Page 1

HP Tower Server tc3100

Operations and Maintenance Guide

Online Version: 1.1

December 2002

Page 2

Notice

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and fitness for a particular purpose. Hewlett-

Packard shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on equipment that is not

furnished by Hewlett-Packard.

This document contains proprietary information that is protected by copyright. All rights are reserved. No

part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Hewlett-Packard Company.

Windows NT

other countries.

®

Torx

Hewlett-Packard Company

Network Server Division

Technical Communications/MS 45SLE

10955 Tantau Avenue

Cupertino, CA 95014 USA

© Copyright 2001, Hewlett-Packard Company.

®

, Windows 95®, and Windows 2000 are registered trademarks of Microsoft in the U.S. and

is a registered trademark of CamCar/Textron, Inc.

Audience Assumptions

This guide is for the person who installs, administers, and troubleshoots LAN servers. Hewlett-Packard

Company assumes you are qualified in the servicing of computer equipment and trained in recognizing

hazards in products with hazardous energy levels and are familiar with weight and stability precautions for

rack installations.

For installation instructions, refer to the Installation Sheet included with the HP Server tc3100.

ii

Page 3

Contents

1 Controls and Indicators ......................................................................................................................... 1

Front Panel ............................................................................................................................................... 1

Additional Controls and Indicators........................................................................................................ 2

Hot Swap Hard Drive Indicators ...........................................................................................................3

Rear Panel ................................................................................................................................................ 4

Applying Power to the HP Server ............................................................................................................. 5

Powering Up the Server ....................................................................................................................... 5

Powering Down the Server ................................................................................................................... 5

Connecting Power to Multiple-Server Configurations .......................................................................... 6

Sleep States (ACPI) ............................................................................................................................. 6

2 External Connectors .............................................................................................................................. 7

Mini-DIN (PS/2) for Mouse and Keyboard ................................................................................................ 7

Serial Port ................................................................................................................................................. 7

Parallel Port .............................................................................................................................................. 8

USB........................................................................................................................................................... 8

Standard Video ......................................................................................................................................... 9

Standard SCSI ..........................................................................................................................................9

Standard LAN ......................................................................................................................................... 10

3 Installing and Configuring................................................................................................................... 11

Opening and Closing the HP Server tc3100........................................................................................... 11

Opening the Upper Bezel ................................................................................................................... 12

Opening the Lower Bezel (Cold Swap Model) ................................................................................... 12

Opening the Side Panel...................................................................................................................... 13

Mass Storage.......................................................................................................................................... 14

Guidelines........................................................................................................................................... 14

Boot Priority ........................................................................................................................................ 15

Installed Mass Storage Devices ......................................................................................................... 16

Installing Hard Disk Drives...................................................................................................................... 16

Flexible Disk Drive .............................................................................................................................. 17

CD-Rom or Optional Tape Disk Drive ................................................................................................ 17

Installing Optional SCSI Accessory Cable ......................................................................................... 18

Installing Optional Internal to External SCSI Cable............................................................................ 19

Installing Cold Swap Hard Drives ........................................................................................................... 20

Removing Cold Swap Hard Drives ......................................................................................................... 21

Installing Hot Swap Hard Drives ............................................................................................................. 22

Removing Hot Swap Hard Drives ........................................................................................................... 23

Memory Modules .................................................................................................................................... 23

Guidelines........................................................................................................................................... 24

Installing Additional DIMMs ................................................................................................................ 24

Removing DIMMs ............................................................................................................................... 26

Processors .............................................................................................................................................. 26

Guidelines........................................................................................................................................... 27

Installing a Second Processor ............................................................................................................ 28

Installing the Heatsink ........................................................................................................................ 30

Removing a Processor and Heatsink ................................................................................................. 31

Firmware and Software Changes ........................................................................................................... 32

iii

Page 4

Contents

Upgrading the Firmware ..................................................................................................................... 32

Reinstalling the NOS .......................................................................................................................... 32

Accessory Boards ................................................................................................................................... 32

Tested PCI Boards ............................................................................................................................. 32

Remote Control Card.......................................................................................................................... 32

Guidelines........................................................................................................................................... 32

IRQ Settings ....................................................................................................................................... 32

Boot Priority ........................................................................................................................................ 33

Using the Primary or Secondary PCI Bus ..........................................................................................33

Installing a Disk Array Controller Board ............................................................................................. 33

Installing an Accessory Board ............................................................................................................ 33

Removing an Accessory Board .......................................................................................................... 36

Racking the Server ................................................................................................................................. 36

Connecting Peripheral Devices .............................................................................................................. 36

Monitor, Keyboard, and Mouse .......................................................................................................... 36

Uninterruptible Power Supply (UPS) .................................................................................................. 37

Configuring the HP Server tc3100 .......................................................................................................... 37

HP Server Navigator CD-ROM ............................................................................................................... 37

Contents of the HP Server Navigator CD-ROM ................................................................................. 37

Obtaining HP Server Navigator Release History ............................................................................... 38

Accessing the HP Server Navigator CD-ROM ................................................................................... 38

Viewing the Readme File.................................................................................................................... 38

BIOS Setup Utility ................................................................................................................................... 39

Accessing the Setup Utility ................................................................................................................. 39

Menu Bar ............................................................................................................................................ 39

Using the Setup Screens .................................................................................................................... 40

Changing the System Date and Time ................................................................................................ 40

Setting the HP Server's Boot Passwords ........................................................................................... 41

Remote Console Feature........................................................................................................................ 42

Enabling the Remote Console Feature .............................................................................................. 42

About the Remote Console Feature................................................................................................... 43

SCSI Configuration Utility ....................................................................................................................... 44

4 Diagnostics ........................................................................................................................................... 45

Power-On Self Test (POST) ................................................................................................................... 45

No Error Messages Displayed............................................................................................................ 46

POST Error Messages ....................................................................................................................... 46

Clearing the CMOS Configuration .......................................................................................................... 47

HP Management Solutions ..................................................................................................................... 48

HP Server DiagTools .............................................................................................................................. 49

HP TopTools ........................................................................................................................................... 50

5 Error Messages .................................................................................................................................... 53

Power-On Self Test (POST) Error Codes............................................................................................... 53

Beep Codes ............................................................................................................................................ 62

6 Troubleshooting ................................................................................................................................... 63

Troubleshooting Tools ............................................................................................................................ 64

Troubleshooting .................................................................................................................................... 64

BIOS/Reset/Update/Recovery................................................................................................................ 66

Clearing the BIOS Configuration.............................................................................................................. 67

Password Problems............................................................................................................................... 68

iv

Page 5

Contents

'Operating System Not Found' Message Appears................................................................................. 68

Server Stops or Hangs While Starting Up.............................................................................................. 69

Power Problems .................................................................................................................................... 69

Video/Monitor Problems ......................................................................................................................... 70

Configuration Problems ..........................................................................................................................72

Printer Problems .................................................................................................................................... 72

The Keyboard Does Not Work................................................................................................................ 73

The Mouse Does Not Work..................................................................................................................... 73

Flexible Disk Drive Problems .................................................................................................................. 74

CD-ROM Problems ................................................................................................................................. 74

SCSI Problems....................................................................................................................................... 75

7 Replacing Parts .................................................................................................................................... 81

Safety Information................................................................................................................................... 81

Service Tools Required .......................................................................................................................... 81

Chassis Fan ............................................................................................................................................ 81

Power Supply.......................................................................................................................................... 82

Battery..................................................................................................................................................... 84

System Board ......................................................................................................................................... 85

8 Parts Identification ............................................................................................................................... 87

Exploded View – Covers and Bezels...................................................................................................... 87

Exploded View – Drives (Cold Swap) ..................................................................................................... 88

Exploded View – Drives (Hot Swap)....................................................................................................... 89

Exploded View – Drives (Hot Swap)....................................................................................................... 89

Exploded View – Power Supply, Fan, I/O Retainer, System Board ....................................................... 90

Exploded View – Back Plane and PCI Card Guide Assemblies............................................................. 91

Exploded View – System Board ............................................................................................................. 92

Replaceable Parts List ............................................................................................................................ 93

9 Specifications ....................................................................................................................................... 97

Power Supply Requirements .................................................................................................................. 97

Environment............................................................................................................................................ 97

Weight and Dimensions .......................................................................................................................... 98

Hardware Specifications ......................................................................................................................... 98

System Board Layout ......................................................................................................................... 99

Index ......................................................................................................................................................... 101

v

Page 6

Page 7

1 Controls and Indicators

This chapter describes the controls, ports, and indicators on the front and rear of the HP Server tc3100.

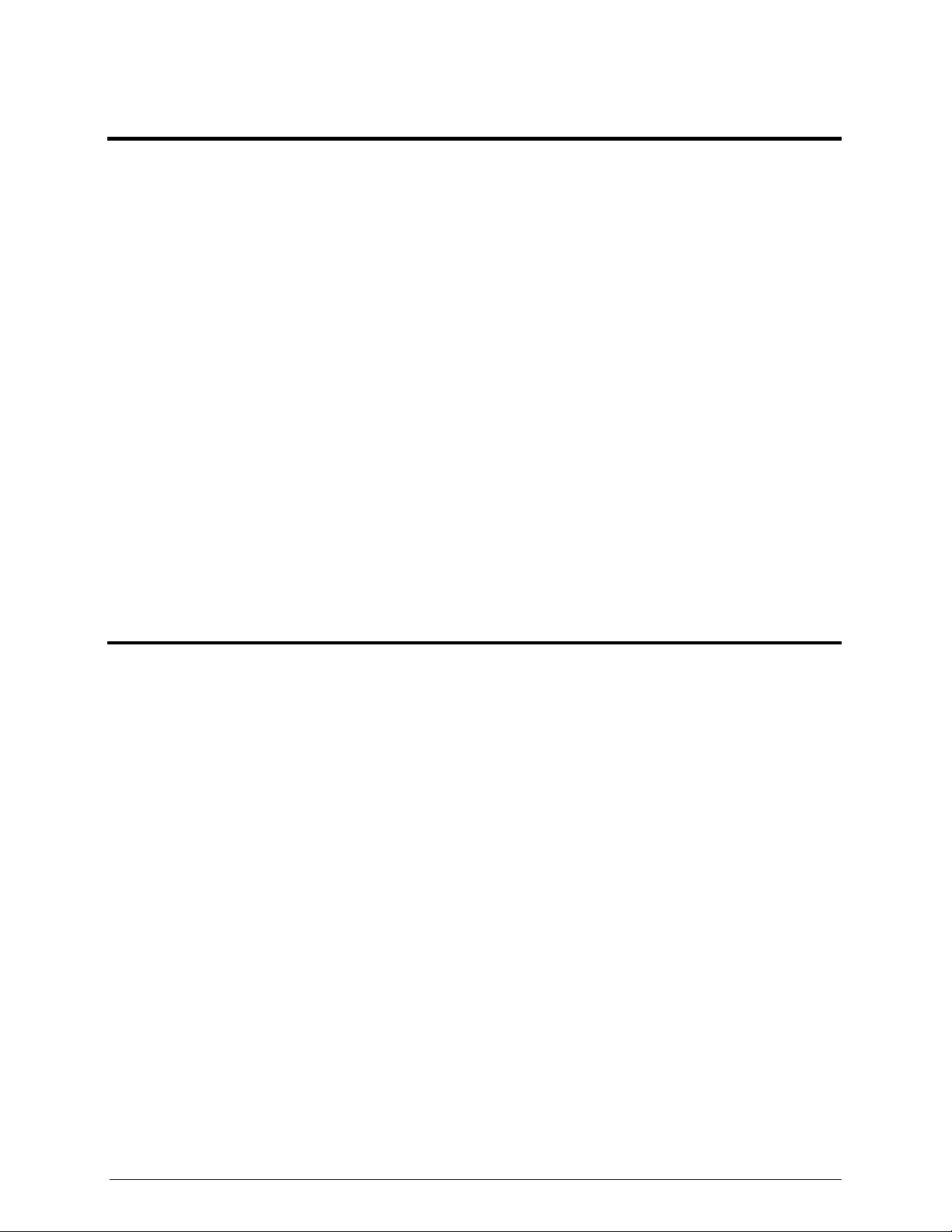

Front Panel

The front panel of the HP Server tc3100 provides the controls and indicators commonly used when operating

the server. See Figure 1-1 and Figure 1-2. Table 1-1 describes the LED indicators.

