Infiniti Q50 2015 Maintenance Manual

MAINTENANCE

Revision: 2015 January 2015 Q50

A

B

SECTION MA

CONTENTS

PREPARATION ............................................3

PREPARATION ...................................................3

Special Service Tool . ... ... ... .... ...................................3

Commercial Service Tool ..........................................3

PERIODIC MAINTENANCE ..........................4

GENERAL MAINTENANCE ................................4

Explanation of General Maintenance ........................4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance ........................6

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

Fluids and Lubricants ..............................................10

Engine Oil Recommendation ..................................11

Anti-Freeze Coolant Mixture Ratio ..........................11

ENGINE MAINTENANCE ...................................12

DRIVE BELT ..............................................................12

DRIVE BELT : Exploded View ..... ... .... ... ... ... .... .......12

DRIVE BELT : Checking .........................................12

DRIVE BELT : Tension Adjustment ....... ...... .... .......12

10

MAINTENANCE

AIR CLEANER FILTER : Inspection (Viscous Pa-

per Type) ............................................... .... ... ... ... .....

ENGINE OIL .......................... ... ..................................19

ENGINE OIL : Draining ............................................19

ENGINE OIL : Refilling ............................................19

OIL FILTER ................................................................19

OIL FILTER : Removal and Installation ...................19

OIL FILTER : Inspection ..........................................21

SPARK PLUG ............................................................21

SPARK PLUG : Removal and Installation ...............21

SPARK PLUG : Inspection ......................................21

EVAP VAPOR LINES .............. .... ... ... ... ....... ... ... ... .....22

EVAP VAPOR LINES : Inspection ...........................22

CHASSIS MAINTENANCE ...............................23

EXHAUST SYSTEM ...................................................23

EXHAUST SYSTEM : Inspection ............................23

A/T FLUID ..................................................................23

A/T FLUID : Inspection ............................................23

A/T FLUID : Changing .............................................23

A/T FLUID : Adjustment ...........................................25

19

C

D

E

F

G

H

I

J

K

L

M

ENGINE COOLANT ...................................................12

ENGINE COOLANT : Draining ................................12

ENGINE COOLANT : Refilling ................................13

ENGINE COOLANT : Flushing ...............................15

RESERVOIR TANK CAP ..........................................16

RESERVOIR TANK CAP : Inspection .....................16

RADIATOR ................................................................17

RADIATOR : Inspection ..........................................17

FUEL LINES ............................. ... ... ... .... ....................17

FUEL LINES : Inspection ........................................17

AIR CLEANER FILTER .............................................18

AIR CLEANER FILTER : Removal and Installation

....

TRANSFER FLUID ....................................................25

TRANSFER FLUID : Inspection ......... ... .... ... ... ... .....25

TRANSFER FLUID : Draining ............ ... .... ... ... ... .....26

TRANSFER FLUID : Refilling ....... ... ... ... .... ... ... ... .....26

FRONT PROPELLER SHAFT: 2S56A ......................26

FRONT PROPELLER SHAFT: 2S56A : Inspec-

tion ................................ ................................... ........

REAR PROPELLER SHAFT: 3S80A-R ....................26

REAR PROPELLER SHAFT: 3S80A-R : Inspec-

tion ................................ ................................... ........

REAR PROPELLER SHAFT: 3F80A-R .....................27

REAR PROPELLER SHAFT: 3F80A-R : Inspec-

18

tion ................................ ................................... ........

MA-1

N

O

26

MA

26

27

FRONT DIFFERENTIAL GEAR OIL: F160A ............ 27

Revision: 2015 January 2015 Q50

FRONT DIFFERENTIAL GEAR OIL: F160A : In-

spection ..................................................................

27

FRONT DIFFERENTIAL GEAR OIL: F160A :

Draining ..................................................................

27

FRONT DIFFERENTIAL GEAR OIL: F160A : Re-

filling .......................................................................

28

REAR DIFFERENTIAL GEAR OIL: R190 ................ 28

REAR DIFFERENTIAL GEAR OIL: R190 : Inspec-

tion ................................... .......................................

28

REAR DIFFERENTIAL GEAR OIL: R190 : Drain-

ing ................................. ..........................................

28

REAR DIFFERENTIAL GEAR OIL: R190 : Refill-

ing ................................. ..........................................

29

WHEELS (BONDING WEIGHT TYPE) ..................... 29

WHEELS (BONDING WEIGHT TYPE) : Wheel

Balance Adjustment (Aluminum Wheel) .................

29

WHEELS (BONDING WEIGHT TYPE) : Tire Rota-

tion ................................... .......................................

31

POWER STEERING FLUID AND LINES : Inspec-

tion ..........................................................................

34

AXLE AND SUSPENSION PARTS ........................... 34

AXLE AND SUSPENSION PARTS : Inspection .....34

DRIVE SHAFT ...........................................................34

DRIVE SHAFT : Inspection .....................................35

BODY MAINTENANCE ..................................... 36

LOCKS, HINGES AND HOOD LATCH .....................36

LOCKS, HINGES AND HOOD LATCH : Lubricat-

ing ...........................................................................

36

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS ......................................

36

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS : Inspection .................

36

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

37

BRAKE FLUID LEVEL AND LEAKS ........................ 31

BRAKE FLUID LEVEL AND LEAKS : Inspection ... 31

BRAKE LINES AND CABLES .................................. 31

BRAKE LINES AND CABLES : Inspection ....... ...... 31

BRAKE FLUID ................ ... ... .... ... ... .......................... 31

BRAKE FLUID : Changing ...................................... 32

DISC BRAKE ............................................................ 32

DISC BRAKE : Inspection ......................................32

DISC BRAKE : Front Disc Brake ............................ 32

DISC BRAKE : Rear Disc Brake ............................. 33

STEERING GEAR AND LINKAGE ........................... 33

STEERING GEAR AND LINKAGE : Inspection ...... 33

POWER STEERING FLUID AND LINES .................. 33

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

DRIVE BELT .......... ... ... .... ... .......................................37

DRIVE BELT : Drive Belt ........................................37

ENGINE COOLANT ..................................................37

ENGINE COOLANT :

Periodical Maintenance Specification ............. .......

ENGINE OIL ..............................................................37

ENGINE OIL :

Periodical Maintenance Specification ............. .......

SPARK PLUG .................................................... ... ....37

SPARK PLUG : Spark Plug .................................... 37

ROAD WHEEL ..........................................................37

ROAD WHEEL : Road Wheel .................................37

37

37

37

MA-2

< PREPARATION >

Revision: 2015 January 2015 Q50

PREPARATION

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000011284933

The actual shapes of TechMate tools may differ from those of special service tools illustrated here.

