Husqvarna 1330 SB XLS, 96193003100 User Manual

1330SB-XLS

Owner's Manual / 96193003100

IMPORTANT

Safe Operation Practices for Walk-Behind Snow Throwers

This snow thrower is capable of amputating hands and feet and throwing objects. Failure to observe the following safety instructions could result in serious injury.

Look for this symbol to point out important safety precautions. It means CAUTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

WARNING: Always disconnect spark plug wire and place it where it cannot contact plug in order to prevent accidental starting when setting up, transporting, adjusting or making repairs.

WARNING: This snow thrower is for use on sidewalks, driveways and other ground level surfaces. Caution should beexercisedwhileusingonslopingsurfaces. Do not use snow thrower on surfaces above ground level such as roofs of residences, garages, porches or other such structures or buildings.

WARNING: Snow throwers have exposed rotating parts, which can cause severe injury from contact, or from material thrown from the discharge chute. Keep the area of operation clear of all persons, small children and pets at all times including startup.

CAUTION: Muffler and other engine parts become extremely hot during operation and remain hot after engine has stopped. To avoid severe burns on contact, stay away from these areas.

WARNING: Engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Training

1.Read, understand and follow all instructions on the machine and in the manual(s) before operating this unit. Be thoroughly familiar with the controls and the proper use of the equipment. Know how to stop the unit and disengage the controls quickly.

2.Never allow children to operate the equipment. Never allow adults to operate the equipment without proper instruction.

3.Keep the area of operation clear of all persons, particularly small children.

4.Exercise caution to avoid slipping or falling, especially when operating the snow thrower in reverse.

Preparation

1.Thoroughly inspect the area where the equipment is to be used and remove all doormats, sleds, boards, wires, and other foreign objects.

2.Disengage all clutches and shift into neutral before starting the engine (motor).

3.Do not operate the equipment without wearing adequate winter garments. Avoid loose fitting clothing that can get caught in moving parts. Wear footwear that will improve footing on slippery surfaces.

4.Handle fuel with care; it is highly flammable

(a)Use an approved fuel container.

(b)Never add fuel to a running engine or hot engine.

(c)Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors.

(d)Never fill containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always place containers on the ground, away from your vehicle, before filling.

(e)When practical, remove gas-powered equipment from the truck or trailer and refuel it on the ground. If this is not possible, then refuel such equipment on a trailer with a portable container, rather than from a gasoline dispenser nozzle.

(f)Keep the nozzle in contact with the rim of the fuel tank or container opening at all times, until refueling is complete. Do not use a nozzle lock-open device.

(g)Replace gasoline cap securely and wipe up spilled fuel.

(h)If fuel is spilled on clothing, change clothing immediately.

5.Use extension cords and receptacles as specified by the manufacturer for all units with electric drive motors or electric starting motors.

6.Adjust the collector housing height to clear gravel or crushed rock surface.

7.Never attempt to make any adjustments while the engine (motor) is running (except when specifically recommended by manufacturer).

8.Always wear safety glasses or eye shields during operation or while performing an adjustment or repair to protect eyes from foreign objects that may be thrown from the machine.

Operation

1.Do not put hands or feet near or under rotating parts. Keep clear of the discharge opening at all times.

2.Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards or traffic.

3.After striking a foreign object, stop the engine (motor), remove the wire from the spark plug, disconnect the cord on electric motors, thoroughly inspect the snow thrower for any damage, and repair the damage before restarting and operating the snow thrower.

4.If the unit should start to vibrate abnormally, stop the engine (motor) and check immediately for the cause. Vibration is generally a warning of trouble.

5.Stop the engine (motor) whenever you leave the operating position, before unclogging the collector/impeller housing or discharge chute, and when making any

2 |

repairs, adjustments or inspections. |

|

6.Whencleaning,repairingorinspectingthesnowthrower, stop the engine and make certain the collector/impeller and all moving parts have stopped. Disconnect the spark plug wire and keep the wire away from the plug to prevent someone from accidentally starting the engine.

7.Do not run the engine indoors, except when starting the engine and for transporting the snow thrower in or out of the building. Open the outside doors; exhaust fumes are dangerous.

8.Exercise extreme caution when operating on slopes.

9.Never operate the snow thrower without proper guards, and other safety protective devices in place and working.

10.Never direct the discharge toward people or areas where property damage can occur. Keep children and others away.

11.Do not overload the machine capacity by attempting to clear snow at too fast a rate.

12.Never operate the machine at high transport speeds on slippery surfaces. Look behind and use care when operating in reverse.

