Humminbird 425 SX User Manual

OPERATIONS

MANUAL

THANK YOU

THANK YOU FOR CHOOSING YOUR 425SX FISHFINDER, MADE BY

TECHSONIC INDUSTRIES, MANUFACTURER OF AMERICA’S #1 NAME IN

FISHFINDERS, HUMMINBIRD. HUMMINBIRD HAS BUILT ITS REPUTATION

BY DESIGNING AND MANUFACTURING TOP QUALITY, THOROUGHLY

RELIABLE MARINE EQUIPMENT. YOUR HUMMINBIRD PRODUCT IS

DESIGNED FOR TROUBLE-FREE USE IN EVEN THE HARSHEST MARINE

ENVIRONMENT.

IN THE UNLIKELY EVENT THAT YOUR HUMMINBIRD DOES REQUIRE

REPAIRS, WE OFFER AN EXCLUSIVE SERVICE GUARANTEE. COMPLETE

DETAILS ARE INCLUDED AT THE END OF THIS MANUAL.

WE ENCOURAGE YOU TO READ THIS OPERATIONS MANUAL CAREFULLY

IN ORDER TO GET FULL BENEFIT FROM ALL THE FEATURES AND USES OF

YOUR HUMMINBIRD PRODUCT.

WARNING! THIS DEVICE SHOULD NOT BE USED AS A

NAVIGATIONAL AID TO PREVENT COLLISION, GROUNDING,

BOAT DAMAGE, OR PERSONAL INJURY. WHEN THE BOAT IS

MOVING, WATER DEPTH MAY CHANGE TOO QUICKLY TO

ALLOW TIME FOR YOU TO REACT. ALWAYS OPERATE THE BOAT

AT VERY SLOW SPEEDS IF YOU SUSPECT SHALLOW WATER OR

SUBMERGED OBJECTS.

TABLE OF CONTENTS

Section 1: Installation preparation . . . . . . . . . . . . . . . . . . . 2

Parts Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . 2

Alternative Transducers and Mounting Methods. . . . . . 4

Beginning Installation . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 2: USING THE 425SX. . . . . . . . . . . . . . . . . . . . . . . 6

How Sonar Works . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Simulator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

What You See On Screen . . . . . . . . . . . . . . . . . . . 7–12

Control Functions . . . . . . . . . . . . . . . . . . . . . . . . 12–15

Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . 15–25

Section 3: ADVANCED FEATURES. . . . . . . . . . . . . . . . . . . 25

Using Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Section 5: MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . 27

Maintenance and Troubleshooting . . . . . . . . . . . . 27–30

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

INSTALLATION PREPARATION

PARTS SUPPLIED

PARTS SUPPLIED

Before installing your 425SX, please ensure the following parts are included in

the box:

• 425SX fishfinder

• Transducer with 6m (20') of cable and mounting hardware kit

• Mounting system and mounting hardware kit

• 2m (6' ) power cable

• Publications kit

Note: The 425SX+includes speed and temperature sensors with

appropriate hardware and instructions for installation.

If any of these items are missing contact your local dealer.

ACCESSORIES

Humminbird offers a wide assortment of accessories that complement and

expand the capability of your new 425SX. These accessories are designed with

the same high standards. The Humminbird Accessory catalog included with

your unit contains descriptions of the many accessories available and ordering

information. All Humminbird accessories are available through your full-service

Humminbird dealer.

INSTALLATION OVERVIEW

The 425SX consists of two primary components to install: the control head and

the transducer.

The control head contains the sonar transmit and receive circuitry, as well as the

user controls and display. It should be installed in a location that provides access

to the controls and visibility while in use. The control head mounts on a quick

disconnect mounting system that swivels and tilts, providing flexibility for

viewing from almost anywhere on the boat.

2

INSTALLATION PREPARATION

INSTALLATION OVERVIEW

The transducer converts electrical energy from the transmitter into mechanical

pulses or sound waves. The transducer also receives the reflected sound waves

and converts them back into electrical signals for display on the control head. It

should be installed in contact with the surface of the water in an area that has

smooth water flow - usually on the transom of the boat. There are several

mounting options for the transducer. Review

the following section to determine the

method that works for you and your boat.