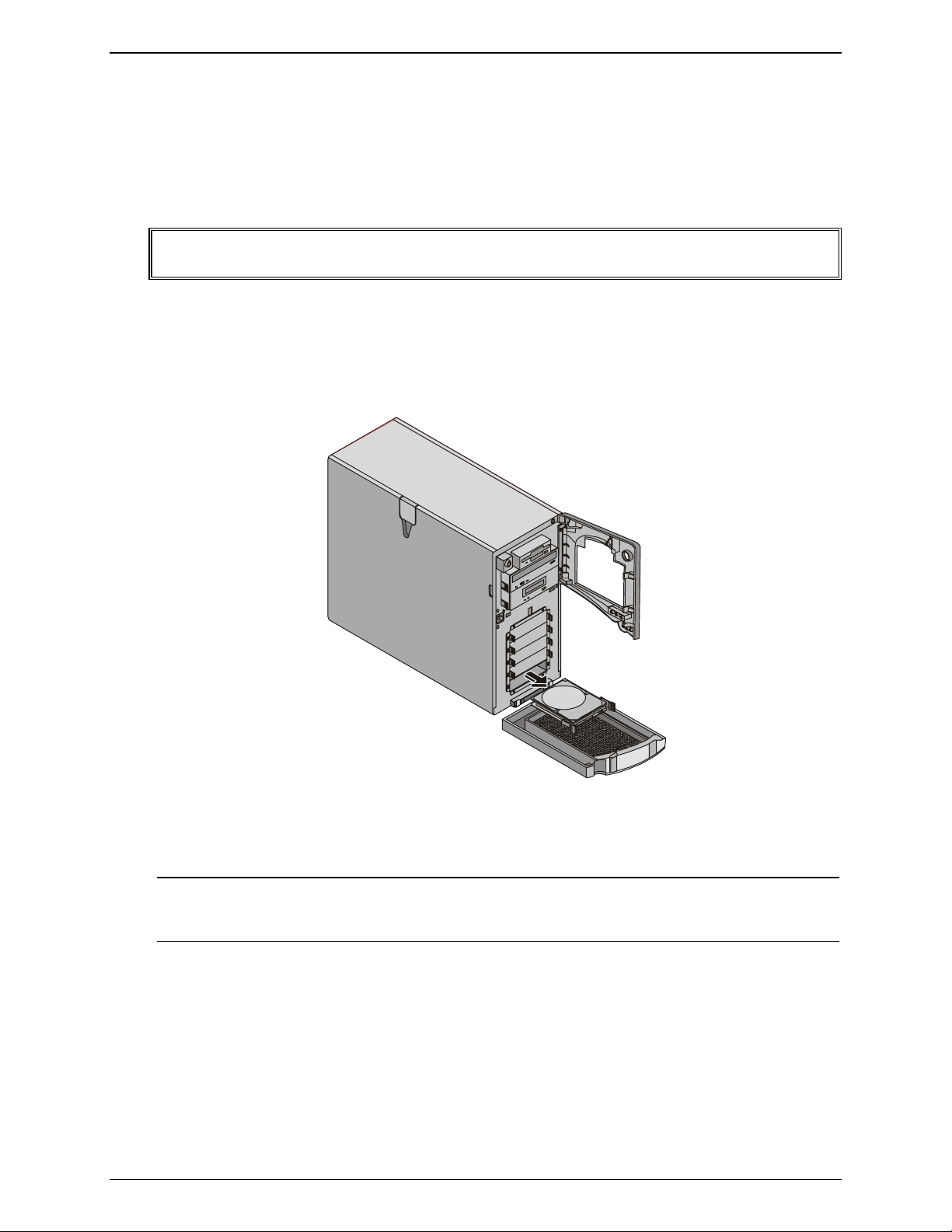

Figure 1-1. HP Server tc3100 with Cold Swap Hard Drives

Figure 1-2. HP Server tc3100 with Hot Swap Hard Drives

1

Page 8

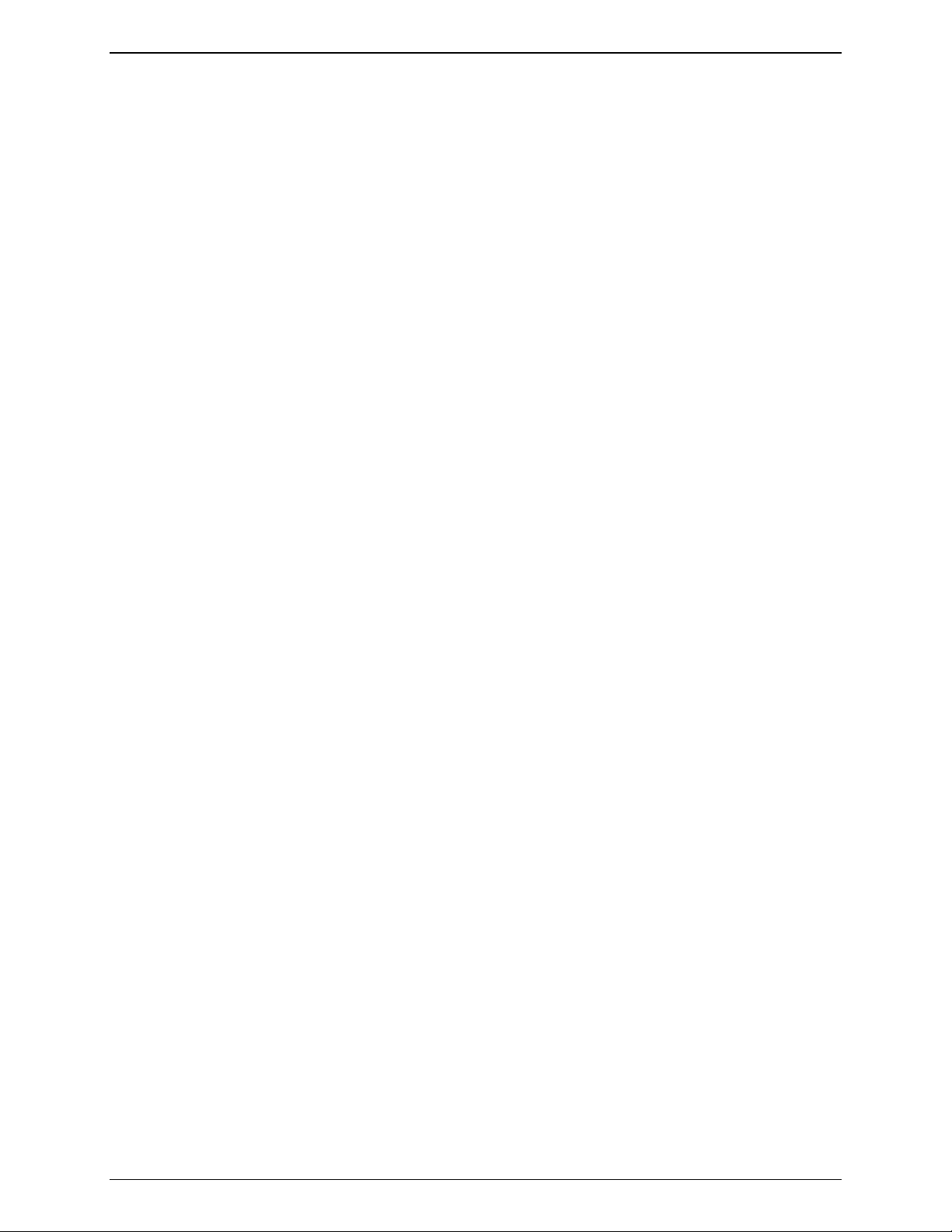

Table 1-1. Control Panel Switches and Indicators

Control/Indicator Description

Power On/Off/Sleep

Button

The power switch turns the HP server power On or Off. If sleep states are

available, it also transitions between Power On and sleep states.

Sleep states are NOS dependent and only available if your NOS supports power

management based on the ACPI (Advanced Configuration and Power Interface)

standard. Refer to "Applying Power to the HP Server" and "Sleep States

(ACPI)" later in this chapter.

Power LED

Disk Activity LED

· Steady green indicates the server is operating normally.

· Blinking green indicates the server is in a sleep state and under ACPI

control.

· Off (unlit) indicates the server is powered off or in standby mode.

· Blinking amber indicates SCSI disk drive activity.

· Off (unlit) indicates inactive operation.

LAN Activity LED

· Blinking green indicates LAN activity.

· Off (unlit) indicates inactive operation.

Controls and Indicators

Additional Controls and Indicators

Storage devices provide additional controls and indicators as shown in Figure 1-3. See Table 1-2 for backup

tape drive LED codes.

Figure 1-3. Control Panel Indicators

2

Page 9

Controls and Indicators

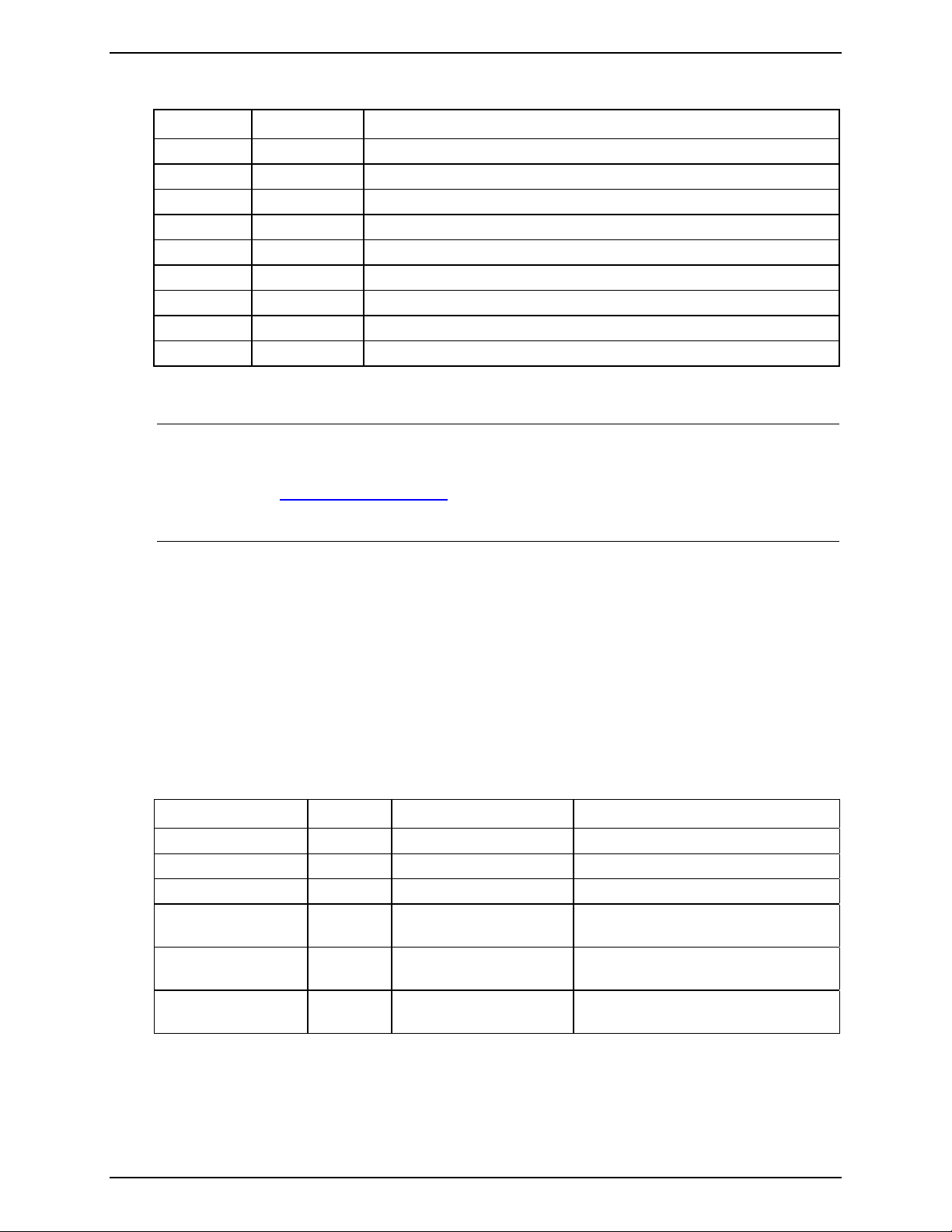

Table 1-2. Backup Tape Drive LED Codes

Left LED Right LED Definition

Off Off No Power

On Off Cartridge Loaded, but No activity

Flashing* Off Cartridge Loaded and Active

Pulsing** Off Loading/Unloading/Ejecting/Power-On

Off On Self Test Fail

Off Pulsing** No Cartridge, but Caution (cleaning required)

On Pulsing** Cartridge Loaded, but Caution (cleaning required)

Flashing* Pulsing** Cartridge Loaded, Drive Active, Caution (cleaning required)

Pulsing** Pulsing** Cartridge Loading/Unloading, Caution (cleaning required)

* Flashing at 4-Hz rate

** Pulsing at 2-Hz rate

NOTE For more information on the HP Tape Drive and its error codes, refer to the

documentation provided with the tape drive or refer to Hewlett-Packard's web site, at:

http://www.hp.com/

Refer to Chapter 3, "Installing and Configuring," for installation information.

Hot Swap Hard Drive Indicators

Each of the hot swap hard drives has two LED indicators:

· Status Indicator

This LED indicates the drive operating condition: normal, warning, or failure.

· Activity Indicator

This LED indicates the disk drive access activity. This LED indicator is controlled by the disk drive

directly. When a drive is accessed, the LED indicator shows a green light.

Table 1-3 and Table 1-4 describe the LED signals used to indicate the operation status of a disk drive.

Table 1-3. Hot Swap Hard Drive Operation Status Conditions

Condition LED Signaling Note

Drive access Activity

Drive fault Status

Drive predictive fault Status

Missing management

Status

Green (flashing)

Amber (solid)

Amber (flashing)

Amber (solid)

PCA or jumper cable

Drive/slot normal

Status

Green

(drive present)

Drive/slot normal

Status

OFF

(drive not present)

1. During disk drive spin-up or a hung-up situation, the activity LED may stay solid green for a long period.

Under HDD control.

For all HDD on SCSI bus A and/or B.

Pass through mode.

Pass through mode.

1

3

Page 10

Table 1-4. Hot Swap Hard Drive LED Indicators

Status LED Activity Status LED

· Off: Normal or unit not powered · Off: Normal

· Green (solid):

- Normal and under power

· - I/O activity

· Amber (flashing):

predictive failure

· Amber (solid): hard drive failure

· Green (flashing): I/O activity

· Green (solid for more than one minute): Disk spinning up

or "hung"

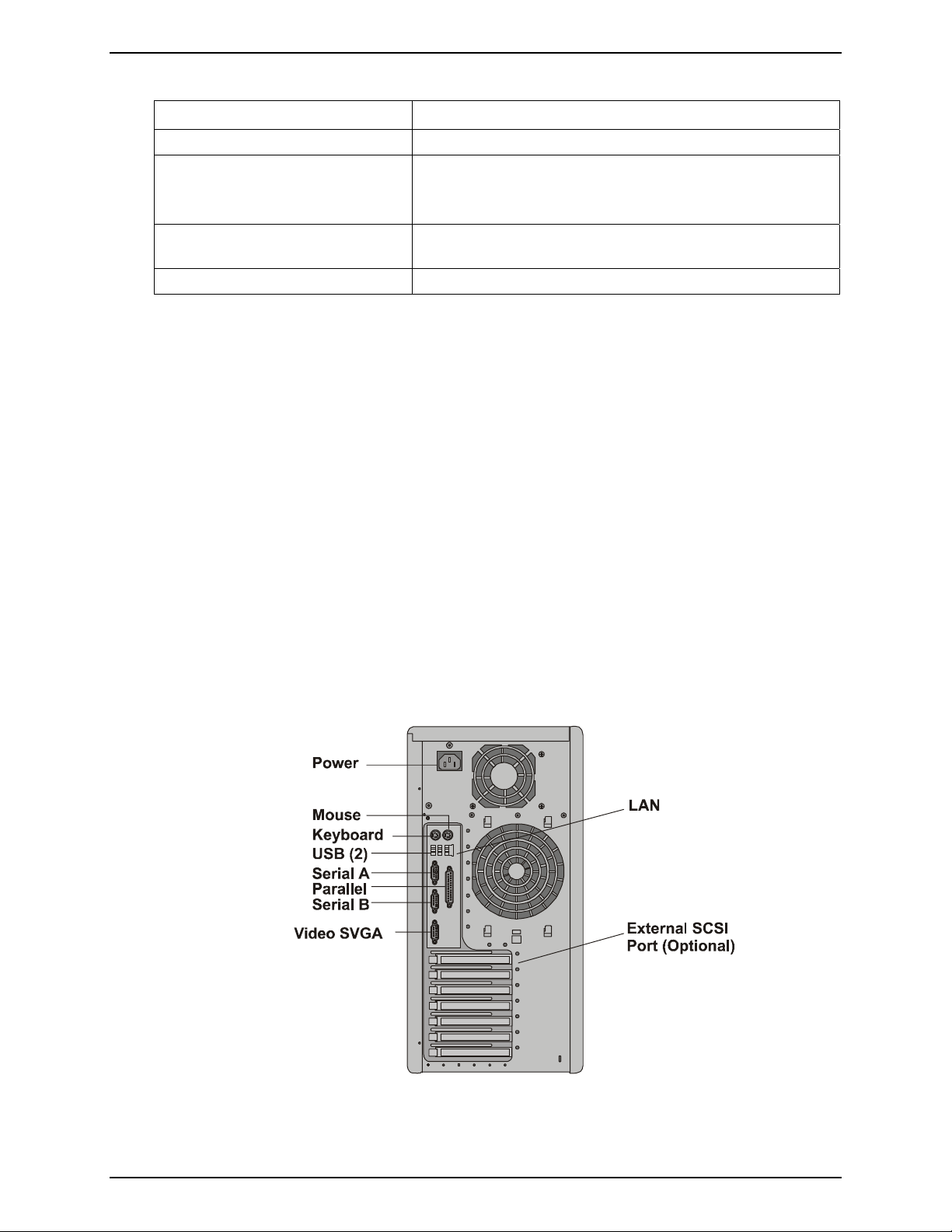

Rear Panel

The ports and connectors at the rear are listed below and shown in Figure 1-4.

