Page 1

35 488 01 a

Calorimeter System C 200

012011

Operating instructions EN

Reg.-No. 4343-01

Page 2

Page 3

Source language: German

EN

Contents

Chapter Page

CE-Declaration of conformity 5

1 Safety instructions 6

2 User information 8

2.1 Information regarding operating instructions 8

2.2 Warranty and liability 8

3 Transport, storage, place of installation 9

3.1 Conditions of transport and storage 9

3.2 Place of installation 9

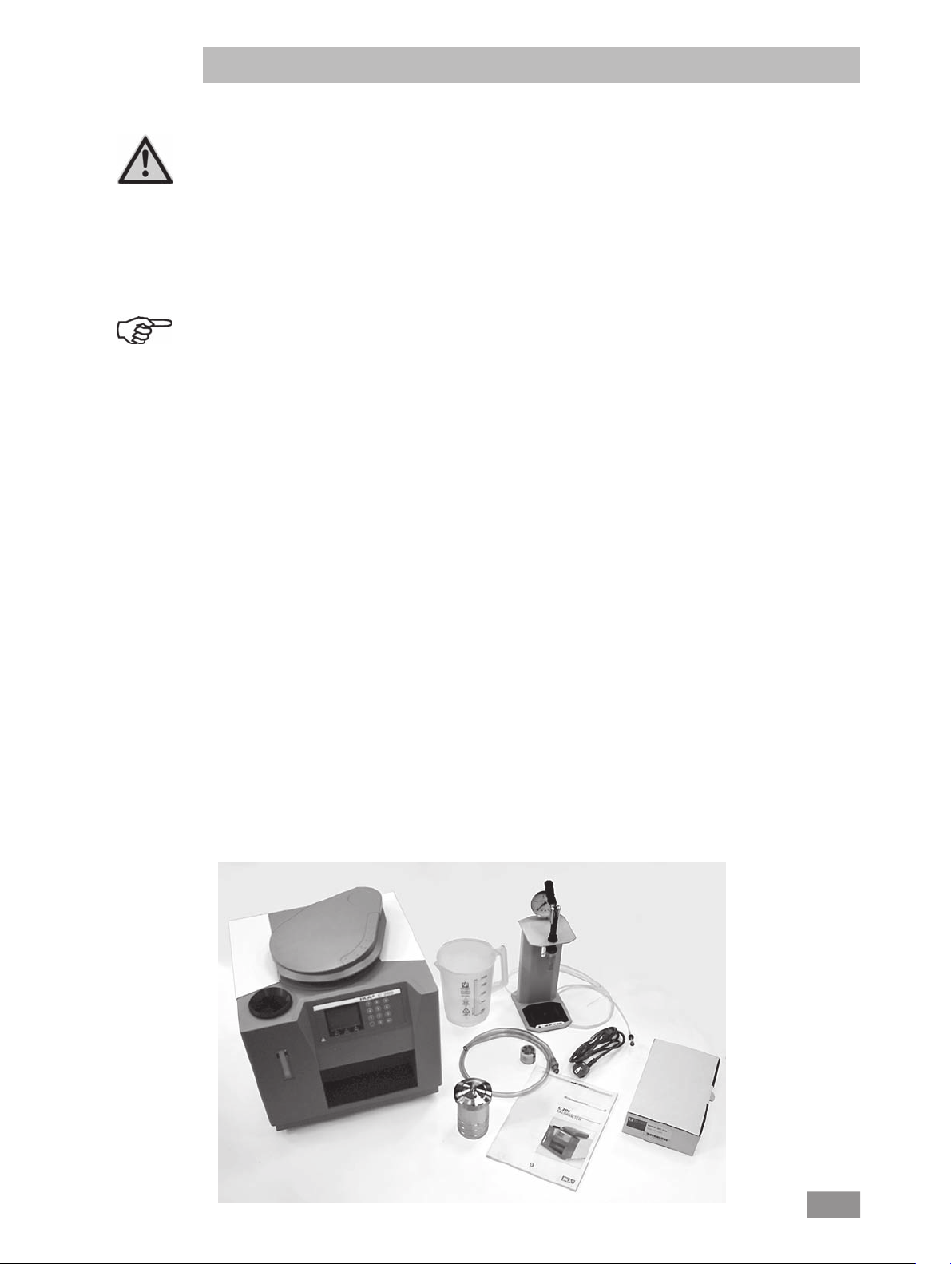

3.3 Unpacking 9

3.4 Delivery scope 9

4 Installations and starting up 10

4.1 Calorimeter C 200 10

4.2 Installation 10

4.3 Switchin on the system 12

4.4 Display and operating elements 12

4.5 Confi guring the system 13

4.6 System settings 14

4.7 Filling the calorimeter for the fi rst time 15

4.8 Switchin off the system 16

4.9 Coding decomposition vessel 16

4.10 Oxygen station C 248 16

5 Calorimetric measurements 17

5.1 Determining the calorifi c value 17

5.2 Corrections 17

5.3 Information about the sample 18

5.4 Calibration 19

6 Preparing and performing measurements 19

6.1 Decomposition vessel C 5010 19

6.2 Preparing the decomposition vessel 20

6.3 Preparing the measurement 21

6.4 Performing the measurement 22

6.5 Cleaning the decomposition vessel 23

6.6 Errors in the measuring procedure 24

3

Page 4

7 Service menue 26

7.1 Operation 26

7.2 Description of service menue options 26

8 Cleaning and maintenance 27

8.1 Inner vessel fi lter 27

8.2 Filler 27

8.3 Micro fi lter 27

8.4 Maintaining the water circulation 28

8.5 Decomposition vessels 28

8.6 Cleaning informations 28

9 IKA® - Accessories and consumables 29

9.1 Accessories 29

9.2 Consumables 29

10 Technical data 30

4

Page 5

CE-Declaration of conformity

CE – KONFORMITÄTSERKLÄRUNG DE

Wir erklären in alleiniger Verantwortung, dass dieses Produkt den Bestimmungen der Richtlinien 89/ 336 EG, 89/ 392

EG und 73/ 23 EG entspricht und mit folgenden Normen und normativen Dokumenten übereinstimmt: EN 61010,

EN 50082, EN 55014 und EN 60555.

CE – DECLARATION OF CONFIRMITY EN

We declare under our sole responsibility that this product corresponds to the regulations 89/ 336 EEC, 89/ 392 EEC

and 73/ 23 EEC and conforms with the standards or standardized documents: EN 61010, EN 50082, EN 55014 and

EN 60555.

DÉCLARATION DE CONFORMITÉ CE FR

Nous déclarons sous notre responsabilité que se prodiut est conforme aux réglementations 89/ 336 CEE, 89/ 392 CEE

et 73/ 23 CEE et en conformité avec les normes ou documents normalisés suivant: EN 61010, EN 50082, EN 55014 et

EN 60555.

DECLARACION DE CONFORMIDAD DE CE ES

Declaramos por nuestra responsabilidad propia que este producto corresponde a las directrices 89/ 336 CEE, 89/ 392

CEE y 73/ 23 CEE y que cumple las normas o documentos normativos siguientes: EN 61010, EN 50082, EN 55014 y

EN 60555.

CE – DICHIARAZIONE DI CONFORMITÀ IT

Dichiariamo, assumendone la piena responsabilità, che il prodotto è conforme alle seguenti direttive CCE 89/ 336, CCE

89/ 392 e CCE 73/ 23, in accordo ai seguenti regolamenti e documenti: EN 61010, EN 50082, EN 55014 e EN 60555.

