Page 1

OWNER’S MANUAL

TS 20

8 H.P. 30" (76,2 cm)

SLEEVE HITCH

TILLER ATTACHMENT

MODEL NUMBER TS200FR

02480

169689 Rev. 2 4.11.03 TR

Printed in U.S.A.

Page 2

SAFETY RULES

Safe Operation Practices for Tiller Attachments.

TRAINING

• Read the operating and service instruction manual

care fully. Be thoroughly familiar with the controls and

the proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

• Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

• Keep the area of operation clear of all persons, par ticu larly small children, and pets.

PREPARATION

• Thoroughly inspect the area where the equipment is to

be used and remove all foreign objects.

• Disengage all clutches and shift into neutral before

starting the engine (motor).

• Do not operate the equipment without wearing ade quate

outer garments. Wear footwear that will improve footing

on slippery surfaces.

• Handle fuel with care; it is highly fl ammable.

• Use an approved fuel container.

• Never add fuel to a running engine or hot engine.

• Fill fuel tank outdoors with extreme care. Never fi ll

fuel tank indoors.

• Replace gasoline cap securely and clean up spilled

fuel before restarting.

• Never attempt to make any adjust ments while the

engine (motor) is running (except where specifi cally

rec om mended by manufacturer).

OPERATION

• Do not put hands or feet near or under rotating parts.

• Exercise extreme caution when oper ating on or crossing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffi c. Do not carry passen gers.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect

the tiller for any damage, and repair the damage before

restarting and operat ing the tiller.

• Exercise caution to avoid slipping or falling.

• If the unit should start to vibrate ab normally, stop the

engine (motor) and check immediately for the cause.

Vi bration is generally a warning of trou ble.

• Stop the engine (motor) when leaving the operating

po si tion, before unclog ging the tines, and when making

any repair, adjustments, and inspections.

• Take all possible precautions when leaving the machine

unattended. Disengage the power take-off, lower the

at tach ment, shift into neutral, stop the engine, and

re move the key.

• Before cleaning, repairing, or inspecting, shut off the

engine and make cer tain all mov ing parts have stopped.

Dis con nect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting.

• Do not run the engine indoors; exhaust fumes are dan ger ous.

• Never operate the tiller without proper guards, plates,

or other safety protective devices in place.

• Keep children and pets away.

• Do not overload the machine capacity by attempting to

till too deep at too fast a rate.

• Never operate the machine at high speeds on slippery

surfaces. Look behind and use care when backing.

• Lift tiller out of the ground when turning corners.

• Do not put tractor in reverse gear while tiller is in the

ground.

• Never allow bystanders near the unit.

• Use only attachments and accessories approved by

the manufacturer of the tiller (such as wheel weights,

counter weights, cabs, etc.

• Never operate the tiller without good visibility or light.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe

working condition.

• Check shear bolts, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to be sure

the equipment is in safe working condition.

• Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such as

hot water and space heaters, clothes dryers, etc. Allow

the engine to cool before storing in any enclosure.

• Always refer to the operator’s guide instructions for im por tant details if the tiller is to be stored for an extended

period.

-IMPORTANT -

Cautions, Importants, and Notes are a means of at tract ing attention to important or critical information in this man ual.

Caution: Look for this symbol to point out

important safety pre cau tions. It means

-- At ten tion! Become Alert! Your safe ty

is involved.

IMPORTANT: USED TO ALERT YOU THAT THERE

IS A POSSIBILITY OF DAMAGING THIS EQUIP MENT.

NOTE: Gives essential information that will aid you to

bet ter understand, incorporate, or execute a particular

set of in struc tions.

2

Page 3

PRODUCT SPECIFICATIONS

GASOLINE CAPACITY: 1 GALLON (3,6L)

UNLEADED REG U LAR

OIL : SAE30W (ABOVE 32°F/0°C)

(CAPACITY: 24 OZ. [0.7L]) 5W-30 (BELOW 32°F/0°C)

TRANSMISSION OIL : SAE 30W

(CAPACITY: 40 OZ. [1,2L])

SPARK PLUG : CHAMPION

(GAP: .030" [0.76MM]) RJ19LM

CONGRATULATIONS on your purchase of a new Tiller Attachment. It has been designed, en gi neered and

manu fac tured to give you the best pos sible de penda bil ity

and per form ance.

Should you experience any prob lems you can not easily

remedy, please contact your nearest authorized service

facility, which has com pe tent, well trained tech ni cians and

the proper tools to service or repair this unit.

Please read and retain this manual. The in struc tions will

enable you to assemble and main tain your tiller at tach ment prop erly. Always observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your tiller attachment.

• Follow the instructions in the Customer Re spon si bil i ties

and Storage sec tions of this Owner's Manual.

IMPORTANT: THIS UNIT IS EQUIPPED WITH AN INTERNAL

COMBUSTION ENGINE AND SHOULD NOT BE USED ON

OR NEAR ANY UNIMPROVED FOREST-COVERED, BRUSHCOVERED OR GRASS COVERED LAND UNLESS THE

ENGINE'S EXHAUST SYSTEM IS EQUIPPED WITH A SPARK

ARRESTER MEETING APPLICABLE LOCAL OR STATE LAWS

(IF ANY). IF A SPARK ARRESTER IS USED, IT SHOULD BE

MAINTAINED IN EFFECTIVE WORK ING ORDER BY THE

OPERATOR.

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

CUSTOMER RESPONSIBILITIES........................... 3,7-9

PRODUCT SPECIFICATIONS ....................................... 3

ASSEMBLY .................................................................... 4

OPERATION ............................................................... 5-6

SERVICE & ADJUSTMENTS ................................. 10-11

STORAGE .................................................................... 12

TROUBLESHOOTING ................................................. 13

REPAIR PARTS - TILLER ....................................... 14-17

3

Page 4

ASSEMBLY

When R.H., (Right Hand) or L.H. (Left Hand) are used, it

means from a position behind the steering wheel as If you

were seated on the tractor seat and facing forward.

