Page 1

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 1

www.reelschematic.com

www.reelschematic.com

Page 2

i

THANK YOU!

Thank you for choosing Humminbird®, America's #1 name in fishfinders.

Humminbird® has built its reputation by designing and manufacturing top-quality,

thoroughly reliable marine equipment. Your Humminbird® is designed for trouble-free

use in even the harshest marine environment. In the unlikely event that your

Humminbird® does require repairs, we offer an exclusive Service Policy - free of charge

during the first year after purchase, and available at a reasonable rate after the one-

year period. For complete details, see the Warranty section in this manual. We

encourage you to read this installation and operations manual carefully in order to get

full benefit from all the features and applications of your Humminbird® product.

Contact our Customer Resource Center at either 1-800-633-1468 or visit our website at

www.humminbird.com.

WARNING! This device should not be used as a navigational aid to prevent collision,

grounding, boat damage, or personal injury. When the boat is moving, water depth may

change too quickly to allow time for you to react. Always operate the boat at very slow

speeds if you suspect shallow water or submerged objects.

WARNING! Disassembly and repair of this electronic unit should only be performed by

authorized service personnel. Any modification of the serial number or attempt to repair the

original equipment or accessories by unauthorized individuals will void the warranty.

Handling and/or opening this unit may result in exposure to lead, in the form of solder.

WARNING! This product contains lead, a chemical known to the state of California to cause

cancer, birth defects and other reproductive harm.

DualBeam PLUS™, Fish ID+™, Humminbird®, HumminbirdPC™, RTS® Window, SmartCast®, WhiteLine®,

X-Press™ Menu, Structure ID®, and WeatherSense® are trademarked by or registered trademarks of

Humminbird®.

© 2005 Humminbird®, Eufaula AL, USA. All rights reserved.

531370-1_A

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 2

www.reelschematic.com

www.reelschematic.com

Page 3

ii

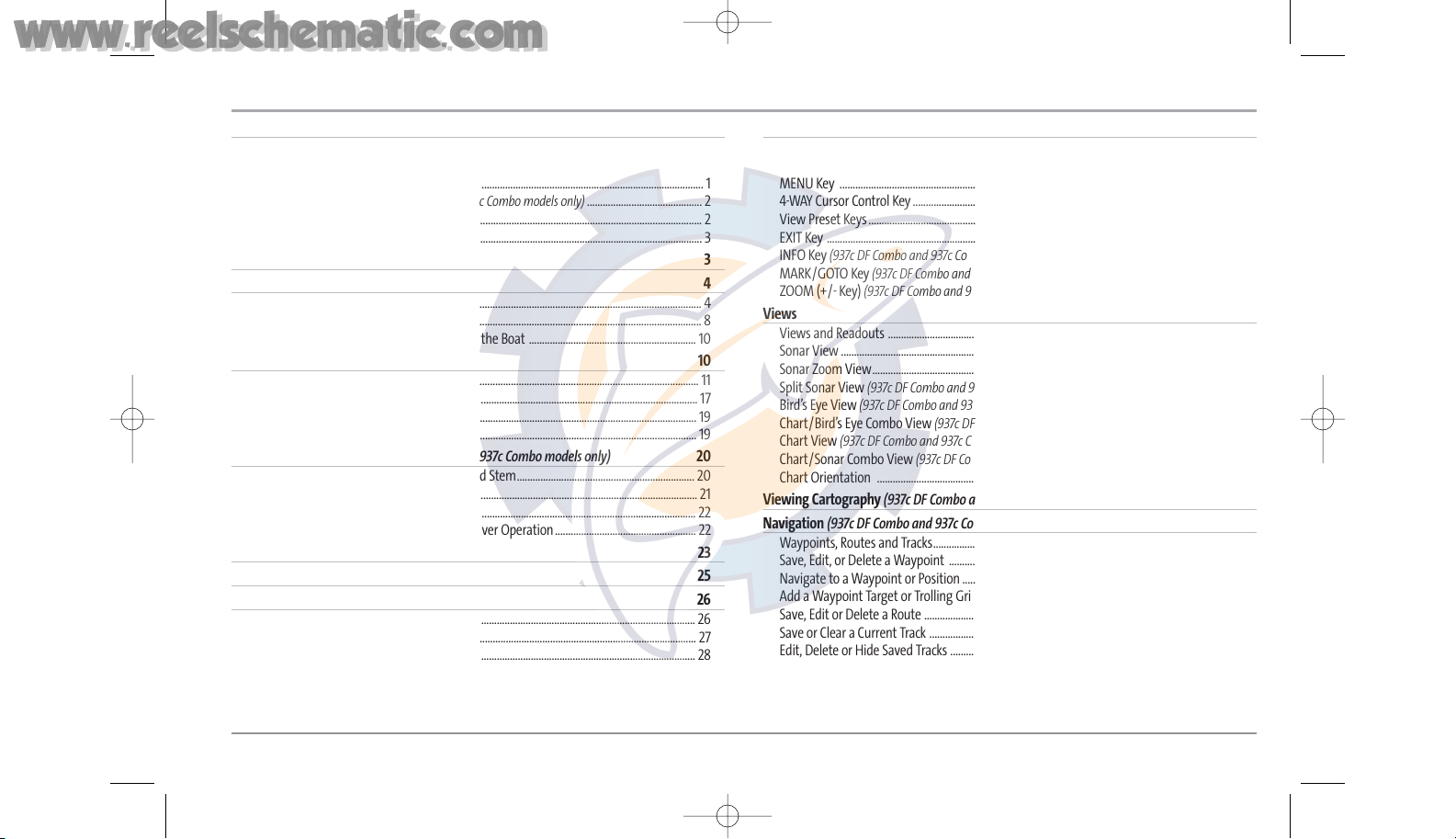

TABLE OF CONTENTS

900 Series™ Introduction 1

How the 900 Series™ Works .................................................................................................................... 1

Single Beam Sonar ........................................................................................................................................ 1

DualBeam PLUS™ Sonar ............................................................................................................................ 1

GPS and Cartography

(937c DF Combo and 937c Combo models only) ............................................ 2

Multi-Media Card (MMC)/SD Slot............................................................................................................ 2

Accessory Bus.................................................................................................................................................. 3

Installation Overview 3

Control Head Installation 4

Gimbal Mounting the Control Head ...................................................................................................... 4

In-Dash Mounting the Control Head ...................................................................................................... 8

Connecting the Control Head Power Cable to the Boat ................................................................ 10

Transducer Installation 10

Transom Transducer Installation ............................................................................................................ 11

Inside the Hull Transducer Installation ................................................................................................ 17

Trolling Motor Transducer Installation ................................................................................................ 19

Test and Finish the Transducer Installation ...................................................................................... 19

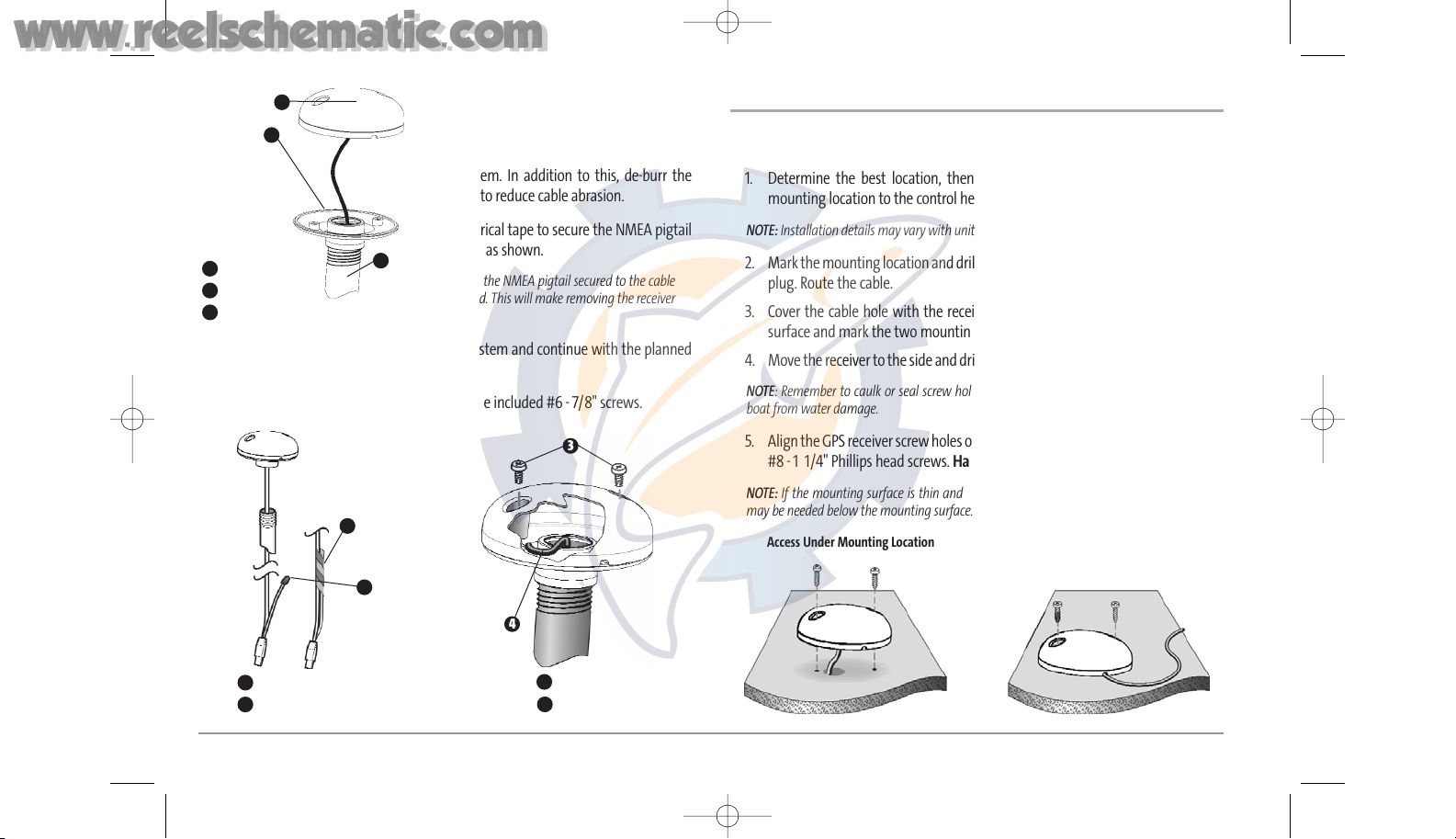

GPS Receiver Installation (937c DF Combo and 937c Combo models only) 20

Stem Mounting with an Existing 1" - 14 Thread Stem.................................................................... 20

Access Under Mounting Location .......................................................................................................... 21

No Access Under Mounting Location .................................................................................................. 22

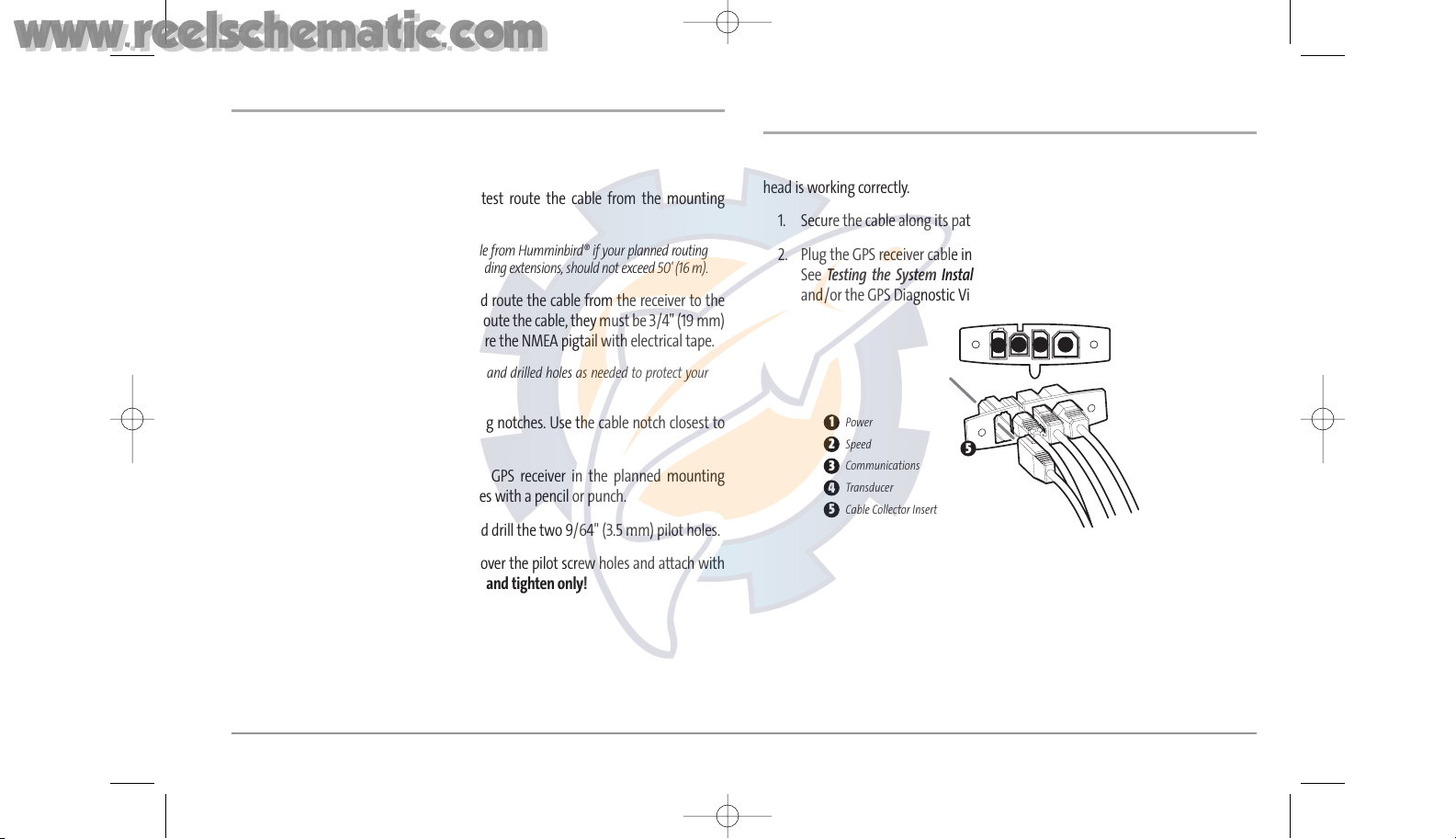

Finish Routing the Cable and Check GPS Receiver Operation...................................................... 22

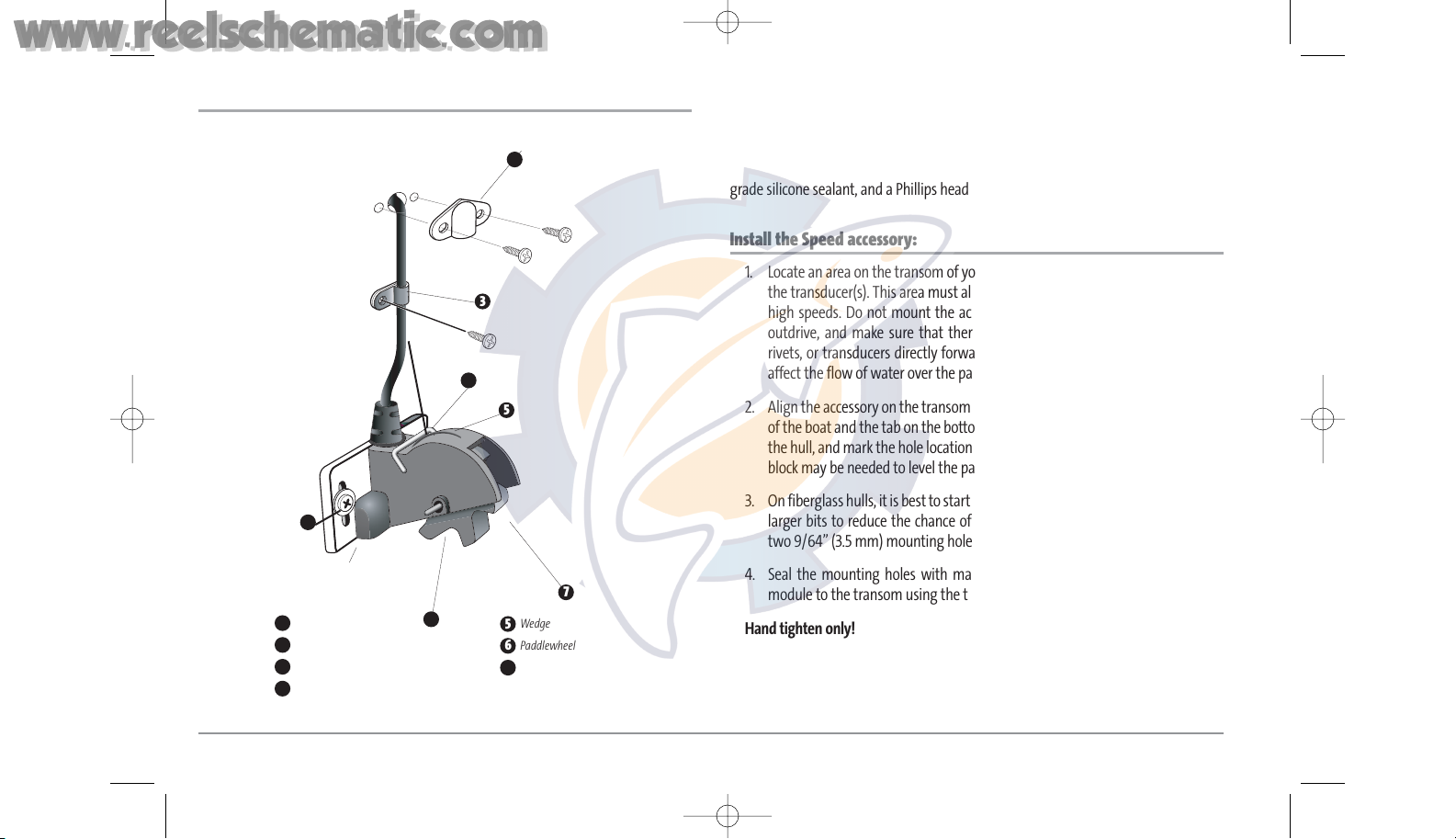

Speed Accessory Installation 23

Testing the System Installation 25

Getting Started - Using Your 900 Series™ 26

Powering Up the Control Head ............................................................................................................ 26

