TEM6A0C42H41S

TEM6A0C48H41S

TEM6A0D48H41S

TEM6A0C60H51S

TEM6A0D60H51S

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

January 2016

The TEM6 series air handler is designed for installation in a closet,

utility room, alcove, basement, crawlspace or attic. These versatile

units are applicable to air conditioning and heat pump

applications. Several models are available to meet the specific

requirements of the outdoor equipment. Field installed electric

resistance heaters are available.

SSAAFFEETTYY WWAARRNNIINNGG

18-GF74D1-1F-EN

SAFETY SECTION

AIR HANDLERS

IImmppoorrttaanntt:: This document contains a wiring diagram,

a parts list, and service information. This is

customer property and is to remain with

this unit. Please return to service

information pack upon completion of work.

IImmppoorrttaanntt:: These instructions do not cover all

variations in systems nor provide for every

possible contingency to be met in

connection with the installation. Should

further information be desired or should

particular problems arise which are not

covered sufficiently for the purchaser’s

purposes, the matter should be referred to

your installing dealer or local distributor.

WWAARRNNIINNGG

HHAAZZAARRDDOOUUSS VVOOLLTTAAGGEE!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaannnnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd..

CCAAUUTTIIOONN

GGRROOUUNNDDIINNGG RREEQQUUIIRREEDD!!

FFaaiilluurree ttoo iinnssppeecctt oorr uussee pprrooppeerr sseerrvviiccee ttoooollss mmaayy

rreessuulltt iinn eeqquuiippmmeenntt ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

RReeccoonnnneecctt aallll ggrroouunnddiinngg ddeevviicceess.. AAllll ppaarrttss ooff tthhiiss

pprroodduucctt tthhaatt aarree ccaappaabbllee ooff ccoonndduuccttiinngg eelleeccttrriiccaall

ccuurrrreenntt aarree ggrroouunnddeedd.. IIff ggrroouunnddiinngg wwiirreess,, ssccrreewwss,,

ssttrraappss,, cclliippss,, nnuuttss,, oorr wwaasshheerrss uusseedd ttoo ccoommpplleettee aa

ppaatthh ttoo ggrroouunndd aarree rreemmoovveedd ffoorr sseerrvviiccee,, tthheeyy mmuusstt

bbee rreettuurrnneedd ttoo tthheeiirr oorriiggiinnaall ppoossiittiioonn aanndd pprrooppeerrllyy

ffaasstteenneedd..

WWAARRNNIINNGG

LLIIVVEE EELLEECCTTRRIICCAALL CCOOMMPPOONNEENNTTSS!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

FFoollllooww aallll eelleeccttrriiccaall ssaaffeettyy pprreeccaauuttiioonnss wwhheenn

eexxppoosseedd ttoo lliivvee eelleeccttrriiccaall ccoommppoonneennttss.. IItt mmaayy bbee

nneecceessssaarryy ttoo wwoorrkk wwiitthh lliivvee eelleeccttrriiccaall ccoommppoonneennttss

dduurriinngg iinnssttaallllaattiioonn,, tteessttiinngg,, sseerrvviicciinngg,, aanndd

ttrroouubblleesshhoooottiinngg ooff tthhiiss pprroodduucctt..

WWAARRNNIINNGG

PPRREESSSSUURRIIZZEEDD RREEFFRRIIGGEERRAANNTT!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

ppeerrssoonnaall iinnjjuurryy

SSyysstteemm ccoonnttaaiinnss ooiill aanndd rreeffrriiggeerraanntt uunnddeerr hhiigghh

pprreessssuurree.. RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree

bbeeffoorree ooppeenniinngg tthhee ssyysstteemm.. DDoo nnoo uussee nnoonn-aapppprroovveedd rreeffrriiggeerraannttss oorr rreeffrriiggeerraanntt ssuubbssttiittuutteess oorr

rreeffrriiggeerraanntt aaddddiittiivveess..

CCAAUUTTIIOONN

SSHHAARRPP EEDDGGEE HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

BBee ccaarreeffuull ooff sshhaarrpp eeddggeess oonn eeqquuiippmmeenntt oorr aannyy

ccuuttss mmaaddee oonn sshheeeett mmeettaall wwhhiillee iinnssttaalllliinngg oorr

sseerrvviicciinngg..

CCAAUUTTIIOONN

HHAAZZAARRDDOOUUSS VVAAPPOORRSS!!

FFaaiilluurree ttoo ffoollllooww tthhiiss ccaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

EEqquuiippmmeenntt ccoorrrroossiioonn ddaammaaggee.. TToo pprreevveenntt

sshhoorrtteenniinngg iittss sseerrvviiccee lliiffee,, tthhee aaiirr hhaannddlleerr sshhoouulldd

nnoott bbee uusseedd dduurriinngg tthhee ffiinniisshhiinngg pphhaasseess ooff

ccoonnssttrruuccttiioonn oorr rreemmooddeelliinngg.. TThhee llooww rreettuurrnn aaiirr

tteemmppeerraattuurreess ccaann lleeaadd ttoo tthhee ffoorrmmaattiioonn ooff

ccoonnddeennssaattee.. CCoonnddeennssaattee iinn tthhee pprreesseennccee ooff

cchhlloorriiddeess aanndd fflluuoorriiddeess ffrroomm ppaaiinntt,, vvaarrnniisshh,, ssttaaiinnss,,

aaddhheessiivveess,, cclleeaanniinngg ccoommppoouunnddss,, aanndd cceemmeenntt

ccrreeaatteess aa ccoorrrroossiivvee ccoonnddiittiioonn wwhhiicchh mmaayy ccaauussee

rraappiidd ddeetteerriioorraattiioonn ooff tthhee ccaabbiinneett aanndd iinntteerrnnaall

ccoommppoonneennttss..

CCAAUUTTIIOONN

CCOOIILL IISS PPRREESSSSUURRIIZZEEDD!!

