Page 1

KS4000_1

KS 4000 i control

KS 4000 ic control

Page 2

Safety instructions

EN

Contents

Page

Warranty 2

Safety instructions 17

Correct use 19

Unpacking 19

Commissioning 19

Switch on 19

Setting the safety limit values 20

Opreator panel and display 20

Function Shaking 21

Timer 21

Function Heating 21

Operating modes 22

Setting the operating mode 22

External temperature sensor 22

Kalibration - temperature 22

Reset 23

Appliance variant KS 4000 ic control 23

Attachments 24

Error codes 24

Interface and outputs 27

Maintenance and cleaning 28

Accessories 30

Technical data 30

• Read the operating instructions in full before starting up

and follow the safety instructions.

Kep the operating instructions in a place where they can be

accessed by everyone.

The media used in the appliance may result in danger specific to the media and the process. This applies, for example, to shaking cultures with living cells and to aggressive

or flammable media.

germents can become, if they arise with one another in

combination, a larger endangerment.

describe the dangers and resulting safety measures in

more detail.

This appliance should only be operated by suitably trained personnel familiar with the appliance and authorized to work in this

area.

• The machine may only be opened by trained specialists - even

during repairs. The machine is to be unplugged from the mains

before opening. Live parts inside the machine may still be live

for some time after unplugging from the mains.

• NOTE ! Covering or parts that are capable of being removed

from the unit without accessory equipment have to be reattached to the unit for safe operation in order to prevent, for

example, the ingress of fluids, foreign matter, etc. .

• Wear your personal protective equipment in accordance with

the hazard category of the medium to be processed.

Otherwise there is a risk of:

- splashing liquids

- projectile parts

- body parts, hair, clothing and jewellery getting caught.

• Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations.

• Beware of the high dead weight of the appliance when transporting. Ensure that your fingers do not get crushed when setting down the appliance.

• Always install the appliance on a flat, stable non-slip base.

• Pay attention to the vessels on the shaking table when setting

the shaking rate. This will prevent any of the medium to be

shaken from spurting out of the sample vessels.

Particulars as small estimated endan-

This manual cannot

17

Page 3

• Ensure that parts of the body, hair or items of clothing cannot

be trapped by the motion parts.

• Never touch moving parts.

Caution! The shaker still runs after the cover has been

opened. Wait for it to stop running.

(Risk of being crushed, shocked or cut, see figure illustrating

danger points).

• Should vessels break during operation or the media be spilt, interrupt the shaking process immediately, remove any vessel residue

and clean the appliance.

Danger of being burnt! Exercise caution when touching

housing components and attachments. They may become

hot. Watch for residual heat after appliance has been switched off.

• Pay attention to the risk of

- flammable materials - glass breakage

- flammable media with low boiling temperatures

- level of medium which is too high

- biological and microbiological materials

• All accessories and vessels in place for the shaking process

must be firmly secured.

• Shaking vessels which are not properly secured could get

damaged or be projected out, thus causing injury. It is essenti-

• If you notice that the device is not running smoothly, the

• Because of improper loading and the position of the center of

• Additional hazards to the user may occur if inflammable mate-

• Furthermore, the shaking unit may only be used to stir those

•

• When using an external temperature sensor, it must always be

• The safety of the user cannot be guaranteed if the appliance is

• Caution! Never process and heat up any media that has a

The safe temperature limit must always be set to at least 25 °C

lower than the fire point of the media used.

• When servicing, the wiring selected by IKA must be set up

• Avoid allowing objects to push or strike the agitation table.

• Keep a minimum distance of 100mm from the appliance on all

al to regularly check that the vessels to be shaken and the

attachments are firmly secured, especially before using the

appliance again.

speed must always be reduced until no more uneveness

occurs in the operation.

gravity, dynamic forces may arise during the agitation process

that cause the shaker to move about on the table.

For restrictions of load capacity and material weight during

high shaking frequencies, please see the description in the

"Attachments" section.

rials are used during the shaking operation.

materials or material mixtures that the user knows will not

react dangerously to the extra energy produced by the stirring.

This also applies to extra energy by means of solar radiation

during the shaking procedure.

