Operator’s manual, Manuel d’utilisation

Manual de instrucctiones,Bedienungsanweisung

Istruzioni per l’uso,

操作手册

K 1270R

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Prima di usare la macchina, leggere per intero le istruzioni per l’uso e accertarsi di averne compreso il contenuto.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

请认真阅读本操作手册,确保在充分理解各项说明之后再使用机器。

EN FR ES DE IT CN

!

!

2

W

W

W

CA

NO

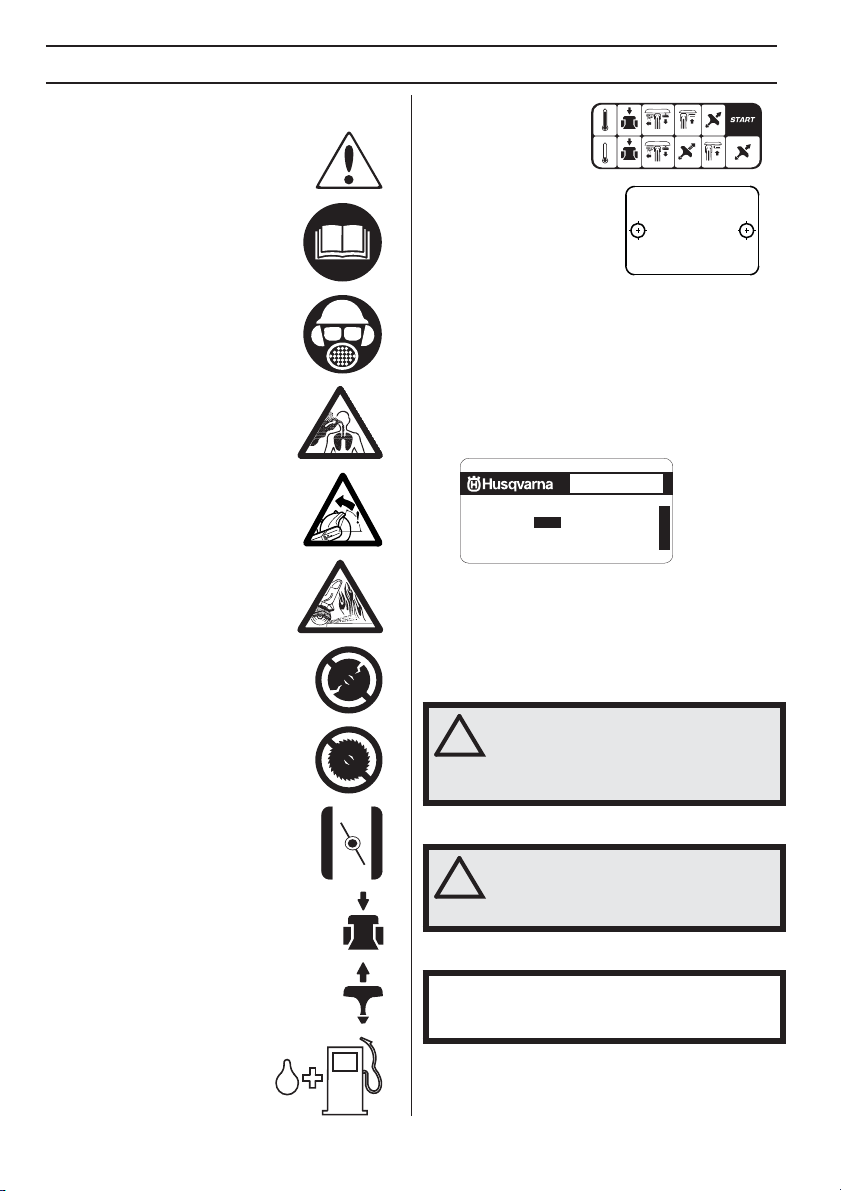

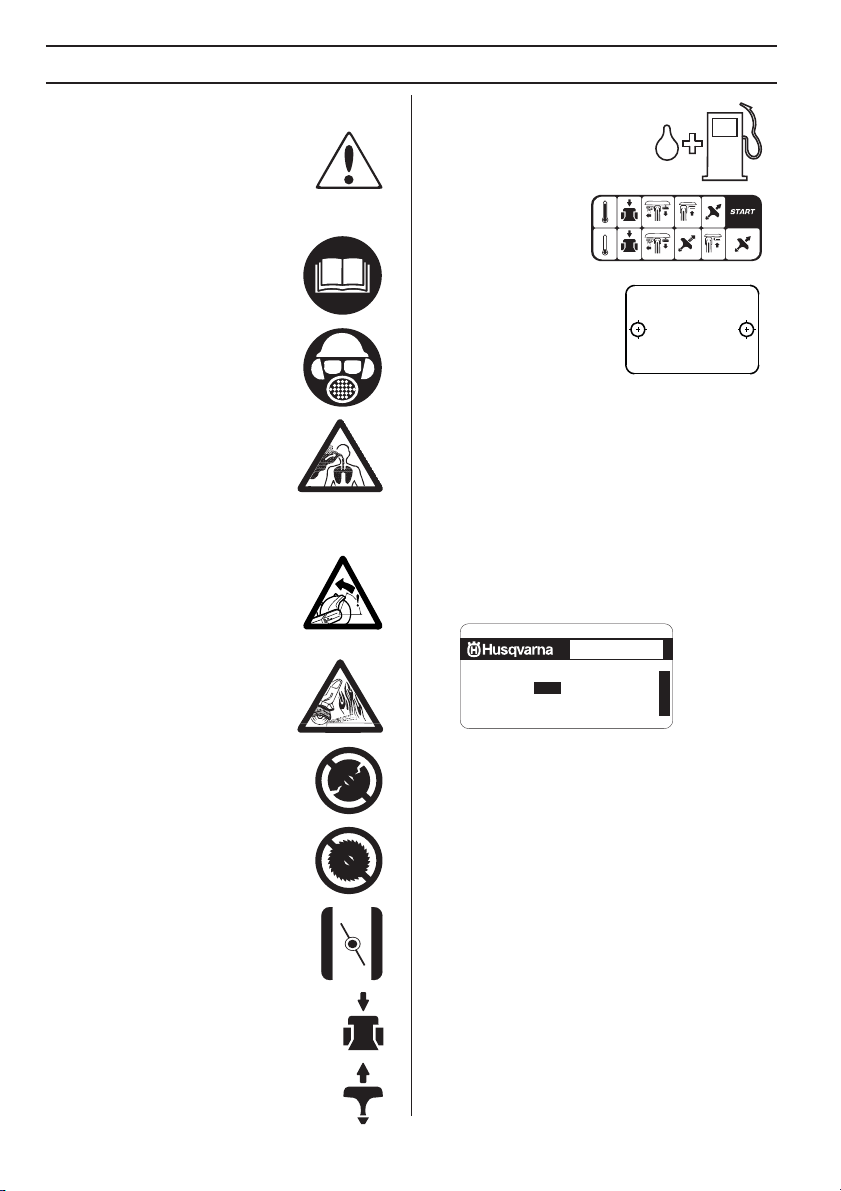

Symbols on the mac hine

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Wear personal protective equipment.

See instructions under the ”Personal

protective equipment” heading.

WARNING! Dust forms when cutting,

this can cause injuries if inhaled. Use

an approved breathing mask. Avoid

inhaling exhaust fumes. Always

provide for good ventilation.

WARNING! Kickbacks can be sudden,

rapid and violent and can cause life

threatening injuries. Read and

understand the instructions in the

manual before using the machine.

WARNING! Sparks from the cutting

blade can cause fire in combustible

materials such as: petrol (gas), wood,

dry grass etc.

Ensure the blades are not cracked or

damaged in any other way.

KEY T O SYMBOLS

Starting instruction

decal See instructions

under the heading

Starting and stopping.

Type plate

Row 1: Brand, Model (X,Y)

Row 2: Serial No. with

manufacturing date (y, W, X):

Year, Week, Sequence No.

Row 3: Product No. (X)

Row 4: Manufacturer

Row 5: Manufacturer address

Row 6-7: If applicable, EC typ-approval (X, Y): Approval

code, Approval stage

The Emissions Compliance Period referred to on the

Emission Compliance label indicates the number of

operating hours for which the engine has been shown to

meet Federal and Californian emissions requirements.

EMISSION CONTROL INFORMATION

HUSQVARNA AB, HUSKVARNA, MADE IN SWEDEN

THIS ENGINE MEETS U.S. EPA EXH/EVP

REGS FOR 2016 SORE. REFER TO

OPERATOR’S MANUAL FOR MAINTENANCE

SPECIFICATIONS AND ADJUSTMENTS.

EMISSIONS COMPLIANCE PERIOD: 300 HRS

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

Explanation of warning le vels

The w arnings are graded in three levels.

ARNING!

2016

XXXXXXXXX YYYY

s / n YYYY WWXXXXX

XXX XX XX-XX

Husqvarna AB

Huskvarna, SWEDEN

XXXXXXXXXXX

XXXXXXXXXXXX (YY)

®

EM/N74ccB0

30-5

43

6

105

Do not use circular saw blades

Choke.

Decompression valve

Starter handle

Refuelling, petrol/oil mix

– English

ARNING! Used if there is a risk of

serious injury or death for the operator

or damage to the surroundings if the

instructions in the manual are not

followed.

CAUTION!

UTION! Used if there is a risk of injury

to the operator or damage to the

surroundings if the instructions in the

manual are not followed.

NOTICE!

TICE! Used if there is a risk of damage to materials

or the machine if the instructions in the manual are not

followed.

u

t

h

m

MA

ST

TR

T

T

Y

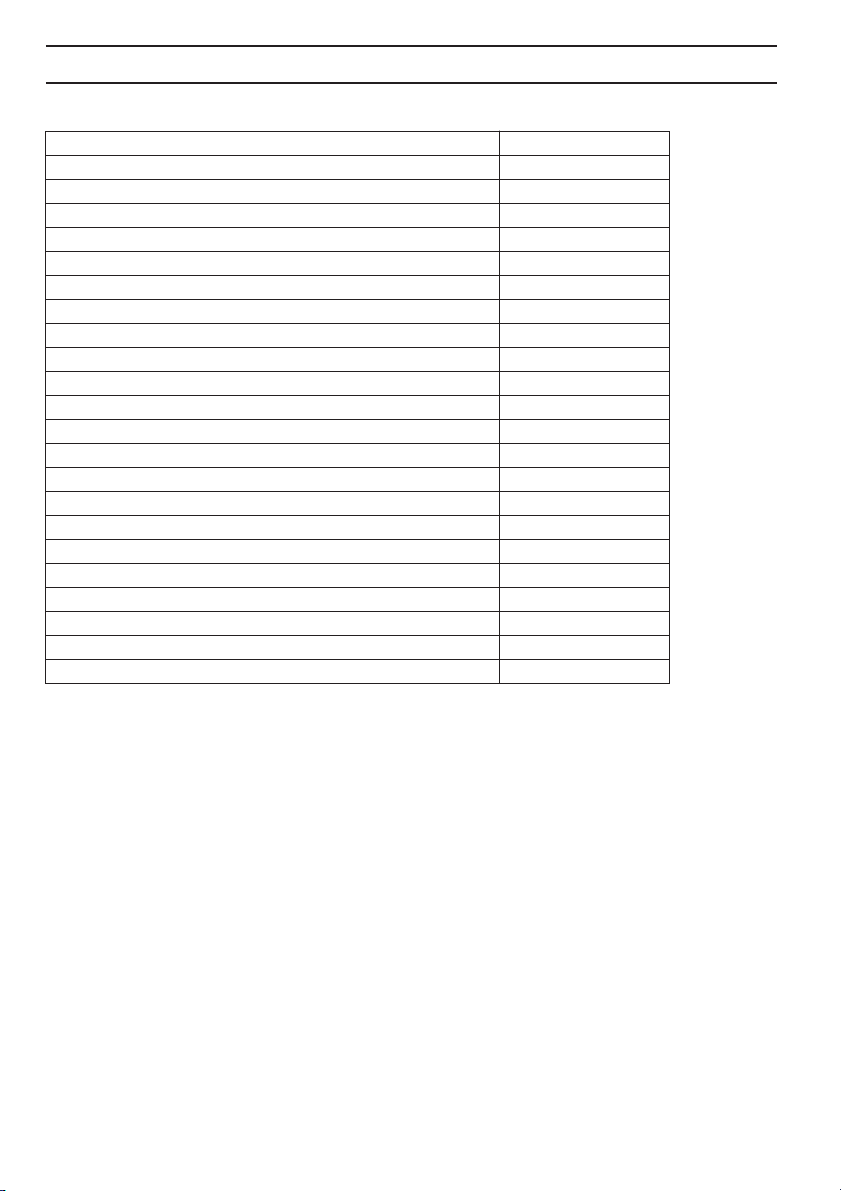

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine ...................................... 2

Explanation of warning levels ............................... 2

CONTENTS

Contents ............................................................... 3

Note the following before starting: ........................ 3

PRESENT ATION

Dear Customer , .................................................... 4

Design and features ............................................. 4

WHA T IS WHAT?

What is what on the machine? ............................. 5

CHINE´S SAFETY EQUIPMENT

Gener al ................................................................. 6

OPERA TING

Protectiv e equipment ............................................ 8

FUEL HANDLING

Gener al ................................................................. 9

Fuel ...................................................................... 9

Fueling .................................................................. 10

Transport and storage .......................................... 10

ARTING AND STOPPING

Bef ore starting ...................................................... 11

Starting ................................................................. 11

Stopping ............................................................... 12

MAINTENANCE

Gener al ................................................................. 13

Maintenance schedule ......................................... 13

Cleaning ............................................................... 13

Functional inspection ............................................ 14

OUBLESHOOTING

roubleshooting schedule ..................................... 17

TECHNICAL D ATA

echnical data ...................................................... 18

Declaration of conformity of partly completed

machinery .............................................................

FEDERAL EMISSION CONTR OL WARRANTY

STATEMENT

OUR WARRANTY RIGHTS AND OBLIGATIONS 20

Note the f ollowing before starting:

The engine exhaust from this prod

contains chemicals known to the S

of California to cause cancer, birt

defects or other reproductive har

NOTICE! CALIFORNIA AIR RESOURCES BOARD

(CARB):

This machine is considered a preempt OffRoad Applicatoin as relating to CARB standards. The

U.S. EPA has sole authority to establish emission

standards for preempt construction equipment. For

more information see www.arb.ca.gov/msprog/offroad/

preempt.htm

19

English

–

3

4

PRESENT A TION

Dear Customer ,

Thank y ou for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product

and that it will be your companion for a long time. A

purchase of one of our products gives you access to

professional help with repairs and services. If the retailer

who sells your machine is not one of our authorized

dealers, ask him for the address of your nearest service

workshop.

