Page 1

HP Tower Server tc2100

Service Manual

Online Version 1.0

Printed August 2001

Page 2

Notice

The information contained in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use

of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on equipment that is not furnished by

Hewlett-Packard.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this

document may be photocopied, reproduced, or translated to another language without the prior written consent of

Hewlett-Packard Company.

®

is a registered trademark of ATI Technologies, Incorporated. Intel®, Celeron®, and Pentium® are registered

ATI

trademark of Intel Corporat ion. Microsoft

Microsoft Internet Explorer

is a registered trademark of Netscape Communications Corporation in the U.S. and other countries. Adobe® and Acrobat®

are registered trademarks of Adobe Systems Incorporated.

®

is a registered trademark of CamCar/Textron, Incorporated. 3M is a trademark or regi stered trademark of 3M.

Torx

Hewlett-Packard Company

Network Server Division

Technical Communications / MS 45SLE

10955 Tantau Avenue

Cupertino, California 95014 USA

© Copyright 2001, Hewlett-Packard Company.

®

are registered trademarks of Microsoft in the U.S. and other countr ies. Netscape Navigator®

®

, Windows NT®, Windows 95®, Windows 98®, Windows 2000®, and

Audience Assumptions

This guide is for the person who installs, administers, and troubleshoots LAN servers. Hewlett-Packard

Company assumes you are qualified in the servicing of computer equipment and trained in recognizing

hazards in products with hazardous energy levels.

ii

Page 3

Contents

1 Specifications .........................................................................................................................................7

Technical Specifications............................................................................................................................7

Environmental.......................................................................................................................................7

Weight and Dimensions........................................................................................................................7

Power Supply Specification s ................................................................................................................7

Hardware Specifications .......................................................................................................................8

Video Display Modes ............................................................................................................................8

System Board Layout............................................................................................................................9

2 Controls, Ports, and Indicators...........................................................................................................11

Front Panel Control and Indicators .........................................................................................................11

Additional Front Panel Controls and Indicators ..................................................................................12

Rear Panel Ports and Features..........................................................................................................13

Applying Power to the HP Server ...........................................................................................................14

Powering-Up the HP Server ...............................................................................................................14

Powering-Down the HP Server...........................................................................................................14

Multiple-Server Configurations ...........................................................................................................15

Sleep States (ACPI)............................................................................................................................15

3 Connector Pinouts ...............................................................................................................................17

Mini-DIN (PS/2) Connectors...............................................................................................................17

Serial Port Connector..........................................................................................................................17

Parallel Port Connector.......................................................................................................................18

USB Connector...................................................................................................................................19

Video Connector .................................................................................................................................19

68-Pin LVD SCSI Port Connector (Low Voltage Differential) .............................................................20

50-Pin Narrow SCSI Port Connector – Accessory Board...................................................................21

LAN Connector – Accessory Board....................................................................................................21

4 Maintenance Guidelines ......................................................................................................................23

Introduction..............................................................................................................................................23

Mass Storage..........................................................................................................................................23

Mass Storage Guidelines....................................................................................................................23

Boot Priority ........................................................................................................................................24

IDE Mass Storage Devices.................................................................................................................25

SCSI Mass Storage Devices ..............................................................................................................25

Memory Guidelines .................................................................................................................................27

Accessory Board Guidelines...................................................................................................................28

Tested PCI Boards..............................................................................................................................28

IRQ Settings........................................................................................................................................28

Processor Guidelines..............................................................................................................................28

5 Error Messages.....................................................................................................................................31

Introduction..............................................................................................................................................31

Beep Codes ............................................................................................................................................31

Power-On Self Test (POST) Error Codes...............................................................................................31

6 Diagnostics ...........................................................................................................................................37

Diagnostic Tests......................................................................................................................................37

Diagnostics Description ......................................................................................................................37

HP DiagTools......................................................................................................................................37

iii

Page 4

Contents

HP DiagTools Capabilities..................................................................................................................37

About Error Messages ........................................................................................................................38

Advantages and Limitations of Hardware Diagnostics.......................................................................38

7 Maintenance and Troubleshooting.....................................................................................................41

Preventive Maintenance Procedures......................................................................................................41

Troubleshooting ......................................................................................................................................41

Troubleshooting Checklist ..................................................................................................................41

Server Does Not Power On ................................................................................................................42

Server Powers On, but Fails POST ....................................................................................................43

Server Passes POST, but Does Not Function....................................................................................43

BIOS Recovery ...................................................................................................................................43

Password Problems ................................................................................................................................44

Clearing the BIOS Configuration ........................................................................................................44

Resetting a Lost Password.................................................................................................................45

General Server Problems........................................................................................................................45

No lights are on and no error message appears ................................................................................45

Operating system or an application is not responding properly .........................................................46

Server stops working (hangs) .............................................................................................................46

Server does not start (boot) ................................................................................................................46

Power Problems..................................................................................................................................47

Video/Monitor Problems......................................................................................................................48

Configuration Problems ......................................................................................................................50

Printer/Datacomm Problems...............................................................................................................51

Keyboard and Mouse Problems .........................................................................................................52

Flexible Disk Drive Problems..............................................................................................................52

CD-ROM Problems.............................................................................................................................53

SCSI Problems ...................................................................................................................................54

Processor Problems............................................................................................................................58

Memory Problems...............................................................................................................................58

Embedded Network Interface Card Problems....................................................................................59

Network Interface Card (Installed) Problems......................................................................................59

8 Parts and Illustrations..........................................................................................................................61

Exploded View – Covers and Bezels......................................................................................................61

Exploded View – Mass Storage Devices ................................................................................................62

Exploded View – Chassis Fan, Power Supply, and System Board........................................................63

Exploded View – System Board Components ........................................................................................64

Replaceable Parts List ............................................................................................................................65

Cables and Part Numbers ..................................................................................................................66

Keyboards...........................................................................................................................................66

Power Cords.......................................................................................................................................67

9 Remove/Replace Procedures..............................................................................................................69

Introduction..............................................................................................................................................69

Safety Information...............................................................................................................................69

Service Tools Required.......................................................................................................................69

Covers.....................................................................................................................................................69

Removing the Left Side Cover............................................................................................................69

Replacing the Left Side Cover............................................................................................................71

Alternate Covers .................................................................................................................................72

Front Bezels............................................................................................................................................72

iv

Page 5

Contents

Removing the Upper Bezel.................................................................................................................72

Replacing the Upper Bezel.................................................................................................................73

Removing the Lower Bezel.................................................................................................................74

Replacing the Lower Bezel.................................................................................................................75

Status Panel Assembly...........................................................................................................................75

Removing the Status Panel Assem bly................................................................................................75

Replacing the Status Panel Assembly................................................................................................76

Mass Storage Devices ............................................................................................................................77

Removing the Flexible Disk Drive.......................................................................................................77

Replacing the Flexible Disk Drive.......................................................................................................78

Removing the CD-ROM......................................................................................................................78

Replacing the CD-ROM ......................................................................................................................79

Removing a Backup Tape Drive.........................................................................................................80

Replacing a Backup Tape Drive .........................................................................................................80

Removing a Hard Disk Drive (Tray Mounted).....................................................................................81

Replacing a Hard Disk Drive (Tray Mounted).....................................................................................82

Removing a Hard Disk Drive (Drive Cage Mounted)..........................................................................83

Replacing a Hard Disk Drive (Drive Cage Mounted)..........................................................................84

DIMMs.....................................................................................................................................................85

Removing DIMMs ...............................................................................................................................85

Replacing DIMMs................................................................................................................................86

Processor................................................................................................................................................87

Removing the Heatsink-Cooling Fan..................................................................................................87

Removing the Processor ....................................................................................................................88

Replacing the Processor.....................................................................................................................89

Replacing the Heatsink-Cooling Fan..................................................................................................90

Accessory Boards ...................................................................................................................................93

Removing Accessory Boards..............................................................................................................93

Replacing Accessory Boards..............................................................................................................94

Power Supply..........................................................................................................................................96

Removing the Power Supply ..............................................................................................................96

Replacing the Power Supply...............................................................................................................97

Battery.....................................................................................................................................................97

Removing the Battery .........................................................................................................................97

Replacing the Battery..........................................................................................................................98

Chassis Fan ............................................................................................................................................98

Removing the Chassis Fan .................................................................................................................98

Replacing the Chassis Fan.................................................................................................................99

System Board........................................................................................................................................100

Removing the System Board............................................................................................................100

Replacing the System Board ............................................................................................................101

Index .........................................................................................................................................................103

Page 6

Page 7

1 Specifications

Technical Specifications

The specifications listed below for HP Tower Server tc2100 may vary if you install a mass storage device in

your server that has more stringent environmental limits. Ensure the operating environment for your server is

suitable for all of the mass storage devices being used.

Environmental

Temperature

Operating

Non-operating

Humidity

Operating

Non-operating

Altitude

Operating

Non-operating

5° to 35° C (41° to 95° F)

-40° to +65° C (-40° to +149° F)

20% to 80% relative humidity, non-condensing

5% to 95% relative humidity, non-condensing

-30 to 3,000 m (~ 10,000 ft)

-30 to 12,000 m (~ 40,000 ft)

Thermal Output

Maximum Operating

1066 BTU/hr

Weight and Dimensions

Weight

Height

Width

Depth

Basic configuration approx. 13.5 kg. (30 lbs) – excludes keyboard and monitor.

Fully loaded approx. 22.6 kg. (50 lbs) – excludes keyboard and monitor.

46.0 cm (18.11 inches)

20.5 cm (8.07 inches)

46.7 cm (18.39 inches)

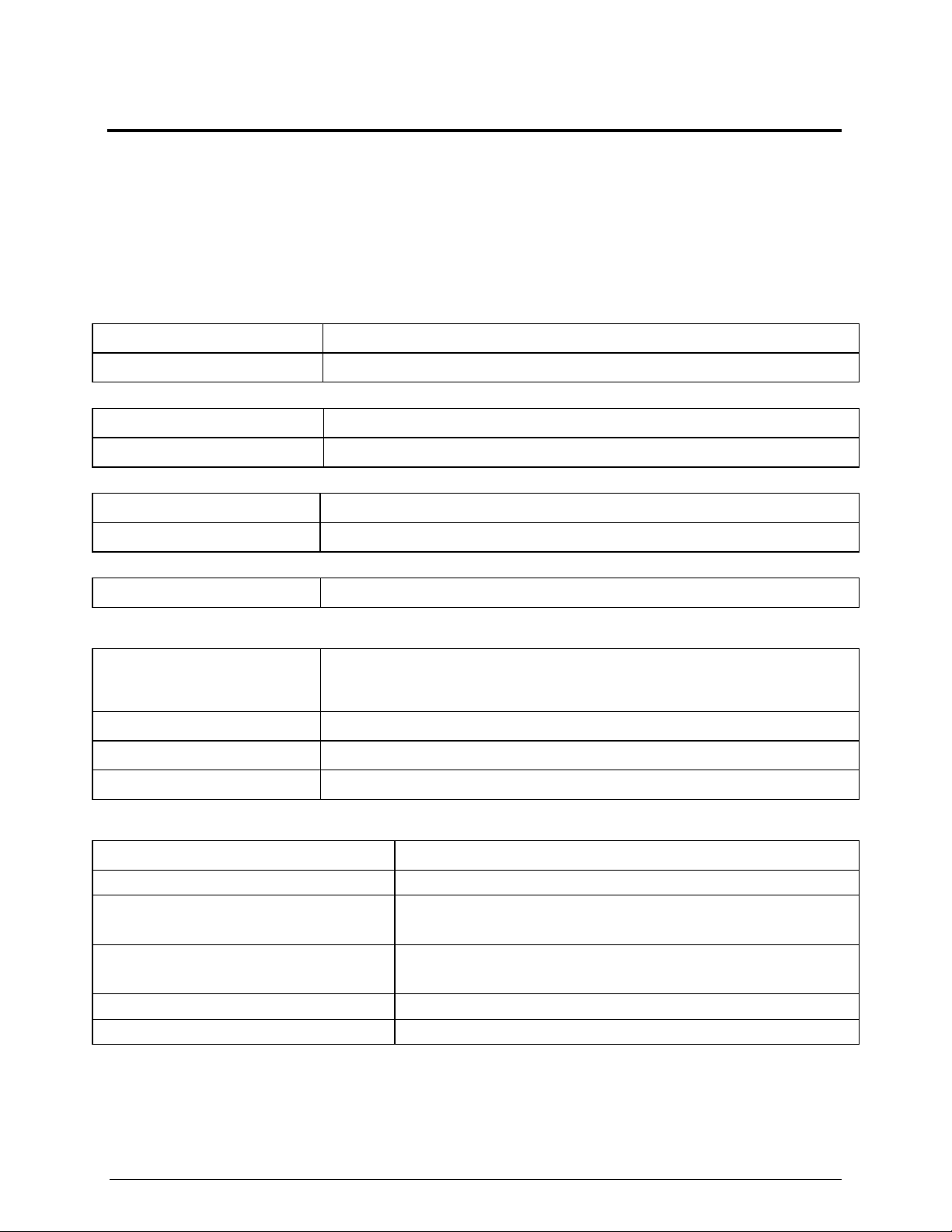

Power Supply Specifications

Parameter Characteristics

Input Type Manual voltage selection

Input – Maximum Range 100 to 127 VAC @ 50/60 Hz

200 to 240 VAC @ 50/60 Hz

Operating Current 100 to 127 VAC: 7.0 A

200 to 240 VAC: 3.5 A

In-rush Current 90 A (cold) 120 A (warm)

Operating Power 250 W Continuous

7

Page 8

Chapter 1 Specifications

Hardware Specificat ions

Specification Characteristics

Processors This HP Server supports Intel Celeron or Intel Pentium III processors (system board

automatically detects processor FSB and changes accordingly):

Intel Celeron - 850 MHz and above with 100 MHz FSB and Integrated 128K L2 cache on

processor

Intel Pentium III - 1.13 GHz and above with 133 MHz FSB and Integrated 512K L2 cache on

processor

Chipset VIA Pro133T chip set with 33 MHz PCI and 133 MHz FSB speed support

Memory Supports up to three SDRAM DIMMS for a maximum total of 1.5 GB.

