Page 1

Ingersoll Rand

System Automation

VX Accessory Box

Visualization Software Manual

Before installing or starting this unit for the rst

time, this manual should be studied carefully to

obtain a working knowledge of the unit and or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

More Than Air. Answers.

Online answers: http://air.ingersollrand.com

C.C.N. : 80445091

REV. : A

DATE : APRIL 2009

Page 2

SECTION 1 TABLE OF CONTENTS

Section 1 - table of contentS .............................2

7.3 EQUIPMENT DETAIL VIEW I/O BOX..................33

Section 2 - intRoDUction ...................................... 3

Section 3 - GettinG StaRteD ................................. 4

3.1 COMMISSIONING PROCEDURES .........................4

3.2 CONNECTING TO A VX BOX VIA PC .....................4

Section 4 - loGin ........................................................8

4.1 LOGIN PROCESS .........................................................8

4.2 DEFAULT ACCOUNTS ................................................9

Section 5 - naViGation ..........................................10

5.1 TITLE BAR ....................................................................10

5.2 TAB NAVIGATION ......................................................10

Section 6 - SYSteM oVeRVieW ..............................12

6.1 THE SYSTEM OVERVIEW SCREEN .......................12

6.1.1 TITLE BAR THE EVENT LOG ................................12

6.1.2 TITLE BAR THE SERVICE UTILITY ....................14

6.2 THE DASHBOARD .....................................................16

6.3 CONFIGURABLE I/O.................................................17

6.4 SYSTEM EFFICIENCY GAUGE ...............................17

6.5 X8I/X12I INTERFACE ................................................18

6.5.1 X8I/X12I CONTROLS ..............................................18

6.5.2 TABLE CONFIGURATION AND CONTROL ......18

6.5.3 PRESSURE SCHEDULE CONTROL .....................20

6.6 COMPRESSOR STATUS OVERVIEW ....................20

6.7 SYSTEM DETAIL VIEW .............................................21

6.7.1 PERFORMANCE REPORT UTILITY .....................21

6.7.2 PRESSURE SCHEDULE ...........................................22

6.7.3 GRAPHING UTILITY ................................................23

6.7.4 ARCHIVING HISTORICAL DATA .........................25

7.4 EQUIPMENT DETAIL VIEW INTELLIFLOW ......34

Section 8 - confiGURation oVeRVieW .............36

8.1 CONFIGURATION OVERVIEW ...............................36

8.2 X8I/X12I SYSTEM SETUP .........................................36

8.2.1 SYSTEM CONFIGURATION ..................................37

8.2.2 USER CONFIGURABLE DATA ITEMS ................. 38

8.3 COMPRESSOR SETUP .............................................39

8.3.1 COMPRESSOR CONFIGURATION....................... 39

8.3.1.1 COMPRESSOR MODEL INFORMATION...................40

8.3.1.2 COMPRESSOR NAMEPLATE DATA...........................41

8.3.1.3 ADDITIONAL DATA ITEMS..........................................41

8.4 I/O BOX AND INTELLIFLOW SETUP ...................46

8.4.1 I/O BOX AND INTELLIFLOW IX

CONFIGURATION ....................................................46

8.4.1.1 ANALOG INPUT CONFIGURATION..........................47

8.4.1.2 RELAY OUTPUT CONFIGURATION...........................48

8.4.1.3 DIGITAL INPUT CONFIGURATION............................48

8.5 ACCOUNT MANAGEMENT ....................................48

8.6 DIAGNOSTICS ............................................................51

8.6.1 SERIAL COMMUNICATIONS DIAGNOSTICS .52

8.6.2 SOFT WARE VERSIONS ..........................................53

8.6.3 VX BOX CONNECTIVITY........................................ 53

8.6.4 ETHERNET CONFIGURATION .............................53

8.7 VX OPTIONS SCREEN ..............................................54

8.7.1 GRAPH SCALING DEFINED VARIABLES ......54

8.7.2 GRAPH SCALING SELECTABLE VARIABLES 55

8.7.3 LANGUAGE ................................................................55

8.7.4 DATE AND TIME .......................................................55

Section 7 - eQUiPMent oVeRVieW ......................29

7.1 EQUIPMENT OVERVIEW ........................................29

7.2 COMPRESSOR DETAIL VIEW ................................30

7.2.1 COMPRESSOR STATUS ..........................................30

7.2.2 COMPRESSOR NAMEPLATE DATA ....................31

7.2.3 USER CONFIGURABLE COMPRESSOR DATA..32

7.2.4 MANUAL START/STOP CONTROL.....................32

2

Page 3

SECTION 2 INTRODUCTION

Ingersoll Rand System Visualization oers a window into a compressed air system by adding a VX Module to an X8I

or X12I control network and using only a web browser on your PC. The VX Box incorporates hardware and software to

allow monitoring of the X8I and X12I Automation system as well as all connected equipment. The software allows you

to monitor your air system at a glance or take a more detailed look into system operation, equipment status and setup

through an intuitive web-page based user interface. To access the application running on the VX Box, simply connect

via a Web Browser from any PC using an Ethernet connection.

The VX Box connects to the X8I or X12I controller via the two-wire RS485 network. The VX Box is suitable for wall

mounting and can be located up to 4,000 ft. (1,219 m) from the X8I or X12I unit. The VX Box connects to the customer’s

PC or LAN via Ethernet, using a RJ45 connector, Cat5e 10/100Base T cable.

The PC can be local “stand alone” or part of a LAN. The VX Box is fully eld congurable using standard screen

templates.

The visualization interface is broken down into three major segments:

Monitor and adjust important air system data such as air system pressure and eciency, air system set points,

status of each compressor, and X8I/X12I status in an easy to read dashboard style interface. The system overview

screen is also the launching point for performance reports and historical trending. See section 5 – System

Overview.

Monitor more detailed compressor information such as the model and manufacturer of the compressor, capacity

and power data, and congurable data points. See section 7 – Equipment Overview.

View and change air system congurations such as adding or removing a compressor, I/O box, or Intelliow valve.

Manage user accounts and network conguration and view diagnostic information. See Section 8 – Conguration

Overview.

The system administrator can assign a user one of three levels of access (view only, user, and administrator) which will

determine which functions will be available to that user. For example, only users with administrator access will be able

to view or modify the conguration overview parameters. See section 8.5 – Account Management.

Please note that this software manual assumes that the Ingersoll Rand Automation VX Box has been installed and

connected to your company’s network. If this is not the case please refer to the Ingersoll Rand Automation VX Box

installation manual CCN 80445083.

3

Page 4

4

SECTION 3 GETTING STARTED

Select Local Area Connection

3.1 Commissioning Procedures

There are certain parameters that must be congured in order for the VX box to properly communicate to the LAN

and to the X8I/X12I control network. Outlined below is a list of steps that must be completed before the visualization

software can be fully utilized.

Most of the setup is conducted using the conguration overview screen described in detail in section 7. Please be sure

that you have ADMIN rights before attempting to congure the VX box.

Install the VX box according to the Installation Manual

1.

Connect to the VX box using a PC – Follow the procedure outlined in section 3.2.

2.

Login to the Visualization Software – Follow the procedures in section 4.1

3.

If you will only be connecting to the VX box using a single PC, go to step 5. If you will be using a static IP or DHCP

assigned IP address on your company’s LAN please continue.

Congure the VX box Ethernet settings – Obtain a static IP address from your IT department or have an

4.

assigned domain name for DHCP access. Follow the procedures in section 8.6.4.

Synchronize VX Box time to PC time – Follow the procedures in section 8.7.4

5.

Congure the X8I/X12I information - Follow the procedures in section 8.2

6.

Congure compressor information – Follow the procedures in section 8.3. Make sure you have the

7.

compressor nameplate data available.

Congure any I/O boxes or Intelliow Valves – Follow the procedures in section 8.4. Make sure you have I/O

8.

conguration information for any I/O boxes on the network. Please refer to the I/O Box operator’s manual.

Set up User accounts – Follow the procedures in section 8.5 if not using default accounts.

9.

Select units on Dashboard – Follow the procedures in section 6.2

10.

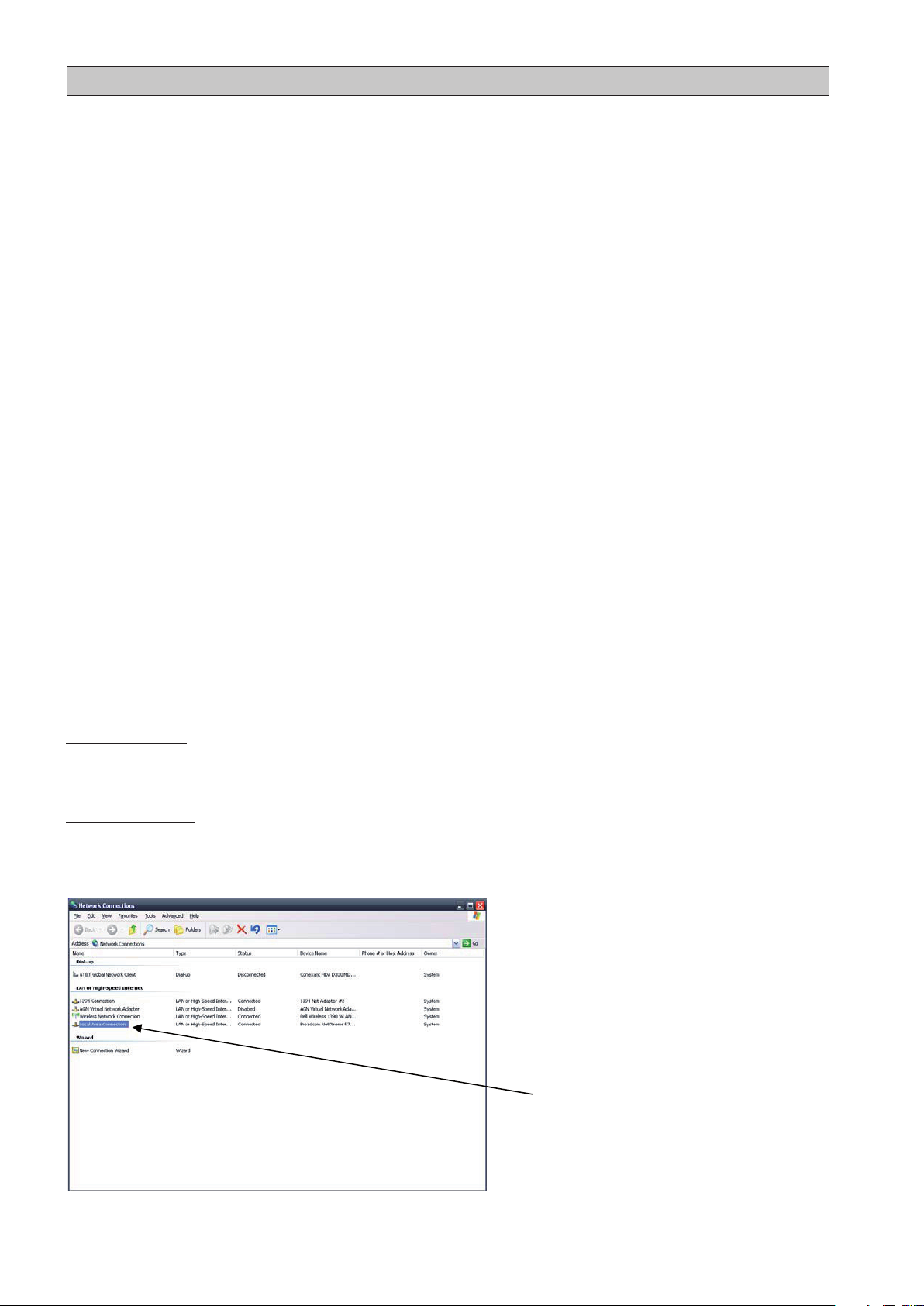

3.2 Connecting to a VX Box via PC

In order to congure your computer to communicate point-to-point with the VX Box, you must rst set the IP

address range of your computer to the default IP address range of the Visualization box. To do this, please follow the

instructions listed below to congure the Computer IP address. These settings are accessible using Windows XP by

selecting:

Please note that the VX Box ships with a default IP address of 192.168.1.1.

