Page 1

Ingersoll Rand

System Automation

I/O Accessory Box

Operator’s Manual

Before installing or starting this unit for the first

time, this manual should be studied carefully to

obtain a working knowledge of the unit and or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

More Than Air. Answers.

Online answers: http://air.ingersollrand.com

C.C.N. : 80444110

: A

REV.

DATE : DECEMBER 2008

Page 2

SECTION 1 TABLE OF CONTENTS

Section 1 - table of contentS .............................2

Section 2 - intRoDUction ......................................

Section 3 - Safety pRecaUtionS .........................

INSTALLATION .............................................................................3

OPERATION ...................................................................................3

MAINTENANCE AND REPAIR .................................................4

Section 4 - inStallation .........................................5

UNIT LOCATION ..........................................................................5

POWER SUPPLY ...........................................................................

RS485 NETWORK ........................................................................

I/O BOX ANALOG CONDITIONING MODULE................... 5

TO CHANGE AN ACM DEVICE: ............................................... 6

TO REMOVE AN ACM DEVICE: ............................................... 7

TO INSTALL AN ACM DEVICE: ...................................

ACM IDENTIFICATION ...............................................

6.5 OPERATION ............................................................

6.6 DIGITAL INPUT STATUS INDICATIONS ................

3

6.7 ANALOG INPUT DISPLAY .........................................

3

6.8 POWER FAILURE AUTORESTART ..........................

6.9 I/O BOX FAULT ..............................................................

6.10 SHUTDOWN FAULTS ...................................................

MANAGEMENT UNIT FAULT CODES .................................

Section 8 - paRtS liSt ..............................................20

Section 9 - technical Data ..................................

5

Section 10 - WiRing DiagRam ..............................

5

XPMTAC24 .................................................................................22

Refer to Section Indicated

7

7

Note

17

17

18

18

18

18

19

20

21

Section 5 - commiSSioning ....................................9

PHYSICAL CHECKS .....................................................................9

NETWORK ID ................................................................................

REFERENCE SYSTEM PRESSURE DISPLAY ......................... 9

I/O CONFIGURATION ................................................................9

VIRTUAL RELAY AUTOMATION .............................................9

Section 6 - DiSplay anD menU opeRation .....10

MENU NAVIGATION .................................................................10

MENU ITEMS AND SETTINGS ..............................................

MENU S01 CONFIGURATION ...............................

MENU D01 THROUGH D08 DIGITAL INPUTS .......

MENUS A01 THROUGH A04 ANALOG INPUTS ....

DIAGNOSTICS ............................................................................16

11

11

12

13

Section 7 - opeRation ............................................17

Important or Caution, Safety

9

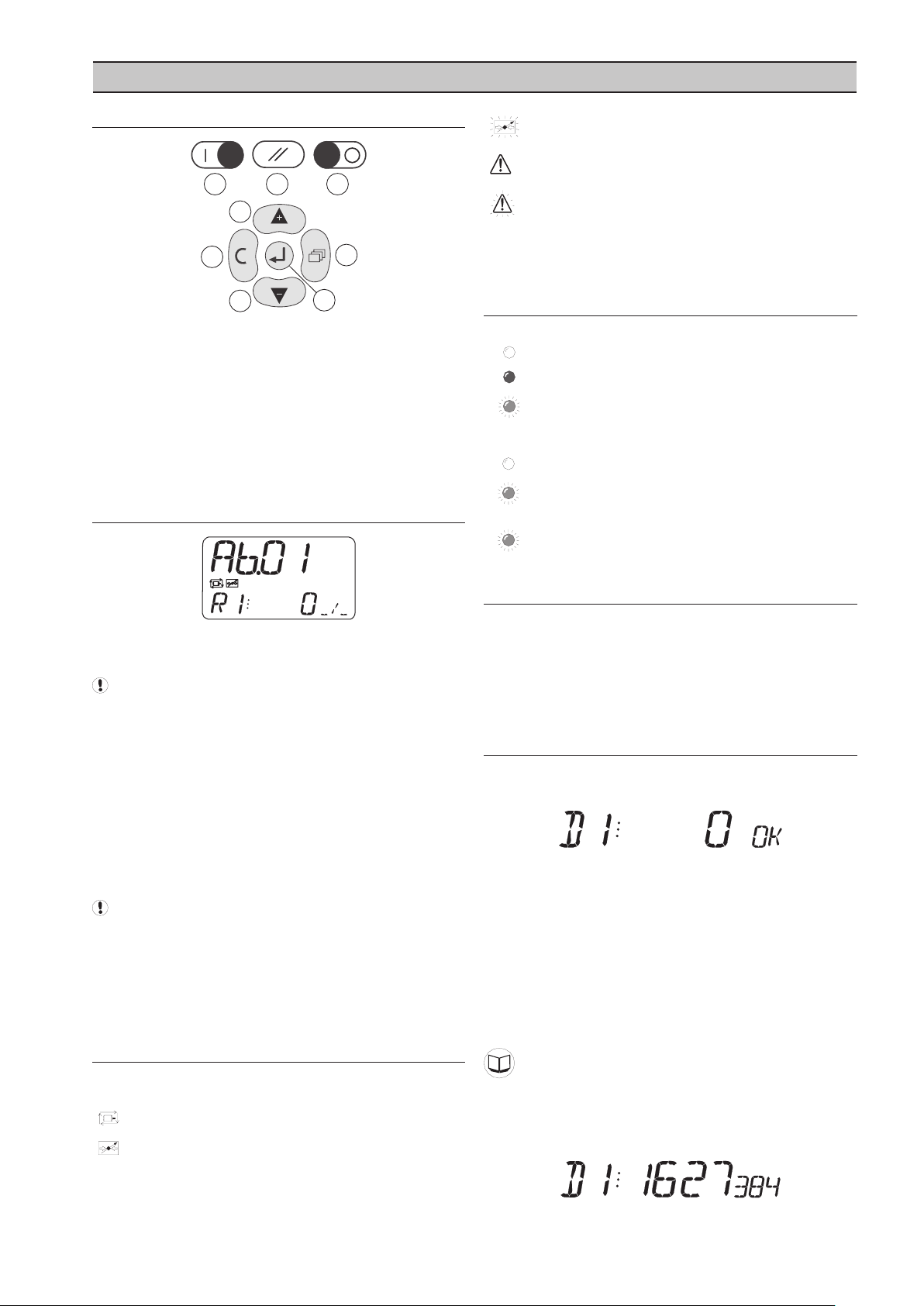

6.1 USER INTERFACE .........................................................17

6.2 DISPLAY ..........................................................................

6.3 STATUS SYMBOLS ....................................................

6.4 INDICATORS ..................................................................

17

17

17

2

Page 3

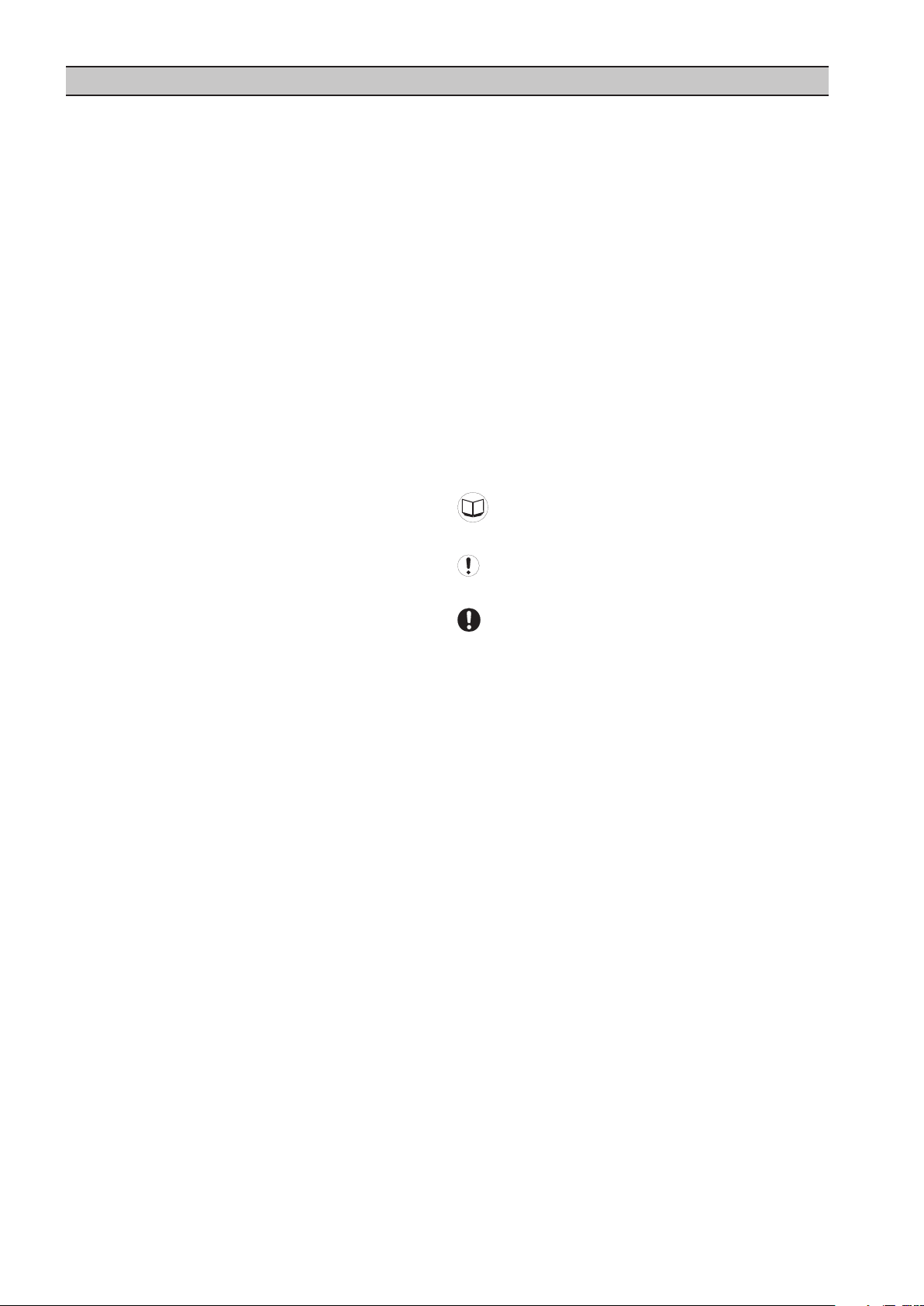

SECTION 2 INTRODUCTION

1 2

A:

85%

Ingersoll Rand

IO

Ab.01

Ingersoll Rand

IO

Ab.02

!

!

An I/O Box provides additional general purpose I/O

(input/output) for system enhancing monitoring

capabilities and for providing distributed system

automation via Virtual Relay.

More than one I/O Box can be installed in a system (up

to a maximum of 2 on an X8I). Each I/O Box features:

8 Digital Inputs

5 4-20 mA Analog Inputs (1 is a dedicated

pressure input)

6 Relay Outputs

Digital inputs can be used to monitor switching contact

devices. Each input can be set to act as an Alarm or

Trip input or used for Virtual Relay Automation. Digital

inputs can also be used for metering (for example m3,

ft3, kWh) providing an accumulative count of pulses

from a metering device.

Analog inputs can be used to monitor sensor

devices (for example: pressure, differential pressure,

temperature, dew point, flow, current, power, bearing

condition). Each input is equipped with adjustable high

or low level detection that can be used to activate an

Alarm or Trip or used for Virtual Relay Automation.

