Oper ator ′ s manual

K3000

K3000 Wet

Please r ead the operator’s manual carefully and make sure you understand the instructions

before using the machine.

EEEEnnnngggglllliiiisssshh

hh

2

W

En

KEY T O SYMBOLS

Symbols on the mac hine:

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with

applicable EC directives.

WARNING! Dust forms when cutting,

which can cause injuries if inhaled. Use

an approved breathing mask. Always

provide for good ventilation.

WARNING! Sparks from the cutting

blade can cause fire in combustible

materials such as: petrol (gas), wood,

dry grass etc.

WARNING! Kickbacks can be sudden,

rapid and violent and can cause life

threatening injuries. Read and

understand the instructions in the

manual before using the machine.

vironmental marking. Symbols on

the product or its packaging indicate that

this product cannot be handled as

domestic waste. It must instead be

submitted to an appropriate recycling

station for the recovery of electrical and

electronic equipment.

By ensuring that this product is taken care of correctly,

you can help to counteract the potential negative impact

on the environment and people that can otherwise result

through the incorrect waste management of this product.

For more detailed information about recycling this

product, contact your municipality, your domestic waste

service or the shop from where you purchased the

product.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

Symbols in the operator’ s manual:

Inspection and/or maintenance should

be carried out with the motor switched

off and the plug disconnected.

Always wear approved protective

gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be

worn.

– English

ST

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ..................................... 2

Symbols in the operator’s manual: ....................... 2

CONTENTS

Contents ............................................................... 3

WHA T IS WHAT?

What is what on the po wer cutter - K3000? ......... 4

WHA T IS WHAT?

