HSM SP 5080 Operating Manual

2.990.999.120_en

SP 5080

Keep this instruction for future use!

OPERATING MANUAL

CHANNEL BALING PRESS

SP 5080

SP 5080

HSM GmbH + Co.KG,

Austrasse 1-9,

88699 Frickingen / Germany

Tel. + 49 75 54 2100-0

Fax + 49 75 54 2100-160

info@hsm.eu

www.hsm.eu

2 2.990.999.120_en 04/2013

SP 5080

Contents

Nameplate 6

Foreword 7

1 Safety 8

1.1 Notes on safety....................................................................................................8

1.1.1 "Work safety" symbol ..........................................................................................................8

1.1.2 "Notice" symbol ...................................................................................................................8

1.2 Classifi cation of hazards......................................................................................8

1.2.1 Danger ................................................................................................................................8

1.2.2 Warning ...............................................................................................................................8

1.2.3 Caution................................................................................................................................8

1.3 Notes on work safety ...........................................................................................9

1.4 Proper use ......................................................................................................... 11

1.5 Inspecting the safety devices ............................................................................12

2 Technical data 15

2.1 Power requirement and fuse rate ......................................................................15

2.2 KP 80 Combined press .....................................................................................15

2.3 FA 500.3 Shredder.............................................................................................16

2.4 Operating conditions ..........................................................................................16

2.5 Accessories .......................................................................................................16

