Fuel System

General Information

Specifications .................................................. FL - 3

Troubleshooting...............................................FL - 5

Electronic Engine Control System

Description.......................................................FL -28

ECU

Components............................................... FL -31

Removal ..................................................... FL -35

Mass Air Flow Sensor

Inspection ................................................... FL -36

Differential Pressure Sensor(DPS)

Components............................................... FL -39

Description ................................................. FL -39

Specifications ............................................. FL -40

Part Circuit Diagram .................................. FL -40

Replacement .............................................. FL -41

Electronic Fuel Supply System

Components ....................................................FL -42

Injector

Components............................................... FL -43

Removal ..................................................... FL -44

Installation .................................................. FL -45

Replacement .............................................. FL -45

Cleaning..................................................... FL -45

Common Rail Assembly

Components............................................... FL -46

Removal ..................................................... FL -47

Installation .................................................. FL -47

Accelerator Pedal

Description ................................................. FL -48

Removal ..................................................... FL -48

Inspection ................................................... FL -48

Fuel Tank And Fuel Filter

Replacement .............................................. FL -49

Inspection ................................................... FL -50

Electronic Injection Pump

Supply Pump

Components............................................... FL -51

Removal ..................................................... FL -52

Installation .................................................. FL -53

DTC Troubleshooting Procedures

Basic Troubleshooting ..................................... FL -55

Schematic Circuit ............................................ FL -63

DTC List ........................................................... FL -80

P0072............................................................... FL -84

P0073............................................................... FL -88

P0088............................................................... FL -92

P0101............................................................... FL -98

P0102............................................................... FL -102

P0103............................................................... FL -106

P0107............................................................... FL -110

P0108............................................................... FL -112

P010A .............................................................. FL -114

P0112............................................................... FL -118

P0113............................................................... FL -122

P0116............................................................... FL -126

P0117............................................................... FL -129

P0118............................................................... FL -132

P0120............................................................... FL -135

P0121............................................................... FL -140

P0122............................................................... FL -145

P0123............................................................... FL -149

P0182............................................................... FL -153

P0183............................................................... FL -156

P0192............................................................... FL -159

P0193............................................................... FL -165

P0194............................................................... FL -171

P0195............................................................... FL -177

P0196............................................................... FL -183

P0201............................................................... FL -189

P0202............................................................... FL -195

P0203............................................................... FL -200

P0204............................................................... FL -205

P0217............................................................... FL -210

P0219............................................................... FL -212

P0220............................................................... FL -217

............................................................... FL -222

P0221

P0222............................................................... FL -227

P0223............................................................... FL -232

P0225............................................................... FL -236

P0226............................................................... FL -240

P0237............................................................... FL -244

P0238............................................................... FL -249

P0335............................................................... FL -254

P0336............................................................... FL -259

P0340............................................................... FL -264

P0341............................................................... FL -269

P0401............................................................... FL -274

P0403............................................................... FL -277

P0404............................................................... FL -280

P0405............................................................... FL -284

P0406............................................................... FL -288

P0501 ............................................................... FL -292

P0502 ............................................................... FL -297

P0503 ............................................................... FL -302

P0541 ............................................................... FL -307

P0542 ............................................................... FL -309

P0562 ............................................................... FL -312

P0563 ............................................................... FL -315

P0601 ............................................................... FL -318

P0602 ............................................................... FL -320

P0603 ............................................................... FL -322

P0604 ............................................................... FL -324

P0606 ............................................................... FL -326

P0607 ............................................................... FL -328

P0615 ............................................................... FL -330

P0627 ............................................................... FL -333

P0629 ............................................................... FL -337

P0642 ............................................................... FL -341

P0643 ............................................................... FL -344

P0652 ............................................................... FL -347

P0653 ............................................................... FL -349

P0698 ............................................................... FL -351

P0699 ............................................................... FL -354

P069E .............................................................. FL -357

P069F ............................................................... FL -360

P0704 ............................................................... FL -363

P0850 ............................................................... FL -366

P1120 ............................................................... FL -369

P1132 ............................................................... FL -374

P1133 ............................................................... FL -377

P1190 ............................................................... FL -380

P1218 ............................................................... FL -384

P1219 ............................................................... FL -388

P1221 ............................................................... FL -391

P1222 ............................................................... FL -397

P1223 ............................................................... FL -400

P1231 ............................................................... FL -403

P1232 ............................................................... FL -406

P1383 ............................................................... FL -409

P1384 ............................................................... FL -411

P1616 ............................................................... FL -414

P1642 ............................................................... FL -419

P1643 ............................................................... FL -422

P2002 ............................................................... FL -425

P2146 ............................................................... FL -427

P2147 ............................................................... FL -432

P2148 ............................................................... FL -437

P2149 ............................................................... FL -442

P2150 ............................................................... FL -448

P2151 ............................................................... FL -453

P2293 ............................................................... FL -458

P2413 ............................................................... FL -462

P2454 ............................................................... FL -466

P2455 ............................................................... FL -471

P2503 ............................................................... FL -476

P2504 ............................................................... FL -478

U0001 .............................................................. FL -480

U0010 .............................................................. FL -483

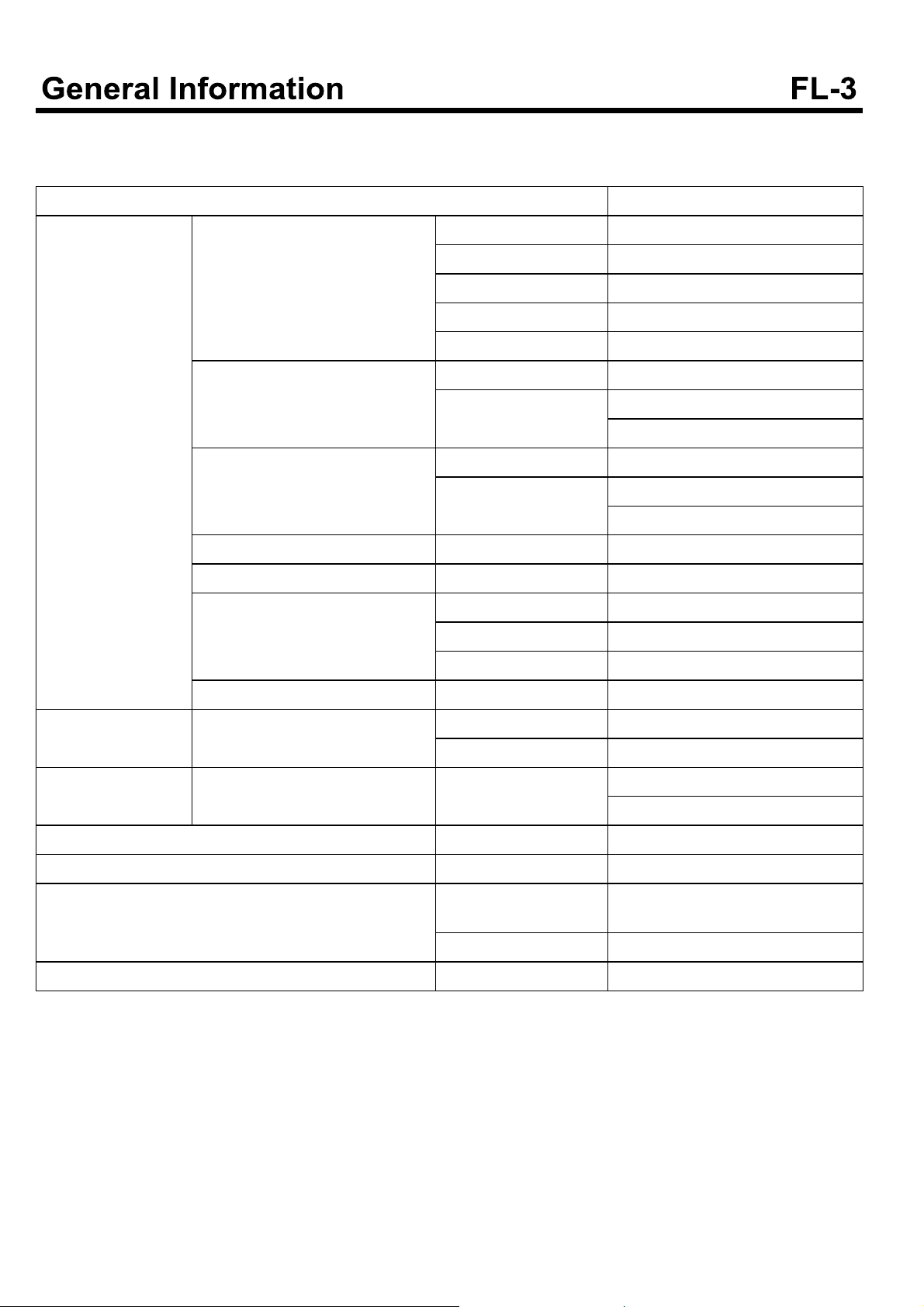

General Information

SPECIFICATIONS

Items Specification

Sensors BPS(Booster pressure sensor) Supply voltage 5V

Operating voltage 0.5~4.5 V

Operating temperature -40~125°C

Operating pressure 50~500 kpa

Current MAX. 10 mA

IAT(Intake air temperature) Type Thermistor

Resistance 2.31~2.56 k [At 20°C(68°F)]

0.30~0.34 k [At 80°C(176°F)]

WTS(Water temperature sensor) Type Thermistor

Resistance 2.31~2.59 k [At 20°C(68°F)]

0.314~0.331 k [At 80°C(176°F)]

TDC(Topdeadcenter)sensor Type Hall sensor

CKP(Crankshaft positon sensor) Type Magnetic

APS(Accel positon sensor) Type Variable resistance(Potentiometer)