This operator’s manual is a valuable document. Make

sure it is always at hand at the work place. By following its

content (operating, service, maintenance etc.) the life

span and the second-hand value of the machine can be

extended. If you will sell this machine, make sure that the

buyer will get the operator´s manual.

More than 300 y ears of innovation

Husqv arna AB is a Swedish company based on a tradition

that dates back to 1689, when the Swedish King Karl XI

ordered the construction of a factory for production of

muskets. At that time, the foundation was already laid for

the engineering skills behind the development of some of

the world's leading products in areas such as hunting

weapons, bicycles, motorcycles, domestic appliances,

sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products

for forestry, park maintenance and lawn and garden care,

as well as cutting equipment and diamond tools for the

construction and stone industries.

Owner responsibility

It is the o wner’s/employer’s responsibility that the operator

has sufficient knowledge about how to use the machine

safely. Supervisors and operators must have read and

understood the Operator’s Manual. They must be aware

of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

National legislation could regulate the use of this

machine. Find out what legislation is applicable in the

place where you work before you start using the machine.

Local regulations could restrict the use of this machine.

Find out what regulations are applicable where you work

before you start using the machine.

The man ufacturer’s reservation

Subsequent to pub lishing this manual Husqvarna may

issue additional information for safe operation of this

product. It is the owner’s obligation to keep up with the

safest methods of operation.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

For customer information and assistance, contact us at

our website: www.husqvarna.com

– English

Design and f eatures

This po wer unit is a partly completed machinery, intended

for OEM design of a hand held high speed power cutter.

Some of the unique features of your product are

described below.

Active Air Filtration™

Centr ifugal air cleaning for longer service life and longer

service intervals.

Smar tCarb™

Built-in automatic fi lter compensation maintains high

power and reduces fuel consumption.

X-T orq®

The X-T orq® engine provides a more accessible torque

for a wider range of speeds which results in maximum

cutting capacity. X-Torq® reduces the fuel consumption

by up to 20% and the emissions by up to 60%.

EasyStar t

The engine and star ter are designed to ensure quick and

easy starting of the machine. Reduces the pull resistance

in the starter cord by up to 40%. (Reduces the

compression during starting.)

Effi cient vibration damping system

Effi cient vibration dampers spare arms and hands.

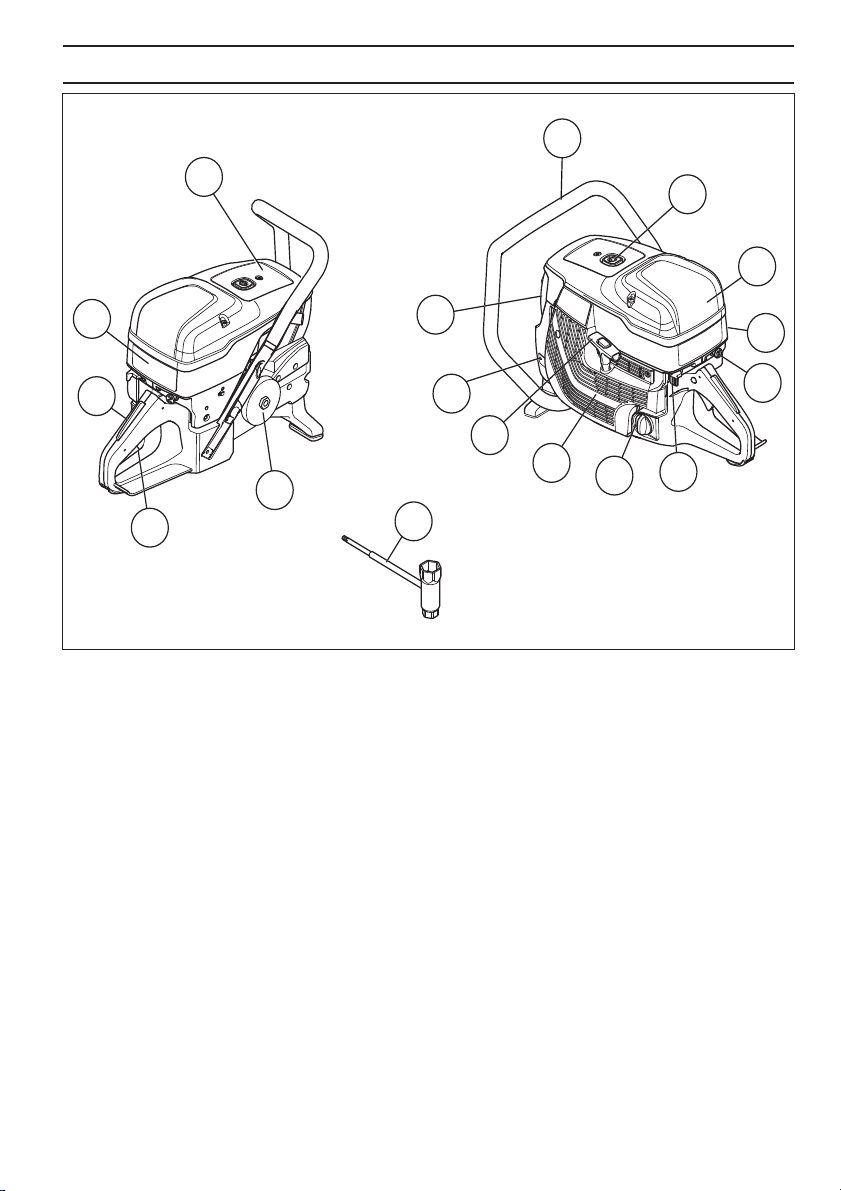

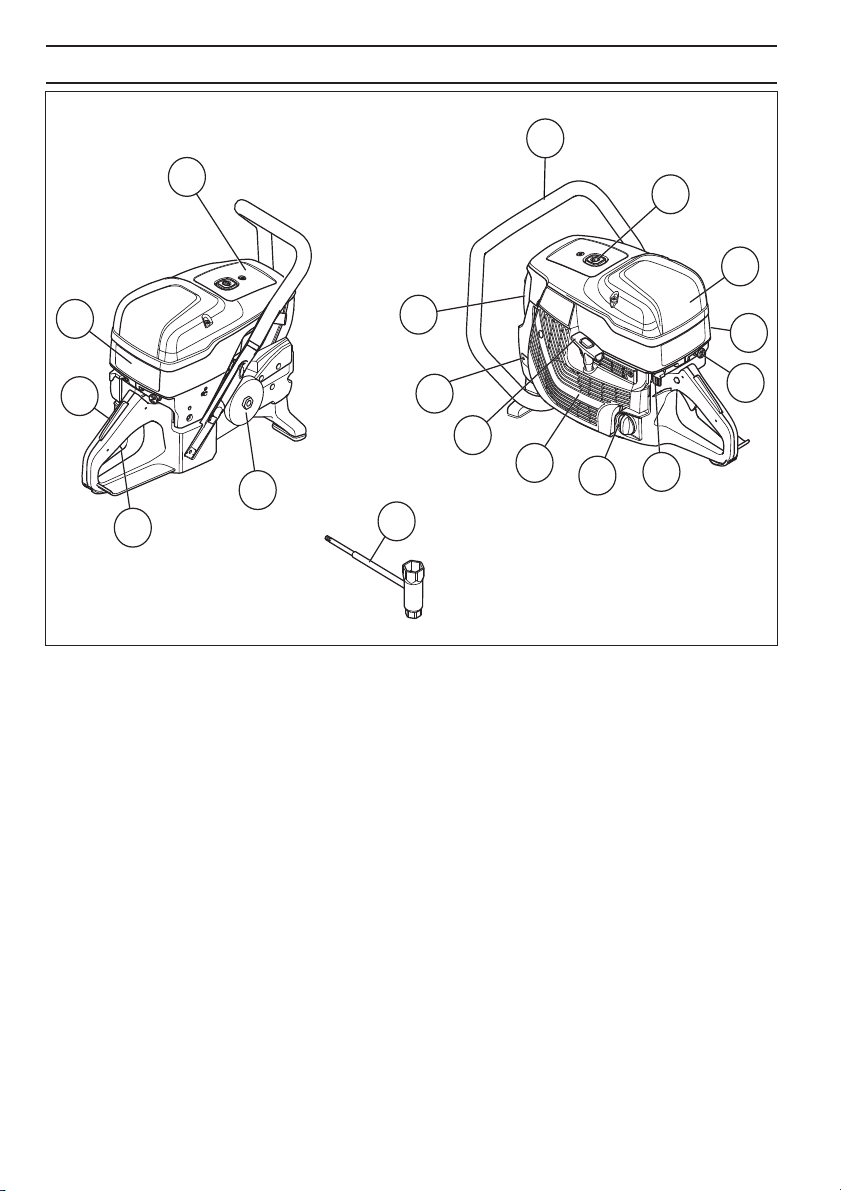

WHA T IS WHA T?

1

1

16

15

14

12

13

What is what on the mac hine?

Front handle

2 Decompression valve

3 Air filter cover

4 Cylinder cover

5 Choke control with start throttle lock

6 Stop switch

7 Fuel cap

8 Starter housing

9 Starter handle

11

10

9

8

17

10 Type plate

11 Muffler

12 Drive gear and clutch

13 Throttle trigger

14 Throttle trigger lockout

15 Starting instruction decal

16 Information and warning decal

17 Combination spanner, torx

2

3

4

5

7

6

English – 5

CHINE´S SAFETY EQ UIPMENT

General

ARNING! Never use a machine that has

faulty safety equipment! If your machine

!

fails any checks contact your service

agent to get it repaired.

The engine should be switched off, and

the stop switch in STOP position.

This section descr ibes the machine´s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly.