Relay outputs use the Virtual Relay Automation

technology and are totally configurable with dual

input logic functions. Relay functions can be assigned

utilizing any status or condition information available

on a system network from any compatible unit

connected to the network.

The I/O Box is designed to connect to a management

system using an industrial 2-wire RS485 data network,

with a total cable length up to 4000 ft (1219 m).

SECTION 3 SAFETY PRECAUTIONS

competent person under qualified supervision.

WARNING : Risk of Danger

WARNING : Risk of Electric Shock

WARNING : Risk of High Pressure

WARNING : Consult Manual

Before installing or operating the I/O Box, take time

•

to carefully read all the instructions contained in this

manual, all compressor manuals, and all manuals of

any other peripheral devices that may be installed or

connected to the unit.

Electricity and compressed air have the potential to

•

cause severe personal injury or property damage.

The operator should use common sense and good

•

working practices while operating and maintaining

this system. All applicable codes should be strictly

adhered to.

Maintenance must be performed by adequately

•

qualified personnel that are equipped with the

proper tools.

INSTALLATION

Installation work must only be carried out by a

•

A fused isolation switch must be fitted between the

•

main power supply and the I/O Box.

The I/O Box should be mounted in such a location

•

as to allow operational and maintenance access

without obstruction or hazard and to allow clear

visibility of indicators at all times.

If raised platforms are required to provide access

•

to the I/O Box they must not interfere with normal

operation or obstruct access. Platforms and stairs

should be of grid or plate construction with safety

rails on all open sides.

OPERATION

The I/O Box must only be operated by competent

•

personnel under qualified supervision.

Never remove or tamper with safety devices, guards

•

or insulation materials fitted to the I/O Box.

The I/O Box must only be operated at the supply

•

voltage and frequency for which it is designed.

When main power is switched on, lethal voltages are

•

present in the electrical circuits and extreme caution

must be exercised whenever it is necessary to carry

out any work on the unit.

Do not open access panels or touch electrical

•

components while voltage is applied unless it is

necessary for measurements, tests or adjustments.

3

Page 4

4

Such work should be carried out only by a qualified

electrician equipped with the correct tools and

wearing appropriate protection against electrical

hazards.

All air compressors and/or other equipment

•

connected to the unit should have a warning sign

attached stating “THIS UNIT MAY START WITHOUT

WARNING” next to the display panel.

If an air compressor and/or other equipment

•

connected to the unit is to be started remotely,

attach two warning signs to the equipment stating

“THIS UNIT CAN BE STARTED REMOTELY”. Attach

one sign in a prominent location on the outside

of the equipment, and the other sign inside the

equipment control compartment.

MAINTENANCE AND REPAIR

Maintenance, repairs or modifications must only

•

be carried out by competent personnel under

qualified supervision.

If replacement parts are required, use only genuine

•

parts from the original equipment manufacturer,

or an alternative approved source.

Carry out the following operations before opening

•

or removing any access panels or carrying out any

work on the I/O Box:

i. Isolate the I/O Box from the main electrical

power supply. Lock the isolator in the “OFF”

position and remove the fuses.

ii. Attach label to the isolator switch and to the

unit stating “WORK IN PROGRESS - DO NOT

APPLY VOLTAGE”. Do not switch on electrical

power or attempt to start the I/O Box if such a

warning label is attached.

Make sure that all instructions concerning

•

operation and maintenance are strictly followed

and that the complete unit, with all accessories

and safety devices, is kept in good working order.

The accuracy of sensor devices must be checked

•

on a regular basis. They must be calibrated when

acceptable tolerances are exceeded. Always ensure

any pressure within the compressed air system is

safely vented to atmosphere before attempting to

remove or install a sensor device.

The I/O Box must only be cleaned with a damp

•

cloth, using mild detergents if necessary. Avoid the

use of any substances containing corrosive acids or

alkalis.

Do not paint the control faceplate or obscure any

•

indicators, controls, instructions or warnings.

Page 5

1

VOLTAGE SELECT

2 3 4

X04

1

VOLTAGE SELECT

2 3 4

X04

230Vac

115Vac

EELN

NLE

X01

1 2 3 4

XPM-TAC24

26

28

25

27

X07

L1

L2

RS485

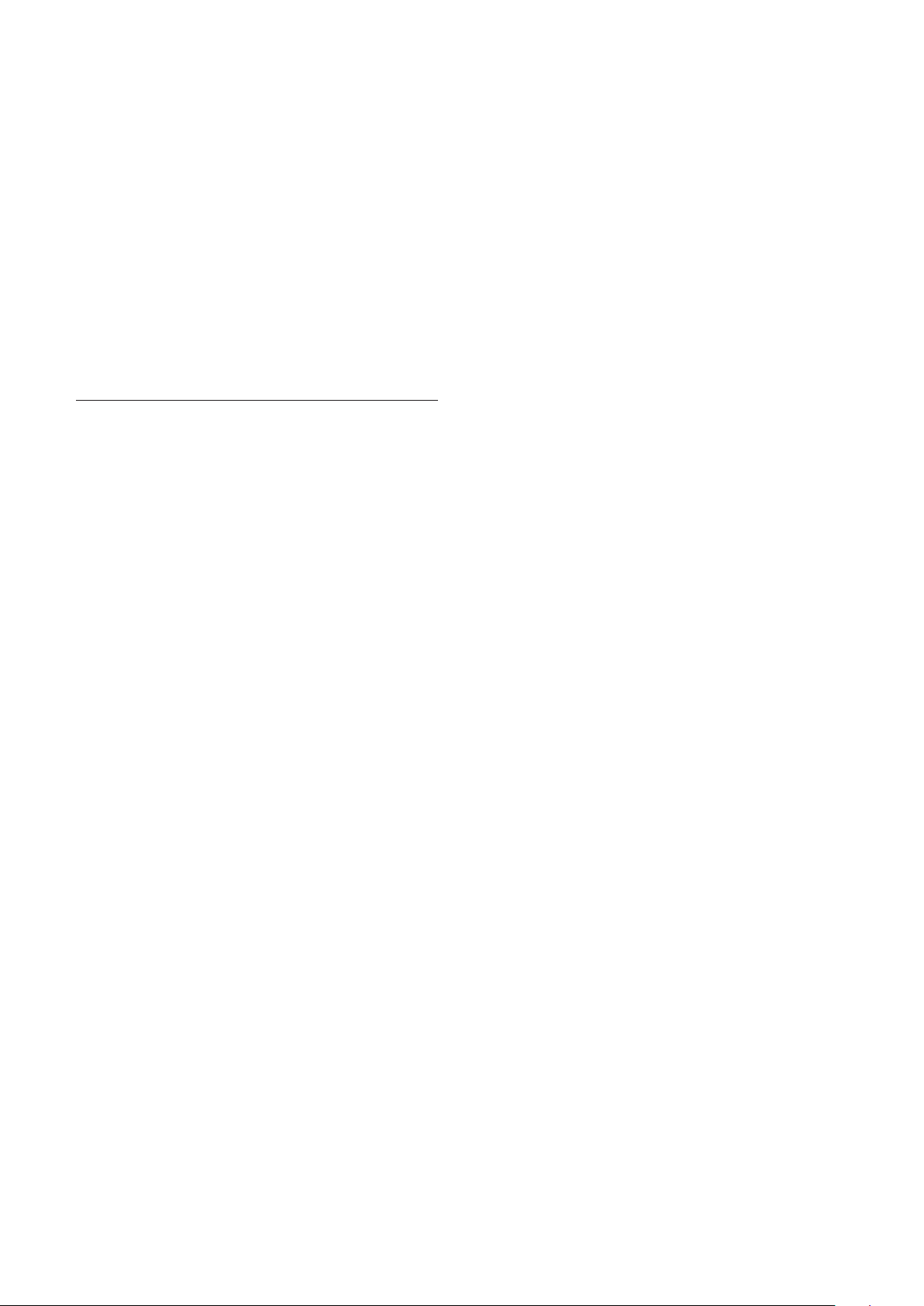

SECTION 4 INSTALLATION

It is recommended that installation and commissioning

be carried out by an authorized and trained product

supplier.

UNIT LOCATION

The I/O Box is wall mounted using conventional screws/

bolts. The maximum distance between the X8I and the

I/O Box is 4000ft (1219 m) of cable length. The maximum

distance between the I/O Box and each compressor

is 330ft (100 m) of cable length and within 330ft (100

m) of cable length from any pressure sensor option (if

applicable).

The cable used between the X8I and the I/O Box is

Belden 9841 (or equivalent). It should be run in grounded

conduit and should not be greater than 4000 feet

(1219m) in length.

POWER SUPPLY

A fused switching isolator must be installed to the

main incoming power supply, external to the I/O Box.

The isolator must be fitted with a properly sized fuse

to provide adequate protection to the power supply

cable used (in accordance with local electrical and safety

regulations).

Belden 9841 (or equivalent). It should be run in grounded

conduit and should not be greater than 4000 feet (1219

m) in length.

RS485 data communications and other low

voltage signals can be subject to electrical interference.

This potential can result in intermittent malfunction

or anomaly that is difficult to diagnose. To avoid this

possibility always use earth shielded cables, securely

bonded to a known good earth at one end. In addition,

give careful consideration to cable routing during

installation.

a) Never route an RS485 data communications or

low voltage signal cable alongside a high voltage

or 3-phase power supply cable. If it is necessary

to cross the path of a power supply cable(s),

always cross at a right angle.

b) If it is necessary to follow the route of power

supply cables for a short distance (for example:

from a compressor X8I to a wall along a

suspended cable tray) attach the RS485 or

signal cable on the outside of an earthed cable

tray such that the cable tray forms an earthed

electrical interference shield.

c) Where possible, never route an RS485 or signal

cable near to equipment or devices that may be

a source of electrical interference (for example:

3-phase power supply transformer, high voltage

switchgear unit, frequency inverter drive module,

radio communications antenna).

POWER SUPPLY TERMINALS

Ensure that the voltage select input is properly

jumpered for the incoming power. Default voltage

configuration is 230Vac.

RS485 NETWORK

The I/O Box is equipped with an RS485 network

communications capability using the IR485 protocol.

The I/O Box is intended to operate as part of the X8I

Management System. Connection to the system

management unit is two-wire, twisted pair, earth

shielded, RS485 data link. Connect the RS485 data cable

wires to terminal X07.

Note: Polarity is important.

