Huebsch HSGLXFGW091CW01 Parts Diagram

Dryer

DRY576R

Refer to Page 4 for Model Identification

Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

Part No. 513001R5

November 2011

NOTE: The WARNING and IMPORTANT

Failure to install, maintain, and/or operate

this machine according to the

manufacturer's instructions may result in

conditions which can produce bodily

injury and/or property damage.

W030

WARNING

instructions appearing in this manual are not meant

to cover all possible conditions and situations that

may occur. It must be understood that common

sense, caution, and carefulness are factors which

cannot be built into these dryers. These factors

MUST BE supplied by the person(s) installing,

maintaining, or operating the dryer.

Always contact the distributor, service agent, or the

manufacturer about any problems or conditions you do

not understand.

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

1

Table of

Contents

Model Identification ........................................................................... 4

Preliminary Information.................................................................... 5

About the Control ................................................................................. 5

Glossary of Terms................................................................................. 5

Power Failure Recovery ....................................................................... 5

Communications ................................................................................... 5

Control Identification......................................................................... 6

SELECT CYCLE Pads......................................................................... 6

START Pad........................................................................................... 6

Display Identification ......................................................................... 7

Light Emitting Diodes (LEDs) ............................................................. 7

Dryer Operation.................................................................................. 8

Start Up................................................................................................. 8

Ready Mode.......................................................................................... 8

Partial Vend Mode................................................................................ 8

Additional Vend Mode ......................................................................... 8

Start Mode ............................................................................................ 8

Entering Coins ...................................................................................... 8

Entering Cards ...................................................................................... 9

Changing Active Cycles ....................................................................... 9

Opening the Dryer Door ....................................................................... 9

Signals................................................................................................... 9

Extended Tumble Mode ....................................................................... 9

Special Features .................................................................................. 10

Programming Control ........................................................................... 10

Collecting Audit Information ............................................................... 10

Testing Machine and Control Functions............................................... 10

Rapid Advance Feature......................................................................... 10

Clearing the Vend Feature .................................................................... 10

Communications Mode......................................................................... 10

Coin Drop ............................................................................................. 10

Start Pulse Operation ............................................................................ 11

Service Door and Coin Vault Openings ............................................... 11

Special Vend......................................................................................... 11

OPL Mode ............................................................................................ 11

Drop-Off Mode..................................................................................... 11

Low Power/Auto-Shutdown Option ..................................................... 11

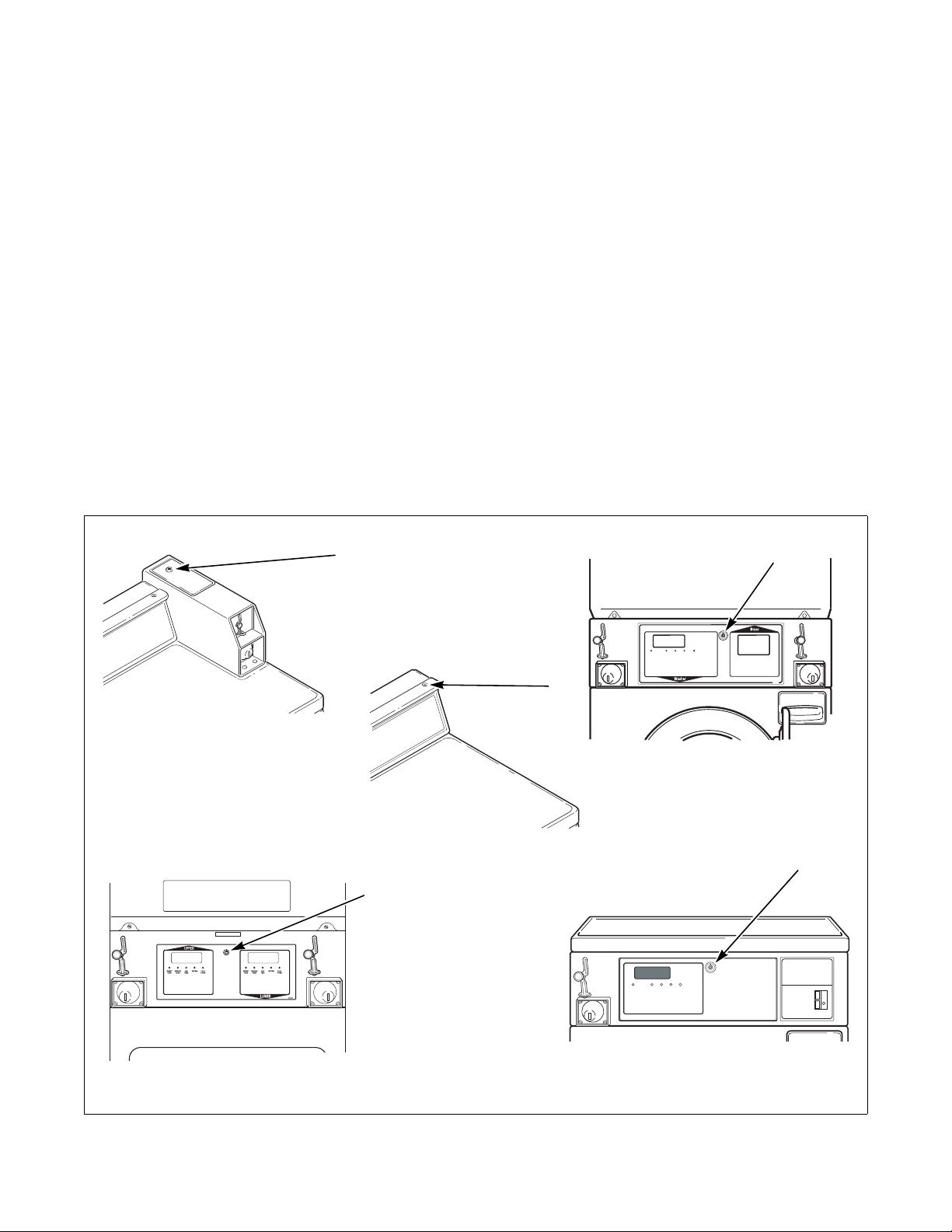

Opening the Service Door .................................................................. 12

Stacked Washers and Dryers, Stacked Dryers,

Front Control Dryers, and Coin Rear Control Dryers........................ 12

Rear Control Dryers with Card Reader ................................................ 12

Entering the Manual Mode................................................................ 13

How to Enter the Manual Mode ........................................................... 13

Programming Control ........................................................................ 15

What Can Be Programmed? ................................................................. 15

© Published by permission of the copyright owner.

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

513001

Programmable Options Available......................................................... 15

1. Heat Vend Price “AtSH” ............................................................ 23

2. Coin #1 Value “dEn1” ................................................................ 24

3. Coin #2 Value “dEn2” ................................................................ 25

4. Start Pulse Value “PLSE” ........................................................... 26

5. Start Pulse Mode “PLSn” ............................................................ 27

6. Available Type “AtyP” ............................................................... 28

7. Default Cycle “dCYC” ............................................................... 29

8. OPL Mode Enable/Disable “oPL” .............................................. 30

9. Audio Signal “Aud” or “AUd”* ................................................. 31

10. Card Reader Display Control “CArd” ........................................ 33

11. Error Code Programming “Err-” ................................................. 34

12. Top-Off Data “toP-” ................................................................... 35

13. Cycle Time “CyC-” ..................................................................... 36

14. Cool Down Time “Cdt-” ............................................................. 37

15. Temperature “tEP-” .................................................................... 38

16. Temperature (Fahrenheit/Celsius) “t FC” ................................... 39

17. No Heat Vend Price “AtSn” ....................................................... 40

18. Set Real-Time Clock “rtC-” ........................................................ 41

19. Special Vend A Data “SPA-” ..................................................... 42

20. Special Vend B Days Enable “SPb-” .......................................... 56

21. Special Vend C Days Enable “SPC-” ......................................... 56

22. Special Vend D Days Enable “SPd-” .......................................... 57

23. Drop Off Mode (On/Off) “droP” ................................................ 58

24. Low Power/Auto Shutdown A Days Enable “LPSA” ................ 58

25. Low Power/Auto Shutdown B Days Enable “LPSb” ................. 59

26. Low Power/Auto Shutdown C Days Enable “LPSC” ................. 59

27. Low Power/Auto Shutdown D Days Enable “LPSd” ................. 60

28. Power Fail Reset “PFr” ............................................................... 60

29. IR Access (On/Off) “IrA” ........................................................... 62

30. Manual Rapid Advance (On/Off) “rAEn” .................................. 62

31. Manual Diagnostics (On/Off) “dAEn” ....................................... 63

32. Production Test Cycle (On/Off) “PtEn” ..................................... 63

Collecting Audit Information ............................................................ 64

Manual Reset....................................................................................... 65

Testing Machine and

Electronic Control Functions............................................................. 66

Diagnostic Test Descriptions................................................................ 68

Production Test Cycle........................................................................... 72

Error Codes......................................................................................... 73

Rapid Advance Feature...................................................................... 75

Clear Vend Feature ............................................................................ 76

Power Fail Recovery........................................................................... 77

Power Fail Reset Disabled.................................................................... 77

Power Fail Reset Enabled..................................................................... 77

Communications Mode ...................................................................... 78

Infra-red Communications.................................................................... 78

Card Reader Communications

(Card Models Only)............................................................................ 78

Network Communications.................................................................... 78

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

3

Model Identification

Information in this manual is applicable to these dryer

models:

.

