Instruction Manual

136LE / 141LE

Read and follow all Safety Rules and Operating

Instructions before using this product. Failureto

do so can result in serious injury.

136 / 141

530163874 6/18/03

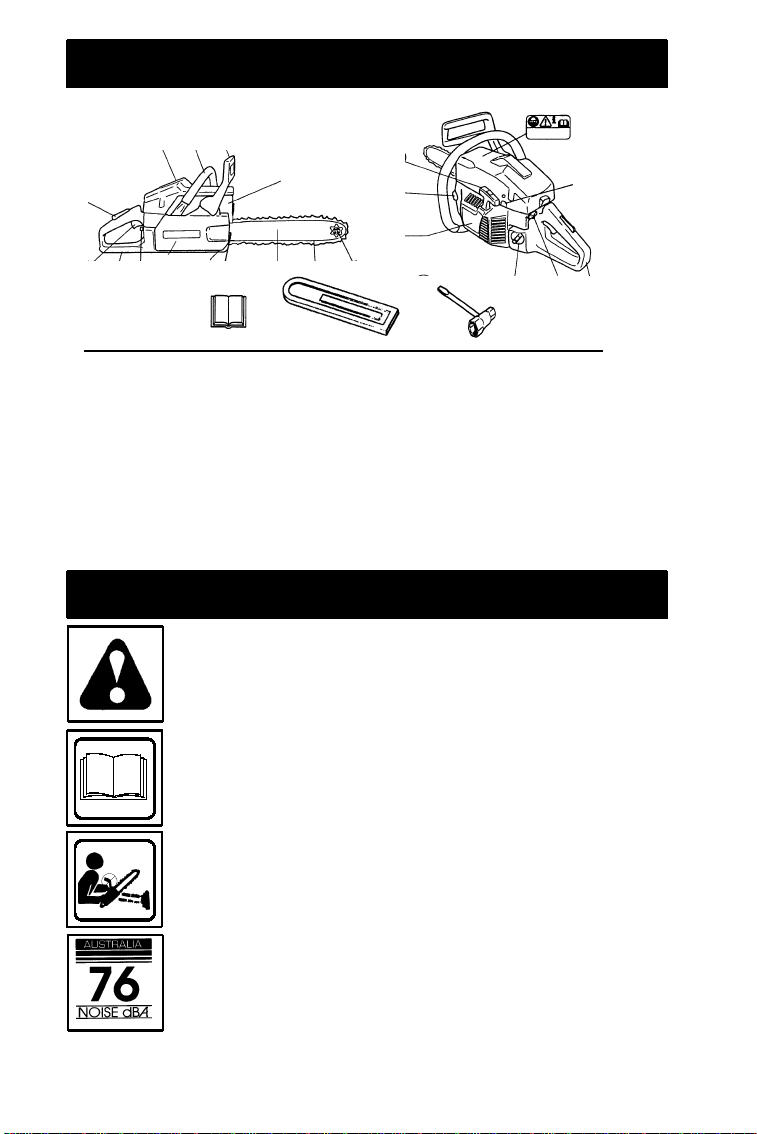

IDENTIFICATION (WHAT IS WHAT?)

321

20

19

18

1. Cylinder Cover

2. Front Handle

3. Front Hand Guard

4. Starter Cover

5. Chain Oil Tank

6. Starter Handle

7. Carburetor AdjustingScrew

8. Choke Control

9. Rear Handle

10. ON/OFF Stop Switch

11. Fuel Tank

12. Muffler

1617

8

22

IDENTIFICATION OF SYMBOLS

WARNING!

use can cause serious or even fatal injury.

21

1

7

10

9

11

6

12

1415

This chain saw can be dangerous! Careless or improper

5

4

13

2423

13. Bar Tip Sprocket

14. Saw Chain

15. Saw Bar

16. Chain Catcher

17. Chain Brake Assembly

18. Rear Hand Guard

19. Throttle Control/Trigger

20. Throttle Lock

21. Bar/Chain Adjustment Tool

22. Chain Tensioning Screw

23. Instruction Manual

24. Guide Bar Cover

Read and understand the instruction manual before using the chain saw.

XX_

Measuredmaximumkickbackvalue without chainbrakefor the bar and

chain combination on the label.

Sound pressure level at 15 meters (50 feet)

There may be more symbols found on your unit other than those listed above. These

symbols may represent compliances, standards, or other matters concerning the product.

2

SAFETY RULES

WARNING:

spark plugwire and place wire where it cannotcontact spark plugto prevent accidental

starting when setting up, transporting,adjusting or making repairs except carburetor

adjustments.

Becausea chain saw is a high-speedwoodcutting tool, special safety precautionsmust

beobserved to reduce the risk of accidents.

Careless or improper use of this tool can

cause serious injury.

PLAN AHEAD

S Readthis manual carefully until you com-

pletely understandand canfollow all safety rules, precautions, and operating instructions before attempting to use the

unit.

S Restricttheuse of yoursawto adult users

who understand and can follow safety

rules, precautions,and operating instructions found in thismanual.

Hearing

Protection

Snug

Fitting

Clothing

Safety

Shoes

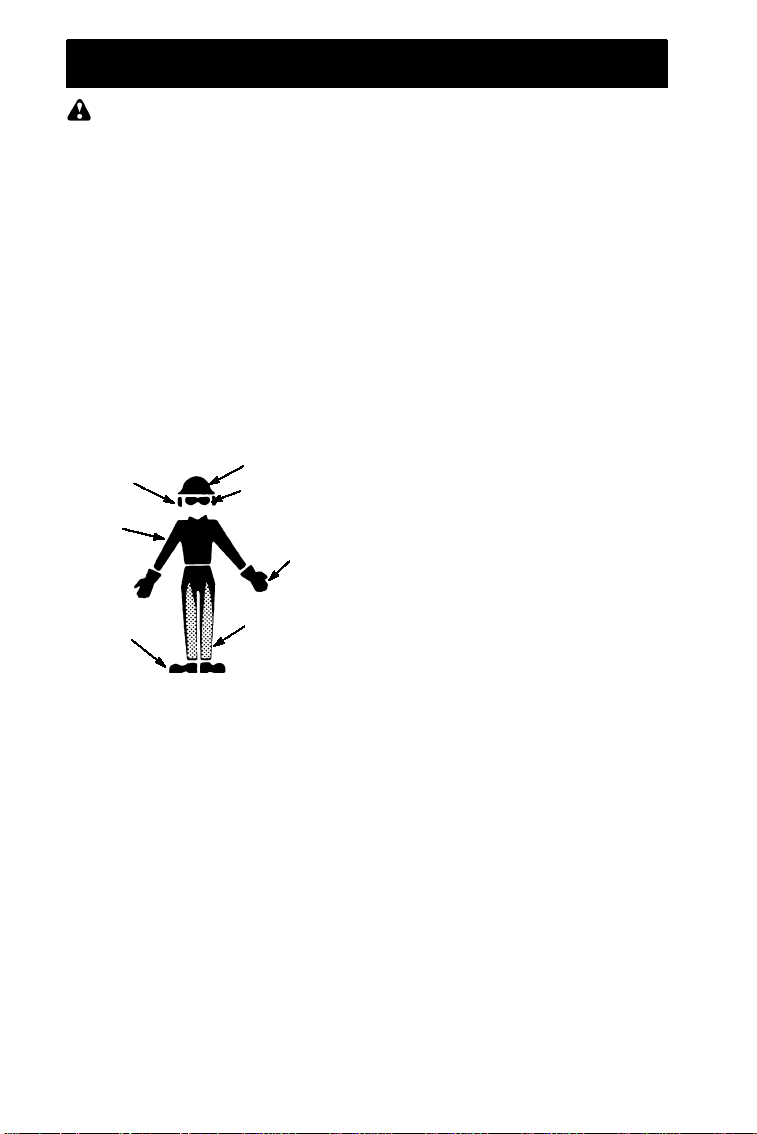

S Wear protective gear. Always use steel-

toed safety footwear with non-slip soles;

snug-fitting clothing; heavy-duty, non-slip

gloves; eye protection such as non-fogging, vented goggles or face screen; an

approvedsafetyhardhat;and soundbarriers (ear plugs or mufflers) to protect your

hearing. Regular users shouldhavehearing checked regularly as chain saw noise

can damage hearing. Secure hair above

shoulder length.

S Keep all parts of your body away from the

chain when the engine is running.

S Keep children, bystanders,andanimals a

minimum of 30 feet (10 meters)awayfrom

the workarea. Do not allow other people

or animalsto be near the chain saw when

starting or operating the chain saw.

S Do not handle or operate a chain saw

whenyouarefatigued,ill,orupset,or if you

have taken alcohol,drugs, or medication.

You must be in good physical condition

and mentally alert. Chain saw work is

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operatinga

chain saw.

Always disconnect

Safety Hat

Eye

Protection

Heavy Duty

Gloves

Safety Chaps

S Carefullyplanyoursawingoperationinad-

vance. Donotstartcuttinguntilyouhavea

clearwork area, secure footing, and, if you

are felling trees,a planned retreat path.

OPERATE YOUR SAW SAFELY

S Donotoperateachainsawwith one hand.

Serious injury to the operator, helpers,bystanders or any combinationof these persons may result from one-handed operation. A chain saw is intended for

two-handed use.

S Operatethechainsaw only inawell-venti-

lated outdoorarea.

S Do not operate saw from a ladder or in a

tree.

S Makesurethechain will notmake contact

with any object while starting the engine.

Never try to startthe saw when the guide

bar is in a cut.

S Do not put pressure onthe saw at the end

of the cut. Applying pressure can cause

you to lose control when the cut is completed.

S Stop the engine before setting the saw

down.

S Do not operate a chain saw that is dam-

aged, improperly adjusted, or not completely and securely assembled. Always

replace bar, chain, hand guard, or chain

brakeimmediately ifit becomesdamaged,

broken or is otherwise removed.

S With the engine stopped, hand carry the

chain saw with the muffleraway from your

body, and the guide bar and chain to the

rear,preferably covered with a scabbard.

MAINT AINYOUR SAW IN GOOD

WORKINGORDER

S Haveall chain saw service performedby a

qualified servicedealer with the exception

ofthe items listed inthe maintenancesectionofthismanual. Forexample,ifimpropertools areusedtoremoveor hold theflywheelwhenservicingtheclutch,structural

damage to the flywheel can occur and

cause the flywheel to burst.

