Page 1

Edition: January 2005

Revision: January 2006

Publication No. SM6E-1Y50U2

QUICK REFERENCE INDEX

A

GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEX

GI

General Information

EM

Engine Mechanical

LU

Engine Lubrication System

CO

Engine Cooling System

EC

Engine Control System

FL

Fuel System

EX

Exhaust System

ACC

Accelerator Control System

AT

Automatic Transmission

TF

Transfer

PR

Propeller Shaft

FFD

Front Final Drive

RFD

Rear Final Drive

FAX

Front Axle

RAX

Rear Axle

FSU

Front Suspension

RSU

Rear Suspension

WT

Road Wheels & Tires

BR

Brake System

PB

Parking Brake System

BRC

Brake Control System

PS

Power Steering System

STC

Steering Control System

SB

Seat Belts

SRS

Supplemental Restraint System

(SRS)

BL

Body, Lock & Security System

GW

Glasses, Window System & Mirrors

RF

Roof

EI

Exterior & Interior

IP

Instrument Panel

SE

Seat

ATC

Automatic Air Conditioner

SC

Starting & Charging System

LT

Lighting System

DI

Driver Information System

WW

Wiper, Washer & Horn

BCS

Body Control System

LAN

LAN System

AV

Audio-Visual System

ACS

Auto Cruise Control System

PG

Power Supply, Ground & Circuit Elements

MA

Maintenance

IDX

Alphabetical Index

A

B

C

D

E

F

G

H

I

J

K

L

M

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or

transmitted in any form, or by any me ans, ele ctronic , me cha nic al, rec ordin g or oth erwise, wit hout th e prior

written permission of Nissan Motor Company Ltd., Tokyo, Japan.

Page 2

This manual contains maintenance and repair procedure for the 2006

INFINITI M35/M45.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by NISSAN must first be completely satisfied that neither personal

safety nor the vehicle’s safety will be jeopardized by the service

method selected.

Page 3

QUICK REFERENCE CHART M35/M45

2006

QUICK REFERENCE CHART M35/M45 PFP:00000

ENGINE TUNE-UP DATA (VQ35DE) ELS0003W

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed

A/T (In “P” or “N” position)

Ignition timing (BTDC at idle speed)

A/T (In “P” or “N” position)

CO% at idle 0.7 - 9.9% and engine runs smoothly

Deflection adjustment Unit: mm (in) Tension adjustment Unit: N (kg, lb)

Drive Belt

Limit After adjustment Limit After adjustment

Alternator and power

steering oil pump belt

A/C compresor belt 12 (0.47)

Applied pushing force 98N (10kg, 22lb) —

Radiator cap relief pressure

Cooling system leakage testing pres sure

Compression pressure

Spark plug Standard type PLFR5A-11

7 (0.28)

Standard 78 - 98 (0.8 - 1.0, 11 - 14)

Limit 59 (0.6, 9)

Standard 1,275 (13.0, 185) /300

Minimum 981 (10.0, 142) /300

Hot type PLFR4A-11

Cold type PLFR6A-11

Used belt

4 - 5

(0.16 - 0. 20)

9 - 10

(0.35 - 0. 39)

kPa (kg/cm

kPa (kg/cm

kPa (kg/cm2 , psi)/rpm

2

, psi)

2

, psi)

rpm

New belt

3.5 - 4.5

(0.138 - 0. 177)

8 - 9

(0.31 - 0.35)

650 ± 50

294 (30, 66)

196 (20, 44)

157 (1.6, 23)

15° ± 5°

Used belt

730 - 818

(74.5 - 83.5,

164 - 184)

348 - 436

( 35.5 - 44.5,

78 - 98)

New belt

838 - 926

(85.5 - 94.5,

188 - 208)

470 - 559

(48 - 57,

106 - 126)

Page 4

QUICK REFERENCE CHART M35/M45

ENGINE TUNE-UP DATA (VK45DE)

Engine model VK45DE

Firing order 1-8-7-3-6-5-4-2

Idle speed

A/T (In “P” or “N” position) rpm

Ignition timing

(BTDC at idle speed)

CO% at idle 0.7 - 9.9% and engine runs smoothly

Tens io ns of drive belts Auto adjustment by auto tensioner

Radiator cap relief pressure

Limit 59 (0.6, 9)

Cooling system leakage testing pressure

kPa (kg/cm

Compression pressure

Minimum 1,130 (11.5, 164) /300

Spark plug Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-1 1

2

, psi)

kPa (kg/cm

kPa (kg/cm

2

, psi)

2

7 8 - 98 (0.8 - 1.0 , 11 - 14)Standard

, psi)/rpm

650 ± 50

12° ± 5°

157 (1.6, 23)

1,320 (13.5, 191) /300Standard

2006

FRONT WHEEL ALIGNMENT (Unl aden* )

Axle 2WD AWD

Tire P245/45R 18 245/40R19 245/45R18

Minimum – 1° 00′ (– 1.00°)

Camber

Degree minute (Decimal degree)

Caster

Degree minute (Decimal degree)

Kingpin inclination

Degree minute (Decimal degree)

Distance (A – B)

Total toe-in

Angle (left plus right)

Degree minute

(Degree)

Nominal – 0° 15′ (– 0.25°)

Maximum 0° 30′ (0.50°)

Left and right difference 33′ (0.55°) or less

Minimum 3° 45′ ( 3.75° )3° 50′ (3.83°)3° 05′ ( 3.08° )

Nominal 4° 30′ ( 4.50° )4° 35′ (4.58°)3° 50′ ( 3.83° )

Maximum 5° 15′ ( 5.25° )5° 20′ (5.33°)4° 35′ ( 4.58° )

Left and right difference 39′ (0.65°) or less

Minimum 6° 30′ (6.50°)

Nominal 7° 15′ (7.25°)

Maximum 8° 00′ (8.00°)

Minimum 0 mm (0 in)

Nominal 1 mm (0.04 in)

Maximum 2 mm (0.08 in)

Minimum 0′ (0°)

Nominal 3′ (0.05°)

Maximum 6′ (0.10°)

ELS0003X

Page 5

QUICK REFERENCE CHART M35/M45

Axle 2WD AWD

Tire P245/45R 18 245/40R19 245/45R18

Inside

Degree minute

Wheel turning

angle (Full turn)

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designa te d posi tions.

(Decimal degree)

Outside

Degree minute

(Decimal degree)

Minimum 36°20′ (36.3°)39°45′ (39.8°)

Nominal 39°20′ (39.3°)42°45′ (42.8°)

Maximum 40°20′ (40.3°)43°45′ (43.8°)

Nominal 33° 25′ (33.4°)33° 20′ (33.3°)32° 30′ (32.5°)

2006

REAR WHEEL ALIGNMENT (Unladen*) ELS0003Y

Axle 2WD AWD

Tire P245/45R18 245/40R19 245/45R18

Minimum – 1° 10′ (– 1.17°)– 1° 20′ (– 1.33°)– 1° 40′ (– 0.67°)

Camber

Degree minute (Decimal degree)

Distance ( A – B )

Total toe-in

Angle (left plus right )

Degree minute

(Decimal degree)

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designa te d posi tions.