Using Classic View:

Select Start

Select Settings

Select Network Connections

Using XP Start View:

Select Start

Select Control Panel

Select Network Connections

Page 5

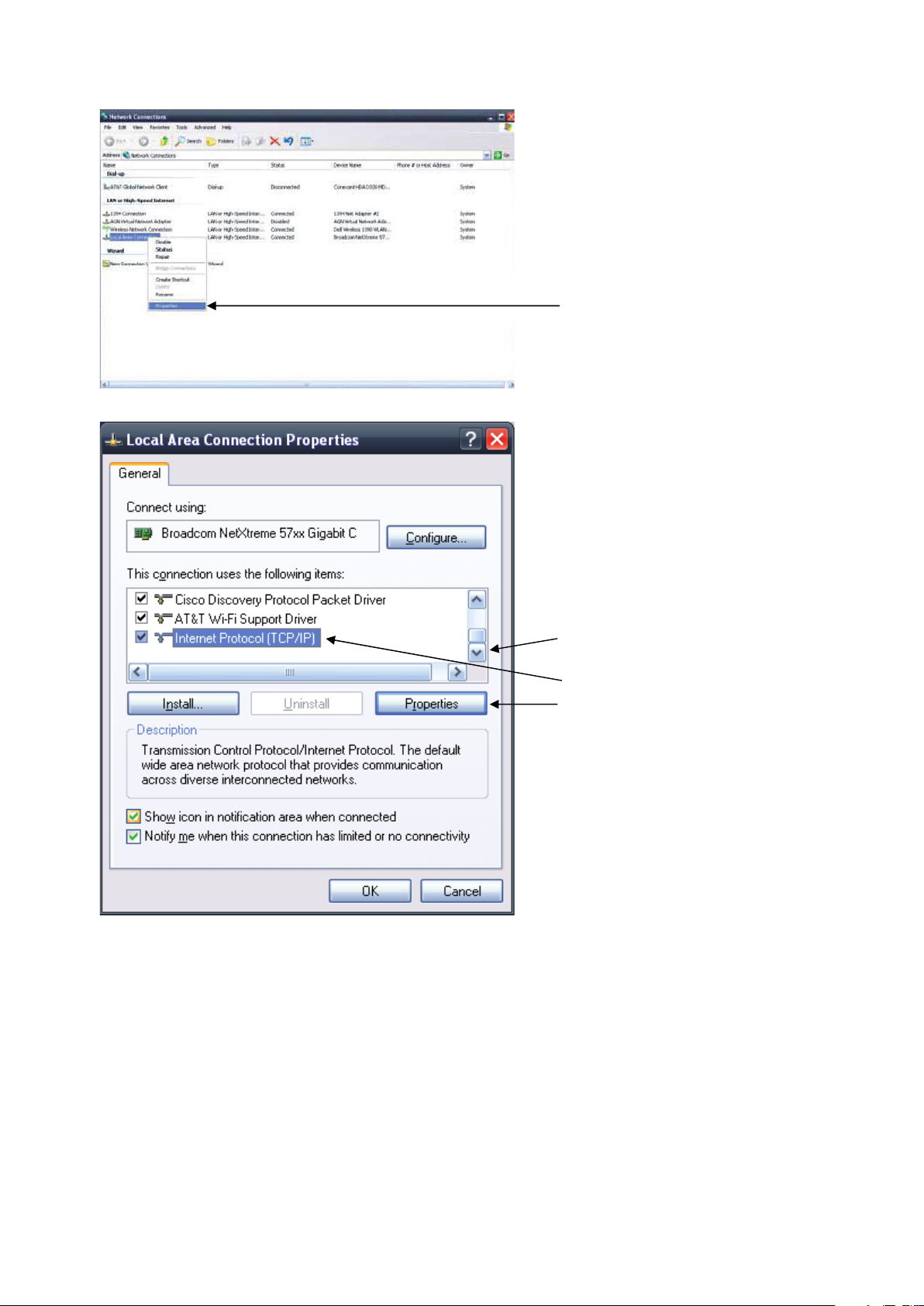

Scroll down the Connection List to find

Internet Protocol (TCP/IP)

Select Internet Protocol (TCP/IP)

Click on Properties

Right Click on the Local Area

Connection

Select Properties

5

Page 6

6

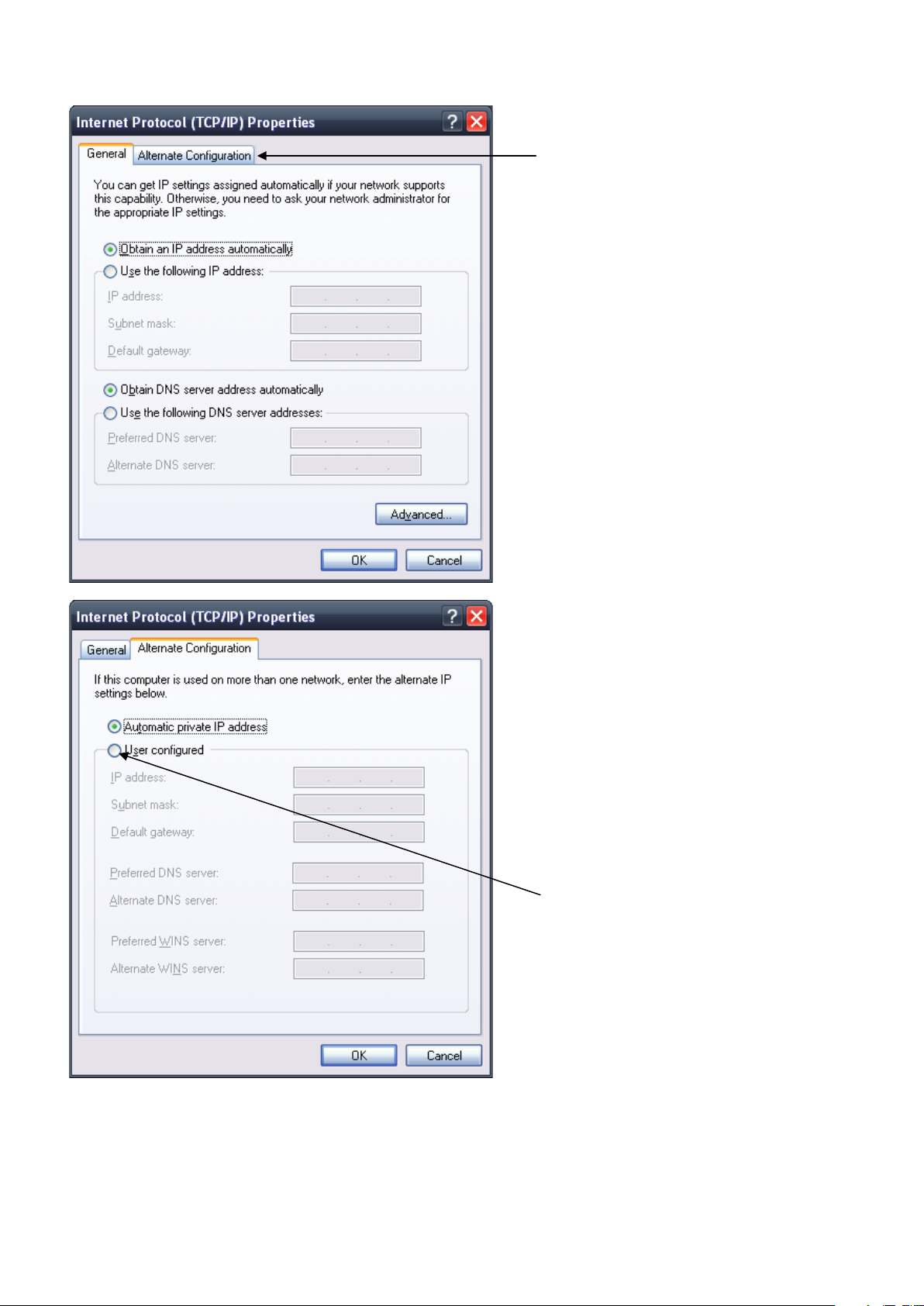

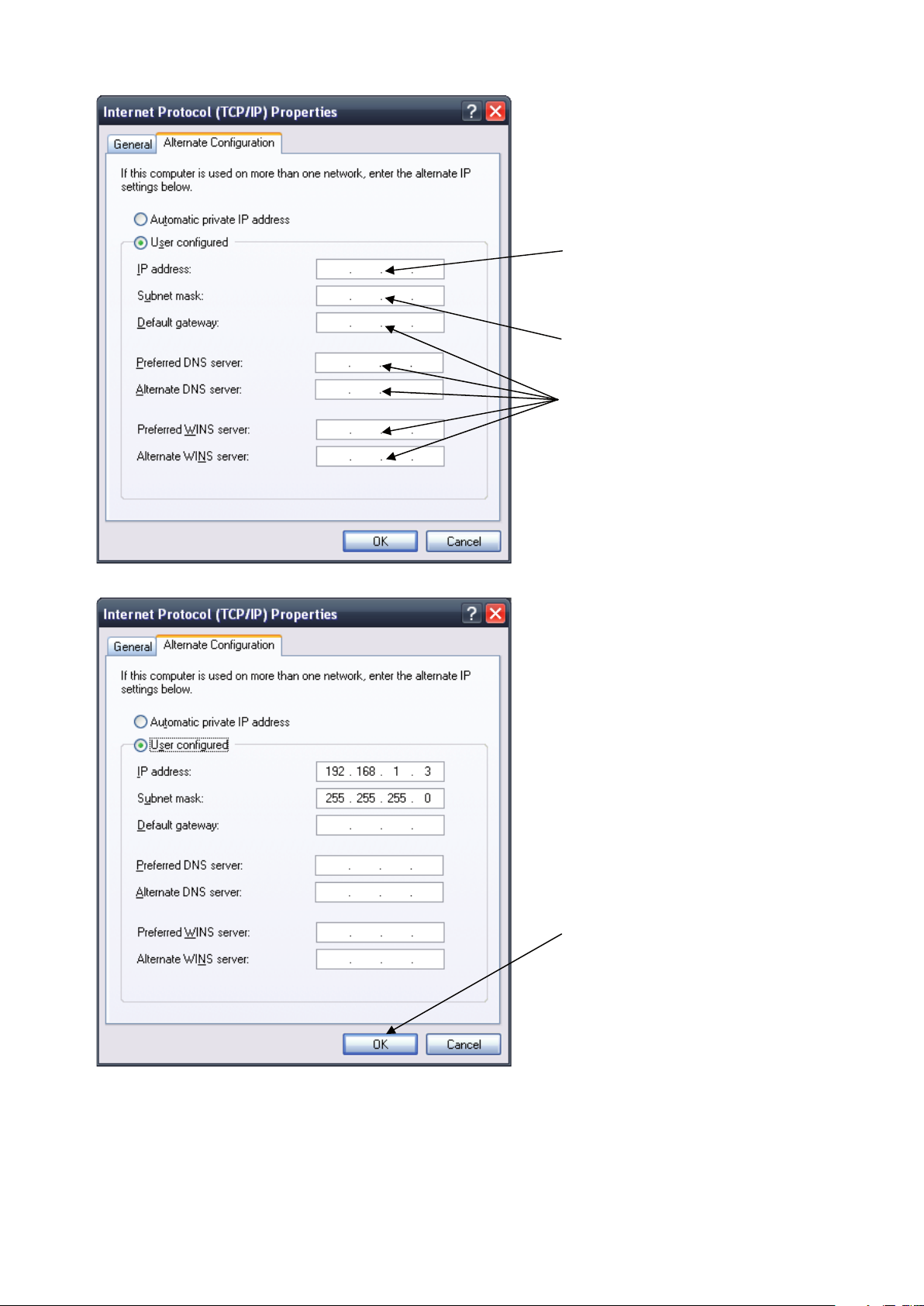

Click on User Configured Button

Click on the Alternate Configuration

Tab

Page 7

Enter IP address for the Computer

192.168.1.3

Enter the Subnet Mask for the Computer

255.255.255.0

Leave all other Fields blank

When complete, Click OK

Connect an Ethernet cable to your Computer and to the Visualization Box. Within a minute, the Computer will make a

connection to the Visualization Box. Once connected, you will be able to log into and congure the Visualization Box.

7

Page 8

8

SECTION 4 LOGIN

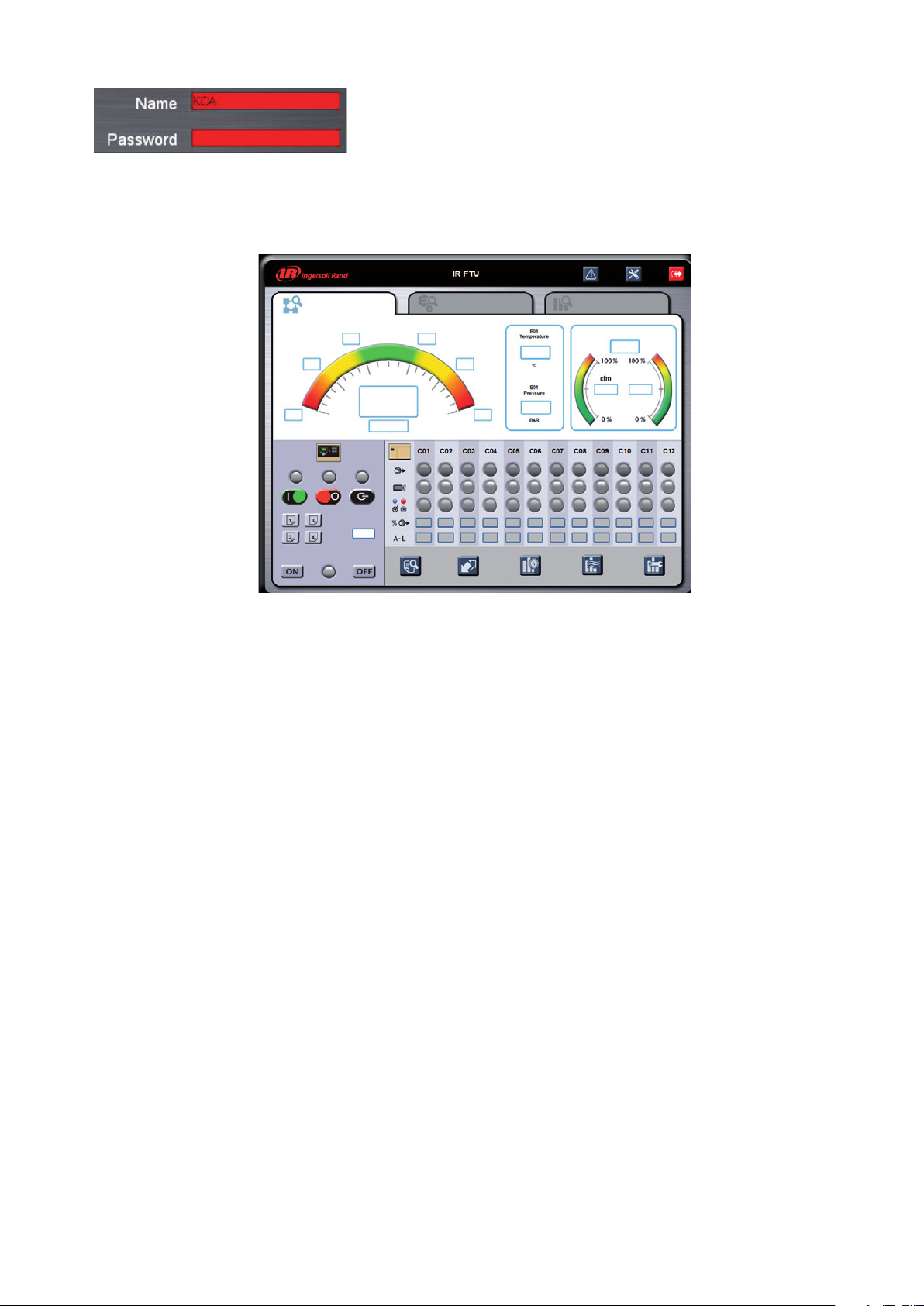

Type in your user name (case sensitive)

Type in your password (case sensitive)

Select your language from the dropdown list

Click the Login button or press enter

4.1 Login Process

During the installation and commissioning process a network address was assigned to the VX Box by your IT

department. This address may be a static IP (e.g. http://192.168.1.1, recommended) or a DHCP assigned domain

name address (e.g. http://myairsystem.com). A domain name address is a web page address chosen by the user to

represent the VX box. The domain name must be approved by your IT department but can generally be any text label

you wish. You must have this address before you can log in to the visualization software. See section 8.6.4 – Ethernet

Conguration.

