Page 1

Oper ator’s manual Manuel d’utilisation

Bedienungsanweisung Gebruiksaanwijzing

Istruzioni per l’uso

K 4000 Cut-n-Br eak

Please r ead the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät

Neem de gebruiksaanwijzing grondig door en gebruik de machine niet voor u alles duidelijk heeft begrepen.

Prima di usare la macchina, leggere per intero le istruzioni per l’uso e accertarsi di averne compreso il contenuto.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

benutzen.

GGGGBBBB FFFFRRRR DDDDEEEE NNNNLLLL IIIITT

TT

Page 2

2

W

En

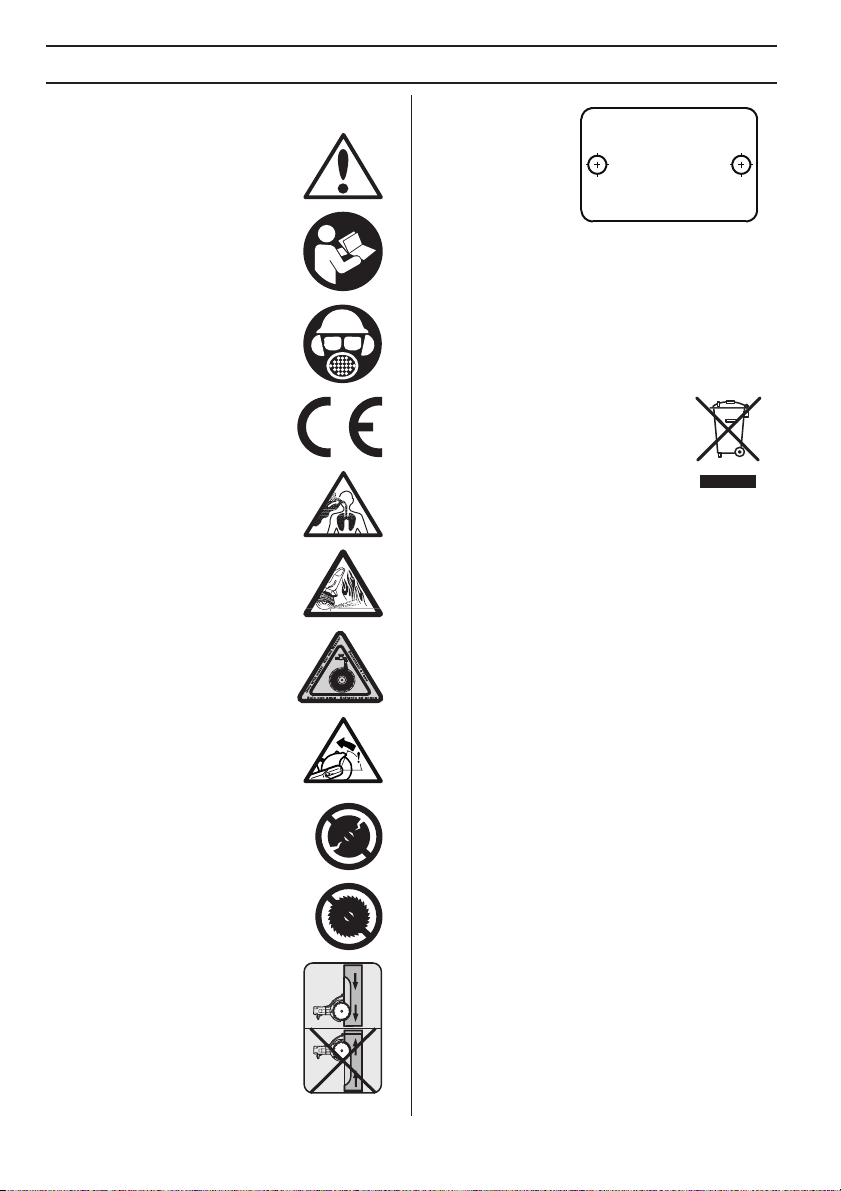

Symbols on the mac hine:

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Wear personal protective equipment.

See instructions under the ”Personal

protective equipment” heading.

This product is in accordance with

applicable EC directives.

WARNING! Dust forms when cutting,

which can cause injuries if inhaled. Use

an approved breathing mask. Always

provide for good ventilation.

WARNING! Sparks from the cutting

blade can cause fire in combustible

materials such as: petrol (gas), wood,

dry grass etc.

Water cooling must always be used.

KEY T O SYMBOLS

Rating plate

Row 1: Brand, Model

(X,Y)

Row 2: Serial No.

with manufacturing

date (Y, W, X): Year,

Week, Sequence No.

Row 3: Product No.

(X)

Row 4: Manufacturer

Row 5: A: Max speed of output shaft, B: Cutting blade

diameter, C: Blade bolt diameter

Row 6: D: Input voltage, E: Input current, F: Input

frequency

Row 7: Country of origin

vironmental marking. Symbols on

the product or its packaging indicate that

this product cannot be handled as

domestic waste. It must instead be

submitted to an appropriate recycling

station for the recovery of electrical and

electronic equipment.

By ensuring that this product is taken care of correctly,

you can help to counteract the potential negative impact

on the environment and people that can otherwise result

through the incorrect waste management of this product.

For more detailed information about recycling this

product, contact your municipality, your domestic waste

service or the shop from where you purchased the

product.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

XXXXXXXXX YYYY

s / n YYYY WWXXXXX

XXX XX XX-XX

Husqvarna AB

AAAAAA BBBBB CC

DDDD EEEE FFFF

XXXXXXXXXXXXXXX

WARNING! Kickbacks can be sudden,

rapid and violent and can cause life

threatening injuries. Read and

understand the instructions in the

manual before using the machine.

WARNING! Ensure the blades are not

cracked or damaged in any other way.

WARNING! Do not use circular saw

blades

Always cut in the correct direction. See

safety instructions!

– English

Page 3

W

W

CA

NO

KEY T O SYMBOLS

Explanation of warning le vels

The w arnings are graded in three levels.

ARNING!

ARNING! Indicates a hazardous

situation which, if not avoided, will result

!

in death or serious injury.

CAUTION!

UTION! Indicates a hazardous

situation which, if not avoided, could

!

result in minor or moderate injury.

NOTICE!

TICE! Is used to address practices not related to

personal injury.

English

–

3

Page 4

4

MA

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ...................................... 2

Explanation of warning levels ............................... 3

CONTENTS

Contents ............................................................... 4

PRESENT ATION

Dear Customer , ..................................................... 5

WHA T IS WHAT?

What is what on the po wer cutter? ....................... 6

CHINE´S SAFETY EQUIPMENT

Gener al ................................................................. 7

CUTTING BLADES

Gener al ................................................................. 9

Diamond blades for different materials ................. 9

Water cooling ........................................................ 9

Sharpening diamond blades ................................. 9

Transport and storage ........................................... 9

ASSEMBL Y

Assemb ly .............................................................. 10

OPERA TING

Protectiv e equipment ............................................ 11

General safety warnings ....................................... 11

Basic working techniques ..................................... 14

ARTING AND STOPPING

Bef ore starting ...................................................... 17

Starting ................................................................. 17

Stopping ................................................................ 17

MAINTENANCE

Gener al ................................................................. 18

Maintenance schedule .......................................... 18

Cleaning ................................................................ 19

Functional inspection ............................................ 19

Replacing the carbon brushes .............................. 20

Water tap .............................................................. 21

Disposal, scrapping .............................................. 21

TECHNICAL D ATA

echnical data ....................................................... 22

Cutting equipment ................................................. 22

Recommended cable dimensions ......................... 22

EC Declaration of Conformity ............................... 23

ST

T

– English

Page 5

PRESENT A TION

Dear Customer ,

Thank y ou for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product

and that it will be your companion for a long time. A

purchase of one of our products gives you access to

professional help with repairs and services. If the retailer

who sells your machine is not one of our authorized

dealers, ask him for the address of your nearest service

workshop.

This operator’s manual is a valuable document. Make

sure it is always at hand at the work place. By following its

content (operating, service, maintenance etc.) the life

span and the second-hand value of the machine can be

extended. If you will sell this machine, make sure that the

buyer will get the operator´s manual.

More than 300 y ears of innovation

Husqv arna AB is a Swedish company based on a tradition

that dates back to 1689, when the Swedish King Karl XI

ordered the construction of a factory for production of

muskets. At that time, the foundation was already laid for

the engineering skills behind the development of some of

the world's leading products in areas such as hunting

weapons, bicycles, motorcycles, domestic appliances,

sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products

for forestry, park maintenance and lawn and garden care,

as well as cutting equipment and diamond tools for the

construction and stone industries.

User responsibility

It is the o wner’s/employer’s responsibility that the operator

has sufficient knowledge about how to use the machine

safely. Supervisors and operators must have read and

understood the Operator’s Manual. They must be aware

of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

National legislation could regulate the use of this

machine. Find out what legislation is applicable in the

place where you work before you start using the machine.

The man ufacturer’s reservation

All inf ormation and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to

print.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

English

–

5

Page 6

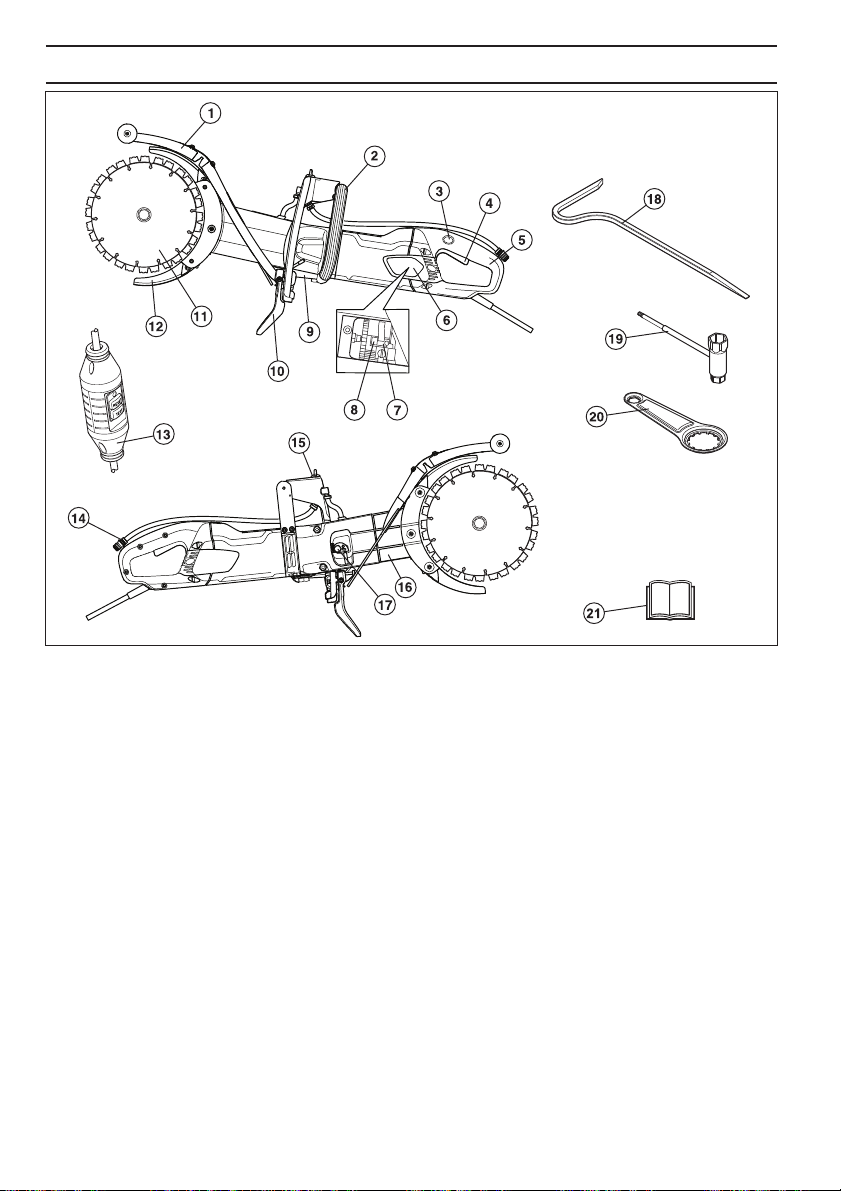

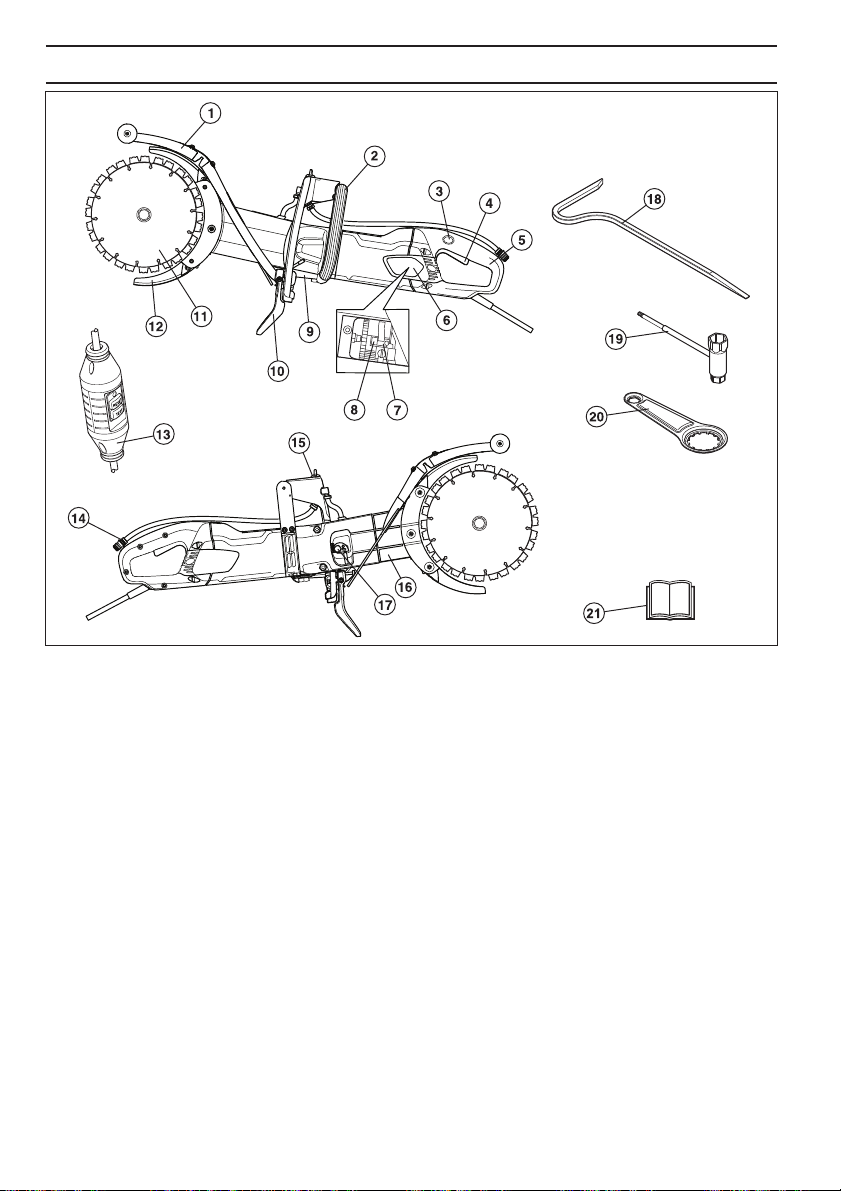

WHA T IS WHA T?