Nominal – 0° 40′ (– 0.67°)– 0° 50′ (– 0.83°)– 0° 10′ (– 0.17°)

Maximum – 0° 10′ (– 0.17°)– 0° 20′ (– 0.33°) 0° 20′ (0.33° )

Minimum 0.1 mm (0.004 in)

Nominal 2.8 mm (0.110 in)

Maximum 5.5 mm (0.217 in)

Minimum 0′ (0°)

Nominal 7′ (0.12°)

Maximum 14′ (0.23°)

BRAKE ELS0003Z

Front brake Pad wear limit 2.0 mm (0.079 in)

Rotor repair limit 26.0 mm (1.024 in)

Rear brake Pad wear limit 2.0 mm (0.079 in)

Rotor repair limit 14.0 mm (0.551 in)

Pedal free height 157 - 167 mm (6.18 - 6.57 in)

Pedal depressed height* 90 mm (3.54 in) or more

* : Under force of 490 N ( 50 kg, 110 lb ) with engine running.

REFILL CAPACITIES ELS00040

UNIT Liter US measure

Fuel tank 76 20 gal

Coolant ( With reservoir tank )

Engine (VQ35DE)

Engine (VK45DE)

VQ35DE 8.9 9 - 3/8 qt

VK45DE 10.4 11 qt

Drain and refill

With oil filter change 4.7 5 qt

Without oil filter change 4.4 4 - 5/8 qt

Dry engine (Overhaul) 5.4 5 - 3/4 qt

Drain and refill

With oil filter change 5.5 5 - 3/4 qt

Without oil filter change 4.9 5 - 1/8 qt

Dry engine (Overhaul) 6.7 7 - 1/8 qt

Page 6

QUICK REFERENCE CHART M35/M45

UNIT Liter US measure

Transmission A/T 10.3 10 - 7/8 qt

Transfer 1.25 2 - 5/8 pt

Differential carrier

Power steering system 1.0 1 - 1/8 qt

Air conditioning system

Front 0.65 1 - 3/8 pt

Rear 1.4 3 pt

Compressor oil 0.15 5.03 fl oz

Refrigerant 0.55 kg 1.21 lb

2006

Page 7

GENERAL INFORMA TION

A GENERAL INFORMATION

GI

B

SECTION GI

CONTENTS

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint Syst em

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS) (If

Equipped) ................. ................................................ 3

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 4

OPERATION PROCEDURE ................................. 4

Precautions for Procedures without Cowl Top Cover ..... 4

General Precautions ................................................ 4

Precautions for Three Way Catalyst ......................... 6

Precaution s for Fuel (Unl eaded Premium Gasoline

Recommended) ........ ............. ............. ............. ......... 6

Precaution s for Fuel (Unl eaded Premium Gasoline

Required) ................................................................. 6

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 7

Precautions for Hoses .............................................. 7

HOSE REMOVAL AND INSTALLATION ............... 7

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 8

HEALTH PROTECTION PRECAUTIONS ............. 8

Precautions for Air Conditioning ............................... 8

HOW TO USE THIS MANUAL ................................... 9

Description ............................................................... 9

Terms ....................................................................... 9

Units ......................................................................... 9

Contents ...................................... ............................. 9

Relation between Illustrations and Desc ript ion s .... 10

Components ................................ ............................11

SYMBOLS ................... .........................................11

How to Follow Trouble Diagnoses .......................... 12

DESCRIPTION ................................ .................... 12

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 12

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ....................................... 13

GENERAL INFORMATION

KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 14

How to Read Wiring Diagrams ............................... 16

CONNECTOR SYMBOLS ...................................16

SAMPLE/WIRING DIAGRAM - EXAMPL - ..........17

DESCRIPTION ............................ ........................18

Abbreviations ........ ................................. ................. 24

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT .............................. ........................................... 25

How to Check Terminal ........................................... 25

CONNECTOR AND TERMINAL PIN KIT ............25

HOW TO PROBE CONNECTORS ......................25

How to Perform Efficient Diagnosis for an Electrical

Incident ........................ ...........................................28

WORK FLOW ......................................................28

INCIDENT SIMULATION TESTS ........................28

CIRCUIT INSPECTION .......................................31

Control Units and Electrical Parts ...........................36

PRECAUTIONS .................................................. 36

CONSULT-II CHECKING SYSTEM .......................... 38

Description ................... ...... ....... ...... ........................ 38

Function and System Application ........................... 38

Nickel Metal Hydride Battery Replacement ............39

Checking Equipment ..............................................39

CONSULT-II Start Procedure ................. ...... ....... .... 39

CONSULT-II Data Link Connector (DLC) Circuit .... 40

INSPECTION PROCEDURE ..............................40

CIRCUIT DIAGRAM ............................................41

LIFTING POINT .........................................................42

Special Service Tools .............................................42

Garage Jack and Safety Stand and 2-Pole Lift ....... 42

Board-On Lift ..........................................................43

TOW TRUCK TOWING .............................................44

Tow Truck Towing ................................................... 44

2WD MODELS .................................................... 44

AWD MODELS ....................................................45

Vehicle Recovery (Freeing a Stuck Vehicle) ........... 45

FRONT ................................................................ 45

REAR ..................................................................45

AUTOMA TIC TRANSMISSION ...........................46

C

D

E

F

G

H

I

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-1

Page 8

TIGHTENING TORQUE OF STANDARD BOLTS ....47

Tightening Torque Table .........................................47

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS ...............................................................48

Recommended Chemical Products and Sealants ...48

IDENTIFICATION INFORMATION ............................49

Model Variation ....................................................... 49

IDENTIFICATION NUMBER ................................50

IDENTIFICATION PLATE ....................................51

ENGINE SERIAL NUMBER .................................51

AUTOMATIC TRANSMISSION NUMBER ...........51

Dimensions .............................................................52

Wheels & Tires ........................................................52

TERMINOLOGY ........................................................53

SAE J1930 Terminology List ...................................53

Revision: 2006 January 2006 M35/M45

GI-2

Page 9

PRECAUTIONS

PRECAUTIONS PFP:00001

Description NAS00073

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Rest raint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, us ed along

with a front seat belt, helps to redu ce th e risk or se verit y of i njury to the driv er and front passenge r for ce rtain

types of collision. This system includes seat belt switch inputs and dual s tage front ai r bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rendering the SRS inopera tive, which c ould increa se the risk of perso nal injury or dea th

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, inc luding incorrect removal and installation of the SRS, can lead to per-

sonal injury ca use d by unintentional activ ation of the system. For removal of Spiral Cable and A ir

Bag Module, see the SRS section.

● Do not use electrical test equ ipment o n any circu it related to the SRS unless in structed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

NAS00074

GI

B

C

D

E

F

G

H

Precautions for NVIS/IVIS (NISSAN/INFINITI VEHICLE IMMOBILIZER SYSTEM NATS) (If Equipped)

NVIS/IVIS (N ATS) will immob il iz e th e e ng ine if s ome on e tri es t o s t ar t it wit h ou t t he r e gi ste re d ke y o f NVI S /IV I S

(NATS).

Both of the originally supplied ignition key IDs have been NVIS/IVIS (NATS) registered.

The security indic ator i s lo cated on the in strum ent panel. T he in di cato r blin ks wh en th e im mobi lizer sys tem i s

functioning.

Therefore, NVIS/IVIS (NATS) warns outsiders that the ve hicle is equipped with the anti-theft system.

● When NVIS/IVIS (NATS) detects trouble, the security i ndicator lamp lights up while ignition switch is in

"ON" position.