Please note that Ingersoll Rand Automation Visualization requires Internet Explorer 7 ( or newer) or Mozilla Firefox

2 (or newer). Certain functions may not behave correctly when using older browser software.

To log in to the visualization program you must rst type the address into your browser and then press the enter

button.

For example, with a DHCP enabled VX box you might type this:

While with a static IP address you might type this:

If the VX box is congured correctly you will then see the Ingersoll Rand Automation splash screen in your browser.

This may take a few seconds depending on our network connection speed.

Page 9

If the user name or password are incorrect the background of the eld will

turn red.

Please see section 4.2 for default account information, and section 8.5 for more detailed information about the account

management process.

Upon successfully logging in you will see the system overview screen shown below:

4.2 Default Accounts

The Visualization software comes precongured with three default user accounts. The system administrator can

assign users one of three levels of access (view only, user, and administrator) which will determine which functions

will be available. For example, only users with administrator access will be able to view or modify the conguration

overview parameters. It is highly advised that the administrator change these accounts as soon as feasible to prevent

unauthorized access to the Visualization software. The three level of access rights are as follows:

VIEW – The user is able to view all information on the SOV and EOV screens and their detail view screens. The

1.

user is unable to change any set points or access the Conguration Overview (COV) screens.

2. USER – The user has all rights available to the VIEW access level as well as being able to change set points on

2.

the table conguration screens, pressure schedule screens, and is able to manually start and stop compressors,

as well as start and stop the X8I/X12I.

3. ADMIN – The user has all rights of the VIEW, and USER access levels as well as full access to the Conguration

3.

Overview (COV) screens, the account management utility, and the diagnostics screen.

Please note that there can be as many as ve (5) maximum users logged into the system at one time, and only one

administrator logged in at one time.

The three default accounts are:

Login: view

1.

Password: pwview

Rights: VIEW

Login: user

2.

Password: pwuser

Rights: USER

Login: admin

3.

Password: pwadmin

Rights: ADMIN

Only a user with ADMIN rights will be able to modify these default accounts.

9

Page 10

10

SECTION 5 NAVIGATION

5.1 Title Bar

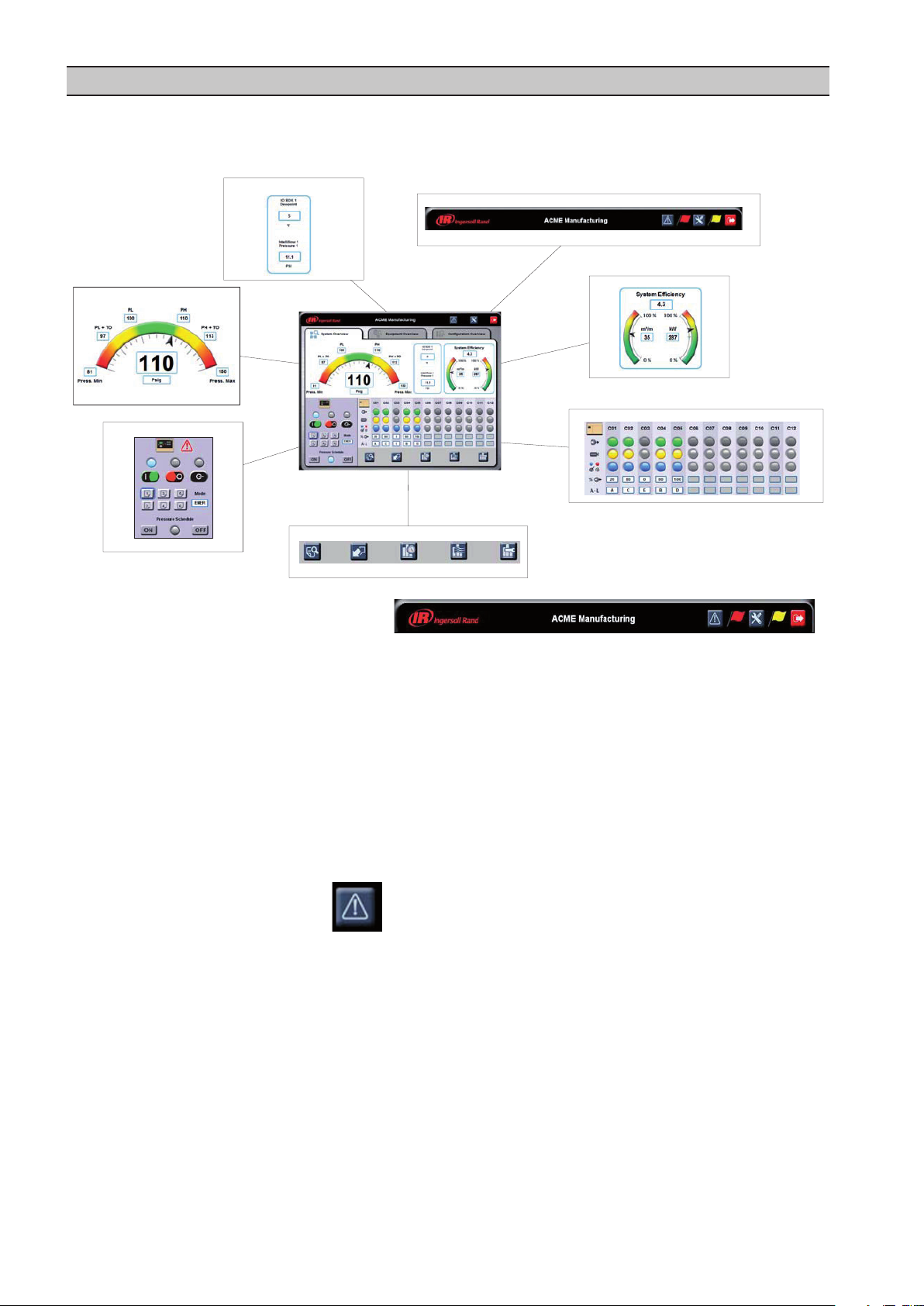

Visualization navigation uses a simple point and click interface. A title bar will be present at the top of every screen and

will display information about system name, alarms, and will provide access to event and service logs.

The components of the title bar are as follows:

Installation Name – This is congured by the system administrators and is a

name that is used to identify the compressed air system.

Event Log Button – Clicking this button will bring the user to the

visualization event log. See section 6.1.1 – Event Log

General Alarm Flag – This ag will appear if there is an alarm condition

present on the X8I/X12I or any of the compressors in the system. If there is

no alarm present or the alarm has been resolved this ag will disappear.

Service Maintenance Button – Clicking this button will bring the user to

the maintenance reminder utility. See section 6.1.2 – Service Reminder

utility.

Service Reminder Flag – This ag will appear if a service reminder has been

set up for a compressor and service is now due. Once the service reminder

has been updated this ag will disappear.

Log Out Button – Clicking this button will log out the current user and

return to the visualization login screen.

5.2 Tab Navigation

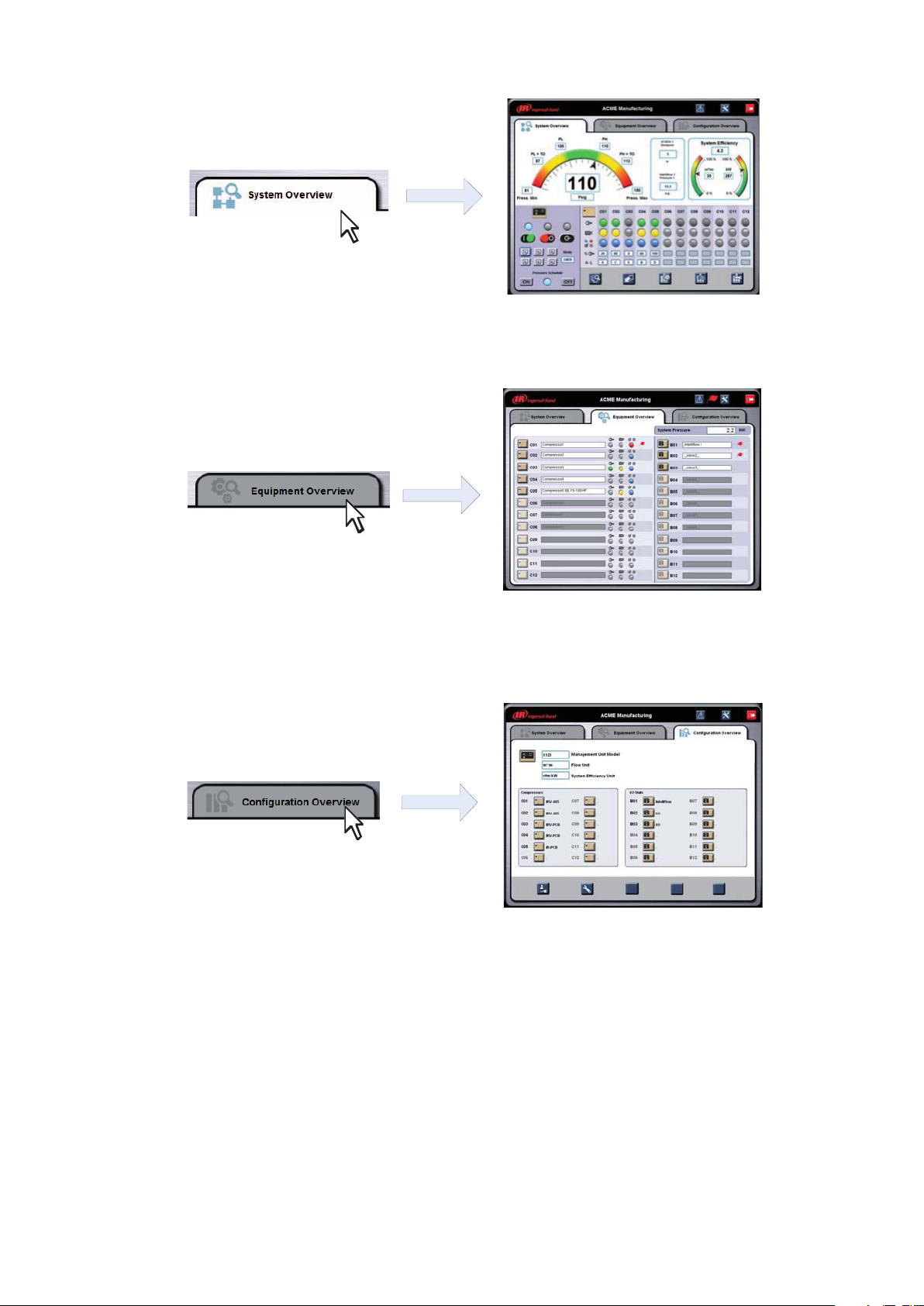

Each of the three main segments: System Overview, Equipment Overview, and Conguration Overview, is represented

by a tab below the title bar.

Clicking on the tab will bring you to the overview screen for that particular segment.

Clicking on the system overview tab will bring the user to the System Overview page. From here the user can monitor

and adjust (with the correct security) important air system data such as air system pressure and eciency, status of

each compressor, and X8I and X12I status in an easy to read dashboard style interface. The system overview screen is

also the launching point for set point and scheduling screens plus performance reports and historical graphing and

trending tools. See section 6 – System Overview.

Page 11

Clicking on the equipment overview tab will bring the user to the Equipment Overview page. From here the user can

monitor more detailed compressor information such as the model and manufacturer of the compressor, capacity and

power data, and congurable data points. See section 7 – Equipment Overview.

Clicking on the conguration overview tab will bring the user to the Conguration Overview page. From here the

system administrator(s) can view and change air system congurations such as adding or removing a compressor,

I/O box, or Intelliow valve. Manage user accounts and network conguration and view diagnostic information. The

conguration overview page is only accessible by users with ADMIN rights. See section 8 – Conguration Overview.

Navigation between tabs is instant; there is no need to save data before moving to another tab. From the overview

tabs the user can navigate to the various associated detail view pages.

11

Page 12

12

SECTION 6 SYSTEM OVERVIEW

Title Bar – Section 5.1 and 6.1

Dashboard – Section 6.2

Efficiency Gauge – Section 6.4

X8I/X12I Interface – Section 6.5

Compressor Status – Section 6.6

System Detailed View – Section 6.7

Configurable I/O – Section 6.3

6.1 The System Overview Screen

The system overview screen presents an overall view of your compressed air system and is broken down into

functional sections.