6

1

What is what on the po wer cutter?

Splash guard

2 Front handle

3 Power switch lock

4 Power switch

5 Rear handle

6 Inspection cover

7 Carbon brushes

8 Brush retainer

9 Rating plate

10 Spray guard

11 Blades

– English

12 Blade guards

13 Residual-current device (not for UK and Ireland 110V)

14 Water connector

15 Water tap

16 Cutting arm

17 Belt tensioner

18 Breaking tool

19 Combination spanner

20 Bearing tool

21 Operator ′ s manual

Page 7

CHINE´S SAFETY EQ UIPMENT

General

This section descr ibes the machine ′ s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

ARNING! Never use a machine that has

faulty safety equipment! Carry out the

!

inspection, maintenance and service

routines listed in this section.

All servicing and repair work on the

machine requires special training. This is

especially true of the machine

equipment. If your machine fails any of

the checks described below you must

contact your service agent. When you

buy any of our products we guarantee

the availability of professional repairs

and service. If the retailer who sells your

machine is not a servicing dealer, ask

him for the address of your nearest

service agent.

s safety

MA

P

•

P

•

W

′

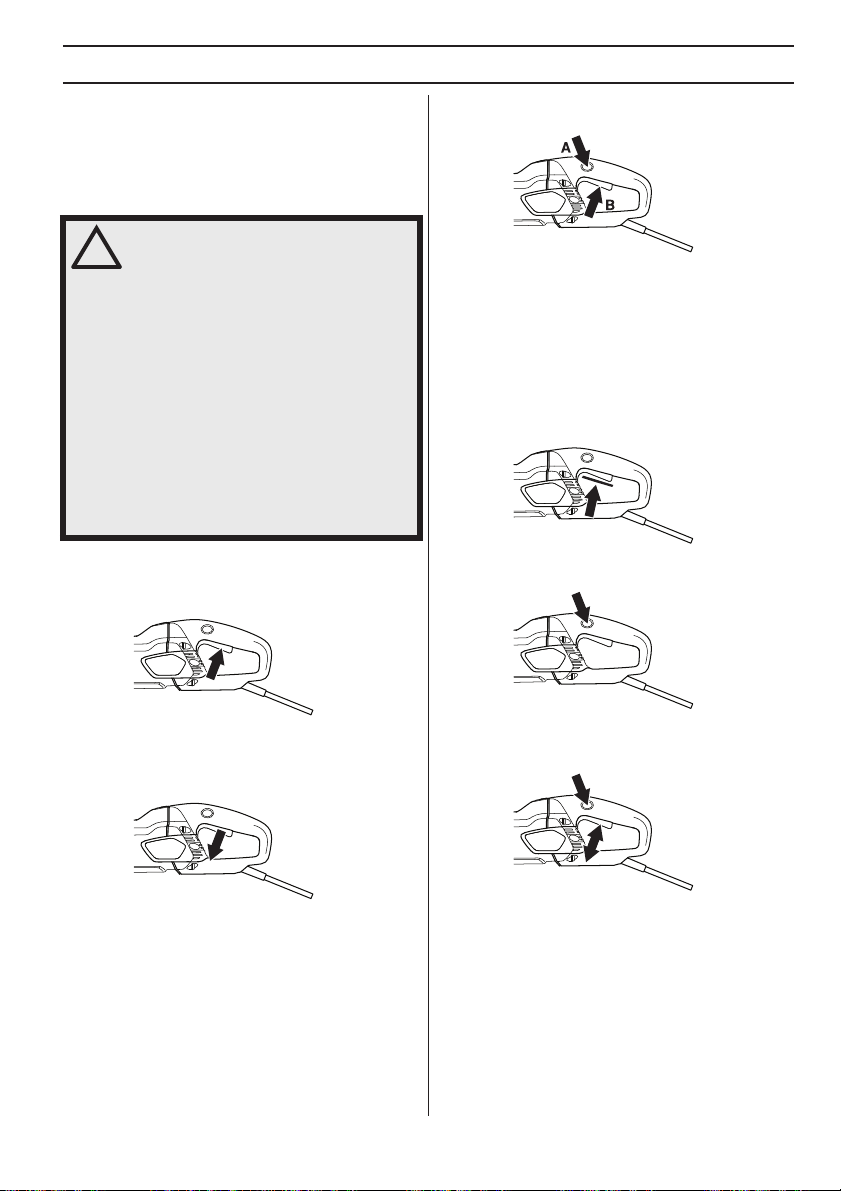

The power switch lock remains depressed as long as the

power switch is depressed. When the grip on the handle

is released both the power switch and power switch lock

are reset. This movement is controlled by two

independent return springs. This position results in the

machine stopping and the power switch being locked.

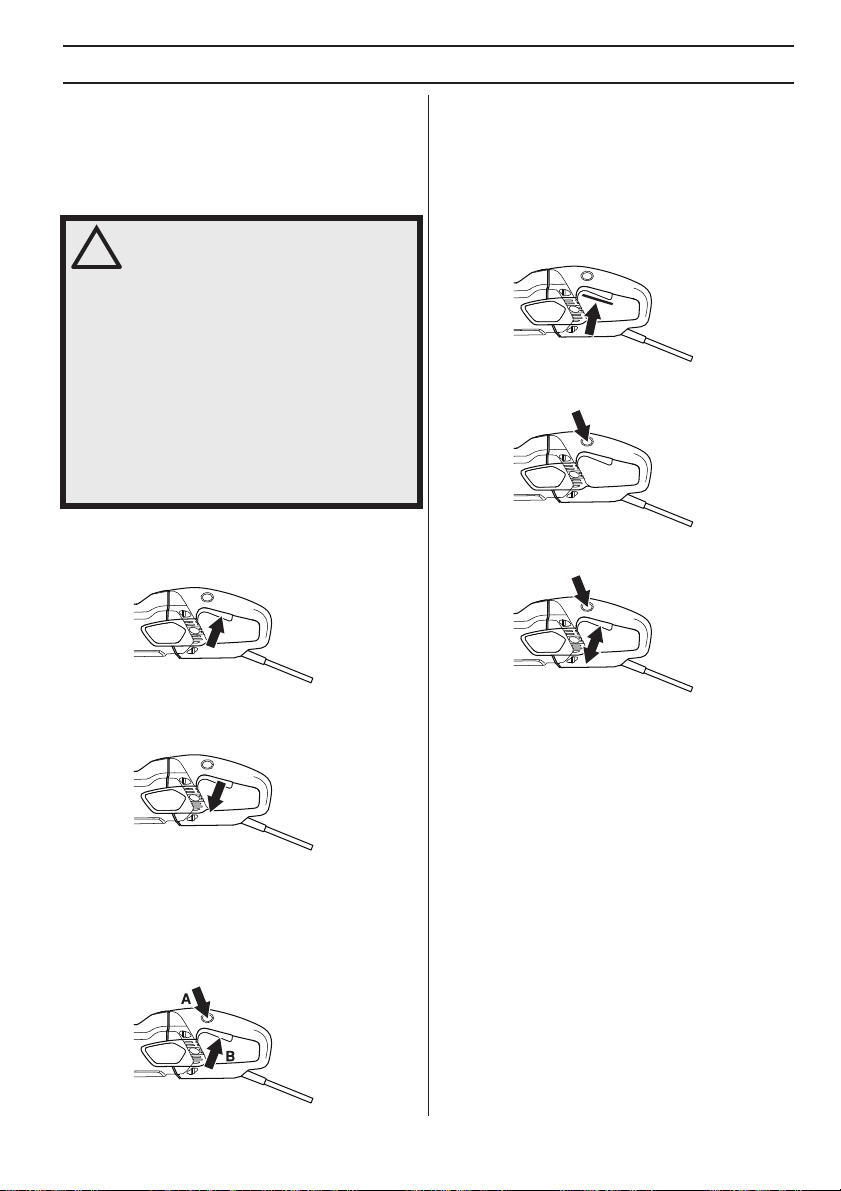

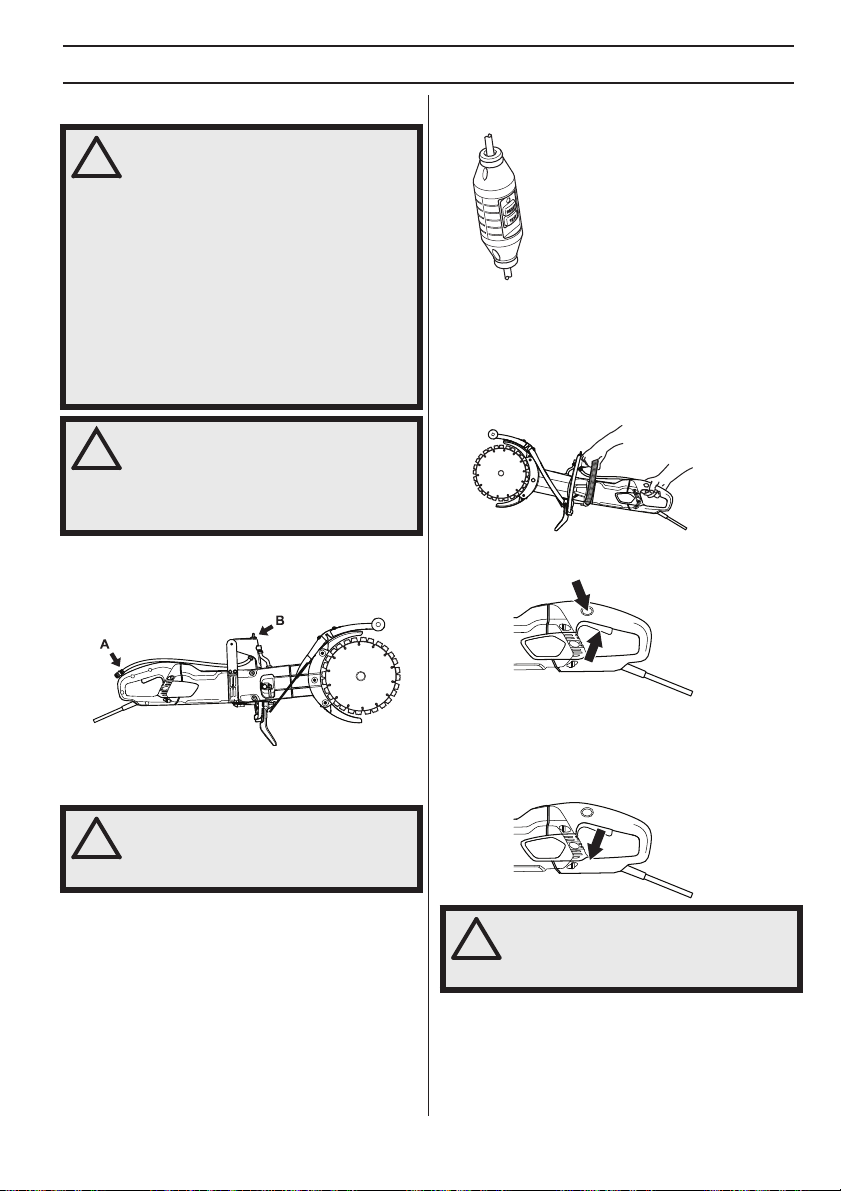

Chec king the power switch lock

Make sure the power switch is locked when the power

switch lock is in its original position.

• Press in the power switch lock and make sure it

returns to its original position when you release it.

ower switch

The po wer switch should be used to start and stop the

machine.

Chec king the power switch

Start the machine, release the power switch and

check that the engine and the cutting blade stop.

• A defective power switch should be replaced by an

authorized service workshop.

ower switch lock

The po wer switch lock is designed to prevent accidental

operation of the switch. When the lock (A) is pressed in

the power switch (B) is released.

• Check that the power switch and power switch lock

move freely and that the return springs work properly.