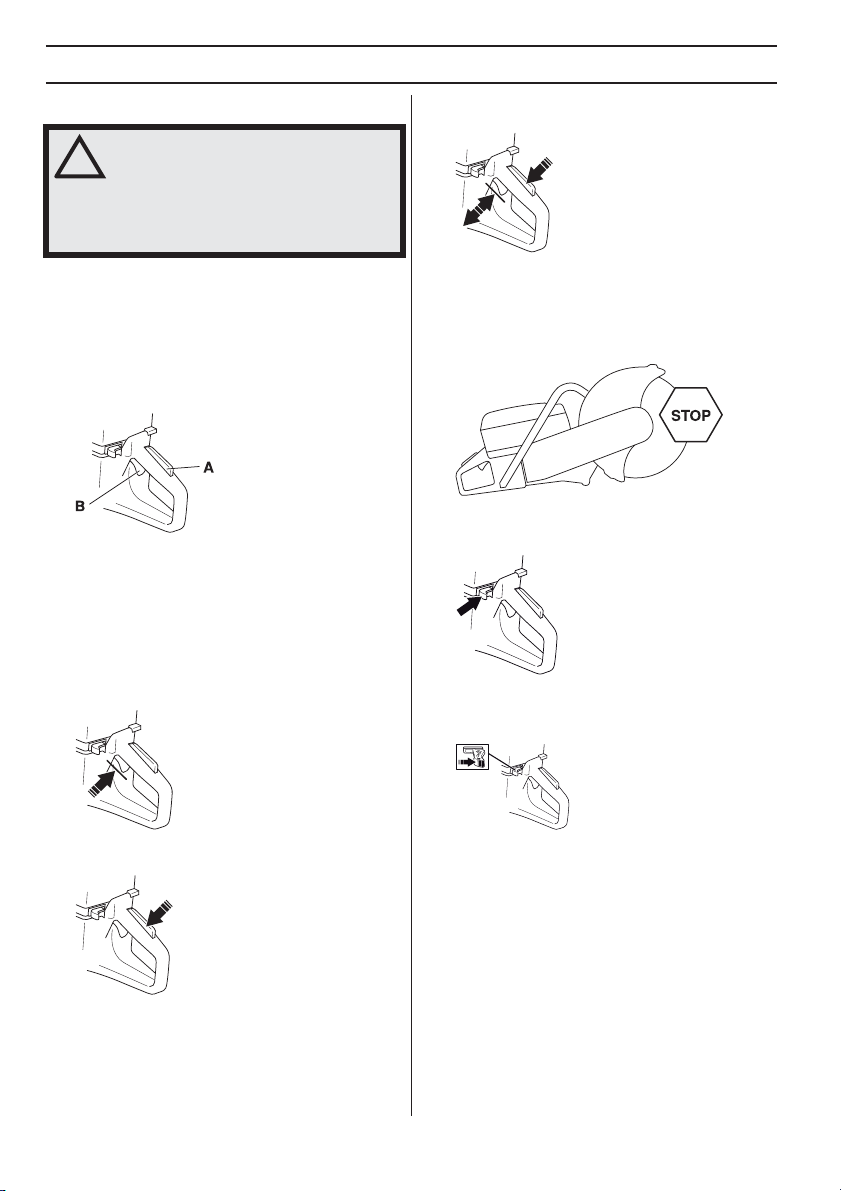

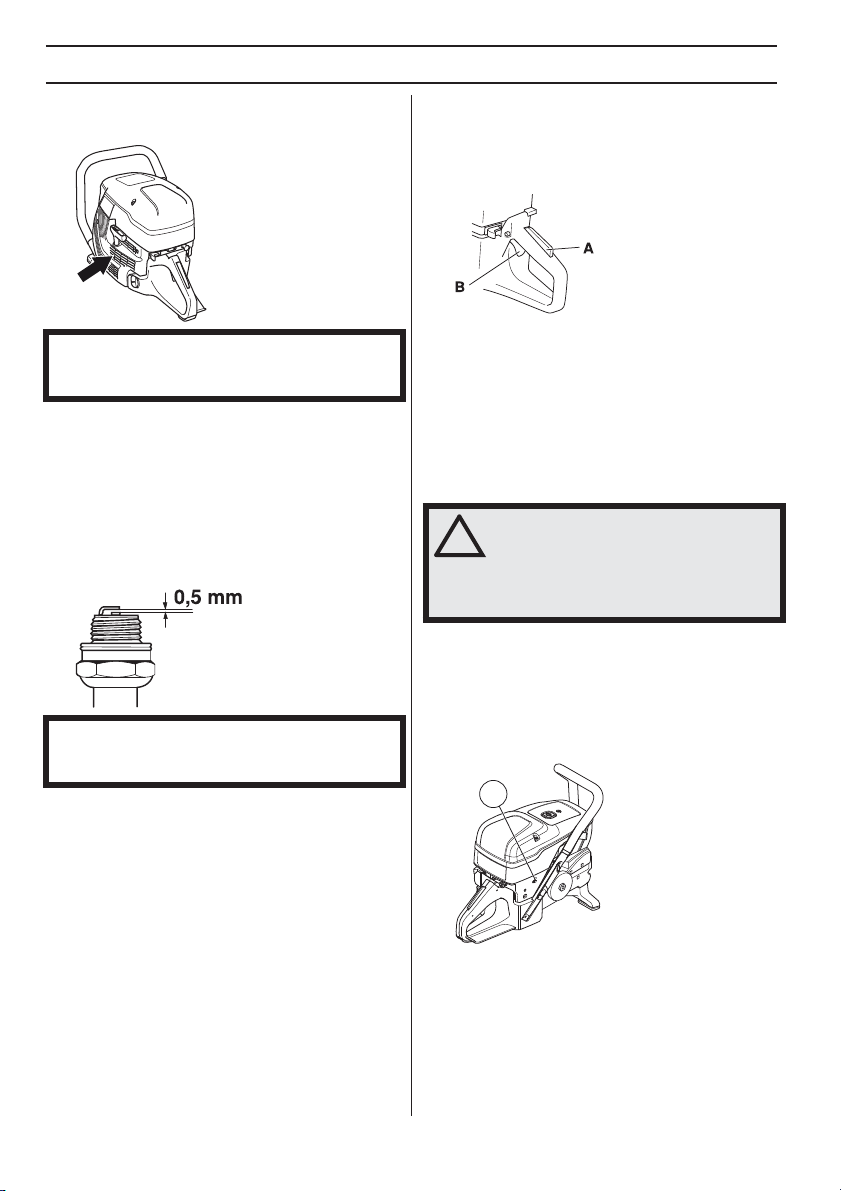

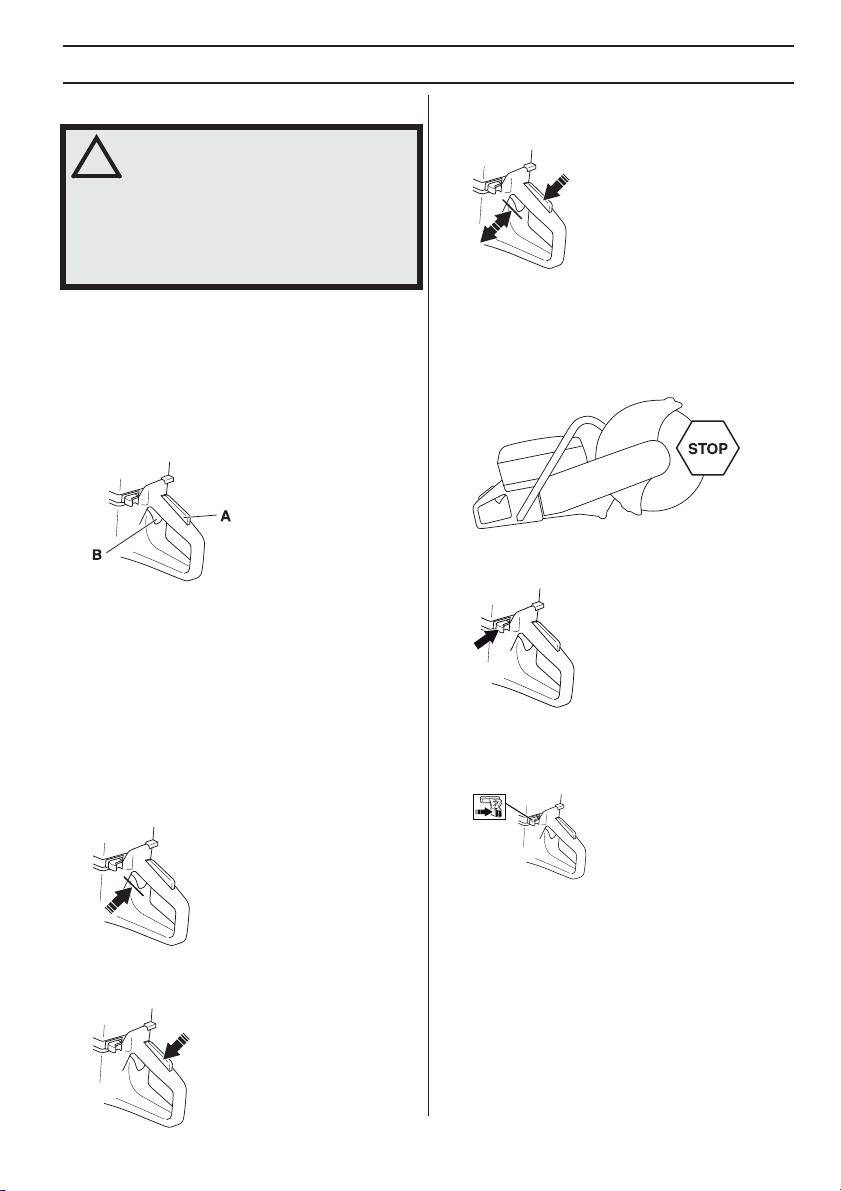

Thr ottle trigger lockout

The throttle tr igger lock is designed to prevent accidental

operation of the throttle. When the lock (A) is pressed in

this releases the throttle (B).

The trigger lock remains pressed in as long as the throttle

is pressed. When the grip on the handle is released the

throttle trigger and the throttle trigger lock both return to

their original positions. This is controlled by two

independent return spring systems. This means that the

throttle trigger is automatically locked in the idle position.

Chec king the throttle lockout

Make sure the throttle control is locked at the idle

setting when the throttle lockout is released.

MA

6

•

• Check that the throttle trigger and throttle lockout

move freely and that the return springs work properly.

• Start the power cutter and apply full throttle. Release

the throttle control and check that the cutting blade

stops and remains stationary. If the cutting blade

rotates when the throttle is in the idle position you

should check the carburettor’s idle adjustment. See

instructions in the section "Maintenance".

Stop s witch

Use the stop s witch to switch off the engine.

Chec king the stop switch

Start the engine and make sure the engine stops

when you move the stop switch to the stop setting.

•

W

• Press the throttle lockout and make sure it returns to

its original position when you release it.

– English

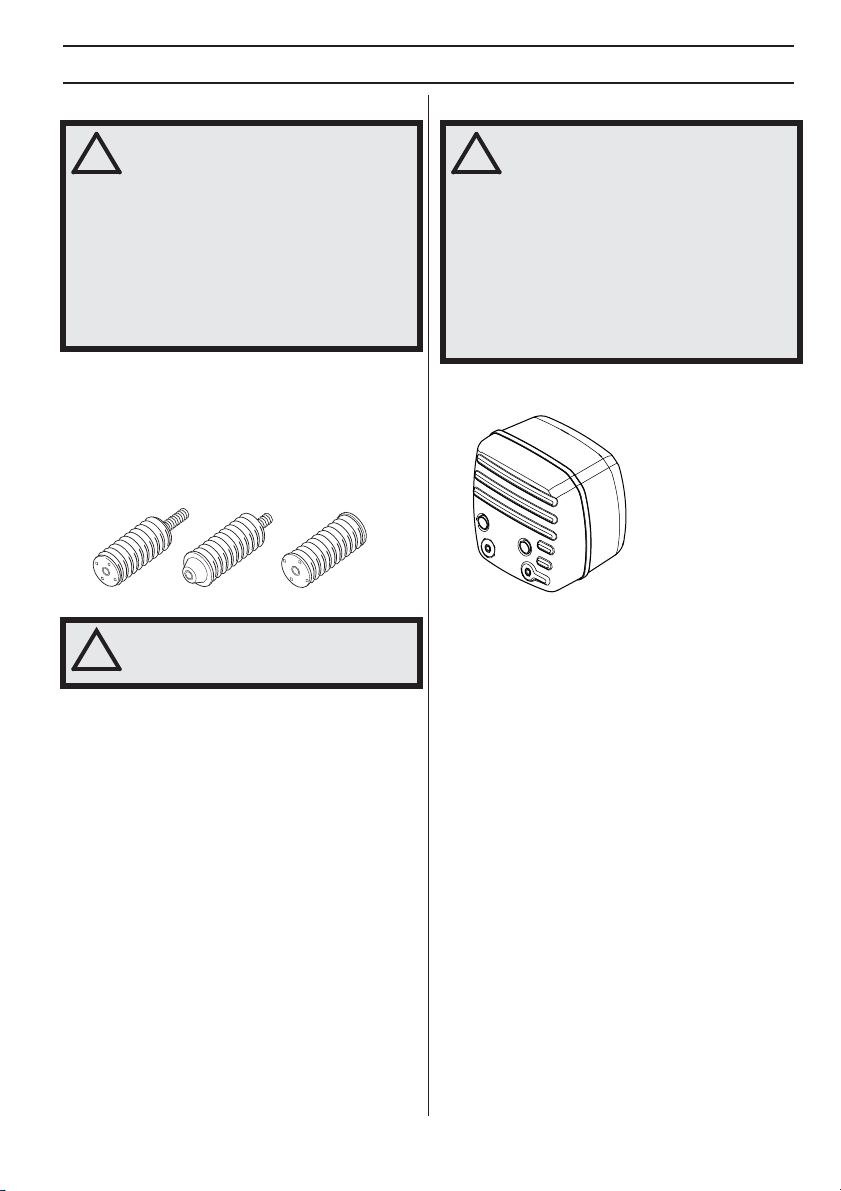

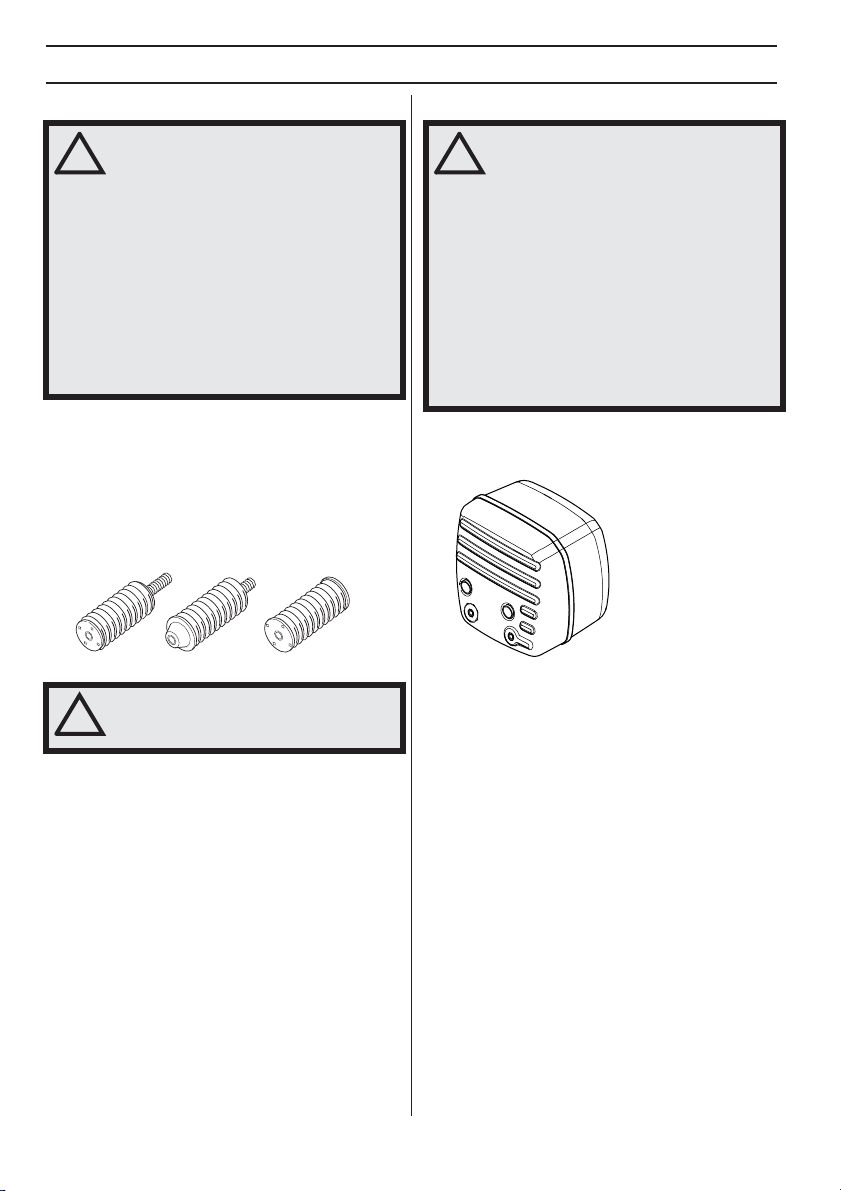

Vibration damping system

!

CHINE´S SAFETY EQ UIPMENT

Muffler

MA

•

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. These

symptoms may be increased in cold

temperatures.

Your machine is equipped with a vibration damping

system that is designed to minimize vibration and

make operation easier.

• The machine ′ s vibration damping system reduces the

transfer of vibration between the engine unit/cutting

equipment and the machine

body, including the cutting equipment, is insulated

from the handles by vibration damping units.

Checking the vibration damping system

WARNING! The engine should be

switched off, and the stop switch in

!

STOP position.

• Check the vibration damping units regularly for cracks

or deformation. Replace them if damaged.

• Check that the vibration damping element is securely

attached between the engine unit and handle unit.

′s handle unit. The engine

WARNING! Never use a machine without

a muffler, or with a faulty muffler. A

damaged muffler may substantially

increase the noise level and the fire

hazard. Keep fire fighting equipment

handy.

The muffler gets very hot during and

after use as well as when idling. Be

aware of the fire hazard, especially when

working near flammable substances and/

or vapours.

Keep fire fighting equipment handy.

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

Inspecting the muffler

Check regularly that the muffler is complete and secured

correctly.

English

–

7

OPERATING

Protective equipment

General

Do not use the machine unless you are able to call for

help in the event of an accident.

Personal protective equipment

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

WARNING! The use of products such as

cutters, grinders, drills, that sand or form

!

material can generate dust and vapours

which may contain hazardous chemicals.

Check the nature of the material you

intend to process and use an appropriate

breathing mask.

Long-term exposure to noise can result

in permanent hearing impairment. So

always use approved hearing protection.

Listen out for warning signals or shouts

when you are wearing hearing

protection. Always remove your hearing

protection as soon as the engine stops.

Always wear:

• Approved protective helmet

• Hearing protection

• Approved eye protection. If you use a face shield then

you must also wear approved protective goggles.

Approved protective goggles must comply with

standard ANSI Z87.1 in the USA or EN 166 in EU

countries. Visors must comply with standard EN 1731.

