Husqvarna NUDA 900 R (2012), NUDA 900 (2012), NUDA 900 (2013), NUDA 900 R (2013) Workshop Manual

NUDA 900 2012/2013

NUDA 900 R 2012/2013

Workshop Manual Ed. 11-2011

Rev 02

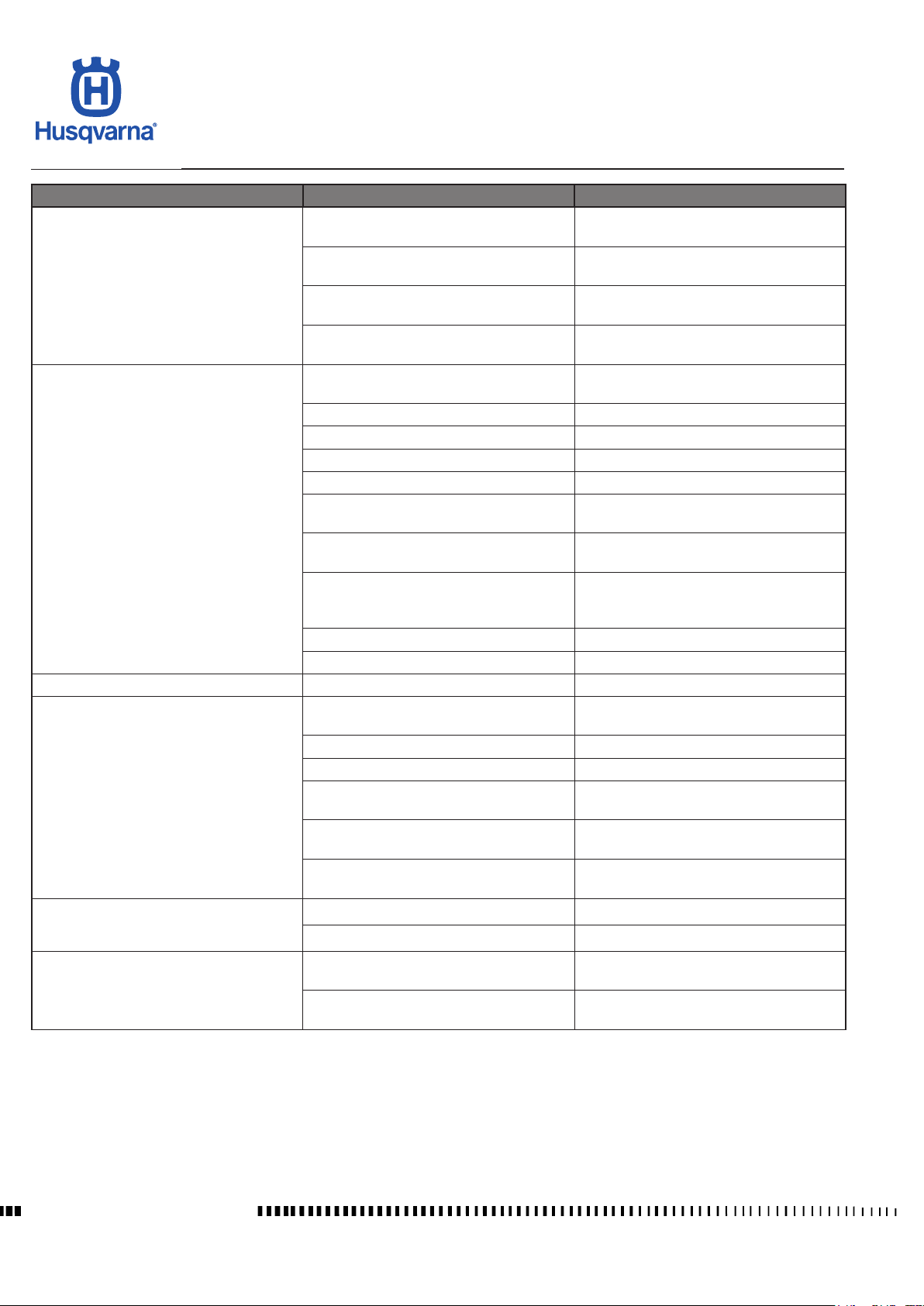

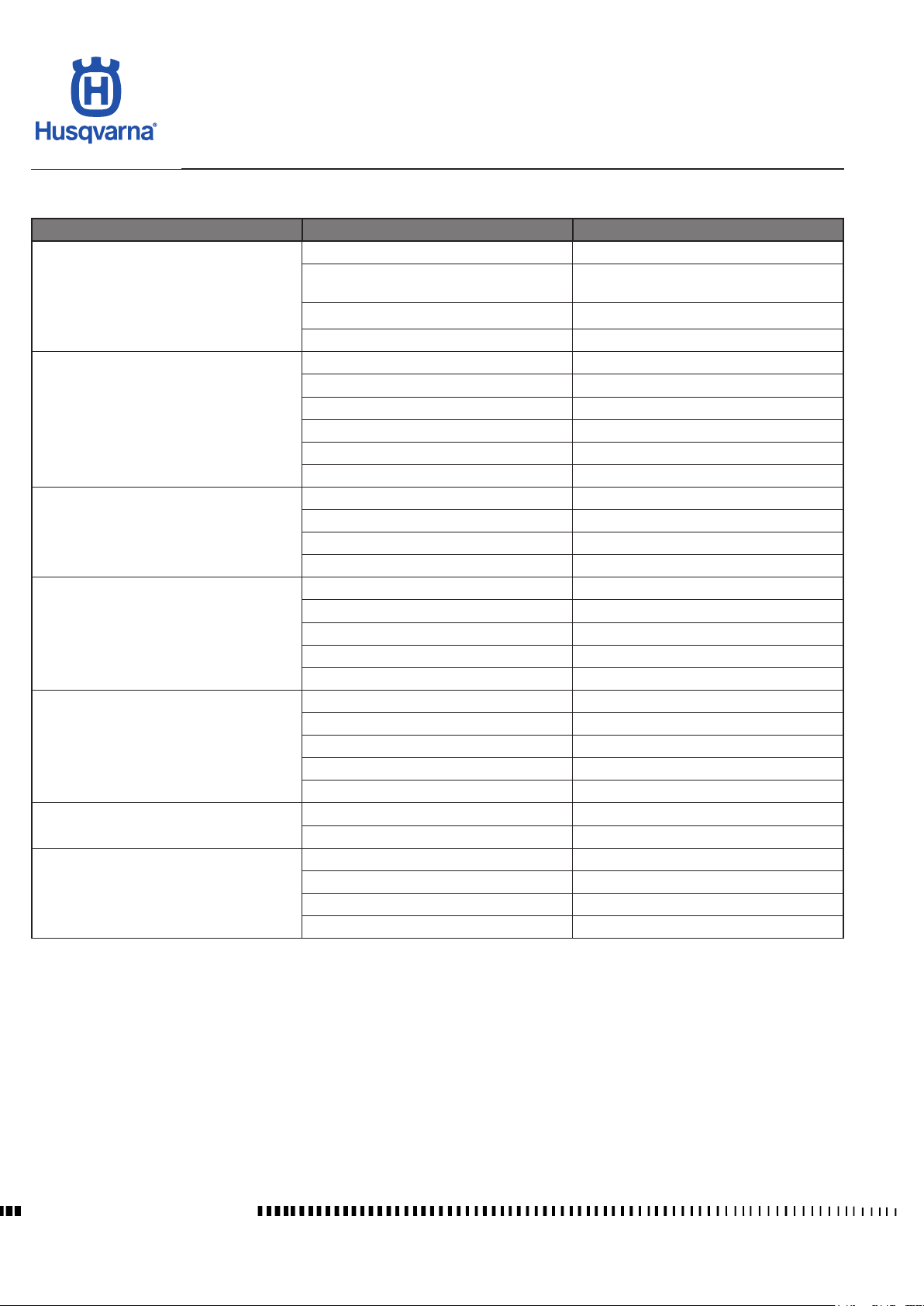

Revision Record

Rev. No. Date Page Description

01 30/03/2012 A.5 "Cold tyre pressure - Rear" value corrected.

02 23/10/2012 All pages Inserted MY13 (section L excluded).

02 08/11/2012 D.18 Added value in the table.

02 08/11/2012 D.19 Applied change.

02 08/11/2012 D.25 Inserted text.

02 23/10/2012 F4.13 H10465 correct drawing in H12017.

02 08/11/2012 I.8 Added value in the table; applied change.

02 23/10/2012 Section L Valid only for MY12 - no ABS version.

02 23/10/2012 Section L1 Valid only for MY13 - ABS version.

02 08/11/2012 M.18 H10939 modiced drawing in H12123.

02 08/11/2012 M.21 H10942 modiced drawing in H12124.

02 23/10/2012 M.28 Delete note.

HUSQVARNA MOTORCYCLES S.R.L. - Varese disclaims all liabilities for any errors or omissions in this manual and

reserves the right to make changes to reect on-going product development. Illustrations in the manual may differ from

actual components. No reproduction in full or in part without written authorisation.

st

1

edition (11-2011) - Rev. 02

FOREWORD, TABLE OF CONTENTS

simbolo

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Workshop Manual

NUDA 900 2012/2013

NUDA 900 R 2012/2013

Copyright by

HUSQVARNA MOTORCYCLES S.R.L.

