Page 1

S25L-1252-04

OEM HARD DISK DRIVE SPECIFICATIONS

for

DNES-318350 / DNES-309170 ( 18 / 9 GB )

3.5-Inch SCSI Hard Disk Drive

Revision (1.2)

Page 2

Page 3

S25L-1252-04

OEM HARD DISK DRIVE SPECIFICATIONS

for

DNES-318350 / DNES-309170 ( 18 / 9 GB )

3.5-Inch SCSI Hard Disk Drive

Revision (1.2)

Page 4

1st Edition (Rev.0.1) S25L-1252-00 (Oct. 22, 1998) Preliminary

2nd Edition (Rev.0.2) S25L-1252-01 (Oct. 30, 1998) Preliminary

3rd Edition (Rev.1.0) S25L-1252-02 (Dec. 16, 1998)

4th Edition (Rev.1.1) S25L-1252-03 (Apr. 20, 1999)

5th Edition (Rev.1.2) S25L-1252-04 (Jul. 29, 1999)

The following paragraph does not apply to the United Kingdom or any country where such provisions are

inconsistent with local law: INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer or express or implied warranties

in certain transactions, therefore, this statement may not apply to You.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in new editions of the publication. IBM may make improvements and/or changes in the product(s) and/or the program(s) described in this publication at any time.

It is possible that this publication may contain reference to, or information about, IBM products (machines and

programs), programming, or services that are not announced in your country. Such references or information must

not be construed to mean that IBM intends to announce such IBM products, programming, or services in your

country.

Technical information about this product is available from your local IBM representative or at

http://www.ibm.com/harddrive

IBM may have patents or pending patent applications covering subject matter in this document. The furnishing

of this document does not give you any license to these patents. You can send license inquiries, in writing, to the

IBM Director of Commercial Relations, IBM Corporation, Armonk, NY 10577.

Copyright International Business Machines Corporation 1999. All rights reserved.

Note to U.S. Government Users —Documentation related to restricted rights —Use, duplication or disclosure is

subject to restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

1.0 General ...................................................... 1

1.1 Introduction ................................................... 1

1.2 References .................................................... 1

1.3 Glossary ..................................................... 2

1.4 General Caution ................................................ 2

1.0 Outline of the drive ............................................... 3

Part 1. Functional Specification ....................................... 5

2.0 Fixed Disk Subsystem Description ....................................... 7

2.1 Control Electronics ............................................... 7

2.2 Head Disk Assembly .............................................. 7

2.3 Actuator ..................................................... 7

3.0 Drive Characteristics ..............................................

3.1 Formatted Capacity ...............................................

3.2 Data Sheet ....................................................

3.3 Cylinder Allocation ..............................................

3.4 Performance Characteristics .........................................

3.4.1 Command overhead ...........................................

3.4.2 Mechanical Positioning .........................................

3.4.3 Drive Ready Time ............................................

3.4.4 Spindle S t o p Time ............................................

3.4.5 Data Transfer Speed ...........................................

3.4.6 Buffering Operation (Lookahead/Write Cache) ...........................

3.4.7 Throughput ................................................

4.0 Data integrity .................................................

4.1 Equipment Status ...............................................

4.2 Error Recovery ................................................ 17

5.0 Physical Format ................................................ 19

5.1 Shipped Fo r m at (PList) ........................................... 19

5.2 Reassigned For m at (G-List) ......................................... 19

6.0 Specification ..................................................

6.1 Electrical Interface Specification ......................................

6.1.1 Power Connector .............................................

6.1.2 SCSI Bus Connector ...........................................

6.1.3 SCSI Cable ................................................

6.1.4 SCSI Bus Terminator ..........................................

6.1.5 H ot Pl ug / Unplug ............................................ 26

6.1.6 SCSI Bus Electrical Characteristics .................................. 26

6.1.7 Auxiliary Connector on 68-pin Model ................................. 27

6.2 Option Jumper Block .............................................

6.2.1 Jumper Pin of 50-pin SE model ....................................

6.2.2 Jumper Pin of 68-pin SE model ....................................

6.2.3 Jumper Pin of 68-pin LVD/SE Multi-mode model .........................

6.2.4 Jumper Pin of 80-pin LVD/SE Multi-mode model .........................

10

10

11

11

13

13

13

14

15

17

17

21

21

21

21

26

26

28

30

31

32

33

9

9

9

Copyright IBM Corp. 1998, 1999 iii

Page 6

6.2.5 Jumper Signal Description o n J-6 ................................... 34

6.2.6 Jumper Signal Description o n J-4 ................................... 34

6.2.7 Ship ping Default ............................................. 38

6.3 LED Circuit .................................................. 39

6.3.1 50- Pin Model ............................................... 39

6.3.2 68- Pin Model ............................................... 40

6.3.3 80- Pin Model ............................................... 41

6.4 Environment .................................................. 42

6.5 Cooling Requirements ............................................ 43

6.6 D C Power Requirements ........................................... 44

6.6.1 Start Up Current ............................................. 46

6.7 Reliability ................................................... 47

6.7.1 Contact Start St op (CSS) ........................................ 47

6.7.2 Data Reliability .............................................. 47

6.7.3 Seek/ID Mis-compare Errors ...................................... 47

6.7.4 Equipment Errors ............................................ 47

6.7.5 Failure Prediction ( P FA / S.M.A.R.T.) ............................... 47

6.7.6 Automatic Drive Maintenance (ADM) ................................ 48

6.7.7 Preventive Maintenance ......................................... 48

6.7.8 Temperature Warning ..........................................

6.8 Mechanical Specifications ..........................................

6.8.1 Outline ..................................................

6.8.2 Mechanical Dimensions .........................................

6.8.3 Interface Connector ...........................................

6.8.4 Mounting Positions and Tappings ..................................

6.8.5 Ship ping Zone and Lock ........................................

6.8.6 Breather Hole ...............................................

6.9 Vibration and Shock .............................................

6.9.1 Operating Vibration ...........................................

6.9.2 Non-Operating Vibrations .......................................

6.9.3 Operating Shock .............................................

6.9.4 Non-Operating Shock ..........................................

6.10 Acoustics ...................................................

6.10.1 Sound Power Levels ..........................................

6.11 Identification Labels ............................................. 59

6.12 Electromagnetic Compatibility ....................................... 59

6.12.1 CE Mark ................................................ 59

6.12.2 C-Tick Mar k .............................................. 59

6.13 Safety ..................................................... 60

6.13.1 Underwriters L a b (UL) Approval ..................................

6.13.2 Canadian Standards Authority (CSA) Approval ..........................

6.13.3 IEC Compliance ............................................

6.13.4 German Safety Mark ..........................................

6.13.5 Flammability ..............................................

6.13.6 Secondary Circuit Protection .....................................

6.14 Packaging ...................................................

48

49

49

51

52

54

55

55

56

56

57

57

57

58

58

60

60

60

60

60

60

60

Part 2. SCSI Interface Specification ................................... 61

7.0 SCSI COMMAND SET ...........................................

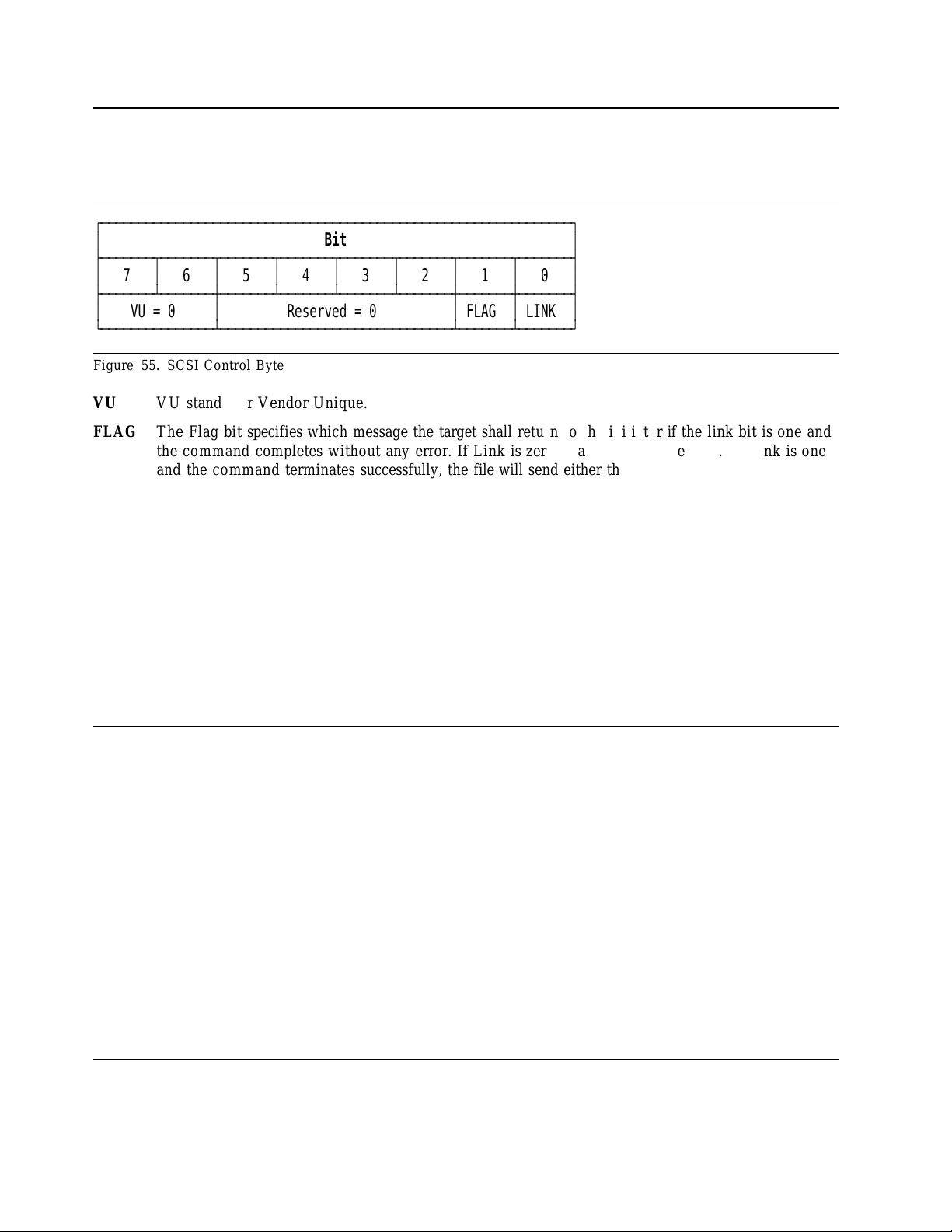

7.1 SCSI Control Byte ..............................................

7.2 Abbreviations

7.3 Byte ordering conventions

7.4 FORMAT UNIT (04) ............................................

.................................................

..........................................

