Page 1

Oper ator ′ s manual

K3000

K3000 Wet

Please r ead the operator’s manual carefully and make sure you understand the instructions

before using the machine.

EEEEnnnngggglllliiiisssshh

hh

Page 2

2

W

En

KEY T O SYMBOLS

Symbols on the mac hine:

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with

applicable EC directives.

WARNING! Dust forms when cutting,

which can cause injuries if inhaled. Use

an approved breathing mask. Always

provide for good ventilation.

WARNING! Sparks from the cutting

blade can cause fire in combustible

materials such as: petrol (gas), wood,

dry grass etc.

WARNING! Kickbacks can be sudden,

rapid and violent and can cause life

threatening injuries. Read and

understand the instructions in the

manual before using the machine.

vironmental marking. Symbols on

the product or its packaging indicate that

this product cannot be handled as

domestic waste. It must instead be

submitted to an appropriate recycling

station for the recovery of electrical and

electronic equipment.

By ensuring that this product is taken care of correctly,

you can help to counteract the potential negative impact

on the environment and people that can otherwise result

through the incorrect waste management of this product.

For more detailed information about recycling this

product, contact your municipality, your domestic waste

service or the shop from where you purchased the

product.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

Symbols in the operator’ s manual:

Inspection and/or maintenance should

be carried out with the motor switched

off and the plug disconnected.

Always wear approved protective

gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be

worn.

– English

Page 3

ST

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ..................................... 2

Symbols in the operator’s manual: ....................... 2

CONTENTS

Contents ............................................................... 3

WHA T IS WHAT?

What is what on the po wer cutter - K3000? ......... 4

WHA T IS WHAT?

