Ingersoll-Rand TAM7A0C36H31EA, TAM7A0C48H41EA, TAM7A0C42H31EA, TAM7A0B30H21EA, TAM7B0C60H51EA Installer Manual

...

Installer’s Guide

Air Handlers

Convertible 2 — 5 Ton

BBllaacckk EEppooxxyy CCooiillss

TAM7A0A24H21EA

TAM7A0B30H21EA

TAM7A0C36H31EA

TAM7A0C42H31EA

TAM7A0C48H41EA

TAM7B0C60H51EA

SSttaannddaarrdd CCooiillss

TAM7A0A24H21SD

TAM7A0B30H21SD

TAM7A0C36H31SD

TAM7A0C42H31SD

TAM7A0C48H41SD

TAM7B0C60H51SC

Scan or click to view

TAM7 Trouble Shooting

Video Library

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

July 2014

NNoottee:: “Graphics in this document are for representation only.

Actual model may differ in appearance.”

NNoottee:: For use with BAYEV or BAYW series heaters ONLY

SSAAFFEETTYY WWAARRNNIINNGG

18-GJ06D2-2E-EN

SAFETY SECTION

AIR HANDLERS

IImmppoorrttaanntt — This document contains a wiring

diagram, a parts list, and service information. This is

customer property and is to remain with this unit.

Please return to service information pack upon

completion of work.

WWAARRNNIINNGG

HHAAZZAARRDDOOUUSS VVOOLLTTAAGGEE!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaannnnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd..

CCAAUUTTIIOONN

GGRROOUUNNDDIINNGG RREEQQUUIIRREEDD!!

FFaaiilluurree ttoo iinnssppeecctt oorr uussee pprrooppeerr sseerrvviiccee ttoooollss mmaayy

rreessuulltt iinn eeqquuiippmmeenntt ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

RReeccoonnnneecctt aallll ggrroouunnddiinngg ddeevviicceess.. AAllll ppaarrttss ooff tthhiiss

pprroodduucctt tthhaatt aarree ccaappaabbllee ooff ccoonndduuccttiinngg eelleeccttrriiccaall

ccuurrrreenntt aarree ggrroouunnddeedd.. IIff ggrroouunnddiinngg wwiirreess,, ssccrreewwss,,

ssttrraappss,, cclliippss,, nnuuttss,, oorr wwaasshheerrss uusseedd ttoo ccoommpplleettee aa

ppaatthh ttoo ggrroouunndd aarree rreemmoovveedd ffoorr sseerrvviiccee,, tthheeyy mmuusstt

bbee rreettuurrnneedd ttoo tthheeiirr oorriiggiinnaall ppoossiittiioonn aanndd pprrooppeerrllyy

ffaasstteenneedd..

WWAARRNNIINNGG

PPRREESSSSUURRIIZZEEDD RREEFFRRIIGGEERRAANNTT!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

ppeerrssoonnaall iinnjjuurryy

SSyysstteemm ccoonnttaaiinnss ooiill aanndd rreeffrriiggeerraanntt uunnddeerr hhiigghh

pprreessssuurree.. RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree

bbeeffoorree ooppeenniinngg tthhee ssyysstteemm.. DDoo nnoo uussee nnoonn-aapppprroovveedd rreeffrriiggeerraannttss oorr rreeffrriiggeerraanntt ssuubbssttiittuutteess oorr

rreeffrriiggeerraanntt aaddddiittiivveess..

CCAAUUTTIIOONN

SSHHAARRPP EEDDGGEE HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

BBee ccaarreeffuull ooff sshhaarrpp eeddggeess oonn eeqquuiippmmeenntt oorr aannyy

ccuuttss mmaaddee oonn sshheeeett mmeettaall wwhhiillee iinnssttaalllliinngg oorr

sseerrvviicciinngg..

IImmppoorrttaanntt:: Panel damage can occur with prolonged

exposure to POE lubricants. Air handler

front panels that come in contact with POE

oil must be washed immediately with

soapy water.

NNoottee:: Representative illustrations only included in this

document. Most illustrations display the upflow

configuration.

WWAARRNNIINNGG

LLIIVVEE EELLEECCTTRRIICCAALL CCOOMMPPOONNEENNTTSS!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

FFoollllooww aallll eelleeccttrriiccaall ssaaffeettyy pprreeccaauuttiioonnss wwhheenn

eexxppoosseedd ttoo lliivvee eelleeccttrriiccaall ccoommppoonneennttss.. IItt mmaayy bbee

nneecceessssaarryy ttoo wwoorrkk wwiitthh lliivvee eelleeccttrriiccaall ccoommppoonneennttss

dduurriinngg iinnssttaallllaattiioonn,, tteessttiinngg,, sseerrvviicciinngg,, aanndd

ttrroouubblleesshhoooottiinngg ooff tthhiiss pprroodduucctt..

©2014 Trane

18-GJ06D2-2E-EN

Table of Contents

Installer Guide Notes . . . . . . . . . . . . . . . . . . . . . . . 4

Unit Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Install Preparation . . . . . . . . . . . . . . . . . . . . . 7

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . 8

Optional Cabinet Disassembly. . . . . . . . . . . . . . 9

Placing Unit at Location . . . . . . . . . . . . . . . . . . . 13

Unit Location Considerations. . . . . . . . . . . . . . 14

Four-Way Conversion. . . . . . . . . . . . . . . . . . . . . . 15

Ducted and Non-Ducted

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Additional Unit Preparation

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Unit — Vertical

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the Unit — Horizontal

Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting the Duct work . . . . . . . . . . . . . . . . . 23

Refrigerant Line . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Refrigerant System Layout . . . . . . . . . . . . . . . 24

Refrigerant Line Brazing . . . . . . . . . . . . . . . . . . . 25

Condensate Drain Piping . . . . . . . . . . . . . . . . . . 29

Electrical — Low Voltage . . . . . . . . . . . . . . . . . . 32

Dip Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Indoor Blower Options . . . . . . . . . . . . . . . . . . . . 41

Control Plate Reinstall . . . . . . . . . . . . . . . . . . . . . 42

Electrical — High Voltage . . . . . . . . . . . . . . . . . . 43

TAM7 OUTLINE DRAWING . . . . . . . . . . . . . . . . 46

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

System Charge Adjustments . . . . . . . . . . . . . 47

System Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

TAM7 Sequence of Operation . . .. . . . . . . . . . 49

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . 51

18-GJ06D2-2E-EN

3

Installer Guide Notes

AALLLL PPhhaasseess ooff tthhiiss iinnssttaallllaattiioonn mmuusstt ccoommppllyy wwiitthh

NNAATTIIOONNAALL,, SSTTAATTEE aanndd LLOOCCAALL CCOODDEESS!!

IImmppoorrttaanntt:: This Document is customer property and is

to remain with t his unit. Please return to

service information upon completion of

work

IImmppoorrttaanntt:: These instructions do not cover all

variations in systems nor provide for every

possible contingency to be met in

connection with the installation. Should

further information be desired or should

particular problems arise which are not

covered sufficiently for the purchaser’s

purposes, the matter should be referred to

your installing dealer or local distributor.

SSeeee TTAAMM77 SSeerrvviiccee FFaaccttss ddooccuummeenntt ffoorr iinnffoorrmmaattiioonn

oonn rreeaaddiinngg tthhee CCoonnttrrooll BBooaarrdd LLEEDDss,, AAiirr FFllooww TTaabblleess

aanndd TTrroouubblleesshhoooottiinngg FFlloowwcchhaarrttss..

NNoottee:: The manufacturer recommends installing ONLY

A.H.R.I. approved, matched indoor and outdoor

systems. Some of the benefits of installing

approved matched indoor and outdoor split

systems are maximum efficiency, optimum

performance, and the best overall system

reliability.

NNoottee:: Condensation may occur on the surface of the air

handler when installed in unconditioned spaces,

verify that all electrical and refrigerant line

penetrations on the air handler are sealed

completely.

The TAM7 air handlers will only use the following

internal electric heaters:

BAYEVAC04BK1AA BAYEVAC10LG1AA

BAYEVAC04LG1AA BAYEVBC15BK1AA

BAYEVAC05BK1AA BAYEVBC20BK1AA

BAYEVAC05LG1AA BAYEVCC25BK1AA

BAYEVAC08BK1AA BAYEVAC10LG3AA

BAYEVAC08LG1AA BAYEVBC15LG3AA

BAYEVAC10BK1AA

NNoottee:: Duct heaters cannot be applied with this air

handler.

