Page 1

HP VISUALIZE B2000 UNIX® Workstations

Parts Removal/Replacement Guide

Manufacturing Part Number: HP Part No. A5983-90060

Edition E0100

Page 2

© Copyright 2000 Hewlett-Packard Company

Notice

UNIX is a registered trademark in the United States and other

countries, licensed exclusively through X/Open Company Limited.

The information contained in this document is subject to change without

notice.

Hewlett-Packard assumes no responsibility for the use or reliability of its

software on equipment that is not furnished by Hewlett-Packard.

This document contains proprietary information that is protected by

copyright. All rights reserved. No part of this document may be

photocopied, reproduced or translated to another language without the

prior written consent of Hewlett-Packard Company.

HEWLETT-PACKARD WARRANTY STATEMENT

HP PRODUCT HP VISUALIZE B2000 Workstations

REFERENCE Warranty and Services/Support Booklet,

Part Number A5014-90140 (E1199)

The warranty statement shipped with your product supersedes any and

all previous workstation Warranty Statements for the Hewlett-Packard

Workstations specified herein. Note: This Parts-Only Base Warranty is

offered only in the US; for country-specific warranties, please contact

your HP country sales representative.

2

Page 3

Year 2000 Compliance

This HP Year 2000 Warranty is in addition to the HP Standard

Commercial Warranties contained in Exhibit E16, HP Terms and

Conditions of Sale and Service. HP warrants that each HP hardware,

software, and firmware Product delivered under this HP Year 2000

Warranty will be able to accurately process date data (including, but not

limited to, calculating, comparing, and sequencing) from, into, and

between the twentieth and twenty-first centuries, and the years 1999

and 2000, including leap year calculations, when used in accordance with

the Product documentation provided by HP (including any instructions

for installing patches or upgrades), provided that all other products (e.g.

hardware, software, firmware) used in combination with such HP

Product(s) properly exchange date data with it.

If the Specifications require that specific HP Products must perform as a

system in accordance with the foregoing warranty, then that warranty

will apply to those HP Products as a system, and Customer retains sole

responsibility to ensure the Year 2000 readiness of its information

technology and business environment. The duration of this warranty

extends through January 31, 2001. The remedies available under this

warranty will be defined in, and subject to, the terms and limitations of

the warranties contained in HP’s standard commercial warranties. To

the extent permitted by local law, this warranty applies only to branded

HP Products and not to products manufactured by others that may be

sold or distributed by HP. This HP Year 2000 Warranty applies only to

HP Products shipped after the effective date, July 01, 1998, of this

warranty. Nothing in this warranty will be construed to limit any rights

or remedies provided elsewhere in the HP Terms and Conditions of Sale

and Service with respect to matters other than Year 2000 compliance.

RESTRICTED RIGHTS LEGEND.

Use, duplication, or disclosure by the U.S. government is subject to

restrictions as set forth in subdivision (c) (1) (ii) of the Rights in

Technical Data and Computer Software Clause in DFARS 252.227.7013.

Hewlett-Packard Co., 3000 Hanover St., Palo Alto, CA 94304.

3

Page 4

4

Page 5

Contents

1. Getting Started

Safety Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . . . . .9

Replacement Part Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Safely Powering Down the B2000 Workstation . . . . . . . . . . . . . . . . . . . .12

Product Exploded Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2. Parts Replacement Procedures

Front Bezel and Left Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Opening the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Closing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Left Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Memory DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Installing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Removing Memory DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Displaying the Current Memory Configuration . . . . . . . . . . . . . . . . . .23

PCI I/O Card(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Removing I/O Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Installing I/O Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

CD Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Removing a CD Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Installing a CD Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Floppy Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Installing a Floppy Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Removing the Floppy Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Verifying the Floppy Drive Configuration. . . . . . . . . . . . . . . . . . . . . . .44

5

Page 6

Contents

Hard Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Installing a Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Removing a Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuring a Hard Disk Drive as a File System . . . . . . . . . . . . . . . . 52

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Removing the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installing the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Voltage Regulator Modules (VRMs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing VRMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Installing VRMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Removing the System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Installing the System Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Fans (I/O and System Board Fan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Removing the I/O Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Installing the I/O Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Removing the System Board Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Installing the System Board Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

LCD Display with Power Switch and Display Cable . . . . . . . . . . . . . . . 77

Removing the LCD Display/Power Switch Assembly . . . . . . . . . . . . . 77

Installing the LCD Display/Power Switch Assembly . . . . . . . . . . . . . 78

Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Removing the Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Installing the Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Real Time Clock Module (Battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3. Wrapping Up

Verifying System Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6

Page 7

Contents

Returning the Defective Exchange Assembly . . . . . . . . . . . . . . . . . . . . .85

7

Page 8

Contents

8

Page 9

1 Getting Started

The following important information must be adhered to for proper removal and

replacement of all Hewlett-Packard parts.

Safety Warnings

WARNING Removing the device cover may expose sharp edges in the equipment

chassis. To avoid injury, use care when installing customer add-on

devices.

NOTE Before performing removal/replacement procedures, position the workstation

on a cushioned flat, stable surface, such as a table top or workbench.

NOTE Installing the recommended HP replacement part in your B2000 workstation

does not affect the regulatory and safety classifications or approvals listed in

the original owner’s guide.

Electrostatic Discharge (ESD) Precautions

Toprevent damage to the B2000 workstation, observe all of the following ESD precautions

while performing removal and replacement procedures:

• Remove all ESD-generating materials from the work area in whichyou will remove and

replace the workstation field replaceable unit(s).

• Open the ESD materials provided with the replacement part kit. Unfold the black

conductive sheeting (antistatic mat) and place it under a corner of the workstation. See

Figure 1-1. on page 10.

9

Page 10

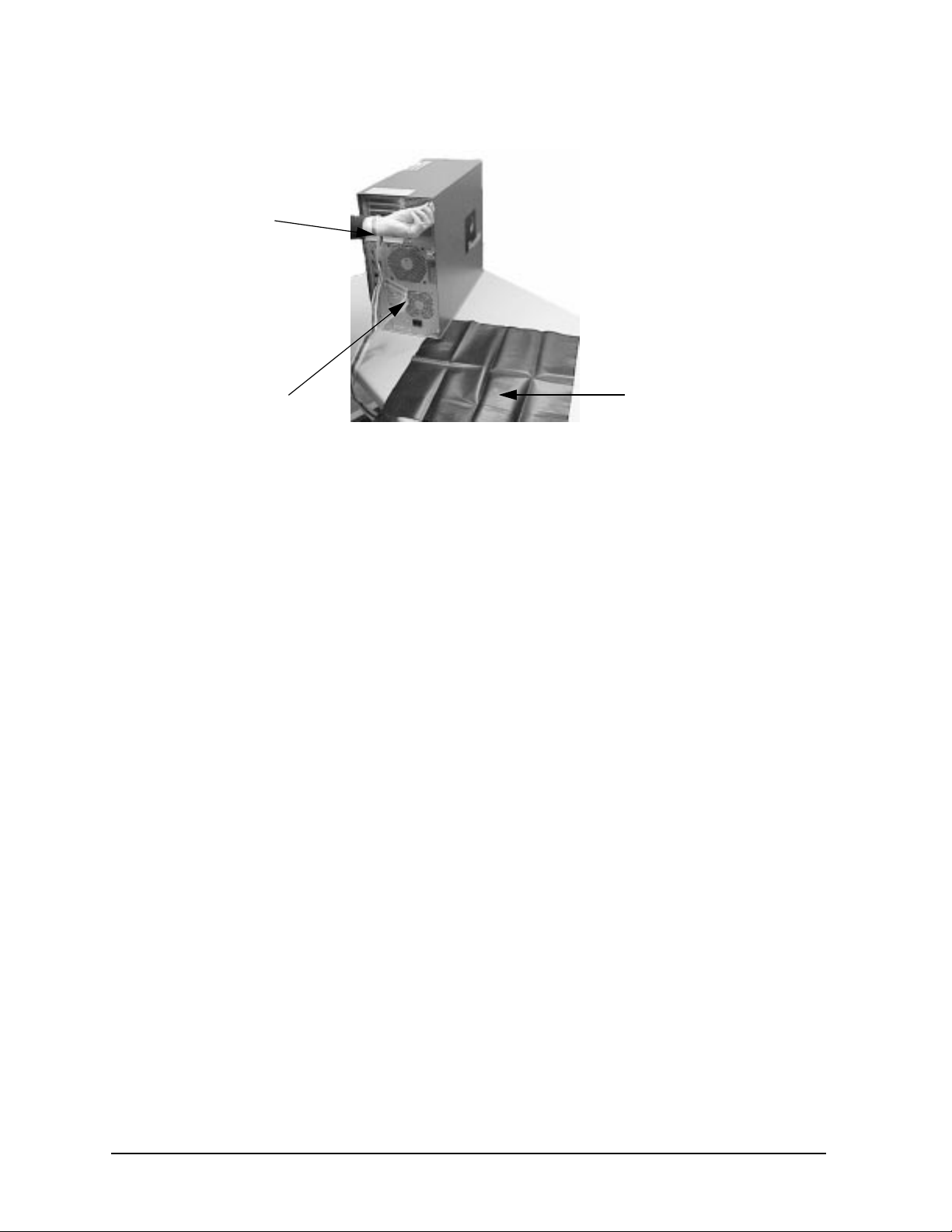

Getting Started

Electrostatic Discharge (ESD) Precautions

Figure 1-1. ESD Precautions

Static Strap

Strap attached

Antistatic Mat

to Bare Metal

• Wear a static strap to ensure that any accumulated electrostatic charge is discharged

from your body to ground. Attach the static-grounding wrist strap by following the

instructions on the package. Attach the sticky end of the wrist strap to bare metal on

the rear panel of the workstation. See Figure 1-1. on page 10.

• Connect all equipment together, including the static-free mat, static strap, clips

attached to the wrist strap, nodes, and peripheral units.

• Keep uninstalled printed circuit boards in their protective antistatic bags.

• Once you have removed printed circuit boards from their protective antistatic bags,

handle the printed circuit boards by their edges only.

10 Chapter1

Page 11

Getting Started

Replacement Part Kit Contents

Replacement Part Kit Contents

Take a moment to verify that your kit contains the following contents:

• Part assemblies matching your order information.

• Part Number: A3024-80004, Electrostatic Discharge (ESD) materials.

• Removal/Replacement Instructions.

• B2000 Owner’s Guide

If you are missing any part or documentation, please call your designated service

representative.

Required Tools

You will need the following tools for removal/replacement procedures:

• T-10 and/or T-15 Torx drivers

• Light-duty flat-blade screwdriver with a 6-inch (150mm) blade

• ESD materials

Chapter 1 11

Page 12

Getting Started

Safely Powering Down the B2000 Workstation

Safely Powering Down the B2000 Workstation

You must complete the following steps before performing any of the removal and

replacement procedures:

NOTE Remove any accessory bag(s) and their black tab screws, if present, from the

rear of the workstation.

1. Power off the workstation by simply pressing the power switch on the front panel of the

workstation. Also, power off the monitor and any attached peripheral devices.

If necessary, shut down the workstation by executing “shutdown -h” as user root).

This ensures that all programs are terminated and all data is saved before switching

the power off.

2. After 30 seconds, unplug the workstation’s power cord and all peripheral devices from

AC power outlets. Before attempting to move the workstation to a disassembly area,

disconnect all peripherals from the back of the system.

Figure 1-2. Unplugging Peripherals

Open the USB clip from the top

to release the USB cables.

Disconnect

all peripherals.

Power Cord Connector

3. Place the workstation on a flat, stable surface, such as a tabletop or floor. To protect

against scratches, remove miscellaneous debris from the work surface.