•• CCooiill iiss pprreessssuurriizzeedd wwiitthh aapppprrooxxiimmaatteellyy 88––1122 ppssii

ddrryy aaiirr aanndd ffaaccttoorryy cchheecckkeedd ffoorr lleeaakkss..

•• CCaarreeffuullllyy rreelleeaassee tthhee pprreessssuurree bbyy rreemmoovviinngg tthhee

rruubbbbeerr pplluugg oonn tthhee lliiqquuiidd lliinnee..

•• IIff nnoo pprreessssuurree iiss rreelleeaasseedd,, cchheecckk ffoorr lleeaakkss..

©2016 Trane

18-GF74D1-1F-EN

SSAAFFEETTYY SSEECCTTIIOONN AAIIRR HHAANNDDLLEERRSS

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

FFiibbeerrggllaassss dduusstt aanndd cceerraammiicc ffiibbeerrss aarree bbeelliieevveedd bbyy

tthhee ssttaattee ooff CCaalliiffoorrnniiaa ttoo ccaauussee ccaanncceerr tthhrroouugghh

iinnhhaallaattiioonn.. GGllaasssswwooooll ffiibbeerrss mmaayy aallssoo ccaauussee

rreessppiirraattoorryy,, sskkiinn,, oorr eeyyee iirrrriittaattiioonn..

PPRREECCAAUUTTIIOONNAARRYY MMEEAASSUURREESS

•• AAvvooiidd bbrreeaatthhiinngg ffiibbeerrggllaassss dduusstt

•• UUssee aa NNIIOOSSHH aapppprroovveedd dduusstt//mmiisstt rreessppiirraattoorr

•• AAvvooiidd ccoonnttaacctt wwiitthh tthhee sskkiinn oorr eeyyeess.. WWeeaarr lloonngg-sslleeeevveedd,, lloooossee ffiittttiinngg ccllootthhiinngg,, gglloovveess,, aanndd eeyyee

pprrootteeccttiioonn

•• WWaasshh ccllootthheess sseeppaarraatteellyy ffrroomm ootthheerr ccllootthhiinngg,,

rriinnssee wwaasshheerr tthhoorroouugghhllyy

•• OOppeerraattiioonnss ssuucchh aass ssaawwiinngg,, bblloowwiinngg,, tteeaarr--oouutt,,

aanndd sspprraayyiinngg mmaayy ggeenneerraattee ffiibbeerr ccoonncceennttrraattiioonnss

rreeqquuiirriinngg aaddddiittiioonnaall rreessppiirraattoorryy pprrootteeccttiioonn.. UUssee

tthhee aapppprroopprriiaattee NNIIOOSSHH aapppprroovveedd rreessppiirraattoorr iinn

tthheessee ssiittuuaattiioonnss

FFIIRRSSTT AAIIDD MMEEAASSUURREESS

•• EEYYEE CCOONNTTAACCTT:: FFLLUUSSHH EEYYEESS WWIITTHH WWAATTEERR TTOO

RREEMMOOVVEE DDUUSSTT.. IIFF SSYYMMPPTTOOMMSS PPEERRSSIISSTT,, SSEEEEKK

MMEEDDIICCAALL AATTTTEENNTTIIOONN..

•• SSKKIINN CCOONNTTAACCTT:: WWAASSHH AAFFFFEECCTTEEDD AARREEAA

GGEENNTTLLYY WWIITTHH SSOOAAPP AANNDD WWAARRMM WWAATTEERR AAFFTTEERR

HHAANNDDLLIINNGG..

TThhiiss wwaarrnniinngg ccoommpplliieess wwiitthh ssttaattee ooff CCaalliiffoorrnniiaa llaaww,,

PPrrooppoossiittiioonn 6655..

NNoottee:: Air handlers have been evaluated in accordance

with the Code of Federal Regulations, Chapter

XX, Part 3280 or the equivalent.“SUITABLE FOR

MOBILE HOME USE.”

NNoottee:: Condensation may occur on the surface of the air

handler when installed in an unconditioned

space. When units are installed in unconditioned

spaces, verify that all electrical and refrigerant

line penetrations on the air handler are sealed

completely.

NNoottee:: The manufacturer recommends installing ONLY

A.H.R.I approved, matched indoor and outdoor

systems. Some of the benefits of installing

approved matched indoor and outdoor split

systems are maximum efficiency, optimum

performance, and the best overall system

reliability.

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

TThhiiss aapppplliiaannccee iiss nnoott ttoo bbee uusseedd bbyy ppeerrssoonnss

((iinncclluuddiinngg cchhiillddrreenn)) wwiitthh rreedduucceedd pphhyyssiiccaall,,

sseennssoorryy,, oorr mmeennttaall ccaappaabbiilliittiieess,, oorr llaacckk ooff

eexxppeerriieennccee aanndd kknnoowwlleeddggee,, uunnlleessss tthheeyy hhaavvee bbeeeenn

ggiivveenn ssuuppeerrvviissiioonn oorr iinnssttrruuccttiioonn..

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

CChhiillddrreenn sshhoouulldd bbee ssuuppeerrvviisseedd ttoo eennssuurree tthhaatt tthheeyy

ddoo nnoott ppllaayy wwiitthh tthhee aapppplliiaannccee..

IImmppoorrttaanntt:: Installation of this unit shall be made in

accordance with the National Electric Code,

NFPA No. 90A and 90B, and any other local

codes or utilities requirements.

IImmppoorrttaanntt:: Air handlers do not require repositioning of

the coil or drain pan for upflow or

horizontal left applications. See the

downflow and horizontal right installation

sections for application instructions.