S Make certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to CARBURETOR ADJUSTMENTS.

S Never modify your saw in any way.

S Keepthehandlesdry,clean,andfreeofoil

or fuel mixture.

S Keep fuel and oil caps, screws, and fas-

teners securely tightened.

S Use only Husqvarna accessories and re-

placement parts as recommended.

HANDLE FUEL WITH CAUTION

S Do not smoke while handling fuel or while

operating the saw.

S Eliminate all sources ofsparks or flame in

the areas where fuel is mixed or poured.

Thereshouldbenosmoking,openflames,

orworkthatcouldcausesparks. Allowengine to cool beforerefueling.

S Mix and pour fuel in an outdoor area on

bare ground; store fuel in a cool, dry, well

3

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuel spills beforestartingsaw.

S Moveat least 10 feet (3meters) from fuel-

ing site before startingengine.

S Turn the engine off and let saw cool in a

non-combustible area, not on dry leaves,

straw,paper,etc. Slowly remove fuel cap

and refuel unit.

S Storetheunitandfuelinanareawherefuel

vapors cannot reach sparks or open

flames from waterheaters,electric motors

or switches, furnaces, etc.

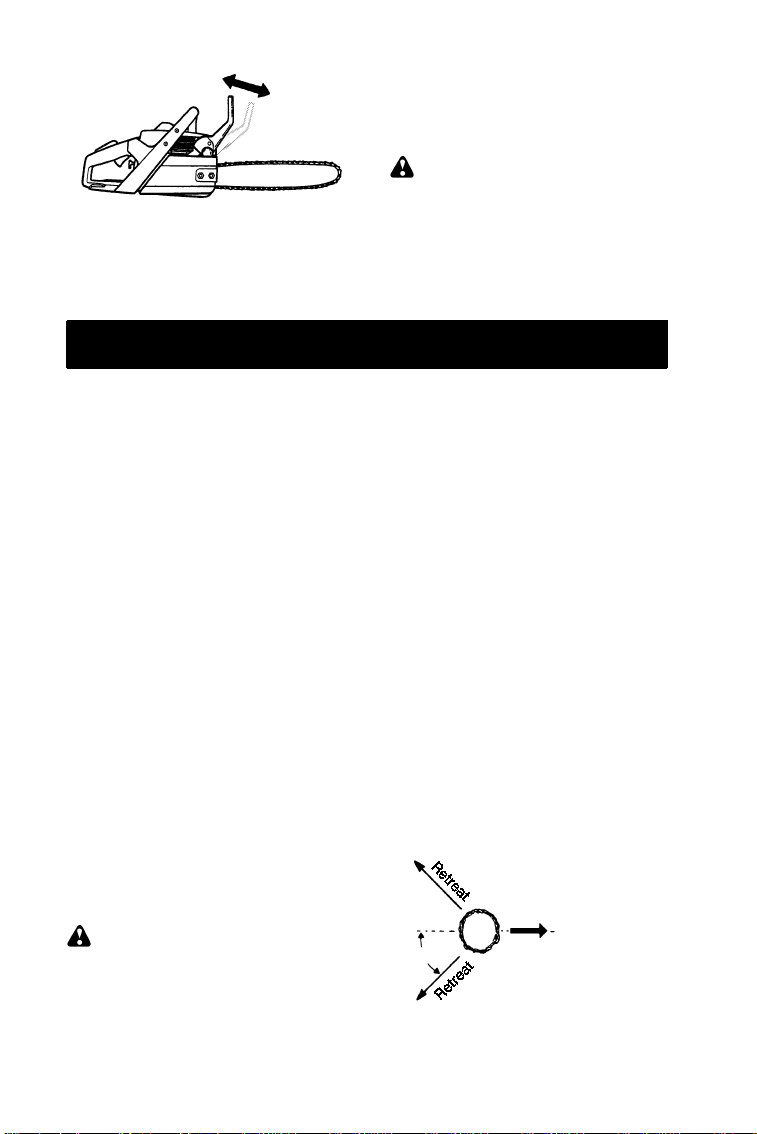

KICKBACK

WARNING:

can resultin seriousinjury. Kickbackisthe

backward,upwardorsudden forwardmotion

of the guide bar occurring when the saw

chainneartheuppertip of theguidebarcontacts any object such as a log or branch, or

when the wood closes in and pinches the

sawchain in thecut.Contactingaforeignobject in the wood can also result in loss of

chain saw control.

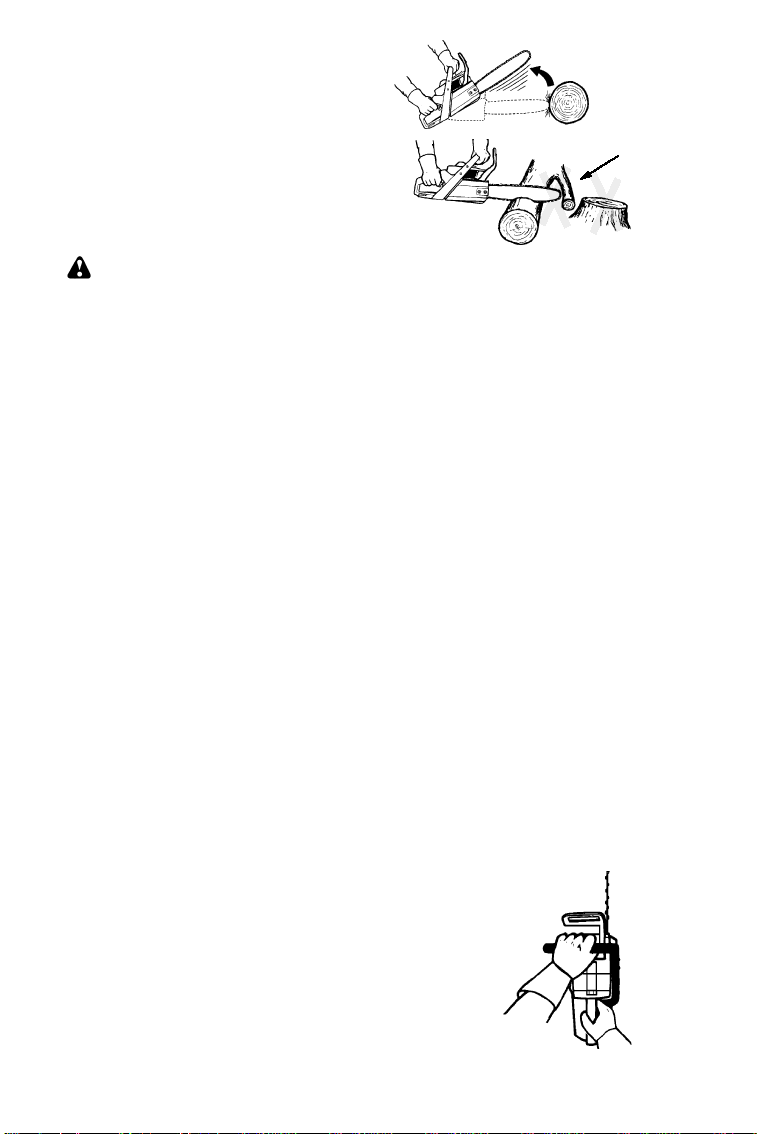

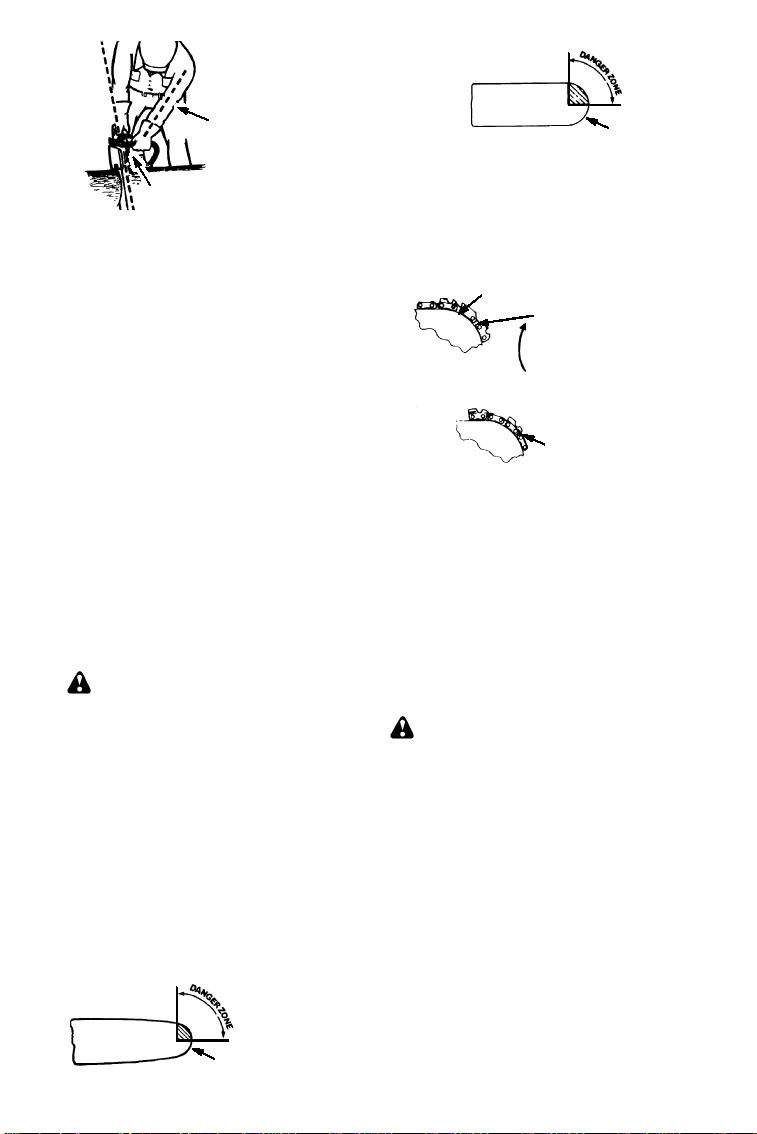

S RotationalKickbackcanoccurwhenthe

moving chain contacts an objectattheupper tip of the guide bar. This contact can

cause the chain to dig into the object,

which stops the chain for an instant. The

result is a lightning fast, reversereaction

which kicks the guide bar up and back toward the operator.

