Page 1

GB Operator’s manual 2-22

SE Bruksanvisning 23-42

DK Brugsanvisning 43-63

FI Käyttöohje 64-84

NO Bruksanvisning 85-105

FR Manuel d’utilisation 106-126

NL Gebruiksaanwijzing 127-147

IT Istruzioni per l’uso 148-168

ES Manual de instrucciones 169-189

DE Bedienungsanweisung 190-210

PT Instruções para o uso 211-231

RU уководство по

эксплуатации 232-253

BG

ъководство за

експлоатациЯ 254-276

HU

Használati utasítás 277-297

Instrukcja obs∏ugi 298-319

PL

EE

Käsitsemisõpetus 320-340

Naudojimosi instrukcijos 341-361

LT

LV

Lieto‰anas pamÇc¥ba 362-382

SK

Návod na obsluhu

HR

Priruãnik

SI

Navodila za uporabo

CZ

Návod k pouÏití

GR

√‰ËÁ›Â˜ ¯Ú‹Ûˆ˜

RO

Instrucöiuni de utilizare 490-510

404-424

383-403

425-445

446-467

468-489

350BT

530BT

Page 2

Symbols

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly

or fatal injury to the operator or

others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

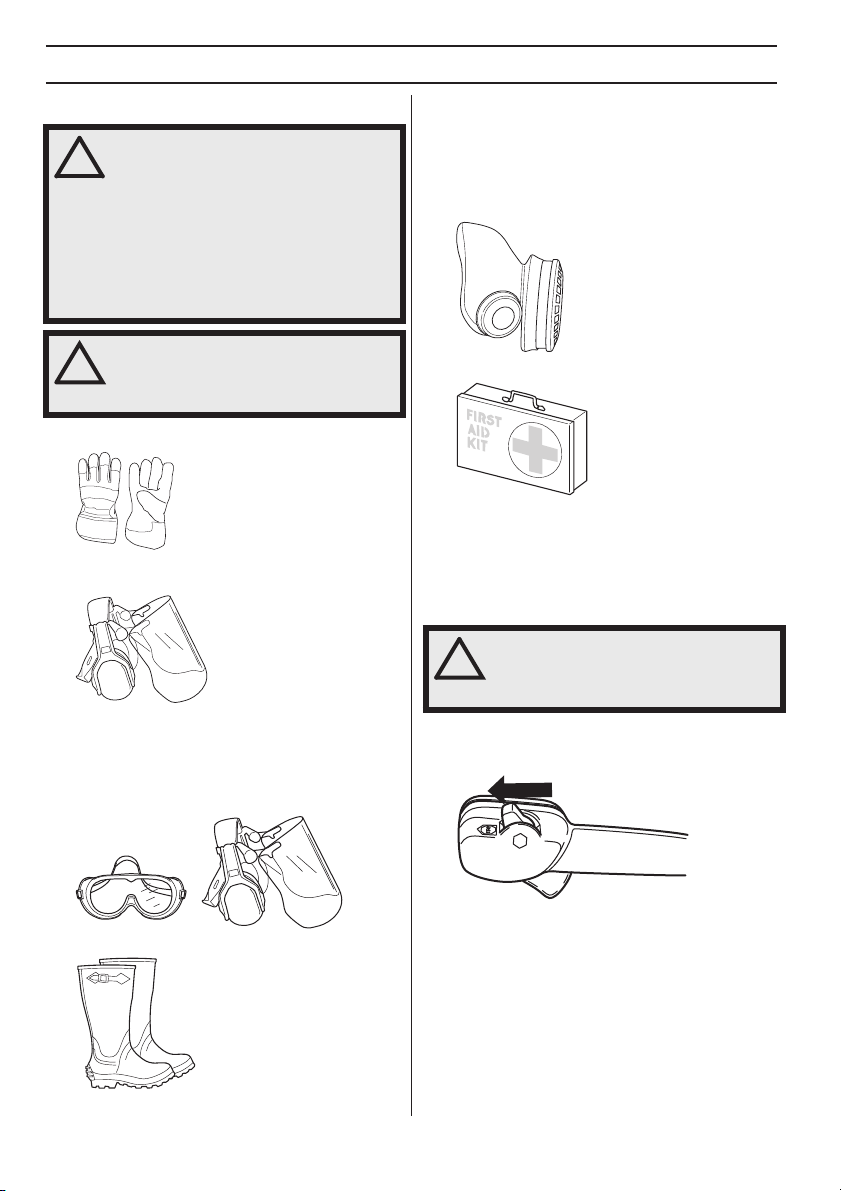

Always wear:

• Hearing protection

• Approved eye protection

, which can cause serious

KEY TO SYMBOLS

Noise emission to the environment

according to the European

unity’s Directive. The

Comm

machine’s emission is specified in

the Technical data chapter and on

the label.

Other symbols/decals on the

machine refer to special certification requirements

for certain markets.

Switch off the engine by moving the stop

switch to the STOP position before

carrying out any checks or

maintenance.

Always wear protective gloves.

This product is in accordance with

applicable EC directives.

Gloves should be worn when

necessary.

The blower can forcibly throw

objects that can bounce bac

This can result in serious eye

injuries if the recommended

safety equipment is not used.

The blower operator

ust ensure that no

m

people or animals come

closer than 15 metres.

When several operators

are working at the same site a safety distance of at least

15 metres must be in effect.

A breathing mask should be used

when there is a r

Keep all parts of your body away

from hot surf

isk of dust.

aces.

k.

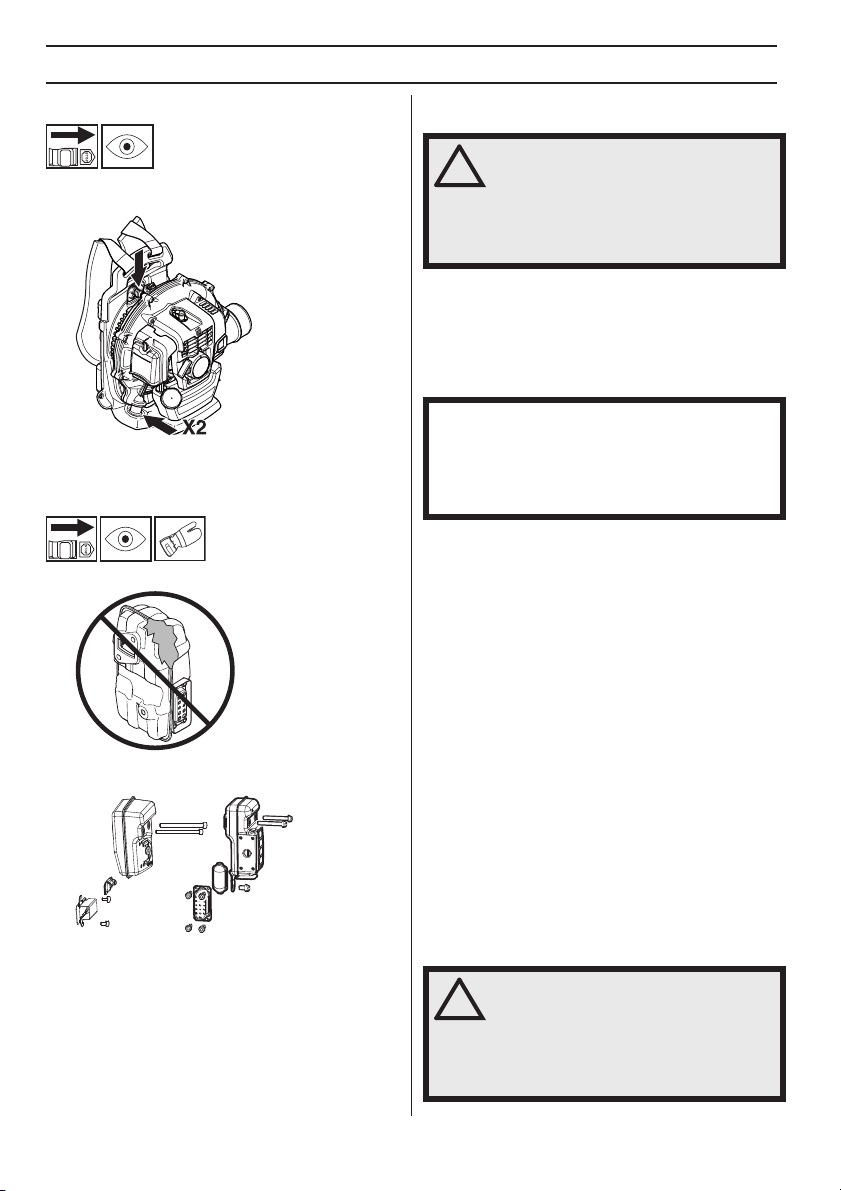

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be

rn.

wo

Refuelling.

Choke lever in ”open position”.

Choke lever in ”closed position”.

2 – English

Page 3

CONTENTS

!

!

!

T

Contents

KEY

TO SYMBOLS

Symbols

................................................................ 2

CONTENTS

Contents

Note the following before starting: ........................ 3

INTR

Dear Customer

WHA

What is what on the b

GENERAL SAFETY PRECA

Gener

SAFETY INSTR

P

Machine

Checking, maintaining and servicing the

machine

General working instructions ................................ 10

ASSEMBL

Assemb

FUEL HANDLING

Fuel

Fueling .................................................................. 15

ST

Star

MAINTENANCE

Gener

Carburettor ........................................................... 17

Muffler .................................................................. 17

Cooling system ..................................................... 17

Air intake screen ................................................... 17

Spark plug ............................................................ 18

Air filter ................................................................. 18

Shoulder strap ...................................................... 19

Maintenance schedule ......................................... 20

TECHNICAL D

EC Declaration of Conformity ............................... 22

............................................................... 3

ODUCTION

, .................................................... 4

T IS WHAT?

lower? ................................ 5

UTIONS

al ................................................................. 6

UCTIONS

ersonal protective equipment ............................. 8

′

s safety equipment ................................. 8

′

s safety equipment ................................. 9

Y

ling the blow pipe and control handle ...... 13

...................................................................... 14

ARTING AND STOPPING

ting and stopping ........................................... 16

al ................................................................. 17

ATA

echnical data ...................................................... 21

Note the f ollowing before starting:

Please read the oper ator's manual carefully.

WARNING! Long-term exposure to noise

can result in permanent hearing

impairment. So always use approved

hearing protection.

WARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use original

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING! A blower is a dangerous tool

if used carelessly or incorrectly and can

cause serious, even fatal injuries. It is

extremely important that you read and

understand the contents of this

Operator’s manual.

Husqvarna AB has a policy of continuous product

velopment and theref

de

the design and appearance of products without prior

notice.

The machine is only designed for blowing lawns,

ays

, asphalt roads and the like.

pathw

ore reserves the right to modify

English

–

3

Page 4

INTRODUCTION

Dear Customer,

Congratulations on your choice to buy a Husqvarna product! Husqvarna is based on a tradition that dates back to 1689,

when the Swedish King Karl XI ordered the construction of a factory on the banks of the Husqvarna River, for production

of muskets. The location was logical, since water power was harnessed from the Huskvarna River to create the waterpowered plant. During the more than 300 years in existence, the Husqvarna factory has produced a lot of different

products, from wood stoves to modern kitchen appliances, sewing machines, bicycles, motorcycles etc. In 1956, the first

motor driven lawn mowers appeared, followed by chain saws in 1959, and it is within this area Husqvarna is working

today.

Today Husqvarna is one of the leading manufacturers in the world of forest and garden products, with quality as our

highest pr

gardening, as well as for the building and construction industry. Husqvarna

ergonomics, usability, security and environmental protection. That is the reason why we have developed many different

features to add to our products within these areas.

We are convinced that you will appreciate with great satisfaction the quality and performance of our product for a very

long time to come.

whenever this may be necessary. If the retailer who sells your machine is not one of our authorised dealers, ask for the

address of your nearest service workshop.

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this

ator

oper

the second-hand value of the machine can be extended. If you sell this machine, make sure that the operator

is passed on to the buyer.

Thank you for using a Husqvarna product.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify the design and

appearance of products without prior notice

. The business concept is to develop, manufacture and market motor-driven products for forestry and

iority

The purchase of one of our products gives you access to professional help with repairs and service

′s manual as a valuable document. By following its content (usage, service, maintenance, etc), the life span and

.

′s aim is also to be at the front edge for

′s manual

4 – English

Page 5

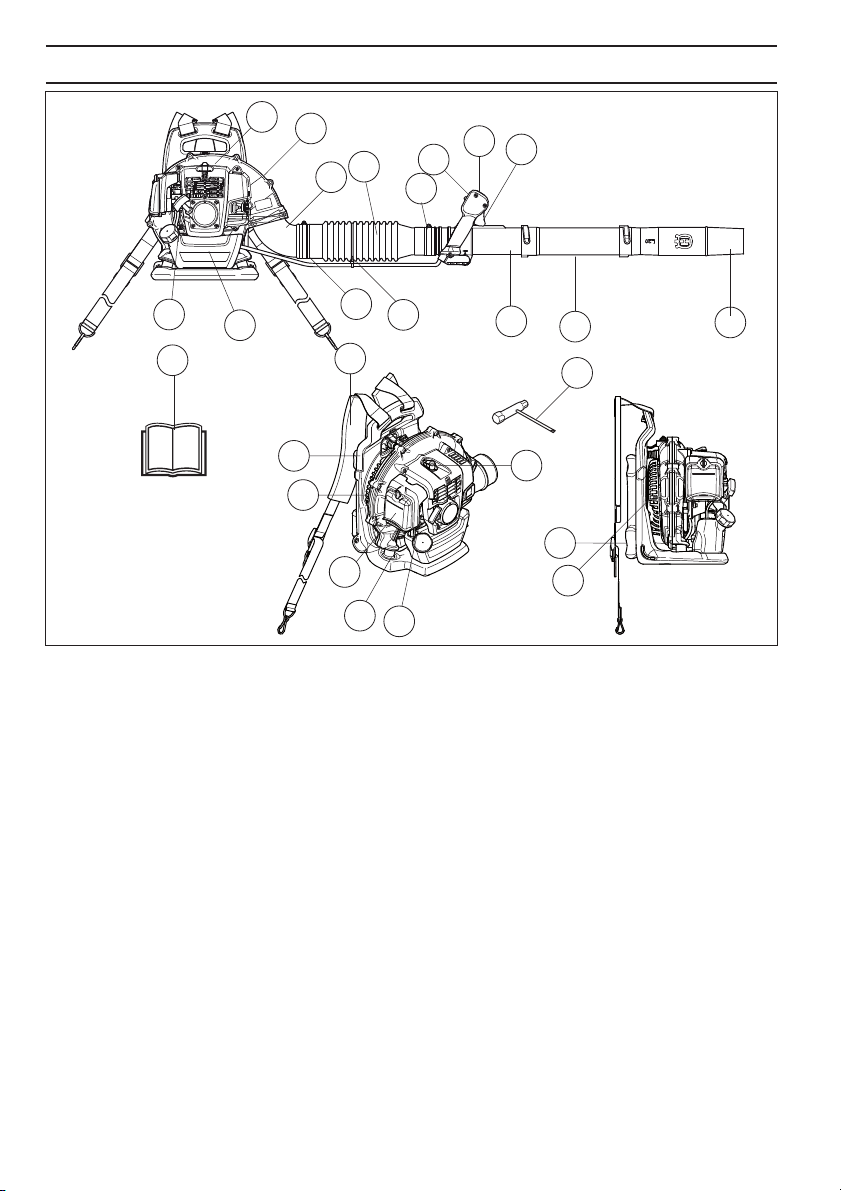

WHAT IS WHAT?

