ST 224, ST 227P, ST 230P, ST 224P

Default Operator's manual 2-25

ES-MX Manual del usuario 26-51

FR-CA Manuel d’utilisation 52-77

79

C

Contents

2

Introduction.....................................................................3

Safety..............................................................................5

Assembly........................................................................ 8

Operation......................................................................11

Maintenance................................................................. 15

Troubleshooting............................................................22

Transportation, storage and disposal........................... 24

Technical data.............................................................. 25

694 - 002 -

I

Introduction

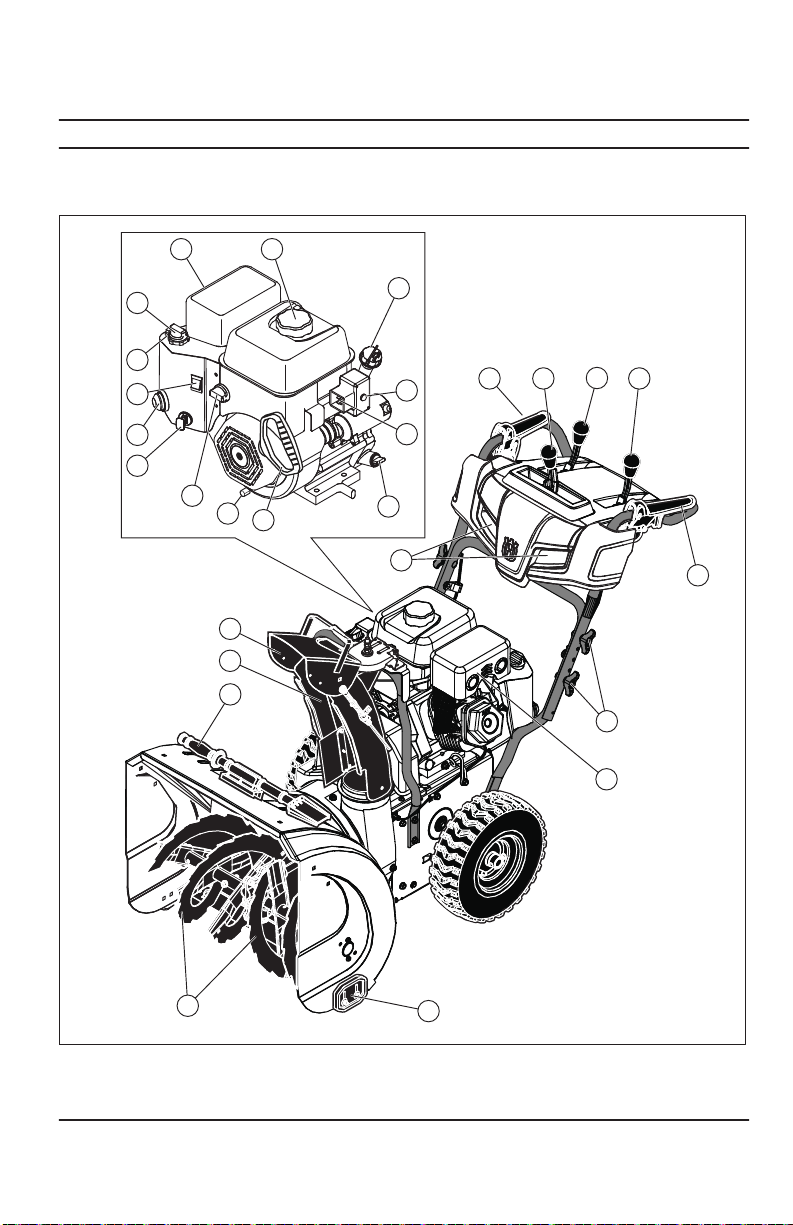

Product overview

3

8 22

21

20

19

18

17

16

15

13

12

11

14

26

23

24

25

6

1 2

3

4

5

7

8

10

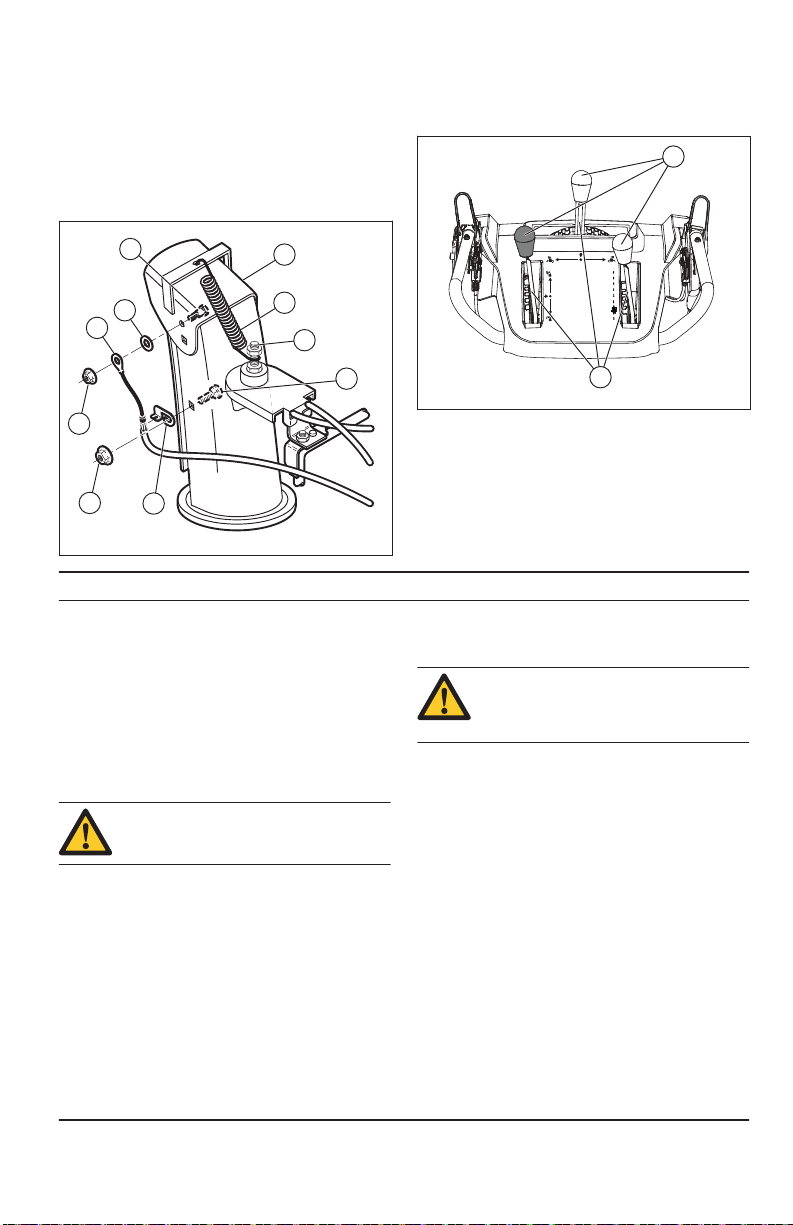

1. Auger engagement

2. Discharge chute control lever

694 - 002 -

9

3. Drive speed control lever

4. Deflector remote control lever

Transport, entreposage et mise au rebut

Transport et entreposage

Mise au rebut

Données techniques

Données techniques

Remarque :

ST 224 ST 227P ST 230P ST 224P

Dimensions

Moteur

Système électrique

77

5. Drive engagement

Product description

Intended use

Symbols on the product

Note

4

6. Light

7. Handle knob

8. Muffler

9. Skid plate

10. Augers

11. Clean-out tool

12. Discharge chute

13. Chute deflector

14. Starter rope handle

15. Oil drain plug

16. Fuel switch

17. ON/OFF key

18. Primer

19. ON/OFF switch

20. Throttle control

21. Choke

22. Gasoline filler cap

23. Oil fill (ST 227P, ST 230P), Dipstick (ST 227P)

24. Electric start button

25. Connection, electric start

26. Oil fill (ST 224, ST 224P), Dipstick (ST 224, ST

230P, ST 224P)

P

The product is a wheeled snow thrower that is used to

remove snow from the ground.

This product can be used to remove snow from fields,

roads, walkways and driveways. Do not use it on slopes

that are greater than 20°. Do not use the product in

areas where there is much debris, dirt and protruding

stones.

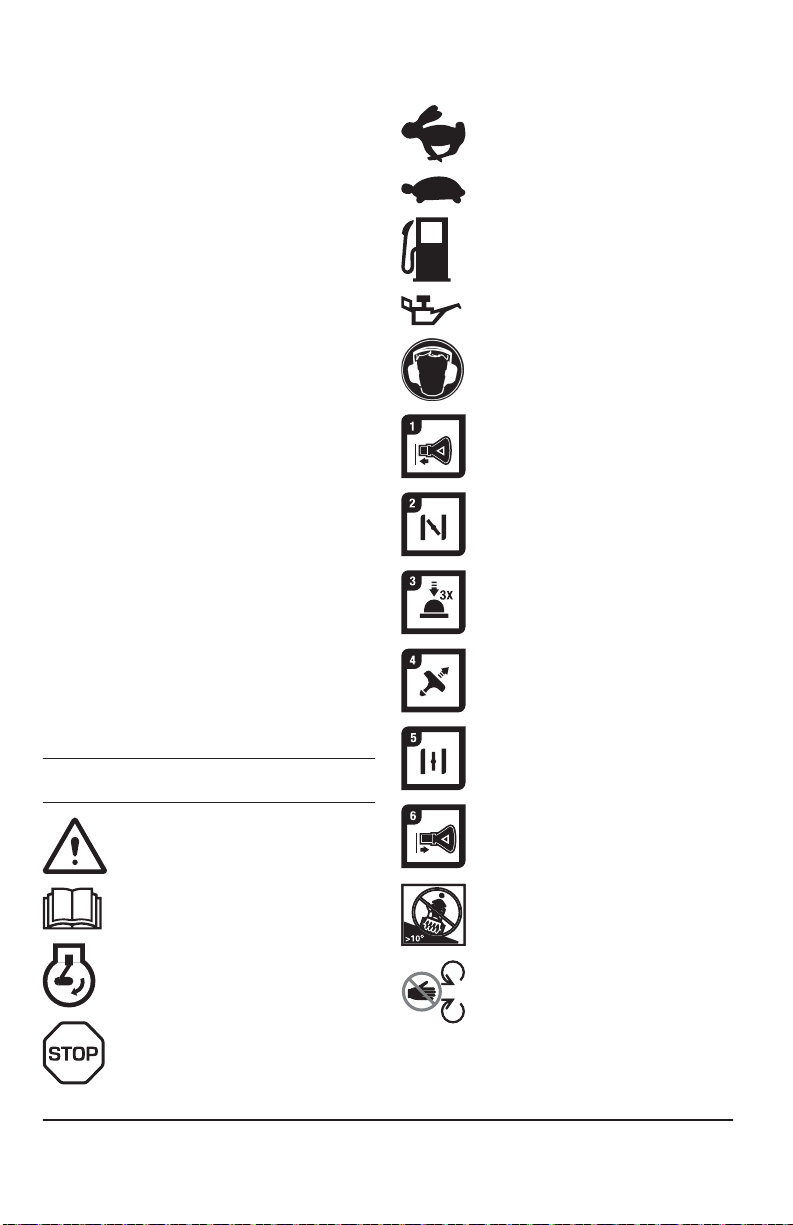

Fast.

Slow.

Fuel.

Oil.

Ear protection recommended.

ON/OFF key. Insert to start and run.

Choke closed (start).

Primer.

Pull starter rope handle to start.

If the decals on the product are damaged, contact

the distributor to replace them.

Warning.

Read the operator's manual.

Engine on

Engine off.

Choke open (run).

ON/OFF key. Pull out to stop.