NOTE: Remove mower deck from tractor before mounting

tiller attachment.

• Remove tiller and bag of parts from carton.

Place tiller on level ground so that tractor can be backed

up to it for assembly.

CAUTION: Tiller will be heavy when

per form ing the following step.

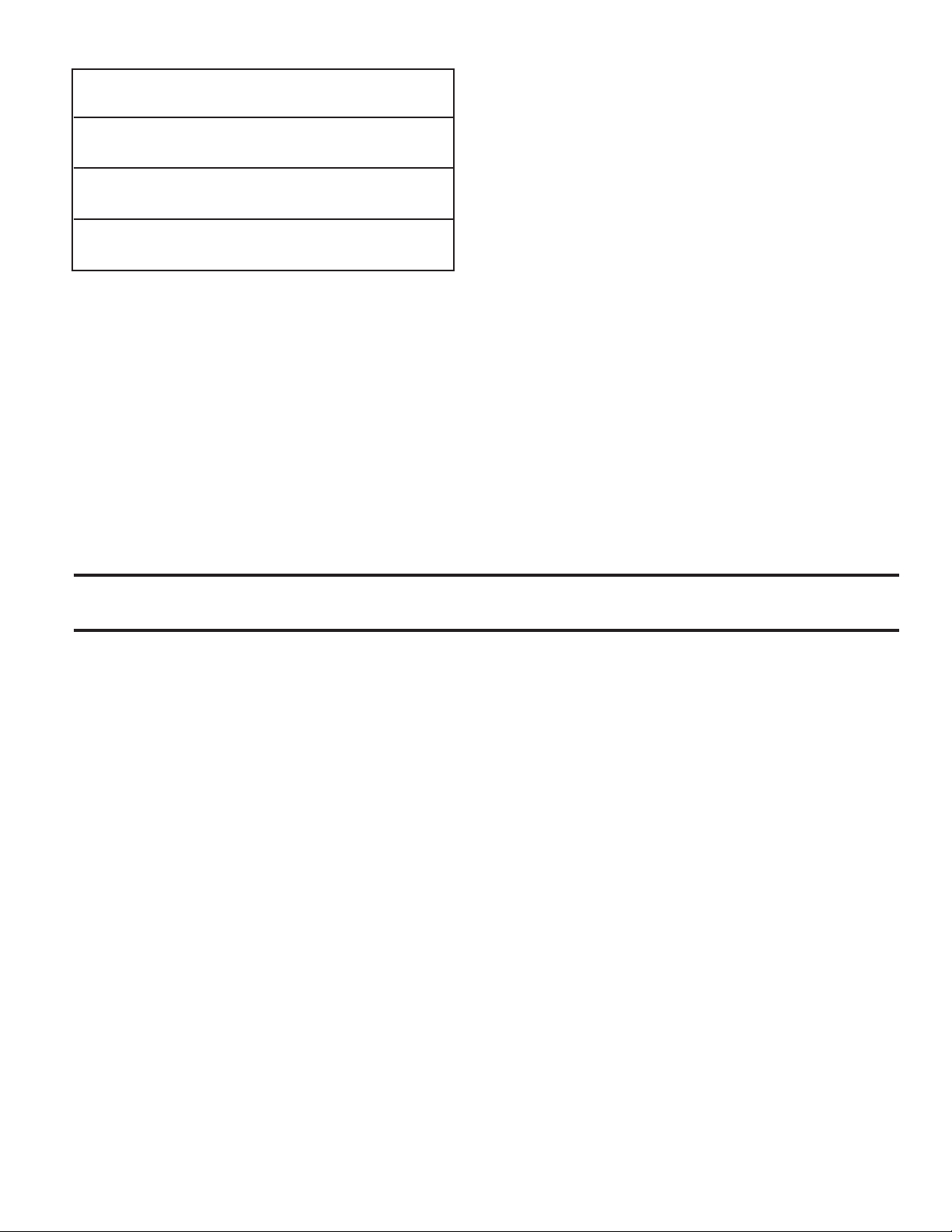

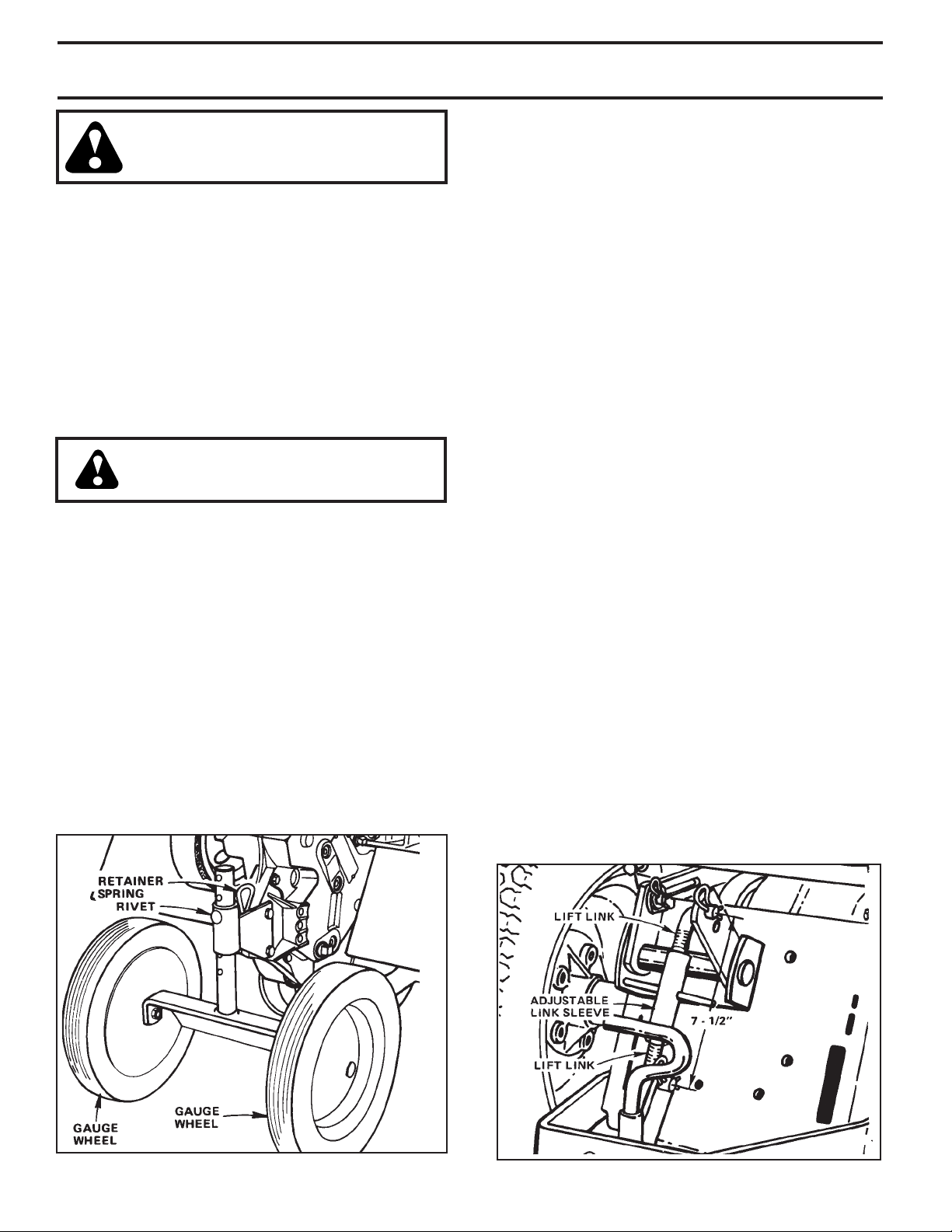

Adjust tiller gauge wheels so that engine is level (Fig. 1).

• Remove retainer spring from drilled rivet.

• Remove rivet and adjust gauge wheels up or down

as re quired to level tiller. Replace rivet and retainer

spring.

ATTACHING TILLER TO TRACTOR

Optional accessory tractor weights and/or tire chains

should be purchased to aid in the operation of this tiller

at tach ment.

• Install one or more wheel weights to each rear wheel

to insure good traction when operating. Tire chains can

be used in place of, or in addition to, wheel weights.

• Adjust stabilizer bolts so that ends are about fl ush with

rear of hitch bail (Fig. 2 - Inset). Leave nuts loose.

• Lower hitch assembly and slide hitch yoke of tiller

(Fig. 2 - Inset) over hitch tube of sleeve hitch so that

the hitch pin holes line up.

• Insert hitch pin until it extends from bottom of hitch

yoke (Fig. 2 - Inset). Insert retainer spring into hitch

pin.