13.Disengage power to the collector/impeller when snow thrower is transported or not in use.

14.Use only attachments and accessories approved by the manufacturer of the snow thrower (such as wheel weights, counterweights, or cabs).

15.Never operate the snow thrower without good visibility or light. Always be sure of your footing, and keep a firm hold on the handles. Walk; never run.

16.Never touch a hot engine or muffler.

Clearing a Clogged Discharge Chute

Hand contact with the rotating impeller inside the discharge chute is the most common cause of injury associated with snow throwers. Never use your hand to clean out the discharge chute. To clear the chute:

1.SHUT THE ENGINE OFF!

2.Wait 10 seconds to be sure the impeller blades have stopped rotating.

3.Always use a clean-out tool, not your hands.

Maintenance and Storage

1.Check shear bolts and other bolts at frequent intervals for proper tightness to be sure the equipment is in safe working condition.

2.Never store the machine with fuel in the fuel tank inside a building where ignition sources are present such as hot water heaters, space heaters, or clothes dryers. Allow the engine to cool before storing in any enclosure.

3.Always refer to operator’s manual for important details if the snow thrower is to be stored for an extended period.

4.Maintain or replace safety and instruction labels, as necessary.

5.Run the machine a few minutes after throwing snow to prevent freeze-up of the collector/impeller.

CONGRATULATIONS on your purchase of a new snow thrower. It has been designed, engineered and manufactured to give best possible dependability and performance.

Should you experience any problem you cannot easily remedy, please contact your nearest authorized service center. We have competent, well-trained technicians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will enable you to assemble and maintain your snow thrower properly. Always observe the “SAFETY RULES”.

SERIAL NUMBER: ___________________________

DATE OF PURCHASE: _______________________

THE MODEL AND SERIAL NUMBERS WILL BE FOUND ON A DECAL ATTACHED TO THE REAR OF THE SNOW THROWER HOUSING.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND DATE OF PURCHASE AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

PRODUCT SPECIFICATIONS

Gasoline Capacity |

4.0 Quarts |

and Type: |

Unleaded Regular only |

|

|

Oil Type |

SAE 30 (above 40°F) |

(API SG–SL): |

SAE 5W-30 or 10W-30 (0° to +40°F) |

|

SAE 0W-30 (below 0°F) |

|

|

Oil Capacity: |

26 Ounces |

|

|

Spark Plug: |

Champion RN4C (Gap: .030") |

|

|

CUSTOMER RESPONSIBILITIES

•Read and observe the safety rules.

•Follow a regular schedule in maintaining, caring for and using your snow thrower.

•Follow the instructions under “Maintenance” and “Storage” sections of this owner’s manual.

TABLE OF CONTENTS

SAFETY RULES ........................................................ |

2-3 |

PRODUCT SPECIFICATIONS...................................... |

3 |

CUSTOMER RESPONSIBILITIES................................ |

3 |

ASSEMBLY / PRE-OPERATION ............................... |

5-7 |

OPERATION ............................................................ |

8-14 |

MAINTENANCE..................................................... |

14-15 |

MAINTENANCE SCHEDULE ..................................... |

14 |

SERVICE AND ADJUSTMENTS........................... |

16-18 |

STORAGE................................................................... |

18 |

TROUBLESHOOTING................................................ |

19 |

REPAIR PARTS ..................................................... |

20-39 |

3 WARRANTY............................................ |

BACK COVER |

PARTS PACKED SEPARATELY IN CARTON

(1) MULTIWRENCH (180684)

(1) SAFTEY IGNITION KEY

(1) POWER CORD (35062)

(198563)

(1) AUGER CONTROL ROD

(1) TRACTION DRIVE CONTROL ROD

(1) DISCHARGE CHUTE

EXTRA SHEAR BOLTS AND NUTS

|

|

|

|

|

|

|

(6) LOCKNUTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(6) SHEAR BOLTS 1/4-20 x 1-3/4 |

(6) SPACERS |

||||||

(198636) |

|

(198638) |

1/4-20 |

||||

|

|

|

|

|

|

|

(73800400) |

ROTATOR HEAD MOUNTING

(3) RETAINER SPRINGS (169675)