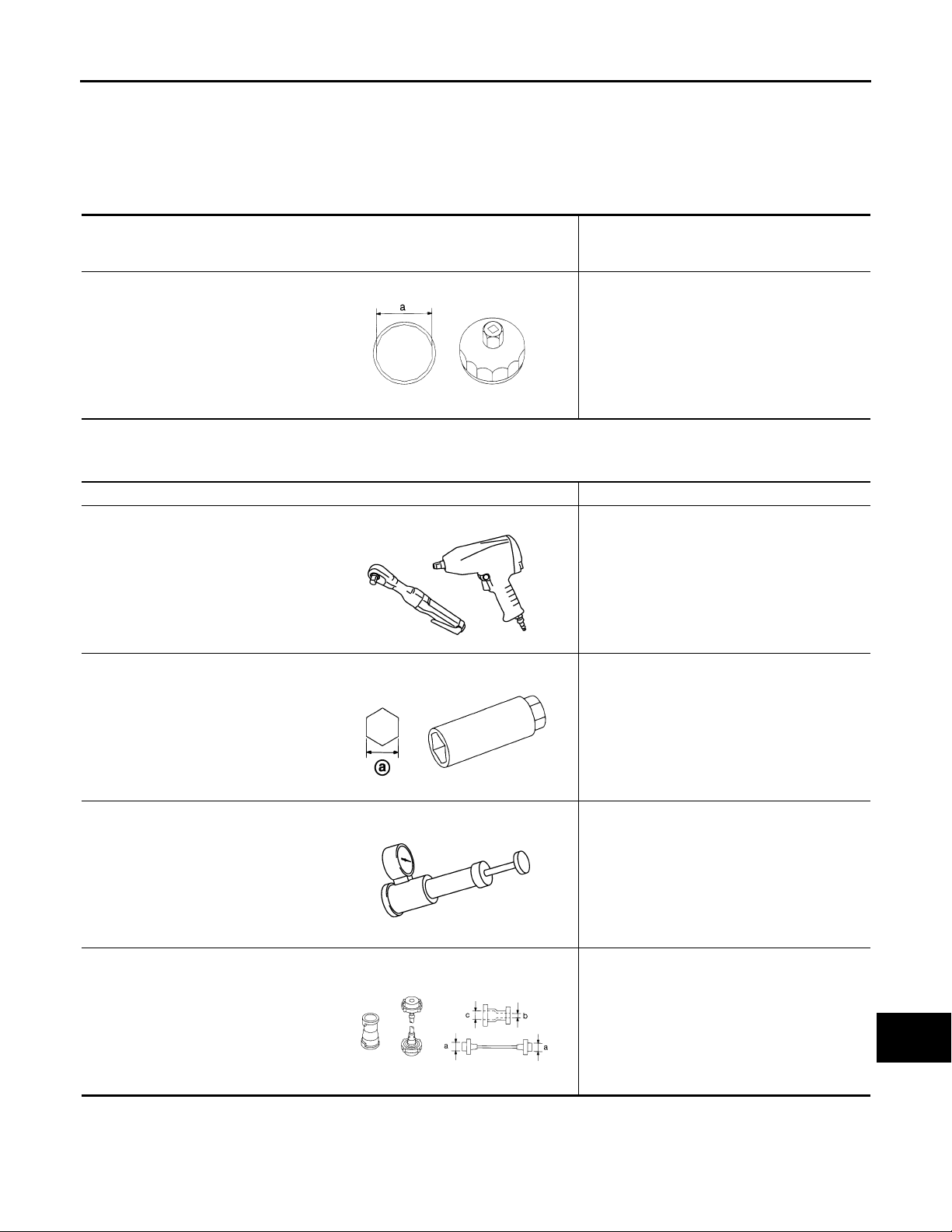

Tool number

(TechMate No.)

Tool name

KV10115801

(J-38956)

