Page 1

IKA® Calorimeter C 1

20000004724

Operating instructions EN

C 1_042016

Page 2

2

EN

We declare under our sole responsibility that this product is in compliance with the regulations

2014/68/EC

(article 3, (3)),

2011/65/EU,

2014/30/EU

and 2014/35/EU

and conforms to the standards or standardized documents: EN 61010-1, EN 61326-1, EN 60529 and EN ISO

12100.

Declaration of Conformity

Explication of warning symbols

User notes

The warranty does not cover worn out parts, nor does it apply

to faults resulting from improper use, insucient care or

maintenance not carried out in accordance with the instructions

in this operating manual.

Please read these operating instructions carefully.

IKA® only

consider themselves to be responsible for the safety, reliability

and performance of the appliance when

• the appliance has been operated in accordance with the

operating instructions,

• only persons authorised by the manufacturer interfere with

the

appliance,

• only original parts and original accessories are used for repairs.

The calorimeter system may be opened only by an authorised

Service Agent or Customer Service Centre.

If service is required, we recommend that you contact our

customer service department. Furthermore, we refer you to the

applicable safety conditions and accident requirements.

IKA® is not responsible for damages or costs resulting from

accident, improper use of the device or impermissible modifications,

repairs or renovations.

Read the operation instructions completely before

starting up and follow the safety instructions.

Keep the operation instructions in a place where they can be

accessed by everyone.

Ensure that only trained staff work with the appliance.

Follow the safety instructions, guidelines, occupational health and

safety and accident prevention regulations.

In this chapter you can find out how to work through these

Operating Instructions most effectively to be able to work reliably

with the calorimeter system.

The instructions in the section “Safety instructions“ must

be complied with.

The chapters are designed for you to work through them in order.

The section “Transport, storage“ is relevant for system reliability

and for ensuring high measuring accuracy.

The calorimeter system is ready to perform measurements once

you have completed the procedures in the section “Setting up

and commissioning“: - “Preparing a measurement“ and “Starting

a measurement“.

Numbers 1, 2, 3 etc. indicate operating instructions in the

following sections. These must always be carried out in the

specified sequence.

Warranty and liability

In accordance with

IKA® warranty conditions, the warranty period

is 12 months. For claims under the warranty please contact your

local dealer. You may also send the machine direct to our factory,

enclosing the delivery invoice and giving reasons for the claim.

You will be liable for freight costs.

DANGER

CAUTION

WARNING

NOTICE

Indicates an imminently hazardous situation, which, if not avoided, will result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in injury.

Indicates practices which, if not avoided, can result in equipment damage.

Reference to exposure to a hot surface!

DANGER

Page 3

3

Page

Declaration of Conformity 02

Explication of warning symbols 02

User notes 02

Contents 03

Safety instructions 04

Correct use 05

System properties 05

Transportation, Storage 06

Transport and Storage conditions 06

Unpacking 06

Scope of delivery 06

Description of the system components 06

Hoses 07

Commissioning 07

Place of installation 07

Cooler connection 08

Venting hose connection 08

Drain hose connection 08

Oxygen supply connection 08

Power supply unit connection 09

Connection of peripherals 09

Handling the unit 09

Control unit with display 10

Dialog box 11

System start 12

Switching on the system (in the open state) 12

Selection of language 12

Pressure test 13

Oxygen pressure 13

System check 13

Heating detected 14

Factory settings 14

Calorimetric measurements 14

Determination of gross calorific value 14

Corrections 15

Notes on the sample 15

Complete combustion 16

Calibration 16

Notes on calibration 16

Overview Main menu 17

Measurements 17

Default settings 17

Settings 17

Maintenance 18

Informations 18

Preparing and performing measurements 18

Performing the measurement 18

Placing the sample 19

Preparing a measurement 20

Close the calorimeter 20

Prerequisite checking for a measurement 21

Measurement procedure 21

Cleaning the inner vessel 23

Follow-up measurement 23

Display the storage overview 23

Use of a disposable crucible 23

Using a scale 24

Permissible weight entries 24

Cancel a measurement 25

Page

Measurements 25

New measurements 25

Last result 25

System test 26

Measurement archive 26

Measurement archive: Edit 27

Measurement archive: Print 27

Measurement archive: Delete 27

Measurement archive: Delete all 28

Calibration archive 28

Calibration archive: Edit 28

Calibration archive: C-Value selectin 29

Calibration archive: Print 29

Calibration archive: Delete 29

Default settings 30

Settings 30

Date / Time 30

Units 30

Display / Keypad 31

Inverted menu view 31

List view 31

Language 31

Accessories 32

Chiller test 32

Maintenance 32

Maintenance menu 32

Change seal 33

Stirrer test 33

O2 System blow 33

Servo up 33

Servo down 33

Informations 33

User information: Memory 34

Prior to input a new measurement 34

After input a new measurement 34

Exchanging off wear parts 34

O2 Valve seal change 34

Change ignition wire 35

Change ignition electrode 35

Change the main seal 35

Change ground electrode 36

Leak test with the system test 36

Fault and troubleshoot 36

E01 STIRRER 36

E02 COMMUNICATION 37

E03 DRIFT ALARM 37

E04 MINTEMPDIFF 37

E05 FILLWATER 37

E06 EMPTYWATER 38

E07 POSTWATERFILLING 38

E10 FILLWATER SENSOR 38

E11 SYSTEM OPEN 38

E12 PRESSURE 38

E13 HEATER 39

E16 MAXTEMPDIFF 39

Accessories and Consumables 39

Maintenance 40

Warranty 40

Technical data 41

Contents

Page 4

4

Read the operating instructions in full before starting up and follow the safety instructions.

Keep the operating instructions in a place where they can be

accessed by everyone.

Ensure that only trained staff work with the appliance.

The calorimeter C 1 may only be used for the determination of

calorific value of solid and liquid materials according to national

and international standards (eg DIN 51900, BS 1016 T5, ISO 1928,

ASTM 5468, ASTM 5865 and ASTM 4809).

The pressure vessel is integrated into the calorimeter C 1. The

maximum extra energy added to the pressure vessel must not

exceed 40,000 J (select the test mass accordingly). The permitted

operating pressure of 142 bar (14.2 MPa) must not be exceeded.

The maximum permitted operating temperature must not exceed

50 °C.

Only fill calorimeter system C 1 with oxygen to a maximum

pressure of 40 bar (4 MPa). Check the pressure setting on the

pressure reducer for your oxygen supply. Perform a leakage test

before each combustion process (see section “Leaktightness

testing with system test“).

Some materials tend to explode when combusted (e.g. due to

formation of peroxides), which could cause the decomposition

vessel to crack. The

IKA® C 1 calorimeter may not be used

for testing explosive samples.

If the burning behaviour of a material is unknown, it must be

tested before combustion in the inner vessel (risk of explosion).

If you are burning unknown samples, leave the room or keep

your distance from the calorimeter.

Benzoic acid may only be combusted in its pressed form! Flammable

dust and powder must be first pressed. Oven-dry dust and powder

such as splints, hay, straw etc. explode when combusted! Always

wet these materials first! Highly flammable liquids with a low

vapour pressure (e.g. tetramethyl dihydrogen disiloxane) must not

directly touch the cotton thread!

Please pay attention to the combustion of metal-containing

substances, that the permissible total energy input is not exceeded!

Furthermore, toxic combustion residue in the form of gases, ashes

or condensation, for example, is possible in the inner wall of the

inner vessel.

Observe the accident prevention requirements applicable to the

activity and the work station.

Wear your personal protective equipment.

DANGER

When handling combustion samples, combustion residue and

auxiliary materials, please observe

the relevant safety regulations.

The following materials, for example, could pose a risk:

- corrosive

- highly flammable

- explosive

- bacteriologically contaminated

- toxic.

Please observe the relevant regulations when handling oxygen.

Warning: oxygen as a compressed gas is oxidising; intensively aids

combustion; can react violently with flammable materials.

Do not use oil or grease!

Tubes and screwed joints for oxygen must be kept free of grease.

DANGER

Combustion gases are hazardous

to health, therefore the venting

hose must be connected to a suitable gas cleaning system or extraction system.

DANGER

Caution! In case of failure Error 04

”Min.Temp.Diff.“ the combustion

chamber could be hot after an ignition/combustion, even though

the message ”No temperature increase!“ is displayed.

At the end of the work period, close the main valve for the oxygen

supply.

Perform servicing work only when the equipment is depressurised.

When using stainless steel crucibles thoroughly check their condition after each experiment.

If the material gets thinner, the crucible may catch fire and damage the pressure vessel. Crucibles must not be used for more

than 25 combustions for safety reasons.

The EC Declaration of Conformity confirms that this pressure vessel was manufactured by the Pressure Equipment Directive

2014/68/EC. (Article 3, paragraph 3).

The pressure vessel has undergone a pressure test with test pressure

of 203 bar (20.3 MPa) and a leakage test with oxygen at 40 bar.

Decomposition vessels are experiment autoclaves and must be tested

by a technical expert after each use. (see capture: “Maintenance“).

Individual use is understood here to include a series of experiments

performed under roughly the same conditions in terms of pressure

and temperature. Experiment autoclaves must be operated in special

chambers.

The pressure vessels must undergo repeated tests (internal tests and

pressure tests) performed by the technical expert. The frequency of

these tests is to be determined by the operator on the basis of experi

-

ence, type of operation and the material used in the pressure vessel.

The declaration of conformity becomes invalid if mechanical

modifications are carried out to the experiment autoclaves or if

tightness can no longer be guaranteed as a result of major corrosion (e.g. pitting by halogens).

In particular the Thread on the lower part of the pressure vessel

and the nut are subject to considerable stress and must therefore

be checked regularly for wear. (see figure “Description of the system components“).