63

64

64

64

65

iv O EM Spec. of DNES-3xxxxx Revision 1.2

Page 7

7.4.1 Defect List ................................................ 66

7.4.2 Defect Descriptor ............................................. 67

7.5 INQUIRY (12) ................................................ 69

7.6 Inquiry data .................................................. 70

7.6.1 Inquiry Data For mat - EVPD = 0 .................................. 71

7.6.2 Inquiry Data For mat - EVPD = 1 - Page Code = 00 ....................... 74

7.6.3 Inquiry Data For mat - EVPD = 1 - Page Code = 80h ...................... 75

7.7 LOG SELECT (4C) ............................................. 76

7.8 LOG SENSE (4D) .............................................. 77

7.8.1 Log Page parameters ........................................... 78

7.8.2 Log Sense Page 0 ............................................. 79

7.8.3 Log Sense Page 2 ............................................. 80

7.8.4 Log Sense Page 3 ............................................. 82

7.8.5 Log Sense Page 5 ............................................. 84

7.8.6 Log Sense Page 6 ............................................. 86

7.8.7 Log Sense Page 2 F ............................................ 87

7.8.8 Log Sense Page 30 ............................................ 88

7.8.9 Log Sense Page 31 ............................................ 88

7.8.10 Log Sense Page 32 ........................................... 88

7.8.11 Log Sense Page 3E ...........................................

7.8.12 Log Sense Page 3 F ...........................................

7.9 MODE SENSE (1A) .............................................

7.9.2 Mode Parameter List ..........................................

7.9.3 Page 0 (Vendor Unique Parameters) ..................................

7.9.4 Page 1 (Read/Write Error Recovery Parameters) ..........................

7.9.5 Page 2 (Disconnect/Reconnect Parameters) .............................

7.9.6 Page 3 (Format Device Parameters) ..................................

7.9.7 Page 4 (Rigid Disk Drive Geometry Parameters) ..........................

7.9.8 Page 7 (Verify Error Recovery Parameters) ..............................

7.9.9 Page 8 (Caching Parameters) ......................................

7.9.10 Page A (Control Mode Page Parameters) ..............................

7.9.11 Page 0 C (Notch Parameters) .....................................

7.9.12 Page 1A (Power Control) .......................................

7.9.13 Page 1C (Informational Exceptions Control) ............................

88

88

89

90

94

98

103

105

107

108

110

113

115

117

118

7.10 MODE SENSE (5A) ............................................ 120

7.11 MODE SELECT (15) ............................................ 121

7.12 MODE SELECT (55) ............................................ 123

7.13 PRE-FETCH (34) .............................................. 124

7.14 READ (08) .................................................. 125

7.15 RE AD CAPACITY (25) ..........................................

7.16 READ DEFECT DATA (37) .......................................

7.16.1 Defect List Header ...........................................

7.16.2 Bytes from Index Fo r m at (100b) ...................................

7.16.3 Physical Sector F or m at (101b) ....................................

7.17 READ DEFECT DATA (B7) .......................................

7.17.1 Defect List Header ...........................................

7.17.2 Bytes from Index Fo r m at (100b) ...................................

126

128

129

129

129

131

132

132

7.17.3 Physical Sector F or m at (101b) .................................... 133

7.18 READ EXTENDED (28) ......................................... 134

7.19 READ BUFFER (3C) ...........................................

7.19.1 Combined Header An d Data (Mode 000) .............................

7.19.2 Read Data (Mode 010b) ........................................

7.19.3 Descriptor (Mode 011b) ........................................

7.20 READ LONG (3E) .............................................

7.21 REASSIGN BLOCKS (07) ........................................

135

135

136

136

138

139

Contents v

Page 8

7.22 RECEIVE DIAGNOSTICS (1C) ..................................... 141

7.22.1 Receive Diagnostic Page 0 .......................................141

7.22.2 Receive Diagnostic Page 40 ...................................... 141

7.23 RELEASE (17) ............................................... 143

7.24 RELEASE (57) ............................................... 144

7.25 REPORT LUN (A0) ............................................ 145

7.26 REQUEST SENSE (03) .......................................... 147

7.27 RESERVE (16) ............................................... 148

7.28 RESERVE (56) ............................................... 149

7.29 REZERO UNIT (01) ............................................ 151

7.30 SEEK (0B) .................................................. 152

7.31 SEEK E XTE ND ED (2B) .........................................153

7.32 SEND DIAGNOSTIC (1D) ........................................ 154

7.32.1 Send Diagnostic Pages 0 ........................................ 155

7.32.2 Send Diagnostic Pages 40 ....................................... 155

7.33 START/STOP UNIT (1B) .........................................157

7.34 SYNCHRONIZE CACHE (35) ...................................... 158

7.35 TEST UNIT READY (00) .........................................159

7.36 VERIFY (2F) ................................................ 160

7.37 WRITE (0A) .................................................

7.38 WRITE EXTENDE D (2A) ........................................

7.39 WRITE AN D VERIFY (2E) .......................................

7.40 WRITE BUFFER (3B) ...........................................

7.40.1 Combined Header An d Data (Mode 000b) .............................

7.40.2 Write Data (Mode 010b) ........................................

7.40.3 Download Microcode (Mode 100b) .................................

7.40.4 Download Microcode and Save (Mode 101b) ...........................

7.41 WRITE LONG (3F) ............................................

7.42 WRITE SAME (41) .............................................

161

162

163

164

164

165

165

166

169

170

8.0 SCSI Status Byte ...............................................

9.0 SCSI MESSAGE SYSTEM .........................................

9.1 Supported Messages ..............................................

9.1.1 COMMAND COMPLETE (00) .................................... 174

9.1.2 SYNCHRONOUS DATA TRANSFER REQUEST (01,03,01H) ................ 174

9.1.3 W IDE DATA TRANSFER REQUEST (01,02,03H) ....................... 177

9.1.4 SAVE DATA POINTER (02) ..................................... 179

9.1.5 RESTORE POINTERS (03) ...................................... 179

9.1.6 DISCONNECT (04) ..........................................

9.1.7 INITIATOR DETECTED ERROR (05) ..............................

9.1.8 ABORT (06) ...............................................

9.1.9 MESSAGE REJECT (07) .......................................

9.1.10 NO OPERATION (08) ........................................

9.1.11 MESSAGE PARITY ERROR (09) .................................

9.1.12 LINKED COMMAND COMPLETE (0A) ............................ 181

9.1.13 LINKED COMMAND COMPLETE WITH FLAG (0B) .................... 181

9.1.14 BUS DEVICE RESET (0C) .....................................181

9.1.15 ABORT TAG (0D) .......................................... 181

9.1.16 CLEAR QUEUE TAG (0E) .....................................

9.1.17 QUEUE TAG MESSAGES(20h, 21h, 22h) ............................

9.1.18 IGNORE WIDE RESIDUE (23h) ..................................

9.1.19 IDENTIFY (80 - FF) .........................................

9.2 Supported Message Functions ........................................

9.3 Attention Condition ..............................................

171

173

173

179

180

180

180

180

181

181

181

182

183

183

185

vi O EM Spec. of DNES-3xxxxx Revision 1.2

Page 9

9.4 SCSI Bus Related Error Handling Protocol ................................ 185

9.4.1 Unexpected B US FREE Phase Error Condition ...........................186

9.4.2 MESSAGE O UT Phase Parity Error ................................. 186

9.4.3 MESSAGE IN Phase Parity Error (Message Parity Error) .....................186

9.4.4 COMMAND Phase Parity Error ................................... 186

9.4.5 DATA OU T Phase Parity Error .................................... 186

9.4.6 INITIATOR DETECTED ERROR Message ............................ 187

9.4.7 MESSAGE REJECT Message .....................................187

10.0 Additional Information ........................................... 189

10.1 SCSI Protocol ................................................ 189

10.1.1 Prio rity of SCSI Status Byte Reporting ............................... 189

10.1.2 Invalid LUN in Identify Message ...................................189

10.1.3 Incorrect Initiator Connection .................................... 190

10.1.4 Command Processing During Execution of Active I /O process .................. 190

10.1.5 Un it Attention Condition ....................................... 193

10.1.6 Command Processing During Start-up and Fo rm a t Operations ................. 193

10.1.7 Internal Error Condition ........................................ 194

10.1.8 Deferred Error .............................................. 194

10.1.9 Degraded Mode .............................................

10.1.10 Command Processing While Reserved ...............................

10.2 Priority C o mm ands .............................................

10.3 Command queuing ..............................................

10.3.1 Queue depth ...............................................

10.3.2 Tagged queuing .............................................

10.3.3 Untagged queuing ............................................

10.3.4 Command queuing rule ........................................

10.3.5 Queue Full status ............................................

10.3.6 Device behavior o n Command queuing ...............................

10.4 Command reordering ............................................

10.5 Concurrent I /O Process ...........................................

10.6 Back t o Back Write .............................................

10.7 Write Cache ..................................................

10.8 Power Saving Mode .............................................

195

201

202

202

203

203

203

203

203

203

204

204

204

205

205

10.9 Automatic Rewrite/Reallocate ....................................... 205

10.10 Segmented Caching ............................................. 207

10.10.1 Overview ................................................ 207

10.10.2 Read Ahead .............................................. 207

10.11 Reselection Timeout ............................................ 207

10.12 Single Initiator Selection ..........................................

10.13 Non-arbitrating systems ..........................................

10.14 Selection without A T N ..........................................

10.15 Multiple Initiator Environment ......................................

10.15.1 Initiator Sense Data ..........................................

207

207

208

208

208

10.15.2 Initiator Mode Select/Mode Sense Parameters ........................... 208

10.15.3 Initiator Data Transfer Mode Parameter ..............................

10.16 Contingent allegiance Condition .....................................

208

209

10.17 Reset .....................................................210

10.17.1 Reset Sources ............................................. 210

10.17.2 Reset Actions .............................................

10.18 Diagnostics .................................................

10.18.1 Power o n Diagnostics

.........................................

10.18.2 Diagnostics Command ........................................

10.18.3 Diagnostics Fault Reporting .....................................

10.19 Idle Time Functions ............................................

210

211

211

211

211

212

Contents vii

Page 10

11.0 SCSI SENSE DATA ............................................ 213

11.1 SCSI Sense Data F ormat .......................................... 213

11.2 Sense Data Description ...........................................214

11.2.1 Valid (Bit 7 of byte 0) ......................................... 214

11.2.2 Error Code (Bit 6 - 0 of byte 0) .................................... 214

11.2.3 ILI : Incorrect Length Indicator (Bit 5 of byte 2) .......................... 214

11.2.4 Sense Key (Bit 3 - 0 of byte 2) .................................... 214

11.2.5 Information Bytes (Byte 3 thru 6) .................................. 215

11.2.6 Additional Sense Length (Byte 7) ................................... 215

11.2.7 Command Specific Information (Byte 8 thru 11) .......................... 215

11.2.8 Additional Sense Code/Qualifier (Byte 12 and 13) ......................... 216

11.2.9 FRU : Field Replaceable U ni t (Byte 14) .............................. 219

11.2.10 Sense Key Specific (Byte 15 thru 17) ................................ 219

11.2.11 Reserved (Byte 18 thru 19) ...................................... 220

11.2.12 Reserved (Byte 20 thru 23) ...................................... 221

11.2.13 Physical Error Record (Byte 24 thru 29) .............................. 221

11.2.14 Reserved (Byte 30 thru 31) ...................................... 221

Index ......................................................... 223

viii O EM Spec. of DNES-3xxxxx Revision 1.2

Page 11

1.0 General

1.1 Introduction

This document describes the specifications of the following IB M 3.5 inch SCSI drives.

DNES-318350

− Fast-20 SE 50-pin (with SCSI active terminator)

− Fast-20 SE 68-pin Wide (with SCSI active terminator)

− Fast-40/20 LVD/SE Multi-mode 68-pin Wide (without SCSI terminator)

− Fast-40/20 LVD/SE Multi-mode 80-pin SCA-2 (without SCSI terminator)

DNES-309170

− Fast-20 SE 50-pin (with SCSI active terminator)

− Fast-20 SE 68-pin Wide (with SCSI active terminator)

− Fast-40/20 LVD/SE Multi-mode 68-pin Wide (without SCSI terminator)

− Fast-40/20 LVD/SE Multi-mode 80-pin SCA-2 (without SCSI terminator)

Note: The specifications i n this document are subject t o change without notice.

1.2 References

'draft' ANSI SCSI-2 standard, Revision 10L, J an 1994 (Document X3.1311-1994)

'draft' ANSI SCSI-3 Fast-20, X3T10/1071D

'draft' ANSI Palallel Interface-2 (SPI-2), T10 Project-1142D Revision 19

SFF-8301 Re v 1.2 (Refer to 6.8, “Mechanical Specifications” on page 49)

Note: Th e interface conforms to the referred documents. Th e vendor specific items a n d options supported

by th e drive are described in each section.

Copyright IBM Corp. 1998, 1999 1

Page 12

1.3 Glossary

Word Meaning

Kbpi 1,000 Bits P er Inch

Mbps 1,000,000 Bits per second

GB 1,000,000,000 bytes

MB 1,000,000 bytes

KB 1,000 bytes unless otherwise specified

32KB 32 x 1,024 bytes

64KB 64 x 1,024 bytes

Mb/sq.in 1,000,000 bits per square inch

MLC Machine Level Control

PFA Predictive Failure Analysis (Trademark of I B M Corp.)

S.M.A.R.T. Self-Monitoring Analysis an d Reporting Technology

ADM Automatic Drive Maintenance

SCAM SCSI Configured AutoMatically

SE Single Ended SCSI

LVD Lo w Voltage Differential SCSI

FC-AL Fiber Channel - Arbitrated Loop

1.4 General Caution

The drive can be easily damaged by shocks o r E S D (Electric Static Discharge), so any damages applied t o

the drive after taking o u t from th e shipping package or opening of the E SD protective bag are the user's

responsibility.

2 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 13

1.0 Outline of the drive

Data capacity 18/9 GB

SE models (50/68-pin with SCSI active terminator)

LVD/SE Multi-mode models (68/80-pin without SCSI terminator)

SCSI-2 Standard

SCSI-3 FAST-20 W ID E ( 40 Mbytes/sec transfer )

LVD FAST-40 WI D E ( 80 Mbytes/sec transfer )

Tagged Command Queuing

Multi-initiator support

512 Bytes/sector

Interleave factor 1:1

Write Cache

2 MB segmented sector buffer, 128KBx14, 256KBx7, 512KBx3 selectable

ECC on the fly

Automatic error recovery procedures for read an d write commands

Self diagnostics on power o n and resident diagnostics

Automatic Defect Reallocatio

7 msec seek time in read operation

7200rpm spindle rotation.

Closed l oo p actuator servo

Dedicated head landing zone

Automatic actuator lock

Temperature warning

PFA (SMART)

Note: PFA which means Predictive Failure Analysis is Trademark of I B M Corporation.

Copyright IBM Corp. 1998, 1999 3

Page 14

4 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 15

Part 1. Functional Specification

Copyright IBM Corp. 1998, 1999 5

Page 16

6 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 17

2.0 Fixed Disk Subsystem Description

2.1 Control Electronics

The drive is electronically controlled by a microprocessor, several logic modules, digital/analogue modules,

and various drivers and receivers. Th e control electronics perform the following major functions:

Conducts a power-up sequence and calibrates t he servo.

