Hyundai HD78 User Manual

Body Electrical

System

General

Generals ....................................................... BE - 3

Specifications ............................................... BE - 6

Diagnosis ...................................................... BE - 7

Fuses and Relays

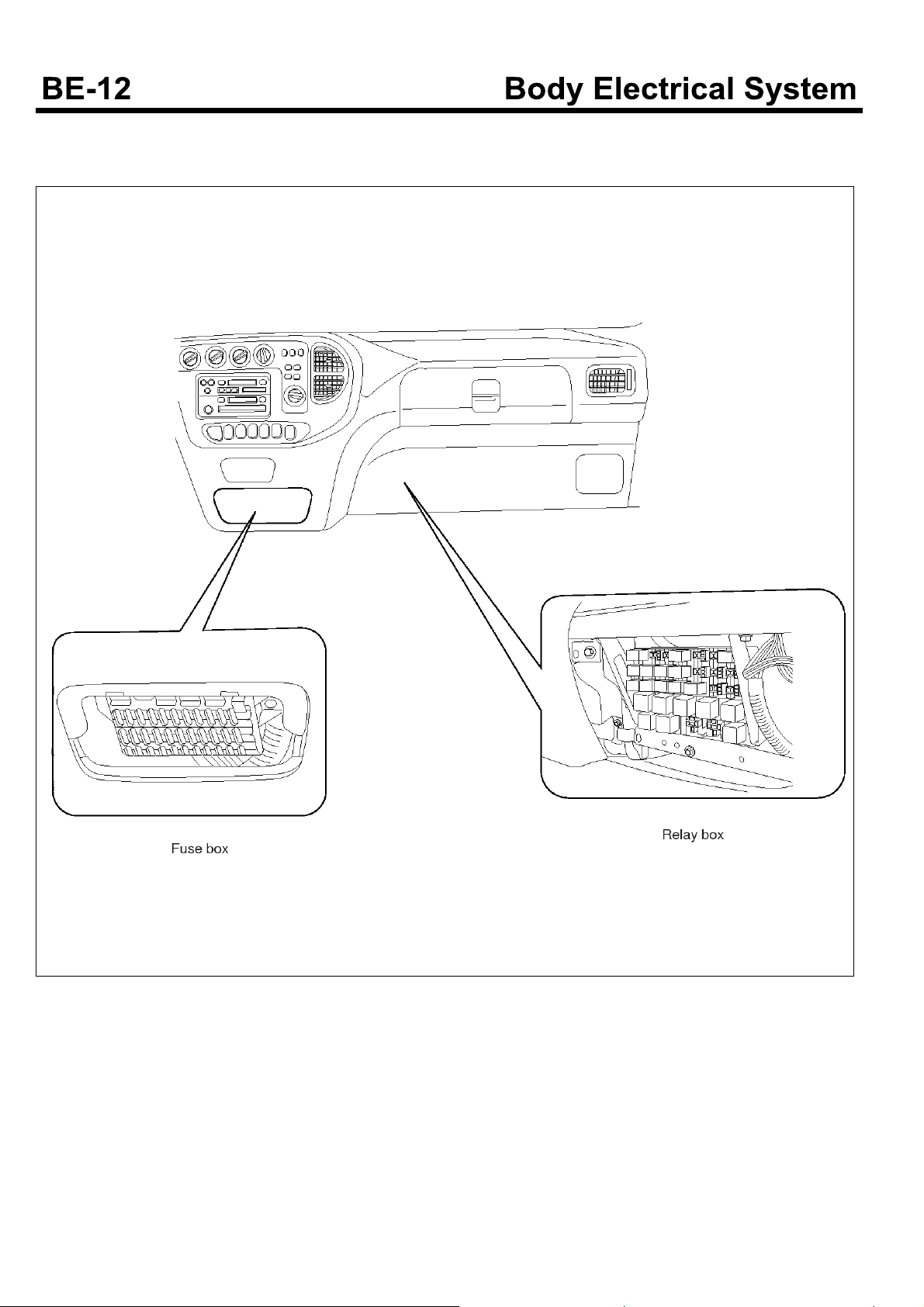

Component Location .................................... BE - 12

Components ................................................. BE - 14

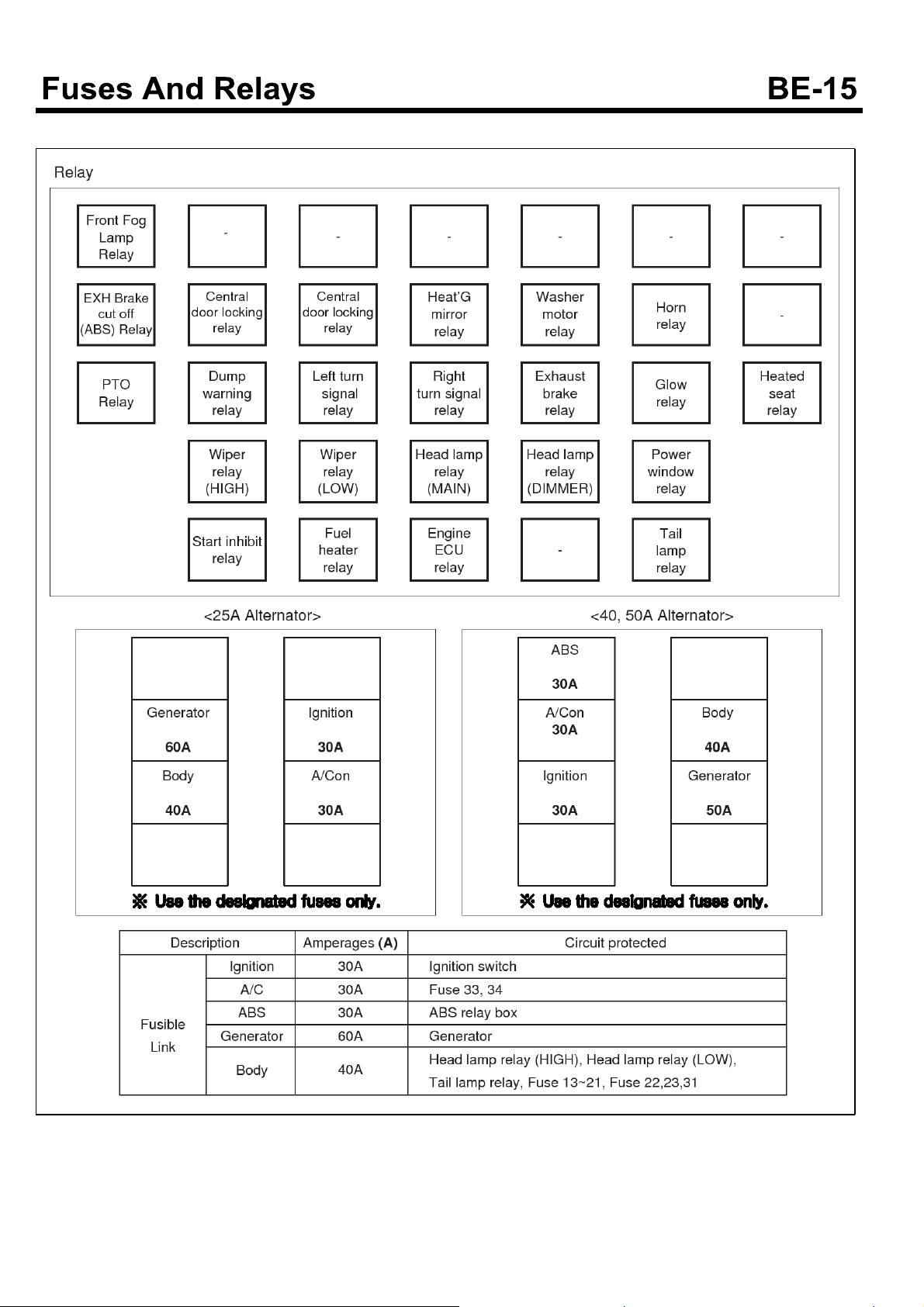

Relay

Inspection ................................................ BE - 16

Fuse

Inspection ................................................ BE - 17

Indicators and Gauges

Instrument Cluster

Components ........................................... BE - 18

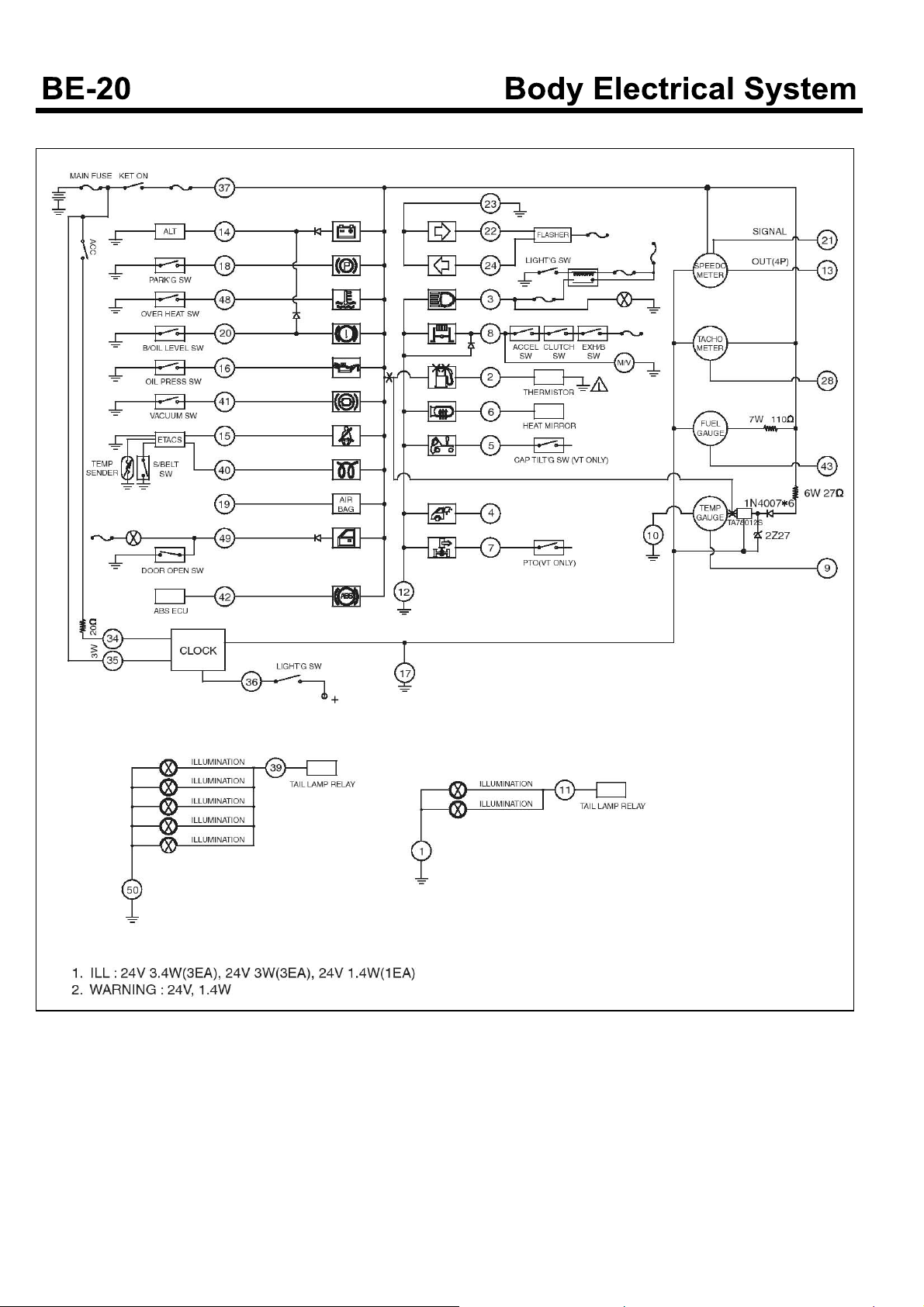

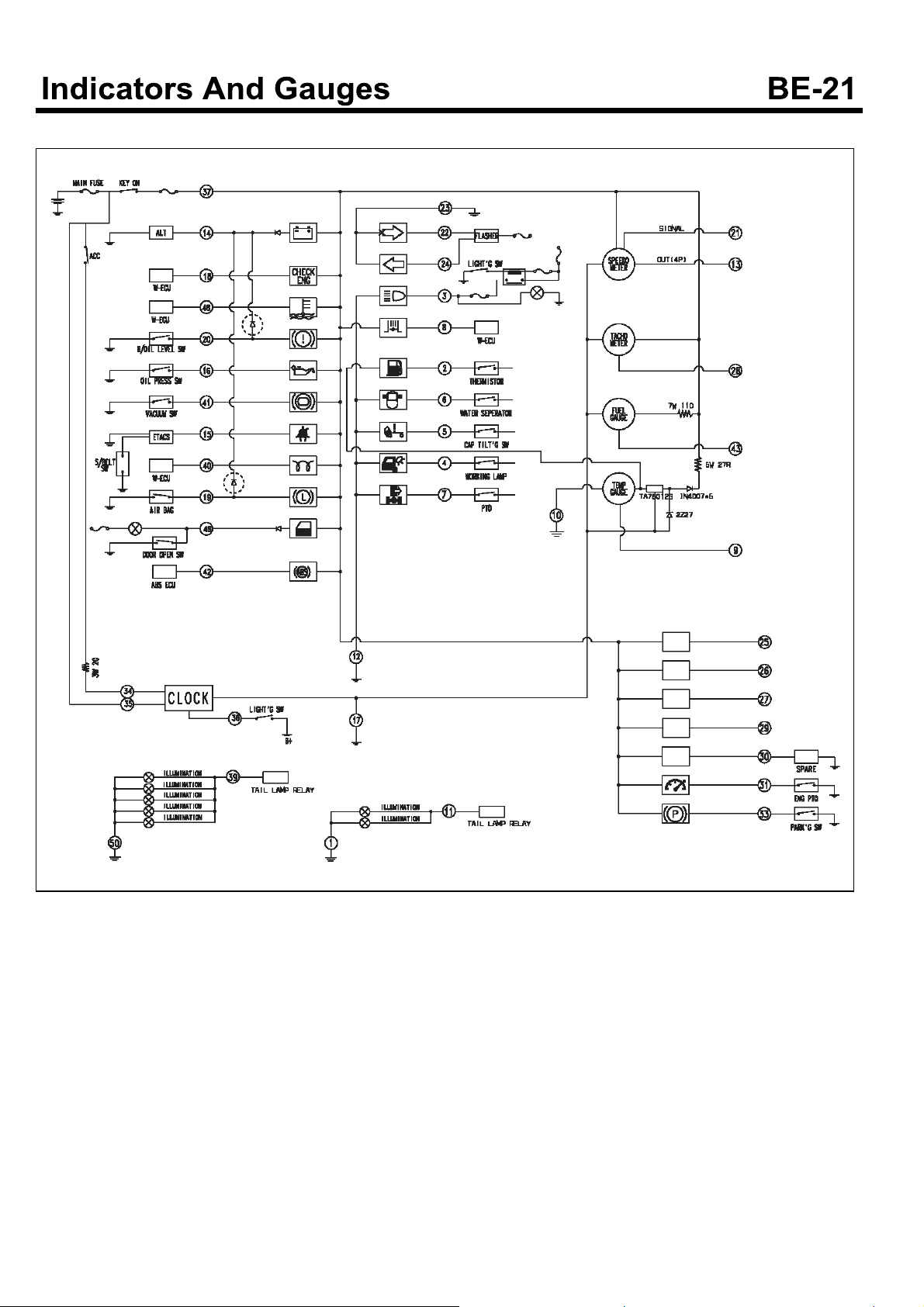

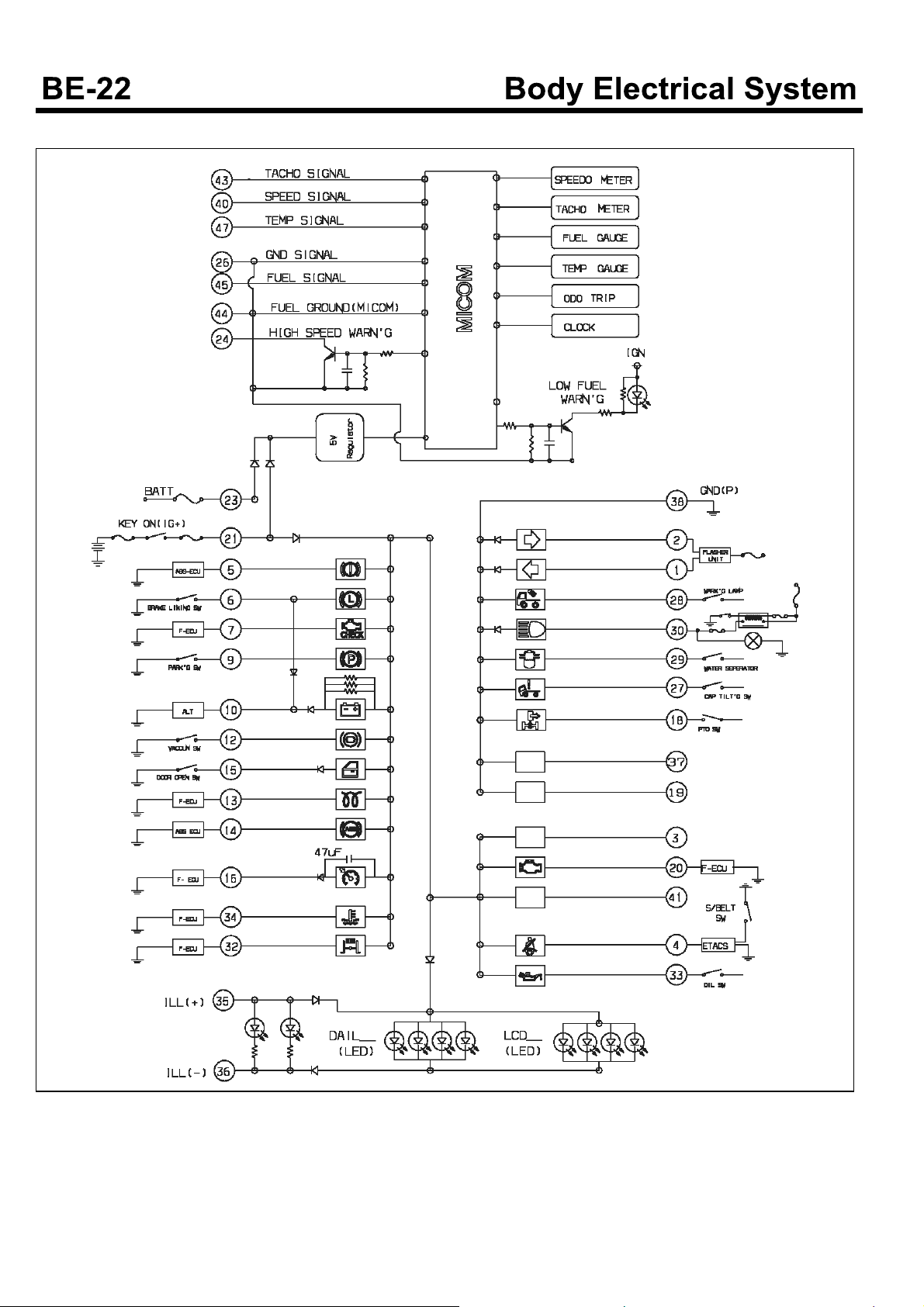

Circuit Diagram ....................................... BE - 20

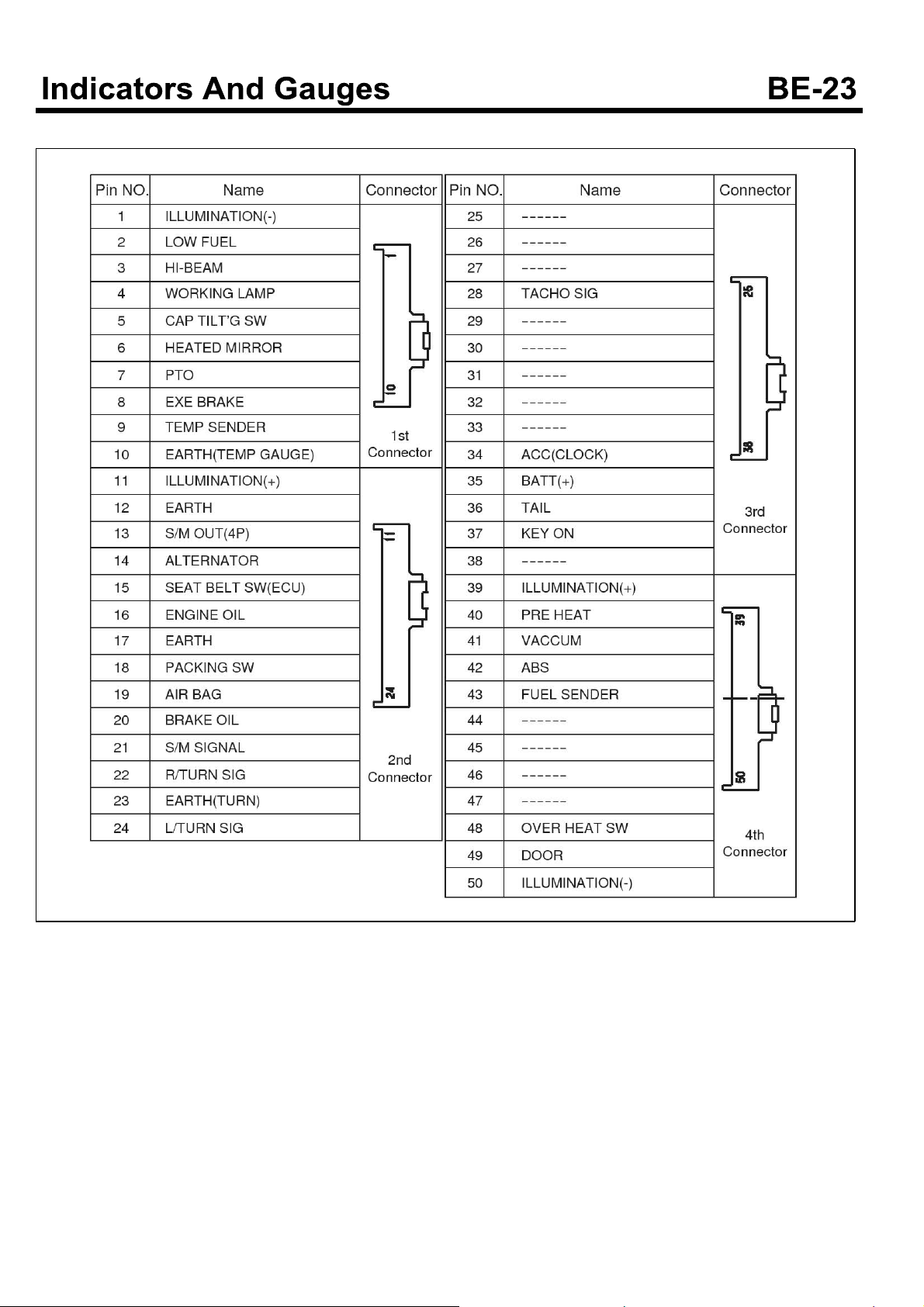

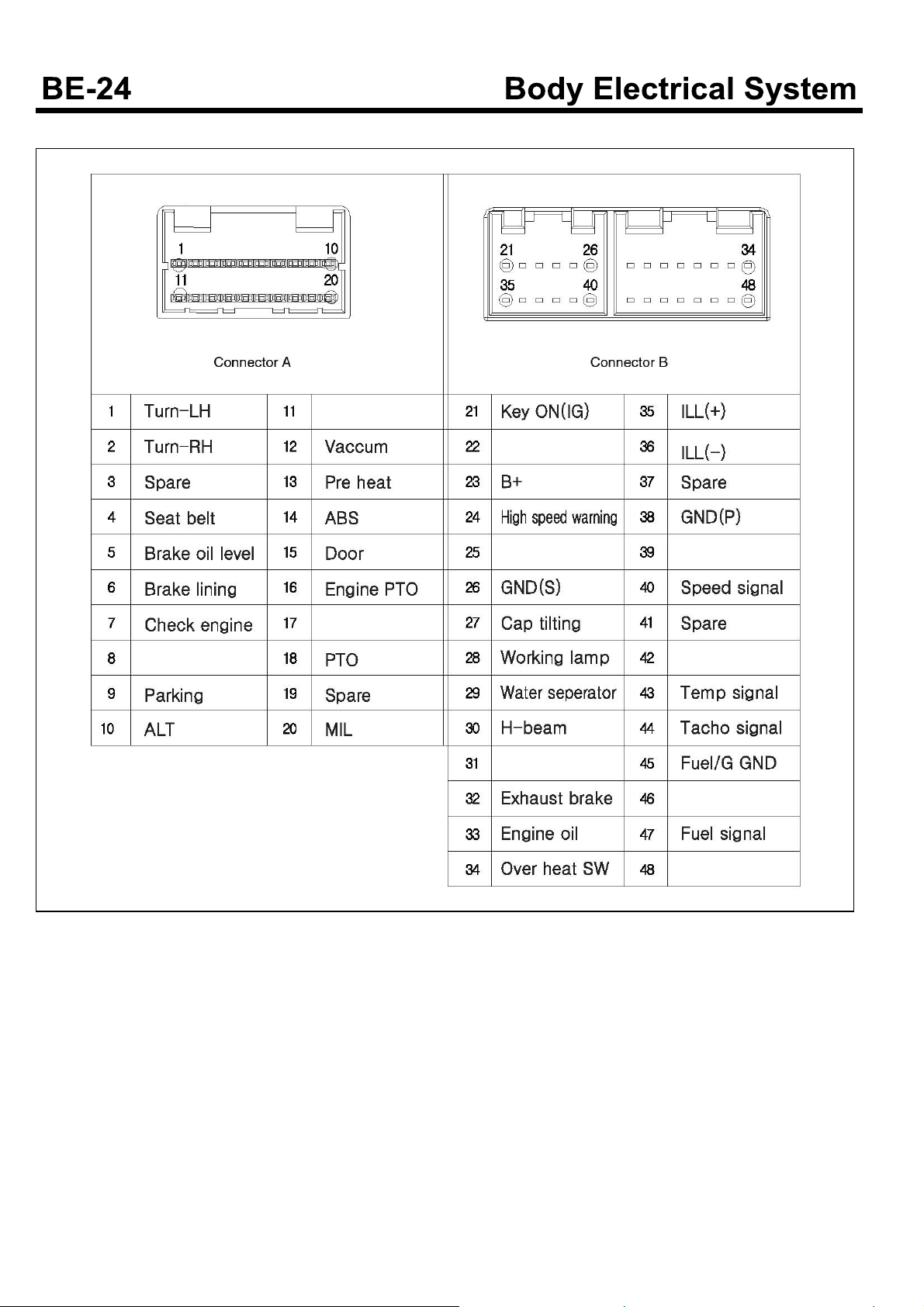

Connector Configuration ........................ BE - 23

Fuel Gauge

Inspection ................................................ BE - 25

Water Temperature Gauge

Inspection ................................................ BE - 26

Tachometer

Inspection ................................................ BE - 27

Speedometer

Inspection ................................................ BE - 28

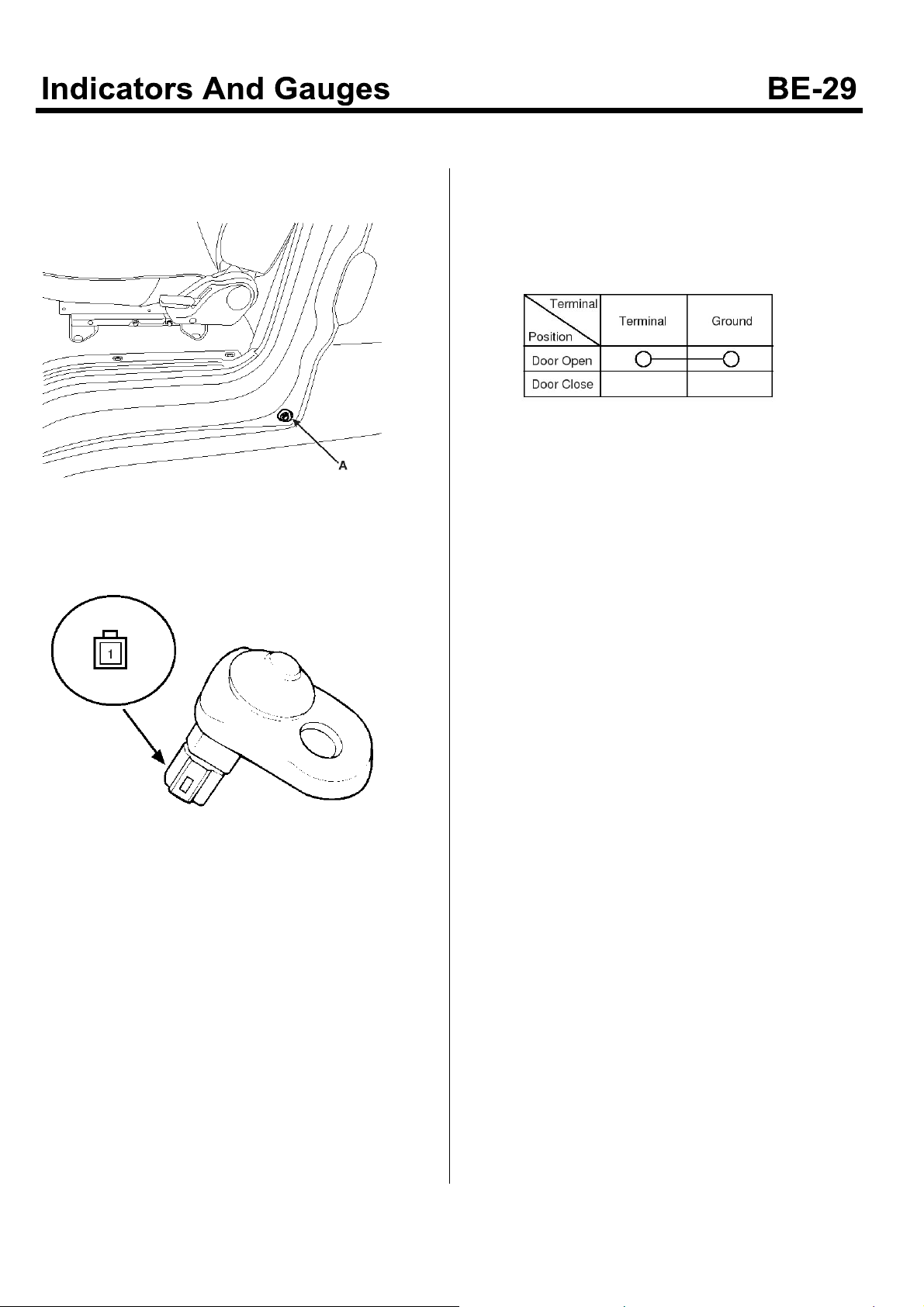

Door Warning Indicator

Inspection ................................................ BE - 29

Seat Belt Warning Indicator

Inspection ................................................ BE - 30

Parking Brake Switch

Inspection ................................................ BE - 31

Tilting Lock Sensor

Inspection ................................................ BE - 32

Hazard Switch

Inspection ................................................ BE - 33

Working Lamp Switch

Inspection ................................................ BE - 34

Front/Rear Fog Lamp Switch

Inspection ................................................ BE - 35

Idle Adjust Switch

Inspection ................................................ BE - 36

Multi Function Switch

Components ................................................. BE - 37

Inspection ..................................................... BE - 38

Windshield Wiper/ Washer

Component Location .................................... BE - 40

