Page 1

IKA® LR 1000 basic

IKA® LR 1000 control

LR 1000 basic/control_012015

20000005830

Operating instructions EN

Page 2

2

Contents

EN

EC

Declaration of Conformity

Explication of warning symbols

Source language: German

We declare under our sole responsibility that this product corresponds to the regulations 2006/42/EC and 2004/108/EC and

conforms with the standards or standardized documents: EN 61010-1, -2-010, -2-051; EN ISO 12100-1, -2; EN 60204-1

and EN 61326-1.

Page

EC Declaration of Conformity 2

Explication of warning symbols 2

Safety instructions 3

Correct use 4

Unpacking 5

System configuration 5

Setting up 7

Safety temperature limit 8

Operator panel and display 9

Commissioning 11

Interface and output 17

Maintenance and cleaning 20

Error codes 22

Warranty 23

Accessories 23

Materials in contact with medium 23

Technical data

24

DANGER

CAUTION

WARNING

NOTICE

indicates an imminently hazardous situation, which, if not avoided, will result in death, serious

injury.

indicates a potentially hazardous situation, which, if not avoided, can result in death, serious

injury.

indicates a potentially hazardous situation, which, if not avoided, can result in injury.

indicates practices which, if not avoided, can result in equipment damage.

Page 3

3

• Socket must be earthed (protective ground contact).

• The voltage stated on the type plate must correspond to

the mains voltage.

Beware of hazards due to:

- flammable materials

-

combustible media with a low boiling temperature

- glass vessel breakage

- overfilling of media

- unsafe condition of container.

• The device will automatically restart in mode B and C fol-

lowing any interruption to the power supply

• The equipment is not designed for overpressure use.

• The equipment is designed for operation at vacuum set-

tings up to 25 mbar.

• Certain applications and materials may be hazardous. You

should take precautions to prevent contact with, or inhalation of, toxic liquids, gases, fumes, vapours or powders.

• Risks may also be posed by biological or microbiological

substances.

The reactor system must always

be ventilated when working under

normal pressure in order to prevent

any pressure build-up caused by highly volatile gases or

unpredictable reaction pressure gradients. Condense volatile gases using a cooler with a standard ground connec-

tor (e.g. a reux condenser) on the reactor cover.

• Observe the maximum permissible temperatures (see sec-

tion “Technical data“) in the reactor vessel.

Before you fill the reactor vessel,

ensure that the reagents used do

not corrode the seal.

• Ensure that the external temperature sensor is inserted in

the media to a depth of at least 20 mm.

• Only use IKA® approved accessories!

• Use only original IKA® spare parts!

•

When the reactor vessel or the vessel cover is removed

during operation, the stirring and the heating function

will be switched off automatically. Restart the stirring and

heating function by pressing on knob (A) and (B)

after the

reactor vessel or vessel cover is placed and locked again

(see Fig. 11 and Fig. 12).

Safety instructions

General instructions:

•

Read the operating instructions fully before starting

up and follow the safety instructions.

• Keep the operating instructions in a place where they can

be accessed by everyone.

• Ensure that only trained staff work with the equipment.

• Follow the safety instructions, guidelines, occupational

health and safety and accident prevention regulations.

• Uncontrolled reactions can be triggered by mixing the

heated material insuciently or by the energy generated

by selecting a speed that is too high. In case of these and

other increased operational hazards, users must take additional appropriate safety precautions. In any case, when

using critical or hazardous materials in your processes,

IKA® recommends to use additional appropriate mea-

sures to ensure safety in the experiment. For example, users can implement measures that inhibit fire or explosions

or comprehensive monitoring equipment. Furthermore,

users must make sure that the unit switch of the IKA®

product can be accessed immediately, directly and without risk at any time.

If installation or positioning cannot ensure this access at all times,

an additional EMERGENCY STOP

switch that can be easily accessed must be installed in

the work area.

• Only process media that will not react dangerously to the

extra energy produced through processing. This also applies to any extra energy produced in other ways, e.g.

through light irradiation.

• Do not operate the instrument in explosive atmospheres,

with hazardous substances or under water.

• Process pathogenic materials only under a suitable fume

hood. Please contact IKA® application support if you

have any question.

• Set up the device in a spacious area on an even, stable,

clean, non-slip, dry and fireproof surface.

• Protect the instrument and accessories from bumping and

impacting.

•

Check the instrument and accessories beforehand for dam-

age each time when you use them. Do not use damaged

components.

• Safe operation is only guaranteed with the accessories described in the ”Accessories” section.

• Always switch the device switch in the OFF position or

disconnect the power before changing and fitting any accessories.

• The instrument can only be disconnected from the mains

supply by pulling out the mains plug or the connector

plug.

• The socket for the mains cord must be easily accessible.

DANGER

WARNING

NOTICE

WARNING

Page 4

4

Cooling:

• Ensure that the thermostat used for tempering is fully efficient. A defective thermostat can cause uncontrolled

reactions.

Using the adequate hoses for cooling

purposes.

Weighing:

Weighing function integrated into

the LR 1000 control feet. Unpack

and set up cautiously.

Maintenance:

• The feet of the equipment must be clean and undamaged.

• The device must only be opened by trained specialists,

even during repair. The device must be unplugged from

the power supply before opening. Live parts inside the instrument may still be live for some time after unplugging

from the power supply.

Covering or parts that are capable of

being removed from the unit with-

out accessory equipment have to be

reattached to the unit for safe operation in order to prevent, for example, the ingress of fluids, foreign matter, etc..

Stirring and dispersing:

• Moving and rotating equipment parts also constitute a

hazard.

Rotating tools are dangerous! The

anchor stirrer and the dispersing el-

ement must only be operated when

the reactor vessel is fully closed. Do not start up the laboratory reactor when it is open.

• If the dispersing element rotate when they are covered in

a product and the reactor is open, this will cause parts or

liquids to be projected outwards.

• Gradually increase the speed.

• The equipment may heat up by stirring.

Heating:

Risk of burns! Exercise caution when

touching the heating block and the

glass vessel. The cover of the vessel could reach high temperature when you boil liquid for

long time. Pay attention to the residual heat after switching off.

Only process and heat up any me-

dia that has a flash point higher

than the adjusted safe temperature

limit that has been set (see section “Technical data“).

