Page 1

Ingersoll Rand

System Automation

Virtual Relay Automation

Operator’s Manual

Before installing or starting this unit for the rst

time, this manual should be studied carefully to

obtain a working knowledge of the unit and or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

More Than Air. Answers.

Online answers: http://air.ingersollrand.com

C.C.N. : 80444433

REV. : A

DATE : DECEMBER

2008

Page 2

SECTION 1 TABLE OF CONTENTS

Section 1 - table of contentS .............................2

Section 2 - Virtual relay automation ............3

21. WHY “VIRTUAL RELAY?” ..................................................3

Section 3 - Virtual relay .......................................4

31. INPUT FUNCTIONS ........................................................... 4

32. LOGIC FUNCTIONS..........................................................4

33. ONDELAY TIMER ..............................................................6

34. OFFDELAY TIMER ............................................................7

35. VIRTUAL RELAY OUTPUT STATE ..................................7

Section 4 - Specialized Virtual relayS ............ 9

41. VIRTUAL RELAYS WITH MODIFIED OUTPUT

STATES ............................................................................................9

411. CYCLING TIMER VIRTUAL RELAYS ............................ 9

412. PULSE VIRTUAL RELAYS .............................................10

42. VIRTUAL RELAYS WITH FIXED INPUT

FUNCTIONS ................................................................................14

4.21. RUNNING VIRTUAL RELAY ........................................ 14

422. LOADED VIRTUAL RELAY ..........................................15

423. AVAILABLE VIRTUAL RELAY ......................................17

72. COMPRESSOR FUNCTION LIST .................................27

721. STATUS FUNCTIONS ....................................................27

73. I/O BOX FUNCTIONS .....................................................28

731. INPUT ALARM WARNING FUNCTIONS .............. 28

732. INPUT TRIP SHUTDOWN FUNCTIONS ...............29

733. INPUT SIGNAL S FUNCTIONS ...............................29

734. RELAY FUNCTIONS ......................................................30

735. STATUS FUNCTIONS ....................................................32

Section 8 - Virtual relay exampleS ................33

81. I/O BOX DRYER CONTROL ...........................................33

82. I/O BOX ISOLATION VALVE CONTROL ....................34

83. I/O BOX CONDENSATE DRAIN VALVE

CONTROL .....................................................................................35

84. I/O BOX WATER PUMP CONTROL .............................37

Refer to Section Indicated

Note

Important or Caution, Safety

Section 5 - phySical i/o and Virtual relayS 19

Section 6 - configuring Virtual relayS .......20

61. DEFINING AN INPUT FUNCTION ..............................20

62. STANDARD VIRTUAL RELAYS R01 R16 ..............20

63. CYCLING TIMER VIRTUAL RELAYS RT1, RT2,

RT3 ................................................................................................21

64. PULSE VIRTUAL RELAYS RP1, RP2, RP3, AND

RP4 ................................................................................................22

65. RUNNING VIRTUAL RELAY RF1 ..................................22

66. LOADED VIRTUAL RELAY LF1 .....................................23

67. AVAILABLE VIRTUAL RELAY AF1 ...............................23

Section 7 - function liStS ...................................25

71. X8I FUNCTION LIST ........................................................25

711. STATUS FUNCTIONS ....................................................25

712. SIGNAL FUNCTIONS ....................................................26

713. RELAY FUNCTIONS ......................................................26

2

Page 3

SECTION 2 VIRTUAL RELAY AUTOMATION

Coil

Unpowered

Coil

Powered

0

1

The Ingersoll Rand Automation X8I system is equipped

with virtual relay capability to expand the control of a

compressed air system. Using virtual relay allows the X8I

system to control and monitor ancillary equipment such

as dryers, ow meters, dew point monitors, etc. When

virtual relay capability is activated all inputs and outputs

in the X8I system can be utilized in much the same way

a Programmable Logic Controller (PLC) would be used to

control a system. Each component in the X8I system has

a list of statuses and functions that can be used as input

functions to trigger the virtual relays. Virtual Relays are

logical constructs that are either true or false based on

the input functions but are not necessarily connected to a

physical relay output. Virtual relays can also be connected

to a physical output and thus allow control of equipment

in the system.

21. WHY “VIRTUAL RELAY?”

The name “Virtual Relay” was selected because a virtual

relay is patterned after an electromechanical relay

used in electrical circuits. A relay consists of two major

components: the coil, which detects whether or not there

is current owing, and the contacts, which change state

based on whether or not the coil is powered. A typical

relay would consist of an electromagnetic coil which

would pull the contacts closed when powered, and let

the contacts open when unpowered. Relay contacts

are designated by the state they are in when the coil

is unpowered, either Normally Open (NO) or Normally

Closed (NC). A single relay would usually have contacts of

each type.

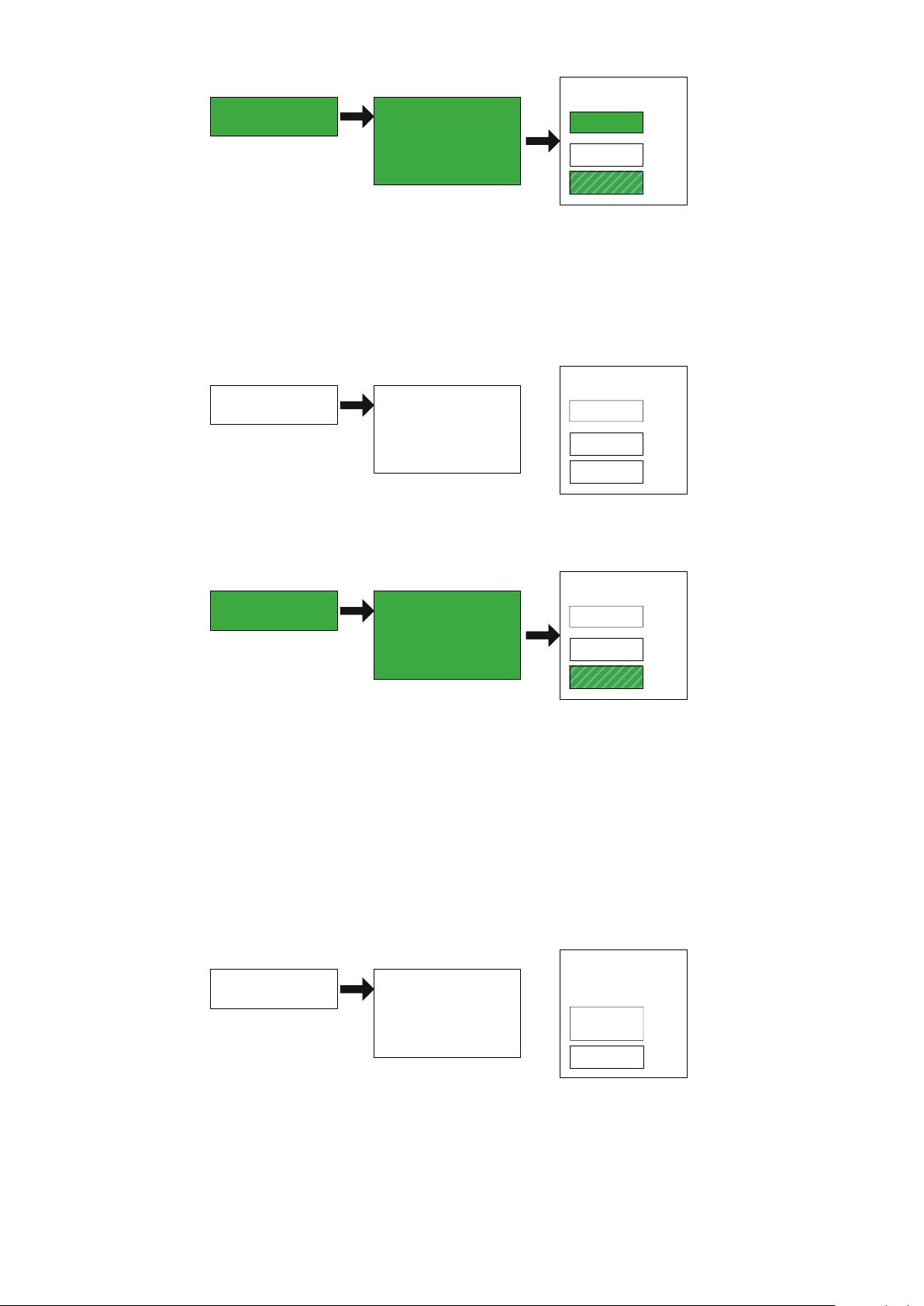

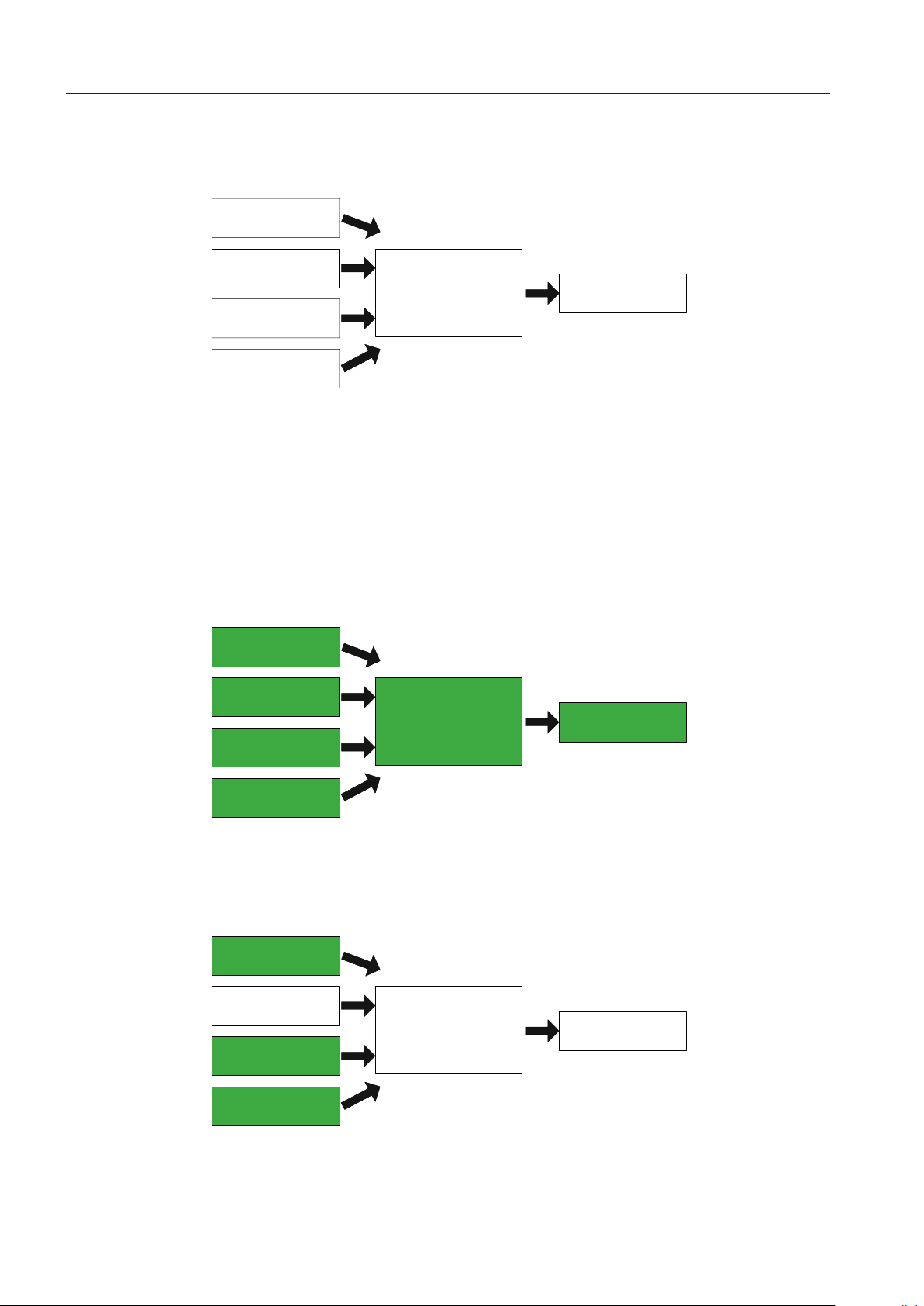

FIGURE 1 TWO STATES OF A NORMALLY OPEN NO

RELAY

A relay allows control of a circuit by switching the current

owing through dierent parts of the circuit. Relays

can be placed in series or in parallel and sequenced

to provide digital logic to an electrical circuit. Before

electronic controllers were commonplace, relays were

used in order to perform control logic operations. The

resulting circuit diagrams looked like a ladder, and the

notation would come to be “ladder logic” that is now used

to program PLCs.

Virtual Relay got its name because it is a software

construct that is equivalent to an electromechanical

relay. It uses conditions called input functions and logic

functions that act in a similar away to the relay coil. Virtual

relays also use conditions known as output states that are

equivalent to the contacts in an electro-mechanical relay.

