GB Operator´s manual

FR Manuel d'utilisation

ES Manual de instrucciones

SAW ATTACHMENT

ACCESSOIRE DE SCIAGE

SUPLEMENTO DE SIERRA

Please read these instructions carefully

and make sure you understand them

before using the machine.

Lire attentivement et bien assimiler le

manuel d’utilisation avant d'utiliser la

machine.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

GB FR ES

Symbols

SYMBOL EXPLANATION

Saw attachment

with shaft

WARNING! Clearing saws, brushcutters

and trimmers can be dangerous!

Careless or incorrect use can result in

serious or fatal injury to the operator or

others.

Read through the Operator‘s Manual

carefully and understand the content

before using the machine.

Always use

• A protective helmet where there is a

risk of falling objects

• Ear protection

• Approved eye protection

This product is in accordance with

applicable CE directives.

This machine is not electrically

insulated. If the machine touches or

comes close to high-voltage power lines

it could lead to death or serious injury.

Electricity can jump from one point to

another by arcing. The higher the

voltage, the greater the distance

electricity can jump. Electricity can also

travel through branches and other

objects, especially if they are wet.

Always keep a safe distance of at least

10 m (30 ft) between the machine and

high-voltage power lines and/or any

objects that are touching them. If you

need to work closer than this always

contact the relevant power company to

make sure the power is switched off

before you start work.

Always wear approved protective gloves.

Use anti-slip and stable boots.

Other symbols/decals on the machine refer to

special certification requirements for certain

markets.

Checks and/or maintenance should be

carried out with the engine switched off,

with the stop switch in the STOP

position.

Always wear approved protective gloves.

Regular cleaning required.

Ocular control.

Saw attachment

without shaft

2 – English

This machine is not electrically

insulated. If the machine touches or

comes close to high-voltage power lines

it could lead to death or serious injury.

Electricity can jump from one point to

another by arcing. The higher the

voltage, the greater the distance

electricity can jump. Electricity can also

travel through branches and other

objects, especially if they are wet.

Always keep a safe distance of at least

10 m (30 ft) between the machine and

high-voltage power lines and/or any

objects that are touching them. If you

need to work closer than this always

contact the relevant power company to

make sure the power is switched off

before you start work.

Approved eye protection must always be

used.

Chain oil and chain oil flow adjustment

CONTENTS

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify the

design and appearance of products without prior notice.

Read through the Operator‘s manual

carefully and understand the content before

using the machine.

These instructions supplement the instructions that were

included with the machine. For other procedures, please

refer to the opertaing instructions for hte machine.

WARNING!

!

!

Under no circumstances may the design

of the machine be modified without the

permission of the manufacturer. Always

use genuine accessories. Non-authorised

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING!

This accessory may only be used together

with the intended clearing saw/trimmer,

see under heading ”Approved

accessories” in chapter Technical data in

the machine's Operator's Manual.

List of contents

SYMBOL EXPLANATION

Symbols ............................................................................... 2

CONTENTS

List of contents .................................................................... 3

SAFETY INSTRUCTIONS

Cutting equipment .............................................................. 4

Specification of blade and chain ........................................... 4

Sharpening your chain and adjusting raker clearance ........... 5

Tensioning the saw chain ..................................................... 7

Lubricating cutting equipment ............................................ 7

Checking wear on cutting equipment .................................. 8

Safety insructions when using the machine .......................... 9

Basic working techniques ................................................... 10

WHAT IS WHAT?

What is what on the machine? ........................................... 12

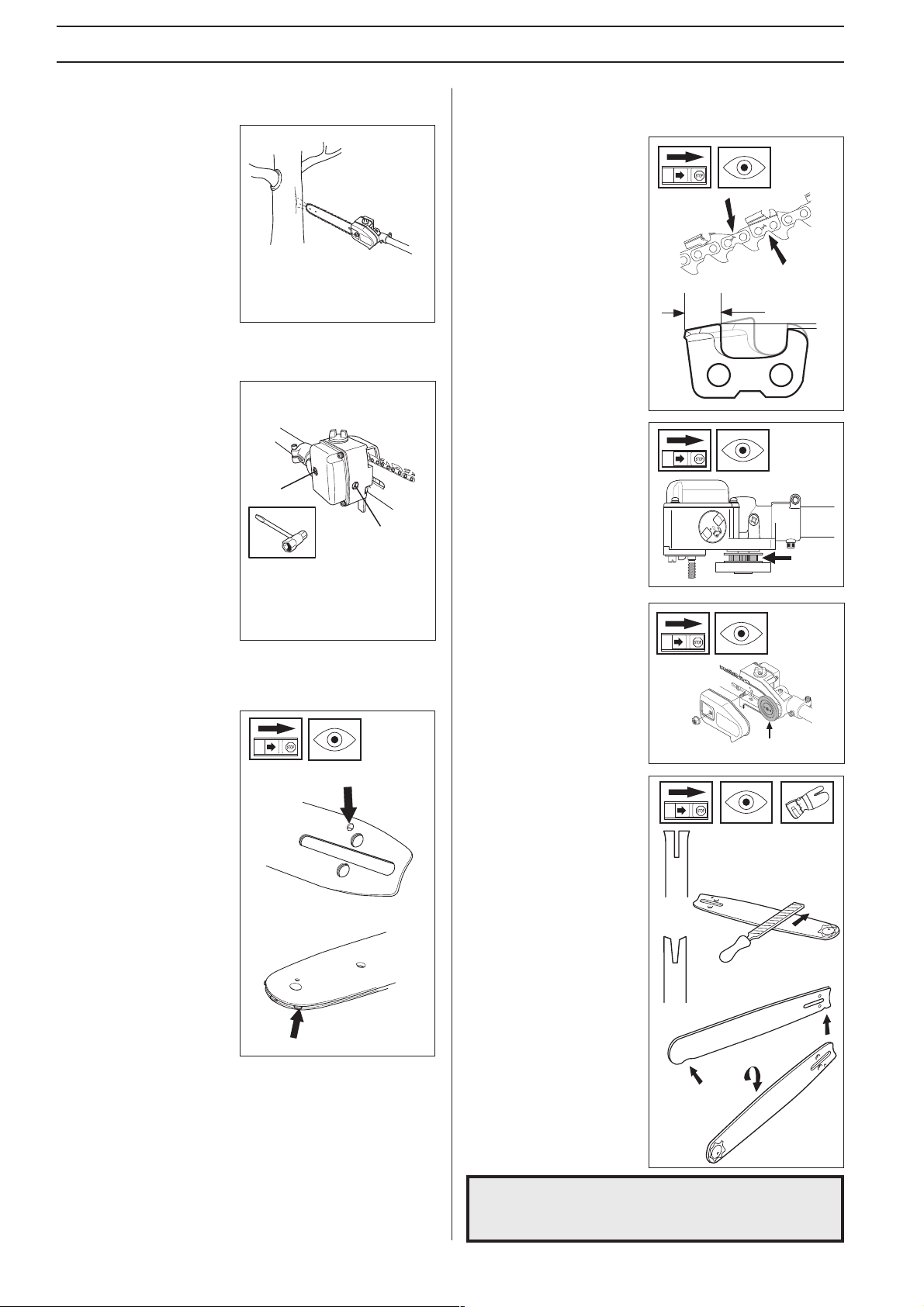

ASSEMBLY

Fitting the cutting head (Saw attachment with shaft ) ........ 14

Fitting the cutting head (Saw attachment without shaft).... 14

Mounting guide bar and chain........................................... 14

Fitting the hanging ring ..................................................... 14

Adjusting the harness ......................................................... 14

Filling with oil ................................................................... 15

Control before starting....................................................... 15

TECHNICAL DATA

Technical data .................................................................... 16

The machine is only designed for tree pruning.

English – 3

SAFETY INSTRUCTIONS

Cutting equipment

This section describes how through correct maintenance and

through using the right type of cutting equipment you can:

• Obtain maximum cutting capacity.

• Increase the service life of the cutting equipment.

1 Check the cutting

equipment with regard to

damage and crack

formation. Damaged

cutting equipment should

always be replaced.

2 Only use cutting

equipment recommended

by us! See the ”Technical

data” section.

3 Keep the chain cutting

teeth properly sharpened!

Follow our instructions

and use the recommended

file gauge. A damaged or

badly sharpened chain

increases the risk of

accidents.

4 Maintain the correct raker

clearance! Follow our

instructions and use the

recommended raker gauge.

Too large a clearance

increases the risk of

kickback.

5 Keep the chain properly

tesioned! If the chain is

slack it is more likely to

jump off and lead to

increased wear on the bar,

chain and drive sprocket.

6 Keep cutting equipment

well lubricated and

properly maintained! A

poorly lubricated chain is

more likely to break and

lead to increased wear on

the bar, chain and drive

sprocket.

WARNING!

Never use a machine with defective

!

!

safety equipment. The safety equipment

should be maintained as described in this

section. If your machine does not meet

any of these controls you should contact

your service workshop.

WARNING!

Always stop the engine before carrying out

any work on the cutting equipment. This

will continue to move even after the throttle

has been released. Make sure the cutting

equipment has stopped completely and

disconnect the HT lead from the spark plug

before you start work on it.