4

18-GJ06D2-2E-EN

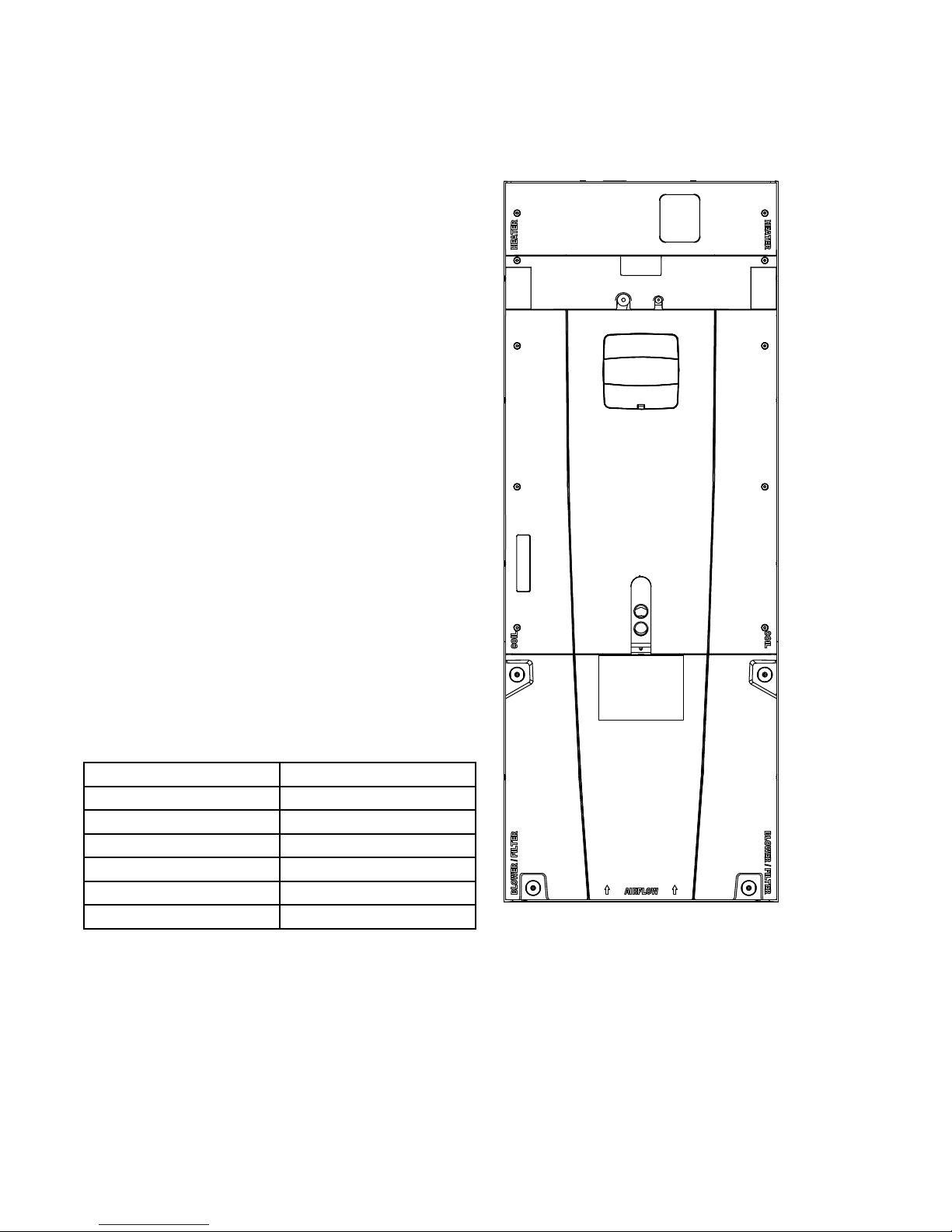

Unit Design

Screws ca n be drilled

into bottom of unit.

(1/2” max. s crew

length)

(Typical all sides)

Screws , saw cuts, and other

penetrations are a llowed in

the blower se ction for low

voltage wiring or installat

io

n

of Side Return Kit.

(Typical both sides)

Screws are a llowed up to 3- 3/4”

from the top of the ca bine t

(heate r compartment).

(Typical both sides)

Screws for flange kit

attachment are allowe

d

along the inte rior of

the cabinet (se e arrows )

(Typical all sides)

No penetrations

allowe d.

(Typical all sides)

Screws allowe d only

in the first 3/4” of front

bottom of unit (in

cross member)

Table 1. Cabinet Penetration

Important: Due to the unique design of this unit, which allows the

electrical wiring to be routed within the insulation, do not

screw, cut, or otherwise puncture the unit cabinet in any

location other than the ones illustrated.

Important: Under no conditions should metal strapping be attached

to the unit to be used as support mechanisms for

carrying or suspension purposes.

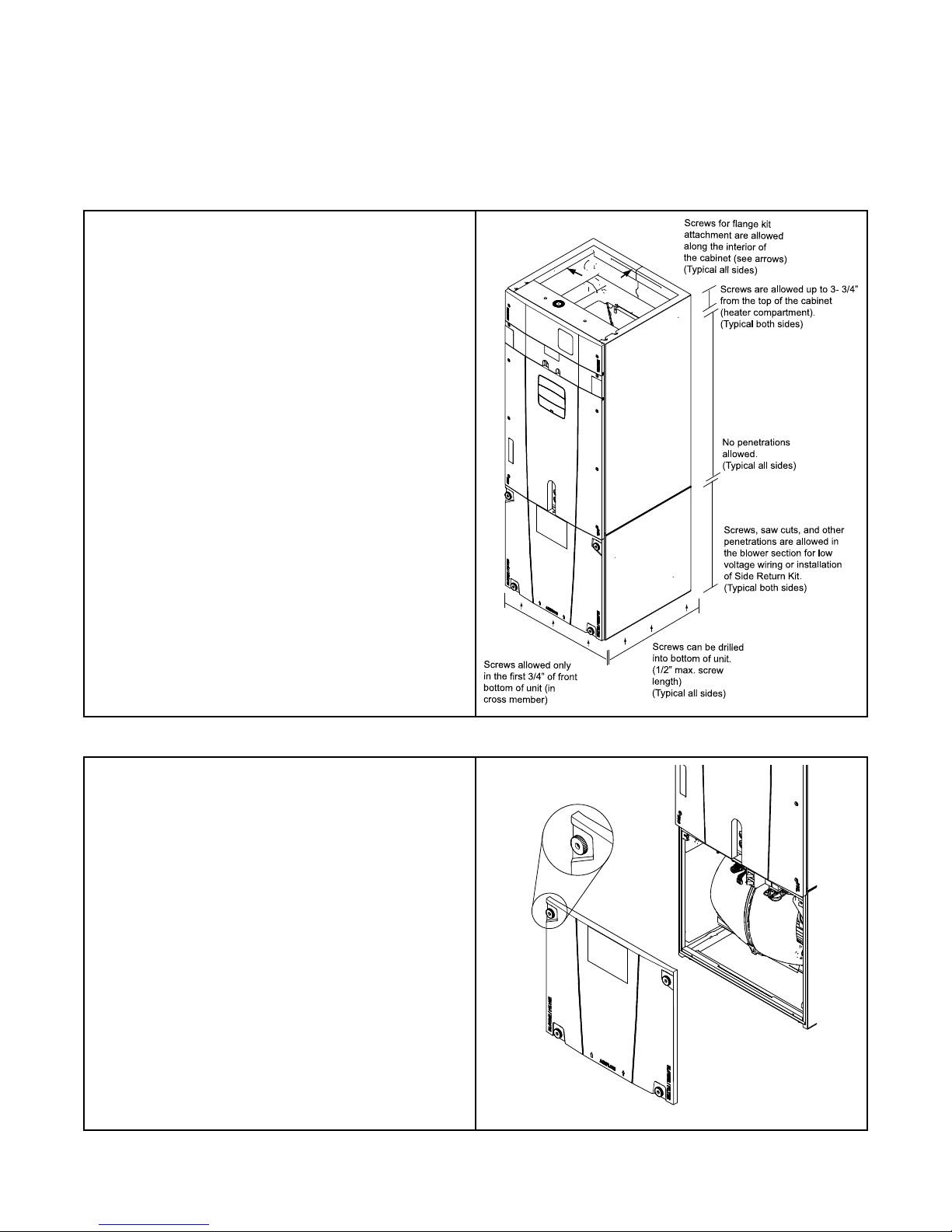

Table 2. Panel Removal

The unit contains four (4) access panels: Blower/Filter, Coil, Line Set,

and Heater.

The Blower/Filter panel is removed using 1/4 turn thumb screws.