(1) WASHER 3/8 |

(1) LOCKNUT 3/8 |

(19131316) |

(73800600) |

CHUTE

DEFLECTOR REMOTE

DEFLECTOR REMOTE

CONTROL

CONTROL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1) LOCKNUT |

(1) CARRIAGE BOLT |

(1) LOCKNUT |

(1) NYLON |

(1) SHOULDER |

(1) SPRING |

||||||||||||||||||||||||||||||||||||||||||

5/16-18 |

5/16-18 x 5/8 |

1/4-20 |

|

|

|

|

|

|

|

|

|

|

|

WASHER |

BOLT 1/4-20 |

||||||||||||||||||||||||||||||||

(751153) |

(72250505) |

|

(191730) |

|

|

|

|

|

|

|

|

(179246) |

(179829) |

|

|

(184505) |

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2) FLAT WASHERS (2) CARRIAGE BOLTS |

(2) HANDLE KNOBS |

3/8-16 x 2.25 |

|

4

ASSEMBLY / PRE-OPERATION

Read these instructions and this manual in its entirety before you attempt to assemble or operate your new snow thrower. Reading the entire manual will familiarize you with the unit, which will assist you in assembly, operation and maintenance of the product.

Your new snow thrower has been assembled at the factory with the exception of those parts left unassembled for shipping purposes. All parts such as nuts, washers, bolts, etc., necessary to complete the assembly have been placed in the parts bag. To ensure safe and proper operation of your snow thrower, all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to ensure proper tightness.

REMOVE SNOW THROWER FROM CARTON

1.Remove all accessible loose parts and parts boxes from carton.

2.Cut down all four corners of carton and lay panels flat.

3.Remove the two (2) screws securing the auger housing to the pallet.

4.Remove all packing materials except plastic tie holding speed control rod to lower handle.

5.Remove the two (2) plastic ties securing the upper handle to the pallet.

6.Remove snow thrower from carton and check carton thoroughly for additional loose parts.

HOW TO SET UP YOUR SNOW THROWER

TOOL BOX (See Fig. 10)

A toolbox is provided on your snow thrower. The toolbox is located on top of the belt cover. Store the extra shear bolts, nuts and multi-wrench provided in parts bag in the toolbox.

NOTE: The multi-wrench may be used for assembly of the chute rotator head to snow thrower and making adjustments to the skid plates.

UNFOLD UPPER HANDLE

1.Raise upper handle to the operating position and tighten handle knobs securely. Additional carriage bolts, washers and handle knobs are in bag of parts. Use to secure upper handle to lower handle. Install in lower holes in handles.

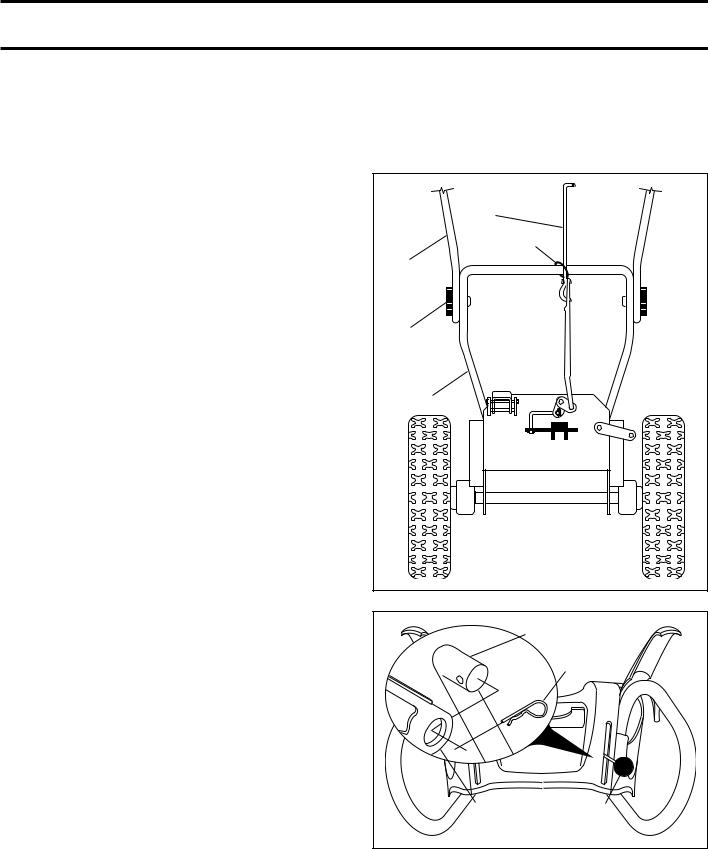

INSTALL SPEED CONTROL ROD (See Figs. 1 and 2)

1.Remove plastic tie securing rod to lower handle.

2.Insert rod into speed control bracket and secure with retainer spring.