• Switch on the machine, release the switch, and check

that the engine and blades stop.

Gradual star t and overload protection

The machine is equipped with electronically controlled

gradual start and overload protection.

The engine starts to pulsate if the machine is loaded

above a specific level. If the load is reduced the engine

reverts to its normal state and cutting can resume.

The electronics will cut the current after a set time if the

machine continues to be run with a pulsating engine. The

higher load the faster the shutoff.

The electronics cut the current immediately if the blade

jams.

English

–

7

Page 8

CHINE´S SAFETY EQ UIPMENT

Blade guar ds

This guard is fi tted above and below the cutting blade and

is designed to prevent parts of the blade or cutting

fragments from being thrown towards the user.

MA

The LED indicates that the ground fault circuit interrupter

is on and that the machine can be switched on. If the LED

is not on, push the RESET button (green).

8

•

Chec king the blade guards

WARNING! Always check that all guards

are correctly fitted before starting the

!

machine. Check that the cutting blade is

fitted correctly and does not show signs

of damage. A damaged cutting blade can

cause personal injury. See instructions

under the heading Assembly.

Check that the guard is complete and without any

cracks or deformations.

• Never use a defective guard or a guard that has not

been fitted correctly.

Spra y guard

The spr ay guard provides protection against ejected

debris, thrown water and concrete slurry.

Chec king the spray guard

Ensure there are no cracks or holes from slurry blasting in

the spray guard. Replace guard if damaged.

Residual-current device

(not for UK and Ireland 110V)

Ground fault circuit interrupters are for protection in case

an electrical fault should occur.

Check the residual-current device

• Connect the machine to the socket. Push the RESET

button (green) and the red LED lights up.

• Start the machine.

• Push the TEST button (blue).

• The ground fault circuit interrupter should trip and the

machine switch off instantly. If not, contact your

dealer.

• Reset with the RESET button (green).

– English

Page 9

CUTTING BLADES

!

General

WARNING! A cutting blade may burst and

cause injury to the operator.

!

A cutting blade should be checked before

it is assembled on the saw and frequently

during use. Look for cracks, lost

segments (diamond blades) or pieces

broken off. Do not use a damaged cutting

blade.

Test the integrity of each new cutting

blade by running it at full throttle for about

1 minute.

Only use original cutting blades designed

by Husqvarna for use on this machine.

Husqvarna issues warnings and

recommendations for the use and proper

care of the cutting blades. Those warnings

come with the cutting blades. Read and

follow all instructions from Husqvarna.

• This machine is only to be used with Husqvarna´s

specially developed diamond blades intended for Cutn-Break. The blades have an integrated belt pulley

and are approved for freehand cutting.

• Diamond blades consist of a steel core provided with

segments that contain industrial diamonds.

• Always use a sharp diamond blade.

• Ensure the blades are not cracked or damaged in any

other way. Replace blades if necessary.

Diamond blades for different

materials

WARNING! Never use a cutting blade for

any other materials than what it was

!

intended to cut.

Never use a diamond blade to cut plastic

material. The heat produced during cutting

may melt the plastic and it can stick to the

cutting blade and cause a kickback.

Cutting metal generates sparks that may

cause fire. Do not use the machine near

ignitable substances or gases.

• Diamond blades are ideal for masonry and reinforced

concrete. Ask your dealer for help in choosing the

right product.

• Diamond blades are available in several hardness

classes. A "soft" diamond blade has a relatively short

service life and large cutting capacity. It is used for

hard materials such as granite and hard concrete. A

"hard" diamond blade has a longer service life and

reduced cutting capacity, and should be used for soft

materials such as brick and asphalt.

Water cooling

WARNING! Cool diamond blades

designed for wet cutting continuously

with water to prevent heating, which can

deform the diamond blade resulting in

damage to the machine and personal

injury.

• Water cooling must always be used.

• Using wet cutting blades without water can cause

excessive heat build-up, resulting in poor

performance, severe blade damage and is a safety

hazard.

• Water cools the blade and increases its service life

while also reducing the formation of dust.

Sharpening diamond blades

Diamond blades can become dull when the wrong feeding

pressure is used or when cutting certain materials such

as heavily reinforced concrete. Working with a dull

diamond blade causes overheating, which can result in

the diamond segments coming loose.

Sharpen the blades by cutting a soft material such as

sandstone or brick.

Transport and storage

• Make sure the machine is secured and that the cutting

blades are properly protected during the transport and

storage of the machine.

• Before use inspect all blades for transport or storage

damage.

English – 9

Page 10

ASSEMBLY

Assembly

WARNING! Always pull out the plug from

the outlet socket before cleaning,

!

maintenance or assembly.

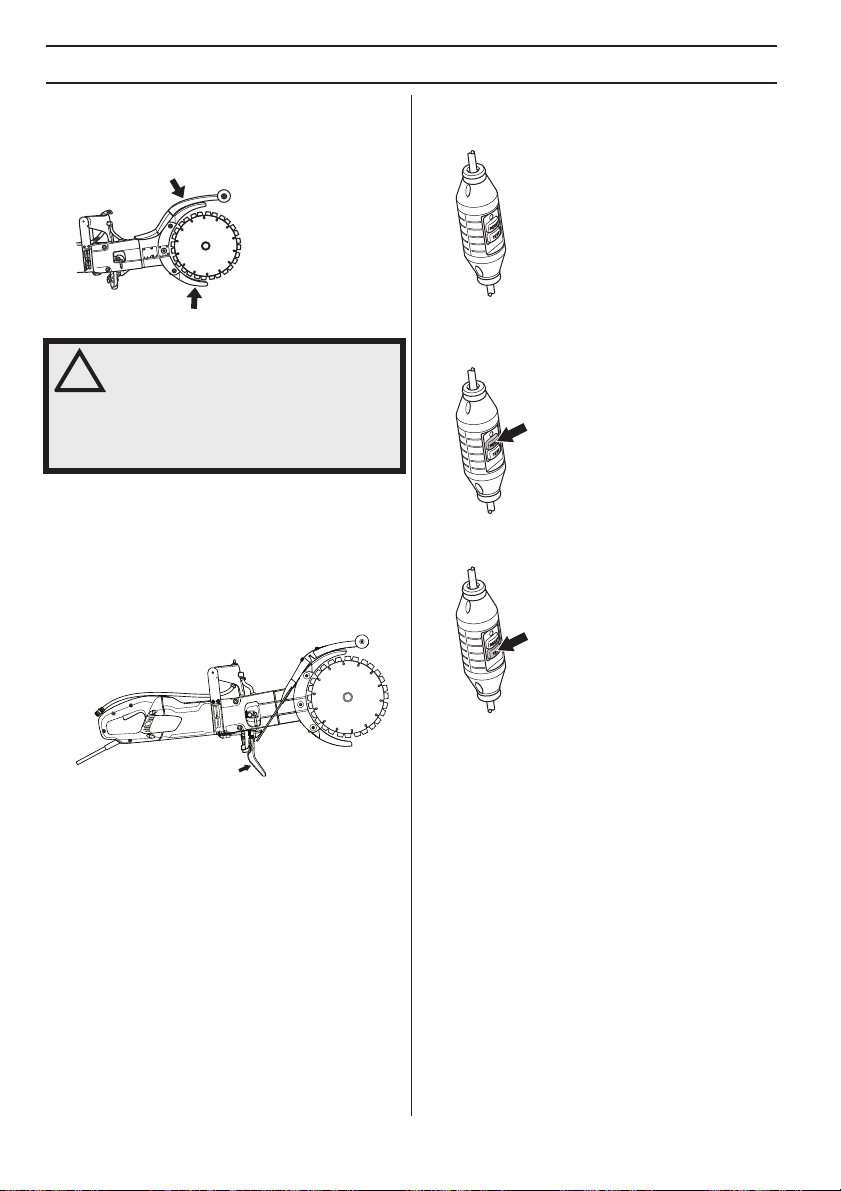

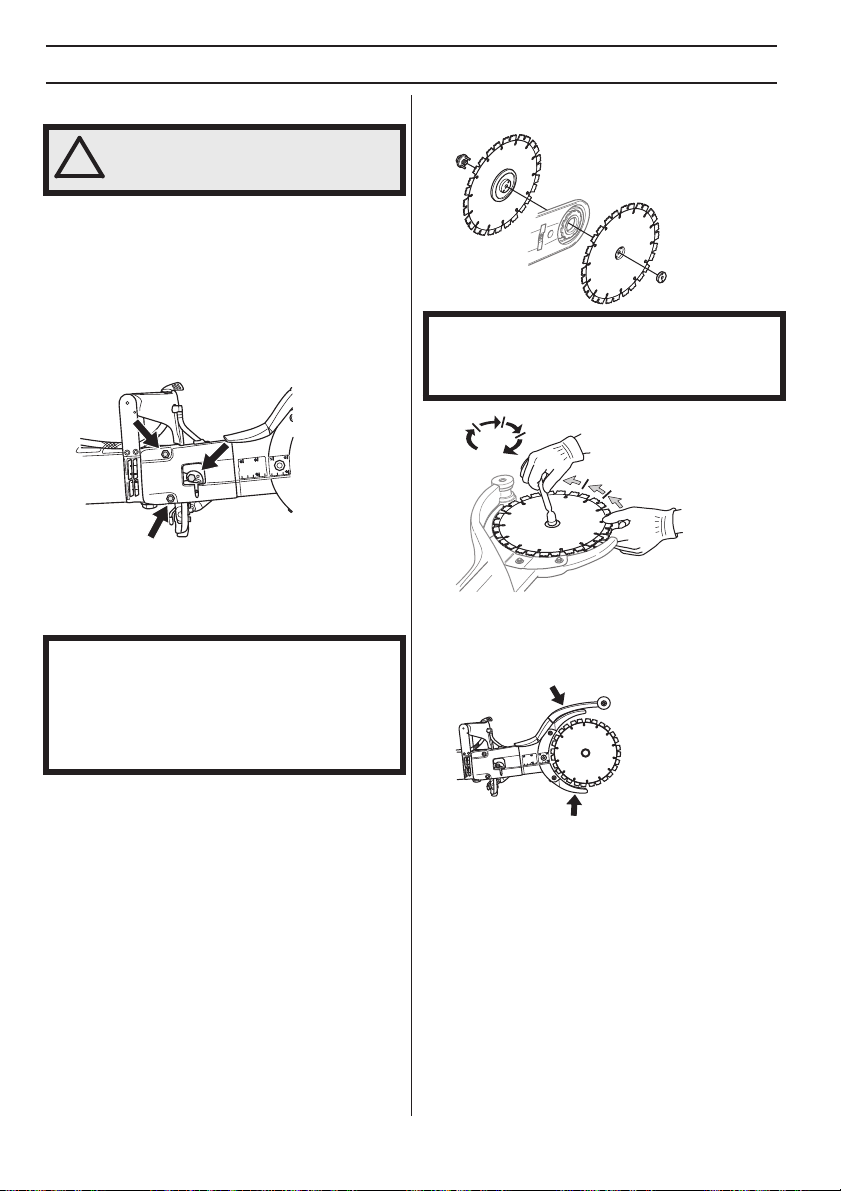

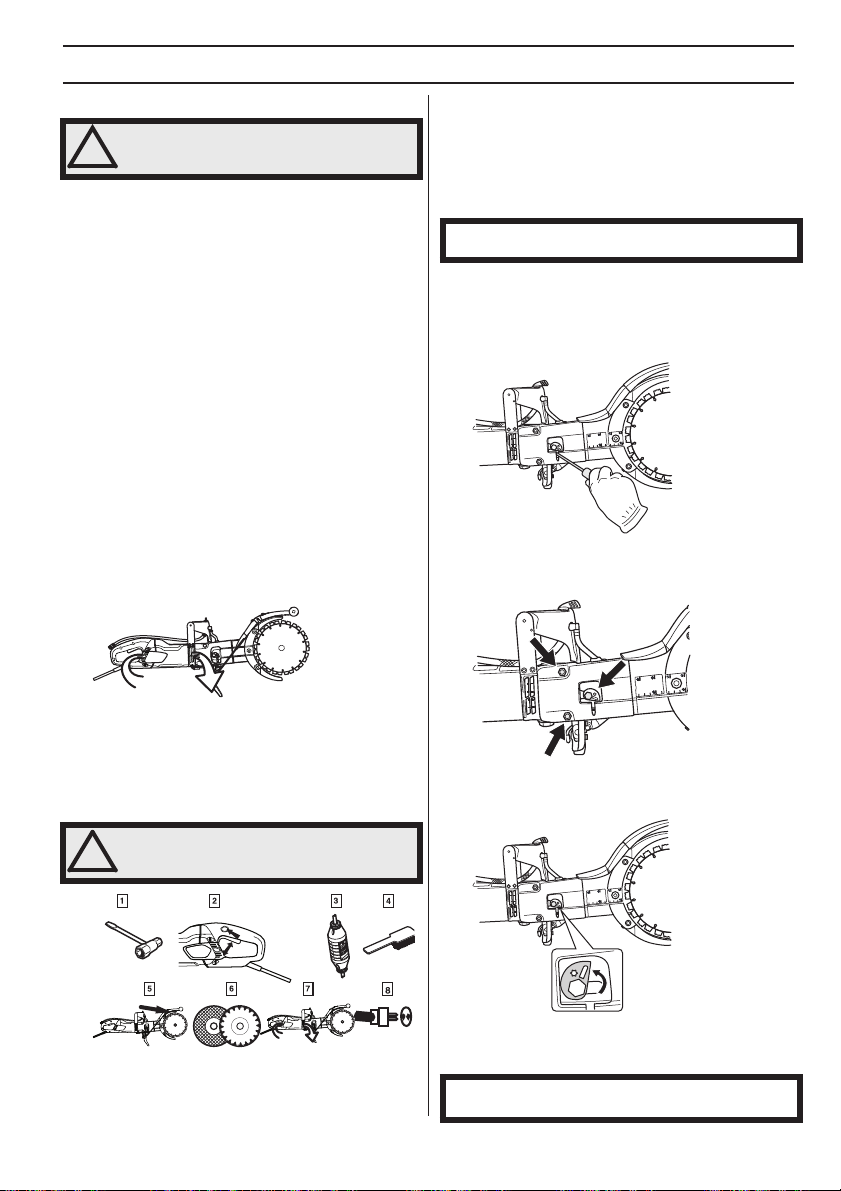

Assembling the blades

• Husqvarna blades are especially manufactured and

approved for freehand cutting with the K 3000 Cut-nBreak. The blades have integrated belt pulley halves

and are to be changed in pairs.