What is what on the po wer cutter - K3000 Wet? .. 5

GENERAL SAFETY PRECA UTIONS

Steps bef ore using a new power cutter ................ 6

Personal protective equipment ............................. 6

Machine ′ s safety equipment ................................. 7

SAFETY INSTR UCTIONS

Gener al safety warnings ....................................... 9

Cutting blades ...................................................... 11

General working instructions ................................ 13

ASSEMBL Y

Assemb ly .............................................................. 15

Fitting the cutting blade ........................................ 15

Guard for the blade ............................................... 15

ARTING AND STOPPING

Bef ore starting ...................................................... 16

Starting ................................................................. 16

Stopping ............................................................... 16

MAINTENANCE

Gener al ................................................................. 17

Cleaning ............................................................... 17

Electrical Feed ...................................................... 17

Replacing the carbon brushes .............................. 17

Bevel gear ............................................................ 18

Checking the drive shaft and flange washers ....... 18

Checking water connection with flow limiter ......... 18

Daily maintenance ................................................ 18

TECHNICAL D ATA

Cutting equipment ................................................ 20

Recommended cable dimensions ........................ 20

EC-declaration of conformity ................................ 21

English

–

3

4

1

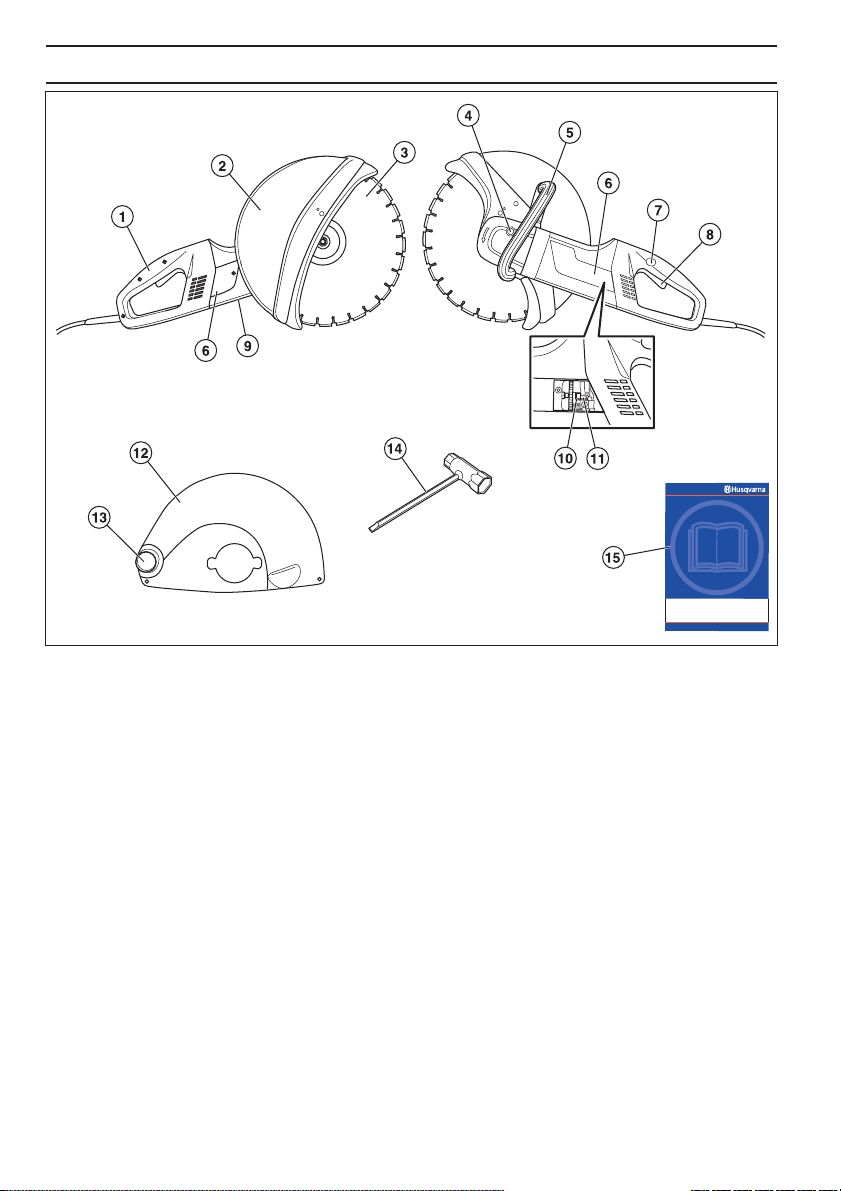

WHA T IS WHA T?

What is what on the po wer cutter - K3000?