What is what on the po wer cutter - K3000 Wet? .. 5

GENERAL SAFETY PRECA UTIONS

Steps bef ore using a new power cutter ................ 6

Personal protective equipment ............................. 6

Machine ′ s safety equipment ................................. 7

SAFETY INSTR UCTIONS

Gener al safety warnings ....................................... 9

Cutting blades ...................................................... 11

General working instructions ................................ 13

ASSEMBL Y

Assemb ly .............................................................. 15

Fitting the cutting blade ........................................ 15

Guard for the blade ............................................... 15

ARTING AND STOPPING

Bef ore starting ...................................................... 16

Starting ................................................................. 16

Stopping ............................................................... 16

MAINTENANCE

Gener al ................................................................. 17

Cleaning ............................................................... 17

Electrical Feed ...................................................... 17

Replacing the carbon brushes .............................. 17

Bevel gear ............................................................ 18

Checking the drive shaft and flange washers ....... 18

Checking water connection with flow limiter ......... 18

Daily maintenance ................................................ 18

TECHNICAL D ATA

Cutting equipment ................................................ 20

Recommended cable dimensions ........................ 20

EC-declaration of conformity ................................ 21

English

–

3

Page 4

4

1

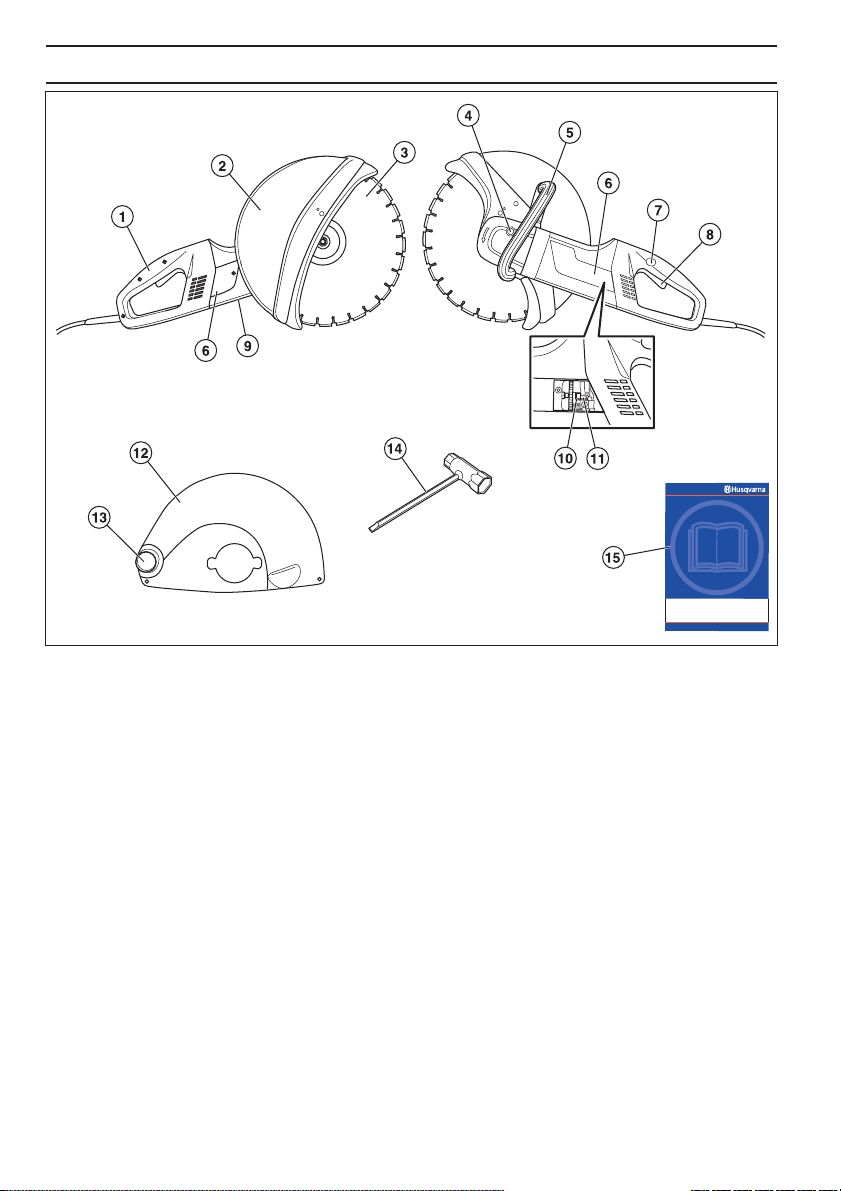

WHA T IS WHA T?

What is what on the po wer cutter - K3000?

Rear handle

2 Guard for the blade 14”

3 Cutting blade

4 Locking the axle

5 Front handle

6 Inspection covers

7 Power switch lock

8 Switch

– English

9 Rating plate

10 Brush retainer

11 Carbon brushes

12 Guard for the blade 12” (Model version)

13 Connection for vacuum cleaner

14 Combination spanner

15 Operator ′ s manual

Page 5

1

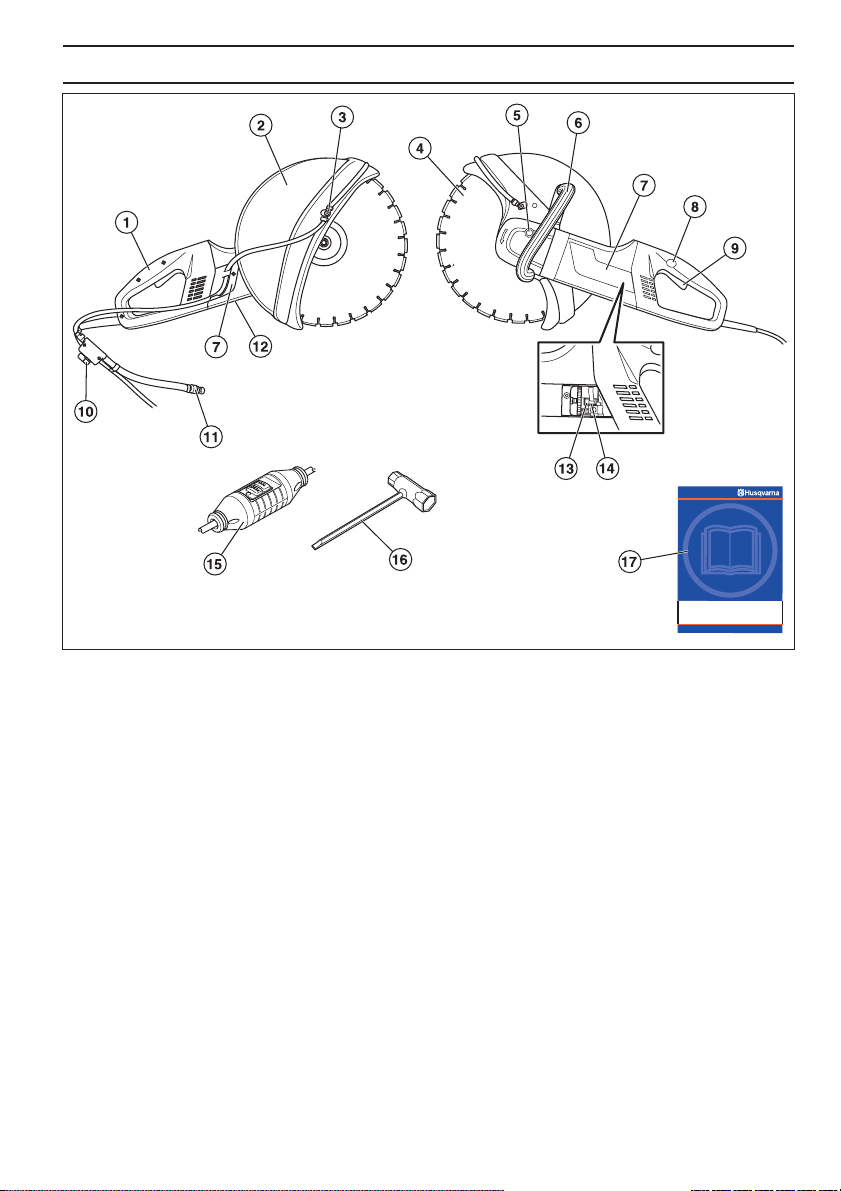

WHA T IS WHA T?

What is what on the po wer cutter - K3000 Wet?

Rear handle

2 Guard for the blade

3 Water kit

4 Cutting blade

5 Locking the axle

6 Front handle

7 Inspection covers

8 Power switch lock

9 Switch

10 Water tap

11 Water connection with flow limiter

12 Rating plate

13 Brush retainer

14 Carbon brushes

15 Ground fault circuit interrupter (not for GB)

16 Combination spanner

17 Operator ′ s manual

English – 5

Page 6

!