Monitors various timers for head settling, servo failure, etc.

Analyzes servo signals to provide closed l oop control. These include position error signal a nd estimated

velocity.

Controls the voice coil motor driver to align t he actuator ont o a desired position.

Monitors the actuator position and determines th e target track for a seek operation.

Constantly monitors error conditions of th e servo and takes corresponding action if an error occurs.

Controls starting, stopping, and rotating speed of the spindle.

Controls and interprets all interface signals between th e host controller and the drive.

Controls read write accessing of th e disk media, including defect management and error recovery.

Performs self-checkout (diagnostics).

2.2 Head Disk Assembly

The head disk assembly (HDA) is assembled in a clean room environment a nd contains a disk and actuator

assembly. Air is constantly circulated and filtered when the drive is operational. Venting of the H DA is

accomplished via a breather filter.

Th e spindle is driven directly by a brushless, sensorless DC drive motor. Dynamic braking is used t o stop the

spindle quickly.

2.3 Actuator

The read/write heads are mounted in the actuator. The actuator is a swing-arm assembly driven by a voice

coil motor. A closed-loop positioning servo controls the movement of the actuator. An embedded servo

pattern supplies feedback to the positioning servo to keep th e read/write heads centered over the desired

track.

The actuator assembly is balanced to allow vertical or hor izontal mounting without adjustment.

When the drive is powered off, the actuator automatically moves the head to a dedicated landing zone

outside of the da ta area, where the actuator is locked.

Copyright IBM Corp. 1998, 1999 7

Page 18

8 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 19

3.0 Drive Characteristics

This chapter provides the characteristics of the drive.

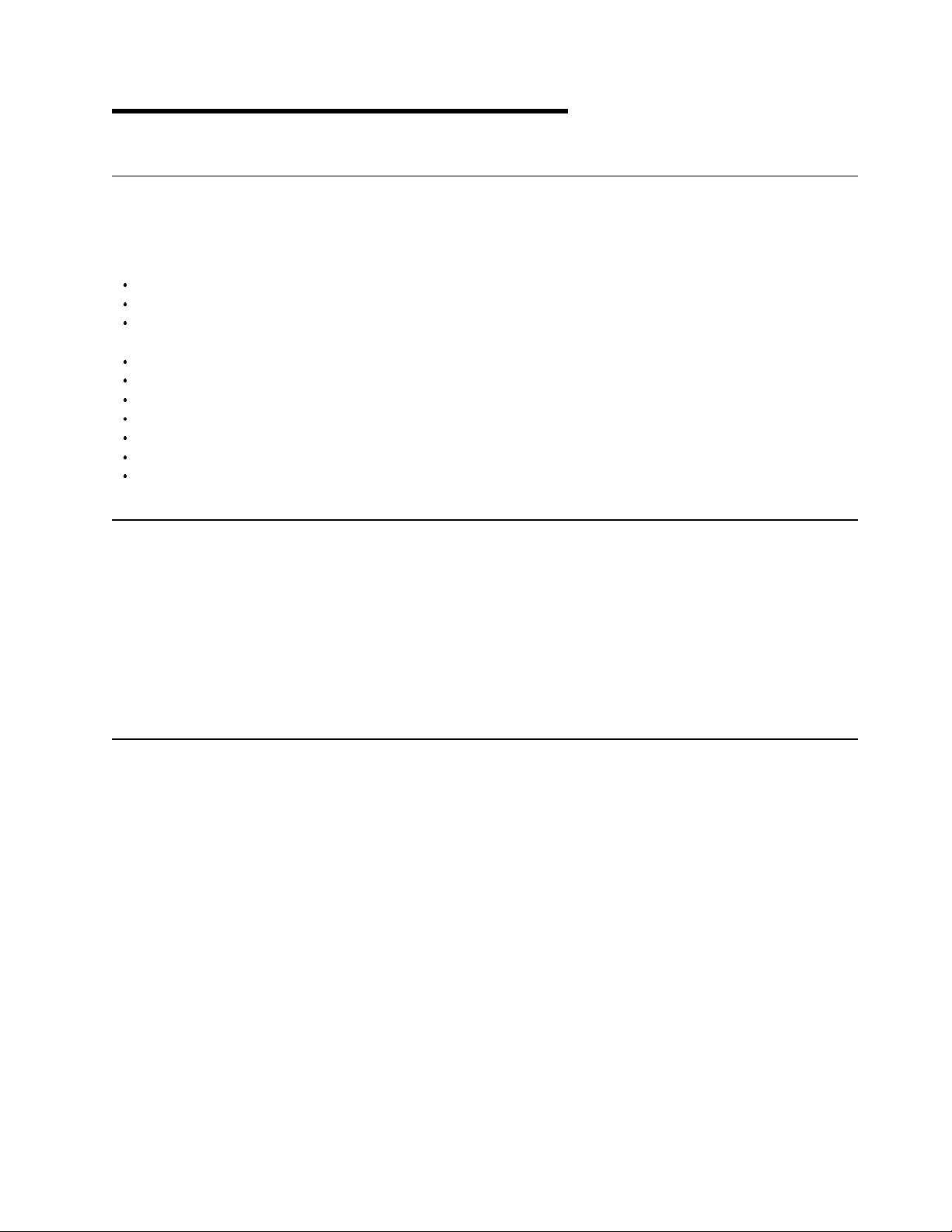

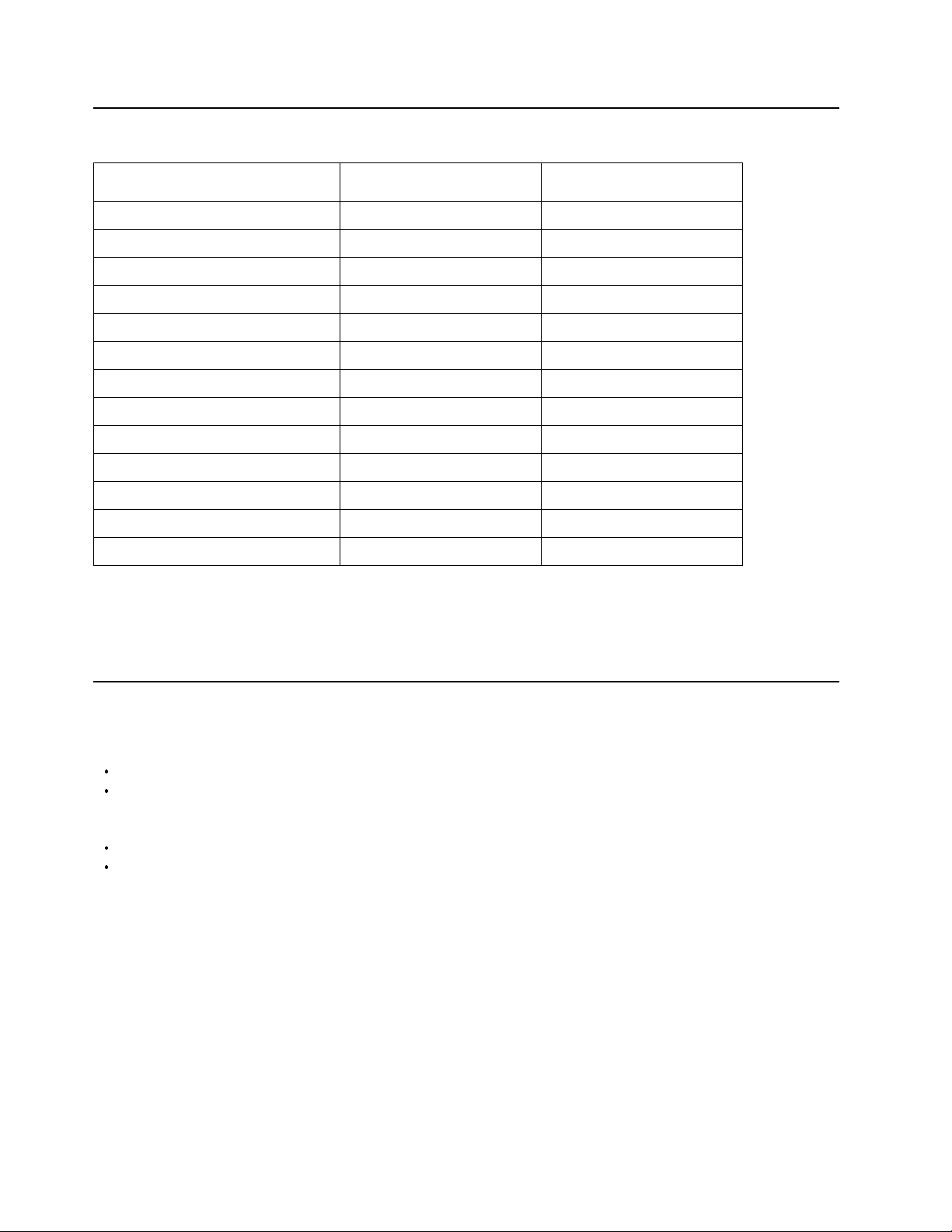

3.1 Formatted Capacity

Description DNES-318350 DNES-309170

Label Capacity (M B ) 18350 9170

Bytes per Sector 512 512

| Sectors per Track| 247-390| 247-390

Number of heads 10 5

Number of disks 5 3

Number of LBAs 35,843,670 17,916,240

Total Logical Data Bytes 18,351,959,040 9,173,114,880

Figure 1. Formatted Capacity

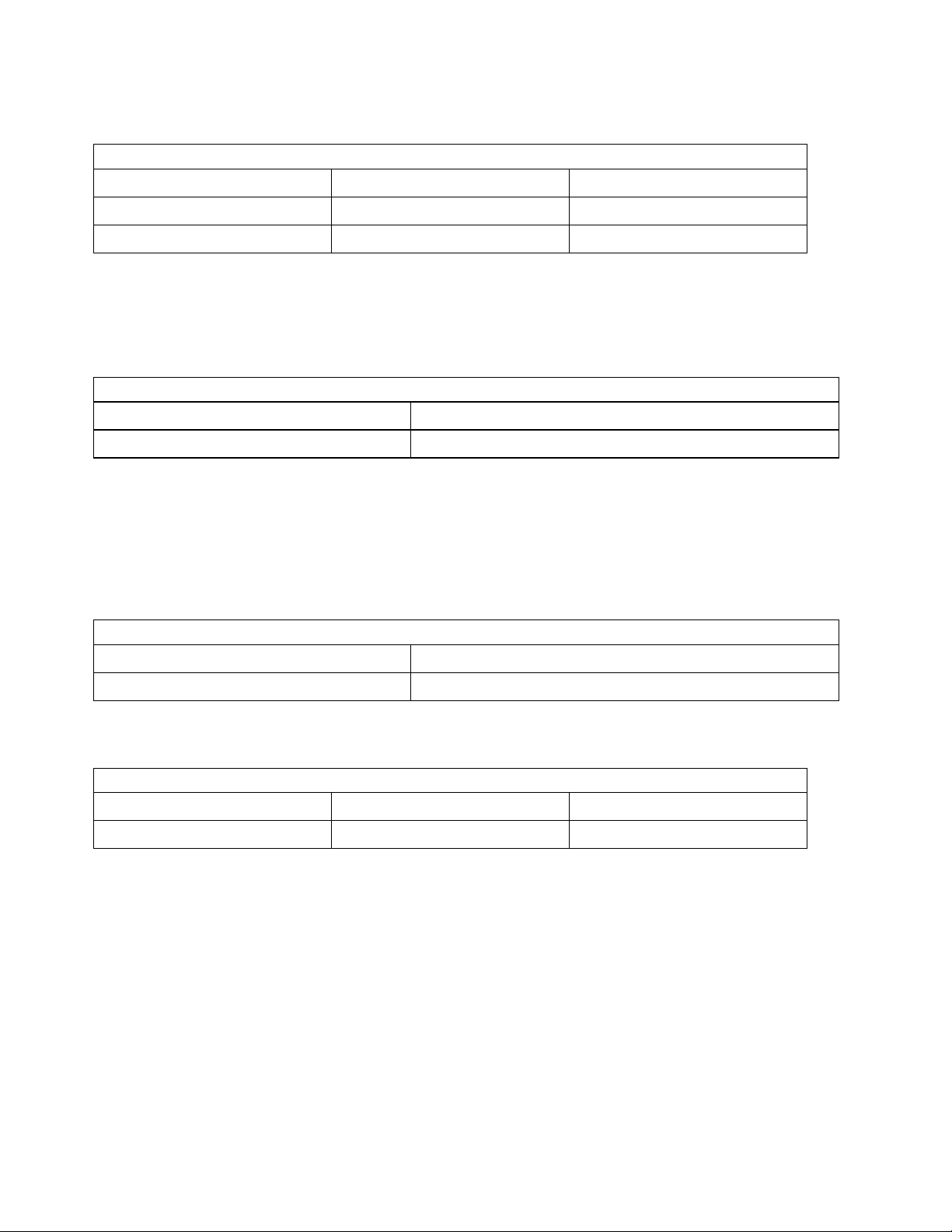

3.2 Data Sheet

Figure 2. Data Sheet

Buffer to/from media [Mbit/sec] 159 to 244

Host to/from buffer ( Interface transfer rate )

