Page 1

Ingersoll Rand System Automation

ENGLISH

FRENCH

GERMAN

DUTCH

PRINT LANGUAGE

ITALIAN

SPANISH

IX IntelliFlow

Operator’s Manual

80445570

Revision D

January 2012

DE

Bedienungshandbuch

EN

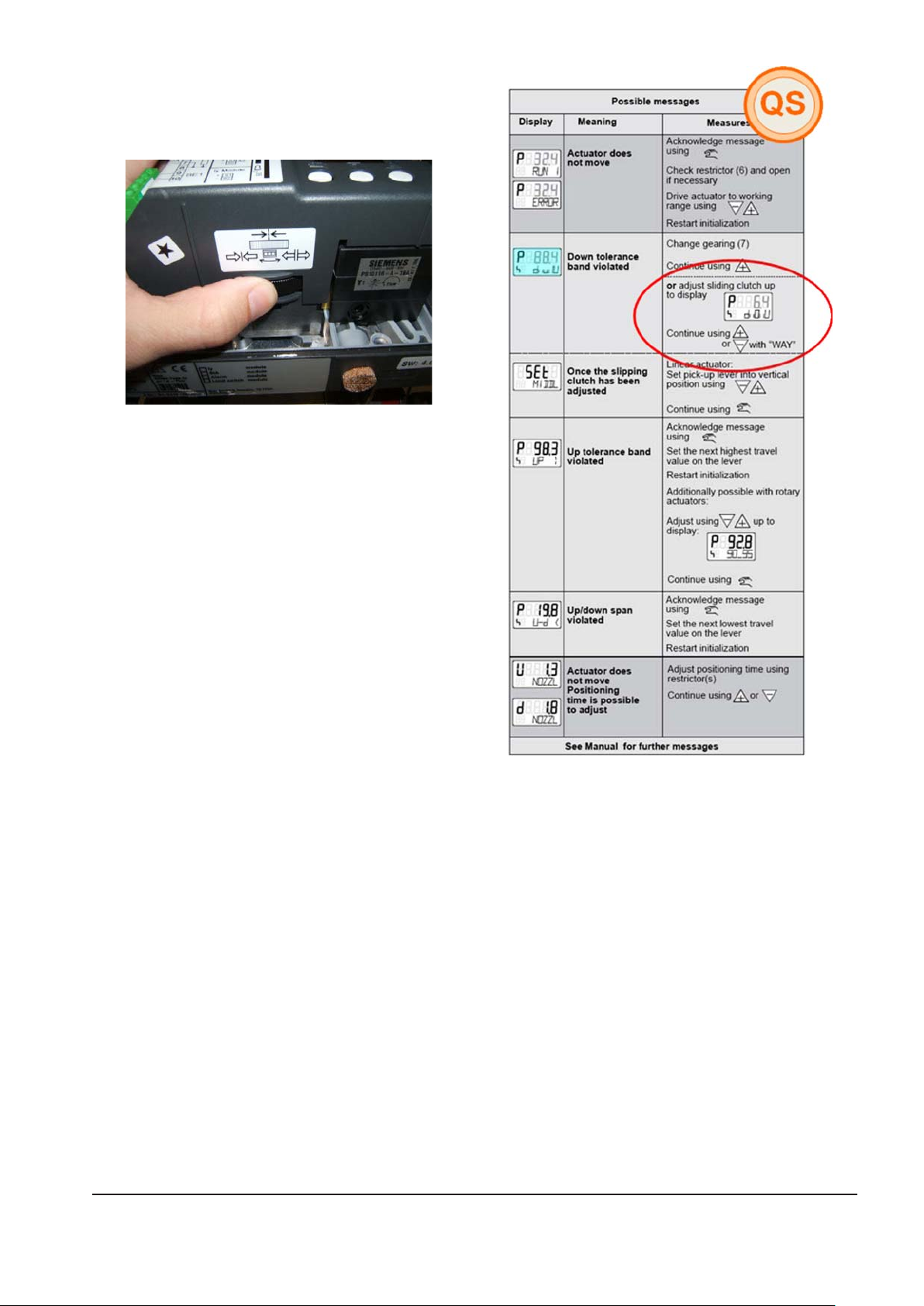

Operator’s Manual

ES

Manual De Operadores

FR

Manuel De L’utilisateur

IT

Manuale D’uso

NL

Gebruiksaanwijzingen

Save These Instruction

Page 2

SECTION 1 TABLE OF CONTENTS

Section 1 - table of contentS .............................2

DeclaRation of confoRMitY ...............................3

Section 3 - intRoDUction ......................................4

Section 4 - SafetY ....................................................4

SAFETY PRECAUTIONS .............................................4

SHIPMENT INSPECTION / PREINSTALLATION CHECK 4

INSTALLATION .............................................................................4

OPERATION ...................................................................................4

MAINTENANCE AND REPAIR .................................................5

Section 5 - connection anD contRol .............6

OPERATING MODES .................................................................6

Section 6 - inStallation .........................................8

IX INTELLIFLOW TECHNICAL DATA .....................................8

IX INTELLIFLOW INSTALLATION ...........................................9

IX BOX POWER SUPPLY ..........................................................10

IX INTELLIFLOW VALVE CONTROLLER CONNECTION

AND SENSOR ARRANGEMENT ............................................10

IX BOX RS485 NETWORK .......................................................11

Section 7 - DiSPlaY anD MenU oPeRation ....12

Section 8 - coMMiSSioninG .................................14

Section 10 - DiaGnoSticS .....................................21

DIAGNOSTIC MENU 5 .............................................................21

Section 11 - faUlt coDeS ......................................22

Section 12 - iX intellifloW contRolleR PaRt

liSt ..................................................................................23

