Ingersoll-Rand ARO 662608, ARO 662609, ARO 662605, ARO 662606 User Manual

OPERATOR’S MANUAL 66260X

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

INCLUDE MANUAL: 6564X-X AIR MOTOR (97999-174), AIRLINE SAFETY INFORMATION (100400-76)

& S-633 GENERAL INFORMATION (PN 97999-624).

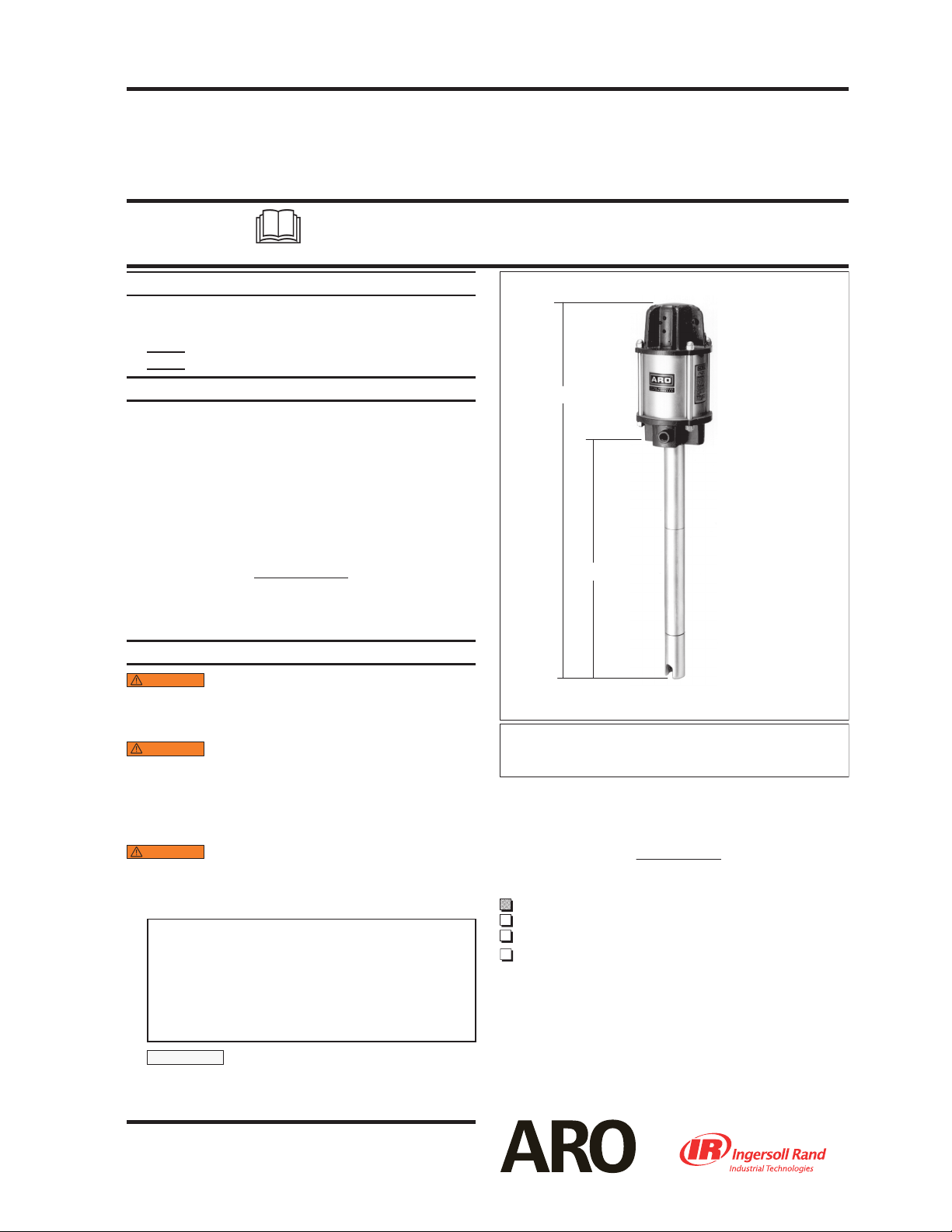

6” AIR MOTOR

100:1 RATIO

0 - 10,000 PSI. RANGE

662605, 662606, 662608 & 662609

PUMP ASSEMBLY

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

RELEASED: 8-26-09

REVISED: 3-17-10

(REV. G)

SERVICE KITS

Use only genuine ARO® replacement parts to assure com-

y

patible pressure rating and longest service life.

65130 packing kit.

y

61355 for air motor service only.

y

SPECIFICATIONS

Model Series . . . . . . . . . 662605, 662606, 662608 & 662609.