BD3LLFGS401UN01

BD3LLFGS401UW01

BD3LLFSS401UN01

BD3LXFGS401UN01

BD3LXFGS401UW01

BD3LXFSS401UN01

BDGLLFGS301EN01

BDGLLFGS301EW01

BDGLLFSS301EN01

BDGLXFGS301EN01

BDGLXFGS301EW01

BDGLXFSS301EN01

BT3LLFSG401UN01

BT3LLFSG401UW01

BT3LLFSP401UN01

BT3LLFSP401UW01

BT3LXFSG401UN01

BT3LXFSG401UW01

BT3LXFSP401UN01

BT3LXFSP401UW01

HDELEFGS151CW01

HDELEFGS151CWNA

HDELEFGS171CQ01

HDELEFGS171CW01

HDELERGS151CW01

HDELERGS151CWNA

HDELERGS171CW01

HDELXFGS151CW01

HDELXFGS171CW01

HDELXFGW171CN01

HDELXFSW171CN01

HDELXRGS151CW01

HDELXRGS171CW01

HDELYFGS151CW01

HDELYFGS171CW01

HDELYRGS151CW01

HDELYRGS151CWNA

HDELYRGS171CW01

HDGLEFGS111CW01

HDGLERGS111CW01

HDGLERGS111CWNA

HDGLXFGS111CW01

HDGLXFGS111CWNA

HDGLXFGW111CN01

HDGLXFSW111CN01

HDGLXRGS111CW01

HDGLYFGS111CW01

HDGLYFGS111CWNA

HDGLYRGS111CW01

HSELXFGW281CW01

HSELXFGW291CW01

HSELYFGW281CW01

HSELYFGW291CW01

HSGLXFGW091CW01

HSGLYFGW091CW01

HTELXFSP281CW01

HTELXFSP291CW01

HTELYFSP281CW01

HTELYFSP291CW01

HTENXFSP281CW01

HTENXFSP291CW01

HTENYFSP281CW01

HTENYFSP291CW01

HTGLXFSP091CW01

HTGNXFSP091CW01

ND3LLFSS401UN01

ND3LXFSS401UN01

NDELXFGS301UW01

NDGLLFSS301EN01

NDGLXFGS301EW01

NDGLXFSS301EN01

NT1LLFSP411CW01

NT1LLFSP411UW06

NT1LXFSP401UN01

NT1LXFSP401UW01

NT2LLFSP401UN01

NT2LLFSP401UW01

NT2LLFSP401UW06

NT2LXFSP401UN01

NT2LXFSP401UW01

NT3LLFSG401UW01

NT3LXFSG401UW01

NT3LLFSP401NN22

NT3LLFSP401NW22

NT3LLFSP401UN01

NT3LLFSP401UW01

NT3LXFSP401UN01

NT3LXFSP401UW01

NTHLXFSP571NW01

NTHLYFSP571NW01

RDELYFGS151CW01

RDELYFGS171CW01

RDGLYFGS111CW01

SDELCFGS171TW01

SDELCFGW171TN01

SDELCFSW171TN01

SDELCRGS151TW01

SDELCRGS171TW01

SDELCRGS171TW02

SDELCRGS171TWNA

SDELXRGS171TW01

SDELXRGS171TW02

SDELXRGS301AW01

SDELYFGS171TW01

SDELYFGW171TN01

SDELYFSW171TN01

SDELYRGS151TW01

SDELYRGS171TW01

SDGLCFGS111TW01

SDGLCFGW111TN01

SDGLCFSW111TN01

SDGLCRGS111TW01

SDGLCRGS111TW02

SDGLCRGS111TWNA

SDGLXRGS111TW01

SDGLYFGS111TW01

SDGLYFGS111TWNA

SDGLYFGW111TN01

SDGLYFSW111TN01

SDGLYRGS111TW01

SDGLYRGS111TWNA

SDGLXRGS111TW02

SDGLXRGS301AW01

SSELCFGS151TW01

SSELCFGS171TW01

SSELCFGW151TW01

SSELCFGW171TN01

SSELCFGW171TW01

SSELXFGW171TW01

SSELYFGS171TW01

SSELYFGW171TN01

SSELYFGW171TW01

SSELYFGW171TWNA

SSGLCFGS111TW01

SSGLCFGS111TWNA

SSGLCFGW111TN01

SSGLCFGW111TW01

SSGLCFGW111TWNA

SSGLXFGW111TW01

SSGLYFGS111TW01

SSGLYFGS111TWNA

SSGLYFGW111TN01

SSGLYFGW111TW01

SSGLYFGW111TWNA

ST3LXFSP401NW22

STELCFSP171TW01

STELXFSP171TW01

STELYFSP171TW01

STENCFSP171TW01

STENXFSP171TW01

STENYFSP171TW01

STGLCFSP111TW01

STGLCFSP111TWNA

STGLXFSG111TW01

STGLXFSP111TW01

STGLYFSP111TW01

STGLYFSP111TWNA

STGNCFSP111TW01

STGNXFSG111TW01

STGNXFSP111TW01

STGNYFSP111TW01

4

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

513001

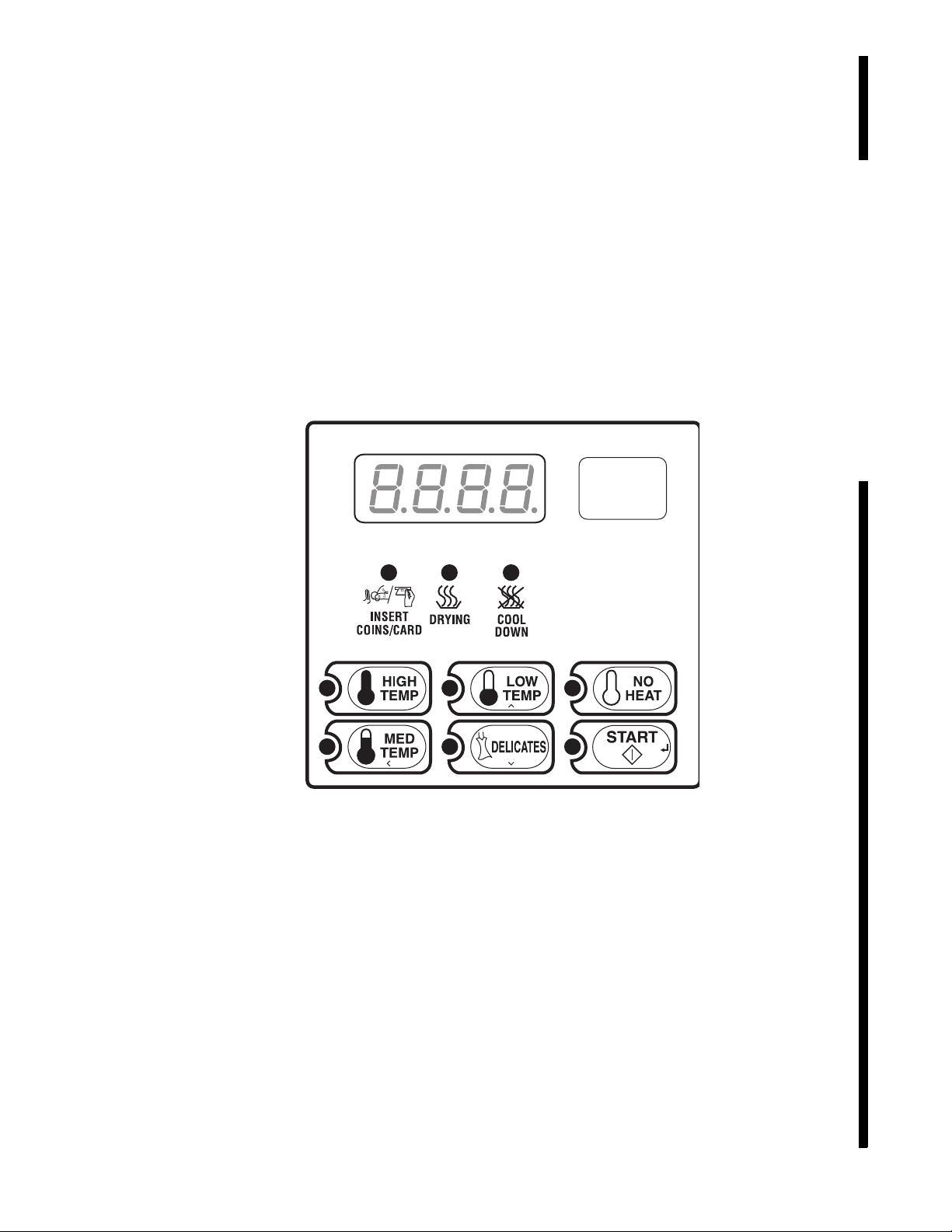

Preliminary Information

About the Control

This control is an advanced, programmable computer

that lets the owner control machine features by

pressing a sequence of SELECT CYCLE pads. Refer

to Figure 1.

The control allows the owner to program custom

cycles, set vend prices, retrieve audit information, run

diagnostic tests, program special vend features and

other programmable features. Refer to Programming

Control for a list of features. Dryers shipped from the

factory have a default cycle (MED TEMP) built in.

However, the owner can change the default cycle, or

any cycle, as needs permit.

IMPORTANT: In the event of a power failure, the

control will not have to be reprogrammed. It is

designed with a memory system that will remember

how it was programmed (for up to 10 years) until

the electrical power is restored.

IMPORTANT: It is extremely important that the

dryer has a positive ground and that all mechanical

and electrical connections to the control are made

before applying power to or operating the dryer.

Glossary of Terms

The following are a few terms and abb reviations to

learn. These are referred to throughout the instructions.

Display – This term refers to the window area of the

control that displays words and values.

LED (Light Emitting Diode) – This term refers to the

lights next to the keypads and status words of

the control.

Power Failure Recovery

If a cycle is in progress and the power fails, the cycle

status is saved in memory. When the power recovers,

the dryer will resume into the previously active cycle

(if so programmed by the owner), by pressing the

START pad. If the power failure occurs while the

control is in a fatal error mode, it will return to Ready

Mode upon recovery.

The owner may program a special feature called

POWER FAIL RESET which sets a maximum power

failure duration. To program this feature, refer to

Programming Control, option 28.