Windshield Wiper/Washer

Removal .................................................. BE - 41

Inspection ................................................ BE - 42

Circuit Diagram ....................................... BE - 42

Connector ............................................... BE - 42

Power Windows

Power Window Motor

Connector Configurations ...................... BE - 43

Circuit Diagram ....................................... BE - 43

Inspection ................................................ BE - 43

Power Window Switch

Inspection ................................................ BE - 44

Circuit Diagram ....................................... BE - 45

Lighting System

Components ................................................. BE - 46

Head Lamp

Replacement........................................... BE - 47

Inspection ................................................ BE - 48

Adjustment .............................................. BE - 49

Turn Signal Lamp

Replacement........................................... BE - 51

Room Lamp

Replacement........................................... BE - 52

Fog Lamp

Replacement........................................... BE - 53

Inspection ................................................ BE - 53

Adjustment .............................................. BE - 54

Head Lamp Leveling Device

Description.................................................... BE - 56

Components ................................................. BE - 56

Part Circuit Diagrams ................................... BE - 57

Keyless Entry System

Components ................................................. BE - 59

Description.................................................... BE - 60

Operation ...................................................... BE - 61

Inspection ..................................................... BE - 71

Adjustment .................................................... BE - 72

Specification ................................................. BE - 72

Door Lock Actuator

Inspection ................................................ BE - 73

Digital Tachograph

Specifications ............................................... BE - 74

Description.................................................... BE - 74

Components ................................................. BE - 75

Part Circuit Diaram ....................................... BE - 76

Replacement ................................................ BE - 77

