HSM SP 4040 Operating Manual

2.513.999.220_en

SP 4040

OPERATING MANUAL

SHREDDER-PRESS COMBINATION

SP 4040

Keep in a safe place for future use!

2 SP 4040 11/2012

SP 4040

HSM GmbH + Co.KG,

Austraße 1-9,

88699 Frickingen, Germany

Tel. +49 7554 2100-0

Fax +49 7554 2100-160

mailto: info@hsm.eu

www.hsm.eu

11/2012 SP 4040 3

SP 4040

Contents

1 Safety 5

1.1 Safety instructions ...............................................................................................5

1.1.1 The Safety symbol ..............................................................................................................5

1.1.2 The Note symbol .................................................................................................................5

1.2 Classifi cation of hazards......................................................................................5

1.2.1 Danger ................................................................................................................................5

1.2.2 Warning ...............................................................................................................................5

1.2.3 Caution................................................................................................................................5

1.3 Safety instructions ...............................................................................................6

1.4 Proper use ...........................................................................................................8

1.5 Inspecting the safety devices ..............................................................................8

1.5.1 Checklist for inspecting the safety devices .........................................................................9

2 Transportation / Installation 11

2.1 Operating conditions.......................................................................................... 11

2.2 Transport ........................................................................................................... 11

2.3 Technical data ...................................................................................................12

2.3.1 Baling Press KP 40 V ....................................................................................................12

2.3.2 Shredder FA 400.2 ........................................................................................................12

2.3.3 Power requirement and fuse rate ..................................................................................13

2.3.4 Noise emission ..............................................................................................................13

2.3.5 Operating conditions .....................................................................................................13

2.3.6 Measurements chart: Baling press HSM KP 40 V + Shredder FA 400.2 ..........................14

2.4 Assembling the shredder ...................................................................................15

2.5 Assembling the press and shredder ..................................................................16

2.6 Start-up ..............................................................................................................18

3 Operation 19

3.1 Machine overview ..............................................................................................19

3.2 Operating and display elements of the baling press .........................................20

3.2.1 Call up the SERVICE menu ..............................................................................................23

3.2.2 Adjusting the user language .............................................................................................24

3.2.3 Select set-up mode ...........................................................................................................25

3.2.4 Leave set-up mode ...........................................................................................................25

3.3 Operating and display elements of the shredder ...............................................26

3.3.1 Emergency stop button .....................................................................................................26

3.3.2 Keypad ..............................................................................................................................26

3.4 Operation ...........................................................................................................27

3.4.1 Repressing ........................................................................................................................28

3.5 Shredder combination shutdown .......................................................................30

3.5.1 Lowering the press ram ....................................................................................................30

4 SP 4040 11/2012

SP 4040

4 Faults / troubleshooting 31

4.1 Malfunctions shredder .......................................................................................31

4.2 Malfunctions baling press ..................................................................................32

5 Maintenance 33

5.1 General instructions...........................................................................................33

5.2 Baling press ......................................................................................................34

5.2.1 Hydraulic fl uid level / venting fi lter.....................................................................................34

5.2.2 Changing the hydraulic fl uid..............................................................................................35

5.3 Shredder ............................................................................................................36

5.3.1 Cleaning cutting device (1x daily) .....................................................................................36

5.3.2 Checking chain tension (2 x annually) FA 400.2 ...............................................................37

5.3.3 Greasing drive chains and cogs (2x annually) FA 400.2 ...................................................38

5.3.4 Tightening the feeding belt FA 400.2 ................................................................................38

5.3.4.1 Check, that the feeding belt runs straight .............................................................................. 39

5.3.4.2 Checking the feeding belt for wear ........................................................................................ 39

6 Disposal instructions 39

6.1 Disposal verifi cation form .................................................................................40

7 Electrical and hydraulic circuit diagrams 41

7.1 Electrical circuit diagrams ..................................................................................41

7.2 Hydraulic diagrams ............................................................................................42

7.3 EC declaration of conformity .............................................................................43

11/2012 SP 4040 5

SP 4040

1 Safety

1.1 Safety instructions

1.1.1 The Safety symbol

You will see this symbol next to all operating safety instructions in this

operating manual where failure to comply may result in injury or death.