• Loosen the nuts and clamping bolt which release the

bar. This will position the drive belt in a more

favourable position with regard to assembling the new

blades.

The drive belt is not clamped so easily.

• Dismantle the old blades by loosening the centre nut.

Check the drive belt for wear when the blades are

dismantled. When changing the drive belt see the

instructions under the heading ”Replacing the drive

belt”.

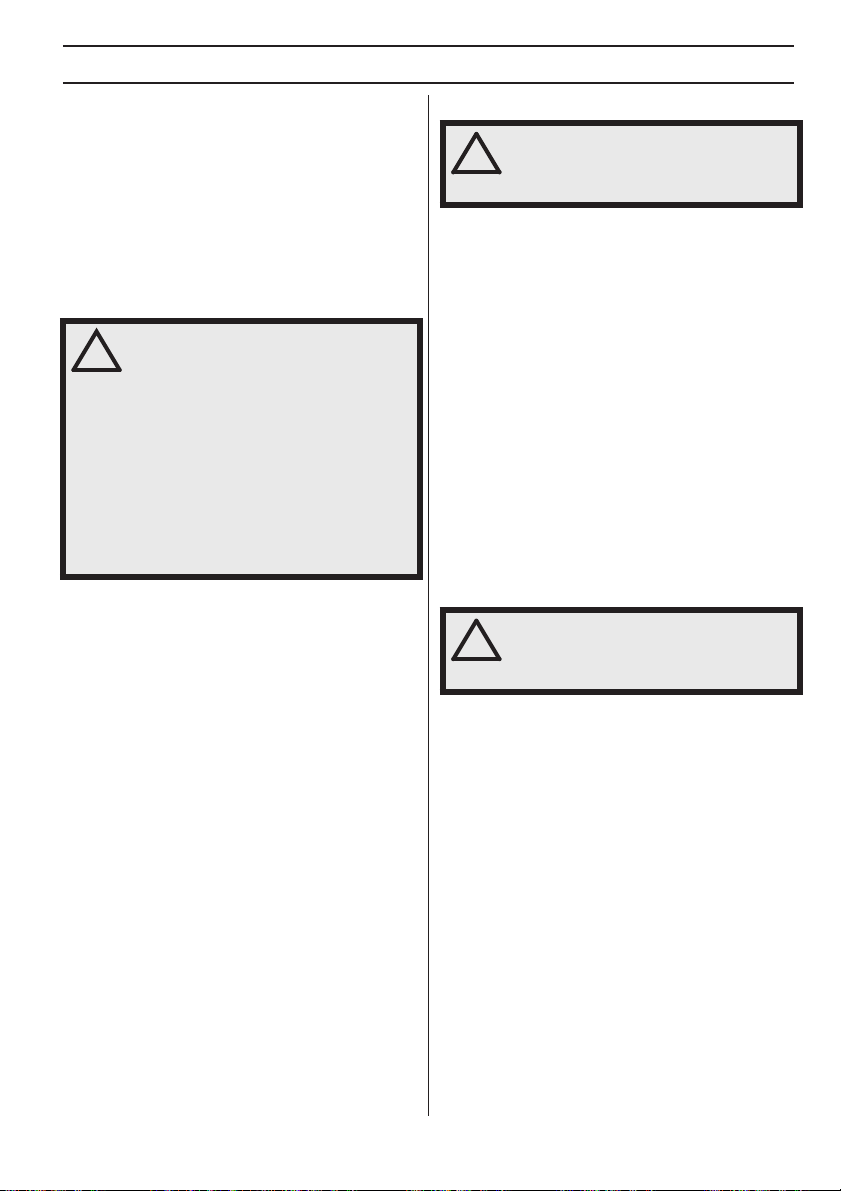

NOTICE! It is very important that the blades rotate when

the nut is tightened. This is to ensure that the belt is not

clamped between the integrated drive belt halves on the

blades when the blades/drive belt are pulled together

with the nut. Ideally this is done alternately, i.e. tighten a

little, rotate a little and repeat until the blades are

secured.

torque for the bolt holding the blade is: 15 Nm (130

in.lb).

NOTICE! Do not forget to tighten the belt and check the

belt adjustment before cutting. See the instructions

under the heading ”Inspecting and adjusting the drive

belt”.

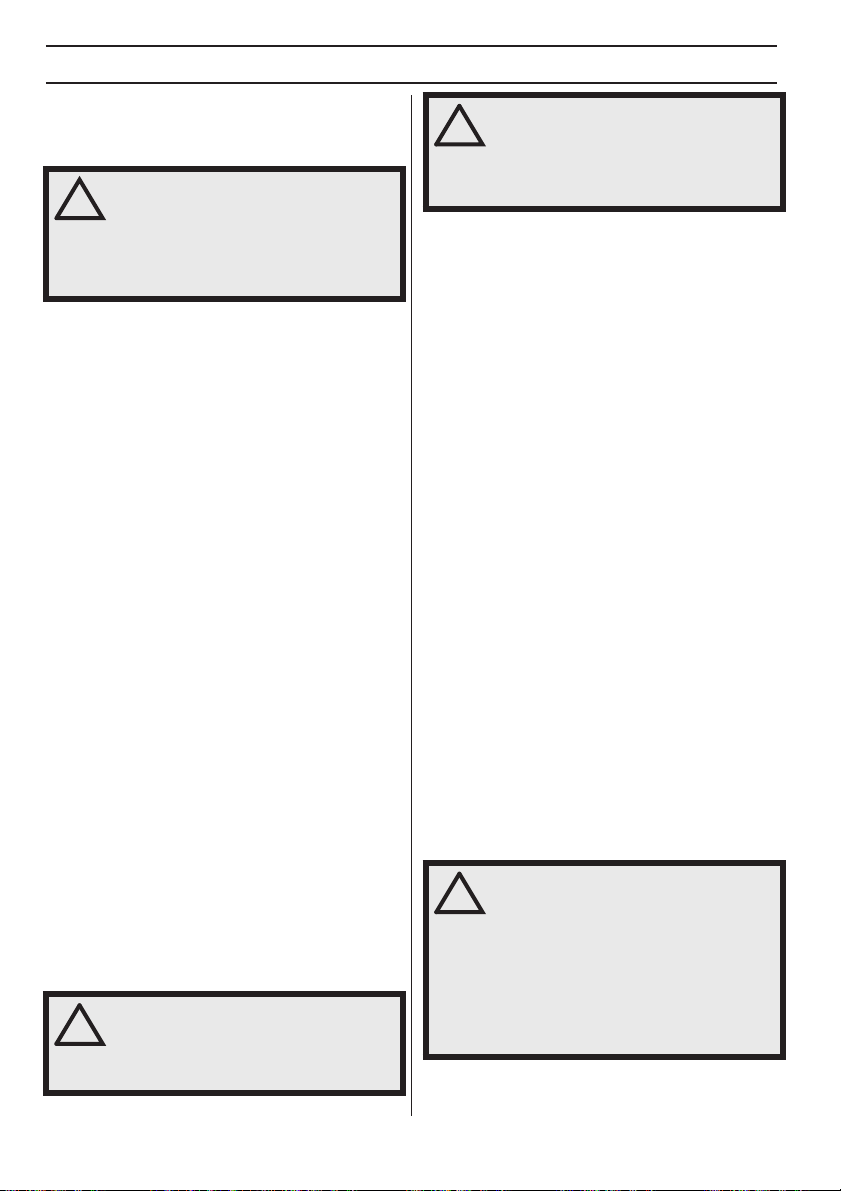

Protection for the blades

• The guards should always be fitted on the machine.

Check that the guards are properly secured and work

before starting to cut.

• Position the blades on each side of the cutting arm.

Make sure that the holes for both guide pins in the

drive belt halves are aligned so that they correspond

with the holes in the washer, and the nut too. Now fit

the bolt and washer unit with guide pins. Tightening

10 – English

Page 11

OPERATING

!

!

Protective equipment

General

Do not use the machine unless you are able to call for

help in the event of an accident.

Personal protective equipment

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

WARNING! The use of products such as

cutters, grinders, drills, saws that sand

!

or form material can generate dust and

vapours which may contain hazardous

chemicals. Check the nature of the

material you intend to process and use

an appropriate breathing mask.

Long-term exposure to noise can result

in permanent hearing impairment.

Always use approved hearing protection.

Listen out for warning signals or shouts

when you are wearing hearing

protection. Always remove your hearing

protection as soon as the motor stops.

Always wear:

• Approved protecting helmet.

• Hearing protection.

• Approved eye protection. If you use a face shield then

you must also wear approved protective goggles.

Approved protective goggles must comply with

standard ANSI Z87.1 in the USA or EN 166 in EU

countries. Visors must comply with standard EN 1731.

• Approved respiratory protection.

• Protective gloves.

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement. Cutting generates

sparks that can ignite clothing. Husqvarna

recommends that you wear flame-retardant cotton or

heavy denim. Do not wear clothing made of material

such as nylon, polyester or rayon. If ignited such

material can melt and cling to the skin. Do not wear

shorts

• Boots with steel toe-caps and non-slip sole.

Other protective equipment

CAUTION! Sparks may appear and start a

fire when you work with the machine.

Always keep fire fighting equipment

handy.

• Fire Extinguisher

• First aid kit

General safety warnings

This section describes basic safety directions for using

the machine. This information is never a substitute for

professional skills and experience. If you get into a

situation where you feel unsafe, stop and seek expert

advice. Contact your dealer, service agent or an

experienced user. Do not attempt any task that you feel

unsure of!

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine. It is recommended that first time operators

also obtain practical instruction before using the

machine.

• Keep in mind that it is you, the operator that is

responsible for not exposing people or their property

to accidents or hazards.

• The machine must be kept clean. Signs and stickers

must be fully legible.

WARNING! Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term ”power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

create sparks which may ignite the dust or fumes.

• Keep children and bystanders away while

operating a power tool.

to lose control.

• Do not use the machine in bad weather, such as

dense fog, rain, strong wind, intense cold, etc.

Working in bad weather is tiring and can lead to

dangerous conditions, e.g. slippery surfaces.

• Never start to work with the machine before the

working area is clear and you have a firm foothold.

Look out for any obstacles with unexpected

Distractions can cause you

Power tools

English – 11

Page 12

OPERATING

!

!

movement. Ensure when cutting that no material can

become loose and fall, causing injury to the

operator.Take great care when working on sloping

ground.

WARNING! The safety distance for the

power cutter is 15 metres (50 foot). You

!

are responsible to ensure that animals

and onlookers are not within the working

area. Do not start cutting until the

working area is clear and you are

standing firmly.

Electrical safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

Unmodified plugs and matching outlets will

reduce the risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet

conditions.

the risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

cord suitable for outdoor use reduces the risk of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected device. Use of an RCD reduces the risk of

electric shock.

• Check that the cord and extension cord are intact and

in good condition. Never use the machine if the cord

is damaged, hand it in to an authorized service

workshop for repair. An undersized cable means a risk

of reduced machine capacity and overheating.

• The machine should be connected to an earthed

outlet socket. Check that the mains voltage

corresponds with that stated on the rating plate on the

machine.

• Ensure the cord is behind you when you start to use

the machine so that the cord will not be damaged.

!

There is an increased risk of electric

Water entering a power tool will increase

Damaged or entangled cords increase

Use of a

WARNING! Do not pressure wash the

machine, as water can enter the

electrical system or the engine and

cause damage to the machine or short

circuit.

WARNING! The machine (United

Kingdom 110V) is not equipped with a

ground fault circuit interrupter. The

machine must always be used with an

isolating transformer for protection in

case an electrical fault should occur.

Personal safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection.

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the OFF-position before connecting to power

source and/or battery pack, picking up or carrying

the tool.

switch or energising power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on.

attached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and

balance at all times.

the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

long hair can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

collection can reduce dust-related hazards.

• Remain at a distance from the blades when the

engine is running.

Protective equipment such as dust

Carrying power tools with your finger on the

A wrench or a key left

This enables better control of

Loose clothes, jewellery or

Use of dust

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. These symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists.

A

12 – English

Page 13

OPERATING

!

!

Power tool use and care

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• The machine is only designed for cutting hard

materials, such as concrete, brick, masonry as well as

cast iron and cement pipes.

WARNING! A power cutter is a

dangerous tool if used carelessly or

!

incorrectly and can cause serious, even

fatal injuries. It is extremely important

that you read and understand the

contents of this Operator’s Manual.

• Do not force the power tool. Use the correct power

tool for your application.

do the job better and safer at the rate for which it was

designed.

• Do not use the power tool if the switch does not

turn it on and off.

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/or

the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools.

measures reduce the risk of starting the power tool

accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

of untrained users.