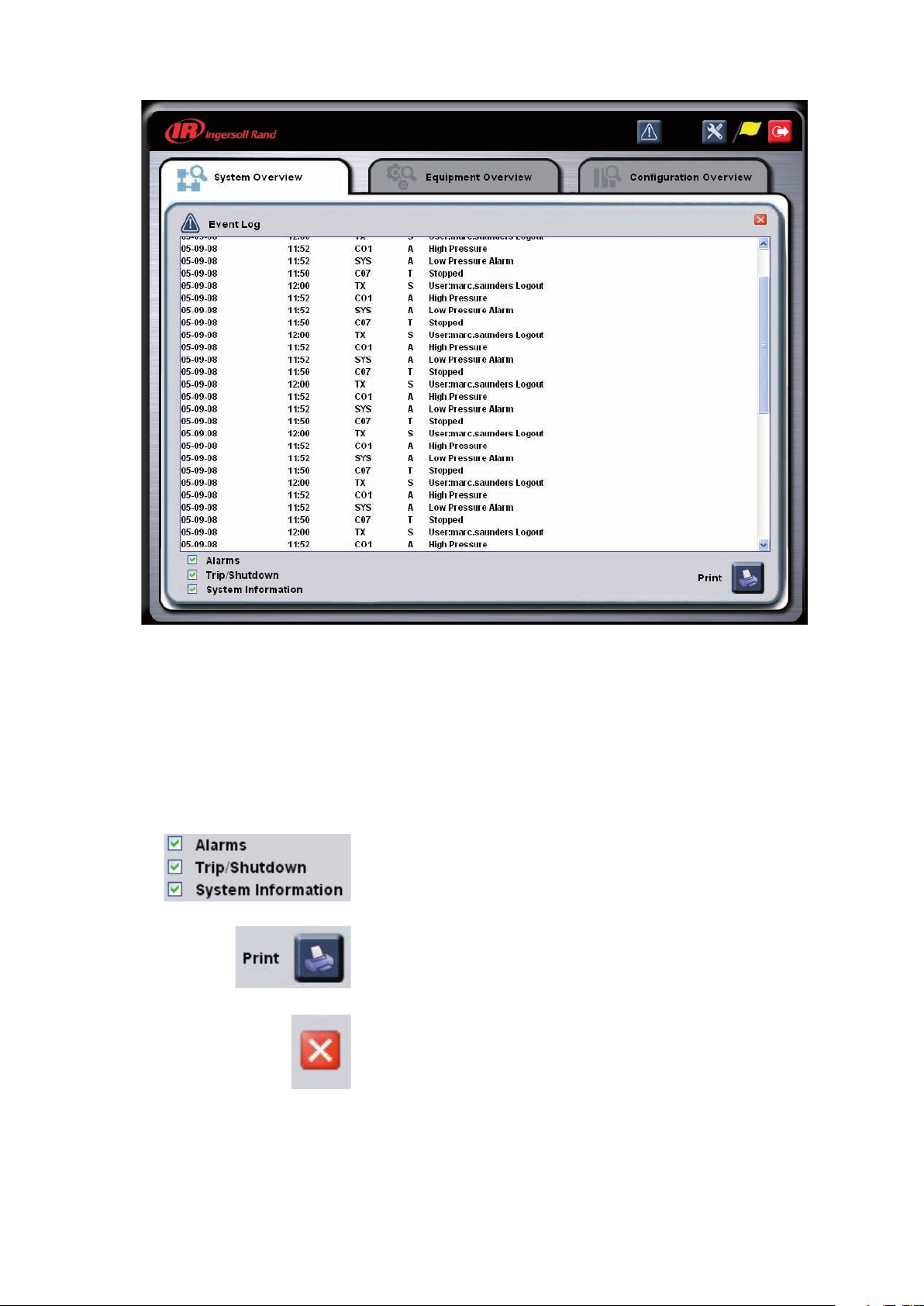

6.1.1 Title Bar - The Event Log

The Visualization Event Log records certain events that occur in your air system or in the visualization software itself.

The events recorded and placed into one of three categories:

1.

2.

3.

The event log will record the last 500 events. Once this 500 event limit has been reached the oldest events will be

cleared and the newest events will appear at the top of the event log.

The event log is accessible from all overview screens using the following procedure:

Alarms – Alarms are events that indicate that an abnormal situation has occurred on a compressor, X8I/X12I, I/O

Box, or Intelliow valve but the piece of equipment is still functioning normally.

Trips/Shutdowns – Trips/Shutdowns are events that indicate that an abnormal situation has occurred on a

compressor, X8I/X12I, I/O Box, or Intelliow valve and the piece of equipment has been stopped.

System Information – System information events record user logins and logouts.

Click the event log button

Page 13

The event log will then appear as shown below

Information in the event log is presented in ve columns. The columns represent, from left to right:

Date of the event (in DD/MM/YY format).

1.

Time of the event (in a 24 hour clock format).

2.

Equipment reporting the event (C01 through C12 for compressors, B01 through B12 for I/O boxes and Intelliow

3.

valves, SYS for the X8I or X12I, and VX for the VX box itself.

Type of event. A(Alarm), T(Trip), or S(Shutdown).

4.

Details of the event.

5.

The event log lters allow you to control which events are displayed

on the event log. A check mark appearing next to the event type

means all events of that type will appear in the log. Uncheck the box

to hide all events of that type.

Clicking the print button will print the event log.

When you are nished with the event log, clicking the exit button will

exit back to the overview screen last viewed.

13

Page 14

14

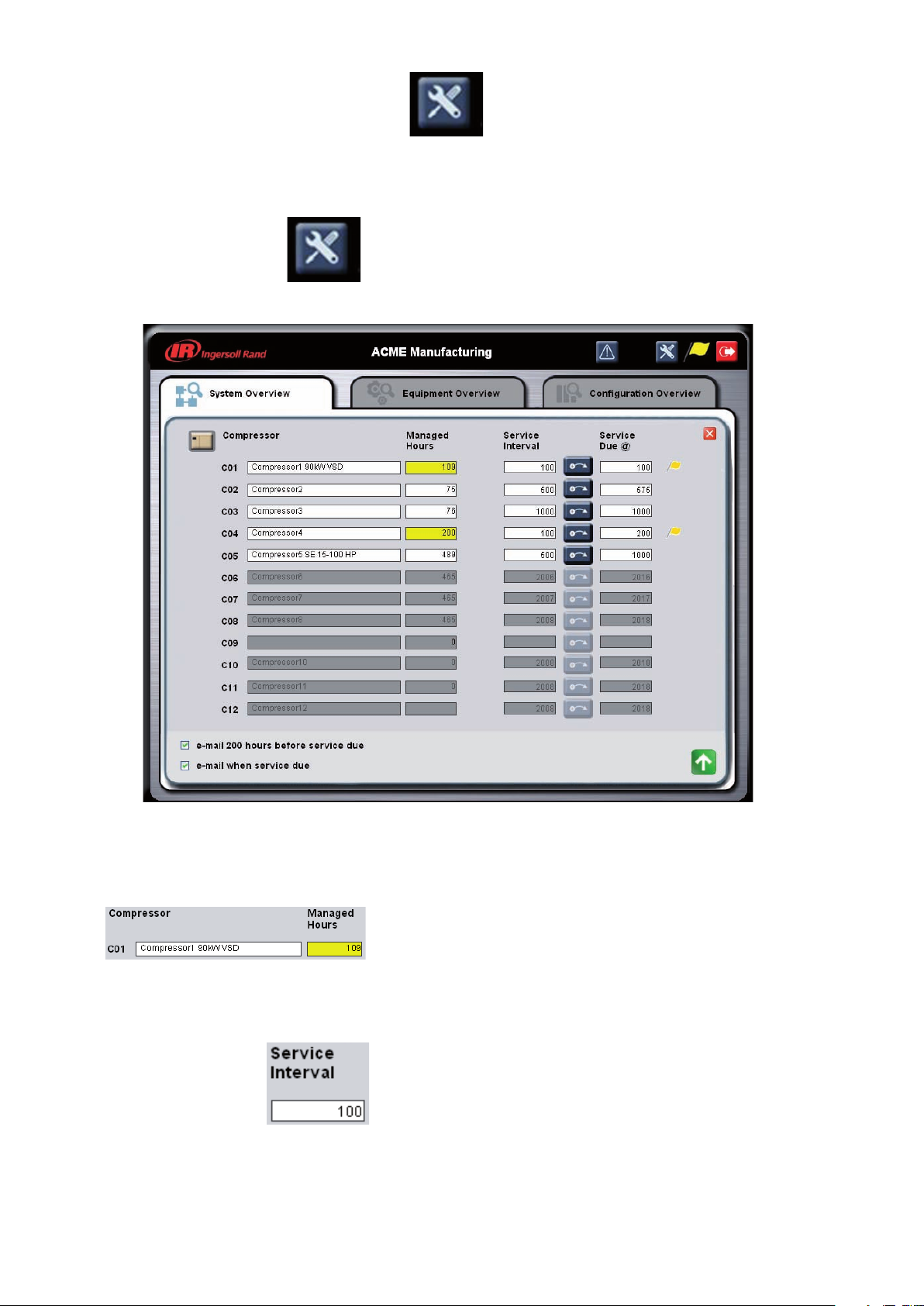

6.1.2 Title Bar - The Service Utility

The Service Utility is used to set up maintenance reminders for compressors in the system. The user enters a specied

maintenance interval based on the compressor’s factory recommendations and the Visualization software will provide

a visual cue on the title bar as well as optional email reminders that are sent to selected users.

The service utility is accessed by clicking the service utility button

on the title bar.

The service utility will appear as shown below:

The service utility has the following data:

Compressor address on the system controller (C01 through

C12) and the compressor name as congured by the system

administrator.

Managed Hours – The number of hours that the X8I/X12I has been

monitoring the compressor. Please note that this value is initially

entered into the X8I/X12I based on the compressor’s local running

hour indicator. This value must periodically be compared to the

actual compressor running hours to maintain consistency. This

value will turn yellow when maintenance is due and the yellow

ag will appear on the title bar.

This value is entered based on the compressor’s maintenance

interval according to OEM recommendations.

User or Administrator access is required to change this value.

Page 15

Pressing this button adds the service interval to the managed

hours. This adds the service interval value to the service due eld

and removes the yellow maintenance due ag for the compressor.

This should be done after maintenance is performed on the

compressor. This button is only available to users with User or

Administrator rights.

When the managed hours reach the service due hours the yellow

maintenance reminder ag will be activated.

The maintenance reminder ag appears when the managed hours

reach the service due hours. There is a ag for each compressor

and a master ag that will appear on the title bar if any compressor

has a maintenance reminder ag active.

The service utility also has the capability of emailing users that service is due.

Checking o this option will instruct the visualization software

to send out emails to any users who have been selected by the

administrator when a compressor is due for service in 200 hours.

Checking o this option will instruct the visualization software

to send out emails to any users to have been selected by the

administrator when a compressor is due for service.

Please see section 6.5 for information on setting up users to receive service due reminder emails.

When you are nished viewing and/or changing the settings in the service utility:

Click the exit button to leave the service utility without saving any

changes. You will be returned to the last overview page viewed.

Click the Save and Exit button to save your changes and return to

the last viewed overview page.

15

Page 16

16

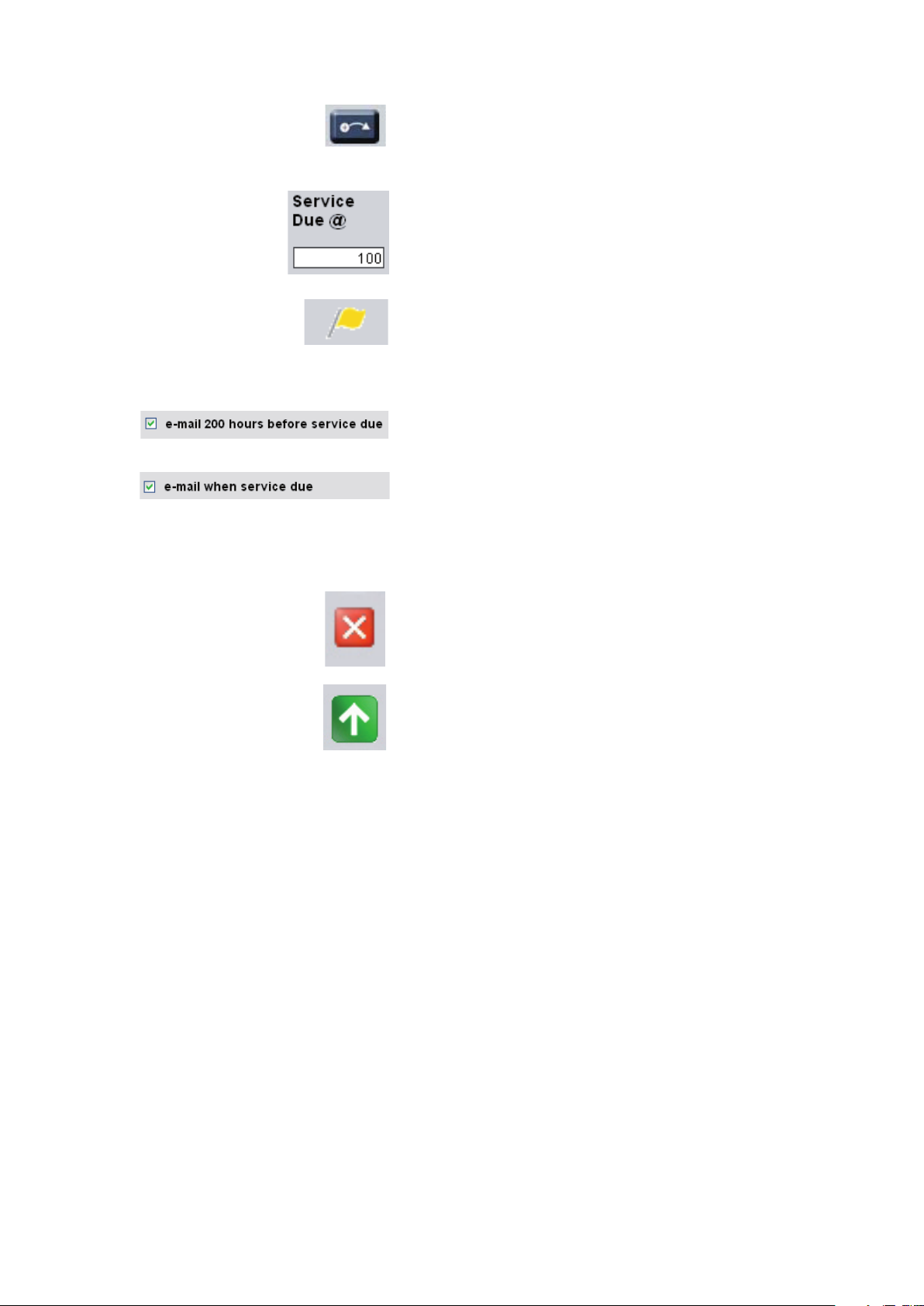

6.2 The Dashboard

The dashboard area of the System Overview page (SOV) is where system pressure information is displayed in an easy

to read gauge interface. The dashboard prominently displays system pressure as well as setpoints from the X8I or X12I

system controller.

The arrow on the pressure gauge represents where the system pressure is in relation to the system controller’s

setpoints. If the arrow is in the green zone system pressure is currently optimal and the system controller will take no

action. If the arrow reaches the yellow zone the system controller will consider actions to load or unload a compressor

to return system pressure to the green zone. In the red zone the system controller is taking increasingly urgent action

to return the system pressure to the green zone. Please see the X8I or X12I operator’s manual for more detailed

information on pressure control.

The other data points shown are (please note that the values below are examples only):

System pressure display units. Clicking on the units will switch between bar and

psig units of measure.

Minimum pressure alarm setting.

Low pressure setpoint minus the tolerance setting.

Low pressure setpoint. This is the pressure setpoint where the X8I or X12I will load

a compressor. This is based on the active table.

High pressure setpoint. This is the pressure setpoint where the X8I or X12I will

unload a compressor. This is based on the active table.