3

4

19

17

18

15

14

16

8

9

24

1

5

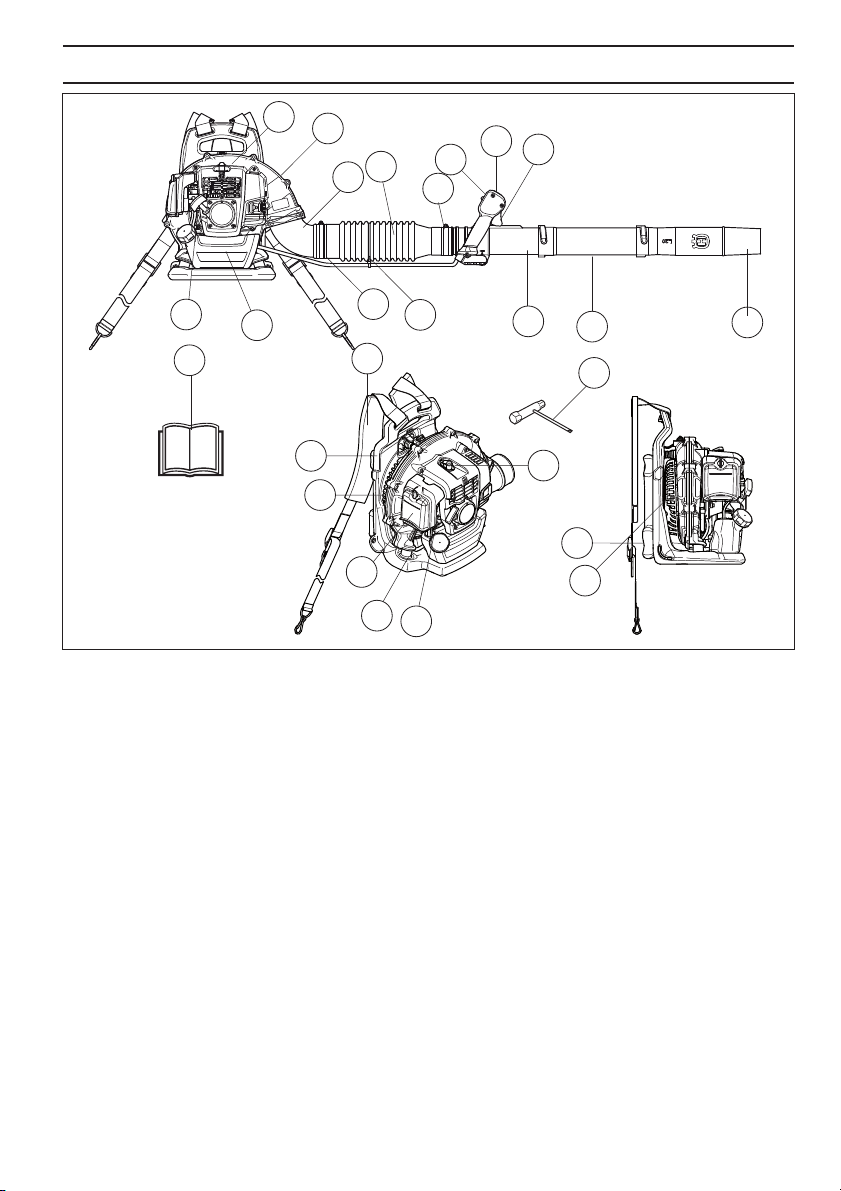

What is what on the blower?

1 Frame

2 Harness (Hip belt only available with 350BT)

3 Engine cover

4 Fan shell

5 Air intake screen

6 Fan

7 Air cleaner

8 Starter handle

9 Fuel tank

10 Pad

11 Spark plug

12 Vibration damping system

13 Choke control

19

21

2

20

22

25

23

11

10

7

12

13

14 Control handle/Operating handle

15 Stop switch with throttle position setting

16 Throttle trigger

17 Elbow

18 Clamp

19 Flexible hose

20 Control pipe

21 Clamp

22 Intermediate pipe

23 Blow pipe

24 Operator

25 Combination spanner

6

′s manual

English – 5

Page 6

GENERAL SAFETY PRECAUTIONS

General

IMPORTANT!

The machine is only designed for blowing lawns,

pathways, asphalt roads and the like.

Carry out an overall inspection of the machine before

use. See the maintenance schedule.

Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the ”Personal protective equipment” heading.

Never use a machine that has been modified in any way

from its original specification.

Never use a machine that is faulty. Carry out the safety

checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. See instructions under the

Maintenance heading.

All covers and guards must be fitted before starting.

Ensure that the spar

undamaged to avoid the risk of electric shock.

The blower operator must ensure that no people or

animals come closer than 15 metres. When several

operators are working at the same site a safety distance

of at least 15 metres must be in effect.

Never allow children to use the machine.

Never allow anyone else to use the machine without first

ensuring that they have read and understood the

contents of the operator’s manual.

Always check for any objects that may block the air

intake screen before beginning work.

Never remove the air intake screen.

In case of emergency, release yourself from the

machine by opening the waist and chest belt and let the

machine fall backwards.

Always contact local authorities and make sure you are

following applicable directives.

Keep all parts of your body away from hot surfaces.

Never touch the spark plug or ignition cable while the

engine is running.

k plug cap and ignition lead are

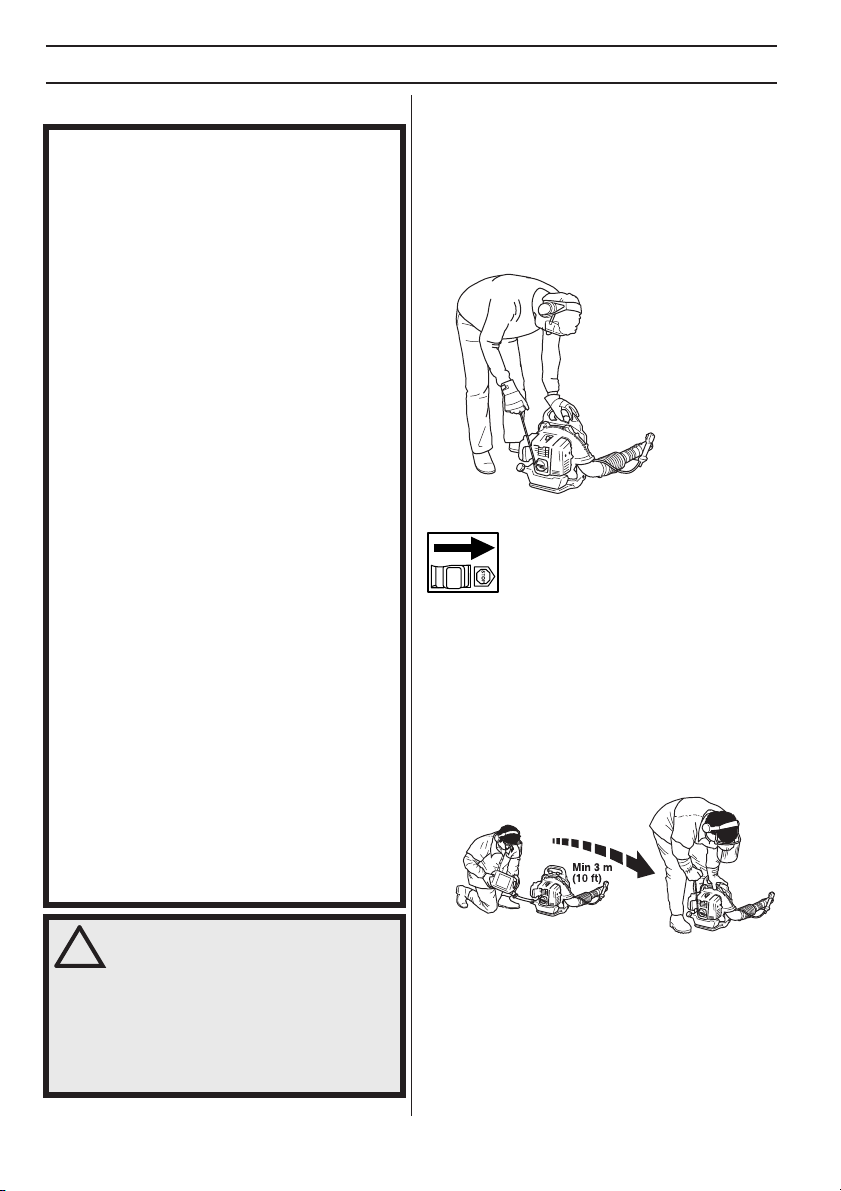

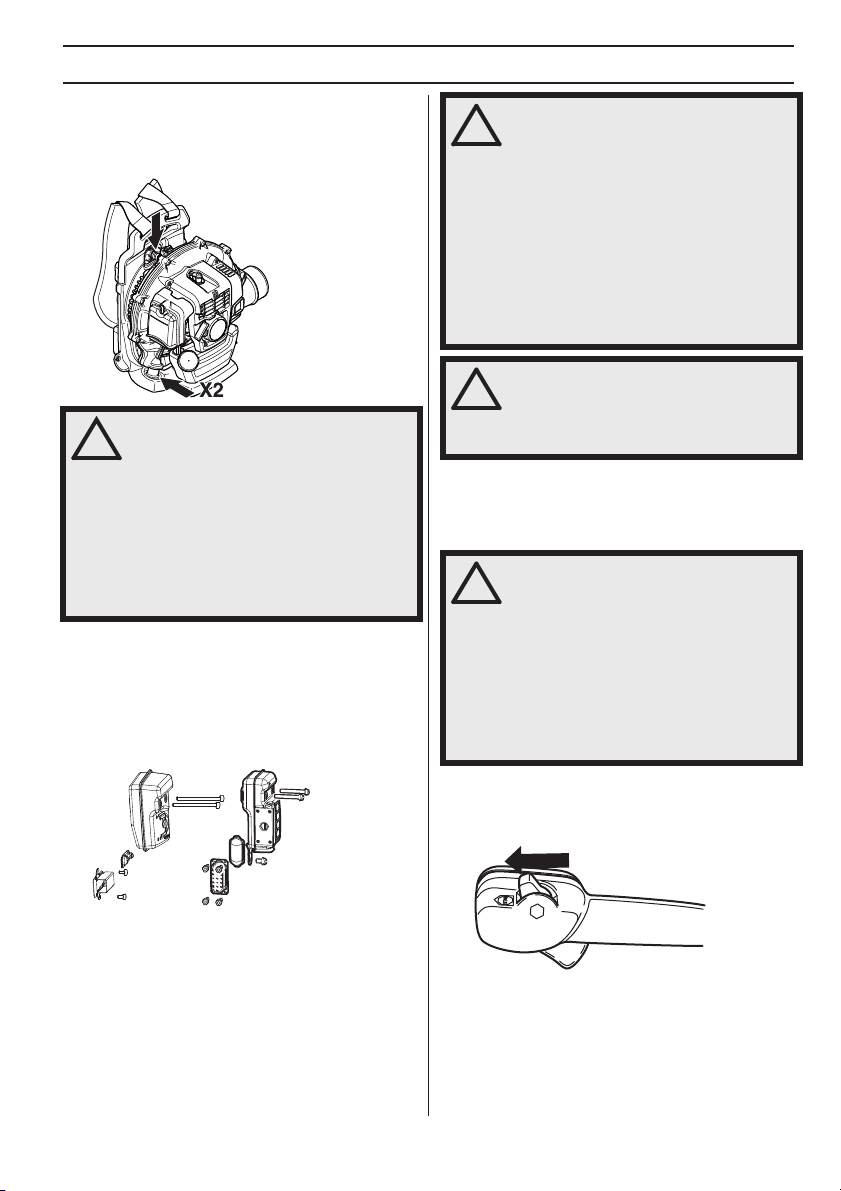

Starting

• Never start the machine indoors. Exhaust fumes can

be dangerous if inhaled.

• Observe the surroundings and ensure that no people

or animals can come into contact with the blower.

• Place the machine on the ground, press the machine

body against the ground with your left hand (NOTE!

Not your foot). Now grasp the starter handle with your

right hand and then pull quickly and firmly.

Fuel safety

• Always use a fuel container with an anti-spill valve.

• Never refuel the machine while the engine is running.

Always stop the engine and let it cool for a few minutes

before refuelling.

• Make sure there is plenty of ventilation when refuelling

or mixing fuel (petrol and 2-stroke oil).

• Avoid all skin contact with fuel. Fuel is a skin irritant

and may even cause skin changes.

• Move the machine at least 3 m from the refuelling

point before starting it.

!

6 – English

WARNING! This machine produces an

electromagnetic field during operation.

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

• Never start the machine:

- If you have spilled fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

- If you have spilled fuel on yourself or your clothes,

change your clothes. Wash any part of your body that has

come in contact with fuel. Use soap and water.

- If the machine is leaking fuel. Check regularly for leaks

from the fuel cap and fuel lines.

