Indesit KD3G11S-G User Manual

Operating Instructions

50cm Free Standing Electric Cooker

GB

English,1

KD3G11/G

KD3G11S/G

Contents

GB

Introduction, 2

Installation, 3-6

Gas connection

Electrial connection

Adapting the cooker to different types of gas

Burner and Nozzle Specifications

Safety Information, 7

Features,8

Control Panel, 9

Use of hotplates, 10

Grilling, 11

Grill Chart, 12

Conventional Oven, 13

Conventional Oven

Cooking Chart MEAT, 14

Conventional Oven

Cooking Chart BAKING,15

Using the Main Oven for Other Functions, 16

Care and Cleaning, 17

Cooking Results Not Satisfactory?, 18

Something Wrong With Your Cooker?, 19

If it Still Wont Work..., 20

Technical Characteristics, 21

Key Contacts, 24

You must read these instructions prior to using your

appliance and retain them for future use.

Introduction

GB

Your new appliance is guaranteed* and will give

lasting service. This guarantee is only applicable if

the appliance has been installed in accordance with

the installation instructions detailed in this booklet.

To help make best use of your cooking equipment,

please read this booklet carefully.

The cooker is designed specifically for domestic use

and responsibility will not be accepted for use in any

other installation.

! When the cooker is first used an odour may be

emitted, this will cease after a period of use.

When first using the cooker ensure that the room is

well ventilated (e.g. open a window or use an

extractor fan) and that persons who may be

sensitive to the odour avoid any fumes. It is

suggested that any pets be removed from the room

until the smell has ceased. This odour is due to

temporary finish on oven liners and elements and

also any moisture absorbed by the insulation.

* The guarantee is subject to the provisions that

the appliance:

a. Has been used solely in accordance with the

Users Instruction Book.

b. Has been properly connected to a suitable supply

voltage as stated on the rating plate attached to

this equipment.

c. Has not been subjected to misuse or accident or

been modified or repaired by any person other

than the authorised employee or agent.

d. Has been correctly installed.

1. This appliance is intended for nonprofessional use

within the home.

2. These instructions are only for those countries

whose symbols appear in the booklet and on the

serial no. plate of the appliance.

3. This owners manual is for a class 1 appliance

(insulated) or class 2, subclass 1 appliances

(installed between two cabinets.

2

Installation

The appliance must$only be installed by a

competent person. In the UK, CORGI registered

installers undertake to work to safe and

satisfactory standards.

Before moving your cooker check that it is cool, and

switch off at the cooker control unit. Movement of

your cooker is most easily achieved by lifting the

front as follows:

Open the grill door sufficiently to allow a comfortable

grip on the underside front edge of the oven roof,

avoiding any grill elements.

Moving the Cooker

! Take care in moving the

cooker as it is heavy. Take

care to ensure that any floor

covering is not damaged. (see

figure)

Splashplate optional, apply to

Parts Department (see Back

Cover for contact number.)

The following instructions should be read by a

qualified technician to ensure that the appliance is

installed, regulated and technically serviced

correctly in compliance with current regulations.

! remember to unplug the appliance from the

mains before regulating the appliance or carrying

out any maintenance work.

! This appliance must not be fitted on a platform.

The cooker is designed to fit between kitchen

cabinets spaced 500mm apart. The space either

side need only be sufficient to allow withdrawal of

the cooker for servicing. It can be used with

cabinets one side or both as well as in a corner

setting. It can also be used free-standing.

Adjacent side walls which project above hob level,

must not be nearer to the cooker than 150mm or

65mm (Fig. A) and should be protected by heat

resistant material. Any overhanging surface or

cooker hood should not be nearer than 750mm.

(Fig.A)

a.The cooker may be located in a kitchen, a kitonen/

diner or bed sitting room, but not in a bathroom or

shower room.

b.The hoods must be installed according to the

requirements in the hood handbook.

c.The wall in contact with the back of the cooker

must be of flameproof material.

d.The cooker is fitted with a safety chain that must

be attached to a hook, secured to the wall behind

the appliance.