2.6 SP 5080 explanatory diagram ...........................................................................17

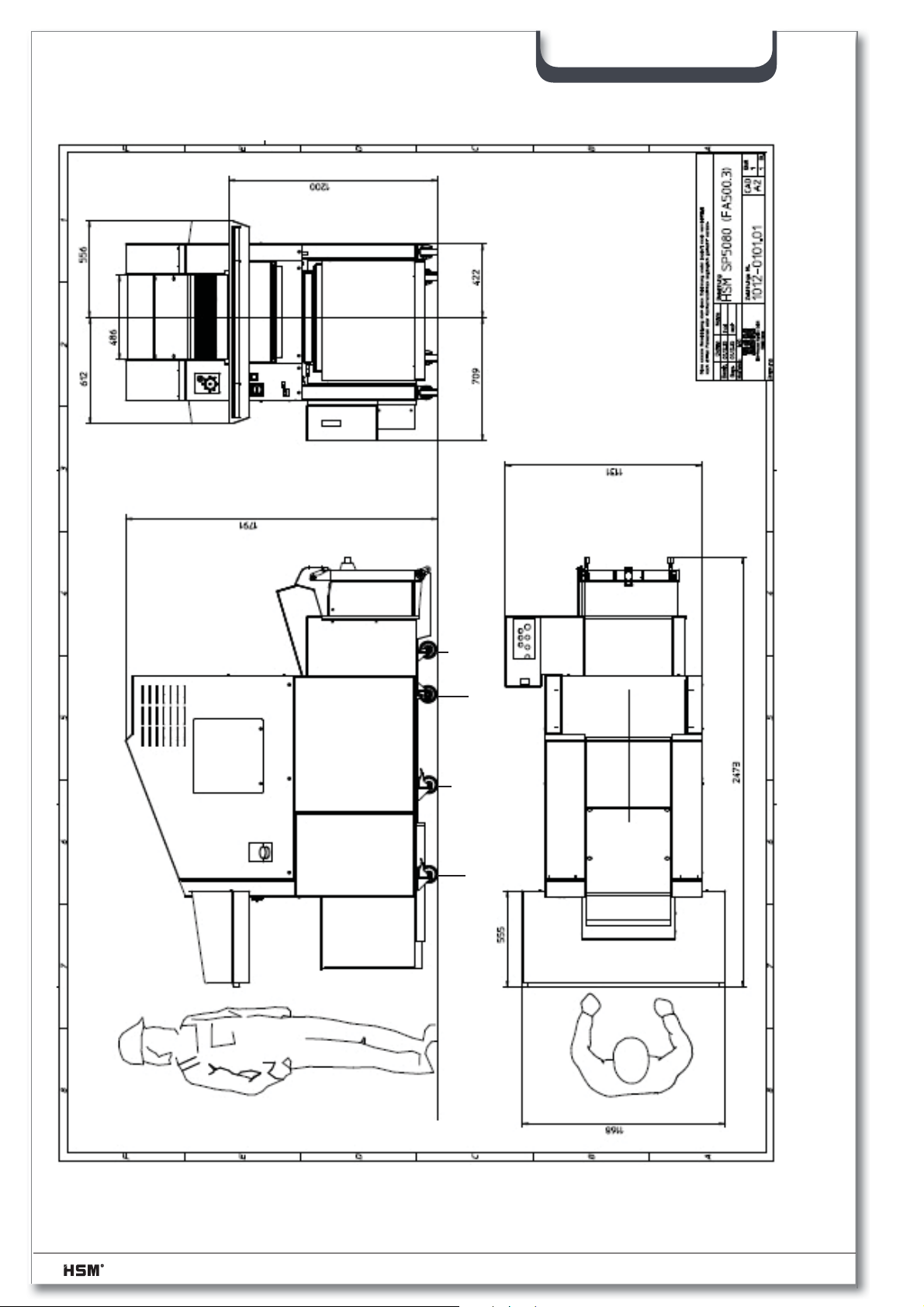

2.7 Machine dimensions ..........................................................................................18

3 Preparations 19

3.1 General instructions...........................................................................................19

3.2 Siting the machine .............................................................................................19

3.3 Supply connections ...........................................................................................19

3.4 Settings..............................................................................................................19

3.5 Transporting the baling press ............................................................................20

3.5.1 Transport to another application site .................................................................................20

3.6 Transporting the shredder .................................................................................21

3.7 Assembling the shredder ...................................................................................22

3.8 Assembling the shredder press combination.....................................................23

04/2013 2.990.999.120_en 3

SP 5080

4 Commissioning 26

4.1 Baling press controls .........................................................................................26

4.1.1 Accessing the SERVICE menu .........................................................................................30

4.1.2 Set-up mode .....................................................................................................................31

4.1.2.1 Pressure plate forward-backward / door lock open-close .....................................................31

4.1.2.2 To exit set-up mode ...............................................................................................................31

4.1.3 To display / clear the daily bale meter ...............................................................................32

4.1.4 To display the total bale meter ..........................................................................................32

4.1.5 To display the service hours meter ...................................................................................32

4.1.6 To set the user language...................................................................................................33

4.1.7 To display the error memory .............................................................................................33

4.1.8 System ..............................................................................................................................33

4.2 Shredder control panel ......................................................................................34

4.2.1 Display: Baling press not in automatic mode ....................................................................34

4.2.2 Display: Status of the baling press....................................................................................34

4.3 Initial start-up .....................................................................................................35

4.4 Using the machine .............................................................................................36

4.4.1 Fit the plastic bag and start the machine ..........................................................................36

4.5 Ejecting and bagging the bale ...........................................................................40

4.6 Malfunctions of the baling press ........................................................................43

4.6.1 Error numbers ...................................................................................................................43

4.7 Malfunctions of the shredder .............................................................................44

4.7.1 Overload due to paper jam ..............................................................................................44

4.7.2 Electric motor overheats ...................................................................................................44

4.7.3 Emergency stop activated.................................................................................................44

4.7.4 Oil reservoir empty ............................................................................................................45

4.8 Stopping the machine ........................................................................................45

4.9 Outdoor use .......................................................................................................45

5 Inspection and maintenance work 46

5.1 Notes on maintenance.......................................................................................46

5.2 Maintenance of the combined press..................................................................47

5.2.1 Changing the hydraulic fl uid / venting fi lter .......................................................................47

5.2.2 Lubricating the movable parts ...........................................................................................48

5.3 Maintenance of the FA 500.3 shredder .............................................................49

5.3.1 Lubricating the drive chains and synchronized wheels (2 x per year) ..............................49

5.3.2 Retighten the feed belt ......................................................................................................50

5.3.3 Check the directional stability of the feed belt ..................................................................50

5.3.4 Check the feed belt for wear .............................................................................................50

5.3.5 Emptying the collecting tray ..............................................................................................51