Specification of blade and chain

When the cutting equipment supplied with your machine

becomes worn or damaged, you will need to replace it. Use

only the manufacturer approved bar and chain.

Guide bar

• Length (inches/cm)

• Number of teeth on bar

tip sprocket (T).

Small number = small tip

radius = low kickback

• Chain pitch (inches)

The spacing between the

drive links of the chain

must match the spacing of

the teeth on the bar tip

sprocket and drive

sprocket.

• Number of drive links

The number of drive links

is determined by the

length of the bar, the

chain pitch and the

number of teeth on the

bar tip sprocket.

• Bar groove width (inches/

mm)

The groove in the bar

must match the width of

the chain drive links.

4 – English

• Saw chain oil hole and

hole for chain tensioner.

SAFETY INSTRUCTIONS

Saw chain

• Saw chain pitch (inches)

Spacing between drive

links.

• Drive link width (mm/

inches).

• Number of drive links.

Sharpening your chain and

adjusting raker clearance

FILE POSITION

ROUND FILE DIAMETER

FILE DEPTH

1

5

WARNING!

!

The risk of kickback is increased with a

badly sharpened chain!

A. General information on sharpening

cutting teeth

• Never use a blunt chain. When the chain is blunt you have

to exert more pressure to force the bar through the wood

and the cuttings will be very small. If the chain is very blunt

it will not produce any cuttings at all, just wood powder.

• A sharp chain eats its way through the wood and produces

long, thick cuttings.

• The cutting part of the

chain is called the

CUTTING LINK and

this consists of a

CUTTING TOOTH (A)

and the RAKER LIP (B).

The cutting depth is

determined by the

difference in height

between the two.

• When you sharpen a

cutting tooth there are five

important factors to

remember:

A

B

It is very difficult to sharpen

a chain correctly without the

right equipment. We recommend you to use a file gauge.

This will help you obtain the

maximum kickback

reduction and cutting

performance from your

chain.

The following faults will increase the

!

risk of kickback considerably.

• FILE ANGLE TOO

LARGE

• CUTTING ANGLE TOO

SMALL

• FILE DIAMETER TOO

SMALL

FILING ANGLE

CUTTING ANGLE

English – 5

SAFETY INSTRUCTIONS

B. Sharpening

cutting tooth

To sharpen cutting teeth you

will need a ROUND FILE

and a FILE GAUGE.

1. Check that the chain is

correctly tensioned. A

slack chain is difficult to

sharpen correctly.

2. Always file cutting teeth

from the inside face,

reducing the pressure on

the return stroke.

File all the teeth on one

side first, then turn the

saw over and file the teeth

on the other side.

3. File all the teeth to the

same length. When the

length of the cutting

teeth is reduced to 4 mm

(.16") the chain is worn

out and should be

replaced.

C. General advice on setting raker

clearance

• When you sharpen the

cutting teeth you reduce

the RAKER

CLEARANCE (cutting

depth). To maintain

cutting performance you

must file back the raker

teeth to the recommended

height.

• On a low-kickback cutting

link the front edge of the

raker lip is rounded. It is

very important that you

maintain this radius or

bevel when you adjust the

raker clearance.

• We recommend the use of

a raker gauge to achieve

the correct clearance and

bevel on the raker lip.

min 4 mm

(0,16")

!

WARNING!

The risk of kickback is increased if the

raker clearance is too large!

6 – English

SAFETY INSTRUCTIONS

D. Adjusting raker clearance

• When correction of the

raker clearance is made

the teeth must be newly

sharpened.

We recommend that you

adjust the raker clearance

every third time you

sharpen the chain.

NOTE! This

recommendation assumes

that the length of the

cutting teeth is not

reduced excessively.

• A FLAT FILE and an

RAKER CLEARANCE

GAUGE are required to

correct the raker

clearance.

• Place the gauge over the

raker lip.

• Place the file over the part

of the lip that protrudes

through the gauge and file

off the excess. The

clearance is correct when

you no longer feel any

resistance as you draw the

file over the gauge.

Tensioning the saw chain

WARNING!

!

• The more you use a chain

the longer it becomes. It is

therefore important to

adjust the chain regularly

to take up the slack.

A slack chain may jump off and cause

serious or even fatal injury.

1. Undo the bar nut.

2. Tension the chain by

turning the chain

tensioning screw

clockwise using the

combination spanner.

Tighten the chain until

it no longer hangs slack

beneath the bar.

3. Use the combination

spanner to tighten the

blade nut while lifting

the tip of the bar at the

same time. Check that

you can pull the chain

round freely by hand.

Lubricating cutting equipment

WARNING!

Poor lubrication of cutting equipment may

!

A. Chain oil

• Chainsaw chain oil must demonstrate good adhesion to the

chain and also maintain its flow caracteristics regardless of

whether it is warm summer or cold winter weather.

• As a chain saw manufacturer we have developed an ideal saw

chain oil that is vegetable-based. We recommend the use of

our own oil for both maximum chain life and to minimise

environmental damage.

• If our own chain oil is not available, standard chain oil is

recommended.

• In areas where oil specifically for lubrication of saw chains is

unavailable, ordinary EP 90 transmission oil may be used.

• Never use waste oil!

This is dangerous for yourself, the saw and the environment.

B. Filling with chain oil

cause the chain to snap and lead to serious,

even fatal injuries.

• Check the chain tension

every time you refuel.

NOTE! A new chain has a

running-in period during

which you should check

and adjust the chain

tension more frequently.

• As a rule the chain should

be tensioned as tightly as

possible, but not so tight

that you cannot pull it

round freely by hand.

The oil pump is preset at

the factory to meet most

lubrication requirements

and a full oil tank will last

about half as long as a tank

of fuel. You should therefore

check the level in the oil

tank regularly to avoid

damaging the chain and bar

by running out of oil.

English – 7

SAFETY INSTRUCTIONS

C. Checking chain lubrication

• Check the chain

lubrication each time you

refuel.

Aim the tip of the saw at a

light coloured surface

about 20 cm away. After 1

minute running at 3/4

throttle you should see a

distinct line of oil on the

light surface.

D. Adjusting chain lubrication

• When cutting dry or hard

species of wood it may be

necessary to increase

lubrication. To increase

the oil flow, first undo

screw (A) then turn the

adjuster screw (B)

anticlockwise. Re-tighten

screw (A). Remember that

this will increase the oil

consumption and you

should therefore check the

level in the oil tank more

frequently.

A

Procedure if the lubrication does not

function:

• Check that the oil channel

in the bar is not

obstructed. Clean if

necessary.

Check also that the O-ring

is in position and is

undamaged.

• Check that the oil channel

in the gear housing is

clean. Clean if necessary.

Checking wear on cutting equipment

A. Saw chain

Check the saw chain daily

for:

• Visible cracks in rivets and

links.

• Whether the chain is stiff.

• Whether rivets and links

are badly worn.

Compare the existing chain

with a new chain to decide

how badly it is worn.

When the length of the

cutting teeth has worn down

to only 4 mm the chain

must be replaced.

B. Chain drive wheel

Check regularly the degree of

wear on the drive wheel.

Change if it is irregularly

worn.

B

C.Vibration

damping system

Check regularly that the

vibration damper i free from

cracks.

Check regularly the degree of

wear on the rubber elements.

Change if worn

D. Guide bar

Check regularly:

• Whether there are burrs

on the edges of the bar.

Remove these with a file if

necessary.

min 4 mm

(0,16")

• Check that the bar tip

sprocket turns freely. If the

chain lubrication system is

still not working after

carrying out the above

measures you should

contact your service agent.

8 – English

• Whether the groove in the

bar has become badly

worn. Replace the bar if

necessary.

• Whether the tip of the bar

is uneven or badly worn. If

a hollow forms on one side

of the bar tip this is due to

a slack chain.

• To prolong the life of the

bar you should turn it over

daily.

WARNING!

Using faulty cutting equipment may

!

increase the risk of accidents.

SAFETY INSTRUCTIONS

Safety instructions when using the

machine

WARNING!

!

!

NOTE! Read the Operator’s Manual carefully before using

the machine.

Personal protection

• Always wear boots, and the

other safety equipment

described in the section

”Personal protective

equipment” in the

machine's Operator's

Manual.

• Always wear working

clothes and thick, long

trousers.

The machine can cause serious injury.

Read the safety instructions carefully.

Learn how to use the machine.

WARNING!

Cutting tool. Do not touch the tool

without first switching off the engine.

Protective instructions while working

• Always ensure you have a

safe and firm working

position.

• Always use both hands to

hold the machine. Hold

the machine on the side

of the body.

• Use your right hand to

operate the throttle.

• Make sure that your

hands and feet cannot

come into contact with

the cuttingequipment

when the engine is

running.

• When the engine is

switched off, keep your

hands and feet away from

the cuttingequipment

until it has stopped.

• Watch out for stumps of

branches that can be

thrown out during

cutting.

• Never wear loose fitting

clothes or jewellery

• Secure hair so it is above

shoulder level.

Protective instructions regarding the

surroundings

• Never allow children to use

the machine.

• Ensure no one comes

within 15 metres while

working.

• Never allow anyone to use

the machine without first

being absolutely sure that

they understand the

contents of the Operator’s

Manual.