What’s on the Sonar Display .................................................................................................................. 27

Understanding Sonar History ................................................................................................................ 28

Real Time Sonar (RTS®) Window .......................................................................................................... 28

Bottom Presentation.................................................................................................................................. 28

Key Functions 29

POWER/LIGHT Key .................................................................................................................................... 29

VIEW Key........................................................................................................................................................ 30

MENU Key .................................................................................................................................................... 30

4-WAY Cursor Control Key ........................................................................................................................ 30

View Preset Keys.......................................................................................................................................... 31

EXIT Key .......................................................................................................................................................... 31

INFO Key

(937c DF Combo and 937c Combo models only) .................................................................. 31

MARK/GOTO Key

(937c DF Combo and 937c Combo models only) .................................................. 31

ZOOM (+/- Key)

(937c DF Combo and 937c Combo models only)...................................................... 31

Views 32

Views and Readouts .................................................................................................................................. 32

Sonar View .................................................................................................................................................... 33

Sonar Zoom View........................................................................................................................................ 33

Split Sonar View

(937c DF Combo and 931c DF models only)............................................................ 34

Bird’s Eye View

(937c DF Combo and 937c Combo models only) ...................................................... 35

Chart/Bird’s Eye Combo View

(937c DF Combo and 937c Combo models only).......................... 36

Chart View

(937c DF Combo and 937c Combo models only) .............................................................. 36

Chart/Sonar Combo View

(937c DF Combo and 937c Combo models only) ................................ 37

Chart Orientation ...................................................................................................................................... 38

Viewing Cartography (937c DF Combo and 937c Combo models only) 38

Navigation (937c DF Combo and 937c Combo models only) 39

Waypoints, Routes and Tracks................................................................................................................ 40

Save, Edit, or Delete a Waypoint .......................................................................................................... 40

Navigate to a Waypoint or Position...................................................................................................... 41

Add a Waypoint Target or Trolling Grid .............................................................................................. 42

Save, Edit or Delete a Route .................................................................................................................... 43

Save or Clear a Current Track .................................................................................................................. 43

Edit, Delete or Hide Saved Tracks .......................................................................................................... 43

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 3

www.reelschematic.com

www.reelschematic.com

Page 4

iii

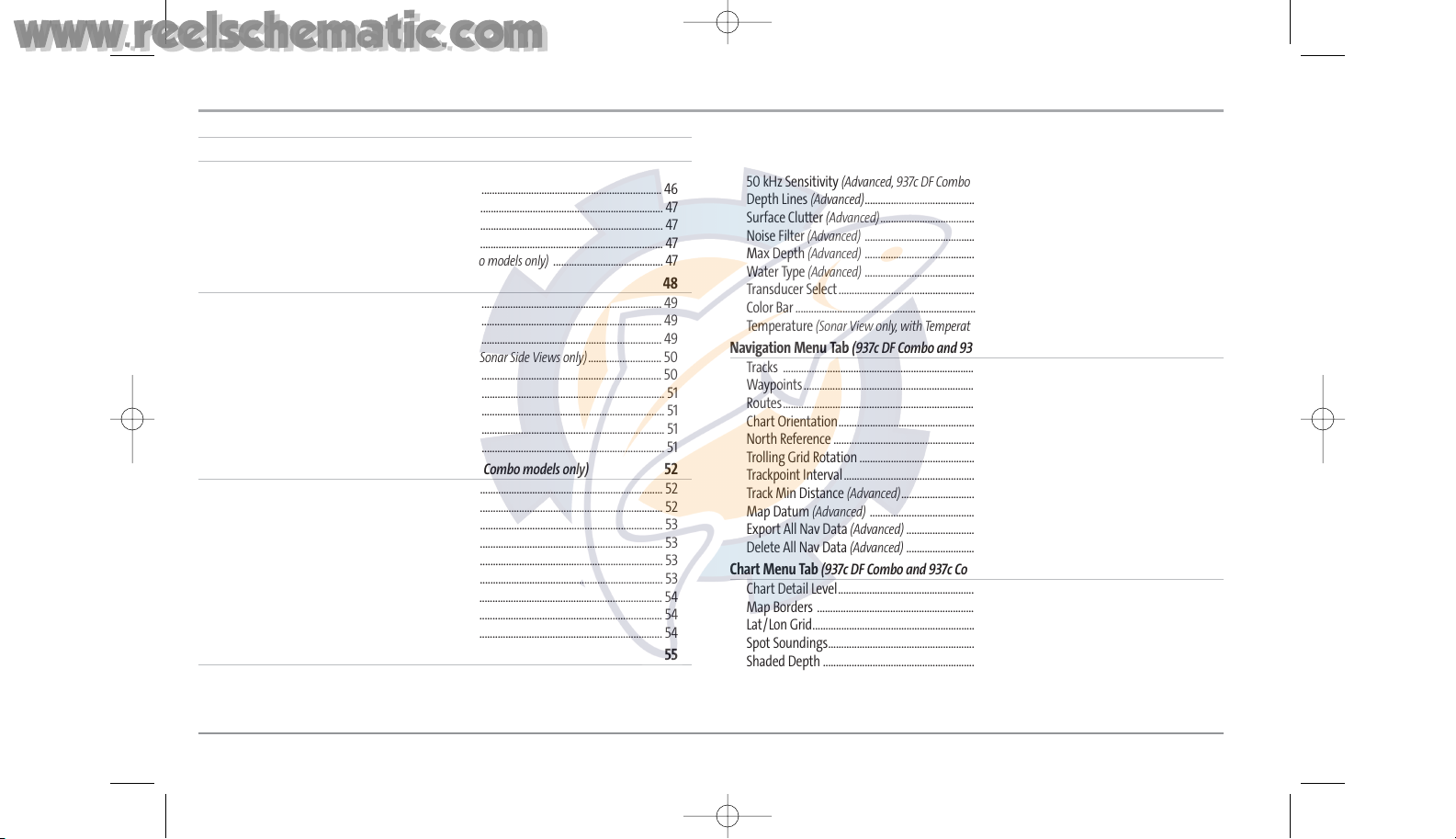

TABLE OF CONTENTS

The Menu System 44

Start-Up Options Menu 45

Normal Operation ...................................................................................................................................... 46

Simulator ...................................................................................................................................................... 46

System Status .............................................................................................................................................. 47

Self Test .......................................................................................................................................................... 47

Accessory Test .............................................................................................................................................. 47

GPS Diagnostic View

(937c DF Combo and 937c Combo models only) .......................................... 47

Sonar X-Press™ Menu 48

Active Side .................................................................................................................................................... 49

Split Position ................................................................................................................................................ 49

Sensitivity .................................................................................................................................................... 49

Upper Range

(Advanced: Sonar, Split Sonar and Active Sonar Side Views only)............................ 50

Lower Range ................................................................................................................................................ 50

Chart Speed .................................................................................................................................................. 51

Zoom Level

(Sonar Zoom View only) ........................................................................................................ 51

Bottom Lock

(Sonar Zoom View only) .................................................................................................... 51

Sonar Colors .................................................................................................................................................. 51

Navigation X-Press™ Menu (937c DF Combo and 937c Combo models only) 52

Active Side .................................................................................................................................................... 52

Split Position ................................................................................................................................................ 52

Save Current Track ...................................................................................................................................... 53

Clear Current Track...................................................................................................................................... 53

Save Current Route

(Only when navigating) ........................................................................................ 53

Skip Next Waypoint

(Only when navigating) ...................................................................................... 53

Cancel Navigation

(Only when navigating) .......................................................................................... 54

Remove Target

(Only if a Target is active).............................................................................................. 54

Remove Grid

(Only if a Grid is active)...................................................................................................... 54

Sonar Menu Tab 55

Beam Select (937c DF Combo and 931c DF models only) .................................................................... 55

Fish ID+™........................................................................................................................................................ 56

Fish ID Sensitivity........................................................................................................................................ 56

Real Time Sonar (RTS®) Window............................................................................................................ 57

Bottom View ................................................................................................................................................ 57

Zoom Width

(Sonar Zoom View only) .................................................................................................... 57

50 kHz Sensitivity

(Advanced, 937c DF Combo and 931c DF models only)...................................... 58

Depth Lines

(Advanced).............................................................................................................................. 58

Surface Clutter

(Advanced)........................................................................................................................ 58

Noise Filter

(Advanced) .............................................................................................................................. 58

Max Depth

(Advanced) .............................................................................................................................. 59

Water Type

(Advanced) .............................................................................................................................. 59

Transducer Select........................................................................................................................................ 59

Color Bar ........................................................................................................................................................ 60

Temperature

(Sonar View only, with Temperature input) ................................................................ 60

Navigation Menu Tab (937c DF Combo and 937c Combo models only) 60

Tracks .............................................................................................................................................................. 61

Waypoints...................................................................................................................................................... 61

Routes.............................................................................................................................................................. 61

Chart Orientation........................................................................................................................................ 62

North Reference .......................................................................................................................................... 62

Trolling Grid Rotation................................................................................................................................ 62

Trackpoint Interval...................................................................................................................................... 62

Track Min Distance

(Advanced)................................................................................................................ 62

Map Datum

(Advanced) ............................................................................................................................ 63

Export All Nav Data

(Advanced) .............................................................................................................. 63

Delete All Nav Data

(Advanced) .............................................................................................................. 63

Chart Menu Tab (937c DF Combo and 937c Combo models only) 64

Chart Detail Level........................................................................................................................................ 64

Map Borders ................................................................................................................................................ 64

Lat/Lon Grid.................................................................................................................................................. 65

Spot Soundings............................................................................................................................................ 65

Shaded Depth .............................................................................................................................................. 65

Set Simulation Position

(Advanced) ...................................................................................................... 65

Set Map Offset

(Advanced) ...................................................................................................................... 66

Clear Map Offset

(Advanced) .................................................................................................................. 66

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 4

www.reelschematic.com

www.reelschematic.com

Page 5

TABLE OF CONTENTS

iv

Alarms Menu Tab 66

Depth Alarm ................................................................................................................................................ 67

Fish ID Alarm ................................................................................................................................................ 67

Low Battery Alarm ...................................................................................................................................... 67

Temp Alarm .................................................................................................................................................. 67

Off Course Alarm

(937c DF Combo and 937c Combo models only).................................................. 68

Arrival Alarm

(937c DF Combo and 937c Combo models only).......................................................... 68

Drift Alarm

(937c DF Combo and 937c Combo models only).............................................................. 68

Alarm Tone .................................................................................................................................................... 69

Setup Menu Tab 70

Units - Depth ................................................................................................................................................ 70

Units - Temp

(International only) ............................................................................................................ 70

Units - Distance

(With Speed input only) ................................................................................................ 71

Units - Speed

(With Speed input only) .................................................................................................... 71

User Mode...................................................................................................................................................... 71

Language

(International only).................................................................................................................... 71

Triplog Reset

(With Speed input only) .................................................................................................... 72

Restore Defaults .......................................................................................................................................... 72

Select Readouts

(Advanced) ...................................................................................................................... 72

Depth Offset

(Advanced)............................................................................................................................ 74

Temp Offset

(Advanced) ............................................................................................................................ 74

Speed Calibration

(Advanced, with Speed paddlewheel only) .......................................................... 74

Local Time Zone

(Advanced, 937c DF Combo and 937c Combo models only) ................................ 74

Daylight Saving Time

(Advanced, 937c DF Combo and 937c Combo models only) ...................... 75

Position Format

(Advanced, 937c DF Combo and 937c Combo models only) ................................ 75

Time Format

(Advanced, 937c DF Combo and 937c Combo Models, International only) ............ 75

Date Format

(Advanced, 937c DF Combo and 937c Combo Models, International only).............. 75

NMEA Output

(Advanced) ........................................................................................................................ 76

Sonar

(937c DF Combo and 937c Combo models only) ........................................................................ 76

Views Menu Tab 77

Accessories Menu Tab 77

Troubleshooting 78

900 Series™ Doesn’t Power Up.............................................................................................................. 78

900 Series™ Defaults to Simulator with a Transducer Attached................................................ 78

Display Problems ........................................................................................................................................ 79

Finding the Cause of Noise...................................................................................................................... 80

1-Year Limited Warranty 81

Humminbird® Service Policy 81

900 Series™ Accessories 82

Specifications 83

Appendix A - Transducer Mounting Template (Single Frequency: XHS-9-20-T) 84

Appendix B - Transducer Mounting Template (Dual Frequency: XHS-9-DB-74-T) 85

Contact Humminbird® 86

NOTE: Entries in this Table of Contents which list (International Only) are only available on

products sold outside of the US and Canada by our authorized International Distributors.

To obtain a list of authorized International Distributors, please visit our website at

www.humminbird.com or contact our Customer Resource Center at 1-800-633-1468 to

locate the distributor nearest you.

NOTE: Entries in this Table of Contents which list (with Speed Input) or (with Temperature

Input) may require the purchase of separate accessories. You can visit our website at

www.humminbird.com to order these accessories online or contact our Customer Resource

Center at 1-800-633-1468.

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 5

www.reelschematic.com

www.reelschematic.com

Page 6

1

900 SERIES™ INTRODUCTION

Your 900 Series™ Ultra Wide Screen Fishing System comes in several different

configurations. See the following list of products, all of which are covered by this

manual, to find your 900 Series™ configuration:

NOTE: Only 937c DF Combo and 937c Combo models come with GPS and built-in

cartography.

• Humminbird® 931c: Ultra Wide Screen Fishing System with Single Frequency

200 kHz Transducer, optional GPS support

• Humminbird® 931c DF: Ultra Wide Screen Fishing System with Dual Frequency

200 kHz and 50 kHz Transducer, optional GPS support

• Humminbird® 937c Combo: Ultra Wide Screen Fishing System with Chartplotter

(Maps) and Single Frequency 200 kHz Transducer, GPS Receiver included

• Humminbird® 937c DF Combo: Ultra Wide Screen Fishing System with

Chartplotter (Maps) and Dual Frequency 200 kHz and 50 kHz Transducer, GPS

Receiver included.

HOW THE 900 SERIES™ WORKS

Sonar technology is based on sound waves. The 900 Series™ Fishing System uses

sonar to locate and define structure, bottom contour and composition, as well as

depth directly below the transducer. Your 900 Series™ Fishing System sends a sound

wave signal and determines distance by measuring the time between the

transmission of the sound wave and when the sound wave is reflected off of an object;

it then uses the reflected signal to interpret location, size, and composition of an

object. Sonar is very fast. A sound wave can travel from the surface to a depth of 240

ft (70 m) and back again in less than ¼ of a second. It is unlikely that your boat can

"outrun" this sonar signal.

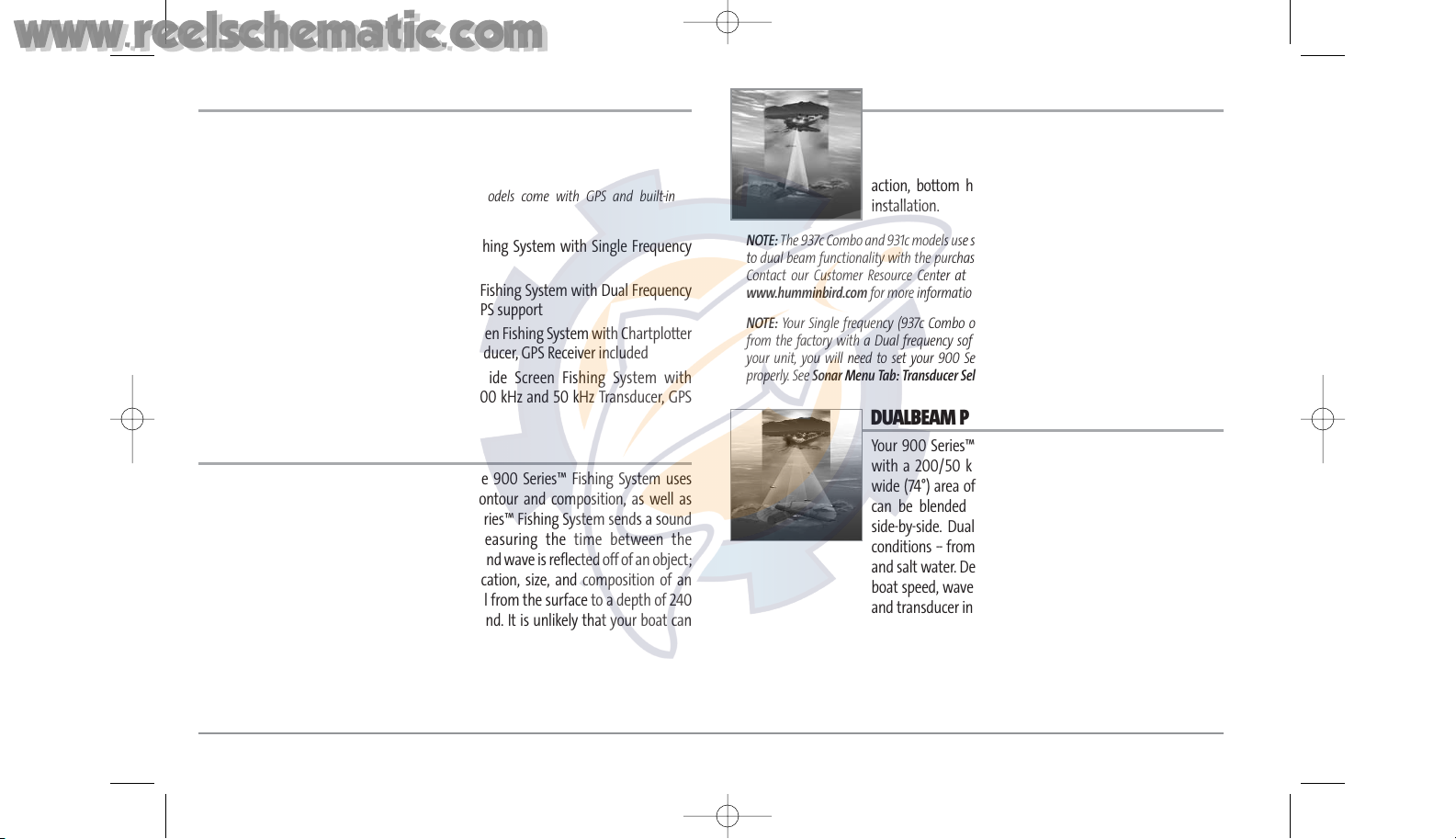

SINGLE BEAM SONAR

Your 900 Series™ 937c Combo and 931c use a 200 kHz single

beam sonar system with a 20° area of coverage. Depth

capability is affected by such factors as boat speed, wave

action, bottom hardness, water conditions and transducer

installation.