Determining How to Mount the

Transducer

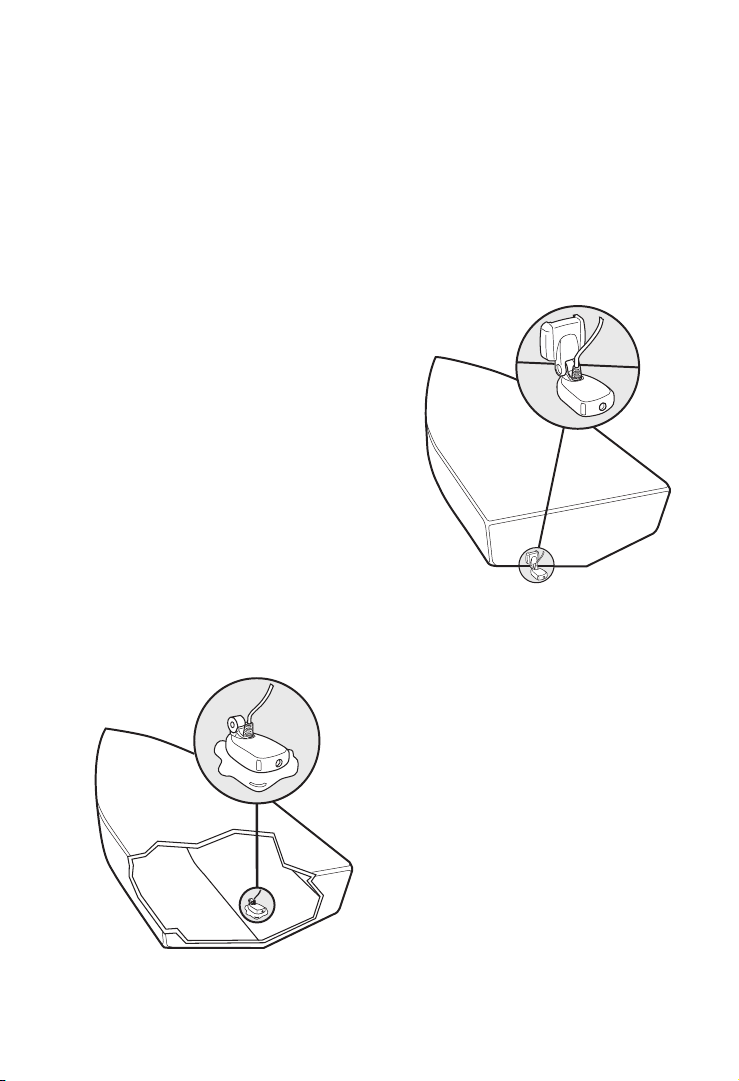

The 425SX includes a model XT-6-24

transducer. This transducer can be mounted

on the transom of the boat, or bonded to

the inside of a fiberglass hull boat.

The transom installation, which is the most

widely used, places the transducer on the

outside of the boat hull. This technique

produces the least signal loss, and provides a

way to adjust the transducer after

installation. The mounting hardware

included is designed to protect both

the boat and the transducer should the

boat strike debris in the water or when

trailering.

Transom Mounted Transducer

Inside the Hull Mounted Transducer

As an alternative to transom mounting,

it is possible on many fiberglass-hulled

boats to glue the transducer on the

inside of the boat hull. Since fiberglass

has similar sonar characteristics as

water, the sonar signal can pass

through the boat hull with minimal

loss. The hull of the boat must be single

layer construction (not double-hulled).

Also, any air trapped in the lamination

of the fiberglass would prevent the sonar

3

INSTALLATION PREPARATION

ALTERNATE TRANSDUCERS AND MOUNTING METHODS

signal from passing through.

Inside the hull installations require no holes to be drilled into the boat and

through experimentation, high-speed operation comparable to transom

mounting can be achieved. Two part, slow cure epoxy is required to glue the

transducer in place.