5

Page 6

1 Safety instructions

For your protection

• Read the operating instructions in full

before starting up and follow the safety

instructions.

• Keep the operating instructions in a place whe-

re they can be accessed by everyone.

• Ensure that only trained staff work with the ap-

pliance.

• Follow the safety instructions, guidelines,

occupational health and safety and acci-

dent prevention regulations.

• Wear your personal protective equipment

in accordance with the hazard category

of the medium to be processed.

• Calorimeter system C 200 may only be used to

determine the calorific value of solid and fluid

materials. Only the appropriate original IKA®

decomposition vessels may be used for this

purpose. For detailed information, please see

the operating instructions for the decomposition vessels.

• The maximum extra energy added to the de-

composition vessel must not exceed 40,000 J

(select the test mass accordingly). The permitted operating pressure of 230 bar must not be

exceeded. The maximum permitted operating

temperature must not exceed 50 °C.

•

Do not overfill the decomposition vessel with

sample. Only fill the decomposition vessel with

oxygen to a maximum pressure of 40 bar.

Check the set pressure on the pressure reducer.

Perform a leakage test before each combustion

process (follow operating instructions for decomposition vessel!).

• Some materials tend to explode when combus-

ted (e.g. due to formation of peroxide), which

could cause the decomposition vessel to crack.

• Standard decomposition vessels may not

be used for testing explosive samples.

• If the burning behaviour of a material is unk-

nown, it must be tested before combustion in

the decomposition vessel (risk of explosion). If

you are burning unknown samples, leave the

room or keep your distance from the calorimeter.

• Benzoic acid may only be combusted in its

pressed form! Flammable dust and powder

must be first pressed. Oven-dry dust and pow

der such as splints, hay, straw etc. explode

when combusted! Always wet these materials first! Highly flammable liquids with a low

vapour pressure (e.g. tetramethyl dihydrogen

disiloxane) must not directly touch the cotton

thread!

• Furthermore, toxic combustion residue in the

form of gases, ashes or condensation, for example, is possible in the inner wall of the decomposition vessel.

• When handling combustion samples, com-

bustion residue and auxiliary materials, please

observe the relevant safety regulations. The

following materials, for example, could pose a

risk:

– corrosive

– highly flammable

– explosive

– bacteriologically contaminated

– toxic

• Please observe the relevant regulations when

handling oxygen.

Warning: oxygen as a compressed gas is

oxidising; intensively aids combustion; can

react violently with flammable materials.

Do not use oil or grease!

• Caution - magnetism! Effects of the mag-

netic field have to be taken into account (e.g.

data storage media, cardiac pacemakers ...).

• When using stainless steel crucibles tho-

roughly check their condition after each expe-

riment. If the material gets thinner, the crucible

may catch fire and damage the decomposition

vessel. Crucibles must not be used for more

than 25 combustions for safety reasons.

• The decomposition vessel is manufactured in

accordance with the directive for pressure

equipment 97/23/EC.

This is indicated by the CE symbol with the ID

number of the notified body. The decompositi-

on vessel is a category III pressure device. The

decomposition vessel has undergone an EC

prototype test. The CE declaration of confor-

mity confirms that this decomposition vessel

corresponds to the pressure device described in

the EC prototype test certificate. The decompo-

sition vessel has undergone a pressure test

6

Page 7

with test pressure of 330 bar and a leaka-

ge test with oxygen at 30 bar.

• Decomposition vessels are experiment autocla-

ves and must be tested by a technical expert

after each use.

Individual use is understood here to include a

series of experiments performed under roughly

the same conditions in terms of pressure and

temperature. Experiment autoclaves must be

operated in special chambers (C 2000, C 5000,

C 7000, C 200).

• The decomposition vessels must undergo re-

peated tests (internal tests and pressure tests)

performed by the technical expert. The frequency of these tests is to be determined by

the operator on the basis of experience, type

of operation and the material used in the decomposition vessel.

• The declaration of conformity becomes

invalid if mechanical modifications are

carried out to the experiment autoclaves

or if tightness can no longer be guaran-

teed as a result of major corrosion (e.g.

pitting by halogens).

• The threads on the body of the decomposition

vessel and the union nut are subject to considerable stress in particular and must therefore be

checked regularly for wear.

• The condition and function of the seals must

be checked and ensured by way of a leakage

test (see operating instructions for decompo-

sition vessel!).

• Only technical experts may perform pressure

tests and service work on the decomposition

vessel.

• We recommend that you send the decomposition vessel to our factory for inspec-

tion, and if necessary, repair after 1000

tests or after one year or sooner depen-

ding on use.

• For the purposes of these operating instructions

a technical expert is someone

1.

who guarantees to conduct the tests properly

on the basis of his training, knowledge and experience gained through practical work,

2. who is sufficiently reliable,

3. who is not subject to any instructions in terms

of the test activity,

4. who has suitable test equipment if necessary,

5. who can provide appropriate proof of the requirements listed in 1.

• National directives and laws must be observed

for operating pressure vessels!

•

Anyone operating a pressure vessel must keep it

in a proper condition, operate it properly, supervise it, carry out the necessary maintenance and

repair work immediately and implement the

safety measures required in the circumstances.

• Pressure vessels must not be used if they have

defects which could pose a risk to staff or third

parties. The pressure equipment directive can

be obtained from Carl Heymanns or Beuth publishers.

•

The C 248 oxygen station must be set up at least

1.5 m far away from the calorimeter.

For protection of the equipment

• The voltage stated on the type plate must cor-

respond to the mains voltage.

• Removable parts must be refitted to the appli-

ance to prevent the infiltration of foreign objects, liquids etc.

• Protect the appliance and accessories from

bumps and impacts.

7

Page 8

2 User information

2.1 Information regarding operating instructions

General hazard

This symbol indicates information which is essential for the safety of

your health. Failure to observe this information can cause damage to

health and injuries.

This symbol indicates information which is important for ensuring that

the appliance functions without any technical problems. Failure to

observe this information could damage the calorimeter system.

This symbol indicates information which is important for ensuring that calorimetric measurements are performed effi ciently and for using the calorimeter

system. Failure to observe this information can result in inaccurate measurements.

TIP

2.2 Warranty and liability

You have purchased an original IKA

manufactured to the latest, highest quality standards. According to IKA®'s conditions of warranty, this product is guaranteed for 12 months.

To ensure the long-term precision and function

of the calorimeter system, we recommend that

you conclude a maintenance agreement (annual

maintenance) with IKA® or an authorised IKA®

workshop. If the fi rst maintenance is carried out

within 12 months of purchase, the warranty will

be extended to 24 months.

In the case of a warranty claim, please contact

the responsible representative or the supplier.

You can also return the appliance directly to

IKA®- WERKE.

Please enclose the sales invoice and the reason

for the claim and state the name of the contact

person at your company. Freight charges are to

be paid by the sender.

This symbol indicates references to the optimization of operatinal sequences

are characterized.

Attention - Risk of damage due to magnetism.

Numbers , , etc. indicate guidelines in the following sections which

must always be carried out in order.

®

product,

Please read these operating instructions carefully.