[ Mbyte/sec]

Data buffer size 1792 Kbyte

Number of buffer segments 3 x 512 KB

Rotational speed [RPM] 7200

Recording density [Kbpi] 220 (Max)

Track density [TPI] 13700

Areal density [Mb/sq.in.] 3025 (Max)

Data zone 11

20 (50-pin FAST-20)

40 (68/80-pin FAST-20 WIDE)

80 (68/80-pin FAST-40 WIDE)

7 x 256 KB

14 x 128 KB

Copyright IBM Corp. 1998, 1999 9

Page 20

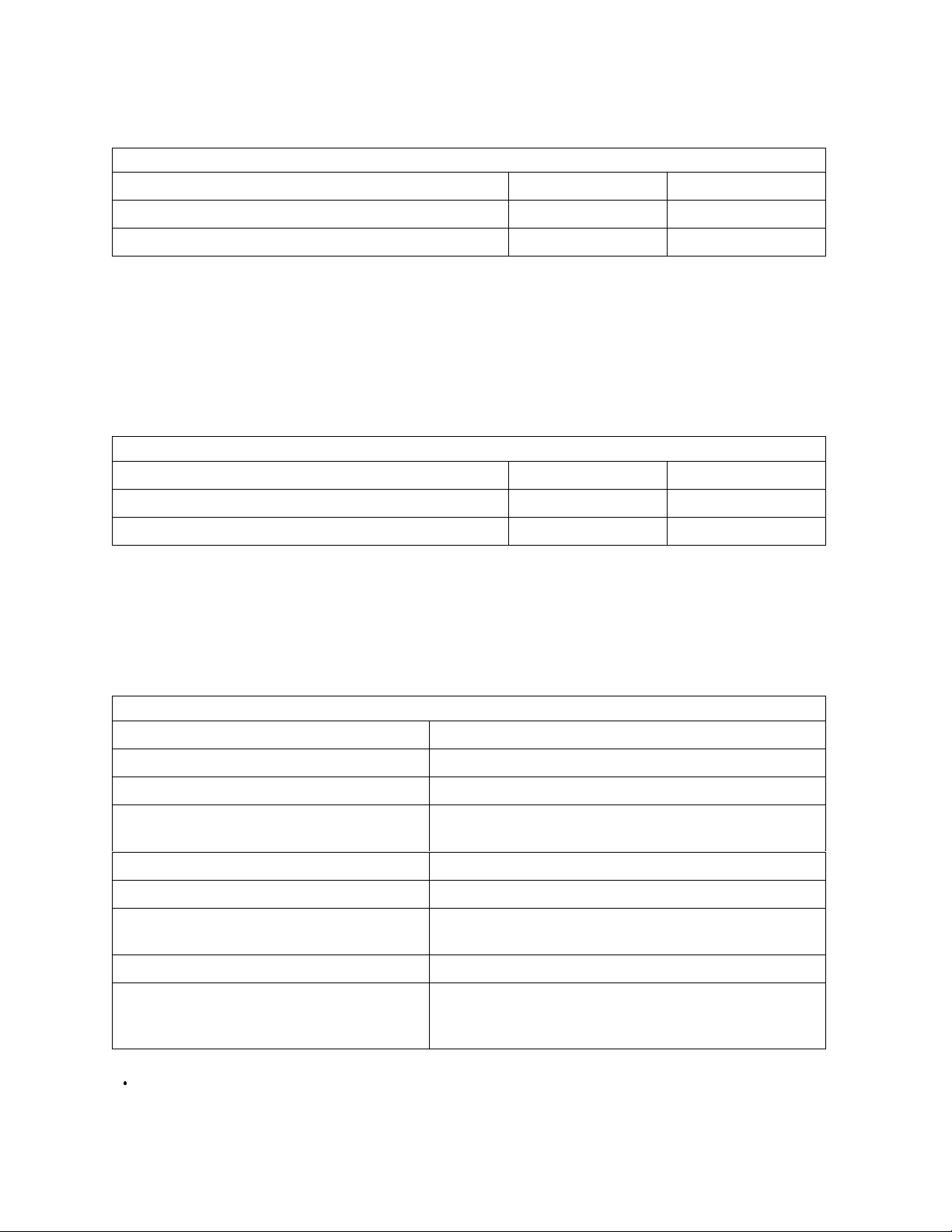

3.3 Cylinder Allocation

Phys. Cyl. Sectors/Trk

System Area

Data Zone 0 0-375 390

Data Zone 1 376-1258 374

Data Zone 2 1259-2238 364

Data Zone 3 2239-3452 351

Data Zone 4 3453-4485 338

Data Zone 5 4486-5504 325

Data Zone 6 5505-7016 312

Data Zone 7 7017-8726 286

Data Zone 8 8727-9776 273

Data Zone 9 9777-10640 260

Data Zone 10 10641-11473 247

System Area

Mode page 03 (Format Device Parameters) and 0C (Notch Parameters) provide methods to determin

medium format and zone parameters. See 7.9.6, “Page 3 (Format Device Parameters)” on page 105, and

7.9.11, “Page 0C (Notch Parameters)” on page 115.

3.4 Performance Characteristics

A drive performance is characterized by t he following parameters:

Command Overhead

Mechanical Positioning

− Seek Time

− Latency

Data Transfer Speed

Buffering Operation (Lookahead/Write cache)

Note: All the above parameters contribute t o drive performance. There are other parameters that contribute

to th e performance of t he actual system. This specification tries t o define t h e bare drive characteristics, not

the system throughput which will depend on the system and the application.

10 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 21

3.4.1 Command overhead

Command overhead is defined as t h e t i me required:

from last by t e of command phase

to the first byte of data phase

excluding

− Physical seek ti me

− Latency time

− Initiator delay with reconnections

Read Command Case with 6x64KB buffer (Drive is in quiescence state) Time

Cache N o t Hit <0.40msec

Cache Hi t <0.03msec

Figure 3. Command Overhead

3.4.2 Mechanical Positioning

3.4.2.1 Average Seek Time (Including Settling)

Figure 4. Mechanical Positioning Performance

Command Type Typical Max

Read 7.0 [msec] 8.0 [msec]

Write 8.0 [msec] 9.0 [msec]

“Typical” a nd “Max” are given throughout the performance specification by;

Typical Average of t he drive population tested a t nominal environmental and voltage conditions.

Max Maximum value measured on any o ne drive over the full range of the environmental and

voltage conditions. (See 6.4, “Environment” on page 42 a nd 6.6, “DC Power

Requirements” o n page 44 for ranges.)

The seek t ime is measured from the start of actuator's motion to the start of a reliable read or write opera-

tion. Reliable read o r write implies that error correction/recovery is n o t used t o correct arrival problems.

The average seek t ime is measured as t he weighted average of all possible seek combinations.

max

( max + 1 − n)(Tn.in + Tn.out)

∑

Weighted Average =

Where:

max = Maximum seek length

n = Seek length (1 t o max)

Tn.in = Inward measured seek time f or an n track seek

Tn.out = Outward measured seek time for a n n track seek

n =1

( max + 1) ( max)

Drive Characteristics 11

Page 22

3.4.2.2 Full Stroke Seek

Figure 5. Full Stroke Seek Time

Function Typical Max.

Read [ msec] 13.0 15.0

Write [msec] 14.0 16.0

Full stroke seek is measured as t he average of 1000 full stroke seeks with a random head switch from bot h

directions (inward a nd outward).

3.4.2.3 Cylinder Switch Time (Cylinder Skew)

Figure 6. Cylinder Skew

Typical

Cylinder Skew 2.6 [msec]

A cylinder switch time is defined as the amount of time required by the fixed disk access th e nex t sequential

block after reading the last sector in t h e current cylinder.

The measured method is given in 3.4.7, “Thr oughput” on page 15.

3.4.2.4 Head Switch Time (Head Skew)

Figure 7. Head Skew

Hea d Skew 1.6 [msec]

3.4.2.5 Average Latency

Figure 8. Latency Time

Rotation Time for a revolution Average Latency

7200 [RPM] 8.33 [ msec] 4.17 [ msec]

Typical

12 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 23

3.4.3 Drive Ready Time

Figure 9. Drive Ready Time

Model Typical Max.

DNES-318350 15.0 [sec] 19.9 [sec]

DNES-309170 11.0 [sec] 19.9 [sec]

Ready The condition in which the drive is able to perform a media access command (eg. read, write)

immediately. If a command is received during power on before ready, th e drive ready ti m e

becomes longer t h an th e specified value.

Power On This includes the t ime required for the internal self diagnostics.

3.4.4 Spindle Stop Time

Figure 10. Spindle Stop Time

Model Typical Max.

DNES-318350 12.0 [sec] 14.0 [sec]

DNES-309170 9.0 [sec] 10.0 [sec]

The period from power off to complete stop of spindle is categolized as operating, a nd Operating Shock

criteria are applied until complete stop of spindle.

Refer t o 6.9.3, “Operating Shock” on page 57.

3.4.5 Data Transfer Speed

Figure 11. Data Transfer Speed

Description Typical

Disk-Buffer Transfer (Zone 0)

(Instantaneous) 32.0 [ Mbyte/sec]

(Sustained) DNES-318350 20.2 [ Mbyte/sec]

DNES-309170 20.0 [ Mbyte/sec]

Disk-Buffer Transfer (Zone 7)

(Instantaneous) 21.0 [ Mbyte/sec]

(Sustained) DNES-318350 12.7 [ Mbyte/sec]

DNES-309170 12.7 [ Mbyte/sec]

Buffer-Host

50-pin FAST-20

68-pin / 80-pin FAST-20 Wide

68-pin / 80-pin FAST-40 Wide

20 [ Mbyte/sec]

40 [ Mbyte/sec]

80 [ Mbyte/sec]

Instantaneous disk-buffer transfer rate (Mbyte/sec) is derived by:

(Number of sectors on a track)*512*(revolution/sec)

Note: Number of sectors per track will vary because of the linear density recording.

Drive Characteristics 13

Page 24

Sustained disk-buffer transfer rate (Mbyte/sec) is defined by considering head/cylinder change time. This

gives a local average da t a transfer rate. It is derived by:

(Sustained Transfer Rate) = A/ (B+C+D)

A = (Number of data sectors per cylinder) * 512

B = ( (# of Surface per cylinder) - 1) * (Head switch time)

C = (Cylinder change time)

D = (# of Surface) * (One revolution time)

Instantaneous Buffer-Host Transfer Rate (Mbyte/sec) defines th e maximum data transfer rate o n SCSI

Bus. It also depends o n the speed of th e host.

The measurement method is given in 3.4.7, “ Th roughput” on page 15.

3.4.6 Buffering Operation (Lookahead/Write Cache)

At shipment, the total 1792K bytes of the buffer is divided into 7 segmented blocks.

The segment size can be changed by Mode Page 8. See 7.9.9, “Page 8 (Caching Parameters)” on page 110

for details.

14 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 25

3.4.7 Throughput

3.4.7.1 Simple Sequential Access

Figure 12. Simple Sequential Access Performance

Operation Typical Max

Sequential Read/Write Zone 0 1400 [msec]

Zone 11 1831 [msec]

The above table gives the time required t o read/write for a total of 8000x consecutive blocks (16,777,216

bytes) accessed b y 128 read/write commands. Typical and Max values are given by 105% and 110% of T

respectively throughput following performance description.

Note: Assumes a host system responds instantaneously.

T = (A * 128) + B + C + 16,777,216/D + 512/E (READ)

T = (A * 128) + B + C + 16,777,216/D (WRITE)

where:

T = Calculated Time (sec)

A = Command Process Time (Pre/Post Command overhead)

B = Average Seek Time

C = Average Latency

D = Sustained Disk-Buffer Transfer Rate (Mbyte/sec)

E = Buffer-Host Transfer Rate (Mbyte/sec)

Zone 0 1408 [msec]

Zone 11 1842 [msec]

3.4.7.2 Random Access

Figure 13. Random Access Performance

Operation Typical Max

Random Read 52.2 [sec] 54.7 [sec]

Random Write 55.2 [sec] 57.8 [sec]

The above table gives the time required t o execute a total of 1000x read/write commands which access a

random LBA.

T = (A + B + C + 512/D + 512/E) * 4096 (READ)

T = (A + B + C + 512/D) * 4096 (WRITE)

where:

T = Calculated Time (sec)

A = Command Process Time (Pre/Post Command overhead)

B = Average Seek Time

C = Average Latency

D = Sustained Disk-Buffer Transfer Rate (Mbyte/sec)

E = Buffer-Host Transfer Rate (Mbyte/sec)

Drive Characteristics 15

Page 26

16 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 27

4.0 Data integrity

The drive retains recorded information under all non-write operations.