! some models can have their gas connection

inverted. It is important to make sure the safety

chain is always situated on the side which

corresponds to the hose holder (Fig. B).

GB

Positioning

! this unit may be installed and used only in

permanently ventilated rooms according to the

British Standards Codes Of Practice: B.S. 6172/B.S.

5440, Par. 2 and B.S. 6891 Current Editions. The

following requirements must be observed:

a. The cooker should not be installed in a bed sitting

room with a volume of less than 20m

installed in a room of volume less than 5m

vent of effective area of 110cm

installed in a room of volume between 5m

3

a supplementary airvent area of 50cm2 is

10m

required, if the volume exceeds 11m

3

. If it is

3

2

is required, if it is

an air

3

and

3

no airvent is

required. However, if the room has a door or a

window which opens directly to the outside no air

vent is required even when the volume is between

3

5m

and 11m3.

b. During prolonged use of the appliance you may

consider it necessary to open a window to the

outside to improve ventilation.

c. If there are other fuel burning appliances in the

same room, B.S.5440 Part 2 Current Edition,

should, be consulted to determine the requisite air

vent feet in the plinth (900mm - 915mm). Adjust

the feet by tilting the cooker from the side. Then

install the product into position.

Tall cupboard on the right hand

side of 50cm gas cooker

65 mm min

750 mm min

500 mm min

150 mm min

Fig. A

Fig. B

Tall cupboard on the left hand

side of 50cm gas cooker

65 mm min

65 mm min

750 mm min

500 mm min

400 mm min400 mm min

3

GB

Gas connection

The cooker should be connected to the gas-supply

by a corgi registered installer. During installation of

this product it is essential to fit an approved gas tap

to isolate the supply from the appliance for the

convenience of any subsequent removal or

servicing. Connection of the appliance to the gas

mains or liquid gas must be carried out according to

the prescribed regulation in force, and only after it is

ascertained that it is adaptable to the type of gas to

be used. If not, follow the instructions indicated in

the paragraph headed Adaptation to different gas

types. On some models the gas supply can be

connected on the left or on the right, as necessary;

to change the connection, reverse the position of the

hose holder with that of the cap and replace the

gasket (supplied with the appliance). In the case of

connection to liquid gas, by tank, use pressure

regulators that conform to the regulation in force. The

gas supply must be connected to the left of the

appliance. Be sure that the hose does not pass

through the rear of the cooker touching hot parts.

! make sure the supply pressure conforms with

the values shown in the table entitled

Caracteristics of the burners and nozzles.

When the cooker is installed between cabinets

(recessed), the gas connection must be effected

by an approved flexible hose with bayonet fitting

(BS669CurrentEdition). The gas inlet for the

cookers is a threaded G 1/2 gas female fitting.