NOTE: The 937c Combo and 931c models use single beam transducers, but may be upgraded

to dual beam functionality with the purchase and installation of a dual beam transducer.

Contact our Customer Resource Center at either 1-800-633-1468 or visit our website at

www.humminbird.com for more information.

NOTE: Your Single frequency (937c Combo or 931c model) 900 Series™ unit was shipped

from the factory with a Dual frequency software configuration. Before trying to operate

your unit, you will need to set your 900 Series™ to Single Beam in order for it to work

properly. See Sonar Menu Tab: Transducer Select for more information.

DUALBEAM PLUS™ SONAR

Your 900 Series™ 937c DF Combo and 931c DF are shipped

with a 200/50 kHz DualBeam PLUS™ sonar system with a

wide (74°) area of coverage. DualBeam PLUS™ sonar returns

can be blended together, viewed separately or compared

side-by-side. DualBeam PLUS™ is ideal for a wide range of

conditions -- from shallow to very deep water, in both fresh

and salt water. Depth capability is affected by such factors as

boat speed, wave action, bottom hardness, water conditions

and transducer installation.

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 6

www.reelschematic.com

www.reelschematic.com

Page 7

GPS AND CARTOGRAPHY

(with 937c DF Combo and 937c Combo models only)

The 937c DF Combo and 937c Combo models use GPS and sonar to determine your

position, display it on a grid, and provide detailed underwater information. The Global

Positioning System (GPS) is a satellite navigation system designed and maintained by

the U.S. Department of Defense. GPS was originally intended for military use; however,

civilians may also take advantage of its highly accurate position capabilities, typically

within +/- 10 meters, depending on conditions. This means that 95% of the time, the

GPS receiver will read a location within 10 meters of your actual position. The GPS

Receiver also uses information from WAAS (the Wide Area Augmentation System),

EGNOS (the European Geostationary Navigation Overlay Service), and MSAS (the

MTSAT Satellite Augmentation System) satellites if they are available in your area.

GPS uses a constellation of satellites that continually send radio signals to the earth.

Your present position is determined by receiving signals from up to 12 satellites and

measuring the distance from the satellites. The GPS Receiver, when attached to your

937c DF Combo or 937c Combo model, allows you to combine easy-to-use FishingGPS™

chartplotter and navigation capabilities with advanced fishfinding. The following GPS

functionality is currently supported by the 937c DF Combo and 937c Combo models

when it is connected to a GPS Receiver:

• View current position

• View current track (breadcrumb trail)

• View precision speed and heading from your GPS receiver

• Save tracks, waypoints and routes

• Travel a route and navigate from one waypoint to the next.

NOTE: Only the 937c DF Combo and 937c Combo models support Navionics® Gold Charts

marine cartography and Navionics® HotMaps™ 2004 Gold for inland fishing. The 900

Series™ does not support Navionics® Classic Charts.

The 937c DF Combo and 937c Combo models also come with a built-in World map with a

more detailed map of North America (Domestic models) or a more detailed map of

Europe and Southeast Asia, including Australia and New Zealand (International models).

Your 937c DF Combo and 937c Combo models use the GPS Receiver to determine the

position of the boat automatically, and uses the zoom level settings on a particular

view to select the best chart to display. See Viewing Cartography for more information.

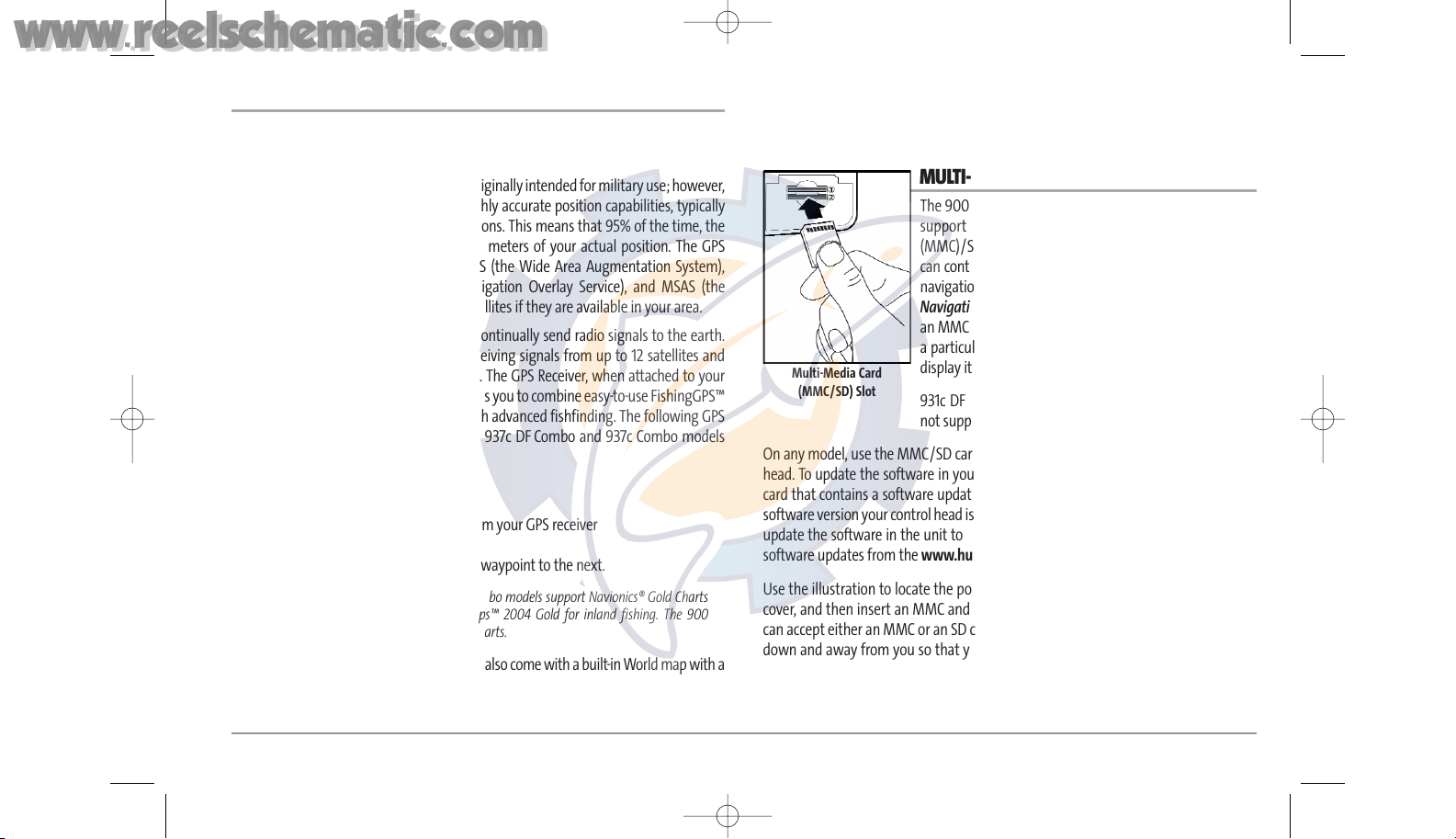

MULTI-MEDIA CARD (MMC)/SD SLOT

The 900 Series™ 937c DF Combo and 937c Combo models

support cartography, and have two multi-media card

(MMC)/SD slots. Optional-purchase MMC and/or SD cards

can contain additional detailed maps. You can also export

navigation data from your unit onto an MMC/SD card (see

Navigation Main Menu: Export All Nav Data). If you insert

an MMC or SD card that contains a more detailed chart for

a particular location, your unit will retrieve that chart and

display it automatically.

931c DF and 931c models have one MMC/SD slot and do

not support cartography.

On any model, use the MMC/SD cards to update the software version of your control

head. To update the software in your control head, plug in the appropriate MMC/SD

card that contains a software update file; the unit will recognize it, will tell you what

software version your control head is currently running, and will ask you if you want to

update the software in the unit to match that on the MMC/SD card. You can obtain

software updates from the www.humminbird.com website.

Use the illustration to locate the position of the MMC and SD slot cover, remove the

cover, and then insert an MMC and/or an SD card into one or both slots - either slot

can accept either an MMC or an SD card. The label on both types of cards should face

down and away from you so that you’re looking at the back of the card. Press down

on the card until it clicks into place, then replace the slot cover and tighten the screw

snugly - do NOT overtighten, as this will not improve water resistance, and may

damage the cover.

Multi-Media Card

(MMC/SD) Slot

2

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 7

www.reelschematic.com

www.reelschematic.com

Page 8

3

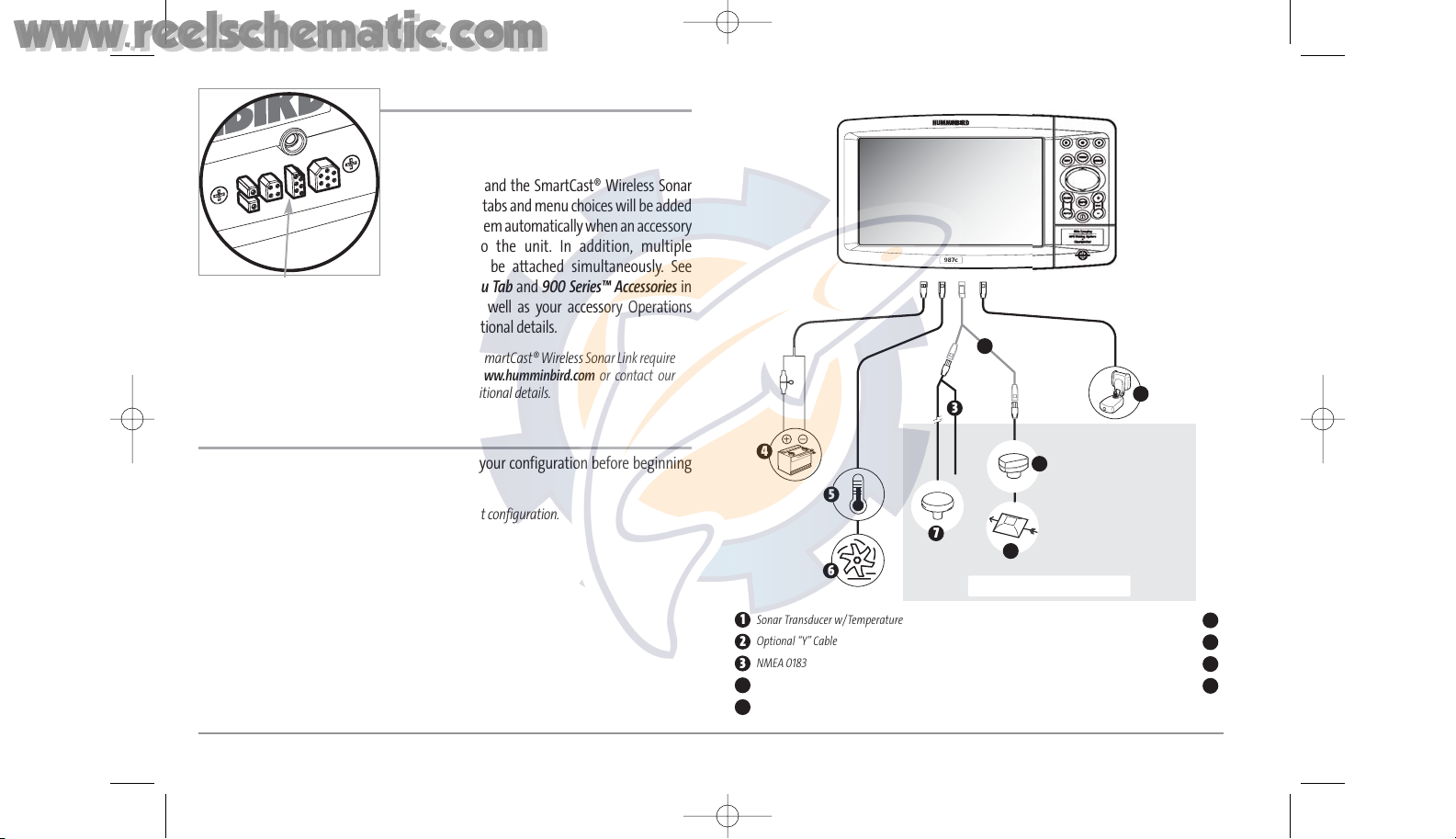

ACCESSORY BUS

Use the Accessory Bus to expand the functionality of

your 900 Series™. Accessories plug directly into the

900 Series™, enabling Advanced features such as

WeatherSense® and the SmartCast® Wireless Sonar

Link. Additional tabs and menu choices will be added

to the menu system automatically when an accessory

is plugged into the unit. In addition, multiple

accessories can be attached simultaneously. See

Accessories Menu Tab and 900 Series™ Accessories in

this manual, as well as your accessory Operations

Manual for additional details.

NOTE: Accessories to enable WeatherSense® and the SmartCast® Wireless Sonar Link require

separate purchases. You can visit our website at www.humminbird.com or contact our

Customer Resource Center at 1-800-633-1468 for additional details.

INSTALLATION OVERVIEW

Please read all instructions that are relevant for your configuration before beginning

the installation process.

NOTE: Installation procedures will depend on product configuration.

The 900 Series™ has a wide variety of configurations.

Sonar Transducer w/Temperature

1

Optional “Y” Cable

2

NMEA 0183

3

Speed through water

GPS Receiver

WeatherSense®

6

7

8

Power

4

SmartCast® Wireless Sonar Link

9

Temperature

5

Accessory Bus

1

2

3

4

5

6

7

8

9

Accessory Bus

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 8

www.reelschematic.com

www.reelschematic.com

987c

Page 9

Inside the boat there is often a channel or conduit used for other wiring, this can be

used to route cables. Be sure to route the cable as far as practical from the antenna

cable of VHF radios or tachometer cables to reduce the possibility of interference. The

transducer and GPS receiver cables should not be cut, and care should be used not to

damage the cable insulation.

Basic installation tasks that you must perform include:

• Installing the control head (choosing either gimbal or in-dash mounting)

• Installing the transducer (choosing either the transom mount, inside the hull

mount, or trolling motor mounting method)

• Installing the GPS Receiver (if included)

• Installing the Speed accessory (if included)

• Testing the complete installation and locking the transducer position.

The supplied Humminbird® transducer uses a two piece kick-up mounting bracket. In

addition, if you purchased a 937c DF Combo or 937c Combo model, you will want to

install the included GPS antenna.

NOTE: Accessories may require a separate purchase. You can visit our website at

www.humminbird.com to order these accessories online or contact our Customer Resource

Center at 1-800-633-1468.

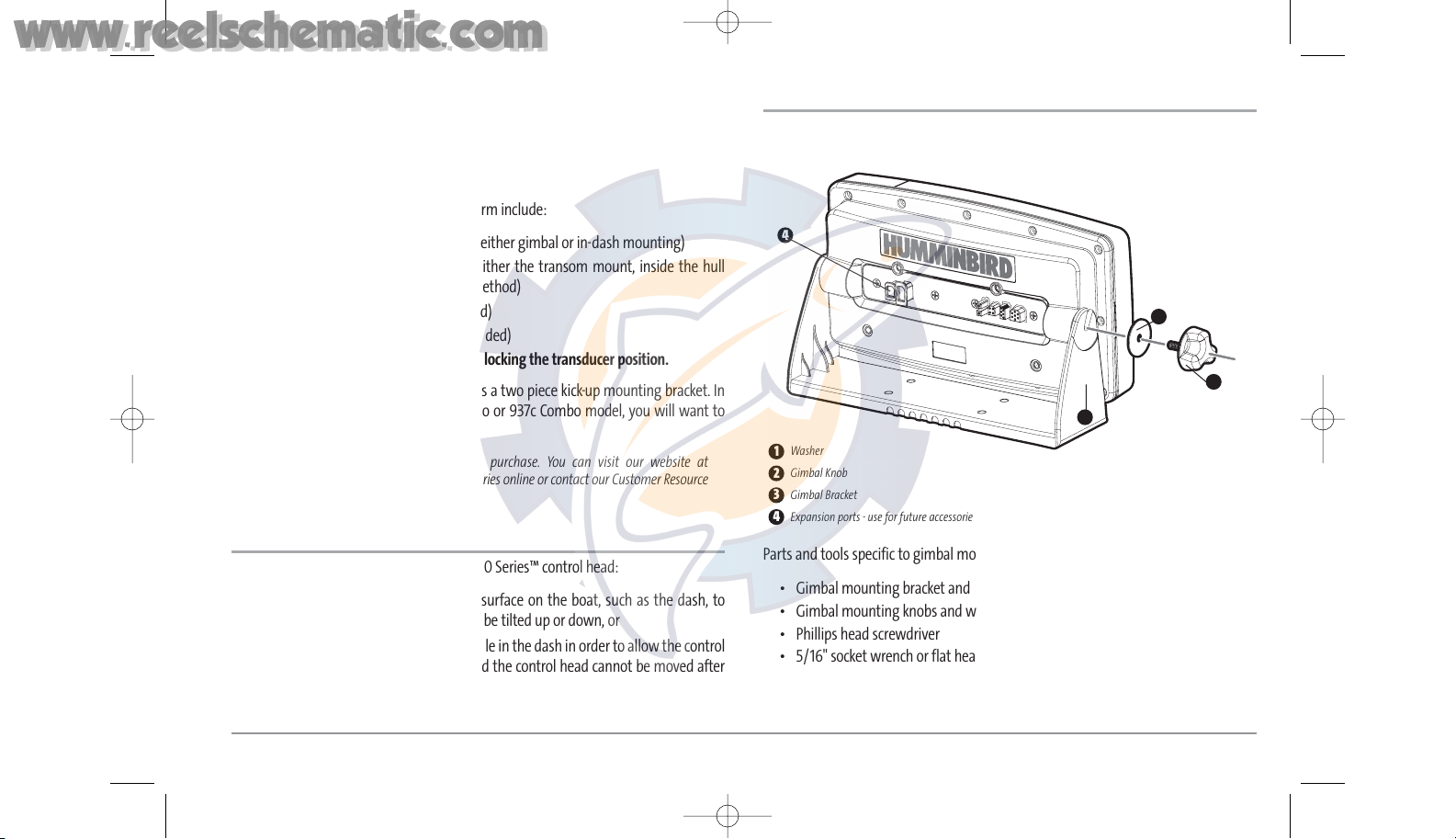

CONTROL HEAD INSTALLATION

You have two choices for mounting your 900 Series™ control head:

• Gimbal mounting, where you use a surface on the boat, such as the dash, to

mount the control head so that it can be tilted up or down, or

• In-dash mounting, where you cut a hole in the dash in order to allow the control

head to be recessed into the dash, and the control head cannot be moved after

mounting.

