Page 1

EN Operator's manual 2-16

ES-MX Manual del usuario 17-33

FR-CA Manuel d’utilisation 34-50

128CD, 128LD

LT28CCHV, LT28CSHV

Page 2

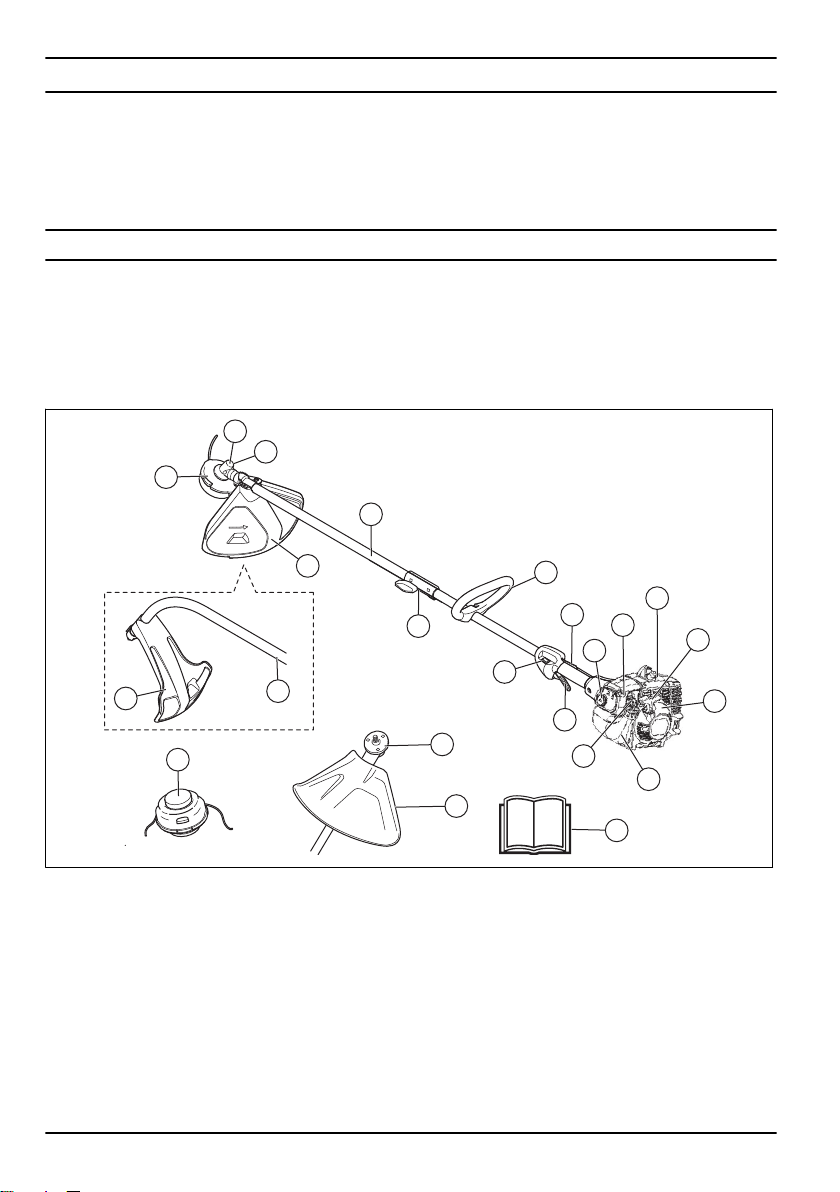

Contents

1

2

3

5

6

7

9

10

8

17

16

11

13

12

14

15

19

4

18

5

1

4

4

Introduction..................................................................... 2

Safety..............................................................................3

Assembly........................................................................ 7

Operation........................................................................ 9

Introduction

Operator's manual

The initial language of this operator's manual is English.

Operator's manuals in other languages are translations

from English.

Overview

Maintenance................................................................. 13

Transportation and storage...........................................15

Technical data.............................................................. 15

Accessories.................................................................. 16

1. Trimmer head

2. Grease filler cap

3. Bevel gear

4. Cutting attachment guard

5. Shaft

6. Shaft coupling

7. Loop handle

8. Throttle trigger

9. Stop switch

10. Throttle trigger lockout

11. Spark plug cap, spark plug

12. Starter housing

13. Starter rope handle

14. Fuel tank

15. Air purge bulb

16. Choke control

17. Air filter cover

18. Drive disc

19. Operator’s manual

2 215 - 004 - 22.05.2020

Page 3

California Proposition 65

WARNING!

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other

reproductive harm.

5

0

F

T

15

m

50F

T

1

5 m

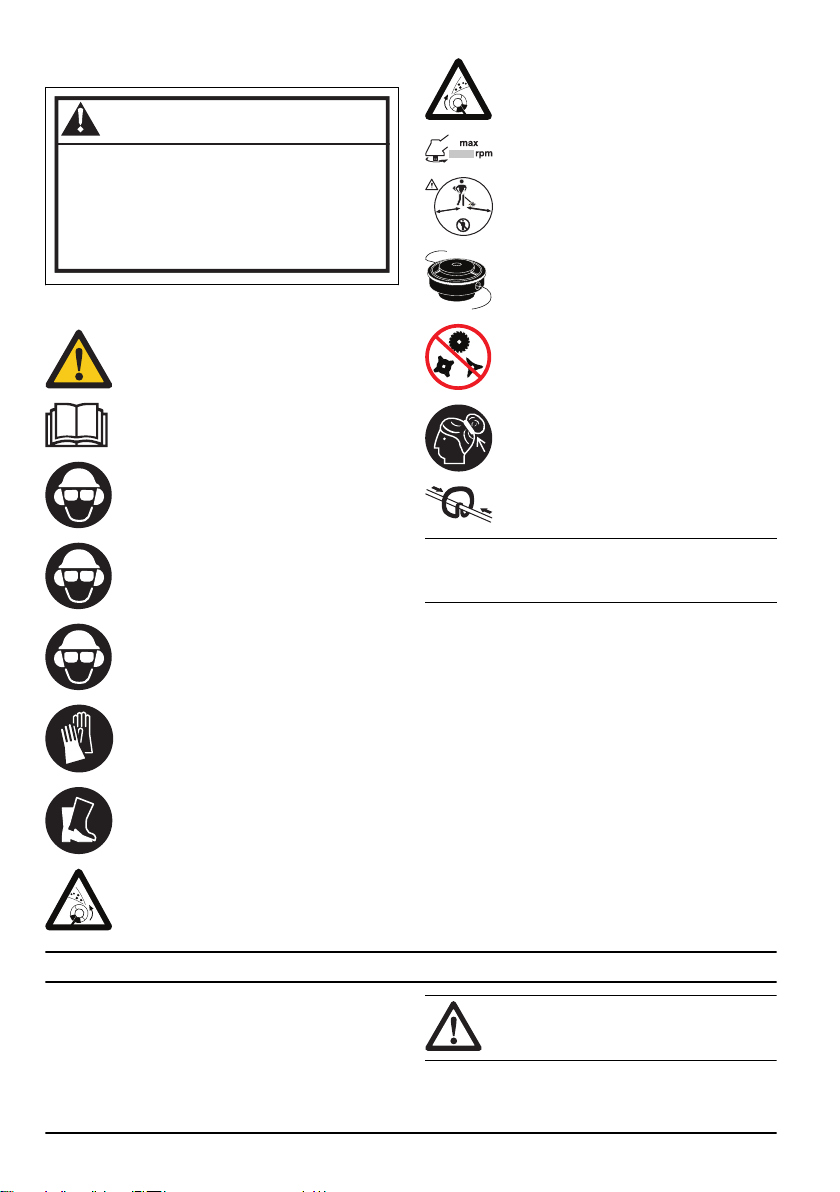

Symbols on the product

Warning

The product can cause objects to eject,

which can cause damage to the eyes.

Max. speed of the output shaft.

Safe distance

Only use an approved trimmer line. Do not

use a blade.

Do not use a cutting attachment made of

metal.

Read this manual.

Use approved head protection.

Use approved hearing protection.

Use approved eye protection.

Use approved protective gloves.

Use protective shoes/boots.

The product can cause objects to eject,

which can cause damage to the eyes.

Note: Other symbols/decals on the product refer to

certification requirements for other commercial areas.

Product liability

As referred to in the product liability laws, we are not

liable for damages that our product causes if:

• the product is incorrectly repaired.

• the product is repaired with parts that are not from

• the product has an accessory that is not from the

• the product is not repaired at an approved service

Make sure that long hair is put up above

your shoulders.

The arrows show the limits for the position of

the handle.

the manufacturer or not approved by the

manufacturer.

manufacturer or not approved by the manufacturer.

center or by an approved authority.

Safety

Safety definitions

The definitions below give the level of severity for each

signal word.

WARNING: Injury to persons.

215 - 004 - 22.05.2020 3

Page 4

CAUTION: Damage to the product.

Note: This information makes the product easier to use.

General safety instructions

WARNING: Read the warning instructions

that follow before you use the product.

• Use the product correctly. Injury or death is a

possible result of incorrect use. Only use the product

for the tasks found in this manual. Do not use the

product for other tasks.

• Obey the instructions in this manual. Obey the safety

symbols and the safety instructions. If the operator

does not obey the instructions and the symbols,

injury, damage or death is a possible result.

• Do not discard this manual. Use the instructions to

assemble, to operate and to keep your product in

good condition. Use the instructions for correct

installation of attachments and accessories. Only

use approved attachments and accessories.

• Do not use a damaged product. Obey the

maintenance schedule. Only do the maintenance

work that you find an instruction about in this

manual. An approved service center must do all

other maintenance work.

• This manual cannot include all situations that can

occur when you use the product. Be careful and use

your common sense. Do not operate the product or

do maintenance on the product if you are not sure

about of the situation. Speak to a product expert,

your dealer, service agent or approved service

center for information.

• Disconnect the spark plug cable before you

assemble the product, put the product into storage or

do maintenance.

• Do not use the product if it is changed from its initial

specification. Do not change a part of the product

without approval from the manufacturer. Only use

parts approved by the manufacturer. Injury or death

is a possible result of incorrect maintenance.

• Do not breathe in the fumes from the engine. Longterm inhalation of the engine's exhaust fumes is a

health risk.

• Do not start the product indoors or near flammable

material. The exhaust fumes are hot and can contain

a spark which can start a fire. Not sufficient airflow

can cause injury or death because of asphyxiation or

carbon monoxide.

• When you use this product the engine makes an

electromagnetic field. The electromagnetic field can

cause damage to medical implants. Speak to your

physician and medical implant manufacturer before

you operate the product.

• Do not let a child operate the product. Do not let a

person without knowledge of the instructions operate

the product.

• Make sure that you always monitor a person, with

decreased physical capacity or mental capacity, that

uses the product. A responsible adult must be there

at all times.

• Lock the product in an area that children and

unapproved persons cannot access.

• The product can eject objects and cause injuries.

Obey the safety instructions to decrease the risk of

injury or death.

• Do not go away from the product when the engine is

on.

• The operator of the product is responsible if an

accident occurs.

• Make sure that parts are not damaged before you

use the product.

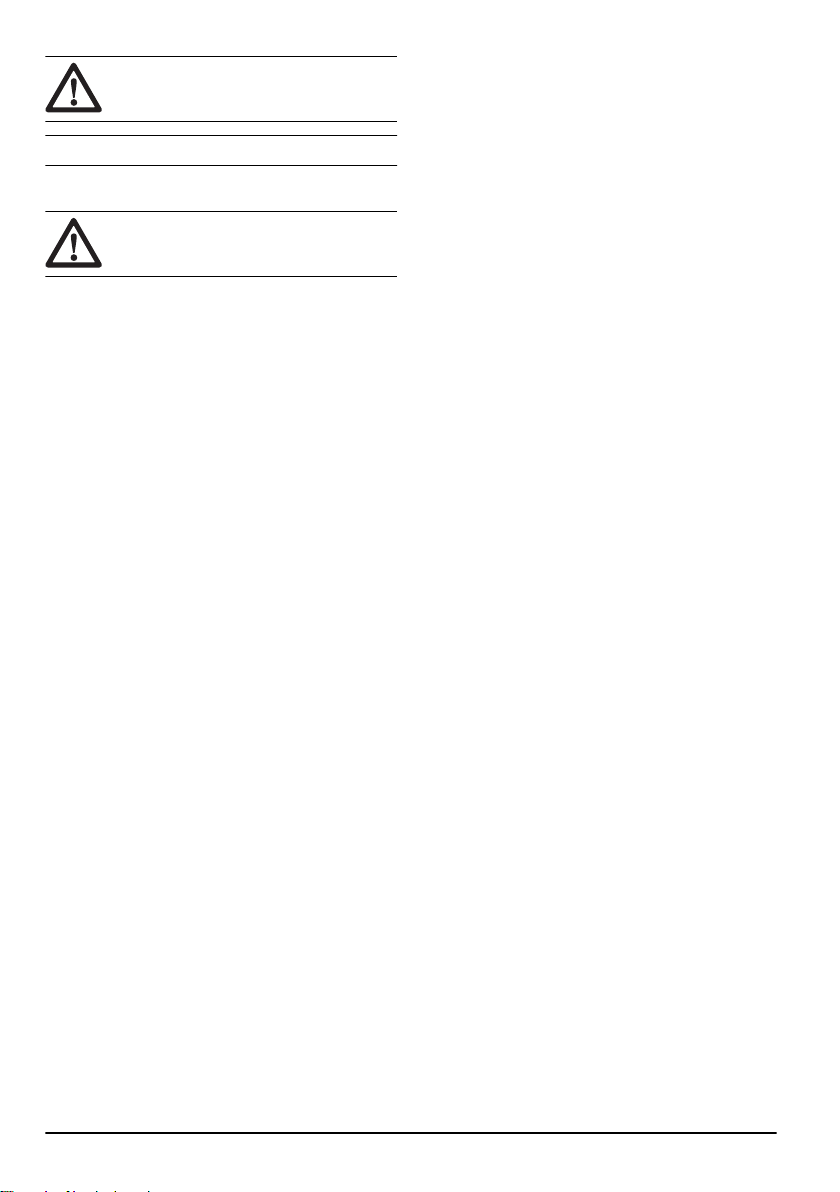

• Make sure that you are at minimum 15 m (50 ft)

away from other persons or animals before you use

the product. Make sure that persons in the adjacent

area know that you will use the product.

• Refer to national or local laws. They can prevent or

decrease the operation of the product in some

conditions.

• Do not use the product if you are fatigued or

influenced by alcohol, drugs or medicine. They can

have effects on your vision, alertness, coordination

or judgment.

Safety instructions for operation

• Make sure the product is fully assembled before you

use it.

• Before a start, move the product 3 m (10 ft) away

from the position where you filled the fuel tank. Put

the product on a flat surface. Make sure that the

cutting attachment does not touch the ground or

other objects.

• The product can cause objects to eject, which can

cause damage to the eyes. Always use an approved

eye protection when you operate the product.

• Be careful, a child can come near the product

without your knowledge during operation.

• Do not operate the product if there are persons in

the work area. Stop the product if a person goes into

the work area.

• Make sure that you are always in control of the

product.

• Do not use the product if you cannot receive aid if an

accident occurs. Always make sure others know you

will operate the product before you start to operate

the product.

• Do not turn with the product before you make sure

that no persons or animals are in the safety area.

• Remove all unwanted materials from the work area

before you start. If the cutting attachment hits an

object, the object can eject and cause injury or

4

215 - 004 - 22.05.2020

Page 5

damage. Unwanted material can wind around the

A

B

cutting attachment and cause damage.

• Do not use the product in bad weather (fog, rain,

strong winds, risk of lightning or other weather

conditions.). Dangerous conditions (such as slippery

surfaces) can occur because of bad weather.

• Make sure that you can move freely and work in a

stable position.

• Make sure that you cannot fall when you use the

product. Do not tilt when you operate the product.

• Always hold the product with your two hands. Hold

the product on the right side of your body.

injury. The personal protective equipment decreases

the grade of injury if an accident occurs.

• Always use an approved eye protection while you

operate the product.

• Do not operate the product with bare feet or with

open shoes. Always use heavy-duty slip-resistant

boots.

• Use heavy, long pants.

• If it is necessary, use approved protective gloves.

• Use a helmet if it is possible that objects fall on your

head.

• Always use approved ear protection while you

operate the product. Noise for a long period can

cause noise-induced hearing loss.

• Make sure that you have a first aid kit near.