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool´s operation. If damaged, have the power tool

repaired before use.

poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed.

Power tools are dangerous in the hands

Use of the power tool for operations

The correct power tool will

Any power tool that cannot be

Such preventive safety

Many accidents are caused by

different from those intended could result in a

hazardous situation.

WARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use original

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

• Make sure that no pipes or electrical cables are routed

in the working area or in the material to be cut.

• Always check and mark out where gas pipes are

routed. Cutting close to gas pipes always entails

danger. Make sure that sparks are not caused when

cutting in view of the risk of explosion. Remain

concentrated and focused on the task. Carelessness

can result in serious personal injury or death.

• Inspect new blades for transport or storage damage.

• The guard for the cutting equipment must always be

on when the machine is running.

Service

• Have your power tool serviced by a qualified

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool

is maintained.

Always use common sense

It is not possible to cover every conceivable situation you

can face. Always exercise care and use your common

sense. If you get into a situation where you feel unsafe,

stop and seek expert advice. Contact your dealer, service

agent or an experienced user. Do not attempt any task

that you feel unsure of!

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Never allow children or other persons

not trained in the use of the machine to

use or service it.

Never allow anyone else to use the

machine without first ensuring that they

have read and understood the contents

of the operator’s manual.

Never use a machine that is faulty. Carry

out the safety checks, maintenance and

service instructions described in this

manual. Some maintenance and service

measures must be carried out by trained

and qualified specialists. See

instructions under the Maintenance

heading.

English – 13

Page 14

OPERATING

Basic working techniques

WARNING! This section describes basic

safety directions for using a power

!

cutter. This information is never a

substitute for professional skills and

experience. If you get into a situation

where you feel unsafe, stop and seek

expert advice. Contact your dealer,

service agent or an experienced power

cutter user. Do not attempt any task that

you feel unsure of!

Do not pull the power cutter to one side,

this can cause the blade to jam or break

resulting in injury to people.

Under all circumstances avoid grinding

using the side of the blade; it will almost

certainly be damaged, break and can

cause immense damage. Only use the

cutting section.

Cutting plastics with a diamond blade

can cause kickback when the material

melts due to the heat produced when

cutting and sticks to the blade. Never cut

plastic materials with a diamond blade!

Cutting metal generates sparks that may

cause fire. Do not use the machine near

ignitable substances or gases.

Water cooling

Water cooling must always be used. Dry cutting causes

immediate overheating and machine and cutting blade

failure with a risk of personal injury.

• Always hold the machine in a firm grip with both

hands. Hold it so that the thumbs and fingers grip

round the handles.

• Check that the blade is not in contact with anything

when the machine is started

• Start cutting with the machine running at maximum

speed.

• Start cutting smoothly, allowing the machine to work

without forcing or pressing in the blade. Always cut at

maximum speed.

• Cut in the same direction when cutting into an existing

cut. Avoid cutting at an angle to the previous cut,

otherwise there is a risk of the blade jamming or that

the machine can ”climb in the cut” and cause a

kickback.

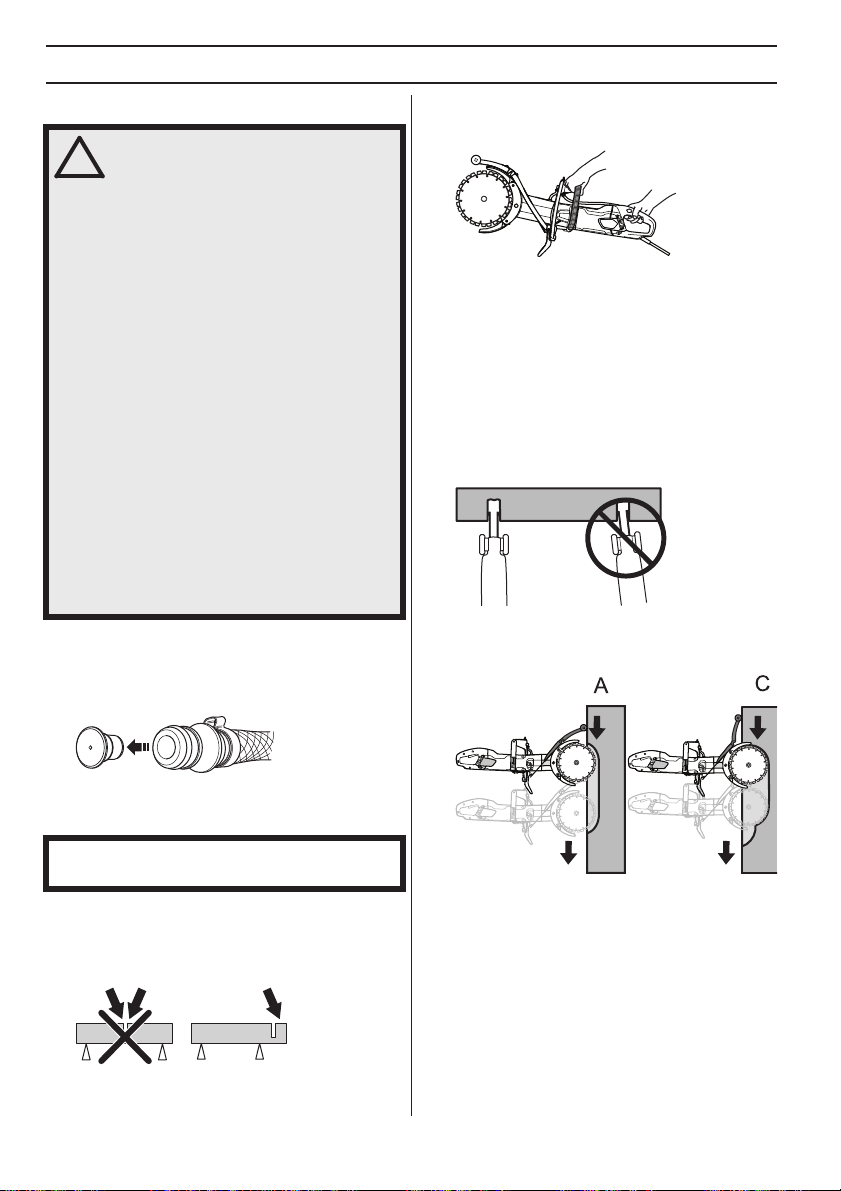

• Always cut from top to bottom (A).

• Remove the cutter and use a crowbar to remove the

material that remains between the cut (B).

At a low water pressure, for example when the water tank

is used, the restrictor can be dismantled to give the

correct water flow.

NOTICE! It is important not to use a too high water flow

without throttling as the belt can then slip.

Cutting technique

• Support the work piece in such a way that it is possible

to predict what will happen, and so that the cut

remains open while cutting.

14 – English

Page 15

OPERATING

!

• Follow the same saw cut, but further in the work piece

(C), and repeat the work with the crowbar.

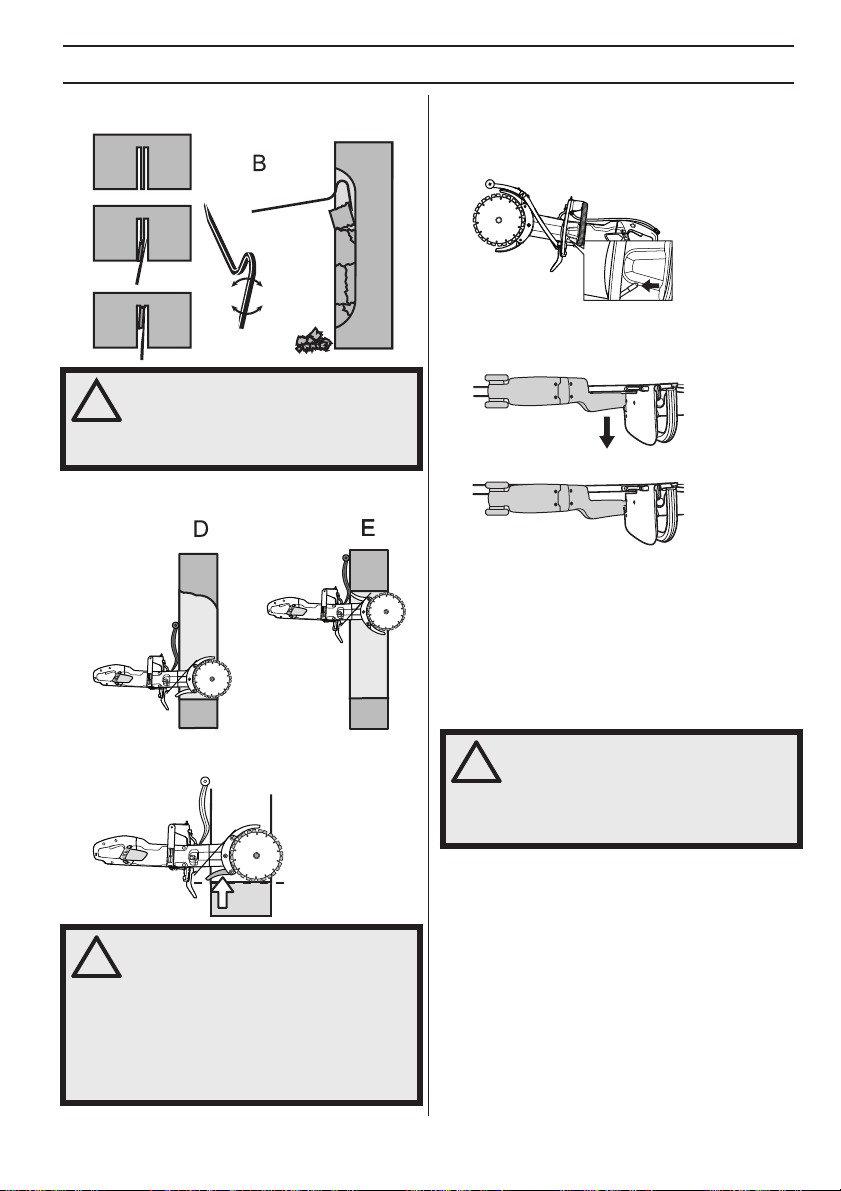

WARNING! When cutting vertically,

always cut from the top of the cut and

!

down. Never cut from the bottom of the

cut and up. This can cause a kickback

and result in personal injury.

• Repeat this working method until the required cutting

depth is achieved (D, E).

• The blade guards are designed to easily adapt to how

deep in the work piece the power cutter is moved.

Smooth cutting

To enable smooth cutting, the splash guard must be

adjusted.

• Release the latch.

• Slide the splash guard sideways.

• Lock the latch.

Kickback

Kickback is a sudden, rearward motion of the saw that can

occur if the blades are stalled (pinched, jammed, twisted)

in the so called kickback zone. Most kickbacks are small

and felt as small ”jerks” in the front handle. However,

kickback can be very powerful. If you are not paying

attention or have a poor grip the saw can be thrown all the

way back at you.

WARNING! Kickback can be very sudden

and viloent, throwing the saw back at

you. It can cause serious or even fatal

injuries. It is vital you understand what

causes kickback and how to aviod it

using proper cutting techique.

WARNING! Under all circumstances

avoid grinding using the side of the

!

blade; it will almost certainly be

damaged or break and can cause

immense damage. Only use the cutting

section.

Do not pull the power cutter to one side,

this can cause the blade to jam or break

resulting in injury to people.

English – 15

Page 16

OPERATING

Cause of kickback

Kickback is caused if you are cutting with the kickback

zone of the blade for example when cutting ”upwards” or

towards you.

General rules

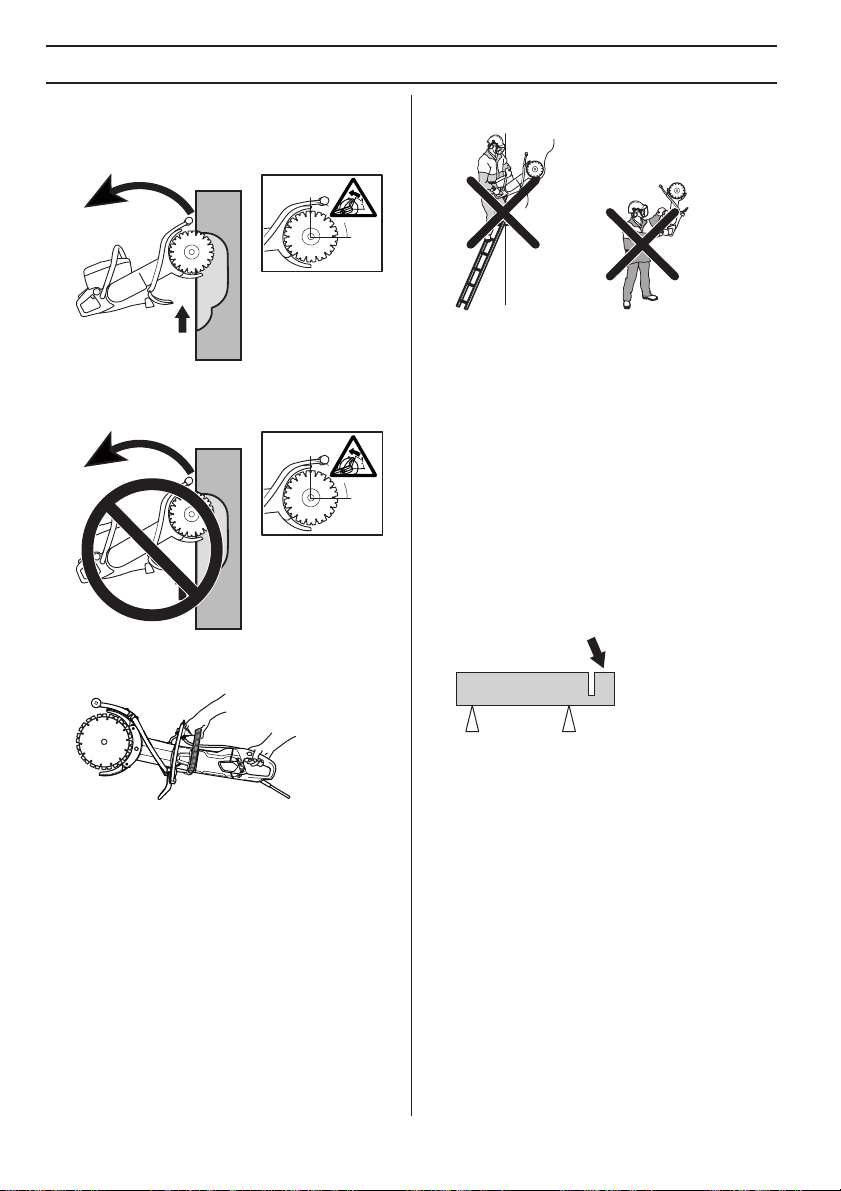

• Never cut upwards or towards you so that the kickback

zone becomes actively cutting.