• Always lay the machine on the ground when you are not

using it.

• Check the working area for foreign objects such as electricity

cables, insects and animals, etc, and for other objects that

could damage the cutting attachment, such as metal items.

• If any object is hit or if vibrations occur stop the machine

immediately. Remove the spark plug cable from the spark

plug. Check that the machine is not damaged. Repair any

damage.

• If anything gets caught up in the cutting equipment while

you are working, switch off the engine and wait for it to stop

completely before cleaning the cutting equipment.

• Never work on a ladder,

stool or any other raised

position that is not fully

secured.

English – 9

SAFETY INSTRUCTIONS

Protective instructions when

work is completed

• The transport guard should always be fitted to the

cuttingequipment when the machine is not in use.

• Ensure the cuttingequipment has stopped and remove the

spark plug cable from the spark plug before carrying out

cleaning, repairs or an inspection.

• Always wear heavy duty

gloves when repairing the

chain. The cuttingequipment is extremely

sharp and can easily

causes cuts.

• Store the machine out of

reach from children.

• Only use original spare

parts when carrying out

repairs.

Observe great care when working close to overhead power

lines. Falling branches can result in short-circuiting.

WARNING!

Observe the applicable safety regulations

!

!

for work in the vicinity of overhead power

lines.

WARNING!

This machine is not electrically insulated. If

the machine touches or comes close to live

electricity lines, it could cause death or

serious injury. Electricity can jump from one

point to another in the form of a highvoltage arc. The higher the voltage, the

further the electricity can jump. Electricity

can also be conducted by branches and

other objects, especially if they are wet.

Always keep a distance of at least 10 m (30

ft) between the machine and live electricity

lines and/or objects that are touching them.

If you have to work closer than this, always

contact the relevant power company to

make sure the power is switched off before

you start your work.

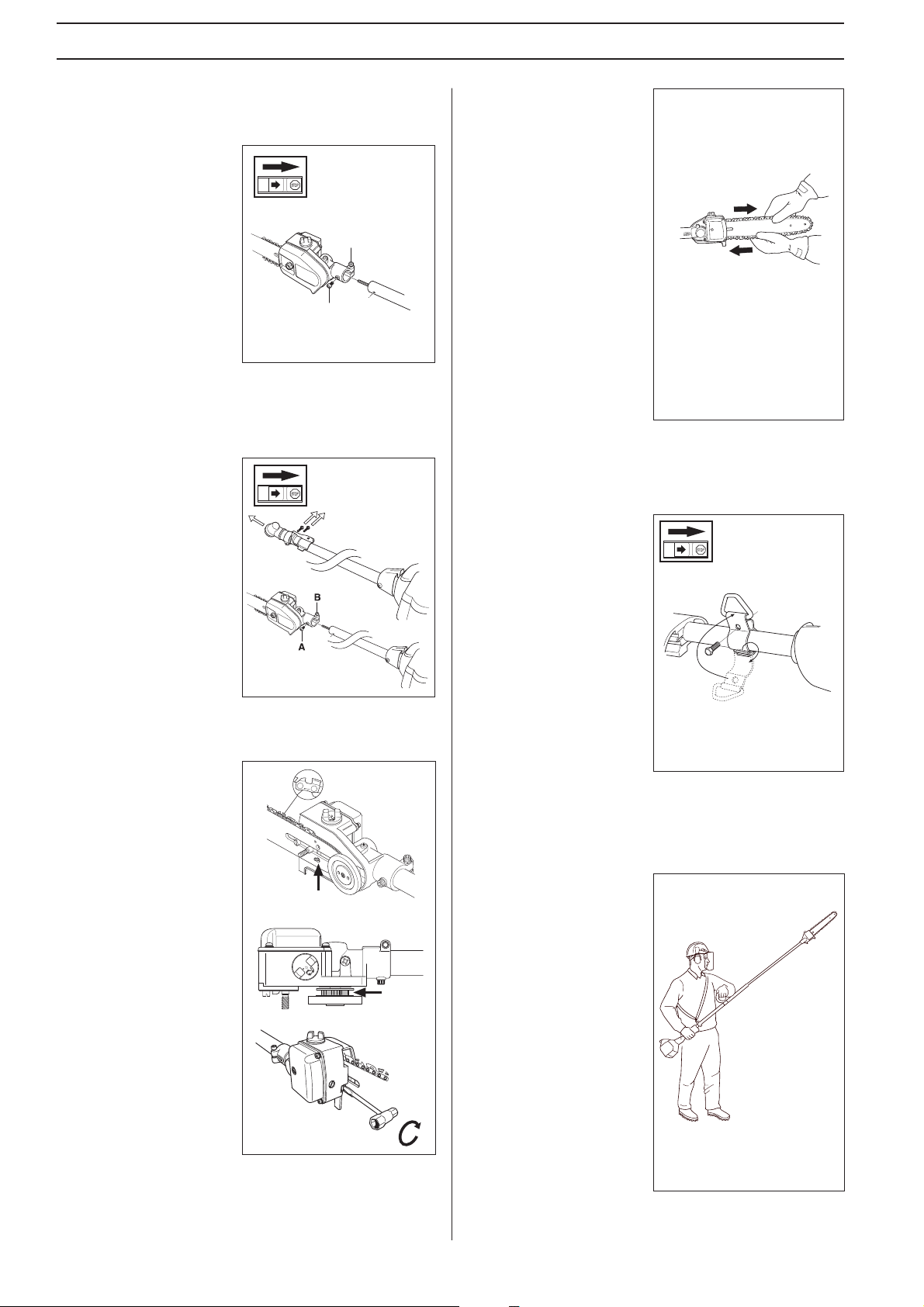

Basic working techniques

• The machine should be

held as close to the body

as possible to get the best

balance.

• Make sure that the tip

does not touch the

ground.

• Do not rush the work,

but work steadily until all

the branches have been

cut back cleanly.

• Always drop to idling

speed after each working

operation. Longer periods

running at full throttle

without loading the

engine can lead to serious

engine damage.

• Allways cut with the engine

at full throttle.

• Let the engine drop back to

idle between each cut. Long

periods at full throttle can

cause serious damage to

the centrifugal clutch.

WARNING!

This machine has a long reach. Make sure

!

• Whenever possible

position yourself so that

you can make the cut at

right angles to the branch.

• Do not work with the shaft

held straight out in front of

you (like a fishing rod).

This increases the apparent

weight of the cutting

equipment.

• Cut large branches in

stages to give better control

over where they fall.

• Never cut through the

swelling at the root of the

branch as this will slow

down healing and increase

the risk of fungal attack.

that no people or animals come closer than

15 m (45 ft) when the machine is running.

90

!

10 – English

Never stand directly underneath a branch

that is being cut, otherwise you may suffer

serious or even fatal injury.

• Use the stop at the base of

the bar to provide support

during cutting. This will

help prevent the cutting

equipment from jumping

on the branch.

• Make an initial cut on the

underside of the branch

before cutting through the

branch from above. This

will prevent tearing of the

bark, which could lead to

slow healing and cause

permanent damage to the

tree. The first cut should

not be deeper than 1/3 of

the branch thickness to

prevent jamming. Keep

the chain running while

you withdraw the cutting

equipment from the

branch to prevent it

jamming.

SAFETY INSTRUCTIONS

• Use the harness to support

the weight of the machine

and make it easier to

handle.

• Make sure you have a firm

footing and will not be

hampered by branches,

stones and other trees.

WARNING!

!

Never use the throttle without having a

full view of the cutting equipment.

English – 11

Saw attachment with shaft

WHAT IS WHAT?

14

11

4

9

3

232315

10

13

12

1

2

8

7

6

5

17

16

What is what on the saw attachment?

1. Lubricant filler hole

2. Bevel gearbox

3. Chain lubrication adjustment screw (B)

4. Chain lubrication locking screw (A)

5. Shaft

6. Hook for harness

7 Chain guard

8. Bar nut

9. Chain tensioning screw

12 – English

10. Chain

11. Bar

12. Chain oil tank

13. Chain oil filler hole

14. Operator’s manual

15. Transport guard

16. Combination spanner

17. Harness

WHAT IS WHAT?

Saw attachment without shaft

13

10

4

9

5

8

3

14

15

12

11

1

2

7

6

16

What is what on the saw attachment?

1. Lubricant filler hole

2. Bevel gearbox

3. Chain lubrication adjustment screw (B)

4. Chain lubrication locking screw (A)

5. Hook for harness

6. Chain guard

8. Bar nut

9. Chain tensioning screw

9. Chain

10. Bar

11. Chain oil tank

12. Chain oil filler hole

13. Operator’s manual

14. Transport guard

15. Combination spanner

16. Harness

English – 13

ASSEMBLY

Fitting the cutting head (Saw

attachment with shaft)

• Fit the cutting head on the

shaft so that the screw (A)

is aligned with the hole in

the shaft as shown.

• Tighten screw A.

• Tighten screw B.

NOTE! Make sure that the

drive shaft inside the shaft

engages with the cut-out in

the cutting head.

A

Fitting the cutting head (Saw

attachment without shaft)

• Remove the mitre gear

from the shaft.