This lighting up indicates that the anti-theft is not functioning, so prompt service is required.

● When servicin g NVIS/IVIS (NATS) (trouble diag noses, syst em initializatio n and addition al registration of

other NVIS/IVIS (NATS) ignition key IDs), CONSULT-II hardware and CONSULT-II NVIS/IVIS (NATS)

software is necessary.

Regarding the procedures of NVI S/IVIS (NATS) initialization and NVIS/I VIS (NATS) ignition key ID re gistration, refer to CONSULT-II operation manual, NVIS/IVIS (NATS).

Therefore, CONSULT-II NVIS/IVIS (NAT S) software (pro gram card an d operatio n manual) m ust be kept

strictly confidential to maintain the integrity of the anti-theft function.

● When servicin g NVIS/IVIS (NATS) (trouble diag noses, syst em initializatio n and addition al registration of

other NVIS/IVIS (NATS) ignition key IDs), it may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner. A maximum of four or five key IDs can be registered into NVIS/IVIS (NATS).

● When failing to start the engine first time using the key of NVIS/IVIS (NATS), start as follows.

1. Leave the ignition key in "ON" position for approximately 5 seconds.

2. Turn ignition key to "OFF" or "LOCK" position and wait approximat ely 5 seconds.

3. Repeat step 1 and 2 again.

4. Restart the engine while keeping the key separate from any others on key-chain.

NAS00075

I

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-3

Page 10

PRECAUTIONS

Precautions Necessary for Steering Wheel Rotation After Battery Disconnect

NAS0008J

NOTE:

● This Procedure is appl ied only to models with Intel ligent Key system and NVI S/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

● Remove and install all control units after disconnect ing both battery cables with the ignition knob in the

″LOCK″ position.

● Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self- diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering whee l rotation will become impossible.

If steering wh eel rotation is required when battery power is interrupted, follow th e procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged .

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return t he ignition switch to the ″LOCK″ positi on before connec ting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Procedures with out Cowl Top Cover NAS00077

When performi ng the pr oced ure af ter remo ving cowl t op cove r, cover

the lower end of windshield with uretha ne, etc.

PIIB3706J

General Precautions NAS00078

● Do not ope rate t he en gine f or an exte nded perio d of t ime wi thou t

proper exhaust ventilation.

Keep the work area well ventilated and free of any flammable

materials. S pecia l car e sh ould be t ake n when hand lin g any flammable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or other enclosed area, be sure to

properly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

SGI285

Revision: 2006 January 2006 M35/M45

GI-4

Page 11

PRECAUTIONS

● Before jackin g up the vehicle, ap ply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving . After

jacking up the vehicle, support the vehicle weight with safety

stands at the points design ated for proper lift ing before working

on the vehicle.

These operat ions should be done on a level surface.

● When removing a heavy component such as the engine or tran-

saxle/transmission, be caref ul not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

● Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the nega tiv e battery terminal.

● If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

● Battery posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

GI

B

C

SGI231

D

E

F

G

SEF289H

● To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

● Dispose of or recy cle dr a in ed oi l or th e solv en t us ed fo r cle an in g

parts in an appropriat e manner.

● Do not attempt to top off the fuel tank after the fuel pu mp no zz le

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

● Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assemb ly.

● Replace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

SGI233

ones.

● Replace inner and outer races of tapered roller bearings and needle bearings as a set.

● Arrange the disassembled parts in accordance with their assembled locations and sequence.

● Do not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal elec tronic components.

● After disconnecting vacuum or air hoses, attach a tag to indicate the proper connect ion.

● Use only the fluids and lubricants specified in this manual.

● Use approved bonding agent, sealants or their equivalents when required.

● Use hand tools, power tools (disassembly only) and recom-

mended special tools where specified for safe and efficient service repairs.

● When repairing the fu el, oil, wate r, vacuum or exhaust sys tems,

check all affected lines for leaks.

H

I

J

K

L

M

PBIC0190E

Revision: 2006 January 2006 M35/M45

GI-5

Page 12

PRECAUTIONS

● Before servicing the vehicle:

Protect fenders, uph olstery and carpet ing with appropria te covers.

Take caution that keys, buckles or buttons do not scratch paint.

SGI234

WARNING:

To prevent ECM from storing the diagnostic tro uble codes, d o not carelessly disconnect th e harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for Three Way Catalyst NAS00079

If a large amount of un bu rne d fu el flows into the catalys t, th e c ataly st te m pe r atu re wi ll b e ex c es si ve ly high. To

prevent this, follow the instructions.

● Use unleaded gasoline only. Leaded gasoline will seriously damage the three way cat alyst.

● When checking for i gnition spark or measuri ng engine compressio n, make tests quickly a nd only when

necessary.

● Do not run engine when the fuel tank level is lo w, otherwise the engine may m isfire, causin g damage to

the catalyst.

Do not place the vehi cle on flammab le material. Keep flam mable material off the exhaust pipe and the three

way catalyst.

Precautions for Fuel (Unleaded Premium Gasoline Recommended) NAS0007A

Use unleaded reg ular gaso line with an oc tane rati ng of at le ast 8 7 AKI (Anti-Kn ock Index ) num ber (Re searc h

octane numb er 91).

For improved ve hicle performance, NISSAN/INFINITI recommend the use o f unleaded premium gasoline with

an octane rating of at least 91 AKI number (Research octane number 96).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel othe r than that specified could ad versely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Precautions for Fuel (Unleaded Premium Gasoline Required) NAS0007B

Use unleaded premiu m gas olin e wit h an o ct ane ratin g of at le ast 91 A KI ( Anti- Knoc k Ind ex) numbe r (Res ear ch

octane numb er 96).

If unleaded premium gasoline is not avai lable, unleade d regular gasoli ne with an octane rating of at least 87

AKI number (Research oct ane number 91) can be used, but only under the following p recautions:

● have the fuel tank filled on ly partially with unleaded re gular gasoline, and fil l up with unleaded prem ium

gasoline as soon as possible.

● avoid full throttle driving and abrupt acceleration.

However, for maximum vehicle performance, the use of unleade d premi um ga sol ine is recom mende d.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

Revision: 2006 January 2006 M35/M45

GI-6

Page 13

PRECAUTIONS

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel other than that specified could adversely affect

the emission control devi ces and systems, and could also affect the wa rranty cover age validity.

Precautions for Multiport Fuel Injection System or Engine Control System NAS0007C

GI

● Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there ma y be damage to ECM.

● Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

● Be careful not to jar components such as ECM and mass air

flow sensor.

SGI787

Precautions for Hoses NAS0007D

HOSE REMOVAL AND INSTALLATION

● To p revent damage to rubb er hose, do not pry off rubber hose

with tapered tool or screwdriv er.

SMA019D

B

C

D

E

F

G

H

I

● To reinstall the rubber hose secu rel y, make sure that hose inser-

tion length and orientation is correct. (If tube is equipped with

hose stopper, insert rubber hose into tube until it butts up

against hose stopper.)

HOSE CLAMPING

● If old rubber hose is re-used, install hose clamp in its original

position (at the indentation where the old clamp was). If there is

a trace of tube bulging left on the old rubber hose, align rubber

hose at that position.

● Discard old clamps; repla ce with new ones.

SMA020D

SMA021D

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-7

Page 14

PRECAUTIONS

● After installing plate clam ps, apply f orce to th em in the d irectio n

of the arrow, tightening rubber h ose equally all around.