IKA®- WERKE only consider themselves to be

responsible for the safety, reliability and performance of the appliance when

• the appliance has been operated in accordance

with the operating instructions,

• only persons authorised by the manufacturer

interfere with the appliance,

•

only original parts and original accessories are

used for repairs.

IKA®- WERKE do not accept liability for damage

or costs resulting from accidents, misuse of the

appliance or unauthorised changes, repairs or

upgrades.

8

Page 9

3 Transport, storage, place of installation

3.1 Conditions of transport and storage

• The system must be protected against mecha-

nical impact, vibrations, dust deposits and corrosive ambient air during transportation and

storage.

• It is also important to ensure that the relative

humidity does not exceed 80%.

3.2 Place of installation

Please observe the respective country-specifi c regulations for operating pressure equipment when

installing the appliance. A constant ambient temperature is an important requirement for ensuring

the high measuring accuracy of the system. The

following conditions must therefore be fulfi lled at

the place of installation:

• No direct solar radiation

• No draughts (e.g. beside windows, doors, air

conditioning)

• Sufficient distance to radiators and other heat

sources

3.3 Unpacking

• Only the original packing may be used for trans-

portation.

• The appliance must be completely emptied be-

fore storing and transportation.

• The (constant) room temperature should be

around 20 °C ... 25 °C

• The system must be installed on a level surface.

• An adequate power supply corresponding to

the nameplates on the system components.

• Oxygen supply (99.95 % pure oxygen, quality

3.5; pressure 30 bar) with pressure display and

shut-off device (C 29 reducing valve, acces-

sories)

Please unpack the system components carefully

and check for any damage. When you unpack

the equipment, check for any damages which

may have occurred during transportation.

3.4 Delivery scope

1 x Basic device C 200

1 x Decomposition vessel C 5010

1 x Ignition adaptor

1 x Attachment set

1 x Table power supply

Make a note of any damage and report it immediately (post, railway, shipping company).

1 x Power cable

1 x Operating instructions

1 x Water emptying hose (length: 1 m)

1 x Oxygen station C 248

1 x Measuring cup (2 l)

9

Page 10

4 Installation and starting up

4.1 Calorimeter C 200

Measuring cell cover

Tank fillers

Display

Keyboard

Fill level display

4.2 Installation

All the connections for draining as well as the peripherals are on the back of the appliance.

Connecting the table power supply

Connect the calorimeter to the table power supply (4-pin plug ). Check that the voltage information on the rating plate of the power supply

unit matches your mains supply. Connect the power line of the plug to the voltage source.

PC connector

Printer connector

ON/OFF switch

Table power supply connector

Table power supply

Connecting peripherals

When connecting peripherals make sure that

both they and the calorimeter are switched off at

ON/OFF switch .

10

Page 11

Connecting the water drain

Inner vessel

emergency drain

Tank drain

Inner vessel drain

TIP

Insert the emptying hose (included in package

contents) into plug-in coupling . Place this in

the mould so that it is sloping. This must always

be connected for operation.

If the inner vessel ever requires emergency drainage, insert the emptying hose into plugin coupling . To empty the tank container, insert the

emptying hose into plug-in coupling (see service menu section 7.2).

Opening the calorimeter cover:

The calorimeter cover is opened by hand by lifting the cover by the gripping groove and raising it until

it automatically swivels to the right and locks in position.

If you use a thermostat to fill the tank, you can

also hang the drain hose in the thermostat. Check

that the thermostat is below the calorimeter. If

the thermostat is self-priming in the return line,

you can also install the thermostat beside the calorimeter.

Raise Swivel to right

11

Page 12

4.3 Switching on the system

Switch the calorimeter on at ON/OFF switch

(back of appliance). The appliance is now in

standby mode.

Press ON (F1) to work with the appliance. The

start screen will appear.

The operating console features the following elements:

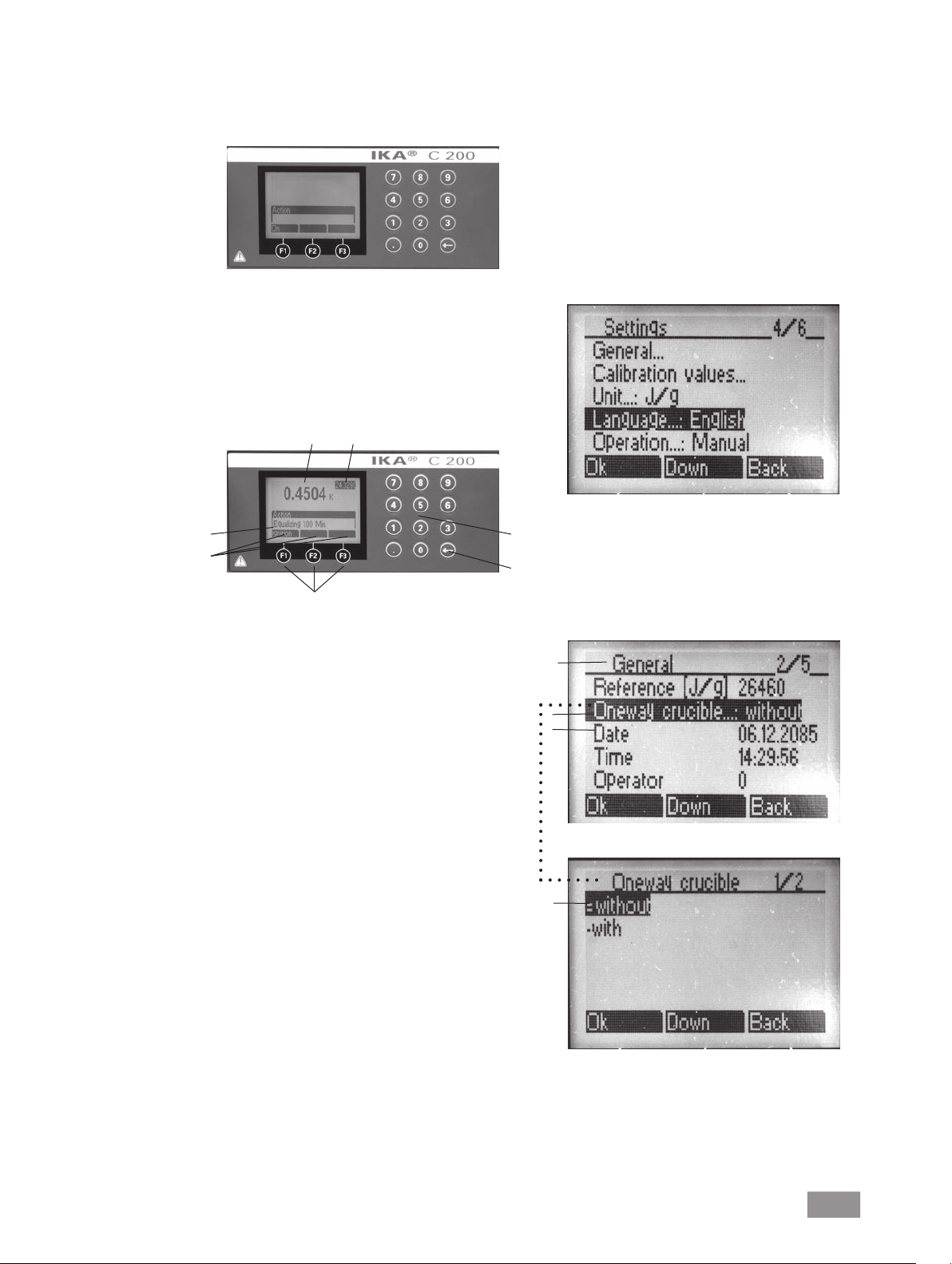

4.4 Display and operating elements

Delete button: this key is used to delete the

last character entered.