No more t han one sector can be lost by power down during write operation while write cache is disabled.

If power do wn occurs before completion of data transfer from write cache to disk while write cache is

enabled, t he d at a remaining in write cache will be lost. T o prevent this data loss at power off, t he following

action is recommended:

To confirm successful completion of SYNCHRONIZE CACHE (35h) command.

4.1 Equipment Status

Equipment status is available to the host system any tim e th e drive is n ot ready to read, write, or seek. T his

status normally exists at power-on time and will be maintained until the following conditions are satisfied.

Access recalibration/tuning is complete.

Spindle speed meets requirements for reliable operations.

Self-check of drive is complete.

Appropriate error status is made available to th e host system if any of the following condition occurs after

the drive h as become ready:

Spindle speed goes outside of requirements for reliable operation.

“Write fault” is detected.

4.2 Error Recovery

Errors occurring with th e drive are handled by the error recovery procedure.

Errors that are uncorrectable after application of the error recovery procedures are reported to the host

system as non-recoverable errors.

Copyright IBM Corp. 1998, 1999 17

Page 28

18 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 29

5.0 Physical Format

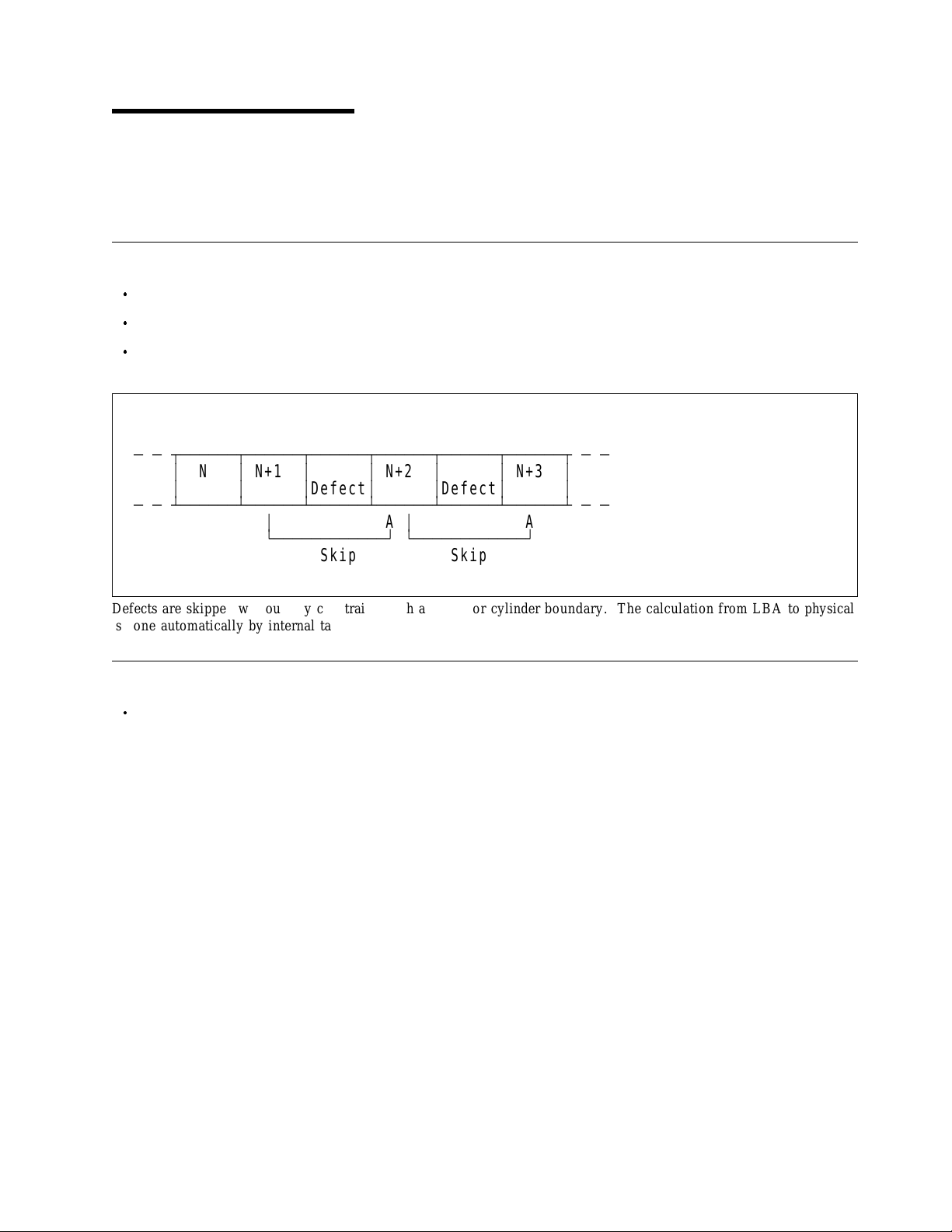

Media defects ar e remapped t o the next available sector during Form at Process in manufacturing. Th e

mapping from L BA t o the physical locations is calculated b y a n internal maintained table.

5.1 Shipped Format (PList)

Data areas are optimally used.

No extra sector is wasted as a spare throughout user data areas.

All pushes generated by defects ar e absorbed by spare tracks of inner zone.

PList Physical Format

Ä Ä ВДДДДДДВДДДДДДВДДДДДДВДДДДДДВДДДДДДВДДДДДДВ Ä Ä

³

N

³

N+1

³³

³³³

Ä Ä БДДДДДДБДДДДДДБДДДДДДБДДДДДДБДДДДДДБДДДДДДБ Ä Ä

Defect

³

АДДДДДДДДДДДДЩ АДДДДДДДДДДДДЩ

Skip Skip

N+2

³³

³³

A

Defect

³

N+3

³

³³

A

Defects ar e skipped without any constraint, such as track or cylinder boundary. The calculation from L B A to physical

is done automatically by internal table.

5.2 Reassigned Format (G-List)

G-List is prepared for 3327 LBAs.

Re-re-assign of the same L B A does not increase G-List entry.

A cylinder for spare sectors is prepared in every 256 cylinders.

Note: There is possibility to have G-List entry during the drive usage including early period. It is mainly

caused by handling problem, and G-List entry is normal maintenance work of Hard Disk Drive.

Copyright IBM Corp. 1998, 1999 19

Page 30

20 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 31

6.0 Specification

6.1 Electrical Interface Specification

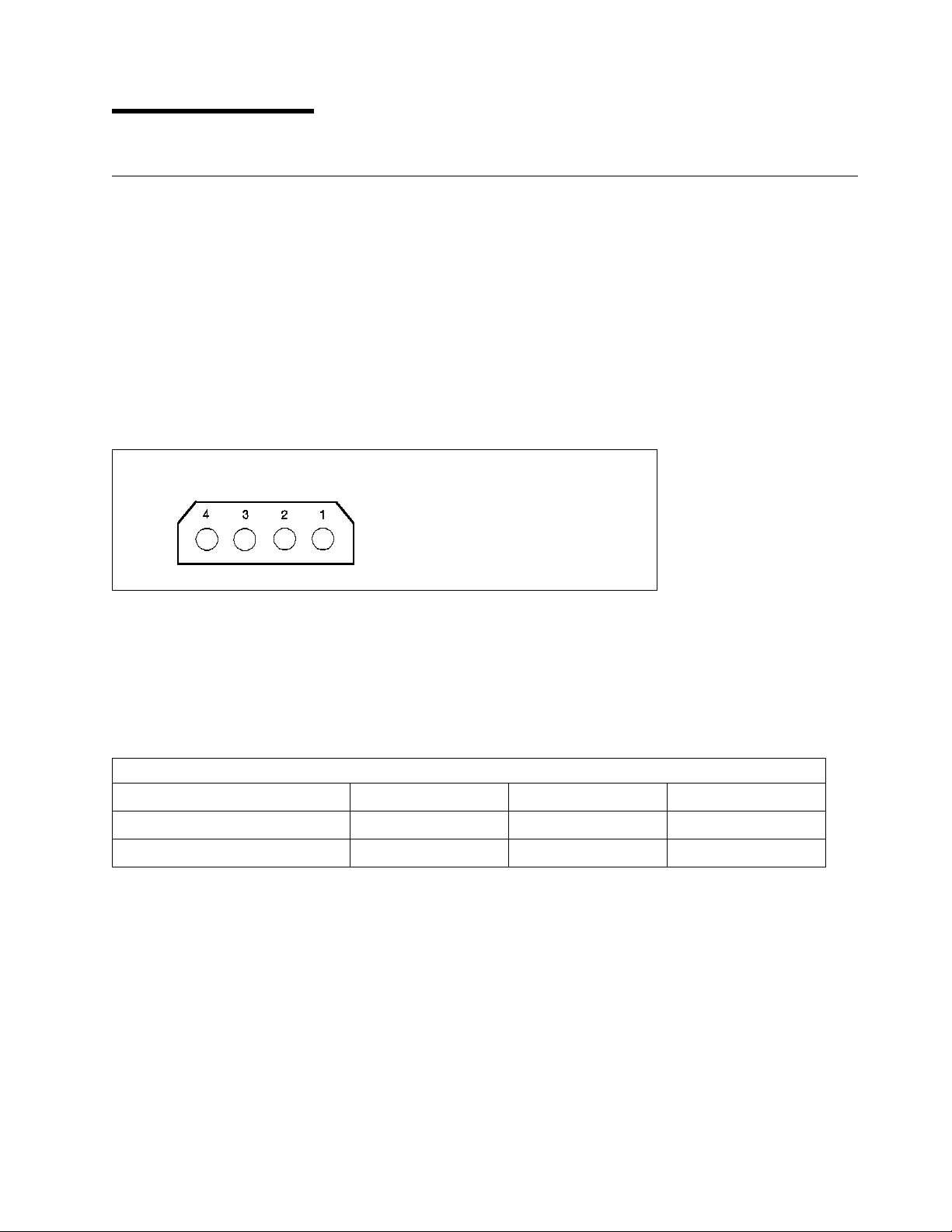

6.1.1 Power Connector

Power pin assignment of 80-pin (SCA-2) model is shown in 6.8.3.3, “80-pin Model” on page 53 and 6.1.2.4,

“SCSI Signal Connector (80-pin SCA-2 LVD/SE Multi-mode)” o n page 25.

Power connector of 50-pin models comply with the ANSI SCSI"A" connector specifications.

Power connector of 68-pin models comply with the ANSI SCSI"P" connector specifications.

Connector of 80-pin models comply with SFF-8046 Revision 2.1.

Power pin assignment of 50-pin a nd 68-pin models is as shown below.

Pin

1

2

3

4

Figure 14. Power Connector Pin Assignments

Voltage

+12V

GND

GND

+5V

6.1.2 SCSI Bus Connector

DNES-3xxxxx has 50-pin, 68-pin or 80-pin SCA-2 SCSI connectors as follows.

Figure 15. SCSI Connector vs Models

Model 50-pin 68-pin 80-pin SCA-2

SE model Yes Yes No

LVD/SE Multi-mode model No Yes Yes

Copyright IBM Corp. 1998, 1999 21

Page 32

6.1.2.1 SCSI Signal Connector (50-pin SE)

The SCSI signal connector complies wi th ANSI SCSI-2.

Figure 16. Table of Signals

PIN SIGNAL PIN SIGNAL

01

03

05

07

09

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

47

49

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Open

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

02

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

-DB(0)

-DB(1)

-DB(2)

-DB(3)

-DB(4)

-DB(5)

-DB(6)

-DB(7)

-DB(P)

Ground

Ground

Ground

T RM Power

Ground

Ground

-ATN

Ground

-BSY

-ACK

-RST

-MSG

-SEL

-C/D

-REQ

-I/O

22 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 33

6.1.2.2 SCSI Signal Connector (68-pin SE)

Th e pin assignments of interface signals conforms t o ANSI SCSI-3 X3T10/855D as follows.

Figure 17. Table of Signals

Connector

Contact

Number

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Signal Name Connector

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

TERMPWR

TERMPWR

(Open)

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Ground

Contact

Number

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

Signal Name

-DB(12)

-DB(13)

-DB(14)

-DB(15)

-DB(P1)

-DB(0)

-DB(1)

-DB(2)

-DB(3)

-DB(4)

-DB(5)

-DB(6)

-DB(7)

-DB(P0)

Ground

Ground

TERMPWR

TERMPWR

(Open)

Ground

-ATN

Ground

-BSY

-ACK

-RST

-MSG

-SEL

-C/D

-REQ

-I/O

-DB(8)

-DB(9)

-DB(10)

-DB(11)

Note: 8 bit devices which connect t o t he P-cable should be the following signals inactive (high):

-DB(8),-DB(9),-DB(10),-DB(11),-DB(12),-DB(13),-DB(14),-DB(15),-DB(P1)

All other signals shall be connected as defined.

Specification 23

Page 34

6.1.2.3 SCSI Signal Connector (68-pin LVD/SE Multi-mode)

Th e pin assignments of interface signals conforms t o ANSI SPI-2 T10 Project 1142D Revision 19 as follows.

