Ingersoll-Rand 66942-XXX, 66941-XXX User Manual

OPERATOR’S MANUAL 6694X-XXX

INCLUDING: SERVICE KITS, TROUBLESHOOTING, PARTS LIST & DISASSEMBLY & REASSEMBLY.

TWO-BALL STYLE LOWER PUMP ENDS

66941-XXX (400 Series Stainless Steel)

66942-XXX (300 Series Stainless Steel)

Also covers 637211-XX3 service kits.

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

RELEASED: 11-27-90

REVISED: 6-2-10

(REV. R)

SERVICE KITS

Use only genuine ARO® replacement parts to assure com-

y

patible pressure rating and longest service life.

637211-XX3 for general repair of 6694X-XXX lower pump

y

ends.

GENERAL DESCRIPTION

WARNING

PRESSURE AS INDICATED ON PUMP MODEL PLATE.

WARNING

FOR ADDITIONAL SAFETY PRECAUTIONS AND IMPORTANT INFORMATION.

This manual only covers the lower pump section. It is one

y

of four documents which support an ARO pump. Replacement copies of these forms are available upon request.

650XXX-X Pump Model Operator’s Manual

General Information - Air / Hydraulically Operated Piston

Pumps

Lower Pump End Operator’s Manual

:

Air / Hydraulic Motor Operator’s Manual

The two-ball design provides better priming of the lower

y

foot valve. The double acting feature is standard in all ARO

industrial pumps. Material is delivered to the pump discharge

outlet on both the up and down stroke.

DO NOT EXCEED MAXIMUM OPERATING

REFER TO GENERAL INFORMATION SHEET

MAINTENANCE

The air / hydraulic motor is completely separate from the

lower pump end. This helps to keep the motor from being

contaminated by the material being pumped. Periodically,

ush the entire pump system with a solvent that is compatible with the material being pumped.

Keep the solvent cup lled with this compatible solvent. This

will keep the material from drying on the piston rod, which

could drag through the packings, ruin them and eventually

scour the piston rod.

Provide a clean work surface to protect sensitive internal

moving parts from contamination from dirt and foreign matter during disassembly and reassembly.

Before reassembly, lubricate parts as required. When assembling “O” rings or parts adjacent to “O” rings, exercise care to

prevent damage to “O” rings and “O” ring groove surface.

LOWER PUMP END DESCRIPTION CHART

6694X - X X X

Pump Material

1 - 400 series stainless steel

2 - 300 series stainless steel

Packing Material

C - UHMW-PE (upper and lower)

K - Carbon Graphite lled PTFE with Nitrile Energizer

(upper and lower)

L - Mineral lled PTFE (upper and lower)

P - UHMW-PE / Mineral lled PTFE staggered (upper)

UHMW-PE (lower)

R - Mineral lled PTFE / UHMW-PE staggered (upper)

Mineral lled PTFE (lower)

Spring Arrangement (Service kit spring designation)

3 - No spring (3)

6 - Wave spring (6)

C - No spring with alternate seat material (3)

D - Wave spring with alternate seat material (6)

Plunger Type

3 - Hardened stainless steel with hard chrome plating (threaded)

6 - Stainless steel with hard chrome plating (threaded)

D - Hardened stainless steel with hard chrome plating (large motors)

F - Stainless steel with hard chrome plating (large motors)