Display elements in menu mode:

If you press the Menu (F3) key, a menu will appear in the display which allows you to enter settings. There are six submenus:

GENERAL

CALIBRATION VALUES

UNIT OF MEASUREMENT

LANGUAGE

MEASURING PROCEDURE

SERVICE

TIP

Display elements during operation:

Status line: shows the current status of the

appliance.

Footer: shows what the function keys cur-

rently do.

Exception: a progress bar is displayed during

automatic measuring runs.

Reading value: shows the current tempera-

ture increase in minute intervals during the

measurement or the measurement result after

the measurement.

Current temperature value: shows the cur-

rent temperature in second intervals at the

sensor in the inner vessel.

Operating elements:

Function keys F1, F2, F3: what these keys

do depends on the operating state of the appliance. The footer of the display shows what

the function keys currently do.

Die Fußzeile des Displays zeigt die aktuelle Be-

legung der Funktionstasten an.

Pressing the DOWN (F2) key selects the menu

line below. Double clicking (F2) allows you to

switch between UP and DOWN. The current di-

rection of movement is displayed in the footer.

BACK (F3) allows you to exit a menu without

confi rming new settings.

Selection menu (e.g. combustible crucible)

Numerical keypad: this is used to enter digits

and the decimal point into command lines.

12

Page 13

Menu header:

shows the name of the submenu and the currently selected menu line of the total number of

menu lines (for example, 2/5: you are in the second of fi ve lines).

There are three different menu lines , and :

Submenu line:

“. . .“ this line indicates that a submenu is called

up with OK (F1). “. . . :“ indicates that it is a

selection menu.

If you press OK (F1) on a selection line in this

selection menu, this selection will be confi rmed

and you will exit the menu. The current selection

is marked with ” = ” and is displayed after the ”:”

in the submenu line.

Command line:

this line allows you to directly enter numerical values using the keyboard. If you press OK (F1),

the menu settings will be saved and you will exit

the menu.

Set date

MENU (F3)

UP/DOWN (F2) to "General"

OK (F1)

UP/DOWN (F2) to "Date"

Enter the date in the format dd.mm.yyyy

(e.g: 06.12.2005)

OK (F1)

BACK (F3)

Set time

4.5 Confi guring the system

In order to ensure that the appliance works

properly, you must set some parameters the

fi rst time you use it.

Select language

MENU (F3)

UP/DOWN (F2) to "Language"

OK (F1)

UP/DOWN (F2) select desired language

(default: English)

OK (F1)

BACK (F3)

MENU (F3)

UP/DOWN (F2) to "General"

OK (F1)

UP/DOWN (F2) to "Time"

Enter the time in the format hh:mm:ss

(e.g: 14:29:56)

OK (F1)

BACK (F3)

Reference

In order to calibrate the appliance you must state

the exact calorifi c value of the calibration substance used (usually benzoic acid).

The set language will appear in the "Language"

submenu line.

13

Page 14

MENU (F3)

UP/DOWN (F2) to "General"

OK (F1)

Enter the calorific value in the format xxxxx

(default: 26460)

OK (F1)

BACK (F3)

Calibration values

Once you have calibrated the appliance, you will

need to enter the calculated C-values (calibration

values) of all the decomposition vessels used.

MENU (F3)

UP/DOWN (F2) to "Calibration values"

OK (F1)

UP/DOWN (F2) select desired decompositi-

on vessel

Enter the C-value in the format xxxx

(default: 1)

OK (F1)

BACK (F3)

MENU (F3)

UP/DOWN (F2) to "General"

OK (F1)

UP/DOWN (F2) to "Combustible crucible"

OK (F1)

Select the options "with" oder "without"

(default: without)

OK (F1)

BACK (F3)

Operator

You can assign each operator an ID number (0-9).

This number will appear on the results report.

See the advice in section 5.4 Calibration.

4.6 System settings

In addition to the confi guration described in section 4.5, you can apply other settings which are

not necessary for the correct functioning of the

appliance or which are only required for special

applications.

Combustible crucible

If you are using a combustible crucible, you can

enter this here. The value for the external energy

QExternal1 will then be automatically reduced by

50 joules as no cotton thread is used. The combustible crucible itself must be weighed and the

resulting calculated energy value manually entered under QExternal2 (see section . 6.3, ) so

that it can be taken into account as external energy when calculating the calorifi c value.

MENU (F3)

UP/DOWN (F2) to "General"

OK (F1)

UP/DOWN (F2) to "Operator"

Enter ID code (default: 0)

OK (F1)

BACK (F3)

Unit of measure

You can set the unit of measure you want the

measuring results to be displayed in. The currently selected unit of measure is marked with "=".

14

Page 15

MENU (F3)

UP/DOWN (F2) to "Unit"

OK (F1)

UP/DOWN (F2) select the desired unit

(default: J/g)

OK (F1)

BACK (F3)

Time control

Calorimeter C 200 performs the measurement

automatically according to a set period of time

and calculates the provisional result. The measuring time is set at 14 minutes.

4.7 Filling the calorimeter for the fi rst time

Measuring procedure

You can choose between four measuring procedures:

MENU (F3)

UP/DOWN (F2) to "Measuring procedure"

OK (F1)

UP/DOWN (F2) select desired measuring

procedure

(default: Isoperibol)

OK (F1)

BACK (F3)

Isoperibol

Calorimeter C 200 automatically performs the

measurement according to the standard for isoperibol calorimeters and calculates the provisional

result for you. The measurement takes approx. 17

minutes with excellent result reproducibility.

Manual

This is ”student mode”. You work according to

the standard for isoperibol / isothermal calorimeters. You read the temperature values off yourself

every minute, calculate the temperature drift before ignition, ignite and end the experiment by

pressing F1, calculate the temperature drift after

the temperature increase and calculate the result

itself.

Before using the calorimeter for the fi rst time

you must fi ll the outer vessel with tap water.

Destilled and/or deactveted water may not be

used!

To do this, pour two litres of tap water into the

fi ller of tank (see section 4.1) using the measuring cup provided.

The water must fi rst be maintained at a constant

temperature. To ensure accurate results, the initial temperature must not fl uctuate too much.

Water temperature 18 °C - 25 °C with an accuracy of ±1 °C during a measurement series.

You must now pump the water out of the tank

into the outer vessel:

MENU (F3)

1st FILL (F2)

Pumping procedure is started

TIP

Dynamic

Calorimeter C 200 performs the measurement

automatically and calculates the provisional result. The measuring time is reduced to approx. 8

minutes thanks to a dynamic correction process.

It is still possible, however, to meet the accuracy

specifi cations of the international standards.

Keep an eye on the water by pulling the fi ller of

tank (see section 4.1) out the top.

When the overfl ow causes the water to run back

in the side of the tank, the outer vessel is full and

you must switch off the pump again by pressing

STOP OK (F2) once more.

You should change the water if it has been sitting

for a long time, see section 8.3.

15

Page 16

4.8 Switching off the system

4.10 Oxygen station C 248

TIP

Standby mode

In order to switch off the calorimeter system, the

start screen must be displayed.