The safe temperature limit must always be set to at least

25 °C lower than the fire point of the media used.

• Use:

The IKA® LR 1000 system is a compact reactor system.

It has been designed to simulate and optimize chemical

reaction processes and can also be used for mixing, dispersion and homogenization in modeling processes.

Operating mode: Tabletop device.

• Range of use (indoor use only):

- Laboratories - Schools

- Pharmacies - Universities

Correct use

This equipment is suitable for use in all areas except:

- Residential areas

-

Areas that are connected directly to a low-voltage supply

network that also supplies residential areas.

The safety of the user cannot be guaranteed:

- if the instrument is operated with accessories that are not

supplied or recommended by the manufacturer

- if the instrument is operated improperly or contrary to the

manufacturer’s specifications

- if the instrument or the printed circuit board are modified

by third parties.

DANGER

CAUTION

NOTICE

NOTICE

DANGER

CAUTION

Page 5

5

• Unpacking:

- Please unpack the device carefully

- In the case of any damage a detailed report must be

sent immediately (post, rail or forwarder).

• Delivery scope:

LR 1000 basic:

- LR 1000 basic base

- Reactor vessel LR 1000.1 (see Fig. 4)

- Temperature sensor

- Receptacle for temperature sensor

- Support rod

- 2 pieces hose connectors

- Mains cable

- Tool kit (see Fig. 1)

- Operating Instructions

- Warranty card.

Unpacking

Fig. 1

System configuration

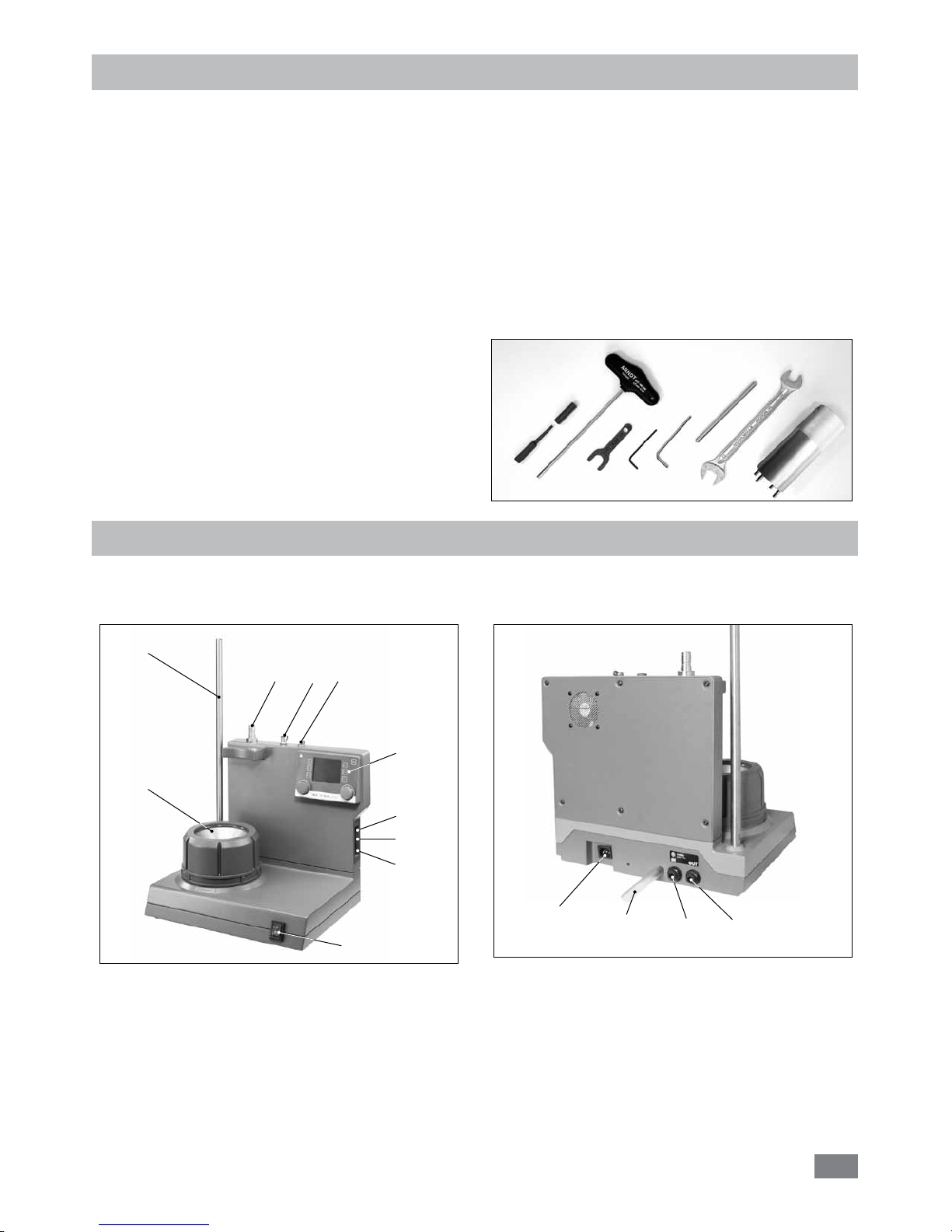

IKA® LR 1000 basic/control laboratory reactor comprises:

• LR 1000 basic/control base:

1: Mains switch

2: Control elements and display

3: Heating block (with integrated cooling coils for

connecting external cooling systems)

4: Support rod, for securing accessories

5: Temperature sensor socket

6*: pH-probe socket (for LR 1000 control only)

7: Reception for disperser (Park station)

Fig. 2

4

1

3

2

57

8

9

10

Fig. 3

11

12

13

14

6*

8: Adjustable safety circuit

9: USB port

10: RS 232 port

11: Power socket

12: Condensate drain*

13: Cooling connection IN*

14: Cooling connection OUT*

*

Note: Cooling connections can be used only for cooling purpose.

LR 1000 control:

- LR 1000 control base

- Reactor vessel LR 1000.3 (see Fig. 5)

- Temperature sensor

- Receptacle for temperature sensor

- Support rod

- 2 pieces hose connectors

- USB cable

- Mains cable

- Tool kit (see Fig. 1)

- Operating Instructions

- Warranty card.

