GB

Operator’s manual

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

ES

DE

FR

Manual de instrucciones

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

PP 325 E

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

GGGGBBBB EEEESSSS DDDDEEEE FFFFRR

RR

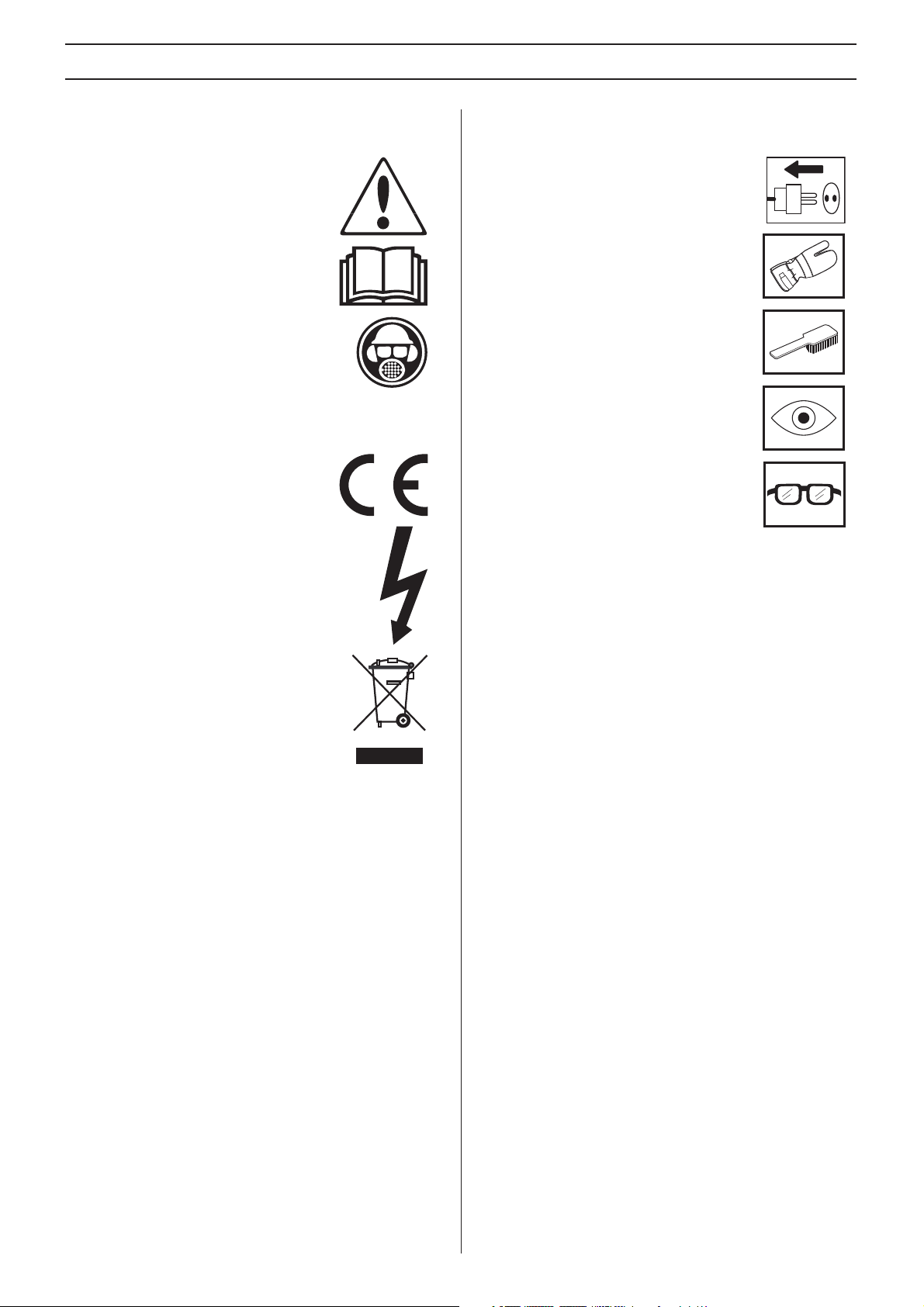

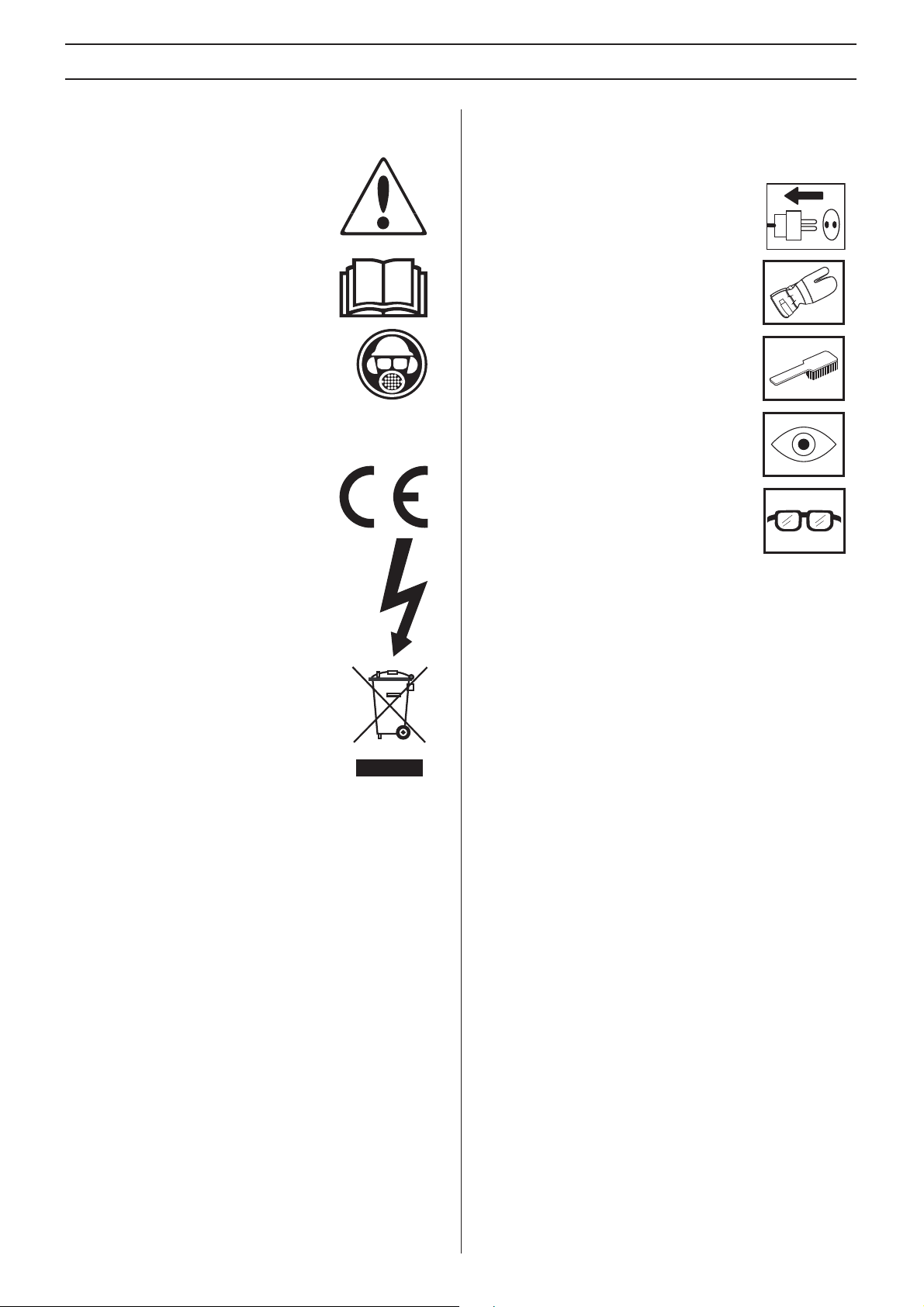

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the machine.

