Page 1

Before installing or starting this unit for the first

time, this manual should be studied carefully to

obtain a working knowledge of the unit and/or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This

Technical manual contains IMPORTANT

SAFETY DATA and should be kept with the unit

at all times.

More Than Air, Answers.

Online answers: http://www.air.irco.com

Ingersoll Rand

System Automation

VSD V Box

Operator’s Manual

C.C.N. : 80444136

REV. A

DATE DECEMBER 2008

Page 2

TABLE OF CONTENTS

TABLEOFCONTENTS..................................................2

SECTION1–INTRODUCTION......................................3

SECTION2—SAFETY.................................................3

S

AFETYPRECAUTIONS.......................................................3

NSTALLATION.................................................................3

I

PERATION....................................................................3

O

AINTENANCEANDREPAIR..............................................4

M

SECTION3—COMPRESSORCONNECTIONAND

CONTROL...................................................................5

S

TANDARDCONTROLFEATURESANDFUNCTIONALITY............5

VBOXOPERATION...................................................6

VSD

SECTION4—INSTALLATION......................................7

U

NITLOCATION..............................................................7

OWERSUPPLY...............................................................7

P

NETWORK...........................................................7

RS485

VBOXANDPRESSURESENSORCONNECTIVITY...............8

VSD

RESSURESENSORCONNECTIONS.....................................10

P

ISCHARGE(DELIVERY)PRESSURESENSORINTERCONNECT....10

D

ISCHARGE(DELIVERY)PRESSURESENSORANDINTERNAL

D

PRESSURESENSORINTERCONNECT....................................11

COMPRESSORWITHPRESSURESWITCHREGULATED

VSD

COMPRESSORINTERCONNECT..........................................12

VANDIR‐PCBCOMPRESSORCONNECTIVITY...............13

VSD

COMPRESSORSTATUSMONITORING......................13

IR‐PCB

RESSURESWITCHREGULATIONCONTROL.........................15

P

SECTION5—DISPLAYANDMENUOPERATION........19

OPERATION...............................................................19

SECTION6—COMMISSIONING................................21

C

OMMISSIONINGPROCEDURE..........................................21

HYSICALCHECKS..........................................................21

P

OMPRESSORPRESSURESETPOINTS.................................21

C

VBOXCONFIGURATION..........................................22

VSD

RESSURESETPOINTS....................................................24

P

SECTION7—SYSTEMCONFIGURATION...................25

D

ISPLAYITEMSTRUCTURE...............................................25

CCESSINGTHEX12ICONFIGURATIONSCREENS.................25

A

ENUITEMSANDSETTINGS............................................27

M

SECTION8—DIAGNOSTICS.....................................31

SECTION9—FAULTCODES......................................32

SECTION10—VSDVBOXSTATUSBLOCKDIAGRAM 32

SECTION11—PARTSLIST........................................34

SECTION12—TECHNICALDATA..............................34

SECTION13—WIRINGDIAGRAM............................35

VSD

VBOXSCHEMATIC..................................................35

XPM‐TAC24

XPM‐V

XPM‐PSU24

SCHEMATIC...............................................36

O2(+VDCANALOGOUTPUT)................................36

(24VACTO24VDC)....................................36

SECTION14—COMMISSIONINGFORM...................37

Refer to Section Indicated

Note

Important or Caution, Safety

2

Page 3

SECTION 1 – INTRODUCTION

The VSD V (Voltage) Box is intended to provide a

method of system integration for a VSD (Variable Speed

Drive) air compressor equipped with a Voltage Pressure

Sensor that is not equipped with any accessible means of

remote connectivity (such as the Ingersoll Rand Nirvana).

SECTION 2 — SAFETY

SAFETY PRECAUTIONS

WARNING :

!

WARNING :

WARNING :

!

WARNING :

• Before installing or operating the VSD V Box,

take time to carefully read all the instructions

contained in this manual, all compressor

manuals, and all manuals of any other

peripheral devices that may be installed or

connected to the unit.

• Electricity and compressed air have the

potential to cause severe personal injury or

property damage.

• The operator should use com m on sense and

good working practices while operating and

maintaining this system. All applicable codes

should be strictly adhered to.

• Maintenance must be performed b y adequately

qualified personnel that are equipped with the

proper tools.

INSTALLATION

• Installation work must only be carried out by a

competent person under qualified supervision.

• A fused isolation switch must be fitted between

the main power supply and the VSD V Box.

• The VSD V Box should be mounted in such a

location as to allow operational and

maintenance access without obstruction or

hazard and to allow clear visibility of indicators

at all times.

• If raised platforms are required to provide

access to the VSD V Box, they must not

interfere with normal operation or obstruct

access. Platforms and stairs should be of grid or

plate construction with safety rails on all open

sides.

Risk of Danger

Risk of Electric Shock

Risk of High Pressure

Consult Manual

The VSD V Box will provide the required functionality to

enable system integration and efficient control using the

X8I or X12I Automation System.

.

OPERATION

• The VSD V Box must only be operated by

competent personnel under qualified

supervision.

• Never remove or tamper with safety devices,

guards or insulation materials fitted to the VSD

V Box.

• The VSD V Box must only be operated at the

supply voltage and frequency for which it is

designed.

• When main power is switched on, lethal

voltages are present in the electrical circuits and

extreme caution must be exercised whenever it

is necessary to carry out any work on the unit.

• Do not open access panels or touch electrical

components while voltage is applied unless it is

necessary for measurements, tests or

adjustments. Such work should be carried out

only by a qualified electrician equipped with the

correct tools and wearing appropriate protection

against electrical hazards.

• All air compressors and/or other equipment

connected to the unit should have a warning

sign attached stating “THIS UNIT MAY START

WITHOUT WARNING” next to the display panel.

• If an air compressor and/or other equipment

connected to the unit is to be started remotely,

attach two warning signs to the equipment

stating “THIS UNIT CAN BE STARTED

REMOTELY”. Attach one sign in a prominent

location on the outside of the equipment, and

the other sign inside the equipment control

compartment.

3

Page 4

MAINTENANCE AND REPAIR

• Maintenance, repairs or modifications must onl y

be carried out by competent personnel under

qualified supervision.

• If replacement parts are required, use only

genuine parts from the original equipment

manufacturer, or an alternative approved

source.

• Carry out the following operations before

opening or removing any access panels or

carrying out any work on the VSD V Box:

o Isolate the VSD V Box from the main

electrical power supply. Lock the

isolator in the “OFF” position and

remove the fuses.

o Attach labels to the isolator switch and

to the unit stating “WORK IN

PROGRESS - DO NOT APPLY

VOLTAGE”. Do not switch on electrical

power or attempt to start the VSD V

Box if such a warning label is attached.

• Make sure that all instructions concerning

operation and maintenance are strictly followed

and that the complete unit, with all accessories

and safety devices, is kept in good working

order.

• The accuracy of sensor devices must be

checked on a regular basis. They must be

calibrated when acceptable tolerances are

exceeded. Always ensure any pressure within

the compressed air system is safely vented to

atmosphere before attempting to remove or

install a sensor device.

• The VSD V Box must only be cleaned with a

damp cloth, using mild detergents if necessary.

Avoid the use of any substances containing

corrosive acids or alkalis.

• Do not paint the control faceplate or obscure

any indicators, controls, instructions or warnings

4

Page 5

SECTION 3 — COMPRESSOR CONNECTION AND CONTROL

The VSD V (Voltage) Box is designed to connect to an

X8I or X12I Automation System unit, using a 2-wire

RS485 data cable.

The VSD V Box is intended to provide a method of

system integration for 3

not equipped with any accessible means of remote

connectivity. The VSD V Box is used to integrate with

VSD Air Compressors that are controlled by Voltage

Pressure Sensors.

Each air compressor in a system that requires VSD V

Box integration must be equipped with an individual VSD

V Box. Any number of VSD V Boxes can be connected to

the Automation System unit as long as the total number

of compressors does not exceed the total number of

compressors for the Automation System model.

In conjunction with a ‘speed monitoring kit’ (available

separately) the VSD V Box will provide all required

functionality to maximize the ENER, Energy Control

Mode, in the X8I or X12I Automation System.

rd

party air compressors that are

STANDARD CONTROL FEATURES AND

FUNCTIONALITY

The air compressor must be equipped with a 0-5VDC, 15VDC or 0.5-4.5VDC type pressure sensor that is used

for regulation control. For VSD type air compressors; the

compressor must be equipped with a 0-5VDC, 1-5VDC or

0.5-4.5VDC type pressure sensor that is used for variable

speed drive regulation. The VSD V Box will

accommodate a pressure sensor range of 1.0bar to

600bar.

Various Compressor Configurations and Characteristics

Can Be Accommodated by the VSD V Box. These

include::

• Air compressors that are equipped with a package

discharge (delivery) pressure sensor and a second

internal pressure sensor. The internal pressure

sensor is generally used for internal air/oil filtration

differential pressure monitoring and/or internal

pressure safety functions. The VSD V Box is able to

accommodate this requirement without affecting

functionality of the compressor control system

internal pressure sensor feature(s).

• VSD air compressors that are equipped with t wo

pressure sensors that both monitor package

discharge (delivery) pressure. One sensor is

dedicated to compressor control system basic

regulation functions; the other is dedicated to

variable speed drive unit regulation. The VSD V Box

is able to accommodate this requirement without

affecting compressor control system functionality.

• VSD air compressors that are equipped with a

pressure switch dedicated to basic compressor

control system load/unload regulation; and a

pressure sensor dedicated to variable speed drive

unit regulation. The VSD V Box is able to

accommodate pressure switch regulation in

conjunction with variable speed drive pressure

sensor regulation without affecting compressor

control system functionality.

VSD air compressor types that are unable to

maintain maximum speed operation for a prolonged

period of time. In these instances the controller may

automatically reduce speed regardless of demand. The

VSD V Box and management system unit will recognize

this if it occurs and will, if necessary, utilize an additional

compressor to meet demand.

VSD air compressor types are unable to maintain

minimum speed operation for a prolonged period of time.

In these instances the controller may automatically stop

the compressor regardless of demand. The VSD V Box

will recognize and accommodate this behavior. The

management system unit will indicate and record the

compressor status correctly without fault indication.

5

Page 6

VSD V BOX OPERATION

All air compressors are equipped with a method of

sensing pressure. An air compressor regulates using the

compressor package discharge pressure as the control

variable.

The VSD V Box monitors the compressor pressure

sensor as an input and simulates the pressure sensor

signal as an output. The VSD V Box uses this method to

modify the pressure signal and manipulate the behavior

of the air compressor. In other words, the VSD V Box

becomes the air compressor pressure sensor. This

functionality enables the Automation System unit to

utilize the compressor effectively and optimize total

system efficiency and maintain air quality.

The VSD V Box also monitors compressor status (Ready,

Run, and Load/Unload) and continuously reports this

information to the Automation System unit. This function

enables the VSD V Box to simulate all features of a

standard X8I or X12I network compressor integration.

Actual System pressure and the Automation System

‘target’ pressure information is routinely transmitted from

the X8I or X12I to the VSD V Box. The VSD V Box uses

this information to calculate the difference between the

compressor discharge pressure and the system ‘target’

pressure. The VSD V Box utilizes pressure signal

manipulation to continuously re-align compressor output

with system requirements.

This functionality also enables the VSD V Box to

continuously compensate for any pressure differential

that may occur across local air treatment, along air pipe

work or between different locations in a compressed air

network.