High pressure setpoint plus the tolerance setting.

Maximum pressure alarm setting.

Please refer to the X8I or X12I operator’s manual for further information on the system pressure setpoints.

Page 17

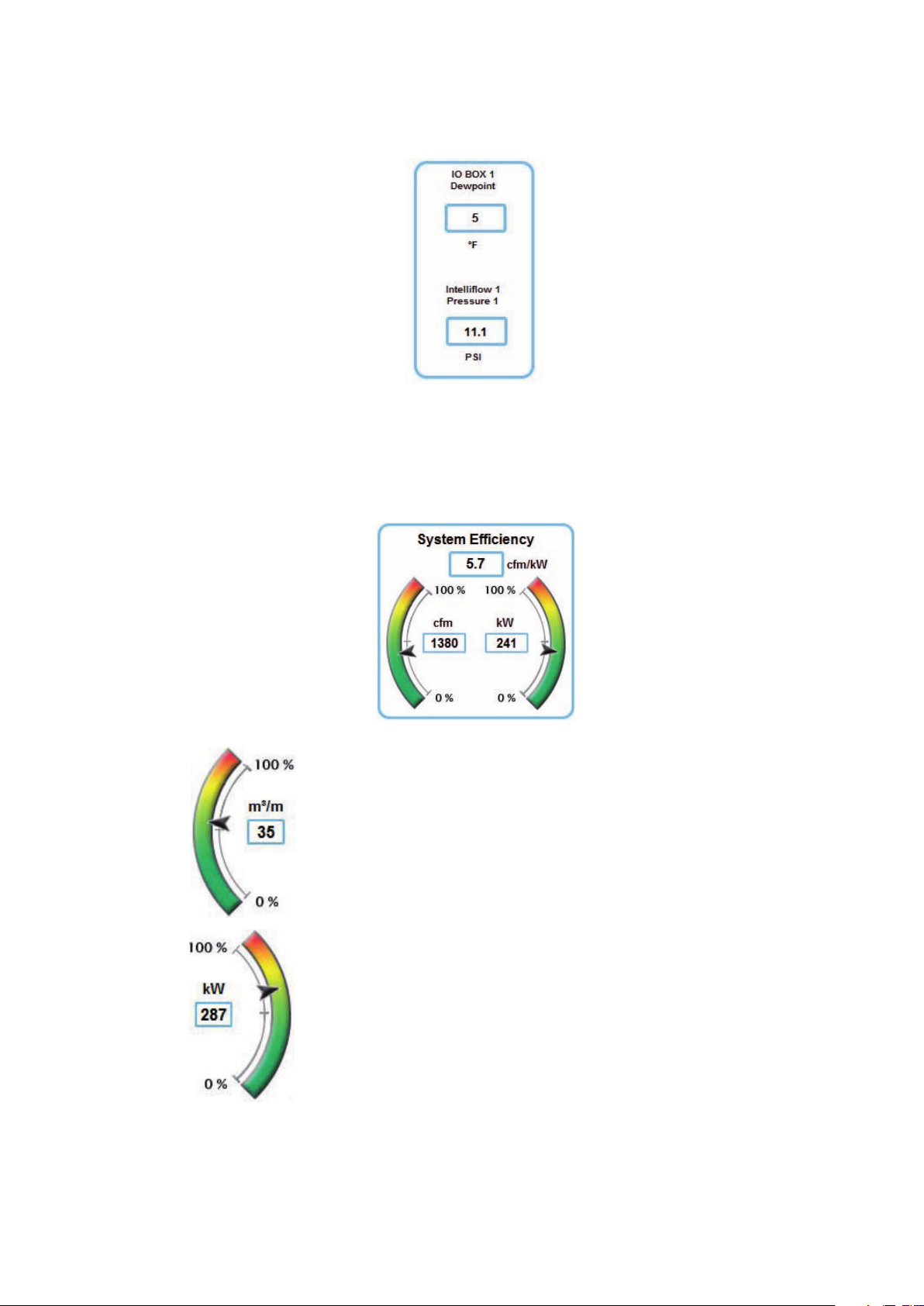

6.3 Congurable I/O

The congurable I/O section of the SOV screen allows the user to select two data points to display on the SOV. The

user congurable I/O may be from the X8I or X12I, an Intelliow valve, or an I/O box. The congurable I/O may only be

congured by a user with administrator rights, see section 8.2.2 – User Congurable Data Items.

6.4 System Eciency Gauge

The system eciency gage calculates and displays an overview of air system energy eciency. This is intended to be a

guide only and is based on user input, monitored status, and in some cases, measured data. The system eciency units

are congurable by a user with administrator rights. System eciency can be displayed in units of cfm/kW, kW/cfm, or

kW/m3/min.

The system output gauge uses the name plate capacity of the compressors

in the air system as well as monitoring compressor load states to

determine how much compressed air is being placed into the system.

The gauge shows how much capacity is being utilized in relation to the

capacity of all compressors in the system. A ow meter can also be used

for this value. Units and data source can only be changed by a user with

administrator rights, see section 8.2 – System Setup.

The system power consumption gauge uses the name plate power

consumption of the compressors in the air system as well as monitoring

compressor load states to determine the current power draw of the

compressors. The gauge shows how much power is being consumed

in comparison to the power consumed when all compressors are at

maximum load. Units are always kW.

The system eciency reading is only a guideline and should be used for monitoring day to day changes in compressed

air system eciency. True system eciency can only be determined with accurate ow and power meters and detailed

calculations.

17

Page 18

18

6.5 X8I/X12I Interface

The X8I and X12I interface allows remote control of the system controller from the visualization software. The user can

monitor and change the current operating state as well as change system controller setpoints.

If an X8I or X12I system alarm occurs this caution symbol will

appear next to the system controller icon on the X8I/X12I

interface.

6.5.1 X8I/X12I Controls

The X8I/X12I controls can only be used by users with USER or ADMIN rights. All other users will only be able to view the

status.

Pressing the start button will start the X8I or X12I. The blue indicator light

above the button will light up to conrm that the system controller has started.

The indicator will also change state if the X8I/X12I has been started or stopped

remotely.

Pressing the stop button will stop the X8I or X12I and place the compressors into

local control. The blue indicator light above the button will light up to conrm

that the system controller has stopped. The indicator will also change state if the

X8I/X12I has been started or stopped remotely.

Pressing the standby button will place the X8I or X12I into a standby state and

hold all compressors unloaded. The blue indicator light will light up to conrm that

the system controller is in standby. WARNING – The standby button will stop all

compressors in the system from producing air. Be sure this is what you intend

to do before pressing the standby button.

6.5.2 Table Conguration and Control

The X8I and X12I control interface allows the user to see which table is currently active and which sequencing

algorithm the system controller is currently utilizing. The user can also edit any table setpoints. Please note that the X8I

has four tables while the X12I has six tables.

The current active table will be highlighted in blue, such as table 1 in the picture above. If the active table changes;

either by the pressure schedule or by a user changing the default table on the X8I/X12I the highlight will move within

two seconds of the change being made. If the system controller is in a standby state no table will be highlighted.

Page 19

The mode shows the sequencing algorithm that is currently being utilized by the

system controller. If a change is made, this will be updated within two seconds.

Clicking on a table will bring up a table conguration screen where the user can

edit the pressure setpoints in the system controller. This function is only available

to users with USER or ADMIN rights.

The table conguration screen allows anyone with USER or ADMIN rights to change the X8I/X12I table setpoints.

Users with VIEW rights will only be able to view the settings. The X8I/X12I setpoints are described in detail in the X8I or

X12I operator’s manual.

High Pressure Setpoint – The X8I/X12I will unload a compressor when

system pressure rises above this value.

Low Pressure Setpoint – The X8I/X12I will load a compressor when system

pressure drops below this value..

Minimum Pressure Alarm – The X8I/X12I will report an alarm condition if

system pressure drops below this value.

Sequencing Algorithm – The sequencing currently utilized by the X8I/

X12I.

Compressor Priority – Set each compressors priority in the X8I/X12I

sequence. Please see the X8I/X12I operator’s manual for more information

about compressor priority.

When you are nished viewing and/or changing the settings in the table conguration screen:

Click the exit button to leave the table conguration page without

saving any changes. You will be returned to the SOV screen.

Click the Save and Exit button to save your changes and return to

the SOV screen.

19

Page 20

20

6.5.3 Pressure Schedule Control

The pressure schedule control allows a user with USER or ADMIN rights to activate or deactivate the pressure schedule

on the X8I/X12I. The X8I/X12I’s pressure schedule allows the user to switch between pressure tables or standby mode

based on date and time. The pressure schedule is activated by clicking the ON button. The indicator light will turn blue

to conrm that the pressure schedule has been activated. The pressure schedule can be deactivated by clicking the

OFF button. The indicator will then turn grey to conrm that the pressure schedule has been deactivated. The indicator

will also change state if the pressure schedule has been activated or deactivated from the X8I/X12I.

Please see section 6.7.2 – Pressure Schedule for information on setting up the pressure schedule. Also please refer to

the X8I or X12I operator’s manual for detailed information about the pressure schedule functionality of the X8I/X12I.

6.6 Compressor Status Overview

The compressor status overview gives the current operating condition of all compressors that are connected to the

X8I/X12I. The overview duplicates the data that is given on the X8I/X12I control panel, using the same style of lights.

The compressor status overview is view only and may not be adjusted by any users.

Compressor address.

Compressor Load Status – This indicator will be green when the

compressor is in a loaded condition and grey when the compressor is

unloaded.

Compressor Running Status – This indicator will be yellow when the

compressor’s motor is running and grey when the compressor’s motor

is not running.

System Control Indicator – This indicator will be blue when the

compressor is under X8I/X12I control and red when the compressor is

under local control or placed into service maintenance mode, or

otherwise unavailable to the X8I/X12I.

Compressor Load Percentage – This value displays the load percentage

the compressor is currently reporting. This will vary for variable speed

drive compressors and be either 0% or 100% for xed speed

compressors.

Compressor Sequence Position – This letter will display which place in

the sequence the compressor is assigned. This letter can range from A

to K for a 12 compressor system, with A being the 1st compressor in the

sequence and K being the 12th. An @ symbol in this eld will indicate

that the compressor has been restricted from use in the priority

settings.

Page 21

6.7 System Detail View

Performance Report Utility

Pressure Schedule

System Pressure Graph

Total Flow Graph

Configurable Graph

The system detail view buttons provide access to the visualization software’s reporting and graphing utilities. The

system detail view buttons also provide access to the X8I/X12I pressure schedule.

6.7.1 Performance Report Utility

The performance report provides a summary of the compressed air system’s performance for the past hour, day, week,

or 4 week period. The performance report provides information on the average and maximum output capacity, power

consumption, and utilization of the entire air system. Information on the utilization of each individual compressor

is also displayed. The time period of the performance report is selected based on the current graph being viewed.

For example, if you are currently viewing the 4 week graph, clicking the performance report utility will produce a

performance report for that 4 week period of time.

Click the Performance Report Utility button to open the

performance report. From the system overview page the

performance report will be based on the last complete seven days

of operation (one calendar week; 168hrs).

Clicking the graph button will open the graph utility.

Clicking on the print button will print the performance report

currently being viewed.

Click the exit button to leave the Performance Report Utility.

You will be returned to the system overview page.

21

Page 22

22

6.7.2 Pressure Schedule

The X8I/X12I pressure schedule can be modied from the visualization software by users with USER or ADMIN rights.

The pressure schedule lets you schedule when the 4 (X8I) or 6 (X12I) pressure tables are utilized. Users with VIEW

rights can only view the current pressure schedule. Please see the X8I or X12I operator’s manual for more detailed

information about the pressure schedule function.

Click the pressure schedule button to open the pressure

schedule conguration screen.

Conguring the pressure schedule in the visualization software is identical to conguring the pressure schedule from

the X8I/X12I control panel. Days are entered as numbers, where 1 is Monday and 7 is Sunday. 8 means the event occurs

every day and 9 means the event occurs every day except for weekends. Hours are entered in a 24 hour format. Please

note that the pressure schedule conguration screen rearranges entries automatically.

When you are nished viewing and/or changing the settings in the pressure schedule conguration screen:

Click the exit button to leave the pressure schedule conguration

page without saving any changes. You will be returned to the SOV

screen.

Click the Save and Exit button to save your changes and return to

the SOV screen.