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement. Cutting generates

sparks that can ignite clothing. Husqvarna

recommends that you wear flame-retardant cotton or

heavy denim. Do not wear clothing made of material

such as nylon, polyester or rayon. If ignited such

material can melt and cling to the skin. Do not wear

shorts

• Boots with steel toe-caps and non-slip sole.

Other protective equipment

CAUTION! Sparks may appear and start a

fire when you work with the machine.

!

Always keep fire fighting equipment

handy.

• Fire Extinguisher

• First aid kit

8 – English

FUEL HANDLING

General

WARNING! Running an engine in a

confined or badly ventilated area can

!

result in death due to asphyxiation or

carbon monoxide poisoning. Use fans to

ensure proper air circulation when

working in trenches or ditches deeper

than one meter.

Fuel and fuel fumes are flammable and

can cause serious injury when inhaled or

allowed to come in contact with the skin.

For this reason observe caution when

handling fuel and make sure there is

adequate ventilation.

The exhaust fumes from the engine are

hot and may contain sparks which can

start a fire. Never start the machine

indoors or near combustible material!

Do not smoke and do not place any hot

objects in the vicinity of fuel.

Fuel

NOTICE! The machine is equipped with a two-stroke

engine and must always be run using a mixture of petrol

and two-stroke oil. It is important to accurately measure

the amount of oil to be mixed to ensure that the correct

mixture is obtained. When mixing small amounts of fuel,

even small inaccuracies can drastically affect the ratio of

the mixture.

Petrol

• Use good quality unleaded or leaded petrol.

• The lowest octane recommended is 90 (RON). If you

run the engine on a lower octane grade than 90 socalled knocking can occur. This gives rise to a high

engine temperature, which can result in serious

engine damage.

• When working at continuous high revs a higher octane

rating is recommended.

Environment fuel

HUSQVARNA recommends the use of alkylate fuel,

either Aspen two-stroke fuel or environmental fuel for

four-stroke engines blended with two-stroke oil as set out

below. Note that carburettor adjustment may be

necessary when changing the type of fuel (see the

instructions under the heading Carburettor).

Ethanol blended fuel, E10 may be used (max 10%

ethanol blend). Using ethanol blends higher than E10 will

create lean running condition which can cause engine

damage.

Two-stroke oil

• For best results and performance use HUSQVARNA

two-stroke engine oil, which is specially formulated for

our air-cooled two-stroke engines.

• Never use two-stroke oil intended for water-cooled

engines, sometimes referred to as outboard oil (rated

TCW).

• Never use oil intended for four-stroke engines.

Mixing

• Always mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to

be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

petrol.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

Mixing ratio

• 1:50 (2%) with HUSQVARNA two-stroke oil or

equivalent.

Petrol, litre Two-stroke oil, litre

2% (1:50)

5 0,10

10 0,20

15 0,30

20 0,40

• 1:33 (3%) with oils class JASO FB or ISO EGB

formulated for air-cooled, two-stroke engines or mix

as per recommendation from the oil manufacturer.

English – 9

Fueling

!

FUEL HANDLING

WARNING! Taking the following

precautions, will lessen the risk of fire:

Do not smoke and do not place any hot

objects in the vicinity of fuel.

Always stop the engine and let it cool for

a few minutes before refuelling. The

engine should be switched off, and the

stop switch in STOP position.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Clean the area around the fuel cap.

Tighten the fuel cap carefully after

refuelling.

If the cap is not properly tightened the

cap might vibrate lose and fuel may

escape from the fuel tank creating a fire

hazard.

Move the machine at least 3 m from the

refuelling point before starting it.

Never start the machine:

• If you have spilled fuel or engine oil on the machine.

Wipe off the spill and allow the remaining fuel to

evaporate.

• If you have spilled fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

• If the machine is leaking fuel. Check regularly for

leaks from the fuel cap and fuel lines.

• Unless the fuel cap is securely tightened after

refueling.

Transport and storage

• Store and transport the machine and fuel so that there

is no risk of any leakage or fumes coming into contact

with sparks or open flames, for example, from

electrical machinery, electric motors, electrical relays/

switches or boilers.

• When storing and transporting fuel always use

approved containers intended for this purpose.

Long-term storage

• When storing the machine for long periods the fuel

tank must be emptied. Contact your local petrol

station to find out where to dispose of excess fuel.

10 – English

STARTING AND STOPPING

Before starting

WARNING! Note the following before

starting: Please read the operator’s

!

manual carefully and make sure you

understand the instructions before using

the machine.

Wear personal protective equipment. See

under heading ”Personal protective

equipment”.

Do not start the machine without the belt

and belt guard fitted. Otherwise the

clutch could come loose and cause

personal injuries.

Check that the fuel cap is properly

secured, and that there is no fuel

leakage.

Make sure no unauthorised persons are

in the working area, otherwise there is a

risk of serious personal injury.

• Perform daily maintenance. See instructions in the

section "Maintenance".

Starting

WARNING! The cutting blade rotates

when the engine is started. Make sure it

!

can rotate freely.

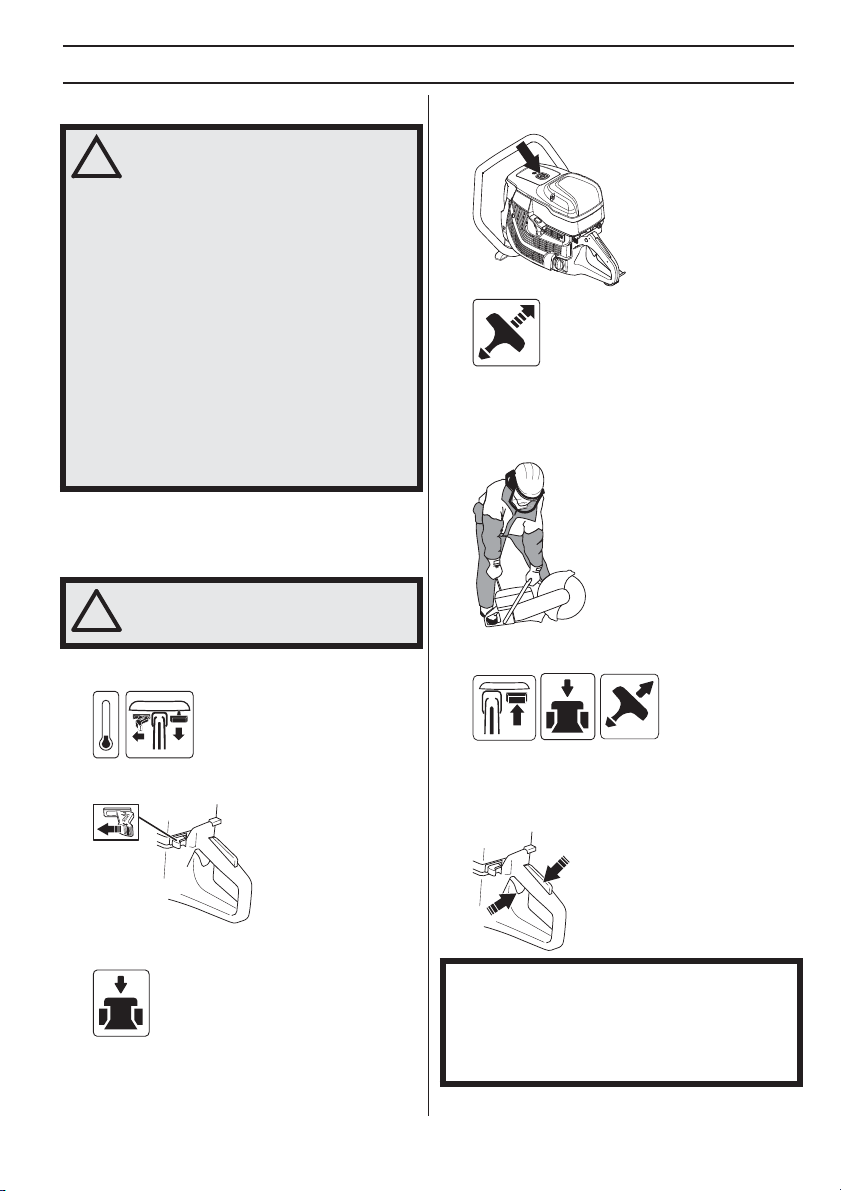

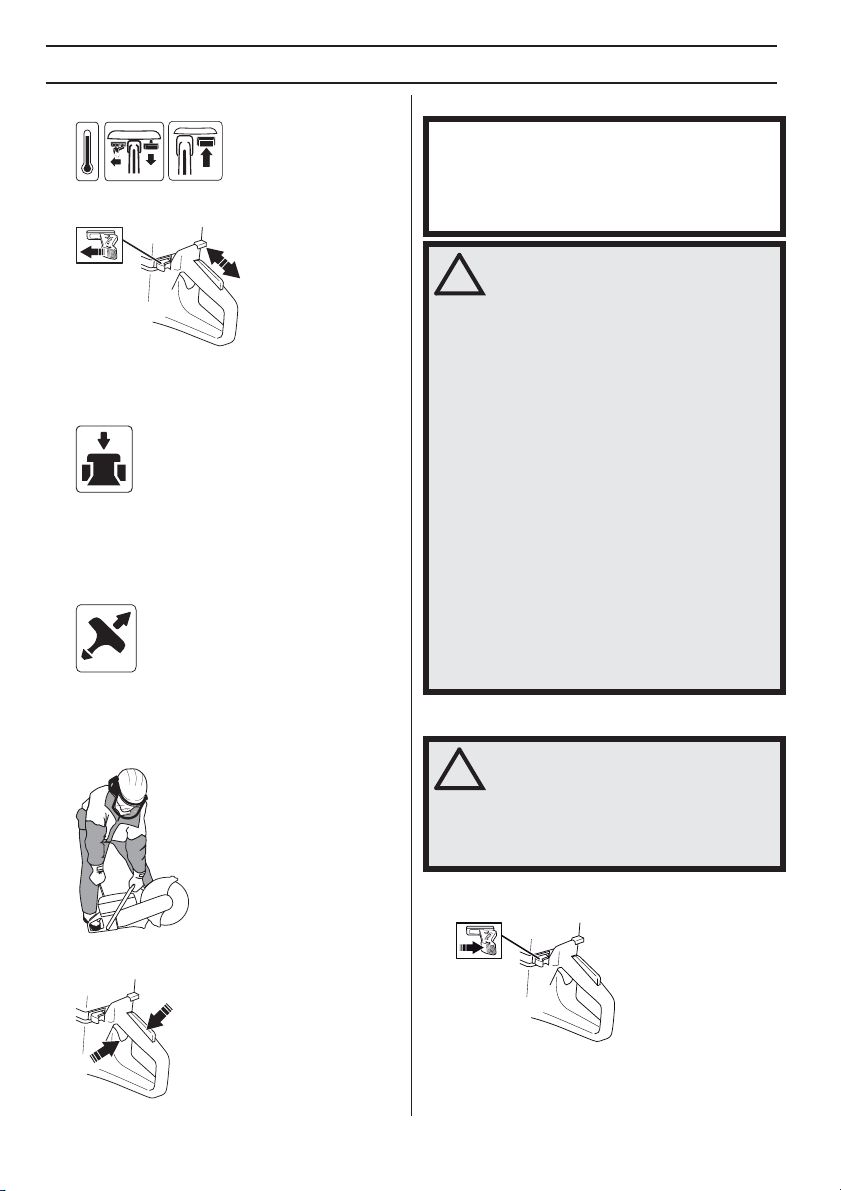

With a cold engine:

automatically returns to its initial position when the

machine starts.

• Grip the front handle with your left hand. Put your right

foot on the lower section of the rear handle pressing

the machine against the ground. Pull the starter

handle with your right hand until the engine starts.

Never twist the starter cord around your hand.

• The machine stops when the engine fires because the

choke control is pulled out.

• Make sure that the stop switch (STOP) is in the left

position.

• Start throttle position and choke is obtained by pulling

out the choke control completely.

• Decompression valve: Press in the valve to reduce

the pressure in the cylinder, this is to assist starting

the power cutter. The decompression valve should

always be used when starting. The valve

• Press the choke control and the decompression valve.

• Pull the starter handle until the engine starts.

• When the machine starts, press the throttle trigger to

disengage the start throttle, and the machine will idle.

NOTICE! Pull with your right hand out the starter cord

slowly until you feel a resistance (as the starter pawls

engage) and then pull firmly and rapidly.

Do not pull the starter cord all the way out and do not let

go of the starter handle when the cord is fully extended.

This can damage the machine.

English – 11

STARTING AND STOPPING

!

!

With a warm engine:

• Make sure that the stop switch (STOP) is in the left

position.

• The correct choke/start throttle setting is obtained by

pulling the choke control to the choke position and

then pushing it in again. This only engages the start

throttle setting without any choke.

• Decompression valve: Press in the valve to reduce

the pressure in the cylinder, this is to assist starting

the power cutter. The decompression valve should

always be used when starting. The valve

automatically returns to its initial position when the

machine starts.

• Grip the front handle with your left hand. Put your right

foot on the lower section of the rear handle pressing

the machine against the ground. Pull the starter

handle with your right hand until the engine starts.

Never twist the starter cord around your hand.

NOTICE! Pull with your right hand out the starter cord

slowly until you feel a resistance (as the starter pawls

engage) and then pull firmly and rapidly.

Do not pull the starter cord all the way out and do not let

go of the starter handle when the cord is fully extended.

This can damage the machine.

WARNING! When the engine is running

the exhaust contains chemicals such as

unburned hydrocarbons and carbon

monoxide. The content of the exhaust

fumes is known to cause respiratory

problems, cancer, birth defects or other

reproductive harm.

Carbon monoxide is colorless and

tasteless and is always present in

exhaust fumes. The onset of carbon

monoxide poisoning is distinguished by

a slight dizziness which may or may not

be recognized by the victim. A person

may collapse and lapse into

unconsciousness with no warning if the

concentration of carbon monoxide is

sufficiently high. Since carbon monoxide

is colorless and odorless, its presence

can not be detected. Any time exhaust

odors are noticed, carbon monoxide is

present. Never use a petrol powered

power cutter indoors or in trenches more

than 3 foot (1 meter) deep or in other

areas with poor ventilation. Ensure

proper ventilation when working in

trenches or other confined areas.

Stopping

CAUTION! The cutting blade continues to

rotate up to a minute after the motor has

stopped. (Blade coasting.) Make sure

that the cutting blade can rotate freely

until it is completely stopped.

Carelessness can result in serious

personal injury.

• When the machine starts, press the throttle trigger to

disengage the start throttle, and the machine will idle.

12 – English

• Stop the engine by moving the stop switch (STOP) to

the right.