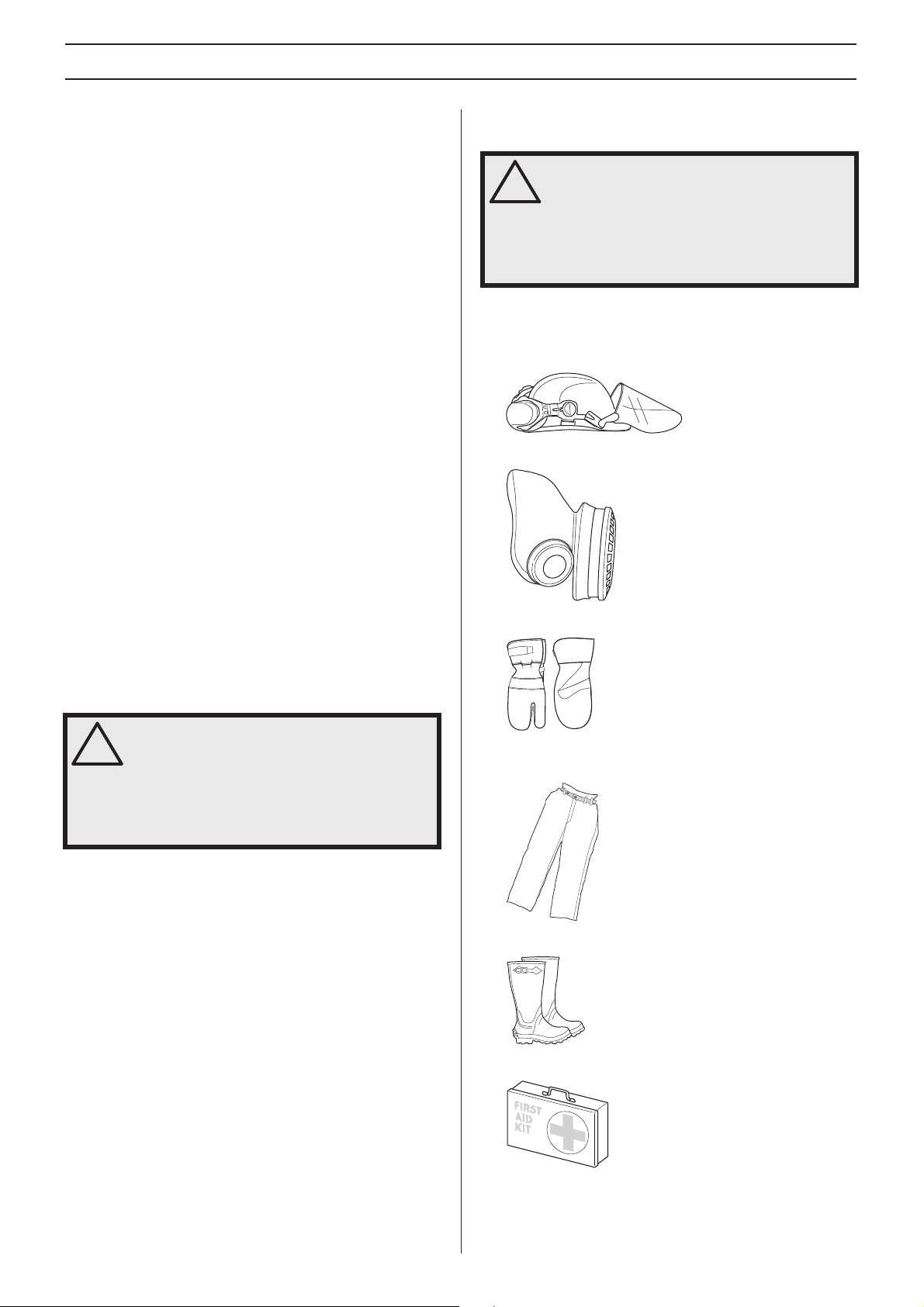

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

• Breathing mask

This product is in accordance with

applicable EC directives.

WARNING! High current.

Symbols in the operator’s manual:

Inspection and/or maintenance should be

carried out with the motor switched off and

the plug disconnected.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

Environmental marking.

Symbols on the product or its packaging

indicate that this product cannot be handled

as domestic waste. It must instead be

submitted to an appropriate recycling station

for the recovery of electrical and electronic

equipment.

By ensuring that this product is taken care of correctly, you

can help to counteract the potential negative impact on the

environment and people that can otherwise result through the

incorrect waste management of this product.

For more detailed information about recycling this product,

contact your municipality, your domestic waste service or the

shop from where you purchased the product.

2 – English

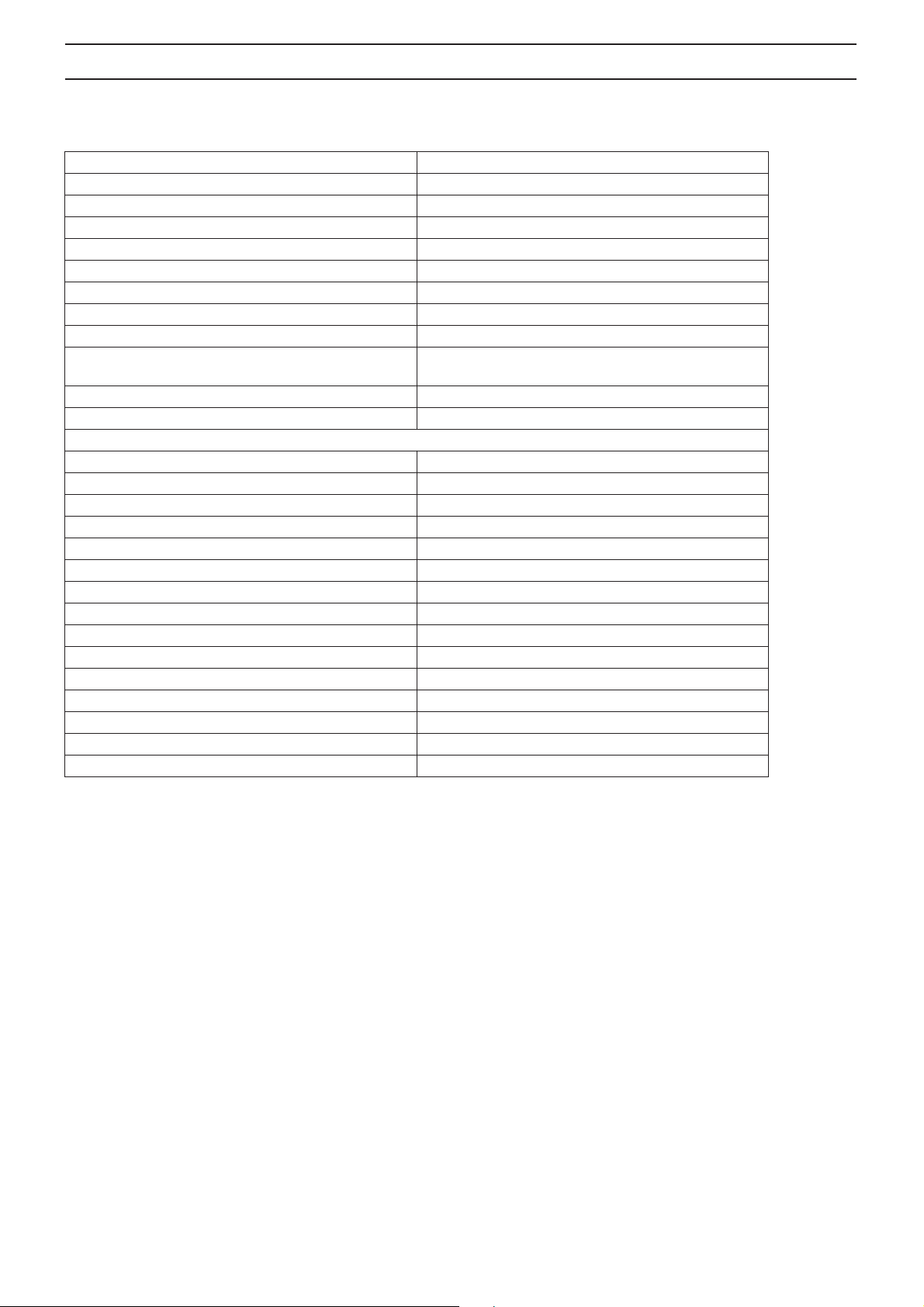

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ............................................. 2

Symbols in the operator’s manual: ............................... 2

CONTENTS

Contents ...................................................................... 3

WHAT IS WHAT?