Section 13 - iX intellifloW contRolleR

tecHnical Data .........................................................23

Section 14 - iX intellifloW contRolleR

WiRinG DiaGRaM .......................................................24

ENCLOSURE MOUNTING .......................................................26

Section 15 - iX intellifloW contRolleR

ReMote inPUtS ..........................................................27

IX BOX INPUT FUNCTIONS ...................................................27

VIRTUAL RELAY AUTOMATION ...........................................27

Section 16 - iX intellifloW contRolleR RS485

MoDbUS ReGiSteRS ...................................................28

Section 17 - iX intellifloW DiGital

PoSitioneR ..................................................................29

IX INTELLIFLOW DIGITAL POSITIONER SETUP

PROCEDURE ...............................................................................29

Section 18 - iX intellifloW actUatoR fail

oPen to fail cloSeD ................................................39

PHYSICAL CHECKS ...................................................................14

PRESSURE DISPLAY .................................................................14

OPERATING MODE ...................................................................14

PRESSURE SET POINTS ...........................................................14

IX BOX OPTIONAL FEATURES AND FUNCTIONS .........14

IX INTELLIFLOW STARTUP ...................................................14

SETTING THE TUNING PARAMETERS ................................15

Section 9 - SYSteM confiGURation .................16

DISPLAY AND MENU OPERATION......................................16

ACCESSING THE IX CONFIGURATION SCREENS ...........16

CONFIGURATION MENU OVERVIEW ................................17

USER CONFIGURATION MENU 1 ........................................18

PRESSURE TARGET MENU 2 .................................................20

SENSOR CALIBRATION MENU 3 ..........................................20

RELAY CONFIGURATION MENU 4 ......................................20

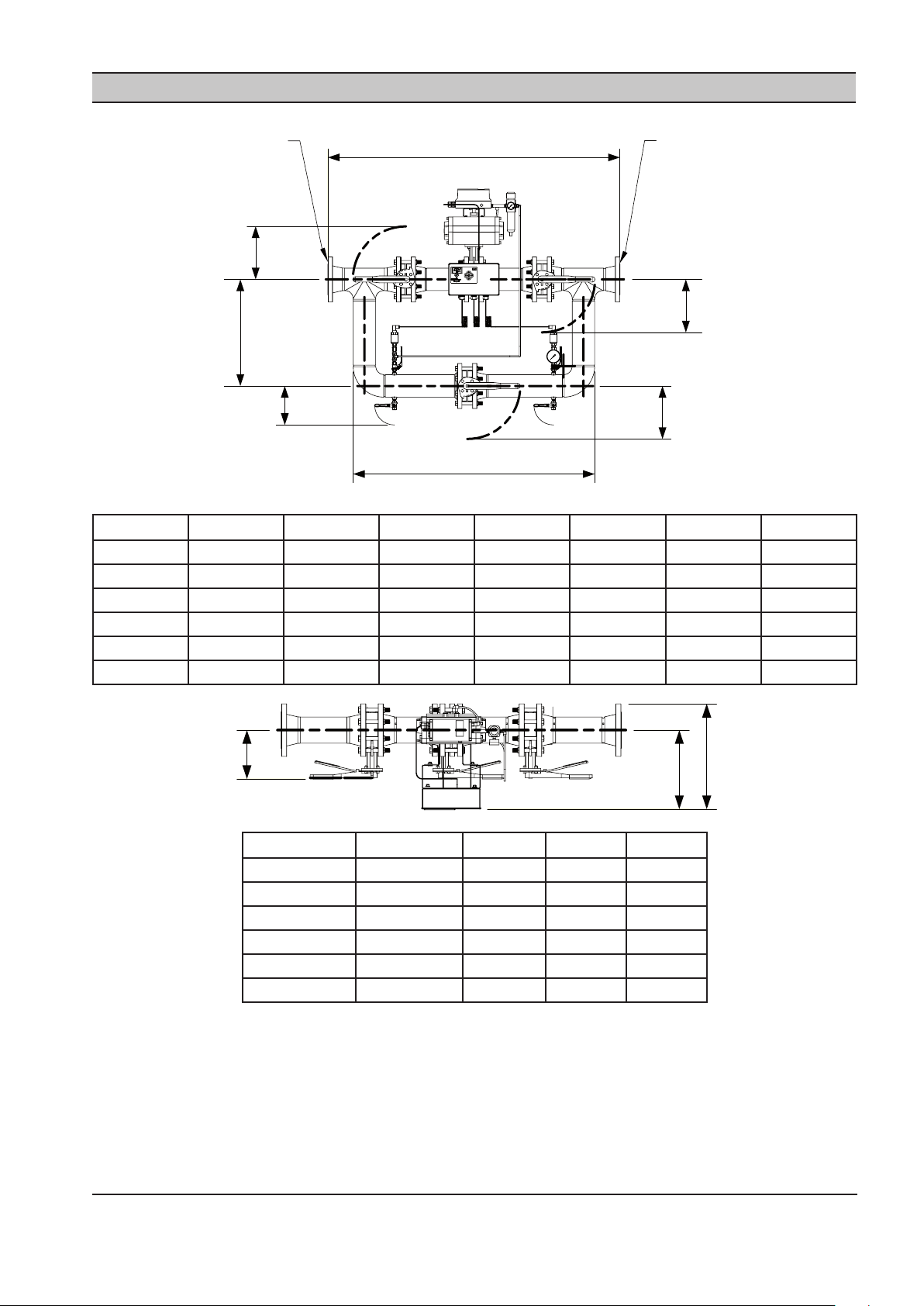

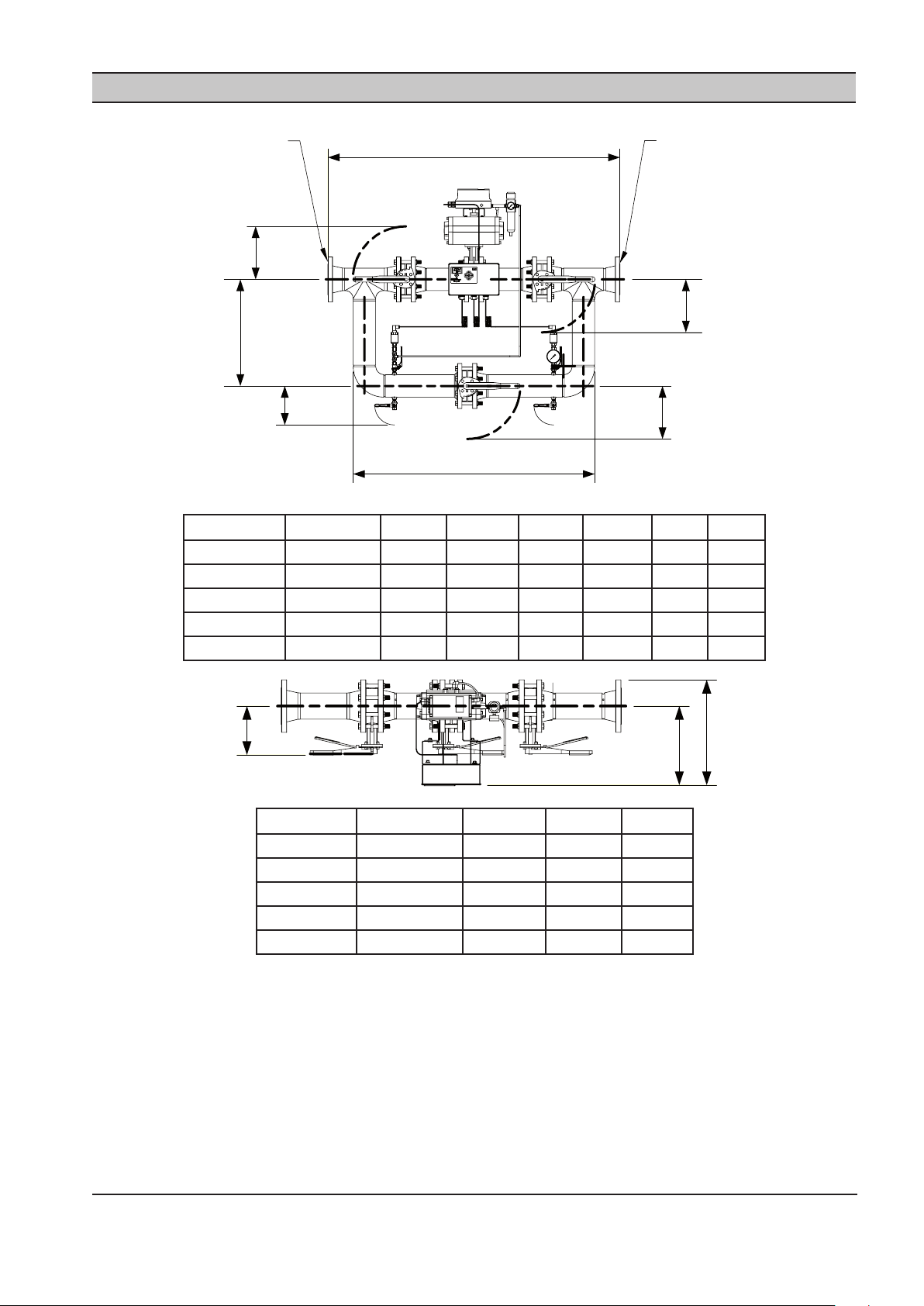

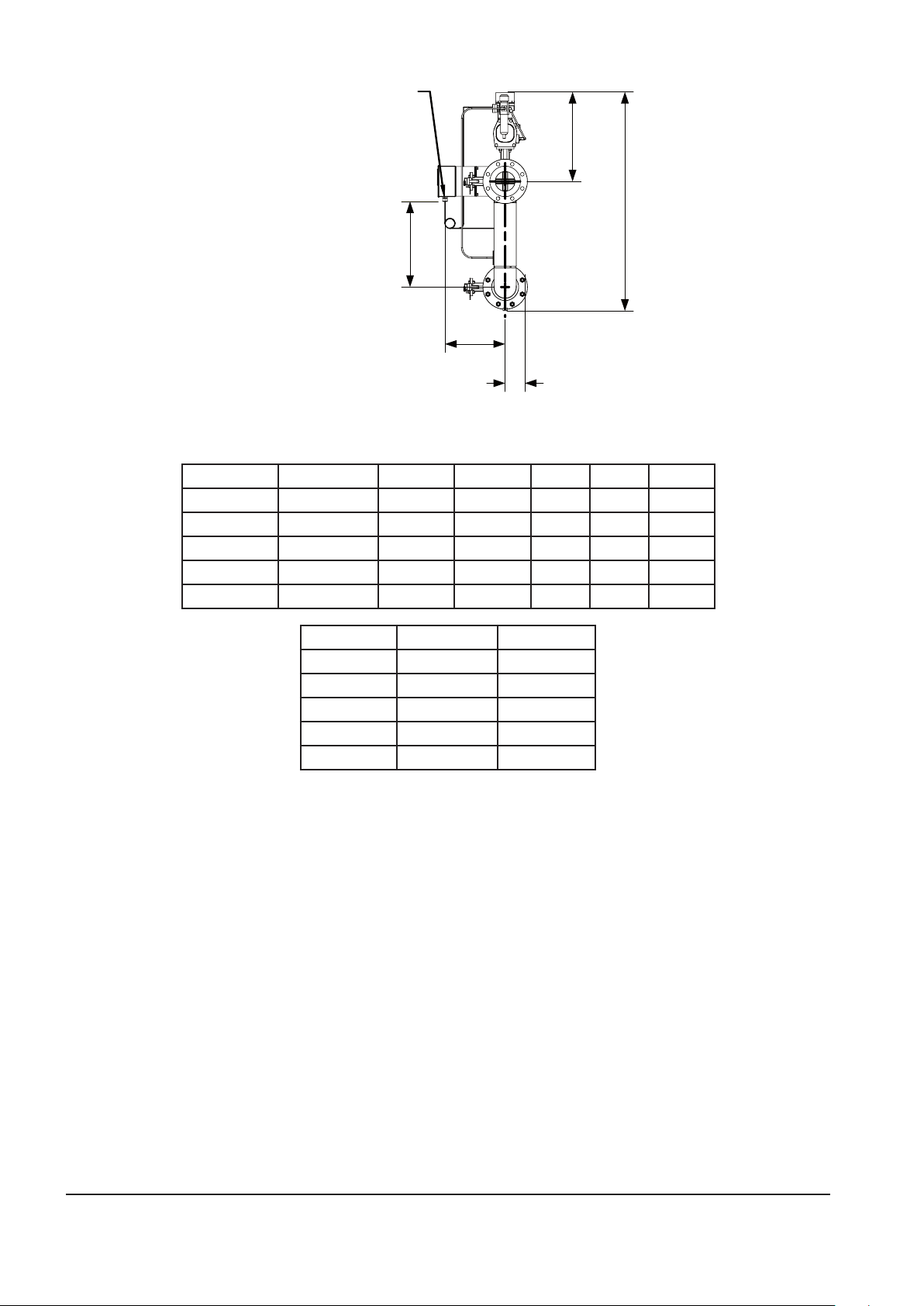

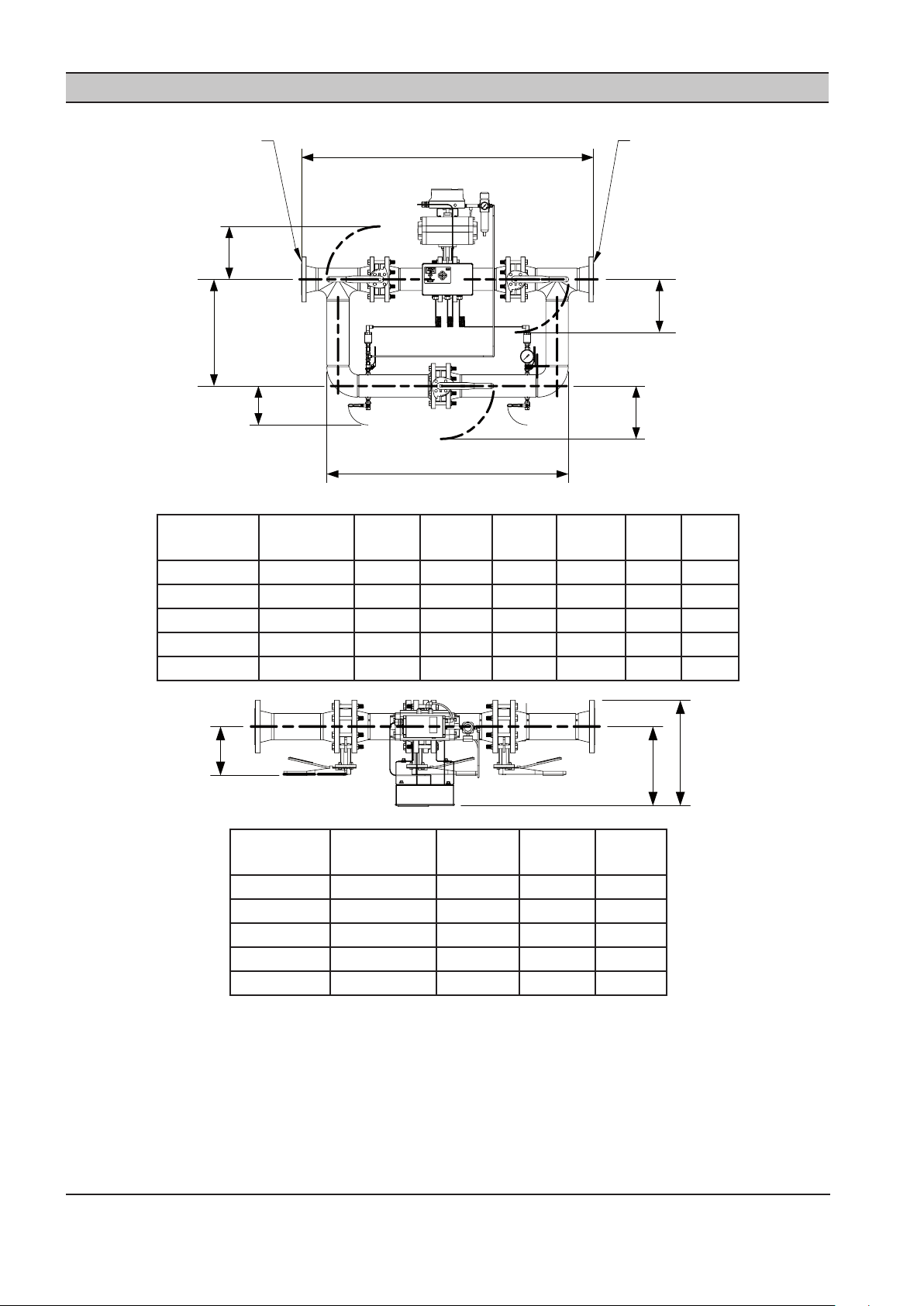

Section 19 - iX intellifloW aSSeMblY

oVeRVieW DRaWinG .................................................40

Section 20 - iX intellifloW aSSeMblY

DiMenSionS “incHeS” ..............................................41

Section 21 - iX intellifloW aSSeMblY

DiMenSionS “MilliMeteR” ......................................43

Section 22 - iX intellifloW aSSeMblY SPaRe

PaRtS liSt .....................................................................45

REFER TO SECTION INDICATED

NOTE

IMPORTANT OR CAUTION, SAFETY

2 Ingersoll Rand System Automation IX Intelliow

ingersollrandproducts.com

Page 3

DECLARATION OF CONFORMITY

(ES) DECLARACIÓN DE CONFORMIDAD (FR) CERTIFICAT DE CONFORMITÉ (IT) DICHIARAZIONE DI CONFORMITÀ

(DE) KONFORMITÄTSERKLÄRUNG (NL) SCHRIFTELIJKE VERKLARING VAN CONFORMITEIT (DA) FABRIKATIONSERKLÆRING

(SV) FÖRSÄKRAN OM ÖVERENSSTÄMMELSE (NO) KONFORMITETSERKLÆRING (FI) VAKUUTUS NORMIEN TÄYTTÄMISESTÄ

(PT) DECLARAÇÃO DE CONFORMIDADE (EL) ΗΛΣΗ ΑΝΑΓΝΡΙΣΗΣ (SL) IZJAVA O SKLADNOSTI (SK) PREHLÁSENIE O

ZHODE (CS) PROHLÁŠENÍ O SHODĚ (ET) VASTAVUSDEKLARATSIOON (HU) MEGFELELŐSÉGI NYILATKOZAT (LT) ATITIKTIES

PAREIŠKIMAS (LV) ATBILSTĪBAS DEKLARĀCIJA (PL) DEKLARACJA ZGODNOŚCI

Ingersoll Rand 1302 GOSHEN PARKWAY, WEST CHESTER, PA 19380

DECLARE THAT UNDER OUR SOLE RESPONSIBILTY FOR MANUFACTURE AND SUPPLY, THE PRODUCT(S),

IX-050, IX-080, IX-100, IX-150, IX-200, IX-050HT, IX-080HT, IX-100HT, IX-150HT, IX-200HT

(ES) Declaramos que, bajo nuestra responsabilidad exclusiva, el producto: (FR) Déclarons sous notre seule responsabilité que le produit:

(IT) Dichiariamo sotto la nostra unica responsabilità che il prodotto: (DE) Erklären hiermit, gemäß unserer alleinigen Verantwortung, daß

die Geräte: (NL) Verklare n, onder onze uitsluitende aansprakelijkheid, dat het produkt: (DA) Erklærer som eneansvarlig, at nedenstående

produkt: (SV) Intygar härmed, i enlighet med vårt fullständiga ansvar, att produkten: (NO) Erklærer som eneansvarlig at produktet:

(FI) Vakuutamme ja kannamme yksin täyden vastuun siitä, että tuote: (PT) Declaramos sob a nossa exclusiva responsabilidade que o

produto: (EL) ηλώνουε ότι ε δική α ευθύνη το προϊόν: (SL) Pod polno odgovornostjo izjavljamo, da se izdelek: (SK) Prehlasujeme na

svoju zodpovednost’, že produkt: (CS) Prohlašujeme na svou zodpovědnost, že výrobek: (ET) Deklareerime oma ainuvastutusel, et toode:

(HU) Kizárólagos felelősségünk tudatában kijelentjük, hogy a termék: (LT) Prisiimdami atsakomybę pareiškiame, kad gaminys:

(LV) Uzņemoties pilnīgu atbildību, apliecinām, ka ražojums: (PL) Oświadcza, że ponosi pełną odpowiedzialność za to, że produkt:

To which this declaration relates, is in compliance with provisions of Directive(s): 97/23/EC., 93/68/EEC, 2004/108/EC, 2006/95/EC

(ES) a los que se reere la presente declaración, cumplen con todo lo establecido en las directivas: (FR) objet de ce certicat, est conforme

aux prescriptions des Directives: (IT) a cui si riferisce la presente dichiarazione è conforme alle normative delle direttive: (DE) auf die sich

diese Erklärung bezieht, den Richtlinien: (NL) waarop deze verklaring betrekking heeft overeenkomt met de bepalingen van directieven:

(DA) som denne erklæring vedrører, overholder bestemmelserne i følgende direktiver: (SV) som detta intyg avser, uppfyller kraven i

Direktiven: (NO) som denne erklæringen gjelder for, oppfyller bestemmelsene i EU-d irektivene: (FI) johon tämä vakuutus viittaa, täyttää

direktiiveissä: (PT) ao qual se refere a presente declaração, está de acordo com as prescrições das Directivas: (EL) τα οποία αφορά αυτή

η δήλωση‚ είναι σύφωνα ε τι προβλέψει των Eντολών: (SL) Na katerega se ta izjava o skladnosti nanaša, sklada z določili smernic:

(SK) Ku ktorému sa toto prehlásenie vzt’ahuje, zodpovedá ustanoveniam smerníc: (CS) Ke kterým se toto prohlášení vztahuje, odpovídají

ustanovením směrnic: (ET) Mida käesolev deklaratsioon puudutab, on vastavuses järgmis(t)e direktiivi(de) sätetega: (HU) Amelyekre ezen

nyilatkozat vonatkozik, megfelelnek a következő irányelv(ek) előírásainak: (LT) Kuriems taikomas šis pareiškimas, atitinka šios direktyvos

nuostatas: (LV) Uz kuru šī deklarācija attiecas, atbilst direktīvas(u) nosacījumiem: (PL) Do których ta deklaracja się odnosi, są zgodne z

postanowieniami Dyrektywy (Dyrektyw):

By using the following Principle Standards: ASME B31.1, EN61000-6-2:2001, EN61000-6-4:2001, EN60204-1:1997

(ES) conforme a los siguientes estándares: (FR) en observant les normes de principe suivantes: (IT) secondo i seguenti standard:

(DE) unter Anlehnung an die folgenden Grundnormen entsprechen: (NL) overeenkomstig de volgende hoofdstandaards: (DA) ved at

være i overensstemmelse med følgende hovedstandard(er): (SV) Genom att använda följande principstandard: (NO) ved å bruke følgende

prinsipielle standarder: (FI) esitetyt vaatimukset seuraavia perusnormeja käytettäessä: (PT) observando as seguintes Normas Principais:

(EL) Χρησιοποιώντα ια παρακάτω κύρια πρότυπα: (SL) Uporabljeni osnovni standardi: (SK) Použitím nasledujúcich zákonných noriem: (CS) Použitím následujících zákonných norem: (ET) Järgmiste põhistandardite kasutamise korral: (HU) A következő elvi szabványok

alkalmazásával: (LT) Remiantis šiais pagrindiniais standartais: (LV) Izmantojot sekojošos galvenos standartus: (PL) Przy zastosowaniu

następujących podstawowych norm:

Date: May, 2010

(ES) Fecha: Mayo, 2010: (FR) Date: Mai, 2010: (IT) Data: Maggio, 2010: (DE) Datum: Mai, 2010: (NL) Datum: Mei, 2010:

(DA) Dato: Må, 2010: (SV) Datum: Maj, 2010: (NO) Dato: Mai, 2010: (FI) Päiväys: Toukokuu, 2010: (PT) Data: Maio, 2010:

(EL) Ηεροηνία: Μάιο, 2010: (SL) Datum: Maj, 2010: (SK) Dátum: Máj, 2010: (CS) Datum: Květen, 2010: (ET) Kuupäev: Mai, 2010: (HU) Dá-

tum: Május, 2010: (LT) Data: Gegužė , 2010: (LV) Datums: Maijs, 2010: (PL) Data: Maj, 2010

Approved By:

(ES) Aprobado por: (IT) Approvato da: (FR) Approuvé par: (DE) Genehmigt von: (NL) Goedgekeurd door: (DA) Godkendt af:

(SV) Godkänt av: (NO) Godkjent av: (FI) Hyväksytty: (PT) Aprovado por: (EL) Eγκρίθηκεαπό: (SL) Odobril: (SK) Schválil: (CS) Schválil: (ET)

Kinnitatud: (HU) Jóváhagyta: (LT) Patvirtinta: (LV) Apstiprināja: (PL) Zatwierdzone przez

H. MARK

H. MARK, ENGINEERING MANAGER

J. FARLEY, QUALITY ASSURANCE MANGER

J. FARLEY

ingersollrandproducts.com 3

Page 4

SECTION 3 INTRODUCTION

!

!

IX IntelliFlow is an intermediate system controller that

controls the system air pressure. The IX IntelliFlow can

control the Demand Side, Supply Side, or a combination

of both using user selectable set-points.

SECTION 4 SAFETY

SAFETY PRECAUTIONS

WARNING : Risk of Danger

WARNING : Risk of Electric Shock

WARNING : Risk of High Pressure

WARNING : Consult Manual

Before installing or operating the IX IntelliFlow, take

•

time to carefully read all the instructions contained

in this manual, all compressor manuals, and all

manuals of any other peripheral devices that may be

installed or connected to the unit.

Electricity and compressed air have the potential to

•

cause severe personal injury or property damage.

The operator should use common sense and good

•

working practices while operating and maintaining

this system. All applicable codes should be strictly

adhered to.

Maintenance must be performed by adequately

•

qualied personnel that are equipped with the

proper tools.

SHIPMENT INSPECTION / PRE

INSTALLATION CHECK

The crating should be inspected for shipping

•

damage after the unit has arrived.

The lter regulator assembly is shipped loose

•

with the IX controller. The assembly is packaged

in a box that is stored underneath the controller

mounting bracket. Please notify the shipper if this

box is missing or if tampering has occurred with the

shipping crate.

After the unit has been removed from the crate,

•

re-tighten all bolt connections as required prior to

installation to the appropriate torque specication.

The IX IntelliFlow is equipped with a locally mounted

PID controller (IX Box) which modulates the valve to

maintain a constant pressure [+/- .75 psi (0.05 bar)]

given the application of appropriately sized storage.

INSTALLATION

Installation work must only be carried out by a

•

competent person under qualied supervision.

A fused disconnect / isolation switch must be

•

tted between the main power supply and the IX

IntelliFlow. This should be located in close proximity

to the controller. The power consumption of the

controller is listed in the IX IntelliFlow Controller

Technical Data section of this manual. The power

installation shall be performed in accordance to

locally and nationally recognized electrical codes.

The IX IntelliFlow should be mounted in such a

•

location as to allow operational and maintenance

access without obstruction or hazard and to allow

clear visibility of indicators at all times.

If raised platforms are required to provide access

•

to the IX IntelliFlow, they must not interfere with

normal operation or obstruct access.

OPERATION

The IX IntelliFlow must only be operated by

•

competent personnel under qualied supervision.

Never remove or tamper with safety devices, guards

•

or insulation materials tted to the IX IntelliFlow.

The IX IntelliFlow must only be operated at the

•

supply voltage and frequency for which it is

designed.

When main power is switched on, lethal voltages are

•

present in the electrical circuits and extreme caution

must be exercised whenever it is necessary to carry

out any work on the unit.

Do not open access panels or touch electrical

•

components while voltage is applied unless it is

necessary for measurements, tests or adjustments.

Such work should be carried out only by a qualied

electrician equipped with the correct tools and

wearing appropriate protection against electrical

hazards.

All air compressors and/or other equipment

•

connected to the unit should have a warning sign

attached stating “THIS UNIT MAY START WITHOUT

WARNING” next to the display panel.

4 ingersollrandproducts.com

Page 5

If an air compressor and/or other equipment

•

connected to the unit is to be started remotely,

attach two warning signs to the equipment stating

“THIS UNIT CAN BE STARTED REMOTELY”. Attach

one sign in a prominent location on the outside

of the equipment, and the other sign inside the

equipment control compartment.

The IX IntelliFlow is designed for use on air piping

•

systems with a maximum pressure of 200 PSIG

(13.78 bar) at a maximum temperature of 150˚F

(65˚C).

Operation of equipment outside of stated

•

conditions may result in equipment damage or

injury. A eld supplied and installed pressure

limiting device (e.g. pressure relief valve) must be

installed in piping system.

MAINTENANCE AND REPAIR

Maintenance, repairs or modications must only

•

be carried out by competent personnel under

qualied supervision.

If replacement parts are required, use only genuine

•

parts from the original equipment manufacturer, or

an alternative approved source.

Make sure that all instructions concerning

•

operation and maintenance are strictly followed

and that the complete unit, with all accessories

and safety devices, is kept in good working order.

The accuracy of sensor devices must be checked

•

on a regular basis. They must be calibrated when

acceptable tolerances are exceeded. Always ensure

any pressure within the compressed air system is

safely vented to atmosphere before attempting to

remove or install a sensor device.

The IX IntelliFlow must only be cleaned with a

•

damp cloth, using mild detergents if necessary.

Avoid the use of any substances containing

corrosive acids or alkalis.

Do not paint the control faceplate or obscure any

•

indicators, controls, instructions or warnings.

Carry out the following operations before opening

•

or removing any access panels or carrying out any

work on the IX IntelliFlow:

i. Isolate the IX IntelliFlow from the main

electrical power supply. Lock the isolator in the

“OFF” position and remove the fuses.

ii. Attach labels to the isolator switch and to the

unit stating “WORK IN PROGRESS - DO NOT

APPLY VOLTAGE”. Do not switch on electrical

power or attempt to start the IX IntelliFlow if

such a warning label is attached.

ingersollrandproducts.com 5

Page 6

SECTION 5 CONNECTION AND CONTROL

70

psi

80

90

100

110

120

130

140

150

160

P4

P3

Ao

105

P4 Target = 95

1

2

100%

0%

115

95

P3 P4

3

70

psi

80

90

100

110

120

130

140

150

160

P4

P3

Ao

100

110

1

P3 P4

P3 Target = 80

2

3

0%

100%

100

110

80

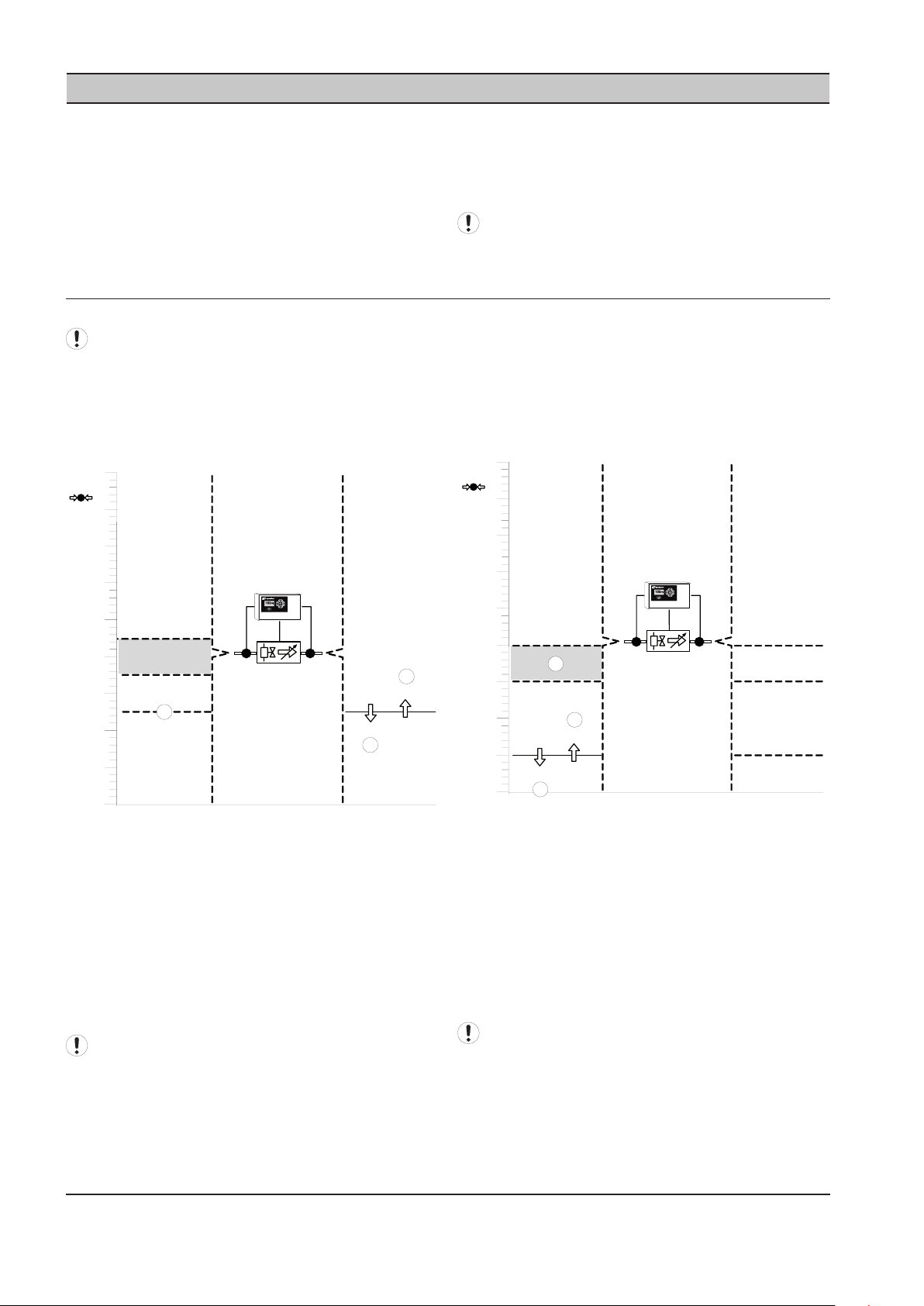

The IX IntelliFlow Air System Pressure/Flow Controller

can provide precise pressure control for Demand Side

(compressed air usage), Supply Side (compressed air

generation or Back Pressure control) applications as well

as a combination of Demand/Supply control applications.