Protective devices on the product

• Make sure that you regularly do the maintenance to

the product.

• The life of the product increases.

• The risk of accidents decreases.

Let an approved dealer or an approved service

center regularly examine the product to do

adjustments or repairs.

• Do not use a product with damaged protective

equipment. If the product is damaged, speak to an

approved service center.

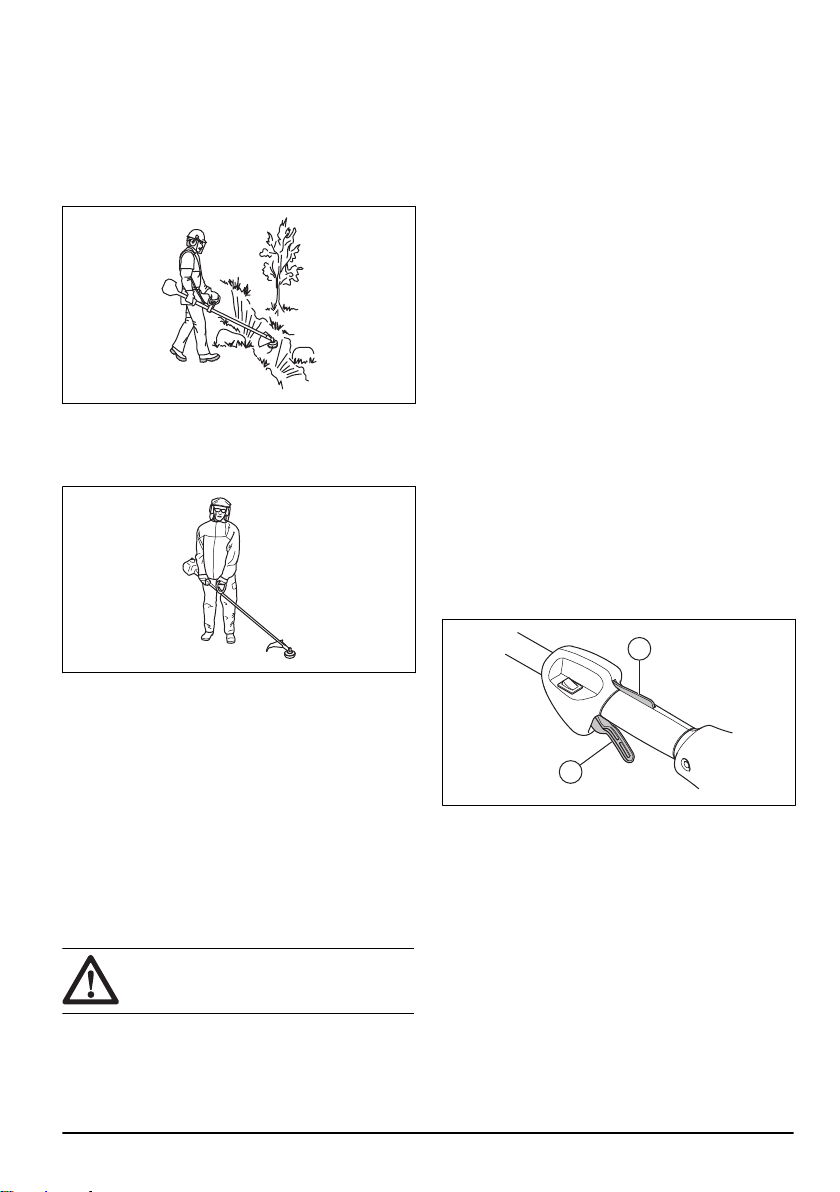

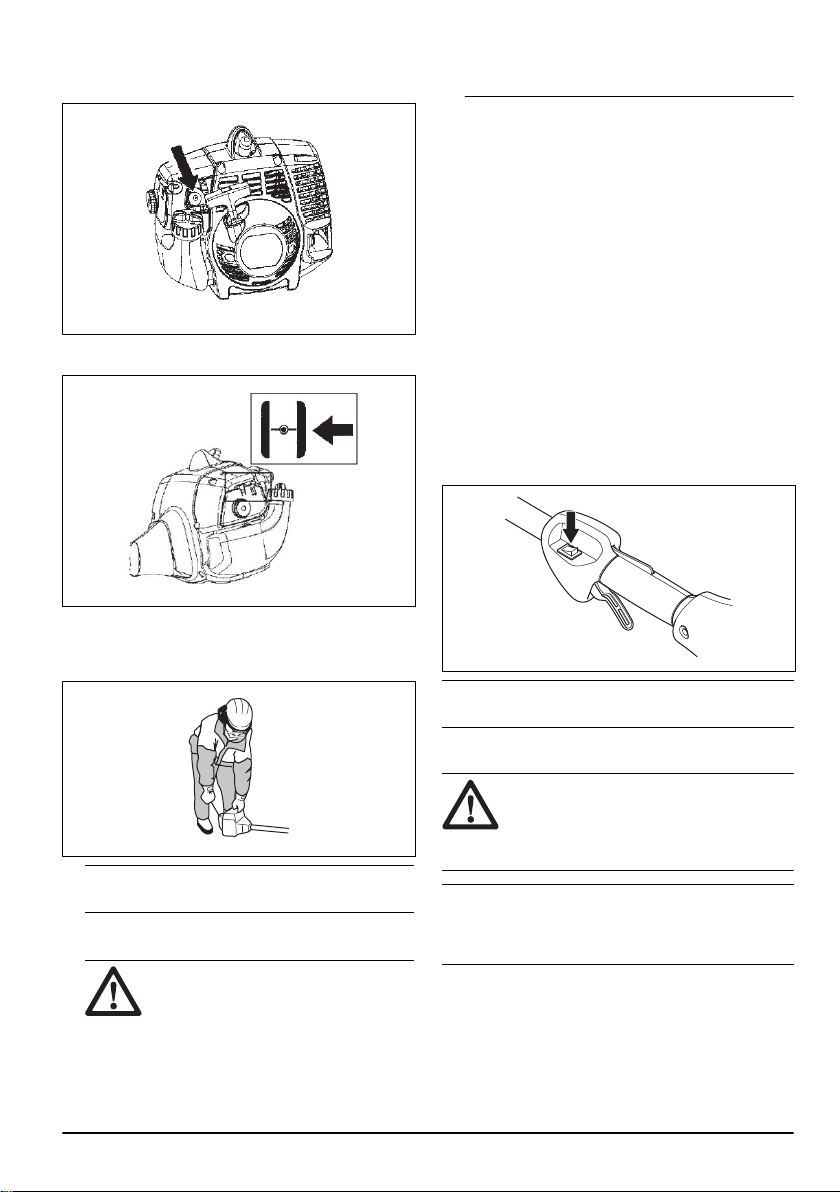

Throttle trigger lockout

The throttle trigger lockout locks the throttle trigger.

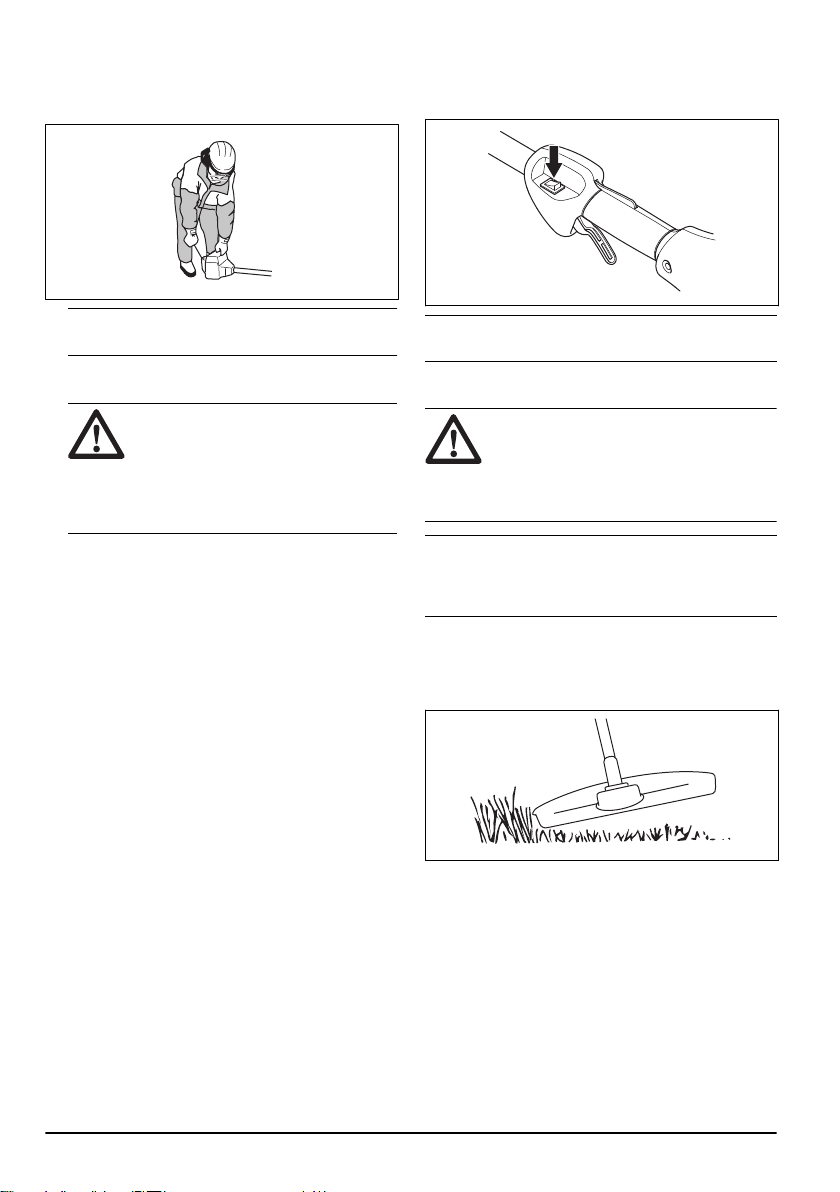

• Operate the product with the cutting attachment

below your waist.

• If the choke control is in the choke position when the

engine starts, the cutting attachment starts to turn.

• Do not touch the bevel gear after the engine stops.

The bevel gear is hot after the engine stops. Hot

areas can cause injury.

• Stop the engine before you move the product.

• Do not put down the product with the engine on.

• Before you remove the unwanted materials from the

product, stop the engine and wait until the cutting

attachment stops. Let the cutting attachment stop

before you or an aid remove the cut material.

Personal protective equipment

WARNING:

that follow before you use the product.

• Always use correct personal protective equipment

when you operate the product. The personal

protective equipment does not erase the risk of

215 - 004 - 22.05.2020

Read the warning instructions

Push the throttle trigger lockout (A) to release the

throttle trigger (B). When you release the handle, the

throttle trigger lockout and the throttle trigger go back to

their initial positions.

1. Make sure that the throttle trigger (B) is locked at idle

when you release the throttle trigger lockout (A).

2. Push the throttle trigger lockout (A) and make sure

that it goes back to its initial position when you

release it.

3. Push the throttle trigger (B) and make sure that it

goes back to its initial position when you release it.

Start the engine, and then apply full throttle. Release the

throttle trigger and examine if the cutting attachment

stops. If the cutting attachment turns with the throttle in

the idle position, examine the idle adjustment screw of

the carburetor.

5

Page 6

Stop switch

Start the engine. Make sure that the engine stops when

you move the stop switch to the stop position.

Cutting attachment guard

The cutting attachment guard prevents a loose object to

eject in the direction of the operator.

Examine the cutting attachment guard for damage and

replace if it is damaged. Only use the approved guard

for the cutting attachment.

Muffler

• Do not use an engine with a damaged muffler. A

damaged muffler increases the noise level and the

risk of fire. Keep a fire extinguisher near.

• Examine regularly that the muffler is attached to the

product.

• Do not touch the engine or the muffler when then

engine is on. Do not touch the engine or the muffler

for a while after the engine stops. Hot surfaces can

cause injuries.

• A hot muffler can cause a fire. Be careful, if you use

the product near flammable liquids or fumes.

• Do not touch the parts in the muffler, if the muffler is

damaged. The parts can contain some carcinogenic

chemicals.

Cutting attachment

WARNING:

that follow before you use the product.

Read the warning instructions

• Do the regular maintenance. Let an approved

service center regularly examine the cutting

attachment to do adjustments or repairs.

• The performance of the cutting attachment

increases.

• The life of the cutting attachment increases.

• The risk of accidents decreases.

• Only use an approved cutting attachment guard.

Refer to

• Do not use a damaged cutting attachment.

Accessories on page 16

.

Grass trimmer head

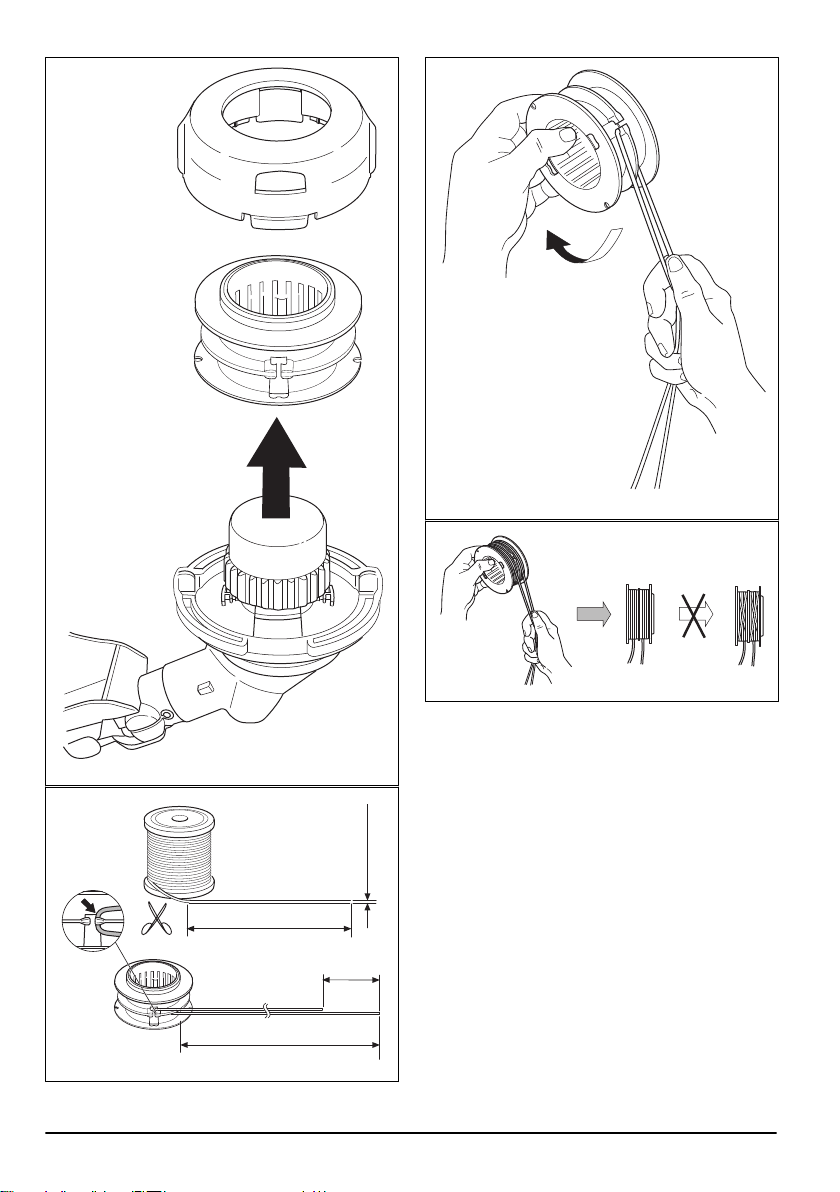

• Make sure that you wind the grass trimmer line

tightly and equally around the drum to decrease the

vibration.

• Use only the approved grass trimmer heads and

grass trimmer lines. Refer to

16

.

• Use a correct length of the grass trimmer line. A long

grass trimmer line uses more engine power than a

short grass trimmer line.

• Make sure that the cutter on the cutting attachment

guard is not damaged.

• Soak the grass trimmer line in water for 2 days

before you attach the grass trimmer line to the

product. This increases the life of the grass trimmer

line.

• Refer to the instructions for the cutting attachment to

use the correct procedure to load the cord and the

correct cord diameter.

Accessories on page

Fuel safety

• Do not start the product if there is fuel or engine oil

on the product. Remove the unwanted fuel/oil and let

the product dry. Remove unwanted fuel from the

product.