The cable used between the X8I and the I/O Box is

5

Page 6

6

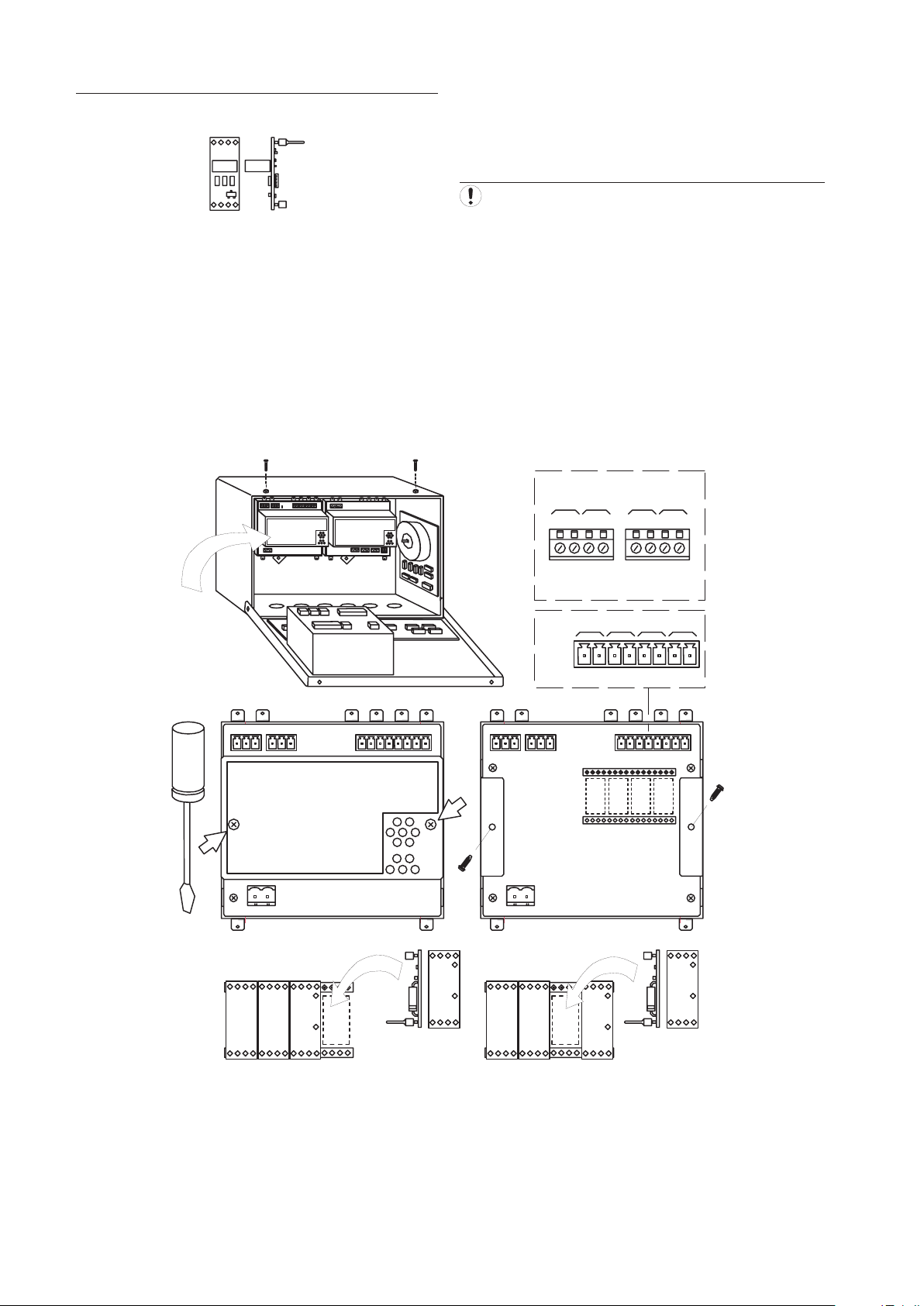

I/O BOX ANALOG CONDITIONING MODULE

1

2

34

4 3 1

X04

XPM-Ai4

XPM-Ai4

1234

30X20X10X

X04

ACM

XPM-Ai4

1

34

4 3 2

Ai1

Ai2

Ai1

Ai2Ai3Ai4

12345678

Ai1

Ai2Ai3Ai4

XPM-Ai4

3338

X10

3437 3235

X09

3136

Ai1

Ai2Ai3Ai4

CAi1CAi2CAi3CAi4

X03

I/O Box

The electrical input characteristics of the four adjustable

analog inputs can be individually altered to suit a sensor

or signal type using Analog Conditioning Modules

(ACM).

ACM devices are hardware modules that plug in to the

analog input circuit and condition the incoming signal.

For a particular sensor type the correct ACM device

must be selected and fitted.

TO CHANGE AN ACM DEVICE:

Remove the power from the unit.

ACM devices for analog inputs 1 to 4 are located within

the unit’s XPM-Ai4 module.

To gain access to the ACM devices remove the cover of

the XPM-Ai4 module. The ACM devices can be removed

and inserted by hand without the use of a tool.

Page 7

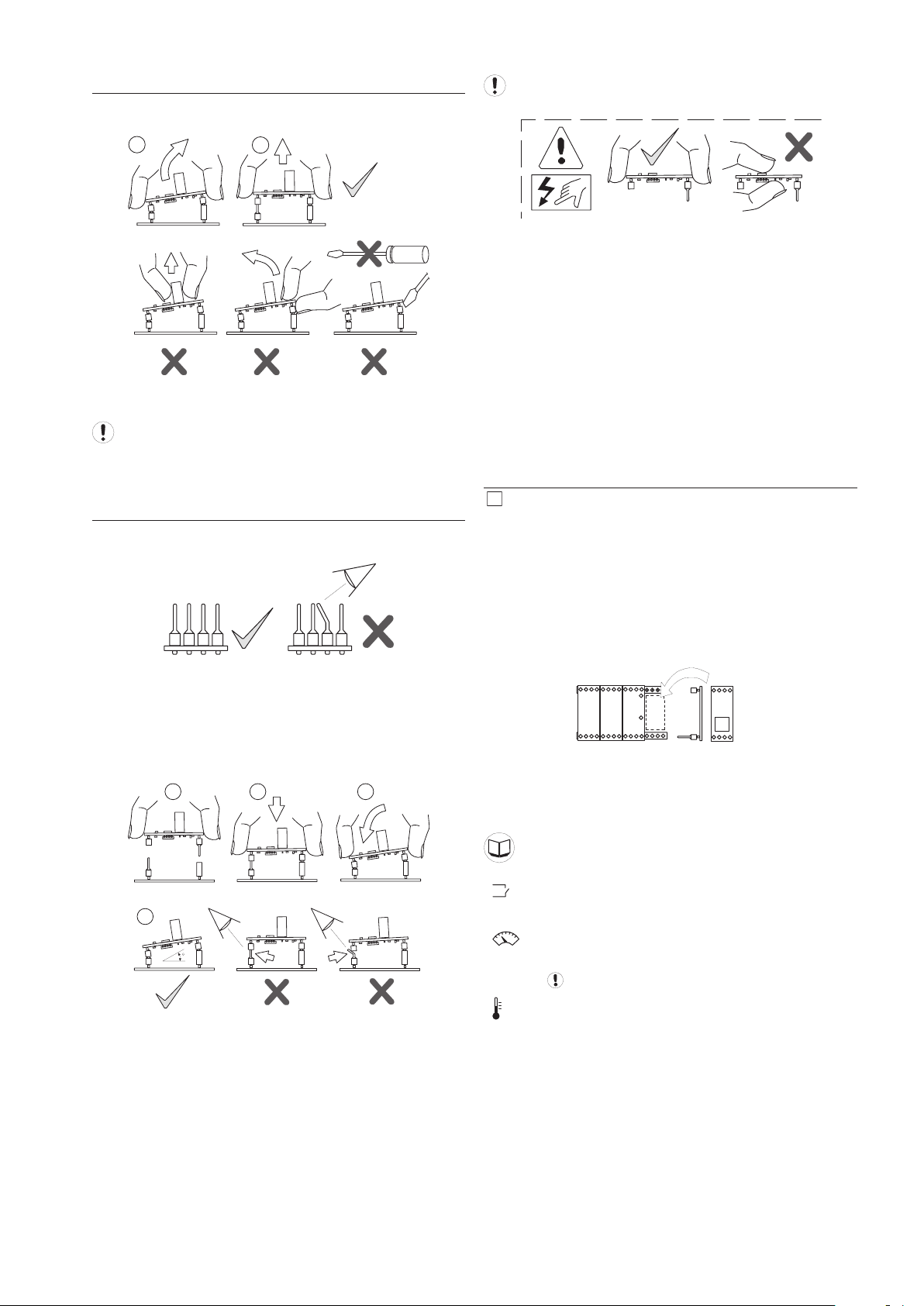

TO REMOVE AN ACM DEVICE:

2

1

1 2 3

4

1

2

34

#

Ai4 Ai3 Ai2 Ai1

ACM

Never use a metallic tool (screwdriver tip for example)

to remove an ACM device.

TO INSTALL AN ACM DEVICE:

Antistatic Precaution

ACM devices contain electronic components; take all

necessary antistatic precautions including:

Before handling an ACM device touch an exposed

1)

earthed surface to discharge any body static.

Always store in an anti-static container or package;

2)

never place on a non anti-static surface.

Handle the device by the edges; never touch the

3)

electronic com[ponenets on the device.

ACM IDENTIFICATION

# ACM devices are classified by a number and can be

readily identified by color:

Any ACM type can be fitted to an analog input socket.

ACM devices can be fitted in the XPM-Ai4 module in any

required combination.

The I/O Box is shipped with four type 3 ACMs installed

and two spare type 6 ACMs.

Example: for analog input 1 (Ai1):

Before inserting an ACM device check the pins of the ACM

and the XPM-Ai4 socket.

ACM devices are designed to mount in the XPM-Ai4

socket at an angle. This is intended to retain the device

securely in the socket in the instance of mechanical

vibration.

When an ACM device is fitted the ‘AT: Input Type’ menu

setting for the analog input must be adjusted to match

the ACM type number.

Menu Items: Analog Inputs A01-A04

Digital Input:

Remote volt-free switching contact

Analog Signal:

DC Voltage or Current

wire polarity is important

Temperature Sensor

7

Page 8

8

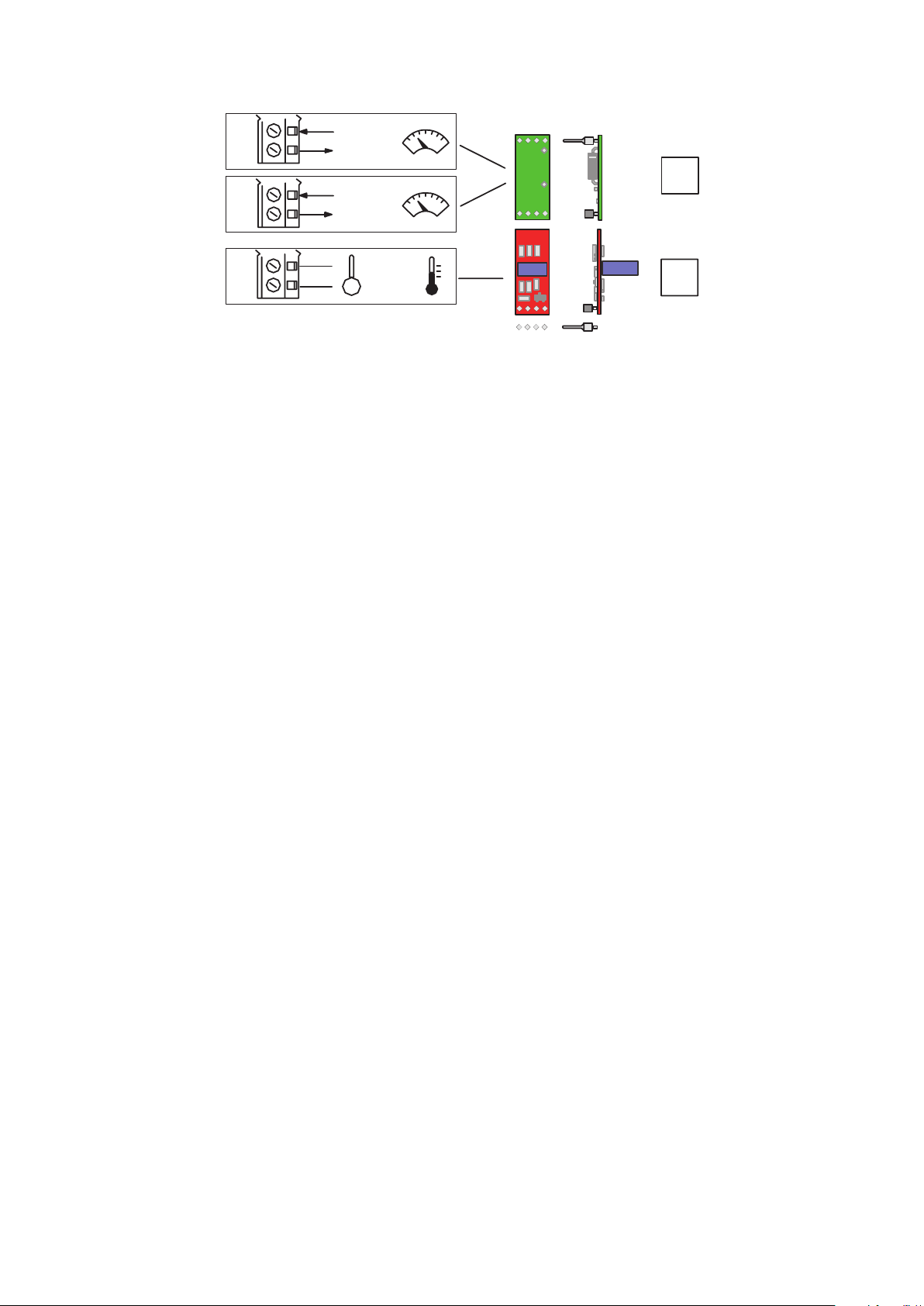

3: 0mA

0-20mA

+24VDC

3: 4mA

4-20mA

+24VDC

6: PT1

PT100

3

6

3

2

3

1

3

2

3

1

3

2

3

1

GREEN

RED (Blue)

Page 9

1 2

A:

85%

Ingersoll Rand

IO

Ab.01

Ingersoll Rand

IO

Ab.02

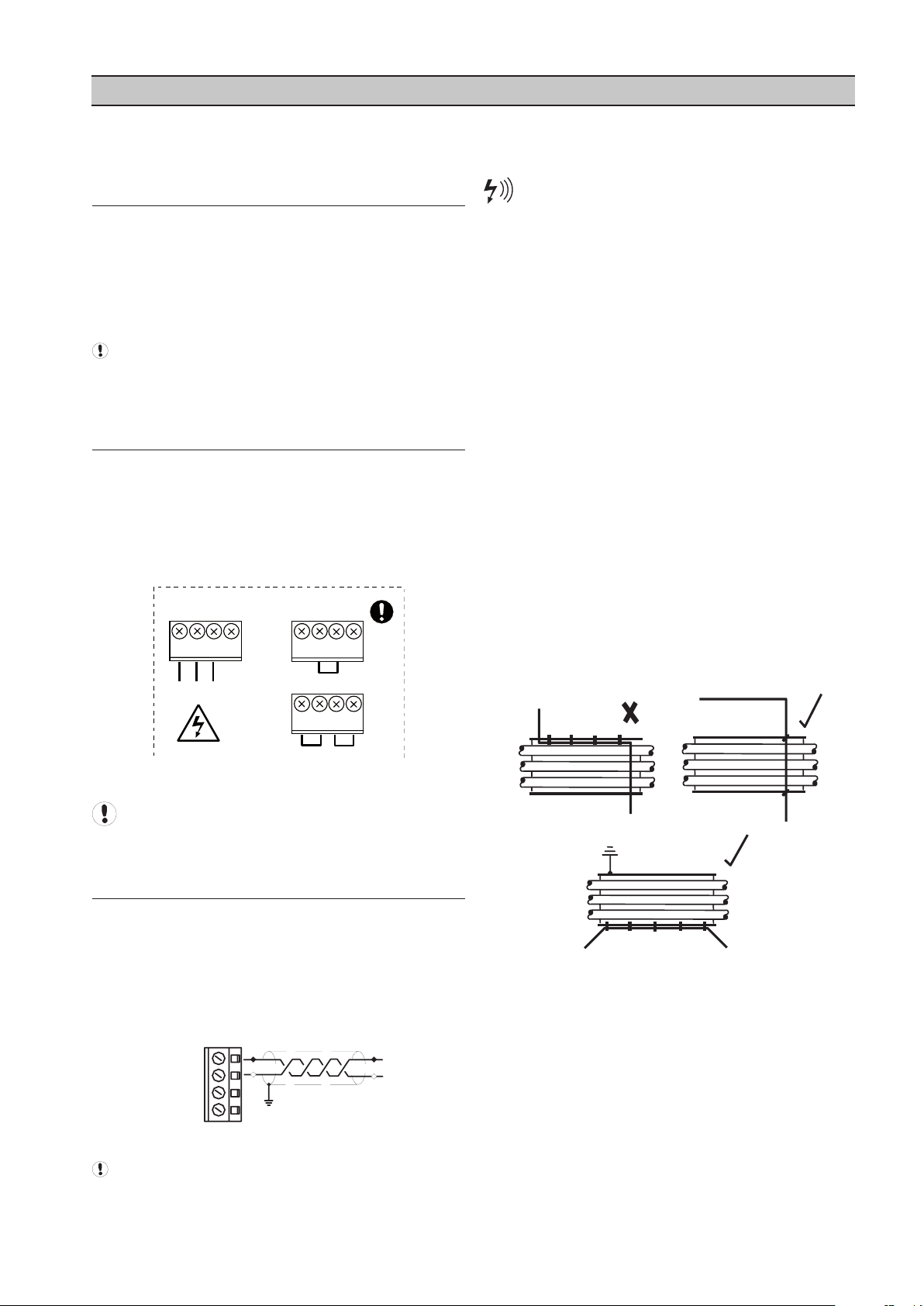

SECTION 5 COMMISSIONING

When commissioning the I/O Box, carry out the following

procedures before attempting to start.

It is recommended that an authorized and trained

service technician perform the commissioning.

PHYSICAL CHECKS

1. Before applying power to the I/O Box, ensure the

power supply connections are correct and secure

and the operating voltage selector is set correctly for

the power supply voltage in use (115Vac or 230Vac

(+-10%), 50/60Hz).

2. Open the front panel of the I/O Box and check the

location of the link wire(s) connected to the “Voltage

Selection” terminals of the power supply PCB. If

necessary, change the link wire locations to those

illustrated for the voltage in use.

See the section on Installation for more

information.

3. Check and ensure all sensor, input, relay and other

connections are correctly installed and secure.

4. Close the front panel of the I/O Box.

5. Switch on the power supply to the I/O Box.

6. The control program identification will be displayed

for a short period followed by the normal operational

user display.

NETWORK ID

The network ID of each I/O Box connected to a system

must be unique. The ID of an I/O Box can be adjusted

from 1 to 12; this also sets the network ID. Assign each

I/O Box a different ID number; starting at ‘1’ increasing

sequentially up to the number of I/O Boxes connected to

the network system.

S01 – Ad

ID and Network Address

sensor and carry out the pressure sensor commissioning

and calibration procedure.

S01 - Po

S01 - Pr

Sensor Offset Calibration

Sensor Range Calibration

Menus and Menu Items

I/O CONFIGURATION

For each I/O function and feature to be utilized, configure

the appropriate I/O configuration items in the associated

menu. Each Input or Output has a dedicated menu.

Menus and Menu Items

Digital Inputs

Analog Inputs

Virtual Relay Automation

For analog inputs; check the type and location of the

ACM devices fitted.

ACM (Analog Conditioning Modules)

VIRTUAL RELAY AUTOMATION

The Ingersoll Rand Automation X8I system is equipped

with virtual relay capability to expand the control of a

compressed air system. Using virtual relay allows the X8I

system to control and monitor ancillary equipment such

as dryers, flow meters, dew point monitors, etc.

When virtual relay capability is activated all inputs and

outputs in the X8I system can be utilized in much the

same way a Programmable Logic Controller (PLC) would

be used to control a system. Each component in the X8I

system has a list of statuses and functions that can be

used as input functions to trigger the virtual relays, which

are logical constructs that are either true or false based on

the input functions but are not necessarily connected to a

physical relay output. Virtual relays can also be connected

to a physical output and thus allow control of equipment

in the system.

An I/O Box must be installed in the automation system

to be able to use virtual relay automation. Please see

the Virtual Relay Automation user’s guide for complete

information.

Menus and Menu Items

REFERENCE SYSTEM PRESSURE DISPLAY

S01- PD Pressure Detect Enable

Check the displayed system pressure if the RP, ‘Reference

Pressure’ , sensor function is utilized. If the pressure is

incorrect, or inaccurate, check the type and range of the

9

Page 10

10

SECTION 6 DISPLAY AND MENU OPERATION

MENU NAVIGATION

Display Item Structure:

All value, parameter or option selection displays are

grouped into menu lists. Items are assigned to a list

according to type and classification. Items that can be

used to select options or modify functions are assigned to

‘menu mode’ lists. Items that a User may require to view

during routine operation, detected pressure for example,

are assigned to the normal operational mode list. Lists

are identified by page number; the normal User display

list is page ‘P00’. All parameters and options are assigned

to menu mode pages ‘P01’ or higher. All page ‘P00’ items

are view only and cannot be adjusted.

Normal Operational Mode (Page P00):

At controller initialisation, all display elements and LED

indicators are switched on for three seconds, the display

will then show the software version code for a further

3 seconds before initialisation is complete and the

normal operating display (Page P0) is shown. In page

P00 ‘normal operational display mode’ the main display

will continuously show the detected delivery pressure

and the Item display will show the first item of the ‘User’

menu. User menu ‘Items’ can be selected using the Up or

Down buttons at any time. Pressing the Enter button will

lock any selected Item display and inhibit return to the

default display. When an Item display is locked the lock

key symbol will slow flash. To unlock an Item display press

Up or Down to view an alternative Item display or press

Reset or Escape. No Item values, options or parameters

can be adjusted in page ‘P00’. If a fault condition occurs

the fault code becomes the first list item and the display

will automatically jump to display the fault code. More

than one active fault code item can exist at any one time.

Access Code:

Access to page list displays higher than page ‘P00’ is

restricted by access code. To access menu mode pages

press MENU, an access code entry display is shown and

the first code character will flash. Use PLUS or MINUS to

adjust the value of the first code character then press

ENTER. The next code character will flash; use UP or

DOWN to adjust then press ENTER. Repeat for all four

code characters.

Menu Mode Navigation:

In menu mode the main value display will flash and show

the Page number. To select a page press UP or DOWN. For

each page the display will show the first Item of the page

list. To view a page list press ENTER, the Page number will

stop flashing and the Item display will flash. Press UP or

DOWN to view the selected page list items. To select an

Item value for modification press ENTER, the Item display

will stop flashing and the value display will flash. The

value or option can now be modified by pressing UP(Plus)

or DOWN(Minus). To enter a modified value or option in

memory press ENTER; alternatively the modification can

be abandoned, and the original setting maintained, by

pressing ESCAPE.