4 2.990.999.120_en 04/2013

SP 5080

6 Storage 52

7 Disposal instructions 52

7.1 Disposal verifi cation form .................................................................................53

8 Using and ordering spare parts 54

8.1 Customer service address .................................................................................54

9 Electrical circuit diagrams 55

10 KP 80 hydraulic diagram 56

11 EC declaration of conformity 57

04/2013 2.990.999.120_en 5

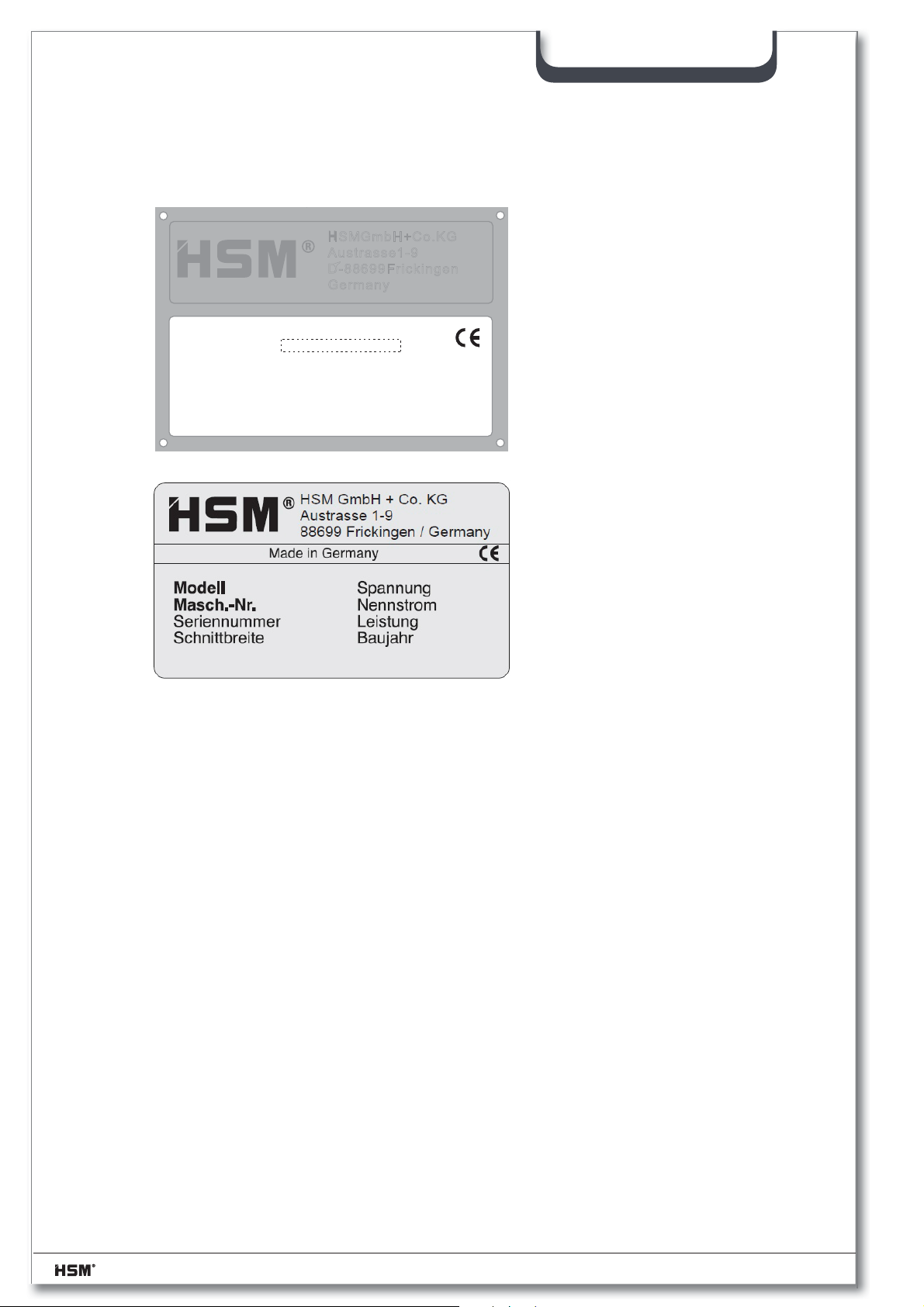

Nameplate

MODELL

MASCH.-NR.:

SERIEN - NR.:

PRESSKRAFT: kN

BAUJAHR:

HSM GmbH+Co.KG

Austrasse 1-9

D-88 699 Frickingen

Germany

LEISTUNG: kW

zH V :GNUNNAPS

NENNSTROM: A

SP 5080

The machine number is specifi ed on the nameplate of the baling press, shown above. Guaran-

tee claims and inquiries cannot be processed if you do not quote the machine number.