• Fit the cutting attachment

to the shaft.

• Tighten screw A.

• Tighten screw B.

NOTE! Make sure that

the drive shaft inside the

shaft engages with the cutout in the cutting head.

• The chain is correctly

tensioned when there is no

slack on the underside of

the bar, but it can still be

turned easily by hand.

Hold up the bar tip and

tighten the bar nuts with

the combination wrench.

B

• When fitting a new chain,

the chain tension has to be

checked frequently until

the chain is run-in. Check

the chain tension regularly.

A correctly tensioned chain

gives good cutting

performance and long

lifetime.

Fitting the hanging ring

Fit the hanging ring between

the rear handle and the loop

handle. Position the hanging

ring so that the machine is

balanced and comfortable to

work with.

Mounting guide bar and chain

• Unscrew the bar nut and

remove the guard.

• Fit the bar over the bar

bolt.Place the bar in its

rearmost position. Place

the chain over the drive

sprocket and in the groove

on the bar. Begin on the

top side of the bar.

• Make sure that the edges

on the cutting links are

facing forward on the top

side of the bar.

• Fit the clutch cover and

locate the chain adjuster

pin in the hole on the bar.

Check that the drive links

of the chain fit correctly on

the drive sprocket and that

the chain is in the groove

on the bar. Tighten the bar nut finger tight.

A

Adjusting the harness

You should always use the

harness with the machine to

give maximum control and

reduce strain on your arms

and back.

B

1. Put on the harness.

2. Hook the machine onto

the hook on the harness.

3. Adjust the length of the

harness so that the hook

is roughly level with your

right hip.

• Tension the chain by using the combination wrench. Turn

the chain adjuster screw clockwise. The chain should be

tensioned until it fits snugly on the underside of the bar.

14 – English

ASSEMBLY

Filling with oil

• Open the cap on top of the

cutting head.

• Fill with Husqvarna Chain

Oil.

• Refit the cap.

Control before starting

• Inspect the working area. Remove objects that can be

thrown.

• Check the cutting-

equipment. Never use

blunt, cracked or

damaged equipment.

• Check that the machine

is in full working order.

Check that all nuts and

bolts are tightened

correctly.

• Make sure the chain is always well lubricated.

• Ensure the cuttingequipment always stop when the engine

is idling.

• Only use the machine for what it is intended for.

• Ensure that the handle and safety functions are in order.

Never use a machine that lacks a part or has been modified

outside of the specifications.

English – 15

TECHNICAL DATA

Saw attachment without

shaft

Saw attachment with

shaft

Lubrication system

Oil tank capacity, US pint/litres

0,17

0,17

Weight

Weight without fuel, cutting tool and guard, Lbs/kg

0,8

1,4

Sound levels

(see note 1)

Equivalent noise pressure level at the user’s ear, measured

according to EN ISO 11680-1:

95

96

Equivalent noise power level at the user’s ear, measured

according to EN ISO 11680-1 and ISO 10884, dB(A):

106

106

Vibration levels

Vibration levels on the handles, measured according to EN ISO

11680 m/s

When idling, left/right handles:

At max. speed, left/right handles:

2

1,0/3,0

5,5/3,6

1,2/2,3

6,0/5,5

Note 1: Equivalent sound pressure level is calculated as the time-weighted energy total for sound pressure levels under various

working conditions with the following time distribution: 1/2 idling and 1/2 max speed.

Bar and chain combinations

The following combinations are CE approved.

Bar Chain

Length, Pitch, Max. no of teeth

inches inches on tip sprocket

10 3/8 7 T Husqvarna S 36/

12 3/8 7 T Husqvarna S 36/

10 3/8 7 T Oregon 90 SG

12 3/8 7 T Oregan 90 SG

Type Inch Inch/mm Inch/mm Angle Angle Angle Inch/mm Inch/cm: dl

91VG 3/8" 0,050"/1,3 5/32" /4,0 85° 30° 0° 0,025"/0,65 10"/25:40

S 36 3/8" 0,050"/1,3 5/32" /4,0 85° 30° 0° 0,025"/0,65 10"/25:40

Oregon 91 VG

Oregon 91 VG

1

5

L

12"/30:45

12"/30:45

90SG 3/8" 0,028"/1,1 5/32" /4,0 85° 30° 0° 0,025"/0,65 10"/25:40

12"/30:45

16 – English

EC declaration of conformity (Only applies to Europe)

We, Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel +46-36-146500, declare that this saw attachment from 2002's

serial numbers and onwards (the year is clearly stated in plain text on the type plate, with subsequent serial number),

complies with the requirements of the COUNCIL’S DIRECTIVE:

- of June 22, 1998 ”relating to machinery” 98/37/EC, annex IIA.

The following standards have been applied: EN292-2, EN ISO 11680-1.

Notified body: 0404, SMP Svensk Maskinprovning AB, Fyrisborgsgatan 3, 754 50 Uppsala, Sweden, has carried out EC

type examination in accordance with the machinery directive's (98/37/EC) article 8, point 2c. The certificate for EC type

examination in accordance with annex VI, has number: 404/02/858.

The supplied saw attachment conforms to the example that underwent EC type examination.

Huskvarna January 3, 2002

Bo Andréasson, Development manager

English – 17

Symboles

EXPLICATIONS DES SYMBOLES

AVERTISSEMENT! Les

débroussailleuses, les tranche-bordures et et

les coupe-herbes peuvent être dangereux!

Une utilisation erronnée ou négligeante

peut occasionner des blessures graves, voire

mortelles pour l’utilisateur et les autres.

Lire attentivement le mode d’emploi et

assimiler son contenu avant d’utiliser la

machine.

Les autres symboles/autocollants présents sur la

Toujours porter:

• un casque de protection car il existe

toujours un risque de chute d’objet

• protège-oreilles

• des lunettes de protection homologuées

Ce produit est conforme à la directive

CE en vigueur.

machine concernent des exigences de certification

spécifiques à certains marchés.

Utiliser toujours des gants de protection

homologués.

Utiliser des bottes stables et

antidérapantes.

Contrôles et/ou entretiens sont effectués

avec le moteur arrêté et le contacteur

d’Arrêt en position STOP.

Accessoire de

sciage avec tube

de transmission

Accessoire de

sciage sans tube

de transmission

Cette machine ne comporte pas d'isolation

électrique. Si elle entre en contact avec ou est

utilisée à proximité de lignes conductrices de

tension, ceci peut résulter en des blessures

corporelles graves voire mortelles. L'électricité

peut être transmise d'un point à un autre par

un arc de tension. Plus la tension est élevée et

plus la longueur de transmission de la tension

est élevée. L'électricité peut également être

transmise par des branches et d'autres objets,

particulièrement s'ils sont mouillés. Toujours

conserver une distance d'au moins 10 mètres

(30 pieds) entre la machine et la ligne

conductrice d'électricité et/ou les objets en

contact avec cette ligne. S'il est nécessaire que

le travail soit effectué avec des distances de

sécurité plus courtes, toujours contacter la

compagnie électrique afin de s'assurer que la

tension est bien coupée avant de commencer

les travaux.

Cette machine ne comporte pas d'isolation

électrique. Si elle entre en contact avec ou est

utilisée à proximité de lignes conductrices de

tension, ceci peut résulter en des blessures

corporelles graves voire mortelles. L'électricité

peut être transmise d'un point à un autre par

un arc de tension. Plus la tension est élevée et

plus la longueur de transmission de la tension

est élevée. L'électricité peut également être

transmise par des branches et d'autres objets,

particulièrement s'ils sont mouillés. Toujours

conserver une distance d'au moins 10 mètres

(30 pieds) entre la machine et la ligne

conductrice d'électricité et/ou les objets en

contact avec cette ligne. S'il est nécessaire que

le travail soit effectué avec des distances de

sécurité plus courtes, toujours contacter la

compagnie électrique afin de s'assurer que la

tension est bien coupée avant de commencer

les travaux.

Utiliser toujours des gants de protection

homologués.

La machine demande un nettoyage

régulier.

Contrôle visuel.

Le port de lunettes de protection

homologuées est obligatoire.

Remplissage d’huile et réglage du débit

d’huile.

18 – Français

SOMMAIRE

Husqvarna AB travaille continuellement au développement de

ses produits et se réserve le droit d’en modifier, entre autres, la

conception et l’aspect.

Lire attentivement le manuel d’utlilisation et

assimiler son contenu avant d’utiliser la

machine.

Ces instructions son un complément au manuel qui

accompagne la machine. Pour les autres instructions, se

reporter au manuel d´utilisation de la machine.

AVERTISSEMENT!

!

!

En aucun cas, la conception d’origine de

la machine ne doit être modifiée sans

l’accord du fabricant. Toujours utiliser

des pièces de rechange d’origine. Des

modifications et/ou des pièces de

rechange non autorisées peuvent

entraîner des blessures graves, ou

mortelles, pour l’utilisateur, comme pour

autrui.

AVERTISSEMENT!

Cet accessoire ne peut être utilisé que

pour les débroussailleuses/coupebordu-

res auxquels il est expressément destiné.

Voir la section ”Accessoires

homologués” au chapitre

Caractéristiques techniques dans le

manuel d'utilisation de la machine.