Page 7

GENERAL SAFETY PRECAUTIONS

Transport and storage

• Store and transport the machine and fuel so that there

is no risk of any leakage or fumes coming into contact

with sparks or open flames, for example, from

electrical machinery, electric motors, electrical relays/

switches or boilers.

• When storing and transporting fuel always use

appro

ved containers intended for this purpose.

• When storing the machine for long periods the fuel

tank must be emptied. Contact your local petrol

station to find out where to dispose of excess fuel.

Empty the fuel tank and press the primer until all fuel

has been emptied.

• Remove the spark plug and drop a spoon of 2-stroke

oil in the cylinder

then put the spark plug back in place.

• Ensure the machine is cleaned and that a complete

ser

vice is carried out before long-term storage.

• Secure the machine during transport.

• Store the machine in a dry, cool, well-aired and dustfree location. Store the machine out of reach of

children.

!

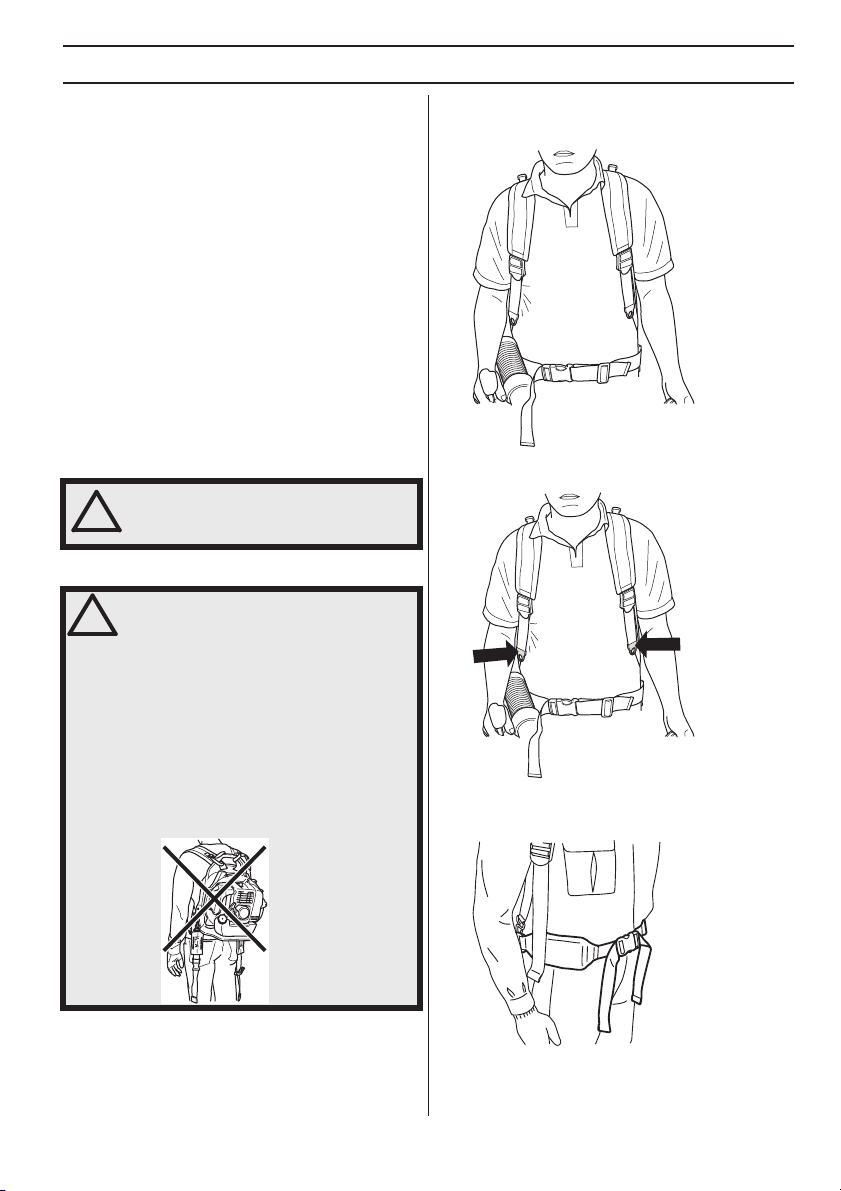

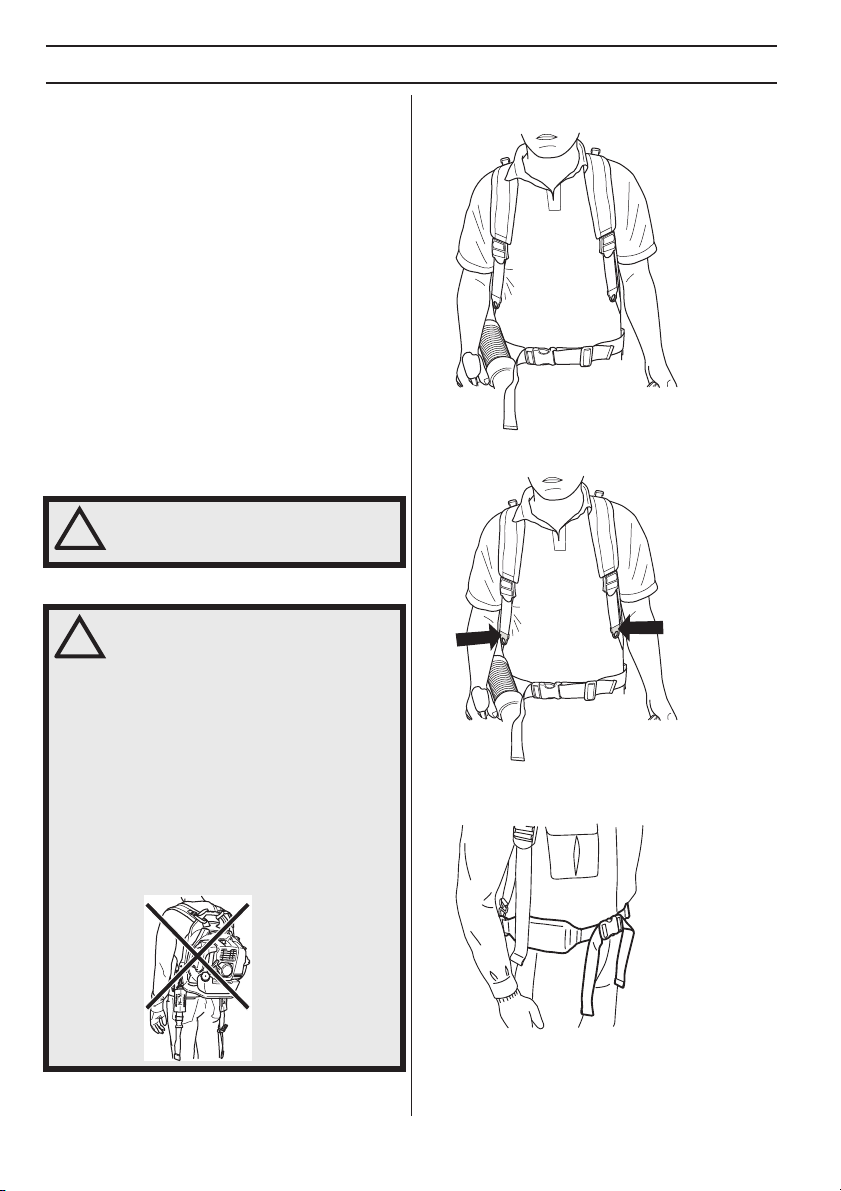

Adjusting the harness

!

. Turn over the engine a few times and

WARNING! Take care when handling fuel.

Bear in mind the risk of fire, explosion

and inhaling fumes.

WARNING! The harness must always be

worn when working with the machine.

Failure to do so means you will be unable

to manoeuvre safely and this can result in

injury to yourself or others.

Make sure that the waist belt is closed and

correctly adjusted.

If you not using a waist belt, be sure to

remove it from the unit and store it. There

is a risk that the belt will be caught,

toppling the unit.

There is a risk that an unclosed belt can

get stuck or sucked into the fan of the

machine.

A correctly adjusted harness and machine significantly

facilitates the work. Adjust the harness to give the best

working position.

Tighten the side straps so that the pressure is evenly

ibuted across the shoulders.

distr

Place the hip strap over the hip and not too far down on

the stomach. Tighten the hip strap so that you feel the

weight of the blower resting on your hip.

NOTE!

The 530BT has no waist belt.

English – 7

Page 8

SAFETY INSTRUCTIONS

Personal protective equipment

WARNING! You must use approved

personal protective equipment whenever

!

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of

injury if an accident does happen. Ask

your dealer for help in choosing the right

equipment. Please read the operator’s

manual carefully and make sure you

understand the instructions before using

the machine.

WARNING! Listen out for warning signals

or shouts when you are wearing hearing

!

protection. Always remove your hearing

protection as soon as the engine stops.

• Gloves should be worn when necessary.

• Wear hearing protection that provides adequate noise

reduction.

• Always wear approved eye protection. If you use a

visor then you must also wear approved protective

goggles. Approved protective goggles must comply

with the ANSI Z87.1 standard in the USA or EN 166 in

EU countries. Blows from branches or objects that are

thrown can damage the eyes.

• Always wear heavy, long pants, boots, gloves, and a

• A breathing mask should be used when there is a risk

• Always have a first aid kit nearby.

ve shirt. To reduce the risk of injury

long-slee

associated with objects being drawn into rotating

parts, do not wear loose clothing, scarves, jewelry,

etc. Secure hair so it is above shoulder level.

of dust.

Machine′s safety equipment

This section describes the machine′s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

WARNING! Never use a machine that has

faulty safety equipment! Carry out the

!

inspection, maintenance and service

routines listed in this section.

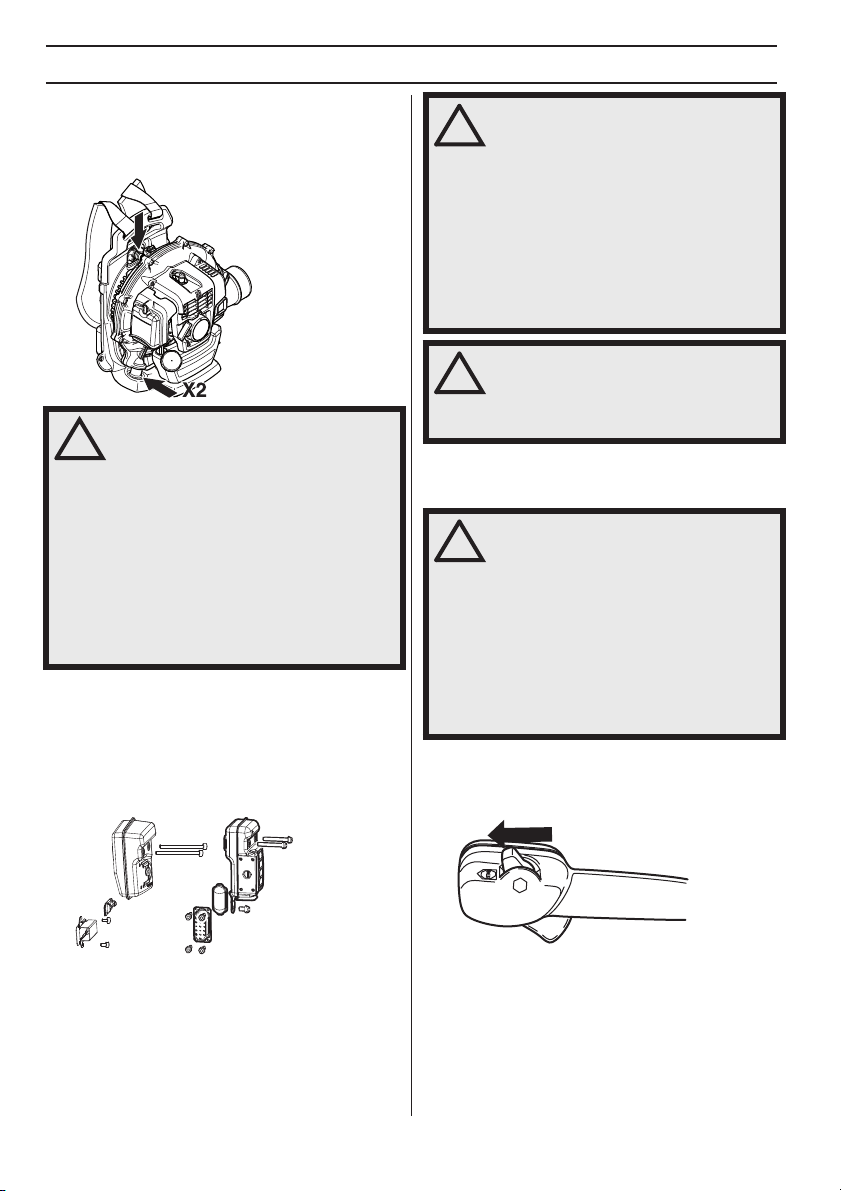

Stop switch

Use the stop switch to switch off the engine.

• Wear sturdy, non-slip boots.

8 – English

Remove the ignition cable and the spark plug to carry out

inspection and maintenance.

Page 9

SAFETY INSTRUCTIONS

Vibration damping system

Your machine is equipped with a vibration damping

system that is designed to minimize vibration and make

operation easier.

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. The risk

increases at low temperatures.

Muffler

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

In countries that have a warm and dry climate there is a

significant risk of fire. Consequently, we have equipped

the muffler with a spark arrestor mesh mounted inside the

muffler.

WARNING!

!

Bear in mind that: Engine exhaust fumes

contain carbon monoxide, which can

cause carbon monoxide poisoning. For

this reason you should not start or run

the machine indoors, or anywhere that is

poorly ventilated.

The exhaust fumes from the engine are

hot and may contain sparks which can

start a fire. Never start the machine

indoors or near combustible material!

WARNING! The inside of the muffler

contain chemicals that may be

!

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

Checking, maintaining and

servicing the machine′s safety

equipment

WARNING! All servicing and repair work

on the machine requires special training.

!

This is especially true of the machine′s

safety equipment. If your machine fails

any of the checks described below you

must contact your service agent. When

you buy any of our products we

guarantee the availability of professional

repairs and service. If the retailer who

sells your machine is not a servicing

dealer, ask him for the address of your

nearest service agent.

