MAINTENANCE

L MAINTENANCE

A

B

SECTION MA

CONTENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

GENERAL MAINTENANCE ....................................... 5

Explanation of General Maintenance ....................... 5

PERIODIC MAINTENANCE ....................................... 7

Introduction of Periodic Maintenance ....................... 7

Schedule 1 ............................................................... 7

EMISSION CONTROL SYSTEM MAINTE-

NANCE ............................... ...... ............................. 7

CHASSIS AND BODY MAINTENANCE ............... 8

Schedule2 ................................................................ 9

EMISSION CONTROL SYSTEM MAINTE-

NANCE ............................... ...... ............................. 9

CHASSIS AND BODY MAINTENANCE ............. 10

RECOMMENDED FLUIDS AND LUBRICANTS .......11

Fluids and Lubricants ..............................................11

SAE Viscosity Number ............................................11

GASOLINE ENGINE OIL .....................................11

Anti-Freeze Coolant Mixture Ratio ......................... 12

ENGINE MAINTENANCE . ....... ...... ....... ...... ....... ....... 13

Checking Drive Belts .............................................. 13

Tension Adjustment ................................................ 13

Changing Engine Coolant .................. ...... ....... ....... 13

DRAINING ENGINE COOLANT ......................... 13

REFILLING ENGINE COOLANT ........................ 14

FLUSHING COOLING SYSTEM ......................... 15

Checking Fuel Lines ............................................... 16

Changing Air Cleaner Filter .................................... 16

VISCOUS PAPER TYPE ..................................... 16

Changing Engine Oil .......................... ...... ....... ....... 16

Changing Oil Filter ................................... ....... ....... 17

REMOVAL ........................................................... 17

INSTALLATION ................................................... 17

INSPECTION AFTER INSTALLATION ............... 17

Changing Spark Plugs (Platinum- Tipped Type) ..... 18

MAINTENANCE

REMOVAL ...........................................................18

INSPECTION AFTER REMOVAL .......................18

INSTALLATION ...................................................19

Checking EVAP Vapor Lines .................................. 19

Checking Cooling Fan Fluid Level and Lines .........19

CHASSIS AND BODY MAINTENANCE ................... 20

Checking Exhaust System ...................................... 20

Checking A/T Fluid ................................................. 20

Changing A/T Fluid .................................................21

Checking Propeller Shaft ........................................ 22

Checking Differential Gear Oil ................................ 22

Changing Differential Gear Oil ................................ 22

Balancing Wheels (Bonding Weight Type) ............. 24

REMOVAL ...........................................................24

WHEEL BALANCE ADJUSTMENT .....................24

Tire Rotation ... ...... ....... ...... .....................................25

Checking Brake Fluid Level and Leaks ..................25

Checking Brake Lines and Cables .........................26

Changing Brake Fluid .............................................26

Checking Disc Brake ..............................................26

ROTOR ........................................ ....... ...... ........... 26

CALIPER .............................................................27

PAD .....................................................................27

Checking Steering Gear and Linkage ..................... 27

STEERING GEAR ............................................... 27

STEERING LINKAGE .........................................27

Checking Power Steering Fluid and Lines .............. 27

Axle and Suspension Parts .................................... 28

Drive Shaft ................................ ..............................28

Lubricating Locks, Hinges and Hood Latch ............ 29

Checking Seat Belts, Buckles, Retractors, Anchors

and Adjusters .......................................................... 29

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 30

Standard and Limit .................................................. 30

BELT DEFLECTION AND TENSION ..................30

ENGINE COOLANT CAPACITY .......................... 30

RADIATOR ..........................................................30

ENGINE OIL CAPACITY ..................................... 30

SPARK PLUG (PLATINUM-TIPPED TYPE) ........ 30

C

D

E

F

G

H

I

J

K

MA

M

Revision; 2004 April 2003 M45

MA-1

WHEEL BALANCE ..............................................30

Tightening Torque ...................................................30

Revision; 2004 April 2003 M45

MA-2

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

ALS000QG

A

The Supplemental Rest raint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used al ong

with a front seat belt, helps to redu ce th e risk or se verit y of i njury to the driv er and front passenge r for ce rtain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rendering the SRS ino perative, whi ch could incr ease the risk of pe rsonal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, inc luding incorrect removal and installation of the SRS, can lead to per-

sonal injury ca use d by unintentional ac tiv atio n o f the s ys tem . F or re moval of Spiral C ab le and Air

Bag Module, see the SRS section.

● Do not use electrical test equ ipment o n any circu it related to the SRS unless in structed to in this

Service Manual. SRS wiring harnesses can be id entified by yellow and/or orange harnesses or

harness connectors.