SPEED |

CONTROL |

ROD |

PLASTIC TIE |

UPPER |

HANDLE |

HANDLE |

KNOB |

LOWER |

HANDLE |

FIG. 1

SPEED CONTROL ROD |

|

|

RETAINER |

|

SPRING |

SPEED |

SPEED |

CONTROL |

CONTROL |

BRACKET |

LEVER |

FIG. 2

5

ASSEMBLY / PRE-OPERATION

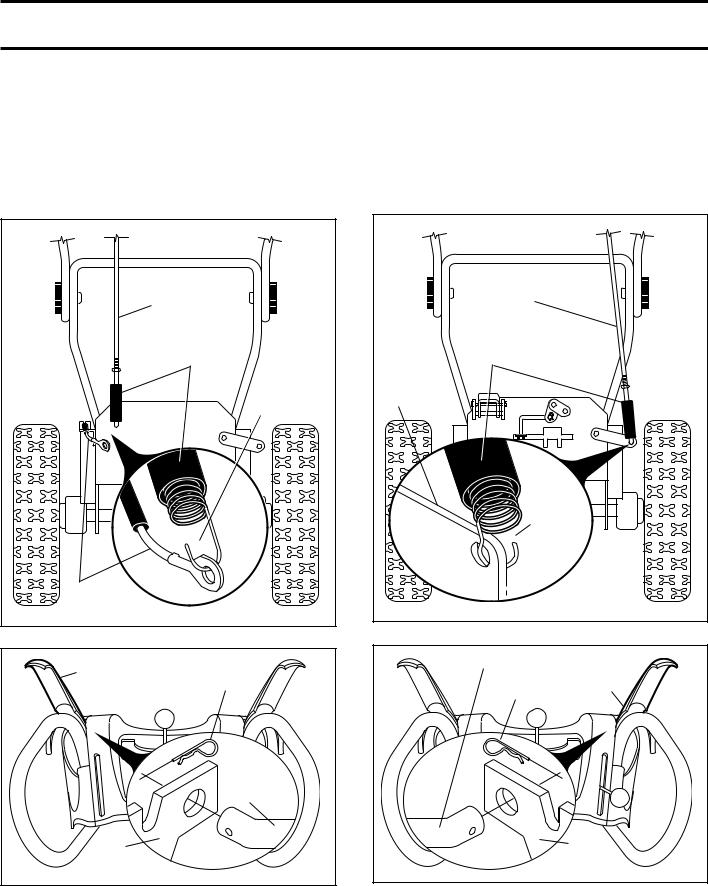

INSTALL TRACTION DRIVE CONTROL ROD (See Figs. 3 and 4)

The traction drive control rod has the long loop on the end of the spring as shown.

1.Slide rubber sleeve up rod and hook end of spring into eye of cable with loop opening down as shown.

2.With top end of rod positioned under left side of control panel, push rod down and insert top end of rod into hole in drive control bracket. Secure with retainer spring.

TRACTION DRIVE |

CONTROL ROD |

RUBBER |

SLEEVE |

LOOP |

OPENING |

DOWN |

CABLE |

FIG. 3

TRACTION DRIVE |

RETAINER |

CONTROL LEVER |

SPRING |

|

TRACTION |

|

DRIVE |

|

CONTROL |

|

ROD |

DRIVE |

|

CONTROL |

|

BRACKET |

|

FIG. 4

INSTALL AUGER CONTROL ROD (See Figs. 5 and 6)

The auger control rod has the short loop on the end of the spring as shown.

1.Slide rubber sleeve up rod and hook end of spring into control arm with loop opening up as shown.

2.With top end of rod positioned under right side of control panel, push down on rod and insert end of rod into hole in auger control bracket. Secure with retainer spring.

AUGER |

CONTROL |

ROD |

RUBBER |

SLEEVE |

CONTROL |

ARM |

LOOP |

OPENING |

UP |

FIG. 5

AUGER CONTROL ROD |

AUGER |

|

RETAINER |

CONTROL |

|

LEVER |

||

SPRING |

||

|

||

|

AUGER |

|

CONTROL |

||

BRACKET |

||

FIG. 6

6

ASSEMBLY / PRE-OPERATION

INSTALL DISCHARGE CHUTE / CHUTE ROTATOR HEAD (See Fig. 7)

NOTE: The multi-wrench provided in your parts bag may be used to install the chute rotator head.

1.Place discharge chute assembly on top of chute base with discharge opening toward front of snow thrower.

