Page 1

Operatorʹs manual

Manual de usuario

Manual do operador

TF338

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Leia atentamente o manual do operador e certifique se de que tenha entendido as instruções antes de usar a máquina.

внимательно прочитайте инструкцию и

переконайтесЯ, що ‚и зрозум´ли вс´ вказ´вки.

убедитесь, что ‚ам все понЯтно.

GB RU UA

ES PT

Page 2

1 1•1 1•

A

G

K

N

D

F

1

2

X

X

5

4

J

5

6

X

X

9

4

E

H

B

I

M

For tines only, только для фрез, тільки для ножів

6

2

X

13

8

X

2

X

C

24

4

3

L

X

X

4

4

4

7 X

8

4

X

17

14

16

13

12

10

10

8

9

10

X

X

2

2

12

11

X

X

24

4

2

Page 3

Right side , правая сторона,

правасторона

1 2

•

Right Blade

право лезвие

право лезо

12

11

Right Blade

право лезвие

право лезо

Right side, правая сторона,

правасторона

1

Left Short

левый короткое лезвие

лівий коротке лезо

13

4

Right side, правая сторона,

правасторона

11

12

Right side, правая сторона,

правасторона

13

Right Blade

Правый нож фрезы

право лезо

10

Right side, правая сторона,

2

правасторона

Right Blade

право лезвие

право лезо

12

11

Right side, правая сторона,

5

правасторона

Left Blade

левая сторона

ліва сторона

13

3

3

•

6

4

12

11

13

Left Blade

левая сторона

ліва сторона

7

10

8

6

9

8

11

3

9

12

+

-

Page 4

13

14

15

3

1

5

6

8

2

2

6

8

16

17

1

5

5

7

Page 5

1 3•

11

12

1 4•

13

1

3

9

6

1

8

4

2

5

10

7

1 5•

Page 6

2 1•

0,6 L / 0,6л

SAE-10W-30

2 2•

1,1 L / 1,1 л

SAE-10W-30

Recommend to USE

Octane Value over 90

Бензин с октановым

2 3•

числом не ниже 90

4,8 L / 4,8 л

2 4•

Oil Level

Уровень масла

SAE-10W-30

2 7•

2 8•

2 5•

2 6•

2 9•

ON

2 10•2 10•

2 10•

2 1•

1

Page 7

3 1•

2

3 2•

R

1

1

1 2,

2

A

B

4 1•

4 2•

A

B

4 3•

N

Page 8

4 4•

4 5• 4 6•

OFF

5 1•

OFF

A

B

Page 9

CONTENTS

Contents

CONTENTS

Contents ...................................................................... 2

KEY TO SYMBOLS

Symbols ....................................................................... 3

Explanation of warning levels ...................................... 3

SAFETY INSTR UCTIONS

Gener al ........................................................................ 4

Preparation .................................................................. 4

Use .............................................................................. 4

Maintenance ................................................................ 5

Transport and storage .................................................. 5

Fueling ......................................................................... 5

ASSEMBLING AND ADJUSTMENTS

Unpac

king .................................................................... 6

Assembly ..................................................................... 6

Description of the components .................................... 6

Type plate ..................................................................... 6

Transport wheel ........................................................... 6

ST

ARTING AND STOPPING

Bef

ore starting ............................................................. 7

Start the machine. ........................................................ 7

Use .............................................................................. 7

Forwards ...................................................................... 7

Reverse ........................................................................ 7

Stopping ....................................................................... 7

Moving the machine ..................................................... 7

MAINTENANCE AND SER

Maintenance schedule

General ........................................................................ 8

TECHNICAL D

T

echnical data .............................................................. 9

EC Declaration of Conformity ...................................... 9

ATA

VICE

................................................. 8

English

– 2

Page 10

3

W

W

KEY T

Symbols

These symbols are on the machine and in the instr uctions.

WARNING! Careless or incorrect use can

result in ser

operator or others.

Please read the operator’s manual

carefully and make sure y

the instructions before using the machine.

Use a helmet with hearing protector

This product is in accordance with applicable

EC directives

Reverse

Neutral

ious or f

atal injury to the

ou understand

.

O SYMBOLS

Explanation of warning le vels

The w arnings are graded in three levels.

ARNING!

ARNING! Used if there is a risk of serious

injury or death f

!

the surroundings if the instructions in the

manual are not followed.

IMPORTANT!

IMPOR

TANT! Used if there is a risk of injury to the operator

or damage to the surroundings if the instr

man

ual are not followed.

CAUTION!

CAUTION! Used if there is a risk of damage to materials or

the machine if the instructions in the manual are not

followed.

or the operator or damage to

uctions in the

Fast forward

Slow forward

Fast

Slow

Warning: rotating parts. Keep hands and

f

eet clear

The ignition lead should always be

remov

cleaning or maintenance work.

Keep your distance!

.

ed from the spark plug before repair,

–

English

Page 11

SAFETY INSTRUCTIONS

General

• These instructions are for your safety. Read them

carefully.

• Read all the instructions in this operator’s manual and on

the machine before you start it. Ensure you understand

them and then observe them.

• If you have any problems or questions about the tiller,

please contact your Husqvarna dealer for more

information.

WARNING! Only use the machine for the

purpose it is designed for, tilling the ground.

!

Any other use may be dangerous or cause

damage to the machine.

• Learn how to use the machine and its controls safely and

learn to how to stop quickly. Also learn to recognize the

safety decals.

• The operator is responsible for any unsafe situations or

risks that people and property are exposed to.

• Never start to work with the machine before the working

area is clear and you have a firm foothold. Look out for any

obstacles with unexpected movement. Take great care

when working on sloping ground.

• Only allow the machine to be used by adults who are

familiar with its use.

• Never allow children or other persons not trained in the

use of the machine to use or service it. Local laws may

regulate the age of the user.

• Keep unauthorised persons at a distance. Children,

animals, onlookers and helpers should be kept outside the

safety zone of 20 m. Stop the machine immediately if

anyone approaches.

• Never use the machine if you are tired, if you have

consumed alcohol, if you are taking other drugs or

medication that can affect your vision, judgement or coordination.

• Pay particular attention on hard ground.

• The machine has the tendency to be much less stable on

cultivated ground.

Preparation

• Inspect the working area. Remove all loose objects, such

as stones, broken glass, nails, steel wire, string, etc. that

could be projected by the machine.

• Check the entire machine before starting. Replace worn

or damaged parts. Check that there are no fuel leaks and

that all guards and covers are complete and fastened

securely. Check all nuts and screws.

• Check that the electrical wires are intact and in good

condition.

Use

• Never use the machine itself to transport people.

• Compliance with and strict adherence to the conditions of

operation, service and repair as specified by the

manufacturer also constitute essential elements of the

intended use.

• Stop the engine when the machine is not in use.

• Walk with the machine, do not run.

• Pay close attention when pulling the machine towards you

or reversing the direction of rotation.

• Keep a safe distance from the rotating blades, set by the

length of the steering column. Keep your hands and feet

away from the rotating blades.

• The engine and the exhaust system become very hot

during operation. Risk of burn injuries if touched.

• Only use the machine in daylight or in other well-lit

conditions.

• Do not use the machine on ground that slopes more than

20 ° .

• Work across slopes, not up or down.

WARNING! Under no circumstances should

you modify the original design of the

!

machine without approval from the

manufacturer. Always use original spare

parts. Unauthorized modifications and/or

accessories may lead to serious injury or

death to the user or others.

WARNING! This machine produces an

electromagnetic field during operation. This

!

field may under some circumstances

interfere with active or passive medical

implants. To reduce the risk of serious or

fatal injury, we recommend persons with

medical implants to consult their physician

and the medical implant manufacturer

before operating this machine.

• Never use the machine when barefoot. Always wear

protective shoes or protective boots, preferably with steel

toes. Never wear loose-fitting clothing, jewellery or similar

that can get caught in moving parts. Use hearing

protection to minimise the risk of hearing impairment.

The warranty is not valid if non genuine

parts are used.

Stop the engine immediately if the following occurs:

• Excessive vibration and / or noise.

• Mechanical jam preventing engine from turning.

• Difficulties to engage or disengage the clutch.

• A collision with a foreign object.

• Deterioration of the engine stop cable.

If the engine halt cable is severed, use the starter control to

stop the engine. For more information see section ”Start the

engine”

Allow the machine to cool down. Disconnect the HT lead from

the spark plug. Check that the machine is not damaged. If the

machine is damaged, hand it in to an authorized service

workshop for repair.

– 4

English

Page 12

5

•

T

•

•

W

SAFETY INSTR

Maintenance

Always stop the engine before repair, cleaning,

maintenance wor

machine.

• Regular maintenance is essential for safety and to

maintain the lev

• Wear heavy-duty gloves when changing the tools on the

machine.

Replace the rotating blade in complete sets to keep them

•

balanced. Alw

• Check that nuts and screws are tight.

• Never use a machine that has a faulty muffler. Contact an

ised ser

author

IMPORTANT! For your own safety, do not alter the

characteristics of the machine. Do not change the engine

speed settings and do not run the engine at excess speed.

ransport and storage

Allow the machine to cool before putting it in storage.

• Store the machine and fuel in such a way that there is no

risk that leaking fuel or fumes can cause an

• The machine should always be stored in a dry place away

from open fire, spar

• Fuel and fuel vapour are highly flammable. Take care

when handling fuel and oil. Bear in mind the r

explosion and inhaling fumes.

• When storing and transporting fuel always use approved

containers intended for this pur

• Do not try to lift the machine. Use a method of handling

adapted to the weight of the machine and to the situation.

Take extra care when loading it onto or off a vehicle or

•

. Use a suitable ramp.

trailer

• Use an approved trailer to transport the machine. Secure

the machine with approv

no part of the machine are squashed or damaged by the

tightening straps. It is a good idea to cover the machine.

• For more information about moving of the machine during

k, see section "Moving".

wor

k or when changing the tools on the

els of performance.

ays use genuine parts.

vice workshop.

y damage.

ks or intense heat.

isk of fire,

pose.

ed tightening straps. Ensure that

UCTIONS

Fueling

Always stop the engine and let it cool for a few minutes

before refuelling.

•

Refuel in a well ventilated area with the engine turned off.

ARNING! Petrol is highly inflammable.

Exercise care and refuel outdoors. Fire,

!

open flame and smoking are prohibited.

Clean the area around the fuel cap. Tighten

the fuel cap carefully after refuelling. If the

cap is not properly tightened the cap might

vibrate lose and fuel may escape from the

fuel tank creating a fire hazard. Move the

machine at least 3 m from the refuelling

point before starting it.

• Bear in mind the risk of fire, explosion and inhaling

fumes.Do not fill so that the fuel r

spillage on the ground and machine. If you spill fuel on

yourself or your clothes. Change your clothes. Move the

machine at least 3 metres away from the refuelling area

before starting.

• The engine emits carbon monoxide, which is a colourless,

poisonous gas.

spaces.