Oil filter wrench

S-NT375

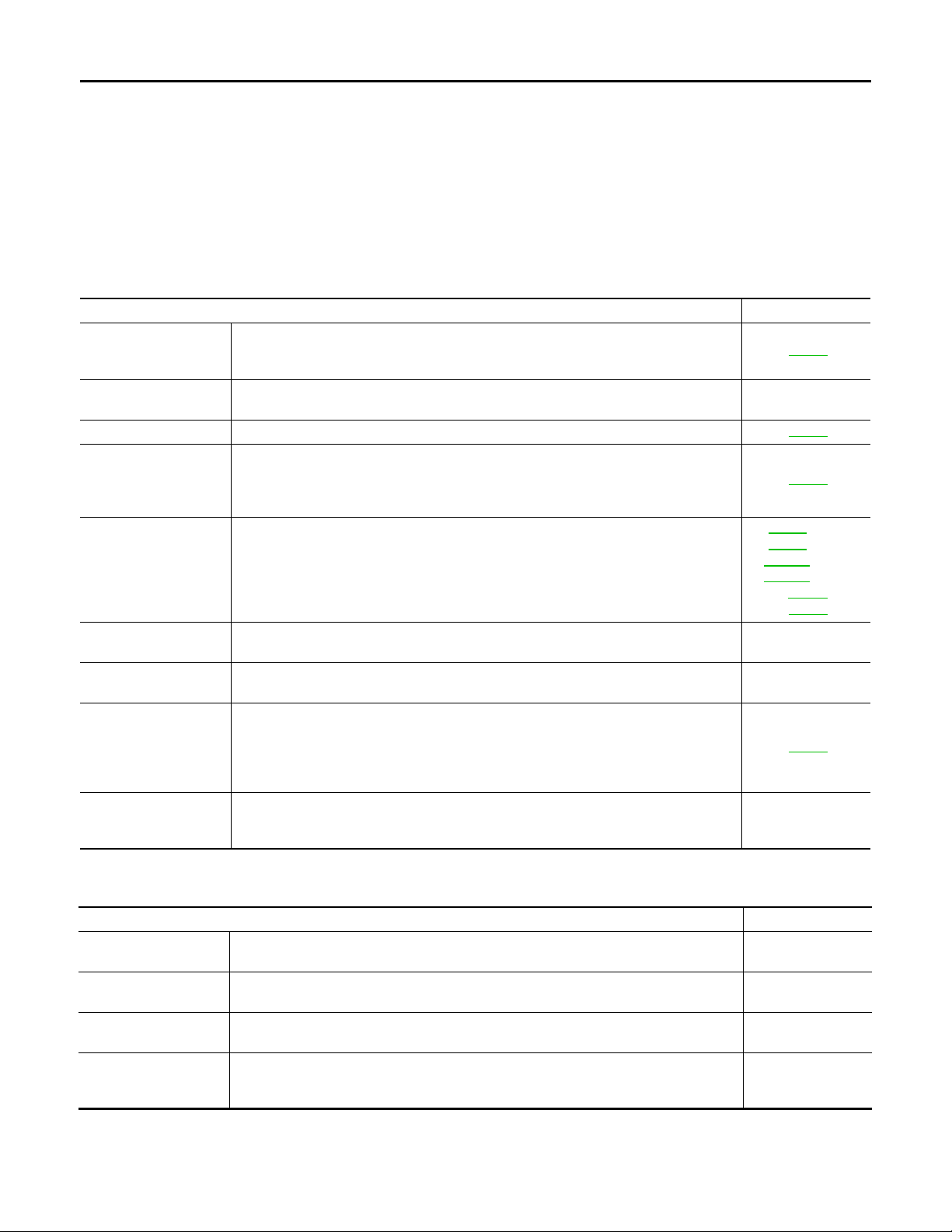

Commercial Service Tool INFOID:0000000011284934

Tool name Description

Power tool Loosening nuts and bolts

Description

Removing and installing oil filter

a: 64.3 mm (2.531 in)

A

B

C

D

E

F

G

H

PBIC0190E

Spark plug wrench Removing and installing spark plug

a : 14 mm (0.55 in)

JPBIA0399ZZ

Radiator cap tester Checking radiator and radiator cap

PBIC1982E

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and water outlet (front) filler neck

a : 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

I

J

K

L

M

N

O

MA

S-NT564

MA-3

GENERAL MAINTENANCE

Revision: 2015 January 2015 Q50

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of General Maintenance INFOID:0000000011284935

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI retailers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Tires Check the pressure with a gauge o ften and always prior to long distance trips. Adjust

the pressure in all tires, inc luding t he sp are, t o the pr essure spe cified. Check carefull y

for damage, cuts or excessive wear.

Wheel nuts When checking the tires, make sure no nuts are missing, and check for any loose nuts.

Tighten if necessary.

Tire rotation Tires should be rotated every 5,000 miles (8,000 km). MA-31

Tire Pressure Moni-

toring System (TPMS)

transmitter components

Wheel alignment and

balance

Windshield

Windshield wiper

blades

Doors and engine

hood

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and other

Replace the TPMS transmitter grommet seal, valve core and cap when the tires are

replaced due to wear or age.

If the vehicle should pull to either side while driving on a straight and level road, or if

you detect uneven or abnormal ti re we ar, there may be a need for wheel alignment. If

the steering wheel or seat vibrat es at normal highway speeds , wheel balancing may be

needed. For additional information regardi ng tires, refer to "lmport ant T i re Safety Information" (US) or "Tire Safety Information" (Canada) in the INFINITI Warranty Information Booklet.

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary.

Check for cracks or wear if they do not wipe properly. —

Check that all doors and the engine hood operate properly. Also make sure that all

latches lock securely. Lubricate if necessary. Make sure that the secondary latch keeps

the hood from opening when th e primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrication frequently.

lamps are all operating properly and installed securely. Also check headlamp aim.

Clean the headlamps on a regular basis.

WT-75

WT-70

FSU-8

FSU-9

FSU-31

FSU-32

RSU-6

MA-29

MA-36

—

(2WD)

(2WD)

(AWD)

(AWD)

—

—

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Warning lamps and

chimes

Windshield wiper and

washer

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient quantity

Steering wheel Check that it has the specified play. Check for changes in the steering condition, such

Make sure that all warning lamps and chimes are operating properly. —

Check that the wipers and washer operat e properly and that the wipers do not streak. —

when operating the heater or air condi tioner.

as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)

MA-4

—

—

< PERIODIC MAINTENANCE >

Revision: 2015 January 2015 Q50

GENERAL MAINTENANCE

Item Reference page

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to make

sure they operate smoothly and that all latches lock securely in every position. Check

that the head restrains mov e up and down smoothly and that the locks (if equipped ) hold

securely in all latched posi tions. Check that the latches lock securely for folding-down

rear seatbacks.

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and retrac-

tors) operate properly and smoothly, and are installed securely. Check the belt webbing

for cuts, fraying, wear or damage.

Accelerator pedal Check the pedal for smooth oper ation and make sure the pedal does not catch or re-

quire uneven effort. Keep the floor mats away from the pedal.

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster

Parking brake Check that the lever or pedal has the proper travel and make sure that the vehicle is

Automatic transmission “Park” mechanism

Check the pedal for smooth operation and make sure it has the proper distance under

it when depressed fully. Check the brake booster function. Be sure to keep the floor

mats away from the pedal.

held securely on a fairly steep hill when only the parking brake is applied.

Check that the lock release button on the selector lever operates properly and smoothly.

On a fairly steep hill check that the vehicle is held securely with the selector lever in the

P (Park) position without applying any brakes.

—

MA-36

—

BR-9

BR-16

PB-6

—

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Item Reference page

Windshield washer

fluid

Engine coolant level Check the coolant level when the engine is cold. CO-8

Radiator and hoses Check the front of the radiato r and clean off any dirt , insects, leaves, etc ., that may have

Brake fluid level Make sure that the brake fluid l evel is between t he “MAX” an d “MIN” lin es on th e reser-

Battery Check the fluid level in each cell. I t should be between the “MAX” and “MIN” lines. Ve-

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. MA-12

Engine oil level Check the level on the oil level gauge af ter park ing the ve hicle on a lev el spot and t urn-

Power steering fluid

level and lines

Exhaust system Make sure there are no loose supports, cracks or holes. If the sound of the exhaust

Underbody The underbody is frequently exposed to corrosiv e sub stance s su ch as thos e us ed on

Fluid leaks Check under the vehicle for fuel, oi l, water or other fluid leaks after the vehicle has b een

Check that there is adequat e fluid in the tank. —

accumulated. Make sure the hoses have no cracks, deformation, deterioration or loose

connections.

voir.

hicles operated in high temperatures or under severe conditions require frequent

checks of the battery fluid level.

ing off the engine.

Check the level when the fluid is cold, with the engine off. Check the lines for proper

attachment, leaks, cracks, etc.

seems unusual or there is a smell of exhaust fumes, immediately locate the trouble and

correct it.

icy roads or to control dust. I t is very import ant to remove these su bst ances, otherwise

rust will form on the floor pan, frame, fuel lines and around the exhaust system. At the

end of winter, the underbody should be thoroughly flushed with plain water, being careful to clean those areas where mud and dirt can easily accumulate.

parked for a while. Water dripping from the air conditioner after use is normal. If you

should notice any leaks or gasoline fumes are evident, check for the cause and correct

it immediately.