B

C

D

E

F

G

H

I

J

K

MA

M

Revision; 2004 April 2003 M45

MA-3

PREPARATION

PREPARATION PFP:00002 Special Service Tools ALS00026

The actual shapes of Kent-Moore tools may differ from those of spe ci al se rvice tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

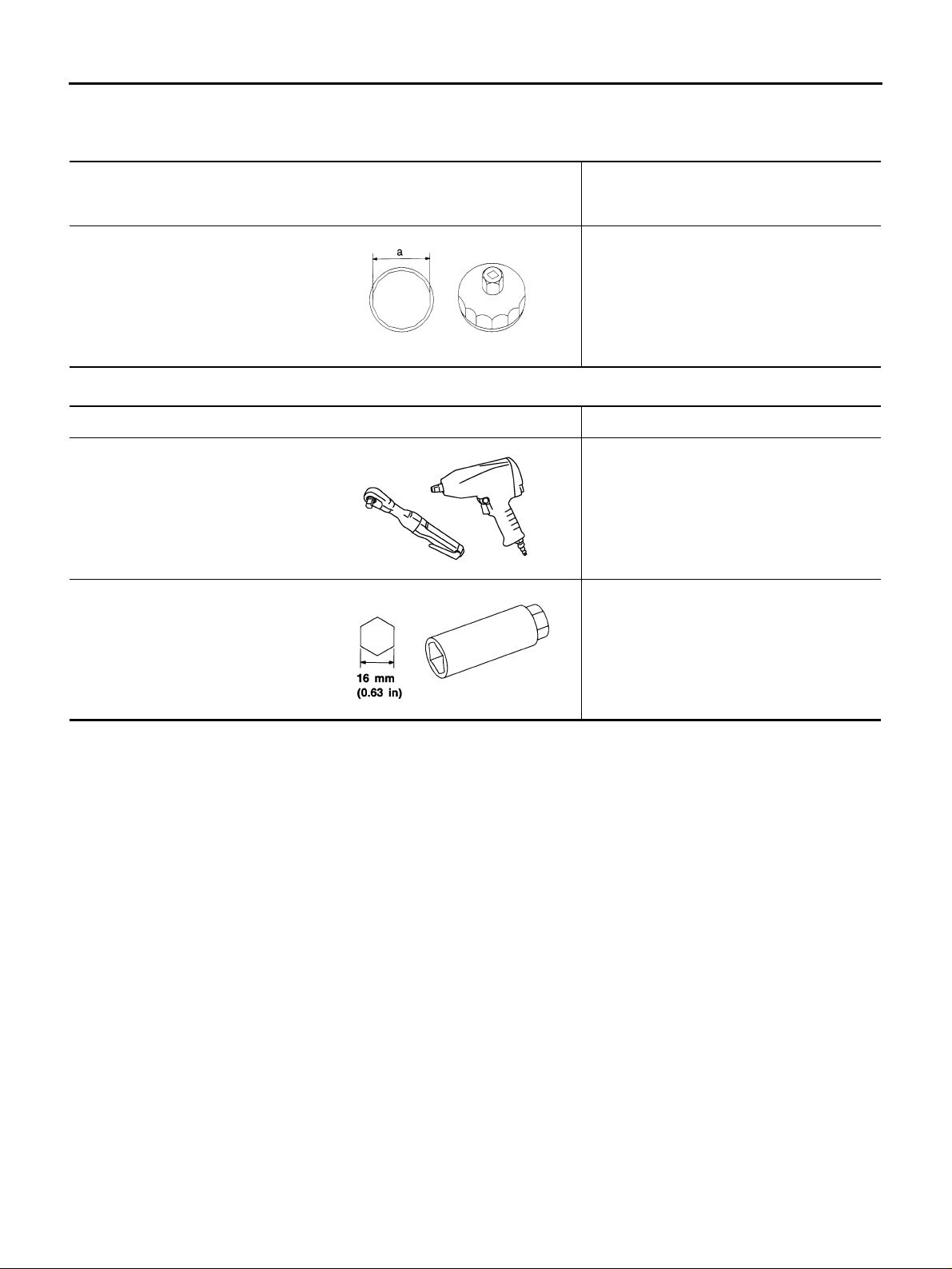

KV10115801

(J38956)

Oil filter wrench

S-NT375

Removing and installing oil filter

a: 64.3 mm (2.531 in)