S Pinch-Kickbackcan occur when the the

wood closes in and pinches the moving

saw chain in the cut along the top of the

guide bar and the saw chain is suddenly

stopped. This sudden stopping of the

chain results in a reversal of the chain

force used to cut wood and causes the

sawtomoveintheopposite direction of the

chain rotation. The saw is driven straight

back toward theoperator.

S Pull-Incan occurwhen the moving chain

contactsaforeignobject in thewoodinthe

cut along the bottom of the guide bar and

the saw chain is suddenly stopped. This

suddenstoppingpullsthesawforwardand

away from the operator and could easily

cause the operator to lose control of the

saw.

Avoid Pinch--Kickback:

S Be extremely aware of situations or ob-

structions that can causematerial topinch

the top of or otherwise stop the chain.

S Donot cut morethan one log at a time.

S Do not twist the saw as the bar is with-

drawn from an undercut when bucking.

AvoidPull--In:

S Alwaysbegincutting withtheengineatfull

speedandthe saw housingagainst wood.

S Use wedges made of plastic or wood.

Never use metal to holdthe cut open.

Avoid kickback which

Kickback Path

Avoid Obstructions

Clear The Working Area

REDUCETHE CHANCE OF

KICKBACK

S Recognize that kickback can happen.

With a basic understanding of kickback,

you can reduce the element of surprise

which contributes to accidents.

S Neverletthemovingchaincontactanyob-

ject at the tipof the guide bar.

S Keep the working area free from obstruc-

tionssuchasoth ertrees,branches,rocks,

fences, stumps, etc. Eliminate or avoid

any obstructionthatyour sawchain could

hit while you are cutting. When cutting a

branch, do not let the guide bar contact

branch or other objects around it.

S Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase the chanceof kickback occurring.

Follow manufacturer’s chain sharpening

andmaintenanceinstructions. Check tension at regular intervals with the engine

stopped, never with the engine running.

Makesurethebarclamp nutsaresecurely

tightened after tensioning the chain.

S Beginandcontinue cutting atfull speed. If

the chain is moving at a slower speed,

thereis greaterchanceofkickback occurring.

S Cutone log at a time.

S Use extreme caution when re-entering a

previous cut.

S Do not attempt cuts startingwith the tip of

the bar (plunge cuts).

S Watch for shifting logs or other forces that

could close a cut and pinch or fall into

chain.

S Use the Reduced--Kickback Guide Bar

and Low--Kickback Chain specified for

your saw.

MAINTAINCONTROL

Stand to the left of

the saw

Never reverse

hand positions

4

Symmetrical Guide Bar

Elbow locked

Thumb on underside of

handlebar

S Keep a good,firm gripon thesawwithboth

hands when the engine is running and

don’tlet go. Afirmgrip will helpyoureduce

kickback and maintain control of the saw.

Keep the fingers of your left hand encircling and your left thumb under the front

handlebar. Keep your right hand completely around the rear handle whether

yourarerighthandedorlefthanded. Keep

your left arm straight with the elbow

locked.

S Positionyourleft hand onthe front handle-

bar so it is in a straight line with your right

hand on the rear handle when making

bucking cuts. Never reverserightandleft

hand positionsfor any type of cutting.

S Stand withyourweightevenly balancedon

both feet.

S Stand slightly to the left side of the saw to

keep your body from being in a direct line

with the cuttingchain.

S Donotoverreach. Youcould be drawnor

thrown off balance and losecontrol of the

saw.

S Donotcut aboveshoulderheight. Itisdiffi-

cult to maintain control of saw above

shoulder height.

KICKBACKSAFETY FEATURES

WARNING:

are included on your saw to helpreduce the

hazard of kickback; however,such features

will not totally eliminate this dangerousreaction. As achainsaw user,donotrely onlyon

safety devices. You must follow all safety

precautions, instructions, and maintenance

in this manual to help avoid kickback and

other forces which can result in serious

injury.

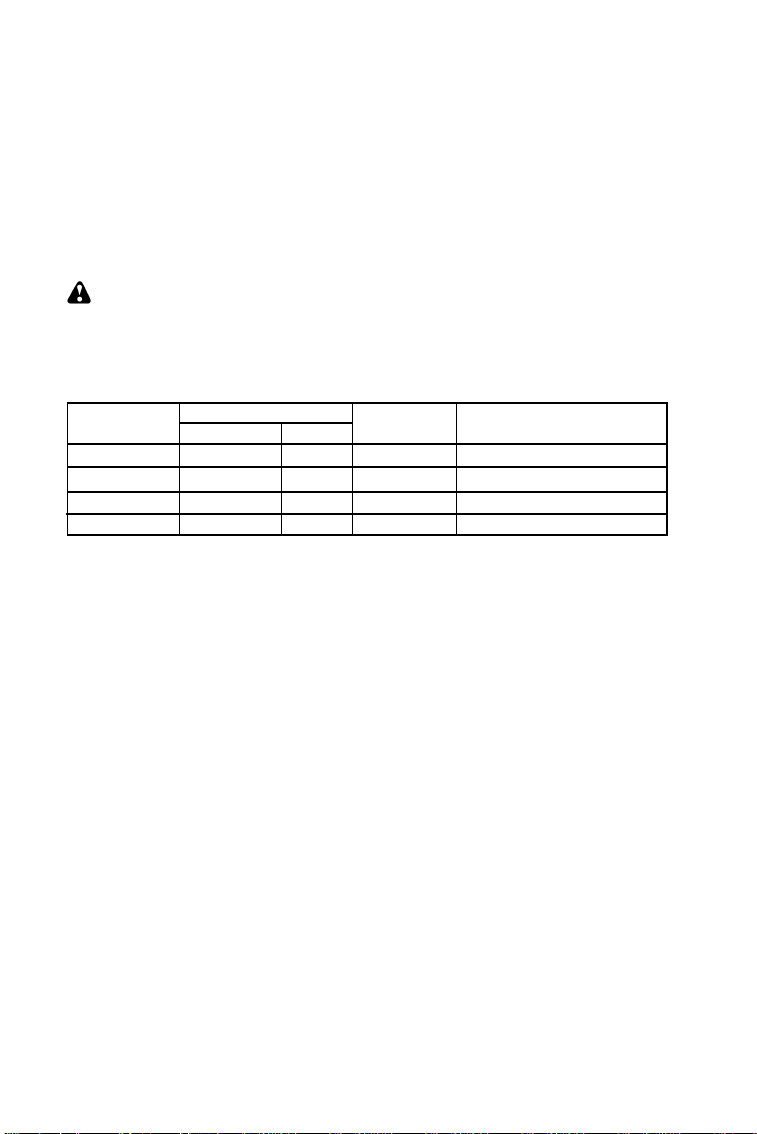

S Reduced--Kickback Guide Bar, designed

with a small radius tip which reduces the

size of the kickback danger zone on the

bar tip. A Reduced--Kickback Guide Bar

has been demonstrated to significantlyreducethe number and seriousnessof kickbacks when tested in accordance with

safety requirementsfor gasolinepowered

chain saws as set by ANSI B175.1.

Reduced Kickback Symmetrica l Guide Bar

The following features

Small Radius Tip

S Low--Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter.

Low--Kickback Chain has met kickback

performance requirements when tested

on a representative sampleof chain saws

below 3.8 cubic inch displacement specified in ANSI B175.1.

Low---Kickback

Chain

Not a Low ---Kickback Chain

S FrontHandGuard,designedtoreducethe

chance of your left hand contacting the

chainif your handslips offthefronthandlebar.

S Position of front and rear handlebars, de-

signedwithdistancebetweenhandlesand

“in-line” with each other. The spread and

“in-line” position of the hands provided by

this design work together to give balance

and resistance in controlling the pivot of

the saw back toward the operator if kickback occurs.

CHAIN BRAKE AND CKA ANGLE

S ChainBrake, designed to stop thechainin

the event of kickback.

WARNING:

RESENT AND YOU SHOULD NOT ASSUME THAT THE CHAIN BRAKE WILL

PROTECT YOU IN THE EVENT OF A

KICKBACK. Kickback is a lightning fastaction which throws the bar and rotating chain

back and up toward the operator. Kickback

can be caused byallowing contactofthebar

tip in the danger zone with any hard object.

Kickback canalsobecausedbypinchingthe

sawchainalongthetopoftheguidebar. This

action may push the guidebar rapidly back

toward the operator. Either of these events

may cause you to lose control of the saw

which could result in serious injury or even

death. DONOT RELYUPONANY OF THE

DEVICES BUILT INTO YOUR SAW. YOU

SHOULDUSETHESAW PROPERLYAND

CAREFULLY TO AVOID KICKBACK. Reduced--kickback guide bars and low--kickback saw chains reduce the chance and

magnitude of kickback and are recommended. Yoursawhasalowkickback chain

andbaras originalequipment. Repairs on a

Contoured Depth Gauge

Large Radius Tip

Elongated Guard Link

Deflects

kickback force

and allows wood

to gradually ride

into cutter

Can Obstruct Material

WE DO NOT REP-

5

chain brake should be made by an authorized servicing dealer. Take your unit to the

place of purchase if purchased from a

Husqvarna servicing dealer, or to the near-

est authorized Husqvarna service dealer.

S Tip contact in some cases may cause a

lightning fast reverse REACTION, kicking

theguidebarupandbacktowardtheoperator.

S Pinchingthesawchainalongthetopofthe

guide bar may push the guide bar rapidly

back toward theoperator.

S Eitherofthesereactionsmaycauseyouto

lose control of the sawwhich couldresult

in serious injury. Do not rely exclusively

uponthesafety devicesbuiltintoyoursaw.

WARNING:

angle (CKA) listed on your saw and listed in

the CKA table below represents angle of

kickback your bar and chain combinations

will have when tested in accordance with

CSA(CanadianStandardsAssociation) and

Computed kickback

Computedkickback angle (CKA) Table

BAR

MODEL

136

136

141

141 0.050 GA 18

NOTE:

commercial logging, a chain brake is

required and shall not be removed or

otherwise disabled to comply with Federal

OSHARegulationsforCommercialLogging.

Contact your authorized Husqvarnaservice

dealer.

SAFETY NOTICE:

vibrations throughprolongeduseofgasoline

powered hand tools could cause blood

vessel or nerve damage in the fingers,

hands, and joints of people prone to

circulation disordersor abnormal swellings.