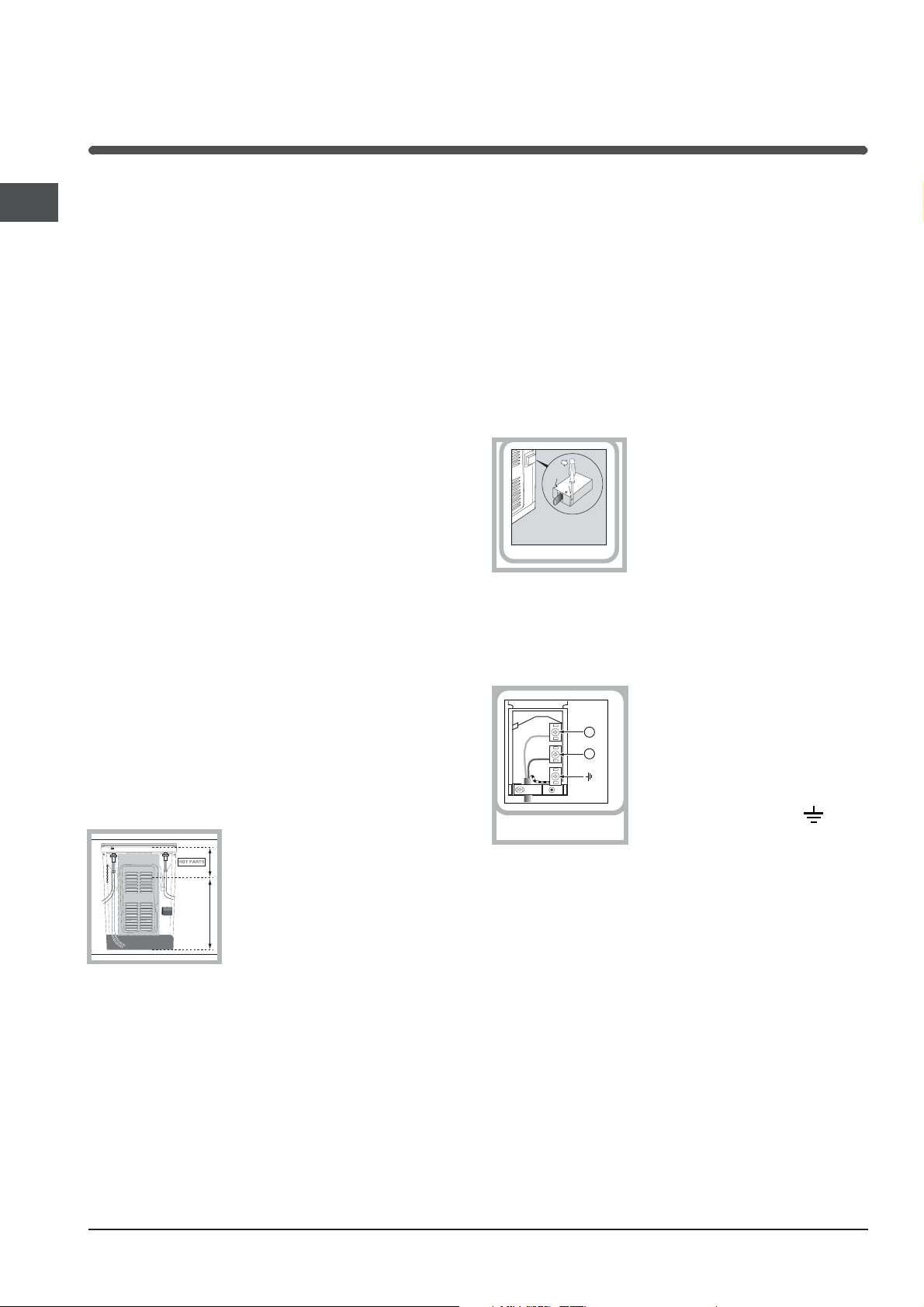

Connecting the gas supply

To make the connection, a

HOT PARTS

the hose must never be longer than 1,5 metre;

the hose must not be subject to any tension or

torsional stress and it must not have any

excessively narrow curves or bottlenecks;

the hose must be easy to inspect along its entire

length to check its condition;

the hose must always be in good condition, never

attempt to repair.

! the installation must comply with gas safety

(installation and use) regulations 1984. In all cases

for the above, by low, a qualified, corgi approved

engineer must be called for installation.

flexible hose should be used

corresponding to the current

gas regulations which are:

the hose must never be at

600 mm

any point in its lenght in

contact with the hot parts of

the cooker;

Electrial connection

Electric cookers come without a power supply cable.

The cooker is designed to operate on an electricity

supply which conforms to the electrical data shown

on the Rating Plate. The cooker can be connected to

the mains only after removing the back panel of the

cooker itself with a screwdriver.

! the following installation procedure must be carried

out by a qualified electrician. The electrical

installation must comply with the IEE Regulations,

Building & local By-Lays.