BMW Group

Technical Service

Via Nino Bixio, 8

21024

(Varese) - Italy

tel. ++39 0332 75.61.11

tel. ++39 0332 756 558

www.husqvarna-motorcycles.com

1st edition (11-2011) - Rev. 02

Printed in Italy

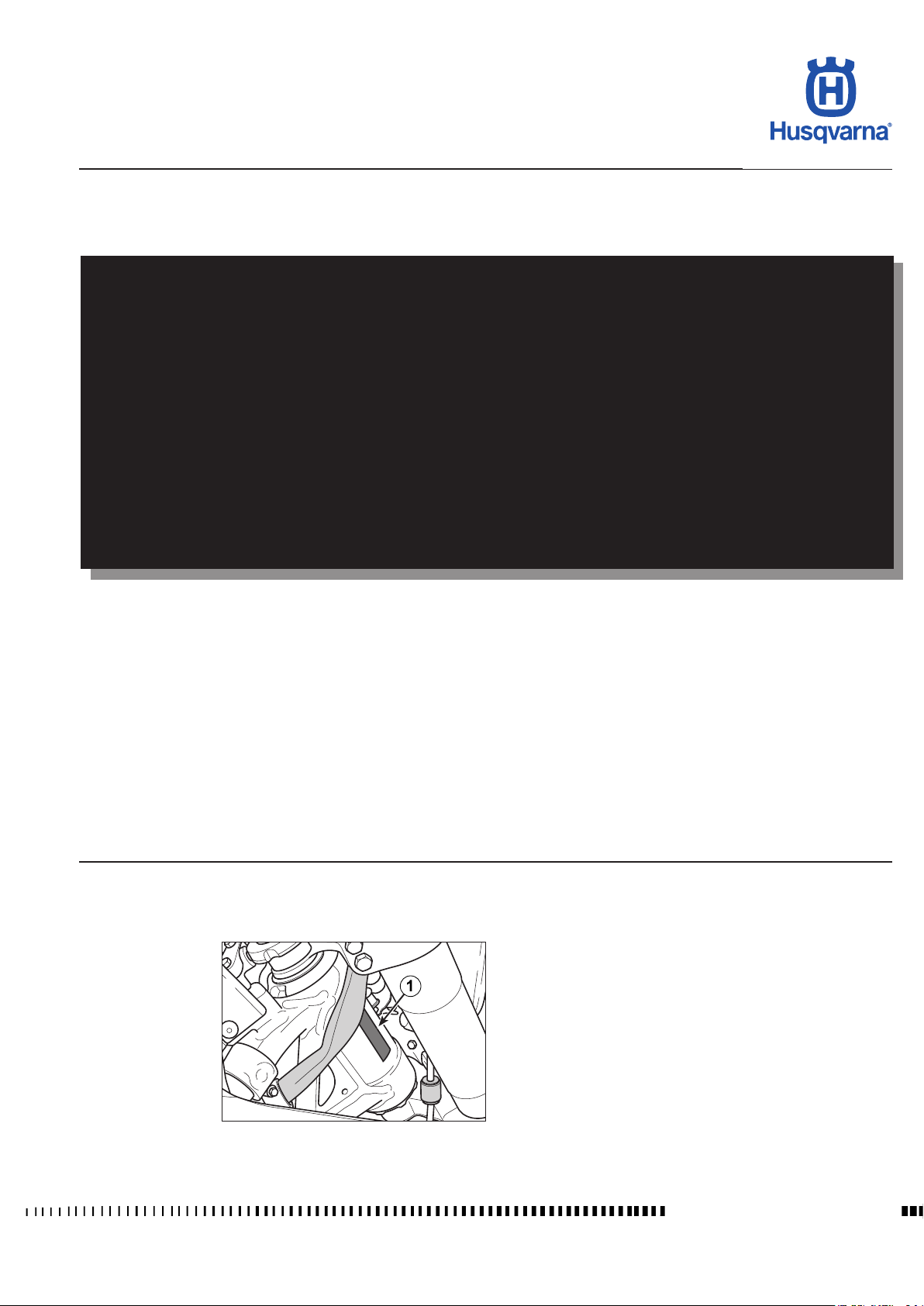

MODELS COVERED (from serial number onwards)

NUDA 900: ZKHA700A#CV000001

NUDA 900 R: ZKHA700B#CV000001

1. Chassis serial number

Workshop Manual Ed. 11-2011

a.1

FOREWORD, TABLE OF CONTENTS

simbolo

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Foreword

This publication is designed for use by HUSQVARNA Service Centres to assist authorised personnel in the maintenance

and repair of the models covered in this manual. The technical information provided in this manual is a critical complement to operator training and operators should become thoroughly familiar with it.

This publication is for the exclusive use of those HUSQVARNA technicians who have an adequate basic mechanical

preparation and a good knowledge of the vehicles repair procedures. Thus much information has been intentionally

omitted as it was considered superuous. The technicians must adopt special safety procedures that they will deem

necessary in order to prevent damages to the motorbike, to its components, and to people.

For ease of understanding, diagrams and photographs are provided next to the text.

Notes with special signicance are identied as follows throughout the manual:

Accident-prevention rules for operator and persons working nearby.

Damage to vehicle and/or its components may result from incompliance with relevant instructions.

Additional information concerning the operation covered in the text.

Useful tips

To prevent problems and ensure effective service work, observe the following HUSQVARNA recommendations:

– before repair, evaluate the customer's description of the problem and ask the appropriate questions to clearly identify

problem symptoms;

– diagnose the problem and identify the causes clearly. This manual provides basic background information that must

be supplemented with the operator's expertise and specic training available through HUSQVARNA held at regular

periods;

– plan ahead before starting work: gather any spare parts and tools to avoid unnecessary delays;

– avoid unnecessary disassembly work to get to the part that needs repairing.

Always read the relevant instructions and follow the disassembly sequence outlined in this manual.

Workshop Manual Ed. 11-2011

a.2

FOREWORD, TABLE OF CONTENTS

simbolo

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Table of Contents

Title Section

Foreword, Table of Contents ...............................................................................a

Important Notices ................................................................................................b

General Information

Maintenance ........................................................................................................B

Troubleshooting

Settings and Adjustments ................................................................................... D

General Procedures ............................................................................................E

Egine settings and adjustments...........................................................................F

General engine procedures ...............................................................................F1

Cylinder head removal/disassembly ..................................................................F2

Crankcase disassembly.....................................................................................F3

Engine torque gures ........................................................................................F4

Wear limits of engine parts ................................................................................F5

Front Suspension .................................................................................................I

Rear Suspension .................................................................................................J

Brakes (NON-ABS Version - MY12 ONLY) .........................................................L

Brakes (ABS Version - MY13 ONLY) .................................................................L1

Electrical System ................................................................................................M

Engine Cooling ................................................................................................... N

Tightening Torque Figures ...................................................................................X

Chassis and Wheels ............................................................................................Y

.............................................................................................A

.................................................................................................. C

NOTES

Unless otherwise specied, data and specications apply to all models.

a.3

Workshop Manual Ed. 11-2011

IMPORTANT NOTICES

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Section

b

b.1

Workshop Manual Ed. 11-2011

IMPORTANT NOTICES

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

GENERAL SAFETY WARNINGS

Read these general recommendations carefully before using the vehicle.

Carbon monoxide

Only run the engine in an open or very well ventilated area. If you do work in an enclosed area, make sure you use a fume extraction

system.

Exhaust emissions contain carbon monoxide, a poisonous gas which can cause loss of consciousness and even

death if inhaled.

Parts of the vehicle that become hot

Before working on the engine and the exhaust unit, wait for them to cool down; while the vehicle is running, these parts become very

hot and remain hot for some time after turning off the engine.

Risk of burns - work with caution and wear suitable PPE if necessary.

Fuel

The fuel used to power internal combustion engines is highly ammable and explosive.

Do all fuelling and maintenance operations with the engine switched off and in ventilated areas; do not

smoke and avoid contact between the fuel and naked ames, sparks, etc. that may cause an explosion.

Do not dispose of fuel in the environment.

Keep out of reach of children.

Do not tilt the vehicle excessively since this may cause fuel to leak.

Engine

In some cases, coolant may become inammable and if burnt, produce invisible ames which cause burns.

Do not spill coolant onto hot components like the engine or exhaust pipe, etc. since it may ignite.

During maintenance work, wear latex gloves.

Never leave the coolant in open containers in areas accessible to children and animals since it is toxic.

DO NOT remove the radiator cap when the engine is hot; the coolant is pressurised and may cause scalding.

Engine oil

Do not dispose of oil in the environment since it is highly polluting.

Keep out of reach of children.

Wear latex gloves since prolonged contact with the skin can cause serious damage.

Send used oil to special authorised recyclers in accordance with the legal requirements in force in the country where

the vehicle will be used.

Brake uid

Brake uid is highly corrosive and may damage the rubber and painted parts of the vehicle.

While performing maintenance work, protect your eyes by wearing special goggles and wear protective gloves.

In the event of accidental contact with the eyes, rinse them with plenty of clean, running water and seek medical advice

immediately.

Keep out of reach of children.

Workshop Manual Ed. 11-2011

b.2

1

2

IMPORTANT NOTICES

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Battery

Recharge the battery in well ventilated areas since the battery produces toxic, highly inammable gases when being

recharged; do not smoke or use naked ames or sparks.

The liquid in the battery is highly corrosive. If it comes into contact with the skin, rinse thoroughly with running water.

It is extremely important to protect your eyes because even a small amount of liquid can cause irreversible damage

to the eyes.

If it comes into contact with the eyes, rinse thoroughly with clean, running water and if swallowed accidentally , drink

plenty of water or milk.

In all cases, seek medical advice immediately.

The battery liquid is corrosive and should not be poured onto the painted or rubber parts.

The battery liquid is highly polluting. DO NOT dispose in the environment; at the end of its service life, take the battery

to the special authorised recycling centres in accordance with the legal requirements in force in the country where

the vehicle will be used.

Keep out of reach of children.