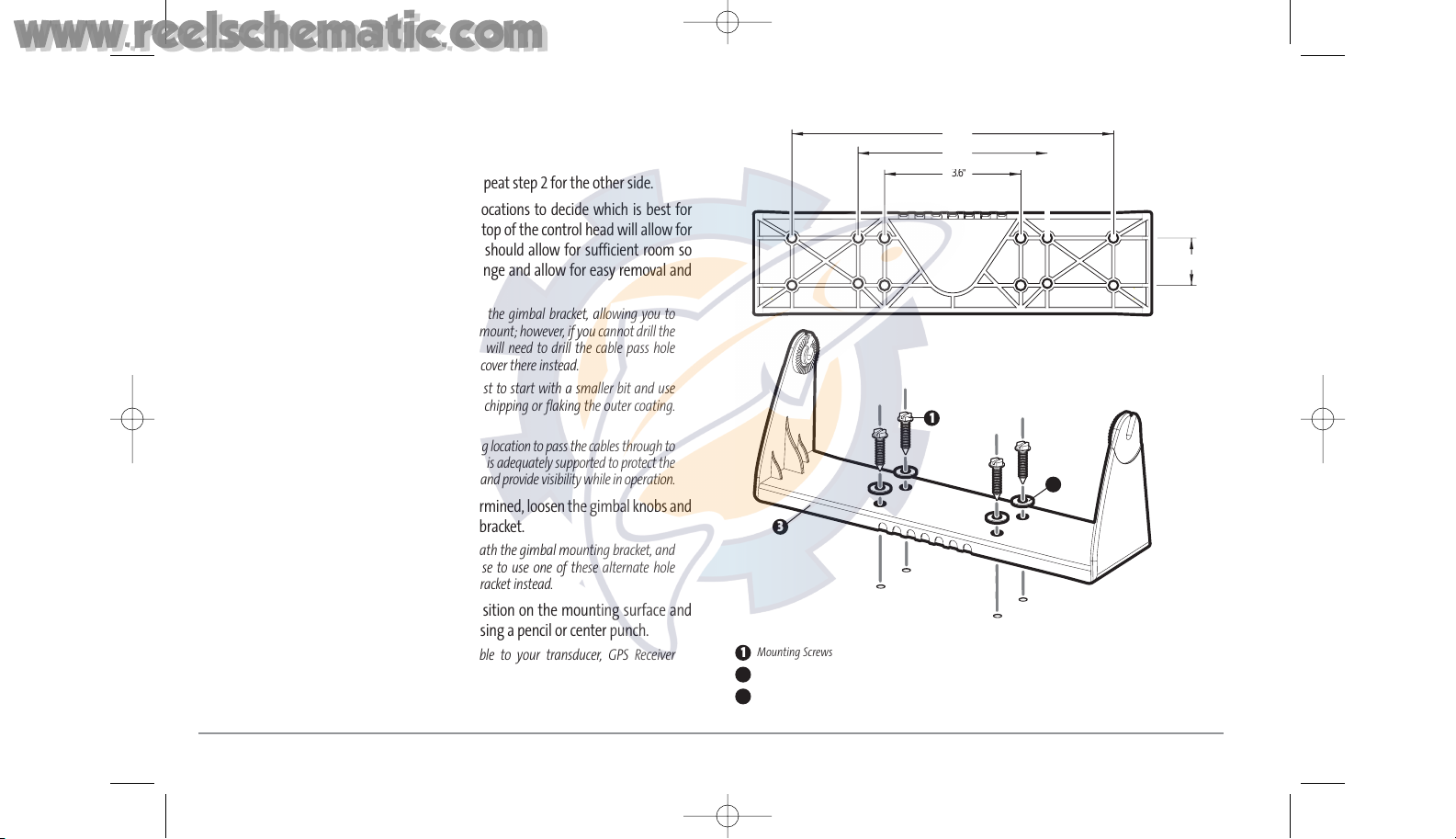

GIMBAL MOUNTING THE CONTROL HEAD

If you are gimbal mounting the Humminbird® 900 Series™, you can pre-assemble the

unit in order to plan the best mounting location.

Parts and tools specific to gimbal mounting are:

• Gimbal mounting bracket and screws

• Gimbal mounting knobs and washers

• Phillips head screwdriver

• 5/16" socket wrench or flat head screw driver

• Hand drill with various drill bits

• Marine-grade silicone sealant.

Washer

1

Gimbal Knob

2

Gimbal Bracket

3

Expansion ports - use for future accessories

4

1

2

3

4

4

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 9

www.reelschematic.com

www.reelschematic.com

Page 10

5

1. Place the control head into the gimbal bracket. Make sure that the straight side

of the gimbal arm is against the back side of the control head.

2. Place a 1" (25 mm) diameter black washer on the gimbal knob and then thread

the knob and washer into the housing. Tighten the gimbal knob to secure the

900 Series™ control head to the mount. Repeat step 2 for the other side.

You can now place the control head in various locations to decide which is best for

mounting. Rotating the mounting bracket to the top of the control head will allow for

overhead mounting. The chosen mounting area should allow for sufficient room so

the control head can pivot through the full tilt range and allow for easy removal and

installation.

NOTE: You can drill the cable pass hole underneath the gimbal bracket, allowing you to

thread the cables through the knock-out holes in the mount; however, if you cannot drill the

hole directly under the mounting bracket, then you will need to drill the cable pass hole

behind the bracket, and will need to mount the hole cover there instead.

NOTE: When drilling holes in fiberglass hulls, it is best to start with a smaller bit and use

progressively larger drill bits to reduce the chance of chipping or flaking the outer coating.

Fill all holes with marine grade silicone sealant.

NOTE: You must have underside access to the mounting location to pass the cables through to

the surface. Also, make sure that the mounting surface is adequately supported to protect the

control head from excessive wave shock and vibration and provide visibility while in operation.

3. After the mounting location has been determined, loosen the gimbal knobs and

remove the control head from the gimbal bracket.

NOTE: Alternate hole patterns are available underneath the gimbal mounting bracket, and

may match existing holes on the boat. If you choose to use one of these alternate hole

patterns, simply drill it out and use it to mount the bracket instead.

4. Place the gimbal bracket in the chosen position on the mounting surface and

mark the four mounting screw locations using a pencil or center punch.

NOTE: Go to the installation instructions applicable to your transducer, GPS Receiver

and accessories. Make the required installations and then run the cables to your control

head mounting location. Do not cut any cabling (except the power cable). If your cables

are too short, extensions are available from your local dealer or online from

www.humminbird.com.

8.5"

5"

3.6"

1.25"

Mounting Screws

1

Washer

2

Gimbal Mounting Bracket

3

1

3

2

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 10

www.reelschematic.com

www.reelschematic.com

Page 11

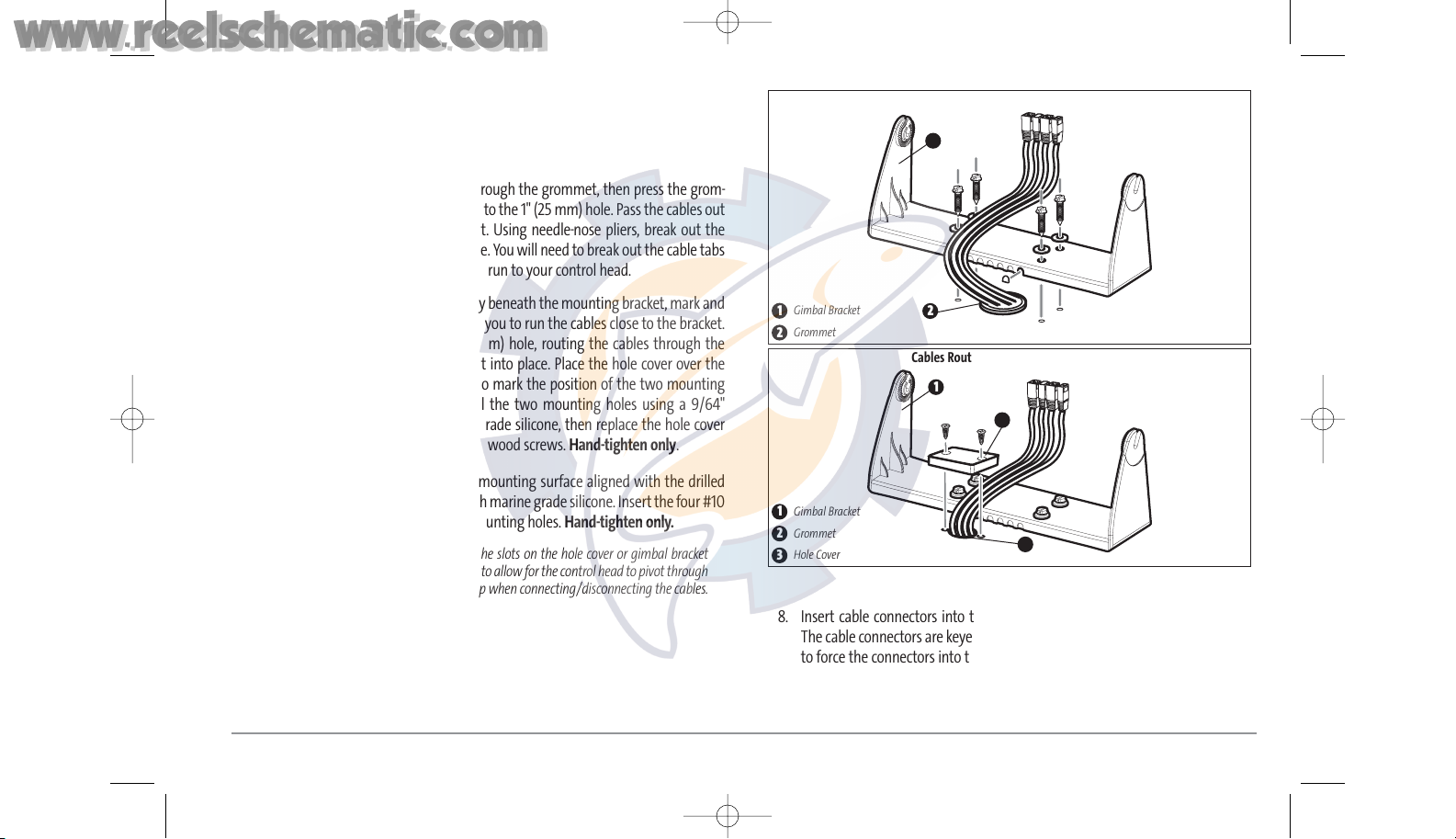

5. Set the gimbal bracket aside and drill the four mounting screw holes using a

5/32" (4.0 mm) drill bit.

6a. If the cables must pass through a hole directly beneath the mounting bracket,

mark and drill an additional 1" (25 mm) hole centered between the four

mounting holes. Route the cables through the grommet, then press the grom-

met in place around the cables and into the 1" (25 mm) hole. Pass the cables out

of the back of the mounting bracket. Using needle-nose pliers, break out the

tabs on the rear of the mounting base. You will need to break out the cable tabs

for the number of cables you want to run to your control head.

6b. If the cables cannot be routed directly beneath the mounting bracket, mark and

drill a 1" (25 mm) hole that will allow you to run the cables close to the bracket.

Pass the cables through the 1" (25 mm) hole, routing the cables through the

grommet and pressing the grommet into place. Place the hole cover over the

mounting surface hole, then use it to mark the position of the two mounting

screws. Remove the hole cover, drill the two mounting holes using a 9/64"

(3.5 mm) bit, fill them with marine-grade silicone, then replace the hole cover

and insert the #8 Phillips countersink wood screws. Hand-tighten only.

7. Place the mounting bracket on the mounting surface aligned with the drilled

holes and fill the mounting holes with marine grade silicone. Insert the four #10

Slotted-Hex wood screws into the mounting holes. Hand-tighten only.

NOTE: Be sure that the cables pass through the slots on the hole cover or gimbal bracket

break out tabs and there is enough cable slack to allow for the control head to pivot through

its full tilt range. Extra cable slack will also help when connecting/disconnecting the cables.

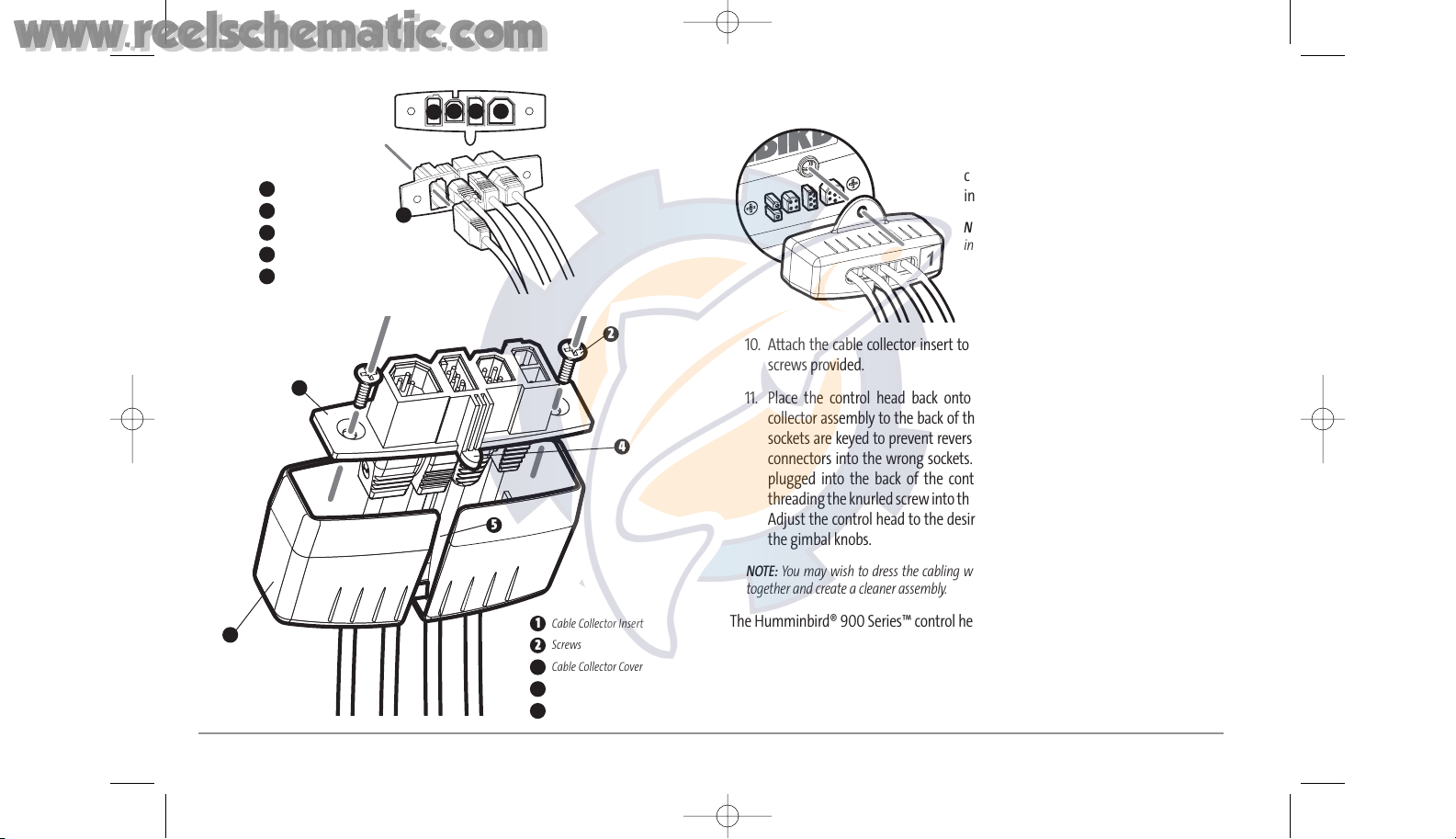

8. Insert cable connectors into the proper recesses on the cable collector insert.

The cable connectors are keyed to prevent reverse installation, so be careful not

to force the connectors into the wrong slots. If you don’t have a cable for every

hole in the insert, install the blank plugs to protect the control head from the

weather.

1

2

Cables Routed Directly Beneath Mounting Bracket

Gimbal Bracket

1

Grommet

2

1

Cables Routed Near Mounting Bracket

Gimbal Bracket

1

Grommet

2

Hole Cover

3

3

2

6

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 11

www.reelschematic.com

www.reelschematic.com

Page 12

7

9. While holding cables in place in the cable

collector insert, thread the cables through

the slot in the bottom of the cable collector

cover, line up the cable collector insert and

cover, then slide the cover into place on the

insert.

NOTE: The tab on the Cable Collector insert goes

into the slot on the cover.