1. Turn thumb screws on Blower/Filter panel.

2. Pull top of panel out, away from cabinet.

3. Lift panel up out of channel.

4. Set aside.

18-GJ06D2-2E-EN

5

0

0

0

0

UUnniitt DDeessiiggnn

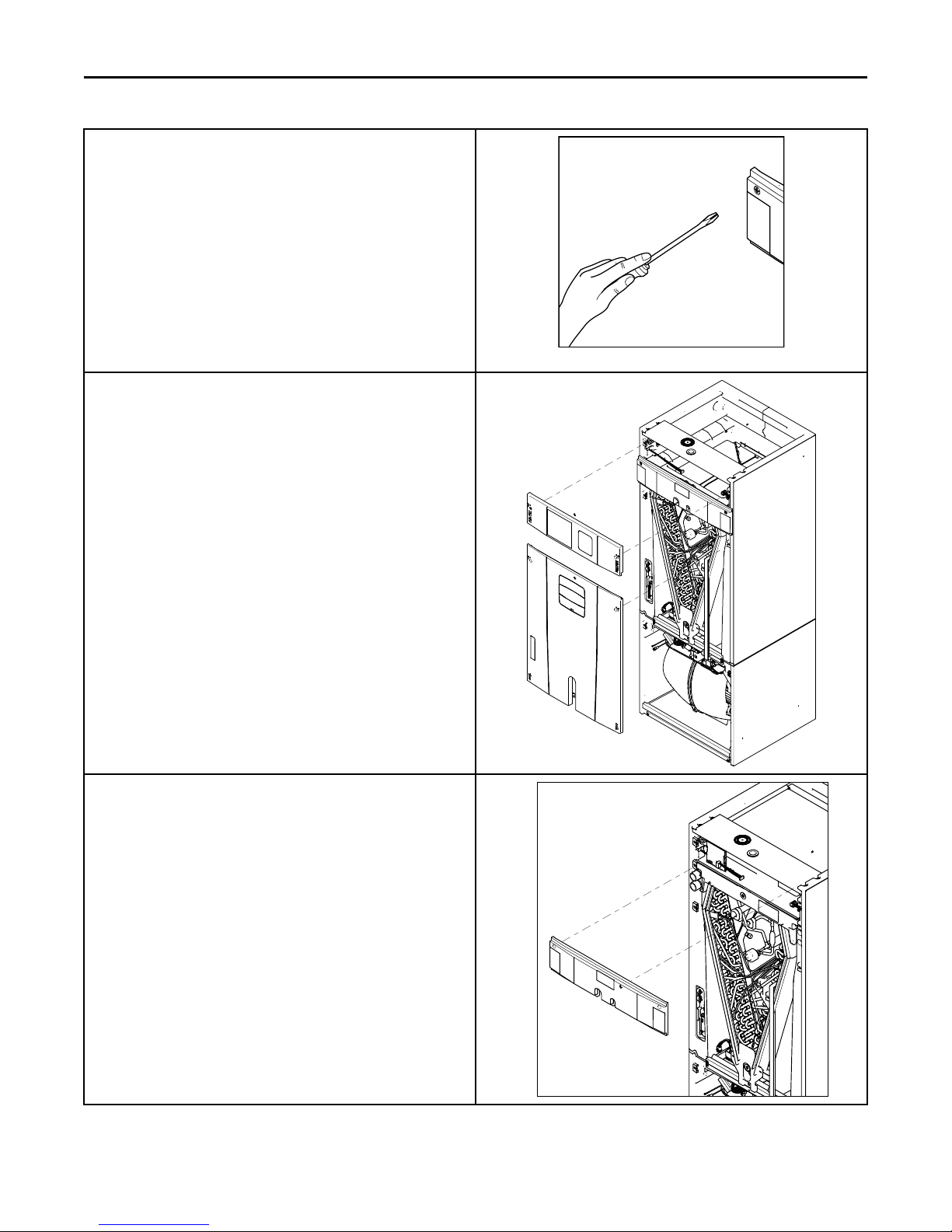

The Coil, Line Set, and Heater panels are removed using Phillips head

screws.

Removal requires #3 Size Phillips

Coil and Heater panels must be removed prior to removing the Line

Set panel.

To remove Coil Panel:

1. Turn screws on Coil panel.

2. Pull bottom of panel out, away from cabinet.

3. Pull panel down and out of channel.

4. Set aside.

To remove Heater Panel:

1. Turn screws on Heater panel.

2. Pull panel straight out, away from cabinet.

3. Set aside.

Removal of the Line Set panel is required for all refrigerant line brazing

and some condensate line assembly depending on your orientation.

To remove Line Set panel:

1. Remove both Heater and Coil panels.

2. Turn screws on Line Set panel.

3. Pull panel straight out, away from cabinet.

4. Set aside.

Note: After replacing all panels, loosen the Line Set panel screws

approximately 1/4 — 1/2 turn. This will improve the seal

between the Heater Panel and Line Set panel.

6

18-GJ06D2-2E-EN

Unit Install Preparation

1. Check for damage and report promptly to the carrier any damage

found to the unit.

Note: If the unit must be transported in a horizontal position, it must

be laid on its back (marked “REAR” on carton).

Note: After unit is removed from the carton, verify coil is pressurized.

Carefully remove the liquid line plug. If no pressure is released,

check for leaks.

Note: Remove the cardboard from the bottom of the blower. Cut the

tie wrap and remove the foam shipping block located at the

motor.

18-GJ06D2-2E-EN

7

Optional Equipment

Accessory Number Description

BAYEVAC04BK1AA

BAYEVAC04LG1AA

BAYEVAC05BK1AA

BAYEVAC05LG1AA

BAYEVAC08BK1AA

BAYEVAC08LG1AA

BAYEVAC10BK1AA

BAYEVAC10LG1AA

BAYEVBC15BK1AA

BAYEVBC20BK1AA

BAYEVCC25BK1AA

BAYEVAC10LG3AA

BAYEVBC15LG3AA

BAYSUPFLGAA

BAYSUPFLGBA

BAYSUPFLGCA

BAYRETFLGAA

BAYRETFLGBA

BAYRETFLGCA

BAYSRKIT100A Side Return Kit A to C

BAYFLR1620A

BAYFLR2020A

BAYFLR2220A

TASB175SB

TASB215SB

TASB235SB

MITISRKIT01A Side Return Kit with 16” x 20” Filter A to C

BAYFRKIT175 Front Return Kit for 17.5” Cabinet A

BAYFRKIT210 Front Return Kit for 21.0” Cabinet B

BAYFRKIT235 Front Return Kit for 23.5” Cabinet C

BAYBAFKT175A Sound Baffle Kit for 17.5” Cabinet A

BAYBAFKT215A Sound Baffle Kit for 21.0” Cabinet B

BAYBAFKT235A Sound Baffle Kit for 23.5” Cabinet C

TASSBK175 Sound Baffle Kit for 17.5” Cabinet A

TASSBK210 Sound Baffle Kit for 21.0” Cabinet B

TASSBK235 Sound Baffle Kit for 23.5” Cabinet C

BAYICSKIT01A Internal Condensate Switch Kit A to C

BAYHHKIT001A

BAYUVCLK001A

BAYLVKIT100A

BAYSPEKT200A

BAYWVAA05SC1AA

BAYWVBB07SC1AA

BAYWVCC08SC1AA

BAYWACC11SC1AA

BAYWVBRD485A RS-485 Control for BAYWACC11SC1AA C to C

BAYINSKT175A

BAYINSKT215A

BAYINSKT235A

BAYCNDPIP01A

Electric Heater, 4kW, Breaker, RS-485 Control, 1 Ph

Electric Heater, 4kW, Lugs, RS-485 Control, 1 Ph

Electric Heater, 5kW, Breaker, RS-485 Control, 1 Ph

Electric Heater, 5kW, Lugs, RS-485 Control, 1 Ph

Electric Heater, 8kW, Breaker, RS-485 Control, 1 Ph

Electric Heater, 8kW, Lugs, RS-485 Control, 1 Ph

Electric Heater, 10kW, Breaker, RS-485 Control, 1 Ph

Electric Heater, 10kW, Lugs, RS-485 Control, 1 Ph

Electric Heater, 15kW, Breaker, RS-485 Control, 1 Ph

Electric Heater, 20kW, Breaker, RS-485 Control, 1 Ph

Electric Heater, 25kW, Breaker, RS-485 Control, 1 Ph

Electric Heater, 10kW, Lugs, RS-485 Control, 3 Ph

Electric Heater, 15kW, Lugs, RS-485 Control, 3 Ph

Supply Duct Flange A

Supply Duct Flange B

Supply Duct Flange C

Return Duct Flange A

Return Duct Flange B

Return Duct Flange C

High Velocity Filter Kit, 16” x 20” x 1” (10 filters)