H10571

NUDA 900 and NUDA 900 R models are STREET LEGAL motorcycles; they are

guaranteed exempt from functional defects and covered with legal guarantee, as

far as the STANDARD CONFIGURATION IS MAINTAINED and the suggested

maintenance table shown in Section "B" is observed.

* In order to maintain the vehicle’s “Guarantee of Functionality”, the client must

follow the maintenance programme indicated in Section B by having the required

maintenance inspections carried out at authorised HUSQVARNA dealers. The

cost for cha nging par ts and for t he labour nec essar y in ord er to comply w ith

the maintenance p lan is char ged to the Cli ent. The war ranty b ecome s NULL

AND VOID if the motorcycle is rented.

Notes

Left and right side is determined when seated on motorcycle.

Z: number of teeth

A: Austria

AUS: Australia

B: Belgium

BR: Brazil

CDN: Canada

CH: Switzerland

D: Germany

E: Spain

F: France

FIN: Finland

GB: Great Britain

I: Italy

J: Japan

USA: United States of America

Unless otherwise specied, data and instructions apply to all market variants.

Workshop Manual Ed. 11-2011

b.3

IMPORTANT NOTICES

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

RECOMMENDED SHOP PRACTICES

Before disassembling components or before performing repair operations, clean the motorbike removing possible mud, dust, or

foreign bodies.

- Put the vehicle in a well lit area;

- Fasten the vehicle in a steady position so that it cannot overturn; use suitable stands and belts.

- Use suitable equipment for lifting/removing heavy parts.

- Use appropriate keys (not pliers) to loosen/tighten nuts and screws.

- When loosening or tightening nuts or bolts, always begin with the bigger ones or from the centre. Tighten to the specied torque

and follow a cross pattern or a dedicated pattern as outlined in the relevant section.

- Always mark any parts or positions that might be confused upon assembly.

- Use special tools where specied.

- Clean thoroughly the removed components before retting them

- During the reassemb ly, make sure that the bearin gs turn f reely wi thout obs truc tion o r without g ettin g stuck, ot her wise r eplace

them

- Always replace the sea ls, the se aling r ings , the spli t pins, th e screw s with da mage d threa d, and the s elf- lo cki ng nuts w ith new

parts.

- Use genuine HUSQVARNA parts and the recommended lubricant brands.

- At the end of a repair or periodic maintenance, test the vehicle before delivering it to the customer.

Electrical parts

- Disconnect the electrical component connectors by pressing the special safety hooks.

- Make sure that inside the connector there is no dirt or rust; if need be, clean them with an air jet or suitable products.

- Make sure that the cables are correctly seamed to the connector terminals.

- When you reconnect the connectors, ensure the correct coupling.

Do not disconnect the connectors by pulling the electrical cables.

- Technical Bulletins might contain more up-to-date setting data and procedures than this manual. Be sure to read them.

Where not specied, ret the previously removed components following the procedures in the reverse order with

respect to the removal.

Workshop Manual Ed. 11-2011

b.4

GENERAL INFORMATION

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Section

A

A.1

Workshop Manual Ed. 11-2011

GENERAL INFORMATION

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Sommario

Engine ..........................................................................................................A.3

Timing system ..............................................................................................A.3

Lubrication ....................................................................................................A.3

Ignition ..........................................................................................................A.3

Fuel system ..................................................................................................A.3

Primary drive ................................................................................................A.3

Clutch ...........................................................................................................A.3

Transmission ................................................................................................A.3

Secondary drive............................................................................................A.4

Final ratios ....................................................................................................A.4

Chassis .........................................................................................................A.4

Front suspension ..........................................................................................A.4

Rear suspension...........................................................................................A.4

Front brake

Rear brake ....................................................................................................A.5

Rims

Tyres .............................................................................................................A.5

Weight, capacity

Table for lubrication, supplies .......................................................................A.5

Electrical components location .....................................................................A.6

Dimension.....................................................................................................A.7

...................................................................................................A.4

.............................................................................................................A.5

...........................................................................................A.5

Workshop Manual Ed. 11-2011

A.2

GENERAL INFORMATION

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Engine

Type

....................... inline twin cylinder, 4 stroke, with four valves per cylinder

Cooling

Bore ......................................................................................... 3,31 in. (84 mm)

Stroke ...................................................................................... 3,19 in. (81 mm)

Displacement

Compression ratio

Starting ..................................................................................................electric

Type of fuel

Timing system

type

4 valves per cylinder

Valve clearance (with engine cold)

Intake .........................................................0,0091 ÷ 0,013 in. (0.23 ÷ 0.33 mm)

Exhaust...................................................0,0118 ÷ 0,0161 in. (0.30 ÷ 0.41 mm)

.............................................................................liquid and electric fan

........................................................................ 54,8 in3 (898 cm3)

......................................................................................13:1

............................................................. unleaded fuel 95ROZ/RON

................................................ double overhead camshaft chain operated;

Lubrication

...........................................................dry sump oil circuit with built-in tank,

type

cartridgelterandoil/waterheatexchanger

Ignition

type .....................................Electronic with adjustable advance (digital control)

Spark plug type......................................................................“NGK” LMAR8C-9

Spark plug electrode gap ...........................0,0315 ÷ 0,0354 in. (0.8 ÷ 0.9 mm)

Fuel system

type ...............................................................................Electronic injection feed

Primary drive

Drive gear on crankshaft

Driven gear on clutch housing .................................................................... Z 68

Transmission ratio ....................................................................................1.943

Clutch

..........................................oil bath multiple disc clutch, mechanical control

type

Transmission

type

.............................................................................constant mesh gear type

............................................................................ Z 35

Transmission ratio

1st gear.........................................................................................2.462 (32/13)

2nd gear .......................................................................................1.750 (28/16)

3rd gear ........................................................................................1.381 (29/21)

4th gear ........................................................................................1.174 (27/23)

5th gear ........................................................................................1.042 (25/24)

6th gear ........................................................................................0.960 (24/25)

A.3

Workshop Manual Ed. 11-2011

GENERAL INFORMATION

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Secondary drive

transmission sprocket (NUDA 900) ...........................................................Z 17

Transmission sprocket (NUDA 900 R) ........................................................ Z 16

Rear wheel sprocket ................................................................................... Z 42

Transmission ratio (NUDA 900) ...................................................................2.47

Transmission ratio (NUDA 900 R) .............................................................2.625

Transmission chain dimensions

FINAL RATIOS

NUDA 900

1st gear....................................................................................................11,815

2nd gear

3rd gear

4th gear .....................................................................................................5,634

5th gear .....................................................................................................5,000

6th gear

NUDA 900 R

1st gear....................................................................................................12,557

2nd gear

3rd gear

4th gear

5th gear

6th gear

....................................................................................................8,398

.....................................................................................................6,627

.....................................................................................................4,607

....................................................................................................8,925

.....................................................................................................7,043

.....................................................................................................5,987

.....................................................................................................5,314

.....................................................................................................4,896

.............................................5/8” x 5/16” (525)

Chassis

type

............................... tubular steel trellis with removable steel rear chassis.

Front suspension

NUDA 900

Type upside-down hydraulic fork

Wheel travel........................................................................... 8,27 in. (210 mm)

NUDA 900 R

Type upside-down hydraulic fork (adjustable compression,

rebound and spring reload) ....................................... ø 1,89 in. (ø 48 mm) legs

Wheel travel........................................................................... 8,27 in. (210 mm)

Rear suspension

NUDA 900

.................................................................direct with hydraulic monoshock

Type

(adjustable spring preload and hydraulic rebound damping)

Wheel travel........................................................................... 7,09 in. (180 mm)

NUDA 900 R

Type .................................................................direct with hydraulic monoshock

(adjustable spring preload and hydraulic compression

and rebound damping; adjustable length)

Wheel travel........................................................................... 7,09 in. (180 mm)

...................................1,89 in. (ø 48 mm) legs

Front brake

.....................................................twinoatingdiscø12,6in.(ø320mm)

Type

with radial pump and radial callipers

Workshop Manual Ed. 11-2011

A.4

GENERAL INFORMATION

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Rear brake

Type ...............................xeddiscø10,43in.(ø265mm)andoatingcalliper

Rims

Front .................................................................................in light alloy: 3.5”x17”

Rear ..................................................................................in light alloy: 5.5”x17”

Tyres

............................................................................................120/70xZR17”

Front

Rear .............................................................................................180/55xZR17”

Cold tyre pressure

Front ................................................................................32,71 psi (2.3 kg/cm2)

Rear .................................................................................41,25 psi (2.9 kg/cm2)

Weight, capacity

Kerb weight, without fuel.

Dry weight...............................................................................383,6 lb. (174 kg)

Fuel tank capacity reserve included ...........................................2,86 Imp. Gall

3,43 U.S. Gall. / 13 l

Fuel reserve...................................................................approx. 0,66 Imp. Gall.

approx. 0,79 U.S. Gall.

approx. 3 l

Coolant tank capacity .................................................................0,31 Imp. Gall.

0,37 U.S. Gall.

1.4 l

Transmission oil

Oilandoillterreplacement ....................................................... 0,73 imp. Gall.

0,87 U.S. Gall.

3.3 l

Oil replacement ............................................................................0,7 Imp. Gall.

0,85 U.S. Gall.

3.2 l

Oil top up between minimum and maximum level .......................0,09 Imp. Gall

0,11 U.S. Gall.

0.4 l

......................................................407,85 lb (185 kg)

Table for lubrication, supplies

Engine, gearbox and primary drive lubricating oil

1) CASTROL POWER1 RACING SAE 5W-40

2) SAE rating: 15W-40 API: SG/SH JASO: MA

Engine coolant .....................................CASTROL MOTORCYCLE COOLANT

Brakeuid...........................................CASTROL RESPONSE SUPER DOT 4

Grease lubrication

Secondary drive chain lubrication................CASTROL CHAIN LUBE RACING

Front fork oil.............................................................TITAN SAF 1091 (FUCHS)

Rear shock absorber oil............................SYNTHETIC FORK OIL SAF 1091 *

Electric contact protection ......................CASTROL METAL PARTS CLEANER

* NOTE: Only an authorised Ohlins centre can service the rear shock absorber of the R version.