• Tighten both stabilizer bolts against the hitch yoke

until there is no looseness at the hitch point. (The

frame assembly does not swing sideways relative to

the hitch bail (Fig. 2). Be sure the frame assembly is

per pen dic u lar (square) to the centerline (direction of

trav el) of the tractor. This can be determined by measuring the dis tance between the edge of tine shield

(Fig. 2) and the back of the rear tires. This distance

should be the same on the R.H. and L.H. sides within

1/2 inch. Se cure ly tighten the nuts on the stabilizer

bolts.

NOTE: The stabilizer bolts should be loosened before

removing the tiller from the tractor. This will make it easier

to remove the hitch pin and to line up hitch pin holes when

installing an oth er attachment. If tractor is to be used without

a rear attachment, the stabilizer bolt should be secured

by tightening the nuts (Fig. 2-Inset).

FIG. 1

• Install two front end weights to the front of the tractor.

This will aid steering control.

• Check tractor tires for proper air pressure. See your

tractor's Own er's Man u al.

• Assemble sleeve hitch to tractor. See hitch Owner's

Manual.

FIG. 2

4

Page 5

OPERATION

IMPORTANT: READ THE “RULES FOR SAFE OP ER A TION”

CAREFULLY BEFORE OPERATING YOUR TILLER

ATTACHMENT.