12 Chapter1

Page 13

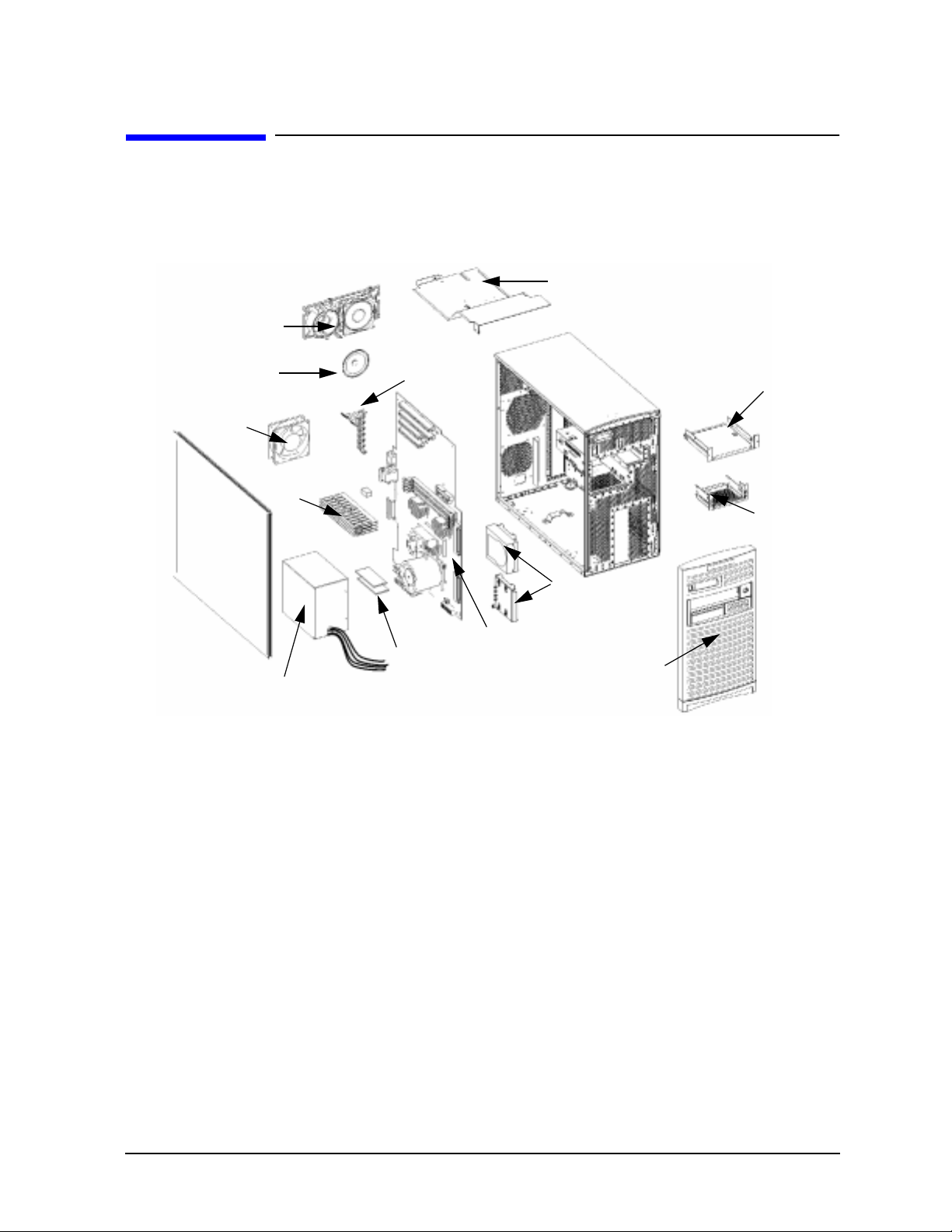

Product Exploded Diagram

Product Exploded Diagram

Refer to the figure below for a basic parts overview of the B2000 workstation.

Figure 1-3. Exploded View

Air Divider

PCI Fan

Assembly

Speaker

System

Fan

PCI

Retainer

Getting Started

CD Drive

Bracket

Left

Side

Panel

Power Supply

Memory

System Board

Voltage Regulator

Modules (VRMs)

Floppy

Drive

Bracket

Hard Disk

Drive & Bracket

Front

Bezel

Chapter 1 13

Page 14

Getting Started

Product Exploded Diagram

14 Chapter1

Page 15

2 Parts Replacement Procedures

This section describes how to remove and replace components andassemblies in the B2000

workstation.

Front Bezel and Left Side Panel

Figure 2-1. Front Bezel

Power

Switch

Latch Buttons

Opening the Front Bezel

Perform the following steps to open the workstation.

1. Power off the workstation and unplug the workstation.

2. Attach the static-grounding wrist strap by following the instructions on the package.

Attach the sticky end of the wrist strap to bare metal on the back panel of the

workstation.

3. Unlatch the front bezel by pressing in on the two latch buttons located on the right side

of the front bezel. See Figure 2-1.

4. Swing the panel outward on its left snap hinges until the panel releases and place the

front bezel in a safe location to avoid damage.

15

Page 16

Parts Replacement Procedures

Front Bezel and Left Side Panel

Closing the Front Bezel

Perform the following steps to close the workstation.

1. Locate the hinges on the left side of the front bezel, and insert them into the holes

located along the left edge of the workstation.

2. Rotate the front bezel inward until you hear the two latch buttons snap in place. The

front bezel is now closed.

3. Plug in the workstation’s power cord, and power on the workstation.

Left Side Panel

This section explains how to open and close the left side panel of the workstation. This side

panel will have to be opened whenever you need access to the internal components of the

workstation.

Opening the Left Side Panel

Perform these steps to open the left side panel.

WARNING Always unplug the workstation’s power cord from the electrical

outlet or power source before opening the workstation. Reference

“Safely Powering Down the B2000 Workstation” on page 12.

1. Power off the workstation, and unplug the workstation’s power cord from the electrical

outlet.

2. Attach the static-grounding wrist strap by following the instructions on the package.

Attach the sticky end of the wrist strap to bare metal on the back panel of the

workstation. See Figure 1-1. on page 10.

3. Turn the workstation around so its back is facing you. Remove the two T-15 Torx

thumbscrews as shown in Figure 2-2.

16 Chapter2

Page 17

Parts Replacement Procedures

Front Bezel and Left Side Panel

4. Grasp the back edge of the left side panel and rotate it outward approximately 30 degrees to the

workstation. Next, pull the panel toward you as shown in Figure 2-2. This releases the panel’s

top and bottom left side hook hinges from their hinge slots. See Figure 2-2.

Figure 2-2 Opening the Left Side Panel

T-15 Torx

Screw

T-15 Torx

Screw

Hinge Hook

EMI Gasket

Hinge Slot

Left Side Panel

NOTE The EMI gasket, as shown in Figure 2-2, must not be removed from the side

panel.

Closing the Left Side Panel

Perform these steps to close the left side panel.

1. Hold the left side panel so that the top and bottom hinge hooks can be inserted into

their hinge slots. See Figure 2-2. Note that the hinge slots are located on the far right

edge of the workstation (using the back of the workstation as the reference).

2. Swing the back edge of the panel toward the workstation’s back edge and press the

outside edges of the side panel tightly against the workstation. This will ensure a tight

seal of the EMI gaskets.

3. Secure the side panel in place and tighten the two T-15 Torx thumbscrews you

previously removed.

Chapter 2 17

Page 18

Parts Replacement Procedures

Memory DIMMs

Memory DIMMs

This section describes how to remove and replace the Memory DIMMs for the B2000

workstations.

Installing Memory

Perform the following steps to add memory (DIMM cards) to your workstation.

WARNING Turn the workstation off and unplug the power cord before

installing additional memory. Reference “Safely Powering Down the

B2000 Workstation” on page 12.

CAUTION To prevent damage to the B2000 workstation, observe all of the ESD

precautions as described in the “Electrostatic Discharge (ESD) Precautions”

on page 9.

1. Open the side panel of the workstation as explained in the section “Opening the Left

Side Panel” on page 16 in this chapter.

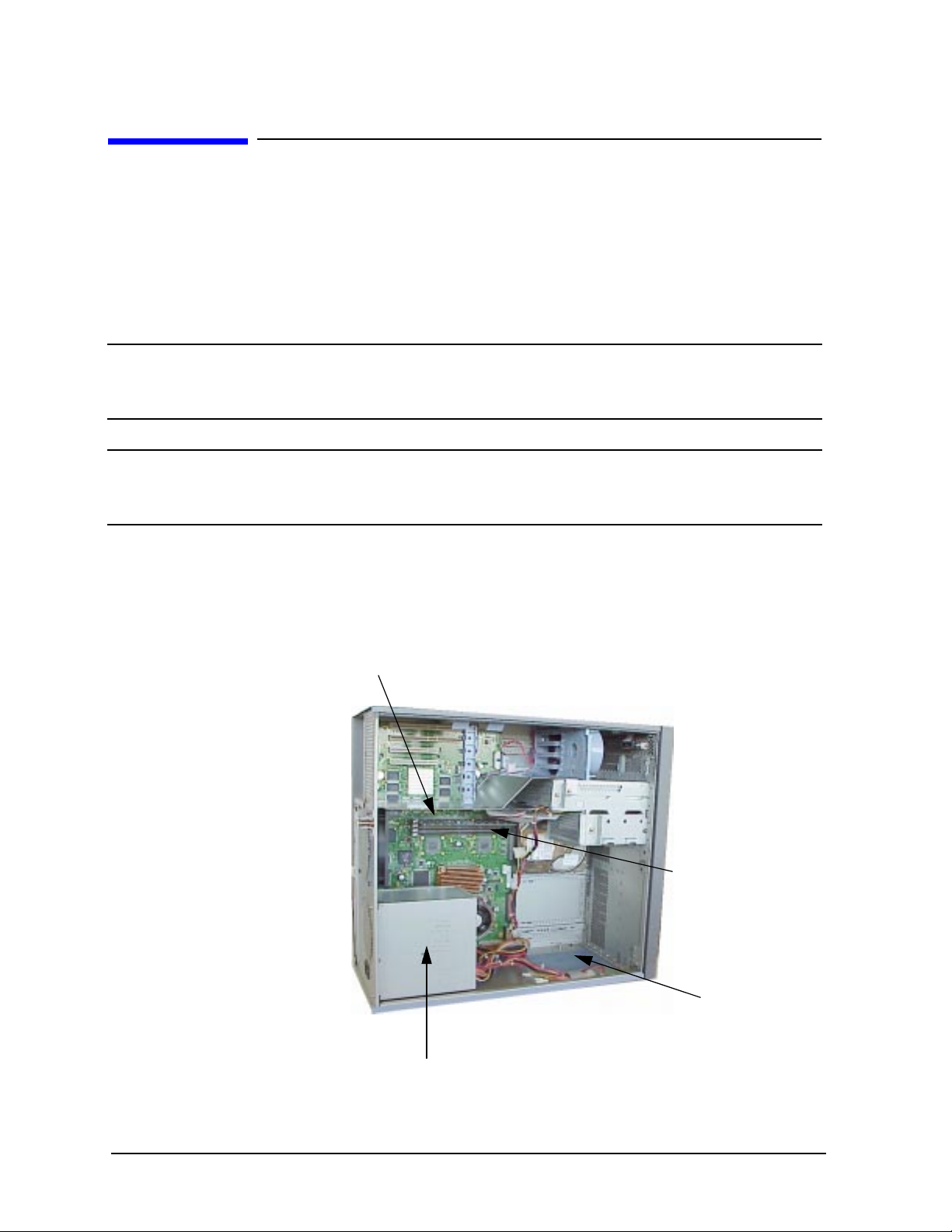

Figure 2-3 View of System Board

DIMM Card

DIMM Connector

B2000 System

Label

Power Supply

18 Chapter2

Page 19

Parts Replacement Procedures

Memory DIMMs

NOTE Reference the B2000 system label for the correct memory loading sequence.

