Page 1

GB

Operator’s manual

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

ES

DE

FR

Manual de instrucciones

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

PP 480 HF

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

GGGGBBBB EEEESSSS DDDDEEEE FFFFRR

RR

Page 2

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the machine.

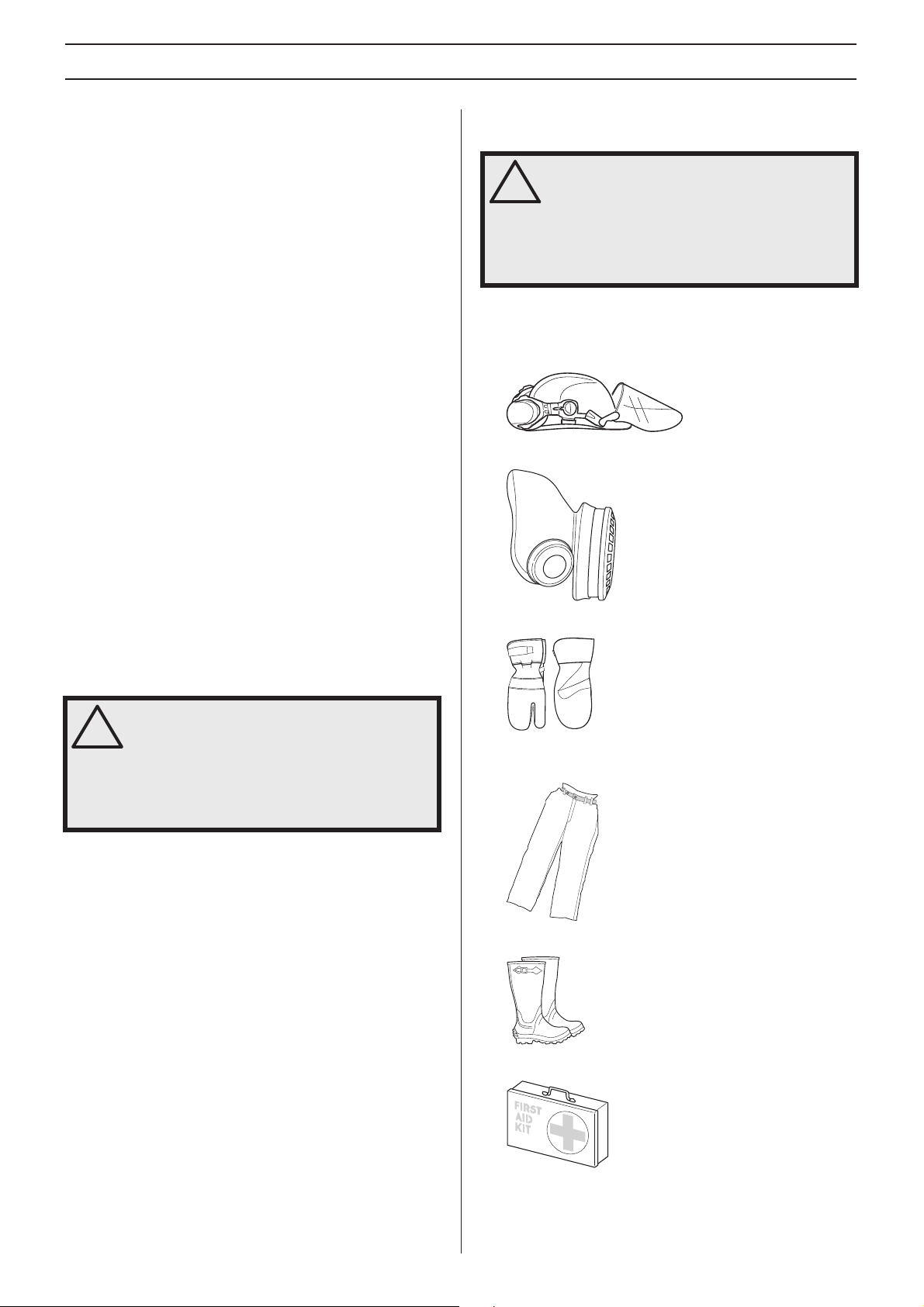

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

• Breathing mask

This product is in accordance with

applicable EC directives.

WARNING! High current.

Symbols in the operator’s manual:

Inspection and/or maintenance should be

carried out with the motor switched off and

the plug disconnected.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

Environmental marking. Symbols on the

product or its packaging indicate that this

product cannot be handled as domestic

waste. It must instead be submitted to an

appropriate recycling station for the recovery

of electrical and electronic equipment.

By ensuring that this product is taken care of

correctly, you can help to counteract the

potential negative impact on the environment and people that

can otherwise result through the incorrect waste

management of this product.

For more detailed information about recycling this product,

contact your municipality, your domestic waste service or the

shop from where you purchased the product.

2 – English

Page 3

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ............................................. 2

Symbols in the operator’s manual: ............................... 2

CONTENTS

Contents ...................................................................... 3

WHAT IS WHAT?

What is what on the power unit? .................................. 4

SAFETY INSTRUCTIONS

Steps before using a new power unit ........................... 5

Personal protective equipment ..................................... 5

Machine′s safety equipment ........................................ 6

General safety precautions .......................................... 7

General working instructions ....................................... 7

PRESENTATION

PP 480 HF ................................................................... 8

ASSEMBLY

Assembling/Installing equipment ................................. 9

SETTINGS AND ADJUSTMENTS

Start menu ................................................................... 10

Operations menu ......................................................... 10

STARTING AND STOPPING

Before starting ............................................................. 11

Starting ........................................................................ 11

Stopping ....................................................................... 12

After work is completed ............................................... 12

MAINTENANCE

Service ......................................................................... 13

