Page 1

HP UPS R3000

User Guide

Part Number 192131-007

December 2009 (Seventh Edition)

Page 2

© Copyright 2000, 2009 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft, Windows, and Windows Server are U.S. registered trademarks of Microsoft Corporation.

Intended audience

This guide is for the person who operates, configures, maintains, and troubleshoots UPSs. HP assumes

you are qualified in the servicing of high-voltage equipment and trained in recognizing hazards in

products with hazardous energy levels.

Page 3

Contents

Component identification ............................................................................................................... 6

UPS R3000 overview ................................................................................................................................... 6

UPS front panel ............................................................................................................................................ 6

UPS front panel controls ................................................................................................................................ 7

UPS front panel LED indicators ....................................................................................................................... 8

HP UPS R3000 models ................................................................................................................................. 8

UPS R3000 NA and R3000j JPN rear panel................................................................................................... 9

UPS R3000h NA and R3000h JPN rear panel .............................................................................................. 10

UPS R3000 INT rear panel ......................................................................................................................... 11

REPO port ................................................................................................................................................. 11

ERM rear panel .......................................................................................................................................... 12

Installation ................................................................................................................................. 13

Precautions ................................................................................................................................................ 13

Preparing to install the hardware ................................................................................................................. 13

Tools and materials .......................................................................................................................... 13

Selecting a site ................................................................................................................................ 14

Readying the equipment ................................................................................................................... 14

Installing the mounting rails ......................................................................................................................... 14

Installing the UPS ....................................................................................................................................... 18

Connecting the battery leads ............................................................................................................. 19

Attaching the UPS front bezel ............................................................................................................ 19

Connecting the serial communications port ......................................................................................... 19

Connecting the REPO port ................................................................................................................. 20

Connecting the ground bonding cable ............................................................................................... 22

Connecting the UPS to utility power.................................................................................................... 22

Connecting devices to the UPS .......................................................................................................... 23

Connecting the UPS cord retention clips ............................................................................................. 23

Charging the UPS batteries ............................................................................................................... 24

Starting power to the load ................................................................................................................. 24

Installing the ERM ....................................................................................................................................... 24

Attaching the ERM front bezel ........................................................................................................... 25

Switching off the ERM circuit breaker ................................................................................................. 25

Connecting the ERM to the UPS ......................................................................................................... 25

Switching on the ERM circuit breaker ................................................................................................. 26

Charging the ERM batteries ............................................................................................................... 26

UPS operations ........................................................................................................................... 27

Modes of operation .................................................................................................................................... 27

Standby mode ................................................................................................................................. 27

Operate mode ................................................................................................................................. 27

Configure mode ............................................................................................................................... 28

Auto-Bypass mode ............................................................................................................................ 28

Configuring the UPS ................................................................................................................................... 28

Available voltage settings ................................................................................................................. 30

Initiating a self-test ...................................................................................................................................... 30

Silencing an audible alarm ......................................................................................................................... 31

Page 4

Verifying the REPO port connection .............................................................................................................. 31

Powering down the UPS .............................................................................................................................. 31

Power management .................................................................................................................... 32

Power management software ....................................................................................................................... 32

Maintenance .............................................................................................................................. 33

Removing the UPS front bezel ...................................................................................................................... 33

Removing the ERM front bezel ..................................................................................................................... 33

Replacing the UPS electronics module .......................................................................................................... 33

Replacing the UPS option card .................................................................................................................... 34

Replacing the batteries ............................................................................................................................... 35

Important battery safety information ................................................................................................... 35

Battery care and storage guidelines ................................................................................................... 36

Determining when to replace batteries ................................................................................................ 36

Obtaining new batteries ................................................................................................................... 36

UPS battery replacement procedure ................................................................................................... 36

Testing the new battery module .......................................................................................................... 38

Replacing the UPS ...................................................................................................................................... 38

Replacing the ERM ..................................................................................................................................... 38

Updating the UPS firmware ......................................................................................................................... 39

Configuring a USB to serial converter ................................................................................................. 39

Reassigning the USB COM ports........................................................................................................ 40

Troubleshooting .......................................................................................................................... 41

LED and audible alarm troubleshooting ........................................................................................................ 41

UPS is in Auto-Bypass mode ........................................................................................................................ 42

General alarm condition ............................................................................................................................. 42

Bypass is out of range ................................................................................................................................ 43

Battery condition ........................................................................................................................................ 43

UPS is on battery ........................................................................................................................................ 43

Input voltage is out of range ........................................................................................................................ 43

Utility power condition ................................................................................................................................ 44

Internal UPS fault condition ......................................................................................................................... 44

REPO condition .......................................................................................................................................... 44

Site wiring condition ................................................................................................................................... 44

Overload condition .................................................................................................................................... 44

UPS does not start ...................................................................................................................................... 44

Low battery shutdowns ................................................................................................................................ 45

UPS does not provide the expected backup time ........................................................................................... 45

UPS frequently switches between utility and battery power ............................................................................. 45

ERM cannot be configured from the UPS front panel ...................................................................................... 45

Specifications ............................................................................................................................. 46

UPS physical specifications ......................................................................................................................... 46

ERM physical specifications ......................................................................................................................... 46

UPS input specifications ................................................................................................

UPS output specifications ............................................................................................................................ 47

Power protection specifications .......................................................................................................... 47

Voltage specifications ....................................................................................................................... 47

Output tolerance specifications .......................................................................................................... 48

Output feature specifications ............................................................................................................. 48

Battery specifications .................................................................................................................................. 48

Battery runtime ........................................................................................................................................... 48

Environmental specifications ........................................................................................................................ 49

.............................. 46

Page 5

REPO port specifications ............................................................................................................................. 49

Spares ....................................................................................................................................... 50

Ordering spares ......................................................................................................................................... 50

UPS spare parts list..................................................................................................................................... 50

ERM spare parts list .................................................................................................................................... 51

Hardware options ...................................................................................................................................... 51

Technical support ........................................................................................................................ 52

Before you contact HP ................................................................................................................................ 52

HP contact information ................................................................................................................................ 52

Warranty information .................................................................................................................. 53

Limited warranty ........................................................................................................................................ 53

$250,000 Computer Load Protection Guarantee ........................................................................................... 53

Pre-Failure Battery Warranty ........................................................................................................................ 53

Recommended duration of use ..................................................................................................................... 54

Regulatory compliance notices ..................................................................................................... 55

Regulatory compliance identification numbers ............................................................................................... 55

Federal Communications Commission notice ................................................................................................. 55

FCC rating label .............................................................................................................................. 55

Class A equipment ........................................................................................................................... 55

Class B equipment ............................................................................................................................ 55

Declaration of conformity for products marked with the FCC logo, United States only ........................................ 56

Modifications ............................................................................................................................................. 56

Cables ...................................................................................................................................................... 56

Canadian notice (Avis Canadien) ................................................................................................................ 57

European Union regulatory notice ................................................................................................................ 57

Disposal of waste equipment by users in private households in the European Union .......................................... 57

Japanese notice ......................................................................................................................................... 58

BSMI notice ............................................................................................................................................... 59

Korean notice ............................................................................................................................................ 59

Battery replacement notice .......................................................................................................................... 59

Taiwan battery recycling notice ................................................................................................................... 60

Power cord statement for Japan ................................................................................................................... 60

Electrostatic discharge ................................................................................................................. 61

Preventing electrostatic discharge ................................................................................................................ 61

Grounding methods to prevent electrostatic discharge .................................................................................... 61

Acronyms and abbreviations ........................................................................................................ 62

Index ......................................................................................................................................... 63

Page 6

Component identification

UPS R3000 overview

The HP UPS R3000 features a 2U rack-mount design and offers power protection for loads up to 3000

VA/2700 W.