Please note these instructions and exercise particular care in such cases. Pass on all safety instruction to other persons using the machine. In

addition to the instructions in this manual, the safety and accident prevention regulations which generally apply must also be observed.

1.1.2 The Note symbol

This symbol indicates particularly important instructions in this manual

which must be observed in order to ensure that guidelines and regulations are correctly adhered to, that work is carried out in the proper

order, and that damage to the machine or other plant compo- nents is

prevented.

1.2 Classifi cation of hazards

1.2.1 Danger

Indicates an immediate danger. Failure to take heed of this warning will

result in death or very serious injury.

1.2.2 Warning

Indicates a potentially dangerous situation. Failure to take heed of this

warning may result in death or very serious injury.

1.2.3 Caution

Indicates a potentially dangerous situation. Failure to take heed of this

warning may result in minor injury.

Also used to warn about material damage.

6 SP 4040 11/2012

SP 4040

1.3 Safety instructions

Pay particular attention to the following safety instructions:

– The shredder-press combination SP 4040 has been inspected for safety by the exam-

ination board of the technical committee of TÜV Rheinland. Nevertheless, incorrect

operation and misuse can result in:

• injury or death to the operator

• damage to the machine and other material assets of the company

• ineffi cient machine operation

– The shredder-press combination SP 4040 baling press has been built with the most up-

to-date technology. However, the machine can be dangerous if improperly used, even

by trained staff, or if used for purposes other than those for which it was designed.

– The operation of the shredder-press combination is always subject to local safety and

accident prevention regulations.

– The employer has to observe and to keep the „Minimum safety and health require-

ments for use of the work equipment by workers at work. (2009/104/EG)

– The shredder-press combination may not be operated by anyone under 16 years of

age.

– All those charged with installation, assembly, disassembly, start-up, operation, inspec-

tion, maintenance or repair of the shredder-press combination must have fi rst read and

fully understood the entire operating manual, paying particular attention to the "Safety"

section.

– The shredder-press combination may only be operated, serviced and repaired by au-

thorised, trained staff. These staff must have been given special instructions on any

dangers which may possibly arise.

– Areas of personal responsibility for installation, assembly, re-assembly, set-up, opera-

tion and maintenance must be clearly defi ned and strictly adhered to, in order to avoid

confusion which might compromise safety.

– When carrying out installation, disassembly, re-assembly, maintenance, operation, ad-

justment and maintenance work always observe the shut-down procedures described

in the operating manual. Never perform this kind of work on the machine unless it is

fully shut down.

– Before performing such tasks make sure the drives and additional mechanisms of

the shredder-press combination cannot be switched on unintentionally. Turn the main

switch to the "0" position and secure it. Pull out the mains plug.

– Before starting the machine after repairs, make sure all protective devices are in place.

11/2012 SP 4040 7

SP 4040

– Do not carry out any tasks which may endanger your safety while operating the ma-

chine.

– Any changes which take place and could impair safety should be reported immediately.

Put the machine out of operation until the damage is rectifi ed.

– Always make sure the machine is in perfect condition before you switch it on.

– Make sure the area around the shredder-press combination is clean and safe.

– Unauthorised modifi cations and changes to the machine are strictly prohibited. Protec-

tive devices may not be removed or otherwise rendered inoperative.

– No work on the machine which is not part of its normal operation may be performed

while the machine is still running.

– Never open doors and fl aps before the machine has been shut down. Note the instruc-

tion plate.

– Test the protective measures installed after any electrical or repair work.

– No platforms or other raised surfaces may be placed near the shredder-press combina-

tion if they encroach on the specifi ed safety clearances.

– Connecting cables must be laid in such a way that they cannot be tripped over.

– Only persons with the appropriate skills and experience in hydraulics may carry out

work on the hydraulic equipment.

– All lines, pipes and bolted joints must be regularly inspected for looseness, leaks and

visible damage. Any damage must be repaired immediately. Escaping oil can cause

fi re and injury!

– Any parts of the system and hydraulic pressure lines that need to be opened must be

depressurised according to the assembly instructions before commencing repair work.

8 SP 4040 11/2012

SP 4040

1.4 Proper use

The shredder-press combination SP 4040 is solely to be used for pressing paper and

cardborad (shredded or not shredded). The sturdy cutting mechanism is not damaged by

paper clips and staples, credit cards, CD-ROMs and fl oppy discs.