6

•

P

•

W

W

W

GENERAL SAFETY PRECA UTIONS

W

Steps bef ore using a new power cutter

Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• The machine is only designed for cutting hard

materials, such as concrete, brick, masonry as well as

cast iron and cement pipes.

• Let your Husqvarna dealer regularly check the power

cutter and make essential adjustments and repairs.

ARNING! Under no circumstances

should you modify the original design of

!

the machine without approval from the

manufacturer. Always use original spare

parts. Unauthorized modifications and/or

accessories may lead to serious injury or

death to the user or others.

ARNING! Use of products which cut,

grind, drill, sand or shape material can

!

generate dust and vapors which may

contain harmful chemicals. Know the

nature of the material being worked on

and wear appropriate dust mask or

respirator protection.

ARNING! A power cutter is a

dangerous tool if used carelessly or

!

incorrectly and can cause serious, even

fatal injuries. It is extremely important

that you read and understand the

contents of this Operator’s Manual.

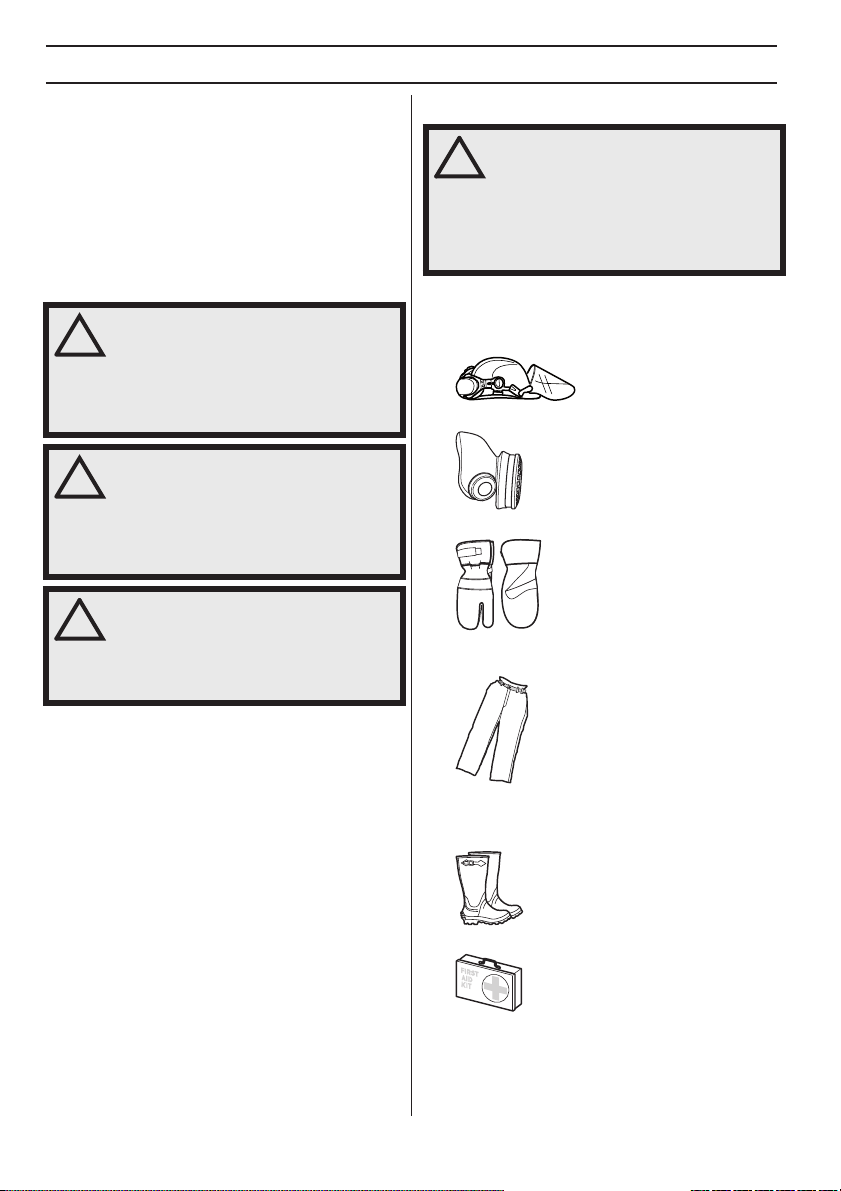

ersonal protective equipment

ARNING! You must use approved

personal protective equipment whenever

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of

injury if an accident does happen. Ask

your dealer for help in choosing the right

equipment.

Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

Husqvarna Construction Products has a policy of

continuous product development. Husqvarna reserves

the right to modify the design and appearance of products

without prior notice and without further obligation

introduce design modifications.

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to

print.

– English

• Use leg-guards recommended for the material to be

cut.

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

Page 7

GENERAL SAFETY PRECA UTIONS

Mac hine ′′

This section descr ibes the machine ′ s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

′′

s safety equipment

ARNING! Never use a machine that has

faulty safety equipment! Carry out the

!

inspection, maintenance and service

routines listed in this section.

All servicing and repair work on the

machine requires special training. This is

especially true of the machine

equipment. If your machine fails any of

the checks described below you must

contact your service agent. When you

buy any of our products we guarantee

the availability of professional repairs

and service. If the retailer who sells your

machine is not a servicing dealer, ask

him for the address of your nearest

service agent.