2. Position the memory slots so they face you as shown in Figure 2-4. Note that Figure 2-4 also

provides the loading sequence for the DIMM cards. This loading sequence must be maintained

when you install the DIMM cards, but the size of the DIMM card put in each slot can vary. For

example, you can install a 256Mbyte card before a 512Mbyte card and then follow the

installation of the 512Mbyte card with another 256Mbyte card. The B2000 workstations

supports 128 Mbyte, 256 Mbyte and 512 Mbyte DIMM cards.

3. Locate the four internal memory slots, and load the DIMM cards in the slots using the

loading sequence provided in Figure 2-4. Note that the label located on the floor of the

chassis describes the installation sequence.

Figure 2-4 Memory Card Slot Numbers and Loading Sequence

SL3

SL1

SL2

Load 1st

Load 4th

Load 2nd

Load 3rd

Memory Slots

(four slots)SL0

Chapter 2 19

Page 20

Parts Replacement Procedures

Memory DIMMs

NOTE When installing memory, you need to orient the notches on the bottom edge of

the DIMM card so that they are aligned with the keys on the DIMM connector.

See Figure 2-6. The keyed DIMM connectors prevent you from installing the

DIMM cards backwards.

For referencing the DIMM loading sequence see the label on the chassis floor. See

Figure 2-5.

Figure 2-5. B2000 System Label

Front of the

B2000

workstation

Memory Loading Sequence on

B2000 System Label

4. Press downward on the ejector tabs located on each side of the DIMM connector. See Figure 2-6.

This opens the connector for DIMM card insertion.

20 Chapter2

Page 21

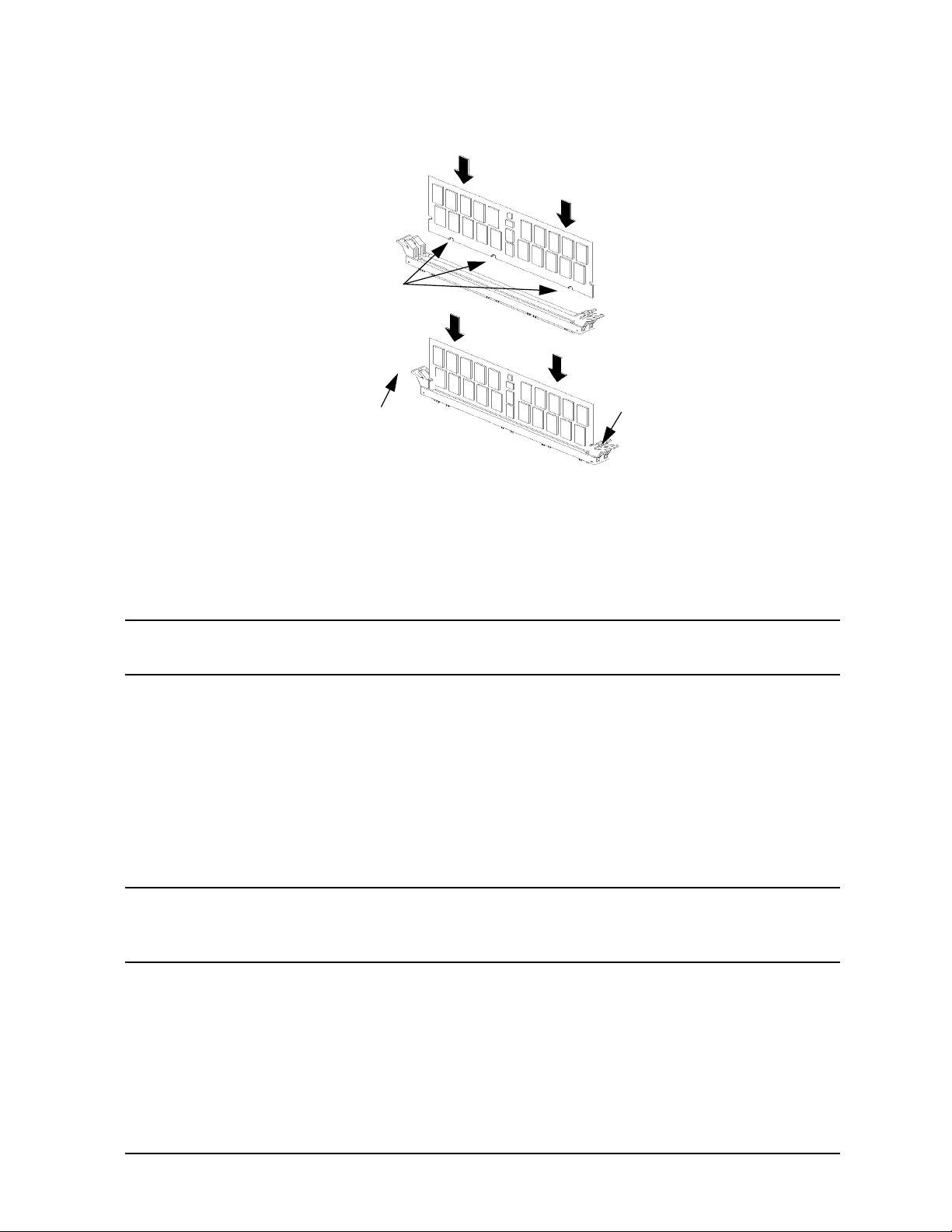

Figure 2-6 Installing Memory Cards

Parts Replacement Procedures

Memory DIMMs

Step 1

Notches

Press down on ejector tabs to

open them and place the

DIMM card in the connector

so that your fingers are on

the edge of the DIMM card.

Step 2

Push the DIMM card down

firmly and evenly into the

connector to be sure it is

properly seated.

Black

Ejector Tab

5. Place the DIMM card in the connector, lining it up with the guides. Make sure you align

the notches on the bottom edge of the DIMM card with the DIMM connector keys. See

Figure 2-6.

6. Press firmly and evenly on the DIMM card to ensure that it seats properly.

White

Ejector Tab

NOTE The ejector tabs will return to the locked position when the DIMM card is

fully seated in the connector.

7. Replace the left side panel as explained in the section “Replacing the left side panel” in

this chapter. Plug the power cord into the electrical outlet.

8. Verify that this installation was successful by following the steps in “Displaying the

Current Memory Configuration” on page 23.

Removing Memory DIMMs

Perform the following steps to remove memory (DIMM cards) from your workstation.

WARNING Always unplug the workstation’s power cord from the electrical

outlet or power source before opening the workstation. Reference

“Safely Powering Down the B2000 Workstation” on page 12.

Chapter 2 21

Page 22

Parts Replacement Procedures

Memory DIMMs

CAUTION To prevent damage to the B2000 workstation, observe all of the ESD

precautions as described in the “Electrostatic Discharge (ESD) Precautions”

on page 9.

1. Open the side panel of the workstation as explained in the section “Opening the Left

Side Panel” on page 16 in this chapter.

Figure 2-7 System Board View

B2000

System Label

Power

Supply

DIMM connectors

Figure 2-8. DIMM Slot Close-Up on System Board

DIMM Connectors

(4 slots)

22 Chapter2

Page 23

Parts Replacement Procedures

Memory DIMMs

2. Press downward on the ejector tabs located on each side of the DIMM connector. See Figure 2-9.

This raises the DIMM card for easy extraction.

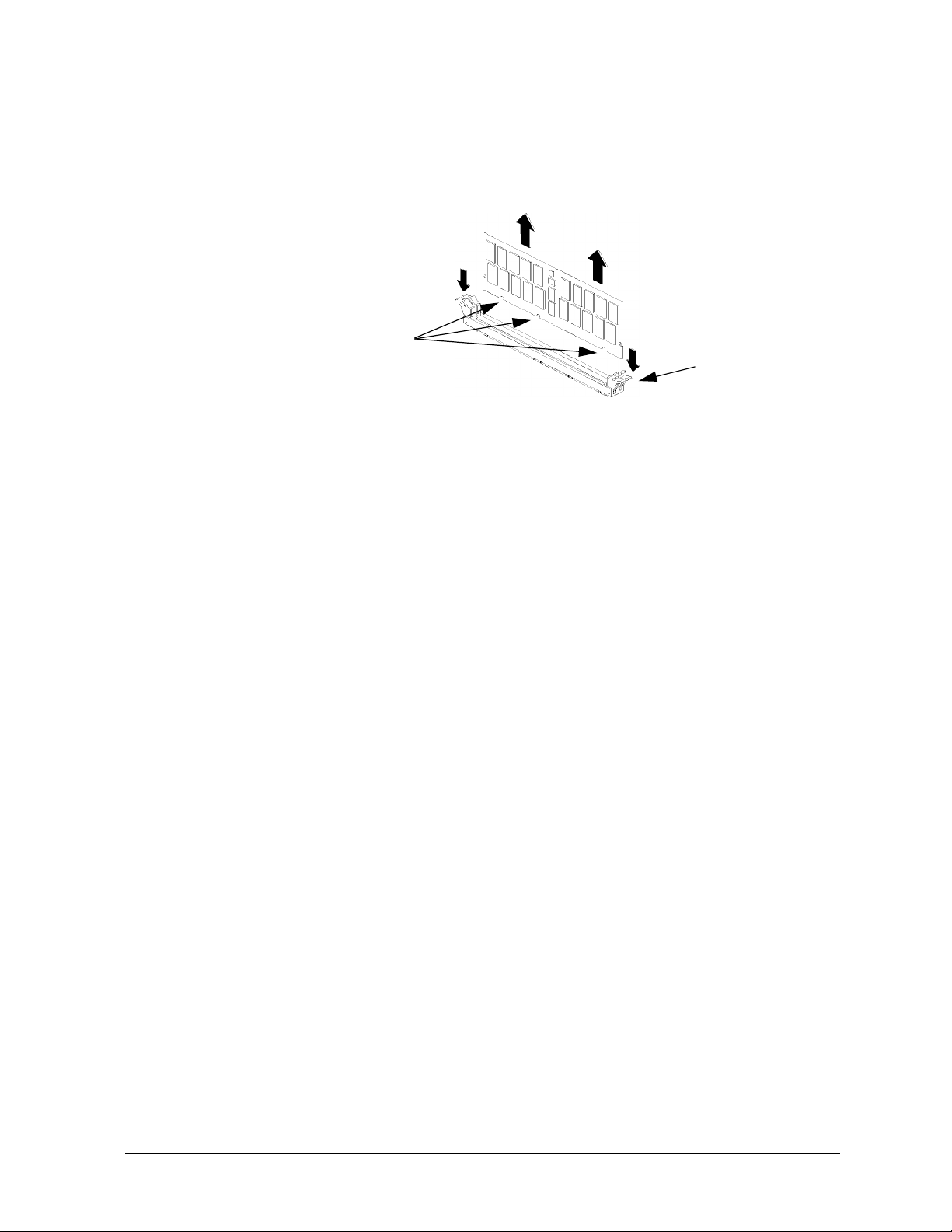

Figure 2-9 Removing Memory Cards

Notches

Ejector Tab

3. Lift up evenly on the outside edges of the DIMM card to remove it. See Figure 2-9.

4. Install the remaining DIMM cards in the correct order. See Figure 2-4 or the system

label.

5. Replace the left side panelas explained inthe section “Replacing the Left Side Panel” in

this chapter. Plug the power cord back in to the electrical outlet.

6. Verify that this removal was successful by “Displaying the Current Memory

Configuration” on page 23. Note that you can also use SAM and select the

Performance Monitor icon, then the System Properties icon, and in the window

that appears, select the tab labeled Memory. See the B2000 Owner’s Guide for more

detailed instructions.