Voltage 5V±1%

Current Max. 10 mA

Fuel pressure sensor Type Piezo electricity

Actuator Injector Type Electromagnetic

Resistance 0.45

Supply control valve SCV Current Active : Below 1.29 A

When stopped :Below 1.16 A

Fuel tank Capacity 100 L

Fuel pressure of high pressure side Max. pressure 1,800 bar

Supply pump Type Included into high pressure pump

mechanical type

Power Mechanical gear type

Fuel filter Type Filter

EGR Valve specification

Items Specification

Valve type Flap type

Control type Electric DC motor

Sealant

Water temperature sensor(Coolant temperature sensor) Loctite 200 or equivalent

Inspection

Item Reference value

Idle speed(rpm) 650±25

Tightening torque

Items Kgf.m N.m lb-ft

ECM mounting bolt 1.9~2.8 18.6~27.4 13.8~20.4

Mass air flow sensor mounting bolt 0.8~1.2 7.8~11.8 5.8~8.7

Crankshaft position sensor mounting bolt 0.8~1.2 7.8~11.8 5.8~8.7

TDC sensor mounting bolt 0.8~1.2 7.8~11.8 5.8~8.7

EGR valve mounting bolt(Inlet pipe) 1.0~1.4 9.8~13.7 7.2~10.1

EGR valve mounting bolt(EGR cooler) 1.0~1.4 9.8~13.7 7.2~10.1

High pressure pipe(rail-injector 1,2,3,4,5,6) 4~5 39~49 29~36

Common rail assembly mounting bolt 1.9~2.8 18.6~27.4 13.8~20.4

Fuel filler pipe assembly mounting bolt 0.8~1.2 7.8~11.8 5.8~8.7

Fuel return pipe mounting bolt 0.8~1.2 7.8~11.8 5.8~8.7

Fuel supply pump flange mounting bolt 10~13 98.6~128 72.3~94

Fuel supply pump mounting bolt 1.9~2.8 18.6~27.4 13.8~20.4

Injector clamp bolt 2.9~3.1 28.42~29.4 21~22.4

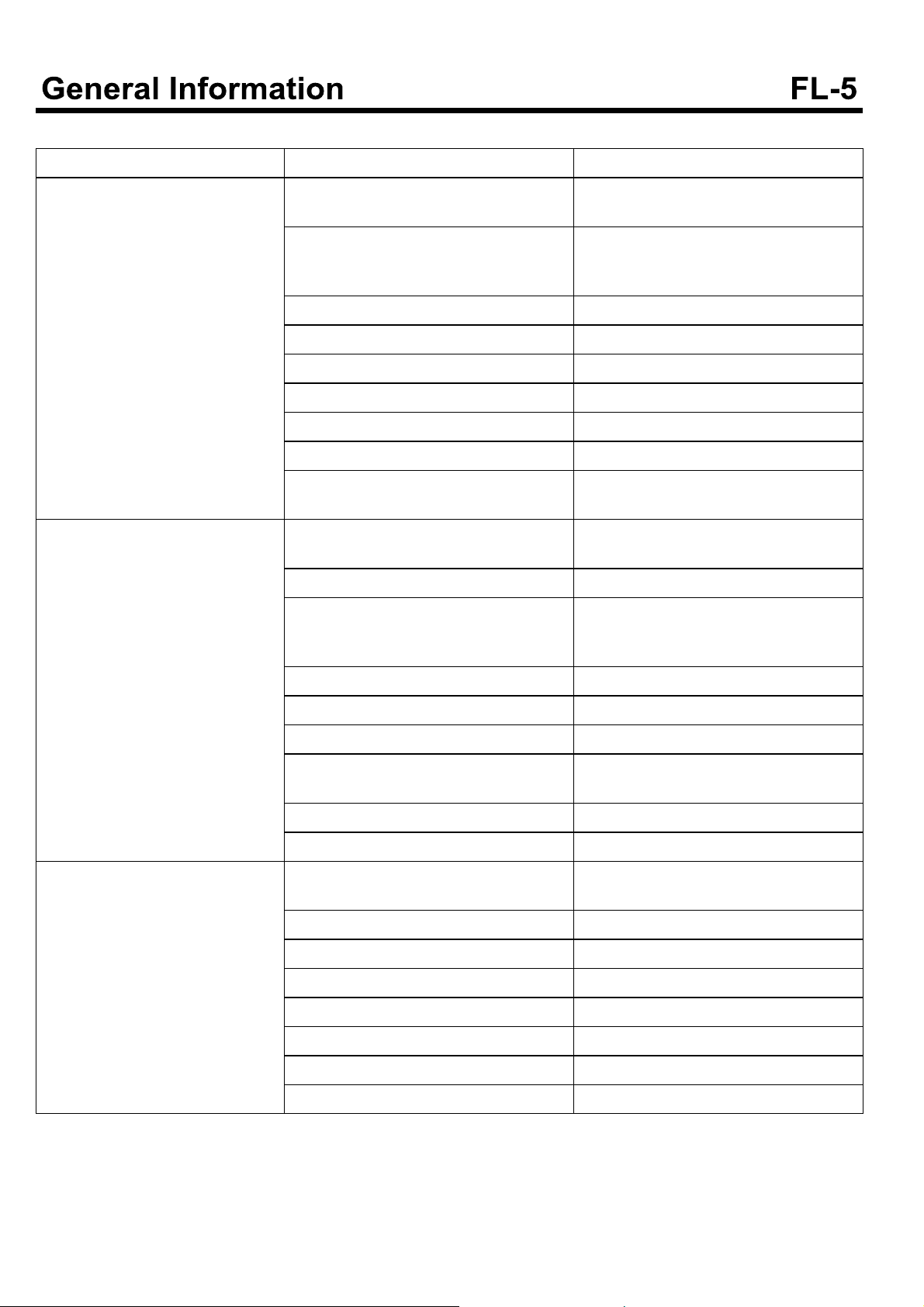

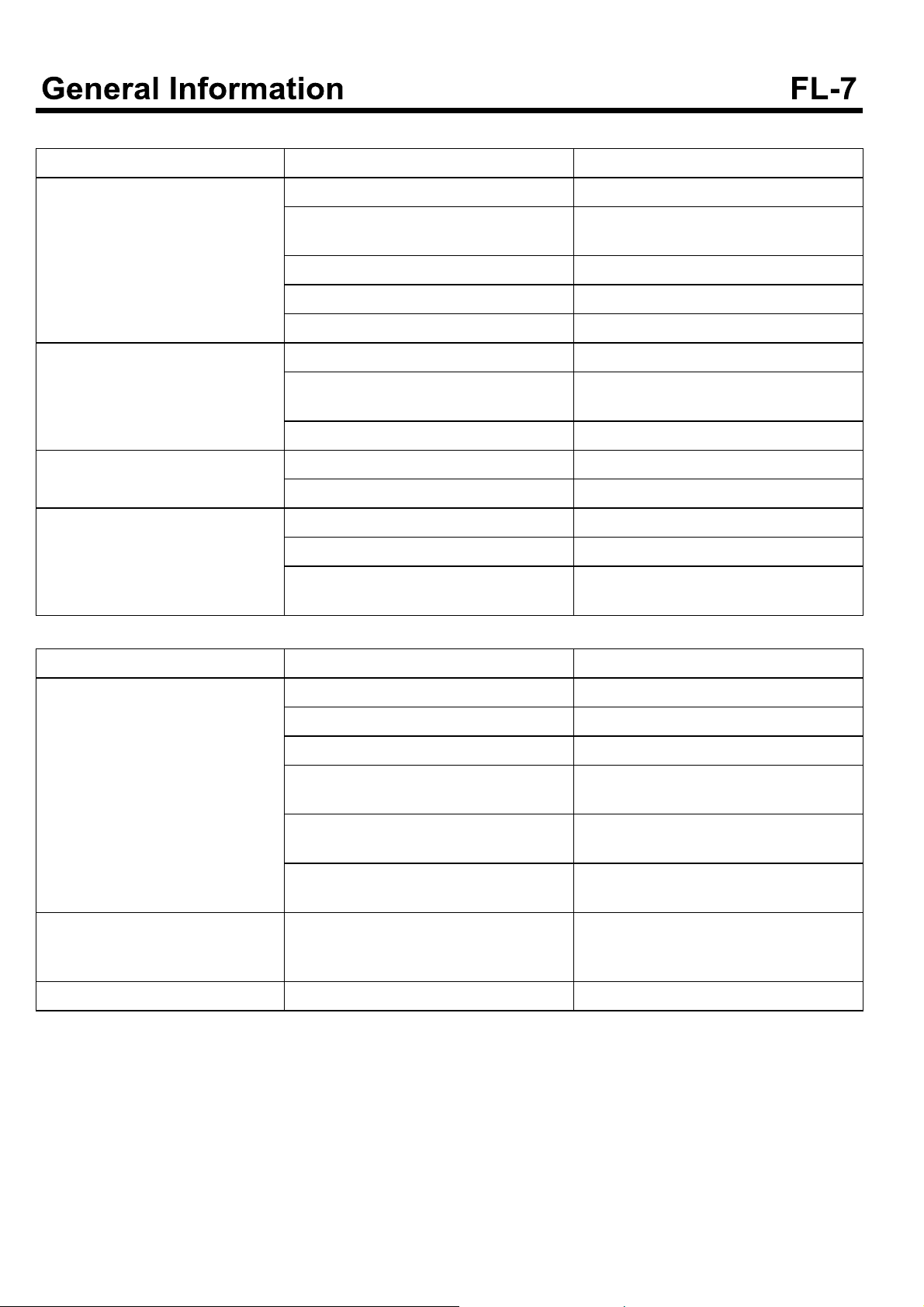

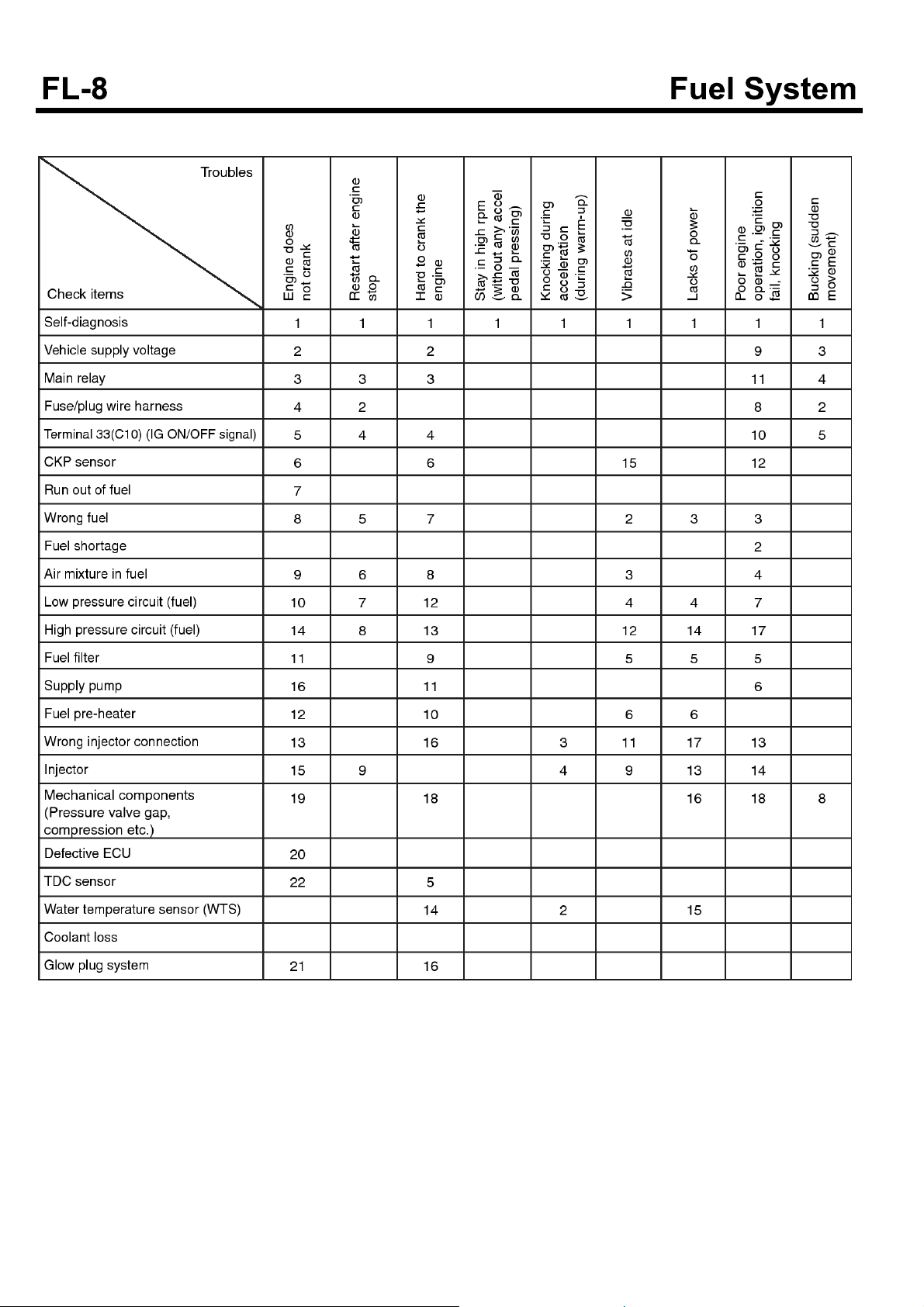

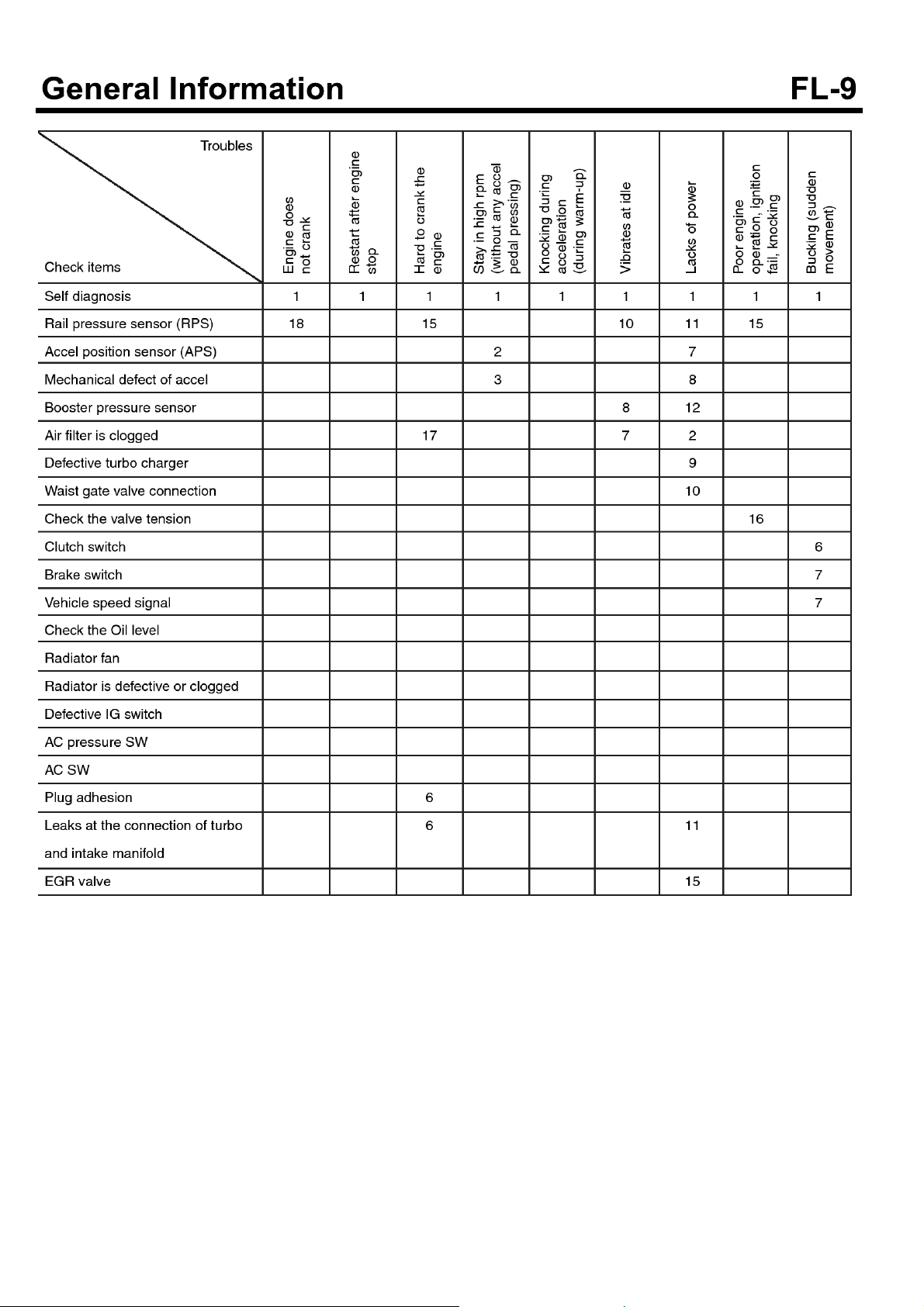

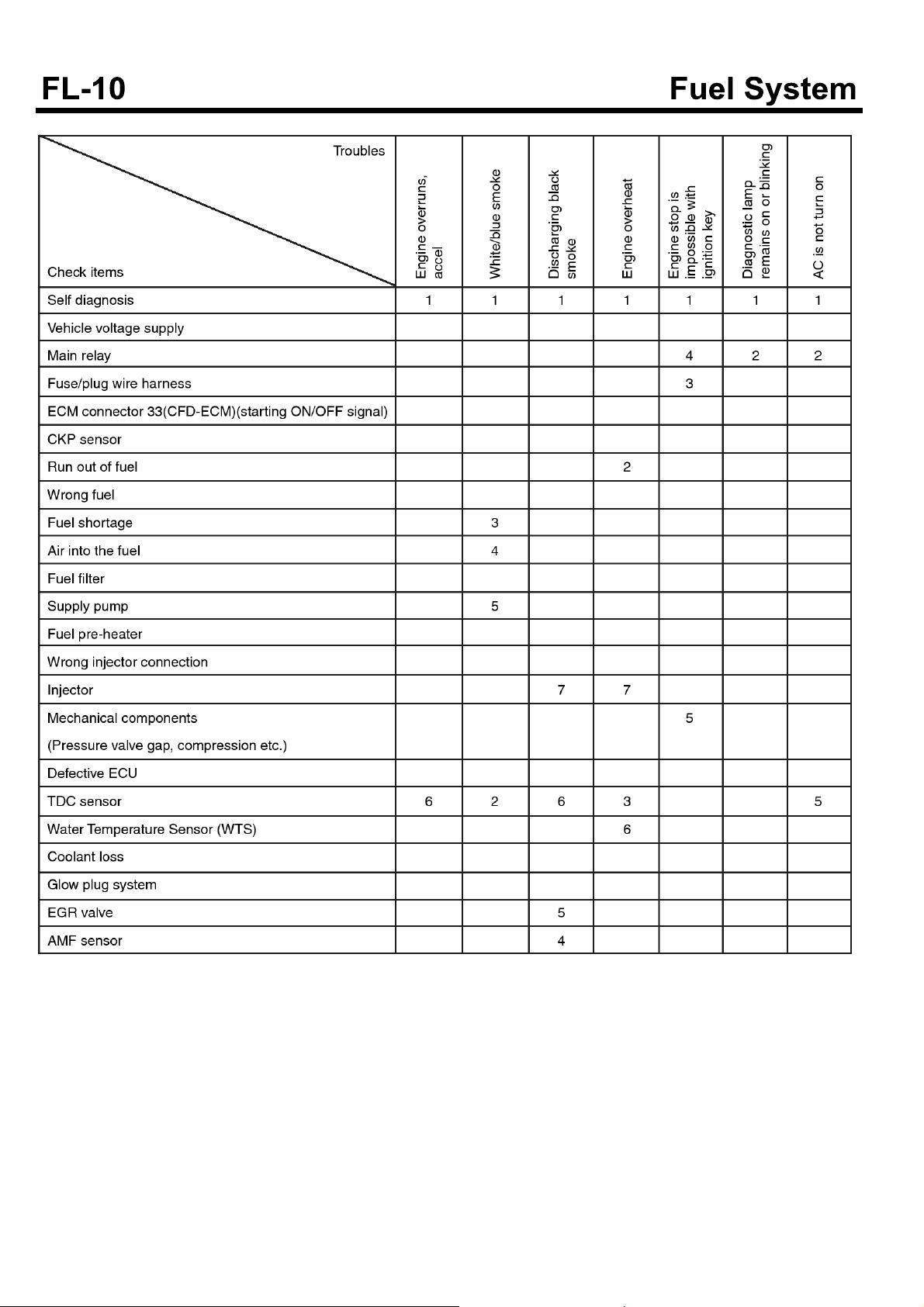

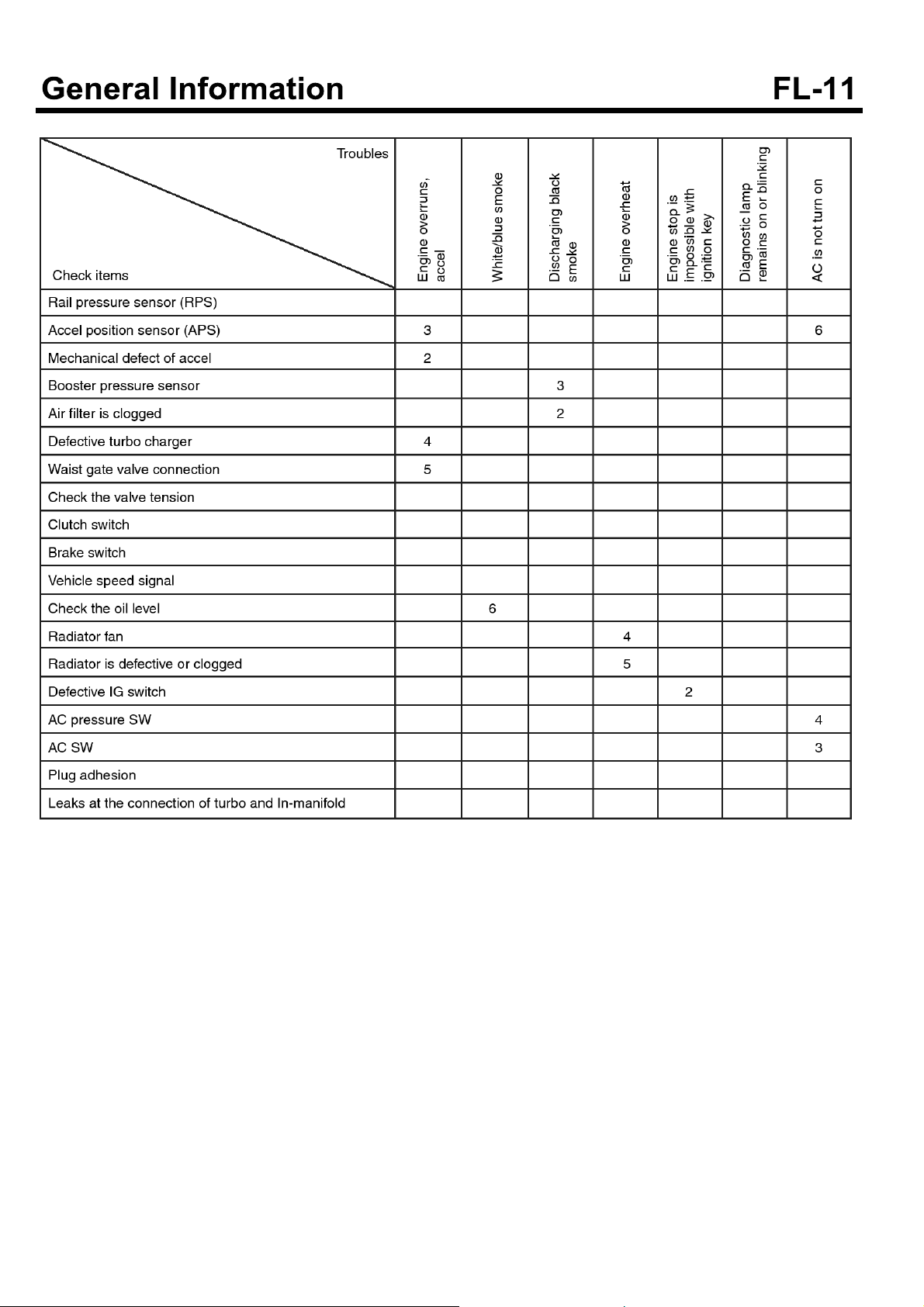

TROUBLESHOOTING

Symptom Possible causes Remedy

Engine does not crank.

Idle is improper or idle speed is unstable or irregular.

Low cranking speed

Low voltage to glow plug system If the test light turns on indicating low vo-

Defective glow plug Replace the glow plug.

Air in the fuel system Air bleeding of fuel system

Injection pipe is connected incompletely. Connect the pipe correctly

Improper injection timing Check ECM.

Poor injection Check, replace injector.

Mechanical defect of engine Test compression, repair engine.

Simultaneous failures of TDC sensor and

CKP sensor

Loose fuel hose connection between filter and supply pump.

Air in the fuel system Air bleeding of fuel system

Fuel filter is clogged. Or fuel supply is no

good because fuel line or injection pipe leaks, pinched or pressed.

Repairthestarterorchargeorreplacebattery.

ltage when it turns “ON”, check relay and

wiring.

Check and tighten correctly.

Tighten or repair.

Check hose or fuel line. Replace fuel filter if necessary.

Poor injection Check, replace injector.

Improper injection timing Check ECM.

Mechanical defect of engine Test compression, repair engine.

Defective supply pump

Engine defect at high gear range Observe correct shift speed.

EGR valve malfunction Check or replace EGR valve.

Exhaust gas (Black, blue, white) Engine temperature stays below engine

operating temperature.

Abnormal at max. RPM Check and replace supply pump.

Defective Injection nozzle Check and repair or replace.

Improper injection timing Check ECM.

Exhaust system malfunction Check for deformed or clogged.

Mechanical defect of engine Test compression, repair engine.

Defective supply pump Replace supply pump.

EGR valve malfunction Check or replace EGR valve.

Let the engine at idle after replacing pump.

Check cooling system. Replace thermostat.

Symptom Possible causes Remedy

Engine lacks power, acceleration is delayed(Speedometer is normal,

no clutch slip)

Excessive fuel consumption Contaminated air cleaner filter Clean, replace air cleaner filter.

Abnormal at max. RPM Check, replace supply pump.

Contaminated air cleaner filter Clean or replace.

Fuel filter is clogged. Or fuel supply is no

good because fuel line or injection pipe leaks, pinched or pressed.Or fuel filter leaks.

Air in fuel system Air bleeding of fuel system

Defective supply nozzle Check, repair or replace.

Improper injection timing Check ECM.

Mechanical defect of engine Test compression, repair engine.

Defective injection pump Check after replacing pump.

EGR valve malfunction Check, replace EGR valve.

Fuel leaks Check all pipes, hoses and connection.

Clogged return pipe and hose. Check and replace the return line, blow

Defective injection nozzle Check. Repair or replace.

Check hose or fuel line. Replace fuel filter if necessary.

Replace or tighten as required.

air if clogged and drain the fuel.

Mechanical defect of engine Compression test, replace engine.

Defective supply pump Replace pump.

EGR valve malfunction Check or replce EGR valve.

Engine control

Symptom Possible causes Remedy

Engine will not turn off. Injector wiring short Check injector wiring.

Starting switch harness is damaged. Replace.

Engine starting system

Symptom Possible causes Remedy

Engine does not crank Low battery voltage Recharge or replace the battery.

Battery cable connection is loose, corroded or worn.

Fusible link is swelled. Replace the fusible link.

Defective starter motor. Repair.

Defective injector Replace.

Cranking speed is low Low battery voltage Recharge or replace the battery.

Battery cable connection is loose, corroded or worn

Defective starter motor Repair

Starter motor continues to run. Defective starter motor Repair

Defective ignition switch Replace the ignition switch.

Starter motor runs but engine is not cranking.

Defective wiring Repair wiring.

Starter motor, pinion gear damaged Repair starter motor.

Ring gear damaged Replace flywheel or torque converter ge-

Replace or retighten.

Repairorreplace.

ar.

