Page 1

M35

41

ARO

Tool Products

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

SECTION

MANUAL

Released: 6-1-96

3/4” CAPACITY IMPACT WRENCH

Model: WG068A-F4-( )

The ARO WG068A-F4 3/4” Impact Wrench is designed for use in the construction industry and

in the production of heavy equipment such as locomotive, bulldozers, tractors and ships.

ARO is not responsible for customer modification of tools for applications on which ARO was

not consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

Always operate, inspect and maintain this tool in accordance with American National Standards Institute

Safety Code for Portable Air Tools (ANSI Bl86.1)

For safety, top performance, and maximum durability

of parts, operate this tool at 90 psig (6.2 bar/620 kPa)

maximum air pressure at the inlet with 3/4” (19 mm)

inside diameter air supply hose.

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool, or before performing any

maintenance on this tool.

Do not use damaged, frayed or deteriorated air hoses

and fittings.

Be sure all hoses and fittings are the correct size and

are tightly secured. See Dwg. TPD905-1 for a typical

piping arrangement.

Always use clean, dry air at 90 psig (6.2 bar/620 kPa)

maximum air pressure. Dust, corrosive fumes and/or

excessive moisture can ruin the motor of an air tool.

Do not lubricate tools with flammable or volatile liquids such as kerosene, diesel or jet fuel.

Do not remove any labels. Replace any damaged label.

USING THE TOOL

l

Always wear eye protection when operating or performing maintenance on this tool.

.

Always wear hearing protection when operating this

tool.

.

Keep hands, loose clothing and long hair away from

rotating end of tool.

.

Note the position of the reversing lever before operating the tool so as to be aware of the direction of rotation when operating the throttle.

.

Anticipate and be alert for sudden changes in motion

during start up and operation of any power tool.

.

Keep body stance balanced and firm. Do not overreach when operating this tool. High reaction torques

can occur at or below the recommended air pressure.

.

Tool shaft may continue to rotate briefly after throttle

is released.

.

Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may be

harmful to your hands and arms. Stop using any tool

if discomfort, tingling feeling or pain occurs. Seek

medical advice before resuming use.

.

Use accessories recommended by ARO.

.

Use only impact sockets and accessories. Do not use

hand (chrome) sockets or accessories.

.

Impact wrenches are not torque wrenches. Connections requiring specific torque must be checked with a

torque meter after fitting with an impact wrench.

.

This tool is not designed for working in explosive atmospheres.

.

This tool is not insulated against electric shock.

The use of other than genuine ARO replacement parts may result in safety hazards, decreased tool performance,

and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized trained personnel. Consult your nearest ARO Tool Products Authorized

Servicenter.

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll-Rand Distribution Center,

White House, TN at PH: (615) 6724321, FAX: (615) 672-0601

ARO Tool Products

Ingersoll-Rand Company

1725 U.S. No. 1 North l P.O. Box 8000 l Southern Pines, NC 283884000

©1996 INGERSOLL-RAND COMPANY. PRINTED IN U.S.A.