Commercial Service Tools ALS00027

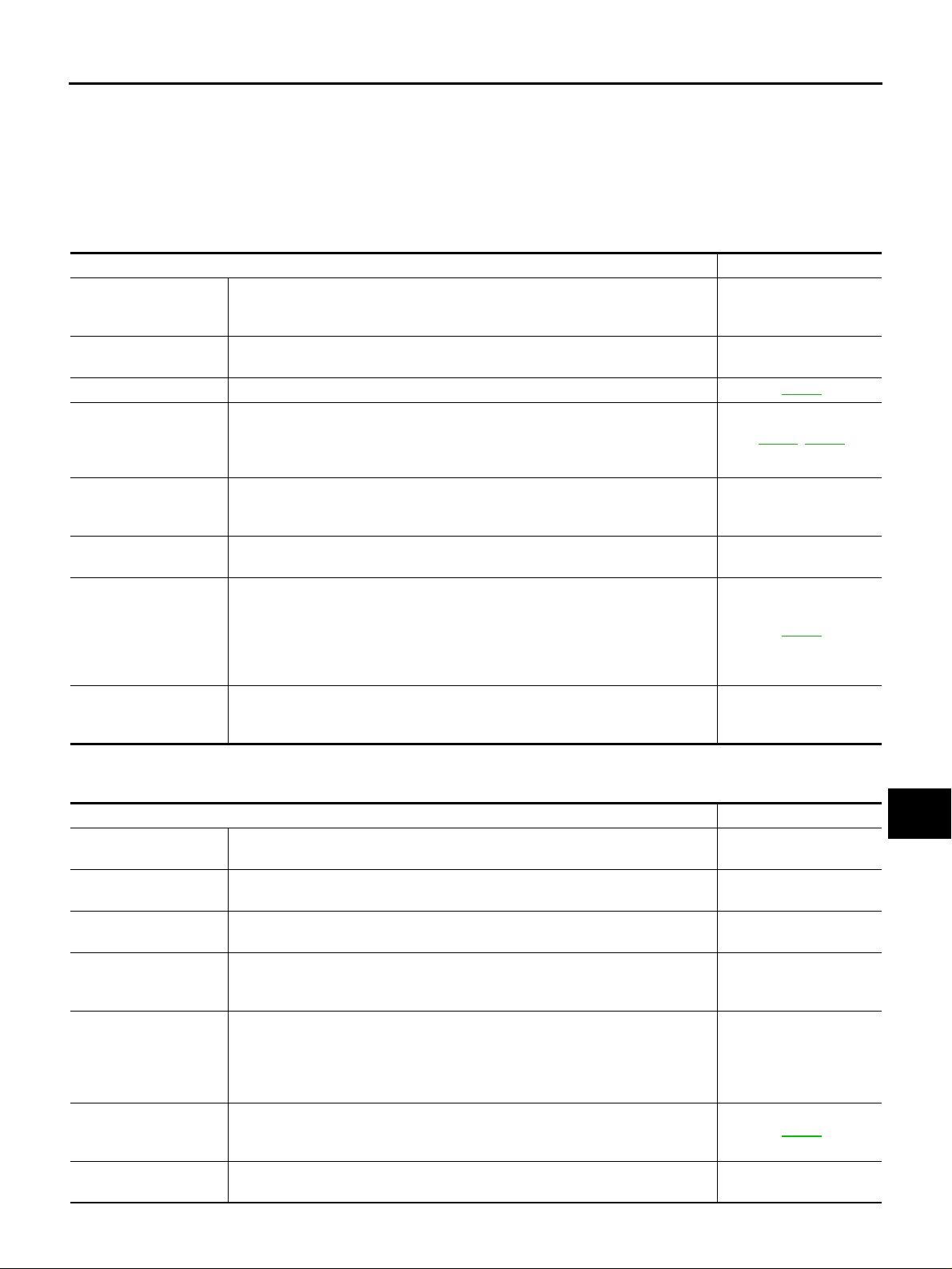

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

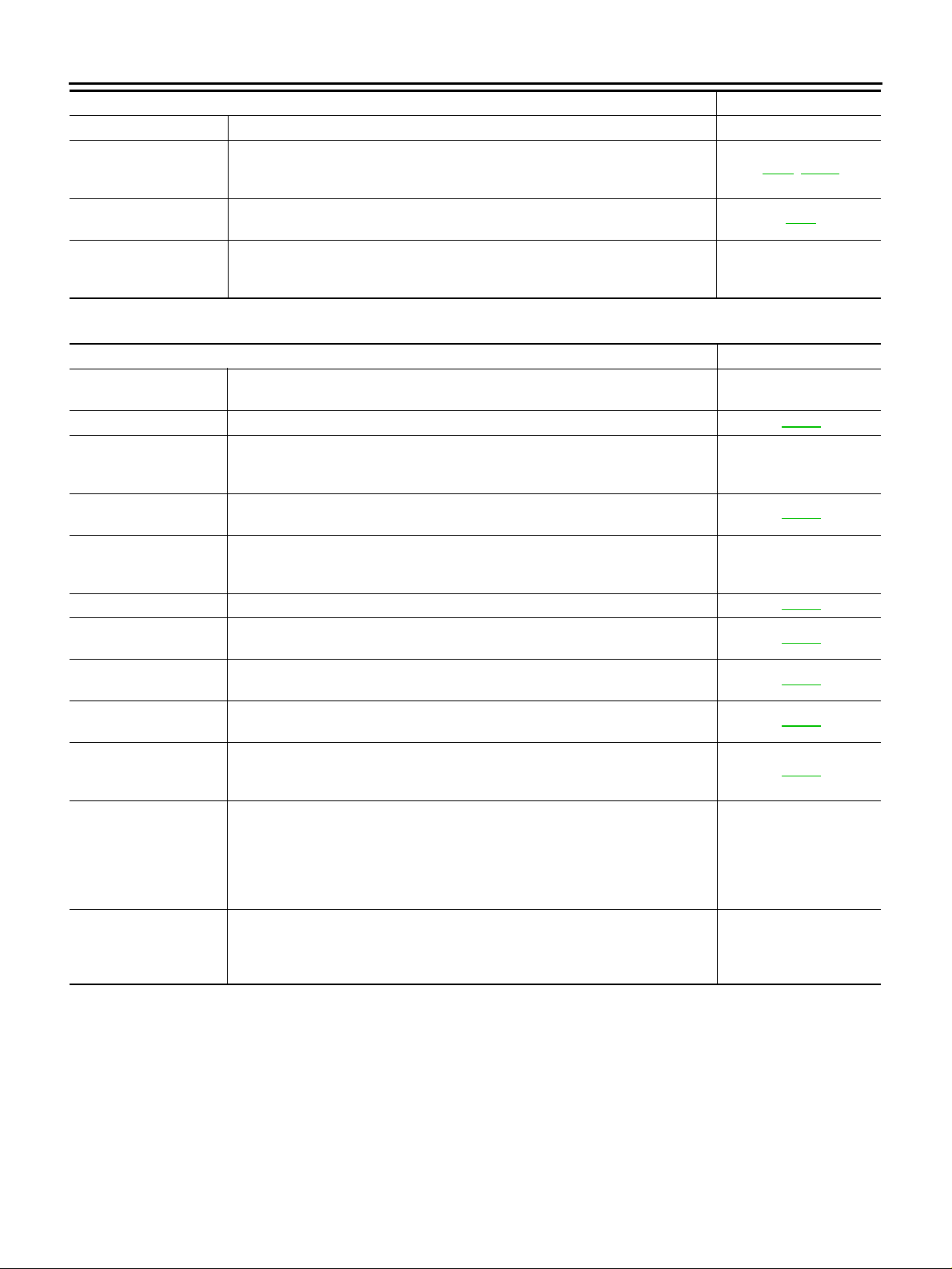

Spark plug wrench Removing and installing spark plug

S-NT047

Revision; 2004 April 2003 M45

MA-4

GENERAL MAINTENANCE

GENERAL MAINTENANCE PFP:00000

Explanation of General Mai ntenance ALS00098

General maintena nce inclu des those item s which sho uld be checke d during the normal day-t o-day opera tion

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their IN FINITI dealers d o them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be pe rf ormed from time to time, unless otherwise specified .

Item Reference page

Tires Check the pressure with a gauge, including the spare, at least once a month

and always prior to a long distance trips. Adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive wear.

Wheel nuts When checking the tires, make sure no n uts are missi ng, and chec k fo r any

loose nuts. Tighten if necessary.

Tire rotatio n Tires should be rotated every 12,000 km (7,500 miles). MA-25

Wheel alignment and

balance

Windshield Clean the windshield on a regular basis.

Windshield wiper

blades

Doors and engine

hood

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

If the vehicle pulls to either side while driving on a straight and leve l road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel alignment. If the steering wheel or seat vibrates at norma l highway speeds, wheel

balancing may be needed.

Check the windshield at least every six months for cracks or other damage.

Repair as necessary.

Check for cracks or wear if they do not wipe properly. —

Check that all doors and the engine hood operate smoothly as well as the trunk

lid and back hatch. Also make sure that all latches lock securely. Lubricate if

necessary. Make sure that the secondary latch keeps the hood from opening

when the primary latch is released.

When driving in areas using road salt or other corr osi ve mat er ials, check lubrication frequently.

other lamps are all operating properly and installed securely. Also check headlamp aim. Clean the headlamps on a regular basis.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regu lar basis, such as w hen performin g periodic mai ntenanc e, cleaning the

vehicle, etc.

Item Reference page

Warning lamps and

chimes