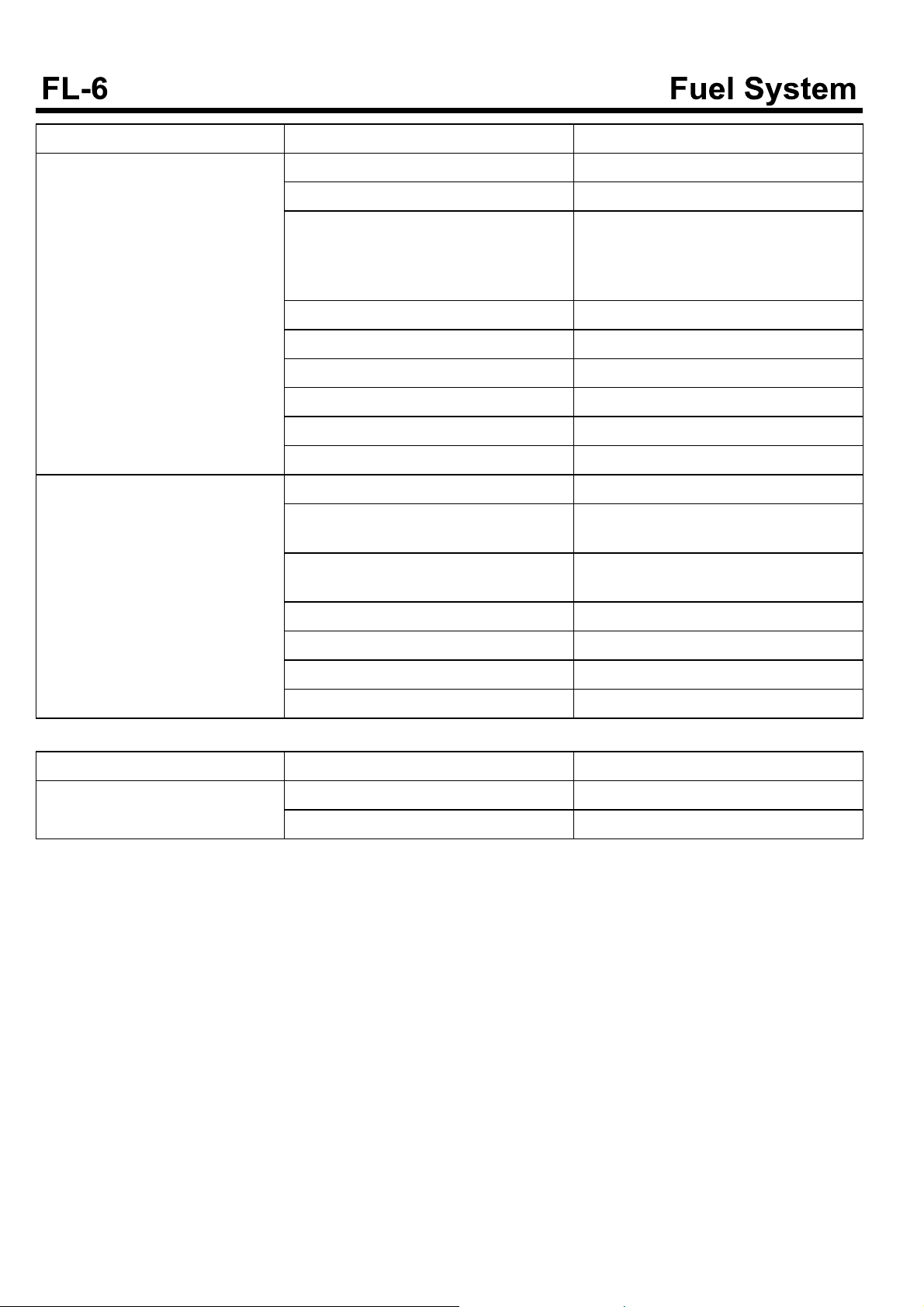

Fuel tank and fuel line

Symptom Possible causes Remedy

Poor engine performance due to insufficient fuel supply

Fuel filter warning lamp blinks. Excessive water is in fuel filter. Drain the water collected in the fuel filter

Engine check lamps blinks. Clogged fuel filter. Replace fuel filter.

Fuel pipe is twisted or bended Repair or replace.

Fuel pipe or hose is clogged Clean or replace.

Fuel filter is clogged Replace.

Entry of water to fuel filter Replace fuel filter or clean fuel tank or f-

uel line.

Foreign materials intrude in fuel tank.

Fuel tank rusts.

Defective supply pump operation

(Clogged filter in pump)

Clean or replace.

Replace.

(Loosen the drain plug at the bottom of fuel filter.)