Do not use the machine in enclosed

uns over. Wipe up all

–

English

Page 13

ASSEMBLING AND ADJUSTMENTS

Unpacking

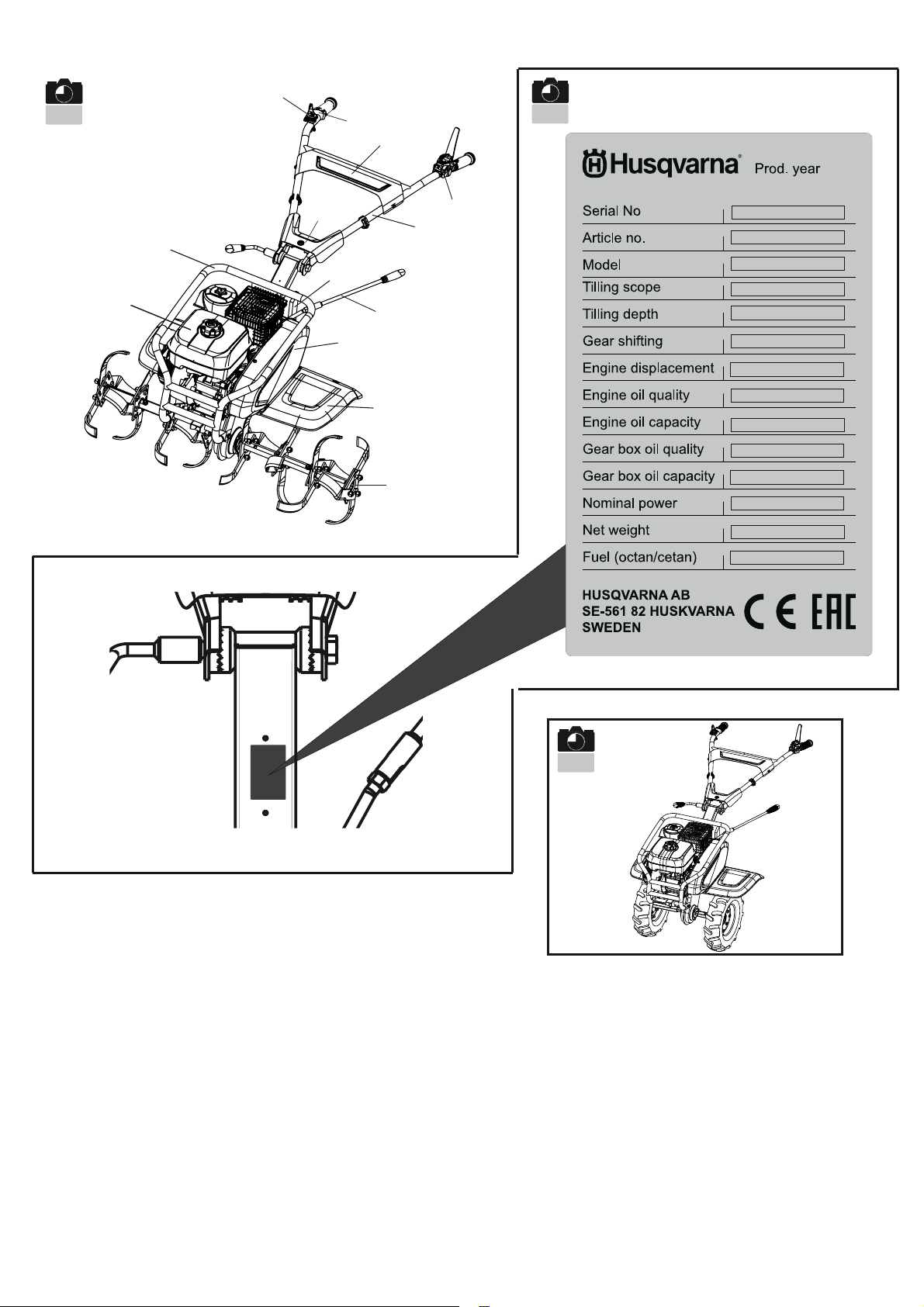

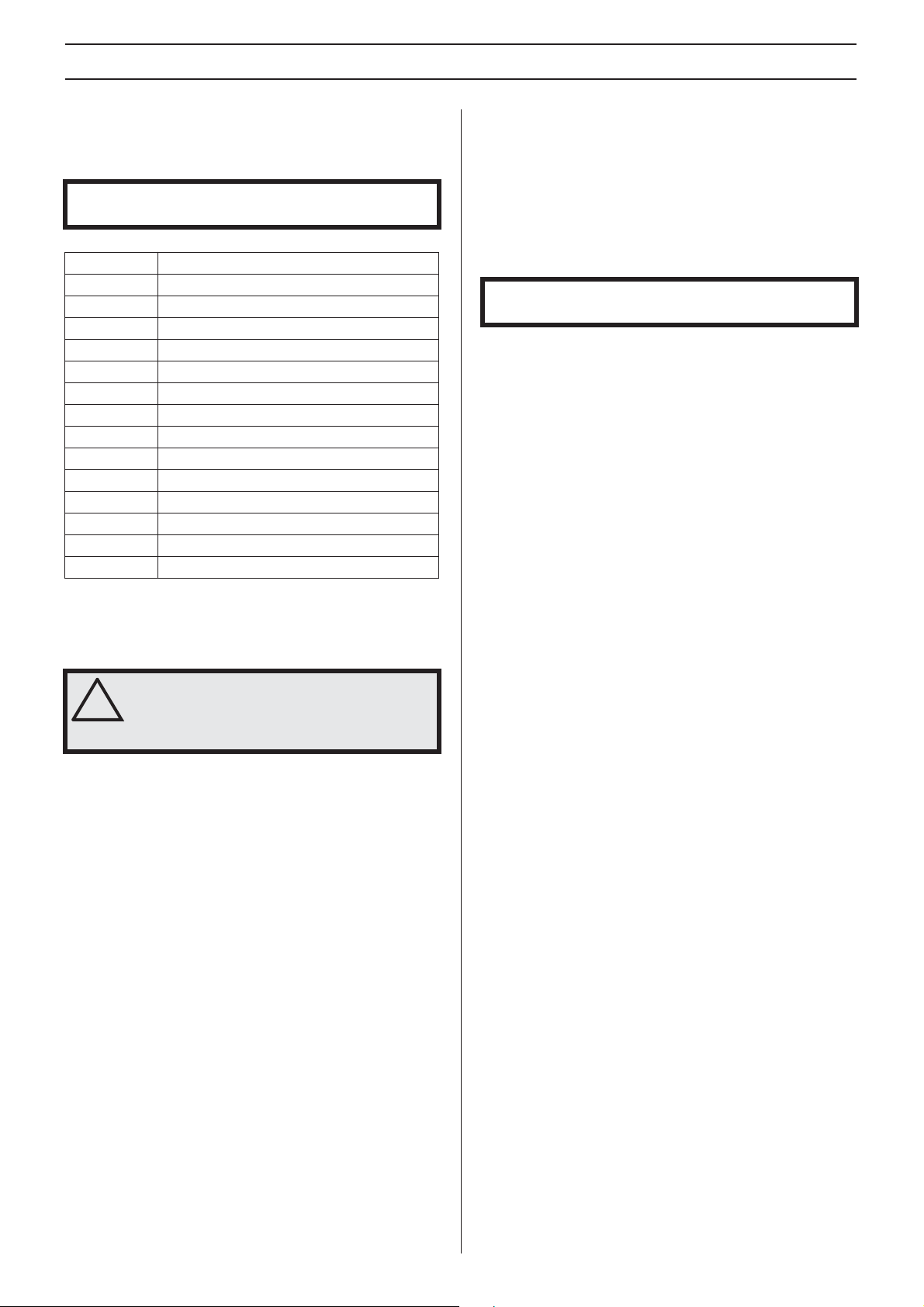

Illustration: 1 • 1

IMPORTANT! Make sure to not cut the cables/wires or

scratch the machine when cutting the edges of the case.

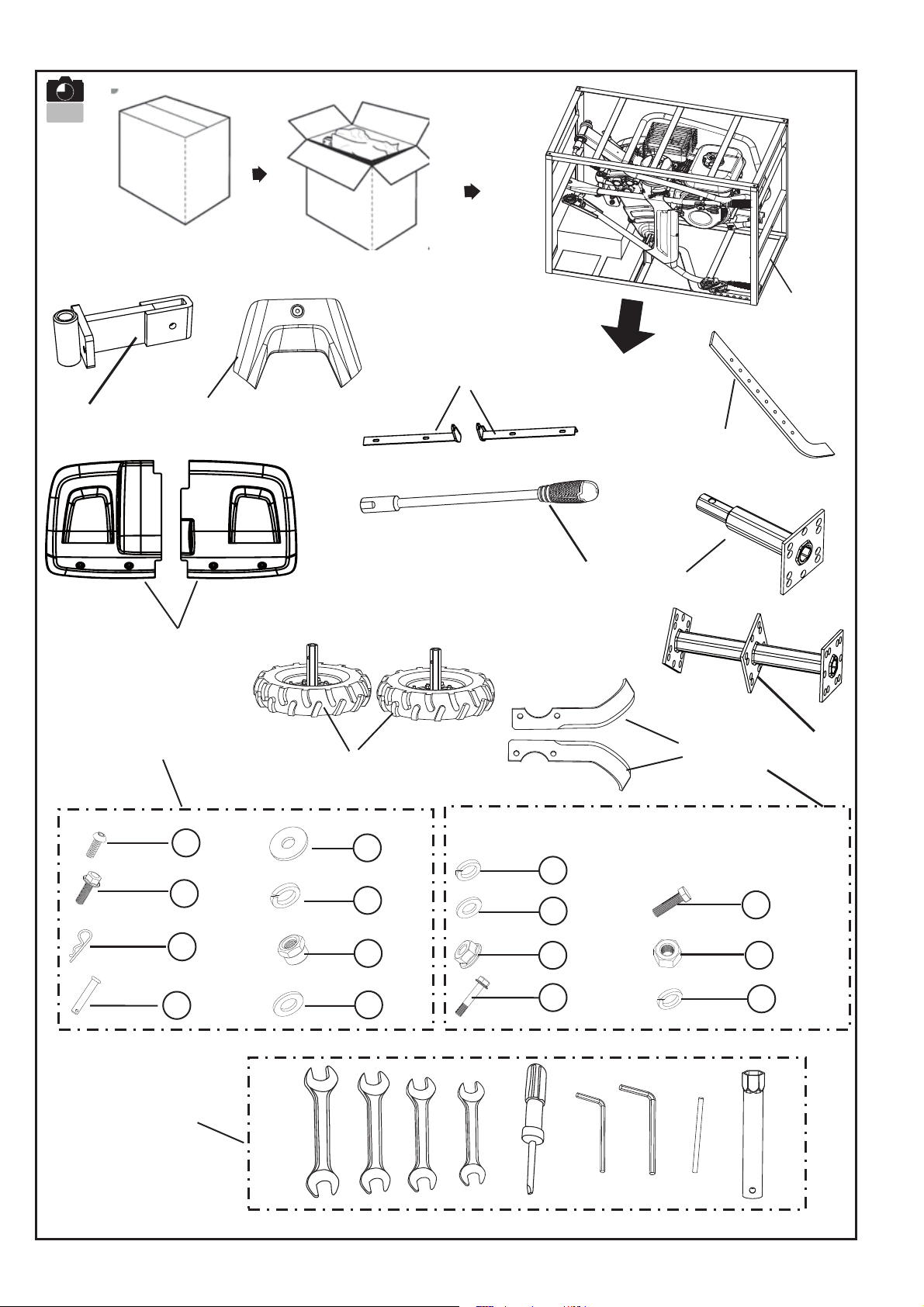

References Content of the case

A Engine parts

B Holder comp

C Holder main comp

D Lower tidy cover

E Drag bar

F Tine cover

G Tine cover bracket

H Lever shifting

I Blades

J Wheel

K Connector joint

L Tool bag

M Hardware bag tines only

N Hardware bag

Assembly

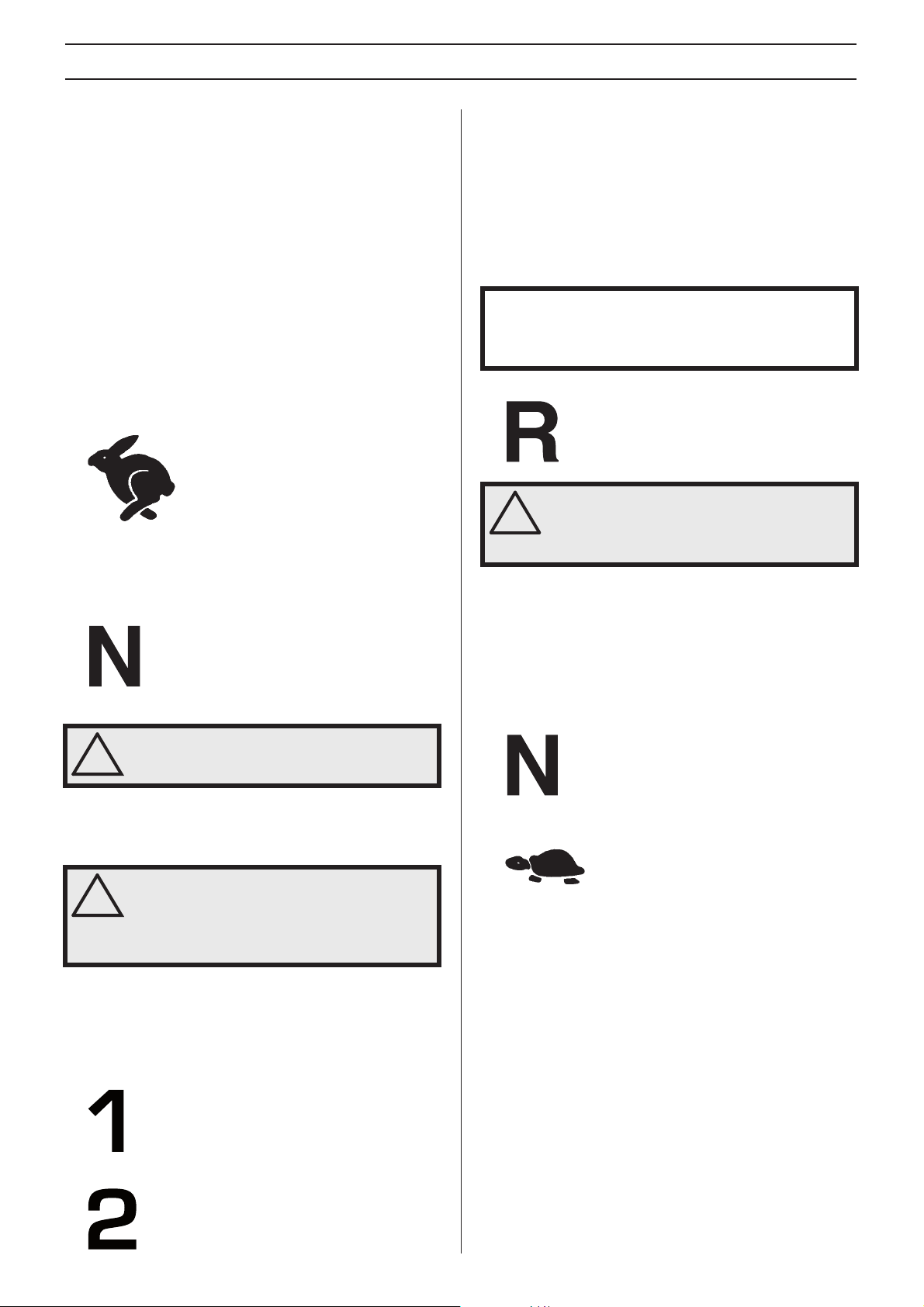

Illustration: 1 • 2

WARNING! Inappropriate assembly of this

rotary tiller could cause severe injuries.

!

Ensure that you follow all the instructions

carefully.