Sommaire

EXPLICATIONS DES SYMBOLES

Symboles ........................................................................... 18

SOMMAIRE

Sommaire .......................................................................... 19

CONSIGNES DE SECURITE

Equipement de coupe ........................................................ 20

Terminologie concernant guide-chaîne et chaîne ................ 20

Affûtage et réglage de profondeur

de la chaîne .................................................................. 21

Tension de la chaîne........................................................... 23

Lubrification de l’équipement de coupe ............................. 23

Contrôle d’usure de l’équipement de coupe ....................... 24

Instruction de sécurité pour l'utilisation de la tronçonneuse à

manche ........................................................................ 25

Tecniques de travail de base ............................................... 26

QUELS SONT LES COMPOSANTS?

Quels sont les composants? ................................................ 28

MONTAGE

Montage de la tête de coupe

(Accessoire de sciage avec tube de transmission) ........... 30

Montage de la tête de coupe

(Accessoire de sciage sans tube de transmission)............ 30

Montage du guide-chaîne et de la chaîne ........................... 30

Montage de l’œillet de suspension...................................... 30

Réglage du harnais ............................................................. 30

Remplissage d’huile............................................................ 31

Contrôles avant le démarrage ............................................. 31

CARACTERISTIQUES TECHNIQUES

Caracteristiques techniques ................................................ 32

La machine est uniquement construite pour le sciage des

branches et rameaux.

Français – 19

CONSIGNES DE SECURITE

Equipement de coupe

Le choix judicieux de l’équipement de coupe et son entretien

correct permettront :

• D’obtenir la meilleure coupe possible

• D’augmenter la durée de vie de l’équipement de coupe.

1N’utiliser que

l’équipement de coupe

recommandé (voir

”Caractéristiques

techniques”)

2 Tenir les dents de la

chaîne bien affûtées,

suivre les instructions et

utiliser le gabarit

d’affûtage recommandé,

une chaîne émoussée

augmente le risque

d’accidents.

3 Suivre les instructions

d’entretien et utiliser la

jauge de profondeur

recommandée, une

profondeur incorrecte

augmente le risque de

rebond.

4 Maintenir la tension de

chaîne correcte, une

tension insuffisante

augmente le risque de

chaîne sautée, d’usure

du guide, de la chaîne

et du pignon.

AVERTISSEMENT!

!

!

Ne jamais utiliser une machine avec des

dispositifs de sécurité défectueux. Il faut

contrôler et entretenir les dispositifs de

sécurité en fonction des indications de

ce chapitre. Si la machine ne satisfait pas

à l’un des contrôles, contacter un atelier

de service.

AVERTISSEMENT!

Toujours arrêter le moteur avant d’entamer

des travaux sur l’équipement de coupe.

Celui-ci continue à tourner après avoir

relâché l’accélérateur. S’assurer que

l’équipement de coupe est entièrement

immobilisé et retirer le câble de la bougie

d’allumage avant d’effectuer des travaux

sur l’équipement de coupe.

Terminologie concernant guidechaîne et chaîne

En cas d’usure et de remplacement nécessaire, n’utiliser que les

accessoires d’origine (guide-chaîne et chaîne), voir

”Caractéristiques techniques” pour les modèles recommandés

pour chaque tronçonneuse.

Guide-chaîne

• Longueur (cm)

• Nombre de dents par

pignon (T). Nombre réduit

= petit rayon = tendance au

rebond limitée.

• Pas de chaîne (pouce). Le

pignon du nez et le pignon

d’entraînement doivent

correspondre à l’espace

entre les maillons.

5 Maintenir l’équipement

bien lubrifié et bien

entretenu un

équipement

insuffisamment lubrifié

augment le risque de

chaîne sautée, d’usure

du guide, de la chaîne

et du pignon.

20 – Français

• Nombre de maillons

entraîneurs (pce). La

longueur du guide, le pas

de chaîne et le nombre de

dents au pignon donnent

un nombre déterminé de

maillons entraîneurs.

• Largeur de gorge du guidechaîne (mm). Celle-ci doit

correspondre à la largeur

des maillons entraîneurs de

la chaîne.

• Trou de graissage de chaîne

et trou du tendeur de

chaîne. Le guide-chaîne

doit correspondre au

modèle de tronçonneuse.

CONSIGNES DE SECURITE

Chaîne

• Pas de chaîne (=PITCH)

(pouce)

• Largeur de gorge du

guide-chaîne (mm).

• Nombre de maillons

entraîneurs (pce)

Affûtage et réglage de profondeur

de la chaîne

POSITION DE LA LIME

DIAMÈTRE DE LA LIME

RONDE

PROFONDEUR

D’AFFÛTAGE

Affûter une chaîne sans outils

spéciaux est très difficile. Il est

donc recommandé d’utiliser

notre gabarit, qui assure un

affûtage maximal et une

réduction optimale du risque

de rebond.

1

5

Une chaîne émoussée augmente le risque de

rebond !

AGénéralités relatives à l’affûtage des

dents

• Ne jamais utiliser une tronçonneuse dont les dents sont

émoussées. Une chaîne est émoussée quand les dents de la

chaîne doivent être forcées contre le bois et si les copeaux

sont très petits. Une chaîne très usée ne produits aucuns

copeaux, rien que de la poudre.

• Une chaîne bien affûtée entame le bois par elle-même et sans

forcer, laissant de gros et longs copeaux.

• LA PARTIE COUPANTE

de la chaîne consiste en un

MAILLON COUPANT

qui comporte une dent (A)

et UN LIMITEUR (ou

cale) DE

PROFONDEUR (B).

L’espace entre les deux

détermine la profondeur de

coupe.

Négliger comme suit les paramètres

d’affûtage augmente nettement le risque de

rebond :

• ANGLE D’AFFÛTAGE

TROP ÉTROIT

• ANGLE D’IMPACT

TROP ÉTROIT

• DIAMÈTRE DE LIME

TROP COURT

• En affûtant la dent il faut

tenir compte de 5

dimensions :

ANGLE D’AFFÛTAGE

ANGLE D’IMPACT

Français – 21

CONSIGNES DE SECURITE

B Affûtage de la

dent

Cette opération nécessite

UNE LIME RONDE et UN

GABARIT.

1 S’assurer que la chaîne

est tendue, sinon

l’instabilité latérale

gênera l’affûtage de la

chaîne.

2 Toujours limer de

l’intérieur de la dent vers

l’extérieur, soulager la

lime pendant le

mouvement de retour.

Commencer par limer

toutes les dents du

même côté, retourner la

tronçonneuse et limer de

l’autre côté.

3 Amener toutes les dents

à la même hauteur. Si la

hauteur de dent est

inférieure à 4 mm, la

chaîne est usée et doit

être remplacée.

min 4 mm

(0,16")

C Généralités sur

le réglage de

profondeur

• En affûtant la dent, LA

PROFONDEUR DE

COUPE diminue. Prévoir

celle-ci de façon à avoir la

performance de coupe

optimale.

Voir aux ”Caractéristiques

techniques” les cotes de

profondeur correspondant

à la chaîne utilisée.

• Sur le modèle de maillon

AVEC RÉDUCTION

DE REBOND, la cale de

profondeur est arrondie

par devant. Cette

caractéristique doit être

soigneusement conservée

lors de l’affûtage.

• Nous recommandons la

jauge de profondeur qui

permet à la fois un

affûtage correct et

préserve la forme arrondie

de la cale de profondeur.

Une profondeur excessive augmente le

risque de rebond !

22 – Français

CONSIGNES DE SECURITE

D. Correction de la profondeur

• Pour ce faire, les dents

doivent être nouvellement

affûtées.

Un réglage de profondeur

est recommandé tous les

trois affûtages

ATTENTION: à

supposer que la longueur

des dents n’est pas

anormalement réduite.

• Cette opération nécessite

UNE LIME PLATE et

UNE JAUGE DE

PROFONDEUR.

• Placer le gabarit sur la cale

de profondeur.

• Placer la lime plate sur la

partie dépassante de la

cale de profondeur et

limer celle-ci. Quand

aucune résistance ne se

fait sentir, la cale est à la

hauteur correcte.

1. Dévisser l’écrou du

guide-chaîne.

2. Tendre la chaîne en

serrant le tendeur de

chaîne dans le sens des

aiguilles de la montre

avec la clé universelle.

Tendre jusqu’à ce que la

chaîne ne pende plus

sous le guide.

3. Avec la clé universelle,

serrer l’écrou du guide-

chaîne, tout en tenant le

nez du guide levé.

S’assurer que la chaîne

peut être tournée

manuellement.

Lubrification de l’équipement de

coupe

Un graissage insuffisant de l’équipement de

coupe augmente le risque de rupture de

chaîne et donc de blessures graves et

même mortelles.

Tension de la chaîne

Une tension insuffisante de la chaîne

augmente le risque de chaîne sautée et donc

de blessures graves et même mortelles.

• Plus on utilise une chaîne

plus elle s’allonge. Il

importe de vérifier

l’équipement de coupe

après chaque utilisation.

• Il importe de vérifier la

tension de la chaîne après

chaque plein d’essence.

ATTENTION : Une

nouvelle chaîne exige une

période de rodage durant

laquelle il faut vérifier la

tension plus souvent.