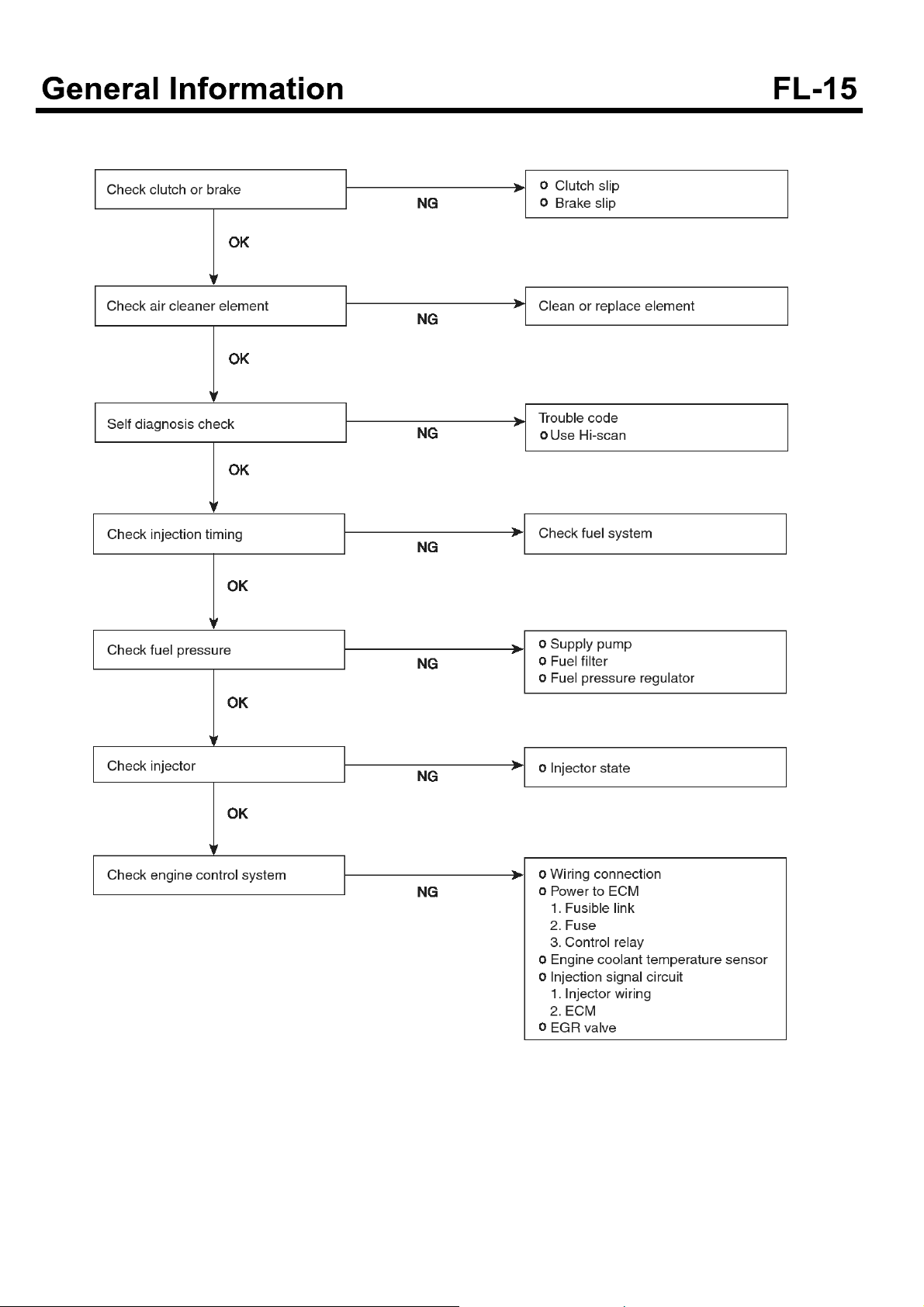

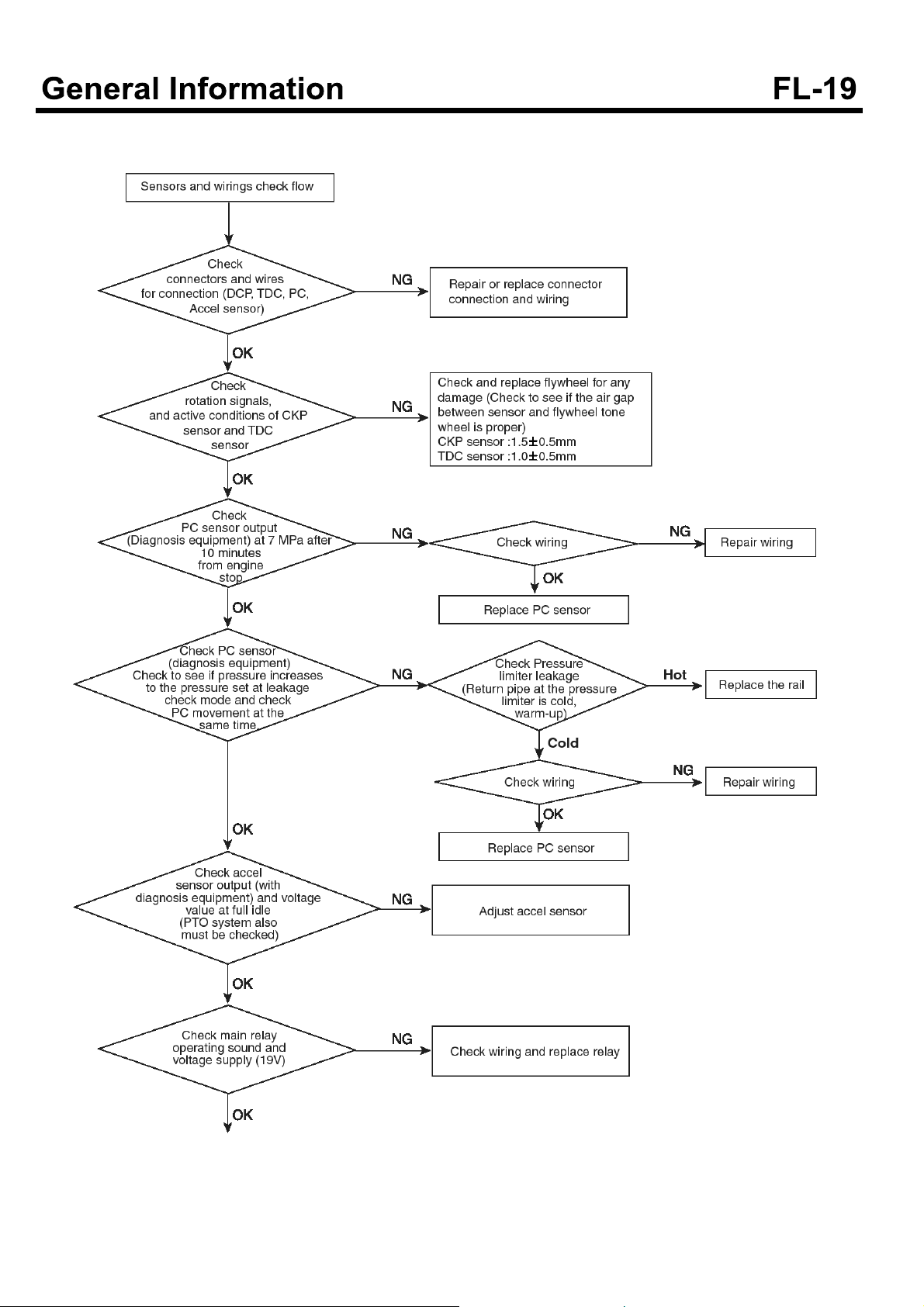

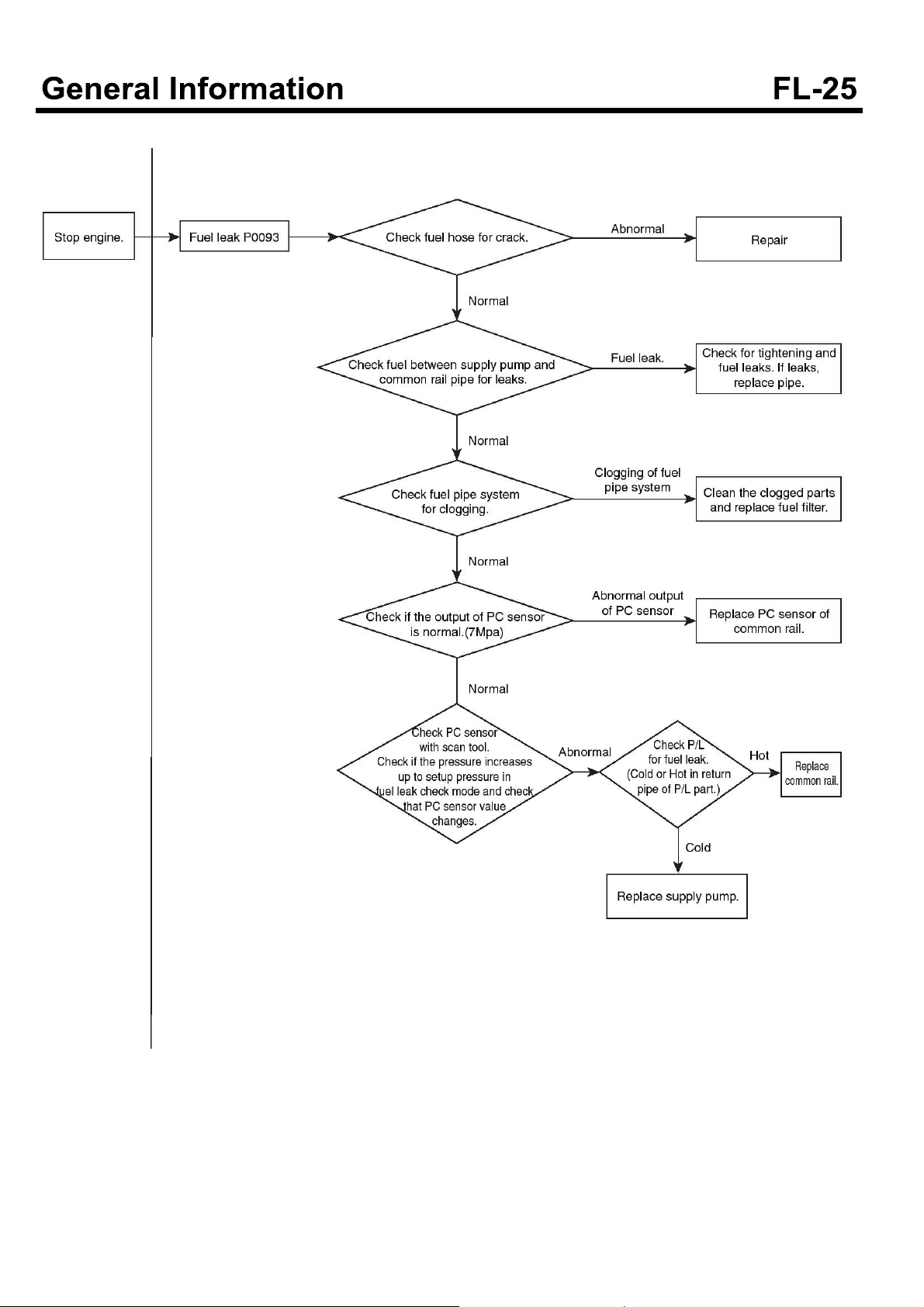

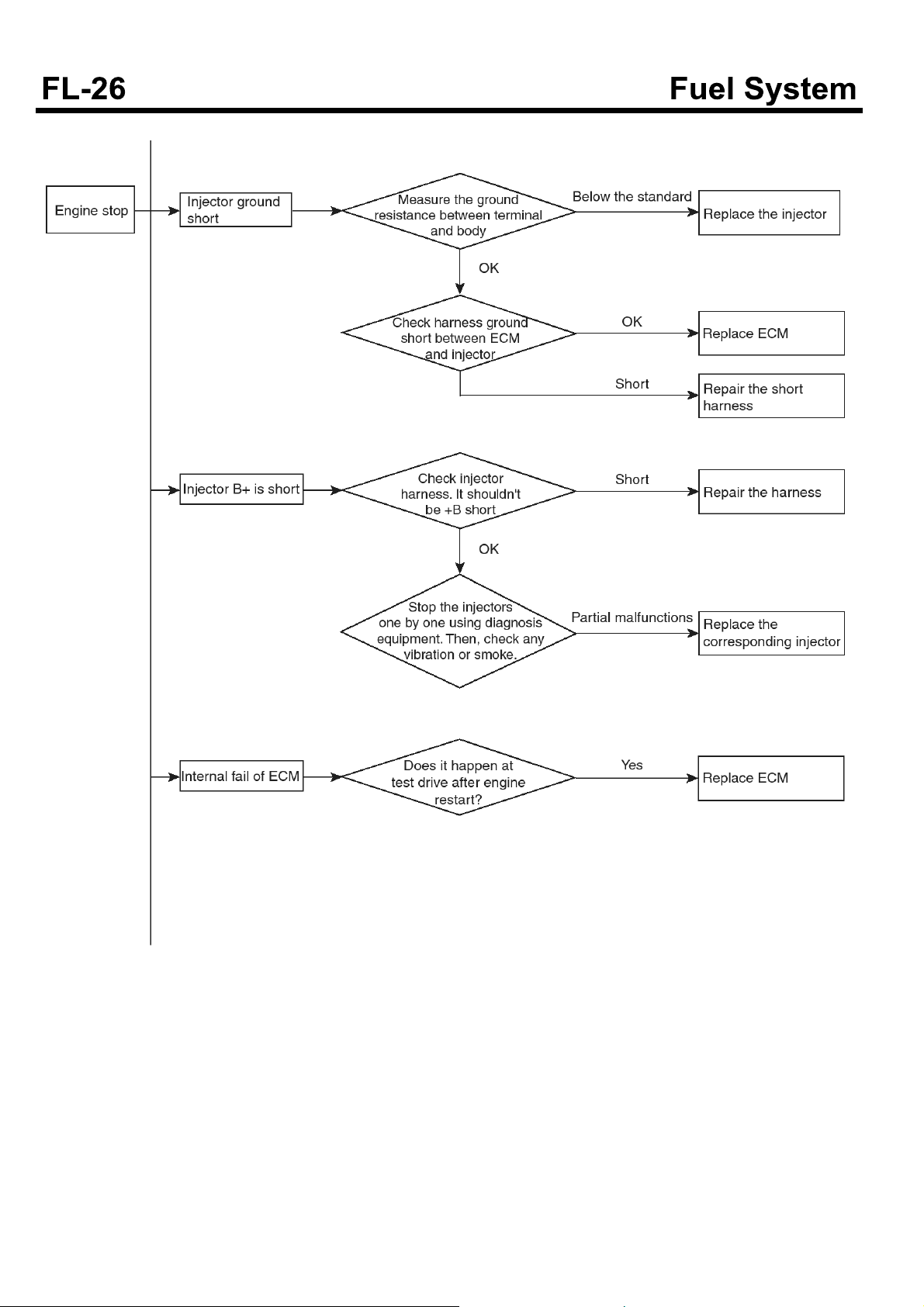

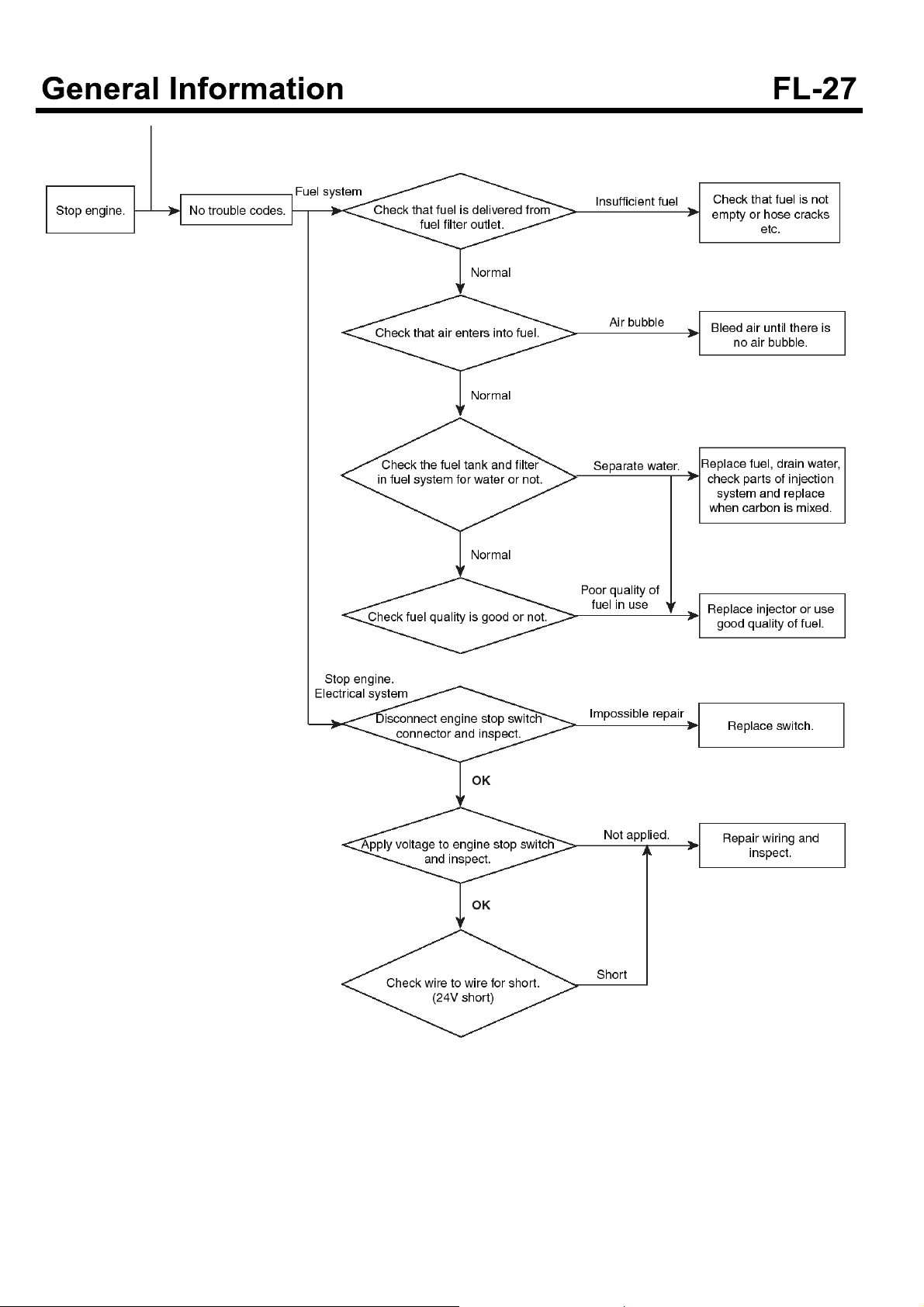

Troubleshooting procedure

SDGFL9001L

SUDFL9001L

SUDFL9002L

SDGFL9004L

SERVICE PROCEDURE

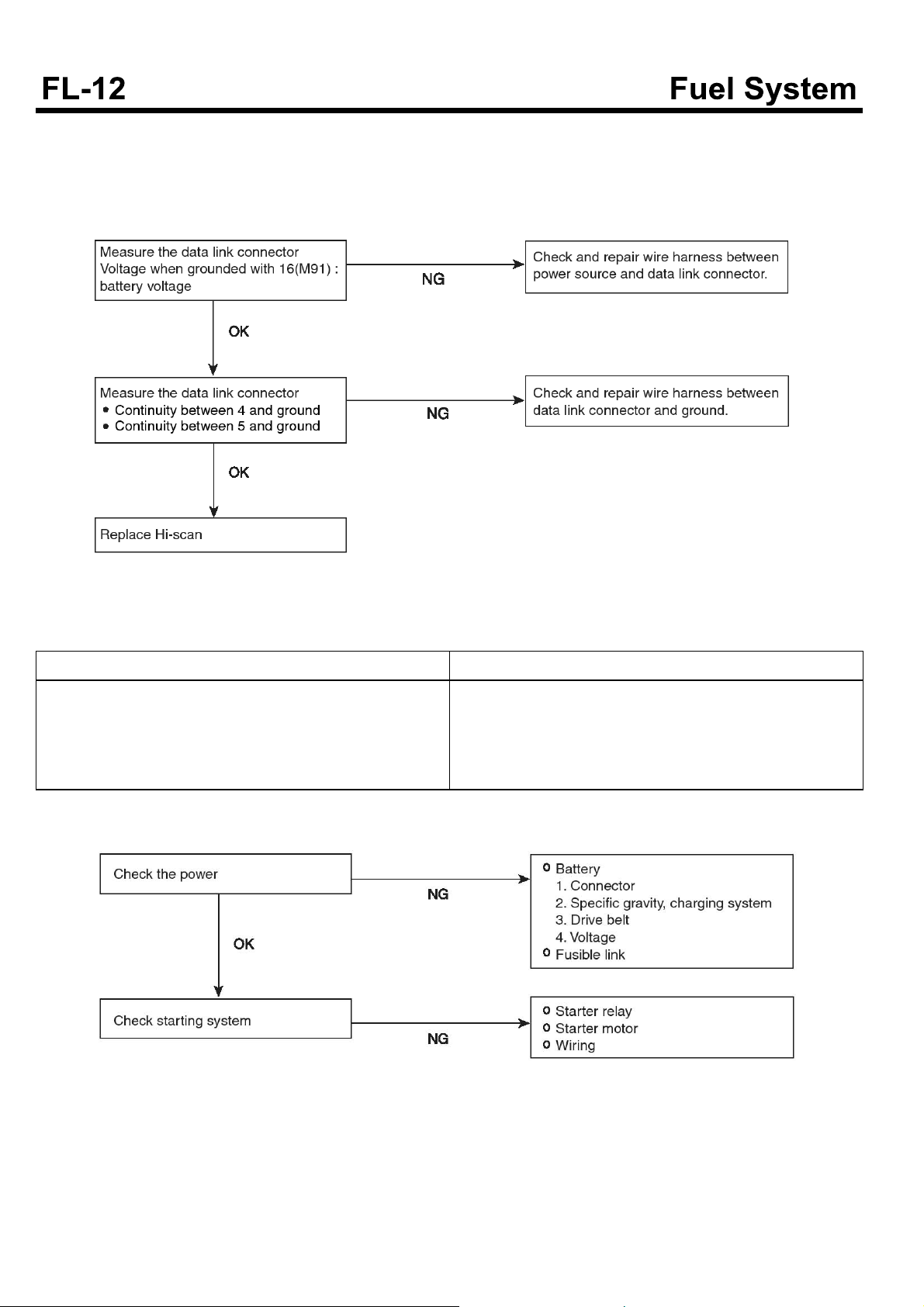

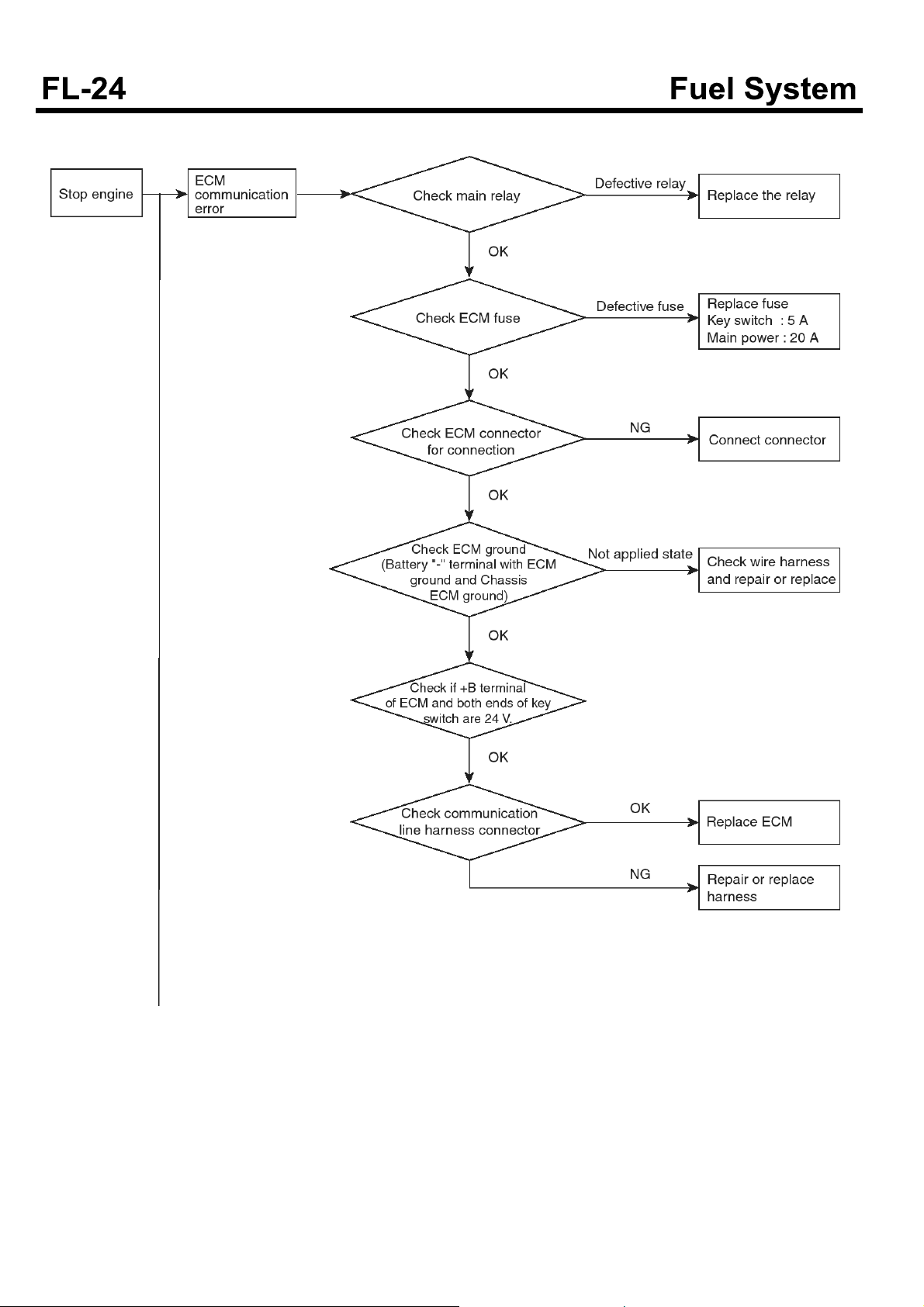

Communication with diagnosis equipment is not possible

(Impossible communication with all systems)

When communication between diagnosis equipment and

ECM is not possible

Trouble symptoms

It shows at least one of the following symptoms.

When power is not supplied to ECM,

ECM ground circuit is defective.

Defective ECM

Wrong communication line between ECU and Hi-scan

Engine does not start.

SDGFL9005L

Probable causes

Power supply circuit to ECM is defective.ECM

Malfunction ECM

Circuit between ECU and DLC is open.

SDGFL9006L

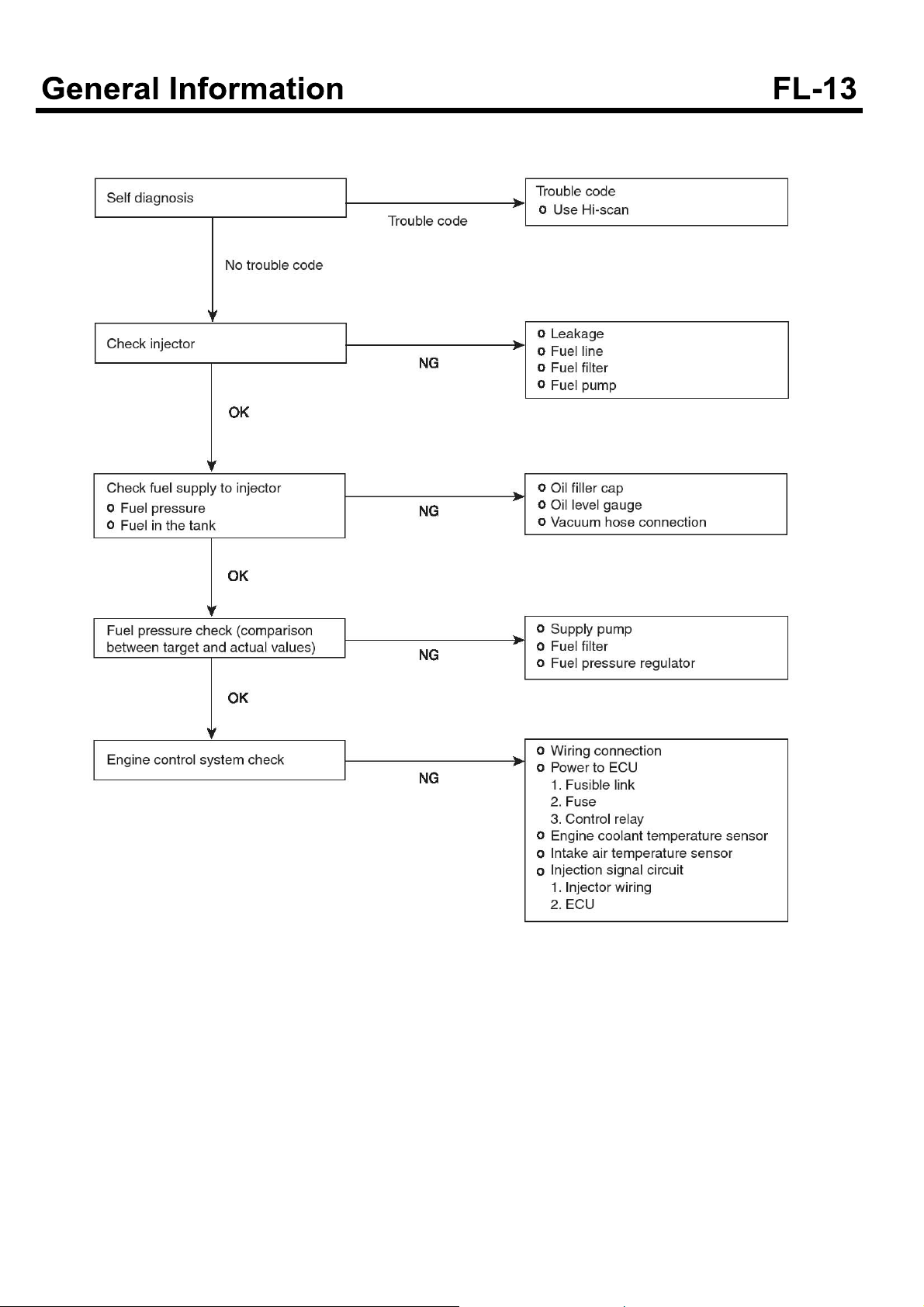

It is difficult to start the engine. (Possible cranking)

SDGFL9007L

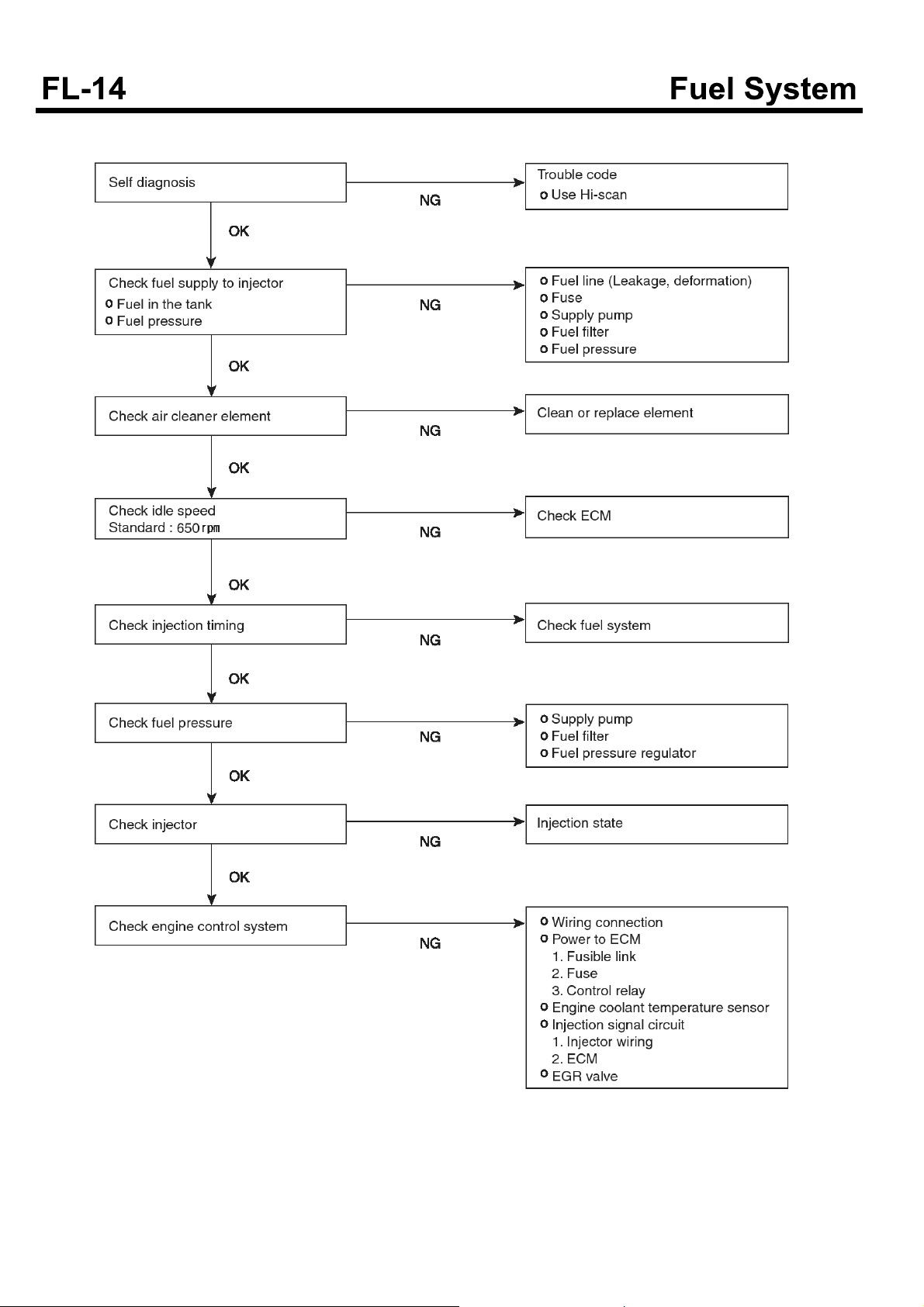

Unstable idle or engine stall.

