Ingersoll-Rand 3940P2Ti Maintenance Information

80183387

Edition 1

January 2006

Air Impact Wrench

3940P2Ti

Maintenance Information

Save These Instructions

2 80183387_ed1

WARNING

Always wear eye protection when operating or performing maintenance on this tool.

Always turn off the air supply and disconnect the air supply hose before installing, removing or adjusting any accessory on this tool, or before

performing any maintenance on this tool.

Note: When reading the instructions, refer to exploded diagrams in Parts Information Manuals when applicable (see under Related

Documentation for form numbers).

Lubrication

Each time a Model 3940P2Ti Impactool is disassembled for maintenance

and repair or replacement of parts, lubricate the tool as follows:

1. Work approximately 6 cc of Ingersoll-Rand No. 170 Grease into the

impact mechanism. Coat the Anvil (40) lightly with grease around the

Hammer Case Bushing (42). Inject approximately 6 cc of grease into

the Grease Fitting.

2. Inject approximately 3 cc of No. 10 oil into the air inlet before

attaching the air hose.

Disassembly

General Instructions

1. Do not disassemble the tool any further than necessary to replace or

repair damaged parts.

2. Whenever grasping a tool or a part in a vise, always use leathercovered or copper-covered vise jaws to protect the surface of the

part and help prevent distortion. This is particularly true of threaded

members and housings.

3. Do not remove any part which is a press fit in or on a subassembly

unless the removal of that part is necessary for repairs or

replacement.

4. Do not disassemble the tool unless you have a complete set of new

gaskets and O-rings for replacement.

Disassembly of the Impactool

1. Clamp the handle of the Impactool in a vise with the square drive

upward.

2. Remove Exhaust Deflector (4) and Silencer (5).

3. Unscrew and remove the four Hammer Case Cap Screws (45).

4. While lightly tapping on the end of the Anvil (40) with a plastic

hammer, lift off the Hammer Case Assembly (41).

5. Remove the Hammer Case Gasket (36).

6. Grasp Hammer Frame (37) and carefully lift off entire impact

mechanism, making certain not to drop the two Hammer Pins (38).

Disassembly of the Impact Mechanism

1. Set the mechanism, driver end up, on the workbench.

NOTICE

Note the twin Hammers (39) within the Hammer Frame

Assembly (37). These are identical but must be placed in

the Hammer Frame Assembly in a certain relationship.

Using a felt-tipped pen, mark the top Hammer “T↑” and

the bottom Hammer “B↑” with the arrows pointing

upward. Mark both hammers on the same end.

2. With mechanism sitting upright on the workbench, slowly rotate

Anvil (40) in a clockwise direction until it comes up solid.

NOTICE

If you continue to rotate the Anvil, it will cam the

Hammers out of engagement. Do not allow this to

happen; merely rotate the Anvil until it comes up solid.

3. Hold the Hammer Frame firmly and, without disturbing Hammers,

gently lift the Anvil, simultaneously rotating it counterclockwise about

1/8 of a turn, from the Hammer Frame.

NOTICE

The twin Hammers will be free to slide from the Hammer

Frame when the Hammer Pins (38) are removed. Do not

drop the Hammers.

4. With Anvil removed, lift out the two Hammer Pins (38).

5. Remove the twin Hammers.

Disassembly of the Reverse Valve

1. Unscrew the four Housing Cover Cap Screws (25) and remove the

Housing Cover Assembly (21), Housing Cover Gasket (27), and

Motor Clamp Washer (26).

2. Grasp the Reverse Lever (20) and withdraw the Reverse Valve

Assembly (18) from the Motor Housing Assembly (1), taking care not

to lose the Reverse Lock Plunger (23) and Reverse Lock Plunger

Spring (24).

Disassembly of the Motor

1. While holding the Impactool over the workbench, turn Impactool

to bring the square drive side upward. This will allow the motor parts

to slide out of the Motor Housing Assembly (1). If the motor parts do

not slide out freely, gently tap the side of the Motor Housing

Assembly with a plastic hammer to jar them loose. Often, all of the

motor parts except the Front End Plate (34) and Cylinder (33) will

slide out easily. Tap the Motor Housing to remove the Front End Plate

and Cylinder.

2. Inspect the Vanes (32) for wear. If a Vane is chipped or otherwise

damaged, replace the complete set.

3. Check the bore of the Cylinder and the faces of the End Plates for

scoring. Replace any scored parts.

4. Remove two Air Port Gaskets (16) and Air Port Gasket Retainers

(17) from Housing.

Disassembly of the Throttle Mechanism

1. Place the tool on the workbench with the handle pointing toward you

and the square drive side upward. Use a punch to tap out the Throttle

Valve Assembly Retaining Pin (15) from the right to the left hand side

of the handle. Pull upward on the Trigger (7) to remove the complete

Throttle Valve Assembly (6).

2. Punch out the Trigger Retaining Pin (14) from the Throttle Valve

Bushing Assembly (8) to separate Throttle Valve Assembly (6) from

the Throttle Valve Bushing Assembly.

Assembly

General Instructions

1. Always press on the inner ring of a ball-type bearing when installing

the bearing on a shaft.