18-GF74D1-1F-EN

3

Table of Contents

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Instructions . . . . . . . . . . . . . . . . . . . 5

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Data . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Performance and Electrical Data . . . . . . . . . . . 12

Minimum Airflow CFM . . . . . . . . . . . . . . . . . . . . 19

Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Heater Pressure Drop Table . . . . . . . . . . . . . . . . 22

Subcooling Adjustment . . . . . . . . . . . . . . . . . . 22

Subcooling Adjustment for

TEM6A0C48H41 & TEM6A0C60H51 . . . . . . . 22

Coil Conversion Instructions. . . . . . . . . . . . . . . 23

Coil Conversion . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . 36

4

18-GF74D1-1F-EN

Features

Table 1. Standard Features

• MULTI-POSITION UPFLOW, DOWNFLOW, HORIZONTAL LEFT

AND HORIZONTAL RIGHT

• PAINTED FINISH ON GALVANIZED STEEL EXTERIOR WITH

FULLY INSULATED CABINET THAT MEETS R4.2 VALUE

• STURDY POLYCARBONATE DRAIN PANS

– The TEM air handler has factory installed drain pans and

is shipped for upflow and horizontal left applications

• 208/230 VAC OPERATION

• VARIABLE-SPEED DIRECT DRIVE BLOWER.

• FACTORY INSTALLED R-410A THERMAL EXPANSION VALVE

• ALL ALUMINUM COIL

• BOTTOM RETURN

• MEETS THE MINIMUM LEAKAGE REQUIREMENTS FOR THE

FLORIDA AND CALIFORNIA BUILDING CODES

Table 2. Optional Accessories

• 4,5,8,10,15,20, and 25 KW SINGLE PHASE ELECTRIC

HEATERS

– Circuit breakers available on single phase 4, 5, 8, 10,

15, 20, and 25 KW heaters

– Lugs available on single phase 4, 5, 8, and 10 KW

heaters

– Lugs available on three phase 10 and 15 KW heaters

• SINGLE POINT POWER ENTRY KIT (for 15 and 20 KW

heaters)

• SUPPLY DUCT FLANGE KIT

• DOWNFLOW SUB-BASE KITS - TAYBASE185, TAYBASE235,

TAYBASE260

• SLIM FIT FILTER BOX KIT — BAYSF1185AAA,

BAYSF1235AAA, BAYSF1265AAA

Installation Instructions

1. UUnnppaacckkiinngg

Carefully unpack the unit and inspect the contents

for damage. If any damage is found at the time of

delivery, proper notification and claims should be

made with the carrier.

Check the rating plate to assure model number and

voltage, plus any kits match with what you ordered.

The manufacturer should be notified within 5 days

of any discrepancy or parts shortage.

2. LLooccaattiioonn

The air handler should be centrally located and may

be installed in a closet, alcove, utility room,

basement, crawl space or attic. Minimum

clearances must be met.

IIMMPPOORRTTAANNTT:: The downflow sub-base may be

required with electric heat applications.

See minimum clearance table.

The unit must be installed in a level position to

ensure proper condensation drainage. Make sure

the unit is level in both directions within 1/8" on

either side.

When the unit is installed in a closet or utility room,

the room should be large enough, and have an

opening to allow replacement of the unit. All

servicing is done from the front and a clearance of

21" is needed for service unless the closet door

aligns with the front of the air handler.

If you are installing the unit in an unconditioned

space such as an attic or crawl space, you must

ensure that the area provides sufficient air

circulation to prevent moisture collection on the

cabinet during high dew point conditions. A drain

pan must be installed under the entire unit when it

is installed in or above a finished ceiling or in an

unconditioned space.

3. DDuucctt WWoorrkk

The duct work should be installed in accordance

with the NFPA No. 90A "Installation of Air

Conditioning and Ventilating systems" and No. 90B

"Residential Type Warm Air Heating and Air

Conditioning Installation."

The duct work should be insulated in accordance

with the applicable requirements for the particular

installation as required by HUD, FHA, VA the

applicable building code, local utility or other

governing body.

4. CCoonnddeennssaattee DDrraaiinn

The unit is supplied with primary and auxiliary

condensate drains that have 3/4" NPT connections.

The primary drain must be trapped outside the unit

and piped in accordance with applicable building

codes. Do not reduce the drain line size less than

the connection size on the drain pan. Condensate

should be piped to an open drain or to the outside.

All drains must pitch downward away from the unit

a minimum of 1/4" per foot of line to ensure proper

drainage.

IIMMPPOORRTTAANNTT:: If cleanout Tee is used, stand pipe

must be sealed/capped.

Insulate the primary drain line to prevent sweating

where dew point temperatures may be met.

(Insulation is optional depending on climate and

application needs.)

18-GF74D1-1F-EN

5

CFM

SELECTION

LIGHT

DIP

SWITCHES

DIP SWITCHES (TYPICAL SETTINGS)

COOLING

HEATING

AIRFLOW

FAN OFF

DELAY

AUXILARY

HEAT SPEEDS

OFF OFF

50%

80%

100% if necessary

50%

Dehumidify

Warm Air Heating

Fast Coil Cooling

Fast Coil Heating

Efficiency

7.5

minutes

3

minutes

1

minute

FAN OPERATION (CFM)

as required

COMPRESSOR OPERATION ON

OFF

FFeeaattuurreess

5. RReeffrriiggeerraanntt PPiippiinngg

Refrigerant piping external to the unit shall be sized

in accordance with the instructions of the

manufacturer of the outdoor equipment.

6. MMeetteerriinngg DDeevviiccee

All units are shipped and installed with an

internally-checked, non-bleed TXV designed for air

conditioning or heat pump operation. Some

outdoor models may require a start assist kit. See

outdoor unit for more information.

7. BBlloowweerr

This unit is supplied with a variable speed motor

with a direct drive blower wheel which can obtain

various air flows. The unit is shipped with factory

set cooling and heating air flows. Performance

tables are available for additional airflow settings.

Disconnect all power to the unit before making any

adjustments to the airflow settings. Be sure to check

the air flow and the temperature drop across the

evaporator coil to ensure sufficient air flow.

8. AAiirrffllooww AAddjjuussttmmeenntt

CCAAUUTTIIOONN

EEQQUUIIPPMMEENNTT DDAAMMAAGGEE!!