ARO

Part of worldwide Ingersoll-Rand

Page 2

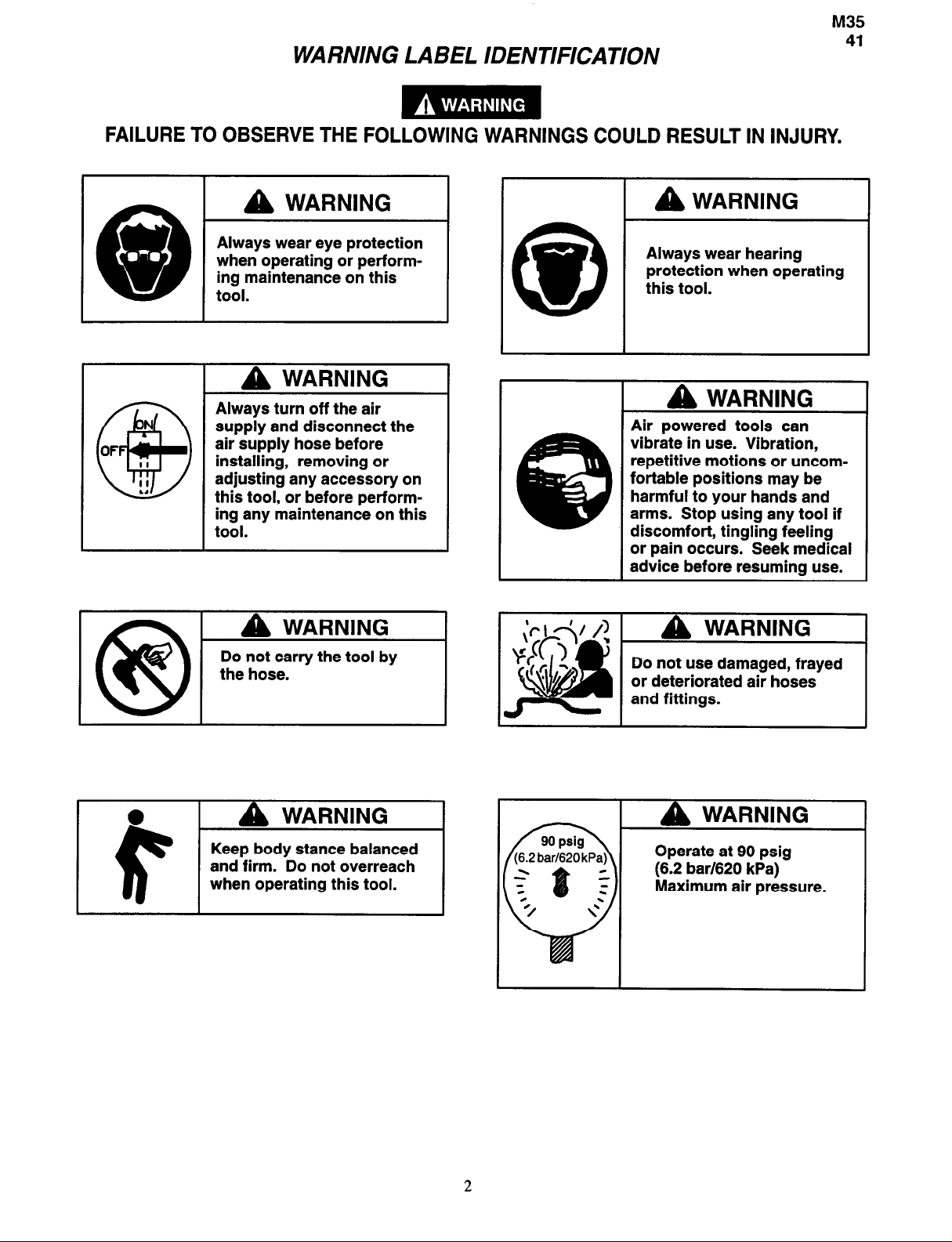

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

WARNING

Always wear eye protection

when operating or performing maintenance on this

tool.

WARNING

Always turn off the air

supply and disconnect the

air supply hose before

installing, removing or

adjusting any accessory on

this tool, or before performing any maintenance on this

tool.

WARNING

Do not carry the tool by

the hose.

WARNING

Always wear hearing

protection when operating

this tool.

I

WARNING

Air powered tools can

vibrate in use. Vibration,

repetitive motions or uncomfortable positions may be

harmful to your hands and

arms. Stop using any tool if

discomfort, tingling feeling

or pain occurs. Seek medical

advice before resuming use.