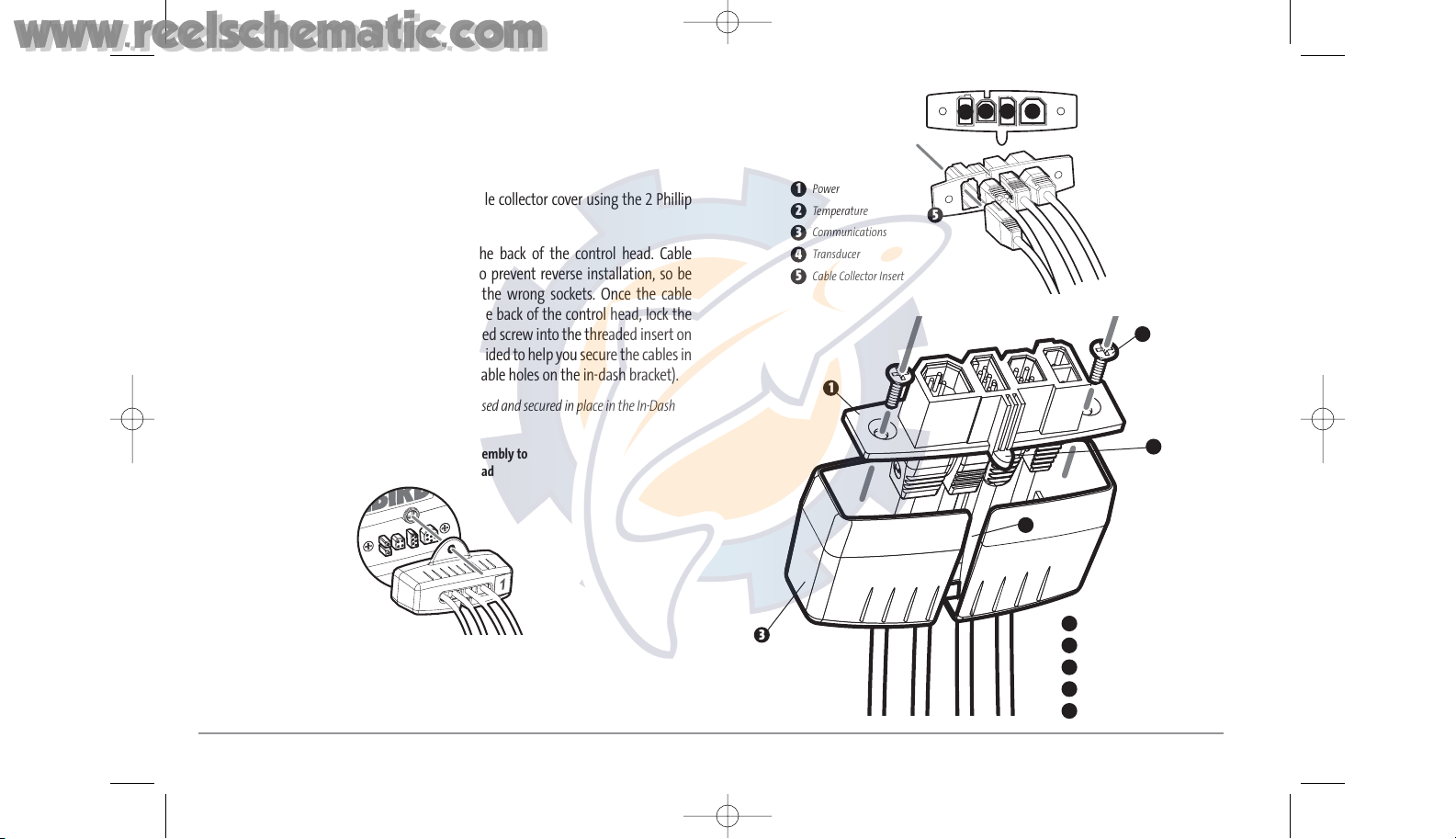

10. Attach the cable collector insert to the cable collector cover using the 2 Phillip

screws provided.

11. Place the control head back onto the mounting bracket. Plug in the cable

collector assembly to the back of the control head. Cable connectors and cable

sockets are keyed to prevent reverse installation, so be careful not to force the

connectors into the wrong sockets. Once the cable collector and all cables are

plugged into the back of the control head, lock the assembly into place by

threading the knurled screw into the threaded insert on the back of the housing.

Adjust the control head to the desired viewing angle and secure by tightening

the gimbal knobs.

NOTE: You may wish to dress the cabling with nylon wire ties in order to hold the cables

together and create a cleaner assembly.

The Humminbird® 900 Series™ control head is now ready for operation.

Plug Cable Connector Assembly to

Back of Control Head

Cable Collector Insert

1

Screws

2

Cable Collector Cover

3

Tab on Insert

4

Slot on Cover

5

1

2

3

Power

1

Speed

2

Communications

3

Transducer

4

Cable Collector Insert

5

1

2 3 4

5

4

5

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 12

www.reelschematic.com

www.reelschematic.com

Page 13

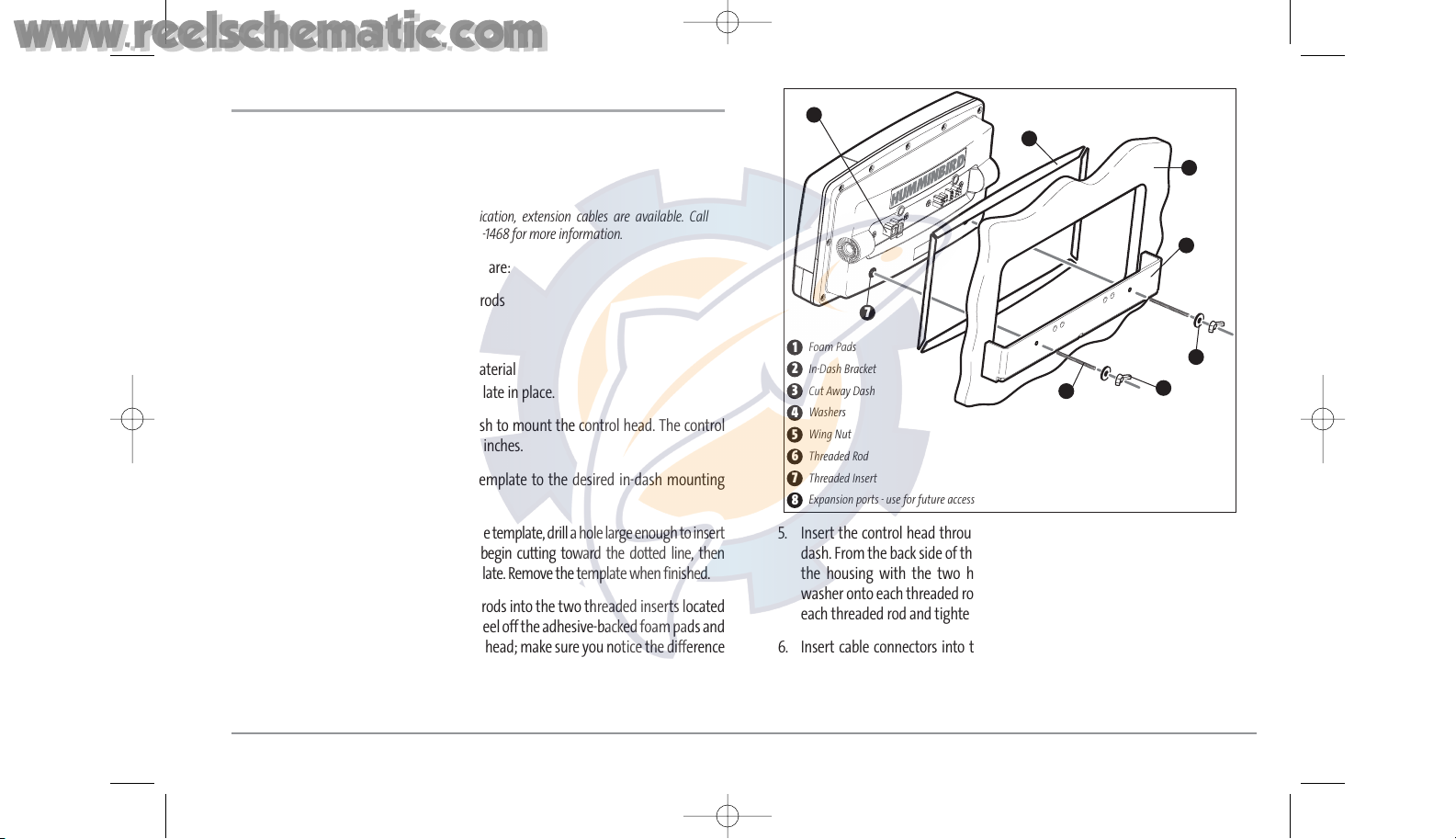

IN-DASH MOUNTING THE CONTROL HEAD

If you are in-dash mounting the control head, start by placing the components on the

surfaces where you intend to install them before installation. Make sure that the

surfaces you have chosen provide adequate protection from wave shock, and that all

cables can reach the control head.

NOTE: If a cable is too short for your application, extension cables are available. Call

Humminbird® Customer Support at 1-800-633-1468 for more information.

Parts and tools specific to In-dash mounting are:

• In-dash mount bracket and threaded rods

• In-dash mounting foam pads

• In-dash mounting template

• Reciprocating saw for cutting dash material

• Masking tape to hold mounting template in place.

1. Locate a suitable, flat area of the dash to mount the control head. The control

head requires a depth of at least 3 ½ inches.

2. Tape the paper In-Dash Mounting template to the desired in-dash mounting

location.

3. At a location inside the dotted line on the template, drill a hole large enough to insert

blade of reciprocating saw. Carefully begin cutting toward the dotted line, then

follow the dotted line around the template. Remove the template when finished.

4. Insert and tighten the two threaded rods into the two threaded inserts located

on the back side of the control head. Peel off the adhesive-backed foam pads and

place them on the back of the control head; make sure you notice the difference

between the longer top/bottom and shorter side pads.

5. Insert the control head through the mounting hole from the front side of the

dash. From the back side of the dash, align the two threaded rods on the rear of

the housing with the two holes on the in-dash mounting bracket. Place a

washer onto each threaded rod, then secure bracket by placing a wing nut onto

each threaded rod and tighten fully.

6. Insert cable connectors into the proper recesses on the cable collector insert.

The cable connectors are keyed to prevent reverse installation, so be careful not

to force the connectors into the wrong slots. If you don’t have a cable for every

hole in the insert, install the blank plugs to protect the unit from the weather.

Foam Pads

1

In-Dash Bracket

2

Cut Away Dash

3

Washers

4

Wing Nut

5

Threaded Rod

6

Threaded Insert

7

Expansion ports - use for future accessories

8

1

3

2

4

5

6

7

8

8

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 13

www.reelschematic.com

www.reelschematic.com

Page 14

9

7. While holding cables in place in the cable collector insert, thread the cables

through the slot in the bottom of the cable collector cover, line up the cable

collector insert and cover, then slide the cover into place on the insert.

NOTE: The tab on the cable collector insert goes into the slot on the cover.

8. Attach the cable collector insert to the cable collector cover using the 2 Phillip

screws provided.

9. Plug the cable collector assembly into the back of the control head. Cable

connectors and cable sockets are keyed to prevent reverse installation, so be

careful not to force the connectors into the wrong sockets. Once the cable

collector and all cables are plugged into the back of the control head, lock the

assembly into place by threading the knurled screw into the threaded insert on

the back of the housing. (Cable ties are provided to help you secure the cables in

place by threading them through the available holes on the in-dash bracket).

NOTE: It is very important that the cable collector is used and secured in place in the In-Dash

installation.

Cable Collector Insert

1

Screws

2

Cable Collector Cover

3

Tab on Insert

4

Slot on Cover

5

1

2

3

Power

1

Temperature

2

Communications

3

Transducer

4

Cable Collector Insert

5

1

2 3 4

5

4

5

Plug Cable Connector Assembly to

Back of Control Head

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 14

www.reelschematic.com

www.reelschematic.com

Page 15

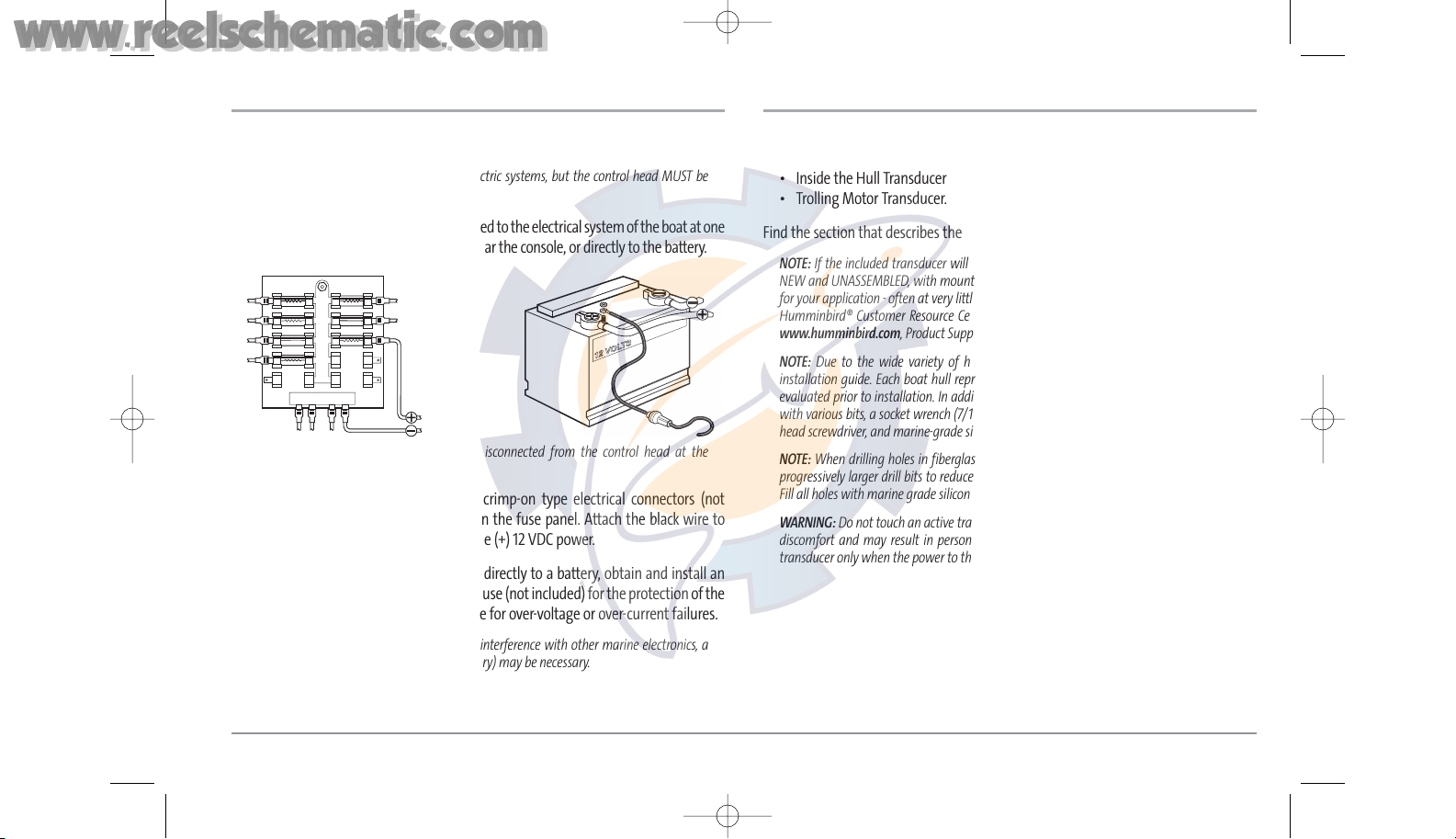

CONNECTING THE CONTROL HEAD POWER CABLE TO THE BOAT

A 6' (2 m) long power cable is included to supply power to the control head. You may

shorten or lengthen the cable using 18 gauge multi-stranded copper wire.

CAUTION: Some boats have 24 or 36 Volt electric systems, but the control head MUST be

connected to a 12 VDC power supply.

The control head power cable can be connected to the electrical system of the boat at one

of two places: a fuse panel usually located near the console, or directly to the battery.

NOTE: Make sure that the power cable is disconnected from the control head at the

beginning of this procedure.

1a. If a fuse terminal is available, use crimp-on type electrical connectors (not

included) that match the terminal on the fuse panel. Attach the black wire to

ground (-), and the red wire to positive (+) 12 VDC power.

1b. If you need to wire the control head directly to a battery, obtain and install an

inline fuse holder and a 2.5 to 3 Amp fuse (not included) for the protection of the

unit. Humminbird® is not responsible for over-voltage or over-current failures.

NOTE: In order to minimize the potential for interference with other marine electronics, a

separate power source (such as a second battery) may be necessary.

You are now ready to install the transducer. Find the section that refers to your specific

transducer installation method.

TRANSDUCER INSTALLATION

There are three different installation methods for your transducer:

• Transom Transducer

• Inside the Hull Transducer

• Trolling Motor Transducer.

Find the section that describes the method of installation you will be using.

NOTE: If the included transducer will not work for your application, you may exchange it,

NEW and UNASSEMBLED, with mounting hardware included, for a transducer appropriate

for your application - often at very little or no charge, depending on the transducer. Call the

Humminbird® Customer Resource Center (1-800-633-1468) for details and pricing, or visit

www.humminbird.com, Product Support/Transducer Exchange for more information.

NOTE: Due to the wide variety of hulls, only general instructions are presented in this

installation guide. Each boat hull represents a unique set of requirements that should be

evaluated prior to installation. In addition to the parts supplied, you will need a hand drill

with various bits, a socket wrench (7/16" or 5/16", depending on transducer type), a Phillips

head screwdriver, and marine-grade silicone sealant.

NOTE: When drilling holes in fiberglass hulls, it is best to start with a smaller bit and use

progressively larger drill bits to reduce the chance of chipping or flaking the outer coating.

Fill all holes with marine grade silicone sealant.