2.Position chute rotator head over chute bracket. If necessary,rotatechuteassemblytoalignsquareandpinonunderside of chute rotator head with holes in chute bracket.

3.With chute rotator head and chute bracket aligned, position chute rotator head on pin and threaded stud of mounting bracket.

4.Install 3/8 washer and locknut on threaded stud and tighten securely.

CHUTE |

|

|

ROTATOR |

|

3/8 LOCKNUT |

HEAD |

|

|

|

|

3/8 WASHER |

|

|

PIN |

|

|

THREADED |

|

|

STUD |

|

|

ROTATOR HEAD |

CHUTE |

ALIGN BEFORE |

MOUNTING |

BRACKET |

TIGHTENING LOCKNUT |

BRACKET |

FIG. 7

INSTALL CHUTE DEFLECTOR REMOTE CONTROL

(See Figs. 8 and 9)

1.Install remote cable bracket to discharge chute with 5/16-18 carriage bolt and 5/16-18 locknut as shown. Tighten securely.

2.Install remote cable eyelet to chute deflector with 1/4-20 shoulder bolt, nylon friction washer and 1/4-20 locknut as shown. Tighten securely.

3.Install spring hooks between hex nuts on chute rotator head and into hole in chute deflector as shown.

1/4-20 |

SPRING |

|

CHUTE |

||

SHOULDER |

||

DEFLECTOR |

||

BOLT |

||

|

||

|

HOOK |

|

NYLON |

BETWEEN HEX |

|

WASHER |

NUTS |

|

1/4-20 |

ON CHUTE |

|

ROTATOR HEAD |

||

LOCKNUT |

|

|

|

5/16-18 |

|

|

CARRIAGE |

|

|

BOLT |

|

CABLE |

|

|

EYELET |

|

|

REMOTE |

|

|

CABLE |

|

|

BRACKET |

|

|

5/16-18 |

|

|

LOCKNUT |

|

FIG. 8

CHUTE DEFLECTOR |

CONTROL LEVER |

FIG. 9

CHECK TIRE PRESSURE

The tires on your snow thrower were overinflated at the factory for shipping purposes. Correct and equal tire pressure is important for best snow throwing performance.

•Reduce tire pressure to 14-17 PSI (19-24.5 N-m).

7

OPERATION

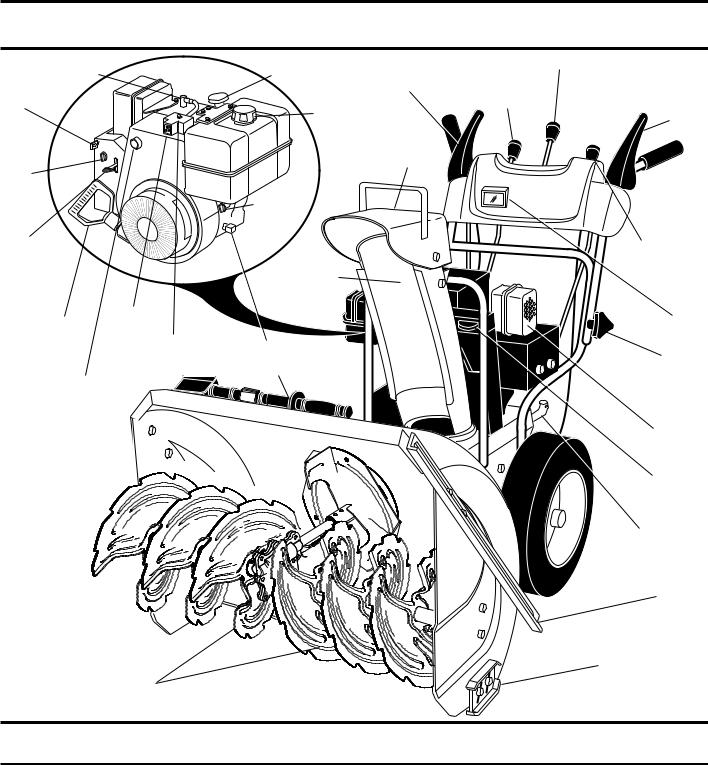

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUAL AND ALL SAFETY RULES BEFORE OPERATING YOUR SNOW THROWER. Compare the illustrations with your snow thrower to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference.

These symbols may appear on your snow thrower or in literature supplied with the product. Learn and understand their meaning.