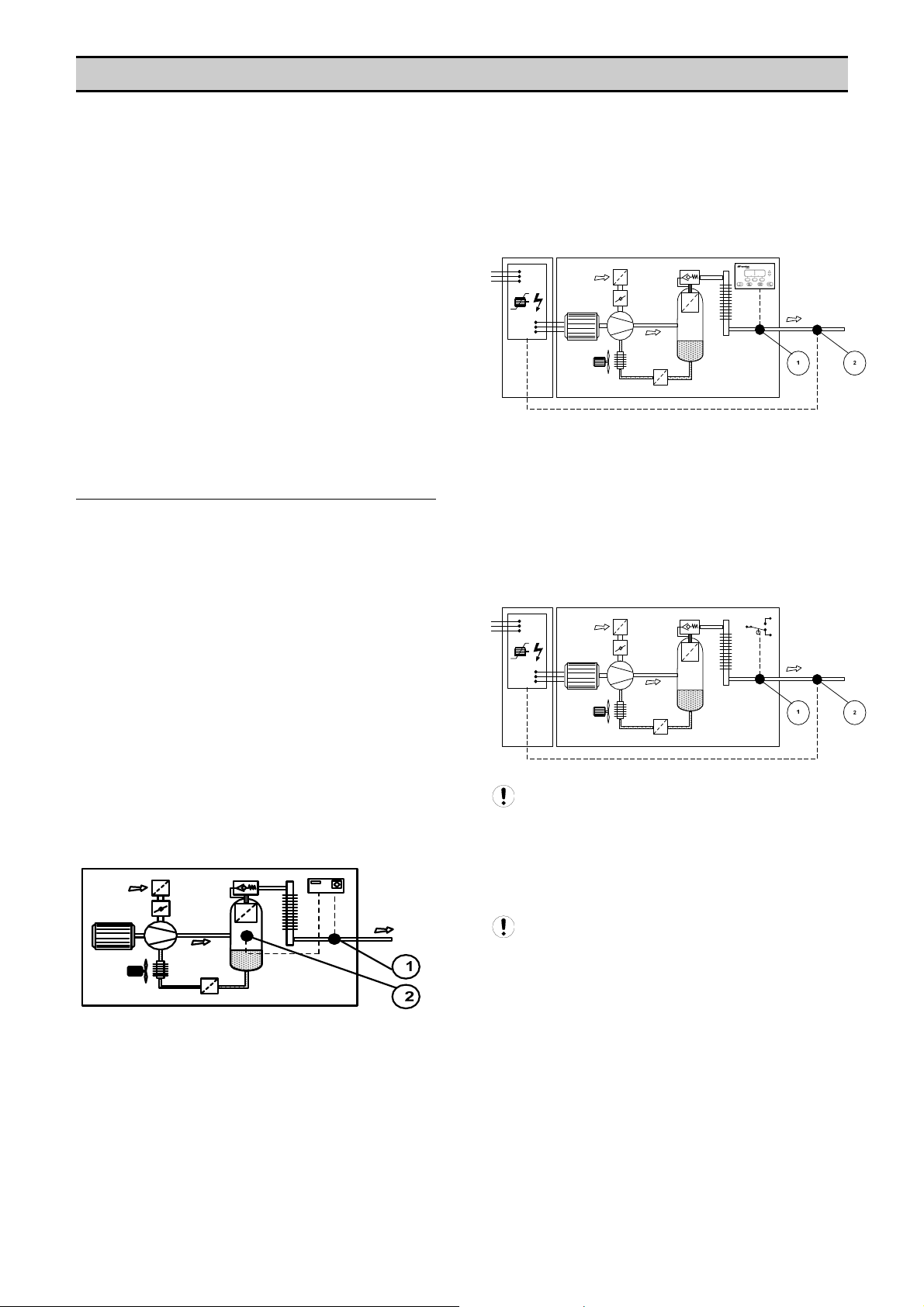

VSD V Box Operation Example:

If the Automation System unit is detecting a network air

pressure (PN) of 100psi (6.9bar), and the system target

pressure requirement (P) is 103psi (7.1bar), the VSD V

Box will immediately calculate that a pressure rise of 3psi

(0.2bar) is required to achieve and maintain system

target pressure (P). Due to pressure differential across a

local compressed air treatment system (PD) the

compressor is currently operating at 107psi (7.4bar). The

VSD V Box will manipulate the compressor pressure

signal (PS) to cause the compressor to increase

discharge (delivery) pressure (PC) to 110psi (7.6bar).

This action will increase system pressure to the required

target pressure. The VSD V Box will continuously recalculate and manipulate the compressor pressure signal

(PS) to accommodate changes in demand and

compensate for any local or compressed air network

pressure differentials.

PC

PS

VSD

PD

P

PN

6

Page 7

SECTION 4 — INSTALLATION

It is recommended that installation and commissioning be

carried out by an authorized and trained product supplier.

Information regarding the compressor control system,

method of operation and regulation settings, is required.

Knowledge of VSD compressor regulation methods,

experience working with compressor control systems and

basic principle knowledge of compressed air systems, is

also required to be able to successfully install and

commission this product.

Dependent on compressor type and installation

environment additional fixings, wiring, cabling,

terminations and terminals will be required for installation.

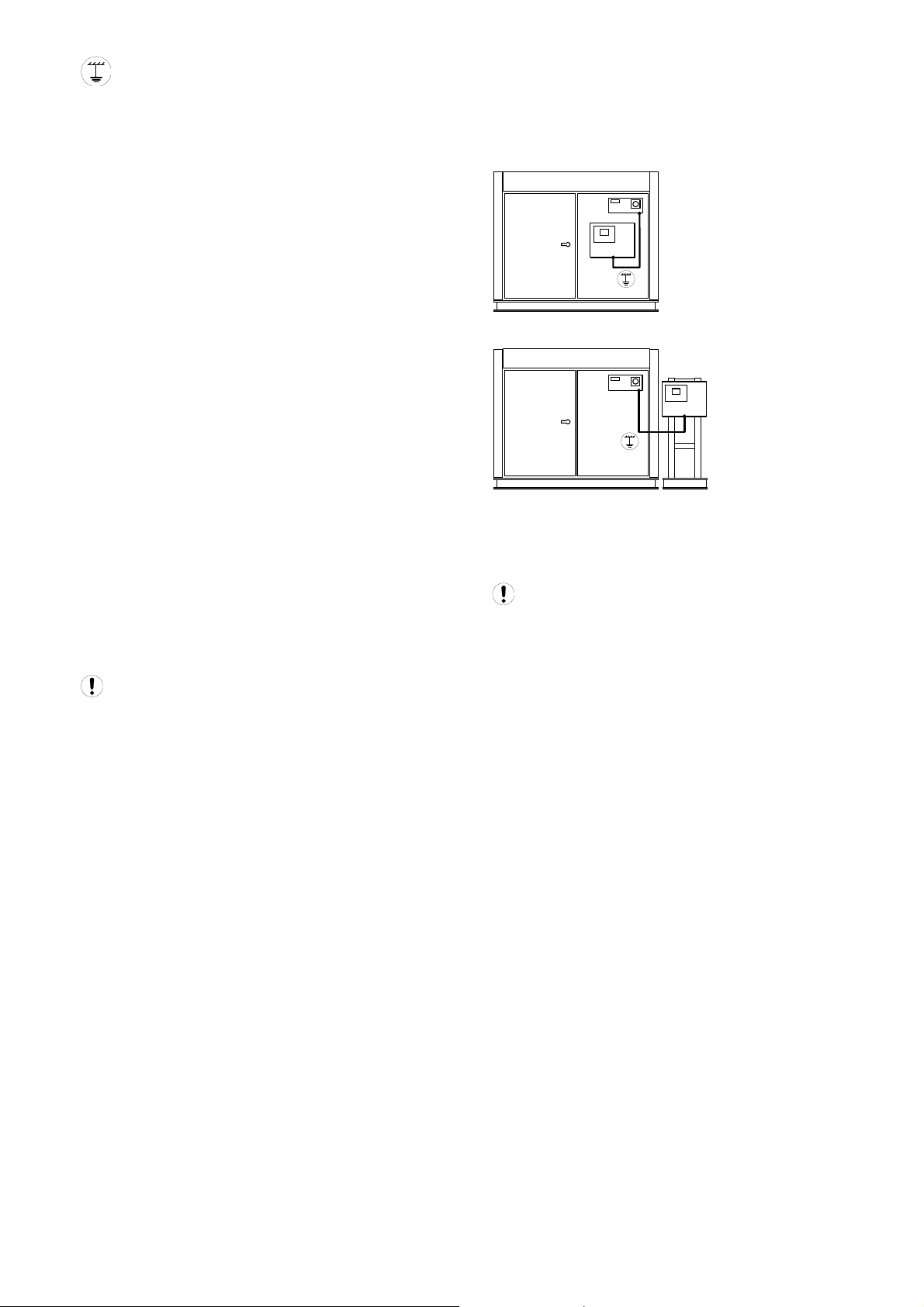

UNIT LOCATION

The VSD V Box is wall or panel mounting using

conventional screw fixings. The maximum distance

between the X8I or X12I and the VSD V Box is 4000ft

(1219 meters) of cable length. The VSD V Box must be

located adjacent to the compressor unit within 6ft (2m)

with total length of interconnecting cables not exceeding

10ft (3m).

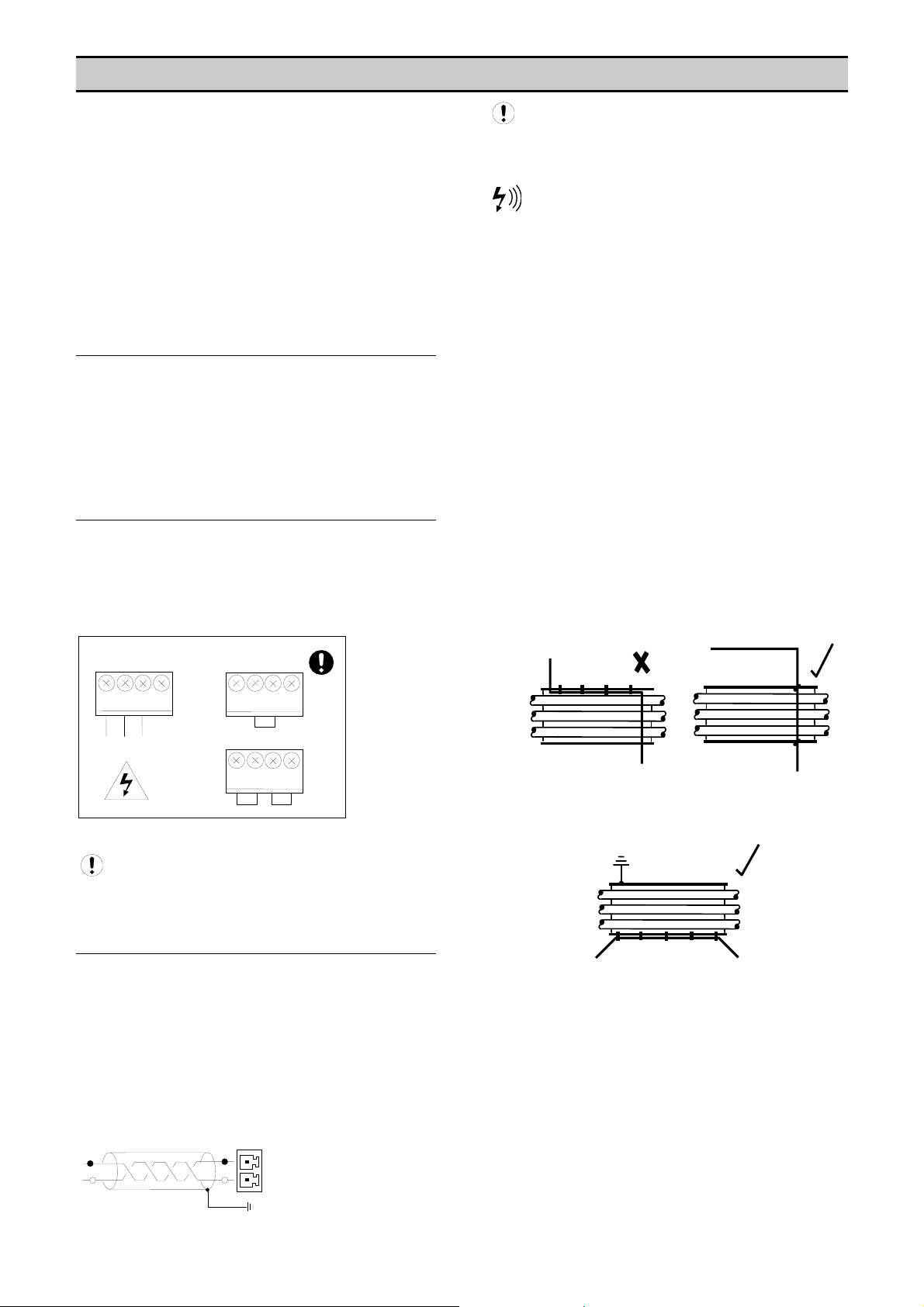

POWER SUPPLY

A fused switching isolator must be installed to the main

incoming power supply, external to the VSD V Box. The

isolator must be fitted with a properly sized fuse to

provide adequate protection to the power supply cable

used (in accordance with local electrical and safety

regulations).