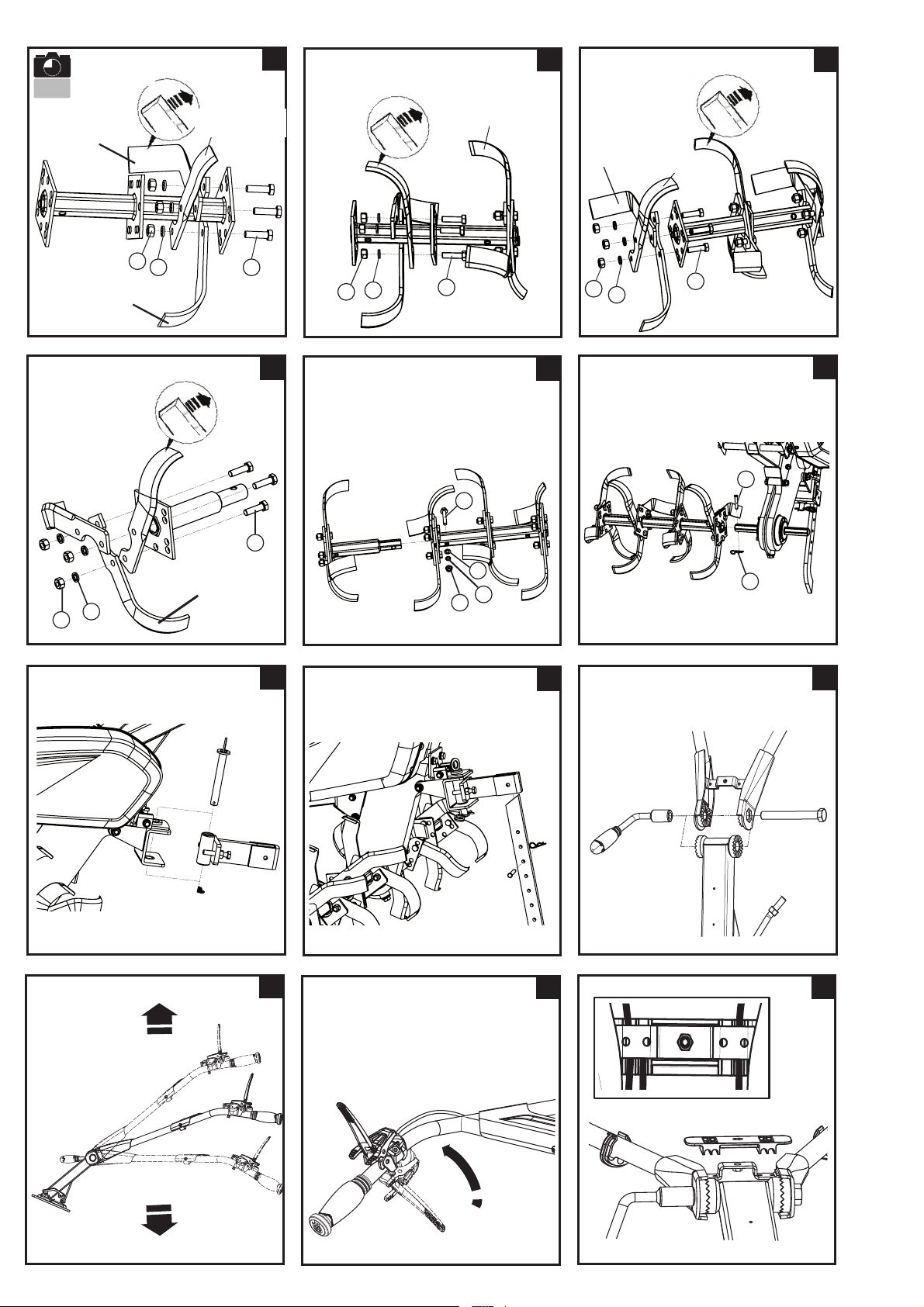

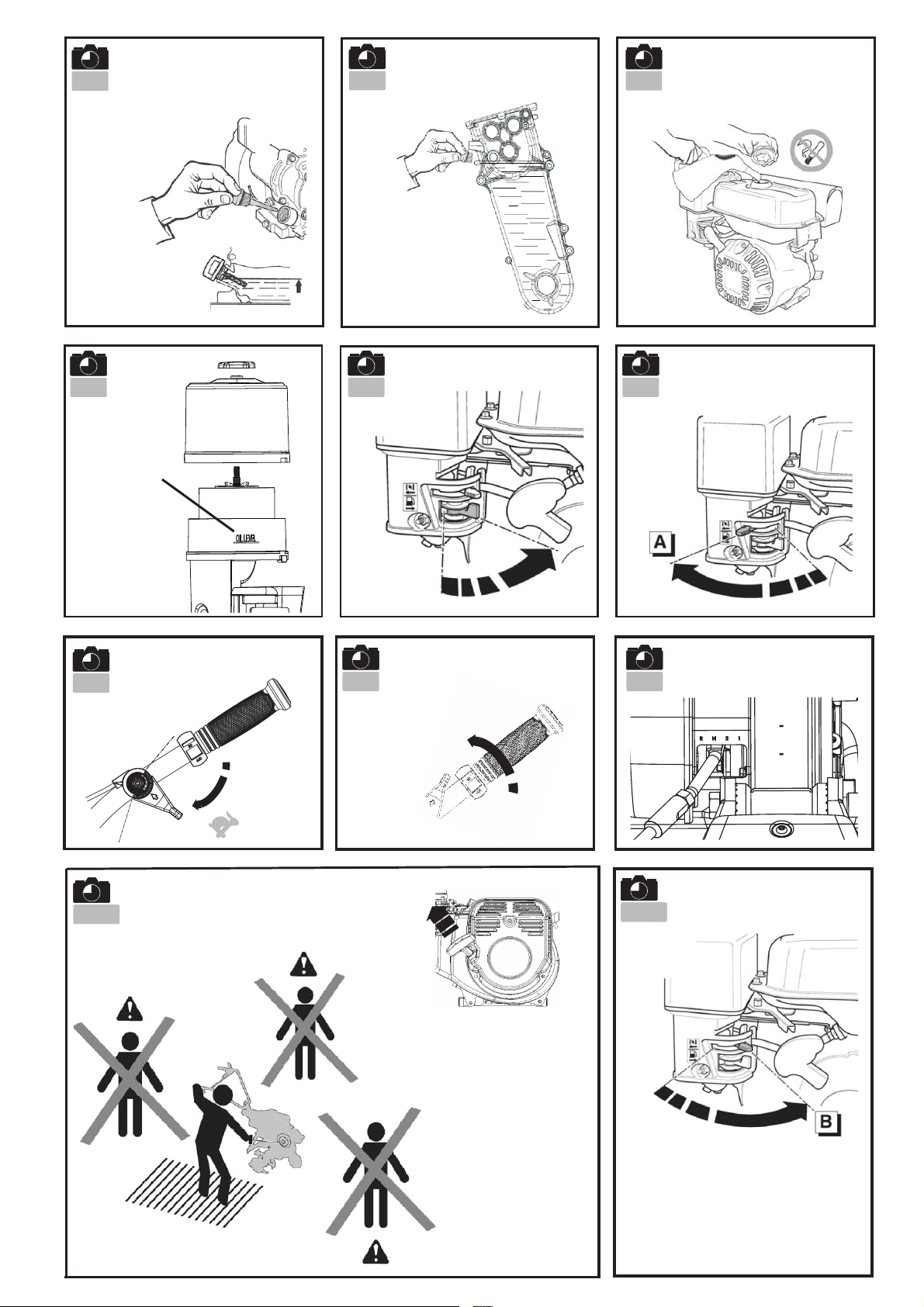

• Fitting the tine blades Illustrations only shows assembly of

the tine blades on the right side. Make sure that the sharp

edges face one side on both right and left side tines. There

is one piece of short blade on each side that need bending

to the gearbox when assembling. (Figure 1 - 6)

• Fitting the connecting joint. (Figure 7)

• Fitting the drag bar. (Figure 8)

• Fitting the handle bar. (Figure 9)

• Adjust the hight of the handle and tighten the knobs

securely. (Figure 10)

• Fitting the clutch control. (Figure 11)

- Turn to proper side and fasten the bolt.

• Fitting the tine cover. (Figure 14 - 16)

- Do not tighten the bolt immediately after installed.

- Install all 4 bolts and nuts first, then tighten one by one.

• Fitting the shifting lever. (Figure 17)

Any dismantling operation must only be performed by an

authorized service workshop.

CAUTION! After assembling the machine completly, tighten

the bolts and screws with modertion. Do not overtighten.

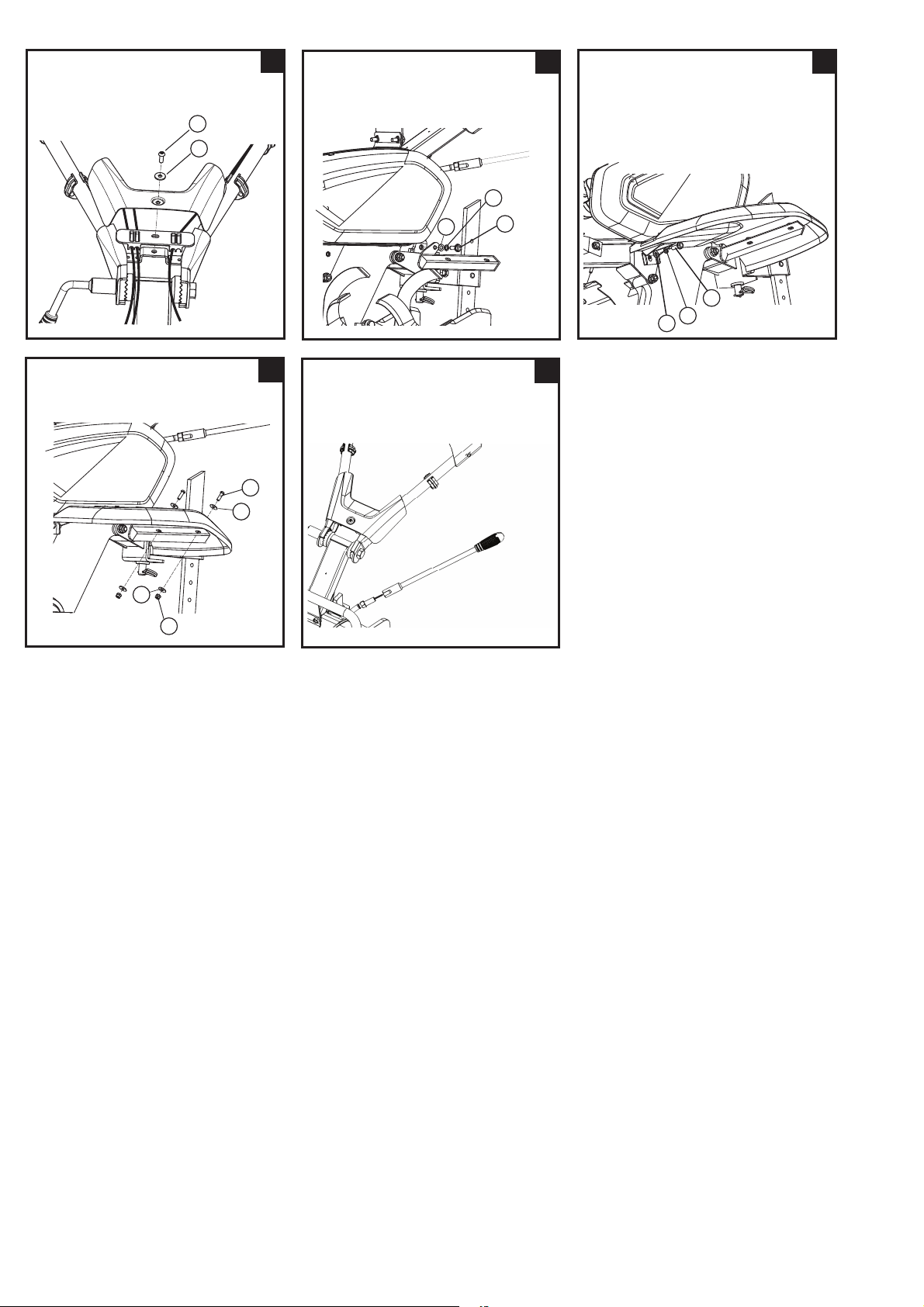

Description of the components

Illustration: 1 • 3

1 Engine

2 Tine cover

3 Lower tidy cover

4 Belt cover

5 Blades

6 Drag bar

7 Handle

8 Lever shifting

9 Bumper

10 Clutch control

11 Throttle control

12 ON/OFF switch

13 Upper tidy cover

Type plate

Illustration: 1 • 4

1 Serial number

2 Article number

3 Tilling scope

4 Gear shifting

5 Engine displacement

6 Engine oil Quality (viscosity):

7 Engine oil capacity

8 Gear box oil quality

9 Gear box oil capacity

10 Nominal power

11 Net weight

12 Fuel

• Fitting the lower tidy cover. (Figure 12 - 13)

- Tidy the cables.

- Fit the rubber holder properly.

- Fit the cover and tighten the screws.

Transport wheel

Illustration: 1 • 5

Change the tines to wheels when transporting.

For more information about moving of the machine, see

section "Moving".

English

– 6

Page 14

7

•

•

ST AR TING AND ST

Bef ore starting

Check the engine oil level and top up if necessary.

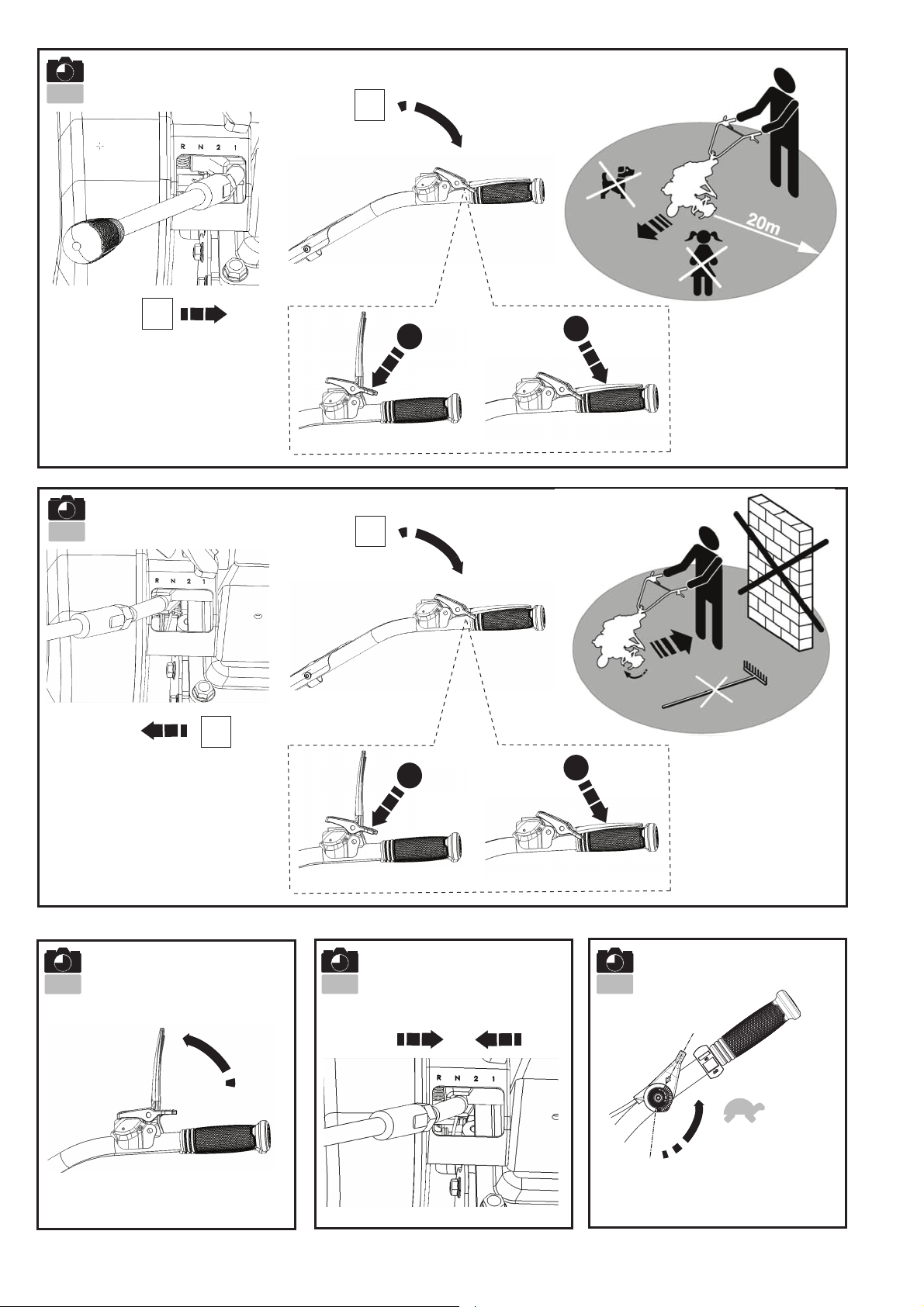

Illustration: 2 • 1

•

Check the oil level of the gear box, and top up if

necessary.

• Check the fuel level. Fill if necessary. Illustration: 2 • 3

- Recommended to use: Octane Value over 90.

• Oiling the air filter Illustration: 2 • 4

Star t the machine.

Open the fuel tap. Illustration: 2 • 5

• Set the choke control in the A position. Illustration: 2 • 6

• Throttle control Illustration: 2 • 7

- Push the throttle control to full throttle position.

• Set the on/off switch to ON to attain start throttle setting.

Illustr

•

Shifting lever Illustration: 2 • 9

- Put the gear shift lever in the ”N” position (neutral).

Illustration: 2 • 2

ation: 2 • 8

OPPING

• Press down the trigger lock on the handle (A) and push

the clutch lever in to

• The cultivator starts to rotate when you push the clutch lever

down tow

release the clutch lever.

ards the handle and stops rotating when you

Reverse

Illustration: 3 • 2

IMPORTANT! The cultivator starts to rotate when you push

the clutch down towards the handle and stops rotating

when you release the clutch. It is important to release the

clutch lever before using reverse.