WARNING: Do not touch an active transducer during operation, as this may cause physical

discomfort and may result in personal injury in the form of tissue damage. Handle the

transducer only when the power to the control head is off.

10

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 15

www.reelschematic.com

www.reelschematic.com

POSITIVE

GROUND

Page 16

11

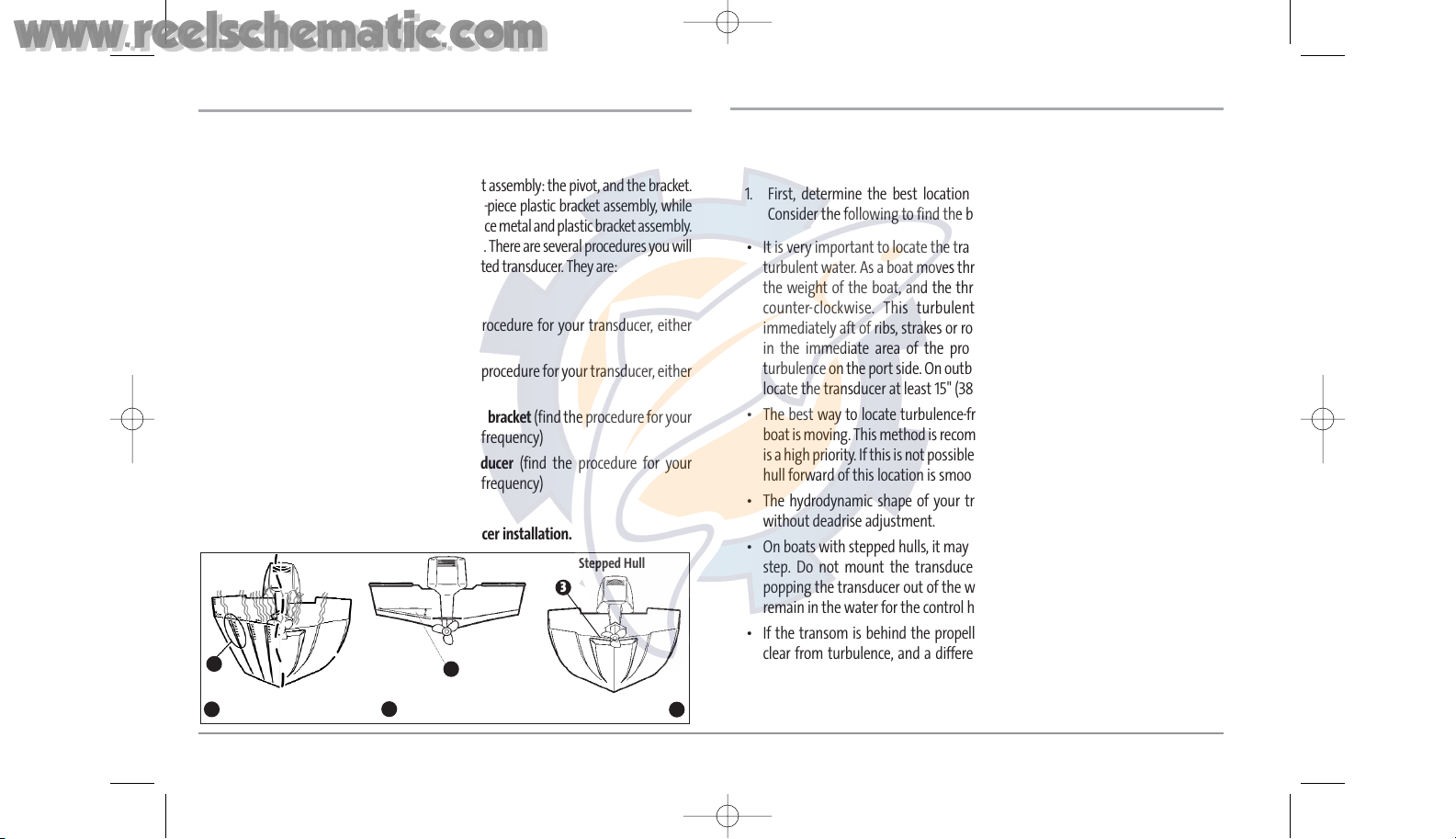

TRANSOM TRANSDUCER INSTALLATION

If you will be installing a transom mounted transducer, use the procedures in this section.

You will have one of two different types of transducer, based on whether you have a Single

(931c or 937c Combo) or a Dual (931c DF or 937c DF Combo) frequency 900 Series™ control

head. There are two pieces to the transducer mount assembly: the pivot, and the bracket.

The Single frequency transducer comes with a two-piece plastic bracket assembly, while

the Dual frequency transducer comes with a two-piece metal and plastic bracket assembly.

Find the correct procedures for your transducer type. There are several procedures you will

have to perform in order to install a transom-mounted transducer. They are:

• Determine transducer mounting location

• Mount the bracket to the boat (find the procedure for your transducer, either

Single frequency or Dual frequency)

• Attach the pivot to the transducer (find the procedure for your transducer, either

Single frequency or Dual frequency)

• Mount the transducer pivot assembly to the bracket (find the procedure for your

transducer, either Single frequency or Dual frequency)

• Adjust the running position of the transducer (find the procedure for your

transducer, either Single frequency or Dual frequency)

• Route the transducer cable

• Perform a final test of the transom transducer installation.

To determine transducer mounting location:

NOTE: If transom mounting is not possible because of a stepped hull or cavitation noise, and

you have a single layer fiberglass hull, In-hull installation is an option. See Inside the Hull

Transducer Installation for more information.

1. First, determine the best location on the transom to install the transducer.

Consider the following to find the best location:

• It is very important to locate the transducer in an area which is relatively free of

turbulent water. As a boat moves through the water, turbulence is generated by

the weight of the boat, and the thrust of the propeller(s) - either clockwise or

counter-clockwise. This turbulent water is normally confined to areas

immediately aft of ribs, strakes or rows of rivets on the bottom of the boat, and

in the immediate area of the propeller(s). Clockwise propellers create more

turbulence on the port side. On outboard or inboard/outboard boats, it is best to

locate the transducer at least 15" (380 mm) to the side of the propeller(s).

• The best way to locate turbulence-free water is to view the transom while the

boat is moving. This method is recommended if maximum high-speed operation

is a high priority. If this is not possible, select a location on the transom where the

hull forward of this location is smooth, flat and free of protrusions or ribs.

• The hydrodynamic shape of your transducer allows it to point straight down

without deadrise adjustment.

• On boats with stepped hulls, it may be possible to mount the transducer on the

step. Do not mount the transducer on the transom behind a step to avoid

popping the transducer out of the water at higher speeds; the transducer must

remain in the water for the control head to maintain the sonar signal.

• If the transom is behind the propeller(s), it may be impossible to find an area

clear from turbulence, and a different mounting technique or transducer type

should be considered (see Inside the Hull Transducer Installation).

Stepped Hull

Rivets/Strakes

1

Deadrise Angle

2

Step

3

1

2

3

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 16

www.reelschematic.com

www.reelschematic.com

Page 17

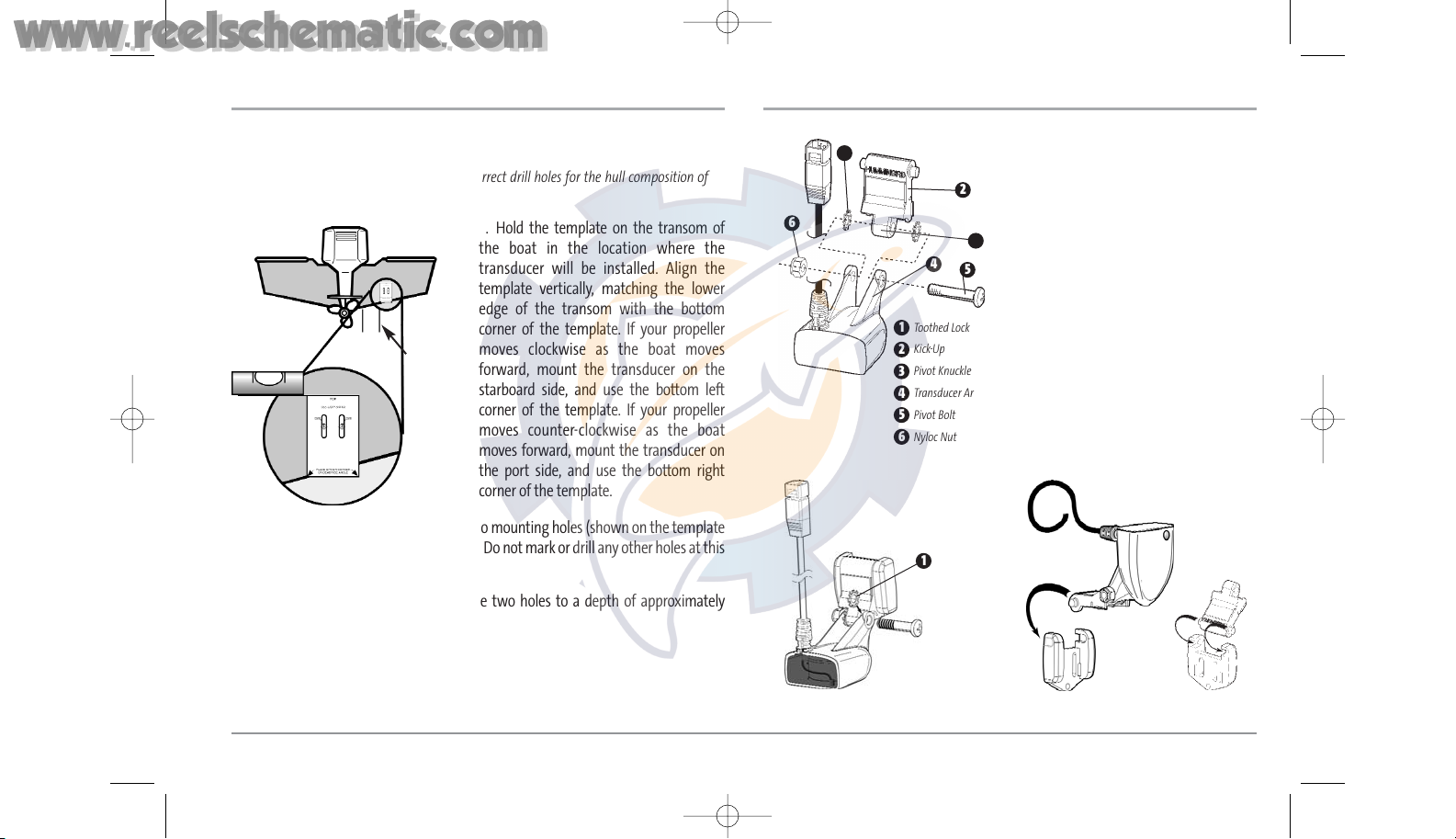

To mount the transducer bracket to the boat (Single frequency unit):

1. Remove the transducer mounting template from this manual. See Appendix A

for the Single Frequency Mounting Template.

NOTE: Please make sure that you use the correct drill holes for the hull composition of

your boat.

2. Hold the template on the transom of

the boat in the location where the

transducer will be installed. Align the

template vertically, matching the lower

edge of the transom with the bottom

corner of the template. If your propeller

moves clockwise as the boat moves

forward, mount the transducer on the

starboard side, and use the bottom left

corner of the template. If your propeller

moves counter-clockwise as the boat

moves forward, mount the transducer on

the port side, and use the bottom right

corner of the template.

3. Using a pencil or punch, mark the two mounting holes (shown on the template

for your type of hull) on the transom. Do not mark or drill any other holes at this

time.

4. Using a 9/64" (3.5 mm) bit, drill the two holes to a depth of approximately

1" (25 mm).

To attach the pivot to the transducer (Single frequency unit):

1. Attach the Two Piece Kick-Up pivot to

the transducer body, using the 1/4" - 20 x

1 1/4" Phillips head pivot bolt, the nyloc

nut, and the two toothed lock washers.

NOTE: The toothed lock washers must be

positioned between the transducer arms

and the pivot knuckle regardless of

mounting bracket type.

2. Using a Phillips screwdriver and a 7/16”

wrench, loosely tighten the pivot bolt. Do

not completely tighten the assembly at

this time, so that the pivot angle can be

adjusted later.

1

Toothed Lock Washer

1

Kick-Up

2

Pivot Knuckle

3

Transducer Arms

4

Pivot Bolt

5

Nyloc Nut

6

1

2

3

4

5

6

Level

15” (380 mm)

from prop(s)

12

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 17

www.reelschematic.com

www.reelschematic.com

Page 18

13

To mount the transducer pivot assembly to the bracket

(Single frequency units):

1. Insert the pivot/transducer assembly into the mounting bracket.

2. Do not snap the assembly closed.

3. Apply marine-grade silicone sealant to the mounting holes drilled into the

transom.

4. Align the transducer assembly with the drilled holes in the transom.

5. Using the appropriate tool for your mounting hardware,

attach the transducer assembly to the boat transom as

shown, using #8 x 5/8” (16 mm) wood screws. Do not fully

tighten the mounting screws in order to adjust the

transducer vertically. Snap the pivot down into place.

NOTE: The running position of the transducer is now

completely adjustable. Subsequent adjustment may be

necessary to tweak the installation after high speed testing.

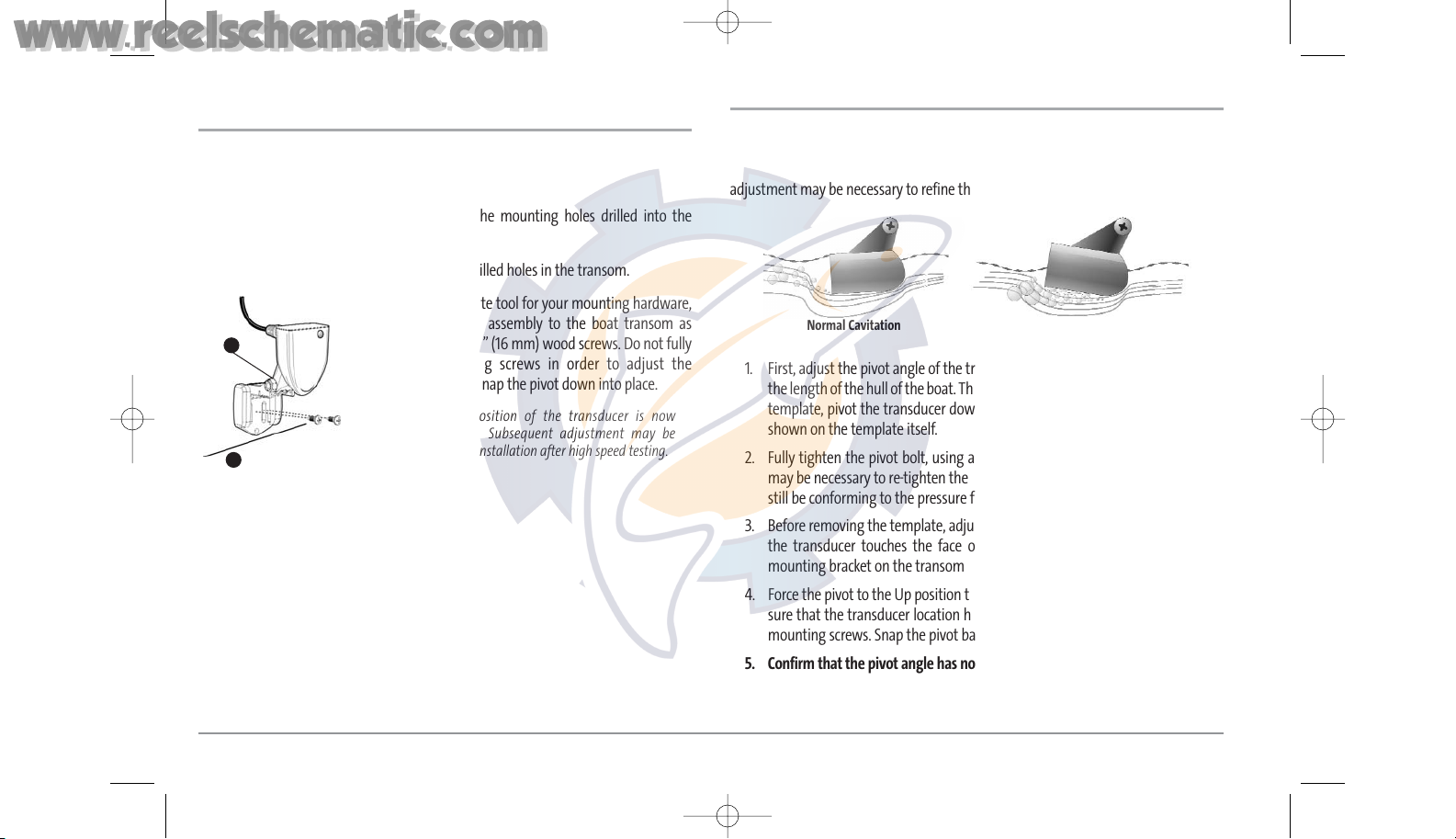

To adjust the running position of the transducer (Single frequency unit):

The transducer mounting bracket allows height and tilt adjustment, while the pivot

bolt allows angular adjustment. These adjustments will help reduce cavitation.

Initially, adjust the transducer as described in the following paragraphs. Further

adjustment may be necessary to refine the installation after high-speed testing.

1. First, adjust the pivot angle of the transducer body, so its length is parallel with

the length of the hull of the boat. Then, using the angle portion of the mounting

template, pivot the transducer down so that it matches the template angle as

shown on the template itself.

2. Fully tighten the pivot bolt, using a Phillips head screwdriver and a wrench. It

may be necessary to re-tighten the pivot bolt after initial use as the plastic may

still be conforming to the pressure from the lock washers.

3. Before removing the template, adjust the height of the assembly so the face of

the transducer touches the face of the template. Mark the position of the

mounting bracket on the transom with a pencil.

4. Force the pivot to the Up position to gain access to the mounting screws. Make

sure that the transducer location has not changed, then hand tighten the two

mounting screws. Snap the pivot back down.

5. Confirm that the pivot angle has not changed.

NOTE: when you are done with this procedure, go to the section entitled: To route the

transducer cable.