No operation on slopes more than 10

degrees.

Do not remove shields while engine is

running.

694 - 002 -

Remove spark plug cable before

Product liability

Safety

Safety definitions

WARNING

CAUTION

Note

5

maintenance.

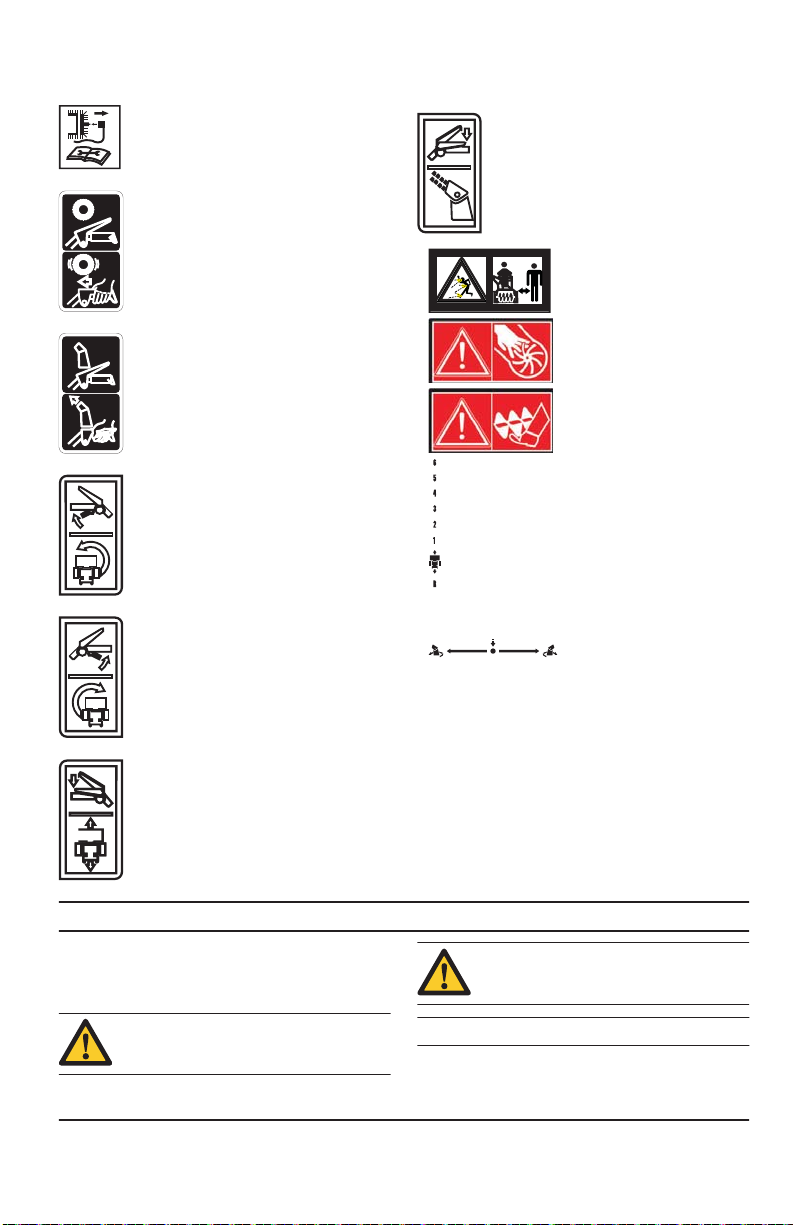

Traction drive off/on.

Snow discharge off/on.

Snow discharge.

Beware of thrown objectskeep bystanders away.

Warning, keep hands

away.

Warning, keep feet away.

Forward/reverse.

Steer left.

Steer right.

Traction drive control.

The definitions below give the level of severity for each

signal word.

Injury to persons.

694 - 002 -

Rotate left/push down/

rotate right.

As referred to in the product liability laws, we are not

liable for damages that our product causes if:

• the product is incorrectly repaired.

• the product is repaired with parts that are not from

the manufacturer or not approved by the

manufacturer.

• the product has an accessory that is not from the

manufacturer or not approved by the manufacturer.

• the product is not repaired at an approved service

center or by an approved authority.

Damage to the product.

This information makes the product easier to use.

Problème Cause possible Solution

75

G

General safety instructions

Safety instructions for operation

6

• Use the product correctly. Injury or death is a

possible result of incorrect use. Only use the product

• Obey the instructions in this manual. Obey the safety

• Do not discard this manual. Use the instructions to

• Do not use a damaged product. Obey the

• This manual cannot include all situations that can

• Disconnect the spark plug cable before you

• Do not use the product if it is changed from its initial

• Do not breathe in the fumes from the engine. Long

• Do not start the product indoors or near flammable

• When you use this product the engine makes an

• Do not let a child operate the product. Do not let a

• Make sure that you always monitor a person, with

• Lock the product in an area that children and

for the tasks found in this manual. Do not use the

product for other tasks.

symbols and the safety instructions. If the operator

does not obey the instructions and the symbols,

injury, damage or death is a possible result.

assemble, to operate and to keep your product in

good condition. Use the instructions for correct

installation of attachments and accessories. Only

use approved attachments and accessories.

maintenance schedule. Only do the maintenance

work that you find an instruction about in this

manual. An approved service center must do all

other maintenance work.

occur when you use the product. Be careful and use

your common sense. Do not operate the product or

do maintenance to the product if you are not sure

about of the situation. Speak to a product expert,

your dealer, service agent or approved service

center for information.

assemble the product, put the product into storage or

do maintenance.

specification. Do not change a part of the product

without approval from the manufacturer. Only use

parts that are approved by the manufacturer. Injury

or death is a possible result of incorrect

maintenance.

term inhalation of the engine's exhaust fumes is a

health risk.

material. The exhaust fumes are hot and can contain

a spark which can start a fire. Not sufficient airflow

can cause injury or death because of asphyxiation or

carbon monoxide.

electromagnetic field. The electromagnetic field can

cause damage to medical implants. Speak to your

physician and medical implant manufacturer before

you operate the product.

person, without knowledge of the instructions

operate the product.

decreased physical capacity or mental capacity, that

uses the product. A responsible adult must be there

at all times.

unapproved persons cannot access.

• The product can eject objects and cause injuries.

Obey the safety instructions to decrease the risk of

injury or death.

• Do not go away from the product when the engine is

on.

• The operator of the product is responsible if an

accident occurs.

• Before and while you walk rearward, look behind and

down for small children, animals or other risks that

can cause you to fall.

• Make sure that parts are not damaged before you

use the product.

• Make sure that you are at a minimum 15 m (50 ft)

away from other persons or animals before you use

the product. Make sure that a person in adjacent

area knows that you will use the product.

• Refer to national or local laws. They can prevent or

decrease the operation of the product in some

conditions.

• Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

• Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

• After striking a foreign object, stop the engine

(motor), remove the wire from the spark plug,

disconnect the cord on electric motors, thoroughly

inspect the product for any damage, and repair the

damage before restarting and operating the product.

• If the product starts to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

• Stop the engine (motor) whenever you leave the

operating position, before unclogging the auger

housing or chute deflector, and when making any

repairs, adjustments or inspections.

• When cleaning, repairing or inspecting the product,

stop the engine and make certain the augers and all

moving parts have stopped. Disconnect the spark

plug wire and keep the wire away from the plug to

prevent someone from accidentally starting the

engine.

• Do not run the engine indoors, except when starting

the engine and for transporting the product in or out

of the building. Open the outside doors; exhaust

fumes are dangerous.

• Exercise extreme caution when operating on slopes.

• Never operate the product without proper guards,

and other safety protective devices in place and

working.

• Never direct the chute deflector toward people or

areas where property damage can occur. Keep

children and others away.

• Do not overload the product capacity by attempting

to clear snow at too fast a rate.

694 - 002 -

• Never operate the product at high transport speeds

Work area safety

Personal protective equipment

Safety devices on the product

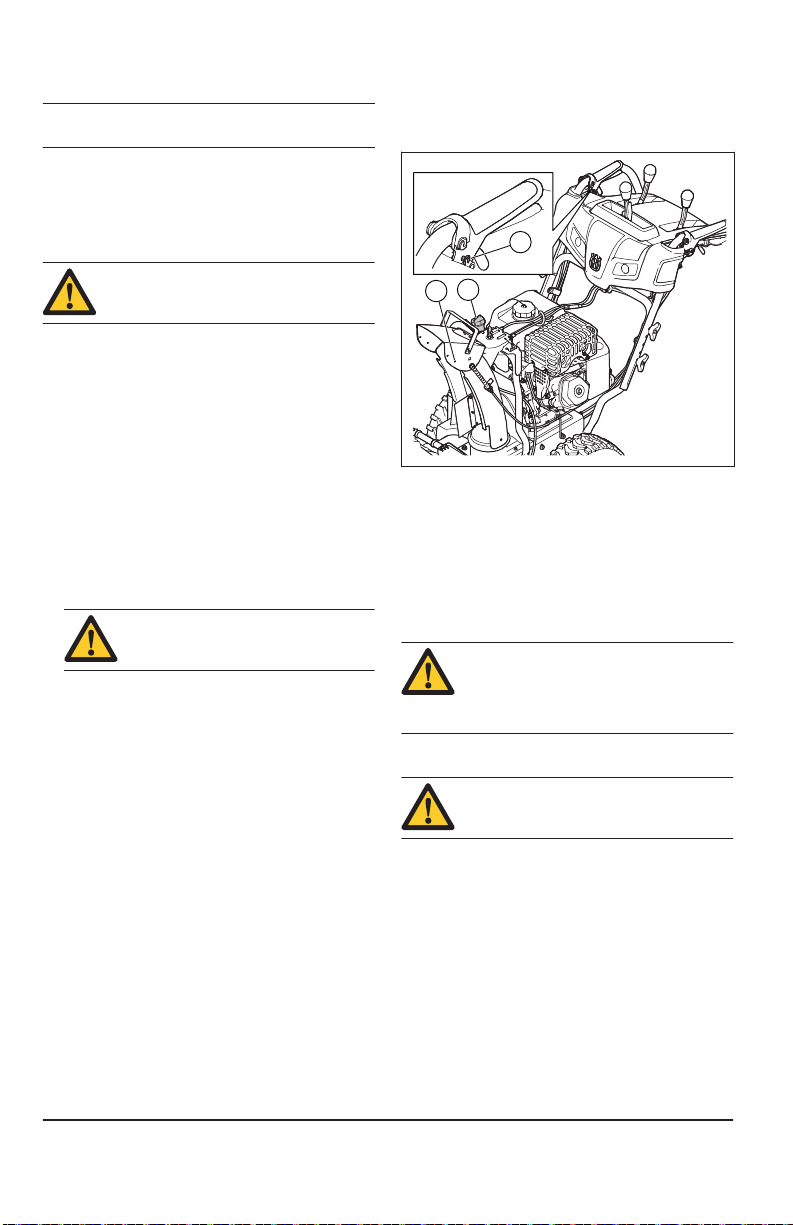

Muffler

CAUTION

Fuel safety

WARNING

7

on slippery surfaces. Look behind and use care

when operating in reverse.

• Disengage power to the augers when the product is

transported or not in use.

• Use only attachments and accessories approved by

the manufacturer of the product (such as wheel

weights, counterweights, or cabs).

• Never operate the product without good visibility or

light. Always be sure of your footing, and keep a firm

hold on the handles. Walk; never run.

• Never touch a hot engine or muffler.

W

• Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

• Disengage all clutches and shift into neutral before

starting the engine (motor).

• Do not operate the product without wearing

adequate winter garments. Avoid loose fitting

clothing that can get caught in moving parts. Wear

footwear that will improve footing on slippery

surfaces.

• Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• Never add fuel to a running engine or hot engine.

• Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

• Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground, away from your

vehicle, before filling.

• When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the

ground. If this is not possible, then refuel such

equipment on a trailer with a portable container,

rather than from a gasoline dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times, until

refueling is complete. Do not use a nozzle lockopen device.

• Replace gasoline cap securely and wipe up

spilled fuel.

• If fuel is spilled on clothing, change clothing

immediately.

• Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive

motors or electric starting motors.

• Adjust the auger housing height to clear gravel or

crushed rock surface.

• Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by the manufacturer).

• Always wear safety glasses or eye shields during

operation or while performing an adjustment or

repair to protect eyes from foreign objects that may

be thrown from the machine.

Always use the correct personal protective equipment

when you operate the product. This includes, at

minimum, sturdy footwear, eye protection and hearing

protection. Personal protective equipment does not

erase the risk of injury but may decrease the grade of

injury if an accident occurs.

• Always wear safety glasses or eye protection while

you operate the product or do maintenance or

repairs.

• Always wear appropriate winter garments when you

operate the product.

• Always use heavy-duty slip-resistant boots with good

ankle support while you operate the product.

• Do not wear loose fitting clothing that can get caught

in moving parts.

• Use approved protective gloves, if necessary. For

example, when attaching, examining or cleaning the

blade.

• Always use approved ear protection while you

operate the product. Noise for a long period can

cause noise-induced hearing loss.

• Make sure that you regularly do the maintenance to

the product.

• The life of the product increases.

• The risk of accidents decreases.

Let an approved dealer or an approved service

center regularly examine the product to do

adjustments or repairs.

• Do not use a product with damaged protective

equipment. If the product is damaged, speak to an

approved service center.

The muffler keeps the noise levels to a minimum and

sends the exhaust fumes away from the operator.

Do not use the product if the muffler is missing or

defective. A defective muffler increases the noise level

and the risk of fire.

Examine the muffler regularly to make sure that it is

attached correctly and not damaged.

The muffler becomes very hot

Read the warning instructions

during and after use and when the engine

operates at idle speed. Be careful near

flammable materials and/or fumes to prevent

fire.

that follow before you use the product.

694 - 002 -

Pour nettoyer l’outil

73

• Do not start the product if there is fuel or engine oil

Proposition 65

Safety instructions for maintenance

WARNING

Assembly

To remove the product from the carton

Loose parts

8

on the product. Remove the unwanted fuel/oil and let

the product dry.

• If you spill fuel on your clothing, change clothing

immediately.

• Do not get fuel on your body, it can cause injury. If

you get fuel on your body, use soap and water to

remove the fuel.

• Do not start the product if the engine has a leak.

Examine the engine for leaks regularly.

• Be careful with fuel. Fuel is flammable and the fumes

are explosive and can cause injuries or death.

• Do not breathe in the fuel fumes, it can cause injury.

Make sure that there is a sufficient airflow.

• Do not smoke near the fuel or the engine.

P

• Do not put warm objects near the fuel or the engine.

• Do not add the fuel when the engine is on.

• Make sure that the engine is cool before you refuel.

• Before you refuel, open the fuel tank cap slowly and

release the pressure carefully.

• Do not add fuel to the engine in an indoor area. Not

sufficient airflow can cause injury or death because

of asphyxiation or carbon monoxide.

• Tighten the fuel tank cap fully. If the fuel tank cap is

not tightened, there is a risk of fire.

• Move the product a minimum of 3 m (10 ft) from the

position where you filled the tank before a start.

• Do not put too much fuel in the fuel tank.

WARNING

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm.

• The exhaust fumes from the engine contain carbon

• Before you do the maintenance on the product, stop

• Use protective gloves when you do maintenance on

1. Remove loose parts included with the product. Cut

2. Remove the two screws that attach the auger

3. Cut the cable ties that hold the product to the pallet

that follow before you use the product.

monoxide, an odorless, poisonous and very

dangerous gas. Do not start the engine indoors or in

closed spaces.

the engine and remove the ignition cable from the

spark plug.

the blades. The blades are very sharp and cuts can

easily occur.

the four corners of the carton and put the end panels

down flat.

housing to the pallet. Remove the steel brackets

from the skid plates if they have it.

and remove them.

Read the warning instructions

• Accessories and changes to the product that are not

approved by the manufacturer, can cause serious

injury or death. Do not change the product. Always

use accessories that are approved by the

manufacturer.

• If the maintenance is not done correctly and

regularly, the risk of injury and damage to the

product increases.

• Only do the maintenance as given in this operator's

manual. All other servicing must be done by an

approved service agent.

• Let an approved service agent do servicing on the

product regularly.

• Replace damaged, worn or broken parts.

4. Remove all package materials.

5. Remove the product from the carton and make sure

no loose parts are left in the carton.

Knob (3)

694 - 002 -

Multi-wrench (1)

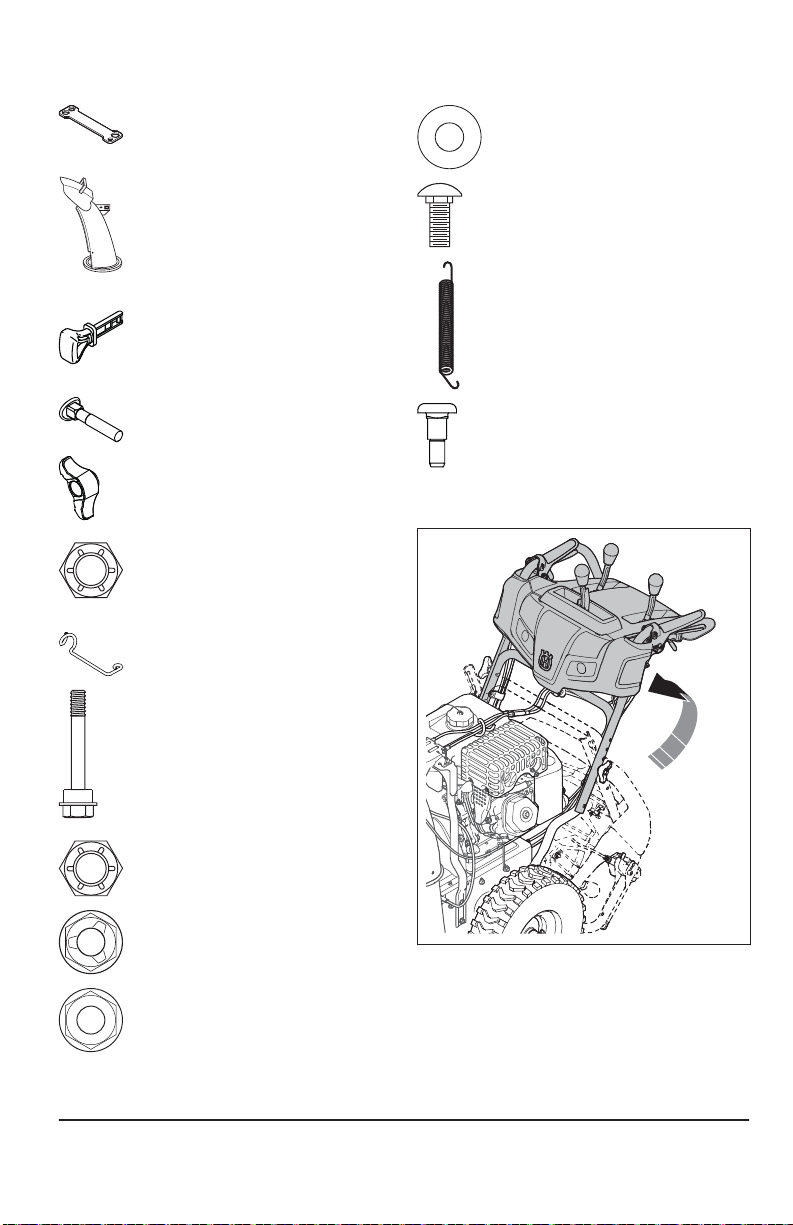

To install the handle

9

Discharge chute (1)

ON/OFF key (s)

Carriage bolts 5/16-18 x 2 ¼” (2)

Nylon washer (1)

Carriage bolt 5/16-18 x 5/8 (1)

Spring (1)

Shoulder bolt ¼-20 (1)

Handle knobs (2)

Locknut 3/8 (1)

Cable guide (1)

Shear pins ¼-20 x 1-¾ (6)

Locknuts ¼-20 (6)

Locknut 5/16-18 (1)

Locknut ¼-20 (1)

1. Raise the upper handle to the operating position.

694 - 002 -

Installation du carter de la courroie

Retrait de la courroie de tarière

Installation de la courroie de tarière

MISE EN GARDE :

71

2. Adjust the handle position to one of the mounting

To install the chute deflector and chute

rotator head

To install the chute deflector remote

control

10

holes (B) and tighten the handle knobs (C) with the

carriage bolts (D).

B

D

C

3. Install more carriage bolts (D) and handle knobs (C)

to secure the upper handle (A) to the lower handle

(E).

A

2. Put the chute rotator head (A) on the chute bracket

(B). Rotate the chute assembly to align the pins

under the chute rotator head with the holes in the

chute bracket if it is necessary.

3. Put the chute rotator head on the pin (C) and the

threaded stud (D) on the mounting bracket (E).

4. Attach a locknut (G) on the threaded stud and

tighten.

A

FG

B CDE

5. Put the cables through the cable guide (F) and the

double clip (I) to attach the rotator cable (H) to the

lower handle.

H

F

D

C

E

1. Put the chute deflector assembly on the top of the

chute base with the discharge opening in the

direction of the front of the product.

I

1. Attach the remote cable bracket (A) to the discharge

chute with a carriage bolt (B) and a 5/16-18 locknut

(D). Tighten the bolt.

694 - 002 -

2. Install the remote cable eyelet (E) to the chute

Operation

Before you start the product

To fill the engine with oil

CAUTION

To fill fuel

CAUTION

To adjust the discharge chute and the

chute deflector

11

deflector (F) with a shoulder bolt (G), a nylon washer

(C), and tighten with a ¼-20 locknut (K). The cable

eyelet will be loose on the shoulder bolt.

3. Attach the spring (L) between the hex nut (M) on the

chute rotator head and the hole on the chute

deflector.

4. Attach the lever control knobs (N) by pressing them

down on the control levers (O).

N

G

C

E

F

L

M

B

K

D

• Keep persons and animals away from the work area.

• Do daily maintenance. See

on page 15

• Make sure the ignition lead fits correctly on the spark

plug.

• Add oil or gasoline, if necessary. See

on page 25

1. Remove the oil cap and clean the dipstick. See

Product overview on page 3

dipstick.

2. Add oil to the top mark on the dipstick. Use the

dipstick to do a check of the oil level at regular

intervals.

3. Put the oil cap back.

If available, use low-emission/alkylate gasoline. If lowemission/alkylate gasoline is not available, use good

quality unleaded gasoline or leaded gasoline. Use

A

.

.

you check the oil. Do not fill above the mark.

Maintenance schedule

Technical data

Do not rotate the dipstick when

for the location of the

O

gasoline with an octane number of 90 RON out of North

America (87 AKI in North America) or higher, and with a

maximum of 10% ethanol (E10).

octane number less than 90 RON out of

North America (87 AKI in North America).

This can cause damage to the product.

1. Open the fuel tank cap slowly to release the

pressure.

2. Fill slowly with a fuel can. If you spill fuel, remove it

with a cloth and let remaining fuel dry off.

3. Clean the area around the fuel tank cap.

4. Tighten the fuel tank cap fully. If the fuel tank cap is

not tightened, there is a risk of fire.

5. Move the product a minimum of 3 m (10 ft) from the

position where you filled the tank, before a start.

1. To adjust the discharge chute position, move the

discharge chute control lever (A) back and to the left

or right direction.