What is what on the hydraulic unit? ............................. 4

SAFETY INSTRUCTIONS

Steps before using a new hydraulic unit ..................... 5

Personal protective equipment ..................................... 5

Machine′s safety equipment ........................................ 6

General safety precautions .......................................... 6

General working instructions ....................................... 7

ASSEMBLING AND ADJUSTMENTS

Check the oil level ........................................................ 8

Check the air pressure in the tyres .............................. 8

Connect the hydraulic hoses. ....................................... 8

Connect the water cooling ........................................... 8

Connect a power source .............................................. 9

STARTING AND STOPPING

Before starting ............................................................. 10

Starting ........................................................................ 10

Stopping ....................................................................... 10

After work is completed ............................................... 10

MAINTENANCE

Service ......................................................................... 11

Maintenance ................................................................ 11

TECHNICAL DATA

PP 325 E ...................................................................... 13

EC-declaration of conformity ........................................ 14

English – 3

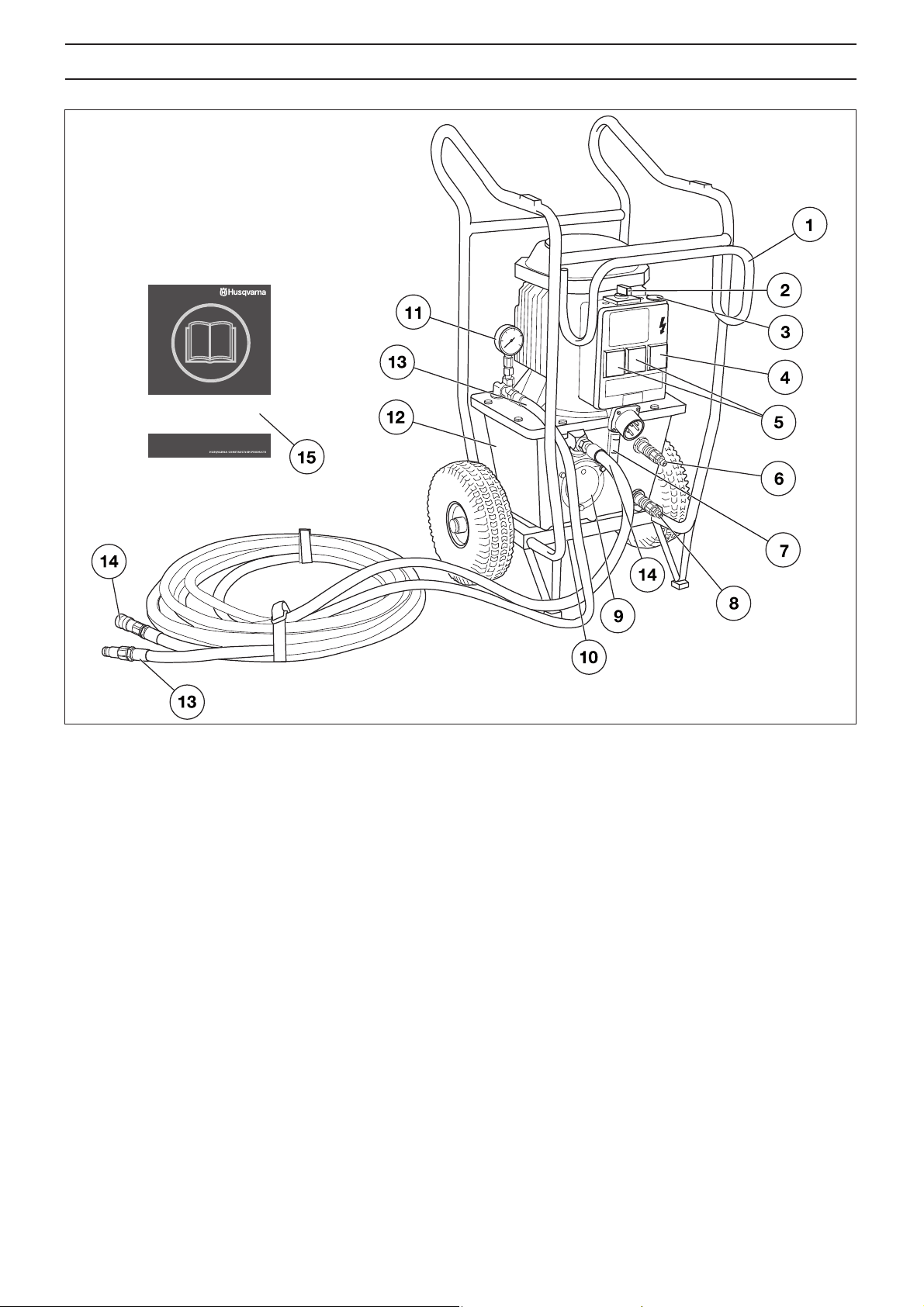

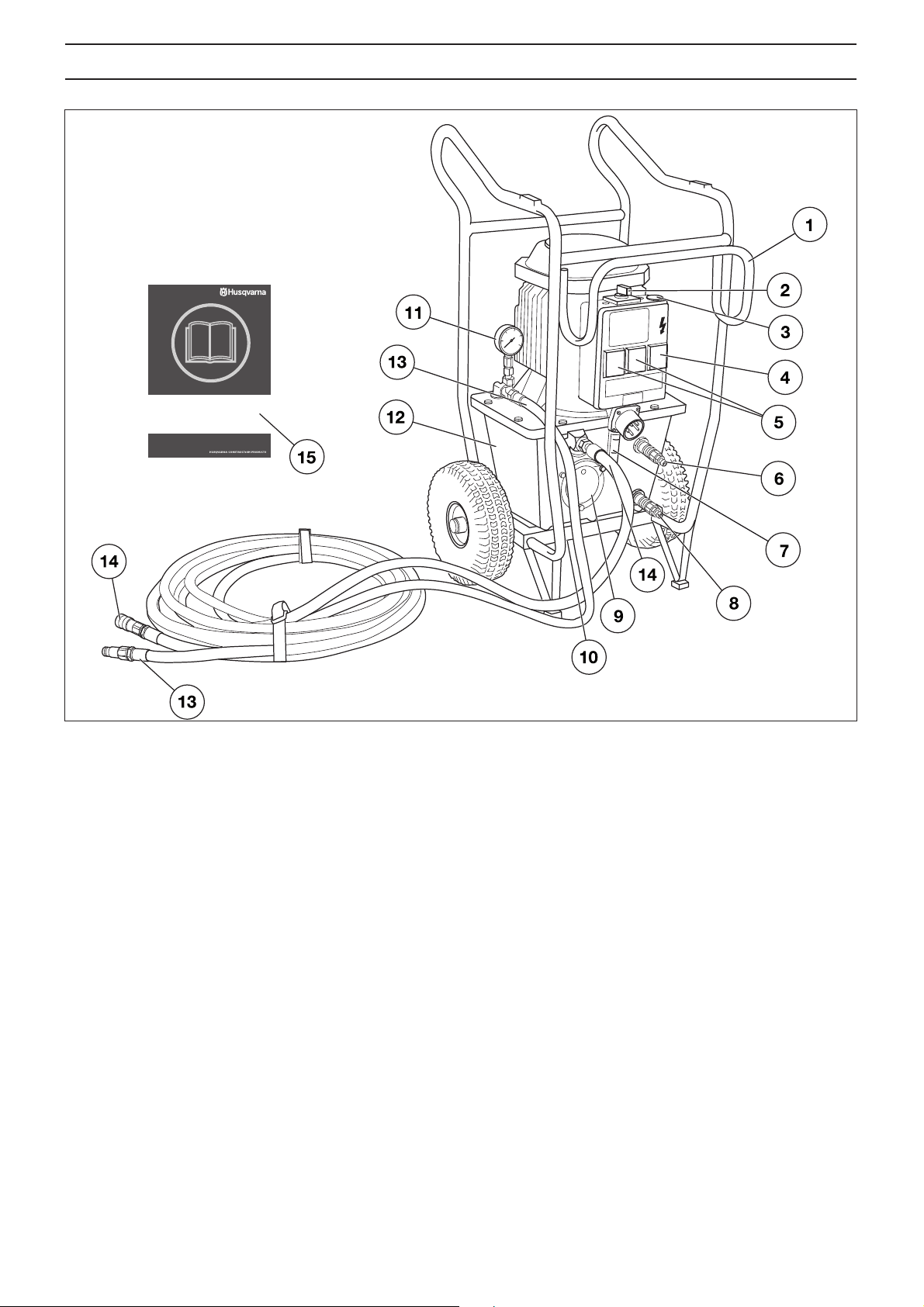

WHAT IS WHAT?

What is what on the hydraulic unit?

1 Frame for hydraulic hose

2 Switch

3 Emergency stop

4 Residual Current Circuit Breaker with Overcurrent

Protection (Only on 5-pin machines.)

5 Wall socket 2x230 V (Only on 5-pin machines.)

6 Connection for outgoing cooling water

7 Sight gauge

8 Connection for incoming cooling water

9 Hydraulic oil filter

10 Drain plug

11 Hydraulic pressure gauge

12 Hydraulic oil tank

13 Hydraulic hose, pressure OUT

14 Hydraulic hose, return IN

15 Operator′s manual

4 – English

SAFETY INSTRUCTIONS

Steps before using a new hydraulic unit

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• This machine is primarily intended for WS 325, DM 406 H,

HS 170 and HH 170, but is also highly suitable as power

source for other equipment, e.g. Husqvarna ring saw.

• Read through the manual supplied with the hydraulic tool

before starting to use the machine.

• The machine can cause serious personal injury. Read the

safety instructions carefully. Learn how to use the

machine.

Always use common sense

It is not possible to cover every conceivable situation you can

face. Always exercise care and use your common sense.

Avoid all situations which you consider to be beyond your

capability. If you still feel uncertain about operating

procedures after reading these instructions, you should

consult an expert before continuing.

Do not hesitate to contact your dealer if you have any more

questions about the use of the machine. We will willingly be of

service and provide you with advice as well as help you to use

your machine both efficiently and safely.

Let your Husqvarna dealer regularly check the machine and

make essential adjustments and repairs.

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to print.

Personal protective equipment

WARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

WARNING! Under no circumstances should

you modify the original design of the

!

machine without approval from the

manufacturer. Always use original spare

parts. Unauthorized modifications and/or

accessories may lead to serious injury or

death to the user or others.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

English – 5

SAFETY INSTRUCTIONS

Machine′′′′s safety equipment

This section describes the machine′s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

WARNING! Never use a machine that has

faulty safety equipment!

!

All servicing and repair work on the machine

requires special training. This is especially

true of the machine

your machine fails any of the checks

described below you must contact your

service agent. When you buy any of our

products we guarantee the availability of

professional repairs and service. If the

retailer who sells your machine is not a

servicing dealer, ask him for the address of

your nearest service agent.

Emergency stop

The emergency stop at the machine breaks the mains power

supply.

Testing the emergency stop