FFaaiilluurree ttoo ffoollllooww tthhiiss pprroocceedduurree mmaayy rreessuulltt iinn

eeqquuiippmmeenntt ddaammaaggee..

DDiissccoonnnneecctt ppoowweerr ttoo tthhee aaiirr hhaannddlleerr bbeeffoorree

cchhaannggiinngg ddiipp sswwiittcchh ppoossiittiioonnss..

Blower speed changes are made on the ECM Fan

Control. The ECM Fan Control controls the variable

speed motor.

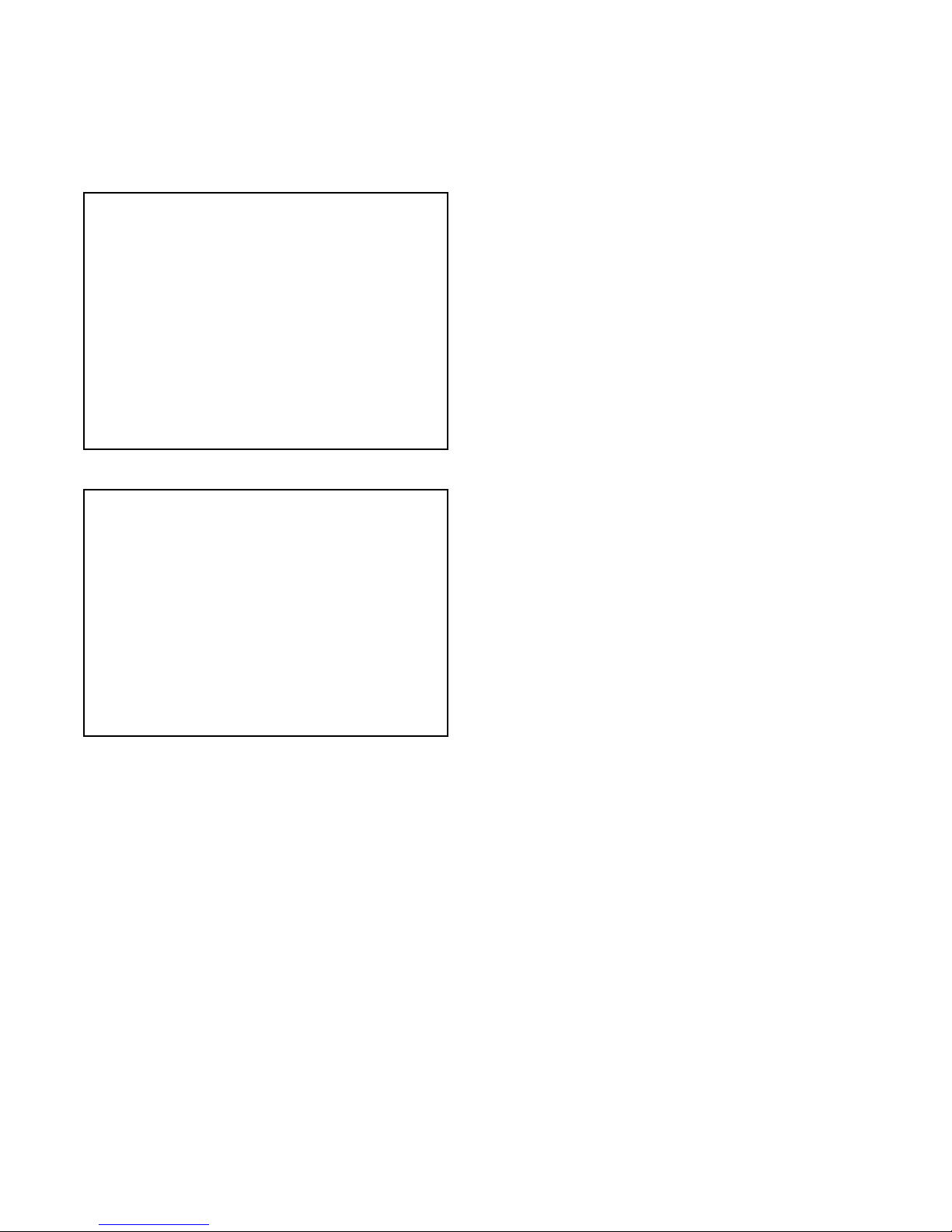

There is a bank of 8 dip switches. The dip switches

work in pairs to match the airflow for the outdoor

unit size (tons). cooling airflow adjustment, Fan offdelay options, and heating airflow adjustment. The

switches appear as shown in Figure 2, p. 6

Figure 1. ECM Fan Control

Figure 2. Dip Switches

If the airflow needs to be increased or decreased,

see the Airflow Label on the air handler or Blower

Performance Table.

Be sure to set the correct airflow for cooling and

heating.

Switches 1–4 Cooling Airflow

Switches 5–6 Fan Off Delay Options

Switches 7–8 Auxiliary Heat

IInnddoooorr BBlloowweerr TTiimmiinngg

IIMMPPOORRTTAANNTT:: Leave dip switches 5 and 6 in the “as-

shipped” positions during system startup and check out. Afterwards, adjust as

desired.