The shaker may not been used in explosive atmospheres, for

mixing dangerous substances or under water.

in the medium. Immerse the external temperature sensor at

least 20mm into the medium.

operated with accessories that are not supplied or recommended by the manufacturer or if the appliance is operated improperly, contrary to the manufacturer’s specifications.

flash point higher than the adjusted safe temperature limit that

has been set.

again!

sides.

18

Page 4

Correct use

Commissioning

• Use

- For mixing and/or heating liquids

• Range of use

- Laboratories - Schools

- Pharmacies

This device is suitable for use in all areas except:

- Residential areas

- Areas that are connected directly to a low-voltage supply network that also supplies residential areas.

The safety of the user cannot be guaranteed if the appliance is

operated with accessories that are not supplied or recommended by the manufacturer or if the appliance is operated improperly contrary to the manufacturer’s specifications or if the appliance or the printed circuit board are modified by third parties.

Unpacking

•

Unpacking

- Please unpack the device carefully

- In the case of any damage a detailed report must be set immediately (post, rail or forwarder)

Contents of package

•

KS 4000 i control KS 4000 ic control

- Shaking device

-

Mains cable - Mains cable

- Operating instructions - Operating instructions

- 4 clamping screws short - 4 clamping screws short

- 2 clamping screws long - 2 clamping screws long

-

Temperature sensor PT 1000.60- Temperature sensor PT 1000.60

- Shaking device (temperierbar)

- 2 hose connecting pieces

- unlocking handle

Make sure before start-up of the equipment that the drain hose

leads into a drain!

Check whether the voltage specified on the type plate matches

the mains voltage available. The power socket used must be earthed (protective earth conductor contact). If these conditions are

met, the device is ready to operate after plugging in the mains

plug. If these procedures are not followed, safe operation cannot

be guaranteed and/or the equipment may be damaged.

Observe the ambient conditions (temperature, humidity, etc.)

listed under Technical Data.