Rear handle

2 Guard for the blade 14”

3 Cutting blade

4 Locking the axle

5 Front handle

6 Inspection covers

7 Power switch lock

8 Switch

– English

9 Rating plate

10 Brush retainer

11 Carbon brushes

12 Guard for the blade 12” (Model version)

13 Connection for vacuum cleaner

14 Combination spanner

15 Operator ′ s manual

1

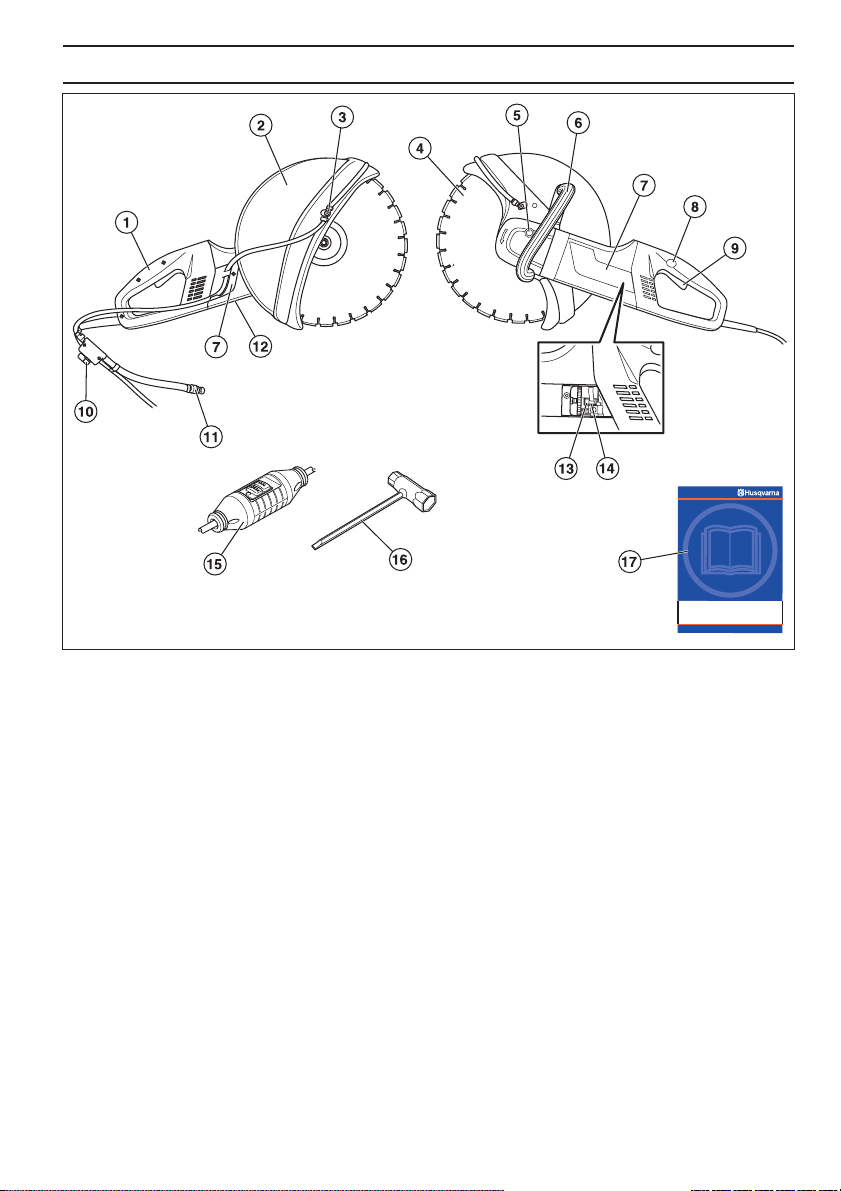

WHA T IS WHA T?

What is what on the po wer cutter - K3000 Wet?

Rear handle

2 Guard for the blade

3 Water kit

4 Cutting blade

5 Locking the axle

6 Front handle

7 Inspection covers

8 Power switch lock

9 Switch

10 Water tap

11 Water connection with flow limiter

12 Rating plate

13 Brush retainer

14 Carbon brushes

15 Ground fault circuit interrupter (not for GB)

16 Combination spanner

17 Operator ′ s manual

English – 5

!

6

•

P

•

W

W

W

GENERAL SAFETY PRECA UTIONS

W

Steps bef ore using a new power cutter

Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• The machine is only designed for cutting hard

materials, such as concrete, brick, masonry as well as

cast iron and cement pipes.

• Let your Husqvarna dealer regularly check the power

cutter and make essential adjustments and repairs.

ARNING! Under no circumstances

should you modify the original design of

!

the machine without approval from the

manufacturer. Always use original spare

parts. Unauthorized modifications and/or

accessories may lead to serious injury or

death to the user or others.

ARNING! Use of products which cut,

grind, drill, sand or shape material can

!

generate dust and vapors which may

contain harmful chemicals. Know the

nature of the material being worked on

and wear appropriate dust mask or

respirator protection.

ARNING! A power cutter is a

dangerous tool if used carelessly or

!

incorrectly and can cause serious, even

fatal injuries. It is extremely important

that you read and understand the

contents of this Operator’s Manual.