SUDFL9003L

Engine hesitation or poor acceleration

SDGFL9009L

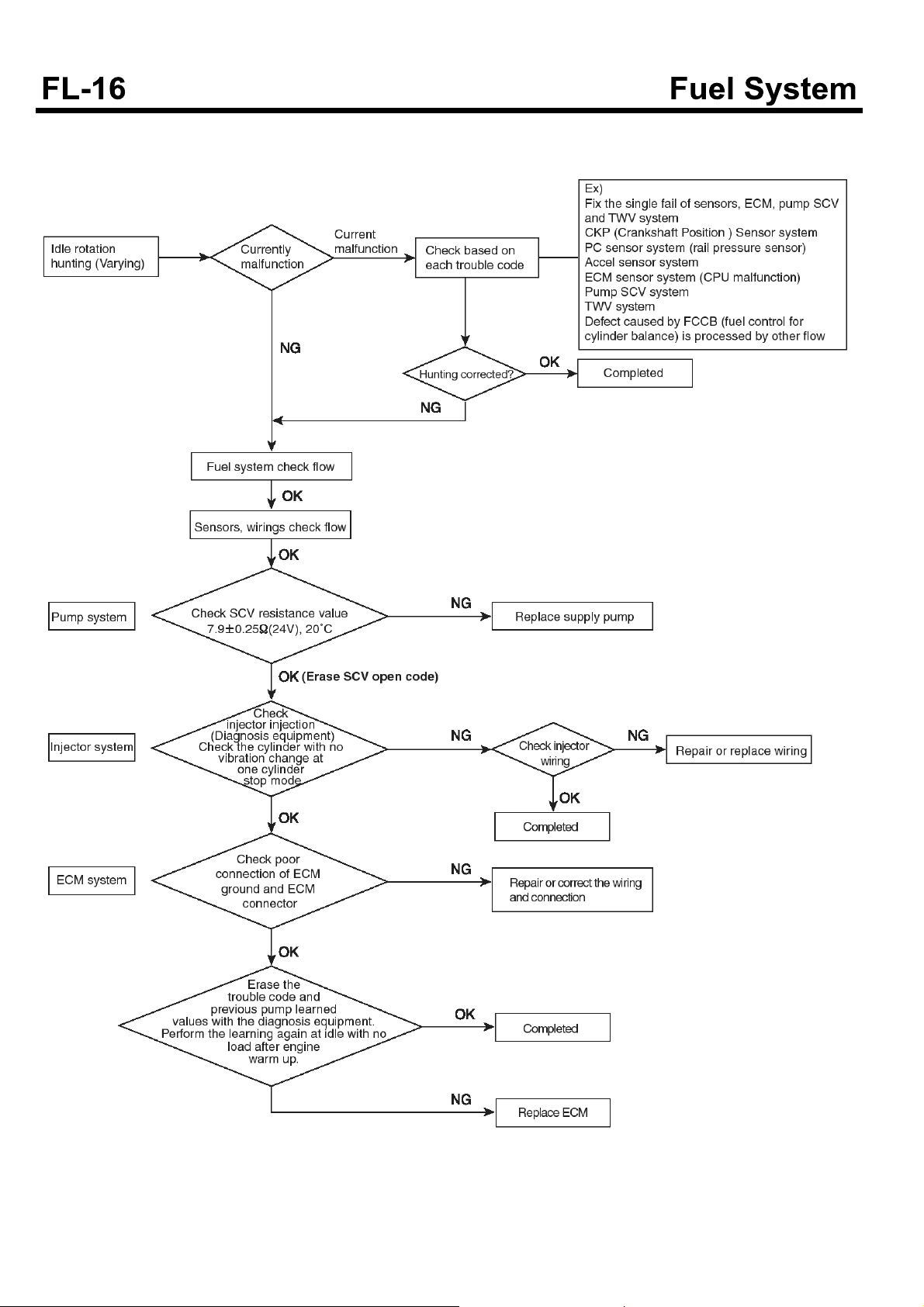

Troubleshooting flow chart when HUNTING(Varying)

occurs

SUDFL9004L

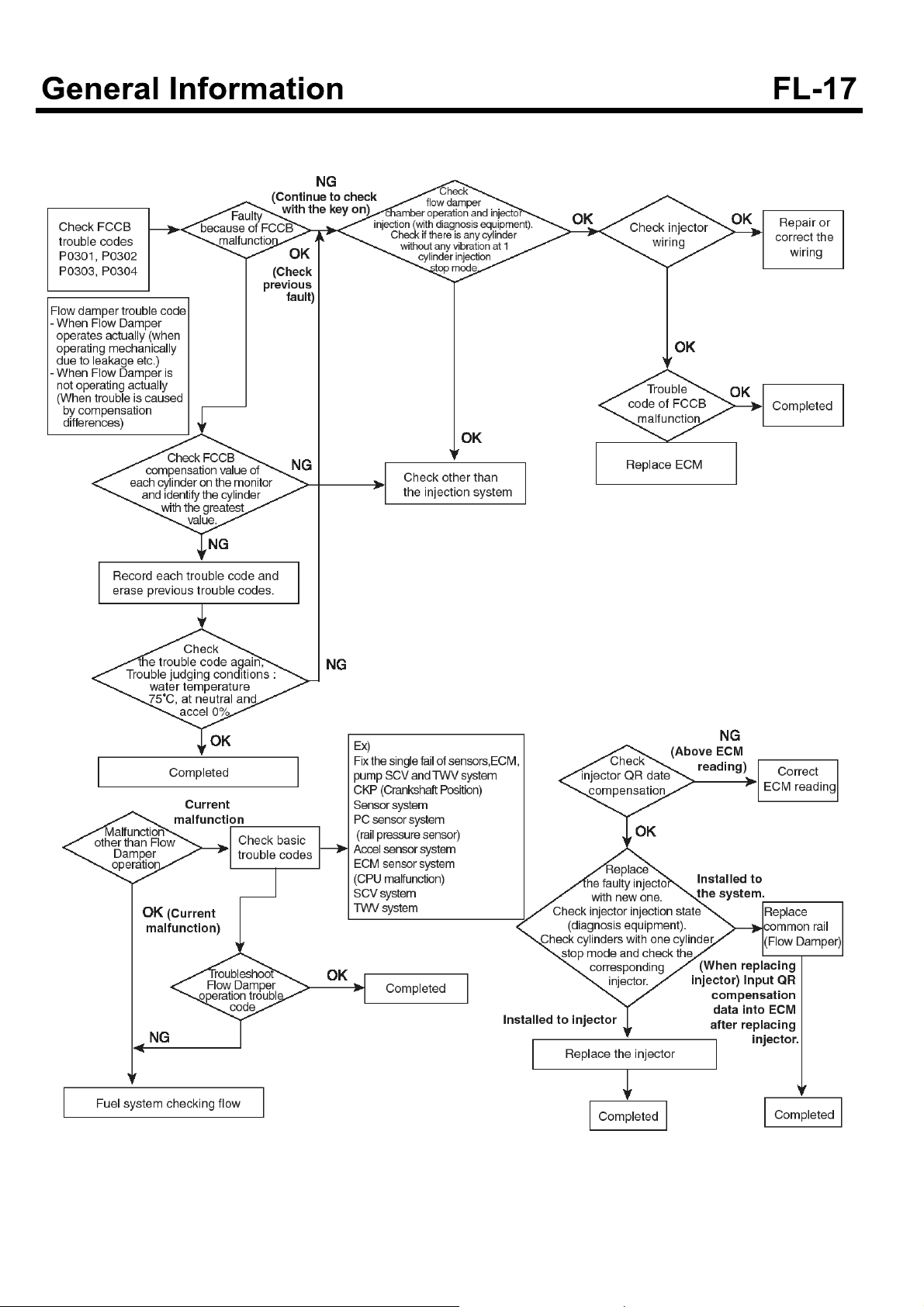

Troubleshooting flow chart when FCCB(Fuel control

cylinder balance) fails.

SUDFL9005L

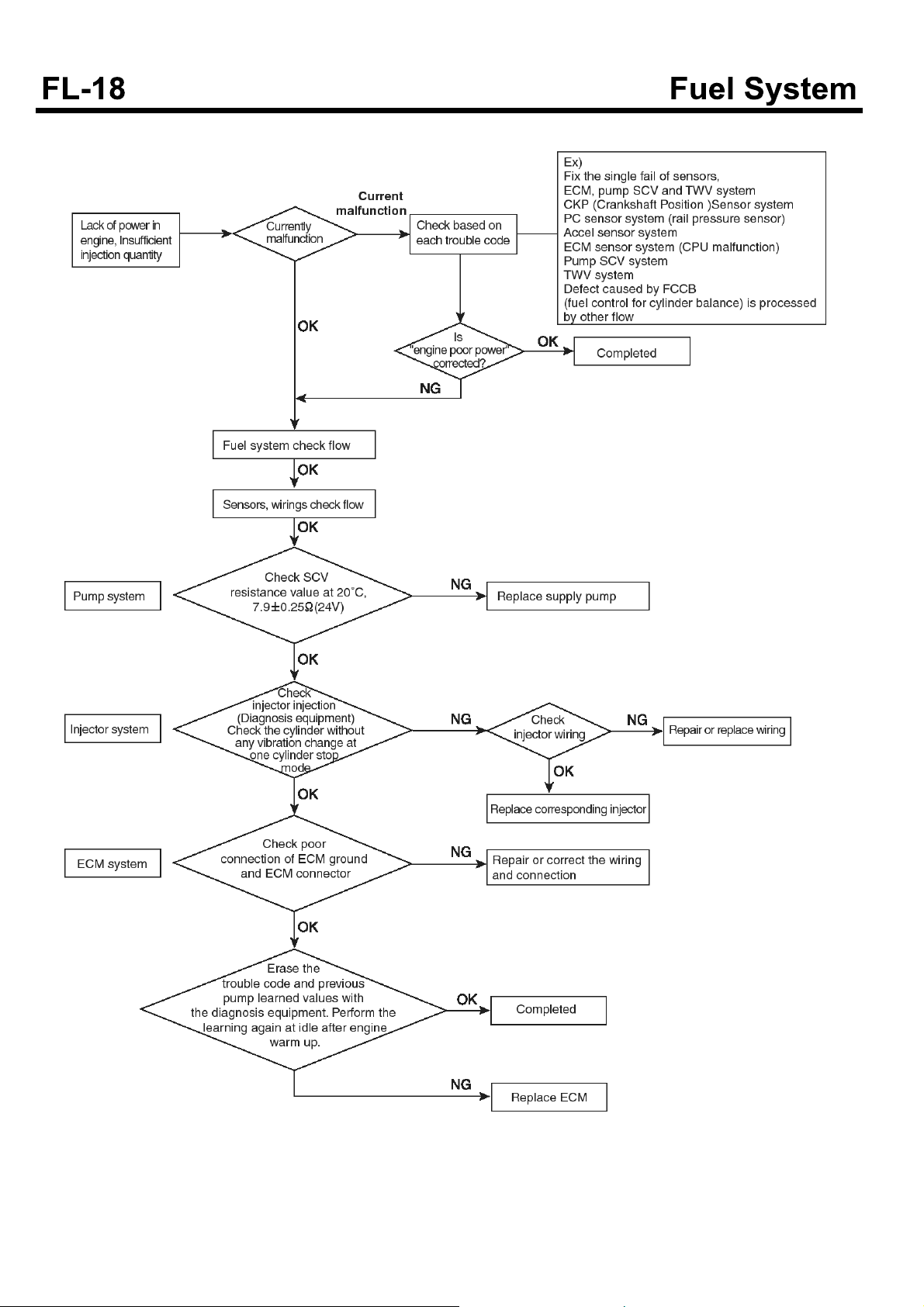

Troubleshooting flow chart when engine is lack of power

SUDFL9006L

Troubleshooting flow chart in systems of sensors and

wirings

SDGFL9013L

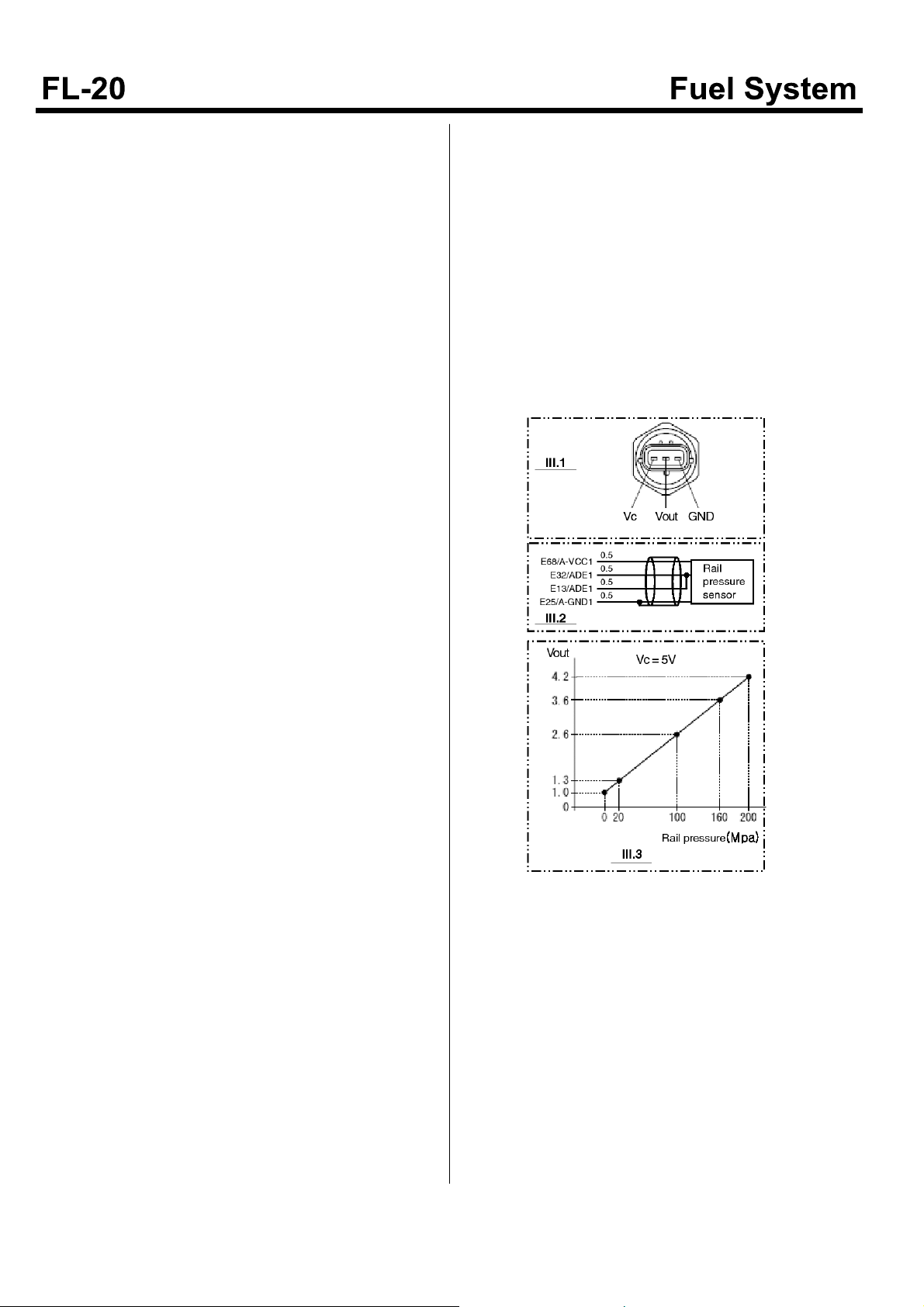

CRS RAIL PRESSURE CHECK

■

Items to check in the vehicle

1. Check for customer complaint and trouble symptoms.

2. Check reoccurrence or not for customer complaint

and trouble symptoms mentioned above.

3. Record DTC codes or record the detailed DTC codes

by using Hi-scan.

Inspect and repair causes due to DTC codes.

4. Check rail pressure when turning ignition key to

NO(Engine OFF).

If the rail pressure is displayed, check it according to

inspection procedure of remaining pressure.

5. Check for connector of rail pressure sensor.

Check for wiring tension between rail pressure

sensor and connector of vehicle side.

Check that wiring between rail pressure sensor and

connector of vehicle side is tight or not due to

vibration(under driving) with interference in bracket of

engine/vehicle etc.

Check rail pressure sensor wire for clamp conditoin.

Check that wire of rail pressure senor is clamped

securely or not.

Check rail pressure sensor and connector of vehicle

side for connection conditon.

With connector connected, check connector for

shaking(with right and left/ back and forth).

7. Visual check of connector

Check each terminal contact part of rail pressure

sensor for wear.

Check connector housing of rail pressure sensor for

wear.

Check locking part/ guide part of rail pressure sensor

connector for damage or deformation.

Check the inside of rail pressure sensor connector for

foreign materials(such signs as water, oil, spark,

tracking etc.).

Check the opposite connector for foreign materials,

wear, damage, existence or not of rubber seal or

shrinkage of rubber seal etc..

If there is free play, check for output of rail

pressure/rail pressure sensor using Hi-scan or

oscilloscope.

6. Check for wiring related to the output of rail pressure

sensor.

Check for voltage between each terminal of rail

pressure sensor in the ECM side and terminal (-) of

battery.

Check wire between rail pressure sensor and ECM

for continuity(resistance).

SDGFL9014L

Rail pressure sensor

terminal

Voltage check

Check wiring between rail pres -

sure sensor and ECM

Measured v-

Item Pin No. Check condition

ECM terminal side r-

eference value

alue noise

or

Reference value/me-

asured condition

not

Vc E68 Key On 4.9~5.1 Below 2[ohm]/Key Off

Measured

value

Vout E32

Key On/EngineOff 0.9~1.1 Below 2[ohm]/Key Off

Engine On/at Accel. Refer to illustration 3 Below 2[ohm]/Key Off

Key On/Engine Off 0.9~1.1 Below 2[ohm]/Key Off

Vout E13

Engine On/at Accel. Refer to illustration 3 Below 2[ohm]/Key Off

GND E25 Key On 0±0.1 Below 2[ohm]/Key Off

CRS Rail pressure check flow chart

SDGFL9015L

Fuel system check processor

SUDFL9007L

Troubleshooting flow chart when the engine stops

SUDFL9008L

SUDFL9009L

SDGFL9019L

SUDFL9010L

Electronic Engine Control System

DESCRIPTION

DIESEL CONTROL SYSTEM

Inspection of the diesel control system

If the components of the diesel control system (sensor,

ECM, injector etc.) have a problem, the proper amount of

fuel for various engine-operating conditions can not be

supplied and also the following situations can occur.

1. It is hard to start the engine or does not start the

engine at all.

2. Idling is unstable.

3. Engine driving performance is bad.

If any of the above conditions are met, first perform a

routine diagnosis that includes basic engine checks

(ignition system malfunction, incorrect engine

adjustment etc). Then, inspect the components of the

diesel control system with multi-purpose tester or

digital multi-meter.

CAUTION

Before removing or installing any part, read t he

diagnostic trouble codes and then, disconnect

the battery negative (-) terminal.

Before disconnecting the cable from battery

terminal, turn the ignition switch to OFF. If the

battery cable is removed or connected during

engine operation or the situation in which the

ignition switch is ON, then the ECU

semiconductor could be damaged resulting in

inaccurate operation.