Supported DIMM type and sizes: 128MB, 256MB, or 512MB registered, 168-pin, 3.3 volts, 72

bits wide, ECC single-bit correcting, multi-bit de tecting.

Video Embedded ATI Rage XL video chip with 4MB SDRAM. Supports up to 1600x1200, @ 65K

colors. Refer to “Video Display Modes” for more details.

SCSI SCSI model only; single channel Ultra-160 SCSI LVD (Adaptec AHA 29160LP) board at 160

MB/s transfer rate with two 68-pin connectors

IDE Embedded Enhanced-IDE 33/66/100 dual-channel controller.

PCI Bus Five full-length 32-bit PCI slots at 33 MHz and 5 volts

LAN Embedded Intel 82559 10/100 PCI Fast Ethernet Controller.

I/O Two Serial ports; one bi-directional parallel port with ECP/EPP high-speed support; PS/2 style

mouse and keyboard connectors; two USB ports – supports USB printers, external modems, and

mouse and keyboard, but NOS dependant

CD-ROM Bundled CD-ROM drive; IDE interface; 48x speed or faster

Video Display Modes

Resolution

640x480 200 Hz 200 Hz 200 Hz

800x600 200 Hz 200 Hz 160 Hz

1024x768 150 Hz 150 Hz 120 Hz

1152x864 120 Hz 120 Hz 85 Hz

1280x1024 100 Hz 100 Hz 85 Hz

1600x1200 76 Hz 76 Hz Not available

Max. Refresh Rate @ 256

Colors

Max. Refresh Rate @ 65K

Colors

Max. Refresh Rate @ 16.7M

Colors

8

Page 9

Chapter 1 Specifications

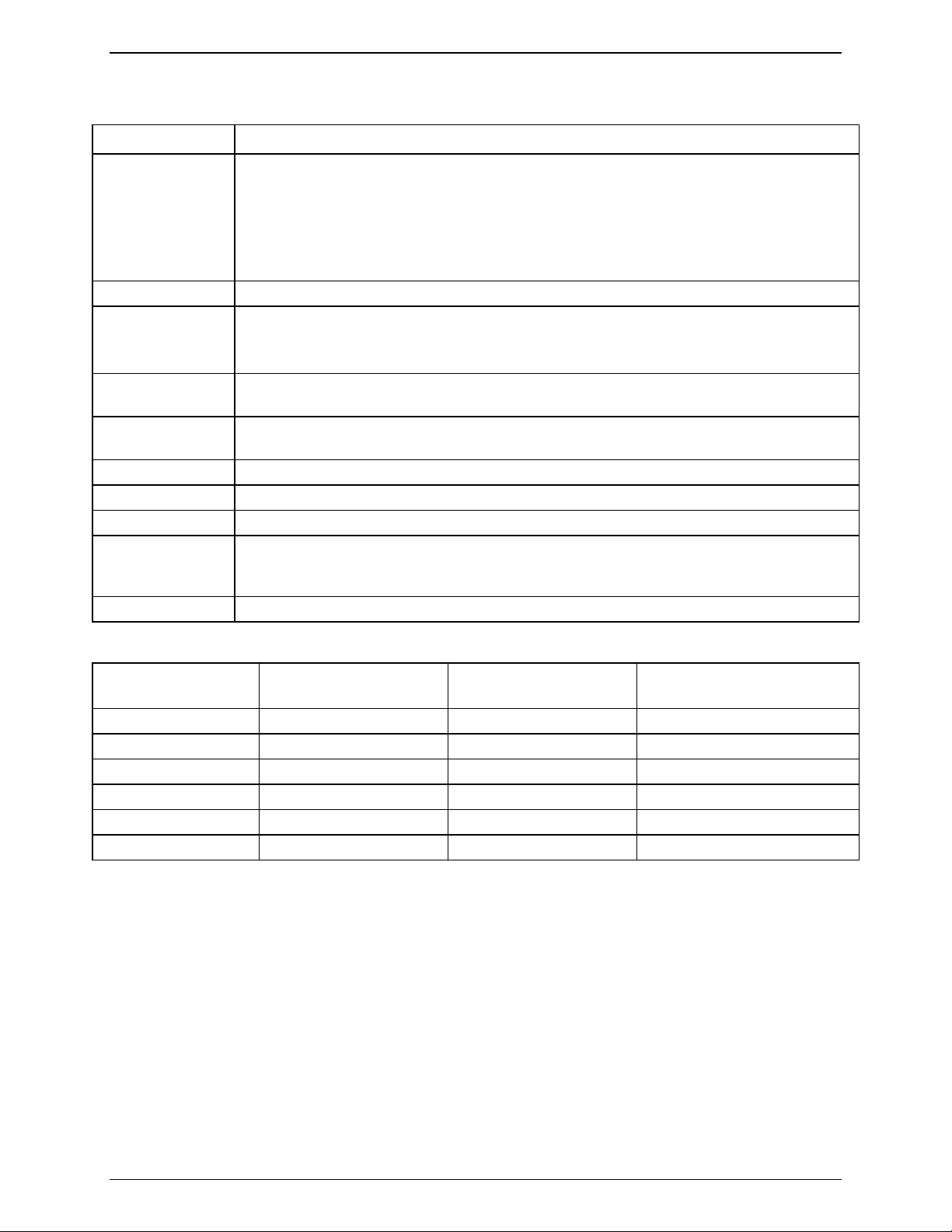

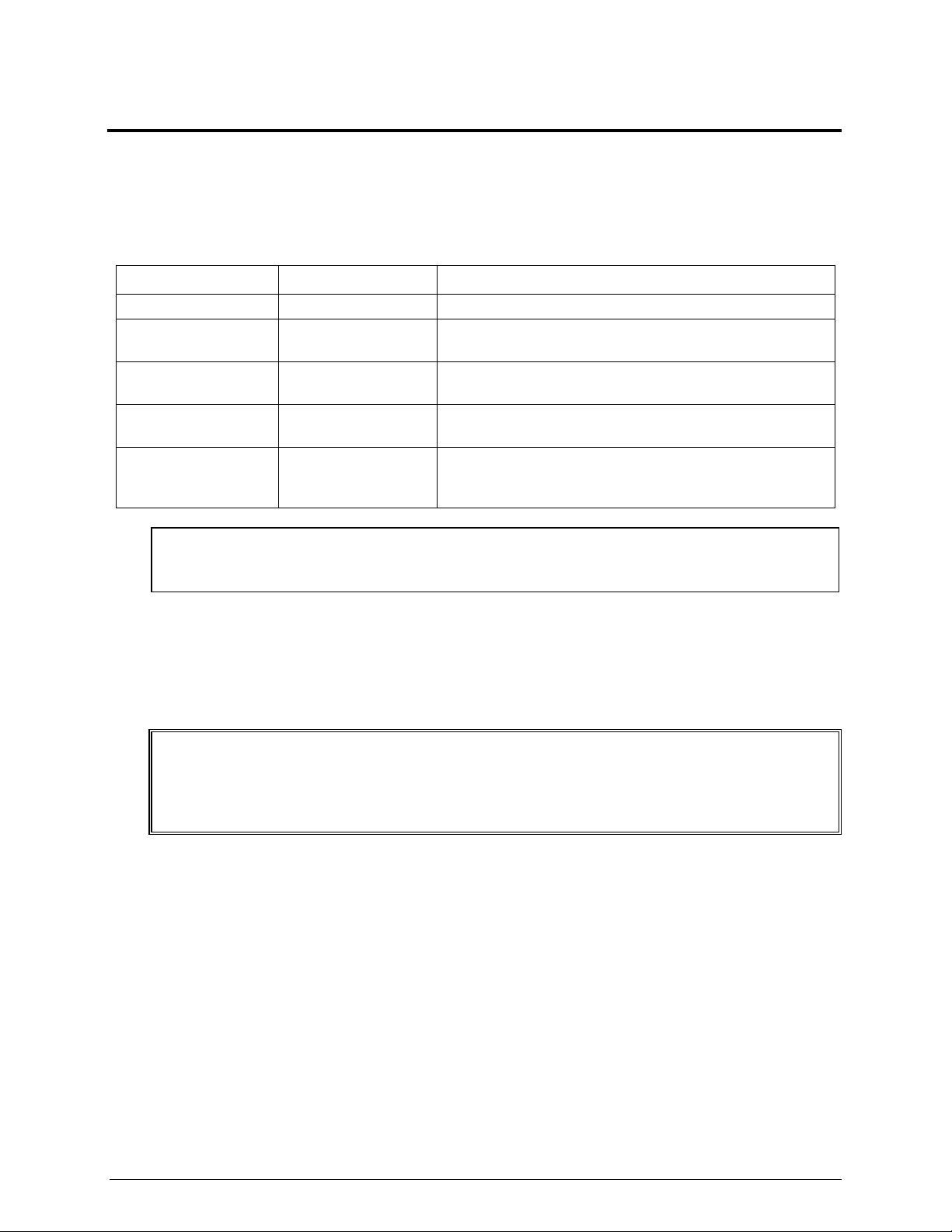

System Board Lay out

Processor,

Connector

Heatsink Fan

Mouse (U)

Keyboard (L)

LAN (U)

2 USB (L)

Com 1 (L)

Parallel (U)

Video (L)

Heatsink

& Fan

Power

DIMM Slots

2

3

1

FDD

IDE-2

Com 2

Connector

Chassis Fan

PCI Slot P1

PCI Slot P2

PCI Slot P3

PCI Slot P4

PCI Slot P5

Pin 3

Pin 1

Battery

CMOS

Clear Jumper

System Board Components/Connectors

Illustration Notes

(L) = Lower connector(s)

(U) = Upper connector(s)