Displaying the Current Memory Configuration

The following sample screen output uses the memory command to show a memory

configuration table with properly-installed and configured memory.

To display the current memory configuration for your system, from the Information Menu

of the boot console interface, follow the directions in “Accessing the Boot Console Interface”

earlier in this chapter. Once you are in the Boot Console Interface Main Menu, type the

following at the prompt and press

Main Menu: Enter command> information

This places you in the Information Menu. From here, type the following at the prompt and

press

Enter:

Enter:

Information Menu: Enter command> memory

The screen displays status and configuration informationfor the memory DIMMs installed

in your workstation. See the section “Memory Information Sample.”

Chapter 2 23

Page 24

Parts Replacement Procedures

Memory DIMMs

Memory Information Sample

The following example shows the memory information when memory modules areproperly

installed and configured:

MEMORY INFORMATION

MEMORY STATUS TABLE

Slot Size Status

---- ------ ------------ 0 256MB Active

1 256MB Active

2 128MB Active

TOTAL MEMORY = 640MB

MEMORY FAULT TABLE

Slot Size Status

---- ------ -------------

Active, Installed Memory : 640MB of SDRAM

Deallocated Pages : 0 Pages

---------- Available Memory : 640MB

Good Memory Required by OS : 0 (Not Initialized)

Memory

HVERSION SVERSION

-------- --------- 0x0860 0x0900

24 Chapter2

Page 25

Parts Replacement Procedures

PCI I/O Card(s)

PCI I/O Card(s)

This section describes how to remove and install I/O cards.

Your B2000 workstation’s system board has four Peripheral Connect Interface (PCI) slots

for option boards. Slots 1 and 2 are full-size PCI slots. Slots 3 and 4 are half-size PCI slots.

Figure 2-10. PCI Card Slot Numbering and Capabilities

Slot 1

Slot 2

Slot 3

Slot 4

64 bits, 33MHz, 5V

64 bits, 33MHz, 5V

32 bits, 33MHz, 5V

32 bits, 33MHz, 5V

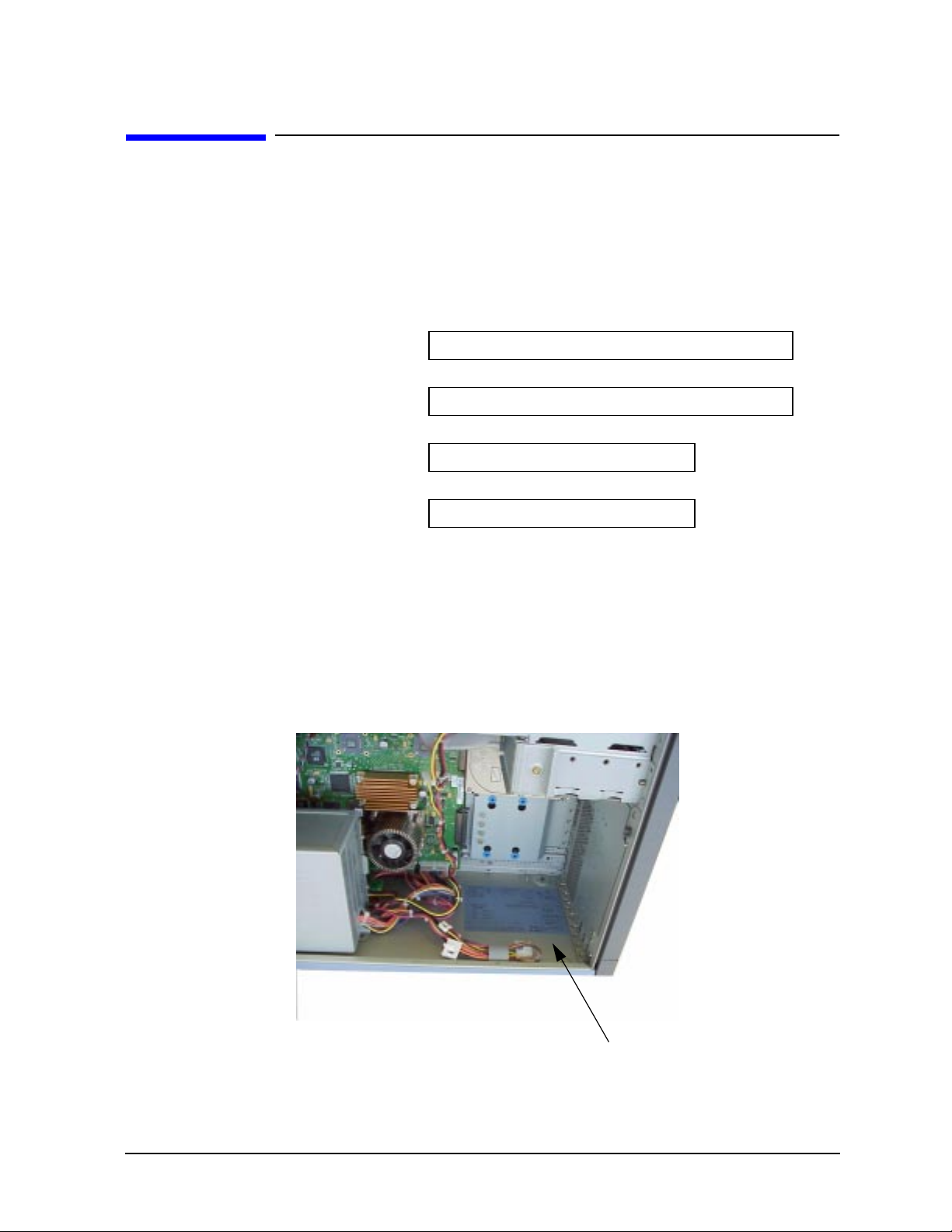

The information described in Figure 2-10. is located inside your workstation on the chassis

floor. See Figure 2-11. for the physical location of the B2000 workstation label.

Figure 2-11. Location of B2000 System Label

B2000 System Label

Chapter 2 25

Page 26

Parts Replacement Procedures

PCI I/O Card(s)

CAUTION If you are installing an additional graphics card, you must insert the fx card

in Slot 1 for optimal performance.

After you connect themonitor to the additional graphics card,you will need to

change the graphics path for that monitor. To do this read the section

“Displaying and Setting the Monitor Type” in the chapter “The Boot Console

Interface” of your Owner’s Guide.

The label on the chassis floor of your workstation contains important information for I/O

configuration. See Figure 2-12.

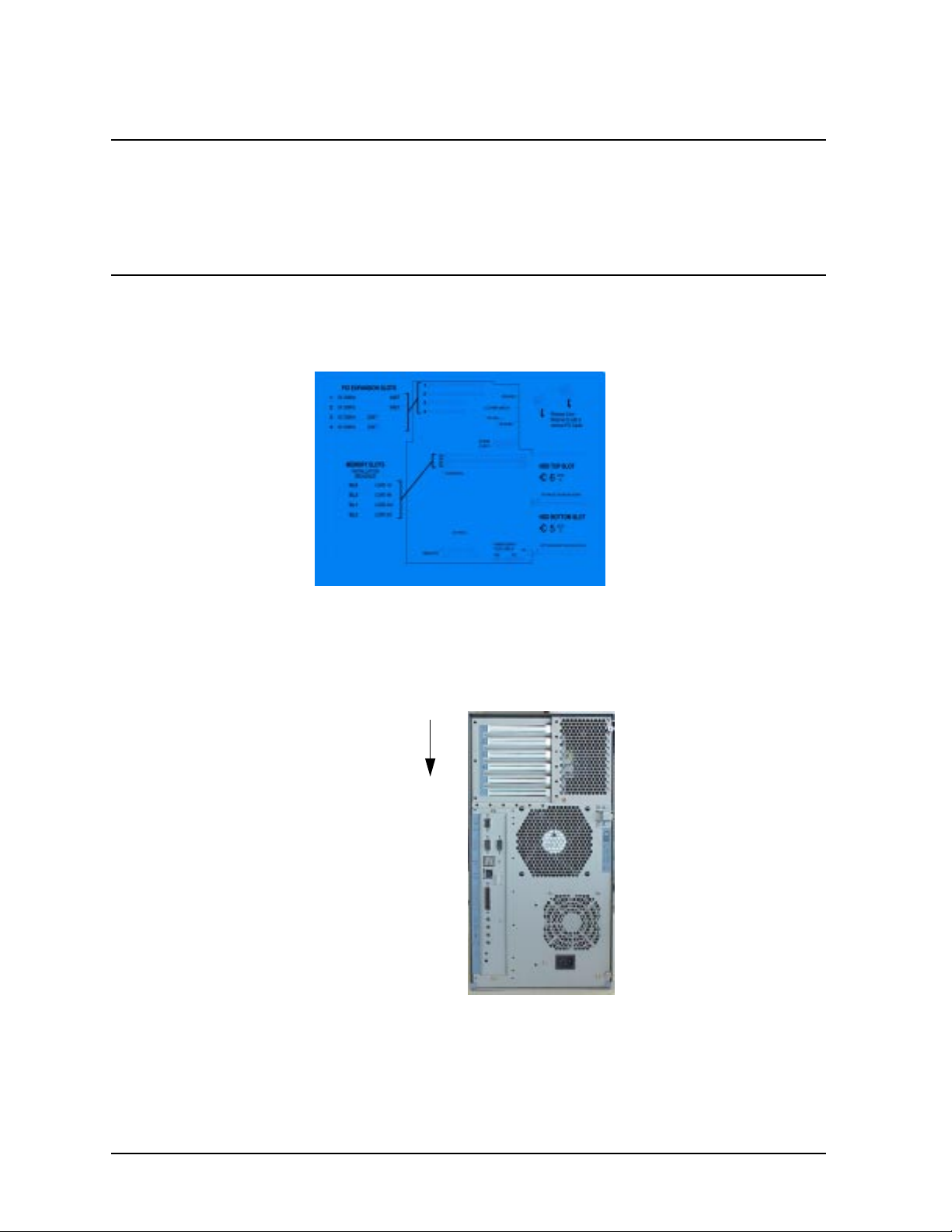

Figure 2-12. B2000 System Label

Note that the four I/O slots as seen from the back of the workstation are labeled from top

to bottom starting with one. See Figure 2-13.