DANGER |

|

|

|

|

|

|

|

|

|

PRIMER |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

||||||||

OR WARNING

READ AND FOLLOW ALL SAFETY INFORMATION

AND INSTRUCTIONS BEFORE USE OF THIS PRODUCT. FORWARD REVERSE KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

IGNITION KEY. |

|

INSERT TO START |

|

AND RUN, |

|

PULL OUT TO STOP. |

|

DISENGAGED |

|

ENGAGED |

|

SNOW |

TRACTION |

DISCHARGE |

DRIVE CONTROL |

|

8 |

OPERATION

SPARK |

ENGINE OIL CAP |

AUGER |

PLUG |

WITH DIPSTICK |

CONTROL |

SAFETY |

|

LEVER |

IGNITION |

|

KEY |

GASOLINE |

|

|

|

FILLER |

|

CAP |

CHOKE |

|

|

CHUTE |

|

|

|

DEFLECTOR |

||

CON- |

|

|

||

|

|

|

||

TROL |

|

|

|

|

|

|

|

FUEL |

|

|

|

|

SHUT-OFF |

|

|

|

|

VALVE |

|

THROTTLE |

|

|

|

|

/ ENGINE |

|

|

|

|

CONTROL |

|

|

DISCHARGE |

|

|

|

|

||

|

|

|

CHUTE |

|

RECOIL |

POWER |

|

|

|

(AUXILIARY) |

|

|

||

CORD |

|

|

||

STARTER |

|

|

||

PLUG |

ELECTRIC |

|

||

HANDLE |

OIL DRAIN PLUG |

|||

|

||||

|

|

START |

|

|

|

|

BUTTON |

CLEAN-OUT TOOL |

|

PRIMER |

|

|

|

|

NOTE: ITEMS ABOVE |

|

|

||

ARE SHOWN IN |

|

|

|

|

THEIR TYPICAL |

|

|

|

|

LOCATION ON THE |

|

|

|

|

ENGINE. ACTUAL |

|

|

|

|

LOCATION MAY VARY |

|

|

||

WITH THE ENGINE |

|

|

|

|

ON YOUR UNIT. |

|

|

|

|

AUGERS

FIG. 10

DISCHARGE CHUTE CONTROL LEVER

DRIVE SPEED CONTROL LEVER

TRACTION

DRIVE

CONTROL

LEVER

LH TURN TRIGGER

LH TURN TRIGGER

DEFLECTOR REMOTE CONTROL LEVER

LIGHT

HANDLE

KNOB

MUFFLER

TOOLBOX

FREEWHEEL CONTROL

DRIFT

CUTTER

SKID PLATE

MEETS A.N.S.I. SAFETY REQUIREMENTS

Our snow throwers conform to the standards of the American National Standards Institute.

Toolbox - used to store spare shear bolts, locknuts and wrench.

Safety ignition key - must be inserted for the engine to start and run. Remove when snow thrower is not in use.

Electric start button - used for starting the engine.

Recoil (auxiliary) starter handle - used for starting engine.

Primer - pumps additional fuel from the carburetor to the cylinder for use when starting a cold engine.

Choke Control - used for starting a cold engine.

Throttle/engine control - used to select either FAST or SLOW engine speed and to STOP the engine.

LH and RH turn triggers - used to steer the snow thrower.

Drive speed control lever - used to select forward or reverse motion and speed of snow thrower.

Traction drive control lever - used to engage power-pro- pelled forward or reverse motion of snow thrower.

Auger control lever - used to engage auger motion (throw snow).

Discharge chute control lever - used to change the direction the snow is thrown.

Deflector remote control lever - used to change the distance the snow is thrown.

Skid plate - used to adjust height of scraper bar from the ground.

9 Drift cutter - used to cut through deep snowdrifts.

OPERATION

The operation of any snow thrower can result in foreign objects thrown into the eyes, which can result in severe eye damage. Always wear

safety glasses or eye shields while operating your snow thrower or performing any adjustments or repairs. We recommend standard safety glasses

safety glasses or eye shields while operating your snow thrower or performing any adjustments or repairs. We recommend standard safety glasses

or a wide vision safety mask worn over spectacles.

HOW TO USE YOUR SNOW THROWER

Know how to operate all controls before adding fuel or attempting to start the engine.

STOPPING

TRACTION DRIVE

•Release traction drive control lever to stop the forward or reverse movement of the snow thrower.

AUGER

•Release the auger control lever to stop throwing snow.

ENGINE

1.Move throttle control to “STOP” position.

2.Remove (do not turn) safety ignition key to prevent unauthorized use.

NOTE: Never use choke to stop engine.