The condition and function of the seals must be checked and ensured by way of a system test (see capture “system check“).

Check the seals for damage before each use (see chapter

“Maintenance“.

DANGER

If the maintenance, and especially

the pressure testing, is not performed or is performed incorrectly,

there is a risk the decomposition vessel may burst or an uncontrolled internal fire may occur at the electrodes which could burn away the

seals (oxyacetylene torch effect),

thus posing a risk to life and limb!

Only technical experts may perform pressure tests and service

work on the decomposition vessel.

Safety instructions

Page 5

5

We recommend that you send the C 1 calorimeter system

to our factory for inspection, and if necessary, repair after

1000 tests or after one year or sooner depending on use.

For the purposes of these operating instructions a technical

expert is someone

1. who guarantees to conduct the tests properly on the

basis of his training, knowledge and experience gained

through practical work,

2. who is suciently reliable,

3. who is not subject to any instructions in terms of the test

activity,

4. who has suitable test equipment if necessary,

5. who can provide appropriate proof of the requirements

listed in 1.

National directives and laws must be observed for operating

pressure vessels!

Anyone operating a pressure vessel must keep it in a proper

condition, operate it properly, supervise it, carry out the necessary

maintenance and repair work immediately and implement the

safety measures required in the circumstances.

A pressure container must not be operated if it exhibits defects

that could endanger those working with it or third parties.

You can obtain a copy of the pressure vessel regulation from

Beuth Press.

The IKA® C 1 calorimeter system is used for calorific value determination of solid and liquid substances.

This is done by placing a known quantity of a substance in a decomposition vessel which is surrounded by a water jacket. The

sample is then combusted in an oxygen atmosphere . The calorific

value of the sample can then be calculated from the resulting

increase in temperature, the sample mass and the known thermal

capacity of the overall system.

The C 1 calorimeter system is subject to the Pressure Vessel Directive

2014/68/EC. Comply with the safety instructions accordingly.

For adaptation to individual laboratory tasks, use original

IKA®

consumables and accessories.

System properties

The

IKA® C 1 calorimeter is a combustion calorimeter for deter-

mining gross calorific values of liquid and solid non-explosive substances. The samples were burned at an excess of oxygen under

pressure in a closed vessel. The resulting amount of heat, measured

in a previously calibrated system, allows the determination of the

calorific value of the sample after preliminary various globally ap

-

plied standards and regulations.

The necessary corrections after combustion in the calorimeter

can then, for example, about our CalWin

®

C 6040 calorimeter

software (accessories), from the acid corrections up to the calorific value according to DIN, ISO, ASTM, GB, and GOST standards

typed, corrected and calculated. By a transfer of the results to

Excel can quickly and easily adapt special or own calculations.

The worldwide unique patented

IKA® calorimeter C 1 operates on

the globally applied isoperibolic measurement procedure at 22 °C

and 30 °C. The temperature values are output every 12 seconds,

and the calculation of the temperature correction according to

standards Regnault Pfaundler.

Measurement times of the system:

- Sample preparation time: < 1 minute

-

from the start of measurement until the start of the next: 12 minutes

- Pre-experimental period: Response of the system 3 minutes

- Main experiment: after ignition of the sample: 4 minutes

To a supply of cooling water, the calorimeter can with a conventional thermostat / cooler operate for example such as the

IKA®

KV 600 (accessory).

Do not use distilled or demineralized water (increased risk

of corrosion)!

Fill the cooler according to the cooler operating instructions.

Cooling water temperature settings on the thermostat / cooler:

- in mode of opretaion isoperibol 22 °C: 18–21 °C

- in mode of opretaion isoperibol 30 °C: 26–29 °C

Alternatively, the device can also be operated via an optionally

available heating C 1.20 (accessories) at a fixed water connection.

The accessories for connection to the water pipe or the thermostat is contained in the corresponding delivery.

Requirements for the operation of the C 1 with the C 1.20 heating

on a water pipe:

- tap water: is recommended in drinking tap water quality. Mix in

(max. 1 ml for 4-5 l of water) of the supplied water additive.

Thus, the durability of the water is improved.

- temperature range: 12 °C – 28 °C

(according to the water temperature, the measuring mode

22 °C or 30 °C must be selected).

- water pressure: max. 1 – 1.5 bar

(at higher or constant pressure, we recommend using the

C 25 water pressure regulating valve available as an

accessory)

- water consumption per measurement: about 4 liters

Automatic internal system checks enable the identification and

monitoring

• the presence of oxygen pressure

• the controlled stirrer speed

• the the availability of water in the system

• the input water temperature

• of inner vessel

• the correct shutter of the measuring cell with locking

• Ignition counter with memory function for the next due

maintenance

Correct use

Page 6

6

Transport and Storage conditions

The system must be protected against mechanical impact, vibrations, dust deposits and corrosive ambient air during transportation and storage. It is also important to ensure that the relative

humidity does not exceed 80%.

The appliance must be completely emptied before storing and

transportation.

In case of repair the device has to be cleaned and free from any

materials which may constitute a health hazard.

Unpacking

Please unpack the system components carefully and check for

any damage. When you unpack the equipment, check for any

damages which may have occurred during transportation.

In the case of any damage a fact report must be sent immediately

(post, rail or forwarder).

If you require servicing, return the appliance in its original packaging. Storage packaging is not sucient. Please also use suitable

transport packaging.

•

IKA® C 1 Calorimeter

• Power supply unit

• Inflow conduit

• Return conduit

• Discharge hose

• Round cable clamp

• Connection tube

• Venting hose

• Mains cable

• 1 Tool

• 5 O-ring FPM 11.0 x 2.0

• 2 O-ring FPM 6.0 x 2.0

• 2 O-ring FPM 15.0 x 2.0

• 5 O-ring FPM 10.0 x 2.5

• 5 O-ring FPM 8.0 x 2.5

• 5 O-ring FPM 4.0 x 1.5

Interfaces on

rear of the unit

Controller unit with

display, Multifunctional

element and keybord

Inner vessel (IB)

Manual,

pivotable lift

A

A-A

Base

Ignition wire

Ground electrode

Ignition

electrode

Crucible

holder

Sectional view

inner vessel

Measuring cell as

a pressure vessel

Rotary

handle

Threaded nut

Threaded base

• 1 O-ring FPM 3.1 x 1.6

• 5 O-ring FPM 3.0 x 1.5

• 5 O-ring FPM 48.0 x 2.0

• 1 Quad-Ring NBR 92.0 x 4.5

• 1 X-Ring NBR 6,07 x 1,78

• C 1.104 water bath additive

• C 723 Benzoic acid

• C 1.1012 Organizer

• 4 base

• O-ring-grease Molykote 55

• Handle

• Operationg instructions C 1

• Safety instructions C 1/C 6000

• Technical information C 1

• Insert sheet C 1 (4 steps to use)

• Warranty card

C 1.1012

Organizer

Transportation, Storage

Scope of delivery

Description of the system components

Page 7

7

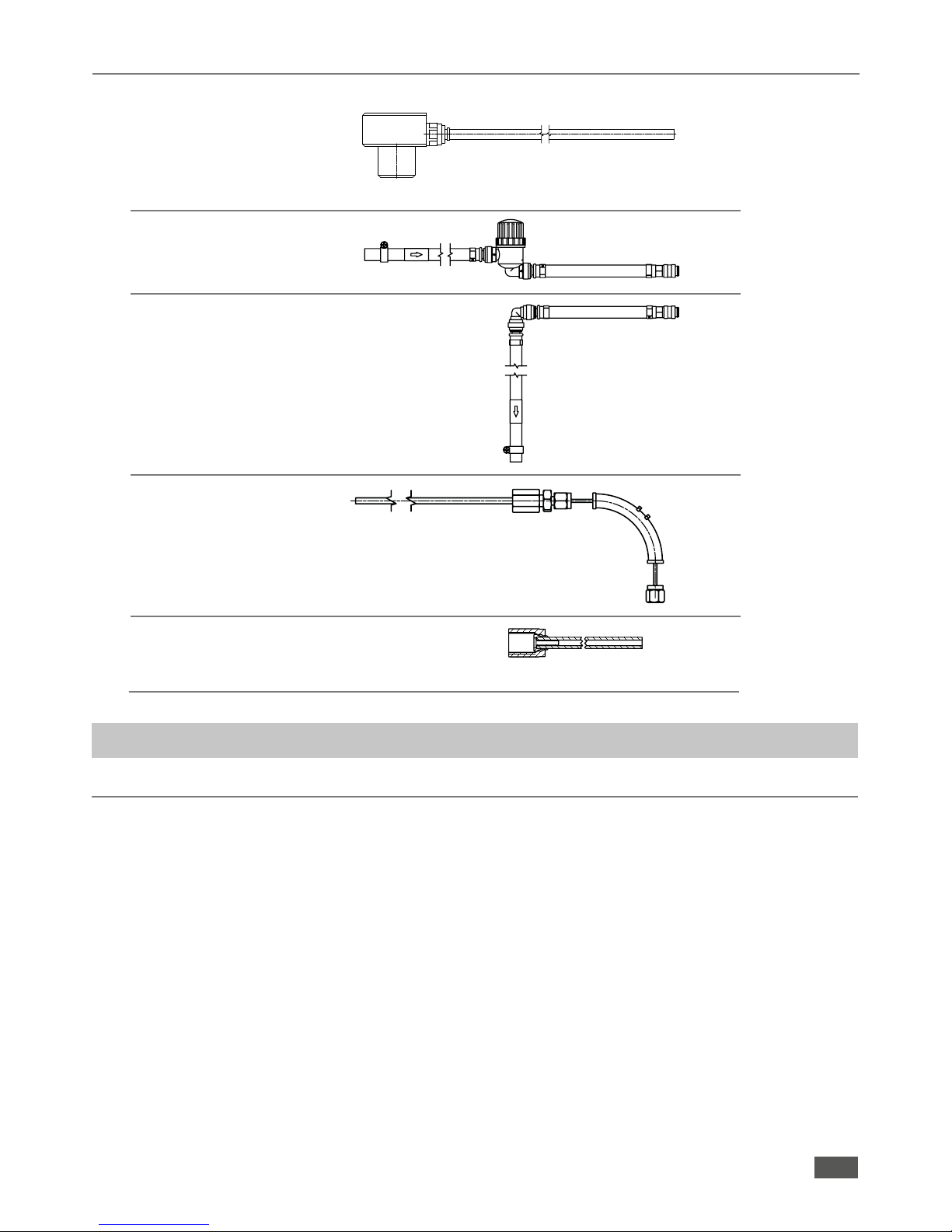

Hoses

• Discharge hose

• Inflow conduit

• Return conduit

• Venting hose

• Connection tube

SW8

Cooler

C 1

C 1

Cooler

C 1

C 1

(O)