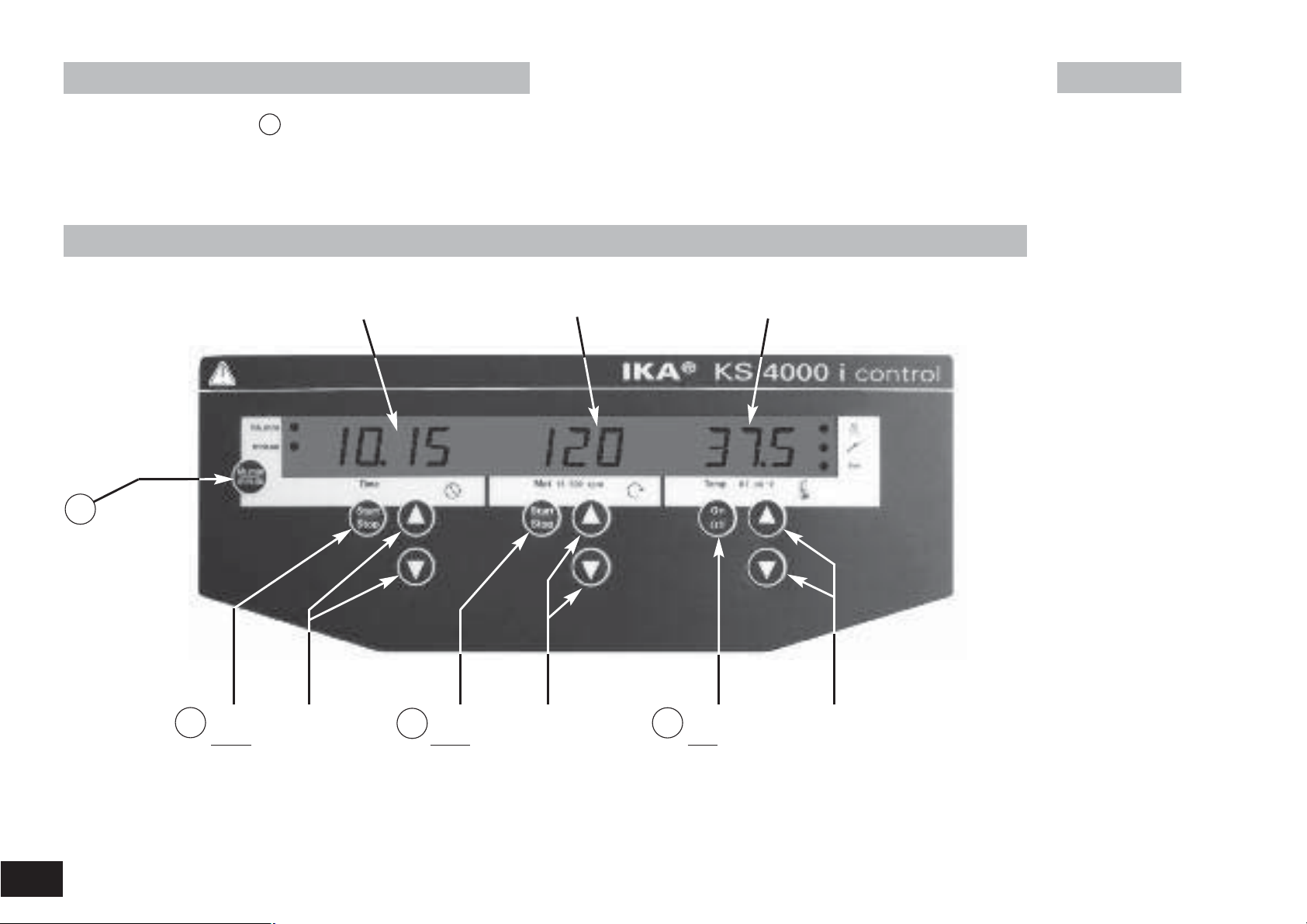

Switching on

The appliance is switched on using

the switch on the side of the appliance. Once it has been switched on, all

of the LEDs light up briefly during the

self test.

1

2

3

8888 888 888

Display fields

Main switch I / 0

A01

Operating mode

Software

version

SAFE 275 55.5

Safety max. ad- max. adlimit adjustable ajustable

values speed temperature

Note the load guideline values for the attachments prior to

switching appliance on (see "Attachments").

19

Page 5

Setting the safety limit values

If the Time Start/Stop key 2 is held down while "SAFE" is displayed, the safety limit values can be changed using the respective up/down keys.

Operator panel and display

1

Shift key

hh : mm

mm : ss

2

Time

Start

Stop

Display

Time

Time

up

down

3

Speed

Start

Stop

Display

Speed

Speed

up

down

Temperature

4

On

Off

Display

Temperature

Temperature

up

down

20

Page 6

Tapping the Start/Stop keys or On/Off key starts the particular functions

Timer

The desired default values can be changed using the or keys.

Use the shift key 1 to switch from hour/minute mode to minute/second mode.

If the elapsed time exceeds the value of 100 hours, the display

switches from hour/minute mode

to hour mode

Only whole hours are displayed in hour mode.

The following sections contain detailed information about the individual functions.

The desired shaking duration is set on the operator panel of the

timer using the Time up/down keys. The shift key can be used to

switch from hour mode to minute mode.

The Time Start/Stop key activates the timer and shaking functions.

When the time is up, the shaking function stops and an acoustic

signal is given off. If the cover is opened before the time is up, the

timer goes to "pause" and the display flashes. If the cover remains

open for more than 15 minutes, the timer switches off and an

error code appears on the display. The shaker no longer starts

when the cover is closed.

If the timer is not activated, the Time display automatically shows

the operating time following the start of the shaking function.

Function Shaking

Function Heating

Press the 3 key to start or stop the shake function. The speed

can be adjusted during operation. The displayed value flashes until

the pre-set speed has been reached.

When the shaking function is started using button 3 , the timer

automatically starts measuring the time until the next switch-off.

Note:

The shaking function can only be started when the cover is closed.

When the cover is opened, the shaker automatically switches off

the shaking and heating functions.

Once the appliance starts, the display indicates the actual value for

the set temperature.

Press the 4 key to start or stop the heating function. The temperature is entered using the Temp up/down keys. In operation, the

temperature is displayed in 0.1 °C steps.

The target value appears approx. every 5 seconds and remains on

the display for 2 seconds.