Normal Cavitation Cavitation that will cause

erratic sonar readings

1

Kick-Up Bracket

1

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 18

www.reelschematic.com

www.reelschematic.com

Page 19

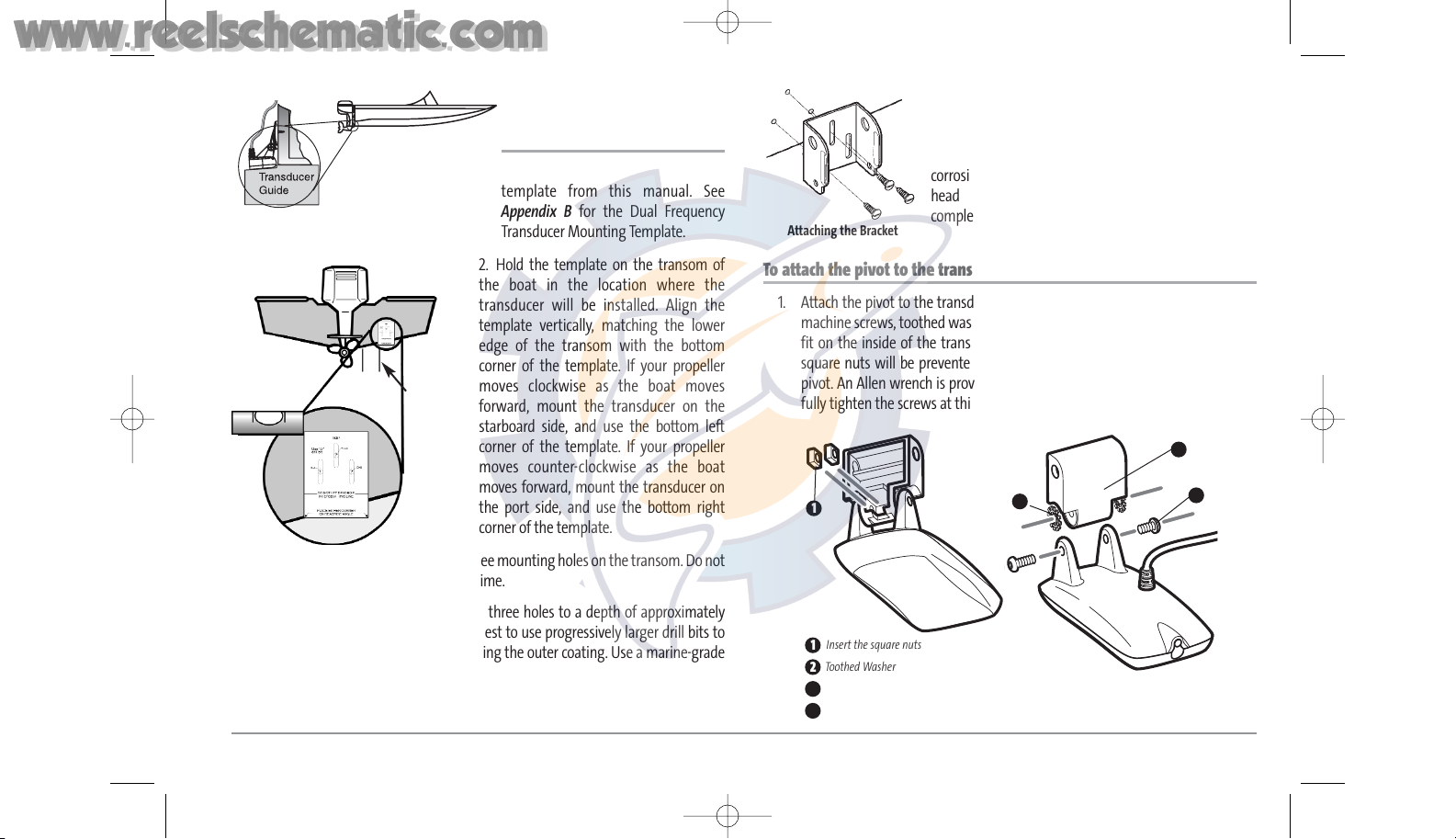

To mount the transducer

bracket to the boat

(Dual frequency unit):

1. Remove the transducer mounting

template from this manual. See

Appendix B for the Dual Frequency

Transducer Mounting Template.

2. Hold the template on the transom of

the boat in the location where the

transducer will be installed. Align the

template vertically, matching the lower

edge of the transom with the bottom

corner of the template. If your propeller

moves clockwise as the boat moves

forward, mount the transducer on the

starboard side, and use the bottom left

corner of the template. If your propeller

moves counter-clockwise as the boat

moves forward, mount the transducer on

the port side, and use the bottom right

corner of the template.

3. Using a pencil or punch, mark the three mounting holes on the transom. Do not

mark or drill any other holes at this time.

4. Using a 5/32" (4.0 mm) bit, drill the three holes to a depth of approximately

1" (25 mm). On fiberglass hulls, it is best to use progressively larger drill bits to

reduce the chance of chipping or flaking the outer coating. Use a marine-grade

silicone sealant to fill the drilled holes.

5. Align the metal mounting bracket with the mounting

holes. The center slot should be above the two outer

slots. (This bracket and all other hardware supplied is top

quality stainless steel for maximum strength and

corrosion protection.) Insert the three 1" (25 mm) flat

head wood screws into the drilled holes, but do not

completely tighten.

To attach the pivot to the transducer (Dual frequency unit):

1. Attach the pivot to the transducer body, using the two 1/4"-20 x 5/8" (16 mm)

machine screws, toothed washers, and square nuts. The toothed washers must

fit on the inside of the transducer ears, between the pivot and the ears. The

square nuts will be prevented from rotating by the pocket in the back of the

pivot. An Allen wrench is provided which fits all the 1/4"-20 screws, but do not

fully tighten the screws at this time.

Attach the Pivot

2

3

4

1

Insert the square nuts

1

Toothed Washer

2

Pivot

3

Machine Screw

4

Attaching the Bracket

Level

15” (380 mm)

from prop(s)

14

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 19

www.reelschematic.com

www.reelschematic.com

Page 20

15

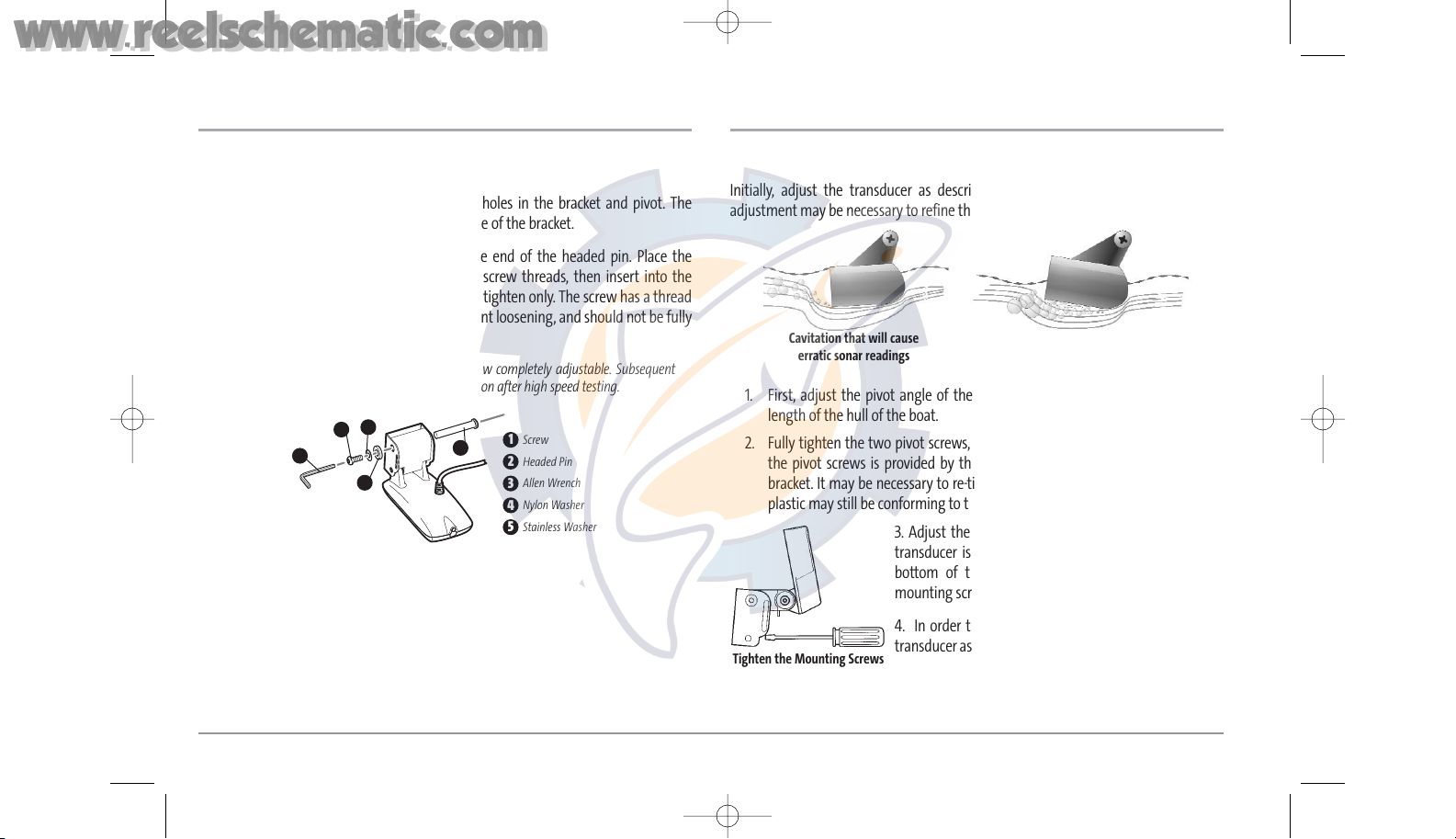

To mount the transducer pivot assembly to the bracket

(Dual frequency units):

1. Slide the assembled transducer into the metal bracket from the bottom,

aligning the large hole at the top of the bracket with the hole in the pivot.

2. Insert the headed pin through the pivot holes in the bracket and pivot. The

headed pin can be inserted from either side of the bracket.

3. Place the nylon washer over the opposite end of the headed pin. Place the

stainless washer over the 1/4"-20 x 5/8" screw threads, then insert into the

opposite end of the headed pin and finger tighten only. The screw has a thread

locking compound on the threads to prevent loosening, and should not be fully

tightened until all adjustments are made.

NOTE: The running position of the transducer is now completely adjustable. Subsequent

adjustment may be necessary to tweak the installation after high speed testing.

To adjust the running position of the transducer

(Dual frequency units):

The transducer mounting bracket allows height and tilt adjustment, while the pivot

bolt allows angular adjustment. These adjustments will help reduce cavitation.

Initially, adjust the transducer as described in the following paragraphs. Further

adjustment may be necessary to refine the installation after high-speed testing.

1. First, adjust the pivot angle of the transducer body, so it is parallel with the

length of the hull of the boat.

2. Fully tighten the two pivot screws, using the supplied Allen wrench. Access to

the pivot screws is provided by the lower holes in the side of the mounting

bracket. It may be necessary to re-tighten the pivot bolt after initial use as the

plastic may still be conforming to the pressure from the lock washers.

3. Adjust the height of the assembly so the face of the

transducer is 1/8" (3 mm) to 1/4" (6 mm) beneath the

bottom of the transom, and fully tighten the three

mounting screws.

4. In order to gain access to the mounting screws, the

transducer assembly must be pivoted up in the bracket as

shown. Be careful not to alter the running angle as some

force is necessary to pivot the assembly.

Tighten the Mounting Screws

Cavitation that will cause

erratic sonar readings

Normal Cavitation

Screw

1

Headed Pin

2

Allen Wrench

3

Nylon Washer

4

Stainless Washer

5

3

1

5

4

2

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 20

www.reelschematic.com

www.reelschematic.com

Page 21

5. If access to the top mounting hole is not possible due to the selected height of

the transducer, fully tighten the two lower screws, then simply remove the

headed pivot pin and the transducer assembly, and tighten the top screw, then

reassemble.

6. Confirm that the pivot angle has not changed and that all mounting screws are

fully tightened.

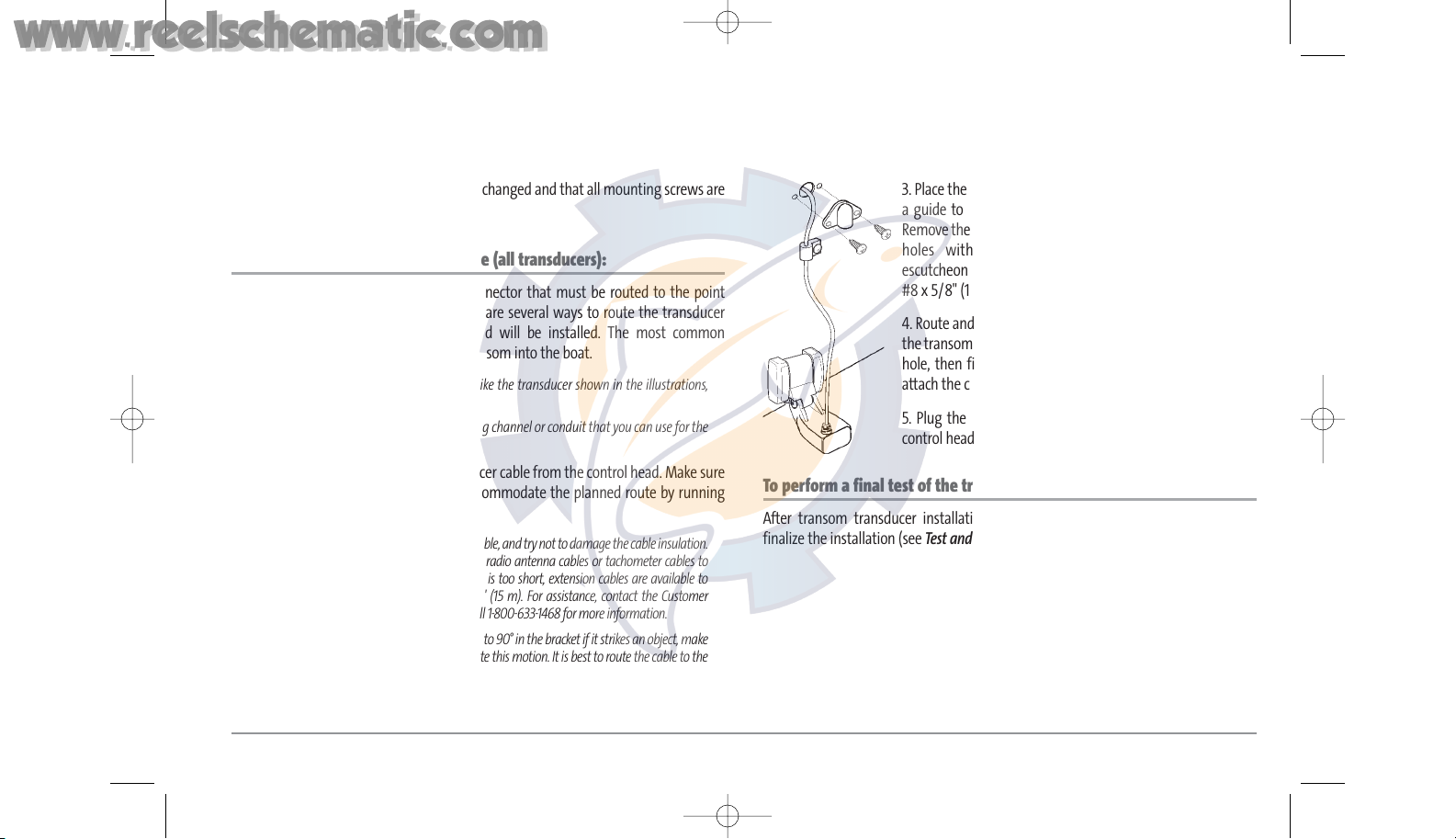

To route the transom transducer cable (all transducers):

The transducer cable has a low profile connector that must be routed to the point

where the control head is mounted. There are several ways to route the transducer

cable to the area where the control head will be installed. The most common

procedure routes the cable through the transom into the boat.

NOTE: Your transducer may not look exactly like the transducer shown in the illustrations,

but it will mount in exactly the same way.

NOTE: Your boat may have a pre-existing wiring channel or conduit that you can use for the

transducer cable.

1. Unplug the other end of the transducer cable from the control head. Make sure

that the cable is long enough to accommodate the planned route by running

the cable over the transom.

CAUTION! Do not cut or shorten the transducer cable, and try not to damage the cable insulation.

Route the cable as far as possible from any VHF radio antenna cables or tachometer cables to

reduce the possibility of interference. If the cable is too short, extension cables are available to

extend the transducer cable up to a total of 50' (15 m). For assistance, contact the Customer

Resource Center at www.humminbird.com or call 1-800-633-1468 for more information.

NOTE: Since the transducer may need to pivot up to 90° in the bracket if it strikes an object, make

sure there is sufficient cable slack to accommodate this motion. It is best to route the cable to the

side of the transducer so the cable will not be damaged by the rotation of the transducer.

2. If you will be routing the cable through a hole in the transom, drill a 5/8"

diameter (16 mm) hole above the waterline. Route the cable through this hole,

then fill the hole with marine-grade silicone sealant and proceed to the next

step immediately.

3. Place the escutcheon plate over the cable hole and use it as

a guide to mark the two escutcheon plate mounting holes.

Remove the plate, drill two 9/64" (3.5 mm) holes, then fill both

holes with marine-grade silicone sealant. Place the

escutcheon plate over the cable hole and attach with two

#8 x 5/8" (16 mm) wood screws.

4. Route and secure the cable by attaching the cable clamp to

the transom; drill one 9/64" dia. (3.5 mm) x 5/8" deep (16 mm)

hole, then fill hole with marine-grade silicone sealant, then

attach the cable clamp using a #8 x 5/8" (16 mm) screw.

5. Plug the other end of the transducer cable back into the

control head connection holder.