MA-17

MA-31

PG-114

LU-9

MA-34

MA-23

—

—

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

MA

MA-5

PERIODIC MAINTENANCE

Revision: 2015 January 2015 Q50

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

Introduction of Periodic Maintenance INFOID:0000000011284937

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

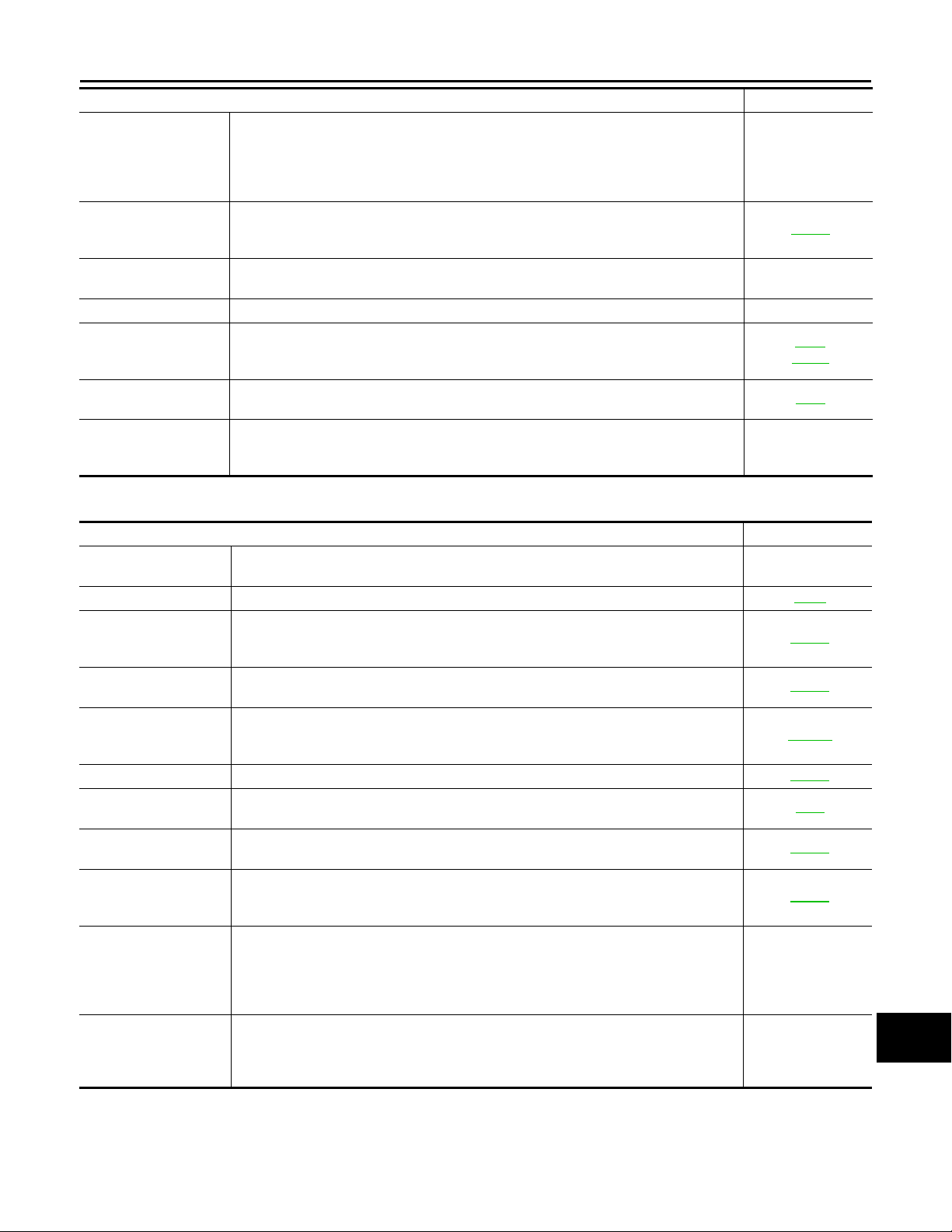

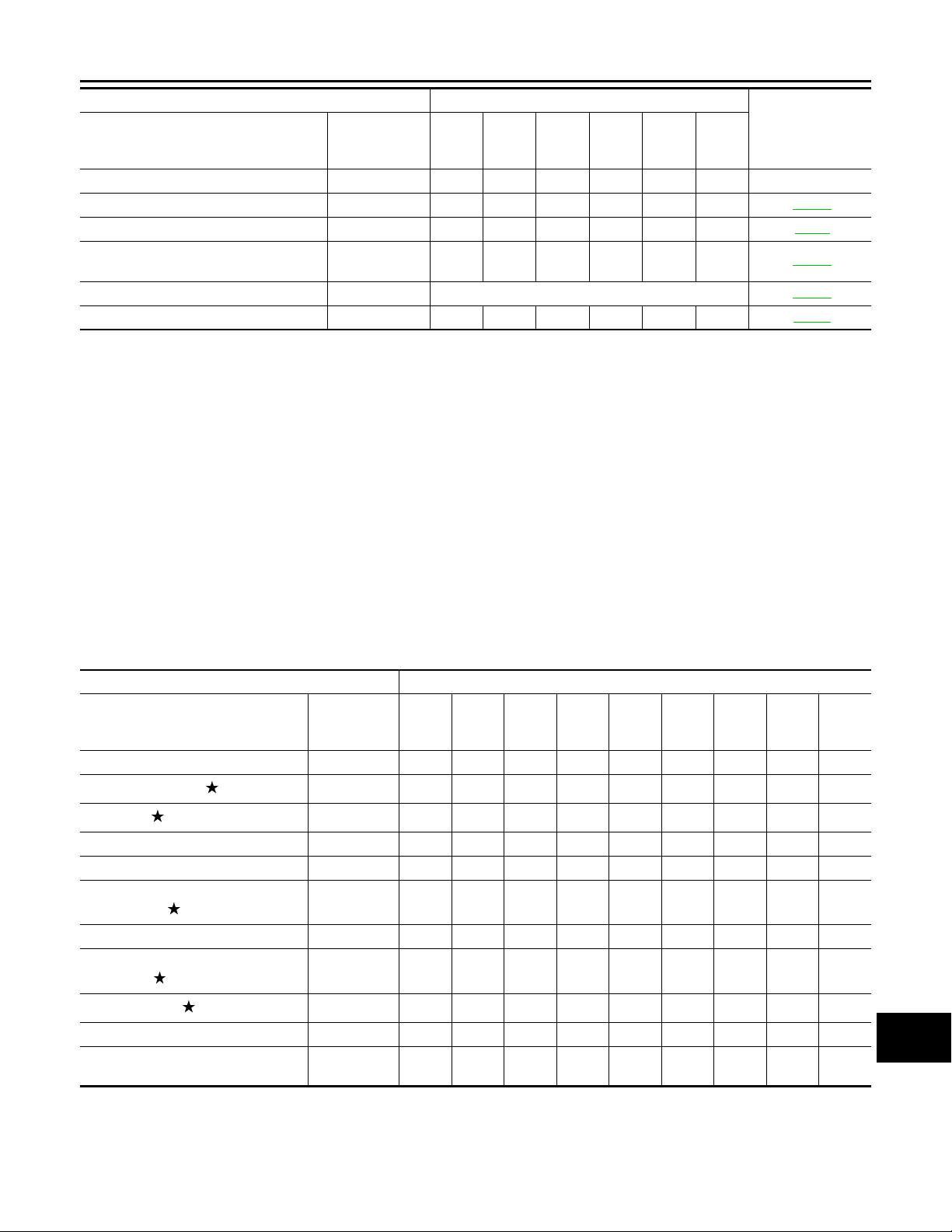

Emission Control System Maintenance

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.

Drive belt NOTE (1) I*

Air cleaner filter NOTE (2) R

EVAP vapor lines I* I*

Fuel lines I* I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRRRR

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent)

Spark plugs (Iridium-tipped type) NOTE (6) Replace every 105,000 miles (168,000 km)

Intake and exhaust valve clearance* NOTE (7)

Miles x 1,000

(km x 1,000)

Months

5

(8)

6

RRRRRRRRR

10

(16)

12

15

(24)

18

20

(32)

24

25

(40)

30

30

(48)

36

35

(56)

42

40

(64)

48

45

(72)

54

MAINTENANCE OPERAT ION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.