Note:

The heating function can only be started when the cover is closed.

When the cover is opened, the shaker automatically switches off

the shaking and heating functions.

21

Page 7

Operating modes

External temperature sensor

You can choose between operating modes

and

Appliance does not start up again following power

outage Safety limit value for speed and temperature

adjustable

Appliance starts up again following power outage

Safety limit value for speed and temperature adjustable

Appliance starts up again following power outage

Safety limit values cannot be changed

If external temperature sensor PT1000.60 is connected to the

internal slide-on receptacle, the temperature can be measured at

any place in the medium.

Setting the operating mode

Switch on appliance and simultaneously hold down the Time

Start/Stop key 2 and the shift key 1 .

The display indicates either or depending on the operating mode set (factory default setting A).

(Connector for PT1000.60)

The temperature control of the

heating works automatically with

this display or measuring value.

This is indicated by the lighting up

of the LED next to the temperature sensor symbol

Locate the external

temperature sensor

and the connecting

cable so that the shaking motion is unimpeded and no vessels are damaged or

tipped over.

22

Switching the appliance off and on switches to the next operating

mode

Following the selection of the operating mode, the corresponding

letter appears on the display for 5 seconds, the appliance is ready

for operation.

Calibration - temperature

The appliance is calibrated at the factory.

This function allows the temperature to be calibrated to a desired

value.

This may be necessary, for example, if special sample containers,

their arrangement or external influences (e.g. sunshine) cause the

measuring value for the temperature to be incorrect.

Page 8

Calibration without inserted sensor:

CAL

- Fill Erlenmeyer flask (250ml) with water to the 100ml mark

- Place the Erlenmeyer flask in the centre

- Immerse the sensor of the external measuring device in the

water

- Set the target temperature

- Close the cover and start the Temp function

- Wait until the temperature in the incubation cover has stabilised.

- While holding down the shift key 1 , briefly press the Temp

On/Off key 4 , the

the shift key 1 .

- Set the temperature value read off the external measuring device using the Temp up down keys

- Calibration is complete when you release the shift key

Calibration with inserted sensor:

Calibration with inserted sensor takes place in the same way as

described above.