Stop switch

• Start the engine and make sure the engine stops

when you move the stop switch to the stop setting.

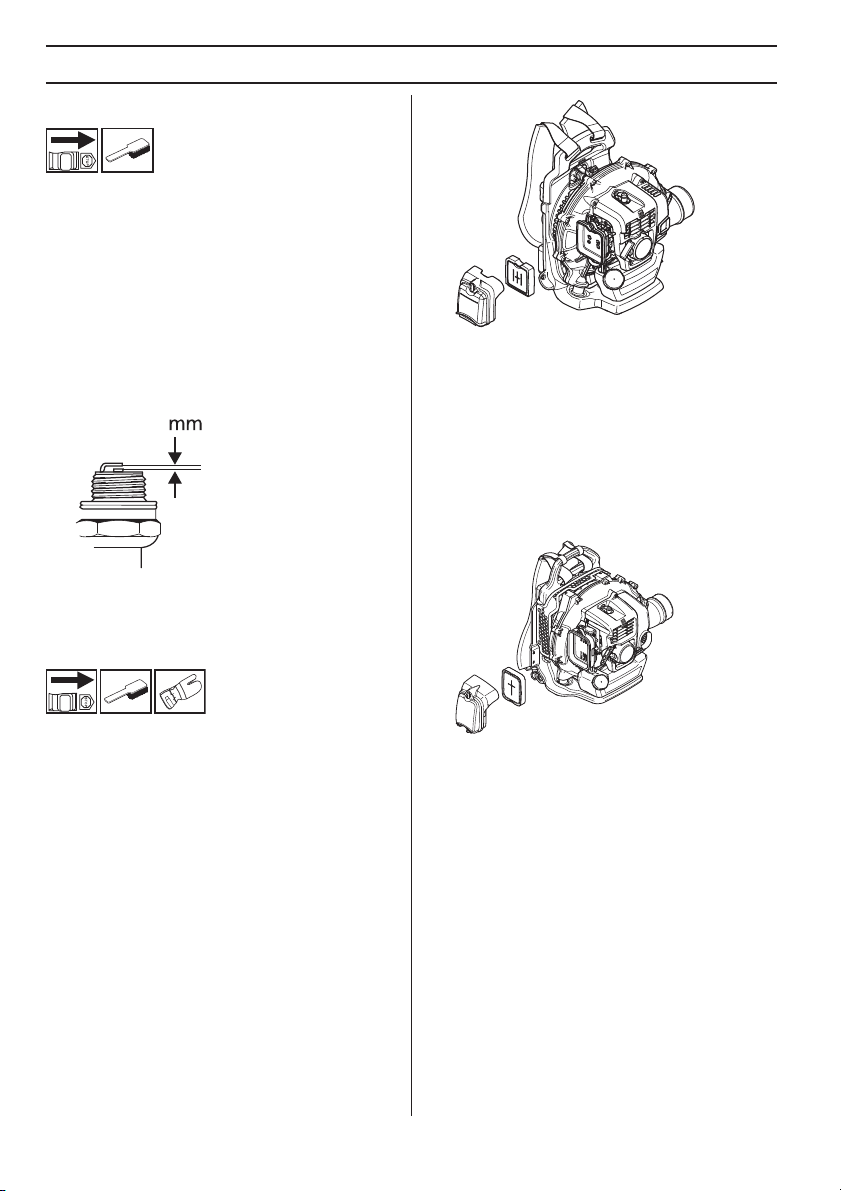

530BT

For mufflers it is very important that you follow the

instructions on checking, maintaining and servicing your

machine. See instructions under the heading Checking,

maintaining and servicing the machine’s safety

equipment.

350BT

English – 9

Page 10

SAFETY INSTRUCTIONS

Vibration damping system

• Check the vibration damping units regularly for cracks

or deformation. Replace them if damaged.

• Check that the vibration damping element is

undamaged and securely attached.

Muffler

• Never use a machine that has a faulty muffler.

• Regularly check that the muffler is securely attached

to the machine.

530BT

• The muffler on your machine is equipped with a spark

arrestor mesh; this must be cleaned regularly. See the

heading Muffler in the Maintenance chapter. A

blocked mesh will cause the engine to overheat and

350BT

may lead to serious damage. Never use a muffler with

a defective spark arrestor mesh.

WARNING! Never use a machine with

faulty safety equipment. The machine's

!

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

Air filter

Never use the leaf blower without an air filter or with a

damaged or deformed filter element as unfiltered, dusty

air can quickly destroy the engine.

General working instructions

IMPORTANT! This section considers basic safety rules

when working with blowers. If you encounter a situation

where you are uncertain how to proceed you should ask

an expert. Contact your dealer or your service

workshop. Avoid all usage which you consider to be

beyond your capability.

Show consideration to persons in your surroundings by

avoiding using the machine at unsuitable times, such as

late in the evening or early in the morning. Reduce the

noise levels by limiting the number of equipment units

used simultaneously. Read through and follow the simple

directions so that you disturb your surroundings as little as

possible.

• Use the blower with the lowest possible throttle. It is

seldom necessar

procedures can be done at half throttle. A lower

throttle means less noise and less dust, and it is also

easier to keep control over the rubbish collected

together/moved.

• Use a rake or a brush to release rubbish stuck to the

round.

g

• Hold the opening of the blower as close to the ground

as possible. Utilise the entire length of the blow pipe

to keep the air current close to the ground.

• Clean up afterwards. Make sure that you have not

blown rubbish into someone’s garden. Dispose of

debris in trash receptacles.

• Use the machine during normal working hours to

avoid unnecessary noise. Avoid working early in the

morning or late at night.

!

y to use full throttle, and many work

WARNING! Be aware of your

surroundings. If anyone approaches your

work area, set the throttle control to the

lowest throttle until the person is at a

safe distance. Direct the blower away

from people, animals, play areas, open

windows and cars etc.

10 – English

Page 11

SAFETY INSTRUCTIONS

Basic safety rules

• No unauthorised persons or animals may be present

in the working area, which is 15 metres.

• Allow the engine to cool before refuelling.

• Keep all parts of your body away from hot surfaces.

• If the machine catches fire or other emergency occurs

which f

orces you to release yourself from the

machine, open the harness straps and let the

machine fall backwards.

• The powerful currents of air can move objects at such

a speed that the

eye injuries.

• Do not direct the air jet towards people or animals.

• Stop the engine before assembling or dismantling

accessories or other parts.

• Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

Working in bad weather is tiring and can lead to

dangerous conditions, e.g. slippery surfaces.

• Minimise the blowing time by lightly wetting dusty

areas or using spr

• Reduce water consumption by using blowers instead

of water hoses for different applications around the

lawn and garden, such as lattices, screens, grills,

porches, etc

• Make sure you can move and stand safely. Check the

area around y

branches, ditches, etc.) in case you have to move

suddenly. Take great care when working on sloping

ground.

y can bounce back and cause serious

ay equipment.

ou for possible obstacles (roots, rocks,

• Never put the machine down with the engine running

• Engine exhaust fumes contain carbon monoxide,

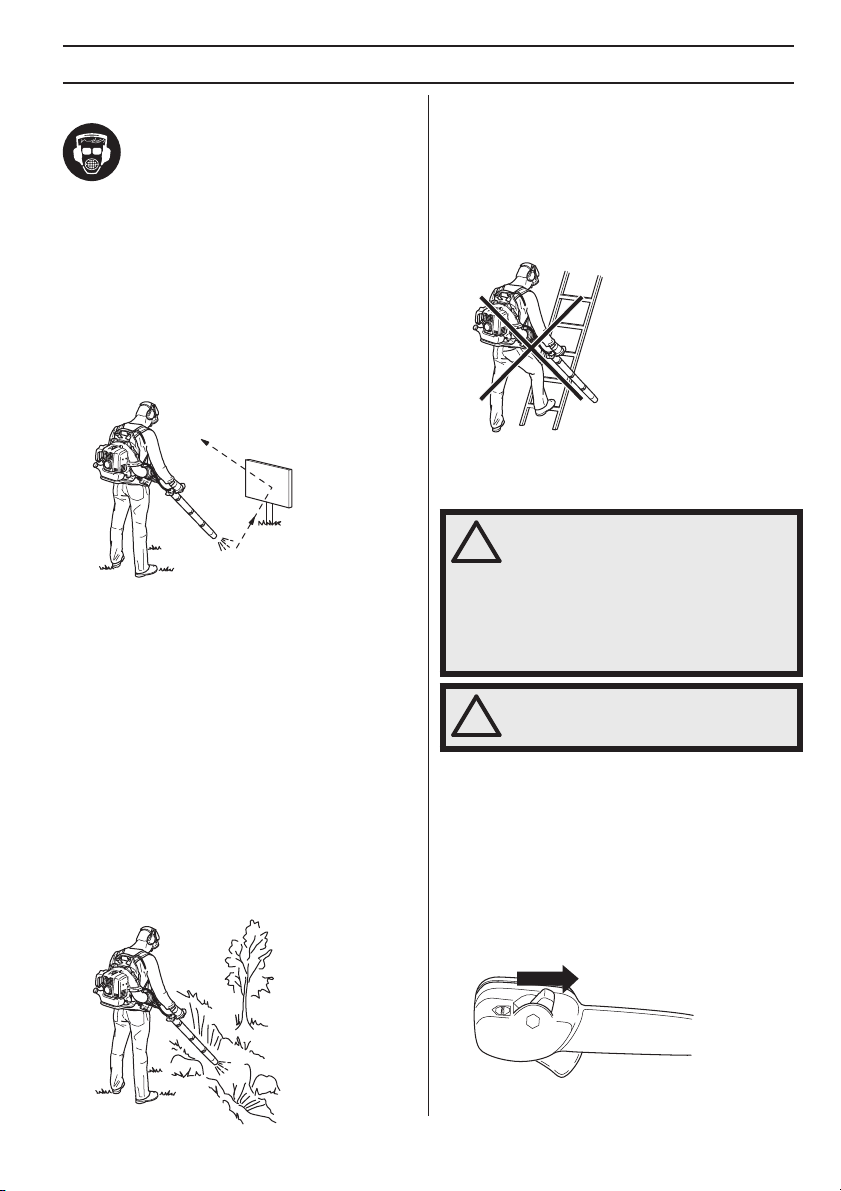

• The blower must not be used while on a ladder or

• CAUTION! Do not use the machine unless you are

ou have it in clear sight.

unless y

which can cause carbon monoxide poisoning. For this

reason you should not start or run the machine

indoors, or anywhere that is poorly ventilated.

olding, or in high places (such as roofs). Their

scaff

work could result in severe injury.

le to call for help in the event of an accident.

ab

Basic working techniques

WARNING! Watch out for thrown objects.

Always wear eye protection. Stones,

!

rubbish, etc. can be thrown up into the

eyes causing blindness or serious injury.

Keep unauthorised persons at a

distance. Children, animals, onlookers

and helpers should be kept outside the

safety zone of 15 m. Stop the machine

immediately if anyone approaches.

WARNING! Always stop the engine

before cleaning.

!

• This blower is a backpack type, and is carried using a

shoulder harness while operating. It is operated and

controlled with the handle on the tube using the right

hand.

• The speed of the air jet is regulated by means of the

You can set the throttle position using the ”stop switch”

and by doing so not need to hold your finger on the throttle

all the time you are using the blower. Full throttle is

obtained when the control is held back fully.

. Select the speed best suited for respective

throttle

tasks.

English – 11

Page 12

SAFETY INSTRUCTIONS

• Check that the air intake is not blocked, for example,

by leaves or rubbish. A clogged air intake reduces the

machine’s blowing capacity and increases the

engine’s working temperature, which can result in

engine failure. Stop the engine and remove the object.

• Be aware of the wind direction. Work with the wind to

e your work easier.

mak

• Using the blower to move large piles is time

consuming and creates unnecessary noise.

• Keep a good balance and a firm foothold.

• When work is finished the machine should be stored

vertically.