• If you spill fuel on your clothing, change clothing

immediately.

• Do not get fuel on your body, it can cause injury. If

you get fuel on your body, use a soap and water to

remove the fuel.

• Do not start the engine if you spill oil or fuel on the

product or on your body.

• Do not start the product if the engine has a leak.

Examine the engine for leaks regularly.

• Be careful with fuel. Fuel is flammable and the fumes

are explosive and can cause injuries or death.

• Do not breathe in the fuel fumes, it can cause injury.

Make sure that there is a sufficient airflow.

• Do not smoke near the fuel or the engine.

• Do not put warm objects near the fuel or the engine.

• Do not add the fuel when the engine is on.

• Make sure that the engine is cool before you refuel.

• Before you refuel, open the fuel tank cap slowly and

release the pressure carefully.

6

215 - 004 - 22.05.2020

Page 7

• Do not add fuel to the engine in an indoor area. Not

sufficient airflow can cause injury or death because

of asphyxiation or carbon monoxide.

• Tighten the fuel tank cap carefully or a fire can

occur.

• Move the product at a minimum of 3 m (10 ft) from

the position where you filled the tank before a start.

• Do not put too much fuel in the fuel tank.

• Make sure that a leak cannot occur when you move

the product or fuel container.

• Do not put the product or a fuel container where

there is an open flame, spark or pilot light. Make

sure that the storage area does not contain an open

flame.

Assembly

WARNING: Read the safety chapter before

you assemble the product.

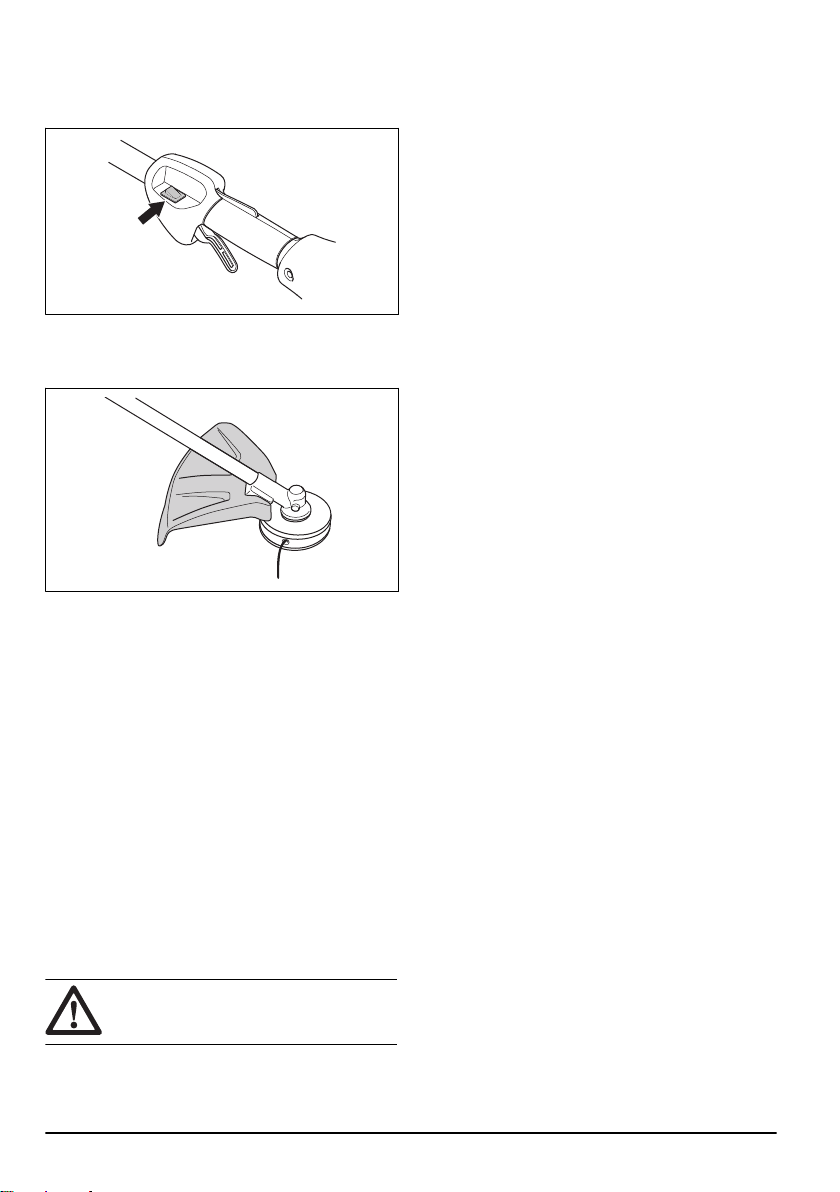

To attach the loop handle

1. Attach the loop handle to the shaft in compliance

with the illustration and tighten.

• Only use approved containers when you move the

fuel or put the fuel into storage.

• Empty the fuel tank before long-term storage. Obey

the local law on where to dispose fuel.

• Clean the product before long-term storage.

• Remove the spark plug cable before you put the

product into storage to make sure that the engine

does not start accidentally.

Safety instructions for maintenance

• If you cannot adjust the idle speed to make the

cutting attachment stop, speak to your service

center. Do not use the product until the product is

correctly adjusted or repaired.

2. Move the locking/release button (A) into the guide

recess. Push the attachment into the coupler until

the locking/release button sets into the primary hole

(B).

3. Insert the shaft into the shaft coupling. The button

2. Make sure that the loop handle attaches between

the arrows on the shaft.

To assemble the two-piece shaft

1. Turn the knob to loosen the shaft coupling.

215 - 004 - 22.05.2020 7

must go through the hole.

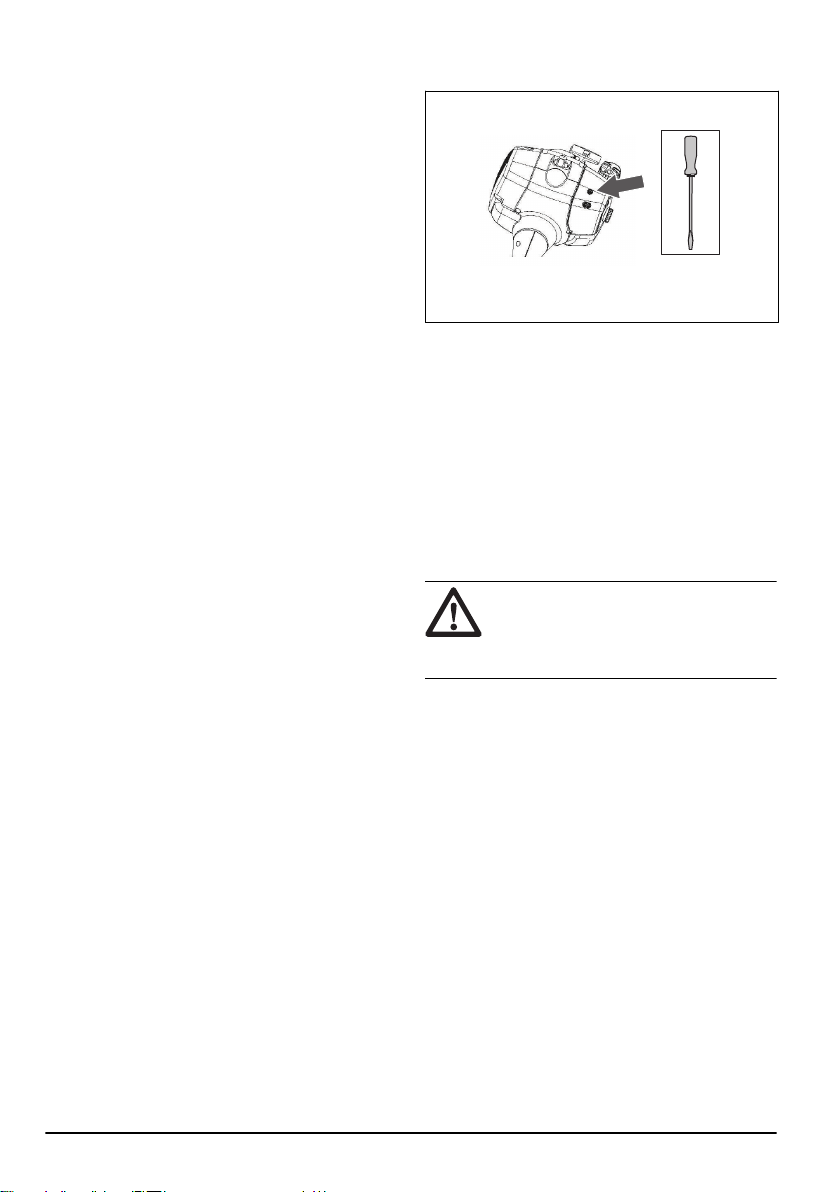

Note: If the attachment does not go fully into the

upper shaft, use a small screwdriver to push the

internal drive shaft deeper into the tube. It can be

necessary to turn the screwdriver while you push.

4. Make sure that you fully tighten the knob before you

operate the product.

Page 8

To disassemble the two-piece shaft

L

A

C

A

B

L

A

C

A

B

H

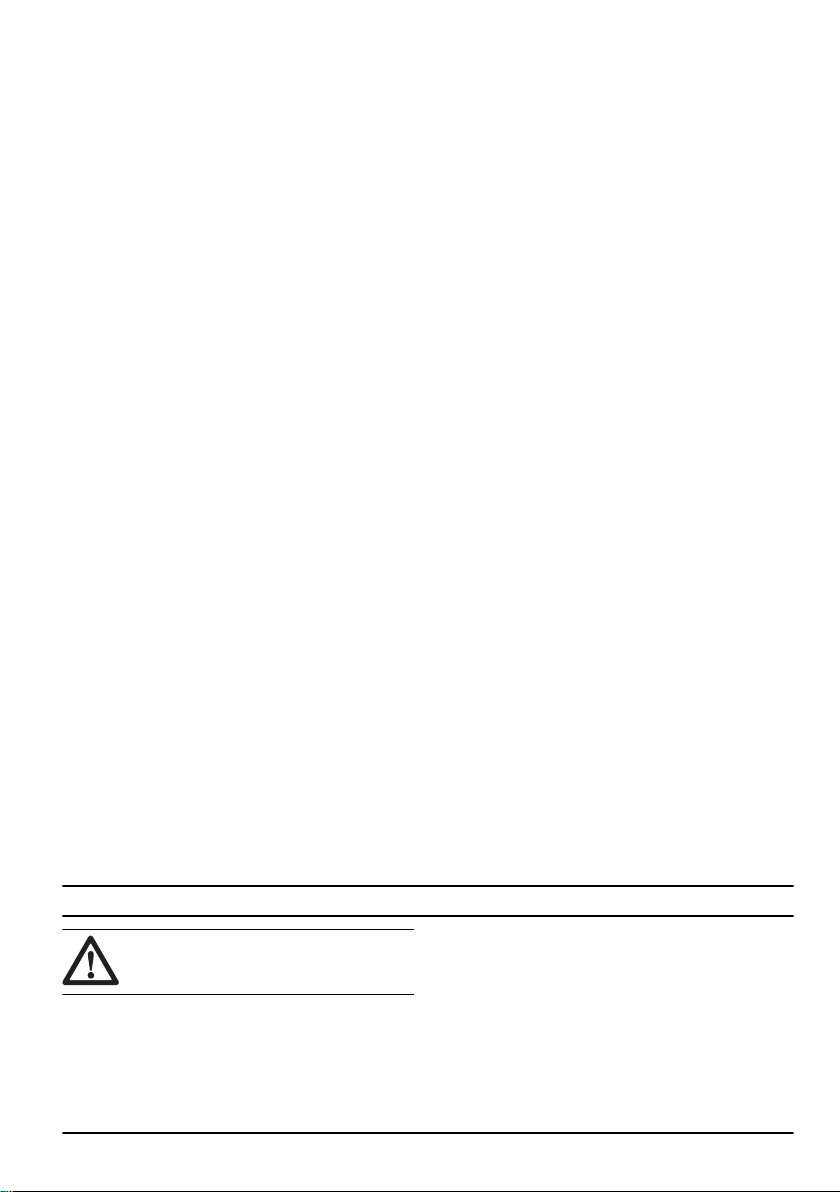

1. Turn the knob to loosen the shaft coupling.

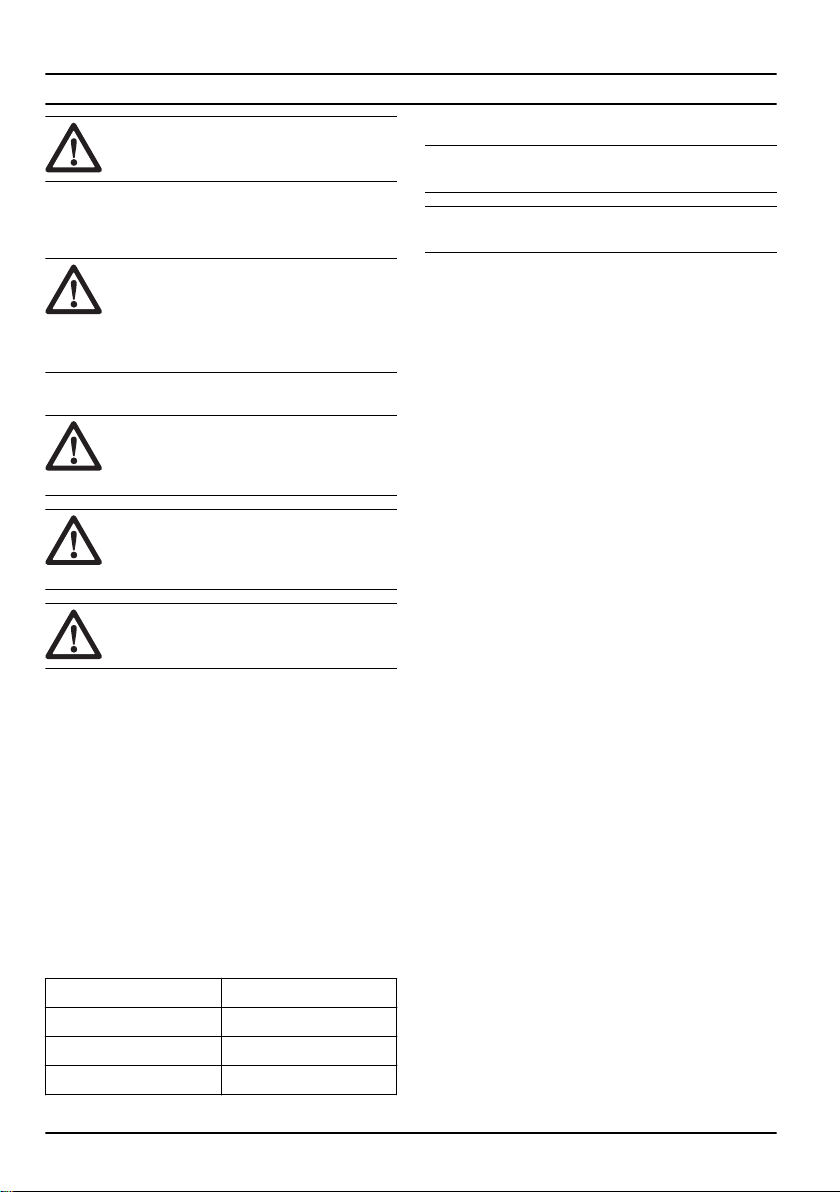

4. Put a small screwdriver (C) in the hole to lock the

shaft.

2. Push and hold the locking/release button (B). Pull

the shafts apart.