HOW TO USE YOUR TILLER

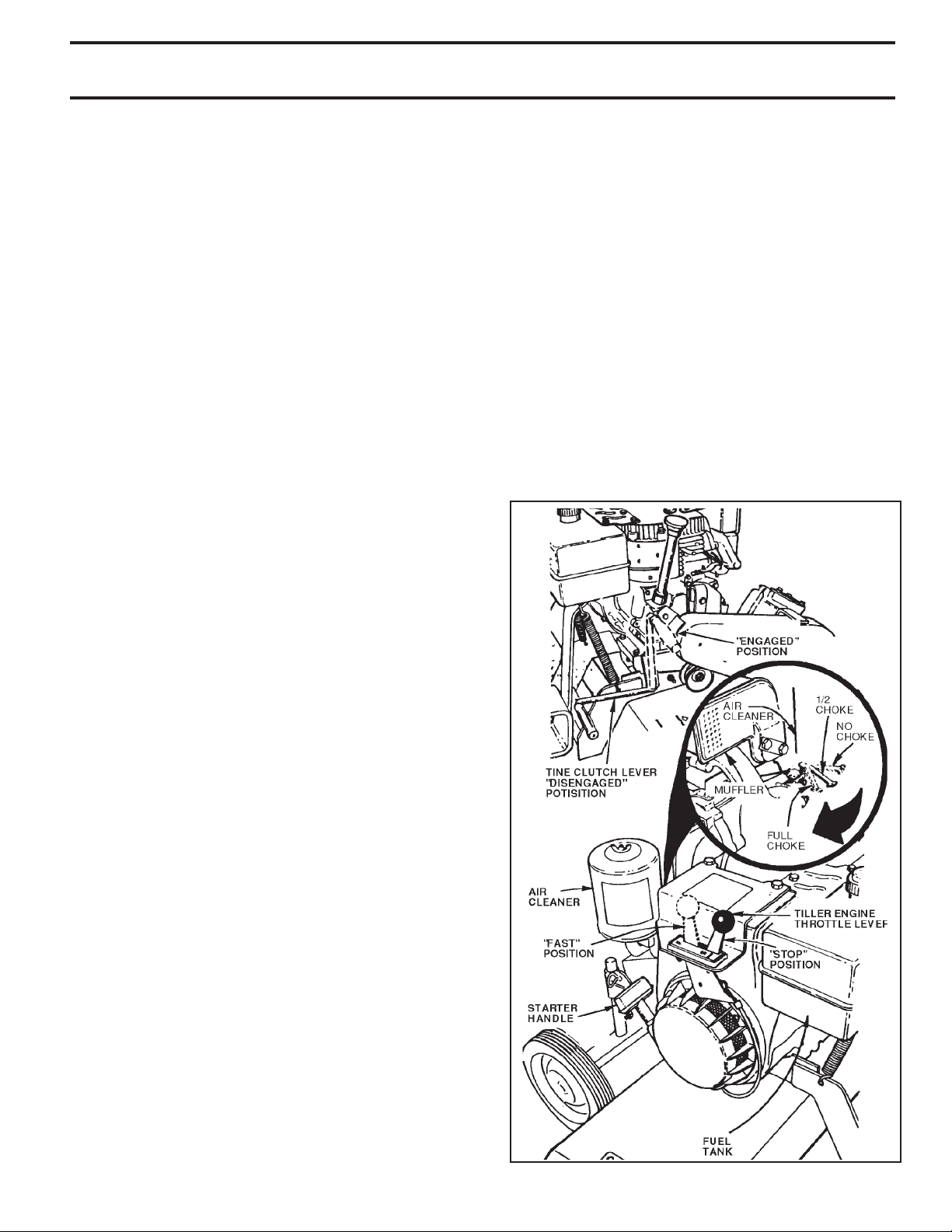

STOPPING (See Fig. 3)

TINES

• Move tine clutch lever to “DISENGAGED” position.

ENGINE

• Move engine throttle lever to “STOP” position.

• Never use choke to stop engine.

TO USE CHOKE CONTROL (See Fig. 3-Inset)

Use choke control whenever you are starting a cold engine.

Do not use choke to start a warm engine.

• To engage choke, slowly move lever to desired po si tion.

TO ADJUST TILLING DEPTH (See Figs. 4 & 5)

The tilling depth is controlled by the gauge wheels and to

some extent by the adjustable link sleeve. When deeper

tilling is required, the gauge wheels must be raised. Wheels

must be lowered for shal low er tilling,

• Remove retainer spring from drilled rivet. Adjust gauge

wheels up or down as desired and replace rivet and

retainer spring.

NOTE: Each hole will raise or lower gauge wheels 1 inch.

• Tiller can be leveled from front to rear by turning ad just able link sleeve. The adjustable link sleeve also

controls tilling depth. Shortening the adjustable link

sleeve and lift links will decrease tilling depth and

lengthening will in crease tilling depth.

CHECK ENGINE OIL LEVEL (See Fig. 1)

The engine on your tiller has been shipped from the factory, already fi lled with summer weight oil.

• Check engine oil with engine leveled on level

ground.

• Remove dipstick and wipe clean, replace, wait for a

few seconds, remove and read oil level. If necessary,

add oil until “FULL” mark on dipstick is reach. Do not

overfi ll.

• For cold weather operation you should change oil for

easier starting (See “OIL VISCOSITY CHART” in the

Customer Responsibilities section of this manual).

• To change engine oil, see the Customer Re spon si bil i ties section in this manual.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded gas o line. (Use of leaded gasoline will increase carbon

and lead oxide deposits and reduce valve life).

IMPORTANT: WHEN OPERATING IN TEMPERATURES BELOW

32°F (0°C), USE FRESH CLEAN WINTER GRADE GASOLINE

TO HELP INSURE GOOD COLD WEATHER STARTING.

TO OPERATE TILLER (See Fig. 3)

• Select desired tilling depth.

• Raise tiller with tractor lift control and disengage tiller

clutch control.

• Start tiller engine. See “BEFORE STARTING EN GINE”

in this section of manual.

• Move tine clutch lever to “ENGAGED” position. Dis en gage and engage several times to check the clutching action of the belt.

• Slowly lower tiller with tractor lift control and begin

tractor forward movement.

• Never operate tractor in reverse when tiller is in the

ground.

• To stop tiller and engine, disengage tine clutch lever

and move throttle lever to “STOP” position.

BEFORE STARTING THE ENGINE

CHECK TRANSMISSION OIL LEVEL

(See Fig. 1)

• The transmission has been fi lled at the factory.

• Check transmission oil with the tiller leveled on level

ground.

• Remove oil fi ll plug. Oil should be level with the bottom

of tiller plug hole. If necessary add oil until it is level

with hole.

5

FIG. 3

Page 6

OPERATION

CAUTION: Fill to bottom of gas tank

fi ller neck. Do not overfi ll. Wipe off any

spilled oil or fuel. Do not store, spill or

use gas o line near an open fl ame.

WARNING: Experience indicates that alcohol blended fuels

called gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine problems,

the fuel system should be emptied before storage of 30

days or longer. Drain the gas tank, start the engine and

let it run until the fuel lines and carburetor are empty.

Use fresh fuel next season. See Storage sections of this

manual for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

TO START TILLER ENGINE (See Fig. 3)

CAUTION: Keep the tine clutch lever in

“DIS EN GAGED” position when start ing engine.

•

Make sure spark plug wire is connected to spark plug.

• Move choke control lever to “FULL CHOKE” position

for cold engine start. For warm engine start do not

use choke control.

• Move tiller engine throttle to midway between “FAST”

and “SLOW” positions.

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope will

pull slightly harder at this point).

• Pull rope with a rapid, continuous, full arm stroke. Keep

a fi rm grip on starter handle and let rope rewind slowly.

Do not let starter handle snap back against starter.

• When engine starts, slowly move choke control on

en gine “1/2 CHOKE” position and then to “NO CHOKE”

position as engine warms up.