Please therefore enter this number into the grey fi eld of the nameplate immediately after re-

ceipt of the baling press.

6 2.990.999.120_en 04/2013

Foreword

This Operating Manual informs you in detail about the start-up and maintenance of your

new baling press. It also contains notes on safety which must be observed.

To a great extent, the performance of your baling press depends on its proper application and thorough maintenance. You should carefully read this Operating Manual and

the notes on safety and always keep them safe at hand. You can thus prevent accidents,

maintain your guarantee claims against the manufacturer and always have an operative

baling press.

HSM GmbH + Co. KG permanently aspire to improve their products. They reserve the

right to perform any changes and modifi cations which are deemed necessary. Howev-

er, this does not imply the obligation for a subsequent modifi cation of already delivered

machines.

Technical modifi cations as compared to the representations and statements in this Oper-

ating Manual which become necessary to improve the baling press are reserved.

SP 5080

This Operating Manual is intended for staff installing, operating and servicing the baling

press. It includes technical specifi cations and drawings which must not be copied, distrib-

uted or used for competitive purposes or given to third parties completely or in part.

Please contact your local dealer if you still have questions after having read this Operating Manual.

04/2013 2.990.999.120_en 7

1 Safety

1.1 Notes on safety

1.1.1 "Work safety" symbol

This symbol marks all work safety notes in this Operating Manual which

endanger the health or life of people. Please pay attention to this symbol and

exercise particular care in such cases. Please also forward all work safety

notes to other users.

Apart from the instructions in this manual, you must also follow generally

applicable safety and accident prevention regulations..

1.1.2 "Notice" symbol

This symbol marks information in this manual which requires particular

attention so that guidelines, regulations, instructions and correct working

procedures are followed and damage to or ruin of the machine and/or other

equipment prevented.

SP 5080

1.2 Classifi cation of hazards

1.2.1 Danger

identifi es an immediate danger. If not avoided, it will result in death or severe

injuries (crippling).

1.2.2 Warning

identifi es a possibly dangerous situation. If not avoided, it could result in

death or severe injuries.

1.2.3 Caution

identifi es a possibly dangerous situation. If not avoided, it could result in light

or minor injuries. Is also used for warnings concerning damage to material.

8 2.990.999.120_en 04/2013

1.3 Notes on work safety

Please pay particular attention to the following notes on work safety:

– The SP 5080 shredder press combination has been safety-tested by an accredited testing

station.

Nevertheless, incorrect operation and misuse can result in:

• the health or life of the operator

• the machine and other valuable equipment

• the effi cient operation of the shredder

– The SP 5080 shredder press combination has been built with the most up-to-date

technology. However, the machine can be dangerous if improperly used, even by trained-

staff, or if used for purposes other than those for which it was designed.

– The operation of the shredder press combination is always subject to local safety and acci-

dent prevention regulations.

SP 5080

– The employer must observe and comply with the “minimum safety and health requirements-

for the use of work equipment by workers at work”. Machinery Directive 2009/104/EC

– The shredder press combination may not be operated by anyone under 16 years of age.

– All those charged with installation, assembly, disassembly, start-up, operation, inspection,

maintenance or repair of the baling press must have fi rst read and fully understood the en-

tire operating manual, paying particular attention to the “Safety” section.

– The shredder press combination may only be operated, serviced and repaired by authorised,

trained staff. These staff must have been given special instructions on any dangers which

may possibly arise.

– Areas of personal responsibility for installation, assembly, re-assembly, set-up, operation and

maintenance must be clearly defi ned and strictly adhered to, in order to avoid confusion

which might compromise safety.

– When carrying out installation, disassembly, re-assembly, maintenance, operation, adjust-

ment and maintenance work always observe the shut-down procedures described in the

operating manual. Never perform this kind of work on the machine unless it is fully shut

down.