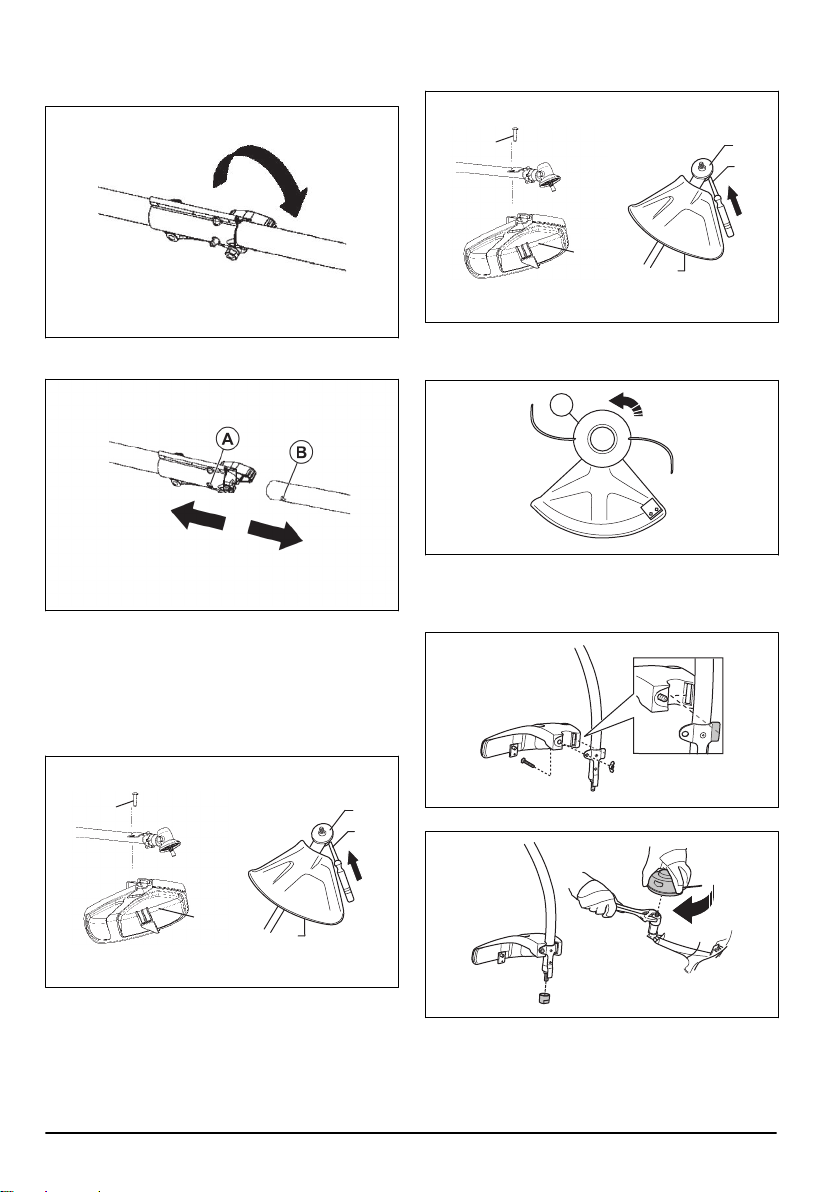

To assemble the cutting attachment

To attach the cutting attachment guard and the trimmer head (straight shaft)

1. Attach the cutting attachment guard (A) to the shaft

with the bolt (L). Make sure to use the correct cutting

attachment guard and the correct trimmer head.

5. Turn the trimmer head (H) counterclockwise to

tighten the trimmer head to the gearbox. (Left hand

threads.)

To attach the cutting attachment guard and trimmer head (curved shaft)

1. Attach the guard. Tighten the nut.

2. Attach the dust cup on the shaft.

2. Attach the drive disc (B) to the output shaft.

3. Turn the output shaft until the hole in the drive disc

aligns with the hole in the gear housing.

8

3. Hold the dust cup with an adjustable wrench to make

sure the shaft does not turn.

4. Attach the trimmer head to the shaft. Turn the

trimmer head clockwise.

215 - 004 - 22.05.2020

Page 9

Operation

WARNING: Read and understand the safety

chapter before you operate the product.

Fuel

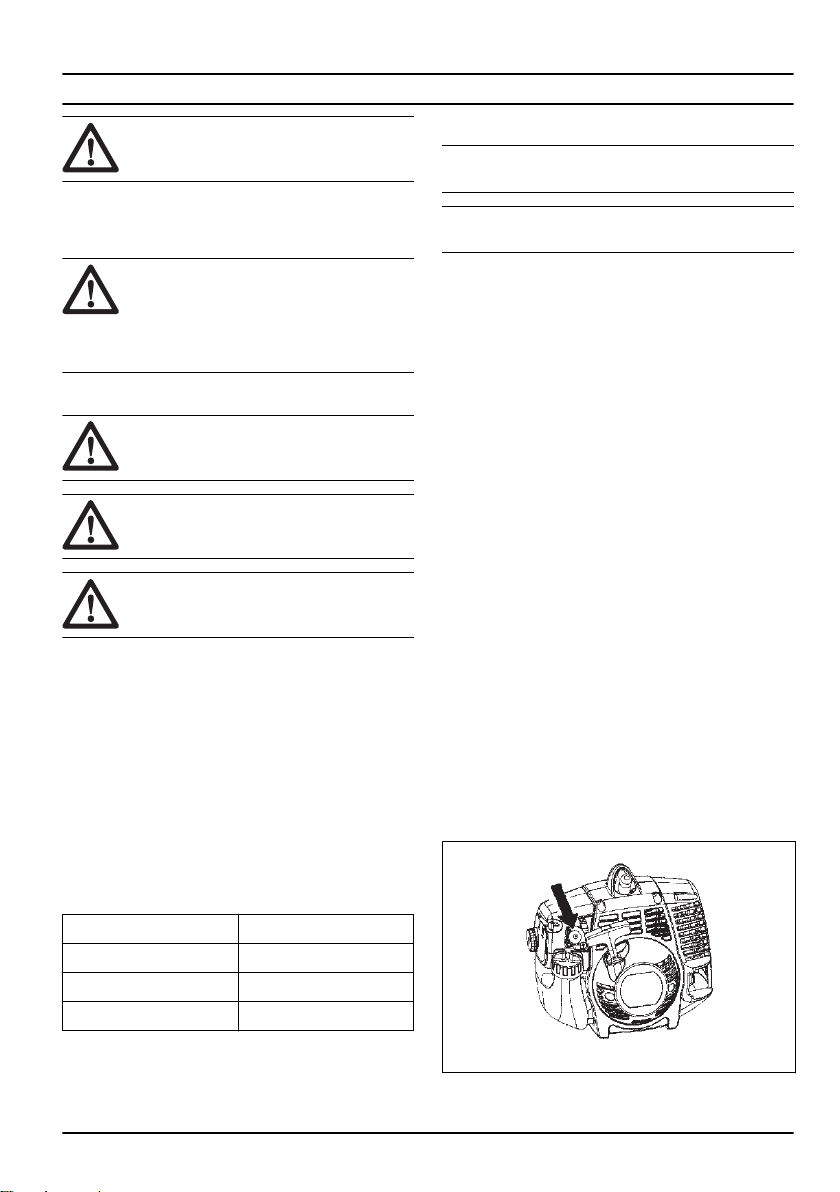

To use fuel

CAUTION: This product has a two-cycle

engine. Use a mixture of gasoline and twocycle engine oil. Make sure to use the

correct quantity of oil in the mixture.

Incorrect ratio of gasoline and oil can cause

damage to the engine.

Gasoline

CAUTION: Do not use gasoline with an

octane number less than 90 RON (87 AKI).

This can cause damage to the product.

CAUTION: Do not use gasoline with more

than 10% ethanol concentration (E10). This

can cause damage to the product.

CAUTION: Do not use leaded gasoline. This

can cause damage to the product.

• Always use new unleaded gasoline with a minimum

octane number of 90 RON (87 AKI) and with less

than 10% ethanol concentration (E10).

• Use gasoline with a higher octane number if you

frequently use the product at continuously high

engine speed.

• Always use a good quality unleaded gasoline/oil

mixture.

Two-cycle engine oil

• Use only high quality two-cycle engine oil. Use only

an air cooled engine oil.

• Do not use other types of oil.

• Mixture ratio 50:1 (2%)

Gasoline

1 U.S. Gal. 77 ml (2,6 oz)

1 UK Gal. 95 ml (3,2 oz)

5 l 100 ml (3,4 oz)

Oil

To make the fuel mixture

Note: Always use a clean fuel container when you mix

the fuel.

Note: Do not make more than 30 days quantity of fuel

mixture.

1. Add half of the gasoline quantity.

2. Add the full quantity of oil.

3. Shake the fuel mixture to mix the contents.

4. Add the remaining gasoline quantity.

5. Shake the fuel mixture to mix the contents.

6. Fill the fuel tank.

To add fuel

• Always use a fuel container with an antispill valve.

• If there is some fuel on the container, remove the

unwanted fuel and let the container dry.

• Make sure that the area near the fuel tank cap is

clean.

• Shake the fuel container before you add the fuel

mixture to the fuel tank.

To start and stop

To examine before an engine start

• Examine the product for missing, damaged, loose or

worn parts.

• Examine the nuts, screws and bolts.

• Examine the air filter.

• Examine the throttle trigger lockout and the throttle

control for correct operation.

• Examine the stop switch for correct operation.

• Examine for fuel leaks.

To start a cold engine

1. Push the air purge bulb 10 times.

215 - 004 - 22.05.2020

9

Page 10

2. Move choke control to the full choke position.

To stop the product

• Push the stop switch to stop the engine.

3. Hold the body of the product on the ground with your

left hand. Do not step on the product. Pull the starter

rope handle slowly until you feel some resistance.

Note: Do not pull the throttle trigger while you start

the engine.

4. Pull the starter rope handle 3 times with force.

CAUTION:

until it stops. Do not let go of the starter

rope when it is fully extended. Release

the starter rope slowly. Failure to obey

these instructions can cause damage to

the engine.

5. Move the choke control to the half choke position.

6. Pull the starter rope handle until the engine starts.

7. Let the engine run for 10 seconds.

8. Move the choke control to the no choke position.

Do not pull the starter rope

To start a warm engine

1. Slowly push the air purge bulb 10 times.

2. Move the choke lever to the HALF CHOKE position.

3. Pull the starter rope handle quickly until the engine

runs.

4. Move the choke lever to the NO CHOKE position.

Note: The stop switch automatically goes back to its

initial position.

To operate the grass trimmer

CAUTION: Make sure that you slow the

engine to idle speed after each operation. A

long period at full throttle without a load on

the engine can cause damage to the engine.

Note: Clean the cover of the trimmer head when you

attach a new trimmer line to prevent vibrations. Examine

other parts of the trimmer head and clean if it is

necessary.

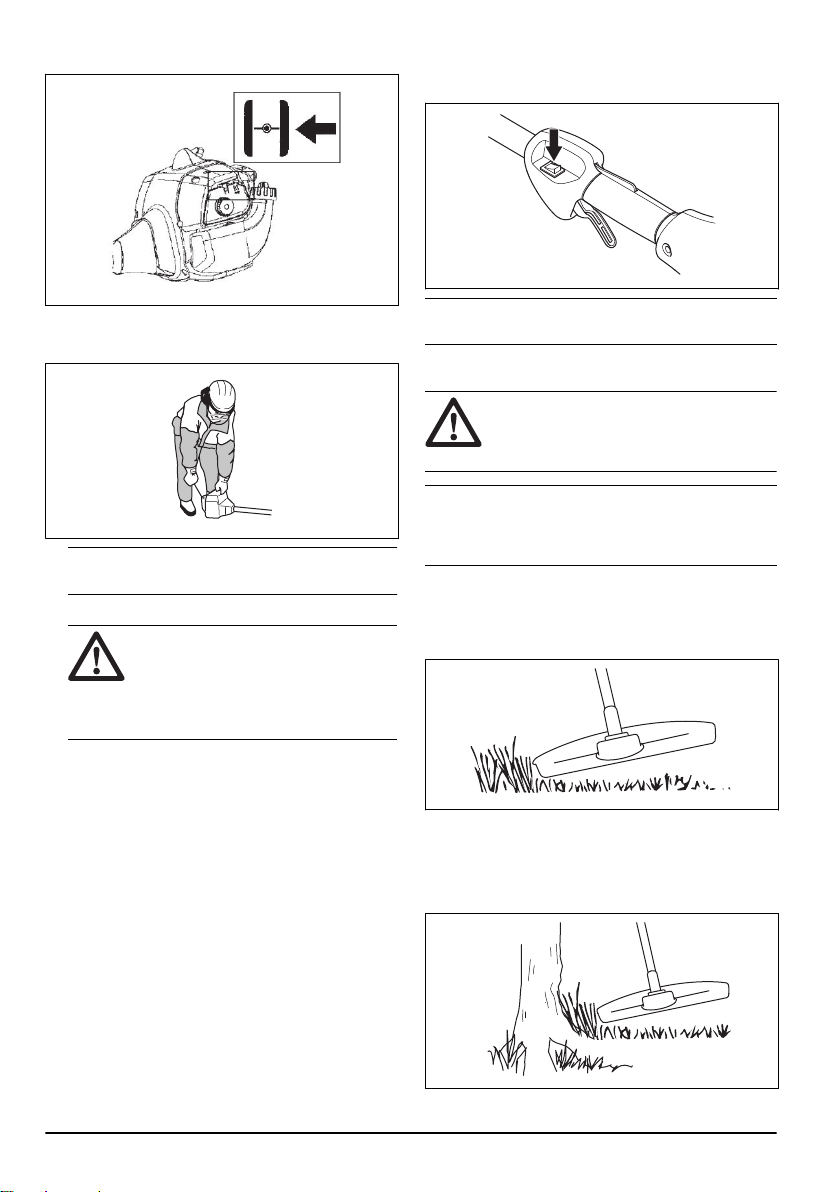

To trim the grass

1. Hold the trimmer head immediately above the

ground at an angle. Do not push the trimmer line into

the grass.

2. Decrease the length of the trimmer line by 10-12

cm / 4-4.75 in.

3. Decrease the engine speed to decrease the risk of

damage to plants.

4. Use 80 % throttle when you cut grass near objects.

10

215 - 004 - 22.05.2020

Page 11

To cut the grass

6,0 m

18'

3,05 m

9'

2,0-2,4 mm

.079-.095"

10 cm

4"

1. Make sure that the trimmer line is parallel to the

ground when you cut the grass.

2. Do not push the trimmer head to the ground. This

can cause damage to the product.

3. Move the product from side to side when you cut

grass. Use full speed.