C 1

(degas)

(water in)

(water out)

(overflow)

filter 10m

Cooler

Exhaust

air

Pressure reducer C 29

Adapter

SW10

Place of installation

A constant ambient temperature is an important requirement

for ensuring the high measuring accuracy of the system. The

following conditions must therefore be fulfilled at the place of

installation:

• No direct solar radiation

• No draughts (e.g. beside windows, doors, air conditioning)

• Sucient distance to radiators and other heat sources

• The minimum distance between the wall and the rear side

of the device must be at least 25 cm.

• The system must not have laboratory hardware such as

shelves, wire ducts, ring lines, etc. installed above it.

• The (constant) room temperature should be around

20 °C ... 25 °C.

• The system must be set up on a horizontal surface.

For operation of the system the following must be available at the

place of installation:

- A power supply corresponding to the nameplates on the system

components,

- An oxygen supply (99.95 % pure oxygen, quality 3.5; pressure

30 bar) with pressure gauge.

A shut-off valve for the oxygen supply must be installed. Observe

the instructions on handling oxygen given in the chapter “Safety

instructions“.

Observe the instructions on handling oxygen given in the chapter

“Safety instructions“. Please read these operating instructions

carefully.

IKA® consider themselves responsible for the safety,

reliability and performance of the appliance only when

• the device has been operated in accordance with the

operating instructions

• the specifications for the place of installation have been met.

max. 1.5 bar

Commissioning

Page 8

8

Cooler connection

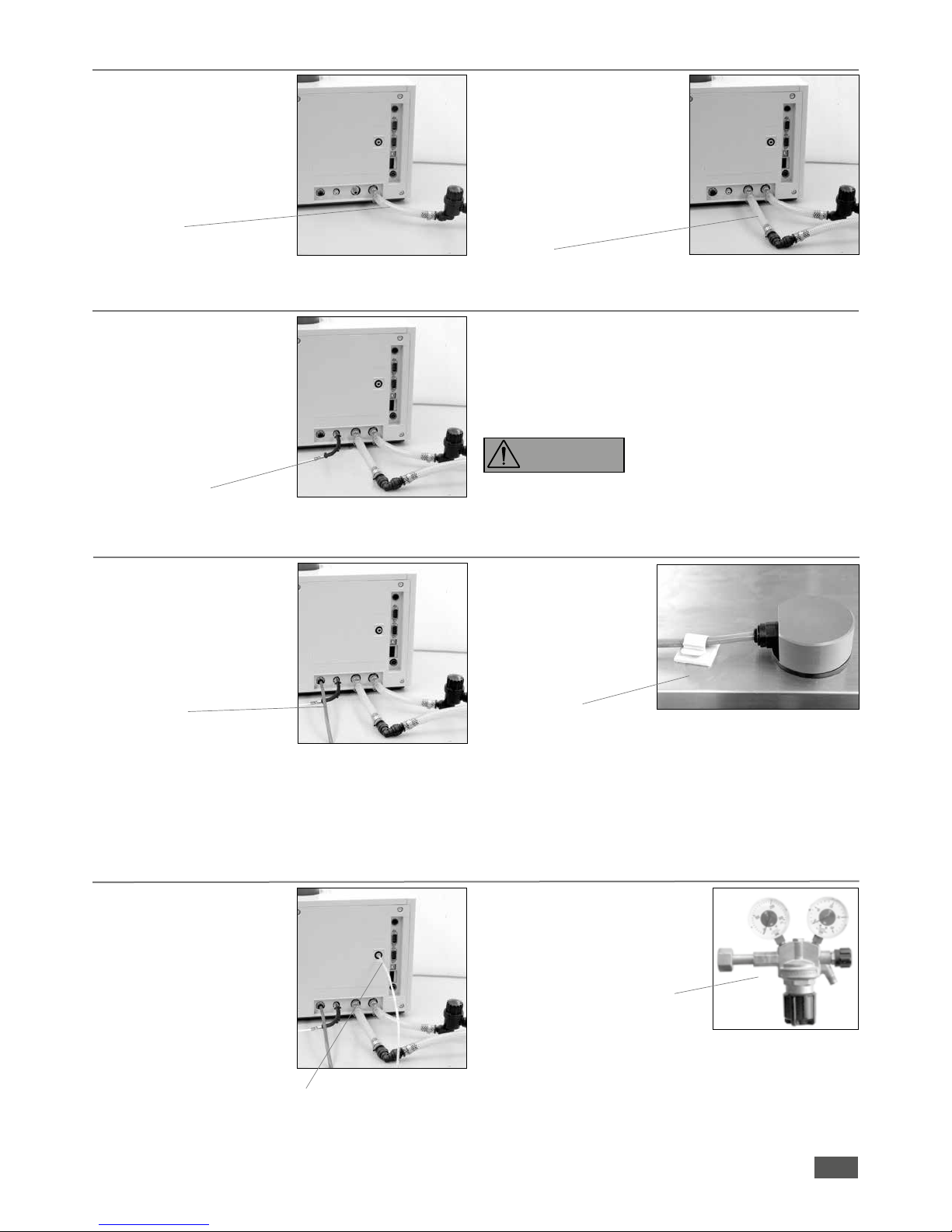

1. Connect the inflow pipe to the

quick coupling to the “water

in“ (on the calorimeter) port.

Connect the other end of the

radiator side of “water out“

and tighten the hose clamp.

Inflow pipe

Return pipe

2. Connect the return pipe to the

quick coupling to the “water

out“ (on the calorimeter) port.

Connect the other end to

“water in“ (on the cooler) and

tighten the hose clamp.

Venting hose connection

1. Screw the venting hose to

to “degas“ screw coupling

(SW8; on the calorimeter) and

lay the free end in the extractor.

Connect the free end to a gas

scrabber gadget.

Venting hose

Observe the applicable safety regulations..

The combustion gases are vented from the decompstion vessel

after each combustion test on the vent hose. The vent hose must

not be kinked or pinched during installation.

3. Do not use distilled or demineralized water (increased

risk of corrosion)! Fill the cooler according to the cooler

operating instructions. is recommended in drinking tap water

quality. Mix in (max. 1 ml for 4-5 l of water) of the supplied

water additive. Thus, the durability of the water is improved..

4. Adjust the cooler temperature corresponding to the calori meter operating temperature.

Drain hose connection

1. Insert the drain hose fully into

the “tap-water“ connection

(on the calorimeter). Lay the

other end of the drain hose to

the cooler filler neck.

Drain hose

2. Secure the hose end with

an attachable adhesive

protection.

The hose end must always

have free access of air and

never immerse themselves

in the cool water!

Cooler

Oxygen supply connection

1. Insert the connection tube fully

into the coupling (“O

2

in“; on

the calorimeter) and connect

the free end on the pressure

reducer

IKA® C 29 (possibly

with the C 29 adapter, included with).

Connection tube allowable

operating pressure 40 bar

IKA

®

C 29 Pressure reducer

Combustion gases are dangerous

to health, so the venting hose

must be connected to a suitable

gas cleaning and extraction.