Page 6

6

• Reactor vessel (LR 1000.1):

15: Glass vessel (Borosilicate glass 3.3)

16: Handle

17: Cover latch

18: Vessel locker

19: Anchor stirrer

21: NS 29/32 (1x)

22: NS 14/23 (3x)

24: Safety clips NS 29/32 (1x)

25: Stopper NS 29/32 (1x)

26: Safety clips NS 14/23 (3x)

27: Stopper NS 14/23 (2x)

28: Vacuum cock NS 14/23 (1x)

Fig. 4

21

22

24

25

26

27

28

Reactor vessel (LR 1000.3):

20

21

22

15: Glass vessel (Borosilicate glass 3.3)

16: Handle

17: Cover latch

18: Vessel locker

20: Anchor stirrer with scraper (PEEK)

21: NS 29/32 (2x)

22: NS 14/23 (2x)

23: Neck with GL 14 thread (2x)

24: Safety clips NS 29/32 (2x)

25: Stopper NS 29/32 (2x)

26: Safety clips NS 14/23 (2x)

27: Stopper NS 14/23 (1x)

28: Vacuum cock NS 14/23 (1x)

29: Screw cap GL 14 (2x)

30: Hose connector and nut GL 14 (2x)

Fig. 5

24

25

26

27

28

18

16

23

15

17

16

18

17

19

15

29

30

Page 7

7

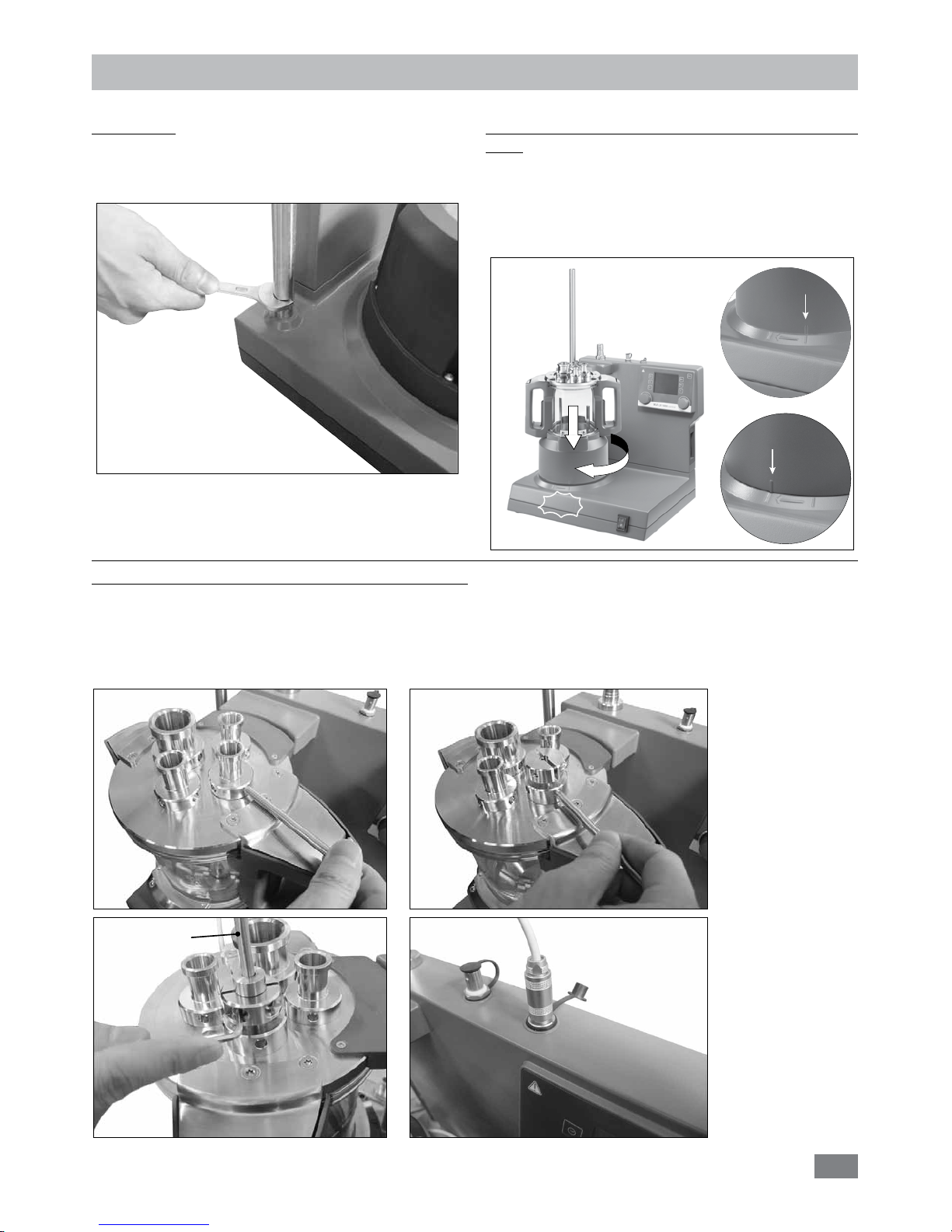

Attach the reactor vessel to the LR 1000 basic/control

base:

Ensure the LR 1000 basic/control is set up on an even,

stable, clean and non-slip working table.

Set the reactor vessel to the LR 1000 basic/control base

carefully and ensure it is properly attached as indicated in

following image.

Setting up

CLICK

Unlock

Lock

Fig. 7

Support rod:

Screw the support rod onto the LR 1000 basic/control

base with the double open end wrench included with the

device until the end stop is reached.

Fig. 6

Installation and connection Pt 100 temperature sensor:

Remove a standard connection NS 14/23 from the reactor cover for connection the temperature probe.

Screw the LR 1000.61 sensor receptacle with sealing in the reactor cover.

Plug in the probe and pay attention to the minimum immersion depth and freewheeling of the anchor mixer. Fix the position

in the housing with the two screws for sliding stop.

Connect the temperature probe with the appropriate socket.

Fig. 8

Pt 100

Page 8

8

Connect external cooler:

The reactor can connect an external cooler (e.g. IKA®

RC 2 basic or RC 2 control)

via the connections (13,

14, see Fig. 3) at the back of the device. The cooling con-

nections IN and OUT is labelled accordingly at the back of

the device. There are two connectors included for connecting cooling hoses. They can be connected to a hose with a

10 mm inner diameter. By positioning and light pressure in

the direction of the connector, the connector is locked/connected to the cooling connections IN/OUT on the housing.