– Before performing such tasks make sure the drives and additional mechanisms of the baling

press cannot be switched on unintentionally. Turn the main switch to the “0” position and se-

cure it. Pull out the power plug.

– Before starting the machine after repairs, make sure all protective devices are in place.

04/2013 2.990.999.120_en 9

SP 5080

– Do not carry out any tasks which may endanger your safety while operating the machine.

– Any changes which take place and could impair safety should be reported immediately. Put

the machine out of operation until the damage is rectifi ed.

– Always make sure the machine is in perfect condition before you switch it on.

– Make sure the area around the machine is clean and safe.

– Unauthorised modifi cations and changes to the machine are strictly prohibited. Protective

devices may not be removed or otherwise rendered inoperative.

– No work on the machine which is not part of its normal operation may be performed while

the machine is still running.

– Never open doors and fl aps before the machine has been shut down. Note the instruction

plate.

– Test the protective measures installed after any electrical or repair work.

– No platforms or other raised surfaces may be placed near the shredder press combination

if they encroach on the specifi ed safety clearances.

– Connecting cables must be laid in such a way that they cannot be tripped over.

– Only persons with the appropriate skills and experience in hydraulics may carry out work

on the hydraulic equipment.

– All lines, pipes and bolted joints must be regularly inspected for looseness, leaks and vis-

ible damage. Any damage must be repaired immediately. Escaping oil can cause fi re and

injury

– Any parts of the system and hydraulic pressure lines that need to be opened must be de-

pressurised according to the assembly instructions before commencing repair work.

10 2.990.999.120_en 04/2013

1.4 Proper use

The SP 5080 shredder press combination is intended solely for shredding and pressing

paper and cardboard. The robust cutting unit is unaffected by staples and paper clips and

is even suitable for the destruction of whole volumes of fi les and folders. Excluding other

types of materials.

Mode of operation:

The above mentioned material is fed into the Shredder. The shredded material falls

through the discharge chute of the shredder directly into the hopper of the press. The

press cycle is initiated by a light barrier in the hopper when it has been fi lled to a certain

level. The press ram is extended and pushes the material into the press chamber, where

it is compacted. The shredder continues to run during the press cycle. As soon as the

bale has reached a certain length, it has to be ejected into a gusseted bag. Thereafter

pressing can continue.

Any other use is considered improper. The manufacturer accepts no liability for damage

resulting from improper use - the operator carries sole responsibility for such use.

SP 5080

Proper use also includes carrying out installation, assembly, disassembly, start-up, operation

and maintenance work as prescribed by the manufacturer. The baling press may

only be operated, serviced and repaired by staff who are familiar with these regulations

and aware of the dangers.

The shredder press combination may only be operated by authorised, trained staff. Do

not carry out any tasks which may endanger your safety while operating the machine.

The relevant accident prevention regulations and any other generally recognised health

and safety standards must also be observed.

04/2013 2.990.999.120_en 11

1.5 Inspecting the safety devices

Check the safety devices:

• at the start of every work shift (when operation was interrupted)

• at least once a week when the operation is interrupted

• after each maintenance or repair

Check the safety devices for:

• specifi ed condition

• specifi ed position

• safe attachment

• specifi ed function

Use the following checklist for your inspection. Correct any defects before starting

the machine!

If any defects arise during operation stop the machine immediately and ensure that the

defect is corrected.

SP 5080

Do not modify or remove any of the protective devices. Do not deactivate any of the protective

devices by modifying the machine.

Modifi cations to the machine are prohibited for safety reasons!

12 2.990.999.120_en 04/2013

Checklist for inspecting the safety devices

Use the following list for your inspection of the safety devices.

Photocopy it for regular inspections.

Tick off the boxes if the check was successful.

Do not start the machine until you have checked every point.