To benefit from the latest product enhancements, update to the latest versions of UPS firmware and

software.

NOTE: To download the latest versions of UPS firmware and software, see the HP website

UPS front panel

(http://www.hp.com/go/rackandpower

).

Item Description

1 Battery compartment

2 Control buttons

3 LED display

Component identification 6

Page 7

UPS front panel controls

The front panel is shown with the bezel removed.

Item Description Function

1 On button

Powers up the UPS ("Starting power to the

load" on page 24)

2 Standby button

Places the UPS in Standby mode (on page

27)

3 Test/Alarm Reset button

Silences UPS alarms ("Silencing an audible

alarm" on page 31)

Initiates a self-test ("Initiating a self-test" on

page 30)

4 Configure button

Places the UPS in Configure mode (on

page 28)

Component identification 7

Page 8

UPS front panel LED indicators

•

•

•

The front panel is shown with the bezel removed.

Item LED description

1 Configure Mode On

2 General Alarm

3 On Battery

4 Battery Fault

5 Site Wiring Fault

6 Utility

7 Overload

8 76% to 100% load

9 51% to 75% load

10 26% to 50% load

11 0% to 25% load

For more information, see "LED and audible alarm troubleshooting (on page 41)" .

HP UPS R3000 models

UPS model Description

R3000 NA ("UPS

R3000 NA and

R3000j JPN rear

panel" on page

9)

Domestic

Low-voltage

Nondetachable NEMA L5-30 plug

Component identification 8

Page 9

UPS model Description

•

•

•

•

•

•

•

•

•

•

•

•

R3000j JPN

("UPS R3000 NA

and R3000j JPN

rear panel" on

page 9)

R3000h NA

("UPS R3000h

NA and R3000h

JPN rear panel"

on page 10)

R3000h JPN

("UPS R3000h

NA and R3000h

JPN rear panel"

on page 10)

R3000 INT ("UPS

R3000 INT rear

panel" on page

11)

Japanese

Low-voltage

Nondetachable NEMA L5-30 plug

Domestic

High-voltage

Nondetachable NEMA L6-20 plug

Japanese

High-voltage

Nondetachable NEMA L6-20 plug

International

High-voltage

Detachable country-specific plug

UPS R3000 NA and R3000j JPN rear panel

Item Description

1 REPO port

2 ERM connector

3 Serial communications port/options slot

4 Load segment 1 (two NEMA 5-15 receptacles)

5 Load segment 2 (two NEMA 5-15 receptacles)

6 Load segment 3 (two NEMA 5-15 receptacles)

7 Load segment circuit breakers

Component identification 9

Page 10

Item Description

8 PDU output (NEMA L5-30) receptacle (load segment 1)

9 Cord retention clip attachment locations

10 Ground bonding screw

11 Power cord with L5-30 plug

UPS R3000h NA and R3000h JPN rear panel

Item Description

1 REPO port

2 ERM connector

3 Serial communications port/options slot

4 Load segment 1 (three IEC-320-C13 receptacles)

5 Load segment 2 (three IEC-320-C13 receptacles)

6 Load segment 3 (three IEC-320-C13 receptacles)

7 Load segment circuit breakers

8 PDU output (L6-20) receptacle (load segment 1)

9 Cord retention clip attachment locations

10 Ground bonding screw

11 Power cord with L6-20 plug

Component identification 10

Page 11

UPS R3000 INT rear panel

Item Description

1 REPO port

2 ERM connector

3 Serial communications port/options slot

4 Load segment 1 (three IEC-320-C13 receptacles)

5 Load segment 2 (three IEC-320-C13 receptacles)

6 Load segment 3 (three IEC-320-C13 receptacles)

7 Load segment circuit breakers

8 PDU output (IEC-320-C20) receptacle (load segment 1)

9 Cord retention clip attachment locations

10

11 Ground bonding screw

Input power receptacle (IEC-320-C19) for country-specific plug

attachment

REPO port

The UPS includes an isolated REPO port. When properly wired, the REPO feature enables the power at

the UPS output receptacles to be switched off from a remote location. To use this feature, the REPO port

must be connected to a remote, normally open switch (not supplied). The REPO switch is used in

conjunction with a main disconnect device that removes the AC source from the input of the UPS. When

the switch is closed:

• The REPO feature immediately powers down protected devices and does not utilize the orderly

shutdown procedure initiated by power management software.

• The REPO feature shuts down UPS units operating under either utility or battery power.

Component identification 11

Page 12

NOTE: If the UPS was operating on battery power when the remote switch was closed, no

power is available to the load devices until utility power is restored and the UPS has been

manually powered up.

To restore power to the load devices after the REPO feature is activated, press the On button after the AC

source is reconnected to the UPS.

IMPORTANT: Pressing and holding the On button without utility present normally initiates a

battery start and the UPS assumes the load. However, if the On button is pressed and a REPO

is detected, battery start is inhibited and the UPS is not able to assume the load. The

electronics module fan spins and the General Alarm LED and an audible alarm are active as

long as the On button is held.

To power down the entire network in the event of an emergency, the REPO ports of multiple UPS units can

be connected to a single switch.

ERM rear panel

Item Description

1 ERM input connector (from another ERM output)

2 Circuit breaker

3 ERM output connector (to the UPS or another ERM)

Component identification 12

Page 13

Installation

Precautions

Save these instructions. This document contains important safety instructions that should be followed

during installation, operation, and maintenance of the UPS and batteries.

WARNING: A risk of personal injury from electric shock and hazardous energy levels exists.

The installation of options and routine maintenance and service of this product must be

performed by individuals who are knowledgeable about the procedures, precautions, and

hazards associated with AC power products.

37 kg

82 lb

45 kg

100 lb

WARNING: To prevent personal injury from earth conductor leakage current:

• Do not operate the UPS while disconnected from the utility power source.

• Disconnect load devices before disconnecting the UPS from the utility power source.

This symbol indicates that the UPS exceeds the recommended weight for one

individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment,

observe local occupational health and safety requirements and guidelines for

manual material handling.

This symbol indicates that the ERM exceeds the recommended weight for one

individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment,

observe local occupational health and safety requirements and guidelines for

manual material handling.