Drive belt NOTE (1)I*I*I*I*I*

Air cleaner filter NOTE (2) R R

EVAP vapor lines I* I*

Fuel lines I* I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRRRR

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent)

Spark plugs (Iridium-tipped type) NOTE (6) Replace every 105,000 miles (168,000 km)

Intake and exhaust valve clearance* NOTE (7)

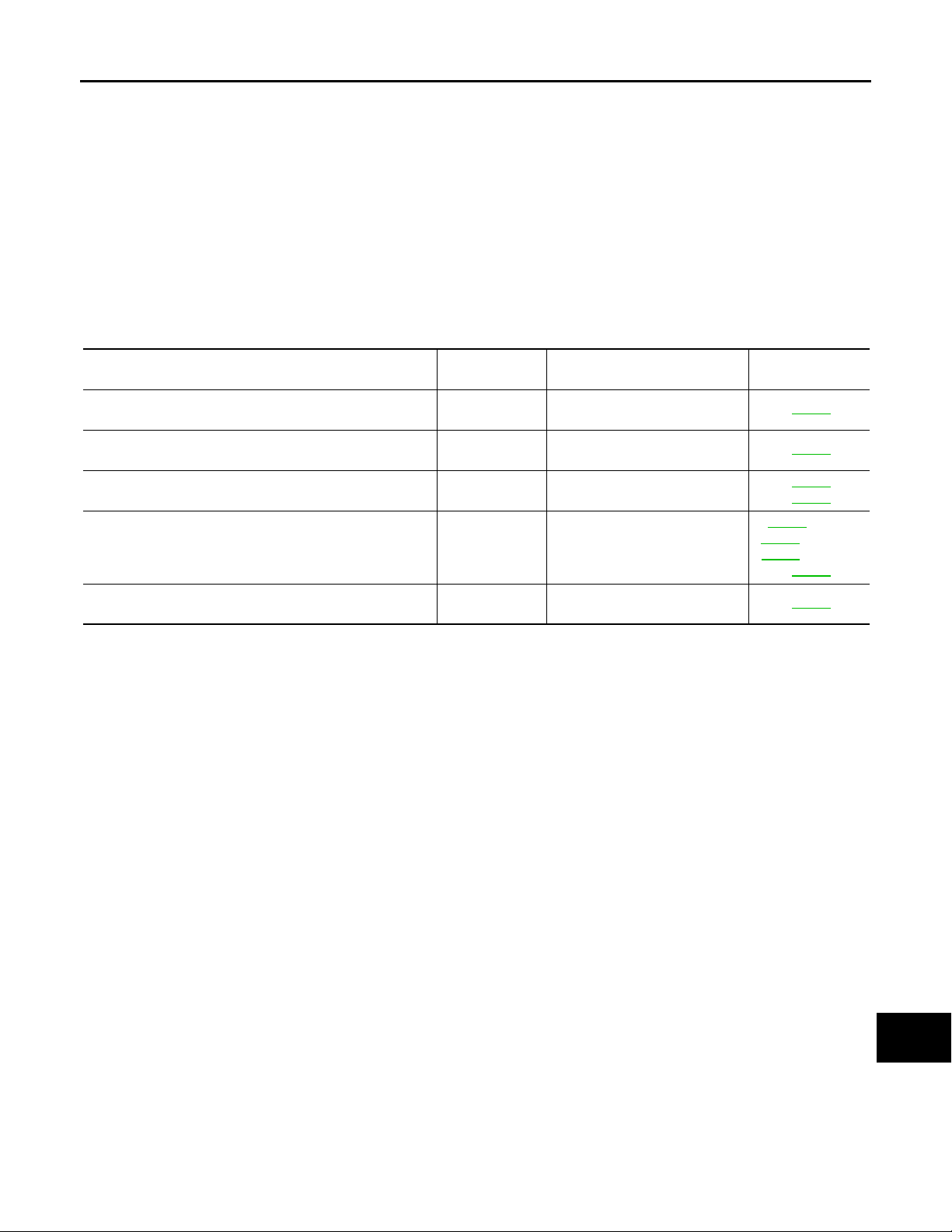

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.

Drive belt NOTE (1) I* I* I* MA-12

Air cleaner filter NOTE (2) R MA-18

EVAP vapor lines I* I* MA-22

Fuel lines I* I* MA-17

Miles x 1,000

(km x 1,000)

Months

Miles x 1,000

(km x 1,000)

Months

50

(80)

60

RRRRRRRRR

55

(88)

66

95

(152)

114

60

(96)

72

100

(160)

120

65

(104)

78

105

(168)

126

70

(112)

84

110

(176)

132

75

(120)

90

115

(184)

138

80

(128)

96

120

(192)

144

85

(136)

102

Reference Page

90

(144)

108

MA-6

< PERIODIC MAINTENANCE >

Revision: 2015 January 2015 Q50

PERIODIC MAINTENANCE

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.