Daily maintenance ....................................................... 13

TECHNICAL DATA

PP 480 HF ................................................................... 14

EC-declaration of conformity ........................................ 15

English – 3

Page 4

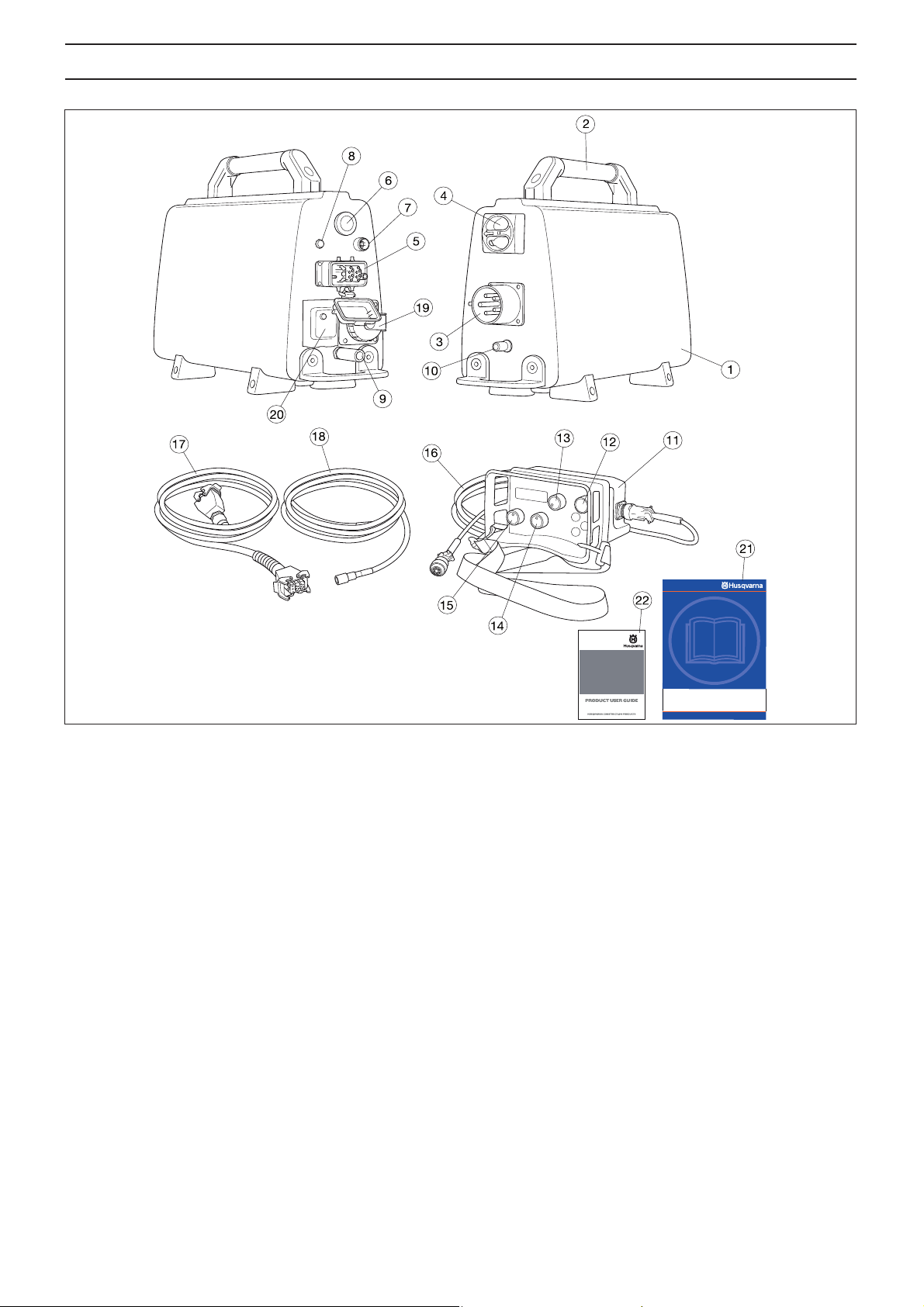

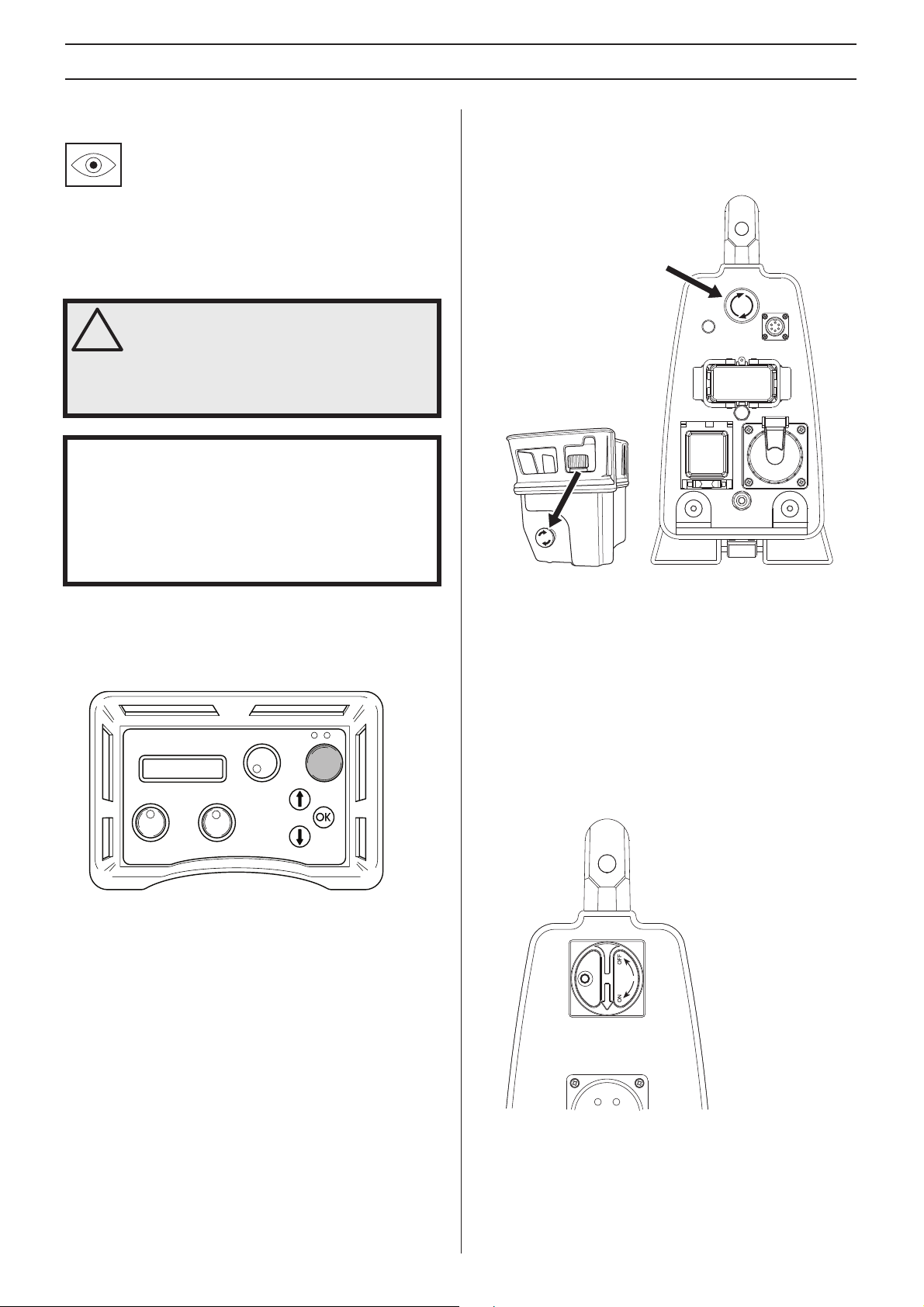

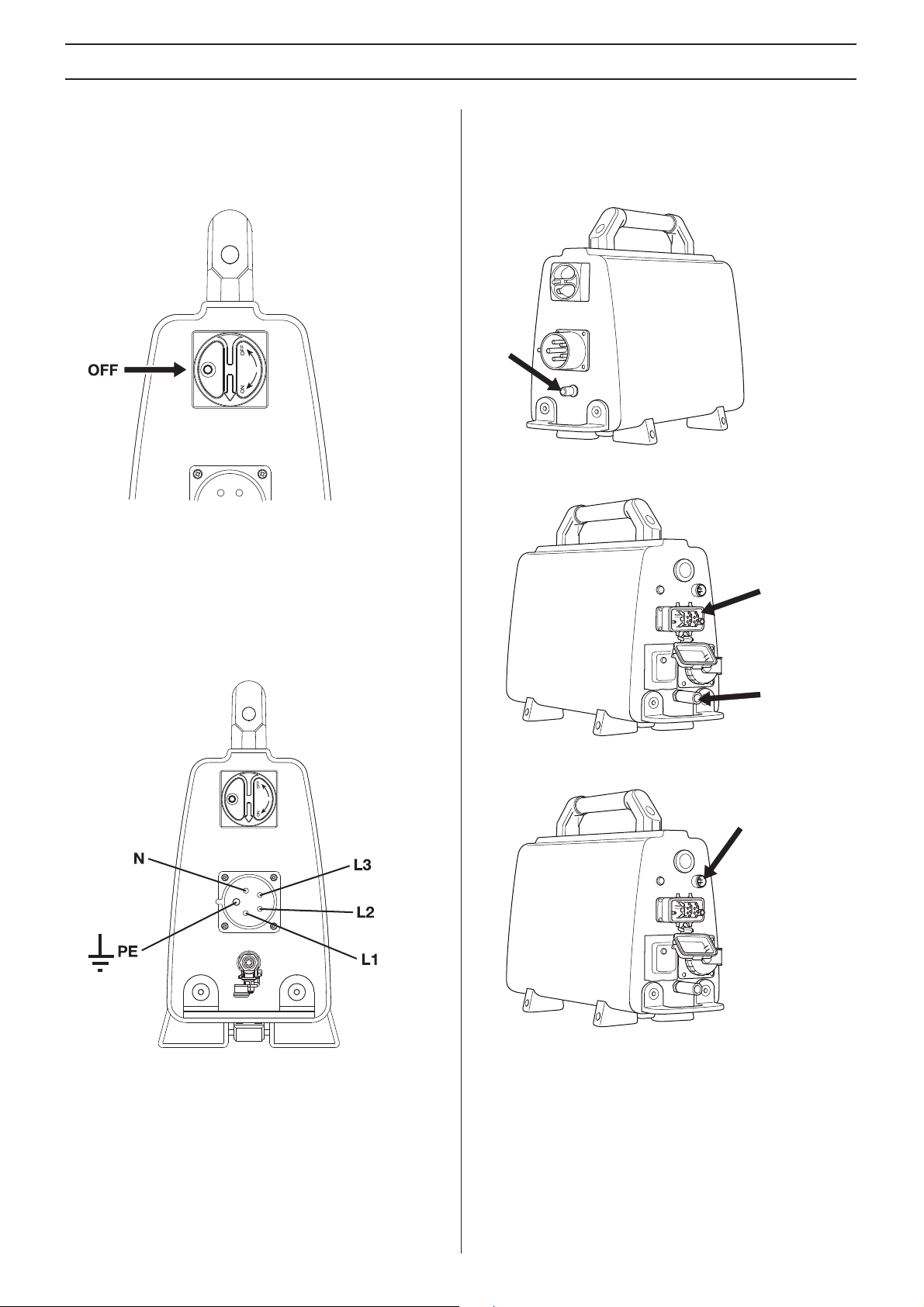

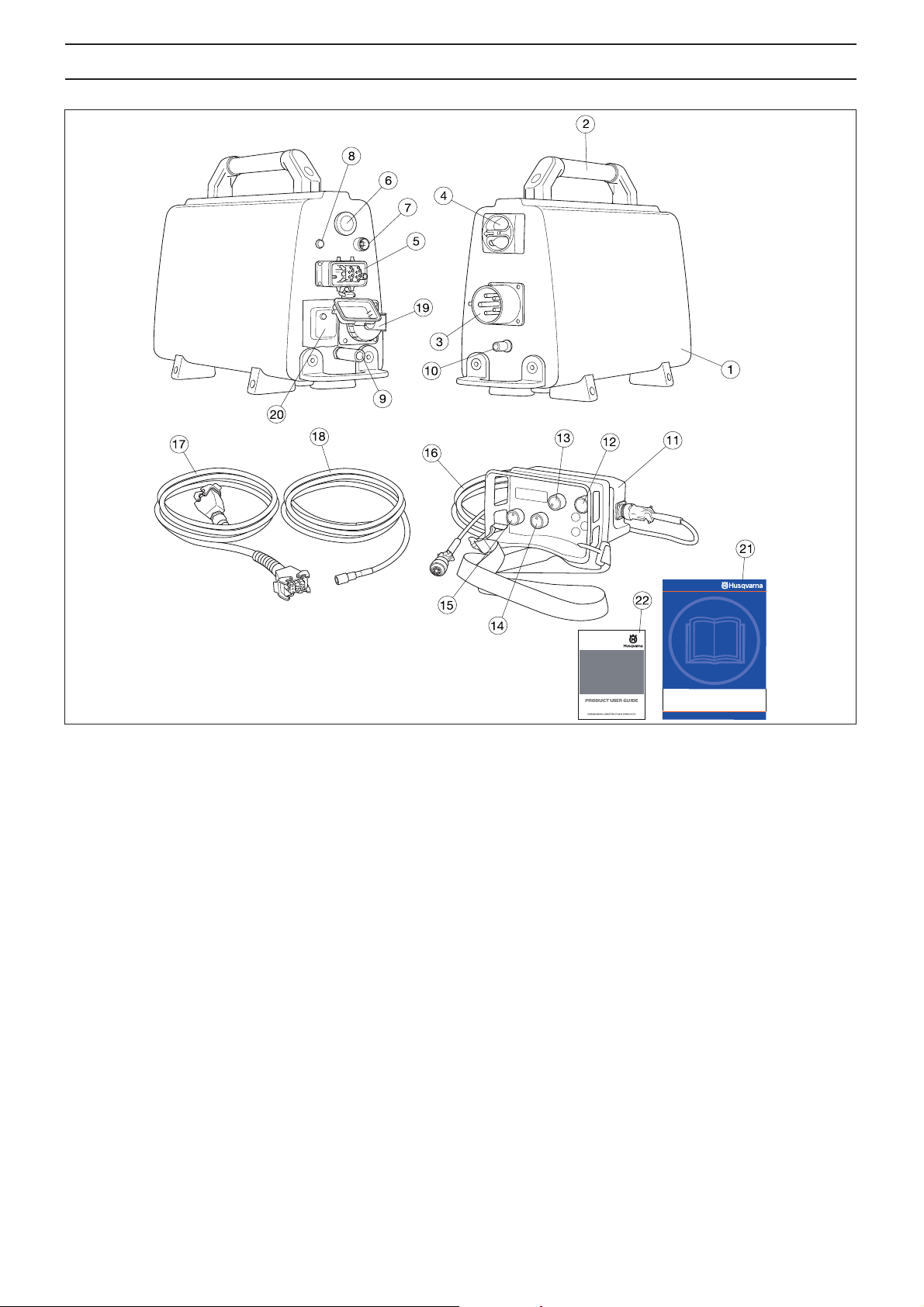

WHAT IS WHAT?

What is what on the power unit?

1 Power unit

2 Handle

3 Electrical socket

4 Main switch

5 Cable connection

6 Emergency stop

7 Canbus port

8 Power indicator

9 Water connector, out

10 Water connector, in

11 Remote control

12 Start button

13 Blade rotation and start water coolant

14 Travel feed

15 Depth feed

16 Canbus cable

17 Power cable

18 Water hose

19 Single phase socket - Only 5-pin machines

20 Ground-fault circuit breaker - Only 5-pin machines

21 Operator′s manual

22 DVD - Product user guide

4 – English

Page 5

SAFETY INSTRUCTIONS

Steps before using a new power unit

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• See the supplied DVD for working technique tips.

• This machine is only intended for use together with a

Husqvarna WS 482 HF. All other use is forbidden.

• Read through the manual supplied with the wall saw

before starting to use the hydraulic unit.

• The machine can cause serious personal injury. Read the

safety instructions carefully. Learn how to use the

machine.

Always use common sense

It is not possible to cover every conceivable situation you can

face. Always exercise care and use your common sense.

Avoid all situations which you consider to be beyond your

capability. If you still feel uncertain about operating

procedures after reading these instructions, you should

consult an expert before continuing.

Do not hesitate to contact your dealer if you have any more

questions about the use of the machine. We will willingly be of

service and provide you with advice as well as help you to use

your machine both efficiently and safely.

Let your Husqvarna dealer regularly check the machine and

make essential adjustments and repairs.

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to print.

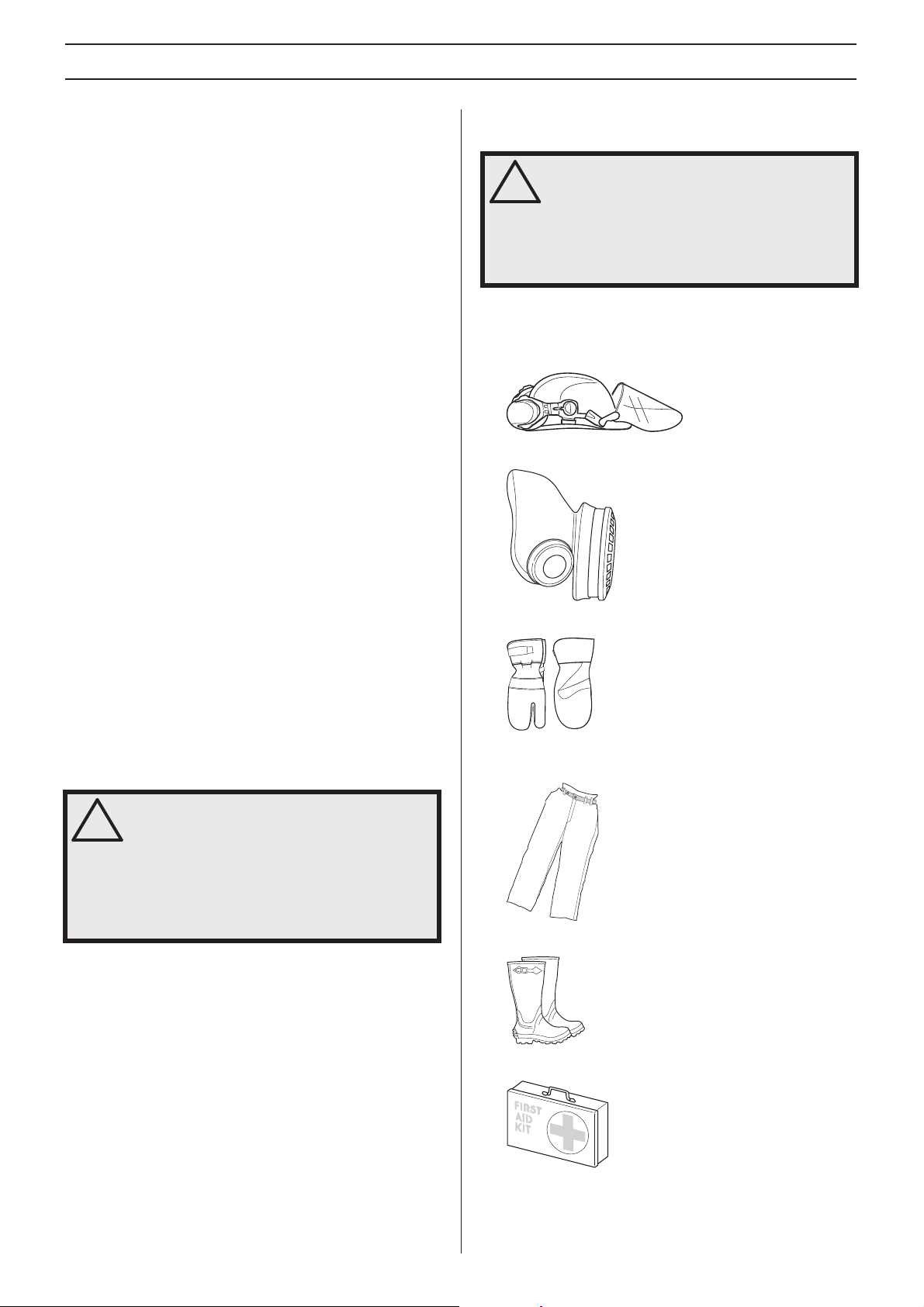

Personal protective equipment

WARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

WARNING! Under no circumstances should

you modify the original design of the

!

machine without approval from the

manufacturer. Always use original spare

parts. Unauthorized modifications and/or

accessories may lead to serious injury or

death to the user or others.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