Preparing to install the hardware

Before installing the hardware:

1. Be sure the necessary tools and materials (on page 13) are available.

2. Select an installation site ("Selecting a site" on page 14).

Tools and materials

3. Prepare the equipment ("Readying the equipment" on page 14) for installation in the rack.

The following tools are required for installation:

• Phillips screwdriver

• 10-mm hex-nut driver

The following items are supplied with the rack:

• Screws

Installation 13

Page 14

• Hex nuts

• Cage nuts

• Cage nut-fitting tool

Selecting a site

WARNING: To prevent fire or electric shock, install the unit in a temperature- and humidity-

When selecting a site, consider the following factors:

• Elevated operating ambient temperature—If the equipment is installed in a closed or multi-unit rack

• Reduced air flow—In the rack, the rate of air flow required for safe operation of the equipment must

• Circuit overloading—Consideration should be given to the connection of the equipment to the supply

• Reliable earthing—Reliable earthing of rack-mounted equipment should be maintained. Particular

controlled indoor environment, free of conductive contaminants.

assembly, the operating ambient temperature of the rack environment might be greater than room

ambient temperature. Install the equipment in an environment compatible with the operating

temperature ("Environmental specifications" on page 49).

not be compromised.

circuit and the effect that overloading of the circuits might have on overcurrent protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing

this concern.

attention should be given to supply connections other than direct connections to the branch circuit,

such as the use of power strips.

• Electrical requirements—All models require a dedicated (unshared) branch circuit, suitably rated for

the specific UPS as stated in "Input specifications ("UPS input specifications" on page 46)" .

Readying the equipment

1. Check the battery recharge date specified on the label that is affixed to the shipping carton.

IMPORTANT: Do not use the battery if the recharge date has passed. If the date on the

battery recharge date label has passed without the battery being recharged, contact an HP

2. Transport the packaged unit to its installation location.

3. Unpack the equipment near the rack where the unit will be assembled.

authorized service representative for directions.

CAUTION: Always plan the rack installation so that the heaviest item is on the bottom of the

rack. Install the heaviest item first, and continue to populate the rack from the bottom to the

top.

Installing the mounting rails

Installation 14

Page 15

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

NOTE: If preparing the rails for integrated shipping, follow the same instructions as in

"Installing the UPS (on page 18)."

NOTE: Mounting hardware for square- and round-holed racks is included in the UPS kit.

1. Loosen the wing nuts or hex nuts, and then extend the brackets to the desired length.

Installation 15

Page 16

2.

Insert screws through the rack into the mounting rail and the front of each mounting bracket.

3. Install cage nuts or clip nuts into the rear of the rack.

Installation 16

Page 17

4.

Insert screws through the mounting rail into the cage nuts or clip nuts.

5. Tighten the wing nuts or hex nuts.

Installation 17

Page 18

6.

Install the rear stabilization bracket using hex nuts. Wait until the unit is installed and the brackets

are adjusted before tightening the nuts.

Installing the UPS

Before installing the unit, review and adhere to all warnings provided in "Precautions (on page 13)."

WARNING: A risk of personal injury or damage to the equipment exists. Uneven loading of

equipment in the rack might cause the rack to become unstable. Install the heavier

1. Install the mounting rails ("Installing the mounting rails" on page 14).

2. With one person on each side, lift the chassis to rail level and slide the chassis on the mounting rails.

3. Attach the chassis to the rack using the supplied screws.

components first, and then continue to populate the rack from the bottom to the top.

Installation 18

Page 19

Connecting the battery leads

Attaching the UPS front bezel

Connecting the serial communications port

CAUTION: Use only the computer interface cable supplied with the UPS to connect the

communications port to the host computer.

IMPORTANT: Power management software requires the communications port to be

appropriately cabled to the host computer.

Installation 19

Page 20

Connecting the REPO port

WARNING: The pins on the REPO port are polarity sensitive. Be sure to verify polarity while

connecting the REPO port.

WARNING: To meet the requirements stated in NEC (NFPA 70) Articles 645-10 and 645-11,

a UPS installed in a computer equipment room must be connected to a REPO circuit.

IMPORTANT: The remote switch must be in the Off (open) position to enable power to the

output receptacles.

Installation 20

Page 21

NOTE: Wire the connector block using stranded, nonshielded wire (AWG #22 - #18, or

equivalent).

Separate wire pairs are attached to a single, normally-open contact in a parallel connection. HP

recommends using different colors for the positive and negative wires.

If a connector becomes disconnected and is reconnected with reversed polarity, a REPO is initiated. To

avoid REPO port disconnect:

• Minimize wire strain while connecting the REPO port.

• Avoid allowing the wires to hang in the rear of the UPS.

• Use tie wraps and tie wrap blocks to secure the wires tightly to the rack and the rear of the UPS.

For more information about the REPO port, see "REPO port (on page 11)" .

For information about verifying the REPO connection, see "Verifying the REPO port connection (on page

31)" .

Installation 21

Page 22

Connecting the ground bonding cable

NOTE: UPS appearance might vary depending on the specific unit installed.

The ground bonding screw is provided as an attachment point for conductors. Use a ground bonding

cable if the rack contains any conductors for the purpose of functional grounding or bonding of

ungrounded metal parts.

The ground bonding cable is not included.

Connecting the UPS to utility power

Installation 22

Page 23

WARNING: To prevent injury from electric shock or damage to the equipment:

• Plug the input line cord into a grounded (earthed) electrical outlet that is installed near the

equipment and is easily accessible.

• Do not disable the grounding plug on the input line cord. The grounding plug is an

important safety feature.

• Do not use extension cords.

Connect the UPS to a grounded utility power outlet. When the UPS is plugged in, it automatically enters

Standby mode and begins charging the batteries.

Connecting devices to the UPS

CAUTION: Do not plug laser printers into the UPS output receptacles. The instantaneous

current drawn by this type of printer can overload the UPS.

Before connecting devices, verify that the UPS will not overload by checking that the ratings of the devices

do not exceed the UPS capacity. If the equipment rating is listed in amps, multiply the number of amps by

the selected output voltage to determine the VA.

After verifying that the UPS will not overload: (depending on your model)

• Connect the device power cords to the output receptacles on the rear panel of the UPS.

-or-

• Connect devices to the output receptacles on the rear panel of the UPS using the jumper cords

included with the UPS.

To provide additional receptacles, plug a PDU into the PDU output receptacle. The PDU output receptacle

is part of load segment 1 and can be turned off and on using power management software (on page 32).

Connecting the UPS cord retention clips

NOTE: UPS appearance might vary depending on the specific unit installed.

Installation 23

Page 24

Charging the UPS batteries

Allow the batteries to charge before putting the UPS into service.

IMPORTANT: Charge the batteries for at least 24 hours before supplying backup power to

devices. The batteries charge to:

• 90% of their capacity within 4 hours

• 100% of their capacity within 24 hours

Starting power to the load

Start power to the load by placing the UPS in Operate mode (on page 27).

IMPORTANT: AC power must be available the first time the UPS is started.

Installing the ERM

Before installing the unit, review and adhere to all warnings provided in "Precautions (on page 13)."