SMA022D

Precautions for Engine Oils NAS0007E

Prolonged and re peated con tact with use d engine oil m ay cause s kin cancer. Try to avoid direct skin co ntact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

● Avoid prolonged and repeated contact with oils, particularly used engine oils.

● Wear protective clot hing, including impervious gloves where pr acticable.

● Do not put oily rags in pockets.

● Avoid contaminating clothes, particularly underpants, with oil.

● Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regu-

larly.

● First aid treatment should be obtained immediately for open cuts and wounds.

● Use barrier creams, app lying them bef ore each work period, to help the removal of oil from the skin.

● Wash with soap and water to ens ure all oil is remo ved (ski n cle anse rs and nail brush es wil l help ). Prepa-

rations con taining lanolin replace the natural skin o ils which have been removed.

● Do not use gasoline, kerosen e, die s el fue l, gas oil , t hin ne rs or solv en ts for clea ni ng skin .

● If skin disorders develop, obtain medical advice without delay.

● Where pract ical, degrease component s prior to handling.

● Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face

shields; in additio n an eye was h fac il ity sho ul d be pro vi de d.

Precautions for Air Conditioning NAS0007F

Use an approved refrigerant recov ery unit any tim e the air conditi oning sys tem must be dis charged. Refer to

ATC/MTC section “HFC-134a (R-134a) Service Procedure”, “REFRIGERANT LINES” for specific instructions.

Revision: 2006 January 2006 M35/M45

GI-8

Page 15

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL PFP:00008

Description NAS0007G

This volume exp lains “Removal, Disassembly, Installation, Inspecti on and Adjustment” and “Trouble Diagnoses”.

Terms NAS0007H

GI

B

● The captions WARNING and CAUTION warn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WARNING indicates the possibility of personal injury if instructions are not followed.

CAUTION indicates the possibilit y of component damage if instructions are not followed.

BOLD TYPED STATEMENTS except WARNING and CAUTION give you helpful information.

Standard value:Tolerance at inspection and adjustment.

Limit value:The maximum or minimum limit value that should not be exceeded at inspection and adjustment.

Units NAS0007I

● The UNITS given in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

Also with regard t o ti gh te nin g t orq ue of bolts and nuts, there are de s cri pti on s both about range and a bo ut

the standard tightening torque.

“Example”

Range

Outer Socket Lock Nut : 59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

Standard

Drive Shaft Installation Bolt : 44.3 N·m (4.5 kg-m, 33 ft-lb)

Contents NAS0007J

● ALPHABETICAL INDEX is provided at the en d of this manual so that you can rapidly find the item an d

page you are searching for.

C

D

E

F

G

H

I

J

● A QUICK REFERENCE INDEX, a black tab (e .g. ) is provided on th e first page. You can quickly find

the first page of each section by matching it to the section's black tab.

● THE CONTENTS are listed on the first page of each section.

● THE TITLE is indicated on the upper portion of each page and shows the part or system.

● THE PAGE NUMBER of each sectio n cons ists of two or th ree lett ers whic h desig nate th e particul ar sec-

tion and a number (e.g. “BR-5”).

● THE SMALL ILLUSTRATIONS show the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky st eps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle or transmission, etc. are presented in a step-by-step format where nec essary.

K

L

M

Revision: 2006 January 2006 M35/M45

GI-9

Page 16

HOW TO USE THIS MANUAL

Relation between Illustrations and Descriptions NAS0007K

The following sample explains the ralationship between the part description in an illustration, the part name in

the text and th e service procedures.

SAIA0519E

Revision: 2006 January 2006 M35/M45

GI-10

Page 17

HOW TO USE THIS MANUAL

Components NAS0007L

● THE LARGE ILLUSTRATIONS are exploded views (see the following) and contain tightening torques,

lubrication points, section number of the P ARTS CATALOG (e. g. SE C. 440) and ot her in for matio n neces -

sary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriate PARTS CATALOG .

Components shown in an illustration may be identified by a circled number. When this style of illustration

is used, the text description of the components will follow the illustration.

GI

B

C

D

E

F

G

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Out er shi m 24. Oute r shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease

Refer to GI section for additional symbol defi ni tions .

2: Rubber grease : Brake fluid

SYMBOLS

SFIA2959E

H

I

J

K

L

M

SAIA0749E

Revision: 2006 January 2006 M35/M45

GI-11

Page 18

HOW TO USE THIS MANUAL

How to Follow Trouble Diagnoses NAS0007M

DESCRIPTION

NOTICE:

Trouble diagnoses indi cate work proce dures req uired to diag nose proble ms effec tivel y. Observe the following

instructions before diagnosing.

1. Before performing trouble diagnoses, read the “ Preliminary Check”, the “Sy mptom Chart” or the

“Work Flow”.

2. After repairs, re-check that the problem has been complete ly eli min ate d.

3. Refer to Component Parts and Harn ess Connector Location for the Systems de scribed in each

section for identification/location of components and harness connectors.

4. Refer to the Circuit Diagram for quick pinpoint check.

If you need to check circuit continuity between harness connectors in more detail, such as when a

sub-harness is used, refer to Wiring Diagram in each individual section and Harness Layout in PG

section for identification of harness connectors.

5. When checking circuit continuity, ignition switch should be OFF.

6. Before checking voltage at connectors, check battery voltage.

7. After accomplishing the Diagnostic Procedures and Electrical Components Inspection, make sure

that all harness connectors are reconnected as they were.