Beep Code

Speaker

IDE-1

SCSI

Controller

LED

Headers

Front

Panel

Display

Header

9

Page 10

Page 11

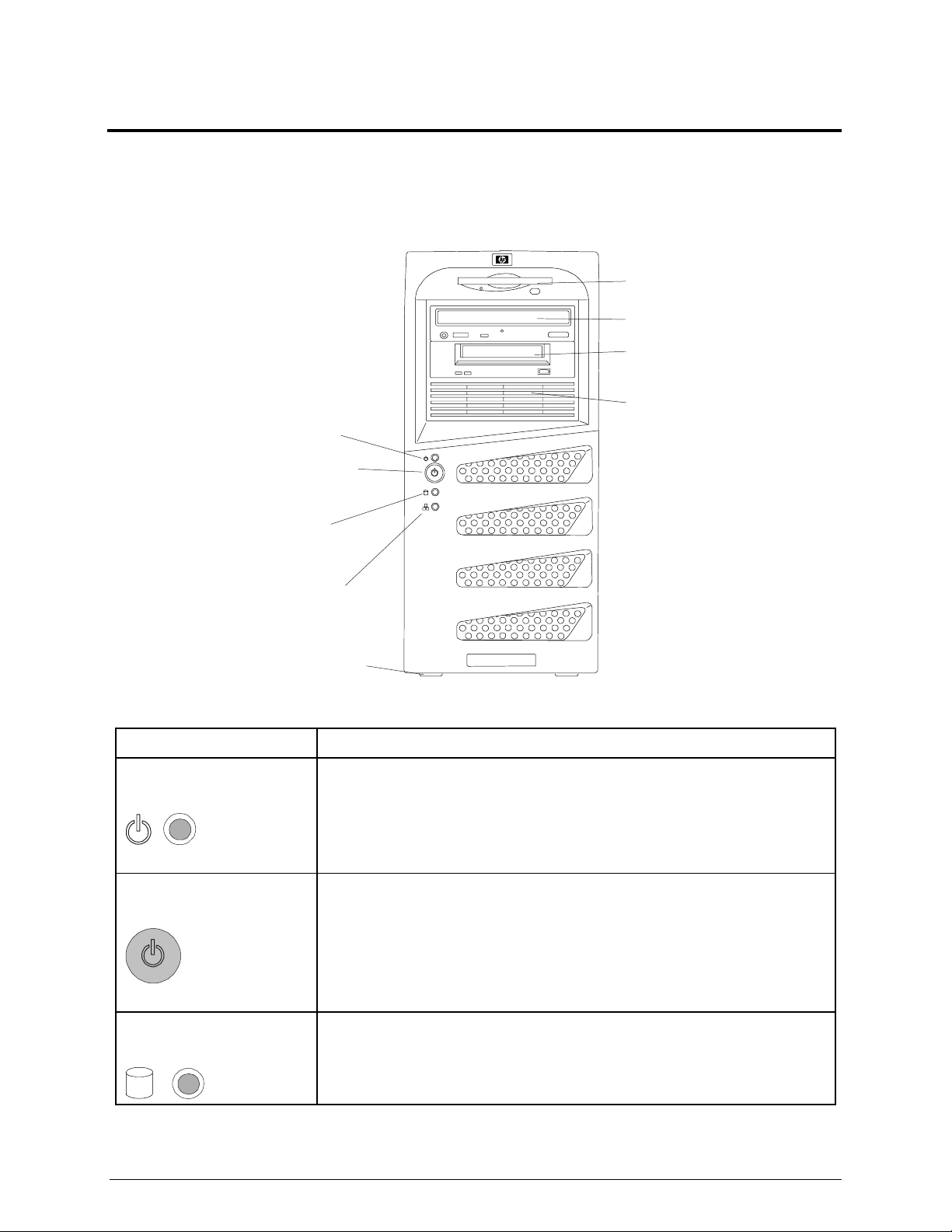

2 Controls, Ports, and Indicators

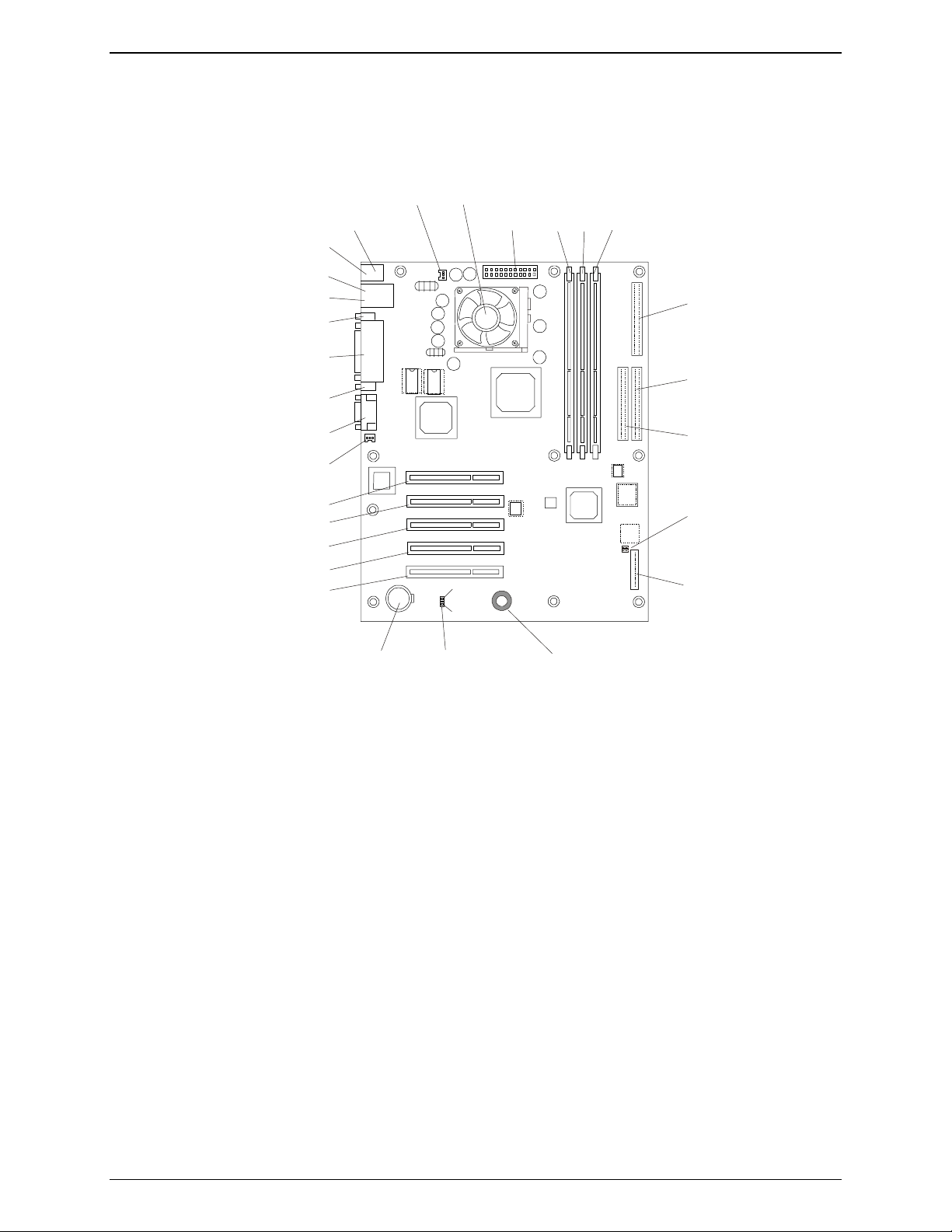

Front Panel Control and Indicators

The HP Tower Server tc2100’s controls, indicators, and user-serviceable internal components are shown in

the following illustrations.

Flexib l e Dis k

Drive (FDD)

CD-ROM Drive

Backup Tape

Drive (Optional)

3rd Hard Drive

Power On/Off/

Sleep LED

Power On/Off/

Sleep Switch

IDE/SCSI

Device

Activity LED

(Optional)

LAN Activity

LED

Rubber Feet (4)

Front Panel Switch and Indicators

Control / Indicator Description

On/Off/Sleep LED

This green LED indicator provides the power state of the Server:

Steady green when the Server is operating normally.

Off when the Server is powered off.

Steady amber indicates the Server is in a sleep state and under ACPI

(Advanced Configuration and Power Management Interface) control.

Power On/Off/Sleep Switch

This button turns the HP Server power On or Off, and if available, also

transitions the Server between Power On and sleep states. If sleep states are not

available, then this button only turns power On or Off.

The sleep states are NOS dependent and only available if your NOS supports

power management based on the ACPI (Advanced Configuration and Power

Management Interface) standard. Refer to "Applying Power to the HP Server"

and "Sleep States (ACPI)" later in this chapter.

Drive Active LED

Flickering orange LED during any IDE or SCSI device activity, including the

CD-ROM drive(s), IDE hard disk drives, and SCSI devices connected to the

SCSI controller board.

Off when there is no IDE or SCSI device activity.

Server – Front View

11

Page 12

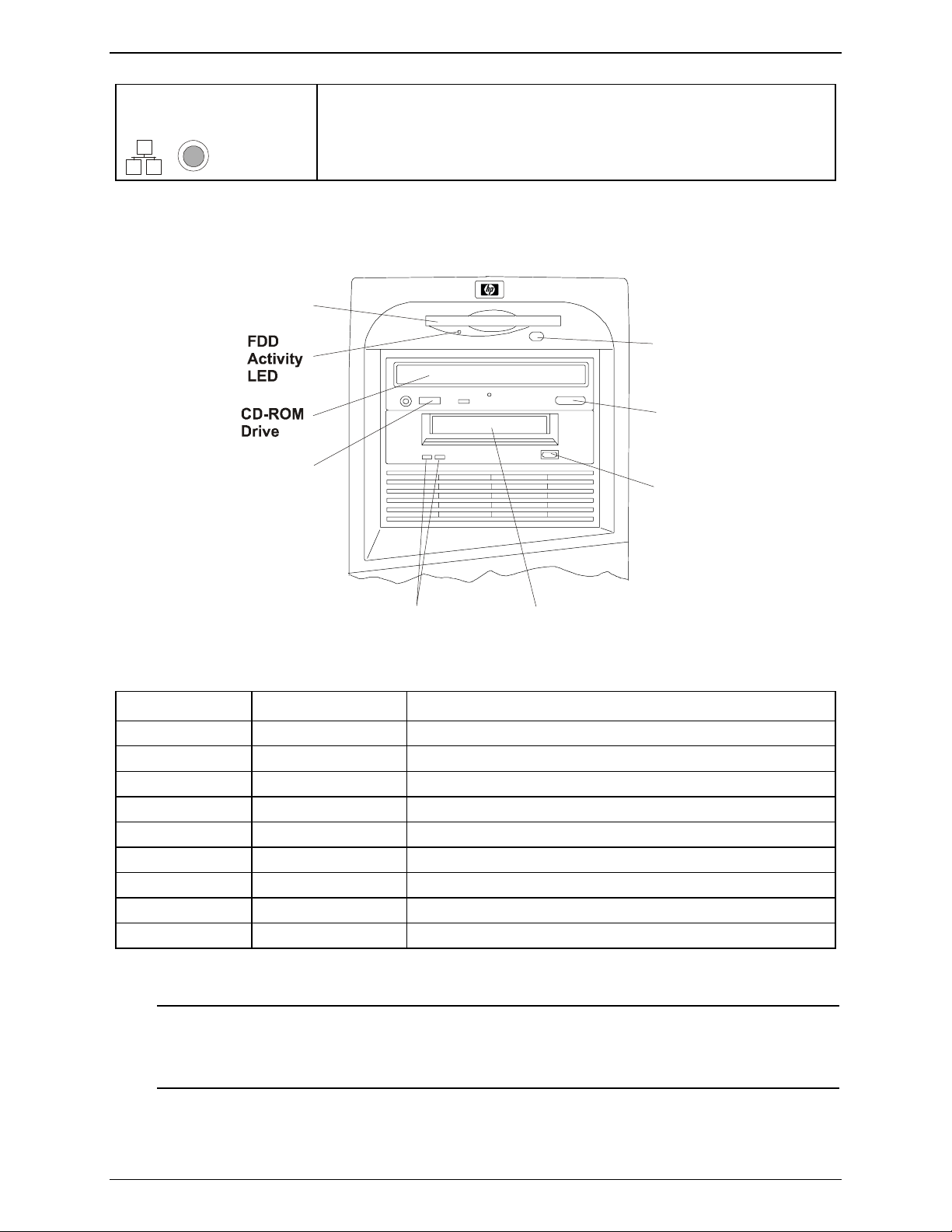

Chapter 2 Controls, Ports, and Indicators

LAN Activity LED

Flickering green LED during any embedded LAN activity.

Off when there is no embedded LAN activity.

Additional Front Panel Controls and Indicators

The Mass Storage devices have additional controls and indicators p r oviding the user with external controls to

these devices and the related operational status. See the following table for Backup Tape drive LED Codes.

FDD

Eject Button

Eject Button

CD-ROM

Activity

LED

Eject Button

Status LEDs

Storage Devices - Controls and Indicators

Backup Tape Drive LED Codes

Left LED Right LED Definition

Backup Tape

Drive (Optional)

Off Off No Power

On Off Cartridge Loaded, but No activity

Flashing* Off Cartridge Loaded and Active

Pulsing** Off Loading/Unloading/Ejecting/Power-On

Off On Self Test Fail

Off Pulsing** No Cartridge, but Caution (cleaning required)

On Pulsing** Cartridge Loaded, but Caution (cleaning required)

Flashing* Pulsing** Cartridge Loaded, Drive Active, Caution (cleaning required)

Pulsing** Pulsi ng** Cartridge Loading/Unloading, Caution (cleaning re quired)