OPERATING MODES

1) Demand Side or Forward Mode Pressure Control

This is the Default, As Shipped, from the Factory

Conguration

Used to accurately control Demand Side pressure (P4)

system using air from the Supply Side (P3).This mode of

operation is intended to ensure that a constant Demand

or Outlet side pressure is maintained.

The IX IntelliFlow separates the supply side from the

demand side. By doing so, the supply side is not aected

by specic demand events. The IntelliFlow is able to

handle transient demand events without the need for

extra compression equipment to come on-line.

All IX IntelliFlow applications must include the

installation of the proper receiver volume.

2) Supply Side / Back Pressure or Backward Mode

Pressure Control

Used to protect the Inlet or Supply Side (P3) system from

pressure decay due to excess air usage from the Demand

Side (P4). This mode of operation is intended to ensure

that a minimum specied Supply or Inlet side pressure is

maintained.

If P3 remains above 95psi (6.55 bar):

P4 is maintained at P4 target:

If demand increases and P4 falls below 95psi (6.55 Bar):

Valve opens towards 100% (1)

If demand decreases and P4 increases above 95psi (6.55

Bar):

Valve closes towards 0% (2)

If P3 falls below 95psi (6.55 Bar):

Valve will open 100% and P4 pressure will equal

Valve remains fully open and P4 pressure will

equal P3 pressure (1).

If P3 falls to 80psi (5.51 bar):

P3 is protected from falling below 80psi:

If P3 falls below 80psi (5.51 bar):

Valve closes towards 0% (2)

If P3 increases above 80psi (5.51 bar):

Valve opens towards 100% (3) and P4 pressure

will equal P3 pressure.

P3 pressure (3).

The IX IntelliFlow is set to Fail Open by Default. To

If P3 remains above 80psi (5.51 bar):

The IX IntelliFlow is set to Fail Open by Default

6 ingersollrandproducts.com

change to Fail Closed, Please refer to Section 16

Page 7

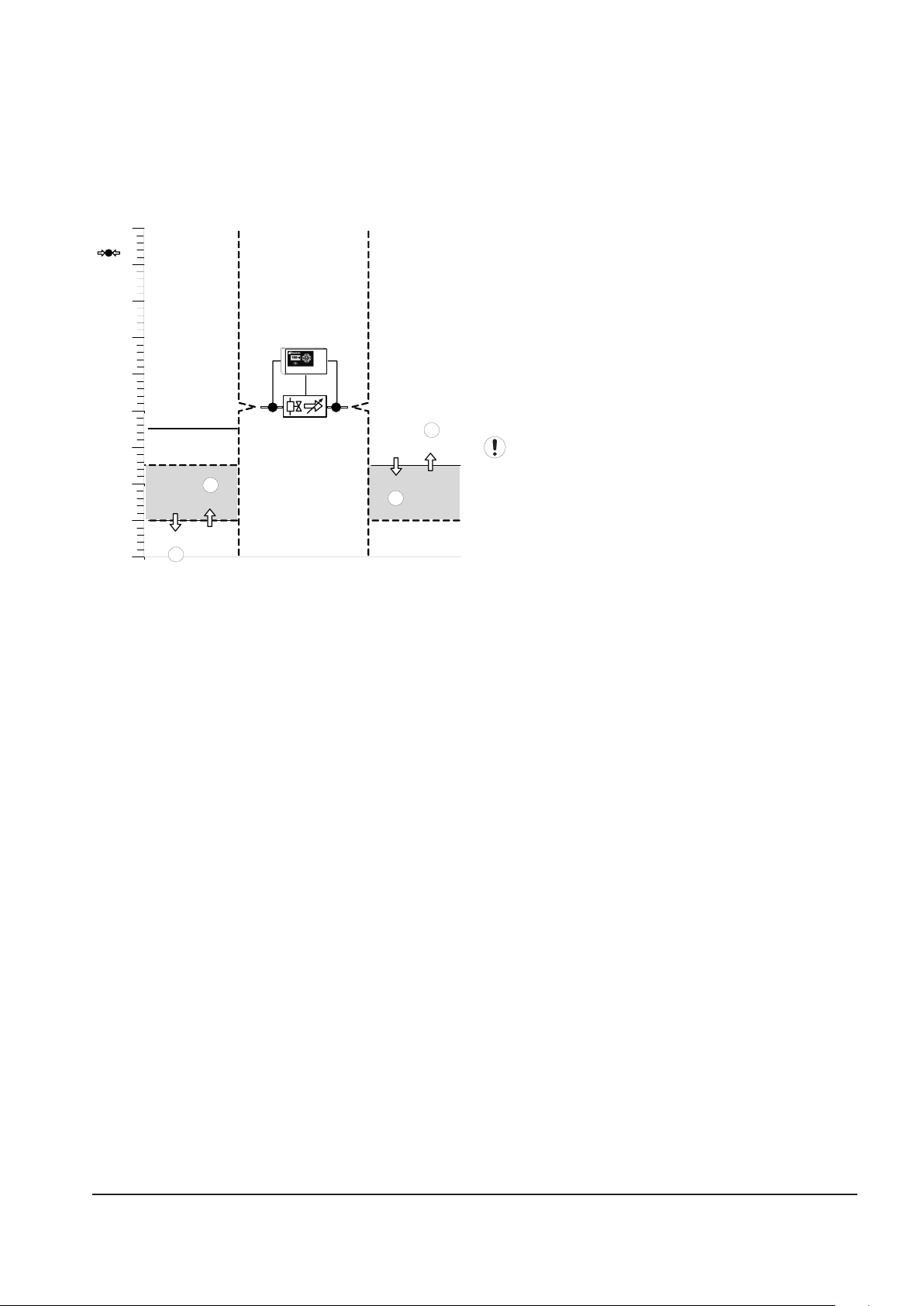

3) Combination Demand / Supply Side or Combination

70

psi

80

90

100

110

120

130

140

150

160

P4

P3

Ao

105

P3 Target = 80

P4 Target = 95

1

2

100%

0%

3

4

0%

100%

80

P3 P4

Mode Pressure Control

Used to accurately control pressure of the Demand Side

pressure (P4) system using air from the Supply Side (P3)

system while protecting the Supply Side (P3) system from

pressure decay due to excess air usage from the Demand

Side (P4) system

If P3 remains above 95psi (6.55 bar):

P4 is maintained at P4 target:

If demand increases and P4 falls below 95psi (6.55 bar)

Valve opens towards 100% (1)

If demand decreases and P4 increases above 95psi (6.55

bar):

Valve closes towards 0% (2)

If P3 falls below 95psi (6.55 bar) but remains above 80psi

(5.51 bar):

Valve will open 100% and P4 pressure will equal

P3 pressure.

If P3 falls to 80psi (5.51 bar):

P3 is protected from falling below 80psi (5.51

bar):

If P3 falls below 80psi (5.51 bar):

Valve closes towards 0% (3)

If P3 increases above 80psi (5.51 bar):

Valve opens towards 100% (4)

The IX IntelliFlow is set to Fail Open by Default. To

change to Fail Closed, Please refer to Section 16

ingersollrandproducts.com 7

Page 8

SECTION 6 INSTALLATION

IX INTELLIFLOW TECHNICAL DATA

VALVE ASSEMBLY

Available in 2” to 8” (50 to 200mm) congurations.

•

Piping is A53, Grade B, Type E, Schedule 40 welded

•

steel.

Connections are ANSI / DIN Raised Face anges and

•

are design rated for 200 lb (13.87 Bar) ANSI / DIN.

The valve body material is cast iron ASTM A126 Class

•

B design.

The valve stem material is 416 stainless Steel ASTM

•

A582 Type 416 design.

The valve seat material is bonded Buna-N Food

•

Grade design.

The valve disc material is Nylon 11 coated ductile

•

iron ASTM A536 Gr.65-45-12 design.

Taps: 1 upstream of the valve for control air and

•

pressure transducer (P3), 1 downstream of the valve

for the pressure gage and pressure transducer (P4),

1 upstream & 1 downstream of the valve for drain

ports, 1 upstream & 1 downstream of the valve for

eld instruments.

Assemblies are assumed to be installed in a building

•

and thereby protected from the elements. Electrical

enclosures are designed to meet the requirements

for a NEMA 12 / IP54 rating. Assembly is CRN listed

Ambient Operating Conditions: between 35°F and

•

115°F (2°C and 46°C), humidity from 0-95% noncondensing and inlet pressures not to exceed

200 PSIG (13.78 bar).

Downstream set point should be at least 5 PSIG (0.3

•

bar) below minimum upstream pressure.

Pressure turndown typically ≤ 30% maximum.

•

The valve has no eld adjustments necessary to

•

maintain optimum eld performance.

Inlet air temperature to valve not to exceed 150°F

•

(66°C).

Minimum control supply pressure (upstream of

•

valve) of 80 PSIG (5.5 bar).

Nominal pressure drop should not exceed 1 PSIG

•

(0.06 bar) across entire assembly with valve fully

open.

The valve actuator is a direct mounted pneumatic,

•

rack & pinion actuator with spring return.

The valve positioner is a single acting type with

•

visual digital indicator.

The lter regulator assembly has a 5-micron rating.

•

The Bowl is metal with an adjustment knob and a

Sight Glass.

An Assembly mounted PID Controller is standard.

•

Control valve defaults open on loss of control signal

•

to provide maximum security to process.

Flow range on each size is based upon the ability of

•

the valve to maintain +/- 1.0 PSIG (0.05 bar) tolerance

at max. & min. ow conditions.

CONTROLLER ASSEMBLY

Forward, backpressure and combination control

•

4 Target Setpoints

•

6 Remote Input Functions

•

o Select 1 of 3 Target Pressure Setpoints

o Select Manual Mode

o Force Valve Open

o Force Valve Closed

2 Output Relays – Congurable via Virtual Relay

•

Programming

Dual pressure sensors - one for Inlet Pressure (P3)

•

and one for Outlet Pressure (P4)

Modbus RTU communications capabilities

•

Interfaces with a X8I or X12I system with

•

Visualization

Power supply input that will accept 100Vac to

•

240Vac, 50/60Hz

Enclosure is NEMA 12 / IP54 rated

•

Provided the application of a properly

sized receiver tank for system storage.

8 ingersollrandproducts.com

Page 9

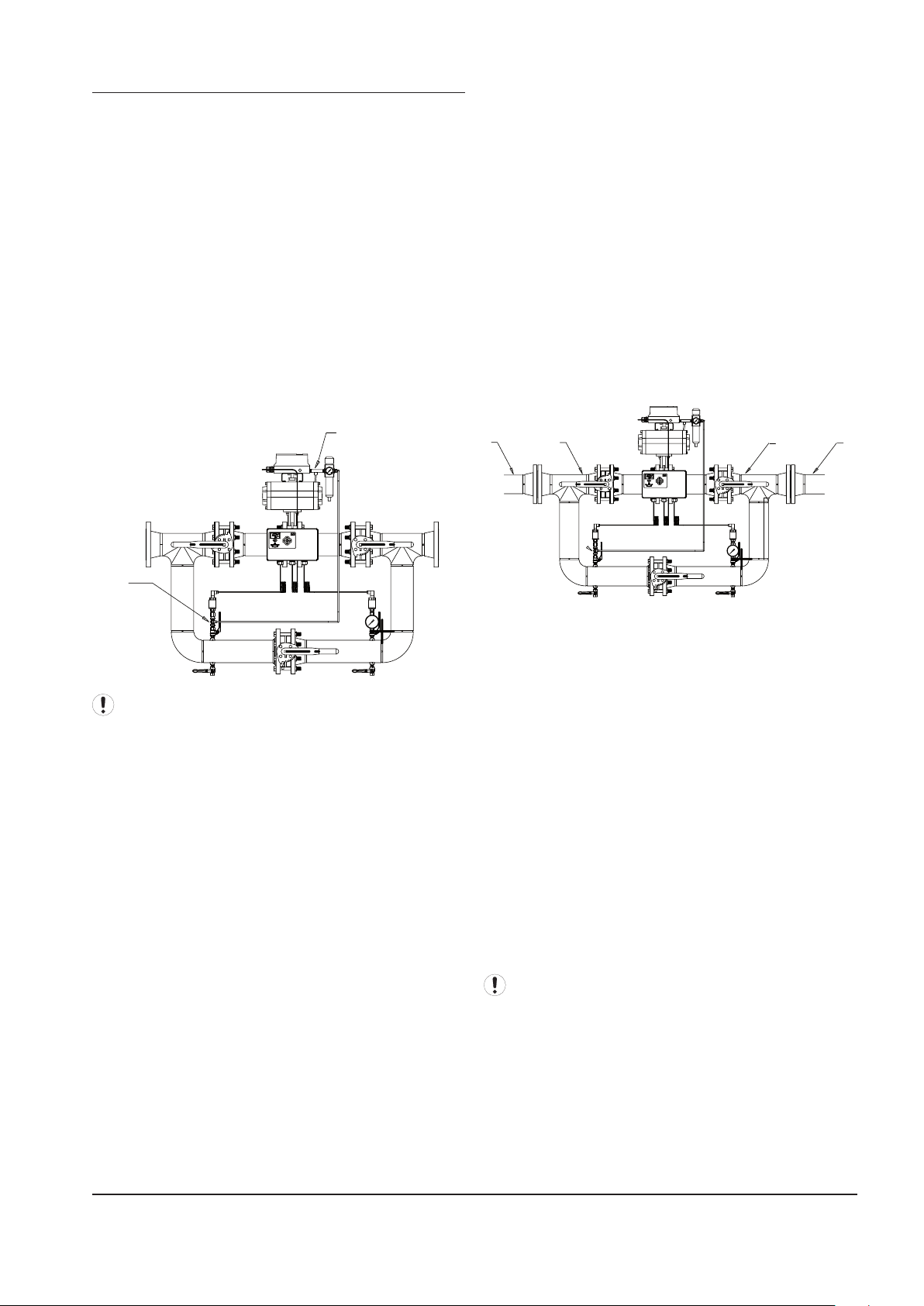

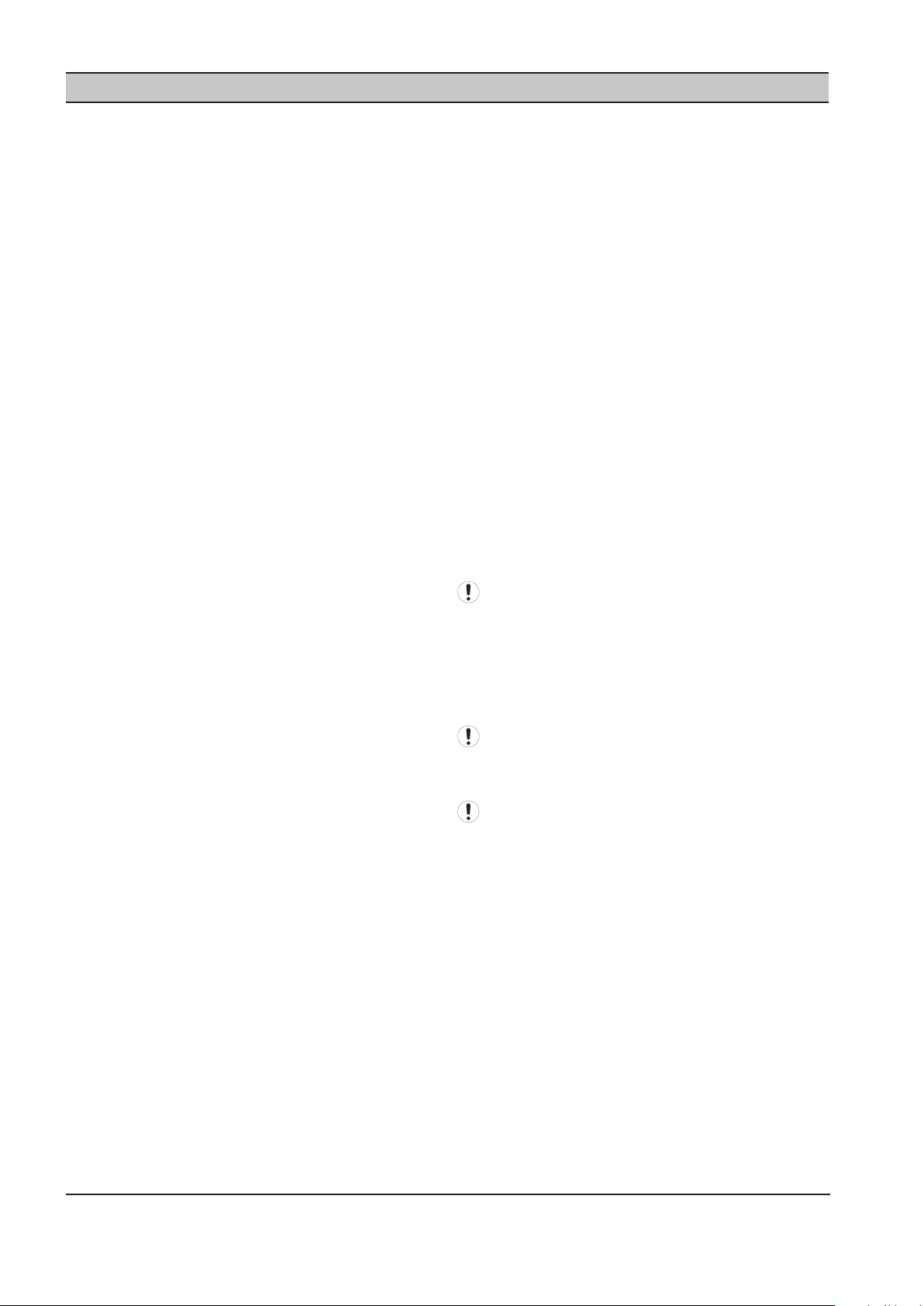

IX INTELLIFLOW INSTALLATION

B

A

B A BA

The IX IntelliFlow controller unit has been tested for

functionality and is ready for installation. Ingersoll

Rand recommends that a no-loss drain valve (CCN

38445920) be installed on the condensate drain valve

below the pressure transducer. (Other condensate drain

mechanisms can be installed/used. Consult Technical

Support or AfterMarket for assistance.) Inspect the unit

upon receipt. Immediately report any damage to the

shipping carrier.

FILTER INSTALLATION

The lter regulator assembly is shipped loose with

the IX controller. The assembly is packaged in a box

that is stored underneath the controller mounting

bracket. Please remove and mount as shown below

(A). The control air line for the lter assembly should be

connected to the tee tting connected to P3 (B).