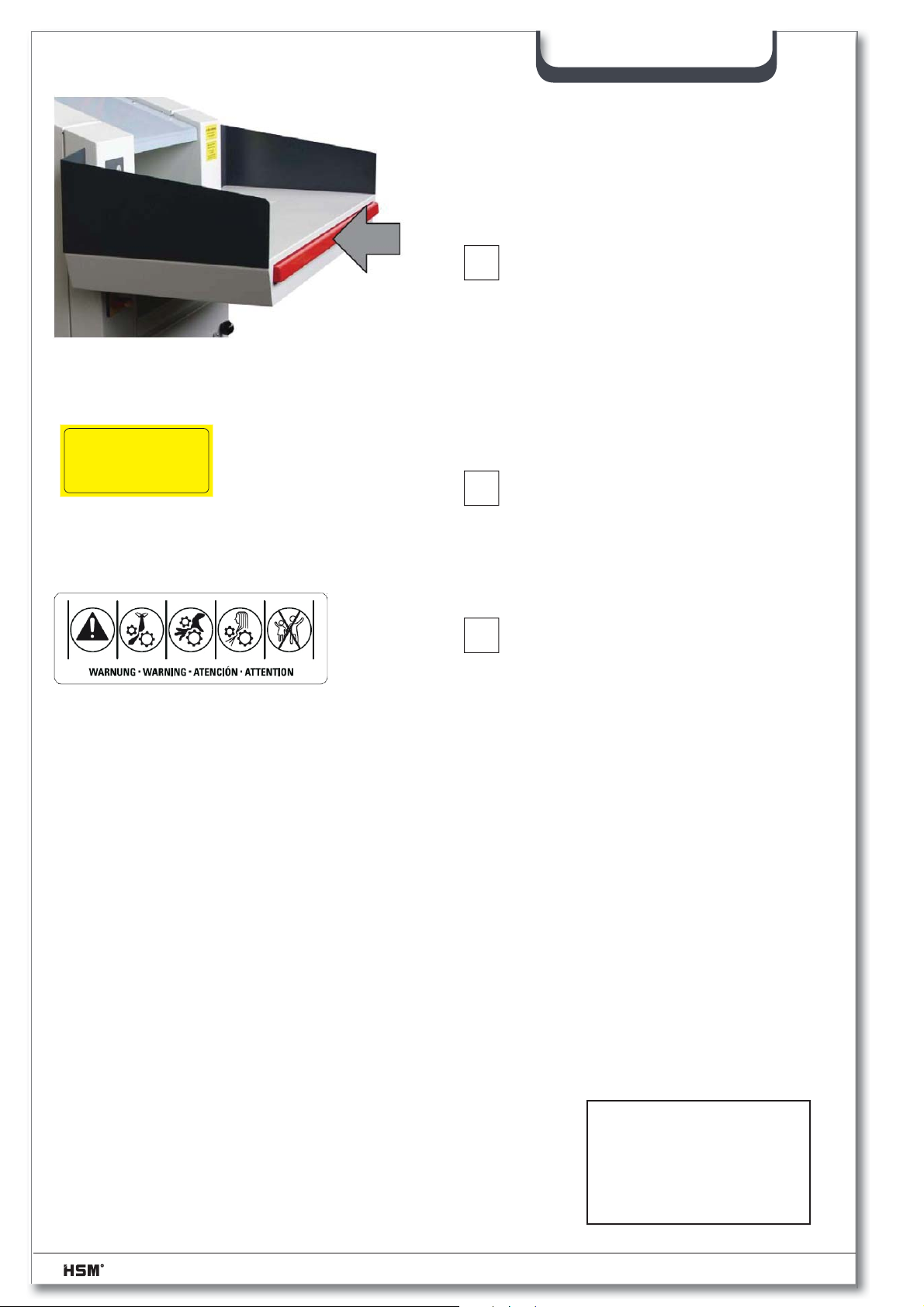

1. All protective plates must be mounted and fi rmly

bolted on. (see picture)

SP 5080

The control cabinet must be closed and the

2.

“Lightning symbol” warning sign affi xed to it.

3. Check the safety switch on the hopper. The

safety switch switches the shredder press combination off immediately and prevents it from being

switched on again when the inspection fl ap is

opened.

Try this function out!

04/2013 2.990.999.120_en 13

SP 5080

Ein-Mann-Bedienung

One-man operation

Un seul opérateur

4. When you press the emergency stop switch bar

whilst the machine is running, the shredder and

baling press must switch off immediately. The

machines can only be switched on again once

you have pulled out the switch bar.

Try this function out!

5. The safety sticker “One-man operation” must be

fi xed to the shredder.

6. The “Safety instruction symbol” sticker must be

fi xed to the shredder.