Self-diagnosis

The ECM sends the input/output signals to various parts

of engine(some signals at all times and the others under

specified conditions).

After the specific time elapses the first detection of

irregular signal, the ECU judges this as an irregularity

and it records the diagnostic trouble code. And then it

sends the signal to the self-diagnosis output terminal.

The diagnosis results can be checked by the Hi-scan. In

addition, Diagnostic Trouble Codes (DTC) will be directly

backed up by the battery so that it will remain in the ECM

even if the ignition switch is turned off. The diagnostic

trouble codes will, however, be erased when battery

terminal or ECM connector is disconnected.

negative terminal (-) is disconnected for 15 seconds

or more, then the diagnosis memory will be erased.

Self-diagnosis check procedure

CAUTION

As DTC code may not be detected due to low battery

voltage, the battery condition should be checked

prior to inspection.

Since DTC code is erased if the battery or the ECM

connector is disconnected, don't disconnect the

battery until the diagnostic trouble codes are

completely read and recorded safely.

It is most desirable to erase the diagnostic trouble

codes using Hi-scan after completing check and

repair. After disconnecting ground cable from the

battery negative ( -) terminal for 15 seconds or more,

reconnect the cable and check if the trouble codes

have been erased. (At this time, ignition switch must

be turned off).

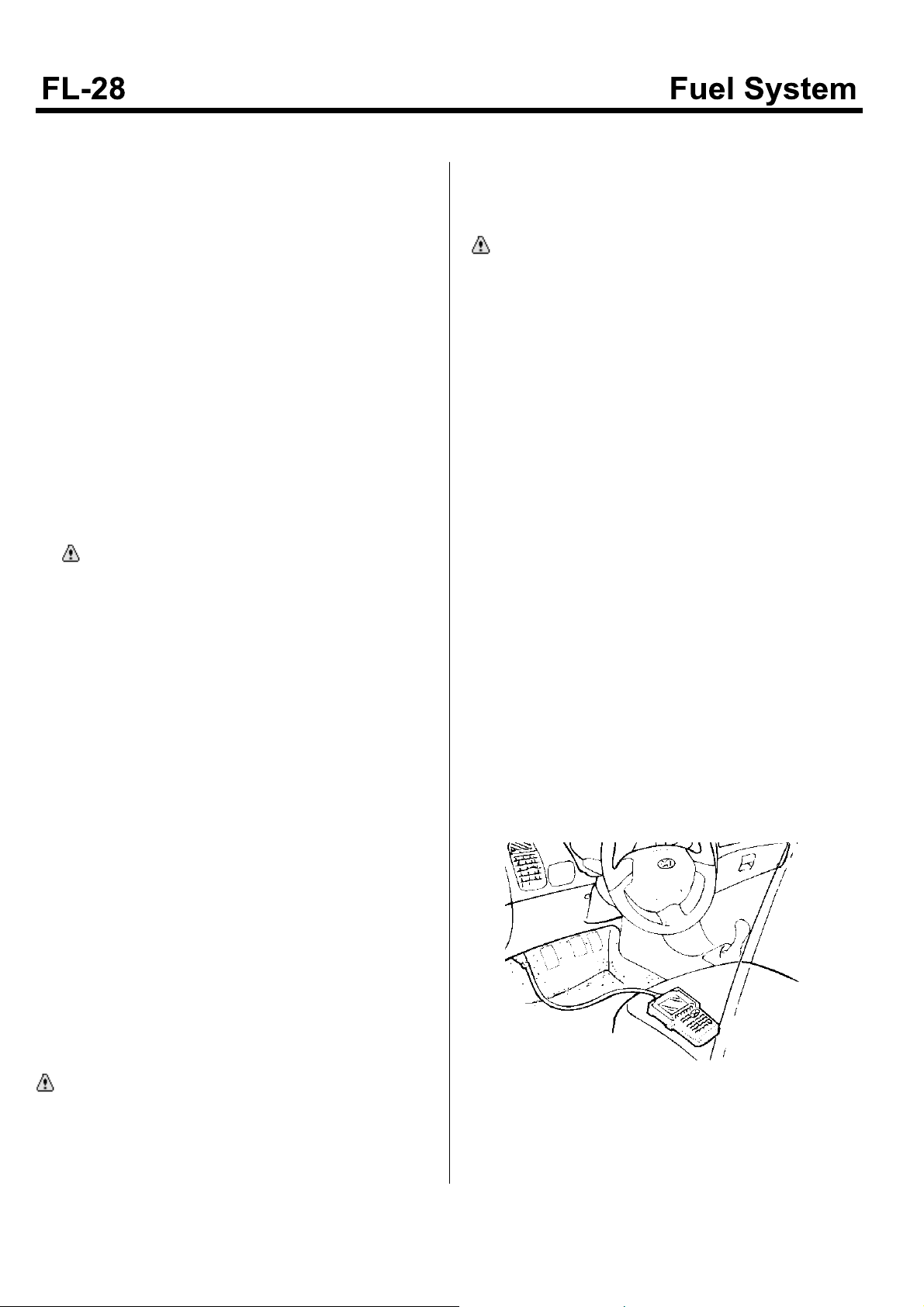

Inspection procedure (Using Hi-scan)

1. Turn off the ignition switch.

2. Connect the Hi-scan connector to the connector of

DLC (Data Link Connector) for the trouble diagnosis

as shown in the figure.

3. Turn the ignition switch ON.

4. Check the diagnostic code using Hi-scan.

5. Repair the parts having faults shown in the diagnosis

chart.

6. Erase the diagnostic trouble codes.

7. Disconnect the Hi-scan.

CAUTION

If, in most of diesel control system, the connector

of a sensor is disconnected with the ignition switch

turned ON, the diagnostic trouble code (DTC) is

recorded in the ECM. In this case, if the battery

KDDFL5019A

NOTICE

When using a tester manufactured by other

company, operate the tester by referring to the

manual of the company.

When erasing the diagnostic trouble codes, use

Hi-scan if possible. Though DTC can be erased by

disconnecting the battery terminal, doing so, the

data for learning control in ECM would be erased at

the same time.

DIESEL CONTROL SYSTEM COMPONENTS

LOCATION

1. Intake air temperature sensor and intake air pressure

sensor

3. Water temperature sensor(Coolant temperature

sensor)

SDFFL7505D

4. Camshaft sensor

2. Crankshaft position sensor

SDFFL7503D

SDFFL7506D

5. Injector(A)

SDFFL7504D

SDFFL7009D

6. Rail pressure sensor(A)

9. Accelerator position sensor

7. Supply control valve(SCV, A)

8. ECM(Engine control module, A)

SDFFL7006D

SDFFL7007D

SUDFL9016L

10. DLC connector

SDFFL7314D

11. DPS(Differential Pressure Sensor)

SDFFL7008D

SUDFLDTC9108L

ECU(Engine Control Unit)

COMPONENTS

ECM PIN CONNECTOR

SUDFL9011L

Vehicle side(80pin connector) - ECM connector(CFD-ECM)

Termi-

nal

1

2 PWR-ACT1 - 42 SWV23 Stop lamp switch

3 OUTV1 Main relay 43 SWV21 Self-diagnosis switch

4 OUTV2 Exhaust brake relay 44 SWV19 Cruise main ON/OFF switch

5 OUTV3 Starter relay 45 A-ground 10 Sensor ground10

6 SOUT6

7 SOUT4 Glow lamp 47 ADV1 Accelerator position sensor 1

8 SOUT2 PTO lamp 48 ADV3 -

9 SOUT1 MIL lamp 49 ADV5 Exhaust temperature sensor 1

10 SWV6 PTO emergency switch 50 A-VCC10 Sensor power supply 10

11 SWV4 Neutral switch 51 A-VCC11 Sensor power supply 11

12 SWV2 Starter switch 52 SWV17

13 SWV1 Ignition switch 53 SWV15

Abbr. Terminal name

+

BF

+

B(Forflyback)

Check engine lamp and fuel pressure flashing

Termi-

nal

41 SWV25 -

46 A-ground 12 Sensor ground 12

Abbr. Terminal name

Remote PTO idle up & engine service start switch

Idle down & PTO idle down & cruise resume switch

14 VS Vehicle speed sensor 54 SWV13 A/C switch

15 POUT1 A/C control 55 SWV11 Clutch switch

16 CAN1L CAN1L 56 SWV9 Exhaust brake switch

17 CAN2L CAN2L 57 CAN-SLD CAN1 shield ground

+

18

19 BATT Battery 59 P-ground Power ground

20 CASE-ground Case ground 60 ground Signal ground

21

22 OUTV4 Warning lamp relay 62 SWV24 Starter relay monitor switch

23 OUTV1 Main relay 63 SWV22 Idle warm up switch

24 OUTV5 Heater relay 64 SWV20 Built-in data capture switch

25 SOUT8 Alternator control cut 65 A-ground 11 Sensor ground 11

26 SOUT7 Cruise lamp 66 A-ground 13 -

27 SOUT5 Overheat lamp 67 ADV2 Accel position sensor 2

28 SOUT3 Exhaust brake lamp 68 ADV4 PTO accel position sensor

29 SWV8 Door open switch 69 ADV6 Exhaust temperature sensor 2

B

+

BF

+

B

+

B(forflyback)

+

58

61 SWV26 PTO switch(Cap outside)

B

+

B

30 SWV7 Bus rear flap switch 70 ADV7 Differential pressure sensor

31 SWV5 PTO switch 71 A-VCC12 Sensor power supply 12

Termi-

nal

Abbr. Terminal name

Termi-

nal

Abbr. Terminal name

32 SWV3 Engine stop switch 72 SWV18

33 SWV1 Key switch 73 SWV16 QT cut switch

34 TAC1 Tachometer 74 SWV14

35 PIN5 - 75 SW V 12 Brake switch

36 CAN1H CAN1H 76 SWV10 Idle switch

37 CAN2H CAN2H 77 KWP -

+

38

39 P-ground Power ground 79 P-ground Power ground

40 Ground Signal ground 80 P-ground Power ground

B

+

B

78

+

B

Remote PTO idle down & engine

service stop switch

Idle up & PTO idle up & cruise set

switch

+

B

Engine side(80 pin connector) - ECM connector(EFD-ECM)

Termi-

nal

80 OUTE5 DC motor 1H 40 SWE1 Heater monitor switch

79 OUTE1 - 39 SWE3 -

78 OUTE3 Fan ON/OFF 2 38 ADE9 -

Abbr. Terminal name

Termi-

nal

Abbr. Terminal name

77 PWR-ACT2 Power ACT2 37 ADE7 Ambient temperature sensor

76 AUX2 - 36 ADE13 EGR valve position sensor

75 PWR-PCV Not in use 35 ADE6 -

74 PCV1 Not in use 34 ADE4 Intake temperature sensor

73 PCV2 Not in use 33 ADE2 Fuel temperature sensor

72 SCV-HI HP-4 high 32 ADE1 Rail pressure sensor

71 SCV-LO HP-4 low 31 PIN2

70 AUX1 Not in use 30 PIN1

69 A-VAF MAF power supply 29 NE

68 A-VCC1 Sensor power supply 1 28 G-VCC Cam angle sensor power

67 COM1 Injection power 1 27 G-ground Cam angle sensor ground

66 TWV1 Injection #1 26 INJ-SLD Injection shield ground

65 TWV3 Injection #3 25 A-ground1 Sensor ground 1

64 TWV5 - 24 A-ground3 Sensor ground 3

63 COM2 Injection power2 23 A-ground5 Sensor ground 5

62 TWV2 Injection #2 22 CAN3H CAN3H

+

+

+

-

-

Engine RPM sensor

+

61 TWV4 Injection #4 21 TWV6 -

60 OUTE6 DC motor 1L 20 SWE2 Fuel inlet pressure switch

Termi-

nal

Abbr. Terminal name

Termi-

nal

Abbr. Terminal name

59 OUTE2 Fan ON/OFF 1 19 ADE10 -

58 OUTE4 - 18 ADE8 -

57 PWR-ACT2 Power ACT2 17 ADE14 -

56 PWR-ACT2 Power ACT2 16 ADE12 -

55 PWR-PCV Not in use 15 ADE5 Water temperature sensor

54 PCV1 Not in use 14 ADE3 Boost sensor

53 PCV2 Not in use 13 ADE1 Rail pressure sensor

52 SCV-HI HP-4 high 12 ADE11 Air MAS flow sensor

51 SCV-LO HP-4 low 11 PIN2- -

50 NE(MRE) - 10 PIN1- -

49 PRD

+

Not in use 9 NE- Engine RPM sensor -

48 A-VCC2 Sensor power supply 2 8 G Cam angle sensor signal

47 COM1 Injection power1 7 PIN3 -

46 TWV1 - 6 NE-SLD NE Shield ground

45 TWV3 - 5 A-ground 2 Sensor ground 2

44 TWV5 - 4 A-ground 4 Sensor ground 4

43 COM2 Injection power 2 3 A-ground 6 Sensor ground 6

42 TWV2 - 2 CAN3L CAN3L

41 TWV4 - 1 TWV6 -

REMOVAL

1. After the engine stops, wait for about 30 seconds.

2. Disconnect the battery ground line.

3. Remove ECU connector wiring sequentially.

4. Loosen ECU bracket mounting bolt and remove

ECU(A).

SDFFL7008D

5. Installation is in the reverse of removal.

Adjustment procedure after replacing ECU

1. Perform work procedure using diagnostic tool when

replacing with a new ECU.

2. Input injector QR correction value using diagnostic

tool with the ignition key ON.

Follow the instructions on the diagnostic tool as to

how to input injector QR correction value.

If the input of injector QR correction value was

completed, start the engine in 10 sec. after turning

the ignition key OFF.

CAUTION

In case QR correction value described on the

injector is not input in the ECU, there may cause

engine performance and exhaust gas problem.

3. Select learning initialization instructed by diagnostic

tool and perform pump learning initialization and

accelerator sensor learning.

4. According to the instructions on diagnostic tool,

select parameter setting and perform work in

sequence.

Mass Air Flow Sensor

INSPECTION

DESCRIPTION

MAF sensor is built into the vehicle for controlling the

EGR system precisely.

The air flow, supplied to an engine, is measured lower

than actual air flow due to contamination of MAF sensor.

Then EGR system can't be controlled precisely.

To prevent it in advance, you have to clean the MAF

sensor periodically.

Clean the MAF sensor every 6 months or 60,000 km

using "Carb and Choke Cleaner".

VISUAL INSPECTION

CAUTION

1. Don't impact or drop the sensor when replacing

it.

SGZFL9028L

2. Don't use the sharp tool at removing the sensor,

otherwise the O-ring may be damaged.

Procedure and caution when cleaning the sensor

SGZFL9029L

CAUTION

1. To remove the O-ring of MAF sensor

- Remove the O-ring of MAF sensor to prevent

it from damage by cleaning spray and clean

the sensor element.

SGZFL9030L

2. Procedure of atomizing the spray

- Atomize the spray to the end part of sensor

housing.

- Don't use the nozzle of spray to prevent the

sensor element from damage.

- Atomize the spray with 2~3timesfor2~3

seconds.

3. To dry the sensor element

- Using the air gun : Below 5 bar, within 30

seconds.

- After atomizing the spray, dry the sensor like

below picture for 20 minutes.

SGZFL9032L

4. To install the O-ring of MAF sensor

- Install the O-ring after completing to dry the

sensor.

SGZFL9031L

SUDFL9500L

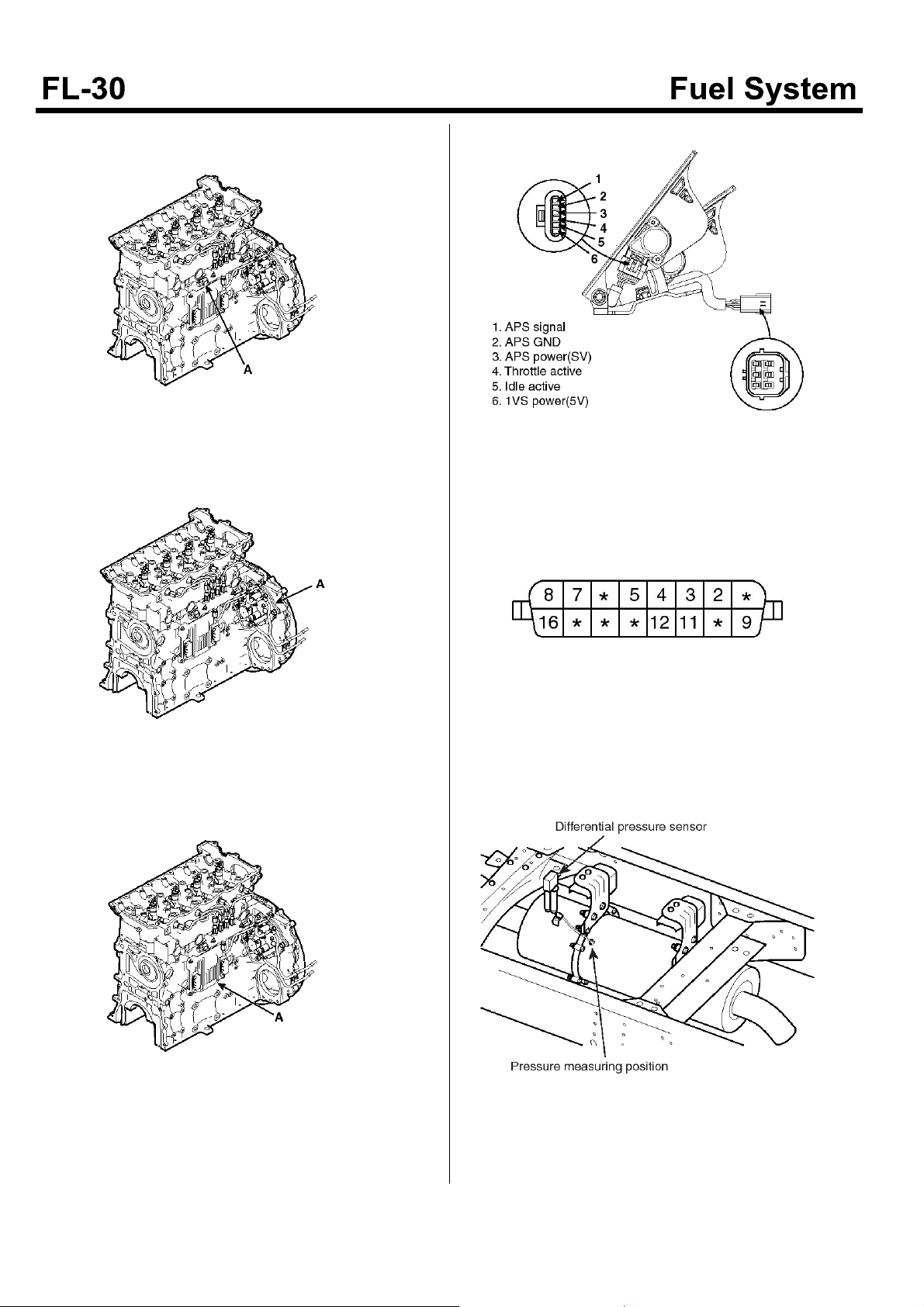

Differential Pressure Sensor(DPS)

Components

Description

The differential pressure sensor is installed upper side of

PMC and measures the pressure difference between

before and after PMC.