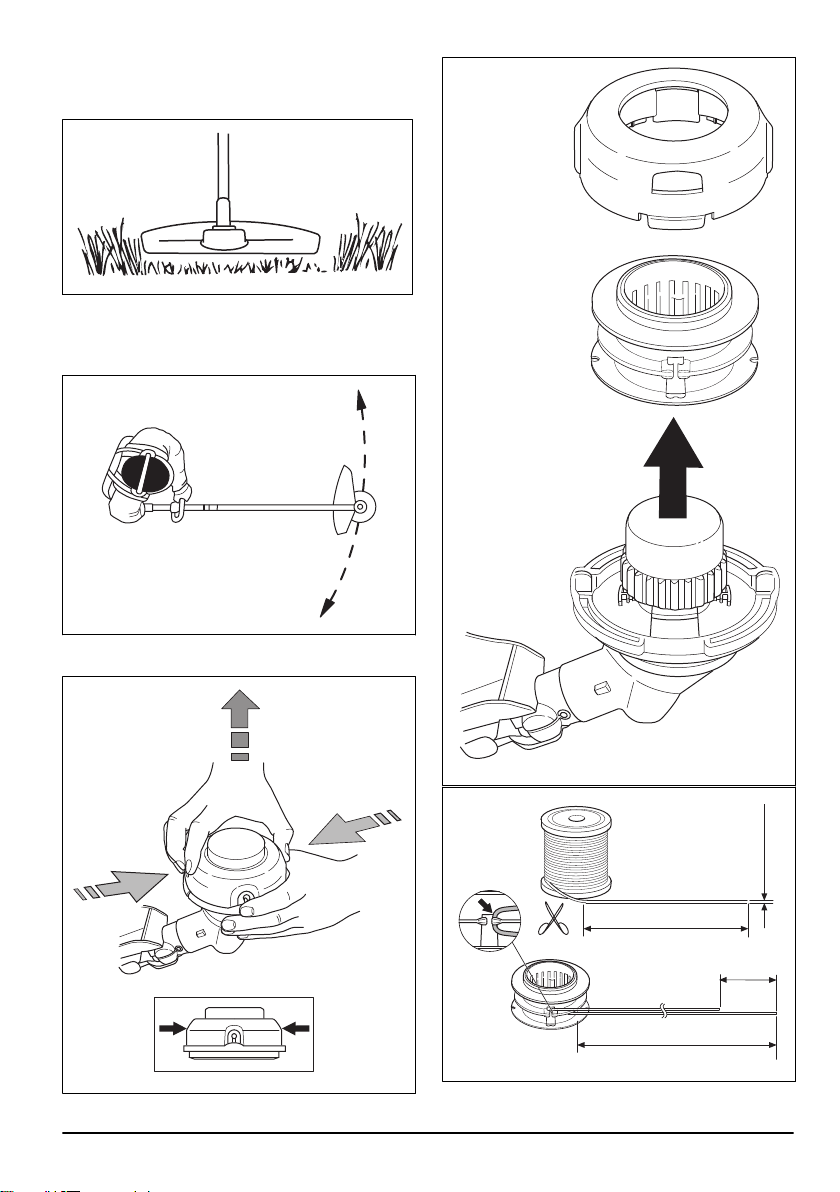

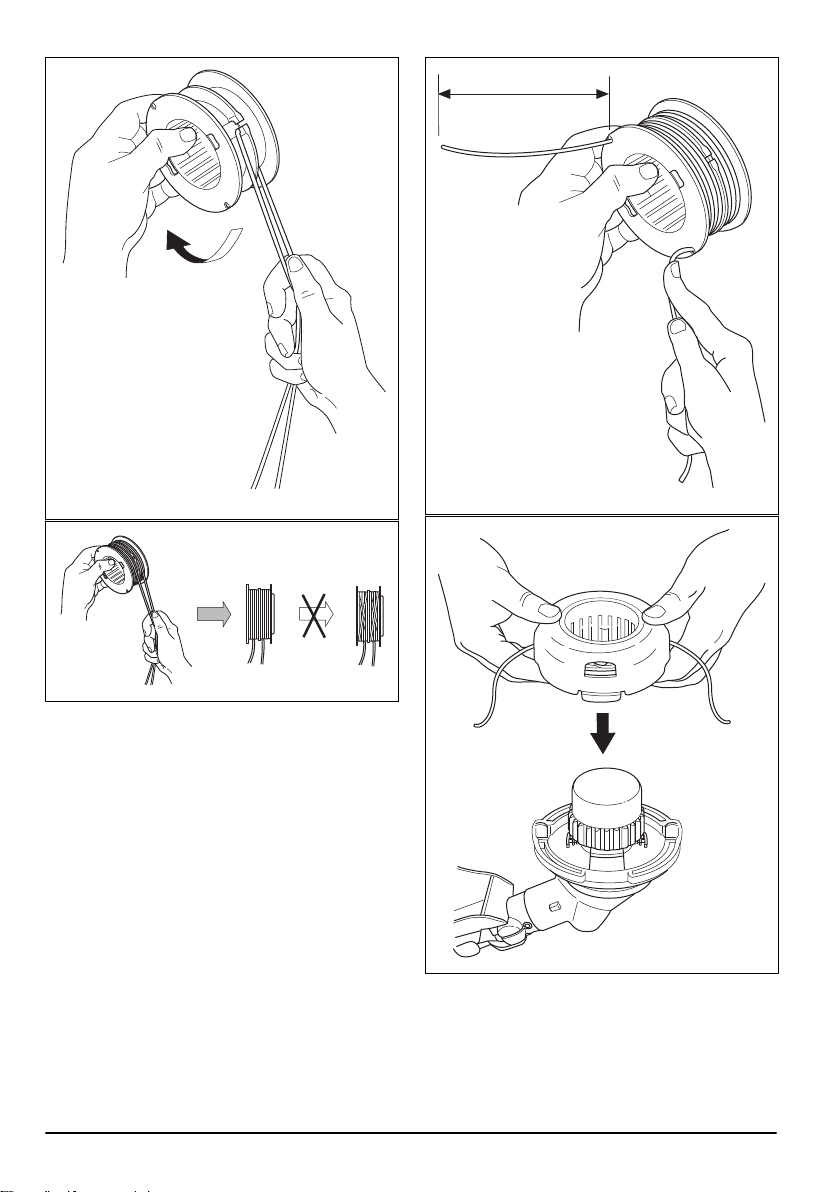

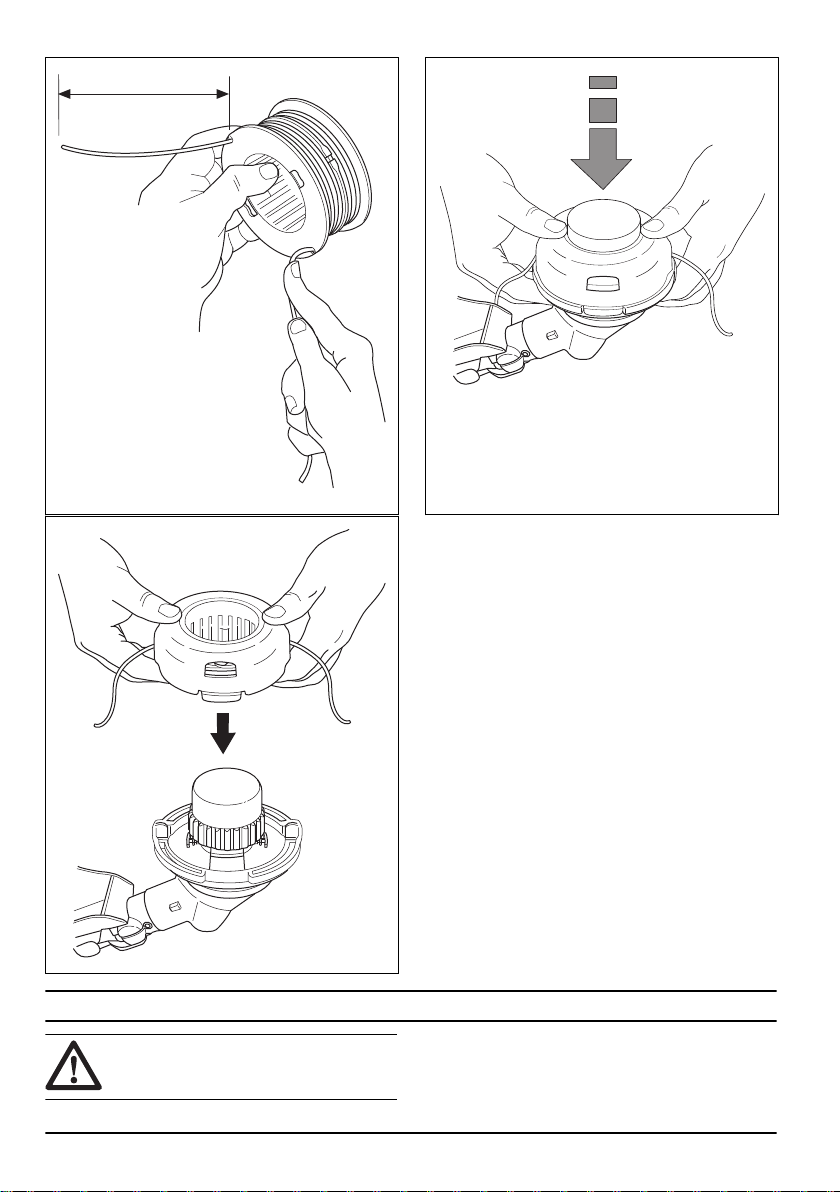

To replace the trimmer line

215 - 004 - 22.05.2020

11

Page 12

6"

15 cm

12 215 - 004 - 22.05.2020

Page 13

"Click"

Maintenance

WARNING: Read and understand the safety

chapter before you clean, repair or do

maintenance on the product.

Maintenance schedule

Make sure that you obey the maintenance schedule.

The intervals are calculated from daily use of the

product. The intervals are different if you do not use the

product each day. Only do the maintenance work that is

found in this manual. Speak to an approved service

center about other maintenance work not found in this

manual.

Weekly maintenance

• Clean the external surfaces.

• Examine the idle speed.

• Examine the bevel gear grease (straight shaft).

Monthly maintenance

• Examine the starter rope handle and the starter

rope.

Yearly maintenance

• Examine the spark plug.

• Apply grease to the end of the drive shaft (two-piece

shaft).

• Clean the external surfaces of the carburetor and its

adjacent areas.

• Clean the cooling system.

• Examine the spark arrester screen.

• Examine the fuel filter.

• Examine the fuel hose for damage.

• Examine all cables and connections.

50 hours maintenance

• Have an approved service center repair or replace

the muffler.

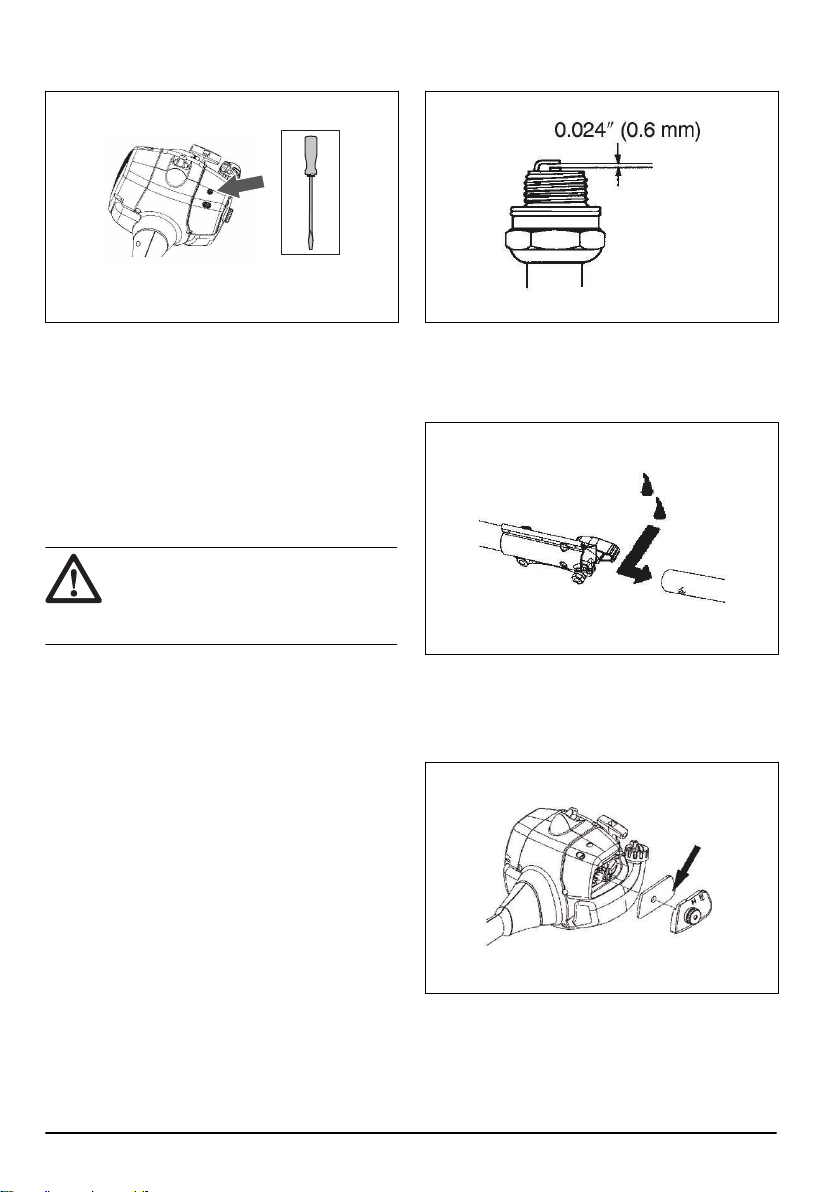

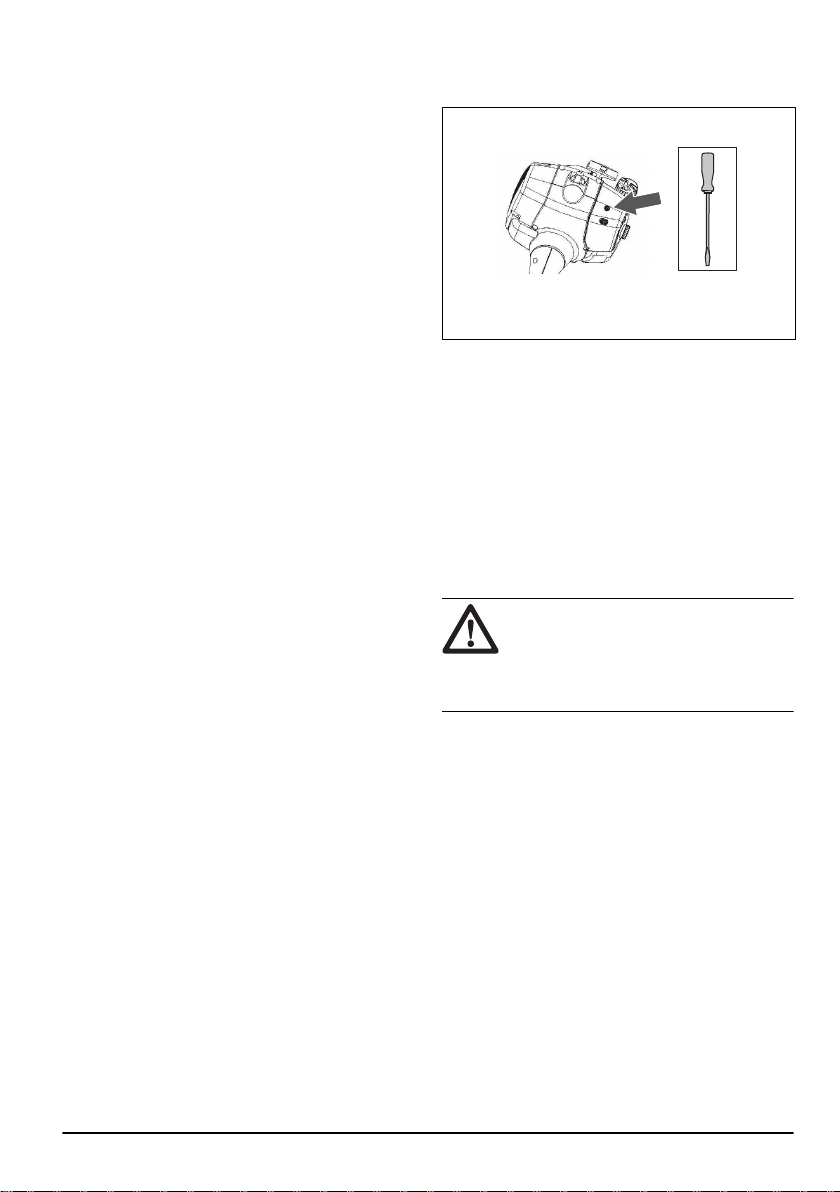

To adjust the idle speed

• Make sure that the air filter is clean and the air filter

cover is attached before you adjust the idle speed.

• Adjust the idle speed with the idle adjustment screw

T which is identified with "T" mark.

• The idle speed is correct when the engine operates

smoothly in all positions. The idle speed must be

below the speed when the cutting attachment starts

to turn.

215 - 004 - 22.05.2020 13

Page 14

1. Turn the idle adjustment screw clockwise until the

cutting attachment starts to turn.