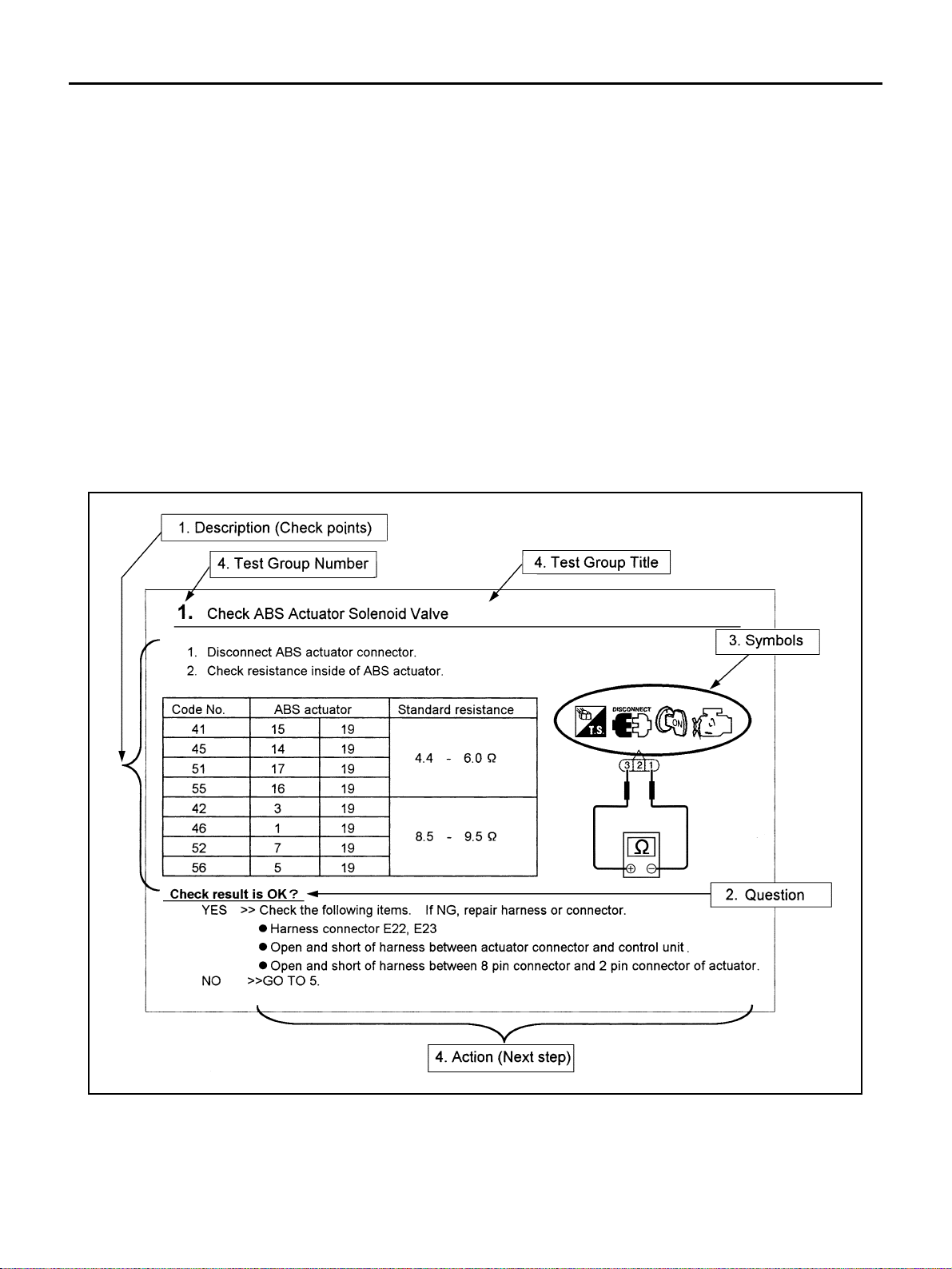

HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES

SAIA0256E

1. Work a nd diagnostic procedure

Start to diagnose a problem using procedures indicated in enclosed test groups.

2. Questions and required results

Questions and required results are indicated in bold type in test group.

The meaning of are as follows:

Revision: 2006 January 2006 M35/M45

GI-12

Page 19

HOW TO USE THIS MANUAL

a. Battery voltage → 11 - 14V or approximately 12V

b. Voltage : Approxima tely 0V → Less than 1V

3. Symbol used in illustration

Symbols included in illustrations refer to measurements or procedures. Before diagnosing a problem,

familiarize y ourself with ea ch symbol. R efer to "Connec tor Symbols" in GI Section a nd "KEY TO SYMBOLS SIGNIFYING MEASUREMENTS OR PROCEDURES" below.

4. Action items

Next action for ea ch te st gr o up is ind ic at e d base d on r es ult o f e ach qu es ti o n. Test group n umber i s sh own

in the left upper portion of each test group.

HARNESS WIRE COLOR AND CONNECTOR NUMBER INDICATION

There are two types of harness wire color and connector number indication.

TYPE 1: Harness Wire Color and Connector Number are Shown in Illustration

● Letter designations next to test meter probe indicate harness

wire color.

● Connector numbers in a single circle (e.g. M33) indicate har-

ness connectors.

● Connector numbers in a double circle (e.g. F211) indicate com-

ponent connectors.

GI

B

C

D

E

F

G

H

AGI070

I

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-13

Page 20

HOW TO USE THIS MANUAL

TYPE 2: Harness Wire Color and Connector Number are Shown in Text

KEY TO SYMBOLS SIGNIFYING MEASUREMENTS OR PROCEDURES

SGI144A

SAIA0750E

Revision: 2006 January 2006 M35/M45

GI-14

Page 21

HOW TO USE THIS MANUAL

GI

B

C

D

E

F

G

H

K

M

I

J

L

SAIA0751E

Revision: 2006 January 2006 M35/M45

GI-15

Page 22

HOW TO USE THIS MANUAL

How to Read Wiring Diagrams NAS0007N

CONNECTOR SYMBOLS

Most of connector symbols in wir ing diagrams are shown from the terminal sid e.

● Connector symbols shown from the terminal side are enclosed

by a single line and followed by the direction mark.

● Connector symbols shown from the harness side are enclosed

by a double line and followed by the direction mark.

● Certain systems and components, especially those related to

OBD, may use a new style slide-locking type harness connector.

For description and how to disconnect, refer to PG section,

“Description”, “HARNESS CONNECTOR”.

● Male and female terminals

Connector guides for male terminals are shown in black and

female terminals in white in wiring diagrams.

SAIA0257E

SGI363

Revision: 2006 January 2006 M35/M45

GI-16

Page 23

HOW TO USE THIS MANUAL

SAMPLE/WIRING DIAGRAM - EXAMPL -

● For detail, refer to following “DESCRIPTION”.

GI

B

C

D

E

F

G

H

K

M

I

J

L

SGI091A

Revision: 2006 January 2006 M35/M45

GI-17

Page 24

Optional Splice

HOW TO USE THIS MANUAL

DESCRIPTION

Num-

ber

1 Power condition

2 Fusible link

Fusible link/fuse loca-

3

tion

4Fuse

5 Current ra ting

6 Connectors

7 Optional splice

8 Splice

9 Page crossing

10 Common connector

11 Option abbreviation

12 Relay

13 Connectors

SGI942

Item Description

● This shows the condition when the system receives battery positive voltage (can be oper-

ated).

● The doubl e line shows that this is a fusible link.

● The open ci rc le sh ow s cur ren t flow in, and the shaded circle shows current flow out.

● This sho w s the loca tion of the fusibl e l ink or fuse in the fusi bl e link or fuse bo x. F or arrange-

ment, refer to PG section, POWER SUPPLY ROUTING.

● The sing le line shows that this is a fuse.

● The open ci rc le sh ow s cur ren t flow in, and the shaded circle shows current flow out.

● This sho w s the current rati ng of the fu si ble link or fuse .

● This sho ws tha t con nect or E3 is fem ale and connector M1 is male.

● The G/R wire is located in the 1A terminal of both connectors.

● Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ connec-

tor. Refer to PG section, SMJ (SUPER MULTIPLE JUNCTION).

● The open ci rc le sh ow s th at the spli ce is optional depending on vehicle application.

● The shaded circle shows that the splice is always on the vehicle.

● This arrow shows that the circuit continues to an adjacent page.

● The A will match with the A on the pre ceding or next page.

● The dotted lines between terminals show that these terminals are part of the same connector.

● This sho w s tha t the circu it is op tiona l dep endi ng on vehicle application.

● This sho ws an in ternal rep res entation of the relay. For details, refer to PG section, STAN-

DARDIZED RELAY.

● This sho w s tha t the conn ect or is connected to the body or a terminal with bolt or nut.

Revision: 2006 January 2006 M35/M45

GI-18

Page 25

HOW TO USE THIS MANUAL

Num-

ber

Item Description

14 Wire color

15 Option description

16 Switch

17 Assembly parts

18 Cell code

19 Current flow arrow

20 System branch

21 Page crossing

22 Shielded line

Component box in

23

wave line

24 Component name

25 Connector number

26 Ground (GND)

27 Ground (GND)

28 Connector views

29 Common component

30 Connector color

● This shows a code fo r th e color of the wire .