• Make sure that the hydraulic hoses are connected to each

other.

• Start the machine.

• Press the emergency stop and check that the engine

stops.

′′′′s safety equipment. If

• Check that the cord and extension cord are intact and in

good condition.

• Never use the machine if the cord is damaged, hand it in

to an authorized service workshop for repair.

• Do not use an extension cord while it is rolled up to avoid

overheating.

• The machine should be connected to an earthed outlet

socket.

• Check that the mains voltage corresponds with that stated

on the rating plate on the machine.

• Always switch off the power to the hydraulic unit and pull

out the electric cable before moving the equipment.

• Keep all parts in good working order and ensure that all

fixtures are properly tightened.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Do not modify safety equipment. Check regularly that they

function as they should. The machine must not be run with

defective or disassembled safety equipment.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• People and animals can distract you causing you to lose

control of the machine. For this reason, always remain

concentrated and focused on the task.

• Make sure no unauthorised persons are in the working

area, otherwise there is a risk of serious personal injury.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

General safety precautions

Do not use the machine without first reading and

understanding the contents of this Operator’s Manual.

WARNING! There is always a risk of shocks

from electrically powered machines. Avoid

!

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Always follow the instructions in the

Operator’s manual to avoid damage.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

• Never pull out the plug by pulling the cord.

• Keep all cords and extension cords away from water, oil

and sharp edges. Make sure the cord is not pinched in

doors, fences or the like. Otherwise it can cause the object

to become live.

Transport and storage

• Always switch off the power to the hydraulic unit and pull

out the electric cable before moving the equipment.

• If there is a risk of freezing, the machine must be drained

of any remaining water coolant.

• The power unit is constructed as a wheeled cart with the

possibility of hanging hydraulic hoses for simple

transportation at the workplace.

• For transportation between workplaces, the power unit

should be stored in vertical position with the distribution

box facing upwards.

• Store the equipment in a lockable area so that it is out of

reach of children and unauthorized persons.

6 – English

SAFETY INSTRUCTIONS

General working instructions

WARNING! This section describes basic

safety directions for using the machine. This

!

information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced user. Do not

attempt any task that you feel unsure of!

• All operators shall be trained in the use of the machine.

The owner is responsible for ensuring that the operators

receive training.

• Check that all couplings, connections and hydraulic hoses

are in full working order.

• Keep the hydraulic hoses and couplings free from dirt.

• Do not misuse hoses.

• Do not use hoses that are distorted, worn or damaged.

• Make sure that all hoses and electrical cables are

connected to the machine correctly before you start the

machine.

• Check that the hoses are connected correctly to the

machine and that the hydraulic couplings lock as intended

before pressurising the hydraulic system. The couplings

are locked by turning the outer sleeve on the female

coupling so that the slot moves away from the ball.

The pressure hoses in the system must always be

connected to the tool’s intake. The return hoses in the

system must always go to the tool’s outlet. Confusing the

connections can cause the tool to work in reverse, which

can result in personal injury.

• Never use the hydraulic hoses to lift the machine.

• Check the machine, couplings and hydraulic hoses daily

for leakage. A rupture or leak can cause a ”hydraulic fluid

injection” in the body or result in other serious physical

injury.

• Never disconnect the hydraulic hoses without first shutting

off and disconnecting the hydraulic unit and ensuring the

motors have stopped completely.

• If an emergency situation should arise anyway, push the

red emergency stop button on the power unit.

• Do not exceed the specified hydraulic fluid flow or

pressure for the tool being used. Excessive pressure or

flow can result in rupturing.