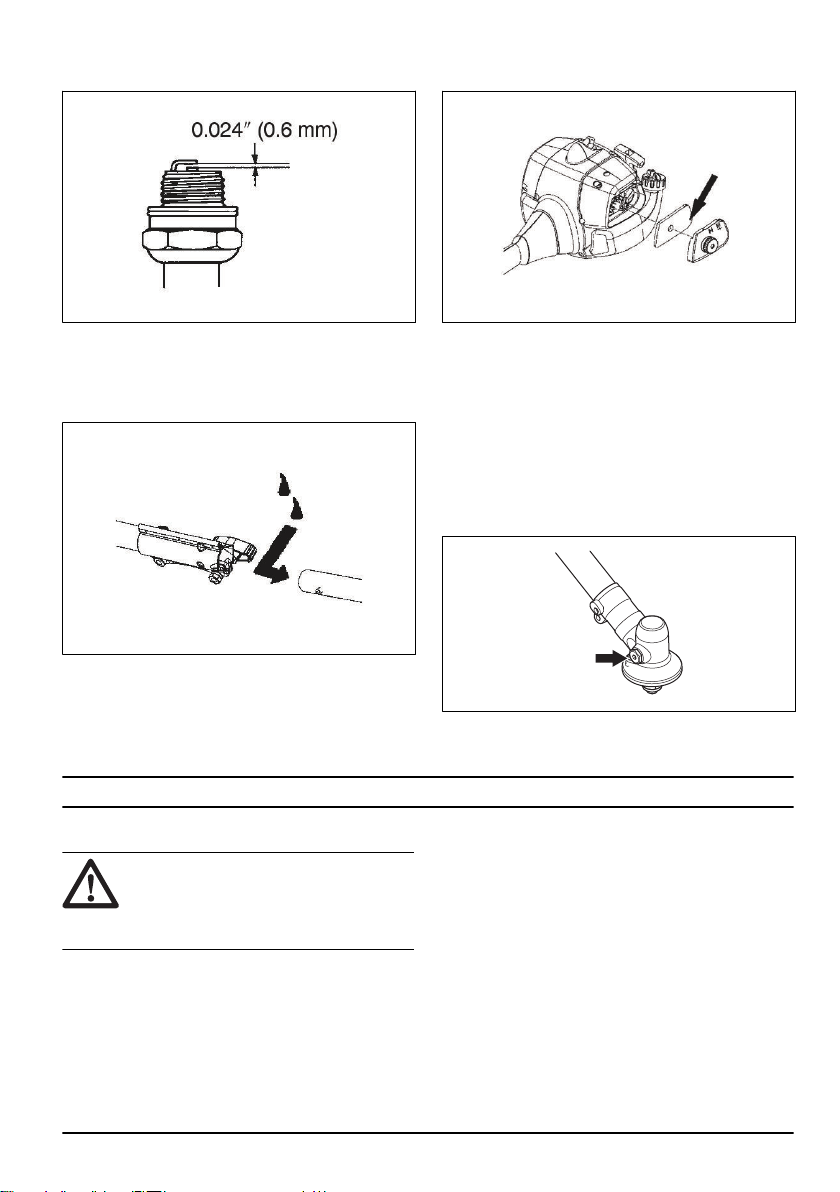

3. Clean the spark plug if it is dirty. Examine that the

electrode gap is correct.

2. Turn the idle adjustment screw counterclockwise

until the cutting attachment stops.

To clean the cooling system

Clean the parts of the cooling system with a brush.

To do maintenance on the spark arrester screen

Use a wire brush to clean the spark arrester screen.

To examine the spark plug

CAUTION: Use the recommended spark

plug. Make sure that the replacement is the

same as the manufacturer supplied part. An

incorrect spark plug can cause damage to

the product.

1. Examine the spark plug when:

a) the engine is low on power.

b) the engine is not easy to start.

c) the engine does not operate correctly at idle

speed.

2. If, the engine is not easy to start or operate, examine

the spark plug for unwanted materials. To decrease

the risk of unwanted material on the spark plug

electrodes:

a) make sure that the idle speed is correctly

adjusted.

b) make sure that the fuel mixture is correct.

c) make sure that the air filter is clean.

4. Replace the spark plug when it is necessary.

To apply grease to the two-piece shaft

• Apply grease to the end of the drive shaft after each

30 hours of operation.

To do the maintenance to the air filter

To clean the air filter

1. Remove the air filter cover and remove the air filter.

2. Clean the air filter with warm soap water. Make sure

that the air filter is dry before you install it.

3. Replace the air filter if it is too dirty to fully clean it.

Always replace a damaged air filter.

14

215 - 004 - 22.05.2020

Page 15

To add grease to the bevel gear

• Make sure that the bevel gear is filled ¾ full with

bevel gear grease.

Transportation and storage

Transportation and storage

WARNING: To prevent the risk of fire, make

sure that there are no leaks or fumes during

transportation or storage. Make sure that

there is no risk of sparks or fire.

• Empty the fuel tank before transportation or longterm storage. Push the air purge bulb to make sure

that all fuel is removed. Discard the fuel at an

applicable disposal location.

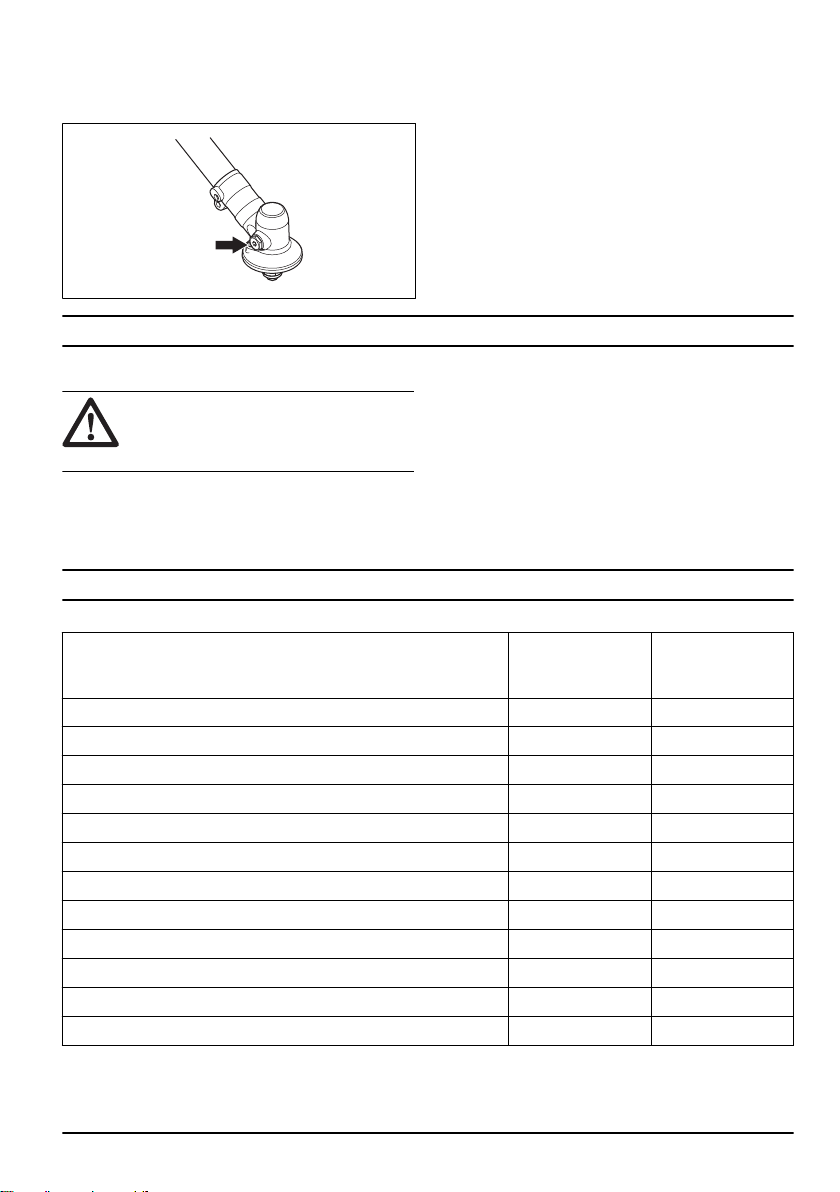

Technical data

• Make sure that the product is clean and that a full

servicing is done before long-term storage.

• Remove the spark plug and put approximately 15 ml

of two-stroke oil into the cylinder. Turn the product 3

times and install the spark plug again.

• Attach the product safely to the vehicle during

transportation.

• Keep the product in a dry, cool and clean space with

good airflow. Keep the product away from children.

128CD

LT28CCHV

Engine Specifications

Cylinder displacement, cm

Electrode gap, mm 0.6 0.6

Fuel tank volume, cm

Idling speed, min

Maximum power speed, min

Power output, kW 0.7 0.7

Spark plug Champion QCJ-8Y Champion QCJ-8Y

Maximum output shaft rotation, min

Emissions durability period, h 125 125

Product Dimensions

Weight (excluding cutting equipment), kg 5.0 5.0

215 - 004 - 22.05.2020 15

3

3

-1

-1

-1

28 28

400 400

2300-3200 2300-3200

8000 8000

8000 8000

128LD

LT28CSHV

Page 16

Note 1: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s2.

Note 2: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive

2000/14/ EC. Reported sound power level for the machine has been measured with the original cutting attachment

that gives the highest level. The difference between guaranteed and measured sound power is that the guaranteed

sound power also includes dispersion in the measurement result and the variations between different machines of

the same model according to Directive 2000/14/EC.

Note 3: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard deviation) of 1 dB (A).

Accessories

128CD

Approved accessories Type Cutting attachment guard

Thread shaft (3/8 RH)

Trimmer head T25 545 03 11-01

128LD

Approved accessories Type Cutting attachment guard

Threaded shaft (M10L)

Trimmer head T25 545 03 09-01

Plastic blades Tricut 300 mm 545 03 09-01

16 215 - 004 - 22.05.2020

Page 17

Contenido

1

2

3

5

6

7

9

10

8

17

16

11

13

12

14

15

19

4

18

5

1

4

4

Introducción.................................................................. 17

Seguridad..................................................................... 18

Montaje......................................................................... 22

Funcionamiento............................................................ 24

Introducción

Manual del usuario

El idioma original de este manual de usuario es el

inglés. Los manuales de usuario en otros idiomas son

traducciones del inglés.

Descripción general

Mantenimiento.............................................................. 29

Transporte y almacenamiento...................................... 31

Datos técnicos.............................................................. 32

Accesorios.................................................................... 32

1. Cabezal de corte

2. Tapón de llenado de grasa

3. Engranaje angulado

4. Protección del equipo de corte

5. Eje

6. Acoplamiento de eje

7. Mango cerrado

8. Gatillo del acelerador

9. Interruptor de detención

10. Bloqueo del acelerador

11. Sombrerete de bujía y bujía

12. Cuerpo del mecanismo de arranque

13. Empuñadura de la cuerda de arranque

14. Depósito de combustible

15. Bulbo de la purga de aire

16. Estrangulador

17. Cubierta del filtro de aire

18. Disco de arrastre

19. Manual del usuario

215 - 004 - 22.05.2020 17

Page 18

Propuesta 65 de California

¡ADVERTENCIA!

Los gases de escape del motor de este

producto contienen sustancias químicas

conocidas en el Estado de California

como causantes de cáncer, defectos

congénitos y otros daños reproductivos.

5

0

F

T

15

m

50F

T

1

5 m

Símbolos en el producto

El producto puede provocar que los objetos

salgan expulsados, lo que puede causar

daños a los ojos.

Velocidad máxima del eje de salida.

Distancia de seguridad

Utilice solo hilos autorizados para la

recortadora. No utilice una cuchilla.

Advertencia

Lea este manual.

Use protección para la cabeza aprobada.

Use protección auricular aprobada.

Use protección ocular aprobada.

Use guantes protectores aprobados.

Use zapatos/botas de protección.

El producto puede provocar que los objetos

salgan expulsados, lo que puede causar

daños a los ojos.

No utilice un equipo de corte de metal.

Si tiene el cabello largo, asegúrese de

amarrarlo sobre sus hombros.

Las flechas muestran los límites de la

posición de la palanca.

Tenga en cuenta: Otros símbolos o etiquetas del

producto hacen referencia a requisitos de certificación

para otras zonas comerciales.

Responsabilidad del fabricante

Como se menciona en las leyes de responsabilidad del

fabricante, no nos hacemos responsables de los daños

que cause nuestro producto si:

• el producto se repara incorrectamente

• el producto se repara con piezas que no son del

fabricante o que este no autoriza

• el producto tiene un accesorio que no es del

fabricante o que este no autoriza

• el producto no se repara en un centro de servicio

autorizado o por una autoridad aprobada.

Seguridad

Definiciones de seguridad

Las siguientes definiciones proporcionan el nivel de

gravedad de cada palabra clave.

18 215 - 004 - 22.05.2020

ADVERTENCIA: Lesiones a personas.

Page 19

AVISO: Daños en el producto.

Tenga en cuenta: Esta información hace que el

producto sea más fácil de usar.

Instrucciones generales de seguridad

ADVERTENCIA: Lea atentamente las

instrucciones de advertencia siguientes

antes de usar el producto.

• Utilice el producto correctamente. Las lesiones

graves o fatales son un posible resultado de un uso

incorrecto. Solo utilice el producto para las tareas

que aparecen en este manual. No utilice el producto

para otras tareas.

• Obedezca las instrucciones contenidas en este

manual. Obedezca los símbolos y las instrucciones

de seguridad. Si el usuario no obedece las

instrucciones y los símbolos, es posible que se

produzcan daños y lesiones tanto graves como

fatales.

• No deseche este manual. Utilice las instrucciones

para montar, operar y mantener el producto en buen

estado. Utilice las instrucciones para la correcta

instalación de piezas y accesorios. Utilice solamente

piezas y accesorios homologados.

• No use un producto dañado. Cumpla con el

programa de mantenimiento. Realice solamente las

tareas de mantenimiento en las que se detallan

instrucciones en este manual. Un centro de servicio

autorizado debe realizar todos los demás trabajos

de mantenimiento.

• En este manual no se pueden abarcar todas las

situaciones que pueden ocurrir cuando se utiliza el

producto. Tenga cuidado y use el sentido común. No

haga funcionar el producto ni le realice

mantenimiento si no está seguro de la situación.

Hable con un experto en el producto, su distribuidor,

el agente de servicio o un centro de servicio

autorizado para obtener más información.

• Desconecte el cable de la bujía antes de montar o

almacenar el producto, o realizar tareas de

mantenimiento.

• No utilice el producto si cambia su especificación

inicial. No cambie una parte del producto sin la

aprobación del fabricante. Utilice solo piezas

aprobadas por el fabricante. Las lesiones graves o

fatales son un posible resultado de un

mantenimiento incorrecto.

• No respire los humos del motor. La inhalación

prolongada de los gases de escape es un riesgo

para la salud.

• No encienda el producto en interiores o cerca de

materiales inflamables. Los gases de escape están

muy calientes y pueden crear incendios debido a la

creación de chispas. Un flujo de aire insuficiente

puede causar lesiones graves o fatales por asfixia o

debido al monóxido de carbono.

• Cuando utilice este producto, el motor crea un

campo electromagnético. El campo

electromagnético puede causar daños a implantes

médicos. Hable con su médico y fabricante del

implante antes de utilizar el producto.

• No deje que un niño utilice el producto. No permita

que una persona que no conozca las instrucciones

utilice el producto.

• Asegúrese de supervisar siempre a una persona con

capacidades físicas o mentales limitadas que utilice

el producto. Debe haber un adulto responsable en

todo momento.

• Mantenga el producto en un área a la cual los niños

y las personas no autorizadas no puedan acceder.

• El producto puede expulsar objetos y causar

lesiones. Siga las instrucciones de seguridad para

reducir el riesgo de lesiones graves o fatales.

• No se aleje del producto cuando el motor esté en

marcha.

• El operador del producto es responsable en caso de

un accidente.

• Asegúrese de que las piezas no estén dañadas

antes de utilizar el producto.

• Asegúrese de estar al menos a 15 m (50 pies) de

distancia de otras personas o animales antes de

utilizar el producto. Asegúrese de que las personas

en el área adyacente sepan que utilizará el

producto.

• Consulte las leyes locales o nacionales. Estas

pueden evitar o disminuir el funcionamiento del

producto en algunas condiciones.

• No utilice el producto si está cansado o bajo la

influencia de alcohol, drogas o medicamentos.

Pueden tener efectos sobre su visión, estado de

alerta, coordinación o criterio.

Instrucciones de seguridad para el funcionamiento

• Asegúrese de que el producto esté completamente

montado antes de usarlo.

• Antes de comenzar, mueva el producto 3 m

(10 pies) de distancia desde la posición donde llenó

el depósito de combustible. Coloque el producto

sobre una superficie plana. Asegúrese de que el

equipo de corte no toque el suelo u otros objetos.

• El producto puede provocar que los objetos salgan

expulsados, lo que puede causar daños a los ojos.

Use siempre protección ocular autorizada cuando

utilice el producto.

• Tenga cuidado, un niño puede acercarse al producto

sin que lo note mientras se encuentra en

funcionamiento.

• No utilice el producto si hay personas en el área de

trabajo. Detenga el producto si una persona entra al

área de trabajo.

• Asegúrese de estar siempre en control del producto.

215 - 004 - 22.05.2020

19

Page 20

• No utilice el producto si no puede recibir ayuda en

caso de un accidente. Asegúrese siempre de que

los demás sepan que va a utilizar el producto antes

de comenzar a utilizarlo.

• No gire con el producto sin asegurarse de que no

haya personas ni animales en la zona de seguridad.

• Retire todos los materiales no deseados del área de

trabajo antes de empezar. Si el equipo de corte

choca contra un objeto, el objeto se puede expulsar

y causar lesiones o daños. El material no deseado

puede enredarse en el equipo de corte y causar

daños.