• Slide the control to ”R” position.

WARNING! The use of reverse is dangerous!

Ensure that there are no obstacles behind

!

you and reduce the engine revs before

engaging the clutch.

• Press down the trigger lock on the handle (A) and push

the clutch lever in to

wards the handle (B).

wards the handle (B).

• Pull the recoil start handle Illustration: 2 • 10

WARNING! When the machine starts, remain

within the safety zone.

!

• Set the choke control in the B position. Illustration: 2 • 11

Use

WARNING! Keep unauthorised persons at a

distance. Children, animals, onlookers and

!

helpers should be kept outside the safety

zone of 20 m. Stop the machine immediately

if anyone approaches.

Forwar ds

Illustration: 3 • 1

• Use the shifting lever to control the drive speed.

Slow

Fast

Stopping

• Release the clutch lever. Illustration: 4 • 1

• Put the gear shift lever in the ”N” position (neutral).

Illustration: 4 • 2

Move the throttle control to the MIN. position. Illustration:

•

4 • 3

• Use the stop switch to switch off the engine. Illustration: 4

• 4

• Close the fuel tap. Illustration: 4 • 5

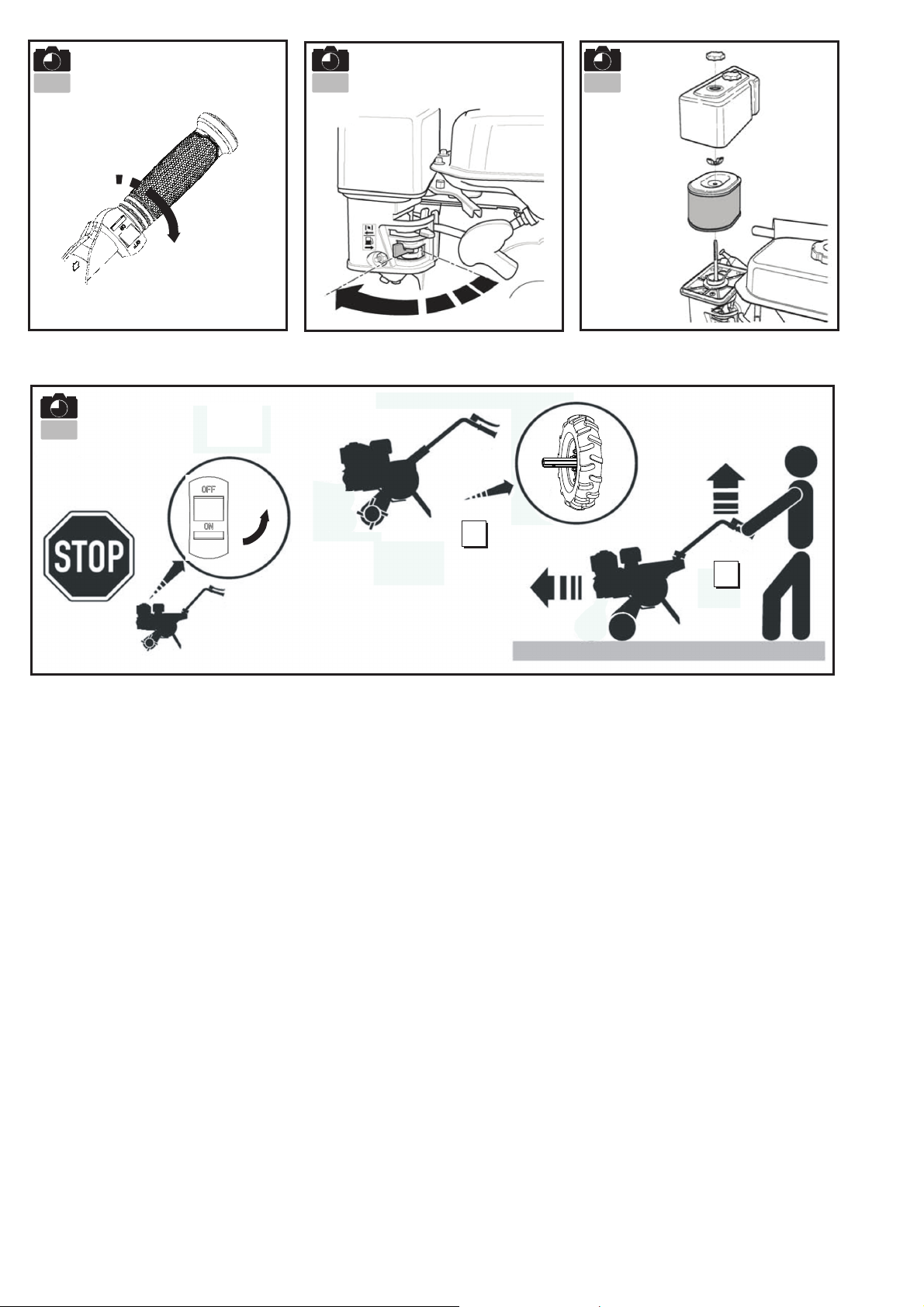

Moving the machine

Illustration: 5 • 1

• The engine must be switched off before moving. See

instructions under section Stopping.

• Change the blades to wheels when transporting.

A)

• Lift the drag bar from the ground using the handlebar and

then advance forwards.

(Figure B)

(Figure

–

English

Page 15

MAINTENANCE AND SERVICE

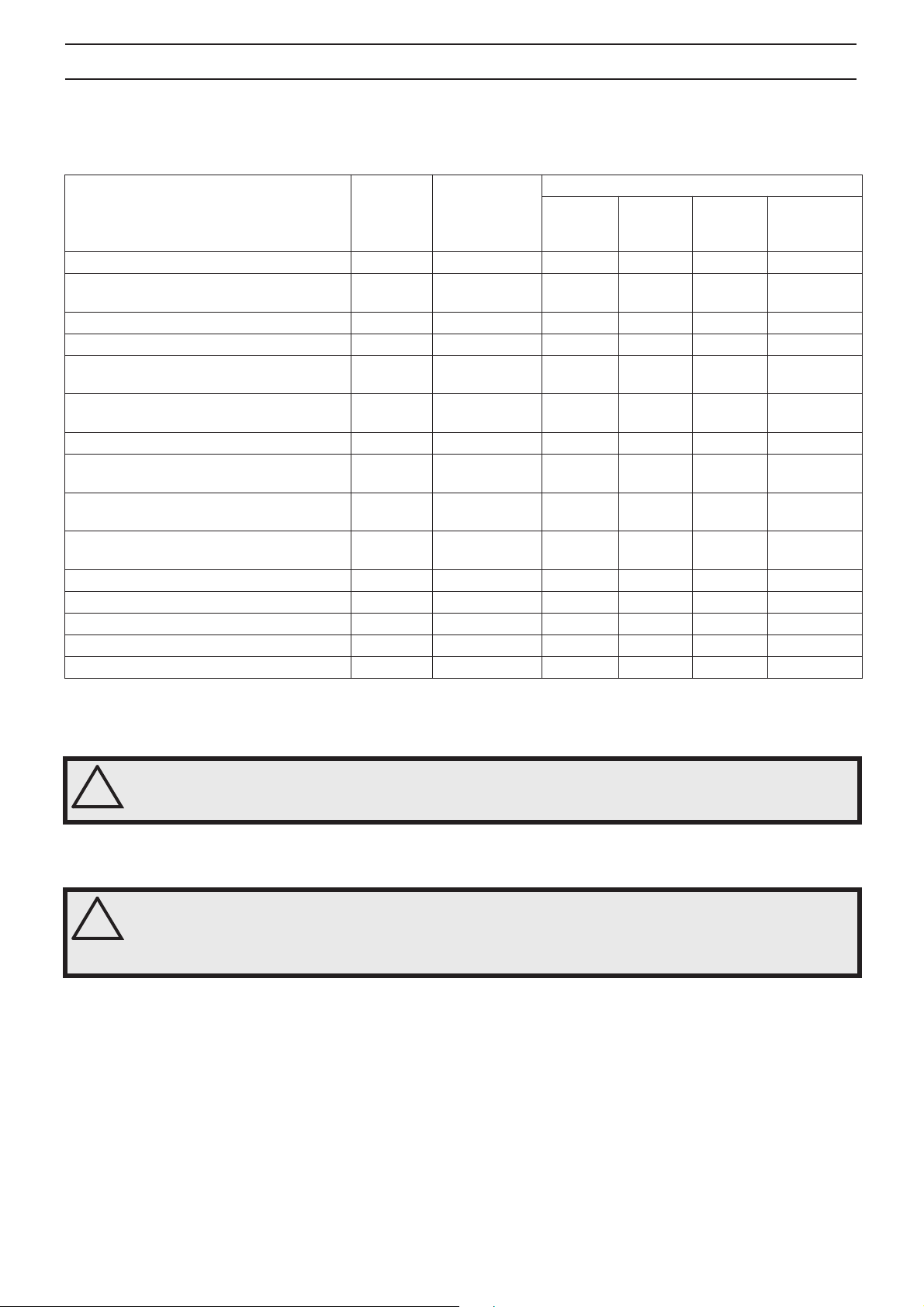

Maintenance schedule

The following is a list of the maintenance steps that must be performed on the machine.

Daily

Maintenance Illustration

Clean the machine. X

Check that nuts and screws are tight and

without damage.

Clean the air filter. Replace if necessary. 4 • 6 X X* X**

Check the engine’s oil level 2 • 1, 2 • 4 X

Check the oil level of the gear box, and top up

if necessary.

Check for any leakage of fuel, engine oil and

lubrication.

Check the fuel level. Fill if necessary. 2 • 3 X

If the machine starts to vibrate abnormally,

immediately check.

Change the oil and lubrication of the engine

and the gearbox.

Clean the fuel filter and its surrounding

components.

Clean the spark plug and the spark plug cap. X

Replace the spark plug. X

Check/Adjust the play in the engine valves X**

Clean the combustion chamber X**

Check the fuel circuit X**

2 • 2 X

maintenance

before starting

X

X

X

Maintenance interval in hours

20 hours

or every

month

XX

50 hours

or evry 3

months

100 hour

or evry 6

months

X X**

300 hours or

once a year

* Clean more often in condition of use where the air is dusty or laden with aerial debris.

** Not essential except in the event of performance problems. Contact an authorised service workshop.

WARNING! Remove the foam plastic filter. Wash the filter well in tepid soapy water. After cleaning, rinse the

filter well in clean water. Squeeze out and allow the filter to dry. NOTE! High pressure compressed air can

!

damage the foam. Do not use compressed air or solvent with petroleum to clean the air filter.

General

WARNING! Before carrying out repair work, cleaning or inspection, the machine must be in standstill and

turned off.

!

Never make adjustments with the machine running.

Always use genuine parts.

• Never wear jewellery, watches or similar when cleaning, carrying out repair work on or inspecting the machine.

Do not modify safety equipment. Check regularly to be sure it works properly.

Always exercise care and use your common sense. Avoid all situations which you consider to be beyond your capability. If you still

feel uncertain about operating procedures after reading these instructions, you should consult an expert before continuing. Contact

an authorised service workshop.

English

– 8

Page 16

TECHNICAL DATA

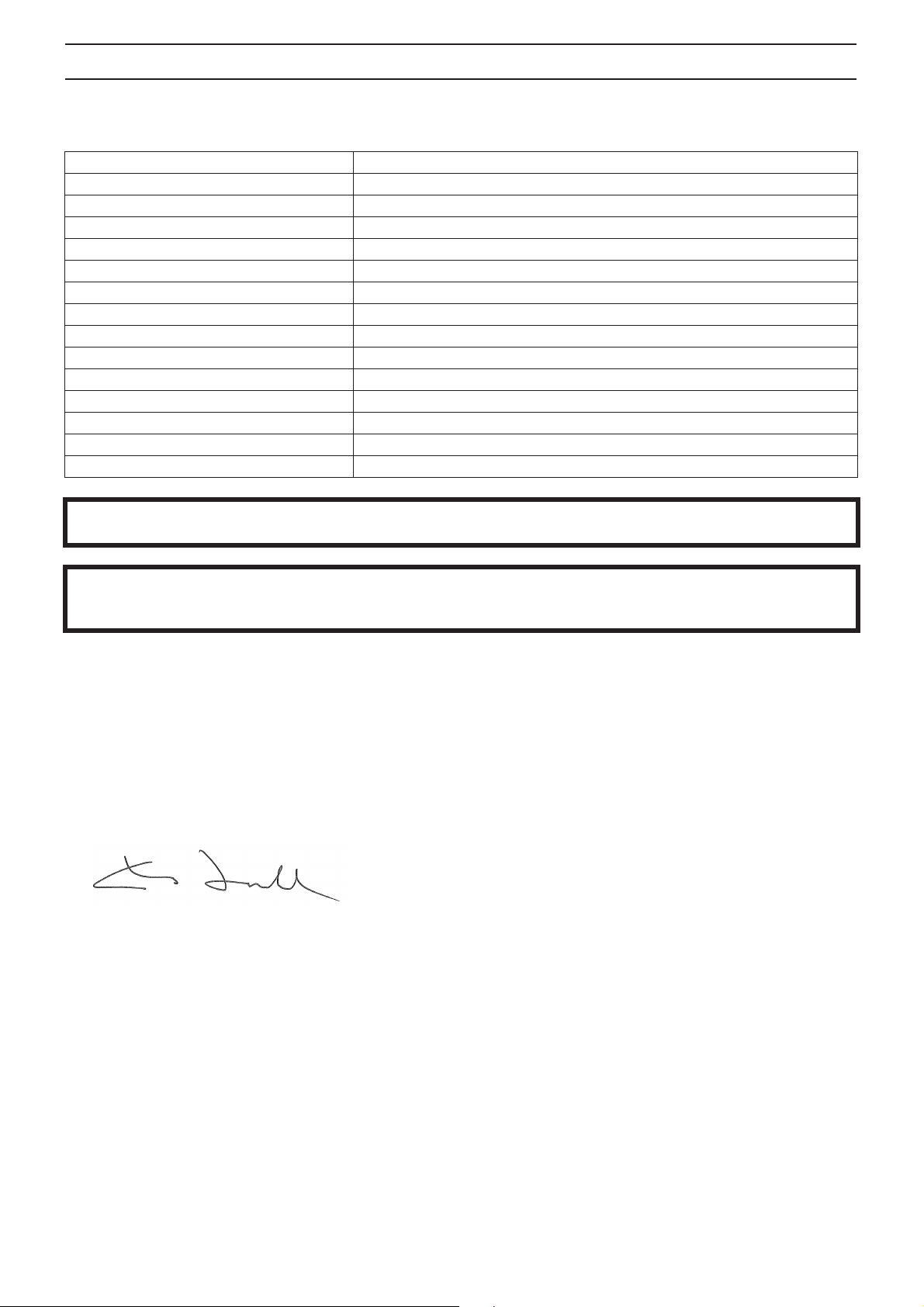

Technical data

TF338

Tilling width, mm 950

Tilling depth, mm 150 - 300

Engine WM170FB/P-2

Fuel Petrol

Fuel tank capacity, liters 4,8

Oil tank capacity, litre 0,6

Cylinder displacement, cm

Max power hp (kW) @ rpm 4,9 (3,6) @3100

Gears R, N, 2, 1

Oil capacity gearbox, liters 1,1

Gross weight, kg 106

Net weight, kg 93

Packaging size, mm 860x490x860

Certification CE, EAC

IMPORTANT! When the service life of this product has been served and it is no longer used it should be returned to the dealer

or to an applicab

le station f

3

or recycling.