I

WARNING

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

2

Page 3

PLACING TOOL IN SERVICE

@35

41

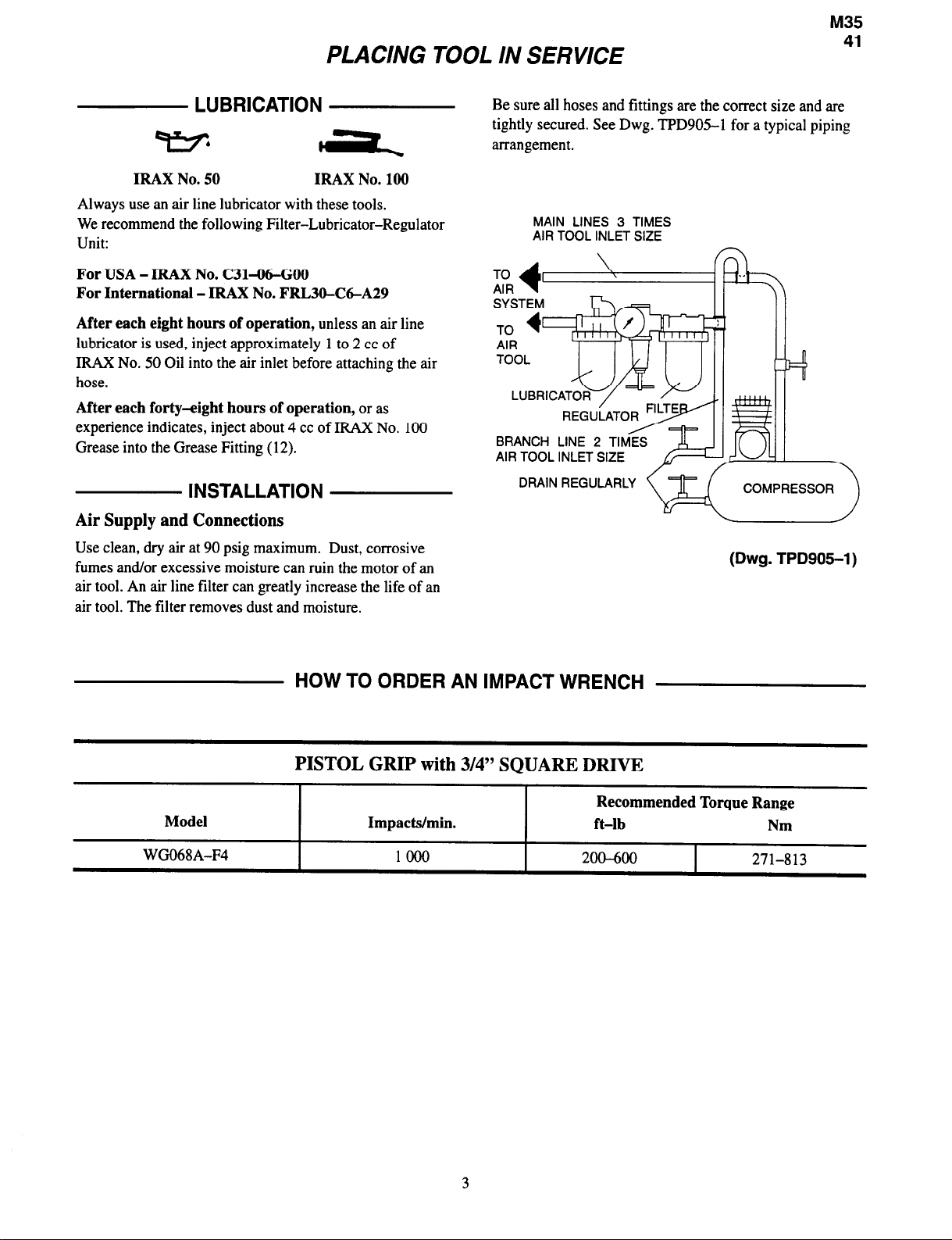

LUBRICATION

IRAX

No. 50 IRAX No. 100

Always use an air line lubricator with these tools.

We recommend the following Filter-Lubricator-Regulator

Unit:

For USA - IRAX No. C31-06-G00

For International - IRAX No. FRL30-C6-A29

After each eight hours of operation, unless an air line

lubricator is used, inject approximately 1 to 2 cc of

IRAX No. 50 Oil into the air inlet before attaching the air

hose.

After each forty-eight hours of operation, or as

experience indicates, inject about 4 cc of IR4X No. 100

Grease into the Grease Fitting (12).

INSTALLATION

Air Supply and Connections

Use clean, dry air at 90 psig maximum. Dust, corrosive

fumes and/or excessive moisture can ruin the motor of an

air tool. An air line filter can greatly increase the life of an

air tool. The filter removes dust and moisture.