Type . . . . . . . . . . . . . . . . . Air Operated Grease Pump

Ratio . . . . . . . . . . . . . . . 100:1

Air Motor Diameter. . . . . . . . . . . . . . 6” (15.2 cm)

Stroke. . . . . . . . . . . . . . . . . . . . . . 4” (10.2 cm)

Air lnlet (female) . . . . . . . . . . . . . 1/2-14 N.P.T.F.

Material Outlet (female). . . . . . . 1/2 - 14 N.P.T.F.

Dimensional Data . . . . . . . . . . . . . . . . see chart

PERFORMANCE

Air Inlet Pressure Range . . . . .

0 - 100 p.s.i.g (0 - 6.9 bar)

Fluid Pressure Range . . . . . . . 0 - 10,000 p.s.i.g (0 - 690 bar)

Maximum Delivery/ Min . . . . 2.1 lbs (0.95 kg)

OPERATING AND SAFETY PRECAUTIONS

WARNING

UAL INCLUDED FOR ADDITIONAL OPERATING AND

SAFETY PRECAUTIONS AND OTHER IMPORTANT INFORMATION.

WARNING

explosion resulting in severe injury or death. Do not

exceed maximum operating pressure of 10,000 p.s.i.g

(690 bar) at 100 p.s.i.g (6.9 bar) inlet air pressure. Do

not run pump without using a regulator to limit air

supply pressure to the pump.

WARNING

equipment failure resulting in severe injury or property damage. Do not exceed the maximum material

pressure of any component in the system.

INLET PRESSURE TO PUMP MOTOR FLUID PRESSURE

Pump ratio is an expression of the relationship between the pump

motor area and the lower pump end area. EXAMPLE: When 100 p.s.i.g

(6.9 bar) inlet pressure is supplied to the motor of a 100:1 ratio pump it

will develop a maximum of 10,000 p.s.i.g (690 bar) uid pressure (at no

ow) - as the uid control is opened, the ow rate will increase as the

motor cycle rate increases to keep up with the demand.

terial lines is exposed to elevated temperatures. Example: Material lines

located in a non-insulated roof area can warm due to sunlight. Install a

pressure relief valve in the pumping system.

READ THE GENERAL INFORMATION MAN-

EXCESSIVE INLET PRESSURE. Can cause

EXCESSIVE MATERIAL PRESSURE. Can cause

NOTICE

PUMP RATIO X

Thermal expansion can occur when the uid in the ma-

MAXIMUM PUMP

=

662605

662606

662608

662609

“A”

“B”

Figure 1

NOTE: Dimensions are shown in inches and (mm), supplied for reference

only and are typically rounded up to the nearest 1/16 inch.

MODELS

662605, 662606

662608, 662609

“A” (mm)

39-5/8” (1006)

49-7/16” (1256)

IMPORTANT

This is one of four documents which support the pump.

Replacement copies of these forms are available upon request.

66260X MODEL OPERATOR’S MANUAL

6564X-X AIR MOTOR OPERATOR’S MANUAL

100400-76 AIRLINE SAFETY INFORMATION MANUAL

S-633

GENERAL INFORMATION LUBRICATION PISTON PUMPS

“B” (mm)

25-7/16” (646)

35-1/4” (895)

Drum Size

120 lb.

400 lb. (55 gal.)