ALTERNATE TRANSDUCERS AND MOUNTING METHODS

The 425SX comes with everything necessary for installation and operation on

most boats. However, there are several situations which may require a different

type of transducer. Inboard boats, wood or metal hulls, and sail boats create

unique transducer mounting needs. Alternate transducers and mounting

methods are detailed below.

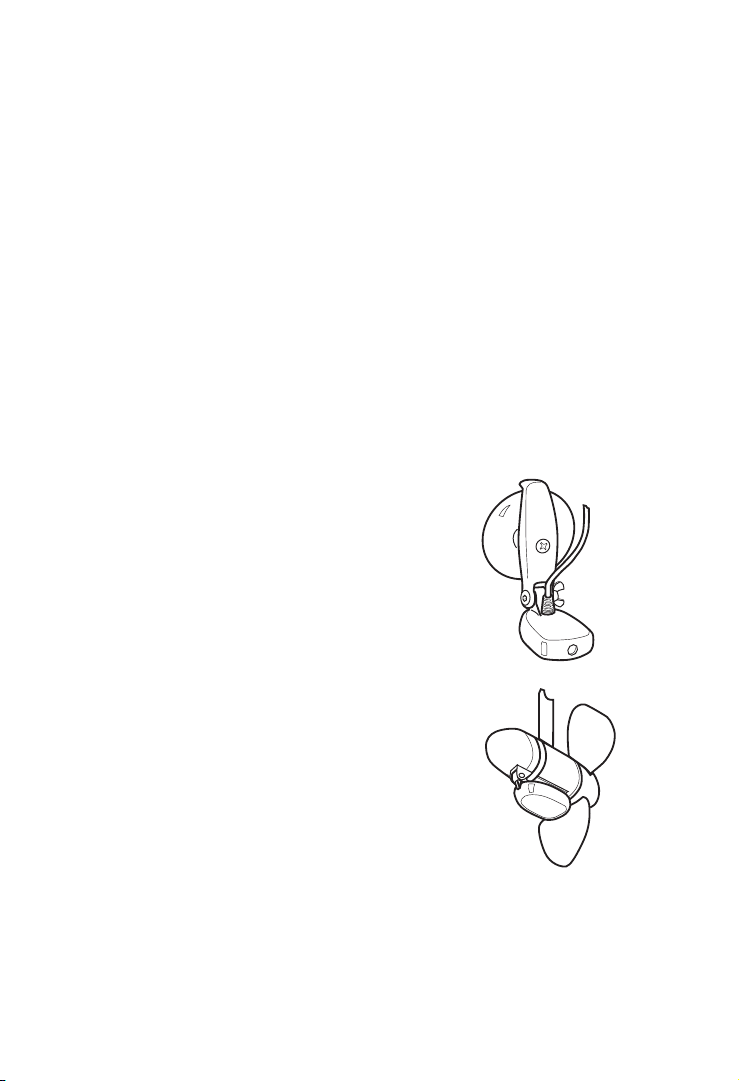

Portable Mounting

The standard transducer can be adapted for

portable installations using part number MHX-PT2.

This accessory adapts your transducer to a suction

cup mount for temporary installation on the boat

hull or other surface.

Trolling Motor Mounting

The standard transducer can also be adapted to

mount on most trolling motors using part number

AD-STM-7. This accessory includes a bracket and

hose clamp that allows mounting the transducer to

the body of most trolling motors.

TRANSDUCER EXCHANGE

Other transducers are available as replacements for the standard transducer.

You may exchange your new and unassembled transducer for another type by

returning it to the address listed in Customer Support. Some transducers may

have additional costs. Refer to the Accessory catalog or call Customer Support

for information.