Press OFF (F1). The appliance will switch to

standby mode.

Switching off

Only switch the appliance off in standby mode.

To do this, press the ON/OFF switch (see section 4.2) on the back of the appliance.

4.9 Coding decomposition vessels

You can use several decomposition vessels (max.

4) when working with calorimeter C 200. You

can code these to distinguish between them by

sticking the black coding strips into the special

slots on the decomposition vessels.

Decomposition vessel no.:

The C 200 does not have an integrated oxygen

fi lling point for the decomposition vessel. You

can use oxygen station C 248 for fi lling.

The C

248 oxygen station must be set up at least 1.5 m

far away from the calorimeter.

For information on

how to operate and connect the oxygen station,

please see the accompanying operating instructions.

Operation:

• Place decomposition vessel C 5010 on the

marked position.

• Move the lever down and centre the de-

composition vessel below the fi ll head .

• Lock the lever in place.

•

Fill the decomposition vessel for approx. 30

secs.

• Move the lever back to its original position.

Lever

Slot for

coding strips

1 2

without coding

3

Fill head

4

16

Page 17

5 Calorimetric measurements

5.1 Determining the calorifi c value

Combustion is carried out in a calorimeter under

specifi c conditions. The decomposition vessel is

fi lled with a weighed fuel sample, the fuel sample

is ignited and the temperature increase in the calorimeter system measured. The specifi c calorifi c

value of the sample is calculated as follows:

Ho = (C * DT - QExt1 - QExt2) / m (1)

m

Weight of fuel sample

C

Heat capacity (C-value) of calorimeter system

DT

Calculated temperature increase of water in inner

vessel of measuring cell

QExt1

Correction value for the heat energy generated

by the cotton thread as ignition aid

QExt2

Correction value for the heat energy from other

burning aids

The decomposition vessel is fi lled with pure oxy-

gen (99.95 %) to optimise the combustion pro-

cess. The pressure of the oxygen atmosphere in

the decomposition vessel is max. 30 bar. Formula

(1) for the calorifi c value of a material requires

that combustion takes place under specifi cally

defi ned conditions. The relevant standards are

based on the following assumptions:

In many cases, however, not just the combustion products referred to in the standards are

produced. In such cases the fuel sample and the

combustion products must be analysed to provide data for a revised calculation. The standard

calorifi c value is then calculated from the measured calorifi c value and the analysis data. The heat

value Hu is the same as the calorifi c value, minus

the condensation energy of the water contained

in the fuel and formed through combustion. The

heat value is the more important parameter from

a technical point of view because in all major,

technical applications only the heat value can be

evaluated in terms of energy.

The complete bases of calculation for the calorifi c and heat value can be found in the relevant

standards (e.g.: DIN 51 900; ASTM D 240; ASTM

D 5865..). They are also contained in the CalWin

calorimeter software.

5.2 Corrections

Due to the nature of the system a combustion

test does not just produce the combustion heat

of the sample, but also heat from external energy

(QExternal).

This can fl uctuate considerably in relation to the

heat quantity of the fuel sample.

• The temperature of the fuel and its combustion

products is 25 °C.

• The water contained in the fuel before combus-

tion and the water formed whilst combusting

the hydrogenous compounds of the fuel is in

fl uid form after combustion.

• The atmospheric nitrogen has not oxidised.

• The gaseous products after combustion consist

of oxygen, nitrogen, carbon dioxide and sulphur dioxide.

• Solid materials may form (e.g. ashes).

The combustion heat of the cotton thread which

ignites the sample and the electric ignition energy

would distort the measurement. This infl uence is

taken into account in the calculation by way of a

correction value.

17

Page 18

Note: in all the automatic calculations an extra

100 J have already been included for the electric

ignition energy. This value cannot be set.

Materials which are diffi cult to ignite or combust

are combusted together with a burning aid. The

burning aid is fi rst weighed and then put into

the crucible with the sample. The additional heat

quantity can be determined from the weight of

the burning aid and its known specifi c calorifi c

value. You must correct the test result by this heat

quantity.

®

IKA

- combustible crucible C 14 is a combustible

crucible, which can be used instead of a standard

crucible. The combustible crucible burns without

leaving any residue whatsoever. When using a

combustible crucible you do not need an extra

cotton thread. The crucible is placed directly on

the permanent ignition wire in the decomposition vessel and ignited.

The cleanliness of the material used in the combustible crucible prevents chemical contamination of the sample (no blank values).

Decomposition vessels, in which the combustible

crucible is used, must be fi tted with an extra part

(support C 5010.4, see Accessories). The sample

is weighed out into the combustible crucible as

normal. In most cases no additional burning aid

is required because the combustible crucible itself

serves as a burning aid.

Virtually all of the materials to be studied contain

sulphur and nitrogen. Under the conditions in calorimetric measurements, sulphur and nitrogen

combust to SO2, SO3 and NOx. Together with

the water from combustion and moisture, sulphuric and nitric acid as well as heat of solution

are produced. In order to obtain the standard calorifi c value, the infl uence of the heat of solution

on the calorifi c value is corrected. The calculation

formulae depend on the standard used. These

are not taken into account in the calculation for

C 200. Use IKA®'s CalWin software for this.

Failure to observe these instructions could result in damage to the decomposition vessel.

Exploding decomposition vessels present a risk

of serious injury or death. When working with

unknown substances, select very small weighted

samples at the start in order to determine the natural energy.

Normally solid materials in powder form can be

combusted directly. Materials which com-

bust quickly (e.g. benzoic acid) must not

be burnt loose. These materials tend to splash

and there is therefore no guarantee of complete

combustion.

Furthermore, this can damage the inner

wall of the decomposition vessel.

®

pelleting press C 21 and IKA® analytical mill

IKA

A 11 basic (see Accessories) are available for sample preparation.

Materials which are diffi cult to burn (materials

with a high mineral content, low caloric materials) can often only be fully combusted using IKA®

acetobutyrate capsules C 10, IKA® combustion

bags C 12 or IKA® combustible crucible C 14 (see

Accessories). It is also possible to use liquid burning aids such as paraffi n oil.

Before fi lling the capsule or the combustion bag

with the substance to be determined, weigh

them to calculate the extra external energy added by the burning aid from the weight and the

calorifi c value. This must be taken into account

in QExternal2. You should keep the amount of

burning aid used to a minimum.

Most fl uid substances can weighed out directly

into the crucible. Highly volatile substances are

poured into combustion capsules (IKA

®

gelatine

capsules C 9 or IKA® acetobutyrate capsules C

10, see Accessories) and combusted together

with the capsules.

The burning aids (e.g. cotton thread) must also

fully combust. If there is any unburnt residue, the

test must be repeated.

5.3 Information about the sample

FIt is essential that the sample fully combusts

to ensure correct determination of the calorifi c

value. After each experiment check the crucible

and all the solid residue for signs of incomplete

combustion.

As a rule the weighted sample must be selected in such a way that the temperature

increase during the measurement is below 4 K

and comes close to the temperature increase

of the calibration (max. extra energy: 40,000 J).

.

When working with unknown substances, select

very small weighted samples at the start in order

to determine the natural energy. If you are burning unknown samples, leave the room or keep

your distance from the calorimeter.

After combustion the water produced is collected and the decomposition vessel is thoroughly

rinsed with distilled water. The water used for

rinsing and the solution produced are combined

and examined for their acidity. If the sulphur content of the fuel and the nitric acid correction are

known, it is not necessary to analyse the water.