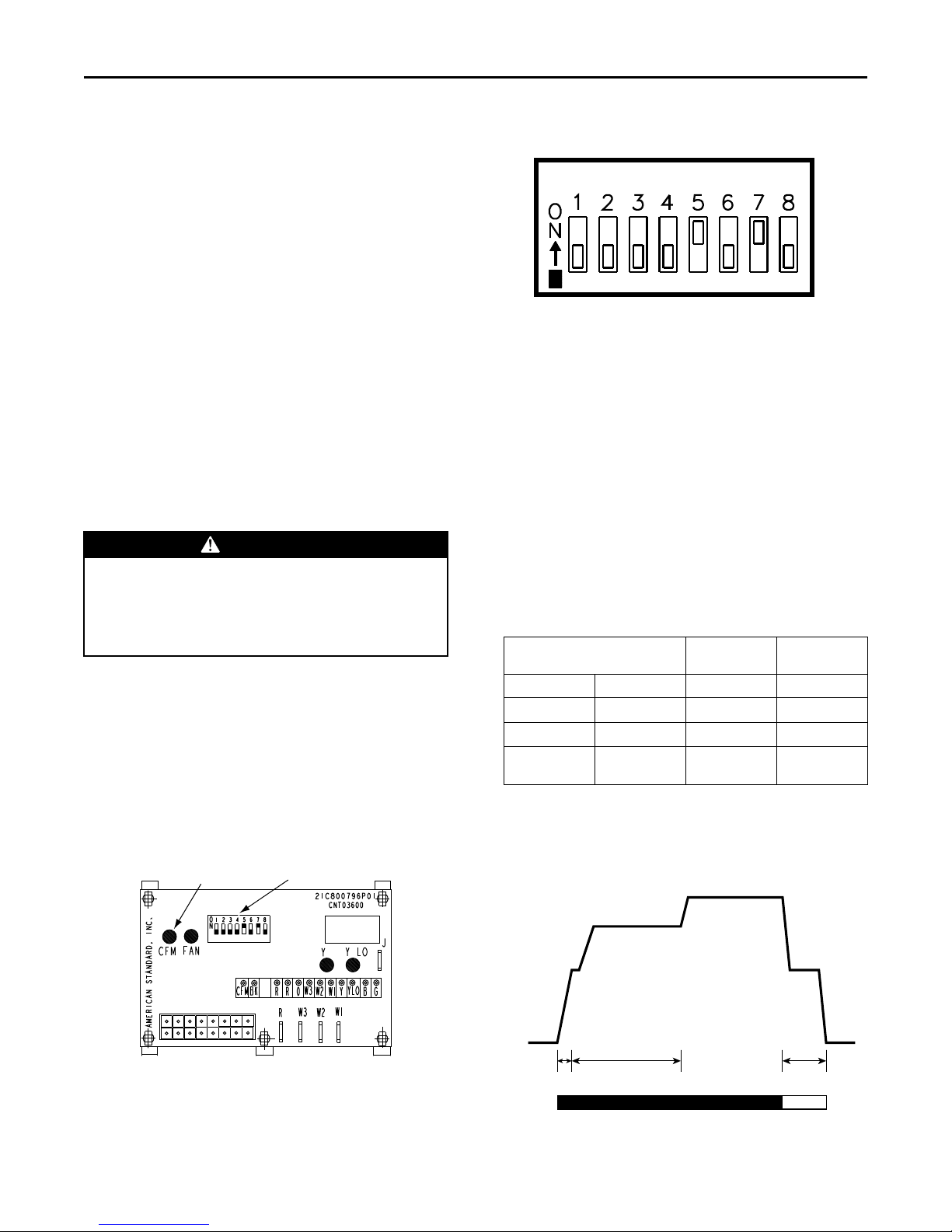

Table 3. Cooling Off — Delay Options

SWITCH SETTINGS SELECTION NOMINAL

5 — OFF 6 — OFF NONE SAME

5 — ON 6 — OFF 1.5 MINUTES 100%

5 — OFF 6 — ON 3 MINUTES 50%

5 — ON 6 — ON ENHANCED

(a)

Default setting

(b)

This ENHANCED MODE selection provides a ramping up and ramping

down of the blower speed to provide improved comfort, quietness,

and potential energy savings. The graph shows the ramping process.

(b)

AIRFLOW

50–100%

(a)