The shredder-press combination may only be operated by authorised, trained staff. Do

not carry out any tasks which may endanger your safety while operating the machine.

Any other use is considered improper. The manufacturer accepts no liability for damage

resulting from improper use - the operator carries sole responsibility for such use.

1.5 Inspecting the safety devices

Check the safety devices:

• At the start of each shift (if operation was interrupted)

• At least once a week if the machine is operated continuously

• After any maintenance or repair work

Check that the safety devices:

• Are in the correct condition

• Are in the correct position

• Are fi rmly secured

• Are working properly

If any defects arise during operation stop the machine immediately and ensure that the

defect is corrected.

Do not modify or remove any of the protective devices. Do not deactivate any of the protective devices by modifying the machine.

Modifi cations to the machine are prohibited for safety reasons!

Warning!

Defective safety devices can lead to serious accidents!

Ensure that the shredder has been completely shut down immediately,

should the safety devices become defective!

Never reach into the cutting device while it is running, this could result in

very serious injuries!

The shredder may only be started, if all the safety devices are functioning correctly.

Use the following checklist for your inspection. Correct any defects before starting the

machine!

11/2012 SP 4040 9

SP 4040

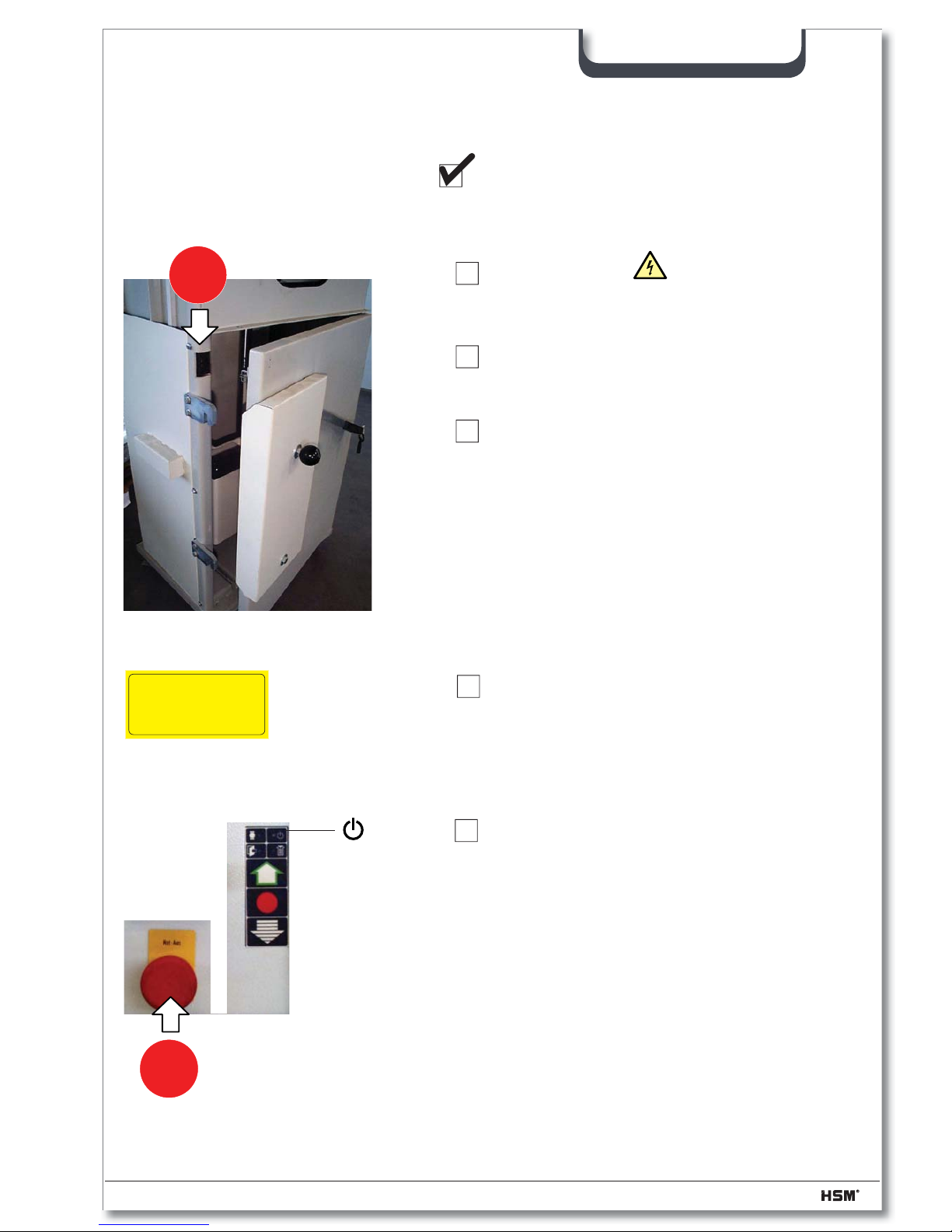

1.5.1 Checklist for inspecting the safety devices

Photocopy this checklist for regular inspections.

Tick off the points if they are OK.

Do not start the machine until you have checked every point.

The warning sign

must be fi xed to the

control cabinet of the shredder-press

combination.

All protective covers must be mounted and

fi rmly bolted onto the shredder and the shredder-press combination (see picture)

Check the safety switch on the bale removal