Fuel filter NOTE (3) —

Engine coolant* NOTE (4)(5) MA-12

Engine oil RRRRRR LU-11

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent)

Spark plugs (Iridium-tipped type) NOTE (6) Replace every 105,000 miles (168,000 km) MA-21

Intake and exhaust valve clearance* NOTE (7) EM-11

NOTE:

• (1) After 40,000 miles (64 ,000 km) or 48 months, inspect every 10,000 mile s (16,000 km) or 12 months. Replace the drive belts if

found damaged.

• (2) If operating mainly in dusty conditions , more frequent maintenance may be required.

• (3) Maintenance-free item. For service procedures, refer to the FL section.

• (4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles

(120,000 km) or 60 months.

• (5) Use only Genuine NISSAN long life Antifreeze/Coolant (blue) or equivalent with proper mixture rat io of 50% anti-freeze and 50%

demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life expectancy of the

factory fill coolant.

• (6) Replace spark plug when the plug gap exceeds 1.4 mm (0.055 in) even if within specified periodic replacement mileage.

• (7) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

Miles x 1,000

(km x 1,000)

Months

95

(152)

114

RRRRRR MA-19

100

(160)

120

105

(168)

126

110

(176)

132

115

(184)

138

120

(192)

144

Reference Page

A

B

C

D

E

F

G

H

I

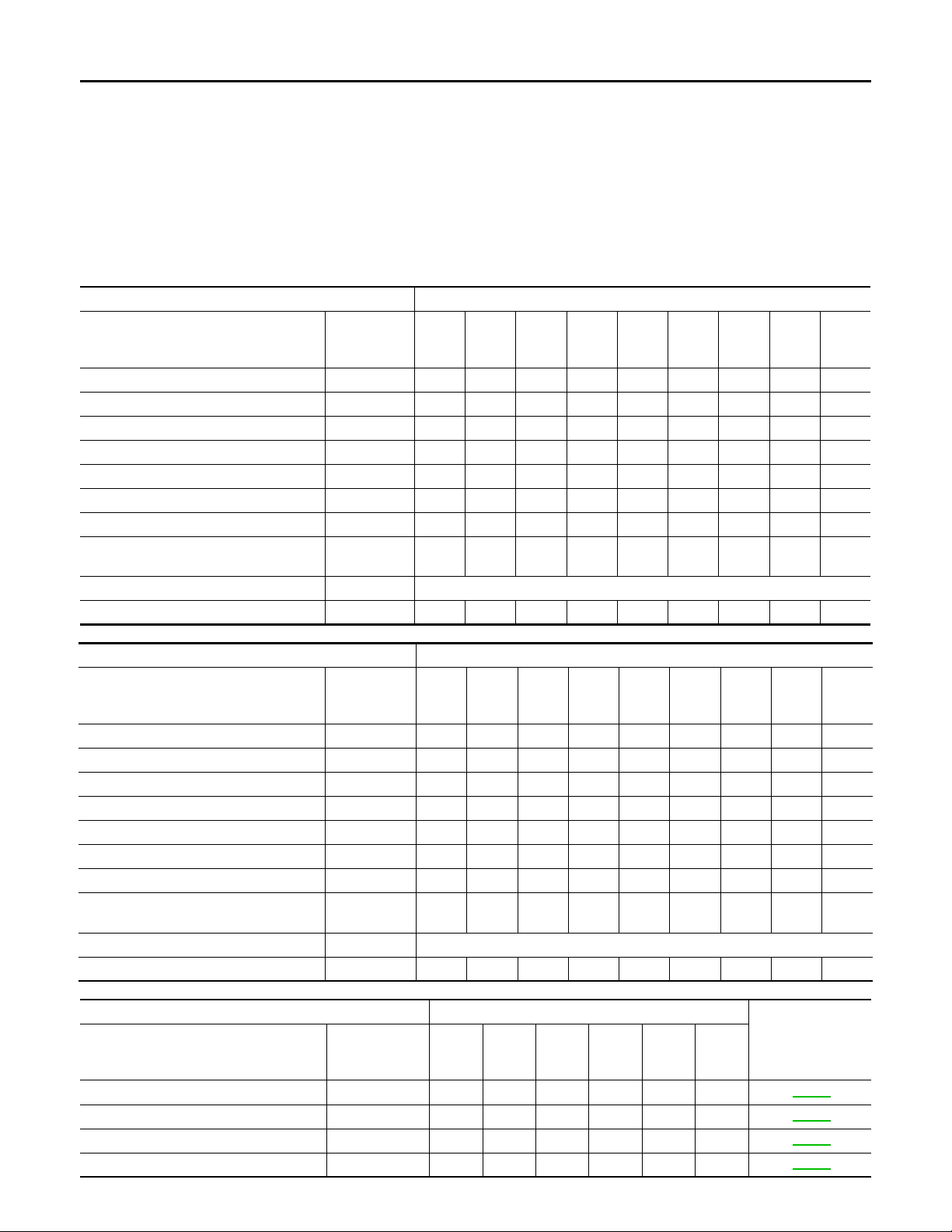

Chassis and Body Maintenance

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilome-

ters or months, whichever comes

first.

Brake lines & cables I I I I

Brake pads & rotors

Brake fluid

Automatic transmission fluid NOTE (1)

Transfer fluid & differential gear oil NOTE (2) I I I I

Steering gear & linkage, axle & sus-

pension parts

Tire rotation NOTE (3)

Propeller shaft (A WD models) & drive

shaft boots

Exhaust system

In-cabin microfilter R R R

Stop lamp switch & brake pedal posi-

tion switch

Miles x 1,000

(km x 1,000)

Months

NOTE (4) I I I I

5

(8)

6

10

(16)

12

IIII

IIII

15

(24)

18

20

(32)

24

RR

II

II

25

(40)

30

30

(48)

36

35

(56)

42

40

(64)

48

45

(72)

54

J

K

L

M

N

O

MA

MA-7

PERIODIC MAINTENANCE

Revision: 2015 January 2015 Q50

< PERIODIC MAINTENANCE >

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilome-

ters or months, whichever c omes

first.

Brake lines & cables IIIII

Brake pads & rotors

Brake fluid

Automatic transmission fluid NOTE (1)

Transfer fluid & differential gear oilNOTE (2)IIIII

Steering gear & li nkage, axle & sus-

pension parts

Tire rotation NOTE (3)

Propeller shaft (AWD models) & drive

shaft boots

Exhaust system

In-cabin microfilter R R R

Stop lamp switch & brake pedal posi-

tion switch

Miles x 1,000

(km x 1,000)

Months

NOTE (4)IIIII

50

(80)

60

IIIII

IIIII

55

(88)

66

60

(96)

72

RR

II

II

65

(104)

78

70

(112)

84

75

(120)

90

80

(128)

96

85

(136)

102

90

(144)

108

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilomete rs

or months, whichever comes first.