′′

′′

s safety

•

P

•

W

ower switch lock

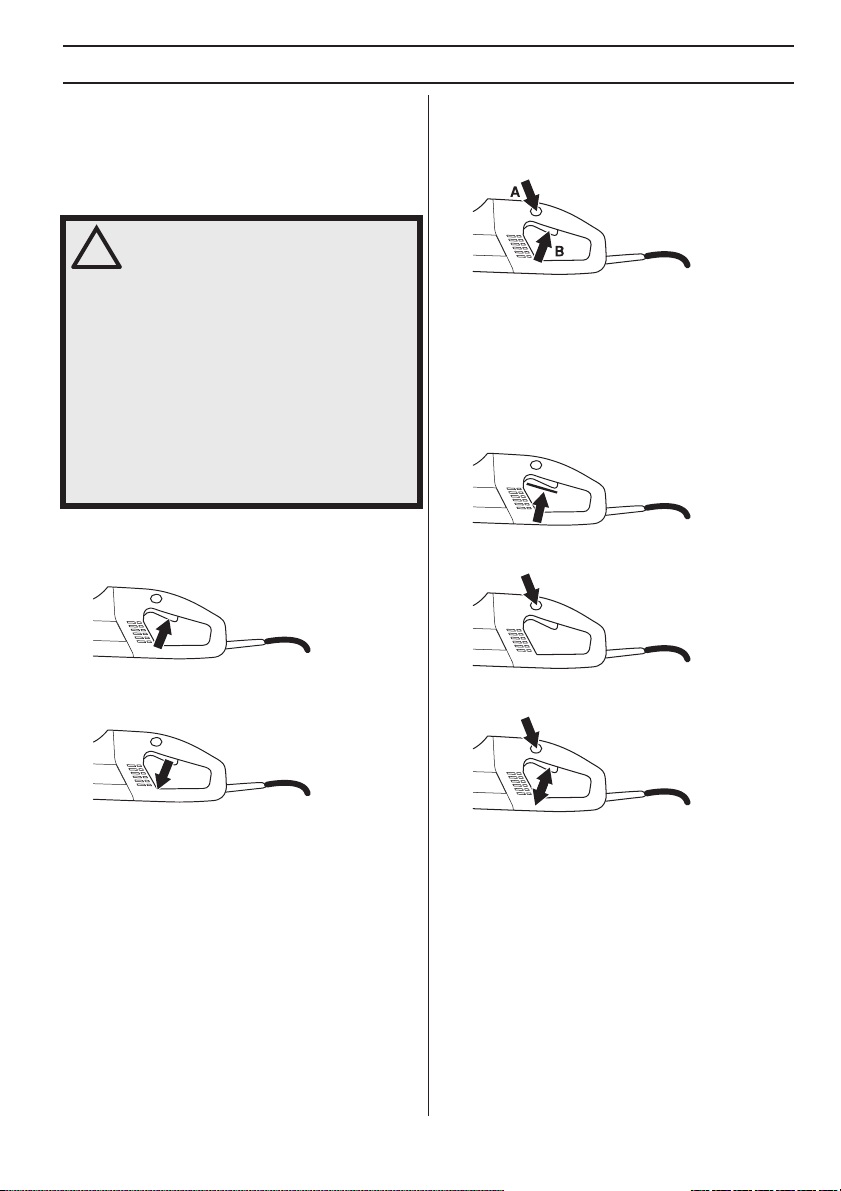

The po wer switch lock is designed to prevent accidental

operation of the switch. When the lock (A) is pressed in

the power switch (B) is released.

The power switch lock remains depressed as long as the

power switch is depressed. When the grip on the handle

is released both the power switch and power switch lock

are reset. This movement is controlled by two

independent return springs. This position results in the

machine stopping and the power switch being locked.

Chec king the power switch lock

Make sure the power switch is locked when the power

switch lock is in its original position.

Switc h

The po wer switch should be used to start and stop the

machine.

Chec king the power switch

Start the machine, release the power switch and

check that the engine and the cutting blade stop.

• A defective power switch should be replaced by an

authorized service workshop.

• Press in the power switch lock and make sure it

returns to its original position when you release it.

• Check that the power switch and power switch lock

move freely and that the return springs work properly.

• Start the machine, release the power switch and

check that the engine and the cutting blade stop.

Gradual star t and overload protection

The machine is equipped with electronically controlled

gradual start and overload protection.

The engine starts to pulsate if the machine is loaded

above a specific level. If the load is reduced the engine

reverts to its normal state and cutting can resume.

The electronics will cut the current after a set time if the

machine continues to be run with a pulsating engine. The

higher load the faster the shutoff.

The electronics cut the current immediately if the blade

jams.

English

–

7

Page 8

GENERAL SAFETY PRECA UTIONS

Guar d for the blade

This guard is fi tted above the cutting blade and is

designed to prevent parts of the blade or cutting

fragments from being thrown towards the user.

Checking the blade guard

WARNING! Always check that the guard

is correctly fitted before starting the

!

machine. Check that the cutting blade is

fitted correctly and does not show signs

of damage. A damaged cutting blade can

cause personal injury. See instructions

under the heading Assembly.

• Check that the guard is complete and without any

cracks or deformations.