· The power connector accepts a standard power cable to connect the HP Server with a UPS or the site

power source.

· The mouse port accepts a standard mouse with a PS/2 connector.

· The keyboard port accepts a standard keyboard with a PS/2 connector.

Controls and Indicators

· Two USB ports are provided for printers, scanners, and external modems.

· The LAN port is an embedded controller based on Intel's 82550 10/100 BaseT Fast Ethernet controller.

It has an RJ-45 LAN connector and two LEDs to indicate LAN speed and valid connection or activity.

Table 1-5 describes the LED indicators.

· The Serial Port A is a standard serial port.

· The Parallel Port is a standard parallel port, which supports Extended Capabilities Port (ECP)/Enhanced

Parallel Port (EPP).

· The Serial Port B is a standard serial port.

· The external SCSI port provides access to external SCSI devices, typically an external SCSI tape

backup device.

4

Figure 1-4. Rear Panel and Ports

Page 11

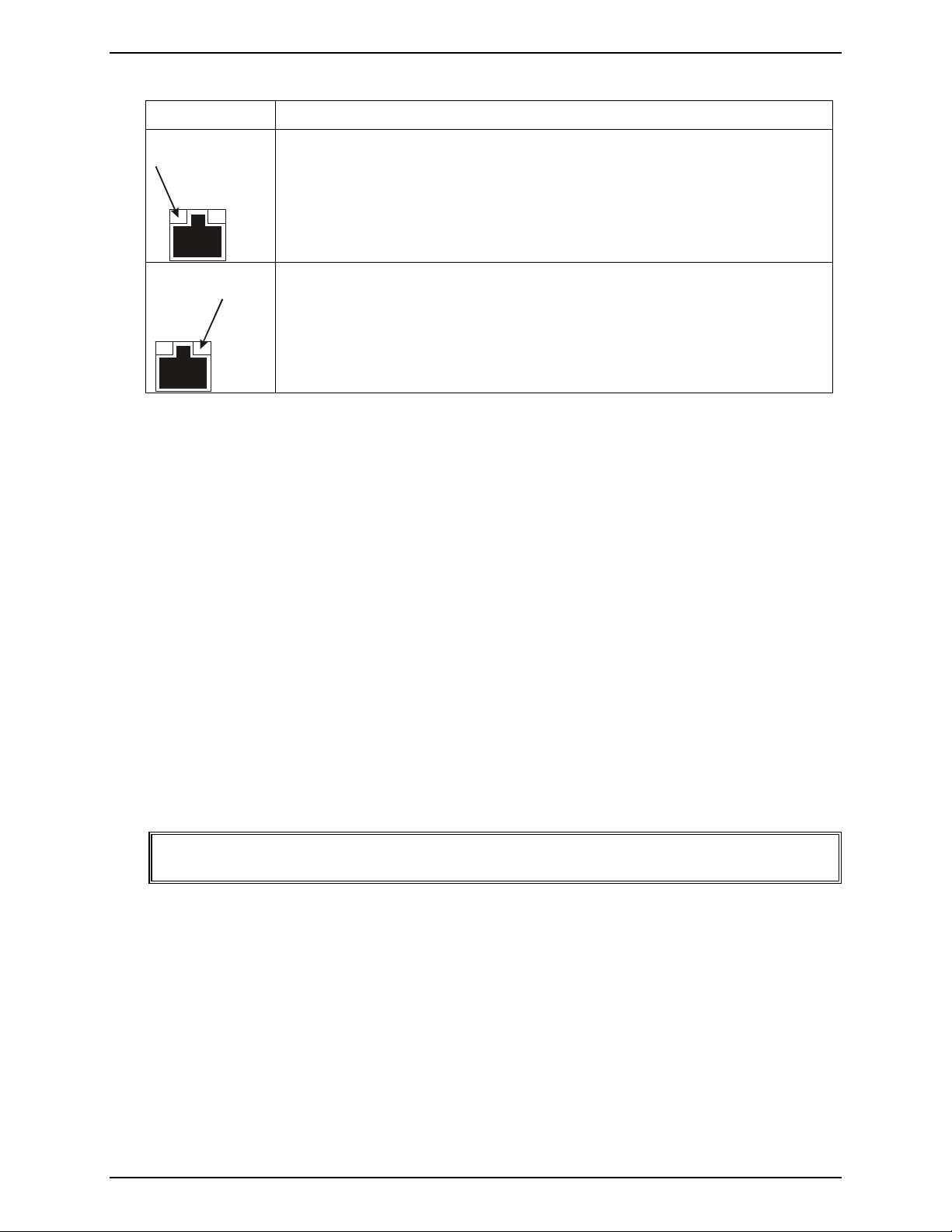

Table 1-5. LAN Port (RJ45) LED Indicators

Indicator Definition

Controls and Indicators

LAN Speed LED

Link LED

This LED is the LAN speed indicator.

· Steady amber indicates the LAN is operating at 100 Mbps LAN speed.

· Off indicates the LAN is operating at 10 Mbps LAN speed.

This LED is the activity/link indicator.

· Steady green indicates a valid LAN link.

· Flashing green indicates there is LAN activity.

Applying Power to the HP Server

Powering Up the Server

1. Turn on power to the monitor connected to the HP Server.

Turning on the monitor first ensures that video output auto-configures properly as the server boots up.

2. Press the power button on the front control panel. See Figure 1-1.

When you press the power button, the server powers up and loads the operating system. The system

runs a set of power-on self tests (POST) during this process. For details refer to Chapter 6,

"Troubleshooting."

Powering Down the Server

1. Log off all users and, if necessary, back up files.

o Schedule the power down for a time when the server being down will affect the fewest users.

o If you will be performing a hardware or software upgrade, ensure the server's data has been backed

up.

o Follow instructions in your network operating system (NOS) documentation to shut down all

networking software and applications.

WARNING The power supply will continue to provide standby current to the HP Server until the

power cable is disconnected from the rear panel.

2. Press the power button on the HP Server's control panel when prompted by the operating system.

Normally this completes the power-down procedure.

5

Page 12

Controls and Indicators

Connecting Power to Multiple-Server Configurations

The HP Server temporarily draws a large "inrush current" when first connected to an AC power source. The

inrush current is much greater than the server's normal operating current and generally, the AC power source

can handle the normal inrush current.

However, if you install several HP Servers on one circuit, precautions are necessary. If there is a power

failure and power is then restored, all the servers immediately begin to draw inrush current at the same time.

If the circuit breakers on the incoming power line have insufficient capability, the breaker may trip and thus

prevent the servers from powering up.

When preparing your site for installation, allow for the additional inrush current. Refer to "Power Supply

Requirements" in Chapter 9, "Specifications."

Sleep States (ACPI)

The HP Server supports the ACPI (Advanced Configuration and Power Interface) standard, which is a key

component of a NOS's directed power management. The supported features are only available when an

ACPI-compliant NOS is installed on the HP Server. The term "sleep state" refers to any of several reduced

power consumption states in which normal NOS activity has ceased.

The HP Server supports several sleep states. One of these is "standby" or "suspend" sleep state, which has a

short wake-up time. In this sleep state, the server appears to be off – the monitor appears blank and there is no

CD-ROM or SCSI hard drive activity, however, the front panel power LED flashes slowly and the fans

continue to operate.

The HP Server has another sleep state with a slower wake-up time, sometimes referred to as "hibernate" by

various operating systems. In this sleep state, the server appears to be off as described earlier, but the fans and

the front panel power LED are also turned off. The unique feature of this sleep state (and the reason for its

slower wake-up time) is that information about the server's NOS state (open applications, screens, and so on)

is saved to disk before the server is placed in the sleep state. Upon wake-up, this information must be restored

from the disk. This method of restoring the server's operation is much faster than a complete rebooting of the

server. It still requires running all the start-up self-tests before starting the NOS, but loading the NOS and all

the previously opened applications is much faster.

The HP Server supports certain types of system activity, which is used as wake-up events from these sleep

states. These wake-up events can be generated from the power button, LAN activity, and scheduled events.

NOTE The HP Server’s power management policies (transitions between various power states)

and the user options are specific to the particular ACPI-compliant NOS installed on the

server. If your NOS is ACPI-compliant, refer to the power management features in the

instructions provided for more information.

The HP Server’s power button can be configured to initiate a graceful shutdown of the NOS rather than an

immediate shutdown of the power supply. The power button configurations are dependent on the user

interface provided by the ACPI-compliant NOS. While power management is under the control of the ACPIcompliant NOS, the HP Server’s power button is capable of an override in case of a non-responsive NOS.

NOTE The HP Server power button will force a power-down without waiting for the NOS to

gracefully shut down the server, if the power button is pressed and held more than four

seconds.

6

CAUTION If the power button override is used, there is a strong possibility that data will be

corrupted or lost.

Page 13

2 External Connectors

Unless otherwise noted, the following features apply to all models. Some features are factory installed; others

are optional.

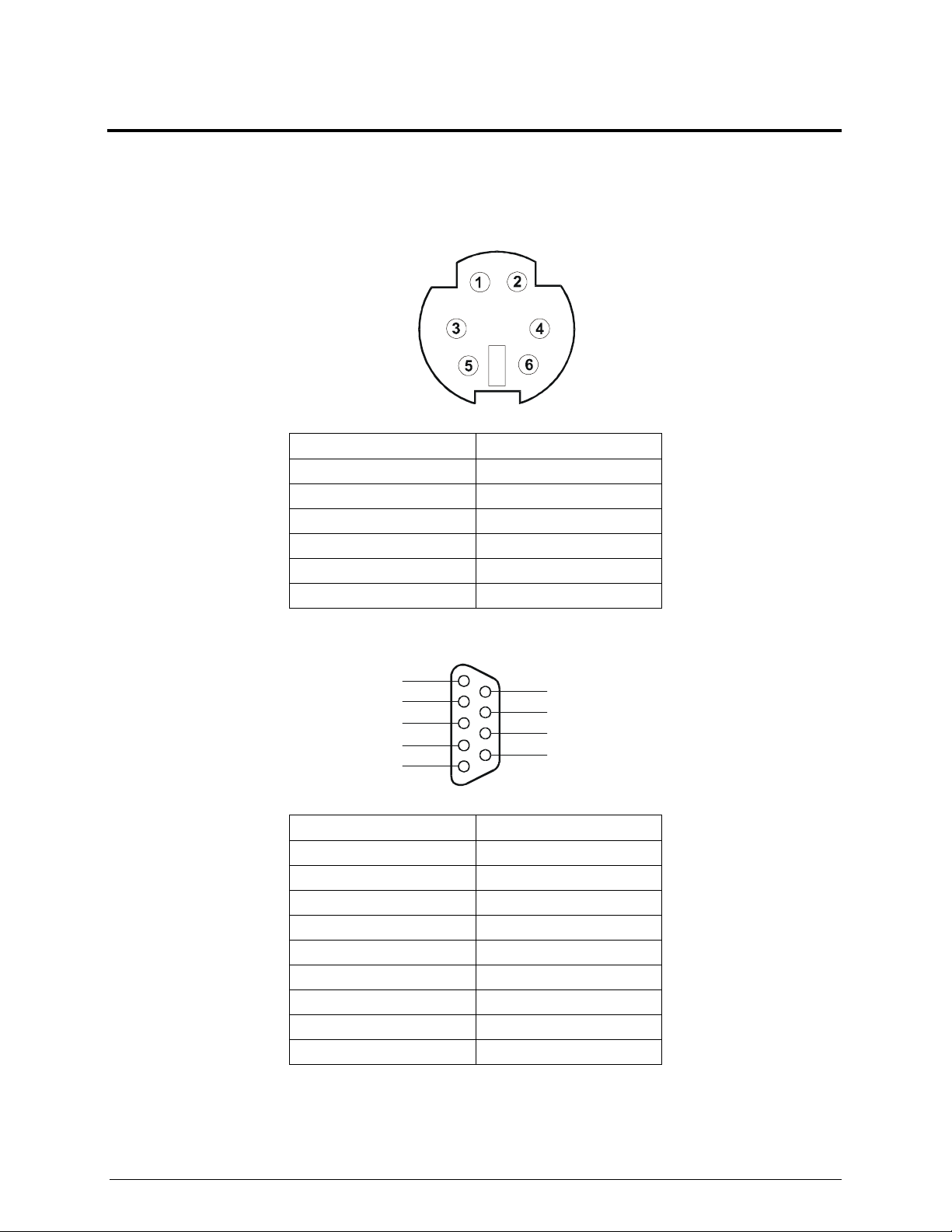

Mini-DIN (PS/2) for Mouse and Keyboard

Pin Number Signal Description

1 Data signal

2 Not used

3 Ground

4 Power (+5 V dc)

5 Clock signal

6 Not used

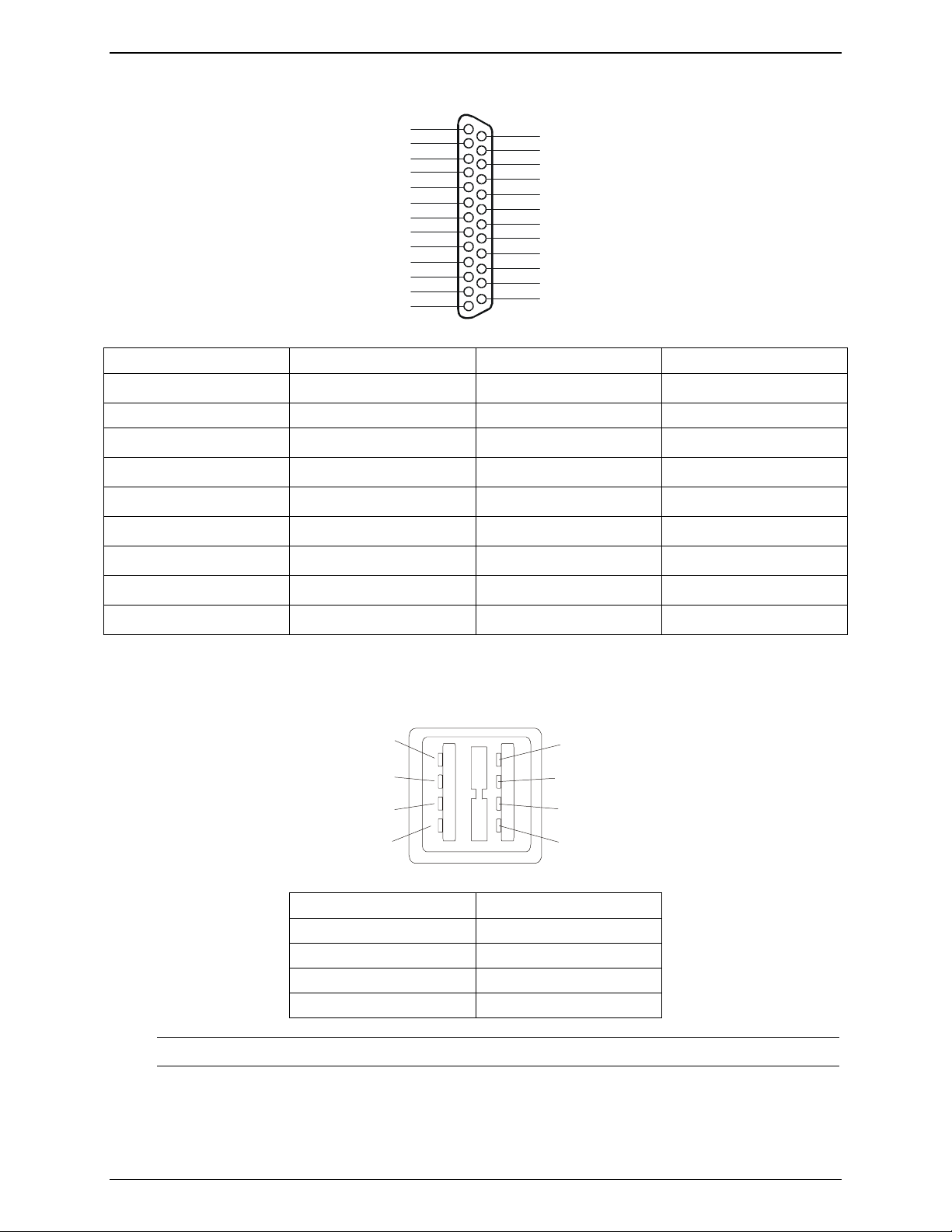

Serial Port

5

4

3

2

1

Pin Number Signal Description

1 Data carrier detect

2 Receive data

3 Transmit data

4 Data term ready

5 Signal ground

6 Data set ready

7 Request to send

8 Clear to send

9 Ring indicator

9

8

7

6

7

Page 14

Chapter 2 External Connectors

Parallel Port

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Pin Number Signal Description Pin Number Signal Description

1 Strobe5 10

Acknowledgeb

2 Data bit 06 11 Busy

3

4

5

6

7

8

9

a. All data bits are sent to a printer in an 8-bit parallel format.

b. The signal is active low.