4

INSTALLATION PREPARATION

BEGINNING INSTALLATION

BEGINNING INSTALLATION

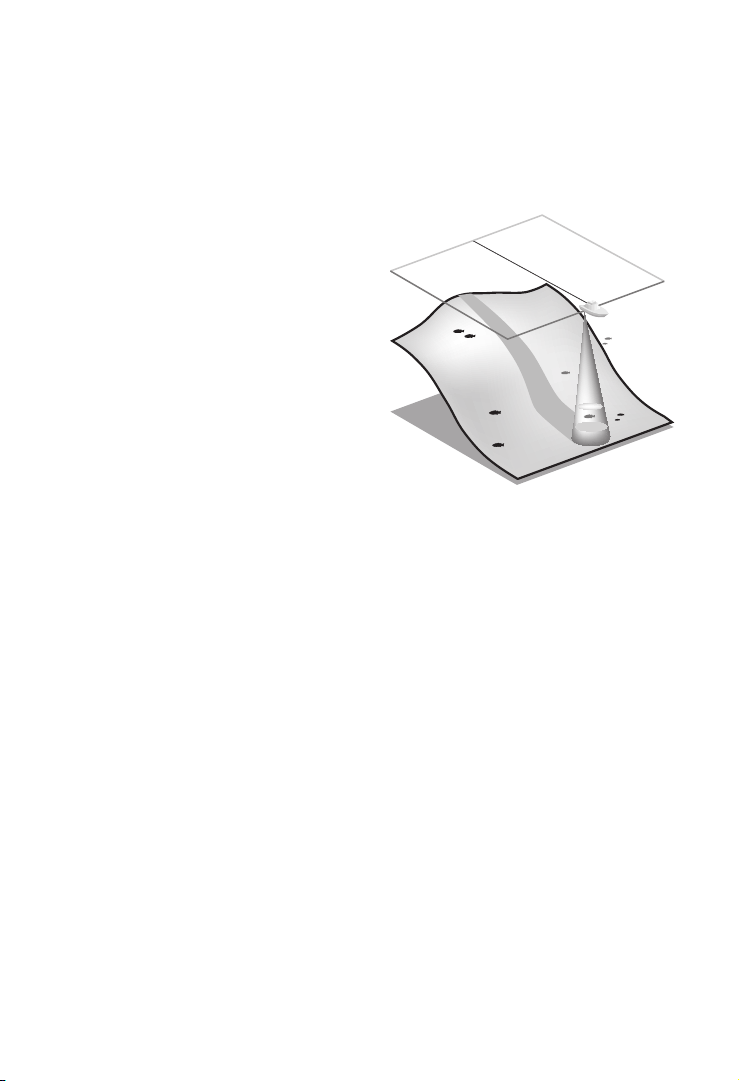

Now that you have determined the transducer mounting method, you can

begin installation of the 425SX. The fold out installation guide included

provides detailed step by step instructions for installation of the control head

and transducer. For transom mount transducer installations, you will need the

mounting template at the back of this manual.

In addition to the parts included you need the following for installation and

operation:

• A powered hand drill and various drill bits

• Phillips and flat-head screw drivers

• A ruler or measuring tape

• Pen or pencil

• 12 volt power source (your boat’s battery)

• A 1-amp fuse

• A fuse holder (if you are wiring directly to the boat’s battery)

• Silicone sealant (for sealing drilled holes)

• 2-part, slow-cure epoxy (for inside the hull transducer installations)

Note: If you have purchased the 425SX+you will have in addition

to the parts and instructions above:

• Speed and Temperature sensors

• Instructions for installing speed and temperature sensors

• Appropriate hardware to mount sensors

5

USING THE 425SX

HOW SONAR WORKS

HOW SONAR WORKS

Your Humminbird unit uses sonar to

locate and define underwater objects,

define the bottom terrain, as well as

determine distance.

Sonar technology is based on sound

waves. Your Humminbird unit sends out

a sound wave signal. With this signal it

determines distance by measuring the

time between the transmission of the

sound wave and when the sound wave

is reflected off an object. Your

Humminbird uses the reflected signal to

interpret location, size and composition of an object.

Sonar is very fast. A sound wave can travel from the surface to a depth of 70m

(240') and back again in less than ¹⁄₄ of a second. It is unlikely that your boat

can "outrun" this sonar signal.

The 425SX is a 200 kHz, single-beam fishfinder. The 200 kHz frequency

provides excellent sonar resolution (the ability to distinguish small returns or

returns which are close to the bottom), while providing depth capabilities to

185m (600’). The shape of the sonar beam is symmetrical and covers an area

of approximately 24 degrees side to side and front to rear.