Prolonged use in cold weather has been

linked to blood vessel damage in otherwise

healthy people. If symptoms occur such as

numbness, pain, loss of strength, changein

skin color or texture, or loss of feeling in the

fingers,hands, or joints, discontinuetheuse

of this tool and seek medical attention. An

anti-vibrationsystemdoesnotguaranteethe

avoidance of these problems. Users who

operate power tools on a continual and

regular basis must monitor closely their

physical condition and the condition of this

tool.

SPECIALNOTICE:

with a temperaturelimitingmuffler andspark

arresting screen which meets the

requirements of CaliforniaCodes 4442 and

If this saw is to be used for

Type Length CHAIN TYPE

0.050 GA 14!91VG/VJ--- 52

0.050 GA

0.050 GA

Exposure to

Y oursaw isequipped

16

16

!

!

!

ANSI standards.Whenpurchasing replacement bar and chain, considerations should

be given to the lower CKA values. Lower

CKA values represent safer angles to the

user,higher values indicate moreangle and

higher kick energies.Computedangles represented in the non-activated column indicatetotal energy andangle associated without activation of the chain brake during

kickback. Activated angle representschain

stopping time relative to activation angle of

chain breakandresulting kick angle of saw.

In all cases lower CKA values representa

safer operating environmentfor the user.

The followingguide bar and chain combinations meet kickback requirements of CSA

Standards Z62.1, Z62.3, & ANSI B175.1

when used on saws listed in this manual.

Use of bar and chain combinations other

than those listed is not recommended and

may not meet the CKA requirements per

standard.

CKA WITHOUT

CHAIN BRAKE

25_

_

91VG ---56

91VG ---56

H 3 0 --- 7 2

4443. All U.S. forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey, Oregon, and Washington require

many internal combustion engines to be

equipped with a spark arrestor screen by

law. If you operate a chain saw in a state or

locale wheresuch regulations exist, you are

legally responsible for maintaining the

operatingconditionofthese parts. Failureto

do so is a violation of the law. Refer to the

SERVICEANDADJUSTMENTS section for

maintenanceof theSparkArresting Screen.

Failure to follow all Safety Rules and

Precautions can result in serious injury. If

situationsoccurwhicharenotcoveredinthis

manual,usecareandgoodjudgement.Ifyou

need assistance, contact your authorized

service dealer.

STANDARDS

CSA Z62.1 “Chain Saws -- Occupational

Health and Safety”

CSA Z62.3 “Chain Saw Kickback Occupational Health and Safety”

ANSI B175.1--2000 -- “American National

Standard for Powered Tools -- Gasoline

Powered Chain Saw -- Safety Requirements”

25

25

38_

_

6

ASSEMBLY

p

Protective gloves (not provided) should be

wornduring assembly.

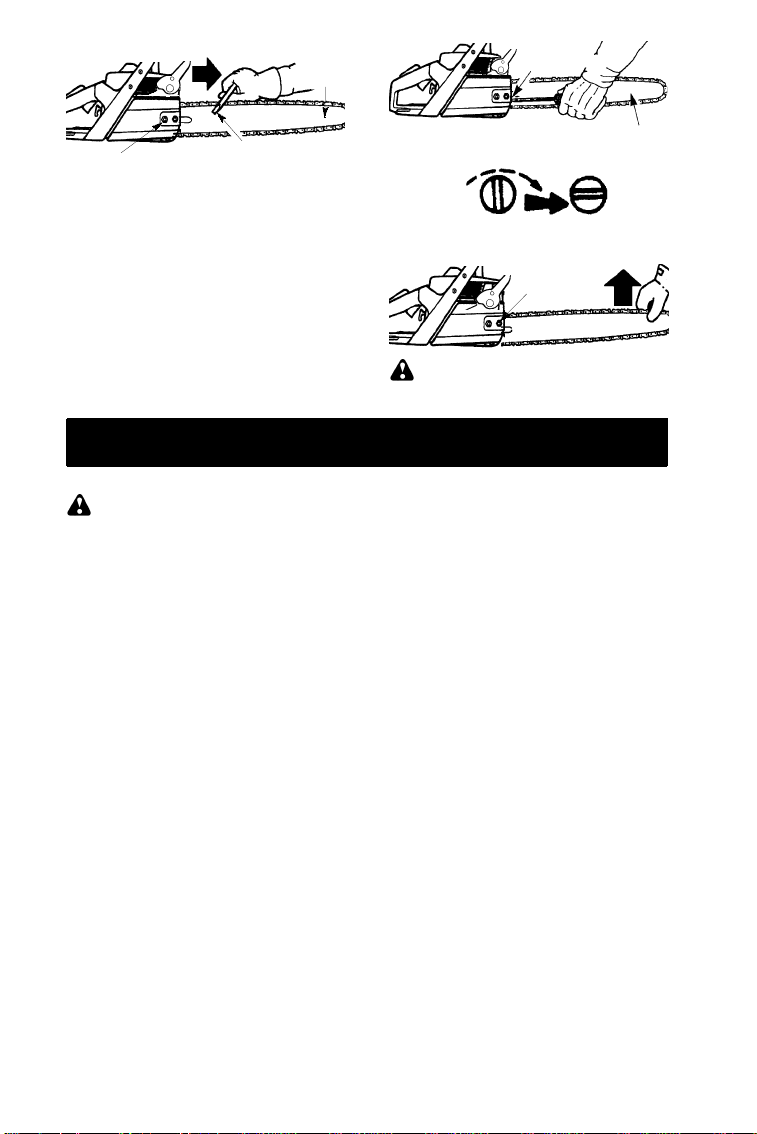

ATTACHINGTHE BAR & CHAIN

not alreadyattached)

WARNING:

blystepif the saw is receivedassembled.Always wear gloveswhen handlingthe chain.

The chain is sharp and can cut you even

when it is not moving!

1. Loosen and remove the clamp nuts and

the bar clamp fromthe saw.

2. Remove the plastic shipping spacer (if

present).

Bar Clamp/

Chain Brake

3. Anadjustingpinandscrew is usedtoadjust the tensionofthechain. It is very important when assembling the bar, that

the pin located on the adjusting screw

aligns into a hole in the bar. Turning the

screw will move the adjustment pin up

anddown the screw. Locate thisadjustment before you beginmounting the bar

ontothe saw. Seeillustration.

Adjustmentlocatedon Bar Clamp

4. Turn the adjusting screw counterclockwise to move the adjusting pin almostas

farasit will gototherear.This should allow the pin to be near the correct position. Furtheradjustment may be necessary as you mount the bar.

5. Slide guide bar behind clutch drum until

guide bar stops against clutch drum

sprocket.

Recheck each assem-

Location of shipping spacer

Bar Clamp Nuts

Mount the Bar

Bar Tool

Inside view of

Chain Brake

6. Prepare the chain by checking the proper

direction.With outfollo w ingtheillustratio nit

(If

is easytoplace the chainonthe saw in the

wron gdir ection. Use the illustratio n of the

chain to determinethe proper direction.

Tip of

Bar

CUTTERS MUST FACE IN

DIIRECTION OF ROTATION

Cutters

7. Place chain over and behind clutch, fitting the drive links in the clutch drum

sprocket.

Place chain onto thes

8. Fit bottom of drive links between the

teeth in the sprocket in the nose of the

guide bar.

9. Fit chain drive links into bar groove.

10. Pull guide bar forwarduntil chainis snug

in guide bar groove. Ensure all drive

links arein the bar groove.

11 Now,installchainbrakemakingsurethe

adjusting pin is positioned in the lower

hole in the guidebar. Remember this pin

moves the bar forwardand backwardas

the screwis turned.

12. Installchainbrakenuts and fingertighten

only. Once the chain is tensioned, you

will need to tighten chain brake nuts.

Drive Links

CHAIN TENSION

chain already installed)

: When adjusting chain tension,

NOTE

make sure the bar nuts are finger tight only.

Attemptingtotensionthechain when the bar

nuts are tight can cause damage.

Checking the tension:

Use the screwdriver end of the combination

screwdriver/wrench tool to move the chain

aroundthebar.Ifthechain does not rotate, it

istootight.Iftoo loose, the chain will sagbelow the bar.

Depth Gauge

rocket

(Includingunitswith

7

Guide

Bar

Adjusting

Screw

Chain Brake Nuts

Adjustingthe tension:

Chain tension is very important. Chain

stretches during use.This is especially true

during thefirst few times you use your saw.

Always check chain tension each time you

use and refuel your saw.

Y oucan adjust the chain tensionby loosening

the bar clamp nuts and turning the adjusting

screw 1/4 of a tu rn while lifting up on the bar.

S If chain is too tight, turn adjusting

screw 1/4 turn counterclockwise.

S If chain is too loose, turn adjusting

screw 1/4 turn clockwise.

Chain Adjustment

Tool (BarTool)

FUELING & LUBRICATION

FUELING ENGINE

WARNING:

when refueling.

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed witha good quality

synthetic 2-cycle air-cooled engine oil

designed to be mixed at a ratio of 40:1. A

40:1ratioisobtainedbymixing3.2ouncesof

oil with 1 gallon of unleadedgasoline. DO

NOT USE automotive oil or boat oil. These

oilswill causeenginedamage.When mixing

fuel, follow instructionsprinted on container.

Once oil is added to gasoline, shake

containermomentarily to assure that the fuel

is thoroughly mixed. Always read and follow

thesafety rules relating to fuel beforefueling

your unit.

BAR AND CHAIN LUBRICATION

The bar and chain require continuous lubrication. Lubrication is provided by the automatic oiler system when the oil tank is kept

filled.Lack ofoil will quickly ruin the barand

chain. Too little oil will cause overheating

shownbysmoke coming from the chainand/

or discoloration of the bar.

Removefuel cap slowly

Chain Brake Nuts

Adjusting Screw -- 1/4 Turn

S Lift up the tip of the bar and tighten the

chain brake nuts withthe bar tool.

S Recheck chain tension.

WARNING:

with a loose chain, the chain could jump off

the guide bar and result in serious injury.

Infreezingweatheroil will thicken, making it

necessary to thin bar and chain oil with a

small amount(5 to 10%) of#1 Diesel Fuel or

kerosene. Bar and chain oil must be free

flowing for the oil system to pump enough oil

for adequate lubrication.

Genu ine Husqvarna bar and chain oil is recommended to protect yo urunit against excessive wearfrom heat andfriction. Husqvarnaoil

resists high tempera tu rethinning.

IfHusqvarnabaroil isnotavailable, use agood

grade SAE 30 oil.

S Never use waste oil for bar and chain lu-

brication.

S Always stop the engine before removing

the oil cap.