Data bit 1a

Data bit 2a

Data bit 3a

Data bit 4a

Data bit 5a

Data bit 6a

Data bit 7a

12 Paper end

13 Select

14

Auto line feedb

15 Error1

16

17

Initialize printerb

Select inb

18-25 Signal ground

USB

1

2

3

4

1

2

3

4

Pin Number Signal Description

1 VBUS

2 D+

3 D-

4 GND

NOTE Use of the USB port is supported for printers, scanners, and external modems.

8

Page 15

Chapter 2 External Connectors

Standard Video

The built-in video uses the standard 15-pin analog display pinout configuration. The pinouts for your monitor

may vary. For the pinouts for your monitor, refer to the manual provided with your monitor.

6

1

7

2

8

3

9

4

10

5

Pin Function Pin Function Pin Function

1 Red 6 Red return (ground) 11 Monitor ID bit 0

2 Green 7 Green return (ground) 12 Monitor ID bit 1

3 Blue 8 Blue return (ground) 13 Horizontal sync (+)

4 Monitor ID bit 2 9 Key (no pin) 14 Vertical sync (-)

5 Monitor self test (ground) 10 Sync return (ground) 15 Not used

11

12

13

14

15

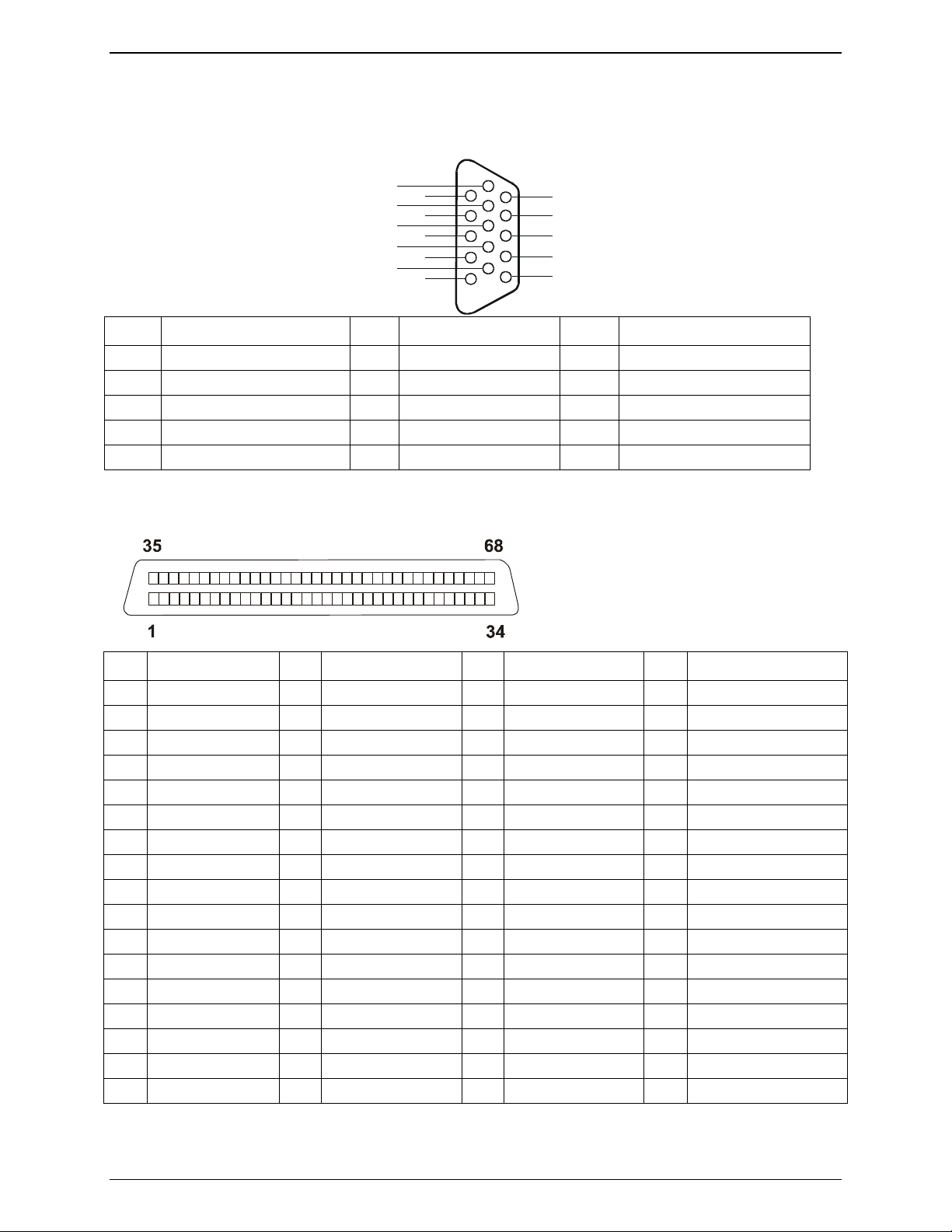

Standard SCSI

Pin Signal Pin Signal Pin Signal Pin Signal

1 S1 (+DB 12) 18 S18 (TERMPWR) 35 S35 (-DB 12) 52 S52 (TERMPWR)

2 S2 (-DB 13) 19 S19 (RESERVED) 36 S36 (-DB 13) 53 S53 (RESERVED)

3 S3 (+DB 14) 20 S20 37 S37 (-DB 14) 54 S54

4 S4 (+DB 15) 21 S21 (+ATN) 38 S38 (-DB 15) 55 S55 (-ATN)

5 S5 (+DB P1) 22 S22 39 S39 (-DB P1) 56 S56

6 S6 (+DB 0) 23 S23 (+BSY) 40 S40 (-DB 0) 57 S57 (-BSY)

7 S7 (+DB 1) 24 S24 (+ACK) 41 S41 (-DB 1) 58 S58 (-ACK)

8 S8 (+DB 2) 25 S25 (+RST) 42 S42 (-DB 2) 59 S59 (-RST)

9 S9 (DB 3) 26 S26 (+MSG) 43 S43 (-DB 3) 60 S60 (-MSG)

10 S10 (+DB 4) 27 S27 (+SEL) 44 S44 (-DB 4) 61 S61 (-SEL)

11 S11 (+DB 5) 28 S28 (+C/D) 45 S45 (-DB 5) 62 S62 (-C/D)

12 S12 (+DB 6) 29 S29 (+REQ) 46 S46 (-DB 6) 63 S63 (-REQ)

13 S13 (+DB 7) 30 S30 (+I/O) 47 S47 (-DB 7) 64 S64 (-I/O)

14 S14 (+DB P) 31 S31 (+DB 8) 48 S48 (-DB P) 65 S65 (-DB 8)

15 S15 32 S32 (+DB 9) 49 S49 66 S66 (-DB 9)

16 S16 (DIFFSENS) 33 S33 (DB 10) 50 S50 67 S67 (-DB 10)

17 S17 (TERMPWR) 34 S34 (DB 11) 51 S51 (TERMPWR) 68 S68 (-DB 11)

9

Page 16

Chapter 2 External Connectors

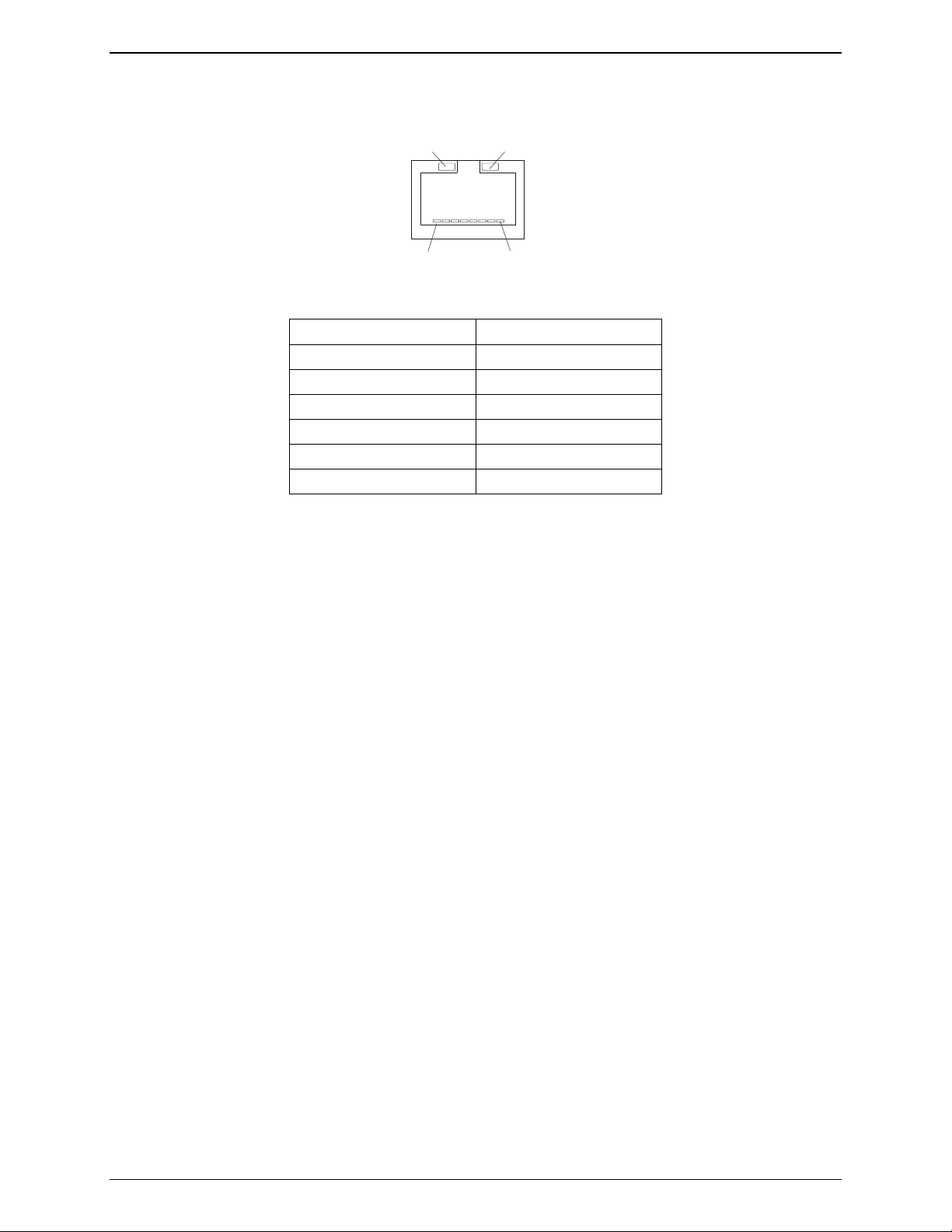

Standard LAN

GRN LED YEL LED

81

Pin Number Signal Description

1 Data signal

2 Not used

3 Ground

4 Power (+5 V dc)

5 Clock signal

6-8 Not used

10

Page 17

3 Installing and Configuring

Opening and Closing the HP Server tc3100

This section describes how to open and close the front bezel, lower bezel, and side panel of the HP Server

tc3100.

WARNING Before opening the server, always disconnect the power cord and unplug cables.

Disconnect the power cord to avoid exposure to high energy levels that may cause burns

when parts are short-circuited by metal objects such as tools or jewelry. Disconnect

telephone cables to avoid exposure to shock hazard from telephone ringing voltages.

Wear a wrist strap and use a static-dissipating work surface connected to the chassis

when handling components. Ensure the metal of the wrist strap contacts your skin.

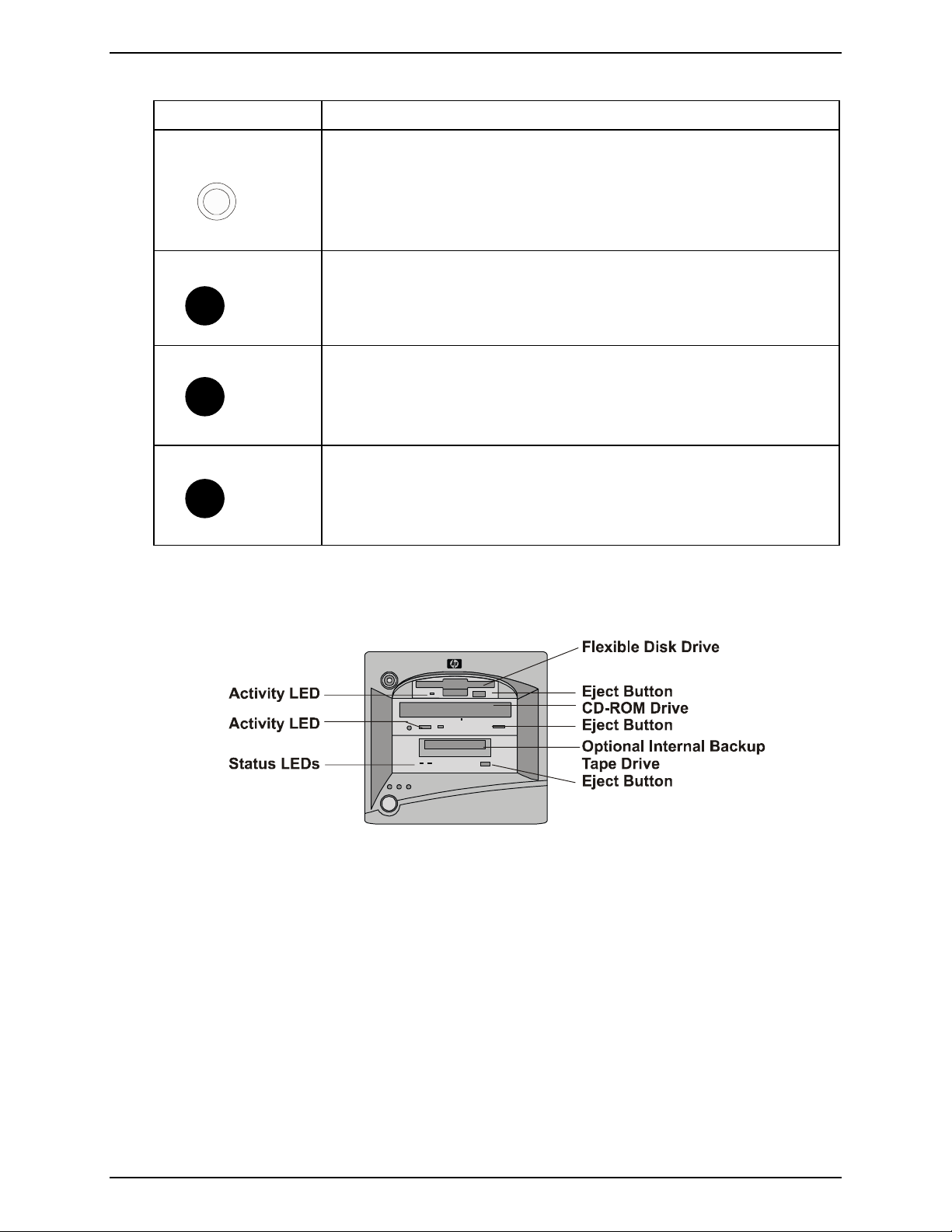

Figure 3-1 shows the HP Server tc3100 with SCSI cold swap hard drives. The tc3100 is also available with

SCSI hot swap hard drives.