The connectors are unlocked by coaxially positioning the

unlocking lever and pressing slightly.

Fig. 9

Safety temperature limit

Fig. 10

Potentiometer

The maximum attainable heating temperature is restricted

by an adjustable safety circuit. Once the safety temperature

has been attained, the instrument switches off the heating

function.

The safety temperature must always

be set to at least 25 ºC lower than

the flash point of the fluid used.

Factory setting: max. value

Setting the safety temperature limit

After switching on the instrument, the safety temperature

can be adjusted with screwdriver delivered with the device.

The safety temperature setting will appear on the display.

Do not turn the potentiometer beyond the clockwise or anti-clockwise

stop, since this will damage the po-

tentiometer irreparably.

WARNING

NOTICE

Page 9

9

A

B

F

O

L

C

Fig. 11

D

E

G H I

J

K

M

N

P

R

Operator panel and display

•

LR 1000 basic:

Item Designation Function

A Rotating/pressing knob: Start/stop the stirring function

Change the settings of stirring speed

B Rotating/pressing knob: Start/stop the heating function

Change the settings of the temperature

C

Counter/Timer (C/T) button:

Switch between “Counter“ and “Timer“ function

D Timer (+): Increase the “Timer“ value

E Timer (-): Decrease the “Timer“ value

F Key button: Lock/unlock knobs and keys

G Display, temperature: Display the set and actual temperature

H Display, counter/timer: Display the counter and timer values

I Display, stirring speed Display the set and actual stirrer speed

J LED, timer The LED indicates the “Timer“ function is activated

K LED, counter The LED indicates the “Counter“ function is activated

L LED, hh:mm The LED indicates the “Timer“ or “Counter“ is working with unit hh:mm

M LED, mm:ss The LED indicates the “Timer“ or “Counter“ is working with unit mm:ss

N LED, key button Indicates that the function of key and knobs is deactivated

O LED, heating The LED indicates the heating function is activated

P LED, temperature sensor The LED indicates the external temperature sensor is connected

R LED, Set The LED lights simultaneously with the display of the set value for heating function.

Page 10

10

Item Designation Function

A Rotating/pressing knob: Start/stop the stirring function

Change the settings of stirring speed in working screen

Navigation, selecting and changing the settings in the menu

B Rotating/pressing knob: Start/stop the heating function

Change the settings of the temperature in working screen

F Key button: Lock/unlock knobs and keys

S “Menu” button: Press it once: main menu is displayed

Press it a second time: back to the working screen

T “Back” button: Return to the previous menu level

U Timer button: Enable timer display

V Weighing button: Enable weight display

W Display: Display and setting information

X F1 button: not currently assigned

Y F2 button: not currently assigned

A

B

S

T

F

U

V

X

Y

Fig. 12

•

LR 1000 control:

W

Page 11

11

Check whether the voltage specified on the type plate

(LR 1000 basic/control base) matches the mains voltage

available.

The power socket used must be

earthed (protective earth conductor

contact).

Commissioning

Safety temperature

Default working setting

Standby

•

LR 1000 basic

Switch on the instrument:

After switching on the mains switch on the front of the

device, all LED segments light up during the self-test.

Then the software version, operation mode, safety temperature and working settings will be shown. Then the

device enters standby status and is ready for operation.

Software version

Starting

Operating mode

Operation mode

The instrument can be operated in three different modes

(A, B, C).

Operation mode A:

After power on/power failure no automatic restart of functions.

Operation mode B:

After power on/power failure automatic restart of functions, depending on previous settings.

Operation mode C:

Set values (set in A or B) cannot be changed.

After power on/power failure automatic restart of functions,

depending on previous settings.

Factory setting: mode A

Turn the rotating/pressing knob (A), the speed value can

be adjusted. Press right rotating/pressing knob (A, see

Fig. 11) to activate the stirring function.

Turn the rotating/pressing knob (B), the temperature value can be adjusted. Press left rotating/pressing knob (B,

see Fig. 11) to activate the heating function.

Changing the mode

Switch off the instrument with the mains switch

Press and hold rotating/pressing knob (B)

Switch on the instrument with the mains switch

Release rotating/pressing knob (B)

The operation mode will be change to next operation

mode in the sequence A – B – C – A – B – C – A etc.

Heating function:

The heating function can be started or stopped by pressing

the left rotating/pressing knob (B). Then, the target temperature value and the actual temperature value will ap-

pear on display (G, see Fig. 11) alternately. When the set

temperature value is display, LED (R, see Fig. 11) lights up.

The heating temperature value can be adjusted by turning

the left rotating/pressing knob (B).

The value could be changed in standby or operation process.

Temperature sensor calibration:

Press and hold the Knob B for more than 5 seconds to

enter calibration mode.

“CAL“ will be shown on display (H)

Turn Knob B to adjust the value on display (G) to the

calibration value.

Press Knob A to confirm the value and finish the calibration.

Note: Pressing and holding the knob A for more than 5

second will reset the calibration to factory setting.

If these conditions are met, the device is ready for operating

after plugging in the mains plug.

If these procedures are not followed, safe operation cannot

be guaranteed and/or the equipment may be damaged.

Observe the ambient conditions (temperature, humidity,

etc.) listed under “Technical Data”.

Fig. 13

Page 12

12

Counter and timer function:

Counter function:

When the heating function is started, the counter will start

automatically. The counter is displayed with 4 digits.

When the operating time is less than 1 hour, the counter

work with minute/second (mm:ss) mode and LED (M, see

Fig. 11) lights.

If the operating time exceeds 1 hour, the display switches

from minute/second mode to hour/minute (hh:mm) mode.

LED (L, see Fig. 11) lights indicate the status.

If the operating time exceeds 100 hours, the display switches from hour/minute mode to hour mode .

In hour mode, only whole hours are displayed.

In day mode, only whole days are displayed.

Hour mode

Day mode

Stirring function:

The stirring function can be started or stopped by pressing

the right rotating/pressing knob (A). The speed can be adjusted during operation.

The displayed value will flash until reaching the target speed.