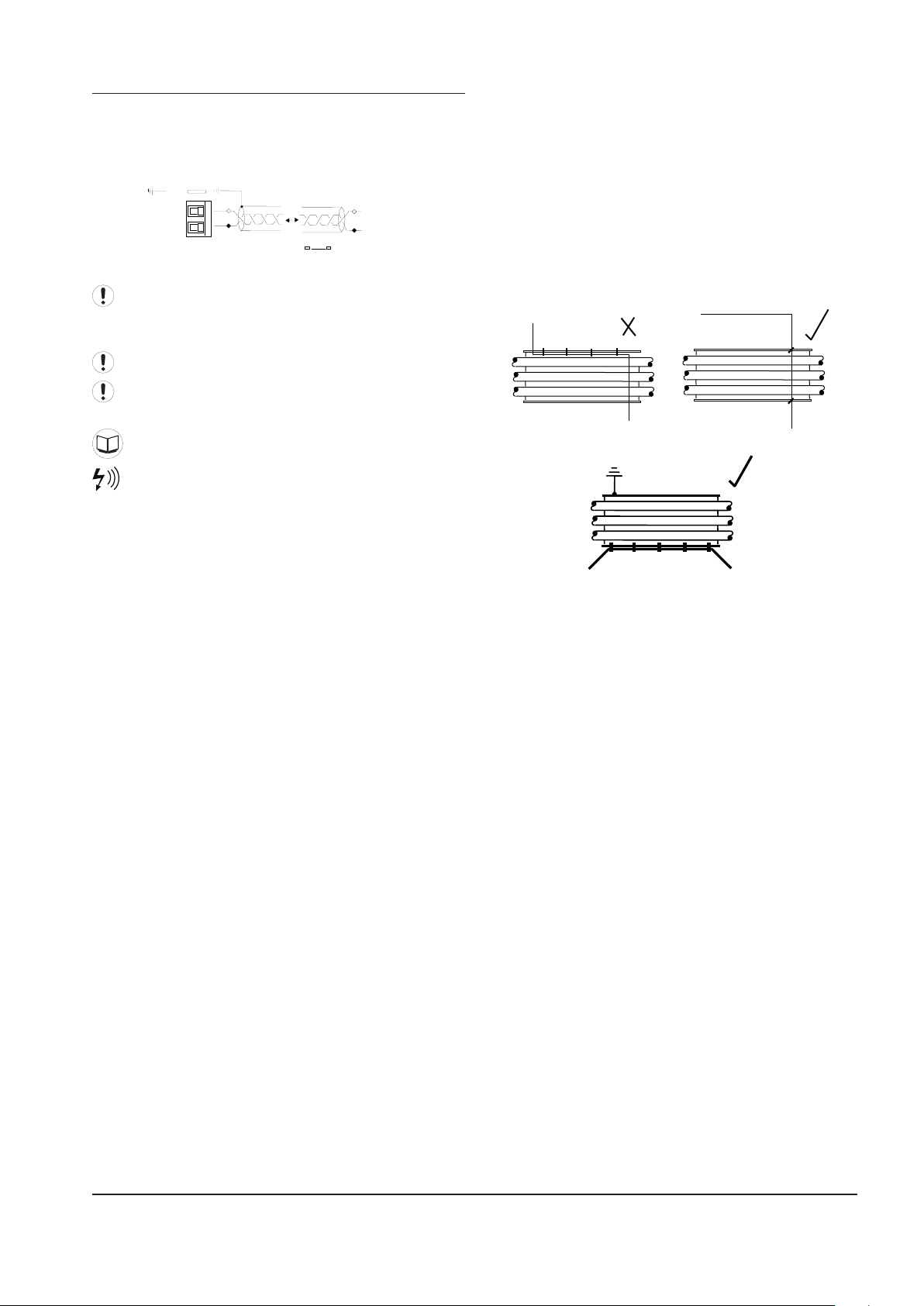

MOUNTING POSITION & SUPPORT

The unit can be installed in any plane and is capable

of being installed vertically or horizontally. Additional

work is required when installing in the vertical mounting

position.

Horizontal Mounting

The unit is to be supported appropriately taking

into consideration the weight of the unit (reference

the respective drawings in the diagrams section for

approximate weights). Support should be provided

through:

The main piping (A) of the unit (not the control

A.

elements, the associated control piping, or valve

assemblies), and/or

The system piping (B).

B.

Consult Technical Support for further information.

•

Wire the unit in accordance with the wiring

•

schematic in the DIAGRAMS section of this manual.

Incoming power should be connected via the Gland

It may be necessary to add a drain line to the control

air lter to relieve buildup of condensate in the lter.

DIRECTION OF AIR FLOW

The unit has directional ow arrows. Orient the unit in

accordance with the compressed air ow system. The

factory unit is congured such that the air ows from

left to right when looking at the controller display. There

may be some cases when installing the IX IntelliFlow

unit where the air ows from right to left placing the

controller away from view. In these instances, re-mount

the bracket supporting the controller enclosure to the

opposite side of the IX IntelliFlow unit and rotate the

pressure gauge 180 degrees. Then mount the IntelliFlow

in the direction of the air ow (right to left). The air ow

will follow the air ow decals (entering on the P3 pressure

transducer side).

Holes using the necessary wire glands.

Fix any loose pre-wired connections.

•

Vertical Mounting

For vertical mounting, the pressure transducers and the

ltered pressure regulator are to be re-oriented 90˚.

The pressure transducers must be re-oriented such

•

that the body of the transducer is directed upwards.

The sensor cable should be on top of the sensor.

Additional elbows required to re-orient these devices

•

shall be eld supplied and installed.

o The ttings must be rated for 200 PSI (13.78

Bar) minumum.

It may be necessary to add a eld installed drain

connected at the bottom piping run to allow for proper

drainage of condensate that may collect in the piping.

ingersollrandproducts.com 9

Page 10

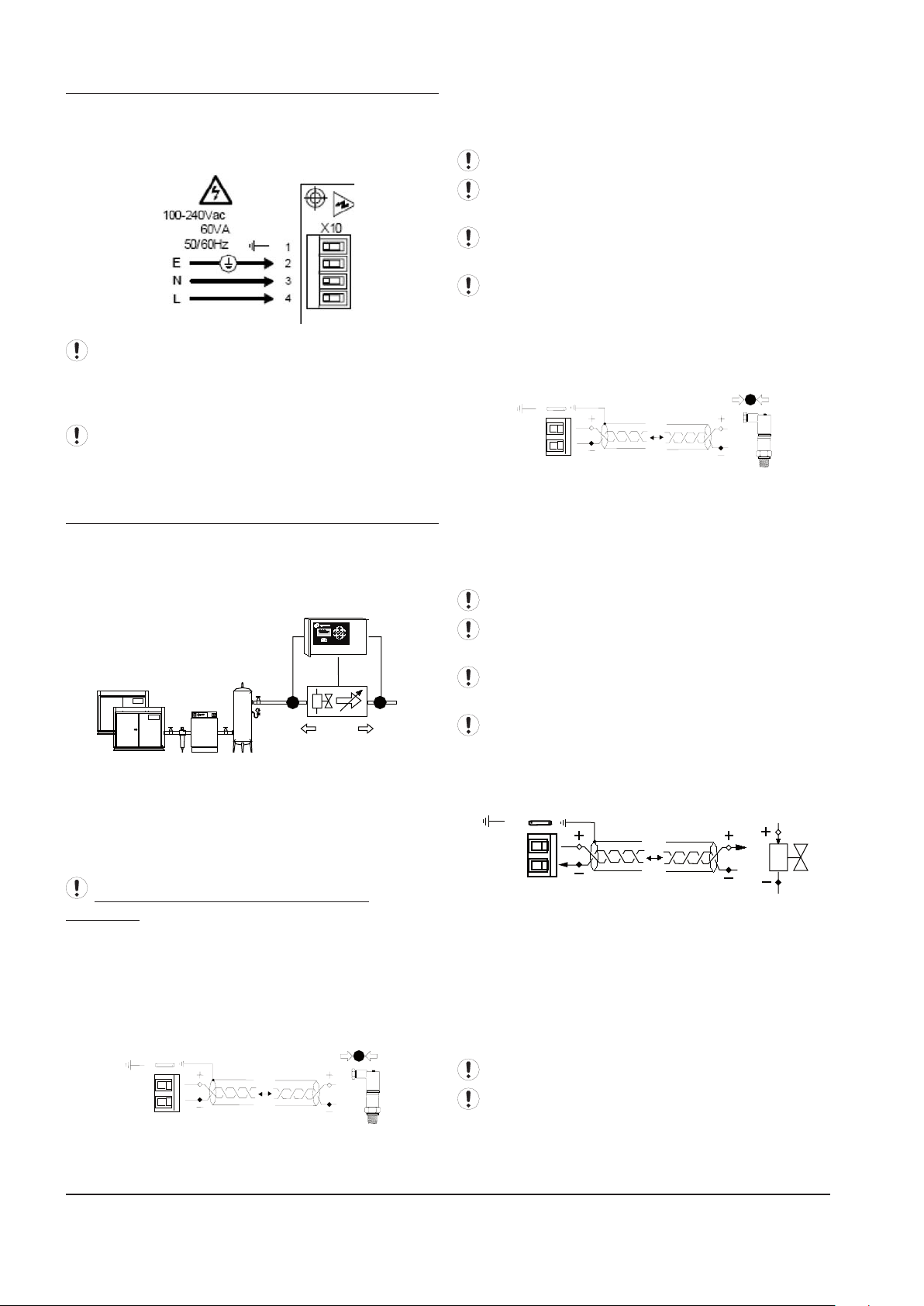

IX BOX POWER SUPPLY

X02 X01

X03

P4

P3

Ao

4-20m

A

100m (330ft) max

2

1

X01

+C

A

i1

P4

4-20mA

100m (330ft) max

2

1

X02

+C

A

i2

P3

4-20mA

100m (330ft) max

2

1

X03

Ao

A-GND

The IX IntelliFlow Controller Unit is equipped with a

power supply input that will accept 100Vac to 240Vac,

50/60Hz.

Before applying power to the IX IntelliFlow Controller

unit ensure that the power supply connections are

correct and secure and that the supply voltage is 100Vac

to 240Vac (+-10%), 50/60Hz.

Wiring run through the enclosure must be made

using Type 12 UL rated ttings which are eld provided.

pressure, Demand side or outlet side, of the IX IntelliFlow

Valve assembly. Use shielded (earth screened), twoconductor (2 core), 20 gauge (0.5mm2 CSA) minimum,

cable no greater than 330ft (100m) in length.

Connection polarity is important.

For ‘Backward’ mode it is not necessary to connect a

‘P4’ pressure sensor.

For ‘Forward’ or ‘Combination’ Modes a ‘P4’ sensor

must be connected.

Re-use electrical ttings provided for pressure

transducer wiring.

P3 Pressure Sensor, 4-20mA: For Supply Side / Back

Pressure / Backward Mode or Combination Demand /

Supply Side / Combination Mode Pressure Control.

IX INTELLIFLOW VALVE CONTROLLER

CONNECTION AND SENSOR ARRANGEMENT

The IX IntelliFlow assembly ships with both the P3 and

the P4 pressure transducers installed and prewired to

the IX controller inputs. The control valve positioner

is also prewired to the controller output.

P3 Supply Side, High Pressure Side (IX IntelliFlow

Inlet) pressure transducer.

P4 Demand Side, Low Pressure Side (IX IntelliFlow

Outlet) pressure transducer.

Ao Analog output to the IX Control Valve positioner.

If it is necessary to remote mount the IX

IntelliFlow controller, the following diagrams depict

the electrical connections between the controller, the

pressure transducers, and the control valve positioner.

P4 Pressure Sensor, 4-20mA: For Demand Side /

Forward Mode Pressure Control (Factory Default) or

Combination Demand / Supply Side / Combination

Mode Pressure Control (Optional)

Pressure Sensor ‘P3’ must be installed on the High

Pressure or inlet side, of the IX IntelliFlow Valve assembly.

Use shielded (earth screened), two-conductor (2 core),

20 gauge (0.5mm CSA) minimum, cable no greater than

330ft (100m) in length.

Connection polarity is important.

For ‘Forward’ mode it is not necessary to connect a ‘P3’

pressure sensor.

For ‘Backward’ or ‘Combination’ Modes a ‘P3’ sensor

must be connected.

Re-use electrical ttings provided for pressure

transducer wiring.

Valve Control Analog Output, 4-20mA: For Control of

the Control Valve Positioner

Connect the controller ‘Ao’ 4-20mA control output to the

valve 4-20mA input. Use shielded (earth screened), twoconductor (2 core), 20 gauge (0.5mm2 CSA) minimum,

cable no greater than 330ft (100m) in length.

The ‘Ao’ 4-20mA output is active at a voltage of 24VDC

(+-2VDC) and is intended for connection to devices with a

‘loop powered’ 4-20mA input.

Connection polarity is important.

Re-use electrical ttings provided for pressure

transducer wiring.

Pressure Sensor ‘P4’ must be installed on the Low

10 ingersollrandproducts.com

Page 11

IX BOX RS485 NETWORK

2

1

+L1 (A)

RS485

-L2 (B)

+L1 (A)

-L2 (B)

X13

Modbus RTU or IRBus/RS485

The IX IntelliFlow Valve Controller is equipped with an

RS485 network communications capability using Modbus

RTU or being connected to the X-Series compressor

control products.

The cable used should be Belden 9841 (or equivalent).

It should be run in grounded conduit and should not be

greater than 4000 feet (1219 meters) in length.

Connection polarity is important.

Wiring run through the enclosure must be made

using Type 12 UL rated ttings which are eld provided.

Menus and Menu Items

RS485 data communications and other low voltage

signals can be subject to electrical interference. This

potential can result in intermittent malfunction or

anomaly that is dicult to diagnose. To avoid this

possibility always use earth shielded cables, securely

bonded to a known good earth at one end. In addition,

give careful consideration to cable routing during

installation.

a) Never route an RS485 data communications or

low voltage signal cable alongside a high voltage

or 3-phase power supply cable. If it is necessary

to cross the path of a power supply cable(s),

always cross at a right angle.

b) If it is necessary to follow the route of power

supply cables for a short distance, attach

the RS485 or signal cable on the outside of a

grounded (earthed) cable tray such that the

cable tray forms a grounded (earthed) electrical

interference shield.

c) Where possible, never route an RS485 or signal

cable near to equipment or devices that may be

a source of electrical interference (for example:

3-phase power supply transformer, high voltage

switchgear unit, frequency inverter drive module,

radio communications antenna).

ingersollrandproducts.com 11

Page 12

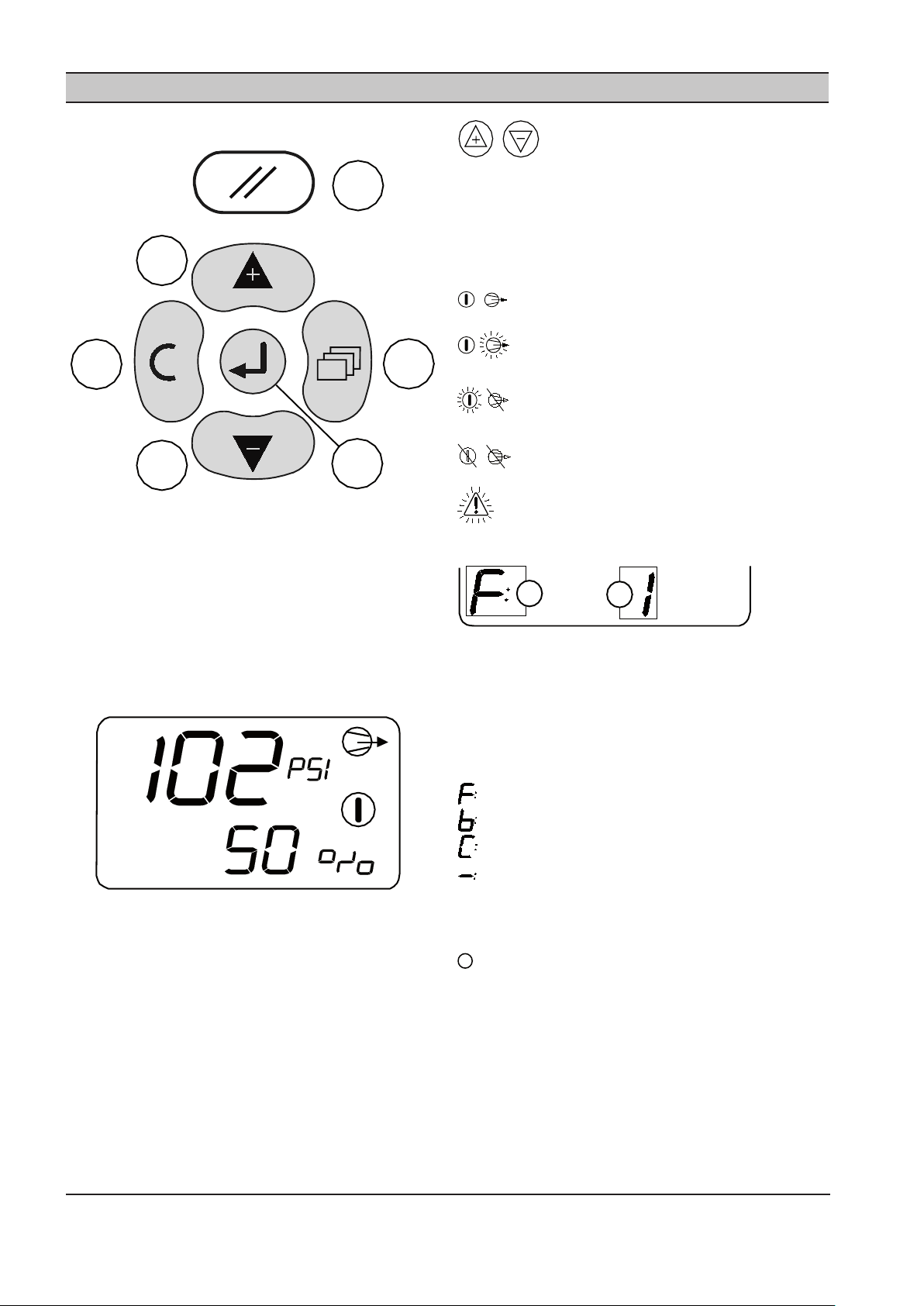

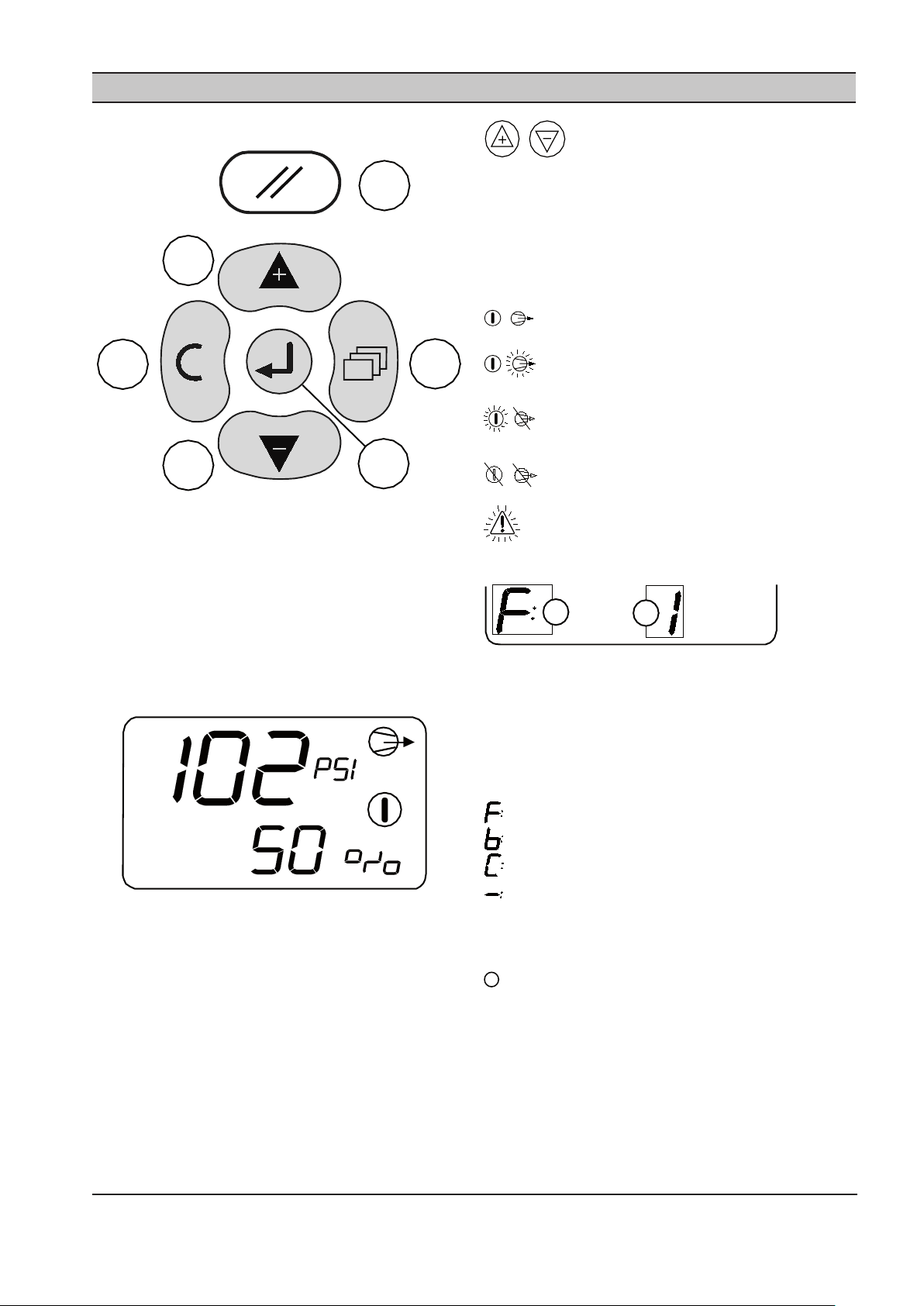

Keypad:

a

f

e

d

c

b

A

B

i

SECTION 7 DISPLAY AND MENU OPERATION

Press UP or DOWN to view other user menu

items.