• No utilice el producto en malas condiciones

climáticas (niebla, lluvia, vientos fuertes, riesgo de

rayos u otros tipos de condiciones climáticas). Las

condiciones peligrosas (como superficies

resbaladizas) se pueden producir debido al mal

clima.

• Asegúrese de poder moverse libremente y trabajar

en una posición estable.

• Asegúrese de no correr riesgos de caídas cuando

utilice el producto. No se incline cuando utilice el

producto.

• Siempre sostenga el producto con las dos manos.

Mantenga el producto al lado derecho de su cuerpo.

• Utilice el producto con el equipo de corte por debajo

de la cintura.

• Si el estrangulador está en la posición de

estrangulamiento cuando el motor arranca, el equipo

de corte comienza a girar.

• No toque el engranaje angulado después de que se

detenga el motor. El engranaje angulado está

caliente después de que el motor se detiene. Las

áreas calientes pueden causar lesiones.

• Detenga el motor antes de mover el producto.

• No deje el producto en el suelo con el motor

encendido.

• Antes de eliminar el material no deseado del

producto, detenga el motor y espere hasta que el

equipo de corte se detenga. Deje que el equipo de

corte se detenga antes de que usted o un ayudante

quiten el material de corte.

Equipo de protección personal

ADVERTENCIA: Lea atentamente las

instrucciones de advertencia siguientes

antes de usar el producto.

• Utilice siempre el equipo de protección personal

adecuado cuando utilice el producto. El equipo de

protección personal no elimina el riesgo de lesiones.

El equipo de protección personal disminuye el grado

de la lesión en caso de un accidente.

• Use siempre protección ocular autorizada cuando

utilice el producto.

• No utilice el producto con los pies descalzos o con

zapatos abiertos. Use siempre botas antideslizantes

de servicio pesado.

• Utilice pantalones largos y gruesos.

• Si es necesario, utilice guantes de protección

aprobados.

• Use un casco si existe la posibilidad de que caigan

objetos sobre su cabeza.

• Use siempre protectores auriculares autorizados

cuando utilice el producto. Escuchar ruidos durante

un largo período puede provocar pérdida de

audición inducida por el ruido.

• Asegúrese de tener un botiquín de primeros auxilios.

Dispositivos de protección en el producto

• Asegúrese de realizar el mantenimiento del producto

frecuentemente.

• Esto aumenta la vida útil del producto.

• Disminuye el riesgo de accidentes.

Permita que un concesionario autorizado o un centro

de servicio autorizado examinen frecuentemente el

producto para realizar ajustes o reparaciones.

• No use un producto con equipo de protección

dañado. Si el producto está dañado, comuníquese

con un centro de servicio autorizado.

Bloqueo del acelerador

El bloqueo del acelerador bloquea el acelerador.

20

215 - 004 - 22.05.2020

Page 21

A

B

Presione el bloqueo del acelerador (A) para liberar el

acelerador (B). Cuando suelta la manija, tanto el

bloqueo del acelerador como el acelerador vuelven a

sus posiciones iniciales.

1. Asegúrese de que el acelerador (B) se encuentre

bloqueado al ralentí cuando suelte el bloqueo del

acelerador (A).

2. Presione el bloqueo del acelerador (A) y asegúrese

de que vuelva a su posición inicial cuando lo suelte.

3. Presione el acelerador (B) y asegúrese de que

vuelva a su posición inicial cuando lo suelte.

Encienda el motor y aplique la aceleración máxima.

Suelte el acelerador y examine si el equipo de corte se

detiene. Si el equipo de corte gira con el acelerador en

la posición de ralentí, examine el tornillo de ajuste de

ralentí del carburador.

Interruptor de detención

Arranque el motor. Asegúrese de que el motor se

detenga cuando mueva el interruptor de detención a la

posición de detención.

Protección del equipo de corte

La protección del equipo de corte evita que un objeto

suelto salga expulsado en dirección al usuario.

Examine la protección del equipo de corte en busca de

daños y reemplácela si está dañada. Utilice solamente

la protección aprobada para el equipo de corte.

Silenciador

• No utilice un motor con un silenciador dañado. Un

silenciador dañado aumenta el nivel de ruido y el

riesgo de incendio. Mantenga un extintor de

incendios cerca.

• Examine frecuentemente que el silenciador esté

unido al producto.

• No toque el motor o el silenciador cuando el motor

esté en marcha. No toque el motor o el silenciador

por un tiempo después de que el motor se detenga.

Las superficies calientes pueden causar lesiones.

• Un silenciador caliente puede provocar un incendio.

Tenga cuidado si utiliza el producto cerca de

líquidos inflamables o gases.

• No toque las piezas del silenciador si el silenciador

está dañado. Las piezas pueden contener algunos

productos químicos cancerígenos.

Equipo de corte

ADVERTENCIA: Lea atentamente las

instrucciones de advertencia siguientes

antes de usar el producto.

• Realice el mantenimiento periódico. Permita que un

centro de servicio autorizado examine

frecuentemente el equipo de corte para realizar

ajustes o reparaciones.

• El rendimiento del equipo de corte aumenta.

• La vida útil del equipo de corte aumenta.

• Disminuye el riesgo de accidentes.

• Solamente utilice una protección aprobada para el

equipo de corte. Consulte

32

.

• No utilice un equipo de corte dañado.

Cabezal de corte para hierba

• Asegúrese de enrollar el hilo de la recortadora de

césped firme y equitativamente alrededor del tambor

para disminuir la vibración.

• Utilice solamente cabezales e hilos de corte para

hierba aprobados. Consulte

32

.

• Utilice una longitud correcta de hilo para la

recortadora. Un hilo largo para la recortadora utiliza

más potencia del motor que un hilo corto.

• Asegúrese de que la cortadora en la protección del

equipo de corte no está dañada.

• Empape el hilo de la recortadora de césped en agua

durante 2 días antes de conectarlo al producto. Esto

aumenta la vida útil del hilo de la recortadora de

césped.

Accesorios en la página

Accesorios en la página

215 - 004 - 22.05.2020

21

Page 22

• Consulte las instrucciones del equipo de corte para

usar el procedimiento adecuado para cargar el hilo

de la recortadora y su diámetro adecuado.

Seguridad de combustible

• No arranque el producto si hay combustible o aceite

de motor en el producto. Quite el combustible o

aceite no deseado y deje secar el producto. Quite el

combustible no deseado del producto.

• Si derrama combustible en su ropa, cámbiese la

ropa inmediatamente.

• No permita que le caiga combustible en el cuerpo,

ya que puede causar lesiones. Si le cae combustible

en el cuerpo, utilice jabón y agua para quitarlo.

• No arranque el motor si derrama aceite o

combustible en el producto o en su cuerpo.

• No arranque el producto si el motor tiene una fuga.

Examine frecuentemente el motor en busca de

fugas.

• Tenga cuidado con el combustible. El combustible

es inflamable y los gases son explosivos y pueden

causar lesiones graves o fatales.

• No respire los gases del combustible, ya que

pueden causar lesiones. Asegúrese de que haya

suficiente flujo de aire.

• No fume cerca del combustible o del motor.

• No coloque objetos calientes cerca del combustible

o del motor.

• No agregue combustible cuando el motor esté en

marcha.

• Asegúrese de que el motor se enfríe antes de llenar

el depósito de combustible.

• Antes de llenar el depósito de combustible, abra

lentamente la tapa del depósito de combustible y

libere la presión con cuidado.

• No agregue combustible al motor en un área interior.

Un flujo de aire insuficiente puede causar lesiones

graves o fatales por asfixia o debido al monóxido de

carbono.

• Apriete la tapa del depósito de combustible con

cuidado para evitar incendios.

• Mueva el producto a un mínimo de 3 m (10 pies) de

la posición en la que se llenó el depósito antes de

empezar.

• No ponga demasiado combustible en el depósito de

combustible.

• Asegúrese de que no se puedan provocar fugas

cuando mueva el producto o el recipiente de

combustible.

• No coloque el producto ni un recipiente de

combustible donde haya una llama expuesta, una

chispa o una fuente de calor. Asegúrese de que no

haya una llama expuesta en el área de

almacenamiento.

• Utilice solamente contenedores aprobados cuando

mueva el combustible o coloque el combustible en el

almacenamiento.

• Vacíe el depósito de combustible antes de un

almacenamiento a largo plazo. Cumpla con las leyes

locales en cuanto al lugar en dónde se puede

deshacer del combustible.

• Limpie el producto antes de un almacenamiento a

largo plazo.

• Retire el cable de la bujía antes de almacenar el

producto, para asegurarse de que el motor no

arranque accidentalmente.

Instrucciones de seguridad para el mantenimiento

• Si no puede ajustar el régimen de ralentí para

detener el equipo de corte, comuníquese con su

centro de servicio. No utilice el producto hasta que

esté correctamente ajustado o reparado.

Montaje

ADVERTENCIA: Lea el capítulo de

seguridad antes de montar el producto.

22 215 - 004 - 22.05.2020

Para conectar el mango cerrado

1. Conecte el mango cerrado al eje como se muestra

en la ilustración y apriete.

2. Asegúrese de conectar el mango cerrado entre las

flechas del eje.

Page 23

Para montar el eje de dos piezas

L

A

C

A

B

1. Gire la perilla para aflojar el acoplamiento del eje.

Para desmontar el eje de dos piezas

1. Gire la perilla para aflojar el acoplamiento del eje.

2. Mueva el botón de bloqueo/liberación (A) a la

posición de receso de la guía. Empuje el accesorio

en el acoplador hasta que el botón de bloqueo/

liberación se fije en el orificio primario (B).

3. Inserte el eje en su acoplamiento. El botón debe

pasar a través del orificio.

Tenga en cuenta:

completamente en el eje superior, utilice un

destornillador pequeño para empujar el eje propulsor

interno más hacia el interior del tubo. Puede ser

necesario girar el destornillador mientras empuja.

4. Asegúrese de apretar completamente la perilla antes

de operar el producto.

Si el accesorio no se inserta

2. Mantenga presionado el botón de bloqueo/liberación

(B). Aparte los ejes.

Para montar el equipo de corte

Para conectar la protección del equipo de corte y el cabezal de corte (eje recto)

1. Conecte la protección del equipo de corte (A) al eje

con el perno (L). Asegúrese de utilizar la protección

correcta para el equipo de corte y el cabezal de

corte correcto.

215 - 004 - 22.05.2020

2. Conecte el disco de arrastre (B) al eje de salida.

3. Gire el eje de salida hasta que el orificio en el disco

de arrastre se alinee con el orificio en la caja de

engranajes.

23

Page 24

4. Coloque un destornillador pequeño (C) en el orificio

L

A

C

A

B

H

para bloquear el eje.

5. Gire el cabezal de corte (H) hacia la izquierda para

apretar el cabezal de corte a la caja de cambios.

(roscas izquierdas).

Para conectar la protección del equipo de corte y el cabezal de corte (eje curvado)

1. Fije la protección. Apriete la tuerca.

2. Fije el cubo guardapolvo en el eje.

3. Fije el cubo guardapolvo con una llave ajustable

para asegurarse de que el eje no gire.

4. Conecte el cabezal de corte al eje. Gire el cabezal

de corte hacia la derecha.

Funcionamiento

ADVERTENCIA: Asegúrese de leer y

comprender el capítulo de seguridad antes

de utilizar el producto.

Gasolina

Combustible

Para utilizar combustible

AVISO: Este producto tiene un motor de dos

ciclos. Utilice una mezcla de gasolina y de

aceite del motor de dos ciclos. Asegúrese

de utilizar la cantidad correcta de aceite en

la mezcla. Una relación incorrecta de

24 215 - 004 - 22.05.2020

gasolina y aceite puede provocar daños al

motor.

AVISO: No utilice gasolina con un octanaje

inferior a 90 RON (87 AKI). Esto puede

provocar daños al producto.

AVISO: No utilice gasolina con más de un

10 % de etanol concentrado (E10). Esto

puede provocar daños al producto.

Page 25

AVISO: No utilice gasolina con plomo. Esto

puede provocar daños al producto.

• Siempre utilice gasolina sin plomo nueva con un

octanaje mínimo de 90 RON (87 AKI) y con menos

de un 10 % de etanol concentrado (E10).

• Use gasolina con un octanaje superior si con

frecuencia utiliza el producto a velocidades de motor

continuamente altas.

• Utilice siempre una mezcla de aceite/gasolina sin

plomo de buena calidad.

Aceite para motor de dos ciclos

• Use solamente aceite de motor de dos ciclos de alta

calidad. Utilice solamente aceite de motor enfriado

por aire.

• No utilice otros tipos de aceite.

• Proporción de mezcla 50:1 (2 %)

Gasolina

1 gal EE. UU. 77 ml (2,6 oz)

1 gal británico 95 ml (3,2 oz)

5 l 100 ml (3,4 oz)

Aceite

Para hacer la mezcla de combustible

Tenga en cuenta: Use siempre un recipiente de

combustible limpio cuando mezcle el combustible.

Tenga en cuenta: No realice una cantidad de mezcla de

combustible para más de 30 días.

Para arrancar y detener

Para examinar antes de arrancar el motor

• Examine el producto para ver si hay piezas

dañadas, sueltas, desgastadas o faltantes.

• Examine las tuercas, los tornillos y los pernos.

• Examine el filtro de aire.

• Examine el bloqueo del acelerador y el control del

acelerador para un funcionamiento correcto.

• Examine el interruptor de detención para su correcto

funcionamiento.

• Revise si hay fugas de combustible.

Para arrancar un motor frío

1. Presione el bulbo de la bomba de combustible de

aire 10 veces.

2. Mueva el estrangulador a la posición de

estrangulamiento totalmente abierta.

1. Agregue la mitad de la cantidad de gasolina.

2. Agregue la cantidad total de aceite.

3. Agite la mezcla de combustible para mezclar el

contenido.

4. Agregue la cantidad restante de gasolina.

5. Agite la mezcla de combustible para mezclar el

contenido.

6. Llene el depósito de combustible.

Para agregar combustible

• Utilice siempre un recipiente de combustible con una

válvula antiderrames.

• Si hay combustible en el recipiente, retire el

combustible no deseado y deje que el contenedor se

seque.

• Asegúrese de que el área cerca de la tapa del

depósito de combustible está limpia.

• Agite el recipiente de combustible antes de agregar

la mezcla de combustible al tanque de combustible.

215 - 004 - 22.05.2020

25

Page 26

3. Mantenga el cuerpo del producto en el suelo con la

mano izquierda. No se pare sobre el producto. Tire

de la empuñadura de la cuerda de arranque

lentamente hasta que sienta resistencia.

Para detener el producto

• Presione el interruptor de detención para detener el

motor.

Tenga en cuenta: No tire del acelerador cuando

arranque el motor.

4. Tire de la empuñadura de la cuerda de arranque tres

veces con fuerza.

AVISO: No tire de la cuerda de arranque

hasta que se detenga. No suelte la

cuerda de arranque cuando esté

totalmente extendida. Suelte la cuerda

de arranque lentamente. Si no se siguen

estas instrucciones, se pueden producir

daños en el motor.

5. Mueva el estrangulador a la posición de

estrangulamiento media.

6. Tire de la empuñadura de la cuerda de arranque

hasta que el motor arranque.

7. Deje que el motor se caliente durante 10 segundos.

8. Mueva el estrangulador a la posición de

estrangulamiento apagada.

Para arrancar un motor caliente

1. Presione lentamente el bulbo de la purga de aire 10

veces.

2. Mueva la palanca del estrangulador a la posición

HALF CHOKE (Estrangulador en posición media).

3. Tire de la empuñadura de la cuerda de arranque

rápidamente hasta que arranque el motor.

4. Mueva la palanca del estrangulador a la posición NO

CHOKE (Estrangulador apagado).

Tenga en cuenta: El interruptor de detención regresa

automáticamente a su posición inicial.

Para utilizar la recortadora de césped

AVISO: Asegúrese de disminuir la velocidad

del motor hasta un régimen de ralentí

después de cada operación. Un largo

período con el acelerador al máximo y sin

carga en el motor puede causar daños a

este último.

Tenga en cuenta: Limpie la cubierta del cabezal de

corte cuando coloque un nuevo hilo para la recortadora

a fin de evitar las vibraciones. Examine otras piezas del

cabezal de corte y límpielas si es necesario.

Para recortar el césped

1. Sostenga el cabezal de corte inmediatamente sobre

el nivel del suelo en un ángulo. No presione el hilo

de la recortadora de césped contra este último.