display appears; keep holding down

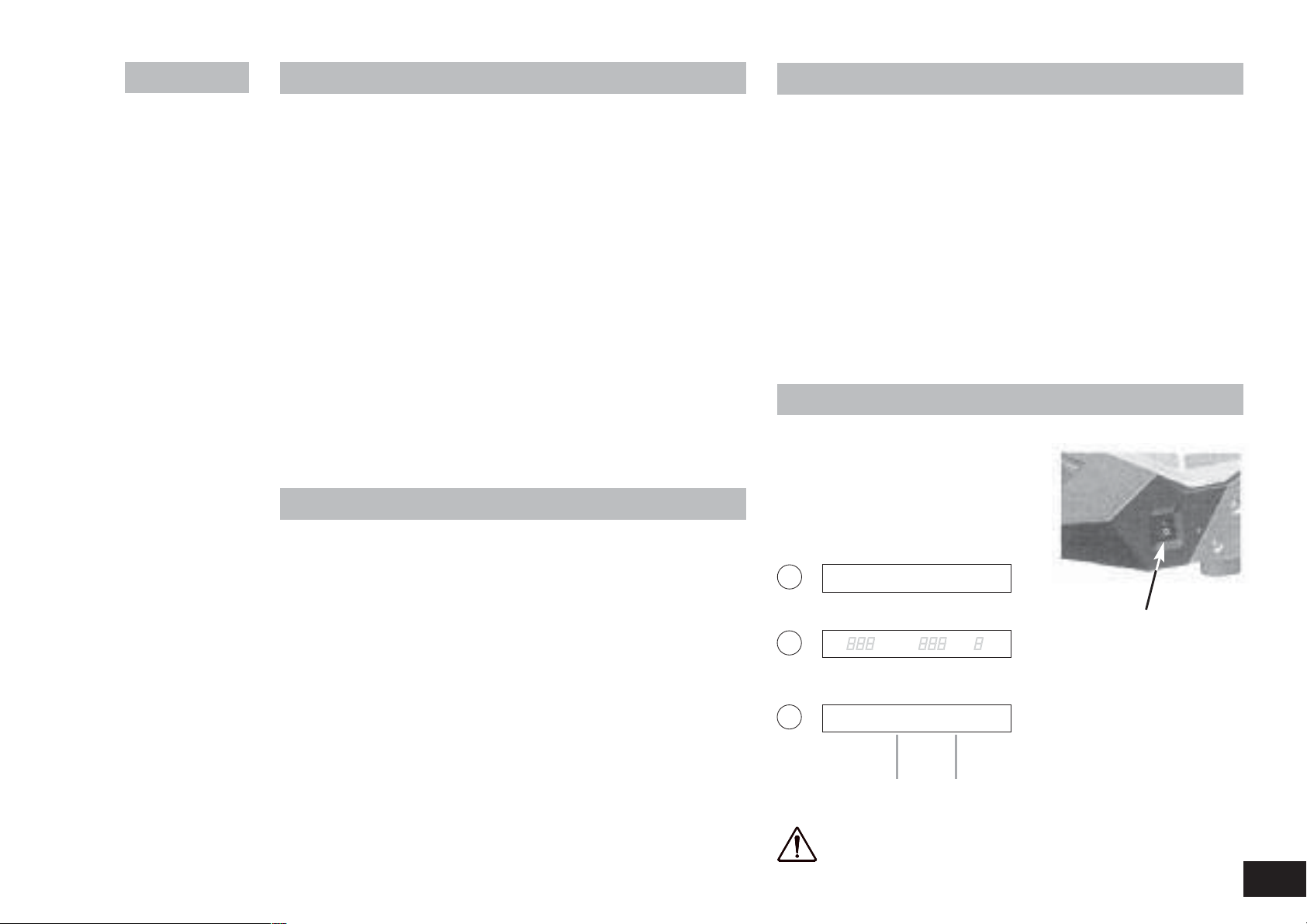

Appliance variant KS 4000 ic control

There is a cooler built into this appliance variant.

By using an external cooling unit, the working temperature can be

lowered in relation to the room temperature (depending on the

supply temperature).

The cooler is connected to an external cooling unit (e.g. IKA KV

600) via the plug connection at the back of the appliance. The inlet

and outlet connections are labelled accordingly at the back of the

appliance. To connect the cooling pipes there are two hose

connection pieces included. They can be connected to a hose with

a 10mm interior diameter. The connectors are unlocked by coaxially positioning the unlocking lever and pressing slightly in the

direction of the arrow. By positioning and light pressure in the

direction of the plug, the connectors are locked/connected to the

inlet/outlet plug connections on the housing.

Reset

To restore the factory settings, hold down the Mot key and the

Temp key and press the main switch I/O.

Factory setting: Operating mode A

Upper speed limit 500 rpm

Safety temperature limit 90 °C

Temperature calibration

Drain hose

Unlocking lever

Plug connection

cooler inlet

Plug connection

cooler outlet

23

Page 9

Water is the only coolant that may be used (with antifreeze, e.g. ethylene glycol).

Permissible cooling agents - inlet temperature >3°C

Observe the maximum permissible pressure of 1 bar! As

a safeguard, we recommend using a pressure limiter (e.g.

IKA C25). This is not necessary when using an IKA

KV600.

Accumulated condensate is drained out of the cooler through the

drain hose.

Assembly information for AS 4000.1

Attachments

The following attachments are offered as accessories

AS 4000.1 universal attachment AS 4000.2 bracket attachment

Error codes

An error is indicated by an acoustic signal and an error code is displayed.

24

E.g.:

AS 4000.3 bowl attachment

Note:

During continuous operation, the load may slip, for example, resulting in the appliance becoming excessively unbalanced. To prevent this, there is a motion sensor built in which reduces the

speed gradually once a critical limit has been reached.

The attachments are affixed to the shaking table using the four

clamping screws provided.

Load (standard values)

Load / kg 6 12 15 20

Max. speed / rpm 500 400 300 120

When faults are not specified in the table, you switched the

appliance off and again on.

If faults cannot be eliminated directly, you must perform a

RESET (see "Resetting parameters to the factory settings")!