• Always hold the machine in a firm grip with both

hands. Hold it so that the thumbs and fingers grip

round the handles.

• Never cut from a ladder. Use a platform or scaffold if

the cut is above shoulder height.

• Be alert to movement of the work piece or anything

else that can occur, which could cause the cut to close

and pinch the blade.

Pull in

Pull in occurs when the blades’ lower sections suddenly

stop or when the cut closes. (To avoid, see the

instructions under the heading ”General rules” and

”Pinching/rotation”, here below.).

Pinching/rotation

If the cut is pressed together this can lead to jamming.

The machine can be pulled down suddenly with a very

powerful jerk.

How to avoid pinching

Support the work piece in such a way that the cut remains

open during the cutting operation and when the cut is

finished.

• Keep a good balance and a firm foothold.

• When cutting vertically, always cut from the top of the

cut and down.

• Always cut at maximum speed.

• Do not cut with the upper quadrant (kickback zone) of

the blade. Avoid twisting or pushing the blades

sideways in the cut. This can cause kickback.

• Take care when inserting the blade in an existing cut.

Make certain that the cut is wide enough and that the

blades are not angled in the cut. This can cause

kickback.

• Stand at a comfortable distance from the work piece.

• Never cut above shoulder height.

16 – English

Check the engine speed

Use a revolution counter regularly to check the engine

speed at the working temperature, at full throttle and

without a load.

Page 17

STARTING AND STOPPING

!

Before starting

WARNING! Note the following before

starting:

!

The machine should be connected to an

earthed outlet socket.

Check that the mains voltage

corresponds with that stated on the

rating plate on the machine.

Make sure you have a secure footing and

that the cutting blade cannot touch

anything.

Keep people and animals well away from

the working area.

WARNING! The machine (UK and Ireland

110V) is not equipped with a ground fault

!

circuit interrupter. The machine must

always be used with an isolating

transformer for protection in case an

electrical fault should occur.

Water connector

• Connect the water hose to the water supply (A). The

water flow is regulated using the water tap (B).

switched on. If the LED is not on, push the RESET

button (green).

• Check the ground fault circuit interrupter. See

instructions under the heading Checking, maintaining

and servicing the machine’s safety equipment.

Starting

• Grip the front handle with the left hand.

• Grip the rear handle with your right hand.

• Press in the power switch lock with your right-hand

thumb and press in the power switch.

Residual-current device

(not for UK and Ireland 110V)

WARNING! Never use the tool without the

ground fault circuit interrupter delivered

!

with the tool. Carelessness can result in

serious personal injury or even death.

• Make sure the ground fault circuit interrupter is

switched on. The LED indicates that the ground fault

circuit interrupter is on and that the machine can be

• Run the machine unloaded and in a safe manner for

at least 30 seconds.

Stopping

• Stop the motor by releasing the power switch.

WARNING! Make sure that the cutting

blade can rotate freely until it completely

stops. Carelessness can cause serious

personal injury.

English – 17

Page 18

MAINTENANCE

General

WARNING! The user must only carry out the maintenance and service work described in this

Operator's Manual. More extensive work must be carried out by an authorized service workshop.

!

Inspection and/or maintenance should be carried out with the motor switched off and the plug

disconnected.

Wear personal protective equipment. See instructions under the ”Personal protective equipment”

heading.

The life span or the runtime of the machine can be reduced and the risk of accidents can increase

if machine maintenance is not carried out correctly and if service and/or repairs are not carried

out professionally. If you need further information please contact your nearest service workshop.

Maintenance schedule

In the maintenance schedule you can see which parts of your machine that require maintenance, and with which

intervals it should take place. The intervals are calculated based on daily use of the machine, and may differ depending

on the rate of usage.

Daily maintenance Weekly maintenance/40 hours Monthly maintenance

Cleaning

Functional inspection

Clean the machine.

Cooling air intake

General inspection Carbon brushes Drive wheel

Water system Drive belt

Power switch*

Power switch lock*

Blade guard*

Cutting blade**

18 – English

Page 19

MAINTENANCE

Cleaning

WARNING! Do not use a high pressure

washer when rinsing the inside of the

!

machine.

The machine can withstand taking in damp air and

splashes during the cutting process. Clean water does

not affect the machine’s function.

When cutting materials such as concrete or brick, which

can contain salt, you must rinse the machine after the

work is finished. The cleaning reduces the risk for

accretions building up inside the engine, which can cause

leakage current between electric components, which in

turn can cause the ground fault circuit interrupter to turn

off without intention.

• Clean the machine daily by rinsing it with clean water

after the work is finished.

• Place the machine with the rear handle facing

upwards. Rinse the air intakes at the rear handle with

clean water. The water will run out through the front air

outlets.

• Connect the plug and run the engine dry for approx.

30 sec in order to speed up the drying of the engine.

Cooling system

• The machine is equipped with an efficient fan to cool

the motor. Cooling air which is drawn in through the

grille by the machines rear handle passes over the

stator and rotor and out through the front of the motor

housing.

6 Check the condition of the cutting blade.

7 Check and clean the cooling air openings.

8

Check that the cord and extension cord are intact and

in good condition. Never use the machine if the cord is

damaged, hand it in to an authorized service workshop

for repair.

Drive belt

NOTICE! The drive belt is fully enclosed and well-protected

from dust, dirt and mechanical damage when cutting.

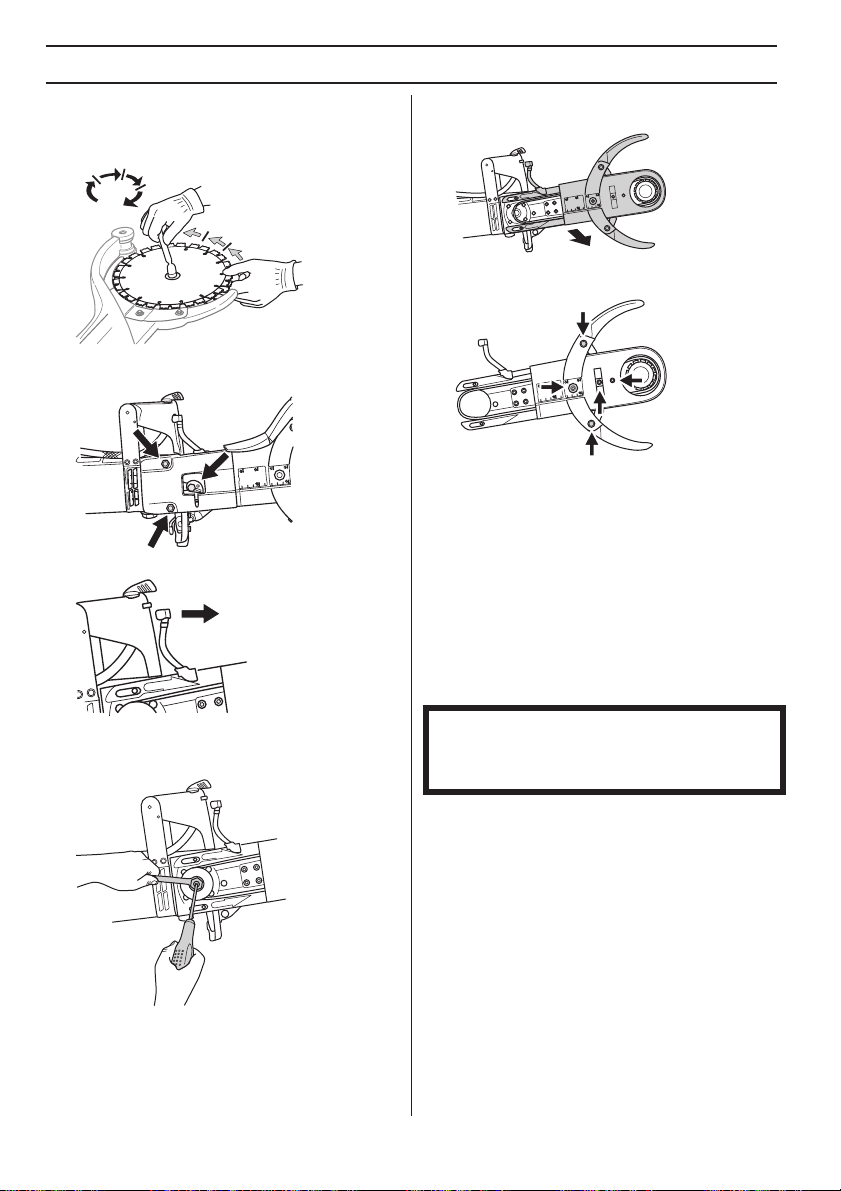

Tensioning the drive belt

• Check the tension of the drive belt. Stick a screwdriver

in the notch.

• A correctly adjusted drive belt should have about 5

mm of movement.

• Tighten the drive belt.

• Loosen the two nuts.

• Loosen the clamping bolt.

• In order for the machine to always be cooled

sufficiently the cooling air openings must be kept clear

and clean. Blow down the machine regularly with

compressed air.

Functional inspection

General inspection

WARNING! Never use damaged cables.

They can cause serious, even fatal,

!

personal injuries.

1 Check that nuts and screws are tightened.

2 Check that the power switch unit works smoothly.

3 Check the residual-current device

4 Clean the outside of the machine.

5 Checking the blade guard

• Turn the eccentric plate anti-clockwise with a

screwdriver or a torx driver. This tightens the drive belt

by pushing the bar forwards.

• Tighten the nuts.

•

Screw the bolt tight. Hold still the eccentric plate so that

it doesn’t move along when you tighten the screws.

NOTICE! A new drive belt shall be tightened once after

30-60 minutes operation.

English – 19

Page 20

MAINTENANCE

Replacing the drive belt

• Release the belt tension.

• Remove the blades.

• Remove the belt cover by loosening the nuts, the

clamping bolt and the eccentric cam.

• Loosen water hose.

• Remove the cutting arm by pulling it straight out from

the machine.

• Loosen the five screws holding the guards on the

cutting arm.

• Remove the old drive belt and put in a new one.

• Refit the guards on the cutting arm.

• Fit the cutting arm on the machine while fastening the

drive wheel.

• Replace the water hose.

• Refit the belt cover, the nuts, the clamping bolt and the

eccentric cam.

• Refit the blades and tighten the nut. See instructions

under Heading ”Assembling the blades”.

• Tighten the drive belt and the nuts and bolt. See the

instructions under the heading ”Inspecting and

adjusting the drive belt”.

• Loosen the drive gear. Use a spanner as a

counterhold. (The combination spanner or bearing

tool can be used as a counterhold.)

20 – English

IMPORTANT! Do not forget to tighten the belt and check

the belt adjustment before cutting. See the instructions

under the heading ”Inspecting and adjusting the drive

belt”.

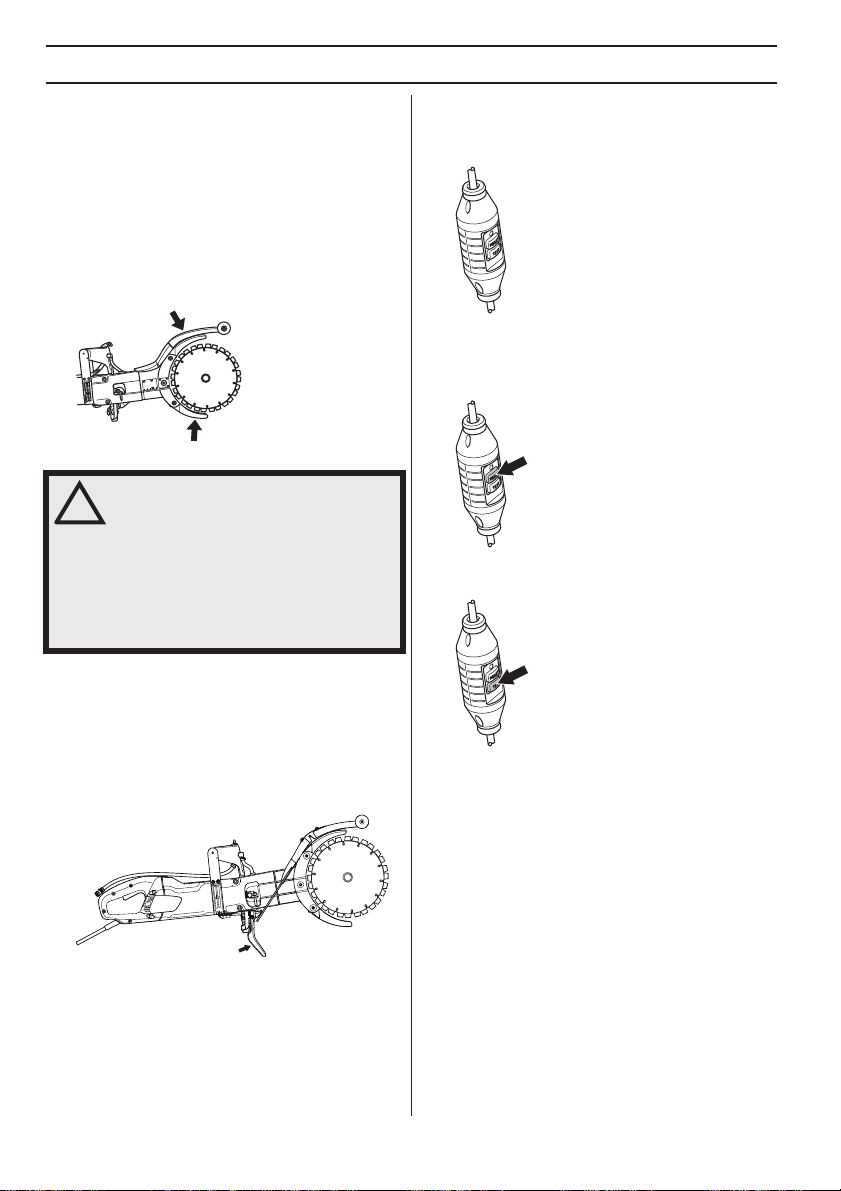

Replacing the carbon brushes

• Check the carbon brushes at least once a month. The

carbon brushes should be replaced with new brushes

if they are worn, cracked or in any other way

deformed.