If the length of the power failure is greater than the

POWER FAIL RESET time, the control will end the

cycle and the display will revert back to the Ready

Mode rather than resume the previously active cycle.

If the length of the power failure is less than the

POWER FAIL RESET time and the power failure is

greater than 2 seconds, or the POWER FAIL RESET

is turned off, the dryer will enter START mode.

Communications

The control may be programmed manually, by

infra-red with an external device or by the network. A

limited number of features can be programmed by a

card reader.

Infra-red Communications (Optional)

An external device, such as a PDA, allows the owner

to program and retrieve information from the control

without touching the keypad. An external device

greatly expands the programming options available to

the owner. However, the external device is not required

to program and operate the dryer. The operation of an

external device and the advanced features available are

covered separately in the instructions included with

the external device software. Contact Alliance

Laundry Systems for a list of approved PDAs and

other external devices.

Serial Card Reader Communications

(Card Models Only)

The control will accept communication with a serial

card reader in order to perform vending transactions

when a card is inserted to pay for cycles. The card

reader can also allow the owner to program and collect

audit information.

For detailed information on serial card reader

communications, refer to instructions included with

card reader.

Network Communications

The control will also accept communication with a

network interface board which allows the control to be

linked to a personal computer. This network link

allows an owner to program, collect data and run

diagnostics on any machine.

For detailed information on network communications,

refer to the network instructions.

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

5

Control Identification

6

1

2

3

Electronic Control

5

4

SELECT CYCLE Pads

(Refer to Figure 1)

SELECT CYCLE pads are used to select the specific

dryer cycle and temperature. These pads include

HIGH TEMP, MED TEMP, LOW TEMP,

DELICATES and NO HEAT. The selection of one of

these cycles will light up the corresponding LED. The

factory default cycle is MED TEMP.

START Pad

(Refer to Figure 1)

The START pad is used to start the dryer after the full

vend price has been satisfied and the dryer door is closed.

Both the START pad and the SELECT CYCLE pads are

used in various combinations for programming cycles,

retrieving audit information, running diagnostic tests,

and other operations. During an active cycle (card reader

equipped machines only), the START pad may be

pressed (with a card inserted) to add time to a cycle.

1 Display

2 7-Segment Digits

3 START Pad

4 SELECT CYCLE Pads

5 LED Light

6 LED Status Lights

6

DRY576R

Figure 1

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

DRY576R

513001

Display Identification

Light Emitting Diodes (LEDs)

(Refer to Figure 1)

LIGHT EMITTING DIODES (LEDs) are used to

indicate the chosen temperature and cycle status. See

below for information on each LED.

INSERT COINS/CARD LED

The INSERT COINS/CARD LED is lit to prompt the

user to insert coins or a card to satisfy the vend price

for the chosen cycle. The LED is lit during the

“Ready” mode. During Partial and Additional Vend,

the LED flashes one second on and one second off.

The INSERT COINS/CARD LED will shut off when

the vend price has been satisfied.

START LED

The START pad LED flashes whenever the dryer is

not in a cycle, the full vend price has been satisfied,

and the dryer door is closed. When the START pad is

pressed, the cycle will begin or resume. The START

LED will shut off when the START pad is pressed.

The START LED will also flash any time a card is

inserted to add time to the current cycle.

COOL DOWN LED

The COOL DOWN LED is lit whenever the COOL

DOWN portion of a heated cycle is active. It is also lit

when the NO HEAT cycle is in operation. The COOL

DOWN LED will shut off when a cycle ends or more

time is added, pushing the cycle back into the heated

portion of a cycle.

Four 7-Segment Digits

The 7-SEGMENT DIGITS are used to display the

time remaining in a cycle, vend price, error messages

and descriptive codes. During diagnostic testing or

manual programming of the control, these digits will

display descriptive codes and values (as described in

Entering the Manual Mode).

DRYING LED

The DRYING LED is lit to indicate that one of the

heated cycles (HIGH TEMP, MED TEMP, LOW

TEMP, DELICATES) is currently in operation. The

DRYING LED goes off at the end of a heated cycle, if

the heated cycle is changed to a NO HEAT cycle, or

when the COOL DOWN cycle begins.

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

Dryer Operation

Start Up

When power is applied to the dryer, the control

becomes active and will display its software version as

“SXX” (“XX” is the version number) for one second

and then the subversion as “XX” (if subversion isn’t

zero) for one second. If the control was not powered

down during a running cycle, it will enter the Ready

Mode.

Ready Mode

In Ready Mode, the default cycle LED is lit, and the

full vend price is displayed.

The user may select a different cycle, if desired. If the

vend price is not satisfied within 4.25 minutes, the

dryer control will return to the Ready Mode. The

display will continue to show the remaining vend

needed to start a cycle.

Partial Vend Mode

The control enters this mode when part of the vend

price has been entered, but not enough vend is entered

to satisfy the vend price. The control will display the

remaining vend price needed to start the cycle and the

INSERT COINS/CARD LED is lit.

Start Mode

Vends may be satisfied by a coin drop, start pulses, or

by a third party card reader. If a coin drop is used, the

remaining vend price will decrease with each coin

entry. If start pulses are used, the remaining vend price

will decrease with each received pulse. Once the vend

is satisfied, the START LED will begin to flash and

signal will sound for ten seconds. If a third party card

reader is used, the START LED will begin to flash

when a valid cash card is entered into the reader.

When the START keypad is pressed, the dryer will

start. The START LED will stop flashing and either

the DRYING LED or the COOL DOWN LED will be

lit. The display will change to show the remaining

cycle time on the display. The DRYING LED will be

lit during the heat portion of a heat cycle. The COOL

DOWN LED will be lit during the cool down portion

of a heat cycle and during an entire no heat cycle.

When a cycle is complete, the display will show “00”

until the door is opened, a key is pressed, a coin or

card is entered, or a start pulse is received. When any

of the above happens, the display will revert back to

the Ready Mode.

Entering Coins

Additional Vend Mode

The control enters this mode if the cycle is changed to

a cycle that requires more money. If the vend price is

not satisfied within 60 seconds, the control will go

back to the first selection and the cycle will continue.

Coins are entered to satisfy the programmed vend

price for a selected cycle. Coins may be entered before

selecting a cycle or during an active cycle. When coins

are entered during an active cycle, the time remaining

is increased by the amount programmed by the owner

(refer to Programming Control).

The owner may choose to add additional time for each

coin entered. If coins are entered for an active cycle

currently in the COOL DOWN Mode, coins entered

may push the cycle back into the DRYING Mode. The

maximum time for any cycle is 99 minutes.

8

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

513001

Dryer Operation

Entering Cards

A card is entered to satisfy the programmed vend price

for a selected cycle. The card may be entered before

selecting a cycle or during an active cycle. When the

card is entered during an active cycle and the START

keypad is pressed, the time remaining is increased by

the amount programmed by the owner. Refer to

Programming Control section.

The owner may choose to add additional time by

deducting a vend from the card or may require an

additional full vend price be deducted from the card. If

vend is deducted during an active heated cycle that is

currently in the COOL DOWN Mode, the additional

time added may put the cycle back into the DRYING

Mode. The maximum time for any cycle is 99 minutes.

Additional time cannot be added if it exceeds the

99 minute limit on a drying cycle.

Changing Active Cycles

In OPL machines, the active cycle may be changed at

any time during dryer operation. In vend machines, the

active cycle may be changed in the first five minutes

for more expensive cycles. Cycles that are the same

price or less expensive can be chosen anytime. The

last five minutes of cycle can be changed with no

change to vend or time remaining.

Signals

There are six instances when a signal may sound

during dryer operation. The owner may program the

signal to be turned on or off (refer to Programming

Control, option 9). These six instances are listed

below:

1. End of Cycle Signal

By default, this signal is turned off. If turned on,

the signal will sound for three seconds at the end

of a cycle.

2. Keypad Depression Signal

The signal will sound for a quarter of a second

each time a keypad is pressed.

3. Coin Input/Start Pulse Input/Card Insertion

Signal

The signal will sound for a quarter of a second

each time a coin or start pulse is received or a

card is entered.

4. Remove Card Signal

This signal will sound one second on and one

second off while the control prompts for card

removal.

5. Start Pad Flashing Signal

Opening the Dryer Door

Opening the dryer door in a running cycle will

automatically stop the cycle. When the dryer door is

opened, the DRYING LED or COOL DOWN LED is

turned off.

NOTE: When the door is opened during an active

cycle, the time will continue to count down and the

display will toggle every five seconds between

showing “door” and the remaining cycle time.

Once the dryer door is closed, the START pad LED

flashes at one second intervals until the START pad is

pushed. Pressing the START pad will start or resume

the active cycle.

This signal will sound one second on and one

second off when the START LED is flashing, for

the first ten seconds after vend has been satisfied.

6. Extended Tumble Mode Signal

This signal cannot be disabled. While in

extended tumble mode, the signal will sound one

second on and one second off for five seconds

and then continuously for five seconds before

starting the extended tumble.

Extended Tumble Mode

The control enters Extended Tumble Mode twenty

minutes after a cycle has ended. The signal will sound

one second on and one second off for five seconds and

then continuously for five seconds before starting the

extended tumble, which lasts two minutes, every hour,

for up to 18 hours. Extended Tumble Mode ends with

any user interaction.

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

9

Special Features

Programming Control

The control allows the dryer owner to program the

control with the use of the keypad. Cycle and vend

information may be programmed, audit information

may be viewed and diagnostic tests may be run by

pressing keypad combinations.

For details on programming cycle and vend information,

refer to Programming Control.

Collecting Audit Information

The control will store audit information in its memory

that can be retrieved by pressing various keypad

combinations. The control will record coins entered,

total machine cycles, top-offs, and total start pulses.

For more information on the audit features, refer to

Collecting Audit Information.

NOTE: Additional audit information is retrievable

with an external device, a card reader or a

network. Refer to the appropriate instruction

manual.