High Velocity Filter Kit, 20” x 20” x 1” (10 filters)

High Velocity Filter Kit, 22” x 20” x 1” (10 filters)

Plenum Stand with integrated sound baffle A

Plenum Stand with integrated sound baffle B

Plenum Stand with integrated sound baffle C

Horizontal Hanger Kit

UVC Lights

Low Voltage Conduit Entry Kit

Single Power Entry Kit

Hydronic Coil — 50,000 BTUH — Slide-in with control

Hydronic Coil — 70,000 BTUH — Slide-in with control

Hydronic Coil — 80,000 BTUH — Slide-in with control

Hydronic Coil — 100,000 BTUH — Add on

Solcoustic® Liner Kit for 17.5” cabinet

Solcoustic® Liner Kit for 21.5” cabinet

Solcoustic® Liner Kit for 23.5” cabinet

3/4” PVC Threaded Pipe Kit foam Seal (10 per box)

A to C

A to C

A to C

A to C

A to C

A to C

A to C

A to C

B to C

C

C

A to C

B to C

A

B

C

A

B

C

A

B

C

A

B

C

A to C

A to C

A to C

A to C

A to A

B to B

C to C

C to C

A

B

C

A to C

Fits Cabinet Size

8

18-GJ06D2-2E-EN

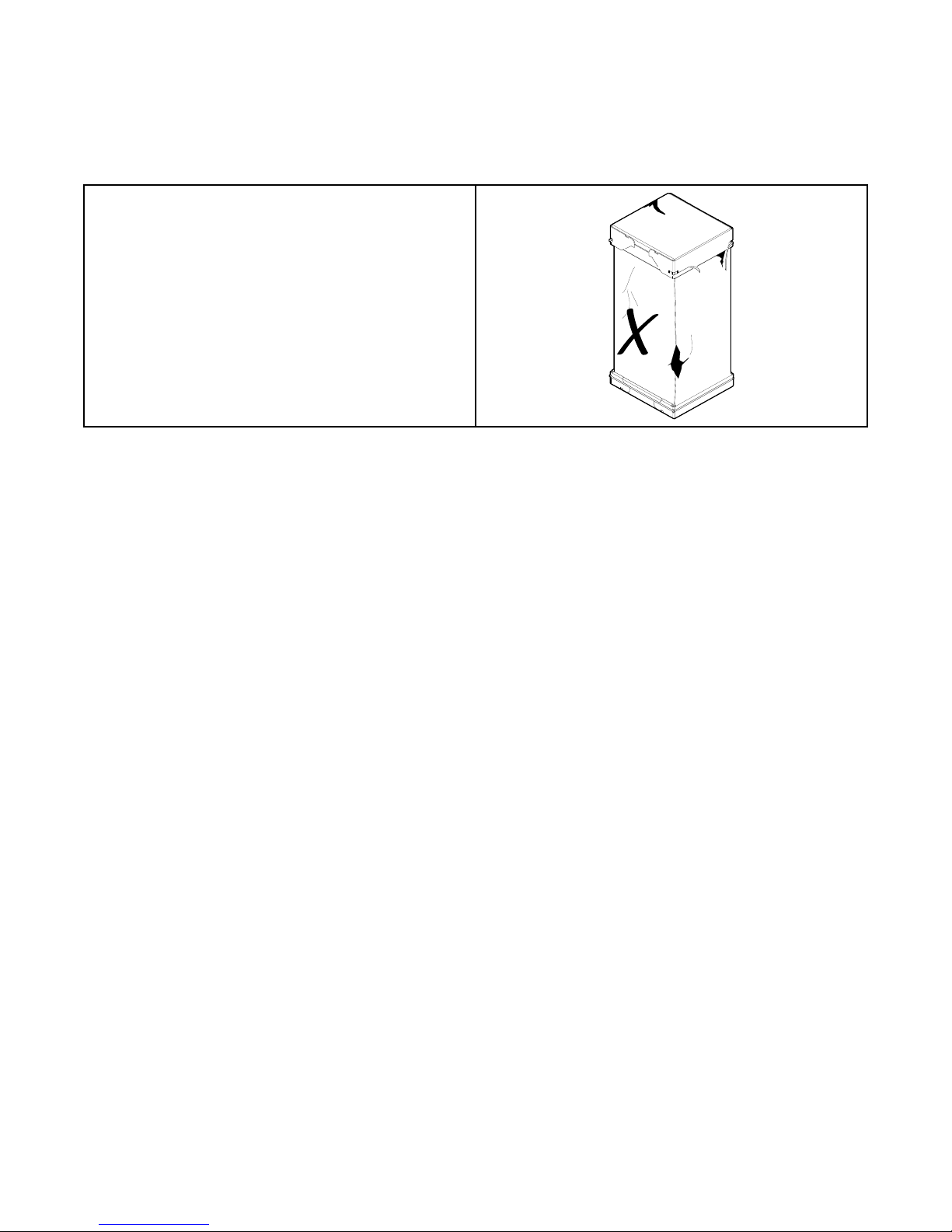

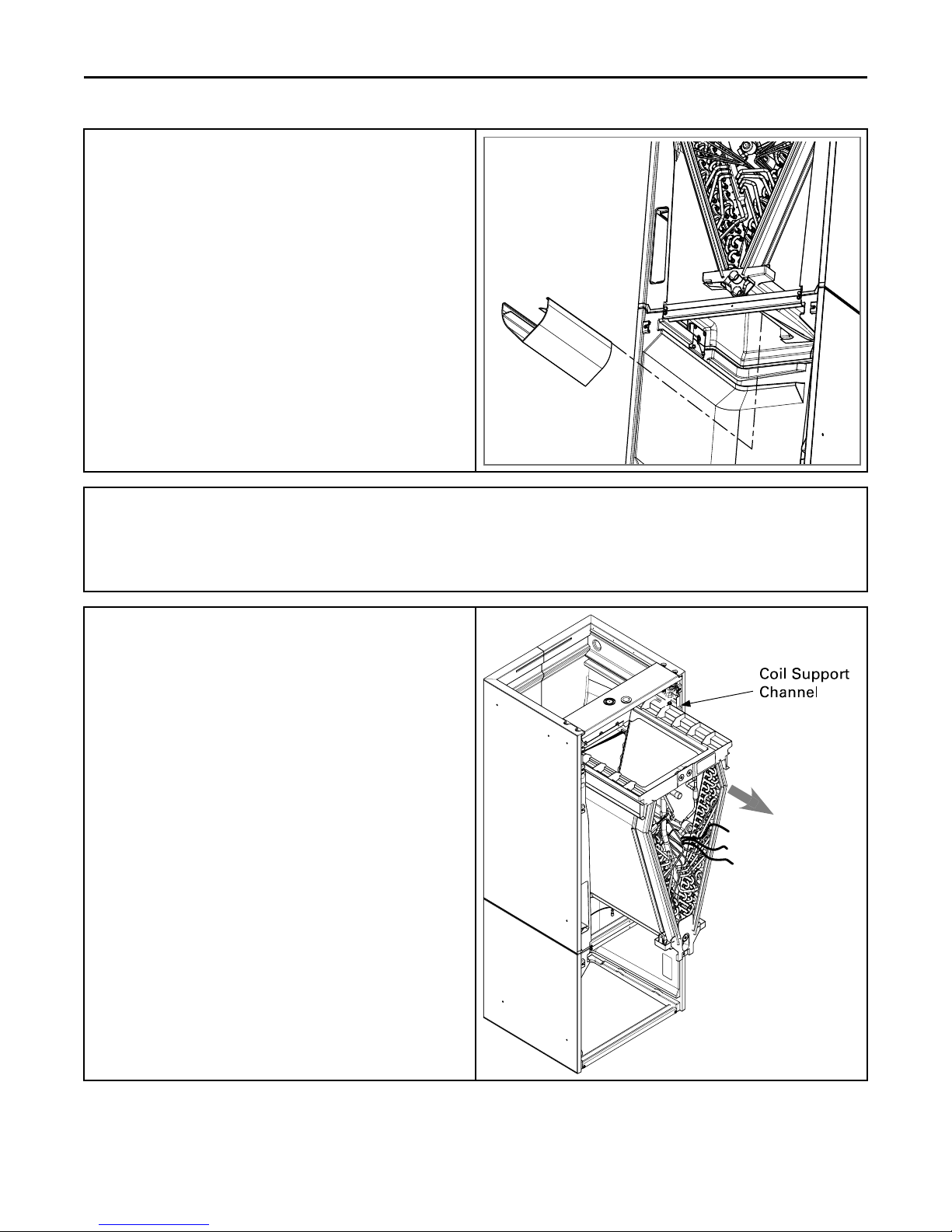

Optional Cabinet Disassembly

Note: If the unit must be transported in a horizontal position, it must be

laid on its back (marked “REAR” on carton).