* Flashing at 4 Hz rate

** Pulsing at 2 Hz rate

NOTE For more information on the HP Tape Drive and its error codes, refer to the

documentation provided with the tape drive or refer to Hewlett-Packard's web site, at:

http://www.hp.com/

12

Page 13

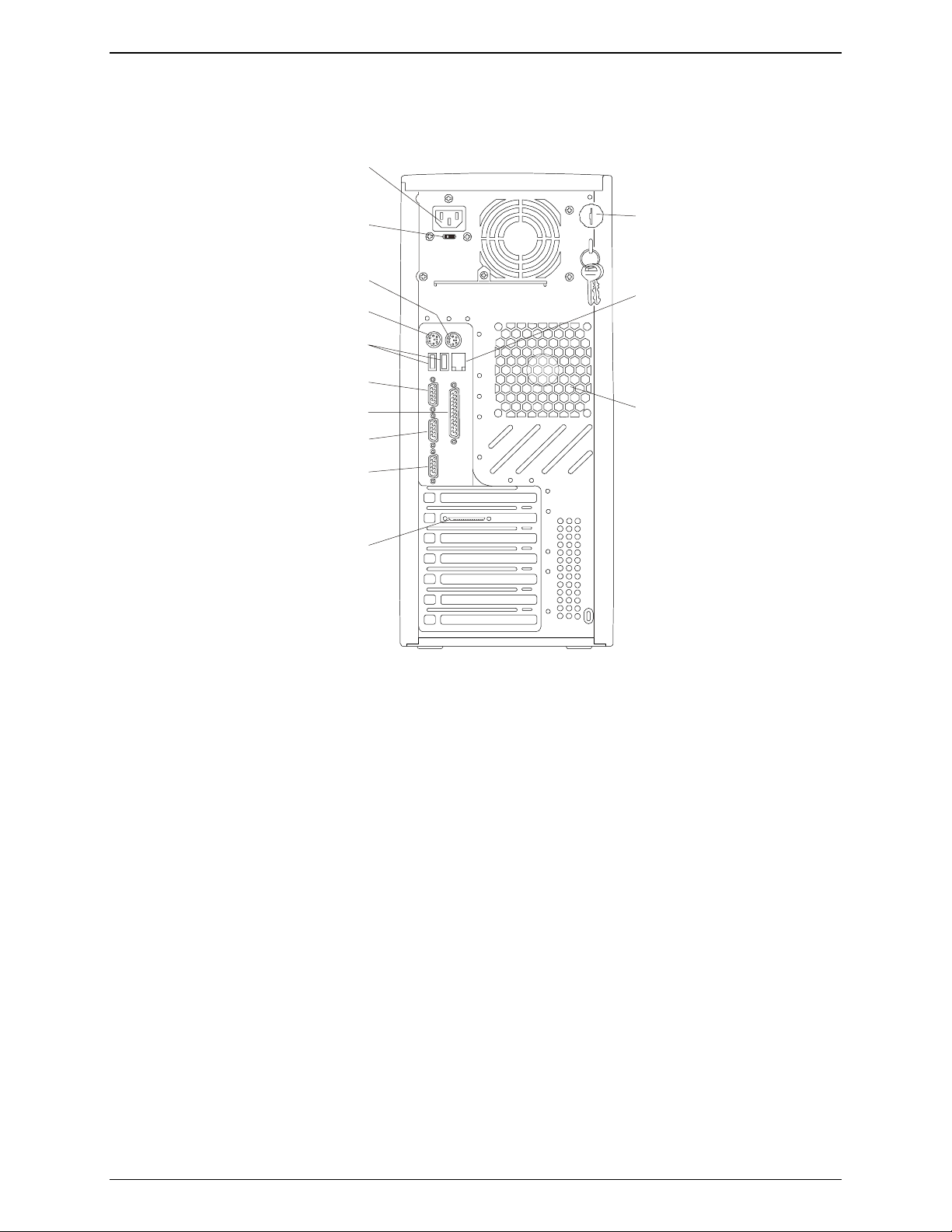

Chapter 2 Controls, Ports, and Indicators

Rear Panel Ports and Featur es

The following text and illustration describe the ports, switches, and unique features on the Server's rear panel.

Power

Input

Voltage

Switch

Mouse

Keyboard

USB (2)

COM 1

Parallel

Video

COM 2

External

SCSI

(SCSI

Model

only)

Keylock

LAN

System

Fan

HP Server – Rear View

• The power connector accepts a standard power cable to connect the HP Server tc2100 with the site

power source.

• The input voltage selector switch is used to adapt the power supply to the input line voltage. The two

switch settings are 115 volts or 230 volts, and 230 volts is the default setting.

• The mouse port accepts a standard mouse with a PS/2 connector.

• The keyboard port accepts a standard keyboard with a PS/2 connector.

• Two USB ports are provided for printers, external modems, a keyboard and a mouse, but these features

are NOS dependent.

• The COM 1 port is a standard serial port.

• The Parallel Port is a standard parallel printer port, which supports Extended Capabilities Port

(ECP)/Enhanced Parallel Port (EPP).

• The Monitor Port (SVGA) interface specifications are listed in the following tables "HP Server

Hardware Specifications" and "Video Display Modes" of Chapter 1, "Specifications."

• The COM 2 port is a standard serial port.

• The SCSI model has an external SCSI port for external SCSI devices provided by the single channel

SCSI controller board, but can only be used when no SCSI devices are connected internally.

• Keylock mechanism provides mechanical security for the left side panel to prevent access to the internal

components.

13

Page 14

Chapter 2 Controls, Ports, and Indicators

• The LAN port is included as an embedded controller based on Intel's 82559 10/100 BaseT Fast Ethernet

Controller. It has a RJ-45 LAN connector on the rear panel. The LED on the front panel is used to

indicate LAN activity.

• System Fan is a variable speed fan controlled by thermal sensors on the system board. The system fan

speed can also be controlled by the fan speed settings in the (BIOS) Setup Utility.

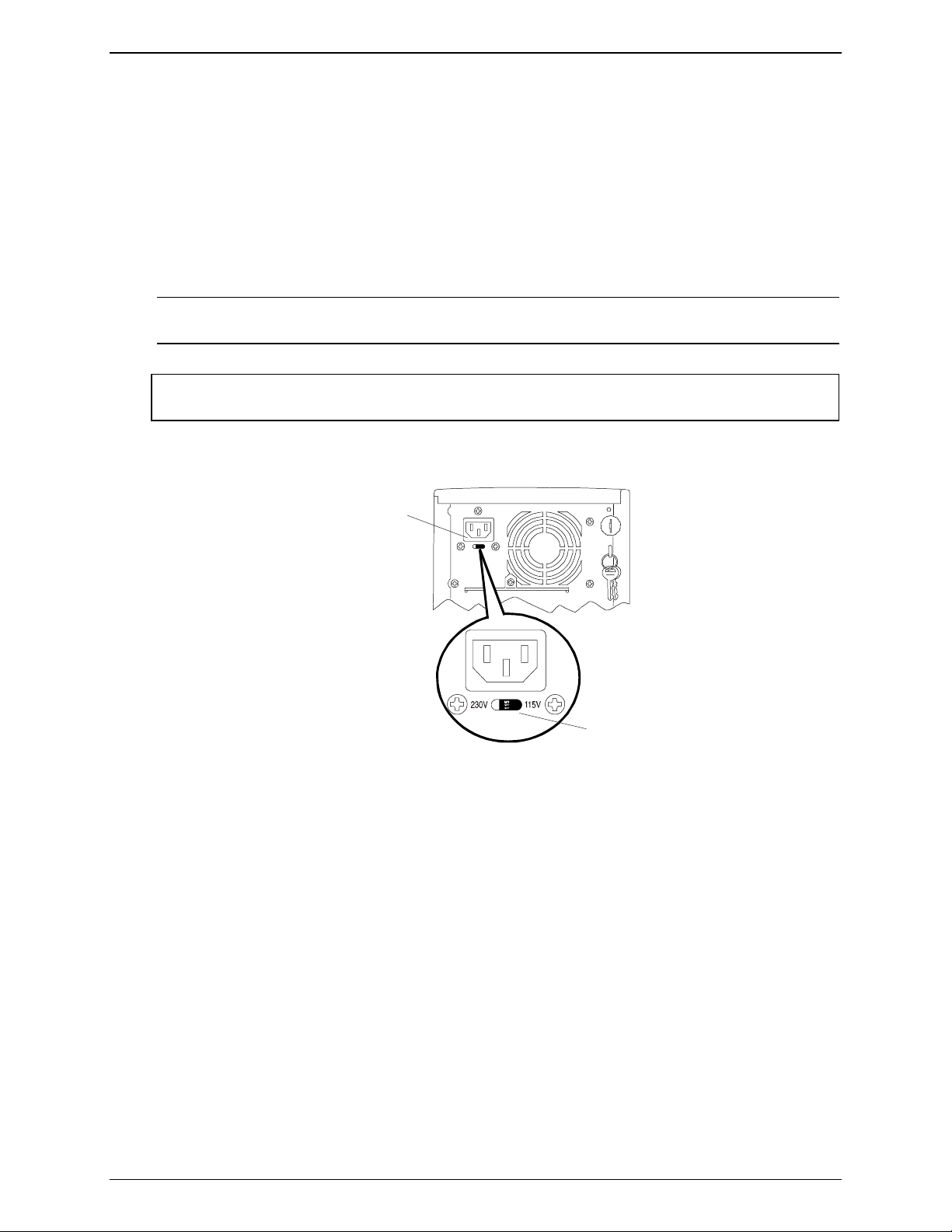

Applying Power to the HP Server

Powering-Up the HP Serv er

NOTE Turn on power to the monitor connected to the HP Server before you power-on the HP

Server. This allows proper auto-configuration of video output of the Server as it boots up.

CAUTION To prevent damage to the power supply, check the Input Voltage selector switch before

connecting the Server and its power cord to a voltage source.

1. Ensure the Input Voltage selector switch is set for the correct input voltage, before connecting the power

cord to a voltage source. See Figure 2-4.

Power

Connector

(Switch show n in

11 5 vol t s position.)

2. Ensure the HP Server's power cord is connected to the power source. See Figure 2-4.

3. Press the Power button on the lower front bezel. See Figure 2-1.

When you press the power button on the front bezel, the Server powers up and loads the operating

system. The system runs a set of Power On Self Tests (POST) during this process. For details refer to

Chapter 8, "Configuring the HP Server" and Chapter 9, "Troubleshooting."

Power ing -Do wn the HP Ser v er

1. Log off all users and if necessary, back up files.

Input Voltage Selection Switch

Input Voltage

Switch

14

o Schedule the power down for a time when the fewest users will be affected by the Server's

downtime.

o If you will be doing any kind of hardware or software upgrade , be sure your Server's data has been

backed up.

2. Follow instructions in your network operating system (NOS) documentation to gracefully shut down all

networking software and applications.

3. Press the power switch on the HP Server's control panel when prompted by the operating system.

Normally this completes the power down procedure.

Page 15

Chapter 2 Controls, Ports, and Indicators

NOTE The power supply will continue to provide standby current to the Server until the power

cable is disconnected from the rear panel.

Multiple-Server Configurat ions

The HP Server temporarily draws a large "inrush current," when first connected to an AC power source. This

also occurs when the Server is in a standby mode (power is turned off and the power cord is plugged into AC

power). The inrush current is much greater than the Server's normal operating current and general ly, the AC

power source can handle the normal inrush current.

However, if you install several HP Servers on one circuit, precautions are necessary. If there is a power

failure and power is then restored, all the servers immediately begin to draw inrush current at the same time.

If the circuit breakers on the incoming power line have insufficient capability, the breaker may trip and thus

prevent the servers from powering up.

When preparing your site for installation, allow for the additional inrush current. See "Power Specifications"

in Chapter 1.

Sleep States (AC PI)

The HP Server supports the ACPI (Advanced Configuration and Power Management Interface) standard,

which is a key component of a NOS's directed power management. The supported features are only available

when an ACPI-compliant NOS is installed on the Server. The term “sleep state” refers to any of several

reduced power consumption states in which normal NOS activity has ceased.

The Server supports several sleep states, including a sleep state with a short wake-up time, sometimes

referred to as “standby” or “suspend” by various operating systems. In this sleep state the Server appears to

be off, and is indicated by no display on the monitor and no activity for the CD-ROM or internal hard drives.

However, the power LED is a steady orange and the fans are operating.

The Server may also support another sleep state with a slower wake-up time, sometimes referred to as

“hibernate” by various operating systems. In this sleep state, the Server appears to be off as described earlier,

but the system fan and the front panel power LED are also turned off. The unique feature of this sleep state

(and the reason for its slower wake-up time) is that information about the Server’s NOS state (open

applications, screens, and so on) is saved to disk before the Server is placed in the sleep state. Upon wake-up,

this information is restored from disk. This method of restoring the Server's operation is much faster tha n a

complete rebooting of the Server. It still requires running all the start-up self-tests before starting the NOS,

but loading the NOS and all the previously opened applications is much faster.

The Server supports certain types of system activity, which are used as wake-up events from sleep states.

These wake-up events can be generated from the power button, keyboard and mouse activity, and scheduled

events.

NOTE The HP Server’s power management policies (transitions between various power states)

and the user options are specific to the particular ACPI-compliant NOS installed on the

Server. If your respective NOS is ACPI-compliant, refer to the (BIOS) Setup Utility and

the power management features described in the instructions provided for more

information.

The HP Server’s power button can be configured to initiate a graceful shutdown or "soft off" of the NOS,

rather than an immediate shutdown of the power supply. The power button configurations are dependent on

the user interface provided by the ACPI-compliant NOS. While power management is under the control of

the ACPI-compliant NOS, the HP Server’s power button is capable of an override in case of a non-responsive

NOS.

NOTE The HP Server power button will force a power down without waiting for the NOS to

gracefully shut down the Server when the power button is pressed and held in excess of

four seconds.

15

Page 16

Chapter 2 Controls, Ports, and Indicators

CAUTION If the power button override is used; there is a strong possibility of corrupted or lost data.