Windshield wiper and

washer

Windshield defroster Check that the air comes out of the def ros ter out le ts properly and i n sufficient

Steering wheel Check that it has the specified play. Be sure to check for changes in the steering

Seats Check seat position controls such as seat adju sters, seatback recliner, etc. to

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

Accelerator p e d al Check the pedal for smooth operation and m ake sure the pedal does not catch

Make sure that all warning lamps and chimes are oper at in g prop erly. —

Check that the wipers and washer operate properly and that the wipers do not

streak.

quantity when operating the heater or air co nditioner.

condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for f ol d in g-down rear seatbacks.

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.

or require uneven effort. Keep the floor mats away from the pedal.

FSU-6

MA-29

MA-29

—

—

, MA-24

—

—

—

—

—

—

—

A

B

C

D

E

F

G

H

I

J

K

MA

M

Revision; 2004 April 2003 M45

MA-5

GENERAL MAINTENANCE

Item Reference page

Brakes Check that the brake does not pull the vehicle to one side wh en appl i ed. —

Brake pedal and

booster

Parking brake Check that the lever has the proper travel and make sure that the vehicle is held

Automatic transmission “Park” mechanism

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Item Reference page

Windshield washer

fluid

Engine coolant level Check the coolant level when the engine is cold. MA-13

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves , etc. , that

Brake fluid level Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

Battery Check the fluid level in each cell. It should be between th e “MAX” and “MIN”

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. MA-13

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and turn-

Power steering fluid

level and lines

Cooling fan fluid level

and lines

Exhaust system Make sure the re ar e no lo ose supports, cracks or holes. If the sound of the

Underbody The underbody is frequen tly exp o sed to cor ros iv e subs tances such as t hose

Fluid leaks Check under the vehicle for fuel, oil, water or oth er fluid leaks after the vehicle

Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep the floor mats away from the pedal.

securely on a fairly steep hill when only the parking brake is applied.