• Do not check for leakage with your hands. Contact with

the leak can result in serious personal injury caused by

the high pressure in the hydraulic system.

• Check the power supply and the power cables and make

sure that they are not damaged.

• Working close to power lines:

Hoses that are marked and approved as electrically non

conductive must be used when using hydraulic tools on or

in the vicinity of electrical cables. The use of other types

of hoses can result in serious physical injury or even

death.

When replacing hoses, hoses marked 'non-conducting

dielectric” must be used. The hoses must be regularly

checked for their electrical conductive insulation in

accordance with special instructions.

• Working close to gas conduits:

Always check and mark out where gas pipes are routed.

Cutting close to gas pipes always entails danger. Make

sure that sparks are not caused when cutting in view of

the risk of explosion. Remain concentrated and focused

on the task. Carelessness can result in serious personal

injury or death.

• Run the hydraulic system until it reaches its operation

temperature of 30

return pressure and other wear.

• Never leave the machine unsupervised with the motor

running.

• Always saw in a manner that permits easy access to the

emergency stop.

• Make sure that there is always another person close at

hand when you use the machines, so that you can call for

help if an accident should occur.

• People that need to be in close proximity of the machine

must wear hearing protection as the sound level when

cutting exceeds 85 dB(A).

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Always ensure you have a safe and stable working

position.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

°C before starting to saw, to reduce

English – 7

ASSEMBLING AND ADJUSTMENTS

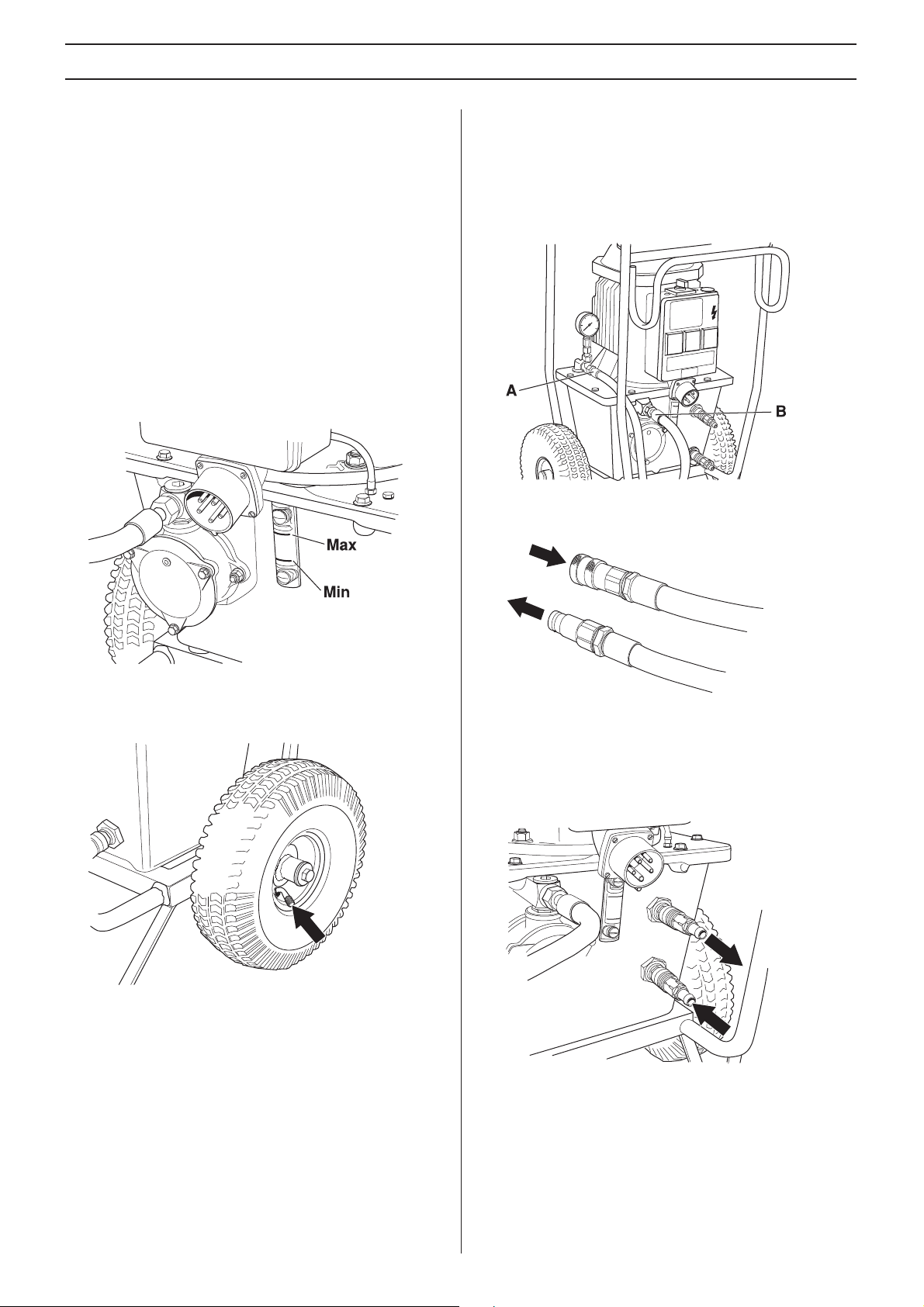

Check the oil level

The power pack is supplied with 12 litres of hydraulic oil 466

cSt HSH of a well-known brand. The oil is an environmentally

adapted and SP approved ester oil that will drastically reduce

the risk of allergic reaction or skin irritation upon contact. In

addition, the oil is quickly degradable in case of unintentional

release.

• Check the hydraulic fluid level in the power unit. This is

checked with the level indicator.

Min. level = red line

Max. level = black line

Do not exceed the max. level when filling the tank with

hydraulic fluid. The hydraulic fluid expands when it gets hot

and can overflow if the level is too high. Tank volume 12 l (3.2

US gallons).