DANGER

Page 9

9

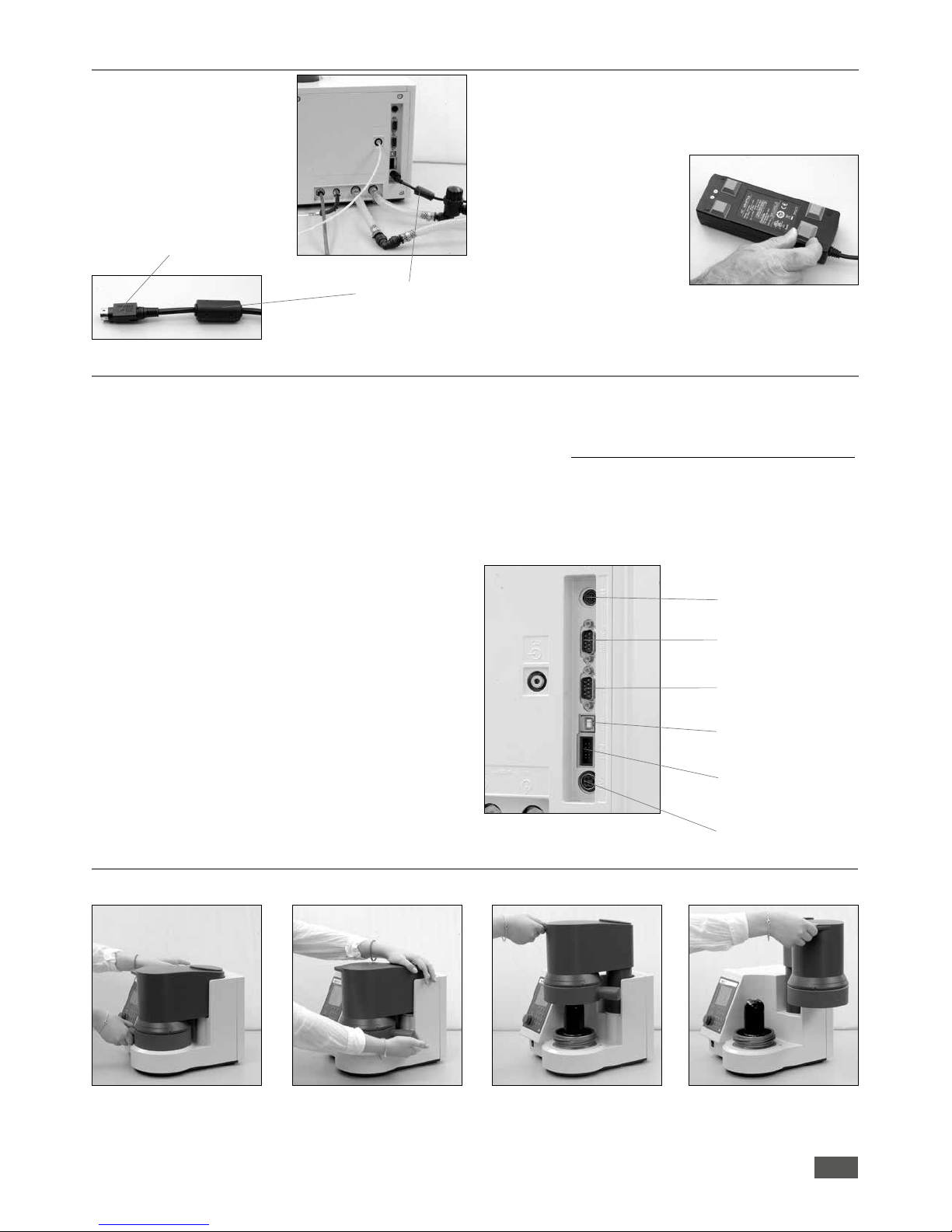

Power supply unit connection

1. Connect the power supply

connecting cable (24 V)

NOTE: Note the correct inser tion position (flat side

of the connector

pointing to the right).

Connecting cable

The desktop power supply (scope of delivery) must not be placed

flat on the laboratory table. It must be protected against moisture

and water penetration and must not be wet.

2. Tape the supplied rubber feet

to the power supply.

Place the power supply on the

rubber feet.

Connect the connection cable

to the DC power supply to

your supply network

(100-240V AC 50/60 Hz).

flat side of the connector

Connection of peripherals

Heating: Control output for the connection of the

IKA®

heating.

Scale: RS232 interface for connection of a scale

(Mettler, Ohaus, Sortorius, Kern)

Interface parameters: Baud rate: 1200

Data its: 7

Parity: odd

Stop its: 1

Handshake: none

PC/Printer: RS232 interface for connecting a PC to control

the C 1 (CalWin

®

C 6040) or a

printer to output the

measurement data.

Interface parameters: Baud rate: 9600

Data its: 8

Parity: none

Stop its: 1

Handshake: none

USB-B: USB device interface for connection the calori-

meters to the PC (CalWin

®

C 6040).

The connection simulates a serial interface on the

PC.

Installation:

After the C 1 was connected with the supplied

data cable to the PC, the C 1 tells the Windows

operating system, which device driver is required.

24 V =

Programming (Prog)

interface

USB-B (USB)

PC / Printer (PC)

Scale (balance)

Heating (ext)

This driver can be downloaded from the

IKA® website.

Find your driver at the following website:

http://www.ika.com/ika/lws/download/usb-driver.zip.

Programming-

(only for service)

interface:

24V= 24 V Voltage input for the included power

supply table.

Handling the unit

1. Opening the unit

The closing of the unit in the reverse order

Q

h

h

1

2

Q

Page 10

10

2. Removing the inner vessel

Inserting the inner vessel takes place in the reverse

order

h

3. Removing the inner vessel base

h

4. Switch on the device

Open the device and

switch the device on

and off with the front

power switch.

h

Display

Numbers

bloc

Del button

Multifunction

element

Esc button

Display: View system information, test data, as well as

menus and dialog boxes for the data input

Numbers bloc:

Entering numbers and decimal points

Del button: Deleting an entered character string to the left of

the cursor (eg the weight of a combustion

sample)

Multifunction element

Made possible by turning the scroll and select

menu items, as well as by pressing the Change

and confirm input values

Esc button: The Esc-(Escape) function is active in the menu

structure, the input window and input fields.

• In the menu structure (if any) change to the

parent menu

• In the input window is changed to the higher

level menu structure

• When the ESC button is pressed in an editable

field, the editing is finished and the original

value is restored.

Q

Control unit with display

Page 11

11

Dialog box

The dialog boxes are equipped with the following elements:

Menu-heading

Selected menu item

(blue)

Scrollbar

Menu options resp. user notification

Editable

input field

(yellow)

Status field

• ‚Back‘:

Closing a info window without information input

values and return to the parent menu.

Also possible using [ESC].

• ‚Accept‘:

Closing a window. Changes made are saved by

the system.

• ‚Start‘:

Starting a measurement.

• ‚Details‘:

Detailed information during a running

measurement.

• ‚Graph‘:

View graph during a running

measurement.

Editable input field:

They can be enabled for value entry by pressing

the multi-function element. The background color

of the active field is indicated in yellow. By using

the numeric keys or by turning the multi-function

element, the input values can be changed.

Status field:

Display the device status, which is important for

the user and operation.

Menu-heading:

The name of the currently displayed window

Selected menu item:

The blue background (cursor) marks the selected

item. The position can be changed by

turning the multifunction element.

Scrollbar: If a menu window more entries can be displayed as

the current is displayed a scrollbar.

Turn the multi-function element, the other menu

items are visible.

User notifications:

Some windows have a field in the user notes will

be displayed.

Menu options:

They allow a “getting ahead“ from the current

window.

In the following example, the most frequently

displayed menu options are listed and described:

• “Break off“:

Closing a window, the changes made will not be

accepted by the system.

Also possible using [ESC].