Check that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the “P” position without appl ying any br akes.

Check that there is adequate fluid in the tank. —

may have accumulated. Make sur e the hoses have no cracks, deformation,

deterioration or loose connections .

reservoir.

lines. Vehicles operated in high temperatures or under severe conditions require

frequent checks of the battery fluid level.

ing off the engine.

Check the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

Check the level when the fluid is cold and the engi ne is turned off. Check th e

lines for proper attachment, leaks, cracks, etc.

exhaust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it.

used on icy roads or to control dust. It is very important to remov e the se substances, otherwise rust will form on the floor pan, frame, fuel lines and ar ound

the exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate.

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasol ine fum es are evident, check for

the cause and correct it immediately.

BR-6

, BR-21

PB-3

—

—

MA-25

—

MA-16

MA-27

MA-19

MA-20

—

—

Revision; 2004 April 2003 M45

MA-6

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE PFP:00026

Introduction of Periodic Maintenance ALS00099

Two different maintenance sche dules are provided, and sho uld be used, depending upon the conditions in

which the vehi cl e is main ly op erate d. After 6 0,00 0 miles (96,00 0 km ) or 48 months , continue the pe riodic

maintenance at the same milea ge /tim e inte r va ls.

Schedule 1

Schedule 2

Follow Periodic Maintenance Schedule 1 if the drivi ng habits frequently include

one or more of the following driving conditions:

● Repeated short trips of less than 5 miles (8 km).

● Repeated short trips of less than 10 miles (16 km) with outside temper at ure s

remaining below freezing.

● Operating in hot weather in stop-and-go “rush hour ” t raffic.

● Extensive idling and/or low speed driving for long distances , suc h as poli ce,

taxi or door-to-door delivery use.

● Driving in dusty conditions.

● Driving on rough, muddy, or salt spread roads.

● Towing a trailer, using a camper or a car-top carrier.

Follow Periodic Maintenance Schedule 2 if none of driving conditions shown in

Schedule 1 apply to the driving habits.