DTC Chart ..................................................... BE - 77

Audio System

Audio Unit

Components ........................................... BE - 78

Replacement........................................... BE - 80

Cleaning ................................................. BE - 80

Speaker

Replacement........................................... BE - 81

Inspection ................................................ BE - 82

Horns

Horns

Component Location .............................. BE - 83

Replacement........................................... BE - 84

Inspection ................................................ BE - 84

Electronic Time And Alarm Control System

Components ................................................. BE - 85

Circuit Diagram ............................................. BE - 86

Connector ..................................................... BE - 88

Specifications ............................................... BE - 90

Generals ....................................................... BE - 91

Operating Principle ...................................... BE - 91

General

Generals

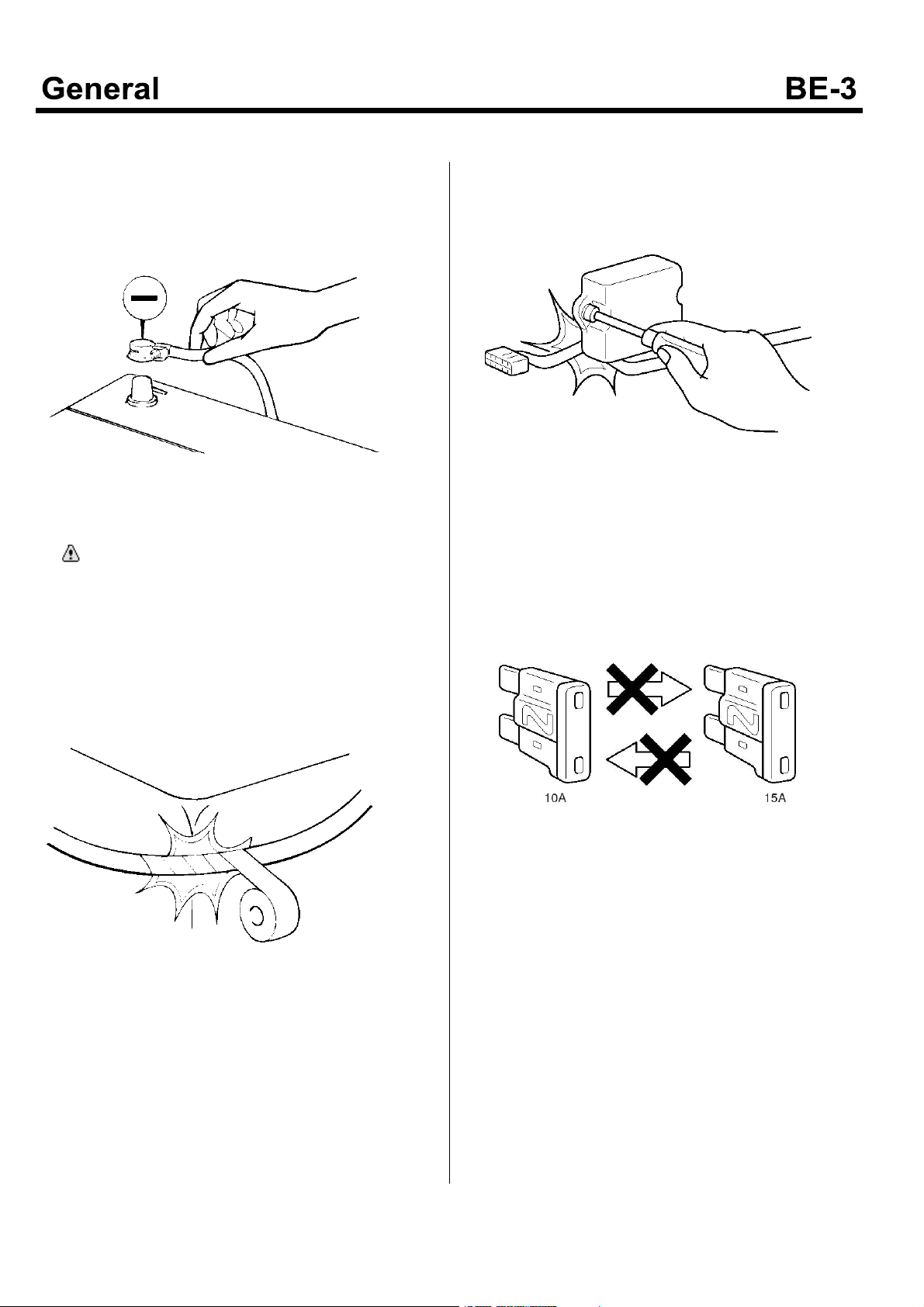

1. For servicing the electric system, the battery (-)

terminal should be disconnected first.

KMTBE5001A

CAUTION

Before connecting or disconnecting the (-)

terminal, all lamp switches should be turn "OFF".

(Otherwise, the semiconductor devices would be

damaged)

2. If the harness can be contacted with a sharpened

part or corner, wrap those portion with a tape for

preventing the harness from being damaged.

3. When the parts are installed at the vehicle, be careful

that the wiring harness is not torn off or damaged.

KMTBE5003A

4. When the fuse is burn-out, replace it with a new one

of rated ampere. If one of higher than nominal

capacity is used, the electric parts may be damaged

or fire may be occurred.

KMTBE5002A

KMTBE5004A

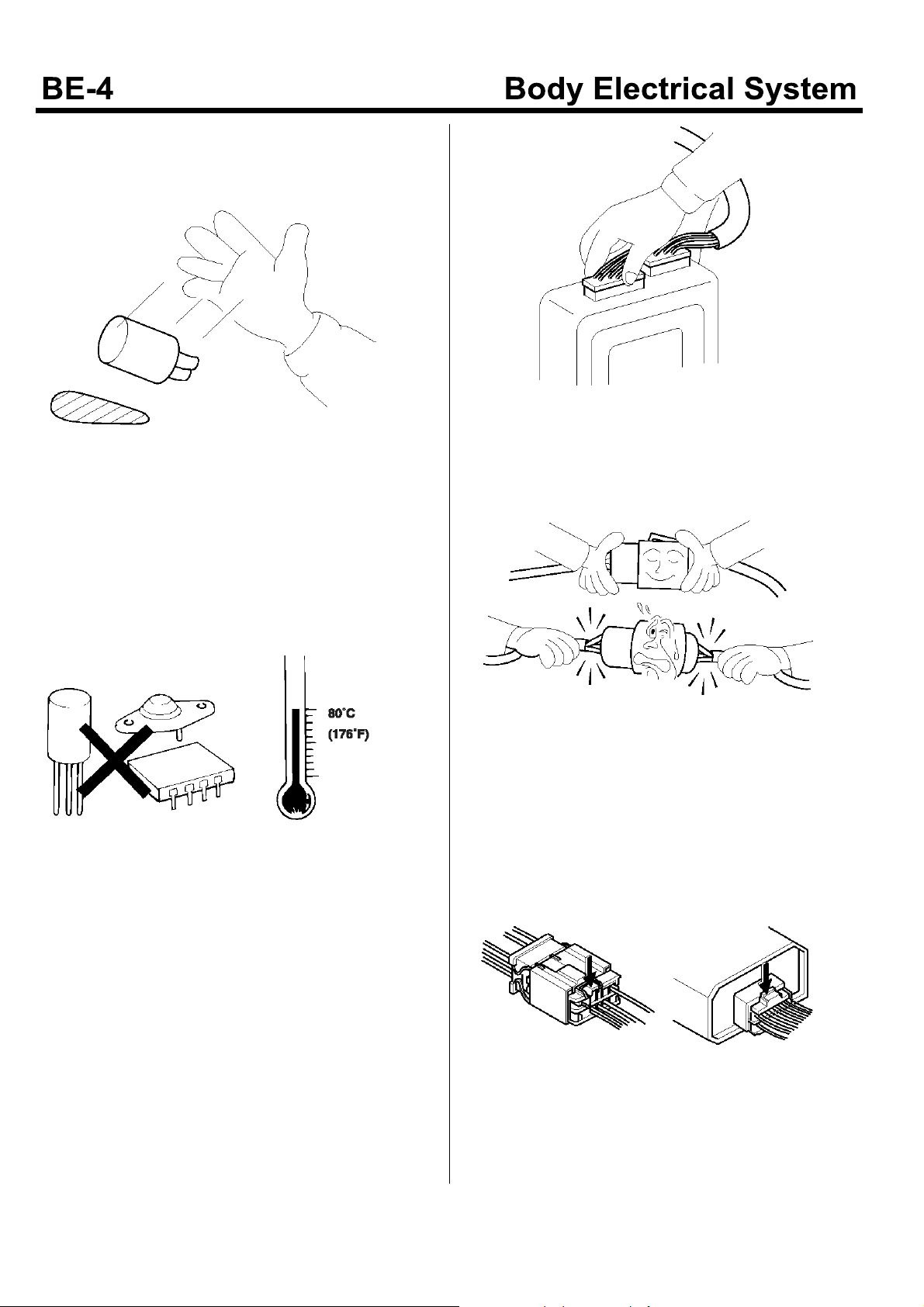

5. Be careful that the sensors or the relays are not

shocked. Do not drop them down to the floor. Do not

throw them recklessly.

KMTBE5005A

6. As the electric components used for computer or

relay are easily damaged by a heat, if the service is

performed under the high temperature over 80°C,

these electric components should be removed in

advance.

KMTBE5007A

8. When disconnecting the harness, hold the connector

and pull it. Do not pull the harness to disconnect it.