6

Figure 3. Enhanced Mode

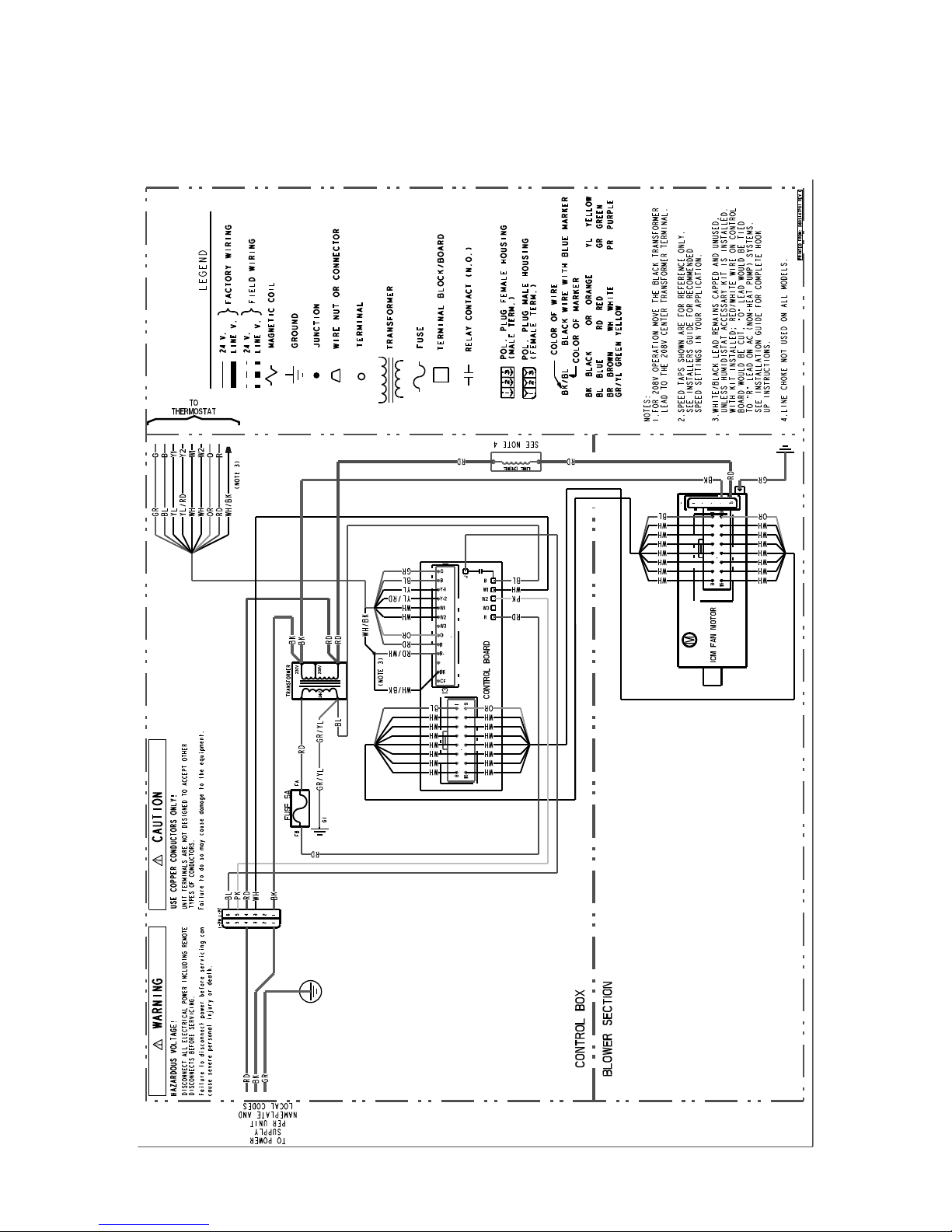

9. WWiirriinngg

18-GF74D1-1F-EN

FFeeaattuurreess

Consult all schematic and pictorial wiring diagrams

of this unit and the outdoor equipment to determine

compatibility of wiring connections and to

determine specific requirements.

All field wiring to the air handler should be installed

in accordance with the latest edition of the National

Electric Code NFPA No. 70 and any local codes.

Check rating plates on unit for rated volts, minimum

circuit ampacity and maximum over current

protection. Supply circuit power wiring must be 75

degree C (167 degree F) minimum copper

conductors only. Copper supply wires shall be sized

to the National Electric Code or local code

requirements, whichever is more stringent.

The unit is shipped wired for 230/240 Volt AC 60 HZ

1 Phase Operation. If the unit is to be operated at

208 VAC 60HZ, follow the instructions on the indoor

unit wiring diagram to change the low voltage

transformer to 208 VAC operation (Ensure unit is

properly grounded).

Class 2 low voltage control wiring should not be run

in conduit with power wiring and must be

separated from power wiring unless class 1 wire

with proper voltage rating is used.

Low voltage control wiring should be 18 Awg, color

coded (105 degree C minimum). For lengths longer

than 100ft., 16 Awg wire should be used. Make

certain that separation of control wiring and power

wiring has been maintained.

10. AAiirr FFiilltteerr

To protect the coil, blower and other internal parts

from excessive dirt and dust an air filter must be

installed before air enters the evaporator coil. A

remote filter must be installed. Consult the filter

manufacturer for proper sizing and maximum

velocity requirements.

IImmppoorrttaanntt:: Air filters shall meet the test requirements

in UL 900.

11. TThheerrmmoossttaatt

Select a thermostat that is commonly used with HP

or AC single stage heating/cooling with electric

heat. The thermostat will energize the fan on a

demand for heat or cool.

Install the thermostat on an inside wall, away from

drafts, lights or other heat sources in a location that

has sufficient air circulation from other rooms being

controlled by the thermostat.

12. SSeeqquueennccee ooff OOppeerraattiioonn

CCoooolliinngg ((CCoooolliinngg oonnllyy))

When the thermostat calls for cooling, the circuit

from R to G is completed. The blower motor is

energized directly by the ECM fan control, which

receives the 24VAC signal from the thermostat.

The circuit from R to Y is also complete energizing

the compressor contactor of the outdoor unit. The

contactor will close and start the compressor and

condenser fan motor.

CCoooolliinngg ((hheeaatt ppuummpp))

When the thermostat calls for cooling, the circuit

from R to G is completed. The blower motor is

energized directly by the ECM fan control, which

receives the 24VAC signal from the thermostat.

The circuit from R to Y is also complete energizing

the compressor contactor of the outdoor unit. The

contactor will close and start the compressor and

condenser fan motor.

Circuit R to O energizes the reversing valve to the

cooling position.

HHeeaattiinngg ((hheeaatt ppuummpp))

When the thermostat calls for heating, the circuit

from R to G is completed and the blower motor is

energized directly by the ECM fan control, which

receives the 24VAC signal from the thermostat.

The circuit from R to Y is also complete energizing

the compressor contactor of the outdoor unit. The

contactor will close and start the compressor and

condenser fan motor.

18-GF74D1-1F-EN

7

FFeeaattuurreess

In the heating mode, the reversing valve of the

outdoor unit is not energized.

If the indoor temperature continues to fall, the R to

W circuit is completed energizing the electric heat

contactor(s).

HHeeaattiinngg ((eelleeccttrriicc hheeaatt oonnllyy))

NNoottee:: The thermostat must be setup to bring the

blower on when the electric heat is energized.

When the thermostat calls for heating, the circuit

from R to G is completed and the blower motor is

energized directly by the ECM fan control, which

receives the 24VAC signal from the thermostat. The

circuit from R to W is completed energizing the

heating contactor(s).

DDeeffrroosstt

Supplemental heat during defrost can be provided

by connecting the X2 (black) wire from the outdoor

unit to W1 or W2 at the indoor unit. This will

prevent cold air from being discharged from the

indoor unit during defrost.

13. OOppeerraattiioonnaall aanndd CChheecckkoouutt PPrroocceedduurreess

To obtain proper performance, all units must be

operated and charge adjustments made in

accordance with procedures found in the Service

Facts document of the outdoor unit. After

installation has been completed, it is recommended

that the entire system be checked against the

checkout list located at the back of this document.