door (1). If the bale removal door is opened

during operation, The shredder-press combination and the shredder should switch

off immediately. It should not be possible to

turn on any of the machines as long as the

bale removal door is open. After the bale removal door has been shut, the "Ready" lamp

on the shredder should light up again.

1

If you press the "Emergency Stop" button

(2) on the shredder, it should switch off immediately and the "Ready" lamp should stop

glowing. It should not be possible to turn the

shredder on as long as the "Emergency Stop"

button is locked. After the "Emergency Stop"

has been unlocked, the "Ready" lamp should

light up again.

2

Ein-Mann-Bedienung

One-man operation

Un seul opérateur

The safety label "One-man operation" must

be attached on the shredder.

10 SP 4040 11/2012

SP 4040

Date……………………

Inspected:

Signed ……………………………………………

Only for shredder type FA 400.2:

Check the safety switch (3) on the front door:

If the door is opened then the shredder must

switch off immediately and the "Door open"

lamp should light up.

It should not be possible to turn the shredder

on as long as the door is open.

After the door has been shut, the "Door open"

lamp must go off.

3

11/2012 SP 4040 11

SP 4040

2 Transportation / Installation

Danger!

The baling press should only be transported upright with the press ram

lowered.

If this is not done the baling press can topple over!

If the machine is to be transported with a fork lift truck, the bearing points indicated in the

diagram should always be used. Note that the shredder and the baling press have a high

centre of gravity!

2.2 Transport

2.1 Operating conditions

The machines should only be operated in dry rooms.

If the temperature is less than 0°C, a different hydraulic fl uid with a more suitable viscosi-

ty will be required.

- Place the machines on a smooth level surface

- Remove the packaging

The shredder or the baling press can now be rolled onto its installation site.