1 2 3 4

L

N

N LE

XPM-TAC24

EE

X01

X04

VOLTAGE SELECT

X04

VOLTAGE SELECT

1

234

1

234

230Vac

115Vac

Power Supply Terminals

Ensure that the voltage select input is properly

jumpered for the incoming power. Default voltage

configuration is 230Vac.

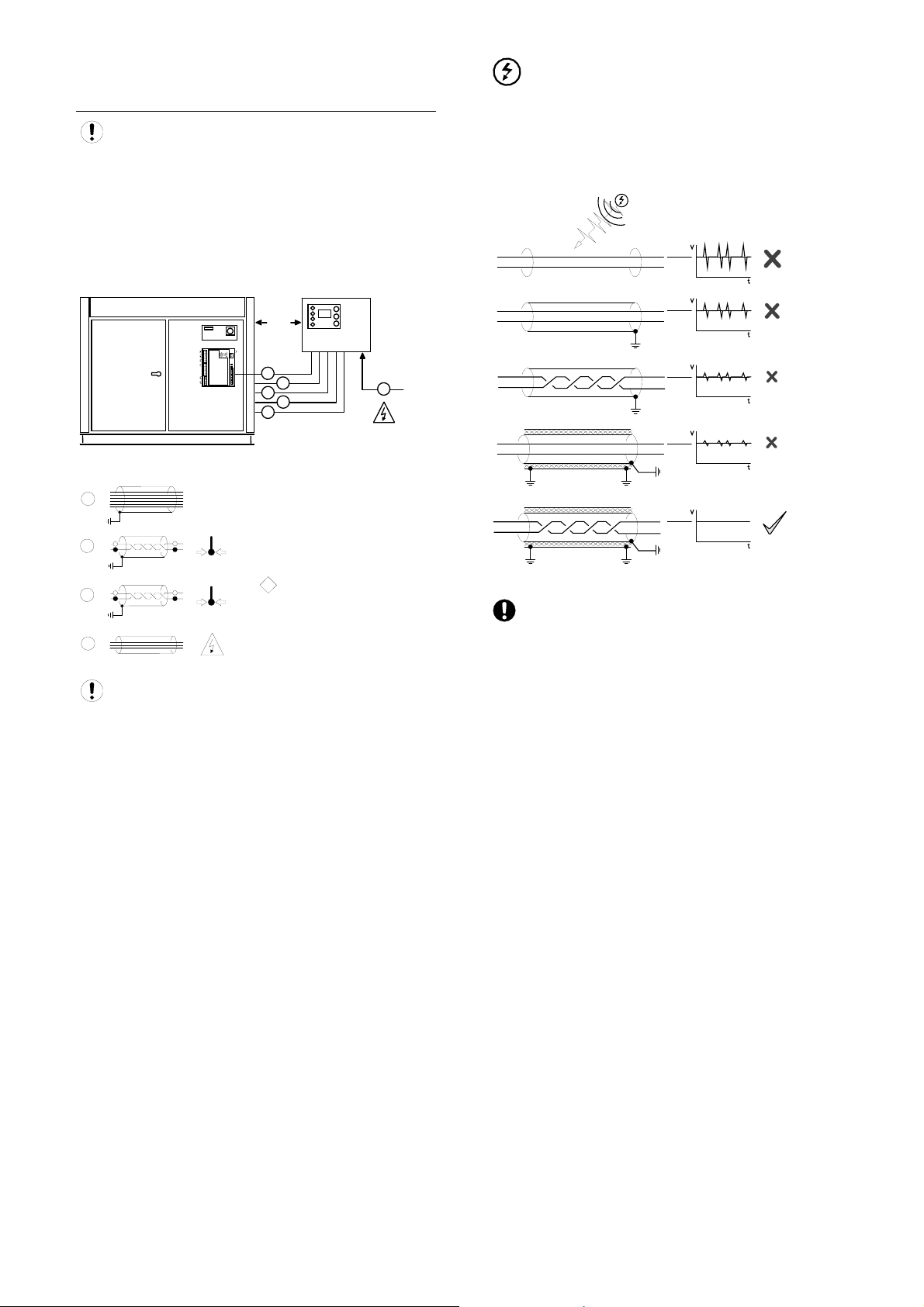

RS485 NETWORK

The VSD V Box is equipped with an RS485 network

communications capability using the ir485 protocol. The

VSD V Box is intended to operate as part of the X8I or

X12I Automation System. Connection to the system

management unit is two-wire, twisted pair, ground (earth)

shielded, RS485 data link. Connect the RS485 data

cable wires to terminal X07 located on the VSD V Box

controller.

The cable used between the X8I or X12I and the

VSD V Box is Belden 9841 (or equivalent). It should be

run in grounded conduit and should not be greater than

4000 feet (1219 meters) in length.

RS485 data communications and other low voltage

signals can be subject to electrical interference. This

potential can result in intermittent malfunction or anomaly

that is difficult to diagnose. To avoid this possibility

always use ground (earth) shielded cables, securely

bonded to a known good ground (earth) at one end. In

addition, give careful consideration to cable routing

during installation.

a) Never route an RS485 data communications or low

voltage signal cable alongside a high voltage or 3-phase

power supply cable. If it is necessary to cross the path of

a power supply cable(s), always cross at a right angle.

b) If it is necessary to follow the route of power supply

cables for a short distance (for example: from a

compressor X8I to a wall along a suspended cable tray)

attach the RS485 or signal cable on the outside of an

grounded (earthed) cable tray such that the cable tray

forms an grounded (earthed) electrical interference

shield.

c) Where possible, never route an RS485 or signal cable

near to equipment or devices that may be a source of

electrical interference (for example: 3-phase power

supply transformer, high voltage switchgear unit,

frequency inverter drive module, radio communications

antenna).

L2

L1

Note: Polarity is important.