IMPORTANT

Experience indicates that alcohol--blended

fuels (called gasohol or using ethanol or

methanol) can attract moisturewhich leads

to separation and formationof acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage. To

avoid engine problems, the fuel system

should be emptied before storage for 30

days or longer. Drainthegas tank,start the

engine and let it run until the fuel lines and

carburetor are empty. Use fresh fuel next

season. See STORAGE section for additional information.

Chain Brake

Nuts

If the saw is operated

Guide Bar

8

OPERATING YOUR UNIT

WARNING:

whenthe engine runs at idlespeed.Ifthe chain

moves at idle speed refer to CARBURETOR

ADJUS TMENTwithinthismanual.Avoidcontact with the muffler. A hot muffler can cause

serious burns.

Tostop the engine move the switch to the

STOP position.

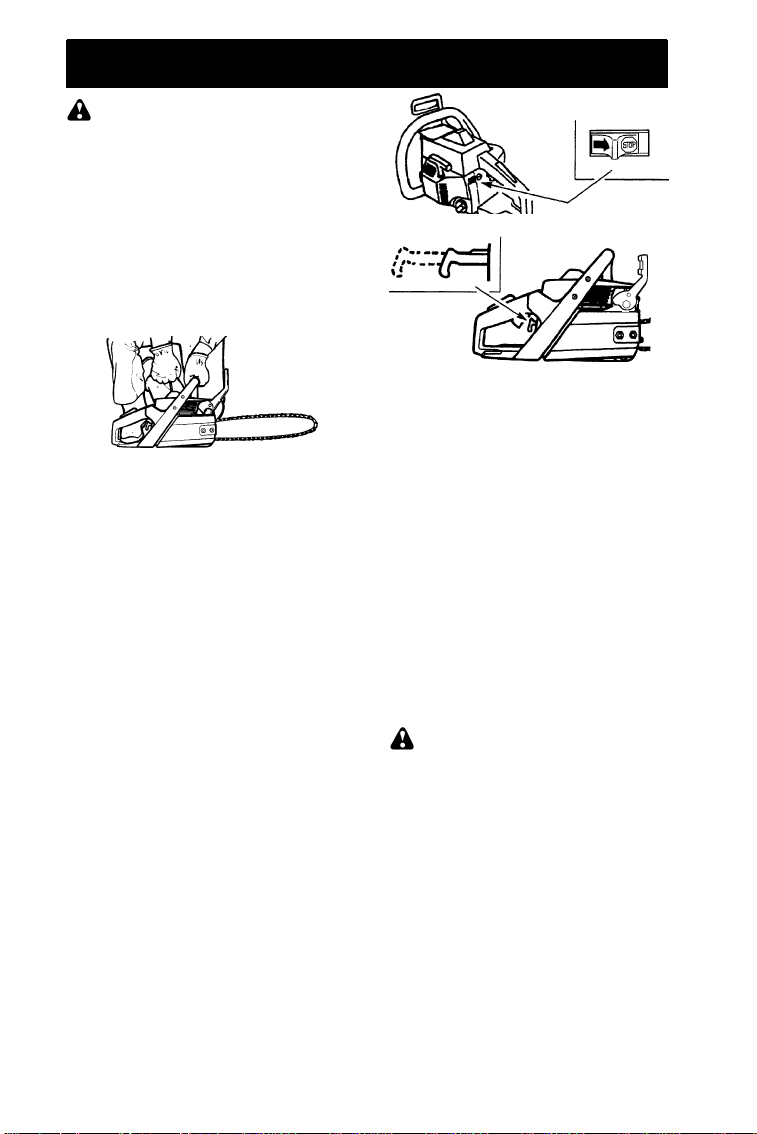

To start the engine hold the saw firmly on

the ground as illustrated below. Make sure

the chain is free to turn without contacting

any object.

Use only 15”--18” of rope per pull.

Hold saw firmly while pulling starter rope.

Importantpoints to remember

Whenpullingthestar terro pe,d onotuseth efull

extentof the rope asthis can causethe ropeto

break. Donot let starter rope snap back. Hold

the handle and let the ro pe rewind slowly.

Forcold weatherstarting,starttheunit at full

choke; allow the engine to warm up before

squeezing the throttletrigger.

Do not cut materialwith the choke/

NOTE:

fast idle lever at the FULL CHOKEposition.

The chain must notmove

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

: In the following steps,when the cho-

NOTE

ke/fast idle lever is pulled out to the full exte nt,

the correct throttle settingfor starting is set automa tically.

1. MoveON/STOPswitch to the ONposition.

2. Pullthechoke/fastidleleverouttothefull

extent.

3. Pull starter rope quickly with your right

handamaximum of 10times. Then, proceed to the next step.

If theengine sounds as ifit is trying

NOTE:

tostart before the 10th pull, stop pulling and

immediately proceed to the next step.

4. Push the choke/fast idle lever in completely (to the OFF CHOKEposition).

5. Pull the starter rope quickly with your

right hand until the engine starts.

6. Allow the enginetorunforapproximately

5 seconds. Then,squeeze and release

throttletriggertoallowengineto returnto

idle speed.

ON/STOP SWITCH

CHOKE/FAST IDLE LEVER

FULL OFF

STARTING A WARM ENGINE

1. MoveON/STOPswitch to the ONposition.

2. Pullthechoke/fastidleleverouttothefull

extent; then, push the choke/fast idle

lever in completely (to the OFF CHOKE

position).

3. Pull the starter rope quickly with your

right hand until the engine starts.

4. Squeeze and release throttle trigger to

allow engine to return to idle speed.

DIFFICULT STARTING (or starting a

flooded engine)

The engine may be flooded with too much

fuel if it has not startedafter 10 pulls.

Flooded engines can be cleared of excess

fuel by following the warm engine starting

procedure listed above. Insure the ON/

STOPswitch is in the ON position.

Startingcouldrequire pulling the starterrope

handle many times dependingon how badly

theunitis flooded. Ifenginefails to startrefer

to the TROUBLESHOOTINGTABLE.

CHAIN BRAKE

WARNING:

too thin it may break when the chain brake is

triggered. Witha broken brake band, the chain

brake will not stopthe chain. The chain brake

should be replaced by an authorized service

dealer if any part is worn to less than 0.020!

(0.5 mm) thick. Repairs on a chain brake

should be madeby an authorizedservice dealer. Take your unit to the place of purchase if

purchased from a servicing dealer, or to the

nearest authorizedHusq varnaSer v iceD ealer.

S This saw is equipped with a chain brake.

The brakeis designed to stop the chain if

kickback occurs.

S The inertia--activated chain brake is

activated if the front handguardis pushed

forward, either manually (by hand) or

automatically (by sudden movement).

S If the brake is already activated, it is

disengagedbypullingthefronthandguard

back toward the front handle as far as

possible.

If the brake band is worn

9

S Whencuttingwiththesaw,thechainbrake

must be disengaged.

Disengaged

Engaged

Braking functioncontrol

CAUTION:

checked several times daily. The engine

mustberunningwhenperformingthisprocedure. This istheonlyinstance when the saw

should be placed on the ground with the engine running.

The chain brake must be

CUTTING METHODS

Place the saw on firm ground. Hold thehandles with both hands and apply full throttle.

Activate the chainbrake by turning your left

wrist against the hand guard without releasing your grip around the front handle. The

chain should stop immediately.

Inertia activating function control

WARNING:

lowing procedure, the engine must be turned

off.

The chain brake must be checked several

times daily. Hold thechain sawapproximately 14! (35 cm) above a stump or other firm

object. Release your grip on thefronthandle

and let the saw, by its own weight, rotate

around the rearhandle. When the tip of the

barhitsthestump,thebrakeshouldactivate.

When performing the fol-

IMPORTANTPOINTS

S Check chain tension before first use and

after 1 minute of operation. See CHAIN

TENSION in the ASSEMBLY section.

S Cut wood only. Do not cut metal, plastics,

masonry ,non- w ood buildingmate r ials, etc.

S Stopthesa wifthechainstrikesaforeignob-

ject. Inspect the saw and repair parts as

necessary.

S Keep thechainoutofdirtandsand. Evena

small amountof dirtwillquicklydullachain

and increase thepossibility of kickback.

S Practicecutting a few small logs using the

following techniquestogetthe“feel”ofusing your saw before you begin a major

sawing operation.

S Squeeze the throttle trigger and allow

the engine to reach full speed before

cutting.

S Begin cutting with the saw frame

against the log.

S Keep the engine at full speed the en-

tire time you are cutting.

S Allow the chain to cut for you. Exert

only light downward pressure.

S Release the throttle triggeras soonas

the cut is completed, allowing the engine to idle. If you run the saw at full

throttle without a cutting load, unnecessary wear can occur.

S To avoid losing control when cut is

complete, do not put pressureonsaw

at end of cut.

S Stop the engine before setting the saw

down after cutting.

TREE FELLING TECHNIQUES

WARNING:

dead branches which can fall while cutting

causingserious injury. Donotcut nearbuildingsor electricalwires if youdonotknowthe

directionof treefall, norcut atnightsince you

will not be ale to see well, nor during bad

weathersuchasrain, snow,orstrongwinds,

etc. Ifthetreemakescontactwithanyutility

line, the utility company should be notified

immediately.

Check for broken or

S Carefully plan your sawing operation in ad-

vance .

S Clear the work area. Youneed a cleararea

all around the tree so yo u can have secure

footing.

S The chain saw operator shouldkeep on the

uph illsideofth et erra inasth etreeislikelyto

roll or slide downhill after it is felled.

S Study the natural condition s that can cause

the tree to fall in a particular direction.

Natural conditions that can cause a tree to fall

in a particular dire ction include:

S The wind directionand speed.

S Thelean of the tree. The lean of a tree might

notbeapparentdueto unevenor slopingter-

rain. Use a plumb or level to determine the

direction of tree lean.

S Weight and branches on one side.

S Surrounding trees and obstacles.

Look for decay and rot. If the trunk is rotted, it

can sn apand fall toward the operator. Check

for broken or dead branches which can fall on

you while cutt ing.

Make surethere is enough ro omfor the tree to

fall. Maint ain a dista nce of

from the nearest person or other objects. Engine noise candrown out a warning call.

Remove dirt,stones, loose bark, nails,staples,

and wire from the tree where cuts are to be

made.

Plan a clear retreat path to the rear and diagonal to the line of fall.