Service Kit Selection

EXAMPLE: Lower Pump End # 66941-CDF

Service Kit # 637211-C63

ARO® is a registered trademark of Ingersoll-Rand

y

Loctite® and 242® are registered trademarks of Henkel Loctite Corporation

y

Primer T™ is a trademark of Henkel Loctite Corporation

y

6694X - X X X

637211 - X X 3

Packing Spring

y

y

y

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

CCN 99711764

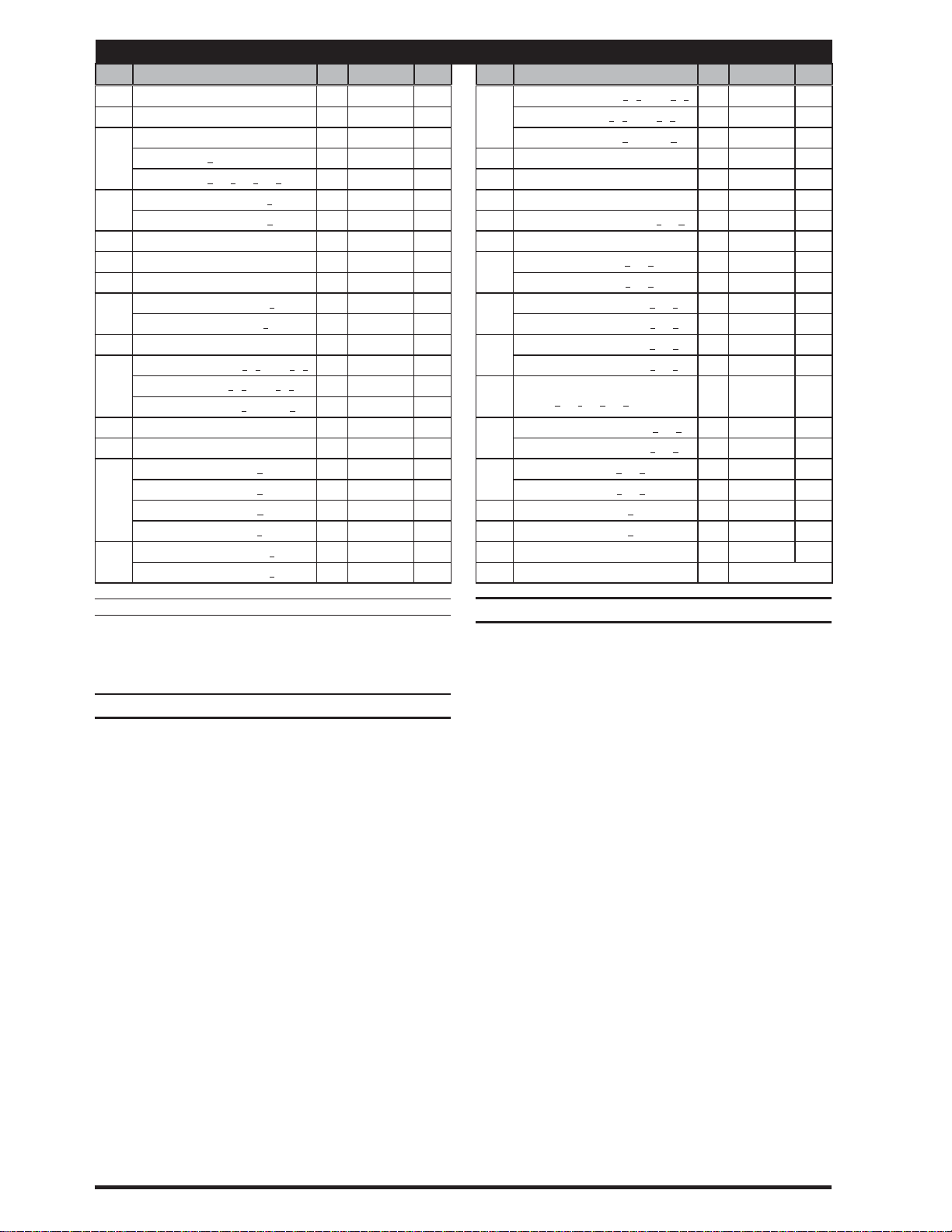

PARTS LIST / 6694X-XXX

Item Description

1 Solvent Cup (1) 66730 [SS]

6 Pump Body (1) 79166 [SS]

“O” Ring

8

9

(models 6694X-KXX)

(models 6694X-CXX, -LXX, -PXX, -RXX)

Suction Tube

9

10 Tie Rod (3) 79156 [SS]

12 Nut

15 Foot Valve Body (1) 92613 [SS]

Ball

17

(5/16” o.d. x 3-7/16”)

20 Pin

Ball Seat

22

23 Gasket (1) 92609 [SS]

9

24 Seat Retainer (1) 92607 [SS]

Plunger

26

Ball

27

(size)

(3/32” x 3-9/16” o.d.)

(models 66941-XXX)

(models 66942-XXX)

(1” - 14)

(1.5000” o.d.) (models 66941-XXX)

(models 66942-XXX)

(models 66941-X3X, 66941-X6X)

(models 66942-X3X, 66942-X6X)

(models 6694X-XCX, 6694X-XDX)

(models 6694X-XX3)

(models 6694X-XX6)

(models 6694X-XXD)

(models 6694X-XXF)

(1.0000” o.d.) (models 66941-XXX)

(models 66942-XXX)

(Qty) Part No. [Mtl] Item Description

(2) 93333 [B]

(2) 92619 [T]

(1) 92599-1 [SH]

(1) 79164 [SS]

(3) 79184 [SS]

(1) Y16-148 [SH]

(1) 79155 [SS]

(1) 79157 [SS]

(1) 92608 [SH]

(1) 77431 [SS]

(1) 95769 [TC]

(1) 60609 [PSH]

(1) 61429 [PSS]

(1) 67204 [PSH]

(1) 67205 [PSS]

(1) Y16-132 [SH]

(1) 90948 [SS]

(size)

Ball Seat

28

29 Gasket (1) 92612 [SS]

9

(models 66941-X3X, 66941-X6X)

(models 66942-X3X, 66942-X6X)

(models 6694X-XCX, 6694X-XDX)

(Qty) Part No. [Mtl]

(1) 92610 [SH]

(1) 77430 [SS]