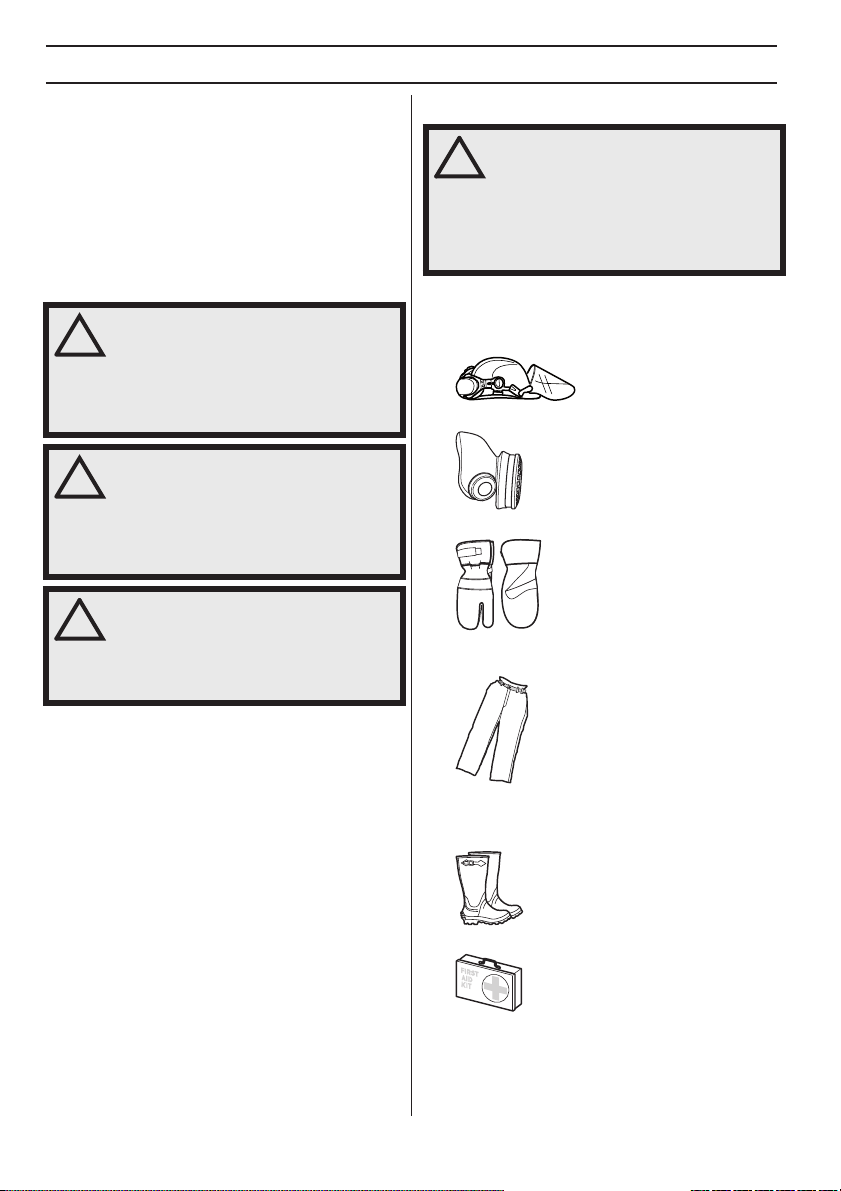

ersonal protective equipment

ARNING! You must use approved

personal protective equipment whenever

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of

injury if an accident does happen. Ask

your dealer for help in choosing the right

equipment.

Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

Husqvarna Construction Products has a policy of

continuous product development. Husqvarna reserves

the right to modify the design and appearance of products

without prior notice and without further obligation

introduce design modifications.

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to

print.

– English

• Use leg-guards recommended for the material to be

cut.

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

GENERAL SAFETY PRECA UTIONS

Mac hine ′′

This section descr ibes the machine ′ s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

′′

s safety equipment

ARNING! Never use a machine that has

faulty safety equipment! Carry out the

!

inspection, maintenance and service

routines listed in this section.

All servicing and repair work on the

machine requires special training. This is

especially true of the machine

equipment. If your machine fails any of

the checks described below you must

contact your service agent. When you

buy any of our products we guarantee

the availability of professional repairs

and service. If the retailer who sells your

machine is not a servicing dealer, ask

him for the address of your nearest

service agent.