2. Always press on the outer ring of a ball-type bearing when pressing

the bearing into a bearing recess.

3. Whenever grasping a tool or part in a vise, always use leathercovered or copper-covered vise jaws. Take extra care with threaded

parts and housings.

4. Always clean every part and wipe every part with a thin film of oil

before installation.

5. Apply a film of O-ring lubricant to all O-rings before final assembly.

80183387_ed1 3

Assembly of the Throttle Mechanism

1. Apply O-ring lubricant to the O-rings and place them on the Throttle

Valve Bushing (8), large ring on the large diameter grooves, the two

smaller rings in the smaller grooves.

2. Insert the Throttle Valve Assembly (6), small end first, into the small

diameter of the Throttle Valve Bushing.

3. Align the slot in the Throttle Valve Assembly with the slot in the

Throttle Valve Bushing and replace the Trigger Retaining Pin (14).

Press on the Trigger (7).

4. Place the Impactool on the workbench with the handle pointing

toward you and the square drive upward. Align the hole in the

Throttle Valve Bushing Assembly with the hole in the Housing and

drive in the Throttle Valve Assembly Retaining Pin (15) from left to

right.

Assembly of the Motor

NOTICE

Periodically, as experience indicates and always after

disassembly, clean the air strainer screen in the Inlet

Bushing (3). Torque the Inlet Bushing to 50 to 60 ft-lb (68

to 81 Nm).

Before assembling the Motor, wipe a thin film of oil on the Rotor (31), End

Plates (30 and 34), Cylinder (33), and Vanes (32).

1. Using a sleeve that will contact only the outer ring of the Front Rotor

Bearing (35), press the bearing into the Front End Plate (34).

2. Slide the Front End Plate (34), bronze face first, over the splined hub

of the Rotor (31).

3. Stand the assembled Rotor and End Plate upright, grasping the

splined rotor hub with leather-covered or copper-covered vise jaws.

4. Place a Vane (32) in each vane slot in the Rotor.

5. Slide the Cylinder (33) down over the Rotor, aligning the holes in the

Cylinder with those in the Front End Plate.

6. Using a sleeve that will contact only the outer ring of the Rear Rotor

Bearing (29), press the bearing into the Rear End Plate (30).

7. Using a sleeve that will contact only the inner ring of the Rear Rotor

Bearing, press the assembled bearing and end plate onto the short

hub of the Rotor.

8. Before installing the Motor Assembly in the Motor Housing (1), be

certain that the Air Port Gaskets (16) and Gasket Retainers (17) are

in good condition and positioned with large open end down in the

recess in the Motor Housing.

9. Using a 3/16” x 8” rod, insert the rod through the Cylinder Dowel

Holes in both End Plates and Cylinder. This will hold all the motor

parts in alignment. Allow the 3/16” rod to protrude from the Front End

Plate far enough to enter the dowel hole at the bottom of the bore of

the Motor Housing.

10. Put the rod into the Dowel Hole in the Motor Housing, then slide the

assembled Motor into the Housing. Remove the rod and install the

Cylinder Dowel (28).

11. Place the Motor Clamp Washer (26) concave side first, over the hub

of the Rear End Plate so that the outer rim of the Washer contacts

the End Plate.

Assembly of the Reverse Valve

1. Dampen the Reverse Valve Seal (19) with O-ring lubricant and install

the Seal in the groove on the Reverse Valve Assembly (18).

2. Slide the Reverse Valve Assembly into the Motor Housing

Assembly (1).

3. Aligning the flats on the Reverse Lever (20) with those on the

Reverse Valve Assembly, slide the Reverse Lever on the Reverse

Valve Assembly. Place the Housing Cover Gasket (27) on the Motor

Housing.

4. Put the Reverse Lock Spring (24) followed by the Reverse Lock

Plunger (23) in the small hole at the bottom of the Housing Cover

Assembly (21).

5. Install the Motor Housing Cover (21). Tighten the Motor Housing

Cover Cap Screws to 10 to 12 ft-lb (14 to 16 Nm).