• Move throttle control to desired running position.

• Allow engine to warm up for a few minutes before

engaging tines.

NOTE: If at a high altitude (Above 3000 feet) or in cold

temperatures (below 32°F), the carburetor fuel mixture may

need to be adjusted for best engine performance. See “TO

ADJUST CARBURETOR” in the Service and Ad just ments

section of this manual.

TILLING

The most effi cient tillage is obtained when tiller engine is

operated at full throttle. The sound of tiller engine will tell

you when tiller engine is lightly loaded. Raise gauge wheels

to increase tilling depth. If engine seems to be overloaded

or stalls out, lower gauge wheels for shallower tilling.

Operate tiller engine at full throttle and operate tractor in

slowest forward speed, with tractor engine at idle speed or

just above idle. You will soon learn the proper combination

of tilling depth and speed for good tillage.

Soil conditions will determine how deep tiller can penetrate

on the fi rst pass. In extremely hard ground, several passes

may be necessary to till to a depth of 5 inches while in

soft ground, tiller may penetrate to a depth of 5 inches in

the fi rst pass.

CULTIVATING

Set gauge wheels so that tiller will penetrate soil to a

depth of 2 to 3 inches. Place rivet in the second or third

hole from the bottom to attain this depth. The tiller engine

should be run at full throttle except when cultivating small

plants, a slower engine speed is necessary to prevent

burying the plants.

OPERATION DO’S AND DON’TS

Always dis en gage tine clutch lever (Fig. 3) and stop engine

when traveling to or from fi eld (garden) or when not tilling.

Lift tiller out of the ground when turning corners.

Do not put tractor in reverse gear while tiller is in the ground.

Before leaving tractor seat, stop tractor, shift tractor to

“NEUTRAL” position, throttle down and stop tractor en gine,

set parking brake, remove ignition key and then dis en gage

tine clutch lever, throttle down and stop tiller engine, lower

tiller to ground. Disconnect spark plug.

Disconnect spark plug wires before making any ad just ments, repairs or to remove debris in tines.

FIG. 4

6

FIG. 5

Page 7

CUSTOMER RESPONSIBILITIES

MAINTENANCE

SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

Check Engine Oil Level

Change Engine Oil

Oil Pivot Points

Inspect Spark Arrester / Muffler

Inspect Air Screen

BEFORE EACH USE

FIRST 2 HOURS

EVERY 25 HOURS

EVERY 5 HOURS

EVERY 50 HOURS

EVERY 100 HOURS

BEFORE STORAGE

SERVICE DATES

Clean Air Filter/Foam Pre-Cleaner

Clean Engine Cylinder Fins

Replace Air Filter/Paper Cartridge

Replace Spark Plug

1 - Change more often when operating under a heavy load or in high ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions.

GENERAL RECOMMENDATIONS

The warranty on this attachment does not cover items that

have been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must main tain

unit as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your unit.

All adjustments in the Service and Adjustments section

of this manual should be checked at least once each

season.

• Once a year you should replace the spark plug, clean

or replace air fi lter, and check tines and belts for wear.

A new spark plug and clean air fi lter assure proper

air-fuel mixture and help your engine run better and

last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check for loose fasteners.

2

TILLER

TRANSMISSION LUBRICATION (See Fig. 6)

Check transmission oil level after fi rst fi ve (5) hours of

operation and every ten (10) hours thereafter.

• Check transmission oil with the tiller leveled on level

ground.

• Remove oil fi ll plug. Oil should be level with the bottom of fi ller plug hole. If necessary add SAE 30 motor

oil or equivalent. SAE 5W-30 motor oil may be used

in areas where temperature is consistently 32°F or

lower.

• Tighten oil fi ll plug securely each time you check the

oil level.

NOTE: It is not necessary to change the oil in tiller trans mis sion. If for any rea son, it must be changed, ca pac i ty

is 1-1/4 quarts.

7

Page 8

CUSTOMER RESPONSIBILITIES

TO CHANGE ENGINE OIL (See Figs. 6 and 7)

Determine temperature range expected before oil change.

All oil must meet API service classifi cation SF or SG.

• Be sure tiller engine is level.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• Remove drain plug.

• Tip tiller forward to drain oil.

• After oil has drained completely, replace oil drain plug

and tighten securely.

• Remove oil fi ller plug. Be careful not to allow dirt to

enter the engine.

• Refi ll engine with oil. See “CHECK ENGINE OIL

LEVEL” in the Operation section of this manual.

AIR FILTER FOAM PRE-CLEANER

(See Fig. 8)

Your engine will not run properly and may be damaged by

using a dirty air fi lter. Remove cartridge every 25 hours

and tap to clean. Replace paper cartridge once a year or

after every 100 hours of operation, more often if used in

very dusty, dirty conditions.

• Remove wing nut and cover.

• Remove foam pre-cleaner element by sliding it off of

the paper cartridge.

• Wash foam pre-cleaner in liquid detergent and water.

• Wrap foam pre-cleaner in cloth and squeeze dry.

• Lightly coat foam pre-cleaner with clean engine oil.

Squeeze in towel to remove excess oil. Do not saturate.

• Install foam pre-cleaner over paper cartridge.

FIG. 6

• Reassemble cover and tighten wing nut securely.

ENGINE

LUBRICATION

Use only high quality detergent oil rated with API service

classifi cation SF or SG. Select the oil’s SAE viscosity

grade according to your expected temperature.

SAE VISCOSITY GRADES

SAE 30

5W-30

-20 0 30 40

F

C

-30

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

-20 0

-10

32

60

10

80

20 30 40

FIG. 7

NOTE: Although multi-viscosity oils (5W-30, 10W-30, etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F (0°C). Check your engine oil level more frequently to

avoid possible engine damage from running low on oil.

Change the oil after the fi rst two hours of operation and

every 25 hours thereafter or at least once a year if the

tiller is not used for 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each fi ve (5) hours of continuous use. Add SAE

30 motor oil or equivalent. Tighten oil fi ller plug securely

each time you check the oil level.