Refer to the BIOS Setup Utility in Chapter 8, “Configuring the HP Server” and your NOS documentation for

instructions on setting up Sleep States and transitioning into and out of the various states.

16

Page 17

3 Connector Pinouts

Unless otherwise noted, the following features apply to all models. Some features are factory installed; others

are optional.

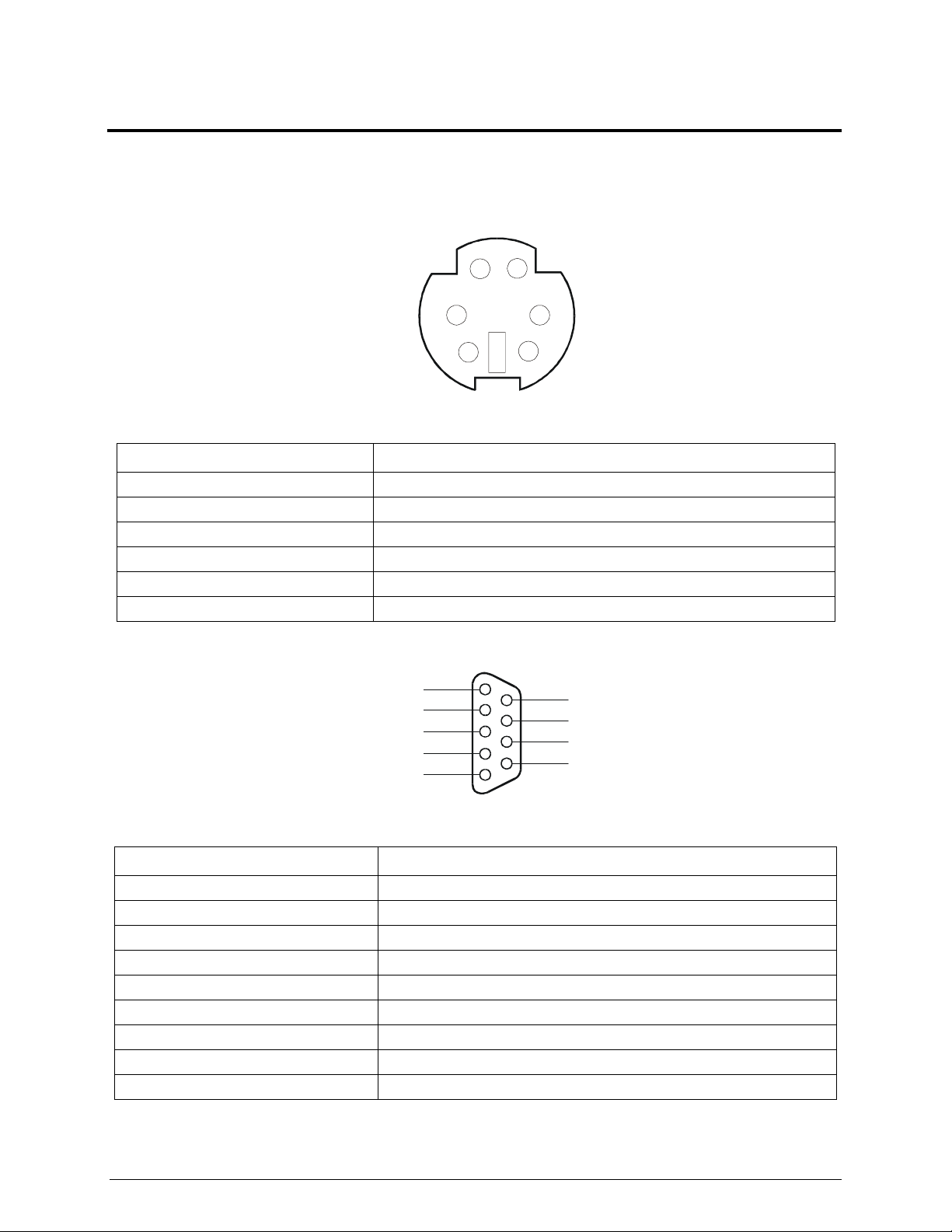

Mini-DIN (PS/2) Connectors

2

1

3

5

Mini-DIN Connector (female) for the Mouse and Keyboard

Mini-DIN Connector Pinouts for the Mouse and Keyboard

Pin Number Signal Description

1 Data signal

2 Not used

3 Ground

4 Power (+5 V dc)

5 Clock signal

6 Not used

4

6

Serial Port Connector

5

4

3

2

1

Serial Port Connector

Serial Port Connector (male) Pinouts

Pin Number Signal Description

1 Data carrier detect

2 Receive data

3 Transmit data

4 Data term ready

5 Signal ground

6 Data set ready

7 Request to send

8 Clear to send

9 Ring indicator

9

8

7

6

17

Page 18

Chapter 3 Connector Pinouts

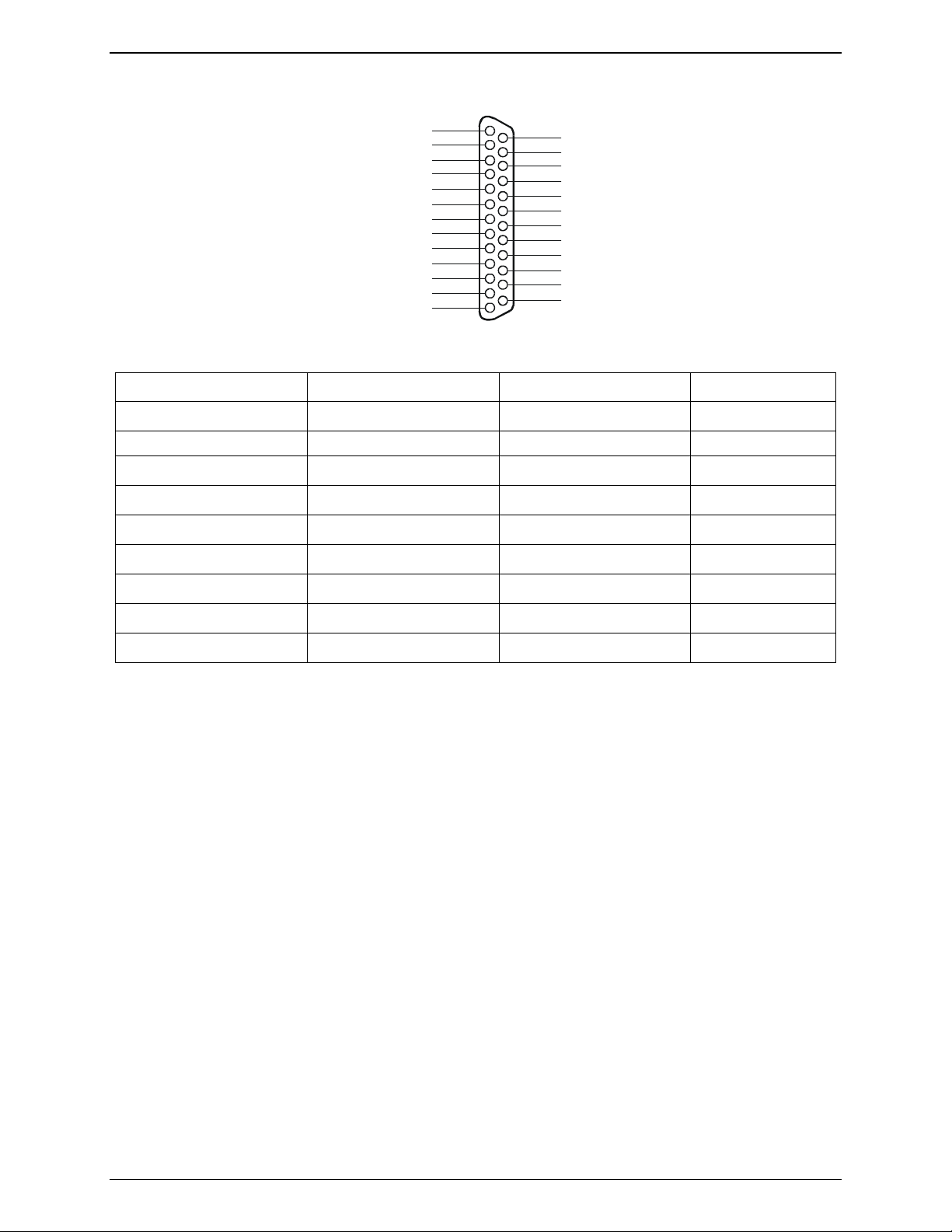

Parallel Port Conn ector

1

2

3

4

5

6

7

8

9

10

11

12

13

Parallel Connector

Parallel Port Connector (female) Pinouts

Pin Number Signal Description Pin Number Signal Description

1 Strobe5 10

14

15

16

17

18

19

20

21

22

23

24

25

Acknowledgeb

2 Data bit 06 11 Busy

3

4

5

6

7

8

9

a. All data bits are sent to a printer in an 8-bit parallel format.

b. The sign al is active low.

Data bit 1a

Data bit 2a

Data bit 3a

Data bit 4a

Data bit 5a

Data bit 6a

Data bit 7a

12 Paper end

13 Select

14

Auto line feedb

15 Error1

16

17

Initialize printerb

Select inb

18-25 Signal ground

18

Page 19

Chapter 3 Connector Pinouts

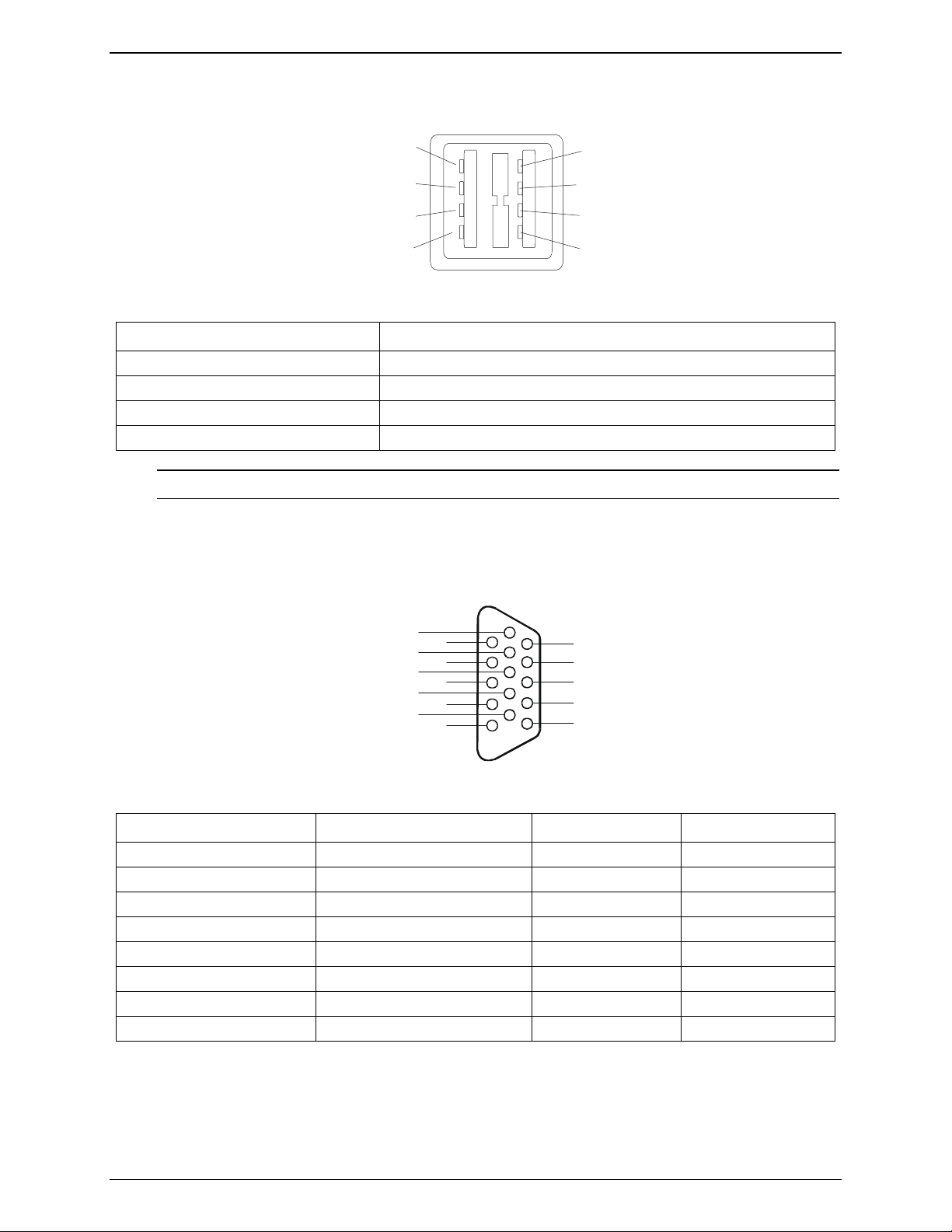

USB Connector

1

2

3

4

USB Connector

Universal Serial Bus Connector Pinouts

Pin Number Signal Description

1

2

3

4

1 VBUS

2 D+

3 D4 GND

NOTE Use of the USB port is supported for printers, scanners, and external modems.