The display will remain on the selected ‘User’ menu item

indenitely.

At power-up, or reset, the display will default to the rst

user menu list item.

Status Symbols:

ON/ON Operating

ON/Flash Manual Mode

Flash/OFF Forced Open/Closed

OFF/OFF Fault Shutdown

Reset

a)

Menu

b)

Enter

c)

Down (Minus)

d)

Up (Plus)

e)

Escape (Cancel)

f)

Display

Pressure = Main Display Pressure

% = Valve percentage open (0-100%)

The main display pressure is dependent on the Operating

mode or the Combi. Mode Display Pressure (1.dP) setting.

The Main Display Pressure will display the pressure value

as follows:

Forward Mode = P4 Pressure

Backwards Mode = P3 Pressure

Combination Mode = menu 1.dP setting

Manual Mode = menu 1.dP setting

Flash Fault

Status:

‘A’ = Active Target Pressure Setting

1, 2, 3 or 4 (1 = default)

Manual Mode = “-“(dash)

‘B’ = Mode

Forward Mode

Backward Mode

Combination Mode

Manual Mode

or Forced Closed

or Forced Open

see ‘Status Symbols’

12 ingersollrandproducts.com

Page 13

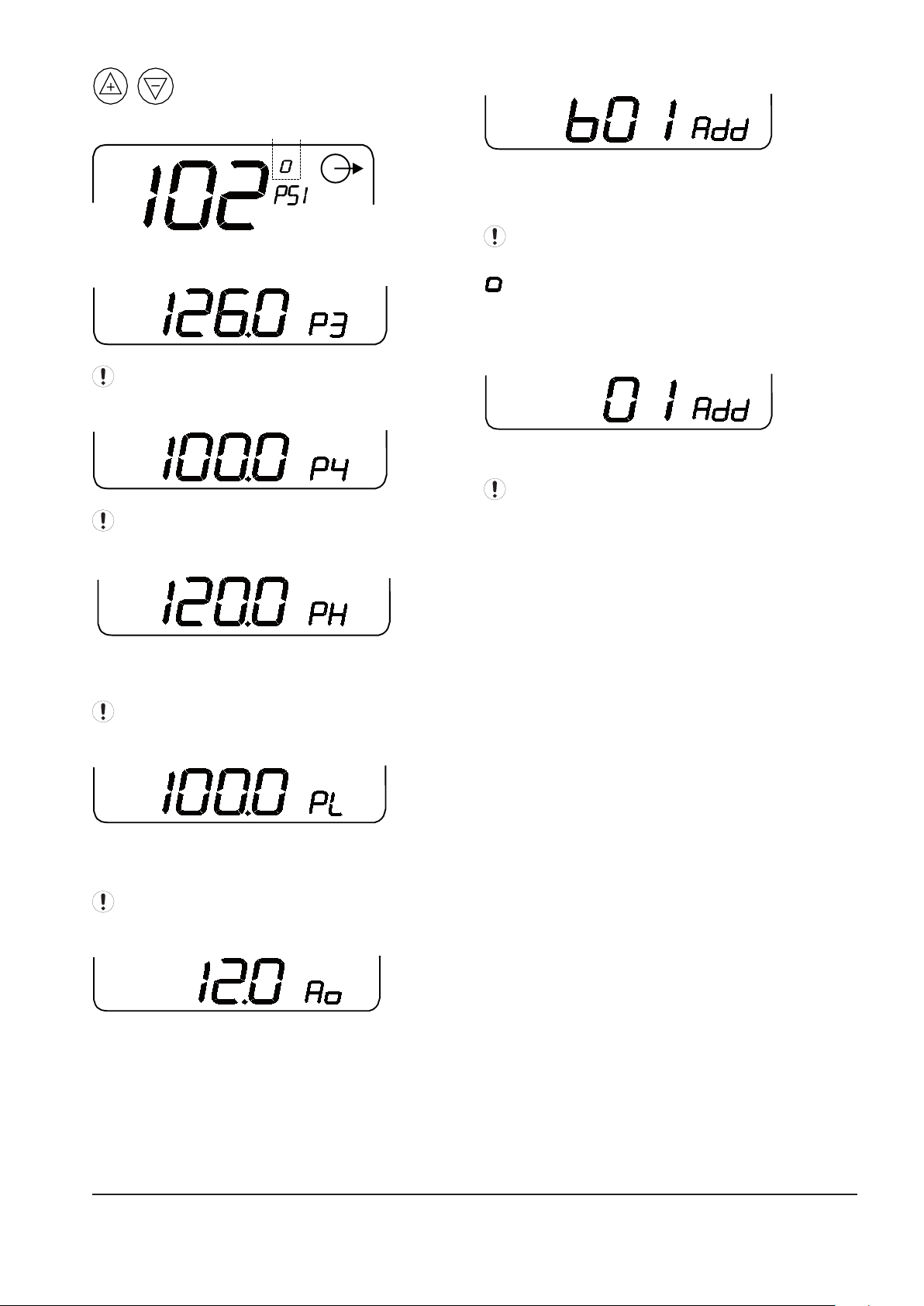

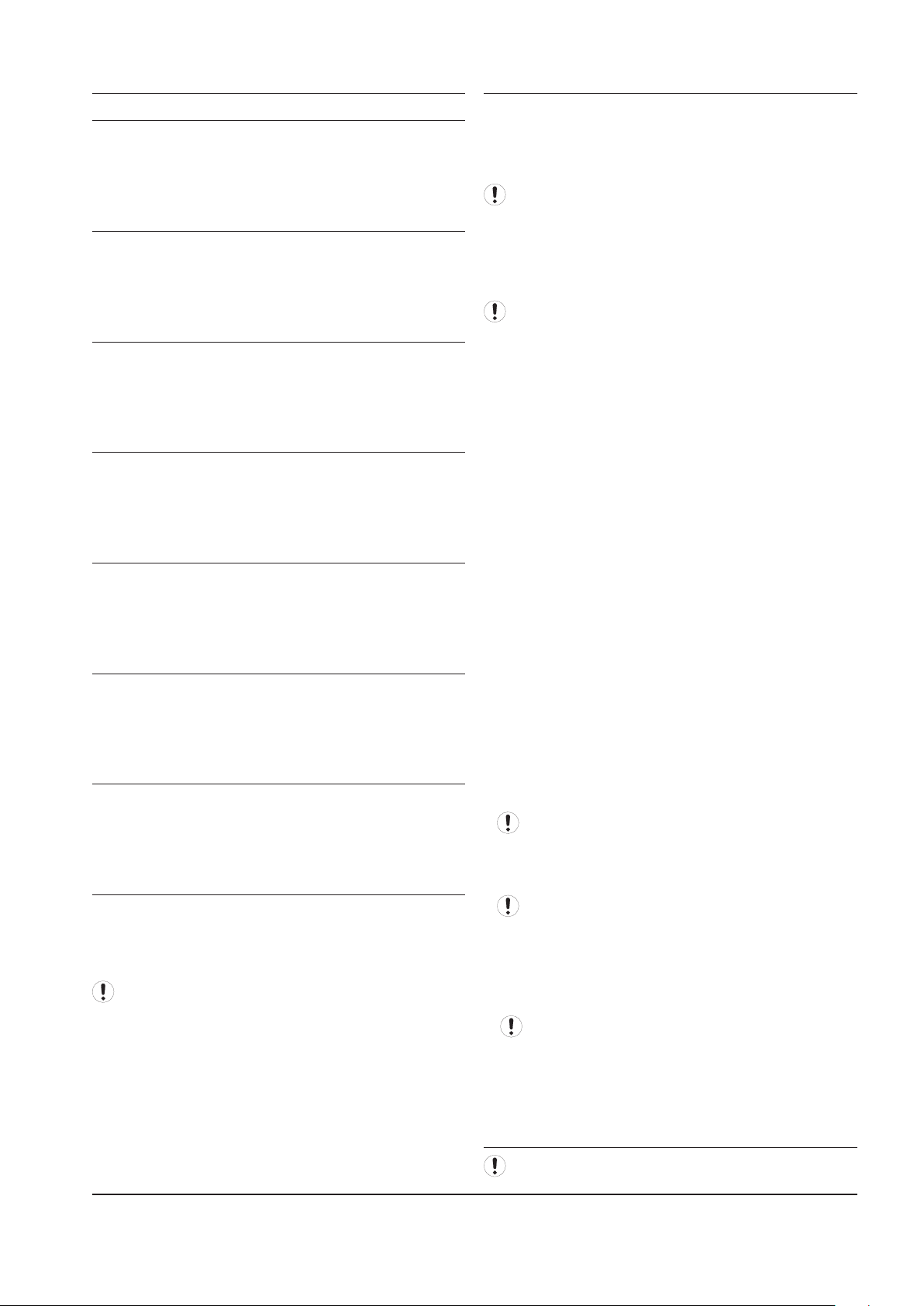

Press UP or DOWN to view other user menu

items.

P3 High Pressure, Generation Side, Inlet:

Only shown in ‘Forward’ mode if P3 sensor tted.

P4 Low Pressure, Demand Side, Outlet:

Only shown in ‘Backwards’ mode if P4 sensor tted.

Network Address (IRBUS Mode):

B01 = Network I/O Box number

In IRBUS Mode the IX Box simulates a network I/O Box.

For networks that have I/O Box(s) ensure the I/O Box

number is unique.

When the unit is detecting valid IRBUS

communications from the XI management system unit

the communications indicator symbol will show:

Network Address: Modbus Mode

Modbus Address – decimal 01 to 99

The communications indicator symbol will not show

in Modbus mode.

Active ‘High Target’ Pressure:

In accordance with the active target pressure H1, H2, H3

or H4

Not shown in Forward or Manual Mode.

Active ‘Low Target’ Pressure:

In accordance with the active target pressure L1, L2, L3 or

L4

Not shown in Backwards or Manual Mode.

Valve Control Output (4-20mA):

Example: 12.0 Ao = 12.0mA, 50%

ingersollrandproducts.com 13

Page 14

SECTION 8 COMMISSIONING

When commissioning the IX Box, carry out the following

procedures before attempting to start.

Menus and Menu Items

It is recommended that an authorized and trained

service technician perform the commissioning.

PHYSICAL CHECKS

1. Before applying power to the IX Box, ensure the

power supply connections are correct and secure

(115Vac or 230Vac (+-10%), 50/60Hz).

2. Open the front panel of the IX Box and ensure all

pressure sensor, RS485, and other connections are

correctly installed and secure.

See the section on Installation for more

information.

3. Close the front panel of the IX Box.

4. Switch on the power supply to the IX Box.

5. The control program identication will be displayed

for a short period followed by the normal operational

user display.

PRESSURE DISPLAY

Check the displayed delivery pressure. If the pressure is

incorrect, or inaccurate, check the type and range of the

sensor and carry out the pressure sensor commissioning

and calibration procedure.

3.3o P4 Outlet Pressure Oset

3.3r P4 Outlet Pressure Range

3.4o P3 Inlet Pressure Oset

3.4r P3 Inlet Pressure Range

User Conguration Menu 1

PRESSURE SET POINTS

Set the Forward Mode Target pressure set point to suit

system requirements in the appropriate control menu:

2.L1 Low Target Pressure #1

Menus and Menu Items

Target Conguration Menu 2

IX BOX OPTIONAL FEATURES AND

FUNCTIONS

Installation requirements may involve the

implementation of additional or optional functions and

features.

As default, additional optional functions and features

are deactivated or inhibited.

Features and Functions; Menu Items

IX INTELLIFLOW STARTUP

1. At initial start-up, begin with the bypass open.

2. Set the controller setpoint to a pressure at

the bottom of the Existing Upstream pressure

bandwidth. This will provide a changing system to

manually tune the control variables (proportional

pressure and integral time) and verify stable control.

See the Setting the Tuning Parameters section

for a description of how these values aect the

control system.

Menus and Menu Items

Sensor Calibration Menu 3

OPERATING MODE

Set the operating mode for the IX Box to Forward Mode in

the appropriate control menu:

1.oP Operating Mode

0: Forward Mode

This is the Default, As Shipped from the Factory,

Conguration

Set the Tuning Parameters for Forward Control mode in

the appropriate control menu:

1.3P P4 Proportional Pressure

Default is 20

1.3I P4 Integral Time

Default is 10

3. Slowly close the bypass.

4. Monitor the system and validate stable control. If

stable control is not achieved, open the bypass,

adjust control variables, and return to step 3.

Otherwise, continue to step 5.

5. Once stable control has been achieved, gradually

lower the setpoint until the optimal value has been

reached.

EXAMPLE:

Existing Upstream Pressure: 100-110 psi (6.9 to 7.6 bar)

Critical Pressure (minimum): 85 psi (5.8 bar)

1. Begin with the bypass valve fully open.

2. Set the controller setpoint to 100 psi (6.9 bar).

3. Slowly close the bypass valve.

4. If the control is not stable (valve is overshooting the

correct position or the setpoint is not being reached),

open the bypass, adjust the control variables, and

return to Step 3. If the control is stable, continue to

step 5.

14 ingersollrandproducts.com

Page 15

5. Gradually lower the setpoint (pausing to verify that

the control is still stable) until the optimal setpoint

has been reached.

In this example, the optimal setpoint might be 90 psi (6.2

bar) with the downstream pressure uctuating between

89.25 psi (6.1 bar) and 90.75 psi (6.25 bar) in regular

operation. This would provide a 5 psi (0.3 bar) safety that

would prevent the downstream pressure from going

below 85 psi (5.8 bar) in the event of a sudden change in

air demand or supply.

SETTING THE TUNING PARAMETERS

1.3P P4 Proportional Pressure

Default is 20

1.3I P4 Integral Time

Default is 10

PROPORTIONAL PRESSURE

Proportional control varies the signal sent to the valves

as a linear response to the dierence between the actual

system pressure and the system pressure setpoint. Valve

responsiveness can be adjusted through the IntelliFlow

Controller with the proportional pressure (1.3P.), setpoint.

This scaling factor is the amount of change in the input

variable (actual minus setpoint pressures) to cause a full

scale change in the output variable (valve position).

In other words, if the pressure in the air system uctuates

frequently, it would be prudent to set the proportional

pressure to a low value (a value / number greater than

the factory default of 20) to keep up with those system

changes. Otherwise, if the system is very stable, it would

be prudent to set the proportional pressure to a high

value (a value / number less than the factory default

of 20) to keep up with those system changes. The

proportional pressure is directly related to valve life and

indirectly related to valve cycling; so, as band decreases,

valve life decreases and cycling increases.

As stated earlier, the IntelliFlow Controller uses a

proportional plus integral control algorithm. The

result of proportional only control is oset from the

controlled variable discharge pressure. This means that

if the setpoint pressure is 100, the actual pressure may

only be 95. The value of this oset depends upon the

proportional pressure value.

What is the valve response when the dierence between

actual and setpoint pressures is zero? There is no

response. Proportional control only functions when a

dierence or error exists. Design discharge pressure could

not be attained in a proportional only control system.

Therefore, an integral control algorithm is added to

achieve the desired discharge pressure.

INTEGRAL TIME

The oset produced by the proportional control

algorithm could be eliminated by manually readjusting

the system pressure setpoint. Using the example above,

the setpoint could be reset to 105 to obtain the 100

desired. Manually resetting the setpoint would be

required as the system demand uctuated. Integral

control, also known as reset control, automatically resets

the desired system pressure setpoint. For the IntelliFlow

controller, the rate at which the controller resets the

system pressure setting is known as Integral Time, (1.3I.),

and is expressed in minutes between reset.

If precise control of the specied discharge pressure is

required, the Integral Time setpoint should be set for a

fast value. In other words, if the pressure in the air system

uctuates frequently, it would be prudent to set the

Integral Time to a high value (a value / number greater

than the factory default of 10) to keep up with those

system changes. Otherwise, if the system is very stable,

it would be prudent to set the Integral Time to a low

value (a value / number less than the factory default of

10) to keep up with those system changes. It is directly

related to valve life and inversely related to valve cycling,

so, as Integral Time increases, the valve life increases and

cycling decreases.

When band is low and Integral Time is fast, valve activity

is signicant in both magnitude and frequency to obtain

the desired setpoint. The other scenario, band is high and

Integral Time is slow, has relatively little valve activity, and

may never reach the setpoint position.

Proportional pressure and Integral Time are variables

used internally by the control system to determine

valve response and direction for a given compressed

air system. Each has an optimum value based upon the

system’s characteristics. Determining these optimum

values is a trial and error exercise. These setpoints should

be re-evaluated any time there is a major change in the

compressed air system.

ingersollrandproducts.com 15

Page 16

SECTION 9 SYSTEM CONFIGURATION

DISPLAY AND MENU OPERATION

All value, parameter or option selection displays are

grouped into menu lists. Items are assigned to a list

according to type and classication. Items that can be

used to select options or modify functions are assigned to

‘menu mode’ lists. Items that a User may require to view

during routine operation, detected pressure for example,

are assigned to the normal operational mode list.

Each menu has a unique access code. Only one menu can

be entered at a time.

ACCESSING THE IX CONFIGURATION

SCREENS

To access a menu press MENU.

The display will show four “0” characters;

the rst character will ash.

Press Up or Down to adjust the rst

character to match the rst character of the required

access code. If the access code number is ess than ‘1000’

the rst character will be ‘0’. Press Enter to increment to

the second code character.

code is incorrect the display will return to the normal

operational display.

To select a menu item for adjustment press

Up or Down until the menu item is displayed.