For the installation of the feeding cable carry out the

following operations:

Using a screwdriver, prise

on the side tabs of the

terminal board cover (see fig.

A);

Pull and open the junction

Fig. A

! The wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow Earth

Blue Neutral

Brown Live

L

2

N

4

Fig. B

Brown wire to terminal marked L or coloured Red.

Blue wire to terminal marked N or coloured Black

(see fig. B).

fix the feeding cable in the special cable stop and

close the cover.

! The power supply cable must have these minimum

requirements:

Type: H05RR-F

Section: 3x1.5 mm

Ensure that the mains cable is routed away from any

brackets affixed to the rear panel and is not trapped

to the rear wall when pushing the cooker into

position between cabinets.

blok lid

As the colours of the wires in

the mains lead may not

correspond with the coloured

markings identifying the

terminals in your plug,

proceed as follows:

Green & Yellow wire to

terminal marked E or

coloured Green or Green &

Yellow.

2

or

4

Disposing of the appliance

When disposing of the appliance please remove the

plug by cutting the mains cable as close as

possible to the plug body and dispose of it as

described above.

Adapting the cooker to different types of

gas

In order to adapt the cooker to a different type of

gas with respect to the gas for which it was

produced (indicated on the label attached to the lid),

follow these steps:

a)replace the hose holder mounted on the appliance

with that supplied in the bag of cooker

accessories.

b)Replacing the burner nozzles on the hob:

remove the grids and slide the burners from their

housings;