Be sure all hoses and fittings are the correct size and are

tightly secured. See Dwg. TPD905-1 for a typical piping

arrangement.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

I I

COMPRESSOR

(Dwg. TPD905-1)

Model

WG068A-F4

HOW TO ORDER AN IMPACT WRENCH

PISTOL GRIP

Impacts/min.

with

1000

3/4” SQUARE DRIVE

Recommended Torque Range

ft-lb

200-600

Nm

271-813

3

Page 4

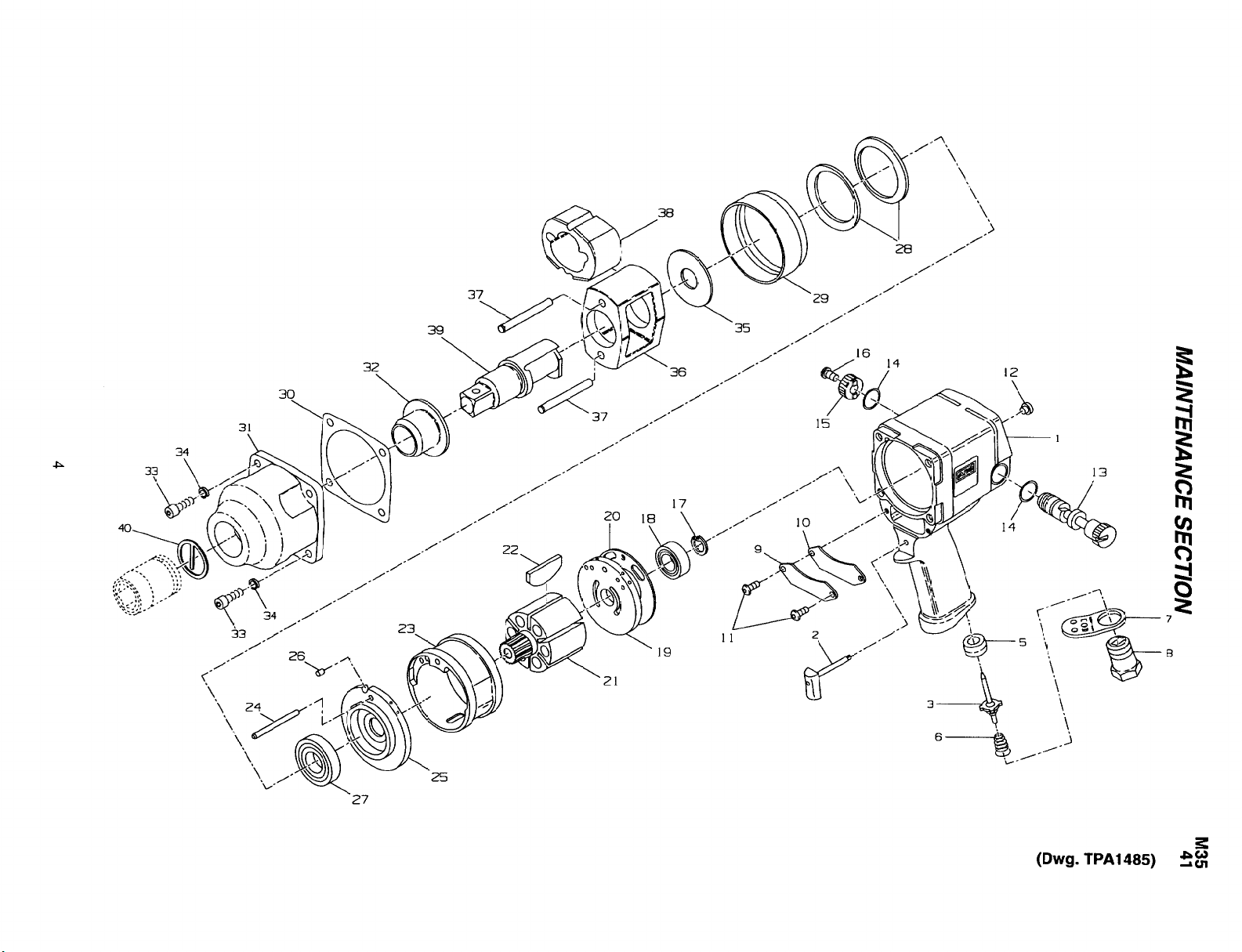

MAINTENANCE SECTION

Page 5

+ 3

+ 5

+ 6

l

10

11

12

13

l

14

15

16

+ 17

4 18

19

+ 20

21

+ 22

23

24

25

26

+ 27

PART NUMBER FOR ORDERING

1

Motor Housing Assembly

2

7

8

9

Trigger Assembly

Throttle Valve

Throttle Valve Seat

Throttle Valve Spring

Exhaust Deflector

Inlet Bushing

Housing Plate

Housing Plate Gasket

Housing Plate Screw (2)

Grease Fitting

Reverse Valve

Reverse Valve Seal (2)

Reverse Valve Knob

Reverse Valve Knob Screw

Rear Rotor Bearing Retainer

Rear Rotor Bearing

Rear End Plate

.......................

Rear End Plate Gasket

Rotor ..............................

Vane Packet (set of 6 Vanes)

Cylnder

Cylinder Dowel

Front End Plate

End Plate Dowel

............................

......................

......................

.....................

Front Rotor Bearing

..............

..................

....................

.................

...............

.................

.....................

.....................

...............

............

.....................

.....................

..............

................

............

...................

.................

............

...................

..........

VW-1083

2920P-A93

DG230-302

DG230-303

1720P-51

1720P-23

2920P-465

1720P-230

172OP-231

FEAl00-112

13OSR-188

1710B-329

261-283

23l-666

23l-665

MVA008-218

4E-510

2920-12

2920B-283

2910B-53

2910-42-6

2920-3

910-98

2920-l1

2920-74

834-24

PART NUMBER FOR ORDERING

28

Motor Clamp Washer (2)

29

Motor Retainer

l

30

Hammer Case Gasket

31

Hammer Case Assembly

.........................

.................

....................

for models ending in -EU .......

32

*