WARNING: A risk of personal injury or damage to the equipment exists. Uneven loading of

equipment in the rack might cause the rack to become unstable. Install the heavier

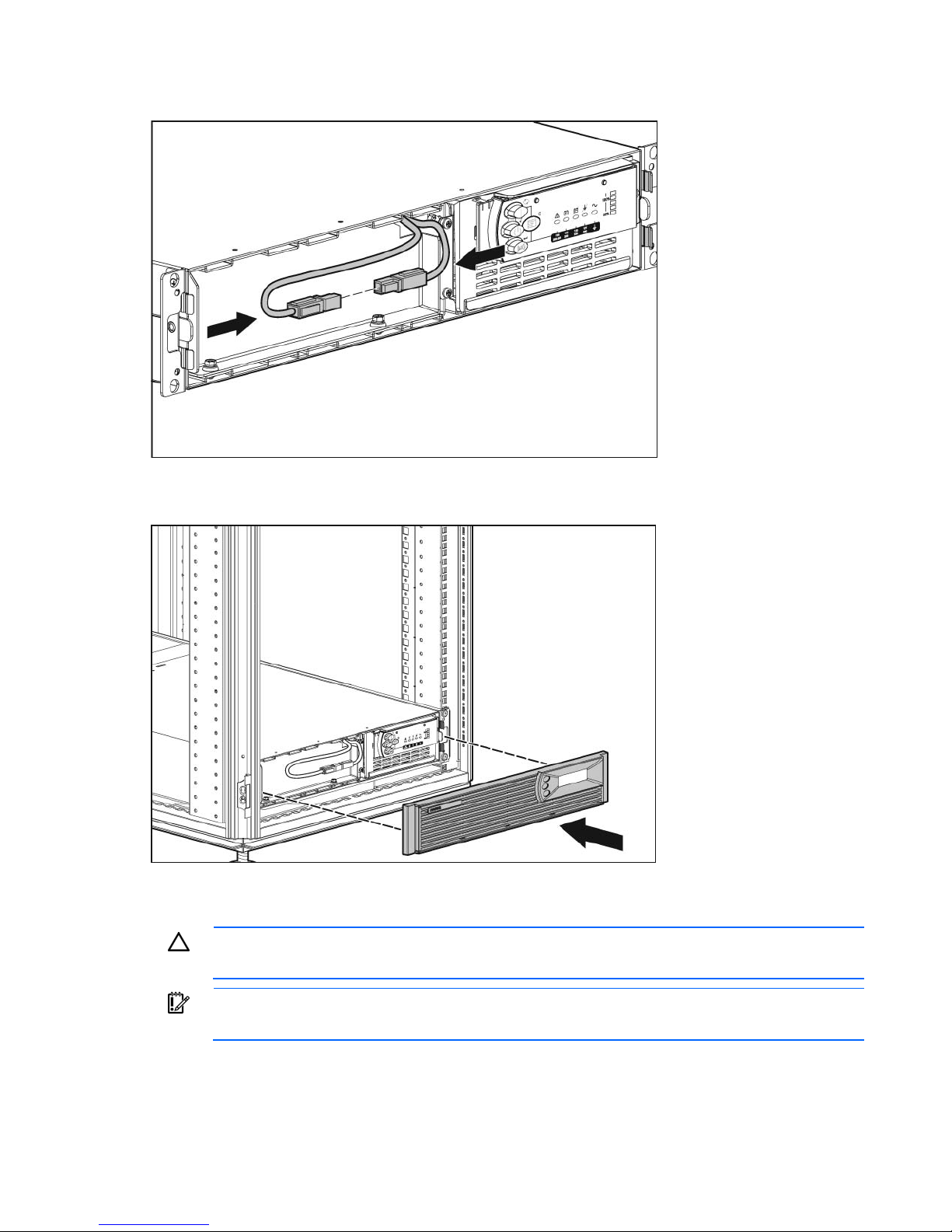

1. Install the mounting rails ("Installing the mounting rails" on page 14).

2. With one person on each side, lift the chassis to rail level and slide the chassis on the mounting rails.

3. Attach the chassis to the rack using the supplied screws.

components first, and then continue to populate the rack from the bottom to the top.

Installation 24

Page 25

Attaching the ERM front bezel

Switching off the ERM circuit breaker

WARNING: To prevent personal injury from electric shock or damage to the equipment,

verify that the circuit breaker is in the Off position.

Connecting the ERM to the UPS

NOTE: Before connecting an ERM to a UPS, remove the label from the ERM connector.

Installation 25

Page 26

Plug the ERM cable (1) in the socket (2) at the rear of the UPS.

NOTE: To install a second ERM, plug the cable from the second ERM into the socket at the

rear of the first ERM. Up to two ERM units can be connected.

Switching on the ERM circuit breaker

Charging the ERM batteries

Connect the UPS to a grounded utility power outlet. When the UPS is plugged in, the unit automatically

enters Standby mode and begins charging the ERM batteries. Allow 24 hours for the ERM to fully charge.

Installation 26

Page 27

UPS operations

Modes of operation

The UPS has four modes of operation:

• Standby mode (on page 27)

• Operate mode (on page 27)

• Configure mode (on page 28)

• Auto-Bypass mode (on page 28)

Standby mode

In Standby mode:

• No power is available at the UPS output receptacles.

• The UPS charges the batteries as necessary.

The UPS can be placed in Standby mode when the UPS is in Operate mode (on page 27).

To place the UPS in Standby mode, press and hold the Standby button until the audible alarm sounds and

the Utility LED flashes. Power to the load ceases.

IMPORTANT: While in Standby mode, the UPS maintains the charge on the batteries, but no

power is available at the output receptacles. The UPS remains in Standby mode until an

For the location of buttons, see "UPS front panel controls (on page 7)."

For the location of LEDs, see "UPS front panel LED indicators (on page 8)."

alternate mode is selected or until utility power is removed.

Operate mode

In Operate mode:

• Power is available at the UPS receptacles.

• The UPS charges the batteries as necessary.

The UPS can be placed in Operate mode if either of the following conditions apply:

• The UPS is powered up and in Standby mode (on page 27).

• The UPS is powered down and no utility power is available.

To place the UPS in Operate mode, press the On button. The Utility LED turns solid green, indicating that

power is available at the UPS output receptacles. The UPS acknowledges compliance with a short beep.

UPS operations 27

Page 28

NOTE:

• If the UPS is using battery power (no utility power is present and the Utility LED is red),

press and hold the On button until the audible alarm sounds.

• If the UPS is off (no LEDs are illuminated), press the On button to start the UPS on battery

power.

For the location of buttons, see "UPS front panel controls (on page 7)."

For the location of LEDs, see "UPS front panel LED indicators (on page 8)."

Configure mode

In Configure mode:

• Power is available at the UPS receptacles.

• The UPS charges the batteries as necessary.

• The UPS configuration can be updated.

The UPS can be placed in Configure mode while in Operate mode (on page 27) or Standby mode (on

page 27).

To place the UPS in Configure mode:

1. Remove the front bezel ("Removing the UPS front bezel" on page 33).

2. Press and hold the Configure button until the front panel LEDs flash in unison and the Configure

Mode On LED illuminates solid green.

For the location of buttons, see "UPS front panel controls (on page 7)."

For the location of LEDs, see "UPS front panel LED indicators (on page 8)."

Auto-Bypass mode

The UPS automatically enters Auto-Bypass mode when either of the following conditions occurs:

• The power from the UPS reaches a percentage greater than 110 percent for more than 10 cycles or

between 103 percent and 110 percent for more than 2 minutes.

• The UPS electronics module fails or is removed.

Configuring the UPS

NOTE: If the UPS firmware version is 2.00 or later, follow the instructions in “Configuring the

UPS.” If the UPS firmware version is earlier than 2.00, or the ERM cannot be configured from

the UPS front panel, use the ERM configurator tool. To update the UPS firmware or download

After the ERMs are installed, place the UPS in Configure mode (on page 28), and use the UPS front panel

controls and LED indicators to configure the UPS for the number of attached ERMs. Other UPS parameters

that can also be configured are the nominal utility voltage level and Site Wiring Fault detection.