18

Page 19

5.4 Calibration

The calorimeter system must be calibrated before

accurate measurements are possible. This is done

by combusting tablets made of certifi ed benzoic

acid (see Accessories) with a known calorifi c value. The heat quantity required to raise the tem-

perature of the calorimeter system by one Kelvin

is used to determine the heat capacity of the socalled "C-value" of the system. For this calculation the formula (1) (see section 5.1) is adapted:

C = (Ho * m + QExt1 + QExt2) / DT (2)

This value is used for determining the following

calorifi c values.

The heat capacity is determined by the measuring cell and the decomposition vessel. It has a

signifi cant infl uence on the calorifi c value to be

calculated and must be redetermined in particular

when using for the fi rst time, after servicing and

when parts are replaced. A monthly control measurement is recommended.

The system must be calibrated in every work

mode used.

If a calorimeter is operated with several decomposition vessels, you will need to determine the heat capacity of the system for each

decomposition vessel.

Ensure that calibration is carried out under the

same conditions as the subsequent tests. If substances are used in the decomposition vessel in

combustion tests (e.g. distilled water or solutions), you must use exactly the same amount of

this substance for calibration.

For more detailed information on calibration, please see the relevant standards.

6 Preparing and performing measurements

The term "measurements" below refers to both

the measurements to calibrate the calorimeter

system (calibration measurements) and the actual

measurements for determining the calorifi c value.

The difference lies in the calculation (cf. section

5, formulae (1) and (2)), whereas preparation and

performance are virtually identical.

Exact measurements are only possible when the

individual test steps are carried out carefully.

You must therefore follow the exact procedure described in section 1 "For your safe-

ty” and in the following sections

Please also see section 5 "Calorimetric measurements”.

Failure to observe these instructions could result in damage to the decomposition vessel.

Damaged decomposition vessels could crack!

Follow the operating instructions for the decomposition vessel!

6.1 Decomposition vessel C 5010

Union nut

Oxygen valve

Electric

ignition

contact

Cover

Crucible

Ignition

wire

Crucible

holder

If several decomposition vessels are used,

their individual parts must not be interchanged (see Stamping individual parts).

To prolong the life of wearing parts (o-rings,

seals, etc.) we recommend that you always

work with a water trap.

19

Page 20

6.2 Preparing the decomposition vessel

Prepare the decomposition vessel as follows:

Cover

Union nut

Handle

Cotton thread

Unscrew the union nut and remove the cover

using the handle.

Attach a cotton thread to the centre of the

ignition wire using a loop.

Weigh out the substance directly into the

crucible with an accuracy of 0.1 mg. Note the

weight or enter directly into the calorimeter. (See

section 6.3 "Preparing the measurement").

Insert the crucible into the crucible holder.

If necessary put some distilled water or a solution

into the decomposition vessel.

See section 5.3 "Information about the sample" and section 1 "Safety precautions”.

Using tweezers, align the cotton thread so that

it hangs inside the crucible and is immersed in the

sample. This will ensure that the burning thread

ignites the sample during the ignition process.

Attention! Place the cover onto the lower

section and push down until it presses against the

stop piece in the lower section. Place the union

nut onto the lower section and tighten by hand.

Max. 1 mm

Fill the decomposition vessel using oxygen station C 248 (see section 4.10).

Slide the ignition adaptor onto the decomposition vessel.

For information on how to operate the decomposition vessel, please see the operating instructions

provided.

20

Page 21

Attaching

the ignition

adaptor

Place the decomposition vessel into the inner

vessel of calorimeter C 200. The decomposition

vessel must be placed between the three locating

bolts.

Detaching

the ignition

adaptor

1.

2.

6.3 Preparing the measurement

The calorimeter is in ”waiting” mode.

Selecting MEASUREMENT (F2) will take you

to the "Prepare measurement" menu.

Locating bolt

Magnetic stirring bar

Pour approx. 2 l tap water maintained at a constant temperature into the tank using the measu-

ring cup. Keep an eye on the level indicator!

Enter the noted weighted sample in the

marked "Einwaage" (weighted sample) field with

an accuracy of 0.0001 g using the keyboard.

You can access all the other options by pressing

UP/DOWN (F2):

CALIBRATION

Enter "1" here to perform a calibration.

Check the other presettings:

DECOMPOSITION VESSEL

Enter the number of the decomposition vessel

used for this test. If you are only using one decomposition vessel, you can leave the "1" in the

"decomposition vessel" fi eld.

QEXTERNAL1

Correction value for the heat energy generated

by the cotton thread ignition aid. A default value

of 50 J is specifi ed here. The default value for the

combustible crucible option is 0 J. If you use a

burning aid other than the C 710.4 IKA®-cotton

thread, change this value.

21

Page 22

QEXTERNAL2

Correction value for the heat energy from other

burning aids e. g. combustible crucible). The default value is 0.

TESTNO

For each measurement the software automatically assigns a number in the form of yymmddnn,

with jj representing the year, mm the month, dd

the day and nn a consecutive number. You can

also assign your own numbers to the measurements.

Example: TestNo = 0509150 represents the fi rst

measurement on 15 September 2005

Press OK (F1) to apply your entries.

Close the cover by moving it to the left out

of the locking position until it slides down by itself. The decomposition vessel comes into contact

with the igniters via the ignition adaptor.

The "Fill" message will appear.

6.4 Performing the measurement

Once you have done all the necessary preparatory work as described above, the message

”Storage fi lled?” (Tank fi lled?) will appear. Check

that the tank is fi lled with water maintained at

a constant temperature and confi rm by pressing

CONTINUE (F1).

The message appears “Vessel safe locked?“

Make sure the fact that the the decomposition

vessel is duly locked and confi rms you this with

OK (F1).

After in each case 1000 ignitions of an decomposition vessel you are with the message “Vessel x :

1000 ignitions!” pointed out that this decomposition vessel reached one point of maintenance

time and must be submitted of a security examination.

Confi rming these references by you successively

OK(F1) and OK(F2) press.

This reference does not relieve you of the obligation to already constandly examine decomposition vessel also before on wear and accomplish the

safety examination if neccessary.

The inner vessel will be filled with water (approx. 70 s). The measurement process will begin

as soon as it is full.

The message appears “Close the cover“.

22

Page 23

a) The measurement process is fully automatic

for automatic measuring procedures (isoperibol,

dynamic and time-controlled, see section 4.6).

The result will appear once the measuring process is complete.

After the measurement open the cover to automatically empty the inner vessel. Remove the

decomposition vessel and the ignition adaptor. To

release tension in the decomposition vessel use

venting button under a fume hood or venting

station C 5030 available in our accessories range.

See also section 1 "Safety precautions".

Open the decomposition vessel and check the

crucible for signs of incomplete combustion. If

combustion is incomplete, discard the test result.

Repeat the test.

b) With the manual measuring procedure the

user decides when ignition is to take place and

when the measurement is complete.

To start ignition press IGNITE (F1)

Press the same key END (F1) again to end the

measurement

In the case of manual ignition / completion, "Preparing to ignite" or „Preparing to complete" will

appear in the status line. Ignition/completion is

only fi nished when this display disappears (max.

60 sec.).