Press ESCAPE at any time in menu mode to step

backwards one stage in the navigation process. Pressing

ESCAPE when the page number is flashing will exit menu

mode and return the display to normal operational mode;

page ‘P00’.

Press and hold RESET for two seconds at any time

to immediately exit menu mode and return to the

normal operational mode display. Any value or option

adjustment that has not been confirmed and entered

into memory will be abandoned and the original setting

maintained.

A flashing Key symbol displayed with any Item

indicates the Item is locked and cannot be modified. This

will occur if the Item is view only (non adjustable) or in

instances where the item cannot be adjusted while the

I/O Box is in ‘Remote Mode’.

If the code number is less than 1000 then the first code

character will be 0(zero). To return to a previous code

character press ESCAPE. When all fourcode characters

have been set to an authorized codenumber press

ENTER. An invalid code will return the display to normal

operational mode; page ‘P00’.

Access Code Timeouts:

When in menu mode, if no key activity is detected for a

period of time the display will automatically reset to the

normal operational display; Page ‘P00’.

Page 11

MENU ITEMS AND SETTINGS

MENU S01CONFIGURATION

1 Ad ID and Network Address

2 PD Pressure Detect Enable

3 Po Pressure Sensor Calibration Offset

4 Pr Pressure Sensor Calibration Range

5 P> Pressure Display Units

6 ID User Menu Item Default

7 RP Pulse Counter Reset Enable

MENU D01 THROUGH D08DIGITAL INPUT FUNCTION

1 ST Normal State (NO or NC)

2 Fn Function (‘-’, A, T, S or P)

3 DT Delay Time

4 RF Reset Function

MENU A01 THROUGH A04ANALOG INPUT CONFIGURATION

1 AT Input Type

2 Ut Display units

3 Vo Value Offset

4 Vr Value Range

5 DF Display Function

6 FH Fault High Level Setpoint

7 FL Fault Low Level Setpoint

8 Fn

9 FI Fault Inhibit Enable

10 Dt Delay Time

11 RT Reset Function

Fault Function

MENU RP1 AND RP2PULSE RELAY

1 F1 Input Function #1

2 F2 Input Function #2

3 Fu Input Logic Function

4 On On Time

5 FS Function State (NO or NC)

6 CF Comms failure function

MENU RF1COMPRESSOR RUNNING RELAY

1 01 Compressor #1 Select

2 02 Compressor #2 Select

... ...

12 12 Compressor #12 Select

13 FN Logic Function

MENU LF1COMPRESSOR LOADED RELAY

1 01 Compressor #1 Select

2 02 Compressor #2 Select

... ...

12 12 Compressor #12 Select

13 FN Logic Function

MENU AF1COMPRESSOR NOT AVAILABLE RELAY

1 01 Compressor #1 Select

2 02 Compressor #2 Select

... ...

12 12 Compressor #12 Select

13 FN Logic Function

MENU R01 THROUGH R06PHYSICAL RELAY

CONFIGURATION

1 F1 Input Function #1

2 F2 Input Function #2

3 Fu Input Logic Function

4 On On Time

5 Of Off Time

6 ST Normal State (NO or NC)

7 CF Comms failure function

MENU R07 THROUGH R13VIRTUAL RELAY CONFIGURATION

Virtual relay will be implemented in a future release

MENU RT1 AND RT3TIME RELAY CONFIGURATION

1 F1 Input Function #1

2 F2 Input Function #2

3 Fu Input Logic Function

4 On On Delay Time

5 Of Off Dellay Time

6 SS

Start State (NO or NC)

7 CF Comms failure function

MENU F10SPM BEARING MONITORING

1 R1 Shaft Speed #1

2 D1 Shaft Diameter #1

3 A1 dBi #1 (View Only)

4 R2 Shaft Speed #2

5 D2 Shaft Diameter #2

6 A2 dBi #2 (View Only)

7 R3 Shaft Speed #3

8 D3

Shaft Diameter #3

9 A3 dBi #3 (View Only)

10 R4 Shaft Speed #4

11 D4 Shaft Diameter #4

12 A4 dBi #4

Analog Inputs: SPMTM Bearing Monitoring Function

MENU 7DIAGNOSTICS

See ‘Diagnostics’

Access Code = 0021

11

Page 12

12

MENU S01 CONFIGURATION

Ad: Box Number and Network Address

I/O Box number and network address. For each I/O Box

in a system assign an I/O Box number starting from ‘1’

increasing sequentially to the number of I/O Boxes in

the system.

For example:

1=I/O Box 01

105=network address; decimal value

Network address values do not always sequentially

follow the I/O Box number sequence; this is normal and

can be ignored.

The I/O Box number must be unique; if two I/O Boxes

are assigned the same number (same network address)

the system will be disrupted.

PD: Pressure Detect Enable

Enables the dedicated reference pressure sensor input.

0 = Disable, no pressure sensor connected

1 = Enable

Po: Reference Pressure Offset Calibration

The value can be adjusted between –22 PSI and +22

PSI (-1.5 bar to +1.5 bar).

Default = 0 PSI (0.0 bar).

The ‘offset’ value can be used for atmospheric

(0psig)calibration; expose the reference pressure sensor

to atmosphere and adjust until the display pressure

shows 0 PSI. The main display value will show the actual

detected pressure when this menu item is selected.

Pr: Reference Pressure Range Calibration

The value can be adjusted for any 4-20mA sensor range

between 14.5 PSI (1 bar) and 9135 PSI (630 bar). Default

= 232 PSI (16 bar).

If the sensor does not have a 0 (zero) PSI offset then

the range value must be the same as the ‘maximum’

pressure value of the sensor.

For example: if the sensor is a –14.5 PSI (-1.0bar) to

217.5 PSI (15 bar) type then:

Offset = -14.5 PSI Range = 217.5 PSI

The ‘range’ value can be used for calibration: expose

the senor to a known accurate pressure and adjust the

‘range’ value until the display pressure matches the

applied pressure. The main display value will show

the actual detected pressure when this menu item is

selected.

P>: Pressure Display Units

0 = bar

1 = psi

2 = kPa

Only applicable to the Reference Pressure display

value.

ID: User Menu Item Default

RP, D1-D8, A1-A4 or R1-R6

Default User menu display item.

After a short period of no keypad activity the User

menu display item will automatically change to show

the item defined by this setting.

RP: Pulse Counter Reset Enable

For any digital input set for ‘pulse count’ mode, this

setting determines if the pulse count can be reset

manually from the User menu.

0 = Remote serial communications reset only

1 = Allow manual reset from User menu

Digital Inputs: Pulse Count Mode

MENU D01 THROUGH D08 DIGITAL

INPUTS

The I/O Box is equipped with 8 digital inputs. A digital

input can be used to monitor the state of a remote voltfree contact that is rated for 24VDC @ 10mA minimum.

The state of a remote contact can be:

a)

Open Circuit (off or ‘0’ state)

Closed Circuit (on or ‘1’ state)

b)

ST Normal State NO/NC

This setting defines if the normal, or OK, state is ‘NO’

normally open circuit (0) or ‘NC’ normally closed circuit

(1).

If the remote contact is detected to change state to the

not normal, or not OK, state the I/O Box will respond in

accordance with the set ‘Fn’ response function.

Fn Function

If the remote contact state is not normal, or not OK, the

I/O Box will indicate:

‘-’ NOK (not OK) – no other action

A

Alarm Condition

T

Trip Condition

S

Signal Connection

The state of the digital input, and any associated

Alarm or Trip condition, is available on remote

communications.

The system management unit will also indicate the

Alarm or Trip condition (dependant on model and

configuration).

The ‘Signal’ state will not activate any alarm condition

but can be detected remotely and used for local or

remote automation.

Virtual Relay Automation

DT Delay Time

If the digital input state changes to the not normal,

or not OK, state the I/O Box will delay any ‘A’, ‘T’ or

‘S’ function response until the state has remained

constantly in the not OK condition for the set delay

time.

Page 13

RF Reset Function

> 0.5 sec > 0.5 sec > 0.5 sec

1

2

0: An ‘A’ Alarm or ‘T’ Trip condition will automatically

reset when the digital input returns to the normal, or

OK, state.

1: An ‘A’ Alarm or ‘T’ Trip condition must be reset

manually by pressing the I/O Box RESET button. The

condition will remain on the display, regardless of input

state, until a manual reset occurs.

Digital Inputs 1 to 8, menus D01 to D08 are identical.

Pulse Count Mode:

Fn

(Function) = P

The function (Fn) of digital Inputs 2 to 7 (D02 to D07)

can be set to monitor a remote volt-free switching

contact and count the number of times the contact

changes state from open circuit to closed circuit and

back to open circuit again; a pulse.

Installation:

ACM - Analog Conditioning Modules

Ut Display Units

The display units item selects the ‘text’ that will be

shown in the user menu item display together with the

analog input value.

Ut = mBr, BAR, PSI, kPa, mPa, dP, oC, oF, m3m,

m3h, cfm, m3, ft3, L/s, L/m, L/h, rpm, SPM, dBn, kW,

kWh, mV, V, kV, mA, A, %

There are 27 ‘unit texts’, any of which can be selected.

Alternatively select “- - -“ (dashes) for no units text

display; the analog input value will be displayed with no

units.

For example:

If the displayed value for analog input #1is tempeature

in degrees celsius; select “oC” as the units text.

The number of detected pulses is displayed in the User

menu and will represent an accumulative metered

value dependant on the device providing the pulses.

The pulse count is stored in non-volatile memory

and will continue to accumulate until reset to zero.

A pulse count can be reset to zero using remote

communications.

If the ‘manual pulse count reset’ option is enabled

(menu S01) each individual digital input pulse count

can be manually reset from the keypad:

Press and hold ENTER then press CANCEL.

The pulse count will be cleared and start immediately

again from zero.

MENUS A01 THROUGH A04 ANALOG

INPUTS

The I/O Box is equipped with 4 adjustable analog

inputs. An analog input can be used to monitor the

signal of a remote compatible device and display an

associating value.

AT Input Type

The input type is dependent on the ACM

(analog conditioning module - hardware) fitted in the

I/O Box for the analog input.

ACM’s are defined by number (1 to 8).

3:0mA

3:4mA

6:PT1

The ‘Input Type’ must be set to match the ACM

device fitted. It is not possible to adjust input signal

types from this setting alone.

0-20mA

4-20mA

PT100 type temperature sensor

The display units ‘text’ has no influence on the

analog input or used in any calculation or remote

communications.

Vo Value Offset

This is the ‘value’ that must be displayed when the

signal is at minimum.

Example #1:

ACM type 3

AT: 3:4mA

Sensor: 4-20mA, 0-232 PSI

The display must show 0 (zero) when the signal is

4.0mA; set ‘Vo’ to 0 (zero).

Example #2:

ACM type 2

AT: 2

Sensor: 1-5 VDC, 0-232 PSI

The display must show 0 (zero) when the signal is 1.0

VDC.

In this instance the analog input (AMC type) is 0-10VDC.

A 0(zero)VDC signal will represent a minus pressure and

a signal voltage greater than 5.0VDC will represent a

pressure greater than 232 PSI. Calculate what the ‘value’

at 0.0VDC must be to achieve a display value of 0(zero)

at 1.0VDC. This will depend on a required ‘value’ of 232

PSI at a signal of 5.0VDC.

To achieve a display ‘value’ of 0(zero)PSI at 1.0VDC, and

232 PSI at 5.0VDC, the ‘Vo’ offset must be set to:

232 PSI divided by (5 – 1)VDC = 58 PSI per 1.0VDC:

therefore 0VDC must be (0 PSI – 58 PSI) = -58 PSI.