Do not use gasoline with an

694 - 002 -

Pour examiner les pneus

Dégagement d’un déflecteur de

goulotte bouché

AVERTISSEMENT :

Remplacement de la barre de racleur

Courroies d’entraînement

AVERTISSEMENT :

AVERTISSEMENT :

Remarque :

Remarque :

Préparation du remplacement des courroies

69

2. To adjust the snow throwing distance of the chute

To start the engine, manual start

CAUTION

CAUTION

Note

To start the engine, electric start

WARNING

CAUTION

CAUTION

12

deflector, move the deflector remote control lever (B)

down to decrease the distance and up to increase

the distance.

AB

quickly. Move it back to the start position

much rope out of the starter as possible and release

the starter rope handle. If the engine does not start,

repeat the procedure or use the electric starter.

6. If the choke was used to start the engine, slowly

move the choke (D) to the OFF position.

7. Run the engine 2-3 minutes at idling speed before

you start to throw snow.

8. If the engine does not run as it should, turn it off.

slowly.

If the rope starter has frozen, slowly pull out as

Do not release the grip

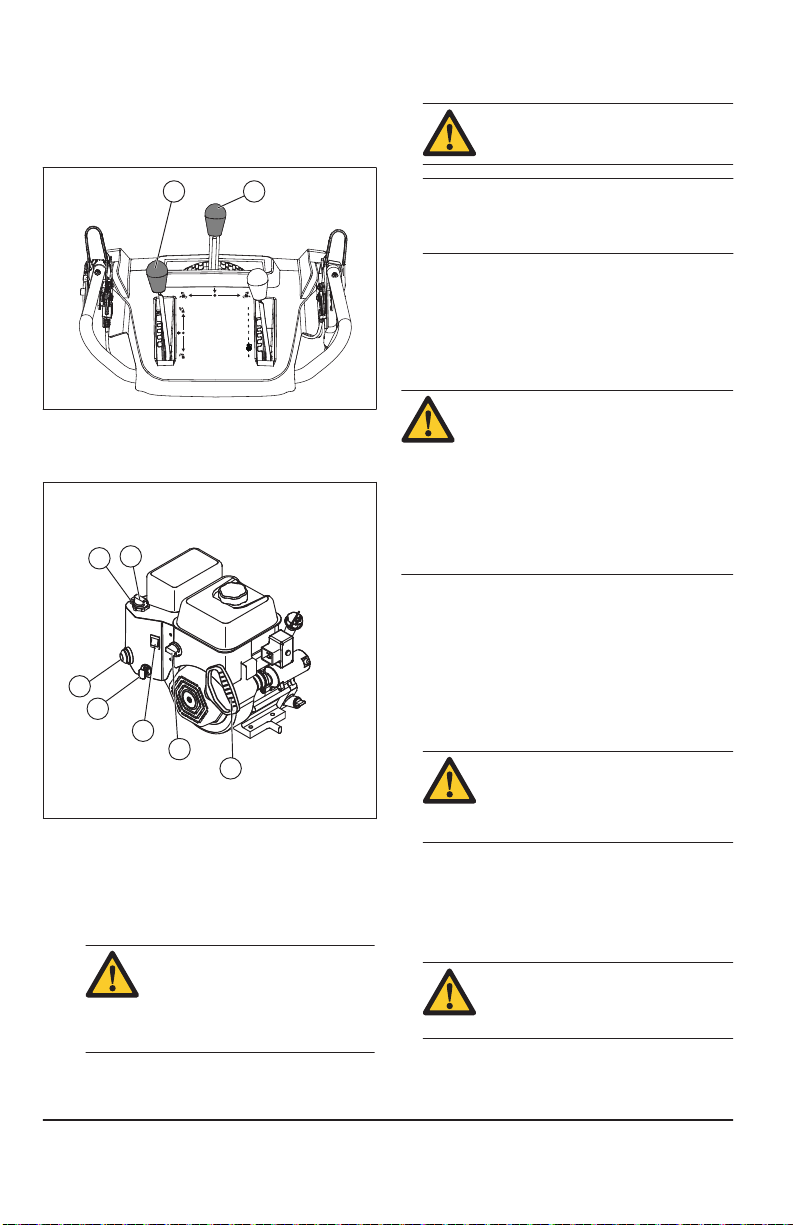

1. Insert the ON/OFF key (A) into the ignition slot until it

clicks. Do not turn the key.

D

B

E

A

C

F

G

2. Turn the fuel ON/OFF switch (F) to the ON position.

3. Put the throttle control (B) to the FAST position.

4. Put the ON/OFF switch (C) to the ON position.

a) If the engine is cold, rotate the choke (D) to the

FULL position and push the primer (E) three

times.

engine. It can prevent the engine

from starting. If the engine is over

primed, wait a few minutes before

attempting to start and do not push

the primer.

5. Pull the starter rope handle (G).

Do not over prime the

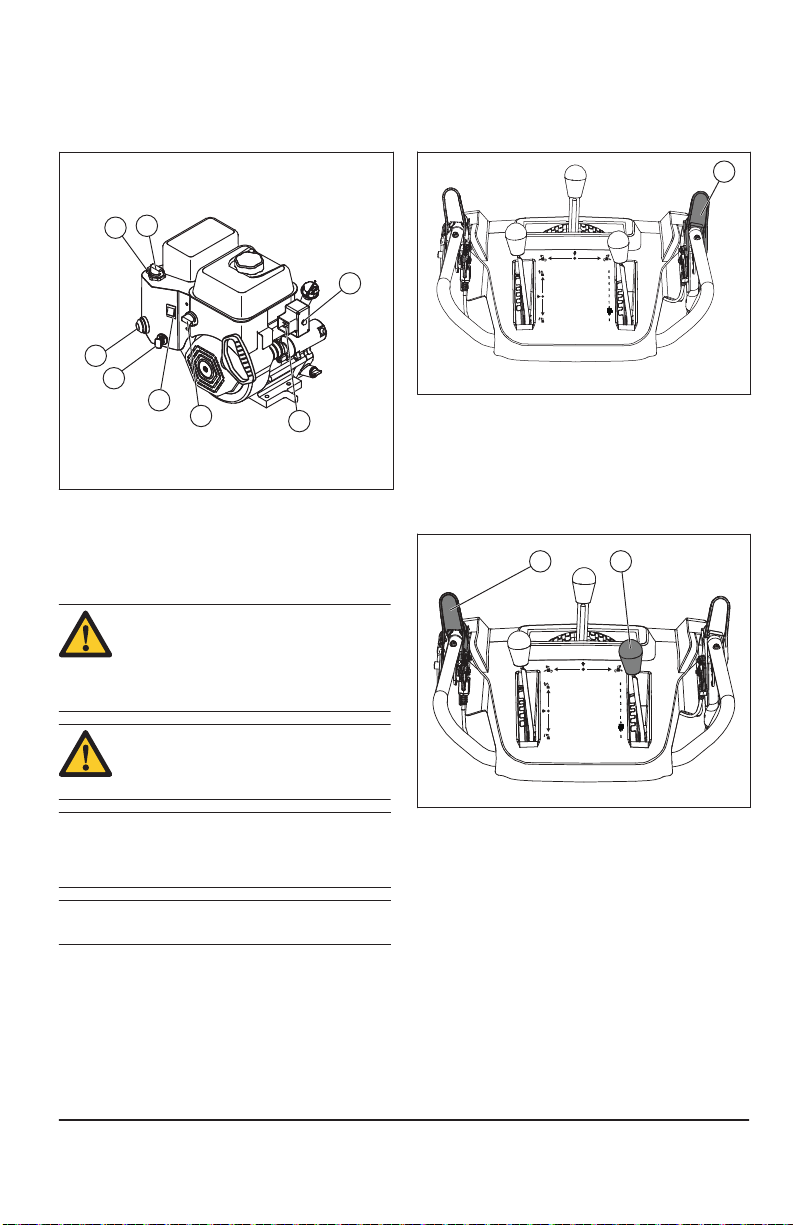

1. Insert the ON/OFF key (A) into the ignition slot until it

2. Turn the fuel ON/OFF switch (F) to the ON position.

3. Put the throttle control (B) to the FAST position.

4. Put the ON/OFF switch (C) to the ON position.

5. Push the primer (E) three times.

6. Connect the extension cord to the connector on the

7. Connect the other end of the extension cord into a

8. Push the electric start button (H) until the engine

electric starter. Do not use the electric

starter if your house is not a 120 V A.C.

three-wire grounded system. Serious

personal injury or damage to the product

could occur. The electric starter has a threewire power plug, and is designed to use 120

V A.C. household current. Make sure that

your house is a 120 V A.C. three-wire

grounded system. If you are uncertain, ask a

licensed electrician.

clicks. Do not turn the key.

a) If the engine is cold, turn the choke (D) to the

FULL position.

engine (G).

three-hole grounded 120 V A.C. receptacle.

starts.

The product has a 120 V A.C.

It can prevent the engine from starting. If

the engine is over primed, wait a few

minutes before trying to start and do not

push the primer.

than five continuous seconds between

each time you try to start. Wait 5 to 10

seconds between each try.

Do not over prime the engine.

Do not crank the engine more

694 - 002 -

9. If the choke was used to start the engine, release the

To operate the product

CAUTION

CAUTION

Note

Note

13

electric start button and slowly move the choke (D)

to the OFF position.

D

B

H

E

A

C

F

10. Disconnect the extension cord from the receptacle

first and then from the engine.

11. Run the engine 2-3 minutes at idling speed before

you start to throw snow.

G

T

water to lubricate the auger blades. Incorrect

use can cause high temperatures in the

auger blades, especially if the product is

new. This can cause damage to the auger

blades and scraper bar.

Do not operate without snow or

1. To engage the auger blades, push the auger

engagement (A) to the handle to engage the auger

and throw snow.

A

2. Raise the drive speed control lever (B) from the

middle position to make the product move forward

when the drive engagement (C) is engaged. Do not

change the speed when the augers are engaged.

This can cause damage to the transmission.

3. Lower the drive speed control lever from the middle

position to make the product move rearward when

the drive engagement is engaged.

C B

auger levers for an extended period of time;

this can lead to premature wear or burning

of the belts.

When both the drive engagement and auger

engagement are engaged, the drive engagement will

lock the auger engagement in position. Use the right

hand to control the snow discharge chute.

Do not change the speed when the augers are

engaged. This can cause damage to the transmission.

694 - 002 -

Do not partially engage drive or

4. To make the product move in the selected direction,

hold the drive engagement against the handle .

Entretien Quotidien 20 heures 50 heures 100 heures

Remarque :

Pour effectuer une inspection générale

Vérification du niveau d’huile

MISE EN GARDE :

Vidange de l’huile

AVERTISSEMENT :

Lubrification de la machine

Silencieux

MISE EN GARDE :

67

5. If the product has power steering, hold the left

To stop the product

To use the throttle control

To use the fuel switch

To use the choke control

To adjust the skid plates

To prevent freeze-up after use

Note

14

steering trigger (D) to turn left. Hold the right steering

trigger to turn right.

• Turn the choke (A) to open or close the choke valve.

Use the choke to start a cold engine.

D

1. Move the ON/OFF switch to the OFF position.

2. Remove the ON/OFF key.

• Turn the throttle control (A) to change the amount of

fuel used. Always operate the engine at full throttle.

CONTROL

CHOKE

A

TRUCTIONS

• Turn the fuel switch to open or close the fuel valve.

Operate the product with the fuel switch in the OPEN

position.

A

CHOKE

TRUCTIONS

CONTROL

No adjustment is required for normal installation.