′′

′′

s safety

•

P

•

W

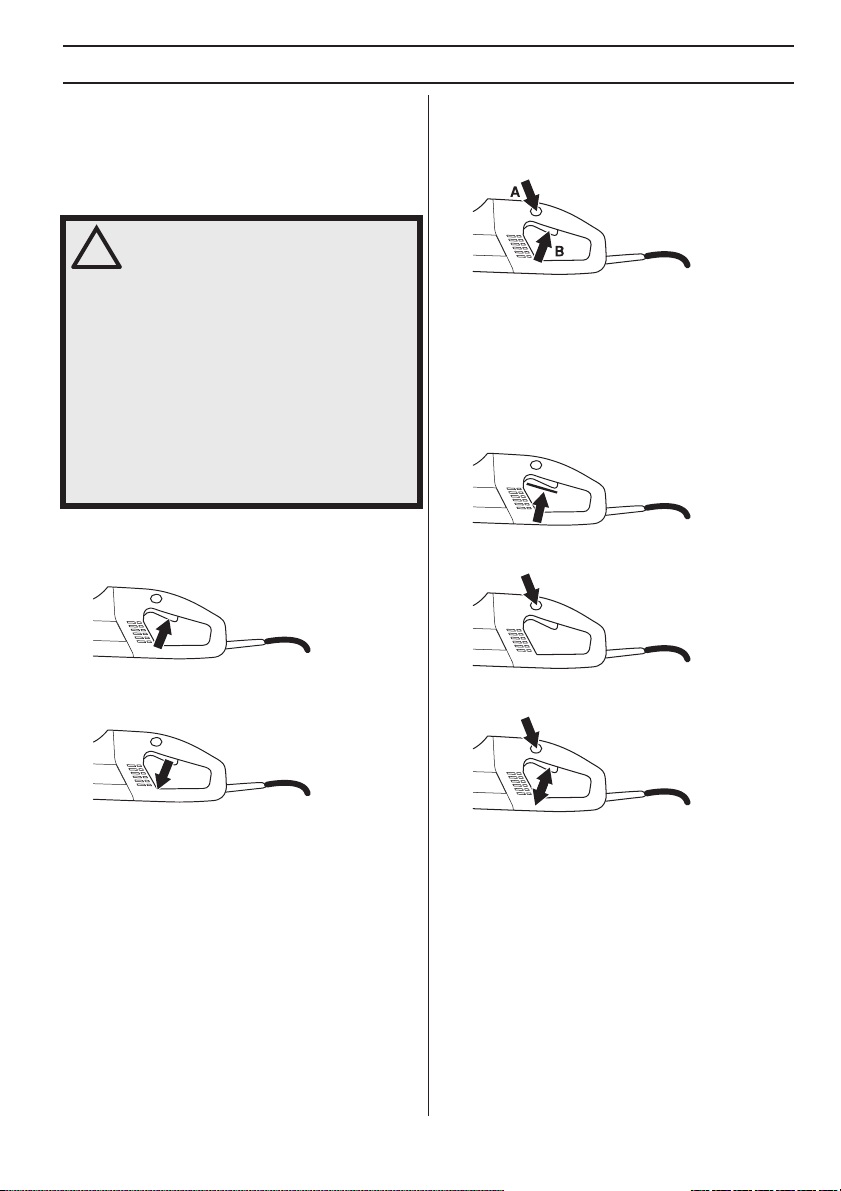

ower switch lock

The po wer switch lock is designed to prevent accidental

operation of the switch. When the lock (A) is pressed in

the power switch (B) is released.

The power switch lock remains depressed as long as the

power switch is depressed. When the grip on the handle

is released both the power switch and power switch lock

are reset. This movement is controlled by two

independent return springs. This position results in the

machine stopping and the power switch being locked.

Chec king the power switch lock

Make sure the power switch is locked when the power

switch lock is in its original position.

Switc h

The po wer switch should be used to start and stop the

machine.

Chec king the power switch

Start the machine, release the power switch and

check that the engine and the cutting blade stop.

• A defective power switch should be replaced by an

authorized service workshop.

• Press in the power switch lock and make sure it

returns to its original position when you release it.

• Check that the power switch and power switch lock

move freely and that the return springs work properly.

• Start the machine, release the power switch and

check that the engine and the cutting blade stop.

Gradual star t and overload protection

The machine is equipped with electronically controlled

gradual start and overload protection.

The engine starts to pulsate if the machine is loaded

above a specific level. If the load is reduced the engine

reverts to its normal state and cutting can resume.

The electronics will cut the current after a set time if the

machine continues to be run with a pulsating engine. The

higher load the faster the shutoff.

The electronics cut the current immediately if the blade

jams.

English

–

7

Loading...

Loading...