212

IMPORTANT! We reserve the right to change specifications and designs without prior notice so as to implement improvements.

Note that no legal claims are valid on the basis of information in this manual. Use only genuine parts for repairs. The warranty is

not valid if non genuine parts are used.

EC Declaration of Conformity (Applies to Europe only)

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500, declares under sole responsibility that the Tillers Husqvarna

TF 338 from serial number 1447000139, and onwards (the subsequent serial number is clearly stated in plain text on the type

plate), are in conformity with the requirements of the COUNCIL’S DIRECTIVES:

of May 17, 2006 ”relating to machinery”

of December 15, 2004 ”relating to electromagnetic compatibility”

The following harmonised standards have been applied:

Huskvarna December 10, 2014

Claes Losdal, Development Manager/Garden Products

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

2006/42/EC.

2004/108/EC.

EN 709:1997, A4:2009

9 – English

Page 17

‘„…†ˆ…

‘одержание

‘„…†ˆ…

‘одержание ...................................................................... 10

Ÿ‘…ˆ… ‘ˆŒ‚‹‚

“словные обозначениЯ ............................................... 11

оЯснение к уровнЯм предупреждений ............... 11

ˆ‘’“Š–ˆŸ ’…•ˆŠ… …‡‘‘’ˆ

бщие сведениЯ ............................................................. 12

одготовка ....................................................................... 12

ксплуатациЯ .................................................................. 12

’ехническое обслуживание ...................................... 13

’ранспортировка и хранение .................................... 13

‡аправка топливом ........................................................ 13

‘Š ˆ ‘’‰Šˆ

аспаковка ........................................................................ 14

‘борка ................................................................................. 14

писание компонентов ............................................... 14

ˆдентификационнаЯ табличка ............................... 14

’ранспортное колесо ................................................... 14

‡“‘Š ˆ ‘’‚Š

еред началом работы ................................................ 15

‡апуск .................................................................................. 15

ксплуатациЯ .................................................................. 15

„вижение вперед ............................................................ 15

‡адний ход ........................................................................ 15

становка .......................................................................... 15

еремещение культиватора ..................................... 15

’…•‘‹“†ˆ‚ˆ… ˆ …Œ’

ƒрафик технического обслуживаниЯ .................... 16

бщие сведениЯ ............................................................. 16

’…•ˆ—…‘Šˆ… „›…

’ехнические данные .................................................... 17

„…Š‹–ˆŸ ‘’‚…’‘’‚ˆŸ …‘ ....................... 17

Russian

– 10

Page 18

11

Ÿ‘…ˆ… ‘ˆŒ‚‹‚

“словные обозначениЯ

ти символы находЯтсЯ на устройстве и в

руководстве.

…„“…†„…ˆ…! ебрежное или

неправильное применение может

привести к серьезной или

смертельной травме оператора

или окружающих.

режде чем приступить к работе с

машиной, внимательно прочитайте

инструкцию и убедитесь, что ‚ам

все понЯтно.

ользуйтесь средствами защиты

органов слуха, чтобы свести к

минимуму возможность нарушениЯ

слуха.

„анное изделие отвечает

требованиЯм соответствующих

директив EC.

‡адний ход

оЯснение к уровнЯм

предупреждений

‘уществует три уровнЯ предупреждений.

…„“…†„…ˆ…!

…„“…†„…ˆ…! ˆспользуетсЯ,

когда несоблюдение инструкций

!

руководства может создать угрозу

причинениЯ серьезных травм или

смерти оператора или повреждениЯ

находЯщегосЯ рЯдом имущества.

‚†!

‚†! ˆспользуетсЯ, когда несоблюдение

инструкций руководства может создать угрозу

причинениЯ травм оператору или повреждениЯ

находЯщегосЯ рЯдом имущества.

‚ˆŒˆ…!

ейтраль

ыстрое движение вперед

Œедленное движение вперед

ыстро

Œедленно

редупреждение: вращающиесЯ

части. „ержите руки и ноги на

безопасном расстоЯнии.

„о проведениЯ ремонта, очистки

или обслуживаниЯ необходимо

снЯть провод со свечи зажиганиЯ.

‚ˆŒˆ…! ˆспользуетсЯ, когда несоблюдение

инструкций руководства может создать угрозу

повреждениЯ материалов или машины.

‘охранЯйте дистанцию!

–

Russian

Page 19

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

ˆ‘’“Š–ˆŸ ’…•ˆŠ… …‡‘‘’ˆ

бщие сведениЯ

ти инструкции предназначены длЯ

обеспечениЯ безопасности персонала. ˆзучите

инструкции.

еред запуском машины прочтите все

инструкции, приведенные в данном

руководстве и на самой машине. “бедитесь в

том, что вы их понЯли, и затем выполнЯйте их.

‚ случае возникновениЯ проблем или вопросов

относительно работы культиватора обратитесь

к дилеру Husqvarna длЯ получениЯ

дополнительных сведений.

…„“…†„…ˆ…! ˆспользуйте

оборудование только в целЯх, длЯ

!

которых оно предназначено

(культивациЯ земли). ˆспользование

оборудованиЯ в других целЯх чревато

рисками или может привести к

повреждению оборудованиЯ.

ˆзучите инструкции по безопасной

эксплуатации машины и использованию средств

управлениЯ, а также научитесь быстро

останавливать машину. ’акже необходимо

разбиратьсЯ в значении предупредительных

наклеек.

ператор несет ответственность при

возникновении рисков или ситуаций, опасных

длЯ людей и их собственности.

икогда не начинайте использовать

оборудование, пока участок работы не будет

очищен, а вы не будете устойчиво стоЯть.

‘ледите за возможными препЯтствиЯми при

неожиданном перемещении. удьте особенно

осторожны при работе на склонах.

озволЯйте использовать машину только

взрослым, которые знакомы с правилами ее

эксплуатации.

‡апрещаетсЯ допускать к управлению или

ремонту машины детей или взрослых, не

имеющих соответствующей подготовки.

Œестные законы могут устанавливать возраст

пользователЯ.

‚ зоне работ не должны находитьсЯ

посторонние. „ети, животные, зрители и

помощники должны быть вне зоны работы на

расстоЯнии более 20

приближаетсЯ к вам во времЯ работы,

немедленно остановите машину.

икогда не пользуйтесь машиной, если вы

устали, принимали алкоголь или медицинские

препараты, использование которых может

отразитьсЯ на вашем зрении, сознании или

координации движений.

‘облюдайте особую осторожность при

обработке твердой почвы.

…„“…†„…ˆ…! ‚о времЯ работы

устройство создает электромагнитное

!

поле. ‚ определенных обстоЯтельствах

это поле может создавать помехи длЯ

пассивных и активных медицинских

имплантатов. ‚о избежание риска

серьезной или смертельной травмы

лицам с медицинскими имплантатами

рекомендуетсЯ проконсультироватьсЯ

с врачом и изготовителем имплантата,

прежде чем приступать к эксплуатации

данного устройства.

ì. …ñëè êòî-ëèáî

икогда не пользуйтесь машиной босиком.

‚сегда надевайте защитные сапоги или

ботинки, лучше всего со стальным носком.

росторнаЯ одежда или украшениЯ могут

застрЯть в движущихсЯ частЯх. ользуйтесь

средствами защиты органов слуха, чтобы

свести к минимуму возможность нарушениЯ

слуха.

одготовка

роверьте участок работы. “берите все

посторонние предметы, которые могут быть

отброшены оборудованием, включаЯ камни,

разбитое стекло, гвозди, стальную проволоку,

веревки и прочее.

еред началом работы проверЯйте состоЯние

культиватора. ‡амените изношенные или

поврежденные детали. “бедитесь в отсутствии

утечек топлива и проследите, чтобы все

защитные ограждениЯ и щитки были

установлены на своих местах и надежно

закреплены. роверьте крепление гаек и

винтов.

“бедитесь, что электрические кабели не

повреждены и изолированы.

ксплуатациЯ

Šультиватор не предназначен длЯ перевозки

людей.

‘оответствие условиЯм работы, обслуживаниЯ

и ремонта, указанным производителем, и

строгое их соблюдение также ЯвлЯютсЯ

важным составным компонентом использованиЯ

по назначению.

станавливайте двигатель, когда работа

культиватором закончена.

ри работе культиватором перемещайтесь

равномерно, без рывков и ускорений.

удьте особо внимательны, если крен

культиватора в вашу сторону или включаетсЯ

задний ход.

„ержитесь на безопасном расстоЯнии от

вращающихсЯ фрез в соответствии с

положением рукоЯток. е приближайте руки или

ноги к вращающимсЯ фрезам.

„вигатель и выхлопнаЯ система сильно

нагреваютсЯ во времЯ работы. ‘уществует риск

ожогов при прикосновении.

ˆспользуйте машину только в дневное времЯ

или при хорошем освещении.

‡апрещаетсЯ использовать машину на участках

с уклоном более 20 ° .

аботайте поперек склона, а не вверх и вниз.

Russian

– 12

Page 20

13

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

ˆ‘’“Š–ˆŸ ’…•ˆŠ… …‡‘‘’ˆ

…„“…†„…ˆ…! ‹юбые изменениЯ

оригинальной конструкции

!

культиватора без разрешениЯ

производителЯ запрещены. ˆспользуйте

только оригинальные запасные части.

‚несение неразрешенных изменений и/

или использование нерекомендованных

приспособлений может привести к

серьезной травме или даже к

смертельному исходу длЯ

пользователЯ или других лиц.

ри использовании неоригинальных

запасных частей гарантийные

обЯзательства терЯют свою силу.

емедленно остановите двигатель в следующих

случаЯх:

чрезмернаЯ вибрациЯ и/или шум;

заедание механизма, ведущее к остановке

вращениЯ двигателЯ;

трудности при включении и выключении

сцеплениЯ;

столкновение с посторонним предметом;

износ кабелЯ останова двигателЯ.

…сли кабель остановки двигателЯ к рукоЯткам

оборван, используйте длЯ остановки двигателЯ

рычаги заслонок на двигателе. „лЯ получениЯ

дополнительных сведений см. раздел '‡апуск

двигателЯ'

„ождитесь охлаждениЯ машины. тсоедините

провод высокого напрЯжениЯ от свечи зажиганиЯ.

“бедитесь в отсутствии повреждений узлов и

агрегатов. …сли оборудование повреждено,

обратитесь к официальному дилеру длЯ

проведениЯ диагностики и ремонта.

’ехническое обслуживание

‚сегда останавливайте двигатель перед

проведением ремонта, очистки, технического

обслуживаниЯ или замены аксессуаров на

культиваторе.

„лЯ безопасной работы и поддержаниЯ

производительности на должном уровне

необходимо регулЯрно проводить техническое

обслуживание.

адевайте прочные перчатки при замене

аксессуаров на культиваторе.

‡аменЯть вращающиесЯ фрезы следует

комплектом длЯ сохранениЯ их балансировки.

‚сегда используйте оригинальные детали.

роверьте затЯжку гаек и винтов.

икогда не используйте устройство с

неисправным глушителем. братитесь к

официальному дилеру.

‚†! ‚ целЯх безопасности запрещаетсЯ

изменЯть характеристики культиватора.

‡апрещаетсЯ изменЯть регулировку частоты

вращениЯ двигателЯ и эксплуатировать

двигатель на слишком высоких оборотах.

’ранспортировка и хранение

„айте машине остыть перед отправкой на

хранение.

•раните культиватор и топливо в сухом месте,

вдали от источников открытого огнЯ, искр и

чрезмерного тепла, избегаЯ утечек и испарениЯ

топлива.

‚ летнее времЯ срок хранениЯ топлива не более

трех месЯцев. еред хранением зимой

необходимо топливо слить, а остатки

выработать до конца, заведЯ двигатель.

’опливо и его пары легковоспламенЯемы.

удьте осторожны при обращении с топливом и

маслом. омните об опасности пожара, взрывов

и вдыханиЯ паров.

’опливо всегда следует хранить и

транспортировать в специальных емкостЯх,

предназначенных длЯ этой цели.

е пытайтесь поднимать оборудование. ри

выполнении манипулЯций с оборудованием

используйте методы, соответствующие его весу

и ситуации.

‘облюдайте особую осторожность при погрузке

оборудованиЯ на транспортное средство/

платформу или его разгрузке. ˆспользуйте

соответствующую рампу.

„лЯ перевозки используйте грузовую

платформу соответствующей

грузоподъемности. Œашину следует закреплЯть

только утвержденными длЯ таких работ

стропами. ‘тропы не должны деформировать

компоненты машины. ‚ качестве

дополнительной защиты при транспортировке

машину можно накрыть.

„ополнительные сведениЯ о перемещении

оборудованиЯ во времЯ работы см. в разделе

'еремещение'.

‡аправка топливом

еред заправкой следует обЯзательно

выключить двигатель и дать ему охладитьсЯ в

течение нескольких минут.

‡аправку необходимо производить в местах с

хорошей циркулЯцией воздуха и с выключенным

двигателем.

…„“…†„…ˆ…! ензин ЯвлЯетсЯ

легковоспламенЯемой жидкостью.

!

удьте осторожны и заправлЯйте

машину только на улице. ‡апрещаетсЯ

курить и использовать источники

открытого огнЯ.

чистите поверхность вокруг крышки

топливного бака. осле заправки

плотно затЯните крышку топливного

бака. …сли крышка неплотно затЯнута,

то под воздействием вибрации крышка

может открутитьсЯ, что приведет к

вытеканию топлива из топливного бака

и риску возникновениЯ пожара. еред

запуском переместите культиватор как

минимум на 3 м от места заправки.

омните об опасности пожара, взрывов и

вдыханиЯ паров. е заливайте столько топлива,

чтобы оно переливалось. “страните разлитое

топливо на поверхности и культиваторе. ‚

случае пролива топлива на себЯ или на одежду.

‡амените одежду. еред запуском переместите

оборудование не менее чем на 3 метра от места

заправки.

ри работе двигатель выделЯет окись

углерода, бесцветный токсичный газ. е

пользуйтесь машиной в замкнутых

пространствах.

–

Russian

Page 21

‘Š ˆ ‘’‰Šˆ

•

•

•

•

•

•

•

•

аспаковка

исунок: 1 ¥ 1

‚†! ри разрезании краев коробки

старайтесь не повредить кабели и не поцарапать

оборудование.