See “Checkout Procedures,” p. 36

14. MMaaiinntteennaannccee

The system air filter(s) should be inspected, cleaned

or replaced at least monthly. Make certain that the

access panels are replaced and secured properly

before placing the unit back in operation. This

product is designed for dependable service;

however, periodic maintenance should be

scheduled and conducted by trained professional

service personnel. This service should be

conducted at least annually, and should include

testing and inspection of electrical and refrigerant

components. The heat transfer surface should be

cleaned. The blower motor is permanently

lubricated for normal operating conditions.

8

18-GF74D1-1F-EN

Field Wiring

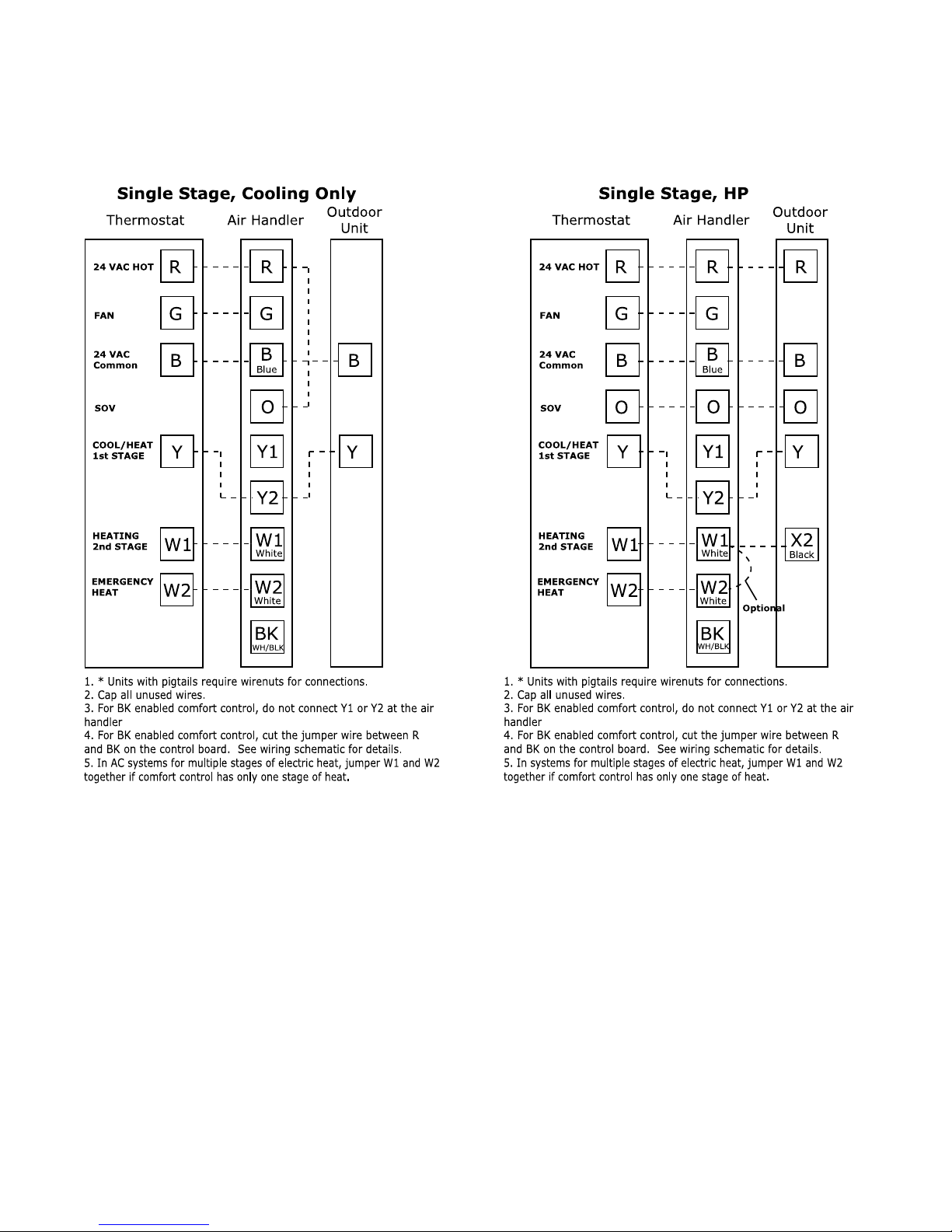

Sing le St age, C o o lin g On ly

The rm ostat Air H andler

Outdoor

Unit

R

G

B

W1

W2

B

Y

R

G

B

Y

W1

Blue

24 VAC HOT

FAN

24 VAC

Common

SOV

COOL/HEAT

1st STAGE

HEATING

2nd STAGE

EMERGENCY

HEAT

White

White

W2

O

Y1

1. * Uni ts wi th pi gtai ls re quire wirenut s for conn ections.

2. Cap al l unu sed wire s.

3. F or BK ena b led com fort control, do not conn e ct Y1 or Y2 at the air

handl e r

Y2

BK

WH/BLK

4. F or BK ena b led com fort control, cut the jumpe r wire betw een R

and BK on the control board. See wi ring schematic for d e tails.

5. In AC s yst em s for mult iple s tages of e lectric heat , jumper W1 a n d W2

tog ether if c o m fort control h as o nly one sta g e of heat.

Sing le St age, HP

The rm ostat Air H andler

Outdoor

Unit

R

G

B

W1

W2

R

B

O

Y

X2

R

G

B

O

Y

W1

Blue

24 VAC HOT

FAN

24 VAC

Common

SOV

COOL/HEAT

1st STAGE

HEATING

2nd STAGE

EMERGENCY

HEAT

White

Black

White

W2

O

Y1

Y2

BK

Optional

WH/BLK

1. * Uni ts wi th pi gtai ls re quire wirenut s for conn ections.

2. Cap al l unu sed wire s.

3. F or BK ena b led com fort control, do not conn e ct Y1 or Y2 at the air

handl e r

4. F or BK ena b led com fort control, cut the jumpe r wire betw een R

and BK on the control board. See wi ring schematic for d e tails.

5. In s ystem s fo r m u ltiple stage s of electric he a t, jum per W1 a n d W2

tog ether if c o m fort control h as o nly one sta g e of heat.