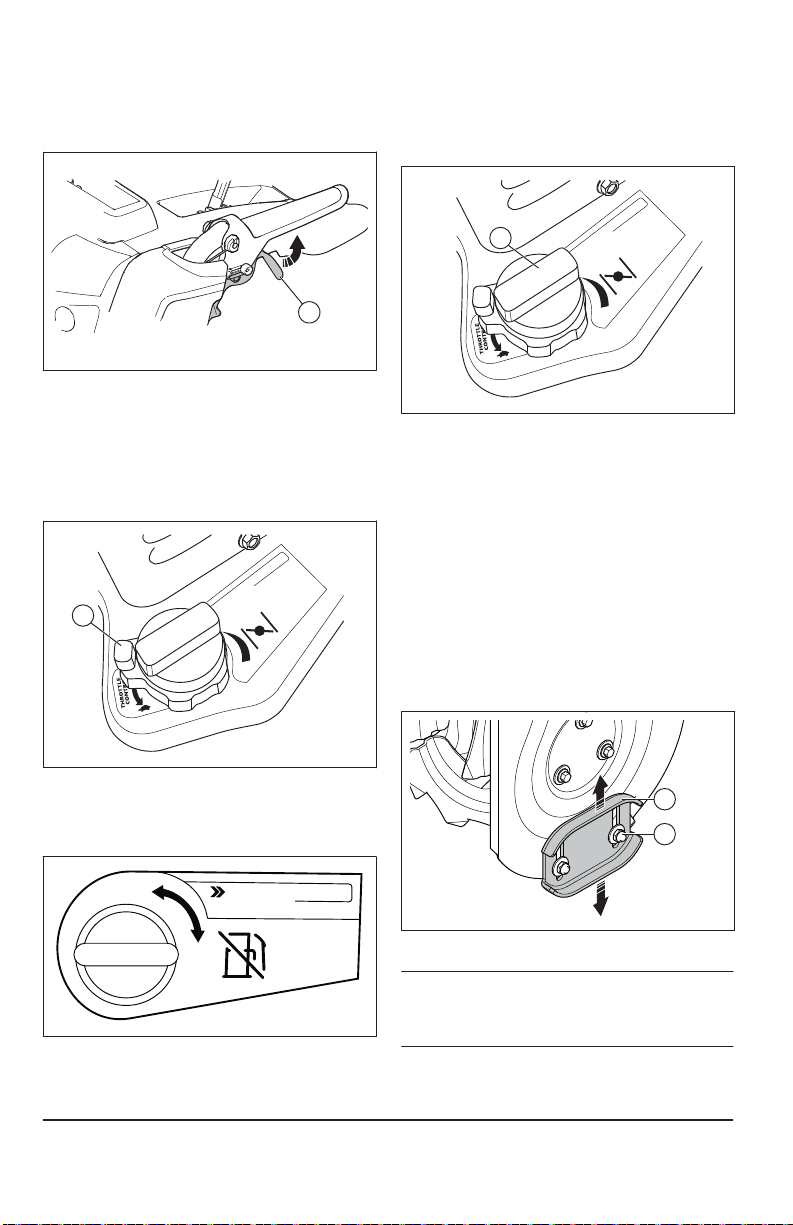

1. When the lock nut (B) is loose or the skid plate (A) is

not high enough from the ground, unlock the lock nut

(B) with a 13 mm open-ended wrench, to move the

skid plate up or down.

2. On flat surfaces, like asphalt roads, raise the skid

plates (A) 5-6 mm (0.2-0.25 in) off the ground. On

uneven surfaces, like gravel roads, make the

clearance between the ground and the product

larger with the skid plates to get the scraper bar

above the top of the gravel. Make sure that the

gravel and stones do not enter into the product. It

can cause personal injuries if objects are ejected at

high speed.

3. Tighten the lock nut (B).

A

B

OFF

FUELCONTROL

INSTRUCTIONS

ON

Controls and moving parts can be blocked by ice.

Do not apply much force to the controls. If you cannot

operate a control or a part, start the engine and let it

operate for some minutes.

1. Start the engine and let it operate for some minutes.

Stop the engine and wait for all moving parts to stop.

694 - 002 -

2. Remove snow and loose ice from the product.

To get a good result

Maintenance

Introduction

Maintenance schedule

Maintenance Daily 20 hours 50 hours 100 hours

15

3. Remove snow and loose ice from the base of the

chute.

4. Turn the chute deflector to the left direction and to

the right direction to remove ice and water.

5. Set the key to the "OFF" position.

6. If the product does not have an electric starter, pull

the starter rope handle several times to remove ice

and water.

7. If the product has an electric starter, connect the

product to power and push the start button once to

remove ice and water.

T

• Always run the engine at full throttle or near full

throttle.

• Always adapt the speed of the product to the snow

situation and adjust the speed with the drive speed

control lever. Make sure that the product throws

snow evenly.

When the product is in use, bolts can loosen and

components can become worn. This can cause

• It is easier and more efficient to remove snow

immediately after it falls.

• Always throw snow downwind whenever possible.

• On flat surfaces, like asphalt roads, raise the skid

plates up to 5-6 mm (0.2-0.25 in) off the ground.

• The scraper bar is reversible. When it becomes worn

almost to the edge of the housing, reverse it.

Replace the scraper bar if it is damaged, or if both

sides are worn.

• Do not dispatch the chute deflector if it is clogged.

• If the product does not move forward due to

unforeseen circumstances, release the drive

engagement immediately or pull out the ON/OFF key

to OFF position.

malfunction like incorrect tolerance clearance, increased

oil consumption, or misalignment of various

components. Do regular maintenance on the product to

prevent malfunction.

Make sure that nuts

and screws are tightened

Do a check of the engine oil level

Replace oil

Make sure there are

no fuel or oil leaks

Remove clogging,

foreign objects in

auger

Inspect the tire pressure

Inspect and change

the spark plug

1

2

3

X

X

XXX

X

X

X

X

1

Replace the oil after the first 20 h, 50 h, 100 h and then every 100 h.

2

See Technical data for correct tire pressure.

3

Check and clean spark plug before use each year.

694 - 002 -

Utilisation de la commande

d’accélérateur

Utilisation du commutateur de

carburant

Utilisation de la commande du volet de

départ

Réglage des plaques de protection

65

N

Note

To do a general inspection

To do a check of the oil level

CAUTION

To replace the engine oil

WARNING

To lubricate the product

Muffler

CAUTION

To examine the spark plug

CAUTION

16

It is not necessary to add grease or to do other

maintenance to the gearbox.

• Make sure that the nuts and screws on the product

are tightened.

• Apply a small amount of lithium grease to the

interlock bosses (C) at the beginning of each season

or every 25 hours of use.

C

1. Put the product on level ground.

2. Remove the oil tank cap with the attached dipstick.

3. Clean the oil from the dipstick.

4. Put the dipstick fully into the oil tank to give a correct

5. Remove the dipstick.

6. Examine the oil level on the dipstick.

7. If the oil level is low, fill with engine oil and do a

to the engine. Do a check of the oil level

before you start the product.

picture of the oil level.

check of the oil level again.

A too low oil level can do damage

1. Run the engine a few minutes to make the oil warm.

Warm oil flows better and includes more

contaminants.

skin contact with the used engine oil.

2. Put the product on level ground.

3. Remove the ON/OFF key.

4. Put a container below the oil drain plug.

5. Remove the oil drain plug, tip the product and drain

the used oil in the container.

6. Put the product back to the operating position.

7. Install the oil drain plug and tighten it by hand.

8. Fill the engine with oil, see

on page 11

• Lubricate the pivot points (A) with oil.

• Lubricate the engine (B) with oil.

.

The engine oil is hot. Avoid

To fill the engine with oil

B

A

The muffler keeps the noise levels to a minimum and

sends the exhaust fumes away from the operator.

Do not use the product if the muffler is missing or

defective. A defective muffler increases the noise level

and the risk of fire.

Examine the muffler regularly to make sure that it is

attached correctly and not damaged.

during and after use and when the engine

operates at idle speed. Be careful near

flammable materials and/or fumes to prevent

fire.

• Examine the spark plug if the engine is low on

• To decrease the risk of unwanted material on the

spark plug type. Incorrect spark plug type

can cause damage to the product.

power, is not easy to start or does not operate

correctly at idle speed.

spark plug electrodes, obey these instructions:

a) Make sure that the idle speed is correctly

adjusted.

b) Make sure that the fuel mixture is correct.

c) Make sure that the air filter is clean.

The muffler becomes very hot

Always use the recommended

694 - 002 -

• If the spark plug is dirty, clean it and make sure that

To inspect the augers and the scraper

bar

To replace the auger shear pins

CAUTION

To replace the impeller shear pins

CAUTION

17

the electrode gap is correct, see

page 25

.

• Replace the spark plug if it is necessary.

1. Before each use, inspect the augers and the scraper

bar for wear.

2. If the edge of the scraper bar is worn, reverse the

scraper bar. If the scraper bar has damages or is

worn on both edges, replace it.

3. If the edges of the augers are worn, contact an

authorized service center to replace them.

The auger shear pins protect the product from damage.

The auger shear pins break if an object comes into the

moving parts.

shear pins supplied with the product.

1. If an auger shear pin breaks, stop the engine and

2. Remove the ON/OFF key and disconnect the spark

3. Align the hole in the auger hub (B) with the hole in

wait for the moving parts to stop.

plug cable.

the auger shaft (C) and install a new ¼ - 20 x 2

shear pin (A)

Use only original equipment

Technical data on

4. Install a ¼-20 locknut (D) and tighten.

A B

C

DB

5. Put the ON/OFF key in the ignition and connect the

spark plug cable to the spark plug.

The impeller shear pins protect the product from

damage. The impeller shear pins break if an object

comes into the moving parts.

shear pins supplied with the product.

1. If an impeller shear pin breaks, stop the engine and

2. Remove the ON/OFF key and disconnect the spark

3. Align the hole in the impeller hub (A) with the holes

wait for the moving parts to stop.

plug cable.

in the impeller shaft (B) and install a new ¼-20 shear

pin (C).

Use only original equipment

694 - 002 -

MISE EN GARDE :

MISE EN GARDE :

Remarque :

Démarrage du moteur (électrique)

AVERTISSEMENT :

MISE EN GARDE :

MISE EN GARDE :

63

4. Install a ¼-20 locknut (D) on the shear pin and

To examine the tires

To clear a clogged chute deflector

WARNING

To replace the scraper bar

Drive belts

WARNING

WARNING

Note

Note

To prepare for replacement of the belts

18

tighten.

A C B

1. Put the scraper bar (A) in a reversed position when it

is worn to the edge of the housing.

A

2. Replace the scraper bar if it is worn on both sides or

if it is damaged.

D

5. Put the ON/OFF key in the ignition and connect the

spark plug cable to the spark plug.

• Keep the tires free of fuel, oil and chemicals to

prevent damage to the rubber.

• Keep the tires away from stumps, stones, ruts, sharp

objects and other objects which can cause damage

to the tires.

• Keep the tire pressure correct, see

on page 25

Do not unclog the chute deflector before the following

operations are made.

1. Release the auger engagement and the drive

engagement at the same time.

2. Wait 10 seconds to make sure that the augers have

stopped.

3. Stop the product.

4. Use the clean-out tool (at least 15" long, included in

some models) to remove the clog.

.

the chute deflector or inside the auger

housing.

Do not put your hands into

Technical data

adjustable. Replace the belts if they are damaged or

begin to slip from wear. It is recommended to have the

belts replaced by a qualified service center.

auger belt at the same time.

1. Remove the fuel from the fuel tank.

of special construction and should be

replaced by original equipment manufacturer

(OEM) belts available from your nearest

service center. Using other than OEM belts

can cause personal injury or damage to the

product.

separation of the product. While separating

the auger housing from the frame, it is

important that an assistant stands in the

operating position and holds the product

handles. Serious personal injury and/or

damage to the product could occur if the

product falls during the belt replacement

process.