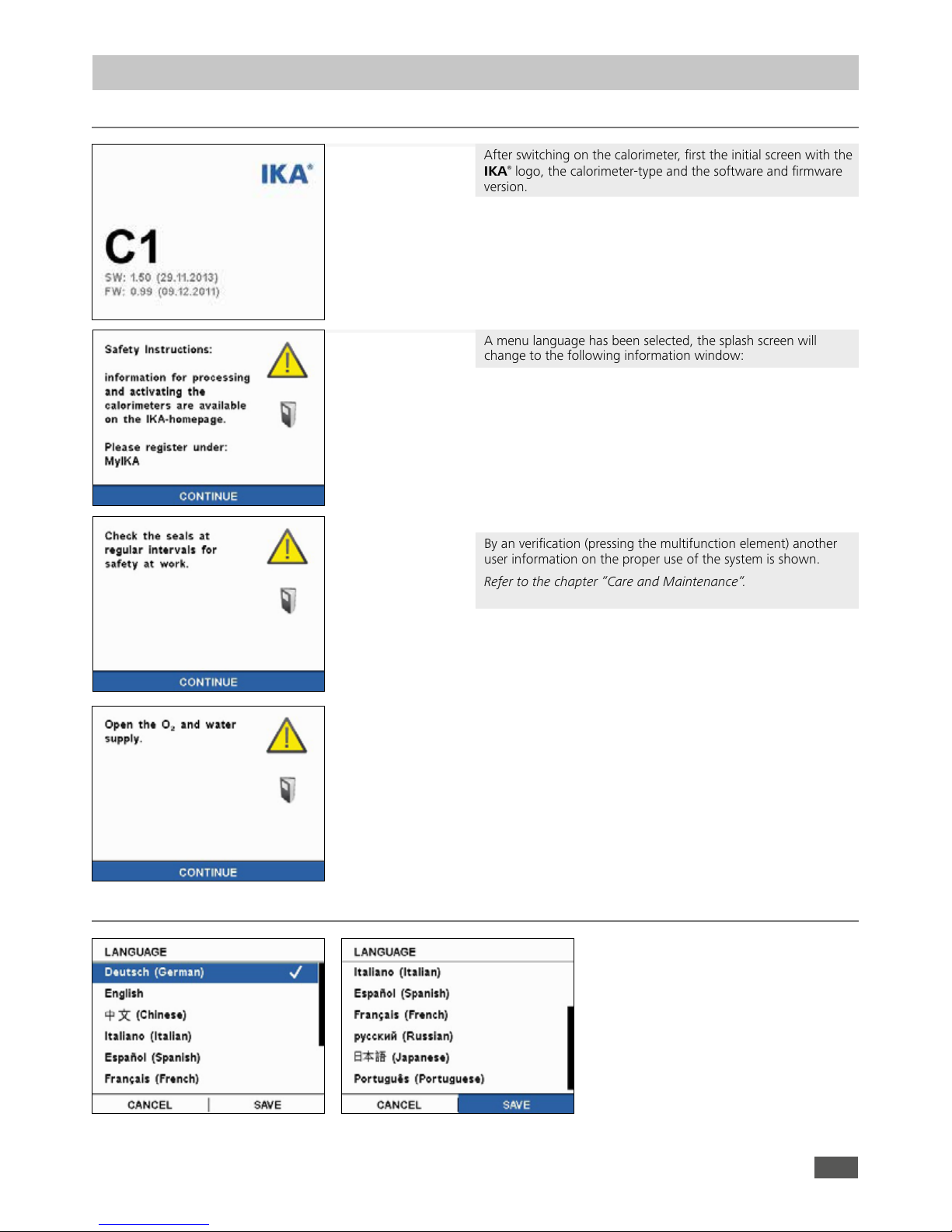

On confirmation changes

will be applied

On confirmation

changes will not be

applied

Page 12

12

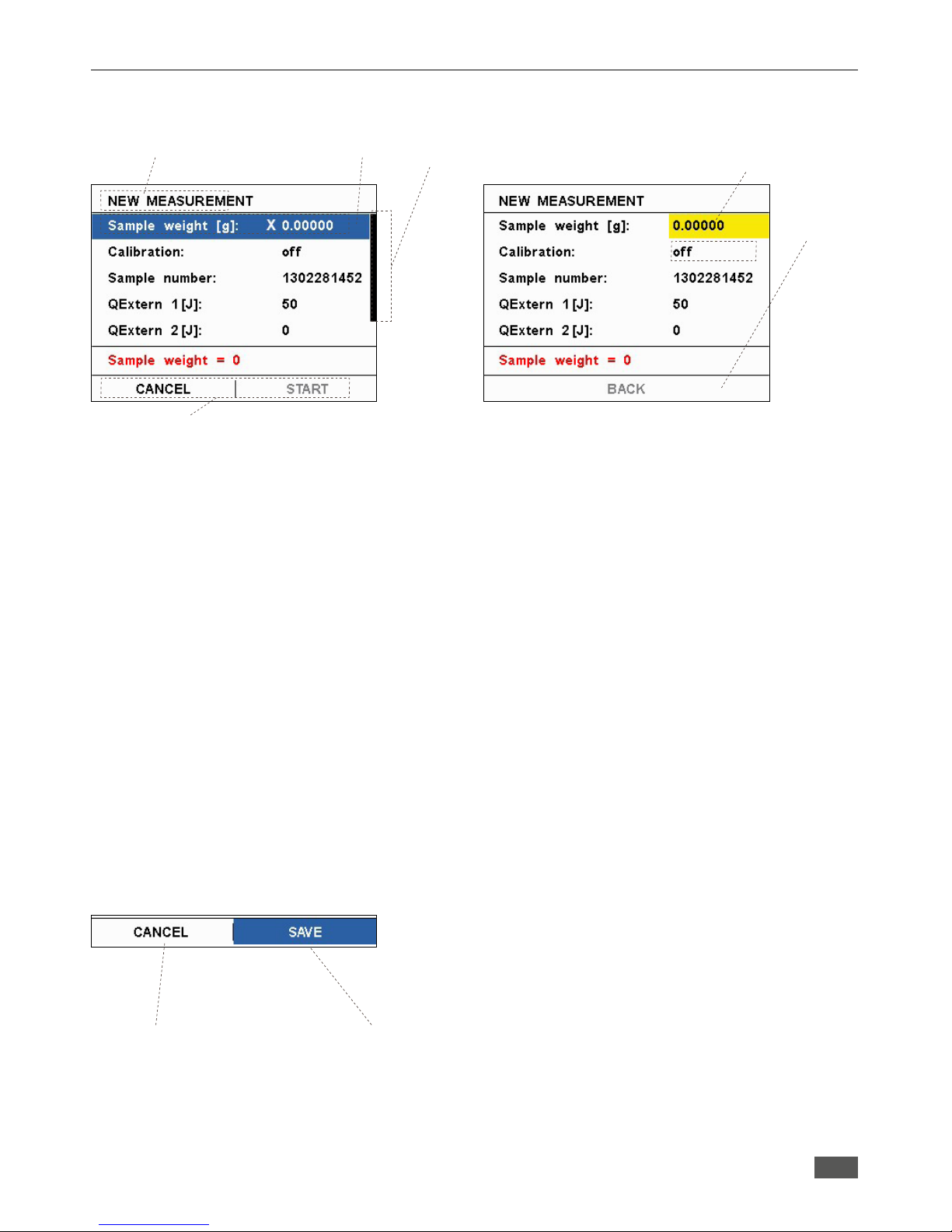

A menu language has been selected, the splash screen will

change to the following information window:

INFO: Exceed the number of ignitions devices, the maximum

recommended number of ignition, a pressure test must

be performed with the device.

An additional information window is displayed.

See capture - “Pressure test“

INFO: If the oxygen pressure is too low, a corresponding user

information is displayed.

See capture - “Oxygen pressure too low“

By an verification (pressing the multifunction element) another

user information on the proper use of the system is shown.

Refer to the chapter “Care and Maintenance“.

INFO: When the system is closed, a purge routine is started.

See capture - “System check“

INFO: Has been selected in the settings menu under accessories

heating option, but this is not detected, user information

is displayed.

See capture - “Heating detection - System start“

Switching on the system (in the open state)

After switching on the calorimeter, first the initial screen with the

IKA® logo, the calorimeter-type and the software and firmware

version.

INFO: Upon initial system start, the menu language must be

selected.

See capture - “Selection of language“

Selection of language

System start

Page 13

13

Pressure test

Oxygen pressure

Information screen: oxygen pressure is too low.

NOTE:

The calorimeter C 1 required for functionality an oxygen

pressure of at least 20 bar.

Reproducible measurements for a working pressure

of 30 bar is required.

System check

System start when the device is closed.

The system is brought through the system check in a safe

and completely deflated state. For this, the oxygen and water

discharge is performed.

Here, the following information screen is displayed:

INFO: During the system check detected no oxygen or the oxygen

pressure is too low, the following error message is displayed:

A pressure test must be performed after a decomposition vessel

has reached or exceeded the recommended number of ignition

cycles.

Once the pressure test has been performed a release code can be

entered to enable the unit to be used for further measurements.

The warning message will then disappear. The enable code can

be in the following screen, by pressing the “Next button“ to be

entered.

INFO: Using the unit may be further worked.

Contact for performing the pressure test, the

service department from

IKA® Works.

Observe the safety instructions!

service@ika.de

Page 14

14

Heating detected

If the use of heating selected C 1.20 (accessories) in the Setting

menu, but this is not recognized, the following user information

is displayed.

NOTE:

Check that the heater is correctly connected and turned on.

Factory settings

Settings:

• Menu: animated

• Color palette: white

• Key tones: on

• Date device: 01.01.2012

• Time device: 00:00:00 Uhr

• Units: J/g

• Heating: off

• Disposable crucible: no

• Printer: off

• Service Info: no

• Scale: off

Basic settings:

• C-value IB1: 0

• C-value IB2: 0

•

Reference calorific value:

26457

• Start temperature: 22 °C

•

HO Combustible crucible

: 19839

• QExternally 1: 50

• QExternally 2: 0

• Controlled time: off

• O rinsing: off

• Cooling: on

• Prolonged venting: 0

As delivered, the C 1 calorimeter system is configured as follows:

Test condition

Combustion is carried out in a calorimeter under specific

conditions.

The

IKA® C 1 is filled with a weighed fuel sample, the fuel sample

is ignited and the temperature increase in the calorimeter system

measured.

The specific calorific value of the sample is calculated as follows:

• Weight of fuel sample

• Heat capacity (C-value) of calorimeter system

• Calculated temperature increase of water in the calorimeter

system

For complete combust on the inner vessel is filled with pure

oxygen (quality 3.5). The pressure of the oxygen atmosphere in

the inner vessel is max. 40 bar.

The exact determinat on of the gross calorific value of a

substance requires that the combust on proceed under precisely

defined conditons. The applicable standards are based on the

following assumptons:

• Depending on the start temperature that is set, the tempera ture of the fuel before the combustion is 20 °C upto 30 °C.

• The water contained in the fuel before the combustion and

the water that is formed when compounds comprising the

fuel containing hydrogen undergo combustion is present in

a liquid state.

• No oxidation of the atmospheric nitrogen has taken place.

• The gaseous products after combustion consist of oxygen,

nitrogen, carbon dioxide, sulfur dioxide and the oxidation

products of the sample.

• Solid substances may be formed (for example ash).

Often, however, the combustion products that form the basis

of the standards are not the only products that are formed. In

such cases, an analysis of the fuel sample and the products of

combustion are necessary to provide data for a correction calculation. The standard gross calorific value is then determined

from the measured gross calorific value and the analysis data.

The gross calorifc value Ho is formed as the quotient of the

amount of heat liberated upon total combustion of a solid or

liquid fuel and the weight of the fuel sample. The compounds

comprising the fuel that contain water must be present in liquid

state after the combustion.

The heat value Hu is equal to the gross calorific value less

the energy of condensation of the water that was contained

in the fuel and was formed by the combustion. The heat value

is the more important quantity for technical purposes, since in

all important technical applications, the heat value is the only

quantity that can be evaluated in terms of energy.

For information on the fundamental principles of calculation for gross calorific value and heat value, please refer

to the applicable standards (for example: DIN 51 900;

ASTM D 240;ASTM D 1989, ISO 1928).

Determination of gross calorific value

Calorimetric measurements

Page 15

15

Fuel

sample

Burning

aid

Igniter

Formation of

sulphuric acid

Formation of

nitric acid

Heat quantity from:

External energy

Corrections

As determined by the system, during a combustion experiment,

not only is heat generated from the combustion of the

sample, but heat also occurs in the form of extraneous energy.

This may fluctuate considerably in proportion to the heat energy

of the fuel sample.

The combustion heat of the cotton threat that ignites the sample

and the electrical ignition energy would result in distorted values

of the measurement. This effect is taken into consideration in the

calculation with a correction value.

Substances with low flammability or substances that burn poorly

undergo combustion in combination with combustion aids.

The combustion aid is first weighed and then added to the crucible

with the sample. From the weight of the combustion aid and its

known specific gross calorific value, it is then possible to determine

the quantity of heat that is introduced thereby. The result of the

experiment must be corrected by this amount of heat.

The C 14 disposable crucible is a combustible crucible that can

be used instead of a traditional crucible. The disposable crucible

undergoes total combustion with no residue. If a disposable

crucible is used, there is then no need for a cotton thread. The

crucible is in direct contact and is ignited by the fixed ignition

wire of the inner vessel.