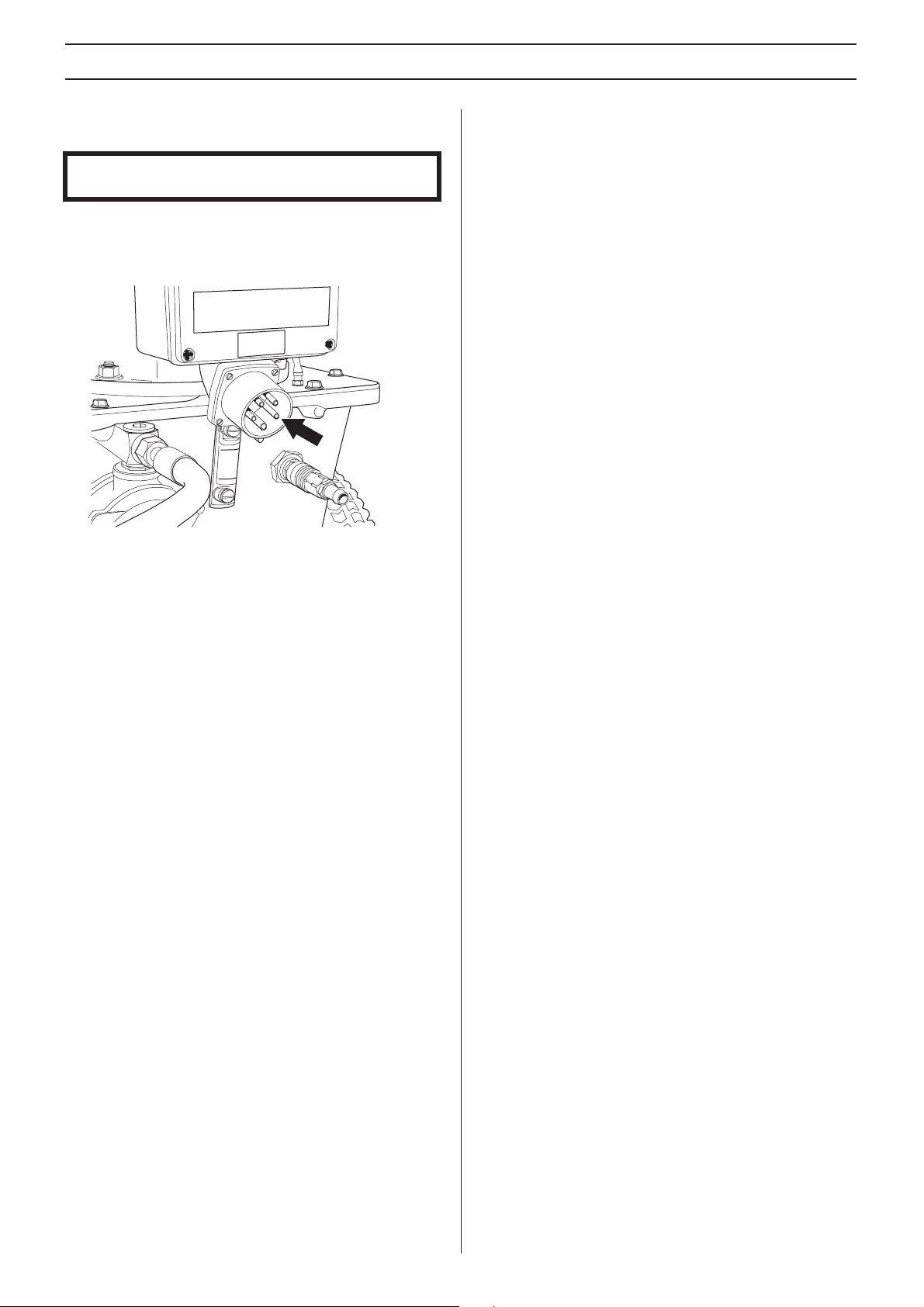

Connect the hydraulic hoses.

• The couplings should be wiped clean to reduce the risk of

leakage before the hoses are fitted.

• The couplings are locked by turning the outer sleeve on

the female coupling so that the slot moves away from the

ball.

Hydraulic hose, return IN (B)

Hydraulic hose, pressure OUT (A)

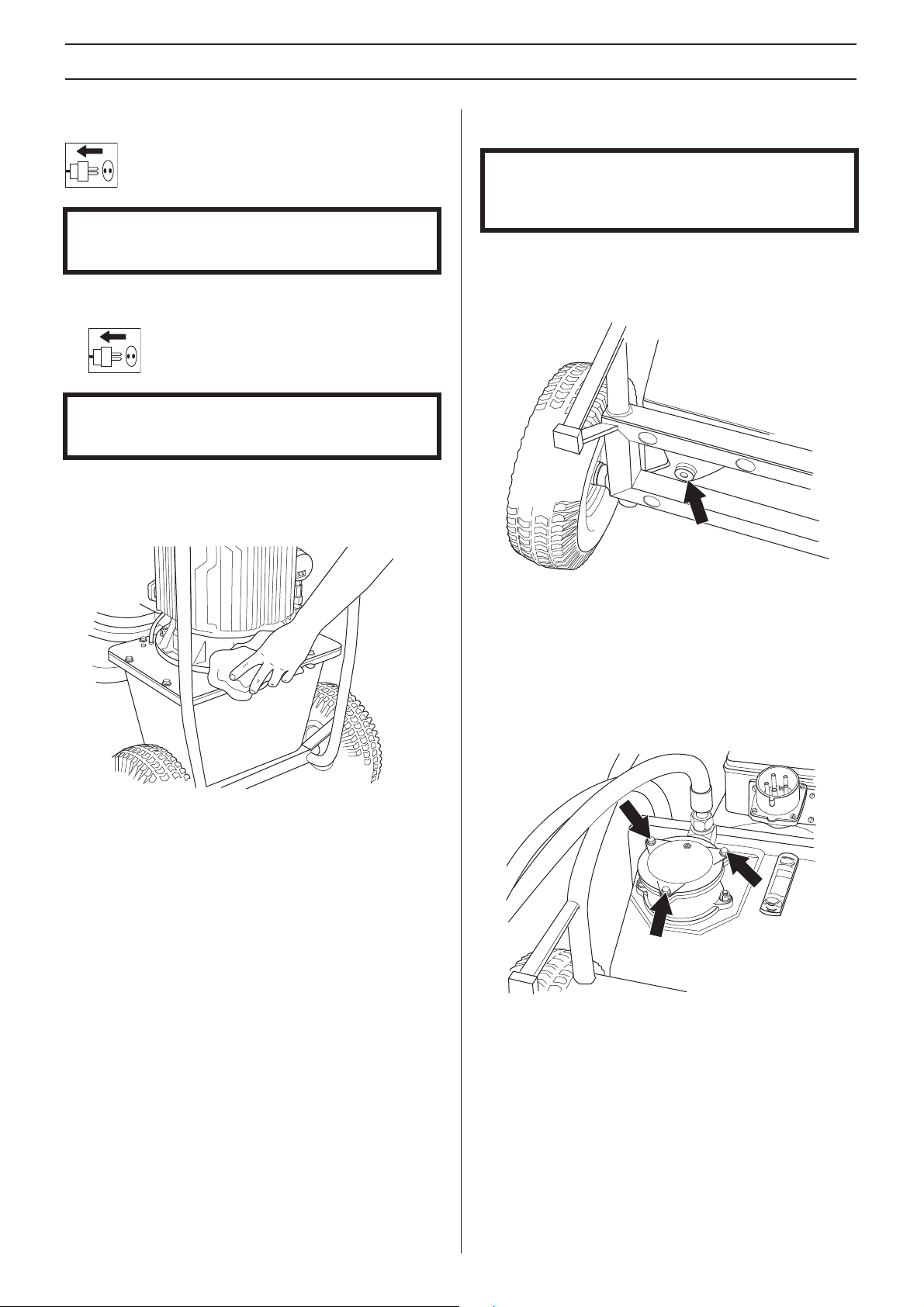

Check the air pressure in the tyres

• Check the air pressure in the tyres. This should be 2 bar.

Connect the water cooling

• Connect a water hose between the upper cooling

connection on the hydraulic oil tank and the working tool,

and also a hose from the closest hydrant via a tap to the

lower cooling connection on the tank.

• If no tool requiring water is used, just let the cooling water

flow to the closest floor drain.

8 – English

ASSEMBLING AND ADJUSTMENTS

Connect a power source

IMPORTANT! Check that the mains voltage corresponds

with that stated on the rating plate on the machine.

• Connect the incoming power cable. The cable must have

three phases and grounding. Neutral should also be

available as the single phase sockets on the distribution

box will not work otherwise. (Only on 5-pin machines.)

• The single phase sockets are protected with a 16 A

residual current circuit breaker with overcurrent protection

(C type). Following the connection on incoming current,

the single phase sockets can be used for e.g. a drilling

machine, water suction apparatus, etc.

English – 9

STARTING AND STOPPING

Before starting

Make sure that:

• The machine is correctly connected to a suitable power

supply and correctly fused.

• The hoses have been connected to a device.