English – 5

Page 6

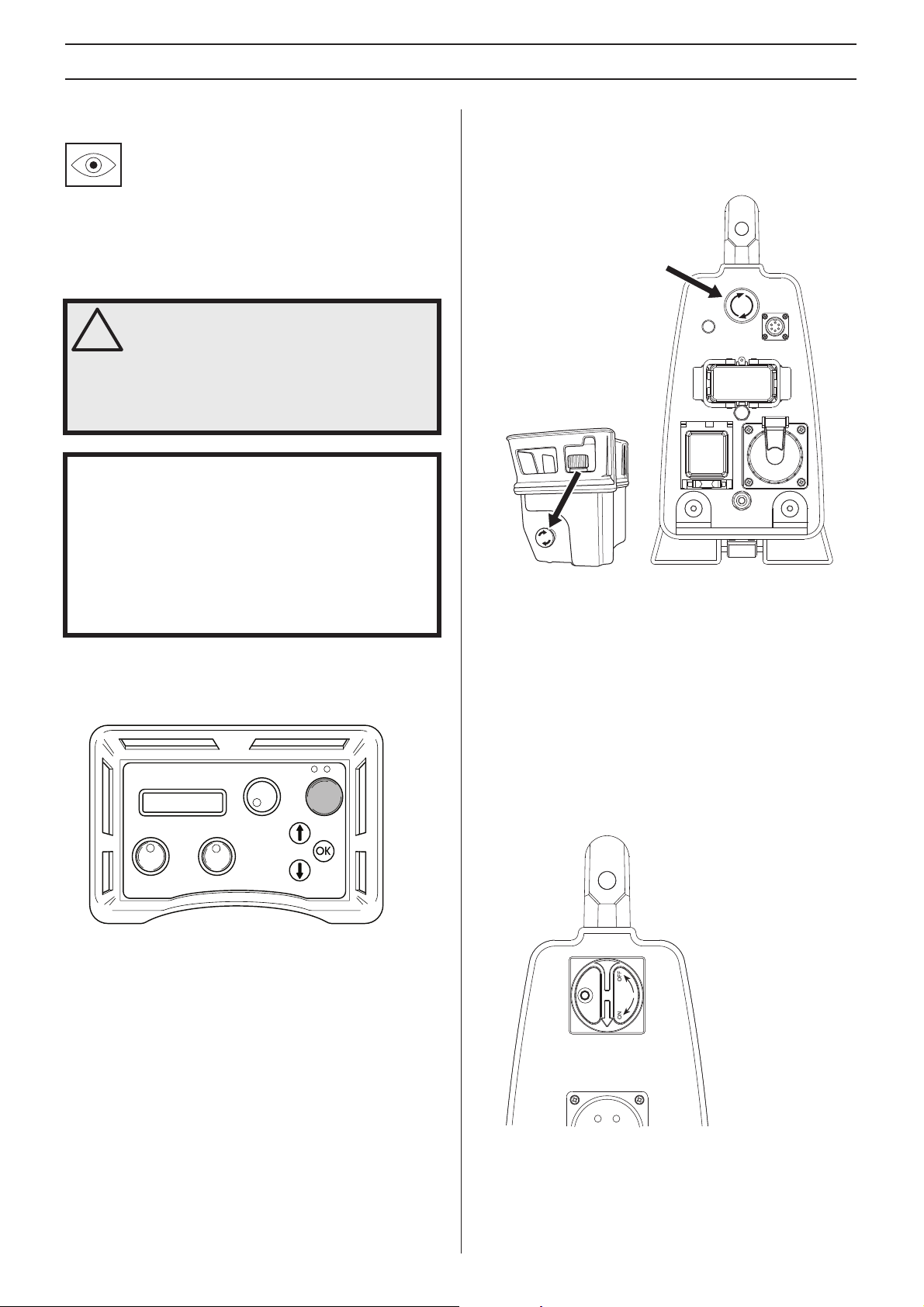

SAFETY INSTRUCTIONS

Machine′′′′s safety equipment

This section describes the machine′s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

WARNING! Never use a machine with faulty

safety equipment. The machine’s safety

!

equipment must be checked and maintained

as described in this section. If your machine

fails any of these checks contact your

service agent to get it repaired.

IMPORTANT! All servicing and repair work on the machine

requires special training. This is especially true of the

machine′s safety equipment. If your machine fails any of the

checks described below you must contact your service

agent. When you buy any of our products we guarantee the

availability of professional repairs and service. If the retailer

who sells your machine is not a servicing dealer, ask him for

the address of your nearest service agent.

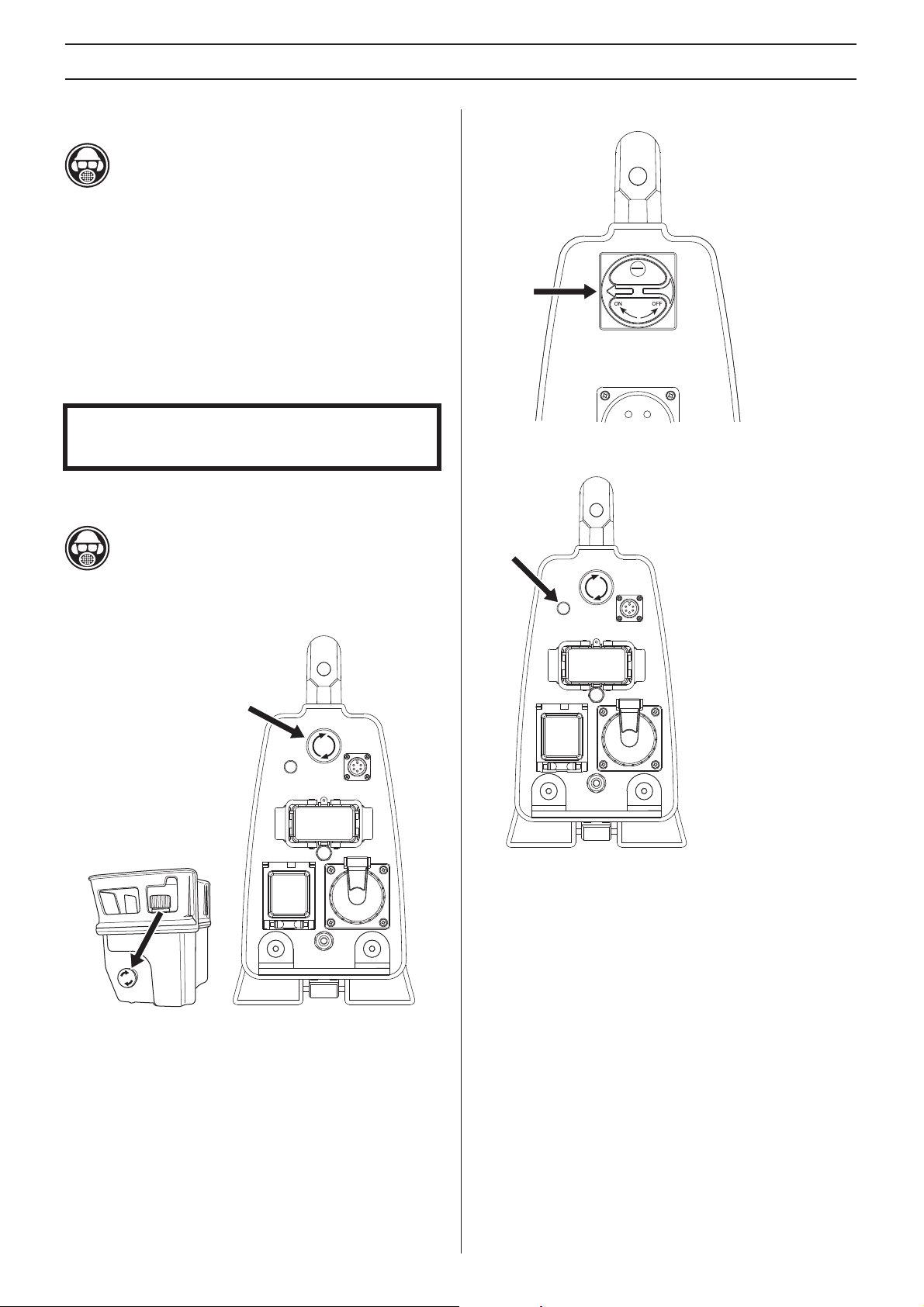

Start button

Emergency stop and stop button

The power unit is equipped with an emergency stop and the

remote control with a stop button. These are used to be able

to quickly shut down the power unit.

Check the emergency stop and stop button

The start button must be pushed and held to be able to start

the blade rotation. This in order to prevent unintended starting

of the blade rotation.

Checking the start button

• Turn the knob for blade rotation without pushing and

holding the start button.

The blade rotation must not start.

• Push and hold the start button and turn the knob for blade

rotation.

Now the blade rotation shall start.

• Start the blade rotation.

• Push the emergency stop on the power unit and check

that the blade rotation stops. Check the stop button on the

remote control in the same way.

Main switch

The main switch is used to switch the electricity supply to the

power unit on and off. The main switch must be in the "0"position when the incoming cable is connected.

6 – English

Checking the main power switch

• Turn the main switch to the "0"-position.

• Try to start the saw.

The saw must not start.

Page 7

SAFETY INSTRUCTIONS

General safety precautions

WARNING! Do not use the machine without

first reading and understanding the contents

!

of this Operator’s Manual.

There is always a risk of shocks from

electrically powered machines. Avoid

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Always follow the instructions in the

Operator’s manual to avoid damage.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

• Never carry the machine by holding the cable and never

pull the plug by pulling the cable.

• Keep all cables away of water, oil and sharp edges. Make

sure the cable is not pinched in doors, fences or the like.

It can cause the object to become live.

• Check that the cables are intact and in good condition.

Never use the machine if any cable is damaged, but hand

it in to an authorized service workshop for repair.

• Do not use an extension cord while it is rolled up to avoid

overheating.

• The machine should be connected to an earthed outlet

socket.

• Always connect the machine through an ground fault

circuit interrupter with personal protection, i.e. an ground

fault circuit interrupter that trips at an ground fault of 30

mA.

• Check that the mains voltage corresponds with that stated

on the rating plate on the machine.

• Keep all parts in good working order and ensure that all

fixtures are properly tightened.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Do not modify safety equipment. Check regularly that they

function as they should. The machine must not be run with

defective or disassembled safety equipment.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• People and animals can distract you causing you to lose

control of the machine. For this reason, always remain

concentrated and focused on the task.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

Transport and storage

• Always switch of the power unit and pull out the electric

cable before moving the equipment.

• Store the equipment in a lockable area so that it is out of

reach of children and unauthorized persons.

• Store the machine and its equipment in a dry and frost

proof place. If there is a risk of freezing, the machine must

be drained of any remaining water coolant.

• Use the cases provided to store the equipment.

• Do not expose the machine to temperatures exceeding

45

°C or to direct sunlight.

General working instructions

WARNING! This section describes basic

safety directions for using the machine. This

!

information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced user. Do not

attempt any task that you feel unsure of!

• All operators shall be trained in the use of the machine.

The owner is responsible for ensuring that the operators

receive training.

• Check that all couplings, connections and cables are

intact and free from dirt.

• Check that all cables and the water supply are correctly

connected to the machine before starting it.

• Never pull out the power cable without first switching off

the power unit and waiting for the engine to come to a

complete halt.

• If an emergency situation should arise anyway, push the

red emergency stop button on the power unit or the stop

button on the remote control.

• Always check and mark out where gas pipes are routed.

Cutting close to gas pipes always entails danger. Make

sure that sparks are not caused when cutting in view of

the risk of explosion. Remain concentrated and focused

on the task. Carelessness can result in serious personal

injury or death.

• Make sure that no pipes or electrical cables are routed in

the area to be cut.

• Check that electrical cables within the working area are

not live.

• Never leave the machine unsupervised with the motor

running.

• Always saw in a manner that permits easy access to the

emergency stop.

• Make sure that there is always another person close at

hand when you use the machines, so that you can call for

help if an accident should occur.

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Always ensure you have a safe and stable working

position.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

• Do not expose the machine to temperatures exceeding

45

°C or to direct sunlight.

• Do not use the machine in wet or humid surroundings,

close to water, in the rain or snow.

• Do not wash the machine with water, as water can enter

the electrical system or the engine and cause damage to

the machine or short circuit.

English – 7

Page 8

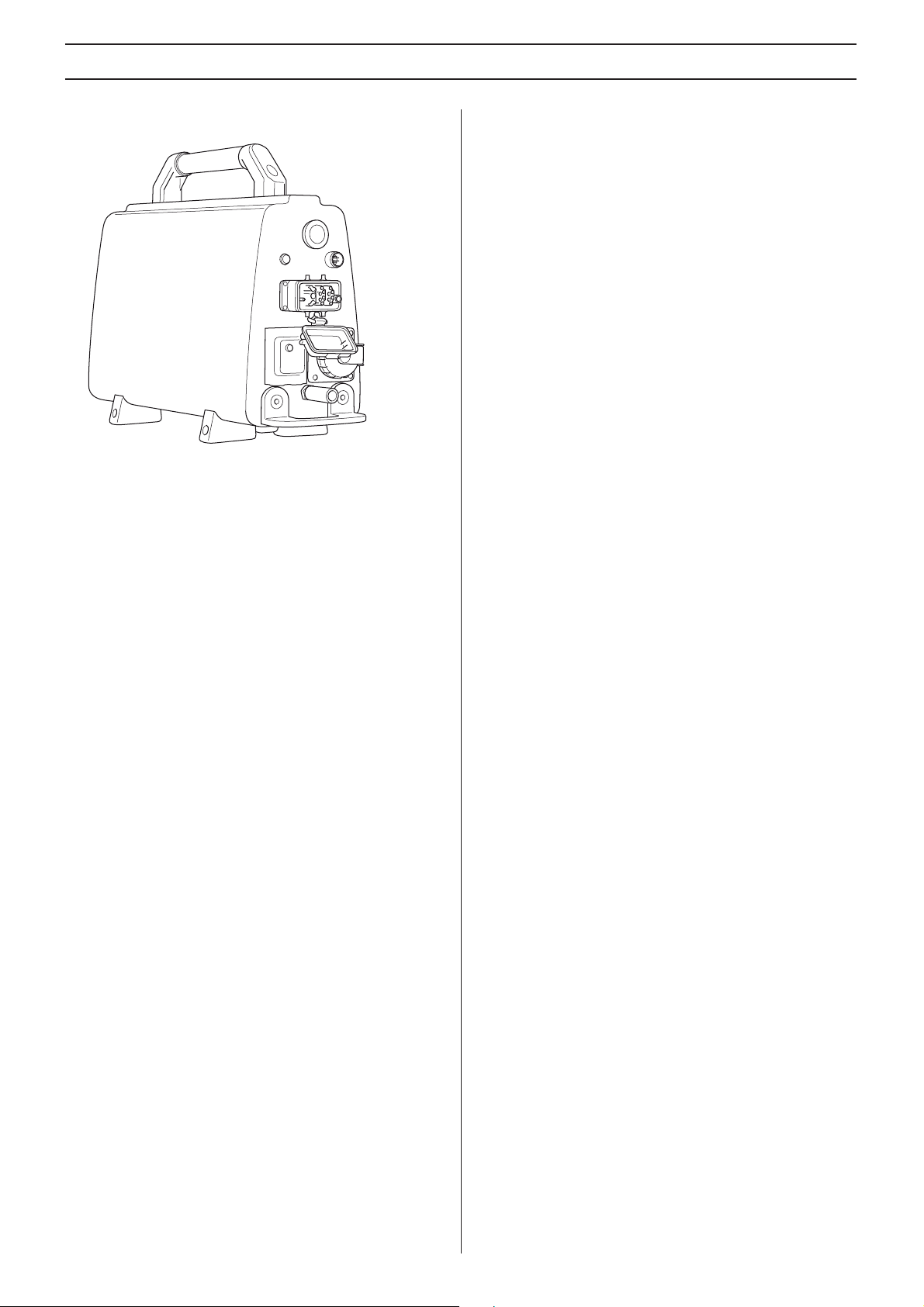

PRESENTATION

PP 480 HF

It is our wish that you will be satisfied with your product and

that it will be your companion for a long time. Think of this

operator′s manual as a valuable document. By following its′

content (using, service, maintenance etc) the life span and

the second-hand value of the machine can be extended. If

you will sell this machine, make sure that the buyer will get the

operator′s manual.