Emission Control System Maintenance

Chassis and Body

Maintenance

Emission Control System Maintenance

Chassis and Body

Maintenance

MA-7

MA-8

MA-9

MA-10

A

B

C

D

E

F

G

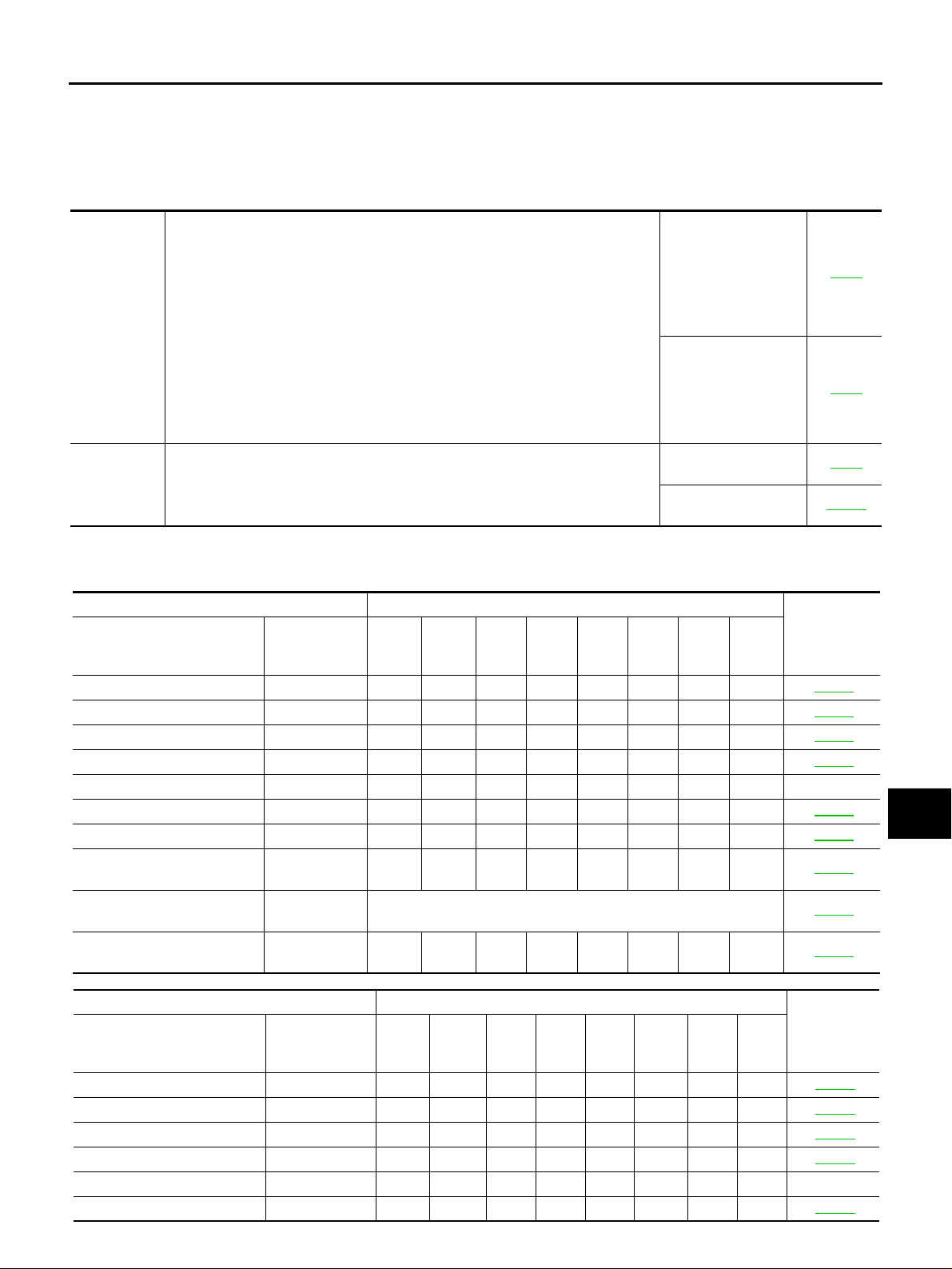

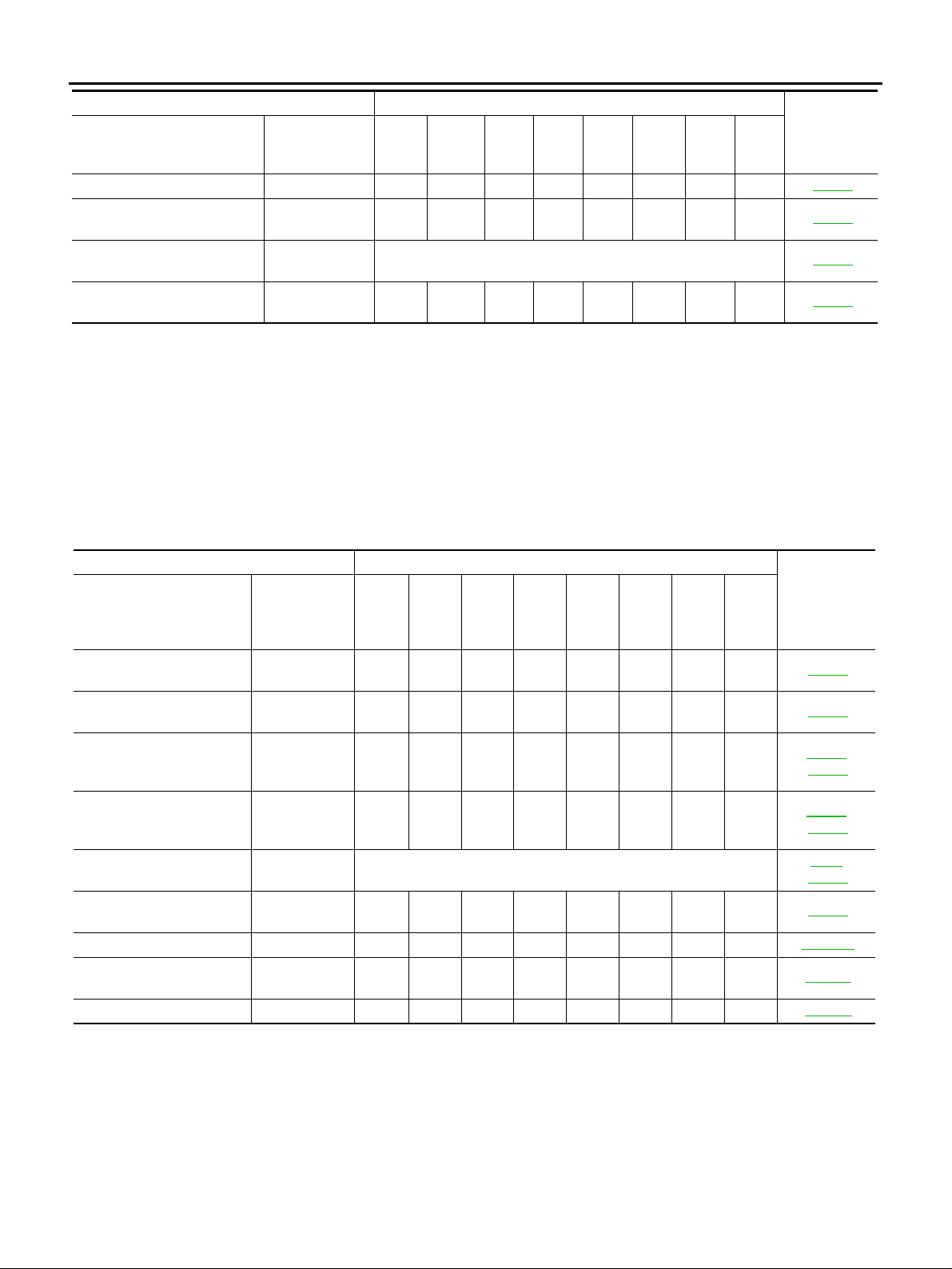

Schedule 1 ALS0009A

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months, whichever comes first.