....................................................CASTROL LM GREASE 2

Workshop Manual Ed. 11-2011

A.5

GENERAL INFORMATION

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Electrical components location

The ignition system includes the following elements:

- Generator on the inner side of R.H. crankcase half cover;

- Electronic ignition coil with integrated spark plug cap positioned on cylinder head;

- Electroniccontrolunitonthefrontpartinfrontofthelterbox;

- Spark plugs on the cylinder heads;

- Starter motor in front of the cylinders@ block;

- Solenoid starter on the central part behind the battery;

- Potentiometer on throttle body;

- Voltage regulator on a support on the battery.

- Crankshaft position sensor on the right-hand side of the engine.

The electrical system includes the following elements:

- 12V - 12Ah battery in the central part;

- Turningindicatorasherintegratedinthedigitalinstrument;

- Relay for fuel pump, general relay and fan positioned on the front part in front of the control unit;

- Electric fan;

- Secondary fuses positioned on the rear part under the saddle; two 30A main fuses on the solenoid starter;

- Coolant temperature sensor on the cylinder head;

- Lambda sensor;

- Headlamp with H4-12V-55/60W halogen bulb and 12V-5W parking light bulb;

- LED tail light with stop light bulb;

- 12V-10W turning indicator bulbs;

- Fuel pump inside the tank.

- Multifunction digital instrument.

Workshop Manual Ed. 11-2011

A.6

GENERAL INFORMATION

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

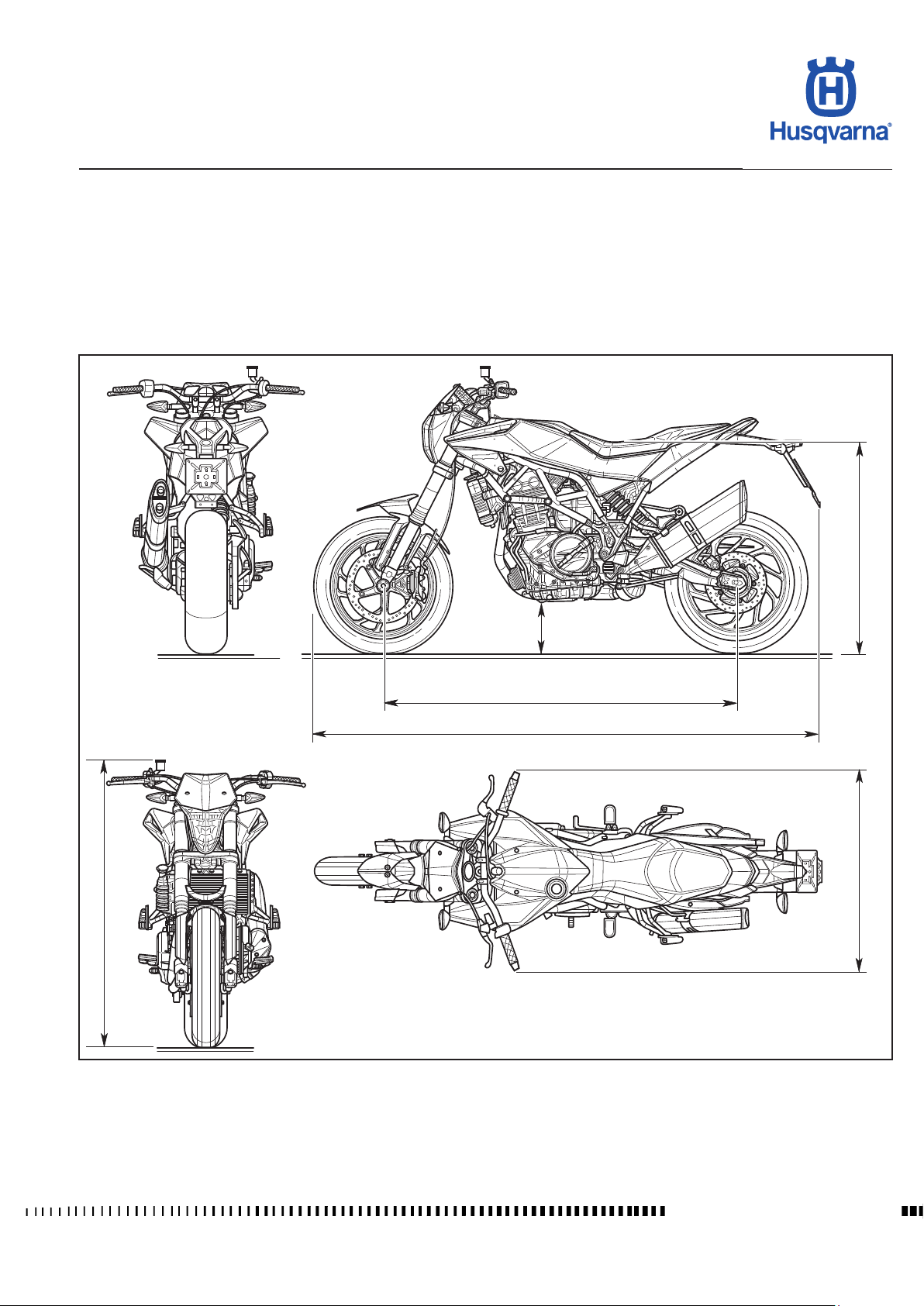

Dimension

Wheelbase ........................................................................ 58,86 in. (1495 mm)

Overall length .................................................................... 86,22 in. (2190 mm)

Overall width ....................................................................... 35,16 in. (893 mm)

Max. height ........................................................................ 48,03 in. (1220 mm)

A= Seat height (NUDA 900) ...............................................34,25 in. (870 mm)

A= Seat height (NUDA 900 R) ......................34,45 ÷ 35,04 in. (mm 875 ÷ 890)

Min. ground clearance ........................................................... 7,68 in. (195 mm)