Note: To reassemble cabinet, follow the steps in reverse order. Ensure

electrical connections are secure and the plug clips are engaged.

1. Remove all four front panels.

2. Remove the two screws on the seal bar and pull the seal bar

straight out.

3. Disconnect all wiring connections routed to the blower assembly.

See Table 2, p. 5

4. Slide Blower assembly out of unit using built-in blower support

channels and set aside.

Note: Remove the cardboard from the bottom of the blower. Cut the

tie wrap and remove the foam block located at the motor.

18-GJ06D2-2E-EN

9

Coil Support

Channel

OOppttiioonnaall CCaabbiinneett DDiissaasssseemmbbllyy

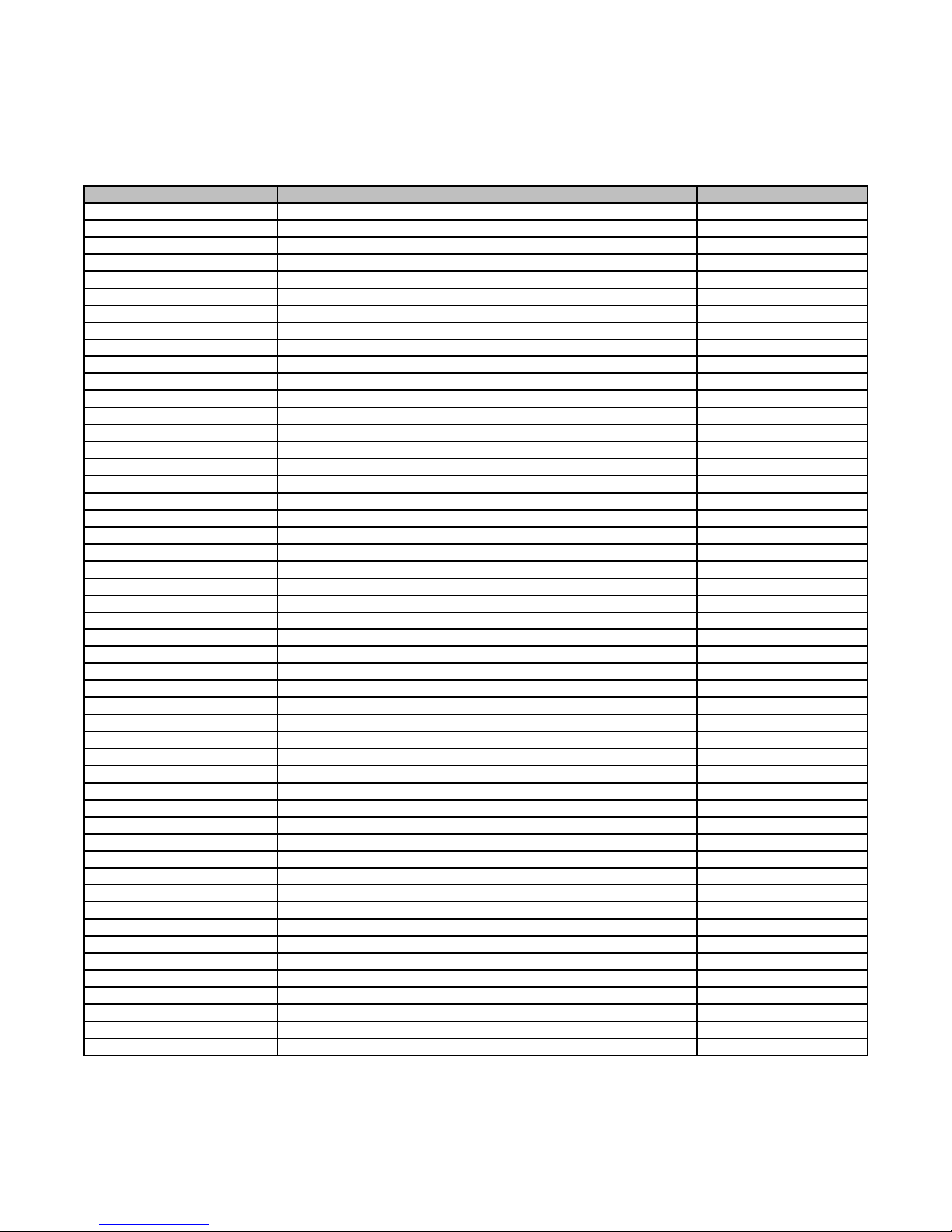

5. Remove airflow diverter from the bottom of coil drain pan by

gripping the plastic diverter while using your thumbs to spread

the top of the diverter slightly outwards and then pulling down

and out through the blower opening as illustrated.

6. Disconnect wires to the EEV motor and sensors. Cut the wire ties on

those wire harnesses if necessary and replace after re-installing.

Note: If cut, wire ties that held the sensor must be replaced after the coil is

placed back into the cabinet.

7. Slide Coil assembly out of unit using built-in coil support channels

and set aside

10

18-GJ06D2-2E-EN

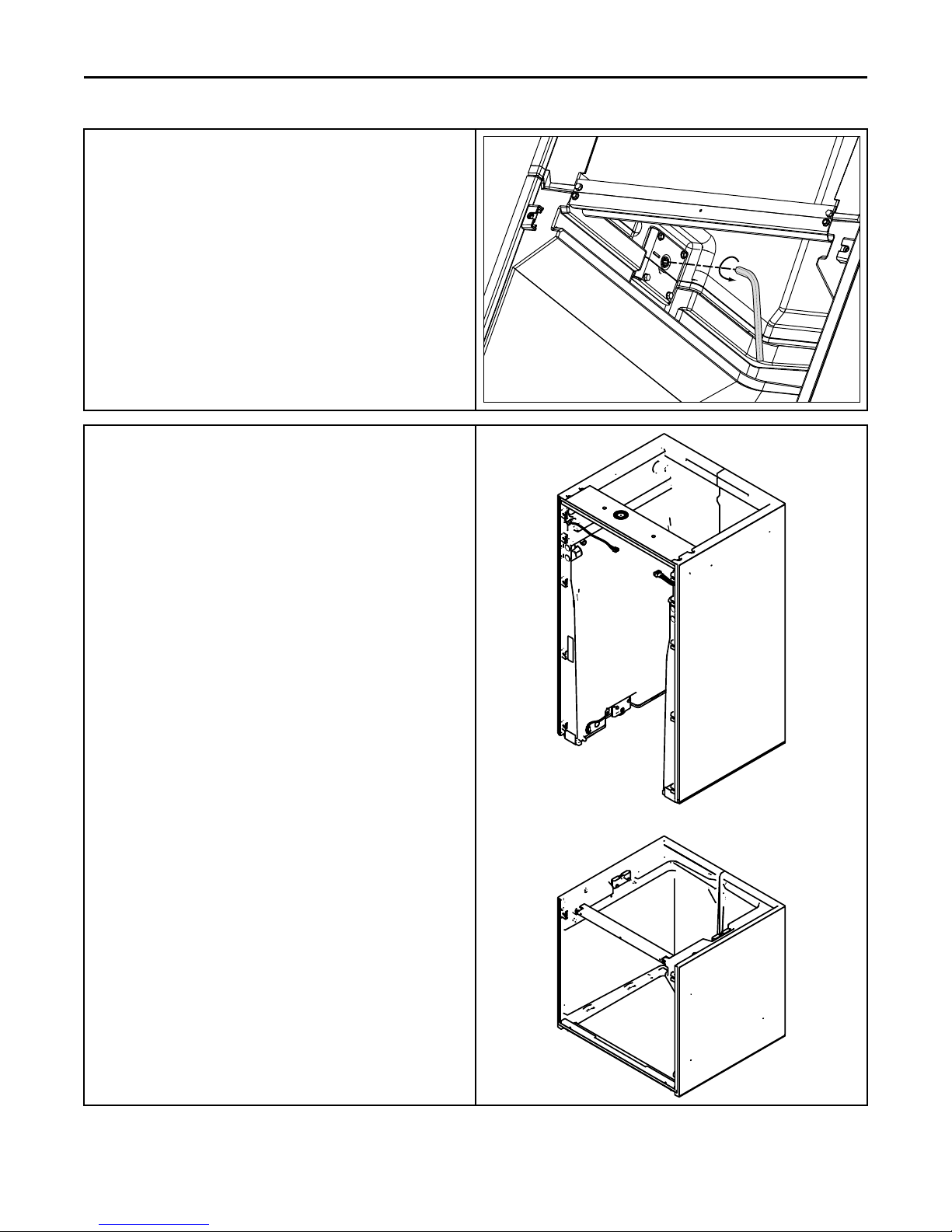

8. Use a 5/16 Allen wrench on the locking mechanism on each side

of the bottom half of the cabinet to loosen the locking mechanism.