KMTBE5006A

7. As the loosened connector may be the causes of

troubles, connecting of the connector should be

ensured.

KMTBE5008A

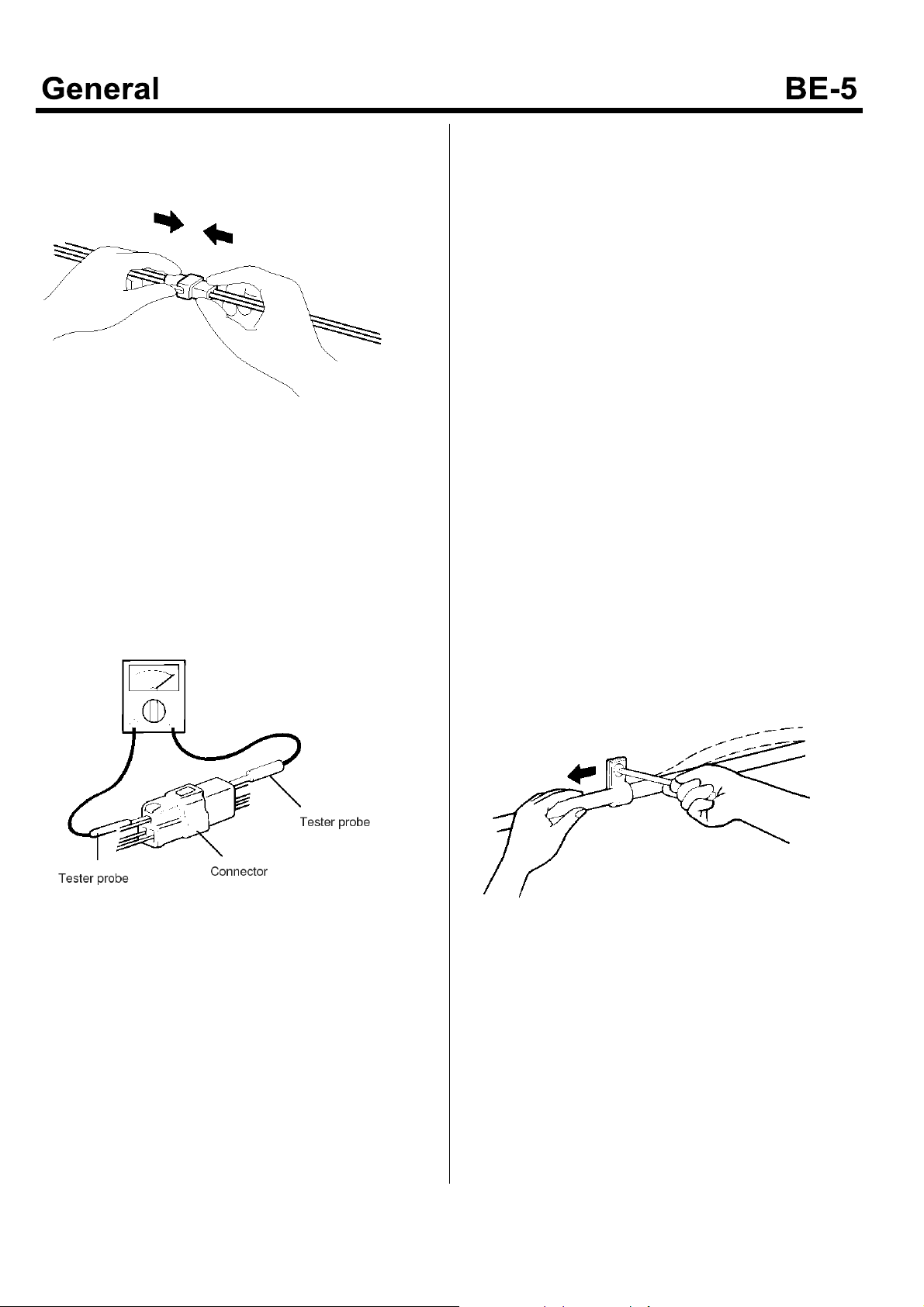

9. When disconnect the connector having a locking

device, press the lock to the arrow direction as shown

in the following figure to remove the connector.

KMTBE5009A

10.When connecting the connector, insert the connector

until "Tag" sound can be heard.

KMTBE5010A

11.When checking the electric current or voltage at the

connector terminal using a circuit tester, insert the

tester probe from the harness side. When the

connector is the sealed type, insert the probe through

the hole in the wiring rubber cap. At that time, be

careful that the insulating of the wire is not damaged.

Insert the probe until it contacts with the connector

terminal completely.

Inspection of Cable and Wire

1. Check that the connecting portion is loosened or

rusted.

2. Check that the terminal or wire is corroded by the

battery electrolyte.

3. Check that the circuit of the terminal or the wire is

opened.

4. Check that the wire is properly insulated or the

sheath is damaged, cracked or deteriorated.

5. Check that the conductive material of the wire

contacts with metal parts of other components (body

or other parts).

6. Check that the fixing bolt is electrically connected to

the body completely.

7. Check that the wiring is properly performed.

8. Fix the wiring firmly to preventing it from contacting

with the sharpened parts of body or the portions

making a high temperature (exhaust manifold or

exhaust pipe).

9. The wire should be fixed with enough clearance from

the fan pulley, the fan belt and other rotating parts or

vibrating parts.

10.Thewiringbetweenthebody,thefixedpart,andthe

engine, the vibrating part, should be fixed after

distancing or slacking the wire somewhat.

EMTBE5007A

KMTBE5012A

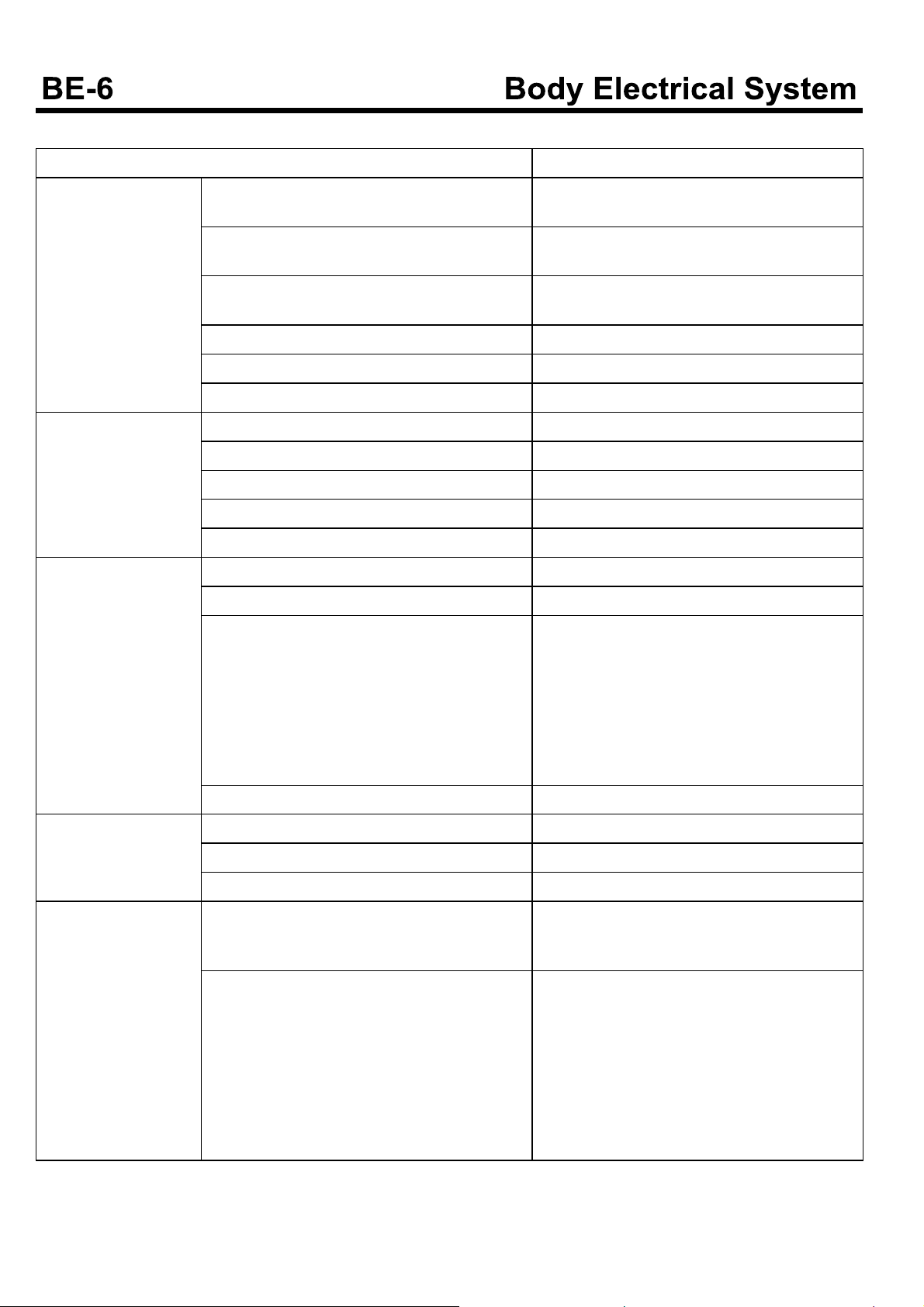

Specifications

Item Specifications

Indicator and Gauge

(Except D4GA engine)

Indicator and gauge

(D4GA engine)

Multi function switch Nominal voltage DC 24V

Fuel gauge type

Unit type

Water temperature gauge type

Unit type

Tachometer type

Sensor type

Speedometer type Pulse type

Odometer type Gear eddy current type

Indicator type Bulb type

Fuel gauge type Stepper motor

Water temperature gauge Stepper motor(M iddle fixing type)

Tachometer type Stepper motor

Speedometer type Stepper motor

Indicator type LED type

Operating tempera ture range -30~+80°C

Nominal load

Dimmer and Passing switch

Lightening switch

Turn signal lam p switch

Wiper switch

Washer switch

Exhaust brake

Change of volume

Cross coil type(Scale fixing type)

Variable resistor type

Cross coil type (Middle fixing type)

Thermistor typ e

Cross coil type

Moving coil type

0.12A (R e lay load)

0.12A (R e lay load)

21W x 2+1.7W (Lamp load)

0.12A (R e lay load)

1.75A (Motor load)

0.8A (Coil load)

Max 10mA

Insulating resistance 1M or more at 500MV

Wind shield wiper/Washer

Power window Power window motor

Wiper motor type Ferrite magnetic type

Washer motor type Ferrite magnetic type

Washer tank capacity 2.8 or more

Nominal voltage

Operating tempera ture range

Power window switch

Nominal voltage

Operating tempera ture range

Power window switch nominal load current

Power window switch max load current

Window lock switch nominal load current (Driver's seat)

Window lock switch max load current (Driver's

seat)

DC 24V

-30~+70°C

DC 24V

-40~+100°C

4A (Switch current)

10A (Flowing current)

4A (Switch current)

10A (Flowing current)

Item Specifications

Lightening system Lamp capacity

Head lamp (Up/Down)

Turn lamp

Position lamp

Tail / Brake lamp

Room lamp

Fog lamp

Back up lamp

License plate lamp

Luminescent lamp

Horn Type Flat type

Nominal voltage DC 24V

Frequency 415±20Hz

Decibel 100~112 dB

Cigar lighter Type Bimetal Type

Nominal voltage DC 24V

Nominal current 5A

Returning time after pressing the plug 13±5sec.

75W70W

21W

5W

5/21W

10W

70W

21W

12W

10W

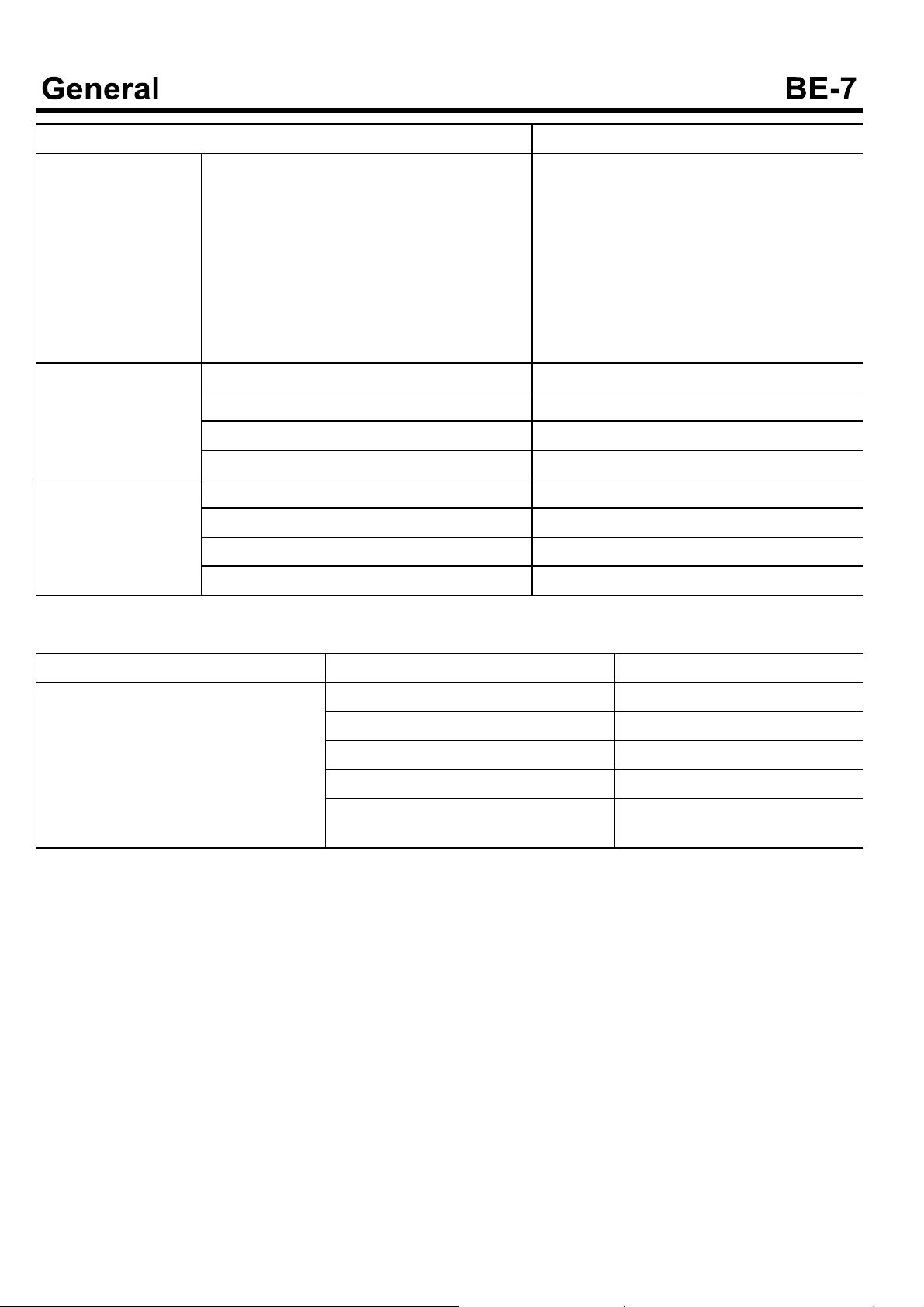

Diagnosis

Ignition Switch

Symptom Causes Remedy

When turning the ignition switch to the START, the starter is not working.