Inner vessel in which the combustible crucible is to be used, must

be fitted with an additional overlay (see accessories). The sample

is weighed directly into the disposable crucible. In most cases, no

additional combustion aid is necessary because the disposable

crucible itself acts as the combustion aid.

Acid correction

Almost all substances to be analyzed contain sulfur and nitrogen.

Under the conditions that pre-vail during calorimetric measurements, sulfur and nitrogen undergo combustion and form SO2,

SO

3

and NOX. Sulfuric and nitric acid arise in combination with

water resulting from combustion and humidity. Heat of solution is

also generated. To obtain the standard gross calorific value, the

effect of the heat of solution on the gross calorific value is

corrected.

To obtain a defined final status and to record all acids quantitatively, approx 5ml distilled water or another suitable absorption

solution is placed in the inner vessel. With this absorption fluid

and the combustion water, the combustion gases form acids.

After the combustion, the decomposition vessel is thoroughly

washed with distilled water so as to collect the condensate that

has settled on the inner wall of the vessel as well. The solution

obtained in this manner can now be examined with a suitable

peripheral detection device for aqueous decomposition into the

respective acid content.

For more information on this subject, please contact

IKA®‚ or

your nearest authorized dealer.

When calculating the energy value in C 1 external energies are

taken into account from kiln furniture, however, there is no

correction of acid. The calorific value is not calculated.

To do this, use the calorimeter software

IKA® CalWin®.

The calorimeter system

IKA® C 1 is a precision measuring instru-

ment for the routine determination of calorific values of solid and

liquid substances. Exact measurements can however be achieved

only if the individual steps of the trial are performed with care.

The procedure as described in the “For your safety“ section 1 and

in the following sections must therefore be adhered to exactly.

If you are burning unknown samples,

leave the room or keep well away

from the calorimeter!

A few points should be noted in respect of the substances to be

combusted:

• Normally, solid substances can be burned directly in powder

form. Rapidly burning substances (for example benzoic acid)

must not undergo combustion in loose form.

Benzoic acid must only be burned in the form of pellets! Com bustible dust and powder must be compressed into pellets

before combustion. Oven-dry dust and powder such as wood

chips, hay, straw etc. burn in an explosive manner! They must

be moistened first! Readily combustible liquids with a low va por pressure must not be come in direct contact with the

cotton thread (e.g. tetramethyl dihydrogen disiloxan).

Notes on the sample

Rapidly burning substances tend to squirt. Such substances

must be pressed into tablets before combustion. Suitable

for this is e.g. the

IKA

®

pelleting press C 21.

• Most liquid substances can be weighed directly into the cru cible. Liquid substances exhibiting turbidity or containing water

that will settle out must be dried or homogenized before they

are weighed in. The water content of these samples must be

determined.

• Highly volatile substances are placed in combustion capsules

(gelatin capsules or acetobutyrate capsules, see “Accessories“)

and undergo combustion together with the capsules.

• For substances with low flammability or low calorific substances

use combustion aids (see “Accessories“). Before the capsules or

the combustion bag is fi lled with the substance to be deter mined, it must be weighed in order to determine the additional

extraneous energy introduced into the system from the weight

and the gross calorific value. This is taken into consideration

with QExtern2. The amount of combustion aid should be as little

as possible.

The external energy must be determined externally.

DANGER

Page 16

16

To correctly determine the gross calorific value, it is of fundamental importance that the sample undergoes complete combustion.

After each experiment, the crucible and all solid residues must be

examined for any signs that combustion was not complete.

In case of using substances tending to squirt it is not possible to

ensure complete combustion.

Substances with low flammability (substances with a high

content of mineral matterand low-calorific substances) will often

Complete combustion

undergo complete combustion only with the aid of combustion

capsules or combustion bags (C 10/ C 12 see “Accessories“). It is

also possible to use liquid combustion aids such as paran oil.

The combustion aids as well (for example the cotton thread) must

undergo complete combustion. If unburned residues are left over,

the experiment must be repeated.

To ensure precise, reproducible results of the measurement, the

calorimeter system is calibrated after it is initially placed in service,

after service jobs, after parts are replaced and at specific time intervals. During calibration, the heat capacity of the calorimeter system

is redetermined.

Regular calibration is absolutely essential to obtain accurate

measurements!

For this purpose, a specific quantity of a reference substance

undergoes combustion in the

IKA® C 1 under the conditions of

the experiment. Since the gross calorific value of the reference

substance is known, it is possible after combustion has occurred

Calibration

to calculate the heat capacity based on the increase in temperature

of the calorimeter system. The reference substance for calorimetry

on an international level is benzoic acid of the National Bureau of

Standards (NBS Standard Sample 39 J) with a guaranteed gross

calorific value.

For more detailed information on calibration please see the relevant

standards.

If the

IKA® C 1 is operated with several different decomposition

vessels, you will need to determine the heat capacity of the system

for each decomposition vessel. The parts of each decomposition

vessel must then not be swapped with parts from other vessels.

Ensure that calibration is carried out under the same conditions as

the subsequent tests. If substances are used in the decomposition

vessel in combustion tests (e.g. distilled water or solutions), you

must use exactly the same amount of this substance for calibration.

Notes on calibration

For determination of calorific values the increase in temperature

must be about as great as for the calibration (± 30%). 1g benzoic

acid =˜ 6K. The optimum sample quantity must de determined by

several trials where necessary.

• Under the conditions that prevail during calorimetric mea surements, sulfur and nitrogen un-dergo combustion and form

SO2, SO3 and NOX. Sulfuric and nitric acid arise in combinati on with the water resulting form combustion. Heat of solution

is also generated. This heat of solution is taken into conside ration in calculating the gross calorific value. In order to quanti tatively record and determine all acids that have been formed,

about 5 ml of distilled water or another suitable substance can

be added to the decomposition vessel before the experiment.

The calibration of the system must have been performed in

accordance with the instructions!

Remove after measuring the complete inner vessel. Turn the inner

container upside down, loosen gently the internal container bottom. Rinse thoroughly with distilled water, the inner area of the

inner container. The rinsing water and the solution formed from

the water that was added are combined and the acid content of

the combined solution is examined. If the sulfur content of the

combustion aid and the nitric acid correction are known, the water

does not need to be analyzed.

These correction values can not be entered in C 1. For this, use the

IKA® calorimeter software CalWin®.

To increase the service life of parts to wear and tear (O rings,

seals etc.) we recommend to work with water added to the

experiment as a matter of general principle.

Halogen rich substances can cause corrosion on the inner container.

These substances must not be burned in C 1 with the

standard inner vessel.

In halogen-rich substances of special halogen-resistant

inner vessel C 1.12 must be used.

Handle

h

h

h

Page 17

17

The user has two display modes are available.

Measurements

The following submenus are available:

• New measurement

• Last result

• System test

• Measurement archive

• Calibration archive

• Memory overview

Default settings

The following submenus are available:

• C-value IB1

• ID IB1

• C-value IB2

• ID IB2

• Ref. cal. value

• Ho Comb. cruc.

• Start temperature

• QExtern 1

• QExtern 2

• O2 rinse

• Cool Down

• Extend. O2 Emptying

Animated view List view

Settings

The following submenus are available:

• Date / Time

• Units

• Display / Keypad

• Language

• Accessories

• Cooler test

Overview Main menu

Page 18

18

Maintenance

The following submenus are available:

• Change seal

• Test stirrer

• O2 System blow

• Servo up

• Servo down

INFO: When performing maintenance programs, the system

must be open !

Information

The following informations are available:

• Software

• Firmware

• Serial number

• Service

• Pressure test

• Ignitions

• Next test

• Support

The term “measurements“ below refers to both the measurements to calibrate the calorimeter system (calibration measurements) and the actual measurements for determining the calorific

value. The difference lies mainly in the evaluation, whilst preparation and performance make virtually no difference.

Performing the measurement

Select and confirm “Measurements“ in the main menu with the

multi-function element.

In the submenu select and confirm the option “New

measurement“.

Preparing and performing measurements

Page 19

19

Input window NEW MEASUREMENT

Select and confirm the menu item “Sample weight“. Enter the

sample weight with numeric keypad and confirm.

INFO:

A distinction is made between the use and non disposable

cup. Use of disposable crucible can be selected in Settings

" Accessories.

INFO: For automatic input of the weight may be a connected

scale can be used

INFO: The inputted weight values are checked for permissibility.

INFO: The existing store will be reviewed after the entry of a

new measurement / calibration and a user note displayed

if it is not possible to save the measurement / calibration.

NOTE:

Ensure that a maximum energy input of from 40,000 joules is not

exceeded.

NOTE:

For more, detailed descriptions of the individual menu items are

treated in the chapter “Calorimetric Measurements“.

INFO: If a scale is used in activation of the input field, the

weight is automatically queried. It can be pressed on the

scale alternatively, the transmit button.

Fill in the sample weight.

Calibration off.

When you are ready with your input, press “OK” button.

Don’t close the C 1 before you have pressed “OK“

button!

During the prerequisite checking, the cotton thread can be

attached to the ignition wire, hung the crucible in the provided

holder and the sample are contacted with the ignition wire.

Placing the sample

When using a disposable crucible of contact between the ignition

wire and the combustible crucible must be present. The fixing of

the cotton thread is not necessary.

Page 20

20

To increase the service life of wearing parts (O-rings, seals,

etc.) it is advisable to always work with a water template.

Generally, the test sample must be selected so that the temperature elevation during the measurement is below 10 K and

the temperature increase of the calibration comes close (max.

energy input: 40,000 J). Such exposure may damage the

calorimeter.

When exceeding the maximum energy input is recommended

to return the calorimeter.

To determine the potential energy initially very small sample

weights (approx. 0.2g) must be chosen when working with

unknown substances. If you burn unknown samples, leave

the room or keep your distance from the calorimeter.