The auger and traction drive belts are not

It is recommended to replace the drive belt and

The v-belts on your product are

The belt replacement requires

694 - 002 -

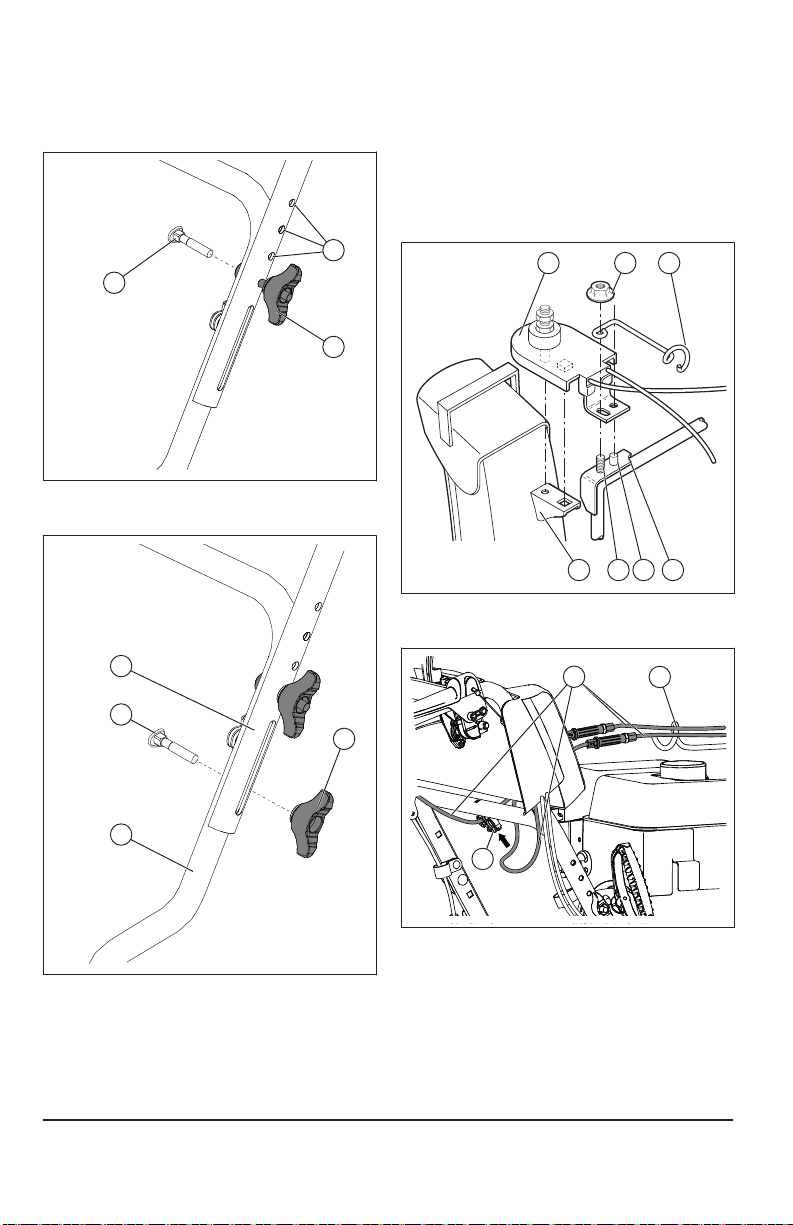

2. Loosen the lock nut (A) that secures the chute

To remove the drive belt

To install the drive belt

Note

19

rotator head (B) to the mounting bracket (C) to

remove the discharge chute.

B

2. Remove the tensioner spring (A) attached to the

drive belt tensioner arm (B).

E

FG

A

C

3. Loosen the two screws (A) that secure the belt cover

(B) to the frame (C) and remove the belt cover.

C A

B

1. Remove the auger belt. See

belt on page 20

.

To remove the auger

B

A

H

I

C

J

D

3. Remove the return spring (C) holding the swing plate

(D) in place.

4. Remove the arm bolt (E) and drive belt tensioner

arm.

5. Remove the pulley bolt (F), engine pulley (G) and

drive belt (H) from the engine.

6. Remove the top bolt (I) holding the swing plate to the

frame

7. Pivot and hold the swing plate away from the product

and remove the drive belt from the drive pulley (J).

1. Pivot and hold the swing plate (D) away from the

product.

E

B

A

FG

H

I

C

J

D

694 - 002 -

2. Put the drive belt (H) onto the drive pulley (J).

Make sure that the drive belt is routed in the

drive pulley groove properly before you lower the

swing plate.

3. Install and tighten the top bolt (I).

Installation de la télécommande du

déflecteur de goulotte

61

4. Put the drive belt in the grove of the engine pulley

To install the belt cover

To remove the auger belt

To install the auger belt

CAUTION

20

(G) before installing on the engine shaft.

5. Install the pulley bolt (F) and attach the engine pulley

on the engine. Tighten the pulley bolt (30-35 Ft.

Lbs. / 41-47 Nm).

6. Install the drive belt tensioner arm (B) and tighten

the arm bolt (E) on the engine.

7. Install the return spring (C) on the swing plate.

8. Install the tensioner spring (A) on the tensioner arm.

9. Operate all controls to make sure that the drive belt

is installed correctly and that all components are

moving correctly.

T

1. Install the belt cover (B) on the frame (C) and tighten

the two screws (A).

C A

B

2. Install the discharge chute.

1. Remove the 5/16'' bolts (A) and the lower ¼" bolts

(B) from the 2 sides of the frame assembly. Do not

discard the bolts.

A

C

B

2. Loosen but do not remove the lower 5/16" bolts (C)

on the 2 sides of the frame assembly.

3. Remove the auger belt from the engine pulley.

4. Tilt the rear section down. The front section is tilted

forward at the same time. The bottom bolt (C) is a

hinge between the front and rear sections.

5. Put a wooden block below the hinge point to set the

product in the tilted position.

6. Move the auger belt tensioner arm and remove the

auger belt from around the arm.

1. Move the belt tensioner arm and put the auger belt

around and in the groove of the auger pulley.

caught between the frame and auger

housing as you put the unit together.

2. Remove the wooden block from below the product.

3. Lift the handle to tilt the rear section up. The front

section will tilt back and pivot to attach the rear

section.

4. Make sure that the belt is put in the auger pulley

groove correctly.

Make sure that the belt is not

694 - 002 -

5. Install the 5/16'' bolts (A), (C) and tighten (8-12

To adjust the tension of the cable for

the discharge chute deflector

To adjust the auger control cable

Note

Note

To remove the wheels

21

Ft.Lbs / 11-16 Nm).

A

C

B

6. Install the ¼'' bolts (B) and tighten (4-6 Ft.Lbs / 5-8

Nm).

7. Install the auger belt on the engine pulley. Make sure

that the belt is put correctly around the idler pulley

and installed correctly in the engine pulley groove.

8. Operate all controls to make sure that the auger belt

is installed correctly and that all components are

moving correctly.

1. Loosen the jam nuts (B) to adjust the tension of the

cable for the discharge chute adjacent to the

adjuster turnbuckle (A).

A B

C

If you do not feel comfortable making this

adjustment yourself, please contact an authorized

service center. Adjustments can be needed if the

impeller and auger rotation is sluggish when engaging

the auger control lever, or if the auger belt has been

replaced.

1. Loosen the jam nuts (B) next to the turn buckle (A) to

adjust the cable tension in the auger control cable

(D).

A B

D

2. Hold the short section and turn the long section.

Turn it 360 degrees.

3. Test the auger engagement. Repeat the adjustment

until only a small amount of tension remains in the

cable when the lever is disengaged.

4. Tighten the bottom jam nut to lock in the tension.

5. Ask an assistant to stand 10 feet / 3 meters in front

of the product, on the opposite side of the chute. The

assistant observes the rotation of the auger and

measures the time it takes for the auger to stop

rotating after the lever is released. If the auger stops

rotating after 5 seconds, adjust the cable by rotating

the center barrel 360 degrees, to contract the

adjuster. Test the auger engagement and measure

the stop time again. If the auger stops rotating in less

than 5 seconds, continue with the next step.

6. Tighten the jam nut on the auger cable.

If the adjustment does not resolve the problem,

replace the auger belt. See

on page 20

.

To remove the auger belt

2. Hold the short section and turn the long section to

increase the adjuster.

3. Adjust until the cable for the discharge chute

deflector (C) has a tight fit. Tighten the jam nuts.

694 - 002 -

1. Remove the wheel pin (A) and the retainer pin (B).

Consignes de sécurité pour la

maintenance

AVERTISSEMENT :

Montage

Retrait du produit du carton

Pièces libres

59

2. Remove the wheel from the axle (C).

To clean the product

Troubleshooting

Troubleshooting

Problem Possible cause Solution

22

• Clean plastic parts with a clean and dry cloth.

A

C

• Do not use a high pressure washer to clean the

product.

• Do not flush water directly on the motor.

• Use a brush to remove leaves, grass and dirt.

B

The product does not start The safety ignition key is not inserted. Insert the safety ignition key.

The product is out of fuel. Fill the fuel tank with fresh, clean

The ON/OFF key is OFF. Move the ON/OFF key to ON posi-

The choke is in OFF (CLOSE) position. Move the choke to ON (FULL,

The primer is not depressed. Press the primer.

The engine is flooded. Wait a few minutes before restarting,

The spark plug cable is not connected. Connect the cable to the spark plug.

The spark plug is bad. Replace the spark plug.

There is water in the fuel or the fuel is too old. Empty the fuel tank and carburetor.

There is vapor locked in the fuel line. Make sure that all the fuel line is be-

Other causes. Inspect the starting procedures care-

The fuel switch (if equipped) is in CLOSE (OFF)

position.

The throttle is in STOP position. Move the throttle to FAST position.

gasoline.

tion.

OPEN) position.

DO NOT prime.

Restart the engine while full throttle

and the choke in OFF (CLOSE) position.

Fill the fuel tank with fresh, clean

gasoline.

low the outlet of the fuel tank. The

fuel line should run continuously

down from fuel tank to carburetor.

fully in this manual.

Turn the fuel switch to OPEN (ON)

position.

694 - 002 -

P

Problem Possible cause Solution

23

Decreased power The spark plug cable is not connected. Connect the cable to the spark plug.

The product throws too much snow. Decrease the speed and the width of

The fuel tank cap is covered with ice or snow. Remove the ice and the snow on and

the swath.

around the fuel tank cap.

The muffler is dirty or clogged. Clean or replace the muffler.

Improper cable length. Adjust the cable.

The engine idles or runs

roughly

The muffler is blocked. Make sure that the engine is cool.

The air intake of the carburetor is blocked. Make sure that the engine is cool.

The choke is in ON (FULL, OPEN) position. Move the choke to OFF (CLOSE) po-

Clear the blockage.

Clear the blockage.

sition.

The fuel line is blocked. Clean the fuel line.

There is water in the fuel or the fuel is too old. Empty the fuel tank and carburetor.

Fill the fuel tank with fresh, clean

gasoline.

The carburetor needs to be replaced. Contact an authorized service center.

The belt is stretched. Replace the auger v-belt.

Excessive vibration / Handle movement

The starter rope handle is

hard to pull

Some parts are loose. The augers are damaged.

The handles are not positioned correctly. Make sure that the handles are

The adjustment lever nuts are loose. Tighten the nuts until the handle feels

The starter rope handle is frozen. Slowly pull out as much rope out of

The starter rope is interfering with components. The starter rope should not touch any

Tighten all fasteners. Replace the

damaged parts. If vibration remains,

contact an authorized service center.

locked into position.

safe.

the starter as possible and release

the starter rope handle. If the engine

does not start, repeat the procedure

or use the electrical starter.

cables or hoses.