Page 23

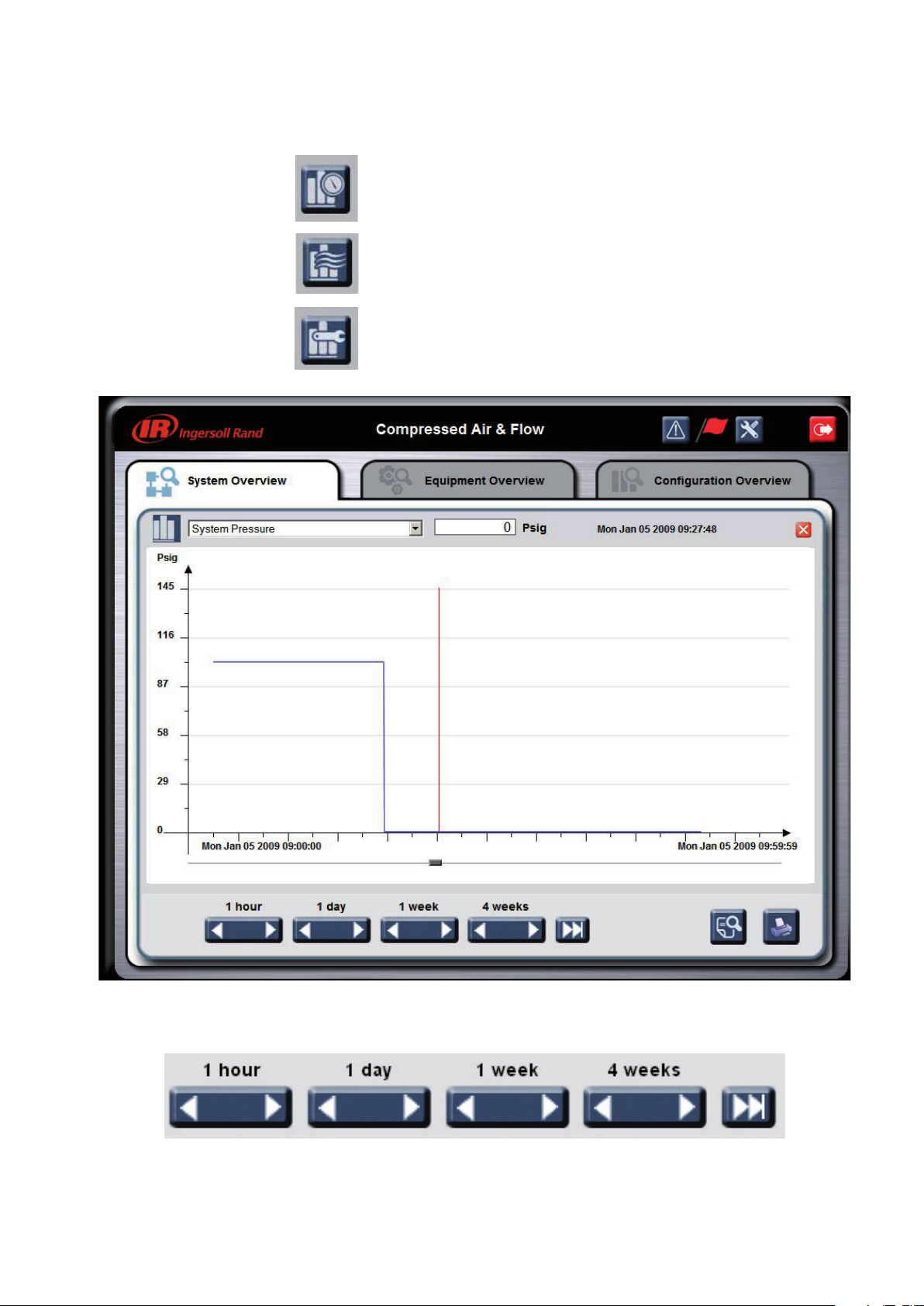

6.7.3 Graphing Utility

The graphing utility allows the user to plot certain data points, such as system pressure, output ow, or compressor

load percentages for hour, day, week, or 4 week periods. There are three graphing utility buttons on the system

overview screen.

Precongured Graph, System Pressure - Click the system

pressure graph button to bring up a graph of the past hour of

system pressure data.

Precongured Graph, Total Flow - Click the system ow graph

button to bring up a graph of the past hour of system ow data.

Congurable Graph - Click on the congurable graph

button to select a variable to graph.

Once the graphing utility has been opened the navigation buttons can be used to see data from dierent time periods.

The VX box will store the last 90 days of data.

23

Page 24

24

Clicking the left arrow will show the previous hour’s data.

Clicking the right arrow will show the next hour’s data (if applicable).

Clicking the left arrow will show the previous day’s data.

Clicking the right arrow will show the next day’s data (if applicable).

Clicking the left arrow will show the previous week’s data.

Clicking the right arrow will show the next week’s data (if applicable).

Clicking the left arrow will show the previous 4 week’s data.

Clicking on the right arrow will show the next 4 week’s data (if

applicable).

Clicking the double right arrow button will bring you to the latest

collected data of the current time period. For example if you are

currently viewing 1 day’s time period you will go to the current day’s

data.

The graph can also be navigated by using the grey slider below the time axis. Sliding the cursor all the way to the left

will navigate to previous data using the same time scale currently selected. Sliding the cursor all the way to the right

will navigate to the next data using the same time scale.

The slider can also be used to view the value of the graph at the selected point in time.

The drop down menu allows you to choose a variable to view on

the graph. Available variables include system pressure, system ow,

compressor load percentages, compressor load status, compressor run

status, user congurable data points, dewpoint (if installed), power, and

eciency.

Dragging the cursor to a point on the graph will display the value in

this box next to the selected variable.

The units of the current variable are displayed.

Page 25

Click the Performance Report Utility button to open the performance

Typical PC USB A Port Connection

USB 2.0 Universal Serial Bus Cable A to B

VX Box USB B Port Connection

report for the currently displayed time period.

Clicking the print button will print the current graph view.

Click the exit button to exit the graphing utility and return to

the system overview screen.

6.7.4 Archiving Historical Data

The VX Box stores up to three months of data for all data points that can be graphed using the graphing utility. In order

to retrieve this data rst follow the USB connection procedure on page 4 of the VX Accessory Box Installation Manual

(CCN: 80445083). Once connected, follow the procedure outlined below.

NOTE: During the le copy, the VX Box will not accept Logins. Any user connected will be logged out and the web

browser will display the message “SD Card Unreachable” when logins are attempted.

To initiate the le transfer, connect your PC to VX Box using a standard USB 2.0 Universal Serial Bus Cable A to B

25

Page 26

26

Upon connection, the following drive folder will appear on your PC.

NOTE: The drive designation will be dependent on your PC conguration.

Click the Name column to sort by name.

Scroll down the list of le names until you see the LOGDAY01.TXT

Select the les by clicking on the LOGDAY01.TXT le and then pressing SHIFT and the DOWN ARROW. This will

highlight the les to be copied.

Page 27

Now press CNTL C or right click and select COPY.

Paste the les into the directory of your choice on your PC.

After the copy and paste is complete, remove the USB cable from the VX Box. The VX box will be return to normal

operation.

To use the data for reports, you can use EXCEL or any other Database program to import and extract the data as

desired. All data is saved in comma separated variable (CSV) format which can easily be imported into Excel using the

import wizard.

The text le has data formatted in the following manner. In order to provide the proper header information for your

spreadsheet you will need to add the information to the rst row of your spreadsheet.

27

Page 28

28

*1 Please note that the Compressors Available data is in binary format where each digit represents a compressor

(compressor 1 being the right most digit). If a digit is 0 that means the compressor is available for the X8I or X12I to use.

If a digit is 1 that means the compressor is unavailable.

For example, 4 would be 100 in binary, where compressors 1 and 2 are available and compressor 3 is unavailable.

*2 Other compressor data marked with *2 is also binary, but if a digit is 1, that means the condition is true

(the compressor is loaded, running, alarmed, or in maintenance mode). If a digit is 0 the conditions is false (the

compressor is unloaded, not running, not alarmed, or not in maintenance mode.

It is recommended that the log les are archived periodically, at least once every 90 days in order to maintain a proper

historical archive.

Page 29

SECTION 7 EQUIPMENT OVERVIEW

100

Psig

Load Status

Run Status

System Control Status

Alarm

Alarm

7.1 Equipment Overview

The Equipment Overview screen (EOV) gives a summary of the operating conditions of all compressors, I/O boxes,

and Intelliow Valves in the compressed air system. Compressors are shown along the left side of the screen with their

user assigned name, load state, running state, system control state, and an alarm ag if the compressor is currently

in an alarm or trip condition. I/O boxes and Intelliow valves are shown on the right side of the screen with their user

assigned name and an alarm ag if the unit is in an alarm or trip condition. The EOV screen contains only view only

data.

The system pressure is displayed in the upper right corner using

the same units selected on the SOV screen.

Compressor Information is displayed as shown below. The compressor name is assigned by an administrator following

section 8.3.1 – compressor conguration:

I/O Box and Intelliow Information is displayed as shown below. The equipment name is assigned by an administrator

following section 8.4.1 I/O Box conguration:

29

Page 30

30

7.2 Compressor Detail View

The Compressor Detail View (CDV) screen shows relevant data about the selected compressor. The CDV contains view

only data with the exception of the manual controls. Manual controls are only usable by users with USER or ADMIN

rights.

Clicking the compressor icon next to the compressor address

on the Equipment Overview Screen will open that compressor’s

CDV screen.

The compressor name and address are shown at the top of the CDV screen.

7.2.1 Compressor Status

The compressor status box duplicates the status indicator lights shown on the SOV and EOV screens as well as

providing more detailed information about the compressor. The graphic represents the compression method of the

compressor, a picture of a pair of rotors for example, for a rotary screw compressor, or a piston for a reciprocating

compressor.

Page 31

The compressor status indicator shows the current state of the compressor as shown below, this is equivalent to the

Load Status

Motor Status

System Control Status

Load Percentage

Sequence Position

indicators on the SOV:

The model, manufacturer, and X8I/X12I interface type

are displayed as entered by the administrator during

system setup. Please see section 8.3 – Compressor

Conguration for further information on compressor

setup.

7.2.2 Compressor Nameplate Data

The nameplate data section shows the power consumption and output characteristics of the compressor. This

data is usually taken from the compressor specications and motor nameplate data. This data must be input by an

administrator and is used in calculating the system eciency as displayed on the System Overview screen. Care must

be taken to enter the correct information for accurate performance data.

Capacity is the volume of air ow from the compressor at its rated pressure. Capacity will be in the units selected by

the administrator.

Package Power is the power consumption of the compressor at full load at its rated pressure. Pressure units will again

be selected by the administrator. Power units are always in kW.

Unloaded Power is the power consumption of the compressor running in an unloaded state. Units are always kW.

VSD Minimum Capacity is the volume of air ow from a variable speed compressor when it is running at its minimum

load percentage. This value will always be 0 for a xed speed machine. Units will be selected by the administrator.

VSD Minimum Power is the power consumption of a variable speed compressor when it is running at its minimum

speed. The units are always kW.

Warning State will show a text description of the current alarm or trip aecting the compressor. This value will be

blank and the red alarm ag will disappear if there is no alarm. Please note that text descriptions are only available for

IntelliSys controlled compressors with IR-485 or IRV-485 interface types.

Managed Hours show how many hours the compressor has been running while under control of the X8I/X12I.

31

Page 32

32

7.2.3 User Congurable Compressor Data

112

146

0.7

2

180

82

Administrators can set up to six additional data points to be read from each compressor. These data points will be

displayed on the CDV screen with administrator dened titles and units. Data points may come from the compressor or

any I/O box connected to the system. Please see section 7.3.1.3 – Additional Date Items for information on setting up

these data points. These additional data points are only available for IntelliSys controlled compressors with IR-485 or

IRV-485 interface types.

7.2.4 Manual Start/Stop Control

The Manual Start/Stop control allows a user with User or Administrator rights to take the compressor out of X8I/X12I

control to start and stop the compressor remotely using the interface on the CDV screen. The Manual Control interface

will only appear for IntelliSys controlled compressors with IR-485 or IRV-485 interface types. The compressor’s local

controller must also be set to accept remote start/stop commands before Manual Control will function.

Manual Control is currently o when the button reads “On” and the

indicator light is grey.

Clicking the “On” button will place the compressor into service

maintenance mode and remove the compressor from X8I/X12I control.

The indicator light will turn blue to conrm that the compressor is in

service maintenance mode.

Clicking the “O” button will place the compressor back under X8I/X12I

control and return the Manual Control button to “On.”

If Manual Control is on the compressor can be started by pressing

the green start button. The indicator light above the start button will

turn blue to conrm the compressor has started. If Manual Control is

o the compressor will not respond to the manual start command but

the indicator lights will report the operating state of the compressor.

When Manual Control is on the compressor can also be stopped by

pressing the red stop button. The indicator light above the stop

button will turn blue to conrm that the compressor has stopped. If

Manual Control is o the compressor will not respond to the manual

stop command but the indicator light will report the operating state of

the compressor.

Click the exit button to exit the CDV screen and return to the EOV

screen.

Page 33

7.3 Equipment Detail View - I/O Box

99

The I/O Box Equipment Detail View (EDV) screen shows all data from the I/O box’s analog and digital inputs and

outputs. Please refer to the I/O box manual for detailed information about the I/O box’s functionality.

Clicking the I/O Box icon next to the desired I/O Box on the EOV screen

will open the EDV screen.

The system pressure is displayed in the upper right corner using

the units selected on the SOV screen.

The I/O box’s name is displayed next to its network address across the top of the EDV screen. An alarm state will cause

the red alarm ag to be displayed on the upper left part of the EDV screen.

Analog input information is displayed as congured by the

Administrator when setting up the I/O Box conguration.

Please see section 8.4.1 – I/O Box Conguration for information

about I/O Box Conguration. Labels and values shown here are

only Samples.

The alarm symbol will appear next to any analog input value

which is currently in an alarm condition. These alarm limits are

programmable at the I/O Box.

The output states of the I/O box’s six relay outputs are shown on

the EDV screen. A blue indicator means the relay is in its

energized state while a gray indicator means that the relay is in

its de-energized state.

33

Page 34

34

The input states of the I/O box’s eight digital inputs are shown. A

check mark indicates that the input is in its energized state while

an empty circle indicates that the input is in its de-energized

state.

The alarm symbol will appear next to any digital input value

which is currently in an alarm condition. Alarm conditions are

congured at the I/O box.

Click the exit button to exit the EDV screen and return to the EOV

screen.

7.4 Equipment Detail View - Intelliow

The Equipment Detail View (EDV) screen shows the current operating condition of any connected Intelliow valves.

Please refer to the Intelliow operator’s manual for more detailed information about the data. Visualization is only

compatible with Intelliow valves equipped with the IX controller (Mid-2009).

Clicking the Intelliow icon next to the desired Intelliow valve

on the EOV screen will open the EDV screen.

The system pressure is displayed in the upper right corner using

the units selected on the SOV screen.

Page 35

The Intelliow box’s name is displayed next to its network address across the top of the EDV screen. An alarm state will

Forward Flow Control

Backward Flow Control

Combination Flow Control

cause the red alarm ag to be displayed on the upper left part of the EDV screen.

P4 Outlet Pressure is the pressure read on the demand (process)

side of the Intelliow Valve.

P3 Inlet Pressure is the pressure read on the supply (compressor)

side of the Intelliow Valve.

% Open is the Intelliow Valve current position.

The selected control method is also shown, forward control,

backward control, or both, indicated by the indicator light turning

blue beside the current method.

Any current alarms will cause a red ag to appear. A text readout of

the alarm will appear next to the alarm ag.

The target pressure selection for the Intelliow valve is shown.

A check mark indicates that the selection is true while an empty

circle indicates that the input is false. The IX Intelliow has 4

programmable and selectable pressure sets.

Click the exit button to exit the EDV screen and return to the EOV

screen.

35

Page 36

36

SECTION 8 CONFIGURATION OVERVIEW

8.1 Conguration Overview

The Conguration Overview (COV) screen is only accessible by users with Administrator rights. The COV gives

administrators access to change the conguration of system parameters as well as access to account management and

diagnostic utilities.