Figure 2-13 I/O Slot Numbering

I/O Slot 1

I/O Slot 4

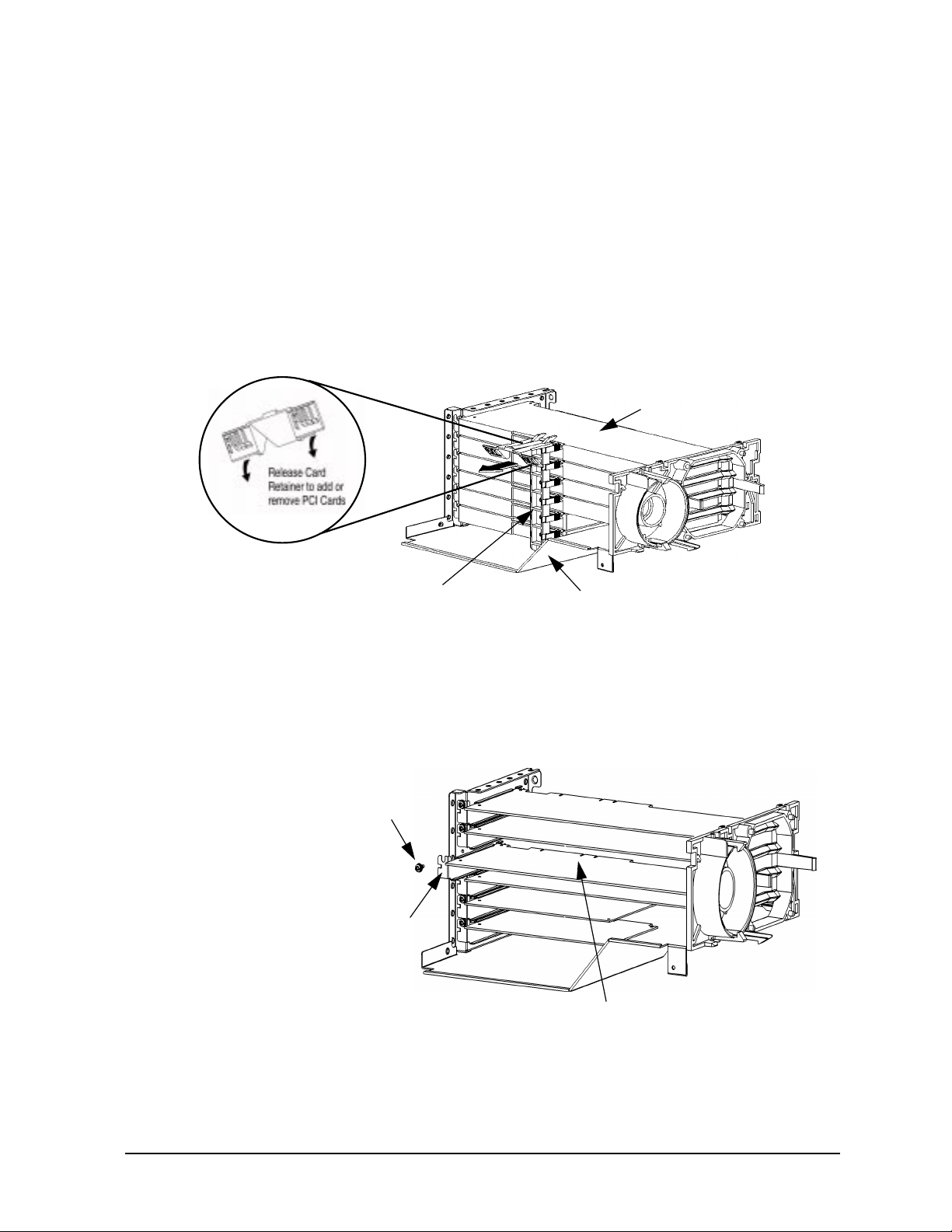

Removing I/O Cards

You will need a T-15 Torx driver or flathead screwdriver to remove the I/O slot bulkhead

screws.

26 Chapter2

Page 27

Parts Replacement Procedures

PCI I/O Card(s)

The steps required for removing an I/O card from the workstation are:

1. Power off the workstation, and unplug the workstation’s power cord from the electrical

outlet. Note that when you press the workstation’s power switch, the workstation

automatically performs a shutdown -h.

2. Open the side panel of the workstation as explained in the section “Opening the Left

Side Panel” in this chapter.

3. Pull downward in the direction of the arrow on both PULL tabs of the I/O card retainer

to remove it. See Figure 2-14.

Figure 2-14 Removing the I/O Card Retainer

I/O Card

I/O Card Retainer

Air Divider

4. Locate the I/O card you want to remove and using a T-15 Torx driver remove the I/O

card’s bulkhead screw as shown in Figure 2-15.

Figure 2-15 Removing the I/O Card

I/O Card

Bulkhead

Torx Screw

I/O Card

Bulkhead

I/O Card Being Removed

5. Pull evenly on the outside edges of the I/O card to remove it. See Figure 2-15.

Chapter 2 27

Page 28

Parts Replacement Procedures

PCI I/O Card(s)

Installing I/O Cards

To install an I/O card into your workstation, follow these steps.

CAUTION To prevent damage to I/O cards, observe all of the ESD precautions as

described in the “Electrostatic Discharge (ESD) Precautions” on page 9.

NOTE The built-in VISUALIZE fxe graphics is the primary graphics slot and is

referred to as slot 0. Use the secondary graphics slot (slot 1) for the highest

performance graphics card and PCI slot 2 for the second graphics card and

then any of the remaining 32 bit slots for the third PCI graphics card.

1. Open the left side panel of the workstation as explained in the section “Opening the

Left Side Panel” in this chapter.

2. Locate the appropriate slot for the I/O card that is to be installed. See Figure 2-10.

3. Remove the T-15 Torx screw and remove the bulkhead blank of the slot you have

chosen. If no blank is present, you may skip to step four.

4. Pull downward in the direction of the arrow on both PULL tabs of the I/O card retainer

to remove it. See Figure 2-14.

5. Insert the I/O card into the slot you have chosen with the bulkhead appropriately

positioned. See Figure 2-15. If the card is full length, the non-bulkhead end of the card

should be placed in the I/O card guide. Press firmly and evenly on the I/O card until it is

in the connector. Secure the I/O card to the bulkhead with the T-15 Torx screw.

6. Replace the I/O card retainer by placing the bottom retainer hook in the slot on the air

divider and the clips on the PULL tabs into their slots on the chassis wall. See Figure

2-14.

7. Close the left side panel of the workstation by following the procedure “Closing the Left

Side Panel” on page 17.

NOTE If you connect a monitor to a graphics card, you will need to change the

console path. See Chapter 5, “The Boot Console Interface” in the B2000

Owner’s Guide.

28 Chapter2

Page 29

Parts Replacement Procedures

CD Drive

CD Drive

This section explains how to remove and replace the CD drive.

Removing a CD Drive

This section explains how to remove a CD drive from your workstation.

WARNING Turn the workstation off and unplug the power cord before

removing the CD drive.

CAUTION CD drives are susceptible to mechanical and electronic shock. When handling

the drive, always wear the static-grounding wrist strap that came in the CD

drive kit. Always handle the drive carefully.

1. Perform the procedures in the sections “Opening the Front Bezel” and “Opening the

Left Side Panel.” The front bezel needs to be opened so you can remove the CD drive

from the workstation chassis. The left side panel needs to be opened so you can get to

the CD drive’s audio, ATAPI and power connectors.

2. Remove the CD drive bay’s EMI shield by unscrewing the T-15 Torx/slotted screw as shown in

Figure 2-16. Note that the CD drive bay’s EMI shield is located on the back of the removable

media chassis inside the workstation. Push the cover handle away from the back of the

removable media chassis approximately one inch. Next pull the cover handle toward you. The

audio, ATAPI and power cables are now accessible to you. Disconnect these cables from the CD

drive.

Chapter 2 29

Page 30

Parts Replacement Procedures

CD Drive

Figure 2-16 Removing the CD Drive Bay’s EMI Shield

Rear

Cover

Audio

Cable

Ferrite Bead

ATAPI Cable

Power Cable

3. Rotate the workstation around until you see the front of the unit as shown in Figure 2-17.

Figure 2-17 Front of the Workstation with the Front Bezel Removed

LCD Display

Power Switch

EMI Shield

Handle

T-15

Torx/Slotted

Screw

Bracket Screw

Bracket Screw

(hidden)

30 Chapter2

Page 31

Parts Replacement Procedures

CD Drive

4. Remove both CD drive bracket screws (T-15 Torx/slotted screws) and pull the CD drive out of the

chassis assembly as shown in Figure 2-18.

Figure 2-18 Removing the CD Drive

Bracket Guide

CD Drive

Bracket Runner

CD Drive Mounting

Screws (T-15 Torx Screws)

CD Drive Bracket

Bracket Screws

(T-15 Torx Screws)

5. Remove the four CD drive mounting screws (T-15 Torx/slotted screws) as shown in Figure 2-18

and remove the CD drive from the bracket.

Installing a CD Drive

Install the CD drive by following the procedure covered in this section.

WARNING Turn the workstation off and unplug the power cord before

installing the CD drive.

CAUTION To avoid damage to the CD drive, verify that your static-grounding strap is

securely attached to your wrist and to bare metal on the workstation chassis.

Note that the installed CD drive will not need any jumpers set on the back of your CD

drive, as they are set at the factory. However, if you bought a new CD drive to install in

Chapter 2 31

Page 32

Parts Replacement Procedures

CD Drive

your workstation, you must verify that the master/slave/CSEL jumper is set in the CSEL

position. Since different manufacturers of CD drives have different locations for the CSEL

jumper, look at the documentation that is supplied with your CD drive for the proper

location of this jumper.

CAUTION CD drives are susceptible to mechanical and electronic shock. When handling

the drive, always wear the static-grounding wrist strap that came in the CD

drive kit. Always handle the drive carefully.

1. Perform the procedures in the sections “Opening the Front Bezel” and “Opening the

Left Side Panel.”The front bezel needs to be opened so you can insert the CD drive into

its proper location in the chassis. The left side panel needs to be opened so you can get

to the CD drive’s audio, ATAPI and power connectors.

2. Remove the CD drive bay’s EMI shield by unscrewing the T-15 Torx/slotted screw as

shown in Figure 2-19. Note that the CD drive’s EMI shield is located on the rear of the

removable media chassis inside the workstation. Push the cover handle away from the

rear of the removable media chassis approximately one inch. Next pull the cover handle

toward you. The audio, ATAPI and power cables are now accessible.

Figure 2-19 Removing the CD Drive Bay’s EMI Shield

EMI Shield Handle

EMI Shield

Audio

Cable

T-15

Torx/Slotted

Screw

Ferrite Bead

ATAPI Cable

Power Cable

3. Rotate the workstation around to view the front of the workstation as shown in Figure

2-20.

32 Chapter2

Page 33

Parts Replacement Procedures

CD Drive

Figure 2-20 Front of Workstation with the Front Bezel Removed

LCD Display

Power Switch

CD drive

Blank

Floppy Disk

Blank

4. Remove both CD drive bracket screws (T-15 Torx/slotted screws) and pull the CD drive

bracket out of the chassis assembly as shown in Figure 2-21. Next remove the four CD

drive blank filler screws (T-15 Torx/slotted screws) as shown in Figure 2-21 and remove

the blank filler from the bracket. You are now ready to mount the CD drive into the CD

drive bracket. Note you will need the blank filler screws to mount the CD drive.

Figure 2-21 Removing the CD Drive Bracket and Blank

CD drive Bracket

Blank Filler Screws

(T-15 Torx Screws)

Bracket Screws

Blank

CAUTION CD drives are susceptible to mechanical and electronic shock. When handling

the drive, always wear the static-grounding wrist strap that came in the CD

drive kit. Always handle the drive carefully.

Chapter 2 33

Page 34

Parts Replacement Procedures

CD Drive

5. Remove the CD drive from its shipping container and verify that the jumper on the back of the

CD drive is set to the C Select position. Using the four blank filler screws (T-15 Torx/slotted

screws) that were just removed, mount the disk drive to the bracket as shown in Figure 2-22.

Note that the CD drive should extend approximately one inch out from the front of the CD drive

bracket.

Figure 2-22. Installing the CD Drive

CD Drive Bracket Guide

CD Drive

Blank Filler Screws

Bracket Screws

6. Slide the CD drive and its bracket into the workstation chassis as shown in Figure2-22.

There are runners on the side of each bracket and guides inside the CD drive chassis

that will help the assembly to slide into place.

34 Chapter2

Page 35

Parts Replacement Procedures

CD Drive

7. Plug the audio, ATAPI and power cables into their appropriate connectors. Note that the

connectors are keyed for proper insertion. To help with plugging in the audio connector, you can

pull its cable through the back of the CD drive chassis to the front of the CD drive chassis and

connect it. Note that you should connect the audio cable first.

NOTE The red striped side of the data cable should be positioned next to the power

cable.