Virtual relays can be used as input functions to “power”

the coils of another virtual relay. The resulting logic

functions in much the same way a series of relays would.

3

Page 4

4

SECTION 3 VIRTUAL RELAY

Input Function 1

Input Function 2

(

Optional

)

Logic Function

(F1,AND, OR ,

XOR )

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

(

Optional

)

Logic Function

(F1,AND, OR ,

XOR )

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Logic Function F 1

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Logic Function F 1

Virtual Relay

Output State

On Delay

Time

O Delay

Time

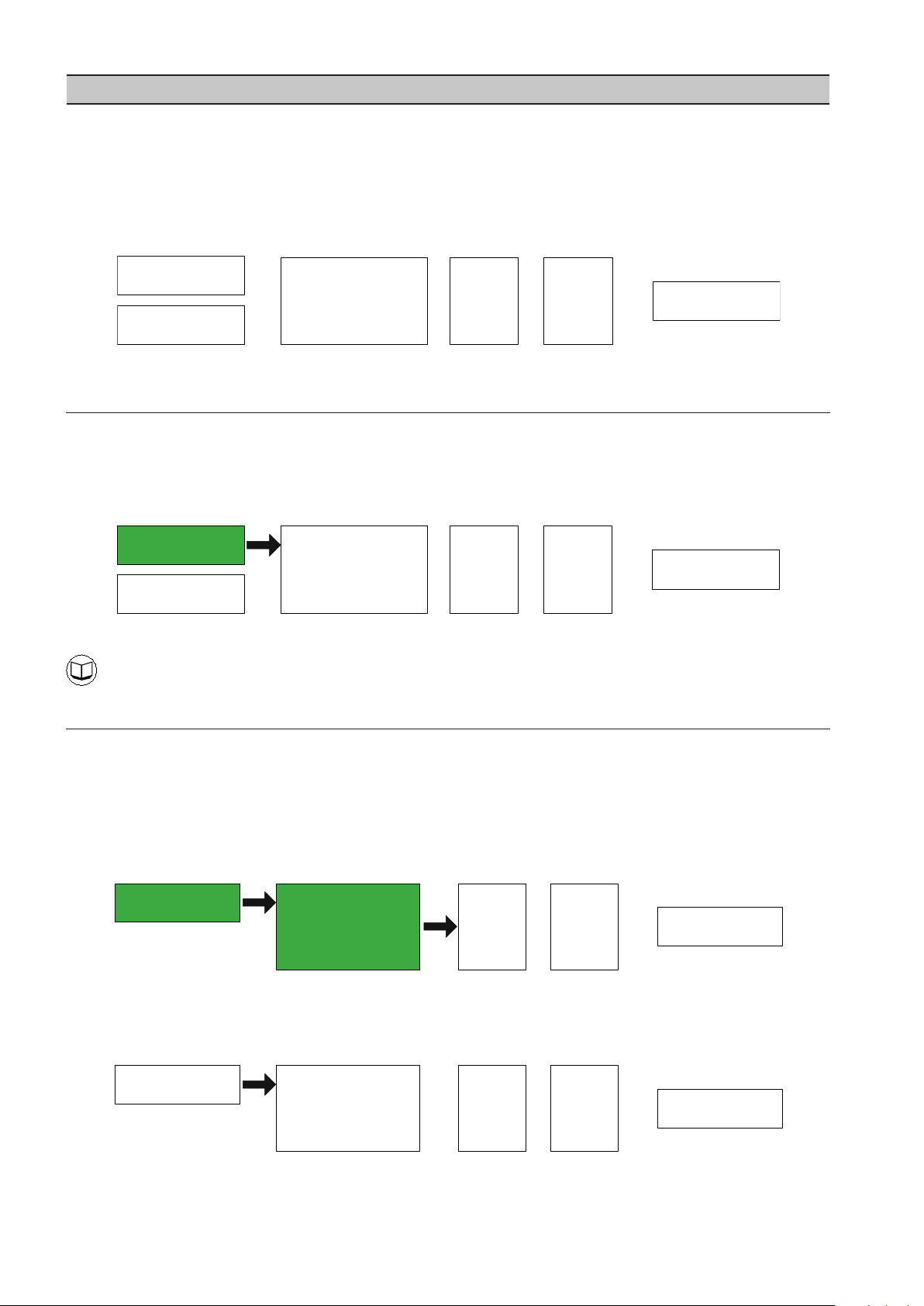

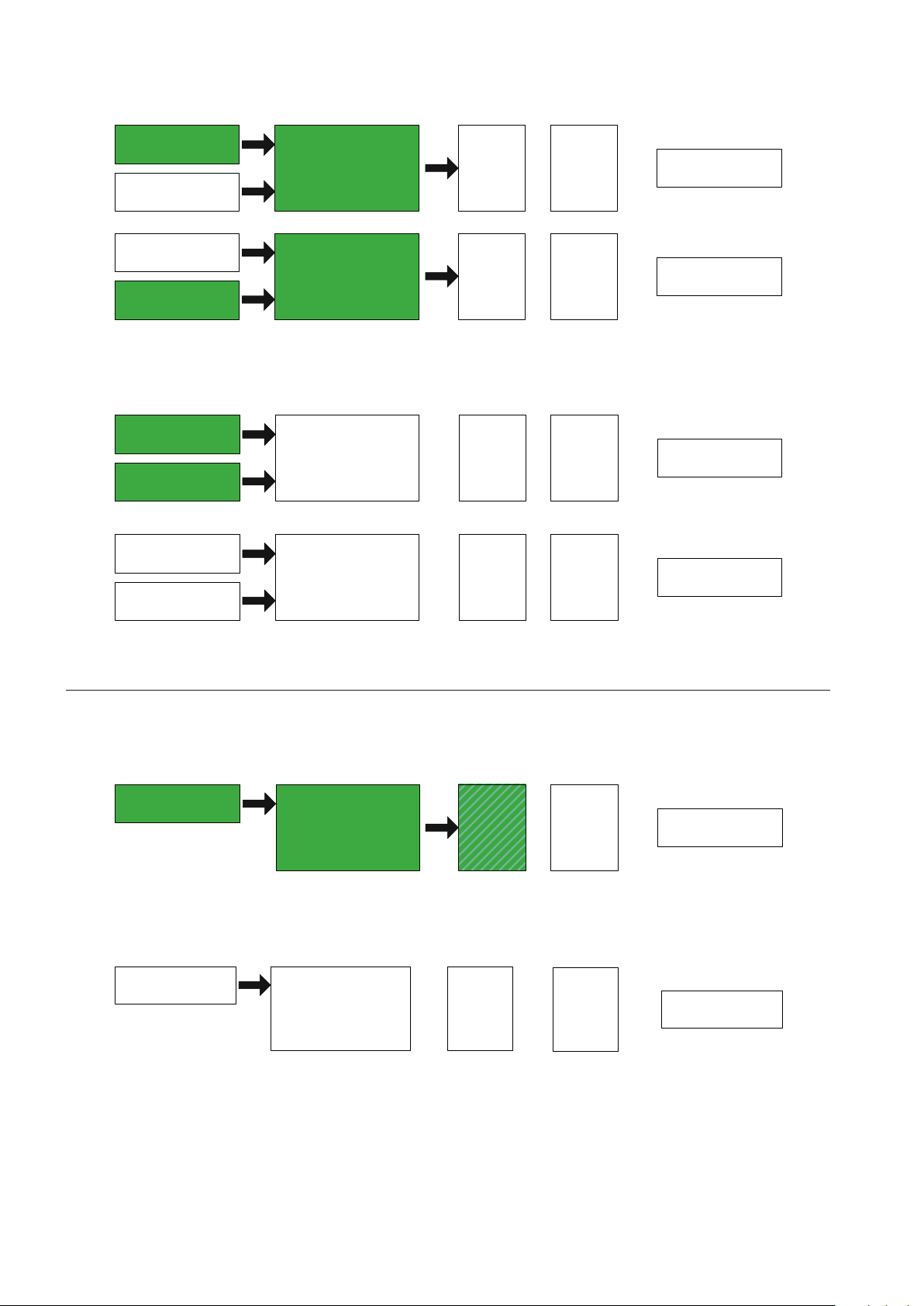

A virtual relay is a way for the user to create customized control for their air system using predened status registers in

the various X8I system components. Virtual relays should be thought of as a series of conditions that must be satised

in order to turn the output from false to true. The standard virtual relay consists of 5 conditions: Input Functions, Logic

Functions, On Delay Time, O Delay Time, and the Virtual Relay Output State. Each condition can only have two values,

it is either True (equal to 1) or False (equal to 0). The relationship of the conditions is shown below and the diagram is

read from left to right. The conditions on the very left must be True before moving onto the next condition until the

virtual relay output state is reached.

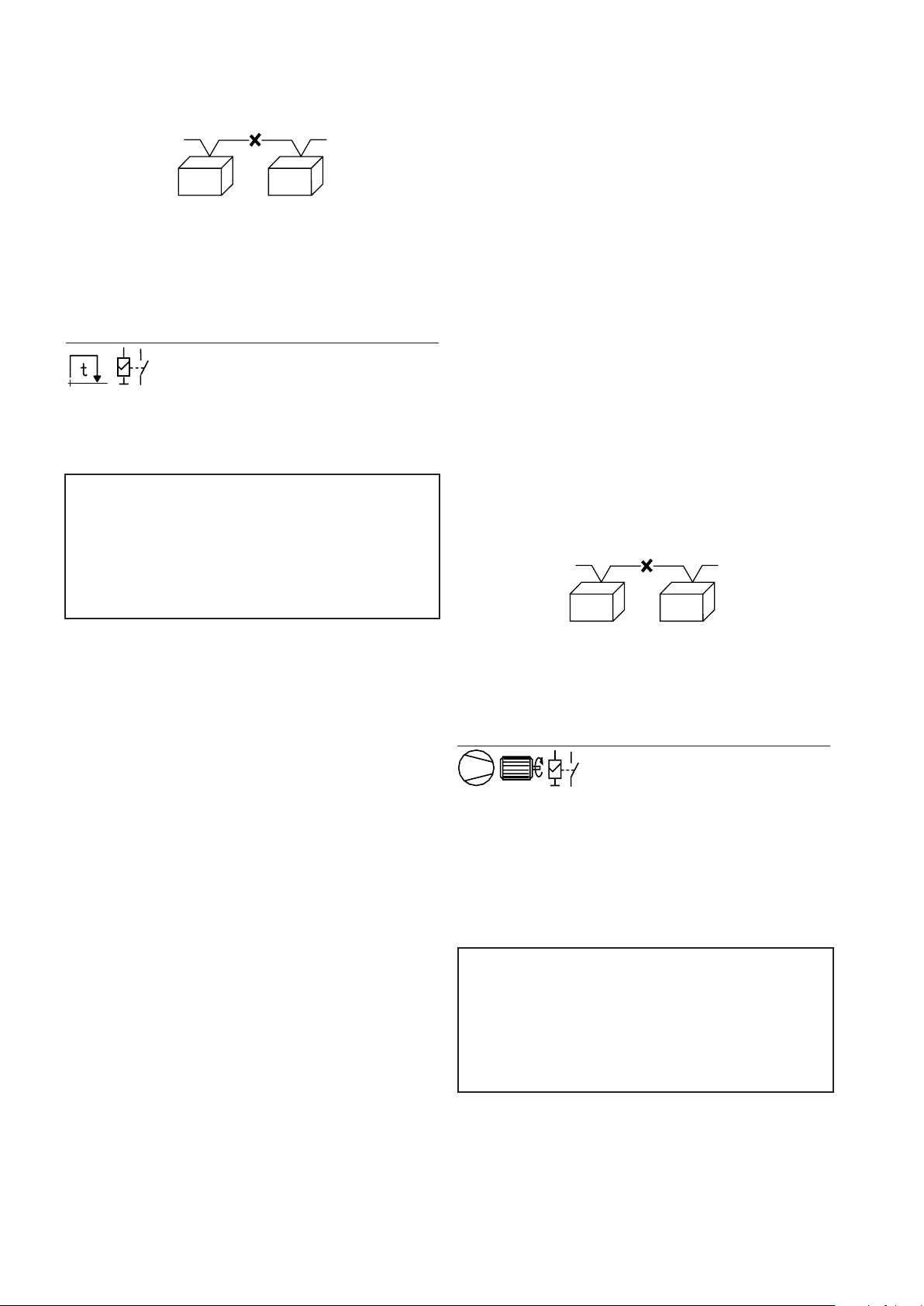

FIGURE 2 VIRTUAL RELAY WITH ALL CONDITIONS FALSE

31. INPUT FUNCTIONS

An input function is the rst condition that is evaluated in a virtual relay. The input function is entered by the user and

can be the running condition of the X8I, whether or not Table #1 is active, compressor 1’s load state, or even if the X8I

is currently running in Energy Control mode. The input function will constantly be evaluated and when a True value

is encountered the next condition of the virtual relay will be evaluated. In all diagrams below a green box denotes a

condition that is evaluated as True.