100

oil_visc_chart1_e

FIG. 8

8

Page 9

CUSTOMER RESPONSIBILITIES

COOLING SYSTEM (See Fig. 9)

Your engine is air cooled. For proper engine performance

and long life keep your engine clean.

• Clean air screen frequently using a stiff bristled

brush.

• Remove blower housing and clean as necessary.

• Keep cylinder fi ns free of dirt and chaff.

MUFFLER

Do not operate tiller without muffl er. Do not tamper with

exhaust system. Damaged muffl ers or spark arresters

could create a fi re hazard. Inspect periodically and

replace if necessary. If your engine is equipped with a

spark arrester screen assembly, remove every 50 hours

for cleaning and inspection. Replace if damaged.

SPARK PLUG

Replace spark plugs at the beginning of each tilling season or after every 50 hours of use, whichever comes fi rst.

Spark plug type and gap setting is shown in “PRODUCT

SPEC I FI CA TIONS” on page 3 of this manual.

CLEANING

• Clean engine, wheels, fi nish, etc. of all foreign mat-

ter.

• Keep fi nished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean

your unit unless the muffl er, air fi lter and carburetor are

covered to keep water out. Water in engine can result in

a shortened engine life.

FIG. 9

9

Page 10

SERVICE AND ADJUSTMENTS

CAUTION: Disconnect spark plug wires from spark plug and place wire where it cannot come into

contact with plug.

TILLER

TO ADJUST GAUGE WHEELS

See “TO ADJUST TILLING DEPTH” in Operation section

of this manual.

TO ADJUST BELT (See Fig. 10)

The clutch is a belt-tightener type. Belt should be just tight

enough to prevent slipping. Over-tightening will reduce

belt life.

• To tighten belt, remove retainer spring securing belt

tight en er link to clutch lever and arm.

• Standing in front of tiller, turn link in a coun ter clock wise

direction one turn at a time, until belt no longer

slips.

• After initial ad just ment, a force of approximately 10

Ibs. at the end of the lever should engage the clutch.

This would be heavy thumb pressure.

TO REPLACE BELT (See Fig. 10)

• Remove the three bolts holding belt guard to tiller.

Re move guard.

• Remove old belt.

• Install new belt so that lower side of belt is above idler

as shown.

• Adjust belt (see “TO ADJUST BELT” above).

• Replace belt guard. Make sure all moving parts will

clear belt guard.

NOTE: If it should become necessary to remove the engine

sheave, be sure that it is reinstalled so that the set screw

end is toward the outside.

FIG. 10

10

Page 11

SERVICE AND ADJUSTMENTS

ENGINE

TO ADJUST CARBURETOR (See Fig. 11)

The carburetor has been preset at the factory and ad just ment should not be necessary. However, minor ad just ments may be required to com pen sate for differences in

fuel, temperature, altitude or load. If the carburetor does

need adjustment, pro ceed as follows.

In general, turning the adjust needles in (clock wise) de creas es the supply of fuel to the engine giving a leaner

fuel/air mixture. Turning the adjust needles out (coun ter clock wise) increases the sup ply of fuel to the engine

giving a richer fuel/air mixture.

IMPORTANT: DAMAGE TO THE NEEDLES AND THE SEATS

IN CARBURETOR MAY RESULT IF SCREWS ARE TURNED

IN TOO TIGHT.

PRELIMINARY SETTING

• Air cleaner assembly must be assembled to the car bu re tor when making carburetor adjustments.

• With engine off turn high speed adjust needle in

(clock wise) closing it fi nger tight and then turn out

(coun ter clock wise) 1-1/2 turns.

• Turn idle adjust needle in (clockwise) closing it fi nger

tight and then out (counterclockwise) 1-1/4 turns.

FINAL SETTING

• Start engine and allow to warm for fi ve minutes. Make

fi nal adjustments with engine running and tine clutch

control lever in “DISENGAGED” position.

• With throttle control lever in “SLOW' position, turn

idle adjust needle(clockwise) until engine begins to

die then turn out (counterclockwise) until engine runs

roughly. Turn needle to a point midway between those

two po si tions.

• With throttle control lever in “FAST” position, turn

high speed adjust needle.

IDLE RPM ADJUSTMENT-

• With engine at idle speed, turn the idle adjust screw

slowly counterclockwise until the engine begins to

falter.

• Then raise the engine speed by turning the idle adjust screw clockwise until the engine holds a smooth

con stant speed.

ACCELERATION TEST -

• Move throttle control lever from “SLOW” to “FAST”

po si tion. If engine hesitates or dies, turn idle adjust

needle out (coun ter clock wise) 1/8 turn. Repeat test

and con tin ue to adjust, if necessary, until engine ac cel er ates smoothly.

High speed stop is factory adjusted. Do not adjust or damage may result.

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOV ER NOR, WHICH IS FACTORY SET FOR PROPER ENGINE

SPEED. OVER-SPEEDING THE ENGINE ABOVE THE FAC TO RY

HIGH SPEED SETTING CAN BE DANGEROUS. IF YOU THINK

THE ENGINE-GOVERNED HIGH SPEED NEEDS AD JUST ING,

CONTACT YOUR NEAREST AUTHORIZED SERVICE CENTER,

WHICH HAS PROPER EQUIPMENT AND EXPERIENCE TO

MAKE ANY NECESSARY ADJUSTMENTS.

11

FIG. 11

Page 12

STORAGE

Immediately prepare your tiller for storage at the end of

the season or if the unit will not be used for 30 days or

more.

CAUTION: Never store the tiller with

gasoline in the tank inside a build ing

where fumes may reach an open fl ame

or spark. Allow the engine to cool

before storing in any en clo sure.

TILLER

• Clean entire tiller (See “CLEANING” in the Customer

Responsibilities section of this manual).

• Inspect and replace belts, if necessary (See belt re place ment instructions in the Ser vice and Ad just ments

section of this manual).