MAINTENANCE

General

WARNING! The user must only carry out the maintenance and service work described in this

Operator's Manual. More extensive work must be carried out by an authorized service workshop.

!

The engine should be switched off, and the stop switch in STOP position.

Wear personal protective equipment. See instructions under the ”Personal protective equipment”

heading.

The life span of the machine can be reduced and the risk of accidents can increase if machine

maintenance is not carried out correctly and if service and/or repairs are not carried out

professionally. If you need further information please contact your nearest service workshop.

• Let your Husqvarna dealer regularly check the machine and make essential adjustments and repairs.

Maintenance schedule

In the maintenance schedule you can see which parts of your machine that require maintenance, and with which

intervals it should take place. The intervals are calculated based on daily use of the machine, and may differ depending

on the rate of usage.

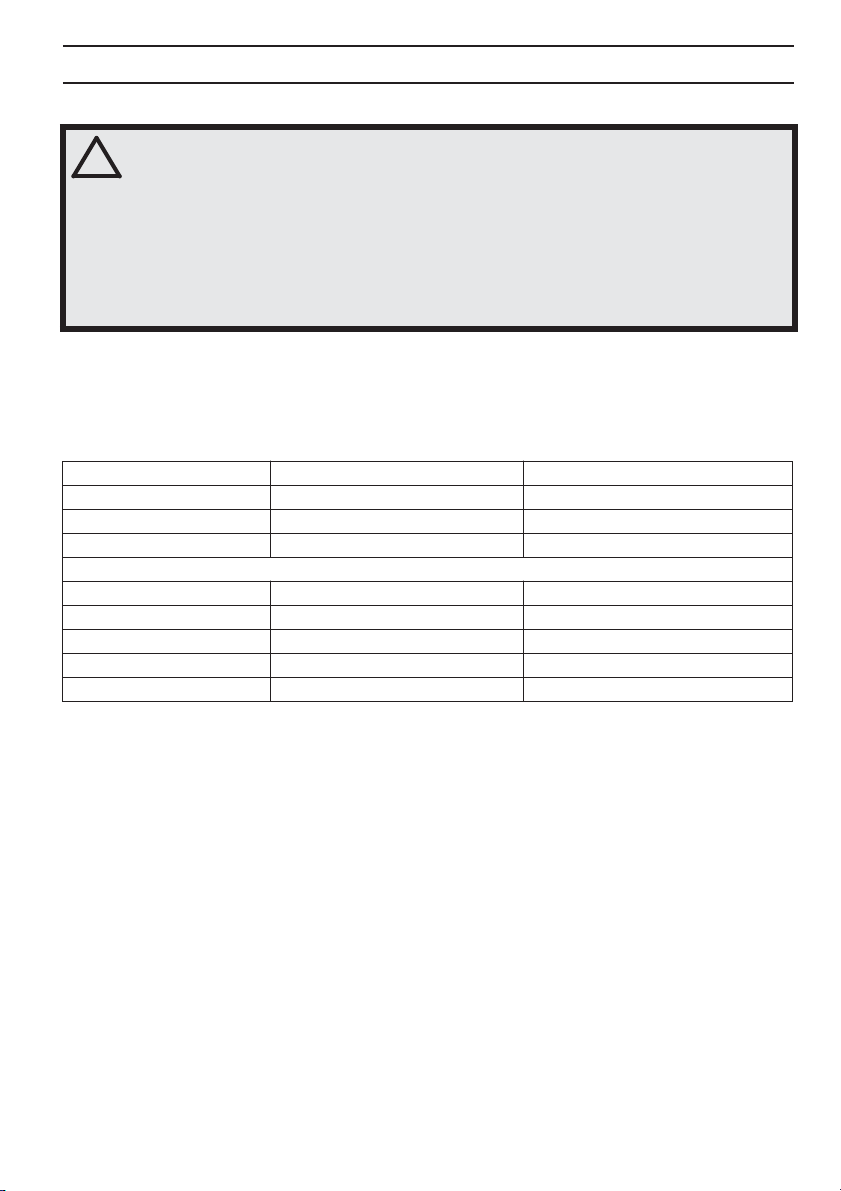

Daily maintenance Weekly maintenance Monthly maintenance

Cleaning Cleaning Cleaning

External cleaning Spark plug

Cooling air intake Fuel tank

Functional inspection Functional inspection Functional inspection

General inspection Vibration damping system Fuel system

Throttle trigger lockout Muffler Air filter

Stop switch Carburettor Drive gear, clutch

Starter housing

Cleaning

External cleaning

Clean with a rag or brush.

English – 13

Cooling air intake

!

• Clean the cooling air intake when needed.

MAINTENANCE

Throttle trigger lockout

The throttle trigger lock is designed to prevent accidental

operation of the throttle trigger. When the lock (A) is

pressed into the handle (= when you hold the handle) the

throttle trigger (B) is released.

NOTICE! A dirty or blocked air intake results in the

machine overheating which causes damage to the

piston and cylinder.

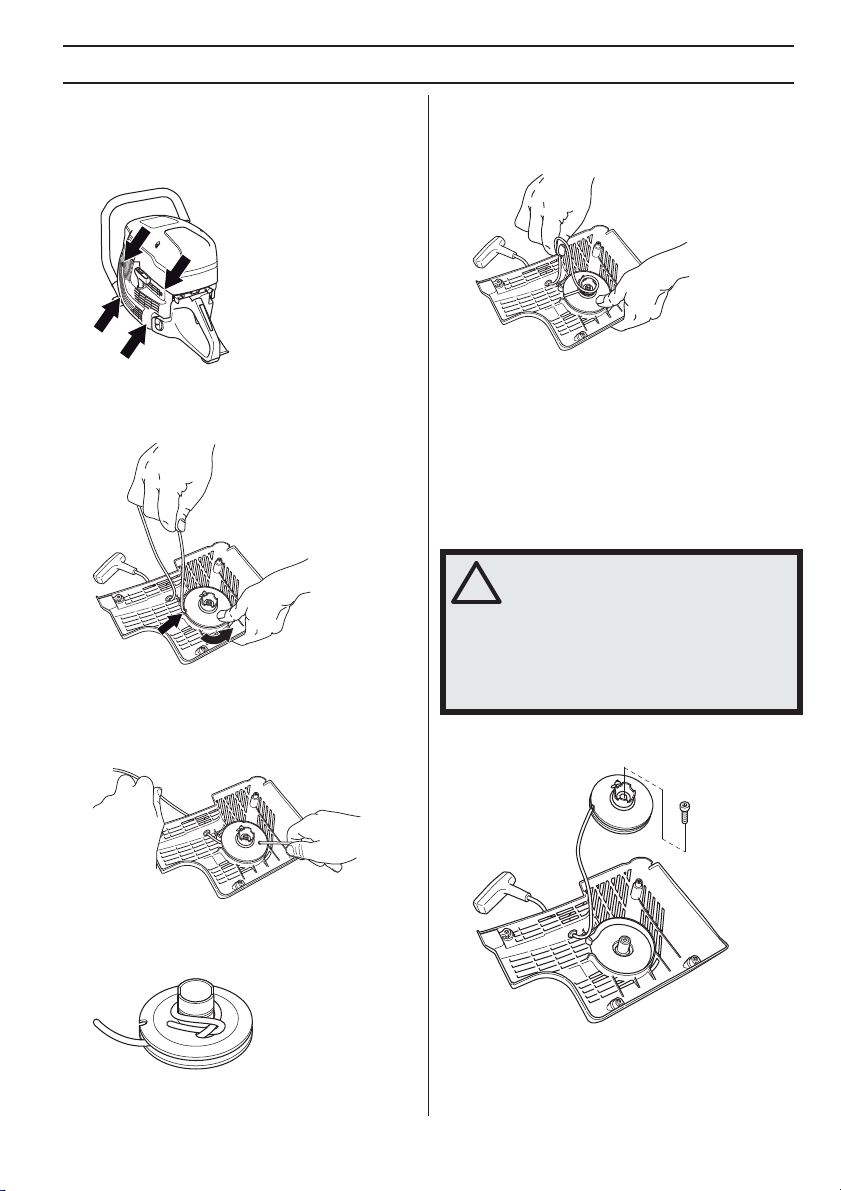

Spark plug

• If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking other steps.

• Ensure that the spark plug cap and ignition lead are

undamaged to avoid the risk of electric shock.

• If the spark plug is dirty, clean it and at the same time

check that the electrode gap is 0.5 mm. Replace if

necessary.

NOTICE! Always use the recommended spark plug

type! Use of the wrong spark plug can damage the

piston/cylinder.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

Functional inspection

General inspection

• Check that nuts and screws are tight.

Carburettor

The carburettor is equipped with fixed needles to ensure

the machine always receives the correct mixture of fuel

and air. When the engine lacks power or accelerates

poorly, do the following:

• Check the air filter and replace if necessary. When this

does not help, contact an authorised service

workshop.

Adjusting the idle speed

CAUTION! If the idle speed cannot be

adjusted so that the cutting attachment

stops, contact your dealer/service

workshop. Do not use the machine until

it has been correctly adjusted or

repaired.

Start the engine and check the idling setting. When the

carburettor is set correctly the cutting blade should be still

while engine is idling.

• Adjust the idle speed using the T screw. When an

adjustment is necessary, first turn the screw clockwise

until the blade starts to rotate. Now turn the screw

anti-clockwise until the blade stops rotating.

T

Rec. idle speed: 2700 rpm

14 – English

MAINTENANCE

!

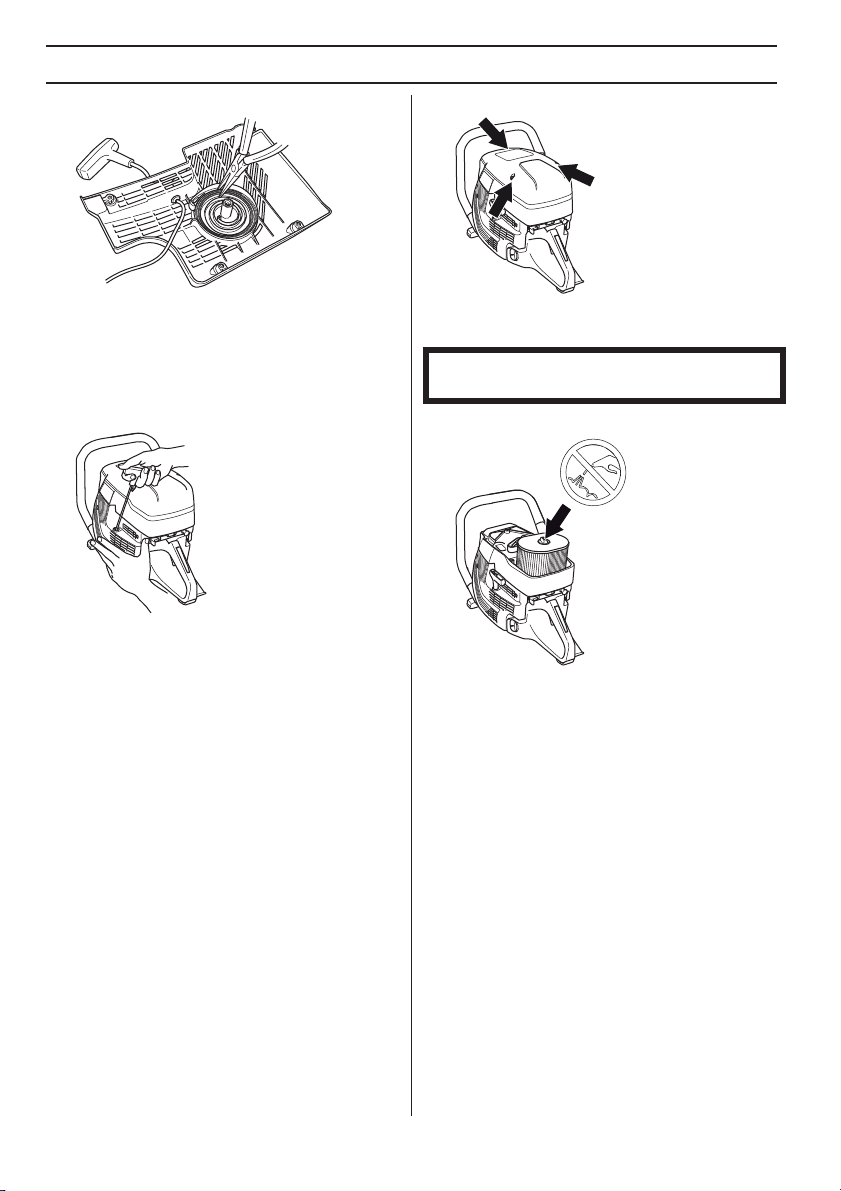

Starter housing

Checking the starter cord

• Loosen the screws that hold the starter against the

crankcase and remove the starter.

Tensioning the recoil spring

• Guide the cord through the cut-out in the periphery of

the pulley and wind the cord 3 times clockwise around

the centre of the starter pulley.

• Pull the cord out about 30 cm and lift it into the cut-out

in the periphery of the starter pulley. When the cord is

intact: Release the spring tension by letting the pulley

rotate slowly backwards.

Changing a broken or worn starter cord

• Remove any remnants of the old starter cord and

check that the return spring works. Insert the new

starter cord through the hole in the starter housing

and in the cord pulley.

• Secure the starter cord around the cord pulley as

illustrated. Tighten the fastening well and ensure that

the free end is as short as possible. Secure the end of

the starter cord in the starter handle.

• Now pull the starter handle and in doing so tension the

spring. Repeat the procedure once more, but this time

with four turns.

• Note that the starter handle is drawn to its correct

home position after tensioning the spring.

• Check that the spring is not drawn to its end position

by pulling out the starter line fully. Slow the starter

pulley with your thumb and check that you can turn the

pulley at least a further half turn.

Changing a broken recoil spring

WARNING! When the recoil spring is

wound up in the starter housing it is

under tension and can, if handled

carelessly, pop out and cause personal

injury.

Always be careful when changing the

recoil spring or the starter cord. Always

wear protective goggles.

• Undo the bolt in the centre of the pulley and remove

the pulley.

• Carefully lift the cover that protects the spring. Bear in

mind that the return spring lies tensioned in the starter

housing.

English – 15

• Carefully remove the spring using pilers.

MAINTENANCE

• Loosen the screws. Remove the air filter cover.

• Lubricate the recoil spring with light oil. Fit the pulley

and tension the recoil spring.

Fitting the starter

• To fit the starter, first pull out the starter cord and place

the starter in position against the crankcase. Then

slowly release the starter cord so that the pulley

engages with the pawls.

• Tighten the screws.