Drive belts NOTE (1) MA-13

Air cleaner filter NOTE (2) [R] MA-16

EVAP vapor lines I* MA-19

Fuel lines I* MA-16

Fuel filter NOTE (3) Engine coolant NOTE (4) MA-13

Engine oil R RRRRRRR MA-16

Engine oil filter (Use part No.

15208-31U00 or equivalent.)

Spark plugs (PLATINUM-

TIPPED type)

Intake & exhaust valve clear-

ance*

MAINTENANCE OPERATION MAINTENANCE INTERV AL

Perform at number of miles,

kilometers or months, whichever comes first.

Drive belts NOTE (1) I* MA-13

Air cleaner filter NOTE (2) [R] MA-16

EVAP vapor lines I* MA-19

Fuel lines I* MA-16

Fuel filter NOTE (3) Engine coolant NOTE (4) R* MA-13

Miles x 1,000

(km x 1,000)

Months

NOTE (5) EM-52

Miles x 1,000

(km x 1,000)

Months

3.75

(6)

33.75

7.50

(12)

3

R RRRRRRR MA-17

(54)

27

11.25

(18)

6

Replace every 105,000 miles (169,000 km). MA-18

37.5

(60)

41.25

30

9

(66)

33

15

(24)

12

(72)

45

36

18.75

(30)

15

48.75

(78)

39

22.5

(36)

18

52.5

(84)

42

26.25

(42)

21

56.25

(90)

45

30

(48)

24

(96)

60

48

Reference

Section -

Page or -

Content Title

Reference

Section -

Page or -

Content Title

H

I

J

K

MA

M

Revision; 2004 April 2003 M45

MA-7

PERIODIC MAINTENANCE

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months, whichever comes first.

Engine oil R R R R R R R R MA-16

Engine oil filter (Use part No.

15208-31U00 or equivalent.)

Spark plugs (PLATINUM-

TIPPED type)

Intake & exhaust valve clear-

ance*

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service proce dures, refer to FL section.

(4) After 60,000 miles (96,000 km) or 48 months , repl ace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals w ith “*” are recommended by INFINITI for reliable vehicle oper ation. The owner need not perform

such maintenance in order to maintain the emission w arra nty or manufact urer recal l liability. Other maintenance items and interva ls a re

required.

Miles x 1,000

(km x 1,000)

Months

NOTE (5) EM-52

33.75

(54)

27

37.5

(60)

R RRRRRRR MA-17

41.25

(66)

30

Replace every 105,000 miles (169,000 km). MA-18

33

45

(72)

36

48.75

(78)

39

52.5

(84)

42

56.25

(90)

45

(96)

60

48

Reference

Section Page or -

Content Title

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or rep la ce if nece ssar y.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of

miles, kilometers or

months, whichever comes

first.

Brake lines & cables

Miles x 1,000

(km x 1,000)

Months

3.75

(6)

3

7.50

(12)

6

11.25

(18)

9

15

18.75

(24)

12

(30)

IIMA-26

22.5

(36)

15

18

26.25

(42)

21

30

(48)

24

Reference

Section -

Page or -

Content Title

Brake pads & rotors

Automatic transmission

fluid & differential gear oil NOTE (1) I I

Steering gear & linkage,

axle & suspension parts I I I I

Tire rotation NOTE (2)