бозначениЯ ‘одержимое комплекта

A “паковка

B Šомпонент держателЯ

C сновной компонент держателЯ

D ижнЯЯ защитнаЯ крышка

E ‘ошник

F ‡ащита фрез

G Šронштейн защиты фрез

H ычаг переключениЯ

I îæè

J Šолесо

K ‘цепка

L абор инструментов

M Šомплект крепежа, только длЯ фрез

N Šомплект крепежа

‘борка

исунок: 1 ¥ 2

…„“…†„…ˆ…! еправильнаЯ

сборка культиватора может привести к

!

серьезным травмам. ‘трого

соблюдайте приведенные ниже

инструкции.

“становка ножей фрез. а рисунках показана

сборка ножей фрез только с правой стороны.

“бедитесь, что ножи на фрезах левой и правой

стороны установлены лезвием в одну сторону. ‘

каждый стороны имеетсЯ по одному короткому

ножу, который при сборке необходимо отогнуть

в сторону редуктора.

“становка сцепки. (исунок 7)

“становка тЯги. (исунок 8)

“становка рукоЯток. (исунок 9)

астройте высоту рукоЯток и надежно

зафиксируйте крепление.

“становка рычага управлениЯ сцеплением.

(исунок 11)

- оверните в нужную сторону и затЯните болт.

“становка нижней защитной крышки. (исунок

12 - 13)

- удьте аккуратны при фиксации кабелей!

- “становите резиновый держатель надлежащим

образом.

- “становите крышку и затЯните винты.

“становка защит фрез. (исунок 14 - 16)

- е затЯгивайте болт сразу после установки.

- ‘начала установите все 4 болта и гайки, а затем

затЯните их по очереди.

(исунок 1 - 6)

(исунок 10)

• “становка рычага переключениЯ. (исунок 17)

о возникающим вопросам сборки-разборки

рекомендует обращатьсЯ к любому официальному

дилеру.

‚ˆŒˆ…! осле полной сборки оборудованиЯ

затЯните винты и болты с умеренным усилием. е

прикладывайте при затЯжке слишком больших

усилий.

писание компонентов

исунок: 1 ¥ 3

1 „вигатель

2 ‡ащита фрез

3 ижнЯЯ защитнаЯ крышка

4 ‡ащита фрез

5 îæè

6 ‘ошник

7 укоЯтки

8 ычаг переключениЯ

9 ампер

10 “правление сцеплением

11 “правление дросселем

12 ереключатель ‚Š‹/‚›Š‹

13 ‚ерхнЯЯ защитнаЯ крышка

ˆдентификационнаЯ табличка

исунок: 1 ¥ 4

1 ‘ерийный номер

2 ртикул

3 бъем культивации

4 ереключение передачи

5 абочий объем двигателЯ

6 Œоторное масло Šачество (вЯзкость):

7 Œоторное масло, емкость

8 ’рансмиссионное масло, качество

9 ’рансмиссионное масло, емкость

10 оминальнаЯ мощность

11 ‚ес нетто, кг

12 ’опливо

’ранспортное колесо

исунок: 1 ¥ 5

ри транспортировке фрезы следует заменЯть

колесами.

„ополнительные сведениЯ о перемещении

оборудованиЯ см. в разделе 'еремещение'.

Russian

– 14

Page 22

‡“‘Š ˆ ‘’‚Š

еред началом работы

• роверьте уровень масла в двигателе и при

необходимости добавьте масло. исунок: 2 ¥ 1

• роверьте уровень масла в редукторе и при

необходимости долейте масло. исунок: 2 ¥ 2

• роверьте уровень топлива. ри необходимости

заправьте. исунок: 2 ¥ 3

- екомендации по использованию:

еэтилированный бензин с октановым числом

более 90.

• ропитывание воздушного фильтра маслом

исунок: 2 ¥ 4

‡апуск

• ткройте топливный кран. исунок: 2 ¥ 5

• “становите рычаг воздушной заслонки в

положение A. исунок: 2 ¥ 6

• “правление дросселем исунок: 2 ¥ 7

- ереместите ручку газа в положение полного

ãàçà.

• “становите переключатель включениЯ/

выключениЯ в положение ON (‚Š‹) длЯ

переключениЯ дроссельной заслонки в

пусковое положение. исунок: 2 ¥ 8

• ычаг переключениЯ исунок: 2 ¥ 9

- “становите рычаг переключениЯ передач в

положение 'N' (нейтральное).

• ажмите блокиратор газа на рукоЯтке (A) и

нажмите рычаг сцеплениЯ в сторону рукоЯтки

(B).

• ри нажатии рычага в сторону рукоЯтки фрезы

начнут вращатьсЯ; вращение прекратитьсЯ,

если рычаг сцеплениЯ отпустить.

‡адний ход

исунок: 3 ¥ 2

‚†! ри нажатии рычага в сторону рукоЯтки

фрезы начнут вращатьсЯ; вращение прекратитьсЯ,

если рычаг сцеплениЯ отпустить. еобходимо

всегда отпускать рычаг сцеплениЯ перед

включением заднего хода.

• ередвиньте рычаг переключениЯ передач в

положение R.

…„“…†„…ˆ…! ˆспользование

заднего хода опасно! “бедитесь, что

!

позади вас нет никаких препЯтствий, и

уменьшите обороты двигателЯ, прежде

чем включить сцепление.

• ажмите блокиратор газа на рукоЯтке (A) и

нажмите рычаг сцеплениЯ в сторону рукоЯтки

(B).

• отЯните рукоЯтку стартера исунок: 2 ¥ 10

…„“…†„…ˆ…! Šогда культиватор

запуститсЯ, оставайтесь в безопасной

!

çîíå.

• Šогда двигатель заведетсЯ, необходимо

переместить заслонку в положение B. исунок: 2

¥ 11

ксплуатациЯ

…„“…†„…ˆ…! ‚ зоне работ не

должны находитьсЯ посторонние. „ети,

!

животные, зрители и помощники

должны быть вне зоны работы на

расстоЯнии более 20

приближаетсЯ к вам во времЯ работы,

немедленно остановите машину.

ì. …ñëè êòî-ëèáî

„вижение вперед

исунок: 3 ¥ 1

• „лЯ управлениЯ скоростью движениЯ

используйте рычаг переключениЯ.

Œедленно

ыстро

становка

• тпустите рычаг сцеплениЯ. исунок: 4 ¥ 1

• “становите рычаг переключениЯ передач в

положение 'N' (нейтральное). исунок: 4 ¥ 2

• “становите рычаг газа в положение MIN.

исунок: 4 ¥ 3

• „лЯ полной остановки двигателЯ необходимо

переместить выключатель в положение OFF

(‚›Š‹.) исунок: 4 ¥ 4

• осле остановки двигателЯ закройте

топливный кран. исунок: 4 ¥ 5

еремещение культиватора

исунок: 5 ¥ 1

• ри перемещении двигатель должен быть

выключен. ‘м. инструкции в разделе

'становка'.

• ри транспортировке фрезы следует заменЯть

колесами. (исунок A)

• однимите сошник с земли с помощью рукоЯток

и подайте вперед. (исунок B)

15 – Russian

Page 23

’…•‘‹“†ˆ‚ˆ… ˆ …Œ’

ƒрафик технического обслуживаниЯ

иже приведен перечень технического обслуживаниЯ, которое необходимо выполнЯть в зависимости от

наработки в моточасах.

ˆнтервалы между циклами технического

…жедневное

’ехническое обслуживание исунок

чистите машину. X

роверьте затЯжку гаек и винтов и

отсутствие повреждений на них.

рочистите воздушный фильтр. ри

необходимости замените.

роверьте уровень масла в двигателе 2 ¥ 1, 2 ¥ 4 X

роверьте уровень масла в редукторе

и при необходимости долейте масло.

роверьте отсутствие утечек

топлива, моторного масла и смазки.

роверьте уровень топлива. ри

необходимости заправьте.

‚ случае необычной вибрации машины

незамедлительно выполните

проверку.

‡амените масло и смазку двигателЯ и

редуктора.

чистите топливный фильтр и

окружающие компоненты.

чистите свечу зажиганиЯ и колпачок

свечи зажиганиЯ.

‡амените свечу зажиганиЯ. X

егулировка зазоров клапанов

двигателЯ

„иагностика –ƒ X**

роверка топливной системы X**

* ри эксплуатации оборудованиЯ в условиЯх запыленного или загрЯзненного воздуха очистку следует

проводить чаще.

** еобЯзательно, за исключением возникновениЯ проблем с производительностью. братитесь к

официальному дилеру.

4 ¥ 6 X X* X**

2 ¥ 2 X

2 ¥ 3 X

техобслужи

вание перед

запуском

X

X

X

обслуживаниЯ в часах

каждые

20 часов

или раз в

месЯц

X X

каждые

50 часов

или раз в

3 месЯца

каждые

100 часов

или раз в 6

месЯцев

X X**

X

каждые

300 часов

или раз в

год

X**

…„“…†„…ˆ…! егулЯрно обслуживайте губчатый фильтр. ’щательно промывайте фильтр в

растворе теплой мыльной воды. осле этого промойте фильтр в чистой воде. ‚ыжмите и дайте

!

фильтру просохнуть. ‚†! ‘жатый воздух под высоким давлением может повредить его

губчатую структуру. е используйте длЯ очистки губчатого воздушного фильтра сжатый воздух

или содержащие растворители жидкости.

бщие сведениЯ

…„“…†„…ˆ…! еред проведением ремонта, очистки или осмотра машина должна быть

остановлена и выключена.

!

и в коем случае не выполнЯйте регулировку на работающей машине.

‚сегда используйте оригинальные детали.

• икогда не надевайте украшениЯ, часы или прочие аксессуары во времЯ очистки, ремонта или осмотра

машины.

икогда не вносите изменений в конструкцию оборудованиЯ безопасности. егулЯрно проверЯйте его

функционирование.

еобходимо быть осторожным и руководствоватьсЯ здравым смыслом. ˆзбегайте работ, длЯ которых, по

вашему мнению, уровень вашей квалификации недостаточен. …сли после изучениЯ настоЯщих инструкций у

вас возникли вопросы относительно эксплуатации машины, прежде чем приступить к работе, обратитесь за

консультацией к специалисту. братитесь к официальному дилеру.

Russian – 16

Page 24

’…•ˆ—…‘Šˆ… „›…

’ехнические данные

TF338

˜ирина культивации, мм 950

ƒлубина культивации, мм 150 - 300

„вигатель WM170FB/P-2

’опливо еэтилированный бензин

…мкость топливного бака, литров 4,8

…мкость маслЯного бака, литров 0,6

бъем цилиндра, см

Œакс. мощность, л.с. (к‚т) при об/мин 4,9 (3,6) @3100

ередачи R, N, 2, 1

бъем масла в редукторе, л 1,1

áùèé âåñ, êã 106

‚ес нетто, кг 93

азмер упаковки, мм 860x490x860

‘ертификациЯ CE, EAC

‚†! …сли машина не используетсЯ по причине выработки эксплуатационного

ресурса, ее следует сдать в соответствующую организацию длЯ переработки.

3

212

‚†! роизводитель сохранЯет за собой право изменениЯ спецификаций и

конструкции без предварительного уведомлениЯ с целью модернизации машины.

икакие юридические претензии не могут быть предъЯвлены на основании

информации, приведенной в данной инструкции. „лЯ ремонта используйте только

оригинальные детали. ри использовании неоригинальных запасных частей

гарантийные обЯзательства терЯют свою силу.

„…Š‹–ˆŸ ‘’‚…’‘’‚ˆŸ …‘ (’олько длЯ …вропы)

Husqvarna AB, SE-561 82 Huskvarna, ˜вециЯ, тел.: +46-36-146500, настоЯщим заверЯет, что культиваторы

Husqvarna TF 230 и TF 338 с серийными номерами 1447000096 и далее длЯ TF 230, 1447000139 и далее длЯ TF

338 (серийный номер четко указан на табличке с обозначением типа), соответствуют требованиЯм

„ˆ…Š’ˆ‚ ‘‚…’:

от 17 маЯ 2006 года, 'о машинах и механизмах' 2006/42/EC.

от 15 декабрЯ 2004 года, 'об электромагнитной совместимости' 2004/108/EC.

ыли применены следующие стандарты технического соответствиЯ: EN 709:1997, A4:2009

Husqvarna, 10 декабрЯ 2014 г.

Claes Losdal, „иректор отдела разработок/‘адоваЯ техника (уполномоченный представитель Husqvarna AB,

ответственный за техническую документацию.)

17 – Russian

Page 25

‡ì´ñò

‡Œ§‘’

‡ì´ñò ..................................................................................... 18

“Œ‚§ ‡—…Ÿ

означеннЯ ....................................................................... 19

писаннЯ р´вн´в попередженнЯ ................................ 19

§‘’“Š–§º ‡ ’…•§Šˆ …‡…Šˆ

‡агальне ............................................................................. 20

´дготуваннЯ .................................................................... 20

‡астосуваннЯ ................................................................... 20

’ехн´чне обслуговуваннЯ ........................................... 21

’ранспортуваннЯ та збер´ганнЯ .............................. 21

‡аправленнЯ паливом .................................................. 21

Œ’† ’ ‹˜’“‚Ÿ

озпакуваннЯ ................................................................... 22

‡бираннЯ ............................................................................ 22

пис компонент´в ........................................................... 22

’абличка техн´чних даних ........................................ 22

’ранспортне колесо ..................................................... 22

“‘Š ’ ‚ˆŒˆŠŸ

еред початком роботи .............................................. 23

‡апуск. ................................................................................. 23

‡астосуваннЯ ................................................................... 23

‚перед ................................................................................. 23

‡àäí´é õ´ä ........................................................................... 23

‚имкненнЯ ......................................................................... 23

ерем´щеннЯ машини .................................................... 23

‘‹“ƒ‚“‚Ÿ

ƒраф´к техн´чного обслуговуваннЯ ........................ 24

‡агальне ............................................................................. 24

’…•§—§ •Š’…ˆ‘’ˆŠˆ

’åõí´÷í´ äàí´ ...................................................................... 25

„екларац´Я в´дпов´дност´ стандартам

¸вропейського ‘оюзу .................................................. 25

‡Œ§‘’

Ukrainian – 18

Page 26

“Œ‚§ ‡—…Ÿ

означеннЯ

–´ символи зазначено на корпус´ культиватора та в

´нструкц´Ях.

“‚ƒ! едбале чи неправильне

використаннЯ може спричинити

серйозну або смертельну травму

користувача чи ´нших ос´б.

еред експлуатац´¹ю

культиватора уважно прочитайте

це кер´вництво та переконайтесь,

що ‚ам все зрозум´ло.

‚икористовуйте засоби захисту

орган´в слуху, щоб звести до м´н´муму

ризик порушеннЯ орган´в слуху.

–ей вир´б в´дпов´да¹ належним

вимогам ¸‘.

‡àäí´é õ´ä

ейтральна передача

писаннЯ р´вн´в попередженнЯ

§снують три р´вн´ попередженнЯ.