Figure 2-23. Plugging in the Audio, ATAPI and Power Cables

Audio

Cable

Ferrite Bead

ATAPI Cable

Power Cable

8. Tighten the two CD drive bracket screws as shown in Figure 2-24.

Figure 2-24 Tightening the Bracket Screws

Bracket Screw

Bracket

Screw

(hidden)

Chapter 2 35

Page 36

Parts Replacement Procedures

CD Drive

9. Make sure that the audio, ATAPI and power cables are positioned so that they come out of the

bottom edge of the CD drive bay’s EMI shield. This edge is rounded to prevent cutting of the

cables. See Figure 2-25. Next, secure the CD drive bay’s EMI shield using the T-15 Torx/slotted

screw. When you replace the EMI shield, The ferrite bead on the ATAPI cable must remain

outside of the CD drive bay’s EMI shield.

Figure 2-25 Replacing the CD Drive Bay’s EMI Shield

EMI Shield

T-15

Torx/Slotted

Screw

Ferrite Bead

10.Complete the installation of the CD drive by replacing the front and side panels of the

workstation as explained in the sections “Closing the Left Side Panel” and “Closing the

Front Bezel” in this chapter. Before closing the workstation panels, inspect to ensure

that cables are properly stored inside the chassis.

11.Verify that the CD drive is recognized by the system. See the section “Verifying the CD

Drive Operation” in Chapter 2, “Using Your CD Drive.”

36 Chapter2

Page 37

Parts Replacement Procedures

Floppy Drive

Floppy Drive

Installing a Floppy Disk Drive

Install the floppy disk drive by following the procedure covered in this section. Note that there are

no jumper settings required for the installation of the floppy disk drive.

WARNING Turn the workstation off and unplug the power cord before installing the

floppy disk drive.

CAUTION Floppy disk drives are susceptible to mechanical and electronic shock. When

handling the drive, always wear the static-grounding wrist strap that is supplied in

the floppy disk drive kit. Always handle the drive carefully.

1. Perform the procedures in the sections “Opening the Front Bezel” and “Opening the Left Side

Panel.” The front bezel needs to be opened so you can insert the floppy disk drive into its proper

location in the chassis. The left side panel needs to be opened so you can get to the floppy’s data

connector and its power connector.

2. Remove the floppy disk drive bay’s EMI shield by unscrewing the T-15 Torx screw as shown in

Figure 2-26. Note that the floppy disk drive bay’s EMI shield is located on the rear of the

removable media chassis inside the workstation. Push the cover handle away from the rear of

the removable media chassis approximately one inch. Next pull the cover handle toward you.

The floppy data cable and power cable are now accessible to you.

Figure 2-26 Removing the Floppy Disk Drive Bay’s EMI Shield

EMI Shield Handle

Power

Cable

EMI Shield

Data Cable

T-15

Torx/Slotted

Screw

Chapter 2 37

Page 38

Parts Replacement Procedures

Floppy Drive

3. Rotate the workstation around until you see the front of the workstation as shown in Figure

2-27

.

Figure 2-27 Front of Workstation with the Front Bezel Removed

Floppy Drive

Blank

4. Remove both floppy disk bracket screws (T-15 Torx/slotted screws) and pull the floppy disk

bracket out of the chassis assembly as shown in Figure 2-28. Next remove the four floppy disk

blank filler screws (T-15 Torx/slotted screws) as shown in Figure 2-28 and remove the blank

from the bracket. You are now ready to mount the floppy disk drive into the floppy disk bracket.

Figure 2-28 Removing the Floppy Disk Bracket and Blank

Bracket

T-15 Torx

Screw

Blank Filler Screws

(T-15 Torx Screws)

Blank Screw

(T-15 Torx Screw)

38 Chapter2

Blank

Page 39

Parts Replacement Procedures

Floppy Drive

CAUTION Floppy disk drives are susceptible to mechanical and electronic shock. When

handling the drive, always wear thestatic-grounding wrist strap thatcame in

the floppy disk drive kit. Always handle the drive carefully.

5. Remove the floppy disk drive from its shipping container. Using the four T-15 Torx/slotted blank

filler screws, mount the disk drive to the bracket as shown in Figure 2-29.

To help you properly install the floppy disk drive, you need to use the floppy disk drive

holes labeled “A” on the bracket sides. The first T-15 Torx screws should be inserted

through the tab holes of the floppy disk drive bracket that are located on the front part

of both sides of the bracket. These T-15 Torx screws should then be screwed into the

screw holes located on both sides of the floppy disk drive. These holes are located near

the floppy disk drive’s front bezel. The remaining T-15 Torx screws should be insert

through the holes labeled “A” at the back part of the floppy disk drive bracket. These

screws should then be screwed into the rear screw holes located on both sides of the

floppy disk drive. The front of the floppy disk drive should extend one inch from the

front of the floppy disk drive bracket. See Figure 2-29.

Figure 2-29 Installing the Floppy Disk Drive

Floppy Disk

Drive Front

Panel

Floppy Disk Drive Mounting

Screws (T-15 Torx Screws)

Floppy Disk Drive Bracket

Bracket Screws

6. Slide the floppy disk drive and its bracket into the workstation chassis as shown in

Figure 2-29.

7. Plug the floppy power cable into its connector. Next, plug the data cable into its

connector. Note that the connectors are keyed for proper insertion. See Figure 2-30.

Chapter 2 39

Page 40

Parts Replacement Procedures

Floppy Drive

NOTE The red striped side of the floppy data cable is positioned toward the power

cable.

Figure 2-30. Plugging in the Floppy Data and Power Cables

Power

Cable

Data Cable

8. Tighten the two T-15 Torx screws as shown in Figure 2-31.

Figure 2-31 Tightening the Bracket Screws

T-15 Torx

Screw

T-15 Torx

Screw

(hidden)

40 Chapter2

Page 41

Parts Replacement Procedures

Floppy Drive

9. Verify that the floppy data and power cables are positioned so they come out of the top edge of

the floppy disk drive bay’s EMI shield. This edge is rounded to prevent cutting of the cables. See

Figure 2-32. Next, secure the floppy disk drive bay’s EMI shield using the T-15 Torx/slotted

screw. When you replace the EMI shield, the ferrite bead on the data cable must remain inside of

the floppy disk drive bay’s EMI shield.

Figure 2-32 Replacing the Floppy Disk Drive Bay’s EMI Shield

Power Cable

EMI Shield

Data Cable

T-15

Torx/Slotted

Screw

10.Remove the plastic floppy disk drive blank from the workstation’s front bezel.

11.Complete the installation of the floppy disk drive by replacing the front and side panels

of the workstation as explained in the sections “Closing the Left Side Panel” and

“Closing the Front Bezel” in this chapter. You should also make sure that all cables are

neatly folded or positioned within the workstation. This will prevent potential damage

to the cables.

12.Verify that the floppy disk drive is recognized by the system. See “Verifying the Floppy

Drive Configuration” on page 44.

Removing the Floppy Drive

1. Remove the two T-15 Torx screws that secure the floppy drive tray to the front of the

chassis.

Chapter 2 41

Page 42

Parts Replacement Procedures

Floppy Drive

Figure 2-33. Floppy Drive Removal: External

T-15 Torx Screw

T-15 Torx Screw

2. Facing the opened side of the workstation, remove the T-15 Torx screw that secures

the back cover of the floppy drive bay, and then remove the back cover. Reach into the

back of the floppy drive bay and disconnect the two cables: the floppy drive power

cable and the ribbon cable. Disconnect these same cables from the system board and

set them aside.

Figure 2-34. Floppy Drive Removal

T-15 Torx Screw

Ribbon Cable

42 Chapter2

Page 43

Parts Replacement Procedures

Floppy Drive

3. Grasping the front of the floppy drive tray, gently pull it out of the front of the

workstation.

Figure 2-35. Floppy Drive Removal: Physical

Chapter 2 43

Page 44

Parts Replacement Procedures

Floppy Drive

Verifying the Floppy Drive Configuration

To verify that your workstation can communicate with the floppy drive, use the ioscan

command in a terminal window to see which devices are currently in use on your system.

Note that you will have to be superuser or root to use the ioscan command.

Enter the following command at the prompt and press Enter:

/usr/sbin/ioscan -fnC floppy

After a few seconds, the ioscan utility lists all of the I/O devices that use the “floppy”

class. Your floppy drive should be among the devices listed. The list appears similar to the

following:

Class I H/W Path Driver S/W State H/W Type Description

========================================================================

floppy 0 10/0/14/1/4.1 sioflop CLAIMED DEVICE HP_PC_FDC_FLOPPY

/dev/floppy/c0t1d0 /dev/rfloppy/c0t1d0

If ioscan does not detect any usable I/O system devices that use the “floppy” class, such

as the floppy disk drive, nothing is output and you are returned to the system prompt. If

this is the case, refer to Chapter 6, “Solving Problems” in the B2000 Owner’s Guide.

If the floppy disk driver is not configured, ioscan returns the following message:

ioscan: Device driver floppy is not in the kernel

If you receivethis message, go to the section, “Configuring the Floppy Driver” in the B2000

Owner’s Guide for information on adding the sioflop driver to the HP-UX kernel

configuration.

44 Chapter2

Page 45

Parts Replacement Procedures

Hard Disk Drive

Hard Disk Drive

This section explains how to remove and replace the hard disk drive.

Installing a Hard Disk Drive

This procedure explains how to install your hard disk drive in the slot that has been

preassigned to SCSI ID 5. On internal hard disk drives, the slot determines the

addressing. There are no cables required when installing a hard disk drive. Note that to

install the hard disk drive, your workstation must be turned off.

WARNING Turn the workstation off and unplug the power cord before

installing or removing hard disk drives. Reference “Safely Powering

Down the B2000 Workstation” on page 12.

CAUTION To prevent damage to the B2000 workstation, observe all of the ESD

precautions as described in the “Electrostatic Discharge (ESD) Precautions”

on page 9.

NOTE If you are installing a hard disk drive1, you will need to mount it and create a

file system on it. See “Configuring and Hard Disk Drive as A File System” in

your Owner’s Guide. This should be done after you have installed the hard

disk drive.

To mount a hard disk drive and create a file system on it use the procedure

provided “Adding a Hard Disk Drive as a File System Using SAM” found in

this section. See “Configuring a Hard Disk Drive as a File System” on page

52.

1. Remove the side panel of your workstation using the instructions found in the section

“Opening the Side Panel.” As you face the workstation system board, the hard disk

drives are on the right side. The hard disk drive plugged into the lower SCSI connector

(ID 5) is the one discussed in this section. See Figure 2-36.

1. This statement exclusively applies to the disk drive with SCSI ID 5 in the B2000 workstation.

Chapter 2 45

Page 46

Parts Replacement Procedures

Hard Disk Drive

Figure 2-36 The Hard Drive Slots

PCI

Slots

(4)

Power

Supply

Memory slots (4)

SCSI ID 6

SCSI ID 5

2. Loosen the captive T-15 Torx thumbscrew securing the disk drive bracket to the system

board. As you grasp the tray and slide to the front of the workstation, the tray will

unseat from the chassis rail. See Figure 2-37. Youmay need to angle the disk drive tray

slightly to disengage the hooks as you slide it along the rail.

Figure 2-37 Removing the Hard Disk Drive Bracket

Captive T-15 Torx

Thumbscrews

46 Chapter2

Page 47

Parts Replacement Procedures

Hard Disk Drive

3. Mount the hard disk drive on the hard drive bracket using the four T-15 Torx screws

that are stored on the mounting bracket. See Figure 2-38. for location of the shoulder

screws and Figure 2-39. for positioning the bracket to the hard disk drive.