Actual depth capability depends on factors such as bottom hardness, water

conditions, and transducer installation. Units will typically read to deeper

depths in fresh water than in salt water.

SIMULATOR OPERATION

The 425SX contains a simulator that allows you to use the unit as if you are on the

water. The simulator is invaluable for learning how to operate the 425SX.

There are two ways to start the simulator. If the unit is powered off, press and hold

the POWER button for approximately three seconds until you hear a continuous chirp.

6

USING THE 425SX

SIMULATOR OPERATION

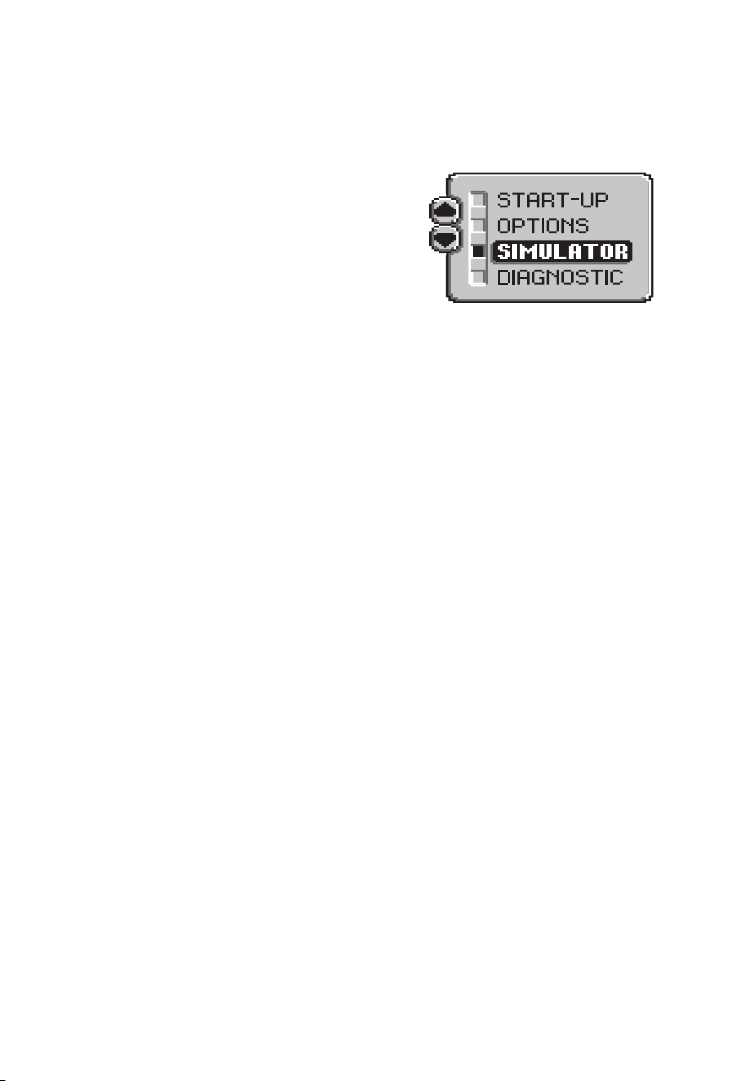

The simulator can also be started by selecting

the Simulator option on the start-up screen

after you power-up the unit. When this

screen is shown, simply press the DOWN

ARROW until “Simulator” is highlighted.

When the screen times out, the unit will be

in simulator mode.

When in simulator operation, the 425SX responds to control inputs as if it is in

actual operation, so feel free to experiment, or to customize the unit for your

particular operation.

To exit Simulator mode, power the unit off.

FEATURE MEMORY

If your 425SX is installed with a transducer connected, any changes you make

to the set-up or User Options (see Control Functions) while in Simulator are

retained in the unit’s memory. This allows you to use simulator to experiment

with the various set-up options, and retain your selected settings for normal

operation.

If you are using the 425SX in Simulator when no transducer is connected, any

selected options are lost when the unit is powered off. The 425SX will return

to Factory Settings, or options selected when last used with a transducer, if no

transducer is connected.

IMPORTANT: A transducer must be connected to the 425SX in

order to retain user settings selected when in simulator mode. If

no transducer is detected, the unit defaults to pre-selected

options when powered off.