Exhaust system

In-cabin microfilt e r R R ATC-121

Climate controlled seat fil-

ter

ASCD vacuum hoses I I ACS-27

IIIIMA-26

MA-20

MA-22

MA-27

MA-28

MA-5

MA-25

IIIIMA-20

R SE-132

,

,

,

Revision; 2004 April 2003 M45

MA-8

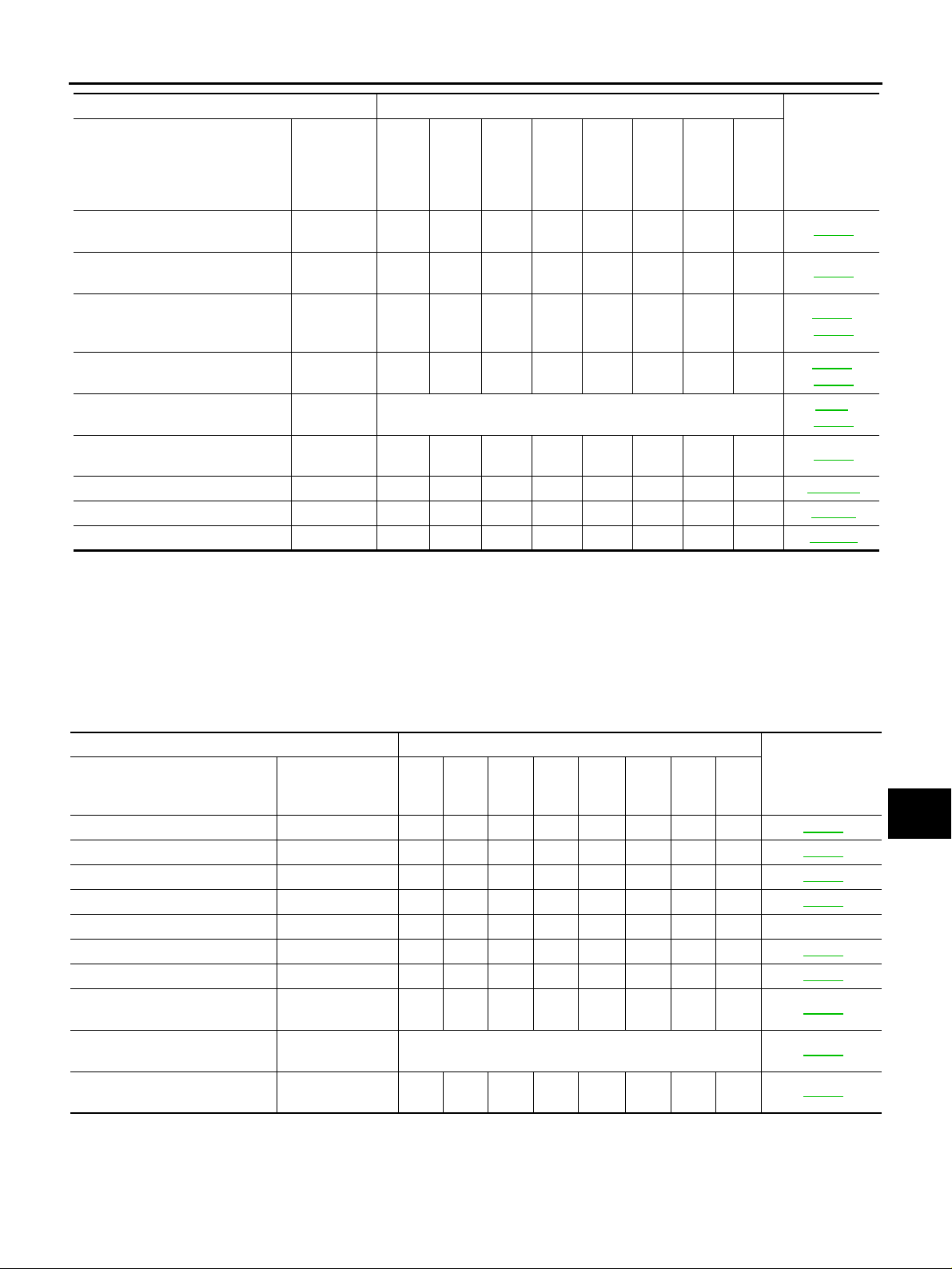

PERIODIC MAINTENANCE

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Miles x

Perform at number of miles, kilometers or months, whichever

comes first.

Brake lines & cables

Brake pads & rotors

Automatic transmission fluid & differential gear oil N O TE (1 ) I I

Steering gear & linkage, axle &

suspension parts

Tire rotation NOTE (2)

Exhaust system

In-cabin microfilter R R ATC-121

Climate controlled seat filter R SE-132

ASCD vacuum hoses I I ACS-27

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every

30,000 miles (48,000 km) or 24 months. Using automatic transmission fluid other than Genuine Nissan ATF Matic Fluid J will

cause deterioration in driveability and automatic transmission durabi l ity, and may damage the automatic transmission,

which is not covered by the INFINITI new vehicle limited warranty.

(2) Refer to “Tire rotation” under the “General maintenance” heading earlie r in this secti on.

1,000

(km x

1,000)

Months

33.75

(54)

27

37.5

41.25

(60)

(66)

30

33

IIIIMA-26

IIII

IIIIMA-20

45

48.75

(72)

(78)

36

IIMA-26

39

52.5

(84)

42

56.25

(90)

45

60

(96)

48

Reference

Section Page or -

Content Title

,

MA-21

MA-22

MA-27,

MA-28

MA-5

,

MA-25

A

B

C

D

E

F

G

H

I

Schedule2 ALS0009B

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months, whichever

comes first.

Drive belts NOTE (1) I* MA-13

Air cleaner filter [R] [R] MA-16

EVAP vapor lines I* I* MA-19

Fuel lines I* I* MA-16

Fuel filter NOTE (2) Engine coolant NOTE (3) R* MA-13

Engine oil RRRRRRRR MA-16

Engine oil filter (Use part No.

15208-31U00 or equivalent.)

Spark plugs (PLATINUM-

TIPPED type)

Intake & exhaust valve clear-

ance*

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading reaches the maximum lim it.

(2) Maintenance-free item. For service procedures, refer to FL section.

(3) After 60,000 miles (96,000 km) or 48 months, replac e ever y 30, 000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clea ran ce.

Miles x 1,000

(km x 1,000)

Months

NOTE (4) EM-52

7.5

15

22.5

(12)

(24)

(36)

6

12

RRRRRRRR MA-17

Replace every 105,000 miles (169,000 km). MA-18

18

30

(48)

24

37.5

(60)

30

45

(72)

36

52.5

(84)

42

60

(96)

48

Reference Sec-

tion - Page or -

Content Title

J

K

MA

M

Revision; 2004 April 2003 M45

MA-9

Loading...

Loading...