Testing Machine and Control

Functions

Special programmable diagnostic features built into

the control allow the owner to run specific diagnostic

tests. By opening and closing the service door, with

coin vault closed, and then pressing various sequences

of keypads, the owner may retrieve and perform the

following tests:

Control Software Version Number

Service Door Opening Test

Coin Vault Opening Test

Rapid Advance Feature

This feature allows the user to quickly advance

through an active dryer cycle or advance into a cycle

from the Ready Mode. This feature is useful when

tests must be performed immediately on a dryer

currently in an active cycle. In this case, the user can

quickly advance through the cycle to the Ready Mode.

At this point, the user can perform the required tests

and then return the dryer to the active cycle.

For detailed information on using the Rapid Advance

feature, refer to Rapid Advance Feature.

Clearing the Vend Feature

This feature allows the user to return the control back

to the Ready Mode if coins have been entered but the

full vend price has not yet been satisfied, while in

Partial Vend Mode.

For more information on using the Clear Vend feature,

refer to Clear Vend Feature.

Communications Mode

This feature allows the dryer control to communicate

with an external device, a card reader or a network.

This allows the dryer control to be programmed and

have its data read without using the keypad.

For more detailed information on using the

Communications Mode feature, refer to

Communications Mode.

Coin Drop

The control will accept pulses from a single or dual

coin drop to satisfy vend price. Each coin drop will

have the ability to satisfy the vend.

Coin Drop #1 Input Test

Coin Drop #2 Input Test

Start Pulse Test

Dryer-on Temperature Test

Thermistor Temperature Test

Configuration Display Tests

Coin Header Present Status

For detailed information on running diagnostic tests,

refer to Testing Machine and Electronic Control

Functions.

10

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

513001

Special Features

Start Pulse Operation

The control will accept pulses from optional payment

systems. The machine can be programmed to receive a

single start pulse or multiple start pulses, or the Start

Pulse Option can be turned off. The Start Pulse Mode

allows the machine to go from the “Ready” mode to

the “START” mode after single or multiple pulses are

received.

Service Door and Coin Vault

Openings

The control will capture the times and dates of the

openings of the Coin Vault and the Service Door. The

information is saved in memory. An open service door

combined with various keypad presses allows the

control to enter manual modes of operation if the

Break-In Alarm is not on. These modes include Manual

Programming, Audit Collection, Diagnostics, Rapid

Advance, and reset to factory defaults.

Special Vend

This feature allows the owner to program the control

to allow programmable vend prices for specific hours

and dates.

For details on programming Special Vend, refer to

Programming Control.

OPL Mode

This feature allows the user to start a cycle without

satisfying the vend price.

Press the START keypad to add time to the cycle.

Press the LOW TEMP and DELICATES keypads to

end the cycle.

For details on enabling OPL Mode, refer to

Programming Control.

Drop-Off Mode

This feature allows the owner to limit machine use to

an attendant without requiring vend. Starting the

machine will require the correct sequence of four

keypad presses as programmed by an external device

or a network.

Press the START keypad to add time to the cycle.

Press the LOW TEMP and DELICATES keypads to

end the cycle.

For details on enabling Drop-Off Mode, refer to

Programming Control.

Low Power/Auto-Shutdown Option

This feature allows the owner to program the control

to shut down or enter a low power consumption mode

based on programmable times and dates if either of

these options are enabled.

For details on programming the Low Power/AutoShutdown option, refer to Programming Control.

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

11

Opening the Service Door

FLW6R

3

2

1

OPERATING INSTRUCTIONS

Select Wash Temperature

HOT, WARM, COLD.

Select Fabric Type

NORMAL, PERM PRESS, DELICATE.

Load Supply Dispenser (See Instructions Below).

Load Clothes.

Insert Coin(s) / Card.

To Start Washer-Close Door and Push Start.

1.

2.

3.

4.

5.

6.

Open Dispenser Door.

Load Supplies in Proper

Compartment (as Indicated).

Close Dispenser Door.

1.

2.

3.

Detergent

Liquid Bleach

Fabric Softener

1.

2.

3.

DISPENSER INSTRUCTIONS

685942

DRY580R

INSERT

COIN/CARD

DOOR

LOCKED

WASH

RINSE SPIN

DOOR

LOCKED

SPINRINSEWASHINSERT

COIN / CARD

505617

1

1

Coin Rear Control Dryer

Stacked Washer and Dryer

Stacked Dryer

Front Control Dryer

1

1

DRY578R

DRY579R

DRY580R

Card Rear Control Dryer

W521I

1

FLW6R

Stacked Washers and Dryers, Stacked

Dryers, Front Control Dryers, and

Coin Rear Control Dryers

Manually programming the control requires the user to

open and close the service door. Opening and closing

the service door trips a switch allowing access to

various programming options, diagnostics, and audit

capabilities.

On stacked dryers, stacked washers and dryers, and

front control dryers, the service door is located in the

control panel. On rear control dryers, the service door is

located on the top of the meter case. Refer to Figure 2.

After opening and closing the service door, the

programmer has 4.25 minutes to begin programming.

If a SELECT CYCLE pad has not been pressed in that

time, the control will revert back to the Ready Mode.

Refer to Figure 2.

Rear Control Dryers with Card

Reader

Manually programming the control requires the user to

remove the control panel and unplug the bullet

connector located between the “white/black” and “red/

blue” wires or to insert an appropriate card into the

reader. This will allow the user to access various

programming options, diagnostics and audit

capabilities. The control panel is located on the control

hood. Refer to Figure 2.

1 Service Door

12

W521I

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

Figure 2

513001

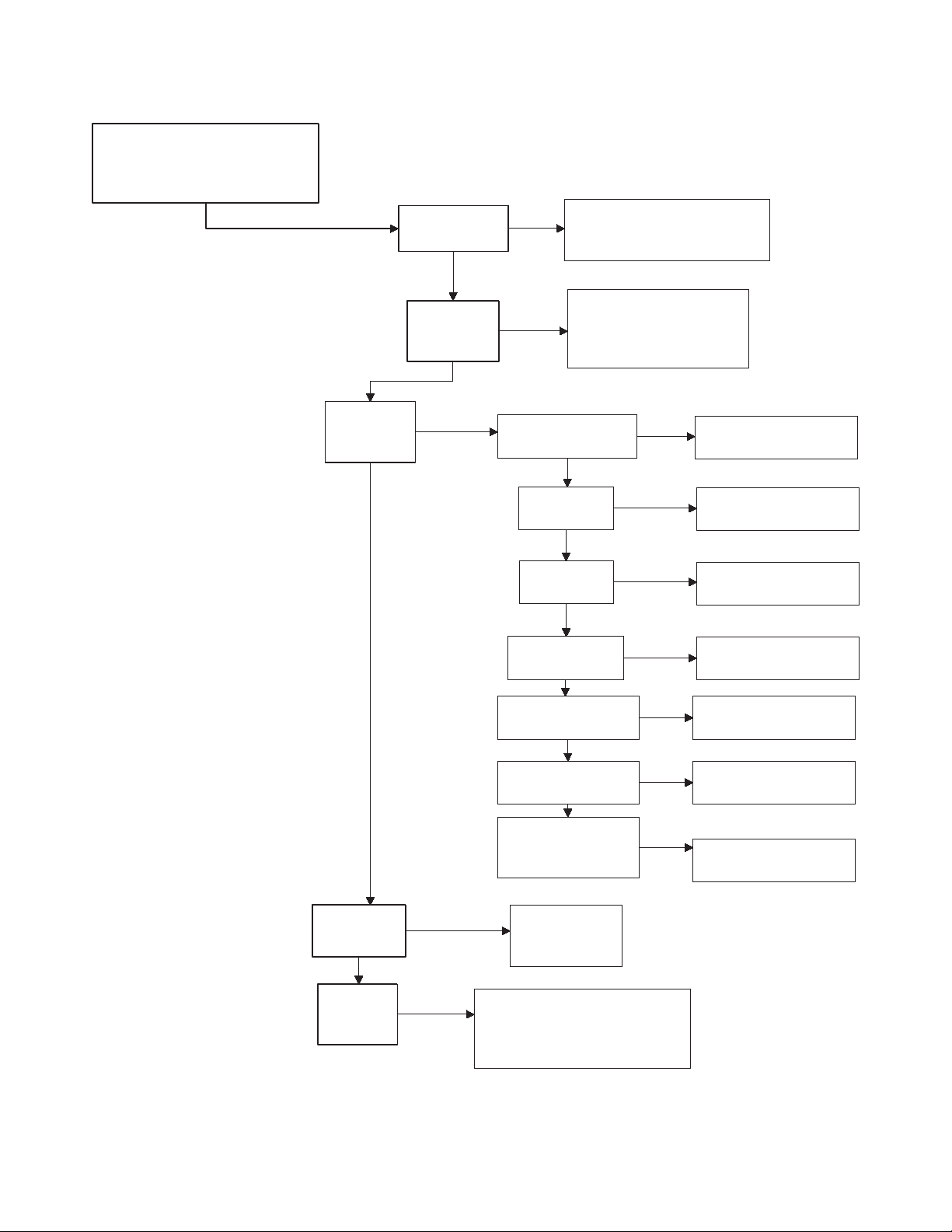

Entering the Manual Mode

>

<

For programming, testing, and retrieving information

from the control, it is often necessary to enter the

Manual Mode by following the four simple steps below.