· The key lock, power button, and system and LAN status indicators are located within the front upper

bezel. See Figure 3-2.

· The SCSI hard drives are accessible from the front lower bezel. See Figure 3-3.

· The system board modules, power supply, fan assembly, and PCI cards are accessible from the side

panel. See Figure 3-4.

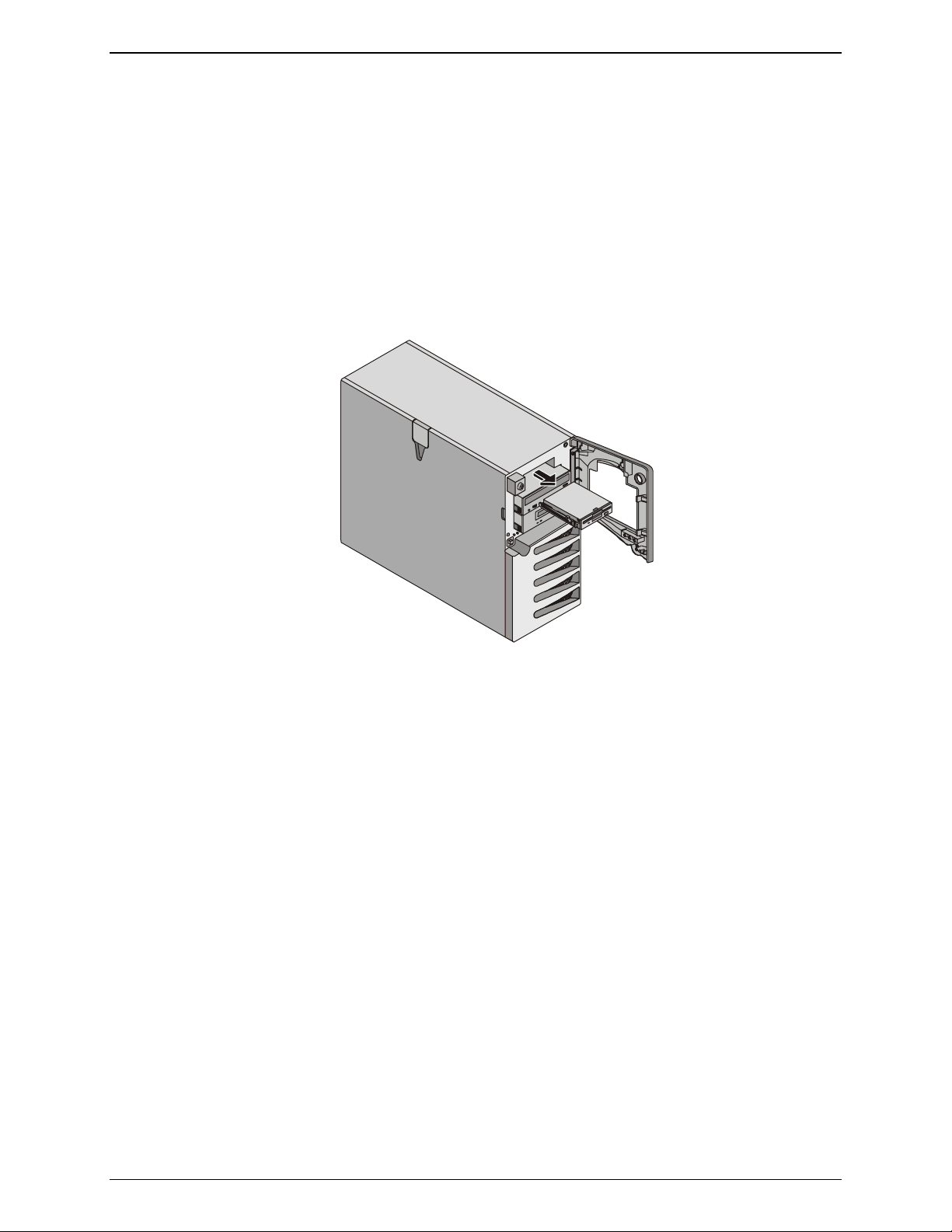

Figure 3-1. HP Server tc3100 Enclosure

11

Page 18

Chapter 3 Installing and Configuring

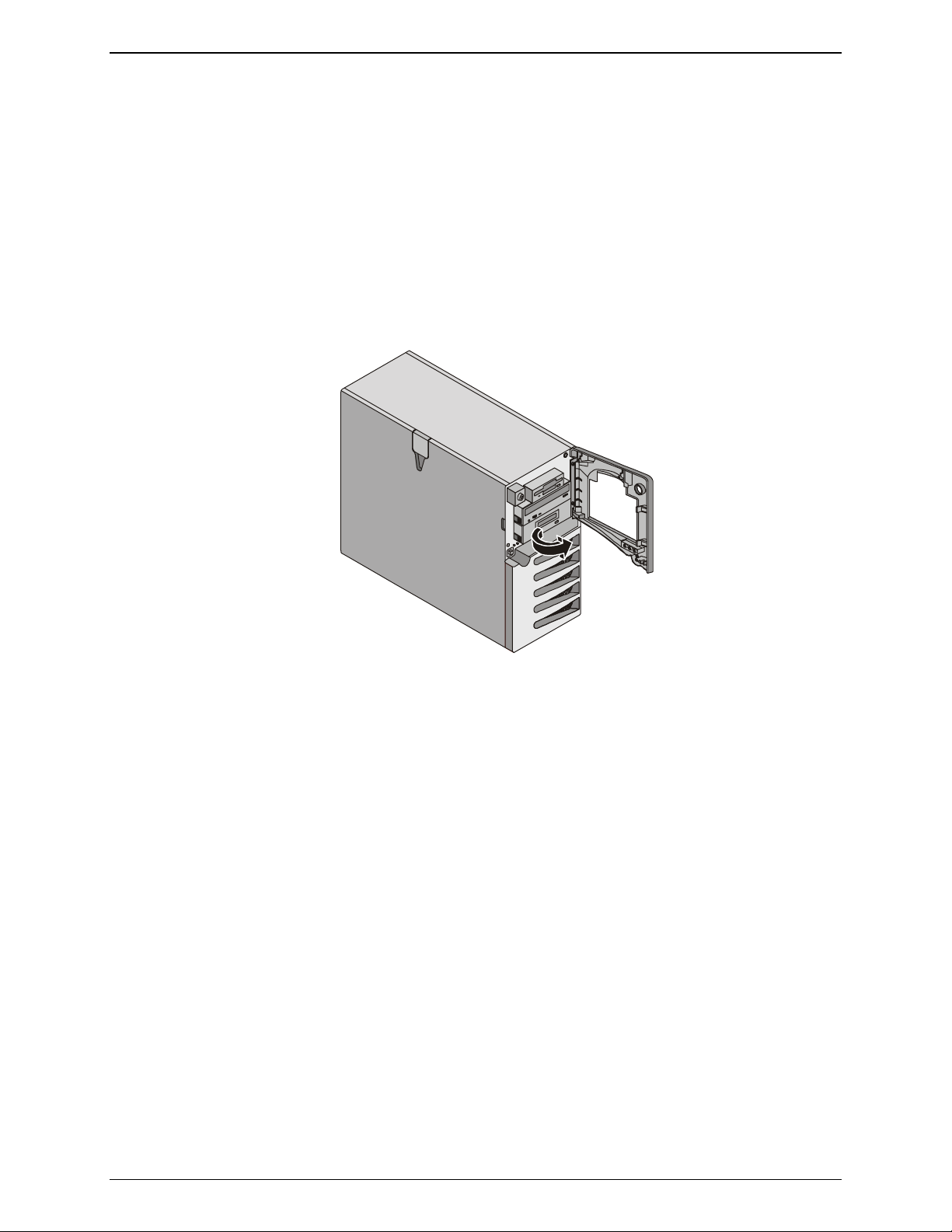

Opening the Upper Bezel

You need to open the upper bezel to remove and replace the flexible disk drive and CD-ROM, or add a tape

device.

· If you are installing or removing SCSI cold swap hard drives, you must open the upper bezel to open the

lower bezel.

· If you are installing hardware options, you need only unlock the front bezel; the bezel does not have to

be open. The hardware options include accessory boards, DIMMs, and an additional processor, which

are accessed through the side panel.

1. Power off the server and disconnect all power cords and any telecommunications cables.

2. Unlock the upper bezel.

3. Hold the bezel at the notch on the side panel and swing the bezel open to the right. See Figure 3-2.

Figure 3-2. Upper Bezel (Open)

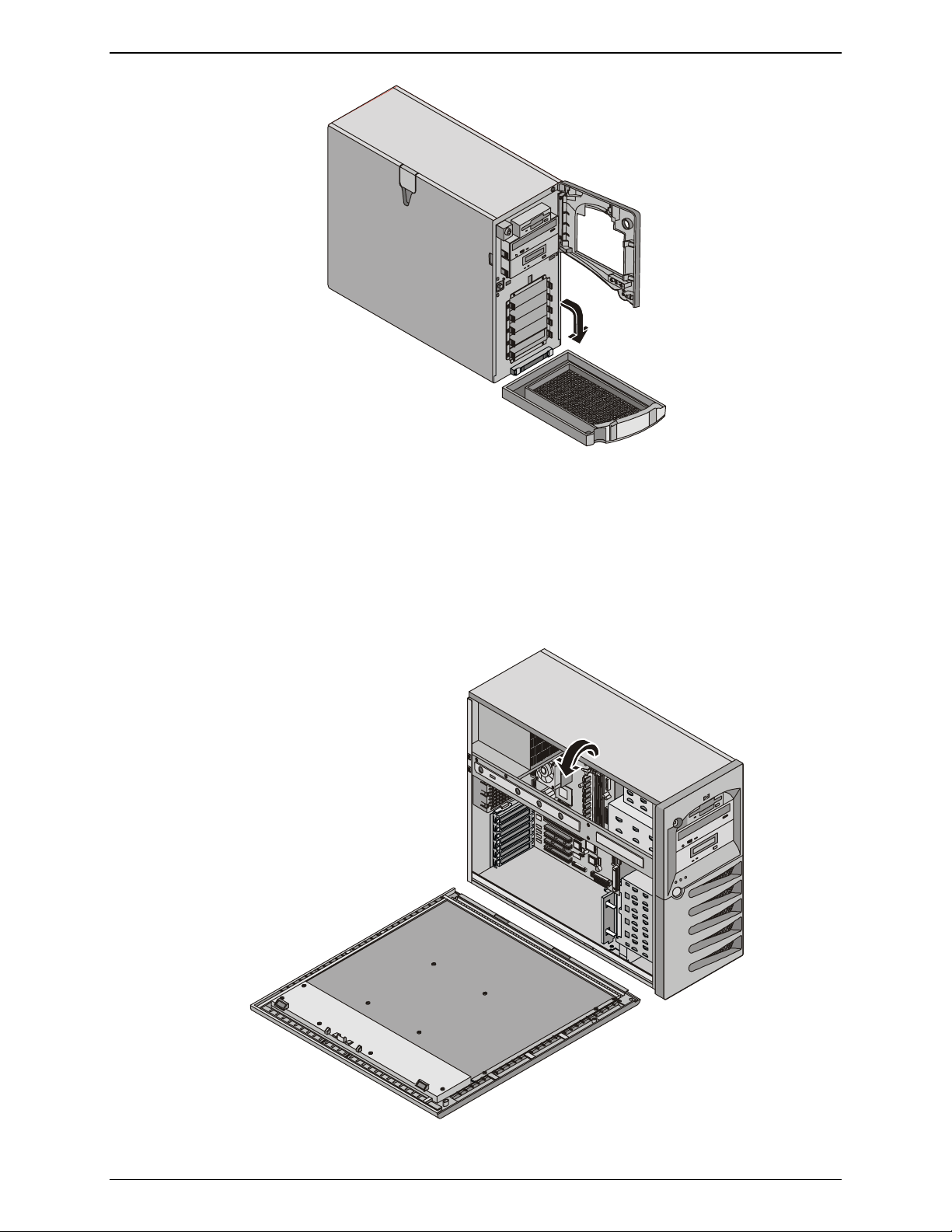

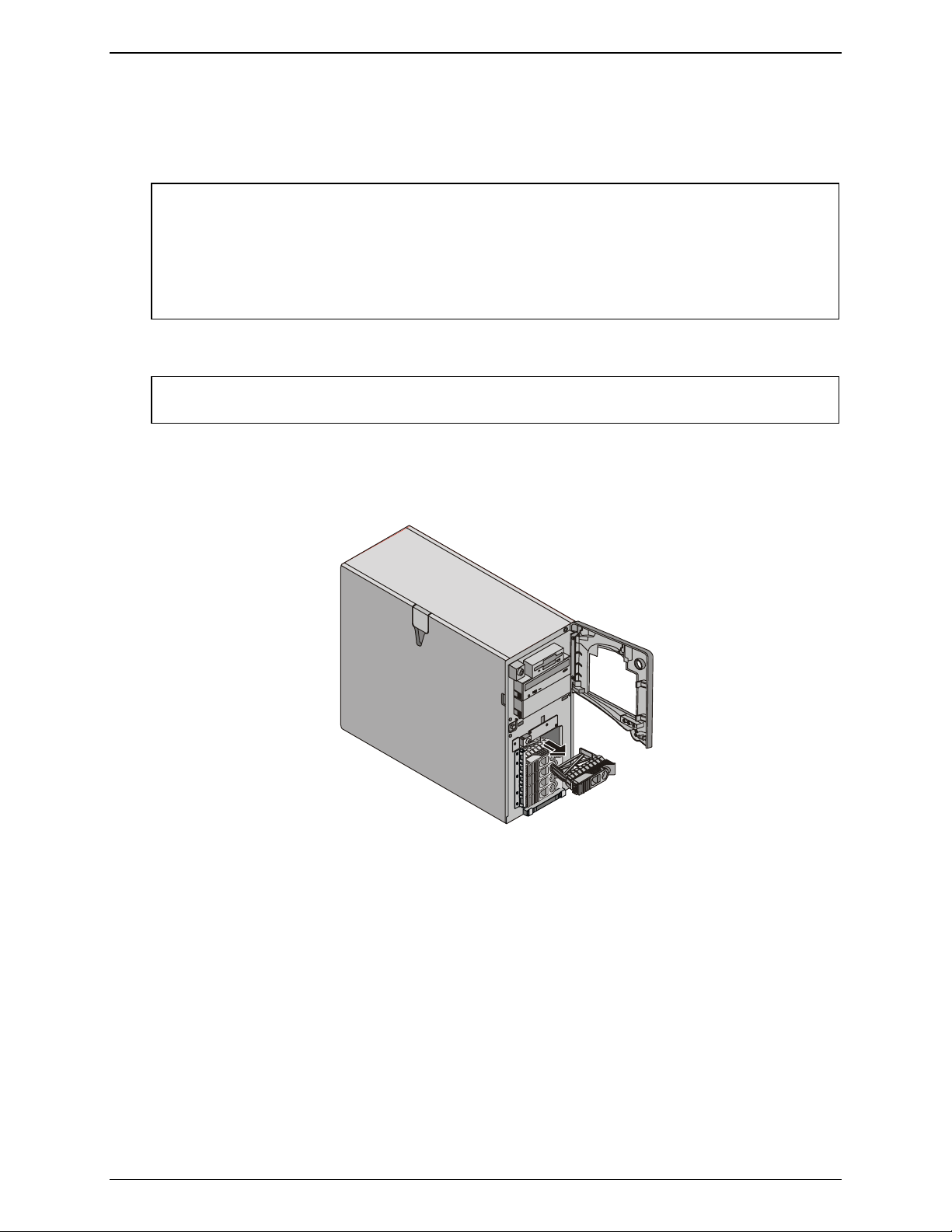

Opening the Lower Bezel (Cold Swap Model)