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light Green

BR = Brown

OR or O = Orange

P = Pink

PU or V (Violet) = Purple

GY or GR = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe color as shown

below:

Example: L/W = Blue with White Stripe

● This shows a description of the option abbreviation used on the page.

● This shows that cont i nui ty exi sts between te rmi nal s 1 and 2 w hen the sw i tch is in the A posi-

tion. Continuity exists between terminals 1 and 3 when the switch is in the B positio n.

● Conne cto r term i nal in component shows that it is a harness incorporated assembly.

● This ident ifies each page of the wiring diagram by section, system and wiring diagr am page

number.

● Arrow indicates electric current flow, especially where the direction of standard flow (vertically

downward or horizontally from left to right) is difficult to follow.

● A double arrow “ ” shows that current can flow in either direction depending on cir-

cuit operation.

● This shows that the system branches to another system ident i fied by ce ll code (section and

system).

● This arrow show s that the circuit continues to another page identified by cell code.

● The C will match with the C on another page within the system other than the next or preced-

ing pages.

● The line enclosed by broken line circle shows shield wire.

● This shows that anot her part of the component is also shown on another page (indicated by

wave line) within the system.

● This shows the nam e of a com ponent.

● This shows the con nect or number.

● The letter show s w hich harness the connector is located in.

● Example: M : main harness. For detail and to locate the connector, refer to PG section "Main

Harness", “Harness Layout”. A coordina te grid is included for complex harnesses to aid in

locating connectors.

● The line splice d and gr ounded under wire color shows that ground line is spliced at the

grounded connector.

● This shows the ground connection. For detailed ground distribution information, refer to

"Ground Distribution" in PG section.

● This area show s t he connector faces of the components in the wiring diagram on the page.

● Conne cto rs encl osed in broken line show that these connectors belong to the same compo-

nent.

● This shows a code for the color of the connector. For code meaning, refer to wire color codes,

Number 14 of this chart.

GI

B

C

D

E

F

G

H

I

J

K

L

M

Fusible link and fuse

31

box

32 Reference area

Revision: 2006 January 2006 M35/M45

● This shows the arrangement of fusible link(s) and fuse(s), use d for connector views of

"POWER SUPPLY ROUTING" in PG section.

The open square shows current flow in, and the shaded square shows current flow out.

● This shows that more information on the Super Multiple Junction (SMJ) and Joint Connectors

(J/C) exists on the PG section. Refer to "Reference Area" for details.

GI-19

Page 26

HOW TO USE THIS MANUAL

Harness Indication

● Letter designations next to test meter probe indicate harness

(connector) wire color.

● Connector numbers in a sing le circ le M3 3 indic ate ha rness co n-

nectors.

Component Indication

Connector numbers in a double circle F211 indicate component connectors.

Switch Positions

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

● ignition switch is “OFF”,

● doors, hood and trunk lid/b ac k door are closed,

● pedals are not depressed, and

● parking brake is released.

AGI070

SGI860

Revision: 2006 January 2006 M35/M45

GI-20

Page 27

HOW TO USE THIS MANUAL

Detectable Lines and Non-Detectable Lines

In some wiring diagrams, two kind s of lin es , rep res en tin g w ire s, with different weight are used.

● A line with regula r weight (wider line) represents a “detectable

line for DTC (Diagnostic Trouble Code)”. A “detectable line for

DTC” is a circu it in which ECM can detect its malf unctions with

the on board diagnostic system.

● A line with less weight (thinner line) represents a “non-detect-

able line for DTC”. A “non-dete ctable line for DT C” is a circuit in

which ECM cannot detect its malfunctions with the on board

diagnostic system.

GI

B

C

D

E

F

G

SGI862-B

H

I

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-21

Page 28

HOW TO USE THIS MANUAL

Multiple Switch

The continuity of multiple switch is described in two ways as shown below.

● The switch ch art is used in schematic diagrams.

● The switch diagram is used in wiring diagrams.

SGI875

Revision: 2006 January 2006 M35/M45

GI-22

Page 29

HOW TO USE THIS MANUAL

Reference Area

The Reference Area of the wiring diagram contains references to additional electrical reference pages at the

end of the manual. If connector numbers and titles are shown in the Reference Area of the wiring diagram,

these connector symbols are not shown in the Connector Area.

GI

B

C

D

E

F

G

SGI092A

H

I

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-23

Page 30

HOW TO USE THIS MANUAL

Abbreviations NAS0007O

The followi ng ABBREVIATIONS are used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automat ic Transaxle/Transmission

ATF Automatic Transmission Fluid

D

1 Drive range 1st gear

2 Drive range 2nd gear

D

3 Drive range 3rd gear

D

D

4 Drive range 4th gear

FR, RR Fro n t, Re ar

LH, RH Left-Hand, Right-Hand

M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel D rive

2 2nd range 2nd gear

2

1 2nd range 1st gear

2

2 1st range 2nd gear

1

1 1st range 1st gear

1

Revision: 2006 January 2006 M35/M45

GI-24

Page 31

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

SERVICE INFORMATION FOR ELECTRICAL INCIDENT PFP:00000

How to Check Terminal NAS0007P

CONNECTOR AND TERMINAL PIN KIT

Use the connector and terminal pin kits listed below when replacing connectors or terminals.

The connector and terminal pin kits contain some of the most commonly used NISSAN/INFINITI connectors

and terminals. For detailed connector and terminal pin replacement procedures, refer to the latest NISSAN/

INFINITI CONNECTOR AND TERMINAL PIN SERVICE MANUAL.

Too l number

(Kent-Moore No.)

Tool name

(J38751-95NI)

Connector and terminal

pin kit (NISSAN)

(J38751-95INF)

Connector and terminal

pin kit (INFINITI)

(J42992-98KIT)

OBD and terminal repair

kit

(J42992-2000UPD)

OBD-II Connector Kit

Update

Description

WAIA0004E WAIA0005E

GI

B

C

D

E

F

G

H

HOW TO PROBE CONNECTORS

Connector damage and an intermittent connection can result from improperly probing of the connector during

circuit checks.

The probe of a digital multimeter (DMM) may not correctly fit the connector cavity. To correctly probe the connector, follow the procedures belo w using a “T” pin. For the b est contact grasp the “T” pin using an alligat or

clip.

Probing from Harness Side

Standard type (not waterproof type) connector should be probed

from harness side with “T” pin.

● If the connector has a rear cover such as a ECM connector,

remove the rear cover before probing the terminal.

● Do not probe waterproof connector from harness side. Damage

to the seal between wire and connector may result.

SGI841

Probing from Terminal Side

FEMALE TERMINAL

● There is a small notch abov e each fe male te rminal. Pro be each

terminal with the “T” pin through the notch.

Do not insert any ob ject other th an the same type male termin al

into female terminal.

I

J

K

L

M

SEL265V

Revision: 2006 January 2006 M35/M45

GI-25

Page 32

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

● Some connectors do not have a notch above ea ch terminal . To

probe each terminal, remove the connector retainer to make

contact space for prob ing.

MALE TERMINAL

Carefully pr obe the cont act surface of each terminal using a “T” pin.

Do not bend terminal.

SEL266V

SEL267V

How to Check Enlarged Contact Spring of Terminal

An enlarged contact spring of a terminal may create intermittent signals in the circuit.