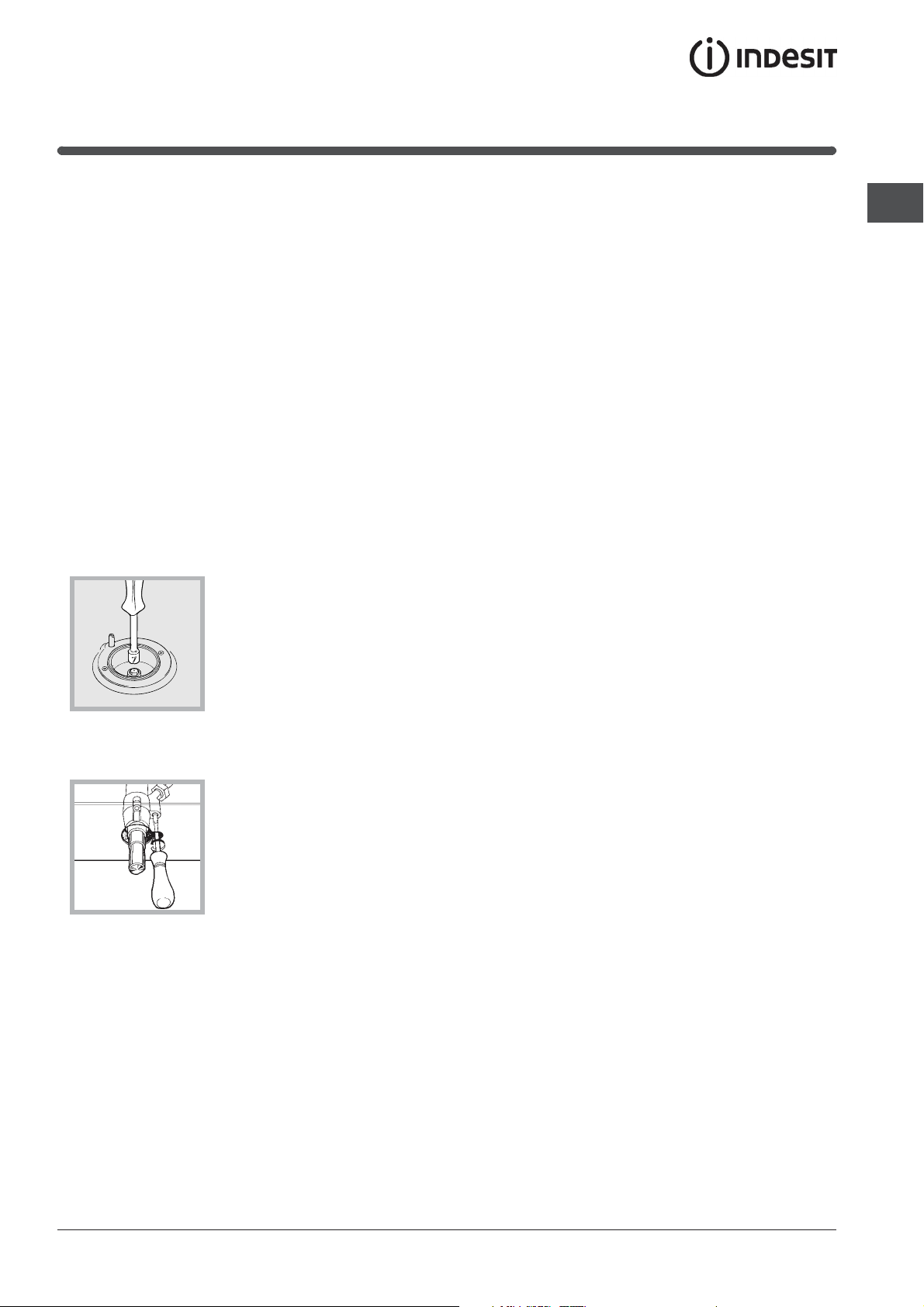

unscrew the nozzles using

a 7 mm socket spanner, and

replace them with nozzles for

the new type of gas (see table

1 Burner and nozzle

characteristics).

replace all the components

by repeating the steps in

reverse order.

Important

On completion of the operation, replace the old

rating sticker with one indicating the new type of gas

used. This sticker is available from our Service

Centres.

Note

Should the pressure of the gas used be different (or

vary) from the recommended pressure, it is

necessary to fit a suitable pressure regulator onto

the inlet pipe in compliance with current National

Regulations relative to regulators for channelled

gas.

GB

c)Minimum regulation of the hob burners:

turn the tap to minimum;

remove the knob and

adjust the regulation screw,

which is positioned in or next

to the tap pin, until the flame

is small but steady.

! in the case of liquid gas, the

regulation screw must be

screwed in to the bottom.

check that the flame does not turn off when you

turn the tap quickly from high to low.

d)Regulating the primary air of the burners:

The primary air of the burners requires no regulation.