If the faults still cannot be eliminated, the appliance must be

inspected by a technical service.

Page 10

Error code

Er 3 Temperature inside unit too high • Permitted ambient temperature has Heating off • Switch off the unit. Allow it to cool down

Er 4 Differanceberween setpoint and • Motor seized or overloaded Heating off •

Er 8 The calibration value of the tempe- • Fault in calibration procedure Heating off • Repeat the calibration procedure

Er 14 External temperature sensor, • Short-circuit at temperature sensor Heating off • Check the plug

Er 16 External temperature sensor has • SAFE Temp is set at a temperature Heating off • Allow the unit to cool

Er 17 Temperature sensor - Incubation- • SAFE Temp is set at a temperature Heating off • Allow the unit to cool

Er 26 Difference between the internal • Ventilation slots in incubation room Heating off • Switch off the unit. Allow it to cool down

Er 60 Power outage • Power outage during operation Interruption of heating • Delete the display by pressing the

Description Cause Effect Solution

been exceeded and then switch on again.

• Ventilation slots or fan housing • Clean ventilation slots or fan

blocked housing

• Observe maximum permissible

ambient temperature

Reduce the torque load

actual speeds is too large

rature sensor is outside the limit •

value • EPROM switching error

short-circuit plug • Substitude the temperature sensor

exceeded the SAFE Temp lower than the actual temperature on •

room has exceeded the lower than the actual temperature on •

SAFE Temp the external t

contro and safety temperature blocked and then switch on again.

sensors too large • Radial-flow fan does not rotaded • Check fan or ventilation slots and

Value was incorrectly stored to memory

• Short-circuit in connecting cable

or on temperature sensor

the external t

• Fault in the control or safety clean if necessary

temperature sensors

emperature sensor

emperature sensor

or shaking function shift key

(load)

• Reduce the setpoint speed

Set the SAFE Temp at a higher temperature

Set the SAFE Temp at a higher temperature

25

Page 11

Error code

PC 1 In remote operation (PC) with • PC does not send data during the Heating off • Change the watchdog time

PC 2 In remote operation (PC) with • PC does not send data during the The setpoint temperature • Change the watchdog time

Description Cause Effect Solution

watchdog function 1 enabled: watchdog time Motor off • Send data from the PC within the

No communication between • The connection/cable to the PC is watchdog time

PC and unit broken • Check the connector cable and plug

watchdog function 2 enabled: watchdog time is set to the WD safety • Send data from the PC within the

No communication between temperature watchdog time

PC and unit • The connection/cable to the PC is The setpoint speed • Check the connector cable and plug

broken is set to the WD safety

speed

Interface and outputs

Configuration

The unit can be controlled from an external PC (using the dedicated software labworldsoft) via the RS 232 C serial interface

fitted to the unit.

To increase safety when controlling the shaking unit from

a PC, enable the watchdog function for monitoring the

continuous serial data flow (see section watchdog function)

• The functions of the inteface lines between laboratory instrument and automation system are selected from the

specfied signals of the EIA-standard RS 232 C, corresponding

with DIN 66020 Part 1. The allotment of the bushing can be

taken from illustration.

• For the electrical properties of the interface lines and for the

allotment of the signal status, standard RS 232 C, corresponding with DIN 66259 Part 1 applies

(see capture PC 2.1 cable).

• Transmission method: Asynchronous signal trans-

mission in start-stop-operation

• Mode of transmission: Fully Duplex

• Character format: Character imaging acc. to data

format DIN 66022 for startstop-operation. 1 start bit;

7 character bits; 1 parity bit

[(straight (even)]; 1 stop bit.

• Transmission speed: 9600 bit/s

• Access method

Instruction syntax

Here applies the following:

• The instructionsare generally sent from the processor

(master) to the laboratory instrument (slave).

• The laboratory instrument exclusively sends on demand of

the processor. Even error codes cannot be spontaneously

communicated from the laboratory instrument to the processor (automatic system)

•Instructions and parameters as well as subsequent para-

meters are separated by at least o n e blank.

: Data communication from

shaker to computer is only

possible on demand of the

computer.