Fuel system

General

• Check that the fuel cap and its seal are not damaged.

• Check the fuel hose. Replace when damaged.

Fuel filter

• The fuel filter sits inside the fuel tank.

• The fuel tank must be protected from contamination

when filling. This reduces the risk of operating

disturbances caused by blockage of the fuel filter

located inside the tank.

• The filter cannot be cleaned but must be replaced with

a new filter when it is clogged.

changed at least once per year.

The filter should be

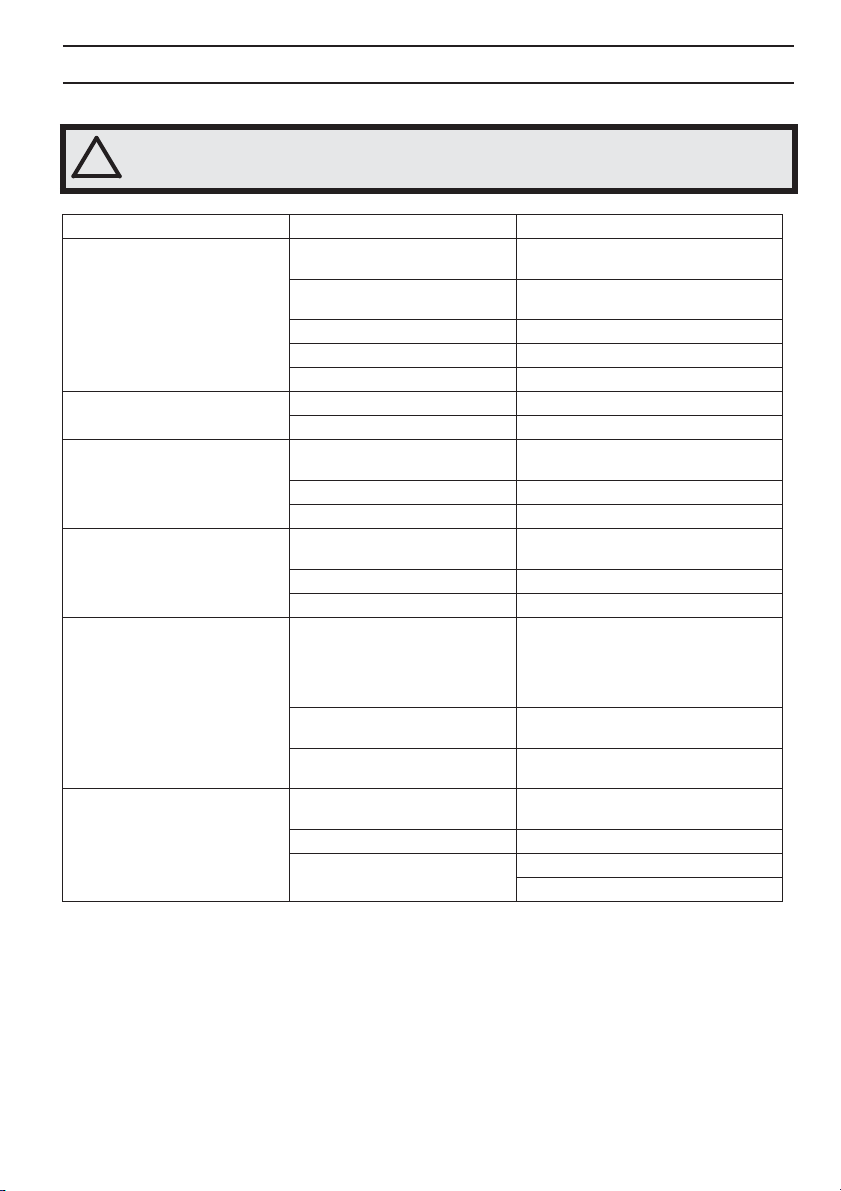

Air filter

The air filter only needs to be checked if the engine drops

in power.

• Check the air filter and replace if necessary.

Replacing the air filter

NOTICE! The air filter must not be cleaned or blown

clean with compressed air. This will damage the filter.

• Loosen the screw.

• Replace the air filter.

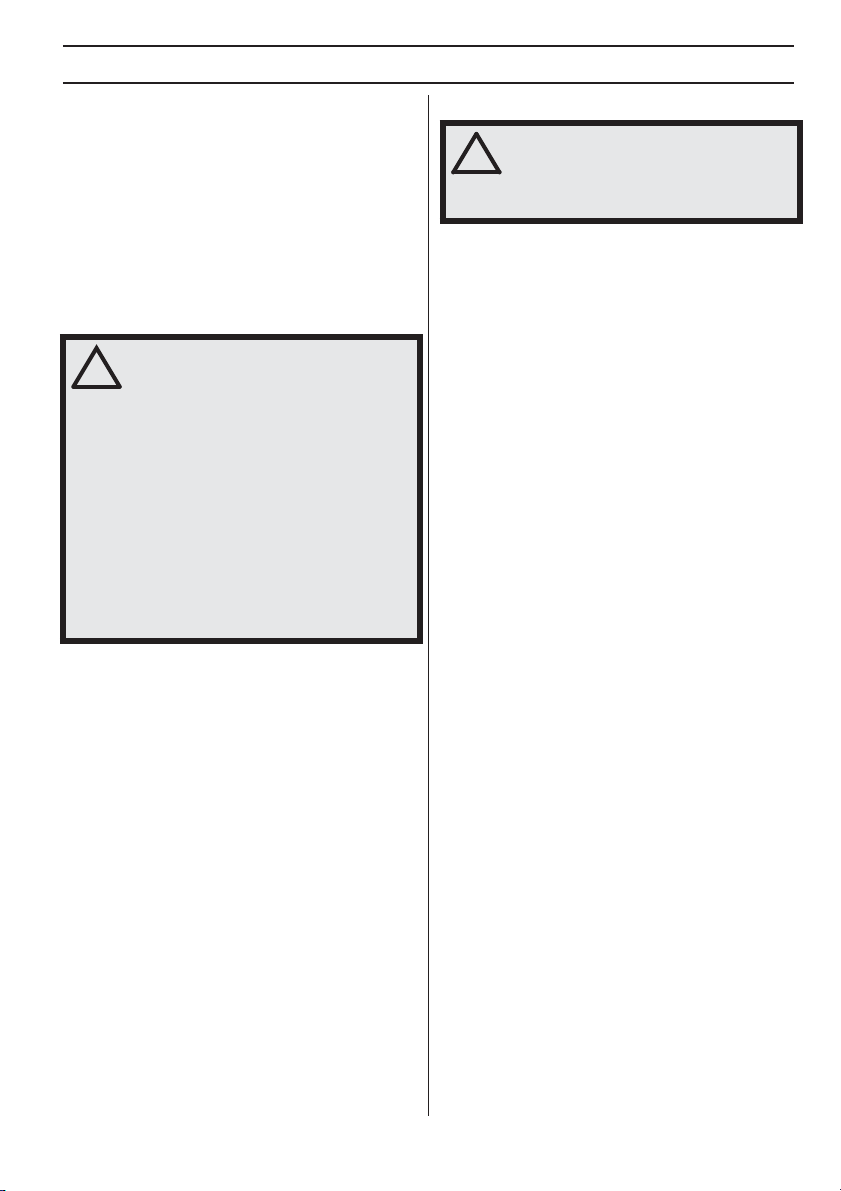

Drive gear, clutch

• Check the clutch centre, drive gear and clutch spring

for wear.

16 – English

TROUBLESHOOTING

Troubleshooting schedule

WARNING! If service operations or troubleshooting does not require the machine to be on, the

engine should be switched off, and the stop switch in STOP position.

!

Problem Probable cause Potential Solution

See instructions under the heading

Starting and stopping.

Make sure that the stop switch (STOP) is

in the left position.

Tighten the belt / Replace the belt with a

new one

Check the air filter and replace if

necessary.

Check that the cutting blade is fitted

correctly and does not show signs of

damage. See the instructions in the

sections "Cutting blades" and "Assembly

and adjustments".

Change the blade and make sure it is

intact.

Contact your service agent.

Clean the machine’s air intake/cooling

flanges

Always cut at full throttle.

Check clutch / contact your service agent

The machine does not start

The blade rotates at idle

The blade does not rotate while

throttling up

The machine has no power while

attempting to throttle up

Vibration levels are too high

Temperature of the machine is too

high

Incorrect starting procedure.

Stop switch in the right (STOP)

position

There is no fuel in the fuel tank Refill with fuel

Spark plug defective Replace the spark plug.

Defective clutch Contact your service agent.

Idle speed too high Adjust the idle speed

Defective clutch Contact your service agent.

Belt too loose or defective

Defective clutch Contact your service agent.

Blade fitted incorrectly Make sure the blade is properly installed.

Clogged air filter

Clogged fuel filter Replace the fuel filter.

Fuel tank vent blocked Contact your service agent.

Blade fitted incorrectly

Blade defective

Vibration damping elements

defective

Air intake or cooling flanges

blocked

Belt slipping Check belt / adjust the tension

Clutch slipping / is defective

English – 17

TECHNICAL DATA

Technical data

Engine

Cylinder displacement, cm3/cu.in 119/7,3

Cylinder bore, mm/inch 60/2,4

Stroke, mm/inch 42/1,7

Idle speed, rpm 2700

Wide open throttle - no load, rpm 9300 (+/- 150)

Power, kW/hp @ rpm 5,8/7,9 @ 8400

Ignition system

Manufacturer of ignition system SEM

Type of ignition system CD

Spark plug NGK BPMR 7A

Electrode gap, mm/inch 0,5/0,02

Fuel and lubrication system

Manufacturer of carburettor Walbro

Carburettor type RWG1

Fuel tank capacity, litre/US fl. Oz 1,25/42

Weight

Weight without fuel, kg/lb 9,9/21,8

Noise emissions (see note 1)

Sound power level, measured dB(A) 116

Sound power level, guaranteed LWA dB(A) 117

Sound levels (see note 2)

Equivalent sound pressure level at the operator’s ear, dB(A) 104

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/

EC. The difference between guaranteed and measured sound power is that the guaranteed sound power also includes

dispersion in the measurement result and the variations between different machines of the same model according to

Directive 2000/14/EC. Stated data applies to power unit only without OEM cutting attachment.

Note 2: Equivalent sound pressure level, according to EN ISO 19432, is calculated as the time-weighted energy total for

different sound pressure levels under various working conditions. Reported data for equivalent sound pressure level for

the machine has a typical statistical dispersion (standard deviation) of 1 dB(A). Stated data applies to power unit only

without OEM cutting attachment.

18 – English

TECHNICAL DATA

Declaration of conformity of partly completed machinery

(Applies to Europe only)

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel +46-36-146500, declares under sole responsibility that the partly

completed power cutter

text on the rating plate with subsequent serial number), complies with the requirements of the COUNCIL’S DIRECTIVES:

• of May 17, 2006 ”relating to machinery” 2006/42/EC.

• of February 26, 2014 ”relating to electromagnetic compatibility” 2014/30/EU.

• of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC.

The following standards have been applied: EN ISO 12100:2010, EN ISO 14982:2009, CISPR12:2007+AMD1:2009,

EN55012:2008+A1:2009, EN ISO 19432:2012

Husqvarna AB undertakes to transmit, in response to a reasoned request by the national authorities, relevant information

on this partly completed machinery.

Husqvarna AB states that this partly completed machinery must not be put into service until the final machinery into

which it is to be incorporated has been declared in conformity with the provisions of directive 2006/42/EC.

Gothenburg, 25 April 2016

Joakim Ed

Global R & D Director

Construction Equipment Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

Husqvarna K 1270R from 2016’s serial numbers and onwards (the year is clearly stated in plain

English – 19

FEDERAL EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The EPA (The US Environmental Protection Agency),

Environment Canada and Husqvarna Construction

Products are pleased to explain the emissions control

system warranty on your 2009 and later small nonroad

engine. In U.S. and Canada, new small nonroad engines

must be designed, built and equipped to meet the federal

stringent anti-smog standards. Husqvarna Construction

Products must warrant the emission control system on

your small nonroad engine for the period of time listed

below provided there has been no abuse, neglect or

improper maintenance of your unit. Your emmission

control system includes Parts such as the carburetor and

the ignition system. Where a warrantable condition exists,

Husqvarna Construction Products will repair your small

nonroad engine at no cost to you. Expenses covered

under warranty include diagnosis, parts and labor.

MANUFACTURER´S WARRANTY COVERAGE

The 2009 and later small nonroad engines are warranted

for two years. If any emission related part on you engine

(as listed above) is defective, the part will be repaired or

replaced by Husqvarna Construction Products.

OWNER´S WARRANTY RESPONSIBILITIES

As the small nonroad engine owner, you are responsible

for the performance of the required maintenance listed in

your Operator´s Manual. Husqvarna Construction

Products recommends that you retain all receipts

covering maintenance on your small nonroad engine, but

Husqvarna Construction Products cannot deny warranty

solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance. As the

small nonroad engine owner, you should, however, be

aware that Husqvarna Construction Products may deny

you warranty coverage if your small nonroad engine or a

part of it has failed due to abuse, neglect, improper

maintenance, unapproved modifications or the use of

parts not made or approved by the original equipment

manufacturer. You are responsible for presenting your

small nonroad engine to a Husqvarna Construction

Products authorized servicing dealer as soon as a

problem exists. The warranty repairs should be completed

in a reasonable amount of time, not to exceed 30 days. If

you have a question regarding your warranty coverage,

you should contact the Husqvarna Construction Products

service center at 1-800-288-5040 or

www.USA.husqvarnacp.com.

WARRANTY COMMENCEMENT DATE

The warranty period begins on the date small nonroad

engine is delivered.

LENGTH OF COVERAGE

Husqvarna Construction Products warrants to the initial

owner and each subsequent purchaser that the engine is

free from defects in materials and workmanship which

cause the failure of a warranted part for a period of two

years.

WHAT IS COVERED

REPAIR OR REPLACEMENT OF PARTS Repair or

replacement of any warranted part will be performed at no

charge to the owner at an approved Husqvarna

Construction Products servicing dealer. If you have a

question regarding your warranty coverage, you should

contact the Husqvarna Construction Products service

center at 1-800-288-5040 or

www.USA.husqvarnacp.com.

WARRANTY PERIOD Any warranted part which is not

scheduled for replacement as required maintenance, or

which is scheduled only for regular inspection to the effect

of 'repair or replace as necessary” shall be warranted for

2 years. Any warranted part which is scheduled for

replacement as required maintenance shall be warranted

for the period of time up to the first scheduled

replacement point for that part.