Video Connector

The embedded video uses the standard 15-pin analog display pinout configuration. The pinouts for your

monitor may vary. For the pinouts for your monitor, refer to the manual provided with your monitor.

6

1

7

2

8

3

9

4

10

5

Video Connector

Video Connector (female) Pinouts

Pin Number Function Pin Number Function

11

12

13

14

15

1 Red 9 Key (no pin)

2 Green 10 Sync return (ground)

3 Blue 11 Monitor ID bit 0

4 Monitor ID bit 2 12 Monitor ID bit 1

5 Monitor self test (ground) 13 Horizontal sync (+)

6 Red return (ground) 14 Vertical sync (-)

7 Green return (ground) 15 Not used

8 Blue return (ground)

19

Page 20

Chapter 3 Connector Pinouts

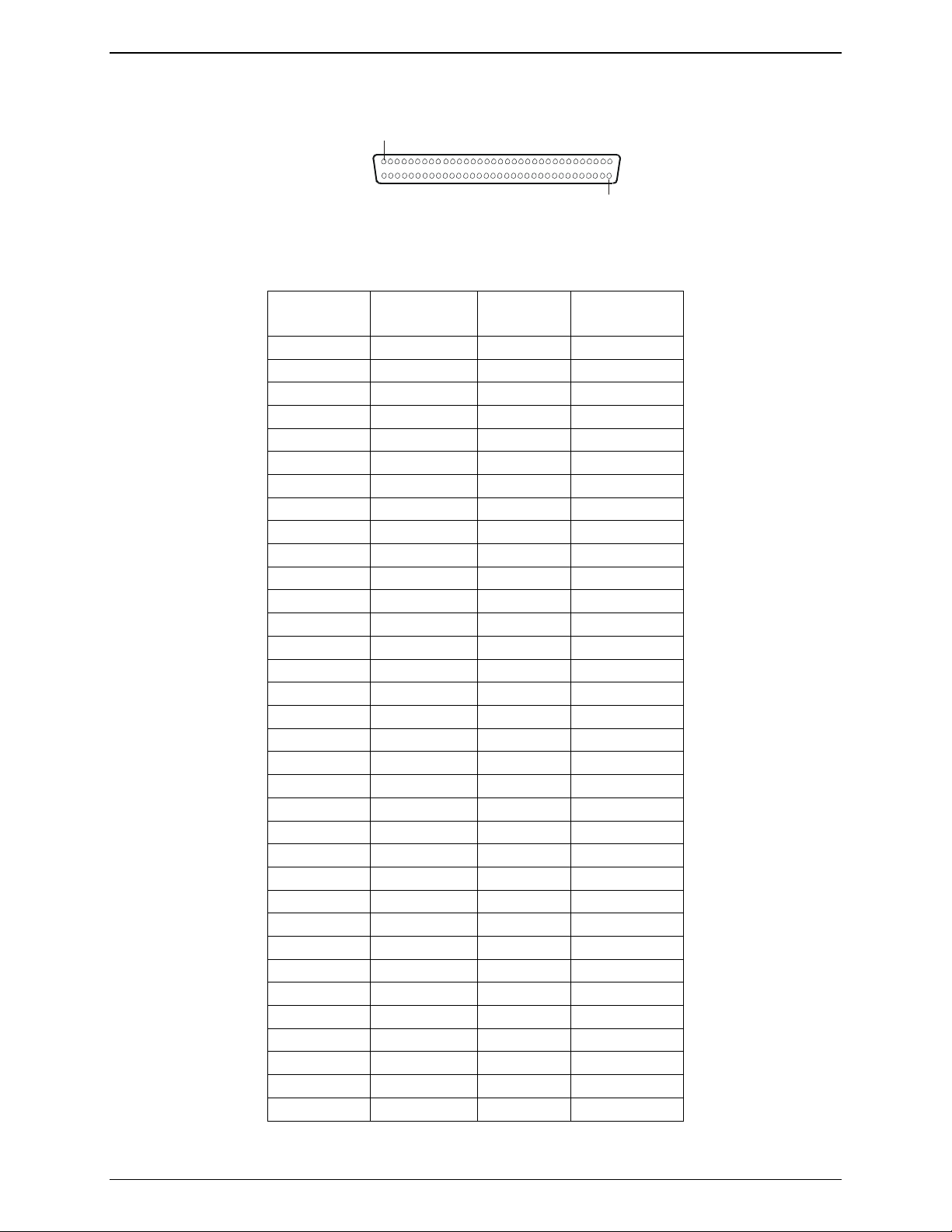

68-Pin LVD SCSI Po rt Connector (Low Vo ltage Diff erential)

Shown as pin matching

Pin 1

Pin Number

1 +DB(12) 35 -DB(12)

2 +DB(13) 36 -DB(13)

3 +DB(14) 37 -DB(14)

4 +DB(15) 38 -DB(15)

5 +DB(P1) 39 -DB(P1)

6 +DB(0) 40 -DB(0)

7 +DB(1) 41 -DB(1)

8 +DB(2) 42 -DB(2)

9 +DB(3) 43 -DB(3)

10 +DB(4) 44 -DB(4)

11 +DB(5) 45 -DB(5)

12 +DB(6) 46 -DB(6)

13 +DB(7) 47 -DB(7)

14 +DB(P0) 48 -DB(P0)

15 Ground 49 Ground

16 DiffSens 50 Ground

17 TermPwr 51 TermPwr

18 TermPwr 52 TermPwr

19 Reserved 53 Reserved

20 Ground 54 Ground

21 +ATN 55 -ATN

22 Ground 56 Ground

23 +BSY 57 -BSY

24 +ACK 58 -ACK

25 +RST 59 -RST

26 +MSG 60 -MSG

27 +SEL 61 -SEL

28 +CD 62 -CD

29 +REQ 63 -REQ

30 +IQ 64 -IQ

31 +DB(8) 65 -DB(8)

32 +DB(9) 66 -DB(9)

33 +DB(10) 67 -DB(10)

34 +DB(11) 68 -DB(11)

LVD SCSI Connector (Male)

68-Pin SCSI Port Connector

Signal

Description

Pin

Number

Pin 68

Signal

Description

20

Page 21

Chapter 3 Connector Pinouts

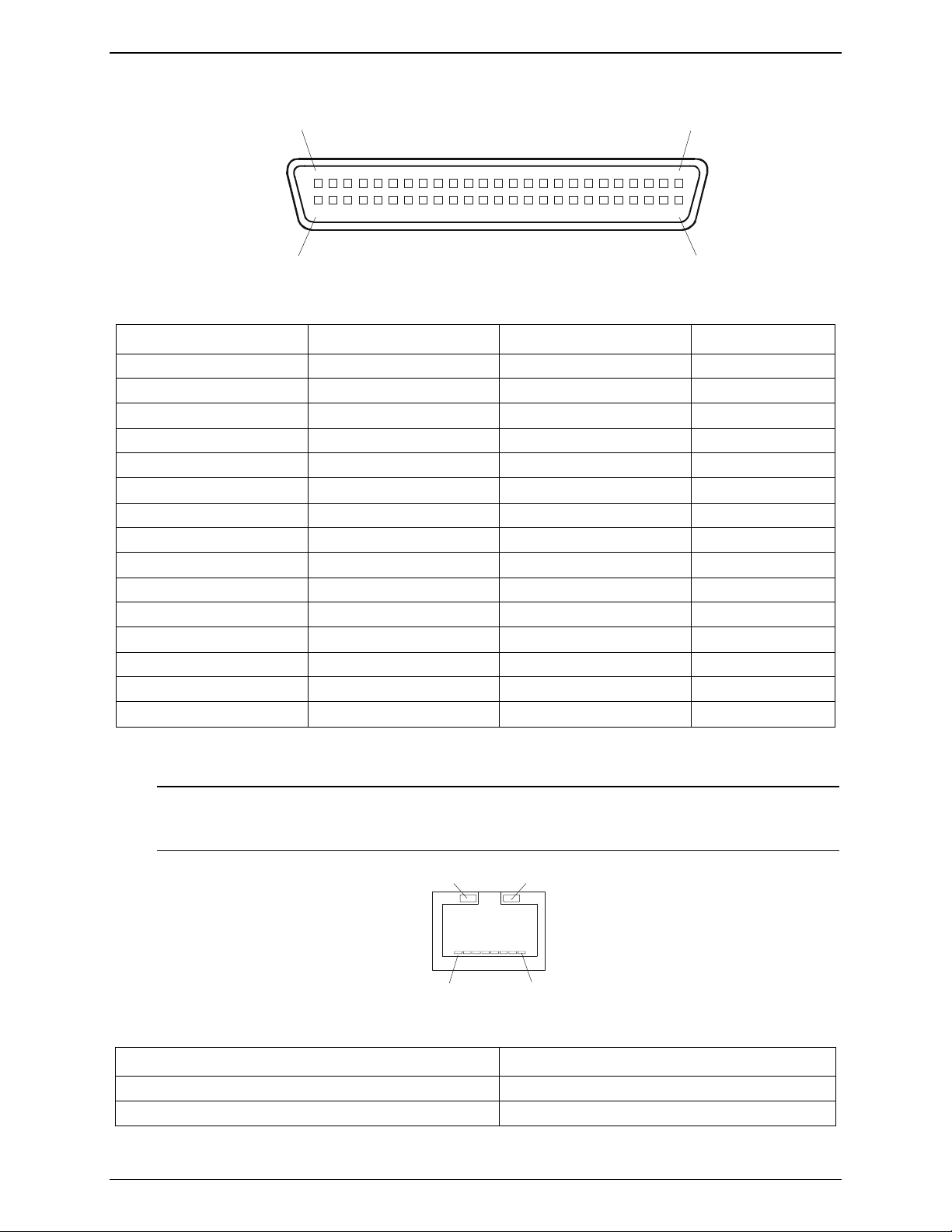

50-Pin Narrow SCSI Po rt Connector – A ccessory Board

Position 25 Position 1

Position 26Position 50

SCSI Port Connector

50-Pin Narrow SCSI Port Connector Pinouts

Pin Number Signal Description Pin Number Signal Description

1-11 Ground 37 Reserved

12 Reserved 38 Termpwr

13 Open 39 Reserved

14 Reserved 40 Ground

15-25 Ground 41 -ATN

26 -DB(0) 42 Ground

27 -DB(1) 43 -BSY

28 -DB(2) 44 -ACK

29 -DB(3) 45 -RST

30 -DB(4) 46 -MSG

31 -DB(5) 47 -SEL

32 -DB(6) 48 -C/D

33 -DB(7) 49 -REQ

34 -DB(P) 50 -I/O

35-36 Ground

LAN Connector – A ccessory Board

NOTE The embedded LAN connector does not have the Green and Yellow LEDs on the

connector to indicate any kind of activity. The embedded LAN activity is indicated by the

LAN activity LED on the front panel.

GRN LED YEL LED

81

LAN Connector

LAN Connector Pinouts

Pin Number Signal Description

1 Data signal

2 Not used

21

Page 22

Chapter 3 Connector Pinouts

Pin Number Signal Description

3 Ground

4 Power (+5 V dc)

5 Clock signal

6-8 Not used

22

Page 23

4 Maintenance Guidelines

Introduction

This chapter provides the HP Tower Server tc2100’s maintenance guidelines when removing or replacing the

mass storage devices, DIMM memory, accessory boards, and processors.

Mass Storage

The HP Server tc2100 comes standard with one IDE CD-ROM and one flexible disk drive with various

possible configurations of SCSI or IDE hard disk drives, depending on the model (SCSI or IDE). The Server

is limited to six internal mass storage devices (including a tape back up drive), four in the front shelves (or

common trays) and two in the removable drive cage accessed from the side of the Server.

Mass Storage G uidelines

• General Guidelines

o Use care when unpacking and handling the hard disk drives.

The hard disk drives are very susceptible to mechanical shock and can be easily damaged by a drop

as short as one-quarter of an inch. If the drop would crack an egg, it will damage the drive.

o Do not stack drives.

o The Server is internally limited to 6 mass storage shelves.

The flexible disk drive and CD-ROM drive, which are standard on all models of the HP Server

tc2100, occupy shelves 1 and 2 respectively. The first four mass storage shelves may also be referred

to as common trays, or drive trays.

o If a backup tape drive is used, it occupies shelf 3, leaving only three mass storage devices available

for shelves 4-6, and at least one is required for the boot drive.

• IDE Devices

o The embedded IDE controller is an Enhanced-IDE dual channel controller and provides two

connectors (IDE-1 and IDE-2) for IDE devices.

Refer to "System Board Layout" in Chapter 1, "Specifications."

o The IDE CD-ROM uses one connector on the cable from the IDE-2 connector, leaving one

connector for the optional third hard drive on the IDE model. The CD-ROM is configured as the

master device, unless a third HDD is installed, which should be configured for the master device.