18-GF74D1-1F-EN

9

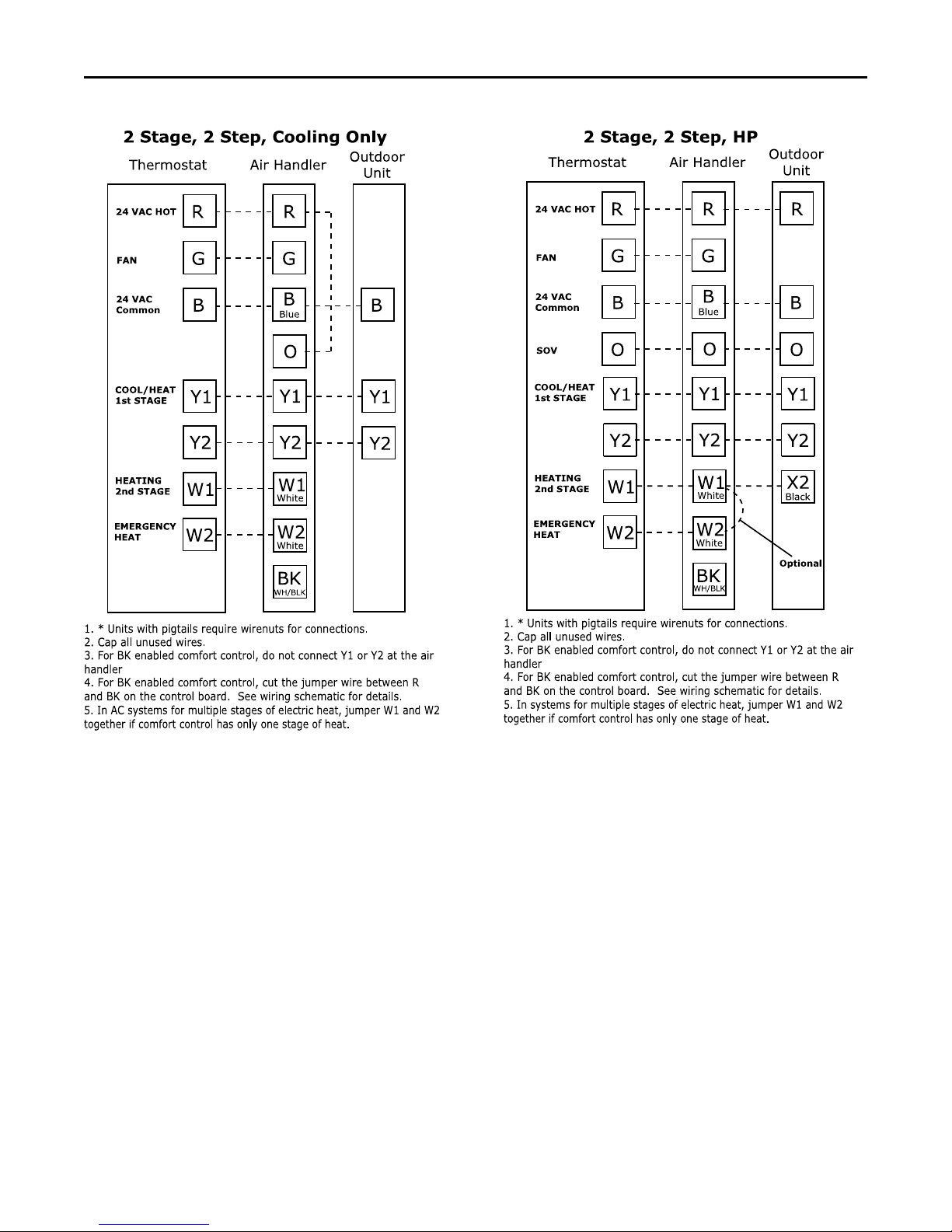

2 St age, 2 Step, Coo lin g O n ly

The rm o

stat

Air H andler

Outdoor

Unit

R

G

B

W1

W2

B

Y1

R

G

B

Y1

W1

Blue

24 VAC HOT

FAN

24 VAC

Common

COOL/HEAT

1st STAGE

HEATING

2nd STAGE

EMERGENCY

HEAT

White

White

W2

O

Y1

Y2

BK

Y2

Y2

WH/BLK

1. * Uni ts wi th pi gtai ls re quire wirenut s for conn ections.

2. Cap al l unu sed wire s.

3. F or BK ena b led com fort control, do not conn e ct Y1 or Y2 at the air

handl e r

4. F or BK ena b led com fort control, cut the jumpe r wire betw een R

and BK on the control board. See wi ring schematic for d e tails.

5. In AC s yst em s for mult iple s tages of e lectric heat , jumper W1 a n d W2

tog ether if c o m fort control h as o nly one sta g e of heat.

2 St age, 2 Step, HP

The rm ostat Air H andler

Outdoor

Unit

R

G

B

W1

W2

R

B

O

Y1

X2

R

G

B

O

Y1

W1

Blue

24 VAC HOT

FAN

24 VAC

Common

SOV

COOL/HEAT

1st STAGE

HEATING

2nd STAGE

EMERGENCY

HEAT

White

Black

White

W2

O

Y1

Y2

BK

Optional

Y2Y2

WH/BLK

1. * Uni ts wi th pi gtai ls re quire wirenut s for conn ections.

2. Cap al l unu sed wire s.

3. F or BK ena b led com fort control, do not conn e ct Y1 or Y2 at the air

handl e r

4. F or BK ena b led com fort control, cut the jumpe r wire betw een R

and BK on the control board. See wi ring schematic for d e tails.

5. In s ystem s fo r m u ltiple stage s of electric he a t, jum per W1 a n d W2

tog ether if c o m fort control h as o nly one sta g e of heat.

FFiieelldd WWiirriinngg

10

18-GF74D1-1F-EN

Electrical Data

18-GF74D1-1F-EN

11

Loading...

Loading...