FIGURE 3 INPUT FUNCTION 1 HAS BEEN EVALUATED AS TRUE

For a complete set of input functions please see 6.0 – Function Lists

32. LOGIC FUNCTIONS

Each virtual relay can have up to two input functions assigned. Once the input functions have been dened the virtual

relay needs to decide how the relationship between the input functions will be evaluated. This next condition is

known as a Logic Function because it will perform a digital logic evaluation on the states of the input functions. The

available Logic Functions are F1, AND, OR, and XOR.

F1 – The logic function F1 is used when there is only one input function dened in the virtual relay. F1 evaluates the

state of the input function and if the input function is True then the logic function will also be evaluated as True. Please

note in the diagram below the Input Function 2 has been omitted.

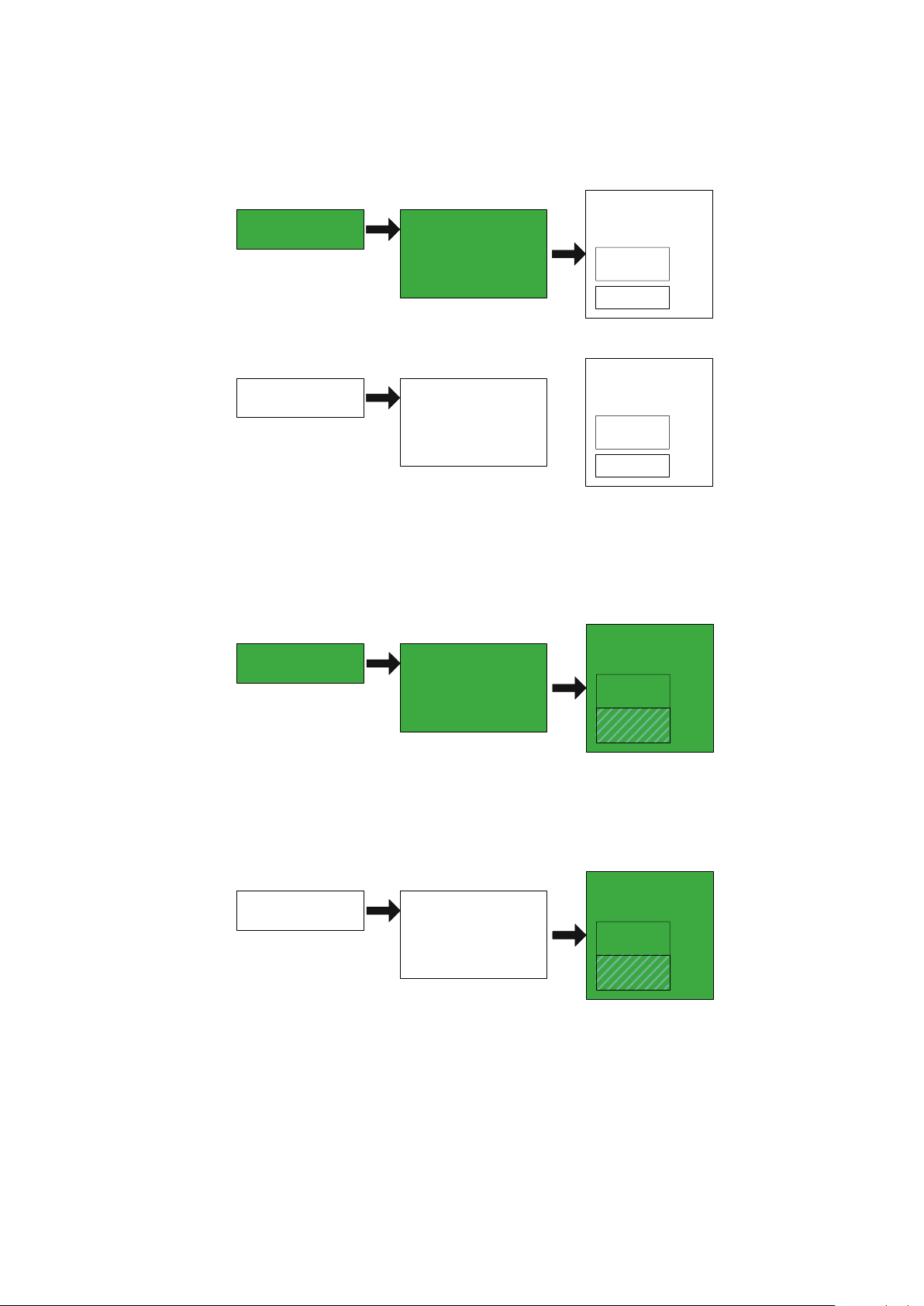

FIGURE 4 LOGIC FUNCTION F1 HAS BEEN EVALUATED AS TRUE

If input function 1 is evaluated as False, logic function F1 will also be evaluated as false and no further conditions will

be checked.

FIGURE 5 LOGIC FUNCTION F1 HAS BEEN EVALUATED AS FALSE

Page 5

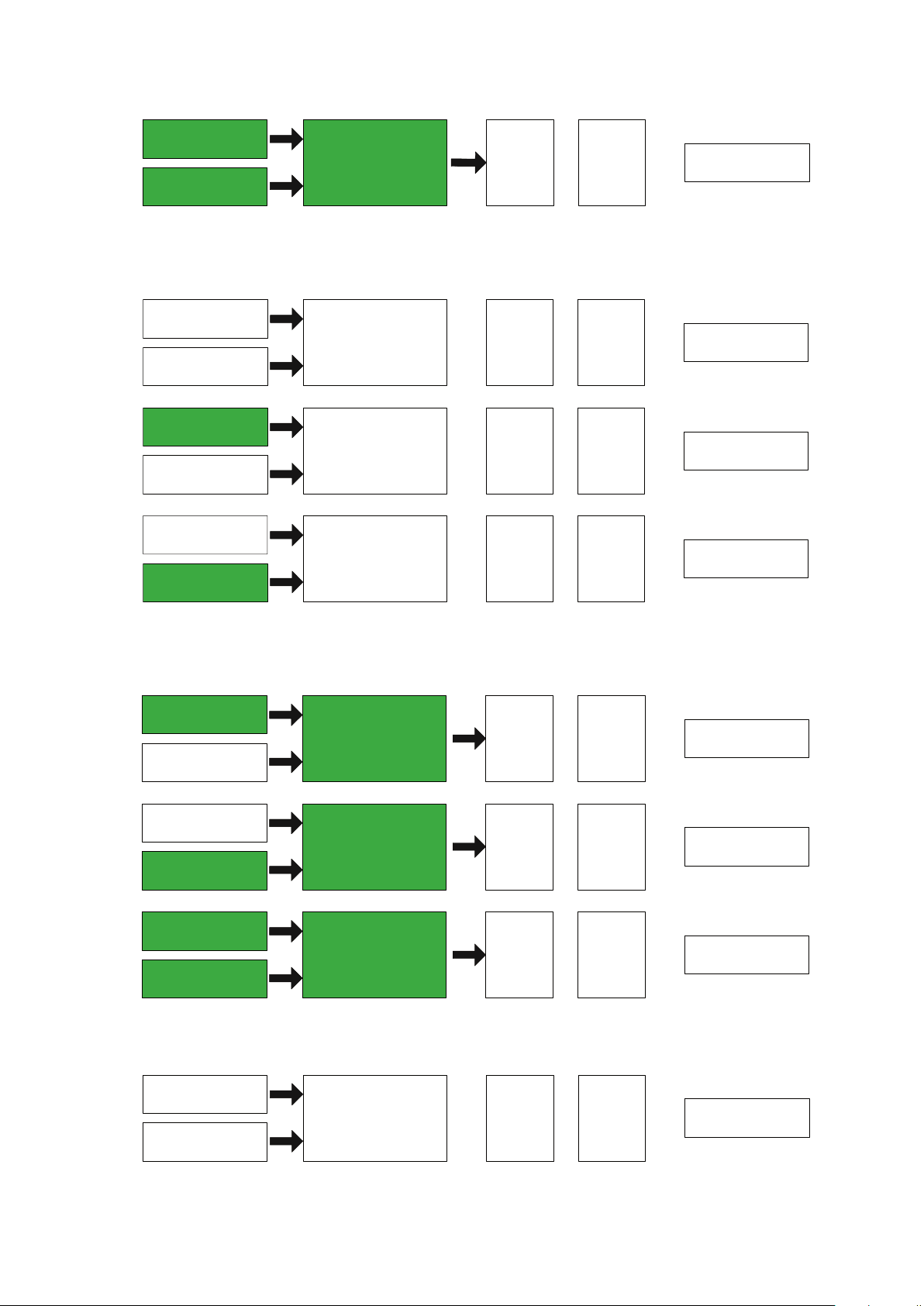

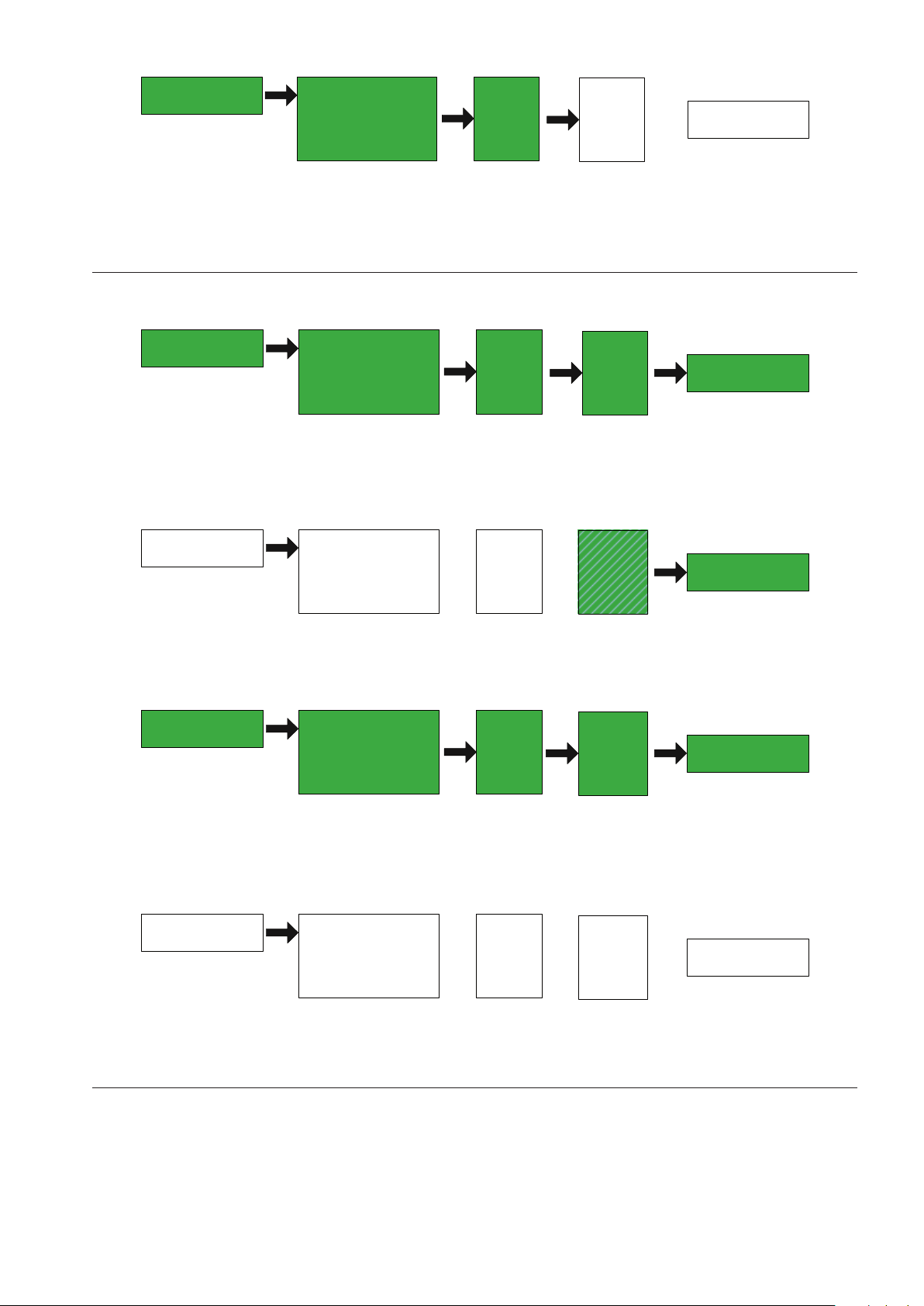

AND – The logic function AND is used with two input functions. The AND function is evaluated as True when both

Input Function 1

Input Function 2

Logic Function A ND

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function AND

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function AND

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function AND

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function OR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function OR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function OR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function OR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