The only reason to open the lower bezel is to access the SCSI cold swap hard drives.

1. Power off the server and disconnect all power cords and any telecommunications cables.

2. Open the upper bezel.

3. Press down on the two tabs at the top of the lower bezel, pull the bezel toward you, and lower the door.

See Figure 3-3.

12

Page 19

Chapter 3 Installing and Configuring

Figure 3-3. Lower Bezel (Open)

Opening the Side Panel

The power supply and fan can be installed and removed through the side panel. The user can also access the

CPU system board, memory DIMMs, and all SCSI and IDE power cords.

1. Power off the server and disconnect all power cords and any telecommunications cables.

2. Unlock the upper bezel.

3. Lift the latch and open the panel. See Figure 3-4.

Figure 3-4. Side Panel (Open)

13

Page 20

Chapter 3 Installing and Configuring

4. To remove the panel, raise the panel up and out of its track.

Mass Storage

The HP Server tc3100 comes standard with an IDE CD-ROM and a flexible disk drive with some

configuration of SCSI hard disk drives and an optional SCSI tape backup drive. The internal mass storage can

hold up to five SCSI hard drives with cabling provided.

This section describes how to install the internal mass storage devices, including the internal SCSI hot swap

hard drives and the optional tape backup (DAT) drive.

Guidelines

· General Guidelines

o Use care when unpacking and handling the disk drives.

The hard disk drives are very susceptible to mechanical shock and can be easily damaged by a drop

as short as one-quarter of an inch. If the drop would crack an egg, it will damage the drive.

o Do not stack drives.

o Do not use high voltage differential (HVD) SCSI devices on any of the SCSI channels or damage

will occur. Use only Single-Ended (SE) or Low-Voltage Differential (LVD) devices.

o The server is internally limited to 5 hard disk drives.

The flexible disk drive and CD-ROM drive, which are standard on all models of the HP Server

tc3100, occupy shelves 8 and 7 respectively. See Figure 3-5 and Figure 3-6.

o If a backup tape drive is used, it occupies shelf 6, leaving five 3.5-inch devices available for shelves

1-5, and at least one is required for the boot drive.

· IDE Devices

o The embedded IDE controller is an Enhanced-IDE single channel controller. Refer to "System Board

Layout" in Chapter 9, "Specifications."

o The IDE CD-ROM uses only one connector on the cable from the IDE channel (IDE2) connector.

· SCSI Device Selection

o Ensure the SCSI devices you install in both non-hot swap and hot swap-drive bays do not have

terminations installed. The non-hot swap SCSI drives are connected to a terminated cable and the hot

swap cage provides the termination for any unused slots in the cage.

o Use only HP LVD SCSI 3.5 inch hard disk drives for the cold swap and hot swap drive cages.

The HP cold swap and hot swap drives come set for LVD SCSI operation and without device ID or

termination. Do not change these settings.

o Use the supported 5.25 inch SCSI devices for the common tray (5.25") shelves.

The available space in the 5.25" common tray shelves supports two half-height (1.6 inch) devices.

You can order HP mounting kits for removable media devices. You may use narrow/wide SCSI

adapters on these devices.

o The embedded dual-channel Ultra-3 SCSI controller includes connectors for SCSI channels A

and B.

14

o Channel A can be used for internal tape backup or to connect to external mass storage devices or to

external backup tape devices. Channel A is connected to the optional internal tape drive.

An additional cable kit is required for external mass storage devices or connecting the optional tape

backup drive. Refer to the appropriate topic later in this chapter.

o Channel B typically is used for cabling the factory installed hard disk drives, which may consists of

five SCSI drives (including an optional tape drive). The standard SCSI cable has five 68-pin, highdensity connectors for the SCSI devices and has a terminator on the end of the cable.

Page 21

Chapter 3 Installing and Configuring

o The optional HP supplied tape drive comes with a 50-to-68-pin adapter to connect to the SCSI

connector on the cable used to connect the tape drive.

· SCSI Drive Addressing

o The drives in the cold swap and hot swap cage are automatically assigned SCSI addresses by the HP

Server.

o The non-hot swap SCSI devices use SCSI IDs from 0 through 15, with the following restrictions:

Ø Narrow SCSI devices must be addressed 0 through 6.

Ø Wide SCSI devices may be addressed 0 through 15, except for ID 7, which is held by the SCSI

controller.

The non-hot swap SCSI devices are all connected to the same cable, which is terminated and

connected to one SCSI controller. Each SCSI device connected to the non-hot swap device

connector must have a unique address.

o The cold swap SCSI back plane is hard wired for SCSI 01238 from bay 1 (bottom) to bay 5

(uppermost cold swap drive bay).

· SCSI Device Installation Order

NOTE The boot drive must be in the bottom slot.

o Add cold swap hard drives starting from the bottom drive cage in the HP Server tc3100.

o Add hot swap hard drives starting from the bottom of the drive cage in the HP Server tc3100.

If you are using one or more filler panels, insert them at the top of the cage. These configurations

may use filler panels to close up the front of the cold swap or hot swap mass storage cage. If there

are gaps in the cage, the drives may not receive the proper ventilation and could suffer thermal

damage.

· Filler Panels

o Ensure all empty slots in the cold swap or hot swap drive cage have filler panels inserted to ensure

proper airflow.

If there are fewer drives than the hot swap drive cage supports, a 1-inch filler panel must be inserted

in each empty disk location. The filler panels ensure the drive cage has the proper ventilation and

airflow.

Boot Priority

This section details the HP Server's boot order by highest to lowest priority. The embedded SCSI controller

consists of two channels, A and B. Channel A typically is used to control the external SCSI devices. Channel

B typically is used to control the SCSI hard drives (5) and optional tape back-up drive. On each SCSI

channel, the controller scans for a boot device starting at device ID 0 and works through the ID numbers. The

server's embedded controller is always SCSI ID 7. If an optional SCSI backup tape drive is used it takes

address ID 4.

The server's boot order should be considered when selecting a boot device. This is especially important if you

are installing a board that requires a higher priority in the boot order. The board's boot priority is set by its

slot location in the boot order.

By default the server searches for boot devices in this order:

1. IDE CD-ROM drive

2. Flexible disk drive

3. Embedded SCSI A channel (external SCSI Drives)

4. Embedded SCSI B channel (SCSI Devices)

5. PCI slot 6

15

Page 22

Chapter 3 Installing and Configuring

6. PCI slot 5

7. PCI slot 4

8. PCI slot 3

9. PCI slot 2

10. PCI slot 1

11. Embedded LAN

For information about booting off of a hard disk connected to an accessory board, see "Installing a Disk

Array Controller Board" later in this chapter.

NOTE The boot order can be changed using the server's (BIOS) Setup Utility and the SCSI

Select Utility. See “BIOS Setup Utility” later in this chapter.

Installed Mass Storage Devices

Table 3-1 lists the number and types of mass storage devices that may be installed in the HP Server tc3100.

Table 3-1. Mass Storage Device Types

Interface Types

Flexible disk drive 1 Factory installed flexible disk

Max Number

of Devices Installed Devices and Addresses

IDE-2 1 Factory installed CD-ROM drive (IDE connector)

Ultra SCSI Adapter 1*

(optional)

Ultra-3 SCSI

up to 15 ** Control of up to 15 external SCSI devices or internal backup

Channel A

Ultra-3 SCSI

up to 5** Up to 5 SCSI hard disk drives (addresses = ID 0, 1, 2, 3, 8)

Channel B

* A 50-to-68-pin SCSI adapter is provided with the HP tape drive.

** Both SCSI channels (A and B) can each support up to 15 devices; however, there are only enough internal storage shelves for five

hard drives and one optional tape backup device. Channel A is used to control external SCSI devices or internal backup tape.

Installing Hard Disk Drives

WARNING Always wear a wrist strap and use a static-dissipating work surface connected to the

chassis when handling components. Ensure the metal of the wrist strap contacts your

skin.

The flexible disk, CD-ROM, and optional disk do not have protective shields; they are

ESD sensitive. Caution must be taken when removing them to avoid electrical shock.

Install and remove connectors carefully, and avoid displacing any of the pins.

Optional SCSI Tape Backup Drive (address = ID 4)

tape.

Embedded SCSI controller (address = ID 7)

16

Page 23

Chapter 3 Installing and Configuring

Flexible Disk Drive

Use the following steps to install a flexible disk drive (FDD):

1. If the server is operating, log off all users, back up files, and power down the server.

2. Disconnect the power cord and any external cables connected to the server. If necessary, label each one

to expedite re-assembly.

3. Open the upper bezel and side panel.

4. Press the two latches of the drive inward and slide the drive out far enough to expose the connectors.

5. Disconnect the power and signal cable connectors.

6. Hold the disk by its sides and gently slide the disk from the chassis. See Figure 3-5.

Figure 3-5. Removing Flexible Disk Drive

7. Connect the power and signal cable to the new drive.

8. Gently slide the drive into the available opening until the eject mechanism clicks.

Watch the cable inside the side panel so it does not get pinched.

9. Close the upper bezel and side panel, and replace the external cables and power cord.

10. Power up the server and return it to normal operation.

CD-Rom or Optional Tape Disk Drive

Use the following steps to install a CD-ROM or optional tape disk drive:

1. If the server is operating, log off all users, back up files, and power down the server.

2. Disconnect the power cord and any external cables connected to the server. If necessary, label each one

to expedite re-assembly.

3. Open the upper bezel and side panel.

4. Disconnect the power and signal cable connector from inside the side panel.

5. Press the two latches of the drive inward and, holding the disk by its sides, gently slide the drive from

the chassis. See Figure 3-6.

17

Page 24

Chapter 3 Installing and Configuring

Figure 3-6. Removing a Hard Disk Drive

6. Gently slide the new drive into the available opening until the eject mechanism clicks.

7. Connect the power and signal cable to the new drive.

8. Close the upper bezel and side panel, and replace the external cables and power cord.

9. Power up the server and return it to normal operation.

NOTE If you will not be replacing the drive, replace the disk with a filler panel to ensure the

integrity of the cooling system.

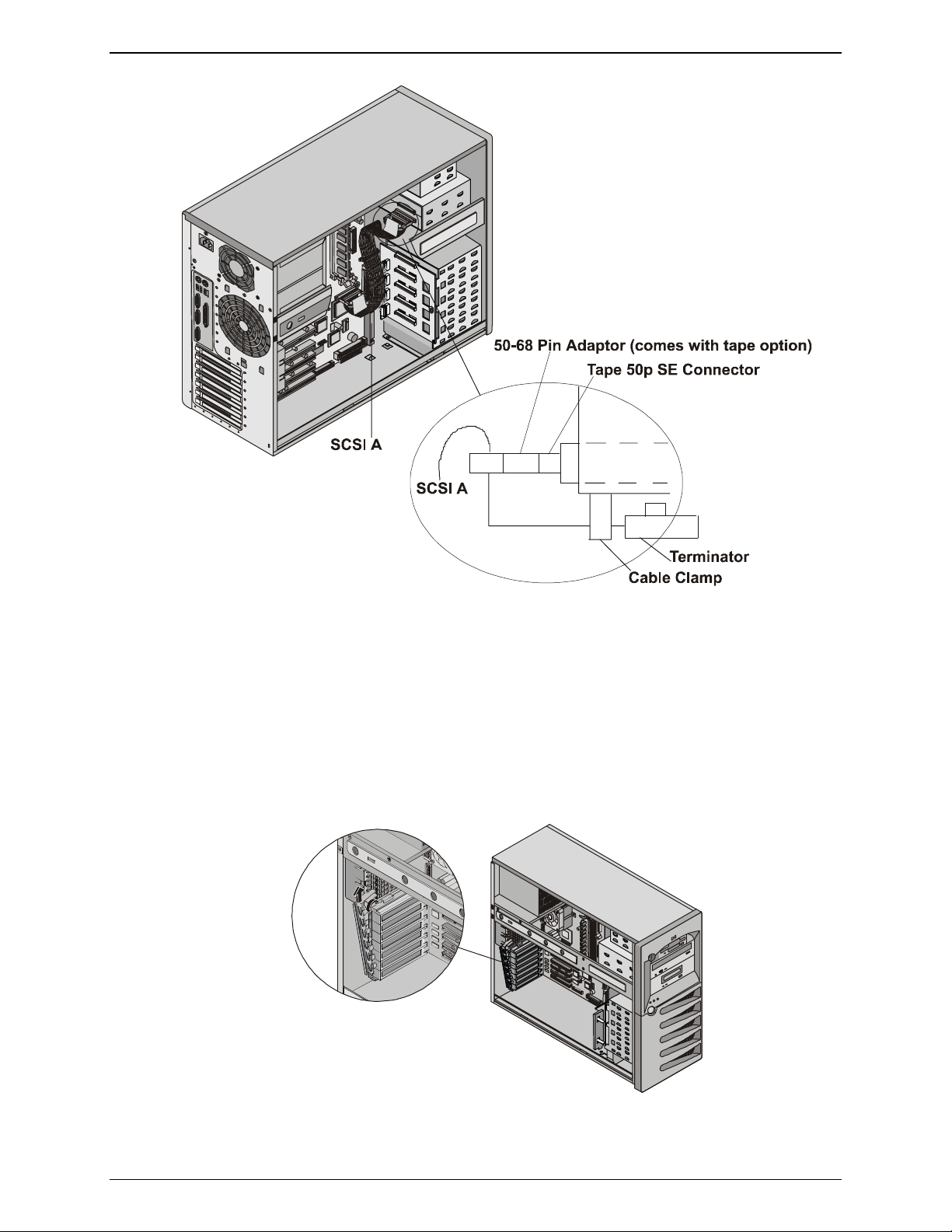

Installing Optional SCSI Accessory Cable

The optional SCSI accessory cable (P/N P1773A) is used to connect the optional tape drive, which will

separate the slower tape drive from the faster Ultra-3 SCSI drives. Refer to Figure 3-7 when installing the

optional SCSI accessory cable into the Channel A connector and cabling the existing cable and channel B

cable to the SCSI disk drives.