Figure 18. Table of Signals

Connector

Contact

Number

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Signal Name Connector

+DB(12)

+DB(13)

+DB(14)

+DB(15)

+DB(P1)

+DB(0)

+DB(1)

+DB(2)

+DB(3)

+DB(4)

+DB(5)

+DB(6)

+DB(7)

+DB(P)

Ground

DIFFSENS

Reserved

Reserved

Reserved

Ground

+ATN

Ground

+BSY

+ACK

+RST

+MSG

+SEL

+C/D

+REQ

+I/O

+DB(8)

+DB(9)

+DB(10)

+DB(11)

Contact

Number

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

Signal Name

-DB(12)

-DB(13)

-DB(14)

-DB(15)

-DB(P1)

-DB(0)

-DB(1)

-DB(2)

-DB(3)

-DB(4)

-DB(5)

-DB(6)

-DB(7)

-DB(P0)

Ground

Ground

Reserved

Reserved

Reserved

Ground

-ATN

Ground

-BSY

-ACK

-RST

-MSG

-SEL

-C/D

-REQ

-I/O

-DB(8)

-DB(9)

-DB(10)

-DB(11)

24 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 35

6.1.2.4 SCSI Signal Connector (80-pin SCA-2 LVD/SE Multi-mode)

The 80-pin SCA-2 model uses an A MP connector which is compatible with SFF-8046 Revision 2.1.

Figure 19. Table of Signals

Connector

Contact

Number

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Signal Name Connector

12 Volt Charge

12 Volt

12 Volt

12 Volt

Reserved

Reserved

-DB(11)

-DB(10)

-DB(9)

-DB(8)

-I/O

-REQ

-C/D

-SEL

-MSG

-RST

-ACK

-BSY

-ATN

-DB(P0)

-DB(7)

-DB(6)

-DB(5)

-DB(4)

-DB(3)

-DB(2)

-DB(1)

-DB(0)

-DB(P1)

-DB(15)

-DB(14)

-DB(13)

-DB(12)

5 Volt

5 Volt

5 Volt Charge

Reserved

RM T START

SCSI I D (0)

SCSI I D (2)

Contact

Number

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Signal Name

12V Ground

12V Ground

12V Ground

MATED 1

Reserved

DIFFSENS

+DB(11)

+DB(10)

+DB(9)

+DB(8)

+I/O

+REQ

+C/D

+SEL

+MSG

+RST

+ACK

+BSY

+ATN

+DB(P0)

+DB(7)

+DB(6)

+DB(5)

+DB(4)

+DB(3)

+DB(2)

+DB(1)

+DB(0)

+DB(P1)

+DB(15)

+DB(14)

+DB(13)

+DB(12)

MATED 2

5V Ground

5V Ground

ACTIVE L ED O UT

DELAYED START

SCSI I D (1)

SCSI I D (3)

Note: Pin #38,39,40,77,78,79,80 work as Logical OR w i th jumper pins on Option Jumper Block.

Specification 25

Page 36

6.1.3 SCSI Cable

6.1.3.1 SE mode

The maximum cumulative cable length whe n using single-ended transceiver shou l d b e 3 meters. Implementations that limit th e transfer rate to a maximum of 5 Mbyte transfers per second may extend the cumulative

cable length t o 6 meters. (ANSI SCSI-3 X3T10/855D Revision 15a).

The maximum cumulative signal path between terminators shall be 3.0 meters w he n using u p to 4 maximum

capacitance (25pF) devices. The maximum cumulative signal pa th length between terminators shall be 1.5

meters w h en using from five to eight maximum capacitance devices. (ANSI SCSI-3 FAST-20

X3T10/1071D).

6.1.3.2 LVD mode

The maximum cumulative cable length whe n using L VD transcever must be 12 meter. For t he details of

specification, refer to ANSI SCSI Parallel Interface-2 (SPI-2) T 10 Project 1142D Revision 19.

6.1.4 SCSI Bus Terminator

6.1.4.1 SE model

Single-ended 50/68-pin models have SCSI active terminator. I t can be enabled by installing a jumper plug at

position #6 of J-4 jumper block, or connecting pins # 9 a nd # 10 of t he auxiliary connector on 68-pin model.

System is responsible for making sure that all required signals are terminated at b o t h ends of t he bus cable.

6.1.4.2 LVD/SE Multi-mode model

Both 68-pin an d 80-pin of LVD/SE Multi-mode models do not have any SCSI Terminator.

It is user responsibility to mak e sure that all required signals are adequately terminated at bo t h ends of the

bus cable.

6.1.4.3 Terminator Power

The 50-pin a nd 68-pin models supply terminator power to pin #26 of 50-pin connector and pin #17,18,51,52

of 68-pin connector through current limiter an d s ho tk y diode w he n jumper plug is set at position # G of J-6

jumper block. F or jumper setting, see 6.2, “Option Jumper Block” on page 28.

The 80-pin models do not supply terminator power.

6.1.5 Hot Plug / Unplug

The 80-pin (SCA-2) model supports Ho t Plug/Unplug.

The 50-pin model and 68-pin model do n ot support H ot Plug/Unplug.

6.1.6 SCSI Bus Electrical Characteristics

SCSI Bus Electrical Characteristics of &modelx. comply with ANSI SPI-2 T10 Project 1142D Revision 19.

26 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 37

6.1.7 Auxiliary Connector on 68-pin Model

The 68-pin models contain Auxiliary Connector between power connector and 68-pin SCSI connector in

addition t o Option Jumper Block. The setting at Option Jumper Block an d t he Auxiliary Connector work

as logical OR. The drive conforms SFF-8009 Rev3.0.

Pin #1,3,5,7 specify SCSI-ID as -DAS0,1,2,3. Tie-down to the ground is to assert.

Pi n #2,4,6,12 are reserved, an d should be open.

Pin #8 is for external L ED cathod.

If pin # 9 is tied-down t o the ground on SE model, SCSI Terminator is enabled.

Enable SCSI Terminator

(Varid only on SE model)

+5V

ДДДДДДДДДДДДДДДДДДДДД¿³³³³ÚÄÄÄ Ä

ДДДДДД¿ ЪДДДДДДДДДДДДДДД Ä

³ ³ ЪДДДДДДДДДДД Ä

³ ³ ³ ЪДДДДДДД Ä

³³³³³³

Pin#: 1197531

ЪДДДДДДДДДДД¿ ЪДДДДДДДДДДД¿

³ ЪДДДДДДДДДЩ АДДДДДДДДД¿ ³

³³ ³³

³³

³³ ³³

³³

³³ ³³

³ ÀÄ¿ ЪДДДДД¿ ÚÄÙ ³

АДДДЩ АДДДДДЩ АДДДЩ

oooooo

oooooo

12108642

³³³³³³

(Reserved)

GROUND

LED Cathod

ДДДДДДДДДДДДДДÙ³³³³ÀÄÄÄ

ДДДДДДДДДДДДДДДДДДДДДДÙ ³ ³ АДДДДДДД

ДДДДДДДДДДДДДДДДДДДДДДЩ АДДДДДДДДДДД

Note: Pin #9 is valid only for SE model.

LVD/SE Multi

Ä

mode model has no terminator.

DAS3

DAS2

DAS1

DAS0

³³

³³

ÄÄ¿

ÃÄÄÄ

³

ÄÄÙ

(Reserved)

(Reserved)

(Reserved)

SCSI ID

Auxiliary Connector

Specification

27

Page 38

6.2 Option Jumper Block

Two jumper blocks, J-4 and J-6, are located on the card of 50/68-pin models as shown below.

One jumper block, J-4, is located on t he card of 80-pin models as shown below.

J-4 has 12 positions (#1 - #12).

Some of jumper pins on J-4 c an be controlled also through Auxiliary Connector on 68-pin models as

descrived i n 6.1.7, “Auxiliary Connector on 68-pin Model” on page 27. These controls work as logical OR

between Option Jumper Block an d Auxiliary Connector.

Some of jumper pins on J-4 c an be controlled also through 80-pin SCA-2 connector as described in 6.1.2.4,

“SCSI Signal Connector (80-pin SCA-2 LVD/SE Multi-mode)” o n page 25. These controls work as logical

O R between Option Jumper Block a nd SCA-2 connector.

J-6 has 7 positions ( # A - # G ) and controls Terminator Power supply.

28 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 39

ЪДДДДВДДДДДДДДДДДДДДВДДДДДДДДДДДДДДДДДДДД¿

³ ³ ÚÄÄÄ´

³³ ³JÄ6³<ÄÄ

³

C

³³³

³

o

³ ÀÄÄÄ´

³

n

³³ ³

³

n

³

Logic card

³

e

³³ ³

³

c

³ ÚÄÄÄ´

³

t

³³³ ³

³

o

³³

³

r

³³³

³³ ³³ ³

³ ³ ÀÄÄÄ´

АДДДДБДДДДДДДДДДДДДДБДДДДДДДДДДДДДДДДДДДДЩ

Position #A

Option Jumper

Block JÄ6

Position #G

³³

Position #1

JÄ4³<ÄÄOption Jumper

Block JÄ4

Position #12

³

³

³

³

³

³

³

³

Note: 80Äpin models do not have Option Jumper Block JÄ6.

Ä

Jumper Block J

6

(50/68Äpin models only)

ЪДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД¿ ³³

ДДДДДДДДДДДДДБД¿

Logic Card³GFEDCBA

ДДДДДДДДДДДДДДД´

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ³

ooooooo

ooooooo

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ ³³

ÚÄÁÄ¿ ³³

³³³³

ГДДДЩ ³³

Disk Enclosure

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ

Ú¿

³³

³³

³

³

³

Ú¿

³³ ЪДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД¿

³³ ÚÄÁÄ¿

³³ ³ ³

³³ ÀÄÄÄ´

³³ АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДЩ

³³

³АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

³

³

³

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Figure 20. Jumper Pins

oooooooooooo

121110987654321

oooooooooooo

Jumpser Block JÄ4

Disk Enclosure

ЪДБДДДДДДДДДДД

³

Logic Card

ГДДДДДДДДДДДДД

Specification

29

Page 40

6.2.1 Jumper Pin of 50-pin SE model

50Äpin SE model

ЪДДДДДДД¿

³JÄ6³

³ АДДДДДД¿

³³

GROUND

ДДДДВДДД ³

Open

SCSI Bus

oAo

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÀÄÄÄ ³

ÄÄÄ ³

ÄÄÄ ³

oBo

oCo

oDo

oEo

³³

oFo

³³

o(G)o

³³

³ ЪДДДДДДЩ

³³

АДДДДДДДЩ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

( x) indicates Ship Default

Reserved

Reserved

Reserved

Reserved

Reserved

Open

Enable Terminator Power Supply

GROUND

ДДДДВДДД ³

LED Anode

ЪДДДДДДД¿

³JÄ4³

³ АДДДДДД¿

³³

o1o

³³ ³

ÃÄÄÄ ³

³ ³ ³ ÃÄÄ

ÃÄÄÄ ³

³³³³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÀÄÄÄ ³

ÄÄÄ ³

o(2)o

o(3)o

o4o

o(5)o

o(6)o

o7o

o8o

o9o

o10o

o11o

³³

o12o

³³

³ ЪДДДДДДЩ

³³

АДДДДДДДЩ

³ ÄÄÄ

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

Reserved

DAS2

ÄÄ¿

SCSI ID

DAS1

DAS0

ÄÄ´

ÄÄÙ

Enable Auto Spin Up

Enable SCSI Terminator

Disable Unit Attention

Enable TIÄSDTR

Enable Auto Start Delay

Delay Start 6/12

Disable SCSI Parity Check

LED Cathod

Figure 21. Jumper Pin of 50-pin SE model

30 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 41

6.2.2 Jumper Pin of 68-pin SE model

68Äpin SE model

ЪДДДДДДД¿

³JÄ6³

³ АДДДДДД¿

³³

GROUND

ДДДДВДДД ³

Open

SCSI Bus

oAo

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÀÄÄÄ ³

ÄÄÄ ³

ÄÄÄ ³

oBo

oCo

oDo

oEo

³³

oFo

³³

o(G)o

³³

³ ЪДДДДДДЩ

³³

АДДДДДДДЩ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

( x) indicates Ship Default

Reserved

Reserved

Reserved

Reserved

Reserved

Open

Enable Terminator Power Supply

GROUND

ДДДДВДДД ³

LED Anode

ЪДДДДДДД¿

³JÄ4³

³ АДДДДДД¿

³³

o1o

³³³³

ÃÄÄÄ ³

³ ³ ³ ÃÄÄ

ÃÄÄÄ ³

³³³³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÀÄÄÄ ³

ÄÄÄ ³

o(2)o

o(3)o

o4o

o(5)o

o(6)o

o7o

o8o

o9o

o10o

o11o

³³

o12o

³³

³ ЪДДДДДДЩ

³³

АДДДДДДДЩ

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

DAS3

DAS2

ÄÄ¿

ÄÄ´

SCSI ID

DAS1

DAS0

ÄÄ´

ÄÄÙ

Enable Auto Spin Up

Enable SCSI Terminator

Disable Unit Attention

Enable TIÄSDTR/WDTR

Enable Auto Start Delay

Delay Start 6/12

Disable SCSI Parity Check

LED Cathod

Figure 22. Jumper Pin of 68-pin SE model

Specification 31

Page 42

6.2.3 Jumper Pin of 68-pin LVD/SE Multi-mode model

68Äpin LVD/SE MultiÄmode model

ЪДДДДДДД¿

³JÄ6³

³ АДДДДДД¿

³³

GROUND

|

ДДДДВДДД ³

Open

SCSI Bus

oAo

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÀÄÄÄ ³

ÄÄÄ ³

ÄÄÄ ³

oBo

oCo

oDo

oEo

³³

oFo

³³

oGo

³³

³ ЪДДДДДДЩ

³³

АДДДДДДДЩ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

Reserved

Reserved

Reserved

Reserved

Reserved

Open

Enable Terminator Power Supply

( x) indicates Ship Default

GROUND

ДДДДВДДД ³

LED Anode

ЪДДДДДДД¿

³JÄ4³

³ АДДДДДД¿

³³

o1o

³³³³

ÃÄÄÄ ³

³ ³ ³ ÃÄÄ

ÃÄÄÄ ³

³³³³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÀÄÄÄ ³

ÄÄÄ ³

o(2)o

o(3)o

o4o

o(5)o

o6o

o7o

o8o

o9o

o10o

o11o

³³

o12o

³³

³ ЪДДДДДДЩ

³³

АДДДДДДДЩ

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

DAS3

DAS2

ÄÄ¿

ÄÄ´

SCSI ID

DAS1

DAS0

ÄÄ´

ÄÄÙ

Enable Auto Spin Up

Force SE Mode

Disable Unit Attention

Enable TIÄSDTR/WDTR

Enable Auto Start Delay

Delay Start 6/12

Disable SCSI Parity Check

LED Cathod

Figure 23. Jumper Pin of 68-pin LVD/SE Multi-mode model

32 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 43

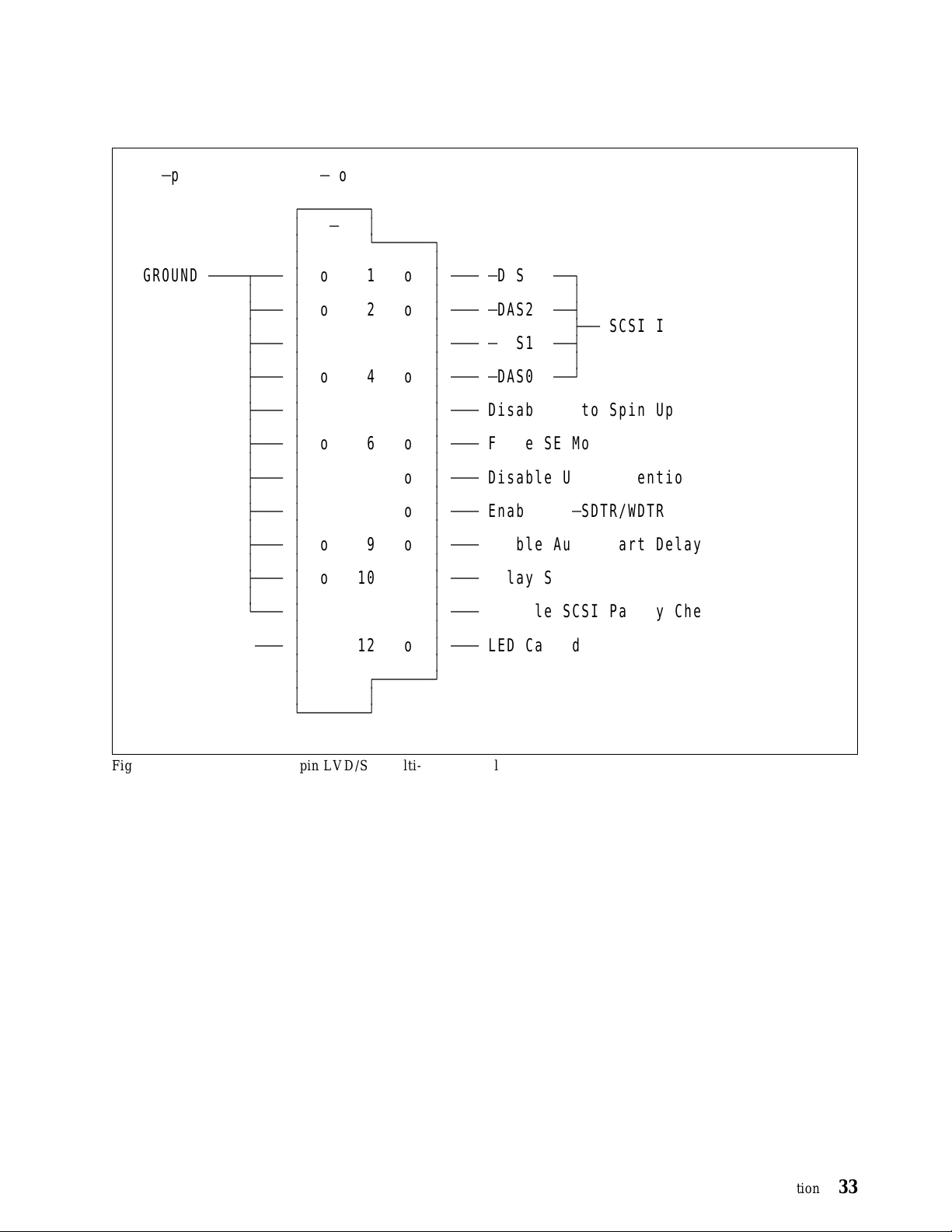

6.2.4 Jumper Pin of 80-pin LVD/SE Multi-mode model

80Äpin LVD/SE MultiÄmode model

( x) indicates Ship Default

ЪДДДДДДД¿

³JÄ4³

³ АДДДДДД¿

³³

GROUND

ДДДДВДДД ³

³³³³

ÃÄÄÄ ³

³ ³ ³ ÃÄÄ

ÃÄÄÄ ³

³³³³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÃÄÄÄ ³

³³ ³

ÀÄÄÄ ³

LED Anode

o1o

o2o

o3o

o4o

o5o

o6o

o7o

o8o

o9o

o10o

o11o

³³

ÄÄÄ ³

o12o

³³

³ ЪДДДДДДЩ

³³

АДДДДДДДЩ

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ Ä

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

³ ÄÄÄ

DAS3

DAS2

ÄÄ¿

ÄÄ´

SCSI ID

DAS1

DAS0

ÄÄ´

ÄÄÙ

Disable Auto Spin Up

Force SE Mode

Disable Unit Attention

Enable TIÄSDTR/WDTR

Enable Auto Start Delay

Delay Start 6/12

Disable SCSI Parity Check

LED Cathod

Figure 24. Jumper Pin of 80-pin LVD/SE Multi-mode model

Specification 33

Page 44

6.2.5 Jumper Signal Description on J-6

6.2.5.1 Position #A - # E on J-6

Reserved.

Jumper setting is n ot allowed.

6.2.5.2 Position # F on J-6

Open.

The pins atre open.

6.2.5.3 Position # G on J-6

Enable Terminator Power Supply.

6.2.6 Jumper Signal Description on J-4

6.2.6.1 Position #1 - #4 on J-4

These four lines (-DAS0, -DAS1, -DAS2, -DAS3) define DNES-3xxxxx device ID o n the SCSI BUS.

-DAS0 is the least significant bi t and -DAS3 is the most significant bit . Device ID is defined as follows.

In case of 50-pin model, Position #1 is Reserved, a nd -DAS3 is not used.

Throughout this paragraph 'on' means a shunt jumper is installed and 'off' means that no shunt jumper is

installed.

Ä

DAS3ÄDAS2ÄDAS1ÄDAS0

Position #

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

ÄÄ

> (1) (2) (3) (4) Device ID

off off off off 0 <

ÄÄÄ

Shipping

off off off on 1 default

off off on off 2 of

off off on on 3 80

Ä

pin

off on off off 4

off on off on 5

off on on off 6 <

ÄÄÄ

Shipping

off on on on 7 default

on off off off 8 of

on off off on 9 50/68

Ä

pin

on off on off 10

on off on on 11

on on off off 12

on on off on 13

on on on off 14

on on on on 15

Note: 50

Ä

pin model does not useÄDAS3, and only Device ID's 0 through 7

can be assigned.

Figure 25. SCSI Device ID

34 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 45

6.2.6.2 Position #5 on J-6

50/68-pin model

Enable Auto Spin Up

If a shunt jumper is installed, the drive will spin up automatically after power on reset. If shunt

jumper is not installed, th e drive will not spin up unless a START UNIT command is received.

80-pin model

− Disable Auto Spin Up

If a shunt jumper is not installed, th e drive will spin up automatically after power on reset. If shunt

jumper is installed, t he drive will not spin up unless a START UNIT command is received.

Note: Th e drive ma y not spin u p while SCSI Bus is disconnected an d internal terminator is disabled.

6.2.6.3 Position #6 on J-4

SE model

− Enable SCSI Terminator

If a shunt jumper is installed, t h e internal SCSI active terminator on the drive works.

LVD/SE Multi-mode model

− Force SE mode

If a shunt jumper is installed, the drive is forced to work as Single-End mode drive.

6.2.6.4 Position #7 on J-4

Disable Unit Attention

Installing a shunt jumper enables control of UAI (Unit Attention Inhibit) bit in Mode Page 0.

6.2.6.5 Position #8 on J-4

50-pin model

− Enable TI-SDTR

Installing a shunt jumper enables Target Initiated Synchronous Data Transfer Request Negotiation.

68/80-pin model

− Enable TI-SDTR/WDTR

Installing a shunt jumper enables the following.

— Target Initiated Wide Data Transfer Request Negotiation

— Target Initiated Synchronous Data Transfer Request Negotiation

Specification 35

Page 46

6.2.6.6 Position #9 - #1 0

Auto Start Delay & Delay Start 6/ 1 2

These pins control when and how the drive spins u p with the combination of Position #5 o n J-4.

When bot h Auto Spin up and Auto Start Delayis are enabled, t h e drive start will be delayed by a period of

time multiplied by its ow n SCSI address. If Auto Spin up is disabled, these jumpers will be ignored.

Throughout this paragraph 'on' means a shunt jumper is installed and 'off' means that no shunt jumper is

installed.

Enable/Disable Auto Delay

Auto Start Start

Spin up Delay 6/12

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Position #Ä> (5) (9) (10) Option

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

off (50/68Äpin) any any Drive will Not spin up

on (80

on (50/68

off (80

on (50/68

off (80

Ä

pin) Requires Start Unit command

Ä

pin) off off Spin up immediately after POR

Ä

pin)

Ä

pin) on off Spin up 6 seconds multiplied

Ä

pin) by SCSI address after POR

on (50/68

off (80

Figure 26. Spin Up Control by Jumper

Ä

Ä

pin) by SCSI address after POR

pin) on on Spin up 12 seconds multiplied

36 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 47

6.2.6.7 Position #1 1 on J-4

Disable SCSI Parity Check

Installing a shunt jumpe disables SCSI Parity checking.

6.2.6.8 Position #1 2

LED pins

The L ED pins are used to drive an external Light Emitting Diode. U p to 30 mA of sink current capability

is provided. Th e L ED Anode must be tied to t h e current limited + 5 V source provided o n the pi n for L ED

Anode at the Location #12 on J-4 jumper block. T h e LED Cathode is then connected t o the pin for LE D

Cathod at the Location #12 on J-4 jumper block to complete the circuit.

Refer t o 6.3, “ LED Circuit” on page 39 for more details.

+5V

o

³

>

< 150 Ohm

> Position #12 on

³

³

АДДДДДДДДДДДДДДДДДДДДДДД

JÄ4 Jumper Block

o to LED Anode

³

ÄÄÄ´

³

Figure 27. LE D Circuit

ЪДДДДДДДДДДДДДДДДДДДДДДД

/

\

АДДДД¿

³

ДДБДД

///

o to LED Cathod

Specification

37

Page 48

6.2.7 Shipping Default

Default jumer setting depends o n model.

50-pin SE model

Refer t o 6.2.1, “Jumper Pin of 50-pin S E model” o n page 30.

68-pin SE model

Refer t o 6.2.2, “Jumper Pin of 68-pin S E model” o n page 31.

68-pin LVD/SE Multi-mode model

Refer t o 6.2.3, “Jumper Pin of 68-pin LVD/SE Multi-mode model” on page 32.

80-pin LVD/SE Multi-mode model

No jumper is set as shipping default.

Refer t o 6.2.4, “Jumper Pin of 80-pin LVD/SE Multi-mode model” on page 33.

38 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 49

6.3 LED Circuit

Position #12 on Jumper Block J-4 is used t o drive an external LED.