• Lubricate as shown in the Customer Responsibilities

section of this manual.

• Be sure that all nuts, bolts and screws are securely

fastened. Inspect moving parts for damage, break age

and wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

ENGINE

ENGINE OIL

Drain oil (with engine warm) and replace with clean oil.

(See “ENGINE” in the Customer Responsibilities section

of this man ual).

CYLINDERS

• Remove spark plug.

• Pour 1 ounce (29 ml) of oil through spark plug hole

into cylinder.

• Pull starter handle slowly several times to distribute

oil.

• Replace with new spark plug.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust. Rust

and/or dirt in your gasoline will cause problems.

• If possible, store your unit indoors and cover it to give

protection from dust and dirt.

• Cover your unit with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows condensation to form

and will cause your unit to rust.

IMPORTANT: NEVER COVER TILLER WHILE EN GINE AND

EX HAUST AREAS ARE STILL WARM.

FUEL SYSTEM

IMPORTANT: IT IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING IN ES SEN TIAL FUEL SYS TEM

PARTS SUCH AS THE CAR BU RE TOR, FUEL FILTER, FUEL

HOSE, OR TANK DURING STOR AGE. ALSO, EXPERIENCE

INDICATES THAT AL CO HOL BLENDED FUELS (CALLED

GASOHOL OR USING ETHA NOL OR METHA NOL) CAN

ATTRACT MOIS TURE WHICH LEADS TO SEPA RA TION AND

FORMATION OF ACIDS DUR ING STOR AGE. ACIDIC GAS

CAN DAMAGE THE FUEL SYSTEM OF AN ENGINE WHILE

IN STOR AGE.

• Drain the fuel tank.

• Start the engine and let it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor cleaner products in

the fuel tank or permanent damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in minimizing the formation of fuel gum deposits during stor age.

Add stabilizer to gasoline in fuel tank or stor age container.

Always follow the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding stabilizer to

allow the stabilizer to reach the carburetor. Do not drain

the gas tank and car bu re tor if using fuel stabilizer.

12

Page 13

TROUBLESHOOTING POINTS

PROBLEM CAUSE CORRECTION

Will not start 1. Out of fuel. 1. Fill fuel tank.

2. Engine not “CHOKED” properly. 2. See “TO START ENGINE” in Operation section.

3. Engine fl ooded. 3. Wait several minutes before attempting to start.

4. Dirty air cleaner. 4. Replace air cleaner cartridge.

5. Water in fuel. 5. Drain fuel tank and carburetor, and refi ll tank with

fresh gasoline.

6. Clogged fuel tank. 6. Remove fuel tank and clean.

7. Loose spark plug wire. 7. Make sure spark plug wire is seated properly on plug.

8. Bad spark plug or improper gap. 8. Replace spark plug or adjust gap.

9. Carburetor out of adjustment. 9. Make necessary adjustments.

Hard to start 1. Throttle control not set properly. 1. Place throttle control in “FAST” position.

2. Dirty air cleaner. 2. Replace air cleaner cartridge.

3. Bad spark plug or improper gap. 3. Replace spark plug or adjust gap.

4. Stale or dirty fuel. 4. Drain fuel tank and refi ll with fresh gasoline.

5. Loose spark plug wire. 5. Make sure spark plug wire is seated properly on plug.

6. Carburetor out of adjustment. 6. Make necessary adjustments.

Loss of power 1. Engine is overloaded. 1. Set depth stake for shallower tilling.

2. Dirty air cleaner. 2. Replace air cleaner cartridge.

3. Low oil level/dirty oil. 3. Check oil level/change oil.

4. Faulty spark plug. 4. Clean and regap or change spark plug.

5. Oil in fuel. 5. Drain and clean fuel tank and refi ll, and clean carburetor.

6. Stale or dirty fuel. 6. Drain fuel tank and refi ll with fresh gasoline.

7. Water in fuel. 7. Drain fuel tank and carburetor, and refi ll tank with fresh

gasoline.

8. Clogged fuel tank. 8. Remove fuel tank and clean.

9. Spark plug wire loose. 9. Connect and tighten spark plug wire.

10. Dirty engine air screen. 10. Clean engine air screen.

11. Dirty/clogged muffl er. 11. Clean/replace muffl er.

12. Carburetor out of adjustment. 12. Make necessary adjustments.

13. Poor compression. 13. Contact an authorized service facility.

Engine overheats 1. Low oil level/dirty oil. 1. Check oil level/change oil.

2. Dirty engine air screen. 2. Clean engine air screen.

3. Dirty engine. 3. Clean cylinder fi ns, air screen, and muffl er area.

4. Partially plugged muffl er. 4. Remove and clean muffl er.

5. Improper carburetor adjustment. 5. Adjust carburetor to richer position.

Excessive bounce/ 1. Ground too dry and hard. 1. Moisten ground or wait for more favorable soil

diffi cult handling conditions.

Soil balls up or clumps 1. Ground too wet. 1. Wait for more favorable soil conditions.

Engine runs but tiller 1. Tine clutch control is not engaged. 1. Engage tine clutch control.

tines won’t move 2. V-belt not correctly adjusted. 2. Inspect/adjust V-belt.

3. V-belt is off pulley(s). 3. Inspect V-belt.

Engine runs but labors 1. Tilling too deep. 1. Set gauge wheels for shallower tilling.

2. Carburetor out of adjustment. 2. Make necessary adjustments.

13

Page 14

REPAIR PARTS

8 HP TILLER ATTACHMENT - - MODEL NUMBER TS200FR

ENGINE AND TINES

14

Page 15

REPAIR PARTS

8 HP TILLER ATTACHMENT - - MODEL NUMBER TS200FR

ENGINE AND TINES

KEY PART DESCRIPTION

NO. NO.