“‚ƒ!

“‚ƒ! ‚икористову¹тьсЯ, Якщо ´сну¹

ризик травмуваннЯ користувача або

!

пошкодженнЯ навколишн´х обХ¹кт´в

внасл´док порушеннЯ ´нструкц´й,

наведених у цьому кер´вництв´.

‚†‹ˆ‚!

‚†‹ˆ‚! ‚икористову¹тьсЯ, Якщо ´сну¹ ризик

травмуваннЯ користувача або пошкодженнЯ

навколишн´х обХ¹кт´в внасл´док порушеннЯ

´нструкц´й, наведених у цьому кер´вництв´.

“‚ƒ!

“‚ƒ! ‚икористову¹тьсЯ, Якщо ´сну¹ ризик

пошкодженнЯ навколишн´х обХ¹кт´в або пристрою,

внасл´док порушеннЯ ´нструкц´й, наведених у

цьому кер´вництв´.

˜видко вперед

ов´льно вперед

˜видко

îâ´ëüíî

“вага: обертальн´ частини. е

наближайте до них руки та ноги.

еред проведеннЯм ремонту,

очищеннЯм або техн´чним

обслуговуваннЯм сл´д завжди

в´дХ¹днувати др´т в´д св´чки

запалюваннЯ.

’римайте дистанц´ю!

19 – Ukrainian

Page 27

§‘’“Š–§º ‡ ’…•§Šˆ …‡…Šˆ

‡агальне

• –´ ´нструкц´» надаютьсЯ длЯ вашо» безпеки.

рочитайте »х уважно.

• еред запуском пристрою прочитайте вс´

´нструкц´» в цьому пос´бнику користувача ´ на

корпус´ машини. ереконайтесЯ, що ви розум´¹те

»х, а пот´м дотримуйтесь »х.

• Ÿкщо у вас виникли будь-Як´ проблеми чи

запитаннЯ стосовно цього культиватора,

звХЯж´тьсЯ з´ сво»м дилером Husqvarna длЯ

отриманнЯ додатково» ´нформац´».

“‚ƒ! ‚икористовуйте машину лише за

призначеннЯм Р длЯ обробки «рунту.

!

‚икористаннЯ з ´ншою метою може бути

небезпечним або може пошкодити

культиватор.

• „´знайтесЯ, Як безпечно користуватисЯ

техн´кою та »» елементами керуваннЯ, а також Як

швидко »» зупинЯти. кр´м цього, необх´дно

навчитисЯ розум´ти зм´ст попереджувальних

наклейок.

• ператор культиватора несе в´дпов´дальн´сть за

виникненнЯ будь-Яких небезпечних ситуац´й та

ризику на Як´ наражаютьсЯ люди та майно.

• ‡аборонЯ¹тьсЯ починати роботу з

культиватором на захаращеному робочому м´сц´,

а також не маючи ст´йко» точки опори. отр´бно

виЯвити будь-Як´ перешкоди, що можуть мати

непередбачуван´ пересуваннЯ. удьте дуже

уважн´, працюючи на схилах.

• „озволЯйте користуватисЯ культиватором

лише дорослим, ознайомленим ´з його роботою.

• ´коли не дозволЯйте користуватисЯ

культиватором д´тЯм та ´ншим особам, Як´ не

мають досв´ду керуваннЯ машиною чи »»

обслуговуваннЯ. ‚´к користувача може

регламентуватисЯ м´сцевими законами.

• е п´дпускайте до себе сторонн´х людей. „´ти,

тварини, особи, що спостер´гають чи

допомагають вам працювати, повинн´

залишатисЯ у безпечн´й зон´ на в´дстан´ б´льше

20 метр´в. егайно вимкн´ть двигун, Якщо хтось

п´д´йде.

• ‚ жодному раз´ не користуйтесЯ культиватором,

Якщо ви втомлен´, вживали спиртн´ напо», чи

прийма¹те л´ки, що можуть негативно вплинути

на ваш з´р, св´дом´сть чи координац´ю рух´в.

• ‡верн´ть особливу увагу на тверд´сть поверхн´.

´дготуваннЯ

• глЯньте зону, де ви працюватимете. ‚идал´ть

ус´ сторонн´ предмети, Як´ культиватор може

в´дкинути у процес´ роботи, так´ Як кам´ннЯ,

розбите скло, цвЯхи, металев´ дроти, мотузки

тощо.

• еред початком роботи перев´рте стан

культиватора. ‡ам´н´ть зношен´ або пошкоджен´

детал´. ереконайтесЯ, що нема¹ витоку палива,

захисн´ детал´ та кожухи в наЯвност´ та над´йно

закр´плен´. ерев´рте закр´пленнЯ гвинт´в ´ гайок.

• ереконайтесЯ, що електричн´ кабел´

неушкоджен´ та в гарному стан´.

‡астосуваннЯ

• Šультиватор не призначений длЯ перевезеннЯ

людей.

• ’акож важливою частиною використаннЯ

культиватора за призначеннЯм ЯвлЯ¹тьсЯ

обслуговуваннЯ та ремонт, зазначен´

виробником, та »х суворе дотриманнЯ.

• ‚имикайте двигун, коли роботу з

культиватором зак´нчено.

• ри робот´ з культиватором рухайтесь

р´вном´рно, без ривк´в та р´зких прискорень.

• удьте особливо уважн´ при нахилен´

культиватора у ваш б´к та при ув´мкненн´

передач´ заднього ходу.

• ’римайтесь на безпечн´й в´дстан´ в´д фрез що

обертаютьсЯ у в´дпов´дност´ з довжиною ручок.

е наближайте руки та ноги до фрез що

обертаютьсЯ.

• „вигун ´ система випуску сильно нагр´ваютьсЯ

п´д час роботи. ’орканнЯ може спричинити оп´ки.

• ‚икористовуйте культиватор т´льки при

денному св´тл´ або за ´нших умов доброго

осв´тленнЯ.

• е використовуйте культиватор на д´лЯнках ´з

нахилом понад 20 °.

• рацюйте культиватором впоперек схилу, а не

вгору чи вниз.

“‚ƒ! ´д час роботи цей ´нструмент

створю¹ електромагн´тне поле. –е поле

!

може за деЯких умов вза¹мод´Яти з

активними чи пасивними медичними

iмплантатами. „лЯ зменшеннЯ ризику

серйозних або смертельних травм,

перед початком роботи з ´нструментом

ми рекоменду¹мо особам з медичними

´мплантатами проконсультуватисЯ з´

сво»м л´карем та виробником медичного

´мплантату.

• ´коли не працюйте з культиватором босон´ж.

‡авжди нос´ть захисн´ туфл´ або черевики,

найкраще з´ сталевим носком. ´коли не нос´ть

в´льний одЯг, коштовност´ чи аналог´чн´ реч´, що

можуть потрапити в рухом´ частини.

‚икористовуйте засоби захисту орган´в слуху,

щоб звести до м´н´муму ризик порушеннЯ орган´в

слуху.

“‚ƒ! ‡а жодних обставин не можна

вносити зм´ни в конструкц´ю

!

культиватора без дозволу виробника.

‚икористовуйте т´льки ориг´нальн´

запчастини. ‚несеннЯ зм´н чи

використаннЯ запчастин та аксесуар´в,

не схвалених виробником, може

привести до травми користувача чи

´нших людей, або до смертельних

насл´дк´в.

“ раз´ використаннЯ неориг´нальних

деталей гарант´Я скасову¹тьсЯ.

Ukrainian – 20

Page 28

§‘’“Š–§º ‡ ’…•§Šˆ …‡…Šˆ

егайно вимкн´ть двигун за наступних ситуац´й:

• àäì´ðí´ â´áðàö´» òà/àáî øóì.

• Œехан´чне за»даннЯ, що може призвести до

зупинки двигуна.

• ’руднощ´ з ув´мкненнЯм чи вимкненнЯм

зчепленнЯ.

• ‡´ткненнЯ з´ сторонн´м обХ¹ктом.

• ог´ршеннЯ стану кабелю зупинки двигуна.

“ випадку пошкодженнЯ чи роз´рваннЯ кабелю

зупинки двигуна скористайтесЯ важелЯми

засл´нок на двигун´, щоб вимкнути двигун.

„окладн´ша ´нформац´Я доступна в розд´л´,

присвЯченому запуску двигуна

„айте ´нструменту час, щоб охолонути.

‚´дХ¹днайте др´т високо» напруги в´д св´чки

запалюваннЯ. ерев´рте, чи не пошкоджено машину.

Ÿкщо машину пошкоджено, передайте »» до

уповноваженого серв´сного центру длЯ ремонту.

’ехн´чне обслуговуваннЯ

• ‡авжди зупинЯйте двигун перед ремонтом,

чищеннЯм, обслуговуваннЯм або зам´ною

деталей та ´нструмент´в.

• „лЯ безпечного використаннЯ ´ длЯ п´дтримки

належного р´внЯ продуктивност´ необх´дне

регулЯрне техн´чне обслуговуваннЯ.

• еред зм´ною фрез на машин´ надЯгайте

спец´альн´ рукавички длЯ важких умов.

• ‡ам´нюйте фрези ц´лим комплектом длЯ

збереженнЯ »х збалансовано» роботи. ‡авжди

користуйтесЯ ориг´нальними запчастинами.

• ерев´рте, щоб гайки ´ гвинти були добре

затЯгнут´.

• ´коли не користуйтесЯ ´нструментом ´з

несправним глушником. ‡верн´тьсЯ до

авторизованого серв´сного центру.

‚†‹ˆ‚! „лЯ вашо» власно» безпеки не зм´нюйте

встановлен´ параметри машини. е зм´нюйте

налаштуваннЯ швидкост´ двигуна ´ не

експлуатуйте двигун на надто висок´й швидкост´.

’ранспортуваннЯ та збер´ганнЯ

• „озвольте машин´ охолонути, перш н´ж сховати »»

п´слЯ роботи.

• ‡бер´гайте культиватор та паливо в сухому

м´сц´, на в´дстан´ в´д джерел в´дкритого вогню,

´скор та черезм´рного тепла, уникаючи витоку та

випаровуванню палива.

• “ л´тн´й пер´од часу терм´н збер´ганнЯ палива

склада¹ не б´льше трьох м´сЯц´в. еред

збер´ганнЯм у зимовий пер´од часу паливо

необх´дно злити, а залишки виробити до к´нцЯ,

зав´вши двигун.

• аливо та його випари дуже вогненебезпечн´.

удьте обережн´, працюючи з паливом, маслом

та мастилом. амХЯтайте про небезпеку

загорЯннЯ, вибуху та вдиханнЯ випар´в.

• „лЯ збер´ганнЯ чи перевезеннЯ палива

користуйтесЯ в´дпов´дними ¹мностЯми,

призначеними длЯ таких ц´лей.

• е намагайтесЯ п´дн´мати машину. оводьтесЯ з

машиною, враховуючи »» вагу та поточну

ситуац´ю.

• удьте особливо обережн´ п´д час завантаженнЯ

»» на транспортний зас´б чи причеп, а також п´д

час в´дпов´дного вивантаженнЯ.

‚икористовуйте належний борт.

• ‚икористовуйте спец´альний причеп длЯ

транспортуваннЯ машини. ‡акр´п´ть машину

спец´альними ременЯми. ереконайтесЯ, що

н´Яку частину машини не стиснуто ´ не

пошкоджено ременЯми. адимо вкрити машину.

• „одаткова ´нформац´Я про перем´щеннЯ машини

п´д час роботи доступна в розд´л´, присвЯченому

перем´щенню.

‡аправленнЯ паливом

• еред заправленнЯм обовХЯзково вимкн´ть

двигун ´ дайте йому охолонути протЯгом

дек´лькох хвилин.

• ‡аправленнЯ палива у бак проводьте у добре

пров´трюваному прим´щенн´ та з вимкненим

двигуном.

“‚ƒ! ензин ¹ легкозаймистою

р´диною. удьте обережн´ та

!

заправлЯйте на в´дкритому пов´тр´.

‚огонь, в´дкрите полумХЯ ´ кур´ннЯ

заборонен´.

‚итр´ть кришку паливного баку та

поверхню б´лЯ горловини. ´слЯ

заправленнЯ обережно, але щ´льно

закрийте кришку. Ÿкщо кришка

паливного баку не затЯгнута достатньо

щ´льно, унасл´док в´брац´й цЯ кришка

може послабитисЯ, що спричинить

вит´каннЯ палива з баку та ризик

виникненнЯ пожеж´. ерем´ст´ть

культиватор принаймн´ на 3 метри в´д

м´сцЯ заправленнЯ перед тим, Як

запустити його.

• амХЯтайте про небезпеку загорЯннЯ, вибуху та

вдиханнЯ випар´в. ‡аборонЯ¹тьсЯ надм´рне

заливаннЯ палива так, що воно вилива¹тьсЯ

назовн´. ‚идал´ть усе пролите на землю та

пристр´й паливо. Ÿкщо ви пролили паливо на

себе чи на св´й одЯг. ереодЯгн´тьсЯ.

ерем´ст´ть пристр´й принаймн´ на 3 м в´д м´сцЯ

заправленнЯ паливом перед тим, Як запустити

його.

• „вигун вид´лЯ¹ окис вуглецю Р безбарвний

отруйний чадний газ. е використовуйте

машину в закритих прим´щеннЯх.

21 – Ukrainian

Page 29

Œ’† ’ ‹˜’“‚Ÿ

озпакуваннЯ

§люстрац´Я: 1 ¥ 1

‚†‹ˆ‚! озр´заючи кра» упаковки, будьте

обережн´, щоб не пошкодити кабел´ та корпус

культиватора.

означеннЯ пис

A „етал´ двигуна

B Šомпонент тримача

C ƒоловний компонент тримача

D

E Šåðìî

F —îõîë äëß çóáö´â

G ‘коба чохлу длЯ зубц´в

H ‚аж´ль перемиканнЯ швидкостей

I ‹îïàò´

J Šолесо

K ‡Х¹днувач

L ‘умка длЯ ´нструмент´в

M крема сумка длЯ зубц´в

N ‘умка длЯ металевих частин

ижн´й чохол длЯ впорЯдкуваннЯ

кабел´в

‡бираннЯ

§люстрац´Я: 1 ¥ 2

“‚ƒ! еправильне збираннЯ цього

культиватора може призвести до

!

серйозних травм. ереконайтесЯ, що ви

точно дотриму¹тесь вс´х ´нструкц´й.

• “становка нож´в на фрези. а ´люстрац´»

в´добража¹тьсЯ лише процес установленнЯ

нож´в на фрези, лише длЯ право» сторони.

ереконайтесЯ, що гостр´ кра» напрЯмлено в

один б´к у ножах Як л´воруч, так ´ праворуч. а

кожному з бок´в ¹ одне коротке лезо, Яке п´д час

збираннЯ сл´д з´гнути вб´к коробки передач.

