Ingersoll-Rand 66651-B User Manual

OPERATOR’S MANUAL 66651-B

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

10” AIR MOTOR

66651-B AIR MOTOR

6” STROKE

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Use only genuine ARO® replacement parts to assure

y

compatible pressure rating and longest service life.

637110 service kit includes the necessary soft parts for

y

normal service of the entire air motor.

637111 service kit is a replacement valve kit.

y

GENERAL DESCRIPTION

The 10” air motor is a power unit used with a two-ball or

chop-check pump. It utilizes tie rod construction for easy

breakdown and it connects to the lower pump end with tie

rods for easy operation. Consult the pump model operator’s

manual for speci c instructions.

RELEASED: 1-21-00

REVISED: 8-1-11

(REV. F)

OPERATING AND SAFETY PRECAUTIONS

DO NOT EXCEED MAXIMUM AIR INLET PRESSURE OF 90

P.S.I. (6.2 bar) OR 75 CYCLES PER MINUTE.

CAUTION: High pressure equipment - Always disconnect air

supply and relieve material pressure before attempting to

service.

A ground lug is located on the air motor. This ground lug allows proper grounding of the pump.

AIR AND LUBE REQUIREMENTS

A filter capable of filtering particles larger than 50 microns

should be used with a lubricator.

Filtered and oiled air will allow the pump to operate more ef ciently and yield a longer life to operating parts and mechanisms.

Use an air line lubricator and keep it supplied with a good

grade of S.A.E. #90W non-detergent gear oil set at a rate not

to exceed approximately 1 drop per minute.

Figure 1

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 y FAX (800) 892-6276 © 2011 CCN 99834889