X07

L2

L1

7

Page 8

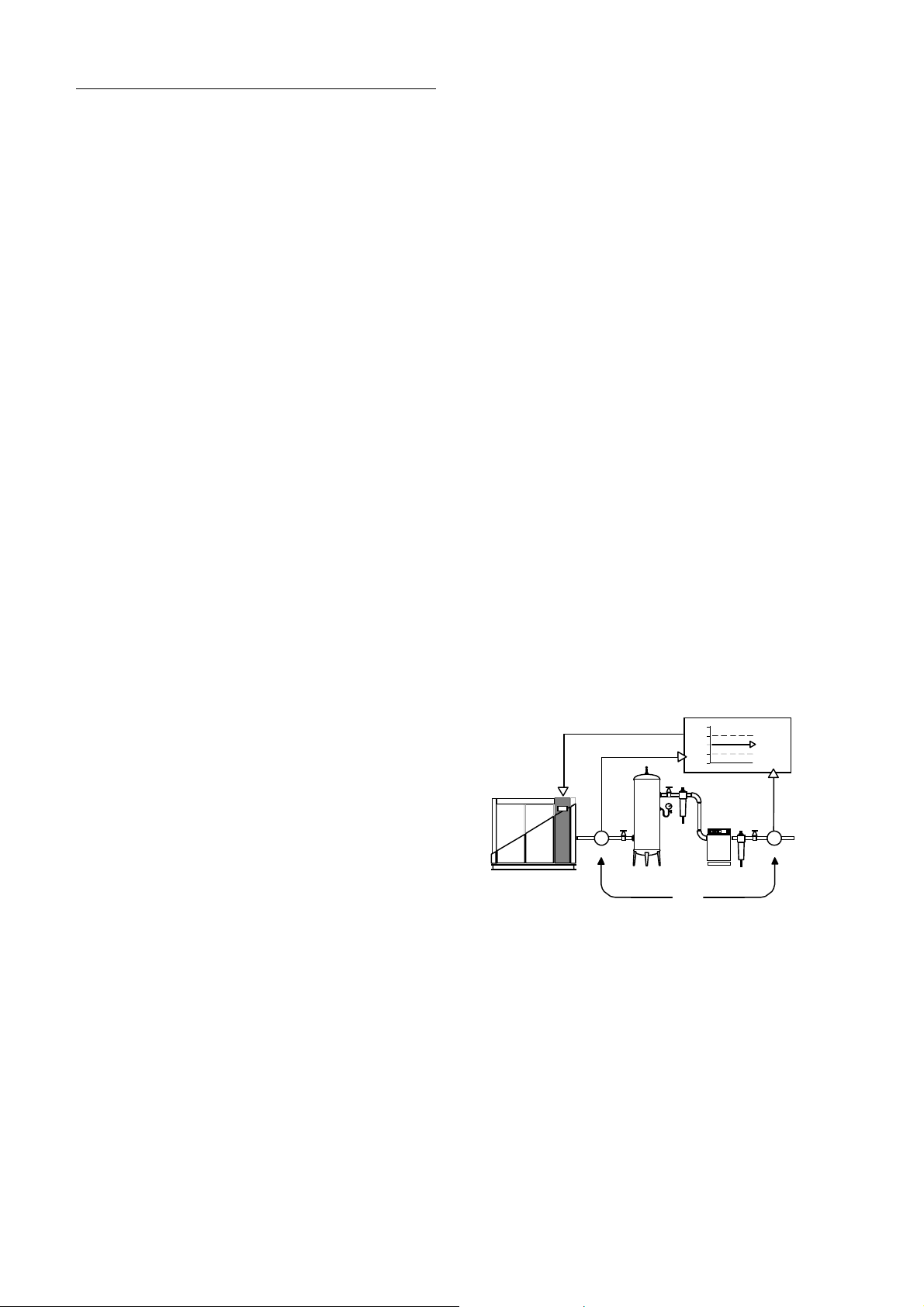

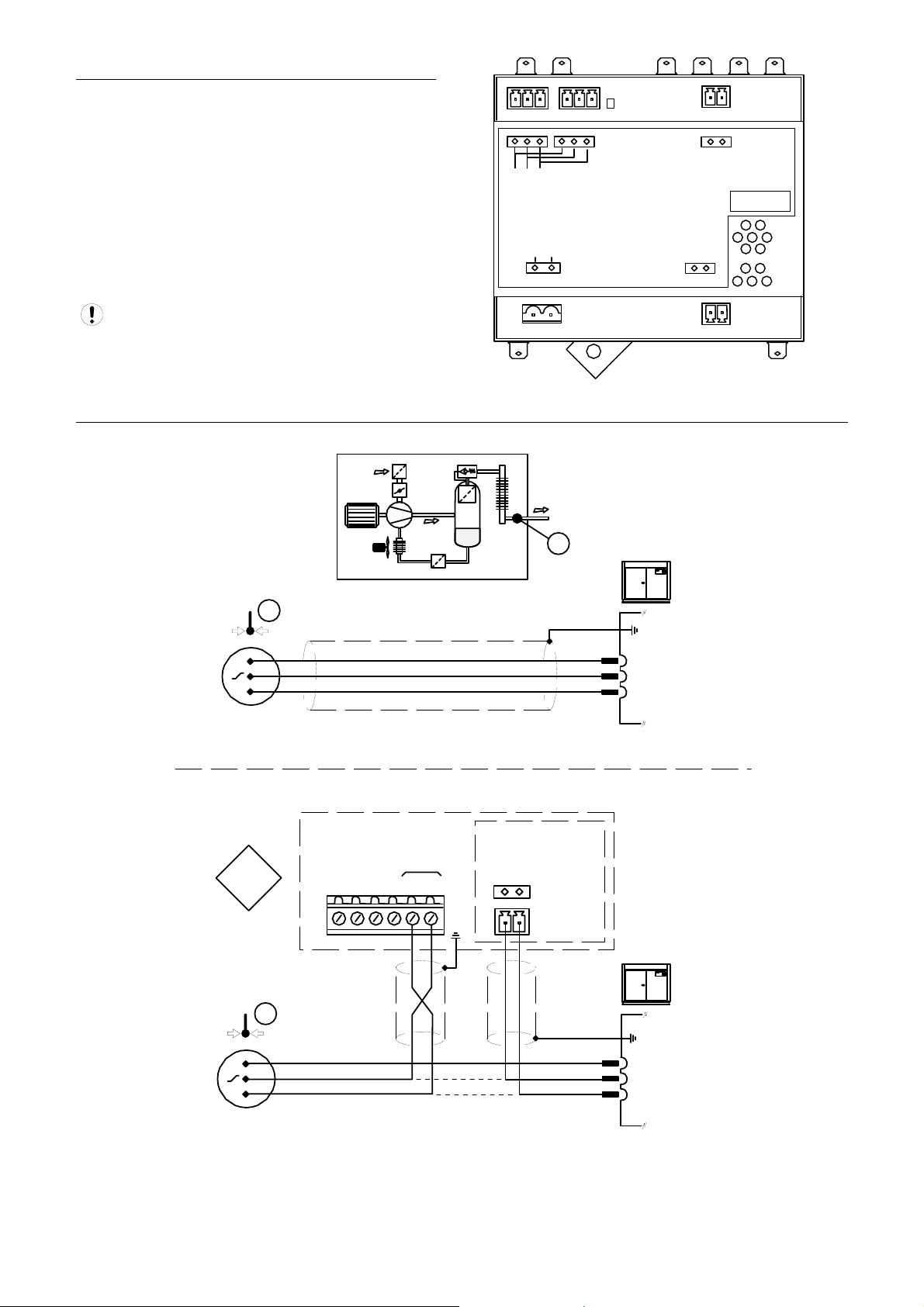

VSD V BOX AND PRESSURE SENSOR

CONNECTIVITY

Consult the X8I OR X12I Interconnect and

Application Guide prior to the installation of the VSD V

Box to the pressure sensor on the VSD and the

compressor.

Pressure sensor connectivity is dependent on

compressor and control system type.

Electrical Interference

0-5VDC, 1-5VDC, or 0.5-4.5VDC Pressure Sensors

Voltage sensors and cables carrying low voltage analog

pressure signals are highly susceptible to interference.

C0

4

C0

2

C0

1

i-PCB

6ft,2m

max

LE

D

LE

2

D

1

C0

3

1

2

3

VSD Box

2

3

1

2

3

4

i-PCB

6wire : 18-20 Gau (1.0-1.5mm)ge

Ground (earth) shielded

Delivery Pressure

2wire, twisted pair, 20 gauge

#1

(0.5-1.0mm

?

Internal Pressure

2wire, twisted pair, 20 gauge

#2

(0.5-1.0mm )

2wire + Ground (earth)

115/230Vac, 5A

2

2

,

Ground (earth) shielded

)

2

,

Ground (earth) shielded

Cables identified as ‘3’ are only required for a two

pressure sensor type compressor installation.

4

Always use shielded, braided (armored), foil

wrapped with a drain wire, 18 / 20 AWG (0.5-1.0mm)

maximum, 2-conductor cable no more than 10 feet (3

meters) in length. Ensure the braided steel wire is

securely connected to a known good earth ground at

both ends. Ensure the internal drain wire is securely

connected to a known good earth ground at the VSD

V Box end only.

Failure to protect low voltage pressure signals between

the compressor and VSD V Box will result in unstable

and/or erratic pressure readings; resulting in unstable

and/or erratic compressor regulation behavior.

8

Page 9

Compressor Ground (earth) Circuit Issues

An air compressor that uses an electrical induction main

motor may experience voltage interference generated in

the compressor’s ground (earth) circuits. An induction

motor will generate induction currents in the ground

(earth) circuit when changing state from loaded to

unloaded, or vice versa, condition. Induction motors that

are driven from a variable frequency drive will

continuously induce ground (earth) currents during

normal load and unload operation.

In some instances the induced current flow in the ground

(earth) circuits may manifest as a small voltage

difference between various parts of the compressor’s

ground (earth) system.

Generally this has no consequence and can be ignored.

As the compressor controller experiences minor ground

(earth) reference fluctuations, all parts of the controller

and control circuits will fluctuate with the same induced

ground (earth) voltage simultaneously. The controller will

be unaffected.

In the case of a low voltage signal that is referenced to a

different ground (earth), remote from the compressor, the

situation may represent an issue. As the compressor’s

ground (earth) reference fluctuates the 0V reference for

any voltage signal will also fluctuate. If a remotely

generated voltage signal (from the VSD V Box for

example) does not fluctuate in the same way

simultaneously the compressor controller will detect a

voltage difference in the signal. This will be seen as a

fluctuating pressure display that will generally indicate a

pressure that fluctuates to a lower pressure than actual.

To avoid this situation the VSD V Box must be securely

bonded too, and referenced too, the same ground (earth)

as the compressor controller.

If the VSD V Box is mounted remote from the

compressor, and pressure signal fluctuations are

experienced, the use of a length of ground (earth) cable,

or the ground (earth) of a steel wire cable, will reduce,

but may not resolve, the issue. Any length of conductive

cable or cable screen will have a small resistance to high

frequency current flow. This will generate a minor voltage

differential alone the cable or cable screen resulting in a

voltage difference between the two ends of the cable or

cable screen. The pressure display may continue to

fluctuate.

This situation can be avoided by mounting the VSD V

Box on, or directly adjacent to, the compressor and

connecting the VSD V Box ground (earth) to the

compressor controller ground (earth) with a large cross

section ground (earth) cable or braided conductor.

VSD Box

VSD Box

This action will ensure the VSD V Box experiences the

same ground (earth) circuit fluctuations simultaneously

with the compressor controller.

The necessity to avoid radiated electrical

interference from the compressor still remains,

particularly in the instance of a variable frequency drive.

The use of twisted pair, ground (earth) shielded cable for

low voltage signals internal to the compressor remains

important.

9

Page 10

PRESSURE SENSOR CONNECTIONS

Pressure sensor connectivity is dependent on

compressor and control system type.

21

1) Disconnect the compressor pressure sensor wires

from the compressor controller and connect to the VSD V

Box terminals as indicated on the following connection

diagrams.

2) Connect the VSD output pressure signal terminals to

the compressor control system pressure sensor terminals

as indicated on the following connection diagrams.

3213

1

n

2

L

e

L

e

r

X05

c

s

C

X01

D

V

4

2

+

RS485

X04

V

0

Pressure signal output terminals are located on the XPMVo2 module within the VSD Voltage Box.

These terminals are not located on the main terminal

PCB of the VSD V Box

DISCHARGE (DELIVERY) PRESSURE SENSOR INTERCONNECT

1

D

E

L

#1

+VDC(1)

X02

21

+VDC(2)