A purchase of one of our products gives you access to

professional help with repairs and services. If the retailer who

sells your machine is not one of our authorised dealers, ask

him for the address of your nearest service workshop.

Husqvarna Construction Products has a policy of continuous

product development. Husqvarna reserves the right to modify

the design and appearance of products without prior notice

and without further obligation introduce design modifications.

PP 480 HF is supplied with the following

equipment:

• 1 x power unit

• 1 x remote control

• 1 x power lead

• 1 x Canbus cable

• 1 x water hose

• Transport boxes for smooth transport.

• DVD - Product user guide

General

• PP 480 HF is a power unit specially developed to be used

with the electric wall saw WS 482 HF.

• It has a compact design and weighs just 23 kg (51 lb).

• Use 32 A for a 400 V system for full power.

• The power unit is connected to the saw with only a power

lead and a water coolant hose.

• Equipped with a 230 V power outlet and a terminal for

Canbus-cable.

• Equipped with an electric water valve which is controlled

from the remote control.

• Through the remote control the operator receives

information on power output, can measure the time and

other things about the sawing process.

8 – English

Page 9

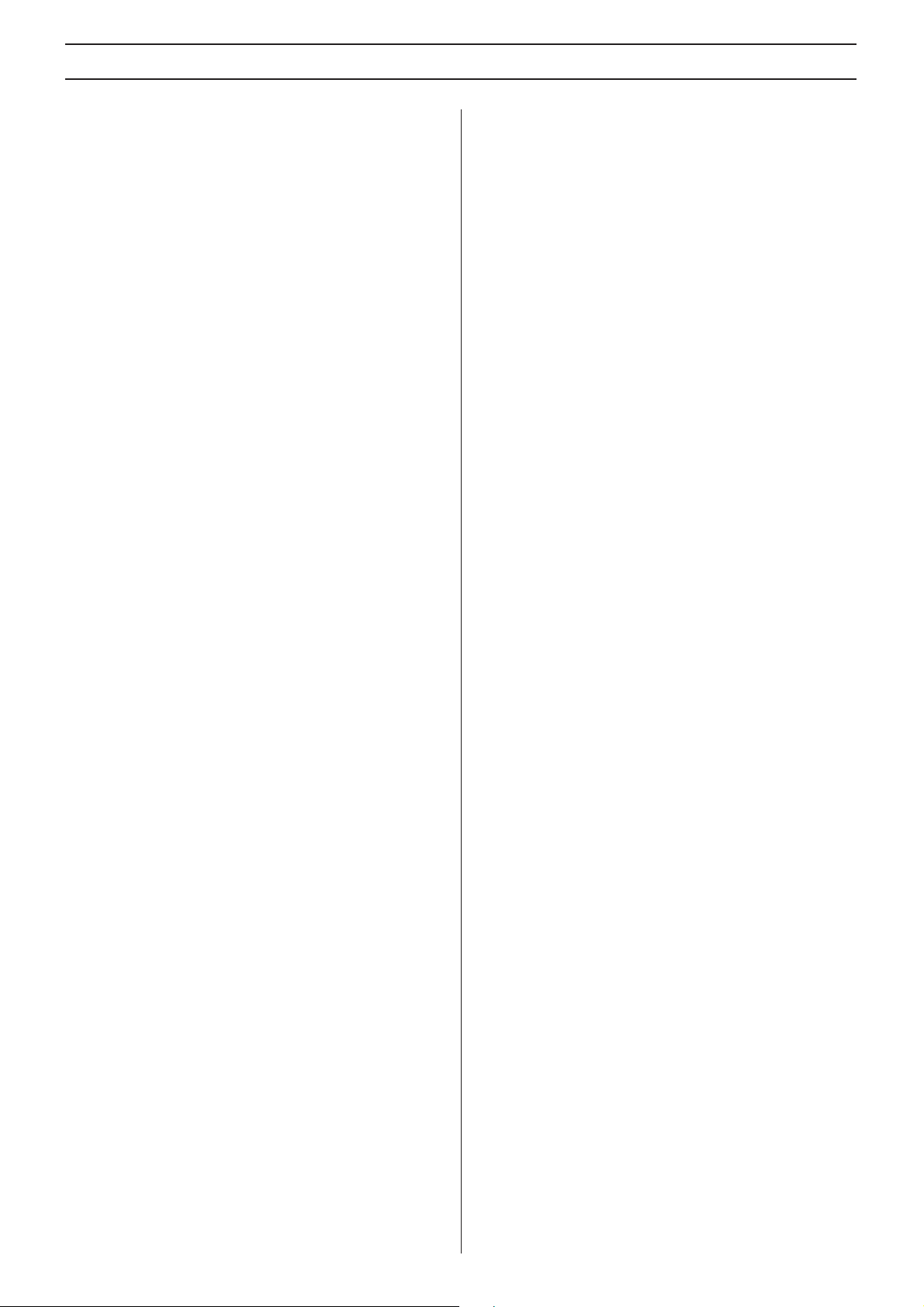

ASSEMBLY

Assembling/Installing equipment

When the machine has been transported to a suitable site, it

should be connected:

• Turn the main switch to the "0"-position.

• Connect the incoming power cable (380-480 V, 32 A

European connector). Power units equipped with a single

phase socket (230 V) must also have a neutral wire in

order for the socket to work. The power pack functions

even it there is no neutral wire present.

To be able to use full power output, the power unit must be

connected to a 32 A fuse. With a 16 A or 25 A fuse the

power output is lower so as not to overload the fuse. This

is selected when starting up the power unit.

• Connect the water hose to the incoming water connector.

The power unit is equipped with an electric water valve,

which is closed when the power pack is activated. When

the power pack is without electricity, the valve is open to

be able to drain water coolant if there is a risk of freezing.

• Connect the supplied power lead and water hose from the

power unit to the saw unit.

• Connect the remote control using the supplied Canbus

cable. Tighten the cable connector screws by hand.

English – 9

Page 10

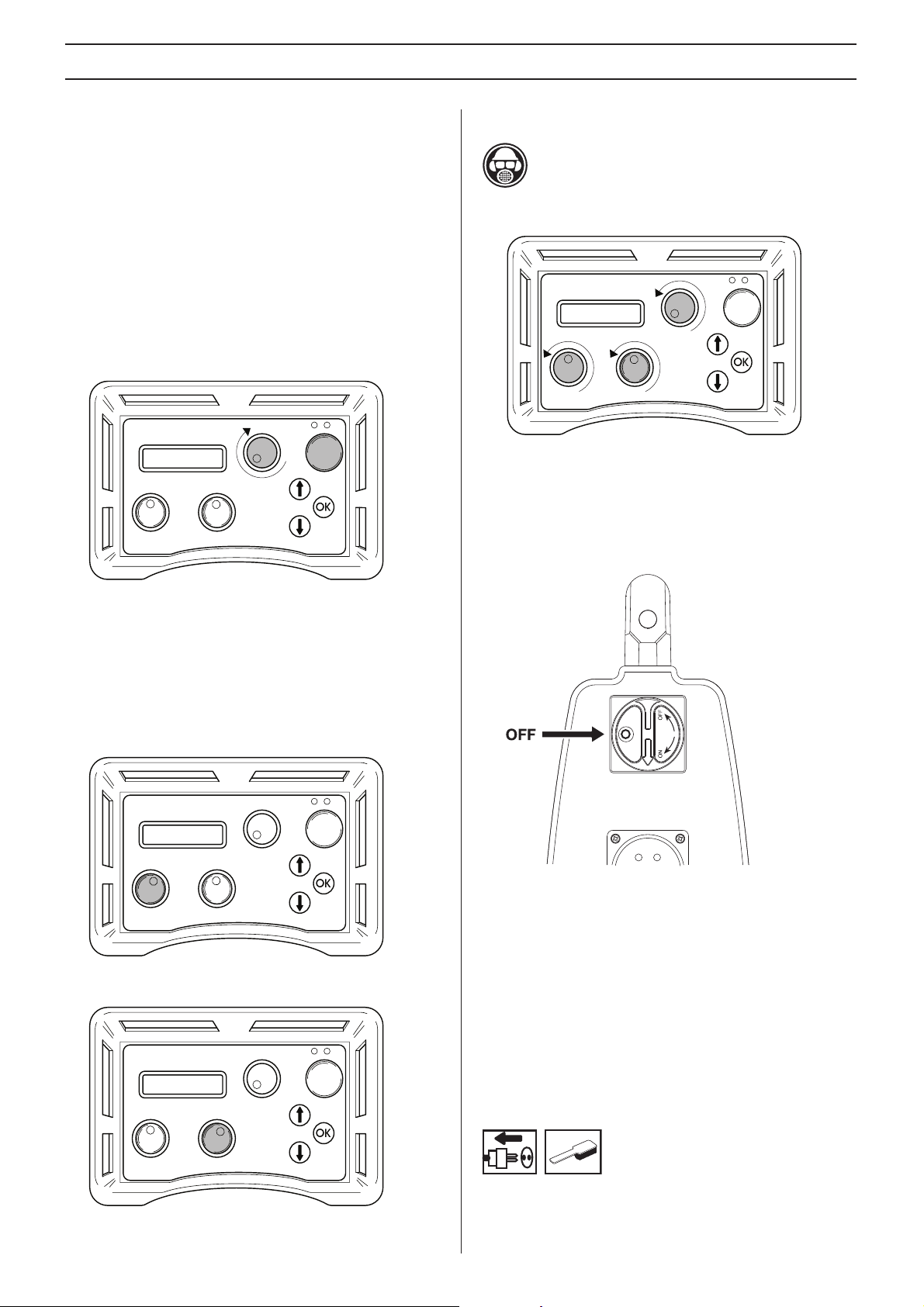

SETTINGS AND ADJUSTMENTS

Start menu

The start menu is shown each time the power to the hydraulic

unit is switched on.

• The remote control display shows "SELECT FUSE". The

last alternative used is preset. Choose another gear using

the arrow keys. Press OK to confirm the selection.

With a 25 A fuse you can use approx. 70% of the full

output. With 16 A you can use approx. 50% of full output.

The function is intended to obtain as high output as

possible without overloading the fuse.

• The remote control display shows "SELECT GEAR". The

last alternative used is preset. Choose another gear using

the arrow keys. Press OK to confirm the selection.

On gear 1, the speed range is 600-900 rpm and on gear

2 the speed range is 800-1200 rpm. Check that the

mechanical gear on the saw unit is corresponding with the

electrically set gear in the remote control.

• The display now shows "HUSQVARNA PP-480 HF

PRESS START".

Operations menu

As long as the power unit has voltage but the blade rotation

stands still, the display shows "Husqvarna PP-480 HF

PRESS START".

Before starting, all controls must be turned to zero position. If

this is not done, a message in the display will prompt this

when the start button is pushed. "TURN OFF TRAVEL

FEEDING" or "TURN OFF DEPTH FEEDING" or "TURN OFF

BLADE".

When the blade rotation is started, the display shows "X RPM,

Y%, Z A", where X equals the engine speed, Y equals the

output percentage of the maximum effect, and Z equals the

selected fuse.

By navigating with the arrow keys, the following settings can

be reached:

• Water coolant

• Select language

• Id power unit

• Time

• Total machine time

• Rotation direction

• Battery status

Select language

Using this sub-menu you can set the language you wish to

use on the display.

Scroll using the arrow keys until the required language is

shown. Confirm with 'OK”.

Id power unit

The display shows the identity number for the power unit.

Time

The function is used to measure the amount of time a job

takes. The time is counted from when the saw starts working.

Select:

• ON, to enable.

• OFF, to disable.

• RESET TIME, to reset.

Browse with the arrow keys and confirm with "OK".

Total machine time

Here the total operation time of the power unit is shown. The

time is shown in hours and minutes (hhhh:mm).

Rotation direction

Here you can set the rotation direction of the blade. Select

standard or backwards by pressing "OK".

Battery status

Here you can see the battery status of the remote control for

machines with radio communication.

• "NO BATT. CONNECT" - The machine does not have

radio communication.

• "CHARGING BATTERY" - The CAN cable is connected

and the battery is charging.

• "0% BATTERY 100%" - The bar shows the battery status.

• "BATTERY FULL" - The battery is fully charged.

Water coolant

Select mode AUTO or ON. If AUTO is selected the water

cooling is activated when the blade rotation starts. If ON is

selected the water valve is always open. The water can be

switched of manually with the water tap. The default mode at

startup is AUTO. Selected mode is shown in the display.

Change mode by pressing OK.

10 – English

Page 11

STARTING AND STOPPING

Before starting

Before starting the saw, check that:

• The incoming electrical cable has been connected to a

fuse rated at least 16 A.

• The power lead is connected to the saw unit.

• All controls on the remote control have been set to zero

position. If this is not done, a message in the display will

prompt this when the start button is pushed.

• Enclose the area to be cut so that unauthorised persons

can not be injured or disturb the operator.

IMPORTANT! A higher speed than the recommended

speed can result in personal injury and damage to the

equipment.

Starting

• Turn the main switch to "1"-position.

ON

• The power unit is activated and this is shown by the

indicator light shining.

• Check that the emergency stop button on the power unit

and the stop button on the remote control are not pressed

by turning the them clockwise.

The water valve in the power unit is now closed. This valve

opens again when the blade rotation is started.

• The remote control display shows "SELECT FUSE". The

last alternative used is preset. Choose another gear using

the arrow keys. Press OK to confirm the selection.

With a 25 A fuse you can use approx. 70% of the full

output. With 16 A you can use approx. 50% of full output.

The function is intended to obtain as high output as

possible without overloading the fuse.