• All carbon brushes must be replaced when the

brushes are replaced.

Page 21

MAINTENANCE

• Remove the inspection cover by loosening both

screws.

• Unscrew the cable holding the carbon brush. Now lift

up the spr

the brush retainer.

• Clean the brush retainers with a dry brush.

• Carefully blow away the dust.

• Fit the new carbon brushes and, at the same time,

chec

• Fold down the springs and tighten the cable.

• New carbon brushes must be run in for approximately

40 min

ing and then lift out the carbon brush from

k that they slide easily in the brush retainers.

utes while idling.

Water tap

• Check and clean the restrictor if necessary. Do not

use hoses that are distorted, worn or damaged.

Disposal, scrapping

This product should be submitted to an appropriate

recycling station in accordance with local requirements.

By ensuring that this product is taken care of correctly,

you can help to counteract the potential negative impact

on the environment and people that can otherwise result

through the incorrect waste management of this product.

For more detailed information about recycling this

product, contact y

service or the shop from where you purchased the

product.

our municipality, your domestic waste

English – 21

Page 22

TECHNICAL DATA

Technical data

Technical data K 4000 Cut-n-Break

Protection class I

Max. blade speed, rpm

Rated voltage, V

Europe 230

United Kingdom 110

Rated output, W

Europe 230V, 50Hz 2700/12 A

United Kingdom 110V, 50Hz 2200/20 A

Weight

Power cutter without cable package (excluding cutting blades), kg / Lbs 8.4 / 18.5

Power cutter without cable package (including cutting blades), kg / Lbs 8.9 / 19.6

Water cooling

Water cooling Ye s

Water connector Type ”Gardena”

Recommended water pressure, bar / PSI 0.5-8 / 7.3-116

Noise emissions (see note 1)

Sound power level, measured dB(A) 115

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 104

Equivalent vibration levels, a

Front handle, m/s

Rear handle, m/s

Note 1: Noise emissions in the environment measured as sound power (LWA) conforming to EN 60745-1. Reported data

for noise power level has an uncertainty of 3 dB(A).

Note 2: Noise pressure level according to EN 60745-1. Reported data for noise pressure level has an uncertainty of 3

dB(A).

Note 3: Equivalent vibration level, according to EN 60745-2-22, is calculated as the time-weighted energy total for

vibration levels under various working conditions. Reported data for vibration level has a typical statistical dispersion

(standard deviation) of 1,5 m/s

2

2

hveq

2

.

(see note 3)

Cutting equipment

230V, 50Hz 4200

120V, 60Hz 3900

3.6

3.8

Cutting blade, mm/inches Gear ratio Max. peripheral speed, m/s Cutting depth, mm/inches

230 / 9 45 / 79 60 400 / 16

Recommended cable dimensions

Cable area 1,5 mm

Input voltage 100-120 V 20 m 40 m

Input voltage 220-240 V 30 m 50 m

22 – English

2

2,5 mm

2

Page 23

TECHNICAL DATA

EC Declaration of Conformity

(Applies to Europe only)

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500, declares under sole responsibility that the portable

cut-off machine

stated on the rating plate, followed by the serial number), complies with the requirements of the COUNCIL’S DIRECTIVE:

• of May 17, 2006 ”relating to machinery” 2006/42/EC.

• of February 26, 2014 ”relating to electromagnetic compatibility” 2014/30/EU.

• of June 8, 2011 on the ”restriction of use of certain hazardous substances” 2011/65/EU.

The following standards have been applied: EN ISO 12100:2010, EN 55014-1:2006+A1:2009+A2:2011, EN 550142:1997+A1:2001+A2:2008, EN 61000-3-2:2014, EN 61000-3-3:2013, EN 60745-1:2009, EN 60745-222:2011+A11:2013.

Partille, 1 January 2018

Joakim Ed

Global R & D Director

Construction Equipment Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

Husqvarna K 4000 Cut-n-Break dating from 2018 serial numbers and onwards (the year is clearly

English – 23

Page 24

EXPLICATION DES SYMBOLES

Symboles sur la machine:

AVERTISSEMENT! La machine

utilisée de manière imprudente ou

inadéquate peut devenir un outil

dangereux, pouvant causer des

blessures graves voire mortelles à

l’utilisateur et aux autres personnes

présentes.

Lire attentivement et bien assimiler le

manuel d’utilisation avant d’utiliser la

machine.

Utiliser les équipements de protection

personnelle. Voir au chapitre

Ӄquipement de protection

personnelle”.

Ce produit est conforme aux

directives CE en vigueur.

AVERTISSEMENT! Au cours de la

découpe, la poussière générée peut

occasionner des blessures si elle est

aspirée. Utiliser une protection

respiratoire approuvée. Veiller à

disposer d'une bonne ventilation.

AVERTISSEMENT! Les étincelles du

disque de coupe peuvent provoquer un

incendie en cas de contact avec des

matières inflammables tels que

l’essence, le bois, l’herbe sèche.

Toujours utiliser le refroidissement par

eau.

AVERTISSEMENT! Les rebonds

peuvent être soudains, rapides et

violents et peuvent générer des

blessures pouvant être mortelles. Lire

et assimiler les instructions du manuel

avant d'utiliser la machine.

AVERTISSEMENT! Vérifier que les

lames ne comportent ni fissures ni autre

dommage.

Toujours couper dans la direction

adéquate. Voir les consignes de

sécurité !

Plaque signalétique

Rangée 1 : Marque,

modèle (X, Y)

Rangée 2 : N° de

série avec date de

fabrication (Y, W, X)

Année, semaine, n

de séquence

Rangée 3 : N° de produit (X)

Rangée 4 : Fabricant

Rangée 5 : A : Vitesse max. de l’arbre de sortie, B :

Diamètre de la lame de coupe, C

lame

Rangée 6 : D : Tension d’entrée, E : Courant d’entrée, F :

Fréquence d’entrée

Rangée 7 : Pays d’origine

Marquage environnemental. Ce

symbole figurant sur le produit ou sur son

emballage indique que ce produit ne peut

pas être traité comme déchet ménager. Il

doit être collecté et amené à une

installation de récupération appropriée

de déchets d’équipements électriques et

électroniques.

En veillant à ce que ce produit soit correctement éliminé,

vous pouvez contribuer à prévenir les conséquences

négatives potentielles sur l’environnement et les

hommes, qui pourraient sinon être le résultat d’un

traitement incorrect des déchets de ce produit.

Pour des informations plus détaillées sur le recyclage de

ce produit, contactez votre commune ou le magasin où

vous avez acheté le produit.

Les autres symboles/autocollants présents sur la

machine concernent des exigences de certification

spécifiques à certains marchés.

:

°

XXXXXXXXX YYYY

s / n YYYY WWXXXXX

XXX XX XX-XX

Husqvarna AB

AAAAAA BBBBB CC

DDDD EEEE FFFF

XXXXXXXXXXXXXXX

: Diamètre du boulon de

AVERTISSEMENT! N’utilisez pas de

lames de scie circulaire.

24 – French

Page 25

EXPLICATION DES SYMBOLES

Explication des niveaux

d'avertissement

Il existe trois niveaux d'avertissement.

AVERTISSEMENT!

AVERTISSEMENT! Désigne une situation

dangereuse qui, si elle n’est pas évitée,

!

peut entraîner des blessures graves,

voire mortelles.

REMARQUE !

REMARQUE ! Désigne une situation

dangereuse qui, si elle n’est pas évitée,

!

peut entraîner des blessures mineures

ou modérées.

REMARQUE !

REMARQUE ! Sert à désigner des pratiques sans

risque de blessures corporelles.

French – 25

Page 26

SOMMAIRE

Sommaire

EXPLICATION DES SYMBOLES

Symboles sur la machine: ..................................... 24

Explication des niveaux d'avertissement .............. 25

SOMMAIRE

Sommaire ............................................................. 26

PRÉSENTATION

Cher client, ............................................................ 27

QUELS SONT LES COMPOSANTS?

Quels sont les composants de la découpeuse? ... 28

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités ........................................................... 29

DISQUES DÉCOUPEURS

Généralités ........................................................... 31

Lames diamant pour matériaux divers .................. 31

Refroidissement par eau ....................................... 31

Affûtage des lames diamant ................................. 31

Transport et rangement ......................................... 31

MONTAGE

Montage ................................................................ 32

COMMANDE

Équipement de protection ..................................... 33

Consignes générales de sécurité ......................... 33

Techniques de travail de base .............................. 36

DÉMARRAGE ET ARRÊT

Avant de démarrer la machine .............................. 40

Démarrage ............................................................ 40

Arrêt ...................................................................... 40

ENTRETIEN

Généralités ........................................................... 41

Schéma d’entretien ............................................... 41

Nettoyage .............................................................. 42

Contrôle fonctionnel .............................................. 42

Remplacement des balais de charbon ................. 44

Robinet d’eau ........................................................ 44

Mise au rebut ........................................................ 44

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques techniques ................................. 45

Équipement de découpe ....................................... 45

Dimensions de câble recommandées ................... 45

Déclaration CE de conformité ............................... 46

26 – French

Page 27

PRÉSENTATION

Cher client,

Nous vous remercions d'avoir choisi un produit

Husqvarna

Nous espérons que cette machine vous donnera toute

satisfaction et qu’elle vous accompagnera pendant de

longues années. L’achat de l’un des nos produits garantit

une assistance professionnelle pour l’entretien et les

réparations. Si la machine n’a pas été achetée chez l’un

de nos revendeurs autorisés, demandez l’adresse de

l’atelier d’entretien le plus proche.

Ce mode d’emploi est précieux. Veillez à ce qu'il soit

toujours à portée de main sur le lieu de travail. En suivant

les instructions qu’il contient (utilisation, révision,

entretien etc.), il est possible d’allonger considérablement

la durée de vie de la machine et d’augmenter sa valeur

sur le marché de l’occasion. En cas de vente de la

machine, ne pas oublier de remettre le manuel

d’utilisation au nouveau propriétaire.

Plus de 300 ans d'innovation

Husqvarna AB est une entreprise suédoise qui a vu le

jour en 1689 lorsque le roi Karl XI décida de construire un

arsenal pour la fabrication des mousquets. À l'époque, les

compétences en ingénierie à la base du développement

de certains des produits leaders du marché mondial dans

des domaines tels que les armes de chasse, les vélos, les

motocycles, l'électroménager, les machines à coudre et

les produits d'extérieur, étaient déjà solides.

Husqvarna est le premier fournisseur mondial de produits

motorisés pour utilisation en extérieur dans la foresterie,

l'entretien de parcs, de pelouses et de jardins, ainsi que

d'équipements de coupe et d'outils diamant destinés aux

industries de la construction et de la pierre.

Responsabilité de l'utilisateur

Il est de la responsabilité du propriétaire/de l’employeur

de s’assurer que l’utilisateur possède les connaissances

nécessaires pour manipuler la machine en toute sécurité.

Les responsables et les utilisateurs doivent avoir lu et

compris le Manuel d’utilisation. Ils doivent avoir

conscience :

• Des instructions de sécurité de la machine.

• Des diverses applications de la machine et de ses

• De la façon dont la machine doit être utilisée et

La législation nationale peut réglementer l'utilisation de

cette machine. Recherchez la législation applicable dans

le lieu où vous travaillez avant d'utiliser la machine.

Droit de réserve du fabricant

Toutes les informations et toutes les données indiquées

dans ce manuel d'utilisation étaient valables à la date à

laquelle ce manuel a été porté à l'impression.

Husqvarna AB travaille continuellement au

développement de ses produits et se réserve le droit d’en

!

limites.

entretenue.

modifier, entre autres, la conception et l’aspect sans

préavis.

French – 27

Page 28

QUELS SONT LES COMPOSANTS?

Quels sont les composants de la découpeuse?