Brake lines & cables I I I MA-31

Brake pads & rotors

Brake fluid

Automatic transmission fluid NOTE (1) MA-23

Transfer fluid & differential gear oil NOTE (2) I I I

Steering gear & linkage, axle & suspension parts

Tire rotation NOTE (3)

Propeller shaft (AWD models) & drive

shaft boots

Exhaust system

In-cabin microfilter R R VTL-18

Stop lamp switch & brake pedal posi-

tion switch

NOTE:

• Maintenance ite ms with “ ” should be performed more frequently a ccordin g to “Mainten ance Under Severe Driving Condi-

tions”.

• (1) Automatic transmission fluid maintenance-free.

• (2) If towing a tra iler, using a camper or car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every

20,000 miles (32,000 km) or 24 mo nths.

• (3) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Miles x 1,000

(km x 1,000)

Months

NOTE (4)IIIBR-9

95

(152)

114

100

(160)

120

RRMA-32

105

(168)

126

III

II

III

IIMA-23

110

(176)

132

115

(184)

138

120

(192)

144

Reference Page

MA-32

BR-17

BR-19

MA-25

MA-27

(F160A)

MA-28

(R190)

MA-33

MA-34

MA-4

MA-31

(2S56A)

MA-26

MA-26

(3S80A-R)

MA-27

(3F80A-R)

MA-35

MA-8

PERIODIC MAINTENANCE

Revision: 2015 January 2015 Q50

< PERIODIC MAINTENANCE >

• (4) Inspect the clearance between the brake pedal and the switches.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be performed on the following items as shown in the table.

Severe driving conditions

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures remaining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long dist ances, such as police, t axi or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer, using a camper or a car-top carrier.

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

Maintenance item

Brake fluid Replace

Brake pads & rotors Inspect

Steering gear & linkage, axle & suspension parts Inspect

Propeller shaft (AWD models) & drive shaft boots Inspect

Exhaust system Inspect

Maintenance

operation

Maintenance interval Reference page

Every 10,000 miles (16,000 km)

or 12 months

Every 5,000 miles (8,000 km) or

6 months

Every 5,000 miles (8,000 km) or

6 months

MA-26

Every 5,000 miles (8,000 km) or

6 months

Every 5,000 miles (8,000 km) or

6 months

MA-26

MA-27

MA-32

MA-32

MA-33

MA-34

(2S56A)

(3S80A-R)

(3F80A-R)

MA-35

MA-23

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

MA

MA-9

RECOMMENDED FLUIDS AND LUBRICANTS

Revision: 2015 January 2015 Q50

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants INFOID:0000000011284939

The following are approximate capacities. The actual refill capacities may be slightly different. When refilling,

follow the procedures described elsewhere in this manual.

Engine oil Drain and

refill

With oil filter

change

Without oil filter change

Capacity (Approximate)

US measure Imp measure Liter

5-1/8 qt 4-1/4 qt 4.9

4-7/8 qt 4 qt 4.6

• Genuine NISSAN engine oil or equivalent

• Engine oil with API Certification Mark

Recommended Fluids/Lubricants

*1: INFINITI recommends Genuine NISSAN Ester

Oil available at an INFINITI retailer.

SAE 5W-30

Dry engine (Overhaul) 6 qt 5 qt 5.7

Cooling system

With reservoir tank

Reservoir

tank

11-4/8 qt

11 qt

*3

1 qt

7/8 qt

*3

*4

*4

9-5/8 qt

9-1/8 qt

6/8 qt

6/8 qt

*3

10.9

*4

10.4

*3

*4

0.9

0.8

*2: For additional information, see “Engine Oil Recommendation”.

*3

*4

• Pre-diluted Genuine NISSAN Long Life Antifreeze/

Coolant (blue) or equivalent

*3

*4

• Genuine NISSAN Matic S ATF

• Using automatic transmission fluid other than Genuine NISSAN Matic S ATF will cause deterioration in

Automatic transmission fluid

9-3/4 qt

*5

8-1/8 qt

*5

9.2

*5

driveability and automatic transmission durability,

and may damage the automatic transmission, which

is not covered by the INFINITI new vehicle limited

warranty.

• Genuine NISSAN Differential Oil Hypoid Super GL-

Front 1-3/8 pt 1-1/8 pt 0.65

Differential gear oil

Rear 2-1/4 pt 1-7/8 pt 1.05

5 80W-90 or API GL-5, Viscosity SAE 80W-90

• For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 32°F (0°C).

• API GL-5 Synthetic gear oil, Viscosity SAE 75W-90

• See an INFINITI retailer for service for synthetic oil.

• Genuine NISSAN Matic J ATF

• Using transfer fluid other than Genuine NISSAN

Transfer fluid 2-1/8 pt 1-3/4 pt 1.0

Matic J ATF will cause deterioration in driveability

and transfer durability, and may damage the transfer, which is not covered by the INFINITI new vehicle

limited warranty.

Power steering fluid (PSF)

*6

1-1/8 qt 7/8 qt 1.0

• Genuine NISSAN PSF or equivalent

• DEXRON™ VI type ATF may also be used.

• Genuine NISSAN Super Heavy Duty Brake Fluid

Brake fluid — — —

equivalent DOT 3 (US FMVSS No. 116)

*: Available in mainland U.S.A. through an INFINITI

retailer.

Multi-purpose grease — — — • NLGI No. 2 (Lithium soap base)

Windshield washer fluid — — —

Fuel recommendation — — — • Refer to GI-28, "

• Genuine NISSAN Windshield Washer Concentrate

Cleaner & Antifreeze or equivalent

Fuel".

*3: With pressurized radiator reservoir tank.

*4: With non-pressurized radiator reservoir tank.

*5: The fluid capacity is the reference value.

*6: Without direct adaptive steering models.

*1

*2

, Viscosity

*

or

MA-10

RECOMMENDED FLUIDS AND LUBRICANTS

Revision: 2015 January 2015 Q50

< PERIODIC MAINTENANCE >

Engine Oil Recommendation INFOID:0000000011284940

NISSAN recommends the use of an energy conserving oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubricant Standardization and Approval Committee (ILSAC) certification and SAE viscosity standard. These oils

have the API certification mark on the front of the container. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

JSPIA0014ZZ

API certification mark API service symbol

A

B

C

D

E

F

Anti-Freeze Coolant Mixture Ratio INFOID:0000000011284941

The engine cooling system is filled at the factory with a pre-diluted mixture of 50% Genuine NISSAN Long Life

Antifreeze/Coolant (blue) and 50% water to provide year-round anti-freeze and coolant protection. The antifreeze solution contains rust and corrosion inhibitors. Additional engine cooling system additives are not necessary.