To adjust an item setting press Enter, the value or

option will ash.

Press Up or Down to adjust as required.

Press Enter to store in memory.

To exit the menu routine and return to the normal

operational display, at any time, press Cancel. The

display will return to the normal operational view. Any

adjustment that has not be entered to memory will be

abandoned and the previous setting maintained.

Menu codes are listed next to each Menu. See

Conguration Menu Overview for codes

When all four access code

characters have been set, and the last code character

is ashing, press Enter. If the access code is correct for

access to one of the accessible menus the rst menu item

of the appropriate menu will be displayed. If the access

16 ingersollrandproducts.com

Page 17

CONFIGURATION MENU OVERVIEW

1. - -

2. - -

3. - -

4. - -

5. - -

Each menu is accessed individually using the access

codes show.

User Conguration Menu 1

Menu Access Code ‘0011’

1.oP Operating Mode

1.3P P4 Proportional Pressure

1.3I P4 Integral Time

1.4P P3 Proportional Pressure

1.4I P3 Integral Time

1.bA Backwards Mode Algorithm

1.Po Manual Mode %Open

1.SP Maximum %Change/Second

1.LP Valve %Open Low Level

1.HP Valve %Open High Level

1.SF Control Pressure Fault Response

1.CF Communication Fault Response

1.Ad Network Address

1.Pd Pressure Display Unit

1.dP Combi. Mode Display Pressure

Target Conguration Menu 2

Menu Access Code ‘0021’

2.L1 Low Target Pressure #1 (default)

2.H1 High Target Pressure #1 (default)

2.L2 Low Target Pressure #2

2.H2 High Target Pressure #2

2.L3 Low Target Pressure #3

2.H3 High Target Pressure #3

2.L4 Low Target Pressure #4

2.H4 High Target Pressure #4

Relay Functions R1 to R6

Menu Access Code ‘0041’ (R1) to ‘0046’ (R6)

4.F1 Input Function #1 (A, b and C)

4.F2 Input Function #2 (A, b and C)

4.Fu Logic Function

4.on On Delay Time

4.oF O Delay Time

4.St Normal State

4.CF RS485 Failure Response

Diagnostic Menu 5

Menu Access Code ‘0051’

5.d1 Digital Input #1 (Di 1)

5.d2 Digital Input #2 (Di 2)

5.d3 Digital Input #3 (Di 3)

5.d4 Digital Input #4 (Di 4)

5.d5 Digital Input #5 (Di 5)

5.d6 Digital Input #6 (Di 6)

5.r1 Output Relay #1 (R1)

5.r2 Output Relay #2 (R2)

5.A1 Analog Input #1 (Ai1)

5.A2 Analog Input #2 (Ai2)

5.Ao Analog Output (Ao)

Sensor Calibration Menu 3

Menu Access Code ‘0031’

3.3o P4 Outlet Pressure Oset

3.3r P4 Outlet Pressure Range

3.4o P3 Inlet Pressure Oset

3.4r P3 Inlet Pressure Range

ingersollrandproducts.com 17

Page 18

USER CONFIGURATION MENU 1

1.oP – Operating Mode

There are 5 Operating Modes for the IX IntelliFlow control.

0: Forward Mode

P4 pressure sensor (Outlet, Low pressure, Demand Side) is

used for Control Pressure in accordance with active ‘Low

Target’ (2.L1 to 2.L4) pressure set point. The ‘High Target’

(2.H1 to 2.H4) pressure set points are inhibited and any P3

pressure sensor fault is ignored.

The valve will regulate using the P4 pressure in

accordance with the ‘1.4P’ proportional pressure and ‘1.4I’

integral time settings.

Forward Mode Control action is:

Target is 95psi (6.55 bar)

If P3 remains above 95psi (6.55 bar):

P4 is maintained at P4 target:

If demand increases and P4 falls below 95psi (6.55 Bar):

Valve opens towards 100%

If demand decreases and P4 increases above 95psi (6.55

Bar):

Valve closes towards 0%

If P3 falls below 95psi (6.55 Bar):

Valve will open 100% and P4 pressure will equal

P3 pressure

This mode of operation is intended to maintain a constant

Demand, or Outlet, side pressure where the Generation,

or Inlet, is at a higher pressure level.

1: Backward Mode

P3 pressure sensor (Inlet, High Pressure, Generation Side)

is used for Control Pressure in accordance with active

‘High Target’ (2.H1 to 2.H4) pressure set point. The ‘Low

Target’ (2.L1 to 2.L4) pressure set points are inhibited and

any P4 pressure sensor fault is ignored.

If ‘1.bA = 0’:

The ‘1.4P’ (P4 Proportional Pressure) and ‘1.4I’ (P4 Integral

Time) algorithm parameters are used.

If ‘1.bA = 1’:

The ‘1.3P’ (P3 Proportional Pressure) and ‘1.3I’ (P3 Integral

Time) algorithm parameters are used.

The valve will regulate using the P3 (Inlet, High Pressure,

Generation Side) pressure sensor in accordance with

the applicable ‘Proportional’ pressure and ‘Integral’ time

settings.

Backward Mode Control action is:

Target is 80psi (5.51 bar)

If P3 remains above 80psi (5.51 bar):

Valve remains fully open and P4 pressure will

equal P3 pressure.

If P3 falls to 80psi (5.51 bar):

P3 is protected from falling below 80psi:

If P3 falls below 80psi (5.51 bar):

Valve closes towards 0%

If P3 increases above 80psi (5.51 bar):

Valve opens towards 100% and P4 pressure will

equal P3 pressure.

This mode of operation is intended to ensure a minimum

specied Generation, or Inlet, side pressure is maintained

in instances where air demand from the Demand side,

or Outlet, becomes excessive and Demand side pressure

begins to decay.

2: Combination Mode

Both the P4 (Outlet, Low pressure, Demand Side) and the

P3 (Inlet, High Pressure, Generation Side) pressure sensors

are used for control. The ‘Forward’ mode and ‘Backwards’

mode control algorithms operate together at the same

time. Whichever control loop algorithm produces the

lowest %Open value will take priority; the valve will follow

the lowest %Open value.

In Combination mode, the operation and use of the valve

is dependent on the relationship between the set ‘Low

Target’ and ‘High Target’ pressure set points.

Backward Mode Control action is:

P4 target is 95psi (6.55 bar)

P3 target is 80psi (5.51 bar)

If P3 remains above 95psi (6.55 bar):

P4 is maintained at P4 target:

If demand increases and P4 falls below 95psi (6.55 bar)

Valve opens towards 100%

If demand decreases and P4 increases above 95psi (6.55

bar):

Valve closes towards 0%

If P3 falls below 95psi (6.55 bar) but remains above 80psi

(5.51 bar):

Valve will open 100% and P4 pressure will equal

P3 pressure.

If P3 falls to 80psi (5.51 bar):

P3 is protected from falling below 80psi (5.51

bar):

If P3 falls below 80psi (5.51 bar):

Valve closes towards 0%

If P3 increases above 80psi (5.51 bar):

Valve opens towards 100%

3: Manual Mode

The valve will open to the percentage open value

specied in ‘1.Po’. The valve will remain xed at this

%Open value regardless of target pressure set points,

variation in detected pressure, pressure sensor availability

or sensor fault state condition.

18 ingersollrandproducts.com

Page 19

4: Forced Closed

The valve is forced ‘Closed’. P3 and P4 pressure sensor

faults are ignored. When ‘Force Closed’ is activated the

valve will close immediately in accordance with the set

‘1.SP’ percent change per second limit. The ‘1.SP’ setting

restricts how fast the valve will close.

1.LP Valve %Open Low Level

If valve %Open < set ‘1.LP’; then Ai#3 ‘S’ state is set to ‘1’.

Ai#3 ‘S’ state will return to ‘0’ if valve %Open >= ‘1.LP’.

This setting has no eect on valve operation or %Open

position but can be used in local and/or system wide

‘Virtual Relay’ automation.

5: Forced Open

The valve is forced ‘Open’. P3 and P4 pressure sensor

faults are ignored. When ‘Force Open’ is activated the

valve will open immediately in accordance with the set

‘1.SP’ percent change per second limit. The ‘1.SP’ setting

restricts how fast the valve will open.

1.3P P3 Proportional Pressure Factor

The pressure range, above and below the set ‘target’

pressure, where integral control will occur.

1.3I P3 Integral Time Factor

The time that the output will execute a full scale change

from 4mA to 20mA, 0-100% (or vice versa).

1.4P P4 Proportional Pressure Factor

The pressure range, above and below the set ‘target’

pressure, where integral control will occur.

1.4I P4 Integral Time Factor

The time that the output will execute a full scale change

from 4mA to 20mA, 0-100% (or vice versa).

1.bA Backwards Mode Algorithm

0 - The ‘1.4P’ (P4 Proportional Pressure) and ‘1.4I’

(P4 Integral Time) algorithm parameters are used

for ‘Backwards’ mode operation.

1 - The ‘1.3P’ (P3 Proportional Pressure) and ‘1.3I’ (P3

Integral Time) algorithm parameters are used

for ‘Backwards’ mode operation (default).

1.HP Valve %Open High Level

If valve %Open > set ‘1.HP’; then Ai#4 ‘S’ state is set to ‘1’.

Ai#4 ‘S’ state will return to ‘0’ if valve %Open <= ‘1.HP’.

This setting has no eect on valve operation or %Open

position but can be used in local and/or system wide

‘Virtual Relay’ automation.

1.SF Control Pressure Fault Response

If a fault with the ‘Control’ pressure sensor occurs, or any

pressure sensor in Combination Mode:

0 - Manual Mode

1 - Force Valve Open (default)

2 - Force Valve Closed

1.CF Communications Fault Response

If a fault with network communications occurs:

0 – Continue normally (default)

1 – Force Valve Open

2 – Force Valve Closed

Only applicable in IRBUS Communications Mode; always

‘0’ (continue normally) in Modbus Mode.

1.Ad Network Address

Modbus:

01 to 99 decimal (0 to 63 Hex)

IRBUS Mode:

b01 to b12 (I/O Box 1 to 12)

1.Po Manual Mode %Open Value

Manual Mode %Open value (0 to 100%)

refer to ‘Manual Mode’ (1.oP)

1.SP %Change/Second

Restricts how fast the valve will open, or close, when

pressure changes abruptly and/or a signicant

‘Target’ pressure change is made. If the applicable, or

predominate, target algorithm produces a change in

%Open that exceeds the ‘1.SP’ setting the change in valve

%Open is restricted to the maximum % change

determined by the ‘1.SP’ setting until the required valve

%Open position is reached.

The ‘1.SP’ setting is expressed in %Change per second

where a setting of 20% will restrict any change to a

maximum of 20%Open per second - the valve will change

from fully open (100%Open) to fully closed (0%Open) in

ve seconds if the required %Open value changes from

100%Open to 0%Open abruptly.

‘1.SP’ is always active in all modes.

IRBUS or Modbus mode is selected automatically

dependant on set address.

1.Pd Pressure Display Units

0 – bar

1 - psi (default)

1.dP Combi. Mode Display Pressure

Determines if the P3 or P4 pressure is displayed as the

‘Main Display Pressure’ when operating in Combination

mode.

0 – P4 (default)

1 – P3

ingersollrandproducts.com 19

Page 20

PRESSURE TARGET MENU 2

2.L1 Low Target Pressure #1 (default)

Normal default outlet side target pressure when no

digital inputs are activated.

Active in ‘Forward’ and ‘Combination’ modes; not used for

‘Backwards’ mode.

2.H1 High Target Pressure #1 (default)

Normal default inlet side target pressure when no digital

inputs are activated.

Active in ‘Backwards’ and ‘Combination’ modes; not used

for ‘Forward’ mode.

2.L2 Low Target Pressure #2

Applicable when ‘Target Pressure Set 2’ digital input

activated.

Active in ‘Forward’ and ‘Combination’ modes; not used for

‘Backwards’ mode.

2.H2 High Target Pressure #2

Applicable when ‘Target Pressure Set 2’ digital input

activated.

Active in ‘Backwards’ and ‘Combination’ modes; not used

for ‘Forward’ mode.

2.L3 Low Target Pressure #3

Applicable when ‘Target Pressure Set 3’ digital input

activated.

Active in ‘Forward’ and ‘Combination’ modes; not used for

‘Backwards’ mode.

2.H3 High Target Pressure #3

Applicable when ‘Target Pressure Set 3’ digital input

activated.

Active in ‘Backwards’ and ‘Combination’ modes; not used

for ‘Forward’ mode.

2.L4 Low Target Pressure #4

Applicable when ‘Target Pressure Set 4’ digital input

activated.

Active in ‘Forward’ and ‘Combination’ modes; not used for

‘Backwards’ mode.

2.H4 High Target Pressure #4

Applicable when ‘Target Pressure Set 4’ digital input

activated.

Active in ‘Backwards’ and ‘Combination’ modes; not used

for ‘Forward’ mode.

If more than one digital input is activated the

following priority will apply:

1: (highest priority) Force Closed

2: Force Open

3: Manual Mode

4: Target Set #2

5: Target Set #3

6: (lowest priority) Target Set #4

SENSOR CALIBRATION MENU 3

3.3o P3 Pressure Sensor Oset

3.3r P3 Pressure Sensor Range

P3 pressure sensor (Inlet, High pressure, Generation Side)

calibration settings.

See ‘Pressure Sensor Calibration Procedure’

3.4o P4 Pressure Sensor Oset

3.4r P4 Pressure Sensor Range

P4 pressure sensor (Outlet, Low pressure, Demand Side)

calibration settings.

see ‘Pressure Sensor Calibration Procedure’

Pressure Sensor Calibration Procedure:

1) Commissioning

Initially set the ‘Oset’ (minimum) to the minimum or

lowest pressure value for the sensor. Set the ‘Range’

(maximum) to the maximum or highest value for the

sensor.

For example:

If the pressure sensor is a 0 to 232psi (0 to 16.0bar)

type set the ‘oset’ to 0psi (0bar) and the ‘Range’ to

232psi (16.0bar).

Execute the calibration procedure.

2) Calibration Procedure

a) Oset: Expose the sensor to atmosphere and adjust

the ‘oset’ setting (if necessary) until the detected

pressure display shows 0psi (0bar).

b) Range: Apply an accurately know pressure to the

pressure sensor and adjust the ‘Range’ setting until

the detected pressure display matches the applied

pressure. An applied pressure equal too, or greater

than, the nominal system working pressure is

recommended.

The detected pressure is displayed with the

calibration menu item and will change to match the

new calibration setting as the setting is adjusted.

There is no need for the applied pressure to be

static; it can be dynamic and changing. This enables

calibration to be carried out on a fully operational

system where changing system pressure can be

accurately veried from another source.

Correct pressure sensor set-up and calibration

is critical for successful system operation. It is

recommended that pressure sensor calibration is

examined, and adjusted if necessary, annually or a

pre-determined routine periodic basis.

RELAY CONFIGURATION MENU 4

see ‘Virtual Relay Automation’

20 ingersollrandproducts.com

Page 21

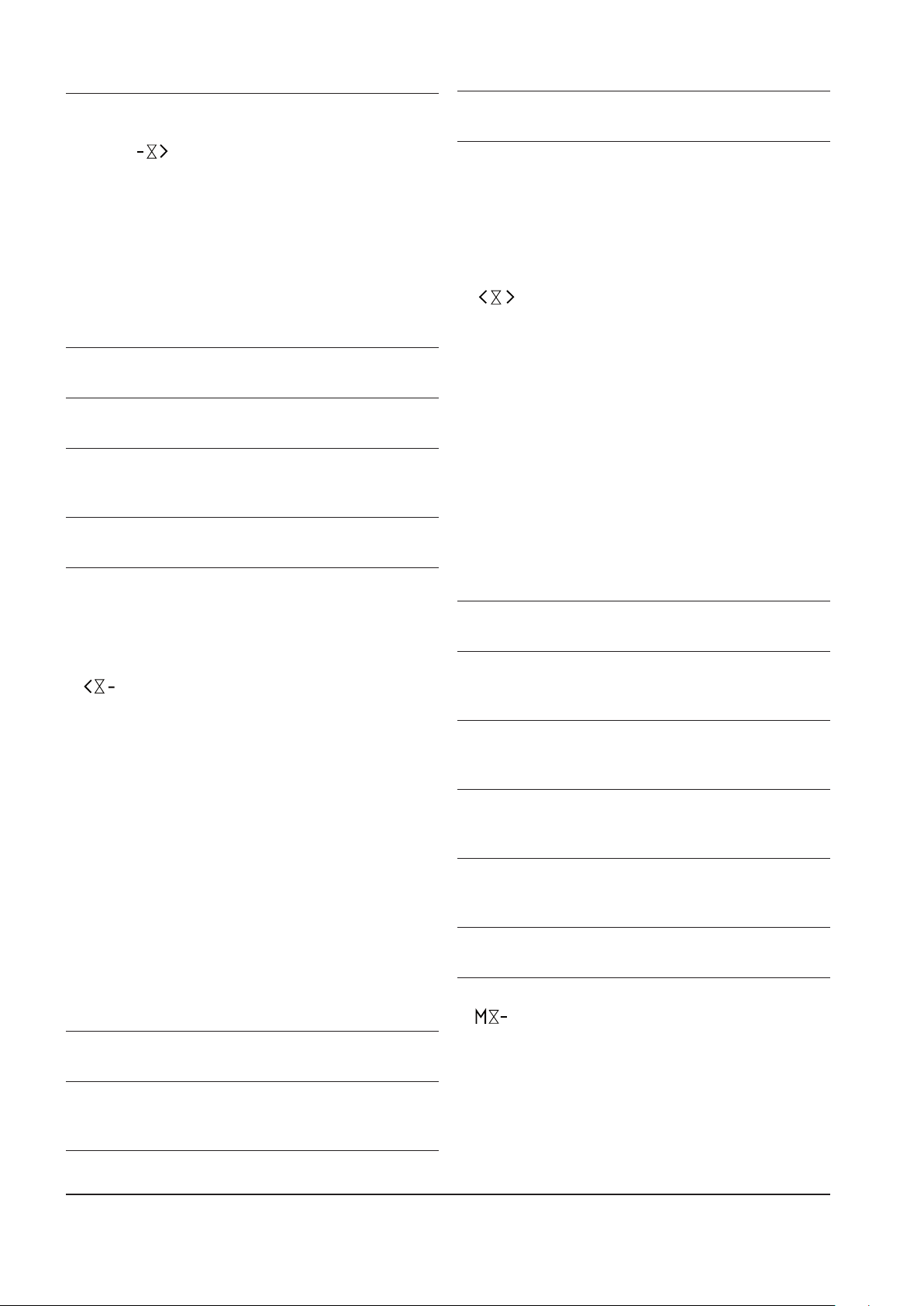

SECTION 10 DIAGNOSTICS

D1 Digital Input 1

D2 Digital Input 2

D3 Digital Input 3

D4 Digital Input 4

D5 Digital Input 5

D6 Digital Input 6

-------------------------------------------------------------

R1 Relay Output 1

R2 Relay Output 2

-------------------------------------------------------------

A1 Analog Input 1 psi <> mA

A2 Analog Input 2 psi <> mA

1: ON

0: OFF

OFF

ON

------------------------------------------------------------Ao Analog Output 0.0 to 20.0mA

DIAGNOSTIC MENU 5

The IX IntelliFlow Controller is equipped with

comprehensive diagnostic functions. Each input can be

examined individually and each output can be manually

activated or manipulated individually.

P2 Controller Diagnostics:

Reset All Settings To Default:

Enter an Access Code of ‘9750’; do not press enter when

the last character is ashing.

Press and hold CANCEL for 10 seconds; the controller will

reset and all settings will be reset to default. All previous

settings will be permanently lost.