(Code: hex 0x20)

26

Page 12

• Each individual instruction including parameters and data as

well as each reply are terminated with CR LF (Code: hex

0x0D and 0x0A) and have a maximum lenght of 80 characters.

• The decimal separator in a floating point number is the point.

(Code: hex 0x2E)

The above statements largely correspond with the recommendations of the NAMUR-Assocation (NAMUR-recommendations for the design of electric plug connections for the analog

and digital signal transmission to labortory - MSR individual

units. Rev. 1.1).

Overview of the NAMUR-instructions

Abbreviations:

X,y = numbering parameter (integer number)

m = variable value, integer

n = value of variable, floating point number

X = 1 Pt1000 medium temperature (external temperature

sensor)

X = 2 temperature (incubations room)

X = 3 safety temperature

X = 4 speed

X = 6 safety speed

X = 50 Pt1000.60 medium temperature sensor offset in K

(-5.0 <= n <=+5.0)

X = 52 incubations room temperature sensor offset in K

(-5.0 <= n <=+5.0)

NAMUR instuctions

IN_NAME Input description name

IN_PV_X Reading the real value

X=1;2;3;4;

IN_SOFTWARE Input software ID number

IN_SP_X Reading the set rated value

X=1;2;3;4;6;12;

42;50;52;53;

IN_TYPE Input laboratory unit ID

OUT_NAME name

OUT_SP_12@n Setting the WD safety temperature with the

OUT_SP_42@n Setting the WD safety speed with the

OUT_SP_X n Setting the rated value to n

X=1;2;4;50;52

OUT_WD1@m Watchdog mode 1: When a WD1 event occurs,

OUT_WD2@m Watchdog mode 2: When a WD2 event occurs,

RESET Switching off the instrument function.

Function

date, version

Output description name. (Max. 10 characters,

default: KS4000 ic)

echo of the set value

echo of the set value

the heating and shaking functions are shutdown

and message PC 1 is displayed.

Set the watchdog time to m (20...1500) seconds,

with echo of the watchdog time. This instruction

starts the watchdog function and must be sent

within the set watchdog time.

the speed setpoint will be set to the WD safety

setpoint speed and the temperature setpoint

will be set to the WD safety setpoint temperature. The PC 2 warning is displayed.

The WD2 event can be reset with OUT_WD2@0resetting also blocks the watchdog function. Set

the watchdog time to m (20...1500) secondes,

with echo of the watchdog time. This command

starts the watchdog function and must be sent

within the set watchdog time.

27

Page 13

START_X Starting the instrument’s (remote) function

X=1;2;4 (Display additionally: PC)

STATUS Display of status

1S: mode of operation A

2S: mode of operation B

3S: mode of operation C

S0: manual opration without fault

S1:

Automatic operation Start (without fault)

S2:

Automatic operation Start (without fault)

<0: error code: (-1)

- 1: error 1

- ... (see table)

-31: error 31

-83: wrong parity

-84: unknown instruction

-85:

wrong instruction sequence

-86: invalid rated value

-87: not sufficient

storage space

STOP_X Switching off the instrument

X=1;2;4

“Watchdog” function, monitoring the serial

data flow

The following applies to situations where the watchdog function is enabled (see Namur instructions). If no new transmissions of these commands from the PC take place within the preset watchdog time, the heating and shaking functions will be

shutdown according to the watchdog mode selected or will be

controlled using the preset setpoints. An operating system

crash, a PC power failure or a fault in the connecting cable to

the instrument can cause an interruption in data transmission.

“Watchdog”– Mode 1

If an interruption in data transmission occurs which is longer

than the preset watchdog time, the heating and shaking functions will be shutdown and the error message PC 1 will be displayed.

on. Variables set with OUT_SP_X are maintained. Contains the instruction RMP_STOP.

(Display additionally: PC)

- (remote) funkti-

“Watchdog”– Mode 2

If an interruption in data transmission occurs which is longer

than the preset watchdog time, the speed setpoint value will

be set to the WD safety speed setpoint and the temperature

setpoint will be set to the WD safety temperature setpoint.

The PC 2 warning message will be displayed.

Connections between shaking instrument and external

devices

PC 1.1 Cable

Cable PC 1.1 for connection to the 9-pin socket on the computer.