For the SCSI model the second IDE-2 connector could be used for any additional IDE device, such

as IDE hard drive.

o The primary IDE connector (IDE-1) and cable is used for the first or standard hard IDE drive and the

second optional hard drive, but this cable is not provided for the SCSI model.

The bundled IDE CD-ROM and hard disk drive were put on separate IDE connectors to improve

performance.

• SCSI Devices

o Use only low-voltage differential (LVD) SCSI devices

o Do not use high voltage differential (HVD) SCSI devices in the Server or damage to the controller

and other devices may occur.

o Ensure the SCSI devices you install do not have terminations installed.

The SCSI drives are connected to a terminated cable and do not require termination on the SCSI

drive.

23

Page 24

Chapter 4 Maintenance Guidelines

o Use only HP Ultra-160 SCSI LVD (1-inch) low profile 3.5-inch hard disk drives for the removable

hard disk drive cage.

o Only use an HP Ultra-160 SCSI LVD drive as the optional third drive.

o The optional HP backup tape drive comes with a 50-to-68-pin adapter to connect to the 68-pin SCSI

connector on the SCSI cable used for connection of backup tape drive.

o The optional HP backup tape drive may slow down access time for the Ultra-160 SCSI hard drives.

If this is the case, HP recommends adding another single channel SCSI controller to control the

slower backup tape drive.

Boot Priority

The HP Server tc2100 is provided in two models, IDE or SCSI, and the model type affects the boot priority.

The HP Server searches for bootable devices in a specific order, which is set up in the BIOS Utility.

IDE Model Boot Order:

1. Flexible disk drive

2. IDE CD-ROM drive

3. IDE hard drive (boot drive)

4. PCI slot P1 (32-bit slot)

5. PCI slot P2 (32-bit slot)

6. PCI slot P3 (32-bit slot)

7. PCI slot P4 (32-bit slot)

8. PCI slot P5 (32-bit slot)

SCSI Model Boot Order:

1. Flexible disk drive

2. IDE CD-ROM drive

3. IDE hard drive (if boot drive)

4. SCSI devices

5. PCI slot P1 (32-bit slot)

6. PCI slot P2 (32-bit slot)

7. PCI slot P3 (32-bit slot)

8. PCI slot P4 (32-bit slot)

9. PCI slot P5 (32-bit slot)

The SCSI Controller in the Server scans for a boot device starting at device ID 0 and works up through the ID

numbers (0-15). The SCSI controller board is always SCSI ID 7. The optional backup tape drive will use

SCSI address ID 3.

NOTE The boot order can be changed using the Server's (BIOS) Setup Utility and the SCSISelect

Utility.

24

Page 25

Chapter 4 Maintenance Guidelines

IDE Mass Storag e Device s

This section provides the configuration of the IDE mass storage devices, if you have selected an IDE version

of the HP Server tc2100.

IDE Controller Configuration

The embedded IDE controller is available for both models (IDE or SCSI) of the HP Server. The embedded

IDE controller is an Ultra DMA33/66/100 E-IDE dual channel controller, which provides IDE-1 and IDE-2

connectors. Each channel can only control two IDE devices.

The IDE Server model uses the IDE-1 for the boot drive and the IDE-2 connector for the IDE CD-ROM. The

Setup Utility (BIOS) can be used to change the boot order of the flexible disk drive and the IDE devices.

Refer to Chapter 8, "Configuring the HP Server," for more information.

IDE Mass Storage Additions

The table below lists the number and types of mass storage devices in or may be added into the IDE model of

the HP Server.

IDE Model Mass Storage Devices

Interface

Types

Max No.

Devices

FDD 1 Factory installed flexible disk drive (FDD) in shelf 1

IDE-2 2 Factory installed CD-ROM drive in shelf 2

IDE-1 2 Factory installed IDE hard drive in shelf 6

SCSI

1 Optional SCSI backup tape drive in shelf 3 (SCSI controller

controller

board

Installed Devices and Addresses

Optional 3rd IDE hard drive in shelf 4

Optional 2nd IDE hard drive in shelf 5

board required for SCSI back up tape drive)

SCSI Mass Stor age Dev ices

This section provides the configuration of the SCSI mass storage devices, if you have selected a SCSI version

of the HP Server tc2100. The base SCSI model configuration has at least one SCSI hard drive (shelf 6)

located in the removable drive cage and connected to the factory installed SCSI controller.

SCSI Controller Configuration

The single channel SCSI controller board provided with the SCSI model uses the SCSISelect Utility, to

control the SCSI controller board settings. If you order the SCSI model, you typically do not need to

configure the SCSI controller, because the SCSISelect utility will automatically recognize all SCSI devices

connected to it.

Run the SCSI Select Utility to verify or modify the SCSI controller settings, low-level format SCSI disks, or

verify SCSI media. Refer to Chapter 8, "Configuring the HP Server," in the HP Server tc2100 Installation

Guide for further information.

CAUTION You must not connect high voltage differential (HVD) SCSI devices on the SCSI bus or

you will damage the other LVD SCSI devices.

The single channel Ultra-160 PCI SCSI controller board provided with the SCSI model includes two SCSI

connectors and is normally installed in PCI slot P1. The SCSI cable provided has 5 connectors, (4 for SCSI

devices and 1 for the SCSI controller board) and one terminator on the end of the cable.

• 1 internal 68-pin connector – This internal connector is used to control the internal SCSI drives; up to a

total of four SCSI devices.

25

Page 26

Chapter 4 Maintenance Guidelines

• 1 external 68-pin connector – This external SCSI connector is only used for external SCSI devices and

requires no additional internal cabling or switch settings. This connector supports up to 15 devices

connected to it externally.

NOTE Only one 68-pin connector on the SCSI controller board can be used as the active SCSI

connector. Therefore, you can not connect external SCSI devices to the external connector

when there are active internal SCSI devices connected to the internal SCSI connector.

The HP Server tc2100 will support an HP NetRAID 1M controller board, separate from the SCSI controller

board.

26

Page 27

Chapter 4 Maintenance Guidelines

SCSI Mass Storage Additions

The table below lists the number and types of mass storage devices in or may added into the SCSI model of

the HP Server.

SCSI Model Mass Storage Devices

Interface

Types

Max No.

Devices Installed Devices and Addresses

FDD 1 Factory installed flexible disk drive (FDD) in shelf 1

IDE-2 2* Factory installed CD-ROM drive in shelf 2

A second IDE device (hard disk drive) could be installed, if shelf 3 is

available.

Internal SCSI

cable

(Ultra-160 SCSI

Adapter)

4*** Factory installed SCSI HDD (shelf 6, address = ID 0

Optional 2nd SCSI HDD (shelf 5, addresses = ID 1).

Optional 3rd SCSI HDD (shelf 4, address = ID 2)

Optional SCSI Tape Backup Drive (shelf 3, address = ID 3) **

SCSI controller (address = ID 7) installed in PCI slot P1

External SCSI

connector

15 *** Only used for control of ext ernal SCSI devices. This SCSI connector

can control up to 15 external SCSI devices

(Ultra-160 SCSI

Adapter)

* The secondary IDE (IDE-2) c able is connected to the factory-installed CD-R O M drive and configured as master, unless 3rd hard

drive installed and configured as master device. The primary IDE connector (IDE-1) is available on the SCSI model, but is not

supported by Hewlett-Packard.

** A 50-to-68-pin SCSI adapter is provided with the HP backup tape drive.

*** The single channel SCSI controller c an support up to 15 devices on one connect or at a time; however, there a r e only enough

internal storage shelves for 3 hard disk drives and 1 optional tape backup device. The external connector is only u sed to control

external SCSI devices when th er e are no internal SCSI devices.

External SCSI Connector

The HP Server tc2100, SCSI model, has an external SCSI connector at the rear of the Server. This SCSI port

cannot be used if there are active internal SCSI devices. The SCSI controller provided with the SCSI model

of the Server is a single channel controller and cannot support internal and external SCSI devices at the same

time.

Memory Guidelines

• The HP Server tc2100 only uses 133 MHz (PC133) SDRAM DIMMs, which are electrically different

from the EDO and PC100 SDRAM memory modules used in previous HP Server models.

• DIMMs sizes supported are 128 MB, 256 MB, or 512 MB buffered in any combination.

• Supported memory capacity ranges from 128 MB to 1.5 GB maximum (512 MB per DIMM slot x 3

DIMM slots total). The minimum capacity is 128 MB (one DIMM).

• DIMM sizes may be mixed on the system board and may be loaded in any order (1 through 3).

However, HP recommends starting at slot 1 and filling the slots in order: 1, 2, and 3.

• Empty slots between DIMMs are permitted.

• When handling DIMMs, observe anti-static precautions to avoid damage.

To ensure you have the correct DIMMs before installation, refer to one of the following for a list of qualified

DIMMs:

• HP Order Assistant on the HP web site at:

27

Page 28

Chapter 4 Maintenance Guidelines

http://www.hp.com/go/Server

• HP Customer Service

The video memory is limited to 4 MB on the system board and cannot be upgraded.

Accessory Board Guidelines

The system board in the HP Server tc2100 provides up to five 32-bit PCI slots (P1 through P5).

Tested PCI Board s

For a list of tested PCI boards, check for compatibility under the Hardware Tested Products list for the HP

Server tc2100 under the Technical Support topic for the specific NOS used in the Server at HP’s web site:

http://Server.hp.com/Server/support/compatibility/compatibility.asp

CAUTION Some accessory board outputs may exceed U.S. National Electrical code (NFPA 70)

Class 2 or limited power source limits and must use appropriate inter-connecting cabling

in accordance with the National Electrical Code. (All HP boards comply with Class 2.)

IRQ Settings

The IRQ settings are automatically assigned and do not require user intervention. The HP Server uses the

Plug-and-Play feature of the PCI boards to correctly assign the resources automatically.

Processor Guidelines

This HP Server supports the Celeron and Pentium III processors and each one should have its own heatsink

and cooling fan.

CAUTION If good contact is not made between the processor and the thermal patch on the heatsink,

the processor will overheat and possible damage may occur.

• Ensure you open the ZIF lever before removing or installing the processor into the socket.

The processor socket uses a ZIF (Zero Insertion Force) lever to secure the processor in the socket.

• The ZIF lever should make a clicking sound when it closes completely.

• Ensure you align Pin-1 of the processor with Pin-1 of the processor socket when installing the

processor, or processor pins will be damaged.

• Each processor requires a heatsink with a cooling fan attached.

The Celeron processors use a slightly different heatsink with a smaller cooling fan than the Pentium III

heatsink-co oling fan a ssembly.

CAUTION To prevent damage to the thermal patch, do not slide the heatsink around on the

processor once it is in place. Rocking it slightly to one side or the other to install both

latches is acceptable.

28

• Each heatsink should have an undamaged thermal patch on the bottom of the heatsink.

The thermal patch provides the thermal bonding between the processor and the heatsink.

• The plastic sheet/tab on the thermal patch must be removed before placing the heatsink on the processor.

Some thermal patches come with a small plastic sheet (with a finger tab) covering the non-adhesive side

of the patch to help protect the thermal material.

Page 29

Chapter 4 Maintenance Guidelines

• Ensure the front ridge on the bottom of the heatsink fits into the groove between the processor socket

and processor and both ridges should straddle the processor.

The bottom of each heatsink has two ridges, which are used to align the heatsink with the processor.

• Both latches (hook and thumb) on the heatsink must be connected to the processor socket base or the

processor will overheat.

The mechanical latches on the heatsink ensure a good thermal bond between the heatsink and the

processor through the thermal patch.

• If the processor is upgraded to a faster processor speed with a different front side bus (FSB) speed than

the previous processor, the circuitry on the system board detects the change and automatically adjusts to

the faster fron t side bus speed.

• The HP Server tc2100 only supports 100 MHz and 133 MHz FSB speeds.

29

Page 30

Page 31

5 Error Messages

Introduction

This chapter describes the beep codes and the POST error codes that may occur during the boot process or

normal operation of the HP Tower Server tc2100.

Beep Codes

If the POST routines cannot display messages when an error occurs before the video displa y is i nitial ized, the

HP Server emits a series of beeps. If you get a blank screen on boot, but hear beeps, refer to the table below

to interpret the meaning of the beeps.

Beep Codes for Fatal Errors

P = Check and replace processor

S = Check and replace system board +

M = Check and replace DIMMs

R = Replace ROM chip +

Note: + If this occurs, contact your service representative to replace your HP Server tc2100.

Beep Code Test Failure I/O port 80H Repair

1-2-2-3 BIOS ROM checksum 16 R

1-3-1-1 Test DRAM refresh 20 S, P

1-3-1-3 Test 8742 Keyboard Controller 22 S, P

1-3-3-1 Auto size DRAM 28 M

1-3-4-1 RAM failure on address line 2C M, P

1-3-4-3 RAM failure on data bits of low byte of

memory bus

2-1-2-3 Check ROM copyright notice 46 R

2-2-3-1 Test for unexpected interrupts 58 S, P

1-2 Search for optional ROMs. One long,

two short beeps on checksum failure

2E M, P

98 S, C

Power-On Self Test (POST) Error Codes

Error codes (POST Codes) are encountered if an error condition occurs during the boot process of the HP

Server tc2100. All codes and the respective descriptions are listed in the following table for the HP Server

tc2100.