1220 mm

A

195 mm

1495 mm

2190 mm

893 mm

A.7

H10575

Workshop Manual Ed. 11-2011

MAINTENANCE

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Section

B

B.1

Workshop Manual Ed. 11-2011

MAINTENANCE

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

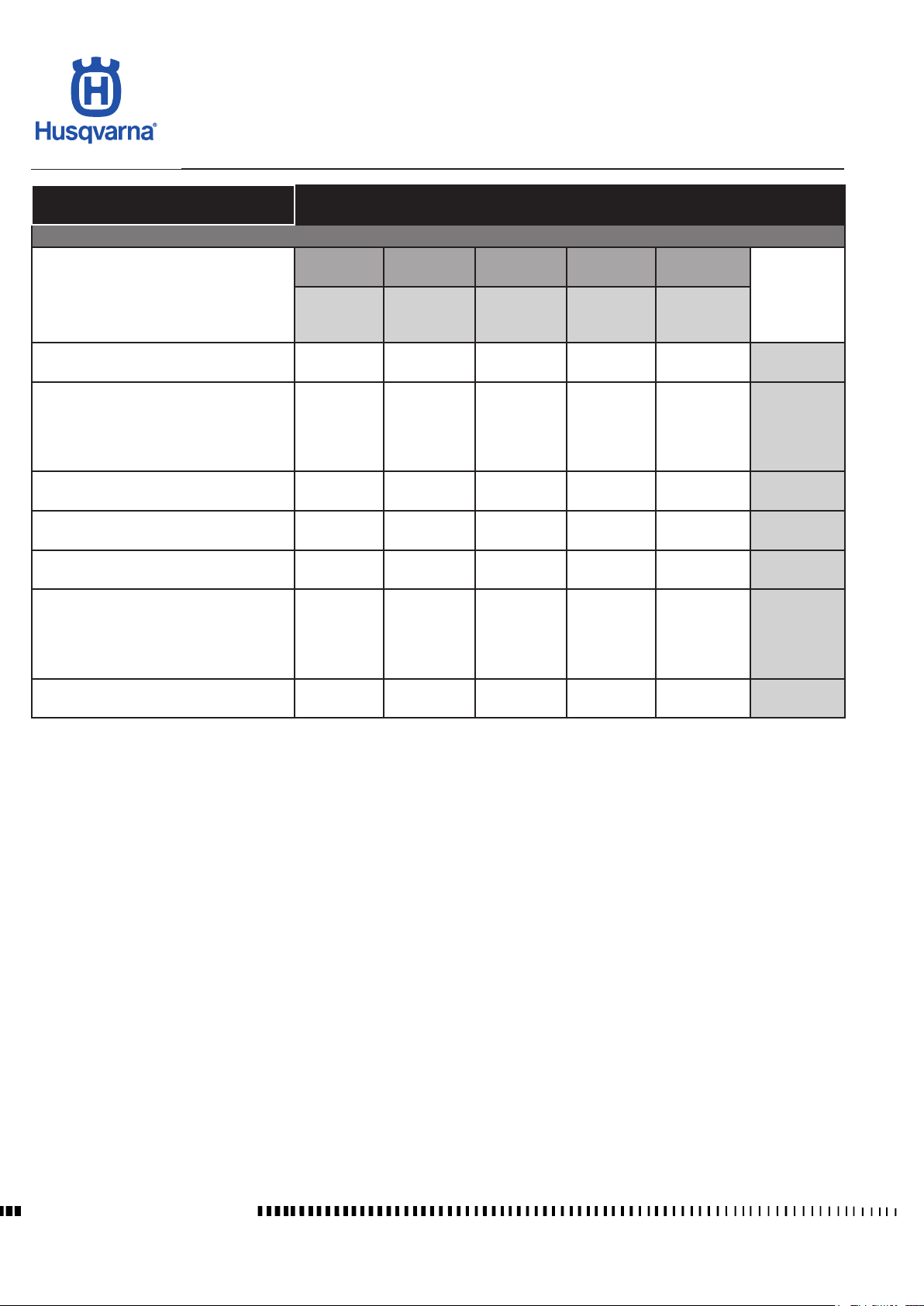

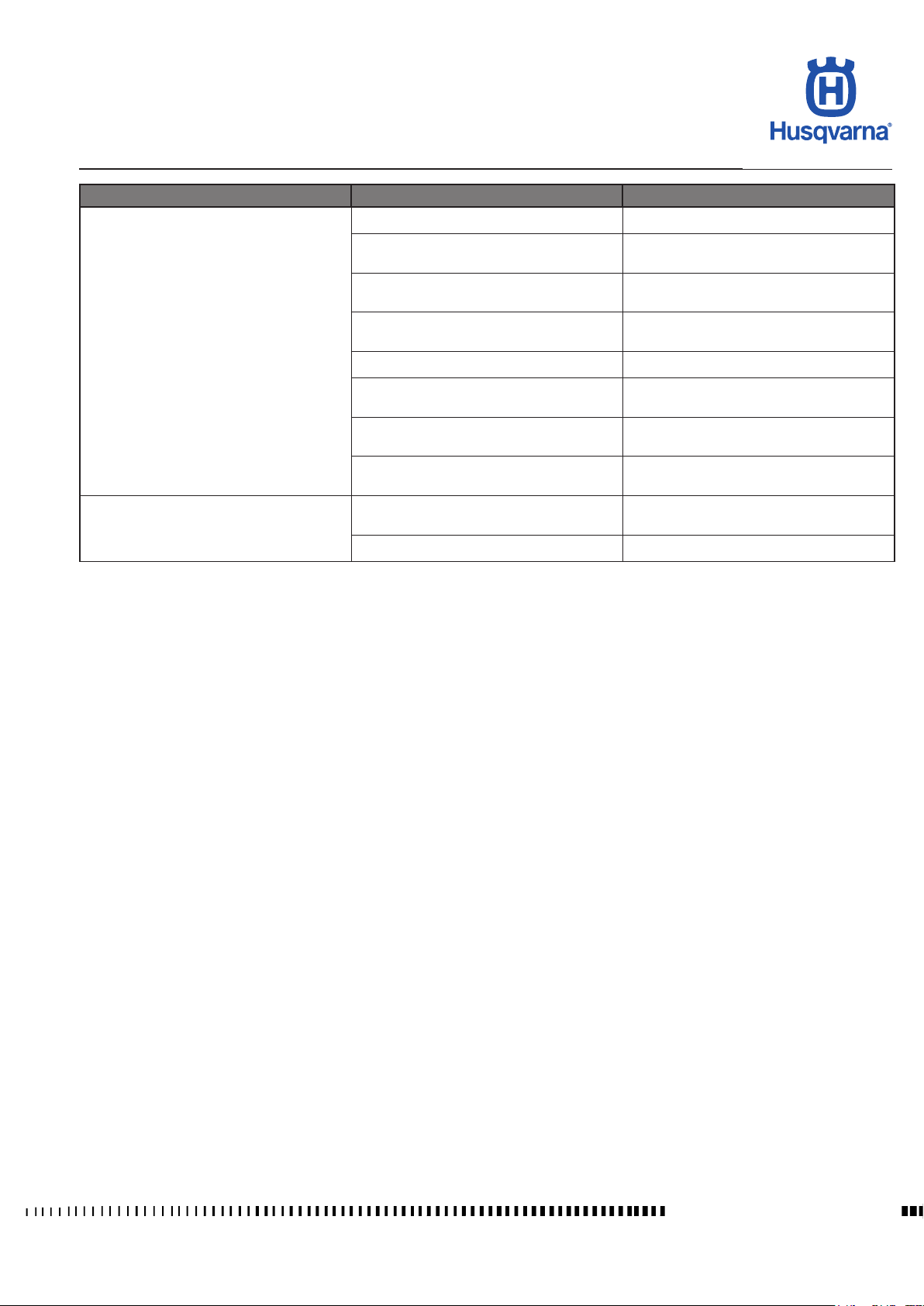

NUDA 900 / NUDA 900 R SCHEDULED MAINTENANCE CHART

(TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

ENGINE

Check engine oil level

Replace engine oil together with oil lter,

clean magnetic plug M24x2

Check / adjust valve play

Replace spark plugs

Check coolant level

Replace coolant

Check / adjust clutch play

SERVICE

COUPON

After the

rst

1.000 Km

X X X X X

X X X X X

X

X X X X X

SERVICE

COUPON

EVERY

10.000 Km

SERVICE

COUPON

EVERY

20.000 Km

X X

X X

X X

SERVICE

COUPON

EVERY

30.000 Km

SERVICE

COUPON

EVERY

40.000 Km

EVERY

1.000 Km

EVERY

10.000 Km

or

ONCE A

YEAR

EVERY

20.000 Km

EVERY

20.000 Km

EVERY

1.000 Km

EVERY

20.000 Km

or

EVERY 2

YEARS

EVERY

1.000 Km

Workshop Manual Ed. 11-2011

B.2

MAINTENANCE

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

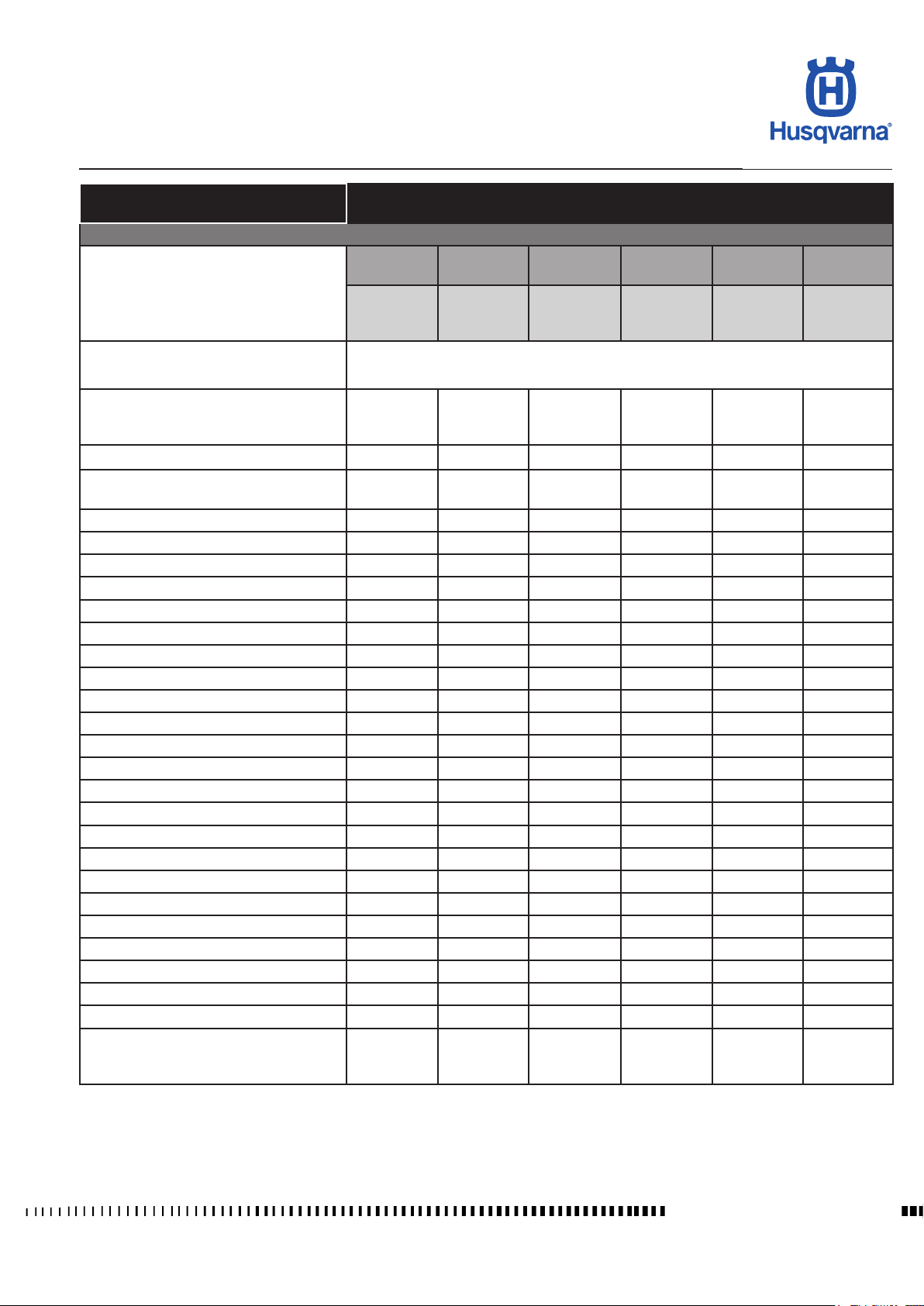

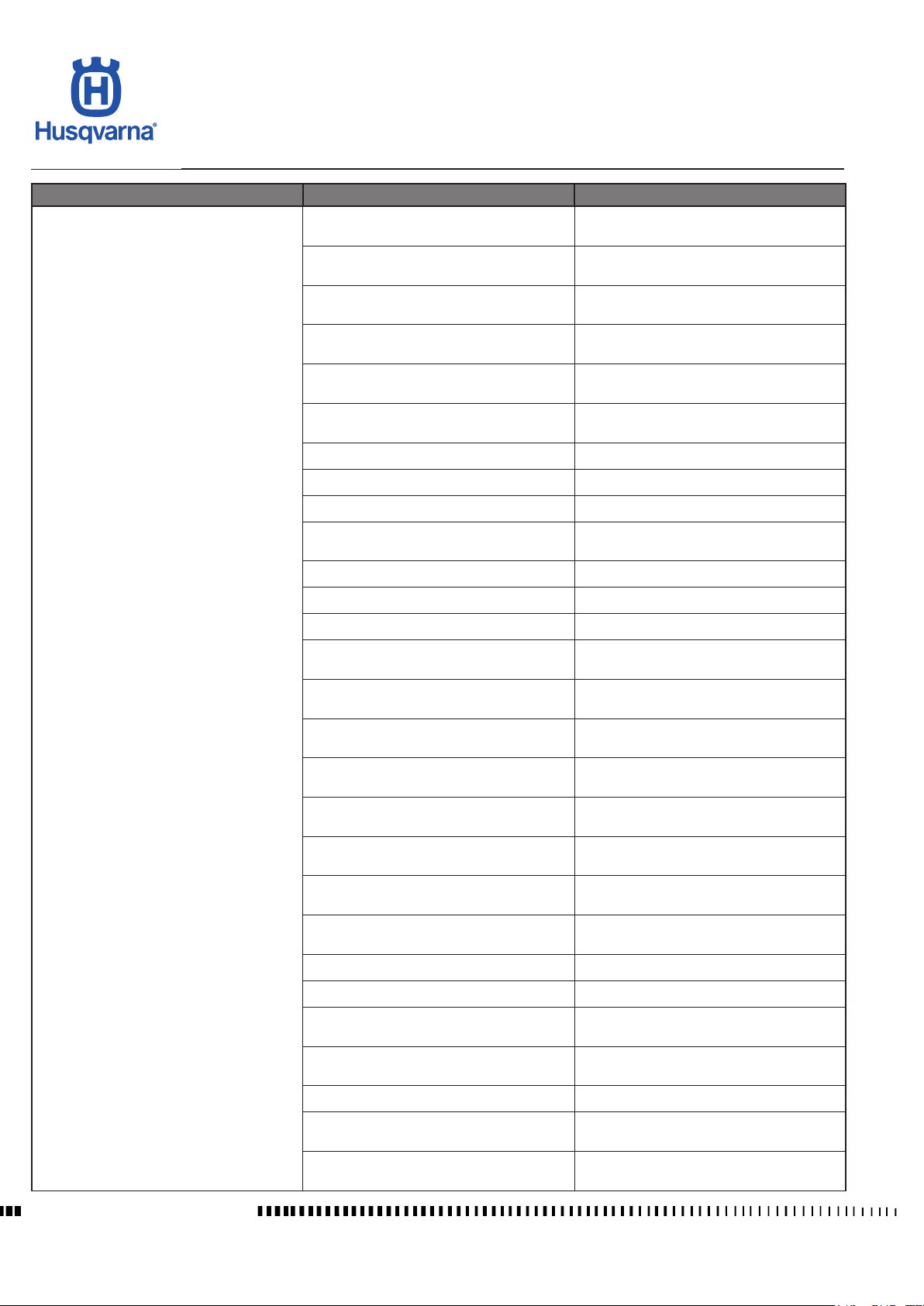

NUDA 900 / NUDA 900 R SCHEDULED MAINTENANCE CHART

(TO BE CARRIED OUT AT THE HUSQVARNA DEALER)

CHASSIS