The ignition switch is faulty. Replace

The battery is discharged. Charge

The starter relay or the starter is faulty. Replace

The starter fuse is short. Replace

The wiring circuit is opened or the contact is faulty.

Repair

Lighting System

Symptom Causes Remedy

General Light When turning the switch ON,

the lamp is not lightened.

Lamp is dark. Thelifetimeofbulbisoverorthebulbis

Head Lamp The head lamp is not workin-g.Thelampswitchisfaulty. Replace

Turn, Hazard Lamp

The lamp is not blinking. Theswitchofturnoremergencylampis

Thebulbisshort. Replace

The battery is discharged. Charge

The switch is faulty. Replace

The fuse is short. Replace

The wiring circuit is opened or the contact is faulty.

faulty.

The battery is discharged. Charge

The switch does not properly contact. Replace

The wiring or terminal is faulty in contact. Repair

Thedimmerswitchisfaulty. Replace

Theheadlamprelayisfaulty. Replace

faulty.

The blinking relay is faulty. Replace

Repair

Replace

Replace

The lamp is lightening conti nually.

The blinking interval is too long.

The blinking interval is too short.

Other Lamp The brake lamp is not lighte-

ning.

The tail lamp, position lamp

or the number plate lamp is

not lightening.

Back up lamp is not lightening.

The fog lamp is not lightenin-g.The fog lamp switch is faulty. Replace

The blinking relay is faulty. Replace

The power of the bulb is lower than nominal.

The blinking relay is faulty. Replace

Thebulbisshort. Replace

The blinking relay is faulty. Replace

The brake lamp switch is faulty. Replace

The brake lamp switch is not installed properly.

The light switch is faulty. Replace

The tail lam p relay is faulty. Replace

Back up lamp switch is faulty. Replace

TheBackuplampswitchisnotinstalled

properly.

The fog lamp relay is faulty. Replace

Replace

Repair

Repair

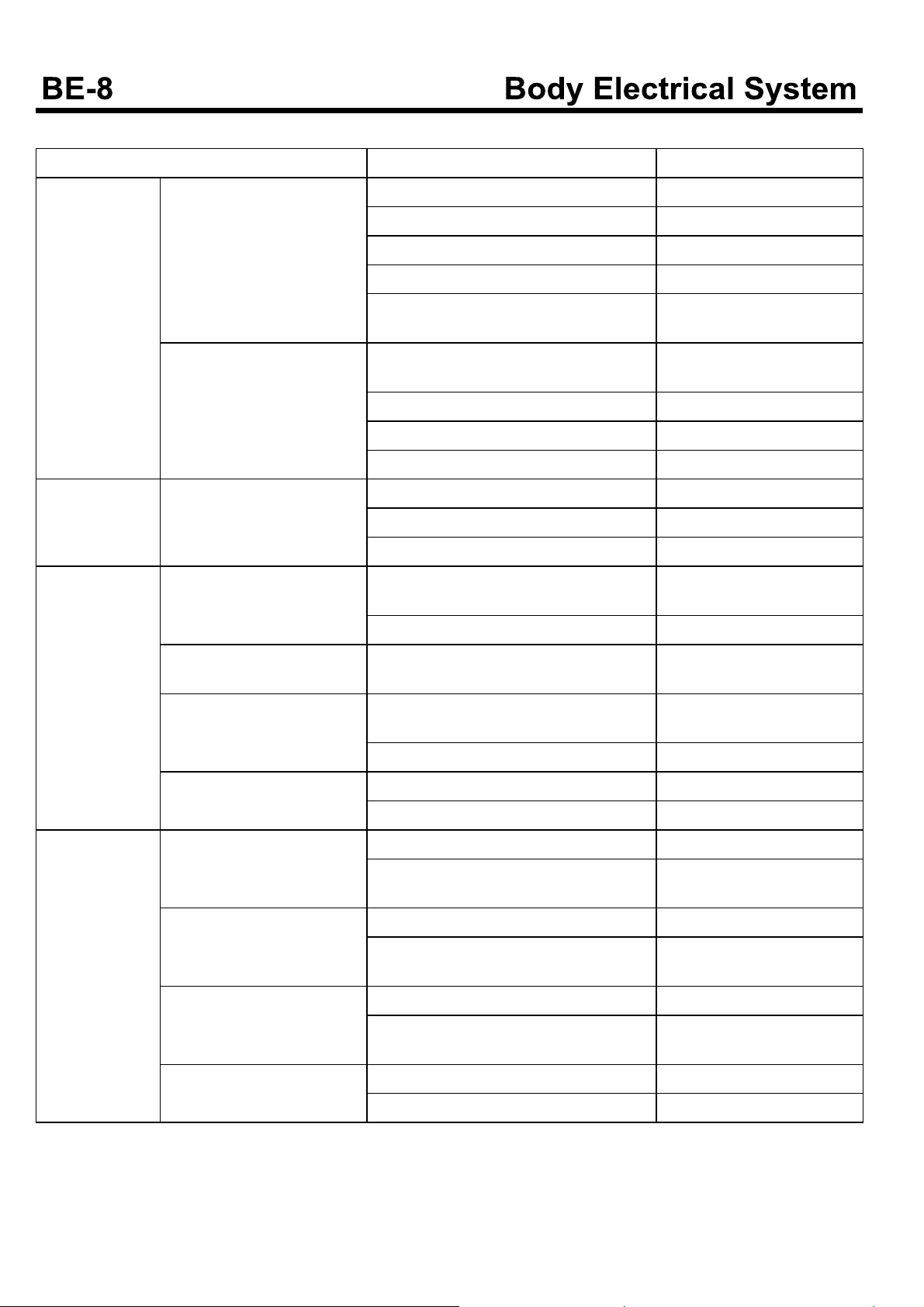

Meter and Gauge

Symptom Causes Remedy

The speedometer does not work. The speed sensor is faulty. Replace

The fuse is opened or blow. Replace

The speedometer is faulty. Replace

The needle of the speedometer is unstable. The speed sensor is faulty. Replace

The speedometer is faulty. Replace

The tolerance of the speedom eter is too large.

The tachometer does not work. The tachometer sensor is faulty. Replace

The needle of the tachometer is unstable, or

its tolerance is too large.

The coolant temperature gauge does not work.

The needle of the coolant temperature gauge is unstable, or its tolerance is too large.

Thetiresizeisnotproper. Replace

The speedometer is faulty. Replace

The tachometer is faulty. Replace

The fuse is short. Replace

The tachometer sensor is faulty. Replace

The tachometer is faulty. Replace

The wiring is faulty Replace

The fuse is short. Replace

The coolant temperature gauge is faulty. Replace

The coolant temperature gauge unit is faulty. Replace

The coolant temperature gauge is faulty. Replace

The coolant temperature gauge unit is faulty. Replace

The wiring is faulty. Repair

The thermostat is faulty. Replace

Indicating and Warning Lamp System

Symptom Causes Remedy

When switch is ON, each unit is working but

the indicating lamp is not lightened.

When the parking brake knob is pulled, the

brake lamp is not lightened.

After releasing the parking brake, the brake

lamp is not off.

Thebulbisopen. Replace

The wiring circuit is opened, or it contact is faulty.

The switch is working abnorm ally. Replace

Thebulbisshort. Replace

The spring brake switch is faulty. Replace

The fuse is short. Replace

The wiring circuit is opened, or it contact is faulty.

The spring brake switch is faulty. Replace

The wiring is faulty. Repair

Repair

Repair

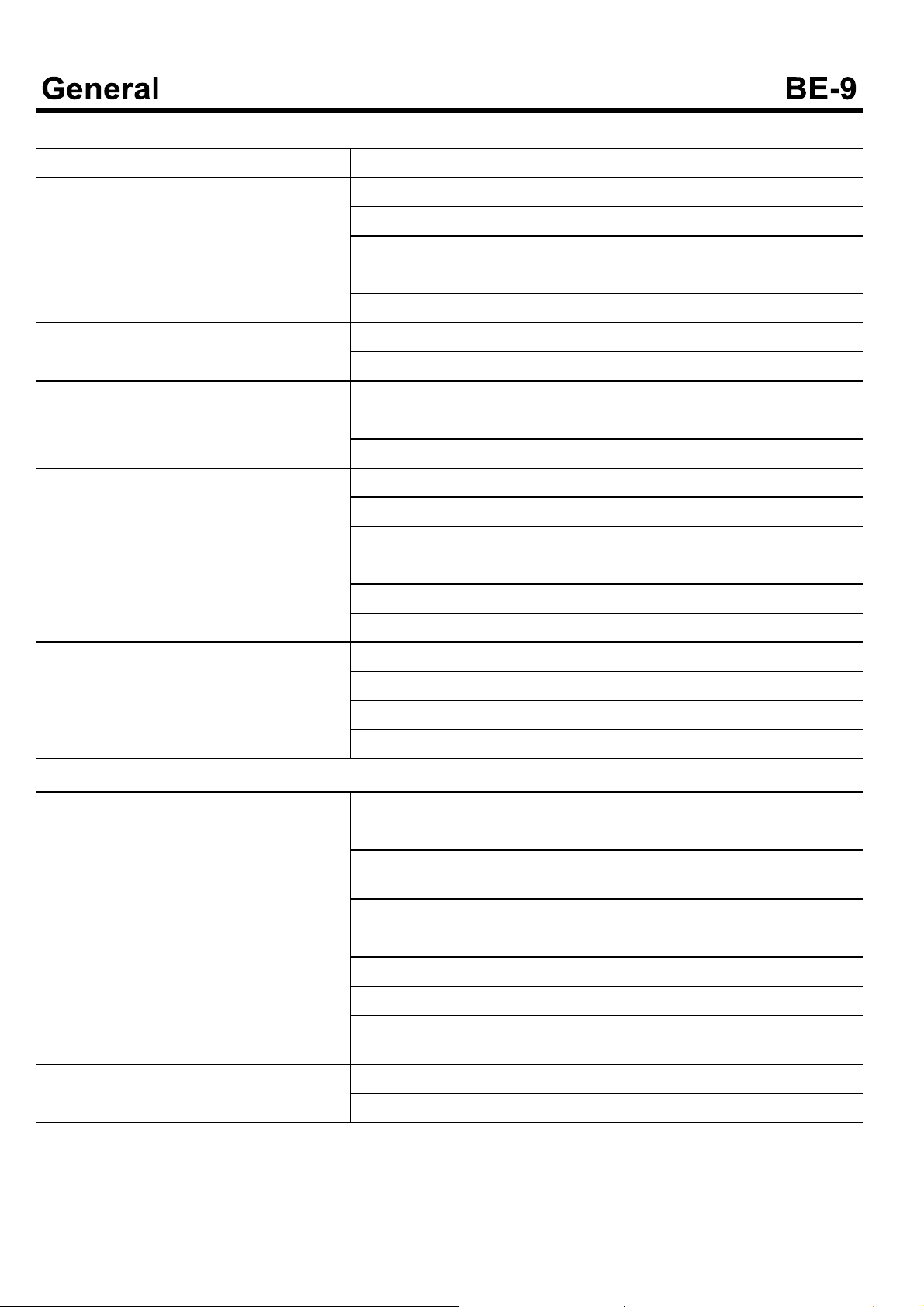

Symptom Causes Remedy

The brake lamp does not work. Thebulbisshort. Replace

The fuse is short. Replace

The wiring circuit is opened, or it contact is faulty.

During working of engine, the oil warning lamp turns on.

During working of engine, the charging warning lamp turns on.

The overheat warning lamp turns on. The coolant water is not enough. Adjust

Theengineoilpressureistoolow. Adjust

The engine oil is leak or it level is too low. Adjust

The oil pressure switch is faulty. Replace

The oil filter is clogged. Replace element

The V-belt is sagging or broken. Replace or adjust

The alternator is faulty. Repair

The overheat sensor is faulty. Replace

Repair

Wiper

Symptom Causes Remedy

The wiper does not work. The wiper motor is faulty. Replace

The wiper switch is faulty. Replace

The fuse is short. Replace

The wiring circuit is opened, or it contact is faulty.

Repair

Thewipercannotstop. The wiper switch is faulty. Replace

The wiper motor is faulty. Replace

The wiper does not perform the intermittent

operation.

The blade does not stop on proper position. The wiper link is positioned abnormally. Adjust

The wiping condition is faulty. The blade is faulty. Replace

During working, the wiper makes an abnormal noise.

The ETACS is faulty. Replace

The wiper switch is faulty. Replace

The wiper motor is faulty. Replace

The wiper arm is faulty. Replace

The wiper motor is faulty. Replace

The blade is faulty Replace

The wiper link or the wiper arm contact is faulty.

Repair

Washer System

Symptom Causes Remedy

The washer motor does not work. The washer motor or pump is faulty. Replace

The washer switch is faulty. Replace

The fuse is short. Replace

The wiring circuit is opened, or it contact is faulty.

The spaying amount of the washer liquid is too small.