DIAGNOSIS The owner shall not be charged for

diagnostic labor which leads to the determination that a

warranted part is defective, if the diagnostic work is

performed at an approved Husqvarna Construction

Products servicing dealer.

CONSEQUENTIAL DAMAGES Husqvarna Construction

Products may be liable for damages to other engine

components caused by the failure of a warranted part still

under warranty.

WHAT IS NOT COVERED

All failures caused by abuse, neglect or improper

maintenance are not covered.

ADD -ON OR MODIFIED PARTS

The use of add-on or modified parts can be grounds for

disallowing a warranty claim. Husqvarna Construction

Products is not liable to cover failures of warranted parts

caused by the use of add-on or modified parts.

HOW TO FILE A CLAIM

If you have a question regarding your warranty coverage,

you should contact the Husqvarna Construction Products

service center at 1-800-288-5040 or

www.USA.husqvarnacp.com.

WHERE TO GET WARRANTY SERVICE

Warranty services or repairs shall be provided at all

Husqvarna Construction Products authorized servicing

dealers.

20 – English

FEDERAL EMISSION CONTROL WARRANTY STATEMENT

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION-RELATED PARTS

Any Husqvarna Construction Products approved

replacement part used in the performance of any

warranty maintenance or repairs on emission-related

parts, will be provided without charge to the owner if the

part is under warranty.

EMISSION CONTROL WARRANTY PARTS LIST

1 Carburetor and internal parts

2 Intake pipe, airfilter holder and carburetor bolts.

3 Airfilter and fuelfilter covered up to maintenance

schedule.

4 Ignition System

1Spark Plug, covered up to maintenance schedule

2Ignition Module

5 Fuel tank, line and cap

MAINTENANCE STATEMENT

The owner is responsible for the performance of all

required maintenance, as defined in the operator’s

manual.

English – 21

EXPLICATION DES SYMBOLES

Symboles sur la machine

AVERTISSEMENT! La machine utilisée

de manière imprudente ou inadéquate

peut devenir un outil dangereux, pouvant

causer des blessures graves voire

mortelles à l’utilisateur et aux autres

personnes présentes.

Lire attentivement et bien assimiler le

manuel d’utilisation avant d’utiliser la

machine.

Utiliser les équipements de protection

personnelle. Voir au chapitre

Ӄquipement de protection

personnelle”.

AVERTISSEMENT! Au cours de la

découpe, la poussière générée peut

occasionner des blessures si elle est

aspirée. Utiliser une protection

respiratoire approuvée. Éviter

d'inhaler des vapeurs d'essences et

des gaz d'échappement. Veiller à disposer d'une bonne

ventilation.

AVERTISSEMENT! Les rebonds

peuvent être soudains, rapides et

violents et peuvent générer des

blessures pouvant être mortelles. Lire

et assimiler les instructions du manuel

avant d'utiliser la machine.

AVERTISSEMENT! Les étincelles du

disque de coupe peuvent provoquer

un incendie en cas de contact avec

des matières inflammables tels que

l’essence, le bois, l’herbe sèche.

Vérifier que les lames ne comportent

ni fissures ni autre dommage.

Remplissage d’essence/de

mélange d'huile

Autocollant des

instructions de

démarrage Voir les

instructions au chapitre

Démarrage et arrêt.

Plaque d’identification

Rangée 1 : Marque, modèle

(X, Y)

Rangée 2 : N° de série avec

date de fabrication (y, W, X)

Année, semaine, n

° de

XXXXXXXXX YYYY

s / n YYYY WWXXXXX

Huskvarna, SWEDEN

:

XXXXXXXXXXXX (YY)

XXX XX XX-XX

Husqvarna AB

XXXXXXXXXXX

séquence

Rangée 3 : N° de produit (X)

Rangée 4 : Fabricant

Rangée 5 : Adresse du fabricant

Rangées 6-7 : Type d’homologation CE, le cas échéant

(X, Y)

: Code d’homologation, étape d’homologation

La période de conformité des émissions à laquelle il est

fait référence sur l’étiquette de conformité des émissions

indique le nombre d’heures de fonctionnement pour

lesquelles il a été établi que le moteur répond aux

exigences californiennes et fédérales en matière

d’émissions.

EMISSION CONTROL INFORMATION

HUSQVARNA AB, HUSKVARNA, MADE IN SWEDEN

THIS ENGINE MEETS U.S. EPA EXH/EVP

OPERATOR’S MANUAL FOR MAINTENANCE

SPECIFICATIONS AND ADJUSTMENTS.

EMISSIONS COMPLIANCE PERIOD: 300 HRS

®

REGS FOR 2016 SORE. REFER TO

2016

EM/N74ccB0

30-5

43

6

105

Les autres symboles/autocollants présents sur la

machine concernent des exigences de certification

spécifiques à certains marchés.

N’utilisez pas de lames de scie circulaire.

Starter.

Décompresseur

Poignée de lanceur

22 – French

EXPLICATION DES SYMBOLES

Explication des niveaux d'avertissement

Il existe trois niveaux d'avertissement.

AVERTISSEMENT!

AVERTISSEMENT! Symbole utilisé en

cas de risque de blessures très graves

!

ou de mort pour l'utilisateur ou de

dommages pour les environs si les

instructions du manuel ne sont pas

suivies.

REMARQUE !

REMARQUE ! Symbole utilisé en cas de

risque de blessures pour l'utilisateur ou

!

de dommages pour les environs si les

instructions du manuel ne sont pas

suivies.

ATTENTION !

ATTENTION ! Symbole utilisé en cas de risque de

dommages pour les matériaux ou la machine si les

instructions du manuel ne sont pas suivies.

French – 23

SOMMAIRE

Sommaire Contrôler les points suivants

EXPLICATION DES SYMBOLES

Symboles sur la machine ...................................... 22

Explication des niveaux d'avertissement .............. 23

SOMMAIRE

Sommaire ............................................................. 24

Contrôler les points suivants avant la mise en

marche: .................................................................

PRÉSENTATION

Cher client, ............................................................ 25

Conception et propriétés ....................................... 25

QUELS SONT LES COMPOSANTS?

Quels sont les composants de la machine ? ........ 26

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités ........................................................... 27

COMMANDE

Équipement de protection ..................................... 29

MANIPULATION DU CARBURANT

Généralités ........................................................... 30

Carburant .............................................................. 30

Remplissage de carburant .................................... 31

Transport et rangement ......................................... 31

DÉMARRAGE ET ARRÊT

Avant le démarrage ............................................... 32

Démarrage ............................................................ 32

Arrêt ...................................................................... 34

ENTRETIEN

Généralités ........................................................... 35

Schéma d’entretien ............................................... 35

Nettoyage .............................................................. 35

Contrôle fonctionnel .............................................. 36

RECHERCHE DE PANNES

Plan de recherche de pannes ............................... 39

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques techniques ................................. 40

Déclaration de conformité de quasi-machine ....... 41

DÉCLARATION DE GARANTIE POUR LA

LUTTE CONTRE LES ÉMISSIONS

VOS DROITS ET OBLIGATIONS EN GARANTIE 42

avant la mise en marche:

24

ATTENTION ! Commission californienne chargée de

la qualité de l’air (CARB)

considérée comme une application tout-terrain de

présérie selon les normes CARB. L’EPA aux États-Unis

est la seule entité habilitée à établir des normes

antipollution pour les équipements de construction de

présérie. Pour plus d’informations, consultez

www.arb.ca.gov/msprog/offroad/preempt.htm

: Cette machine est

24 – French

PRÉSENTATION

Cher client,

Nous vous remercions d'avoir choisi un produit

Husqvarna !

Nous espérons que cette machine vous donnera toute

satisfaction et qu’elle vous accompagnera pendant de

longues années. L’achat de l’un des nos produits garantit

une assistance professionnelle pour l’entretien et les

réparations. Si la machine n’a pas été achetée chez l’un

de nos revendeurs autorisés, demandez l’adresse de

l’atelier d’entretien le plus proche.

Ce mode d’emploi est précieux. Veillez à ce qu'il soit

toujours à portée de main sur le lieu de travail. En suivant

les instructions qu’il contient (utilisation, révision,

entretien etc.), il est possible d’allonger considérablement

la durée de vie de la machine et d’augmenter sa valeur

sur le marché de l’occasion. En cas de vente de la

machine, ne pas oublier de remettre le manuel

d’utilisation au nouveau propriétaire.

Plus de 300 ans d'innovation

Husqvarna AB est une entreprise suédoise qui a vu le

jour en 1689 lorsque le roi Karl XI décida de construire un

arsenal pour la fabrication des mousquets. À l'époque, les

compétences en ingénierie à la base du développement

de certains des produits leaders du marché mondial dans

des domaines tels que les armes de chasse, les vélos, les

motocycles, l'électroménager, les machines à coudre et

les produits d'extérieur, étaient déjà solides.

Husqvarna est le premier fournisseur mondial de produits

motorisés pour utilisation en extérieur dans la foresterie,

l'entretien de parcs, de pelouses et de jardins, ainsi que

d'équipements de coupe et d'outils diamant destinés aux

industries de la construction et de la pierre.

Responsabilité du propriétaire

Il est de la responsabilité du propriétaire/de l’employeur

de s’assurer que l’utilisateur possède les connaissances

nécessaires pour manipuler la machine en toute sécurité.

Les responsables et les utilisateurs doivent avoir lu et

compris le Manuel d’utilisation. Ils doivent avoir

conscience :

• Des instructions de sécurité de la machine.

• Des diverses applications de la machine et de ses

limites.

• De la façon dont la machine doit être utilisée et

entretenue.

La législation nationale peut réglementer l'utilisation de

cette machine. Recherchez la législation applicable dans

le lieu où vous travaillez avant d'utiliser la machine.

Les législations locales peuvent limiter l’utilisation de

cette machine. Recherchez les législations applicables

pour le lieu où vous travaillez avant d’utiliser la machine.

Droit de réserve du fabricant

Husqvarna peut éditer des informations complémentaires

concernant l’utilisation de ce produit en toute sécurité

après la publication du présent manuel. Il incombe au

propriétaire de se tenir informé des méthodes d’utilisation

les plus sûres.

Husqvarna AB travaille continuellement au

développement de ses produits et se réserve le droit d’en

modifier, entre autres, la conception et l’aspect sans

préavis.

Pour obtenir des informations et une assistance client,

contactez-nous via notre site Web

: www.husqvarna.com

Conception et propriétés

Cette unité électrique est une machine partiellement

aboutie, destinée à la conception OEM d’une

découpeuse manuelle haute vitesse.

Certaines des caractéristiques uniques de votre produit

sont décrites ci-dessous.

Active Air Filtration™

Épuration centrifuge de l'air pour une durée de vie

supérieure et un entretien moins fréquent.

SmartCarb™

Un filtre compensateur automatique intégré maintient une

puissance élevée et réduit la consommation en carburant.

X-Torq®

Le moteur X-Torq® apporte un couple encore plus

accessible pour une gamme de vitesses encore plus

large, et donc une capacité de découpe maximale. XTorq® réduit la consommation en carburant de jusqu’à 20

% et les émissions de jusqu’à 60 %.

EasyStart

Le moteur et le lanceur sont conçus de façon à assurer un

démarrage rapide et facile de la machine. Réduit la

résistance à la traction dans la corde du lanceur de

jusqu’à 40 %. (Réduit la compression au démarrage.)

Système anti-vibrations efficace

Bras et aiguilles de rechange pour les amortisseurs de

vibrations efficaces.

French – 25

QUELS SONT LES COMPOSANTS?

1

16

15

14

12

13

Quels sont les composants de la machine ?

1 Poignée avant

2 Décompresseur

3 Carter de filtre à air

4 Capot de cylindre

5 Starter avec blocage du ralenti accéléré

6 Bouton d’arrêt

7 Bouchon du réservoir de carburant

8 Lanceur

9 Poignée de lanceur

11

10

9

8

7

17

10 Plaque d’identification

11 Silencieux

12 Pignon d’entraînement et embrayage

13 Commande de l’accélération

14 Blocage de l’accélération

15 Autocollant des instructions de démarrage

16 Autocollant d’information et d’avertissement

17 Clé universelle, à pointe à six lobes

2

3

4

5

6

26 – French

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités

AVERTISSEMENT! Ne jamais utiliser une

machine dont les équipements de

!

sécurité sont défectueux. Si les

contrôles ne donnent pas de résultat

positif, confier la machine à un atelier

spécialisé.

Le moteur doit être éteint et le bouton

d'arrêt en position STOP.

Ce chapitre présente les équipements de sécurité de la

machine, leur fonction, comment les utiliser et les

maintenir en bon état.

Blocage de l’accélération

Le blocage de l'accélération est conçu pour empêcher

toute activation involontaire de la commande de

l'accélération. Lorsque le blocage (A) est enfoncé, la

commande de l'accélération est embrayée (B).

Le blocage reste enfoncé tant que la commande

d’accélération est sollicitée. Lorsque la poignée est

relâchée, la gâchette d’accélération et le blocage de

l’accélération retrouvent leurs positions initiales. Ceci

s’effectue à l’aide de deux systèmes de retour par

ressorts, indépendants l’un de l’autre. En position initiale,

la gâchette d’accélération est automatiquement bloquée

au régime de ralenti.

Vérification du blocage de la commande

d'accélération

• Vérifier d’abord que la commande de l’accélération

est bloquée en position de ralenti quand le blocage de

l’accélération est en position initiale.

• Vérifier que le blocage de l’accélération, la

commande d’accélération et leurs ressorts de rappel

fonctionnent correctement.

• Démarrer la découpeuse et donner les pleins gaz.

Relâcher la commande de l'accélération et contrôler

que le disque découpeur s'arrête et qu'il demeure

immobile. Si le disque découpeur tourne quand la

commande est en position de ralenti, il convient de

contrôler le réglage du ralenti du carburateur. Voir les

instructions au chapitre «

Entretien ».

Bouton d’arrêt

Le bouton d’arrêt est utilisé pour arrêter le moteur.

Vérification du bouton d'arrêt

• Mettre le moteur en marche et s’assurer qu’il s’arrête

lorsque le bouton d’arrêt est amené en position

d’arrêt.

• Appuyer sur le blocage de l’accélération et vérifier

qu’il revient de lui-même en position initiale quand il

est relâché.

French – 27

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

!

Système anti-vibrations

Silencieux

AVERTISSEMENT! Une exposition

excessive aux vibrations peut entraîner

!

des troubles circulatoires ou nerveux

chez les personnes sujettes à des

troubles cardio-vasculaires. Consultez

un médecin en cas de symptômes liés à

une exposition excessive aux vibrations.