CHECKS SERVICE

COUPON

EVERY

1.000 Km

After the

rst

1.000 Km

Check and lubricate secondary chain

Lubricate the secondary drive chain at least once every 1,000 km.

If used on dusty or wet roads, do this more frequently

Check front/rear sprockets for wear: if ne-

cessary, replace along with the secondary

X X X X X X

drive chain

Air lter

Second.Drive chain: check tension and

(1)

wear

X, L X, L X, L X, L X, L X, L

X X R X R

Transmission cables and controls X X X

Steering bearings and steering clearance X X X

Wheel bearings X X

Control unit diagnosis X X X X X

Brake discs X X X X X X

Front fork X X

Rear shcok absorber X X

General vehicle operation X X X

Cooling system X X X

Braking systems X X X

Lights X X X

Safety switches X X X X X

Brake uid

Coolant

(2)

(2)

X X X X X X

X X X X X X

Light alignment

Cush drive dampers X X

Tyres: pressure / wear X X X X X

Wheels X X X X

Overall tightening of nuts and bolts X X X

Side stand X L L L L L

Suspension and alignment X X X

Fuel hoses

(3)

Brake pad wear X X X X X X

Check cooling-water tubes and water

pump for condition and leakage / replace

if necessary

X: Inspect and clean, adjust, lubricate or replace if necessary.

R: Change.

L: Lubricate.

(1):

Check and clean, adjust or replace if necessary every 1,000 km.

(2):

Replace every 2 years.

(3):

Replace every 4 years.