Set Vo to “–58”

It is not possible to directly implement decimal

point values. In this instance set a value that is ‘10x’ the

required display value then set ‘DF’ to display the value

13

Page 14

14

at “divide by 10 and show to one decimal place” - see DF

setting.

Vr Value Range

This is the ‘value’ that must be displayed when the

signal is at maximum.

Example #1:

ACM type 3

AT: 3:4mA

Sensor: 4-20mA, 0-232 PSI

The display must show 232 when the signal is 20.0mA;

set Vr to “232”

It is not possible to directly implement decimal

point values. In this instance set a value that is ‘10x’ the

required display value then set ‘DF’ to display the value

at “divide by 10 and show to one decimal place” - see DF

setting.

Example #2:

ACM type 2

AT: 2

Sensor: 1-5 VDC, 0-232 PSI

The display must show 232 when the signal is 5.0 VDC.

In this instance the analog input (AMC type) is 0-10VDC.

A 5.0VDC signal is half the input range. Calculate what

the ‘value’ at 5.0VDC must be to achieve a display value

of 232 at 5.0VDC. This will depend on a required ‘value’

of 0(zero) at a signal of 1.0VDC.

To achieve a display ‘value’ of 232 PSI at 5.0VDC, and 0

PSI at 1.0VDC, the ‘Vr’ offset must be to:

232 PSI divided by (5 – 1)VDC = 58 PSI per 1.0VDC:

therefore 10.0VDC must be 522 to achieve a value of

232 at 5.0VDC.

Set Vr to “522”

It is not possible to directly implement decimal

point values. In this instance set a value that is ‘10x’ the

required display value then set ‘DF’ to display the value

at “divide by 10 and show to one decimal place” - see DF

setting.

DF Display Function

The display function determines how the resulting

‘value’ (as determined by the ‘Vo’ and ‘Vr’ settings) is

displayed in the User menu.

Standard DF Functions:

01: Show value directly

Value: 155 = Display: 155

02: Divide ‘value’ by 10

Display to one decimal place

Value: 155 = Display: 15.

03: Divide ‘value’ by 100

Display to one decimal places

Value: 155 = Display: 1.6

04: Divide ‘value’ by 1000

Display to one decimal place

Value: 155 = Display: 0.2

05: Divide ‘value’ by 100

Display to two decimal place

Value: 155 = Display: 1.55

06: Divide ‘value’ by 1000

Display to two decimal places

Value: 155 = Display: 0.16

For DF = 01 to 06 the value transmitted in remote

communications is always the direct result of the set ‘Vo’

and ‘Vr’ settings; any display DF function is ignored.

Any set FH (Fault High Level Set Point) or FL (Fault

Low Level Set Point) is referenced to the direct result of

the set ‘Vo’ and ‘Vr’ settings; any display DF function is

ignored.

Special DF Functions:

F07: oC to oF Conversion

‘Value’ is assumed to be degrees Celsius multiplied

by ten (oC x 10). ‘Value’ is divided by 10, converted to

degrees Fahrenheit, and displayed with no decimal

places.

The value transmitted in remote communications is the

original ‘value’.

F08: oC Dewpoint @ atmosphere to oC Dewpoint @

pressure conversion.

‘Value’ is assumed to be Dewpoint in degrees Celsius

multiplied by ten (oC x 10) sampled at atmospheric

pressure.

‘Value’ is referenced to the RP (reference pressure sensor

input) and converted to Dewpoint @ pressure in exact

accordance with the detected RP pressure value. An RP

pressure sensor must be fitted and activated.

Resulting ‘value’ is transmitted in remote

communication as oC x 10 (Dewpoint @ pressure x 10).

Display is resulting ‘value’ divided by 10 to one decimal

place = oC (Dewpoint @ Pressure).

Any set FH (Fault High Level Set Point) or FL (Fault

Low Level Set Point) is referenced to the resulting value

(Dewpoint @ pressure x10).

F09: Differential Pressure (mBar)

The differential pressure is between the analog input

and the RP reference pressure sensor.

‘Value’ is assumed to be pressure in milliBar (1.0bar =

1000milliBar).

‘Value’ is referenced to the RP (reference pressure sensor

input). Resulting value is the difference between ‘value’

and RP expressed in milliBar; always positive.

Resulting ‘value’ is transmitted in remote

communication as positive integer milliBar (differential

between analog input and RP reference pressure).

Display is resulting ‘value’ in milliBar; always positive.

Any set FH (Fault High Level Set Point) or FL (Fault

Low Level Set Point) is referenced to the resulting value

in milliBar.

Page 15

F10: SPMTM Bearing Monitoring

22

24

X06

21

23

A

B

‘Value’ is assumed to be ‘dBsv’ (0 to 100) from a

compatible SPMTM bearing monitoring 4-20mA unit and

sensor.

‘Value’ is processed in accordance with SPMTM bearing

monitoring specification to provide resulting ‘dBn’ value.

dBn = dBsv – dBi

‘dBi’ is calculated in accordance with SPMTM specification

from ‘shaft speed (rpm)’ and shaft diameter (mm) entered

in menu F10.

dBi = 20 * (LOG(rpm) + 0.6*LOG(shaft diameter in mm)

– LOG(2150))

R1 = shaft speed: analog input 1

D1 = shaft diameter: analog input 1

A1 = ‘dBi’ value (view only)

to

R4 = shaft speed: analog input 4

D4 = shaft diameter: analog input 4

A4 = ‘dBi’ value (view only)

The calculated ‘dBi’ value can be seen in the F10

bearing monitoring menu (items A1 - analog input #1, to

A4 - analog input #4).

Any set FH (Fault High Level Set Point) or FL (Fault

Low Level Set Point) is referenced to the resulting value

(dBn).

TM

SPM

guidelines for dBn Alarm settings:

OK: <20dBn

Warning 20 to 34dBn

Alarm 35dBn+

Due to the nature of rotary screw or vane compression

elements a serviceable bearing may exhibit a higher than

expected base dBsv level. In this instance the trend over

time of dBsv should be monitored to establish a true dBi

level for the bearing.

Alternatively consult the air compressor supplier/

manufacturer for SPMTM bearing monitoring base level

details and appropriate Warning/Alarm dBn levels.

FH Fault High Level Set Point

If ‘Value’ exceeds this setting the ‘Fault Function’ (Fn) is

triggered.

The setting must be referenced to the same value, or

resulting value, units as the set ‘Vo’ and ‘Vr’ settings.

For example:

If the analog input is Temperature the ‘Value’ will be oC

x 10. If a fault condition needs to be triggered when

temperature exceeds 85oC the FH level should be set to

850 (850 / 10 = 85 oC).

If not required set to, or above, the ‘Vr’ setting.

FL Fault Low Level Set Point

If ‘Value’ decreases below this setting the ‘Fault Function’

(Fn) is triggered.

The setting must be referenced to the same value, or

resulting value, units as the set ‘Vo’ and ‘Vr’ settings.

For example:

If the analog input is Temperature the ‘Value’ will be oC

x 10. If a fault condition needs to be triggered when

temperature reduces below -10oC (minus 10oC) the

FLlevel should be set to -100 (-100 / 10 = -10 oC).

If not required set to, or below, the ‘Vr’ setting.

Fn Fault Function

If ‘Value’ reduces below the set ‘FL’ level or increases above

the set ‘FH’ level the fault function is triggered:

“-“ no action

A Alarm

T Trip

S Signal

All analog input Alarm or Trip fault conditions, are

available on remote communications.

The system management unit will also indicate the

Alarm or Trip condition (dependent on model and

configuration).

The ‘Signal’ state will not activate any alarm condition but

can be detected remotely and used for local or remote

automation.

FI Fault Inhibit Enable

If the analog input is set with an Alarm (A) or Trip

(T) function the alarm condition can be inhibited by

activating digital input ‘FI’ when the FI setting is ‘1’.

0: ‘A’ or ‘T’ condition always active regardless of ‘FI’

digital input state.

1:

‘A’ or ‘T’ condition inhibited if digital input ‘FI’ is

active (closed circuit).

Digital Input ‘FI’

A) not active; open circuit

B) active; closed circuit

Dt Delay Time

If the set ‘FH’ or ‘FL’ fault levels are exceeded the I/O Box

will delay any ‘A’, ‘T’ or ‘S’ function response until the

condition has remained constantly in the fault condition

for the set delay time.

RF Reset Function

0: An ‘A’ Alarm or ‘T’ Trip condition will automatically

reset when the ‘value’ returns to normal, or OK, level.

1: An ‘A’ Alarm or ‘T’ Trip condition must be reset

manually by pressing the I/O Box RESET button. The

condition will remain on the display, regardless of the

‘value’, until a manual reset occurs.

Analog Inputs 1 to 4, menus A01 to A04 are identical.

15

Page 16

16

DIAGNOSTICS

The I/O Box controller is equipped with comprehensive

diagnostic functions. Each input can be examined

individually and each output can be manually activated

or manipulated individually.

I/O Box Controller Diagnostics:

Menu P06 Box Controller Diagnostics

D1

Digital Input 1

D2 Digital Input 2 ON

D3 Digital Input 3

D4

Digital Input 4

D5 Digital Input 5

D6 Digital Input 6

D7 Digital Input 7

D8 Digital Input 8

R1 Relay Output 1

R2 Relay Output 2 OFF

R3 Relay Output 3

R4 Relay Output 4 ON

R5 Relay Output 5

R6 Relay Output 6

A1 Analog Input 1 bar <> mA

A2 Analog Input 2

A3 Analog Input 3

state <> V

state <> V

Relay Outputs:

Each relay output can be energized and de-energized

manually by selecting the item. Use PLUS and MINUS to

adjust ‘on’ (1) or ‘off (0) and then ENTER.

OFF

Analog Inputs:

The item will alternate between the detected value and

the electrical measurement on the input terminals. An

independent measuring device can be used to check

the displayed electrical measurement.

A1: Reference Pressure, 4-20mA

A2: Digital Input #1, voltage

A3: Fault Inhibit Digital Input, voltage

Analog inputs 2 and 3 are equipped with Digital ACM

modules designed to function as standard specification

digital inputs.

D02 Diagnostics – XPM-Ai4 Module

A1 Analog Input 1 as ACM

A2 Analog Input 2 as ACM

A3 Analog Input 3 as ACM

A4 Analog Input 4 as ACM

Configurable Analog Inputs A01 to A04:

The four configurable analog inputs are located in the

XPM-Ai4 module.

The item will alternate between the detected value and

the electrical measurement on the input terminals. An

independent measuring device can be used to check

the displayed electrical measurement.

The detected value and the electrical measurement for

each input will be dependant on the ACM type fitted.

ACM (Analog Conditioning Modules)

Page 17

a

b

c

d

f

g

h

e

SECTION 7 OPERATION

6.1 USER INTERFACE

a) Start

b) Reset

c) Stop

d) Menu

e) Enter

f) Escape

g) Up (Plus)

h) Down (Minus)

6.2 DISPLAY

Flashing - No Communications

Input Alarm Condition

Input High Level Alarm Condition

Input Alarm or High Level Alarm conditions do not stop

or inhibit I/O Box operation. Examine the User menu item

list to identify the source of an Alarm indication.