• En règle générale, il faut

tendre la chaîne au

maximum, mais pas au

point de ne pouvoir la

faire tourner

manuellement.

A Huile de chaîne de tronçonneuse

• L'huile de chaîne devra bien adhérer à la chaîne et posséder

d'excellentes qualités de fluidité par tous les temps, aussi

bien en été qu'en hiver.

• En tant que fabricant de tronçonneuses, nous avons

développé une huile de chaîne optimale à base végétale.

Nous recommandons l'utilisation de cette huile pour une

durée de vie maximale de la tronçonneuse et pour la

protection de l'environnement.

• Si notre huile de chaîne n'est pas disponible nous

recommandons l'utilisation d'une huile de chaîne ordinaire.

• Si aucune huile spécialement destinée au graissage des

chaînes de tronçonneuses n'est disponible, l'huile de

transmission EP 90 peut être utilisée.

• Ne jamais utiliser d'huile usagée

L'huile usagée est dangereuse pour vous, pour la

tronçonneuse et pour l'environnement.

B Remplissage d’huile de chaîne

La pompe à huile est préréglée

en usine pour répondre à la

plupart des besoins de

lubrification. Un remplissage

du réservoir d’huile suffit pour

la moitié du réservoir

d’essence. Pour cette raison, il

convient de contrôler

régulièrement la quantité d’huile dans le réservoir d’huile afin

d’éviter toute détérioration de la chaîne et du guide-chaîne à la

suite d’une carence en huile.

Français – 23

CONSIGNES DE SECURITE

C Contrôle de lubrification

• Vérifier la lubrification à

chaque plein d’essence.

Diriger le nez du guide sur

un objet clair, à 20 cm

d’écart. Après 1 minute de

marche aux 3/4

d’accélération, l’objet clair

doit nettement présenter

un film d’huile en forme de

ruban.

D. Réglage du graissage de la chaîne

• Lors du sciage de bois secs

et durs, l’augmentation du

graissage peut s’avérer

nécessaire. Pour régler le

débit d’huile, desserrer

d’abord la vis (A), puis

visser la vis de réglage (B)

dans le sens contraire des

aiguilles de la montre.

Serrer la vis (A). S’assurer

que la consommation d’huile augmente et contrôler la

quantité d’huile dans le réservoir d’huile régulièrement.

A

Mesures à prendre si le graissage ne

fonctionne pas :

1 Vérifier le canal de

graissage du guide-chaîne.

Le nettoyer au besoin.

Comparer avec une chaîne

neuve pour évaluer le degré

d’usure de la chaîne utilisée.

Si la hauteur de dent est

inférieure à 4 mm, la chaîne

est usée et doit être remplacée.

min 4 mm

(0,16")

B. Pignon d’entraînement

Vérifier régulièrement le

degré d’usure du pignon.

Le remplacer en cas

d’usure excessive.

Le pignon doit être

remplacé en même temps

que la chaîne.

B

C. Dispositif anti-vibrations

Contrôler régulièrement que

l’amortisseur de vibrations ne

présente pas de craquelures.

Contrôler régulièrement

l’usure des éléments en

caoutchouc et les remplacer

s’ils sont usés.

2. S’assurer que le canal de

graissage du carter

d’engrenage est propre.

Nettoyer si nécessaire.

3. Vérifier que le pignon du

nez du guide tourne

librement.

Si le graissage de la chaîne

ne fonctionne pas après

les contrôles ci-dessus,

s’adresser obligatoirement

à un atelier d’entretien.

Contrôle d’usure de l’équipement de

coupe

A. Chaîne

Vérifier l’état de la chaîne

journellement, s’assurer :

• que rivets et maillons ne

sont pas criqués

• que la chaîne n’est pas raide

• que rivets et maillons ne

sont pas anormalement

usés.

D. Guide-chaîne

Vérifier régulièrement :

• Qu’il n’y a pas de bavures

sur les côtés extérieurs de la

gorge, les limer au besoin.

• Que la gorge n’est pas

anormalement usée, la

remplacer au besoin.

• Que le nez n’est pas

anormalement usé : si un

creux s’est formé à

l’extrémité du rayon du nez

(bord inférieur) la chaîne

n’était pas suffisamment

tendue.

• Retourner le guide

quotidiennement pour

assurer une durée de vie

optimale.

Un équipement de coupe défectueux peut

augmenter le risque d’accident.

24 – Français

CONSIGNES DE SECURITE

Instruction de sécurité pour

l'utilisation de la tronçonneuse à

manche

AVERTISSEMENT!

!

!

REMARQUE ! Lire attentivement le manuel d'utilisation

avant d'utiliser la machine.

Protection personnelle

• Toujours porter des bottes

et l’équipement décrit dans

Ӄquipement de protection

personnelle” dans le manuel

d'utilisation de la machine.

• Portez toujours des

vêtements de travail et des

pantalons robustes.

• Ne portez jamais de

vêtements larges ou des

bijoux.

• Il est recommandé aux

personnes aux cheveux

longs de les attacher, pour

leur sécurité personnelle.

La machine peut provoquer des blessures

corporelles graves. Lire attentivement les

consignes de sécurité et apprendre à bien

utiliser la machine.

AVERTISSEMENT!

Outil coupant ! Ne pas toucher l’outil

sans avoir coupé le moteur.

Consignes de sécurité pendant le travail

• Veillez à toujours adopter

une position de travail sûre

et stable.

• Tenez toujours la machine

à deux mains. Portez la

machine sur votre côté

droit.

• Utilisez votre main droite

pour manœuvrer

l'accélération.

• Veiller à ce que ni les mains

ni les pieds ne soient en

contact avec l'équipement

de coupe quand le moteur

tourne.

• Après l'arrêt du moteur, maintenir mains et pieds à l'écart de

l'équipement de coupe jusqu'à l'arrêt total de celui-ci.

• Attention aux éclats de bois pouvant être projetés durant le

sciage.

• Toujours poser la machine sur le sol quand elle n'est pas

utilisée.

• Étudier attentivement l'objet à scier afin de détecter les

obstacles éventuels tels que les lignes électriques, les insectes,

les animaux, etc. ou les objets pouvant endommager

l'équipement de coupe comme, par exemple, les objets en

métal.

Mesures de sécurité pour l’environnement

• Ne permettez jamais aux

enfants d’utiliser la

machine.

• Ne permettez à personne de

s’approcher à moins de 15

m lors du travail.

• Ne permettez pas à autrui

d’utiliser la machine sans

vous assurer qu’ils

connaissent parfaitement le

contenu du manuel

d’instructions.

• Ne jamais travailler debout

sur une échelle, un tabouret,

ou dans toute autre position

élevée n’offrant pas une

sécurité maximale.

• Si la machine bûte sur un objet ou si des vibrations se

produisent, arrêter immédiatement le taille-haie. Retirer le

câble de la bougie et vérifier que la machine n’a subi aucun

dommage. Réparer tout éventuel dommage.

• Si un objet se coince dans l’équipement de coupe pendant

l’utilisation de la machine, éteindre le moteur et attendre son

arrêt complet avant de nettoyer l’équipement de coupe.

Français – 25

CONSIGNES DE SECURITE

Consignes de sécurité après le travail

• La protection pour le transport doit toujours être mise sur

l'équipement de coupe quand la machine n'est pas utilisée.

• Avant les travaux de nettoyage, de réparation ou

d'inspection, vérifier que l'équipement de coupe est

totalement arrêté et débrancher le câble d'allumage de la

bougie.

• Toujours utiliser des gants

de protection épais lors de

la réparation de

l'équipement de coupe.

L'équipement de coupe

est très tranchant et peut

facilement provoquer des

coupures.

• Conserver la machine à

l'abri des enfants.

• Utiliser uniquement des

pièces de rechange

d'origine pour les

réparations.

Techniques de travail de base

• Pour un meilleur équilibre,

tenir la machine le plus

près possible du corps.

Faites particulièrement attention aux lignes électriques.

Les branches peuvent entraîner des court-circuits en tombant.

Ne jamais se tenir sous une branche en

train d’être coupée. Une telle position peut

!

!

être la cause de blessures graves voire

mortelles.

Cette machine ne comporte pas d'isolation

électrique. Si elle entre en contact avec ou

est utilisée à proximité de lignes

conductrices de tension, ceci peut résulter

en des blessures corporelles graves voire

mortelles. L'électricité peut être transmise

d'un point à un autre par un arc de tension. Plus la tension est élevée et plus la

longueur de transmission de la tension est

élevée. L'électricité peut également être

transmise par des branches et d'autres

objets, particulièrement s'ils sont mouillés.

Toujours conserver une distance d'au

moins 10 mètres (30 pieds) entre la

machine et la ligne conductrice

d'électricité et/ou les objets en contact

avec cette ligne. S'il est nécessaire que le

travail soit effectué avec des distances de

sécurité plus courtes, toujours contacter

la compagnie électrique afin de s'assurer

que la tension est bien coupée avant de

commencer les travaux.

• S’assurer que l’extrémité

du taille-haie ne touche

pas le sol.

• Ne jamais forcer, mais

adopter un rythme de

travail régulier, de sorte

que toutes les branches

puissent être coupées

uniformément.