Plan a clear retreat path

_

45

tree leng ths

2-1/2

Direction of Fall

FELLING LARGE TREES

(15 cm in diameter or larger)

The notch methodis used to fell large trees.

Anotchis cut on the side of thetreeinthedesired direction of fall. After a felling cut is

10

made on the opposite side of tree, the tree

will tend to fall into the notch.

If the tree has large buttress roots,

NOTE:

removethembeforemakingthenotch. Ifusing saw to removebuttress roots,keep saw

chainfromcontacting groundtopreventdulling of the chain.

NOTCH CUT AND FELLING THE

TREE

S Make notch cut by cutting the top of the

notch first. Cut through

ofthetree.Nextcompletethe notchbycutting the bottom of the notch. See illustration. Once the notch is cut remove the

notch of wood from the tree.

Final (felling) cut here.

2! (5 cm) above center of notch.

First cut

Notch

Second cut

S After removing the cutout of wood, make

the felling cut on the opposite side of the

notch. This is done by making a cut about

two inches higher than the center of the

notch. This will leave enoughuncut wood

between the felling cut and the notch to

form a hinge. This hinge will help prevent

thetreefrom falling in thewrongdirection.

Hinge holds tree on stump and helps

control fall

Closing

of

notch

5cm

1/3

Opening

of felling

cut

of the diameter

5cm

Hinge

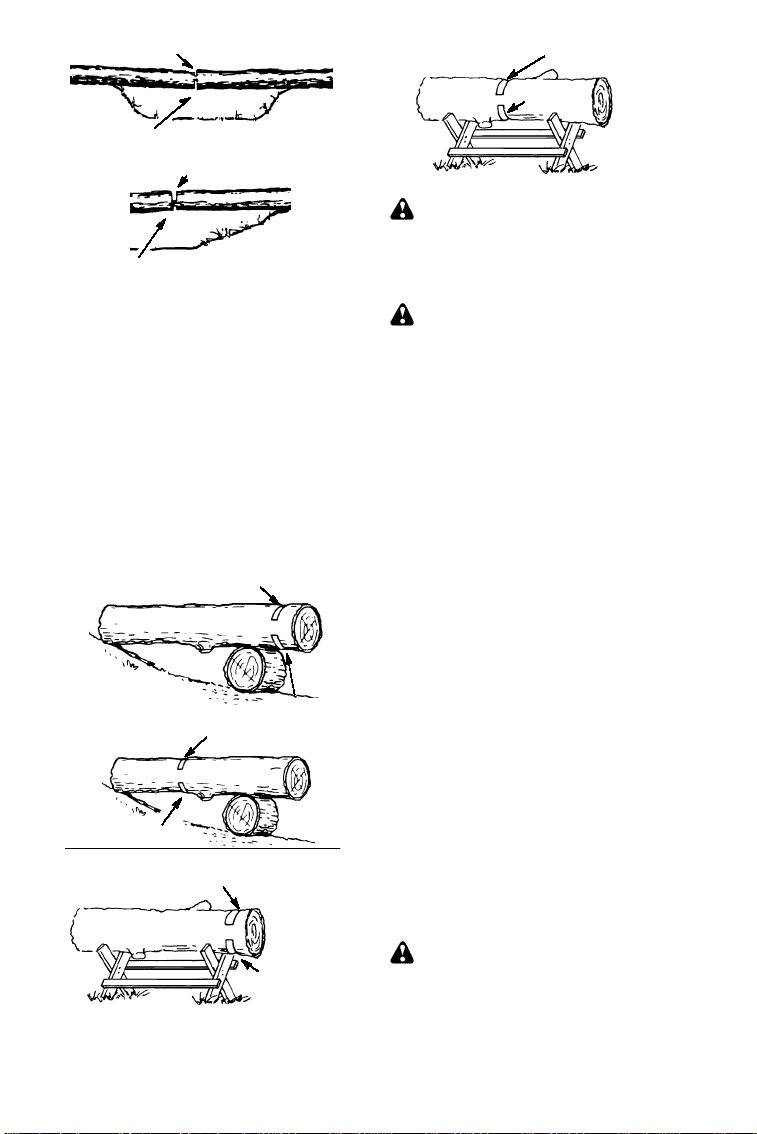

CUTTINGA FALLEN TREE

(BUCKING)

Bucking is the term used for cutting a fallen

tree to the desired log length.

WARNING:

being cut. Any portion can roll causing loss

of footing and control. Do not stand downhill

of the log being cut.

IMPORTANTPOINTS

S Cut only one log at a time.

S Cut shattered wood very carefully; sharp

piecesofwoodcouldbeflungtowardoper-

ator.

S Use a sawhorseto cut small logs. Never

allow another personto holdthe log while

cuttingandneverholdthelogwith your leg

or foot.

S Do not cut in an area where logs, limbs,

androots are tangled.Drag the logs intoa

clearareabeforecuttingbypullingoutex-

posed and cleared logs first.

Do not stand on the log

TYPES OF CUTTINGUSED FOR

BUCKING

WARNING:

or hung in a log, don’t try to forceit out. You

can lose controlof the saw resulting in injury

and/or damage to the saw. Stop the saw,

drive a wedge of plastic or wood into the cut

until thesawcan beremovedeasily. Restart

thesawandcarefully reenter the cut. Do not

attempttorestartyour saw whenit is pinched

or hung in a log.

Use a wedge to remove pinched saw

Tur n saw

wooden wedge to force cut open.

Overcuttingbeginsonthetopsideof thelog

with thesaw against the log. When overcutting use light downward pressure.

Overcutting Undercutting

Ifsawbecomes pinched

OFF

and use a plastic or

: Before felling cut is complete, use

NOTE

wedges to open the cut when necessary to

controlthedirectionoffall. Toavoidkickback

and chain damage, use wood or plastic

wedges, but never steel or iron wedges.

S Be alertto signs that the tree isready to fall:

crackin gsoun ds, wide ning of thefellingcut,

or movement in the upper branches.

S As treestarts to fall, stop saw,put it down,

and get away quickly on your planned retreat path.

S DO NOTcut downa partia llyfallen treewith

your saw. Be extremely cautious with partially fallen trees that may be poorly supported. When a tre e doesn’t fall completely,

set the sawasideandpull downthe tree with

acable winch,block and tackle,ortractor.

Undercuttinginvolves cuttingon theunderside ofthelogwith top of saw against thelog.

When undercutting use light upward pressure. Hold saw firmly and maintaincontrol.

The saw will tend to push back toward you.

WARNING:

down to undercut. The saw cannot be controlled in this position.

Always make your first cut on the compression side of the log. Thecompression side of

the log is where the pressure of the log’s

weight is concentrated.

Never turn saw upside

11

First cut on compression side of log

Second cut

Second cut

First cut on compression side of log

BUCKINGWITHOUT A SUPPORT

S Overcut through

log.

S Roll the log over and finish with a second

overcut.

S Watch for logs with a compression side to

prevent the saw from pinch ing. See illustration for cutting logs with a comp ression side.

of the diameter of the

1/3

BUCKING USING A LOG OR SUPPORT STAND

S Remember your first cut is always on the

compr essionsideofthelog . (Referto theillustration below for your first and second

cuts).

S Your first cut should extend

diameter of the log .

S Finish with your secondcut.

Using a log for support

2ndCut

Using a support stand

nd

2

Cut

st

1

Cut

nd

2

Cut

1stCut

1/3

1stCut

of the

1stCut

nd

Cut

2

LIMBINGAND PRUNING

WARNING:

against kickback. Do not allow the moving

chain to contact any other branches or objects at the noseofthe guide bar when limbingorpruning. Allowingsuchcontactcanresult in serious injury.

WARNING:

limb or prune. Do not stand onladders, platforms, a log, or in any position which can

cause you to loseyour balance or control of

the saw.

IMPORTANTPOINTS

S Work slowly, keeping both hands firmly

gripped on the saw. Maintainsecurefoot-

ing and balance.

S Watch out for springpoles. Use extreme

caution when cutting small size limbs.

Slender materialmaycatch the saw chain

andbe whippedtowardyou or pull you off

balance.

S Be alert for springback. Watch out for

branches that are bent or under pressure.

Avoid being struck by the branch or the

saw when the tensioninthewoodfibers is

released.

S Keep a clear work area. Frequently clear

branches out of the way to avoid tripping

over them.

LIMBING

S Alwayslimb atreeafteritiscutdown. Only

thencan limbing bedonesafely and prop-

erly.

S Leave the larger limbs underneath the

felled tree to supportthe tree as you work.

S Startatbase of thefelled tree and work to-

ward the top, cutting branches and limbs.

Removesmall limbs with one cut.

S Keepthe treebetweenyou and the chain.

Cut from the side of the tree oppositethe

branch youare cutting.

S Remove larger, supporting branches with

thecuttingtechniquesdescribedinBUCK-

ING WITHOUT A SUPPORT.

S Always use an overcut to cut small and

freely hanging limbs. Undercutting could

cause limbs to fall and pinch saw.

Be alert for and guard

Neverclimbintoatreeto

PRUNING

WARNING:

shoulder height or below. Do not cut if

branchesarehigherthanyourshoulder. Get

a professionalto do the job.

Limit pruning to limbs

12

S Makeyour first cut

the bottom of the limb.

S Next make a 2ndcutall the way through

the limb. Thencut a third overcut leaving

a1to2 inch collar from thetrunkofthetree.

of the way through

1/3

SERVICE AND ADJUSTMENTS

Third cut

Collar

Second cut

First cut

Pruning technique

WARNING:

andafteruse. Do not touchthemuffler or allow combustible material such as dry grass

or fuel to do so.

We recommendallservice and adjustments

not listed in this manual be performedby an

Authorized Service Dealer.

MAINTENANCE SCHEDULE

Check:

Fuel mixture level Before each use....

Bar lubrication Before each use.......

Chain tension Before each use.......

Chain sharpness Before each use....

For damaged parts Before each use..

For loose caps Before each use......

For loose fasteners Before each use...

For loose parts Before each use......

Inspect and Clean:

Bar Before each use................

Complete saw After each use.......

Air filter Every 5 hours*.............

Chain brake Every 5 hours*........

Spark arresting screen

and muffler Every 25 hours*.........

Replace spark plug

Replace fuel filter

* Hours of Operation

Mufflerisvery hotduring

Yea rly.

Yea rly...