The locks loosen by turning counter-clockwise approximately 3/4

of a turn.

9. Lift the Coil section up and away from the Blower section. Set

aside.

Note: When separating the two cabinet pieces, make sure the gasket

remains intact.

OOppttiioonnaall CCaabbiinneett DDiissaasssseemmbbllyy

18-GJ06D2-2E-EN

11

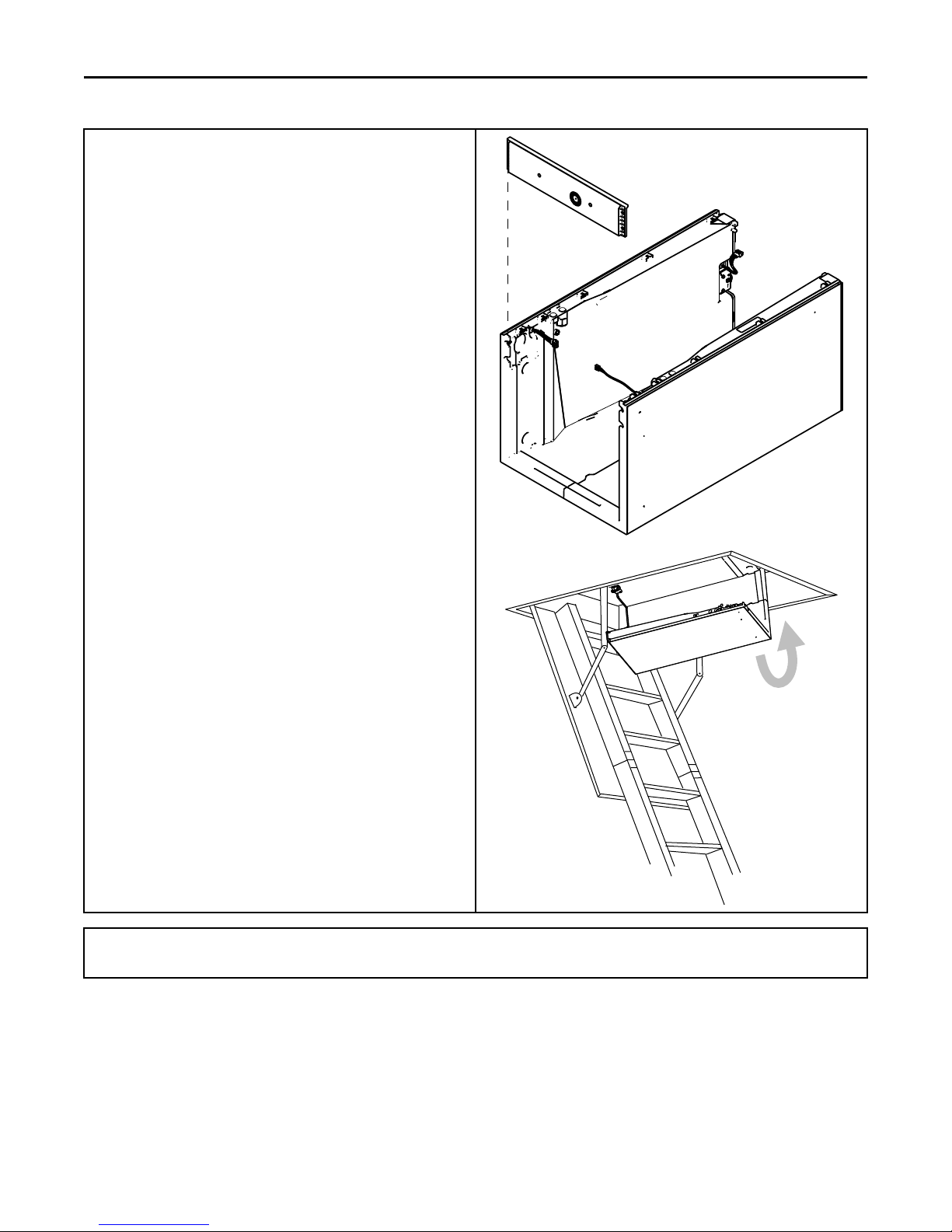

OOppttiioonnaall CCaabbiinneett DDiissaasssseemmbbllyy

10. For extremely tight spaces where the cabinet needs to be rotated

through a small opening, remove the top panel and all cross

members. Use a manual driver to avoid stripping screw holes.