8.2 X8I/X12I System Setup

The X8I/X12I System Setup allows the administrator to change the type of system controller, ow and eciency units,

and set up the user congurable data points that are displayed on the SOV screen.

Management Unit Model – Shows whether the visualization

system is connected to an X8I or X12I.

Flow Unit – Shows the units used in the eciency gauge on

the SOV for ow.

System Eciency Unit – Shows the units used in the

eciency gauge on the SOV for overall system eciency.

Page 37

8.2.1 System Conguration

Click on the icon representing the X8I/X12I to open the System

Setup conguration screen.

Installation Name – Name of the air system, this will be

shown on the title bar on all screens.

Management Model – Select X8I or X12I from the drop

down list according to your air system.

System Eciency Unit – Select the units of measure

to be used for the system eciency reading on the

SOV screen.

System Flow Unit – Select the units of measure to be

used for the system ow reading on the SOV screen.

Flow Data Source – The system ow reading may be

taken from calculated values using the name plate

data entered for the individual compressors or using

a ow meter assigned to either of the user

congurable data items.

37

Page 38

38

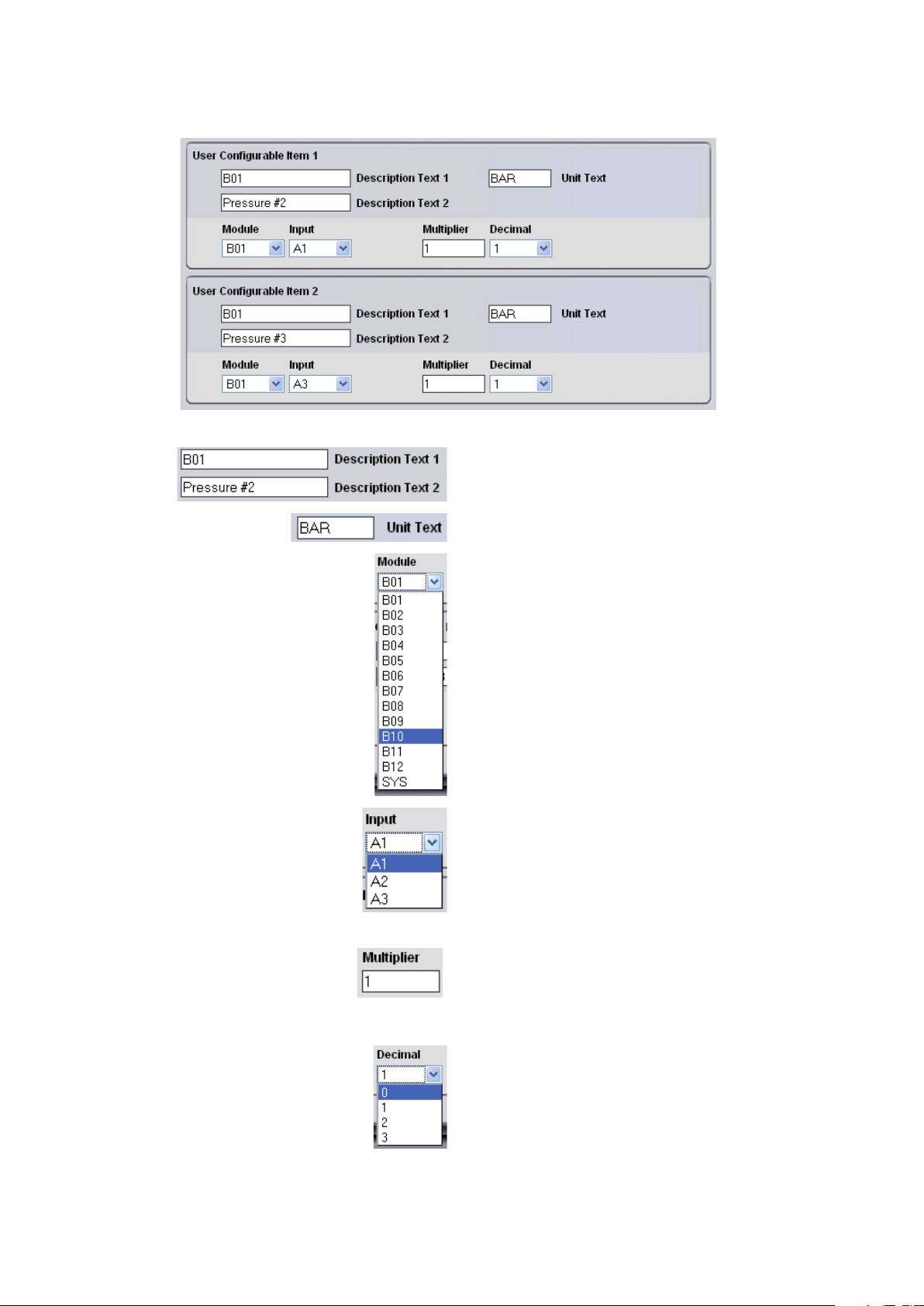

8.2.2 User Congurable Data Items

The administrator can select any two analog inputs in the system to be displayed on the SOV screen and to be archived

for graphing purposes. These analog inputs may be taken from I/O boxes or the system controller.

Description Text – Up to two lines of text can be used

per user congurable data item for ease of identifying

the data.

Unit Text – Type in the units of the analog input used.

Module – Select the module where the desired analog

input resides. Remember that B01 through B12 could

be either I/O boxes or Intelliow Valves. SYS represents

the X8I or X12I.

Input – Select the desired analog input of the I/O box or

X8I/X12I.

Multiplier – Some analog inputs may need to be

multiplied by a value to obtain the correct display value.

For example, if the reading is 100.3 but the analog input

is transmitted as 1003, the multiplier would be 0.1.

Decimal – Select the desired number of decimal places

you wish to display. For example 100.33 would be

displayed as 100 with 0 decimal selected, 100.3 with 1

decimal selected, 100.33 with 2 decimal selected, and

100.330 with 3 decimal selected.

Page 39

When you are nished viewing and/or changing the settings in the System Conguration screen:

Click the exit button to leave the conguration screen without

saving any changes. You will be returned to the COV.

Click the Save and Exit button to save your changes and return to

the COV.

8.3 Compressor Setup

The compressor setup area shows the compressor addresses and the interface type for all compressors.

C01 through C12 – Represents the compressor address of all

possible compressors in the system.

Interface Type – Represents the connection method of the

compressor to the X8I/X12I. This value will be a dash “-“ if the

compressor is not installed in the system.

8.3.1 Compressor Conguration

Click on the compressor icon next to the desired compressor to

open that compressor’s conguration screen.

Type in the name of the compressor for that will appear on the EOV

screen and the EDV screen for that compressor.

39

Page 40

40

8.3.1.1 Compressor Model Information

Type in the model name of the compressor, this is

usually taken from the compressor nameplate.

Type in the name of the compressor manufacturer.

Select the compressor’s compression method from

the dropdown menu. The picture representing the

compressor will change according to the selected

compressor type.

Selecting “---“indicates that no compressor is connected

at this position.

Select the compressor’s interface type. This should

be identical to the interface type used in the X8I/X12I

setup.

Please see the X8I/X12I operator’s manual for more

information.

Select the compressor’s controller type. This

information should be obtained from your compressor

service representative. The controller type will vary

depending on the interface type selected.

Page 41

8.3.1.2 Compressor Nameplate Data

Type in the compressor’s nameplate ow output.

Type in the compressor’s nameplate power

consumption at its rated pressure.

Type in the compressor’s nameplate power

consumption running unloaded.

Type in the minimum ow output of the compressor.

This will be zero for xed speed machines and

dependent on nameplate data for variable speed

machines.

Type in the compressor’s power consumption at

its minimum speed. This will be zero for xed speed

machines and dependent on nameplate data for

variable speed machines.

8.3.1.3 Additional Data Items

Up to six additional data items may be read from the compressor’s local controller to be displayed on the compressor’s

EDV screen. Please note that additional data items may only be congured for compressors with IR- 485 or IRV-485

data types. The administrator also must have a Modbus or Multi485 table to nd the addresses for any desired data

points. Please refer to the SMG manual for Modbus tables for many Ingersoll Rand compressors.

Type in the description for the data point and the

units of measure.

Select the module where the data resides from the

dropdown list. The data can come from the

compressor or from an I/O box installed on the

system.

41

Page 42

42

Select the communication protocol, usually Modbus

for local compressor controllers, and Multi485 for

X8I/X12I modules.

Refer to the System Modbus Gateway manual for

more information.

Type in the Modbus or Multi485 address (in decimal)

and select the proper data type for the controller. Refer

to the controller documentation for more information.

U16 will be the most common data type used.

U16 – Unsigned 16 bit integer

S16 – Signed 16 bit integer

U32 – Unsigned 32 bit integer

S32 – Signed 32 bit integer

HRS – Run Hours

Some analog inputs may need to be multiplied by a

value to obtain the correct display value. For example, if

the reading is 100.3 but the analog input is transmitted

as 1003, the multiplier would be 0.1.

Select the desired number of decimal places you wish

to display. For example 100.33 would be displayed

as 100 with 0 decimal selected, 100.3 with 1 decimal

selected, 100.33 with 2 decimal selected, and 100.330

with 3 decimal selected.

When you are nished viewing and/or changing the settings in the Compressor Conguration screen:

Click the exit button to leave the conguration screen

without saving any changes. You will be returned to the

COV.

Click the Save and Exit button to save your changes and

return to the COV.

The following Intellisys Controller Modbus Tables provide the most common compressor data values that can be

congured and monitored from the VX Box, up to six (6) for each compressor. The VX Box uses the Relative Address

Modbus format. The Register Addresses shown in each of these Tables has been converted and is the Relative Modbus

Address.

TABLE 1 SSR REDEYE CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Inlet Vacuum PSI C0x Modbus 4 U16 0.1 1

Coolant Temperature DEG C0x Modbus 5 U16 1 0

Airend Temperature DEG C0x Modbus 6 U16 1 0

Discharge Temperature DEG C0x Modbus 7 U16 1 0

Low Ambient Coolant Temp. DEG C0x Modbus 8 U16 1 0

“x” is the Compressor number being congured

Page 43

TABLE 2 SSR SG CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Inlet Vacuum PSI C0x Modbus 4 U16 0.1 1

Coolant Temperature DEG C0x Modbus 5 U16 1 0

Airend Temperature DEG C0x Modbus 6 U16 1 0

Discharge Temperature DEG C0x Modbus 9 U16 1 0

Low Ambient Coolant Temp. DEG C0x Modbus 11 U16 1 0

“x” is the Compressor number being congured

TABLE 3 SSR SE 15100HP CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Separator Pressure Drop PSI C0x Modbus 4 U16 1 0

Airend Temperature DEG C0x Modbus 5 U16 1 0

“x” is the Compressor number being congured

TABLE 4 SIERRA REDEYE 125200 HP CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

2nd Stage Inlet Pressure PSI C0x Modbus 3 U16 1 0

2nd Stage Discharge Pressure PSI C0x Modbus 4 U16 1 0

Inlet Vacuum PSI C0x Modbus 5 U16 1 0

Oil Filter In Pressure PSI C0x Modbus 6 U16 1 0

Bearing Oil Pressure PSI C0x Modbus 7 U16 1 0

1st Stage Discharge Temp. DEG C0x Modbus 8 U16 1 0

2nd Stage Inlet Temp. DEG C0x Modbus 9 U16 1 0

2nd Stage Discharge Temp. DEG C0x Modbus 10 U16 1 0

Bearing Oil Temp. DEG C0x Modbus 11 U16 1 0

Package Discharge Temp. DEG C0x Modbus 12 U16 1 0

“x” is the Compressor number being congured

TABLE 5 SIERRA SE 50100 HP CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

Package Discharge Temp. DEG C0x Modbus 3 U16 1 0

Bearing Oil Temp. DEG C0x Modbus 4 U16 1 0

2nd Stage Inlet Temp. DEG C0x Modbus 5 U16 1 0

2nd State Discharge Temp. DEG C0x Modbus 6 U16 1 0

1st Stage Discharge Temp. DEG C0x Modbus 7 U16 1 0

“x” is the Compressor number being congured

43

Page 44

44

TABLE 6 SIERRA SG 125400 HP CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

2nd Stage Inlet Pressure PSI C0x Modbus 3 U16 1 0

2nd Stage Discharge Pressure PSI C0x Modbus 4 U16 1 0

Inlet Vacuum PSI C0x Modbus 5 U16 1 0

Oil Filter In Pressure PSI C0x Modbus 6 U16 1 0

Bearing Oil Pressure PSI C0x Modbus 7 U16 1 0

1st Stage Discharge Temp. DEG C0x Modbus 8 U16 1 0

2nd Stage Inlet Temp. DEG C0x Modbus 9 U16 1 0

2nd Stage Discharge Temp. DEG C0x Modbus 10 U16 1 0

Bearing Oil Temp. DEG C0x Modbus 11 U16 1 0

Package Discharge Temp. DEG C0x Modbus 12 U16 1 0

“x” is the Compressor number being congured

TABLE 7 RECIP REDEYE CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

1st Stage Discharge Pressure PSI C0x Modbus 2 U16 1 0

Package Discharge Pressure PSI C0x Modbus 3 U16 1 0

Air Filter Pressure Drop PSI C0x Modbus 4 U16 1 0

Frame Oil Pressure PSI C0x Modbus 5 U16 1 0

Package Water In Pressure PSI C0x Modbus 6 U16 1 0

Package Water Out Pressure PSI C0x Modbus 7 U16 1 0

Pressure AA PSI C0x Modbus 8 U16 1 0

Pressure BB PSI C0x Modbus 9 U16 1 0

1st Stage Discharge Temp. DEG C0x Modbus 10 U16 1 0

2nd Stage Discharge Temp. DEG C0x Modbus 11 U16 1 0

Frame Oil Temperature DEG C0x Modbus 12 U16 1 0

Package Water In Temp. DEG C0x Modbus 13 U16 1 0

2nd Stage Air In Temp. DEG C0x Modbus 14 U16 1 0

1st Stage Water Out Temp. DEG C0x Modbus 15 U16 1 0

2nd Stage Water Out Temp. DEG C0x Modbus 16 U16 1 0

“x” is the Compressor number being congured

TABLE 8 RECIP SG CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Oil Pressure PSI C0x Modbus 2 U16 1 0