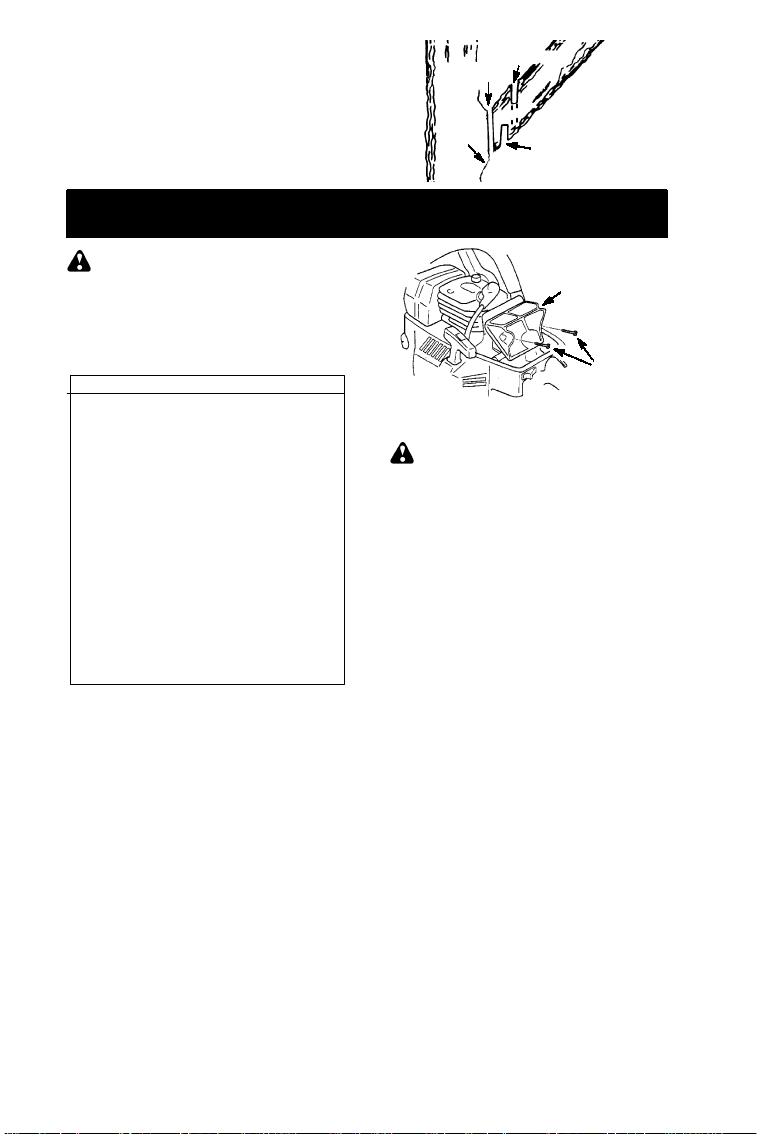

AIR FILTER

CAUTION

or other flammable solventto avoidcreating

a firehazard or producingharmful evaporative emissions.

Cleaning the air filter:

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after 15

tanks of fuel or 5 hours of operation, whichever comes first. Clean more frequently in

dusty conditions. A used air filter can never

becompletely cleaned. It is advisable toreplaceyourairfilter witha newoneafterevery

50hoursofoperation,orannually,whichever

comes fir st.

1. Loosen 3 screwson cylinder cover.

2. Remove cylinder cover.

3. Remove air filter.

4. Clean the air filterusinghotsoapywater.

Rinsewithcleancoolwater. Airdrycompletely before reinstalling.

5. Reinstall air filter.

6. Reinstall cylinder cover and 3 screws.

TIghten securely.

Do not cleanfilter in gasoline

:

Air Filter

Air Filter

Screws

CARBURETOR ADJUSTMENTS

WARNING:

during most of this procedure. Wear your

protective equipmentandobserve all safety

precautions.Thechainmust notmoveatidle

speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if

you noticeany of the followingconditions:

S Chain moves at idle. See IDLESPEED--T

adjusting procedure.

S Sawwill not idle. SeeIDLESPEED--T ad-

justing procedure.

Idle Speed---T

Allow engine to idle. If the chain moves,idle

istoofast. Iftheenginestalls,idleis tooslow.

Adjust speed untilengineruns withoutchain

movement (idle too fast) or stalling (idle too

s l ow ) . T he i dl e s peed s c r ew is labeled "T".

S Tur n i dl e s peed s c r ew ( T ) c l oc k w i s e t o i n-

crease engine speed.

S Turn idle speed screw (T) counterclock-

wise to decrease engine speed.

If you require further assistanceor are unsure

about performing this procedure, contact your

aut h orizedservicedealer.

BAR MAINTENANCE

If your saw cuts to one side, hastobeforced

throughthecut,orbeenrunwithanimproper

amount of bar lubrication it may be necessarytoservice yourbar. Awornbar will damage your chain and make cutting difficult.

After each use, ensure ON/STOP switch is

in the STOP position,thenclean allsawdust

from the guide bar and sprocket hole.

To maintainguide bar:

S MoveON/STOPswitch to the STOPposi-

tion.

S Loosenand removechain brake nuts and

chain brake. Remove bar and chain from

saw.

Thechainwill bemoving

13

S Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process of rail wear. Removethese burrs

with a flat file.

S Whenrailtopisuneven,useaflatfiletore-

store square edges and sides.

Replace guide barwhen the grooveis worn,

the guide bar is bent or cracked, or when

excess heatingorburringoftherailsoccurs.

If replacement is necessary, use only the

guidebar specifiedforyoursaw intherepair

partslist or on the decal locatedon thechain

saw.

CHAIN SHARPENING

Chain sharpening is a complicatedtask that

requires special tools. We recommended

you refer chainsharpeningto a professional

chain sharpener.

IGNITION TIMING

Ignition timing is fixedand nonadjustable.

SPARK PLUG

The spark plug should be replaced each

year to ensure the engine starts easier and

runs better.

1. Loosen 3 screwson cylinder cover.

2. Remove the cylinder cover.

3. Pull off the spark plug boot.

4. Remove spark plug from cylinder and

discard.

5. Replace with Champion RCJ--7Y spark

plug and tighten securely with a 3/4 inch

(19mm) socket wrench. Spark plug gap

should be 0.025 inches (0,6 mm).

File Rail Edges

and Sides

Square

CorrectGrooveWorn Groove

6. Reinstall the spark plug boot.

7. Reinstall the cylinder cover and 3

screws. Tighten securely.

Spark PlugBoot

STORAGE

WARNING:

cool, and secure the unit before storing or

transporting in a vehicle. Store unit and fuel

in an area where fuel vapors cannot reach

sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

Storeunitwithallguardsinplace.Positionso

that any sharp object cannot accidentally

cause injuryto passersby. Store the unit out

of reachof children.

S Before storing, drain all fuel from the unit.

Start engine and allow to rununtil it stops.

S Clean the unit before storing. Pay particu-

lar attention to the air intake area, keeping

it free of debris.Use a mild detergent and

sponge to clean the plastic surfaces.

S Donotstoretheunit or fuel in a closed area

where fuel vapors can reach sparks or an

openflamefromhotwater heaters,electric

motors or switches, furnaces,etc.

S Storein a dry area out of the reach of chil-

dren.

CAUTION

deposits from forming in essential fuel system parts such as the carburetor, fuel filter,

fuel hose, or fuel tank during storage. Alcohol blended fuels (called gasohol or using

ethanol or methanol) can attract moisture

which leads to fuel mixture separation and

formationofacids during storage. Acidicgas

can damage the engine.

Stopengineandallowto

It is importanttoprevent gum

:

14

TROUBLESH

O

O

WARNING:

therecommendedremediesbelow except remediesthatrequireoperationoftheunit.

TINGTABLE

Always stop unit and disconnect sparkplug beforeperforming all of

TROUBLE CAUSE REMEDY

Enginewill not

start or will run

only a few

seconds after

starting.

Enginewill

notidle

properly.

Enginewill not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Chain moves

at idlespeed.

1. Ignition switch off.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

1. Air filterdirty.

2. Spark plug fouled.

3. Chain brake engaged.

4. Carburetor requires

adjustment.

1. Too much oil mixed with

gasoline.

1. Idlespeed requires

adjustment.

2. Clutchrequires repair.

LIMITED WARRANTY STATEMENT

SECTION 1: LIMITED WARRANTY

Husqvarna Forest & Garden Company

(”Husqvarna”) wa rrants Husqvarna product

tothe origina lpurchaserto be free from defects

in material and workmanship from the date of

purchase for the “Warranty Period” of the products as set forth below:

Lifetime Warranty: All tiller tines against

breakage, trimmer shafts, ignition coils and

modules on hand held product.

3 Year Warranty: Spindles (on Zero Turn

Riders and Commercial Walk--Behinds)

2 Year COMMERCIAL Warranty: Husqvarna Commercial Turf Equipment -- zero

turnriders, wide area walks, and groundengaging commercial equipment.

2 Year NON--COMMERCIAL Warranty: Automatic mower, riding lawn mowers, yard and

gar den tractor s, walk behind mowers, tillers,

chain saws, trimmers, brushcutte rs, cle a ring

saws, sno wblowers, handheld blowers,backpack blowers,hedge trimmers, electrical pro

ucts and power--as sist collection systems for

non--commercial, non--p r ofess ional,non--institutional or non- -income producing use, except

as herein stated

Emission control system compon e nts nece ssary to comply with CARB--TIER II and EPA

regulations, except for those components

which are part of engine systems manufactured by third party engine manufacturers for

which the purchaser has received a separate

.

d-

1. Move ignitionswitch to ON.

2. See “Difficult Starting”in

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new sparkplug.

5. Check for dirty fuelfilter; replace.

Check for kinked or split fuel line;

repair or replace.

1. See “Carburetor Adjustment” in the

Service and Adjustments Section.

2. Contactan authorizedservice dealer.

1. Cleanor replace air filter.

2. Cleanor replace plug and regap.

3. Disengagechain brake.

4. Contactan authorizedservice dealer.

1. Empty fuel tank and refill with

correct fuel mixture.

1. See “CarburetorAdjustment” in the

Service and Adjustments Section.

2. Contactan authorizedservice dealer.

warranty with product information supplied at

time of purchase.

1 Year Warranty: Power cutters, stump

grinder,poleprunersandpolesawsfor non-commercial, non--professional, non--institutionalornon--incomeproducinguse.All trimmers, brushcutters,clearingsaws, hovering

trimmers, stick edgers, backpack blowers,

hand held blowers, hedge trimmers, and

power--assist collection systems used for

commercial, institutional, professional, or income producing purposes or use.