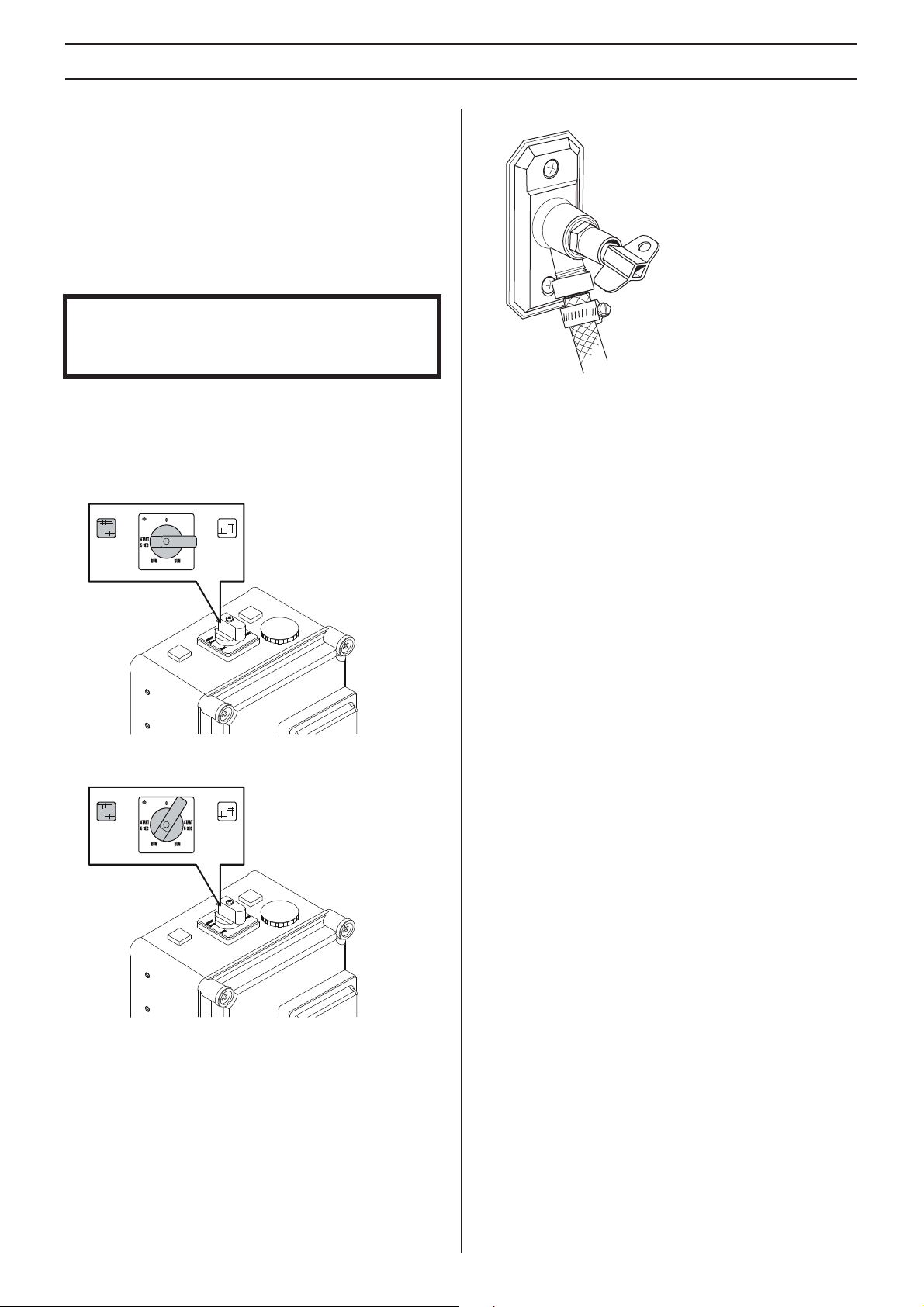

Starting

NOTICE! When starting, the switch must only be turned to

”START 5 SEC” for about 5 seconds. The switch is then

turned to "RUN". The engine may be damaged if the switch

is in the ”START 5 SEC" position too long or when operated.

The engine is started with a Y/D switch. The start takes place

in two steps to avoid overloading the fuse the machine is

connected to.

• Turn the switch to "START 5 SEC" in the direction

indicated by the lit lamp. The direction of rotation of the

engine will then be correct.

• Open the tap to suitable water flow for the tool in question.

If the tool does not require water, cooling water should still

flow through the radiator, and then to the closest floor

drain.

Stopping

Switch off by turning the switch to "0".

After work is completed

• Turn the switch to "RUN" when the engine speed is

constant after about 5 seconds.

• Disconnect the hydraulic hoses.

• If there is a risk of freezing, the machine must be drained

of any remaining water coolant. Disconnect incoming and

outgoing water hoses and tilt the machine forwards.

10 – English

MAINTENANCE

Service

IMPORTANT! All types of repairs may only be carried out by

authorised repairmen. This is so that the operators are not

exposed to great risks.

Maintenance

IMPORTANT! Inspection and/or maintenance should be

carried out with the motor switched off and the plug

disconnected.

Cleaning

Make sure to keep the connectors and pins clean. Clean with

a rag or brush.

Hydraulic oil

IMPORTANT! Changing liquids and filters must be done in

such a way that the machine’s hydraulic system and the

surrounding environment are not damaged. Dispose of

residual products according to local laws.

The hydraulic oil should be replaced when needed or once a

year.

• Place a collecting vessel under the tank’s drain plug and

open the plug.

NB! Do not use a high pressure washer to clean the power

unit. Do not wash the machine with water, as water can enter

the electrical system or the engine and cause damage to the

machine or short circuit.

• Screw on the drain plug when all the liquid has drained

out.

Hydraulic oil is refilled through the filter on the front of the

tank.