18

Page 25

Chapter 3 Installing and Configuring

Figure 3-7. Installing Additional Cabling

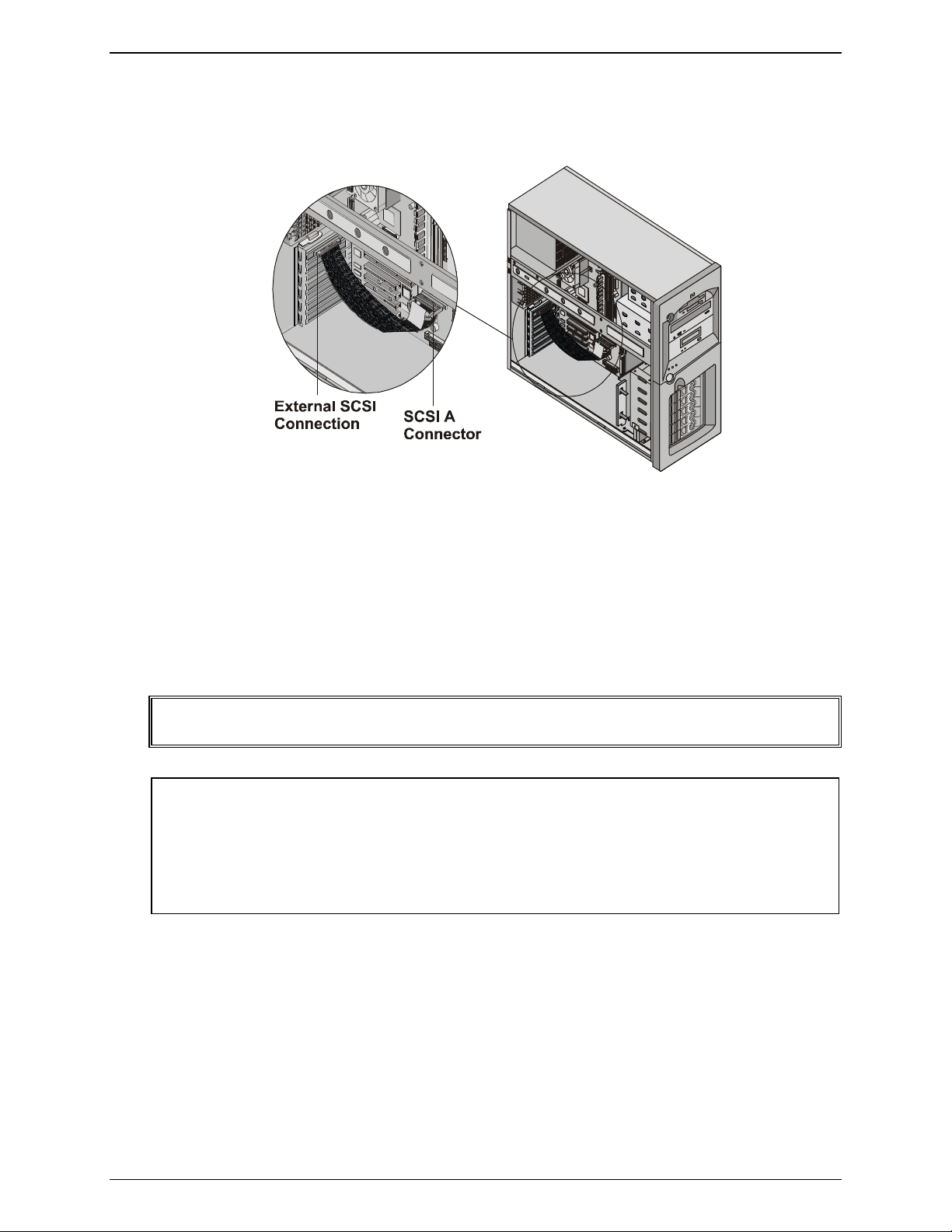

Installing Optional Internal to External SCSI Cable

The HP Server tc3100 can be configured to extend one of its SCSI channels (channel A) to an external SCSI

connector. This allows you to connect additional external mass storage devices to the second channel of the

server's embedded SCSI controller. It requires a second SCSI cable, HP Server tc3100 Internal/External SCSI

Cable Kit, PN: P1774A.

1. Remove the IO locking bracket. See Figure 3-8.

a. Lift the bracket up.

b. Rotate it toward you and slide out.

Figure 3-8. Removing IO Locking Bracket

19

Page 26

Chapter 3 Installing and Configuring

2. Push the top PCI slot cover from the rear of the chassis to remove it.

3. Connect one end to the free SCSI connector (Channel A) on the system board. See Figure 3-9.

4. Route the cable straight back to the open slot and clip it in place at the top.

Figure 3-9. External SCSI Cable

5. Replace the IO locking bracket and rotate it to close.

Installing Cold Swap Hard Drives

Use the following steps to install cold swap hard drives:

1. If the server is operating, log off all users, back up files, and power down the server.

2. Disconnect the power cord and any external cables connected to the server. If necessary, label each one

to expedite re-assembly.

WARNING The power supply will continue to provide standby current to the HP Server until the

power cord is disconnected.

CAUTION Protect the drive from static electricity by leaving it in its anti-static bag until you are

ready to install it. Before handling the drive, touch any unpainted metal surface to

discharge static electricity. When you remove the drive from the anti-static bag, handle it

only by the frame.

Do not touch the electrical components. Place the drive on the anti-static bag whenever

you set it down.

3. Using both hands, grasp the ejector arms of the filler panel in the desired drive slot and press inward

while pulling the filler panel towards you.

20

4. Slide the new drive into the open slot until you feel resistance, and then press firmly until the drive is

fully seated into the connector on the back plane and the latches have fully engaged the chassis.

5. Verify that the drive is flush with the other drives. If the drive is not flush, it is not seated properly in the

drive slot. Remove the drive and repeat Steps 4 and 5.

Page 27

Chapter 3 Installing and Configuring

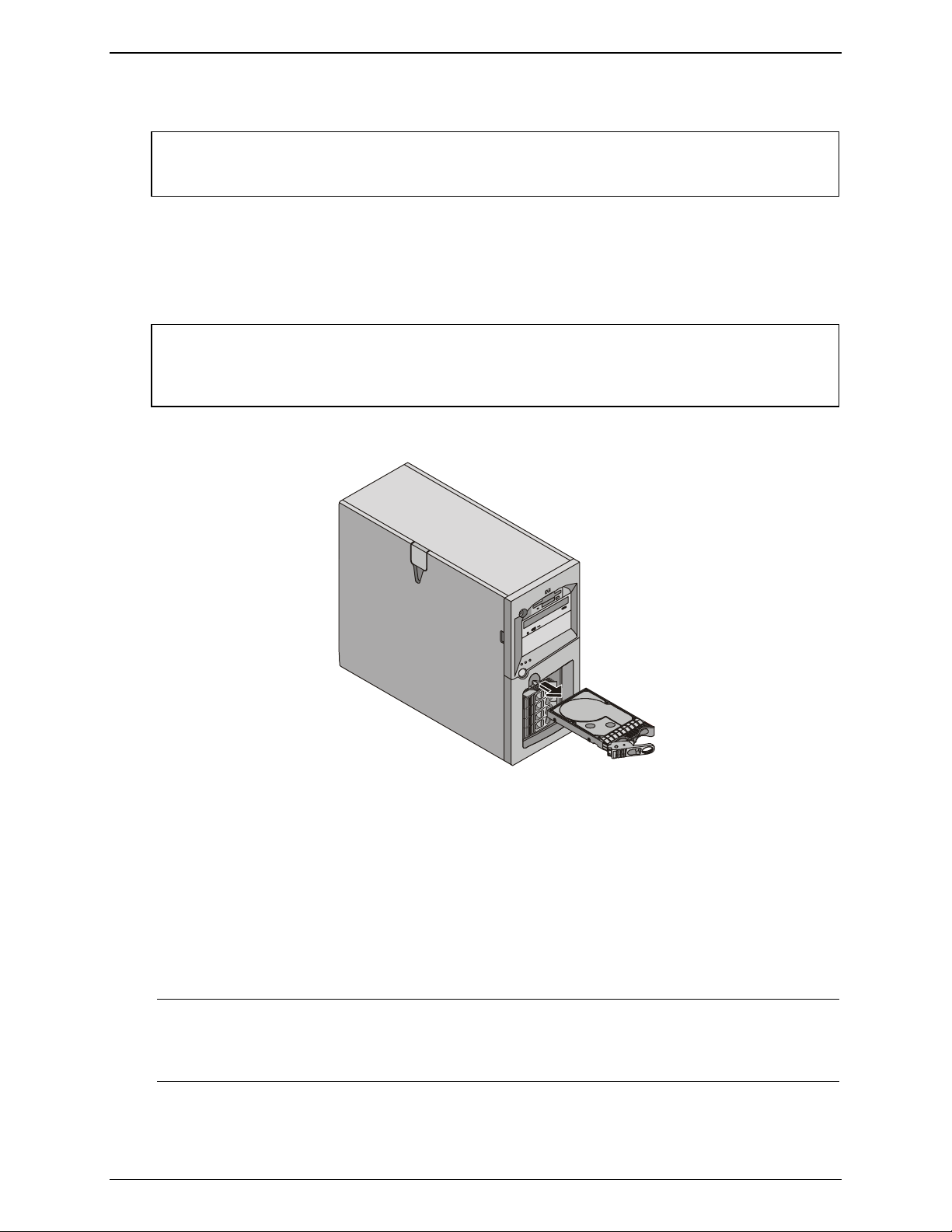

Removing Cold Swap Hard Drives

1. If the server is operating, log off all users, back up files, and power down the server.

2. Disconnect the power cord and any external cables connected to the server. If necessary, label each one

to expedite re-assembly.

WARNING The power supply will continue to provide standby current to the HP Server until the

power cord is disconnected.

3. Using both hands, grasp the ejector arms of the drive to be removed and press inward while pulling the

drive out towards you.

4. Use your hand to support the bottom of the drive, while you slowly pull the drive straight out. See

Figure 3-10.

Do not allow the drive to fall.

Figure 3-10. Removing Cold Swap Hard Drive

5. Place the drive in an electrostatic protected container.

Do not stack drives.

NOTE If you are not replacing the drive, place a filler panel in the drive slot. Operating the HP

Server without filler panels in empty SCSI drive slots may cause the HP Server to suffer

thermal damage.

21

Page 28

Chapter 3 Installing and Configuring

Installing Hot Swap Hard Drives

Use the following steps to install hot swap hard drives:

CAUTION Protect the drive from static electricity by leaving it in its anti-static bag until you are

ready to install it. Before handling the drive, touch any unpainted metal surface to

discharge static electricity. When you remove the drive from the anti-static bag, handle it

only by the frame.

Do not touch the electrical components. Place the drive on the anti-static bag whenever

you set it down.

1. Unlock the hot swap mass storage cage before attempting to remove the drive filler panel.

CAUTION To prevent snapping off the handle, do not use extreme force when opening it. Open the

handle until you feel resistance.

2. Remove any filler panels in the desired drive slot.

a. Press in the locking latch and insert your finger.

b. Using your finger, pull the filler panel straight out. See Figure 3-11.

Figure 3-11. Removing Filler Panel

3. Open the drive module by pressing in on the locking latch at the end of the drive ejector handle and

pulling the handle open.

4. Gently slide the new drive module into the drive slot and stop when you feel resistance.

5. Verify the hooks behind the pivot end of the handle engages the hole in the edge of the cage.

22

6. Press the ejector handle in until you feel the latch click into place.

Closing the ejector handle engages the drive with the electrical connector in the hot swap drive cage and

seats the drive.

7. If the drive is unseated in the cage after closing the ejector handle, remove the drive and insert it once

again.

The handle was probably not pulled out far enough, and the locking latch failed to engage the hot swap

mass storage cage.

Page 29

Chapter 3 Installing and Configuring

Removing Hot Swap Hard Drives

CAUTION You must remove the drive slowly to ensure the drive heads are parked prior to removal.

Ensure you follow these instructions carefully to prevent handling damage, such as head

slaps or head actuator unlocking.

1. Unlock the hot swap mass storage cage before attempting to remove the drive.

2. To unlock the drive, push the locking latch in and then pull the ejector handle toward you.

3. Gently pull the drive straight out to disengage the power connection.

4. Wait about 30 seconds for the drive to stop spinning and the drive heads to park.

CAUTION You must remove the drive slowly about an inch to disconnect from the back plane and

wait 30 seconds for the drive to stop spinning to ensure the drive heads are parked prior

to removal. Ensure you follow these instructions carefully to prevent handling damage,

such as head slaps or head actuator unlocking.

5. Use your hand to support the bottom of the drive, while you slowly pull the drive straight out. Do not

allow the drive to fall. See Figure 3-12.

Figure 3-12. Removing Hot Swap Hard Drive

6. Place the drive in an electrostatic protected container.

Do not stack drives.

Memory Modules

The HP Server's main memory is implemented using four memory slots on the system board which support

up to 4 GB (1 GB x 4) of memory. The server uses only 3.3V, 168-pin, 133 MHz, buffered, ECC, SDRAM

DIMMs and ships with at least one 128 MB DIMM. The embedded video controller is provided with 8 MB

standard video memory and cannot be upgraded.

NOTE Use only PC 133 (133 MHz), buffered, ECC, SDRAM DIMMs acquired from Hewlett-

Packard. The EDO DIMMs and PC 100 SDRAM DIMMs from earlier HP Server models

will fit into the DIMM slots in the HP Server tc3100, but the EDO DIMMs and PC 100

SDRAM will not function properly and are not supported.

23

Page 30

Chapter 3 Installing and Configuring

To ensure you have the correct DIMMs before installation, refer to one of the following for a list of qualified

DIMMs:

· Technical Reference Label inside the HP Server's side panel

· Information Assistant on the HP Server Online Documentation CD-ROM

· HP Customer Service

CAUTION Use an anti static service kit (3M 8501/8502/8503 or equivalent). This kit includes a

static-dissipating work surface, a chassis clip lead, and a wrist strap.

Guidelines

· The HP Server tc3100 uses only PC 133 (133 MHz) buffered, ECC, SDRAM DIMMs, which are

electrically different from the EDO and PC100 SDRAM memory modules used in previous HP Server

models.

· DIMMs sizes supported are 128 MB, 256 MB, 512 MB, or 1 GB in any combination.