In Configure mode, the LED front panel display changes function to enable modification of the UPS

parameters. Each LED is associated with a different parameter.

the ERM configurator tool, see the HP website (http://www.hp.com/go/rackandpower

).

UPS operations 28

Page 29

Available settings Parameter Associated LED Explanation (when LED is illuminated)

Nominal voltage

setting

100/200-208

Nom

General Alarm

(red)

110/220 Nom On Battery (red)

120/230 Nom Battery Fault (red)

127/240 Nom

Site Wiring Fault

(red)

Wiring fault setting Wiring fault Utility (green)

ERM setting 0 ERMs

0% to 25% load

(green)

1 ERM

26% to 50% load

(green)

2 ERMs

51% to 75% load

(green)

NOTE: For units factory-configured for 200 V or 208 V, the Site Wiring Fault function has

been disabled. If reconfiguring a 230 V unit to operate at 208 V, the Site Wiring Fault

function must be manually disabled.

To change the UPS configuration parameters:

Nominal utility voltage level is set to

100/200-208 VAC

Nominal utility voltage level is set to

110/220 VAC

Nominal utility voltage level is set to

120/230 VAC

Nominal utility voltage level is set to

127/240 VAC

Audible alarm will sound when ground is

missing or line and neutral connections are

reversed

(not available on the R3000j JPN, R3000h

NA, and R3000h JPN models)

UPS is configured for no attached ERMs

(factory default)

UPS is configured for 1 attached ERM

UPS is configured for 2 attached ERMs

1. Place the UPS in Configure mode.

The LEDs associated with the currently configured parameters illuminate. A flashing green cursor

indicates where you are in the configuration process as you scroll through the available settings.

2. To change the nominal voltage, press the On button to advance the cursor to the LED associated with

the appropriate nominal voltage parameter. The selected voltage configuration LED flashes.

3. Press the Standby button to select the nominal voltage configuration. The LED associated with the old

input voltage parameter turns off and the LED associated with the new input voltage parameter

illuminates solid green.

NOTE: Only one nominal utility voltage can be configured. When setting voltage

configuration parameters, selecting an On value for any one parameter automatically sets the

4. To enable the Wiring Fault parameter, press the On button to advance the cursor to the Utility LED,

other possibilities to Off.

then press the Standby button. The LED illuminates solid green. This parameter is disabled by default,

and should only be enabled for line-to-neutral connections. Enabling this feature for line-to-line power

sources will cause a false alarm.

5. To configure the UPS for the number of connected ERMs, press the On button to advance the cursor

to the load LED associated with the number of ERMs attached to the UPS.

6. Press the Standby button to select the appropriate ERM configuration. The associated LED illuminates

solid green.

7. To save the configuration settings and exit Configure mode, press the Test/Alarm Reset button.

UPS operations 29

Page 30

NOTE: Configure mode times out after 2 minutes of inactivity. If the Test/Alarm Reset button

has not been pressed, any new selections are not saved.

For the location of buttons, see "UPS front panel controls (on page 7)."

For the location of LEDs, see "UPS front panel LED indicators (on page 8)."

Available voltage settings

NOTE: An asterisk (*) indicates the default setting.

UPS model Available settings utility voltage (VAC)

R3000 NA 100 General Alarm

R3000j JPN 100* General Alarm

R3000h NA, R3000h JPN 200/208* General Alarm

110 On Battery

120* Battery Fault

127 Site Wiring Fault

110 On Battery

120 Battery Fault

127 Site Wiring Fault

220 On Battery

Associated LED ("UPS

front panel LED

indicators" on page 8)

R3000 INT 200/208 General Alarm

Initiating a self-test

To initiate a self-test, press and hold the Test/Alarm Reset button ("UPS front panel controls" on page 7)

for three seconds.

Because a portion of the self-test requires battery power, the self-test cannot be initiated if the batteries are

less than 90 percent charged. If the UPS detects a problem, the appropriate LED ("UPS front panel LED

indicators" on page 8) illuminates and an audible alarm may sound.

For information on what to do if the self-test detects a problem, see "Troubleshooting (on page 41)."

230 Battery Fault

240 Site Wiring Fault

220 On Battery

230* Battery Fault

240 Site Wiring Fault

UPS operations 30

Page 31

Silencing an audible alarm

To silence an alarm, press the Test/Alarm Reset button ("UPS front panel controls" on page 7).

IMPORTANT:

• Although the audible alarm silences, the condition that caused the alarm to sound may still

exist.

• If a utility power failure caused the alarm (the Utility LED or the General Alarm LED

For information about audible alarm conditions, see "LED and audible alarm troubleshooting (on page

41)."

illuminates red), the alarm silences after power is restored.

Verifying the REPO port connection

NOTE: While testing, operate connected equipment in a safe test mode so the effects do not

After connecting the REPO port (on page 20):

1. Initiate a REPO by closing the REPO contact.

2. Verify proper connection of the REPO port:

disrupt critical operations.

The General Alarm LED and Utility LED ("UPS front panel LED indicators" on page 8) flash.

CAUTION: If the polarity is reversed while connecting the REPO port, the UPS powers up

normally.

a. Power up the UPS ("Starting power to the load" on page 24).

b. Disconnect the REPO port.

c. Reconnect the REPO port.

If the polarity is correct, the REPO connectors can be disconnected, and then reconnected,

without initiating a REPO.

d. Verify that the UPS remains in Operate mode (on page 27).

e. If a REPO is initiated, the polarity is reversed. Check and correct the connections.

Powering down the UPS

1. Shut down all load devices.

2. Press the Standby button to take the UPS out of Operate mode. Power to the load receptacles

ceases.

3. Disconnect the UPS from utility power.

4. Wait at least 60 seconds for the UPS internal circuitry to discharge.

UPS operations 31

Page 32

Power management

Power management software

HP Power Manager software ensures maximum power reliability of computer systems through

comprehensive control of UPSs. The easy-to-use browser interface enables novice users to configure and

manage power protection settings. To download the latest version of HP Power Manager software, see

the HP website (http://www.hp.com/go/rackandpower

NOTE: To install and configure the software, see the software user guide. The software user

guide is available for download from the HP website

HP Power Manager:

(http://www.hp.com/go/rackandpower

• Does not require complex management systems, which simplifies deployment, configuration, and

management of UPS-protected environments.

).

).

• Manages a graceful shutdown of attached devices during utility power failures.

• Prioritizes the timing of attached load device shutdowns.

• Shuts down and reboots any UPS and attached load devices based on a user-specified schedule.

• Customizes alert generation with modifiable dialog boxes, command execution, and email and

broadcast messages.

• Monitors the status of the UPS and reports alarms.

• Displays a power log for analysis.

• Manages independent UPS load segments to provide separate power control of attached load

devices.

• Delays reboot by load segment after a power outage to sequence the startup of system components.

Power management 32

Page 33

Maintenance

Removing the UPS front bezel

Removing the ERM front bezel

Replacing the UPS electronics module

This component is hot-swappable and can be replaced without powering down the UPS.

Maintenance 33

Page 34

1.