5

GB

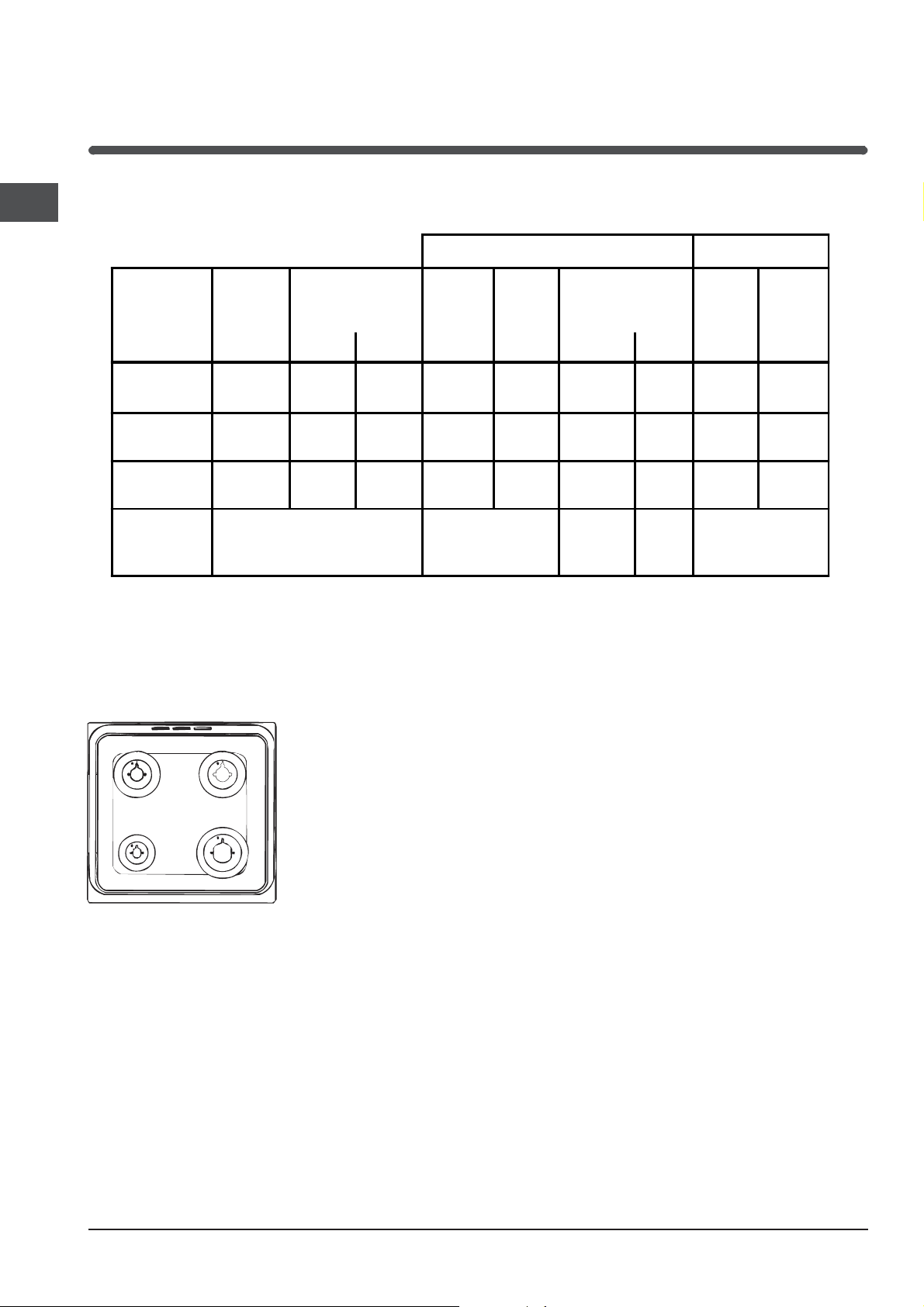

Burner and Nozzle Specifications

Table 1 Liquid Gas Natural Gas

Burner Diameter

(mm)

Thermal Power

kW (p.c.s.*)

Nominal Reduced (mm) (mm) *** ** (mm)

Fast

(Large)(R)

Semi Fast

(Medium)(S)

Auxiliar y

(Small)(A)

Supply

Pressures

* At 15°C and 1013 mbar- dry gas

** Propane P.C.S. = 50,37 MJ/Kg

*** Butane P.C.S. = 49,47 MJ/Kg

Natural P.C.S. = 37,78 MJ/m

100 3.00 0.7 41 87 218 214 128 286

75 1.90 0.4 30 70 138 136 104 181

51 1.00 0.4 30 52 73 71 76 95

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

By-Pass

1/100

3

Nozzle

1/100

28-30

20

35

Flow*

g/h

37

25

45

Nozzle

1/100

Flow*

l/h

20

17

25

A

KD3G11/G

KD3G11S/G

S

S

R

6

Safety Information

When used properly your appliance is completely

safe but as with any electrical product there are

certain precautions that must be observed.

PLEASE READ THE PRECAUTIONS BELOW

BEFORE USING YOUR APPLIANCE.

Always

Remove all packing from inside the oven and grill

compartments before switching on for the first time.

Understand the controls prior to using the appliance.