1 Protection anti-éclaboussures

2 Poignée avant

3 Blocage de l'interrupteur

4 Interrupteur

5 Poignée arrière

6 Capot de contrôle

7 Balais de charbon

8 Support de balais

9 Plaque signalétique

10 Protection anti-éclaboussures

11 Lames

28 – French

12 Protège-lame

13 Disjoncteur de fuite à la terre

14 Raccord de l’eau

15 Robinet d’eau

16 Bras de coupe

17 Tendeur de courroie

18 Outil d'arrachage

19 Clé universelle

20 Dispositif de roulement

21 Manuel d’utilisation

Page 29

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités

Ce chapitre présente les équipements de sécurité de la

machine, leur fonction, comment les utiliser et les

maintenir en bon état. Voir au chapitre Quels sont les

composants? pour trouver leur emplacement sur la

machine.

AVERTISSEMENT! Ne jamais utiliser une

machine dont les équipements de

!

sécurité sont défectueux. Suivre les

directives de maintenance, d’entretien et

les instructions de réparation indiquées

dans ce chapitre.

L’entretien et la réparation de la machine

exigent une formation spéciale. Ceci

concerne particulièrement l’équipement

de sécurité de la machine. Si les

contrôles suivants ne donnent pas un

résultat positif, s’adresser à un atelier

spécialisé. L’achat de l’un de nos

produits offre à l’acheteur la garantie

d’un service et de réparations qualifiés.

Si le point de vente n’assure pas ce

service, s’adresser à l’atelier spécialisé

le plus proche.

bouton de blocage ((A)) est enfoncé, l'interrupteur (B) est

libéré.

Le blocage de l'interrupteur reste enfoncé tant que

l'interrupteur est enfoncé. Quand la poignée est

relachée, l'interrupteur et le blocage de l'interrupteur

reviennent en position initiale. Ce retour s'effectue grâce

à deux systèmes de ressorts de rappel indépendants l'un

de l'autre. Dans cette position, la machine s'arrête et

l'interrupteur se bloque.

Contrôle du blocage de l'interrupteur

• Contrôler que l’interrupteur est bloqué quand le

blocage de l’interrupteur est en position de repos.

Interrupteur

L'interrupteur est utilisé pour démarrer et arrêter la

machine.

Contrôle de l'interrupteur

• Démarrer la machine, relâcher l'interrupteur et

contrôler que le moteur et le disque découpeur

s'arrête.

• Un interrupteur défectueux doit être remplacé par une

atelier d’entretien agréé.

Blocage de l'interrupteur

Le blocage de l'interrupteur a pour fonction d'empêcher

toute activation involontaire de l'interrupteur. Quand le

• Appuyer sur le blocage de líinterrupteur et vérifier quíil

revient en position initiale quand il est relâché.

• Vérifier que l'interrupteur, le blocage de l'interrupteur

et le système de ressorts de rappel fonctionne

correctement.

• Allumez la machine, relâchez l'interrupteur et vérifiez

que le moteur et les disques s'arrêtent.

Démarrage en douceur et protection

contre les surcharges

La machine est équipée d'un dispositif électronique de

démarrage en douceur et d'une protection contre la

surcharge.

Si la charge sur la machine dépasse un certain niveau, le

moteur se met à pulser. Si la charge est allégée, le moteur

retourne à la normale et la découpe peut continuer.

French – 29

Page 30

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Si l'on continue à utiliser la machine avec le moteur qui

pulse, le système électronique coupe le courant après un

certain temps. Plus la charge est élevée, plus la coupure

est rapide.

Si le disque de coupe se coince, le système électronique

coupe immédiatement le courant.

Protège-lame

Cette protection est placée au-dessus et en dessous du

disque de découpe et a pour fonction d’empêcher que

des éclats de disque ou de matériau ne soient projetés en

direction de l’utilisateur.

Contrôle de la protection des lames

AVERTISSEMENT! Vérifiez toujours que

toutes les protections sont montées

!

correctement avant de démarrer la

machine. Contrôler également si le

disque découpeur est correctement

monté et qu’il ne présente aucun

dommage. Un disque découpeur

endommagé peut causer des blessures.

Voir les instructions au chapitre

Montage.

Le voyant lumineux indique que le disjoncteur de fuite à la

terre est activé et que la machine peut être allumée. Si le

voyant lumineux est éteint, appuyez sur le bouton RESET

(vert).

Vérifiez le disjoncteur de fuite à la terre

• Branchez la machine à la prise électrique. Appuyez

sur le bouton RESET (vert) et le voyant lumineux

rouge s'allume.

• Démarrer la machine.

• Appuyez sur le bouton TEST (bleu).

• Contrôler que la protection est entière et qu’elle n’est

ni fissurée, ni déformée.

• Ne jamais utiliser un protège-lame défectueux ou

monté de manière incorrecte.

Protection anti-éclaboussures

La protection anti-projections fournit une protection

contre les projections de débris, d’eau et de béton.

Vérification de la protection anti-projections

Assurez-vous qu’il n’y a aucune fissure ni aucun trou

dans la protection causé(e) par les projections de béton.

Remplacez la protection si elle est endommagée.

Disjoncteur de fuite à la terre

Les disjoncteurs de fuite à la terre constituent une

protection si un défaut d'origine électrique survient.

30 – French

• Le disjoncteur de fuite à la terre devrait s'enclencher

et la machine s'éteint instantanément. Dans le cas

contraire, veuillez contacter votre revendeur.

• Initialisez l'appareil à l'aide du bouton RESET (vert).

Page 31

DISQUES DÉCOUPEURS

!

Généralités

AVERTISSEMENT! Un disque de coupe

peut se briser et blesser gravement

!

l’utilisateur.

Le disque découpeur doit être vérifié

avant d’être assemblé sur la scie, puis

faire l’objet d’un contrôle fréquent en

cours d’utilisation. Vérifiez l’absence de

fissures, de segments perdus (lames

diamant) ou de pièces cassées. Nutilisez

pas de disque découpeur endommagé.

Vérifiez l’intégrité de chaque nouveau

disque découpeur en le faisant

fonctionner à plein régime pendant 1

minute environ.

Utilisez uniquement les disques

découpeurs d’origine conçus par

Husqvarna pour cette machine.

Husqvarna émet des avertissements et

des recommandations pour l’utilisation et

l’entretien adéquats des disques

découpeurs. Ces avertissements sont

fournis avec les disques découpeurs.

Lisez et respectez toutes les instructions

fournies par Husqvarna.

• Cette machine doit uniquement être utilisée avec des

lames diamant Husqvarna spécialement conçues et

destinées au Cut-n-Break. Les lames comportent une

poulie de courroie intégrée et sont homologuées pour

le découpage à la main.

• Les disques diamant se composent d’une structure

en acier et de segments contenant des diamants

industriels.

• Toujours utiliser une lame diamant acérée.

• Vérifier que les lames ne comportent ni fissures ni

autre dommage. Remplacer les lames au besoin.

Lames diamant pour matériaux

divers

AVERTISSEMENT! Ne jamais utiliser un

disque de coupe avec un matériau

!

différent de celui pour lequel il est conçu.

N’utilisez jamais une lame diamant pour

couper de la matière plastique. La chaleur

produite lors de la découpe risque de faire

fondre le plastique, qui risque alors de

coller au disque découpeur et de

provoquer un rebond.

La découpe de métal génère des

étincelles pouvant provoquer un incendie.

N'utilisez pas la machine près de gaz ou

de substances inflammables.

• Les disques diamant conviennent parfaitement pour

la maçonnerie et le béton armé. Demander conseil au

concessionnaire pour choisir le bon produit.

• Les disques diamant sont disponibles en plusieurs

degrés de résistance. Un disque diamant "tendre" a

une durée de vie plus courte et une grande capacité

de découpe. Il est utilisé pour les matériaux durs tels

que le granit et le béton dur. Un disque diamant "dur"

a une durée de vie plus longue, une capacité de

découpe moindre et doit être utilisé pour des

matériaux tendres tels que les tuiles et l’asphalte.

Refroidissement par eau

AVERTISSEMENT! Refroidir

continuellement les disques diamant à

l’eau pour éviter une hausse de

température pouvant provoquer une

déformation de la lame diamant,

endommager la machine et blesser

l’utilisateur.

• Toujours utiliser le refroidissement par eau.

• L’utilisation de lames de découpe à l’eau sans eau

peut induire une accumulation excessive de chaleur,

entraînant des performances médiocres et de graves

dommages sur la lame, et constituant un risque pour

la sécurité.

• L’eau refroidit la lame, augmente sa durée de vie et

limite la formation de poussière.

Affûtage des lames diamant

Les lames diamant peuvent sémousser en cas de

pression davance incorrecte ou de découpe de certains

matériaux comme du béton fortement armé. Le travail

avec un disque diamant émoussé comporte un risque de

surchauffe pouvant provoquer la chute des segments en

diamant.

Affûter les lames en coupant un matériau tendre tel que

du grès ou de la brique.

Transport et rangement

• Assurez-vous que la machine est sécurisée et que les

disques découpeurs sont correctement protégés

pendant le transport ou le remisage de la machine.

• Avant toute utilisation, vérifiez tous les disques et

assurez-vous qu’ils ne comportent pas de défauts

causés par le transport ou le remisage.

French – 31

Page 32

MONTAGE

Montage

AVERTISSEMENT! Toujours débrancher

la prise avant le nettoyage, l'entretien et

!

le montage.

Montage des lames

• Les lames Husqvarna sont spécialement fabriquées

et agréées pour la découpe manuelle avec la

découpeuse K 3000 Cut-n-Break. Les lames

comportent une demi-poulie intégrée et doivent être

remplacées par paire.

• Desserrez les écrous et la vis de serrage, ce qui

relâche la barre. De cette manière, la courroie

d’entraînement est positionnée d’une façon facilitant

le montage des nouvelles lames.

d’entraînement n’est pas coincée aussi

facilement.

La courroie

vis qui maintient le disque de coupe doit être serrée

selon un couple de 15 Nm (130 in.lb).

ATTENTION ! Ne pas oublier de tendre la courroie et de

contrôler la tension de la courroie avant de commencer

la découpe. Voir les instructions au chapitre ”Contrôle et

réglage de la courroie d’entraînement”.

• Démonter les lames usées en desserrant l’écrou

central. Profiter du démontage des lames pour

inspecter la courroie d’entraînement et vérifier qu’elle

n’est pas usée. Pour remplacer la courroie

d’entraînement, voir les indications du chapitre

”Remplacement de la courroie d’entraînement”.

ATTENTION ! Il est très important que les lames

tournent quand l’écrou est serré. Ceci indique que la

courroie n’est pas coincée entre les demi-poulies

intégrées des lames quand les lames/les poulies sont

serrées avec l’écrou. Effectuer le serrage en alternance,

c.-à-d. serrer un peu, faire pivoter et continuer ainsi

jusqu’à ce que les lames soient bien attachées.

• Placer les lames de chaque côté du bras de coupe.

Vérifier que les trous des deux tenons-guides de la

demi-poulie sont orientés de manière à s’adapter aux

trous de la rondelle ainsi que de l’écrou. Monter

ensuite la vis et la rondelle avec les tenons-guides. La

32 – French

Protection des lames

• Les protections doivent toujours être montées sur la

machine. Contrôler que les protections sont bien

attachées et qu’elles fonctionnent correctement avant

de commencer la découpe.

Page 33

COMMANDE

!

!

Équipement de protection

Généralités

Ne jamais utiliser une machine s’il n’est pas possible

d’appeler au secours en cas d’accident.

Équipement de protection personnelle

Un équipement de protection personnelle homologué doit

impérativement être utilisé lors de tout travail avec la

machine. L’équipement de protection personnelle

n’élimine pas les risques mais réduit la gravité des

blessures en cas d’accident. Demander conseil au

concessionnaire afin de choisir un équipement adéquat.

AVERTISSEMENT! L’utilisation de

produits, tels que les couteaux, les

!

broyeurs, les perceuses, les scies qui

sablent ou forment une matière, peut

entraîner la formation de poussière et de

vapeurs qui peuvent contenir des

produits chimiques dangereux. Vérifiez

le type de matériau avec lequel vous

devez travailler et utilisez un masque

filtrant approprié.

Une exposition prolongée au bruit risque

de causer des lésions auditives

permanentes. Utilisez toujours des

protecteurs d’oreilles agréés. Soyez

toujours attentifs aux signaux

d’avertissement ou aux appels lorsque

vous portez des protecteurs d’oreilles.

Enlevez toujours vos protecteurs

d’oreilles dès que le moteur s’arrête.

Toujours utiliser:

• Casque de protection homologué.

• Protecteur d’oreilles.

• Des protège-yeux homologués. L’usage d’une visière

doit toujours s’accompagner du port de lunettes de

protection homologuées. Par lunettes de protection

homologuées, on entend celles qui sont en conformité

avec les normes ANSI Z87.1 (États-Unis) ou EN 166

(pays de l’UE). La visière doit être conforme à la

norme EN 1731.

• Protection respiratoire homologuée.

• Gants de protection.

• Gants solides permettant une prise sûre.

• Vêtements confortables, robustes et serrés qui

permettent une liberté totale de mouvement. La

découpe crée des étincelles qui peuvent enflammer

les vêtements. Husqvarna vous recommande de

porter du coton ignifugé ou du denim épais. Ne portez

pas de vêtements composés de matières comme le

nylon, le polyester ou la rayonne. Si elles

s’enflamment, ces matières peuvent fondre et adhérer

à la peau. Ne portez pas de shorts

• Bottes avec coquille en acier et semelle

antidérapante.

Autre équipement de protection

REMARQUE ! Lorsque vous travaillez

avec la machine, des étincelles peuvent

se former et mettre le feu. Gardez

toujours à portée de main les outils

nécessaires à l'extinction d'un feu.

• Extincteur

• Trousse de premiers secours

Consignes générales de sécurité