for all other models

Hammer Case Bushing

Hammer Case Label

............

...............

for models ending in -EU .......

for all other models

33

Hammer Case Cap Screw (4)

34

Cap Screw Lock Washer (4)

35

Rear Hammer Frame Washer

36

Hammer Frame Assembly

37

38

39

40

*

*

Hammer Pin (2)

Hammer

Anvil

..............................

................................

Socket Retainer

Horizontal Hanger

Nameplate

.....................

........................

......................

............

..............

..............

..............

................

for models ending in -EU .......

for all other models

*

Tune-up Kit (includes illustrated parts

............

3, 5, 6, 10, 14 [2], 17, 18, 20, 22,

27, and 30) ............................

2920-207

2920B-800

910-36

VW-1086EU

VW-1086

2920-641

EU-99

WARNING-2-99

34U-103

T11-58

910-706

2910-A703

1910-704

260-724

260-726

RRl0034S

910-366

VW-l087-EU

VW-1087

1720P-TK2

* Not illustrated.

+ Indicates Tune-up Kit Part.

Page 6

MAINTENANCE SECTION

Always wear eye protection when operating or

performing maintenance on this tool.

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting any

accessory on this tool, or before performing any

maintenance on this tool.

LUBRICATION

Each time a WG068A-F4 Impact Wrench is disassembled

for maintenance and repair or replacement of parts,

lubricate the tool as follows:

1.

Work approximately 12 to 15 cc of IRAX No. 100

Grease into the impact mechanism, particularly around

the Hammer Pins (37), Hammer (38), Hammer Frame

(36), Anvil (39) and inside the Hammer Case Bushing

(32).

2.

Work some IRAX No. 100 Grease into the Rear Rotor

Bearing (18) and Front Rotor Bearing (27).

3.

Inject approximately 4 cc of IRAX No. 100 Grease

into the Grease Fitting (12).

4.

Wipe a thin film of IRAX No. 50 Oil on the Rotor (2 1),

Vanes (22), Reverse Valve (13), Rear End Plate (19),

Front End Plate (25) and the bore of the Cylinder (23).

5.

Use IRAX No. 50 Oil for lubrication the motor. Inject

approximately 1 to 2 cc of oil into the air inlet before

attaching the air hose.