-

+

2

2

A

A

X03

#2

N

N

A

A

Vo2

1

1

A

A

N

N

A

A

-

+

+

-

IP = 0

1

+VDC

1

VSD Box

IC = 1 0 to 5VDC

IC = 2 1 to 5VDC

IC = 3 0.5 to 4.5VDC

X07

26 28

25 27

29

30

+VDC

+

-

XPM-Vo2

#1

X02

+VDC

signal

0VDC

+

v

-

Delivery

Pressure

Sensor

1

+

-

+VDC

signal

0VDC

+VDC

signal

0VDC

+

v

-

Delivery

Pressure

Sensor

10

Page 11

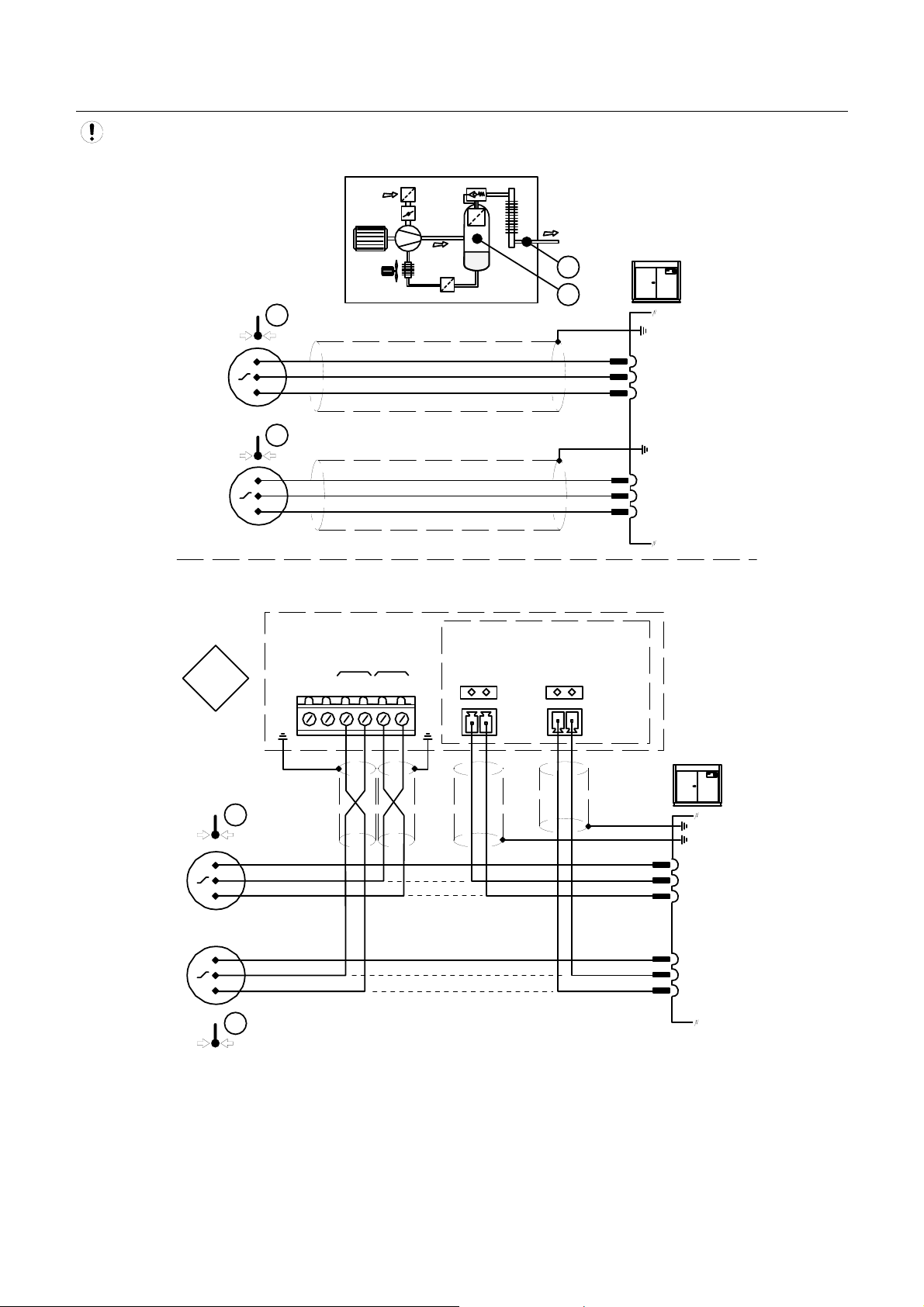

DISCHARGE (DELIVERY) PRESSURE SENSOR AND INTERNAL PRESSURE SENSOR

INTERCONNECT

Internal = Sump

+VDC

1

+VDC

2

1

IP = 1

+

-

+

-

2

VSD Box

X07

25

26

IC = 1 0 to 5VDC

IC = 2 1 to 5VDC

IC = 3 0.5 to 4.5VDC

l

y

r

a

e

n

v

r

i

l

e

t

e

n

I

D

28 30

27 29

#1

+VDC

+

+VDC

signal

0VDC

+VDC

signal

0VDC

XPM-Vo2

+

v

-

+

v

-

Delivery

Pressure

Sensor

Internal

Pressure

Sensor

#2

+VDC

-

X02

-

+

X03

1

+

-

+

-

+VDC

signal

0VDC

+VDC

signal

0VDC

+VDC

signal

0VDC

+VDC

signal

0VDC

+

v

-

+

v

-

Delivery

Pressure

Sensor

Internal

Pressure

Sensor

2

11

Page 12

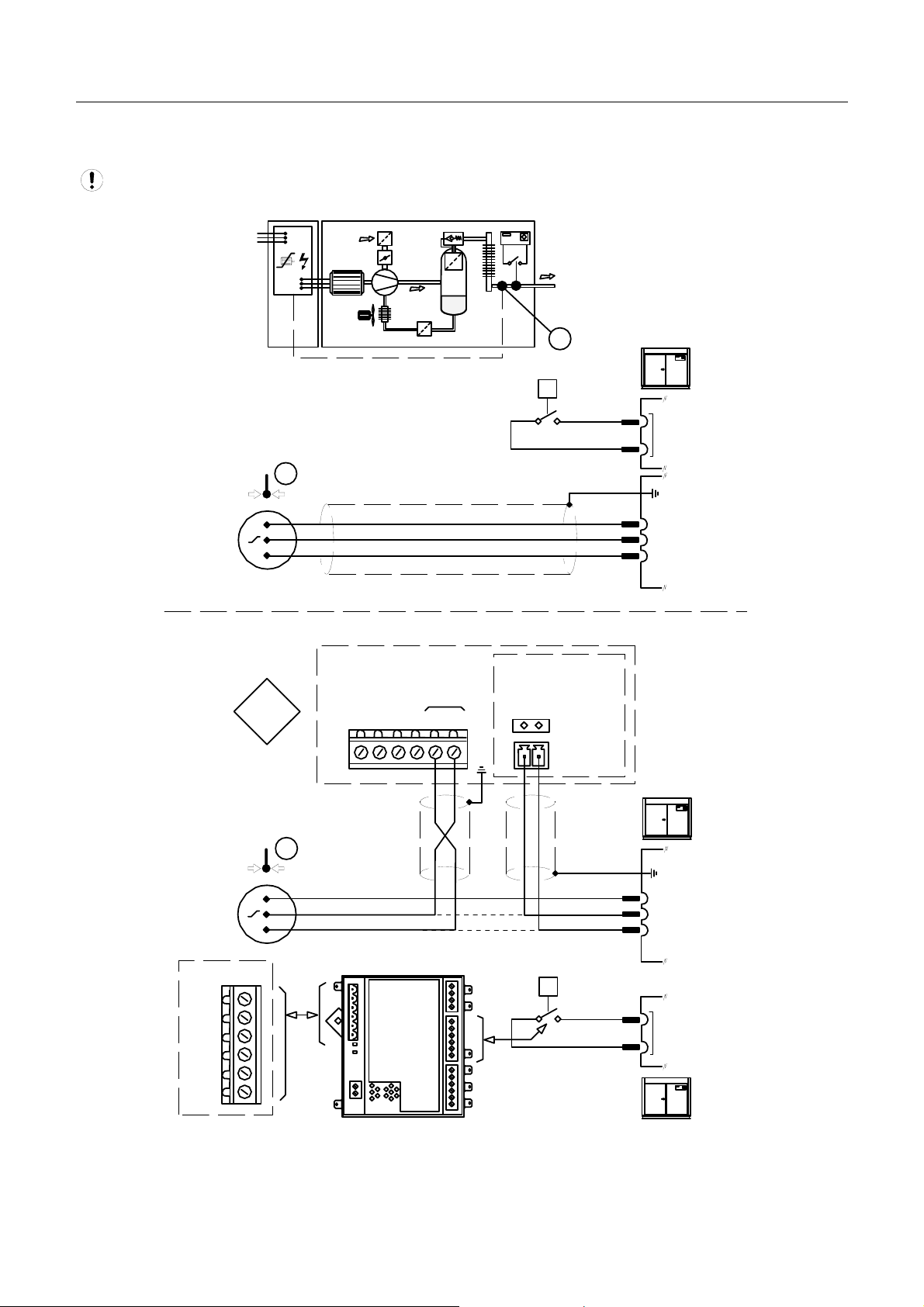

VSD COMPRESSOR WITH PRESSURE SWITCH REGULATED COMPRESSOR

INTERCONNECT

Compressor controller loads and unloads using a

pressure switch; VSD unit regulates using +VDC

discharge (delivery) pressure sensor.

See “i-PCB” Interface Connection

1

+

-

IC = 1 0 to 5VDC

IC = 2 1 to 5VDC

IC = 3 0.5 to 4.5VDC

1

4-20mA

P

Delivery

Pressure

Switch

+VDC

signal

0VDC

+

v

-

Delivery

Pressure

Sensor

VSD Box

6

5

4

1

0

X

3

2

1

IP = 0

+

-

VSD Box

25 27

X07

26 28

29

+VDC

30

XPM-Vo2

-

+

#1

X02

1

+VDC

signal

0VDC

+VDC

signal

0VDC

+

v

-

Delivery

Pressure

Sensor

P

Delivery

i-PCB

LED 1 LED 2

Pressure

Switch

12

Page 13

VSD V AND IR-PCB COMPRESSOR

CONNECTIVITY

ir-PCB COMPRESSOR STATUS

MONITORING

An ir-PCB is a requirement for a VSD V Box installation.

The ir-PCB is a DIN rail mountable unit designed to be

installed within the compressor control or switchgear area

and connected to the VSD V Box using a six-wire cable.

The ir-PCB is used for compressor status monitoring and

in some installations for ‘remote load/unload’ or ‘pressure

switch’ regulation control.

C01 C02 C04

i-PCB

C03

246135

LED 1 LED 2

X01

VSD Box

246135

The ir-PCB uses a 12V to 250V ac/dc input voltage

detection system and universal relay contact control

outputs (250Vac/dc @ 5A maximum). Integrated directly

into the circuits of an air compressor, the ir-PCB avoids

the need for additional relays or remote inputs. The irPCB also acts as an electrical barrier between the

compressor and the VSD V Box providing protection and

voltage isolation.

The ir-PCB is fitted with a six-pin terminal C04 for

compressor monitoring. The ir-PCB uses three inputs

(Ready, Run and Loaded) to determine compressor

status. All three status-monitoring input signals are

required.

READY

The ‘Ready’ connection is intended to indicate that the

compressor is in a ‘started’ state, has no operational

inhibiting fault condition and is ready to respond to VSD

V Box regulation without manual intervention.

Ready Input

READY LAMP

+V

READY

RUN

ALARM

C04

0V

The READY input will accept 12V to 250V ac (50/60Hz)

or dc.

Caution: Do not connect a voltage greater than

250Vac/dc to this input.

This input must be connected to the terminals of a ‘ready’

or ‘operational’ lamp, or other circuit of the compressor

control system, that will be energized when the

compressor is in started (standby or running) condition.

The voltage to this input must de-energies when the

compressor is stopped and unavailable to produce air

upon a load signal or the Emergency Stop button is

pressed or when the compressor experiences a fault that

prevents the compressor from running.

When the compressor ready lamp, or other control circuit,

is energized the ir-PCB will detect the voltage and signal

the VSD V Box that the compressor is ready and

available to load and produce air when a load request

signal is given.

The ir-PCB input common terminal must always be

connected to the neutral, common or 0V line of the

applied input

13

Page 14

Ready Input, Alternative Connection Method:

In instances where a convenient voltage signal for a

compressor ready condition is not available the ‘Ready’

input can be connected directly to a constant compressor

control system power supply voltage (12V to 250Vac or

dc). This will signal the VSD V Box that the compressor is

ready and available at all times when power is applied to

the compressor. The VSD has a built-in function to

determine when a compressor is not responding, or is in

a shutdown condition, regardless of a constant ready

signal. If the VSD V Box requests a compressor to

run/load, but fails to detect a RUN signal within 60

seconds, the VSD V Box will regard the compressor as

‘not ready’ and indicate the compressor as not available.

If a RUN signal is detected at any time, the VSD V Box

will automatically reset the compressor ‘not ready’

condition and re-establish control.

+Vac

F1

0Vac

READY

Safety: Never connect the READY input positive

connection directly to the output of a control system

transformer, always connect after a fuse or circuit

breaker.

If a normally closed contact of an Emergency Stop button

is included in the compressor power supply circuit,

connect after the Emergency Stop button contacts. This

will instantly indicate a compressor ‘not ready’ condition if

the Emergency Stop button is activated.

RUNNING

MAIN (LINE) CONTACTOR

0V

+V

For a fixed speed air compressor this input can be

connected to the control terminals A1 and A2 (coil) of the

main starter contactor of the compressor. When the

compressor control system energizes the main contactor,

the ir-PCB will detect the voltage across the contactor

coil terminals and signal the VSD V Box that the

compressor is running.

MAIN (LINE) CONTACTOR

+V

+V

AUXILIARY SWITCH

ALARM

RUN

C04

READY

0V

0V

Alternatively, if the main contactor coil voltage is greater

than 250Vac, a contactor auxiliary switch can be used to

apply a suitable voltage to the ‘Run’ input terminals.

For a ‘Variable Speed’ air compressor alternative

methods of determining a running condition may have to

be established.

The majority of VSD compressors are fitted with a single

main motor contactor but in most instances this contactor

energizes at compressor initialization and remains

energized regardless of motor running. The following

alternative signals may be used to indicate motor running

in most cases:-

1) The ‘Fan’ contactor – in instances where the

cooling fan energizes and de-energizes in

conjunction with the main motor.

2) The compressor controller ‘run’ signal to the

‘Inverter Drive Unit’; an interface relay may be

required.

The ir-PCB input common terminal must always be

connected to the neutral, common or 0V line of the

applied input voltage.

READY

RUN

ALARM

C04

The RUN input will accept 12V to 250V ac (50/60Hz) only

(DC cannot be used).

Caution: Do not connect a voltage greater than 250V to

this input.

12V to 250Vac must be applied to the ‘Run’ terminals

when the compressor motor is running.