If the intermittent open circuit occurs, follow the procedure below to inspect for open wires and enlarged contact spring of female terminal.

1. Assemble a male terminal and approx. 10 cm (3.9 in) of wire.

Use a male terminal which matches the female terminal.

2. Disconnect the suspected faulty connector and hold it terminal

side up.

SEL270V

3. While holding the wire of the male terminal, try to insert the male

terminal into the female terminal.

Do not force the male terminal into the female terminal with

your hands.

SEL271V

Revision: 2006 January 2006 M35/M45

GI-26

Page 33

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

4. While moving the connector, check whether the male terminal

can be easily inserted or not.

● If the male terminal can be easily inserted into the female termi-

nal, replace the female terminal.

GI

B

C

SEL272V

D

E

F

G

SEL273V

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may lead to intermittent problems.

Check the following items to maintain the original waterproof characteristics.

RUBBER SEAL INSPECTION

● Most waterproof connectors are provided with a rubber seal

between the male and female connectors. If the seal is missing,

the waterpro of performanc e may not meet specifications.

● The rubber seal may come off when connectors are discon-

nected. Whenev er connectors are reco nnected, make sure the

rubber seal is properly installed on either side of male or female

connector.

SEL275V

WIRE SEAL INSPECTION

The wire seal mu st be installed o n the wire insertion ar ea of a wate rproof conn ector. Be sure that the sea l is

installed properly.

Terminal Lock Inspection

Check for unlocked termina ls by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

H

I

J

K

L

M

SEL330V

Revision: 2006 January 2006 M35/M45

GI-27

Page 34

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

How to Perform Efficient Diagnosis for a n Electrical I ncident NAS0007Q

WORK FLOW

SGI838

STEP DESCRIPTION

Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5 Repair or replace the incident circuit or component .

STEP 6

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW

Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Inc id ent Simul ation Tests”.

Get the proper diagnosis materials tog eth er incl udi ng:

● Powe r Supply Rout i ng

● Syste m Oper at io n De scr ip tions

● Applicable Service Manual Sections

● Chec k fo r any Service Bul l etins

Identify where to begin diagnosis base d upon your knowledge of the system operation and the cu st om er com m ents.

Inspect the system for mechanical bi nding, loo se connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inadvertently created a new incident during your diagnosis or repair steps.

System Symptoms, Operating Conditi ons (Ot her Components Interaction).

Service History and if any After Market Accessories have been installed.

INCIDENT SIMULATION TESTS

Introduction

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The following section illustrates ways to simulate the conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

● V ehicle vibration

● Heat sensitive

Revision: 2006 January 2006 M35/M45

GI-28

Page 35

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

● Freezing

● Water intrusion

● Electrical load

● Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

GI

B

Vehicle Vibration

The problem may occu r or be com e wors e wh ile dr iving on a roug h road or whe n eng ine i s vibrat in g (idl e with

A/C on). In such a case , you w ill wan t to ch eck f or a vib rati on rel ated con ditio n. Re fer to th e foll owing i llu stration.

CONNECTORS & HARNESS

Determine which con necto rs an d wirin g ha rness woul d affect t he elec trical s yste m yo u are insp ecti ng. G entl y

shake each connect or and harness while monit oring the system for the inciden t you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moi sture. It is possibl e to get a thin film of corrosion on the co nnector terminals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs intermittently, perhaps the problem is ca used by corrosi on. It is a good i dea to disco nnect, inspec t and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

C

D

E

F

G

H

I

J

SGI839

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

● Connectors not full y se ate d.

● Wiring harness not long enou gh and is being st ressed due to engine vibrations or rocking.

● Wires laying across brackets or moving components.

● Loose, dirty or corroded ground wires.

● Wires routed too clos e to ho t components.

To inspect componen t s u nd er th e ho od, start by ve rif yi ng t h e i nte gr it y o f gro un d con ne ct i ons. ( Re fer t o Gr ou nd

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shak ing the wiring or comp onents as previously explained. Using th e wiring diagrams inspe ct the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehicle vibration can aggravate a harness which is routed along a bracket or near a screw.

K

L

M

Revision: 2006 January 2006 M35/M45

GI-29

Page 36

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

UNDER SEATING AREAS

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibrat ion. If the wiring runs under seating are as, inspect wire routing for possible damage or

pinching.

Heat Sensitive

The customer's concern may occur during h ot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitiv e condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat compo nents above 60°C (140°F). If incident occurs

while heating th e unit, either repla ce o r p rop erl y ins u late the component.

SGI842

Freezing

The customer may indicate the incident goes away after the car

warms up (wint e r tim e) . T he c au se co ul d be r el a ted to wa te r fr ee zi ng

somewhere in the wiring/electrical system.

There are two me thods to check for this. The first is to arra nge for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked outside

overnight. In the morning, do a quick and thorough diagnosis of

those electrical components which could be affected.

The second m ethod is to put the sus pect component int o a freezer

long enough for any water to freeze. Reinstall the part into the car

and check for the re occurrence of the inci dent. If it o ccurs, repair or

replace the compone nt .

SGI843

Water Intrusion

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the in cident could be c aused by wa ter intrusion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

Do not spray water directly on any electrical components.

Electrical Load

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

SGI844

SGI845

Revision: 2006 January 2006 M35/M45

GI-30

Page 37

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Cold or Hot Start Up

On some occas ions an elec trical incide nt may occur on ly when the ca r is started col d, or it may oc cur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagno sis.

CIRCUIT INSPECTION

Introduction

In general, testing electrical circuits is an easy task if it is approached in a logical and organized method.

Before beginning it is important to have all available information on the system to be tested. Also, get a thorough understanding of system opera tion. Then you will be able to use the approp riate equipm ent and follow

the correct test procedure.

Yo u may hav e to sim ulate vehi cle v ibr ation s whil e test ing e lectri cal c ompo nents. Ge ntly s hak e the wi ring h arness or electrical component to do this.

GI

B

C

D

OPEN A circ ui t is open when there is no continuity through a section of the circuit.

There are two types of shorts.

SHORT

● SHORT CIRCUIT

● SHORT TO GROUND When a circuit contacts a ground source and grounds the circuit .

When a circuit contacts another circuit and causes the norm al resistanc e to

change.

NOTE:

Refer to “How to Check Terminal” to probe or check terminal.

Testing for “Opens” in the Circuit

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your working knowledge of the system.

SGI846-A

CONTINUITY CHECK METHOD

The continuity check is used to find an open in the circuit. The digital multimeter (DMM) set on the resistance

function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Make sure to always start

with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circuits, please refer to the previous schematic.

● Disconnect the ba tte ry ne gative cable.

● Start at one end of the circuit and work your way to the other end. (At the fuse block in this example)

● Connect one probe of the DMM to the fuse block terminal on the load side.

● Connect the ot her probe to the fuse b lock (power) side of SW1. Little or no resis tance will indicate th at

portion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an

over limit or infinite resistance condition. (point A)

● Connect the prob es be tw ee n SW 1 an d th e re la y. Little or no resistance wil l ind ic at e th at p ort ion of th e c ir-

cuit has good conti nuity. If there were an open in the circuit, the DMM would in dicate an over limi t or infinite resist ance condition. (point B )

● Connect the probes between the relay and the solenoid. Little or no resistance will indicate that portion of

the circuit ha s g oo d co nt inu it y. If there were an open in t he cir cu it , th e DM M w o uld i n di ca te an ov er l im it o r

infinite resi stance condition. (point C)

Any circuit can be diagnosed using the approach in the previous example.