Figure 2-38. T-15 Torx Shoulder Screws

T-15 Torx Screws

(quantity 4)

Figure 2-39. Positioning the Bracket to the Hard Disk Drive

Chapter 2 47

Page 48

Parts Replacement Procedures

Hard Disk Drive

4. Insert the T-15 Torx Hard Disk Mounting Screws through the rubber mounting grommets and

into the screw holes located on the hard disk drive. See Figure 2-40.

Figure 2-40 Attaching the Hard Disk Drive

T-15 Torx Shoulder Screw

Mounting

Grommets

(do not remove)

Hard Disk

Drive Bracket

Hard Disk

Drive

Bracket Hooks

(quantity 4)

5. Slide the assembly into its hard drive slot, and push inward firmly until the front of the

hard disk drive bracket is flush with the disk drive connector on the system board. See

Figure 2-41. The bracket hooks will lock into the chassis rail.

Figure 2-41. Positioning the Hard Disk Drive Assembly

48 Chapter2

Page 49

Parts Replacement Procedures

Hard Disk Drive

6. Replace the side panel as described in “Closing the Left Side Panel” on page 15.

7. Attach the USB keyboard, USB mouse, LAN, peripherals and power cord to the

workstation.

8. Verify your installation procedure. See “Verifying System Operations” on page 85.

Removing a Hard Disk Drive

This procedure explains how to remove your hard disk drive. Note that there are no cables

to disconnect when removing a hard disk drive. To remove a hard disk drive, your

workstation must be turned OFF.

NOTE If you are removing a hard disk drive that has a mounted file system on it,

you will need to unmount it. This should be done before you remove the hard

disk drive.

To unmount a file system on a hard disk drive use the procedure provided in

the section “Removing a Hard Disk Drive as a File System Using SAM”.

1. Open the side panel of your workstation using the instructions found in the section

“Opening the Side Panel.” As you face the workstation system board, the hard disk

drives are on the right side. The lower slot (ID5) on the right is the one discussed in this

section. See Figure 2-42.

Figure 2-42 The Hard Drive Slots

Hard Disk Drive

SCSI slots

SCSI ID 6

SCSI ID 5

2. Loosen the captive T-15 Torx thumbscrew securing the disk drive bracket to the system

board. As you grasp the bracket and slide to the front of the workstation, the bracket

will unseat from the chassis rail. See Figure 2-43. You may need to angle the disk drive

bracket slightly to disengage the hooks as you slide it along the rail.

Chapter 2 49

Page 50

Parts Replacement Procedures

Hard Disk Drive

Figure 2-43. Removing the Hard Disk Drive

Captive T-15 Torx Thumbscrew

3. Remove the four T-15 Torx shoulder screws from the hard disk drive and bracket. See Figure

2-44

. To avoid damaging the disk drive, you must carefully handle the disk drive when removing

it from the workstation.

Figure 2-44 Removing the Hard Disk Drive from the Bracket

T-15 Torx

Shoulder Screw

Mounting Grommets

(do not remove)

50 Chapter2

Page 51

Parts Replacement Procedures

Hard Disk Drive

4. Replace the four mounting screws on the hard disk drive bracket to store them for future use.

Slide the mounting bracket into its hard drive slot, and push firmly inward to secure the hard

drive bracket to the system board connector. Tighten the T-15 Torx thumbscrew to secure the

bracket to the system board. See Figure 2-45. The side panel should now be replaced as

explained in the section “Closing the Left Side Panel” on page 17 in this chapter.

Figure 2-45 Replacing the Hard Disk Drive Bracket

Chapter 2 51

Page 52

Parts Replacement Procedures

Hard Disk Drive

Configuring a Hard Disk Drive as a File System

This section describes how to add a hard disk drive to your workstation as a file system

using SAM and how to remove the hard disk drive from your workstation. For more

information about configuring a hard disk drive, refer to the manual Managing Systems

and Workgroups.

The procedures in this section require you to log in as root. If you cannot log in as root,

contact your system administrator.

Adding a Hard Disk Drive as a File System Using SAM

Here is the procedure you need to follow to add a hard disk drive as a file system using

SAM.

1. Log in as root.

2. Move the mouse pointer to the Application Manager control for tools and click the

left mouse button. Alternatively you can execute sam at a terminal window command

prompt and skip to step 5.

3. Double click on the System_Admin icon in the Application Manager window.

52 Chapter2

Page 53

Parts Replacement Procedures

Hard Disk Drive

4. Double click on the Sam icon in the Application Manager -- System_Admin window. If you

are root, the System Application Manager (SAM) will appear on your screen.

5. Double click on the Disks and File Systems icon.

6. Double click on the Disk Devices icon.

The following screen message is displayed:

Scanning the system’s hardware...

The Disks and File Systems window opens containing a list of drives installed in this

workstation. From the list of devices, choose the hard disk drive you would like to

configure as a file system by clicking on the device to highlight it.

7. Click on Add in the Actions menu. For this example you will select the item Not Using

the Logical Volume Manager. However,you can select any appropriate item from the

Actions menu.

Chapter 2 53

Page 54

Parts Replacement Procedures

Hard Disk Drive

8. Enter the mount directory name (for example, /disk1) in the Mount Directory field of the

Add Disk without LVM window.

9. Click on the OK button in the Add Disk without LVM window. You will need to wait

for a short time before the new file system is created and the hard disk drive is

mounted. When the Add Disk without LVM window disappears and HFS appears in

the Use column of the Disk and File Systems window, your task will be complete.

Removing a Hard Disk Drive as a File System Using SAM

Here is the procedure you need to follow to remove a hard disk drive as a file system using

SAM.

1. Log in as root.

2. Move the mouse pointer to the Application Manager control for tools and click the

left mouse button. Alternatively you can execute sam at a terminal window command

prompt and skip to step 5.

3. Double click on the System_Admin icon in the Application Manager window.

54 Chapter2

Page 55

Parts Replacement Procedures

Hard Disk Drive

4. Double click on the Sam icon in the Application Manager -- System_Admin window. If you

are root, the System Application Manager (SAM) will appear on your screen.

5. Double click on the Disks and File Systems icon.

6. Double click on the Disk Devices icon.

The following screen message is displayed:

Scanning the system’s hardware...

The Disks and File Systems window opens containing a list of devices installed in

this workstation. From the list of devices, choose the hard disk drive you would like to

remove (unmount) by highlighting that device.

Chapter 2 55

Page 56

Parts Replacement Procedures

Hard Disk Drive

7. Click on Remove in the Actions menu. In the window that next appears, click on the Yes

button. This will unmount the file system located on the hard disk drive you are removing from

the workstation. You will need to wait for a short time before the new file system is unmounted.

The file system is successfully unmounted when you see Unused in the Use column.

56 Chapter2

Page 57

Parts Replacement Procedures

Power Supply

Power Supply

This section explains how to remove and replace the power supply.

WARNING Always unplug the workstation’s power cord from the electrical

outlet or power source before opening the workstation. Reference

“Safely Powering Down the B2000 Workstation” on page 12.

CAUTION To prevent damage to the B2000 workstation, observe all of the ESD

precautions as described in the “Electrostatic Discharge (ESD) Precautions”

on page 9.

Removing the Power Supply

1. Remove the left side panel as described in “Opening the Left Side Panel” on page 16.

Figure 2-46. Opening the Left Side Panel

Left Side Panel

Chapter 2 57

Page 58

Parts Replacement Procedures

Power Supply

2. Remove the four T-15 Torx screws from the rear of the chassis. See Figure 2-47.

Figure 2-47. Power Supply T-15 Torx Screws

T-15 Torx Screws

T-15 Torx Screws

3. Unplug the three power supply cables from the system board. See Figure 2-48.

Figure 2-48. Power Supply Cables

Power Supply

Cables (3)

Bundled Power

Cables

4. Detach the bundled power cables from the cable management clip on the chassis floor.

See Figure 2-48.

58 Chapter2

Page 59

Parts Replacement Procedures

Power Supply

5. Remove the T-15 Torx screw, EMI shield from the rear of the CD drive and disconnect

the power cable. If the optional floppy drive is installed, you will need to repeat this

step. See Figure 2-49. Grasp the EMI shield and swing out away from therear of the CD

drive or Floppy disk drive. Pull slightly outward to detach the hinged EMI shield from

the slot in the CD or Floppy drive bay.

Figure 2-49. EMI Shield

EMI Shield(s) and

T-15 Torx Screw(s)

CD Drive and

Floppy Drive

Power Cables

Chapter 2 59

Page 60

Parts Replacement Procedures

Power Supply

6. Grasp the power supply and slide to the front of the workstation. You will need to

disengage the hook (see Figure 2-50.) on the power supply from the support strap (see

Figure 2-51.) in the chassis floor.

Figure 2-50. Power Supply Hook

Support Strap

Power Supply Hook

Figure 2-51. Support Strap in the Chassis Floor

Support Strap

60 Chapter2

Page 61

Parts Replacement Procedures

Power Supply

Installing the Power Supply

To install the power supply perform the following steps.

1. Grasp the power supply and position the external power cord connector facing the

corresponding hole in the chassis.

2. Align the power supply hook with the support strap and slide the power supply to the

rear chassis wall. The hook will slide into the support strap notch. See Figure 2-50. on

page 60.

3. Replace the four T-15 Torx screws for securing the power supply to the chassis. See

Figure 2-47. on page 58.

4. Connect the three main power cables to the system board and connect the removable

media power cables. Remember to reattach the EMI shields to the rear of the CD drive

and the floppy drive (if installed).

Figure 2-52. Location of Power Supply Cables on System Board

I/O Cards

Power Supply Cables

Chapter 2 61

Page 62

Parts Replacement Procedures

Power Supply

5. Clip the remaining power cable bundle into the cable management clip in the floor of

the chassis.

6. Replace the four T-15 Torx screws for the power supply on the rear of the workstation.

7. Replace the left side panel. Reference “Closing the Left Side Panel” on page 17.

8. Attach all peripherals, keyboard, mouse, LAN and power cables to the workstation

9. Reference Chapter 3, “Wrapping Up,” on page 85 for completion of this procedure.

62 Chapter2

Page 63

Parts Replacement Procedures

Voltage Regulator Modules (VRMs)

Voltage Regulator Modules (VRMs)

This section explains how to remove and replace the voltage regulator modules (VRMs).

WARNING Turn the workstation off and unplug the power cord before

removing or installing voltage regulator modules. Reference “Safely

Powering Down the B2000 Workstation” on page 12.

CAUTION To prevent damage to the VRMs, observe all of the ESD precautions as

described in the “Electrostatic Discharge (ESD) Precautions” on page 9.

VRMs are installed on the system board in pairs. The top VRM is a master and the bottom

VRM is the slave.

Figure 2-53. VRMs on the System Board

VRM Master

VRM Slave

Removing VRMs

To replace defective VRMs follow the steps below:

1. Remove the left side panel. See “Opening the Left Side Panel” on page 16.

Chapter 2 63

Page 64

Parts Replacement Procedures

Voltage Regulator Modules (VRMs)

2. Remove the four power supply T-15 Torx screws and slide the supply to unlatch from

the support bracket. Without disconnecting the power cables, move the supply to the

side.

Figure 2-54. Power Supply T-15 Torx Screws

T-15 Torx Screws

(quantity 4)

3. Press outward on the ejector tabs located on each side of the VRM connectors. See

Figure 2-55.

NOTE The top connector from the chassis floor is the master; while the bottom

connector is the slave.

Figure 2-55. VRM Ejector Tabs

Ejector

Tabs

Ejector

Tabs

4. Firmly grasp the master VRM and pull outward from the system board connector.

5. Firmly grasp the slave VRM and pull outward from the system board connector.

64 Chapter2

Page 65

Parts Replacement Procedures

Voltage Regulator Modules (VRMs)

Installing VRMs

To install VRMs follow these steps.