TO USE FUEL SHUT-OFF VALVE (See Fig. 11)

The fuel shut-off valve is located beneath the fuel tank on the engine. Always operate the snow thrower with the fuel shut-off valve in the OPEN position.

OFF

OPEN

FIG. 11

TO USE THROTTLE CONTROL (See Fig. 12)

The throttle control is located on the engine. Always operate the snow thrower with the engine at full throttle. Full throttle offers the best snow thrower performance.

FAST

SLOW

FIG. 12

TO USE CHOKE CONTROL (See Fig. 13)

The choke control is located on the engine. Use the choke control whenever you are starting a cold engine. Do not use to start a warm engine.

•To engage choke, turn knob clockwise. Slowly turn knob counterclockwise to disengage.

OFF |

FULL |

FIG. 13

TO CONTROL SNOW DISCHARGE (See Fig. 14)

WARNING: Snow throwers have exposed rotating parts, which can cause severe injury from contact, or from material thrown from the discharge chute. Keep the area of operation clear of all persons, small children and pets at all times including startup.

WARNING: If the discharge chute or auger become clogged, shut-off engine andwaitforallmovingpartstostop.Use the clean-out tool, NOT YOUR HANDS, to unclog the chute and/or auger.

The DIRECTION in which snow is to be thrown is controlled by the discharge chute control lever.

•Tochangethedischargechuteposition,pressdownward on discharge chute control lever and move lever left or right until chute is in desired position. Be sure lever springs back and locks into desired position.

The DISTANCE that snow is thrown is controlled by the position of the chute deflector. Set the deflector low to throw snow a short distance; set the deflector higher to throw snow farther.

•Press downward on chute deflector control lever and move lever forward to lower the deflector and decrease the distance. Move lever back to raise the deflector and increase the distance. Be sure lever springs back and locks into desired position.

DISCHARGE CHUTE

CONTROL LEVER

CHUTE DEFLECTOR

REMOTE CONTROL LEVER

FIG. 14

TO THROW SNOW (See Fig. 15)

The auger rotation is controlled by the auger control lever located on the right side handle.

•Squeeze auger control lever to handle to engage the auger and throw snow.

10 • Release the auger control lever to stop throwing snow.

OPERATION

AUGER

CONTROL

LEVER

FIG. 15

USING THE CLEAN-OUT TOOL (See Fig. 16)

In certain snow conditions, the discharge chute may become clogged with ice and snow. Use the clean-out tool to dislodge this blockage.

When cleaning, repairing, or inspecting, make certain all controls are disengaged and the auger/impeller and all moving parts have stopped. Disconnect the spark plug wire and keep the wire away from the spark plug to prevent accidental starting.

•Release the auger control lever and shut off the engine.

•Remove the clean-out tool from it's mounting clip. Grasp the tool firmly by the handle and push and twist the tool into the discharge chute to dislodge the blockage.

After the packed snow has been dislodged, return the cleanout tool to it's mounting clip by pushing it into the clip.

•Make sure the discharge chute is pointed in a safe direction (no vehicles, buildings, people, or other objects are in the direction of discharge) before restarting engine.

•Restart the engine, then squeeze the auger control lever to the handle to clear snow from the auger housing and the discharge chute.

DISCHARGE CHUTE |

CLEAN-OUT |

TOOL |

MOUNTING |

CLIP |

FIG. 16

TO MOVE FORWARD AND BACKWARD (See Fig. 17)

SELF-PROPELLING, forward and reverse movement of the snow thrower, is controlled by the traction drive control lever located on the left side handle.

•Squeeze traction drive control lever to handle to engage the drive system.

•Release traction drive control lever to stop the forward

or reverse movement of the snow thrower. |

11 |

|

SPEED and DIRECTION are controlled by the drive speed control lever.

•Move speed control lever to desired position AFTER engaging the traction drive control lever.

CAUTION: Do not move speed control lever unless engine is running. Damage to the snow thrower can result.

•Slower speeds are for heavier snow and faster speeds are for light snow and transporting the snow thrower. It is recommended that you use a slower speed until you are familiar with the operation of the snow thrower.

NOTE: When both traction drive and auger control levers are engaged, the traction drive control lever will lock the auger control lever in the engaged position. This will allow you to release your right hand from the handle and adjust the discharge chute direction without interrupting the snow throwing process.

TRACTION DRIVE

CONTROL LEVER DRIVE

SPEED

CONTROL

LEVER

FIG. 17

POWER STEERING OPERATION (See Fig. 18)

Steering triggers are used to assist in steering your snow thrower. The triggers are located on the underside of each handle. When a trigger is squeezed, it disengages the drive wheel on that side of snow thrower and allows it to turn in that direction.