What You See On-Screen

Your 425SX uses a 160 x 160 matrix FSTN LCD display. This display provides

outstanding viewability in all light conditions over a wide range of

temperatures.

7

USING THE 425SX

WHAT YOU SEE ON-SCREEN

At initial power-up, the 425SX uses settings that were set at the factory. After

initial use, the 425SX will remember the settings you enter.

There are several elements on-screen that are common to all modes of

operation.

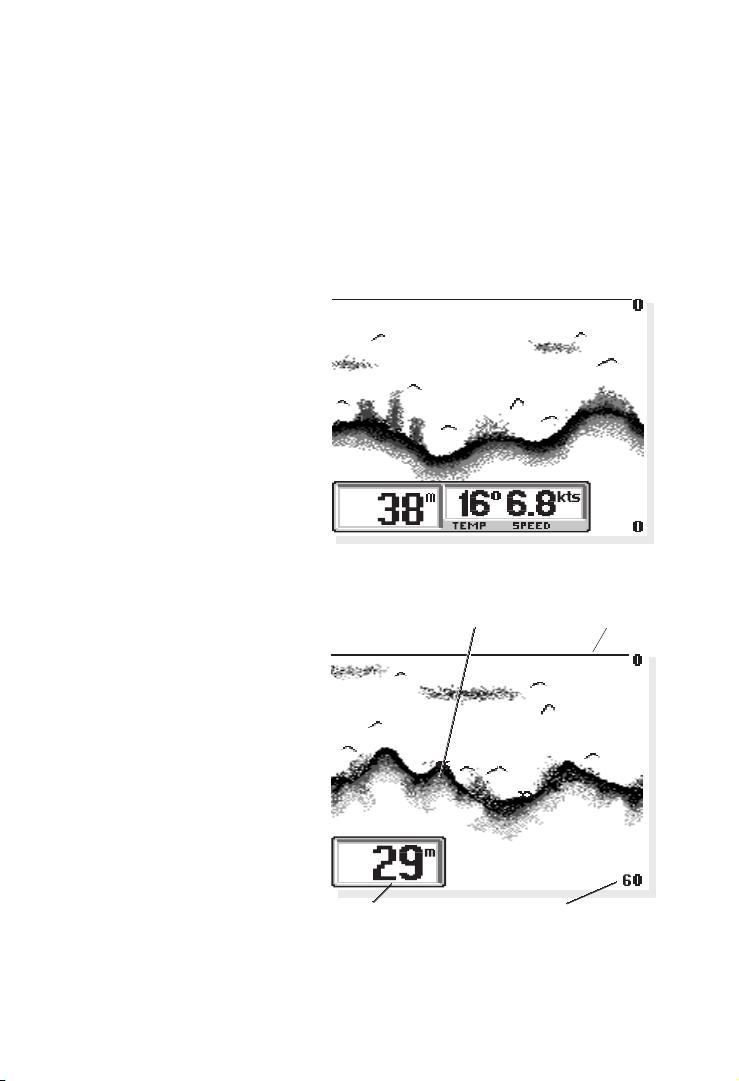

Temperature/Speed. The

initial screen layout takes one

of two basic forms depending

on whether the optional

Temp/Speed accessory is

installed. Figure A shows the

default view when the

Temp/Speed accessory is

installed. Figure B shows the

default view when the

Temp/Speed accessory is not

installed.

Figure A

6

Depth. The digital depth

number shows the water

depth directly beneath the

transducer location.

Depth Range. The depth range

is shown to the right of the screen.

The upper number is 0 indicating

the surface of the water. The lower

number is one of the nine depth

ranges available that best match

the depth of the water. As the

depth of the water changes, the

range changes as necessary in

order to retain a bottom

representation on-screen.