6.4 INDICATORS

Run Indicator (Green LED)

OFF I/O Box Shutdown Fault

ON I/O Box Active

Slow Flash I/O Box Network Fault

Fault Indicator (Red LED)

OFF - No fault

Slow Flash:

RP Sensor fault (display “_ _ _ _”)

Flash Flash:

I/O Box Shutdown Fault

6.5 OPERATION

The I/O Box is always active and cannot be stopped.

The upper display will continuously show the assigned

I/O Auxiliary Box number.

If the ‘Reference Pressure’ function is active the upper

display item will continuously show the detected pressure

instead of the I/O Auxiliary Box number.

The lower display will show the default, or selected, user

menu item.

User menu items show the value being detected on

analog input(s) and the state or condition of digital

input(s) and relay outputs.

After a period of no keypad activity the User menu item

will automatically default to show the set ‘default item’

(adjustable in menu S01).

Digital or analog inputs that have not been activated

will not be shown in the User menu item list.

User Menu Items:

A01-A04 Analog Inputs 1 to 4

D01-D08 Digital Inputs 1 to 8

R01-R06

Relay Outputs 1 to 6

The Start and Stop buttons (if fitted) DO NOT affect the

operation of the I/O Box.

The start and stop buttons do have uses in Virtual

Relay Automation, however. Please see the virtual relay

automation manual for details.

6.6 DIGITAL INPUT STATUS INDICATIONS

When activated a ‘Digital Input’ will show the input status

and condition in the User menu item list.

0 = remote contact is open circuit

1 = remote contact is closed circuit

Dependent on the input setup, the display will also show:

OK OK Condition

NOT Not OK Condition

A Alarm State Condition

T

Trip State Condition

S Signal State Condition

6.3 STATUS SYMBOLS

I/O Box Status (always displayed):

Power Failure Auto Restart (always on)

Network communications established

Digital Inputs: Configuration

Pulse Count Mode:

If the digital input is setup in pulse count mode, the User

menu item will show the ‘pulse count’ since last reset.

17

Page 18

18

The number of detected pulses will represent an

1sec

accumulative metered value dependant on the device

providing the pulses.

For example: 1627384 may represent ft3 of air produced

or kWh of power consumed.

If the ‘manual pulse count reset’ option is enabled each

individual digital input pulse count can be reset from the

keypad:

Press and hold ENTER then press CANCEL. The

pulse count will be cleared and start immediately again

from zero.

6.7 ANALOG INPUT DISPLAY

When activated, an ‘Analog Input’ will show a value in

the User menu item list. The value displayed will be

dependant on analog input setup and configuration.

6.10 SHUTDOWN FAULTS

The Fault LED will ‘fast flash’ to indicate a Shutdown

condition. A Shutdown condition will stop normal

operation of the I/O Box. All Shutdown conditions must

be manually reset.

Fault Codes:

Each individual fault has a unique numeric code.

E0010

The wire link between terminals ‘+C’ and ‘C1’ of the unit’s

controller is open circuit. These terminals are permanently

connected together on the IO Box Terminal PCB: this error

will never occur in normal operational circumstances.

Emergency Stop

Analog inputs can be set to indicate an Alarm, High Level

Alarm or Signal condition.

If one of these conditions occurs the analog input

Usermenu item will also display:

A Alarm Condition

T High Level Alarm Condition

S Signal Condition

Analog Inputs: Configuration

Relay Output Display

When activated, a ‘Relay Output’ will show the output

status of the contacts in the User menu item list.

Relay Off: contacts open circuit

Relay On: contacts closed circuit

The function and activation of each relay output is

dependant on setup and configuration.

Virtual Relay Automation

6.8 POWER FAILURE AUTORESTART

The I/O Box will always automatically start when power is

re-applied after a power supply disruption or failure.

6.9 I/O BOX FAULT

If an RP pressure sensor fault is detected (if the RP

pressure sensor option is enabled) the I/O Box will display

“- - - -“ dashes on the upper display and indicate the

condition with an Alarm symbol. The I/O Box will continue

to operate normally without interruption.

E0506

Short circuit condition has been detected on the XPMAi4

module (Analog inputs 1 to 4).

E0821

Short Circuit condition detected on the main controller

unit (digital inputs).

E0836

Internal failure or excessively high external electrical

interference detected.

The main timing circuit (processor clock) has been

disrupted and the processor is running on an ‘internal to

chip’ back-up clock.

The controller’s main power supply must be removed and

re-applied to reset this condition.

E0840

Data communications with the XPM-Ai4 module (analog

inputs 1 to 4) have been disrupted or lost.

E5000

The unit’s controller has detected disruption to the

internal operational memory storage (RAM). The integrity

of the RAM memory contents are suspect; the controller

must be reset to clear and re-map the memory. Renew

the controller if this fault condition persists.

The controller’s main power supply must be removed and

re-applied to reset this condition.

E5001

The unit’s controller has detected disruption to the

internal permanent application memory storage (FLASH).

The integrity of the FLASH memory contents is suspect.

Reload the main application software in the first instance;

renew the controller if the condition persists.

The controller’s main power supply must be removed and

reapplied to reset this condition.

XPM-Ai4 Short Circuit

Short Circuit

PLL Unlock

XPM-Ai4 Communications

Internal Memory Map Error

Internal Memory Failure

Page 19

MANAGEMENT UNIT FAULT CODES

The X8I unit can be set to monitor an IO Box. In this

condition any ‘A’ Alarm or ‘T’ Trip indication will also be

displayed by the X8I.

The X8I will display an IO Box fault code that describes the

IO Box system number and the input (digital or analog)

identification. All inputs on all system IO Box(s) will have a

unique alarm code in the format:

B’nn’ . ’XX’

‘nn’ = IO Box number (01 or 2)

‘XX’ = Input identification Code

The alarm code will also differ dependent on the alarm

type for a particular input (Alarm ‘A’ or Trip ‘T’).

Digital; Input Identification Codes:

Input No. A T

1 01 17

2 02 18

3 03 19

4 04 20

5 05 21

6 06 22

7 07 23

8 08 24

Analog; Input Identification Codes:

Input No. A T

1 49 57

2 50 58

3 51 59

4 52 60

Network Communications Error:

B’nn’. - - -

(IO Box identification followed by dashes)

This message indicates an IR485 network communication

disruption or loss. The management system is no longer

receiving data from the IO Box.

19

Page 20

20

24mm

238mm

24mm

188mm

8mm Ø

236mm

286mm

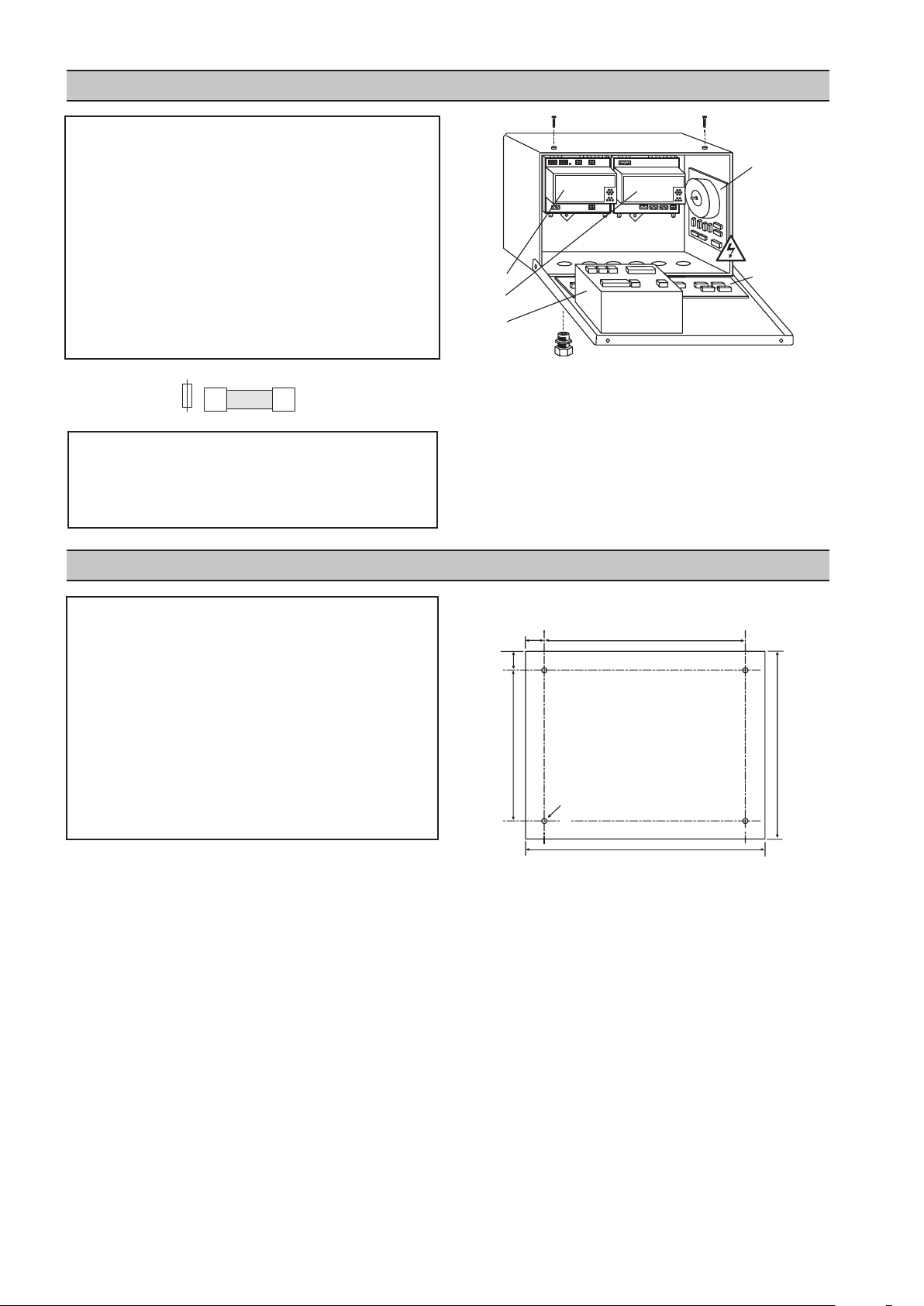

SECTION 8 PARTS LIST

20mm

5mm

IEC

X

P

M

-

T

A

C2

4

XPM-PSU24

XPM-Ai4

6

4

3

2

1

5

Item Part No. Description

- 42659409 IO Box Kit

- 23242209 IO Box Unit

- 80444086 Manual, User CD

1 42659482 Controller, IO

2 42659284 XPM-PSU24

3 42659326 XPM-Ai4

4 39265913 Unit, XPM-TAC24

5 39265905 PCB, Terminal

6 38036703

Qty Part No. Description

10 39265962 IEC Fuse T1.0A

10 39265970 IEC Fuse T1.6A

10 39265988 IEC Fuse T3.15A

Gland, Set - Pg13.5

SECTION 9 TECHNICAL DATA

Dimensions 291mm x 241mm x 152mm

11.45” x 9.45” x 6.0”

Weight 6.5kg (14Ib)

Mounting wall, 4 x screw fixings

Enclosure IP54, NEMA 12

Supply 230Vac +/- 10%

115Vac +/- 10%

Power 50VA

Temperature 0°C to 46°C (32°F to 115°F)