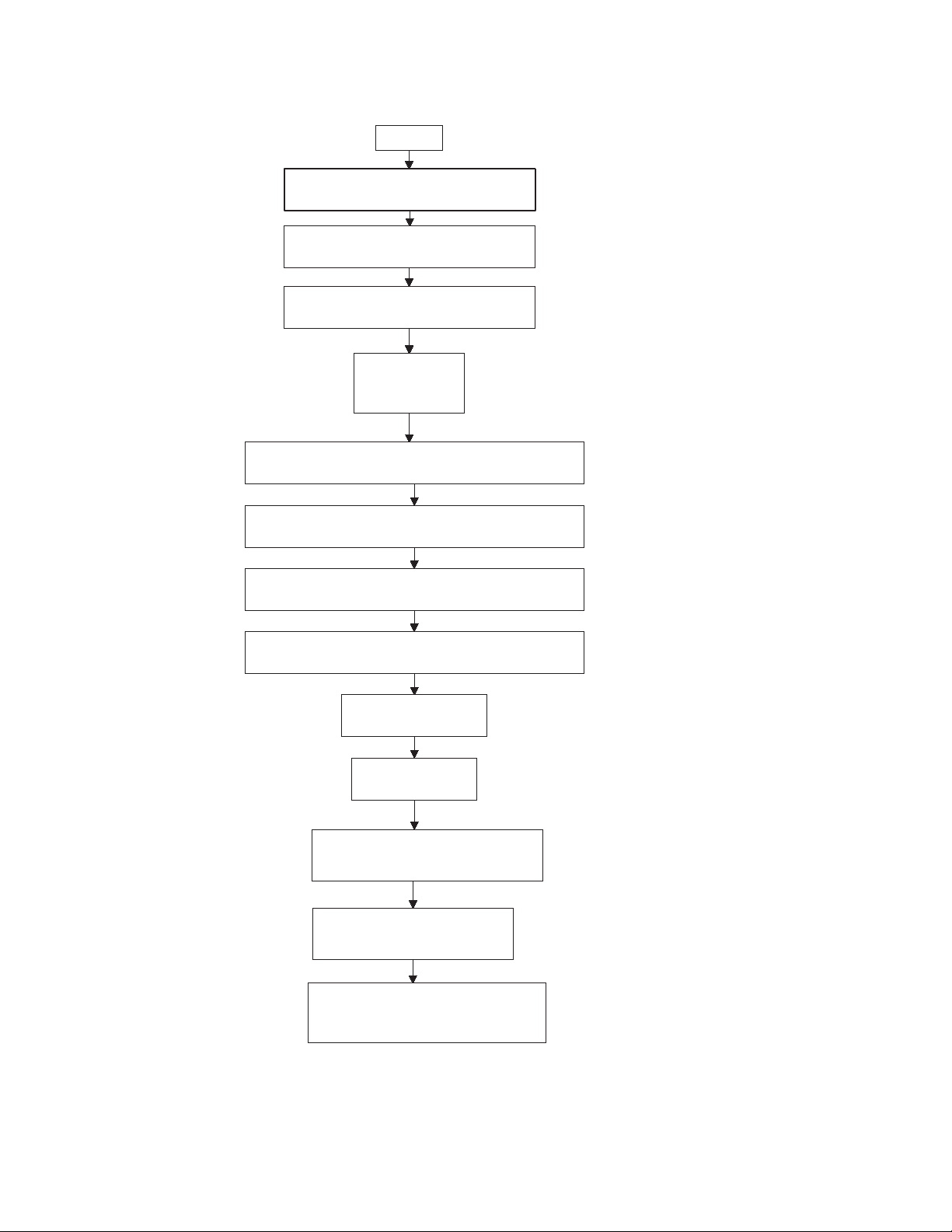

For an overview of entering the manual mode, refer to

the flowchart on the following page.

How to Enter the Manual Mode

1. If accessing Diagnostic Tests, be sure the dryer is

in the Ready Mode before continuing to step 2. If

the dryer is in an active cycle, rapid advance

through the cycle. Refer to Rapid Advance

Feature. If coins or a card has been entered, refer

to Clear Vend Feature.

2. Open the service door. Refer to Opening the

Service Door.

NOTE: Coin Models – The coin vault switch must

be closed to enter the Manual Mode. Card Reader

Models – Unplug bullet connector.

3. While pressing and holding the HIGH TEMP

keypad with one hand, press the MED TEMP

keypad with the other hand.

4. The display will show “rAPd”.

5. Press the LOW TEMP ( ) or the

DELICATES ( ) keypad to scroll through the

options until the desired option appears in the

display.

Manual Programming can only be turned on or off

with an external device or a network. Refer to the

appropriate instruction manual. Manual Rapid Advance

and Diagnostics can be turned on and off using an

external device by manual programming (refer to

options 30 and 31 of Programming Control), or with

the network.

By default, Manual Programming is turned “ON”.

The manual features available in each group are as

follows (the menu displayed on the display in this

mode is in parenthesis).

Rapid Advance (rAPd)

Manual Programming (Prog)

Manual Read Audit (AUdt)

Manual Reset (rSEt)

Diagnostic Tests (diAg)

If a manual parameter is turned off or unavailable (i.e.

attempting to enter diagnostics while a cycle is

running), the display will change from the selected

feature to “oFF”, an audio signal will sound for one

second and the features in the parameter cannot be

entered. The display will then return to the selected

feature.

6. Press the START (enter) keypad to enter the

displayed mode.

7. To exit, press the MED TEMP(<) keypad. The

control will revert back to Ready Mode.

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

13

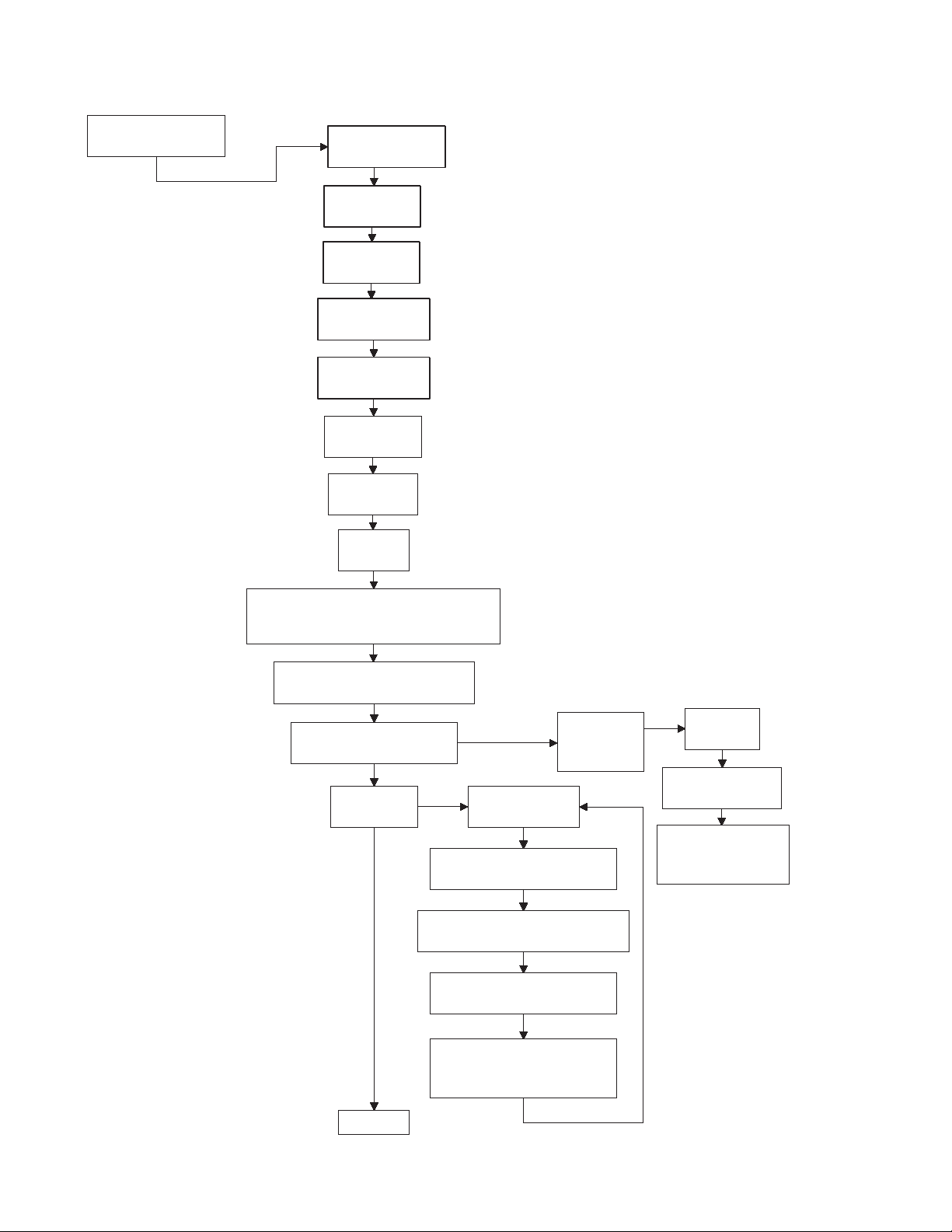

Entering the Manual Mode

Manual Mode : Enter by opening

and closing service door. Then

press HIGH TEMP and MED

TEMP keypads pads at same time.

"rAPd"

Rapid Advance

"Prog"

Manual

Programming

"AUdt"

Manual Read

Audit

"rSEt"

Manual Reset

"dIAg"

Diagnostic

Te st s

Press the LOW TEMP or

the DELICATES keypad

to scroll through the

Manual Mode options.

Press the START keypad to

begin Rapid Advance cycle and

to advance through cycle steps.

Press the START keypad to

enter Manual Programming.

Refer to Manual

Programming flowchart.

"CyC"

Total machine cycles

"Coi1"

Total coins #1

"PLSE"

Total start pulses

"Coi2"

Total coins #2

Press the

LOW TEMP

or the

DELICATES

keypad to

scroll through

the Audit

options.

Press the

START keypad.

Press the

START keypad

to reset control.

Press the START keypad to

enter Diagnostic Tests. Refer to

Diagnostic Tests flowchart.

DRY581R

Press the START (enter)

keypad to read audit.

Press the START (enter)

keypad to read audit.

Press the START (enter)

keypad to read audit.

Press the START (enter)

keypad to read audit.