(optional) To replace the component with the UPS powered down, refer to "Powering down the UPS

(on page 31)."

2. Disconnect the communications cable from the option card.

3. Remove the option card ("Replacing the UPS option card" on page 34).

4. Remove the UPS front bezel ("Removing the UPS front bezel" on page 33).

5. Remove the screws securing the electronics module and slide the module out.

CAUTION: To avoid dropping the load while hot-swapping the electronics module, press and

hold the Test/Alarm Reset button until the electronics module is firmly seated in the connector,

6. Replace the electronics module while holding down the Test/Alarm Reset button. Do not release the

and the Load Bar LED is illuminated.

button until the electronics module is firmly seated in the connector, and the Load Bar LED is

illuminated.

7. Replace the screw.

8. Replace the option card.

9. Reconnect the external cable to the card.

10. Verify that the UPS is configured to the proper voltage and number of attached ERMs. See

"Configuring the UPS (on page 28)."

11. Replace the front bezel.

Replacing the UPS option card

This component is hot-swappable and can be replaced without powering down the UPS.

1. (optional) To replace the component with the UPS powered down, refer to "Powering down the UPS

(on page 31)."

2. Disconnect the communications cable from the option card.

Maintenance 34

Page 35

3.

Remove the two screws securing the option card and slide the card out.

To replace the component, reverse the removal procedure.

NOTE: Replacing the option card might require power management software to be restarted

or reconfigured.

Replacing the batteries

To replace the batteries:

1. Read and observe the requirements in "Important battery safety information (on page 35)" and

"Battery care and storage guidelines (on page 36)."

Important battery safety information

2. Follow the instructions in "UPS battery replacement procedure (on page 36)."

WARNING: The unit contains sealed lead-acid battery modules. To prevent fire or chemical

burns:

• Do not attempt to recharge batteries after removal from the unit.

• Do not disassemble, crush, or puncture the batteries.

• Do not short the external contacts of the batteries.

• Do not immerse the batteries in water.

• Do not expose to temperatures higher than 60°C (140°F).

WARNING: To prevent personal injury from hazardous energy:

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Do not place tools or metal parts on top of batteries.

Maintenance 35

Page 36

WARNING: To prevent personal injury, prepare the area and observe all materials-handling

procedures when transporting a battery module. Battery modules weigh 20 kg (44.1 lb).

NOTE: Replace all battery modules at the same time.

Battery care and storage guidelines

• Minimize the amount of time the UPS uses battery power by matching the UPS configuration with the

utility voltage. Refer to "Configuring the UPS (on page 28)."

• Keep the area around the UPS clean and dust-free. If the environment is very dusty, clean the outside

of the UPS regularly with a vacuum cleaner.

• Maintain the ambient temperature at 25°C (77°F).

• If storing a UPS for an extended period, recharge the batteries every 6 months:

CAUTION: Because of the short shelf life of the batteries, avoid storing a battery spare as a

backup. Do not maintain an inventory of spare batteries on site unless a procedure to keep

these batteries charged while in storage is implemented.

a. Connect the UPS to utility power.

b. Allow the UPS to remain in Standby mode.

c. Allow the UPS to charge the batteries for at least 24 hours.

d. Update the battery recharge date label.

Determining when to replace batteries

When the Battery Fault LED illuminates, batteries might need to be replaced within 30 to 60 days.

When a battery alarm sounds, initiate a UPS battery self-test to verify that battery replacement is required.

If the Battery Fault LED remains illuminated, replace the batteries as soon as possible.

For more information on initiating a self-test, see "Initiating a self-test (on page 30)."

For the location of LEDs, see "UPS front panel LED indicators (on page 8)."

Obtaining new batteries

New batteries may be required within 30 to 60 days when the Battery Fault LED illuminates red. Obtain

spare batteries for the UPS when this occurs.

Spare battery modules are supplied for this UPS. The UPS spare battery kit part number is 407407-001.

CAUTION: Because of the short shelf life of the batteries, avoid storing a battery spare as a

backup. Do not maintain an inventory of spare batteries on site unless a procedure to keep

these batteries charged while in storage is implemented.

UPS battery replacement procedure

This component is hot-swappable and can be replaced without powering down the UPS.

Maintenance 36

Page 37

1.

(optional) To replace the component with the UPS powered down, refer to "Powering down the UPS

(on page 31)."

CAUTION: When hot-swapping batteries, the UPS is not protected in the event of a utility

power failure, unless at least one ERM is installed.

2. Remove the UPS front bezel ("Removing the UPS front bezel" on page 33).

3. Disconnect the battery leads.

4. Remove the UPS battery bracket.

5. Remove the UPS battery modules.

To replace the components, reverse the removal procedure.

IMPORTANT: Charge the batteries for at least 24 hours before supplying backup power to

devices. The batteries charge to:

• 90% of their capacity within 4 hours

• 100% of their capacity within 24 hours

Maintenance 37

Page 38

Testing the new battery module

After installing the new battery module, press the Test/Alarm Reset button to initiate a self-test ("Initiating a

self-test" on page 30).

IMPORTANT: The UPS does not execute a self-test until the batteries are 90 percent charged.

IMPORTANT: Charge the batteries for at least 24 hours before supplying backup power to

devices. The batteries charge to:

• 90% of their capacity within 4 hours

If the installation has been successful, the Battery Fault LED is not illuminated. If the installation has not

been successful, the Battery Fault LED illuminates. If this occurs, repeat the UPS battery replacement

procedure (on page 36), and check the battery terminal connections. If the Battery Fault LED is still

illuminated, see "LED and audible alarm troubleshooting (on page 41)."

For the location of buttons, see "UPS front panel controls (on page 7)."

• 100% of their capacity within 24 hours

For the location of LEDs, see "UPS front panel LED indicators (on page 8)."

Replacing the UPS

To remove the UPS:

1. Power down all attached load devices.

2. Power down the UPS ("Powering down the UPS" on page 31).

3. Switch the circuit breaker for any attached ERMs to the Off position.

4. Unplug the UPS power cord.

5. Disconnect the communications cable from the option card.

6. Disconnect the ground bonding cable.

7. Disconnect the REPO port.

8. Unplug the load devices.

9. Unplug the ERM connected to the UPS.

10. Remove the UPS front bezel ("Removing the UPS front bezel" on page 33).

11. Disconnect the battery leads.

12. Remove the UPS battery bracket.

13. Remove the UPS battery modules.

14. Remove the screws securing the UPS to the rack.

15. Remove the UPS from the rack.

To replace the component, reverse the removal procedure.

Replacing the ERM

To remove the ERM:

Maintenance 38

Page 39

1.

Switch the circuit breaker for any attached ERMs to the Off position.

2. Unplug the ERM from the back of the UPS.

3. Unplug the ERM from a second connected ERM.

4. Remove the front bezel ("Removing the ERM front bezel" on page 33) on the ERM that is being

replaced.

5. Disconnect the battery leads.

6. Remove the screws securing the ERM to the rack.

7. Remove the ERM from the rack.

To replace the component, reverse the removal procedure.

Updating the UPS firmware

Configuring a USB to serial converter

To update the UPS firmware, see the HP website (http://www.hp.com/go/rackandpower).

NOTE: This procedure was tested on the Windows

2003 operating systems using the HP USB to serial converter (part number 304098-001).