INGERSOLL RAND COMPANY LTD

P.O. BOX 151 y ONE ARO CENTER y BRYAN, OHIO 43506-0151

(800) 276-4658 y FAX (800) 266-7016

© 2010 CCN 99711251

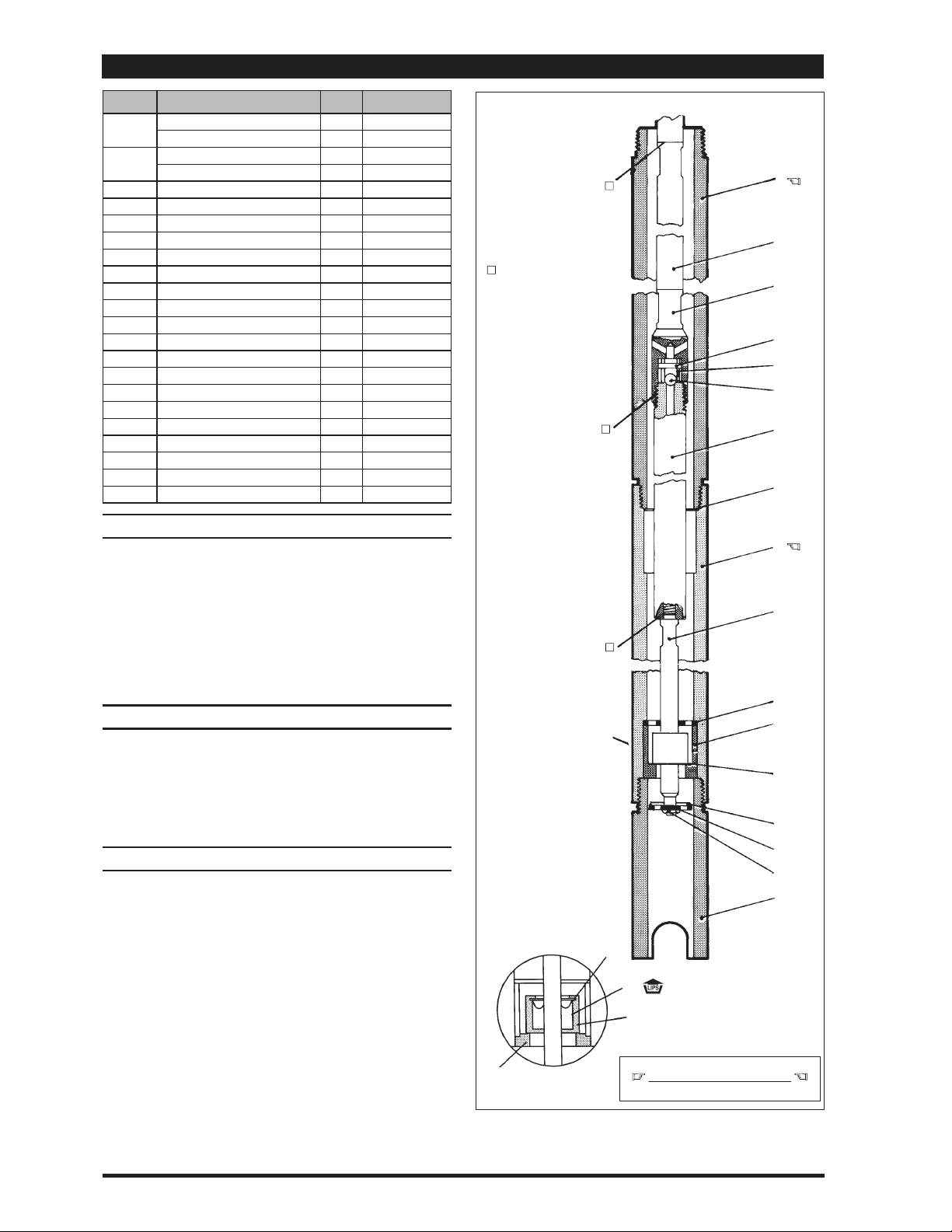

PARTS LIST / LOWER PUMP END

Item Description

1 Tube

2 Rod

3 Adapter (1) 92621

4 Pin (1) 92624

5 BaIl Guide (1) 92623

6 BalI (1) Y16-211

7 Piston and CyIinder (1) 66714

8 Gasket (1) 92628

9 Tube (1) 92627

10 Primer Rod (1) 90131

11 Washer (1) 90136

12 Foot Valve Sleeve (1) 4170

13 Snap Ring (1) Y147-77

14 Cup (1) 90757

15 Body (1) 90756

16 Washer (1) F21-56

17 Foot Valve Seat (1) 93269-1

18 Washer (1) 90133

19 Washer (1) 92630

20 Elastic Stop Nut (1) 95977302

21 Primer Tube (1) 92626

(size in inches)

(662605 & 662606)

(662608 & 662609)

(662605 & 662606)

(662608 & 662609)

Qty Part No.

(1) 92625-1

(1) 92625-2

(1) 92629-1

(1) 92629-2

INSTALLATION

Remove pump from packaging material and install and secure

pump to cover, bung or other mounting accessory as ordered.

See gure 2 for view of complete assembly.

1.

Before connecting pump, first blow out material line

with air.

.

2

After the system is hooked up, pump a small amount

of material through the line. This material should be

discarded. (Do this to clear any foreign material out of

lines).

OPERATING INSTRUCTIONS

Be sure material hose, lines and other components are

able to withstand pressure developed by pumps.

When a pump is installed and ready to operate: Connect air

1.

supply to air motor inlet. Regulate air pressure from p.s.i.g

(2.07 bar) to 50 p.s.i.g (3.4 bar). Allow pump to cycle slowly

to prime with material and bleed all air from system

.

MAINTENANCE

If the pump is to be inoperative for a lengthly period of time (a

few hours), disconnect air and relieve all pressure from system.

Periodically flush pump with a solvent that is compatible

with material being pumped.

Disassembly should be done on a clean work bench with

clean cloths to keep parts clean.

If replacement parts are necessary, consult drawings containing parts for identi cation.

Before reassembling, lubricate parts where required. When

assembling “0” rings or parts adjacent to “0” rings, care must

be exercised to prevent damage to “0” rings and “0” ring

groove surfaces.

Clean threads with

solvent and apply

Loctite 271 sealant

to threads.

See View “A”

17

View “A”

13

14

15

TORQUE REQUIREMENTS

(1 & 9) 300 ft lbs (406.8 Nm) minimum.

Figure 2

1

2

3

4

5

6

7

8

9

10

11

12

16

18

19

20

21

Page 2 of 4 66260X

Loading...

Loading...