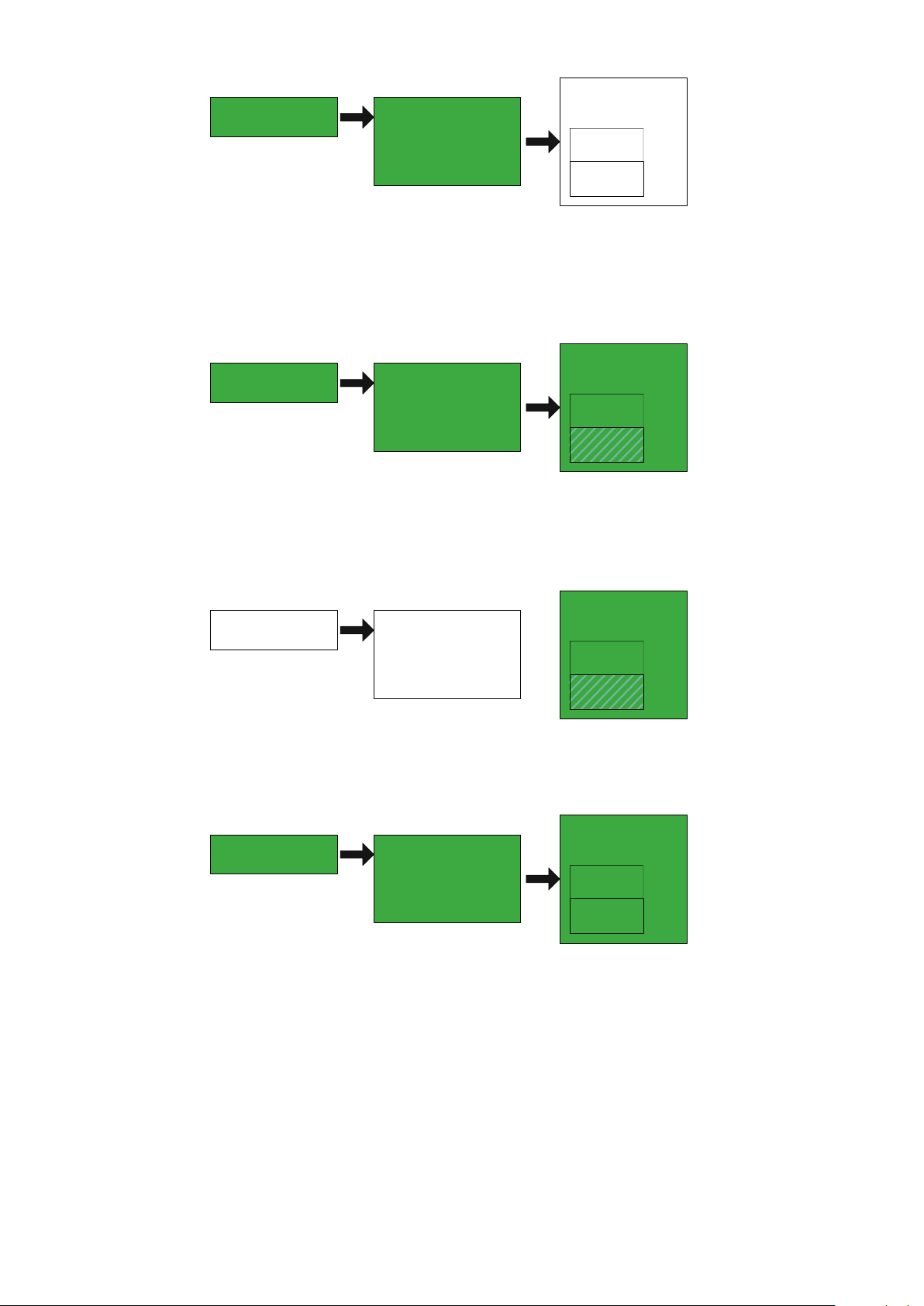

input function 1 and 2 are evaluated as True.

FIGURE 6 LOGIC FUNCTION AND HAS BEEN EVALUATED AS TRUE

Any other combination of input function states is evaluated as false and no further virtual relay conditions will be

checked.

FIGURE 7 LOGIC FUNCTION AND HAS BEEN EVALUATED AS FALSE

OR – The logic function OR is used with two input functions. The OR function will be evaluated as True when at least

one input function is True. The OR function will also be evaluated as True if both input functions are True.

FIGURE 8 LOGIC FUNCTION OR HAS BEEN EVALUATED AS TRUE

If both input functions are evaluated as false the logic function OR will also be evaluated as false.

FIGURE 9 LOGIC FUNCTION OR HAS BEEN EVALUATED AS FALSE

5

Page 6

6

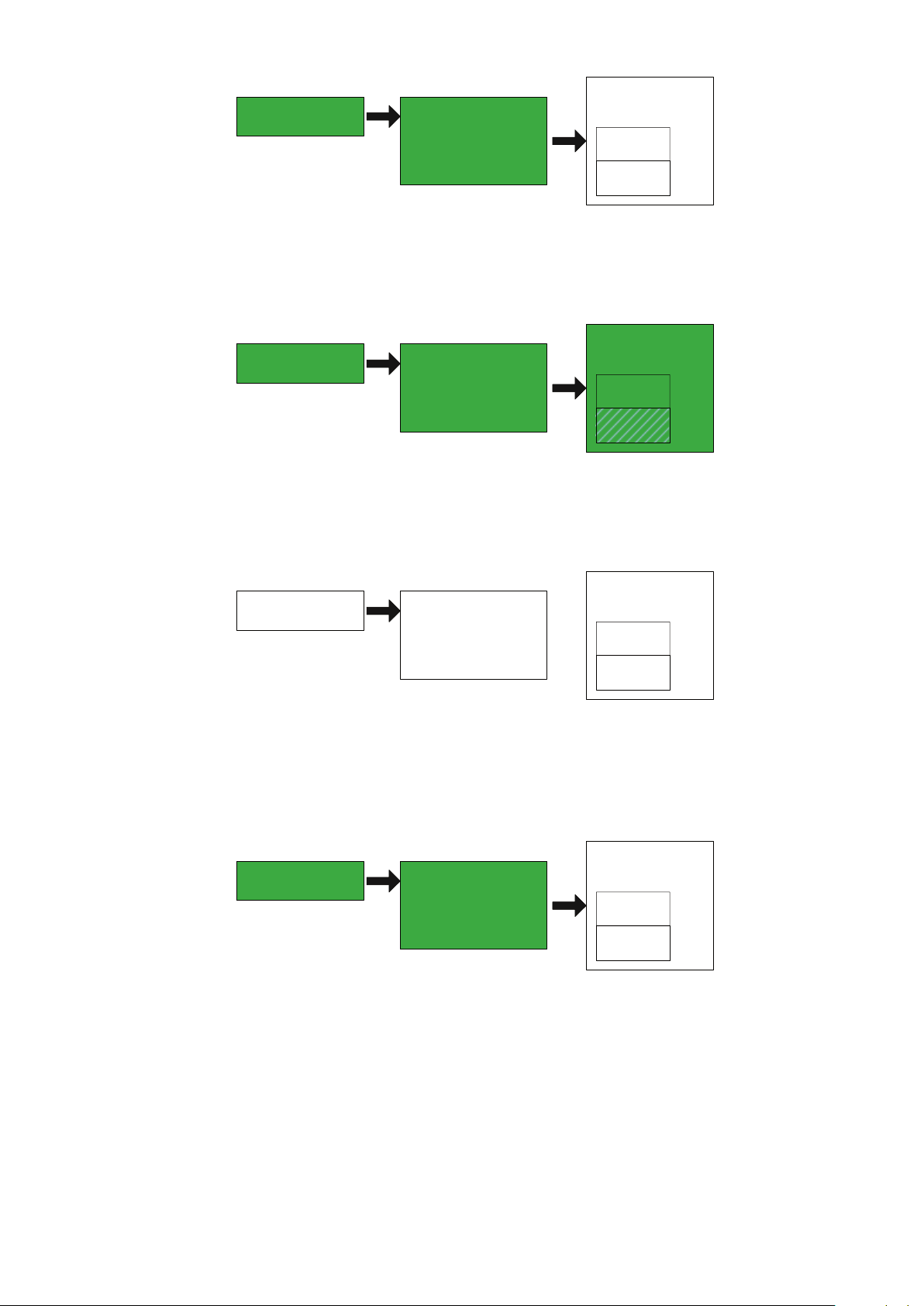

XOR – The logic function XOR (Exclusive OR) is used with two input functions. The XOR function will be evaluated as

Input Function 1

Input Function

2

Logic Function XOR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function XOR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function XOR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Input Function 2

Logic Function XOR

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Input Function 1

Logic Function F 1

Virtual Relay

Output State

On Delay

Timer

(counting)

O Delay

Time

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Delay

Timer

(Reset to

0)

O Delay

Time

True when one, and only one, input function is True.

FIGURE 10 LOGIC FUNCTION XOR HAS BEEN EVALUATED AS TRUE

If neither input function is evaluated True or both of the input functions are evaluated as True then the XOR logic

function is evaluated as False.

FIGURE 11 LOGIC FUNCTION XOR HAS BEEN EVALUATED AS FALSE

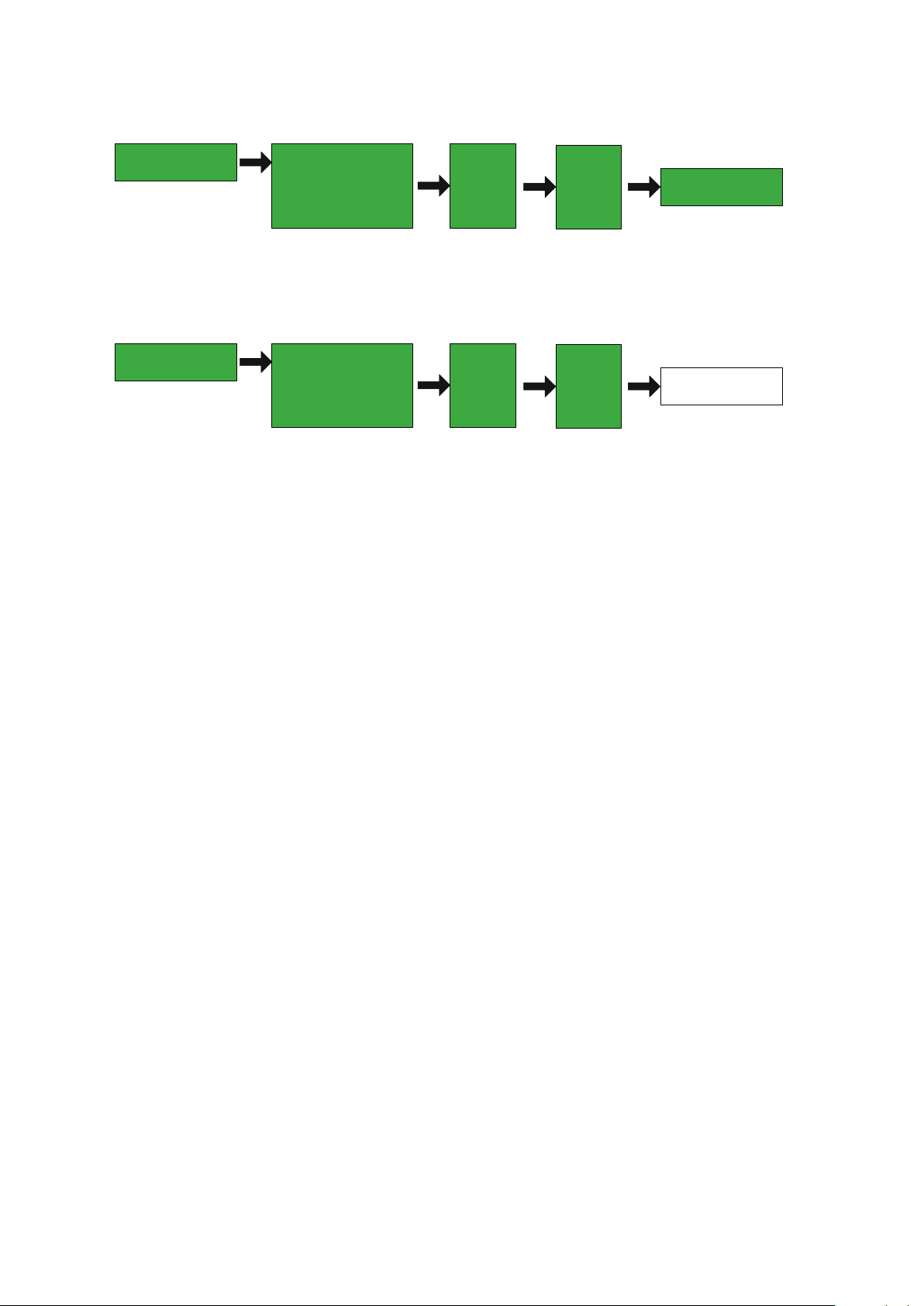

33. ONDELAY TIMER

Virtual relays also have the capability to be used as time delay relays. The same input function and logic function rules

described above apply, but a time factor can be added. In the case of an on-delay timer virtual relay the logic function

must remain True for a specied amount of time before the on-delay timer is evaluated as True. This time is congured

by the user and is based in seconds. The on-delay timer begins timing when the Logic Function is evaluated as True.