694 - 002 -

Sécurité de l’aire de travail

Équipement de protection personnelle

57

P

Problem Possible cause Solution

Transportation, storage and disposal

Transportation and storage

24

Loss of traction drive/

slowing of drive speed

Loss of snow discharge or

slowing of snow discharge

Failure of auger rotation

after the grip is released

The lights are not on (if so

equipped)

The chute rotator is difficult to move

The product turns to one

side

The belt slips. Adjust the cable. Adjust the belt.

The belt is worn. Check / replace the belt. Adjust the

The belt is off the pulley. Check / reinstall the belt. Adjust the

The chute deflector is clogged. Clean the chute deflector.

Foreign objects clog the augers. Remove the debris or the foreign ob-

The shear pin is broken. Replace the broken shear pin.

Excessive snow and ice build up in between

track components.

The friction drive wheel is worn. Contact an authorized service center.

The friction disc is wet Let the friction disc dry

The drive belt is not aligned. Adjust the drive belt.

The discharge deflector is not aligned. Adjust the discharge deflector.

The engine is not running. Start the engine.

The cable connection is loose. Check the cable connections at the

The LED is burnt out. Replace the LED light module. Indi-

There is debris in the chute rotator mechanism. Clean the internal parts of the chute

The cables are kinked or damaged. Make sure that the cables are not

The tire pressure is not equal. Adjust the tire pressure and fill the

The product drives with only one wheel. Inspect the tire lock pin.

Uneven sled adjustment. Adjust the skid plates and the sledge.

Uneven skid plates adjustment. Adjust the skid plates and the sledge.

pulley.

pulley.

ject from the augers.

Remove snow and ice build up from

in between track components.

engine and the lights.

vidual LEDs can not be replaced.

rotator mechanism.

kinked. Replace the cables that are

damaged.

tire.

• For storage and transportation of the product and

fuel, make sure that there are no leaks or fumes.

Sparks or open flames, for example from electrical

devices or boilers, can start a fire.

• Always use approved containers for storage and

transportation of fuel.

• Empty the fuel tank before you put the product in

storage for a long period of time. Discard the fuel at

an applicable disposal location

• Safely attach the product during transportation to

prevent damage and accidents.

• Keep the product in a locked area to prevent access

for children or persons that are not approved.

• Keep the product in a dry and frost free area.

694 - 002 -

D

Disposal

Technical data

Technical data

Note

ST 224 ST 227P ST 230P ST 224P

Dimensions

Engine

Electrical system

25

• Obey the local recycling requirements and applicable

regulations.

• Discard all chemicals, such as engine oil or fuel, at a

service center or at an applicable disposal location.

• When the product is no longer in use, send it to a

Husqvarna dealer or discard it at a recycling

location.

All data, images and specifications are typical and

for reference only, and may be changed due to product

improvement without prior notice.

Weight, lb / kg 198.6 / 90 212 / 96 237.8 / 108 198.6 / 90

Max Operating Tire Pressure, PSI 18 18 20 18

Brand / Model

Displacement, cc 208 254 291 208

Fuel type Unleaded regular (maximum 10% ethanol)

Fuel capacity, gallons / liters 0.31 / 1.17 0.35 / 1.33 0.62 / 2.35 0.31 / 1.17

Oil SAE 5W30 (below 0°C (32°F))

Oil capacity ounces / liters 16 / 0.47 20 / 0.59 32 / 0.95 16 / 0.47

Spark plug F6RTC

Spark plug gap (in / mm) 0.030 / 0,762 mm

Husqvarna Husqvarna Husqvarna Husqvarna

694 - 002 -

Responsabilité concernant le produit

Sécurité

Définitions relatives à la sécurité

AVERTISSEMENT :

55

C

Contenido

26

Introducción.................................................................. 27

Seguridad..................................................................... 29

Montaje.........................................................................33

Funcionamiento............................................................ 36

Mantenimiento.............................................................. 40

Solución de problemas................................................. 48

Transporte, almacenamiento y eliminación de

residuos........................................................................ 50

Datos técnicos.............................................................. 51

694 - 002 -

I

Introducción

Descripción general de la máquina

27

21

20

19

18

17

8 22

16

15

14

13

12

11

26

23

24

25

6

1 2

3

4

5

7

8

10

1. Acoplamiento del barreno

2. Palanca de control del conducto de expulsión

694 - 002 -

9

3. Palanca de ajuste del régimen de velocidad

4. Palanca del control remoto del deflector

Introduction

Présentation de la machine

53

5. Acoplamiento de la transmisión

Descripción de la máquina

Uso específico

Símbolos en el producto

Tenga en cuenta:

28

6. Luz

7. Perilla del mango

8. Silenciador

9. Plancha protectora

10. Barrenos

11. Herramienta de limpieza

12. Conducto de expulsión

13. Deflector del conducto

14. Empuñadura de la cuerda de arranque

15. Tapón de vaciado de aceite

16. Interruptor de combustible

17. Llave de encendido/apagado (ON/OFF)

18. Cebador

19. Interruptor ENCENDER/APAGAR

20. Control del acelerador

21. Estrangulador

22. Tapón de llenado de gasolina

23. Llenado del aceite (ST 227P, ST 230P), varilla de

nivel (ST 227P)

24. Botón de arranque eléctrico

25. Conexión, arranque eléctrico

26. Llenado del aceite (ST 224, ST 224P), varilla de

nivel (ST 224, ST 230P, ST 224P)

D

El producto es un quitanieves con ruedas que se utiliza

para retirar la nieve del suelo.

Este producto puede utilizarse para retirar la nieve de

campos, caminos, senderos y accesos. No lo utilice en

pendientes superiores a 20°. No utilice el producto en

áreas con muchos residuos, suciedad y piedras

protuberantes.

Motor apagado.

Rápido.

Lento.

Combustible.

Aceite.

Protectores auriculares recomendados.

Llave para encender/apagar la máquina.

Colóquela para encender la máquina y

ponerla en marcha.

Estrangulador cerrado (arranque).

Cebador.

dañadas, comuníquese con el distribuidor para

sustituirlas.

Si las etiquetas del producto están

¡Advertencia!

Lea el manual de instrucciones.

Motor en marcha

Tire la empuñadura de cuerda de arranque

para poner la máquina en marcha.

Estrangulador abierto (puesta en marcha).

Llave para encender/apagar la máquina.

Sáquela para detener la máquina.

Sin funcionamiento en pendientes de más

de 10 grados.

694 - 002 -

No retire las protecciones mientras el motor

Responsabilidad del fabricante

Seguridad

Definiciones de seguridad

ADVERTENCIA:

29

se encuentre funcionando.

Retire el cable de la bujía antes del

mantenimiento.

Tracción activada/desactivada.

Descarga de nieve activada/desactivada.

Girar a la izquierda.

Girar a la derecha.

Descarga de nieve.

Tenga cuidado con los objetos que salgan disparados; mantenga a los

transeúntes lejos de la

máquina.

Advertencia: Mantenga

las manos alejadas.

Advertencia: Mantenga

los pies alejados.

Marcha hacia delante/

atrás.

Girar a la izquierda/presionar/girar a la derecha.

Como se menciona en las leyes de responsabilidad del

fabricante, no nos hacemos responsables de los daños

que cause nuestro producto si:

• el producto se repara incorrectamente

• el producto se repara con piezas que no son del

fabricante o que este no autoriza

• el producto tiene un accesorio que no es del

fabricante o que este no autoriza

• el producto no se repara en un centro de servicio

autorizado o por una autoridad aprobada.

Control de tracción.

Las siguientes definiciones proporcionan el nivel de

gravedad de cada palabra clave.

694 - 002 -

Lesiones a personas.

Eliminación

Datos técnicos

Datos técnicos

Tenga en cuenta:

ST 224 ST 227P ST 230P ST 224P

Dimensiones

Motor

Sistema eléctrico

51

A

AVISO:

Tenga en cuenta:

Instrucciones generales de seguridad

Instrucciones de seguridad para el

funcionamiento

30

Daños en el producto.

Esta información hace que el

producto sea más fácil de usar.

• Utilice el producto correctamente. Las lesiones

• Obedezca las instrucciones contenidas en este

• No deseche este manual. Utilice las instrucciones

• No use un producto dañado. Cumpla con el

• En este manual no se pueden abarcar todas las

• Desconecte el cable de la bujía antes de montar o

• No utilice el producto si cambia su especificación

• No respire los humos del motor. La inhalación

• No encienda el producto en interiores o cerca de

• Cuando utilice este producto, el motor crea un

graves o fatales son un posible resultado de un uso

incorrecto. Solo utilice el producto para las tareas

que aparecen en este manual. No utilice el producto

para otras tareas.

manual. Obedezca los símbolos y las instrucciones

de seguridad. Si el usuario no obedece las

instrucciones y los símbolos, es posible que se

produzcan daños y lesiones tanto graves como

fatales.

para montar, operar y mantener el producto en buen

estado. Utilice las instrucciones para la correcta

instalación de piezas y accesorios. Utilice solamente

piezas y accesorios homologados.

programa de mantenimiento. Realice solamente las

tareas de mantenimiento en las que se detallan

instrucciones en este manual. Un centro de servicio

autorizado debe realizar todos los demás trabajos

de mantenimiento.

situaciones que pueden ocurrir cuando se utiliza el

producto. Tenga cuidado y use el sentido común. No

haga funcionar el producto ni realice mantenimientos

si no está seguro acerca de la situación. Hable con

un experto en el producto, su distribuidor, el agente

de servicio o un centro de servicio autorizado para

obtener más información.

almacenar el producto, o realizar tareas de

mantenimiento.

inicial. No cambie una parte del producto sin la

aprobación del fabricante. Utilice solamente las

piezas que están aprobadas por el fabricante. Las

lesiones graves o fatales son un posible resultado

de un mantenimiento incorrecto.

prolongada de los gases de escape es un riesgo

para la salud.

materiales inflamables. Los gases de escape están

muy calientes y pueden crear incendios debido a la

creación de chispas. Un flujo de aire insuficiente

puede causar lesiones graves o fatales por asfixia o

debido al monóxido de carbono.

campo electromagnético. El campo

electromagnético puede causar daños a implantes

médicos. Hable con su médico y fabricante del

implante antes de utilizar el producto.

• No deje que un niño utilice el producto. No permita

que una persona que no conozca las instrucciones

utilice el producto.

• Asegúrese de supervisar siempre a una persona con

capacidades físicas o mentales limitadas que utilice

el producto. Debe haber un adulto responsable en

todo momento.

• Mantenga el producto en un área a la cual los niños

y las personas no autorizadas no puedan acceder.

• El producto puede expulsar objetos y causar

lesiones. Siga las instrucciones de seguridad para

reducir el riesgo de lesiones graves o fatales.

• No se aleje del producto cuando el motor esté en

marcha.

• El operador del producto es responsable en caso de

un accidente.

• Antes de caminar hacia atrás y mientras lo hace,

mire hacia atrás y hacia abajo para cerciorarse de

que no haya niños pequeños, animales u otros

riesgos que puedan provocar caídas.

• Asegúrese de que las piezas no estén dañadas

antes de utilizar el producto.

• Asegúrese de estar al menos 15 m (50 pies) de

distancia de otras personas o animales antes de

utilizar el producto. Asegúrese de que una persona

en el área adyacente sepa que utilizará el producto.

• Consulte las leyes locales o nacionales. Estas

pueden evitar o disminuir el funcionamiento del

producto en algunas condiciones.

• No ponga las manos ni los pies cerca o debajo de

las piezas giratorias. Manténgase alejado de la

abertura de descarga en todo momento.