6.5 Cleaning the decomposition vessel

If you suspect that the combustion sample,

the combustion gases produced or the combustion residue could be harmful to health,

wear personal protective equipment (e.g.

protective gloves, breathing masks) when

handling these materials. Harmful or polluting

combustion residue must be disposed of as

hazardous waste. Express reference is made

to the applicable regulations.

In order to obtain accurate measurements it is

essential that the decomposition vessel is clean

and dry. Impurities alter the heat capacity of the

decomposition vessel and thus cause inaccurate

measuring results. It is important to thoroughly

clean the inner walls of the vessel, the internal

fi ttings (brackets, electrodes etc.) and the combustion crucible (inside and out!) after each combustion test.

In most cases, you will only need to remove condensate from the inner walls of the vessel and the

internal fi ttings. It is suffi cient to thoroughly wipe

the parts with an absorbent, non-fi brous cloth. If

the decomposition vessel cannot be cleaned in

the above way (e.g. due to baking, pitting, corrosion etc.), please contact the Technical Service.

23

Page 24

The combustion residue in the crucible, e.g. soot

or ashes, should also be wiped away with an absorbent non-fi brous cloth.

6.6 Errors in the measuring procedure

Errors in the measuring procedure are shown in

the alarm line of the display and remain there until they are appropriately acknowledged by the

user.

Message:

Cover open!

Cause:

Sample not combusted.

(Cotton thread had no contact to sample)

User action:

Open cover and remove decomposition vessel. If

the cotton thread has not combusted, check the

ignition contacts and the ignition wire. Otherwise, start a test and use ignition aid if necessary.

Cause:

Decomposition vessel may not have been fi lled

with oxygen.

Cause:

The cover was opened during the measuring process.

User action:

The inner vessel will be emptied automatically,

after which a new measurement can be started..

Note:

if the cover was opened within a minute of ignition, automatic emptying will be delayed by approx. 2 mins for safety reasons.

Cause:

No ignition contact during the measurement.

User action:

Open the cover and check the ignition wire and

ignition contacts. If necessary, clean the ignition

contacts or change the ignition wire. Check that

the ignition adaptor is in the right position.

Message:

No temperature increase

Appears if the value specifi ed for the temperature

increase is not reached within one minute of ig-

nition (0.05 K).

User action:

Open the cover to cancel the test and perform a

new measurement.

Message:

A/D converter error

Cause:

An error has occurred in the temperature measuring system.

User action:

If the measurement is still active, open the cover

to cancel the test. Then reinitialise the converter

(see section 7.2 ”ReInit”). If this does not work,

switch the appliance off and then back on again.

If this does not work either, please contact IKA®Service.

24

Page 25

Message:

Fill time exceeded

Cause:

Start temperature of inner vessel is not in range

22 ± 3 °C.

User action:

Open cover to cancel measurement, or press

CONTINUE (F1) to continue the measurement

anyway.

Note:

A measuring result obtained in this way does not

correspond to the standard conditions.

Cause:

No water in tank.

User action:

Check the fi ll level in the tank and top up with

water if necessary. Press CONTINUE (F1) to repeat the fi lling process and continue the measurement.

Cause:

Filter in inner vessel is dirty.

User action:

Open the cover to cancel the test. Remove and

clean the inner vessel fi lter.

Cause:

Pump for fi lling inner vessel is not working.

User action:

Open the cover to cancel the test. Switch on

the pump in the service menu (see section 7.2

”Pump”) and check water jet in tank. If there is no

water fl ow, please contact IKA

®

-Service.

Cause:

Fine fi lter clogged.

User action:

Clean the fi ne fi lter (see section 8.3 "Fine fi lter").

User action:

Check the water temperature for the tank. Check

the temperature shown. If it does not change

within 5 to 10 secs, reinitialise the A/D converter

(see section 7.2 ”ReInit”).

Message:

Drift unstable

Cause:

There is no magnetic rod in the inner vessel or

the magnetic rod is outside of the magnetic fi eld.

User action:

Open the cover to cancel the test and check the

position of the magnetic rod. If necessary, insert

the rod or position properly (see section 6.2, ).

Cause:

The stirrer is not working.

Message:

Start temperature outside

User action:

Open the cover to cancel the test. Half fi ll the

inner vessel with water (via Service menu see section 7.2) and then manually switch the stirring

motor on and off (also via Service menu). If the

stirring motor does not work, please contact the

IKA®-Service.

25

Page 26

Meldung:

Füllzeit überschritten

7.1 Operation

7 Service menu

This menu allows you to directly control and test

various actions and statuses of the calorimeter

without performing a measurement. There are

also menu items which can be used to start up

and shut down the appliance. The service menu

can only be run if the calorimeter displays the

start screen.

Perform the desired action using:

MENU (F3)

UP/DOWN (F2) to "Service"

OK (F1)

There are now eight actions to choose from

Please note that you must stop every started action.

Exceptions:

The "Ignite” action ends automatically after a set

time period (approx. 2 seconds).

With actions "Reset” and "ReInit” you will automatically exit the menu after the actions have

been performed.

If you exit the service menu, all the started actions

will be stopped and the system will be restored to

its original state. This will allow you to continue

without any errors.

7.2 Description of service menu options

Ignition

This menu item allows you to check the ignition

function.

Requirement:

There must be a decomposition vessel without

sample, but with ignition thread in the inner vessel and the cover must be closed.

Select the desired action with UP/DOWN (F2

OK (F1) starts the action

OK (F1) stops the action again

Fill IV

This menu item allows you to fi ll the inner vessel

manually.

Requirement:

There must be enough water in the tank.

Empty IV

This menu item allows you to empty the inner

vessel.

Requirement: the emptying hose must be locked

in place in the plug-in coupling (section 4.2).

Stirrer

This menu item allows you to switch on the stirrer drive and check that the magnetic rod is also

rotating in the inner vessel.

)

Requirement:

There must be approx. 0.5 l water in the inner

vessel.

26

Page 27

Pump

Switch the pump on with this menu item. The

outer vessel will be fi lled and rinsed (see also section 4.7).

Requirement:

Check that there is water in the tank.

Empty outer vessel

This menu item allows you to empty the outer

vessel.

Note:

Shut-down, completely empty appliance.

Requirement:

The emptying hose must be locked in place in

plug-in coupling (section 4.2).

8 Cleaning and maintenance

Reset

This menu item allows you to restore the default

settings.

Reinit

This menu item allows you to reinitialise the

A / D converter.

In order to ensure trouble-free operation over a

long period of time, it is important to carry out

the following maintenance work to the calorimeter system.

8.1 Inner vessel fi ller

Remove the fi lter element from the inner vessel

and clean the inner vessel fi lter in clear water or

an ultrasonic bath if there is any dirt visible. Also

clean the inner vessel, by re-moving the positioning mount for the decomposition vessel. Place

the fi lter back on the inner vessel connector after

cleaning.

Operation without the fi lter element causes dirt

in the valves and thus appliance failure.

8.2 Filler

8.3 Micro fi lter

In the back plate of the equipment is additionally

a micro fi lter. If the micro fi lter is dirty, the water

fl ow in the equipment is reduced. Thus the water

fi lling time of the inner vessel extends. Thereby

if the upper time limiting is exceeded by 120 seconds, the system indicates the disturbance and

breaks the measurement off.

There is also a fi lter in the fi ller. This prevents dirt

in the storage container. If the fi lter is dirty, remove the entire fi ller and clean the fi lter (see section

4.1, ).