FIGURE 12 ONDELAY TIMER BEGINS TO COUNT

If at any point the logic function turns False the on-delay timer will stop timing and will reset to zero elapsed time. If

the logic function again turns True the on-delay timer will start over.

FIGURE 13 ONDELAY TIMER RESETS AS THE LOGIC FUNCTION HAS BEEN EVALUATED AS FALSE

Once the on-delay timer reaches the specied amount of time it is evaluated as True and the next condition in the

virtual relay can be evaluated.

Page 7

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Delay

Timer

(Done )

O Delay

Time

FIGURE 14 ONDELAY TIMER HAS ELAPSED AND BEEN EVALUATED AS TRUE

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Delay

Timer

(Set to 0)

O Delay

Timer

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Delay

Timer

(Set to 0)

O Delay

Timer

(Counting)

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Delay

Timer

(Set to 0)

O Delay

Timer

(Reset)

Input Function 1

Logic Function F 1

Virtual Relay

Output State

On Delay

Timer

(Set to 0)

O Delay

Timer

(Done)

Please note that 0 seconds is a valid value for the on-delay timer duration. If the on-delay timer duration is set to zero

the on-delay timer will be evaluated as True as soon as the Logic Function is evaluated as True.

34. OFFDELAY TIMER

There is also an o-delay timer which works in an opposite way of the on-delay timer. The o delay timer be evaluated

as True as long as the logic function and on-delay timer are evaluated as True.

FIGURE 15 OFFDELAY TIMER HAS BEEN EVALUATED AS TRUE

Once the logic function is evaluated as False the o-delay timer will begin to count for a specied duration. After the

specied duration the o-delay timer will be evaluated as False. This time is congured by the user and is based in

seconds. While the O-Delay Timer is counting down the virtual relay output state will be maintained.

FIGURE 16 OFFDELAY TIMER BEGINS TO COUNT DOWN

If at any point the logic function and on-delay timer turn True the o-delay timer will stop timing and will reset to zero

elapsed time. If the logic function and on-delay timer again turn False the o-delay timer will start over.

FIGURE 17 OFF DELAY TIMER RESETS AS THE LOGIC FUNCTION AND

ONDELAY TIMER HAVE BEEN EVALUATED AS TRUE

Once the o-delay timer reaches the specied amount of time it is evaluated as False and the next condition in the

virtual relay can be evaluated.

The characteristics described so far are all considered part of a standard virtual relay. A standard virtual relay will be

designated as r01 through r16 on a virtual relay equipped component.

35. VIRTUAL RELAY OUTPUT STATE

The Virtual Relay Output State is the nal output of the virtual relay logic. The Virtual Relay Output State can be

operated in two dierent logic modes, Normally Open (NO) and Normally Closed (NC). These logic modes determine

how the output state will behave when all conditions in the virtual relay are evaluated as True.

7

Page 8

8

When the virtual relay is set to operate in NO mode the virtual relay output state will be evaluated as False until all

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Delay

Timer

(Set to 0)

O Delay

Timer

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Delay

Timer

(Set to 0)

O Delay

Timer

conditions in the virtual relay are evaluated as True. Once all conditions are satised the output state will turn True.

This is the most common type of logic and is used in examples throughout the remainder of this manual.

FIGURE 18 NORMALLY OPEN VIRTUAL RELAY OUTPUT STATE EVALUATED AS TRUE

When the virtual relay is set to operate in NC mode the virtual relay output state will be evaluated as True until all

conditions in the virtual relay are evaluated as True. Once all conditions are satised the output state will turn False

and remain there until one of the conditions is evaluated as False.

FIGURE 19 NORMALLY CLOSED VIRTUAL RELAY EVALUATED AS FALSE

Changing the output state can be used to invert logic without changing any of the input functions. This allows for an

eective doubling of logic options.

Page 9

SECTION 4 SPECIALIZED VIRTUAL RELAYS

Input Function 1

Input Function 2

Logic Function (F 1,

AND, OR , XOR )

Virtual Relay

Output State

On Timer

O Timer

Start State

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

O Timer

Start State

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

O Timer

Start State

In addition to the standard virtual relays the automation component may be equipped with specialized virtual relays

with unique behaviors. The specialized virtual relays can generally be divided into two groups; virtual relays with

unique behavior on the Virtual Relay Output State, and virtual relays with unique, xed, input functions.

41. VIRTUAL RELAYS WITH MODIFIED OUTPUT STATES

411. CYCLING TIMER VIRTUAL RELAYS

The cycling timer virtual relays are used to periodically cycle the Virtual Relay Output State between True and False

as long as all of its conditions are met. The conditions for the cycling timer virtual relay are: Input functions, logic

function, and the Virtual Relay Output State.

FIGURE 20 CYCLING TIMER VIRTUAL RELAY WITH ALL CONDITIONS FALSE

Input and Logic Functions

The cycling timer virtual relay input and logic functions are exactly the same as the standard virtual relay.

Virtual Relay Output State

The Virtual Relay Output State for a cycling timer virtual relay is “activated” when the logic function is evaluated as True.

Activated in this case does not necessarily mean the output state is evaluated as True as the output state has its own

internal conditions that must be evaluated: Start State, On Timer, and O Timer.

The Start State determines the initial True or False state of the Virtual Relay Output State when the logic function is

rst evaluated as True. If the Start State is set to True, when the logic function is rst evaluated as True the Virtual Relay

Output State will be evaluated as True and the On Timer will begin to count.

The on timer is a user adjustable setting that is either measured in seconds (rt1 and rt2) or hours (rt3). If the logic

function turns false before the on timer elapses the cycling timer virtual relay will return to the state shown in Figure 19.

After the on timer has elapsed the virtual relay output state will be evaluated as False even though the logic function is

still True. The o timer will now, however, begin to count.

FIGURE 21 VIRTUAL RELAY OUTPUT STATE WITH A START STATE

FIGURE 22 VIRTUAL RELAY OUTPUT STATE HAS BEEN EVALUATED

OF TRUE HAS BEEN EVALUATED FALSE

TRUE AND THE ON TIMER BEGINS COUNTING

9

Page 10

10

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

O Timer

Start State

FIGURE 23 THE ON TIMER ELAPSES, THE VIRTUAL RELAY OUTPUT STATE

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

O Timer

Start State

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

O Timer

Start State

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Function

Select

HAS BEEN EVALUATED FALSE AND THE OFF TIMER BEGINS COUNTING

After the o timer has elapsed, the virtual relay output state will return to Figure 20 and this cycle will repeat until the

logic function is evaluated as False. The on timer and the o timer can never be active at the same time.

If the Start State is set to False, when the logic function is rst evaluated as True the Virtual Relay Output State will be

evaluated as False and the O Timer will begin to count.

FIGURE 24 VIRTUAL RELAY OUTPUT STATE WITH A START

STATE OF FALSE HAS BEEN EVALUATED FALSE

FIGURE 25 VIRTUAL RELAY OUTPUT STATE HAS BEEN EVALUATED

FALSE AND THE OFF TIMER BEGINS COUNTING

Once the o timer has elapsed the virtual relay output state turns True and the On timer begins counting. The cycling

timer virtual relay then continues to cycle as normal.

Cycling Timer Virtual Relays will be designated rt1, rt2, and rt3 on a virtual relay equipped component. Cycling Timer

Relays are not available on all components.

412. PULSE VIRTUAL RELAYS

The Pulse Virtual Relays are used to set the virtual relay output state to True for a xed period of time when the logic

function is rst evaluated as True. The conditions for the Pulse Virtual Relay are the Input Functions, Logic Function,

and Virtual Relay Output State.

FIGURE 26 PULSE VIRTUAL RELAY WITH ALL CONDITIONS FALSE

Input and Logic Functions

The Pulse Virtual Relay input and logic functions are exactly the same as the standard virtual relay.

Page 11

Virtual Relay Output State

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Function

Select = 0

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Function

Select = 0

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Counting

Function

Select = 1

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Counting

Function

Select = 1

The virtual relay output state for a pulse relay reacts to a True logic function evaluation dependent on how the

Function Select register is set by the user. There are four possible Function Select options that all behave dierently.

Function Select 0 – When the function select register is set to 0 the virtual relay output state will always remain False

regardless of whether the logic function is evaluated as True or False.

FIGURE 27 PULSE VIRTUAL RELAY WITH FUNCTION SELECT 0 NEVER

TURNS THE OUTPUT STATE TO TRUE

Function Select 1 – When the function select register is set to 1 the virtual relay output state will be evaluated as True

when the logic function is rst evaluated as True. The on timer will begin to count. The on timer is user specied and is

measured in seconds for rP1 and in minutes for rP2.

FIGURE 28 PULSE VIRTUAL RELAY WITH FUNCTION SELECT 1

TURNS THE OUTPUT STATE TRUE

When using Function Select 1, the virtual relay output state will always remain true while the on timer is counting. If

the logic function is evaluated as false it has no eect on the output and the output remains True.

FIGURE 29 OUTPUT REMAINS TRUE WHILE THE ON TIMER IS ACTIVE

If the logic function again turns true while the virtual relay output state is still true, there is no eect, the on timer

continues counting until it has completed its full duration. After the on timer has elapsed the virtual relay output state

will turn False and remain in the False state until the logic function is evaluated as False and subsequently evaluated as

True again.

11

Page 12

12

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Done

Function

Select = 1

FIGURE 30 ON TIMER ELAPSES AND THE VIRTUAL RELAY

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Counting

Function

Select = 2

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Counting

Function

Select = 2

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Reset

Function

Select = 2

OUTPUT STATE CHANGES TO FALSE

Function Select 2 – When the function select register is set to 2 the virtual relay output state will be evaluated as True

when the logic function is rst evaluated as True. The on timer will begin to count. The on timer is user specied and is

measured in seconds for rP1 and in minutes for rP2.

FIGURE 31 PULSE VIRTUAL RELAY WITH FUNCTION SELECT 2

TURNS THE OUTPUT STATE TRUE

When using Function Select 2, the virtual relay output state will always remain true while the on timer is counting. If

the logic function is evaluated as false it has no eect on the output and the output remains True.

FIGURE 32 OUTPUT REMAINS TRUE WHILE THE ON TIMER IS ACTIVE

If the logic function again turns true while the virtual relay output state is still true, the pulse will continue and the On

Timer is reset to zero and begins to count again.

FIGURE 33 LOGIC FUNCTION TRANSITIONS FROM FALSE

TO TRUE AND RESETS THE ON TIMER

After the on timer has elapsed the virtual relay output state will turn False and remain in the False state until the logic

function is evaluated as False and subsequently evaluated as True again.

Page 13

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Done

Function

Select = 2

FIGURE 34 ON TIMER ELAPSES AND THE VIRTUAL RELAY

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Counting

Function

Select = 3

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Reset

Function

Select = 3

Input Function 1

Logic Function F1

Virtual Relay

Output State

On Timer

Done

Function

Select = 3

OUTPUT STATE CHANGES TO FALSE

Function Select 3 - When the function select register is set to 3 the virtual relay output state will be evaluated as True

when the logic function is rst evaluated as True.

FIGURE 35 PULSE VIRTUAL RELAY WITH FUNCTION SELECT 2

TURNS THE OUTPUT STATE TRUE

When using Function Select 3, if the logic function turns False at any time, the Virtual Relay Output State will turn False

and the on timer will be reset.

FIGURE 36 LOGIC FUNCTION EVALUATED AS FALSE CAUSES

THE VIRTUAL RELAY OUTPUT STATE TO TURN FALSE

If the logic function again turns True the on timer will begin counting from 0 and the virtual relay output state will stay

True until the on timer has elapsed.

FIGURE 37 ON TIMER ELAPSES AND THE VIRTUAL RELAY OUTPUT

STATE CHANGES TO FALSE

Pulse Virtual Relays will be designated rP1, and rP2 on a virtual relay equipped component.

Pulse Virtual Relays are not available on all components.

13

Page 14

14

42. VIRTUAL RELAYS WITH FIXED INPUT FUNCTIONS

Compressor 2

Run State

Logic Function

(AND or OR)

Virtual Relay

Output State

Compressor 3

Run State

Compressor 1

Run State

Compressor X

Run State

Compressor 2

Run State

Logic Function

AND

Virtual Relay

Output State

Compressor 3

Run State

Compressor 1

Run State

Compressor X

Run State

Compressor 2

Run State

Logic Function

AND

Virtual Relay

Output State

Compressor 3

Run State

Compressor 1

Run State

Compressor X

Run State

4.21. RUNNING VIRTUAL RELAY

The Running Virtual Relay allows the user to monitor the running states of any or all compressors in the system and to

use the status as an input function. The conditions that are used for the Running Virtual Relay are the compressor run

state, the logic function, and the virtual relay output state.