8

– English

Page 9

SAFETY INSTRUCTIONS

!

!

General safety warnings

WARNING! Read all safety warnings and

all instructions. Failure to follow the

!

warnings and instructions may result in

electrtic shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term ”power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the

dust or fumes.

• Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

• Do not use the machine in bad weather, such as

dense fog, rain, strong wind, intense cold, etc.

Working in bad weather is tiring and can lead to

dangerous conditions, e.g. slippery surfaces.

• Ensure when cutting that no material can become

loose and fall, causing operating injury. Take great

care when working on sloping ground.

WARNING! The safety distance for the

power cutter is 15 metres. You are

!

responsible to ensure that animals and

onlookers are not within the working

area. Do not start cutting until the

working area is clear and you are

standing firmly.

Electrical safety

• Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce the risk of electric

shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• The power tool should not be exposed to more

moisture than what is supplied by the low flushing

water system. Do not expose the power tool to rain.

Water entering a power tool will increase the risk of

electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oli, charp edges or moving parts.

Damaged or entangled cords increase the risk of

electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of cord

suitable for outdoor use reduces the risk of electric

shock.

• Check that the cord and extension cord are intact and

in good condition. Never use the machine if the cord

is damaged, hand it in to an authorized service

workshop for repair.

• Do not use an extension cord while it is rolled up to

avoid overheating.

• When using an extension cable, use only certified

extension cables with sufficient reach. For more

information, see "Recommended cable dimensions"

in the "Technical data" section. An undersized cable

means a risk of reduced machine capacity and

overheating.

• The machine should be connected to an earthed

outlet socket. Check that the mains voltage

corresponds with that stated on the rating plate on the

machine.

• Ensure the cord is behind you when you start to use

the machine so that the cord will not be damaged.

WARNING! The machine (Great Britain

110V) is not equipped with a ground fault

circuit interrupter. The machine must

always be used with an isolating

transformer for protection in case an

electrical fault should occur.

K3000

WARNING! Do not wash the machine

with water, as water can enter the

electrical system or the engine and

cause damage to the machine or short

circuit.

English – 9

Page 10

SAFETY INSTRUCTIONS

Personal safety

• Stay alert, watch what you are doing and use common

sense when operaing a power tool. Do not use a

power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention

while operating power tools may result in serious

personal injury.

• Use personal protective equipment. Always wear eye

protection. Protetctive equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

• Prevent unintentional starting. Ensure the switch is in

the OFF-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites

accidents.

• Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

• Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool

in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jeweller y or long

hair can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure that these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

• Remain at a distance from the blades when the

engine is running.

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. These symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists.

Power tool use and care

• Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was

designed.

• Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool´s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in

hazardous situations.

• Never use a machine that has been modified in any

way from its original specification.

• Make sure that no pipes or electrical cables are routed

in the working area or in the material to be cut.

• Always check and mark out where gas pipes are

routed. Cutting close to gas pipes always entails

danger. Make sure that sparks are not caused when

cutting in view of the risk of explosion. Remain

concentrated and focused on the task. Carelessness

can result in serious personal injury or death.

• The guard for the cutting equipment must always be

on when the machine is running.

Service

• Have your power tool serviced by a qualified repair

person unsing only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

10 – English

Page 11

SAFETY INSTRUCTIONS

Cutting blades

WARNING! A cutting blade may burst

and cause injury to the operator.

!

Never use a cutting blade at a lower

speed rating than that of the power

cutter.

Never use a cutting blade for any other

materials than that it was intended for.

General

• Cutting blades are available in two basic designs;

abrasive baldes and diamond blades.

• High-quality blades are often most economical. Lower

quality blades often have inferior cutting capacity and

a shorter service life, which results in a higher cost in

relation to the quantity of material that is cut.

• Make sure that the right bushing is used for the cutting

blade to be fitted on the machine. See the instructions

under the heading Assembling the cutting blade.

Suitable cutting blades

Cutting blades K3000 K3000 Wet

Abrasive blades Ye s Yes*

Diamond blades Ye s Ye s

Rescue blade No No

*Without water

Cutting blades for different materials

Concrete Metal Plastic

Abrasive blades X X X

Diamond blades X

Hand-held, high-speed machines

Our cutting blades are manufactured for high-speed,

portable power cutters. If blades from other

manufacturers are used, ensure that the blades conform

to all regulations and demands that concern this type of

power cutter.

Special blades

Some cutting blades are designed for stationary

equipment and for use with attachments.Such cutting

blades must not be used on portable power cutters.

Always contact local authorities and make sure you are

following applicable directives.

Blade vibration

The blade can become out-of-round and vibrate if an

excessive feed pressure is used.

A lower feed pressure can stop the vibration. Otherwise

replace the blade. The blade must be of the

recommended type for the material to be cut.

Abrasive blades

The cutting material on abrasive blades consists of grit

bonded using an organic binder. ”Reinforced blades” are

made up of a fabric or fibre base that prevents total

breakage at maximum working speed if the blade should

be cracked or damaged.

A cutting blade’s performance is determined by the type

and size of abrasive corn, and the type and hardness of

the bonding agent.

Check that the blade is approved for the same or higher

speed according to the aproval plate of the engine. Never

use a cutting blade with a lower speed rating than that of

the power cutter.