12 – English

Page 13

ASSEMBLY

Assembling the blow pipe and

control handle

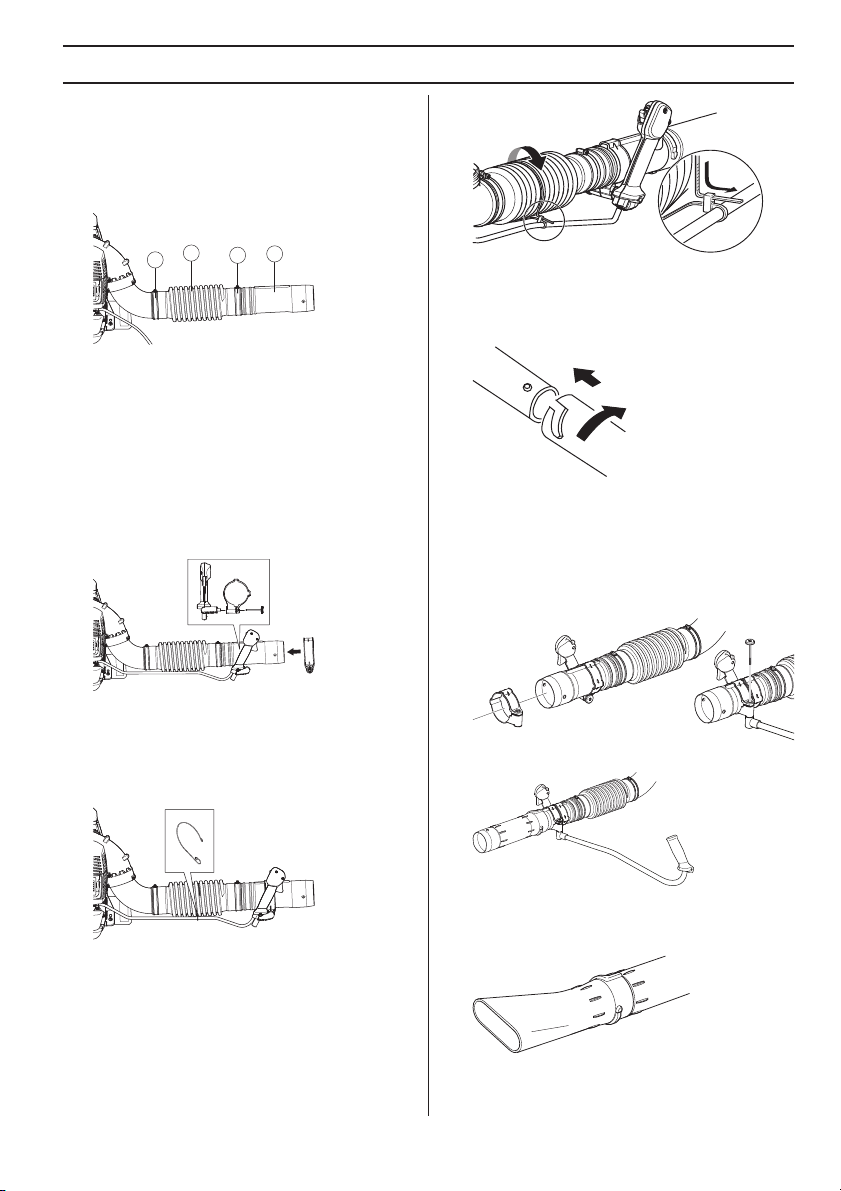

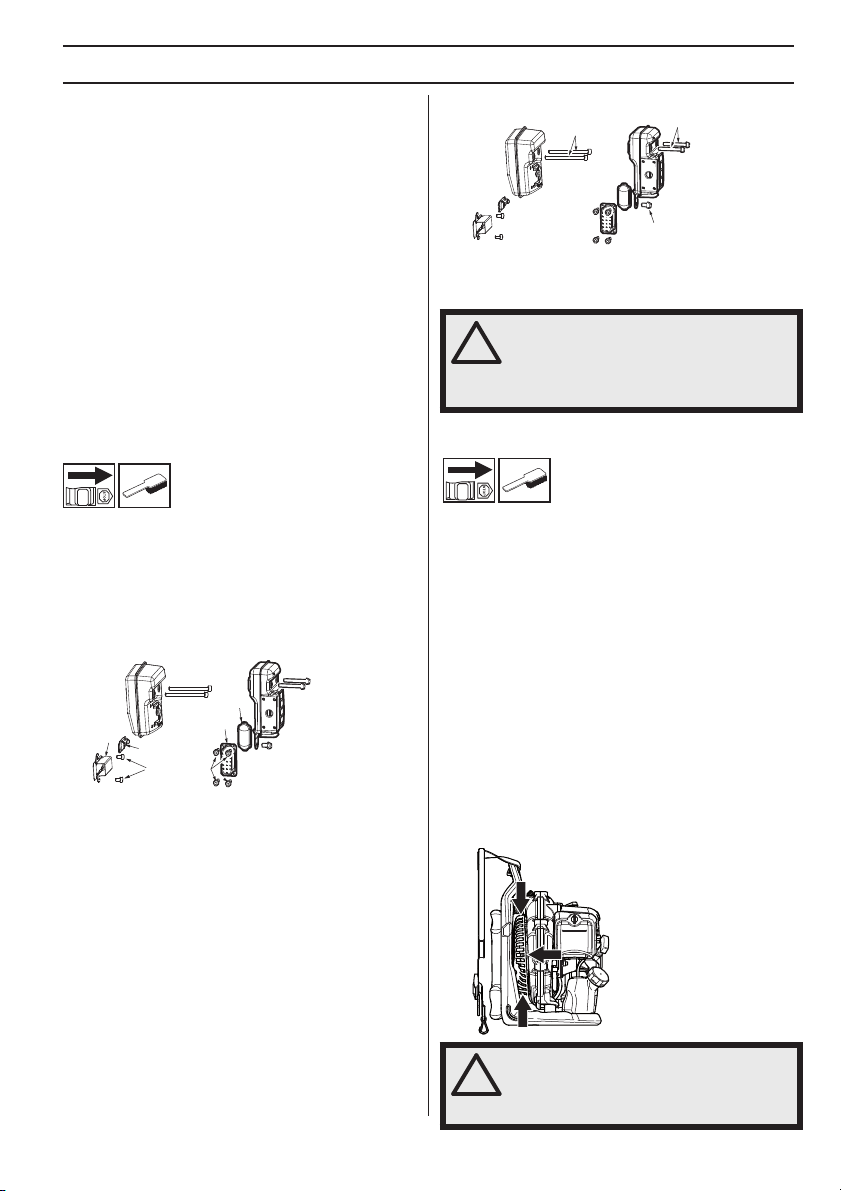

• Connect the blower and control pipe with the flexible

hose. Clamp both ends of the flexible hose in place.

Use the accompanying hardware.

1

3

1 Flexible hose

2 Control pipe

3 Clamp

4 Clamp

NOTE!

Lubricate the pipes a little to facilitate assembly.

• Fasten the handle holder to the control pipe and

tighten the knob on the holder

align the handle holder with the convex of the control

pipe.

• Adjust the position and angle to achieve a comfortable

working position, and tighten.

2

4

. Please make sure to

350BT

• Use the clamp to fasten the cabling to the flexible

hose.

Blow pipe

Assemble the intermediate pipe and the blow pipe. It is

possible to add more intermediate pipes if longer blow

pipes are required.

Optional equipment

(Not included in the box).

Handlebar

Disassemble the intermediate pipe. Disassemble the

knob from the holder and puch the holder on to the holder

pipe. Assemble the knob and tighten.

Assemble the intermediate pipe.

• Connect the straight pipe and pipe end. Push the

pipes together and turn them so they lock.

530BT

• Fasten the cabling at the centre of the hose using the

strap provided with the cabling.

• First, wrap the flexible hose with the strap. Start at the

bottom. Then run the strap through the hole in the

strap as shown in the figure. Please note that there is

a possibility of damaging the hose if the strap is

tightened too hard.

Flat nozzle

• If higher air speed is required, the round blow pipe is

replaced by the flat nozzle.

English – 13

Page 14

FUEL HANDLING

Fuel

CAUTION! The machine is equipped with a two-stroke

engine and must always be run using a mixture of petrol

and two-stroke oil. It is important to accurately measure

the amount of oil to be mixed to ensure that the correct

mixture is obtained. When mixing small amounts of fuel,

even small inaccuracies can drastically affect the ratio of

the mixture.

WARNING! Always ensure there is

adequate ventilation when handling fuel.

!

Petrol

CAUTION! Always use a good quality petrol/oil mixture (at

least 90 octane).

• The lowest recommended octane rating is 90. If you

run the engine on a petrol with a lower octane rating

than 90 this can cause knocking. This leads to an

increased engine temperature, which can result in

serious engine damage.

• When working at continuous high revs a higher octane

ating is recommended. Use good quality unleaded

r

petrol.

Ethanol blended fuel, E10 may be used (max 10%

ethanol blend). Using ethanol blends higher than E10 will

create lean running condition which can cause engine

damage.

Two-stroke oil

• For best results and performance use HUSQVARNA

two-stroke oil, which is specially formulated for our

two-stroke engines. Mixture 1:50 (2%).

• If HUSQVARNA two-stroke oil is not available, you

may use another two-stroke oil of good quality that is

intended for air cooled engines. Contact your dealer

when selecting an oil. Mixing ratio 1:33 (3%).

• Never use two-stroke oil intended for water-cooled

outboard engines

oil.

• Never use oil intended for four-stroke engines.

, sometimes referred to as outboard

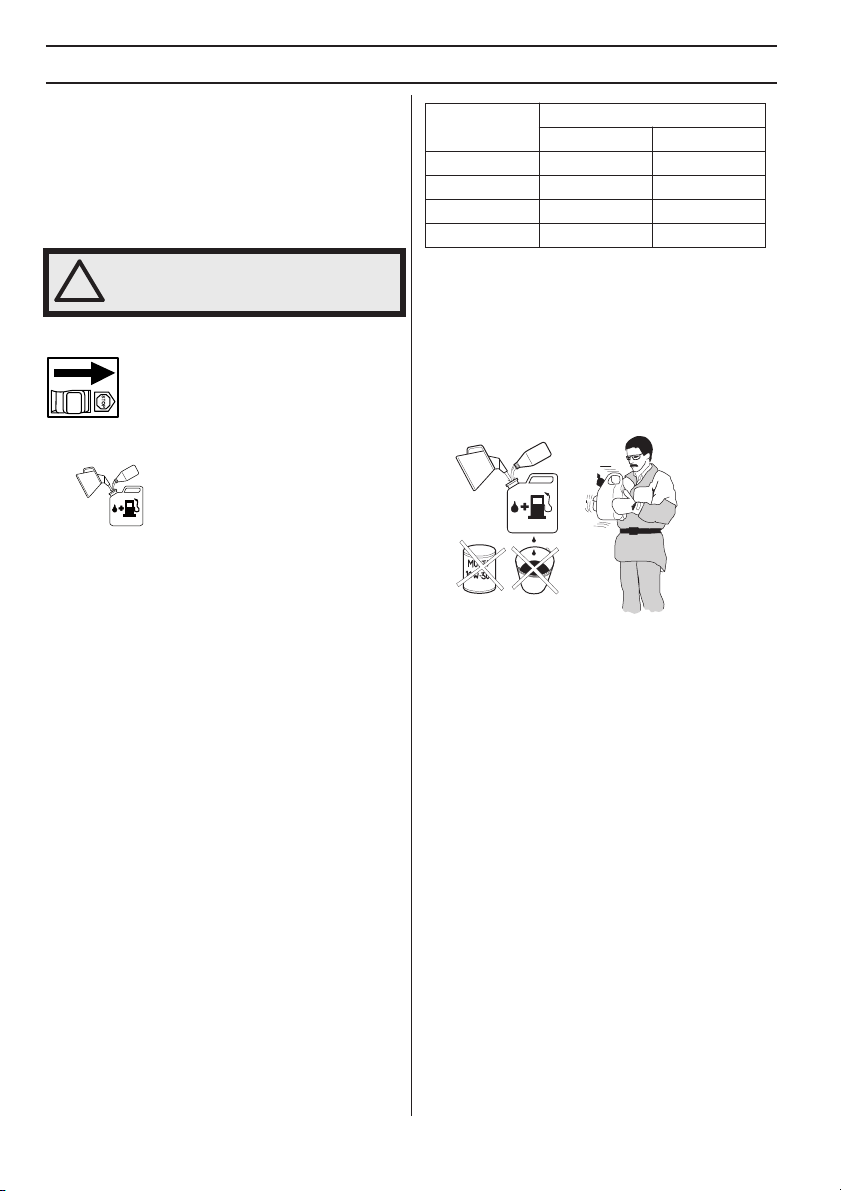

Petrol, litre

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Two-stroke oil, litre

2% (1:50) 3% (1:33)

Mixing

• Always mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to

be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

petrol.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

s fuel tank.

14 – English

Page 15

Fueling

!

FUEL HANDLING

WARNING! Taking the following

precautions, will lessen the risk of fire:

Refuel in a well ventilated area. Never

fuel the machine indoors.

Do not smoke or place hot objects near

fuel.

Always shut off the engine before

refuelling.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

If you have spilled fuel on it. Wipe off the

spillage and allow remaining fuel to

evaporate.

Always move the machine away from the

refuelling area and source before

starting.

• Move the machine at least 3 m from the refuelling

point before starting it.

• Clean the area around the fuel cap. Contamination in

the tank can cause operating problems.

• Ensure that the fuel is well mixed by shaking the

container before filling the tank.

• Check the fuel level before each use and leave space

for the fuel to expand, because the heat from the

engine and the sun may otherwise cause the fuel to

expand and overflow.

English – 15

Page 16

Starting and stopping

WARNING! Always move the machine

away from the refuelling area and source

!

before starting. Place the machine on a

flat surface.

Make sure no unauthorised persons are

in the working area. Otherwise there is a

risk of serious personal injury. The safety

distance is 15 meters.

The machine may only be started in its

complete design. If the machine is

started without all the guards fitted there

is a risk of personal injuries.

STARTING AND STOPPING

Starting

Hold the body of the machine on the ground using your

left hand (CAUTION! Not with your foot!). Grip the starter

handle, slowly pull out the cord with your right hand until

you feel some resistance (the starter pawls grip), now

quickly and powerfully pull the cord.

starter cord around your hand.

Never twist the

Cold engine

Ignition: Set the stop switch to the start position. About

one third open.

(2)

(3)

(4)

530BT

• Idle speed (3)

350BT

• About one third open. (2)

It is not allowed to set the stop switch in full throttle

position.

Choke: Set the choke control in the choke position.

Primer bulb: Press the air purge repeatedly until fuel

begins to fill the bulb. The bulb need not be completely

filled.

(1)

Warm engine

Use the same starting procedure as for a cold engine but

without setting the choke control in the choke position.

Repeat pulling the cord until the engine starts. When the

engine starts, return choke control to run position.

CAUTION! Do not pull the star ter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

Air is released as soon as the engine is started, even

when idling. Do not allow anyone to stand close to the

blower or the blower tube.

Set the required engine speed with the throttle control.

(2)

(3)

(4)

Allow the engine to warm for a few minutes.

1 Full throttle

2 About one third open.

3 Idle speed

4 Stop switch

(1)

Stopping

The engine is stopped by moving the stop switch to the

stop position.

16 – English

Page 17

MAINTENANCE

General

Remove the ignition cable and the spark plug to carry out

inspection and maintenance. Keep all parts of your body

away from hot surfaces.

Carburettor

Adjustment of the idle speed

Before any adjustments are made, make sure that the air

filter is clean and the air filter cover is fitted.

350BT

The factory idle speed setting is: 2200 rpm.

530BT

The factory idle speed setting is: 3000 rpm.

Use the adjustment screw at the upper edge of the

carburettor if the idle speed has to be adjusted.

Muffler

• 530BT 7-11 Nm. (2)

(2)

530BT

Check that the spark arrester and the exhaust duct are

scre

wed in place correctly (5). Tighten to 2-3 Nm.

WARNING! The muffler gets very hot

during use and remain so for some time

!

after stopping. This also applies at idle

speed. Contact can result in burns to the

skin. Remember the risk of fire!

350BT

(1)

(1)

Cooling system

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

The muffler is equipped with a special spark arrestor

The spark arrestor mesh should be cleaned once

mesh.

a month. This is best done with a wire brush.

(3)

(4)

(3)

(5)

530BT

To remove the spark arrestor mesh proceed as follows:

• Remove the exhaust duct (4, 5).

• Remove the spark arrester (3).