Depending on your system configuration, a driver download might be required to successfully

install the converter. The driver can be downloaded from the USB-Drivers website

(http://www.usb-drivers.com/drivers/123/123294.htm

To configure a USB port to the COM 1 port on systems that do not have available serial ports:

1. Connect the USB to serial converter to the USB port on your system.

2. Click Start, select Control Panel, and then double-click System.

The System Properties screen appears.

3. Click the Hardware tab.

4. Click Device Manager.

®

XP Professional and Windows Server®

).

The Device Manager screen appears.

5. In the tree displayed in the left panel, click the Ports (COM & LPT) branch to expand.

6. Double-click the port that is assigned to your USB to serial converter device. This port is usually

named with the device manufacturer's name followed by "USB to Serial Bridge (com 4)."

The Port Properties screen appears.

7. Click the Port Settings tab.

The Port Settings screen appears.

8. Click Restore Defaults.

The following default settings appear:

o Bits per second: 9600

o Data Bits: 8

o Parity: None

o Stop bits: 1

o Flow control: None

Maintenance 39

Page 40

9.

Click Advanced.

The Advanced Settings screen appears.

10. From the COM Port Number drop down menu, select Com 1 for the USB port number.

If COM 1 is being used by another USB port, the following message appears:

This COM name is being used by another device. Using duplicate names can

lead to inaccessible devices and changed settings. Do you want to

continue?

a. Click YES.

b. Reassign the COM ports so that the USB to serial converter is using COM 1. See "Reassigning

the USB COM ports."

11. Reduce the Receive Buffer and Transmit Buffer to the low setting by scrolling down to select low (1).

12. Be sure that the Use FIFO buffers (requires 16550 compatible UART) checkbox is selected.

Depending on your operating system, the USB settings might be different. Choose the lowest, most

dependable Receive and Transmit buffers by using the drop down menus, radio buttons, or other

selection methods.

13. Click OK to close the Advanced screen.

14. Click OK to close the Device Manager screen.

15. Run the firmware Flash batch file program. Follow the instructions provided with the program.

Reassigning the USB COM ports

To reassign a device from COM 1 to another port:

1. From the open Device Manager screen, locate the USB device that is assigned to COM 1.

2. Double-click the port name.

The Port Properties screen appears.

3. Click the Port Settings tab.

The Port Settings screen appears.

4. Click Advanced.

The Advanced Settings screen appears.

5. Select an available USB port number from the COM Port Number drop down menu.

6. Click OK to close the Advanced screen.

7. Click OK to close the Port Settings screen.

8. Verify that the Device Manager screen shows that the USB to serial converter is assigned to COM 1,

and that the other USB device is assigned to a different port.

If the Device Manager screen does not automatically refresh to show the change:

a. Click Action.

The Action Menu appears.

b. Click Scan for hardware changes to refresh the screen and display the changes.

Maintenance 40

Page 41

Troubleshooting

LED and audible alarm troubleshooting

Genera

l Alarm

LED

On

Batter

y LED

Batter

y Fault

LED

Site

Wiring

Fault

Utility

LED

LED

Off Off Off Off Green Off

Off Off Off Off

Off Off Off Off Red Off

Flashing

red

Off Off Off Off

Off Off

Off

Off Off

Off Red Off Off Off Off

Off Off Off Red Off

Off Off Off

Off Off Off

Flashin

g red

Flashin

g red

Off Off Off Off

Flashin

g red

Flashin

g

green

Flashin

g red

Overloa

d LED

Off

Off

Audible

alarm

No audible

alarm

No audible

alarm

On—1 beep

every 5

seconds

On—1 beep

every 5

seconds

On—1 beep

every 5

seconds

On—1 beep

every 5

seconds

On—1 beep

every 5

seconds

On—1 beep

every 5

seconds

On—1 beep

every 5

seconds

Can

alarm be

silenced

("Silencin

g an

audible

alarm"

on page

31)?

N/A

N/A

Yes

Yes

Yes

Yes

No

Yes

Yes

Condition

UPS is in Operate

mode (on page 27)

UPS is in Standby

mode (on page 27)

UPS is in Auto-Bypass

mode (on page 28)

General alarm

condition—UPS is in

Auto-Bypass mode

("General alarm

condition" on page

42)

Bypass is out of range

(on page 43)

Battery test failure

("Battery condition"

on page 43)

Low battery (no utility

power) ("UPS is on

battery" on page 43)

Batteries are

disconnected ("Battery

condition" on page

43)

On battery—No utility

power ("UPS is on

battery" on page 43)

Troubleshooting 41

Page 42

Off

Flashing

red

Red Off Off Off Off Off

Flashing

red

Off Off Off Red Off Off

Flashing

red

For the location of individual LEDs, see "UPS front panel LED indicators (on page 8)."

Flashin

g red

Flashin

g red

Off Off Off

Off Off Off Off Red

Off Off

Flashin

g red

Flashin

g red

Flashin

g red

Flashin

g red

Flashin

g

green

Off

Flashing

red

Off

On—1 beep

every 5

seconds

On—

Continuous

On—

Continuous

On—

Continuous

On—1 beep

every 5

seconds

On—

Continuous

Yes

No

Yes

Yes

Yes

Yes

On battery—Input

voltage is out of range

(on page 43)

Internal UPS fault

condition (on page

44)

Self-test failure

("Battery condition"

on page 43)

REPO condition (on

page 44)

Site wiring condition

(on page 44)

UPS power capacity is

exceeded ("Overload

condition" on page

44)

UPS is in Auto-Bypass mode

Action:

1. If power management software is being used, check the log files to obtain specific error information

to help identify the problem.

For more information about the causes of a general fault condition, see the HP Power Manager user

guide available for download from the HP website (http://www.hp.com/go/rackandpower

2. Verify that no blockage of airflow to the front bezel and rear panel exists.

3. If the LED does not turn off, replace the electronics module. ("Replacing the UPS electronics module"

on page 33)

General alarm condition

Action:

1. If power management software is being used, check the log files to obtain specific error information

to help identify the problem.

For more information about the causes of a general alarm condition, see the HP Power Manager

user guide available for download from the HP website (http://www.hp.com/go/rackandpower

2. Check the batteries:

a. Allow the UPS batteries to charge for 24 hours.

).

).

b. If the Battery Fault LED is red, replace the batteries ("UPS battery replacement procedure" on

page 36).

3. Reduce the load:

a. Power down the UPS ("Powering down the UPS" on page 31).

Troubleshooting 42

Page 43

b.

Remove one or more load devices to reduce the power requirements.

c. Wait at least 5 seconds and restart the UPS.

d. If the condition persists, verify that the load devices are not defective.

4. Allow the UPS to cool:

a. Power down the UPS ("Powering down the UPS" on page 31).

b. Clear vents and remove any heat sources.

c. Verify that the airflow around the UPS is not restricted.

5. Wait at least 5 minutes and restart the UPS.

6. If the condition persists, contact an HP authorized service representative.

Bypass is out of range

The input voltage is not within ±12 percent of nominal voltage.

The UPS is receiving utility power that might be unstable or in brownout conditions. The UPS continues to

supply power to the connected equipment. If conditions worsen, the UPS might switch to battery power.