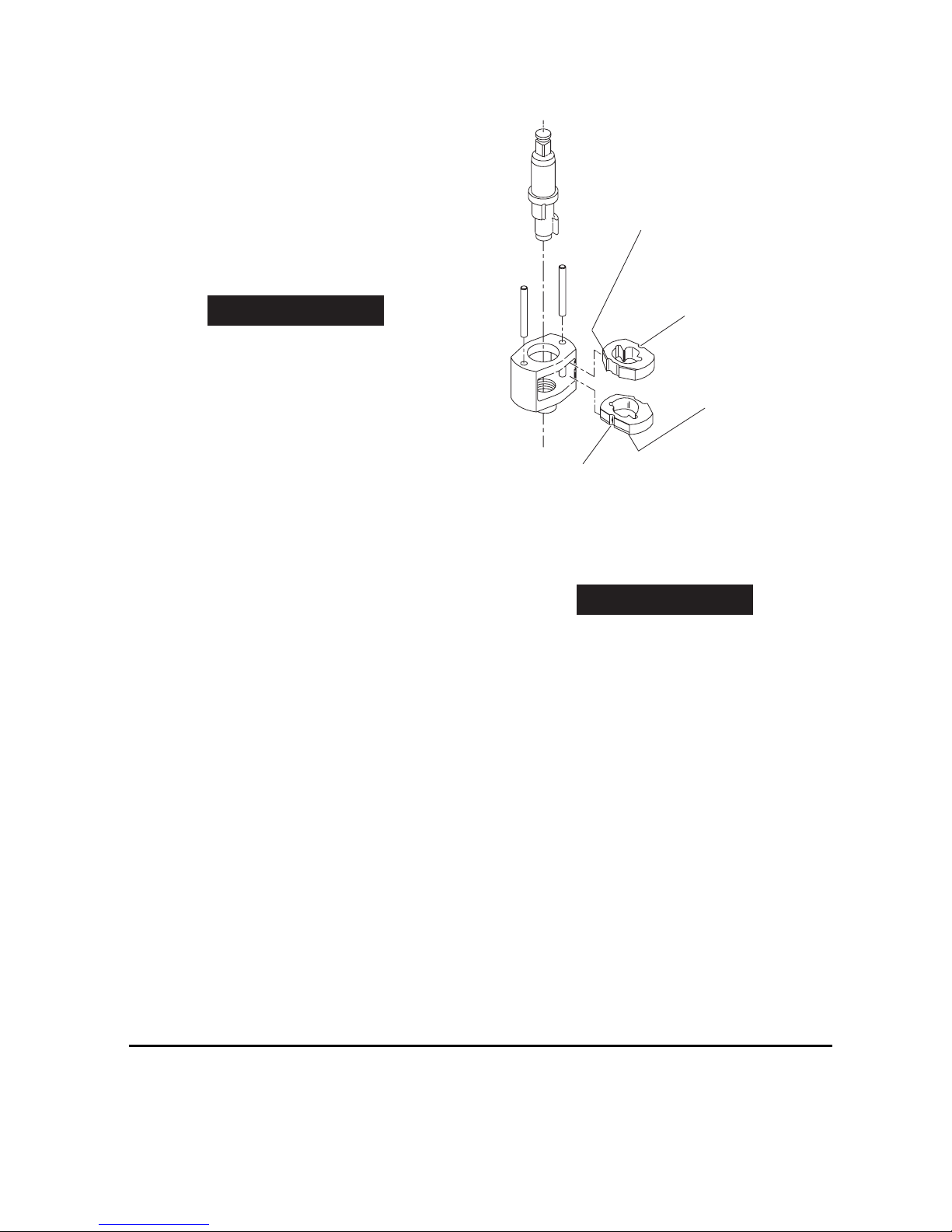

Assembly of the Impact Mechanism

(Dwg. TPD652)

1. Coat Hammers (39) with a light film of Ingersoll-Rand

Grease No. 170.

2. Replace Hammers in the Hammer Frame Assembly (37) exactly as

they were when you marked them prior to disassembly.

NOTICE

If you are installing new Hammers, or want to change

the location of the existing Hammers to utilize both

impacting surfaces, slide the Hammers in the Hammer

Frame so that the half-round notch on one Hammer is

located on one side of the Frame and the half-round

notch on the other Hammer is located on the other side

of the Frame.

Each Hammer is undercut on one side. When properly

installed in the Hammer Frame, these undercuts must

face each other.

3. Replace Hammer Pins (38).

4. Examine base of Anvil (40) and note its contour. While looking down

through Hammer Frame, swing the top Hammer to its full extreme

one way or other until you can match the contour of the Anvil. Put the

Anvil into the Hammer Frame and through the first Hammer. Swing

the bottom Hammer in opposite direction from the top Hammer and

maneuver Anvil slightly until it drops through the bottom Hammer.

Assembly of the Impactool

1. Secure Impactool in vise.

2. Set assembled hammer mechanism onto rotor shaft spline.

3. Place Hammer Case Gasket (36) over mechanism and against face

of Motor Housing.

4. Grease Anvil and top of Hammer Frame.

5. Reinstall the Hammer Case Assembly (41).

6. Assemble Dead Handle (44) to Dead Handle Bracket (43). Insert two

Hammer Case Cap Screws (45). Position assembly against

Hammer Case and thread the Screws into Housing.

7. Secure the Hammer Case Assembly with four Hammer Case Cap

Screws (45). Tighten to 20-25 ft-lb (27-34 Nm) torque.

8. Install a new Exhaust Silencer (5) in Motor Housing Assembly (1)

and install the Exhaust Deflector (4).

Cap Screw Specifications

Tighten the Hammer Case Cap Screws to a minimum of 20 ft-lb (27.1 Nm) torque.

Tighten the Housing Cover Cap Screws to a minimum of 10 ft-lb (13.5 Nm) torque.

TOP HAMMER

WIDE BEVEL UP

TOP HAMMER

HALF–ROUND NOTCH ON RIGHT

BOTTOM HAMMER

WIDE BEVEL DOWN

BOTTOM HAMMER

HALF–ROUND NOTCH ON LEFT

Loading...

Loading...