8

Bottom Depiction

Water Depth

Figure B

Zero Line

Depth Range

USING THE 425SX

WHAT YOU SEE ON-SCREEN

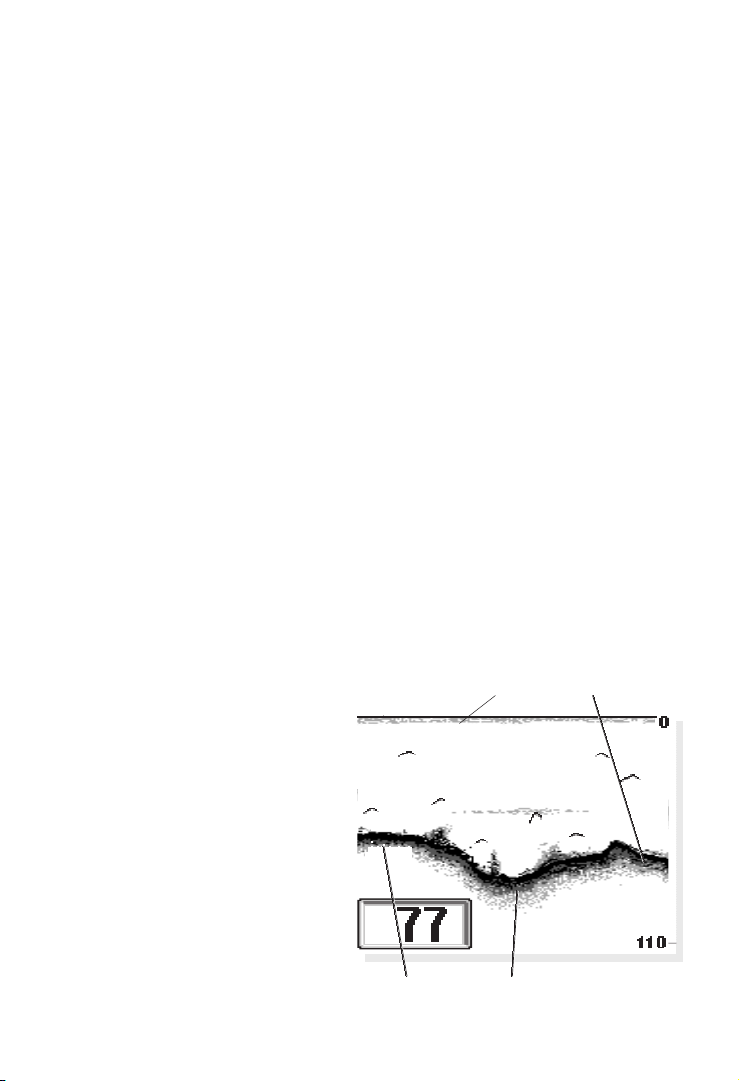

When in Auto mode, the horizontal line at the top of the screen is the “zero

line,” representing the surface of the water. Occasionally there is a gap in this

line. This gap indicates the unit is updating the display even if the bottom is not

visible on-screen, or if the bottom information is not changing.

New sonar information appears on the right side of the graphic area of the

display and moves to the left as new information is displayed. The 425SX

automatically selects the appropriate depth range to show the depth of water

beneath the transducer. This range is selected so the bottom representation is

typically shown about ²⁄₃ down the display.

Bottom. The graphic depiction of the bottom provides the user with an

effective tool for understanding the composition of the bottom. The FSTN type

display uses 4 discrete levels of gray to indicate the intensity of the returned

sonar signal. The 425SX can display even the smallest sonar returns with light

gray pixels. Larger returns are displayed with darker shades of gray. If the

bottom is hard and smooth, the bottom depiction is narrow and dense. If the

bottom is soft mud or sand, the depiction will be thick and less dense. This

indicates that much of the signal is absorbed by the soft bottom. If the bottom

is rocky or rugged in composition, the depiction is of varying density and

textured in appearance.

Wave action also affects the bottom

depiction. The information drawn is

a distance measurement, so if the

boat is moving up and down over

flat bottom, the bottom depiction

often appears in regular variations

that match wave timing.

Surface Clutter Rocky Bottom

Structure. Structure is defined as

any object physically attached to the

bottom. The sonar configuration of

the 425SX is optimized to give the

most accurate depiction of bottom

structure possible. Grass, trees,

stumps, wrecks or other debris are

accurately displayed, however the

m

Hard Bottom Soft Bottom

9

Loading...

Loading...