• Ramener le moteur au

régime de ralenti après

chaque phase de travail. Le

fait de laisser le moteur

tourner aux pleins gaz sans

le charger peut entraîner

des dommages moteur

importants.

• Toujours travailler à pleins gaz.

• Mettre le moteur au ralenti après chaque coupe. Le

fonctionnement du moteur à pleins gaz pendant une période

prolongée peut endommager l’accouplement centrifuge.

La machine peut être dangereuse. Vérifier

qu'aucune personne et qu'un animal ne se

!

• Se tenir droit par rapport à

la branche, de sorte que la

coupe se fasse à un angle de

90° si possible par rapport

à la branche.

• Ne pas travailler avec la

machine droit devant le

corps (comme avec une

canne à pêche). Dans une

telle position, l’équipement

de coupe semble plus

lourd.

• Couper les grosses

branches par sections, de

sorte que l’emplacement où

elles vont tomber soit plus

facile à contrôler.

trouvent à moins de 15 mètres (45 pieds)

quand la machine est utilisée.

90

!

26 – Français

AVERTISSEMENT !

Ne vous placez jamais sous la branche où

vous travaillez. Risque de graves accidents.

• Ne jamais scier dans un

nœud (ceci favorise la

cicatrisation et ralentit la

décomposition) !

• Utiliser la surface d’appui

de la tête de coupe pour

s’appuyer contre la

branche pendant la coupe.

Cette précaution empêche

l’équipement de coupe de

« sauter » sur la branche.

• Réaliser une entaille de

décharge sur la partie

inférieure de la branche

avant de couper cette

dernière. Cette entaille

empêche l’écaillage de

l’écorce de l’arbre, dont il

résulterait des blessures

durables et difficiles à

guérir pour l’arbre. Pour

éviter tout blocage, la

profondeur de cette

entaille ne doit pas

dépasser 1/3 de l’épaisseur

de la branche. Toujours

retirer l’équipement de

coupe de la branche avec

la chaîne qui tourne afin

d’éviter le blocage de

l’équipement de coupe.

CONSIGNES DE SECURITE

• Utiliser le harnais pour

faciliter la manipulation

de la machine et en alléger

le poids.

• Veiller à se tenir

fermement et à pouvoir

travailler sans être gêné

par les branches, les

pierres et les arbres.

Ne jamais accélérer si l’équipement de

!

coupe n’est pas entièrement visible.

Français – 27

QUELS SONT LES COMPOSANTS?

Accessoire de sciage avec

tube de transmission

14

11

4

9

3

232315

10

13

12

1

2

8

7

6

5

17

16

Quels sont les éléments de kit de

tronçonnage?

1. Remplissage de lubrifiant

2. Engrenage angulaire

3. Vis de réglage lubrification de la chaîne (B)

4. Vis de blocage lubrification de la chaîne (A)

5. Tube de transmission

6. Crochet pour harnais

7. Capot de protection de la chaîne

8. Ecrou de guide-chaîne

9. Vis de tendeur de chaîne

28 – Française

10. Chaîne

11. Guide-chaîne

12. Réservoir d’huile de chaîne

13. Remplissage d’huile de chaîne

14. Manuel d’utilisation

15. Protection de transport

16. Clé universelle

17. Harnais

QUELS SONT LES COMPOSANTS?

Accessoire de sciage sans

tube de transmission

13

10

4

9

5

8

3

14

15

12

11

1

2

7

6

16

Quels sont les éléments de kit de

tronçonnage?

1. Remplissage de lubrifiant

2. Engrenage angulaire

3. Vis de réglage lubrification de la chaîne (B)

4. Vis de blocage lubrification de la chaîne (A)

5. Crochet pour harnais

6. Capot de protection de la chaîne

7. Ecrou de guide-chaîne

8. Vis de tendeur de chaîne

9. Chaîne

10. Guide-chaîne

112. Réservoir d’huile de chaîne

12. Remplissage d’huile de chaîne

13. Manuel d’utilisation

14. Protection de transport

15. Clé universelle

16. Harnais

Français – 29

MONTAGE

Montage de la tête de coupe

(Accessoire de sciage avec tube de

transmission)

• Monter la tête de coupe sur

le tube de transmission de

manière à positionner la vis

(A) au centre du trou du tube

de transmission comme sur la

figure.

• Serrer la vis A.

• Serrer la vis B.

• Attention ! S’assurer que l’axe

d’entraînement du tube de

transmission pénètre dans la

rainure de la tête de coupe.

B

A

Montage de la tête de coupe

(Accessoire de sciage sans tube de

transmission)

• Démonter le renvoi d’angle

du tube de transmission.

• Monter la tête de coupe

sur le tube de transmission.

• Serrer la vis A.

• Serrer la vis B.

• Attention ! S’assurer que l’axe

d’entraînement du tube de

transmission pénètre dans la

rainure de la tête de coupe.

• Tendre la chaîne tout en

mettant le guide à

l’horizontale. La chaîne est

tendue correctement quand

elle ne pend plus sous le

guide et peut être avancée à

la main sans difficulté.

Serrer les écrous du guide à

l’aide de la clé universelle

tout en maintenant le guide

horizontal.

• La tension d’une chaîne

neuve doit être vérifiée

fréquemment pendant son

rodage. Vérifier

régulièrement. Une tension

correcte est synonyme de

bonne capacité de coupe et

de longue durée de vie.

Montage de l’œillet de suspension

L’œillet de suspension doit

être monté entre la poignée

arrière et la poignée en

boucle. Placer l’œillet de

suspension de telle sorte que

la machine soit bien

équilibrée et la position de

travail confortable.

Montage du guide-chaîne et de la

chaîne

• Déposer l’écrou du guidechaîne et le capot de

• Positionner le guide-chaîne

sur le goujon.

Placer la chaîne sur le pignon

d’entraînement et sur le

guide-chaîne. Commencer

par le dessus du guide.

S’assurer que la face

tranchante des dents est vers

l’avant sur le dessus du guide.

• S’assurer que la face

tranchante des dents est vers

l’avant sur le dessus du guide.

• Monter le carter d’embrayage

(frein de chaîne) et centrer le

goujon de tension de la

chaîne dans l’ouverture du

guide. S’assurer que les

maillons d’entraînement

s’engagent dans le pignon et que la chaîne est correctement placée

dans la gorge du guide. Serrer les écrous du guide à la main.

• Tendre la chaîne en tournant à droite la vis de tension de chaîne à

l’aide de la clé universelle. Tendre la chaîne jusqu’à ce qu’elle ne

pende plus sous le guide.

A

B

Réglage du harnais

Le harnais doit toujours être

utilisé avec la machine pour

garantir à l'utilisateur un

contrôle maximal sur la

machine et réduire le risque

de fatigue au niveau des bras

et du dos.

• Enfiler le harnais.

• Accrocher la machine dans

le crochet de suspension du

harnais.

• Régler la longueur du

harnais de telle sorte que le

crochet de suspension soit à

peu près à la hauteur de la

hanche droite de

l'utilisateur.

30 – Française

MONTAGE

Remplissage d’huile

• Ouvrir le couvercle sur la

partie supérieure de la tête

de coupe.

• Faire l’appoint avec de

l’huile de chaîne

Husqvarna.

Refermer le couvercle.

Contrôles avant le démarrage

• Inspecter la zone de travail. Retirer tout object susceptible

d’être projeté.

• Vérifier les lames. Ne

jamais utiliser un

équipement émoussé,

fissuré ou endommagé.

• Vérifier que le taille-haie

est en parfait état

d’utilisation. Contrôler

que tous les écrous et

boulons sont

correctement serrés.

• S’assurer que la chaîne est suffisamment lubrifiée.Voir le

chapitre “Lubrification des lames“.

• Contrôler que l'équipement de coupe s'arrête toujours au

ralenti.

• N’utiliser le taille-haie que pour l’usage auquel il est destiné.

• Contrôler que la poignée et les dispositifs de sécurité sont en

bon état de fonctionnement. Ne jamais utiliser une machine

à laquelle il manque des pièces, ou une machine qui a été

modifiée à l’encontre de ses spécifications.

Français – 31

CARACTERISTIQUES TECHNIQUES

Accessoire de sciage

sans tube de transmission

Accessoire de sciage

avec tube de transmission

Système de graissage

Volume du réservoir d’huile, litres

0,17

0,17

Poids

Poids, sans carburant, équipement de coupe et dispositifs de

sécurité, kg

0,8

1,4

Niveaux sonores

(voir remarque 1)

Pression acoustique équivalente au niveau des oreilles de

l’utilisateur, mesurée selon EN ISO 11680-1, dB(A), min./max.

95

96

Puissance acoustique équivalente mesurée selon EN ISO 11680-1

et ISO 10884, dB(A), min./max.

106

106

Niveaux de vibrations

Niveau de vibrations au niveau des poignées mesuré selon EN

ISO 11680-1, m/s

Au ralenti, poignée gauche/droite:

A plein régime, poignée gauche/droite:

2

1,0/3,0

5,5/3,6

1,2/2,3

6,0/5,5

Remarque 1: le niveau de pression acoustique équivalent correspond à la somme d’énergie pondérée en fonction du temps pour les

niveaux de pression acoustique à différents régimes pendant les durées suivantes: 1/2 ralenti et 1/2 plein régime.