DISASSEMBLY

M35

41

2. Unscrew and remove the four Hammer Case Cap

Screws (33).

3. While lightly tapping on the end of the Anvil (39) with

a plastic hammer, lift off the Hammer Case (3 1) and

remove the Hammer Case Gasket (30).

4. Grasp the Hammer Frame (36) and carefully lift off the

entire impact mechanism, making certain not to drop

the two Hammer Pins (37).

Disassembly of the Impact Mechanism

1. Set the mechanism, driver end up, on the workbench.

Using a felt tipped pen, mark one end of the Hammer

“?” with the arrow pointing upward.

2. With the mechanism sitting upright on the workbench,

slowly rotate the Anvil in a clockwise direction until it

comes up solid.

If you continue to rotate the Anvil, it will cam the

Hammer out of engagement. Don’t do this; merely

rotate the Anvil until it comes up solid.

3. Hold the Hammer Frame (38) firmly and, without

disturbing the Hammer, gently lift the Anvil from the

Hammer Frame.

4. With the Anvil removed, lift out the two Hammer Pins

(37).

The Hammer is now free to slide from the Hammer

Frame. Be careful not to drop it.

General Instructions

1.

Do not disassemble the tool any further than necessary

to replace or repair damaged parts.

2.

Whenever grasping a tool or part in a vise, always use

leather-covered or copper-covered vise jaws to protect

the surface of the part and help prevent distortion. This

is particularly true of threaded members and housings.

3.

Do not remove any part which is a press lit in or on a

subassembly unless the removal of that part is

necessary for repairs or replacement.

4.

Do not disassemble the tool unless you have a

complete set of new gaskets and G-rings for

replacement.

2.

Slide assembled motor out of Motor Housing.

Disassembly of the Impact Wrench

1. Clamp the handle of the tool in leather-covered or

copper-covered vise jaws with the square driver

upward.

* Registered trademark of Loctite Corporation.

Disassembly of the Reverse Valve

1. Unscrew the Reverse Valve Knob Screw (16) and

remove the Reverse Valve Knob (15).

This Screw is installed with LoctiteB*. You may

have to heat the Screw slightly to loosen it.

2. While slowly rotating the Reverse Valve (13),

withdraw it from the reverse valve bushing in the

Motor Housing. Remove the Housing from the vise.

Disassembly of the Motor

1. Grasp the Motor Retainer (29) and lift it from the

Motor Housing (1).

2. Lift the Rear Hammer Frame Washer (35) and the two

Motor Clamp Washers (28) from the front of the motor.

3. Grasping the spline of the Rotor (21), carefully lift the

assembled motor from the Motor Housing.

Page 7

MAINTENANCE SECTION

The End Plate Dowel (26) will be free to move when

the the Front End Plate (25) clears the Housing. Do

not lose it.

Remove the Rear End Plate Gasket (20).

4.

5.

Slide the Front End Plate and Front Rotor Bearing (27)

from the Rotor.

Remove the Cylinder Dowel (24), Cylinder (23) and

6.

Vanes (22) from the Rotor.

Using snap ring pliers, remove the Rear Rotor Bearing

7.

Retainer (17) and slide the Rear End Plate (19) and

Rear Rotor Bearing (18) from the Rotor.

If the Front Rotor Bearing or Rear Rotor Bearing

8.

requires replacement, press it from the End Plate with

an arbor press.

Disassembly of the Throttle Mechanism

Unscrew the Inlet Bushing (8) and remove the Exhaust

1.

Deflector (7), Throttle Valve Spring (6) and the

Throttle Valve (3).

The Trigger (2) will be free to fall out of the

Housing when the Throttle Valve is removed.

Do not lose it.

If the Throttle Valve Seat (5) requires replacement,

2.

insert a hooked tool through the center of the Valve

Seat. Catching the backside of the Seat with the hook,

pull the Seat from the Housing.

Remove the two Housing Plate Screws (11) and the

3.

Housing Plate (9) if the Housing Plate Gasket (10)

needs to be replaced.