(§люстрац´Я 1-6)

• “становленнЯ зХ¹днувача. (§люстрац´Я 7)

• “становленнЯ керма. (§люстрац´Я 8)

• “становленнЯ ручки. (§люстрац´Я 9)

• ‚´дрегулюйте висоту ручки та над´йно затЯгн´ть

ф´ксуюч´ гол´вки.

• “становленнЯ перемикача зчепленнЯ.

(§люстрац´Я 11)

- оверн´ть у потр´бний б´к ´ затЯгн´ть болт.

• “становленнЯ нижнього чохла длЯ

впорЯдкуваннЯ кабел´в.

- удьте уважн´ при ф´ксац´» кабел´в.

- равильно встанов´ть гумовий тримач.

- “станов´ть чохол ´ закрут´ть гвинти.

• “становленнЯ чохла длЯ зубц´в. (§люстрац´Я 14-

16)

- е закручуйте болт в´дразу п´слЯ встановленнЯ.

- ‘початку розм´ст´ть ус´ 4 болти та гайки, а пот´м

закрут´ть по черз´.

(§люстрац´Я 10)

(§люстрац´Я 12-13)

• “становленнЯ перемикача швидкостей.

(§люстрац´Я 17)

ри виникненн´ питань з приводу зборки/розборки

рекоменду¹мо звернутись до будь Якого оф´ц´йного

дилера.

“‚ƒ! ´слЯ повного збираннЯ машини пов´льно

затЯгн´ть болти ´ гвинти. е затЯгуйте надто

сильно.

пис компонент´в

§люстрац´Я: 1 ¥ 3

1 „вигун

2 —охол длЯ зубц´в

3 ижн´й чохол длЯ впорЯдкуваннЯ кабел´в

4 Šришка длЯ ременЯ

5 ‹опат´

6 Šермо

7 учка

8 ‚аж´ль перемиканнЯ швидкостей

9 ампер

10 еремикач зчепленнЯ

11 егулЯтор дроселЯ

12 еремикач ув´мкненнЯ/вимкненнЯ

13 ‚ерхн´й чохол длЯ впорЯдкуваннЯ кабел´в

’абличка техн´чних даних

§люстрац´Я: 1 ¥ 4

1 ‘ер´йний номер

2 ртикул товару

3 ˜ирина захвату

4 еремиканнЯ передач

5 бХ¹м цил´ндра

6 ’ип масла длЯ двигуна

7 бХ¹м масла у двигун´

8 ’ип масла длЯ Š

9 бХ¹м масла у Š

10 ом´нальна потужн´сть

11 ‚ага нетто, кг

12 альне

’ранспортне колесо

§люстрац´Я: 1 ¥ 5

„лЯ транспортуваннЯ культиватора зам´н´ть фрези

на колеса.

„одаткова ´нформац´Я про перем´щеннЯ машини

доступна в розд´л´, присвЯченому перем´щенню.

Ukrainian – 22

Page 30

“‘Š ’ ‚ˆŒˆŠŸ

еред початком роботи

• ерев´рте р´вень оливи у двигун´ ´ за необх´дност´

долийте »». §люстрац´Я: 2 ¥ 1

• ерев´рте р´вень оливи в коробц´ передач ´ за

необх´дност´ долийте »». §люстрац´Я: 2 ¥ 2

• ерев´рте р´вень палива. ‡а необх´дност´

додайте палива. §люстрац´Я: 2 ¥ 3

- екоменду¹тьсЯ використовувати: ктанове

число понад 90.

• ерев´рте р´вень масла у пов´трЯному ф´льтр´ ´ за

необх´дност´ додайте §люстрац´Я: 2 ¥ 4

‡апуск.

• ‚´дкрийте паливний кран. §люстрац´Я: 2 ¥ 5

• еревед´ть перемикач пов´трЯно» засл´нки в

положеннЯ . §люстрац´Я: 2 ¥ 6

• егулЯтор дроселЯ §люстрац´Я: 2 ¥ 7

- ерем´ст´ть регулЯтор дроселЯ в положеннЯ

повн´стю в´дкрито» дросельно» засл´нки.

• ерем´ст´ть перемикач ув´мкненнЯ/вимкненнЯ в

положеннЯ ON (“‚§ŒŠ.) длЯ переходу в режим

початкового положеннЯ дроселЯ. §люстрац´Я: 2 ¥

8

• еремикач швидкост´ §люстрац´Я: 2 ¥ 9

- “станов´ть перемикач швидкост´ в положеннЯ 'N'

(нейтральне положеннЯ).

• атисн´ть перемикач блокуваннЯ на ручц´ (A) та

перем´ст´ть важ´ль керуваннЯ зчепленнЯм у б´к

ручки (B).

• ”рези починають обертатись, коли ви

перем´щу¹те зчепленнЯ по напрЯмку до ручки, та

припинЯ¹ обертатисЯ, коли ви в´дпуска¹те

зчепленнЯ.

‡àäí´é õ´ä

§люстрац´Я: 3 ¥ 2

‚†‹ˆ‚! ”рези починають обертатись, коли ви

перем´щу¹те зчепленнЯ по напрЯмку до ручки, та

припинЯ¹ обертатисЯ, коли ви в´дпуска¹те

зчепленнЯ. ‚ажливо в´дпускати важ´ль зчепленнЯ

перед перемиканнЯм швидкост´ на зворотн´й х´д.

• ерем´ст´ть перемикач у положеннЯ 'R'.

“‚ƒ! ‚икористаннЯ зворотнього ходу

небезпечно! ереконайтесЯ, що позаду

!

вас нема¹ н´Яких перешкод, ´ зменш´ть

оберти двигуна перед застосуваннЯм

зчепленнЯ.

• атисн´ть перемикач блокуваннЯ на ручц´ (A) та

перем´ст´ть важ´ль керуваннЯ зчепленнЯм у б´к

ручки (B).

• отЯгн´ть ручку стартера §люстрац´Я: 2 ¥ 10

“‚ƒ! ´д час запуску машини

залишайтесЯ в безпечн´й зон´.

!

• еревед´ть перемикач пов´трЯно» засл´нки в

положеннЯ ‚. §люстрац´Я: 2 ¥ 11

‡астосуваннЯ

“‚ƒ! е п´дпускайте до себе

сторонн´х людей. „´ти, тварини, особи,

!

що спостер´гають чи допомагають вам

працювати, повинн´ залишатисЯ у

безпечн´й зон´ на в´дстан´ б´льше 20

метр´в. егайно вимкн´ть двигун, Якщо

хтось п´д´йде.

‚перед

§люстрац´Я: 3 ¥ 1

• Šеруйте швидк´стю за допомогою перемикача

швидкостей.

îâ´ëüíî

˜видко

‚имкненнЯ

• ‚´дпуст´ть важ´ль зчепленнЯ. §люстрац´Я: 4 ¥ 1

• “станов´ть перемикач швидкост´ в положеннЯ 'N'

(нейтральне положеннЯ). §люстрац´Я: 4 ¥ 2

• ерем´ст´ть регулЯтор дроселЯ в положеннЯ

MIN. §люстрац´Я: 4 ¥ 3

• ™об зупинити двигун, переключ´ть вимикач.

§люстрац´Я: 4 ¥ 4

• ‡акрийте паливний кран. §люстрац´Я: 4 ¥ 5

ерем´щеннЯ машини

§люстрац´Я: 5 ¥ 1

• еред перем´щеннЯм культиватора, вимкн´ть

двигун. „ив. ´нструкц´» в розд´л´ зупиненнЯ.

• „лЯ транспортуваннЯ культиватора зам´н´ть

фрези на колеса. (§люстрац´Я A)

• ´дн´м´ть кермо за ручки та рухайтесЯ вперед.

(§люстрац´Я B)

23 – Ukrainian

Page 31

‘‹“ƒ‚“‚Ÿ

ƒраф´к техн´чного обслуговуваннЯ

ижче наведено перел´к заход´в техн´чного обслуговуваннЯ, Як´ сл´д виконувати.

™оденне

’ехн´чне обслуговуваннЯ

чист´ть машину. X

ереконайтесЯ, що гайки та гвинти

затЯгнуто ´ не пошкоджено.

очист´ть пов´трЯний ф´льтр. ‡ам´н´ть в

раз´ потреби.

ерев´рте р´вень оливи у двигун´

ерев´рте р´вень оливи в коробц´

передач ´ за необх´дност´ долийте »».

ерев´рте, чи нема¹ витоку палива,

моторного мала.

ерев´рте р´вень палива. ‡а необх´дност´

додайте палива.

Ÿкщо ´нструмент почина¹ незвично

в´брувати, необх´дно негайно перев´рити

його.

‡ам´н´ть оливу ´ мастило у двигун´ та

коробц´ передач.

чист´ть паливний ф´льтр ´ його

навколишн´ компоненти.

чист´ть св´чку запалюваннЯ та »»

ковпачок.

еобх´дно зам´нити св´чку запалюваннЯ. X

егулюваннЯ зазору X**

„´агностика –ƒ X**

ерев´рка паливно» системи X**

§ëþñò

ðàö´ß:

4 ¥ 6 X X* X**

2 ¥ 1, 2

¥ 4

2 ¥ 2 X

2 ¥ 3 X

обслуговува

ннЯ перед

початком

роботи

X

X

X

X

§нтервали техн´чного обслуговуваннЯ в

годинах

20 годин

або

щом´сЯцЯ

X X

50 годин

або кожн´

3 м´сЯц´

100 годин

або кожн´

6 м´сЯц´в

X X**

X

300 годин

або щороку

* ‚иконуйте процедуру чищеннЯ част´ше при робот´ за умов запиленого або забрудненого пов´трЯ.

** е важливо, Якщо нема¹ проблем ´з продуктивн´стю. ‡верн´тьсЯ до авторизованого серв´сного центру.

“‚ƒ! егулЯрно обслуговуйте губчастий ф´льтр. ромийте його ретельно у тепл´й мильн´й вод´.

´слЯ цього ретельно мийте ф´льтр у чист´й вод´. ‚´д´жм´ть ф´льтр та дайте висохнути. ‡‚…§’œ

!

“‚ƒ“! ‘тиснене пов´трЯ може пошкодити п´ну його губчасту структуру. е використовуйте

стиснене пов´трЯ або розчинники на основ´ нафти длЯ очищеннЯ пов´трЯного ф´льтра.

‡агальне

“‚ƒ! еред проведеннЯм ремонтних роб´т, очищеннЯ або перев´рки машина повинна бути у стан´

спокою та з вимкненим двигуном.

!

‡аборонЯ¹тьсЯ виконувати регулюваннЯ за ув´мкненому двигуна.

‡авжди користуйтесЯ ориг´нальними запчастинами.

• ‡н´м´ть прикраси, годинники та аналог´чн´ реч´ перед чищеннЯм, ремонтом або оглЯдом машини.

е зм´нюйте конструкц´ю захисного обладнаннЯ. егулЯрно перев´рЯйте обладнаннЯ, щоб переконатисЯ, що

воно працю¹ належним чином.

‡авжди будьте обережн´ та керуйтесЯ здоровим глуздом. “никайте ситуац´й, Як´ виходЯть за меж´ ваших

можливостей. Ÿкщо п´слЯ ознайомленнЯ з ´нструкц´Ями у вас залишатьсЯ сумн´ви щодо того, Як

користуватисЯ ´нструментом, перед продовженнЯм необх´дно проконсультуватисЯ у спец´ал´ста. ‡верн´тьсЯ

до авторизованого серв´сного центру.

Ukrainian – 24

Page 32

’…•§—§ •Š’…ˆ‘’ˆŠˆ

’åõí´÷í´ äàí´

TF338

˜ирина зр´заннЯ, мм 950

ƒлибина зр´заннЯ, мм 150 - 300

„вигун WM170FB/P-2

альне ензин

¸мн´сть паливного бака, американських р´дких унц´й/л 4,8

бХ¹м масла у двигун´, л´три 0,6

бХ¹м цил´ндра, см

Œакс. потужн´сть, к.с. (к‚т) @ оберт´в на хвилину 4,9 (3,6) @3100

ередач´ R, N, 2, 1

Œ´стк´сть оливи в коробц´ передач, л´три 1,1

‚ага брутто, кг 106

‚ага нетто, кг 93

озм´р упаковки, мм 860x490x860

‘ертиф´кац´Я CE, EAC

‚†‹ˆ‚! Šоли терм´н служби цього продукту минув, ´ в´н б´льше не використову¹тьсЯ,

його сл´д повернути до дилера або у в´дпов´дне м´сце длЯ утил´зац´».

3

212

‚†‹ˆ‚! Œи залиша¹мо за собою право зм´нювати техн´чн´ характеристики та

конструкц´ю, а також впроваджувати вдосконаленнЯ без попереднього пов´домленнЯ.

‡ауважте, що жодн´ правов´ претенз´» на основ´ ´нформац´», що м´ститьсЯ в цьому пос´бнику, не

¹ д´йсними. „лЯ ремонту використовуйте лише ориг´нальн´ детал´. “ раз´ використаннЯ

неориг´нальних деталей гарант´Я анулю¹тьсЯ.

„екларац´Я в´дпов´дност´ стандартам ¸вропейського ‘оюзу (‹ише

длЯ кра»н ¸вропи)

Œи, Husqvarna ‚, SE-561 82 м´сто •ускварна, ˜вец´Я, телефон: +46-36-146500, заЯвлЯ¹мо п´д свою виключну

в´дпов´дальн´сть, що культиватори Husqvarna TF 230 та TF 338 ´з сер´йними номерами, починаючи з

1447000096 длЯ TF 230 та 1447000139 длЯ TF 338 (сер´йний номер зазначено нешифрованим текстом на

заводськ´й табличц´ техн´чних даних), в´дпов´дають вимогам „ˆ…Š’ˆ‚ „ˆ ¸‘:

в´д 17 травнЯ 2006 р. 'стосовно механ´чного обладнаннЯ' 2006/42/EC.

в´д 15 груднЯ 2004 р. 'про електромагн´тну сум´сн´сть' 2004/108/EC.

‡астосовано так´ гармон´зован´ стандарти: EN 709:1997, A4:2009

ƒускварна, 10 ƒрудень 2014 р.

Šлаес ‹осдал (Claes Losdal), „иректор в´дд´лу розробок / ‘адова техн´ка (“повноважений представник

компан´» Husqvarna AB, що в´дпов´да¹ за техн´чну документац´ю).

25 – Ukrainian

Page 33

A

D

Índice

ÍNDICE

Índice ........................................................................... 26

CLARACIÓN DE LOS SÍMBOLOS

Símbolos ...................................................................... 27

Explicación de los niveles de advertencia ................... 27

INSTR UCCIONES DE SEGURIDAD

Gener alidades .............................................................. 28

Preparación .................................................................. 28

Aplicaciones ................................................................. 28

Mantenimiento ............................................................. 29

Transporte y almacenamiento ...................................... 29

Repostaje ..................................................................... 29

MONT AJE Y AJUSTES

Desembalaje ................................................................ 30

Montaje ........................................................................ 30

Descripción de los componentes ................................. 30