The power output for the chosen fuse is shown in percent

on the display.

• The remote control display shows "SELECT GEAR". The

last alternative used is preset. Choose another gear using

the arrow keys. Press OK to confirm the selection.

Check that the mechanical gear on the saw unit is

corresponding with the electrically set gear in the remote

control. On gear 1, the speed range is 600-900 rpm and

on gear 2 the speed range is 800-1200 rpm. For more

information on recommended blades and speeds, see

"Recommended blade speeds" in the "Technical data"

section.

English – 11

Page 12

STARTING AND STOPPING

• The display now shows "HUSQVARNA PP-480 HF

PRESS START".

• On the saw unit WS 480 HF, the blade’s rotation direction

is adjustable.

Press "arrow up" on the remote control unit’s membrane

key to select the direction. The display shows "BLADE

ROTATION STANDARD" or "BLADE ROTATION

REVERSE". To change the current selection, press "OK".

This must only be done when the blade is not moving.

• Start the blade rotation by pushing and holding the green

start button while turning the control for rotation direction

clockwise. There is a three seconds delay before the

blade rotation starts. You can follow the countdown in the

display. The delay is to cool down the power unit which

can get hot when active and no cooling water is

circulating.

Stopping

• To switch off the blade rotation, turn the blade rotation

control anti-clockwise back to its zero position.

• The water coolant is turned off automatically with a 3 sec

delay. NOTE! Applies only if the water coolant mode is set

to AUTO.

Also turn the depth feeding and travel feeding controls to

their zero positions.

• Turn the main switch on the power unit to "0"-position.

• There is no delay If selected mode for water coolant is

ON.

• The water cooling starts automatically when the knob for

blade rotation is turned from its zero position. NOTE!

Applies only if the water coolant mode is set to AUTO. The

water flow is adjusted with the ball valve at the incoming

water connector on the power unit.

• Start the depth feeding of the blade by turning the depth

feeding control in the desired direction.

• Start the saw unit's travel feed by turning the travel feed

control in the desired direction.

After work is completed

Dismantling the equipment

• Disconnect the incoming power lead and incoming water

hose.

• Disconnect the power lead and water hose between the

power unit and the saw unit.

• If there is a risk of freezing, the machine must be drained

of any remaining water coolant.

• Read through the manual supplied with the wall saw for

further instructions in sawing technique.

12 – English

Cleaning

Make sure to keep the connectors and pins clean. Clean with

a rag or brush.

Do not use a high pressure washer to clean the power unit.

Page 13

MAINTENANCE

Service

IMPORTANT! All types of repairs may only be carried out by authorised repairmen. This is so that the operators are not

exposed to great risks.

After 100 hours of operation, the message "Time for servicing" is displayed. The entire equipment shall then be taken to an

authorized Husqvarna dealer for servicing. The message reappears 100 hours after each service.

Error messages

In case of any defects, an error message appears on the display. Follow the directions supplied or contact an authorized dealer.

Fault Code Error message Procedure Steps

F01

F02

F03 LOW VOLTAGE

F04 HIGH VOLTAGE High voltage to the power unit.

F05 OVER CURRENT Over current to saw motor

F06

F07

F08

F09

F10 BLADE JAM Blade can not rotate. Remove the blade from the cut and start the blade rotation.

F11

F12

F13

F14

MOTOR

OVERHEATED

POWER

OVERHEATED

NO HALL SENS.

TRAVEL MOTOR

NO HALL SENS.

DEPTH MOTOR

TRAVEL MOTOR

OVERLOADED

DEPTH MOTOR

OVERLOADED

GROUND FAULT

OR NO SAW HEAD

NON-COMPATIBLE

SAW UNIT

NO CONTACT

CHECK CANCABLE

NO RADIO

CONTACT

Water coolant lacking/insufficient

to saw motor.

Water coolant lacking/insufficient

to power unit.

Low voltage supply to the power

unit.

Fault on HALL-sensor card for

travel feed

Fault on HALL-sensor card for

depth feeding

Travel motor overloaded.

Depth motor overloaded.

Incorrect earthing of power pack/

saw or no saw unit connected to

the power pack.

Incorrect saw unit connected to

the power pack.

No contact between power unit

and remote control

No radio contact between remote

control and power unit.

Check that the water coolant flows to the saw motor and

that it is max. 25ºC and min 3.5 l/min.

Check that the water coolant flows to the power unit and

that it is max 25

up when the blade rotation is started - go to the operations

menu and ”Water coolant” and select ”ON”. Let the water

coolant circulate the power unit for a minute before you turn

the blade rotation on again.

Check the voltage during operation. Check that all three

phases exist. Check that incoming cables have sufficient

cross-sectional area.

Check the voltage during operation. This message is

shown mainly when using a generator as power source.

Check that the power lead is fitted correctly and that it is not

damaged. The message can appear in case of a loose

contact.

Take the equipment to an authorized service shop.

Take the equipment to an authorized service shop.

To reset, reverse the feeding function. If the fault message

returns, grease the feeder gears, clean the rails and adjust

the saw carriage. If this does not help, hand in the

equipment to an authorized Husqvarna service workshop.

To reset, reverse the feeding function. If the fault message

returns, grease the feeder gears. If this does not help, hand

in the equipment to an authorized Husqvarna service

workshop.

Check the incoming electrical connection to the power pack

and that the saw unit is connected to the power pack. If this

does not help, hand in the equipment to an authorized

Husqvarna service workshop.

Connect a compatible saw unit to the power pack.

Replace the Canbus-cable.

Check that the power pack is activated and that the green

indicator light is on. If this does not help, hand in the

equipment to a Husqvarna service workshop. The machine

can be used with the Canbus cable between the power

pack and remote control.

°C and min 3.5 l/min. If the message pops

Daily maintenance

Regularly check:

• Any abnormal noises.

• Make sure to keep the connectors and pins clean. Clean with a rag or brush.

• Do not use a high pressure washer to clean the power unit.

English – 13

Page 14

TECHNICAL DATA

PP 480 HF

Max. output, kW 20 (32 A)

Rated current, A 16-32

Input voltage, V 380-480 V, 50-60 Hz

Output voltage, V 340 V, 0-500 Hz

Sec. output voltage, V 24 V, 0-1500 Hz

Power supply 3P+PE (4-pin) / 3P+N+PE (5-pin)

1x230V one phase outlet Only 5-pin machines

Effect generator - min., kWA

400V, 16A 12

400V, 25A 20

400V, 32A 24

Weight, kg/lbs 23/51

Cooling water pressure - max, bar 7

Water coolant flow min., l/min 3,5

Max cooling water temperature at 3,5 l/min, ºC 25

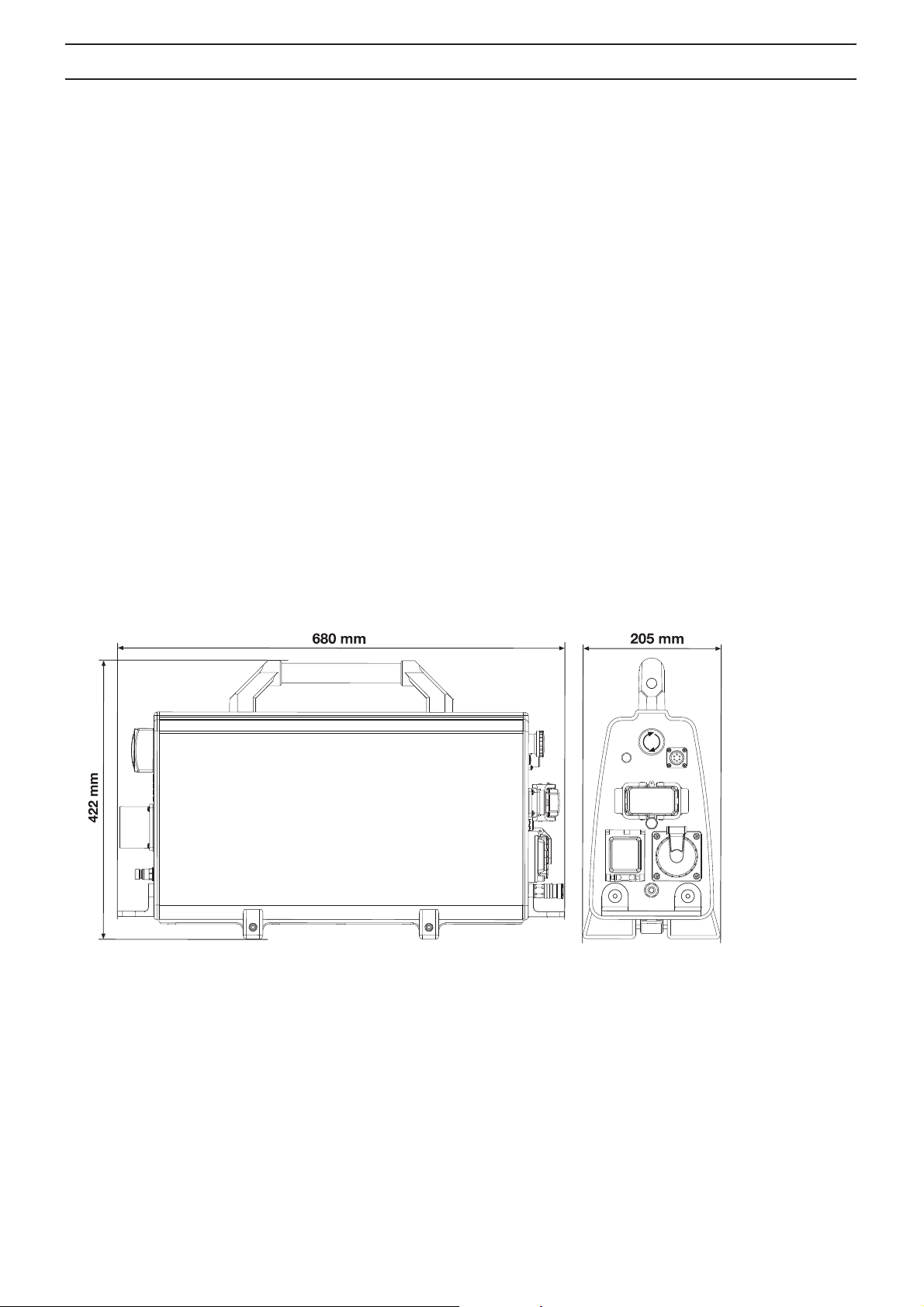

Dimensions

14 – English

Page 15

TECHNICAL DATA

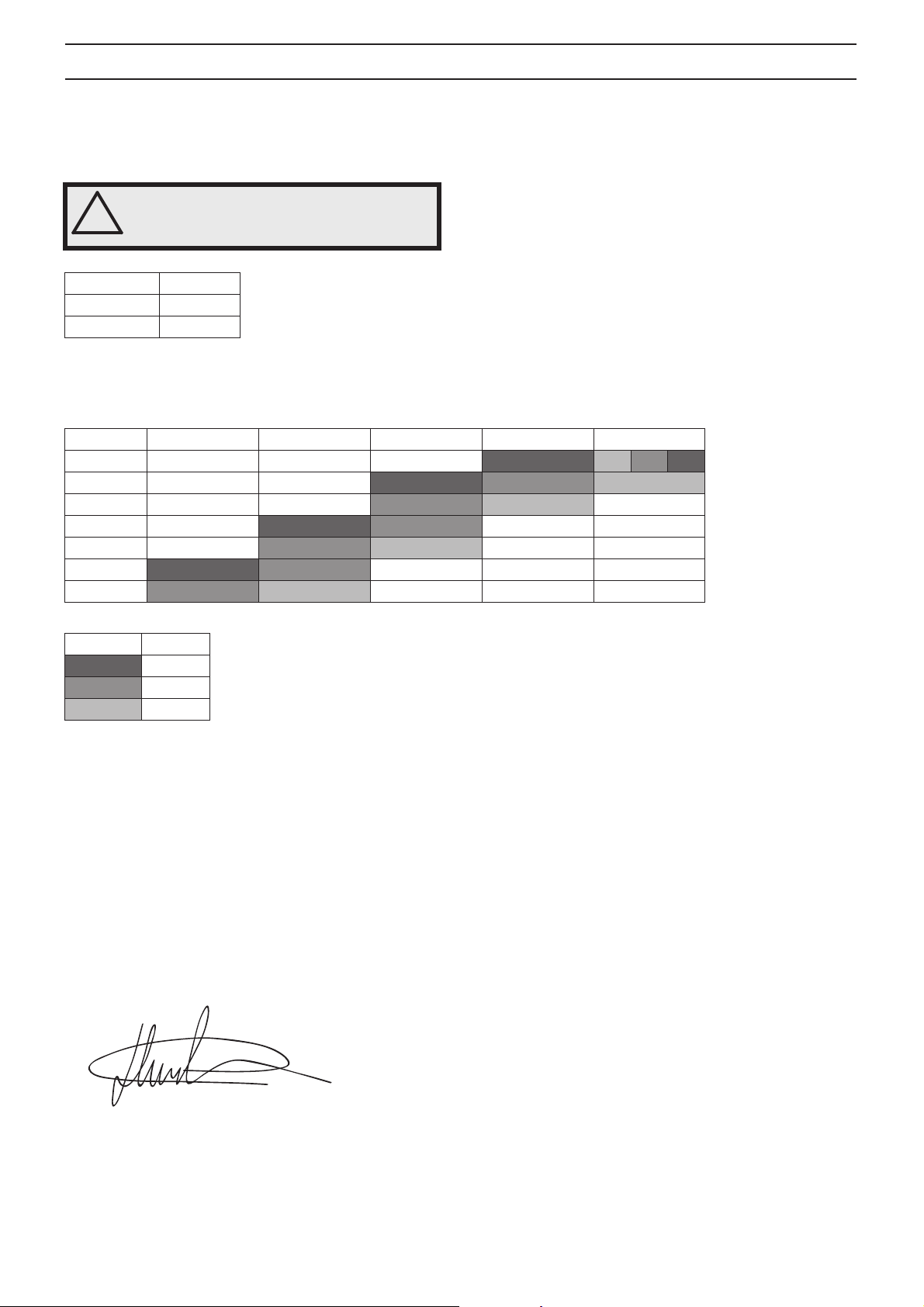

Blade

Recommended blade speed

WARNING! Cutting at too high revs can

cause damage to the blade and lead to

!

personal injury.