If distilled water or solutions presented in the decomposition

vessel during the combustion experiment, the calibration

with the same template must have been performed before.

Close the calorimeter

After the sample is loaded and the contact with the ignition wire

is present and the inner vessel was placed, the calorimeter is

sealed.

The following screen informs the user whether the system is

closed properly and securely.

Are combustion vessel and the complete system properly closed,

the measurement starts automatically.

Note:

Can the inner container and / or closure ring with handle heavy

wire, please follow the instructions for oiling the seals!

2. Weigh the substance with an accuracy of 0.1 mg directly into

the crucible.

Where appropriate distilled water or a solution must be

presented in the inner vessel.

The input of the maximum possible sample weight is limited to a

maximum of 5 g.

1. Attach with a loop a cotton thread centered on the ignition

wire (at the open calorimeter).

The inner container base remains in the control of sample preparation in the calorimeter. But you can also use it by pulling it out

individually, or for consequential - Analysis - determinations, refer

to the closed inner container.

The following preparations must be made to prepare the system

for a measurement:

Preparing a measurement

C 6 Quartz crucible

h

Impression for distilled water or a

solution as a template

Page 21

21

Prerequisite checking for a measurement

When checking the preconditions for a measurement using a

distinction is made with and without C 1.20 heating between. The

following points should be checked:

• Existing Ignition

• Sucient oxygen present

• Open water connection

• Tempered water or using a heating their functionality

• Ignition:

Checking whether ignition contact available

• Oxygen pressure:

Check whether the system has suciently high oxygen pressure

has to make a measurement

• Water detected:

Check whether the system has detected water

• Limit ≤ Water ≤ Start temp:

Check whether there is the current water temperature within the

permissible temperature range

Without

C 1.20

heating:

• Heater test:

Check the heating functionality

With

C 1.20

heating:

Measurement procedure

During a measurement, different phases are passed through.

These phases are described below

• Phase 1:

Filling the calorimeter with water

• Phase 2:

Filling the calorimeter with oxygen (Note: If the option-O

2

flushing under the main menu " Basic Settings is selec ted, the inner vessel is two times with Oxygen rinsed)

NOTE:

Alternatively, to display the graph may also have a detailed

view of be selected with the following information:

• Current temperature:

Mean value of the actual temperatures

• Ignition temperature:

the currently measured temperature

• Measurement time:

Display: duration of the measurement

• Fill time:

Filling the inner vessel with water.

The fill time is user specific and must be kept constant

on each measurement. Check the filter where long fill times

are used.

NOTE:

After switching on the calorimeter C 1 or after a break of 2

hours during the filling of the calorimeter C 1 is still carried

out an intermediate emptying (H2O - purge). Once the

water sensor detects water, the stirrer is switched on.

After a short waiting period begins phase 2.

Page 22

22

• Phase 3:

Filling with oxygen

• Phase 7:

Venting, result is displayed

• Phase 6:

Post test

• Phase 8:

Cooling (if option under the main menu " Basic Settings

" cooling is enabled) and water emptying

NOTE:

With the “cooling“ option, the energy is absorbed (by the

combustion in the calorimeter entered).

Deactivation, the measuring time and the accuracy of the

calorimeter affecting (depending on the sample

throughput).

• Phase 5:

The system ignites and thereby starts the main test

INFO: An ongoing measurement can be stopped by selecting

“Cancel“ at any stage

• Phase 4:

Stabilizing the temperature and preliminary

Page 23

23

• Phase 9:

The system is completely emptied, and can be opened.

The inner vessel can be taken down. Through a visual check

is necessary to ensure that the sample in the crucible was

combusted completely.

After each combustion are all parts of the inner vessel that come

in contact with the combustion products to clean condensate.

It is sucient to parts with an absorbent, lint-free cloth to wipe

off. Combustion residues in the inner vessel, for example, soot

or ash are eliminated in the same way. Can not be cleaned in

the manner described (eg due to burn-in or pitting corrosion) of

Cleaning the inner vessel

the inner vessel, it shall be subjected to no cases of mechanical

cleaning.

Please contact in such cases, contact your local service center or

send the inner vessel for inspection and cleaning to our factory.

Follow-up measurement

By pressing the multi-function element, the result display returns

to the measurement sub-menu and the next attempt can be

started.

Use of a disposable crucible

The disposable crucible can optionally be used instead of metal

or quartz crucible and burned during the measurement complete

(see chap. “Accessories“).

INFO: 50 Joule omitted. With the combustible crucible not a

cotton thread is used.

Display the storage overview

If after pressing the “New Measurement“ button, the memory

overview is displayed, the capacity of the storage spaces for

measurements / calibrations are almost depleted. If the maximum

number is reached, no new measurements / calibrations more can

be saved for this mode. By pressing the OK key to access the screen

“New Measurement“. Delete measurements / calibrations are no

longer needed.

Result Display

NOTE:

Because the calorimeter C 1 (all internal parts) still not in a

first measurement at operating temperature, the result of

the first measurement can differ significantly from the

subsequent measurements of a test series.

We therefore recommend not to evaluate the outcome and

possibly to delete.

Alternatively, a system test can be performed,

see chap. “System Test“.

Page 24

24

Example: sample weight in the limit and initial weight of the

combustible crucible too high

Using a scale

About Settings " accessories can be selected using a scale.

If this option is selected, the displayed on the scale weight is

automatically transmitted to the selected weight input field.

Depending on type of balance this function may need to be be

activated on the scale or the Transfer button must be pressed.

This applies both to the initial sample weight of the sample and

the weight of the disposable crucible.

Permissible weight entries

In a non-permissible weight is the OK button inactive (grayed out)

and can not be selected..

• Sample weight:

There are weights of 0.00001 g to 4.99999 g permitted!

From 2.5 g in addition the message appears that the sample

weight in the limit range is (initial mass in the limit).

• Combustible crucible:

There are weights of 0.00001 g to 0.99999 g permitted!

Weights greater than 0.99999 g are not possible.

Confirm the selection with OK button.

Page 25

25

Cancel a measurement

An ongoing measurement can be canceld at any time.

After ignition, the system waits for 1 minute with the emptying,

as otherwise there is a risk that the sample is not completely

burned.

After confirm the cancellation, the system automatically emptied

and bring it to a safe state. The calorimeter can be opened and

you can return to the main menu.

New measurements

• New measurement:

Preparing and starting a measurement

• Last result:

Displaying the result of the last measurement

• System test:

The functionality of the calorimeter is checked

• Measurement archive:

The system can store up to 100 measurements

• Calibration archive:

The system can be used for both modes of operation (22 °C,

and 30 °C) for each inner container (1 and 2) each

storing 15 calibrations.

• Memory Summary:

Display the memory summary

Last result

This screen shows the results of the measurement carried out

previously successfully.

Measurements

Page 26

26

System test

Functional testing of the system

Use for the system test one or two benzoic acid tablets.

Alternatively, however, for example, an appropriate amount of

sugar or an alternative fuel to be used.

The system test is used to test the functionality of the overall

system. For this purpose all switching operations are carried out,

which take place in a normal measurement. If the system test

performed without error, the functionality is guaranteed.

The system test can be used to create a quick ˝warm up“ the

system. It is faster than a normal measurement, since there is no

analysis and improves the accuracy of the first measurement so

that they need not be discarded

Measurement archive

In measurements Archive up to 100 measurements can be stored.

A measurement taken is automatically added to the archive.

Displays the line number, the name of the measurement as well

as the result.

Further details are displayed by clicking on a measurement.

Page 27

27

Measurement archive: Edit

By clicking on the “EDIT“ button in the list view another screen

for selecting the edit mode.

Print:

• Measurements can be selected and printed

Delete:

• Measurements can be selected and deleted

Delete all:

• All measurements are deleted

By selecting one of these menu items to the list view is displayed

again. As a heading of the screen active editing is displayed. The

“EDIT“ button is replaced with an “OK“ button.

Measurement archive: Delete

By clicking the “OK“ button, the following dialog appears:

By confirming with “OK“, the selected measurements will be

deleted.

Measurement archive: Print

Click on the individual measurements they are selected and

marked with a green tick. By clicking again the selection is

reversed

By confirming the selected measurements with “OK“ followed

by the display of the user note. By confirming with “OK“, the

selected measurements are printed.

Page 28

28

Calibration archive

After selecting the appropriate archive is displayed.

INFO: In each calibration archive up to 15 calibrations can be

stored. A calibration performed is automatically added to

the appropriate archive

Displays the line number, the name of the calibration and the

result (C value).

Below the list of the current C-value of the system is shown (in

red). By confirming the multifunctional element details concerning

the measurement are displayed. For the C-value calculation, select

˝Edit“.

INFO: The C-value can also manually at Main Menu > Basic

settings entered alternative.

Calibration archive: Edit

By clicking the “EDIT“ button in the list view, another screen

appears to select the edit mode.

Selection C values :

• Calibrations can contribute to the redefinition of the C-value

be selected

Print:

• Calibrations can be selected and printed

Delete:

• Calibrations can be selected and deleted

By selecting one of these menu items to the list view is displayed

again. When heading of the screen active editing is displayed.

The “EDIT“ button is replaced with an “OK“ button.

Measurement archive: Delete all

By clicking the “OK“ button, the following dialog appears:

By confirming with “OK“, all measurements will be deleted.

Page 29

29

Calibration archive: C-Value selection

Click on the individual calibrations they are selected and marked

with a green tick.

By clicking again the selection is canceled and the new C-value

(mean value) is displayed below the list view directly.

By clicking the “OK“ button, the following user message appears:

By clicking the “OK“ button, the new value is accepted.

INFO: For RSD calculation of at least two C-values must be

selected. Otherwise, the result is Infinite and it is “Inf“ is

displayed as RSD.