The washer liquid is not sprayed. The jointing of hose is faulty. Repair

The hose is twisted. Adjust

The washer nozzle is clogged. Clear

The washer motor or pump is faulty. Replace

The washer nozzle is clogged. Clear

The washer motor or pump is faulty. Replace

The level of washer liquid is too low Refill

Repair

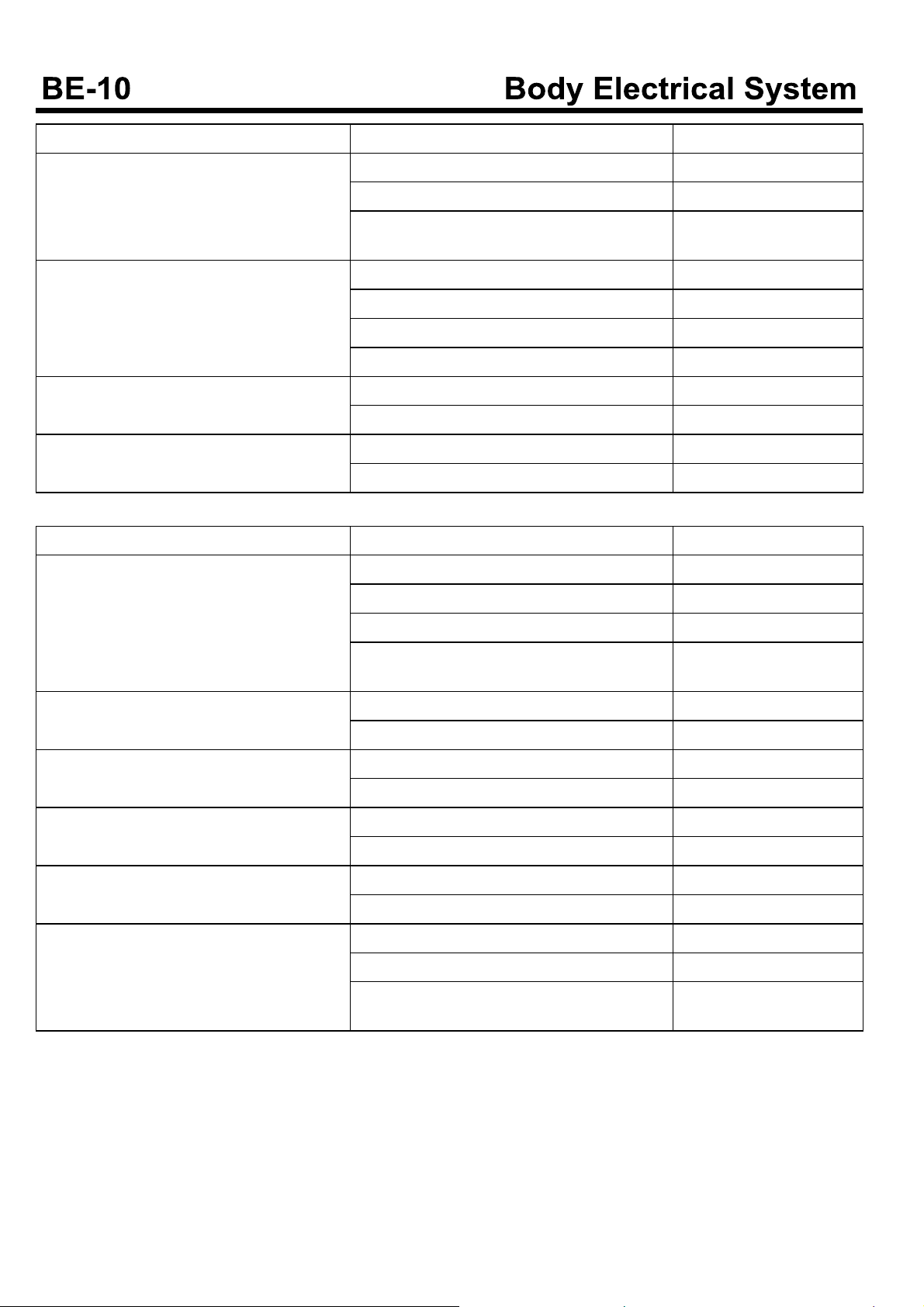

Fuses And Relays

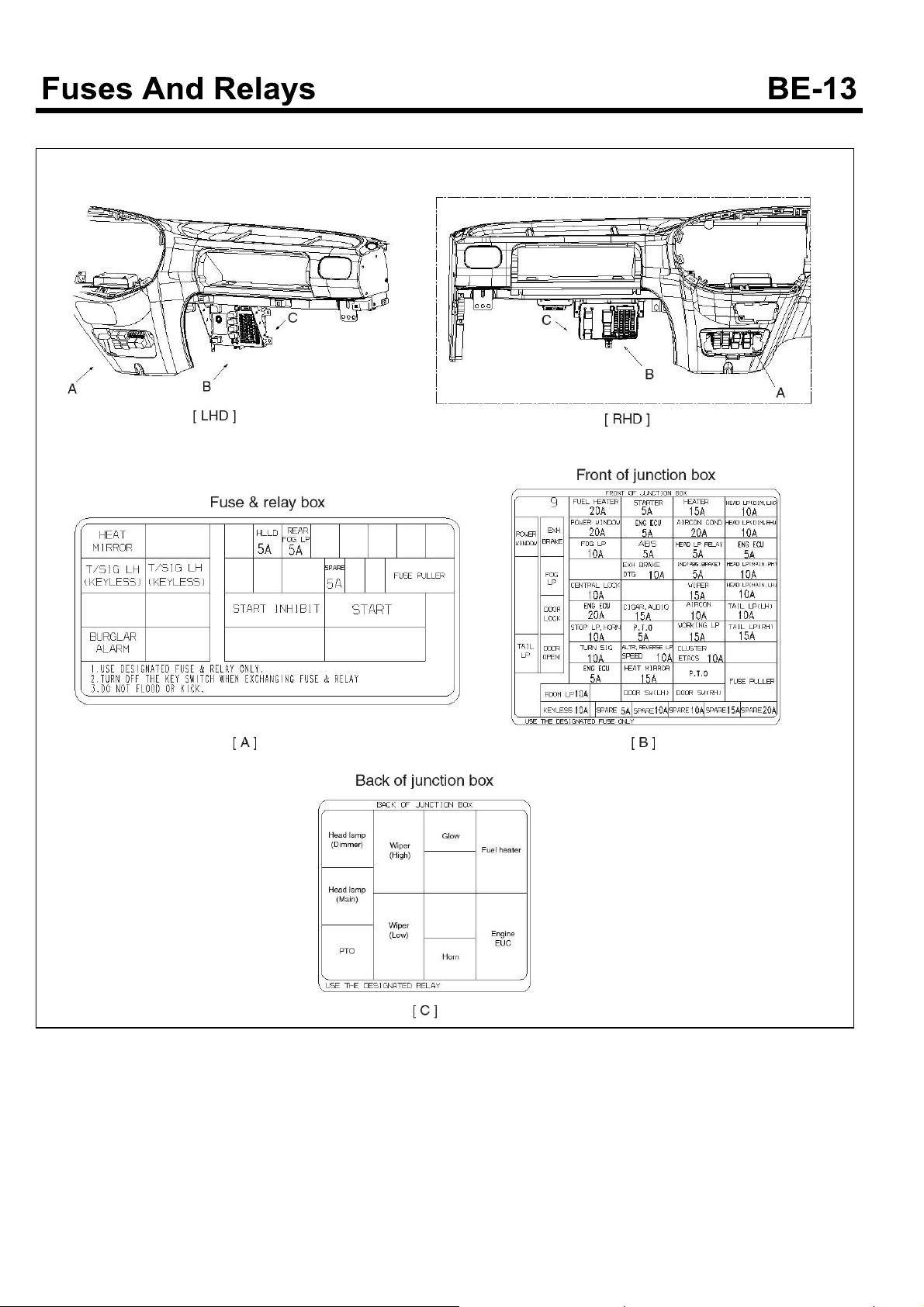

Component Location (Except D4GA engine)

EMTBE5008A

Component (D4GA engine)

SUDBEA0053L

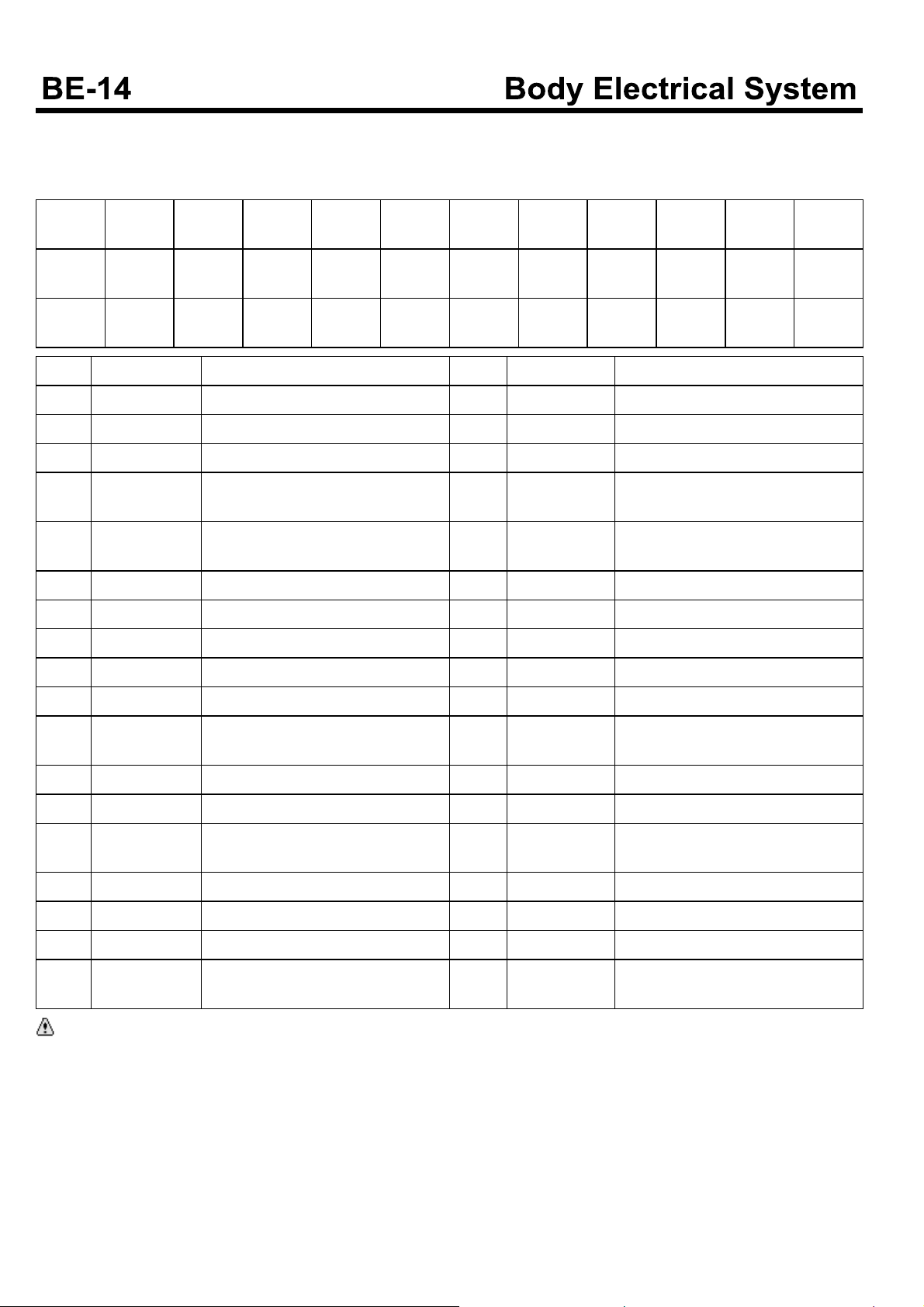

Component(Fuse)

Except D4GA engine

Fuse box

1

15A

13

20A

25

10A

Fuse Amperages Circuit protected Fuse Amperages Circuit protected

1 15A Working lamp 19 15A Outside mirror defogger

2 5A Head lamp relay 20 - -

3 10A Blower and A/C control 21 20A Fuel heater

4 10A

5 15A Wiper and washer 23 10A

6 5A ABS control(ECU) 24 15A Starting

7 5A PTO 25 10A Head lamp(LOW)_LH

8 - - 26 10A Head lamp(LOW)_RH

2

5A

14

10A

26

10A

3

10A

15

10A

27

10A

Exhaust brake, tachograph(EC),

Cold start switch

4

10A

16

10A

28

10A

5

15A

17

10A

29

10A

5A

18

15A

30

10A

6

7

5A

19

15A

31

10A

22 10A -

8

10A

20

20A

32

5A

10A

20A

15A

9

21

33

Tachograph, ETACS, audio, instrument cluster, room lamp

10

15A

22

10A

34

15A

11

10A

23

10A

35

10A

12

10A

24

15A

36

15A

9 10A Sub start 27 10A Head lamp(HIGH)_LH

10 - - 28 10A Head lamp(HIGH)_RH

11 10A

12 10A ETACS, Instrument cluster 30 10A RH Tail lamp

13 20A Power window 31 10A Front fog lamp

14 10A

15 10A Cab tilting switch, hazard lamps 33 15A Condenser fan relay, A/C relay

16 10A RR FOG lamp 34 15A Heater blower

17 10A Power door lock(unlock) 35 10A 12V converter, ETACS

18 15A ABS control(valve) 36 15A

CAUTION

Use the designated fuse only.