•To turn left – squeeze left side trigger.

•To turn right – squeeze right side trigger.

LH TURN |

RH TURN |

TRIGGER |

TRIGGER |

FIG. 18

TO ADJUST SKID PLATES (See Fig. 19)

NOTE: The wrench provided in your parts bag may be used to adjust the skid plates.

Skid plates are located on each side of the auger housing and adjust the clearance between the scraper bar and the ground surface. Adjust skid plates evenly to proper height for current surface conditions. For removal of snow in normal conditions, such as a paved driveway or sidewalk, place skid plates in the highest position (lowest scraper clearance) to give a 1/8" clearance between the scraper bar and the ground. Use a middle position if the surface to be cleared is uneven.

OPERATION

NOTE: It is not recommended to operate the snow thrower over gravel or rocky surfaces. Objects such as gravel, rocks or other debris, can easily be picked up and thrown by the impeller, which can cause serious personal injury, property damage or damage to the snow thrower.

•If snow thrower must be operated over gravel surface, use extra caution and be sure skid plates are adjusted to lowest (highest scraper clearance) position.

1.Shut off engine and wait for all moving parts to stop.

2.Adjust skid plates by loosening the 1/2" hex nuts, then moving skid plate to desired position. Be sure both plates are adjusted evenly. Tighten securely.

SCRAPER BAR (See Fig. 19)

The scraper bar is not adjustable, but is reversible. After considerable use it may become worn. When it has worn almost to the edge of the housing, it can be reversed, providing additional service before requiring replacement. Replace a damaged or worn scraper bar.

HIGH POSITION |

HEX |

(LOW GROUND |

|

CLEARANCE) |

NUTS |

|

AUGER |

|

HOUSING |

LOW POSITION |

SCRAPER |

(HIGH GROUND |

BAR |

CLEARANCE) |

SKID PLATE |

|

FIG. 19

TO USE DRIFT CUTTERS (See Fig. 20)

Use the drift cutters to cut through deep snowdrifts that are higher than the front of the snow thrower.

•Loosen adjustment nuts enough to allow drift cutter to be raised to highest position and tighten nuts securely. Repeat for opposite side of snow thrower.

•When not using drift cutters, loosen adjustment nuts, lower to storage position and tighten nuts securely.

AUGER

HOUSING

STORAGE |

DRIFT |

POSITION |

CUTTER |

ADJUST-

MENT NUTS

FIG. 20

TO TRANSPORT (See Fig. 21)

When pushing or towing your snowthrower, be sure to disengage transmission by placing freewheel control into FREEWHEEL position. Freewheel control is located at the rear of snowthrower.

•Pull freewheel control out to FREEWHEEL position.

•To reengage transmission, push control back in.

FREEWHEEL POSITION |

TRANSMISSION ENGAGED |

FIG. 21

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 22)

The engine on your snow thrower has been shipped, from the factory, already filled with oil.

1.Check engine oil with snow thrower on level ground.

2.Remove oil fill cap/dipstick and wipe clean, reinsert the dipstick and screw tight, wait for a few seconds, remove and read oil level. If necessary, add oil until “FULL” mark on dipstick is reached. Do not overfill.

•To change engine oil, see “TO CHANGE ENGINE OIL” in the Maintenance section of this manual.

CHOKE CONTROL |

THROTTLE PRIMER ENGINE OIL |

|

FILL CAP / |

|

DIPSTICK |

SAFETY

IGNITION

KEY

|

GASOLINE |

|

|

FILLER CAP |

|

|

FUEL SHUT- |

|

|

OFF VALVE |

|

RECOIL |

STARTER BUTTON |

|

STARTER |

||

|

||

HANDLE |

POWER CORD PLUG |

NOTE: ALL ITEMS ARE SHOWN IN THEIR TYPICAL LOCATION. ACTUAL LOCATION MAY VARY WITH ENGINE ON YOUR UNIT.

FIG. 22

ADD GASOLINE (See Fig. 22)

•Fill fuel tank to bottom of tank filler neck. Do not overfill. Use fresh, clean, regular unleaded gasoline with a minimum of 87 octane. Do not mix oil with gasoline. Purchase fuel in quantities that can be used within 30 days to assure fuel freshness.

WARNING: Wipe off any spilled oil or fuel. Do not store, spill or use gasoline near an open flame.

12

Loading...

Loading...