Batteries have a one year prorated limited

warranty with 100% replacement during the

first 6 months.

90 Day Warranty: Automatic mower, chain

saws, power cutters, stump grinders, pole

saws, pole pruners,snow throwers,model series 580 & 600 walk--behindmowers, and commercial turfequipmentor anyHusqvarnaproduct used fo r commercial, institution al,

professional, or income producingpurposes or

use except as otherwise provided herein.

Husqvarna Safe ty Appa rel carries a 90- -day

warrantyfrom the date of the customer’s original purchase for defects inmaterial and workmanship. Normal wear, tear or abuse is not

covered under warranty. Product must be returned to Charlotte with a warranty claim form.

All care and maintena nceinstructionsmust be

followed as stated by the manufacturer on the

15

carela bel. Thef itoftheprotectiveappa rel/b oot

is not covered under warranty.

30 Day Warranty: Replacement parts, accessories including bars and chains, tools and

display items.

SECTION 2: HUSQVARNA’S OBLIG ATIONS UNDER THE WARR ANTY

Husqvarnawill repair or replacedefectivecomponents without charge for parts or labor if a

componentfails because of adefect in ma terial

or workmanship during the warranty period.

SECTION 3: ITEMS NOT COVERED

BY THIS WARR ANTY

The follo wing items are not covered by this

warranty:

(1)Normal customer maintenance items

whichbecomewornthroughnormalregular use, including,but not limitedto, belts,

blades, blade adapters, bulbs, filters,

guide bars, lubricants, rewind springs,

saw chains, spark plugs, starter ropes

and tines;

(2)Naturaldiscolorationofmaterialduetoul-

traviolet light.

(3)Engine and drive systems not manufac-

turedbyHusqvarna;theseitems arecovered by the respective manufacturer ’s

warranty as provided in writing with the

product information supplied at the time

ofpurchase;allclaims must besent tothe

appropriate manufacturer.

(4)Lawn and garden attachments are cov-

ered by a thirdparty which gives a warranty; all claims for warranty should be

sent to the manufacturer; and

(5)Emission control system components

necessaryto comply with CARB--TIERII

andEPAregulations which are manufactured by third party engine manufacturer.

SECTION 4: EXCEPTIONS AND

LIMITATIONS

This warranty shall be inapplicable to defects resulting from the following:

(1)Accident,abuse,misuse, negligenceand

neglect, including stale fuel, dirt, abrasives, moisture, rust, corrosion, or any

adversereactionduetoincorrect storage

or use habits.

(2)Failuretoope r ateormaintaintheunitinac-

cordance with the instructionmanual or instruct ion sheet furnishedby Husqvarna.

(3)Alterations or modifications that change

theintended use of the product oraffects

the product’s performance, operation,

safety,or durability,orcauses theproduct

tofail tocomply with any applicablelaws.

(4)Additional damage to parts or compo-

nents due to continued use occurringaf-

ter any of the above.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE

EXCLUSIVE REMEDY OF THE PURCHASER. HUSQVARNA SHALL NOT BE

LIABLEFOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH

OF ANY EXPRESS OR IMPLIED WARRANTY ON THESE PRODUCTS EXCEPT

TOTHE EXTENT PROHIBITED BYAPPLICABLE LAW. ANY IMPLIED WARRANTY

OR MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE ON

THESEPRODUCTSIS LIMITED INDURATION TO THE WARRANTY PERIOD AS

DEFINED IN THE LIMITED WARRANTY

STATEMENT. HUSQVARNA RESERVES

THE RIGHT TO CHANGE OR IMPROVE

THE DESIGN OF THE PRODUCT WITHOUT NOTICE, AND DOES NOT ASSUME

OBLIGATION TO UPDATE PREVIOUSLY

MANUFACTURED PRODUCTS.

Some states do not allow the exclusionof incidentalor consequential dama ges,orlimitations

on how lo ngan implied warranty lasts, so the

above limitations or exclusions may not apply

to you. Th is warranty gives youspecif ic legal

rights, and you may also have other rights

which vary from state to state.

SECTION 5: CUSTOMER RESPONSIBILITIES

The product must exhibit reasonable care,

maintenance, operation, storage and general

upkeep as written in the maintenance section

of the Owner’s/Operator’s manual. Shouldan

operational problem or failure occur, the productshould not be used, but deliveredasis to an

authorized Husqvarna dealer for evaluation.

Proof of purchase, as explained in Section 6,

rests solely with the customer .

SECTION 6: PROCEDURE TO OBTAIN WARRANTY CONSIDERATION

It is the Owner’s and Dealer’s responsibility

to makecertain that the Warranty Registration Card is properly filled outand mailed to

HusqvarnaForest&GardenCompany. This

card should be mailed within ten (10) days

from the date of purchaseinordertoconfirm

the warranty and to facilitate post--sale service.

Proof of purchasemust bepresented to the

authorized Husqvarna dealer in order to obtain warranty service. This proof must include date purchased, model number,serial

number,andcompletename and addressof

the selling dealer.

To obtain the benefit of this warranty, the

productbelieved tobedefectivemust bedelivered to anauthorizedHusqvarna dealer in

atimely manner,nolaterthanthirty (30)days

from date of the operational problemor failure. The product must be delivered at the

owner’s expense. Pick--up and delivery

charges are not covered by this warranty.

AnauthorizedHusqvarnadealercanbenormally located through the “Yellow Pages” of

the local telephone directory or by calling

1--800--HUSKY62 for a dealer in your area.

7349 StatesvilleRoad

CHARLOTTE,NC 28269

16

U.S. EPA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U. S. Environmental

Protection Agency, Environment Canada

and HUSQVARNA are pleased to explain

the emissions control system warranty on

your year 2002--2004small off--roadengine.

HUSQVARNA must warrant the emission

controlsystemonyoursmalloff--roadengine

for the periods of time listed below provided

therehasbeennoabuse, neglect, orimproper maintenance of your small off--road engine.Youremission control system includes

partssuch as the carburetorandtheignition

system. Where a warrantablecondition exists,HUSQVARNAwillrepairyour smalloff-roadengineat nocost toyou.Expensescoveredunderwarrantyincludediagnosis,parts

andlabor. MANUFACTURER’SWARRAN-

TY COVERAGE: If any emissions related

part on your engine (as listed under Emissions Control Warranty Parts List) is defective or a defect in the materialsorworkmanship of the enginecausesthefailure of such

an emission relatedpart, the part will be repairedorreplacedbyHUSQVARNA. OWN-

ER’S WARRANTY RESPONSIBILITIES:

As the small off--road engine owner, you are

responsible for the performance of the requiredmaintenance listed in your instruction

manual. HUSQVARNA recommends that

youretain all receipts coveringmaintenance

on your small off--road engine, but HUSQVARNA cannot deny warrantysolely for the

lack of receipts or for your failure to ensure

the performance of all scheduled maintenance. As thesmall off--roadengineowner,

you should be aware that HUSQVARNA

may deny you warranty coverage if your

small off--road engine or a part of ithasfailed

due to abuse, neglect, improper maintenance,unapprovedmodifications,ortheuse

ofpartsnotmadeorapprovedby theoriginal

equipment manufacturer. Youareresponsibleforpresentingyoursmall off--roadengine

to a HUSQVARNA authorized repair center

as soon as a problem exists. Warranty repairs should be completed in a reasonable

amountoftime,nottoexceed30days. If you

haveany questions regardingyourwarranty

rights and responsibilities, you should contact your nearest authorized service center

or call HUSQVARNA at 1--800--487--5962.

WARRANTY COMMENCEMENT DATE:

The warranty period begins on the date the

small off--road engine is purchased.

LENGTH OF COVERAGE: This warranty

shall befor a period oftwoyears from theinitial date of purchase. WHATISCOVERED:

REPAIR OR REPLACEMENT OF PARTS.

Repair or replacementofanywarrantedpart

will be performed at no charge to the owner

at an approved HUSQVARNA servicing

center.If you have any questions regarding

your warranty rights and responsibilities,

you should contactyour nearest authorized

service center or call HUSQVARNA at

1--800--487--5962. WARRANTY PERIOD:

Any warranted part which is not scheduled

forreplacementasrequiredmaintenance,or

which is scheduled only for regular inspection to the effect of“repair orreplace as necessary” shall be warranted for 2 years. Any

warranted part which is scheduled for replacementas requiredmaintenanceshallbe

warrantedfortheperiodoftime up to thefirst

scheduled replacement point for that part.

DIAGNOSIS: The owner shall not be

charged for diagnostic labor which leads to

thedeterminationthatawarrantedpartisdefective if thediagnosticwork isperformedat

an approved HUSQVARNA servicing center. CONSEQUENTIAL DAMAGES:

HUSQVARNAmay be liable for damages to

otherenginecomponentscausedby the failure of a warranted part still under warranty.

WHAT IS NOT COVERED: All failures

causedbyabuse,neglect,orimpropermaintenance are not covered. ADD--ON OR

MODIFIED PARTS: The use of add--on or

modified parts can be grounds for disallowingawarrantyclaim. HUSQVARNAis notliable to cover failures of warranted parts

caused by the use of add--on or modified

parts. HOW TO FILE A CLAIM:If you have

any questions regarding your warranty

rights and responsibilities, you should contact your nearest authorized service center

or call HUSQVARNA at 1--800--487--5962.

WHERE TO GET WARRANTY SERVICE:

Warranty services or repairs shall be provided at all HUSQVARNA service centers.

Call 1--800--487--5962. MAINTENANCE,

REPLACEMENT AND REPAIR OF EMISSION RELATED PARTS:Any HUSQVAR-

NA approved replacement part used in the

performance of any warranty maintenance

or repair on emission related parts will be

provided without charge to the owner if the

part is under warranty. EMISSION CON-

TROLWARRANTYPARTSLIST:Carburetor,IgnitionSystem: SparkPlug(coveredup

to maintenance schedule), Ignition Module.

MAINTENANCE STATEMENT: The owner

is responsible for the performanceof all required maintenance as defined in the instruction manual.

17

The informationon the product label indicates which standard your engine is certified.

Example: (Year)EPA Phase 1 or Phase 2 and/or CALIFORNIA.

This engine is certified to be emissions compliant for the following use:

Moderate (50hours)

Intermediate (125hours)

Extended (300 hours)

18

Loading...

Loading...