www.ingersollrandproducts.com

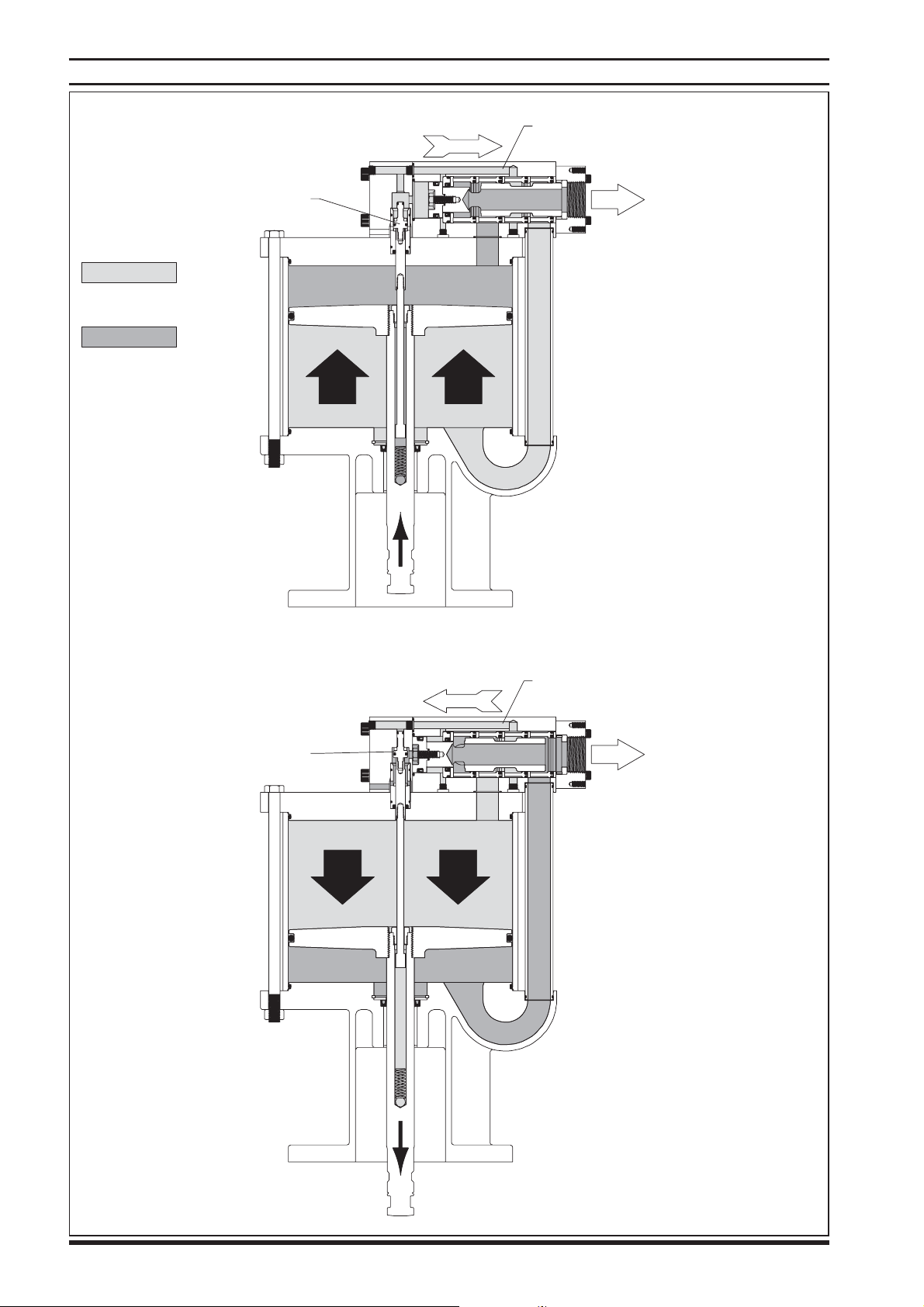

THEORY OF OPERATION

AIR MOTOR FUNCTION DURING UPSTROKE

CONSTANT AIR PRESSURE

SPOOL

Air Pressure

Exhausted Air

Pilot down

EXHAUSTED AIR

AIR MOTOR FUNCTION DURING DOWNSTROKE

Pilot up (exhaust)

CONSTANT AIR PRESSURE

SPOOL

EXHAUSTED AIR

Figure 2

Page 2 of 8 66651-B (en)

DISASSEMBLY / ASSEMBLY

AIR MOTOR DISASSEMBLY

NOTE: All threads are right hand.

Place the air motor in an up-stroke position by pushing

1.

(43) piston assembly toward the top of the motor.

Remove six (26) cap screws from the top of (27 and 30)

2.

blocks.

Remove (27 and 30) blocks from (22) head plate.

3.

Remove (34) tube from (46) base assembly. Remove two

4.

(33) “O” rings from (34) tube and one (33) “O” ring from

the bottom of (30) block manifold.

Remove four (26) cap screws from the end of (27) block.

5.

Separate (27) block from (30) block manifold and remove

6.

(28 and 29) “O” rings.

Remove 3/4 - 14 N.P.T. pipe plugs from the two exhaust

7.

ports, if applicable.

Using a 1/2” socket on (8) cap screw, turn (20) spool

8.

clockwise to align opening or slot in (20) spool with the

3/4 - 14 N.P.T. exhaust port nearest the (8) cap screw.

Insert a 1/4” rod or similar device thru the exhaust port of

9.

(30) block manifold and into the opening or slot of (20)

spool. This rod will prevent rotation of (20) spool when

removing (8) cap screw and (9) washer. CAUTION: Do

not permit this rod to rest against (17) spacer legs,

which could cause breakage of (17) spacer.

Remove (8) cap screw and (9) washer.

10.

Unscrew four (32) cap screws and remove (31) cap as-

11.

sembly.

Remove (20) spool out the “exhaust end” of (30) block

12.

manifold and remove (11) piston out the other end.

From the “exhaust end” of (30) block manifold, remove

13.

four (19) washers, four (17) spacers, four (18) “O” rings,

ve (15) “O” rings, (16) washer, (14) “U” cup, (13) gland and

(10) “O” ring.

Remove (12) “U” cup from (11) piston.

14.

Using the wrench flats provided, remove the (2) piston

15.

assembly from the (5) extension rod.

Remove (1 and 3) “O” rings from (2) piston assembly.

16.

Remove (4) washer, (6) cylinder, two (7) “O” rings and (24)

17.

“U” cup from (22) head plate.

Remove two (7) “O” rings and (24) “U” cup from (6) cylin-

18.

der.