Maintenance and cleaning

The shaker KS 4000 i control and KS 4000 ic control

ace-free. It is subject only to the natural wear and tear of components and their statistical failure rate.

Examine in regular intervals the functionality and the correct

attachment of the two gas-filled supports!

When ordering spare parts, please give the manufacturing

number shown on the type plate, the machine type and

the name of the spare part.

Please send in equipment for repair only after it has been cleaned and is free from any materials which may constitute a

health hazard. Use only cleansing agents which have been

is mainten-

28

Page 14

approved by IKA to clean IKA devices.

To remove use:

Dyes isopropyl alcohol

Construction materials

Cosmetics water containing tenside / isopropyl alcohol

Foodstuffs water containing tenside

Fuels water containing tenside

For materials which are not listed, please request information

from IKA. Wear the proper protective gloves during cleaning of

the devices.

Electrical devices may not be placed in the cleansing agent for

the purpose of cleaning.

Before using another than the recommended method for cleaning or decontamination, the user must ascertain with the

manufacturer that this method does not destroy the instrument.

Collecting tray with drain hose (for picture see below)

(applies to KS4000 i control and KS4000 ic control)

In the event of glass breakage, leaking liquid is collected by the

collecting tray below the shaking table and guided to the drain

hose via a drain at the rear.

water containing tenside / isopropyl alcohol

1. Remove drain hose

from bracket

Cleaning of the collecting tray:

Cleaning the Plexiglas cover:

- Do not dry wipe.

- Do not use abrasive materials.

- Do not use solvents.

Clean dusty surfaces with warm water, detergent and a soft

cloth.

We recommend the anti-static plastic cleaner “AKU” by Burnus

GmbH, Darmstadt.

For disinfecting, only use products prescribed by the manufacturer specially for use on Plexiglas.

- four countersunk

head screw at the

top side of the

shaking table

loosen

- shaking table

upward remove

2. Place drain hose

in laboratory drain

29

Page 15

Accessories

1RWH

AS 4000.1 Universal attachment

AS 4000.2 Holding bracket attachment

AS 4000.3 Dish attachment

PC 1.1 Adapter

Technical data

Design voltage VAC 230±

or VAC 115±

Design frequency Hz 50/60

Heating power W 1000

Input power W 1120

Speed range rpm 10 - 500

Heating temperature range °C RT +5 .... 80

Temperature constancy K 0,1

(200ml water at set

point T=37°C, RT 25°C)

Temperature sensor K ≤±(0,15 + 0,002 x ITI)

PT1000.60 - variation

DIN EN 60751 Kl.A

Permitted duration of operation

Permitted ambient temperature

Permitted relative humidity

Protection class acc. DIN EN 60529

Protection class

Overvoltage category II

Contamination level 2

Operation at a terrestrial altitudemmax. 2000 above sea level

% 100

°C +15 at +32

% 80

10%

10%

IP 30

I

Protection at overload Temperature sensor

in motorwinding

Fuses on apparatus plug

115V A T16A (Id.Nr. 37 368 00) 2x

230V T10A (Id.Nr. 27 554 00) 2x

Radius orit mm 20

Shaking motion orbital

Max. load kg 20

Dimensions (B x H x T) mm 580 x 750 x 520

Weight (i control) kg 50

Weight (ic control) kg 55

Speed setting Digital

Button on front side

Dissolution of adjusting rpm 1

Speed display LED - Display

Max. speed deviation from idle

Temperature settiung Digital

Button on front side

Dissolution of adjusting K 0,1

Temperature display LED - Display

Time setting Digital

Button on front side (altern. Min/Std)

Time display LED - Display

Interface RS 232 C

KS 4000 ic control

Temperature range °C 12 - 80

(inlet T>3°C)

1

&RPSOLHVWR(1VXEMHFWWRFRQGLWLRQDOFRQQHFWLRQ

=PD[ ,IQHFHVVDU\FRQVXOW\RXUHOHFWULFLW\VXSSOLHU

% ±1

1 - 999 hh:min/min:sec

30

Drive Speedcontrol

asynchronous motor

Subject to technical changes!

Loading...

Loading...