• Pull out the spark arrestor mesh and clean using a

wire br

ush. Replace the spark arrestor mesh if it is

defective.

• Remove any carbon deposits in the muffler's inlet and

outlet and in the cylinder's exhaust port.

CAUTION! Never use a machine with a defective muffler.

Check regularly that the muffler is complete and secured

correctly. Tighten the screws.

• 350BT 8-12 Nm. (1)

(4)

(5)

350BT

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

• Cooling fins on the cylinder.

• Air intake screen

Clean the cooling system with a brush once a week, more

often in demanding conditions

system results in the machine overheating which causes

damage to the piston and cylinder. Check that the nozzles

are not blocked.

. A dirty or blocked cooling

Air intake screen

Check that the air intake is not blocked on all sides

including the underside, for example, by leaves or

rubbish. A clogged air intake reduces the machine’s

blowing capacity and increases the engine’s working

temperature, which can result in engine failure. Stop the

engine and remove the object.

WARNING! Never use the blower if the

screen is not in place. Before use, check

!

that the screen is in place and

undamaged.

English – 17

Page 18

MAINTENANCE

Spark plug

The spark plug condition is influenced by:

• Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes

starting difficulties.

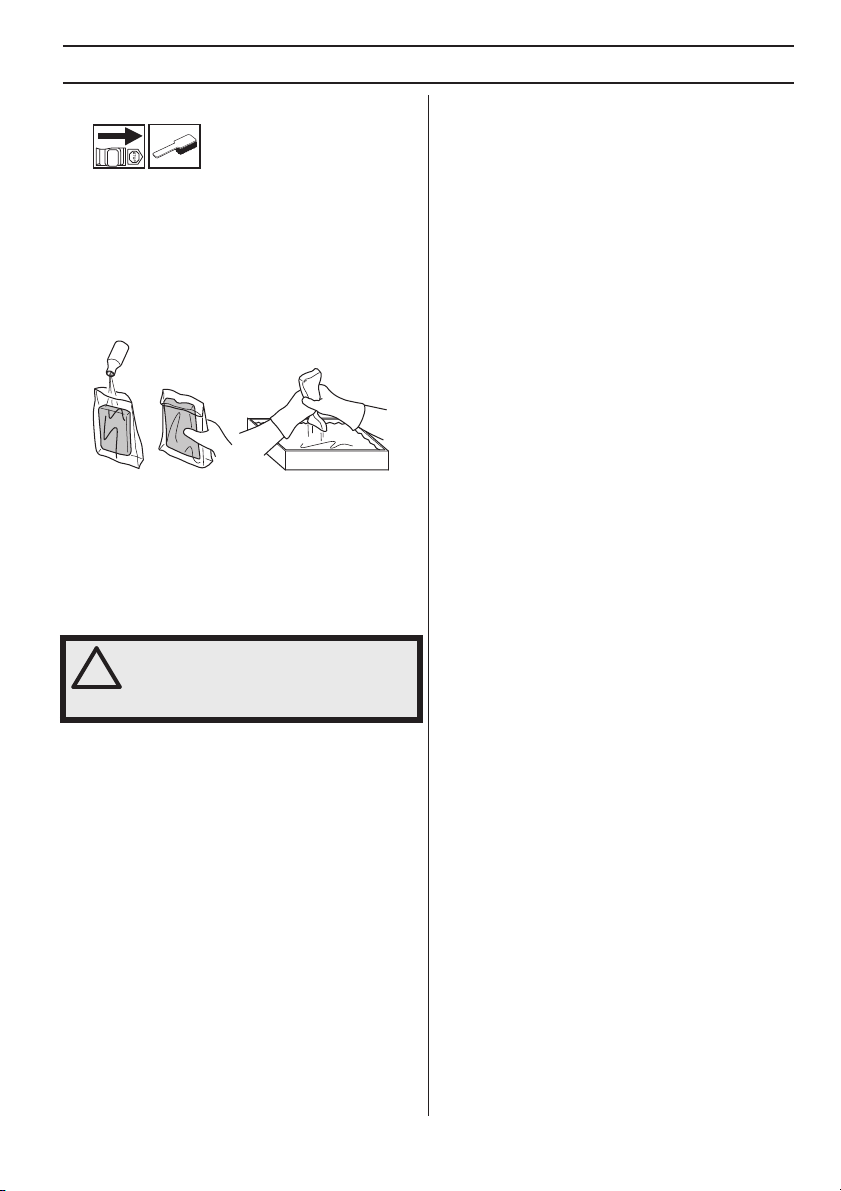

Clean the outside of the spark plug. Remove it and check

the electrode gap. Adjust the gap to 0,6-0,7 mm or

replace the spark plug. Check that the spark plug is fitted

with a suppressor.

, which may result in operating problems and

0,6-0,7

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals.

must always be replaced.

If the machine is used in dusty conditions the air filter

should be soaked in oil. See instructions under the

heading Oiling the air filter.

350BT

• Remove the air filter cover and take out the filter. Wash

it clean in warm, soapy water. Ensure that the filter is

dry before refitting it.

A damaged air filter

CAUTION! Always use the recommended spark plug

type! Use of the wrong spar

cylinder.

k plug can damage the piston/

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts.

• Excessive fuel consumption.

Check the airfilter and clean it when it´s necessary.

Avoid contact with hot surfaces on muffler, cylinder etc.

Contact can result in b

Cleaning the air filter

530BT

• Remove the air filter cover and take out the filter. Wash

it clean in warm, soapy water.

• Refit the air filter and air filter cover. Do not forget to

put the air screen back in place. If the grill is missing,

the air cleaner is not properly sealed, and dust can get

into the cylinder.

18 – English

urns to the skin.

An air filter that has been in use for a long time cannot be

cleaned completely

with a new one at regular intervals.

must always be replaced.

If the machine is used in dusty conditions the air filter

should be soaked in oil. See instructions under the

heading Oiling the air filter.

• Refit the air filter and air filter cover.

. The filter must therefore be replaced

A damaged air filter

Page 19

MAINTENANCE

Oiling the air filter

Always use special filter oil. Filter oil contains a solvent to

make it spread evenly through the filter. You should

therefore avoid skin contact.

Put the filter in a plastic bag and pour the filter oil over it.

Knead the plastic bag to distribute the oil. Squeeze the

excess oil out of the filter inside the plastic bag and pour

off the excess before fitting the filter to the machine. Never

use common engine oil. This would drain through the filter

quite quickly and collect in the bottom.

Shoulder strap

If the shoulder strap is damaged, it may break while in use

and the machine may fall causing personal injury. Follow

the instructions below to replace the shoulder strap.

1 Remove the clamp from the strap.

2 Run the end of the strap through the hanger.

3 Refit the clamp to the strap.

WARNING! Check that the thick round

pin in the clamp is inserted in the strap. If

!

it is inserted incorrectly it may lead to

personal injury.

English – 19

Page 20

MAINTENANCE

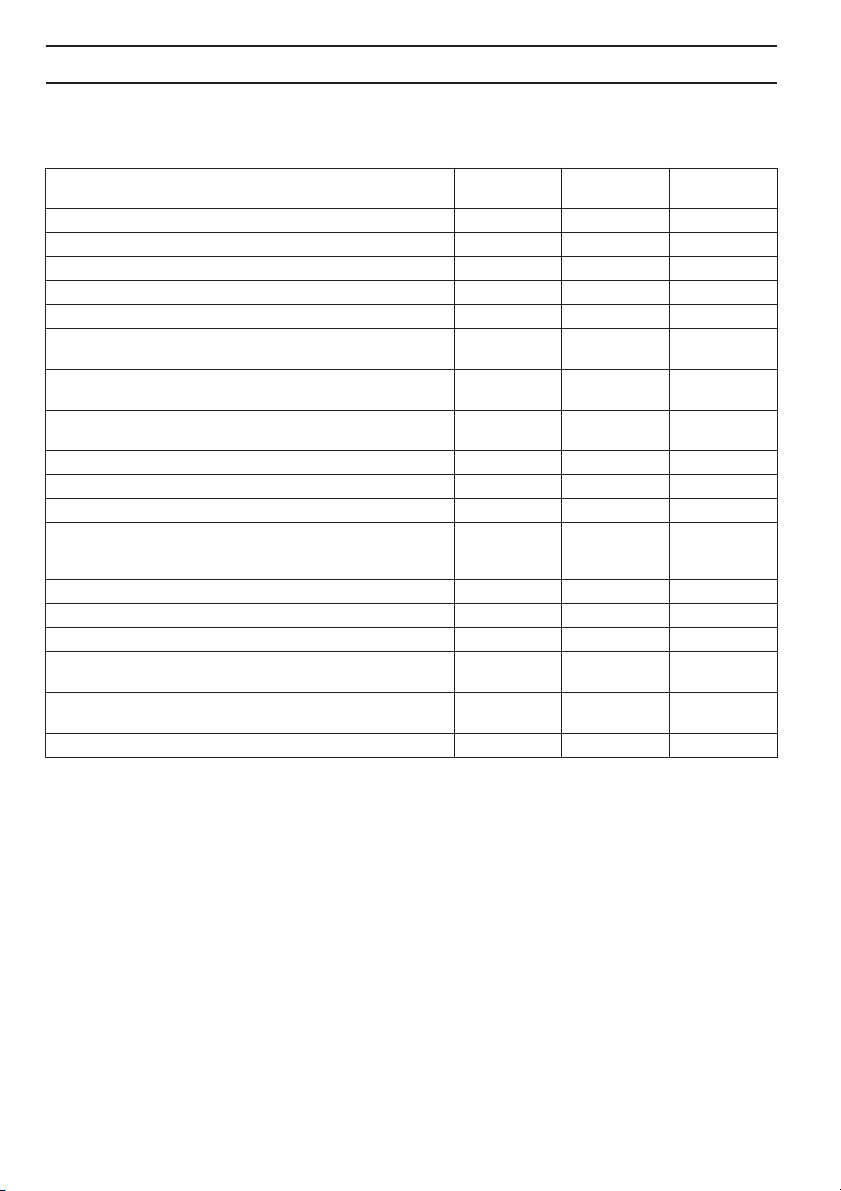

Maintenance schedule

Below you will find some general maintenance instructions. If you need further information please contact your service

workshop.

Maintenance

Clean the outside of the machine. X

Check that the throttle control functions safely. X

Check that the stop switch works correctly. X

Clean the air filter. Replace if necessary. X

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the engine, tank or fuel

lines

.

Check the fuel filter f

or other defects. Replace if necessary.

Clean or replace the spark arrestor mesh on the muffler (only

applies to mufflers without a catalytic converter).

Check that all sides of the air intake screen are not blocked. X

Check the starter and starter cord. X

Check that the vibration damping elements are not damaged. X

Clean the outside of the spark plug. Remove it and check the

electrode gap

plug. Check that the spark plug is fitted with a suppressor.

Clean the machine’s cooling system. X

Clean the outside of the carburettor and the space around it. X

Check all cables and connections. X

Replace the spark plug. Check that the spark plug is fitted with a

suppressor

Check and clean the spar

applies to mufflers fitted with a catalytic converter).

Clean the fuel tank. X

or contamination and the fuel hose for cracks

. Adjust the gap to 0,6-0,7 mm or replace the spar

.

k arrestor mesh on the muffler (only

Daily

maintenance

X

X

X

k

Weekly

maintenance

X

Monthly

maintenance

X

X

20 – English

Page 21

TECHNICAL DATA

Technical data

Technical data 530BT 350BT

Engine

Cylinder displacement, cm

Idle speed, rpm 3000 2200

Max. engine output, acc. to ISO 8893, kW/ rpm

Catalytic converter muffler No No

Speed-regulated ignition system No Ye s

Ignition system

Spark plug

Electrode gap, mm 0,6-0,7 0,6-0,7

Fuel and lubrication system

Fuel tank capacity, litre 0,85 1.25

Weight

Weight without fuel, kg 6,75 10,2

Noise emissions

(see note 1)

Sound power level, measured dB (A) 102 104

Sound power level, guaranteed L

Noise levels

(see note 2)

Equivalent sound pressure level at the operator’s ear, measured

according to EN15503 dB(A)

Vibration levels

(see note 3)

Equivalent vibration levels (a

EN15503, m/s

Fan performance

Max. air velocity with standard nozzle, m/s: 65 80

Air flow with standard nozzle, m

Average air volume at the cover, m3/min 13.1 19,6

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/

EC. Reported sound power level for the machine has been measured with the original cutting attachment that gives the

highest level. The difference between guaranteed and measured sound power is that the guaranteed sound power also

includes dispersion in the measurement result and the variations between different machines of the same model

according to Directive 2000/14/EC.

Note 2: The equivalent sound pressure level value is calculated with a work cycle of a duration of 1/7 for idling and 6/7

or racing.

f

(standard deviation) of 1 dB(A).

Note 3: The equivalent vibration level value is calculated with a work cycle of a duration of 1/7 for idling and 6/7 for racing.

Reported data for equiv

2

Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion

3

dB (A) 102 104

WA

) at handles, measured according to

hv,eq

3

/min 10.6 14

alent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s

29,5 50,2

NGK CMR7H/

TORCH AC7R

91 95

2,5 2,1

NGK CMR7H/

T

ORCH AC7R

2

.

English – 21

Page 22

TECHNICAL DATA

EC Declaration of Conformity (Applies to Europe only)

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel +46-36-146500, declares under sole responsibility that the blowers

Husqvarna 530BT, 350BT with serial numbers dating 2012 and onwards (the year is clearly stated on the rating plate,

followed by the serial number), comply with the requirements of the COUNCIL’S DIRECTIVE:

- of May 17, 2006 ”relating to machinery” 2006/42/EC

- of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

- of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC. Conformity assessment according

to Annex V.

For information relating to noise emissions, see the Technical data chapter. The following standards have been applied:

EN ISO 12100-2/A1:2009, CISPR 12:2009, EN 15503:2009

SMP Svensk Maskinprovning AB, Box 7035, SE-750 07 Uppsala, Sweden, has performed voluntary type examination

on behalf of Husqvarna AB. The certificates are numbered:

SEC/09/2102 - 530BT, SEC/09/2103 - 350BT

Huskvarna, 3 August 2012

Per Gustafsson, Development manager (Authorized representative for Husqvarna AB and responsible for technical

documentation.)