Instead of the the jumper pins, the following pins can be used to drive LED.

68-Pin model : Auxiliary Connector Pin #8 and #11.

Refer t o 6.1.7, “Auxiliary Connector on 68-pin Model” on page 27 and 6.3.2, “68-Pin Model” o n

page 40.

80-Pin model : SCA-2 Connector Pin #77 as shown in 6.8.3.3, “80-pin Model” on page 53 an d 6.3.3,

“80-Pin Model” o n page 41.

Th e schematics of LED circuit on each model are as follows.

6.3.1 50-Pin Model

DNESÄ318350 / DNESÄ309170 50ÄPin Model

+5V

o

³

³

>

< 150 Ohm

>

³

³

³

АДДДДДДДДДДДДДДДДДДДД

Position #12 on

Jumper Block JÄ4

o to LED Anode

ЪДДДДДДДДДДДДДДДДДДДД

³

/

ÄÄÄ´

³

\

АДДДД¿

³

³

ДДБДД

///

Figure 28. LE D Circuit of 50-Pin Model

o to LED Cathod

Specification

39

Page 50

6.3.2 68-Pin Model

DNESÄ318350 / DNESÄ309170 68ÄPin Model : : Example of Us age

5V : :

o::

³

³

ГДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

³

³

>::

< 150 Ohm : :

>::\/

³

³

³

АДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

ЪДДДДДДДДДДДДДДДДВДДДДДДДДДДДДДДДДДДДДДДД

³

/

ÄÄÄ´ ³

³

\

АДДДД¿ ³

³

³

³

³³

³³

ДДБДД ³

///

: : at System Side

::

::

Auxiliary : :

Connector Pin #11 :

oo

for LED Anode : :

::

ДДДДДДДДД¿

³

³

³

ДДДБДДД

: : \ / LED

::

to LED Anode :

o:

Position #12 on : :

Jumper Block JÄ4: :

o:

³

to LED Cathod

:

³

::

::

>::

< 150 Ohm : :

>::

::

Auxiliary : :

Connector Pin #8 :

АДДДДДДДДДДДДДДДДДДДДДДД

oo

ДДДДДДДДДЩ

ÄÂÄ

³

³

³

³

³

³

³

³

³

³

³

³

³

³

³

for LED Cathod : :

::

::

Figure 29. LE D Circuit of 68-Pin Model

40 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 51

6.3.3 80-Pin Model

DNESÄ318350 / DNESÄ309170 80ÄPin (SCAÄ2) Model : : Example of Usage

ЪДДДДДДДДДДДДДДДДВДДДДДДДДДДДДДДДДДДДДДДД

³

/

ÄÄÄ´ ³

³

\

АДДДД¿ ³

³

³

³

³³

³³

ДДБДД ³

///

: : at System Side

::

::

+5V : : +5V

o::o

³

³

>::

< 150 Ohm : :

>::

³

³

³

³

³

³

³

АДДДДДДДДДДДДДДДДДДДДДДД

to LED Anode :

Position #12 on : :

Jumper Block JÄ4: :

³

³

to LED Cathod

>::

< 150 Ohm : :

>::

SCAÄ2 Connector Pin #77 :

АДДДДДДДДДДДДДДДДДДДДДДД

::

::

::

::

::

³

³

³

³

³

³

³

ДДДБДДД

:: \/

: : \ / LED

::

o:

o:

:

::

::

::

::

oo

ДДДДДДДДДЩ

ÄÂÄ

³

³

³

³

³

³

³

³

³

³

³

³

³

³

³

for LED Cathod : :

::

::

Figure 30. LE D Circuit of 80-Pin (SCA-2) Model

Specification 41

Page 52

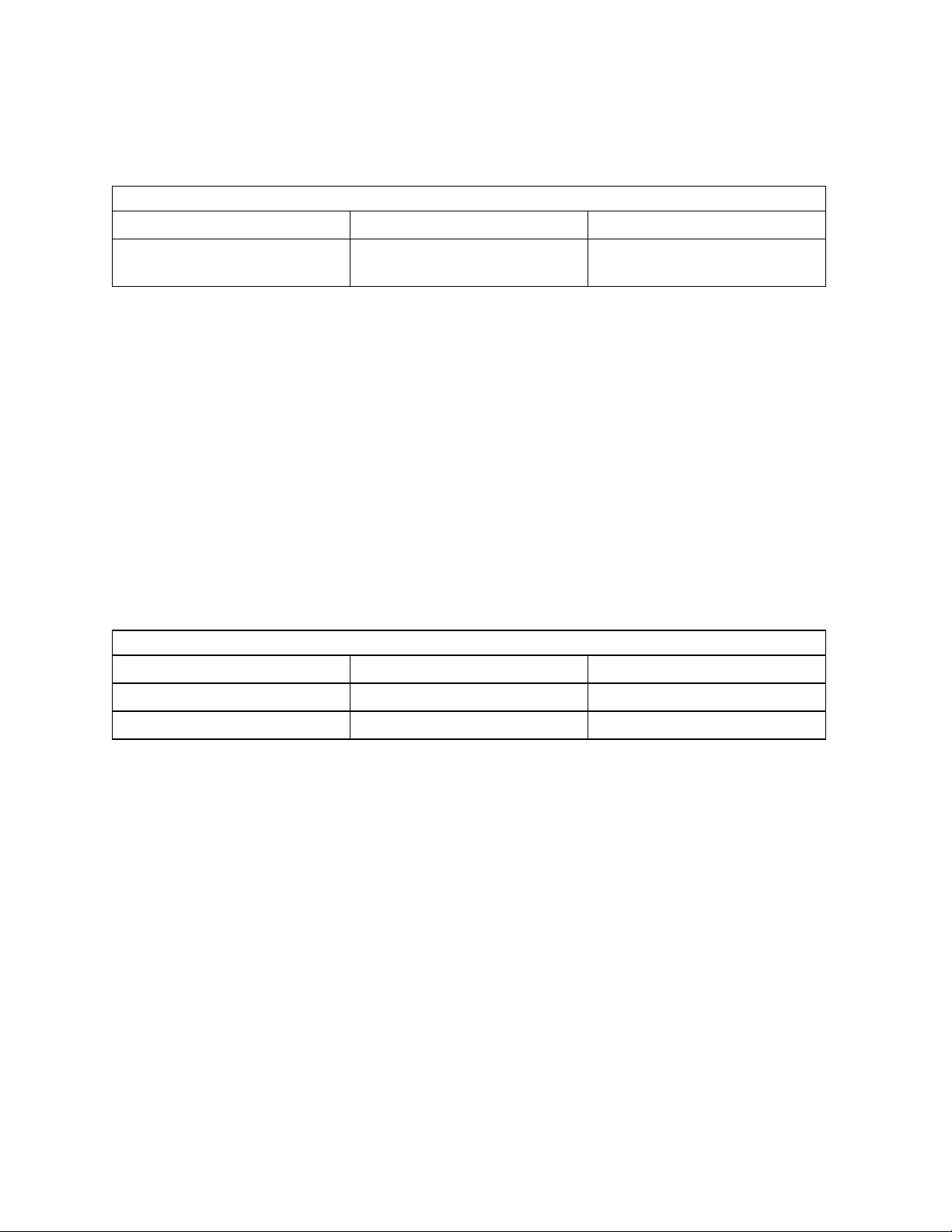

6.4 Environment

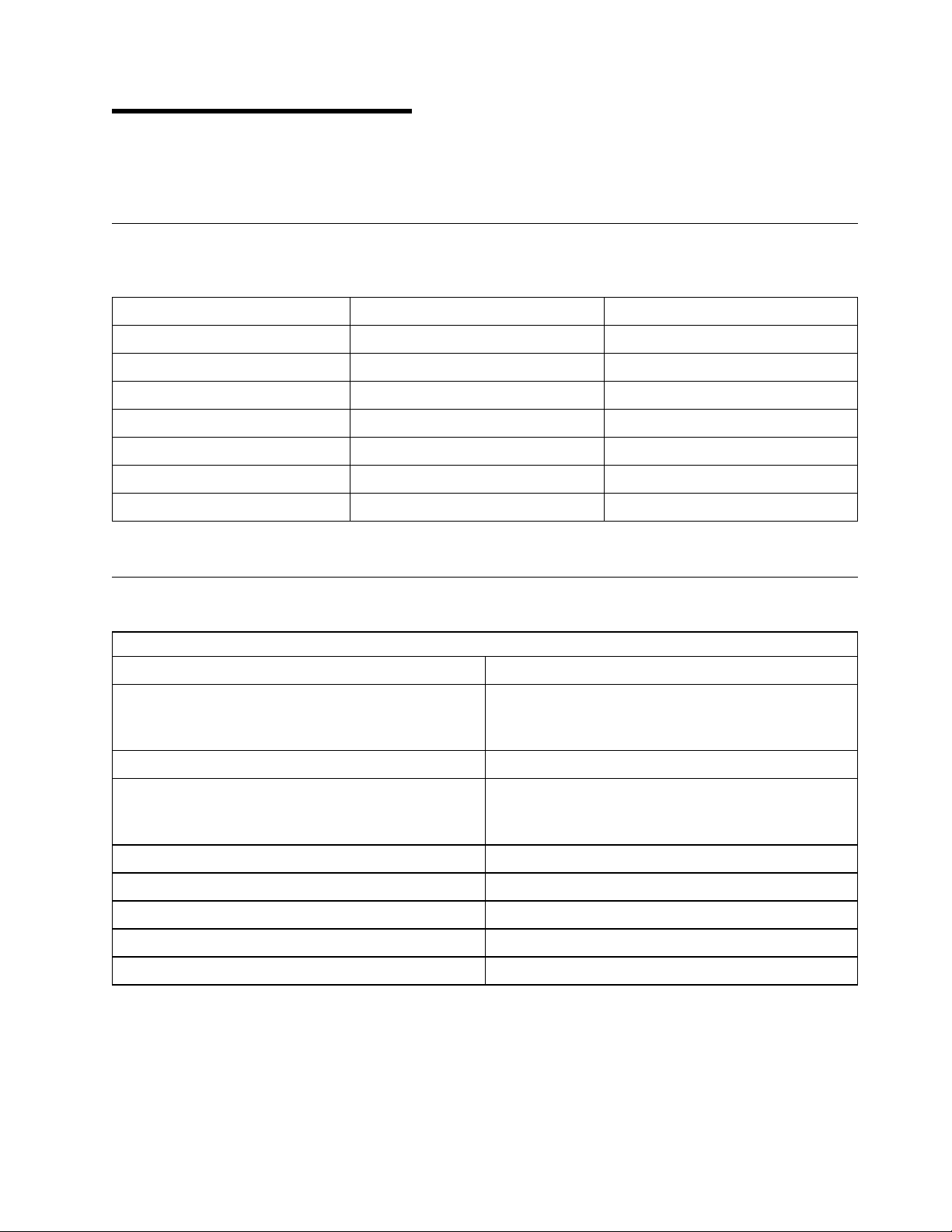

Figure 31. Environmental Condition

Operating Conditions

Temperature 5 to 55 ˚C (See note)

Relative Humidity 8 to 90 %RH

Maximum Wet Bulb Temperature 29.4 ˚C

Maximum Temperature Gradient 15 ˚ C / Hour

Altitude −300 to 3048 m

Non-Operating Conditions

Temperature − 40 to 65 ˚C

Relative Humidity 5 to 95 %RH

Maximum Wet Bulb Temperature 35 ˚C

Maximum Temperature Gradient 15 ˚ C / Hour

Altitude −300 to 12,000 m

Note:

The system ha s to provide sufficient ventilation to maintai n a surface temperature below 60[ ˚C ] at the

center of drive top cover.

Non-condensing should be kept at any time.

Maximum storage period with shipping package is one year.

Figure 32. Limits of Temperature an d Humidity

42 OEM Spec. of DNES-3xxxxx Revision 1.2

Page 53

6.5 Cooling Requirements

The system ha s t o provide sufficient ventilation to m ain ta in a surface temperature below 60˚ C at the center

of t h e top cover of the drive.

The system ha s t o provide sufficient ventilation to keep t he limits of component temperature as shown

below.

Figure 33. Maximum Allowable Module Surface Temperature

Module Name Location Maximum Allowable Surface Temperature

MPU + HDC 1 90˚C

DRAM 2 90˚C

SCSI Terminator 3 90˚C

VCM + Spindle Driver 4 95˚C

Cannel 5 95˚C

Figure 34. Module Location

Specification

43

Page 54

6.6 DC Power Requirements

Connection t o the product should be made in isolated secondary circuits (SELV). T he following voltage

specification is applied a t t h e power connector of the drive.

N o special power on/off sequencing is required.

Figure 35. Input Voltage

During run and spin up Absolute max spike voltage Supply rise time

+ 5 Volts Supply 5V +/- 5% 7V 0 - 200 ms

+12 Volts Supply 12V + /- 5 % (*1) 15V 0 - 400 ms

Figure 36. Power Supply Current of DNES-318350 with SCSI Terminator Enabled

+5Volts +12Volts Total