Formula for calculating: X is a set of data (x1, .... xn)

and N the number

Relative Standard Deviation (RSD)

= (standard deviation / mean value) x 100

Mean value: X = X

Mean

= (Σ

N

n=1

xn )/N

Standard deviation:

σ =

√ Σ

N

n=1

(xn - X

Mean

)2/(N - 1)

INFO: The new value is also displayed under Main menu "

Basic settings.

Calibration archive: Print

Click on the individual measurements they are selected and

marked with a green tick. By clicking again the selection is

reversed.

By clicking on the OK button, the following user dialog appears:

By confirming with “OK“, the selected calibrations are printed.

Calibration archive: Delete

Click on the individual measurements they are selected and

marked with a green tick. By clicking again the selection is

reversed.

INFO: Calibrations that are used to the current C-value

calculation, can not be deleted.

She are grayed out and can not be selected..

By clicking the “OK“ button, the following user dialog appears:

By confirming with “OK“, the selected calibrations will be deleted.

Page 30

30

• C-value IB1; C-value IB2:

C value for the corresponding inner vessel

• ID IB1; ID IB2:

Identification number of the inner vessel

• Ref Energy:

Calorific reference value of benzoic acid

• HO Combustible crucible:

Calorific value of the combustible crucible

• Start temperature:

Changing the mode of operation between 22 °C and 30 °C.

• QExtern 1; QExtern 2:

Default values for the external energies 1 and 2

• O2 rinse:

The inner vessel can before the measurement of oxygen

be rinsed (2x with subsequent filling)

• Cool down:

Cooling the system after measurement

• Extend. O2 Emptying [min]:

0 - 99 adjustable

Settings

Date / Time

The setup menu contains the following menu items

• Date / Time

• Units

• Display / Keypad

• Language

• Accessories

• Chiller temperature

Setting the system time and date.

This data is used for automatic generation of a new measurement

name.

Units

The user can choose between the listed below unity

representations:

• J/g

• cal/g

• BTU/lb

• MJ/kg

NOTE:

When using a gas-washing station, the ventilation time

must be extended.

Default settings

Page 31

31

Display / Keypad

Inverted menu view

List view

Colour range black

Language

Selecting the system language

Colour range white

The user can access this menu

• select and change the background color of the display.

The background color can be selected either white or black

• the key tones on or off

• the appearance of the menus between animated view

and list view move

Page 32

32

Selection of accessories

• Heating:

Use of heating during the measurement C 1.2

• Combustible crucible:

yes / no

Weight input of the combustible crucible in the submenu “New

measurement“ can be done manually or by data transfer from

the balance.

• Printer:

Using a serial printer.

Selection option between:

• off: no expression

• briefly: expression

• standard: result expression with temperature values

• Service Information:

Service information is outputted via the serial interface

• Balance:

Selecting a balance type.

Selection option between:

• out

• Sartorius/Kern

• Mettler-Toledo

• Ohaus

Accessories

Chiller test

Viewing maintenance programs that can be performed by the

user at regular intervals.

Inner vessel and the inner vessel bottom lift out and set

aside.

Maintenance menu:

The system must be open to performing the maintenance programs.

The maintenance menu can be reached at Menu > Maintenance and contains the following points

Check whether the cooling water tem-

perature within the specified range of

19.5 +/- 1.5 °C at the wor-

king temperature 22 °C

or

27.5 +/- 1.5 °C at the wor-

king temperature 30 °C

is located.

Maintenance

Page 33

33

Change seal:

1 In the Menu Maintenance press “change seal“ button. This

requires oxygen pressure be present at C 1.

2 Unscrew the piston (Pos. 38 III) with screwdriver

counterclockwise

3 Remove the O-ring (Pos. 38 VI)

4 Put new O-ring on piston (Pos. 38 VI)

5 Screw in piston and tighten securely

6 “Change seal“ button again actuate pistons move to the

home position

38

38

III

Stirrer test

The stirrer is switched on and off for a visual check.

O2 System blow:

1 Lift out the inner vessel from the bottom and set aside

2 After about 20 seconds the button “O2 system blow“ button.

Keep openings with a paper towel or similar covered by hand

3 After about 3 seconds, this state switches itself off again.

This any remaining condensed water and dirt is

in the line blown out.

This screen shows:

• the software and firmware version

• the serial number of the device

• the date of the last service

• the date of the last pressure test

• the number of performed ignitions

• the number of ignitions in the next pressure test must be

performed

• the number of performed ignitions and support information

•

IKA® - Contact information

blow

O-ring

(Water inlet valve

seal)

Stirrer

Servo up

The locking pin is extended.

Servo down

The locking pin is retracted.

VI (8,0 x 2,5)

locking pin

Informations

Page 34

34

After input a new measurement

Prior to input a new measurement

Information about the available space when you select the menu

item “New Measurement“

This information is displayed when there is a value in the

critical region is located, that is, from 95 out of 100 possible

measurements in memory or from 13 of 15 calibrations in store

for IB1, IB2 at 22 °C or 30 °C operating temperature.

After entering the values for a new measurement archive

database will be checked again and if no free space is available

following message is displayed:

Depending on the selection measurement or calibration, the

screen sample will vary.

The user can skip this message, then the following measurement or

calibration is not saved. However, it can also switch on the button

“Archive“ to the appropriate archive and then delete old or unused

measurements or calibrations.

O2-Valve seal change

Use only original

IKA® spare parts!

1 Bushing (Pos. 33) with the enclosed tool SW11

screw out

2 Lift piston (Pos. 32/21) with tweezers

3 Remove the O-ring (Pos. 40), insert a new O-ring and ensure

the correct position

4 Set piston (Pos. 32/21) back in the opening

5 Bushing (Pos. 33) screw with the enclosed tool SW11

handtight, paying attention to correct position of the

O-ring (Pos. 32/8)

33

32/8

32/21

40

(10,0x 2,5)

(3,0 x 1,5)

User information: Memory

Exchanging of wear parts

Page 35

35

Change ignition wire

1 To release the ignition wire (Pos. 24) on the ignition electrodes

(Pos. 23) are both 6- hexagon nuts (Pos. 13) using

spanner SW 5.5

2 Turn down the upper nut (Pos. 13I1)

3 To release the ignition wire to the ground electrode (Pos. 22)

crucible holders hold hex nut (Pos. 13/3) and solve with

spanner SW 5.5

4 Screw (Pos.25) and remove while holding the crucible holder

5 Remove old ignition wire iand attach new ignition wire

6 Ignition wire (Pos. 24) mounted as shown in figure on the

screw (Pos.25)

7 Screw in screw (Pos.25) into the crucible holder, screw hex nut

(Pos.13/3) on the screw

8 Complete unit (Pos. 25, 24,10,13) srew in the ground electrode,

until the screw the ignition wire clamps

9 Align the crucible holder, no contact to the ignition electrode,

with hexagon nut on the ground electrode counter

10 Align the lower nut on the ignition electrode (Pos.13/2) so that

the ignition wire is horizontal

11 Ignition wire (Pos. 24) on ignition electrodes (Pos. 23) mount

12 Screw the upper hex nut (Pos. 13/1) and tighten the ignition

wire with two nuts by counter holding the lower nut

Change ignition electrode

1 Loosen ignition wire at the ignition electrode as described

previously

2 Hex nut (Pos. 12) and remove on the bottom of the inner

vessel bottom (Pos. 2) loosen with the spanner and screw

down SW7

3 Ignition electrodes (Pos. 23) by pulling it upwards

4 Take O-ring (Pos. 3) and replace with a new one

5 Install new ignition electrode in reverse order, making sure

that the insulating bushing (Pos. 6) located in the inner vessel

bottom

6 Tighten hex nut (Pos.12) by hand

Caution: Risk of short circuit at the nut is tightened

too strong

Change the main seal

1 Remove O-ring with a suitable non-sharp tool

The O-ring can be removed with your fingers, pull the O-ring to

two fingers apart, thus it is pulled out of the groove. Now it can

be removed with your fingers.

Note: Rub the new O-ring before inserting it into the groove with

O-ring grease (O-ring grease supplied).

This facilitates the closing of the C 1 considerably!

13/1

13

13

13

25

22

10

24

23

I

II

III

23

3

2

6

12

(4.0 x 1.5)

Inner vessel

Pos. 15 O-ring (48,0 x 2,0)

Uper part

Pos. 43 Quad-ring (92,0 x 4,5)

2x O-ring

h

Marked with rings must

be greased as needed with

the supplied grease.

h

1x X-ring

Safety note:

Use only original

IKA

®

spare parts!

In particular,

the hex nuts

(Hastelloy!)

Page 36

36

Change ground electrode

1 Loosen ignition wire as described above on the ground

electrode

2 Unscrew the ground electrode (Pos. 22) with spanner SW 7

3 Remove and replace O-ring (Pos. 17) to mount the O-ring on

the new ground electrodes

4 Screw in the new ground electrode

5 Install the new O-rings (Pos. 14) to the ground electrode

17

22

14

Run a full system test to check for leaks:

• “Measurement“ menu " menu ˝System test“.

• To perform a leak test with the system test, you must not use

sample / calibration substance.

• Use to the cotton thread to check whether the ignition

electrode is correctly installed.

The cotton thread is not burned. Reason could be a short to

ground between the ignition electrode and the inner vessel

bottom (e.g. by a wrong-mounted ignition wire).

Follow the instructions of the calorimeter!

Since no sample / calibration substance is used, breaks the

system test with the error message “MINTEMPDIFF“.

The tightness test is passed if the cotton thread burned and the

inner vessel is dry inside. No water should flow from the C 1.

The calorimeter C 1 is subjected during the manufacture to stringent quality controls. Should any malfunctions occur, refer to the

following section for a series of fault and error situations, the suitable remedial measures.