Ensure the blade it not cracked or damaged in any other

way.

Test the abrasive blade by hanging it on your finger and

tapping it lightly with a screwdriver or the like. If the blade

does not produce a resonant, ringing sound it is

damaged.

English – 11

Page 12

SAFETY INSTRUCTIONS

!

!

Abrasive blades for different materials

Blade type Material

Concrete, asphalt, stone

Concrete blade

Metal blade

masonry, cast iron, aluminium,

copper, brass, cables, rubber,

plastic, etc.

Steel, steel alloys and other

hard metals.

Sharpening diamond blades

Diamond blades can become dull when the wrong feeding

pressure is used or when cutting certain materials such

as heavily reinforced concrete. Working with a blunt

diamond blade causes overheating, which can result in

the diamond segments coming loose.

Sharpen the blade by cutting in a soft material such as

sandstone or brick.

Dry cutting with diamond blade

WARNING! Avoid using abrasive blades

with water. The strength is impaired

!

when abrasive blades are exposed to

moisture.

Diamond blades

WARNING! Cutting plastics with a

diamond blade can cause kickback when

!

the material melts due to the heat

produced when cutting and sticks to the

blade.

Diamond blades consist of a steel core provided with

segments that contain industrial diamonds.

Diamond blades ensure lower costs per cutting operation,

fewer blade changes and a constant cutting depth.

When using diamond blades make sure that it rotates in

the direction indicated by the arrow on the blade.

There is an arrow on the machine that indicates the axleís

direction of rotation that the blade is mounted on.

Always use a sharp diamond blade.

Material

Diamond blades are ideal for masonry, reinforced

concrete and other composite materials.

Diamond blades are available in several hardness

classes. A "soft" diamond blade has a relatively short

service life and large cutting capacity. It is used for hard

materials such as granite and hard concrete. A "hard"

diamond blade has a longer service life and reduced

cutting capacity, and should be used for soft materials

such as brick and asphalt.

WARNING! Diamond blades get very hot

when used. A heated blade can be

deformed and cause damage to the

machine as well as the user.

When dry cutting, lift the blade out from

the cut every 30–60 seconds and let it

rotate in the air for 10 seconds to let it

cool.

Wet cutting with diamond blade (K3000 Wet)

Water cooling, which is used when cutting concrete, cools

the blade and increases its service life while also reducing

the formation of dust.

WARNING! Diamond blades get very hot

when used. A heated blade can be

deformed and cause damage to the

machine as well as the user.

When wet cutting, the blade is

continuously cooled to prevent

overheating.

Water connection with flow limiter (K3000 Wet)

There is a flow limiter in the water connector that gives a

constant flow, irrespective of the water pressure. The flow

limiter may not be dismantled.

Transport and storage

• Do not store or transport the power cutter with the

cutting blade fitted. All blades should be removed from

the cutter after use and stored carefully.

• Special care should be taken with abrasive blades.

Abrasive blades must be stored on a flat, level

surface. If an abrasive blades is stored in humid

conditions, this can cause imbalance and result in

injury.

• Inspect new blades for transport or storage damage.

12 – English

Page 13

SAFETY INSTRUCTIONS

!

General working instructions

the material to be cut. This reduces the temperature of

the blade and ensures effective cutting.

WARNING! This section describes basic

safety directions for using a power

!

cutter. This information is never a

substitute for professional skills and

experience. If you get into a situation

where you feel unsafe, stop and seek

expert advice. Contact your dealer,

service agent or an experienced power

cutter user. Do not attempt any task that

you feel unsure of!

Cutting technique

The technique described below is of a general character.

Check information for each blade regarding individual

cutting characteristics (for example, diamond blades

requires less feeding pressure than an abrasive discs).

• Support the work piece in such a way that it is possible

to predict what will happen, and so that the cut

remains open while cutting.

• Ensure that the cutting blade is fitted correctly.

• Always hold the machine in a firm grip with both

hands. Hold it so that the thumbs and fingers grip

round the handles.

• The guard for the cutting equipment should be

adjusted so that the rear section is flush with the work

piece. Spatter and sparks from the material being cut

are then collected up by the guard and led away from

the user.

• Feed down the machine in line with the blade.

Pressure from the side can damage the blade and is

very dangerous.

WARNING! Under all circumstances

avoid grinding using the side of the

blade; it will almost certainly be

damaged, break and can cause immense

damage. Only use the cutting section.

Do not pull the power cutter to one side,

this can cause the blade to jam or break

resulting in injury to people.

• Check that the blade is not in contact with anything

when the machine is started

• Start cutting with the machine running at maximum

speed.

• Start cutting smoothly, allowing the machine to work

without forcing or pressing in the blade. Always cut at

maximum speed.

• Move the blade slowly forwards and backwards to

achieve a small contact area between the blade and

English – 13

Page 14

SAFETY INSTRUCTIONS

How to avoid kickback

WARNING! Kickback can happen very

suddenly and violently; kicking the

!

power cutter and cutting blade back at

the user. If this happens when the cutting

blade is moving it can cause very

serious, even fatal injuries. It is vital you

understand what causes kickback and

that you can avoid it by taking care and

using the right working technique.

What is kickback?

The word kickback is used to describe the sudden

reaction that causes the power cutter and cutting blade to

be thrown from an object when the upper quadrant of the

blade, known as the kickback zone, touches an object.