These codes will appear on the display monitor, provided it and the supporting circuitry are functioning:

NOTE Do not take remove/replacement actions until you have taken other troubleshooting steps.

See the troubleshooting checklist in Chapter 7, “Maintenance and Troubleshooting.”

31

Page 32

Chapter 5 Error Messages

Error Code

Description

(Extended Errors)

Problem/Solution

0200 Fixed Disk Failure POST has detected the specified hard disk drive is not

responding, but is configured in the Setup Utility.

To correct this:

1. If the specified hard disk has just been removed, press

<F2> to automatically validate the change.

2. Verify all data cables and power cables are firmly

connected.

3. If the cable is damaged, connect the hard disk drive to

another IDE cable, if available.

4. If the problem persists, your hard disk drive may need to

be replaced.

5. Contact your service representative.

0210 Stuck Key A key on the keyboard has been pressed during POST of the

HP Server.

To correct this:

1. Ensure nothing is placed on the keyboard and no key is

accidentally pressed down.

2. Reboot the Server.

3. If the error persists, your keyboard may need to be

replaced.

4. Contact your service representative.

0211 Keyboard error The keyboard has reported an error during its self-test.

To correct this:

1. Restart your HP Server.

2. If the error persists, your keyboard may need to be

replaced.

3. Contact your service representative.

0212 Keyboard Controller Failed POST has detected a general failure in the integrated

keyboard controller.

To verify this error:

1. Restart your HP Server.

2. If the error persists, your system board may need to be

replaced.

3. Contact your service representative.

0250 System battery error

(low battery power)

The Server BIOS is not responding due to a possible battery

discharge. If the HP Server was unplugged for a long period

of time, the battery will discharge and not provide enough

current to keep the system date and time current.

To correct this:

1. Verify the battery is properly inserted.

2. If necessary, replace the battery.

3. Set time and date using the Setup Utility or from your

operating system.

32

Page 33

Chapter 5 Error Messages

0251 System CMOS checksum bad –

(Default configuration used)

The BIOS configuration has been lost, cleared, corrupted, or

has not been initialized. When the HP Server remains

unplugged for a long period of time, the battery will discharge

and not provide enough current to keep the CMOS memory

powered.

To correct this:

1. Verify the battery is properly inserted.

2. If necessary, replace the battery as described in your in

this manual or the Installation Guide.

3. Run the Setup Utility to re-configure your Server.

0252 Password checksum bad –

(Passwords cleared)

POST has detected the CMOS memory is corrupted and the

passwords have cleared automatically allowing you to access

the (BIOS) Setup Utility.

To correct this:

1. Reboot the Server

2. Press <F2> early in the boot process to access the

(BIOS) Setup Utility.

3. Set the configuration in the Setup Utility and save

changes (reboot the Server, if it does not do so

automatically).

4. If this error persists with no other error messages, the

battery may need replacement, or you may need to flash

the BIOS with an updated version.

0260 System timer error The Server BIOS is not responding due to a possible battery

discharge. If the HP Server was unplugged for a long period

of time, the battery will discharge and not provide enough

current to keep the system date and time current.

To correct this:

1. Verify the battery is properly inserted.

2. If necessary, replace the battery.

3. Set time and date using the Setup Utility or from your

operating system.

0270 Real time clock error The Server BIOS is not responding due to a possible battery

discharge. If the HP Server was unplugged for a long period

of time, the battery will discharge and not provide enough

current to keep the system date and time current.

To correct this:

1. Verify the battery is properly inserted.

2. If necessary, replace the battery.

3. Set time and date using the Setup Utility or use your

operating system to set the time and date.

0271 Check date and time settings The Server BIOS is not responding due to a possible battery

discharge. If the HP Server was unplugged for a long period

of time, the battery will discharge and not provide enough

current to keep the system date and time current.

To correct this:

1. Verify the battery is properly inserted.

2. If necessary, replace the battery.

3. Set time and date using the (BIOS) Setup Utility

33

Page 34

Chapter 5 Error Messages

0280 Previous boot incomplete The HP Server configuration has been cleared or has not been

initialized and the Default configuration has been used

instead.

• Run the Setup Utility to re-configure your system.

0281 DIMM size boot error The system memory (DIMMs) size detected during POST is

smaller than previously detected. One or several DIMMs are

disconnected, or have been replaced by smaller size DIMMs.

To correct this:

1. If DIMMs have just been removed or replaced by

smaller size DIMMs, press <F2> to automatically

validate the change.

2. If no DIMM has b een removed or changed, ensure all

DIMMs are properly inserted in the slots.

3. If the problem persists, one of DIMMs may need to be

replaced.

4. Contact your service representative.

02B0 Diskette drive A error POST has detected the flexible disk drive (A) reported an

error during its self-test.

To correct this:

1. Verify a diskette can be properly inserted and removed

from the flexible disk drive.

2. Verify the flexible drive type configured in the Setup

Utility matches the flexible disk drive installed in the

HP Server.

3. Verify all data cables and power cables are firmly

connected.

4. If the problem persists, your flexible disk drive may

need to be replaced.

5. Contact your service representative.

02D0 System cache error POST has detected an error in the cache memory module and

the cache has been disabled.

To correct this:

1. Verify the processor has been installed correctly.

2. Refer to the Installation Guide for handling precautions.

3. If the problem persists, the processor module may need

to be replaced.

0230 System RAM Failed

(at offset)

POST has detected an incorrectly installed DIMM or the

failure of one or more DIMMs.

To correct this:

1. If additional memory was just installed in your Server,

please verify the installation conforms to the description

in the Installation Guide.

2. If this error is reported when no additional memory has

just been installed, restart the Server.

3. If the error persists, contact your service representative.

34

Page 35

Chapter 5 Error Messages

0231 Shadow Ram Failed

(at offset)

POST has detected an incorrectly installed DIMM or the

failure of one or more DIMMs.

To correct this:

1. If additional memory was just installed in your Server,

please verify the installation conforms to the description

in the Installation Guide.

2. If this error is reported when no additional memory has

just been installed, restart the Server.

3. If the error persists, contact your service representative.

0232 Extended RAM Failed

(at address line)

POST has detected an incorrectly installed DIMM or the

failure of one or more DIMMs.

To correct this:

1. If additional memory was just installed in your Server,

please verify the installation conforms to the description

in the Installation Guide.

2. If this error was reported when no additional memory

has been just installed, restart the Server.

3. If the error persists, contact your service representative.

0233 Memory type mixing detected POST has detected one or more DIMMs are not the correct

type, or the correct speed for this Server.

To correct this:

1. If additional memory has just been installed in your

Server, please verify the correct DIMM type and speed

was used for this Server.

2. Refer to the DIMM description in the Installation Guide.

3. If this error is reported when no changes to memory has

occurred, restart the Server.

4. If this error persists with no other error messages,

contact your service representative.

8100 Memory decreased in Size The BIOS has detected the usable memory is much less than

the total memory available. Typically, this indicates a DIMM

is defective or is not properly seated in the DIMM slot.

To correct this:

1. Ensure each DIMM is correctly inserted into the DIMM

slot.

2. Ensure both latches are completely closed on each

DIMM.

3. If all latches are completely closed, and the DIMMs are

correctly seated in the DIMM slots, go to the next step.

4. Replace each DIMM with a known good DIMM,

rebooting the Server between each replacement, to

determine which DIMM is defective.

5. If this error persists after you have replaced all the

DIMMs with no other error messages, contact your

service representative. You may have to replace the

system board.

35

Page 36

Chapter 5 Error Messages

Code

Description

(System Monitor Errors)

0A01 Emergency shutdown occurred

(system initiated)

Problem/Solution

The Server has performed an emergency shutdown to prevent

damage to system board.

• To prevent unstable behavior, or a system hang during

the boot process, do not skip this error message or

continue with Server operation.

To verify this error:

1. Reboot the Server.

2. Observer the Server’s operation and error messages

during the boot process and after the login to the NOS

has been completed.

3. If this error continues, the system board may need to be

replaced.

4. Contact your service representative.

36

Page 37

6 Diagnostics

Diagnostic Tests

When the Server boots, a series of tests are displayed on the screen. The number of tests displayed depends

on the configuration of the Server. The following are the types of errors a user might get with the HP Server.

• Built-in diagnostic Error Messages.

• BIOS and other error messages. These are errors detected by the system BIOS outside the built-in

diagnostics or application errors.

To see the Power On Self-Tests (POST):

• The HP Server must be functionally able to run the diagnostics.

• The video system must be functional.

• The keyboard must be func tional.

NOTE BIOS ROM version number is displayed on the monitor screen during power-up.

Diagnostics Description

The diagnostics (Power-On Self-Test "POST") run automatically each time the Server is powered on. These

diagnostics, which reside in the BIOS ROM, isolate server-related logic failures and indicate the board or

component that needs to be replaced, as indicated by the Error Messages. Most Server hardware failures will

be accurately isolated by the diagnostics.

WARNING You should always turn off the power and disconnect the power cord to the Server before

attempting to remove the cover and touch the internal components. Failing to do so can

expose you to electric shock and the server's components to damage. The power switch

does NOT turn off standby power, so disconnect the power cord to turn off standby

power.

HP DiagTools

The purpose of hardware diagnostic software is to provide tools for checking hardware problems. By design,

diagnostic software executes simple tests of each hardware component. Usually, such tests assure the

hardware is not the source of Server problems. This allows the user to eliminate hardware as the cause of the

problem and to focus on operating system configuration parameters, network connections, and application

software configuration parameters as the source of the problem.

If hardware problems are confirmed, the diagnostic software program can sometimes detect and diagnose the

system or specific Server component causing the problem. In addition, diagnostic tools can capture

information that allows support personnel to quickly assess the condition of the Server.

In order to be effective, diagnostic software tools must be used in the context of a wider troubleshooting

procedure.

HP DiagTools Capabilities

HP DiagTools for HP Servers is a set of off-li ne diagnostic tests, including tests for system and processor

components, memory and storage elements, ports, and input/output devices. DiagTools is supplied on the HP

Startup CD-ROM.

37

Page 38

Chapter 6 Diagnostics

The HP DiagTools Utility is run from the Startup CD-ROM, which is a bootable CD-ROM when inserted

into the CD-ROM drive and the Server is rebooted. A basic suite of tools checks key Server components, and

a menu of advanced tests is available for in-depth testing.

DiagTools has the ability to test the following components:

• System board • Processor

• Memo ry module s • Hard disk drives (HDD)

• Flexible disk drive (FDD) • Keyboard

• Parallel ports • CD-ROM drives

• Video monitor

DiagTools is an off-line diagnostic. Off-line diagnostics do not use the main network operating system (NOS)

of the HP Server. The alternate DiagTools OS has far fewer features than the full-fledged NOS. Thus, its

capabilities are limited to a set of basic tests and a series of advanced test s. In addition, DiagTools does not

use any tests, which might write over and thus destroy user data. Tests that require user inputs or decisions

are left to the advanced series of tests.

You can use DiagTools to perform the tasks listed below:

• Display a high-level inventory of the Server under te st

• Save and print a detailed inventory of hardware components

• Conduct a basic test of components listed in the Server inventory

• Display “PASSED” or “FAILED” overall results of b a sic tests

• Record detailed test results of basic Server tests

• Display a menu of advanced tests

• Select and run one or a series of advanced tests

• Add the record of results of advanced tests to the record of basic tests

• View a list to locate the meaning of a specific error code

• View one or more steps to help confirm and isolate error conditions

• Browse the Support Ticket, which contains the detailed inventories and test results

• Add comments to the Support Ticket

About Error Messages

A hexadecimal number designates each error message reported by DiagTools; a short note on the type of

error; and a list of one or more steps the user can take in response. When you run a test, it exercises many

aspects of the hardware, so the number of possible error messages exceeds 300. Most of these are

encountered rarely, if ever.

Error codes can be viewed on line from the DiagTools User menu within the advanced series of tests, or you

can refer to Chapter 3 of the HP Server DiagTools Error Reference and User Guide.

Advantages and Limita tions of Hard ware Diagnostics

Off-line diagnostic software is useful in making sure the hardware has been eliminated as the cause for

possible Server problems. Such diagnostic tools can easily be shipped with a server, and they are relatively

easy to use.

Only experienced personnel knowledgeable of its limitations should use off-line diagnostic software.

Some limitations are:

• Booting the Server from the Startup CD-ROM

38

Page 39

Chapter 6 Diagnostics

• No access to operating system error logs, since the OS is not operating at the same time as the

diagnostic tools

• Limited ability to test only a single component at a time

• Inability to indicate problems with wrongly configured Servers or the network

39

Page 40

Page 41

7 Maintenance and Trou bleshooting