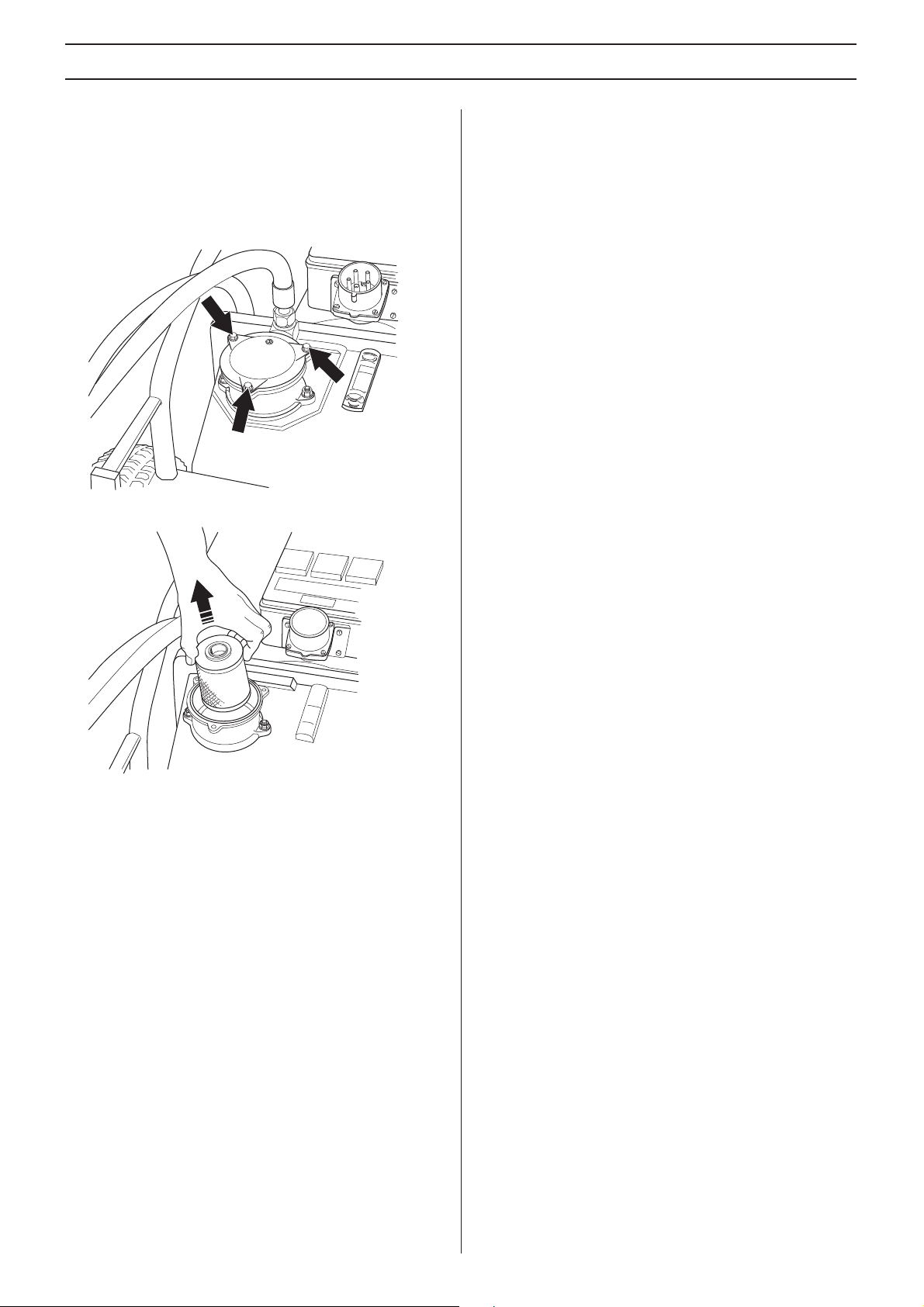

• Lay the power pack down with the filter housing facing

upwards.

• Remove the cover of the filter housing by removing the

three screws.

• Refill hydraulic oil through the filter element.

• Mount the filter housing cover.

• If also the oil filter is replaced, 12 l new hydraulic oil should

be filled.

English – 11

MAINTENANCE

Hydraulic oil filter

The filter should be replaced twice a year.

• Lay the power pack down with the filter housing facing

upwards.

• Remove the cover of the filter housing by removing the

three screws.

• Lift up the filter element.

• Push the new filter in place over the sleeve coupling in the

bottom of the filter housing.

• Mount the filter housing cover.

Tightening torque

When performing repair and maintenance work that include

demounting and subsequent mounting and tightening of

screws, the following torque should be used:

• M6: 10 Nm

• M8: 25 Nm

• M10: 50 Nm

Daily maintenance

Regularly check:

• The hydraulic fluid level in the hydraulic power unit, to

make sure it lies between the marks on the level glass.

• Check the tyre pressures.

• Any abnormal noises.

12 – English

TECHNICAL DATA

PP 325 E

Specified hydraulic output, kW/hp 9,3/12,6

Hydraulic oil flow, l/min / gpm 40/8,8

Hydraulic oil tank, l/gal 12/2,6

Cooling Water cooling

Size, (LxWxH), mm/inch 575x1040x780/22,6x40,9x30,7

Weight, kg/lbs 93/205

Max. working pressure, bar / psi 140/2031

Hose length (1/2" hose), mm/inch

Power supply

Check that the mains voltage corresponds with that stated on the rating plate on the machine.

200 V 50 Hz

200 V 60 Hz

230/400 V 50 Hz

230 V 60 Hz

400 V 50 Hz

440 V 50 Hz

575 V 60 Hz

8/315 (When hoses are extended beyond standard

length, 5/8" hose is recommended.)

Wall socket 2x230 V (Only on 5-pin machines.)

Noise emissions (see note 1)

Sound power level, measured dB(A) 94

Sound power level, guaranteed LWA dB(A) 99

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 83

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/EC.

Note 2: Noise pressure level according to EN ISO 11201. Reported data for noise pressure level has a typical statistical dispersion

(standard deviation) of 1.0 dB(A).

13 – English

TECHNICAL DATA

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that the hydraulic unit

Husqvarna PP 325 E from 2010´s serial numbers and onwards (the year is clearly stated in plain text on the type plate with

subsequent serial number) is in conformity with the requirements of the COUNCIL’S DIRECTIVES:

• of May 17, 2006 "relating to machinery" 2006/42/EC

• of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC.

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-11:2000,

EN 982/A1:2008, EN 60204-1:2006.

Huskvarna December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

14 – English

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina:

¡ATENCIÓN! La máquina, si se utiliza de

forma errónea o descuidada, puede ser

una herramienta peligrosa que puede

causar daños graves e incluso la muerte al

usuario y a otras personas.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

Utilice siempre:

• Casco protector homologado

• Protectores auriculares homologados

• Gafas protectoras o visor

• Máscara respiratoria

Este producto cumple con la directiva CE

vigente.

¡ATENCIÓN! Corriente intensa.

Símbolos en el manual de instrucciones:

El control y/o mantenimiento de la máquina

debe hacerse con el motor parado y el

enchufe desenchufado.

Utilice siempre guantes protectores

homologados.

La máquina debe limpiarse regularmente.

Control visual.

Debe utilizarse gafas protectoras o visor.

Etiquetado ecológico.

El símbolo en el producto o en su envase

indica que no se puede tratar este producto

como desperdicio doméstico. Deberá por lo

tanto depositarse en un centro de recogida

adecuado para el reciclado de equipos

eléctricos y electrónicos.

Haciendo que este producto sea manipulado

adecuadamente, se ayuda a evitar consecuencias negativas

potenciales para el medio ambiente y las personas, lo que

puede ocurrir con la manipulación inadecuada como residuos

del producto.

Para obtener información más detallada sobre el reciclado de

este producto, contacte con la oficina municipal local, con el

servicio de eliminación de desperdicios domésticos o con la

tienda donde compró el producto.

Spanish – 15

ÍNDICE

Índice

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina: ............................................. 15

Símbolos en el manual de instrucciones: .................... 15

ÍNDICE

Índice ........................................................................... 16

¿QUÉ ES QUÉ?

¿Qué es qué en la unidad hidráulica? ......................... 17

INSTRUCCIONES DE SEGURIDAD

Antes de utilizar una nueva unidad hidráulica ............. 18

Equipo de protección personal .................................... 18

Equipo de seguridad de la máquina ............................ 19

Instrucciones generales de seguridad ......................... 19

Instrucciones generales de trabajo .............................. 20

MONTAJE Y AJUSTES

Controle el nivel de aceite ............................................ 21

Comprobación de la presión de aire de los neumáticos 21

Conexión de las mangueras hidráulicas ...................... 21

Conexión de la refrigeración por agua ......................... 21

Conexión de una fuente de alimentación ..................... 22

ARRANQUE Y PARADA

Antes del arranque ....................................................... 23

Arranque ...................................................................... 23

Parada ......................................................................... 23

Después de terminar el trabajo .................................... 23

MANTENIMIENTO

Servicio ........................................................................ 24

Mantenimiento ............................................................. 24

DATOS TECNICOS

PP 325 E ...................................................................... 26

Declaración CE de conformidad .................................. 27

16 – Spanish

¿QUÉ ES QUÉ?

¿Qué es qué en la unidad hidráulica?

1 Soporte para manguera hidráulica

2 Interruptor

3 Parada de emergencia

4 Disyuntor de corriente residual con protección contra

sobrecorriente (solo para dispositivos de 5 pines)

5 Toma de corriente de pared 2 de 230 V (solo para

dispositivos de 5 pines)

6 Conexión para agua de refrigeración saliente

7 Calibrador visual

8 Conexión para agua de refrigeración entrante

9 Filtro de aceite hidráulico

10 Tapón de vaciado

11 Manómetro hidráulico

12 Depósito de aceite hidráulico

13 Manguera hidráulica, salida de presión

14 Manguera hidráulica, entrada de retorno

15 Manual de instrucciones

Spanish – 17

Loading...

Loading...