SERVICE

COUPON

EVERY

10.000 Km

SERVICE

COUPON

EVERY

20.000 Km

SERVICE

COUPON

EVERY

30.000 Km

X

X X X X

Workshop Manual Ed. 11-2011

SERVICE

COUPON

EVERY

40.000 Km

X

B.3

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Section

C

C.1

Manuale d'officina Ed. 11-2011

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

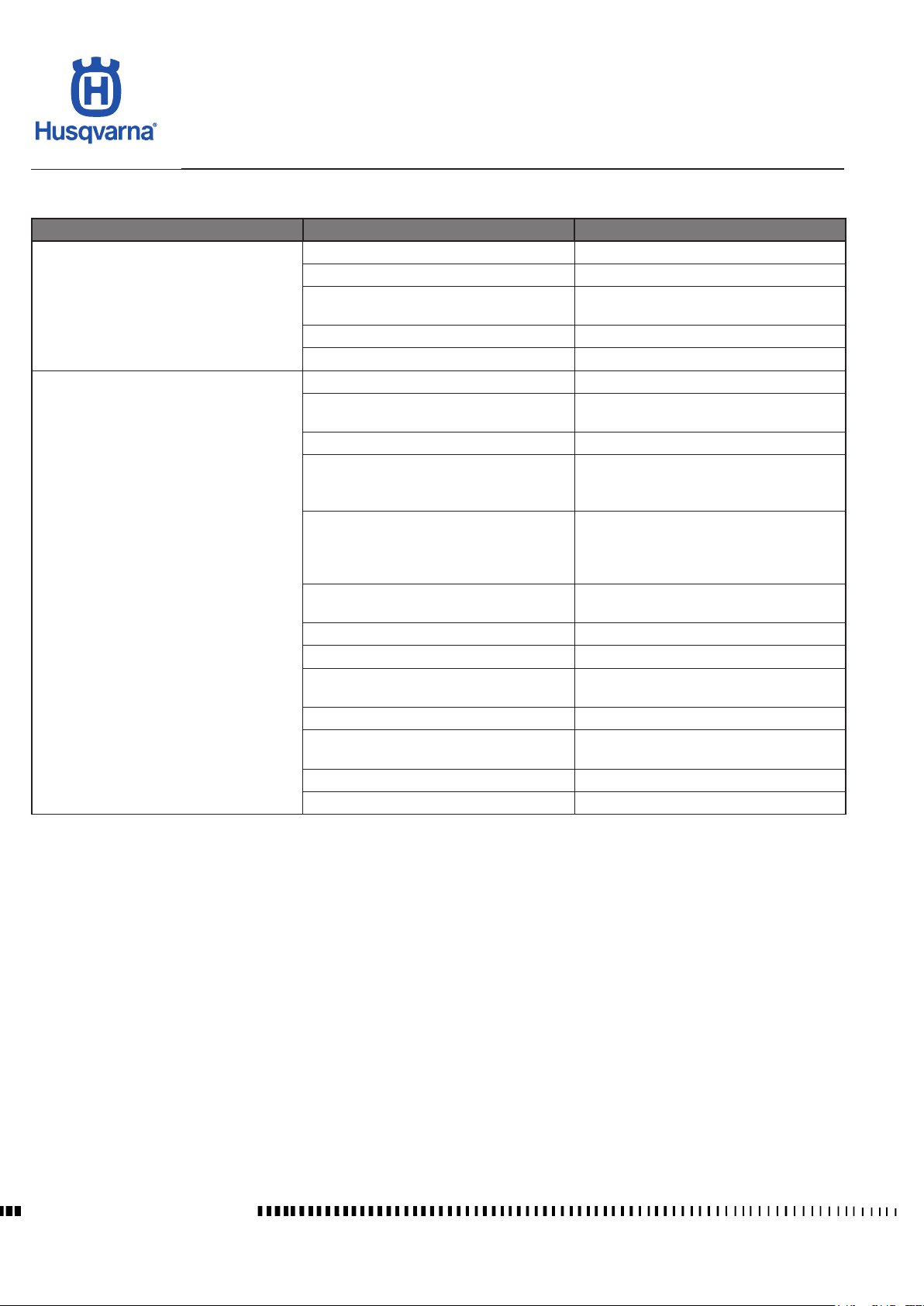

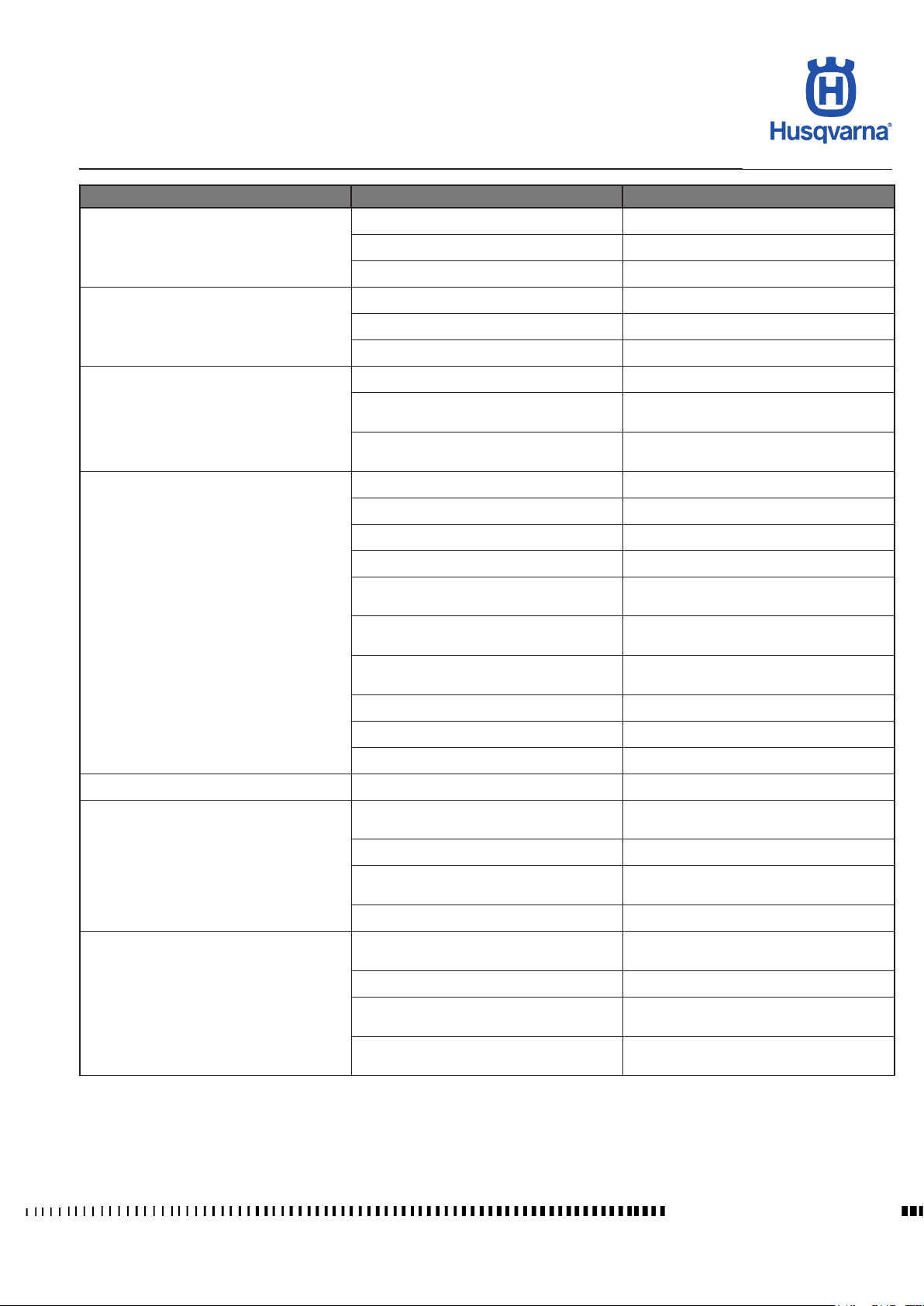

ENGINE

Trouble Possible causes Remedy

Ignition switch not in ON position Switch ignition switch to position ON

Engine-stop-switch on OFF position Switch to position ON

Starter motor does not operate or does not

turn engine over

Engine turns over but does not start engine

or starts hard

Discharged battery, loose or corroded

connections

Ignition circuit in short-circuit Check ignition circuit

Starter motor defect Replace starter motor

Spark plugs loose Tighten spark plugs

Spark plugs not according to specications

or defective

Spark plugs fouled or wet Clean or exchange

Battery nearly discharged, starting rpm

too low

Fuel supply inadequate

Valve clearance below specication

Valve timing incorrect Adjust position of camshaft gears

Ignition coil or ignition cable defective Check / replace

Ignition unit defective, ignition timing in-

correct

Cylinder gasket defective Exchange cylinder head gasket

Valves and valve guides worn or imperfect

valve seat

Piston rings and/or cylinder bore worn Exchange piston rings and/or cylinder

Engine oil too heavy (winter operation) Exchange engine oil

Check/replace battery and check connections, check charging system

Replace spark plug

Check/replace battery and check connections, check if battery is charged by

generator

Check fuel tank if empty

Check / replace fuel lter, fuel supply pipes, fuel pump, fuel pressure sensor and

injectors

Adjust valve clearance according to spe-

cication

Check / replace crank position trigger and

ECU

Exchange valves, rework valve seats or

exchange cylinder head

Manuale d'officina Ed. 11-2011

C.2

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Trouble Possible causes Remedy

Excessive spark plug electrode gap Exchange spark plug

Adjust valve clearance according to spe-

cication

Tighten intake socket or exchange if necessary

Check / replace crank position trigger and

ECU

Check fuel pressure sensor, fuel pump and

fuel supply

Replace spark plug

Adjust valve clearance according to spe-

cication

Check / replace ignition coil

Check / replace crank position trigger and

ECU

Check fuel pressure sensor, fuel pump and

fuel supply

Exchange piston rings and/or cylinder

Engine runs irregularly at idle

Engine runs irregularly at higher speed

Engine has no or insufcient performance

Valve clearance below specication

Intake socket not tight or leaking

Ignition unit defective, ignition timing in-

correct

Valves leaking Rework valve seats

For other possible causes see also "Engine

starts over but does not start engine or

starts hard"

Fuel pressure too low

Leak air Check / replace intake socket

Camshafts worn Check and replace if necessary

For other possible causes see also "Engine

starts over but does not start engine or

starts hard"

Leak air, intake system leaking Check / replace intake socket

Spark plugs not according to specications

or defective

Valve clearance not according specica-

tion

Valve timing incorrect Adjust position of camshaft gears

Ignition coil supplies insufcient ignition

voltage

Ignition unit defective, ignition timing in-

correct

Valves leaking Exchange valves, rework valve seats

Clutch slipping See remedies "clutch is slipping".

Fuel pressure too low

Air lter dirty Exchange

Exhaust system defective Exchange

Excessive Blow-by gases, Piston rings and/

or cylinder bore worn

Engine oil not according to specications Exchange engine oil

C.3

Manuale d'officina Ed. 11-2011

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Trouble Possible causes Remedy

Fuel of too low octane number

Spark plugs not according to specications

Engine knocks or pings

Engine overheats

Engine temperature is too low Thermostat defective Replace thermostat

Engine produces excessive blue smoke or

engine uses too much oil

Engine vibrates

Engine oil quantity increases

or defective

Leak air, intake system leaking

Ignition unit defective, ignition timing in-

correct

Not enough coolant in cooling system, coo-

ling system leaking, air in cooling system

Cooling fan motor defective Replace cooling fan motor

Not enough engine oil in the engine Rell oil

Radiator dirty Clean radiator

Thermostat defective Replace thermostat

Ignition unit defective, ignition timing in-

correct

Water pump, water pump drive defective

Oil pump or oil pump drive defective, re-

taining ring for oil pump gear not tted, oil

circuit blocked

Cylinder head gasket defective Exchange cylinder head gasket

Leak air Check / replace intake socket

Too much oil in the engine (oil in the airbox)

Cylinder head gasket leaking Exchange cylinder head gasket

Valve stem seals leaking Exchange valve stem seals

Oil diluted with fuel / Piston rings and/or

cylinder bore worn

V-ring on water pump drive gear worn/

missing

Oil diluted with fuel / motocycle is only used

in short distances (cold engine)

Engine xation into frame loose Tighten engine xation

Bearing or bearing seat worn Replace bearing or worn component

Oil diluted with fuel / motocycle is only used

in short distances

Oil diluted with fuel / Piston rings and/or

cylinder bore worn

Use fuel of specied octane number (min.

ROZ 95)

Replace spark plug

Check / replace intake socket and intake

system

Check / replace crank position trigger and

ECU

Rell coolant, check system under pres-

sure

Check / replace crank position trigger, ECU

and sensors

Repair water pump, check and renew water

pump drive

Exchange oil pump or oil pump gears,

assemble retaining ring for oil pump gear,

clean oil circuit

Drain engine oil

Exchange piston rings and/or cylinder

Replace V-ring

Use motorcycle at long distances in

between

Use motorcycle at long distances in

between

Exchange piston rings and/or cylinder

Manuale d'officina Ed. 11-2011

C.4

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Trouble Possible causes Remedy

Not enough engine oil in the engine Rell oil

Low or no engine oil pressure

High engine oil pressure

Pressure regulating piston blocked (bypass

valve stuck in opened position)

Oil pump and/or oil pump drive defective

Ignition cover gasket leaking into inside of

engine (leakage of oil pressure circuit)

Oil pump worn Replace oil pump

Oil diluted with fuel / Piston rings and/or

cylinder bore worn

Oil diluted with fuel / motocycle is only used

in short distances

Oil sieve / oil lter dirty/blocked

Pressure regulating piston blocked (bypass

valve stuck in closed position)

Oil circuit blocked Clean oil ducts

Check/replace pressure regulating piston

Check / replace oil pump and/or oil pump

drive

Replace ignition cover gasket and tighten

ignition cover with correct touque

Exchange piston rings and/or cylinder

Use motorcycle at long distances in

between

Clean / replace oil sieve and replace oil

lter

Check/replace pressure regulating piston

C.5

Manuale d'officina Ed. 11-2011

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Trouble Possible causes Remedy