Remove eight (47) nuts from (49) cap screws.

19.

Remove eight (49) cap screws from (22) head plate and

20.

(46) air motor base assembly.

Remove (22) head plate from (37) air cylinder, then re-

21.

move (36) “O” ring from (22) head plate.

Pull upward on (37) air cylinder until (43) piston assem-

22.

bly separates from the (46) base assembly. If, in this step,

the (43) piston assembly is not pulled from the (46) base

assembly, then remove it after removing the (37) air cylinder.

If the (37) air cylinder and (43) piston assembly are re-

23.

moved as one unit, then remove the (43) piston assembly

from the (37) air cylinder.

Remove the (36) “O” ring from the (46) base assembly.

24.

Remove (40) retaining ring, (44) guide washer and (41) “U”

25.

cup from (46) base assembly.

Remove the (50) “O” ring from the (43) piston assembly.

26.

Unscrew (5) extension rod from (39) valve rod by holding

27

.

the (39) valve rod with an adjustable type pliers and using a wrench on the wrench ats provided at the top of

the (5) extension rod.

Remove the (48) screw from the (43) piston assembly.

28.

Remove the (39) valve rod, (45) spring and (42) ball from

29.

the (43) piston assembly.

AIR MOTOR ASSEMBLY

1.

Place the (39) valve rod thru the (48) screw.

2.

Clean the threads of the (39) valve rod and the (5) extension rod. Apply Loctite 271 to these threads and screw

the (5) extension rod to the (39) valve rod and tighten

by holding the (39) valve rod below the threads with an

adjustable type pliers and using a wrench on the ats of

the (5) extension rod. CAUTION: Do not mar or damage

the nish on the (5) extension rod.

Place the (42) ball and (45) spring into the (43) piston as-

3.

sembly.

Place the (39) valve rod and (5) extension rod into the (43)

4.

piston assembly. Apply Loctite 271 to the threads of the

(48) screw and thread the (48) screw into the (43) piston

assembly and tighten.

Assemble the (50) “O” ring to the groove in the (43) pis-

5.

ton assembly.

Assemble the (36) “O” ring to the groove in the (46) air

6.

motor base assembly.

Assemble the (41) “U” cup (lips up), (44) guide washer

7.

and (40) retaining ring into the (46) base assembly.

Assemble the (43) piston assembly into the (46) base as-

8.

sembly, being careful not to damage the (41) “U” cup.

Lubricate the inside diameter of the (37) air cylinder and

9.

slide it down over the (43) piston assembly and onto the

(46) air motor base assembly (see gure 4).

Assemble the (36) “O” ring to the groove in the (22) head

10.

plate.

Align the notch in the (22) head plate with the port in

11.

the (46) air motor base assembly and press the (22) head

plate down until it is seated against the (37) air cylinder.

Assemble eight (49) cap screws thru the (22) head plate

12.

and (46) air motor base assembly.

Assemble eight (47) nuts on the (49) cap screws and

13.

tighten alternately and evenly.

Assemble two (7) “O” rings to the grooves in the (6) cylin-

14.

der.

Assemble the (24) “U” cup into the (6) cylinder, with the

15.

lips facing out.

Assemble the (6) cylinder over the (5) extension rod and

16.

into the (22) head plate. NOTE: Assemble the (6) cylinder

with the “U” cup end onto the (5) extension rod rst.

Assemble the (4) washer over the (5) extension rod and

17.

into the (6) cylinder.

Clean the threads on the (2) piston assembly. Apply

18.

Loctite 271 to the threads and assemble to the (5) extension rod and tighten, using the wrench ats. CAUTION:

Do not mar or damage the surface of either of these

parts.

Assemble the (1 and 3) “O” rings to the grooves in the (2)

19.

piston assembly.

Assemble the (14) “U” cup into the (13) gland, with the

20

.

lips pointed into the gland. Lubricate the bore of the (30)

block manifold and assemble the (13) gland into the (30)

block manifold, with the lips of the (14) “U” cup pointed

into the block manifold. NOTE: Be sure the (13) gland is

seated squarely against the shoulder in the (30) block

manifold.

66651-B (en) Page 3 of 8

Loading...

Loading...