Speed, rpm

Gear 1 600-900

Gear 2 800-1200

When sawing at 800-900 rpm, a higher sawing output is obtained if gear 1 is used.

Follow the blade manufacture´s recommendations regarding material and blade speed when choosing blade. When cutting in hard

concrete, a lower speed or a more shallow cut is required compared to cutting in soft concrete.

600 mm (24”) 800 mm (32”) 1000 mm (40”) 1200 mm (48”) 1600 mm (63”)

600 rpm

700 rpm

800 rpm

900 rpm

1000 rpm

1100 rpm

1200 rpm

Concrete

Hard

Medium

Soft

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Gothenburg, Sweden, tel: +46-31-949000, declares under sole responsibility that the power unit

Husqvarna PP 480 HF from 2010´s serial numbers and onwards (the year is clearly stated in plain text on the type plate with

subsequent serial number) is in conformity with the requirements of the COUNCIL’S DIRECTIVES:

• of May 17, 2006 "relating to machinery" 2006/42/EC

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-11:2000,

EN 60204-1:2006.

Göteborg December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

English – 15

Page 16

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina:

¡ATENCIÓN! La máquina, si se utiliza de

forma errónea o descuidada, puede ser

una herramienta peligrosa que puede

causar daños graves e incluso la muerte al

usuario y a otras personas.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

Utilice siempre:

• Casco protector homologado

• Protectores auriculares homologados

• Gafas protectoras o visor

• Máscara respiratoria

Este producto cumple con la directiva CE

vigente.

¡ATENCIÓN! Corriente intensa.

Símbolos en el manual de instrucciones:

El control y/o mantenimiento de la máquina

debe hacerse con el motor parado y el

enchufe desenchufado.

Utilice siempre guantes protectores

homologados.

La máquina debe limpiarse regularmente.

Control visual.

Debe utilizarse gafas protectoras o visor.

Etiquetado ecológico. El símbolo en el

producto o en su envase indica que no se

puede tratar este producto como desperdicio

doméstico. Deberá por lo tanto depositarse

en un centro de recogida adecuado para el

reciclado de equipos eléctricos y

electrónicos.

Haciendo que este producto sea manipulado

adecuadamente, se ayuda a evitar consecuencias negativas

potenciales para el medio ambiente y las personas, lo que

puede ocurrir con la manipulación inadecuada como residuos

del producto.

Para obtener información más detallada sobre el reciclado de

este producto, contacte con la oficina municipal local, con el

servicio de eliminación de desperdicios domésticos o con la

tienda donde compró el producto.

16 – Spanish

Page 17

ÍNDICE

Índice

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina: ............................................. 16

Símbolos en el manual de instrucciones: .................... 16

ÍNDICE

Índice ........................................................................... 17

¿QUÉ ES QUÉ?

Piezas de la unidad eléctrica ....................................... 18

INSTRUCCIONES DE SEGURIDAD

Antes de utilizar una nueva unidad eléctrica ............... 19

Equipo de protección personal .................................... 19

Equipo de seguridad de la máquina ............................ 20

Instrucciones generales de seguridad ......................... 21

Instrucciones generales de trabajo .............................. 22

PRESENTACIÓN

PP 480 HF ................................................................... 23

MONTAJE

Montaje / instalación del equipo .................................. 24

REGLAJES Y AJUSTES

Menú de arranque ........................................................ 25

Menú de funcionamiento ............................................. 25

ARRANQUE Y PARADA

Antes de arrancar ........................................................ 26

Arranque ...................................................................... 26

Parada ......................................................................... 27

Después de terminar el trabajo .................................... 27

MANTENIMIENTO

Servicio ........................................................................ 28

Mantenimiento diario ................................................... 29

DATOS TECNICOS

PP 480 HF ................................................................... 30

Declaración CE de conformidad .................................. 31

Spanish – 17

Page 18

¿QUÉ ES QUÉ?

Piezas de la unidad eléctrica

1 Unidad eléctrica

2 Mango

3 Toma eléctrica

4 Interruptor principal

5 Conexión del cable

6 Parada de emergencia

7 Puerto CAN-BUS

8 Indicador de corriente

9 Conexión de salida de agua

10 Conexión de entrada de agua

11 Mando a distancia

12 Botón de arranque

13 Rotación de la hoja y activación del agua refrigerante

14 Avance longitudinal

15 Avance de entrada

16 Cable CAN-BUS

17 Conductor de alimentación

18 Manguera de agua

19 Toma monofásica (solo para dispositivos con 5 pines)

20 Interruptor de circuito de pérdida a tierra (solo para

dispositivos con 5 pines)

21 Manual de instrucciones

22 DVD - Guía del usuario del producto

18 – Spanish

Page 19

INSTRUCCIONES DE SEGURIDAD

Antes de utilizar una nueva unidad eléctrica

• Lea detenidamente el manual de instrucciones y

asegúrese de entender su contenido antes de utilizar la

máquina.

• Consulte el DVD suministrado para obtener consejos

sobre técnicas de funcionamiento.

• Esta máquina sólo está destinada a ser utilizada junto con

Husqvarna WS 482 HF. Está prohibida cualquier otra

aplicación.

• Lea el manual de instrucciones suministrado con la sierra

de pared antes de utilizar la unidad hidráulica.

• La máquina puede ocasionar lesiones graves. Lea

atentamente las instrucciones de seguridad. Aprenda a

utilizar la máquina.

Emplee siempre el sentido común

Es imposible abarcar todas las situaciones en las que puede

encontrarse. Utilice siempre el equipo con cuidado y sentido

común. Evite todas aquellas situaciones que considere que

sobrepasan sus capacidades. Si, después de leer estas

instrucciones, no está seguro del procedimiento que debe

seguir, consulte a un experto antes de utilizar el equipo.

No dude en ponerse en contacto con su distribuidor si tiene

preguntas acerca del uso de la máquina. Estaremos

encantados de poder aconsejarle y ayudarle a utilizar la

máquina de manera eficaz y segura.

Diríjase a su distribuidor de Husqvarna para que revise la

máquina regularmente y para que realice ajustes y

reparaciones básicas.

Toda la información y todos los datos contenidos en este

manual de instrucciones son vigentes en la fecha de

impresión del manual.

Equipo de protección personal

¡ATENCIÓN! Para trabajar con la máquina

debe utilizarse un equipo de protección

!

personal homologado. El equipo de

protección personal no elimina el riesgo de

lesiones, pero reduce su efecto en caso de

accidente. Pida a su distribuidor que le

asesore en la elección del equipo.

• Casco protector

• Protectores auriculares

• Gafas protectoras o visor

• Máscara respiratoria

• Guantes resistentes de agarre seguro.

• Prendas de vestir ceñidas, resistentes y cómodas que

permitan una libertad de movimientos total.

¡ATENCIÓN! No está permitido modificar el

diseño original de la máquina, por ningún

!

motivo, sin la autorización del fabricante.

Utilice siempre accesorios originales. Las

modificaciones y/o el uso de accesorios no

autorizados comportan riesgo de daöos

personales graves y peligro de muerte para

el usuario y otras personas.

• Botas con puntera de acero y suela antideslizante.

• Tenga siempre a mano el equipo de primeros auxilios.

Spanish – 19

Page 20

INSTRUCCIONES DE SEGURIDAD

Equipo de seguridad de la máquina

En este capítulo se describen los componentes de seguridad

de la máquina, su función y el modo de efectuar el control y

el mantenimiento para garantizar un funcionamiento óptimo.

En cuanto a la ubicación de estos componentes en su

máquina, vea el capítulo Qué es qué.

¡ATENCIÓN! Nunca utilice una máquina que

tenga un equipo de seguridad defectuoso.

!

Efectúe el control y mantenimiento del

equipo de seguridad de la máquina como se

describió en este capítulo. Si su máquina no

pasa todos los controles, entréguela a un

taller de servicio para su reparación.

¡IMPORTANTE! Todos los trabajos de servicio y reparación

de la máquina requieren una formación especial. Esto es

especialmente importante para el equipo de seguridad de

la máquina. Si la máquina no pasa alguno de los controles

indicados a continuación, acuda a su taller de servicio

local. La compra de alguno de nuestros productos le

garantiza que puede recibir un mantenimiento y servicio

profesional. Si no ha adquirido la máquina en una de

nuestras tiendas especializadas con servicio, solicite

información sobre el taller de servicio más cercano.

Botón de arranque

Mantenga pulsado el botón de arranque para que la hoja

empiece a girar. Así evitará que la hoja gire por accidente.

Parada de emergencia y botón de parada

La unidad eléctrica dispone de parada de emergencia y el

control remoto tiene un botón de parada. Se utilizan para

parar rápidamente la unidad eléctrica.

Verifique la parada de emergencia y el

botón de parada

• Ponga en marcha la rotación del disco.

• Pulse la parada de emergencia de la unidad eléctrica y

compruebe que la rotación de la hoja se detiene.

Compruebe de igual modo el botón de parada situado en

el control remoto.

Control del botón de arranque

• Gire el pulsador para activar la rotación de la hoja sin

mantener pulsado el botón de arranque.

La rotación de la hoja no debería accionarse.

• Mantenga pulsado el botón de arranque y gire el pulsador

para que la hoja rote.

La rotación de la hoja se pondrá en marcha.

Interruptor principal

El interruptor principal se utiliza para conectar y desconectar

la unidad del suministro eléctrico. El interruptor principal

debe estar en la posición «0» al conectar el cable de entrada.

Control del interruptor principal

• Seleccione la posición «0» del interruptor principal.

• Intente poner en marcha la sierra.

La sierra no debe accionarse.

20 – Spanish

Page 21

INSTRUCCIONES DE SEGURIDAD

I

nstrucciones generales de seguridad

¡ATENCIÓN! No utilice la máquina sin haber

leído y comprendido el contenido de este

!

manual de instrucciones.

Existe siempre riesgo de sacudidas

eléctricas al usar máquinas eléctricas. No

usar la máquina en condiciones climáticas

desfavorables y evitar el contacto del cuerpo

con pararrayos y objetos metálicos. Seguir

siempre las instrucciones del manual para

evitar daños.

• Nunca utilice la máquina si está cansado, si ha ingerido

alcohol o si toma medicamentos que puedan afectarle la

vista, su capacidad de discernimiento o el control del

cuerpo.

• Utilice el equipo de protección personal. Vea las

instrucciones bajo el título ”Equipo de protección

personal”.

• No lleve nunca la máquina agarrando el cable y no tire del

cable para desenchufarla.

• Mantenga todos los cables apartados del agua, el aceite

y los bordes agudos. Proceda con cuidado para evitar que

el cable se enganche en puertas, vallas o similares. Hay

riesgo de cargar objetos con electricidad.

• Compruebe que los cables están intactos y en buen

estado. Si se daña un cable, no utilice la máquina. Llévela

a reparar a un taller de servicio oficial.

• Un cable de alargue no debe usarse enrollado porque hay

riesgo de sobrecalentamiento.

• La máquina se debe enchufar a un enchufe con masa.

• Conecte siempre la máquina mediante un interruptor de

fuga a tierra con protección personal, como un disyuntor

de fuga a tierra que se active a 30 mA.

• Compruebe que la tensión de red concuerda con la que

se indica en la placa de características de la máquina.

• Mantener todas las piezas en perfecto estado y

comprobar que todos los elementos de fijación estén bien

apretados.

• No utilice nunca una máquina defectuosa. Siga las

instrucciones de mantenimiento, control y servicio de este

manual. Algunas medidas de mantenimiento y servicio

deben ser efectuadas por especialistas formados y

cualificados. Vea las instrucciones bajo el título

Mantenimiento.

• No modificar nunca los dispositivos de seguridad.

Comprobar regularmente que funcionan como es debido.

La máquina no se debe operar con dispositivos de

seguridad defectuosos o ausentes.

• Nunca deje que terceros utilicen la máquina sin

asegurarse primero de que hayan entendido el contenido

de este manual de instrucciones.

• Las personas y los animales pueden distraer y hacer

perder el control de la máquina. Por consiguiente, el

operador debe estar siempre concentrado en su trabajo.

• Tener en cuenta que las ropas, el pelo largo y las joyas

pueden atascarse en piezas móviles.

• Proceda con cuidado en las elevaciones. Las piezas son

pesadas, por lo que hay riesgo de daños por apriete y

daños personales de otro tipo.

Transporte y almacenamiento

• Desconecte siempre la unidad eléctrica y el cable

eléctrico antes de mover el equipo.

• Guarde el equipo en un lugar seguro fuera del alcance de

los niños y las personas no autorizadas.

• Guarde la máquina y el equipo en un lugar seco y

protegido de la escarcha. Si existe riesgo de congelación,

drene el agua refrigeradora restante del dispositivo.

• Utilice las cajas suministradas para guardar el equipo.

• No exponga la máquina a temperaturas que excedan los

45

°C ni a la luz directa del sol.

Spanish – 21

Page 22

INSTRUCCIONES DE SEGURIDAD

Instrucciones generales de trabajo

¡ATENCIÓN! Este apartado trata las normas

de seguridad básicas para trabajar con el

!

dispositivo. Esta información no sustituye

en ningún caso los conocimientos y la

experiencia de un profesional. Si se

encuentra en alguna situación que le haga

sentirse inseguro, deténgase y consulte con

un experto. Consulte a su distribuidor, al

taller de servicio técnico o a un usuario

experimentado. No emplee la máquina en

aplicaciones para las que no se considere

plenamente cualificado.

• Todos los operadores deben ser formados en el empleo

de la máquina. El propietario es responsable de la

formación de los operadores.

• Compruebe que todas las juntas, conexiones y cables

están intactos y limpios.

• Compruebe que todos los cables y el suministro de agua

están correctamente conectados a la máquina antes de

arrancarla.

• Nunca desconecte el cable sin desconectar antes la

unidad eléctrica y esperar a que la máquina se detenga

por completo.

• En caso de emergencia, pulse el botón rojo de parada de

emergencia de la unidad o el botón de parada del control

remoto.