Timer function:

The Time (+) button (D

, see Fig. 11

) or Time (-) button (D

,

see Fig. 11

) is used to adjust the heating time. If the timer

value is more than 1 hour, the display switch to hour/minute

(hh:mm) mode from minute/second (mm:ss) mode. The

LED (L) lights.

The max. value for timer is 99:59 (hh:mm).

Switching between “Counter” and “Timer” function:

The “Counter” function could be switch to “Timer“ function by pressing the Counter/Timer key (C

, see Fig. 11

).

The timer LED (J

, see Fig. 11

) indicates the “Timer“ func-

tion is activated.

Press the Counter/Timer key (C) again, the “Counter“ func-

tion will be activated and counter LED (K, see Fig. 11) lights.

•

LR 1000 control:

Switch on the device:

After switching on the device using the power switch on

the front panel the device name and the software version

are displayed on the screen.

After a few seconds, the working screen is shown on the

screen,

device

is ready for operation.

Lab Reactor

LR 1000 Control

Version X.X.XXX/X.XX

Fig. 14

A

25.0

actual °C

0 10

set °C set rpm

Safe Temp.: 210 °C

0

actual rpm

Fig. 15

Turn the rotating/pressing knob (A), the target speed setting can be adjusted on the working screen. Press rotating/

pressing knob (A, see Fig. 12), the stirrer start to running.

Turn the rotating/pressing knob (B), the temperature setpoint can be adjusted. Press rotating/pressing knob (B, see

Fig. 12) to activate the heating function.

Explanation of symbols on the working screen:

The symbols displayed change depending on the status and

settings of the instrument. The screen below shows the

most significant symbols on the working screen.

PC

A

Safe Temp.: 200 °C Timer: 00:00:00

pH-Value: 0.0 Δ Torque:

0%

100.0

actual °C

100

actual rpm

100.0

set °C

100

set rpm

Fig. 12

Fig. 16

Page 13

13

Key:

This symbol means that the function of the keys and the

rotary knobs for controlling the device are disabled.

The symbol no longer appears if the functions are enabled

once again by pressing the key button a second time.

Temperature Sensor:

This symbol appears when the external temperature sensor

is connected.

A Operating Mode:

This symbol indicates the operating mode currently selected (A,

B, C).

USB:

This symbol means the device is communicating via a USB cable.

Heating:

This symbol indicated the heating function is activated.

indicated active heating process.

Motor activated:

This symbol indicates the rotation status of the stirrer.

PC PC control:

This symbol indicates the device is control via a PC.

Menu navigation and structure:

Menu navigation:

Press the “Menu” key (S).

Select the menu by

turning the rotating/pressing knob (A) to the right or

left to select the desired menu or sub-menu, which can then be selected by

pressing the rotating/pressing knob (A).

Push or Turn the rotating/pressing knob (A) again to select the desired

menu option and edit the values or settings, or activate/deactivate a function.

Turn the rotating/pressing knob (

A

) on “OK“ or Press the "Back" key (T) or

"Menu" button (S) to end the procedure and return to previous menu or

working screen.

Note: The display shows the activated menu option highlighted in yellow color.

Stirring

Torque trend measurement

Intermittent mode

Speed limit

> Stirring

Torque trend measurement

The torque trend measurement

calculates the relative torque

changing inside the medium.

Note: If you press the “Menu“ key (S), the system skips directly back to the working screen.

If you press the “Back“ key (T), the system skips back to the previous display.

Menu navigation: Press the “Menu “ key (S) and rotate rotating/pressing knob (A)

Press the ”Back” key (T) or the ”Menu” key (S)

Stirring

Menu

A

25.0

actual °C

0 10

set °C set rpm

Safe Temp. 210 °C

0

actual rpm

Menu

Menu

Back

BackBack

Fig. 18

Navigation controls

in the menu

A

S

T

Fig. 17

Page 14

14

Menu structure:

Stirring

Torque trend measurement ……………………………………………………… -

Intermittent mode

Run/Stop

…………………………………........ -

Interval Run Time

…..…………...

01:00 [mm:ss]

Stop Time

……………….

00:10 [mm:ss]

Speed limit ………………………………………………………………………...

150 rpm

Heating

Control method

Accurate …………………………………………

activated

Fast ……………………………………………… -

Limits

Medium limit …………………………………… 120

Limit information Medium limit …………… 120

Heating block …………… 180

Temperature sensor

Calibration 2-point calibration ……… -

3-point calibration ……… -

Reset calibration values ………………………… -

Timer

Set

…………………………………………………………………………………..

00:00:00 [hh:mm:ss]

Display

……………………………………………………………………………..

-

Operating Mode

A

………………………………………………………………….........…………..

activated

B

…………………………………………………………………….........………..

-

C

…………………………………………………………………….........………..

-

Display

Torque trend measurement

……………………………………………………...

-

pH value

……………………………………………………………………...……

-

Timer

…………………………………………………………………..…………..

activated

Safety

Time out

Set ……………………………………………… 00:30 [mm:ss]

Speed …………………………………………… 10 rpm

Temperature …………………………………… 30 ºC

Password

…………………………..…………………………………................

000

Safe Temp. confirmation

…….…………………………………………………

-

Factory settings

Menu

Weighing

pH Probe

Measurement

…………………………………………………………………….. -

Calibration 2-point calibration ……………………………… -

3-point calibration ……………………………… -

Reset calibration values …………………………………………………………… -

Calibration 2-point calibration ……………………………… -

3-point calibration ……………………………… -

Reset pH probe ……………………………………………………………………. -

Display ……………………………………………………………………………… -

Settings

Languages

Display

Sound

Factory settings

Bluetooth

Information

Version

…………………………………………

yes

Operating mode

………………………………

yes

Interval run

………………………….…………

yes

Interval stop

………………………...…………

yes

Medium limit

…………………………………

yes

Heating block Limit

……………………………

yes

Time out

………………………………………

yes

Time out temperature

………………………

yes

Time out speed

……………………………

yes

English

………………………………………….

activated

Deutsch

…………………………………………

-

···

………………………………..……………………………………..…

-

Background Black

………...………....

activated

White

…………………..

-

Key tone

………………………………………..

-

Page 15

15

Menu (Details):

Stirring:

Torque trend measurement:

The torque trend measurement is used to deduce the

change in viscosity of the reaction medium. The device is

not designed to measure absolute viscosity. It only measure

and display the relative change in the viscosity of the medium from a starting point specified by the user.