· Supported memory capacity ranges from 128 MB to 4 GB maximum (1 GB in each of the 4 DIMM

slots).

· DIMM sizes may be mixed on the system board and may be loaded in any order. However, HP

recommends starting at slot 3 and filling the slots in order with the largest size first: 3, 2, 1, and 0.

· Open slots between DIMMs are permitted.

· When handling DIMMs, observe anti-static precautions to avoid damage.

Installing Additional DIMMs

1. If the server is operating, log off all users, back up files, and power down the server.

2. Disconnect the power cord and any external cables connected to the server. If necessary, label each one

to expedite re-assembly.

WARNING The power supply will continue to provide standby current to the HP Server until the

power cord is disconnected.

3. Open the side panel.

NOTE It is not necessary to remove the system board from the HP Server to install the additional

DIMM memory.

4. Choose a DIMM slot for the desired DIMM. See Figure 3-13.

24

Page 31

Chapter 3 Installing and Configuring

Figure 3-13. DIMM Locations on System Board

5. Spread the two retaining latches outward to accept the DIMM.

6. Remove the HP DIMM from its protective container, handling the module by its edges.

If you must lay it down, place it on an anti-static mat.

7. Align the notches on the new DIMM with the keys on the DIMM slot. See Figure 3-14.

Figure 3-14. DIMM to Slot Alignment

25

Page 32

Chapter 3 Installing and Configuring

8. Hold the DIMM at 90 degrees to the system board and press the DIMM firmly and evenly into the slot

until the retaining latches close. See 3-15.

It is important to hold the DIMM firmly with both hands and use even pressure so as not to bend or

break the DIMM connector during installation. If the latches do not close, the DIMM is not inserted

correctly.

Figure 3-15. DIMM Insertion

9. Close the side panel.

10. Reconnect the power cord and all external cables.

11. Power up the server and return it to normal operation.

NOTE If the DIMMs are not seated properly you may get a blank screen.

Removing DIMMs

You may need to remove a DIMM module to downsize your memory configuration or to replace a defective

DIMM.

Follow the steps in the preceding section, but instead of installing a DIMM, remove the DIMM.

NOTE If you power up the HP Server when there are no DIMMs installed, the screen displays an

error message or appears blank and sounds beep codes.

Processors

The HP Server tc3100 ships with at least one processor installed. Both primary and secondary processor

sockets are located on the system board (primary processor socket – CPU 1. The voltage regulator modules

(VRMs) are embedded in the system board. See Figure 3-16.

26

CAUTION Use an anti static service kit (3M

static dissipating work surface, a chassis clip lead, and a wrist strap.

TM

8501/8502/8503 or equivalent). This kit includes a

Page 33

Chapter 3 Installing and Configuring

Guidelines

The HP Server tc3100 supports speeds of 1.13-1.40 GHz with a front side bus (FSB) speed of 133 MHz. For

the most recent support information, visit the HP web site

http:/www.hp.com

and click the support button.

· Both processors must be the same type and have the same product number, which insures the same

clock speed, cache size, and FSB speed.

· The processors must operate at the designated speed stated by the product type on the processor.

· Use only processor upgrade kits with the same HP product number. This ensures the processor type,

clock speed, and cache size are the same.

· Install the second processor in the secondary slot (CPU 2). See Figure 3-16.

Figure 3-16. System Board (top view)

27

Page 34

Chapter 3 Installing and Configuring

Installing a Second Processor

This section provides the instructions for installing a second processor and its heatsink on the system board.

Figure 3-16 indicates the location of the primary and secondary processors.

CAUTION Take the following precautions when installing processors:

- Leave the processor in the anti-static bag until you are ready to install it.

- Wear an anti-static wrist strap and use a static-dissipating work surface or grounding

mat connected to the chassis when handling components.

- Before removing a processor from the anti-static bag, touch a grounded, unpainted

metal surface to discharge static electricity.

1. Unpack the processor shipping box and check the contents against its packing list.

2. Log off all users, back up files, and shut down the NOS according to the instructions in your NOS

documentation.

3. Press the power switch on the HP Server control panel when prompted by the operating system.

Normally, this completes the shutdown procedure.

WARNING Power supplies continue to provide standby current to the HP Server until the power cord

is disconnected.

4. Disconnect the AC power cord.

5. Open the side panel and lay the chassis down to gain access to the system board.

NOTE It is not necessary to remove the system board from the server to install the second

processor (CPU 2).

If you are installing both processors, you may need to remove the power connector to the

system board to have full access to the processor in the primary processor socket (CPU 1).

6. Ensure the processor speed of the second processor (CPU 2) is the same as the primary processor.

If you are upgrading the second processor to a faster processor speed than the primary processor, the

primary processor must also be changed. Both processors must have the same product number, which

includes the same clock speed, cache size, and FSB speed.

The supported processors only perform at the rated speed indicated on the processor in the HP Server.

7. Open the ZIF (Zero Insertion Force) lever to allow removal of the terminator out of the processor

socket.

To open the ZIF lever, pull the lever out away from the ZIF socket and raise it a full 90° to the system

board. See Figure 3-17.

28

Page 35

Chapter 3 Installing and Configuring

Figure 3-17. Removing the Terminator

8. Lift the terminator out of the socket and place it on an anti-static surface or in a container.

NOTE Keep the terminator for future use. The terminator must be installed in the secondary

processor socket when only one processor is used or the HP Server will not operate

properly.

9. Align the second processor over the empty processor socket. See Figure 3-18.

CAUTION Ensure you align pin-1 of the processor with pin-1 of the processor socket or pin damage

will occur.

10. Insert the second processor into the socket and close the ZIF lever to fully seat the processor.

You should hear the ZIF lever click when it closes properly.

Figure 3-18. Installing Processor

29

Page 36

Chapter 3 Installing and Configuring

Installing the Heatsink

Once the processor is installed, the cooling fan-heatsink must be installed on top of the processor. Each

processor requires a heatsink, with its cooling fan attached, and a thermal interface material (grease) between

the processor and the heatsink. The heatsink is mechanically connected to the processor socket with both

latches, mechanically making contact with processor. HP recommends you do not reuse a heatsink.

1. Remove the heatsink-fan assembly from the shipping container and ensure you do not touch the thermal

interface material on the bottom of the heatsink.

2. Ensure the latches are free and pointing away from the heatsink.

3. Position the heatsink over the second processor and:

a. Tilt or roll it slightly to the rear of the chassis to help engage the hook latch and then connect the

hook latch to the tab.

CAUTION Take care not to move the nearby capacitors.

b. Rotate the heatsink back, placing it squarely on top of the processor and connect the thumb latch to

the tabs on the base of the processor socket on the side shown in Figure 3-19.

The rail and guide on the heatsink bottom will help you to center the heatsink.

CAUTION Do not apply too much force when connecting the thumb latch to the tab on the base of

the processor socket, otherwise, you may damage the components on the system board.

The thumb latches hook underneath the tabs extending from the base of the processor socket base.

c. Ensure the ridge on the bottom of the heatsink rests between the processor and the edge of the

processor socket base.

30

Figure 3-19. Installing Heatsink

CAUTION Ensure you have made good contact with the processor to avoid thermal overheating. If

you have not made good contact, the processor will overheat within 20 seconds of power

on and will shut down, possibly causing damage to the processor.

Page 37

Chapter 3 Installing and Configuring

4. Connect the heatsink's cooling fan connector to the 2nd cooling fan connector (CPU 2 Fan) on the

system board. See Figure 3-19.

CAUTION Failure to connect the cooling fan to its power connector will cause the server to shut

down with no messages displayed, possibly causing damage to the processor.

NOTE No speed switch settings are required for the supported processors in the HP Server.

These processors rely on the internal settings within the processors and do not rely on the

external switch settings.

5. Close the side panel.

6. Replace the external cables and power cord.

7. Power up the server and return it to normal operation.

Removing a Processor and Heatsink

Use this procedure to remove a processor and its heatsink. The heatsink and cooling fan must be removed

first, before removing the processor.

CAUTION Always wear a wrist-strap and use a static-dissipating work surface connected to the

chassis when handling components. Ensure the metal of the wrist strap contacts your

skin.

Before you touch the processor to remove it, touch a grounded, unpainted metal surface

on the HP Server to discharge static electricity.

NOTE If you need to remove the primary processor (CPU 1), you may find it necessary to

remove the power and system fan connectors to access the primary processor.

1. Disconnect the cooling fan connector from its respective cooling fan connector on the system board.

2. Unhook the thumb latch on the heatsink and lift the heatsink up slightly from the processor.

3. Rotate the heatsink away from the processor toward the rear of the server, releasing the opposing latch.

4. Lift the heatsink away from the processor and out of the server.

5. Open the ZIF lever to allow removal of the processor. See Figure 3-18.

6. Grasp the processor by its edges and lift it out of the socket and place it on a static-dissipating work

surface or into an anti-static bag.

If you are not replacing the processor with a new or replacement processor, you must install the terminator in

the empty processor socket. See Figure 3-17.

31

Page 38

Chapter 3 Installing and Configuring

Firmware and Software Changes

This section deals with the firmware changes provided by the HP Server Navigator CD-ROM and the

possible reinstalling of the NOS to recognize the second processor.

Upgrading the Firmware

If your processor included a new HP Server Navigator CD-ROM, insert the CD into the HP Server CD-ROM

drive and power on the server. Follow the instructions provided on screen to ensure the system BIOS is up-todate. The system BIOS on the CD will be compared to the server's current BIOS, and if necessary, will

indicate if the BIOS needs to be updated. For more information, see “HP Server Navigator CD-ROM" later in

this chapter.

Reinstalling the NOS

You may need to reconfigure or reinstall your NOS in order to use the additional processor you have

installed. If you have gone from a single-processor to dual-processor configuration, check your NOS

documentation or the Readme file and Configuration Advisor utilities on the HP Server Navigator CD-ROM.

Accessory Boards

The system board in the HP Server tc3100 provides six PCI slots (P1 through P6), with four 32-bits slots and

two 64-bit slots. All PCI slots accept full-length accessory boards.

Tested PCI Boards

For a list of tested PCI boards, check for compatibility in Configuration Assistant on the Navigator CD-ROM

or look for the Hardware Tested Products list for the HP Server tc3100 under the Service and Support topic

for the specific NOS used in the server on the HP web site at:

http:/www.hp.com

Click the support button and then click netservers. Under Support Categories, select compatibility.

All Hewlett-Packard accessory boards comply with the U.S. National Electrical code (NFPA 70) Class 2.

For additional information, refer to the Readme file and Configuration Advisor on your HP Server Navigator

CD-ROM. Refer to the instructions later in this chapter.

CAUTION Some accessory board outputs may exceed U.S. National Electrical code (NFPA 70)

Class 2 or limited power source limits and must use appropriate interconnecting cabling

in accordance with the National Electrical Code.

Remote Control Card

The HP Server tc3100 may use the HP Server remote management card in PCI slot 6 on the system board.

This card supports HP TopTools software. An I

information, see "HP TopTools," in Chapter 4, "Diagnostics."

2

C connector is provided on the system board. For more

Guidelines

The following sections provide guidelines for installing PCI accessory boards into the HP Server tc3100.

IRQ Settings

The HP Server uses the Plug and Play feature of the PCI board to automatically assign its resources.

32

Page 39

Chapter 3 Installing and Configuring

Boot Priority

The server's boot order should be considered when selecting a boot device. This is especially important if you

are installing a board that requires a higher priority in the boot order. The board's boot priority is set by its

slot location in the boot order.

By default the server searches for boot devices in this order:

1. IDE CD-ROM drive

2. Flexible disk drive

3. Embedded SCSI A channel (external SCSI Drives)

4. Embedded SCSI B channel (SCSI Devices)

5. PCI slot 6

6. PCI slot 5

7. PCI slot 4

8. PCI slot 3

9. PCI slot 2

10. PCI slot 1

11. Embedded LAN

Using the Primary or Secondary PCI Bus

The HP Server tc3100 has a Primary and Secondary PCI bus. The two busses are peer-to-peer, which

provides approximately equal performance, except when using the two 64-bit slots versus the 32-bit slots. See

Table 3-2.

Table 3-2. PCI Bus Selection

PCI Slots PCI Bus

Slots 3 through 6 Primary PCI Bus

Slots 1 and 2 Secondary PCI Bus

Installing a Disk Array Controller Board

Adding a disk array controller board provides additional fault tolerance to your internal or external mass

storage devices. HP recommends installing the HP NetRAID-1M PCI board in slot 3, 4, or 5. When installing

a disk array controller board, you may alter the server's boot order to allow the server to boot off one of the

array's drives. This boot order can be changed under the Configuration menu of the server's (BIOS) Setup

Utility and in the SCSI Configuration Utility.

Installing an Accessory Board

Use this procedure to install the accessory board.

NOTE For information about a specific PCI board type, refer to the Readme file, Tested Products

List, or Configuration Advisor on your HP Server Navigator CD-ROM.

1. If the server is operating, log off all users, back up files if necessary, and power down the server.

2. Disconnect the power cord and any external cables connected to the server. If necessary, label each one

to expedite re-assembly.

WARNING The power supply will continue to provide standby current to the HP Server until the

power cord is disconnected.

33

Page 40

Chapter 3 Installing and Configuring

3. Read the documentation included with the accessory board and follow any special instructions. PCI

boards must be set to INT A on the board if jumpers are provided.

NOTE Adding a PCI-to-PCI bridge board to the HP Server may alter the server's boot order. This

boot order can be changed using the Setup Utility (press F2 during the boot process).

Refer to "Boot Priority" earlier in this chapter.

4. Open the side panel.

CAUTION Wear a wrist strap and use a static-dissipating work surface connected to the chassis

when handling components. Ensure the metal of the wrist strap contacts your skin.

5. Remove any cables attached to the accessory board. If necessary, label each one to expedite reassembly.

6. Remove the IO locking bracket. See Figure 3-20.

a. Lift the bracket up.

b. Rotate it toward you and slide out.

Figure 3-20. Removing IO Locking Bracket

7. Identify the accessory slot number to be used. See Figure 3-21.

34

Page 41

Chapter 3 Installing and Configuring

Figure 3-21. Accessory Slots

NOTE Refer to the Readme file, Tested Products List, or Configuration Advisor on your HP

Server Navigator CD-ROM for specific slot recommendations for a particular PCI board

type.

8. Push the PCI slot cover from the rear of the chassis and slide it towards you to remove it. See Figure

3-22.

NOTE Ensure you save the slot covers for use later to prevent EMI interference.

Figure 3-22. Removing Slot Cover

9. If you are installing a long accessory board, open the PCI card guide retainer.

10. Align the new board carefully, slide it into position, and press it firmly into the connector.

35

Page 42

Chapter 3 Installing and Configuring

11. Replace the IO retaining bracket and rotate it to close.

12. Close the PCI card guide retainer if open.

13. Close the side panel.

14. Replace the external cables and power cord.

15. Power up the server and return it to normal operation.

Once the HP server is returned to normal operation, you may need to install software drivers. The drivers for

the new PCI board are either part of your existing server software or included on a flexible disk or CD-ROM

provided with the accessory board.

Removing an Accessory Board

Follow the steps in the preceding section, but instead of installing a card, remove the PCI card and replace the

slot cover.