• Averigüe y marque siempre la ubicación del trazado de

las tuberías de gas. El corte cerca de las tuberías de gas

siempre es peligroso. Procure que no se generen chispas

al cortar, debido al riesgo de explosición. Trabaje

concentrado en su tarea. La negligencia comporta riesgo

de daños personales graves y peligro de muerte.

• Use la máquina exclusivamente en lugares con buena

ventilación. Los descuidos pueden ocasionar daños

graves o mortales.

• Compruebe que los cables eléctricos que haya en el área

de trabajo no tengan tensión.

• Mantenga bajo vigilancia la máquina siempre que el

motor esté en marcha.

• No haga nunca trabajos de corte de forma tal que no

pueda acceder fácilmente a la parada de emergencia.

• Al trabajar con las máquinas, procure siempre que haya

alguien cerca, que pueda prestar ayuda en caso de

accidente.

• No usar en condiciones climáticas desfavorables. Por

ejemplo, niebla densa, lluvia, viento fuerte, frío intenso,

etc. Trabajar con mal tiempo es cansador y puede crear

condiciones peligrosas, por ejemplo suelo resbaladizo.

• Controle que la zona de trabajo esté bien iluminada para

lograr un entorno seguro.

• Cerciórese siempre de tener una posición de trabajo

segura y firme.

• Proceda con cuidado en las elevaciones. Las piezas son

pesadas, por lo que hay riesgo de daños por apriete y

daños personales de otro tipo.

• No exponga la máquina a temperaturas que excedan los

45

°C ni a la luz directa del sol.

• No emplee la máquina en un entorno mojado o húmero,

cerca de agua, en la lluvia o en la nieve.

• No lave la máquina con agua, ya que puede penetrar en

el sistema eléctrico o en el motor y causar daños en la

máquina o un cortocircuito.

22 – Spanish

Page 23

PRESENTACIÓN

PP 480 HF

Esperamos que su máquina le proporcione plena satisfacción

y le sirva de ayuda por mucho tiempo en adelante. Tenga en

cuenta que este manual de instrucciones es un documento

de valor. Siguiendo sus instrucciones (de uso, servicio,

mantenimiento, etcétera) puede alargar considerablemente

la vida útil de la máquina e incrementar su valor de reventa.

Si vende su máquina, entregue el manual de instrucciones al

nuevo propietario.

La adquisición de alguno de nuestros productos da acceso a

asistencia profesional con reparaciones y servicio. Si la

máquina no fue adquirida en un distribuidor oficial, preguntar

en la tienda de compra la dirección del taller de servicio más

cercano.

Husqvarna Construction Products se esfuerza

constantemente por mejorar la construcción de sus

productos. Por consiguiente, Husqvarna se reserva el

derecho a introducir modificaciones de diseño sin previo

aviso y sin compromisos ulteriores.

PP 480 HF se entrega con estos equipos:

• 1 unidad eléctrica

• 1 mando a distancia

• 1 conductor de alimentación

• 1 cable de bus CAN

• 1 Manguera de agua

• Cajas para un transporte más cómodo

• DVD - Guía del usuario del producto

Generalidades

• La PP 480 HF es una unidad desarrollada

específicamente para la sierra de pared WS 482 HF.

• Tiene un diseño compacto y solo pesa 23 kg (51 lb).

• A pleno funcionamiento, utiliza 32 A en sistemas de 400 V.

• La unidad de alimentación está conectada a la sierra

únicamente mediante un conductor de alimentación y una

manguera refrigeradora de agua.

• Incorpora una salida de potencia de 230 V y un terminal

para un cable CAN-BUS.

• Incluye una electroválvula hidráulica que se acciona

mediante el control remoto.

• A través del control remoto, el operario recibe información

acerca de la potencia de salida y puede medir el tiempo y

otros datos del proceso de serrado.

Spanish – 23

Page 24

MONTAJE

Montaje / instalación del equipo

Después de ser transportada a un lugar adecuado, la

máquina debe conectarse:

• Seleccione la posición «0» del interruptor principal.

• Conectar el cable eléctrico entrante (380-480 V, 32-63 A,

enchufe europeo). Las unidades de alimentación con

toma monofásica (230 V) deben tener también un cable

neutro para que la toma funcione. La unidad de

alimentación funciona incluso sin el cable neutro.

Para utilizar toda la potencia de salida, debe conectar la

unidad a un fusible de 32 A. Con un fusible de 16 A o de

25 A, la potencia de salida es inferior para no sobrecargar

el fusible. Puede seleccionarlo al poner en marcha la

unidad.

• Conecte la manguera de agua a la conexión de entrada

de agua.

La unidad incorpora una electroválvula hidráulica, que

permanece cerrada mientras el bloque de alimentación

está activado. Cuando el bloque no recibe corriente, la

válvula se abre para drenar el agua refrigeradora si hay

riesgo de congelación.

• Conecte el conductor de alimentación y la manguera de

agua suministrados de la unidad eléctrica a la unidad de

serrado.

• Conectar el mando a distancia con el cable de bus CAN

incluido en la entrega. Fijar el contacto de cable

enroscándolo a mano.

24 – Spanish

Page 25

REGLAJES Y AJUSTES

Menú de arranque

El menú de arranque se presenta cada vez que se conecta la

corriente del equipo hidráulico.

• En el control remoto aparecerá el mensaje «ELEGIR

FUSIBLE». Quedará preseleccionada la última opción

utilizada. Elija otro engranaje mediante las teclas de

desplazamiento. Pulsar 'OK” para confirmar la elección.

Con un fusible de 25 A puede utilizar aproximadamente

un 70 % de la potencia total. Con 16 A puede utilizar

aproximadamente un 50 % de la potencia total. Con esta

función se pretende obtener tanta potencia como sea

posible sin sobrecargar el fusible.

• En el control remoto aparecerá el mensaje

«SELECCIONE ENGRANAJE». Quedará

preseleccionada la última opción utilizada. Elija otro

engranaje mediante las teclas de desplazamiento. Pulsar

'OK” para confirmar la elección.

En el engranaje 1, el intervalo de velocidad es de 600-900

r/min y en el engranaje 2, de 800-1200 r/min. Compruebe

que el engranaje mecánico de la unidad de serrado se

corresponde con el engranaje eléctrico del control

remoto.

• Aparecerá el mensaje «HUSQVARNA PP-480 HF

PULSAR ARRANQUE».

Menú de funcionamiento

Mientras entre tensión a la unidad eléctrica y la hoja no rote,

se visualizará el mensaje «Husqvarna PP-480 HF PULSAR

ARRANQUE».

Antes de arrancar, todos los controles deben estar en la

posición «0». Si no lo están, aparecerá un mensaje en la

pantalla al pulsar el botón de arranque. «DESCONECTAR

AVANCE», «DESCONECTAR ENTRADA» o

«DESCONECTAR HOJA».

Cuando se pone en marcha la rotación del disco, la pantalla

muestra «X RPM, Y%, Z A», en que X es el régimen del

motor, Y es el porcentaje de salida del efecto máximo y Z es

el fusible seleccionado.

Puede acceder a los siguientes ajustes con las flechas de

dirección:

• Agua refrigerante

• Select language

• ID de la unidad eléctrica

• Cronometraje

• Tiempo total de máquina

• Dirección de la rotación

• Estado de la batería

Agua refrigerante

Seleccione el modo «AUTO» u «ON». Si selecciona «AUTO»,

se activará la refrigeración por agua cuando la hoja empiece

a rotar. Si selecciona «ON», la válvula de agua estará

siempre abierta. El agua puede cerrarse manualmente con el

grifo de agua. Al iniciar, el modo seleccionado por defecto

será «AUTO». El modo seleccionado aparece en pantalla.

Cambie el modo pulsando «OK».

Select language

Con este submenú se puede elegir el idioma que se desea

usar en el display.

Desplazarse con las teclas de flecha hasta que se muestre el

idioma deseado. Confirmar con 'OK”.

ID de la unidad eléctrica

En la pantalla aparecerá el número de identificación de la

unidad eléctrica.

Cronometraje

Esta función se usa para medir el tiempo de un trabajo. El

cronometraje se inicia cuando la sierra empieza a trabajar.

Seleccionar:

• ACT para activar.

• DES para desactivar.

• PUESTA A CERO CRONOMETRAJE para la puesta a

cero.

Desplácese con las flechas de dirección y confirme con

«OK».

Tiempo total de máquina

Aquí se muestra el tiempo total de funcionamiento de la

unidad. Se indica en horas y minutos (hhhh:mm).

Dirección de la rotación

Aquí puede seleccionar el sentido de rotación de la hoja.

Seleccione estándar o hacia atrás pulsando «OK».

Estado de la batería

Aquí puede ver el estado de la batería del control remoto para

máquinas que dispongan de comunicación por radio.

• «NO BATT. CONNECT» (ninguna batería conectada): la

máquina no dispone de comunicación por radio.

• «CHARGING BATTERY» (cargando batería): el cable

CAN está conectado y la batería se está cargando.

• «0% BATTERY 100%» (0 % batería 100 %): la barra

muestra el estado de la batería.

• «BATTERY FULL» (batería cargada): la batería está

cargada completamente.

Spanish – 25

Page 26

ARRANQUE Y PARADA

Antes de arrancar

Antes de poner en marcha la sierra, compruebe si:

• El cable eléctrico entrante esté conectado a como mínimo

un fusible de 16 A.

• El conductor de alimentación está conectado a la unidad

de serrado.

• Todos los controles del control remoto está en la posición

«0». Si no lo están, aparecerá un mensaje en la pantalla

al pulsar el botón de arranque.

• Cerque el área en que va a cortar para impedir la entrada

de personas ajenas al trabajo y evitar el riesgo de que

sufran daños y que le estorben en el trabajo.

¡IMPORTANTE! Una velocidad más alta que la

recomendada comporta riesgo de daños personales y del

equipo.

Arranque

• Coloque el interruptor principal en la posición «1».

ON

• Se activará la unidad, por lo que la luz de indicación

parpadeará.

• Compruebe que ni el botón de parada de emergencia de

la unidad eléctrica ni el botón de parada del control

remoto están pulsados girándolos en el sentido de las

agujas del reloj.

En consecuencia, la válvula hidráulica de la unidad

eléctrica estará cerrada. Se abrirá de nuevo cuando se

active la rotación de la hoja.

• En el control remoto aparecerá el mensaje «ELEGIR

FUSIBLE». Quedará preseleccionada la última opción

utilizada. Elija otro engranaje mediante las teclas de

desplazamiento. Pulsar 'OK” para confirmar la elección.

Con un fusible de 25 A puede utilizar aproximadamente

un 70 % de la potencia total. Con 16 A puede utilizar

aproximadamente un 50 % de la potencia total. Con esta

función se pretende obtener tanta potencia como sea

posible sin sobrecargar el fusible.

El porcentaje de la potencia de salida para el fusible

elegido aparece en pantalla.

• En el control remoto aparecerá el mensaje

«SELECCIONE ENGRANAJE». Quedará

preseleccionada la última opción utilizada. Elija otro

engranaje mediante las teclas de desplazamiento. Pulsar

'OK” para confirmar la elección.

Compruebe que el engranaje mecánico de la unidad de

serrado se corresponde con el engranaje eléctrico del

control remoto. En el engranaje 1, el intervalo de

velocidad es de 600-900 r/min y en el engranaje 2, de

800-1200 r/min. Encontrará más información sobre los

discos y la velocidad recomendados en el apartado

«Velocidad de disco recomendada» del capítulo «Datos

técnicos».

26 – Spanish

Page 27

ARRANQUE Y PARADA

• Aparecerá el mensaje «HUSQVARNA PP-480 HF

PULSAR ARRANQUE».

• Puede ajustar el sentido de rotación de la hoja de la

unidad WS 480 HF.

Pulse la flecha para subir del teclado del control remoto

para seleccionar el sentido. En la pantalla aparecerá el

mensaje «ROTACIÓN DE HOJA: ESTÁNDAR» o

«ROTACIÓN DE HOJA: ATRÁS». Para escoger la opción

resaltada pulse «OK». Solo podrá realizar esta selección

mientras la hoja está parada.

• Active la rotación de la hoja manteniendo pulsado el

botón de arranque verde mientras gira el control de

rotación en el sentido de las agujas del reloj. Existe un

retraso de tres segundos antes de que la hoja empiece a

rotar. Puede seguir la cuenta atrás en la pantalla. El

retraso sirve para enfriar la unidad de alimentación, que

puede calentarse cuando está activa y no hay agua

refrigerada en circulación.

• Si el modo seleccionado para el agua refrigeradora es

«ON», no habrá retraso.

• La refrigeración por agua empieza automáticamente

cuando la manija para la rotación de la hoja se desplaza

de la posición cero. ¡ATENCIÓN! Solo es aplicable si el

modo refrigerador de agua está ajustado en «AUTO». El

flujo de agua se ajusta con la válvula esférica de la

conexión de entrada de agua de la unidad.

• Activar el avance de entrada, girando la manija de avance

de entrada del mando a distancia en la dirección

deseada.

Parada

• Para desactivar la rotación de la hoja, gire el control de

rotación en sentido contrario al de las agujas del reloj,

hasta alcanzar la posición «0».

• El refrigerador de agua se apaga automáticamente con

un retraso de tres segundos. ¡ATENCIÓN! Solo es

aplicable si el modo refrigerador de agua está ajustado en

«AUTO».

Gire los controles de entrada y avance a las posiciones

«0» respectivas.

• Seleccione la posición «0» del interruptor principal de la

unidad eléctrica.

• Active el avance de la unidad de serrado girando el

control de avance en el sentido deseado.

• Para más información sobre la técnica de serrado, lea

detenidamente el manual facilitado con la sierra de pared.

Después de terminar el trabajo

Desmontaje del equipo

• Desconecte el conductor de alimentación de entrada y la

manguera de entrada de agua.

• Desconecte el conductor de alimentación y la manguera

de agua entre la unidad eléctrica y la unidad de serrado.

• Si existe riesgo de congelación, drene el agua

refrigeradora restante del dispositivo.

Limpieza

Asegúrese de que los conectores y los pines están limpios.