Relay Outputs:

Each relay output can be energised and de-energised

manually by selecting the item. Use Up(plus) and

Down(minus) to adjust and Enter.

Analog Inputs:

The item will alternate between the detected value

and the electrical measurement on the controller input

terminals. An independent measuring device can be used

to check the displayed electrical measurement.

A1: P4 Outlet Pressure, 4-20mA

A2: P3 Inlet Pressure, 4-20mA

Analog Output:

The analog output can be manually adjusted to any

desired level. Press Enter then use Up (Plus) and Down

(Minus) to adjust and Enter. The output will return to

normal operational value upon menu exit.

ingersollrandproducts.com 21

Page 22

SECTION 11 FAULT CODES

In the event of a IX IntelliFlow IX Box Fault, the IX Box

display a fault code. The fault code becomes an item

in the User operational display menu. If more than one

active fault occurs each will be displayed as a separate

item in the operational User menu; press Up or Down to

view all active fault codes or to view the normal status

display.

Fault codes are separated in to A: Alarm (Warning) and E:

Shutdown Trip.

Pressure Sensor Faults:

Reaction to a pressure sensor fault is dependent on the

sensor and mode. If the pressure sensor is being used for

‘Control Pressure’, or the unit is in ‘Combination Mode’, the

controller will shutdown.

If the sensor is not being used for ‘Control Pressure’, and

the unit is not in ‘Combination Mode’, the sensor fault will

be ignored and the associating pressure display will show

“- - - -“ (dashes).

Fault Codes:

E0115 P4 Pressure Sensor Fault

E0125 P3 Pressure Sensor Fault

The unit’s controller has detected disruption to the

internal operational memory storage (RAM). The integrity

of the RAM memory contents is suspect; the controller

must be reset to clear and re-map the memory. Renew

the controller if this fault condition persists.

The controller’s main power supply must be removed and

re-applied to reset this condition.

Remote XI Management System Fault Code Display:

When set for an I/O Box address (b01 to b12) the XI

management system can be set to monitor the unit for

fault conditions.

B’nn’57 ‘nn’ = IO Box number (01 to 12)

P4 Demand Side Pressure Sensor Fault when operating in

Forward or Combination mode.

B’nn’58 ‘nn’ = IO Box number (01 to 12)

P3 Generation Side Pressure Sensor Fault when operating

in Backwards or Combination mode.

B’nn’60 ‘nn’ = IO Box number (01 to 12)

General Trip (Shutdown)

B’nn’ - - ‘nn’ = IO Box number (01 to 12)

RS485 communications disruption or loss.

E0821 Short Circuit

Short Circuit condition detected on the main controller

unit (digital inputs)

E0866 DC Power Supply Low

Check voltage of main power supply.

E5000 Internal Memory Map Error

When in IR485 mode, and connected to a network,

the ‘B’ fault codes can be monitored and displayed by an

XI system management unit. The ‘B’ codes do not show on

the IntelliFlow display.

22 ingersollrandproducts.com

Page 23

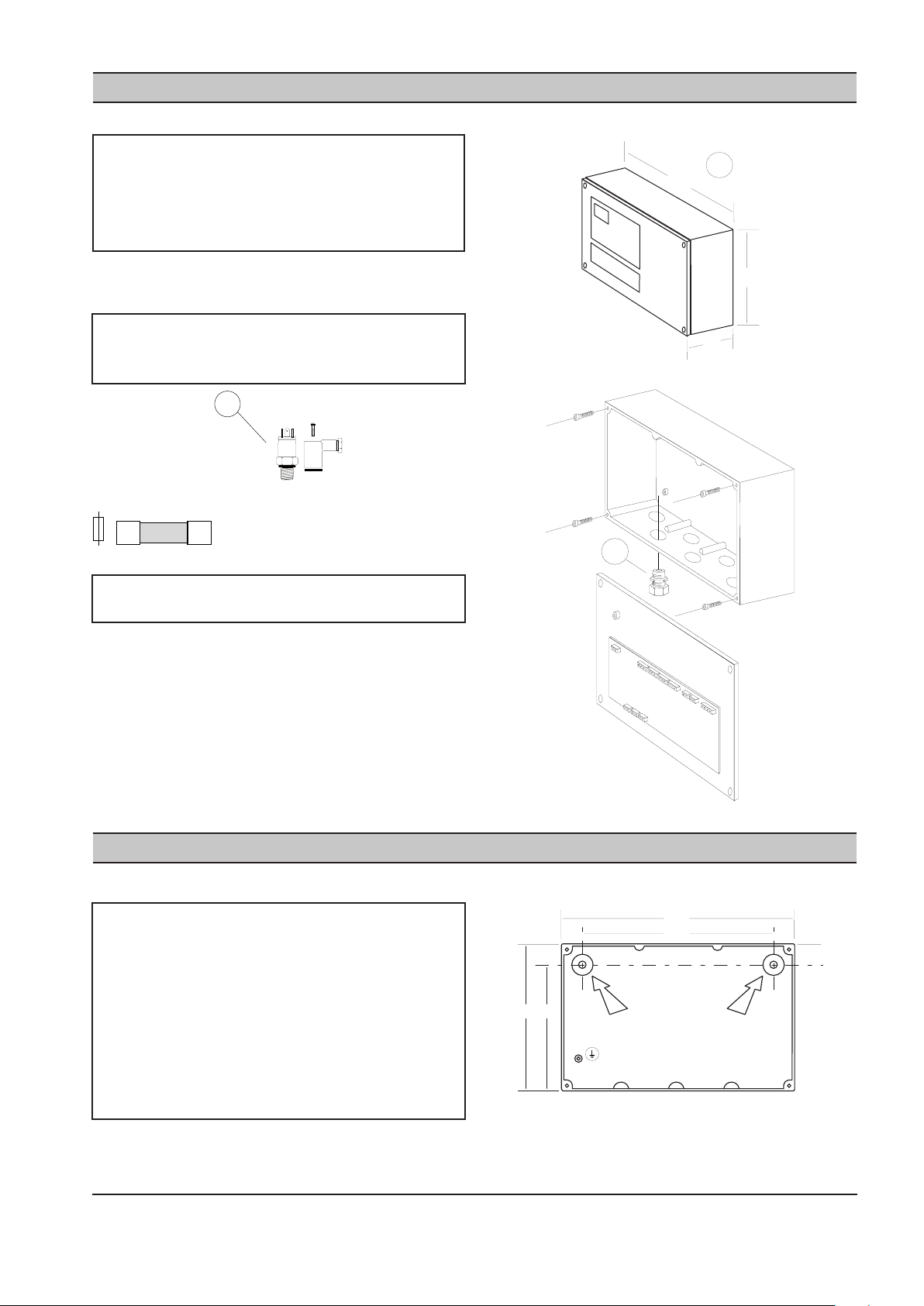

SECTION 12 IX INTELLIFLOW CONTROLLER PART LIST

3

20mm

5mm

IEC

1

253

160

90

2

A

B

205

253

4242

160 136

24

IX Box

Item Part No. Description

- 23451966 IX IntelliFlow

1 23451974 Unit, IX IntelliFlow

2 634067 Gland, Set - Pg13.5

- 80445588 Manual, User CD

ACCESSORIES:

Required For P3 and P4 System Pressure Transducers

Item Part No. Description

3 634065 Sensor, Pressure – Quantity (2)

4-20mA, 0-232 psi (0-16.0bar)

Item Part No. Description

2 634104 IEC Fuse T1.6A

SECTION 13 IX INTELLIFLOW CONTROLLER TECHNICAL DATA

Dimensions 10” x 6.3” x 3.6”

253 x 160 x 90mm

Weight 5.0lb (2.2kg)

Mounting wall, 2 x screw xings (8mm)

Enclosure IP54, NEMA 12

Supply 100 to 240Vac +/- 10%

Power 100VA

Temperature 32°F to 115°F (0°C to 46°C)

Humidity 95% RH, non-condensing

IX Box Technical Data

Mounting Dimensions (mm):

ingersollrandproducts.com 23

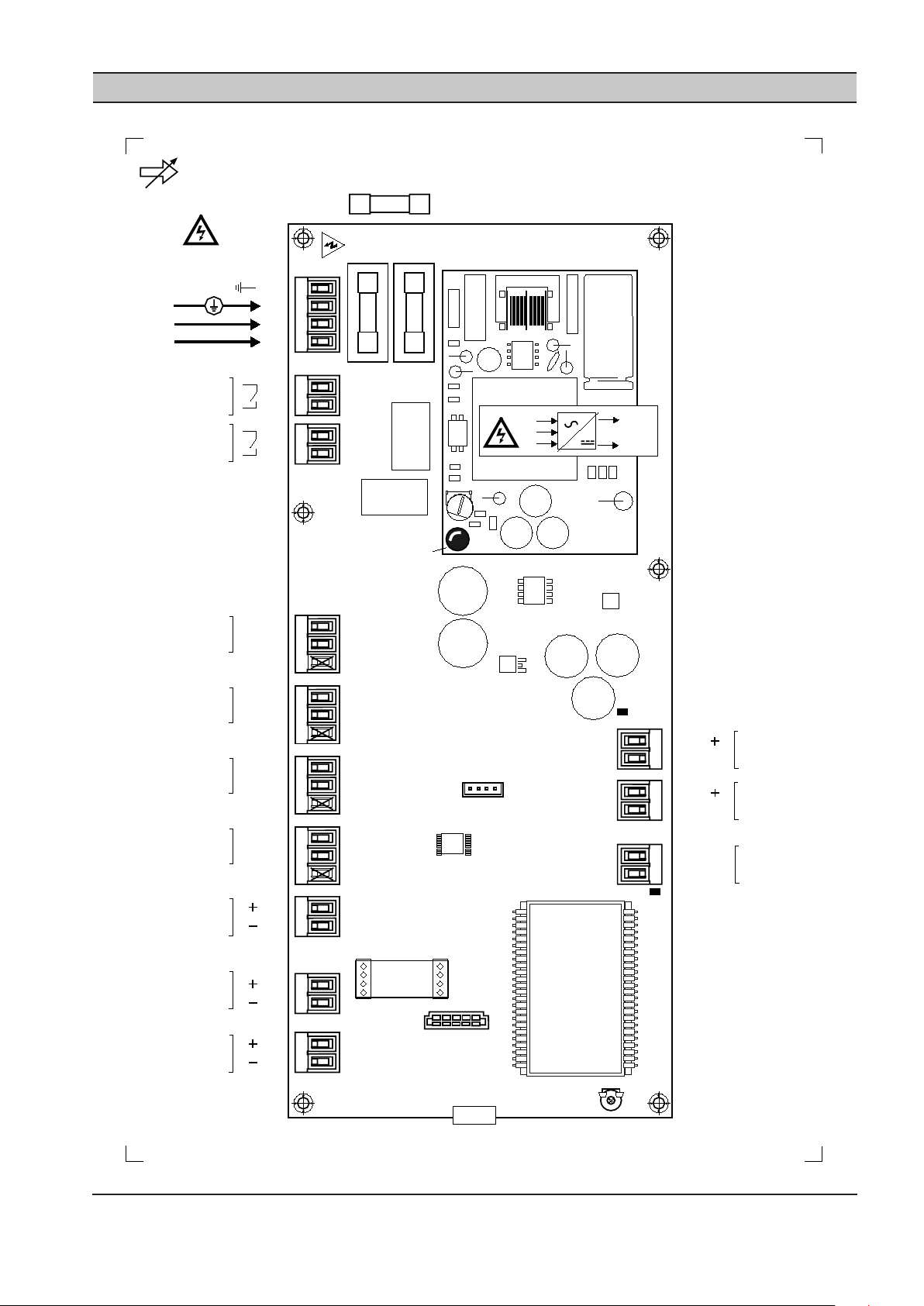

Page 24

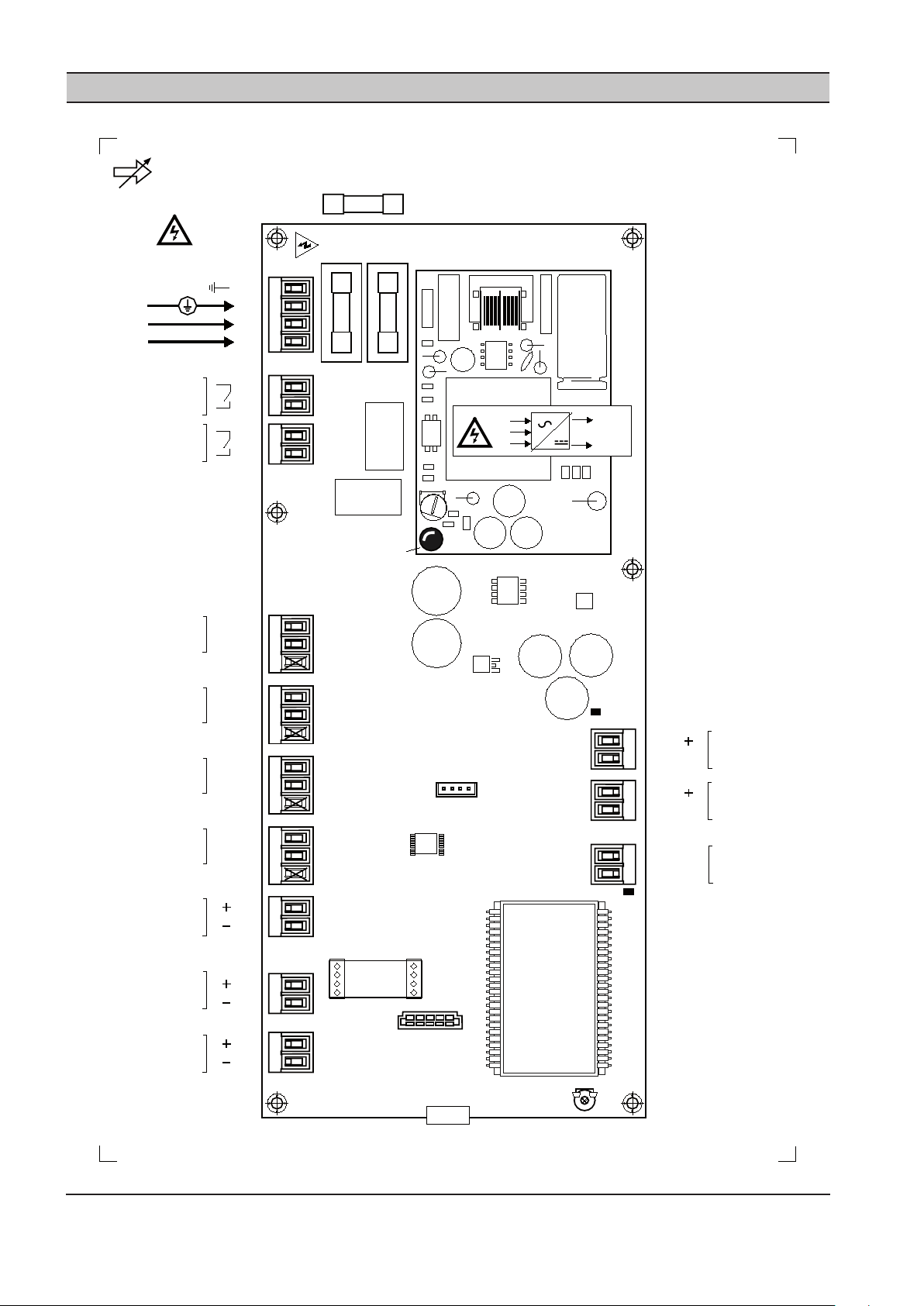

FH1

T1

.6

A

FH2

X10

T1

.6

A

PSU

IEC

20 x 5mm

LED1b

N

L

E

0VDC

+VDC

X09

X08

RL1

RL2

C01

Ai2

ACM

C018

RT1

X07

X06

X05

X04

X03

X02

X01

LCD

Ai2

C

Ai1

+C

Ao

A-GND

R1

R2

1

2

1

2

1

2

3

1

2

1

2

1

2

Di5

+C

Di6

D6

+C

+L1 (A)

RS

48

5

-L2 (B)

D5

2

1

2

1

2

1

4-20mA

4-20mA

4-20mA

Di4

GND

D4

+24 VDC

IR IntelliFlow Valv e

Control Unit - P2

100-240Vac

60VA

50/60Hz

1

2

3

4

E

L

N

X11

X12

X13

P2

4-20mA

LED2

LED1

+C

1

2

3

Di3

GND

D3

+24 VDC

+C

1

2

3

Di2

GND

D2

+24 VDC

+C

1

2

3

Di1

GND

D1

+24 VDC

+C

SECTION 14 IX INTELLIFLOW CONTROLLER WIRING DIAGRAM

24 ingersollrandproducts.com

Page 25

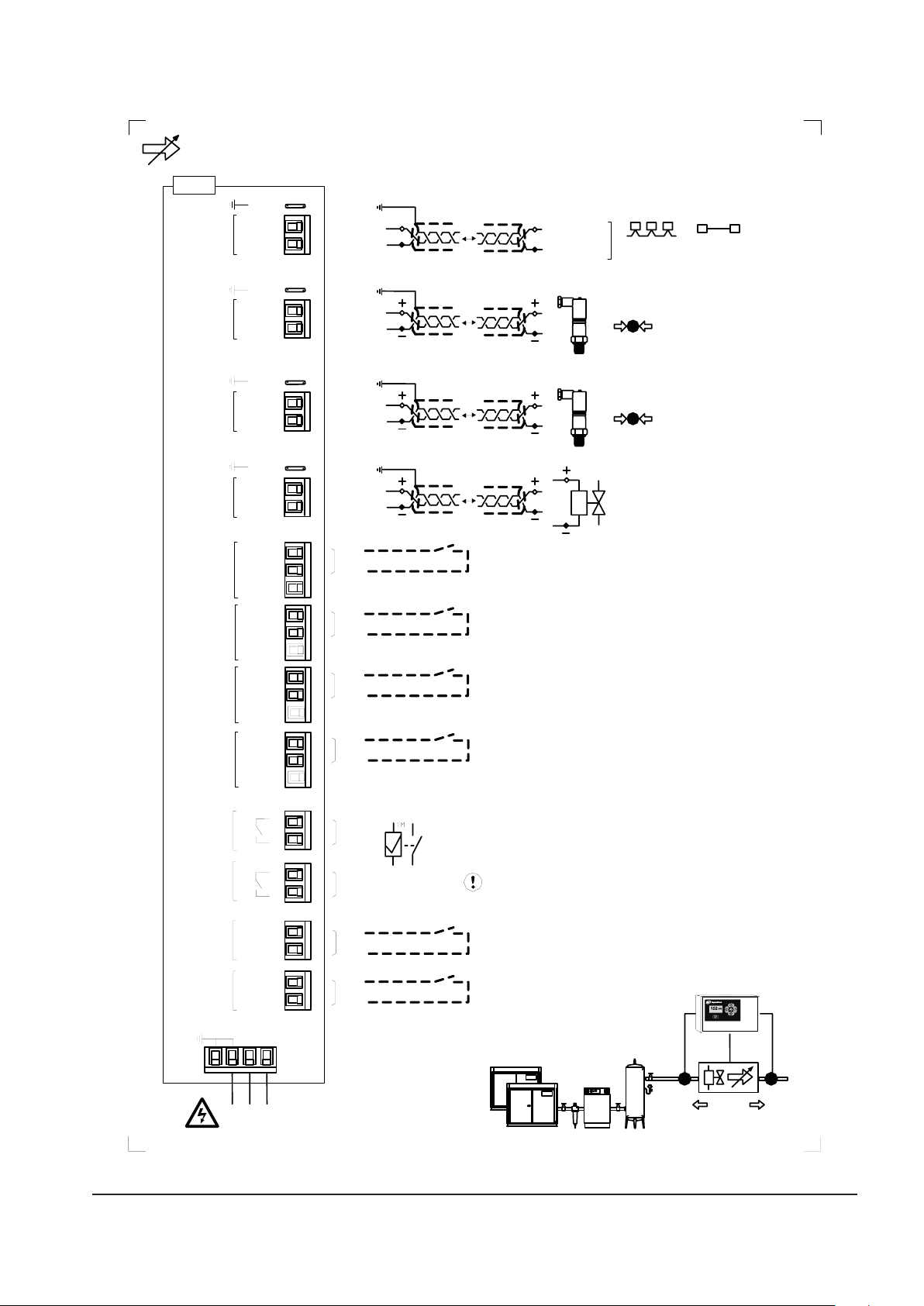

4-20mA

100m (330ft) max

1

2

3

1

2

3

1

2

3

1

2

3

1

2

Ai2

+C

2

1

1

2

+L1

2

1

0VDC

+24VDC

D1

+L1 (A)

RS485

-L2 (B)

+L1 (A)

-L2 (B)

-L2

RS485

X13

X02

X04

X05

X06

X07

Di1

+C

0VDC

+24VDC

D2

0VDC

+24VDC

D3

0VDC

+24VDC

D4

+24VDC

Ai2

4-20mA

100m (330ft) max

1

2

Ai1

+C

2

1

X01

+24VDC

Ai1

P4

P3

Target 2

Target 3

Target 4

Outlet

Demand Side

Inlet

Supply Side

330ft (100m) max

IR IntelliFlow Valve

Control Unit - P2

GND

Pressure

Pressure

Modbus

P2

L NE

X10

1 2 3 4

4-20mA

100m (330ft) max

1

2

A-GND

Ao

2

1

X03

Ao

A-GND

IntelliFlow Valve

4-20mA Output

Ao

100-240Vac

100VA

50/60Hz

Virtual Relay

Configurable

240V 'CE ' / 115V 'UL ' @ 4A

maximum.