Keep children away from the appliance when grilling

as the surfaces will get extremely hot during and

after use.

Turn controls off when you have finished cooking

and when not in use.

Stand back when opening an oven door to allow any

build up of steam or heat to disperse.

Use dry good quality oven gloves when removing

items from the oven/grill.

Place pans centrally over the hotplate making sure

handles are kept away from the edge of the hob and

cannot become heated by other hotplate/pans.

Take care to avoid heat/steam burns when operating

the controls.

Turn off the electricity supply at the wall switch

before cleaning and allow the appliance to cool.

Make sure the shelves are in the correct position

before switching on the oven.

Keep the oven and grill doors closed when the

appliance is not in use.

Take care when removing items from the grill when

the lower oven is on as the contents will be hot.

Keep the appliance clean, as a build up of

grease or fat from cooking can cause a fire.

Follow the basic principles of food handling and

hygiene to prevent the possibility of bacterial

growth.

Keep ventilation slots clear of obstructions.

Refer servicing to a qualified appliance service

engineer.

Take care to avoid touching heating elements inside

the oven, as during use the oven becomes hot.

Never

Never line the interior of the oven with foil as this

may cause the appliance to overheat.

Never leave children unsupervised where a cooking

appliance is installed as all surfaces will be hot

during and after its use.

Do not allow children or persons who are not familiar

with the appliance to use it, without supervision.

Never allow anyone to sit or stand on any part of the

appliance.

Never store items above the appliance that children

may attempt to reach.

Never leave anything on the hob surface when

unattended and not in use.

Never remove the oven shelves whilst the oven is

hot.

Never heat up unopened food containers as

pressure can build up causing the container to

burst.

Never store chemicals/food stuffs, pressurised

container in or on the appliance, or in cabinets

immediately above or next to the appliance.

Never place flammable or plastic items on or near

the hob.

Never fill a deep fat frying pan more than 1/3 full of

oil, or use a lid. DO NOT LEAVE UNATTENDED

WHILE COOKING.

Never operate the grill with the grill door closed as

this will cause the appliance to overheat.

Never use the appliance as a room heater.

Never use the grill to warm plates.

Never dry any items on either the hob or oven doors.

Never install the appliance next to curtains or other

soft furnishings.

Never use steam cleaners.

The appliance should not be operated by people

(including children) with reduced physical, sensory

or mental capacities, by inexperienced individuals

or by anyone who is not familiar with the product.

These individuals should, at the very least, be

supervised by someone who assumes responsibility

for their safety or receive preliminary instructions

relating to the operation of the appliance.

Do not let children play with the appliance.

SAFETY ADVICE IN CASE OF A CHIP-PAN FIRE

In the event of a chip pan fire or any other pan fire.

1. TURN OFF THE COOKER APPLIANCE AT THE

WALL SWITCH.

2. COVER THE PAN WITH A FIRE BLANKET OR

DAMP CLOTH, this will smother the flames and

extinguish the fire.

3. LEAVE THE PAN TO COOL FOR AT LEAST 60

MINUTES BEFORE MOVING IT. Injuries are often

caused by picking up a hot pan and rushing outside

with it.

NEVER USE A FIRE EXTINGUISHER TO PUT OUT

A PAN FIRE as the force

of the extinguisher is likely to tip the pan over.

Never use water to extinguish oil or fat fires.