12 SP 4040 11/2012

SP 4040

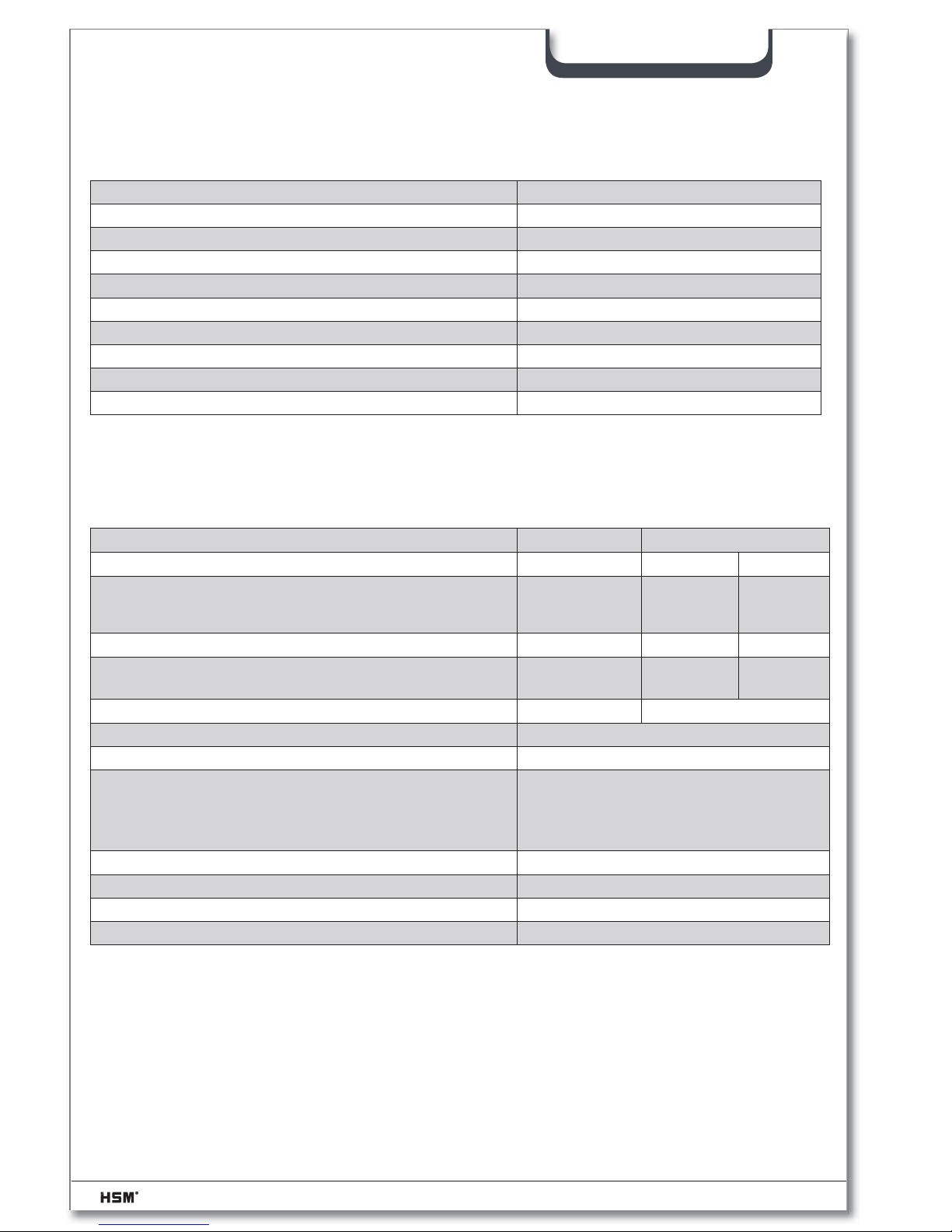

2.3 Technical data

2.3.1 Baling Press KP 40 V

Pressing power 44 kN

Compression time with return stroke 11 s

Rated power P

n

2,2 kW

Rated speed n 3000 min

-1

Connection 3 x 400 V / 50 Hz

Rated current l

n

5 A

Carton size (LxWxH) 590 x 390 x 485 mm

Carton weight, full 25 - 35 kg

Transport height ~ 2150 mm

Weight ~ 500 kg

2.3.2 Shredder FA 400.2

Cutting type

Strip cut Cross cut

Cut size (mm)

5,8 5,8 x 50 3,9 x 40

Safety level DIN 66399

P-2 / O-2 / T-2 /

E-2

P-3 / O-2 /

T-3 / E-2

P-4 / O-3 /

T-4 / E-3 /

F-1

Safety level DIN 32757 - 1

233

Cutting capacity (sheets), DIN A4, 70 g/m²

80 g/m²

130

104

120

96

95 - 100

80 - 85

Cutting speed

210 mm/s 220 mm/s

Effective width

428 mm

Weight

ca 425 kg

Waste container volume

(Solo machines)

1-chamber system

2-chamber system

460 l

2 x 230 l

Power supply

3 x 400 V / 50 Hz

Rated power P

n

4 kW

Max. current

21 A

Sound level (idling / under load)

61 dB (A) / 75 dB (A)