General rules

• Never start to cut with the upper quadrant of the blade

as shown in the figure, also known as the kickback

zone.

Pull in

Pull in occurs when the disc’s lower section suddenly

stops or when the cut closes. (To avoid, see the heading

”Basic rules” and ”Jamming/rotation”, here below.)

Pinching/rotation

If the cut is pressed together this can lead to jamming.

The machine can be pulled down suddenly with a very

powerful jerk.

How to avoid pinching

Support the work piece in such a way that the cut remains

open during the cutting operation and when the cut is

finished.

• Always hold the machine in a firm grip with both

hands. Hold it so that the thumbs and fingers grip

round the handles.

• Keep a good balance and a firm foothold.

• Always cut at maximum speed.

• Stand at a comfortable distance from the work piece.

• Take care when inserting the blade in an existing cut.

• Never cut above shoulder height.

• Be alert to movement of the work piece or anything

else that can occur, which could cause the cut to close

and pinch the blade.

14 – English

Page 15

ASSEMBLY

Assembly

WARNING! Always pull out the plug from

the outlet socket before cleaning,

!

maintenance or assembly.

Fitting the cutting blade

Husqvarna’s blades are approved for hand-held power

cutters. Blades are manufactured with three different

diameters of centre holes: 20 mm (0.787"), 22.2 mm (7/

8") and 25.4 mm (1"). Bushings can be fitted on the

machine axle to adjust the machine to the centre hole of

the blade. Use a bushing with the correct diameter! The

blades are marked with the diameter of the centre hole.

There is an arrow on the machine that indicates the axleís

direction of rotation that the blade is mounted on.

When the blade is replaced with a new one, check the

flange washers and the drive axle. See instructions under

the heading Checking the drive axle and flange washers.

Checking the drive shaft and flange

washers

Check that the threads on the drive shaft are undamaged.

Check that the contact surfaces on the blade and the

flange washers are undamaged, of the correct dimension,

clean, and that they run properly on the drive axle.

The blade is placed on the bushing (C) between the inner

flange washer (A) and the flange washer (B). The flange

washer is turned so that it fits on the axle.

Tightening torque for the bolt holding the blade is: 15-25

Nm (130-215 in.lb).

The cutting blade/axle can be locked by holding in the

locking button on the rear of the machine. The button is

spring-loaded and is reset when button is released.

When a diamond blade is mounted on the power cutter

make sure that the diamond blade will rotate in the

direction indicated by the arrow on the blade.

Do not use warped, notched, indented or dirty flange

washers. Do not use different dimensions of flange

washers.

Guard for the blade

The guard must always be fitted on the machine.

The guard for the cutting equipment should be adjusted

so that the rear section is flush with the work piece.

Spatter and sparks from the material being cut are then

collected up by the guard and led away from the user.

English – 15

Page 16

STARTING AND STOPPING

!

Before starting

WARNING! Note the following before

starting:

!

The machine should be connected to an

earthed outlet socket.

Check that the mains voltage

corresponds with that stated on the

rating plate on the machine.

Make sure you have a secure footing and

that the cutting blade cannot touch

anything.

Keep people and animals well away from

the working area.

K3000 Wet

WARNING! The machine (Great Britain

120V) is not equipped with a ground fault

!

circuit interrupter. The machine must

always be used with an isolating

transformer for protection in case an

electrical fault should occur.

Water connector

• Connect the water hose to the water supply (A). The

water is switched on and off with the water tap (B).

Starting

• Grip the front handle with the left hand.

• Grip the rear handle with your right hand.

• Press in the power switch lock with your right-hand

thumb and press in the power switch.

• Run the machine unloaded and in a safe manner for

at least 30 seconds.

Stopping

WARNING! The cutting blade continues

to rotate for some time after the motor

has stopped.

Stop the motor by releasing the power switch.

16 – English

Page 17

MAINTENANCE

!

General

WARNING! Inspection and/or

maintenance should be carried out with

!

the motor switched off and the plug

disconnected.

Cleaning

Cooling system

The machine is equipped with an efficient fan to cool the

motor. Cooling air which is drawn in through the grille by

the machines rear handle passes over the stator and rotor

and out through the front of the motor housing.

In order for the machine to always be cooled sufficiently

the cooling air openings must be kept clear and clean.

Blow down the machine regularly with compressed air.

K3000

turn can cause the ground fault circuit interrupter to turn

off without intention.

• Clean the machine daily by rinsing it with clean water

after the work is finished.

• Place the machine with the rear handle facing

upwards. Rinse the air intakes at the rear handle with

clean water. The water will run out through the front air

outlets.

• Connect the plug and run the engine dry for approx.

30 sec in order to speed up the drying of the engine.

Electrical Feed

WARNING! Never use damaged cables.

They can cause serious, even fatal,

personal injuries.

Check that the cord and extension cord are intact and in

good condition. Never use the machine if the cord is

damaged, hand it in to an authorized service workshop for

repair.

Replacing the carbon brushes

Check the carbon brushes at least once a month. The

carbon brushes should be replaced with new brushes if

they are worn, cracked or in any other way deformed.

All carbon brushes must be replaced when the brushes

are replaced.

• Remove both inspection covers by loosening both

screws.