14

Page 15

LOADED

ALARM = LOAD

The VSD V Box uses the ir-PCB ALARM input to detect

the load condition of the compressor. There is no Alarm

input facility on the ir-PCB when used with a VSD V Box.

An auxiliary ‘Alarm’ input terminal within the VSD V Box

is available.

A fault, that stops the compressor, and/or prevents

the compressor from running, is determined from the

‘Run’ and ‘Ready’ inputs; Alarm detection is optional and

is not a requirement.

+V

LOAD

SOLENOID

0V

PRESSURE SWITCH REGULATION

CONTROL

In ‘Pressure Control’ mode the VSD V Box will also

control the ir-PCB load/unload relay outputs in

accordance with the set load and unload pressure set

points. The ir-PCB load/unload relay contacts can be

used for compressor controllers that have ‘pressure

switch’ load/unload regulation (fixed speed and variable

speed types).

ir-PCB Internal Output Circuits

OUT

NO

OUT

OUT

NC

1

C

3

2

C

Load

C

Seq

IN

NO

IN

C

IN

NC

READY

ALARM

RUN

C04

The LOAD input will accept 12V to 250V ac (50/60Hz) or

dc.

Caution: Do not connect a voltage greater than

250Vac/dc to this input.

The ‘Load’ input can be connected to the terminals of the

compressor’s load solenoid; or other accessible part of

the control circuit that is energized when the compressor

is loaded.

The ir-PCB input common terminal must always be

connected to the neutral, common or 0V line of the

applied input voltage.

For a compressor that is not equipped with a load

solenoid (a compressor that is loaded at all times while

running) the ‘Load’ input can be connected to the ‘Run’

input.

Running

0v

Contacts :-

SEQ

Relay

1&2

LOAD

Relay

3

250Vac/dc @ 5A

maximum

C03

GND

LOAD

SEQ

UNL

CONT

24Vac

The C01 and C02 terminal functions of the ir-PCB are

intended to control load and unload regulation of the

compressor.

+20VDI2DI1

ALARM

RUN

C04

READY

15

Page 16

Pressure Switch Regulation:

For air compressors fitted with an electro-mechanical

pressure switch a six-pin terminal C02 has been provided

to enable connection to a pressure switch that has a two

wire or three-wire connection.

When connected the pressure switch remains in circuit. If

the VSD V Box is stopped or experiences a failure or loss

of power, pressure control will automatically revert back

to the pressure switch and the compressor will continue

to operate in ‘Local’ mode.

The NC (normally closed) and NO (normally open)

terminal references of the ir-PCB are related to internal

connection functions and should not be referenced to the

connections of a compressor pressure switch (which will

generally be in reverse order).

Caution: Lethal voltages may be present on the

terminals of the air compressor pressure switch. Isolate

the air compressor power supply before starting any

work.

Two Wire Pressure Switch Connections:

Remote Load/Unload Regulation:

For air compressors fitted with a ‘Remote/Local Pressure

Regulation’ and a ‘Remote Load/Unload’ digital input a

four-pin terminal C01 has been provided.

This terminal provides volt free contact closure for load

control and also provides volt free contact closure for

remote pressure control enable.

A remote load enable input provides the facility to change

the compressor load regulation from internal control to a

remote switching source.

Compressors that use electronic pressure detection

but are not equipped with a remote pressure control

enable feature will not automatically revert to local control

if the VSD V Box is stopped or experiences a fault or loss

of power.

Load and Sequence Connection:

COMPRESSOR CONTROLLER

INPUTS

+V

LOAD

SOLENOID

C

C

C

O

N

N

OUT

C02

C

O

N

N

IN

Three Wire Pressure Switch Connections:

SOLENOID

+V

RUN-ON

LOAD

TIMER

0V

Remote Load

Local/Remote

or

Inputs Common

Remote Load Enable

C01

D

C

C

Q

A

E

S

O

L

Compressor controller inputs common voltage may

be 0V or +V.

0V

C

C

C

O

N

N

OUT

C02

C

O

N

N

IN

16

Page 17

The local/remote pressure regulation input and/or remote

load input logic of some electronic pressure sensor type

controllers are reversed, in this instance the ‘pressure

switch’ outputs (terminal C02) can be used to establish

alternative logic control connections.

For Example:

If the compressor controller ‘Local/Remote Pressure

Control’ input is a normally open type; Remote when

closed, but the ‘Remote Load’ input is a normally closed

type; load when open, the ir-PCB pressure switch

terminal contacts can be used to achieve the correct

switching logic.

C02

NO

OUT

C

NC

NO

IN

C

NC

Examine the ir-PCB internal output circuit diagram to

establish any desired switching logic that may differ from

normal practise.

Do not attempt to utilise the Load/Seq ‘Electronic

Pressure Control’ (terminal C01) and the ‘Pressure

Switch Control’ (terminal C02) output connections at the

same time. These two output functions are internally

connected and a short circuit condition and/or

malfunction may result.

Service Maintenance Switch:

(Optional - dependant on management system controller

model)

The ir-PCB is equipped with a volt-free input (terminal

C05) that can be used to remove the compressor from

management system control, without generating a fault

condition, during maintenance or servicing periods.

C05

When the ‘Service Maintenance Switch’ input terminal

pins are connected together, using a volt-free switching

contact, the management unit will indicate that the

compressor is not available but will not generate an

Alarm, Trip or Shutdown condition. The management unit

will also remove the compressor from the sequence

strategy and substitute with an alternative available

compressor if necessary. When the ‘Service

Maintenance Switch’ inputs are open circuit again the

compressor will automatically be accepted back in to the

sequence strategy and will be utilized as and when next

required.

Local/Remote

common

Remote Load

common

1

2

The use of a ‘key switch’ is recommended for this

purpose in order to prevent the switch contacts being

inadvertently left in the closed circuit condition after

service maintenance is complete.

DO NOT connect any external voltage source to the

pins of terminal C05.

This function is only available with management

system unit models equipped with ‘Service Maintenance

Switch’ functionality. For management units that do not

provide this function the pins of terminal C05 must not be

utilized. Activating the ‘Service Maintenance Switch’

function with a management unit not equipped for the

function will disrupt the ‘Compressor Loaded’ detection

facility.

Auxiliary Alarm Input (Option)

The VSD V Box is equipped with an auxiliary ‘Alarm’

input. This input can be used to detect a compressor

‘Warning’ or ‘Alarm’ condition. The input can also be

used to detect an ‘Alarm’ condition of auxiliary equipment

associated with the compressor.

The management system unit will regard the alarm as a

compressor alarm.

X04

6

1

5

1

4

1

3

1

Aux Alarm

As default the auxiliary ‘Alarm’ input is normally open,

Alarm on closed circuit condition. If required this can be

reversed in the VSD V Box setup menu to be normally

closed, alarm on open circuit.

Auxiliary Trip Input (Option)

The VSD V Box is equipped with an auxiliary ‘Trip’ input.

The input can be used to detect a compressor shutdown

trip condition. The input can also be used to monitor

other auxiliary equipment associated with the compressor

and initiate a compressor trip condition.

The management system unit will regard the trip as a

compressor shutdown trip and will remove the

compressor from sequence; the compressor will run-on

for the compressor controller’s set run-on time and stop.

X04

6

1

5

1

4

1

3

1

Aux Trip

As default the auxiliary ‘Trip’ input is normally open, Trip

on closed circuit condition. If required this can be

reversed in the VSD V Box setup menu to be normally

closed, trip on open circuit.

The maximum cable length for Auxiliary ‘Alarm’ or

‘Trip’ inputs is 100m.

17

Page 18

Speed Monitoring Input (Option)

The VSD V Box is equipped with a ‘speed detection’

input designed to function with a ‘VSD Speed Monitoring

Kit’ (available separately). This optional feature will

provide all required functionality to enable total synergy

with the energy control, VSD compressor aware,

functions of the management system unit.

X05

2

2

1

2

0

2

9

1

8

1

7

1

rpm

+

Remote Outputs

Compressor Running:

The VSD V Box is equipped with a volt-free relay contact

output (R5) to indicate when the compressor is detected

as running. The output contacts will close when the

compressor is running.

Group Alarm:

The VSD V Box is equipped with a volt-free relay contact

output (R6) to indicate Group Alarm. The Group Alarm

relay contacts are normally closed and will open in the

following conditions:-

1) VSD V Box power failure

2) VSD V Box internal fault condition

3) Input pressure sensor fault

4) Compressor ‘Not Ready’

X09

4

R6

R5

3

3

3

2

3

1

3

X08

Group Alarm

Compressor

Running

Relay contact rating:

CE: 250V @ 5A max

UL: 115V @ 5A max

18

Page 19

SECTION 5 — DISPLAY AND MENU OPERATION

OPERATION

User Interface

a

b

g

f

h

a) START Button

b) RESET Button

c) STOP Button

d) MENU Button

e) ENTER Button

f) CANCEL Button

g) UP, Plus Button

h) DOWN, Minus Button

Display

Status Symbols

The Status display will continuously show the

current state of the VSD Box (C) by using the

following icons.

Power Failure Auto Restart (always on)

Communicating with System Management Unit

c

Flashing - No Communications System

Management Unit

Compressor Running

Compressor Loaded

d

e

psi

Flashing - Not Responding, Compressor Not

Running When Required

Flashing - Not Responding, Compressor Not

Loading When Required

Service Maintenance function active

Discharge (delivery) pressure or Internal

Pressure has exceeded the maximum set limit

Compressor Not Ready

Fault, Auxiliary Input Alarm/Trip

Pressure Control OFF or inhibited

Load Request to compressor

Unload Request to compressor

Pressure Control Active

Indicators

Run Indicator (Green LED)

OFF - Pressure Control Off, Stopped

The primary display value (A) will continuously show the

detected ‘Delivery’ pressure. The pressure is derived

from the compressor ‘Delivery’ pressure sensor and the

displayed value is not manipulated or adjusted.

The compressor controller ‘Pressure Display’ may

not represent the actual true local pressure(s) when VSD

V Box ‘Pressure Control’ is active. Use the VSD V Box

‘Input’ pressure display(s) for local pressure reference.

The ‘User Menu’ item display (B) will show the selected

user menu item. Press UP or DOWN to scroll through the

display ‘items’ list.

Flashing - Pressure Control ON, waiting for

compressor to respond

ON - Pressure Control On, Started

Fault Indicator (Red LED)

OFF – No fault

Flashing – VSD V Box Fault Condition

(see Fault Codes)

The VSD V Box will report that the compressor is ‘Not

Available’ to the system management unit when the VSD

V Box is in a stopped or fault condition.

19

Page 20

Start

Press START to activate VSD V Box pressure control.

The run indicator will illuminate or flash.

The compressor must be in a started state (running

or in standby) before VSD V Box pressure control will

function.

When started the VSD V Box will begin to manipulate the

pressure signal(s) to the compressor controller –

‘Pressure Control’ is active.

Pressure Control will de-activate

automatically if communications with the system

management unit is disrupted or not connected; the

detected pressure from the pressure sensor(s) is retransmitted to the compressor control directly.

When communications are re-established the

VSD V Box will automatically re-activate ‘Pressure

Control’.

Stop

Press STOP to de-activate VSD V Box pressure control.

The run indicator will extinguish.

When stopped the VSD V Box will not manipulate or

adjust the pressure signal(s) to the compressor

controller; the detected pressure from the pressure

sensor(s) is re-transmitted to the compressor control

directly.

The VSD V Box will report that the compressor is ‘Not

Available’ to the system management unit when the VSD

V Box is in a stopped condition.

During compressor service or routine maintenance

the VSD V Box can be stopped to return the compressor

to normal local pressure regulation.