E

F

G

H

I

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-31

Page 38

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

VOLTAGE CHECK METHOD

To help in understanding the diagnosis of open circuits please refer to the pre vious schemati c.

In any powered circu it, an open can b e fou nd by method ical ly ch ecki ng the syste m for t he p res ence of volt a ge.

This is done by switching the DMM to the voltage function.

● Connect o ne probe of the DMM to a known good ground.

● Begin probing at one end of t he circuit and work your way to the other end.

● With SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

● Close SW1 and probe at relay.

voltage; open is furth er down the circ uit than the relay.

no voltage; open is between SW1 and relay (point B).

● Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

SGI847-A

RESISTANCE CHECK METHOD

● Disconnect the battery negative cable and remove the blown fuse.

● Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the

fuse.

● Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

● With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

● Close SW1 and disconn ect the relay. Put probes at the load side of fuse terminal and a known good

ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

● Close SW1 and jump the relay contacts with jumpe r wire. Put probes at the load side of fuse terminal and

a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

● Remove the bl own fus e and d is con ne ct al l loa ds (i. e. SW 1 ope n, rel ay d is con nect e d an d sole no id di scon-

nected) powered through the fuse.

● Turn the ignition key to the O N or START position. Verify battery voltage at the ba ttery + s ide of the fuse

terminal (on e l ead on th e b at ter y + term in al side of th e fus e b lo ck a nd on e lead on a kn own goo d g rou nd ).

● With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

Revision: 2006 January 2006 M35/M45

GI-32

Page 39

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

no voltage; short is further down the circuit than SW1 .

● With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check

for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

● With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

Ground Inspection

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwant ed resistance. This unwanted resistance can change the way a circuit works.

Electronical ly cont rol l ed ci rcui t s a r e ve ry se ns it ive to prop er gr ou ndin g. A lo ose or co r rod ed gro un d ca n d rast ically affect an elec tronically controlled circui t. A poor or corroded ground c an easily affect the circuit. Eve n

when the groun d connection lo oks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

● Remove the ground bolt or screw.

● Inspect all mating surfaces for tarnish, dirt, rust, etc.

● Clean as required to assure good contact.

● Reinstall bolt or screw securely.

● Inspect for “add-on” accessories which may be interfering with the ground circuit.

● If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the

wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one

eyelet make sure no ground wires have excess wire insulation.

For detailed ground distribution information, refer to “Ground Distribution” in PG section.

GI

B

C

D

E

F

G

H

SGI853

Vo ltage Drop Tests

Voltage drop tests are often used to find co mponents or circuits whic h have excessiv e resistance. A voltage

drop in a circuit is caused by a resistance when the circuit is in operation.

Check the wire in the illustration. When measuring resistance with DMM, contact by a single strand of wire will

give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single strand of wire

is not able to carry the current. The single strand will have a high resistance to the current. This will be picked

up as a slight voltage drop.

Unwanted resistance can be caused by many situations as follows:

● Undersized wiring (single strand example)

● Corrosion on switch contacts

● Loose wire connec tions or splic es.

I

J

K

L

M

Revision: 2006 January 2006 M35/M45

GI-33

Page 40

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

If repairs are needed always use wire that is of the same or larger gauge.

MEASURING VOLTAGE DROP — ACCUMULATED METHOD

● Connect the DMM ac ross the co nnector or part of the circ uit you wa nt to check. The posit ive lead of t he

DMM should be closer to power and the negative lead closer to ground.

● Operate the circuit.

● The DMM will indicate how many volts are being used to “push” current through that p art of the circuit.

Note in the illustration that there is an excessive 4.1 volt drop between the battery and the bulb.

SGI974

MEASURING VOLTAGE DROP — STEP-BY-STEP

The step-by-step method is most useful for isolating excessive drops in low voltage systems (such as those in

“Computer Controlled Systems”).

Circuits in the “Computer Controlled System” operate on very low amperage.

The (Computer Controlled) system operations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corros ion.

The step by step v oltage drop test can identi fy a component or wire with too much resistance.

SAIA0258E

Revision: 2006 January 2006 M35/M45

GI-34

Page 41

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Control Unit Circuit Test

System Description:When the switch is ON, the control unit lights up the lamp.

GI

B

C

D

MGI034A

INPUT-OUTPUT VOLTAGE CHART

Pin

No.

1 Switch

2Lamp

The voltage value is based on the body ground.

*:If high resistance exists in the switch side circu it (caused by a single stran d), terminal 1 doe s not detect ba ttery voltage. Control unit

does not detect the s witch is ON even i f the switch does n ot turn ON . Therefore, the contro l unit doe s not su pply power t o light up the

lamp.

Item Condition

Switch ON Battery voltage Lower than battery voltage Approx. 8 (Example)

Switch OFF Approx. 0 Approx. 0

Switch ON Battery voltage Approx. 0 (Inoperative lamp)

Switch OFF Approx. 0 Approx. 0

Voltage

value [V]

In case of high resistance such as single strand [V ] *

MGI035A

E

F

G

H

I

J

K

L

INPUT-OUTPUT VOLTAGE CHART

Pin

No.

1 Lamp

2Switch

The voltage value is based on the body ground.

*:If high resistance exists in the swi tch side circuit ( caused by a s ingle stran d), ter minal 2 does not dete ct approx. 0V. Control unit d oe s

not detect the switch is ON even if the switch does not turn O N. Ther ef ore , the cont r ol unit does not control ground to light up the lamp.

Item Condition

Switch ON Approx. 0 Battery voltage (Inoperative lamp)

Switch OFF Battery voltage Batte ry vo ltage

Switch ON Approx. 0 Higher than 0 Approx. 4 (Example)

Switch OFF Approx. 5 Approx. 5

Revision: 2006 January 2006 M35/M45

Voltage

value [V]

In case of high resistance such as single strand [V] *

GI-35

M

Page 42

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Control Units and Electrical Parts NAS0008L

PRECAUTIONS

● Never reverse polarity of battery terminals.

● Install only parts specified for a vehicle.

● Before replacing the control unit, check the input and output and

functions of the component parts.

● Do not apply excessive force when disconnecting a connector.

● If a connector is ins talled by tigh tenin g bo lts, loos en bo lt mo unt-

ing it, then take it out by hand.

SAIA0251E

● Before installing a connecto r, make sure the terminal is not ben t

or damaged, and then correc t ly conne c t it .

When installing a con nector by tightening bolts, fix it b y tightening the mount ing bolt u ntil the pain ted projec tion of th e connec tor becomes even with the surface.

● For removal of the l ever type connector, pull the leve r up to th e

direction pointed to by the arrow A in the figure, and then

remove the connector.

● For installation of the lever type connector, pull down the lever to

the direction poin ted by the ar row B in th e figure , and the n push

the connector until a clicking noise is heard.

SAIA0252E

SAIA0253E

SAIA0254E

Revision: 2006 January 2006 M35/M45

GI-36

Page 43

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

● Do not apply excessive shock to the control unit by dropping or

hitting it.

● Be careful to prevent condensation in the control unit due to

rapid temperatur e c ha ng es an d do not let water or rain get o n it .