De tels symptômes peuvent être:

engourdissement, perte de sensibilité,

chatouillements, picotements, douleur,

faiblesse musculaire, décoloration ou

modification épidermique. Ces

symptômes affectent généralement les

doigts, les mains ou les poignets. Ces

symptômes peuvent être accentués par

le froid.

• La machine est équipée d’un système anti-vibrations

conçu pour assurer une utilisation aussi confortable

que possible.

• Le système anti-vibrations réduit la transmission des

vibrations de l’unité moteur/l’équipement de coupe à

l’unité que constituent les poignées. Le corps du

moteur, y compris l'équipement de coupe, est

suspendu à l'unité poignées par l'intermédiaire de

blocs anti-vibrants.

Vérification du système anti-vibrations

AVERTISSEMENT! Le moteur doit être

éteint et le bouton d'arrêt en position

!

STOP.

AVERTISSEMENT! N'utilisez jamais une

machine sans silencieux ou avec un

silencieux défectueux. Si le silencieux

est défectueux, le niveau sonore et le

risque d’incendie augmentent

considérablement. Veillez à disposer des

outils nécessaires à l’extinction d’un feu.

Le silencieux devient très chaud pendant

et après l’utilisation, ainsi qu’au cours du

fonctionnement au ralenti. Soyez attentif

au risque d’incendie, surtout à proximité

de produits inflammables et/ou en

présence de gaz.

Veillez à disposer des outils nécessaires

à l’extinction d’un feu.

Le silencieux est conçu pour réduire au maximum le

niveau sonore et détourner les gaz d’échappement loin

de l’utilisateur.

Contrôle du silencieux

Contrôler régulièrement que le silencieux est entier et

qu’il est attaché correctement.

• Contrôler régulièrement les éléments anti-vibrations

afin de détecter toute éventuelle fissure ou

déformation. Les remplacer s'ils sont endommagés.

• S’assurer de la bonne fixation des éléments antivibrations entre l’unité moteur et l’ensemble poignée.

28 – French

COMMANDE

!

Équipement de protection

Généralités

Ne jamais utiliser une machine s’il n’est pas possible

d’appeler au secours en cas d’accident.

Équipement de protection personnelle

Un équipement de protection personnelle homologué doit

impérativement être utilisé lors de tout travail avec la

machine. L’équipement de protection personnelle

n’élimine pas les risques mais réduit la gravité des

blessures en cas d’accident. Demander conseil au

concessionnaire afin de choisir un équipement adéquat.

AVERTISSEMENT! L’utilisation de

produits tels que des ciseaux, des

!

disques, des forets, des disques fins ou

des formes peut générer de la poussière

et des vapeurs pouvant contenir des

substances chimiques toxiques. Vérifiez

la composition du matériel avec lequel

vous travaillez et portez un masque

respiratoire adapté.

Une exposition prolongée au bruit risque

de causer des lésions auditives

permanentes. Toujours utiliser des

protecteurs d'oreille agréés. Soyez

toujours attentifs aux signaux d’alerte ou

aux appels en portant des protègeoreilles. Enlevez-les sitôt le moteur

arrêté.

Autre équipement de protection

REMARQUE ! Lorsque vous travaillez

avec la machine, des étincelles peuvent

se former et mettre le feu. Gardez

toujours à portée de main les outils

nécessaires à l'extinction d'un feu.

• Extincteur

• Trousse de premiers secours

Toujours utiliser:

• Casque de protection homologué

• Protecteur d’oreilles

• Des protège-yeux homologués. L’usage d’une visière

doit toujours s’accompagner du port de lunettes de

protection homologuées. Par lunettes de protection

homologuées, on entend celles qui sont en conformité

avec les normes ANSI Z87.1 (États-Unis) ou EN 166

(pays de l’UE). La visière doit être conforme à la

norme EN 1731.

• Masque respiratoire

• Gants solides permettant une prise sûre.

• Vêtements confortables, robustes et serrés qui

permettent une liberté totale de mouvement. La

découpe crée des étincelles qui peuvent enflammer

les vêtements. Husqvarna vous recommande de

porter du coton ignifugé ou du denim épais. Ne portez

pas de vêtements composés de matières comme le

nylon, le polyester ou la rayonne. Si elles

s’enflamment, ces matières peuvent fondre et adhérer

à la peau. Ne portez pas de shorts

• Bottes avec coquille en acier et semelle

antidérapante.

French – 29

MANIPULATION DU CARBURANT

Généralités

AVERTISSEMENT! Faire tourner un

moteur dans un local fermé ou mal aéré

!

peut causer la mort par asphyxie ou

empoisonnement au monoxyde de

carbone. Utilisez des ventilateurs pour

assurer une bonne circulation de l'air

lorsque vous travaillez dans des

tranchés ou des fossés d'une profondeur

supérieure à un mètre.

Le carburant et les vapeurs de carburant

sont inflammables et peuvent causer des

blessures graves en cas d’inhalation ou

de contact avec la peau. Il convient donc

d’observer la plus grande prudence lors

de la manipulation du carburant et de

veiller à disposer d’une bonne aération.

Les gaz d’échappement du moteur sont

très chauds et peuvent contenir des

étincelles pouvant provoquer un

incendie. Par conséquent, ne jamais

démarrer la machine dans un local clos

ou à proximité de matériaux

inflammables!

Ne fumez jamais ni ne placez d’objet

chaud à proximité du carburant.

Carburant

ATTENTION ! La machine est équipée d’un moteur

deux temps et doit toujours être alimentée avec un

mélange d'essence et d’huile deux temps. Afin d’obtenir

un mélange approprié, il est important de mesurer avec

précision la quantité d’huile à mélanger. Pour le

mélange de petites quantités de carburant, la moindre

erreur peut sérieusement affecter le rapport du

mélange.

Essence

• Utiliser une essence de qualité, avec ou sans plomb.

• Le taux d’octane minimum recommandé est de 90

(RON). Si l’on fait tourner le moteur avec une essence

d’un taux d’octane inférieur à 90, un cognement

risque de se produire, résultant en une augmentation

de la température du moteur pouvant causer de

graves avaries du moteur.

• Si on travaille en permanence à des régimes élevés,

il est conseillé d’utiliser un carburant d’un indice

d’octane supérieur.

Carburant écologique

HUSQVARNA recommande l'utilisation d'une essence

écologique (dite essence alkylat), soit une essence deux

temps prémélangée Aspen, soit une essence écologique

pour moteurs quatre temps mélangée avec de l'huile deux

temps selon les instructions ci-dessous. Noter qu'il peut

être nécessaire de procéder à un réglage du carburateur

lors du changement de type d'essence (voir les

instructions à la section Carburateur).

Possibilité d’utiliser du carburant mélangé à base

d’éthanol, E10 (la teneur en éthanol ne doit pas dépasser

10 %). L’utilisation de carburants mélangés contenant

plus d’éthanol que l’E10 perturbe le fonctionnement de la

machine et risque d’endommager le moteur.

Huile deux temps

• Pour obtenir un fonctionnement et des résultats

optimaux, utiliser une huile moteur deux temps

HUSQVARNA fabriquée spécialement pour nos

moteurs deux temps à refroidissement à air.

• Ne jamais utiliser d’huile deux temps pour moteurs

hors-bord refroidis par eau, appelée huile outboard

(désignation TCW).

• Ne jamais utiliser d’huile pour moteurs à quatre

temps.

Mélange

• Toujours effectuer le mélange dans un récipient

propre et destiné à contenir de l’essence.

• Toujours commencer par verser la moitié de l’essence

à mélanger. Verser ensuite la totalité de l’huile.

Mélanger en secouant le récipient. Enfin, verser le

reste de l’essence.

• Mélanger (secouer) soigneusement le mélange avant

de faire le plein du réservoir de la machine.

• Ne jamais préparer plus d’un mois de consommation

de carburant à l’avance.

Rapport de mélange

• 1:50 (2%) avec huile deux temps HUSQVARNA ou

équivalent.

Essence, litres Huile deux temps, litres

2% (1:50)

5 0,10

10 0,20

15 0,30

20 0,40

• 1:33 (3 %) avec des huiles de catégorie JASO FB ou

ISO EGB formulées pour moteurs deux temps à

refroidissement à air ou mélange selon les consignes

du fabricant d’huile.

30 – French

MANIPULATION DU CARBURANT

Remplissage de carburant

AVERTISSEMENT! Les mesures de

sécurité ci-dessous réduisent le risque

!

d’incendie:

Ne fumez jamais ni ne placez d’objet

chaud à proximité du carburant.

Arrêter le moteur et le laisser refroidir

pendant quelques minutes avant de faire

le plein. Le moteur doit être éteint et le

bouton d'arrêt en position STOP.

Ouvrir le bouchon du réservoir lentement

pour laisser baisser la surpression

pouvant régner dans le réservoir.

Nettoyez le pourtour du bouchon de

réservoir.

Serrer soigneusement le bouchon du

réservoir après le remplissage.

Si le bouchon n’est pas serré

correctement, il risque de s’ouvrir à

cause des vibrations et du carburant

peut alors s’échapper du réservoir de

carburant, entraînant un risque

d’incendie.

Avant de mettre la machine en marche, la

déplacer à au moins 3 mètres de l’endroit

où a été fait le plein.

Transport et rangement

• Transporter et ranger la machine et le carburant de

façon à éviter que toute fuite ou émanation éventuelle

entre en contact avec une flamme vive ou une

étincelle: machine électrique, moteur électrique,

contact/interrupteur électrique ou chaudière.

• Lors du stockage et du transport de carburant,

toujours utiliser un récipient homologué et conçu à cet

effet.

Remisage prolongé

• Lors des remisages de la machine, vider le réservoir

de carburant. S’informer auprès d’une station-service

comment se débarrasser du carburant résiduel.

Ne jamais démarrer la machine:

• Si du carburant ou de l'huile moteur ont été répandus

sur la machine. Essuyer soigneusement toutes les

éclaboussures et laisser les restes d'essence

s'évaporer.

• Si vous avez renversé du carburant sur vous ou sur

vos vêtements, changez de vêtements. Lavez les

parties du corps qui ont été en contact avec le

carburant. Utilisez de l’eau et du savon.

• S’il y a fuite de carburant. Vérifier régulièrement que

le bouchon du réservoir et la conduite de carburant ne

fuient pas.

• À moins que le bouchon du réservoir ne soit

correctement serré après avoir fait le plein.

French – 31

DÉMARRAGE ET ARRÊT

Avant le démarrage

AVERTISSEMENT! Contrôler les points

suivants avant la mise en marche: Lire

!

attentivement et bien assimiler le manuel

d’utilisation avant d’utiliser la machine.

Portez un équipement de protection

personnelle. Reportez-vous au chapitre

Équipement de protection personnelle.

Ne démarrez pas la machine sans avoir

monté la courroie et le carter de la

courroie. Sinon, l’embrayage risque de

se détacher et de provoquer des

blessures personnelles.

Vérifiez que le bouchon du réservoir est

correctement sécurisé et qu'il n'y a pas

de fuite de carburant.

Veiller à ce qu’aucune personne non

autorisée ne se trouve dans la zone de

travail pour éviter le risque de blessures

graves.

• Effectuez un entretien quotidien. Voir les instructions

au chapitre «

Démarrage

!

Moteur froid:

Entretien ».

AVERTISSEMENT! Le disque se met à

tourner dès le lancement du moteur.

Vérifier qu’il tourne librement.

lancé, le décompresseur se remet automatiquement

en position initiale.

• Saisir la poignée avant avec la main gauche. Placer le

pied droit sur la partie inférieure de la poignée arrière

et appuyer la machine sur le sol. Tirez la poignée du

lanceur d’un coup sec avec la main droite jusqu’à ce

que le moteur démarre.

du lanceur autour de la main.

• La machine s'arrête lorsque le moteur chauffe parce

que la commande de starter est tirée.

Ne jamais enrouler la corde

• Veiller à ce que le bouton d'arrêt (STOP) soit sur sa

position de gauche.

• La position de ralenti accéléré et le starter sont

engagés en tirant complètement le starter.

• Décompresseur: Enfoncer le décompresseur pour

réduire la pression dans le cylindre et faciliter le

démarrage de la découpeuse. Toujours utiliser le

décompresseur au démarrage. Une fois le moteur

32 – French

• Appuyez sur la commande de starter et sur le

décompresseur.

• Tirez la poignée du lanceur jusqu'à ce que le moteur

démarre.

DÉMARRAGE ET ARRÊT

• Lorsque la machine démarre, appuyez sur la gâchette

d’accélération pour désengager le ralenti accéléré

machine tourne alors au ralenti.

ATTENTION ! Tirez lentement sur la corde du lanceur

de la main droite jusqu’à ce qu’une résistance se fasse

sentir (les cliquets se mettent en prise), puis tirez

plusieurs fois rapidement et avec force.

Ne pas sortir complètement la corde du lanceur et ne

pas lâcher la poignée avec la corde du lanceur

complètement sortie. Cela pourrait endommager la

machine.

Avec un moteur chaud :

• Veiller à ce que le bouton d'arrêt (STOP) soit sur sa

position de gauche.

; la

lanceur d’un coup sec avec la main droite jusqu’à ce

que le moteur démarre.

du lanceur autour de la main.

• Lorsque la machine démarre, appuyez sur la gâchette

d’accélération pour désengager le ralenti accéléré

machine tourne alors au ralenti.

ATTENTION ! Tirez lentement sur la corde du lanceur

de la main droite jusqu’à ce qu’une résistance se fasse

sentir (les cliquets se mettent en prise), puis tirez

plusieurs fois rapidement et avec force.

Ne pas sortir complètement la corde du lanceur et ne

pas lâcher la poignée avec la corde du lanceur

complètement sortie. Cela pourrait endommager la

machine.

Ne jamais enrouler la corde

; la

• Pour procéder au réglage du starter/ralenti accéléré,

il convient de tirer la commande du starter sur la

position starter puis de la pousser de nouveau. Cela

ne concerne que le réglage du ralenti accéléré, pas le

starter.

• Décompresseur: Enfoncer le décompresseur pour

réduire la pression dans le cylindre et faciliter le

démarrage de la découpeuse. Toujours utiliser le

décompresseur au démarrage. Une fois le moteur

lancé, le décompresseur se remet automatiquement

en position initiale.

• Saisir la poignée avant avec la main gauche. Placer le

pied droit sur la partie inférieure de la poignée arrière

et appuyer la machine sur le sol. Tirez la poignée du

French – 33

DÉMARRAGE ET ARRÊT

AVERTISSEMENT! Lorsque le moteur

tourne, l’échappement contient des

!

produits chimiques comme des

hydrocarbures non brûlés et du