Compressor Status

The detected status of the compressor is indicated by the

VSD V Box display status symbols (see Status Symbols)

VSD V Box Status

VSD V Box operation is indicated by the ‘Run’ LED

indicator (see Indicators). Pressure Control status is

indicated by the ‘pressure’ status symbols (see Status

Symbols).

User Menu Items

To view the ‘User Menu Items’ press UP or DOWN. The

‘Item’ display value will scroll through the available items.

P1 ‘Delivery’ output pressure transmitted to the

compressor controller.

P2* ‘Internal’ output pressure transmitted to the

compressor controller.

SP** Percent motor speed

C> VSD V Box Status

(*) The ‘Internal’ output pressure item is only shown if the

‘Internal’ pressure control function is activated (IC = 2).

(**) The percentage motor speed item is only shown if a

‘Speed Monitoring Kit’ is fitted and the function is

activated (Menu P08).

Delivery Output Pressure:

The delivery output pressure is manipulated during

‘Pressure Control’ and will differ from the actual ‘Input

Delivery’ pressure displayed as the main display value.

Pressure control function can be observed by comparing

the ‘Output’ discharge (delivery) pressure with the actual

detected ‘Input’ discharge (delivery) pressure. The two

pressures will be identical when ‘Pressure Control’ is not

active.

Internal Output Pressure:

The internal output pressure is manipulated during

‘Pressure Control’ to simulate and maintain the actual

detected differential between the ‘Input’ discharge

(delivery) pressure and the ‘Input’ Internal pressure. This

functionality allows compressor controller differential

pressure monitoring functions to be maintained

regardless of VSD V Box output pressure signal

manipulation.

Percentage Motor Speed:

The percentage of detected motor speed compared to

maximum motor speed. This value provides a direct

indication of variable speed compressor output

regulation.

VSD V Box Status:

The central ‘item’ display value (B) is the compressor

system identification number (network address number).

This is the same as the compressor system identification

number shown on the system management unit.

The ‘right hand’ display value indicates the VSD V Box

status condition (see Status Block Diagram).

Power Failure Auto-Restart

Power failure auto restart is always active and cannot be

de-activated.

The VSD V Box will re-start if the VSD V Box was in an

operational started status before the break or failure of

the main power supply occurred.

The VSD V Box will not re-start if it was not in an

operational started status before the break or failure of

the main power supply occurred.

20

Page 21

SECTION 6 — COMMISSIONING

COMMISSIONING PROCEDURE

It is recommended that installation and commissioning be

carried out by an authorized and trained product supplier.

Information regarding the compressor control system,

method of operation and regulation settings, is required.

Knowledge of VSD compressor regulation methods,

experience working with compressor control systems and

basic principle knowledge of compressed air systems, is

also required to be able to successfully install and

commission this product.

PHYSICAL CHECKS

Before applying power to the VSD V Box ensure that the

power supply connections are correct and secure and

that the operating voltage selector is set correctly for the

power supply voltage in use; 115Vac or 230Vac (+-10%),

50/60Hz; see ‘Installation’.

Check and ensure all pressure sensor, output pressure

signal and ir-PCB connections are correctly installed and

secure.

COMPRESSOR PRESSURE SET POINTS

Establish the following pressure set point values from the

compressor control system.

Establishing the correct compressor pressure set

point values is critical to successful VSD V Box

operation.

1) Compressor ‘Load’ pressure set point.

The pressure at which the compressor will start/load.

On fully integrated VSD compressor controllers this value

may be represented as the ‘Target Pressure’ level.

2) Compressor ‘Unload’ pressure set point.

The pressure at which the compressor will stop/offload.

On fully integrated VSD compressor controllers this value

may be represented as the ‘Controlled Stop Pressure’

level.

3) Compressor ‘Target’ pressure set point.

For VSD type compressors this is the pressure that the

variable speed drive is set to maintain.

This value will generally be the same as the ‘load’

pressure set point for variable speed compressors that

have fully integrated VSD control systems. For variable

speed compressors that do not have fully integrated

control systems this value will generally be the mid-point

between the ‘load’ and ‘unload’ pressure set points.

If the variable speed ‘target’ pressure is set separately

from the compressor controller (in the variable speed

drive controller menu or using a potentiometer connected

to the variable speed drive controller), then the

compressor controller is not a fully integrated type. In this

instance the ‘target’ pressure may have to be determined

by observation and/or experiment.

For fixed speed compressors the ‘target’ pressure can be

set at the mid-point between the compressor ‘load’ and

‘unload’ pressure set points.

4) The maximum Discharge (delivery) pressure level (and

maximum Internal pressure level if used) set in the

compressor controller. This value will be the Excess or

High pressure Alarm safety level. On fully integrated VSD

compressor controllers this value may be represented as

the ‘Immediate Stop Pressure’ level.

COMPRESSOR

Pressure Set Points

Excess or Alarm Pressure

7psi (0.5bar) min

Unload Pressure

Pressure

Target Pressure

Load Pressure

7psi (0.5bar) min

COMPRESSOR

Pressure Set Points

Immediate Stop Pressure

7psi (0.5bar)) min

Controlled Stop Pressure

Pressure

Target Pressure

7psi (0.5bar) min

If the compressor pressure set points have been set with

small differentials then the pressure set points of the

compressor will require adjustment before proceeding.

It is recommended that the pressure differential between

the ‘load’ and ‘unload’ (or ‘target’ and ‘controlled stop’)

pressures is a minimum of 7psi (0.5bar).

It is recommended that the pressure differential between

the ‘unload’ and ‘excess’ (or ‘controlled stop’ and

‘immediate stop’) pressures is a minimum of 7psi

(0.5bar).

21

Page 22

VSD V BOX CONFIGURATION

Apply power to the VSD V Box.

If the VSD V Box automatically starts (the green started

indicator illuminates or flashes) press the STOP button.

Using the VSD V Box menu routines, set the ‘IC’ (I/O

Configuration - Type) item of menu P03 to the correct

setting for the pressure sensor input/output configuration.

See Menu Items and Settings.

VSD V Box Network Address

Each VSD compressor connected to the Automation

System unit must be assigned a unique compressor

identification number (1 to the maximum number of

compressors support by the X-Series controller). This

number will be the ‘network address’ number for the

compressor. The number should be clearly marked on

the compressor for identification purposes.

When connecting a compressor(s) to the VSD Box,

always use the Automation System unit’s unique

identification number as the compressor ‘network

address’ number.

Using the VSD Box menu routines, set the ‘Ad’ (Network

Address) in menu P03 to the Automation System unit’s

compressor identification number.

Input Pressure Sensor(s)

The offset and range of the pressure sensor(s) used on

the compressor must be established for VSD V Box

pressure sensor calibration. Generally this information is

indicated on the pressure sensor label.

The majority of pressure sensor(s) have a minimum

pressure (offset) of 0(zero) bar gauge with a ‘range’

applicable to the application. For example 0 to 232 psi

(0.0 to 16.0 bar) - where 0(zero) psi (0.0(zero) bar) is the

‘offset’ minimum and 232 psi (16.0 bar) is the ‘range’ or

maximum.

Some pressure sensor(s) have non-zero offset. For

example -14.5 psi (minus -14.5), (-1.0 bar) (minus 1bar)

to 218 psi, 15bar; this type of pressure sensor can

measure negative or vacuum pressure. In this instance

the ‘offset’ is -14.5 psi (minus -14.5), (-1.0 bar) (minus

1bar)) and the ‘range’ is 232 psi (16.0 bar). Remember

the ‘range’ is the difference between the minimum and

maximum values and not the maximum value referenced

to 0(zero) bar ‘atmospheric’.

The correct ‘offset’ and ‘range’ values of each pressure

sensor are required for VSD V Box ‘input’ pressure

sensor calibration.

The main value display should show a pressure value; for

example 0 psi (0.0 bar). If the display shows dashes (- - -

-) check the ‘Delivery‘ pressure sensor connections.

Wire polarity is important.

If an ‘Internal’ pressure sensor is in use press DOWN to

view the ‘P2’ pressure value in the User menu ‘items’

display. The ‘P2’ value display should show a pressur e

value; for example 0 psi (0.0 bar). If the display shows

dashes (- - - -) check the ‘Internal‘ pressure sensor

connections.

At this stage the displayed pressure values will probably

be incorrect; this is normal.

Calibrate the input ‘Delivery’ pressure sensor, and input

‘Internal’ pressure sensor if used, following the input

‘Pressure Sensor Calibration’ procedure below:

In many instances where a 0 to 5VDC pressure

sensor is indicated or specified the actual operation is 1

to 5VDC. Request conformation from the compressor

supplier or manufacturer.

Input and Output pressure calibration is critical for

successful VSD V Box operation.

Input Pressure Sensor Calibration

Using the VSD V Box menu navigation procedure, select

menu page P04 (Input Pressure Calibration). The ‘items’

of this menu enable calibration of the pressure sensor(s)

connected to the VSD V Box.

Enter the ‘OFFSET’ value for the ‘Delivery’ pressure

sensor in the ‘Do’ menu item.

For example: if the pressure sensor is 0 tom 232 psi (0 to

16.0 bar), enter 0 psi (0.0 bar) as the offset value; if the

pressure sensor is -14.5 to 218 psi, (–1.0 to 15 bar) enter

-14.5 psi (minus -14.5), (-1.0 bar) (minus 1bar) as the

offset value.

Enter the ‘RANGE’ value for the ‘Delivery’ pressure

sensor in the ‘Dr’ menu item.

For example: if the pressure sensor is 0 tom 232 psi ( (0

to 16.0 bar) enter 232 psi (16.0 bar) as the range value; if

the pressure sensor is -14.5 to 218 psi, (–1.0 to 15 bar)

then the range value is also 232 psi (16.0 bar).

When the ‘Delivery’ pressure sensor offset and range

menu items are selected the menu page display value

will change to show the actual detected ‘Delivery’

pressure measurement. This value can be used to

compare with a ‘known’ pressure applied to the ‘Delivery’

pressure sensor for accurate calibration purposes. An

independent and accurate means of measuring the

applied pressure is required.

1) Subject the ‘Delivery’ pressure sensor to atmosphere

(0bar).

2) Adjust the ‘Do’ pressure ‘offset’ value until the

‘Delivery’ pressure displayed by the VSD V Box sho ws

0(zero) bar.

3) Apply a known pressure to the ‘Delivery’ pressure

sensor. It is recommended that the applied pressure is

representative of normal working pressure levels. It is not

important if the applied pressure is static or continuously

fluctuating.

4) Adjust the ‘Dr’ pressure ‘range’ value until the

‘Delivery’ pressure displayed by the VSD V Box sho ws

the same as the ‘known’ applied pressure.

If an ‘Internal’ pressure sensor is also in use, follow the

same procedure described above applying adjustments

to the ‘Io’ (Internal offset) and ‘Ir’ (Internal range) menu

items. When these menu items are selected the menu

page display value will change to show the actual

detected ‘Internal’ pressure measurement.

Wire polarity is important.

22

Page 23

Output Pressure Signal Calibration

Using the VSD V Box menu navigation procedure, select

menu page P05 (Output Pressure Calibration). The

‘items’ of this menu enable calibration of the pressure

signal(s) transmitted to the compressor controller.

Enter the ‘OFFSET’ value for the ‘Delivery’ pressure

signal in the ‘Do’ menu item. Set this value will to same

as the initial ‘Delivery’ pressure sensor input ‘offset’.

Enter the ‘RANGE’ value for the ‘Delivery’ pressure

signal in the ‘Dr’ menu item. Set this value to the same as

the initial ‘Delivery’ pressure sensor input ‘range’.