Noise is heard when the engine is

started:

Sprag clutch, sprag clutch housing or freewheel gear worn

Teeth of starter motor and/or starter drive

gears worn

Chain tensioner does not work

Noise seems to come from the valve

train:

Excessive valve clearance

Chain tensioner does not work Replace chain tensioner

Camshaft or brackets of camshaft worn Replace camshafts and/or cylinder head

Camshaft drive worn or loose Tighten or replace camshaft gears

Camshaft chain, chain guide or chain tension

guide worn

Noise seems to come from the piston:

Replace Sprag clutch, sprag clutch housing

or freewheel gear

Replace starter motor and/or starter drive

gears

Noise disappears after the engine is started

when oil pressure is available

Adjust valve clearance according to spe-

cication

Replace camshaft chain, chain guide or

chain tension guide

Engine excessively noisy

Piston or cylinder worn Replace piston or cylinder

Piston pin bore or piston pin worn Replace piston pin bore or piston pin

Piston rings broken or ring grooves worn

Noise seems to come from the crankshaft

or balancing swing arm or crankcase:

Bearings of crankshaft or conrods worn

Needle bushing and /or bearings of balan-

cing swing arm and/or balancing rod worn

Noise seem to come from the clutch or

clutch side:

Friction plates (hammer heads) and/or

clutch drum worn

Excessive or insufcient backlash of the

teeth of the primary drive gears

Clutch drum, clutch hub or pressure plate

worn

Bearing of clutch gear worn Replace primary drive assy.

Disk springs of primary drive assy. worn Replace primary drive assy.

Springs and spring retainers of primary

drive assy. Worn

Noise with clutch engaged - ball bearing of

the pressure plate worn

Noise seem to come from the gearbox:

Tooth anks of the gearbox gears worn

Ball bearing of gearbox shafts and/or needle

bearings of gears worn

Replace piston rings broken or ring grooves

Replace crankshaft and/or conrod bearings

and /or replace crankshaft and conrods

Replace balancing swing arm with balancing rod

Replace friction plates and /or clutch

drum

Replace primary drive assy.

Replace clutch drum, clutch hub or pres-

sure plate

Replace springs and spring retainers

Replace ball bearing

Check gears and gear shafts, replace if

necessary

Replace bearings

Manuale d'officina Ed. 11-2011

C.6

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

Trouble Possible causes Remedy

Fatigue of clutch springs Replace clutch springs

Clutch slips

Clutch disengages unsatisfactorily

Clutch "drags" at engagement

Gears do not engage or gears jump out at

start or at abrupt acceleration

Clutch plates worn or warped Replace clutch plates

Engine oil not according to specications Exchange engine oil

Engine oil not according to specications Exchange engine oil

Clutch plates warped Exchange clutch plates

Clutch plates stuck together Clean or exchange

Clutch plates worn or warped Replace clutch plates

Guide slots for friction plates in clutch drum

are worn

Guide slots for steel plates in clutch hub

are worn

Gearshifting action incomplete Always actuate gearshift lever till stop

Gearshift lever incorrectly adjusted Correct position of gearshift lever

Fastener of gearshift lever loose Tighten fastener

Gearshift lever bent Replace gearshift lever

Function of index lever or index spring

imperfect

Adjustment of gearshift pawl incorrect

Engagement teeth and/or windows of ge-

arbox gears badly worn

Gearshift forks are worn or bent Exchange gearshift forks

Replace clutch drum

Replace clutch hub

Check index lever and index spring and

exchange if necessary

Check and adjust pawl wich spring, exchange if necessary

Exchange gears

Gearbox gears are worn or damaged Exchange gearshift gearbox gears

Clutch does not disengage See "Clutch disengages unsatisfactorily"

Gears can be shifted only noisily Clutch does not disengage See "Clutch disengages unsatisfactorily"

Spark plugs overheated, burnt or dirty

Generator does not charge or chargs

incorrectly

Spark plugs not according to specications

Spark plugs loose Tighten spark plugs

Intake socket not tight or leaking

Fuel supply system defective Check and replace if necessary

Battery faulty, loose or corroded connections

Rectier regluator defective Replace rectier regluator

Break in current, short circuit or earthing of

stator windings

Break in cables or short circuit, connections

loose

Replace spark plug

Tighten intake socket or exchange if necessary

Check/replace battery and check connections

Replace stator

Check and replace if necessary

C.7

Manuale d'officina Ed. 11-2011

TROUBLESHOOTING

NUDA 900 2012/2013 - NUDA 900 R 2012/2013

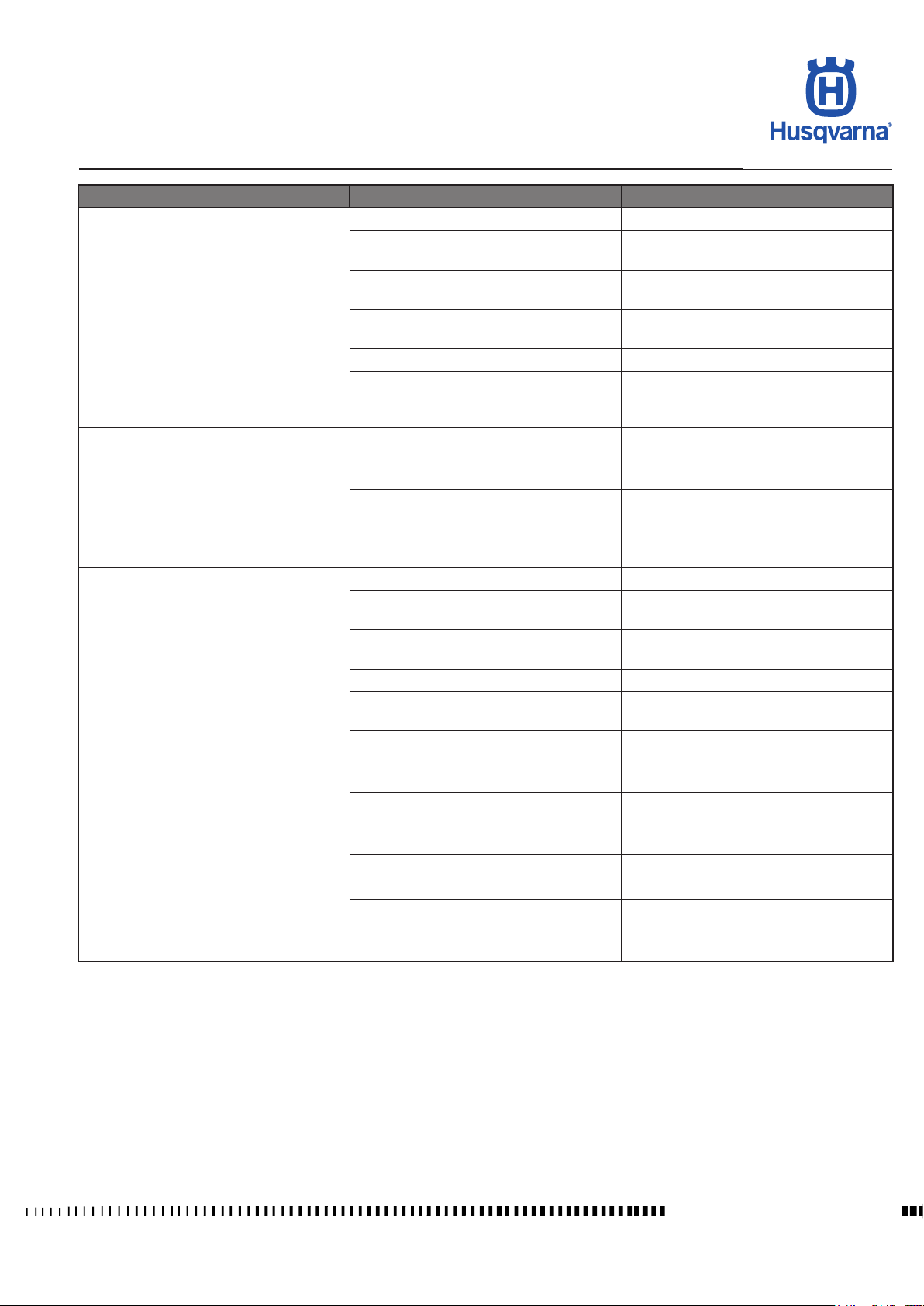

CHASSIS

Trouble Cause Remedy

Insufcient tyre pressure Inate

Handlebar turns hard

Handlebar vibration

Damping is too hard

Damping is too soft

(Front / rear) wheel shakes

Rear suspension is noisy

Poor braking (front and rear)

Bearing adjuster ring nut or steering stem

nut overtightened

Bent steering stem Replace bottom yoke

Worn or seized steering bearings Replace

Bent fork legs Replace

Bent front wheel axle Replace

Warped chassis Replace

Bent front wheel rim Replace

Worn front wheel bearings Replace

Improperly balanced wheel Balance

Too much oil in fork legs Remove excess oil

Fork oil viscosity too high Change

Overinated tyres Deate

Improperly set rear shock absorber Adjust

Insufcient oil in fork legs Top up

Fork oil viscosity too low Change

Weak fork springs Replace

Weak rear shock absorber spring Replace

Improperly set rear shock absorber Adjust

Bent wheel rim Replace

Worn wheel hub bearings Replace

Wheel axle nut loose Tighten

Worn rear swinging arm bearings Replace

Improperly balanced wheel Balance

Worn shock absorber ball joints Replace

Shock absorber faulty Replace

Air in brake system Bleed

Insufcient uid in tank Top up

Worn brake pad and/or disc Replace

Damaged disc Replace

Adjust

Manuale d'officina Ed. 11-2011

C.8

Loading...

Loading...