1

2

1

2

R1

R2

X09

X08

Di6

+C

Di5

+C

1

2

1

2

+24VDC

D5

+24VDC

D6

X12

X11

Force Closed

Force Open

Manual Mode

X02 X01

X03

P4

P3

Ao

Di2

+C

GND

Di3

+C

GND

Di4

+C

GND

330ft (100m) max

330ft (100m) max

330ft (100m) max

330ft (100m) max

330ft (100m) max

ingersollrandproducts.com 25

Page 26

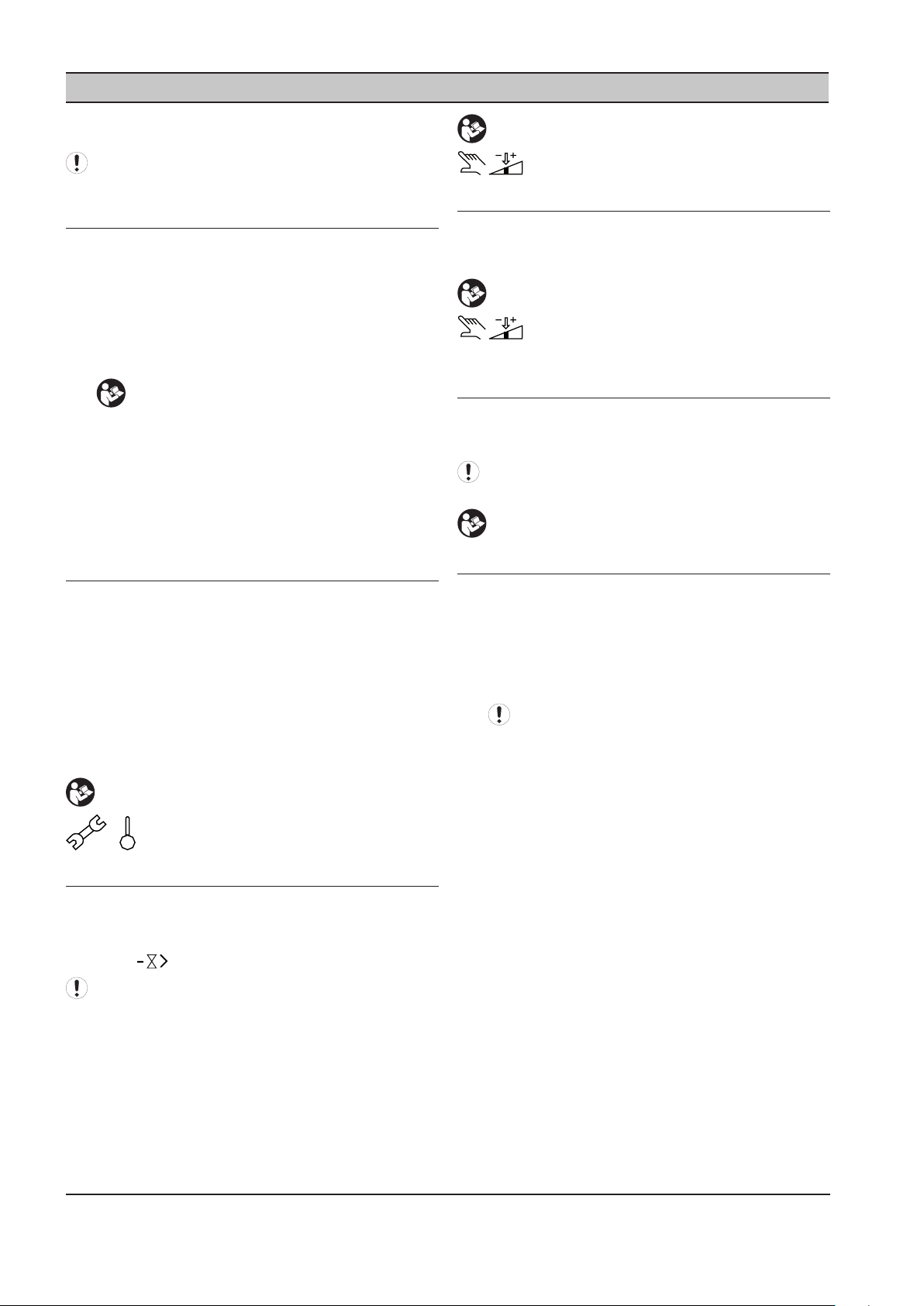

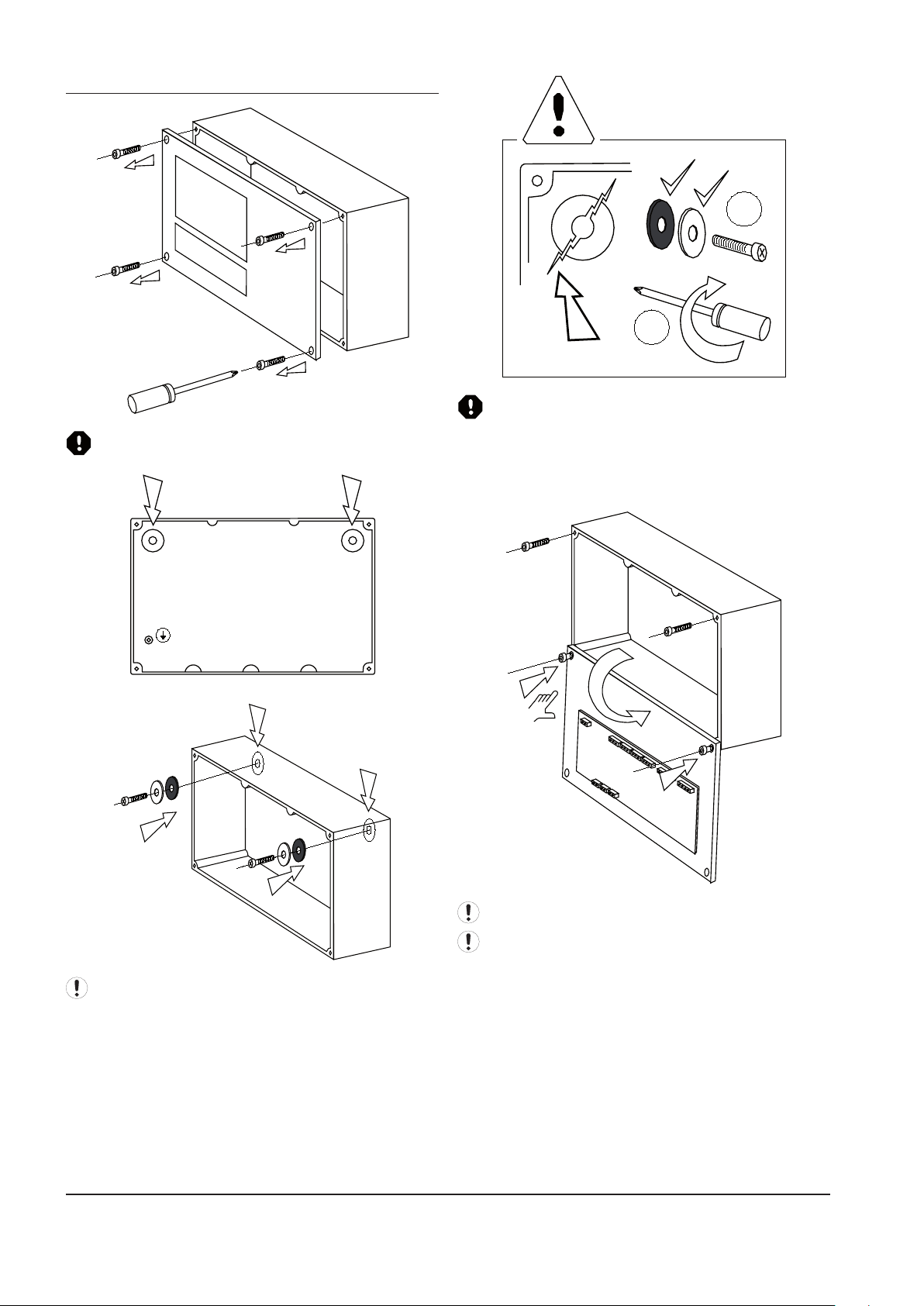

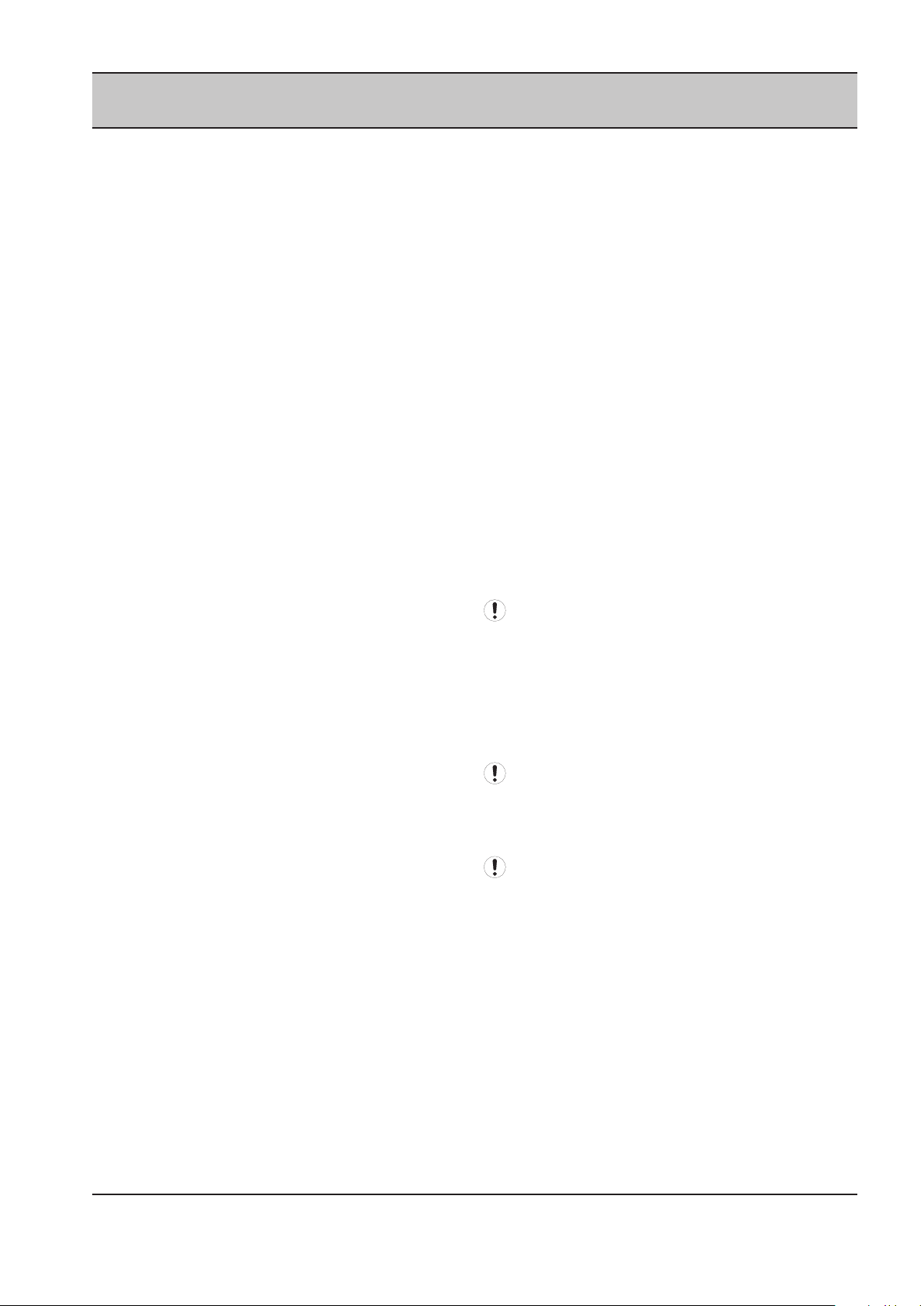

ENCLOSURE MOUNTING

A B

A

B

1

2

Use correct size Torrex Screw Driver

Excessive localized loading or force may fracture the

enclosure:

1. Always use mounting washes provide.

2. Do not over tighten mounting xtures.

See ‘Technical Data’ for enclosure and mounting

dimensions.

26 ingersollrandproducts.com

Cable Installation and Wire Connections:

Invert and secure front panel to the rear enclosure

lower front panel xings.

Page 27

SECTION 15 IX INTELLIFLOW CONTROLLER REMOTE INPUTS

1

2

3

1

2

3

1

2

3

1

2

3

0VDC

+24VDC

D1

X04

X05

X06

X07

Di1

+C

0VDC

+24VDC

D2

0VDC

+24VDC

D3

0VDC

+24VDC

D4

T2

T3

T4

GND

M

Di2

+C

GND

Di3

+C

GND

Di4

+C

GND

Di6

+C

Di5

+C

1

2

1

2

+24VDC

D5

+24VDC

D6

X12

X11

FC

FO

330ft (100m) max

Virtual Relay

'CE' 240V @ 4A

'UL' 115V @ 4A

1

2

1

2

R1

R2

X09

X08

1

2

R1

X08

1

2

3

0VDC

+24VDC

D4

X07

M

IX BOX INPUT FUNCTIONS

Remote ‘Volt-Free’ Switching Contact:

Use 20 gauge (0.5mm CSA) minimum, cable conductors

no greater than 330ft (100m) in length.

T2: Target Pressure Set Points #2

T3: Target Pressure Set Points #3

T4: Target Pressure Set Points #4

M: Manual Mode

FO: Force Open

FC: Force Closed

Remote inputs are intended for remote activation from a

‘volt-free’ switching contact, relay contact, PLC or other

remote logic device.

T2, T3 and T4:

When no ‘target pressure set’ digital inputs (Di1 to Di3) are

activated the controller will use ‘Target Pressure Set #1’.

VIRTUAL RELAY AUTOMATION

The target pressure set (2, 3 or 4), manual mode or force

closed/open selection inputs can also be activated by

the IntelliFlow ‘Virtual Relay’ automation functions by

connecting the appropriate ‘Virtual Relay’ output (R1 or

R2) to the required digital input.

For example:

Virtual Relay output R1 (X08) will activate Manual Mode

(X07).

Combinations of logic involving ‘Virtual Relay’ automation

output(s) and remote switching ‘volt-free’ contact(s) of

other third party devices can be implemented using this

methodology.

Remote Input Priority:

If more than one digital input is activated at the same

time the following priority will apply:

1 (highest priority): Force Closed

2: Force Open

3: Manual Mode

4: Target Set #2

5: Target Set #3

6: (lowest priority): Target Set #4

For example:

If the ‘Force Open’ and ‘Target Set #3’ inputs are both

activated together the unit will respond to the ‘Force

Open’ input.

ingersollrandproducts.com 27

Page 28

SECTION 16 IX INTELLIFLOW CONTROLLER RS485 MODBUS REGISTERS

Modbus RTU Protocol @ 9600, N-8-1

Registers 400XX:

‘XX’ Item, Description

01 Status (R)

Bits:

0 - Forward Mode

1 - Backwards Mode

2 - Combination Mode

3 - Manual Mode

4 - Forced Closed

5 - Forced Open

6 - Control Sensor Fault

7 - General Fault Shutdown

(including control sensor fault)

02 P4 Outlet Pressure, psi (R)

03 P3 Inlet Pressure, psi (R)

04 Valve %Open x 100

0 to 10000 = 0 to 100% (R)

05 Ao - mA x 100

400 to 2000 = 4.0 to 20.0mA (R)

06 Mode (R/W)

0 - Forward Mode

1 - Backward Mode

2 - Combination Mode

3 - Manual Mode

4 - Force Closed

5 - Force Open

07 L1: Low Target #1, psi (R/W)

08 H1: High Target #1, psi (R/W)

09 L2: Low Target #2, psi (R/W)

10 H2: High Target #2, psi (R/W)

11 L3: Low Target #3, psi (R/W)

12 H3: High Target #3, psi (R/W)

13 L4: Low Target #4, psi (R/W)

14 H4: High Target #4, psi (R/W)

15 3P - P4 Proportional Pressure

mBar; 69mBar = 1psi (R/W)

16 3I - P4 Integral Time; secs (R/W)

17 4P - P3 Proportional Pressure (R/W)

mBar; 69mBar = 1psi (R/W)

18 4I - P3 Integral Time; secs (R/W)

19 BA - Backwards Mode Algorithm (0=3P/3I;

1=4P/4I) (R/W)

20 SP - Maximum %Change/Second

100 to 10000 = 1% to 100% (R/W)

21 LP - Valve %Open Low Level

0 to 10000 = 0% to 100% (R/W)

22 HP - Valve %Open High Level

0 to 10000 = 0% to 100% (R/W)

23 SF - Control Sensor Fault (R/W)

0 - manual mode

1 - force valve open

2 - force valve closed

24 CF - Comms Fault (R/W)

0 - continue operating

1 - force valve open

2 - force valve closed

25 Manual Mode %Open value, ‘Po’

0 to 10000 = 0% to 100% (R/W)

(R) = Read Only

(R/W) = Read/Write

Read - function 03Hex

“01 03 00 00 00 01” Status Register

‘XX’ Register address has a ‘1’ oset:

For ‘Status’ (register address 01) use Hex address “00 00”

Write - function 06Hex only (single register)

“01 06 00 05 00 02” set Mode to Combination

‘XX’ Register address has a ‘1’ oset:

For ‘Mode’ (register address 06) use Hex address “00 05”

Mode - Write:

If the ‘P4’ sensor is not tted, or in a fault state, the

controller will not accept a command to change to

‘Forward’ or ‘Combination’ modes; a Modbus exception

response will be returned.

If the ‘P3’ sensor is not tted, or in a fault state, the

controller will not accept a command to change to