11/2012 SP 4040 13

SP 4040

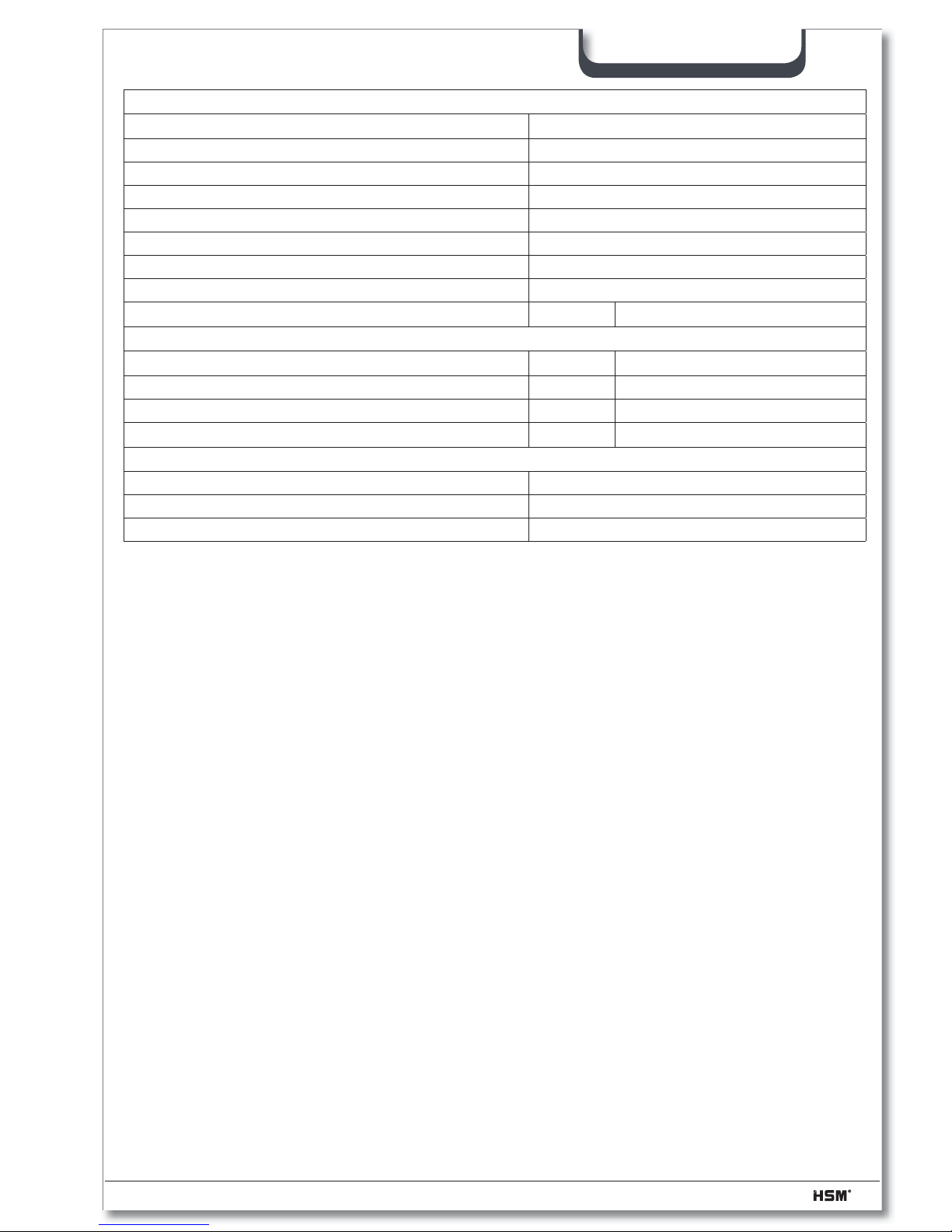

2.3.3 Power requirement and fuse rate

KP 40V + FA 400.2

Voltage 3 x 400 V / 50 Hz

Net 3P+N+PE

Power ~6,2kW

Fuse 25A

(K-Charakteristik)

Control voltage 24VDC

Guideline EN 60204

Plug electrical connection CEE 32

2.3.4 Noise emission

FA 400.2 KP 40 V

Idle 61 dB(A) 69 dB(A)

Loaded 75 dB(A) 75 dB(A)

2.3.5 Operating conditions

Operating temperature - 10°C ÷ + 40°C

Operating humidity max. 90%, non-condensing

Operating altitude max. 2200 m above sea level

Loading...

Loading...