FIGURE 38 RUNNING VIRTUAL RELAY WITH ALL CONDITIONS FALSE

Input Functions

For the Running Virtual Relay the input functions are predened as the running state of each compressor. The

compressor running state is considered True when the compressor’s motor is determined to be operating by the

X8I either serially or electrically. The user selects the compressors that are to be used as input functions. Any or all

compressors may be used as input functions.

Logic Functions

The Running Virtual Relay utilizes the AND and OR logic functions. These logic functions operate in exactly the same

manner as they would in a normal virtual relay. For example, the AND logic function will only be evaluated as True if all

selected compressors’ run states are evaluated as True.

FIGURE 39 ALL COMPRESSORS ARE IN A TRUE RUN STATE WHICH

CAUSES THE LOGIC FUNCTION AND OUTPUT STATE TO BE EVALUATED TRUE

Any other combination of compressor run states will cause the logic function to be evaluated as false and therefore the

virtual relay output state will be evaluated as false.

FIGURE 40 COMPRESSOR 2’S RUN STATE HAS BEEN EVALUATED AS FALSE

WHICH CAUSES THE LOGIC FUNCTION TO BE EVALUATED AS FALSE

Page 15

The OR logic function will be evaluated as True if any or all compressors’ run states have been evaluated as True.

Compressor 2

Run State

Logic Function

OR

Virtual Relay

Output State

Compressor 3

Run State

Compressor 1

Run State

Compressor X

Run State

Compressor 2

Run State

Logic Function

OR

Virtual Relay

Output State

Compressor 3

Run State

Compressor 1

Run State

Compressor X

Run State

Compressor 2

Load State

Logic Function

(AND or OR)

Virtual Relay

Output State

Compressor 3

Load State

Compressor 1

Load State

Compressor X

Load State

FIGURE 41 COMPRESSOR 1’S RUN STATE IS TRUE WHICH CAUSES THE LOGIC

FUNCTION AND OUTPUT STATE TO TURN TRUE

The only input function state that would cause the OR function to be evaluated as False is when none of the

compressor run states are evaluated as True.

The Running Virtual Relay will be designated RF1 on a virtual relay equipped component.

422. LOADED VIRTUAL RELAY

The Loaded Virtual Relay allows the user to monitor the load states of any or all compressors in the system and to use

the status as an input function. The conditions that are used for the Loaded Virtual Relay are the compressor load state,

the logic function, and the virtual relay output state.

Input Functions

For the Loaded Virtual Relay the input functions are predened as the load state of each compressor. The compressor

load state is considered True when the compressor’s inlet valve is determined to be open by the X8I either serially or

electrically. The user selects the compressors that are to be used as input functions. Any or all compressors may be

used as input functions.

Logic Functions

The Loaded Virtual Relay utilizes the AND and OR logic functions. These logic functions operate in exactly the same

manner as they would in a normal virtual relay. For example, the AND logic function will only be evaluated as True if all

selected compressors’ load states are evaluated as True.

FIGURE 42 RUNNING VIRTUAL RELAY WITH OR LOGIC FUNCTION EVALUATED AS FALSE

FIGURE 43 LOADED VIRTUAL RELAY WITH ALL CONDITIONS FALSE

15

Page 16

16

Compressor 2

Load State

Logic Function

AND

Virtual Relay

Output State

Compressor 3

Load State

Compressor 1

Load State

Compressor X

Load State

FIGURE 44 ALL COMPRESSORS ARE IN A TRUE LOAD STATE WHICH CAUSES

Compressor 2

Load State

Logic Function

AND

Virtual Relay

Output State

Compressor 3

Load State

Compressor 1

Load State

Compressor X

Load State

Compressor 2

Load State

Logic Function

OR

Virtual Relay

Output State

Compressor 3

Load State

Compressor 1

Load State

Compressor X

Load State

Compressor 2

Load State

Logic Function

OR

Virtual Relay

Output State

Compressor 3

Load State

Compressor 1

Load State

Compressor X

Load State

THE LOGIC FUNCTION AND OUTPUT STATE TO BE EVALUATED TRUE

Any other combination of compressor load states will cause the logic function to be evaluated as false and therefore

the virtual relay output state will be evaluated as false.

FIGURE 45 COMPRESSOR 2’S LOAD STATE HAS BEEN EVALUATED AS FALSE

WHICH CAUSES THE LOGIC FUNCTION TO BE EVALUATED AS FALSE

The OR logic function will be evaluated as True if any or all compressors’ load states have been evaluated as True.

FIGURE 46 COMPRESSOR 1’S LOAD STATE IS TRUE WHICH CAUSES THE

LOGIC FUNCTION AND OUTPUT STATE TO TURN TRUE

The only input function state that would cause the OR function to be evaluated as False is when none of the

compressor load states are evaluated as True.

FIGURE 47 LOADED VIRTUAL RELAY WITH OR LOGIC FUNCTION EVALUATED AS FALSE

Page 17

The Loaded Virtual Relay will be designated LF1 on a virtual relay equipped component.

Compressor 2

Readiness State

Logic Function

(AND or OR)

Virtual Relay

Output State

Compressor 3

Readiness State

Compressor 1

Readiness State

Compressor X

Readiness State

Compressor 2

Readiness State

Logic Function

AND

Virtual Relay

Output State

Compressor 3

Readiness State

Compressor 1

Readiness State

Compressor X

Readiness State

423. AVAILABLE VIRTUAL RELAY

The Available Virtual Relay allows the user to monitor the readiness states of any or all compressors in the system and

to use the status as an input function. The conditions that are used for the Available Virtual Relay are the compressor

readiness state, the logic function, and the virtual relay output state.

FIGURE 48 AVAILABLE VIRTUAL RELAY WITH ALL CONDITIONS FALSE

Input Functions

For the Available Virtual Relay the input functions are predened as the readiness state of each compressor. The

compressor readiness state is considered True when compressor power is on and the compressor is in a state where

it will respond to X8I control, usually this means the compressor has been started locally. The user selects the

compressors that are to be used as input functions. Any or all compressors may be used as input functions.

Logic Functions

The Available Virtual Relay utilizes the AND and OR logic functions. Operate in an inverse logic manner for the

standard virtual relay AND and OR logic functions. For example, the AND logic function will only be evaluated as

false if all selected compressors’ readiness states are evaluated as True. For the Available Virtual Relay only, the AND

function acts as a logical NAND (Not AND)

Any other combination of compressor readiness states will cause the logic function to be evaluated as True and

therefore the virtual relay output state will be evaluated as True. This functionality allows the Available Virtual Relay to

determine when there is trouble with any or all compressors.

FIGURE 49 ALL COMPRESSORS ARE IN A TRUE READINESS STATE WHICH CAUSES

THE LOGIC FUNCTION AND OUTPUT STATE TO BE EVALUATED FALSE

17

Page 18

18

Compressor 2

Readiness State

Logic Function

AND

Virtual Relay

Output State

Compressor 3

Readiness State

Compressor 1

Readiness State

Compressor X

Readiness State

FIGURE 50 COMPRESSOR 2’S READINESS STATE HAS BEEN EVALUATED

Compressor 2

Readiness State

Logic Function

OR

Virtual Relay

Output State

Compressor 3

Readiness State

Compressor 1

Readiness State

Compressor X

Readiness State

Compressor 2

Readiness State

Logic Function

OR

Virtual Relay

Output State

Compressor 3

Readiness State

Compressor 1

Readiness State

Compressor X

Readiness State

Compressor 2

Readiness State

Logic Function

OR

Virtual Relay

Output State

Compressor 3

Readiness State

Compressor 1

Readiness State

Compressor X

Readiness State

AS FALSE WHICH CAUSES THE LOGIC FUNCTION TO BE EVALUATED AS FALSE

The OR logic function will be evaluated as True if all compressors’ readiness states are evaluated as False. For the

available virtual relay only the OR function operates as a logical NOR (Not OR) function. The OR function is used to

detect a situation when there are no compressors available for the X8I to use for system control.

FIGURE 51 ALL COMPRESSOR READINESS STATES ARE FALSE WHICH

CAUSES THE LOGIC FUNCTION AND OUTPUT STATE TO TURN TRUE

If any one or all compressor readiness states are evaluated as True the virtual relay output state will be evaluated as

False.

The Available Virtual Relay will be designated AF1 on a virtual relay equipped component.

FIGURE 52 AVAILABLE VIRTUAL RELAY WITH OR LOGIC FUNCTION EVALUATED AS FALSE

Page 19

SECTION 5 PHYSICAL I/O AND VIRTUAL RELAYS

Input Function 1

Input Function 2

Logic Function

(F1,AND, OR,

XOR)

Virtual Relay

Output State

On Delay

Time

O Delay

Time

Physical Relay

Output State

Signal Out

Certain components and accessory boxes have physical inputs and outputs that are available for use with virtual relay

automation. Digital Input statuses can be read an d used as an input function to a virtual relay while digital output

states can be read as an input function or connected to a virtual relay.

For certain X8I components the available physical relay outputs will be represented by the rst X virtual relay setup

menus. The physical relay will have the same conditions as a virtual relay: Input functions, Logic Function, On-delay

Timer, O-delay timer, and relay output state. The only dierence is that the physical relay will have contacts that will

match the virtual relay output state.

FIGURE 53 THE VIRTUAL RELAY HAS BEEN OUTPUT EVALUATED AS TRUE

SO THE PHYSICAL RELAY OUTPUT STATE MATCHES AND A SIGNAL IS SENT

Analog inputs can be used by setting up thresholds for Alarms, Trips, and Signals. Thresholds are triggered when the

analog value exceeds a threshold value. When the threshold is triggered a ag is turned true and these ags are what

can be used as an input function to the virtual relay.

Below is a list of virtual and physical relays that are included on automation components.

I/O Accessory Box

Physical I/O

4 Analog Inputs

•

8 Digital Inputs

•

6 Digital Outputs (Equivalent to Virtual Relays 1-6)

•

Virtual Relays

10 Virtual Relays

•

3 Cycling Timer Virtual Relays

•

2 Pulse Virtual Relays

•

1 Running Virtual Relay

•

1 Loaded Virtual Relay

•

1 Available Virtual Relay

•

19

Page 20

20

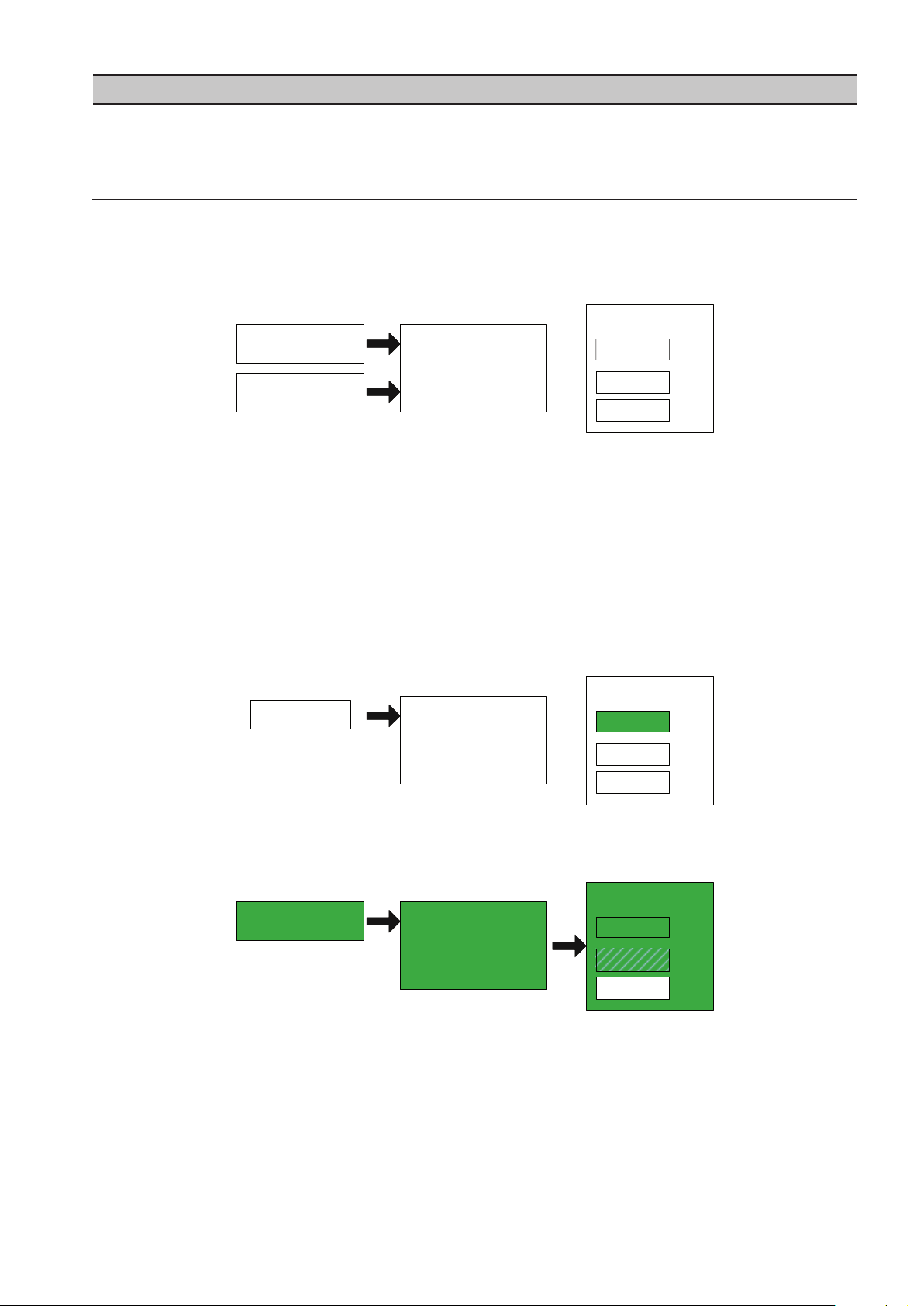

SECTION 6 CONFIGURING VIRTUAL RELAYS

A BBB C DD

Fn =

A

- - -

- - -

Fn =

-

BBB

- - -

Fn =

-

- - -

C

- -

Fn =

- - - -

-

DD

Fn =

Before attempting to program virtual relays to automate

an air system it is prudent to study the function list and

determine which functions you will need. Draw out the

logic that you intend to use so that any mistakes can

be minimized. Please note that while the parameters

for virtual relays are the same across the X8I product

line, the menu navigation will vary depending on which

component you are attempting to program. Be sure to

read the operator’s manual for the specic component

you are programming.