Vehicle speed sensor, Back up lamps

Stop lamp, horn, data link connector

29 10A LH Tail lamp

32 5A Engine ECU

Instrument cluster, audio, cigarette

lighter, clock

Components(Relay, Fuse blink)

EMTBE5009A

Relay

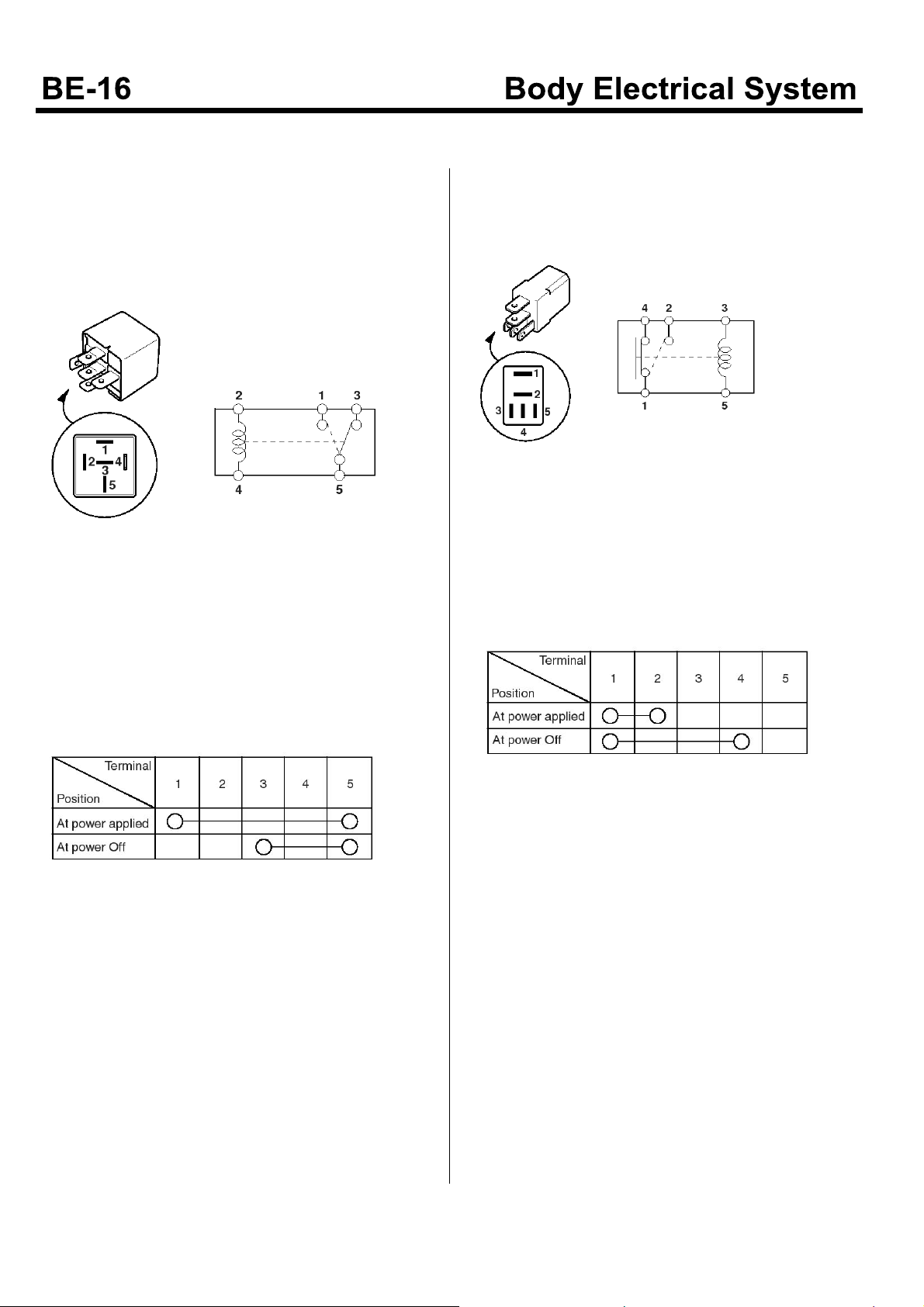

Inspection

Type A relay

1. When an electric power is applied between the power

relay terminal No.2 and No.4, check that there is an

electric current between the term inal No.1 and No.5.

KMTBE5015A

2. When the electric power applied between the power

relay terminal No.2 and No.4 is off, check that there

is an electric current between the terminal No.1 and

No.5.

Type B relay

1. When an electric power is applied between the power

relay terminal No.3 and No.5, check that there is an

electric current between the terminal No.1 and No.2.

KMTBE5016A

2. When the electric power applied between the power

relay terminal No.3 and No.5 is off, check that there

is an electric current between the terminal No.1 and

No.4.

EMTBE5010A

EMTBE5011A

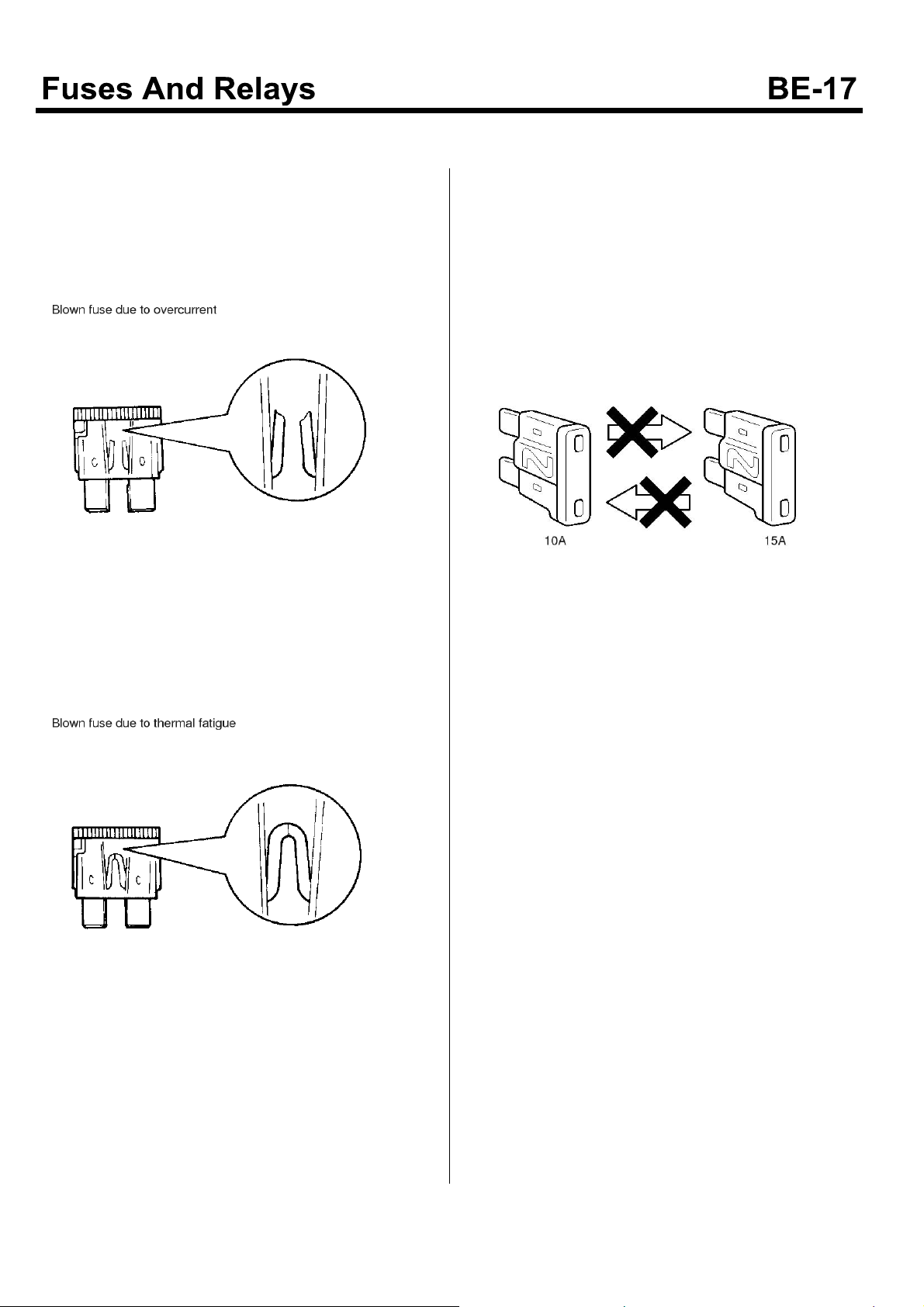

Fuse

Inspection

1. When a fuse is burnt-out, check that there is any

opened or abnorm al component before replacing the

fuse. After replacing the opened or abnormal parts,

install a new fuse of the same ampere.

EMTBE5012A

2. When the fuse is intermittently disconnected, it

means that the fuse does not satisfy the nominal

capacity. If this fuse is used for a long time, it causes

a trouble. At this case, replace with a new one of the

nominal ampere.

3. A blade type fuse is identified by the numbered value

in amperes.

If the fuse is burnt-out, be sure to replace a fuse with

thesameampererating.Ifafuseofhighercapacity

than specified is used, parts may be damaged and

the danger of fire also exists.

To remove or insert a fuse, please use the fuse puller

inthefusebox.

KMTBE5004A

EMTBE5013A

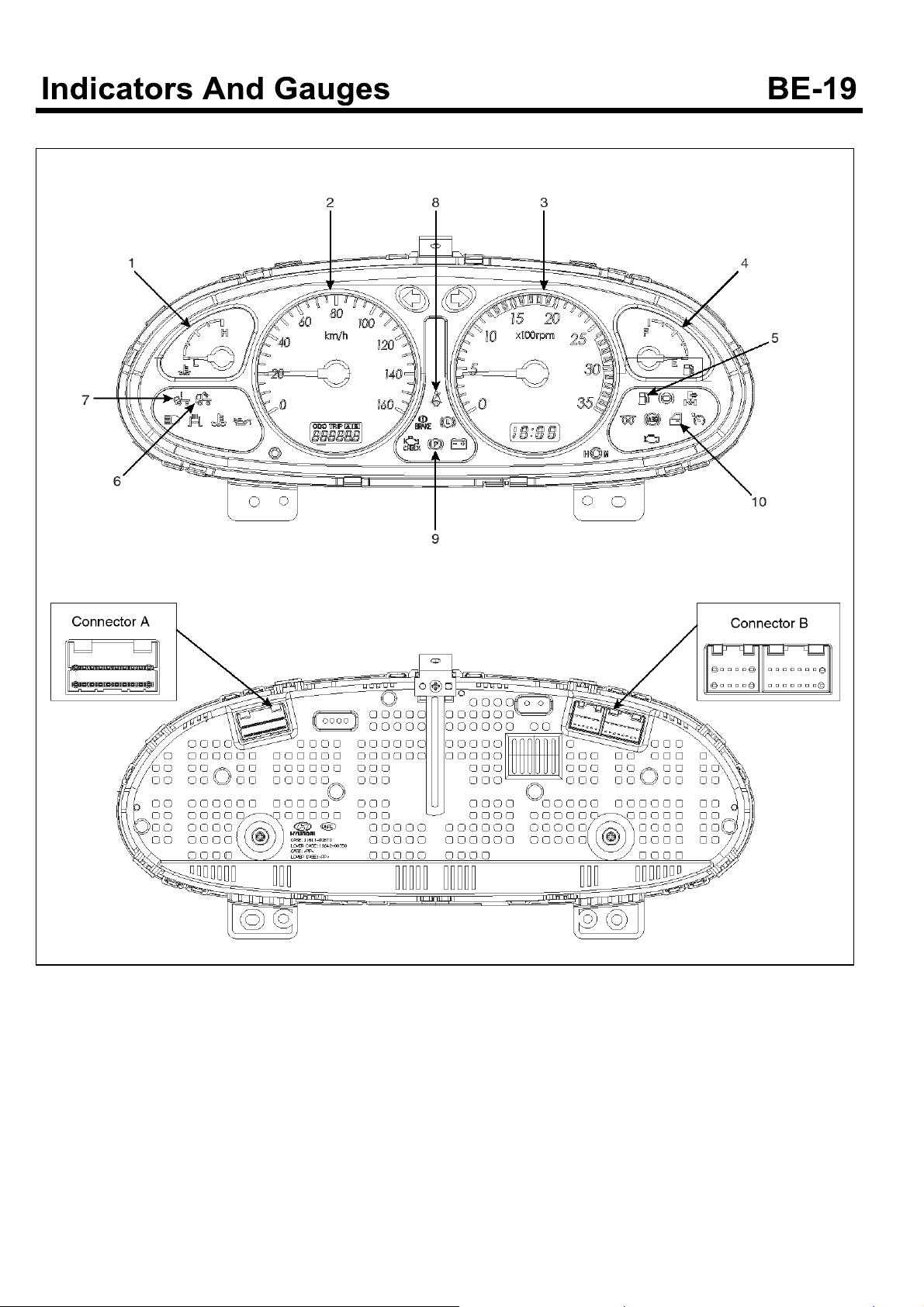

Indicators And Gauges

Instrument Cluster

Components (Except D4GA engine)

1. Temperature gauge

2. Speedometer gauge

3. Tachometer

4. Fuel gauge

5. Fuel warning lamp

6. Working lamp

7. Tilting lock warning lamp

8. Seat belt warning lamp

9. Parking brake warning lamp

10. Door warning lam p

SUDBEA0050L

11. 1st Connector

12. 2nd Connector

13. 3rd Connector

14. 4th Connector

15. Brake oil warning lamp

Components (D4GA engine)

1.Water temperature gauge

2.Speedometer gauge

3.Tachometer

4.Fuel gauge

5. Fuel warning lamp

SUDBEA0051L

6. Working lamp

7. Tilting lock warning lamp

8. Seat belt warning lamp

9. Parking brake warning lamp

10. Door warning lamp

Circuit Diagram (Mechanical engine)

EMTBE5002A

Circuit Diagram (D4DD engine)

SUDBEA0054L

Circuit Diagram (D4GA engine)

SUDBEA0003L

Connector Configurations (Except D4GA engine)

EMTBE5014A

Connector Configurations (D4GA engine)