(1) 95770 [TC]

36 Seat Body (1) 93234 [SS]

40 Retaining Ring (1) 93225 [SS]

44 Wave Spring

9

45 Washer (1) 93041 [Ny]

9

Washer

50

9

9

“V” Packing

51

9

9

“V” Packing

52

9

9

53 Male Packing Washer

9

6694X-CXX, -LXX, -PXX, -RXX)

“W” Packing

71

9

9

Wiper

72

9

9

75 Packing

9

76 Packing

9

Items included in Service Kit 637211-XX3

9

(models 6694X-X6X, -XDX)

(models 6694X-CXX, -PXX)

(models 6694X-LXX, -RXX)

(models 6694X-CXX, -PXX)

(models 6694X-LXX, -RXX)

(models 6694X-CXX, -RXX)

(models 6694X-LXX, -PXX)

(models

(models 6694X-CXX, -PXX)

(models 6694X-LXX, -RXX)

(models 6694X-CXX, -PXX)

(models 6694X-LXX, -RXX)

(models 6694X-KXX only)

(models 6694X-KXX only)

(1) 79175 [SH]

(1) 93756-4 [UH]

(1) 93756-5 [T]

(2) 93683-4 [UH]

(2) 93683-5 [T]

(2) 93683-4 [UH]

(2) 93683-5 [T]

(1) 92602 [SS]

(1) 93758-4 [UH]

(1) 93758-5 [T]

(1) 93757-4 [UH]

(1) 93757-5 [T]

(1) 93568-1 [T]

(1) 93567-1 [T]

MATERIAL CODE

[B] = Nitrile [SS] = Stainless Steel

[Ny] = Nylon [T] = PTFE

[PSH] = Hard Chrome Plated Hard Stainless Steel [TC] = Tungsten Carbide

[PSS] = Hard Chrome Plated Stainless Steel [UH] = UHMW-PE

[SH] = Hard Stainless Steel

LOWER PUMP DISASSEMBLY

Unscrew three (12) nuts from (10) tie rods.

1.

Remove (15) foot valve body from (10) tie rods and (9)

2.

suction tube. NOTE: Use of a soft face mallet might be

helpful to accomplish this step.

Note the position of (20) pin and (17) ball from (15) foot

3.

valve body.

Unscrew (24) seat retainer and remove (22) ball seat, (23)

4.

gasket and (8) “O” ring.

Pull (9) suction tube and (26) plunger from (6) pump

5.

body.

Push (26) plunger assembly out lower end of (9) suction

6.

tube.

Unscrew (36) seat body and remove (29) gasket, (27) ball

7.

and (28) ball seat from (26) plunger. NOTE: (36) seat body

has two 0.250” dia. x 0.250” deep holes. Use a spanner

wrench (ARO tool 637404-B is available) to loosen.

Remove (40) retaining ring from (36) seat body.

8.

Remove (8) “O” ring from (6) pump body.

9.

Unscrew (1) solvent cup from (6) pump body. NOTE: (1)

10.

solvent cup has six 3/8” dia. x 3/8” deep holes. Use a rod

or spanner wrench (ARO tool 637406 is available) to

All threads are right hand.

Apply lubricant to all rubber parts before assembling (it is

not necessary to lubricate UHMW-PE and PTFE packings).

NOTE: All threads are to be cleaned before reassembly.

The cleaning of threads is a benefit to help insure the

overall reassembly process. Please note the use of the

following materials: Loctite® Primer T™ with Loctite 242®

Threadlocker and Loctite Nickel Anti-Seize.

All threaded parts are stainless steel and care should be

taken on threaded connections.

Apply Loctite Nickel Anti-Seize to threads as indicated ( gure

1, page 3) during assembly.

Apply ARO Wet-Sol "Plus" to threads as indicated (figure 1,

page 3) during assembly.

Apply Primer T with Loctite 242 Threadlocker to threads as

indicated (figure 1, page 3) during assembly. Follow these

instructions to apply materials to threads.

a. Clean parts with solvent and allow to dry.

b. Apply Primer T to mating threaded parts and allow 3 to 5

c. Apply Loctite 242 Threadlocker to mating threaded parts

d. Assemble parts within 3 minutes of applying

e. Tighten per "Torque Requirements", (see page 3).

f. Curing times: Fixed in 5 minutes and full cure in 2 hours.

loosen.

Remove (45) washer, (44) wave spring, (53) male washer,

11

.

(51 and 52) packings and (50) female washer from (1)

solvent cup.

Page 2 of 4 6694X-XXX (en)

LOWER PUMP REASSEMBLY

minutes to dry at 72° F.

being assembled.

Threadlocker.

NOTE: If Primer T is not used, the cure time will be

e ected as follows: xed in 20 minutes and full cure in

24 hours.

(continued on page 4)

Loading...

Loading...