61. DEFINING AN INPUT FUNCTION

Input functions are common to all relays except for the

Running, Loaded, and Available virtual relays. Once you

have located the necessary input functions they must be

entered in the virtual relay using the following format:

Where the parameters are dened as follows:

- Species whether the input

function resides locally on the component you are

currently programming or is remote on the network. This

parameter is automatically selected based on the unit

where the input function resides and does not need to be

set by the user. The valid values for this parameter are:

types of functions are available to t your automation

needs. The available parameters are:

A – Alarm (warning) input functions, based on analog

thresholds

T – Trip (shutdown) or not available input functions,

based on analog thresholds

S – Signal input functions, based on analog

thresholds. Signals are informational only and do

not indicate a fault

R – Relay state, tells the output condition of a physical

or virtual relay.

F – Status Function, tells the status of various

conditions throughout the system.

Virtual relays can be used as input functions for other

virtual relays and will be located under the R menu.

For a complete set of input functions please see 10.x

– Function Lists

- Species the specic function

that is used for the virtual relay input function.

62. STANDARD VIRTUAL RELAYS R01

R16

L – The input function is local

R – The input function resides on another component

on the IR485 Network.

Please note that if the function is being transmitted

across the IR485 network there may be a delay between

the change in state of the input function and that change

in state being transmitted to the virtual relay.

Also note that in the case of a network failure or a failure

in the remote component the input function will be

unavailable and the virtual relay will return to a user

denable default state.

- Species the type of unit that the

input function resides on. This is the local unit, another

X8I, I/O box, or a compressor on the IR485 network. The

valid selections for this parameter are:

SYS – The X8I controller

B01 – I/O Box 1

B02 – I/O Box 2

C0X – Compressor X where X is 1 through 8

Compressors 1 through 8 can only be directly accessed if

the compressor is connected to the X8I using an ir-485 or

irV-485 gateway. Any compressor connected to the X8I

using an ir-PCB will have its status available via the SYS

unit type.

- Species the category of the

input function. The categories allow you to see what

The parameter list for a standard virtual relay is as

follows:

01 F1 Input Function #1

02 F2 Input Function #2

03 Fu Logic Function

04 On On Delay Time

05 OF O Delay Time

06 ST Normal State

07 CF RS485 Failure Response

F1 – Input Function 1

F2 – Input Function 2

F1 and F2 are selected using the methods shown in

dening an input function. Please note that it is not

necessary to dene two input functions to use a virtual

relay. If only one input function is used it must be entered

as F1. The default is no input function selected.

Fu – Logic Function

The logic function options are:

F1 – Only one input function is selected

And – Logical AND function

Or – Logical OR function

Eor – Logical Exclusive Or function (XOR)

Page 21

On – On-Delay Time

0

1

NO

NC

Of:

On:

Of:

On:

Of:

On:

Of:

On:

SS: 0 SS: 1

The on-delay time determines the length of time the logic

function must remain True before the virtual relay output

state changes to True. The on-delay time is measured in

seconds and defaults to zero.

Of – O-Delay Time

The o-delay time determines the length of time that a

logic function that is currently True would need to remain

False in order to return the virtual relay output state to

False. The o-delay time is measured in seconds and

defaults to zero.

ST – Normal State

The normal state denes what state virtual relay output

state is in when the logic function is evaluated as False.

The options are:

0 – Normally Open; the output state will remain False

when the logic function is True.

1 – Normally Closed; the output state will remain True

when the logic function is False.

CF – IR485 Failure State

CF denes the state the virtual relay output state will

revert to if there is a communication error on the IR485

network. CF will come into eect if either of the two

input functions suer a network failure. This will only

come happen when at least one of the input functions are

on a remote unit. The options for the CF are:

0 – The virtual relay output state will revert to False

1 – The virtual relay output state will revert to True

01 F1 Input Function #1

02 F2 Input Function #2

03 Fu Logic Function

04 On On Time

05 OF O Time

06 SS Start State

07 CF RS485 Failure Response

F1 – Input Function 1

F2 – Input Function 2

F1 and F2 are selected using the methods shown in

dening an input function. Please note that it is not

necessary to dene two input functions to use a virtual

relay. The default is no input function selected.

On – On Time

The on time determines how long the virtual relay output

state will remain in True state of the cycle when the logic

function is True. On rt1 and rt2 this value is measured in

seconds and has a valid range of 0 to 3600 seconds. The

default value is 0. On rt3 this value is measured in hours

and has a valid range of 0 to 168 hours.

Of – O Time

The o time determines how long the virtual relay

output state will remain in the False state of the cycle

when the Logic Function is True. On rt1 and rt2 this

value is measured in seconds and has a valid range of 0

to 3600 seconds. The default value is 0. On rt3 this value

is measured in hours and has a valid range of 0 to 168

hours.

SS – Start State

The Start State determines the initial state of the virtual

relay output function when the logic function rst turns

True. The valid options for this parameter are:

Please note that the virtual relay will not instantly revert

to the CF state, the IR485 network will rst need to time

out before the failure state is applied. The default state

for this parameter is 0.

63. CYCLING TIMER VIRTUAL RELAYS RT1,

RT2, RT3

The Cycling Timer Virtual Relay behaves a

bit dierently than the standard virtual relay in o-delay

or on-delay mode. The cycling timer will begin to cycle

the virtual relay output state between True and False

when the Logic Function is True. The timing of the True

and False virtual relay output state is user adjustable.

The parameter list for a cycling Timer Virtual Relay is as

follows:

0 – The virtual relay output state is initially in the False

position and will remain there until the o time

elapses

1 - The virtual relay output state is initially in the True

position and will remain there until the on time

elapses.

The default value for this parameter is 0.

CF – IR485 Failure State

CF denes the state the virtual relay output state will

revert to if there is a communication error on the IR485

network. CF will come into eect if either of the two

input functions suer a network failure. This will only

come happen when at least one of the input functions are

on a remote unit. The options for the CF are:

21

Page 22

22

0 – The virtual relay output state will revert to False

1 – The virtual relay output state will revert to True

Please note that the virtual relay will not instantly revert

to the CF state, the IR485 network will rst need to time

out before the failure state is applied. The default state

for this parameter is 0.

64. PULSE VIRTUAL RELAYS RP1, RP2, RP3,

AND RP4

The pulse virtual relays are used to turn

the virtual output state True for a specied period of time

in one single pulse. The pulse will only occur when the

Logic Function switches states. The parameters for the

Pulse Virtual Relay are as follows:

01 F1 Input Function #1

02 F2 Input Function #2

03 Fu Logic Function

04 On On Time

05 FS O Delay Time

06 CF RS485 Failure Response

changes from the False state to the True state. The

pulse will only occur on change of state and will

nish regardless of a later change from True to

False.

2 – The relay will pulse when the Logic Function

changes from the False state to the True state. If

another change of state from False to True occurs

during the pulse the time will be reset. The pulse

will nish regardless of a later change from True to

False.

3 – The relay will pulse when the Logic Function

changes from the False state to the True state. If

the Logic Function later changes from True to False

the pulse will end immediately.

CF – IR485 Failure State

CF denes the state the virtual relay output state will

revert to if there is a communication error on the IR485

network. CF will come into eect if either of the two

input functions suer a network failure. This will only

come happen when at least one of the input functions are

on a remote unit. The options for the CF are:

0 – The virtual relay output state will revert to False

1 – The virtual relay output state will revert to True

F1 – Input Function 1

F2 – Input Function 2

F1 and F2 are selected using the methods shown in

dening an input function. Please note that it is not

necessary to dene two input functions to use a virtual

relay. The default is no input function selected

Fu – Logic Function

The logic function options are:

F1 – Only one input function is selected

And – Logical AND function

Or – Logical OR function

Eor – Logical Exclusive Or function (XOR)

On – On Time

The on time determines how long the pulse will stay

active and hold the virtual relay output state in the True

position. The on time is user adjustable. rP1 is measured

in seconds and is adjustable from 0 to 3600 seconds. The

default setting is 0. rp2 is measured in minutes and is

adjustable from 0 to 3600 minutes. The default setting is

0.

FS – Function Selection

Function select denes on which coil state change the

pulse will be activated. The options are:

0 – The relay is o and no pulse will occur

1 – The relay will pulse when the Logic Function

Please note that the virtual relay will not instantly revert

to the CF state, the IR485 network will rst need to time

out before the failure state is applied. The default state

for this parameter is 0.

65. RUNNING VIRTUAL RELAY RF1

The Running Virtual Relay is a

specialized virtual relay that has input functions already

dened. The input functions are the running states of the

compressors in the X8I system. The running states of the

compressors are determined by the compressors status

register, if connected serially, or the ir-PCB input if the

compressor is wired directly to the automation system.

The parameters used to set up the Running Virtual Relay

are as follows:

01 01 Compressor #1

02 02 Compressor #2

03 03 Compressor #3

to

08 08 Compressor #8

09 Fu Logic Function

01 through 08 – Compressor 1 through 8

Each compressor is selectable from the Running Virtual

Relay parameter list. The options for each compressor

are:

Page 23

0 – The compressor will not be monitored for its

running state, the compressor is ignored for

running virtual relay purposes

1 – The compressor will be monitored for running

state

Fu – Logic Function

The logic functions available for the Running Virtual Relay

are:

And – Logical AND function. All compressors must be

running for the Logic Function to be True.

And – Logical AND function. All compressors must be

loaded for the Logic Function to be True.

Or – Logical OR function. At least one compressor

must be loaded for the Logic Function to be True.

An Example:

01 0 Compressor #1

02 1

03 1

Compressor #2

Compressor #3

Or – Logical OR function. At least one compressor

must be running for the Logic Function to be True.

An example:

01 1

02 1

03 0 Compressor #3

Fu OR Logic Function = OR

The above example conguration set-up shows a system

consisting of three compressors where 1 and 2 have been

selected for monitoring. The logic function (OR) means

the Logic Function will be True if one, or both, of the

selected compressors are detected as running.

Compressor #1

Compressor #2

66. LOADED VIRTUAL RELAY LF1

The Loaded Virtual Relay is a

specialized virtual relay that has input functions already

dened. The input functions are the loaded states of the

compressors in the X8I system. The loaded states of the

compressors are determined by the compressors status

register, if connected serially, or the ir-PCB input if the

compressor is wired directly to the automation system.

The parameters used to set up the Loaded Virtual Relay

are as follows:

01 01 Compressor #1

02 02 Compressor #2

03 03 Compressor #3

to

08 08 Compressor #8

09 Fu Logic Function

01 through 08 – Compressor 1 through 8

Each compressor is selectable from the Loaded Virtual

Relay parameter list. The options for each compressor

are:

0 – The compressor will not be monitored for its load

state, the compressor is ignored for loaded virtual

relay purposes

1 – The compressor will be monitored for load state

Fu – Logic Function

The logic functions available for the Loaded Virtual Relay

are:

Fu AND Logic Function = AND

The above example conguration set-up shows a system

consisting of three compressors where 2 and 3 have been

selected for monitoring. The logic function (AND) means

the logic function will only be True if both of the selected

compressors are detected as being loaded.

67. AVAILABLE VIRTUAL RELAY AF1

The Available Virtual Relay is a

specialized virtual relay that has input functions already

dened. The input functions are the Available states of

the compressors in the X8I system. The Available states

of the compressors are determined by the compressors

status register, if connected serially, or the ir-PCB input

if the compressor is wired directly to the automation

system. A compressor is considered available if it is not

under X8I control and is not tripped.