Combinaisons guide-chaîne et chaîne

Les combinaisons suivantes sont homologuées type CE

Guide-chaîne Chaîne

Longueur Pas Nobre de dents max

(pouces) (pouces) pignon avant

10 3/8 7 T Husqvarna S 36/

12 3/8 7 T Husqvarna S 36/

10 3/8 7 T Oregon 90 SG

12 3/8 7 T Oregan 90 SG

Type Pouces Pouces/mm Pouces/mm Angle Angle Angle Pouces/mm Pouces/cm: dl

91 VG 3/8" 0.050"/1,3 5/32" /4,0 85° 30° 0° 0.025"/0,65 10"/25:40

Oregon 91 VG

Oregon 91 VG

1

5

L

12"/30:45

S 36 3/8" 0.050"/1,3 5/32" /4,0 85° 30° 0° 0.025"/0,65 10"/25:40

90 SG 3/8" 0,028"1/1 5/32" /4,0 85° 30° 0° 0.025"/0,65 10"/25:40

12"/30:45

12"/30:45

32 – Française

Assurance de conformité UE (concerne seulement l'Europe)

Nous, Husqvarna AB, SE-561 82 Huskvarna, Suède, tél. +46-36-146500, déclarons que ce kit de tronçonnage à partir des

numéros de série de l’année de fabrication 2002 et ultérieurement (l’année est indiquée en clair sur la plaque

d’identification et suivie d’un numéro de série) est conforme aux dispositions des DIRECTIVES DU CONSEIL:

- du 22 juin 1998 ”directive machines” 98/37/CE, annexe IIA.

Les normes suivantes ont été appliquées : EN292-2, EN11680-1.

L’organisme notifié: 0404, SMP Svensk Maskinprovning AB, Fyrisborgsgatan 3, 754 50 Uppsala, Suède, a procédé à

des tests de type européen suivant l’article 8, paragraphe 2c de la directive machines (98/37/CE). Le certificat de contrôle

de type EU selon l’annexe VI a le numéro: 404/02/858.

Le kit de tronçonnage livré est conforme à l’exemplaire qui a été soumis au contrôle de type EU.

Huskvarna, le 3 janvier 2002

Bo Andréasson, directeur du développement

Français – 33

SIGNIFICADO DE LOS SÍMBOLOS

Símbolos

Suplemento de

sierra, con tubo

ATENCIÓN: Las desbrozadoras, quita

arbustos y recortadoras pueden ser

peligrosas. Su uso descuidado o erróneo

puede provocar heridas graves o

mortales al operador o terceros.

Antes de utilizar la máquina, lea bien el

manual de instrucciones hasta

comprender su contenido.

Utilice siempre:

• Casco protector cuando exista el

riesgo de objetos que caen

• Protección auditiva

• Protección ocular homologada

Este producto cumple con la directiva

CE vigente.

Esta máquina no tiene aislamiento

eléctrico. Si entra en contacto o está en

las proximidades de cables

conductores de tensión, puede

provocar la muerte o lesiones graves.

La electricidad puede ser transmitida de

un punto a otro formando un ìarco de

tensión". A mayor tensión, mayor es la

distancia que puede ser transmitida la

electricidad. Ésta también puede ser

transmitida a través de ramas y otros

objetos, especialmente si están

mojados. Por eso, mantenga siempre

como mínimo una distancia de 10 m

entre la máquina y un cable conductor

de tensión, u objetos que estén en

contacto con el mismo. Si debe trabajar

con una distancia de seguridad más

corta, póngase en contacto con la

central eléctrica para cerciorarse de

que la tensión está desconectada antes

de empezar a trabajar.

Utilice siempre guantes protectores

homologados.

Utilice botas antideslizantes y seguras.

Los demás símbolos/pegatinas que aparecen en la

máquina corresponden a requisitos de

homologación específicos en determinados

mercados.

Cualquier tipo de control o medida de

mantenimiento a realizar debe efectuarse

con el motor parado, con el mando de

parada en la posición STOP.

Utilice siempre guantes protectores

homologados.

Limpie la máquina regularmente.

Control visual.

Suplemento de

sierra, sin tubo

34 – Español

Esta máquina no tiene aislamiento

eléctrico. Si entra en contacto o está en

las proximidades de cables

conductores de tensión, puede

provocar la muerte o lesiones graves.

La electricidad puede ser transmitida de

un punto a otro formando un ìarco de

tensión". A mayor tensión, mayor es la

distancia que puede ser transmitida la

electricidad. Ésta también puede ser

transmitida a través de ramas y otros

objetos, especialmente si están

mojados. Por eso, mantenga siempre

como mínimo una distancia de 10 m

entre la máquina y un cable conductor

de tensión, u objetos que estén en

contacto con el mismo. Si debe trabajar

con una distancia de seguridad más

corta, póngase en contacto con la

central eléctrica para cerciorarse de

que la tensión está desconectada antes

de empezar a trabajar.

Debe utilizarse protección ocular

homologada.

Carga de aceite y regulación del caudal de

aceite.

CONTENIDO

Husqvarna AB trabaja constantemente para perfeccionar sus

productos y se reserva, por lo tanto, el derecho a introducir

modificaciones en la construcción y el diseño sin previo aviso.

Antes de utilizar la máquina lea bien el manual

de instrucciones hasta comprender su contenido.

Estas instrucciones son complemento del manual que se

adjunta a la máquina. Para más información sobre el manejo,

consultar el manual de la máquina

ATENCIÓN: El diseño original de la

!

!

máquina no debe ser modificado por

ningún motivo sin autorización explícita

del fabricante. Utilice siempre accesorios

originales. Modificaciones y/o accesorios

no autorizados pueden ocasionar heridas

graves y hasta mortales al operario o

terceros.

ATENCIÓN: Este accesorio sólo puede ser

utilizado con las desbrozadoras/

recortadoras destinadas al mismo, vea

”Accesorios aprobados” en el capítulo

Datos técnicos del manual de

instrucciones de la máquina.

Indice

SIGNIFICADO DE LOS SÍMBOLOS

Símbolos ............................................................................ 34

CONTENIDO

Índice ................................................................................ 35

INSTRUCCIONES DE SEGURIDAD

Equipo de corte ................................................................. 36

Expresiones características de las espadas y cadenas ............ 36

Afilado y ajuste de la profundidad de corte de la cadena..... 37

Tensado de la cadena.......................................................... 39

Lubricación del equipo de corte ......................................... 39

Control del desgaste del equipo de corte ............................ 40

Instrucciones de seguridad para utilizar la sierra de podar... 41

Técnica básica de trabajo ................................................... 42

¿QUÉ ES QUÉ?

Qué es qué ......................................................................... 44

MONTAJE

Montaje del cabezal de corte

(Suplemento de sierra, con tubo).................................. 46

Montaje del cabezal de corte

(Suplemento de sierra, sin tubo) ................................... 46

Montaje de la espada y la cadena........................................ 46

Montaje de la argolla de suspensión ................................... 46

Ajuste del arnés .................................................................. 46

Repostado de aceite............................................................ 47

Control antes de arrancar ................................................... 47

DATOS TÉCNICOS

Datos tecnicos.................................................................... 48

La máquina está diseñada exclusivamente para cortar ramas y

ramos.

Español – 35

INSTRUCCIONES DE SEGURIDAD

Equipo de corte

Esta sección muestra cómo, realizando un mantenimiento

correcto y utilizando el equipo de corte debido:

• se obtiene una capacidad máxima

• se prolonga la vida útil del equipo de corte.

1 ¡Utilice solamente el

equipo de corte

recomendado por nosotros!

Vea el capítulo ’Datos

técnicos”.

2 ¡Mantenga los dientes

cortantes de la cadena bien

y correctamente afilados!

Siga nuestras instrucciones

y utilice el calibrador de

afilado recomendado! Una

cadena mal afilada o

defectuosa aumenta el

riesgo de accidentes.

3 ¡Utilice la profundidad de

corte correcta! Siga

nuestras instrucciones y

utilice el calibrador de

profundidad de corte

recomendado. Una

profundidad de corte

demasiado grande aumenta

el riesgo de reculada.

4 ¡Mantenga la cadena

correctamente tensada!

Con un tensado

insuficiente se incrementa

el riesgo de solturas de la

cadena y se aumenta el

desgaste de la espada, la

cadena y el piñón de

arrastre.

5 ¡Mantenga el equipo de

corte bien lubricado y

efectúe el mantenimiento

adecuado! Con una

lubricación insuficiente se

incrementa el riesgo de

roturas de cadena y se

aumenta el desgaste de la

espada, la cadena y el

piñón de arrastre.

ATENCIÓN

No utilice nunca una máquina cuyo

!

!

sistema de seguridad sea defectuoso. El

equipo de seguridad debe ser controlado

y mantenido como se ha descrito en esta

sección. Si su máquina no cumple con

alguno de los requisitos mencionados,

debe dirigirse a un taller de servicio

oficial para la reparación.

ATENCIÓN

Pare siempre el motor antes de trabajar