"C1to"

Total coin 1 top-offs

"Pto"

Total start pulse/card

reader top-offs

"C2to"

Total coin 2 top-offs

Press the START (enter)

keypad to read audit.

Press the START (enter)

keypad to read audit.

Press the START (enter)

keypad to read audit.

To enter a programming option, press the

START keypad. To exit, press the MED

TEMP keypad.

14

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

513001

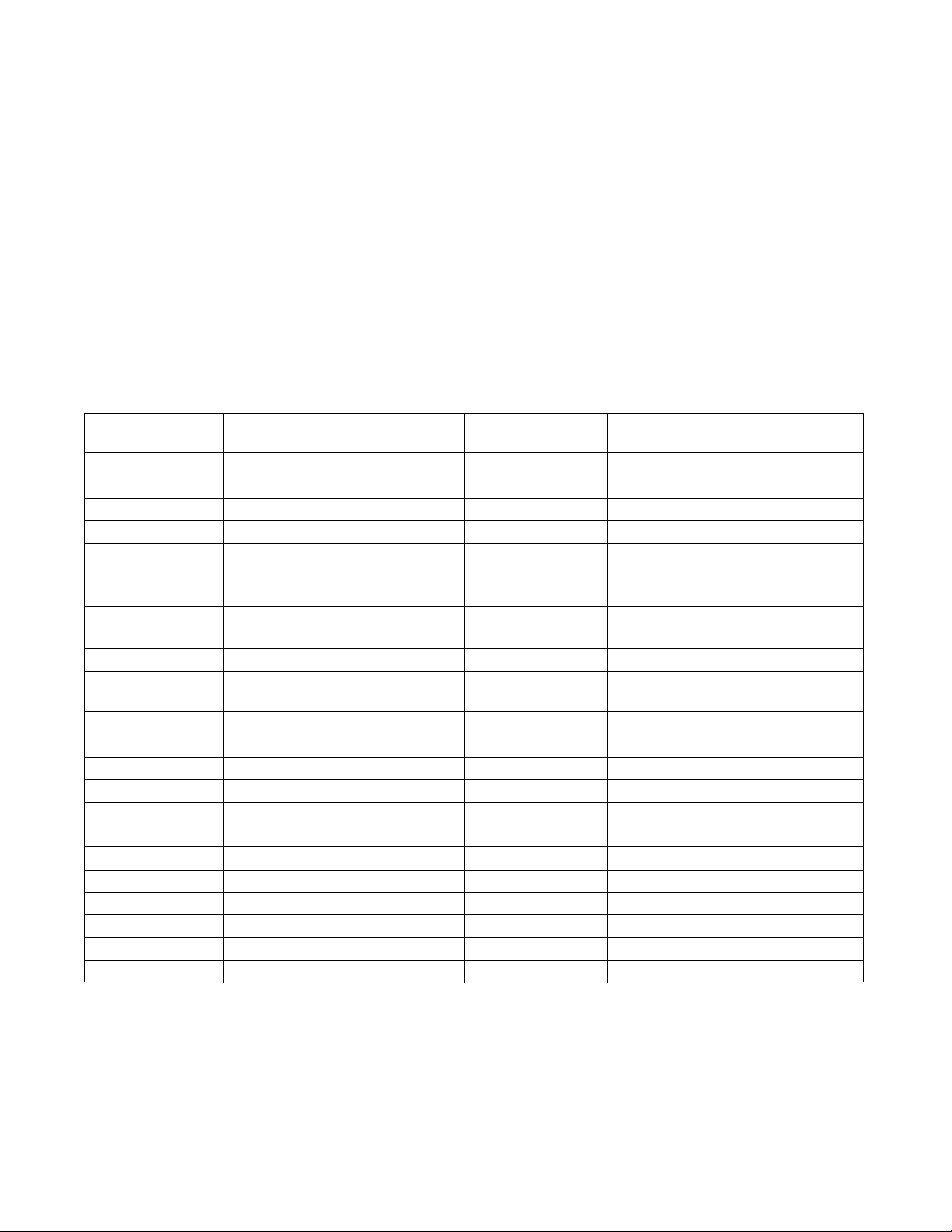

Programming Control

What Can Be Programmed?

This feature allows the owner to program cycle

parameters, standard vend pricing, special vends, and

other features by using the keypads. The control must

have the Manual Programming Mode enabled, which is

the factory default. This mode can only be turned OFF

and ON by using an external device or a network.

Refer to this section when programming the control.

This section offers a detailed description of all

programmable options.

Each description includes instructions on when and

why the option might be used and, more importantly,

how to program the option.

For an overview of the programming organization,

refer to the flowcharts on the following pages.

For more advanced users, a quick reference list of the

options available through the programming mode is

located on this page.

NOTE: The codes in the Option column of the

Programmable Options List are what will show in

the display when that option is selected.

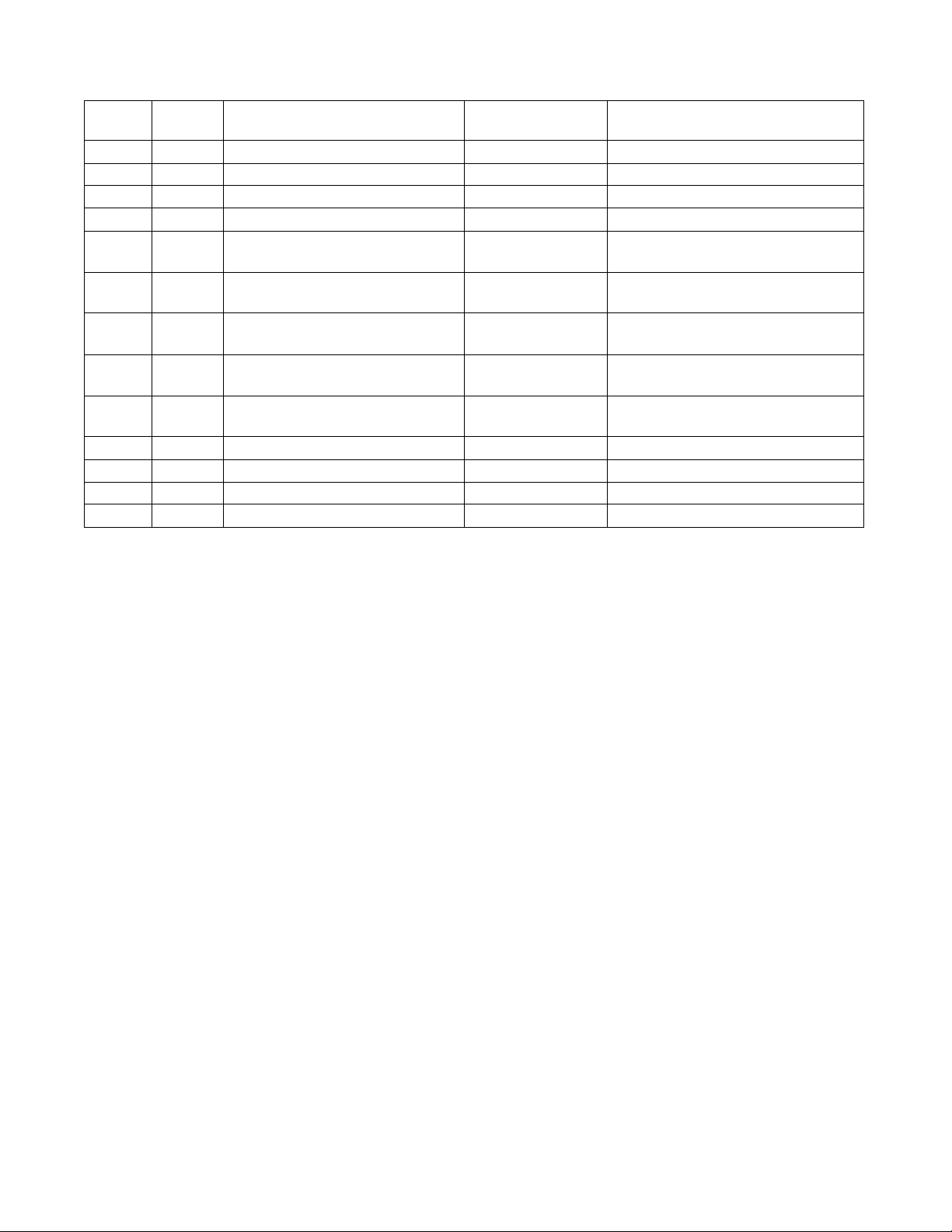

Programmable Options Available

Option

Number

1“AtSH” Heat Vend Price 200 0-65535

2“dEn1” Coin #1 Value 25 1-65535

3“dEn2” Coin #2 Value 100 1-65535

4“PLSE” Start Pulse Value 25 1-65535

5“PLSn” Start Pulse Mode 128 128 (on - single pulse),

6“AtyP” Available Type 0 ** 0-3; 0-7

7“dCyC” Default Cycle 4 1 (High Temp), 2 (Low Temp), 3 (No

8“oPL” OPL Mode oFF on/oFF

9“Aud” or

10 “CArd” Card Reader Display Control oFF on/oFF

11 “Err-”Errors – –

a“CEr-” Coin Error Parameters ––

12 “toP-” Top-Off Data – –

a“toP1” Top-Off on on/oFF

b“toP2” Coin 1 Top-Off Time Minutes 5 1-99

c“toP3” Coin 1 Top-Off Time Seconds 38 0-59

d“toP4” Coin 2 Top-Off Time Minutes 22 1-99

e“toP5” Coin 2 Top-Off Time Seconds 30 0-59

* “Aud” is displayed for Control Software version 01 and “AUd” is displayed for Control Software version 02 or later.