2. Disminuya la longitud del hilo de la recortadora entre

10 y 12 cm/4 y 4,75”.

3. Disminuya el régimen del motor para reducir el

riesgo de dañar las plantas.

26

215 - 004 - 22.05.2020

Page 27

4. Use una aceleración de un 80 % cuando corte el

césped cerca de objetos.

Para cortar el césped

1. Asegúrese de que el hilo de la recortadora de

césped esté paralelo al suelo cuando corte.

2. No presione el cabezal de corte contra el suelo. Esto

puede provocar daños al producto.

3. Mueva el producto de un lado a otro cuando corte.

Utilice la máxima velocidad.

Para sustituir el hilo de la recortadora

215 - 004 - 22.05.2020 27

Page 28

6,0 m

18'

3,05 m

9'

2,0-2,4 mm

.079-.095"

10 cm

4"

28 215 - 004 - 22.05.2020

Page 29

6"

15 cm

"Click"

Mantenimiento

de limpiar, reparar o realizar el

ADVERTENCIA: Asegúrese de leer y

comprender el capítulo de seguridad antes

215 - 004 - 22.05.2020 29

mantenimiento del producto.

Page 30

Programa de mantenimiento

Asegúrese de cumplir con el programa de

mantenimiento. Los intervalos se calculan a partir del

uso diario del producto. Los intervalos son diferentes si

no utiliza el producto todos los días. Realice solamente

las tareas de mantenimiento que se encuentran en este

manual. Hable con un centro de servicio aprobado

acerca de los trabajos de mantenimiento que no

aparezcan en este manual.

Mantenimiento semanal

• Limpie las superficies externas.

• Examine el régimen de ralentí.

• Examine la grasa del engranaje angulado (eje

recto).

Mantenimiento mensual

• Examine la empuñadura de la cuerda de arranque y

la cuerda de arranque.

Mantenimiento anual

• Examine la bujía.

• Aplique grasa en el extremo del eje propulsor (eje de

dos piezas).

• Limpie las superficies externas del carburador y sus

zonas adyacentes.

• Limpie el sistema de refrigeración.

• Examine la rejilla apagachispas.

• Examine el filtro de combustible.

• Examine la manguera de combustible en busca de

daños.

• Examine todos los cables y conexiones.

Mantenimiento de 50 horas

• Recurra a un centro de servicio autorizado para que

reparen o reemplacen el silenciador.

Para ajustar el régimen de ralentí

• Asegúrese de que el filtro de aire esté limpio y que

la cubierta del filtro de aire esté instalada antes de

ajustar el régimen de ralentí.

• Ajuste el régimen de ralentí con el tornillo de ajuste

de ralentí T, el cual se identifica con la marca "T".

• El régimen de ralentí es el correcto cuando el motor

funciona correctamente en todas las posiciones. El

régimen de ralentí debe ser inferior a la velocidad

cuando el equipo de corte empieza a girar.

1. Gire el tornillo de ajuste de ralentí hacia la derecha

hasta que el equipo de corte comience a girar.

2. Gire el tornillo de ajuste de ralentí hacia la izquierda

hasta que el equipo de corte se detenga.

Para limpiar el sistema de refrigeración

Limpie las piezas del sistema de refrigeración con un

cepillo.

Para realizar tareas de mantenimiento en la rejilla apagachispas

Use un cepillo de alambre para limpiar la rejilla

apagachispas.

Para examinar la bujía

AVISO: Utilice la bujía recomendada.

Asegúrese de que la pieza de reemplazo

sea la misma que la que proporcione el

fabricante. Una bujía incorrecta puede

causar daños al producto.

1. Examine la bujía cuando:

a) el motor tenga poca potencia.

b) el motor no arranque fácilmente.

c) el motor no funcione correctamente a régimen de

ralentí.

2. Si el motor no arranca o funciona fácilmente,

examine la bujía en busca de materiales no

deseados. Para disminuir el riesgo de material no

deseado en los electrodos de la bujía:

a) asegúrese de que el régimen de ralentí esté

ajustado correctamente.

b) asegúrese de que la mezcla de combustible es

la correcta.

c) asegúrese de que el filtro de aire esté limpio.

30

215 - 004 - 22.05.2020

Page 31

3. Limpie la bujía si está sucia. Revise que la

separación entre los electrodos sea la correcta.

1. Quite la cubierta del filtro de aire y retire el filtro de

aire.

4. Reemplace la bujía cuando sea necesario.

Aplique grasa al eje de dos piezas

• Aplique grasa al extremo del eje propulsor cada

30 horas de funcionamiento.

Para realizar el mantenimiento del filtro de aire

Para limpiar el filtro de aire

Transporte y almacenamiento

Transporte y almacenamiento

ADVERTENCIA: Para evitar el riesgo de

incendio, asegúrese de que no haya fugas

ni liberación de gases durante el transporte

o el almacenamiento. Asegúrese de que no

haya riesgo de chispas o incendio.

• Vacíe el depósito de combustible antes del

transporte o de un almacenamiento prolongado.

Empuje el bulbo de purga de aire para asegurarse

de que se haya quitado todo el combustible.

Deseche el combustible en un lugar adecuado para

tal propósito.

2. Limpie el filtro de aire con agua jabonosa caliente.

Asegúrese de que el filtro de aire esté seco antes de

instalarlo.

3. Reemplace el filtro de aire si está demasiado sucio

para limpiarlo completamente. Siempre reemplace

un filtro de aire dañado.

Para agregar grasa al engranaje angulado

• Asegúrese de que la grasa del engranaje angulado

llene 3/4 del engranaje angulado.

• Asegúrese de que el producto esté limpio y de que

se le realice un mantenimiento completo antes de un

almacenamiento prolongado.

• Extraiga la bujía y ponga aproximadamente 15 ml de

aceite para motores de dos tiempos en el cilindro.

Gire el producto 3 veces e instale nuevamente la

bujía.

• Fije el producto de manera segura al vehículo

durante el transporte.

• Mantenga el producto en un lugar seco, fresco y

limpio con un flujo de aire adecuado. Mantenga el

producto alejado de los niños.

215 - 004 - 22.05.2020 31

Page 32

Datos técnicos

128CD

LT28CCHV

Especificaciones del motor

Cilindrada, cm

Distancia entre los electrodos, mm 0,6 0,6

Volumen del depósito de combustible, cm

Régimen de ralentí, mín.

Velocidad de potencia máxima, mín.

Salida de potencia, kW 0,7 0,7

Bujía Champion QCJ-8Y Champion QCJ-8Y

Rotación máxima del eje de salida, mín.

Período de durabilidad de las emisiones, h 125 125

Dimensiones del producto

Peso (sin incluir el equipo de corte), kg 5,0 5,0

Nota 1: Los datos informados para nivel de vibración equivalente tienen una dispersión estadística típica (desviación estándar) de 1 m/s2.

Nota 2: Las emisiones sonoras en el medioambiente medidas como potencia acústica (LWA) en conformidad con la

directiva CE 2000/14/CE. El nivel de potencia acústica registrado para la máquina se midió con el equipo de corte

original que proporciona el más alto nivel. La diferencia entre la potencia acústica garantizada y medida es que la

potencia acústica garantizada también incluye la dispersión en el resultado de la medición y las variaciones entre

las distintas máquinas del mismo modelo según la directiva 2000/14/CE.

Nota 3: Los datos registrados para el nivel de presión acústica equivalente para la máquina tienen una dispersión

estadística típica (desviación estándar) de 1 dB (A).

3

3

-1

-1

-1

28 28

400 400

2300-3200 2300-3200

8000 8000

8000 8000

128LD

LT28CSHV

Accesorios

128CD

Accesorios aprobados Tipo Protección del equipo de corte

Eje de roscado (3/8 R)

Cabezal de corte T25 545 03 11-01

128LD

Accesorios aprobados Tipo Protección del equipo de corte

Eje roscado (M10L)

Cabezal de corte T25 545 03 09-01

32 215 - 004 - 22.05.2020

Page 33

Hojas de plástico Tricut de 300 mm 545 03 09-01

215 - 004 - 22.05.2020 33

Page 34

Table des matières

1

2

3

5

6

7

9

10

8

17

16

11

13

12

14

15

19

4

18

5

1

4

4

Introduction................................................................... 34

Sécurité.........................................................................35

Montage........................................................................39

Fonctionnement............................................................ 42

Introduction

Manuel d’utilisation

La langue initiale de ce manuel de l’opérateur est

l’anglais. Les manuels de l’utilisateur fournis dans

d’autres langues sont des traductions de l’anglais.

Vue d’ensemble

Entretien....................................................................... 46

Transport et entreposage............................................. 48

Caractéristiques techniques......................................... 49

Accessoires.................................................................. 49

1. Tête de coupe

2. Bouchon de remplissage de graisse

3. Pignon conique

4. Protection de l’outil de coupe

5. Arbre

6. Raccord de l’arbre

7. Poignée de boucle

8. Commande des gaz

9. Interrupteur d’arrêt

10. Dispositif de verrouillage de la gâchette de

l’accélérateur

11. Capuchon de bougie, bougie d’allumage

12. Boîtier du lanceur

13. Corde du lanceur

14. Réservoir de carburant

15. Pompe de purge d’air

16. Commande de l’étrangleur

17. Couvercle du filtre à air

18. Disque d’entraînement

19. Manuel d’utilisation

34 215 - 004 - 22.05.2020

Page 35

Proposition 65 de la Californie

ATTENTION!

Les émissions du moteur de cet outil

contiennent des produits chimiques

qui, d’après l’État de Californie, peuvent

causer le cancer, des malformations

congénitales ou autre danger pour

la reproduction

5

0

F

T

15

m

50F

T

1

5 m

Symboles figurant sur le produit

Avertissement

L'outil peut provoquer des projections

d’objets, ce qui peut causer des dommages

aux yeux.

Vitesse de rotation maximale de l’arbre de

sortie

Distance de sécurité

Utiliser seulement un fil de coupe-herbe

homologué. Ne pas utiliser de lame

Ne pas utiliser un équipement de coupe en

métal.

Lire attentivement ce manuel.

Utiliser un dispositif de protection

homologué pour la tête.

Utiliser un dispositif de protection

homologué pour les oreilles.

Remarque : Les autres symboles/autocollants présents

sur l'outil renvoient aux exigences en matière de

certification pour d’autres zones commerciales.

Prendre soin de retenir les cheveux longs au

dessus des épaules.

Les flèches indiquent les limites de position

du guidon.

Responsabilité concernant le produit

Utiliser un dispositif de protection

homologué pour les yeux.

Utiliser des gants de protection homologués.

Utiliser des chaussures/bottes de protection.

L'outil peut provoquer des projections

d’objets, ce qui peut causer des dommages

aux yeux.

Comme indiqué dans les lois en vigueur sur la

responsabilité concernant les produits, nous ne serons

pas tenus responsables des dommages que notre

produit causerait dans les situations suivantes :

• Le produit n’est pas réparé de façon adéquate.

• Le produit est réparé avec des pièces qui ne sont

pas fournies ou homologuées par le fabricant.

• Le produit comprend un accessoire qui n’est pas

fourni ou homologué par le fabricant.

• Le produit n’est pas réparé par un centre de service

après-vente agréé ou par une autorité homologuée.

Sécurité

Définitions relatives à la sécurité

Les définitions ci-dessous indiquent le niveau de gravité

pour chaque mot signal.

215 - 004 - 22.05.2020 35

AVERTISSEMENT: Blessures aux

personnes.

Page 36

MISE EN GARDE : Dommages causés à

l'outil.

Remarque : Cette information facilite l’utilisation de

l'outil.

Consignes générales de sécurité

AVERTISSEMENT: Lire les messages

d’avertissement qui suivent avant d’utiliser

l’outil.

• Utiliser l’outil correctement. Des blessures graves ou

mortelles peuvent résulter d’une utilisation non

adéquate. Utiliser l’outil seulement pour les tâches

décrites dans le présent manuel. Ne pas utiliser cet

outil pour d’autres tâches.

• Suivre les instructions de ce manuel. Respecter les

symboles et les instructions de sécurité. Si

l’opérateur ne respecte pas les instructions et les

symboles, il pourrait en résulter des blessures, des

dommages ou la mort.

• Ne pas jeter ce manuel. Utiliser les instructions pour

assembler l’outil, le faire fonctionner et le conserver

en bon état. Suivre les instructions pour l’installation

correcte des équipements et accessoires. Utiliser

uniquement des pièces et accessoires homologués.

• Ne pas utiliser l’outil s’il est endommagé. Respecter

le calendrier d’entretien. N’effectuer que les travaux

d’entretien prescrits dans ce manuel. Un centre

agréé doit effectuer tous les autres travaux

d’entretien.

• Ce manuel ne décrit pas toutes les situations qui

peuvent se produire lorsqu’on utilise l’outil. Rester

prudent et faire preuve de bon sens. Ne pas faire

fonctionner l’outil ni effectuer un entretien sur l’outil

si vous n’êtes pas sûr de la situation. Pour obtenir

plus d’information, s’adresser à un spécialiste de

l’outil, à votre revendeur, à un atelier de réparation

ou à un centre de service après-vente agréé.

• Débrancher le câble d’allumage avant d’installer, de

stocker ou de procéder à l’entretien de l’outil.

• Ne pas utiliser l’outil si des modifications contraires à

ses caractéristiques initiales y ont été apportées. Ne

pas modifier une partie de l’outil sans l’approbation

du fabricant. Utiliser seulement des pièces

approuvées par le fabricant. Des blessures graves

ou mortelles peuvent résulter d’un entretien non

adéquat.

• Ne pas respirer les vapeurs du moteur. L’inhalation à

long terme des produits d’échappement du moteur

représente un danger pour la santé.

• Ne pas démarrer l’outil dans un local clos ou à

proximité de matériaux inflammables. Les gaz

d’échappement sont très chauds et peuvent contenir

des étincelles qui peuvent causer un incendie. Un

débit d’air insuffisant peut entraîner des blessures ou

la mort en raison d’une asphyxie ou du monoxyde de

carbone.

• Lors de l’utilisation de ce produit, le moteur génère

un champ électromagnétique. Le champ

électromagnétique peut endommager les implants

médicaux. Parler à votre médecin et au fabricant de

l’implant avant d’utiliser l’outil.

• Ne pas laisser un enfant utiliser l’outil. Ne laisser

personne utiliser la machine sans connaître les

instructions.

• S’assurer de toujours surveiller les personnes avec

des capacités physiques ou mentales réduites qui

utilisent le produit. Un adulte responsable doit être

présent à tout moment.

• Enfermer le produit dans un endroit verrouillé auquel

les enfants et les personnes non autorisées ne

peuvent pas accéder.

• Le produit peut projeter des objets et causer des

blessures. Respecter les consignes de sécurité afin

de réduire le risque de blessures graves ou

mortelles.

• Ne pas s’éloigner de l’outil lorsque le moteur est

sous tension.

• Tout accident avec cet outil engage la responsabilité

de l’opérateur.

• Avant d’utiliser l’outil, vérifier que les pièces ne sont

pas endommagées.

• S’assurer d’être à au moins 15 m (50 pi) d’autres

personnes ou d’animaux avant d’utiliser le produit.

S’assurer que toutes les personnes dans les

environs immédiats sont informés que vous allez

utiliser le produit.

• Consulter les lois nationales ou locales. Elles

peuvent interdire ou limiter l’utilisation de l’outil dans

certaines conditions.

• Ne pas utiliser le produit en cas de fatigue ou sous

l’emprise de l’alcool, de drogues ou de

médicaments. Ils peuvent avoir des effets

indésirables sur votre vision, votre attention, votre

coordination des gestes ou votre jugement.

Consignes de sécurité pour l’utilisation

• Vérifier que le produit est livré assemblé avant de

l’utiliser.

• Avant de commencer, déplacer le produit à 3 m

(10 pi) de l’endroit où l’appoint de carburant a été

effectué. Placer le produit sur une surface plane.

Vérifier que l’outil de coupe ne touche pas le sol ou

tout autre objet.

• Le produit peut causer des projections d’objets, ce

qui peut causer des dommages aux yeux. Toujours

utiliser un dispositif de protection homologué pour

les yeux lorsqu’on utilise le produit.

• Si un enfant se trouve à proximité, faire preuve de

prudence lors de l’utilisation du produit.

• Ne pas faire fonctionner l’outil s’il y a des personnes

dans la zone de travail. Arrêter l’outil si une

personne passe dans la zone de travail.