1. Perform all of the steps in“Removing VRMs”. Youare ready to install new VRMs if your

system looks like Figure 2-55. on page 64.

2. Carefully unpack the replacement VRMs and identify the Master and Slave. The notch

in the VRM will align with the key in the connector. Also, the part number on the VRM

distinguishes between Master and Slave.

3. Insert the Master VRM firmly in the top slot from the chassis floor.

4. Insert the Slave VRM in the slot closest the chassis floor.

5. Inspect and verify that the ejector tabs are in the locked position. The tabs lock in place

when the VRMs are fully seated in their respective connector.

6. Grasp the power supply and slide the tab into the support strap.

7. Replace the four T-15 Torx screws. Reference Figure 2-54. on page 64.

8. Replace the left side panel. Reference “Left Side Panel” on page 16.

Chapter 2 65

Page 66

Parts Replacement Procedures

System Board

System Board

This section describes how to remove and replace the system board.

Removing the System Board

WARNING Always unplug the workstation’s power cord from the electrical

outlet or power source before opening the workstation.

CAUTION To prevent damage to the B2000 workstation, observe all of the ESD

precautions described in “Electrostatic Discharge (ESD) Precautions” on

page 9.

Perform the following steps to remove the System Board.

1. Remove the workstation left side panel. Position the workstation right-side flat on a

cushioned stable tabletop.

2. Remove the following components:

• Power Supply “Removing the Power Supply” on page 57

• PCI Retainer Clip “Removing the I/O Card Retainer” on page 27

• Air Divider “Removing the Air Divider” on page 72

• I/O Cards (if installed) “Removing I/O Cards” on page 26

• Memory Card(s) “Removing Memory DIMMs” on page 21

• Hard Disk Drive(s) and

hard disk drive bracket(s)

• Voltage Regulator Modules

(Master and Slave VRMs)

“Removing a Hard Disk Drive” on page 49

“Removing VRMs” on page 63

66 Chapter2

Page 67

Figure 2-56. B2000 Components

PCI Retainer

Clip

Air Divider

Memory

Cards

Power Supply

& VRMs

(hidden from view)

3. Unplug the following cables:

• Speaker cable

Parts Replacement Procedures

System Board

Hard Disk Drive

Hard Disk Drive

Bracket

• LCD ribbon cable

• PCI Fan cable

• CD audio cable

• CD drive data cable

• Floppy drive data cable

• System board fan cable

Figure 2-57. System Board Cables

System Fan

Cable

Speaker Cable

LCD Ribbon Cable

PCI Fan Cable

CD Audio Cable

CD Data Cable

Floppy Data Cable

Chapter 2 67

Page 68

Parts Replacement Procedures

System Board

4. Fold back the cables to avoid interference or damage before removal of the system

board.

5. Remove the two T-15 Torx screws from the rear of the chassis. See Figure 2-58.

Figure 2-58. System Board T-15 Torx Screws

T-15 Torx Screws

Note: No other screws need to be removed.

CAUTION Toavoid damaging the processor, do not use the turbo cooler fan housing as a

handhold for removing the system board.

6. Grasp the system board and slide to the front of the workstation.

7. Tilt the system board up and rotate clockwise while lifting out of the chassis.

Installing the System Board

Perform the following steps to replace the defective system board with the new system

board.

CAUTION To avoid system board damage, verify that your static-grounding strap is

securely attached to your wrist and to bare metal on the workstation chassis.

Reference “Electrostatic Discharge (ESD) Precautions” on page 9.

1. Before installing the new System Board assembly fold back the cables to avoid

interference or damage.

68 Chapter2

Page 69

Parts Replacement Procedures

System Board

2. Angle the system board assembly diagonally as you begin installation. Position the

system board flat inside the chassis.

3. Slide the system board slightly to the front and then to the rear of the workstation to

engage the chassis wall hooks. Apply pressure to completely seat the system board.

Figure 2-59. Installing the System Board Replacement

4. Insert and torque the two T-15 Torx screws that secure the system board to the rear of

the chassis. See Figure 2-60.

Figure 2-60. System Board T-15 Torx Screws

T-15 Torx

Screws

(quantity 2)

Chapter 2 69

Page 70

Parts Replacement Procedures

System Board

5. Plug-in the following cables:

• Speaker cable

• LCD ribbon cable

• PCI fan cable

• CD audio cable

• CD data cable

• Floppy drive data cable

• System fan cable

Figure 2-61. System Board Cables

Speaker Cable

LCD Cable

PCI Fan Cable

System

Board Cable

CD Audio Cable

CD Data Cable

Floppy Data Cable

70 Chapter2

Page 71

6. Install the following components:

Parts Replacement Procedures

System Board

• Hard Disk Drive(s) and

bracket(s)

• Memory Card(s) “Installing Memory” on page 18

• Air Divider “Air Divider” figure on page 72

• PCI cards (if installed) “Installing I/O Cards” on page 28

• PCI retainer clip “Retainer Clip” figure on page 27

• Voltage Regulator Modules

(VRMs)

• Power Supply “Installing the Power Supply” on page 61

“Installing a Hard Disk Drive” on page 45

“Installing VRMs” on page 65

See Figure 2-62.

Figure 2-62. B2000 Components

PCI Retainer

Clip

Air Divider

EMI Shields

Memory

Cards

Hard Disk Drive

Hard Disk Drive

Power Supply

Bracket

& VRMs

(hidden from view)

7. Replace the EMI shield(s) and the T-15 Torx screw(s).

8. Replace the left side panel as described in “Closing the Left Side Panel” on page 17.

9. Attach all peripherals, keyboard, mouse, LAN and power to the workstation.

10.Reference Chapter 3, “Wrapping Up,” on page 85 for completion of this procedure.

Chapter 2 71

Page 72

Parts Replacement Procedures

Fans (I/O and System Board Fan)

Fans (I/O and System Board Fan)

This section explains how to remove and replace the I/O fan and the System Board Fan.

WARNING Turn the workstation off and unplug the power cord before

installing or removing fans. Reference “Safely Powering Down the

B2000 Workstation” on page 12.

CAUTION To prevent damage to the B2000 workstation, observe all of the ESD

precautions described in “Electrostatic Discharge (ESD) Precautions” on

page 9.

Removing the I/O Fan

To remove the I/O cooling fan, do the following:

1. Remove the workstation left side panel. See the section “Opening the Left Side Panel”

on page 16.

2. Lay the workstation on its side, and remove all of the I/O cards. See the section

“Removing I/O Cards” on page 26.

3. Remove the system unit air divider as shown in Figure 2-63. by unscrewing the two

T-15 Torx screws, which hold it in place. Next grasp the edge of the air divider and pull

it towards you.

Figure 2-63. Removing the Air Divider

T-15 Screw

T-15 Screw

Air Divider

4. Remove the fan and speaker cables from the system board and lift up on the bracket

mounting clip. See arrow in Figure 2-64. Next grab hold of the fan and speaker bracket

72 Chapter2

Page 73

Parts Replacement Procedures

Fans (I/O and System Board Fan)

and rotate it about 15 degrees to the left. See the arrow in Figure 2-65. The fan and

speaker bracket should now be free of the clip retainer hole and the bracket stop. Now

move the whole mounting bracket to the left or toward the back of the CD Drive chassis.

The fan and speaker mounting bracket is now free of the system unit.

Figure 2-64. Unplugging the I/O Fan and Speaker Cables on the System Board

Speaker

Cable

PCI Fan

Cable

Chapter 2 73

Page 74

Parts Replacement Procedures

g

Fans (I/O and System Board Fan)

Figure 2-65. Removing the Fan/Speaker Assembly from the I/O Area

Speaker Cable

Clips

Fan Power

Cable

Bracket

CD Drive Chassis

Fan

Bracket Stop

Speaker

Bracket Mountin

Clip

Mounting Clip

Retainer Hole

5. To remove the speaker from the mounting bracket, push a finger through the access

hole and spread the two retaining clips. The speaker will pop free of the mounting clips.

Figure 2-66. Fan/Speaker Bracket

Speaker

Fan

Mounting

Clip

Speaker

Cable

Speaker

Bracket Mounting Clip

Power Cable

Channel

Mounting

Bracket

Fan

Mounting

Clip

Fan Key

74 Chapter2

Page 75

Parts Replacement Procedures

Fans (I/O and System Board Fan)

Installing the I/O Fan

Perform the following steps to install the I/O fan:

1. Remove the replacement I/O fan assembly from the ESD protective packaging and

inspect for the correct part match to your order.

2. Install thespeaker in the replacementI/O fan assembly. See “Installing the Speaker” on

page 81.

3. Align the housing fan bracket to the chassis support strut and the two locator tabs.

Hold the fan and speaker cable to the card guide edge of the bracket.

4. Swing the housing bracket into place while holding the retainer tab upward.

5. Plug in the speaker cable and the fan power cable to the system board.

6. Install the air divider. See Figure 2-63.

7. Install the I/O card(s) and the PCI retainer clip. See “Installing I/O Cards” on page 28

8. Replace the left side panel. See “Left Side Panel” on page 16.

9. Follow the instructions in Chapter 3, “Wrapping Up,” on page 85 to complete this

procedure.

Removing the System Board Fan

Perform the following steps to remove the system fan:

1. Remove the left side panel. See “Left Side Panel” on page 16.

2. Remove the four plastic pop rivets to release the system fan from the rear panel. Press

firmly with a flat blade screw driver to relieve the rivet from the chassis wall. See

Figure 2-67.

Figure 2-67. System Fan Rivets

Fan Power Cable

Tip of flat blade screw driver

3. Disconnect the fan power cable from the system board.

Chapter 2 75

Page 76

Parts Replacement Procedures

Fans (I/O and System Board Fan)

Installing the System Board Fan

Perform the following steps to install the system board fan:

1. While grasping the fan withone hand, align the air flow arrow to point tothe rear of the

chassis. You will find the arrow molded on the edge of the fan.

2. Hold the fan flat to the rear of the chassis and align the mounting holes to the chassis.

3. Insert the flat head of the rivet(s) from the rear panel.

Figure 2-68. Placement of Rivets

Flat Head

of Rivets

Flat Head

of Rivets

4. Plug the fan cable into the system board.

5. Replace the left side panel. Refer to the section, “Left Side Panel” on page 16.

6. Follow the instructions in Chapter 3, “Wrapping Up,” on page 85.

76 Chapter2

Page 77

Parts Replacement Procedures

LCD Display with Power Switch and Display Cable

LCD Display with Power Switch and Display Cable

This section explains how to remove and replace the LCD display assembly and the

Display Cable. Note that the power switch is part of the LCD display assembly.

WARNING Turn the workstation off and unplug the power cord before

removing or installing the LCD Display/Power Switch. Reference

“Safely Powering Down the B2000 Workstation” on page 12.

CAUTION To prevent damage to the B2000 workstation, observe all of the ESD

precautions described in “Electrostatic Discharge (ESD) Precautions” on

page 9.

Removing the LCD Display/Power Switch Assembly

To remove the LCD assembly perform the following steps:

1. Open the front bezel as shown in the section “Opening the Front Bezel” on page 15.

2. Unplug the LCD’s connector as shown in Figure 2-69.

Figure 2-69. Removing the LCD Display/Power Switch

LCD Connector

Mount Tab

(right side)

LCD

Mounting Clips

(left side)

3. Press inward on the mount clip located on the left side of the LCD mount and rotate the

left side of the LCD outward in a counterclockwise motion. See Figure 2-69. This action

releases the LCD’s right side mounting tab.

Chapter 2 77

Page 78

Parts Replacement Procedures

LCD Display with Power Switch and Display Cable

Installing the LCD Display/Power Switch Assembly