WARNING:

• Never remove the radiator or coolant reservoir cap when the engine is hot. Wait until the engine and

radiator cool down. Serious burns could be caused by high pressure fluid escaping from the radiator.

• The radiator is equipped with a pressure type radiator cap. To prevent engine damage, use only a

genuine NISSAN radiator cap.

CAUTION:

• When adding or replacing coolant, be sure to use only Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent. Genuine NISSAN Long Life Antifreeze/Coolant (blue) is pre-diluted to provide antifreeze protection to -34°F (-37°C). If additional freeze protection is needed due to weather

where you operate your vehicle, add Genuine NISSAN Long Life Antifreeze/Coolant (blue) concentrate following the directions on the container. If an equivalent coolant other than Genuine NISSAN

Long Life Antifreeze/Coolant (blue) is used, follow the coolant manufactur's instructions to maintain

minimum antifreeze protection to -34°F (-37°C). The use of other types of coolant solutions other

than Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent may damage the engine

cooling system.

• Mixing any other type of coolant other than Genuine NISSAN Long Life Antifreeze/Coolant (blue),

including Genuine NISSAN Long Life Antifreeze/Coolant (green), or the use of non -distilled water will

reduce the life expectancy of the factory-fill coolant.

G

H

I

J

K

L

M

N

MA-11

O

MA

ENGINE MAINTENANCE

Revision: 2015 January 2015 Q50

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

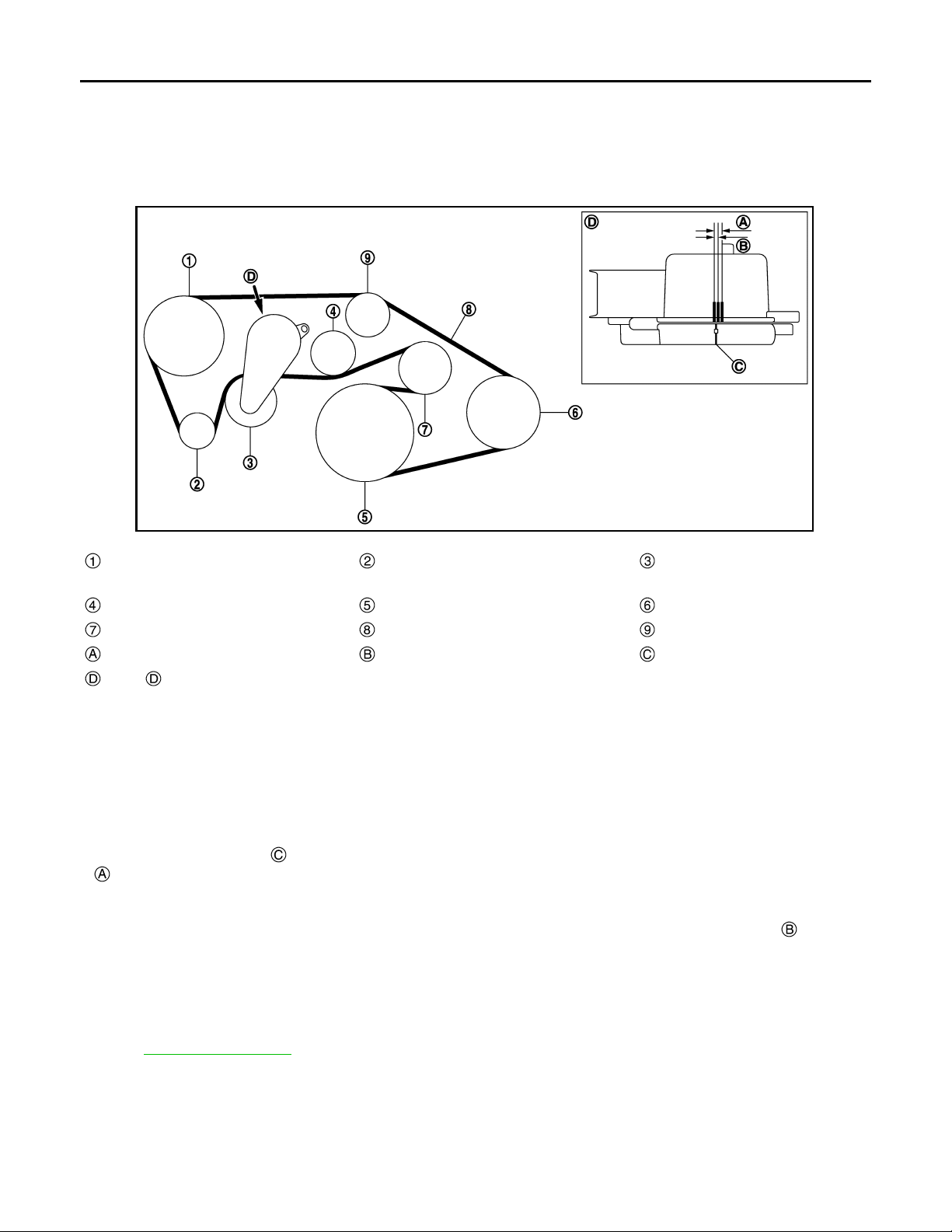

DRIVE BELT

DRIVE BELT : Exploded View INFOID:0000000011284945

JPBIA1060ZZ

Power steering oil pump*1

Idler pulley

Idler pulley Crankshaft pulley A/C compressor

Idler pulley Drive belt Idler pulley

Possible use range Range when new drive belt is installed Indicator

View

• *1: Without DIRECT ADAPTIVE STEERING

• *2: With DIRECT ADAPTIVE STEERING

*2

Alternator Drive belt auto-tensioner

DRIVE BELT : Checking INFOID:0000000011284946

WARNING:

Be sure to perform the this step when engine is stopped.

• Check that the indicator (notch on fixed side) of drive belt auto-tensioner is within the possible use range

.

NOTE:

• Check the drive belt auto-tensioner indication when the engine is cold.

• When new drive belt is installed, the indicator (notch on fixed side) should be within the range in the figure.

• Visually check the entire drive belt for wear, damage or crack.

• If the indicator (notch on fixed side) is out of the possible use range or belt is damaged, replace drive belt.

DRIVE BELT : Tension Adjustment INFOID:0000000011284947

Refer to EM-155, "Drive Belt".

ENGINE COOLANT

ENGINE COOLANT : Draining INFOID:0000000011284948

WARNING:

• To avoid being scalded, never change engine coolant when the engine is hot.

MA-12

Loading...

Loading...