22 – English

Page 23

Symboler

VARNING! Maskinen kan felaktigt

eller slarvigt använd vara ett farligt

redskap, som kan orsaka allvarliga

skador eller dödsfall för

användaren eller andra.

Läs igenom bruksanvisningen

rant och förstå innehållet

nogg

innan du använder maskinen.

Använd alltid:

• Hörselskydd

• Godkända ögonskydd

SYMBOLFÖRKLARING

Bulleremissioner till omgivningen

enligt Europeiska Gemenskapens

direktiv

i kapitel Tekniska data och på dekal.

Övriga på maskinen angivna

symboler/dekaler avser specifika krav för

certifieringar på vissa marknader.

Kontroll och/eller underhåll skall utföras

med motorn frånslagen, med

stoppkontakten i läge STOP.

Använd alltid skyddshandskar.

. Maskinens emission anges

Denna produkt överensstämmer

med gällande EG-direktiv

Handskar ska användas när det

.

behövs

Blåsaren kan våldsamt kasta iväg

föremål som kan studsa tillbaka.

Detta kan leda till allvarliga

ögonskador om inte

rekommenderad

skyddsutrustning används.

Föraren av blåsaren

skall tillse att inga

or eller djur

människ

kommer närmare än 15

meter. Då flera förare arbetar med samma arbetsställe

skall säkerhetsavståndet vara minst 15 meter.

Andningsskydd skall användas då

det finns r

Undvik all kontakt med heta ytor.

isk för damm.

.

Regelbunden rengöring krävs.

Okulär kontroll.

Skyddsglasögon eller visir måste

vändas.

an

Bränslepåfyllning.

Chokereglaget i läge “öppen”.

Chokereglaget i läge “stängd”.

Svenska – 23

Page 24

INNEHÅLL

!

!

!

Innehåll Innan start måste följande

SYMBOLFÖRKLARING

Symboler ............................................................... 23

INNEHÅLL

Innehåll ................................................................. 24

Innan start måste följande observeras: ................. 24

INLEDNING

Bäste kund! ........................................................... 25

VAD ÄR VAD?

Vad är vad på blåsaren? ....................................... 26

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Allmänt .................................................................. 27

SÄKERHETSINSTRUKTIONER

Personlig skyddsutrustning ................................... 29

Maskinens säkerhetsutrustning ............................ 29

Kontroll, underhåll och service av maskinens

säk

erhetsutrustning .............................................. 30

Allmänna arbetsinstr

MONTERING

Montering av blåsrör och reglagehandtag ............ 34

BRÄNSLEHANTERING

Drivmedel .............................................................. 35

Tankning ............................................................... 36

START OCH STOPP

Start och stopp ..................................................... 37

UNDERHÅLL

Allmänt .................................................................. 38

Förgasare ............................................................. 38

Ljuddämpare ......................................................... 38

Kylsystem .............................................................. 38

Luftintagsnät ......................................................... 38

Tändstift ................................................................ 38

Luftfilter ................................................................. 39

Axelrem ................................................................. 39

Underhållsschema ................................................ 40

TEKNISKA DATA

Tekniska data ........................................................ 41

EG-försäkran om överensstämmelse ................... 42

uktioner ................................ 31

observeras:

Läs igenom bruksanvisningen noggrant.

VARNING! Långvarig exponering för

buller kan ge bestående hörselskador.

Använd därför alltid godkända

hörselskydd.

VARNING! Under inga förhållanden får

maskinens ursprungliga utformning

ändras utan tillstånd från tillverkaren.

Använd alltid originaltillbehör. Icke

auktoriserade ändringar och/eller

tillbehör kan medföra allvarliga skador

eller dödsfall för föraren eller andra.

VARNING! En blåsare kan felaktigt eller

slarvigt använd vara ett farligt redskap,

som kan orsaka allvarlig, till och med

livshotande, skada. Det är mycket viktigt

att du läser och förstår innehållet i denna

bruksanvisning.

Husqvarna AB arbetar ständigt med att vidareutveckla

sina produkter och förbehåller sig därför rätten till

ingar beträffande bl.a. form och utseende utan

ändr

föregående meddelande.

Maskinen är endast konstruerad för renblåsning av

gräsmattor, gångar

, asfaltsvägar och liknande.

24 – Svenska

Page 25

INLEDNING

Bäste kund!

Gratulerar till Ditt val att köpa en Husqvarna-produkt! Husqvarna har anor som går tillbaka till 1689 då kung Karl XI lät

uppföra en fabrik på stranden av Huskvarnaån för tillverkning av musköter. Placeringen vid Huskvarnaån var logisk,

eftersom ån användes för att alstra vattenkraft och på så sätt utgjorde ett vattenkraftverk. Under de mer än 300 år som

Husqvarna-fabriken funnits har otaliga produkter tillverkats, allt från vedspisar till moderna köksmaskiner, symaskiner,

cyklar, motorcyklar mm. 1956 lanserades den första motorgräsklipparen som följdes av motorsågen 1959 och det är

inom detta område Husqvarna idag verkar.

Husqvarna är idag en av världens ledande tillverkare av skogs- och trädgårdsprodukter med kvalitet och prestanda som

högsta pr

trädgårdsbruk samt bygg- och anläggningsindustrin. Husqvarnas mål är också att vara i framkant vad gäller ergonomi,

användarvänlighet, säkerhet och miljötänkande, varför en mängd olika finesser tagits fram för att förbättra produkterna

inom dessa områden.

Vi är övertygade om att Ni med tillfredsställelse kommer att uppskatta vår produkts kvalitet och prestanda under en lång

amöver. Ett köp av någon av våra produkter ger Dig tillgång till proffessionell hjälp med reparationer och service om

tid fr

något ändå skulle hända. Om inköpsstället för maskinen inte var någon av våra auktoriserade återförsäljare, fråga dem

efter närmaste serviceverkstad.

Vi hoppas att Du kommer att vara nöjd med Din maskin och att den ska få vara Din följeslagare under en lång tid

amöver

fr

underhåll etc) kan Du väsentligt höja maskinens livslängd och även dess andrahandsvärde. Om Du säljer Din maskin,

se till att överlåta bruksanvisningen till den nya ägaren.

Tack för att du använder en Husqvarna-produkt!

Husqvarna AB arbetar ständigt med att vidareutveckla sina produkter och förbehåller sig därför rätten till ändringar

beträffande bl.a.

Affärsidén är att utveckla, tillverka och marknadsföra motordrivna produkter för skogs- och

ioritet.

. Tänk på att denna bruksanvisning är en värdehandling. Genom att följa dess innehåll (användning, service,

form och utseende utan föregående meddelande.

Svenska – 25

Page 26

VAD ÄR VAD?

3

4

19

17

18

15

14

16

8

9

24

1

Vad är vad på blåsaren?

1 Ram

2 Sele (Höftbälte finns endast på 350BT)

3 Motorkåpa

4 Fläktsnäcka

5 Luftintagsnät

6 Fläkt

7 Luftrenare

8 Starthandtag

9 Bränsletank

10 Dyna

11 Tändstift

12 Avvibreringssystem

13 Chokereglage

19

21

2

20

22

25

23

11

5

10

7

12

13

14 Reglagehandtag/Manöverhandtag

15 Stoppkontakt med gaslägesinställning

16 Gasreglage

17 Böjning

18 Klämma

19 Flexibel slang

20 Manöverrör

21 Klämma

22 Mellanrör

23 Blåsrör

24 Bruksanvisning

25 Kombinyckel

6

26 – Svenska

Page 27

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Allmänt

VIKTIGT!

Maskinen är endast konstruerad för renblåsning av

gräsmattor, gångar, asfaltsvägar och liknande.

Inspektera hela maskinen innan användning. Följ

underhållsschemat under kapitel Underhåll.

Använd aldrig maskinen om du är trött, om du har

druckit alkohol eller om du tar mediciner, som kan

påverka din syn, ditt omdöme eller din kroppskontroll.

Använd personlig skyddsutrustning. Se anvisningar

under rubrik ”Personlig skyddsutrustning”.

Använd aldrig en maskin som modifierats så att den ej

längre överensstämmer med originalutförandet.

Använd aldrig en maskin som är felaktig. Följ

underhålls-, säkerhetskontroll- och serviceinstruktioner

i denna bruksanvisning. Vissa underhålls- och

serviceåtgärder skall utföras av tränade och

kvalificerade specialister. Se anvisningar under rubrik

Underhåll.

Samtliga kåpor och skydd måste vara monterade före

t. Se till att tändhatt och tändkabel är oskadade för

star

att undvika risk för elektrisk stöt.

Föraren av blåsaren skall tillse att inga människor eller

djur kommer närmare än 15 meter. Då flera förare

arbetar med samma arbetsställe skall

säkerhetsavståndet vara minst 15 meter.

Tillåt aldrig barn att använda maskinen.

Låt aldrig någon annan använda maskinen utan att

försäkra dig om att de har läst och förstått innehållet i

bruksanvisningen.

Kontrollera alltid att inga hindrande föremål finns i

luftintagsnätet innan du börjar arbeta.

Ta aldrig av luftintagsnätet.

Vid nödsituation, frigör dig från maskinen genom att

öppna midje- och bröstbältet och låt maskinen falla

bakåt.

Tag alltid kontakt med de lokala myndigheterna och

kontrollera att ni följer tillämpliga bestämmelser.

Undvik all kontakt med heta ytor.

Vidrör aldrig tändstift eller tändkabeln när maskinen är i

drift.

Start

• Starta aldrig maskinen inomhus. Var medveten om

faran med inandning av motorns avgaser.

• Iaktta omgivningen och var säker på att det inte finns

risk att människor eller djur kan komma i kontakt med

utblåset.

• Placera maskinen på marken, tryck maskinkroppen

mot marken med vänster hand (OBS! Ej med foten).

Fatta sedan starthandtaget med högerhanden och

gör därefter snabba och kraftfulla ryck.

Bränslesäkerhet

• Använd bränslebehållare med överfyllnadsskydd.

• Tanka aldrig maskinen när motorn är i drift. Stanna

motorn och låt den svalna några minuter före

tankning.

• Sörj för god ventilation vid tankning och blandning av

bränsle (bensin och 2-taktsolja).

• Undvik all hudkontakt med bränsle. Bränslet ger

upphov till hudirritation och kan även leda till

hudförändringar.

• Flytta maskinen minst 3 m från tankningsstället innan

du startar.

VARNING! Denna maskin alstrar under

drift ett elektromagnetiskt fält. Detta fält

!

kan under vissa omständigheter ge

påverkan på aktiva eller passiva

medicinska implantat. För att reducera

risken för allvarliga eller livshotande

skador rekommenderar vi därför

personer med implantat att rådgöra med

läkare samt tillverkaren av det

medicinska implantatet innan denna

maskin används.

• Starta aldrig maskinen:

- Om du spillt bränsle på den. Torka av allt spill och låt

bensinresterna avdunsta.

- Om du spillt bränsle på dig själv eller dina kläder, byt

kläder. Tvätta de kroppsdelar som varit i kontakt med

bränsle. Använd tvål och vatten.

- Om maskinen läcker bränsle. Kontrollera regelbundet

efter läckage från tanklock och bränsleledningar.

Svenska – 27

Page 28

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Transport och förvaring

• Förvara och transportera maskinen och bränslet så

att eventuellt läckage och ångor inte riskerar att

komma i kontakt med gnistor eller öppen låga,

exempelvis från elmaskiner, elmotorer, elkontakter/

strömbrytare eller värmepannor.

• Vid förvaring och transport av bränsle ska för

ändamålet speciellt a

användas.

• Vid längre tids förvaring av maskin ska bränsletanken

tömmas. Hör med närmaste bensinstation var du kan

göra dig av med bränsleöverskott. Töm bränsletanken

och tryck på flödaren tills den tömts på bränsle.

• Ta bort tändstiftet och droppa en sked 2-taktsolja i

• Se till att maskinen är väl rengjord och att fullständig

• Säkra maskinen under transport.

• Förvara maskinen på ett torrt, kallt, välventilerad och

. Dra runt motorn flera gånger, montera

cylinder

därefter tändstiftet.

service är utförd innan långtidsförvaring.

dammfri plats. Förvara maskinen oåtkomlig för barn.

VARNING! Var försiktig vid hantering av

bränsle. Tänk på brand-, explosions- och

!

inandningsrisker.

Inpassning av sele

VARNING! Vid arbete med maskinen ska

selen alltid vara påtagen. Om det inte

!

sker, kan man inte manövrera säkert och

detta kan orsaka skada på dig själv eller

andra.

Se till att midjebältet är knäppt och rätt

justerad.

Används inte midjebältet, se till att

demontera det från maskinen. Det finns

en riska att bältet fastnar och på så sätt

tippar maskinen.

Det finns en risk att ett oknäppt bälte

fastnar eller sugs in i fläkten på

maskinen.

vsedda och godkända behållare

En väl inpassad sele och maskin underlättar arbetet

avsevärt. Justera selen för bästa arbetsställning.

Spänn sidoremmarna så att trycket blir jämnt fördelat på

na.

axlar

Placera höftbandet över höften och inte för långt ner på

magen. Dra åt höftbandet så att du känner att blåsarens

tyngd vilar på höften.

28 – Svenska

NOTE!

530BT har inget midjebälte.

Page 29

SÄKERHETSINSTRUKTIONER

Personlig skyddsutrustning

VARNING! Vid all användning av

maskinen skall godkänd personlig

!

skyddsutrustning användas. Personlig

skyddsutrustning eliminerar inte

skaderisken, men den reducerar effekten

av en skada vid ett olyckstillbud. Be din

återförsäljare om hjälp vid val av

utrustning. Läs igenom

bruksanvisningen noggrant och förstå

innehållet innan du använder maskinen.

VARNING! Var alltid uppmärksam på

varningssignaler eller tillrop när

!

hörselskydd används. Tag alltid av

hörselskydden så snart motorn stoppats.

• Andningsskydd skall användas då det finns risk för

damm.

• Första förband ska alltid finnas till hands.

• Handskar ska användas när det behövs.

• Hörselskydd med tillräcklig dämpeffekt ska användas.