The value can always be reset to 0% by pressing the “Back”

(T, see Fig. 12) membrane key.

Note: Torque trend measurement only works for a constant set speed for the duration of the measurement.

As a result, intermittent mode cannot be used in conjunction

with torque trend measurement.

The current control variable is saved as the reference 0%,

ΔP and shown on the digital display. The change in the viscosity is then shown in %. Depending on whether the viscosity increases or decreases, the percentage rises or falls

above or below 0% respectively.

Intermittent mode:

The menu allows the user to activate the “Run/Stop“ function. The run time and stop time can be set separately.

Speed limit:

The menu allows the user to set the desired maximum upper speed limit for the reactor system. The initial setting is

the maximum permissible speed of the stirrer. If the user

changes this setting, control system of the reactor saves the

new value for future stirring tasks.

If the “Speed Limit” has been changed, then the speed can

be adjusted only within the new range.

Heating:

Control mode:

In the menu, the user is allowed to select “Accurate” or

“Fast” control mode by rotating and pressing knob (A). The

selected control mode is indicated by a tick.

Fast: reach target temperature quickly but with big overshoot and large hysteresis

at the beginning.

Accurate: Reach the target temperature takes somewhat

longer, but for this reason,

the initial overshoot and

the hysteresis are significantly smaller.

Limits:

In “External (ext)“ option, the user is allowed to set the maximum and minimum temperature for external temperature

control. Confirm and store the setting by pressing on “OK“.

Temperature sensor:

In “Calibration“ option, the user is allowed to calibrate the

external temperature sensor.

Weighing:

Measurement:

With the weighing function, the user can perform simple

weighing tasks.

Note: The heating and stirring functions must be deactivated.

Calibration:

• Open the “Calibration” submenu and confirm by press-

ing the rotary knob (A, see Fig. 12)

• Enter the calibration weight and conrm by pressing the

rotary knob (A, see Fig. 12).

• Place the calibration weight on the device and wait until

the device indicates that the calibration process has been

completed.

Depending on the selected calibration mode, 2-point or

3-point must follow these steps two or three times.

Once the calibration process has been completed successfully, the weighing module is ready for use.

Regularly re-calibrate the device.

Timer:

In the menu the user can specify that the timer is displayed

on the working screen. A tick shows that the option is activated. This setting allows the user to specify the actual time

for the heating procedure.

A default time can also be set for the timer. This setting allows the user to start the heating task for a standard time.

The device stops automatically after expiry of the set time,

and the set time used for the heating procedure appears in

the display.

Note:

The user can stop the stirring function before expiry

of the set time. In this case the countdown of the timer is

interrupted.

pH Probe:

Calibration:

The pH Probe must be calibrated before being used to attempt a pH measurement.

The calibration is used to adjust the pH probe and the device so that they work together correctly. As part of the

process, the neutral and pH gradient are specified for the

measurement chain. To complete the calibration, use buffer

solutions in accordance with DIN 19266.

T

Set

t

Page 16

16

Note: a pH calibration can only be carried out with an inserted temperature sensor.

Reset pH probe:

Reset the pH measuring reference.

Display:

Display the measured pH value on working screen.

Operating Mode:

Mode A:

After power on/power failure no automatic restart of functions.

Mode B:

After power on/power failure automatic restart of functions, depending on previous settings.

Mode C:

Set values (set in A or B) cannot be changed.

After power on/power failure automatic restart of functions,

depending on previous settings.

Display:

Here the user can specify which information (torque trend,

pH value, or timer value) is to be displayed on the working

screen.

Safety:

Time Out:

Here you can set a time out. This time out goes into effect

if the communication between the device and the PC has

failed. In this case, the device continues to run with the

set speed and temperature.

Password:

In the menu, the user can protect the device settings using

a password. The user is requested to input the password in

order to access the working screen (factory setting: 000).

Safe temperature confirmation:

Here you must confirm the safety temperature value of the

heating block.

Settings:

Languages:

Here allows the user to select the desired language by turn-

ing and pressing the rotary/push knob (A). A tick indicates

the language that is set for the system.

Display:

Here allows the user to change the background color of the

working screen.

Sound:

Here allows the user to activate/deactivate the key-press

sound and to set the volume.

Factory settings:

Here the user can reset the device to factory settings. The

system requests confirmation to recreate the factory settings.

Pressing the ”OK” button resets all the system settings to the

original standard values set at dispatch from the factory.

Information:

The ”Information” option offers the user an overview of

the most important system settings of the device.

Page 17

17

Abbreviations used:

X,y = numbering parameter (integer number)

m = variable value, integer

n = value of variable, floating point number

X = 1 Pt100 thermometer (external temperature sensor)

X = 2 temperature (heating block)

X = 3 safety temperature

X = 4 stirring speed

X = 6 safety stirring speed

The device can be operated in “Remote” mode via the RS 232

interface or the USB interface connected to a PC and with the

laboratory software Labworldsoft®.

Note: Please comply with the system requirements together with the operating instructions and help section included

with the software.

USB interface

The Universal Serial Bus (USB) is a serial bus for connecting

the device to the PC. Equipped with USB devices can be con-

nected to a PC during operation (hot plugging). Connected

devices and their properties are automatically recognized.

Use the USB interface in conjunction with

Labworldsoft® for

operation in “Remote” mode and also to update the firmware.

USB device drivers

First, download the latest driver for IKA

®

devices with

USB interface from http://www.ika.com/ika/lws/down-

load/usb-driver.zip and install the driver by running the

setup file. Then connect the IKA® device through the USB

data cable to the PC.

The data communication is via a virtual COM port. Configuration, command syntax and commands of the virtual

COM ports are as described in RS 232 interface.

RS 232 interface

Configuration

- The functions of the interface connections between the

machine and the automation system are chosen from the

signals specified in EIA standard RS 232 in accordance

with DIN 66 020 Part 1.

- For the electrical characteristics of the interface and the

allocation of signal status, standard RS 232 applies in accordance with DIN 66 259 Part 1.

- Transmission procedure: asynchronous character transmis-

sion in start-stop mode.

- Type of transmission: full duplex.

- Character format: character representation in accordance

Interfaces and output

with data format in DIN 66 022 for start-stop mode. 1

start bit; 7 character bits; 1 parity bit (even); 1 stop bit.