It also has a purpose to monitor that PMC is arbitrarily

removed by a user.

SUDFLDTC9109L

SUDFLDTC9110L

Specifications

Differential Pressure (kPa) Output Voltage (V)

Part Circuit Diagram

0 1

10 1.35

20 1.7

30 2.05

40 2.4

50 2.75

60 3.1

70 3.45

80 3.8

90 4.15

100 4.5

SUDFLDTC9112L

Replacement

The differential pressure sensor

1.TurntheignitionswitchOFFanddisconnectthe

battery (-) cable.

2. Disconnect the differential pressure sensor

connector(A).

SUDFLDTC9111L

3. Remove the clip connected to the differential

pressure sensor pipe.

4. Remove the mounting bolt(D).

5. The installation is the reverse order of removal.

NOTICE

Regarding as the tightening torque, refer to

"Components".

The differential pressure sensor pipe

1. Turn the ignition switch OFF and disconnect the

battery (-) cable.

2. Remove the clip connected to the differential

pressure sensor pipe.

SUDFLDTC9111L

3. Remove the bracket bolt(B).

4. Remove the differential pressure sensor pipe(C).

5. The installation is the reverse order of removal.

NOTICE

Regarding as the tightening torque, refer to

"Components".

Electronic Fuel Supply System

COMPONENTS

SUDFL9012L

Injector

COMPONENTS

SUDFL9013L

REMOVAL

CAUTION

• Since common rail fuel injection operates under

high pressure(1,800bar), a special care should be

taken.

• While engine is running or within 1 min. after

engine stops, any works should not be

performedinrelationtocommonrailfuel

injection system.

• In particular, as the injector solenoid generates

high temperature heat, do not touch it with bare

hands. Start the service works only when the

engine has been cooled down enough after

engine stops.

• Always keep the safety precautions.

• Ensure working area cleans all the time, and

place the removed injector on the clean cloth.

And pay attention to injector nozzle so that it is

not contaminated by any foreign materials.

• Remove the protective caps which prevents

foreign material inflow for injector and fuel hose

immediately just before installation.

• When installing or removing injector, clean the

contacting portion of the injector and be sure to

replace O-ring and nozzle gasket with new ones.

• Apply diesel oil to the O-ring of injector and

insert them into the cylinder head.

• Install the injector to the cylinder head vertically

and install it correctly not to cause any damage

such as shock.

• Be sure to observe the specified tightening

torque of bolts when inserting and tightening the

injector.

• Never reuse the high pressure fuel pipe.

1. Turn the ignition key OFF. .

2. Disconnect the negative(-) terminal of battery.

3. Remove the rocker cover.

4. Remove the rocker arm assembly and disconnect the

injector ground(A).

SDFFL7508D

5. Remove the high pressure fuel pipe(A).

SDFFL7509D

6. Loosen the injector clamp bolt(A) and remove the

injector.

SDFFL7510D

INSTALLATION

1. Installation is in the reverse of removal.

2. When installing, tighten the bolts to the specified

torque.

High pressure fuel pipe mounting bolt : 4~5 kgf.m

(39.2~49N.m, 28.9~36.2 Ib-ft)

Injector clamp mounting bolt : 2.9

(28.4~30.4N.m, 21~22.4 Ib-ft)

~

3.1 kgf.m

REPLACEMENT

CAUTION

• Since the common rail fuel injection operates

under high pressure(1,800bar), a special care

should be taken.

• While engine is running or within 1 min. after

engine stops, any works should not be

performedinrelationtocommonrailfuel

injection system.

• In particular, as the injector solenoid generates

high temperature heat, do not touch it with bare

hands. Start the service works only when the

engine has been cooled down enough after

engine stops.

• Always keep the safety precautions.

• Ensure working area cleans all the time, and

place the removed injector on the clean cloth.

And pay attention to injector nozzle so that it is

not contaminated by foreign materials.

• Remove the protective caps which prevents

foreign material inflow for injector and fuel hose

immediately just before installation.

• When installing or removing injector, clean the

injector contacting portion and be sure to

replace O-ring and nozzle gasket with new ones.

• Apply diesel oil to the O-ring of injector and

insert them into the cylinder head.

• Install injector to the cylinder head vertically and

install it correctly not to cause any damage such

as shock.

• Be sure to observe the specified tightening

torque of bolts when inserting and tightening the

injector.

• Never use the high pressure fuel pipe.

1. Remove injector.

2. Install the injector.

3. Input injector QR correction value using diagnostic

tool with the ignition key ON.

Follow the instructions on the diagnostic tool as to

how to input injector QR correction value.

If the input of injector QR correction value was

completed, start the engine in 10 sec. after turning

the ignition key OFF.

CAUTION

In case QR correction value described on the

injector is not input in the ECM, there may cause

engine performance and exhaust gas problem.

CLEANING

Clean the injector as follows to be reused.

1. Clean the injector by setting the injector vertically to

the clean container.

2. Remove dust or dirt from the injector body and nozzle

sealing with clean cloth if necessary.

Common rail Assembly

COMPONENTS

SUDFL9014L

REMOVAL

CAUTION

• Since common rail fuel injection operates under

high pressure(1,800bar), a special care should be

taken.

• While engine is running or within 1 min. after

engine stops, any works should not be

performedinrelationtocommonrailfuel

injection system.

• In particular, as the injector solenoid generates

high temperature heat, do not touch it with bare

hands. Start the service works only when the

engine has been cooled down enough after

engine stops.

• Always keep the safety precautions.

• Never reuse the high pressure fuel pipe.

1. Turn the ignition key OFF.

2. Disconnect the negative(-) terminal of battery.

3. Disconnecthighpressurepipe(A)leadingtoinjector

from rail.

INSTALLATION

1. Install the common rail assembly mounting bolt(A).

SDFFL7515D

Common rail assembly mounting bolt : 1.9~2.8 kgf.m

(18.6~27.5N.m, 13.7~20.3Ib-ft)

2. Tighten the injector pipe(B) connected to the

common rail from the high pressure fuel pipe(A) and

the supply pump.

SDFFL7514D

4. Remove the injector pipe(B) connected from the

supply pump to the common rail.

5. Remove the return fuel hose.

6. Remove the rail pressure sensor.

CAUTION

A special care should be taken as the fuel

remaining in the rail leaks.

7. Remove the common rail assembly mounting bolt

and the common rail assembly(A).

High pressure fuel pipe mounting bolt : 4~5 kgf.m

(39.2~49N.m, 28.9~36.2Ib-ft)

SDFFL7514D

Accelerator Pedal

DESCRIPTION

APS (Accelerator Position Sensor) senses the

acceleration pressure of the driver and delivers it to the

ECM. Output voltage of accelerator position sensor has

a functional relation with the accelerator pedal position.

This functional relation comes from the Potentiometer

built-in the sensor.

In other words, the positon of pedal is calculated from the

output voltage of the sensor.

REMOVAL

1. Disconnect accelerator pedal connector and remove

mounting bolt, accelerator pedal.

2. Installation is the reverse order of removal.

INSPECTION

1. Connect the voltmeter to the terminals No. 1 and 2 of

accelerator position sensor.

2. Connect DC 5 V to terminal No. 3.

3. Check to see if the measurement voltage between

terminal No. 1 and No. 2 satisfies the specified

voltage.

At idle : 0.65 V

At full stroke : 3.85 V

4. Connect DC 5 V to terminal No.4.

1) Check to see if the measurement voltage

between terminal No. 1 and No. 6 satisfies the

specified voltage.

At idle : 5 V

At full stroke : 0 V

2) Check to see if the measurement voltage

between terminal No. 1 and No. 5 satisfies the

specified voltage.

At idle : 0 V

At full stroke : 5 V

SDGFL9026L

SDGFL9027L

Fuel Tank and Fuel Filter

REPLACEMENT

FUEL TANK AND FUEL FILTER (Truck)

1. Park the vehicle on a flat surface, stop the engine

and disconnect the negative(-) terminal of battery.

2. Disconnect the sender connector on the top of fuel

tank.

3. Remove the return hose (A) and the supply hose (B).

SDFFL7400D

4. Support the fuel tank assembly with the jack. Loosen

the fuel tank band mounting nut and remove the fuel

tank assembly by removing the mounting bolt.

5. Disconnect the connector and hose and remove the

fuel filter (C).

6. Installation is in the reverse of removal.

Tighten the lower nut to the 0.8~1.0kgf.m and the

upper nut to the 2~3kgf.m and install the fuel tank

band to the bracket.

Fuel tank mounting bolt : 4.5~6 kgf.m (44.1~58.8N.m,

32.5~43.4Ib-ft)

FUEL TANK AND FUEL FILTER (Bus)

1. Park the vehicle on a flat surface, stop the engine

and disconnect the negative(-) terminal of battery.

2. Disconnect the sender connector on the top of fuel

tank.

3. Removethereturnhose(A)andthesupplyhose(B).

SDFFL7401D

4. Support the fuel tank assembly with the jack. Loosen

the fuel tank band mounting nut and remove the fuel

tank assembly by removing the mounting bolt.

5. Disconnect the connector and hose and remove the

fuel filter (C).

6. Installation is in the reverse of removal.

Tighten the lower nut to the 0.8~1.0kgf.m and the

upper nut to the 1.9~2.8kgf.m and install the fuel

tank band to the bracket.

Fuel tank mounting bolt : 4.5~6kgf.m(44.1~58.8N.m,

32.5~43.4Ib-ft)

Fuel filter mounting bolt : 8~11 kgf.m (78.4~107.9N.m,

57.9~79.6Ib-ft)

INSPECTION

1. General check

a. Crack, bending, deformation, deterioration and

clogging of hose or pipe

b. Clogging or damage of fuel filter

2. When the filter has to be checked

a. When the fuel in the tank is drained out and then

replenished again for maintenance

b. When fuel filter is replaced

c. When fuel main hose (pipe) is removed

Loosen the air plug of fuel filter.

Cover air plug hole with cotton cloth and keep

pumping until it stops bubble.

When bubbles are removed completely, fasten

the air plug and continue to pump until pump

operation effort feels heavy.

3. Water drain from the fuel filter

Check for the water level of transparent bowl and if

water is filled with one-third, be sure to drain water by

the following sequence.

CAUTION

If the vehicle is driven without draining the

water, it may cause fatal trouble to the supply

pump and injector.

a. Drain the water by turning about half way.

CAUTION

Since water is drained even if the plug is not

fully loosened, be careful not to loosen drain

plug fully.

b. If diesel fuel drains after water has been drained

completely, fasten the drain plug by hand.

Tightening torque : 1.7~1.9 kgf.m

(16.7~18.6N.m, 12.3~13.7Ib-ft)

Electronic Injection Pump

Supply Pump

COMPONENTS

SUDFL9015L

REMOVAL

CAUTION

• Since common rail fuel injection operates under

high pressure(1,800bar), a special care should be

taken.

• While engine is running or within 1 min. after

engine stops, any works should not be

performedinrelationtocommonrailfuel

injection system.

• In particular, as the injector solenoid generates

high temperature heat, do not touch it with bare

hands. Start the service works only when the

engine has been cooled down enough after

engine stops.

• Always keep the safety precautions.

• Ensure working area cleans all the time, and

place the removed injector on the clean cloth.

And pay attention to injector nozzle so that it is

not contaminated by any foreign materials.

• Remove the protective caps which prevents

foreign material inflow for injector and fuel hose

immediately just before installation.

• When installing or removing injector, clean the

contacting portion of the injector and be sure to

replace O-ring and nozzle gasket with new ones.

• Apply diesel oil to the O-ring of injector and

insert them into the cylinder head.

• Install the injector to the cylinder head vertically

and install it correctly not to cause any damage

such as shock.

• Be sure to observe the specified tightening

torque of bolts when inserting and tightening the

injector.

• Never reuse the high pressure fuel pipe.

1. Turn the ignition key OFF.

2. Disconnect the negative(-) terminal of battery.

3. Disconnect the supply pump connector.

4. Disconnect the low pressure pipe.

5. Disconnect the high pressure pipe.

6. Remove the flange mounting bolt and remove the

supply pump assembly from the flyhwheel housing.

NOTICE

When removing the supply pump, remove the pump,

flange and the supply pump gear from the assembly.

SUDFL9017L

7. Remove the supply pump mounting hexagon bolt(A)

and remove the supply pump.

SUDFL9018L

INSTALLATION

1. RotatethecrankshafttoalignthecylinderNo.1at

the TDC (Top Dead Center) position.

a. Align the mark(or painting) at damper pulley

circumferential surface of crankshaft with the

direction mark on block surface.

SUDFL9019L

b. Open rocker cover, in view from the rear of

engine, align the mark(or painting) of TDC sensor

gear plate with the head contact surface of block

from the left.

2. Engine installation after assembling pump gear and

plate

a. Assemble plate to pump and temporarily

assemble gear to pump shaft. Assemble to the

direction of flange (d) from pump (b) and insert

O-ring between pump (b) and flange (d), then

tighten bolt (a).

Supply pump mounting bolt : 1.9~2.8 kgf.m (18.6~27.5

Nm, 13.7~20.3 lb.ft)

SUDFL9020L

b. When tightening flange and pump, tighten those

so that the mark(1) of flange backside faces the

upper side of straight line as shown in the figure.

Align the part that the number of supply pump

gear is marked with the mark (1) of flange

backside and assemble supply pump gear to

supply pump.

SDFFL7512D

c. If the above mentioned two items are satisfied,

cylinder #1 is at TDC position.

Supply pump gear mounting nut : 6~7 kgf.m (58.8~68.6

Nm, 43.40~50.6 lb.ft)

SUDFL9021L

c. After assembling as above, and also insert O-ring

between pump assembly and block.

d. When installing supply pump assembly to engine,

double check above mentioned items and engage

supply pump gear part with counterpart gear and

then tighten it with bolts.

Flange mounting bolt : 10~13 kgf.m(98.1~127.5 Nm,

72.3~94.0 lb.ft)

3. Tightenhighpressurepipe.

High pressure pipe mounting bolt : 4~5 kgf.m(39.2~49.0

Nm, 28.9~36.2 lb.ft)

NOTICE

At assembling, assemble those from center to

outside in sequence for convenience's sake.

4. Installl low pressure pipe.

5. Install supply pump connector.

6. Install rocker cover.

7. When replacing with the new pump, erase learning

valueofthepreviouspumpandbesuretoperform

"Pump learning initialization" using the diagnostic tool

to start the learning of new pump newly.

CAUTION

Be sure to perform the above mentioned "Pump

learning initialization" when replacing with the

new pump.

If the above mentioned "Pump learning

initialization" is not performed with the

diagnostic tool after replacing with new pump,

theengineperformancecouldbedeteriorated

and there may have problems in the emission

gas.

DTC Troubleshooting Procedures

BASIC TROUBLESHOOTING

BASIC TROUBLESHOOTING GUIDE

1 Bring Vehicle to Workshop

2 Analyze Customer's Complaint.

• Ask the customer about the conditions and environment relative to the issue (Use CUSTOMER PROBLEM ANALYSIS SHEET).

3 Verify Symptom, and then Check DTC and Freeze Frame Data

• Connect scan tool to Diagnostic Link Connector (DLC).

• Record the DTC and freeze frame data.

NOTICE

To erase DTC and freeze frame data, refer to Step 4.

Confirm the Inspection Procedure for the System or Part

Using the SYMPTOM TROUBLESHOOTING GUIDE CHART, choose the correct inspection procedure for the system or

part to be checked.

4 Erase the DTC and Freeze Frame Data

(WARNING)

NEVER erase DTC and freeze frme data before completing Step 2 MIL/DTC in "CUSTOMER PROBLEM ANALYSIS SHEET".

5 Inspect Vehicle Visually

• GotoStep10,ifyourecognizetheproblem.

6 Recreate (Simulate) Symptoms the DTC

• Try to recreate or simulate the symptoms and conditions of the malfunction as described by customer.

• If DTC(s) is/are displayed, simulate the condition according to troubleshooting procedure for the DTC.

7 Confirm Symptoms of Problem

• If DTC(s) is/are not displayed, go to Step 8.

• If DTC(s) is/are displayed, go to Step 10.

8 Recreate (Simulate) Symptom

• Try to recreate or simulate the condition of the malfunction as described by the customer.

9 Check the DTC

• If DTC(s) does(do) not occur, refer to BASIC INSPECTION in INTERMITTENT PROBLEM PROCEDURE.

• IfDTC(s)occur(s),gotoStep10.

10 Perform troubleshooting procedure for DTC

11 Adjust or repair the vehicle

12 Confirmation test

13 END

CUSTOMER PROBLEM ANALYSIS SHEET

1. VEHICLE INFORMATION

(I) VIN:

(II) Production Date:

(III) Odometer Reading: (km)

2. SYMPTOMS

□

□

Unable to start

Engine does not turn over□Incomplete combustion

□

Initial combustion does not occur

□

Difficult to start

□

Poor idle

□

Engine stall

□

Others

3. ENVIRONMENT

Problem frequency

Weather

Outdoor temperature Approx. _____°C/°F

Place

Engine temperature

□

Engine turns over slowly□Other_________________

□

Rough idle□Incorrect idle

□

Unstable idle(High: ______ rpm, Low: ______rpm)

□

Other __________________________________

□

Soon after starting□After acceleration pedal depressed

□

After acceleration pedal released□During A/C ON

□

Shifting from N to D-range

□

Other _______________________________________________

□

Poor driving (Surge)□Knocking□Poor fuel economy

□

Back fire□After fire□Other ____________________________

□

Constant□Sometimes (_________________)□Once only

□

Other ___________________________________________

□

Fine□Cloudy□Rainy□Snowy□Other __________________

□

Highway□Suburbs□Inner City□Uphill□Downhill

□

Rough road□Other ___________________________________

□

Cold□Warming up□After warming up□Any temperature

Engine operation

4. MIL/DTC

MIL (Malfunction Indicator Lamp)

DTC

□

Starting□Just after starting (____ min)□Idle□Racing

□

Driving□Constant speed□Acceleration□Deceleration

□

A/C switch ON/OFF□Other _____________________________

□

Remains ON□Sometimes lights up□Does not light

□

Normal□DTC (_______________________________________)

□

Freeze Frame Data

BASIC INSPECTION PROCEDURE

The measured resistance at high temperature after

vehicle running may be high or low. So all resistance

must be measured at ambient temperature (20℃,68℉),

unless there is any notice.

NOTICE

Themeasuredresistanceinexceptforambient

temperature (20℃,68℉) is reference value.

Sometimes the most difficult case in troubleshooting is

when a problem symptom occurs but does not occur

again during testing. An example would be if a problem

appears only when the vehicle is cold but has not

appeared when warm. In this case, technician should

thoroughly make out a "CUSTOMER PROBLEM

ANALYSIS SHEET" and recreate (simulate) the

environment and condition which occurred when the

vehicle was having the issue.

1. Clear Diagnostic Trouble Code (DTC).

2. Inspect connector connection, and check terminal for

poor connections, loose wires, bent, broken or

corroded pins, and then verify that the connectors are

always securely fastened.

●

SIMULATING VIBRATION

a. Sensors and Actuators

: Slightly vibrate sensors, actuators or relays with

finger.

WARNING

Strong vibration may break sensors, actuators or

relays

b. Connectors and Harness

: Lightly shake the connector and wiring harness

vertically and then horizontally.