Humidity 95% RH non-condensing

INSTALLATION AND MOUNTING DIMENSIONS

Page 21

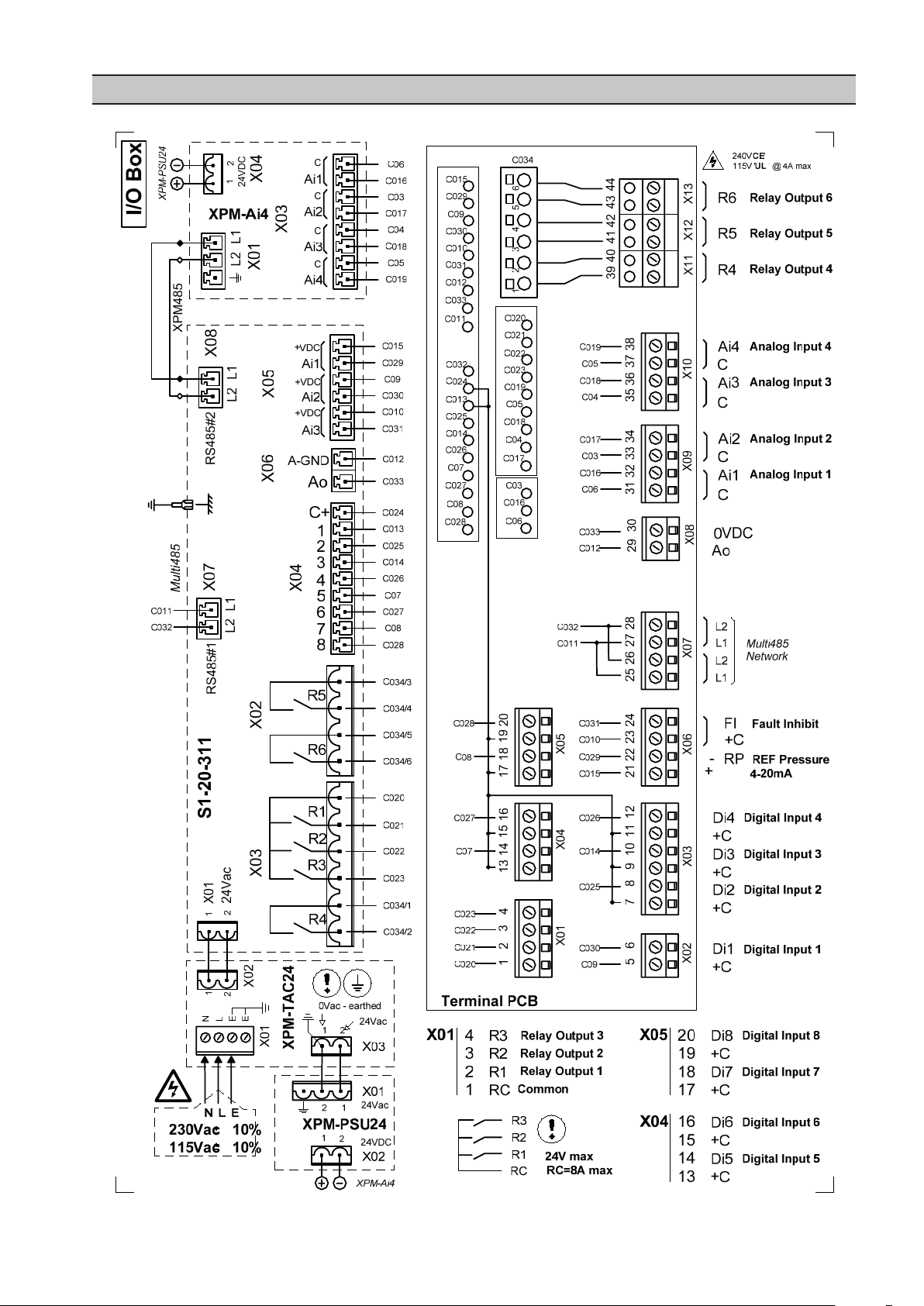

SECTION 10 WIRING DIAGRAM

21

Page 22

22

XPMTAC24

230V

115V

24Vac/1

isolated

24Vac/2

earthed

EE

L

N

N L E

BLUE

BROWN

RED

GREEN

VIOLET

WHITE

ORANGE

BLACK

FH1

FH2FH3

FH4

FH5

1

VOLTAGE SELECT

2 3 4

X04

2 1 2

X03

X02

X01

T3.15A

T1.6A

T1.6A

T1.0A

T1.0A

1 2 3 4

115V +-10%

230V +-10%

1 2 3 4

IEC

5x20mm

Page 23

Customer

Contact

Phone

Installation/Site

Ser No.

Software

Commission Date

Commission Engineer

Customer Ref:

Internal Ref:

S01 Ad Box Number (Network Address)

S01 PD Reference Pressure Detect Enable

isp/ rabnoitarbilaC tesffO PRoP10S

isp/ rabnoitarbilaC egnaR PRrP10S

S01 P> RP Pressure Display Units

S01 ID Default User Menu Item

S01 RP Pulse Counter Reset Enable

1 2 3

4

5

6 7 8 9

10

11

12

bar psi kPa

0 1:on

0 1:on

d01 ST Normal State

d01 Fn Function

d01 DT Delay Time sec

d01 RF Reset Function

“-“ A T

NO NC

0 1:on

S

d02 ST Normal State

d02 Fn Function

d02 DT Delay Time sec

d02 RF Reset Function

“-“ A T

NO NC

0 1:on

S P

d03 ST Normal State

d03 Fn Function

d03 DT Delay Time sec

d03 RF Reset Function

“-“ A T

NO NC

0 1:on

S P

d04 ST Normal State

d04 Fn Function

d04 DT Delay Time sec

d04 RF Reset Function

“-“ A T

NO NC

0 1:on

S P

d05 ST Normal State

d05 Fn Function

d05 DT Delay Time sec

d05 RF Reset Function

“-“ A T

NO NC

0 1:on

S P

d06 ST Normal State

d06 Fn Function

d06 DT Delay Time sec

d06 RF Reset Function

“-“ A T

NO NC

0 1:on

S P

d07 ST Normal State

d07 Fn Function

d07 DT Delay Time sec

d07 RF Reset Function

“-“ A T

NO NC

0 1:on

S P

d08 ST Normal State

d08 Fn Function

d08 DT Delay Time sec

d08 RF Reset Function

“-“ A T

NO NC

0 1:on

S

I/O Commissioning Form

23

Page 24

A01 AT Input Type

A01 Ut Display Units

A01 Vo Value Offset Calibration

A01 Vr Value Range Calibration

A01 DF Display Function

A01 FH Fault High Level Set Point

A01 FL Fault Low Level Set Point

A01 Fn Fault Function

A01 FI Fault Inhibit Function Enable

cesemiT yaleDtD10A

A01 RT Reset Function

“-“

1

0 1:on

0 1:on

“-“ A T S

2 3 4 5 6 F7 F8 F9 F10

1:no 2:10V 3:0mA

7

6 8

1:nc

3:4mA

4:0mA

4:4mA

5:KTY

5:RTD

A02 AT Input Type

A02 Ut Display Units

A02 Vo Value Offset Calibration

A02 Vr Value Range Calibration

A02 DF Display Function

A02 FH Fault High Level Set Point

A02 FL Fault Low Level Set Point

A02 Fn Fault Function

A02 FI Fault Inhibit Function Enable

cesemiT yaleDtD20A

A02 RT Reset Function

“-“

1

0 1:on

0 1:on

“-“ A T S

2 3 4 5 6 F7 F8 F9 F10

1:no 2:10V 3:0mA

7

6 8

1:nc

3:4mA

4:0mA

4:4mA

5:KTY

5:RTD

A03 AT Input Type

A03 Ut Display Units

A03 Vo Value Offset Calibration

A03 Vr Value Range Calibration

A03 DF Display Function

A03 FH Fault High Level Set Point

A03 FL Fault Low Level Set Point

A03 Fn Fault Function

A03 FI Fault Inhibit Function Enable

cesemiT yaleDtD30A

A03 RT Reset Function

“-“

1

0 1:on

0 1:on

“-“ A T S

2 3 4 5 6 F7 F8 F9 F10

1:no 2:10V 3:0mA

7

6 8

1:nc

3:4mA

4:0mA

4:4mA

5:KTY

5:RTD

A04 AT Input Type

A04 Ut Display Units

A04 Vo Value Offset Calibration

A04 Vr Value Range Calibration

A04 DF Display Function

A04 FH Fault High Level Set Point

A04 FL Fault Low Level Set Point

A04 Fn Fault Function

A04 FI Fault Inhibit Function Enable

cesemiT yaleDtD40A

A04 RT Reset Function

“-“

1

0 1:on

0 1:on

“-“ A T S

2 3 4 5 6 F7 F8 F9 F10

1:no 2:10V 3:0mA

7

6 8

1:nc

3:4mA

4:0mA

4:4mA

5:KTY

5:RTD

ACM

ACM

ACM

ACM

mpr1# deepS tfahS1r01F

mm1# retemaiD tfahS1d01F

mpr2# deepS tfahS2r01F

mm2# retemaiD tfahS2d01F

mpr3# deepS tfahS3r01F

mm3# retemaiD tfahS3d01F

mpr4# deepS tfahS4r01F

mm4# retemaiD tfahS4d01F

SPM Bearing Monitoring

24

Page 25

Page 26

LOOK WHAT INGERSOLL RAND CAN DO FOR YOU!

Efficient Field Service

We maintain a highly trained staff of technicians

to service your equipment for preventive

maintenance, or to assist you should emergencies

ever occur.

Complete Repair Service

Our trained technicians will repair or overhaul

your equipment to factory specifications,

using only genuine Ingersoll Rand parts.

Special Engineering Service

We can help you identify and solve your problems

by evaluating your needs and recommending

theproper equipment to give your maximum

efficiency.

Spare Parts

By stocking genuine Ingersoll Rand spare

parts, we can help you avoid costly delays

or substituting inferior parts. Using genuine

Ingersoll Rand parts on you Ingersoll

Rand equipment will help to keep even

older equipment running in good-as-new

Complete Stock of Equipment

We carry a complete line of Ingersoll Rand

equipment and accessories designed to meet

any compressed air application. We are backed

by Ingersoll Rand’s prompt factory shipment to

ensure you on-time delivery.

condition.

A SUBSTITUTE IS NOT A REPLACEMENT!

Ensure you get peak performance and longevity out of your Ingersoll Rand product by insisting on genuine Ingersoll

Rand replacement parts and maintenance kits. Not only are the replacement parts made to precise dimensions and OEMspecified metallurgy, but each part is backed by the Ingersoll Rand warranty. Your local Customer Center, Distributor, or

direct Ingersoll Rand salesperson will work with your to ensure you get the parts you need to do the job right. Equip your

machines with only the best Ingersoll Rand genuine parts.

NOTE: THE USE OF REPAIR PARTS OTHER THAN THOSE INCLUDED WITHIN THE INGERSOLL RAND COMPANY

APPROVED PARTS LIST MAY CREATE UNSAFE CONDITIONS OR MECHANICAL FAILURES OVER WHICH INGERSOLL

RAND COMPANY HAS NO CONTROL. INGERSOLL RAND COMPANY SHALL BEAR NO RESPONSIBILITY FOR

EQUIPMENT ON WHICH NON-APPROVED REPAIR PARTS ARE INSTALLED.

The manufacturer reserves the right to make changes or add improvements without notice and without incurring any

obligation to make such changes to products previously sold.

Loading...

Loading...