11. Continue preparation by following the proper carrying procedures shown in the next section.

12

18-GJ06D2-2E-EN

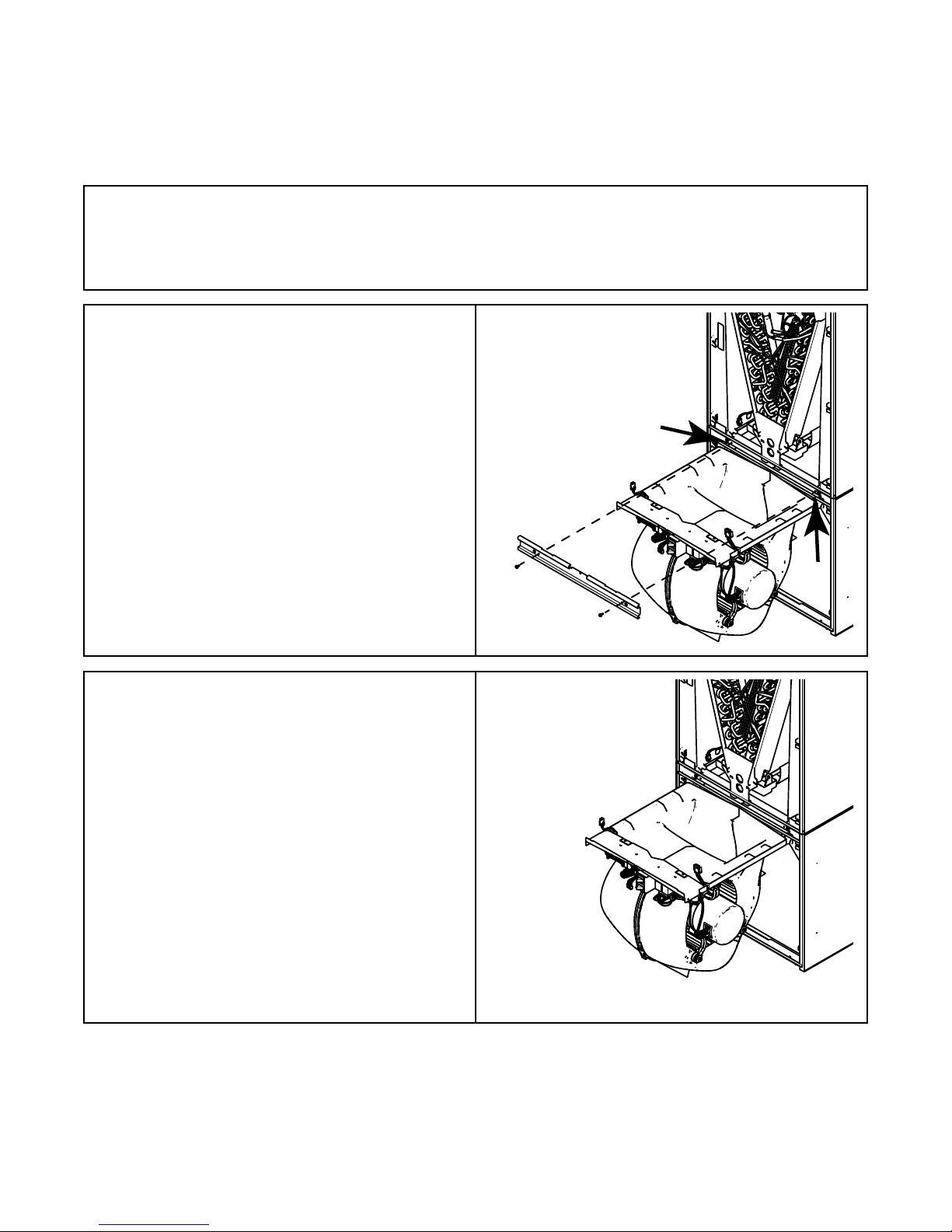

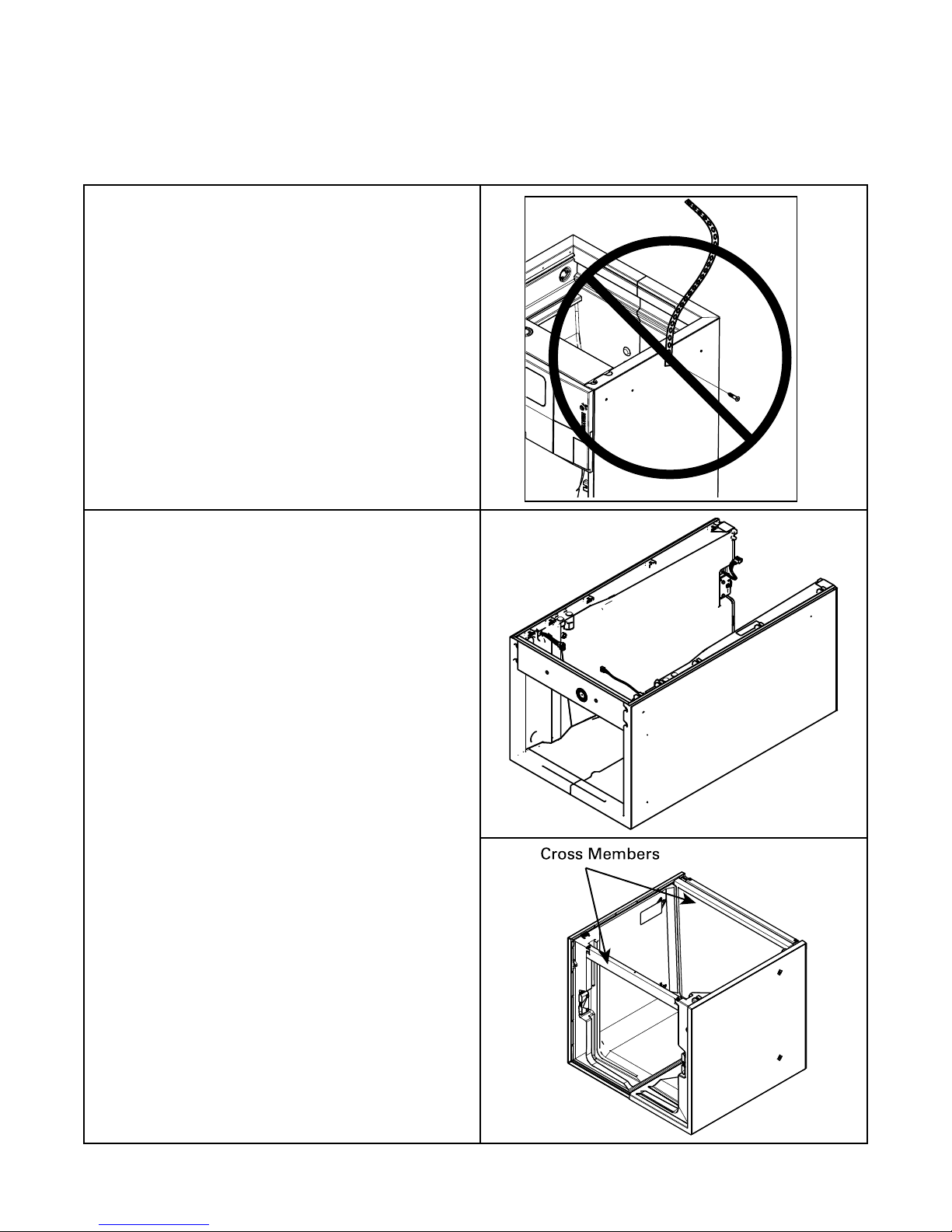

Placing Unit at Location

Cross M em bers

1. Carry the unit to the installation location

2. Reassembly by reversing the steps listed in Section 4 if

disassembly was required. If cut, wire ties that held the sensor

wiring must be replaced.

Important: Under no conditions should metal strapping be attached

Approved Carrying:

• Hold by the cross members within the cabinet or unit top plate and

to the unit to be used as support mechanisms for carrying

or suspension purposes.

use as handles for lifting and carrying the coil and blower sections.

18-GJ06D2-2E-EN

13

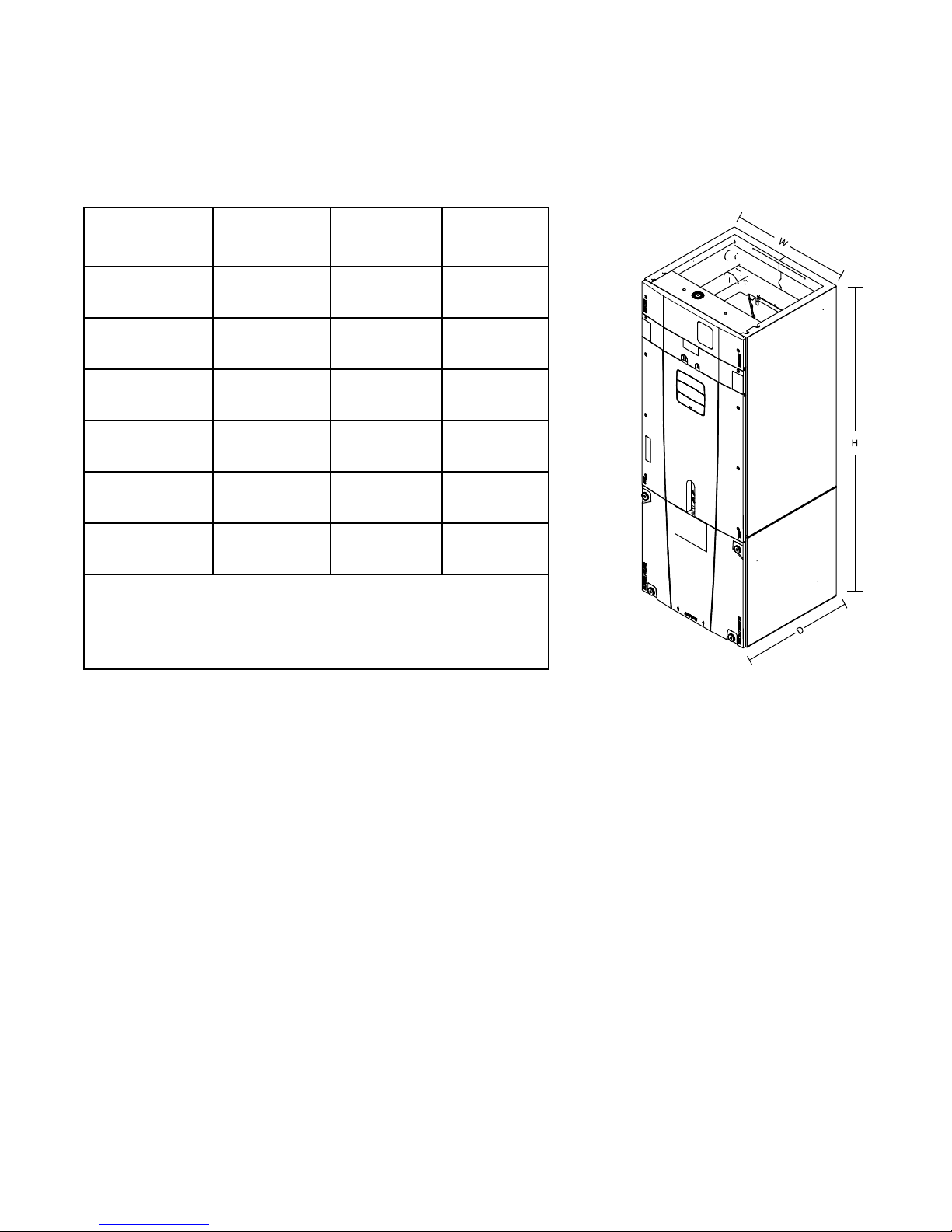

Unit Location Considerations

D

H

W

Table 3. Unit Dimensions and Weight

Coil and Heater

Compartment

Height *

(inches)

Unit Net Weight

(pounds)

MODEL NUMBER

H x W x D

(inches)

TAM7A0A24H21SD

TAM7A0A24H21EA

TAM7A0B30H21SD

TAM7A0B30H21EA

TAM7A0C36H31SD

TAM7A0C36H31EA

TAM7A0C42H31SD

TAM7A0C42H31EA

TAM7A0C48H41SD

TAM7A0C48H41EA

TAM7B0C60H51SC

TAM7B0C60H51EA

* Blower compartment height is 21.8 inches.