Inspected

Date ..........................................

Signature..................................

14 2.990.999.120_en 04/2013

2 Technical data

2.1 Power requirement and fuse rate

Voltage 3 x 400 V / 50 Hz 3 x 400 V / 50 Hz

Net 3P+N+PE 3P+N+PE

Power 11,5 kW 13,5 kW

Fuse 32 A 32 A

Rated current 32 A 32 A

2.2 KP 80 Combined press

Weight approx. 600 kg

Size (L x W x H) 2335 x 945 x 1400 mm

Press data

Pressing force 80 kN

Specifi c pressing force 30 N/cm²

Cycle time when idling (theoretical) 18-20 s

Bale size (L x W x H) 800 x 570 x 490 mm

Bale weight (depending on material)* 50 - 70 kg

SP 5080

Security level 2 - 3 Security level 4

Motor data

Rated power P

Operating voltage U 3 x 400 V / 50 Hz

Rated current l

Protection class IP 55

Hydraulics

Operating pressure 210 bar

Pump

Discharge Q 19,5 l/min

Cylinder

Pressing cylinder Ø 70/50 x 1000 mm

Oil tank

Capacity 20 l

Oil grade multi-grade oil (DIN 51524-T3)

n

n

4,0 kW

8,3 A

ISO viscosity grade HVLP 22

Noise emission

The sound pressure level does not exceed 80 dB(A)

*)Bale weight : The bale weight varies depending on the type, humidity and condition of the

compressed material and on bale length / height.

04/2013 2.990.999.120_en 15

SP 5080

2.3 FA 500.3 Shredder

Cutting type Particle cut

Cutting size (mm)

Security level DIN 66399

Security level DIN 32757

A4 (sheet) cutting performance 70 g/m

80 g/m

Throughput security level 4 200 – 250 kg/h

Intake width 500 mm

Cutting speed 210 mm/s

Power supply 3 x 400 V, 50 Hz

Rated power motor 7,5 kW 5,5 + 4 kW

Rated current at rated

cutting capacity

Plug Industrial plug

Fuse

10,5 x 40 - 76 7,5 x 40 - 76 6 x 40 - 53 1,9 x 1,5

P-2/O-2/T-2/E-2

2

2

2

600 - 650

510 - 550

P-3/O-2/T-3/E-2

2

500 - 550

425 - 470

27 A 31 A

Typ "gl" 35 Ampere

P-3/O-2/T-3/E-23P-5/O-4/T-5/E-4/F-2

400 - 450

340 - 380

4

120 - 130

90 - 100

automatic cutout

Ambient conditions for transport,

storage and operation:

Temperature

Relative humidity

Altitude above sea level

Dimenstions W x D x H 1170 x 1795 x 1795 mm

Weight 790 kg 920 kg

Sound pressure level 75 dB(A)

Shredded material container volume 530 l (2 x 265 l)

max. 90 %, without condensation

K or C / 32 Ampere

-10 °C bis +40 °C

max. 2.000 m

2.4 Operating conditions

Operating temperature - 10°C ÷ + 40°C

Operating humidity max. 90%, without-condensing

Operating altitude max. 2000 m above sea level

2.5 Accessories

PE gusseted bag 570/490 x 1400 x 0,075 mm

Order no.: 6.209.995.000

16 2.990.999.120_en 04/2013

2.6 SP 5080 explanatory diagram

9

3

4

19

SP 5080

1 Press control cabinet

2 Press control panel

3 Press inspection fl ap

4 Safety fl ap door lock

5 Counter plate

6 Door lock

7 Press chamber

8 Hydraulic cover

6

5

9 FA 500.3 Shredder

10 Loading table

11 Shredder control panel

12 Emergency stop switch bar

13 Feed belt

14 Swivel roller with brake

2

14

13

1

7

11

10

12

20

1517 1618

04/2013 2.990.999.120_en 17

8

15 Pressing cylinder

16 Press motor

17 Venting fi lter

18 Hydraulic tank

19 Shredder inspection fl ap

20 Oil reservoir opening

2.7 Machine dimensions

SP 5080

2 x1,5 kN 2 x1,5 kN

2 x2,3 kN 2 x2,3 kN

18 2.990.999.120_en 04/2013

Loading...

Loading...