The parameters used to set up the Available Virtual Relay

are as follows:

01 01 Compressor #1

02 02 Compressor #2

03 03 Compressor #3

to

08 08 Compressor #8

09 Fu Logic Function

01 through 08 – Compressor 1 through 8

Each compressor is selectable from the Available Virtual

Relay parameter list. The options for each compressor

are:

0 – The compressor will not be monitored for its

availability state, the compressor is ignored for

available virtual relay purposes

1 – The compressor will be monitored for availablity

state

Fu – Logic Function

The logic functions available for the Available Virtual

Relay are:

And – Logical AND function. All compressors must be

available for the Logic Function to be False.

Or – Logical OR function. At least one compressor

must be available for the Logic Function to be

False.

23

Page 24

24

An Example:

01 0 Compressor #1

02 1

03 1

04 0 Compressor #4

Fu AND Logic Function = AND

The above example conguration set-up shows a system consisting of four compressors where 2 and 3 have been

selected for monitoring. The logic function (AND) means the Logic Function will be False if ‘all’ of the selected

compressors are detected as being available; the output will be True if ‘any’ of the selected compressors becomes

unavailable.

Compressor #2

Compressor #3

Page 25

R

SYS F

- -

SECTION 7 FUNCTION LISTS

71. X8I FUNCTION LIST

711. STATUS FUNCTIONS

SA: System Alarm (Warning):

True: An alarm condition associated with the X8I

has been detected.

False: No alarm condition associated with the

X8I has been detected.

ST: System Trip (Shutdown):

True: An trip condition associated with the X8I

has been detected.

False: No trip condition associated with the X8I

has been detected.

SF: System Alarm (Warning) or Trip (Shutdown):

True: An alarm or a trip condition associated

with the X8I has been detected.

False: No alarm or trip condition associated with

the X8I has been detected.

CA: Compressor Alarm (Warning):

True: An alarm condition has been detected on

one or more compressors.

False: No compressors are reporting an alarm

condition.

CT: Compressor Trip (Shutdown):

True: A trip condition has been detected on one

or more compressors.

False: No compressors are reporting a trip

condition.

CF: Compressor Alarm (Warning) or Trip

(Shutdown):

True: An alarm or trip condition has been

detected on one or more compressors.

False: No compressors are reporting an alarm or

trip condition.

BA: I/O Box Alarm (Warning):

True: An alarm condition has been detected on

one or more I/O Boxes.

False: No I/O Boxes are reporting an alarm

condition.

BT: I/O Box Trip (Shutdown):

True: A trip condition has been detected on one

or more I/O Boxes.

False: No I/O Boxes are reporting a trip

condition.

BS: I/O Box Signal:

True: A signal condition has been detected on

one or more I/O Boxes.

False: No I/O Boxes are reporting a signal

condition.

BF: I/O Box Alarm (Warning) or Trip (Shutdown):

True: An alarm or trip condition has been

detected on one or more I/O Boxes.

False: No I/O Boxes are reporting an alarm or

trip condition.

LP: Low Pressure Alarm (Warning):

True: System Pressure is below the X8I minimum

pressure setpoint.

False: System Pressure is above the X8I

minimum pressure setpoint.

HP: High Pressure Alarm (Warning):

True: System pressure is above the X8I

maximum pressure setpoint.

False: System pressure is below the X8I

maximum pressure setpoint.

IC: Insucient Capacity Alarm (Warning):

True: There are no available compressors to

meet rising demand

False: There are available compressors to meet

any change in demand

RC: Restricted Capacity Alarm (Warning):

True: There are no available compressors

to meet rising demand and one or more

compressors are removed from sequence by the

user.

False: There are available compressors to meet

any change in demand.

T1: Table #1 Active:

True: Table #1 is the X8I’s currently selected

table.

False: Table #1 is not currently in use.

T2: Table #2 Active:

True: Table #2 is the X8I’s currently selected

table.

False: Table #2 is not currently in use.

T3: Table #3 Active:

25

Page 26

26

True: Table #3 is the X8I’s currently selected

R

SYS S

- -

R

SYS R

- -

table.

False: Table #3 is not currently in use.

T4: Table #4 Active:

True: Table #4 is the X8I’s currently selected

table.

False: Table #4 is not currently in use.

PF: Prell Active:

True: The X8I’s prell function is active.

False: The X8I’s prell function is inactive.

EC: Energy Control Mode Active:

True: The X8I’s sequencing algorithm is set to

Energy Control mode (ENER).

False: The X8I’s sequencing algorithm is set to

something other than ENER.

TM: Timer Rotation Mode Active:

True: The X8I’s sequencing algorithm is set to

Timer Rotation Mode (FILO).

False: The X8I’s sequencing algorithm is set to

something other than FILO.

EH: Equal Hours Mode Active:

True: The X8I’s sequencing algorithm is set to

Equal Hours Mode (EHR).

False: The X8I’s sequencing algorithm is set to

something other than EHR.

PB: Pressure Balancing Function Active

Not available in the X8I

RU: X8I Running

True: The X8I is currently operating in prell,

normal operation, or standby state.

False: The X8I is currently in the stopped or trip

(shutdown) state.

PS: Pressure Schedule Active:

True: The X8I’s pressure schedule function is

active.

False: The X8I’s pressure schedule function is

inactive.

ON: X8I Pressure Regulation Control Active:

True: The X8I is currently operating in the prell

or normal operation state.

False: The X8I is currently operating in the

standby, stopped or tripped (shutdown) state.

DP: Dierential Pressure Alarm (Warning):

True: A high dierential pressure between two

system pressure transducers has been detected.

False: No high dierential pressure has been

detected.

AO: Capacity Alarm Override Active:

True: The insucient capacity and restricted

capacity alarms have been disabled.

False: The insucient capacity and restricted

capacity alarms have been enabled.

NW: Network: IR485 data communications:

True: Network communications are functioning

normally.

False: Network communications have been

disrupted.

712. SIGNAL FUNCTIONS

D1: Digital Input #1:

True: Digital Input #1 is in a True condition

(Actual state depends on whether the input is

Normally Open or Normally Closed).

False: Digital Input #1 is in a False condition

(Actual state depends on whether the input is

Normally Open or Normally Closed).

713. RELAY FUNCTIONS

Where a virtual relay is associated with a real physical

relay output the state of the virtual relay is identical to the

output state of the real physical relay.

01: Output Status of Physical Relay #1:

True: Physical Relay #1 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Physical Relay #1 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

02: Output Status of Physical Relay #2:

True: Physical Relay #2 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Physical Relay #2 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

03: Output Status of Physical Relay #3:

True: Physical Relay #3 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Physical Relay #3 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

04: Output Status of Virtual Relay #4:

Page 27

True: Virtual Relay #4 is in a True condition

R

C01 F

- -

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #4 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

05: Output Status of Virtual Relay #5:

True: Virtual Relay #5 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #5 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

06: Output Status of Virtual Relay #6:

True: Virtual Relay #6 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #6 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

07: Output Status of Virtual Relay #7:

True: Virtual Relay #7 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #7 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

08: Output Status of Virtual Relay #8:

True: Virtual Relay #8 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #8 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

09: Output Status of Virtual Relay #9:

True: Virtual Relay #9 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #9 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

10: Output Status of Virtual Relay #10:

True: Virtual Relay #10 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #10 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

11: Output Status of Virtual Relay #11:

True: Virtual Relay #11 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #11 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

12: Output Status of Virtual Relay #12:

True: Virtual Relay #12 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #12 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

13: Output Status of Virtual Relay #13:

True: Virtual Relay #13 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #13 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

14: Output Status of Virtual Relay #14:

True: Virtual Relay #14 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #14 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

15: Output Status of Virtual Relay #15:

True: Virtual Relay #15 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #15 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

16: Output Status of Virtual Relay #16:

True: Virtual Relay #16 is in a True condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

False: Virtual Relay #16 is in a False condition

(Actual output state depends on whether the

relay is Normally Open or Normally Closed).

72. COMPRESSOR FUNCTION LIST

721. STATUS FUNCTIONS

C01: Compressor #1

to

C08: Compressor #8

RA: Compressor Available:

True: The compressor is in a starting, running, or

auto restart state.

False: The compressor is in an unpowered,

tripped, or locally stopped state.

27

Page 28

28

Rn: Compressor Running: (Clarify with CMC about

B0# A

- -

Auto-Restart)

True: The compressor is in a running (loaded or

unloaded) state.

False: The compressor is not in a running

(loaded or unloaded) state. This includes an

auto-restart condition.

Ld: Compressor Loaded:

True: The compressor’s inlet valve is open and

the compressor is producing air.

False: The compressor’s inlet valve is closed and

the compressor is not producing air.

AL: Compressor Alarm (Warning):

True: The compressor is reporting an alarm

condition.

False: The compressor is not reporting an alarm

condition.

Tr: Compressor Trip (Shutdown) or Unavailable:

True: The compressor is unavailable due to a trip

or local stop or unpowered condition.

False: The compressor is available and able to be

utilized.

Se: Service Maintenance Condition:

True: The ir-PCB Service Maintenance function

has been enabled and the compressor is out-ofservice.

False: The ir-PCB Service Maintenance function

has not been enabled.

GF: Compressor General Fault:

True: The compressor is reporting an Alarm

(Warning), Trip (Shutdown), Stopped, or Not

Available condition.

False: The compressor is not reporting an Alarm

(Warning), Trip (Shutdown), Stopped, or not

Available condition.

Ma: Compressor Maintenance Condition:

True: The compressor has been selected as out-

of-service for long term maintenance in the X8I

compressor maintenance menu.

False: The compressor has not been selected as

out-of-service for long term maintenance in the

X8I compressor maintenance menu.

NW: Network: IR485 data communications:

True: Network communications are functioning

normally.

False: Network communications have been

disrupted.

Note that the NW function is only valid for compressors

connected via an ir-485 or irV-485 gateway.

73. I/O BOX FUNCTIONS

731. INPUT ALARM WARNING FUNCTIONS

Monitors analog and/or digital I/O Box inputs that have

been set for Alarm (Warning) function.

B0# = The I/O Box ID; B01 to B02

= ‘L’ if the local I/O Box

•

= ‘R’ if another remote I/O Box

•

D1: Alarm (Warning): Digital Input #1:

True: Digital Input #1 is reporting an Alarm

(Warning) condition.

False: Digital Input #1 is not reporting an Alarm

(Warning) condition.

D2: Alarm (Warning): Digital Input #2:

True: Digital Input #2 is reporting an Alarm

(Warning) condition.

False: Digital Input #2 is not reporting an Alarm

(Warning) condition.

D3: Alarm (Warning): Digital Input #3:

True: Digital Input #3 is reporting an Alarm

(Warning) condition.

False: Digital Input #3 is not reporting an Alarm

(Warning) condition.

D4: Alarm (Warning): Digital Input #4:

True: Digital Input #4 is reporting an Alarm

(Warning) condition.

False: Digital Input #4 is not reporting an Alarm

(Warning) condition.

D5: Alarm (Warning): Digital Input #5:

True: Digital Input #5 is reporting an Alarm

(Warning) condition.

False: Digital Input #5 is not reporting an Alarm

(Warning) condition.

D6: Alarm (Warning): Digital Input #6:

True: Digital Input #6 is reporting an Alarm

(Warning) condition.

False: Digital Input #6 is not reporting an Alarm

(Warning) condition.

D7: Alarm (Warning): Digital Input #7:

True: Digital Input #7 is reporting an Alarm

(Warning) condition.

False: Digital Input #7 is not reporting an Alarm

(Warning) condition.

D8: Alarm (Warning): Digital Input #8:

True: Digital Input #8 is reporting an Alarm

(Warning) condition.

Page 29

False: Digital Input #8 is not reporting an Alarm

B0# T

- -

B0# S

- -

(Warning) condition.

A1: Alarm (Warning): Analog Input #1:

True: Analog Input #1’s Alarm (Warning)

threshold has been exceeded.

False: Analog Input #1’s Alarm (Warning)

threshold has not been exceeded.

A2: Alarm (Warning): Analog Input #2:

True: Analog Input #2’s Alarm (Warning)

threshold has been exceeded.

False: Analog Input #2’s Alarm (Warning)

threshold has not been exceeded.

A3: Alarm (Warning): Analog Input #3:

True: Analog Input #3’s Alarm (Warning)

threshold has been exceeded.

False: Analog Input #3’s Alarm (Warning)

threshold has not been exceeded.

A4: Alarm (Warning): Analog Input #4:

True: Analog Input #4’s Alarm (Warning)

threshold has been exceeded.

False: Analog Input #4’s Alarm (Warning)

threshold has not been exceeded.

732. INPUT TRIP SHUTDOWN FUNCTIONS

Monitors analog and/or digital I/O Box inputs that have

been set for Trip (Shutdown) function.

B0# = The I/O Box ID; B01 to B02