Action:

1. Check the input voltage and reconfigure the UPS ("Configuring the UPS" on page 28).

2. Contact a qualified electrician to verify that the utility power is suitable for the UPS.

Battery condition

Action:

1. Install the battery module. If the battery module is already installed, remove and reinsert the module.

2. Allow the UPS batteries to charge for 24 hours.

3. If the LED does not turn off, replace the batteries ("UPS battery replacement procedure" on page 36).

4. If the condition persists, contact an HP authorized service representative.

UPS is on battery

Action:

1. Save files and shut down connected equipment.

2. Allow the UPS batteries to charge for 24 hours.

Input voltage is out of range

Action:

1. Check the input voltage and reconfigure the UPS ("Configuring the UPS" on page 28).

2. Contact a qualified electrician to verify that the utility power is suitable for the UPS.

Troubleshooting 43

Page 44

Utility power condition

The utility input voltage is outside the operating range.

Action:

1. Check the input voltage and reconfigure the UPS ("Configuring the UPS" on page 28).

2. Contact a qualified electrician to verify that the utility power is suitable for the UPS.

Internal UPS fault condition

Action:

1. Power down the UPS ("Powering down the UPS" on page 31).

2. If the condition persists, contact an HP authorized service representative.

REPO condition

Action:

• If the remote switch is closed, then open the switch to enable power to the output receptacles.

• If the condition occurred while reconnecting a disconnected REPO port, then verify the polarity of the

REPO connector pins.

For more information about REPO ports, see "Connecting the REPO port (on page 20)."

Site wiring condition

Action: Contact a qualified electrician to be sure that:

• The utility power receptacle is grounded.

• There is a ground wire in the UPS power cord.

• The line and neutral wires are not reversed in the wall outlet.

Overload condition

All the load LEDs are illuminated.

Action:

1. Power down the UPS ("Powering down the UPS" on page 31).

2. Remove one or more load devices to reduce the power requirements.

3. Wait at least 5 seconds and restart the UPS.

4. If the condition persists, verify that the load devices are not defective.

UPS does not start

Action:

Troubleshooting 44

Page 45

1.

Be sure that the power cord is plugged in to a utility power receptacle.

2. Check the power source at the utility power receptacle.

Low battery shutdowns

Ungraceful shutdown of attached servers occurs when the UPS is in a low battery condition.

Action:

1. Verify that the power management software is not delaying the shutdown of attached servers when

the UPS is in a low battery condition.

2. Allow the UPS batteries to charge for 24 hours.

3. If the Battery Fault LED is red, replace the batteries ("UPS battery replacement procedure" on page

36).

UPS does not provide the expected backup time

Action:

1. If the Overload LED ("UPS front panel controls" on page 7) is illuminated, remove one or more load

devices to reduce the power requirements.

2. Power down the UPS ("Powering down the UPS" on page 31).

3. Allow the UPS batteries to charge for 24 hours.

4. Initiate a self-test ("Initiating a self-test" on page 30).

5. During extended power outages, save your work, power down the load devices, and then power

down the UPS ("Powering down the UPS" on page 31) to conserve battery power.

UPS frequently switches between utility and battery

power

Action:

1. Check the input voltage and reconfigure the UPS ("Configuring the UPS" on page 28).

2. Contact a qualified electrician to verify that the utility power is suitable for the UPS.

ERM cannot be configured from the UPS front panel

Action:

See the HP website (http://www.hp.com/go/rackandpower

) to update the UPS firmware.

Troubleshooting 45

Page 46

Specifications

UPS physical specifications

Parameter Value

Height 8.9 cm (3.5 in)

Depth 62.2 cm (25 in)

Width 44.1 cm (17.5 in)

Weight 37 kg (82 lb)

ERM physical specifications

Parameter Value

Height 8.9 cm (3.5 in)

Depth 34.3 cm (13.5 in)

Width 44.5 cm (17.5 in)

Weight 45 kg (100 lb)

UPS input specifications

NOTE: An asterisk (*) indicates the default setting.

UPS model

Utility voltage

frequency (Hz)

Available settings

utility voltage (VAC)

Branch circuit

rating (A)

R3000 NA 50/60 100, 110, 120*, 127 30

R3000j JPN 50/60 100*, 110, 120, 127 30

R3000h NA 50/60

200/208*

1

, 220, 230,

20

240

R3000h JPN 50/60

200/208*

1

, 220, 230,

20

240

R3000 INTL 50/60

200/208, 220, 230*,

16

240

Line cord

Nondetachable power

cord with NEMA L5-30

plug

Nondetachable power

cord with NEMA L5-30

plug

Nondetachable power

cord with NEMA L6-20

plug

Nondetachable power

cord with NEMA L6-20

plug

Detachable power cord

with country-specific

plug

Specifications 46

Page 47

1

The output voltage is 204 for this setting.

UPS output specifications

UPS model Load segment Output receptacles

R3000 NA 1 2 x 5-15R

2 2 x 5-15R

3 2 x 5-15R

R3000j JPN 1 2 x 5-15R

2 2 x 5-15R

3 2 x 5-15R

R3000h NA/JPN 1 3 x IEC-320-C13

2 3 x IEC-320-C13

3 3 x IEC-320-C13

R3000 INTL 1 3 x IEC-320-C13

1 x L5-30R

1 x L5-30R

1 x L6-20R

1 x IEC-320-C20

2 3 x IEC-320-C13

3 3 x IEC-320-C13

Power protection specifications

UPS model VA

Nominal power rating

(W)

R3000 NA 2880 2700 100, 110, 120, 127

R3000j JPN 2400 2250 100, 110, 120, 127

R3000h NA/JPN 3000 2700 200, 220, 230, 240

R3000 INTL 3000 2700

Voltage specifications

Configuration setting (VAC) Available nominal output voltage (VAC)

100 100

110 110

120 120

127 127

200 200

Nominal voltage

setting

200/208, 220, 230,

240

Specifications 47

Page 48

Configuration setting (VAC) Available nominal output voltage (VAC)

208 208

230 230

240 240

Output tolerance specifications

Source of power Regulation

Utility power (nominal

range)

Battery power ±5% of nominal output voltage rating

-10% to +6% of nominal output voltage rating

(within the guidelines of the Computer

Business Equipment Manufacturers

Association)

Output feature specifications

Feature Specification

Online efficiency 94% nominal input voltage

Voltage wave shape Sine wave; 5% THD with typical PFC load

Surge suppression High-energy 6500 A peak

Noise filtering

MOVs and line filter for normal and common mode

use

Battery specifications

Feature Specification

Type

Voltage The battery modules have a battery string voltage of 120 V.

Charging

12 V, 5 AH, sealed, maintenance-free, rechargeable, valve

regulated lead-acid batteries with a 3-5 year service life at

25°C (77°F).

Complete charge takes no more than 24 hours. After

approximately 4 hours, the batteries reach 90% charge at

default nominal utility voltage and no load.

Battery runtime

Load, percent

20 40 minutes 120 minutes 250 minutes

50 12 minutes 45 minutes 100 minutes

80 6.5 minutes 30 minutes 60 minutes

100 5 minutes 20 minutes 40 minutes

Estimated battery

runtime

Runtime with one ERM Runtime with two ERMs

Specifications 48

Page 49

Environmental specifications

Feature Specification