** 0-7 is available in software version “S 05” or higher only.

Option

Display

Audio 29 0-31

“AUd”*

1 “CEr1” Coin Error on on/oFF

2 “CEr2” Coin Error Penalty oFF on/oFF

3 “CEr3” Coin Drops Header Present Error on on/oFF

Description Default Value Value Range

192 (on - multiple pulses) or oFF

Heat), 4 (Med Temp), or 5 (Delicates)

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

15

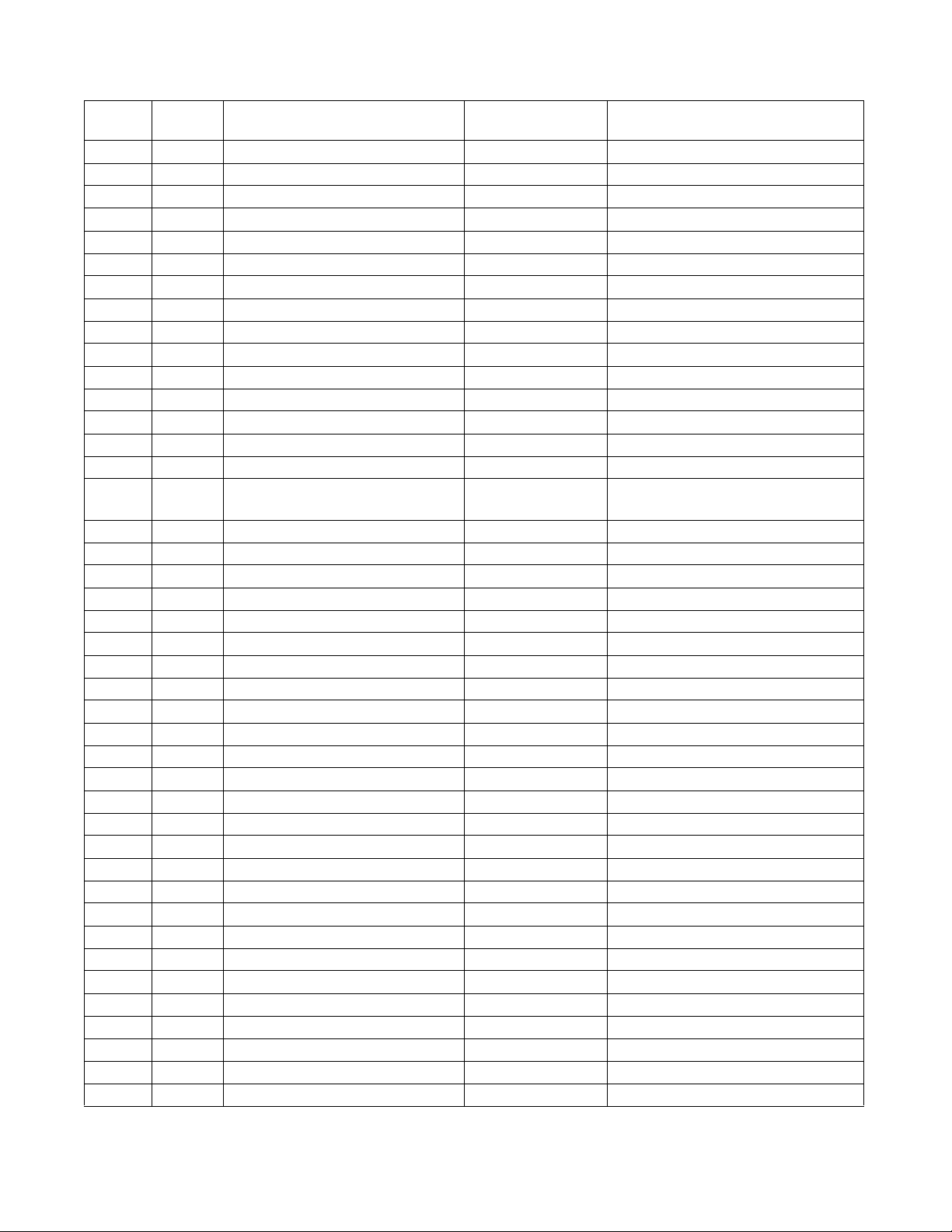

Programming Control

Option

Number

Option

Display

Description Default Value Value Range

13 “CyC-”Cycle Time – –

a“CyC1” Heat Cycle Time Minutes 45 1-99

b“CyC2” Heat Cycle Time Seconds 0 0-59

c“CyC3” No Heat Cycle Time Minutes 45 1-99

d“CyC4” No Heat Cycle Time Seconds 0 0-59

14 “Cdt-” Cooldown Time – –

a“Cdt1” High Temp Cooldown Time 3 1-15

b“Cdt2” Medium Temp Cooldown Time 3 1-15

c“Cdt3” Low Temp Cooldown Time 3 1-15

d“Cdt4”

Delicates Temp Cooldown Time 3 1-15

15 “tEP-” Temperature – –

a“tEP1” High Temperature 160°F/71°C 100°-160°F/38°-71°C

b“tEP2” Medium Temperature 155°F/68°C 100°-160°F/38°-71°C

c“tEP3” Low Temperature 145°F/62°C 100°-160°F/38°-71°C

d“tEP4”

16 “t FC” Temperature

Delicates Temperature 115°F/46°C 100°-160°F/38°-71°C

0 0 (Fahrenheit)/1 (Celsius)

(Fahrenheit/Celsius)

17 “AtSn” No Heat Vend Price 200 0-65535

18 “rtC-”Real Time Clock – –

a“rtC1” Minutes – 0-59

b“rtC2” Hours – 0-23

c“rtC3”Day – 1-7

d“rtC4”Date – 1-31

e“rtC5” Month – 1-12

f“rtC6” Year – 0-99

g“rtC7” Daylight Savings on on/oFF

19 “SPA-” Special Vend A Data – –

a“SA01” Days Enable oFF on/oFF

b“SA02”Start Hour 0 0-23

c“SA03” Start Minute 0 0-59

d“SA04” Length in Hours 0 0-24

e“SA05” Start Month 0 0/1-12

f“SA06” Start Date 0 0/1-31

g“SA07” Start Year 0 0-99

h“SA08” End Month 0 0/1-12

i“SA09” End Date 0 0/1-31

j“SA10” End Year 0 0-99

k“SA11” Heat Price 0 0-65535

l“SA12” No Heat Price 0 0-65535

m“SA13” Heat Time Minutes 1 1-99

n“SA14” No Heat Time Minutes 1 1-99

o“SA15” Coin #1 Top-Off Time Minutes 1 1-99

p“SA16” Coin #2 Top-Off Time Minutes 1 1-99

16

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

513001

Programming Control

Option

Number

Option

Display

Description Default Value Value Range

20 “SPb-” Special Vend B Days Enable oFF on/oFF

21 “SPC-” Special Vend C Days Enable oFF on/oFF

22 “SPd-” Special Vend D Days Enable oFF on/oFF

23 “droP” Drop Off Mode oFF on/oFF

24 “LPSA” Low Power/Auto Shutdown A

oFF on/oFF

Days Enable

25 “LPSb” Low Power/Auto Shutdown B

oFF on/oFF

Days Enable

26 “LPSC” Low Power/Auto Shutdown C

oFF on/oFF

Days Enable

27 “LPSd” Low Power/Auto Shutdown D

oFF on/oFF

Days Enable

28 “PFr” Power Fail Reset oFF on (133 [5 minutes] - 255

[127 minutes])/oFF

29 “IrA” IR Access on on/oFF

30 “rAEn” Manual Rapid Advance on on/oFF

31 “dAEn” Manual Diagnostics on on/oFF

32 “PtEn” Production Test Cycle on on/oFF

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

17

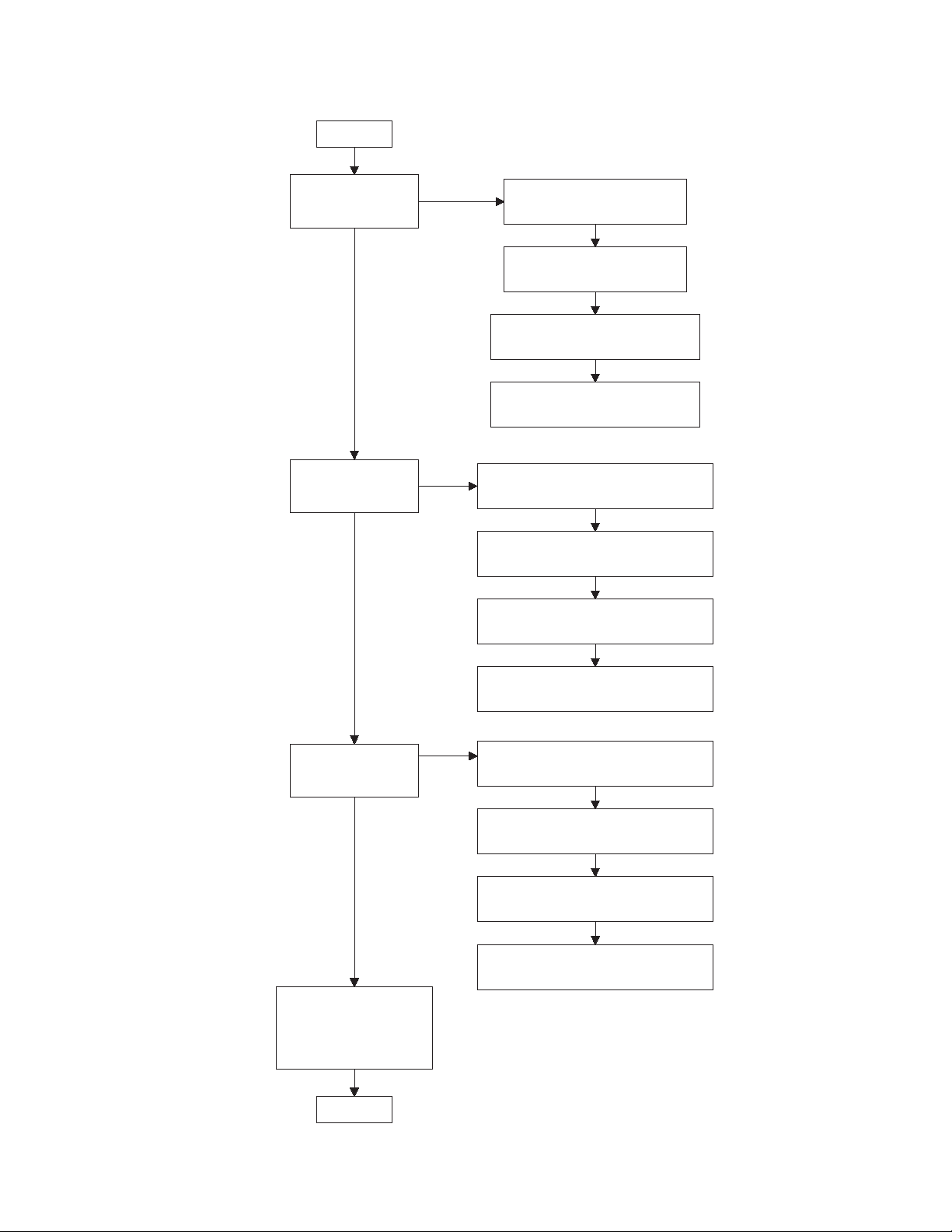

Programming Control

"Prog"

Manual Programming

Press the

START keypad.