- Transmission speed: 9600 bit/s.

- Data flow control: none

- Access procedure: data transfer from the stirrer machine to

the computer takes place only at the computer’s request.

Command syntax and format

The following applies to the command set:

- Commands are generally sent from the computer (Master)

to the stirrer machine (Slave).

- The stirrer machine sends only at the computer’s request.

Even fault indications cannot be sent spontaneously from

the stirrer machine to the computer (automation system).

- Commands are transmitted in capital letters.

- Commands and parameters including successive param-

eters are separated by at least one space (Code: hex 0x20).

- Each individual command (incl. parameters and data) and

each response are terminated with Blank CR LF (Code: hex

0x20 hex 0x0d hex 0x20 hex 0x0A) and have a maximum

length of 80 characters.

- The decimal separator in a number is a dot (Code: hex 0x2E).

The above details correspond as far as possible to the recommendations of the NAMUR working party (NAMUR recommendations for the design of electrical plug connections

for analogue and digital signal transmission on individual

items of laboratory control equipment, rev. 1.1).

The NAMUR commands and the additional specific IKA® commands serve only as low level commands for communication

between the machine and the PC. With a suitable terminal or

communications programme these commands can be transmitted directly to the equipment. The IKA® software package, labworldsoft®, provides a convenient tool for controlling

device and collecting data under MS Windows, and includes

graphical entry features, for motor speed ramps for example.

The following table summarises the (NAMUR) commands

understood by the IKA® control equipment.

Page 18

18

Commands:

NAMUR Commands Function

IN_NAME

Input description name

IN_PV_X

X=1;2;3;4;

Reading the real value

IN_SOFTWARE

Input software ID number date, version

IN_SP_X

X=1;2;3;4;6;

Reading the set rated value

IN_TYPE

Input laboratory unit ID

OUT_NAME

Output description name. (Max. 10 characters, default: LR 1000)

OUT_SP_12@n

Setting the WD safety temperature with the echo of the set value

OUT_SP_42@n Setting the WD safety speed with the echo of the set value

OUT_SP_X n

X=1;2;4;6

Setting the rated value to n

OUT_WD1@m Watchdog mode 1: When a WD1 event occurs, the heating and Stirring functions are shut

down and message PC 1 is displayed. Set the watchdog time to m (20...1500) seconds, with

echo of the watchdog time. This instruction starts the watchdog function and must be sent

within the set watchdog time.

OUT_WD2@m Watchdog mode 2: When a WD2 event occurs, the speed setpoint will be set to the WD safety

setpoint speed and the temperature setpoint will be set to the WD safety setpoint temperature.

The PC 2 warning is displayed. The WD2 event can be reset with OUT_WD2@0-resetting also

blocks the watchdog function. Set the watchdog time to m (20...1500) seconds, with echo of

the watchdog time. This command starts the watchdog function and must be sent within the

set watchdog time.

RESET Switching off the instrument function.

START_X

X=1;2;4

Starting the instrument’s (remote) function

STATUS Display of status

1S: mode of operation A

2S: mode of operation B

3S: mode of operation C

S0: manual operation without fault

S1: Automatic operation Start (without fault)

S2: Automatic operation Start (without fault)

<0: error code: (-1)

- 1: error 1

- ... (see table)

-31: error 31

-83:wrong parity

-84: unknown instruction

-85:wrong instruction sequence

-86: invalid rated value

-87: not sucient storage space

STOP_X

X=1;2;4

Switching off the instrument - (remote) function

Variables set with OUT_SP_X are maintained.

“Watchdog” function, monitoring the serial data flow

The following applies to situations where the watchdog function is enabled (see Namur instructions). If no new transmissions of these commands from the PC take place within the preset watchdog time, the heating and shaking functions will

be shutdown according to the watchdog mode selected or will be controlled using the preset setpoints. An operating

system crash, a PC power failure or a fault in the connecting cable to the instrument can cause an interruption in data

transmission.

“Watchdog”– Mode 1

If an interruption in data transmission occurs which is longer than the preset watchdog time, the heating and shaking functions will be shut down and the error message PC 1 will be displayed.

Page 19

19

“Watchdog”– Mode 2

If an interruption in data transmission occurs which is longer than the preset watchdog time, the speed setpoint value will

be set to the WD safety speed setpoint and the temperature setpoint will be set to the WD safety temperature setpoint.

The PC 2 warning message will be displayed.

PC 1.1 Cable:

Required for connecting the RS 232 port to a PC.

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

9

1

RxD 2

TxD 3

4

GND 5

6

RTS 7

CTS 8

9

PC

1

2

3

4

5

6

7

8

9

9

8

7

6

5

4

3

2

1

Fig. 19

USB cable A - Micro B 2.0:

This cable is required to connect USB port (9, see Fig. 2) to a PC.

USB micro B

USB A

A

Fig. 20

Page 20

20

Maintenance and cleaning

Cleaning:

For cleaning disconnect the main plug!

Disassemble the reactor vessel:

Remove the reactor vessel from the LR basic/control base.

Remove the reactor cover from the reactor vessel.

Remove the glass tube from the base as described below.

Use a screwdriver to loosen and remove the four screws on

the two clamps.

Then, both handles can be removed from the glass vessel.

Note: the screws can only be loosened and cannot be removed from the handles.

Now both clamps can be removed. Then remove the glass

tube with handles from the base.

Remove both handles from the glass vessel as following.

Reserve the glass tube with handles. Loosen both screws

with screw driver at the bottom of handles (see Fig. 22).

Disassemble the anchor stirrer:

After removing the glass tube from the vessel base, the anchor stirrer together with the reactor vessel bottom of the

socket can be taken apart from the vessel base (see Fig. 23).

Please pay attention to the O-ring when you disassemble

the reactor vessel.

Open the screw as described in Fig. 24 with the socket

wrench.

O-ring

Fig. 23

Fig. 22

Fig. 24

Fig. 21

Page 21

21

- Wear protective gloves during cleaning the instrument.

- Electrical devices may not be placed in the cleaning agent

for the purpose of cleaning.

- Do not allow moisture to get into the equipment when

cleaning.

- Please consult IKA® before using any cleaning or decon-

tamination methods, other than those recommended here.

- The handles cannot be place in the cleaning agent for

cleaning.