ASSEMBLY

General Instructions

Always press on the

1.

when installing the bearing on a shaft.

Always press on the

2.

when pressing the bearing into a bearing recess.

Whenever grasping a tool or part in a vise, always use

3.

leather-covered or copper-covered vise jaws. Take

extra care with threaded parts and housings.

Always clean every part and wipe every part with a

4.

thin film of oil before installation.

inner

ring of a ball-type bearing

outer

ring of a ball-type bearing

M35

41

Apply a film of G-ring lubricant to all G-rings before

5.

final assembly.

Assembly of the Throttle Mechanism

1.

If the Housing Plate (9) was removed, position the

Housing Plate Gasket (10) and Housing Plate, convex

side first, against the Motor Housing (1). Apply

Vibra-TiteB** to the two Housing Plate Screws (11)

and secure the Plate and the Gasket with the Screws.

Tighten the Screws to 20 to 25 in-lb (2 to 3 Nm)

torque.

2.

If the Throttle Valve Seat (5) was removed, drop the

Seat into the air inlet chamber in the handle. Install a

new Throttle Valve Seat by pushing it into position

against the shoulder in the air inlet chamber with a 5/8”

(16 mm) dowel.

3.

Wipe the stem of the Trigger Assembly (2) with some

light grease and insert the stem into the trigger

bushing.

4.

Installation of the Throttle Valve (3) is sometimes a bit

tricky due to the smallness of the Valve and the depth

of the bore in which it is located. The difficult part is

in holding the Valve while inserting the long end of the

valve stem through the hole in the trigger stem.

Although the Valve can be held with a push-button

mechanical pencil or a wooden dowel, one of the

easiest ways of holding it is by using a common

wooden pencil with a rubber eraser. Insert the short

end of the valve stem into the rubber eraser, as far as

possible, and then back it out until the Valve is

nicely supported. Insert the Valve into the bore of the

handle so that the long end of the stem enters the hold

in the trigger stem. Pull outward on the Trigger to hold

the Valve while removing the pencil.

5.

Install the Throttle Valve Spring (6), small end first.

6.

Position the Exhaust Deflector (7) in the recess at the

bottom of the handle and install the Inlet Bushing (8).

Tighten the Bushing to 40 to 45 ft-lb (54 to 61 Nm)

torque.

Assembly of the Reverse Valve

1. After applying G-ring lubricant to the Reverse Valve

Seals (14), install them in the undercuts in the reverse

valve bushing. Make certain they are properly seated.

2. Dampen the Reverse Valve (13) with IRAX No. 50 Oil.

With the tool in an upright position, and while facing

the back end of the tool, insert the Reverse Valve from

left to right into the reverse valve bushing.

just

Registered trademark of ND Industries.

**

7

Page 8

MAINTENANCE SECTION

M35

41

3. Place the Reverse Valve Knob (15) on the end of the

Valve and, after applying LoctiteB No. 601 to the

Reverse Valve Knob Screw (16), fasten the Knob to the

Valve with the Screw. Tighten the Knob Screw to 5 to

6 ft-lb (6.75 to 8.15 Nm) torque.

Assembly of the Motor

1.

Using a sleeve that will contact only the outer ring of

the bearing, press the Front Rotor Bearing (27) into the

Front End Plate (25) and the Rear Rotor Bearing (18)

into the Rear End Plate (19).

2.

Slip the Font End Plate and Bearing over the splined

hub of the Rotor (21).

3.

Grasp the splined end of the Rotor in leather-covered

or copper-covered vise jaws with the Rotor in a

vertical position.

Dampen each Vane (22) with IRAX No. 50 Oil and

insert a Vane into each vane slot in the Rotor.

Set the Cylinder (23) over the Rotor and onto the Front

End Plate.

Slide the Rear End Plate and Bearing onto the Rotor

hub and against the Cylinder.

7.

Using snap ring pliers, install the Rear Rotor Bearing

Retainer (17) in the groove on the rotor hub.

8.

Align the dowel hole in both End Plates with the one

through the Cylinder, and insert a guide rod 3/16”

diameter x 8” long (4.7 mm diameter x 203 mm long)

through the holes. Allow the rod to protrude about

3-l/2” (89 mm) from the Rear End Plate.