WARNING! K3000 is not equipped with

ground fault circuit interrupter. Do not

!

wash the machine with water, as water

can enter the electrical system or the

engine and cause damage to the

machine or short circuit.

K3000 Wet

WARNING! Do not use a high pressure

washer when rinsing the inside of the

!

machine.

The machine can withstand taking in damp air and

splashes during the cutting process. Clean water does

not affect the machine’s function.

When cutting materials such as concrete or brick, which

can contain salt, you must rinse the machine after the

work is finished. The cleaning reduces the risk for

accretions building up inside the engine, which can cause

leakage current between electric components, which in

• Unscrew the cable holding the carbon brush. Now lift

up the spring and then lift out the carbon brush from

the brush retainer.

• Clean the brush retainers with a dry brush.

• Carefully blow away the dust.

• Fit the new carbon brushes and, at the same time,

check that they slide easily in the brush retainers.

• Fold down the springs and tighten the cable.

• New carbon brushes must be run in for approximately

40 minutes while idling.

English – 17

Page 18

MAINTENANCE

Bevel gear

The grease in the gear housing should be changed every

4 months. Use high quality gear grease

The gear housing must not be filled completely with

grease. The grease expands as the machine heats up

during operation. If the gear housing was completely filled

with grease it could damage the seals and lead to leakage

of grease.

The gear housing should contain 90 g of grease in total.

Changing the grease

The following parts must be dismantled to change the

grease in the gear housing:

1 Flange washers holding the cutting blade

2 The sealing ring

3 Support flange for the guard

4 Guard for the blade

5 The four screws holding the shield. Lift the shield

together with the drive wheel unit out of the gear

housing.

Checking the drive shaft and

flange washers

Check that the threads on the drive shaft are undamaged.

Check that the contact surfaces on the blade and the

flange washers are undamaged, of the correct dimension,

clean, and that they run properly on the drive axle.

Do not use warped, notched, indented or dirty flange

washers. Do not use different dimensions of flange

washers.

Checking water connection with

flow limiter

Check and clean the filter in the connection regularly and

change it when needed.

1 Unscrew the connector.

2 Press out the filter (A) using a screwdriver or the like.

3 Clean or change the filter.

4 When refitting - make sure that the flow limiter (B) is

correctly adjusted, with the concave face turned

towards the clutch connection.

Daily maintenance

6 Wipe out the grease and fill with new, good quality

gear grease. The gear housing should contain 90 g of

grease in total.

CAUTION! Exercise care when dismantling so as not to

damage the gaskets. These are used both as seals and

spacers for the gear setting.

18 – English

1 Check that nuts and screws are tight.

2 Check that the power switch unit works smoothly.

3 Clean the outside of the machine.

4 Checking the blade guard

5 Check the condition of the cutting blade.

6 Check and clean the cooling air openings.

7 Check that the cord and extension cord are intact and

in good condition.

Page 19

TECHNICAL DATA

Technical data K3000 K3000 Wet

Engine

Protection class I I

Ground fault circuit interrupter No Ye s

Rated voltage, V

Europe 230 230

Great Britain 110 110

USA / Canada / Japan 100-120 100-120

Australia 230 230

Rated output, W

Europe 2700/12 A 2700/12 A

Great Britain 2200/20 A 2200/20 A

USA / Canada / Japan 15 A, 50-60 Hz 15 A, 50-60 Hz

Australia 2300/10 A 2300/10 A

Weight

Machine without blade and cable package, kg 7,6 8,2

Water cooling

Water cooling of blade No Ye s

Connecting nipple Type ”Gardena” Type ”Gardena”

Water pressure - max, bar - 8

Noise emissions (see note 1)

Sound power level, measured dB(A) 104 105

Sound power level, guaranteed dB(A) 104 105

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 95 95

Vibration levels (see note 3)

Front handle, m/s

Rear handle, m/s

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EN 60745-1.

Note 2: Noise pressure level according to EN 60745-1. Reported data for noise pressure level has a typical statistical

dispersion (standard deviation) of 1.0 dB(A).

Note 3: Vibration level according to EN 60745-1. Reported data for vibration level has a typical statistical dispersion

(standard deviation) of 1 m/s

2

2

2

.

3,5 3,5

3,5 3,5

English – 19

Page 20

TECHNICAL DATA

Cutting equipment

Cutting blade, mm/inches Max. peripheral speed, m/s

300/12 80

350/14 100

Max. blade speed, rpm

4500

Recommended cable dimensions

Cable area 1,5 mm22,5 mm

Input voltage 100-120 V 20 m 40 m

Input voltage 220-240 V 30 m 50 m

2

20 – English

Page 21

TECHNICAL DATA

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that the power

cutter

Husqvarna K3000, K3000 Wet dating from 2010 serial numbers and onwards (the year is clearly stated on the

rating plate, followed by the serial number), complies with the requirements of the COUNCILíS DIRECTIVE:

• of May 17, 2006 "relating to machinery" 2006/42/EC

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 610003-2:2006, EN 61000-3-3/A1/A2:2005, EN 60745-1:2009, IEC 60745-2-22:2009.

Göteborg December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

English – 21

Page 22

1153343-26

Original instructions

´®z+UB@¶60¨

´®z+UB@¶60¨

2009-12-29

Loading...

Loading...