To perform a final test of the transom transducer installation:

After transom transducer installation, please perform the final testing and then

finalize the installation (see Test and Finish the Transducer Installation).

16

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 21

www.reelschematic.com

www.reelschematic.com

Page 22

17

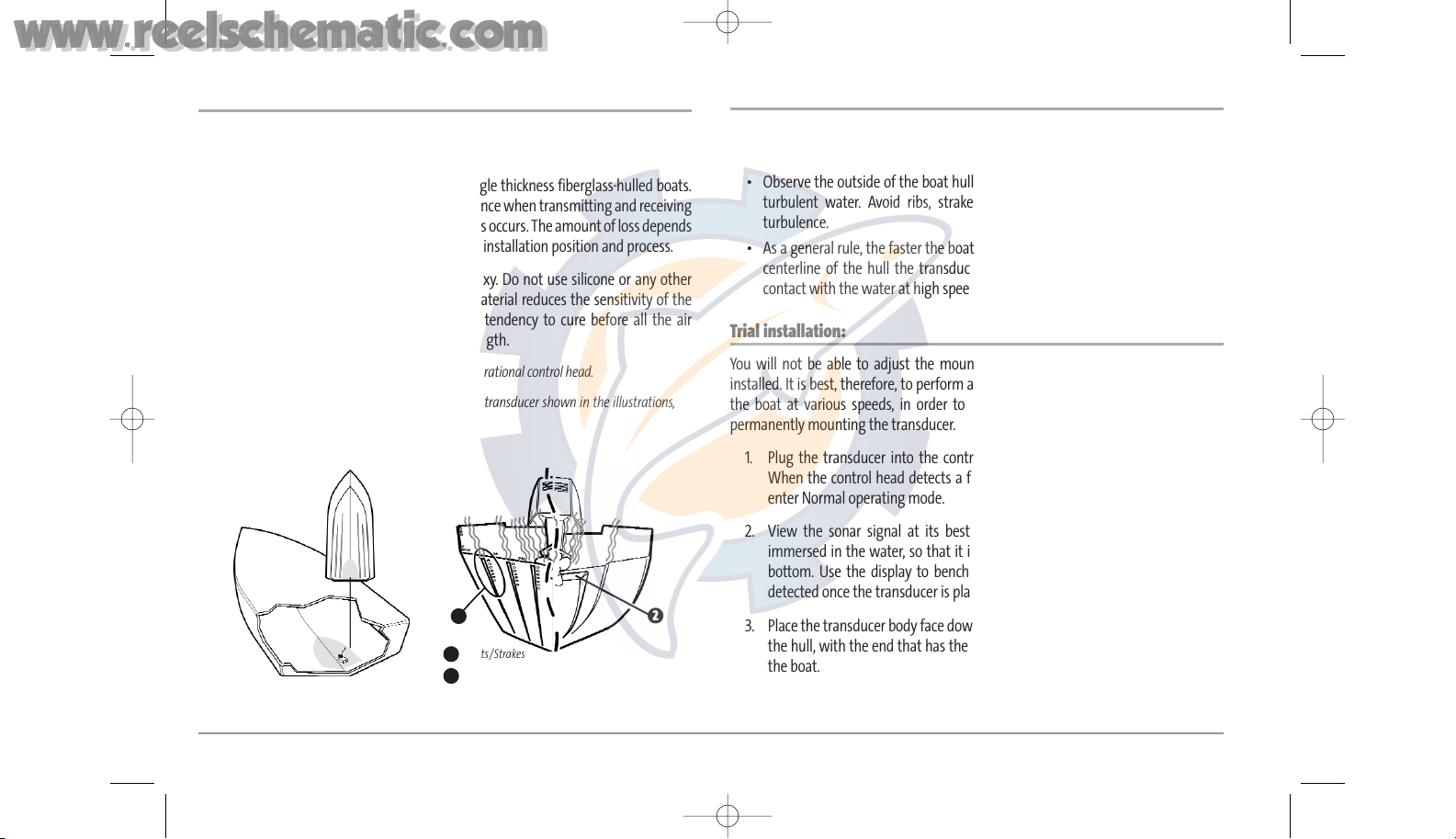

INSIDE THE HULL TRANSDUCER INSTALLATION

If you choose to mount your transducer inside the hull of your boat, perform the

procedures in this section. The inside the hull mounting procedure is identical

regardless of what type of transducer you have (Single or Dual frequency). In-hull

mounting generally produces good results in single thickness fiberglass-hulled boats.

Humminbird® cannot guarantee depth performance when transmitting and receiving

through the hull of the boat, since some signal loss occurs. The amount of loss depends

on hull construction and thickness, as well as the installation position and process.

This installation requires slow-cure two-part epoxy. Do not use silicone or any other

soft adhesive to install the transducer, as this material reduces the sensitivity of the

unit. Do not use five-minute epoxy, as it has a tendency to cure before all the air

bubbles can be purged, thus reducing signal strength.

NOTE: In-hull mounting requires an installed and operational control head.

NOTE: Your transducer may not look exactly like the transducer shown in the illustrations,

but it will mount in exactly the same way.

Determine the transducer mounting location:

Decide where to install the transducer on the inside of the hull. Consider the following

to find the best location:

• Observe the outside of the boat hull to find the areas that are mostly free from

turbulent water. Avoid ribs, strakes and other protrusions, as these create

turbulence.

• As a general rule, the faster the boat can travel, the further aft and closer to the

centerline of the hull the transducer has to be located in order to remain in

contact with the water at high speeds.

Trial installation:

You will not be able to adjust the mounting after an inside the hull transducer is

installed. It is best, therefore, to perform a trial installation first that includes running

the boat at various speeds, in order to determine the best mounting area before

permanently mounting the transducer.

1. Plug the transducer into the control head, then power up the control head.

When the control head detects a functioning transducer, it will automatically

enter Normal operating mode.

2. View the sonar signal at its best by holding the transducer over the side,

immersed in the water, so that it is pointing straight down over a known flat

bottom. Use the display to benchmark against the sonar signal that will be

detected once the transducer is placed in the hull.

3. Place the transducer body face down at the identified mounting location inside

the hull, with the end that has the mounting ears pointed towards the bow of

the boat.

Rivets/Strakes

1

Step

2

1

2

Preferred Mounting Area

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 22

www.reelschematic.com

www.reelschematic.com

Page 23

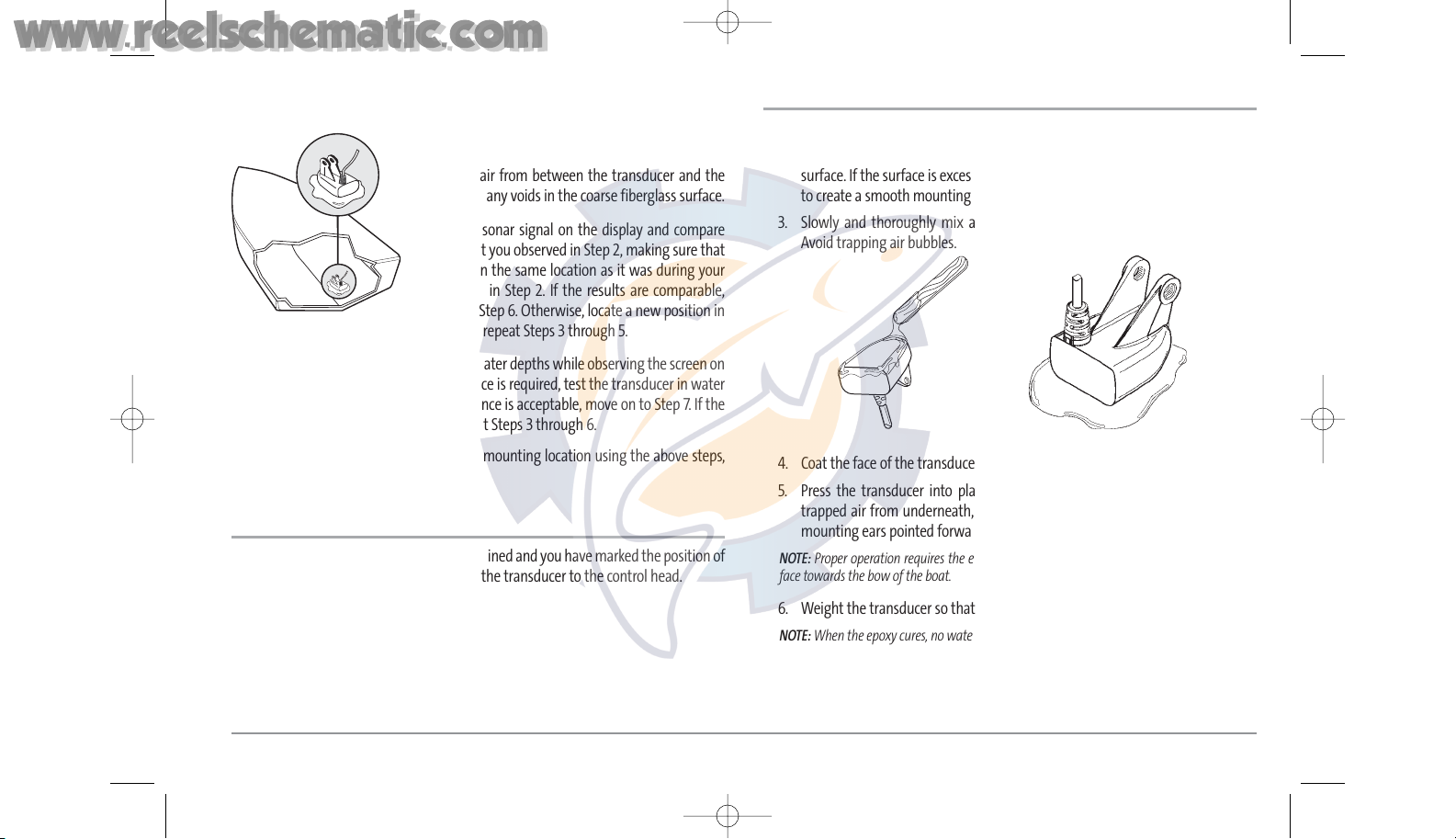

4. Fill the hull with enough water to submerge the

transducer body. Use a sand-filled bag or other heavy

object to hold the transducer in position. The

transducer cannot transmit through air, and the water

purges any air from between the transducer and the

hull, and fills any voids in the coarse fiberglass surface.

5. View the sonar signal on the display and compare

against what you observed in Step 2, making sure that

the boat is in the same location as it was during your

observations in Step 2. If the results are comparable,

move on to Step 6. Otherwise, locate a new position in

the hull and repeat Steps 3 through 5.

6. Run the boat at various speeds and water depths while observing the screen on

the control head. If depth performance is required, test the transducer in water

at the desired depth. If the performance is acceptable, move on to Step 7. If the

performance is not acceptable, repeat Steps 3 through 6.

7. Once you have determined the best mounting location using the above steps,

mark the position of the transducer.

Route the cable:

1. Once the mounting location is determined and you have marked the position of

the transducer, route the cable from the transducer to the control head.

Permanently mount the transducer:

1. Make sure the position of the transducer is marked.

2. Remove the water from inside the hull and thoroughly dry the mounting

surface. If the surface is excessively rough, it may be necessary to sand the area

to create a smooth mounting surface.

3. Slowly and thoroughly mix an ample quantity of two-part slow cure epoxy.

Avoid trapping air bubbles.

4. Coat the face of the transducer and the inside of the hull with epoxy.

5. Press the transducer into place with a slight twisting motion to purge any

trapped air from underneath, keeping the end of the transducer that has the

mounting ears pointed forward, towards the bow of the boat.

NOTE: Proper operation requires the end of the transducer that has the mounting ears to

face towards the bow of the boat.

6. Weight the transducer so that it will not move while the epoxy is curing.

NOTE: When the epoxy cures, no water is necessary inside the hull.

7. If you unplugged the transducer cable at the beginning of this procedure, plug

it back into the control head.

NOTE: Neither water, spilled gasoline, nor oil will affect the performance of the transducer.

Transducer Mounted

Inside the Hull

18

93x_Man_531370-1_A - vs4.qxd 2/18/2005 11:11 AM Page 23

www.reelschematic.com

www.reelschematic.com

Page 24

19

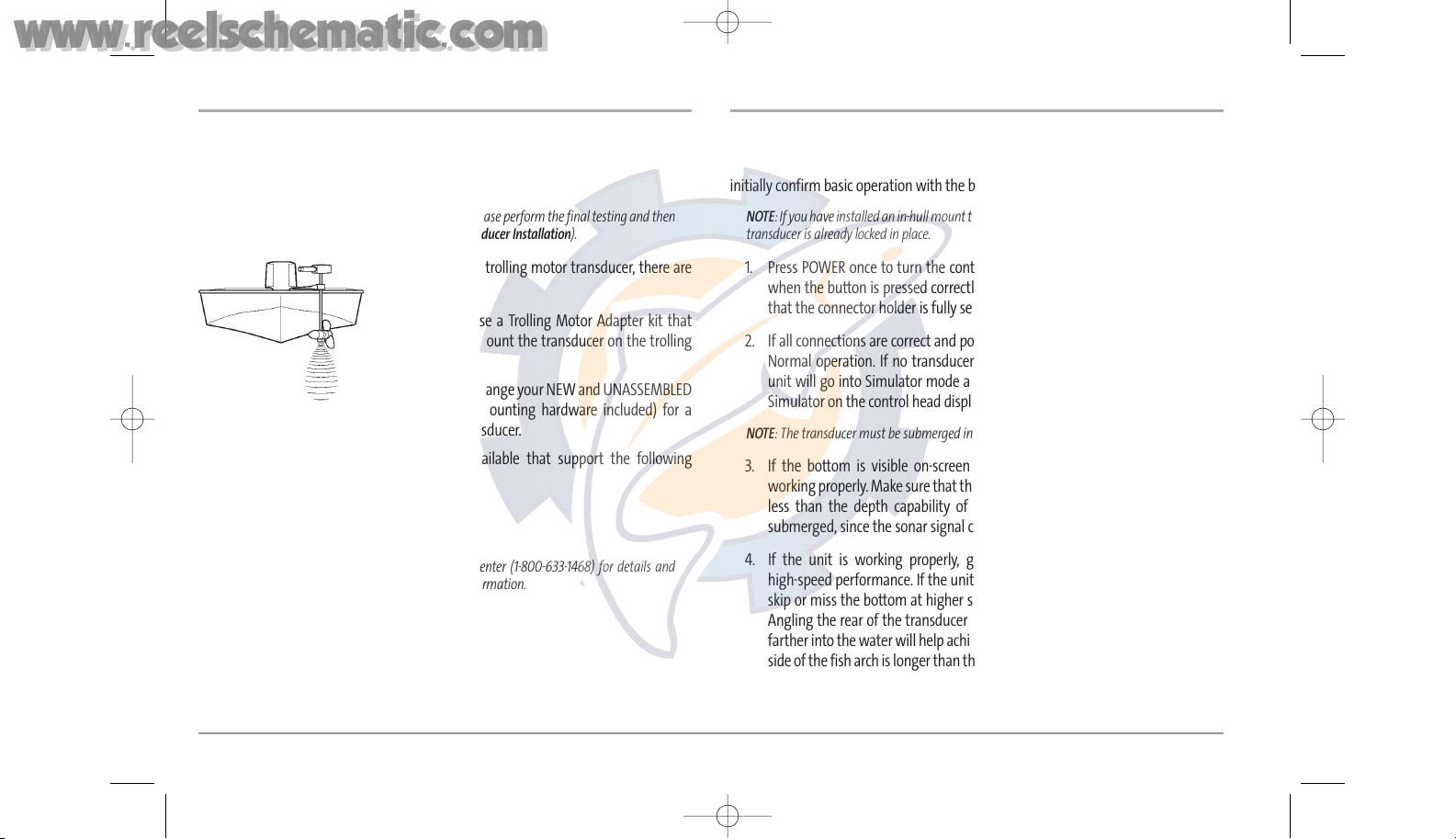

TROLLING MOTOR TRANSDUCER INSTALLATION

If you want to install the transducer on a trolling motor, use this procedure. Several

styles of the transducer are compatible with trolling motor mounting. If you have a

trolling motor bracket, refer to the separate installation instructions that are included

with the bracket.

NOTE: After trolling motor transducer installation, please perform the final testing and then

finalize the installation (see Test and Finish the Transducer Installation).

If you don’t have a trolling motor transducer, there are

several options:

• You may purchase a Trolling Motor Adapter kit that

will allow you to mount the transducer on the trolling

motor.

• You may also exchange your NEW and UNASSEMBLED

transducer (with mounting hardware included) for a

trolling motor transducer.

There are also several transducer switches available that support the following

configurations:

• Two control heads with one transducer

• Two transducers with one control head.

NOTE: Call the Humminbird® Customer Resource Center (1-800-633-1468) for details and

pricing, or visit www.humminbird.com for more information.

TEST AND FINISH THE TRANSDUCER INSTALLATION

When you have installed both the control head, the transducer, and accessories and

have routed all the cables, you must perform a final test before locking the transducer

in place. Testing should be performed with the boat in the water, although you can

initially confirm basic operation with the boat out of the water.

NOTE: If you have installed an in-hull mount transducer, this procedure does not apply, as the

transducer is already locked in place.

1. Press POWER once to turn the control head on. There will be an audible chirp

when the button is pressed correctly. If the unit does not power-up, make sure

that the connector holder is fully seated and that power is available.

2. If all connections are correct and power is available, the control head will enter

Normal operation. If no transducer is detected (or one is not connected), the

unit will go into Simulator mode and will indicate this by displaying the word

Simulator on the control head display.

NOTE: The transducer must be submerged in water for reliable transducer detection.

3. If the bottom is visible on-screen with a digital depth readout, the unit is

working properly. Make sure that the boat is in water greater than 2 ft (.6 m) but

less than the depth capability of the unit, and that the transducer is fully

submerged, since the sonar signal cannot pass through air.

4. If the unit is working properly, gradually increase the boat speed to test

high-speed performance. If the unit functions well at low speeds but begins to

skip or miss the bottom at higher speeds, the transducer requires adjustment.

Angling the rear of the transducer downward and/or lowering the transducer