When the output ‘Delivery’ pressure signal offset and

range menu items are selected the menu page display

value will change to show the actual detected input

‘Delivery’ pressure measurement. This value represents

the pressure the VSD V Box is attempting to transmit to

the compressor controller and can be used to compare

with the compressor controller’s displayed pressure

value.

1) Subject the input ‘Delivery’ pressure sensor to

atmosphere (0bar).

2) Adjust the ‘Do’ pressure signal ‘offset’ value until the

compressor controller’s discharge (delivery) pressure

display value shows 0(zero) bar.

3) Apply a known pressure to the input ‘Delivery’

pressure sensor. It is recommended that the applied

pressure is representative of normal working pressure

levels. It is not important if the applied pressure is static

or continuously fluctuating.

4) Adjust the ‘Dr’ pressure signal ‘range’ value until the

compressor controller’s discharge (delivery) pressure

display value shows the same as the VSD V Box

discharge (delivery) pressure.

If an ‘Internal’ pressure sensor is also in use, follow the

same procedure described above applying adjustments

to the ‘Io’ (Internal offset) and ‘Ir’ (Internal range)

pressure output signal menu items. When these menu

items are selected the menu page display value will

change to show the actual detected ‘Internal’ pressure

measurement.

It is recommended that Input and Output pressure

calibration is examined, and adjusted if necessary, on a

routine periodic basis.

23

Page 24

PRESSURE SET POINTS

Establishing and implementing the correct pressure

set points is critical for successful VSD V Box operation.

Using VSD V Box menu navigation, select menu page

P03 (Configuration).

1) Set the ‘Dm’ Discharge (delivery) pressure Maximum

Limit) to the compressor’s ‘Excess Discharge (delivery)

pressure Alarm’ or ‘Immediate Stop’ pressure setting.

2) If an ‘Internal’ pressure sensor is in use set the ‘Im’

(Internal Pressure Maximum Limit) to the compressor’s

‘Excess Internal Pressure Alarm’ pressure setting.

Typically this value will be at least 12psi (0.8bar) above

the excess or alarm ‘delivery’ pressure limit.

Using VSD V Box menu navigation, select menu page

P01 (Pressure Set Points).

1) Set the ‘Pu’ (Unload) pressure set point to the

compressor’s ‘Unload’ or ‘Controlled Stop’ pressure set

point value.

2) Set the ‘Pt’ (Target) pressure set point to the ‘target’

pressure setting established for the compressor.

3) Set the ‘PL’ (Load) pressure set point to the

compressor’s ‘Load’ or ‘Target’ pressure set point value.

VSD V Box Pressure Set Point Control:

When the VSD V Box ‘loads’ the compressor it will force

the output ‘Delivery’ pressure signal to a pressure value

3psi (0.2bar) below the set ‘Unload’ pressure set point.

This manipulation will force the compressor to respond to

the low pressure value and the compressor will load.

When the VSD V Box detects the compressor has loaded

the pressure signal is returned to normal active ‘pressure

control’ values.

When the VSD V Box ‘unloads’ the compressor it will

force the output ‘Delivery’ pressure signal to a pressure

value 3psi (0.2bar) above the set ‘Load’ pressure set

point. This manipulation will force the compressor to

respond to the high pressure value and the compressor

will unload. The VSD V Box will hold this pressure value

to maintain offload operation regardless of actual

discharge (delivery) pressure fluctuations.

COMPRESSOR

Pressure Set Points

Excess or Alarm Pressure

e

Unload Pressure

r

u

s

s

e

r

Target Pressure

P

Load Pressure

COMPRESSOR

Pressure Set Points

Immediate Stop Pressure

e

Controlled Stop Pressure

r

u

s

s

e

r

P

Target Pressure

Pressure Set Points

- Unload Pressure

Pu

=

=

- Target Pressure

PT

- Load Pressure

PL

Pressure Set Points

- Unload Pressure

Pu

- Target Pressure

PT

& PL - Load Pressure

VSD Box

VSD Box

Pu +0.2bar

Pu -0.1bar

PL -0.2bar

Pu +0.2bar

Pu -0.1bar

PL -0.2bar

VSD Box

Control Pressures

Unload Request Pressure

Max Control Pressure Limit

Load Request Pressure

VSD Box

Control Pressures

Unload Request Pressure

Max Control Pressure Limit

Load Request Pressure

24

Page 25

SECTION 7 — SYSTEM CONFIGURATION

DISPLAY ITEM STRUCTURE

All value, parameter or option selection displays are

grouped into menu lists. Items are assigned to a list

according to type and classification. Items that can be

used to select options or modify functions are assigned to

‘menu mode’ lists. Items that a User may require to view

during routine operation, detected pressure for example,

are assigned to the normal operational mode list. Lists

are identified by page number; the normal User display

list is page ‘P00’. All parameters and options are

assigned to menu mode pages ‘P01’ or higher. All Page

‘P00’ items are view only and cannot be adjusted.

Normal Operational Mode (Page P00)

At controller initialization, all display elements and LED

indicators are switched on for three seconds, the display

will then show the software version code for a further 3

seconds before initialization is complete and the normal

operating display (Page P0) is shown. In page P00

‘normal operational display mode’ the main display will

continuously show the detected discharge (delivery)

pressure and the Item display will show the first item of

the ‘User’ menu. User menu ‘Items’ can be selected

using the Up or Down buttons at any time. Pressing the

Enter button will lock any selected Item display and

inhibit return to the default display. When an Item display

is locked the lock key symbol will slow flash. To unlock

an Item display press Up or Down to view an alternative

Item display or press Reset or Escape. No Item values,

options or parameters can be adjusted in page ‘P00’. If a

fault condition occurs the fault code becomes the first list

item and the display will automatically jump to display the

fault code. More than one active fault code item can exist

at any one time.

ACCESSING THE X12I CONFIGURATION

SCREENS

Access Code

Access to page list displays higher than page ‘P00’ is

restricted by access code. To access menu mode pages

press UP and DOWN together, an access code entry

display is shown and the first code character will flash.

Use PLUS or MINUS to adjust the value of the first code

character then press ENTER. The next code character

will flash; use UP or DOWN to adjust then press ENTER.

Repeat for all four code characters.

If the code number is less than 1000 then the first code

character will be 0(zero). To return to a previous code

character press ESCAPE. When all four code characters

have been set to an authorized code number press

ENTER. An invalid code will return the display to normal

operational mode; page ‘P00’.

Access Code Timeout

When in menu mode, if no key activity is detected for a

period of time the display will automatically reset to the

normal operational display; Page ‘P00’.

Menu Mode Navigation

In menu mode the main value display will flash and show

the Page number. To select a page press UP or DOWN.

For each page the display will show the first Item of the

page list. To view a page list press ENTER, the Page

number will stop flashing and the Item display will flash.

Press UP or DOWN to view the selected page list items.

To select an Item value for modification press ENTER,

the Item display will stop flashing and the Value display

will flash. The value or option can now be modified by

pressing UP(Plus) or DOWN(Minus). To enter a modified

value or option in memory press ENTER; alternatively the

modification can be abandoned, and the original setting

maintained, by pressing ESCAPE.

Page 0

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value

Page 1

Page 2

Page 3

Page 4

Page 5

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

25

Page 26

Press ESCAPE at any time in menu mode to step

backwards one stage in the navigation process. Pressing

ESCAPE when the page number is flashing will exit

menu mode and return the display to normal operational

mode; page ‘P00’.

Page 0

to immediately exit menu mode and return to the normal

operational mode display. Any value or option adjustment

that has not been confirmed and entered into memory will

be abandoned and the original setting maintained.

indicates the Item is locked and cannot be modified. This

will occur if the Item is view only (non adjustable) or in

instances where the item cannot be adjusted while the

VSD V Box is in the operational STARTED state.

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value

Press and hold RESET for two seconds at any time

A flashing Key symbol displayed with any Item

Page 1

Page 2

Page 3

Page 4

Page 5

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

26

Page 27

MENU ITEMS AND SETTINGS

MENU P00 - User

1 P1 Discharge Pressure - Output (view only)

2 P2 Internal Pressure - Output (view only)

3 SP Percent Speed (view only)

MENU P01 - Pressure Set Points

1 Pu Unload Pressure

2 Pt Target Pressure

3 PL Load Pressure

MENU P02 – Error Log

1 Hr VSD Box Operating Hours

2 01 Error Log #1

to

16 15 Error Log #15

MENU P03 - Configuration

1 P> Pressure Units Select

2 Ad Network Address (Compressor No.)

3 PA Pressure Averaging Factor

4 IC I/O Configuration (Type)

5 IP Internal Pressure Enable

6 Dm Discharge Pressure Maximum Level

7 Im Internal Pressure Maximum Level

MENU P04 – Input Pressure Calibration

1 Do Discharge Pressure ‘Offset’

2 Dr Discharge Pressure ‘Range’

3 Io Internal Pressure ‘Offset’

4 Ir Internal Pressure ‘Range’

MENU P05 – Output Pressure Calibration

1 Do Discharge Pressure ‘Offset’

2 Dr Discharge Pressure ‘Range’

3 Io Internal Pressure ‘Offset’

4 Ir Internal Pressure ‘Range’

MENU P06 / Diagnostics

See ‘Diagnostics’

MENU P08 – Speed Monitoring

1 FL Frequency at Minimum Speed

2 FH Frequency at Maximum Speed

3 C> Control Percentage (view only)

MENU P10 – Unit Configuration

1 D7 Aux Alarm Input Configuration

2 D8 Aux Trip Input Configuration

3 SQ ir-PCB Sequence control hold

4 Ao Analog Output Function (4-20mA)

5 Er Error Log Reset

6 Hr VSD Box Operating Hours Adjust

MENU P16 – Analog Output Diagnostic

See ‘Diagnostics’

Note: Menus P07, 9 and 11 to 15 are not used.

Access Code = 0021

MENU P01 - Pressure Set Points

Pu: Unload Pressure

Compressor ‘Unload’ pressure set point: The pressure at

which the compressor will stop/unload. On fully

integrated VSD compressor controllers this value may be

represented as the ‘Controlled Stop Pressure’ level. Set

the ‘Pu’ (Unload) pressure set point to the compressor’s

‘Unload’ or ‘Controlled Stop’ pressure set point value.

Pt: Target Pressure

Compressor ‘Target’ pressure set point. For VSD type

compressors this is the pressure that the variable speed

drive is set to maintain. Set the ‘Pt’ (Target) pressure set

point to the ‘target’ pressure setting established for the

compressor.

PL: Load Pressure

Compressor ‘Load’ pressure set point: The pressure at

which the compressor will start/load. On fully integrated

VSD compressor controllers this value may be

represented as the ‘Target Pressure’ level. Set the ‘PL’

(Load) pressure set point to the compressor’s ‘Load’ or

‘Target’ pressure set point value.

Establishing and maintaining the correct pressure

set point values (Pu, Pt and PL ) is critical to the

successful operation of VSD Box control functions.

See ‘Commissioning - Pressure Set Points’

MENU P02 - Error Log

The first item of the log error menu is the VSD Box

operational hours (Hr). This is an indication of the

accumulated hours the VSD Box has been operational

and is used to time-stamp fault codes in the error log.

The hours counter has no other function.

The VSD Box operating hours counter is NOT

intended as a measure of compressor operation or

running hours; the hours counter will differ from, and

operate independently from, the compressor hours

counter.

Each error log item will show the fault code alternating

with the VSD Box operational hours when the fault

occurred. The error log stores the last 15 faults in

chronological order; item ‘01’ is the most recent fault.

27

Page 28

MENU P03 – Configuration

P>: Pressure Units Select

Selects the display pressure units (bar, psi or kPa)

Ad: Net work Address

Network address; must be set to the compressor