49.9 x 17.5 x 21.8 28.1 120

55.7 x 21.3 x 21.8 33.9 133

56.9 x 23.5 x 21.8 35.1 143

56.9 x 23.5 x 21.8 35.1 158

61.7 x 23.5 x 21.8 39.9 174

61.7 x 23.5 x 21.8 39.9 178

14

18-GJ06D2-2E-EN

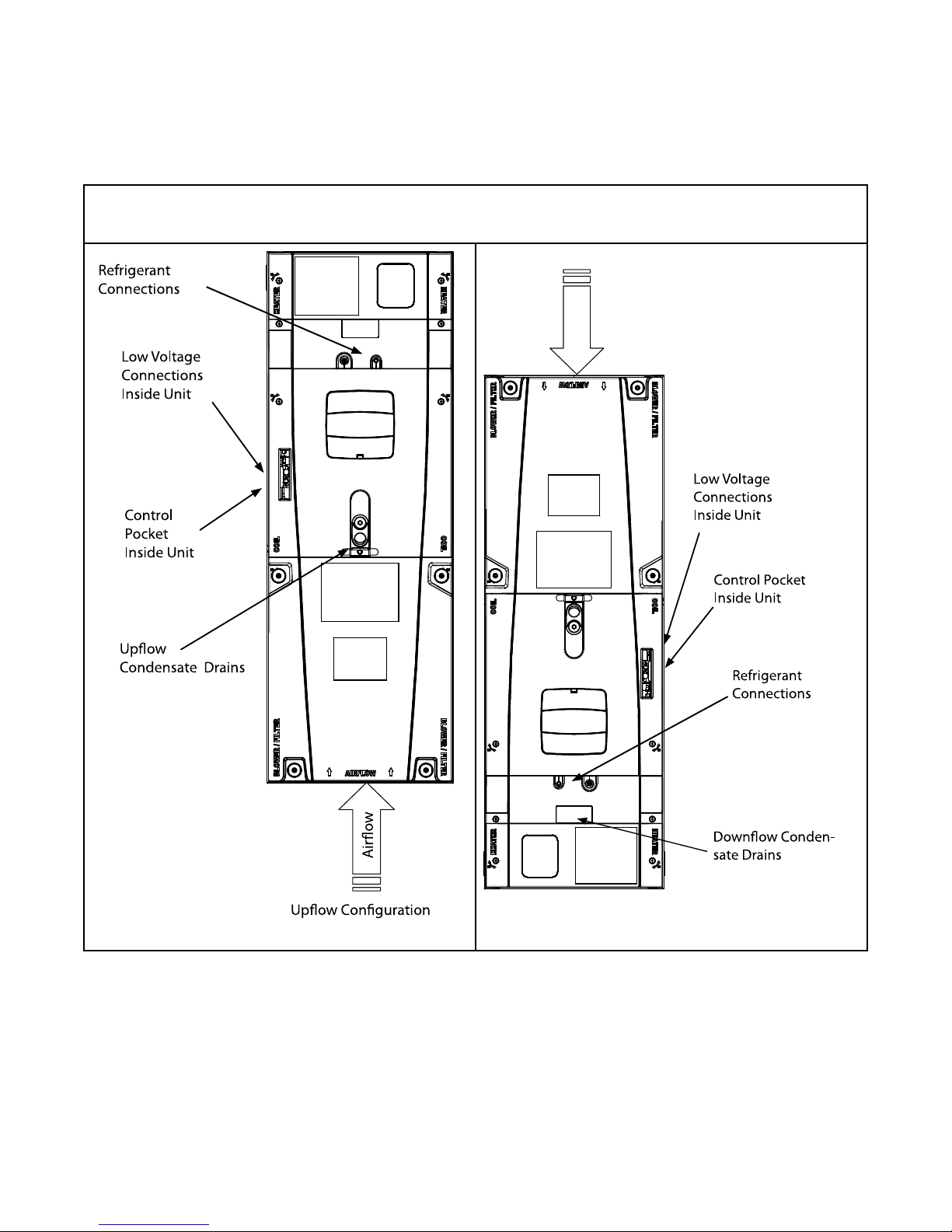

Air ow

Up ow Con guration

Refrigerant

Connections

Low Voltage

Connections

Inside Unit

Control

Pocket

Inside Unit

Upo w

Condensate Drains

Low Voltage

Connections

Inside Unit

Control Pocket

Inside Unit

Refrigerant

Connections

Down ow Conden-

sate Drains

Four-Way Conversion

To place the unit in the configuration your application requires (upflow, downflow, horizontal right, or horizontal left), simply turn the unit to

that orientation. Remember to adjust the badge accordingly.

Note: The air handlers are shipped from the factory suitable for four-way application.

18-GJ06D2-2E-EN

15

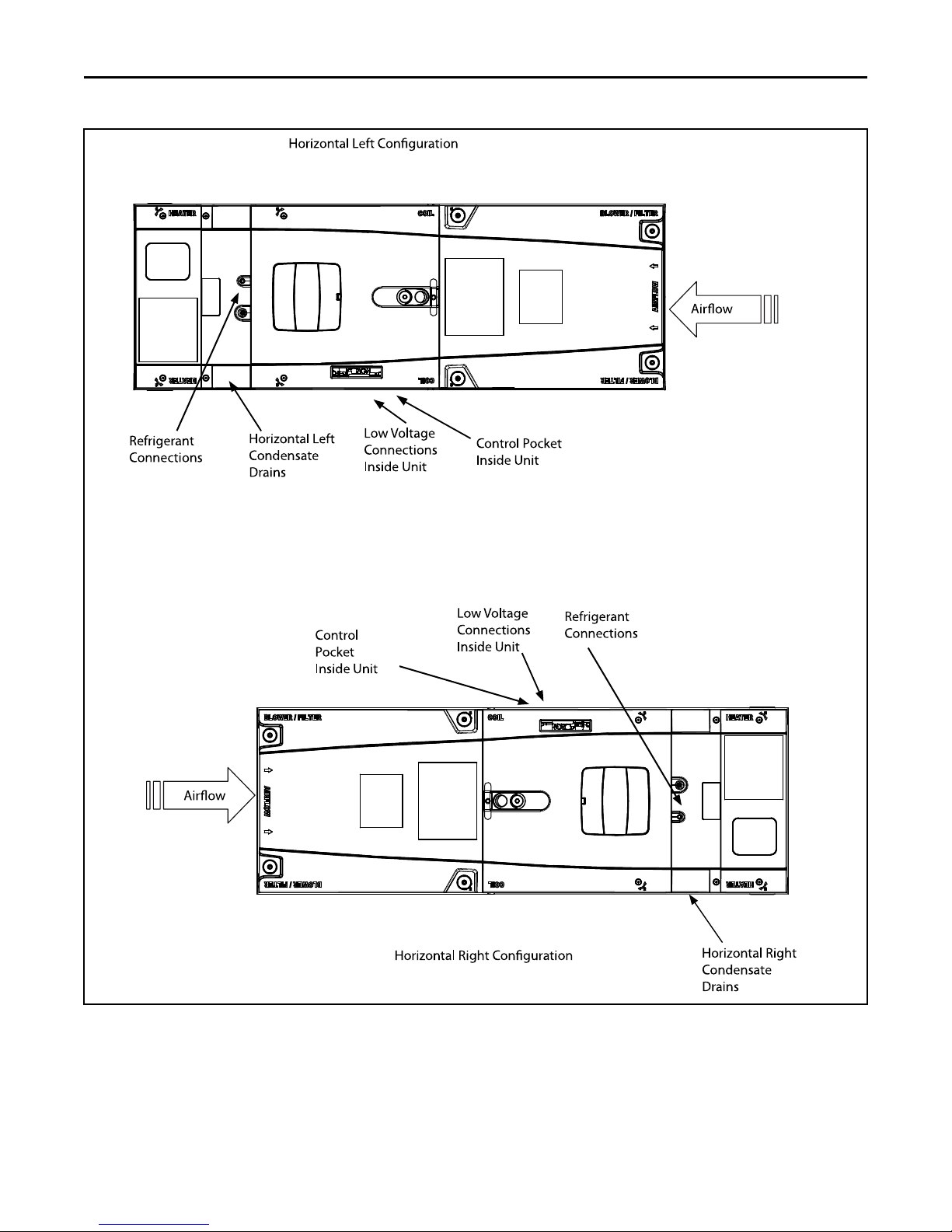

Air ow

Refrigerant

Connections

Horizontal Left

Condensate

Drains

Low Voltage

Connections

Inside Unit

Control Pocket

Inside Unit

Horizontal Left Con guration

Horizontal Right Con guration

Air ow

Control

Pocket

Inside Unit

Low Voltage

Connections

Inside Unit

Refrigerant

Connections

Horizontal Right

Condensate

Drains

FFoouurr--WWaayy CCoonnvveerrssiioonn

16

18-GJ06D2-2E-EN

Loading...

Loading...