●

SIMULATING HEAT

a. Heat components suspected of causing the

malfunction with a hair dryer or other heat sourre.

WARNING

• DO NOT heat components to the point where

they may be damaged.

•DONOTheattheECMdirectly.

●

SIMULATING WATER SPRINKLING

a. Sprinkle water onto vehicle to simulate a rainy day or

a high humidity condition.

WARNING

DO NOT sprinkle water directly into the engine

compartment or electronic components.

●

SIMULATING ELECTRICAL LOAD

a. Turn on all electrical systems to simulate excessive

electrical loads (Radios, fans, lights, etc.).

CONNECTOR INSPECTION PROCEDURE

1. Handling of Connector

a. Never pull on the wiring harness when

disconnecting connectors.

BFGE321A

3. Slightly shake the connector and wiring harness

vertically and horizontally.

4. Repair or replace the component that has a problem.

5. Verify that the problem has disappeared with the road

test.

BFGE015F

b. When removing the connector with a lock, press

or pull locking lever.

BFGE015G

c. Listen for a click when locking connectors. This

sound indicates that they are securely locked.

d. When a tester is used to check for continuity, or

to measure voltage, always insert tester probe

from wire harness side.

BFGE015I

e. Check waterproof connector terminals from the

connector side. Waterproof connectors cannot be

accessed from harness side.

BFGE015H

BFGE015J

NOTICE

• Useafinewiretopreventdamagetothe

terminal.

• Do not damage the terminal when inserting the

tester lead.

2. Checking Point for Connector

a. While the connector is connected:

Hold the connector, check connecting condition

and locking efficiency.

b. When the connector is disconnected:

Check missed terminal, crimped terminal or

broken core wire by slightly pulling the wire

harness.

Visually check for rust, contamination,

deformation and bend.

c. Check terminal tightening condition:

Insert a spare male terminal into a female

terminal, and then check terminal tightening

conditions.

d. Pull lightly on individual wires to ensure that each

wire is secured in the terminal.

WIRE HARNESS INSPECTION PROCEDURE

1. Before removing the wire harness, check the wire

harness position and crimping in order to restore it

correctly.

2. Check whether the wire harness is twisted, pulled or

loosened.

3. Check whether the temperature of the wire harness is

abnormally high.

4. Check whether the wire harness is rotating, moving

or vibrating against the sharp edge of a part.

5. Check the connection between the wire harness and

any installed part.

6. If the covering of wire harness is damaged; secure,

repair or replace the harness.

ELECTRICAL CIRCUIT INSPECTION

PROCEDURE

●

CHECK OPEN CIRCUIT

1. Procedures for Open Circuit

• Continuity Check

•VoltageCheck

If an open circuit occurs (as seen in [FIG. 1]), it can

be found by performing Step 2 (Continuity Check

Method) or Step 3 (Voltage Check Method) as shown

below.

BFGE015K

3. Repair Method of Connector Terminal

a. Clean the contact points using air gun and/or

shop rag.

NOTICE

Never use sand paper when polishing the

contact points, otherwise the contact point may

be damaged.

b. In case of abnormal contact pressure, replace the

female terminal.

BFGE501A

2. Continuity Check Method

NOTICE

When measuring for resistance, lightly shake the

wire harness above and below or from side to side.

Specification (Resistance)

1 or less→Normal Circuit

1M or Higher→Open Circuit

a. Disconnect connectors (A), (C) and measure

resistance between connector (A) and (C) as

shown in [FIG. 2].

In [FIG.2.] the measured resistance of line 1 and

2 is higher than 1 M and below 1

respectively. Specifically the open circuit is line 1

(Line 2 is normal). To find exact break point,

check sub line of line 1 as described in next step.

b. Disconnect connector (B), and measure for

resistance between connector (C) and (B1) and

between (B2) and (A) as shown in [FIG. 3].

In this case the measured resistance between

connector (C) and (B1) is higher than 1M and

the open circuit is between terminal 1 of

connector (C) and terminal 1 of connector (B1).

BFGE501B

BFGE501C

3. Voltage Check Method

a. With each connector still connected, measure the

voltage between the chassis ground and terminal

1 of each connectors (A), (B) and (C) as shown in

[FIG. 4].

The measured voltage of each connector is 5V,

5V and 0V respectively. So the open circuit is

between connector (C) and (B).

BFGE501D

●

CHECK SHORT CIRCUIT

1. Test Method for Short to Ground Circuit

• Continuity Check with Chassis Ground

If short to ground circuit occurs as shown in [FIG. 5], the

broken point can be found by performing below Step 2

(Continuity Check Method with Chassis Ground) as

shown below.

BFGE501E

2. Continuity Check Method (with Chassis Ground)

NOTICE

Lightly shake the wire harness above and below, or from

side to side when measuring the resistance.

BFGE501F

b. Disconnect connector (B), and measure the

resistance between connector (A) and chassis

ground, and between (B1) and chassis ground as

shownin[FIG.7].

The measured resistance between connector (B1)

and chassis ground is 1 or less. The short to ground

circuit is between terminal 1 of connector (C) and

terminal 1 of connector (B1).

Specification (Resistance)

1 or less→Short to Ground Circuit

1㏁or Higher→Normal Circuit

a. Disconnect connectors (A), (C) and measure for

resistance between connector (A) and Chassis

Ground as shown in [FIG. 6].

The measured resistance of line 1 and 2 in this

example is below 1 and higher than 1

respectively. Specifically the short to ground circuit is

line 1 (Line 2 is normal). To find exact broken point,

check the sub line of line 1 as described in the

folowing step.

㏁

BFGE501G

ECM(TICS) Problem Inspection Procedure

1. Test ECM(TICS) connector: Disconnect the

ECM(TICS) connector and visually check the ground

terminals on ECM(TICS) side and harness side for

bent pins or poor contact pressure. If the problem is

found, repair it.

2. If problem is not found step 1, the ECM(TICS) could

be faulty. If so, replace the ECM(TICS) with a new

one, and then check the vehicle again. If the vehicle

operates normally then the problem was likely with

the ECM(TICS).

3. Re-test the original ECM(TICS): Install the original

ECM(TICS)(maybebroken)intoaknown-good

vehicle and check the vehicle. If the problem occurs

again, replace the original ECM(TICS) with a new

one. If problem does not occur, this is intermittent

problem (Refer to Intermittent Problem Procedure in

Basic Inspection Procedure.)

ABBREVIATION

ABS: Anti-lock brake system

APS: Accelerator pedal sensor

A/C: Air conditioning

B: Battery

BATT: Battery

Comp: Compressor

DTC : Diagnostic trouble code

ECTS: Engine coolant temperature sensor

ECU: Electronic control unit

ETCM: Electronic time control module

EUI: Electronic unit injection

IATS : Intake air temperature sensor

IG: Ignition

MIL: Malfunction indicator lamp(Check engine lamp)

NTC: Negative Temperature Coefficient

PTO: Power take-off

NC: Normal close

NO: Normal open

RPM: Revolution per minute

Sw: Switch

Sig: Signal

SCHEMATIC CIRCUIT

Data Link Details (1)

SUDFLDTC9078L

Data Link Details (2)

SUDFLDTC9079L

Engine Control System (D4GA : F-ENG) (1)

SUDFLDTC9080L

Engine Control System (D4GA : F-ENG) (2)

SUDFLDTC9081L

Engine Control System (D4GA : F-ENG) (3)

SUDFLDTC9082L

Engine Control System (D4GA : F-ENG) (4)

SUDFLDTC9083L

Engine Control System (D4GA : F-ENG) (5)

SUDFLDTC9084L

Engine Control System (D4GA : F-ENG) (6)

SUDFLDTC9085L

Starting System (1)

SUDFLDTC9086L

Starting System (2)

SUDFLDTC9087L

Starting System (3)

SUDFLDTC9088L

Charging System (1)

SUDFLDTC9089L

Charging System (2)

SUDFLDTC9090L

Vehicle Speed System (1)

SUDFLDTC9091L

Vehicle Speed System (2)

SUDFLDTC9092L

Exhaust Brake System (1)

SUDFLDTC9093L

Exhaust Brake System (2)

SUDFLDTC9094L

DTC LIST

No Code Description

1 P0072 Intake Air Temp. Sensor(with MAF) Signal Too Low

2 P0073 Intake Air Temp. Sensor(with MAF) Signal Too High

3 P0088 Common Rail Pressure Exceeds Upper Limit

4 P0101 MAF Sensor Performance Invalid

5 P0102 MAF Sensor Signal Too Low

6 P0103 MAF Sensor Signal Too High

7 P0107 Atmosphere Pressure Sensor Signal Too Low

8 P0108 Atmosphere Pressure Sensor Signal Too High

9 P010A M AF Sensor Performance Invalid #2

10 P0112 Intake Air Temp. Sensor Signal Too Low

11 P0113 Intake Air Temp. Sensor Signal Too High

12 P0116 Coolant Temp. Sensor Performance Invalid

13 P0117 Coolant Temp. Sensor Signal Too Low

14 P0118 Coolant Temp. Sensor Signal Too High

15 P0120 Accel. Pedal Sensor No.1 Not Open

16 P0121 Accel. Pedal Sensor No.1 Not Close

17 P0122 Accel. Pedal Sensor No.1 Signal Too low

18 P0123 Accel. Pedal Sensor No.1 Signal Too high

19 P0182 Fuel Temp.(Pump) Sensor Signal Too Low

20 P0183 Fuel Temp.(Pump) Sensor Signal Too High

21 P0192 C/Rail Pressure Sensor Signal Too Low

22 P0193 C/Rail Pressure Sensor Signal Too High

23 P0194 C/Rail Pressure Sensor Signal Keeping the Middle Range

24 P0195 C/Rail Pressure Sensor Signal offsef

25 P0196 C/Rail Pressure Sensor Signal Moment offset

26 P0201 TWV1 Output Open Load/Injector Coil Open

27 P0202 TWV4 Output Open Load/Injector Coil Open

28 P0203 TWV2 Output Open Load/Injector Coil Open

29 P0204 TWV3 Output Open Load/Injector Coil Open

30 P0217 Coolant Temp. Exceeds Upper Limit

31 P0219 Engine Overrun

32 P0220 Accel. Pedal Sensor No.2 Not Open

33 P0221 Accel. Pedal Sensor No.2 Not Close

34 P0222 Accel. Pedal Sensor No.2 Signal Too Low

No Code Description

35 P0223 Accel. Pedal Sensor No.2 Signal Too High

36 P0225 Idle Switch Stuck Closed

37 P0226 Idle Switch Stuck Opened

38 P0237 Boost Pressure Sensor Signal Too Low

39 P0238 Boost Pressure Sensor Signal Too High

40 P0335 Crank Sensor No Pulse

41 P0336 Crankshaft Position Sensor Performance Invalid

42 P0340 Cam Sensor No Pulse

43 P0341 Camshaft Position Sensor Performance Bank 1

44 P0401 EGR Insufficient Flow (EGR Negative Deviation)

45 P0403 EGR Control DC Motor Output 1, 2 Open Load, Motor Open Load

46 P0404 EGR Control DC Motor Output 1, 2 Short to BATT/GND, Motor short

47 P0405 EGR Lift Sensor1 Signal Too Low

48 P0406 EGR Lift Sensor1 Signal Too High

49 P0501 Vehicle Speed Sensor Signal Invalid

50 P0502 Vehicle Speed Sensor Input Open / Short

51 P0503 Vehicle Speed Sensor Frequency Too High

52 P0541 Air Heater Monitor system Failure(LOW)

53 P0542 Air Heater Monitor system Failure(HIGH)

54 P0562 Vehicle System Voltage Too Low

55 P0563 Vehicle System Voltage Too High

56 P0601 Check Sum Error - Flash area

57 P0602 QR Data Is Not Written

58 P0603 QR Data Error

59 P0604 QR Definition Error

60 P0606 ECM Main CPU Fault

61 P0607 ECM Watchdog IC Fault

62 P0615 Starter Switch Short to BATT

63 P0627 SCV(+, -) Output Open Load/Short to GND

64 P0629 SCV(+, -) Output Short to BATT

65 P0642 Battery 5V Reference1 Circuit Low (VCC1L)

66 P0643 Battery 5V Reference1 Circuit High (VCC1H)

67 P0652 Battery 5V Reference2 Circuit Low (VCC2L)

68 P0653 Battery 5V Reference2 Circuit High (VCC2H)

69 P0698 Battery 5V Reference3 Circuit Low (VCC11L=VCC3L)

No Code Description

70 P0699 Battery 5V Reference3 Circuit High (VCC11H=VCC3H)

71 P069E Battery 5V Reference4 Circuit Low (VCC10/12L=VCC4L)

72 P069F Battery 5V Reference4 Circuit High (VCC10/12H=VCC4H)

73 P0704 Clutch Switch Circuit Malfunction(Manual Transmission Only)

74 P0850 Neutral Switch Circuit Malfunction(Manual Transmission Only)

75 P1120 Both Accel. Pedal Sensor Signal Invalid

76 P1132 ASC(PTO) Accel. Pedal Sensor Signal Too low

77 P1133 ASC(PTO) Accel. Pedal Sensor Signal Too high

78 P1190 Actual Rail Pressure Over

79 P1218 Abnormal High Pressure Mode #3

80 P1219 Abnormal High Pressure Mode #1

81 P1221 Actual Rail Pressure Was Less Than Target Pressure

82 P1222 Fuel Filter diagnosis level 1

83 P1223 Fuel Filter diagnosis level 2

84 P1231 Exhaust Brake MV1 Output Open Load/Short to GND

85 P1232 Exhaust Brake MV1 Output Short to BATT

86 P1383 Air Heater[Glow Relay] Output Open Load/Short to BATT

87 P1384 Air Heater[Glow Relay] Output Short to GND

88 P1616 Main Relay Diagnostics

89 P1642 MAF Sensor's Power Supply Failure Short to BATT

90 P1643 MAF Sensor's Power Supply Failure Short to GND

91 P2002 PMC Removal Diagnosis

92 P2146 COM1 Output Open Load (Both TWV 1 and TWV 3 Open Load)

93 P2147 COM1 Output Short to GND (TWV 1 or 3 Output Short to GND)

94 P2148 COM1 Output Short to BATT (TWV 1 or 3 Output Short to BATT)

95 P2149 COM2 Output Open Load (Both TWV 2 and TWV 4 Open Load)

96 P2150 COM2 Output Short to GND (TWV 2 or 4 Output Short to GND)

97 P2151 COM2 Output Short to BATT (TWV 2 or 4 Output Short to BATT)

98 P2293 Pressure Limiter Activated

99 P2413 EGR Valve Open/Close Stuck

100 P2454 Differential Pressure Sensor Signal Too Low

101 P2455 Differential Pressure Sensor Signal Too High

102 P2503 Capacitor Charge-up Circuit Malfunction (Insufficient Charge)

103 P2504 Capacitor Charge-up Circuit Malfunction (Excessive Charge)

104 U0001 CAN1 BUS / Node Error (500K)

No Code Description

105 U0010 CAN2 BUS / Node Error (250K)

P0072 Intake Air Temp. Sensor(with MAF) Signal Too Low

COMPONENT LOCATION

DIAGNOSTIC TROUBLE CODE

DESCRIPTION

1. GENERAL DESCRIPTION

The IATS(Intake air temperature sensor) integrated

with the air amount sensor and the boost pressure

sensor is a thermistor type of negative characteristics

which the more temperature increases the less

voltage gets and it detects the air temperature

entered through the engine.

In Euro-4 diesel engine, the intake air temperature

sensor is installed in the front(built-in intake air

sensor) and rear(built-in boost sensor) of

turbocharger so that it measures both the ambient air

temperature and the air temperature passed through

turbocharger and intercooler to measure more

precise intake air amount.

The ECM which received information from the

sensors controls the correction of EGR and fuel

amount according to intake air temperature.(In the

electronic control diesel engine, it is very important

for the intake air temperature sensor to measure

density according to the air temperature for the exact

EGR feedback control.)

2. DTC DESCRIPTION

If the output voltage of the intake air temperature

sensor is below 0.1V for more than 3,016ms, the

ECM judges this as a fault and DTC P0072 is set.

The possible causes are defective air temperature

sensor, wiring& resistance problem, short to ground

of terminal 37 of ECM connector (EFD-ECM).

Check lamp and MIL come on together when the

condition continued for 2 driving cycle times. Check

lamp will go off after 3 driving cycle times when the

system returns to normal.

The smoke and a lack of power may occur as fuel

quantity correction and injection time correction will

not be controlled by ECM depending on intake air

temperature but the vehicle can be driven.

SUDFL8100D

DTC DETECTING CONDITION

Item Detecting Condition Possible Cause

DTC Strategy • Voltage monitoring

Enable Conditions • Engine running

Threshold Value • Below 0.1V

Diagnosis Time • 3,016ms

Fuel Cut No

Fail Safe

Fuel Limit Yes

Check lamp ON

SPECIFICATION

SIGNAL CIRCUIT INSPECTION

1. Signal Voltage Inspection

1) Leave the air temperature sensor connector

(EFD04) connected.

2) Turn the ignition ON. Leave the engine OFF.

3) Measure voltage between terminal 4 of the air

temperature harness connector and chassis

ground.

■

Specification: Air temperature sensor signal

power approx. 5V

4) Is the voltage measured within specification?

▶

Go to “Component Inspection” procedure.

▶

Go to “Signal Short to Ground Inspection”

procedure.

2. Signal Short to Ground Inspection

1) Turn the ignition OFF.

2) Disconnect the air temperature sensor connector

(EFD04) and the ECM connector(EFD-ECM).

3) Measure resistance between terminal 4 of the air

temperature sensor harness connector and

chassis ground.

■

Specification: Infinite

Intake air temperature

•IGON:-25

• Engine running: 25

℃

4) Is the resistance measured within specification?

▶

▶

“Verification of vehicle repair” procedure.

POWER SUPPLY INSPECTION

1. Power Supply Voltage Inspection

1) Disconnect the air temperature sensor connector

(EFD04).

2) Turn the ignition ON. Leave the engine OFF.

3) Measure voltage between terminal 3 of the air

temperature sensor harness connector and

chassis ground.

■

12.72V

4) Is the voltage measured within specification?

▶

▶

Inspection” procedure.

• Defective wiring and sensor

• Shorttogroundofterminal 37 of ECM connector

(EFD-ECM)

℃

SUDFLDTC9001L

Go to “Power Supply Inspection” procedure.

Repair short to ground and then go to

Specification: ECM output power approx.

Go to “Ground Circuit Inspection” procedure.

Go to “Power Supply Short to Ground

2. Power Supply Short to Ground Inspection

1) Turn the ignition OFF.

2) Disconnect the air temperature sensor connector

(EFD04) and ECM connector(EFD-ECM).

3) Measure the resistance between the terminal 3 of

the intake air temperature sensor harness

connector and chassis ground.

■

Specification: Infinite

4) Is the resistance measured within specification?

▶

Go to “Ground Circuit Inspection” procedure.

▶

Repair short to ground and then go to

“Verification of Vehicle Repair” procedure.

GROUND CIRCUIT INSPECTION

1. Ground Voltage Drop Inspection

1) Disconnect the air temperature sensor connector

(EFD04).

2) Turn the ignition ON. Leave the engine OFF.

3) Measure the voltage drop between the terminal 5