• Tenga extremo cuidado cuando trabaje en caminos,

pasos o accesos de grava o pase por ellos.

Manténgase alerta para detectar riesgos ocultos o

tránsito

• Después de golpear un objeto extraño, detenga el

motor, desconecte el cable de la bujía o desconecte

el hilo en los motores eléctricos. Inspeccione

atentamente la máquina para detectar daños y

repárelos antes de volver a encender y ocupar el

producto.

• Si el equipo comienza a vibrar de manera anormal,

detenga el motor y revise de inmediato para

encontrar la causa. La vibración es generalmente

una advertencia de problemas.

• Detenga el motor siempre que abandone la posición

de operación, antes de destapar la carcasa del

barreno o el deflector del conducto y también

cuando realice reparaciones, ajustes o inspecciones.

• Cuando realice la limpieza, reparación o inspección

del producto, detenga el motor y asegúrese de que

694 - 002 -

los barrenos y todas las piezas móviles se

Seguridad en el área de trabajo

Equipo de protección personal

31

detuvieron. Desconecte el cable de la bujía y

manténgalo lejos de la bujía para evitar que alguien

arranque el motor accidentalmente.

• No haga funcionar el motor en interiores, excepto

cuando arranque el motor y para el transporte del

producto dentro o fuera del edificio. Abra las puertas

externas; los gases de escape son peligrosos.

• Ponga extrema atención cuando trabaje en

pendientes.

• Nunca haga funcionar el producto sin las debidas

protecciones ni los dispositivos protectores de

seguridad en su lugar y en funcionamiento.

• Nunca dirija el deflector del conducto hacia las

personas o hacia zonas donde puedan ocurrir daños

a la propiedad. Mantenga alejados a los niños y a

otras personas.

• No sobrecargue la capacidad del producto

intentando retirar nieve a una velocidad demasiado

rápida.

• Nunca haga funcionar el producto a una alta

velocidad de transporte en superficies resbaladizas.

Mire hacia atrás y tenga cuidado cuando retroceda.

• Desconecte la alimentación de los barrenos para

transportar el producto o cuando no esté en uso.

• Utilice solamente los implementos y accesorios

homologados por el fabricante del producto, por

ejemplo, los pesos de las ruedas, contrapesos o

cabinas.

• Nunca haga funcionar el producto sin buena

visibilidad o luz. Preste atención mientras camina y

mantenga firmes las empuñaduras. Camine, nunca

corra.

• Nunca toque un motor o silenciador calientes.

S

• Inspeccione atentamente el área donde se va a

utilizar el equipo y retire todos los tapetes, trineos,

tablas, cables y otros objetos extraños.

• Desacople todos los embragues y ponga el cambio

en neutro antes de arrancar el motor.

• No maneje el producto sin usar la indumentaria de

invierno adecuada. Evite usar ropa floja que pueda

quedar atrapada en las piezas móviles. Utilice

calzado que mejore la postura en superficies

resbaladizas.

• Manipule el combustible con cuidado; es altamente

inflamable.

• Use un recipiente de combustible aprobado.

• Nunca agregue combustible a un motor en

marcha o caliente.

• Llene el depósito de combustible en el exterior,

con máximo cuidado. Nunca llene el depósito de

combustible en interiores

• Nunca llene los recipientes de combustible

dentro de un vehículo, en un camión o sobre la

plataforma de un remolque con revestimiento

plástico. Siempre coloque los recipientes en el

suelo, alejados del vehículo, antes de rellenar.

• Cuando sea posible, retire el equipo a gasolina

del camión o tráiler y reabastézcalo en el suelo.

Si no es posible, entonces reabastezca el equipo

en un tráiler con un recipiente portátil, en lugar

de hacerlo directamente con la boquilla del

dispensador de gasolina.

• Mantenga la boquilla en contacto con el borde

del depósito o recipiente de combustible

abriéndolo siempre hasta que el abastecimiento

de combustible esté completo. No use un

dispositivo que mantenga abierto el seguro de la

boquilla.

• Vuelva a colocar la tapa de la gasolina con

seguridad y limpie todo el combustible que se

haya derramado.

• Si el combustible se derrama sobre la ropa,

cámbiesela de inmediato.

• Utilice los cables de extensión y receptáculos

especificados por el fabricante para todas las

unidades con motores de transmisión eléctrica o de

arranque eléctrico.

• Ajuste la altura de la carcasa del barreno para

limpiar superficies rocosas o de grava.

• Nunca intente realizar ajustes con el motor en

marcha, excepto si el fabricante lo recomienda

específicamente.

• Siempre utilice gafas protectoras o protectores

oculares durante el funcionamiento o cuando realice

ajustes o reparaciones a fin de proteger los ojos de

objetos extraños que puedan ser eyectados de la

máquina.

Utilice siempre el equipo de protección personal

adecuado cuando use el producto. Esto incluye, como

mínimo, calzado resistente, protección ocular y

protectores auriculares. El equipo de protección

personal no elimina el riesgo de lesiones, pero puede

disminuir el grado de las lesiones en caso de accidente.

• Siempre use gafas de seguridad o protección ocular

cuando opere el producto o realice tareas de

mantenimiento o reparación.

• Utilice siempre indumentaria de invierno adecuada

cuando opere el producto.

• Utilice siempre botas antideslizantes de servicio

pesado con buen soporte de tobillo durante el

funcionamiento del producto.

• No utilice ropa floja que pueda quedar atrapada en

las piezas móviles.

• Utilice guantes protectores homologados, si es

necesario. Por ejemplo, al instalar, examinar o

limpiar la cuchilla.

• Use siempre protectores auriculares autorizados

cuando utilice el producto. Escuchar ruidos durante

un largo período puede provocar pérdida de

audición inducida por el ruido.

694 - 002 -

Problema Causa posible Solución

49

D

Dispositivos de seguridad en el producto

Silenciador

AVISO:

Seguridad de combustible

ADVERTENCIA:

Propuesta 65

32

• Asegúrese de realizar el mantenimiento del producto

frecuentemente.

• No use un producto con equipo de protección

El silenciador mantiene los niveles de ruido al mínimo y

envía los gases de escape lejos del operador.

No utilice el producto si el silenciador no está instalado

o está defectuoso. Un silenciador defectuoso aumenta

el nivel de ruido y el riesgo de incendio.

Examine el silenciador con regularidad para asegurarse

de que está instalado correctamente y que no esté

dañado.

• No arranque el producto si hay combustible o aceite

• Esto aumenta la vida útil del producto.

• Disminuye el riesgo de accidentes.

Permita que un concesionario autorizado o un centro

de servicio autorizado examinen frecuentemente el

producto para realizar ajustes o reparaciones.

dañado. Si el producto está dañado, comuníquese

con un centro de servicio autorizado.

El silenciador se calienta mucho

durante y después del uso y cuando el

motor funciona en régimen de ralentí. Tenga

cuidado cerca de materiales o vapores

inflamables para prevenir incendios.

instrucciones de advertencia siguientes

antes de usar el producto.

de motor en el producto. Quite el combustible o

aceite no deseado y deje secar el producto.

Lea atentamente las

• Si derrama combustible en su ropa, cámbiese la

ropa inmediatamente.

• No permita que le caiga combustible en el cuerpo,

ya que puede causar lesiones. Si le cae combustible

en el cuerpo, utilice jabón y agua para quitarlo.

• No arranque el producto si el motor tiene una fuga.

Examine frecuentemente el motor en busca de

fugas.

• Tenga cuidado con el combustible. El combustible

es inflamable y los gases son explosivos y pueden

causar lesiones graves o fatales.

• No respire los gases del combustible, ya que

pueden causar lesiones. Asegúrese de que haya

suficiente flujo de aire.

• No fume cerca del combustible o del motor.

• No coloque objetos calientes cerca del combustible

o del motor.

• No agregue combustible cuando el motor esté en

marcha.

• Asegúrese de que el motor se enfríe antes de llenar

el depósito de combustible.

• Antes de llenar el depósito de combustible, abra

lentamente la tapa del depósito de combustible y

libere la presión con cuidado.

• No agregue combustible al motor en un área interior.

Un flujo de aire insuficiente puede causar lesiones

graves o fatales por asfixia o debido al monóxido de

carbono.

• Apriete bien la tapa del depósito de combustible. Si

no aprieta la tapa del depósito de combustible, se

genera un riesgo de incendio.

• Mueva el producto a un mínimo de 3 m (10 pies) de

la posición en la que se llenó el depósito antes de

empezar a usarlo.

• No ponga demasiado combustible en el depósito de

combustible.

¡ADVERTENCIA!

694 - 002 -

I

Instrucciones de seguridad para el

mantenimiento

ADVERTENCIA:

Montaje

Para extraer el producto de la caja de

cartón

Piezas sueltas

33

• Los gases de escape del motor contienen monóxido

• Antes de realizar el mantenimiento del producto,

• Utilice guantes protectores cuando realice las tareas

instrucciones de advertencia siguientes

antes de usar el producto.

de carbono, un gas inodoro, tóxico y muy peligroso.

No arranque el motor en interiores o en espacios

cerrados.

detenga el motor y quite el cable de encendido de la

bujía.

de mantenimiento en las cuchillas. Las cuchillas son

muy afiladas y pueden producir cortes con facilidad.

Lea atentamente las

1. Retire las piezas sueltas que se incluyen con el

producto. Recorte las cuatro esquinas de la caja y

coloque los paneles del extremo en una superficie

plana.

2. Extraiga los dos tornillos que sujetan la carcasa del

barreno al palé. Extraiga los soportes de acero de

las planchas protectoras, si tienen.

3. Corte las bridas para cable que sujetan el producto

al palé y sáquelas.

4. Retire todos los materiales de embalaje.

5. Retire el producto de la caja y asegúrese de que no

queden piezas sueltas en la caja.

• Accesorios y modificaciones en el producto que no

estén aprobados por el fabricante pueden causar

lesiones graves o la muerte. No modifique el

producto. Siempre utilice accesorios aprobados por

el fabricante.

• Si el mantenimiento no se realiza de manera

correcta y regular, aumenta el riesgo de sufrir

lesiones y causar daños en el producto.

• Solo realice tareas de mantenimiento como se indica

en el presente manual del usuario. Todas las demás

tareas de mantenimiento se deben realizar en un

taller de servicio aprobado.

• Procure realizar las tareas de mantenimiento con

regularidad en un taller de servicio aprobado.

• Cambie las piezas dañadas, desgastadas o rotas.

Llave(s) de encendido/apagado (ON/OFF)

Tornillo de 5/16-18 x 2 ¼" (2)

Perillas de la empuñadura (2)

Contratuerca de 3/8 (1)

Perilla (3)

Llave multiuso (1)

Conducto de expulsión (1)

694 - 002 -

Guía del cable (1)

Pasadores fusibles de ¼-20 x 1-¾ (6)

Contratuercas de ¼-20 (6)

Para quitar las ruedas

Para limpiar el producto

47

Contratuerca de 5/16-18 (1)

Para instalar la empuñadura

34

Contratuerca de ¼-20 (1)

Arandela de nailon (1)

Tornillo de 5/16-18 x 5/8 (1)

Muelle (1)

Perno de tope de ¼-20 (1)

1. Levante la empuñadura superior hasta la posición

de funcionamiento.

2. Ajuste la posición de la empuñadura en uno de los

orificios de montaje (B) y apriete las perillas de la

empuñadura (C) con los tornillos (D).

B

D

C

694 - 002 -

3. Instale más tornillos (D) y perillas de la empuñadura

Para instalar el deflector del conducto y

el cabezal del rotador del conducto

Para instalar el control remoto del

deflector del conducto

35

(C) para fijar la empuñadura superior (A) a la

empuñadura inferior (E).

A

D