- The only cleaners or disinfectants that may be used are

those that:

- lie in the pH range 5 - 8,

- contain no corrosive alkalis, peroxides, chlorine compounds,

acids or brine.

- All product contacting components are suited for cleaning

in the laboratory dish washers.

Only clean IKA® appliances using these IKA® approved

cleaning agents.

Dirt Cleaning agent

Dyes Isopropanol

Building materials

Water containing detergent, Isopropanol

Cosmetics

Water containing detergent, Isopropanol

Food

Water containing detergent

Fuels

Water containing detergent

Other materials

Please consult IKA

®

Spare parts order:

When ordering spare parts, please give:

- machine type

- serial number, see type plate

- item number and designation of the spare part see

www.ika.com, spare parts diagram and spare parts list.

Repair:

Please send equipment for repair only after it has

been cleaned and is free from any materials which

may constitute a health hazard.

For repairing, please request the “Decontamination Certificate” from IKA®, or download the printout of it from

the IKA® website www.ika.com.

If you require servicing, return the equipment in its original

packaging. Storage packaging is not sucient. Please also

use suitable transport packaging.

Fig. 25

Now you can remove the anchor stirrer as shown in Fig. 25.

All O-rings can now be carefully removed by hand or using a

blunt tool for cleaning too.

Page 22

22

Error codes

The fault is shown by an error message in the display as following if the error occurs.

Proceed as follows in such cases:

Switch off the device using the main switch

Carry out corrective measures

Restart the instrument

Error code Description Effect Corrective action

Error 3

(Er 3)

Internal temperature of device is too high.

Heating off

Motor off

- Switch off the instrument and allow it to cool down.

Error 4

(Er 4)

Motor is blocked or overloaded. Motor off - Switch off the instrument

- Decrease the load and restart again

Error 10

(Er 10)

Remote control is interrupted. Heating off

Motor off

- Change watchdog time

- Check relating connection

Error 11

(Er 11)

External temperature sensor plugged

during heating control.

Heating off - Unplug the external temperature sensor.

Error 12

(Er 12)

External temperature sensor unplugged

during heating control.

Heating off

- Plug in the external temperature sensor

Error 14

(Er 14)

Short circuit of external temperature

sensor or cable.

Heating off

- Check the external temperature sensor and cable

Error 18

(Er 18)

The temperature of safety sensor is

higher than safety temperature setting.

Heating off

- Increase the safety temperature setting or allow

cooling down

Error 51

(Er 51)

Mains voltage is too high. Heating off

Motor off

- Switch off the device and check the mains voltage.

Error 52

(Er 52)

Mains voltage is too low. Heating off

Motor off

- Switch off the device and check the mains voltage.

Er 60

Power is interrupted when heating or

motor control is activated in Mode B and C

–

- Exit error state when any button is pressed.

Only for LR 1000 basic!

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department

- Send the instrument for repair, including a short description of the fault.

Page 23

23

Accessories

T 25 digital Disperser

S 25 KV - 25 F Dispersing element

S 25 KV - 25 G Dispersing element

S 25 KV - 18 G Dispersing element

LR 1000.41 Shaft receptacle

LR 1000.61 Sensor receptacle

LR 1000.65 pH electrode receptacle

LR 1000.64 pH Electrode

Warranty

In accordance with IKA® warranty conditions, the warranty

period is 24 months. For claims under the warranty please

contact your local dealer. You may also send the machine

direct to our factory, enclosing the delivery invoice and giving

reasons for the claim. You will be liable for freight costs.

LR 1000.20 Flow breaker/bae

RC 2 basic Thermostat

RC 2 control Thermostat

HPVC 8 PVC hose

MVP10 basic Vacuum pump

VCV1 Vacuum control valve

VSS1 Vacuum safety set

labworldsoft

®

The warranty does not cover worn out parts, nor does it

apply to faults resulting from improper use, insucient care

or maintenance not carried out in accordance with the instructions in this operating manual.

Only for LR 1000 control!

See more accessories on www.ika.com.

Materials in contact with medium

Reactor cover AISI 316 L / AISI 316 TI / PTFE / Borosilicate glass 3.3

Bottom AISI 316 L / AISI 316 TI

Reactor vessel Borosilicate glass 3.3

Anchor stirrer AISI 316 L / AISI 316 TI

Temperature sensor AISI 316 L / AISI 316 TI

Shaft seal PTFE

LR 1000.1

O-ring FKM

LR 1000.3

O-ring FFKM

Scraper PEEK

Page 24

24

Technical data

LR 1000 basic LR 1000 control

Nominal voltage VAC 100 – 120

230

Frequency Hz 50 / 60

Input power W 1200

Viscosity max. mPas 100000

Usable volume ml 300 – 1000

Useful volume with dispersing ml 500 – 1000

Attainable vacuum mbar 25

Stirring speed range rpm 10 – 150

Speed display LED TFT

Speed setting resolution rpm 1

Speed deviation rpm ± 5

Working temperature max. (medium) °C 120

Temperature display LED TFT

Temperature setting resolution K 1 0.1

Temperature measurement resolution K 0.1

Heating control accuracy K ± 1

Connection for external temperature sensor Pt 100

Control accuracy with external sensor K ± 0.2

Adjustable safety circuit °C 47 (± 10) – 225 (± 20)

Type of cooling Liquid through cooling

Minimum temperature of the cooling medium °C 3

Cooling medium permissible pressure bar 1

Weighing range kg - 0 – 2

Weighing resolution g - 1

pH meter interface no yes

pH value display - TFT

pH display range - 0 – 14

pH display resolution - 0.1

Nominal torque Ncm 3

Torque trend display - TFT

Timer function yes

Timer display LED TFT

Interface USB, RS 232

Protection class acc. to EN 60529 IP 21

Permissible ambient temperature °C +5 ... +40

Permissible ambient humidity (relative) % 80

Dimension (W x D x H) mm 443 x 295 x 360

Weight kg 16

Operation at a terrestrial altitude m max. 2000

Subject to technical changes!

Page 25

IKA

®

- Werke GmbH & Co.KG

Janke & Kunkel-Str. 10

D-79219 Staufen

Tel. +49 7633 831-0

Fax +49 7633 831-98

sales@ika.de

www.ika.com

Loading...

Loading...