9.

While holding the assembled motor intact, remove it

from the vise.

10. Insert the protruding end of the guide into the cast slot

at the bottom of the Motor Housing bore and slide the

assembled motor along the rod until it is completely

seated in the housing.

11. Remove the guide rod and install the Cylinder Dowel

(24).

12. Install the End Plate Dowel (26).

13. Grasp the handle of the Motor Housing in

leather-covered or copper-covered vise jaws with the

open end of the Motor Housing upward.

14. Place a Motor Clamp Washer (28), concave side first,

down over the hub of the Front End Plate so that the

outer rim of the Washer contacts the Front End Plate.

Place the second Motor Clamp Washer, convex side

first, down over the hub of the Front End Plate so that

the inner rims of both Washers are in contact but the

outer rims are separated.

15.

Place the Motor Retainer (29), small bore first, down

over the hub of the Front End Plate and against the

outer rim of the second Motor Clamp Washer.

16.

Place the Rear Hammer Frame Washer (35), hub side

first, over the hub of the Rotor and against the Front

Rotor Bearing.

Assembly of the Impact Mechanism

1.

Coat the Hammer (38) with a light film of IRAX

No. 100 Grease.

2.

Slide the Hammer into the Hammer Frame (36) exactly

as it was when you marked it prior to disassembly.

In order to utilize both impacting surfaces on the

Hammer and thus equalize the wear on each

hammer jaw, the Hammer can be flipped over so

that the arrow is pointing downward.

3.

Replace the Hammer Pins (37).

4.

Examine the base of the Anvil (39) and note its

contour. While looking down through the Hammer

Frame, swing the Hammer to its full extreme one way

or another until you can match the contour of the

Anvil. Enter the Anvil into the Hammer Frame and

through the Hammer.

Assembly of the Tool

1. Set the assembled impact mechanism down over the

splined hub of the Rotor.

2. Position the Hammer Case Gasket (30) on the Housing.

3. Work approximately 12 to 15 cc of IRAX No. 100

Grease into the impact mechanism.

4. Smear a thin film of IRAX No. 100 Grease on the

inside surface of the Hammer Case Bushing (32), and

place the Hammer Case (3 1) down over the Anvil and

against the Motor Retainer.

5. Install the Hammer Case Cap Screws (33) and tighten

them to 20 to 25 ft-lb (27 to 34 Nm) torque.

6. Remove the Impact Wrench from the vise and inject

2 to 4 cc of IRAX No. 100 Grease into the Grease

Fitting (12).

8

Page 9

Double

Low power

Motor will not run

Tool will not impact

MAINTENANCE SECTION

TROUBLESHOOTING GUIDE

I

Dirty Inlet Bushing or Air

Strainer Screen and/or Exhaust

Silencer Bushing and Exhaust Silencer.

Worn or broken Vanes

Worn or broken Cylinder and/or

scored End Plates-

Dirty motor parts

Improper positioning of Reverse

Valve

Incorrect assembly of motor

Insufficient lubricant in the

impact mechanism

Broken or worn impact

mechanism parts

Impact mechanism not assembled

correctly

Probable Cause

Using a suitable cleaning solution, in a well

ventilated area, clean Air Strainer Screen, Inlet

Replace complete set of Vanes.

Examine Cylinder and replace it if it is worn or

broken or if bore is scored or wavy. Replace End

Plates if they are scored.

Disassemble tool and clean all parts with a

suitable cleaning solution, in a well-ventilated area.

Reassemble tool as instructed in this manual.

Make certain that Reverse Valve is fully

engaged to the left or right.

Disassemble motor and replace worn or broken

parts and reassemble as instructed.

Remove Hammer Case Assembly and lubricate

impact mechanism.

Remove Hammer Case and examine impact

mechanism parts. Replace any worn or broken

parts.

Refer to Assembly of the Impact Mechanism.

Solution

M35

41

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

9

Page 10

NOTES

M35

41

Page 11

NOTES

M35

41

Page 12

M35

41

ARO

Part of worldwide Ingersoll-Rand

PN49999-525

Loading...

Loading...