• Godkända ögonskydd skall alltid användas. Används

visir måste även godkända skyddsglasögon

användas. Med godkända skyddsglasögon menas de

som uppfyller standard ANSI Z87.1 för USA eller EN

166 för EU-länder. Slag från grenar eller föremål som

kastas iväg kan skada ögonen.

• Använd halkfria och stadiga stövlar.

Maskinens säkerhetsutrustning

I detta avsnitt förklaras vilka maskinens säkerhetsdetaljer

är, vilken funktion de har samt hur kontroll och underhåll

skall utföras för att säkerställa att de är i funktion. Se

kapitel Vad är vad?, för att hitta var dessa detaljer är

placerade på din maskin.

VARNING! Använd aldrig en maskin med

defekta säkerhetsdetaljer. Följ i detta

!

avsnitt listade kontroll-, underhålls- och

serviceinstruktioner.

Stoppkontakt

Stoppkontakten ska användas för att stänga av motorn.

Vid kontroll och underhåll ta bort tändkabeln och tändstift.

• Använd rivstarkt material i klädseln och undvik alltför

vida kläder som lätt hakar f

alltid kraftiga långbyxor och en långarmad skjorta. Bär

inte smycken, kortbyxor eller sandaler och gå inte

barfota. Se till att håret inte hänger nedanför axlarna.

ast i ris och grenar. Använd

Svenska – 29

Page 30

SÄKERHETSINSTRUKTIONER

Avvibreringssystem

Din maskin är utrustad med ett avvibreringssystem, vilket

är konstruerat att ge en så vibrationsfri och behaglig

användning som möjligt.

VARNING! Överexponering av vibrationer

kan leda till blodkärls- eller nervskador

!

hos personer som har

blodcirkulationsstörningar. Uppsök

läkare om ni upplever kroppsliga

symptom som kan relateras till

överexponering av vibrationer. Exempel

på sådana symptom är domningar,

avsaknad av känsel, ”kittlingar”,

”stickningar”, smärta, avsaknad eller

reducering av normal styrka,

förändringar i hudens färg eller dess yta.

Dessa symptom uppträder vanligtvis i

fingrar, händer eller handleder. Riskerna

kan öka vid låga temperaturer.

Ljuddämpare

Ljuddämparen är konstruerad för att ge så låg ljudnivå

som möjligt samt för att leda bort motorns avgaser från

användaren.

I länder med varmt och torrt klimat är risken för bränder

påtaglig. Vi har därför utrustat ljuddämparen med ett

gnistfångarnät monterat inuti ljuddämparen.

VARNING!

!

Tänk på att: Motorns avgaser innehåller

kolmonoxid vilket kan orsaka

kolmonoxidförgiftning. Starta eller kör

därför aldrig maskinen inomhus, eller där

luftcirkulationen är bristfällig.

Motorns avgaser är heta och kan

innehålla gnistor vilka kan orsaka brand.

Starta därför aldrig maskinen inomhus

eller nära eldfängt material!

VARNING! Ljuddämparen innehåller

kemikalier som kan vara

!

cancerframkallande. Undvik kontakt med

dessa kemikalier ifall ljuddämparen

skulle gå sönder.

Kontroll, underhåll och service av

maskinens säkerhetsutrustning

VARNING! All service och reparation av

maskinen kräver specialutbildning. Detta

!

gäller särskilt maskinens

säkerhetsutrustning. Om maskinen inte

klarar någon av nedan listade kontroller

ska du uppsöka din serviceverkstad. Ett

köp av någon av våra produkter

garanterar att du kan få en

fackmannamässig reparation och service

utförd. Om inköpsstället för maskinen

inte är en av våra servande fackhandlare,

fråga dem efter närmaste

serviceverkstad.

Stoppkontakt

• Starta motorn och kontrollera att motorn stängs av när

stoppkontakten förs till stoppläget.

530BT

För ljuddämpare är det mycket viktigt att instruktionerna

för kontroll, underhåll och service följs. Se anvisningar

under rubrik Kontroll, underhåll och service av maskinens

säkerhetsutrustning.

30 – Svenska

350BT

Page 31

SÄKERHETSINSTRUKTIONER

Avvibreringssystem

• Kontrollera regelbundet avvibreringselementen efter

materialsprickor och deformationer. Byt dem om de är

skadade.

• Kontrollera att avvibreringselementen är hela och fast

ankrade.

för

Ljuddämpare

• Använd aldrig en maskin som har en defekt

ljuddämpare.

• Kontrollera regelbundet att ljuddämparen sitter fast på

motorn.

VARNING! Använd aldrig en maskin med

defekt säkerhetsutrustning. Maskinens

!

säkerhetsutrustning ska kontrolleras och

underhållas som beskrivits i detta

avsnitt. Om din maskin inte klarar alla

kontrollerna ska serviceverkstad

uppsökas för reparation.

Luftfilter

Använd aldrig lövblåsaren utan luftfilter eller med ett

trasigt eller deformerat filterelement, eftersom ofiltrerad,

dammig luft snabbt förstör motorn.

Allmänna arbetsinstruktioner

VIKTIGT! Detta avsnitt behandlar grundläggande

säkerhetsregler för arbete med blåsare När du råkar ut

för en situation som gör dig osäker angående fortsatt

användning ska du rådfråga en expert. Vänd dig till din

återförsäljare eller din serviceverkstad. Undvik all

användning du anser dig otillräckligt kvalificerad för.

Visa personer i din omgivning hänsyn genom att undvika

att använda maskinen under olämpliga tidpunkter,

exempelvis sent på kvällen eller tidigt på morgonen.

Minska ljudnivåerna genom att begränsa det antal

enheter av utrustningen som används samtidigt. Läs

igenom och följ nedanstående enkla råd för att störa din

omgivning så lite som möjligt.

• Använd blåsaren med lägsta möjliga gaspådrag. Det

är sällan nödvändigt att an

Många arbetsmoment kan utföras med halvt

gaspådrag. Lägre gaspådrag innebär mindre buller

och mindre damm. Det är också lättare att ha kontroll

över det skräp som skall samlas ihop/flyttas.

• Använd en kratta eller en sopkvast för att lösgöra

astsittande skräp från marken.

f

• Håll blåsrörets mynning så nära marken som möjligt.

Utnyttja hela förlängningen på blåsröret så att

luftströmmen kan hållas nära marken.

• Städa upp efter dig. Försäkra dig om att du inte har

blåst in skräp på någons tomt. Se till att slänga allt

skräp i en soptunna.

• Använd maskinen vid normala tidpunkter för att

undvika onödigt buller, inte tidigt på morgonen och

inte sent på kvällen.

vända fullt gaspådrag.

530BT

• Din maskins ljuddämpare är utrustad med ett

gnistfångarnät, detta skall rengöras regelbundet. Se

rubrik Ljuddämpare under kapitel Underhåll. Ett

igensatt nät leder till varmkörning av motorn med

allvarlig motorskada som följd. Använd aldrig en

ljuddämpare med ett defekt gnistfångarnät.

350BT

VARNING! Var medveten om din

omgivning. Om någon närmar sig ditt

!

arbetsområde, ställ gasreglaget på

minsta gaspådrag tills personen är på

behörigt avstånd. Rikta luftstrålen bort

från människor, djur, lekplatser, öppna

fönster och bilar etc.

Svenska – 31

Page 32

SÄKERHETSINSTRUKTIONER

Grundläggande säkerhetsregler

• Inga obehöriga personer eller djur får finnas inom

arbetsområdet som är 15 meter.

• Låt motorn svalna, innan du fyller på bränsle.

• Undvik all kontakt med heta ytor.

• Om maskinen fattar eld eller någon annan

nödsituation uppstår som kräv

maskinen, öppna spännena på selen och låt

maskinen falla bakåt.

• Den kraftiga luftströmmen kan förflytta föremål med

sådan hastighet att de kan studsa tillbaka och leda till

arliga ögonskador.

allv

er att du frigör dig från

• Ställ aldrig ner maskinen med motorn i drift utan att du

har uppsikt öv

• Motorns avgaser innehåller kolmonoxid vilket kan

orsaka kolmonoxidförgiftning. Starta eller kör därför

aldrig maskinen inomhus, eller där luftcirkulationen är

bristfällig.

• Blåsaren får ej användas på stegar eller ställningar

eller på höga b

kan orsaka svår skada.

er den.

yggnader (exv. tak). Arbetställningen

• Rikta inte luftstrålen mot människor eller djur.

• Stoppa motorn före montering eller demontering av

tillbehör eller andr

• Undvik användning vid ogynnsamma

väderleksförhållanden. Exempelvis tät dimma, kraftigt

regn, hård vind, stark kyla, osv. Att arbeta i dåligt

väder är tröttsamt och kan skapa farliga

omständigheter, exempelvis halt underlag.

• Minimera blåstiden genom att lätt fukta ytor i dammiga

omgivningar eller an

• Minska vattenförbrukningen genom att använda

blåsare istället för vattenslangar vid olika

tillämpningsområden kring gräsmatta och trädgård,

exempelvis för galler, skärmar, grillar, verandor etc.

• Se till att du kan gå och stå säkert. Titta efter

ventuella hinder vid en oväntad förflyttning (rötter,

e

stenar, grenar, gropar, diken, osv.). Iaktta stor

försiktighet vid arbete i sluttande terräng.

a delar.

vända en dimutrustning.

• OBS! Använd aldrig maskinen utan möjlighet att

kunna påkalla hjälp i händelse a

v olycka.

Grundläggande arbetsteknik

VARNING! Varning för utslungade

föremål. Använd alltid ögonskydd.

!

Stenar, skräp mm kan kastas upp i

ögonen och vålla blindhet eller allvarliga

skador. Håll obehöriga på avstånd. Barn,

djur, åskådare och medhjälpare ska

befinna sig utanför säkerhetszonen på 15

m. Stanna maskinen omedelbart om

någon närmar sig.

VARNING! Stanna alltid motorn vid

rengöring.

!

• Blåsaren är ryggburen och bärs på axlarna när den

används. Den kontrolleras med höger hand på

handtaget på röret.

• Hastigheten på luftstrålen regleras med hjälp av

gasreglaget. Välj den hastighet som passar bäst för

respektive användning.

För att slippa hålla fingret på gasreglaget hela tiden som

blåsaren används kan önskat gaspådrag ställas in med

“stoppreglaget”. Fullt gaspådrag erhålls när reglaget är

helt tillbakadraget.

32 – Svenska

Page 33

SÄKERHETSINSTRUKTIONER

• Kontrollera att luftintaget inte blockeras av exempelvis

löv eller skräp. Ett igensatt luftintag minskar

maskinens blåskapacitet och ökar motorns

arbetstemperatur, vilket kan medföra motorhaveri.

Stanna motorn och avlägsna föremålet.

• Var medveten om vindriktningen. Arbeta i vindens

iktning för att underlätta ditt arbete.

r

• Att använda blåsaren för att flytta stora högar är

tidsödande och skapar onödigt buller.

• Håll god balans och säkert fotfäste.

• Efter avslutat arbete skall maskinen förvaras stående.

Svenska – 33

Page 34

MONTERING

Montering av blåsrör och

reglagehandtag

• Anslut blåsaren och manöverröret med den flexibla

slangen. Kläm fast de båda ändarna på den flexibla

slangen.

Använd medföljande fästdon.

enligt bilden. Tänk på att det finns risk att slangen

skadas om remmen fästs för hårt.

1

3

1 Flexibel slang

2 Manöverrör

3 Klämma

4 Klämma

NOTE!

Smörj in rören lätt för att underlätta ihopsättningen.

• Fäst handtagshållaren på manöverröret och dra åt

vredet på hållaren.

hamnar i linje med manöverrörets välvning.

• Justera läge och vinkel för att åstadkomma en

bekväm arbetsställning. Drag åt.

Se till att handtagshållaren

2

4

350BT

• Använd klämman för att fästa kablaget på den flexibla

slangen.

Blåsrör

Montera mellanröret och blåsröret. Det går att montera

fler mellanrör om längre blåsrör behövs.

Extra utrustning

(Ingår inte.)

Styre

Demontera mellanröret. Skruva bort hållarens vred och

trä på hållaren över manöverröret. Montera vredet och

drag åt.

Montera mellanröret.

• Koppla ihop det raka röret och rörändan. Tryck ihop

rören och vrid dem så att de låses.

530BT

• Fäst kablaget vid mitten av slangen med hjälp av den

rem som tillhör kablaget.

• Vira först remmen runt den flexibla slangen, börja

underifrån. För sedan remmen genom hålet i remmen

34 – Svenska

Platt munstycke

• Önskas högre lufthastighet ersätts det runda

munstycket med ett platt munstycke.

Page 35

BRÄNSLEHANTERING

Drivmedel

OBS! Maskinen är försedd med en tvåtaktsmotor och

måste alltid köras på en blandning av bensin och

tvåtaktsolja. För att säkerställa rätt blandningsförhållande

är det viktigt att noggrant mäta den oljemängd som skall

blandas. Vid tillblandning av små bränslemängder

inverkar även små felaktigheter i oljemängden kraftigt på

blandningsförhållandet.

VARNING! Sörj för god luftventilation vid

bränslehantering.

!

Bensin

OBS! Använd alltid oljeblandad kvalitetsbensin (minst 90

oktan).

• Rekommenderat lägsta oktantal är 90. Om man kör

motorn på bensin med ett lägre oktantal än 90 kan så

kallad knackning uppträda. Detta leder till ökad

motortemperatur, som kan orsaka svåra

motorhaverier.

• Vid arbete med kontinuerligt höga varvtal

ommenderas högre oktantal. Använd blyfri

rek

kvalitetsbensin.

Etanolblandat bränsle, E10, får användas (max 10 %

etanolblandning) Om etanolblandningar högre än E10

används blir körförhållandet för magert, vilket kan leda till

skador på motorn.

Tvåtaktsolja

• För bästa resultat och funktion använd HUSQVARNA

tvåtaktsolja, som är speciellt framtagen för våra

tvåtaktsmotorer. Blandningsförhållande 1:50 (2%).

• Om HUSQVARNA tvåtaktsolja ej finns tillgänglig kan

annan tvåtaktsolja av hög kvalitet och avsedd för

luftkylda motorer användas. Kontakta din

återförsäljare vid val av olja. Blandningsförhållande

1:33 (3%).

• Använd aldrig tvåtaktsolja avsedd för vattenkylda

utombordsmotorer