GB

7

GB

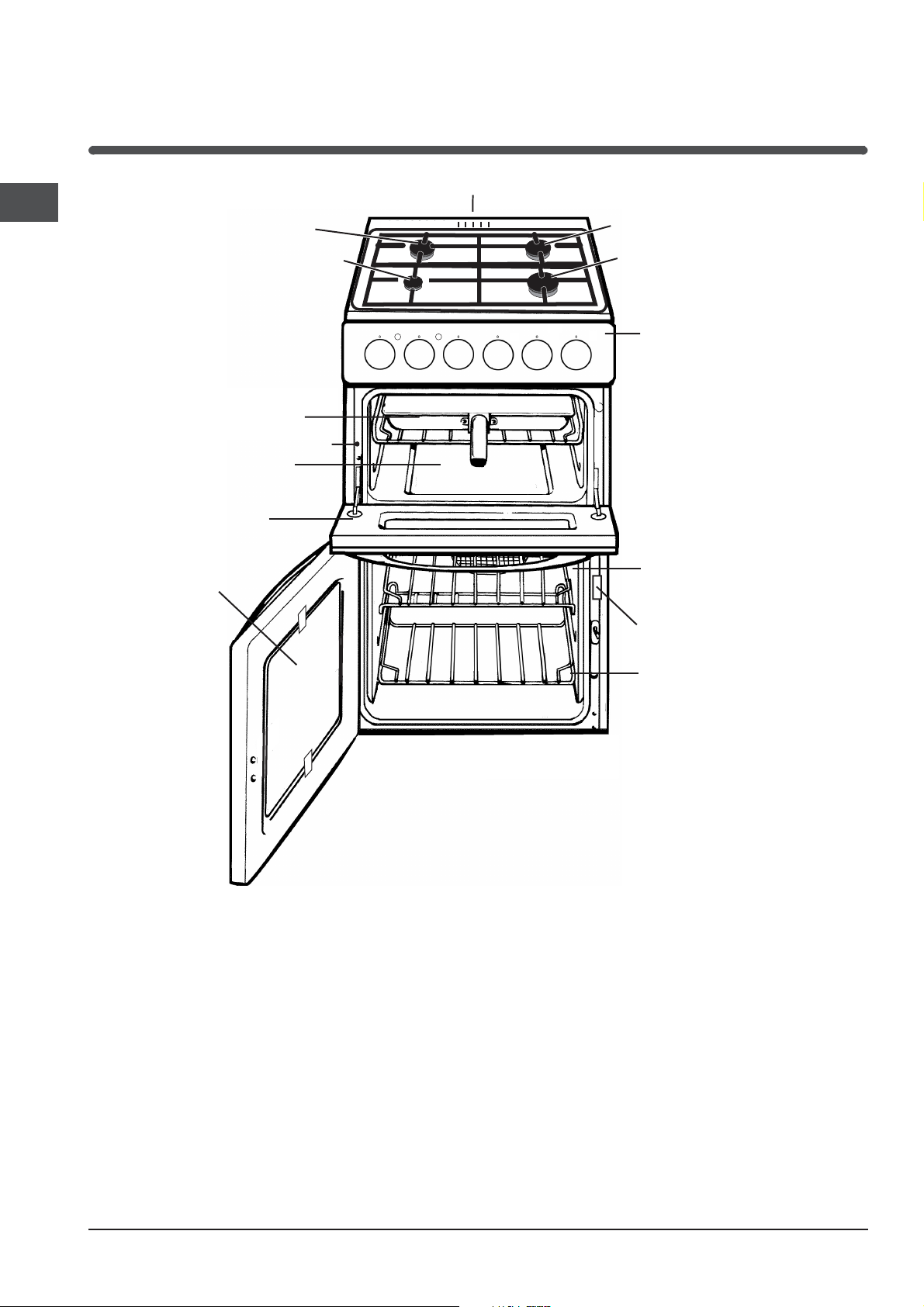

Features

1900W

HOB VENTILATION SLOTS

1900W

GRILL/MEAT PAN

WITH REMOVABLE

HANDLE AND WIRE

FOOD SUPPORT

GRILL DOOR SWITCH

GRILL DOOR

REMOVABLE

INNER GLASS

DOOR

GRILL

1000W

3000W

CONTROL

PANEL

MAIN OVEN

WIREWORK

SHELF

SUPPORTS

MODEL & SERIAL

NUMBER

OVEN ROD

SHELVES

8

Loading...

Loading...