1 124533X Control Throttle

2 6924J Bracket, Throttle Control

3 677A860 Hitch Yoke Assembly

4 4379H Grip, Handle

5 677A855 Hitch Channel Assembly

6 6922R Plate, Adapter

7 - - - - - - - Engine 8 H.P., Tecumseh

8 104867X Decal, In struc tion, Engine

9 4914H Square Key 1/4 x 1-1/4

10 8249R Engine Sheave

11 6652H Belt Tightener Link

12 6656H Adjusting Pin

13 624A12 Idler Support Plate and Pivot

14 2360J Idler Arm

15 19151116 Washer 15/32 x 11/16 x 16 Ga.

(0 - 2 as required)

16 12000015 * E-Ring

17 6683H E-Ring

18 4933H Idler Pulley

19 19131414 Washer 13/32 x 7/8 x 14 Ga.

20 4497H Clip, Hairpin

21 626A430 Lever and Arm

22 634A726 Belt Guard and Supports

24 102655X V-Belt

25 120076X Decal, Caution

26 4929H Drilled Pan Hd. Rivet 3/8 x 1-3/4

27 3146R Clip, Hairpin

28 626A401 Tine Weldment, L.H.

29 174043 Decal, On/Off

30 71180512 Screw, Fl. Hd. Mach. 5/16-24

31 626A402 Tine Weldment, R.H.

32 8224R Tine Shield

33 76020516 Cotter Pin 5/32 x 1

34 8905R Spring

KEY PART DESCRIPTION

NO. NO.

35 76020824 Cotter Pin 1/4 x 1-1/2

36 74760516 * Bolt, Hex 5/16-18 x 1 Gr. 2

37 19131311 Washer 13/32 x 13/16 x 11 Ga.

38 10040600 * Washer Lock, Hvy. Hel. Spring

39 73220600 * Nut, Hex 3/8-16 UNC

40 74760524 * Bolt, Hex 5/16-18 x 1-1/2 Gr. 2

41 73220500 * Nut, Hex 5/16-18 UNC

42 15760512 Hex Bolt with Sems Ext. Washer

Lock 5/16-18 UNC x 3/4

43 74760416 * Hex Bolt 1/4-20 x 1

44 10040400 * Washer Lock 1/4

45 73220400 * Hex Nut 1/4-20 UNC

46 74770512 * Hex Bolt 5/16-24 x 3/4

47 10040500 * Washer Lock 5/16

48 23200506 Hex Socket Set Screw

5/16-18x3/8

49 74760624 * Hex Bolt 3/8-16 x 1-1/2

50 73750600 * Hex Lock Nut 3/8-16 UNC

51 19111116 * Washer 11/32 x 11/16 x 16 Ga.

53 19121214 Washer

52 11050500 Washer Lock External Tooth 5/16

67 72250614 Bolt, Carriage 3/8-16 x 1-3/4

69 71191008 Screw

70 73731000 Nut, Keps #10-24 UNC

71 4171R Clip - Insulated

72 168461 Decal, Throttle

- - 110719X Decal, Oper./Lubrication (Engine)

- - 104959X Decal, Tecumseh Logo (Engine)

- - 169689 Owner’s Manual, English

- - 169690 Owner's Manual, French

*STANDARD HARDWARE--PURCHASE LOCALLY

NOTE: All component dimensions given in U.S. inches.

1 inch = 25.4 mm.

15

Page 16

REPAIR PARTS

8 HP TILLER ATTACHMENT - - MODEL NUMBER TS200FR

TRANSMISSION AND GAUGE WHEELS

16

Page 17

REPAIR PARTS

8 HP TILLER ATTACHMENT - - MODEL NUMBER TS200FR

TRANSMISSION AND GAUGE WHEELS

KEY PART DESCRIPTION

NO. NO.

1 634A562 Transmission

2 9135R Retainer Spring

3 4929H Drilled Pan Head Rivet 3/8 x 1-3/4

4 634A61 Gauge Wheel Sleeve and Brackets

5 634A559 Gauge Wheel Adjusting Shaft and

Bracket

6 169374 Wheel

7 4898H Shoulder Bolt

9 73560600 Locknut 3/8-16 UNC Nylock

10 5020J Needle Bearing

12 4895H Needle Bearing

13 9204 H Locknut 1/2-20 UNF

14 4932H Input Sheave

15 4910H Oil Seal

16 3039R Needle Bearing

17 4877H1 Gear Case Shield L.H.

18 634A553 Gear Case and Bearings L.H. Half

(Inc. Key No's. 10,12,16 & 20)

19 2601R Gasket

20 4870H Thrust Cap

21 634A555 Tine Shaft and Sprocket

24 2600R Roller Chain

26 1370H Thrust Washer

27 4912H Gasket

28 634A59 2nd Reduction Shaft and Gears

29 634A58 1st Reduction Shaft and Gears

30 9858M1 Woodruff Key 3/16 x 5/8

31 634A57 Input Shaft and Pinion

32 5855H Relief Valve

33 6672H Gear Shift Cover

34 4913H Gasket

35 1685H Locknut 5/16-18 UNC

36 13060400 Pipe Plug 1/2-14 N.P.T.

37 634A554 Gear Case and Bearings R.H. Half

(Inc. Key No's. 12, 16 & 20)

38 4878H1 Gear Case Shield R.H.

39 10040600 * Washer Lock 3/8

40 73220600 * Hex Nut 3/8-16 UNC

43 7850H Spacer

44 19111116 * Washer 11/32 x 11/16 x 16 Ga.

45 74760636 * Hex Bolt 3/8-16 x 2-1/4

46 17860524 Hex Hd. Roll-Lok Thd. Forming

48 74760532 * Hex Bolt 5/16-18 x 2

49 20000524 Flat Hd. Slotted Roll-Lok Thd.

Forming Screws 5/16-18 x 3/4

50 74780596 Hex Bolt 5/16-18 x 6 Gr. 5

51 15760512 Screw Mach. Hex Hd. 5/16-18 x 3/4

Screw 5/16-18 x 1-1/2

*STANDARD HARDWARE--PURCHASE LOCALLY

NOTE: All component dimensions given in U.S. inches.

1 inch = 25.4 mm.

17

Page 18

02480

Loading...

Loading...