Press the LOW

TEMP or the

DELICATES keypad

to scroll through the

programmable

options.

"AtSH"

Heat Vend Price

"dEn1"

Coin #1 Value

"dEn2"

Coin #2 Value

"PLSE"

Start Pulse Value

"PLSn"

Start Pulse Mode

"AtyP"

Available Type

"dCYC"

Default Cycle

"oPL"

OPL Mode

To enter a programming

option, press the START

keypad. To exit, press

the MED TEMP keypad.

"Aud" or "AUd"

Audio Signal

(depending on control software version)

"CArd"

Card Reader Display Control

"Err"

Error Code Programming

"toP-"

Top-Off Data

Top-Off On/Off

Coin 1 Top-Off Time Minutes

Coin 1 Top-Off Time Seconds

Coin 2 Top-Off Time Minutes

Coin 2 Top-Off Time

"toP1"

"toP2"

"toP3"

"toP4"

"toP5"

Seconds

"CEr-"

Coin Error

Parameters

"CEr1"

Coin Error

"CEr2"

Coin Error Penalty

"CEr3"

Coin Drops Header

Present Error

18

continued

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

DRY582R-a

513001

Programming Control

DRY582R-b

continued

"CyC-"

Cycle Time

"CyC1"

Heat Cycle Time Minutes

"CyC2"

Heat Cycle Time Seconds

"CyC3"

No Heat Cycle Time Minutes

"CyC4"

No Heat Cycle Time Seconds

"Cdt-"

Cool Down Time

"Cdt1"

High Temp Cooldown Time

"Cdt2"

Medium Temp Cooldown Time

"Cdt3"

Low Temp Cooldown Time

"Cdt4"

Delicates Cooldown Time

"tEP-"

Temperature

"tEP1"

High Temperature

"tEP2"

Medium Temperature

"tEP3"

Low Temperature

"tEP4"

Delicates Temperature

"t FC"

Temperature

(Fahrenheit/Celsius)

continued

Press the LOW

TEMP or the

DELICATES keypad

to scroll through the

programmable

options.

To enter a programming

option, press the START

keypad. To exit, press

the MED TEMP keypad.

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

19

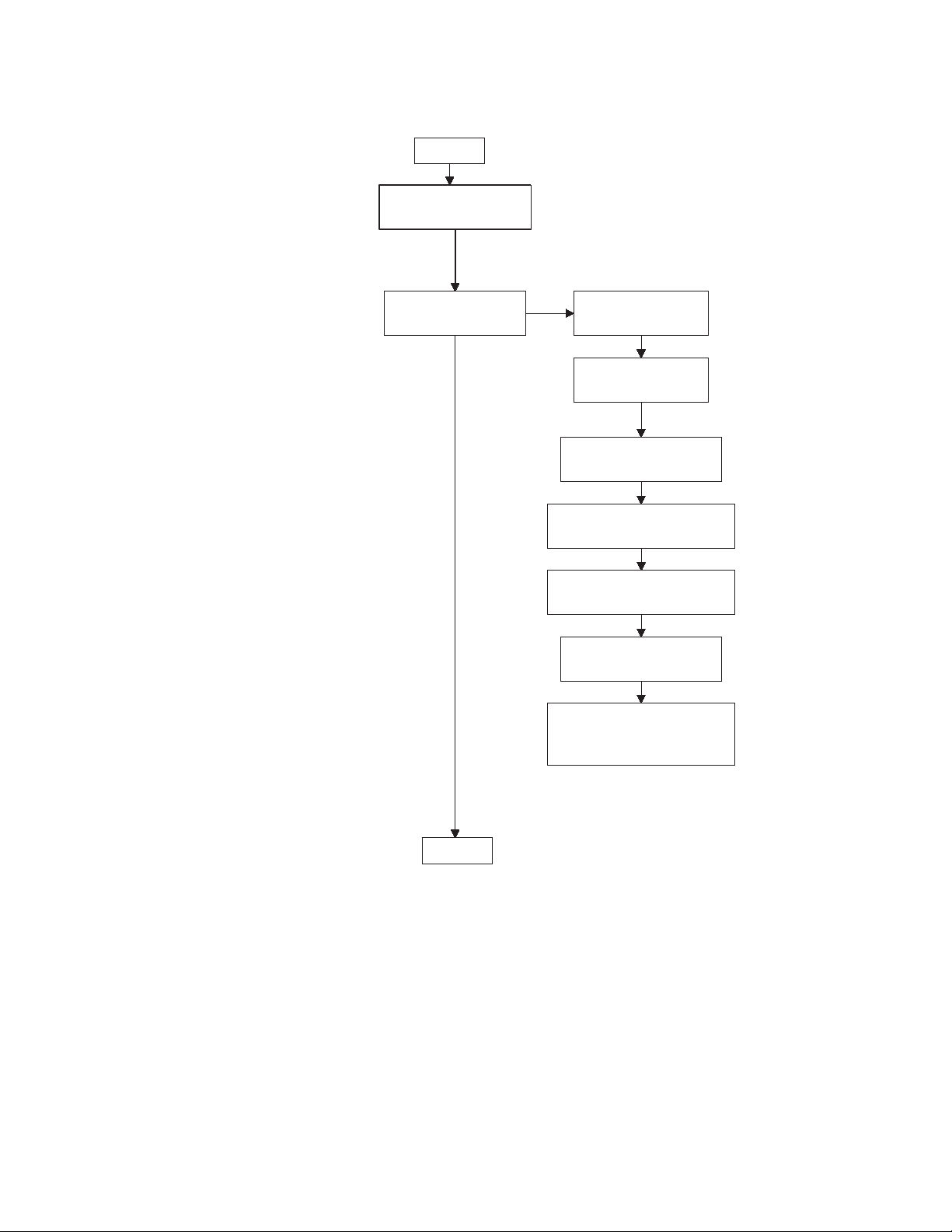

Programming Control

Press the LOW

TEMP or the

DELICATES keypad

to scroll through the

programmable

options.

continued

"AtSn"

No Heat Vend Price

To enter a programming

option, press the START

keypad. To exit, press

the MED TEMP keypad.

"rtC-"

Set Real-Time Clock

"rtC1"

Programs Minutes

"rtC2"

Programs Hours

"rtC3"

Programs Day of Week

"rtC4"

Programs Date of Month

"rtC5"

Programs Month

"rtC6"

Programs Year

"rtC7"

Programs Daylight Savings

20

continued

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

DRY582R-c

513001

DRY582R-d

Press the LOW

TEMP or the

DELICATES keypad

to scroll through the

Special Vend options.

"SPA-"

Special Vend A data

To enter a

special vend

option, press the

START keypad.

To exit, press

the MED TEMP

keypad.

"SA01"

Special Vend A Days Enable

continued

continued

"SA02"

Special Vend A Start Hour

"SA03"

Special Vend A Start Minute

"SA04"

Special Vend A Length in Hours

"SA05"

Special Vend A Start Month

"SA06"

Special Vend A Start Date

"SA07"

Special Vend A Start Year

"SA08"

Special Vend A End Month

"SA09"

Special Vend A End Date

"SA10"

Special Vend A End Year

"SA11"

Special Vend A Heat Price

"SA12"

Special Vend A No Heat Price

"SA13"

Special Vend A Heat Time Minutes

"SA14"

Special Vend A No Heat Time Minutes

"SA15"

Special Vend A Coin #1 Top-Off Time Minutes

"SA16"

Special Vend A Coin #2 Top-Off Time Minutes

Programming Control

513001

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

21

Programming Control

DRY582R-e

"SPb-"

Special Vend B Days Enable (On/Off)

Press the LOW TEMP

or the DELICATES

keypad to scroll through

the programmable

options.

To enter a programming

option, press the START

keypad. To exit, press

the MED TEMP keypad.

continued

"SPC-"

Special Vend C Days Enable (On/Off)

"SPd-"

Special Vend D Days Enable (On/Off)

"droP"

Drop Off Mode

(On/Off)

"LPSA"

Low Power/Auto Shutdown A Days Enable (On/Off)

"LPSb"

Low Power/Auto Shutdown B Days Enable (On/Off)

"LPSC"

Low Power/Auto Shutdown C Days Enable (On/Off)

"LPSd"

Low Power/Auto Shutdown D Days Enable (On/Off)

"PFr"

Power Fail Reset

"IrA"

IR Access (On/Off)

"rAEn"

Manual Rapid Advance (On/Off)

"dAEn"

Manual Diagnostics (On/Off)

"PtEn"

Production Test Cycle (On/Off)

22

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

513001

Loading...

Loading...