SUDBEA0004L

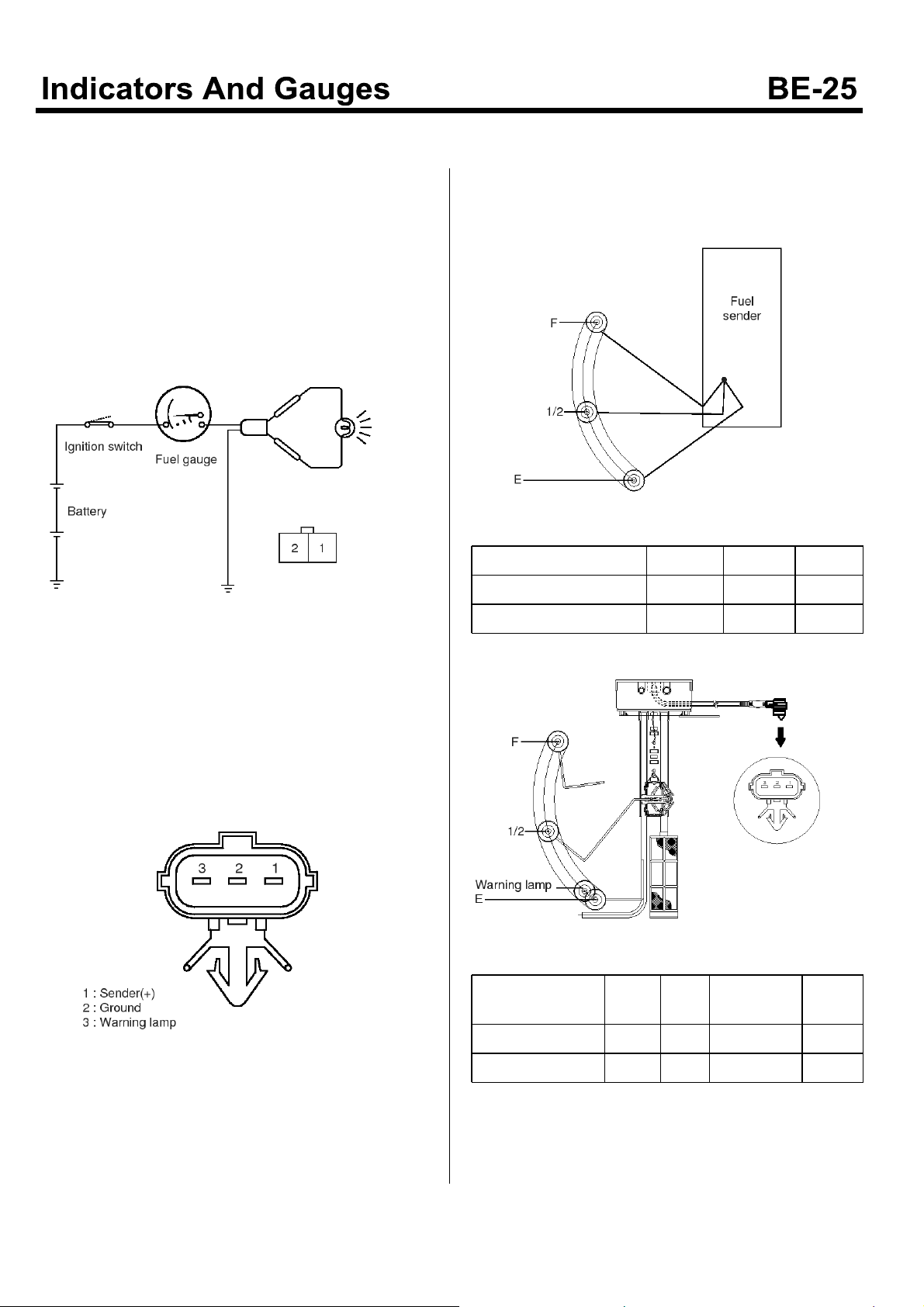

Fuel Gauge

Inspection

Inspection of Fuel Gauge

1. Disconnection the fuel sender connector.

2. After connecting the test bulb to the connector of the

harness in serial, and ground it.

3. Turn the ignition switch to the "ON" position.

4. Check that the test bulb is lightened or the needle of

the fuel gauge is slowly moving to the "F" position.

2. Check that the resistor is varying smoothly, when the

float is moving from "F" to "E" position.

Except D4GA engine

EMTBE5017A

Float Position F 1/2 E

Reference R() 4 32 105

Tolerance of R()

±

2

±

5

±

2

EMTBE5015A

5. If the needle of the fuel gauge is not moving, replace

the cluster.

Inspection of Fuel Sender

1. Setting the float to the "F" and "E" positions, measure

the resistor between the terminal No.1 and No.2,

respectively.

EMTBE5016A

D4GA engine

SUDBEA0038L

Float Position S/F 1/2

Warning la-

mp

S/E

Reference R() 7 32 88 105

Tolerance of R()

±

2.5±2.5

±

2.5

±

2.5

Water Temperature Gauge

Inspection

Inspection of water temperature gauge and

water tem perature sensor

1. If it is not satisfied the tolerance, replace the cluster

and water temperature sensor.

Except D4GA engine

Temperature (

C)

Scale Angle (°) -40 -7 34

Tolerance (°) -

Resistor () 120.5 38~23.4 16.6

D4GA engine

Temperature (°C)

Scale Angle (°) -45 -7 25.5

Tolerance (°) - -3,+2 -5,+5

2. The temperature indicating range is 50~123°C.

°

57 85~105 120

±

5

50 85~105 115

-

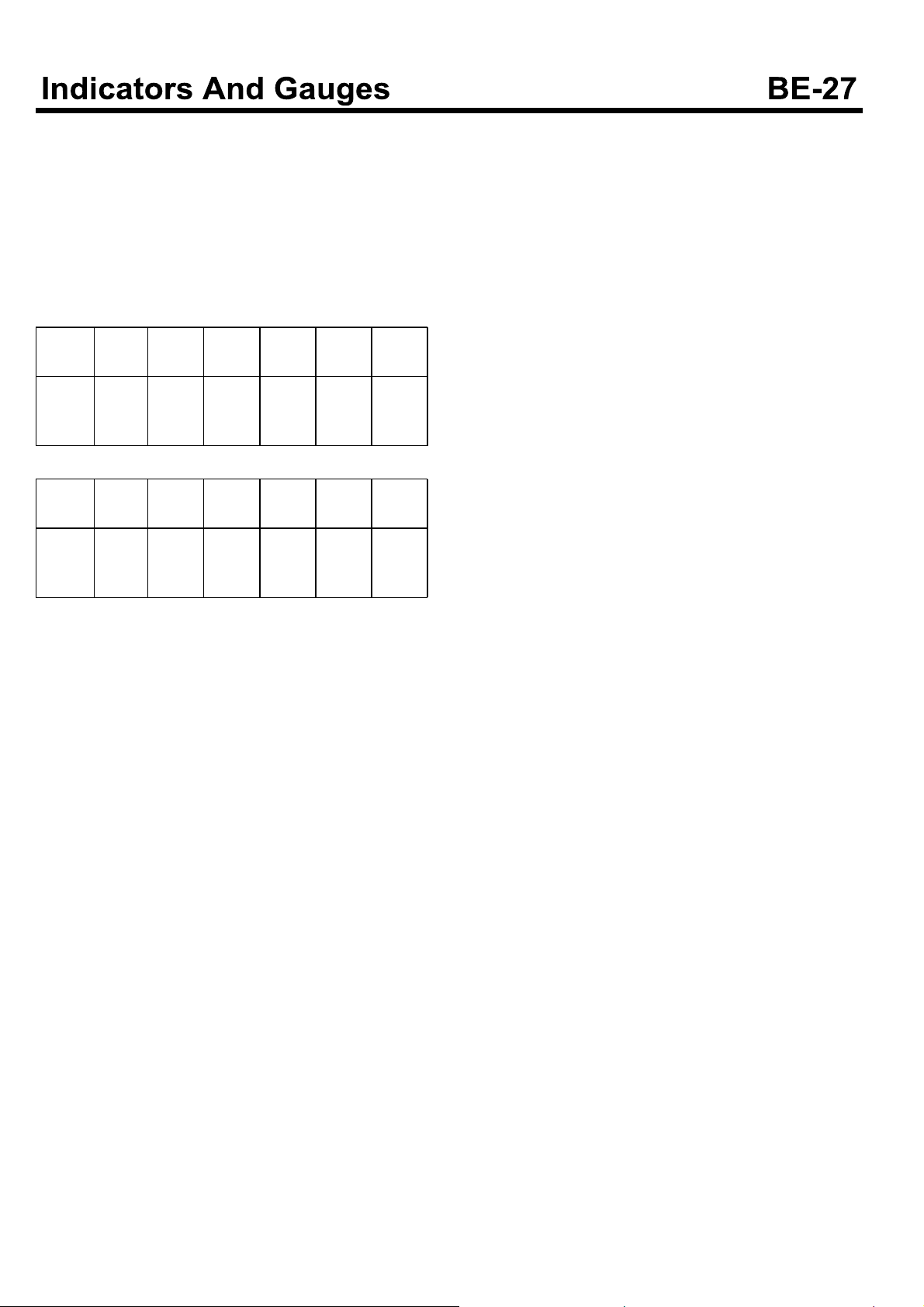

Tachometer

Inspection

1. Connect the tachometer for a tune-up test, start the

engine.

2. By comparing the values indicated by the tester and

the tachometer, if it is over the tolerance, replace the

cluster.

Except D4GA engine

STD

RPM

Tolera-

nce (r-

pm)

D4GA engine

STD

RPM

Tolera-

nce (r-

pm)

3. When performing the test of tachometer, tap the

tachometer to remove the hysteresis.

500 1,000 2,000 3,000 3,500 4,000

±

500 1,000 1,500 2,000 2,500 3,100

±

50

30

±

±

50

50

±

100±150

±

100±100

±

150±150

±

150±150

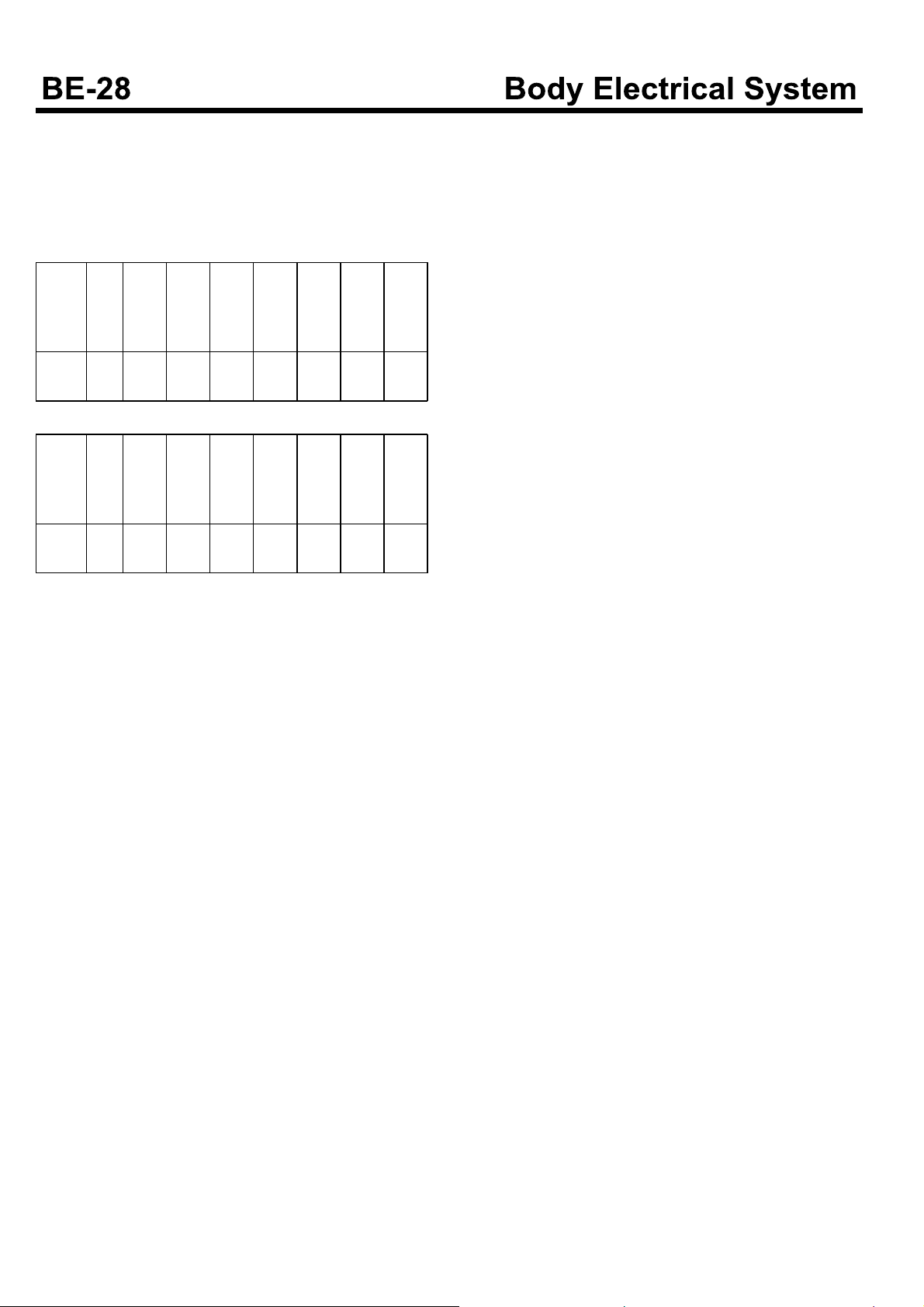

Speedometer

Inspection

1. Using the speedometer tester, check the tolerance of

the speedometer.

Except D4GA engine

STD

Spee-

d(km

20 40 60 80 100 120 140 160

/h)

Tolerance

STD

Spee-

d(km

Tolerance

2. Check that the needle of the speedometer is vibrating

3. When performing the test of speedometer, tap it to

±3+

D4GA engine

20 40 60 80 100 120 140 160

/h)

+

3

0

or the speedometer makes an abnormal noise.

remove the hysteresis.

+

3

0

+

3

0

3.5

0

+

0

+

+

4

0

+

5

5

0

4.5

0

+

0

+

+

5

0

+

5

5

0

+

6

6

0

0

+

5

-

0

Door Warning Indicator

Inspection

1. Remove the door switch(A).

KMTBE5027A

2. Check that there is continuity between the switch's

terminal and ground.

3. If the checking value of the door switch does not

satisfy the specifications, replace the door switch.

EMTBE5018A

KMTBE5028A

Seat Belt Warning Indicator

Inspection

Inspection of seat belt switch

1. Disconnect the seat belt switch connector (A).

EMTBE5019A

2. Check the continuity of the door switch.

Seat Belt Condition

Continuity

Fastened Not fastened

Non-Conductive

(∞)

Conductive (0 )

Inspection of Seat Belt Warning

Check that the following conditions are satisfied when

theignitionswitchisON.

Seat Belt Condition

Warning Lamp OFF ON

Fastened Not fastened

Loading...

Loading...