Límpielos con un trapo o un cepillo.

No utilice un equipo de limpieza a alta presión para limpiar la

unidad.

Spanish – 27

Page 28

MANTENIMIENTO

Servicio

¡IMPORTANTE! Las reparaciones de todo tipo deben ser efectuadas por técnicos autorizados, únicamente. De este

modo se evita someter a los operadores a grandes riesgos.

Después de 100 horas de funcionamiento, se mostrará el mensaje «Time for servicing» («Efectuar mantenimiento»). Deberá llevar

el equipo a un distribuidor autorizado de Husqvarna para que efectúe el mantenimiento de la máquina. El mensaje reaparece 100

horas después de cada servicio.

Mensajes de fallo

Si hubiese defectos, aparecería un mensaje de error en la pantalla. Siga las instrucciones indicadas o póngase en contacto con

un distribuidor autorizado.

Código

de fallo

F01

F02

F03 LOW VOLTAGE (TENSIÓN BAJA)

F04 HIGH VOLTAGE (TENSIÓN ALTA) Tensión alta en la unidad.

F05

F06

F07

F08

F09

F10 BLADE JAM (HOJA ATASCADA) La hoja no puede girar. Retire la hoja del lugar de corte y accione el giro de la hoja.

F11

F12

F13

F14

Mensaje de error Causa Medida

MOTOR OVERHEATED

(SOBRECALENTAMIENTO DEL

MOTOR)

POWER OVERHEATED

(SOBRECALENTAMIENTO

ELÉCTRICO)

OVER CURRENT

(SOBREINTENSIDAD)

NO HALL SENS. TRAVEL

MOTOR (MOTOR DE AVANCE

SIN SENSOR HALL)

NO HALL SENS. DEPTH MOTOR

(MOTOR DE ENTRADA SIN

SENSOR HALL)

TRAVEL MOTOR OVERLOADED

(MOTOR DE AVANCE

SOBRECARGADO)

DEPTH MOTOR OVERLOADED

(MOTOR DE ENTRADA

SOBRECARGADO)

GROUND FAULT OR NO SAW

HEAD (FUGA A TIERRA O

AUSENCIA DE CABEZAL DE

SIERRA)

NON-COMPATIBLE SAW UNIT

(SIERRA INCOMPATIBLE)

NO CONTACT CHECK CANCABLE (NO HAY CONTACTO,

COMPROBAR CABLE CAN)

NO RADIO CONTACT (NO HAY

CONTACTO POR RADIO)

Falta agua refrigeradora

o es insuficiente para el

motor de la sierra.

Falta agua refrigeradora

o es insuficiente para la

unidad.

Tensión eléctrica baja

para la unidad.

Sobreintensidad en el

motor de la sierra.

Avería en la tarjeta del

sensor HALL para el

avance.

Avería en la tarjeta del

sensor HALL para la

entrada.

Motor de avance

sobrecargado.

Motor de entrada

sobrecargado.

La conexión a tierra de la

unidad de alimentación /

sierra es incorrecta o no

hay ninguna sierra

conectada a la unidad de

alimentación.

Se ha conectado una

sierra incorrecta a la

unidad de alimentación.

No hay contacto entre la

unidad eléctrica y el

control remoto.

No hay contacto por

radio entre el control

remoto y la unidad de

alimentación.

Verifique que el agua refrigeradora llega al motor de la

sierra a un máximo de 25

Verifique que el agua refrigeradora llega a la unidad a un

máximo de 25 ºC y a 3,5 l/min como mínimo. Si aparece un

mensaje al iniciar la rotación de la hoja, vaya al menú de

funcionamiento y seleccione «ON» en «Water coolant»

(agua refrigeradora). Deje que el agua refrigeradora

circule por la unidad de alimentación durante un minuto

antes de volver a iniciar la rotación de la hoja.

Controle la tensión durante el funcionamiento. Compruebe

que existen las tres fases. Verifique que los cables de

entrada tienen una sección suficiente.

Controle la tensión durante el funcionamiento. Este

mensaje se muestra normalmente cuando se utiliza un

generador como fuente de alimentación.

Compruebe que el conductor de alimentación está bien

colocado y que no tiene ningún daño. Este mensaje puede

mostrarse si hay algún contacto flojo.

Lleve el equipo a un taller de reparación autorizado.

Lleve el equipo a un taller de reparación autorizado.

Para reiniciarlo, invierta la función de entrada. Si el

mensaje de error vuelve a aparecer, lubrique los

engranajes de entrada, limpie los rieles y ajuste el soporte

de sierra. Si esto no ayuda, lleve el equipo a un taller de

servicio autorizado Husqvarna.

Para reiniciarlo, invierta la función de entrada. Si el

mensaje de error vuelve a aparecer, lubrique los

engranajes de entrada. Si esto no ayuda, lleve el equipo a

un taller de servicio autorizado Husqvarna.

Compruebe la conexión eléctrica de entrada de la unidad

de alimentación y verifique que la sierra está conectada a

la unidad de alimentación. Si esto no ayuda, lleve el equipo

a un taller de servicio autorizado Husqvarna.

Conecte una sierra compatible con la unidad de

alimentación.

Sustituya el cable CAN-BUS.

Compruebe que la unidad de alimentación está activada y

que la luz indicadora verde está encendida. Si esto no

ayuda, lleve el equipo a un taller de servicio de Husqvarna.

La máquina puede utilizarse con el cable CANbus entre la

unidad de alimentación y el control remoto.

°C y a 3,5 l/min como mínimo.

28 – Spanish

Page 29

MANTENIMIENTO

Mantenimiento diario

Controlar rutinariamente:

• Si hay ruidos anormales.

• Asegúrese de que los conectores y los pines están

limpios. Límpielos con un trapo o un cepillo.

• No utilice un equipo de limpieza a alta presión para limpiar

la unidad.

Spanish – 29

Page 30

DATOS TECNICOS

PP 480 HF

Salida máx., kW 20 (32 A)

Amperaje nominal, A 16-32

Tensión de entrada, V 380-480 V, 50-60 Hz

Tensión de salida, V 340 V, 0-500 Hz

Seg. tensión de salida, V 24 V, 0-1500 Hz

Conexión eléctrica 3P+PE (4-pin) / 3P+N+PE (5-pin)

1 toma monofásica de 230 V Solo dispositivos de 5 pines

Resultado del generador: en min y kVA.

400V, 16A 12

400V, 25A 20

400V, 32A 24

Peso, kg/lb 23/51

Presión máx. de la refrigeración hidráulica, bar 7

Caudal mínimo de agua refrigeradora, l/min 3,5

Temperatura máx. de la refrigeración hidráulica a 3,5 l/

min, ºC

25

Dimensiones

30 – Spanish

Page 31

DATOS TECNICOS

Hoja

Velocidad de la hoja recomendada

¡ATENCIÓN! Si corta a revoluciones

demasiado elevadas puede causar daños a

!

la hoja y daños personales.

Velocidad, r/min

Engranaje 1 600-900

Engranaje 2 800-1200

Cuando se sierra a velocidades comprendidas entre las 800 y 900 rpm, se obtiene un resultado de serrado mayor si se utiliza el

engranaje 1.

Siga las recomendaciones del fabricante de la hoja acerca del material y la velocidad cuando elija una hoja. Deberá utilizarse una

velocidad más baja o realizarse un corte más superficial al cortar en hormigón duro que al cortar en hormigón blando.

600 mm (24”) 800 mm (32”) 1000 mm (40”) 1200 mm (48”) 1600 mm (63”)

600 r.p.m.

700 r.p.m.

800 r.p.m.

900 r.p.m.

1000 r.p.m.

1100 r.p.m.

1200 r.p.m.

Hormigón

Duro

Medio

Blando

Declaración CE de conformidad

(Rige sólo para Europa)

Husqvarna AB, SE-443 81 Gothenburg, Suecia, teléfono +46-31-949000, declara bajo su exclusiva responsabilidad que la unidad

eléctrica Husqvarna PP 480 HF, a partir de los números de serie del año 2010 (el año se indica claramente en texto plano en la

placa de modelo, junto con el número de serie), cumple con las disposiciones de las Directivas del Consejo:

• 2006/42/CE «relativa a máquinas» del 17 de mayo de 2006.

• 2004/108/CEE, ”referente a compatibilidad electromagnética”, del 15 de diciembre de 2004.

• 2006/95/CE del 12 de diciembre de 2006 relativa a equipos eléctricos.

Se han aplicado las siguientes normas: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-11:2000, EN

60204-1:2006.

Göteborg, 29 de diciembre de 2009

Henric Andersson

Vicepresidente, jefe de la sección de cortadoras y maquinaria para la construcción

Husqvarna AB

(Presentante autorizado de Husqvarna AB y responsable de la documentación técnica.)

Spanish – 31

Page 32

SYMBOLERKLÄRUNG

Symbole am Gerät:

WARNUNG! Das Gerät kann falsch oder

nachlässig angewendet gefährlich sein

und zu schweren oder gar

lebensgefährlichen Verletzungen des

Benutzers oder anderer Personen führen.

Lesen Sie die Bedienungsanweisung

sorgfältig durch und machen Sie sich mit

dem Inhalt vertraut, bevor Sie das Gerät

benutzen.

Benutzen Sie immer:

• Einen zugelassenen Schutzhelm

• Einen zugelassenen Gehörschutz

• Schutzbrille oder Visier

• Atemschutzmaske

Dieses Produkt stimmt mit den geltenden

CE-Richtlinien überein.

WARNUNG! Hoher Strom.

Symbole in der Bedienungsanweisung:

Kontrollen und/oder Wartungsarbeiten sind

bei abgeschaltetem Motor und

abgezogenem Stecker durchzuführen.

Stets zugelassene Schutzhandschuhe

tragen.

Regelmäßige Reinigung ist notwendig.

Visuelle Kontrolle.

Schutzbrille oder Gesichtsschutz müssen

benutzt werden.

Umweltkennzeichnung. Das Symbol auf

dem Produkt oder der Verpackung gibt an,

dass dieses Produkt nicht im Hausmüll

entsorgt werden darf. Zur Entsorgung ist es

stattdessen an eine entsprechende

Recyclinganlage für elektrische und

elektronische Geräte zu übergeben.

Durch eine korrekte Entsorgung dieses

Produkts tragen Sie dazu bei, mögliche negative

Auswirkungen auf Ihre Umwelt und Mitmenschen zu

verhindern. Durch eine unsachgemäße Entsorgung dieses

Produkts können Schäden entstehen.

Ausführliche Recyclinginformationen zu diesem Produkt

erhalten Sie von Ihrer Kommune, Entsorgungsunternehmen

für Hausmüll oder dem Geschäft, in dem Sie das Produkt

erworben haben.

32 – German

Page 33

INHALT

Inhalt

SYMBOLERKLÄRUNG

Symbole am Gerät: ...................................................... 32

Symbole in der Bedienungsanweisung: ....................... 32

INHALT

Inhalt ............................................................................ 33

WAS IST WAS?

Teile des Aggregats ..................................................... 34

SICHERHEITSVORSCHRIFTEN

Maßnahmen vor dem Einsatz eines neuen Aggregats 35

Persönliche Schutzausrüstung .................................... 35

Sicherheitsausrüstung des Gerätes ............................. 36

Allgemeine Sicherheitsvorschriften .............................. 37

Allgemeine Arbeitsvorschriften .................................... 38

VORSTELLUNG

PP 480 HF ................................................................... 39

MONTAGE

Ausrüstung montieren bzw. installieren ........................ 40

EINSTELLUNGEN UND JUSTIERUNGEN

Startmenü .................................................................... 41

Betriebsmenü ............................................................... 41

STARTEN UND STOPPEN

Vor dem Start ............................................................... 42

Starten ......................................................................... 42

Stoppen ....................................................................... 43

Nach Abschluss der Arbeiten ...................................... 43

WARTUNG

Service ......................................................................... 44

Tägliche Wartung ......................................................... 45

TECHNISCHE DATEN

PP 480 HF ................................................................... 46

EG-Konformitätserklärung ........................................... 47

German – 33

Page 34

WAS IST WAS?

Teile des Aggregats

1 Aggregat

2 Handgriff

3 Steckdose

4 Hauptschalter

5 Kabelanschluss

6 Nothalt

7 CANbus-Anschluss

8 Stromanzeige

9 Wasseranschluss, Auslass

10 Wasseranschluss, Einlass

11 Fernsteuerung

12 Startknopf

13 Klingenrotation und Kühlwasserstart

14 Längsvorschub

15 Tiefenvorschub

16 CANbus-Kabel

17 Stromkabel

18 Wasserschlauch

19 Einphasen-Steckdose - nur 5-polige Geräte

20 FI-Schutzschalter - nur 5-polige Geräte

21 Bedienungsanweisung

22 DVD - Benutzerhandbuch des Produkts

34 – German

Page 35

SICHERHEITSVORSCHRIFTEN

Maßnahmen vor dem Einsatz eines neuen Aggregats

• Lesen Sie die Bedienungsanweisung sorgfältig durch und

machen Sie sich mit dem Inhalt vertraut, bevor Sie das

Gerät benutzen.

• Siehe mitgelieferte DVD für Tipps zur Arbeitstechnik.

• Diese Maschine darf nur zusammen mit Husqvarna WS

482 HF verwendet werden. Alle anderen Einsätze sind

unzulässig.

• Das Handbuch der Wandsäge lesen, ehe Sie mit der

Nutzung des Hydraulikaggregats beginnen.

• Das Gerät kann schwere Verletzungen verursachen. Die

Sicherheitsvorschriften gründlich durchlesen. Lernen Sie,

wie das Gerät anzuwenden ist.

Stets mit gesundem Menschenverstand arbeiten!

Es ist unmöglich, alle denkbaren Situationen abzudecken, die

beim Gebrauch des Geräts auftreten könnten. Gehen Sie

stets mit Vorsicht und Vernunft vor. Vermeiden Sie

Situationen, für die Sie sich nicht ausreichend qualifiziert

fühlen. Falls Sie sich auch nach dem Lesen dieser

Anweisungen nicht über die richtige Vorgehensweise im

Klaren sind, sollten Sie einen Fachmann zu Rate ziehen,