27

Page 28

TIP

• For cleaning the micro fi lter you must empty

the outer vessel (see section 7.2).

8.4 Maintaining the water circulation

In the case of discontinuous use with tap water

(single measurements with long gaps) a stabiliser

must be added to the water circulation to prevent

the formation of algae.

Add approx. 4 ml IKA®-Aqua-Pro C 5003.1 to the

tank (see Accessories).

Switch the pump on via the service menu (section “Pump“). Switch the pump off again after

30 - 60 s.

You can also add the 4 ml Aqua-Pro to the water

maintained at a constant temperature in the last

measurement (before long gaps in measuring).

If the appliance is not going to be in operation for a long period of time, it is advisable

to completely empty the calorimeter's water

circulation.

The water must be drained out before transportation.

• Screw the cover of the micro fi lter down and

pull you out the fi lter element.

•

Clean the fi lter element with clear water.

• Insert the fi lter element after cleaning with the

opening inward again into the housing of the

micro fi lter and screw you on by hand the cover.

• Fill the outer vessel again with water (see sec-

tion 4.7).

• Control the tightness after you the equipment

again fi lled (see section 6.6 “Fill time exceeded).

Empty the outer vessel via the service menu (section 7.2 “Outer vessel“). The emptying hose must

be locked in place in the plug-in coupling (section 4.2).

Empty the tank by locking the emptying hose in

place in the plug-in coupling (section 4.2). The

tank will empty automatically.

Press the locking knob on the plug-in coupling

to remove the hose.

8.5 Decomposition vessels

Please see the operating instructions for

C 5010 for information on decomposition

vessel maintenance!

8.6 Cleaning information

Only clean IKA® appliances using these IKA® approved cleaning agents:

Dirt Cleaning agent

Dyes Isopropanol

Building materials Water containing

detergent,

Isopropanol

Cosmetics Water containing

detergent,

Isopropanol

Food Water containing

detergent,

Fuels Water containing

detergent,

Other materials Please consult IKA

®

28

Page 29

Comment:

- Do not place electrical appliances into the

cleaning agents for cleaning purposes.

- Stainless steel parts can be cleaned using standard stainless steel cleaning agents, but do not

use abrasives.

- We recommend that you wear protective gloves

for cleaning.

- The operator is responsible for ensuring appropriate decontamination in the event that dangerous material is spilt onto or into the appliance.

- Before using a cleaning or decontamination

method other than that recommended by the

manufacturer, check with the manufacturer that

the intended method will not destroy the appliance.

9 IKA® - Accessories and consumables

Spare parts order

When ordering spare parts, please give:

- Machine type

- Manufacturing number, see type plate

- Item and designation of the spare part, see

www.ika.com, spare parts diagram and spare

parts list.

Repair

- In case of repair the device has to be cleaned

and free from any materials which may constitute a health hazard.

- If you require servicing, return the appliance

in its original packaging. Storage packaging is

not suffi cient. Please also use suitable transport

packaging.

9.1 Accessories

C 5010 Decomposition vessel,

standard

C 5010.4 Support for combustible

crucible

C 5010.5 Support for large crucible

C 5030 Venting station

C 5040 CalWin

C 248 Oxygen station

C 21 Pelleting press

C 29 Reducing valve

C 200.1 Measuring cup

A 11 basic Analytical mill

®

, calorimeter software

9.2 Consumables

C 710.4 Cotton thread, cut to length

(500 pieces)

C 5010.3 Ignition wire, replacement

(5 pieces)

C 5003.1 Aqua-Pro bath stabiliser

(30 ml)

C 4 Quartz dish

C 5 VA combustion crucible set

(25 pieces)

C 6 Quartz dish, large

C 710.2 VA combustion crucible set, large

(25 pieces)

C 9 Gelatine capsules

(100 pieces)

C 10 Acetobutyrate capsules

(100 pieces)

C 12 Combustion bag, 40 x 35 mm

(100 pieces)

C 12A Combustion bag, 70 x 40 mm

(100 pieces)

C 43 Benzoic acid

(NBS 39i, 30 g)

C 43A Benzoic acid

(100 g)

C 723 Benzoic acid blister pack

(50 pieces)

C 14 Combustible crucible

(100 pieces)

C 15 Paraffi n strips

(600 pieces)

29

Page 30

10 Technical data

Table power supply (external):

Rated voltage 100 - 240 V AC

Frequency 50 / 60 Hz

Input power max. 150 W

Calorimeter:

Rated voltage 24 V DC 5A

Input power max. 150 W

Fuses (internal) 1x 2,5 AT

Perm. on-time Continuous operation

Protection class as per DIN EN 60 529 IP 20

Protection class III

Overvoltage category 2

Contamination level II

Perm. ambient temperature 20 °C ... 25 °C (constant)

Perm. ambient humidity 80%

Operation at a terrestrial altitude 2000 m above sea level

Dimensions 400 x 400 x 400 (W x D x H)

Weight 21 kg

Measurement ranges 40.000 J

Measuring mode / measurement times Isoperibol / approx. 17 min

Dynamic / approx. 8 min

Time control / 14 min

Manual / approx. 17 min

Interfaces 1 x parallel (Centronics)

1 x serial (RS 232)

Subject to technical changes!

30

Page 31

Page 32

Europe

Middle East Asia

Africa North America China Australia

IKA®- Werke IKA® Works, Inc. IKA® Works Guangzhou IKA® Works (Asia)

GmbH & Co.KG 2635 North Chase Pkwy SE 173 - 175 Friendship Road Sdn Bhd

Janke & Kunkel-Str. 10 Wilmington NC 28405-7419 Guangzhou No. 17 & 19, Jalan PJU 3/50

D-79219 Staufen USA Economic and Technological Sunway Damansara

Tel. +49 7633 831-0 Tel. 800 733-3037 Development District Technology Park

Fax +49 7633 831-98 Tel. +1 910 452-7059 510730 Guangzhou, China 47810 Petaling Jaya

sales@ika.de Fax +1 910 452-7693 Tel. +86 20 8222-6771 Selangor, Malaysia

usa@ika.net Fax +86 20 8222-6776 Tel. +60 3 7804-3322

sales@ikagz.com.cn Fax +60 3 7804-8940

sales@ika.com.my

Japan Korea

IKA® Japan K.K. IKA® Korea Co LTD

3-5-8 Yokonuma-cho, 1710 Anyang Trade Center

Higashiosaka-city, Osaka 1107 Buhung-dong,

577-0808 Japan Dongan-gu

Tel. +81-6-6730-6781 Anyang City, Kyeonggi-do

Fax +81-6-6730-6782 Post code: 431-817

info@ika.ne.jp South Korea

Tel. +82 31-380-6877

Fax +82 31-380-6878

michael@ikakorea.co.kr

India Brasilia

IKA® India Private Limited IKA® Works Inc.

814/475, Survey No. 129/1 Rua São Bento, 701 Sala 1

Mysore Road, Kengeri CEP 13160-000 Centro -

Bangalore - 560 060 Artur Nogueira - SP

Karnataka, India Brasil, South America

Tel. +91 80 26253900 Tel. +55 19 3877 2399

Fax +91 80 26253901 Fax +55 19 3877 2399

www.ika.com

info@ika.in www.ika.net fcabral@ika.net

00/0000/0

Loading...

Loading...