Water In Pressure PSI C0x Modbus 3 U16 1 0

Water Out Pressure PSI C0x Modbus 4 U16 1 0

Package Discharge Pressure PSI C0x Modbus 5 U16 1 0

1st Stage Discharge Pressure PSI C0x Modbus 6 U16 1 0

2nd Stage Discharge Pressure PSI C0x Modbus 7 U16 1 0

Suction Pressure PSI C0x Modbus 8 U16 1 0

Inlet Vacuum PSI C0x Modbus 9 U16 1 0

Oil Temperature DEG C0x Modbus 10 U16 1 0

Water In Temperature DEG C0x Modbus 11 U16 1 0

2nd Stage Inlet Temperature DEG C0x Modbus 12 U16 1 0

Page 45

3rd Stage Inlet Temperature DEG C0x Modbus 13 U16 1 0

Package Discharge Temperature DEG C0x Modbus 14 U16 1 0

1st Stage Discharge Temperature DEG C0x Modbus 15 U16 1 0

2nd Stage Discharge Temperature DEG C0x Modbus 16 U16 1 0

DEG C0x Modbus 17 U16 1 0

“x” is the Compressor number being congured

TABLE 9 NIRVANA SGN CC CONTACT COOLED CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Dry Side Sump Pressure PSI C0x Modbus 4 U16 0.1 1

Coolant Temperature DEG C0x Modbus 10 U16 1 0

Airend Temperature DEG C0x Modbus 11 U16 1 0

Discharge Temperature DEG C0x Modbus 12 U16 1 0

Separator Pressure Drop DEG C0x Modbus 18 U16 1 0

“x” is the Compressor number being congured

TABLE 10 NIRVANA SGNE CC CONTACT COOLED CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Dry Side Sump Pressure PSI C0x Modbus 4 U16 1 0

Interstage Pressure PSI C0x Modbus 5 U16 1 0

Coolant Temperature DEG C0x Modbus 10 U16 1 0

Airend Temperature DEG C0x Modbus 11 U16 1 0

Discharge Temperature DEG C0x Modbus 12 U16 1 0

Inlet Temperature DEG C0x Modbus 13 U16 1 0

Cooler Out Temperature DEG C0x Modbus 14 U16 1 0

Separator Pressure Drop PSI C0x Modbus 18 U16 1 0

“x” is the Compressor number being congured

TABLE 11 NIRVANA SGNE OF OILFREE CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

2nd Stage Inlet Pressure PSI C0x Modbus 3 U16 1 0

2nd Stage Discharge Pressure PSI C0x Modbus 4 U16 1 0

Inlet Vacuum PSI C0x Modbus 5 U16 1 0

Oil Filter Pressure Drop PSI C0x Modbus 6 U16 1 0

Bearing Oil Pressure PSI C0x Modbus 7 U16 1 0

2nd Stage Inlet Temperature DEG C0x Modbus 8 U16 1 0

1st Stage Discharge Temperature DEG C0x Modbus 9 U16 1 0

2nd Stage Discharge Temperature DEG C0x Modbus 10 U16 1 0

Bearing Oil Temperature DEG C0x Modbus 11 U16 1 0

Discharge Temperature DEG C0x Modbus 12 U16 1 0

1st Stage Inlet Temperature DEG C0x Modbus 18 U16 1 0

“x” is the Compressor number being congured

45

Page 46

46

TABLE 12 NIRVANA 1530 KW 2040 HP DF CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Discharge Pressure PSI C0x Modbus 2 U16 1 0

Aftercooler Discharge Pressure PSI C0x Modbus 3 U16 1 0

“x” is the Compressor number being congured

TABLE 13 SSR UP SE CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Package Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Airend Temperature DEG C0x Modbus 4 U16 1 0

Separator Pressure Drop PSI C0x Modbus 5 U16 1 0

“x” is the Compressor number being congured

TABLE 14 ESA SE 22 150 KW CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Package Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Airend Temperature DEG C0x Modbus 4 U16 1 0

Separator Pressure Drop PSI C0x Modbus 5 U16 1 0

“x” is the Compressor number being congured

TABLE 15 RSERIES S3 CONTROLLER REGISTER STRUCTURE

Description Unit Module Type Address Data Multiplier Decimal

Package Discharge Pressure PSI C0x Modbus 2 U16 1 0

Sump Pressure PSI C0x Modbus 3 U16 1 0

Airend Temperature DEG C0x Modbus 6 U16 1 0

Separator Pressure Drop PSI C0x Modbus 9 U16 1 0

“x” is the Compressor number being congured

8.4 I/O Box and Intelliow Setup

The I/O Box and Intelliow Setup area shows the network address and whether an I/O Box or Intelliow Valve is

connected at that address.

B01 through B12 - Represents the address of the I/O box or

Intelliow Valve.

Equipment Type – Intelliow for an Intelliow valve, or I/O

for an I/O Box.

8.4.1 I/O Box and Intelliow IX Conguration

The I/O Box conguration screen is set independently of the I/O Box local conguration but in almost all cases should

be congured identically. Please note that for Intelliow IX congurations only the title and module type need be set.

Page 47

8.4.1.1 Analog Input Conguration

Type in a name so that the I/O Box can be easily

identied.

Select whether the unit is an I/O Box or an Intelliow

Valve from the dropdown menu.

Type in the description for the analog input and type

in the units of measure.

Some analog inputs may need to be multiplied by a

value to obtain the correct display value. For

example, if the reading is 100.3 but the analog input is

transmitted as 1003, the multiplier would be 0.1.

Select the desired number of decimal places you

wish to display. For example 100.33 would be

displayed as 100 with 0 decimal selected, 100.3 with

1 decimal selected, 100.33 with 2 decimal selected,

and 100.330 with 3 decimal selected.

47

Page 48

48

8.4.1.2 Relay Output Conguration

8.4.1.3 Digital Input Conguration

Type in the description of the relay output.

Type in the description of the digital output.

When you are nished viewing and/or changing the settings in the I/O Box Conguration screen:

Click the exit button to leave the conguration screen

without saving any changes. You will be returned to the

COV.

Click the Save and Exit button to save your changes and

return to the COV.

8.5 Account Management

The administrator can create any number of users desired and assign each user one of three levels of access, as well as

assigning email notications to various events that may occur.

Click the account management button on the COV to

open the Account Management utility.

Page 49

`

The list of accounts that currently exist are listed by user

name and access rights. Clicking on an account will

highlight that account in red and display its attributes.

The attributes will be displayed on the right side of the

account management utility.

49

Page 50

50

To modify an account create a new user, start with any account highlighted in red:

Type in a unique user name (new account only).

Type in a password.

Select the access rights from the drop down menu.

Access rights are as follows:

VIEW – The user is able to view all information on the SOV and EOV screens and their detail view screens. The

1.

user is unable to change any setpoints or access the COV screen.

USER – The user has all rights available to the VIEW access level as well as being able to change setpoints on the

2.

table conguration screens, pressure schedule screens, and is able to manually start and stop compressors, as

well as start and stop the X8I/X12I.

ADMIN – The user has all rights of the VIEW, and USER access levels as well as full access to the COV screen, the

3.

account management utility, and the diagnostics screen.

Please note that there can only be ve users logged into the system at one time, and only one administrator logged in

at one time.

Type in the description of the digital output.

Set the email lter settings for the user. The lter will

set which, if any, events will dispatch an email to the

user. Checking an event will cause that event to send an

email. Multiple users may receive emails for any or all

events.

The events lter will determine which types of events will generate an email to the user.

Send an email if the VX box reports a warning or if

communications are interrupted to the VX box.

Send an email if the system controller reports a warning

(Alarm) or shutdown (Trip) condition.

Send an email if a selected compressor reports a

warning (Alarm), shutdown (Trip), or service due

condition as set up using the service reminder utility.

Send an email if a selected I/O Box or Intelliow Valve

reports an alarm or trip condition as congured at the

I/O Box or Intelliow Valve.

Page 51

After selecting which events will generate an email the administrator selects which piece of equipment the user will

receive emails about using the modules lter.

The user will only receive emails about compressors

which are checked in the modules lter.

The user will only receive emails about I/O Boxes and

Intelliow valves which are checked in the modules

lter.

Once you have nished updating all of the elds:

Click the add button to update the information. New

accounts will appear in the list, and modied accounts

will now have their settings saved.

To remove an account:

When you are nished viewing and/or changing the settings in the Account Management screen:

Click the remove button, the account will no longer

appear in the account list. Be sure that the account you

intend to remove is highlighted. Otherwise, the rst

account in the list will be deleted.

Click the exit button to leave the account management

screen. You will be returned to the COV. Since all

information is saved using the add button there is no

save and exit button.

8.6 Diagnostics

The Diagnostics page allows the administrator to view the Ethernet conguration of the VX box, which users are

currently logged in, serial communications information, and VX box software information.

Click on the diagnostics button to open the diagnostics

utility.

51

Page 52

52

8.6.1 Serial Communications Diagnostics

The serial communications diagnostics shows the trac on the RS-485 network, between the compressors, the X8I/

X12I, and the VX box.

Requests:

Stack – Number of communication requests that are

waiting to be sent on the RS-485 network.

Time – The estimated time required to process all

communication requests currently on the stack.

Communications:

Valid – The number of valid communications over the

past minute.

Error – The number of invalid or rejected

communications over the past minute

Broadcasts Received – The number of valid broadcast

messages received from the unit over the past minute.

The number of expected broadcasts per minute is 30 for

the X8I/X12I, 6+ for each compressor, and 6+ for each

I/O Box or Intelliow Valve.

If a failed communication attempt occurs, the broadcasts received eld will turn red until the communication issue is

resolved.

Page 53

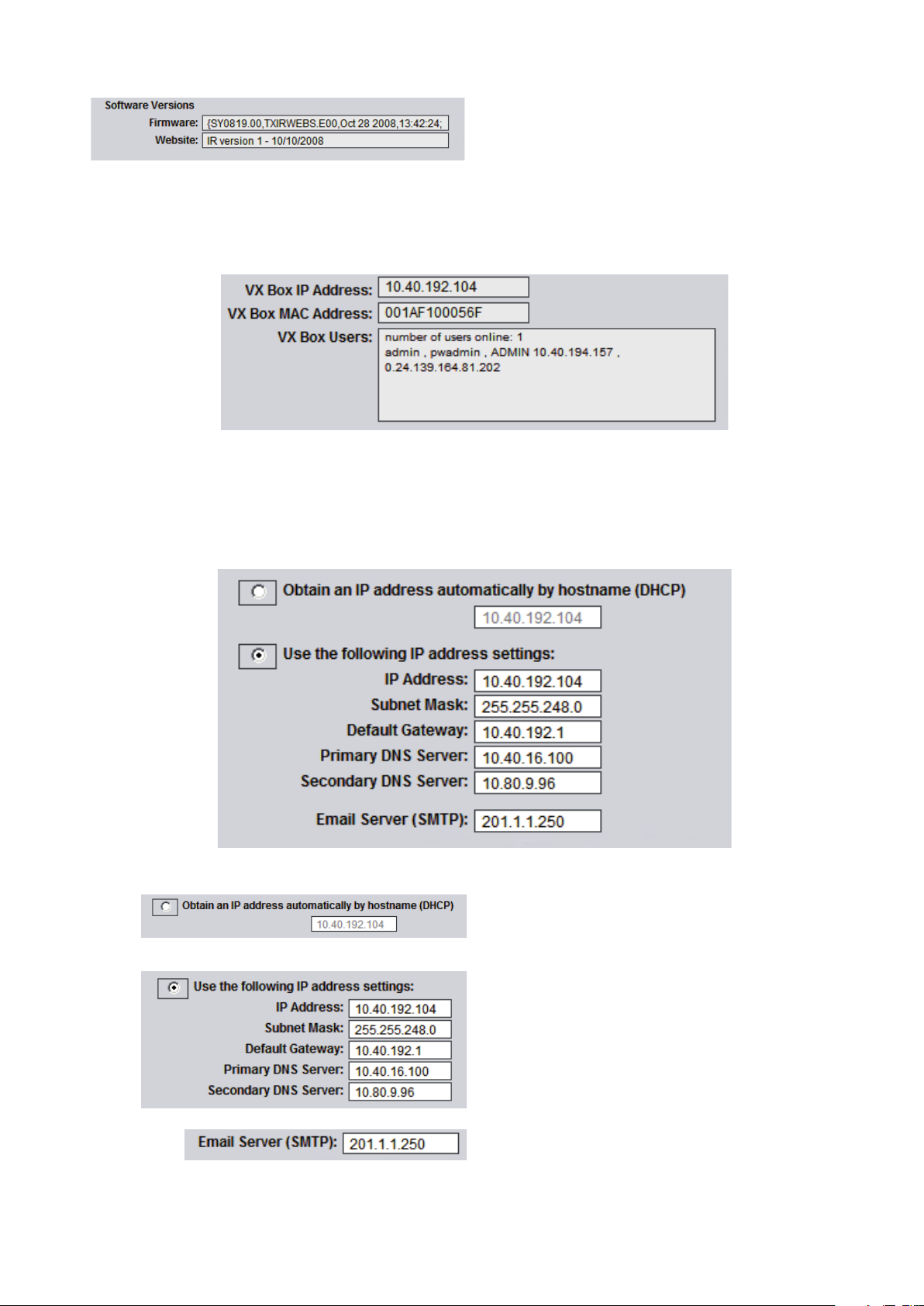

8.6.2 Software Versions

The Firmware represents the embedded software in

the VX Box while the website version represents the

currently loaded graphics. These should be referenced

when troubleshooting any issues.

8.6.3 VX Box Connectivity

The current network information for the VX box is displayed, including the current IP address, the MAC address

(hardware address) of the VX box, and a log of all users who are currently logged into the visualization software. This

information is view only.

8.6.4 Ethernet Conguration

Caution! Changing the Ethernet conguration of the VX box may cause the visualization software to become

unresponsive and require IT or other support to return the VX box to an operational condition. Be certain all Ethernet

settings are correct before saving changes.

The Ethernet conguration allows the user to select how the VX box will be connected to the LAN.

If the VX box is to obtain an IP address via DHCP, click

this radio button. The assigned IP address will appear

below this selection. Please note that depending on the